Ecological type nanometer super high performance cement based composite material and preparation method thereof

A composite material and ultra-high-performance technology, which is applied in the field of building materials or basic engineering construction, can solve the problems of restricting popularization and application, low cost performance, and high price, and achieve the effects of improving mechanical properties, reducing consumption, and reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] A method for preparing an ecological nanometer ultra-high performance cement-based composite material, comprising the steps of:

[0052] (1) Weigh cement, industrial waste, and nano-CaCO according to the formula ratio 3 , river sand and copper-plated steel fiber, stir (2 to 3 minutes) until they are evenly mixed to form a dry material;

[0053] (2) Weigh the admixture and water according to the formula ratio, pour into the container and mix evenly to form a mixed solution;

[0054] (3) Weigh nano-SiO according to the formula ratio 2 , the nano-SiO 2 Pour into the mixed solution and stir ultrasonically until nano-SiO is uniformly formed 2 dispersed phase mixture;

[0055] (4) Nano-SiO 2 Slowly add the dispersed phase mixture to the dry material and stir with a mixer (3-5min) to form a fluid slurry;

[0056] (5) Pour the slurry into the steel mold, carry out vibration molding and vibrate;

[0057] (6) (One day later) Remove the mold, and mark and maintain the test ...

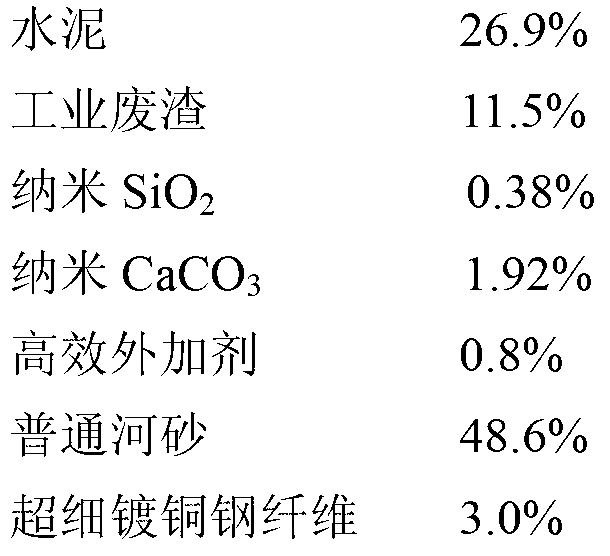

Embodiment 1

[0060]

[0061]

[0062] Among them, the industrial waste residue is composed of 20% silica fume and 80% fly ash, the mixing water is 17% of the total mass of cement and industrial waste residue, and standard curing is adopted. The mechanical properties of the high-performance cement-based composite material prepared by the above-mentioned components according to the aforementioned process are as follows: compressive strength (90d) 148.6MPa, flexural strength (90d) 27.6MPa.

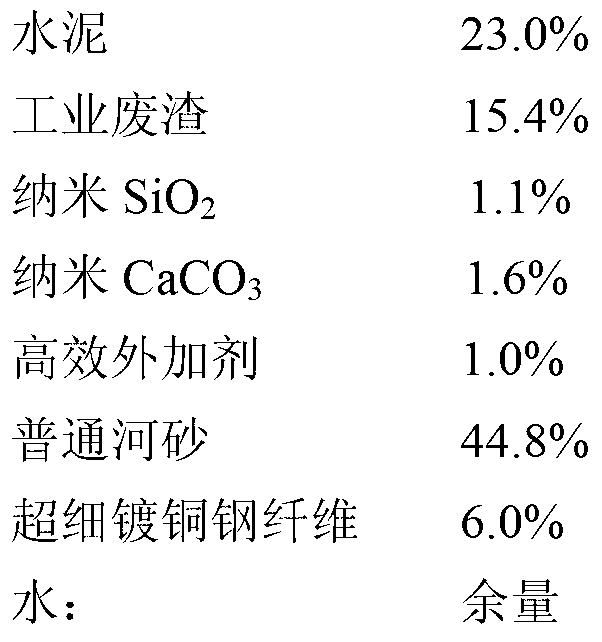

Embodiment 2

[0064]

[0065] Among them, the industrial waste residue is composed of 33.3% silica fume and 66.7% finely ground mineral powder. The amount of mixing water is 18% of the total mass of cement and industrial waste residue. Standard curing is adopted. The mechanical properties of the high-performance cement-based composite material prepared by the above-mentioned components according to the aforementioned process are: compressive strength (90d) 185.6, and flexural strength (90d) 45.4MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com