High-toughness polypropylene fiber reinforced cement-based composite material and preparation method thereof

A polypropylene fiber and cement-reinforced technology, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problem of high requirements for the working environment of the processing technology, insufficient toughness and ultimate tensile strain, and mechanical properties low stability and other issues, to achieve the effect of low processing technology and operating environment requirements, low cost, and strong toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

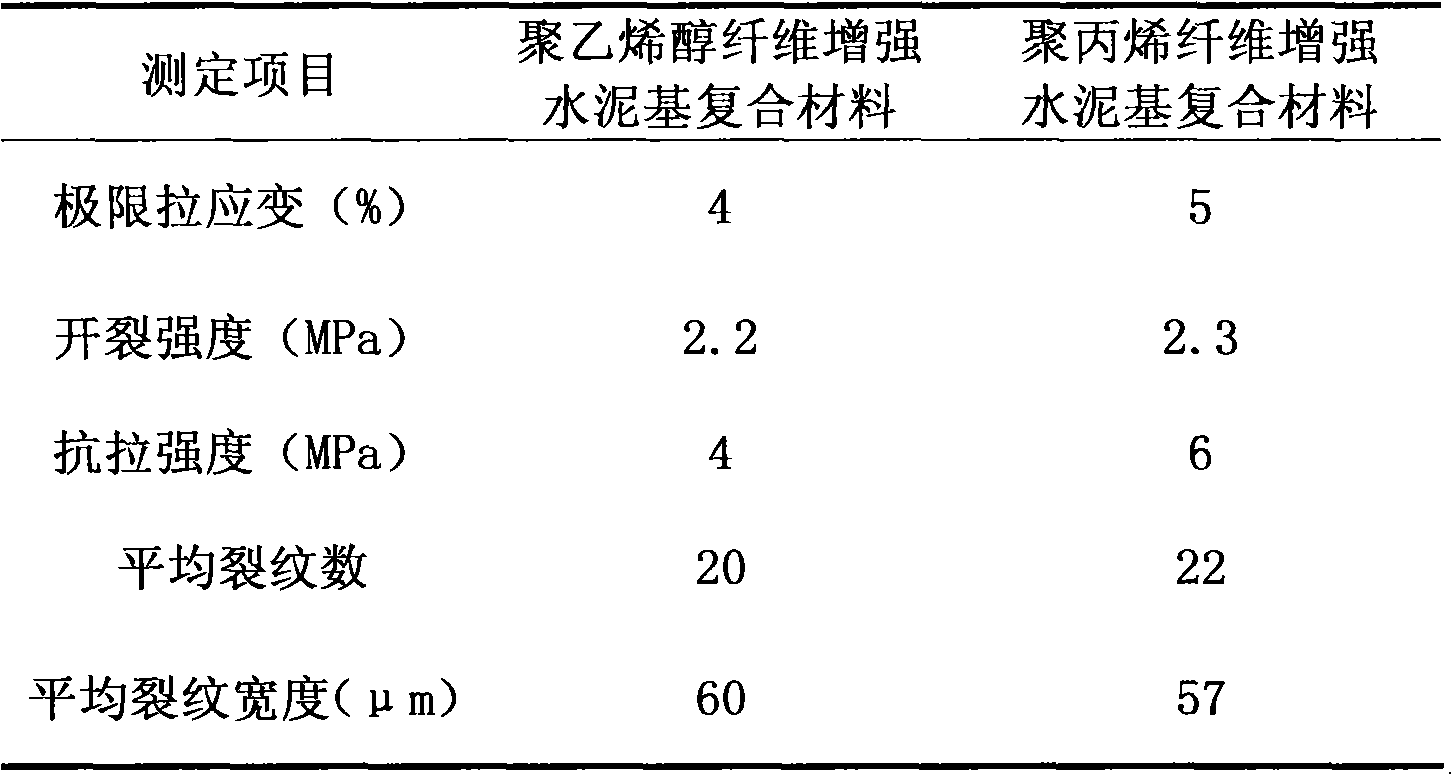

[0026] Example 1: cement 52.5%, fly ash 13.1%, silica sand 26.3%, water 6.6%, TH-928 polycarboxylate superplasticizer 1.3%, hydroxypropyl methylcellulose 0.03%, polypropylene fiber 1.47% %, the chemical binding energy of the polypropylene fiber is 0, the interfacial shear force is 0.5MPa, and the interfacial slip strengthening coefficient is 0.005.

Embodiment 2

[0027] Example 2: Cement 30%, fly ash 24%, silica sand 30%, water 12%, FDN-A II specification naphthalene-based superplasticizer 2.1%, hydroxyethyl cellulose 0.07%, polypropylene fiber 1.83% , the chemical binding energy of polypropylene fibers is 0, the interfacial shear force is 0.65MPa, and the interfacial slip strengthening coefficient is 1.2.

Embodiment 3

[0028] Example 3: Cement 16.7%, fly ash 39%, silica sand 22.2%, water 16.7%, YSP-1 specification naphthalene-based high-performance water reducer 2.8%, methyl hydroxyethyl cellulose 0.1%, polypropylene fiber 2.5%, the chemical binding energy of polypropylene fibers is 0, the interfacial shear force is 1.3MPa, and the interfacial slip strengthening coefficient is 0.56.

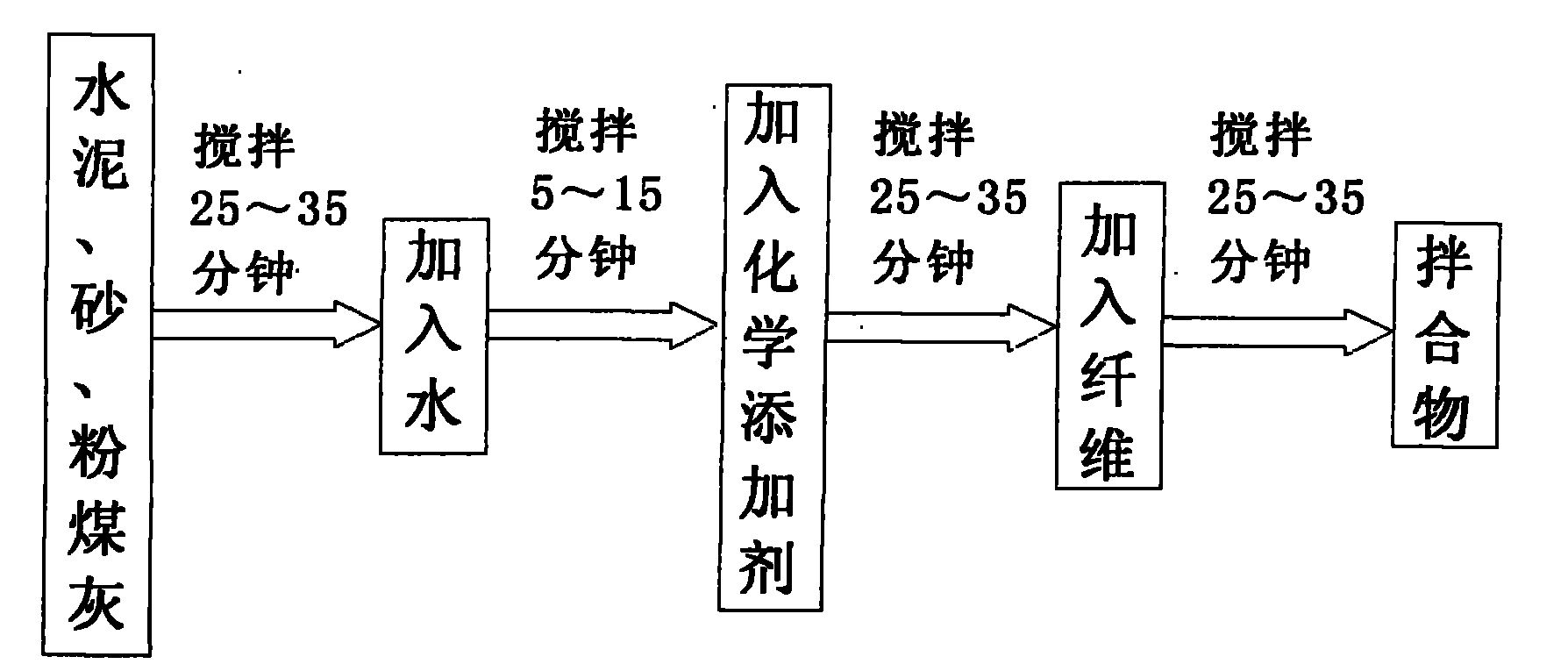

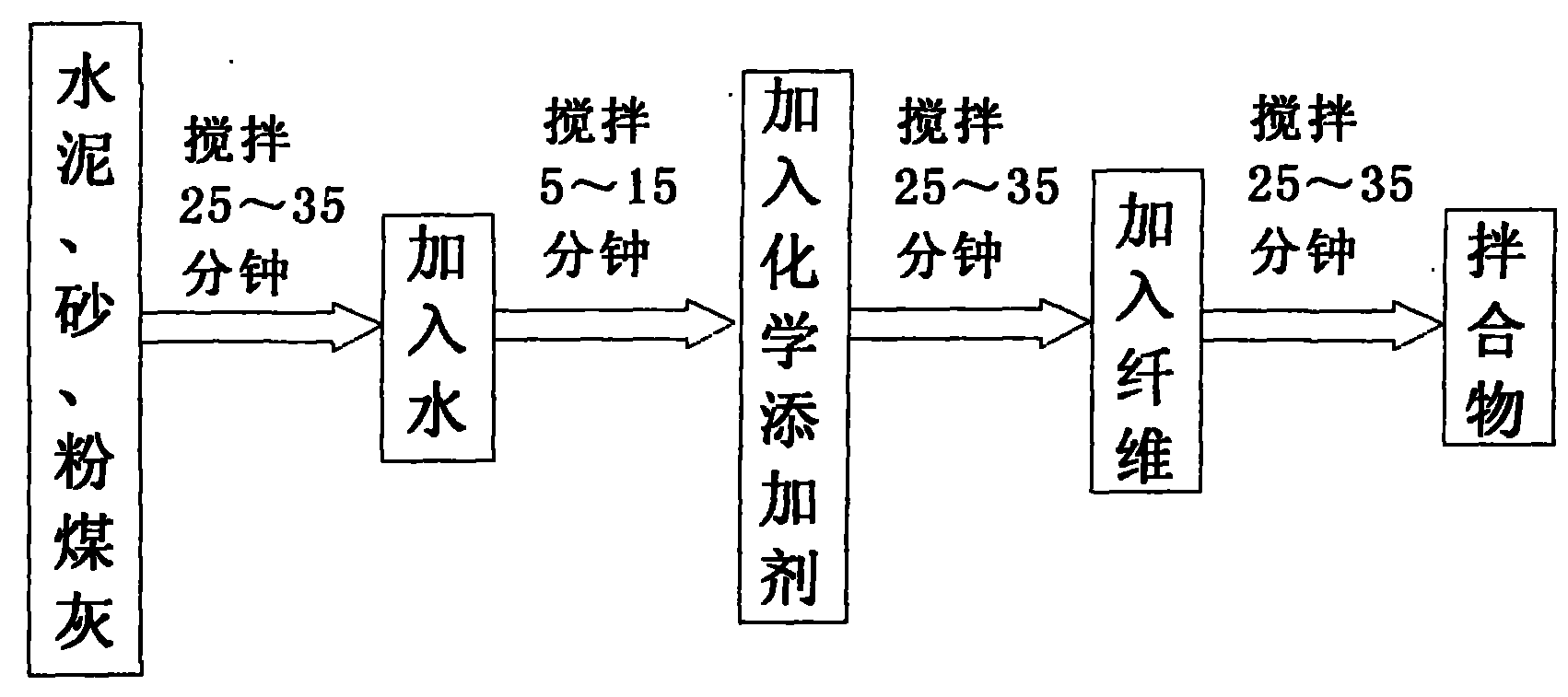

[0029] Examples of the preparation method of the present invention are as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com