Ultra-microporous lightweight insulated firebrick and manufacture method thereof

A technology of light-weight thermal insulation and manufacturing method, applied in the field of refractory bricks, can solve the problems of not being able to be used as refractory materials, etc., and achieve the effects of good thermal insulation effect, obvious economic benefits, and low linear change rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

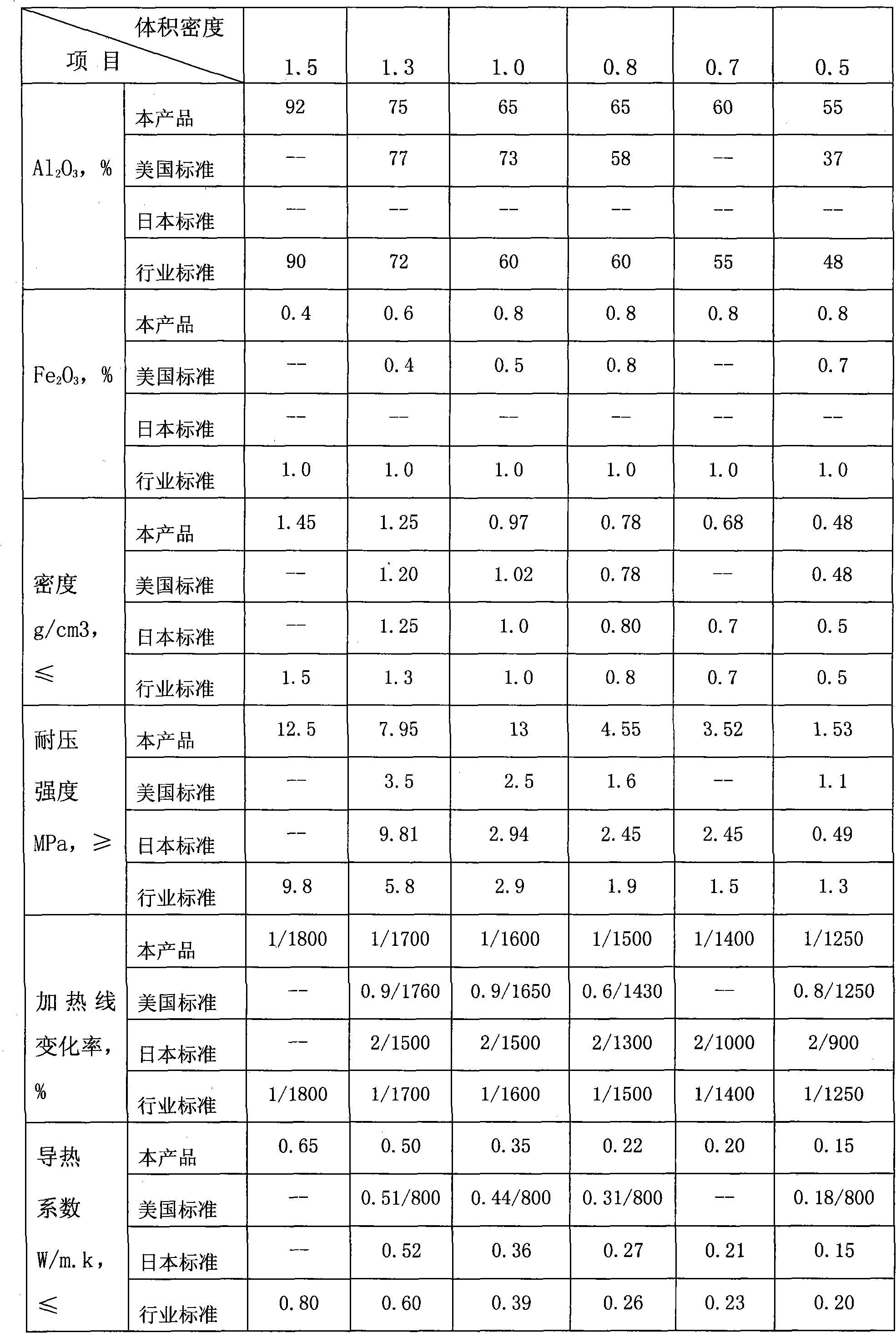

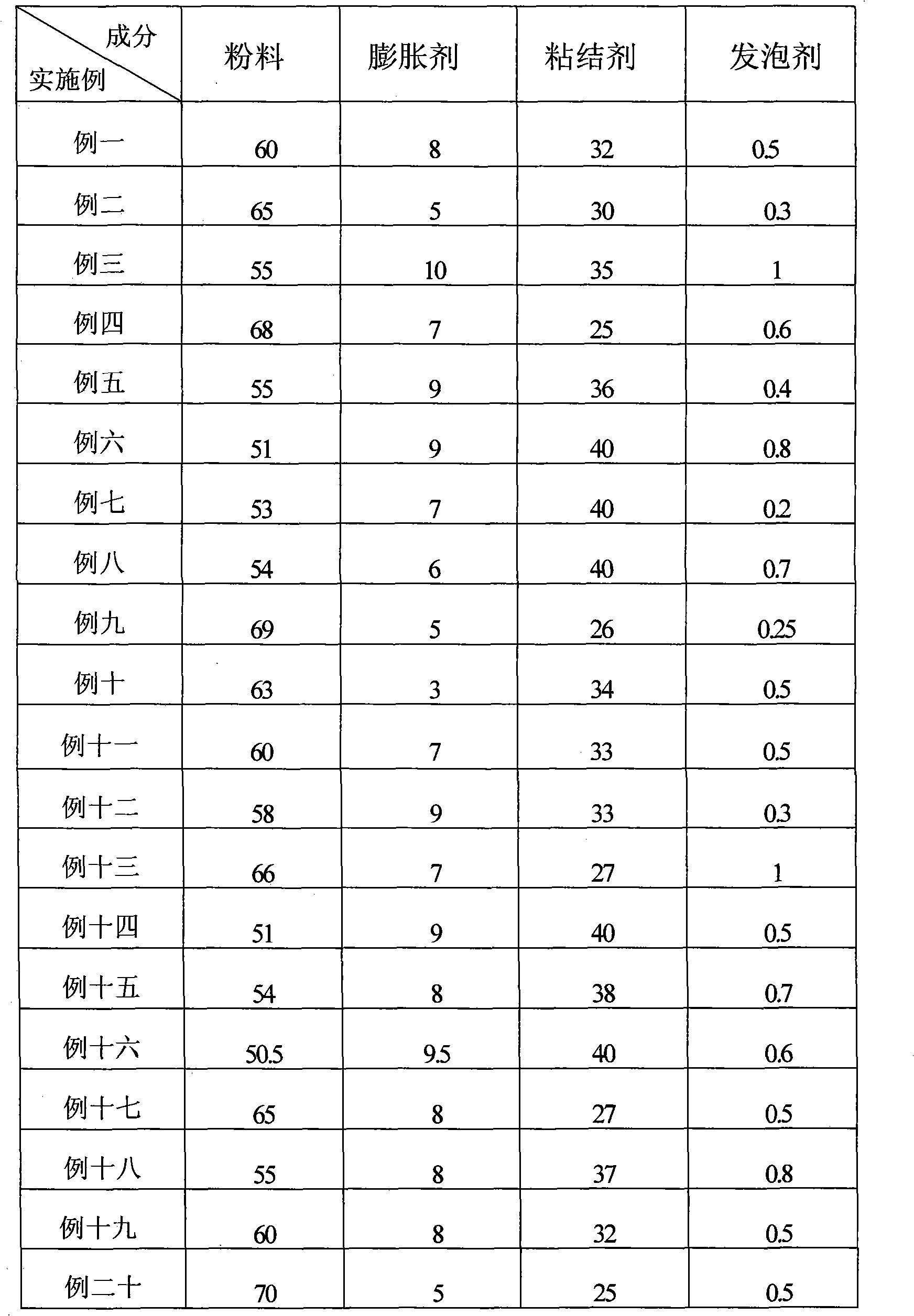

[0030] Example 1: Ultra-microporous lightweight heat-insulating refractory brick and its manufacturing method

[0031] The composition of raw materials is shown in the corresponding data in Table 1, and the data in the table are calculated by weight percentage. For example, taking 100kg of raw materials as an example, 60kg of high-alumina bauxite powder with a particle size of 0.075-4mm, and 8kg of kyanite expansion agent with a particle size of ≤0.124mm, Granularity≤0.074mm kaolin binder 32kg, plus the blowing agent accounting for 0.5% of the above-mentioned raw material gross weight, i.e. 0.5kg, the used blowing agent of this example is cationic surfactant type blowing agent, can adopt dodecyl di methyl ammonium bromide.

[0032] The brick manufacturing method comprises the following steps: uniformly mixing the powder, expansion agent and binder, adding water, the ratio of the mixture to water is 3-4:1, mixing the mixture into a paste, and setting aside; foaming The agent a...

Embodiment 2

[0034] Example 2: Ultra-microporous lightweight heat-insulating refractory brick and its manufacturing method

[0035] See the corresponding data in Table 1 for the composition of raw materials. The powder, expansion agent, binder and particle size used are the same as in Example 1. The foaming agent is a cationic liquid foaming agent which is octadecyltrimethylammonium chloride.

[0036]The manufacturing method of the brick comprises the following steps: uniformly mix the powder, expansion agent and binder, add water, the ratio of the mixture to water is 3-4:1, stir to make a paste, and set aside; Foaming agent and water are mixed at a ratio of 1:16 and then added to a foaming machine to obtain a foam with a pore size of 0.2 to 0.5 mm. Mix the foam with the paste evenly, then pour it into a mold and pour it into adobe, and the adobe is dried. Finally, put the adobe into the kiln, heat it from normal temperature to 1450 ° C, keep it at this sintering temperature for 6 hours, t...

Embodiment 3

[0037] Example 3: Ultra-microporous lightweight heat-insulating refractory brick and its manufacturing method

[0038] The composition of raw materials is shown in the corresponding data in Table 1. The used powder, expansion agent, binding agent and particle size are the same as in Example 1. The foaming agent is an anionic surfactant type foaming agent, using sodium lauryl sulfate, lauryl Sodium sulfonate or sodium secondary alkyl sulfonate.

[0039] The manufacturing method of the ultra-microporous lightweight heat-insulating firebrick comprises the following steps:

[0040] Mix the powder, expansion agent and binder evenly, add water, the ratio of the mixture to water is 3-4:1, stir to make a paste, and set aside; mix the foaming agent and water at a ratio of 1:15 After mixing in proportion, add it to a foaming machine to obtain a foam with a pore size of 0.2-0.5mm, mix the foam with the paste evenly, then pour it into a mold and pour it into adobe, and put the adobe into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com