Patents

Literature

497results about How to "To keep warm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

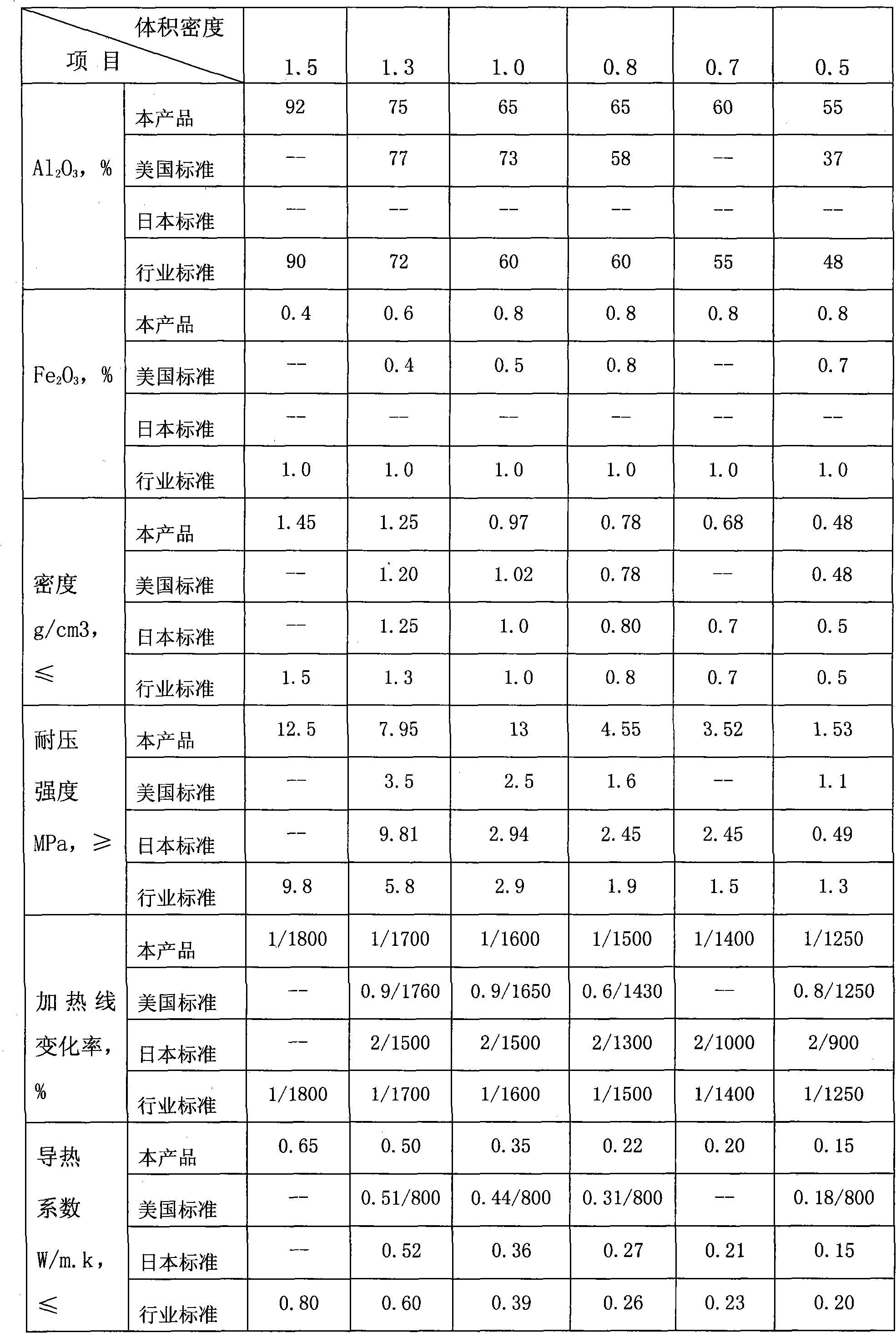

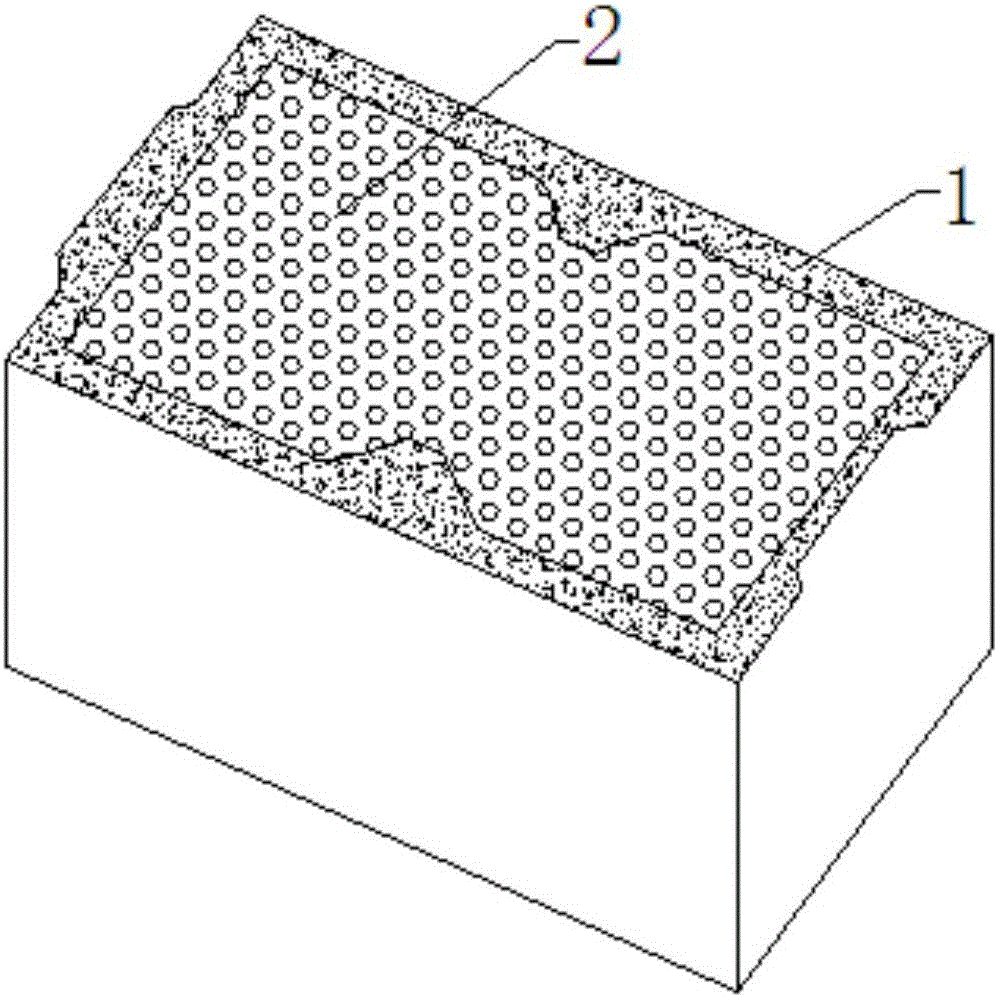

Ultra-microporous lightweight insulated firebrick and manufacture method thereof

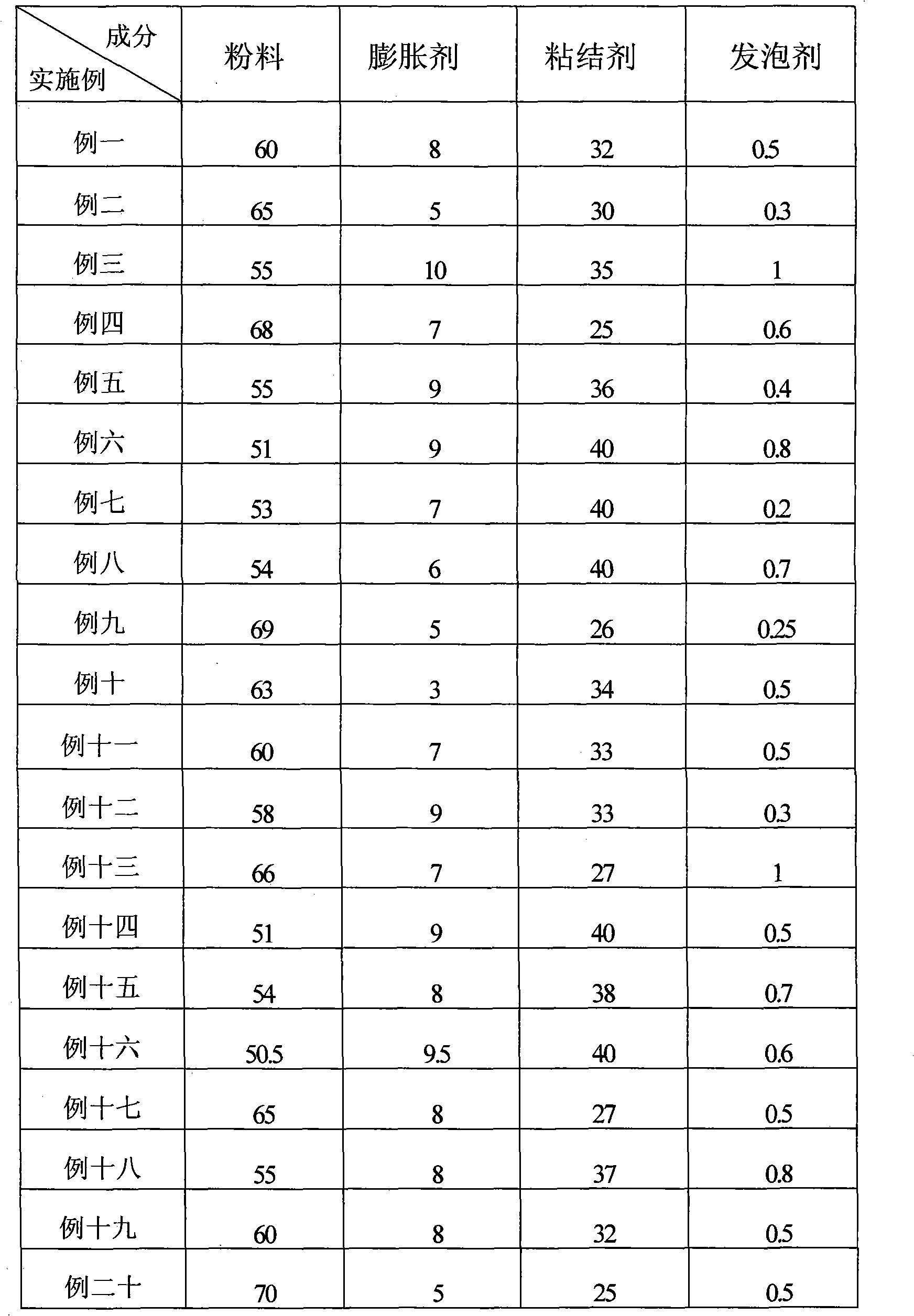

The invention discloses an ultra-microporous lightweight insulated firebrick and a manufacture method thereof. The ultra-microporous lightweight insulated firebrick is prepared by the following raw materials in percentage by weight: powder mainly comprising 50-70 Al2O3 and SiO2, 5-10 expanding agent, 25-40 caking agent and 0.2-1.0 external foaming agent. The manufacture method comprises the following steps: uniformly mixing and stirring the raw materials into pasty material; mixing the foaming agent and water according to a ratio of 1: (15-20); adding the mixture to the pasty material to mix uniformly; then, casting into brick blanks; and drying and keeping the brick blanks at a temperature of 1200-1600 DEG C for 6-8 hours. The firebrick has the advantages of high compressive strength, low coefficient of heat conductivity and low linear change ratio and can be directly used for a fireproof coating of thermal equipment so that the product has the lightweight insulation and fireproofness functions and good insulation effect and is beneficial to energy saving and environmental protection. Compared with the prior art, the invention has obvious economic benefits.

Owner:郑州东方炉衬材料有限公司

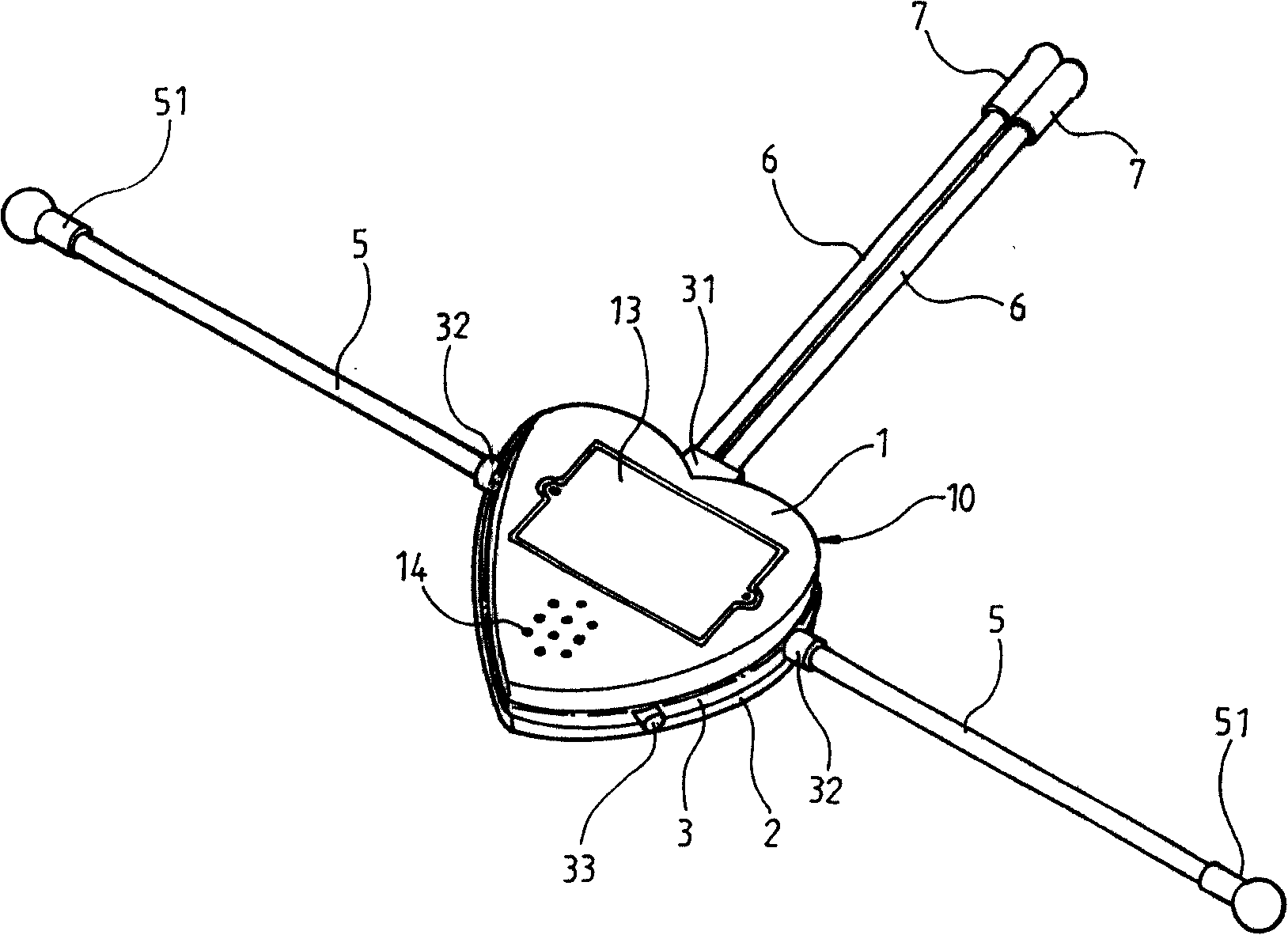

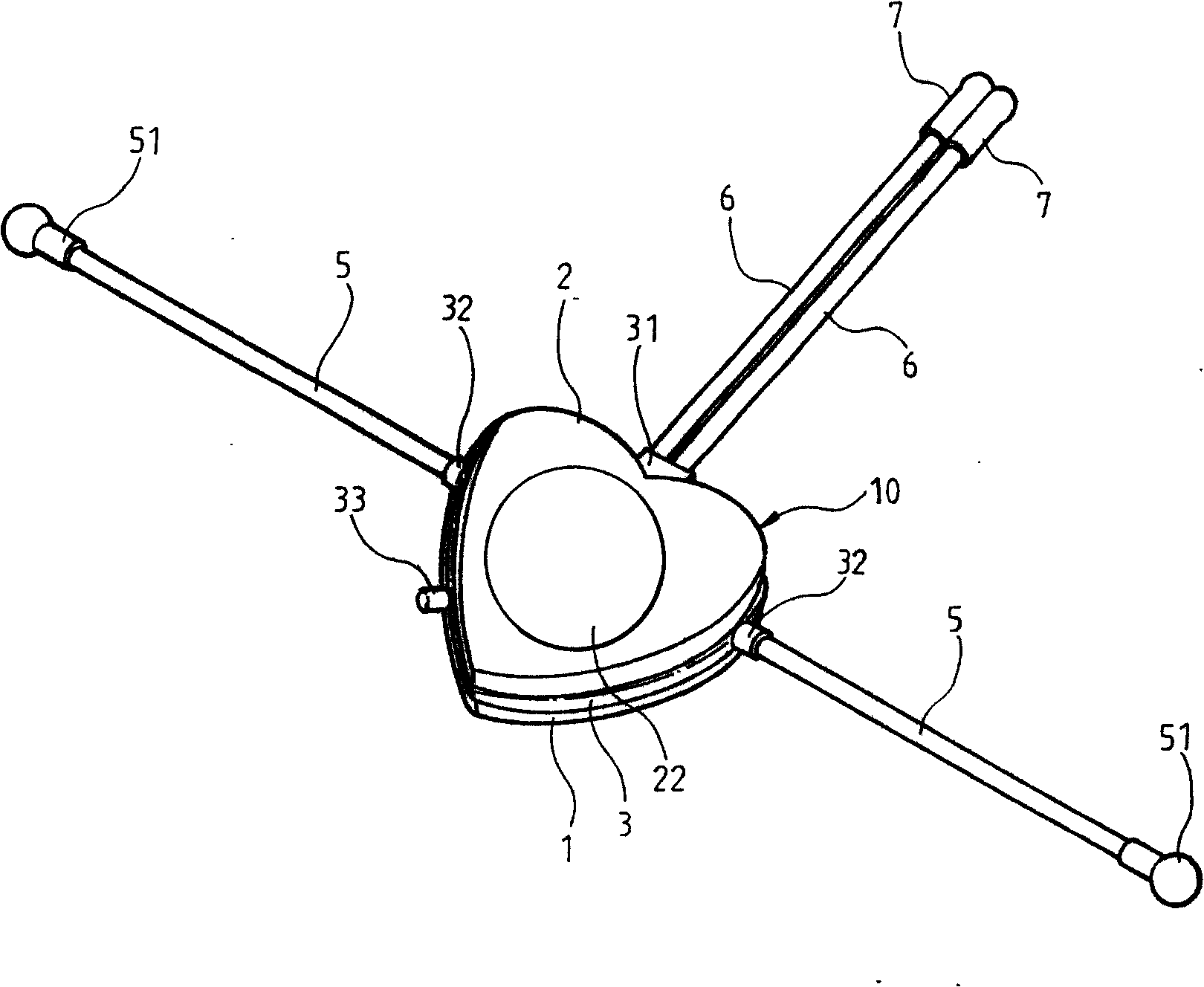

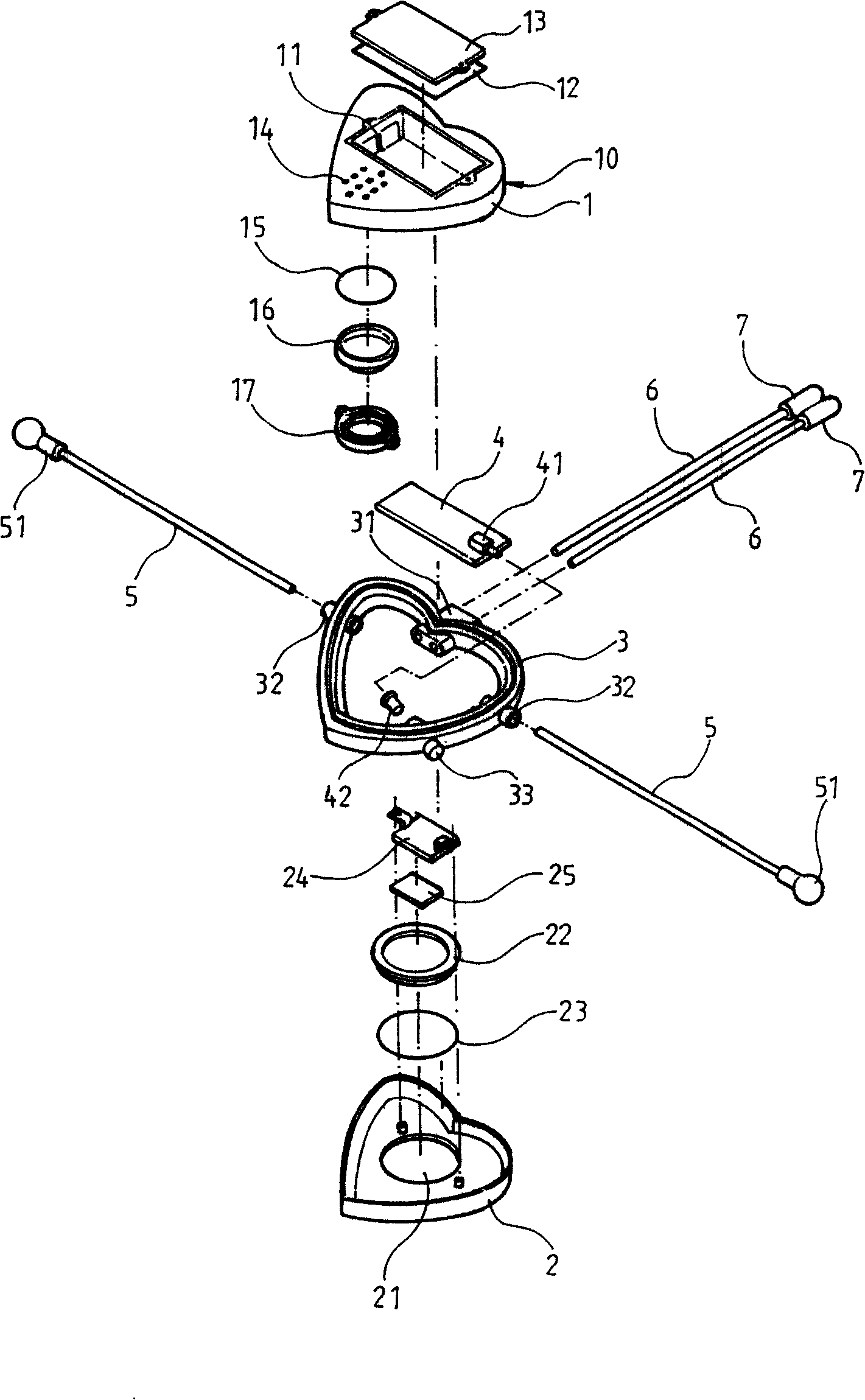

Plush toy warming device

A warmer for a fluffy toy is mainly provided with a body which is internally provided with a warming structure formed by a sheet metal and an electric warming component, etc., a sound element and a circuit board. The circuit board is provided with a temperature control circuit, a light-emitting circuit and a music circuit; the above of the body is provided with a bendable tube, the end of which is provided with a light-emitting diode connected with the circuit board; and both sides of the body are provided with bendable tubes, the ends of which are provided with a push switch that is connected with the circuit board, therefore the body is arranged inside the fluffy toys and produces music, light by pressing the push switch. Besides, constant temperature is produced by the warming structure, which warms human body when the toy is held. The body can wind around different parts of human body by the tubes, thus achieving the thermal effect for different parts.

Owner:德切勒·克里斯托夫·迪亚特曼

Universal health-care board and preparation method thereof

ActiveCN102514254AGood elastic recoveryGood strength and elasticityStuffed mattressesLamination ancillary operationsFiberSurface layer

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Reflective thermal-insulation exterior wall coating

InactiveCN103555102AKeep the decorative functionKeep the protection functionReflecting/signal paintsCelluloseThermal insulation

A reflective thermal-insulation exterior wall coating is characterized in that based on the total weight of the coating, components of the coating contain, by weight, 40-50% of waterborne acrylic resin, 10-20% of water, 10-15% of silica powder, 5-8% of expanded perlite, 3-5% of hollow ceramic microsphere, 2-5% of vermiculite powder, 3-5% of sericite powder, 5-8% of coal ash, 1-2% of an antifreeze agent, 4-6% of titanium dioxide, 4-6% of barium sulfate, 0.1-0.15% of aluminium titanate, 0.1-0.15% of silicon carbide, 0.1-0.15% of cordierite, 0.3-0.8% of an antifoaming agent, 0.1-0.15% of a bactericide, 0.1-0.4% of a dispersant, 1-1.5% of an alkali swelling thickener, 0.1-0.2% of a cellulose thickener, 0.1-0.15% of a wetting agent and 0.5-1% of an film-forming additive.

Owner:苏州富莱希涂料有限公司

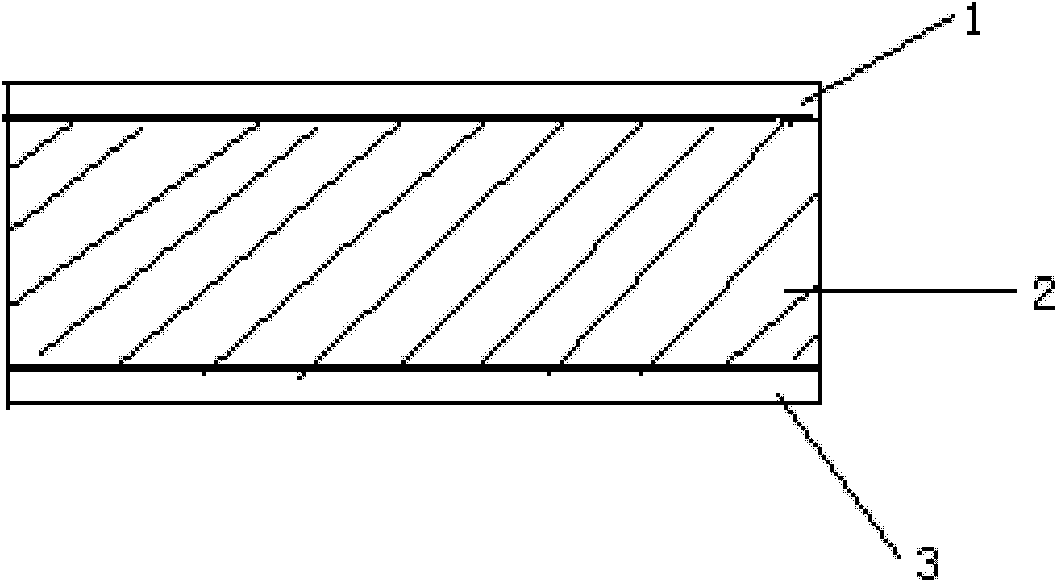

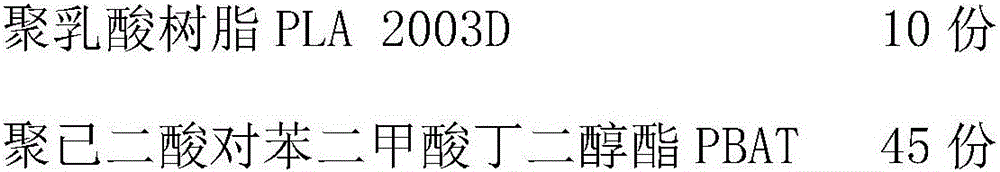

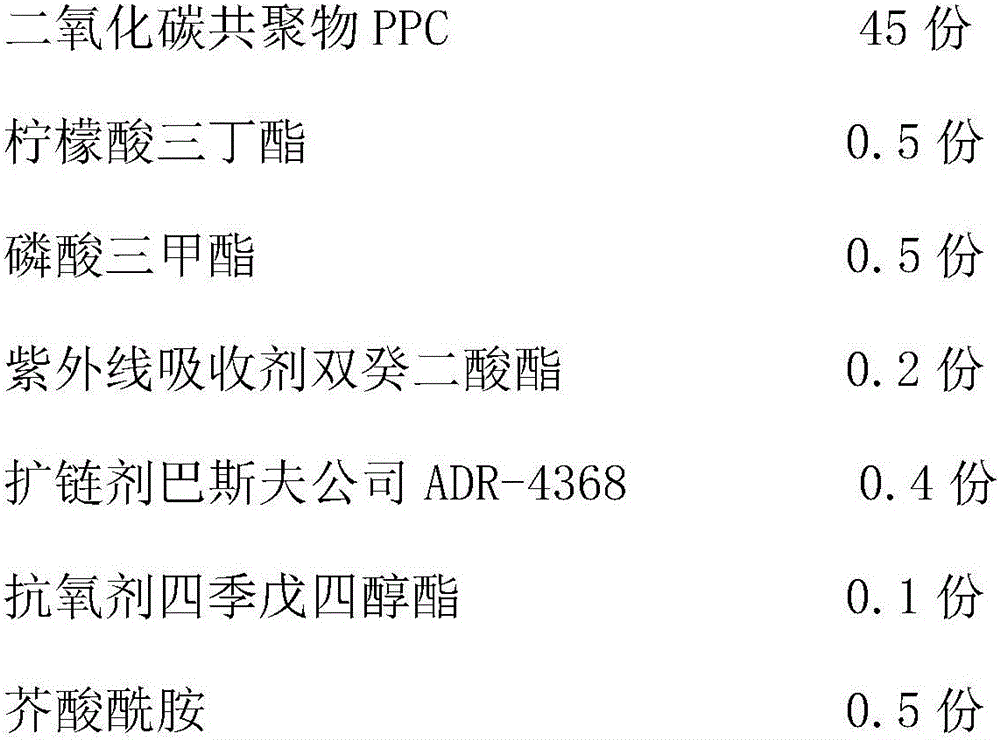

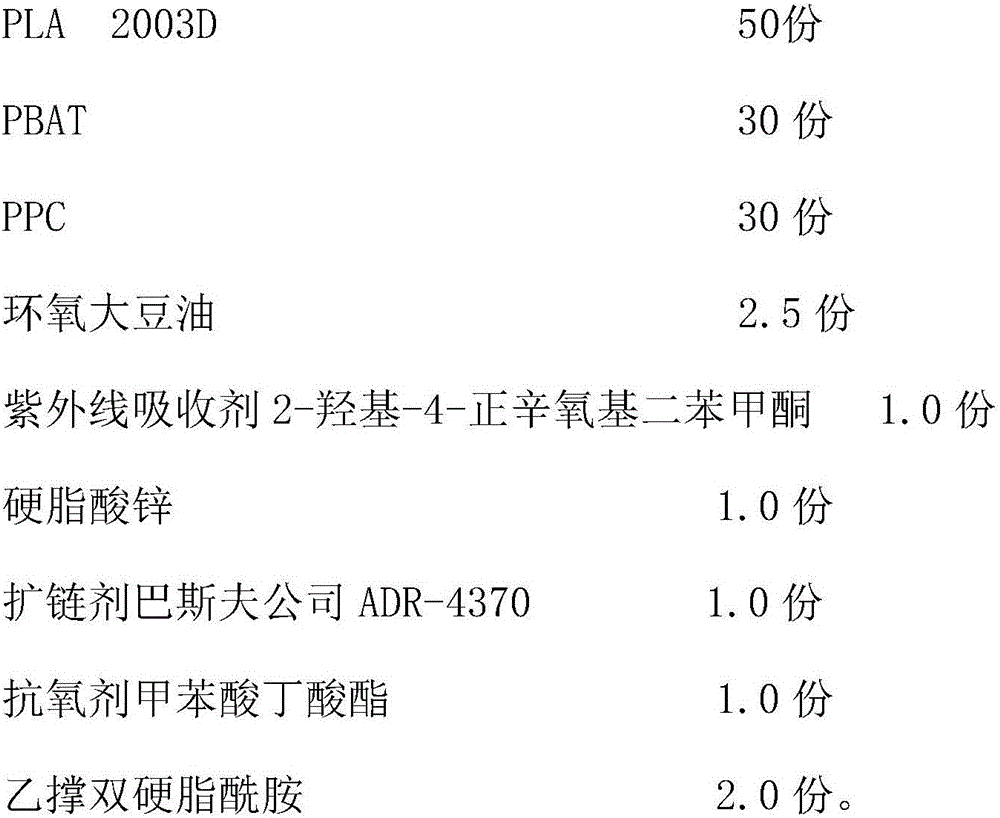

High-barrier-property biodegradable mulching film and preparation method thereof

InactiveCN106046725AFully biodegradableGood mechanical propertiesLow-density polyethyleneAntioxidant

The invention relates to a high-barrier-property biodegradable mulching film and a preparation method thereof, belonging to the field of high-polymer materials. The high-barrier-property biodegradable mulching film is prepared from a polylactic acid resin, a toughener, a heat stabilizer, an ultraviolet absorbent, a chain extender, an antioxidant, an opening agent and the like by using a film blowing machine set. The high-barrier-property biodegradable mulching film can be automatically degraded under the actions of rich oxygen and microbes, does not pollute the environment, has higher barrier property than the LDPE (low-density polyethylene) film with the same thickness by 1.5-2.0 times, and satisfies the functions of moisture retention, water preservation and yield increase for crops. The method has the advantages of simple production technique and high production efficiency, and can easily implement industrial production.

Owner:JILIN COFCO BIOCHEM

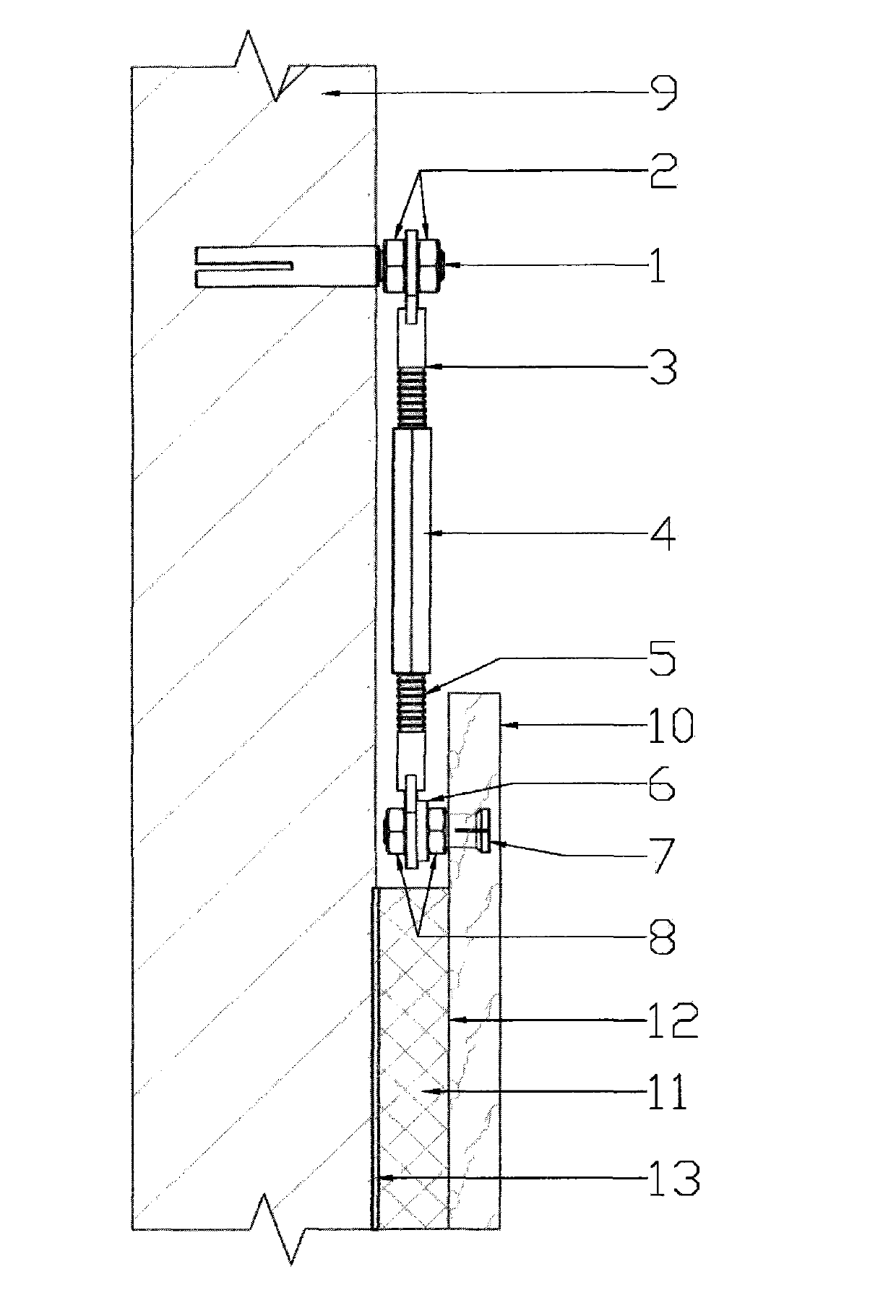

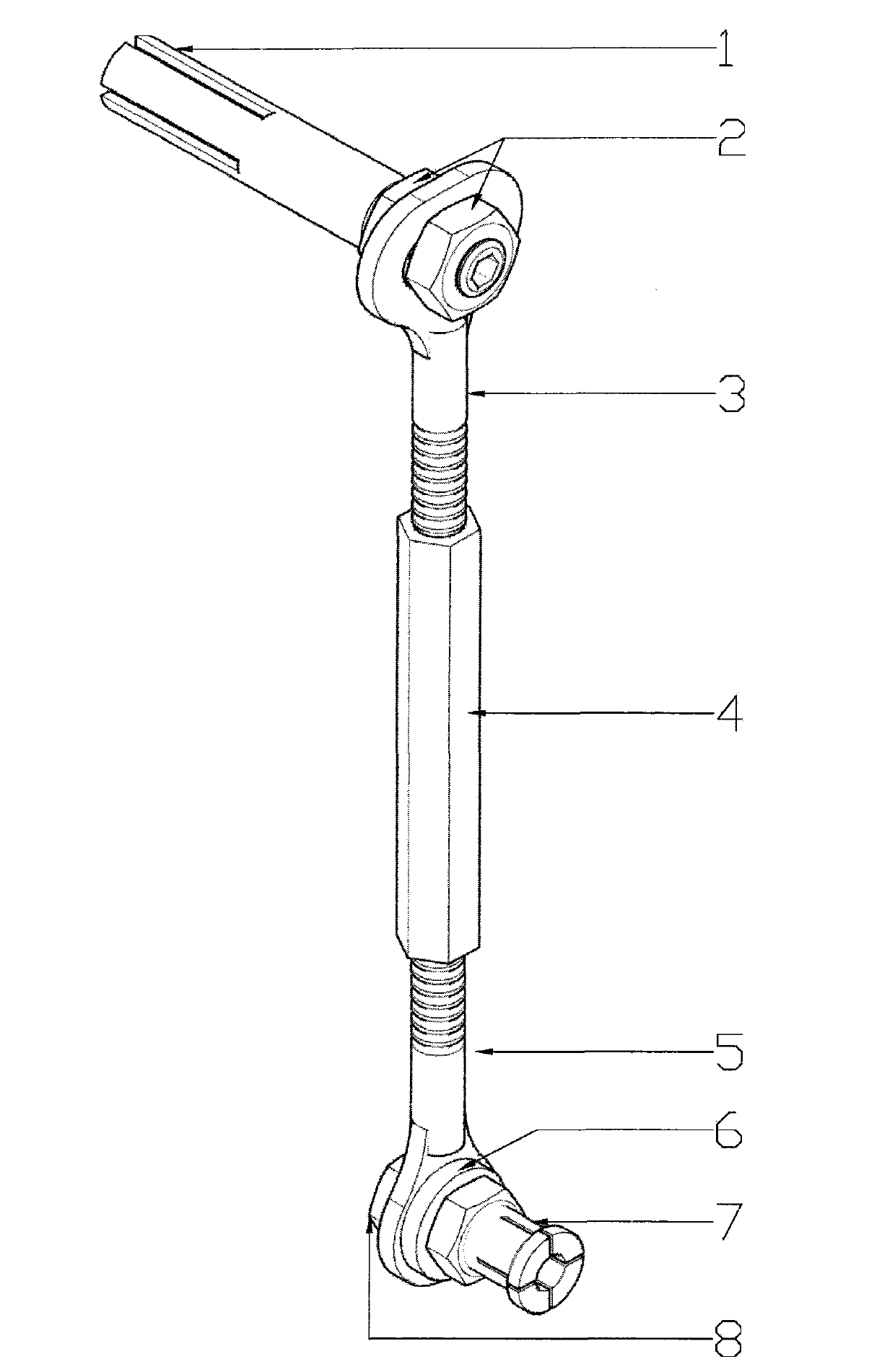

Method for paving and sticking stone materials or ceramic tiles

The invention provides a construction method for paving and sticking stone materials or ceramic tiles on a wall or floor. The construction method comprises the following steps: sticking an extruded sheet on the back of a plate to be paved and stuck in advance and mounting stainless steel back bolts; sticking and hanging materials to be paved and stuck on the wall by using adhesive and hanging pieces so as to achieve a firm paving and sticking effect.

Owner:陈晓通

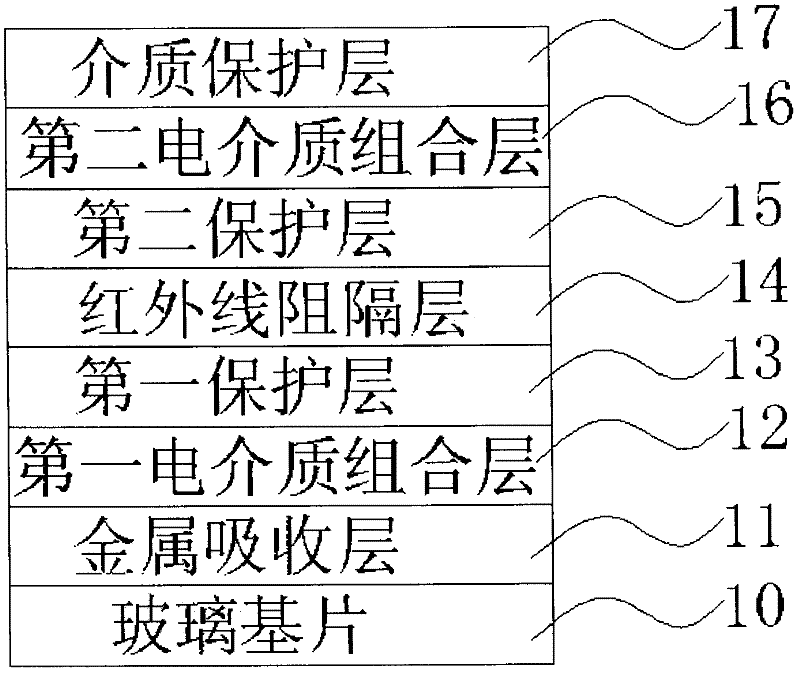

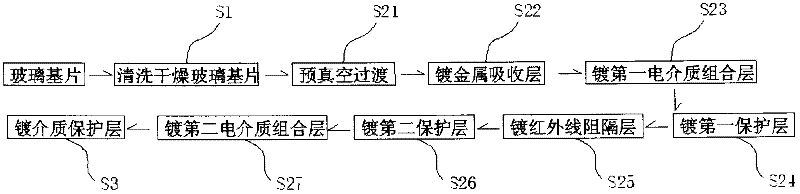

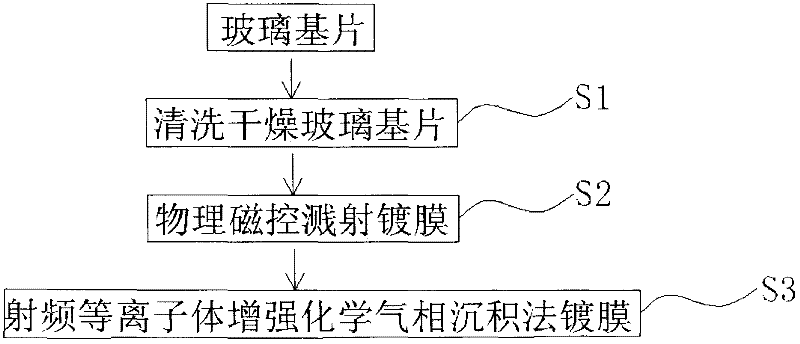

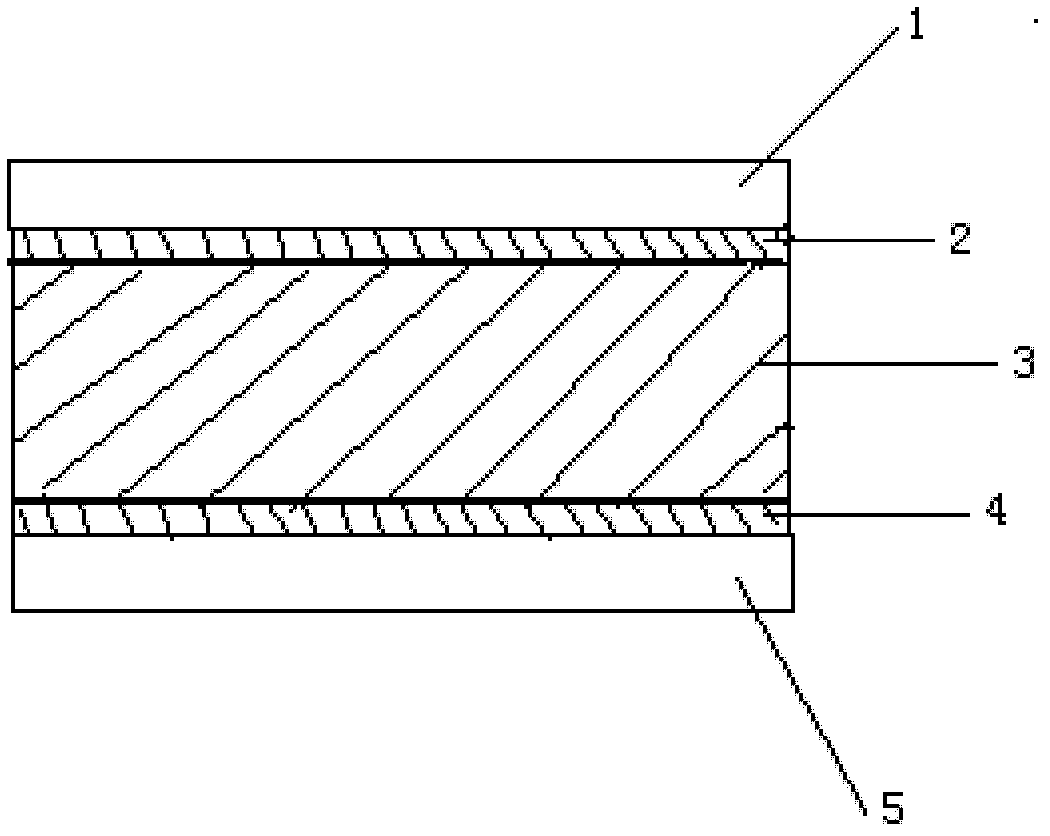

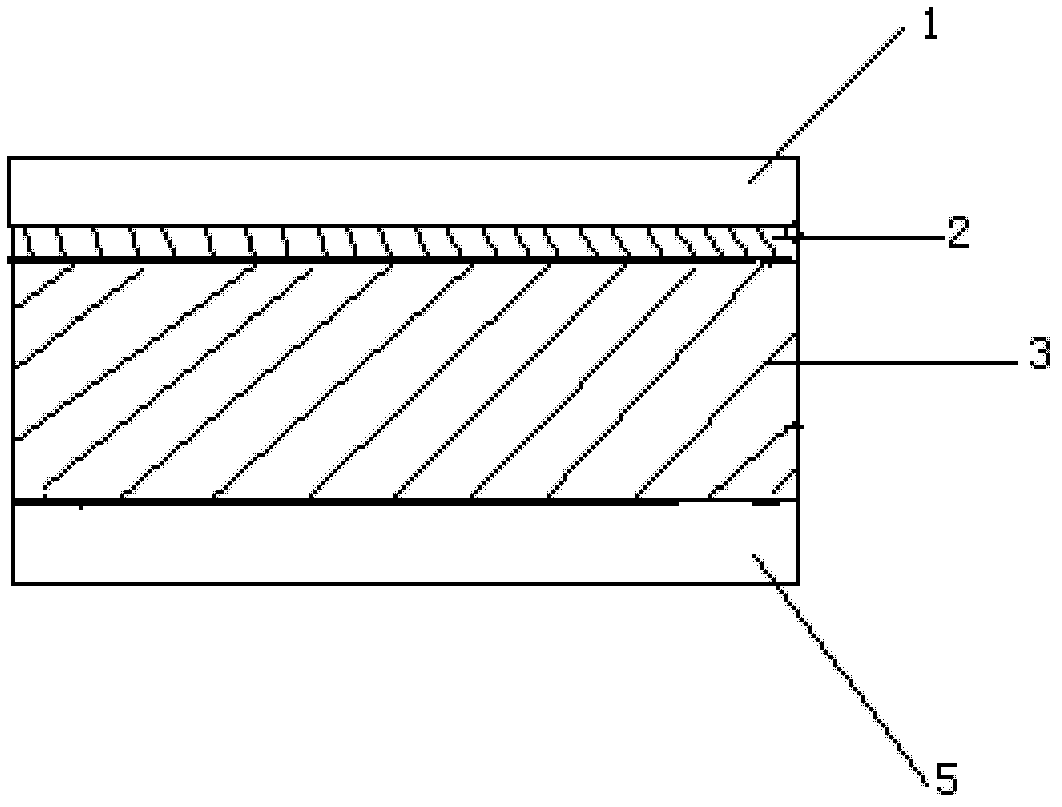

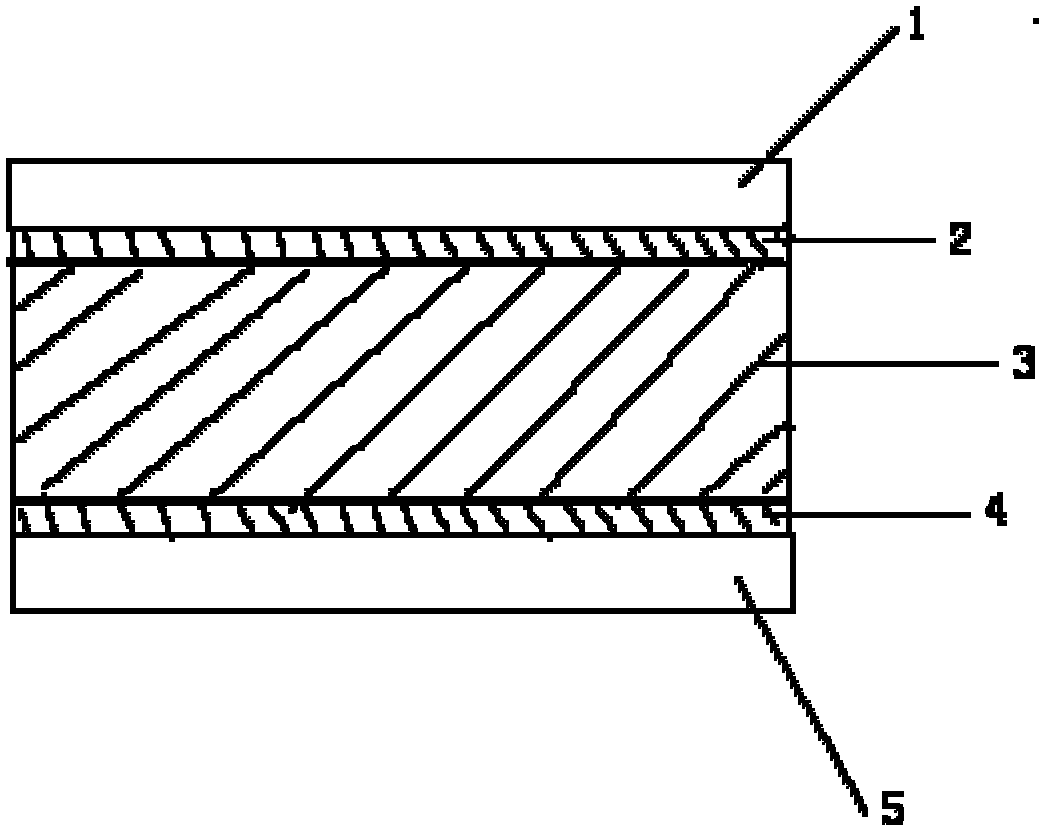

Enhanced protection type toughened low-radiation coated glass and manufacturing process thereof

InactiveCN102529209APromote absorptionReduce reflectionVacuum evaporation coatingSputtering coatingLight pollutionOptical transmittance

A medium protecting layer is added to the outermost layer of ordinary low-radiation coated glass to serve as an enhanced protecting layer so that the ordinary low-radiation coated glass has high chemical stability, abrasion resistance and oxidation resistance and low friction coefficient and particularly improves scratch resistance, toughened low-radiation coated glass is convenient and simple to transport and process, and the finished product rate of production is greatly improved. In particular, the lowered processing requirements enable more small glass deep-processing enterprises to produce the low-radiation coated glass, and a foundation is established for popularization of environment-friendly energy-saving products. In addition, a metal absorbing layer is first coated on the glass, reflectivity of coated products can be greatly reduced, the problem of light pollution of the toughened low-radiation coated glass with low light transmittance is solved, and the toughened low-radiation coated glass products can meet the requirements of the market at present.

Owner:林嘉宏

Composite health care pad and manufacture method thereof

InactiveCN102514257AGuaranteed performanceGuaranteed breathabilityStuffed mattressesLamination ancillary operationsFiberSurface layer

The invention discloses a composite health care pad, which comprises a middle layer, wherein an upper surface layer and a lower surface layer are respectively arranged on the upper surface and the lower surface of the middle layer, a layer of blocking layer is respectively arranged between the middle layer and the upper surface layer and / or between the middle layer and the lower surface layer. The upper surface layer and the lower surface layer are non-woven layers containing 5%-50% low-melting-point fibers, and the middle layer is a non-woven layer containing the following components: fibrilia and 5%-50% of low-melting-point fibers. The blocking layers are non-woven layers containing 5%-100% of fibrilia, and the content of fibrilia in the composite health care pad ranges from 5% to 65%. The invention further discloses a manufacture method of the composite health care pad, which includes the following steps: respectively manufacturing the middle layer, the upper surface layer, the lower surface layer and the blocking layers, sequentially overlaying all the layers, and carrying out procedures including drying in a drying oven, cold rolling, cooling, cutting, inspection and packing. The composite health care pad and the manufacture method thereof solve the problems that the existing mattress can become damp and mildewed easily, can be damaged by worms, is apt to be layered, and is poor in ventilation and inconvenient to use caused by the fact that hard fibers in the middle of the mattress prick out.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

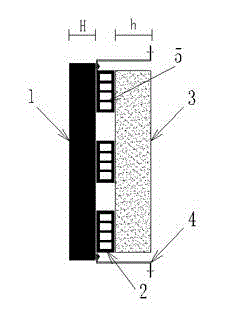

Wall thermal insulation core plate and production method thereof

ActiveCN102875083ASimple processEasy constructionClimate change adaptationInsulation improvementFiberCompression molding

The invention relates to a thermal insulation core plate and a preparation method thereof. The thermal insulation core plate comprises 15 to 75 wt% of superfine silicon dioxide powder, 24 to 84 wt% of filler, 0 to 35 wt% of inorganic core material, 1 to 20 wt% of inorganic fiber, 0 to 3.5 wt% of getter and 0 to 2.8 wt% of vacuum stabilizer. The preparation method for the thermal insulation core plate comprises the following steps: (1) mixing, (2) drying, (3) formation of core material, (4) compression molding, (5) packaging and the like.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

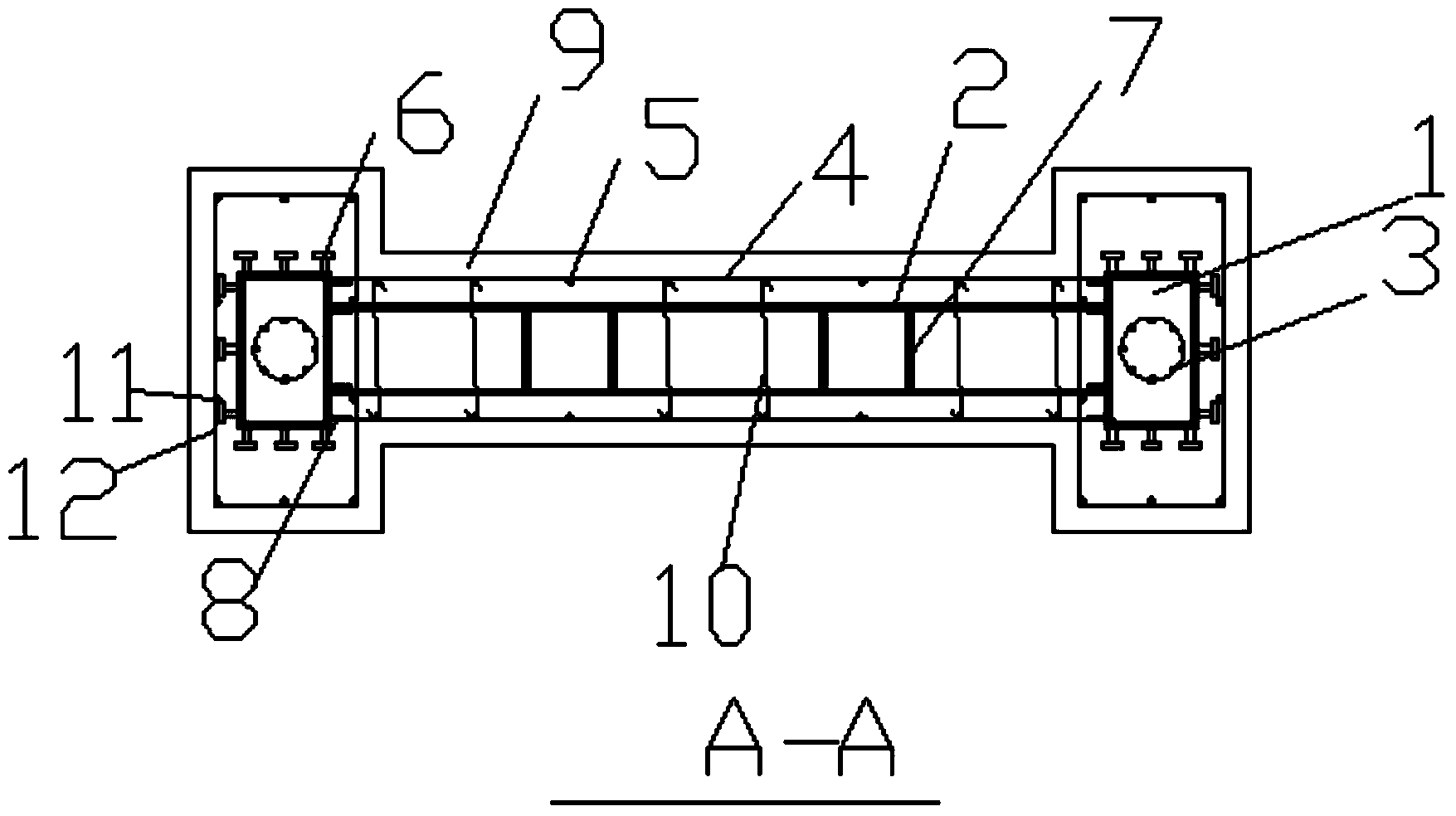

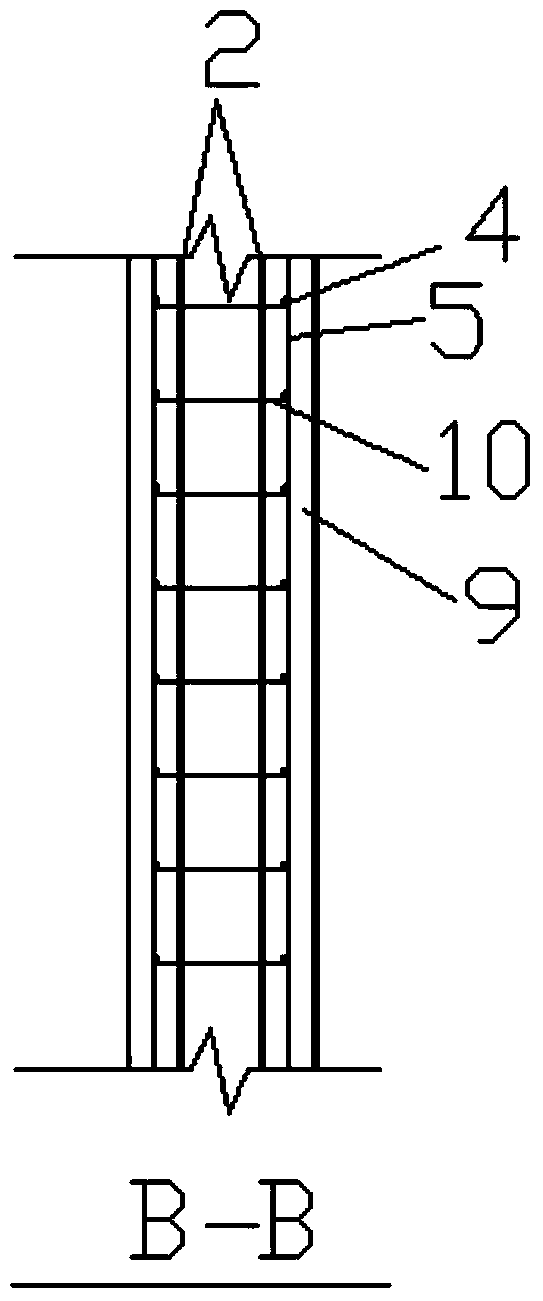

Built-in and multi-cavity double steel plate and concrete filled steel tubular column combined shearing wall and manufacturing method

ActiveCN103726594AReasonable structureExcellent performanceWallsBuilding material handlingRebarSteel plates

The invention discloses a built-in and multi-cavity double steel plate and concrete filled steel tubular column combined shearing wall and a manufacturing method, and relates to the field of the construction technology. According to the built-in and multi-cavity double steel plate and concrete filled steel tubular column combined shearing wall, cast-in-place reinforced concrete, a steel plate shearing wall and a concrete filled steel tube are combined into the combined shearing wall. A plurality of transverse steel plates are arranged between the double steel plates to form a multi-cavity structure between the double steel plates. Bar-mat reinforcements formed by transversal distributed bars and longitudinal distributed bars arranged on the two sides of the combined multi-cavity steel plates are connected through stretching bars. Compared with an existing shearing wall, the built-in and multi-cavity double steel plate and concrete filled steel tubular column combined shearing wall has the advantages of being large in initial rigidity, high in bearing capacity, slow in bearing and rigidity attenuation, good in overall anti-seismic and energy consumption performance and relatively stable in later anti-seismic property of the wall.

Owner:BEIJING UNIV OF TECH

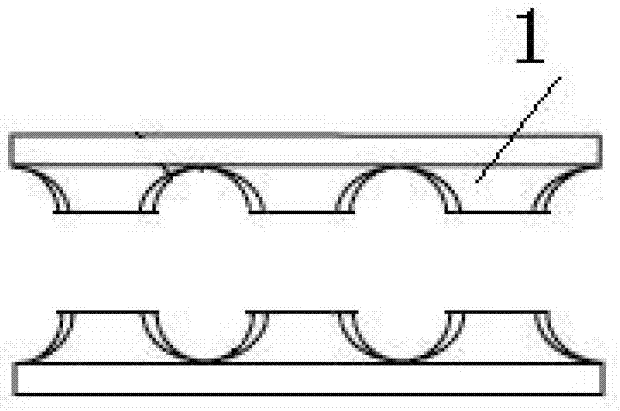

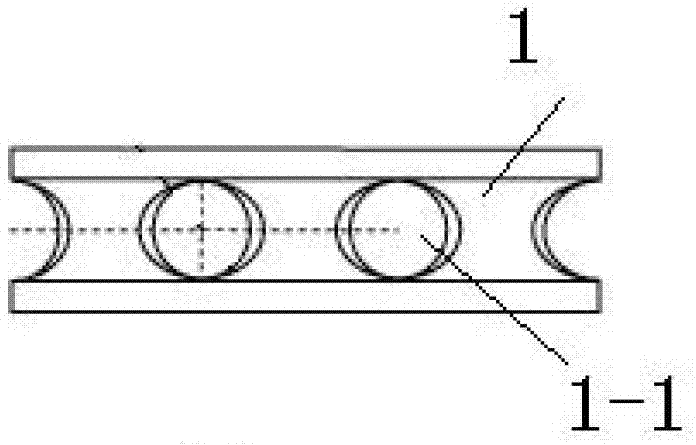

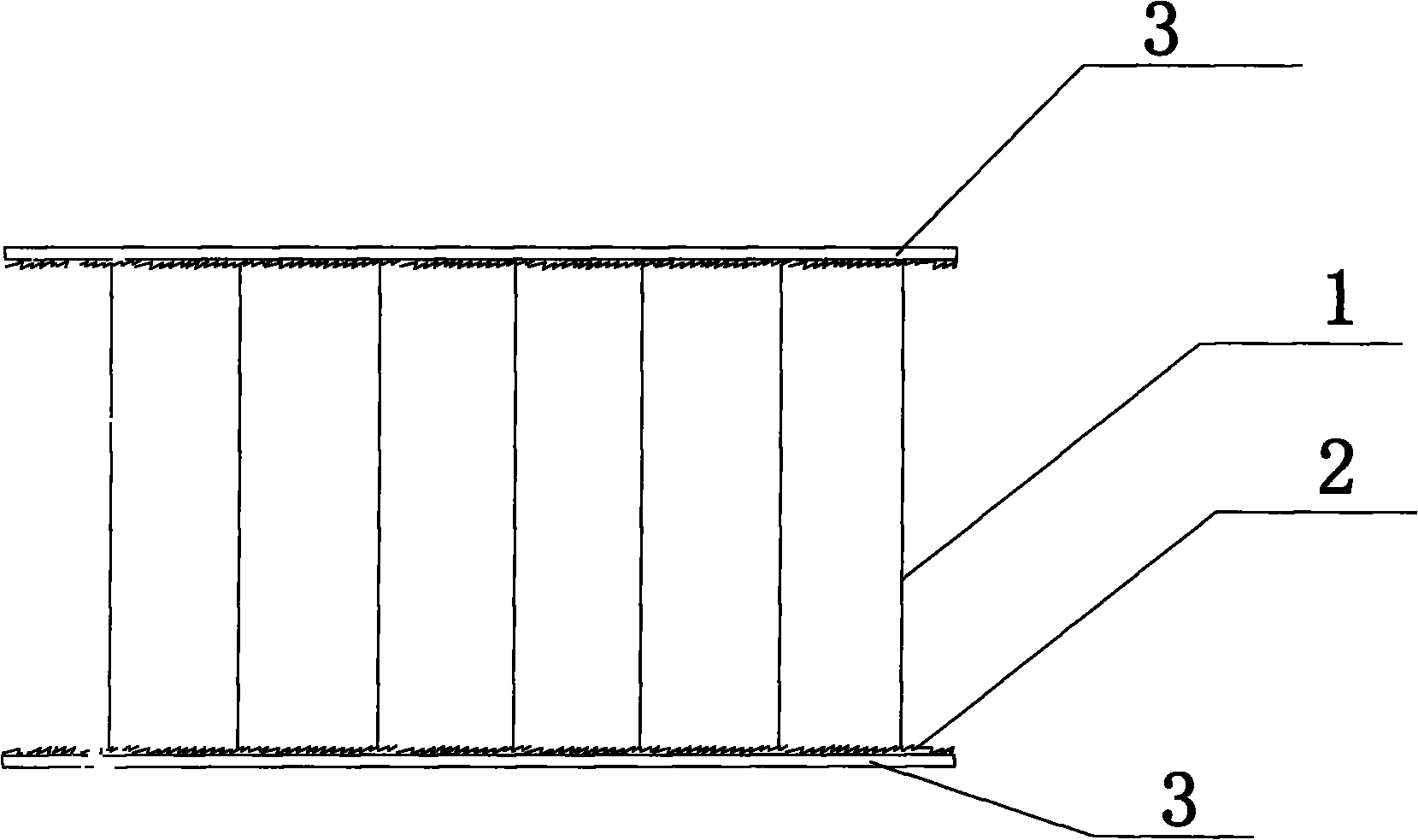

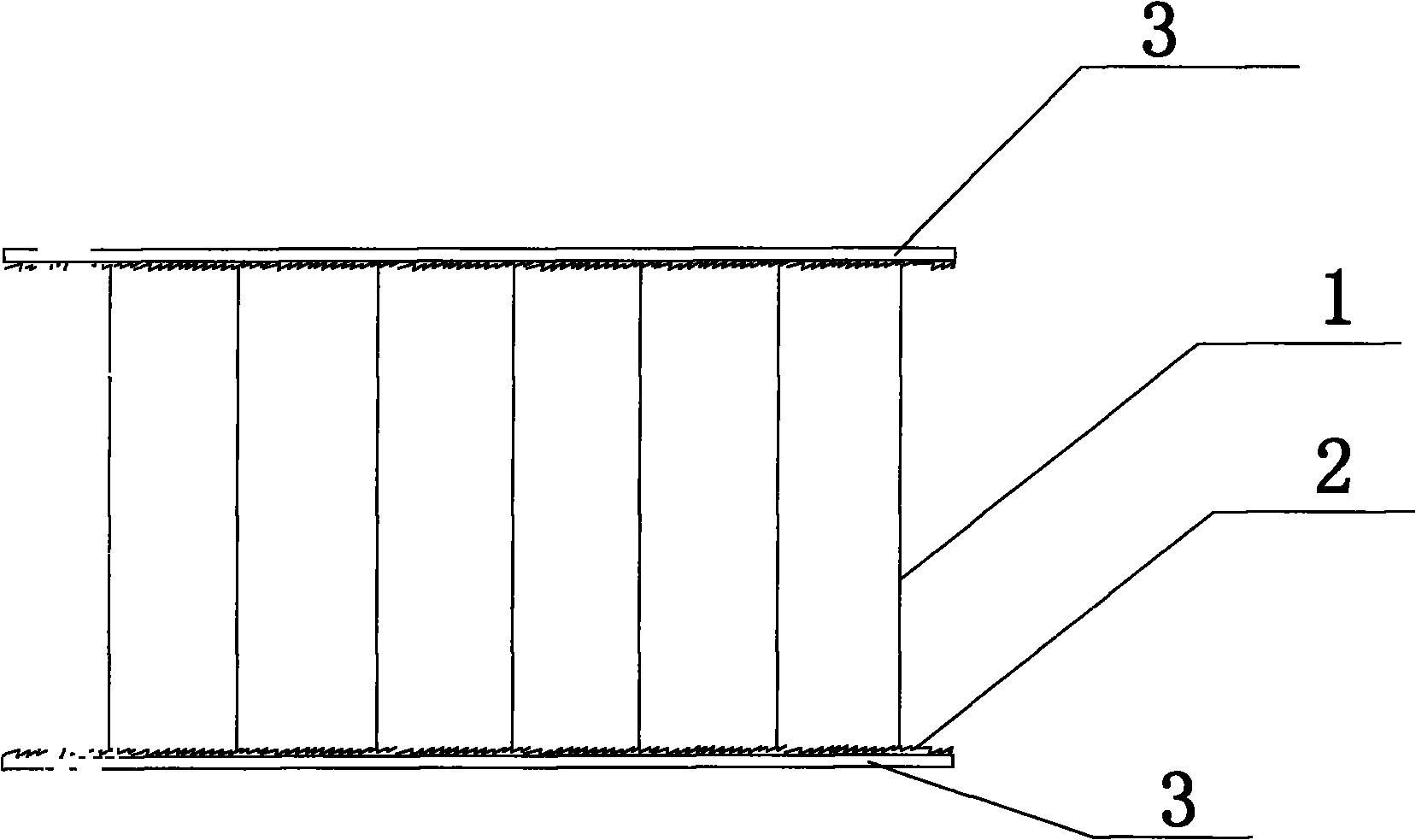

Cement polyphenyl granule concrete lattice composite wall shuttering, its manufacturing method, lattice composite wall and its manufacturing method

InactiveCN102731031AWith insulationWith sound insulationWallsBuilding material handlingReinforced concreteSlag

Disclosed are a cement polyphenyl granule concrete lattice composite wall shuttering, its manufacturing method, a lattice composite wall and its manufacturing method. The invention relates to the lattice composite wall shuttering, its manufacturing method, the lattice composite wall manufactured by the use of the shuttering and the manufacturing method thereof, so as to solve disadvantages of complicated operational processes and inflammable insulation materials in the prior art. The above purpose is realized by the following scheme: the shuttering comprises components of polyphenyl granules, cement, fly ash or slag, a shuttering bonding agent and water; the components are mixed with stirring to prepare a mixture of cement and polyphenyl granules; the shuttering bonding agent is diluted by the use of water, the solution of the shuttering bonding agent is added into the above mixture of cement and polyphenyl granules with stirring, the mixture is poured into a die, followed by compacting into half-plate cement polyphenyl granule concrete lattice composite wall shutterings; the two half plates undergo buckling and butt joint, and the composite wall is composed of the composite wall shuttering and a reinforced concrete core; and the several cement polyphenyl granule concrete lattice composite wall shutterings are respectively spliced in both vertical and transverse directions, steel bar is mounted in a core aperture, and self-compacting concrete is poured.

Owner:葛兆明 +1

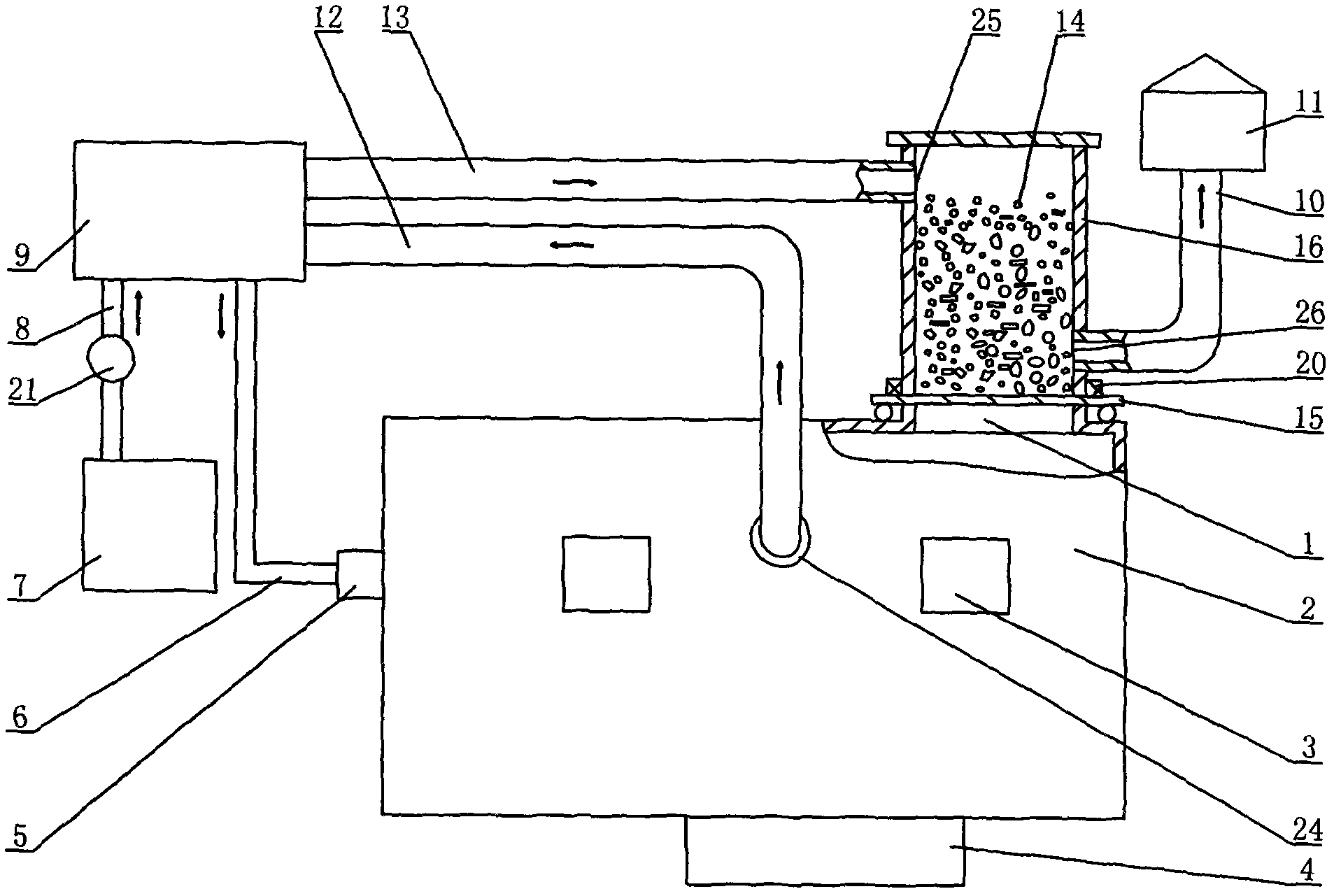

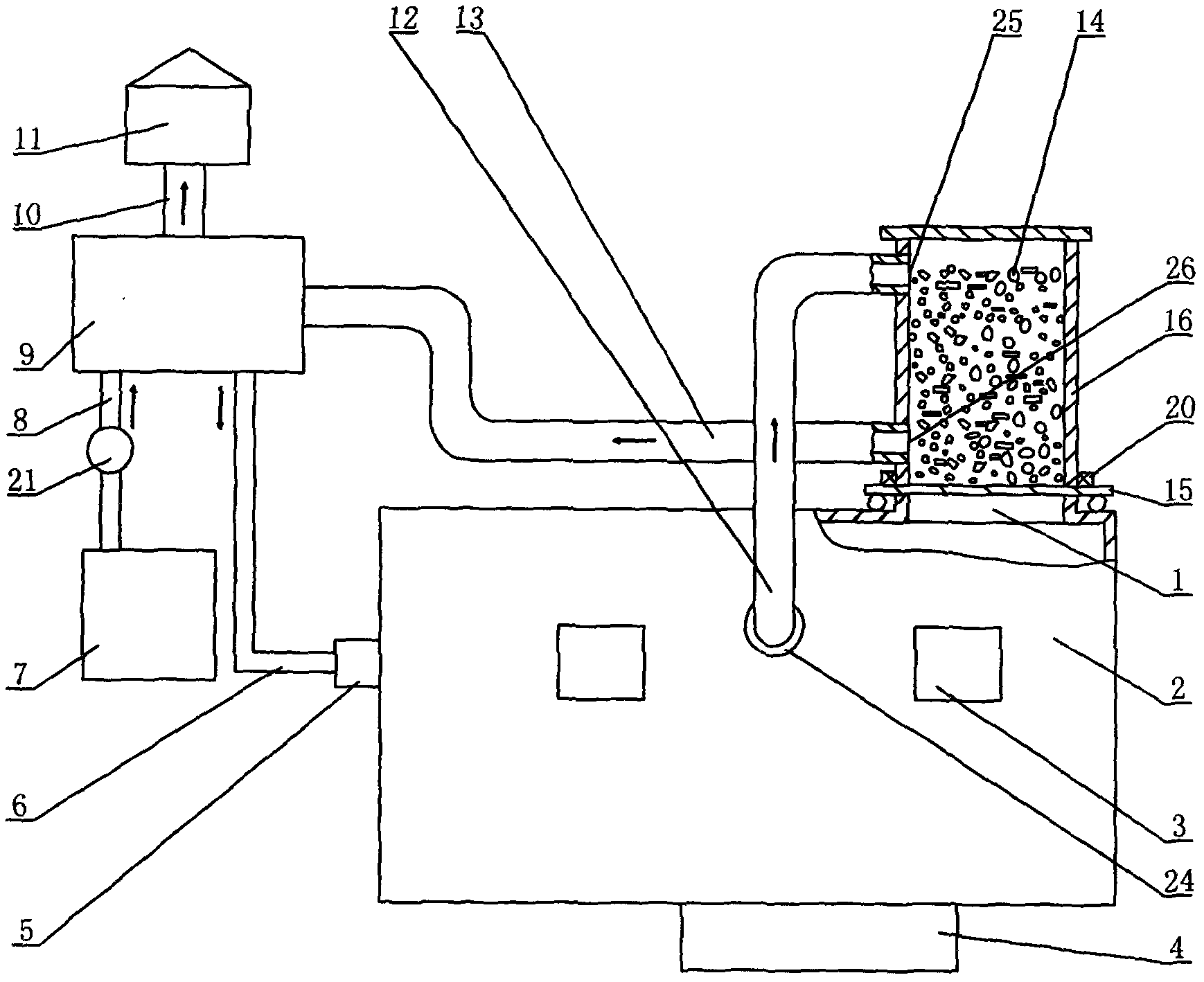

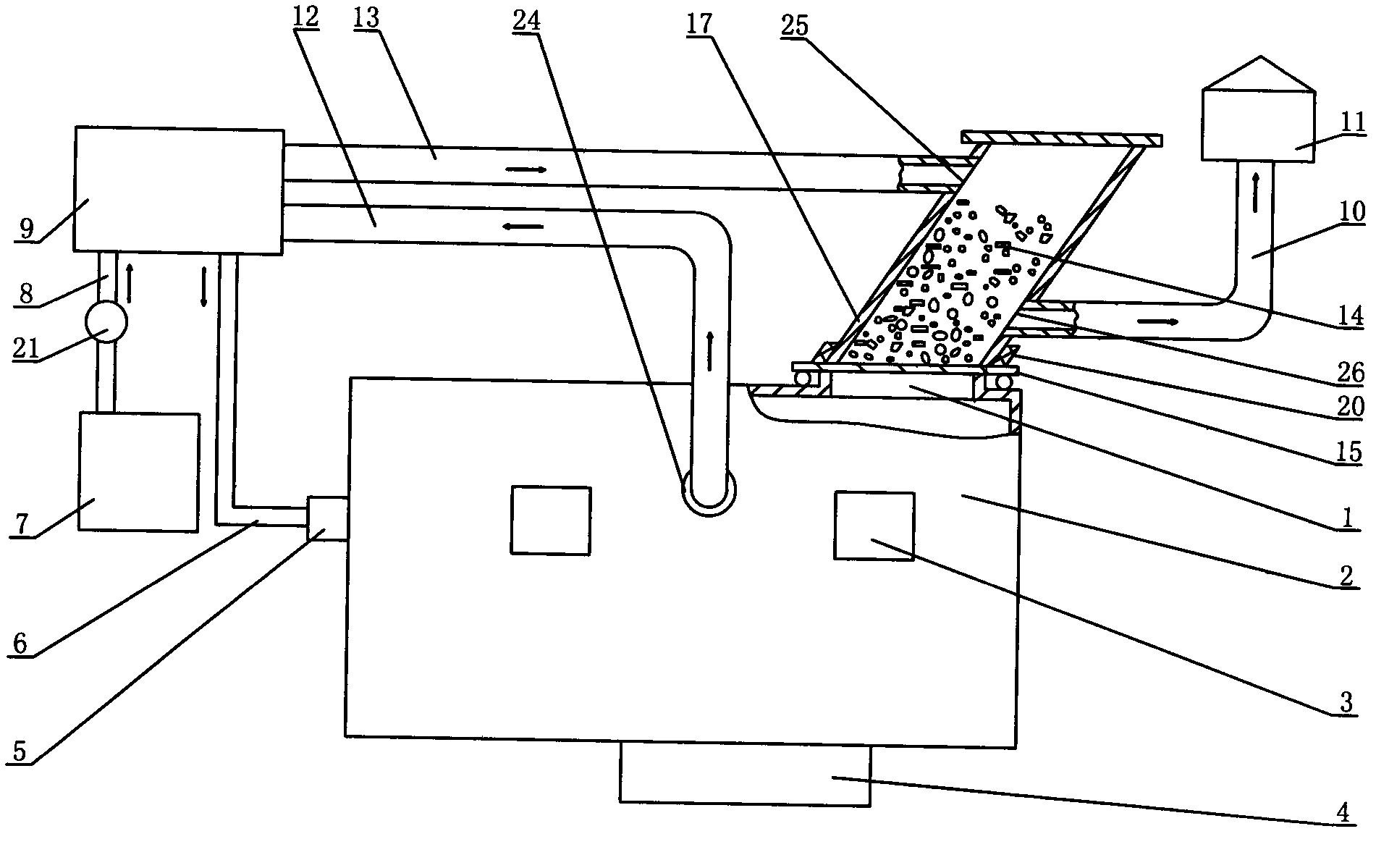

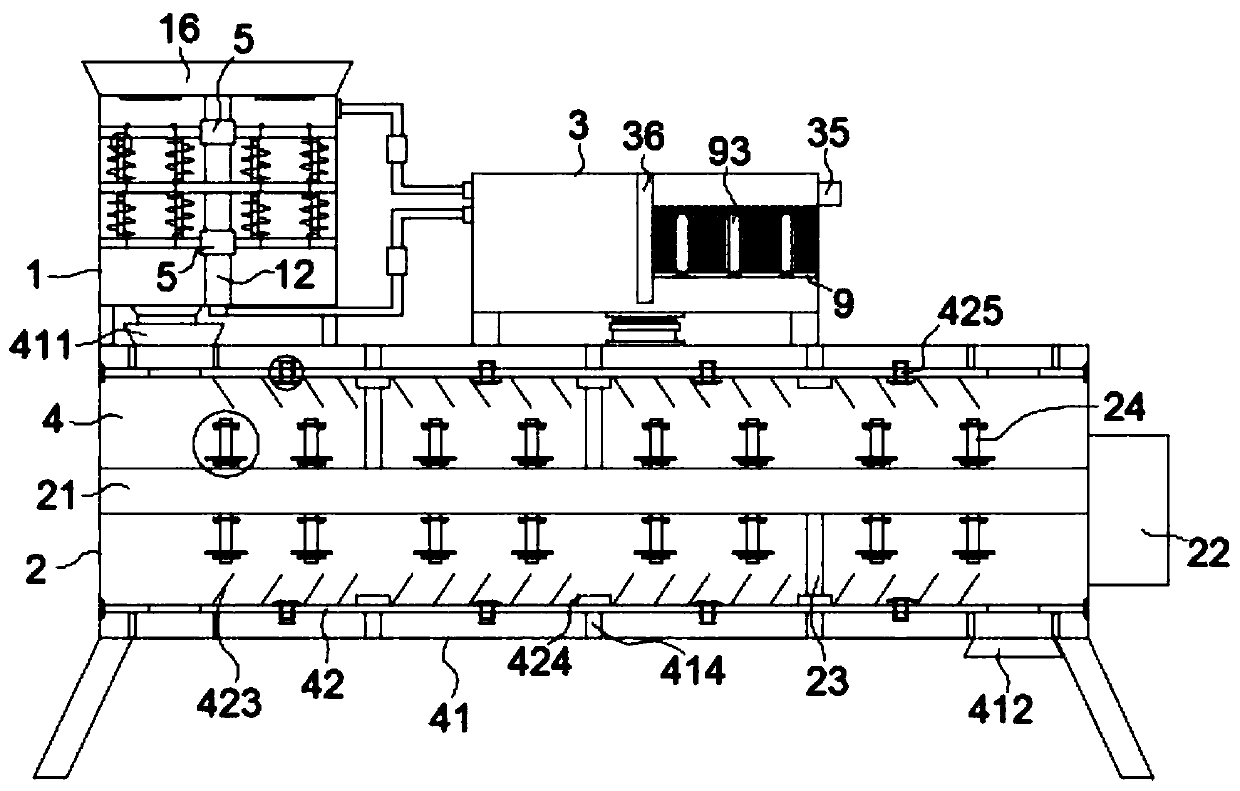

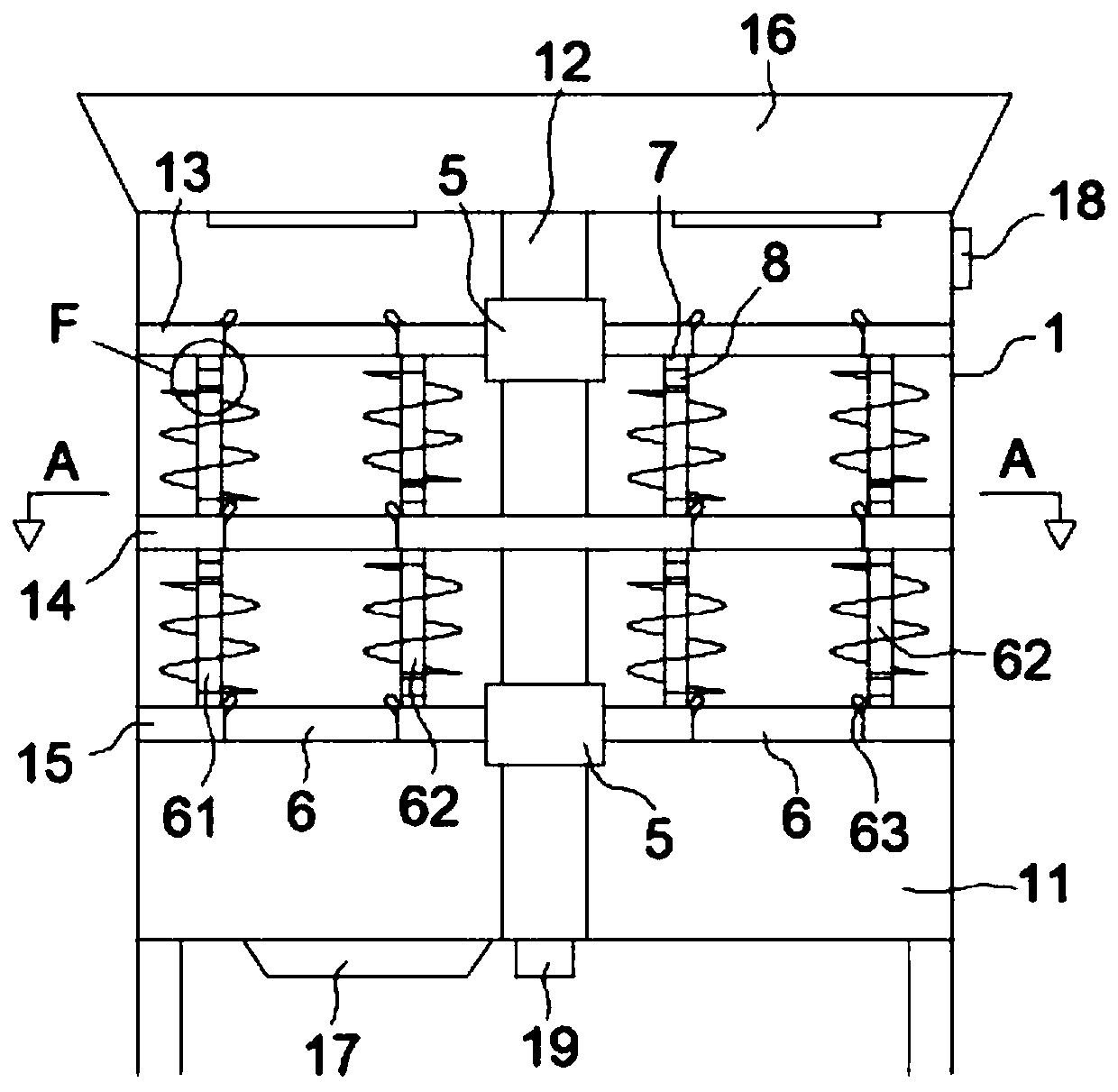

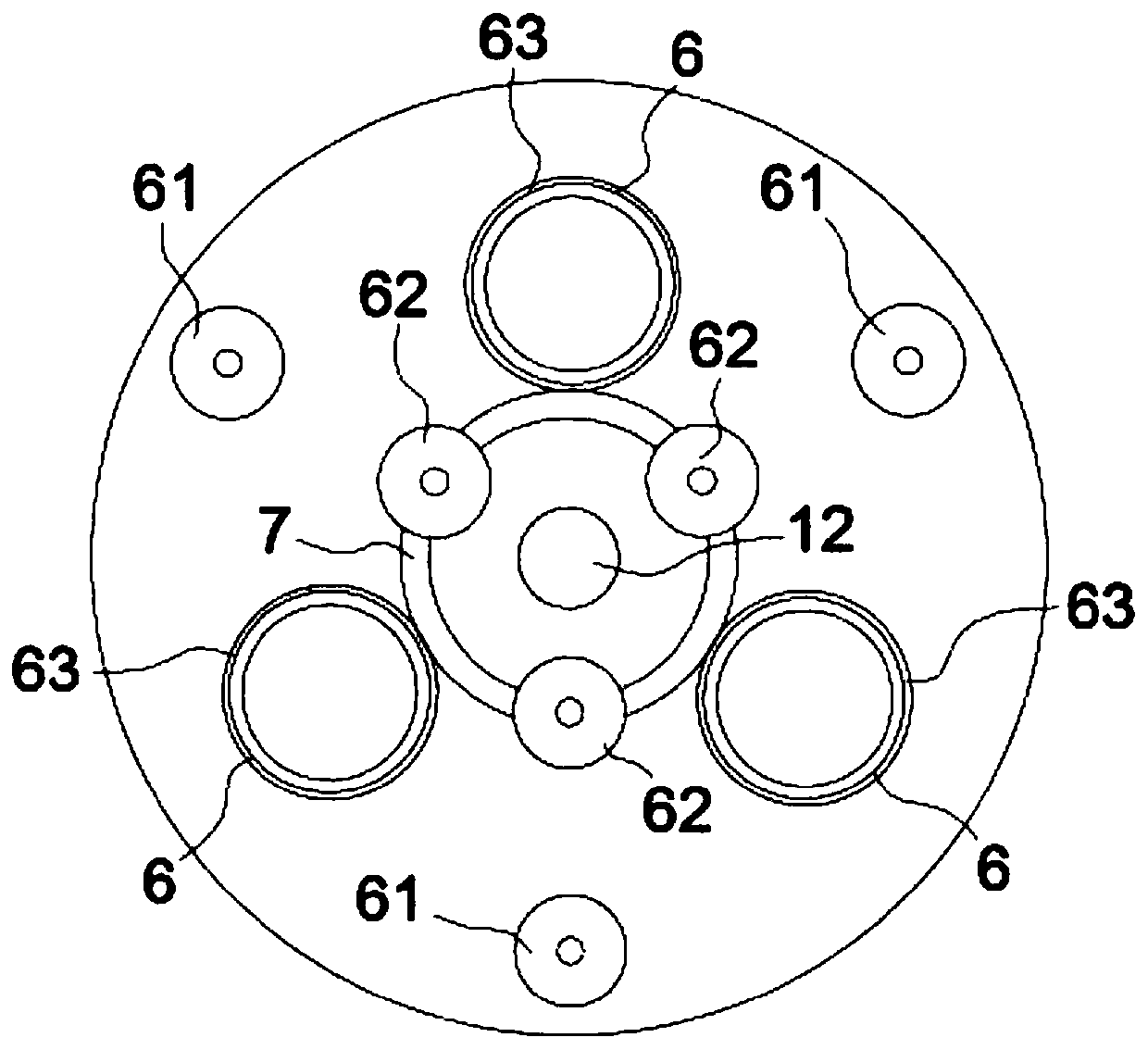

Industrial furnace for non-ferrous metal smelting

InactiveCN102620554AAvoid getting lostFull conversionPreheating chargesWaste heat treatmentNon-ferrous extractive metallurgyExcess heat

The invention discloses an industrial furnace for non-ferrous metal smelting. The industrial furnace comprises a hearth (2), a feed tube, a combustor (5) and a heat exchanger (9), wherein a low-temperature air pipeline (8) is connected between the heat exchanger (9) and a fan (7), a high-temperature air pipeline (6) is connected between the heat exchanger (9) and the combustor (5), a hearth furnace gas outlet (24) is formed on the hearth (2), the feed tube serves as one part of a heat exchange system, and a furnace gas pipeline connects the hearth furnace gas outlet (24), the heat exchanger (9) and the feed tube into a whole. According to the invention, the feed tube can utilize excess heat of waste furnace gas to preheat furnace materials (14) to be melted, and loading process is performed in a closed space, thereby preventing a great deal of heat in the furnace from being lost and greatly reducing the temperature of the waste furnace gas discharged into the atmosphere, therefore, the preheated furnace materials (14) can be quickly melted in the hearth (2) so as to achieve the aims of high efficiency, low energy consumption and low aluminum loss.

Owner:MEISHAN ZHONGNENG ALUMINUM

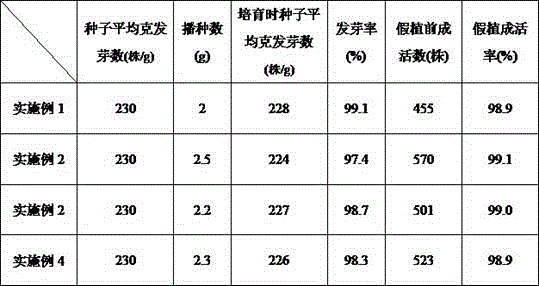

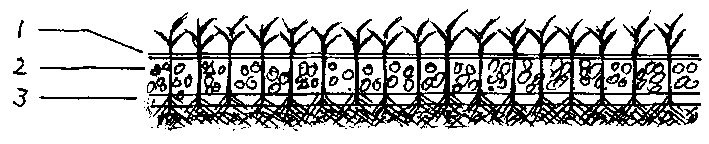

Sugarcane seedling culture method

ActiveCN105660099ALight textureIncrease the content of trace elementsGrowth substratesCulture mediaGreenhouseSeedling

The invention relates to a sugarcane seedling culture method. The method comprises the steps of preparing sugarcane seedling culture matrix, laying the sugarcane seedling culture matrix, sowing seeds, and moving a sowing frame to a greenhouse provided with a sunshade net and peripherally covered with thin film to perform seedling management. According to the method, the matrix is rich in nutrition, the seedling culture operation is simple, the seedling culture cost is low, and the method can be popularized and used on a large scale. According to the sugarcane seedling culture method, the average germination rate of seeds reaches 98.4%, the average survival rate of temporary planting reaches 99.0%, and obtained sugarcane seedlings are robust and excellent.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

Bag for holding animal's dung, device and wearing article combined with the same

InactiveCN1833489AEliminate troubleEasy to cleanAnimal housingOther apparatusFecesBiomedical engineering

A dung / urine bag for recepting the dung and urine of animal has an opening matched with the dung / urine escapement, and a soft holder with a through hole and several tying belts for linking it with the clothing of animal.

Owner:曾天赐

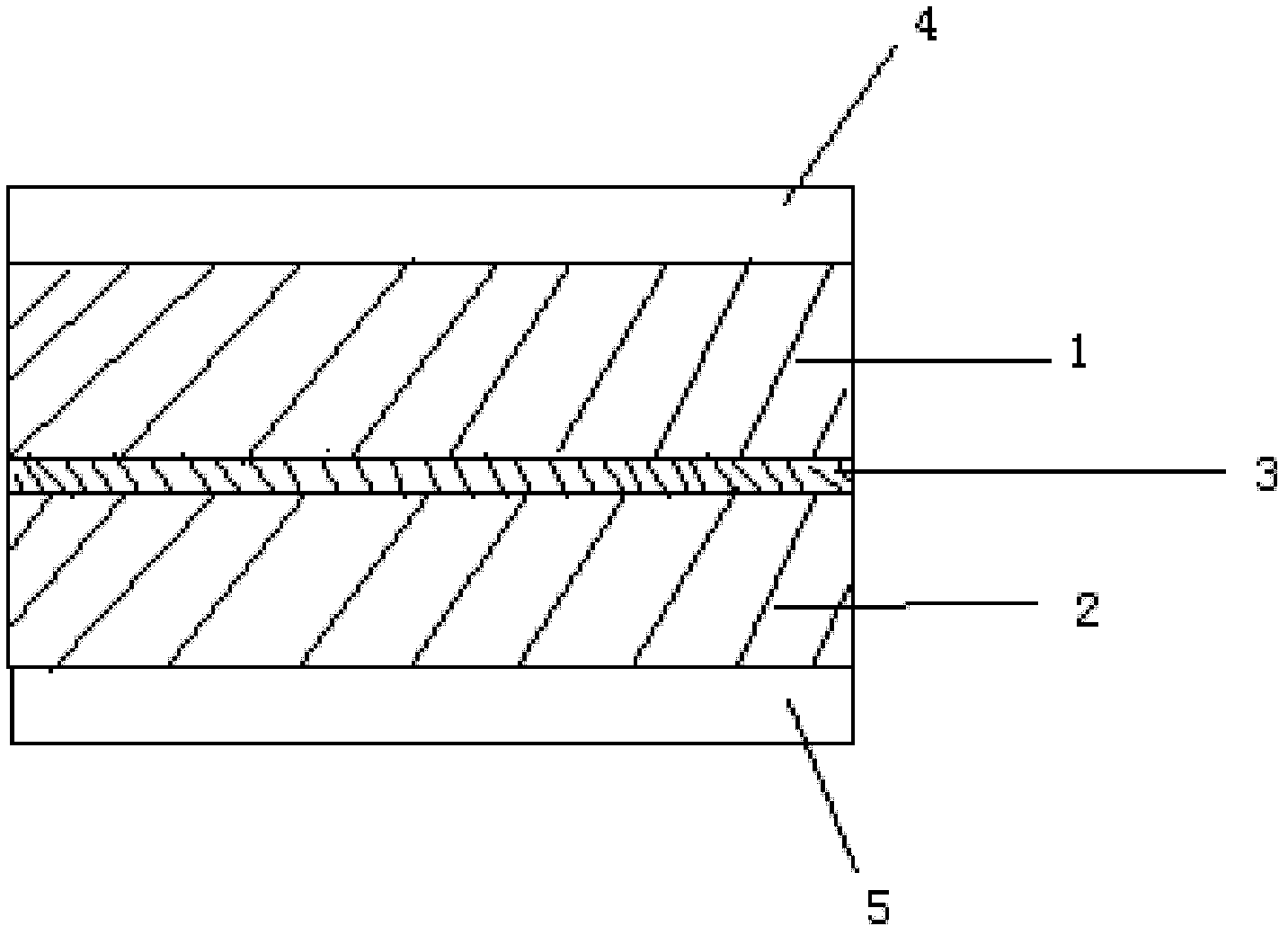

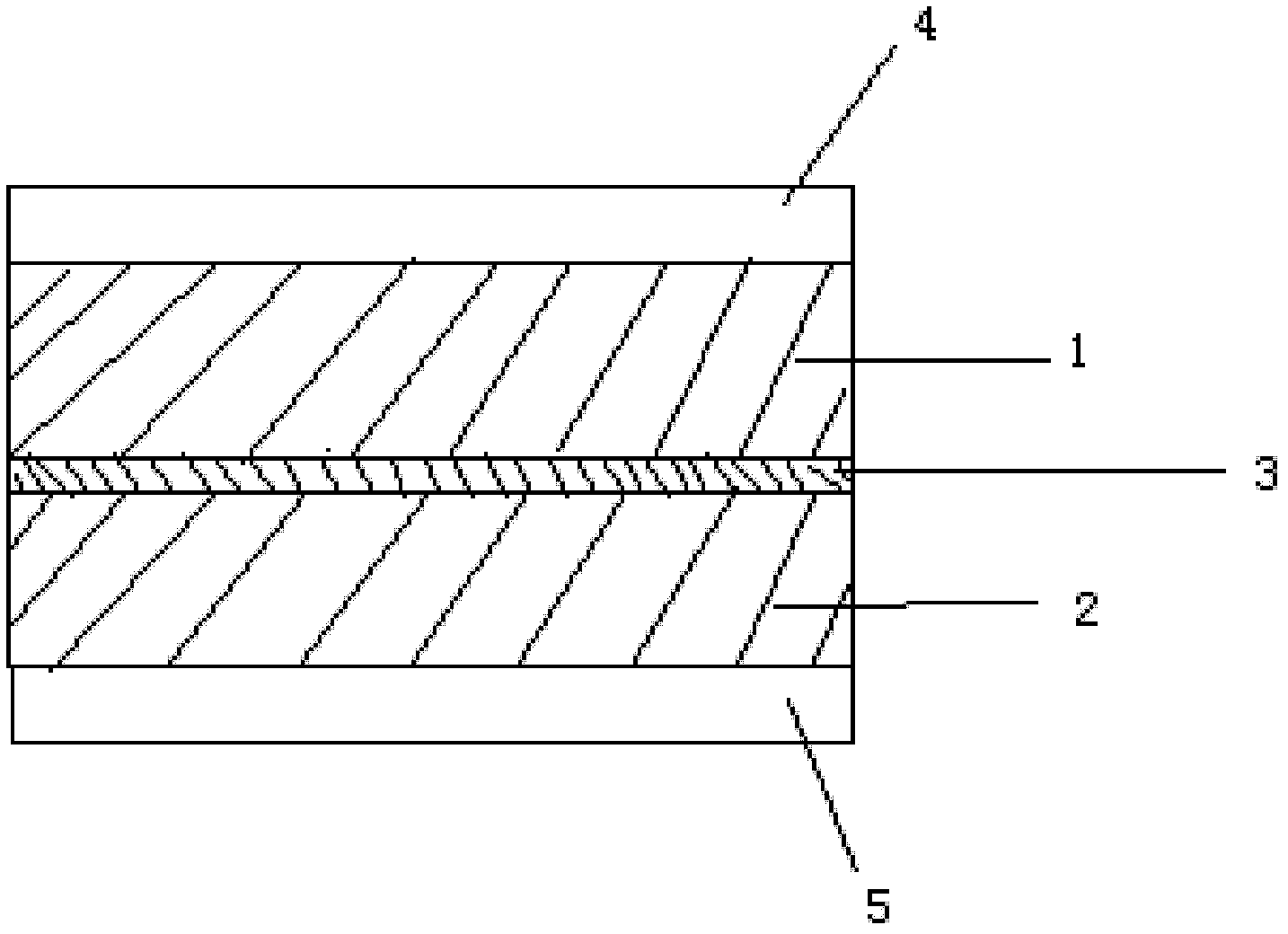

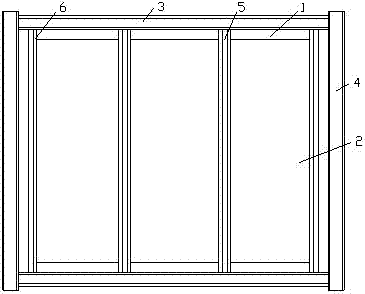

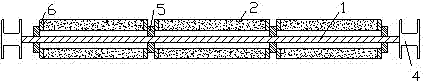

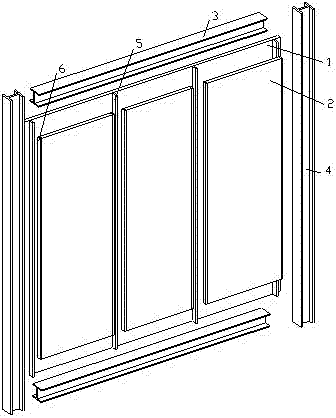

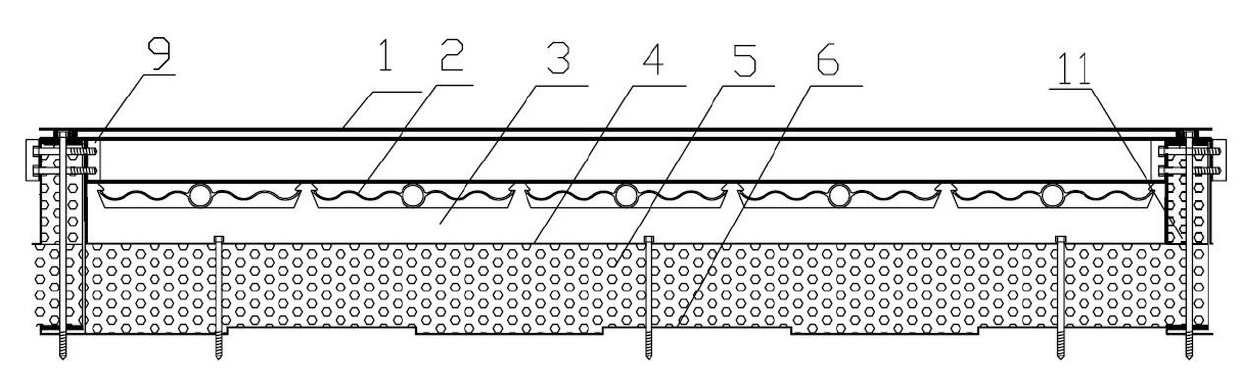

Metallic face sandwiched composite board and assembled composite wall panel

ActiveCN101338607AGuaranteed effectPlay a sealing roleBuilding componentsFixed frameThermal insulation

The invention relates to a metal-surface sandwich composite board and assembly composite wall board which comprises two or more pieces of metal-surface sandwich composite board arranged on a fixing frame. Each composite board is provided with two matching terminals which are opposite, wherein, one is an inserting groove terminal, and the other is an inserting head terminal. At the inserting groove terminal, the end of an external face plate is bent inward to form a fixing platform which is slightly lower than the board surface of the composite board; the wall surface of the end of the external face plate, the wall surface of the end of an internal face plate and the end surface of a sandwich layer form an inserting groove. At the inserting head terminal, the end of the external face plate is bent to from a platform which is slightly lower than the board surface of the composite board; and the wall surface of the end of the external face plate, the wall surface of the end of the internal face plate and the end surface of the sandwich layer form an inserting head which is matched with the inserting groove. Two adjacent composite boards are assembled together by jointing the inserting groove of one composite board with the inserting head of the other composite board; an installing groove is formed at the place of the joint; and in the installing groove, a decoration sealing buckle plate is arranged in a buckling way to play the sealing, decorating and thermal-insulation function.

Owner:HENAN TIANFON ENERGY SAVING PANEL SCI & TECH

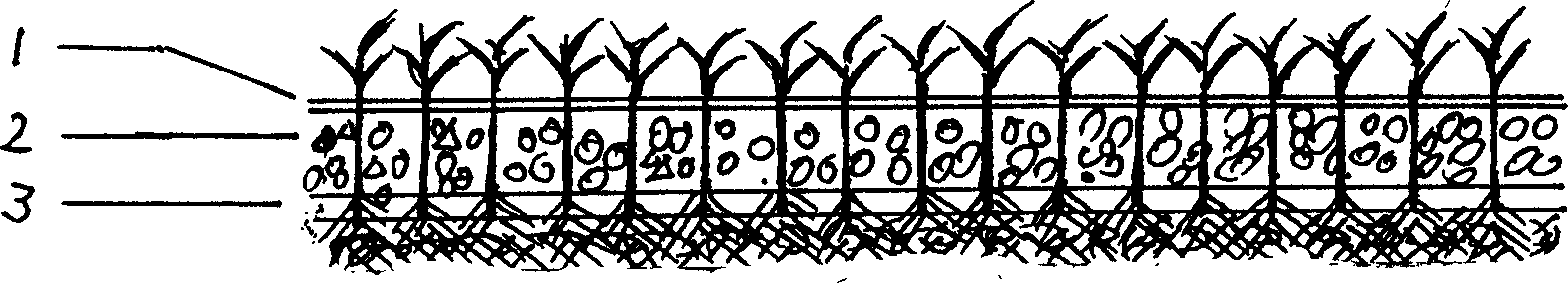

Organic soilless lawn blanket and rapid producing method thereof

InactiveCN1488238AEnhance resiliencePromote growthAgriculture gas emission reductionCultivating equipmentsGreenhouseVegetative reproduction

The invention discloses an organic no-earth lawn blanket and the quick growth method. The lawn blanket comprises grass and two layers of organic non-woven fabric with different thickness. It mainly makes the combination of accelerating germination before seeding and simple greenhouse earth protecting production form on grass seeds or nutritive breeding body, not only to avoid influence of outside bad climate, but also create more proper growth condition, largely shortening production period (by about 50%), enhancing the whole benefit and reducing production cost by 40%-50%.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

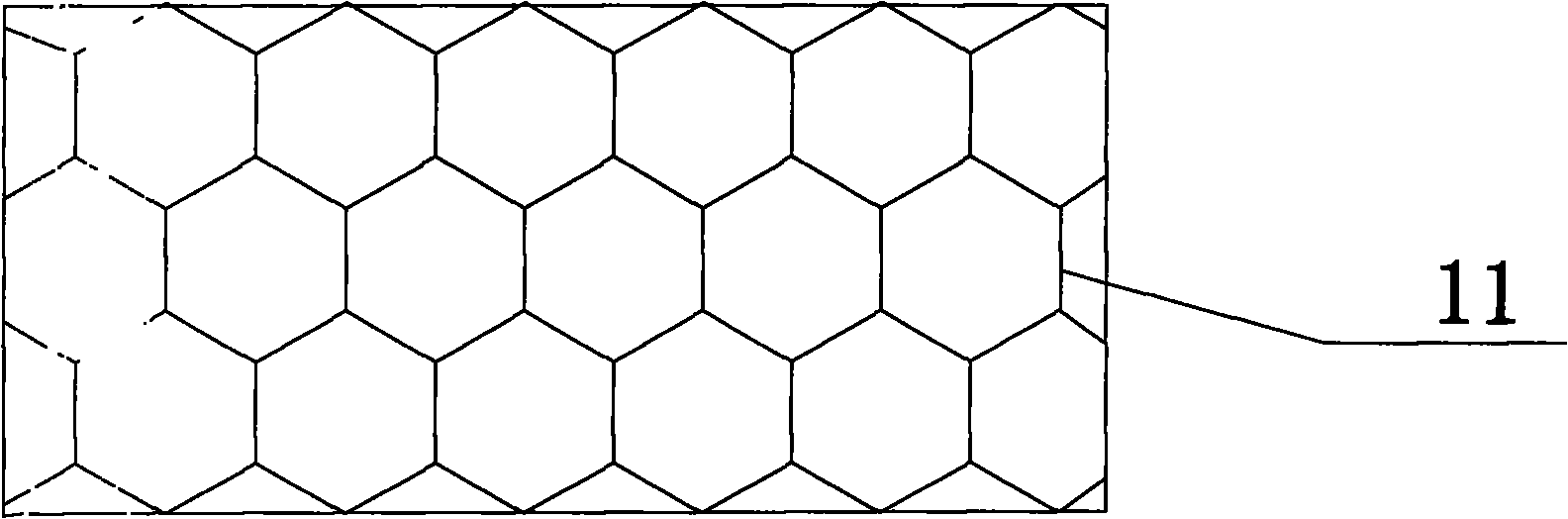

A kind of high-strength polyester fiberglass honeycomb composite board and its production process

InactiveCN102261162AHigh tensile strengthStop the flowConstruction materialCovering/liningsPolyesterThermal insulation

The invention discloses a high-strength polyester glass fiber honeycomb composite board and its production process, which comprises a three-layer structure, the middle layer is a hexagonal honeycomb core; the upper and lower sides of the hexagonal honeycomb core are provided with thin steel wire mesh; The upper and lower sides of the wire mesh are provided with polyester fiberglass boards. The invention adopts the anti-bending principle of the reinforced concrete slab, that is, on the basis of the polyester fiberglass honeycomb composite slab, a thin steel wire mesh with tensile effect is added on both sides, similar to the steel bars in the reinforced concrete slab, so that the polyester fiberglass honeycomb The tensile strength of the composite board has been doubled, and it is used for marine floors, building scaffolding, formwork, etc. Its tensile, bending and impact resistance properties are superior to ordinary boards, and it is light in weight and has a long service life. Obtaining the maximum force with the smallest material is an incomparable feature of other materials, and it is the preferred lightweight material in the construction industry at present. Because the honeycomb core in the honeycomb composite panel is divided into many closed cells, the air flow is prevented, and the heat and sound waves are greatly hindered. Therefore, it has the effect of heat insulation, heat preservation and sound insulation, and the installation is convenient and fast.

Owner:青岛同力得塑料蜂巢有限公司

Composite environmental-friendly cushion and preparation method thereof

InactiveCN102514258AGuaranteed performanceGuaranteed breathabilityStuffed mattressesLamination ancillary operationsFiberSurface layer

The invention discloses a composite environmental-friendly cushion which comprises a middle layer and upper and lower surface layers. The middle layer comprises a first middle layer, a second middle layer and a bonding layer. The upper and lower surface layers are non-woven layers comprising 5 percent to 50 percent of low melting point fibers. The first and second middle layers are non-woven layers which respectively comprise the following components: bastose and 5 percent to 50 percent of low melting point fibers. The bonding layer mainly consists of the low melting point fibers. In the whole composite environmental-friendly cushion, the content of the bastose is within the range of 5 percent to 65 percent. The invention also discloses a preparation method of the composite environmental-friendly cushion, which comprises the following steps of: respectively preparing the middle layer, the upper and lower surface layer and the bonding layer; then sequentially paving the layers; and preparing the composite environmental-friendly cushion by processes of processing by an oven, cold milling, cooling, cutting, inspecting and packaging. Due to the adoption of the composite environmental-friendly cushion and the preparation method thereof, which are disclosed by the invention, the problem that the existing mattress is easy to affect with damp, mildew, breed worms and deteriorate, is easy to layer and has poor air permeability is solved.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Manufacturing method of multifunctional film pasted fabric

InactiveCN106346887AImprove waterproof performanceEasy fit operationDomestic upholsterySynthetic resin layered productsEnvironmental resistanceCompound a

The invention discloses a manufacturing method of a multifunctional film pasted fabric. The multifunctional film pasted fabric is a seamless wall covering fabric or a full shading curtain fabric. The specific manufacturing method comprises the following steps: (1) compounding a surface fabric and a polyurethane TPU (thermoplastic polyurethane) water-resistant air-permeable film or polyurethane TPU black full shading waterproof film: sizing the surface of the film in a point transfer manner by using a special compounding machine, wherein an environment-friendly PU (polyurethane) or PUR (polyurethane resin) adhesive is used for sizing, and the compounding temperature is 125-135 DEG C; (2) curing: standing for 6-8 hours; (3) compounding with a base fabric: after compounding and curing the surface fabric and the polyurethane TPU water-resistant air-permeable film or polyurethane TPU black full shading waterproof film, sizing the other surface of the polyurethane TPU water-resistant air-permeable film or polyurethane TPU black full shading waterproof film by using the special compounding machine, wherein the environment-friendly PU or PUR adhesive is used for sizing, and the compounding temperature is 130-140 DEG C; and (4) finishing, and packaging. The manufacturing method disclosed by the invention is simple, has a favorable required effect and is environment-friendly.

Owner:浙江鸿圣纺织科技有限公司

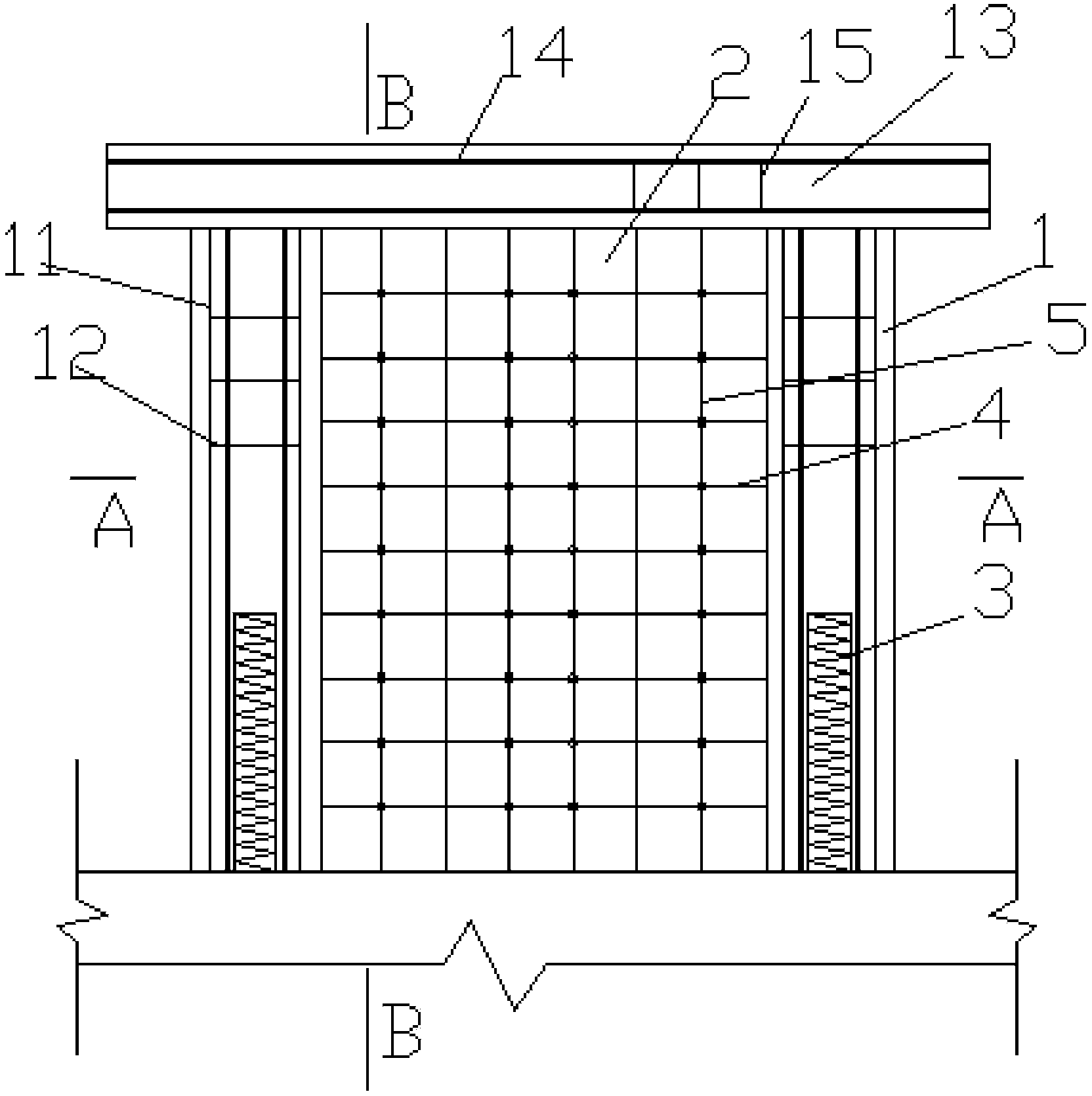

Buckling-restrained stiffened steel plate shear wall

ActiveCN103397718AImprove performanceReduce section sizeWallsShock proofingSheet steelReinforced concrete

The invention discloses a buckling-restrained stiffened steel plate shear wall and belongs to the technical field of structural engineering. The buckling-restrained stiffened steel plate shear wall comprises an embedded steel plate, reinforced concrete cover plates, an edge component, and stiffeners. The edge component comprises edge beams and edge posts. The embedded steel plate is fixedly connected with the upper and lower edge beams. The stiffeners are fixed on two sides of the embedded steel plate. The reinforced concrete cover plates are symmetrically fixed on two sides of the embedded steel plate. Gaps are reserved between each of the reinforced concrete cover plates and each of the embedded steel plate and the edge beams. The buckling-restrained stiffened steel plate shear wall effectively prevents buckling noise like 'drumbeat' and has better 'pinching' of hysteretic curves.

Owner:GUANGZHOU UNIVERSITY

Special white washing agent for apple trees

InactiveCN104430656AGood control effectPure white colorBiocideDead plant preservationPumpkin seedApple peel

The invention discloses a special white washing agent for apple trees, belonging to the technical field of fruit tree trunk protection coatings. The white washing agent comprises the following raw materials: honey, flour, quick lime, table salt, copper sulfate, pricklyash peel extracting liquid, castor-oil plant extracting liquid, garlic extracting liquid, indigowoad root powder, ginger juice, pumpkin seed powder and sulfur powder. The white washing agent disclosed by the invention can be firmly stuck on tree barks aiming at plant diseases and insect pests of the apple trees and the tree bark properties of the apple trees; the honey, the flour and various plant source insecticidal and sterilizing medicines are added into the white washing agent so that light reflecting and warm keeping effects can be realized; and the white washing agent has remarkable prevention and treatment effects on the common plant diseases and insect pests of the apple trees. The white washing agent prepared by the method has a pure white color and long lasting time, and only needs to be coated once in early spring or late fall and early winter in one year, so that the white washing agent has the advantages of saving labor, saving time, saving resources, lasting for a long time and having good prevention and treatment effects on the plant diseases and insect pests.

Owner:孟三军

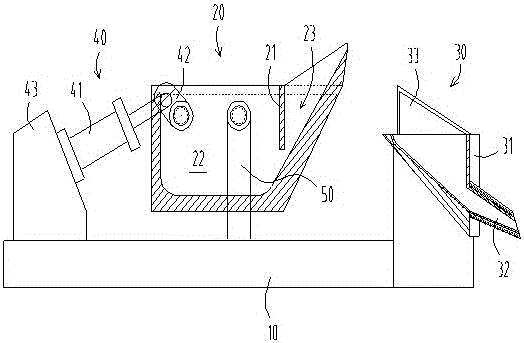

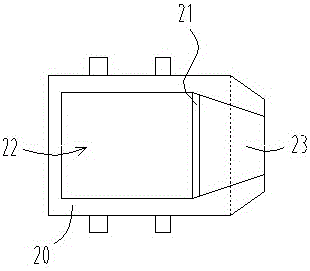

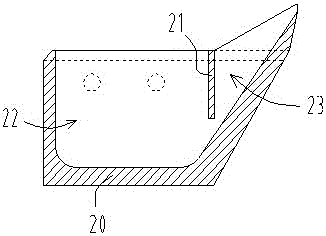

Ceramic pouring ladle for cylinder liner pouring

The invention provides a ceramic pouring ladle for cylinder liner casting, which includes a pouring ladle and a pouring spout. The inside of the pouring ladle is separated into a molten soup chamber and a diversion groove by slag retaining bricks. The pouring spout includes a fixedly connected pouring spout. Main body and diversion groove two, the walls of the melting soup chamber and pouring nozzle body all include refractory ceramic layers, refractory clay and metal outer film arranged in sequence from the inside to the outside, the melting soup chamber, diversion groove one, pouring The mouth body and the diversion groove two are sequentially connected. The invention adds a refractory ceramic layer in the wall body to keep warm and improve the smoothness of the inner surface of the pouring bun, effectively reduce hanging slag, improve the fluidity of molten iron, and make it easier to ensure the flow rate of molten iron after improvement.

Owner:ANQING TP GOETZE LINER

Preparation method of lightweight self-thermal insulation building block containing abandoned brick particles and abandoned foams

InactiveCN106007578AMeet resource utilizationTo keep warmSolid waste managementCeramicwareBrickThermal insulation

The invention relates to a preparation method of a lightweight self-thermal insulation building block containing abandoned brick particles and abandoned foams. The preparation method comprises the following steps: crushing abandoned materials, preparing a cavity module, and preparing and maintaining a precursor. According to the preparation method of the self-thermal insulation building block, the subsidence problem caused by too high water absorption of the cavity module when the cavity module is dried and then is subjected to internal casting is avoided, and the problem that single brick aggregate is poor in strength after building wastes are regenerated in the prior art is effectively solved. The preparation method disclosed by the invention has the advantages of high volume stability, simple preparation process, low requirement to equipment, low production cost, no discharge of wastewater and waste gas, capability of effectively and comprehensively utilizing the building waste, energy conservation and environmental friendliness.

Owner:TONGJI UNIV +1

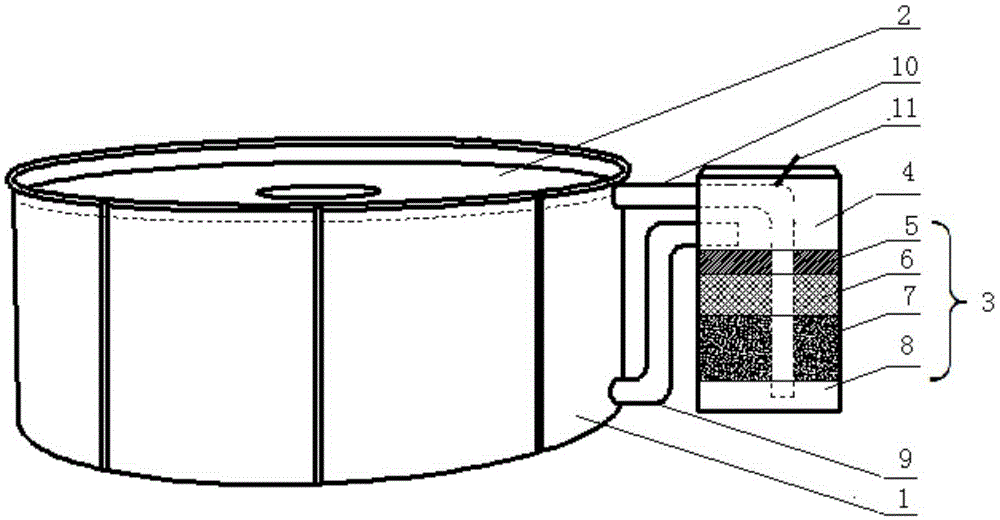

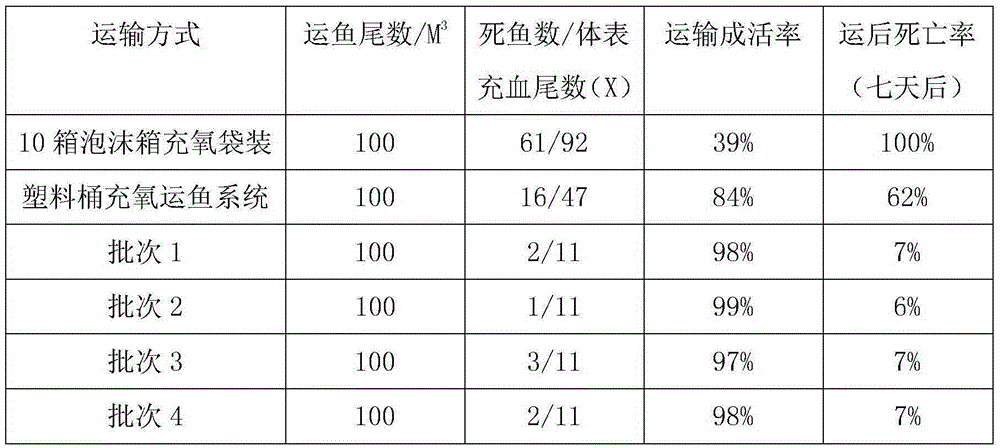

Equipment and method for improving live transportation survival rate of edgy fishes

ActiveCN105393972AGuaranteed bearing capacityHigh hardnessPisciculture and aquariaWater storagePurification methods

The invention provides equipment for improving the live transportation survival rate of edgy fishes. The equipment comprises a tank (1), a plastic cover film (2) matched with the tank (1), and a water purifier (3). The water purifier (3) comprises a water distribution layer (4), an ice cube layer (5), a filter cotton layer (6), an active carbon layer (7), and a water storage layer (8), wherein the above layers are arranged from top to bottom. The lower part of the tank (1) is provided with a water inlet pipe (9) to be connected with the water distribution layer (4) via the water purifier. The upper part of the tank (1) is provided with a provided with a water outlet pipe (10) to be connected with the water storage layer (8) via the water purifier. The water outlet pipe (10) of the water purifier is provided with an airlift pump interface (11). According to the technical scheme of the invention, a water quality purification method for water in transportation facilities is provided for aquaculture practitioners during the transportation process based on the physiological characteristics of saury and shad. In this way, the collision injured risk of fishes when frightened is reduced, and the water quality of the transportation water is improved. Meanwhile, the metabolites of fishes are timely eliminated, so that the stress reactions of edgy fishes, such as saury and shad, are reduced. Moreover, the risk of mechanical traumas and the risk of physiological endogenous injuries during the transportation process are reduced. The live transportation survival rate of fishes is improved. Furthermore, the temporary-rearing or cultivation survival rate of fishes after the transportation process is improved.

Owner:SUZHOU FISHSEEDS BIOLOGICAL TECH CO LTD

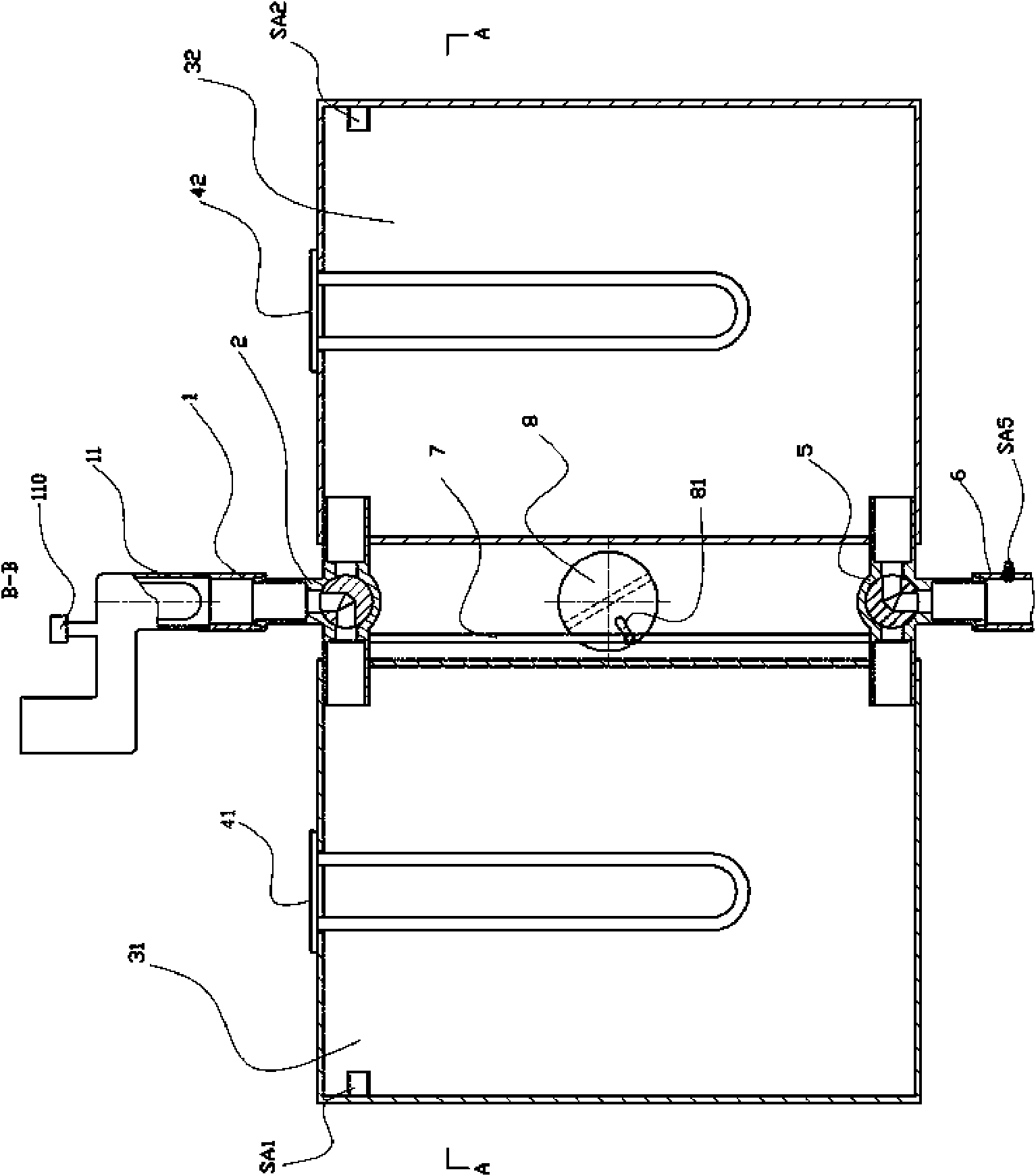

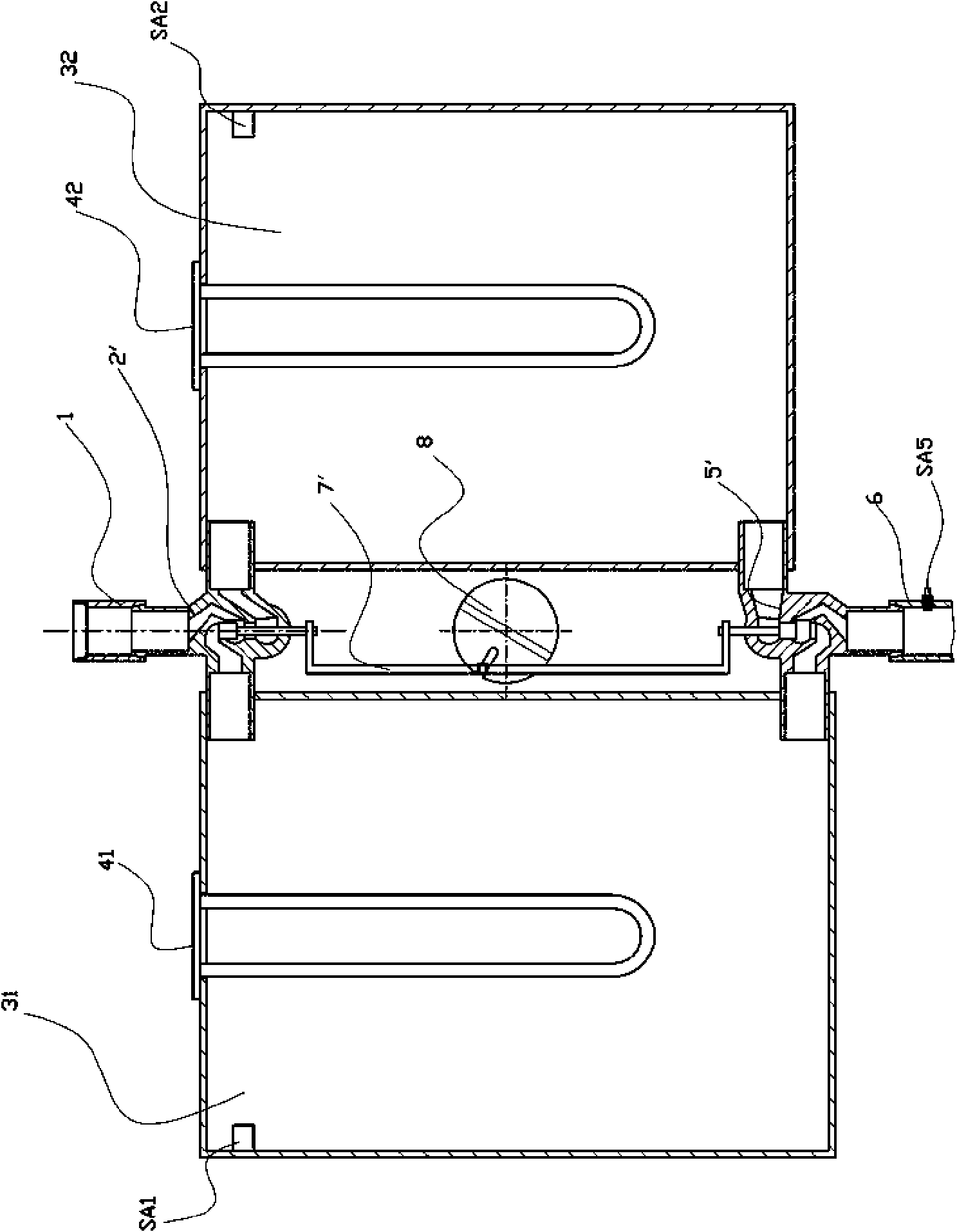

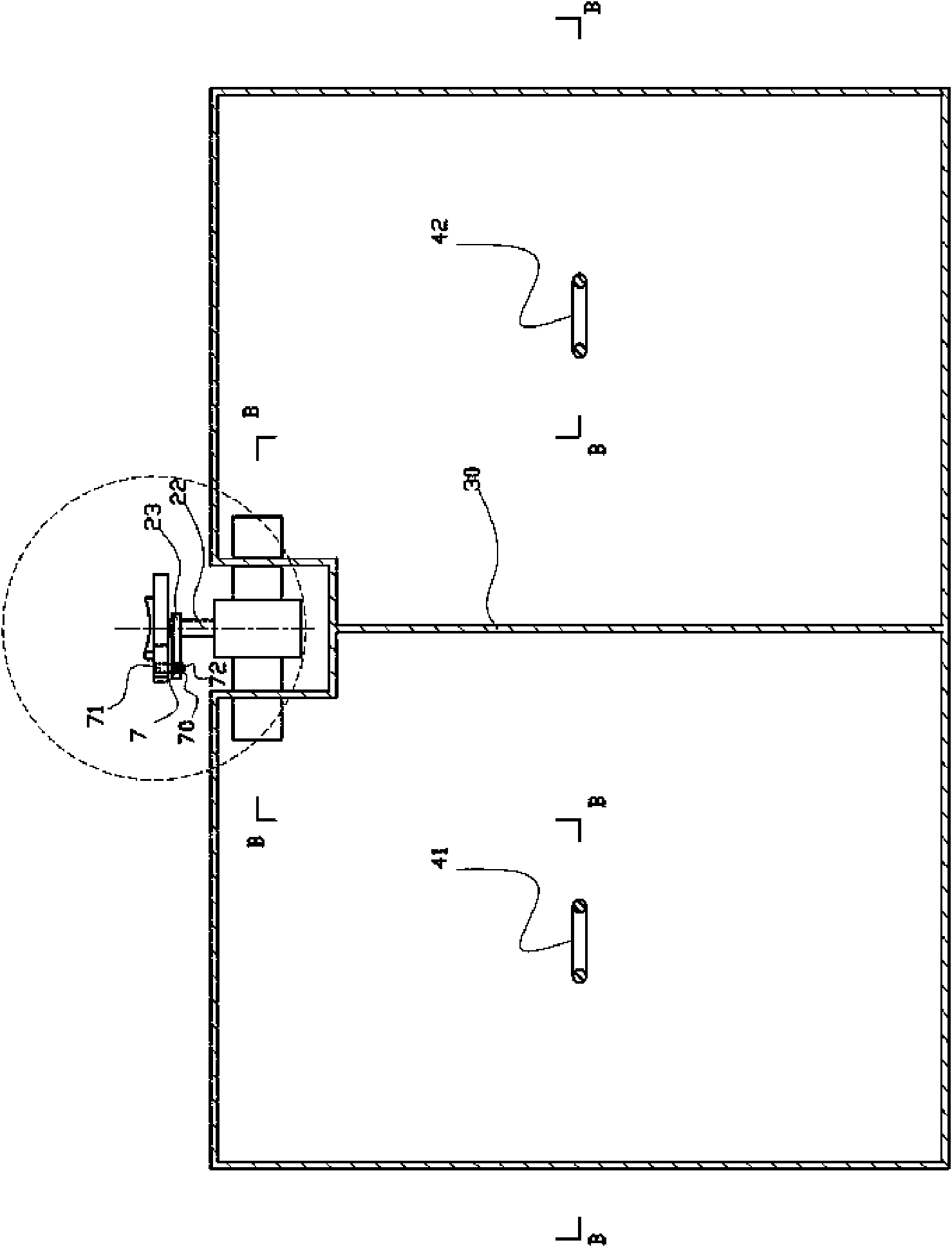

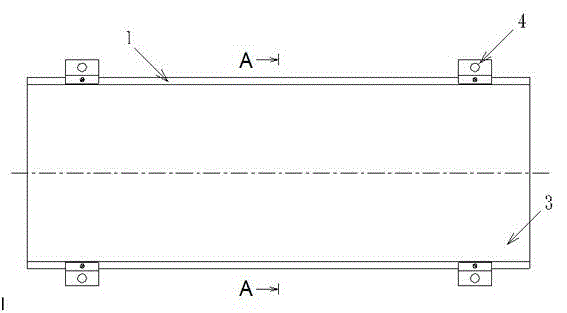

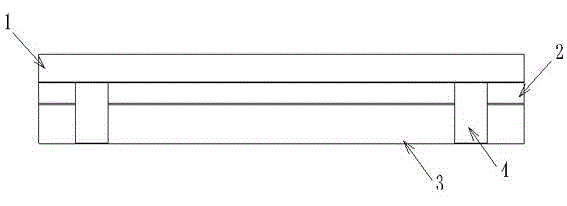

Drinking water dispenser with double heating boxes

InactiveCN101556074APlay a role in heat preservationPrevent the phenomenon of "thousand boiling water"Multiple way valvesWater heatersControl rodHeating element

The invention discloses a drinking water dispenser with double heating boxes, which comprises a liquid inlet pipe, heating boxes, a heating element and a liquid outlet pipe, and is characterized in that the drinking water dispenser is provided with two heating boxes including a first heating box and a second heating box; the liquid inlet pipe is linked with the first heating box and the second heating box by an arranged liquid inlet triple valve, and the liquid outlet pipe is linked with the first heating box and the second heating box by an arranged liquid outlet triple valve; the liquid inlet triple valve is linked with the liquid outlet triple valve by a control rod; when the liquid inlet triple valve communicates the liquid inlet pipe with the first heating box, the liquid outlet triple valve communicates the second heating box with the liquid outlet pipe; when the liquid inlet triple valve communicates the liquid inlet pipe with the second heating box, the liquid outlet triple valve communicates the first heating box with the liquid outlet pipe; and the heating element comprises a first heating element and a second heating element. The drinking water dispenser can prevent long-boiled water caused by repetitive heating and avoid the mixing of raw cooling water and boiled water, and is applicable to heating equipment for liquid such as drinking water, drinks, liquid medicine and the like.

Owner:DONGGUAN SAIKALYULA ELECTROMECHANICAL TECH DEV

Flat-pipe microchannel aluminum radiator

InactiveCN102724853AReduce volumeImprove cooling effectCooling/ventilation/heating modificationsInsulation layerThermal insulation

The invention provides a flat-pipe microchannel aluminum radiator which comprises an aluminum plate and a thermal insulation layer fixed on an air conditioner box, wherein a flat-pipe microchannel heat exchanging pipe is arranged between the aluminum plate and the thermal insulation layer and is of a hollow pipe structure; and the cavity of the flat-pipe microchannel heat exchanging pipe is internally provided with a heat exchange grill. The flat-pipe microchannel aluminum radiator disclosed by the invention is reasonable in structure design, reduces radiator volume while enhancing heat radiating area, effectively controls and recycles heat and improves radiating efficiency during air conditioner running.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

Integrated device for repairing farmland organic polluted soil

ActiveCN110293124AImprove repair efficiencyQuickly put into useGas treatmentDispersed particle separationSoil treatmentPollution soil

The invention discloses an integrated device for repairing farmland organic polluted soil, and the integrated device mainly comprises a soil treatment device, a thermal desorption device and a waste gas treatment device. The soil treatment device is connected with the thermal desorption device through a pipeline, and the waste gas treatment device is respectively connected with thermal desorptiondevice and the soil treatment device through pipelines; the soil treatment device comprises a crushing shell, a crushing main shaft, a first crushing disc, a second crushing disc and a third crushingdisc; the thermal desorption device comprises a heating pipe and a rotating main shaft; the waste gas treatment device comprises a device shell, an air inlet A, an air outlet A, an air inlet B and anair outlet B. Through the combined action of the soil treatment device, the thermal desorption device and the waste gas treatment device, the integrated device has high soil remediation efficiency, energy conservation and low consumption, and can effectively utilize waste gases generated by thermal desorption in multiple effects.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

Natural fiber health-care board and preparation method thereof

ActiveCN102514256AGuaranteed performanceGuaranteed breathabilityLaminationLamination apparatusPolymer scienceSurface layer

The invention discloses a natural fiber health-care board which consists of a middle layer and a surface layer arranged on the upper surface or the lower surface of the middle layer. The surface layer is a non-woven layer comprising 5 percent to 50 percent of low melting point fibers. The middle layer is a non-woven layer which comprises the following components: bastose and 5 percent to 50 percent of low melting point fibers. In the natural fiber health-care board, the content of the bastose is within the range of 5 percent to 65 percent. The invention also discloses a preparation method of the natural fiber health-care board, which comprises the following steps of: respectively preparing the middle layer and the upper or lower surface layer; then sequentially paving the layers; and preparing the natural fiber health-care board by processes of processing by an oven, cold milling, cooling, cutting, inspecting and packaging. Due to the adoption of the natural fiber health-care board and the preparation method thereof, which are disclosed by the invention, the problem that the existing mattress is easy to affect with damp, mildew, breed worms and deteriorate, is easy to layer and has poor air permeability is solved.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

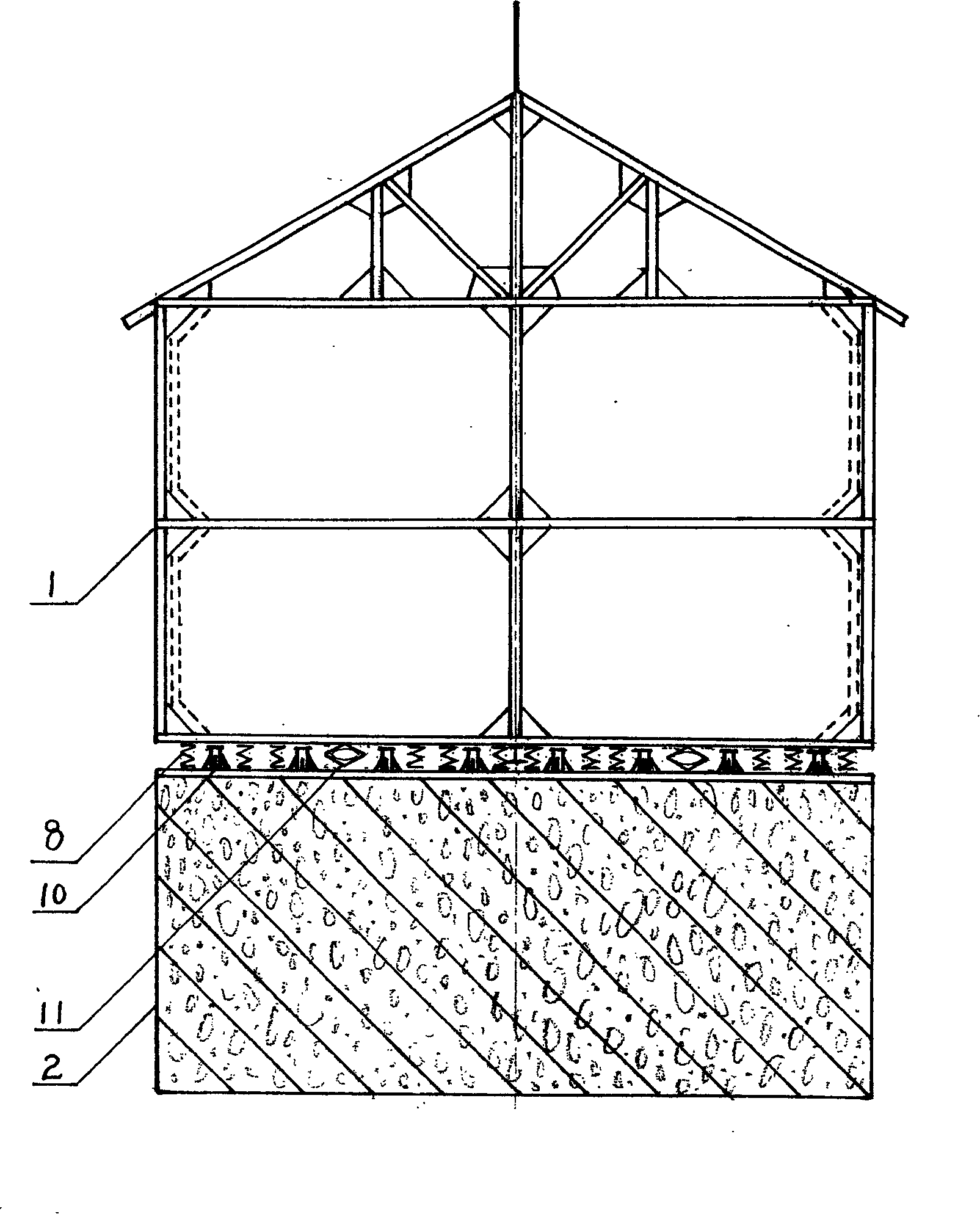

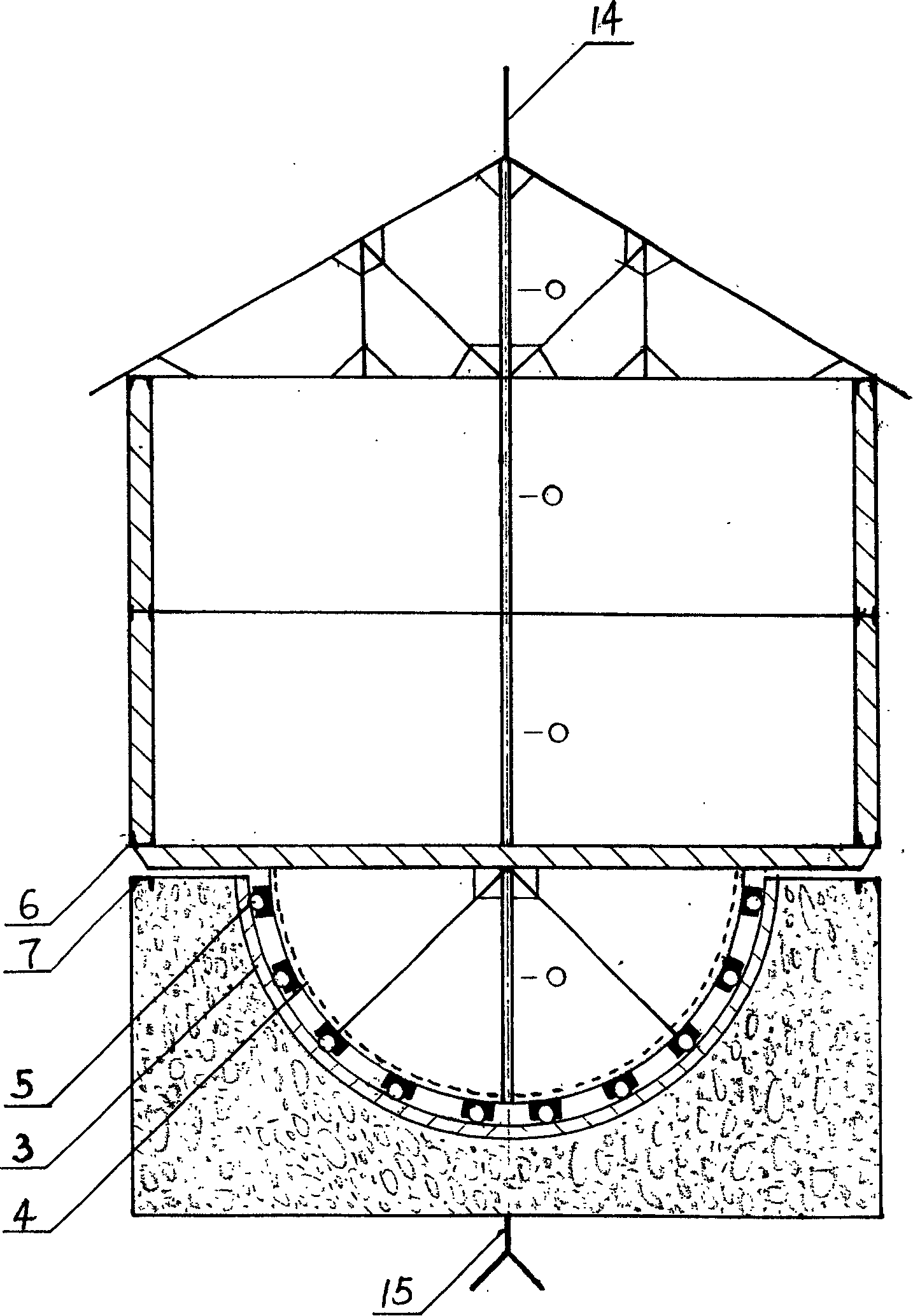

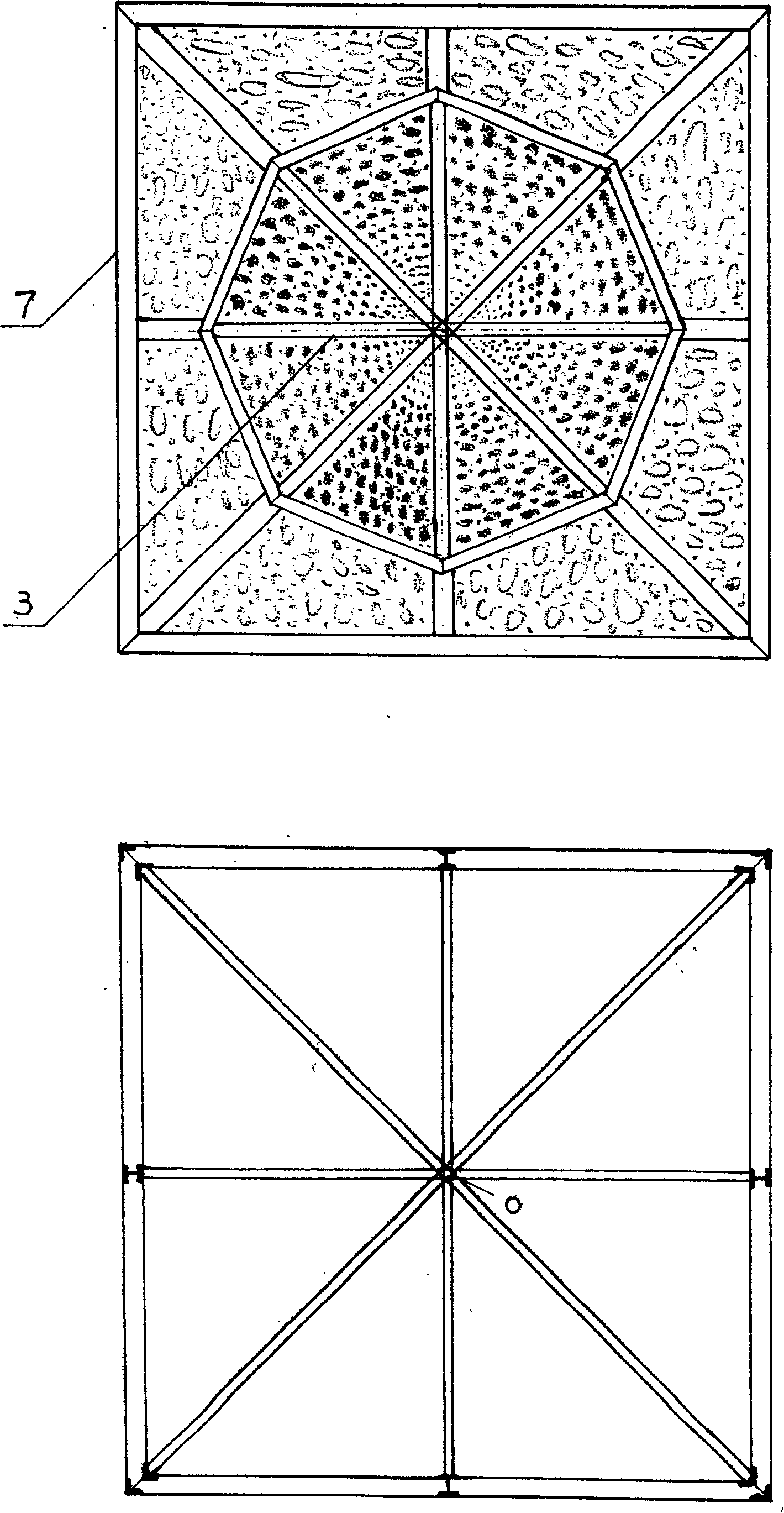

Monolithic-construction automatic damping storied building

"Integral structure, automatic shock-absorbing building" consists of the overall steel structure frame, interior and exterior decoration of the building, automatic shock-absorbing system, horizontal and vertical linkage levers and structural parts outside the building; it can automatically absorb shocks in a major earthquake, but cannot The destruction and collapse of the overall structure cannot cause casualties and deaths. In the design of the main building, bricks and cement in the current construction industry are not used, and all new building materials in the building materials market are used for decoration. This can solve the problem of construction problems. The heavy manual labor problem that the industry has not solved for thousands of years can be factory-produced and installed at the construction site when the number of buildings is large.

Owner:籍跃中

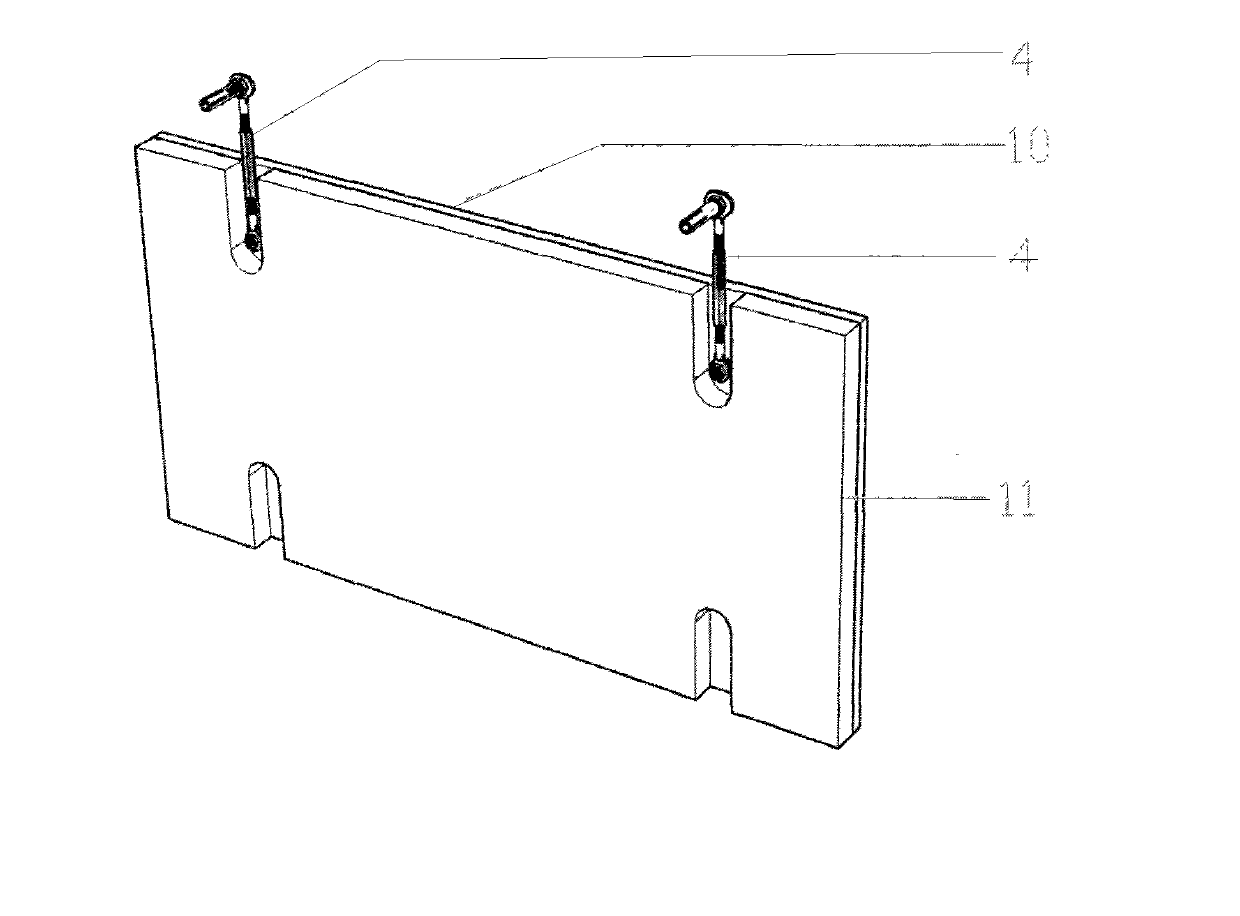

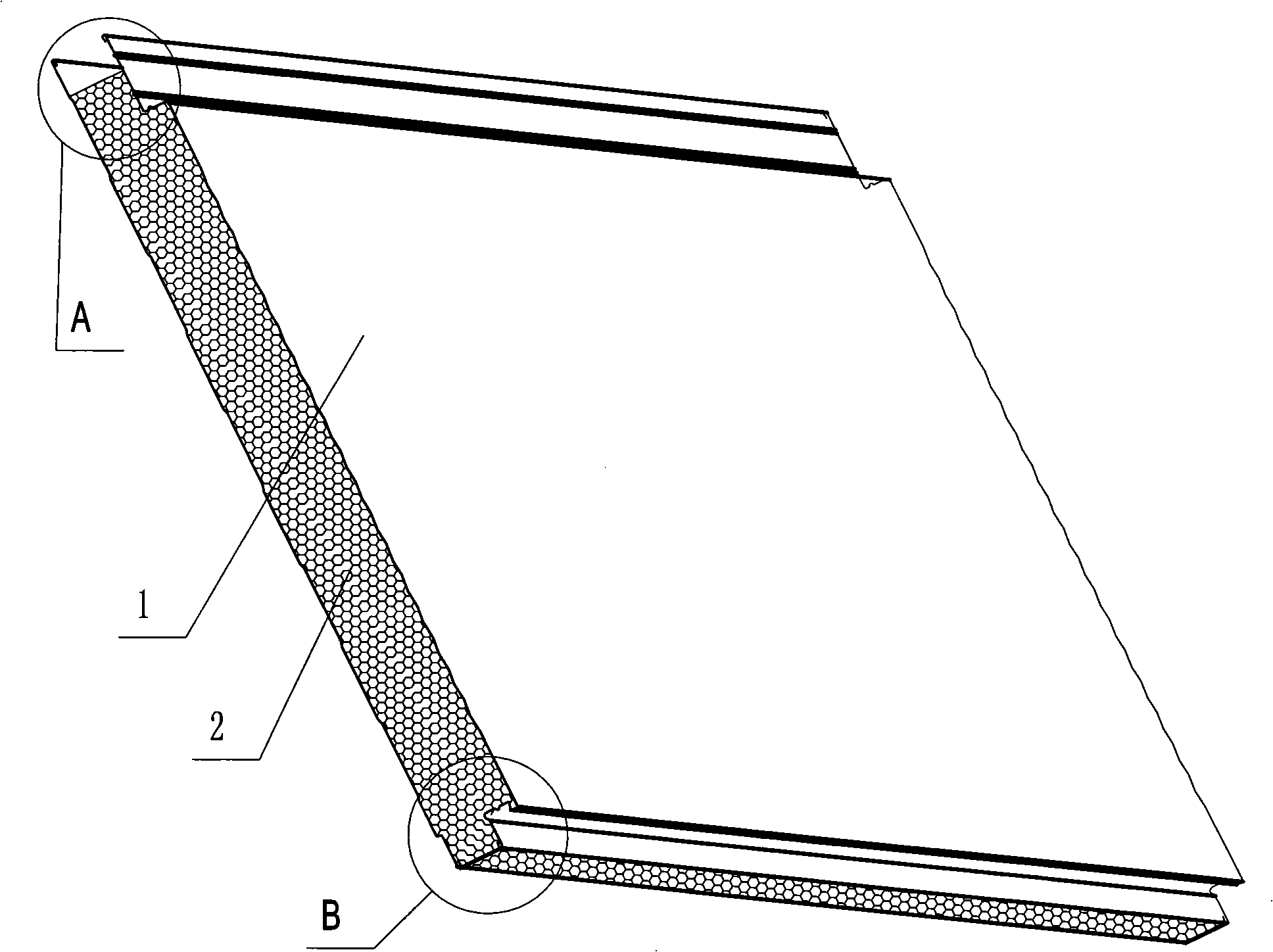

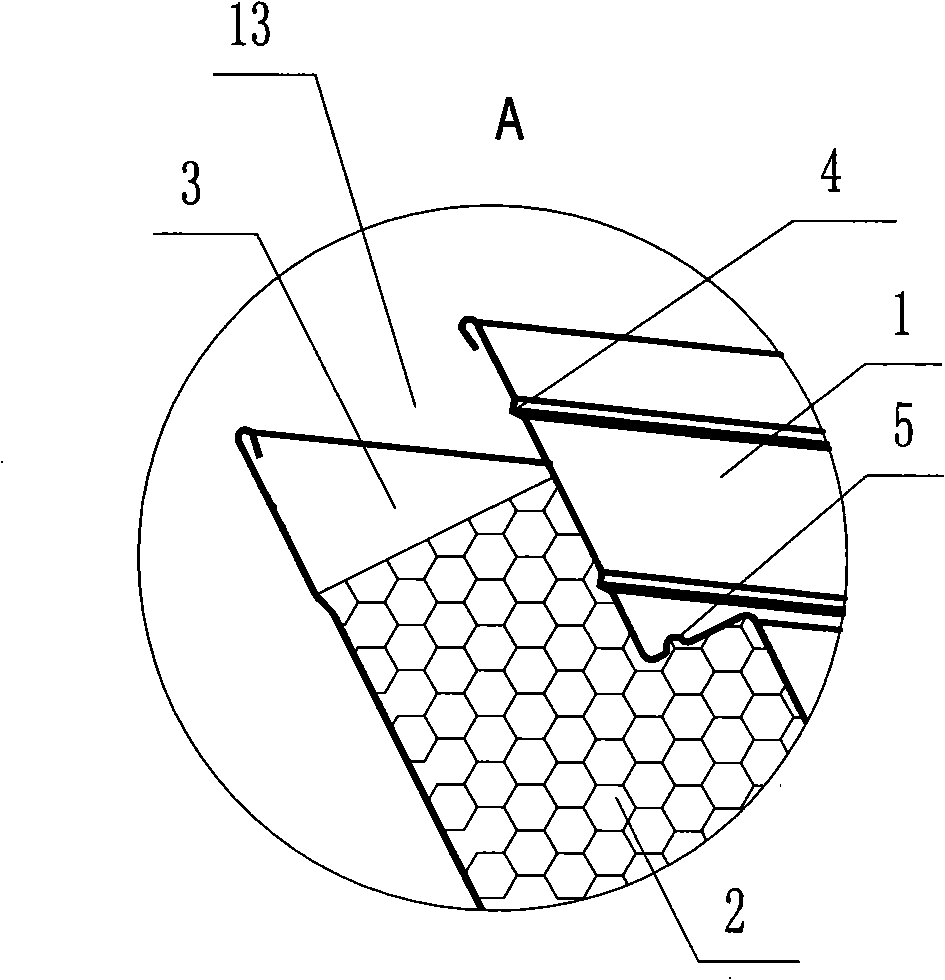

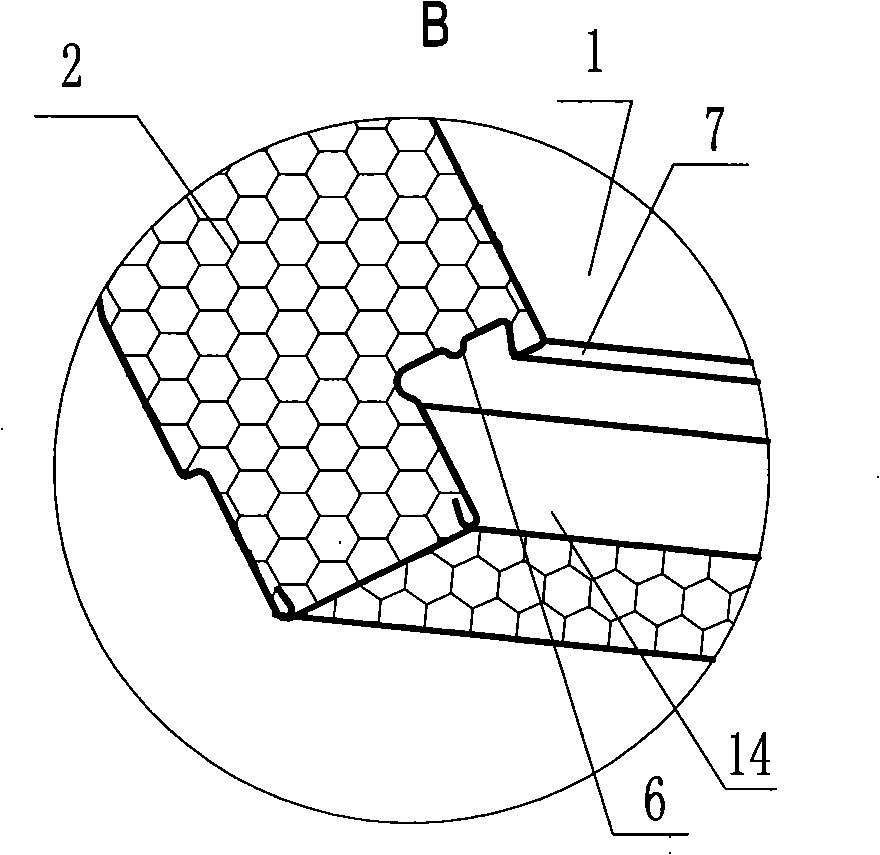

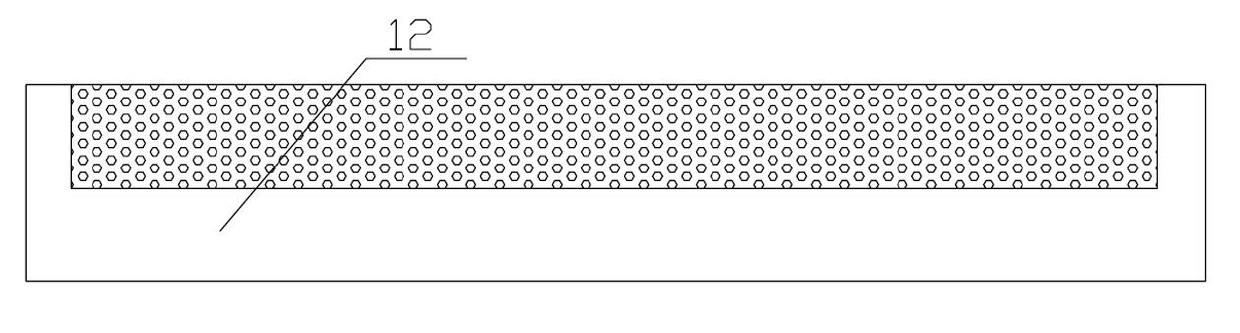

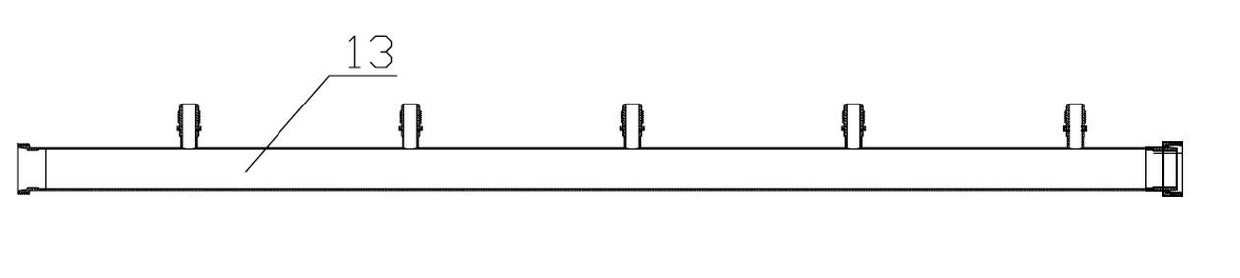

Solar photoelectric photo-thermal building integrated composite plate

InactiveCN102653969ANo insulation requiredMaintenance freeSolar heating energyPhotovoltaic energy generationBuilding integrationButt joint

The invention relates to a solar photoelectric photo-thermal building integrated composite plate which comprises a shell 4, a support frame 3, a heat absorber 2, a connection pipe 13, a vacuum glass plate 1, a thermal insulation plate 5, a thermal insulation side plate 11, a color steel bottom plate 6, sealing plates 12 and the like. The composite plate provided by the invention can be used as a generation heating unit, butt-joint tongue-and-grooves are arranged on the left and right sides, and the sealing plates are arranged at the upper and lower ends; the components are in lap joint with each other to form a whole roof panel or wall facade, and the roof panel and wall decoration can be completely replaced; thermal insulation and waterproof effects can be realized on the roof, and thermal insulation and decoration effects can be realized for the wall facade; particularly, hot water is generated by absorbing the heat of a power generation plate at the time of power generation; and moreover, a lighting window, a ventilating window and the like also can be designed on the roof panel or wall facade. Through the invention, clean energy for solar power generation, lighting, central water heating and central air conditioning can be provided for the building to achieve low-carbon or even micro-carbon life.

Owner:HEBEI SOL MANI SOLAR ENERGY SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com