Built-in and multi-cavity double steel plate and concrete filled steel tubular column combined shearing wall and manufacturing method

A technology of concrete-filled steel tubular columns and composite shear walls, which can be applied to walls, building components, buildings, etc., can solve problems such as out-of-plane instability of core columns, and achieve the advantages of enhancing out-of-plane restraint, improving seismic performance, and improving compressive strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

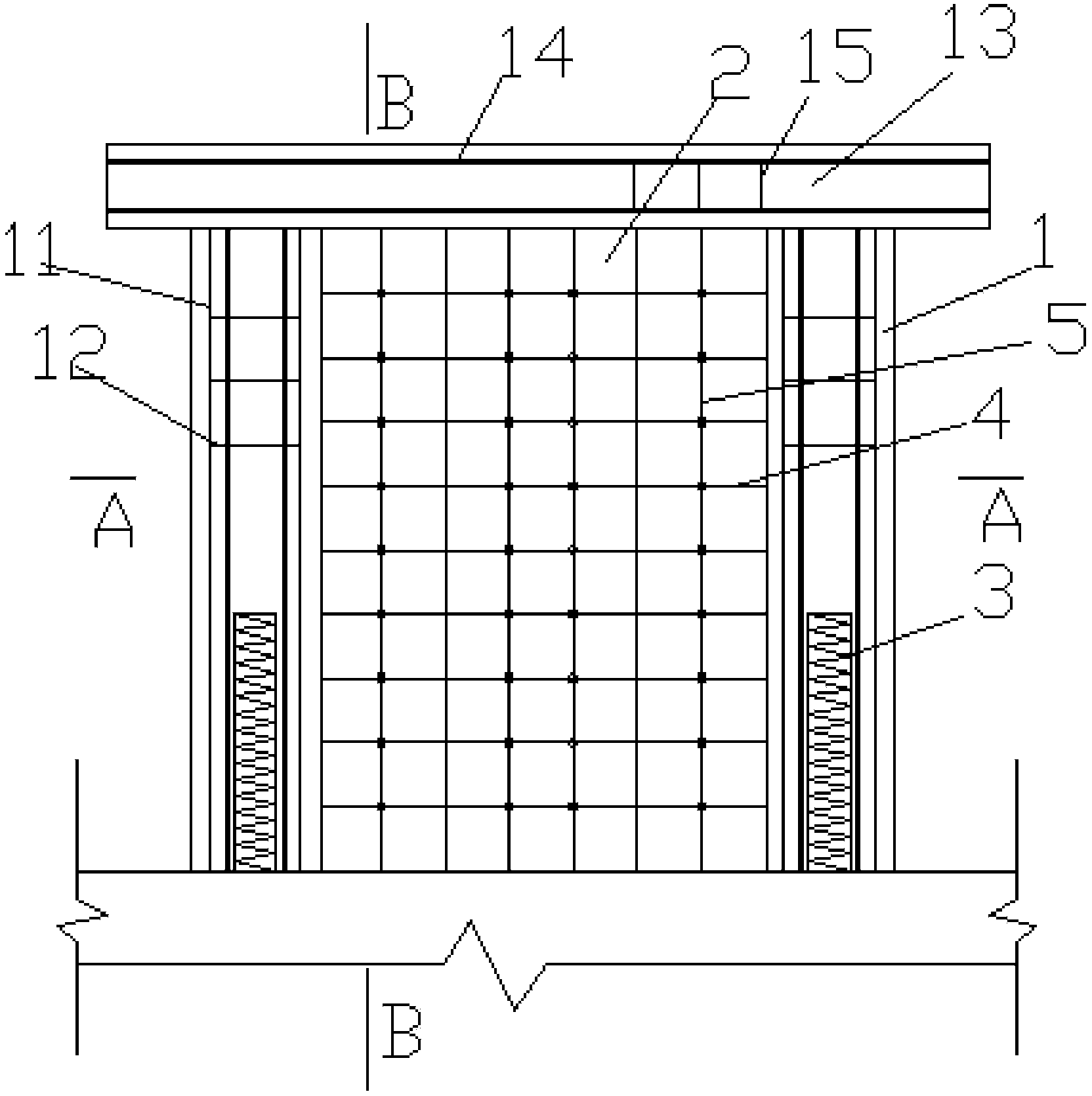

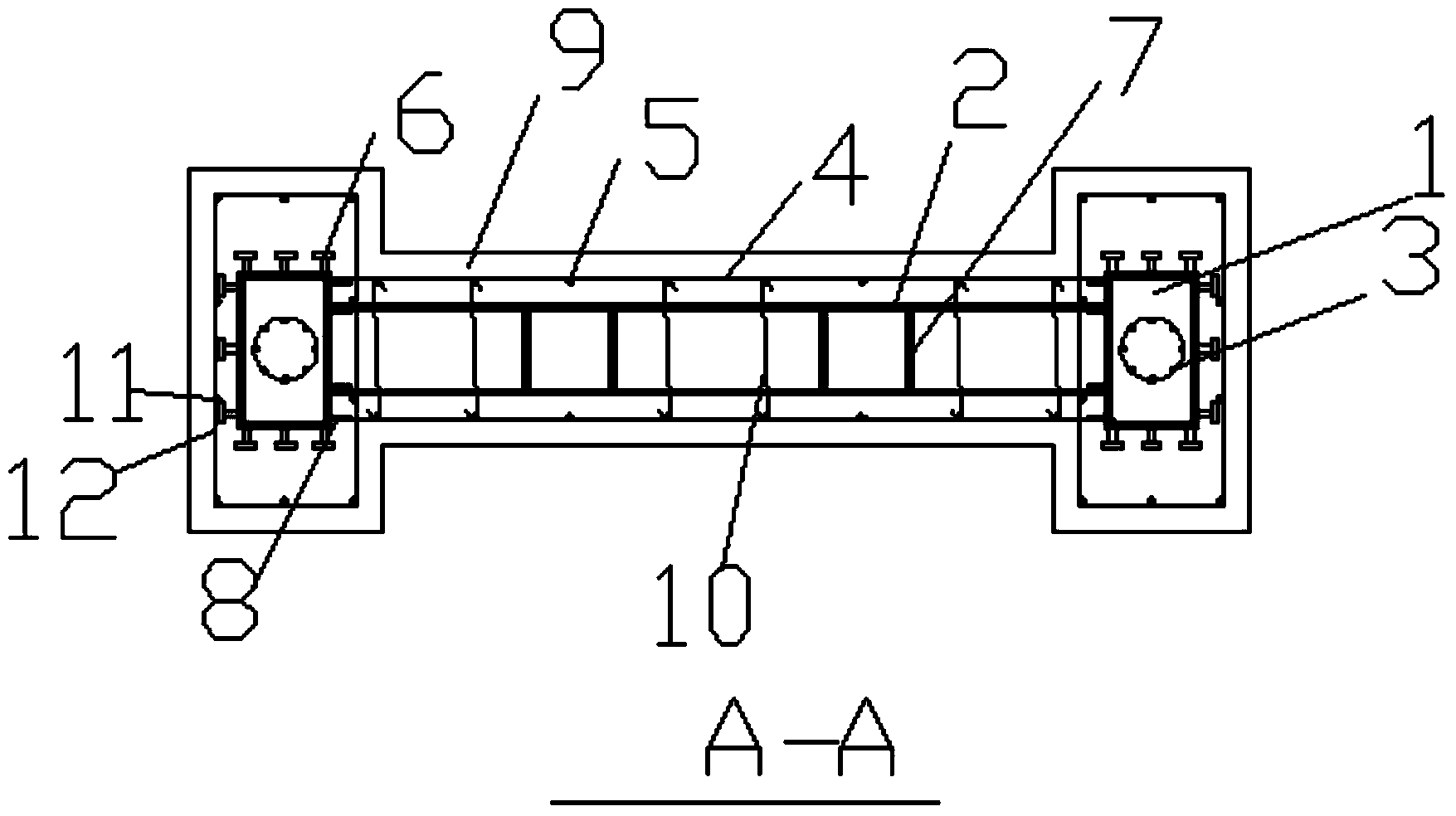

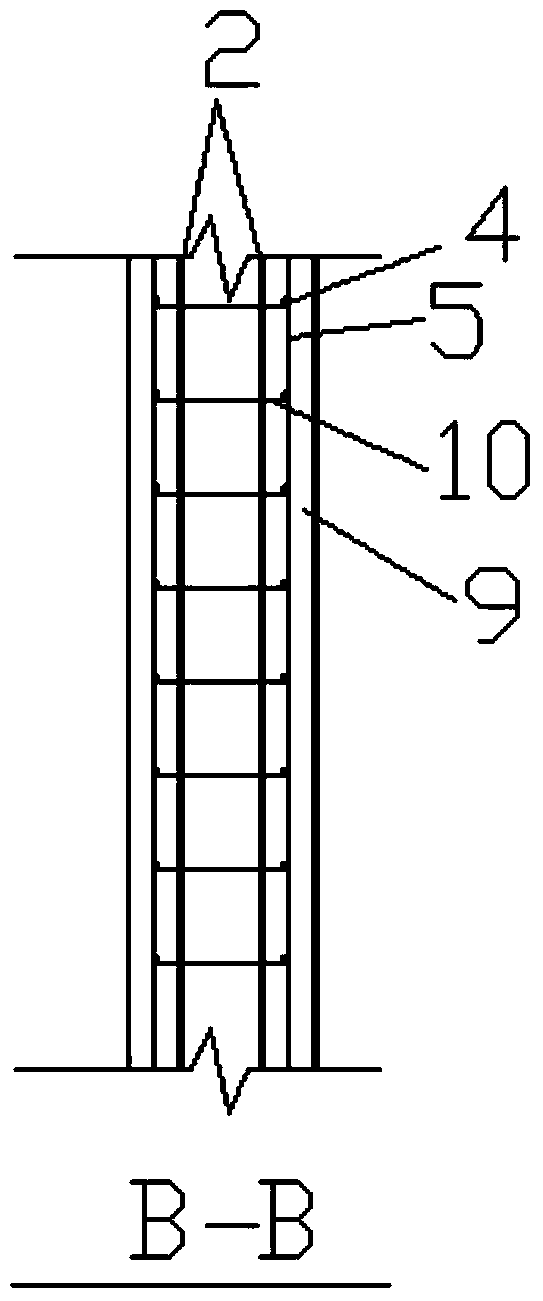

[0033] Combine below figure 1 — image 3 The present invention is described further:

[0034] Schematic diagram of the structural reinforcement of the composite shear wall with built-in multi-cavity double steel plates and steel tube concrete columns figure 1 — image 3 shown.

[0035] Built-in multi-cavity double steel plate and steel pipe concrete column composite shear wall, characterized in that: the wall is I-shaped, and the periphery of the wall is surrounded by reinforced concrete 9; the inside of the wall is equipped with double steel plates 2; double steel plates 2 The interior is separated by a horizontal steel plate 7 into a number of cavities with a square section at intervals; both ends of the double steel plate 2 are respectively equipped with a square steel tube concrete frame column 1 surrounded by steel plates; A reinforcement mesh composed of horizontally distributed reinforcing bars 4; the shear wall side beams are shaped steel beams 13; the steel plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com