Vibratory drive composite micro-power source based on piezoelectric effect and electromagnetic induction

An electromagnetic induction and vibration-driven technology, applied in the field of micro-energy, can solve problems such as research and utilization limitations, and achieve the effects of self-sufficient power supply, easy miniaturization and integration, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

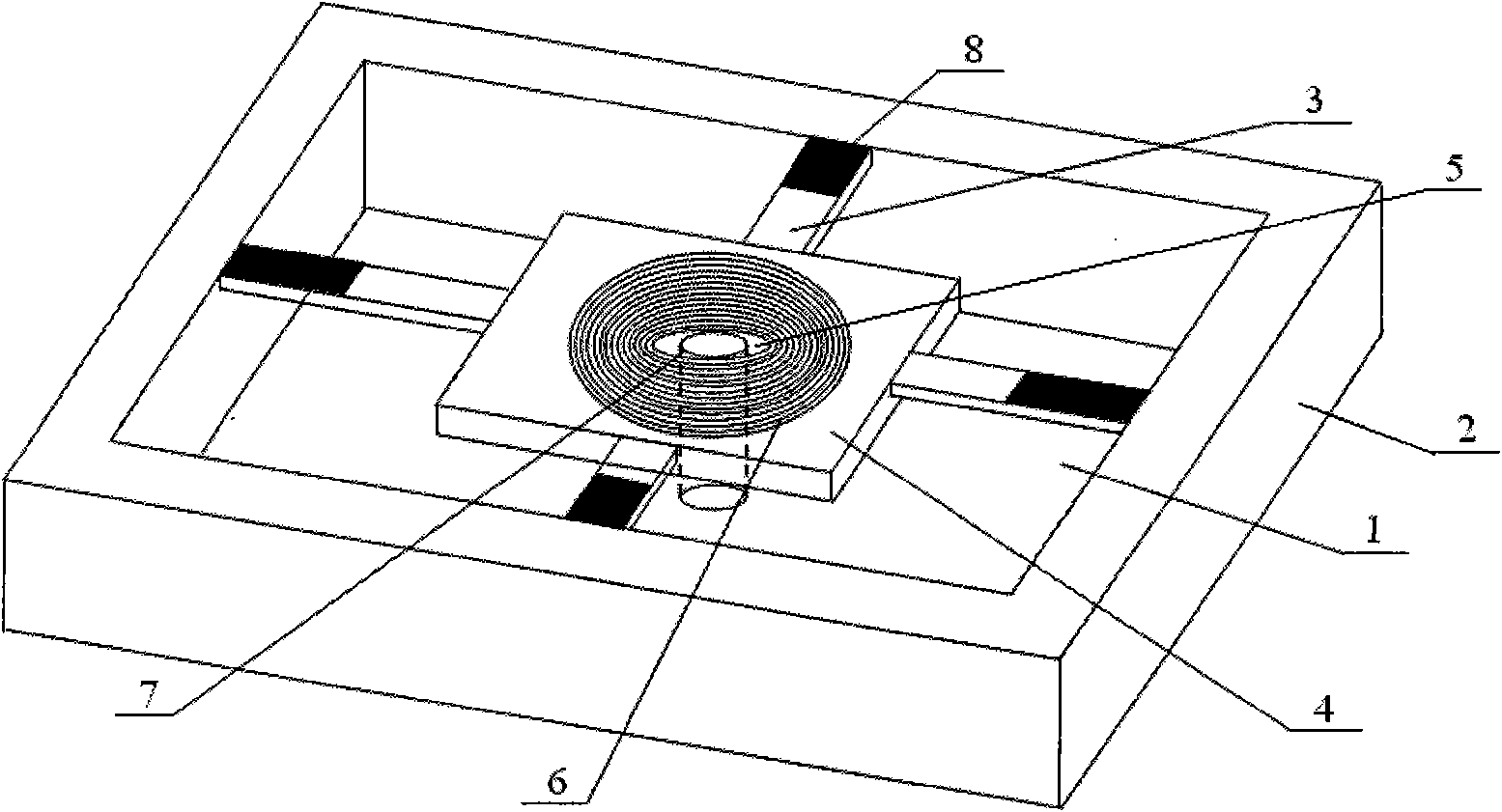

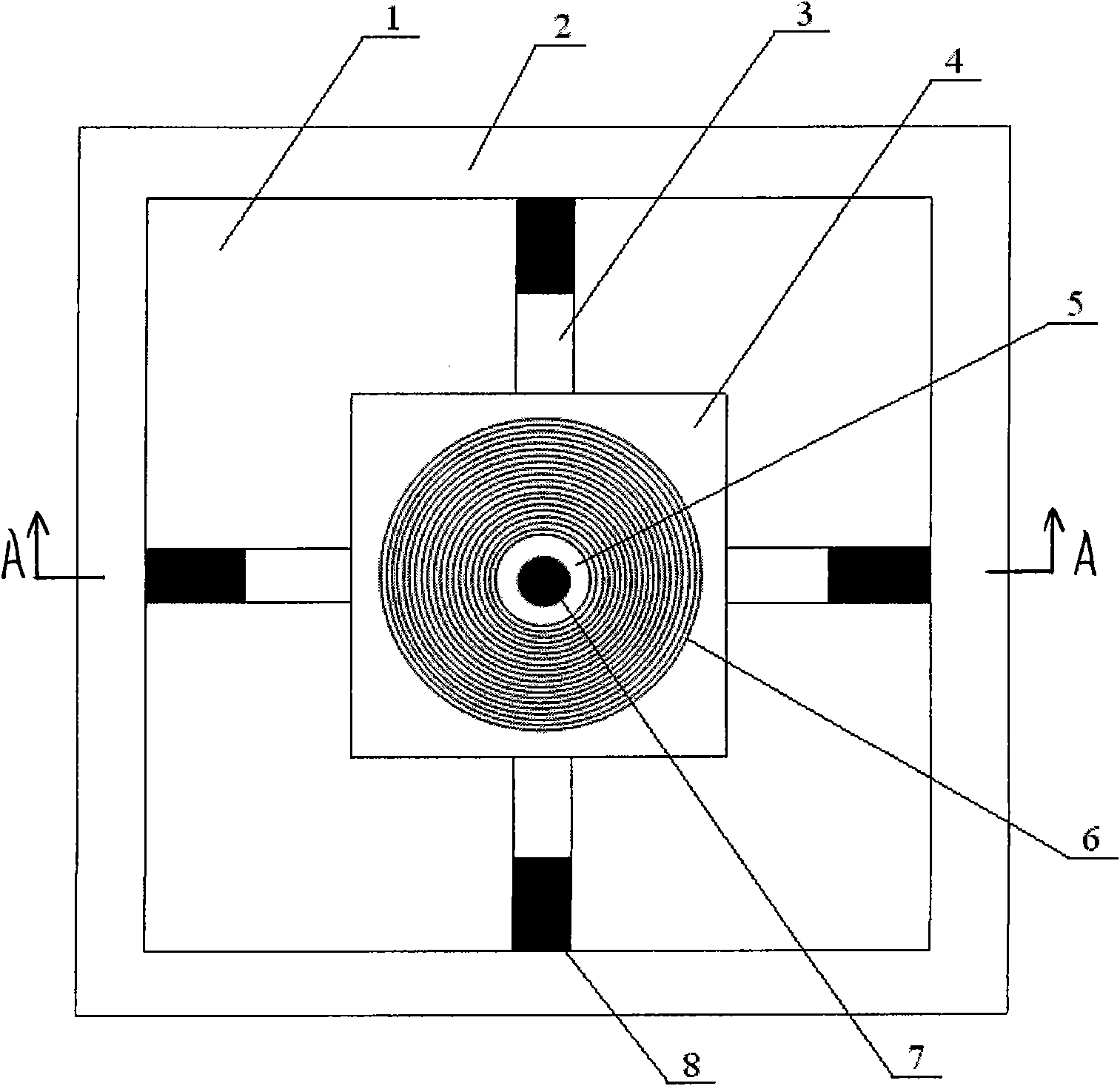

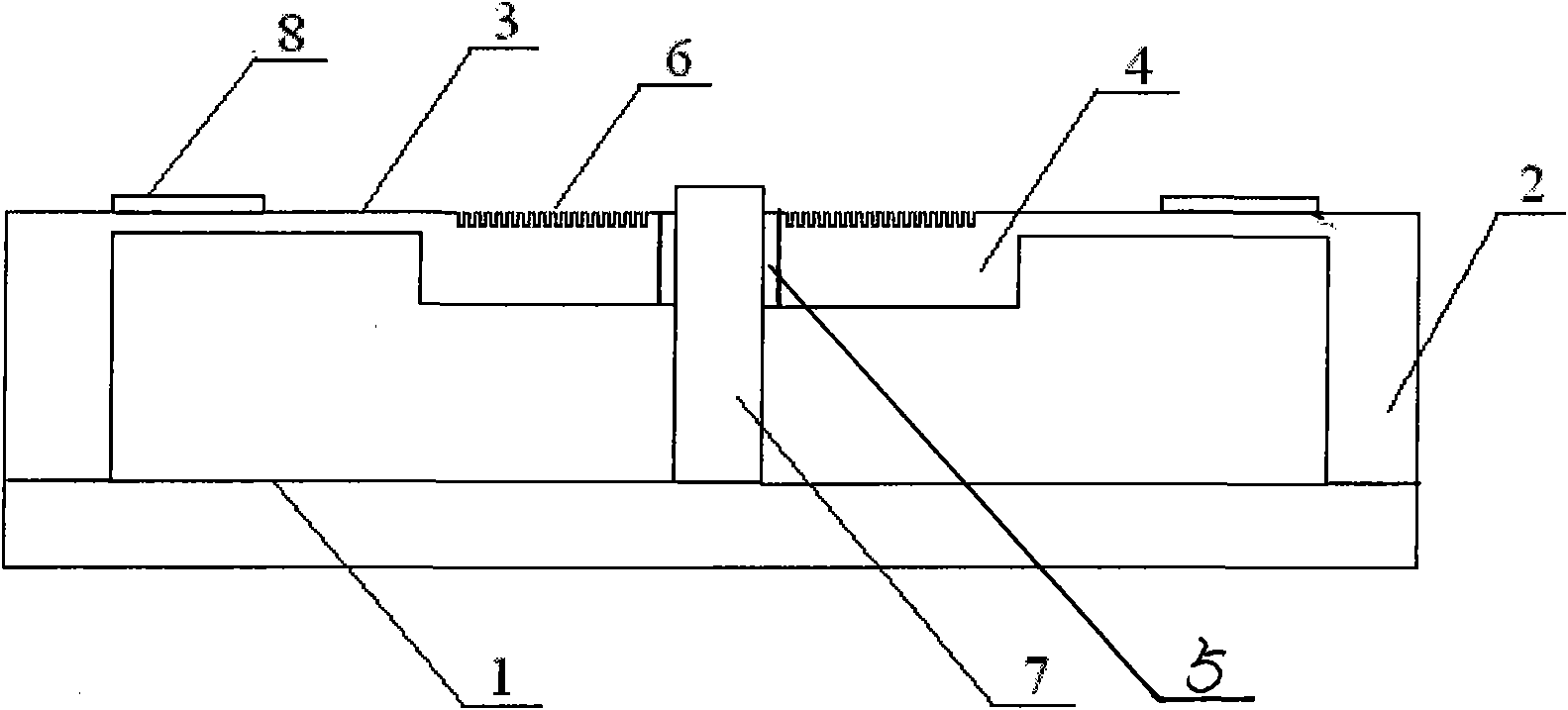

[0021] As shown in Figures 1-4, the vibration-driven composite micro power supply based on the piezoelectric effect and electromagnetic induction phenomenon includes a base 1, which is processed on a semiconductor substrate by using a micro-electromechanical device processing technology: a peripheral base 2, a single One end of the cantilever beam 3 fixed to the peripheral base 2, the mass block 4 fixed to the other end of the cantilever beam 3, the base 1 and the lower surface of the peripheral base 2 are bonded and fixed, and the mass block 4 is suspended from the base 1 through the cantilever beam 3 Directly above the center of the mass block 4 is provided with a vertical through hole 5, and the upper surface and / or lower surface of the mass block 4 is processed with an induction coil 6 arranged around the vertical through hole 5 using a micro-electromechanical device processing technology; 1. A miniature permanent columnar magnet 7 perpendicular to the base 1 is bonded and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com