Patents

Literature

4493 results about "Shear wall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In structural engineering, a shear wall is a vertical element of a seismic force resisting system that is designed to resist in-plane lateral forces, typically wind and seismic loads. In many jurisdictions, the International Building Code and International Residential Code govern the design of shear walls.

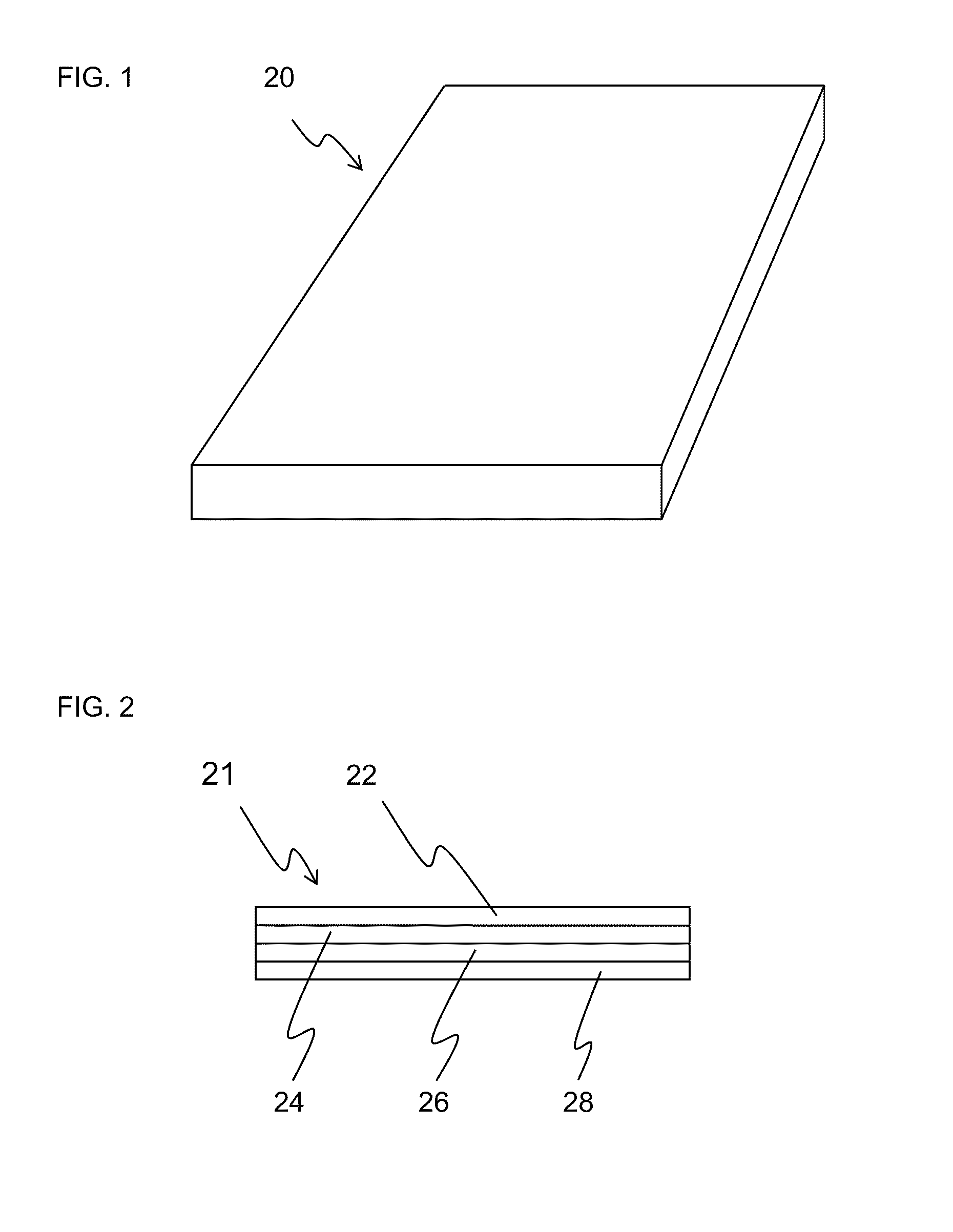

High performance non-combustible gypsum-cement compositions with enhanced water durability and thermal stability for reinforced cementitious lightweight structural cement panels

ActiveUS8038790B1Reduce weightPerformance requirementConstruction materialSolid waste managementOperating energyAir entrainment

Structural cement panel for resisting transverse and shear loads equal to transverse and shear loads provided by plywood and oriented strain board, when fastened to framing for use in shear walls, flooring and roofing systems. The panels provide reduced thermal transmission compared to other structural cement panels. The panels employ one or more layers of a continuous phase resulting from curing an aqueous mixture of calcium sulfate alpha hemihydrate, hydraulic cement, coated expanded perlite particles filler, optional additional fillers, active pozzolan and lime. The coated perlite has a particle size of 1-500 microns, a median diameter of 20-150 microns, and an effective particle density (specific gravity) of less than 0.50 g / cc. The panels are reinforced with fibers, for example alkali-resistant glass fibers. The preferred panel contains no intentionally added entrained air. A method of improving fire resistance in a building is also disclosed.

Owner:UNITED STATES GYPSUM CO

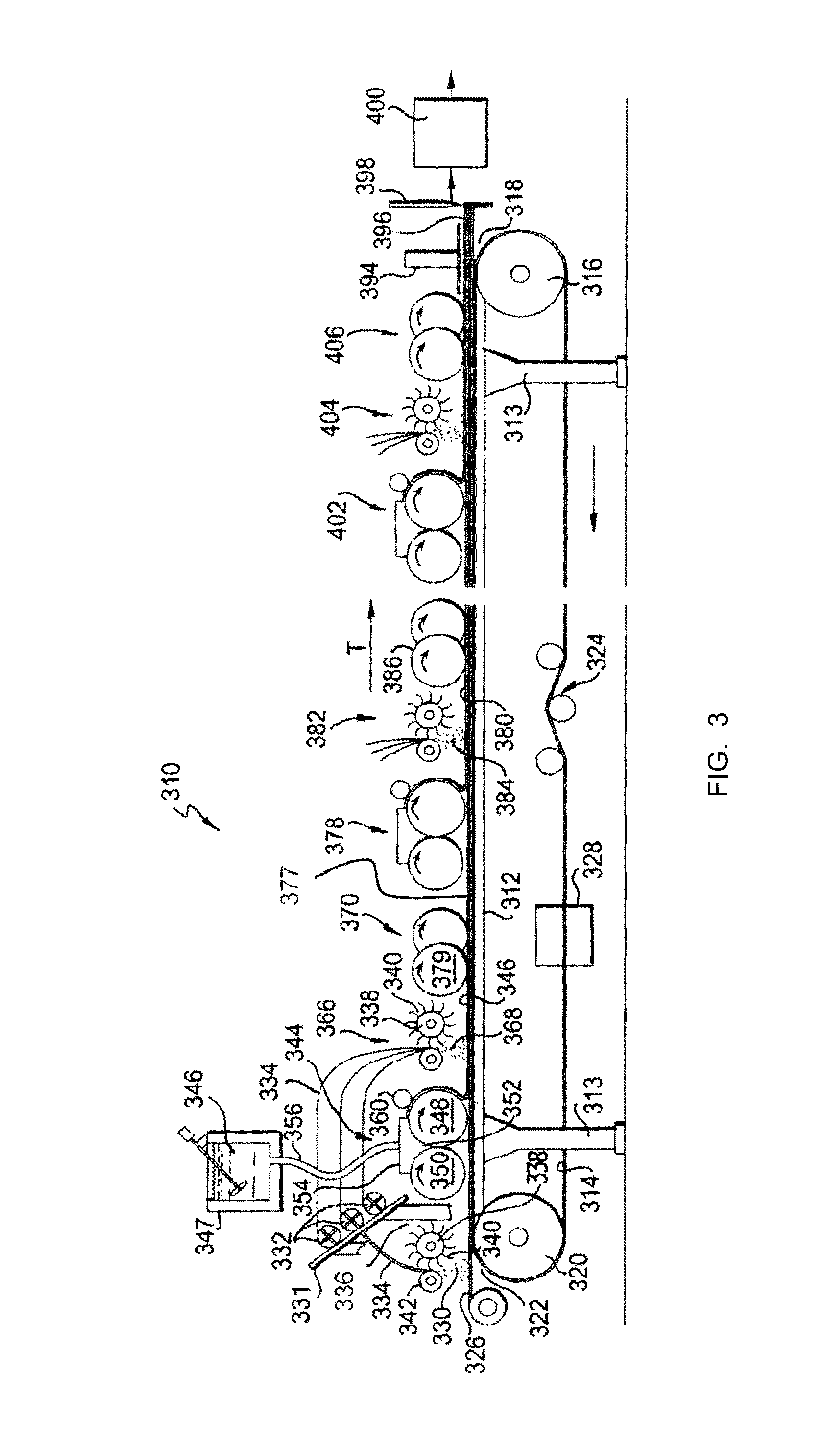

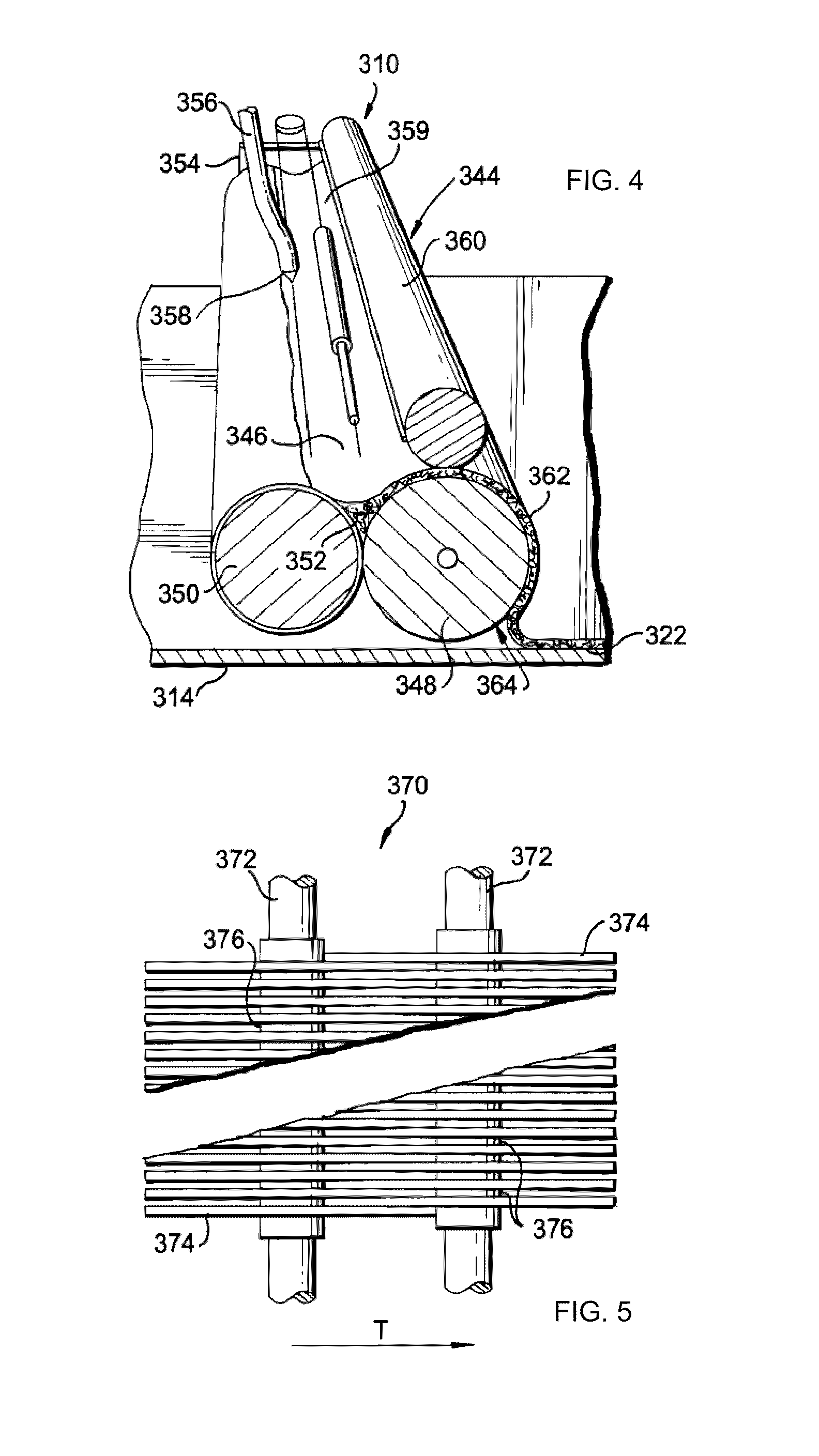

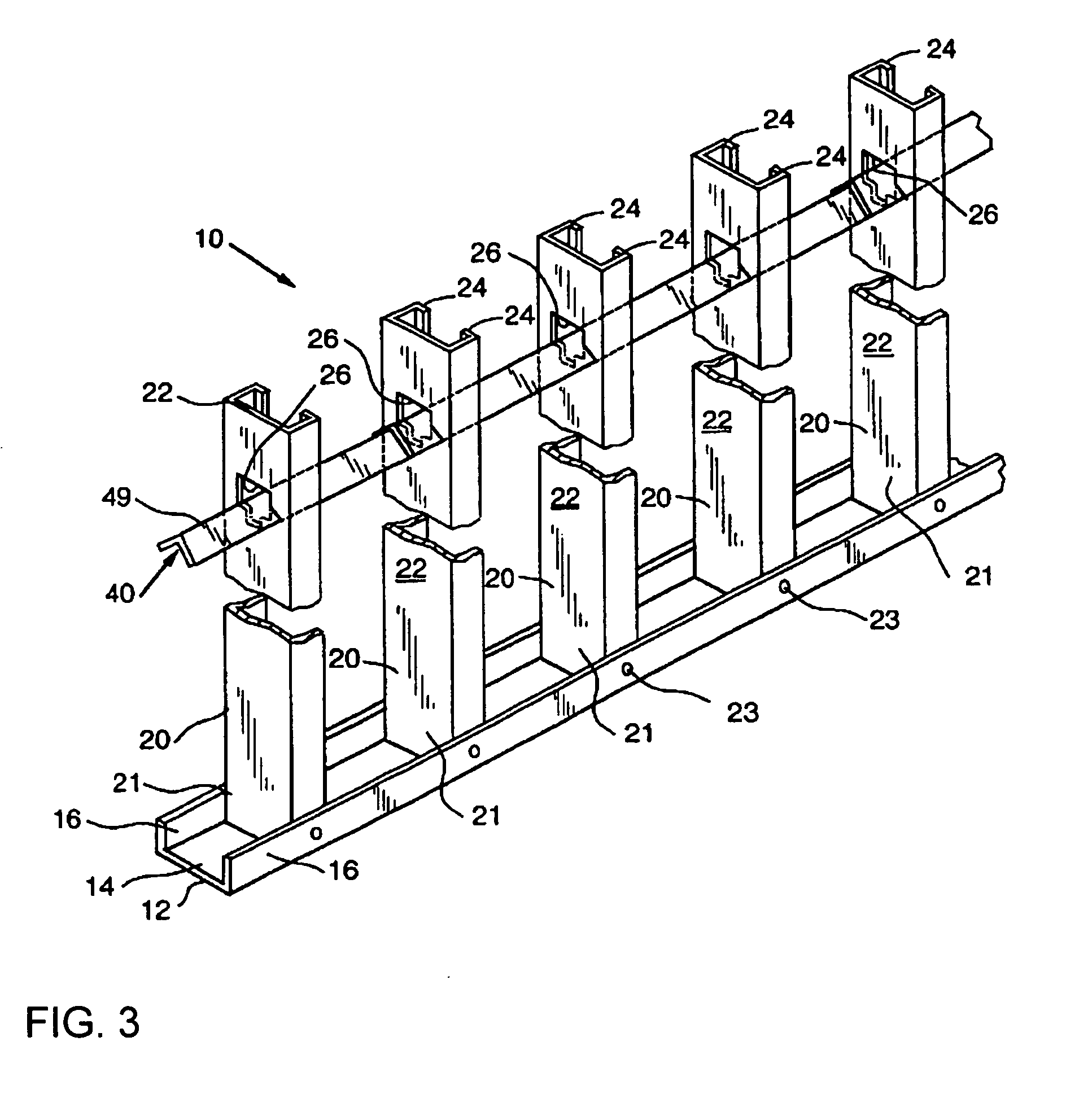

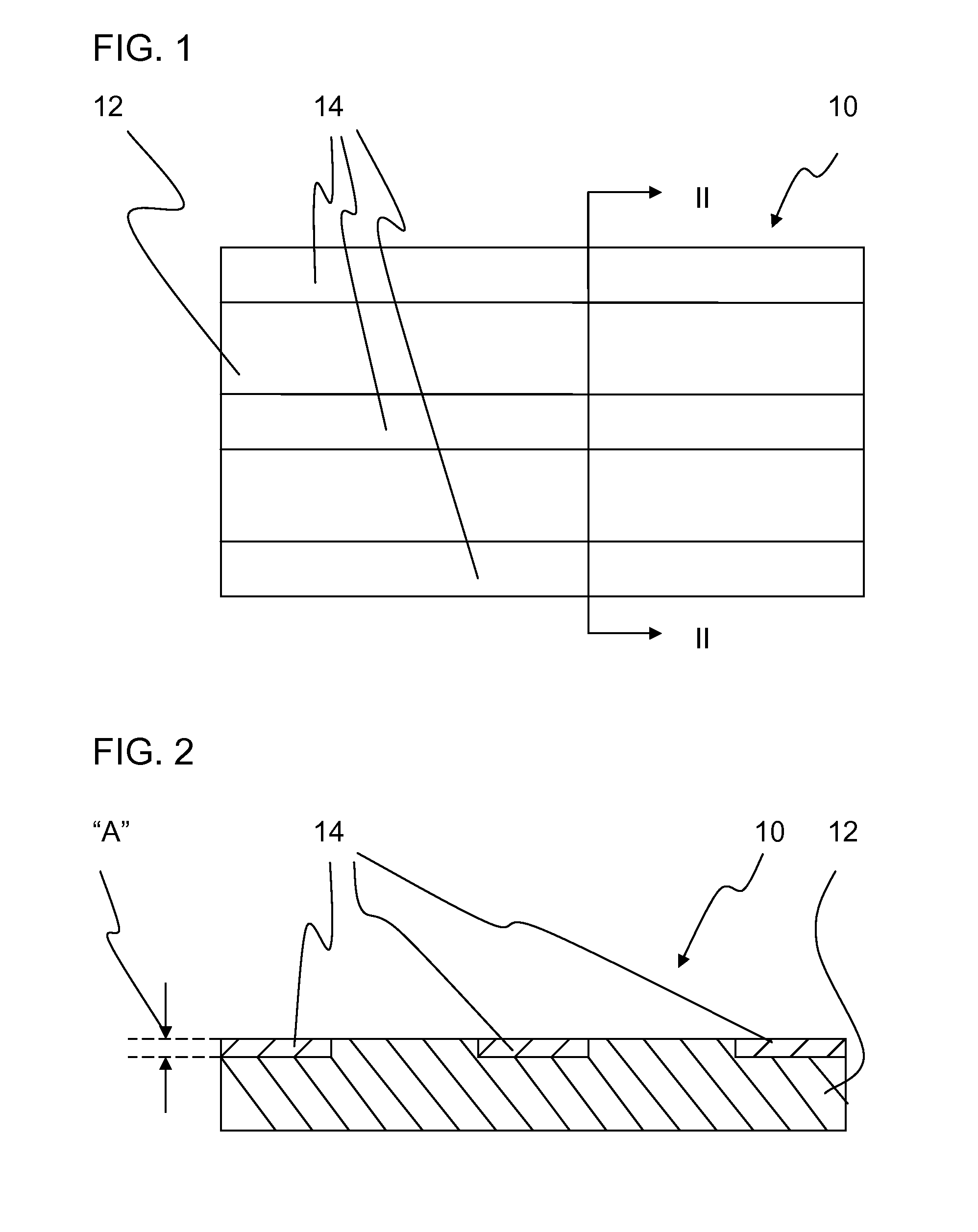

Non-combustible reinforced cementitious lightweight panels and metal frame system for shear walls

ActiveUS20060174572A1Heavy loadMaximization of building volumeSolid waste managementWallsMicrosphereVertical shear

A vertical shear wall system including vertical metal framing members, for example, C-joists, U-joists, open web joists, or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The shear wall system is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

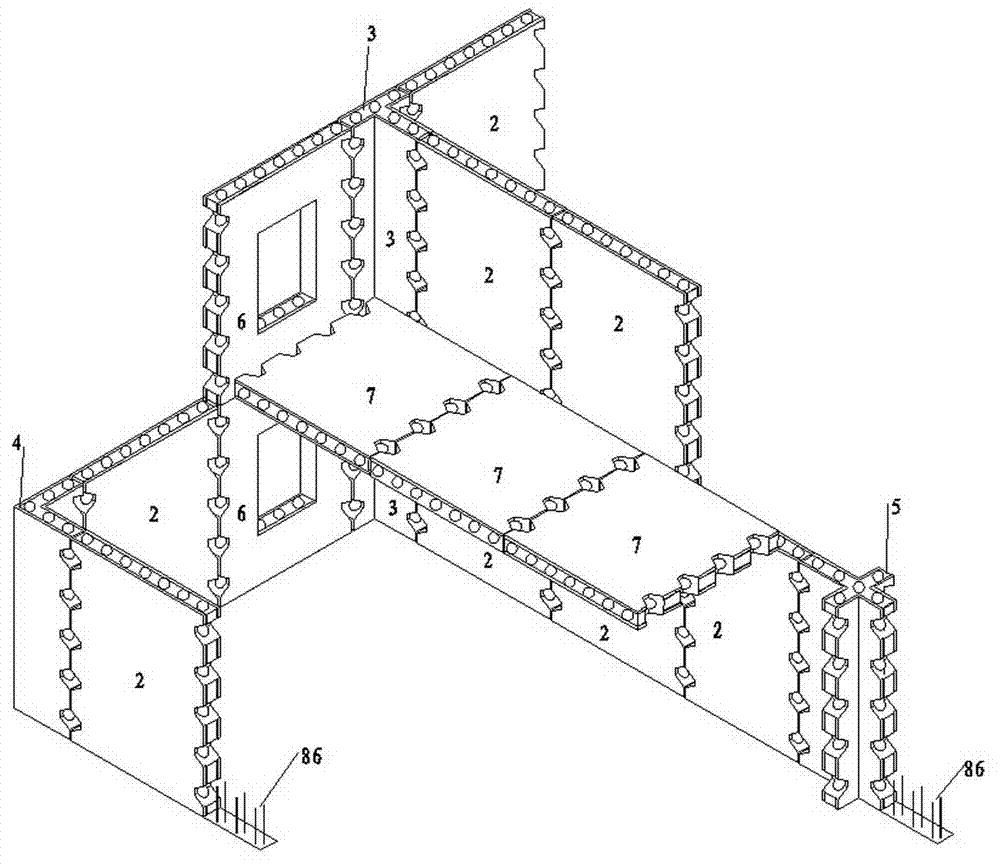

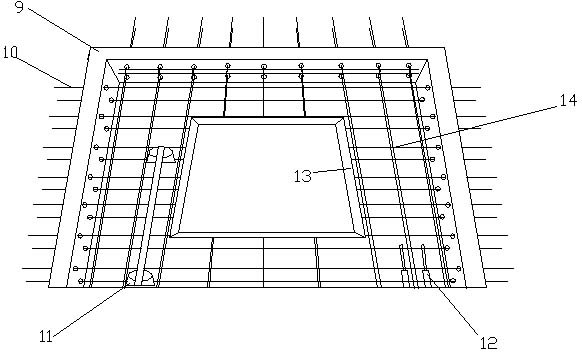

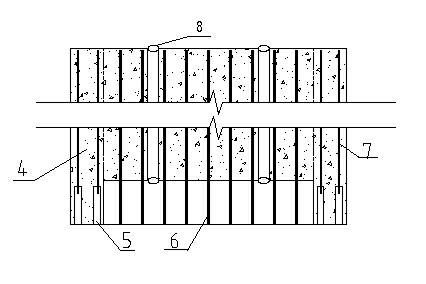

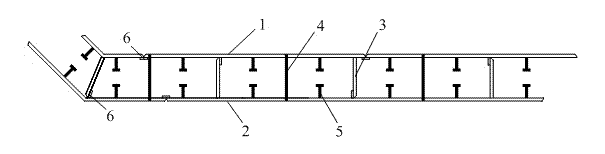

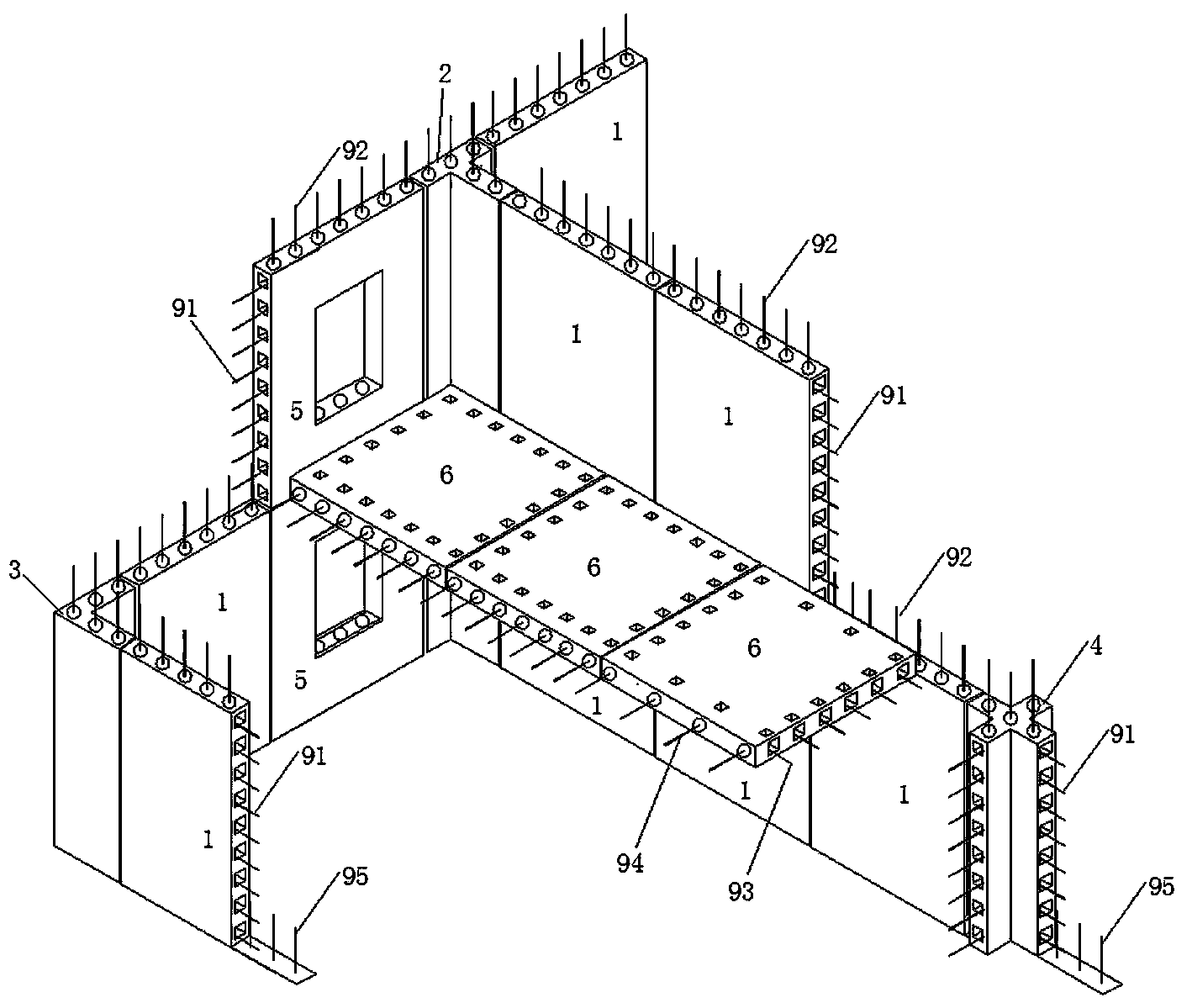

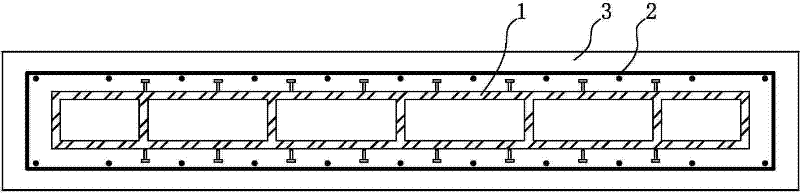

Assembled monolithic shear wall building structure and construction method thereof

InactiveCN102808450AImprove the level of industrializationIncrease productivityConstruction materialWallsTransverse grooveCross wall

The invention relates to an assembled monolithic shear wall building structure and a construction method thereof, and belongs to the technical field of buildings and construction thereof. The assembled monolithic shear wall building structure is formed by connecting prefabricated concrete members which comprise a prefabricated wall plate member, a floor member, a T-shaped wall column member, an L-shaped wall column member, a cross wall column member and a wall member with an opening. The structure is characterized in that a plurality of longitudinal through holes which are parallel to the surface are formed in each prefabricated concrete member; transverse grooves crossed with at least one longitudinal hole are formed on the longitudinal edge at intervals; transverse anchoring steel bars are arranged at the transverse grooves among different prefabricated members; longitudinal anchoring steel bars are arranged in the longitudinal holes; a layer of structural unit or a single-layer building structure is formed by filling concrete in the longitudinal holes and the transverse grooves; and a plurality of structural units are connected to form a multi-layer or high-rise assembled monolithic shear wall structure. The structure can be used in a multi-layer or high-rise shear wall building structure and a frame-shear wall building structure, the industrial level of the building structure can be improved, stress performance is improved, and resources are saved.

Owner:初明进

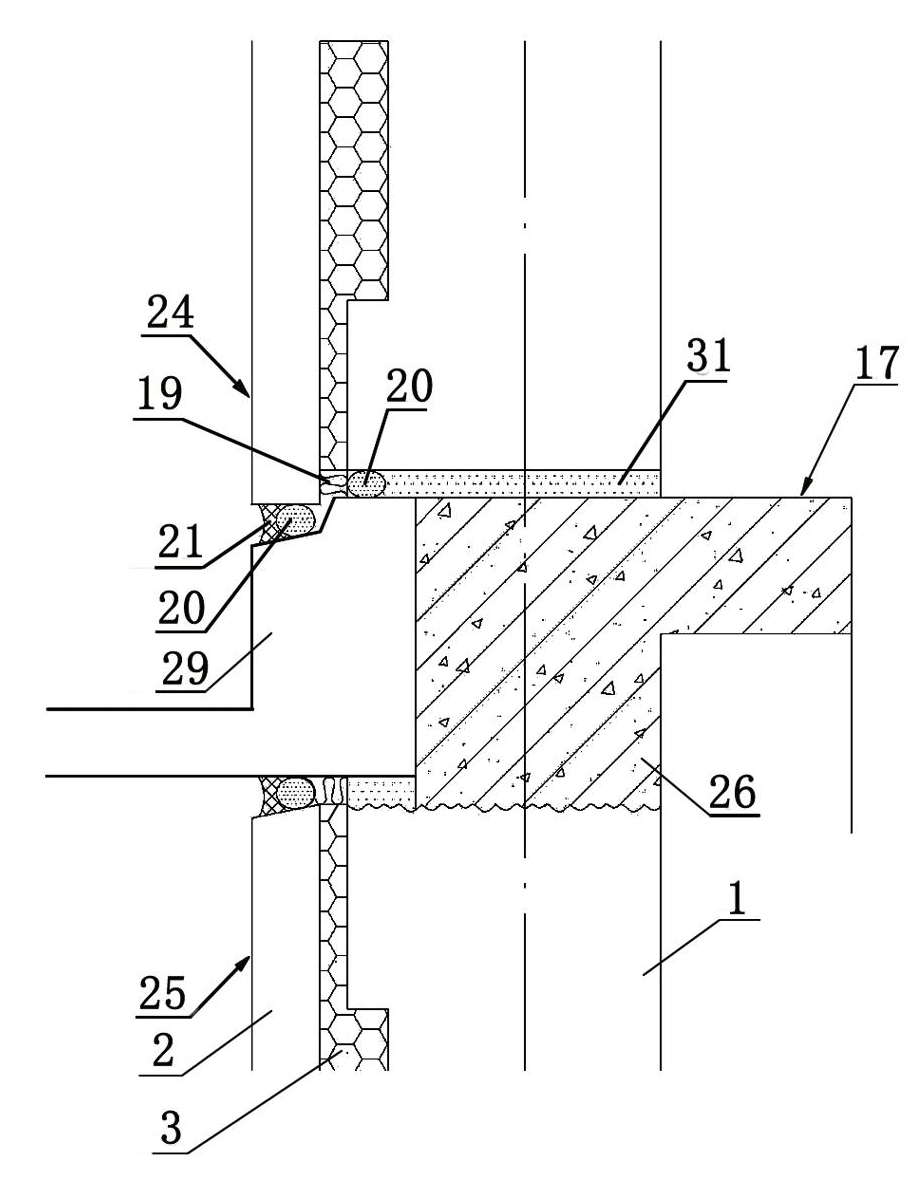

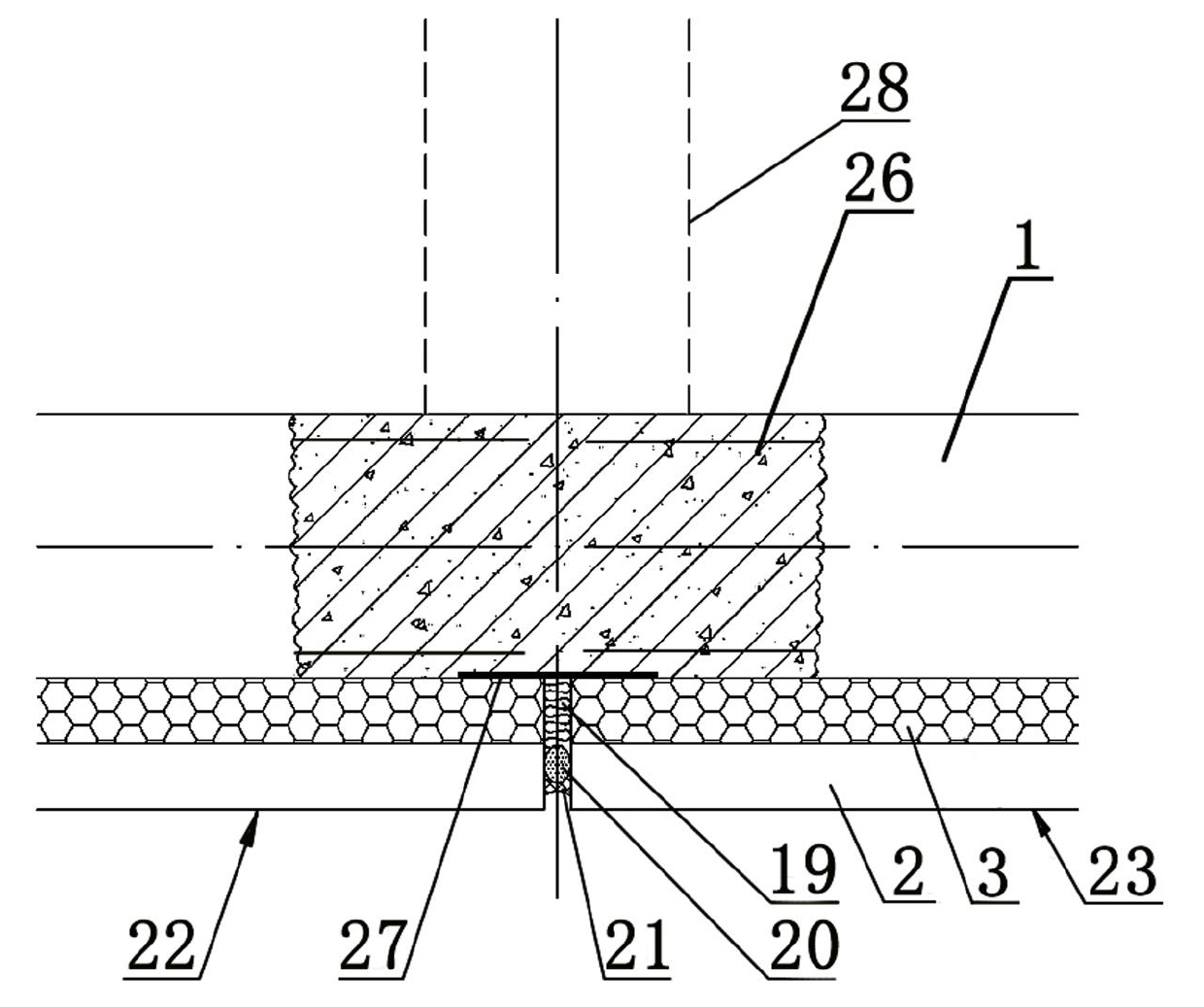

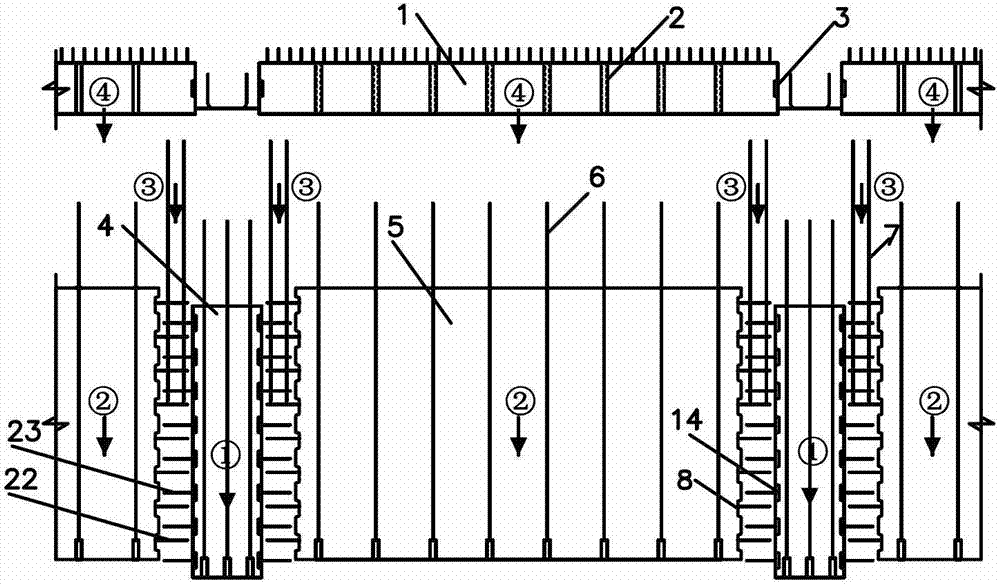

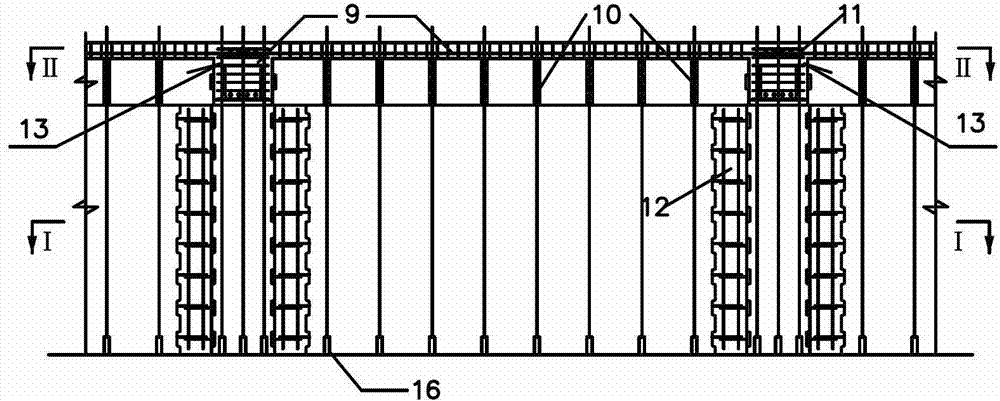

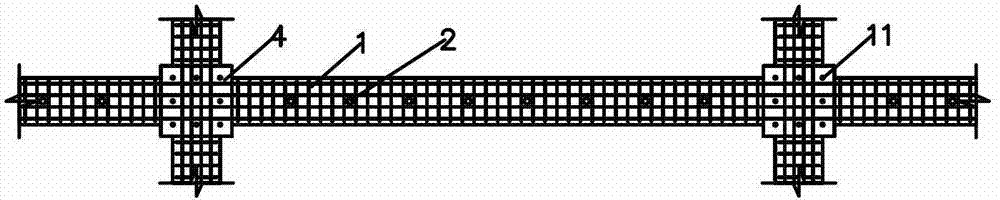

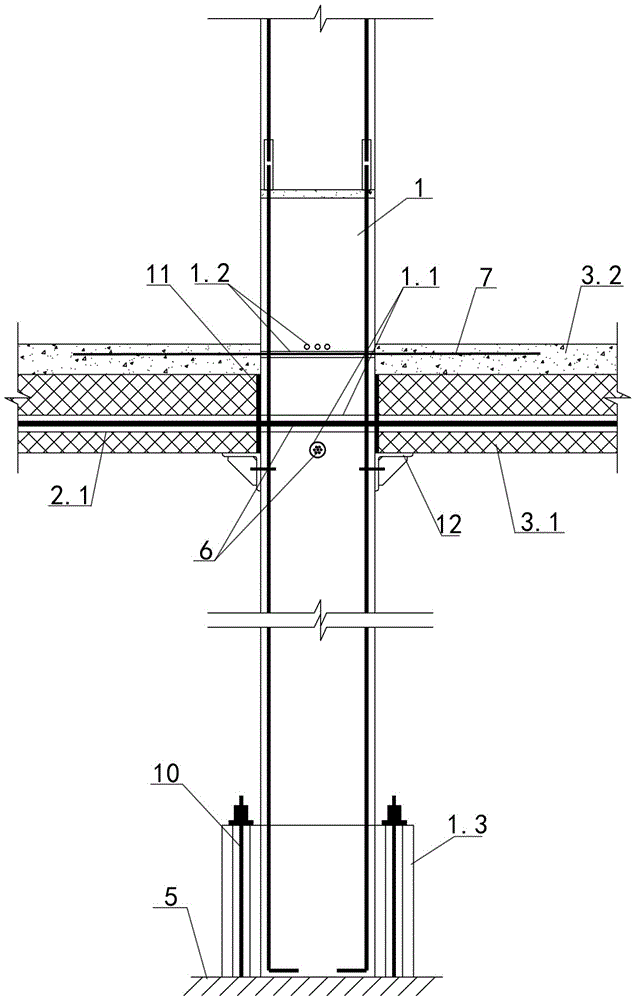

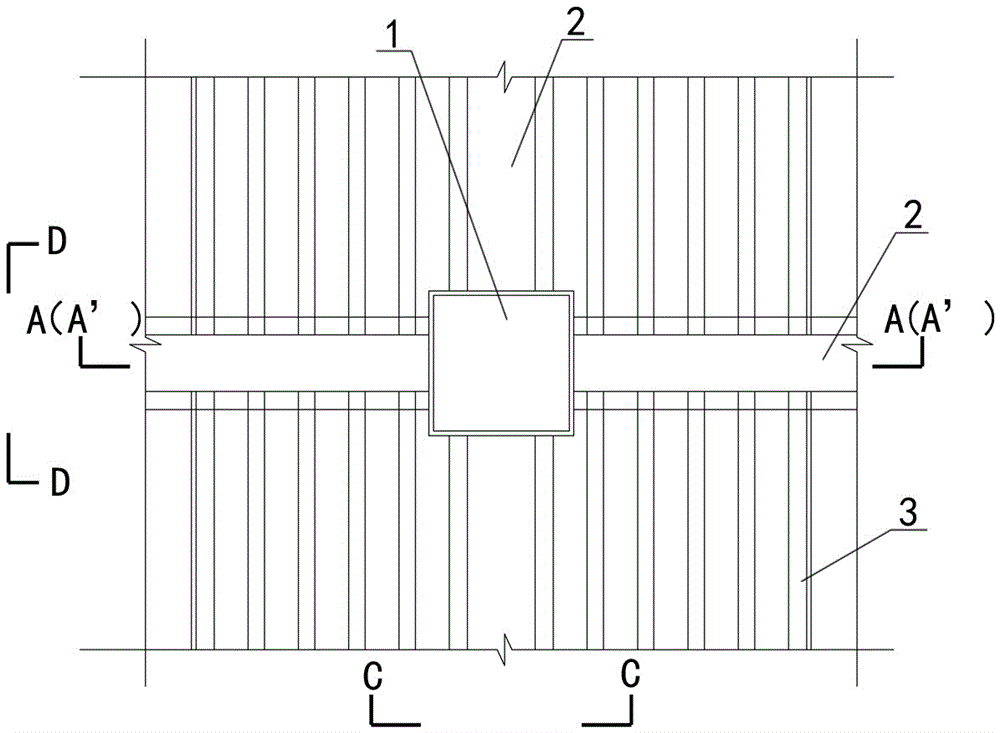

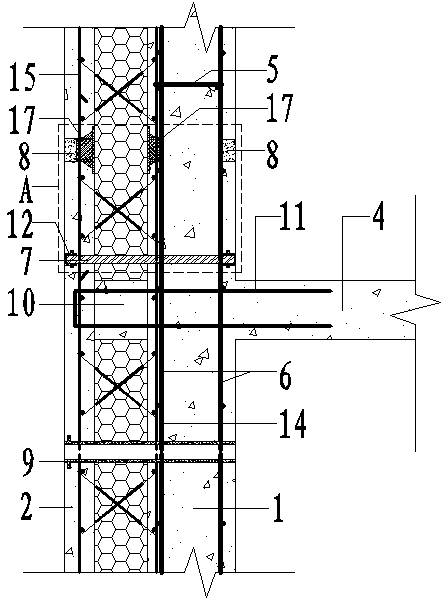

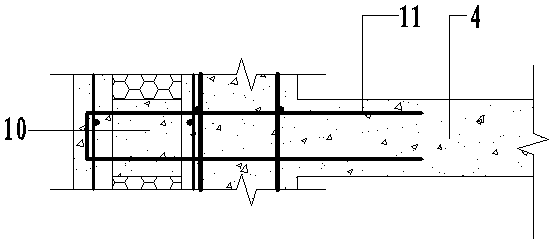

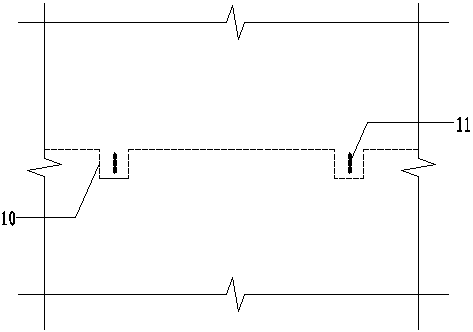

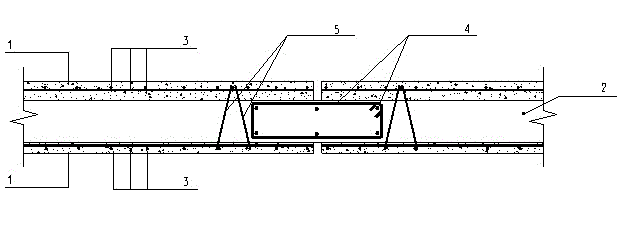

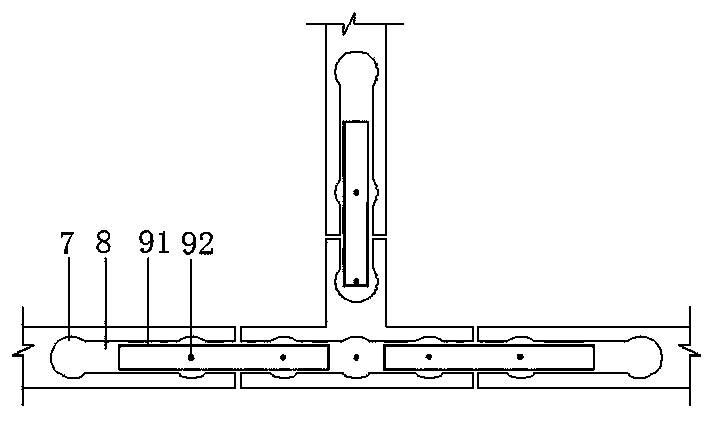

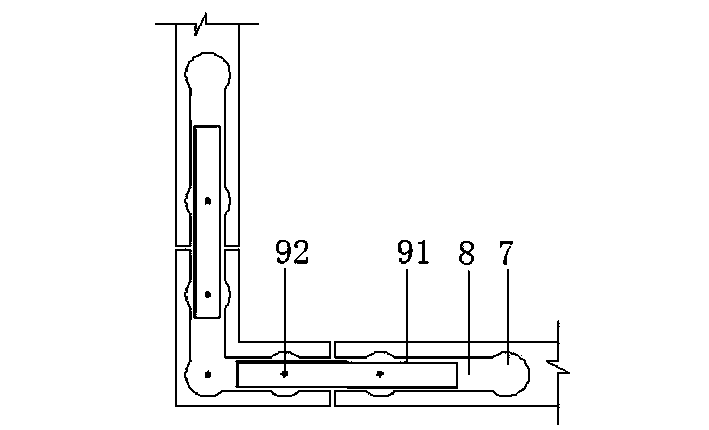

Assembly connecting structure and assembly connecting method of assembled concrete frame and shear wall combination

ActiveCN102808465ASplit location is reasonableEasy to manufactureWallsBuilding material handlingFloor slabRebar

The invention relates to the field of assembled concrete structures, in particular to an assembly connecting structure and an assembly connecting method of an assembled concrete frame and shear wall combination. A cast-in-place strip is disposed between precast columns and precast shear walls to connect column-wall embedded rebars. Vertical through holes are reserved in a precast node-precast beam integrated component to achieve communicated connection of vertical rebars for the upper and lower columns and the upper and lower shear walls. Embedded steel sleeves at the lower ends of the precast columns and the precast shear walls are mutually embedded with projecting rebar segments extending up out of the lower columns and the lower walls, and are integrated with the lower columns and the lower walls through cast mortar. The projecting straight rebars at the upper ends of the precast columns and the precast walls penetrate through the through holes reserved in the precast node-precast beam integrated component and protrude a floor slab, and the precast columns and the precast nodes are firmly integrated with the precast shear walls precast beams by cast mortar. Wet operations such as in-place casting of concrete are reduced to the maximum extent, building quality is improved, construction period is shortened, and energy conservation and emission reduction are achieved.

Owner:SHENYANG JIANZHU UNIVERSITY

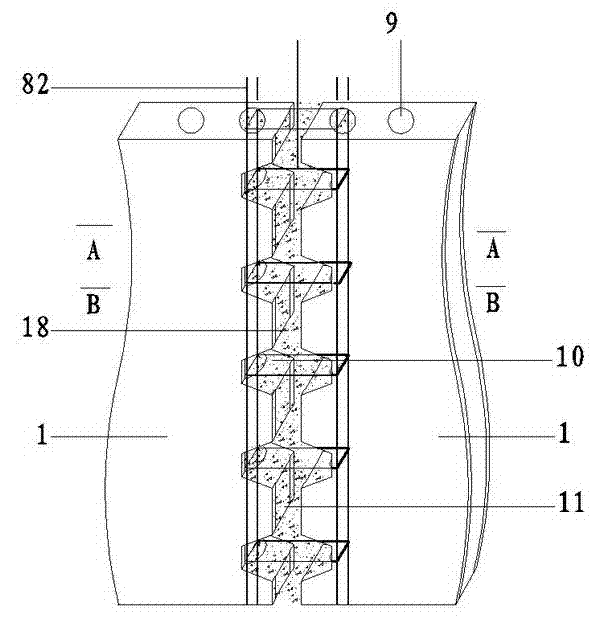

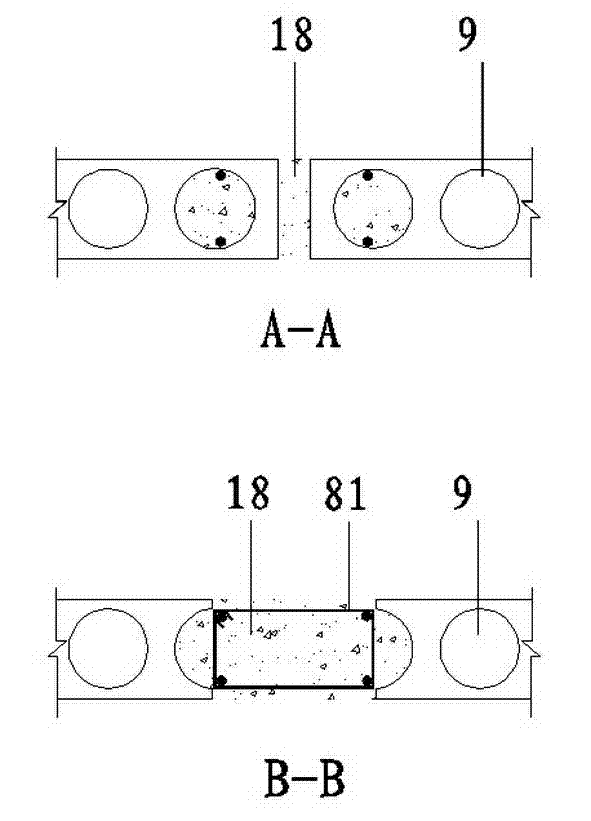

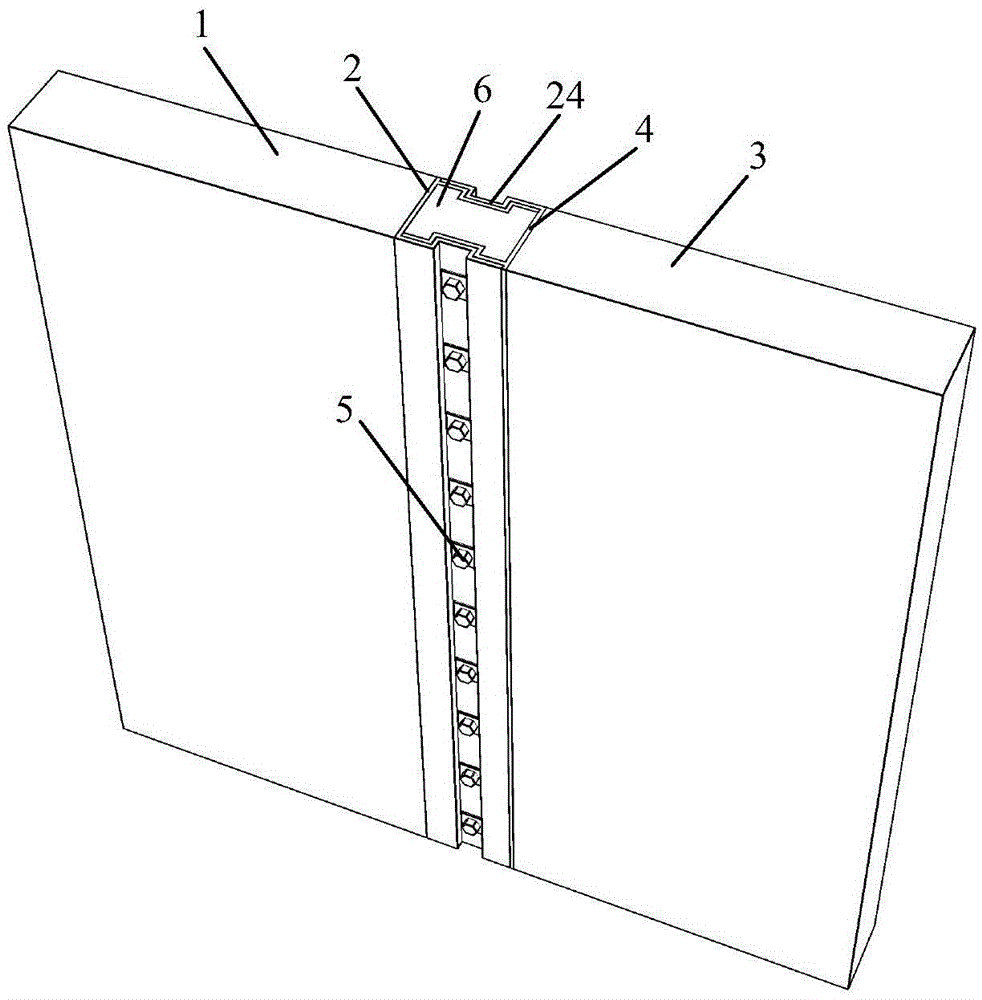

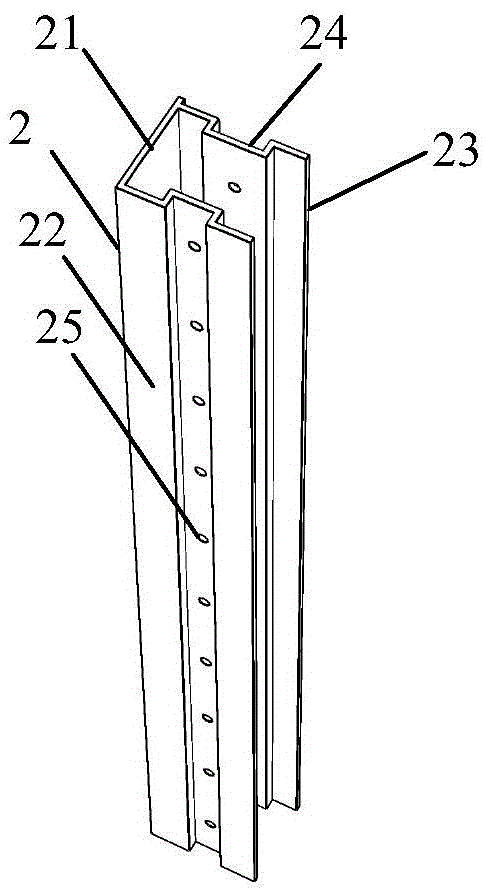

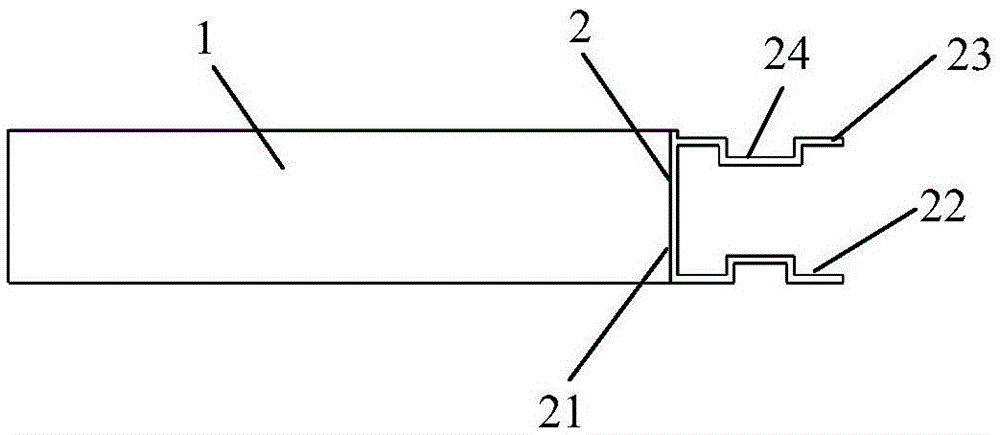

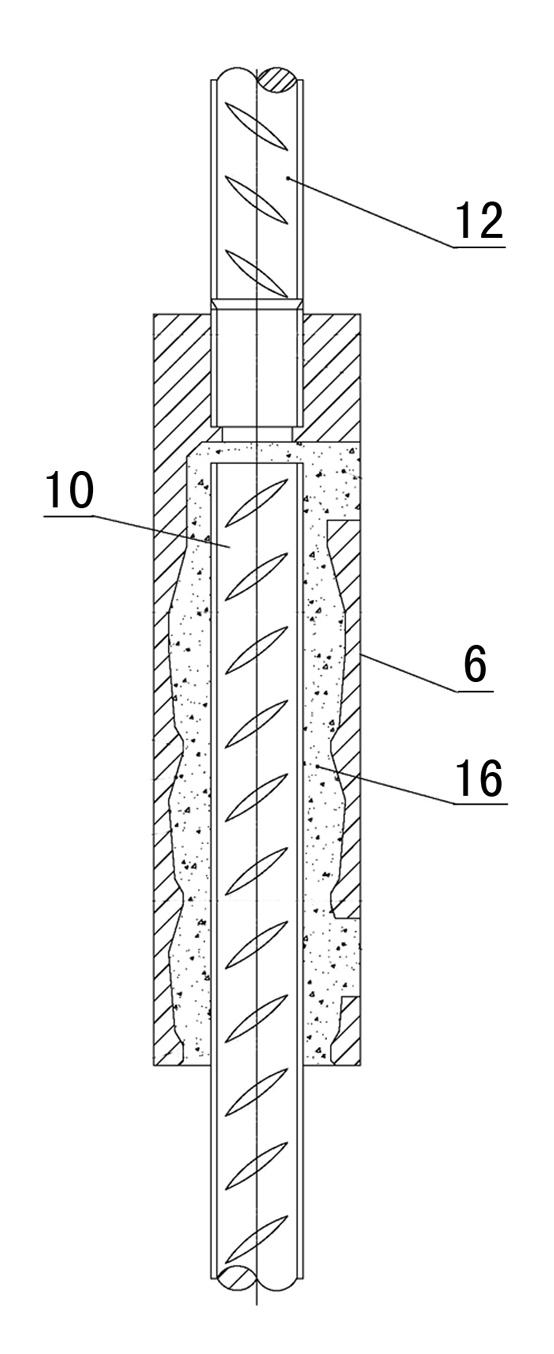

Prefabricated assembly type shear wall vertical slit connecting structure and construction method thereof

The present invention provides a prefabricated assembly type shear wall vertical slit connecting structure which comprises a left side shear wall, left side pre-embedded profile steel, a right side shear wall, right side pre-embedded profile steel, and a plurality of split bolts. The left side pre-embedded profile steel and the right side pre-embedded profile steel are disposed between the left side shear wall and the right side shear wall and have the same structure. The left side pre-embedded profile steel comprises a side plate, a front side plate and a rear side plate, the front side plate and the rear side plate are disposed at front and rear positions of the side plate, each of the front side plate and the rear side plate is inwardly provided with a groove, and the grooves are provided with a plurality of bolt holes. The split bolts are disposed in the bolt holes to lock and fix the left side pre-embedded profile steel and the right side pre-embedded profile steel. The present invention also provides a construction method of the prefabricated assembly type shear wall vertical slit connecting structure. The connecting structure is high in bearing capacity, high in stiffness, good in seismic ductility, excellent in integrity, convenient in construction and good in construction quality, and concrete is effectively restrained.

Owner:FUJIAN UNIV OF TECH

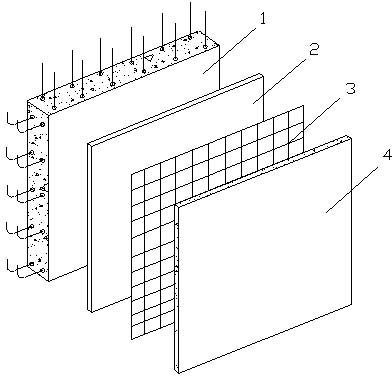

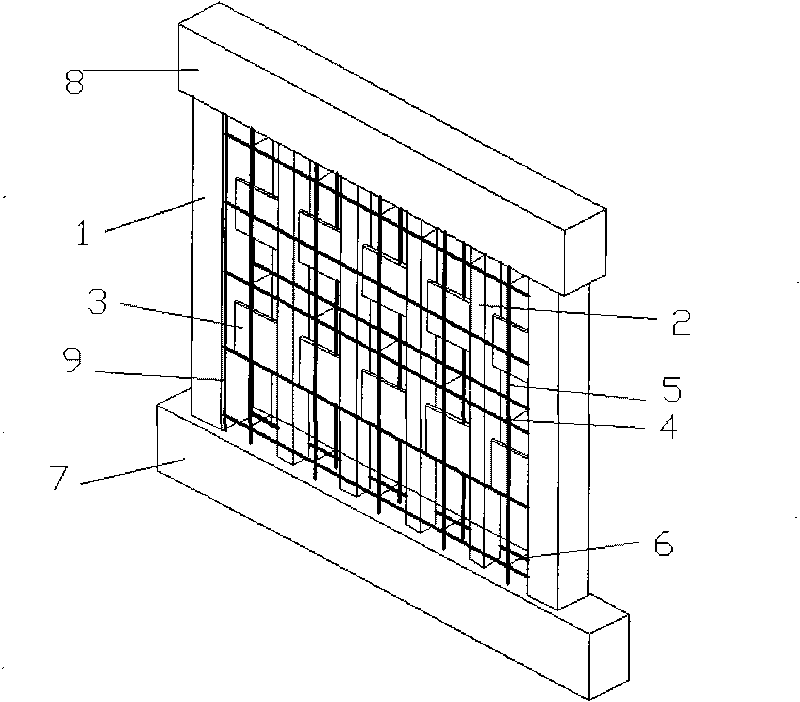

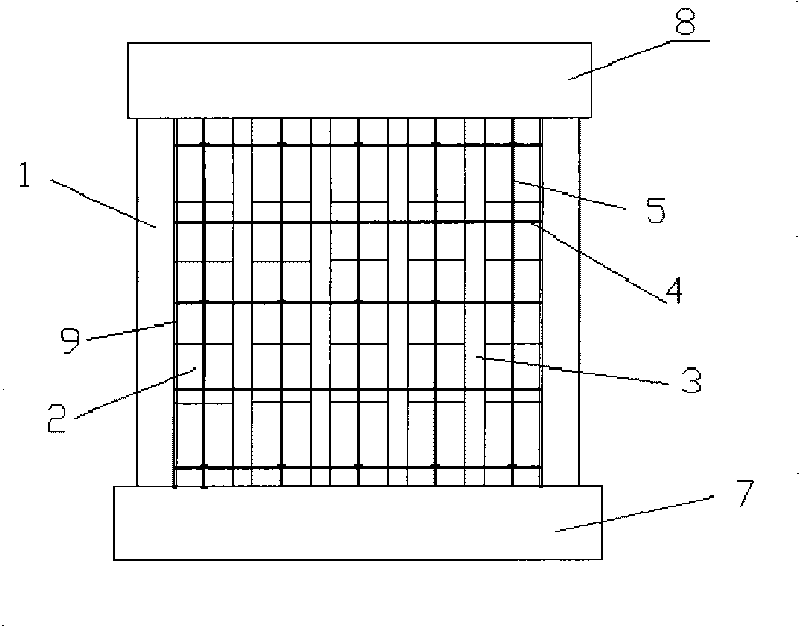

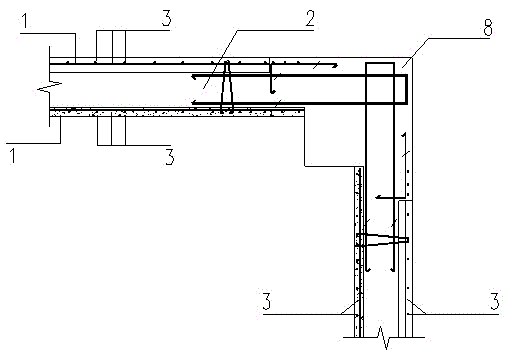

Assembled integral shear wall structure system and construction method thereof

ActiveCN101818527ALow costGuarantee the construction qualityWallsBuilding material handlingReinforced concretePolystyrene

The invention discloses an assembled integral shear wall structure system and a construction method thereof. Prefabricated composite wallboards are hoisted and assembled integrally at a construction site; a board body of the prefabricated composite wallboards comprises a structural layer, an insulating layer and a protective layer from the inside to the outside in turn; a reinforcement cage is arranged in the structural layer; the insulating layer is an extruded polystyrene foam plastic board; steel meshes are arranged in the concrete of the protective layer; and anchor bolts in a dotted distribution are connected among the structural layer, the insulating layer and the protective layer. Vertical seams and horizontal seams of prefabricated composite walls adopt structural self-waterproofing, so that common quality problems such as leakage and cracks and the like in a traditional process are solved. The prefabricated composite walls simplify construction processes, speed up the construction, and lower the construction cost. Furthermore, products prefabricated in a factory have uniform specifications and unified quality, so that the construction quality of a building construction can be sufficiently guaranteed; the industrialization, standardization, and generalization of the building walls are realized; and the products can be widely applicable to the construction of reinforced concrete buildings in the construction industry.

Owner:华筑(辽宁)建筑工程设计有限公司

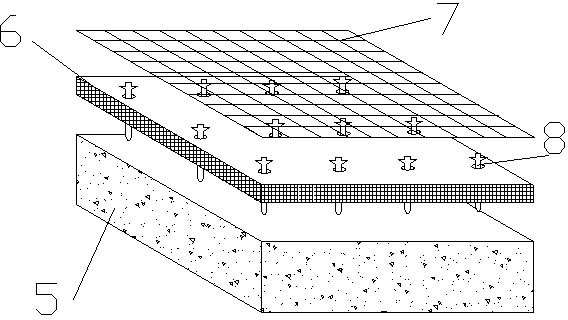

Prefabricated sandwich heat-preservation heat insulation concrete external wall panel and fabrication method

InactiveCN102650152AImprove manufacturing precisionReduce mistakesCeramic shaping apparatusBuilding componentsFire protectionEnergy conservation

The invention discloses a prefabricated sandwich heat-preservation heat insulation concrete external wall panel and a fabrication method. An integral composite wall panel which is structured in a way of wall body- heat insulation-architectural decoration from interior to exterior is adopted, the wall body is a load-bearing concrete structural layer, the middle of the wall panel adopts a heat insulation board, and the outermost side of the wall panel is an architectural decoration cladding panel, the three layers of the wall panel are connected into a whole by heat insulation connectors, so that the composite external wall panel is applicable to assembling an integral shear wall structure or an integral frame-shear wall structure, and also meets the requirements of buildings on energy conservation and fire protection. The prefabricated sandwich heat-preservation heat insulation concrete external wall panel is prefabricated in a factory and is mounted on site, so that the production and construction efficiencies are high, and the quality is also ensured; besides, the external wall panel realizes energy conservation, environmental protection, fire protection and heat insulation, and also has remarkable comprehensive benefits.

Owner:CHINA MCC17 GRP

Splitting and assembling structure and assembling connecting method of assembled type concrete frame-shear wall

ActiveCN102900168ASplit location is reasonableEasy to manufactureWallsBuilding material handlingSteel barEngineering

The invention relates to the field of concrete structures, in particular to a splitting and assembling structure and an assembling connecting method of an assembled type concrete frame-shear wall. The splitting and assembling structure comprises prefabricated pillars, prefabricated beams, prefabricated shear walls and cast-in-situ joints, wherein sleeves are embedded at the lower ends of the prefabricated pillars, mutually embedded with protruding reinforcing steel bar sections which extend from the upper ends of lower layer pillars and are integrally connected with the lower layer pillars by filling mortar; longitudinal prefabricated beam reinforcing steel bars extend into a joint core area to be anchored or connected with side beam ribs in a mechanical manner; a cast-in-situ zone is arranged between the prefabricated pillars and the prefabricated shear walls so as to carry out the connection of the embedded ribs of the pillars and the walls; and the embedded reinforcing steel bar sleeves at the lower ends of the prefabricated shear walls are mutually embedded with protruding reinforcing steel bar sections which extend upwards from the walls at the lower layer and are integrally connected with the walls at the lower layer by filling the mortar. The through connection of the vertical reinforcing steel bars of the share walls at the upper and lower layers is realized by filling the mortar into the through holes and the sleeves at the upper ends of the prefabricated shear walls and the prefabricated beams, so that the key problem that the vertical reinforcing steel bars of the share walls are hard to be continuous because of the isolation of the prefabricated beams is solved.

Owner:SHENYANG JIANZHU UNIVERSITY

Anti-buckling oblique notching steel plate energy dissipation shear wall

InactiveCN103437456AAdjust the lateral stiffnessIncrease lateral stiffnessWallsShock proofingClassical mechanicsEngineering

The invention relates to an anti-buckling oblique notching steel plate energy dissipation shear wall which belongs to the technical field of structural engineering. The anti-buckling oblique notching steel plate energy dissipation shear wall consists of an oblique notching steel plate, concrete slabs and an edge frame, wherein the concrete slabs are arranged at both sides of the steel plate and are used for restraining out-of-plane deformation of the steel plate; the edge frame is connected with the steel plate; the steel plate is provided with different forms of chutes designed as required; the periphery of the steel plate is connected and embedded into the edge frame by bolts; the bolts passing through the chutes are connected with the concrete slabs at both the sides. By forming the different forms of chutes on the steel plate, a complex stress state of the steel plate is changed, and a stress mode of taking tension and compression deformation of the steel plate among the chutes as the major mode is formed, and thus, not only is the anti-buckling oblique notching steel plate energy dissipation shear wall beneficial for implementing stable tension and compression energy dissipation, but also parameters of inclined plates among the chutes can be regulated by changing the forms and the sizes (length and width) of the formed chutes, and an inefficacy mechanism of the shear wall is effectively controlled, so that resist lateral stiffness, intensity and ductility of the shear wall can be regulated. Used as a novel lateral force resisting and energy dissipation component, the anti-buckling oblique notching steel plate energy dissipation shear wall can be widely applied to multilayer and high-rise structures.

Owner:欧进萍

Assembly-type residential shear wall structural wall body vertical connection construction method

ActiveCN102425310AReduce the number of connectionsReduce construction costsBuilding material handlingHigh pressureRebar

The invention relates to a prefabricated shear wall body vertical connection construction method, in particular to an assembly-type residential shear wall structural wall body vertical connection construction method, which is characterized in that: when a prefabricated lower layer wall body is connected with a prefabricated upper layer wall body, supporting leg parts on two ends of the bottom part of a shear wall body are connected with each other through a reinforced bushing anchoring grouting method, and preformed steel reinforced parts on the middle part of the shear wall are connected with each other through a binding and overlapping method. When an upper layer wall body is prefabricated, anchoring connection bushings are respectively embedded on the supporting leg parts on two ends of the shear wall, the middle part of the shear wall is produced into a feeding passage for pouring concrete at a later period by embedding a steel bushing, self-compacting concrete is poured towards the middle part of the shear wall from a feeding port on the top part of the feeding passage, and high-strength grouting materials are fulfilled into the anchoring connection bushing at high pressure through a high-pressure grouting machine. Due to the adoption of the method, the quantity of the connection bushing can be reduced, the cost can be saved, and the connection quality and the connection speed can be improved. The weaknesses of the traditional shear wall vertical connection installation process that the cost is high, the construction speed is slow, the quality is difficult to control, and the like can be overcome.

Owner:CHINA 22MCC GROUP CORP +1

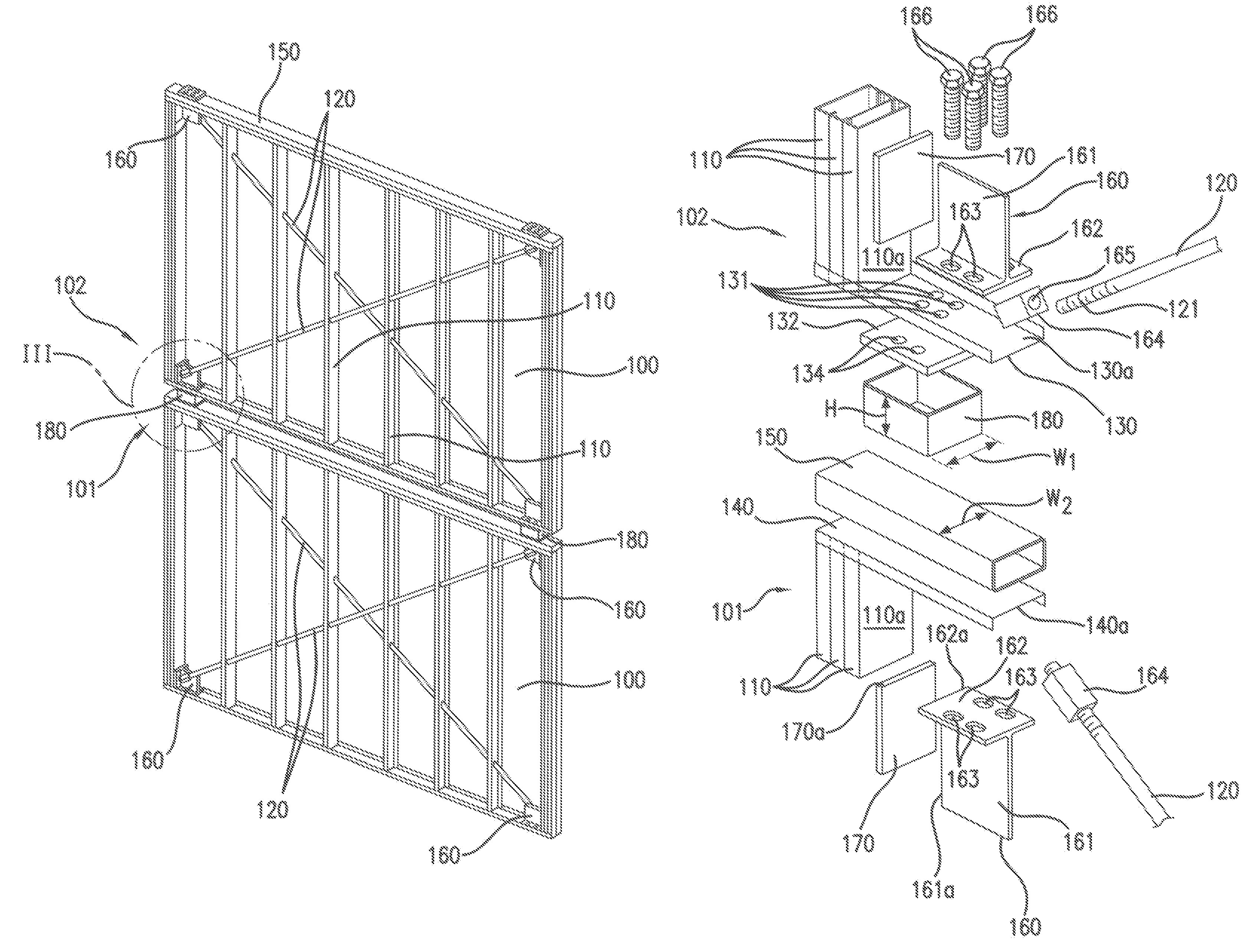

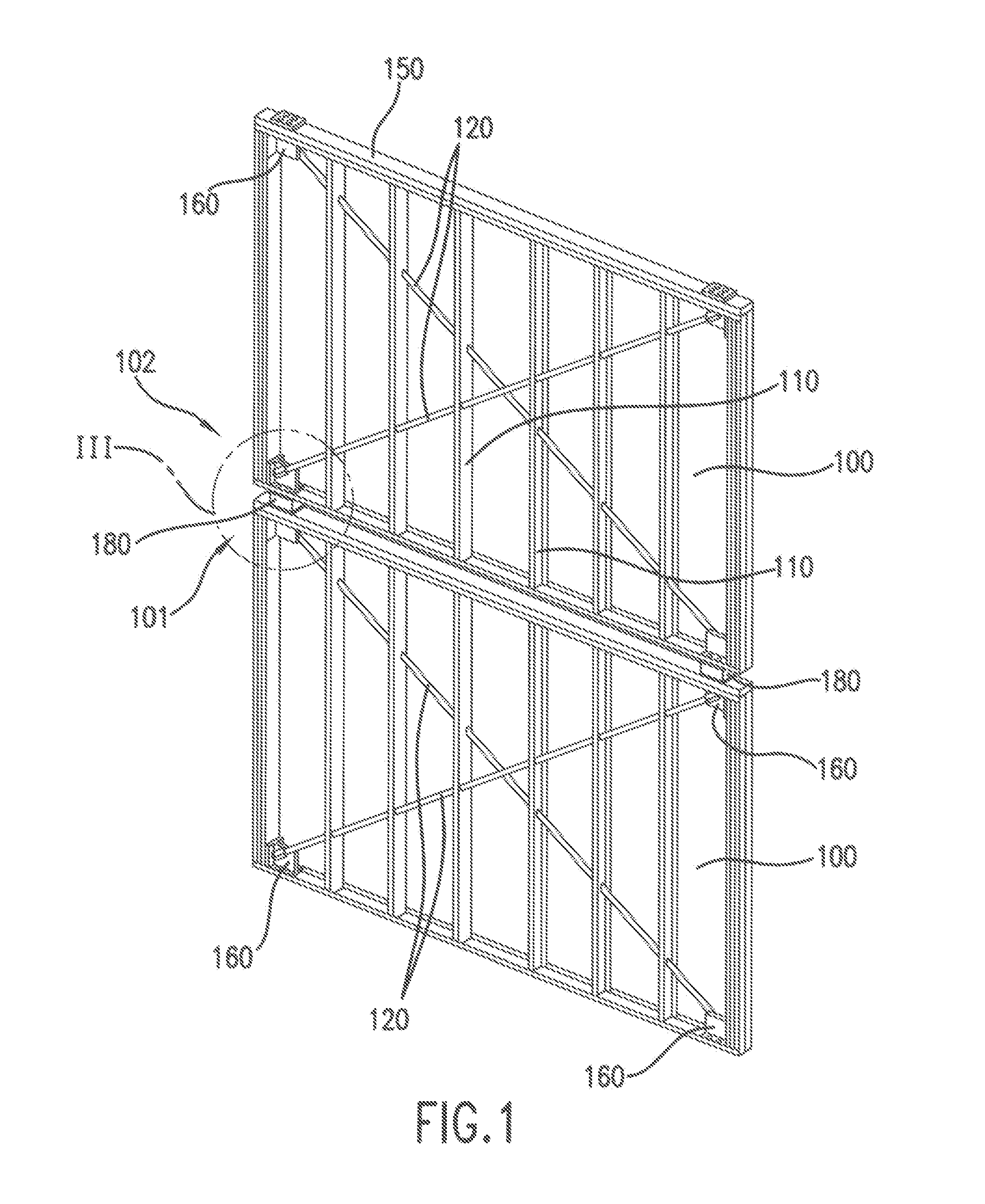

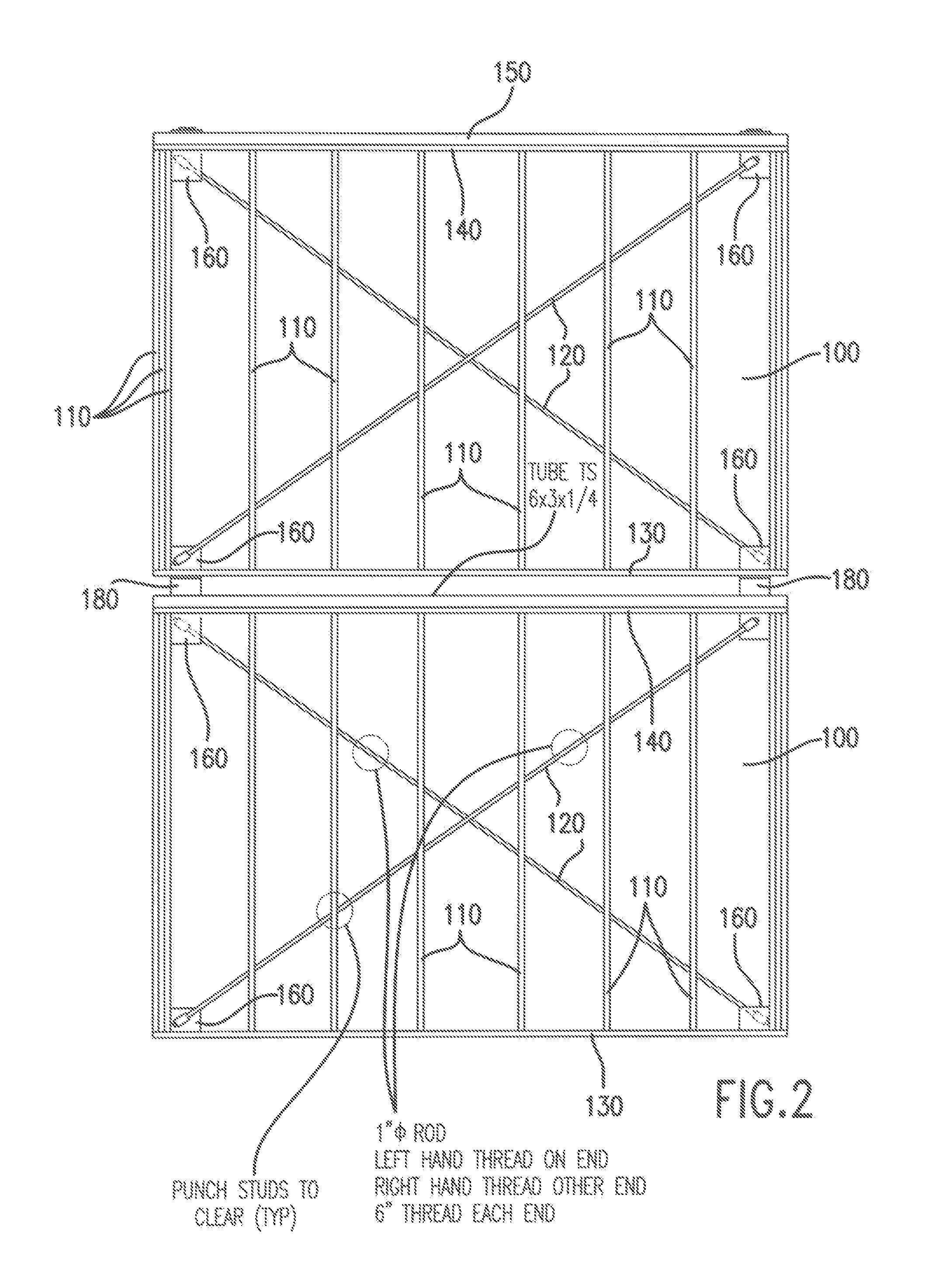

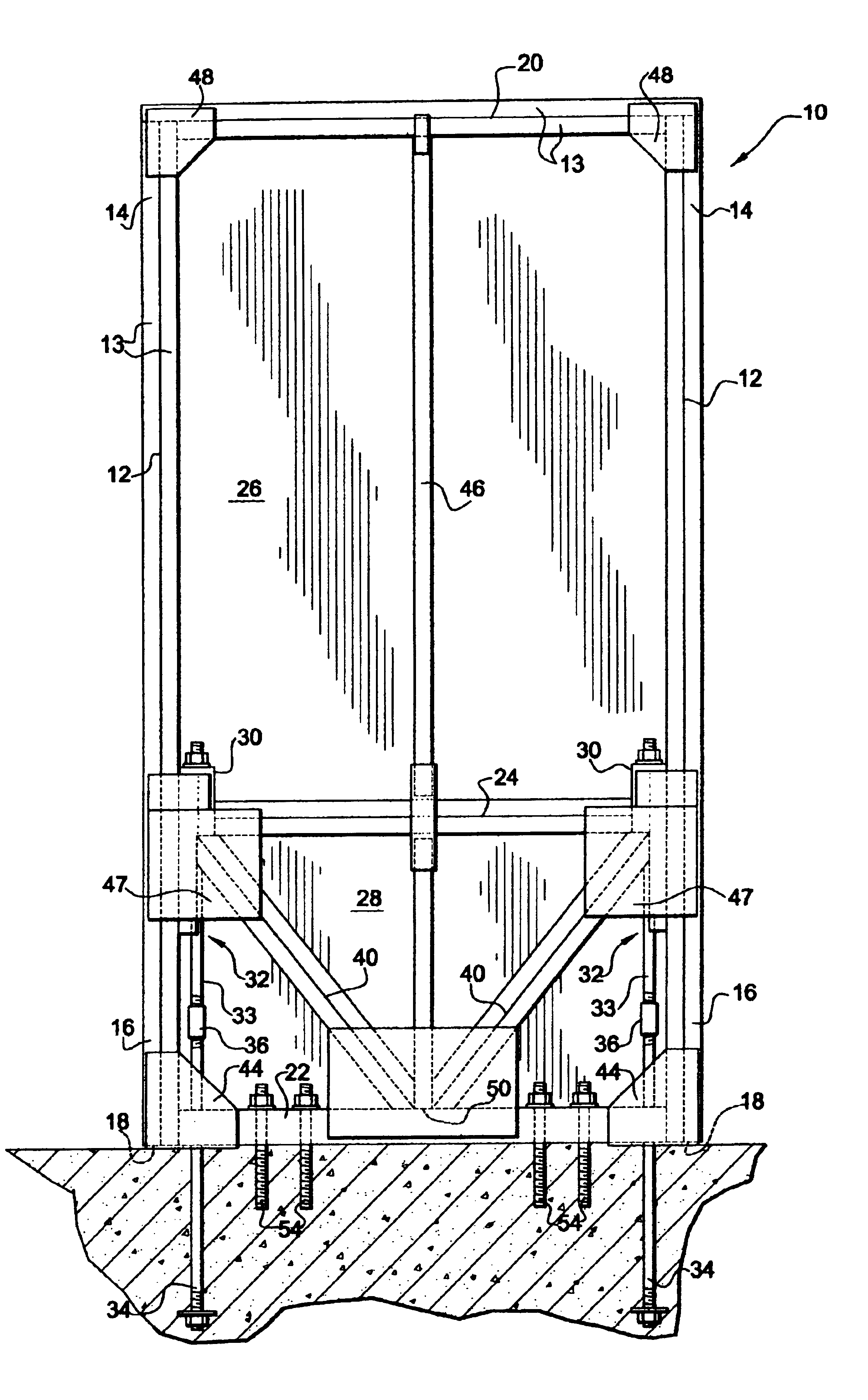

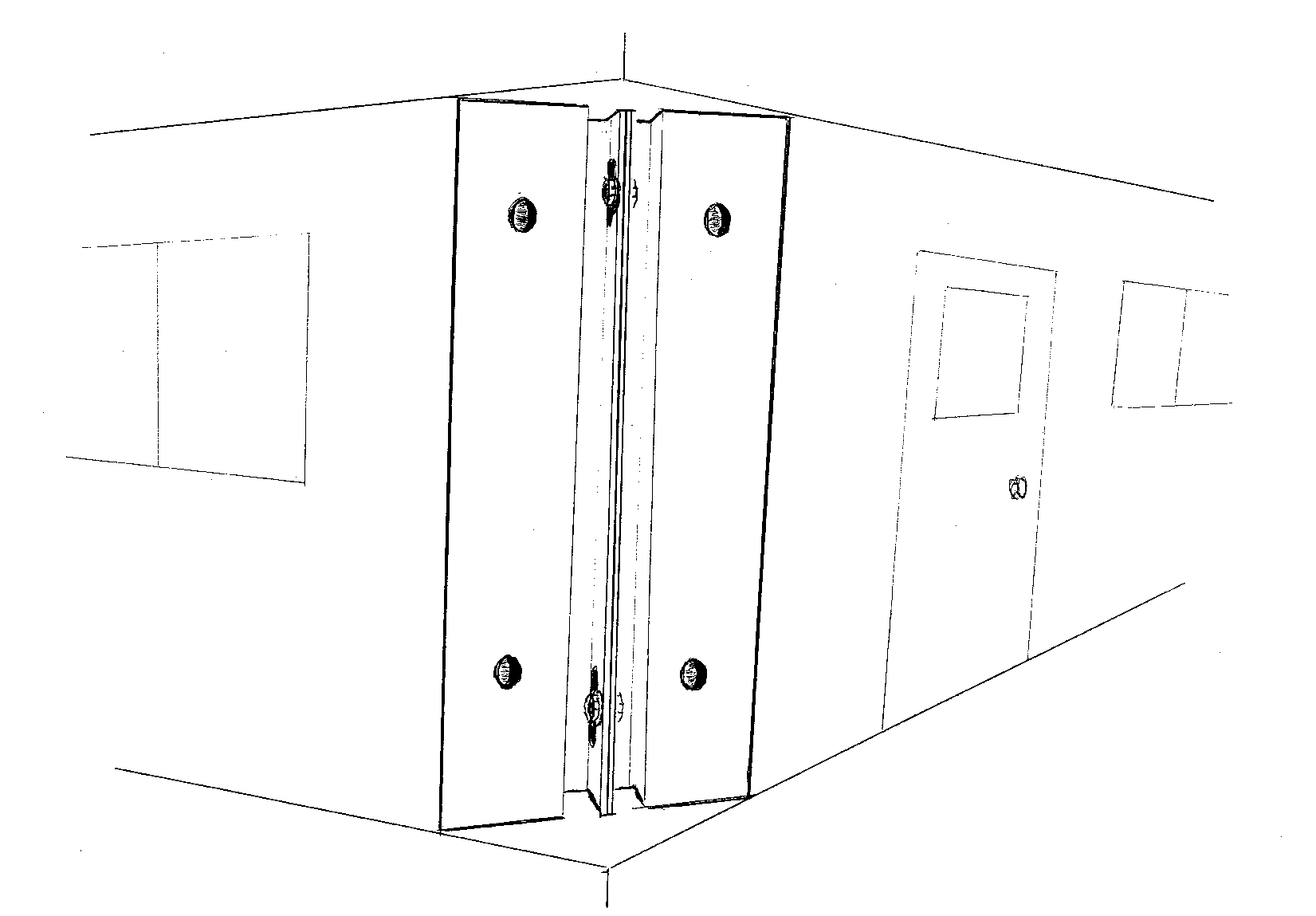

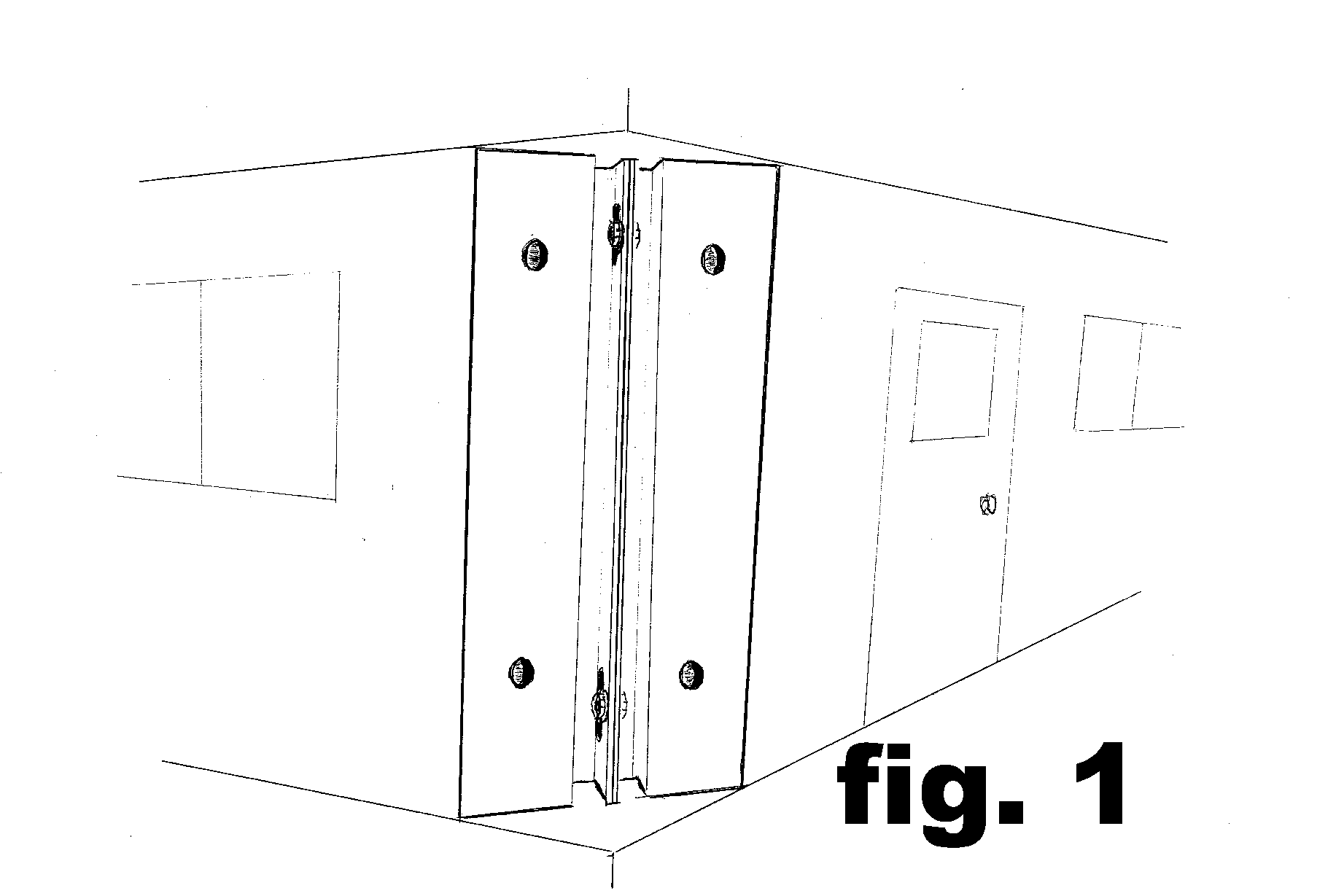

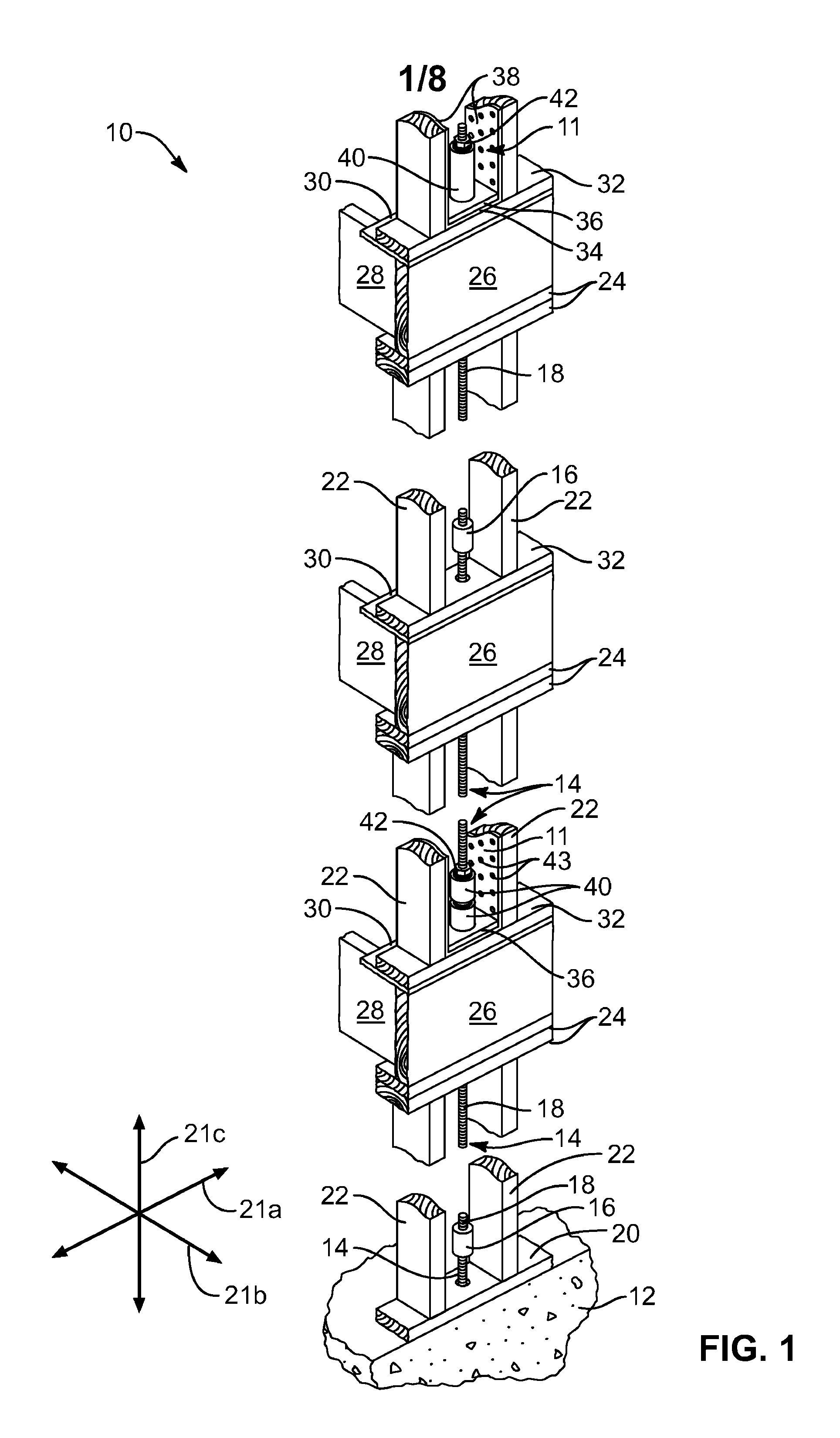

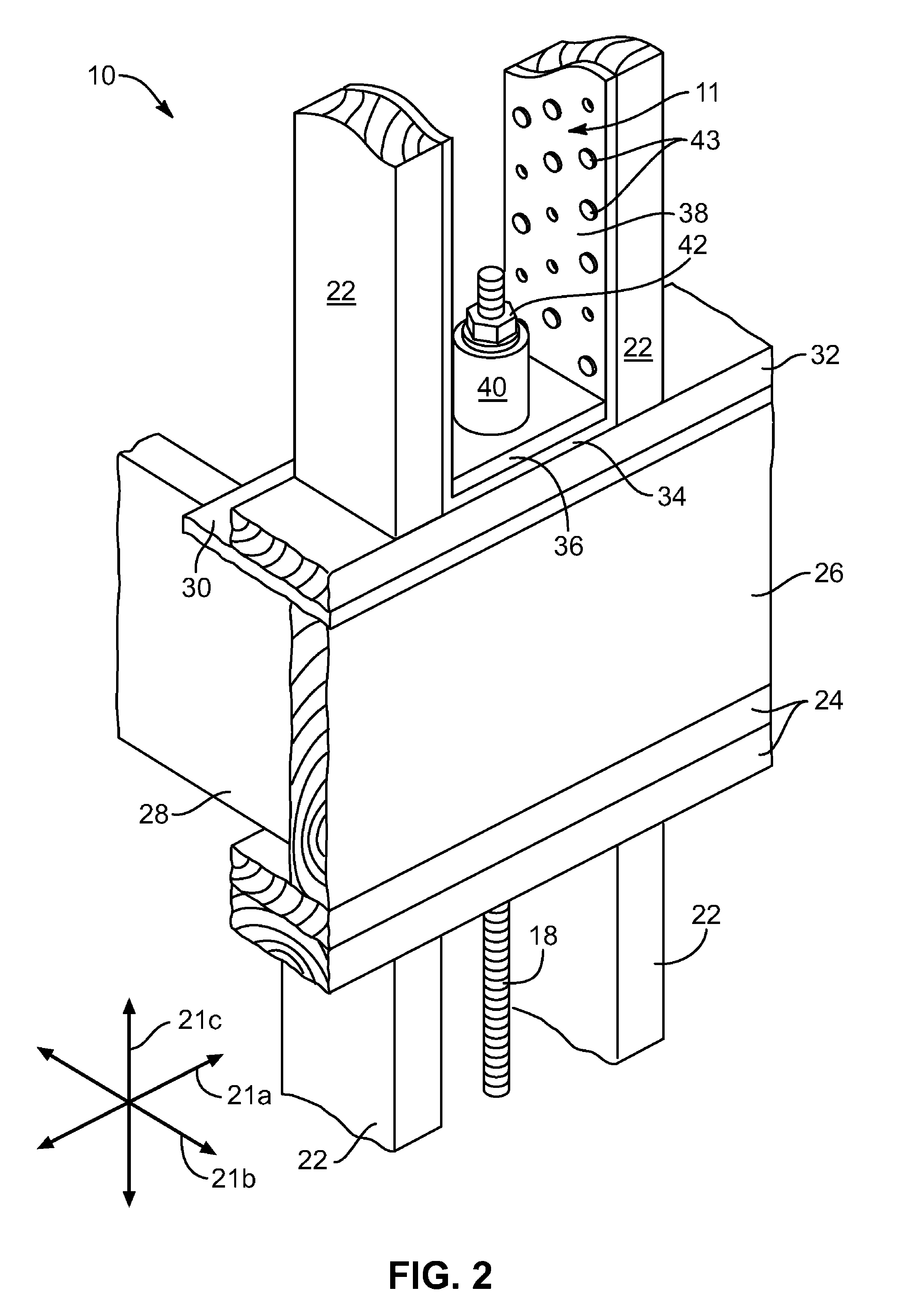

Framing system

A framed shear wall has a pair of crossed tension straps passing through the studs that make up the shear wall. The straps are preferably rods and are preferably attached to upstanding plates installed at the corners of the wall. Each of two straps is preferably attached to an opposite side of the upstanding plate such that the straps do not interfere with each other where the straps cross. The straps preferably include threaded ends and the upstanding plates preferably have threaded receptacles sized to accept the threaded ends of the straps such that the straps can be tensioned before and / or after installation. In one embodiment, the upstanding plates are bolted through a bottom surface of the wall into a threaded anchor plate at floor level, and the threaded anchor plate is attached to a top of a wall on a floor below.

Owner:HILDRETH JOHN

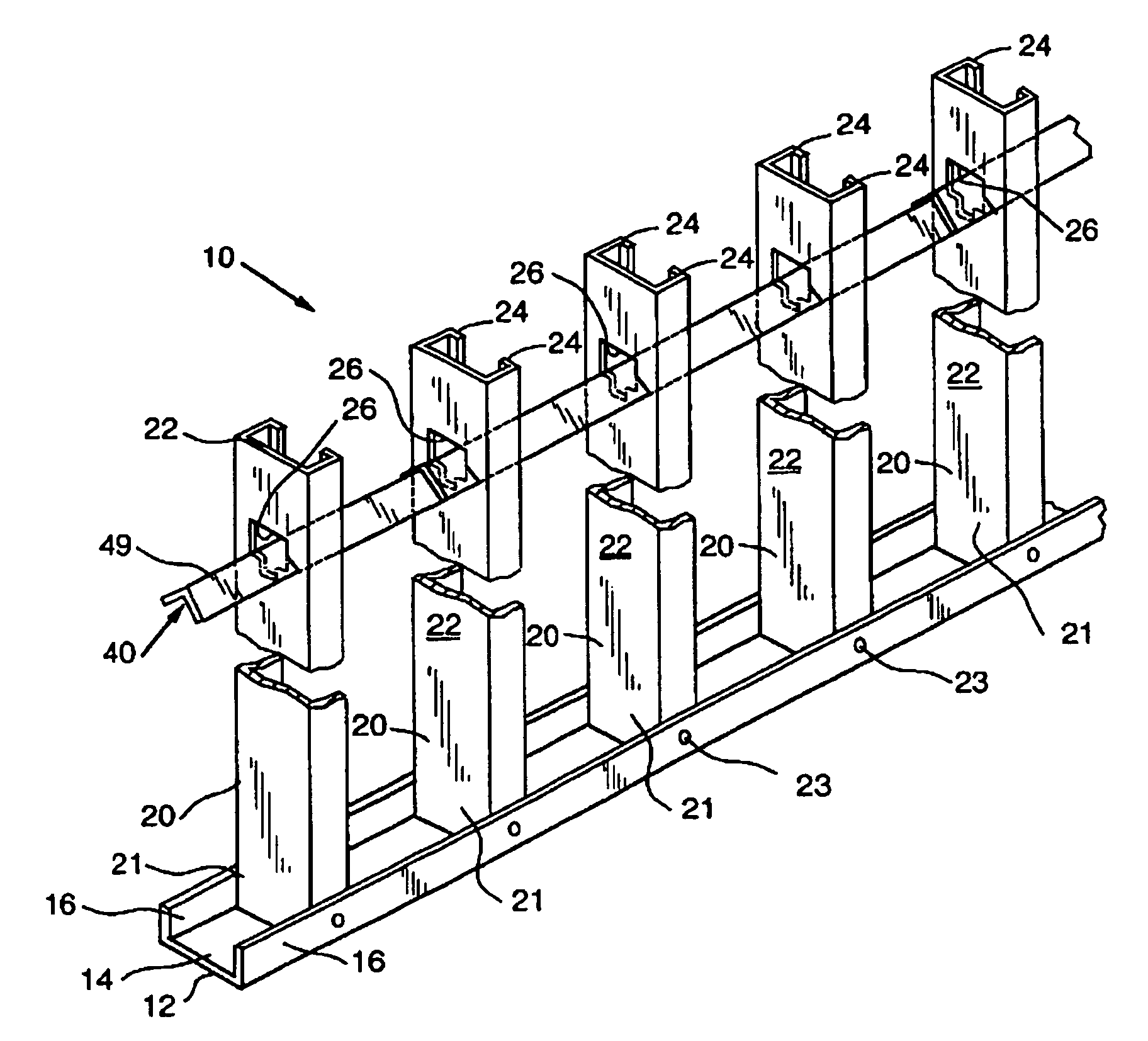

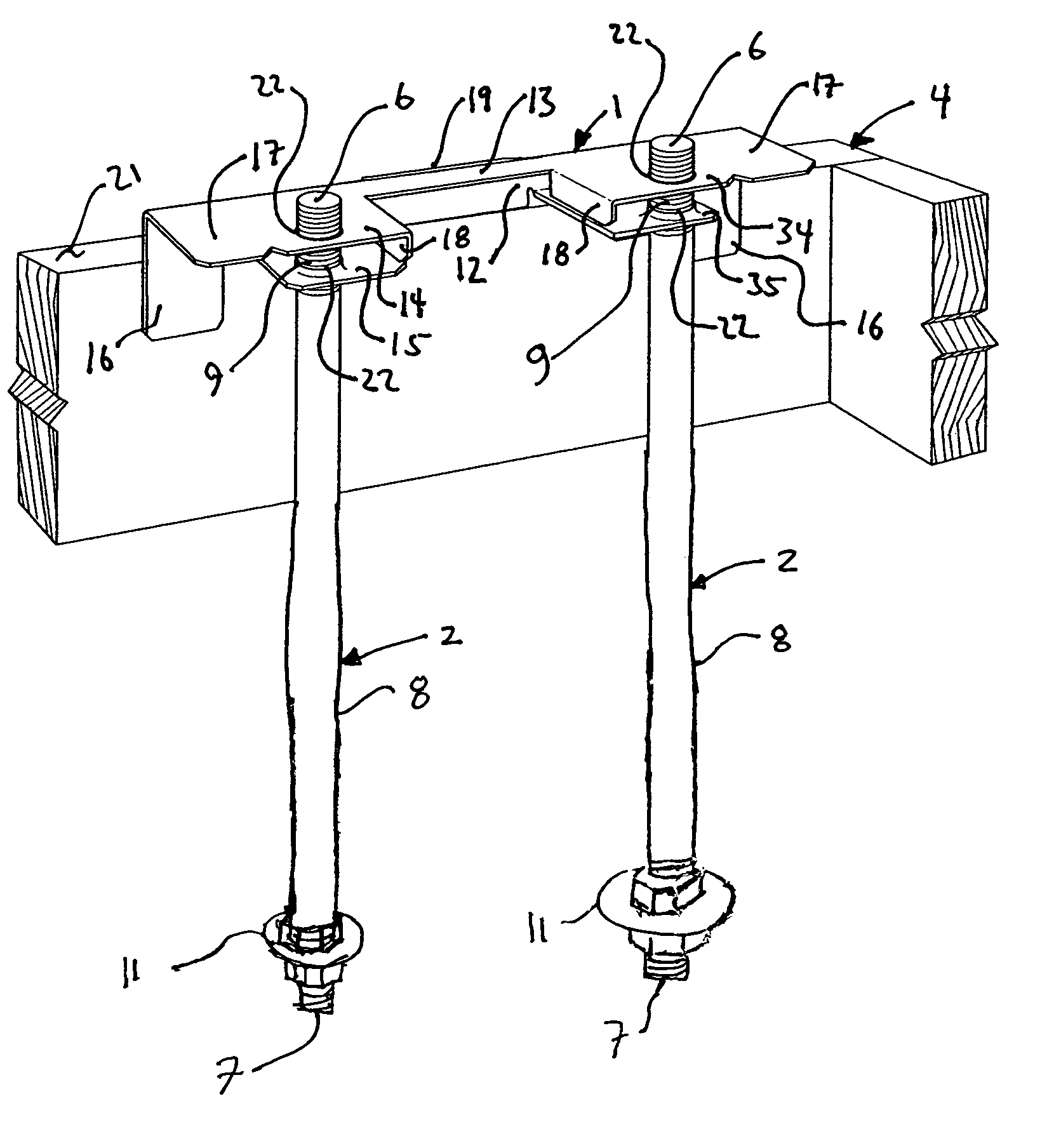

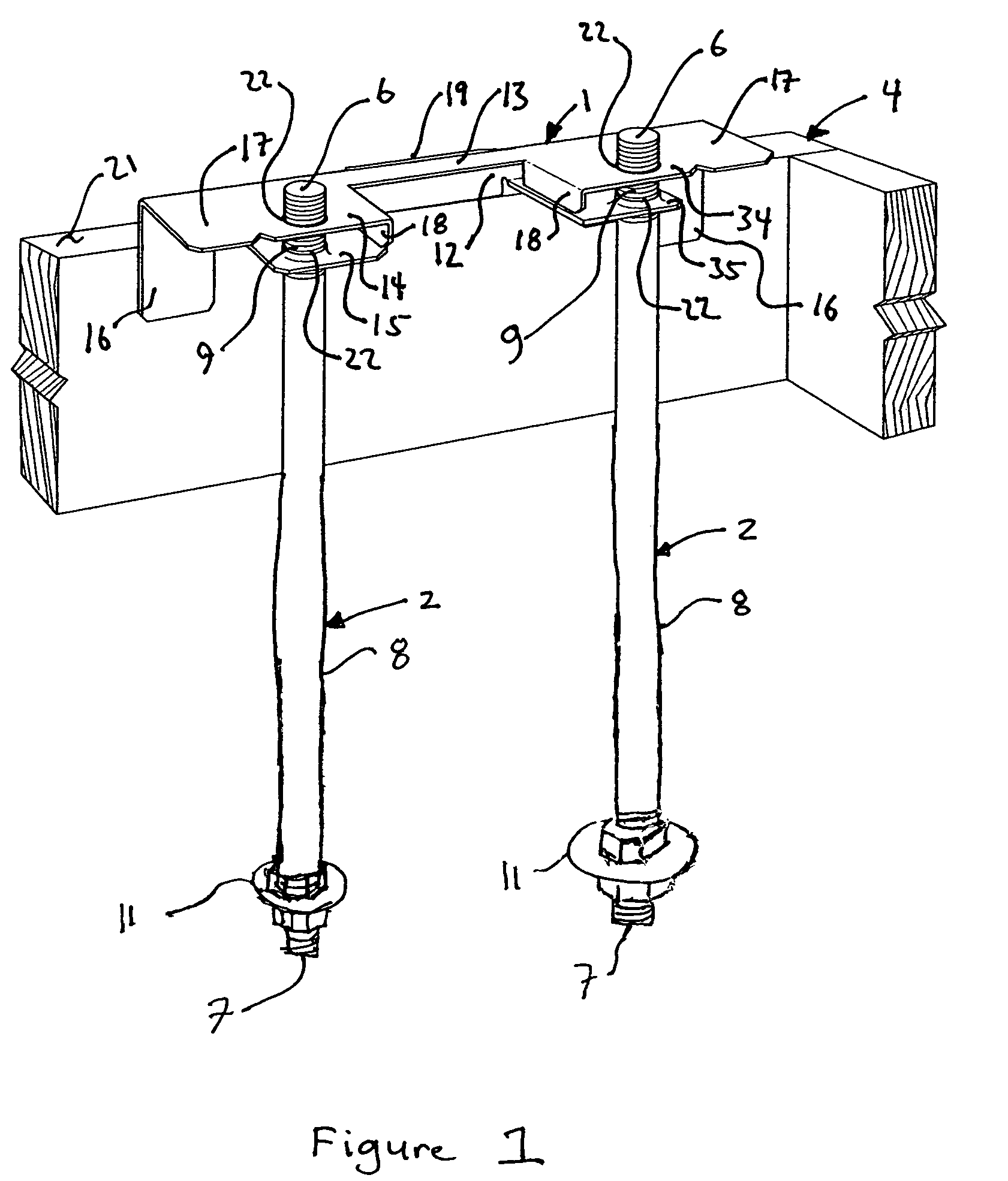

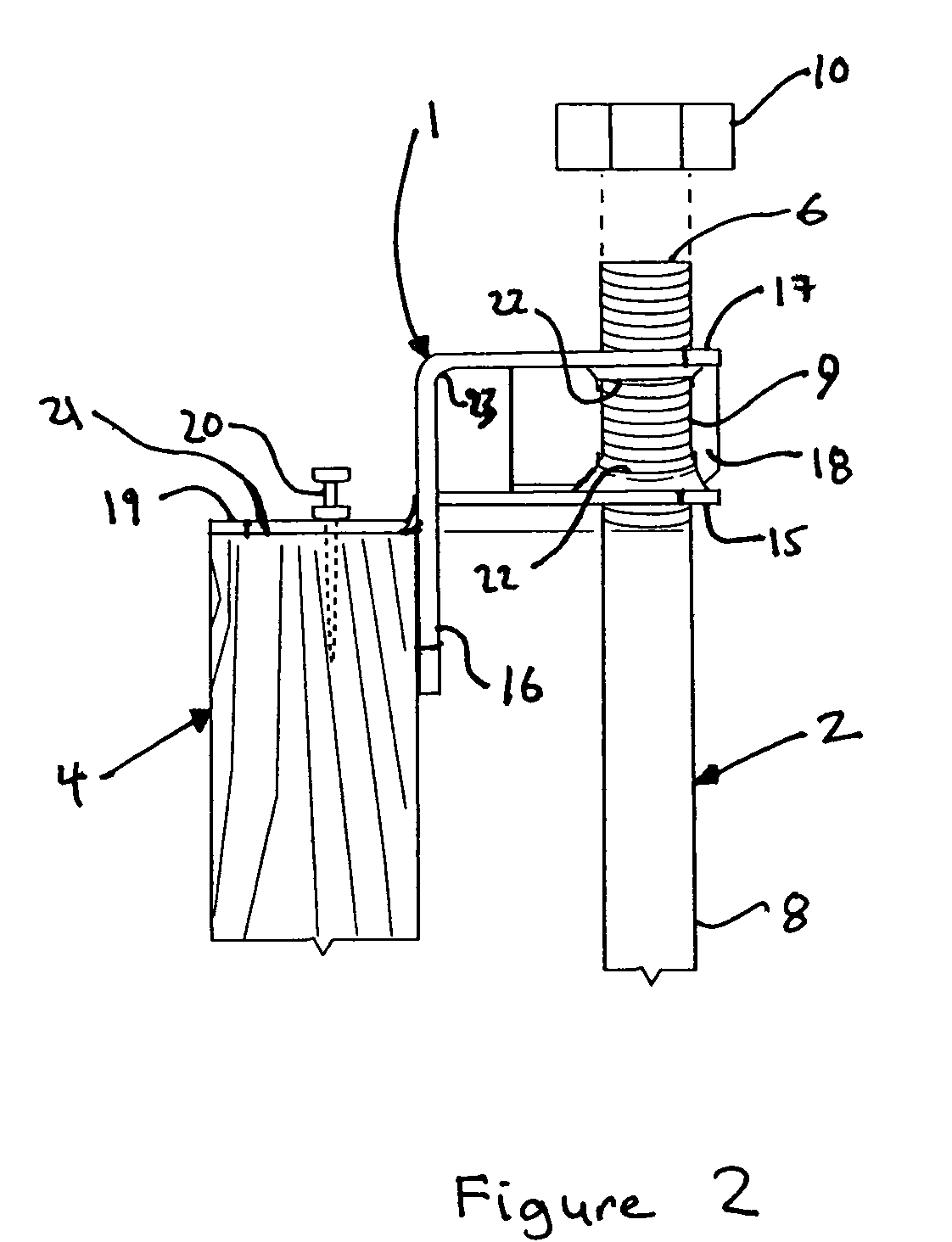

Shear wall template

ActiveUS7445192B2Precise positioningPig casting plantsAuxillary members of forms/shuttering/falseworksEngineeringFastener

A connection is provided between a holder and a plurality of anchor bolts by means of a template. The holder is typically a form board for a cementious member such as a foundation. The template is releasably attached to the form board. The template is formed with a central elongated support, and a plurality of pairs of primary and secondary anchor bolt receiving platforms connected to the central elongated support. The pairs of primary and second anchor bolt receiving platforms are spaced along the central elongated support from each other. Each of the primary and secondary anchor bolt receiving platforms has an opening therein for receiving one of the anchor bolts there through, the openings in each pair of primary and secondary anchor bolt receiving platforms being in alignment so as to receive the same one of the anchor bolts. A plurality of fasteners are releasably connected to the plurality of anchor bolts and are supported by the template to releasably attach the anchor bolts to the template, suspending them in the form where wet cement can surround and envelope the lower portions of the anchor bolts.

Owner:SIMSON STRONG TIE COMPANY

Compound type connection shear wall structure and assembling method thereof

ActiveCN105442727AEasy assembly and constructionPrecise construction and assemblyWallsFloor slabUltimate tensile strength

The invention discloses a compound type connection shear wall structure and an assembling method thereof. The compound type connection shear wall structure comprises N shear wall components of the same structure, wherein every two adjacent shear wall components are connected through a compound shear key and a key groove so that a compound type connection shear wall can be formed. Due to the mutual guide-in effect of the compound shear keys and the key grooves, the construction precision is improved, and eccentric compression generated by inaccurate assembling is avoided. Because the shear key on each shear wall component below can bear the weight of the corresponding shear wall component above when the next layer is assembled, assembling of a wall body of a previous layer can be instantly conducted after floor pouring is completed without waiting till floor concrete reaches the strength, and the assembling cycle of floors can be greatly shortened. The shear keys of the shear wall components below are embedded in the key grooves of the shear wall components above, the shear keys can bear transverse shearing force, the shear resistance of the structure is enhanced, and reliability of the structure is enhanced.

Owner:ZHEJIANG UNIV +2

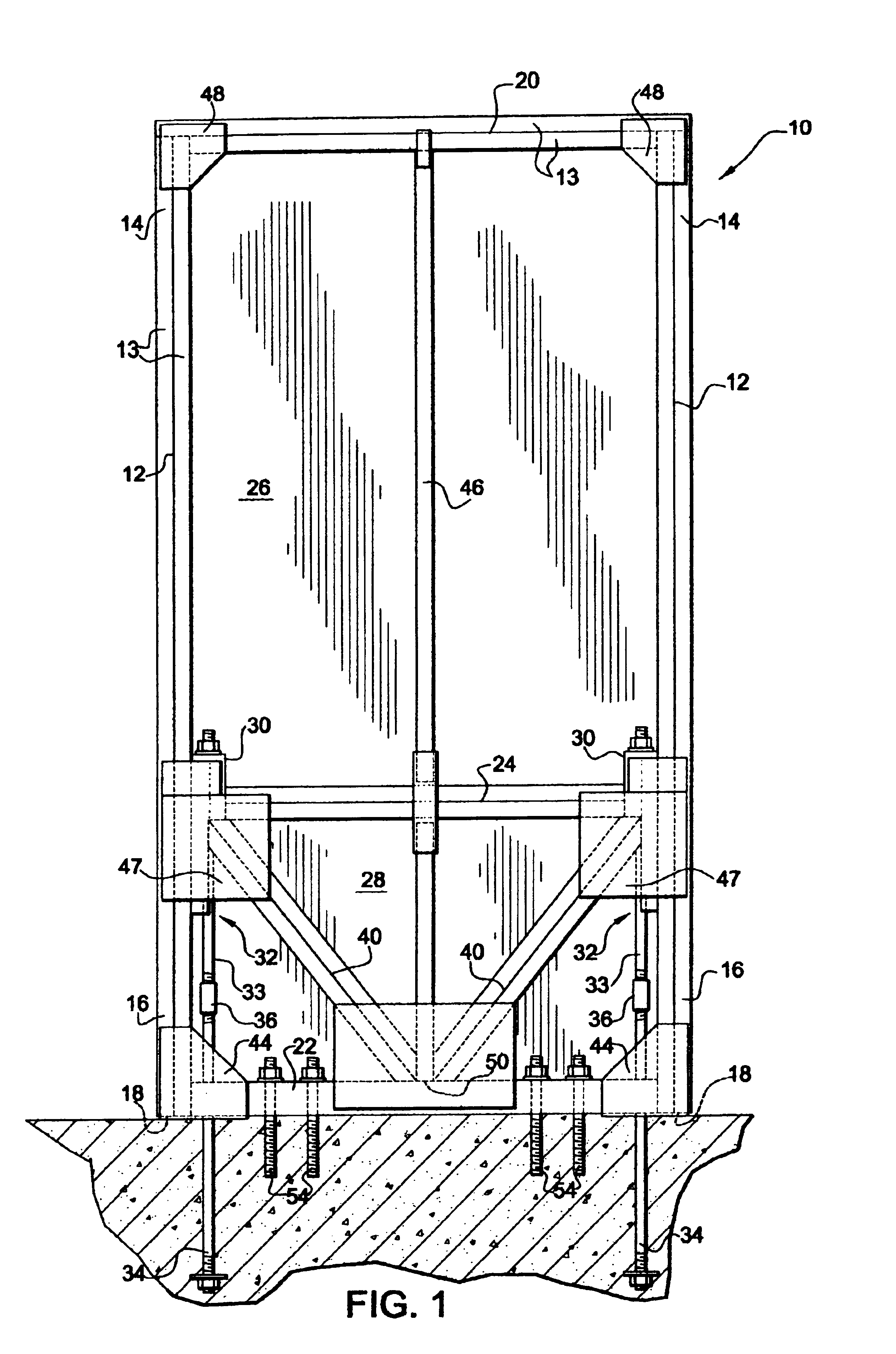

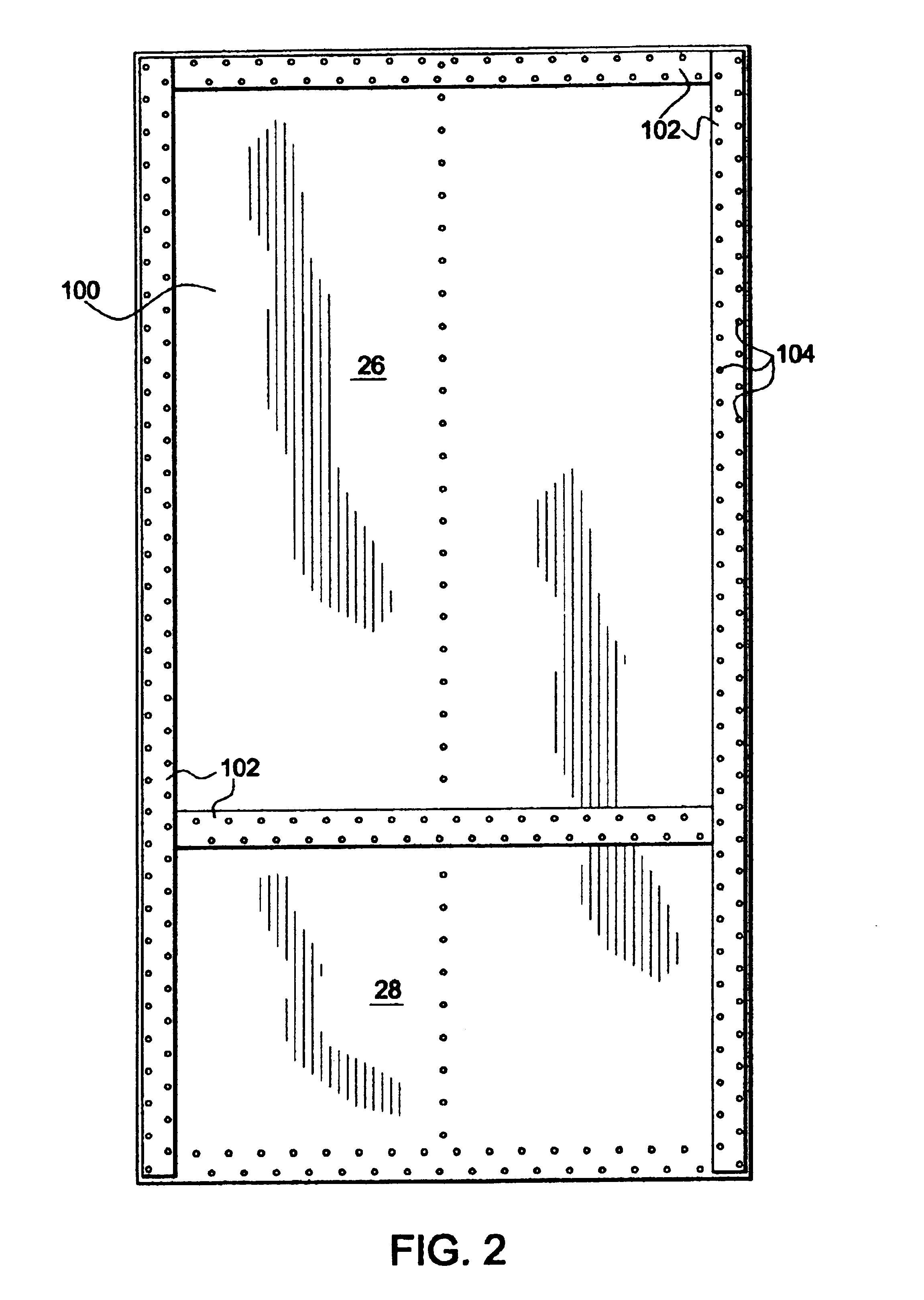

Prefabricated shearwall having improved structural characteristics

InactiveUS6931804B2Improve structural performanceVariable stiffnessBuilding roofsWallsEngineeringUltimate tensile strength

A novel prefabricated shearwall is disclosed with improved structural characteristics in terms of its ability to 1) transfer lateral loads to the foundation, 2) resist bending moments normally arising in conventional shearwalls between hold-down hardware and end posts or vertical framing members, 3) effectively diffuse stresses known to result in nail fatigue, and 4) reduce slippage between the bottom of the end posts and base in response to cyclic loadings. These superior properties result partly from its geometry in lower, or shear force transfer region, accompanied by thrust block / anchor rod assemblies to provide stiffness and strength over the lower portion of the end posts. Furthermore, specialized wrap-around connector plates that cover a portion of the bottom surface of these end posts also contribute to the enhanced prefabricated shearwall design.

Owner:SHEAR FORCE WALL SYST

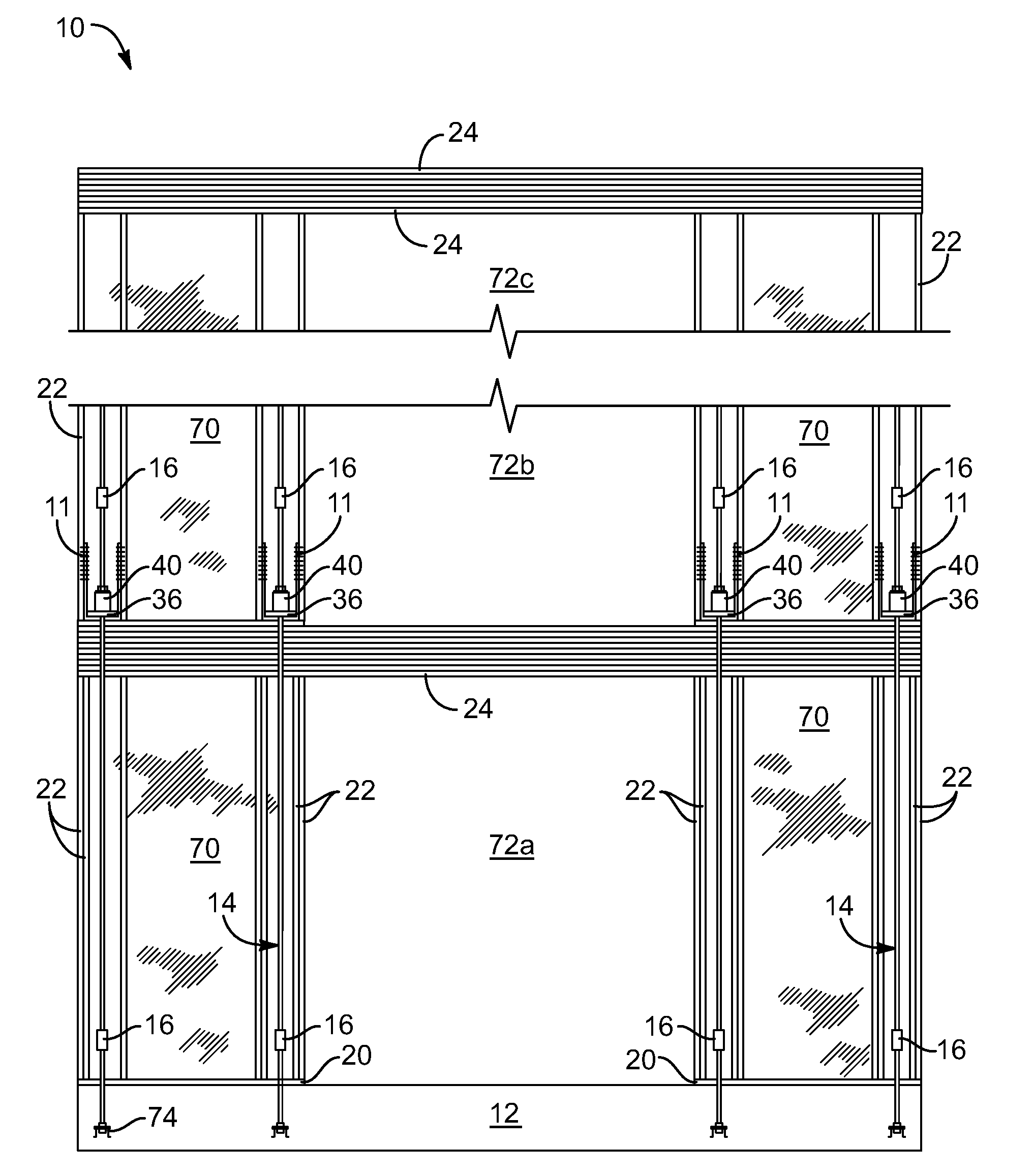

Connectors and Methods of Construction for a Precast Special Concrete Moment Resisting Shear Wall and Precast Special Concrete Moment Resisting Frame Building Panel System

InactiveUS20080098676A1Saving environment protectionThermally efficientMoulding surfacesBuilding roofsComposite constructionInternational Building Code

A precast concrete wall panel molding system for fabricating a wall shell and a plurality of ribs and beams. A precast concrete wall panel molding system with facilities for incorporating door and window frames. A ductile panel end connector for attaching panels one to another whether in parallel or angled as in inside or outside corners. A ductile panel end connector for attaching panels to columns. A wall anchor / shear plate with post-tensioning brace plate. A hybrid precast / cast-in-place special moment resisting shear wall / special moment resisting frame reinforced concrete building system for regions of potential seismic activity. A prescriptive method building system for composite structural building assemblies with conventional wood and light-gauge steel framing, structural steel, and other building code approved and tested building systems, building components, building panel systems, building roofing systems, modular and manufactured buildings, and building electrical, mechanical, and plumbing systems. A precast concrete wall panel system conforming to industry practices and standards as published by the Precast / Prestressed Concrete Institute, (PCI) in it's “PCI Design Handbook” (fifth edition, 1999), the American Concrete Institute “Building Code Requirements for Structural Concrete” (ACI 318-05), The “International Building Code 2006” and the “Uniform Building Code”.

Owner:HUTCHENS JOHN FRANCIS

Shear wall with inbuilt continuous-row steel tube concrete core column and soft steel energy consumption bond and manufacturing method thereof

InactiveCN101761154ASuppression of out-of-plane instability problemsImprove vertical bearing capacityWallsBuilding material handlingRebarUltimate tensile strength

The invention discloses a shear wall with an inbuilt continuous-row steel tube concrete core column and a soft steel energy consumption bond and a manufacturing method thereof, belonging to the field of steel tube concrete combined shear wall. The shear wall comprises a combined steel tube concrete frame and a shear wall body, wherein the shear wall body comprises a steel tube concrete core column and a soft steel energy consumption bond, and the left end and the right end of the steel plate energy consumption bond are fixedly connected with the core column and the steel tube concrete frame; two sides of the continuous-row core column are provided with longitudinal and transverse mat reinforcements, and reinforcements on two sides are connected by binding rebars; soft steel energy consumption short steel plates the strength of which is smaller than that of the steel plate are arranged between the core columns and between the core column and a frame column, thus greatly improving the ductility and the flexural rigidity of the shear wall; meanwhile, because the short steel plate is equivalent to a connecting beam, the effect of invisible 'strong column and week beam' can be realized; and the soft steel energy consumption bond, the concrete wall body, the frame column and the core column jointly form three defensive lines of a lateral force resisting system. The invention adopts the steel tube concrete core column and the soft steel energy consumption bond as the lateral force resisting system, improves the vertical rigidity and the bearing capacity of the shear wall, has the advantages of convenient construction and shortened construction period and is more economical.

Owner:BEIJING UNIV OF TECH

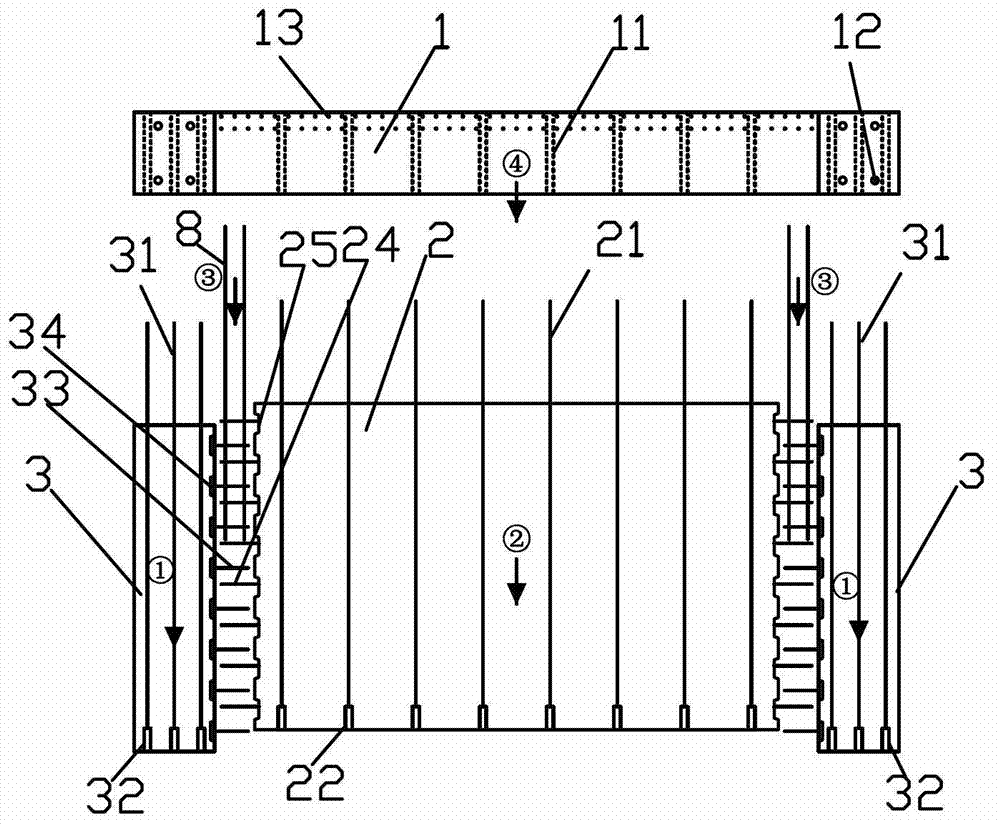

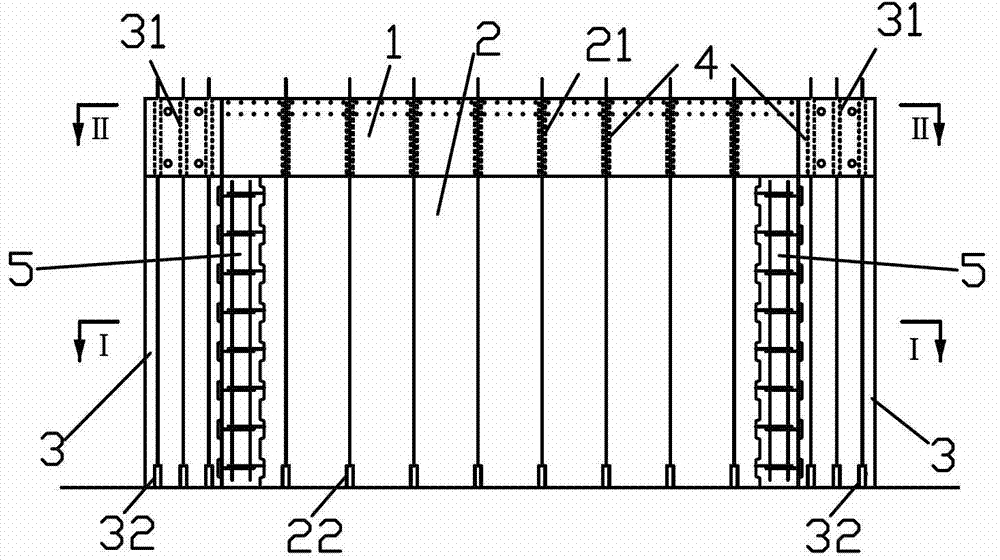

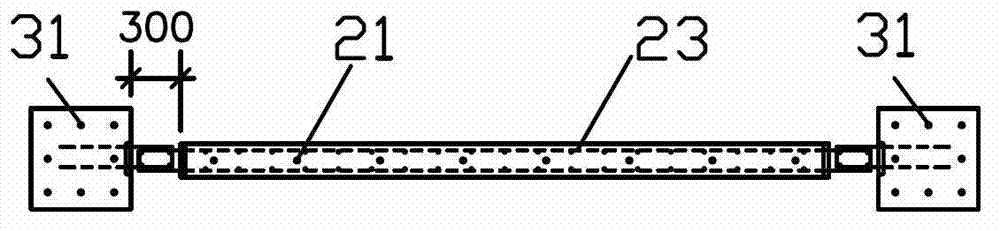

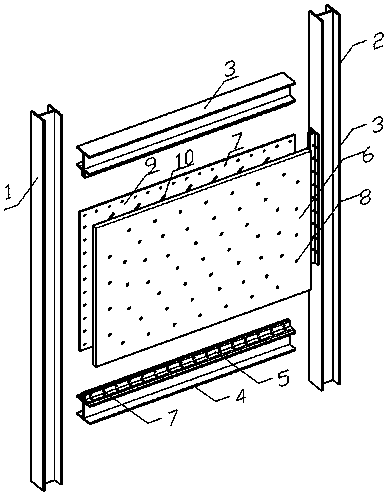

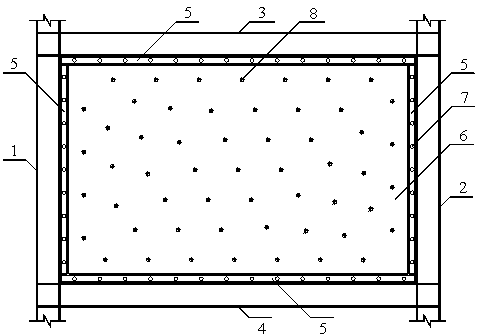

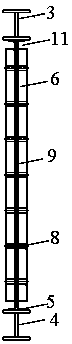

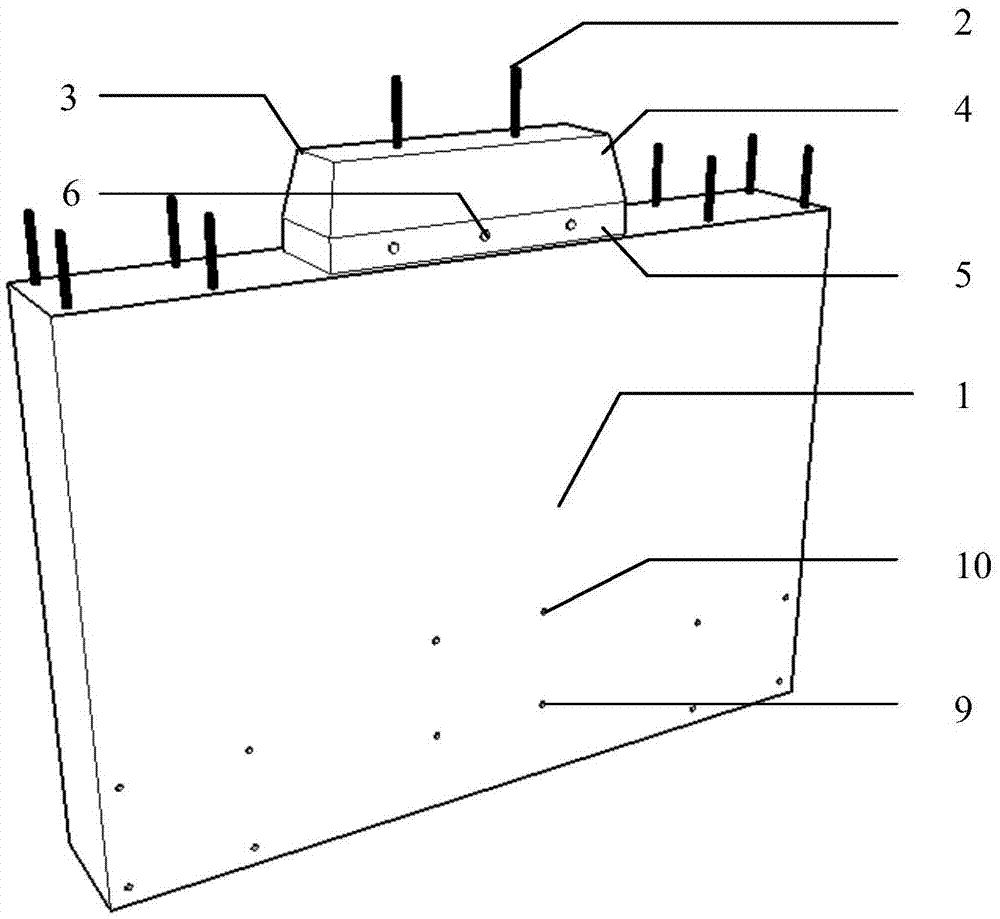

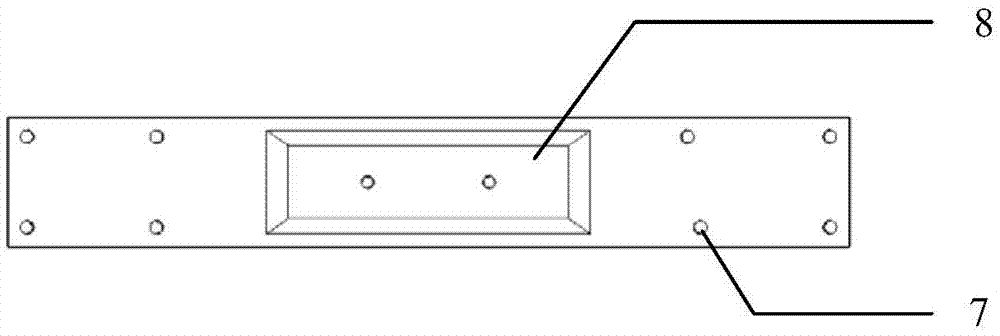

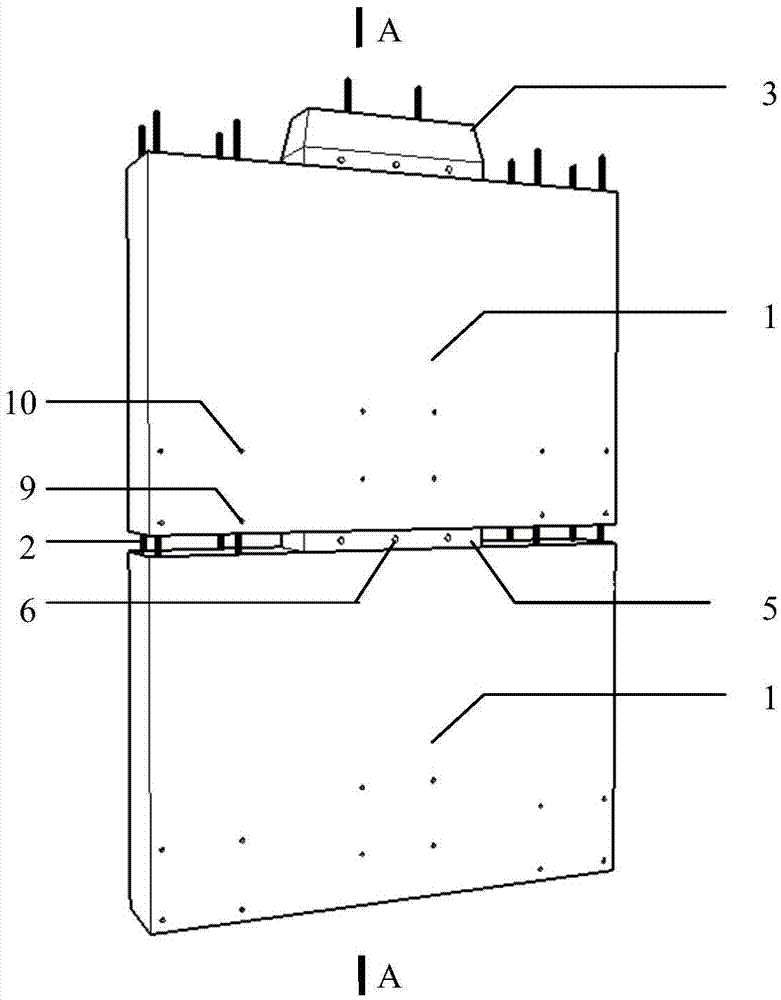

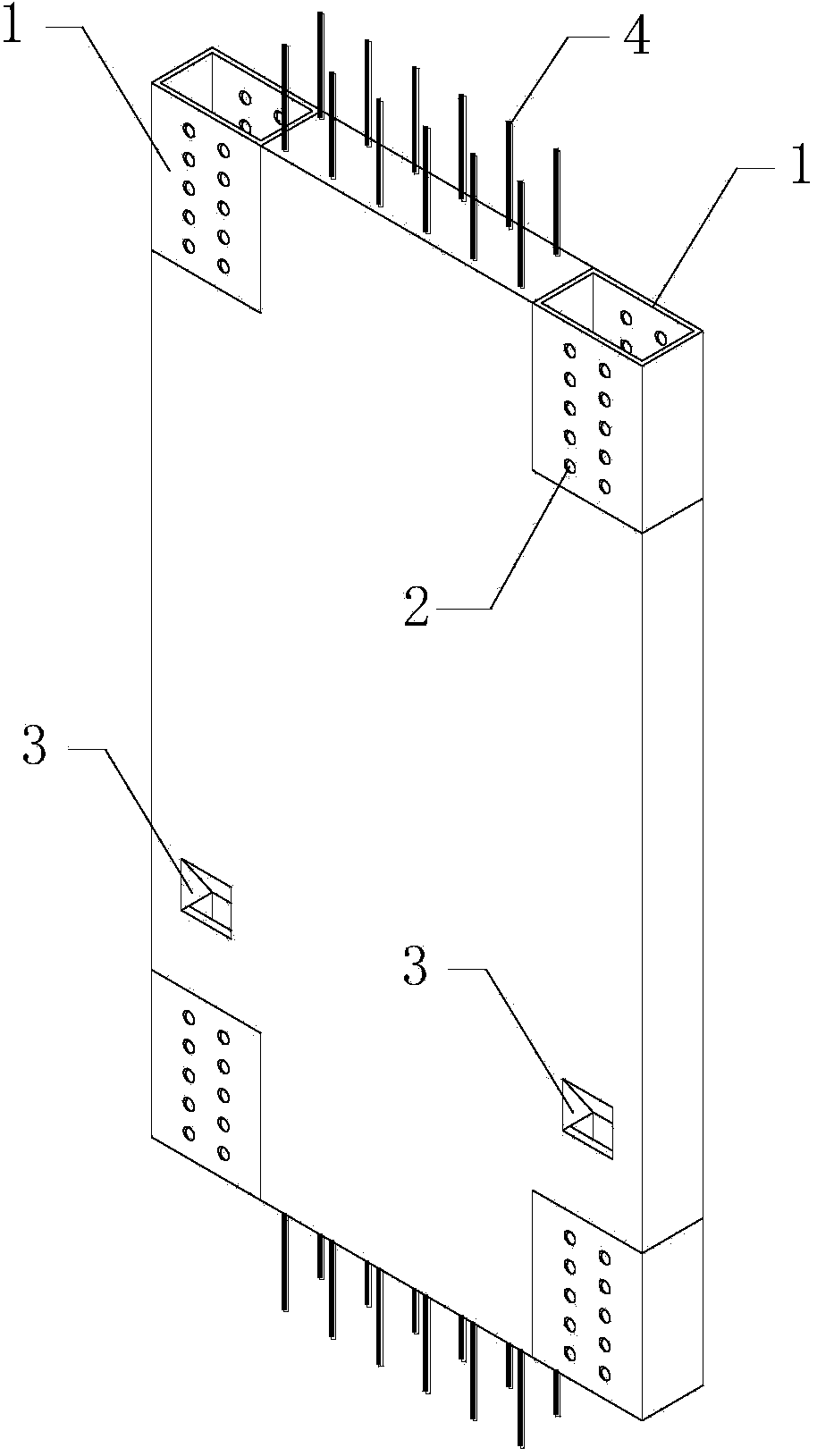

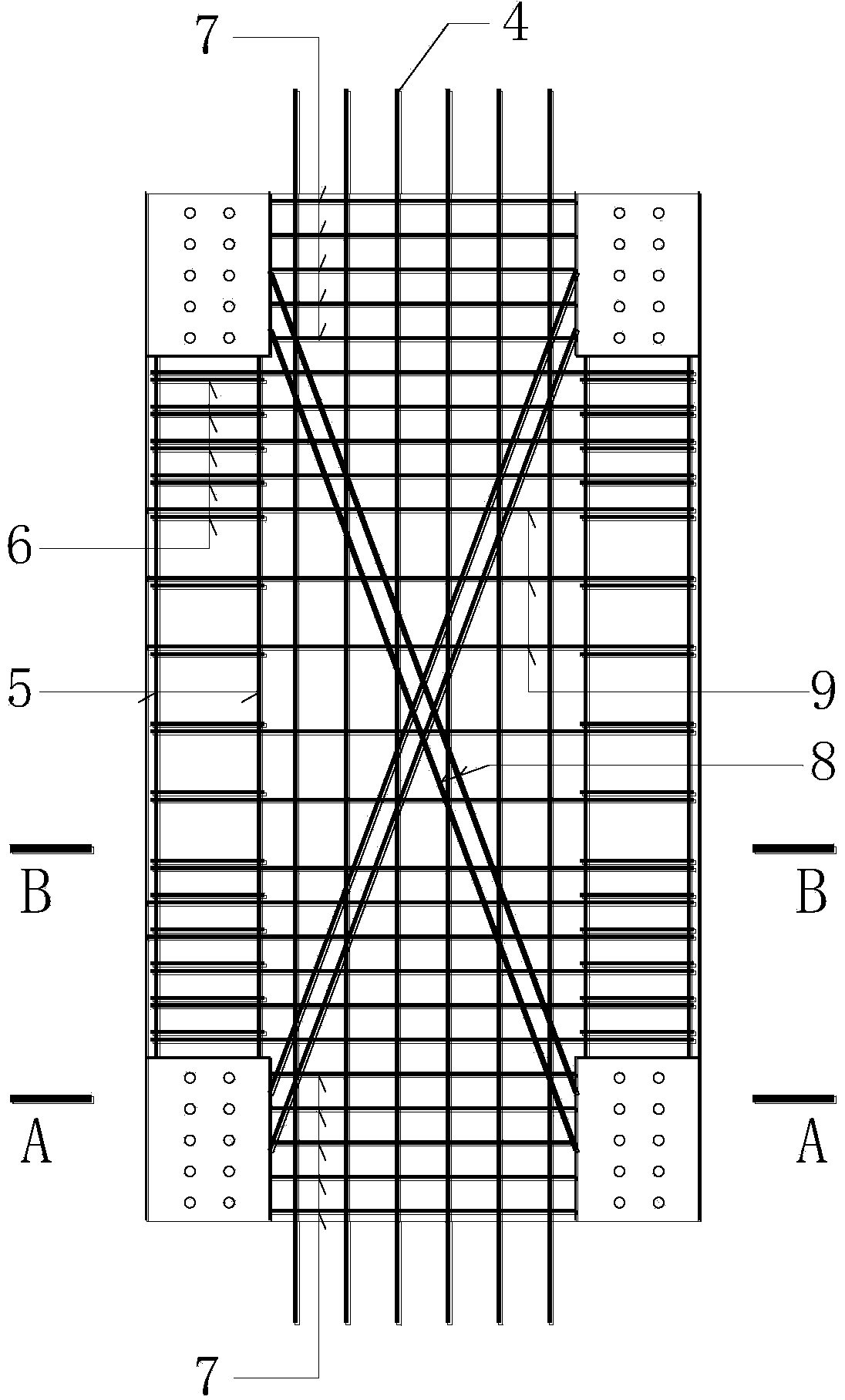

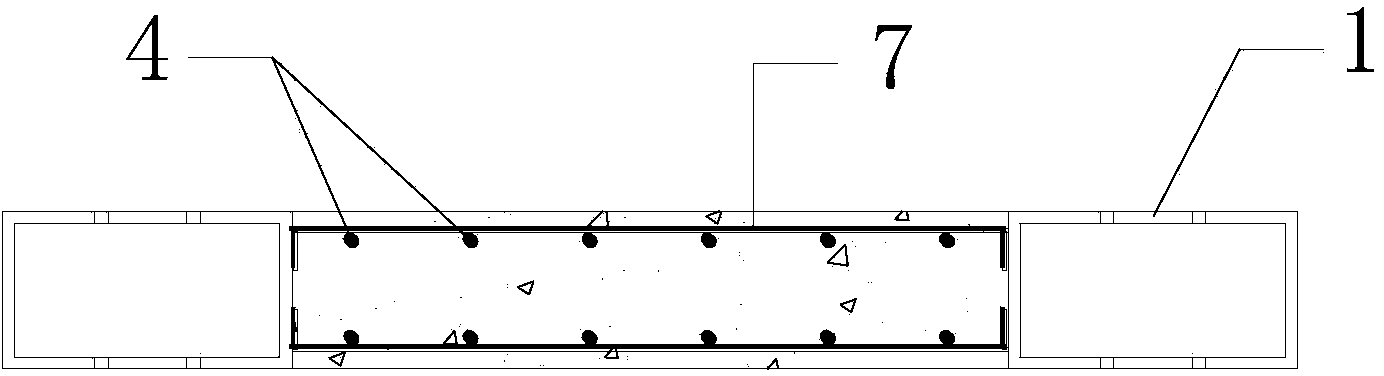

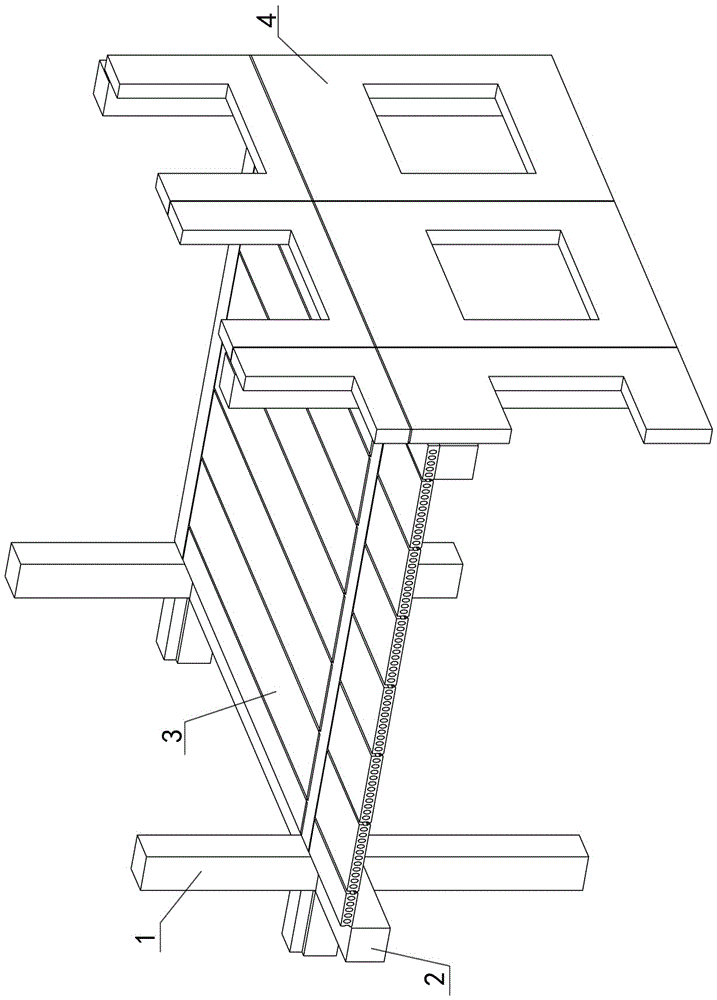

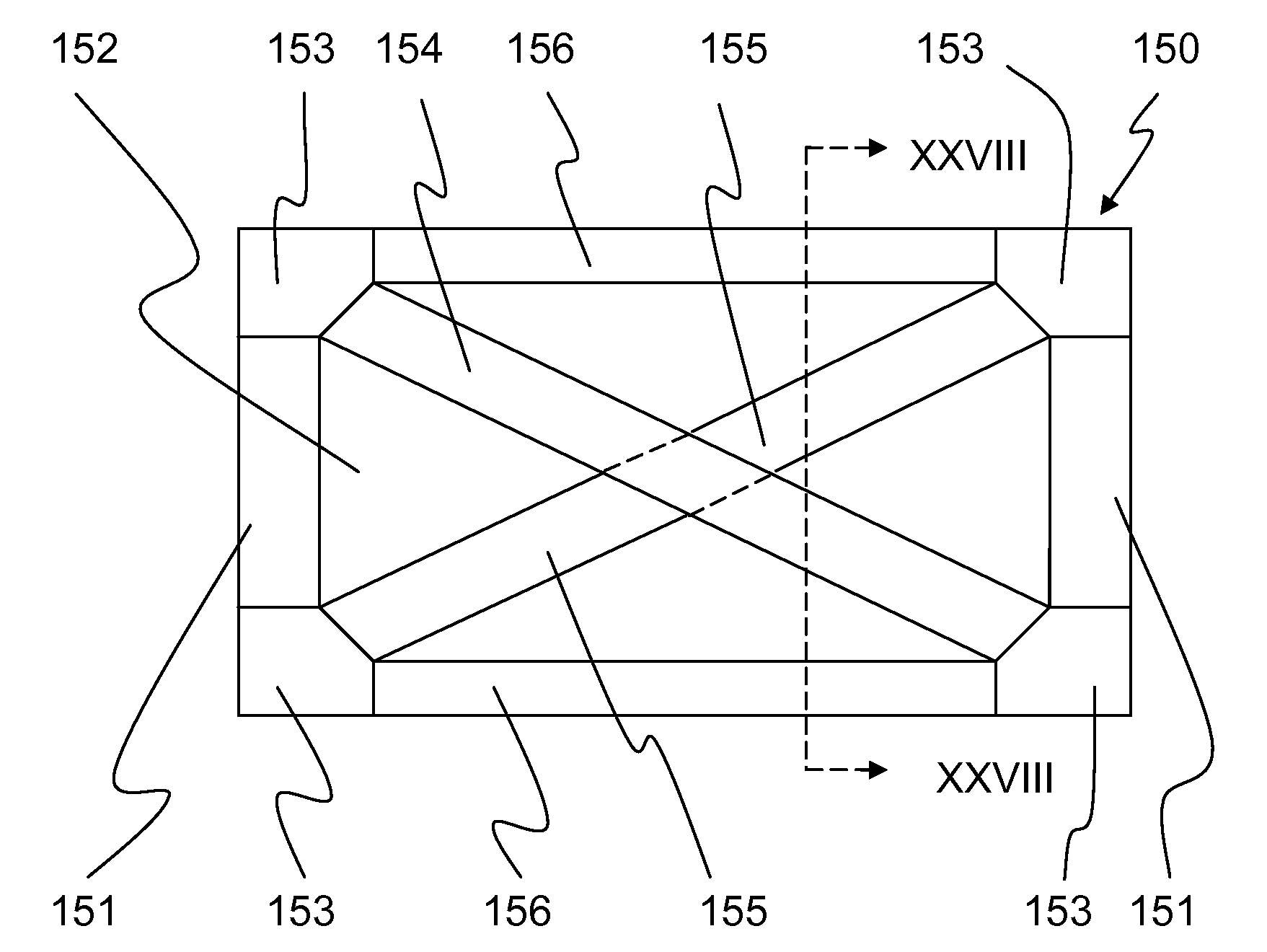

Assembled shear wall and wall-beam connecting structure with edge restraining component

The invention discloses an assembled shear wall and wall-beam connecting structure with an edge restraining component. The structure comprises a shear wall formed by prefabricating concrete and a beam. Rectangular steel tubes are prearranged at the four corners of the shear wall, stretching reinforcing steel bars are prearranged on the upper side and the lower side of the shear wall, and a feed port is formed in the bottom of the shear wall. Hidden columns are arranged on the two sides of the shear wall, and longitudinal ribs of the hidden columns are welded to the inner sides of the rectangular steel tubes. Crossing reinforcing steel bars are arranged in the shear wall, and two ends of the crossing reinforcing steel bars are welded to the outer sides of the rectangular steel tubes. A steel plate and a grouting sleeve are embedded in the beam. An upper-layer wall body and a lower-layer wall body are initially connected through a connecting steel plate, opposite-drawing bolts, the stretching longitudinal ribs on the wall, the embedded sleeve in the beam and the like, and are finally connected through post-cast concrete. The assembled shear wall and wall-beam connecting structure with the edge restraining component has the advantages of being high in energy consumption in an earthquake, convenient to hoist and connect in a butt joint mode, fast to mount and the like, can be widely applied to an assembled integrated frame-shear wall structure, and has the wide engineering application prospect.

Owner:SOUTHEAST UNIV

Column-through assembled prestressed concrete frame system and construction method thereof

ActiveCN106499051AEfficient constructionImprove seismic performanceBuilding constructionsReinforced concrete columnFloor slab

The invention discloses a column-through assembled prestressed concrete frame system and a construction method thereof. The system comprises a foundation, a prefabricated reinforced concrete column, a prefabricated reinforced concrete beam, a superimposed floor slab and an external hung prefabricated wallboard, wherein a column prestressed duct is formed in the prefabricated reinforced concrete column; a beam prestressed duct is formed in the prefabricated reinforced concrete beam; post-tensioned unbonded prestressed tendons are penetrated into the beam prestressed duct and the column prestressed duct; energy-dissipation steel bars are anchored between the prefabricated reinforced concrete column and the superimposed floor slab. The structure provided by the invention has a good seismic performance; the lower part of a beam-column joint is subjected to unreinforced connection so that the structure is simple; the post-tensioned unbonded prestressed tendons and a replaceable column base energy dissipater are used so that the structure is less damaged and easy to be repaired in the earthquake; a construction manner of using the prefabricated superimposed floor slab and prestressed assembly makes site construction convenient and rapid and saves a lot of supports compared with a traditional prefabricated assembly structure; the column-through assembled prestressed concrete frame system provided by the invention is used in combination with lateral supports, shear walls and other lateral force resisting members, and is applicable to most high-rise public buildings.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

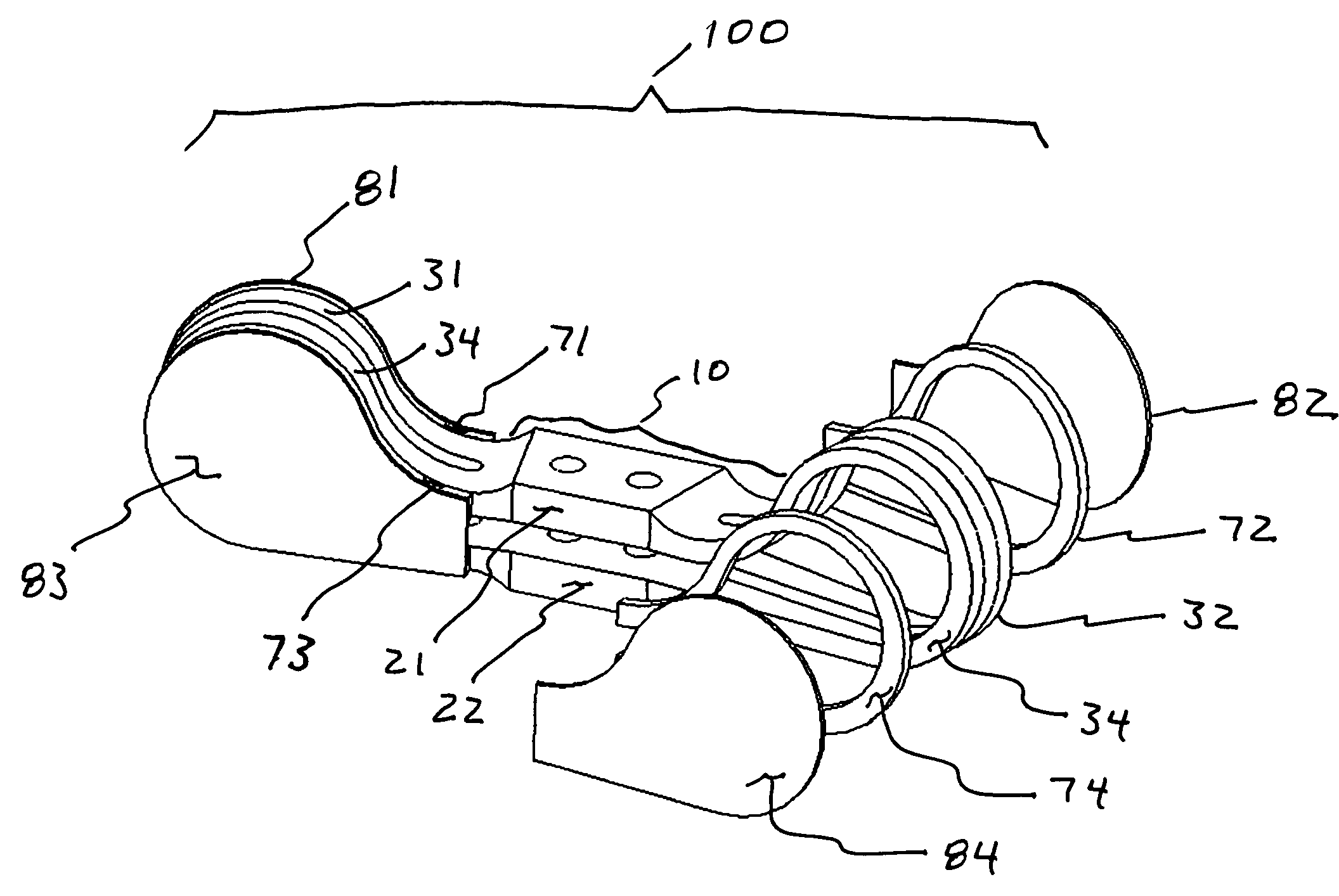

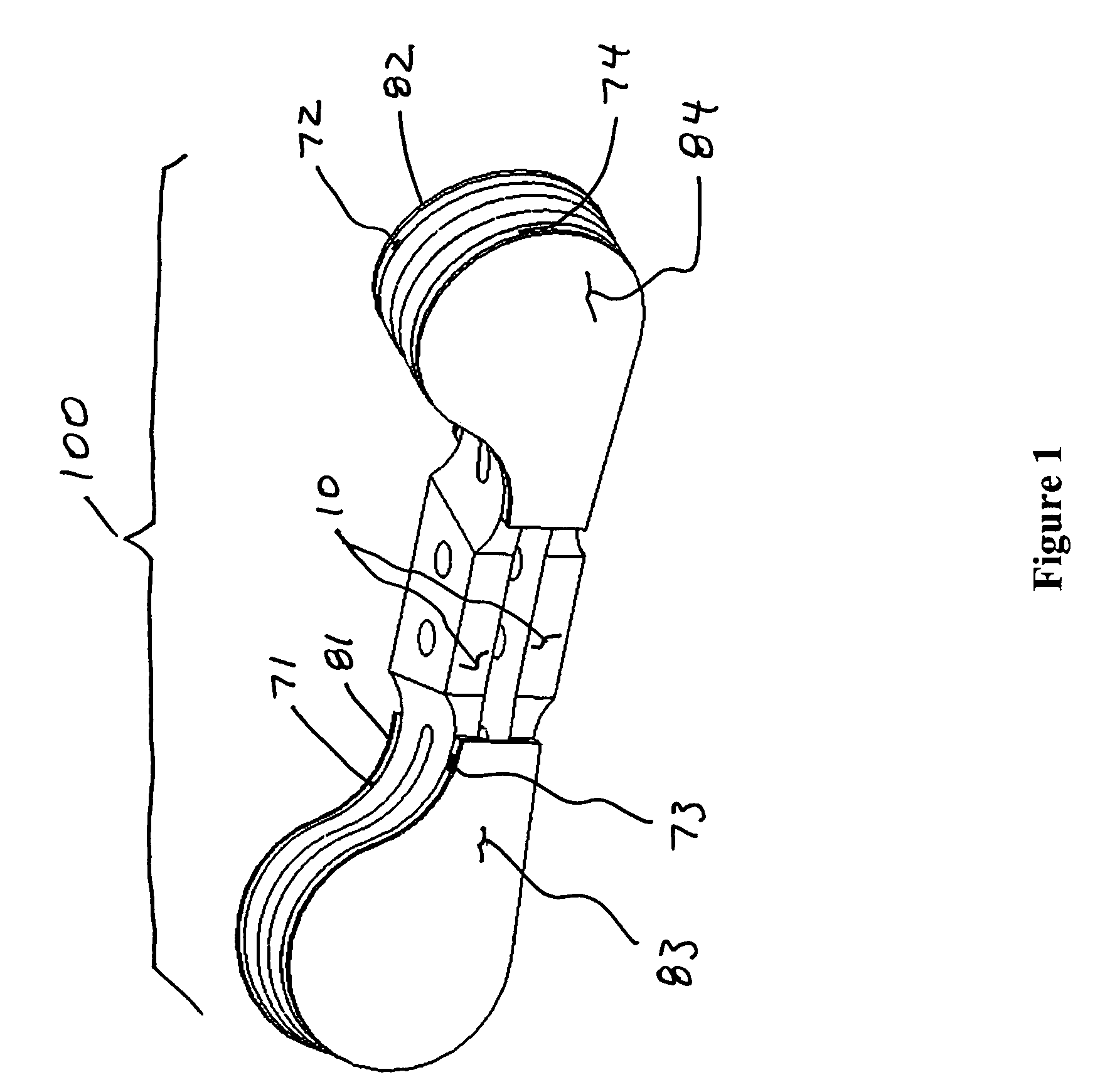

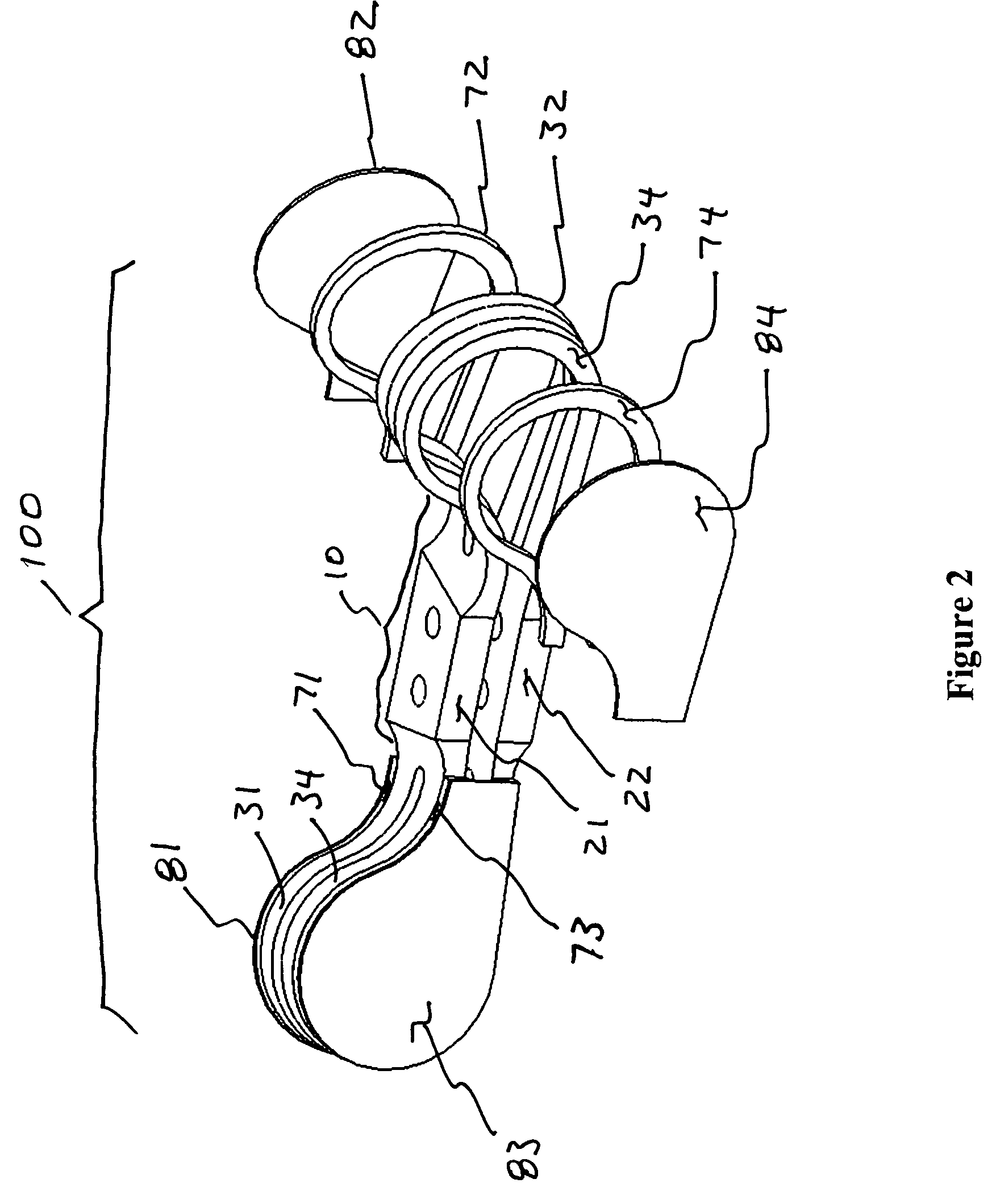

Low-profile, multi-axis, highly passively damped, vibration isolation mount

ActiveUS7249756B1High passive dampingIncrease of longitudinal profilePortable framesCosmonautic vehiclesEngineeringMulti axis

The invention disclosed is a low-profile, multi-axis, highly passively damped, vibration isolation mount which when used in multiplicity provides a complete vibration load isolation mounting system. The device provides in unique fashion a very low profile interface in combination with independently determinable compliance in all directions of vibration loading. Substantial passive damping is afforded without sacrifice to strength and linearity of behavior through adaptation of a shear wall type constrained layer damping. The result is a highly passively damped vibration isolation device that provides a very low profile interface, wide ranging longitudinal and lateral compliance management, in a durable, reliable, lightweight, and compact form.

Owner:MOOG INC

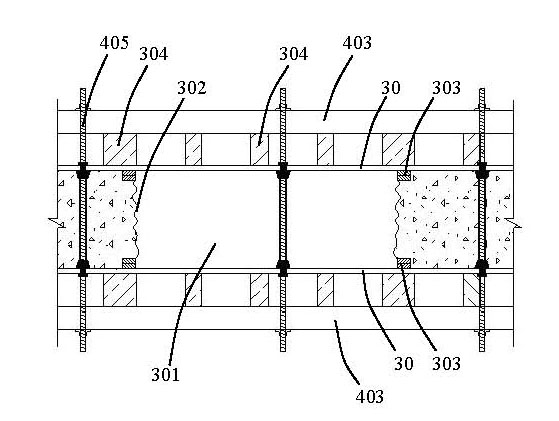

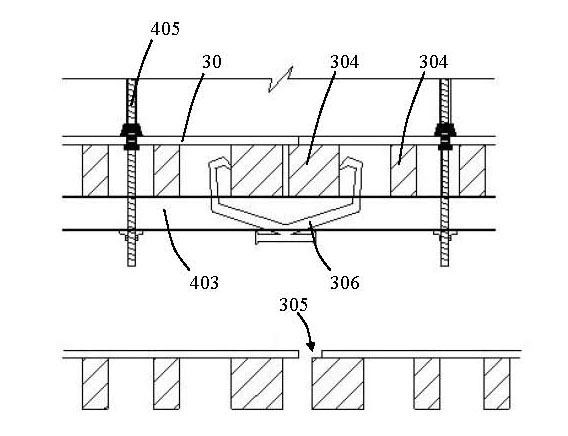

Structure and construction method of cast-in-site style welded steel frame composite concrete shear wall

ActiveCN103195193AGuaranteed section sizeSolving Linear Thermal Bridge ProblemsWallsBuilding material handlingFloor slabSandwich board

The invention relates to a structure and a construction method of a cast-in-style welded steel frame composite concrete shear wall. The structure comprises an indoor concrete layer, an outdoor concrete layer and a wire frame insulation sandwich board. The wire frane insulation sandwich board is coated between the indoor concrete layer and the outdoor concrete layer. At least two rectangular and groove-typed cantilever holes are arranged at the top of the sandwich board, and each cantilever hole is provided with a U-shaped cantilever anchor bar which penetrates through the sandwich board and a floor slab to be fixedly connected with the floor slab. The construction method includes site preparation work, binding of load-bearing steel bars of a wall body and edge member steel bars, custom processing of the sandwich boards, installation of the sandwich boards, pavement of template positioning pieces and wall bushings, fixation of water and electric pipes inside the wall body, binding of ordinary blocks on both sides of the wall body steel bars, erecting of the templates, pouring of the concrete, removing of the templates and concrete curing. Since a series of composite wall construction methods are adopted, problems existing in the prior art are solved, and a composite heat preservation technology is improved.

Owner:石家庄晶达建筑体系有限公司

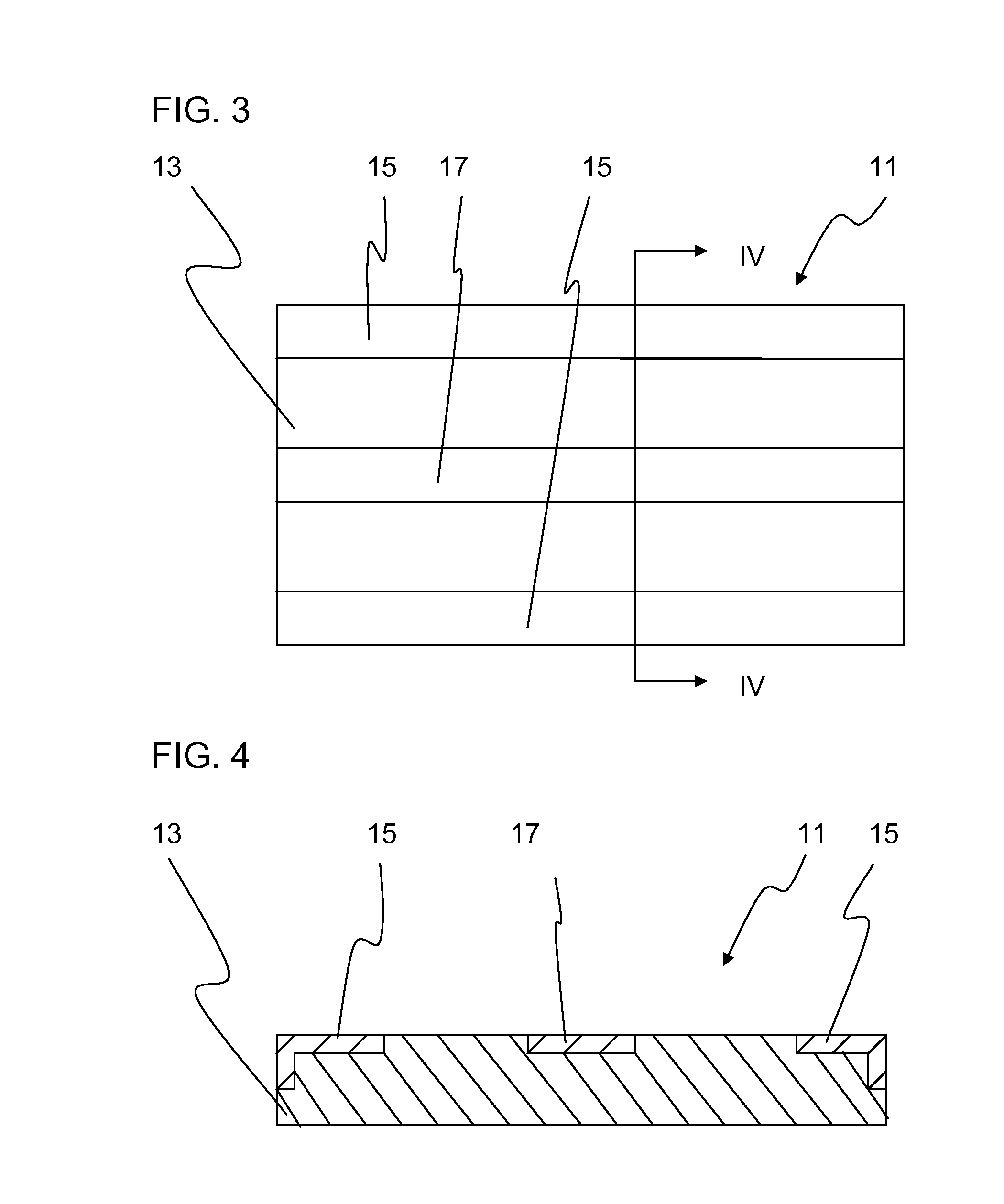

Reinforced Cementitious Shear Panels

ActiveUS20070175126A1Heavy loadImprove clippingBuilding roofsConstruction materialGlass fiberBuilding code

This invention relates to a structural cementitious panel (SCP) panel able to resist lateral forces imposed by high wind and earthquake loads in regions where they are required by building codes. These panels may be used for shear walls, flooring or roofing or other locations where shear panels are used in residential or commercial construction. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder reinforced with glass fibers and containing lightweight filler particles. One or more reinforcement members, such as mesh or plate sheets, are bonded to at least one surface of the panel to provide a completed panel that can breathe and has weather resistant characteristics to be capable of sustaining exposure to the elements during construction, without damage.

Owner:UNITED STATES GYPSUM CO

Double-duty, hold-down system

InactiveUS7971411B2Quick installationMass produced and installed comparatively inexpensivelyHuman health protectionBuilding repairsDual actionEngineering

A method for securing a building to a foundation provides hold-down units that perform double-duty by acting as a compressive load on a floor immediately therebelow due to the force of a seat or base portion thereof. Meanwhile, a flange portion of each hold-down device extends upward to fasten to the upright members in an upper floor applying tension thereto. Thus, an anchoring rod extending through multiple floors of the shear walls may reduce the number of total hold-down devices by an amount approaching half that otherwise required. Likewise, the number of more expensive, automatic, take-up devices used is reduced by approximately half.

Owner:COMMINS ALFRED D

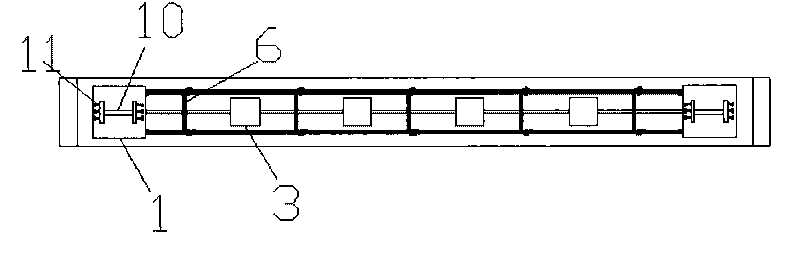

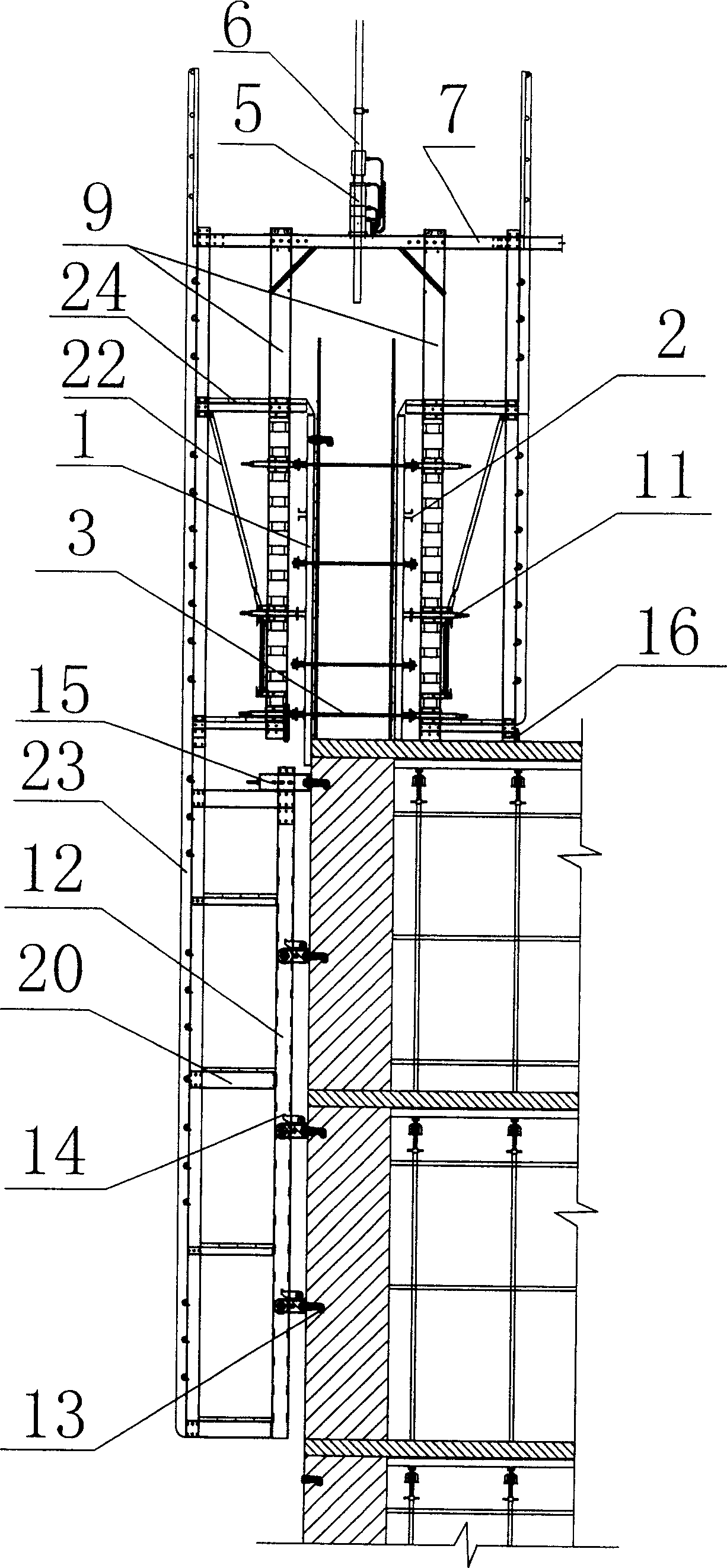

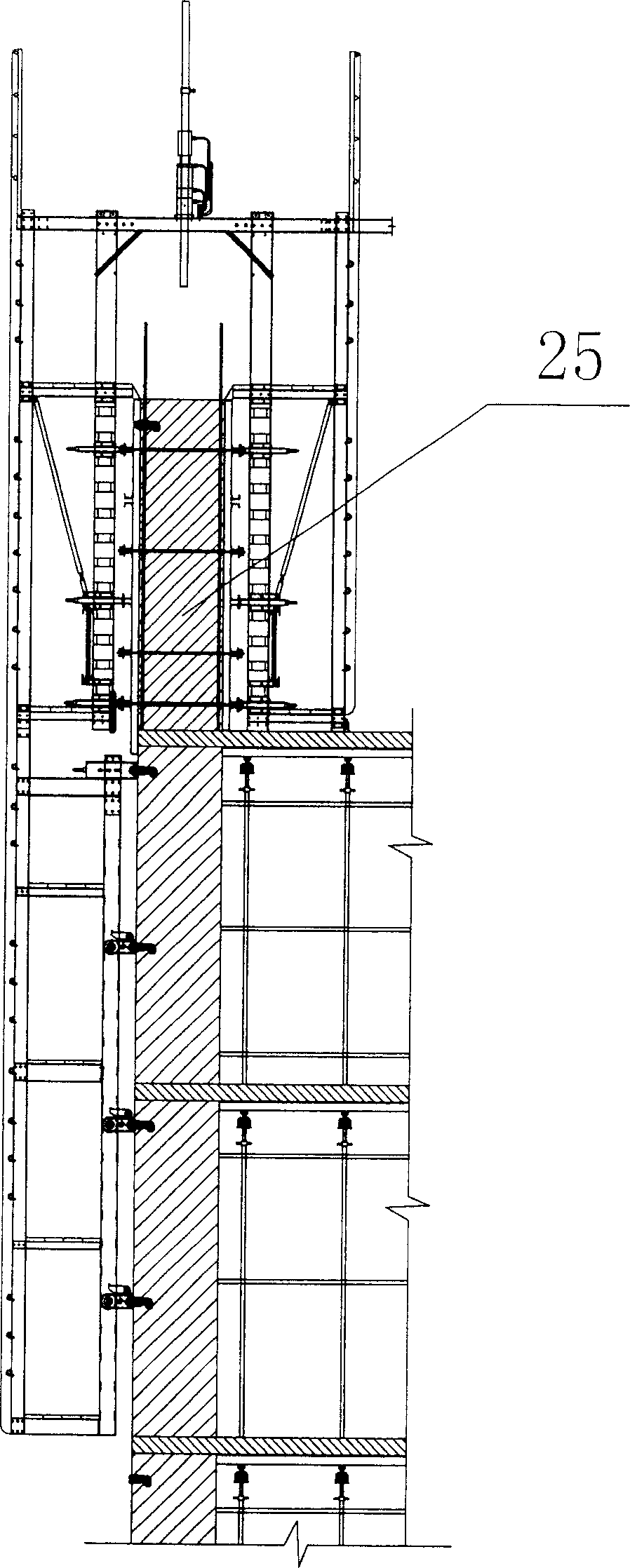

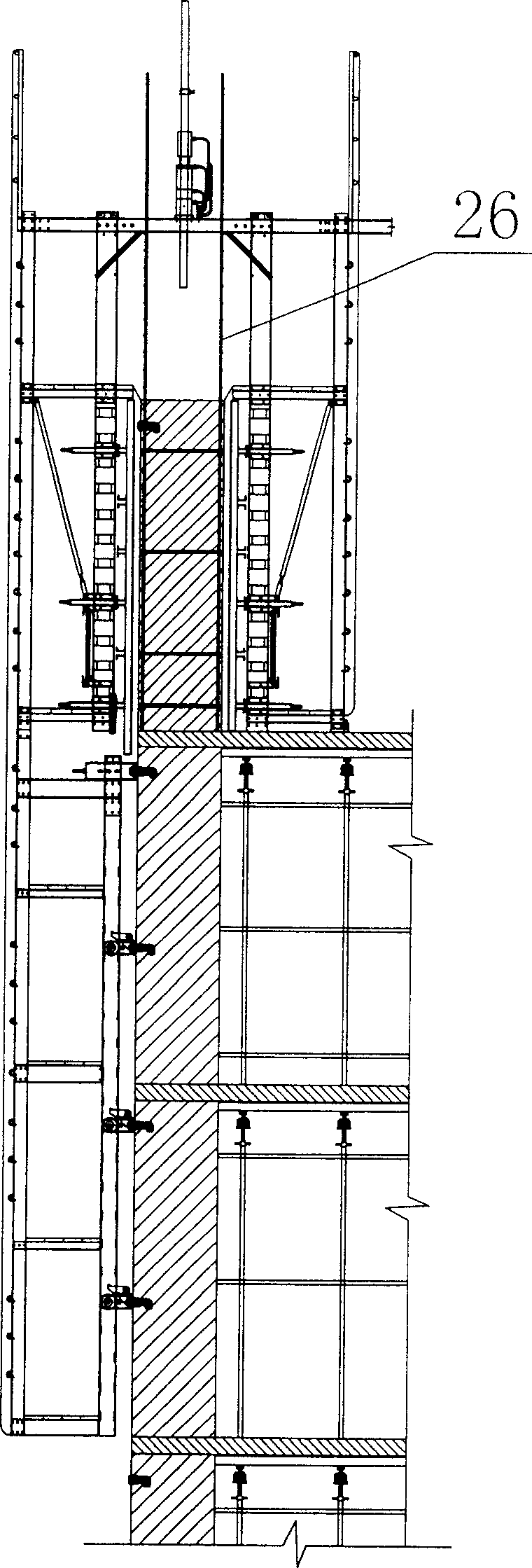

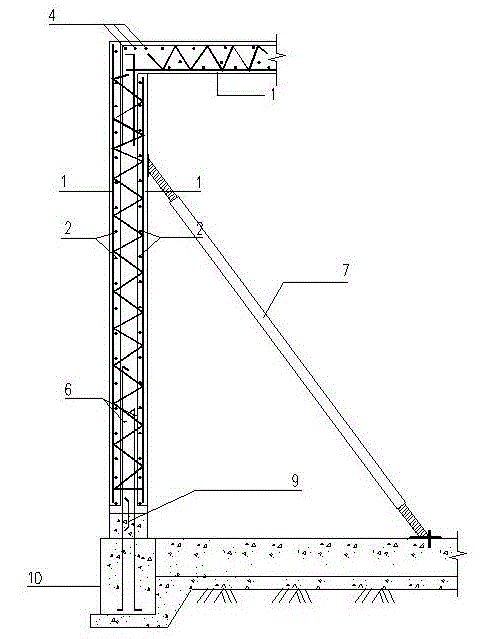

Liftable hydraulic climbing template and construction method thereof

ActiveCN1769623AReduce steel consumptionImprove carrying capacityForms/shuttering/falseworksRidgeShear wall

The invention discloses a liftable hydraulic climbing mould and construction method, which comprises the following parts: mould system, hydraulic elevation system and operation platform system, wherein the mould system connects two moulds through extended bolt, whose back connects the steel back deck; the stripper is set on the mould at each space; the liftable jack of hydraulic elevation system crosses on the top of support rod, which connects the support ridge cross-shape; the elevation rack and operation system are connected under the support ridge; the pillar of elevation rack contains moving support leg and channel clamp; the moving support leg contains horizontal extension lead-screw in the clamp, which connects the mould back ridge; the bottom of elevation pillar connects the adjustment lead-screw vertically.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

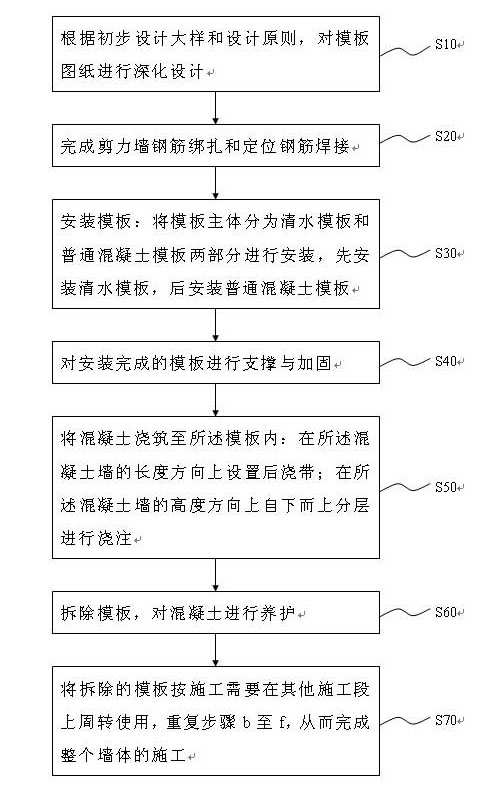

Construction method of overlong and superhigh single-side fair-faced concrete wall

ActiveCN101956458AGuaranteed installation qualityReduce construction costsForms/shuttering/falseworksBuilding material handlingRebarShear wall

The invention relates to a construction method of an overlong and superhigh single-side fair-faced concrete wall. The method comprises the following steps of: (a) carrying out deepening design on a template drawing; (b) finishing binding shear wall reinforcing bars and welding positioning reinforcing bars; (c) mounting a template: mounting the template by dividing the template into a fair-faced template and an ordinary concrete template, mounting the fair-faced template firstly and then mounting the ordinary concrete template; (d) supporting and reinforcing the mounted templates; (e) pouring concrete into the templates: arranging a rear pouring band along the length direction of the concrete wall, and pouring by layers from top to bottom along the height direction of the concrete wall; (f) dismantling the templates to maintain the concrete; and (g) circularly using the dismantled templates on other construction sections according to construction requirements and repeating the steps from (b) to (f) to finish the construction of the whole wall body. The invention is suitable for the construction of the overlong and superhigh single-side fair-faced concrete wall, and not only guarantees the mounting quality of the fair-faced concrete template, but also reduces the construction cost.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Installation construction method for large all-steel formwork at internal corner of shear wall

InactiveCN102704672ATight seamsIncrease stiffnessForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSheet steelShear wall

The invention discloses an installation construction method for a large all-steel formwork at the internal corner of a shear wall. The installation construction method comprises the following steps of: (1) installing an internal corner steel formwork at the internal corner of the wall, wherein the internal corner steel formwork comprises two vertical steel plates which are welded at a right angle, multiple reinforcing ribs are connected between the two vertical steel plates at intervals, two connecting steel plates are respectively welded at the two sides of each reinforcing rib, and each connecting steel plate is respectively and vertically connected with the vertical steel plate at the corresponding side; (2) respectively connecting and installing a groove type steel plate at the outer side edge of each connecting steel plate along the vertical direction through a lead screw; (3) installing large steel formworks at the two sides of the internal corner of the wall; (4) connecting formwork back ribs on the large steel formworks at intervals; (5) connecting internal corner rolling grooves corresponding to each reinforcing rib with holes arranged on the reinforcing ribs through internal corner hook bolts; and (6) pouring concrete into the shear wall. According to the installation construction method provided by the invention, a formwork system at the internal corner of the shear wall firmly and reliably forms a stable integral system.

Owner:天津住宅集团建设工程总承包有限公司

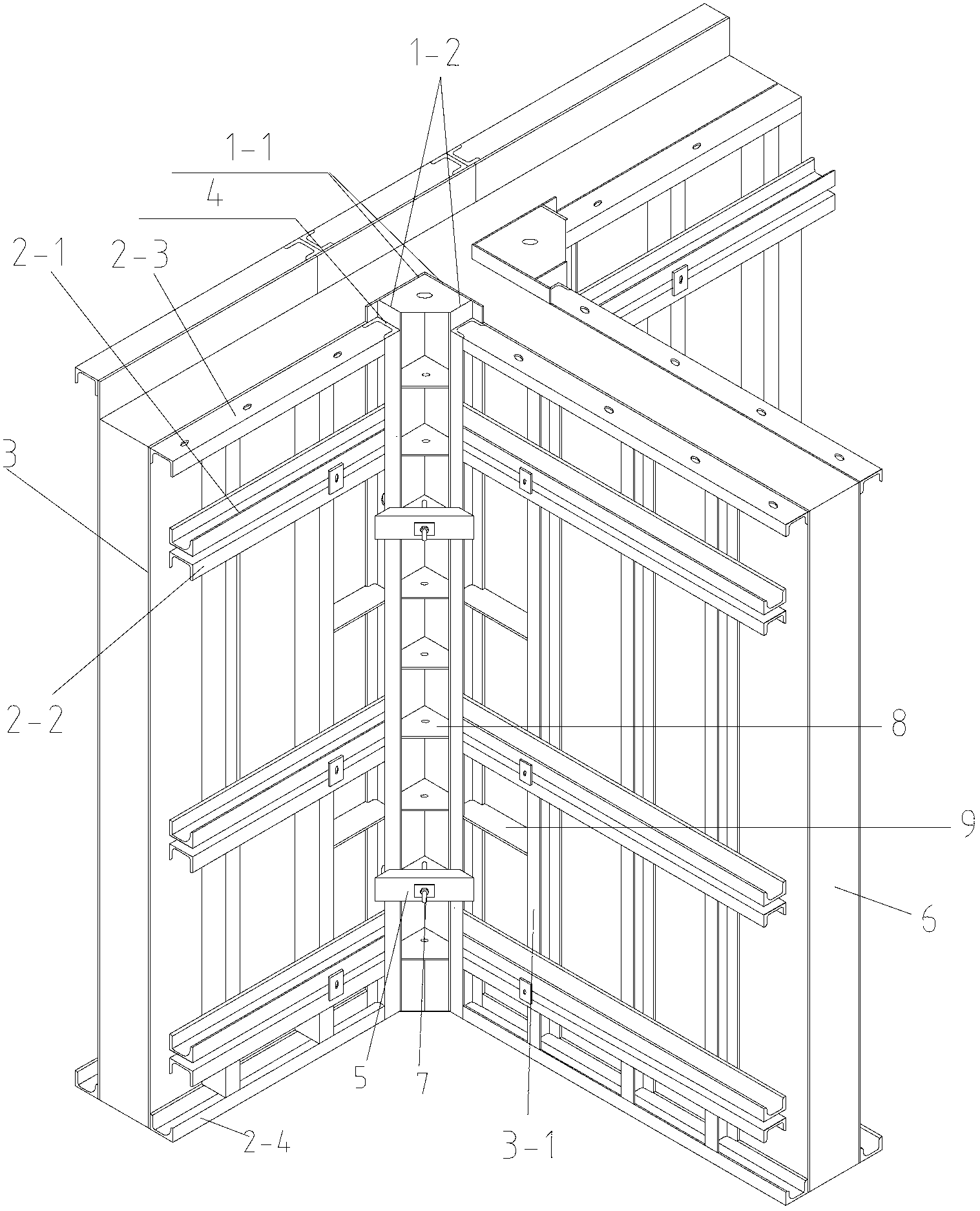

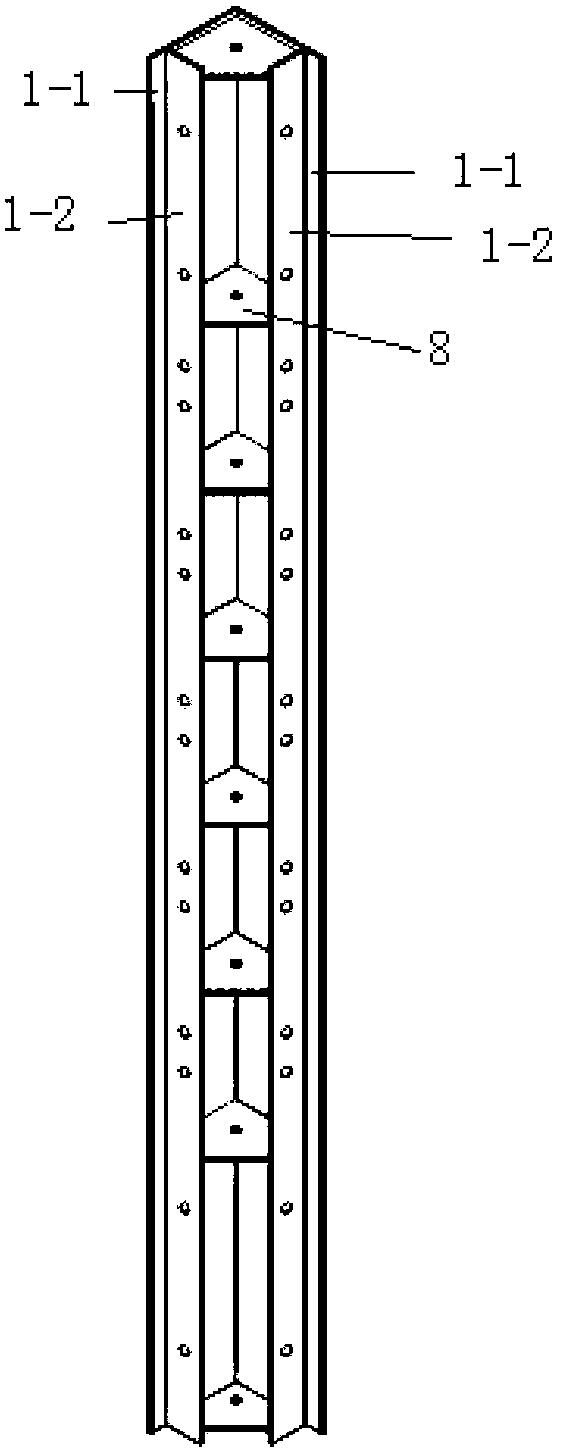

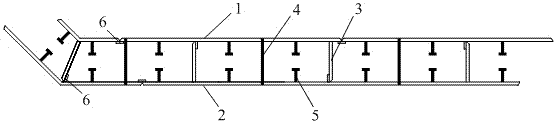

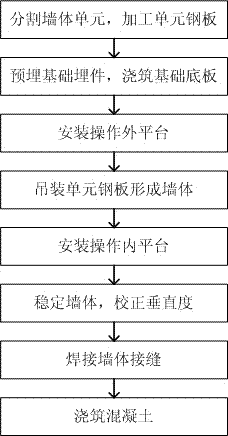

A double steel plate structure shear wall and its construction method

InactiveCN102296728AIncrease lateral stiffnessImprove carrying capacityWallsBuilding material handlingSheet steelLateral stiffness

The invention discloses a shear wall with a double-steel plate structure, which comprises steel plates, stiffening plates, connecting steel bars, and studs; the steel plates are spliced by welding, and the opposite sides thereof are connected together by welding stiffening plates and connecting steel bars; Studs are welded on opposite sides of the inner steel plate and the outer steel plate; concrete is poured in the wall. This kind of structure can strengthen the lateral stiffness of the shear wall, and weaken the shrinkage and creep of the concrete when pouring concrete in the wall, so that the bearing capacity and ductility of the wall are significantly enhanced, and the seismic performance is improved. The invention also discloses a construction method for building the shear wall. Firstly, the processing unit is divided, and then the steel plate of the unit is hoisted on the installation foundation pre-embedded with the foundation embedded parts to form the wall, and then the verticality of the wall is corrected, and the wall joint is welded. , Concrete is poured on the wall; inner and outer operating platforms are also erected during construction.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING

Prefabricated assembled superposed plate type concrete shear wall and construction method thereof

InactiveCN102912900AAchieve standardizationAchieve modularityWallsBuilding material handlingArchitectural engineeringRebar

The invention relates to a prefabricated assembled superposed plate type concrete shear wall and a construction method thereof. The prefabricated assembled superposed plate type concrete shear wall comprises superposed wall plates and a cast-in-place concrete core wall, wherein each superposed wall plate is formed by superposing two prefabricated concrete single wall plates which are of the same specification and are symmetrically arranged at an equal interval; supporting plate steel bar supports are arranged between the two single wall plates; node connection reinforcement steel bars are arranged on end nodes of the superposed wall plates; the superposed wall plates are fixedly integrated with the cast-in-place concrete core wall; and the superposed wall plates, the cast-in-place concrete core wall, the supporting plate steel bars and the node connection reinforcement steel bars are fixedly connected with one another to form the shear wall structure. The invention also provides a construction method for the shear wall structure. By the construction method, when an extensive form building mode is changed, and structural members of a house are standardized and modularized, engineering construction is high in speed, and materials are saved; and the overall structural performance is high.

Owner:ANHUI HUALI CONSTR GRP

Prefabricated integrated shear wall construction method

InactiveCN105464244AImprove construction efficiencyImprove integrityWallsBuilding material handlingFloor slabLine tubing

The invention discloses a prefabricated integrated shear wall construction method. The method includes following steps: step 1, positioning and placing a standard axial line and a control axial line, and mounting an elevation line of a floor and an elevation line of a staircase; step 2, adopting a positioning control steel plate to check and adjust position of reserved joint bars; step 3, hoisting a prefabricated shear wall; step 4, fixing and correcting the shear wall by setting up an adjustable steel pipe sway brace; step 5, grouting the shear wall; step 6, performing edge component rebar binding and formwork mounting on the prefabricated shear wall; step 7, arranging a temporary support on the floor, and correcting height; step 8, hoisting prefabricated beams, prefabricated floorboards, prefabricated balcony boards, air conditioner boards and the staircase; step 9, overlapping splicing beams of the floorboards, and mounting a bottom formwork; step 10, laying pipelines; step 11, binding rebars of a cast-in-place layer; step 12, pouring concrete. The prefabricated integrated shear wall construction method has the advantages of high construction efficiency and high integrity.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING

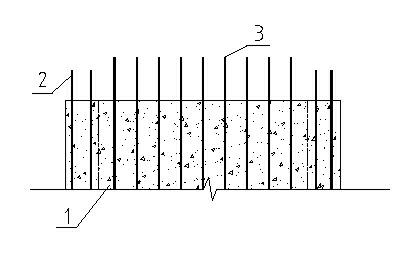

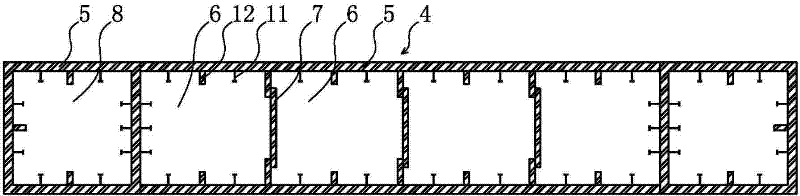

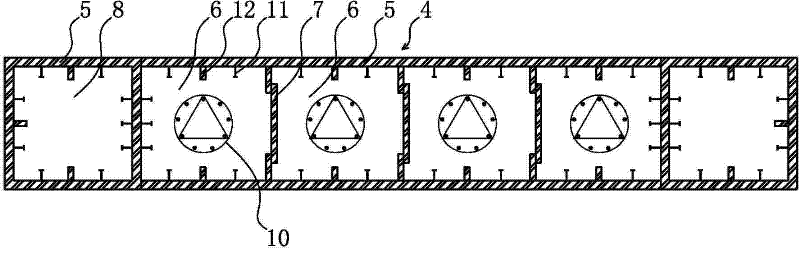

Assembly integral shear wall building structure and building method

ActiveCN103669559AImprove the level of industrializationIncrease productivityWallsBuilding material handlingRebarHigh rise

The invention relates to an assembly integral shear wall building structure and a building method and belongs to the field of buildings and construction technologies of the buildings. The shear wall building structure is formed by connecting prefabricated concrete hollow components through steel bars and cast-in-place concrete, wherein the prefabricated concrete hollow components include prefabricated wall body components, floor board components, T-shaped wall pillar components, L-shaped wall pillar components, cross-shaped wall pillar components and wall body components with holes. Multiple parallel lengthwise through holes are formed in the prefabricated hollow components in the length direction and multiple parallel transverse non-through holes communicated with the lengthwise through holes are formed in the prefabricated hollow components in the width direction. Horizontal anchor connection steel bars inserted into the transverse holes are arranged among the different prefabricated components. Lengthwise anchor connection steel bars are arranged in the lengthwise holes, wherein one end of each lengthwise anchor connection steel bar protrudes out of the surface of the corresponding prefabricated component by a certain length. The concrete is filled into the lengthwise holes and the transverse holes to form a layer of structural unit or a single-layer building structure. Multiple structure units are connected to form a multiple-layer or high-rise assembly integrated shear wall structure. The assembly integral shear wall building structure and the building method can be applied to the multiple-layer or high-rise shear wall building structures and frame-shear wall building structures. Thus, the industrial level of the building structures can be improved, stress performance can be improved and resources are saved.

Owner:初明进

Outsourcing multi-cavity steel plate concrete composite shear wall and its construction method

InactiveCN102296723AReasonable structureImprove performanceWallsBuilding material handlingHigh riseCantilever

Owner:广州容柏生建筑结构设计事务所(普通合伙)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com