Prefabricated assembled superposed plate type concrete shear wall and construction method thereof

A concrete shear wall and prefabricated assembly technology, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of short construction period, large randomness, uneven force, etc., and achieve fast construction speed and good overall performance of the structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

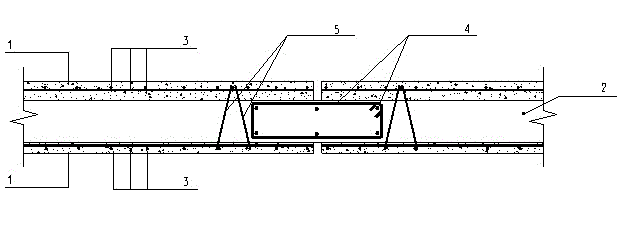

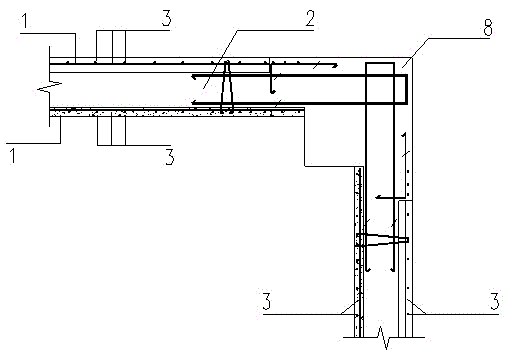

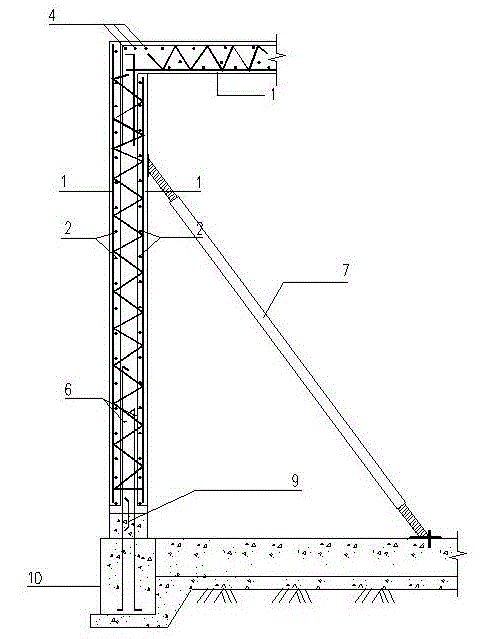

[0020] see Figure 1-3 , the present invention includes a laminated wall panel 1 and a cast-in-place concrete core wall 2. The laminated wall panel 1 is formed by laminating two prefabricated concrete single wall panels with the same specification and arranged symmetrically and equidistantly. The wallboards are supported by strut steel bars 5, and the end nodes of the laminated wallboards 1 are provided with node connection reinforcing steel bars 4, and the inside of the laminated wallboards 1 is a cast-in-place concrete core wall 2, and the two are consolidated into one; The wall board 1, the cast-in-place concrete core wall 2, the steel bar for the brace 5 and the reinforcing steel bar 4 for node connection are mutually installed and fixed to form a shear wall structure. The shear wall structure is combined with the concrete cast-in-place frame column 8 and the frame beam slab to form an overall building space structure.

[0021] Construction method step of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com