Compound type connection shear wall structure and assembling method thereof

A shear wall and composite technology, applied in the direction of walls, building components, building structures, etc., can solve the adverse effects of building appearance and waterproof performance, the impact of shear walls on structural safety, and the difficulty of precise docking between upper and lower walls, etc. problems, to achieve the effect of shortening the assembly cycle, reducing assembly workload, and improving construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

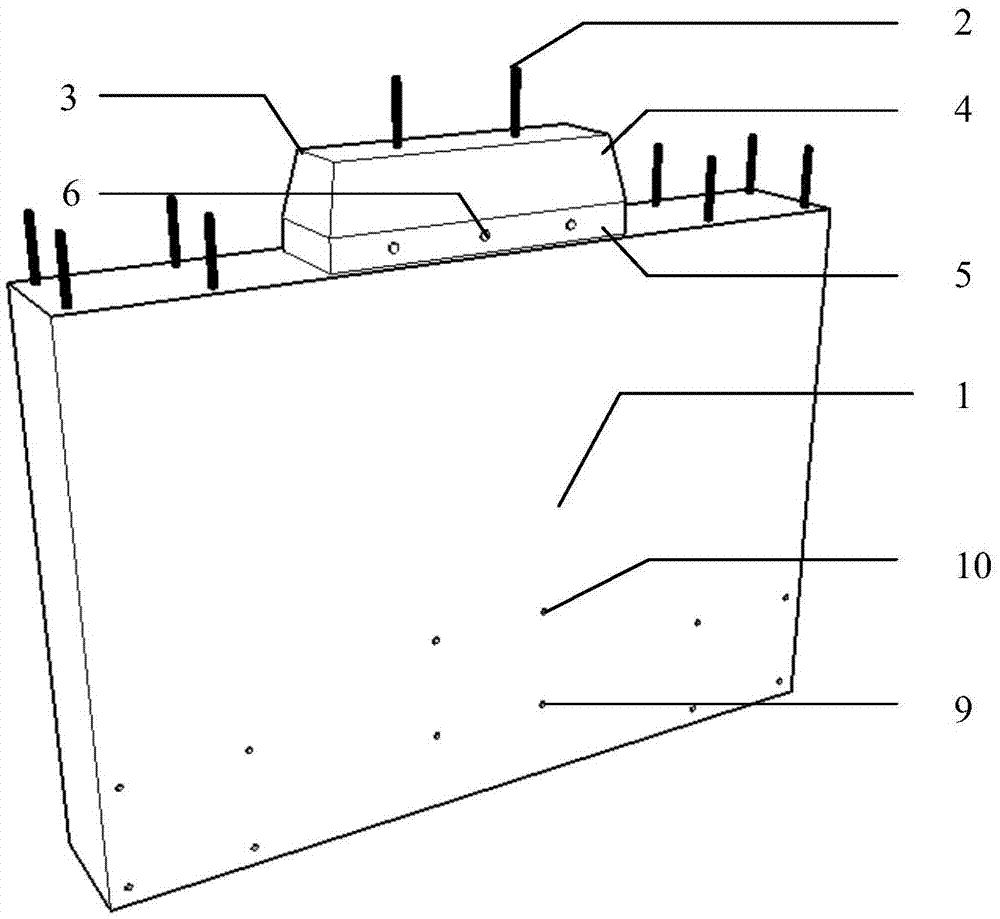

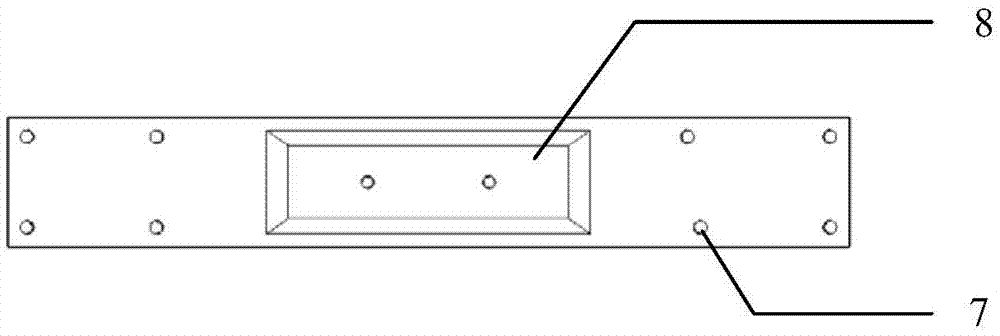

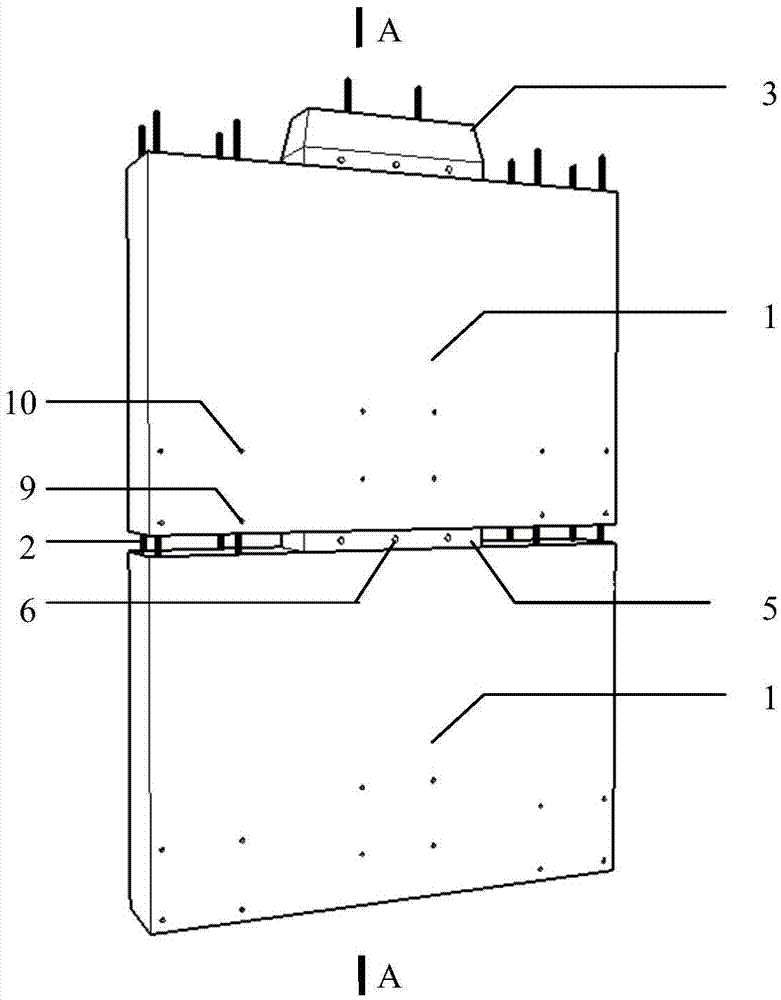

[0032] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes N pieces of shear wall components 1 with the same structure, and every two pieces of shear wall components are connected by composite shear keys 3 and key grooves 8 to form a composite connected shear wall.

[0033] 1-2 rows ( figure 1 , image 3 2 rows in the middle) longitudinal reinforcement 2, and at least one composite shear key 3 is set in the middle of the upper end ( Figure 1~3 The composite shear key is 1), the upper part of the composite shear key is the embedded part 4 of the shear key, and the lower part is the embedded part 5 of the shear key. The thickness of 12 is equal, the width is less than the thickness of the shear wall, and there are a plurality of reserved holes 6 for the reinforcement of the laminated floor 12 on both sides of the shear w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com