Patents

Literature

282results about How to "Control construction quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for carrying out deepwater laying on large-volume reinforced mud-filling tubular bags by using geotextiles-laying vessels

The invention relates to a method for carrying out deepwater laying on large-volume reinforced mud-filling tubular bags by using geotextiles-laying vessels, which comprises the following steps of: carrying out measurement on the underwater terrain by using a GPS (global position system), drawing a cross-section diagram, and marking an embankment axis and a construction side line in a construction area; determining the length of the mud-filling tubular bag according to the measured data and the size of a cross section, determining the width of a bag body according to the length of a roller, and sewing a reinforced belt on the surface of the bag body, wherein the bag body is provided with a mud inlet; rolling the mud inlet of the mud-filling tubular bag inwards on the roller; anchoring a geotextiles-laying vessel with the rolled bag body on the construction side line, and preparing a sand carrier and a sand blowing pump; filling the head part of the mud-filling tubular bag firstly, placing the mud-filling tubular bag on the construction side line, moving the mud-filling tubular bag and continuing to fill the mud-filling tubular bag until the mud-filling tubular bag is completely submerged in an original beach face or on the lower bag body, and then taking back a connecting rope; moving the vessel transversely, and laying the next mud-filling tubular bag. The method disclosed by the invention is accurate in positioning; through carrying out reinforcement treatment on mud-filling tubular bags, the strength of bag bodies is significantly increased, and the influence on construction caused by rising and falling tide is small; and the construction is assisted by using large vessels, so that the operating risk of workers is reduced, and the construction efficiency is improved.

Owner:安徽水利开发有限公司 +1

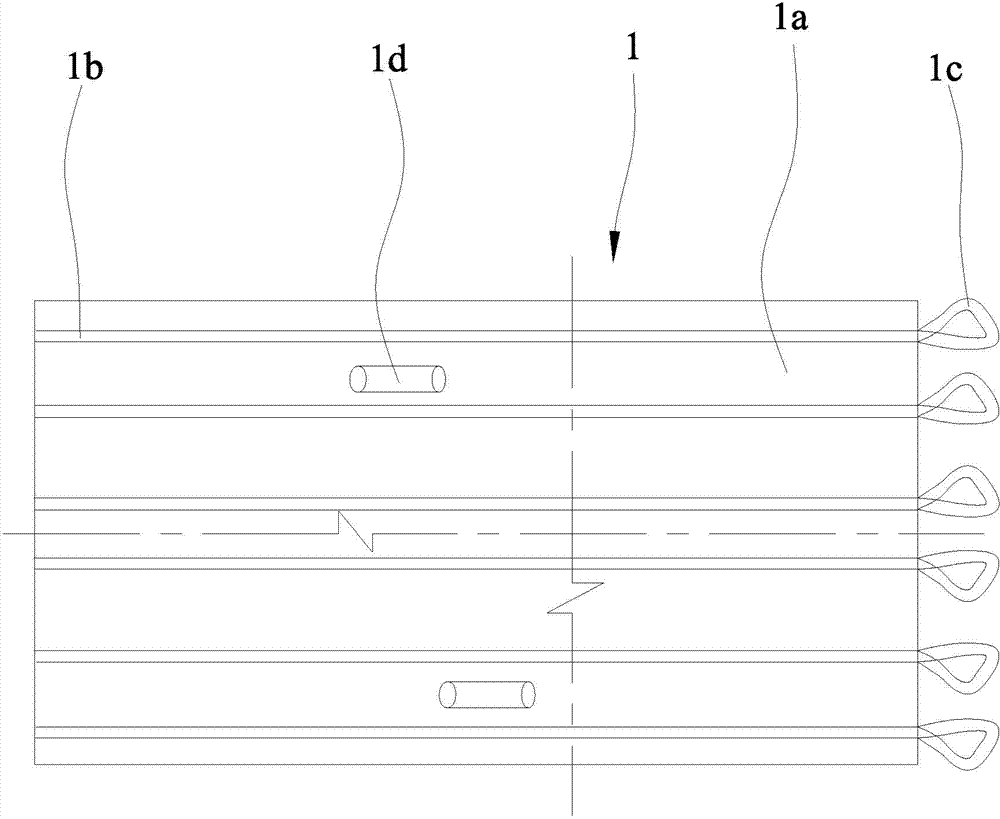

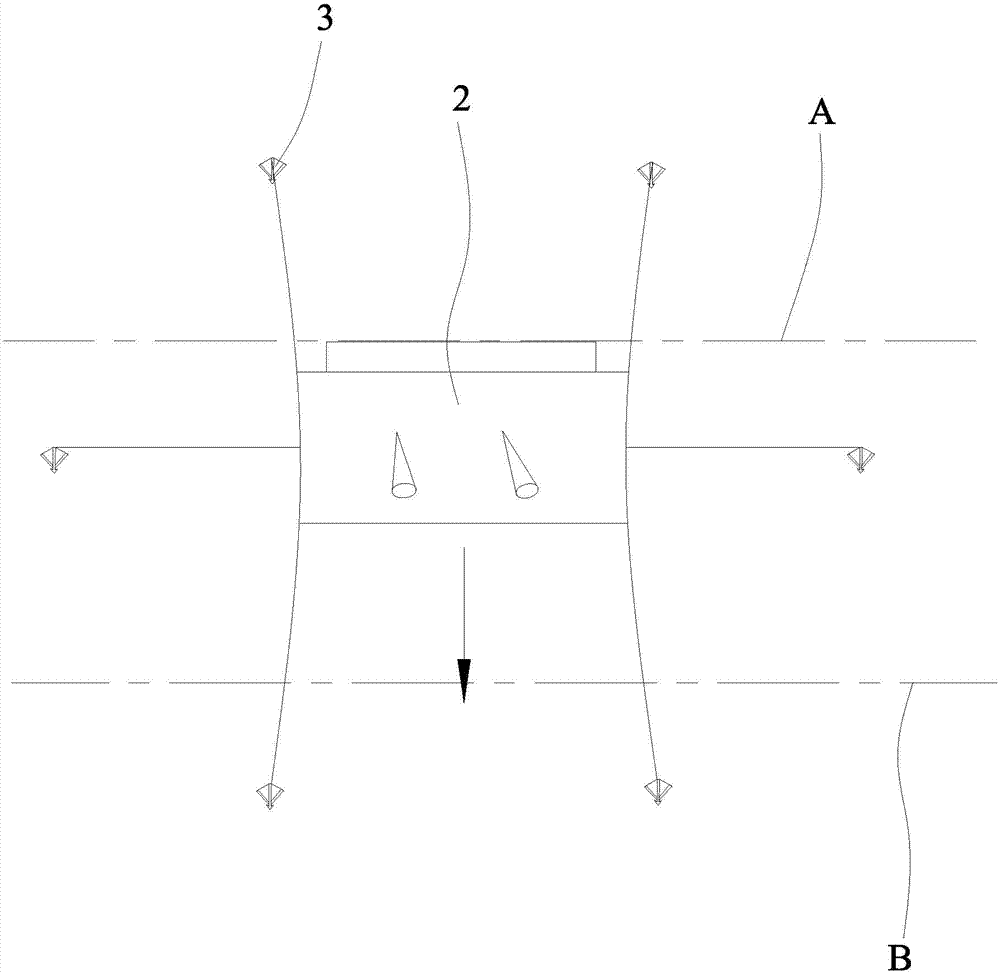

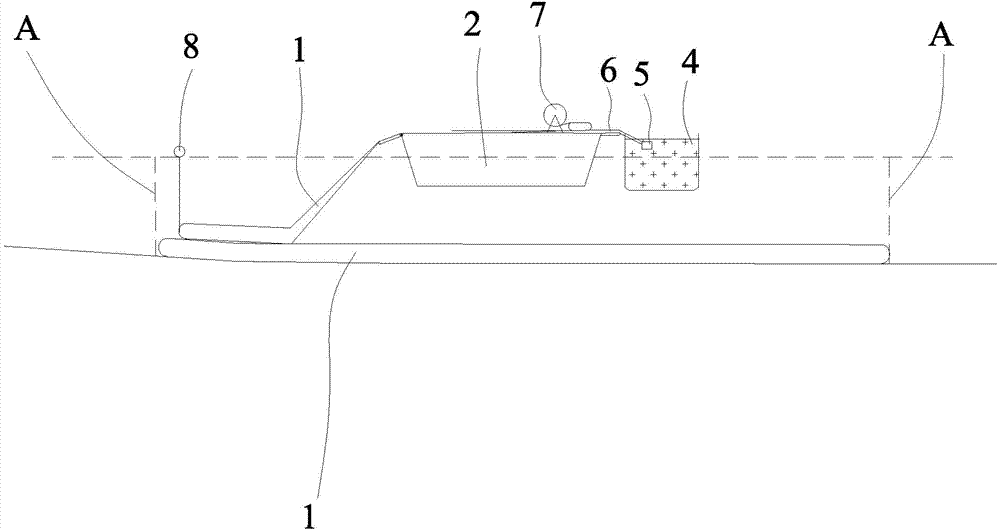

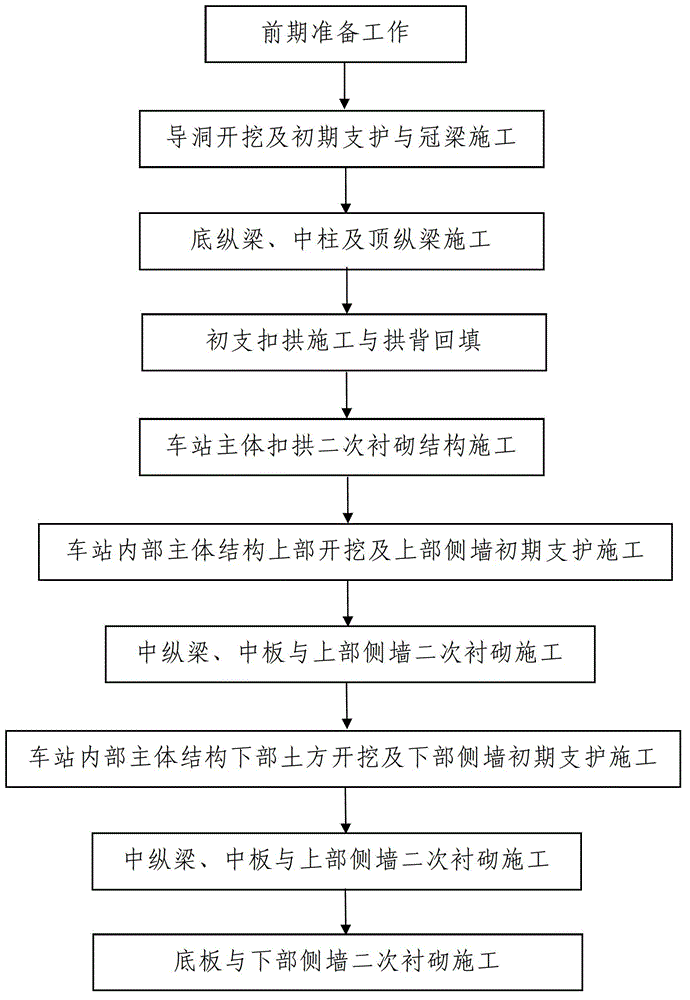

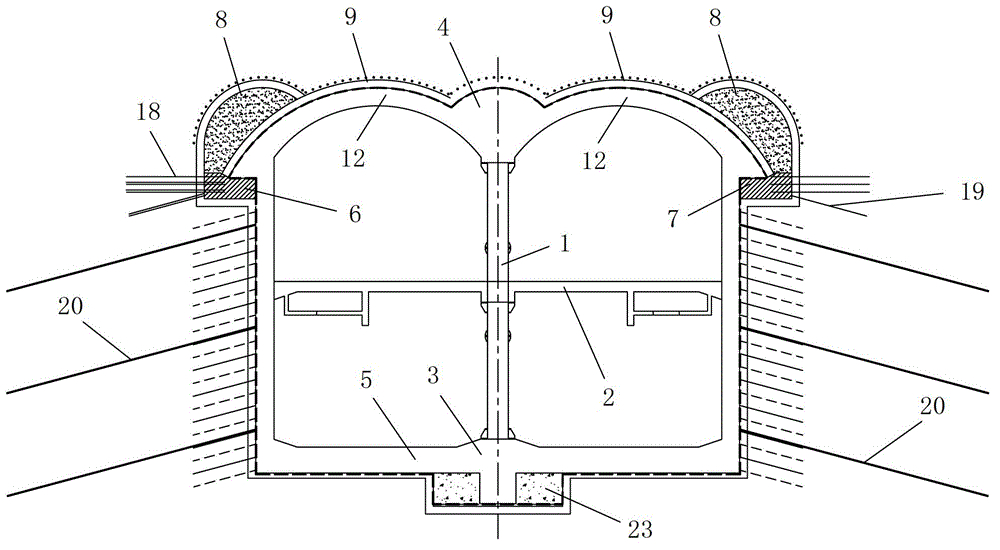

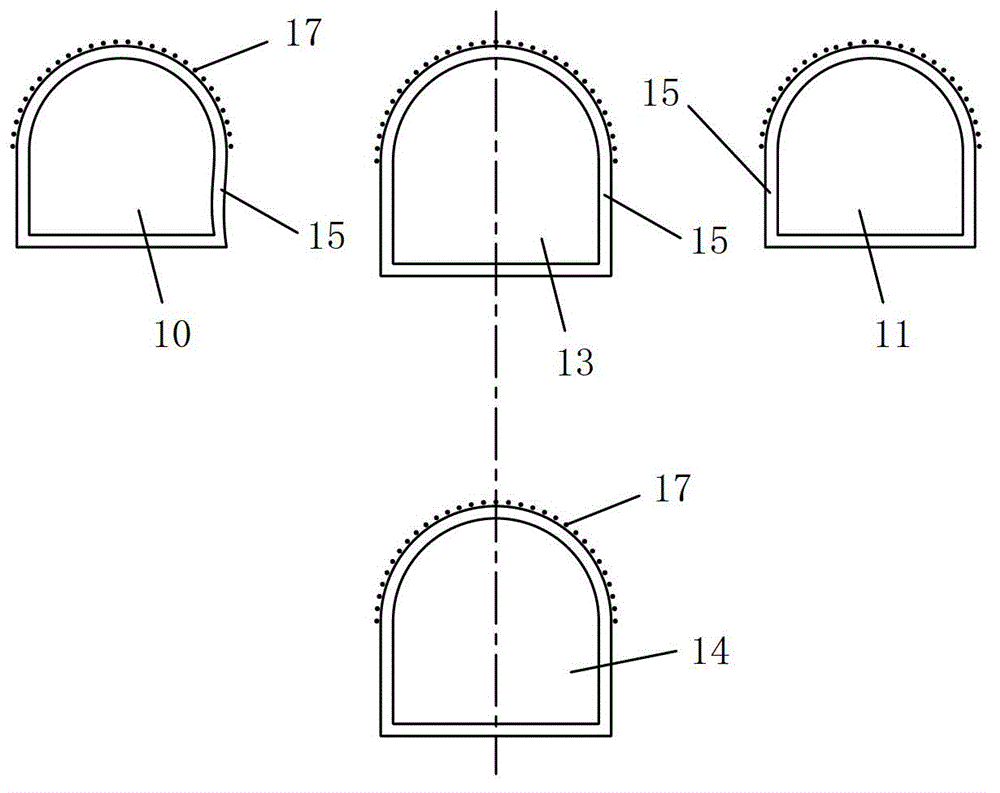

Main structure for metro long-span station and pillar arching construction method thereof

ActiveCN102748040AEasy constructionSimplify construction stepsUnderground chambersEngineeringLong span

The invention discloses a main structure for a metro long-span station and a pillar arching construction method thereof. The main structure comprises a station interior main structure, a plurality of middle pillars, a middle plate and a main arch part, wherein the station interior main structure is dug; the middle plate is located on the middle pillars; the main arch part is located right above the main structure; a bottom longitudinal beam is arranged at the bottom of the station interior main structure; a top longitudinal beam is arranged on the main arch part; and a middle longitudinal beam is arranged between adjacent middle pillars. The construction method comprises the following steps: 1) preparing in earlier stage; 2) digging a guiding hole and performing primary bracing and bridging construction; 3) constructing the bottom longitudinal beam, the middle pillars and the top longitudinal beam; 4) constructing a primary branch arch and refilling an arch back; 5) performing arch secondary lining construction; 6) digging the upper part of the main structure and constructing a primary branch of a side wall of the upper part; 7) performing secondary lining construction of the middle longitudinal beam, the middle plate and the side wall of the upper part; 8) digging the lower part of the main structure and constructing the primary branch of the side wall of the lower part; and 9) performing secondary lining construction for a base plate and the side wall of the lower part. The construction method provided by the invention has the advantages of reasonable design, simple construction step, convenience in realizing, small construction difficulty and high construction speed.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

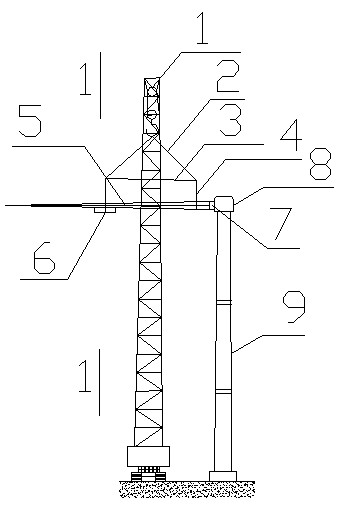

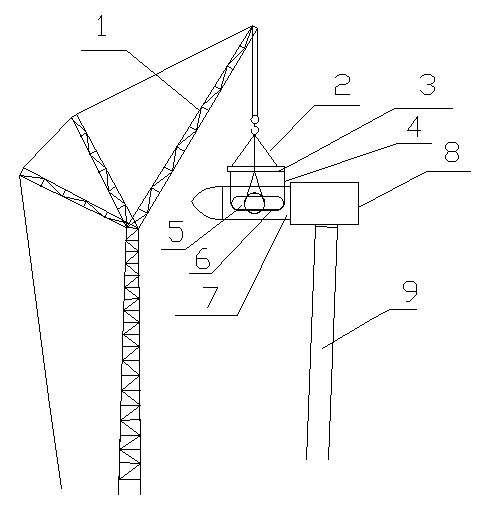

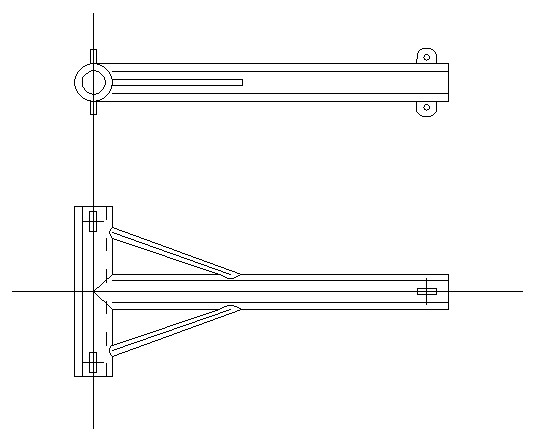

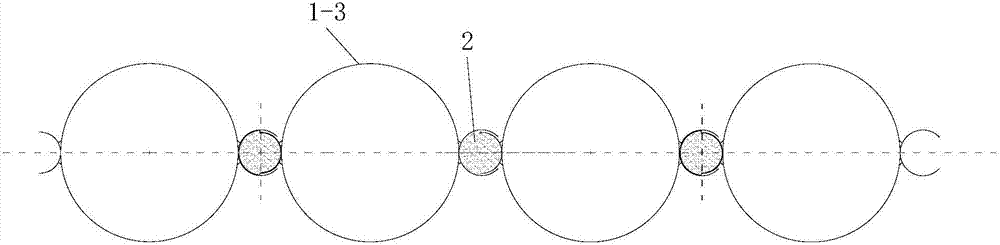

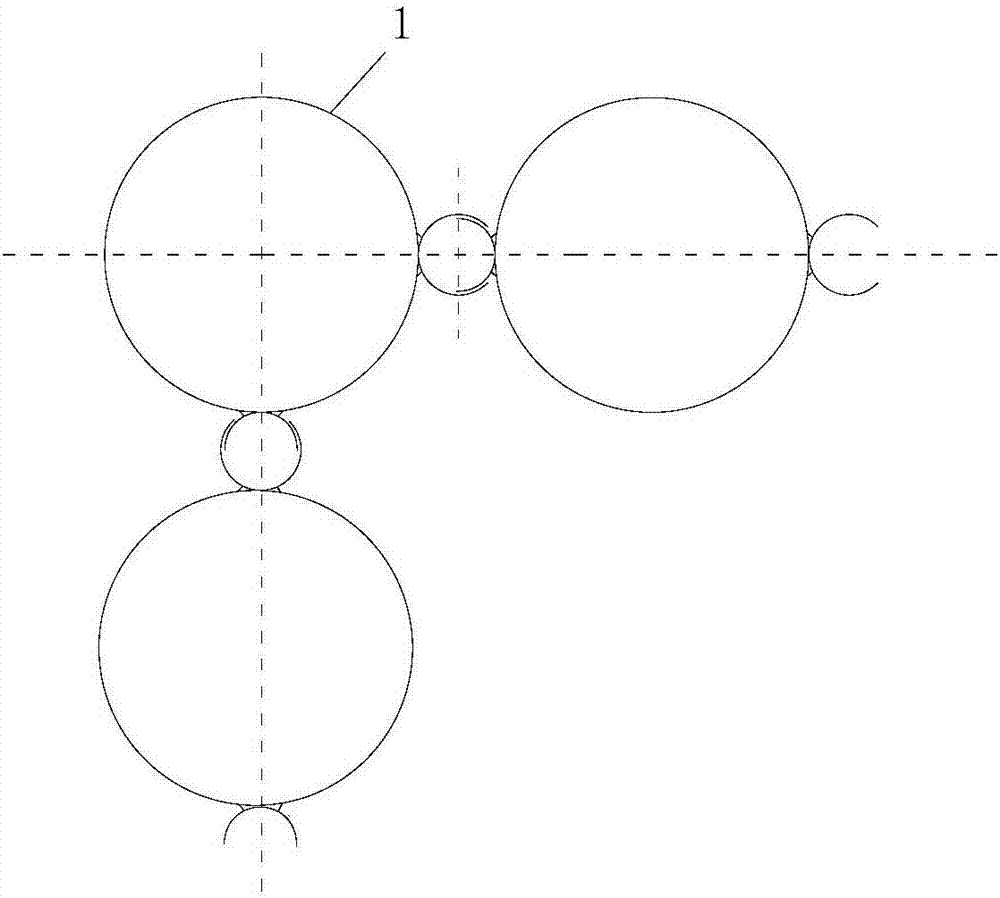

Segmental lifting method for impeller of high-power wind driven generator

InactiveCN102650261AAvoid churnReduce construction land areaMachines/enginesWind energy generationImpellerWind driven

The invention discloses a segmental lifting method for an impeller of a high-power wind driven generator, which is characterized in that after the installation of a tower and an engine room is qualified, a hub and three single vanes are respectively lifted in place and are abutted into one whole body in the air by utilizing a crane for lifting the tower and the engine room, a machine tool and a rope; a girder of a T-shaped shoulder pole beam is welded by adopting a seamless steel pipe with the specification of phi 219*10 mm and has a length of 6 m and a width of 2.5 m; and a reinforcing support is welded with the girder by adopting a seamless steel pipe with the specification of phi 89*6 mm. The segmental lifting method for the impeller of the high-power wind driven generator is carried out according to the steps: carrying out ground assembly on the hub, lifting the hub, lifting a first vane, rotating the impeller by 120 degrees by a hub jigger and mounting second and third vanes. The segmental lifting method has the advantages of reducing the construction land area, preventing the water loss and soil erosion, effectively controlling the construction quality, reducing the safety risk and saving the investment and the construction cost.

Owner:CHINA MCC17 GRP

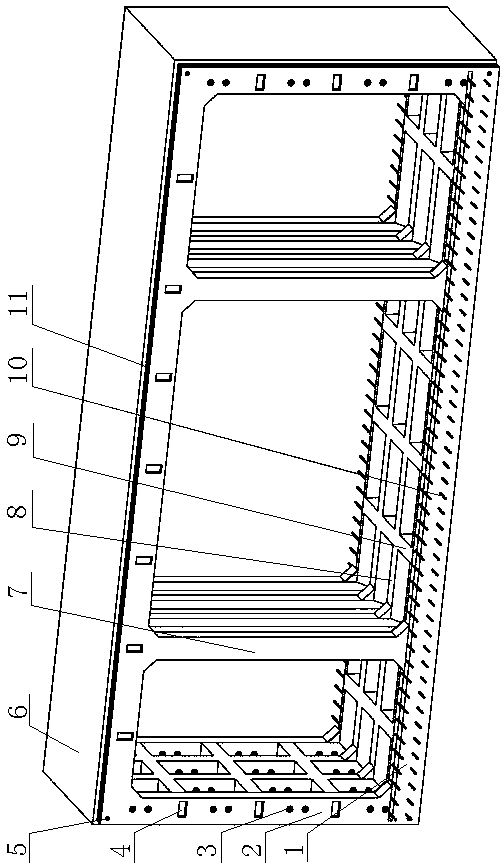

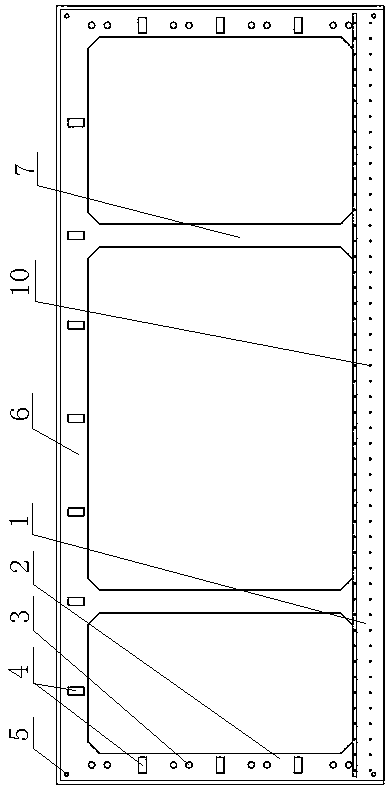

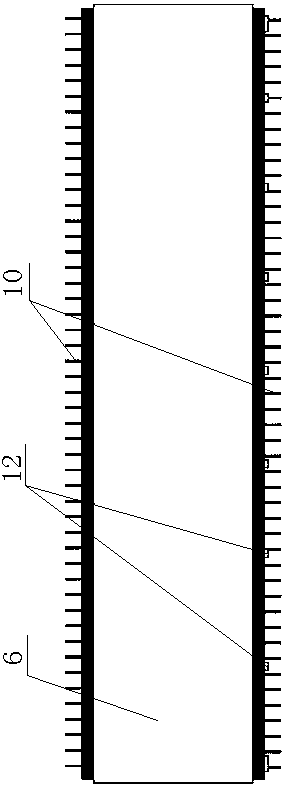

Prefabricated assembled box culvert and construction method thereof

InactiveCN102418319AImprove construction progressQuality assuranceGround-workRc framesArchitectural engineering

The invention discloses a prefabricated assembled box culvert and a construction method thereof. The box culvert is in an assembled structure and consists of a reinforced concrete culvert body, wing walls, a foundation and deformation joints, wherein the culvert body of the box culvert is in an integral closed-type reinforced concrete framework structure formed by combining transition culvert joints, non-standard culvert joints and standard culvert joints. The culvert body and the wing walls adopt assembly and construction. By utilizing the prefabricated assembled box culvert, batch production can be performed in a factory, field assembly is realized, the construction progress of the culvert is accelerated, the construction period is shortened and the quality of the culvert is ensured. Therefore, the problems of long culvert construction period and difficult control on the quality during the current road construction can be solved.

Owner:新疆交通科学研究院有限责任公司

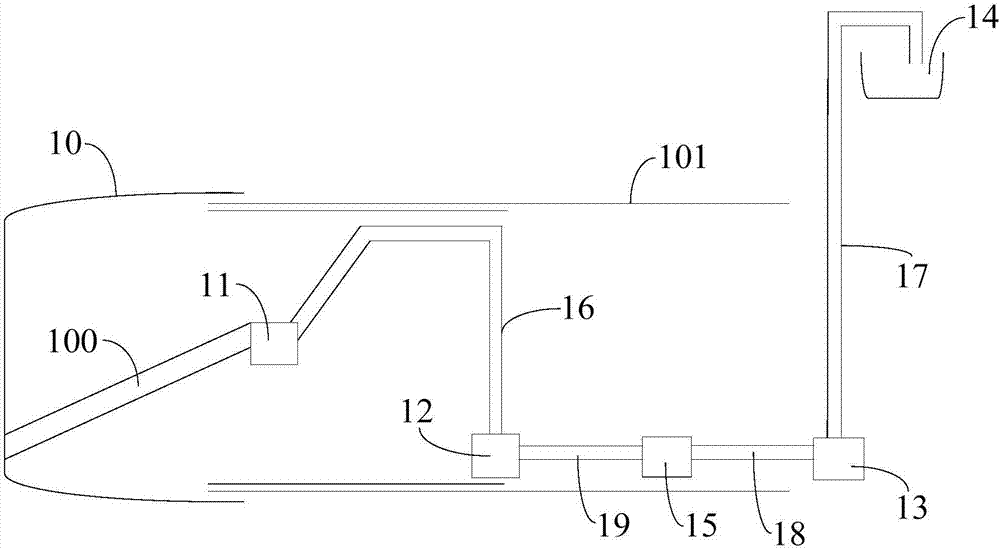

Guiderail device and method for pouring slope roof

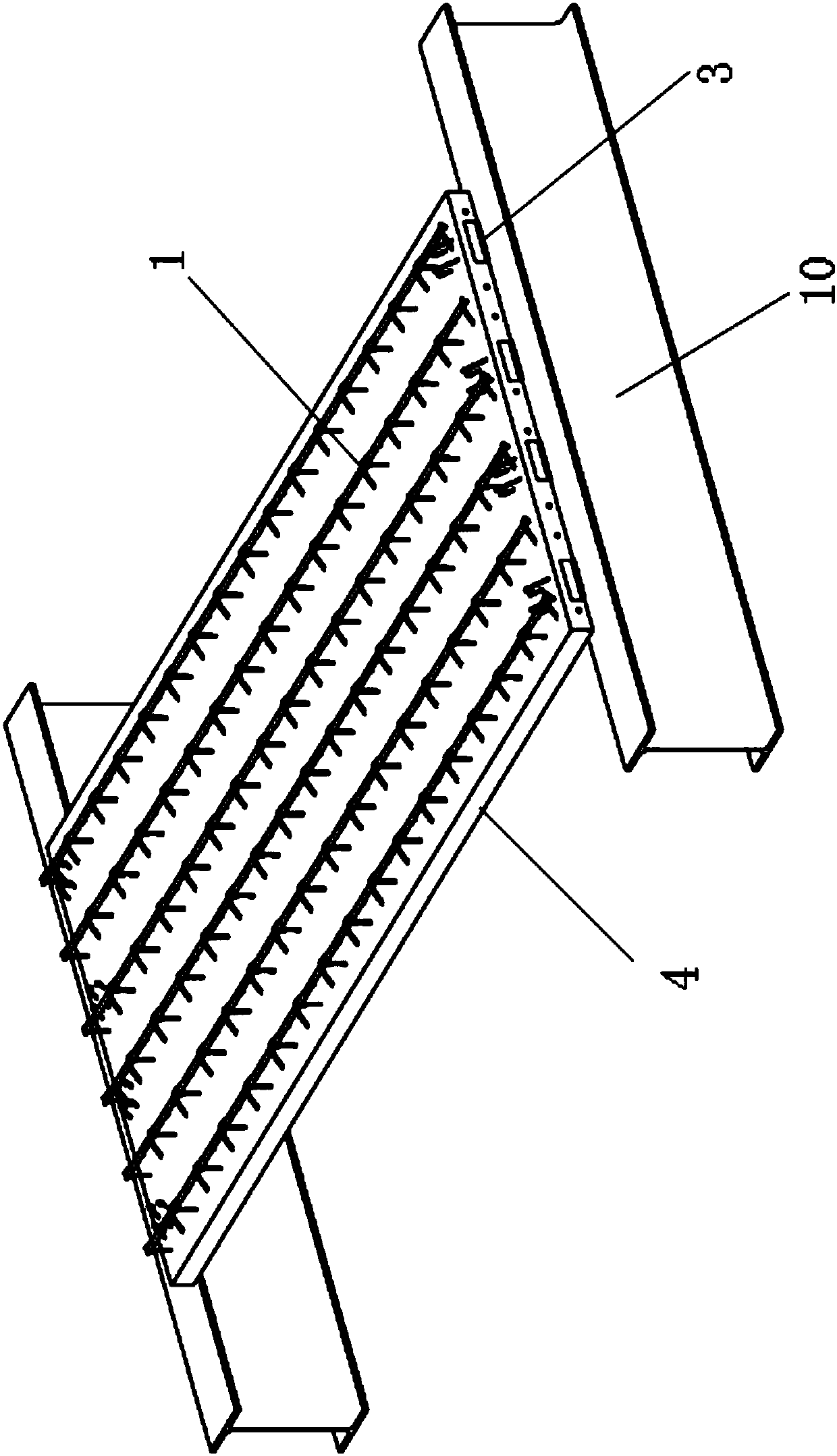

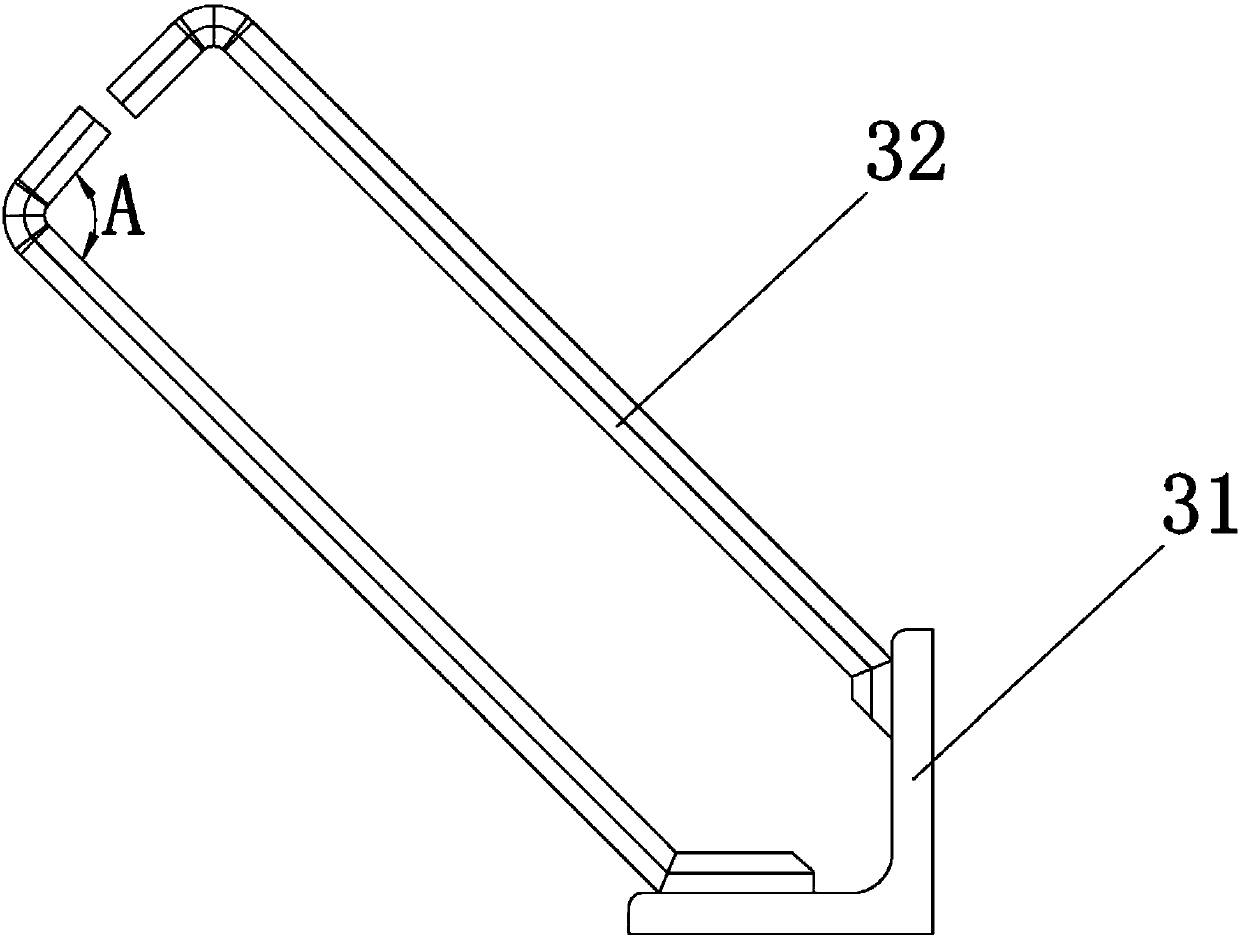

ActiveCN104100092APrevent slippingPouring is easyBuilding roofsBuilding material handlingRebarWire mesh

The invention discloses a guiderail device and method for pouring a slope roof and relates to the technical field of building engineering construction. The guiderail device comprises plate-bottom steel reinforcing bars laid on the top surface of the form board of the slope roof. Plate-surface steel reinforcing bars opposite to the plate-bottom steel reinforcing bars are disposed above the plate-bottom steel reinforcing bars. A plurality of cushion blocks are disposed between the plate-bottom steel reinforcing bars and the form board of the slope roof. A plurality of horse stool steel reinforcing bars and a plurality rows of guiderail support steel reinforcing bars are disposed between the plate-bottom steel reinforcing bars and the plate-surface steel reinforcing bars. A guiderail steel reinforcing bar is fixedly connected to the top surface of each row of guiderail support steel reinforcing bars, and a steel wire mesh is fixedly connected to the bottom of the guiderail steel reinforcing bar. When the guiderail device is used for pouring, the plate-bottom steel reinforcing bars are laid first, the cushion blocks are placed between the plate-bottom steel reinforcing bars and the form board, then the horse stool steel reinforcing bars are fixed and the plate-surface steel reinforcing bars are laid, the guiderail support steel reinforcing bars are disposed and the guiderail steel reinforcing bars are laid, the steel wire meshes are mounted below the guiderail steel reinforcing bars, and finally concrete pouring can be performed. The guiderail device has the advantages that the guiderail device is easy in concrete pouring and dense in vibration, construction progress is accelerated, and construction cost is lowered.

Owner:WUHAN HANYANG MUNICIPAL CONSTR GRP CO LTD

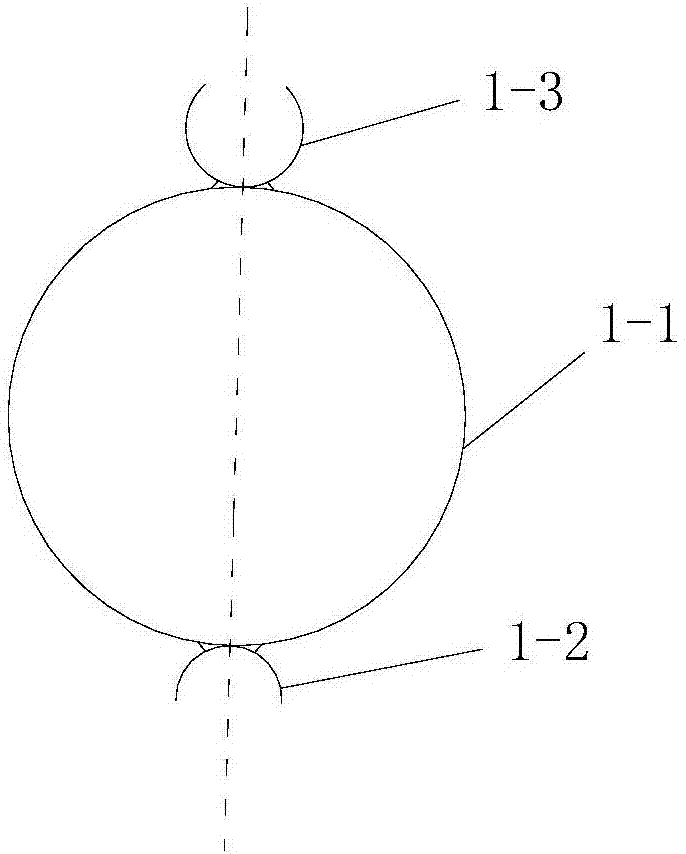

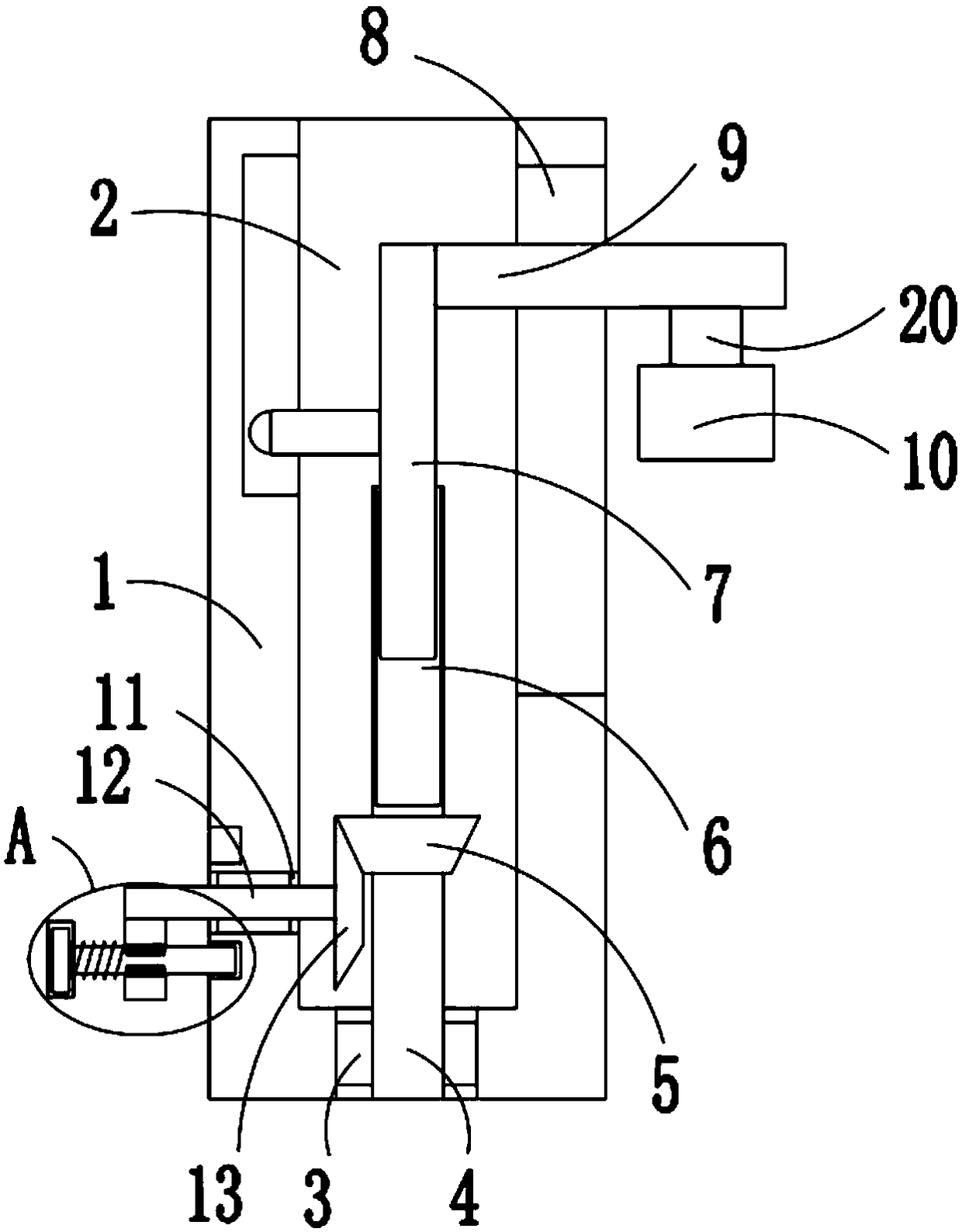

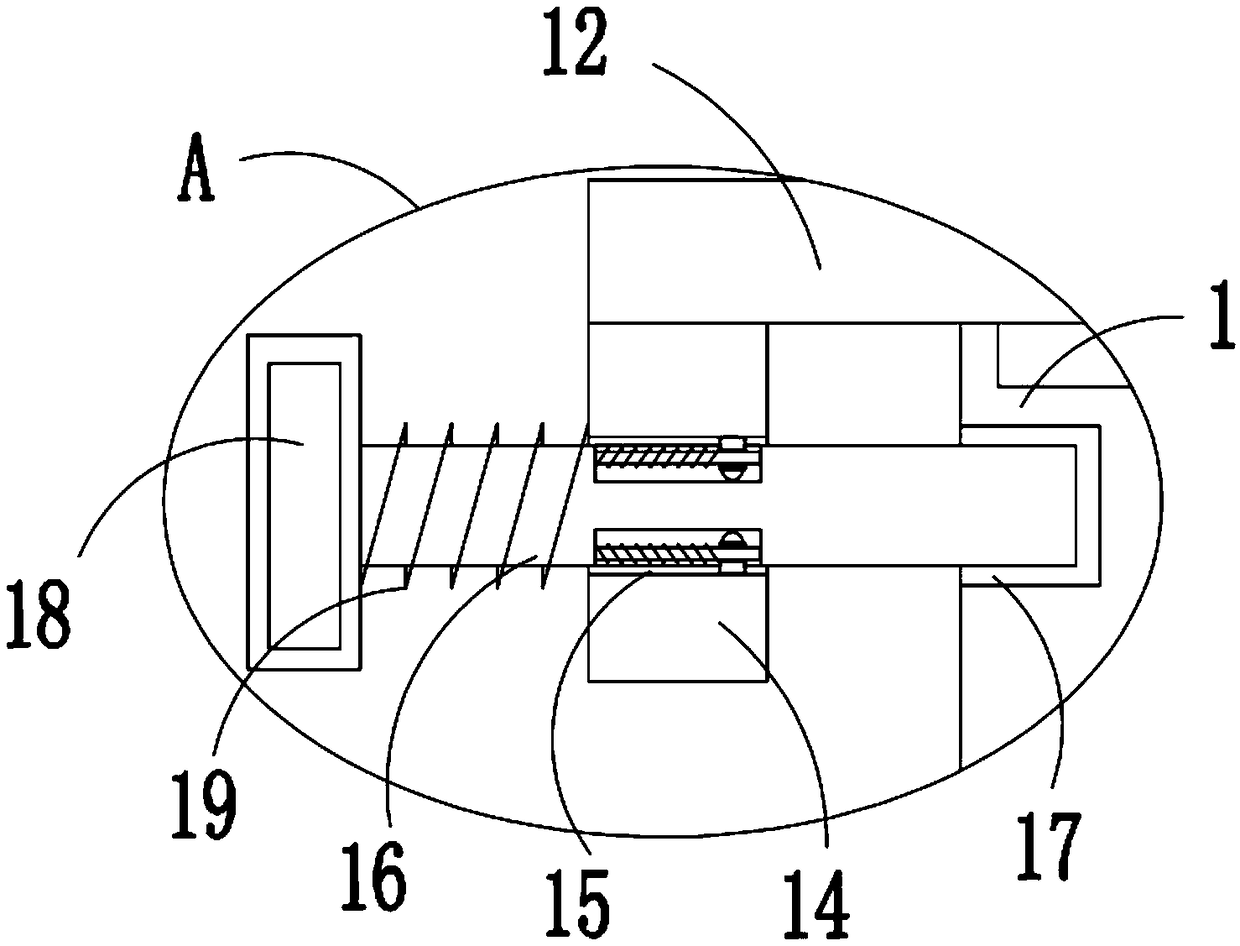

Pile, pole interface positioning device and construction method

InactiveCN101294384AOvercome the disadvantage of easy displacementGuaranteed bottom positioningBulkheads/pilesSteel barMouth structure

The invention discloses a pile / post interface positioning device as well as the construction method thereof. After a pile hole is drilled, a steel reinforcement cage and a steel casing are hung into the pile hole, concrete is poured into the pile hole until exceeding the height mark on the top surface of the pile foundation, then the concrete laitance at the pile head is chiseled off to expose a pre-buried anchoring foundation, and the pile / post interface positioning device is arranged in the steel casing and is permanently connected with the pre-buried anchoring foundation through bolts, and then anchoring concrete is poured; when a steel pipe column is laid, the root part thereof is sleeved at the periphery of the pile / post interface positioning device, and the concrete is poured into a cup-mouth structure, then the concrete is poured into the steel pipe column, and then backfilling sand is filled in until reaching the ground surface; finally, the steel casing is pulled out in a way that the lowermost end of the steel casing is left. The delivering plate of the pile / post interface positioning device is a cross-shaped standing plate, the cross-section of the cross-shaped standing plate presents a cross shape, the diameter of the cross-shaped standing plate gradually diminishes from the middle lower part to the top part, a positioning bottom plate is welded with a ground anchor reinforcing steel bar on the lower surface, and long circular positioning holes which are radially distributed are formed on the positioning bottom plate. The invention solves the problem that the steel pipe column and the foundation pile are not fast and precisely positioned.

Owner:北京住总集团有限责任公司 +1

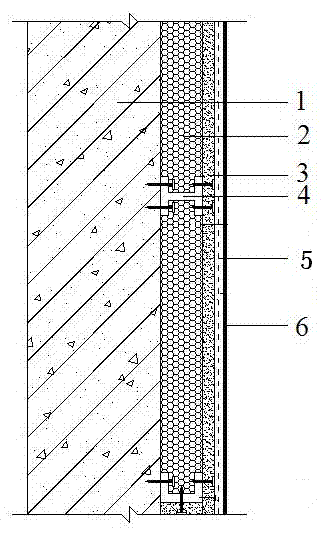

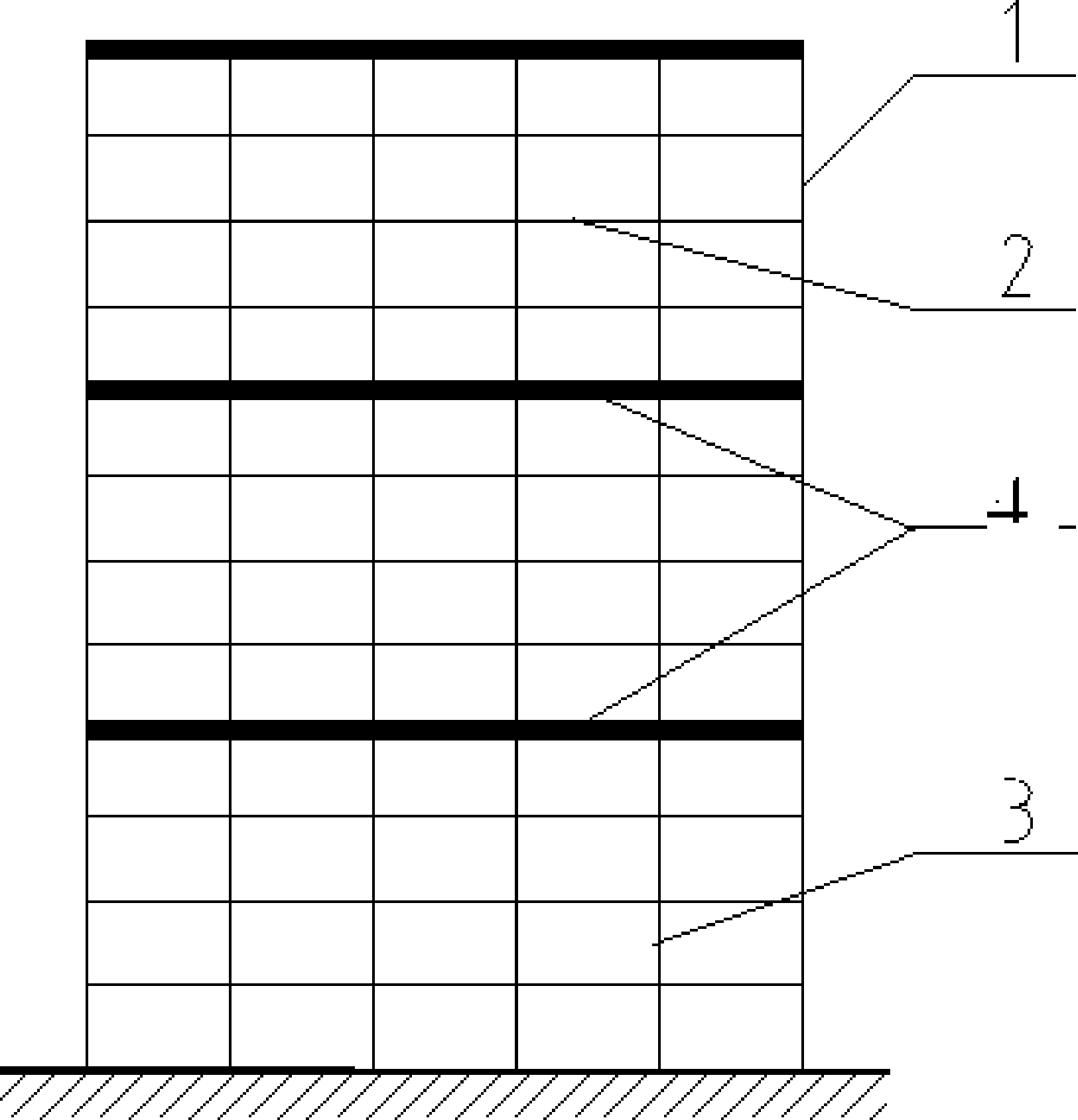

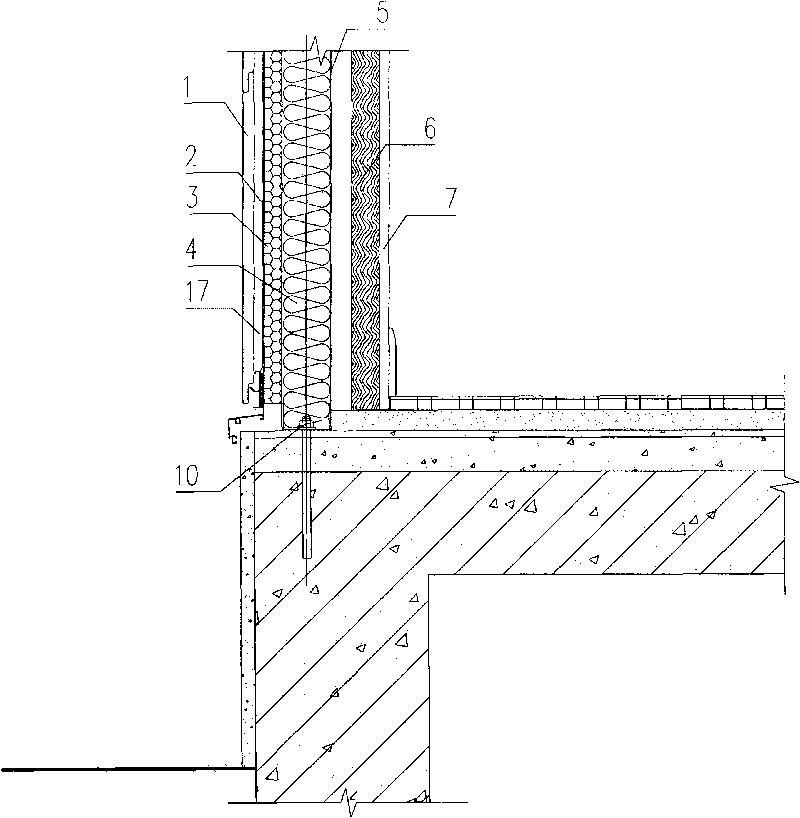

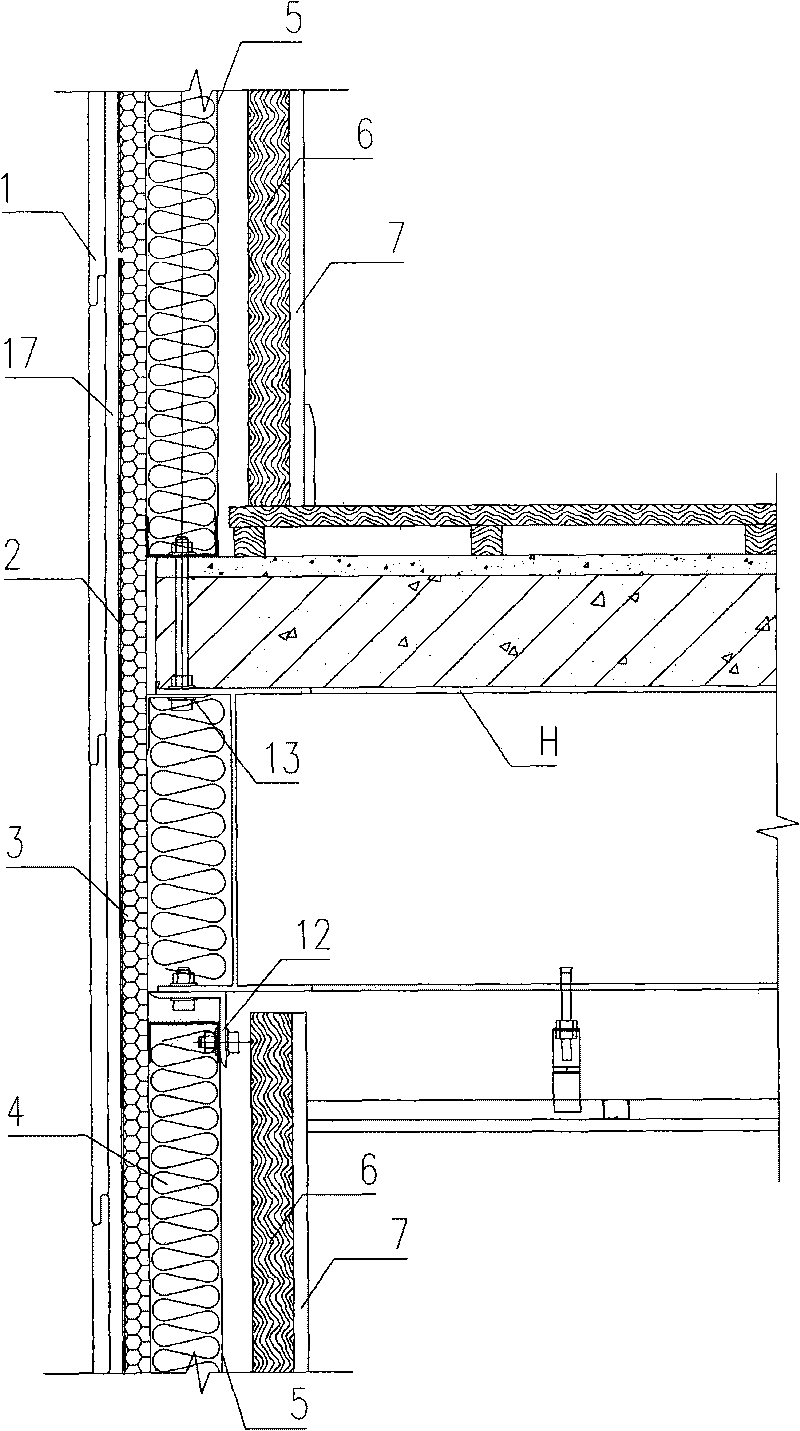

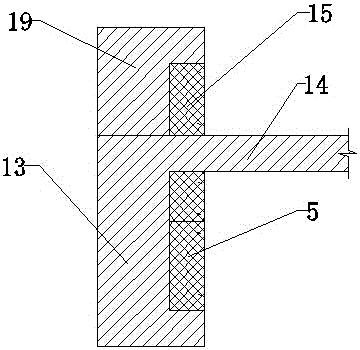

Casting type fireproof external wall insulation system and construction method thereof

ActiveCN102852332ADoes not affect the decorative effectControl construction qualityWallsBuilding material handlingCement boardCasting types

The invention discloses a casting type fireproof external wall insulation system and a construction method thereof. The casting type fireproof external wall insulation system comprises a wall base layer, a thermal insulation layer, a metal anchoring connecting piece, a fiber cement board, a flexible anti-crack layer and a finishing layer, wherein the thermal insulation layer is positioned between the wall base layer and the fiber cement board and is cast by an inorganic thermal insulation material in times; the wall base layer, the thermal insulation layer and the fiber cement board are connected into a whole through the metal anchoring connecting piece; the flexible anti-crack layer is compounded on the outer side of the fiber cement board; and the finishing layer is positioned on the outer side of the flexible anti-crack layer. The casting type fireproof external wall insulation system has the characteristics of firm and reliable structure, high fireproof performance, high wall decoration property, crack difficulty, environment friendliness, economical construction cost, convenient installation, rapid construction and the like.

Owner:CHANGZHOU ARCHITECTUAL RES INST GRP CO LTD +1

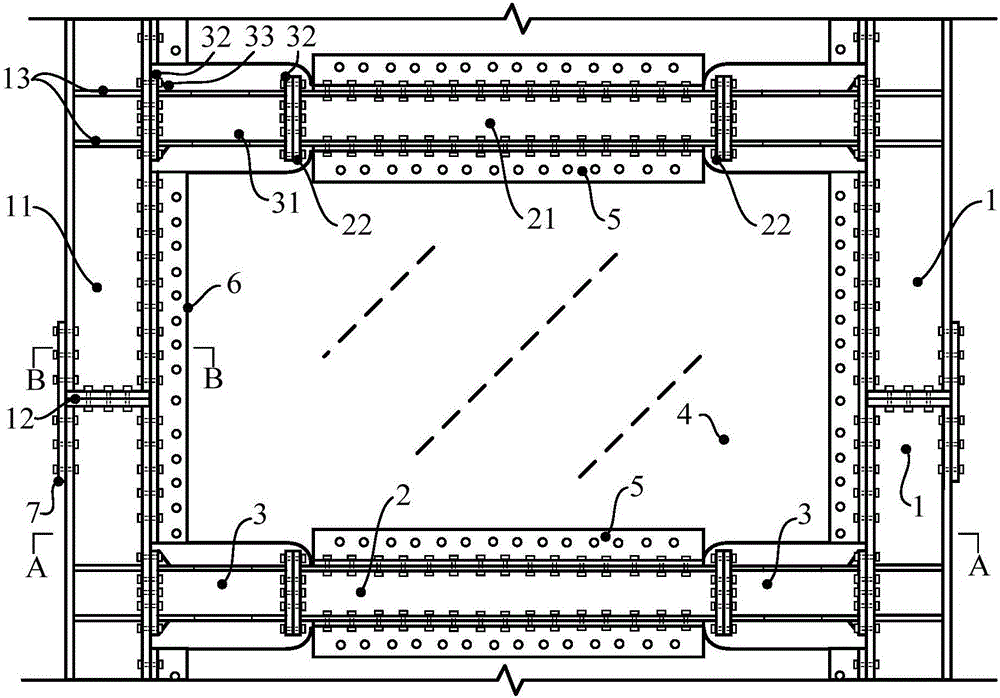

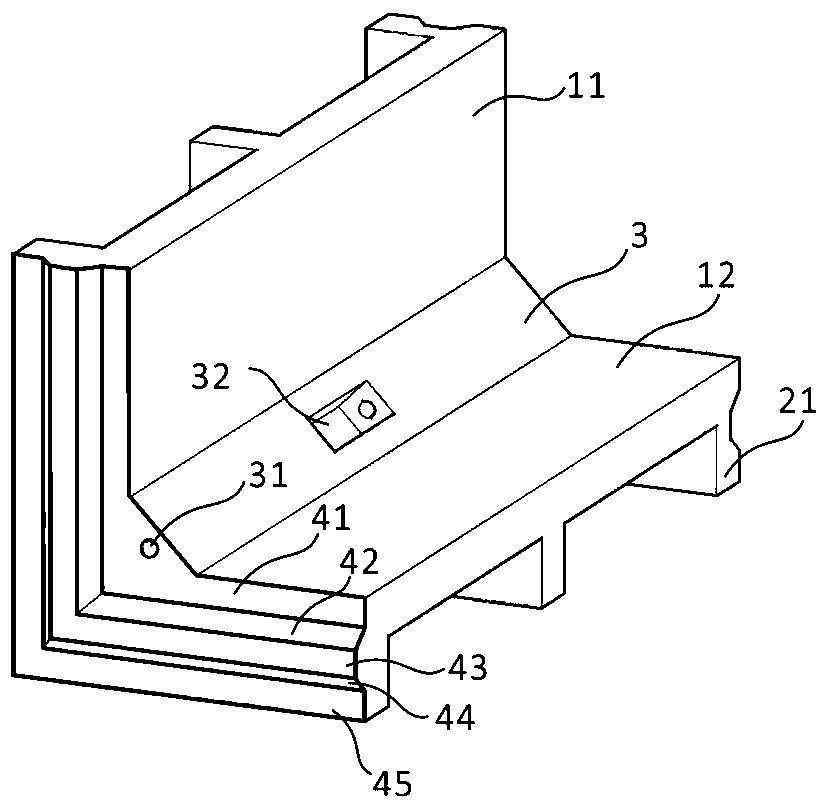

Fabricated steel frame and steel plate shear wall structure replaceable after earthquake

InactiveCN106049671AGuarantee the construction qualityGuaranteed economic lossWallsSteel frameSteel columns

The invention discloses a fabricated steel frame and steel plate shear wall structure replaceable after an earthquake. The fabricated steel frame and steel plate shear wall structure comprises frame steel columns, main steel beams, post-earthquake replaceable energy dissipating joints and post-earthquake replaceable embedded steel plates. Webs of column bodies of the frame steel columns are connected through first end plates. Second end plates of each main steel beam are fixedly arranged at the two ends of a corresponding beam body. Third end plates of each post-earthquake replaceable energy dissipating joint are fixedly arranged at the two ends of a corresponding beam section, and connected with the corresponding second end plate of the corresponding beam body and an inner flange of the corresponding column body through bolts correspondingly. The post-earthquake replaceable embedded steel plates are connected with the inner flanges of the corresponding column bodies and the corresponding beam bodies through bolts, and long grooves are formed in the portions, making contact with the corresponding post-earthquake replaceable energy dissipating joints, of the four corners of each post-earthquake replaceable embedded steel plate. Internal force can be effectively transmitted, and it is guaranteed that the structural integrity and stress performance are given to full play; and structural failure and a failure mechanism are actively controlled, it is guaranteed that a main body structure is kept in an elastic state, plastic energy dissipation and damage occur in designated local positions, post-earthquake replacement and repairing are facilitated, and economic loss is reduced.

Owner:BEIJING JIAOTONG UNIV

Shallowly buried small-spacing rock soil tunnel construction method

ActiveCN104790959AReduce vibrationImprove construction progressUnderground chambersTunnel liningClerestoryConductor pipe

The invention relates to a tunnel construction method, in particular to a shallowly buried small-spacing rock soil tunnel construction method. According to the technical scheme, the shallowly buried small-spacing rock soil tunnel construction method comprises the steps of 1, measuring and setting out; 2, open cutting and supporting at a tunnel portal section, wherein the step of open cutting and supporting at the tunnel portal section comprises the sub-steps that the open cutting is conducted by the cooperation of manpower and machinery, slope cutting is conducted, portal face supporting is formed by adopting a large pipe shed and a steel arch, therefore an open hole is formed, and the step comprises the sub-steps of advanced pre-reinforcement of the large pipe shed and advanced construction of small pipes; 3, shallowly buried small-spacing tunnel excavation; 4, reinforcing of tunnel vault and tunnel spacing rock; 5, monitoring and measuring; 6, secondary lining concrete construction. The shallowly buried small-spacing rock soil tunnel construction method is beneficial for safety construction and improving economical benefits.

Owner:核工业井巷建设集团有限公司

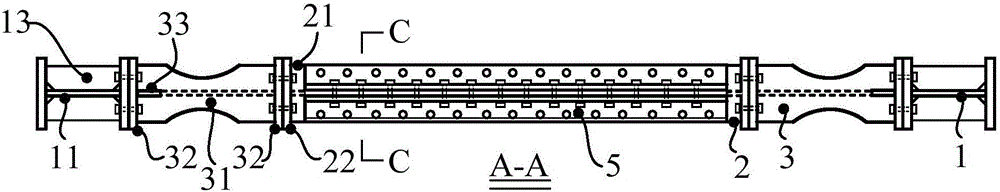

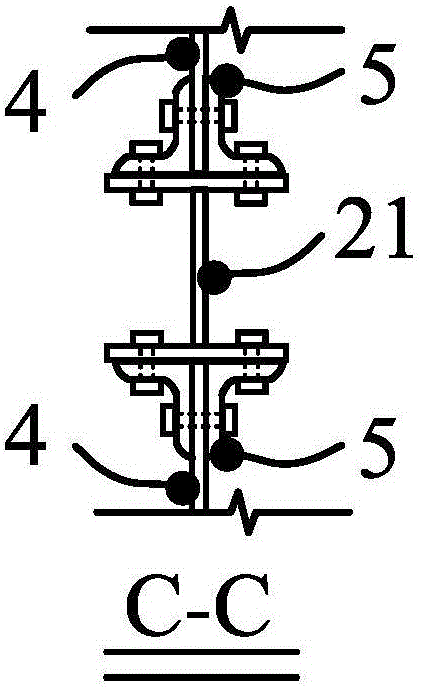

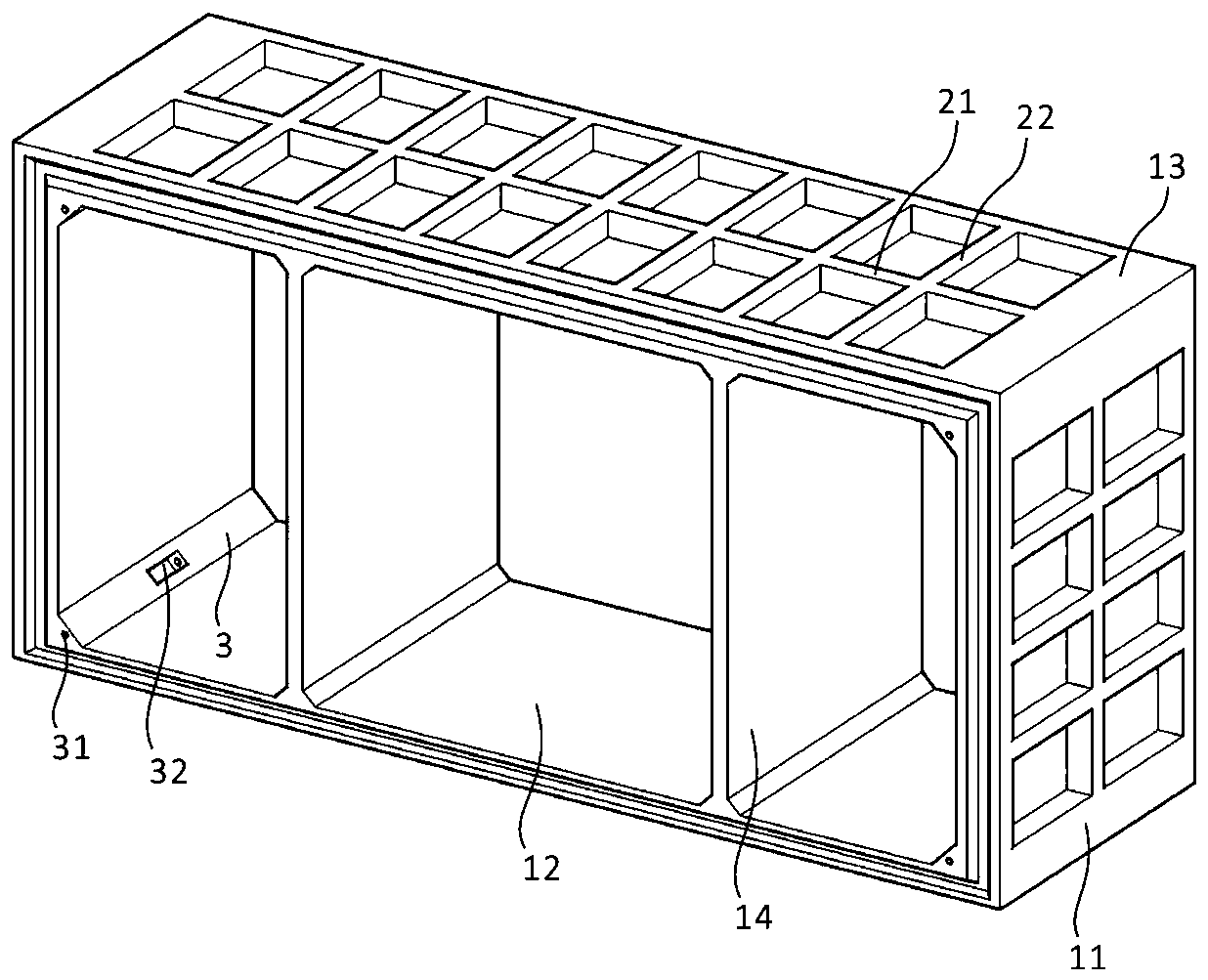

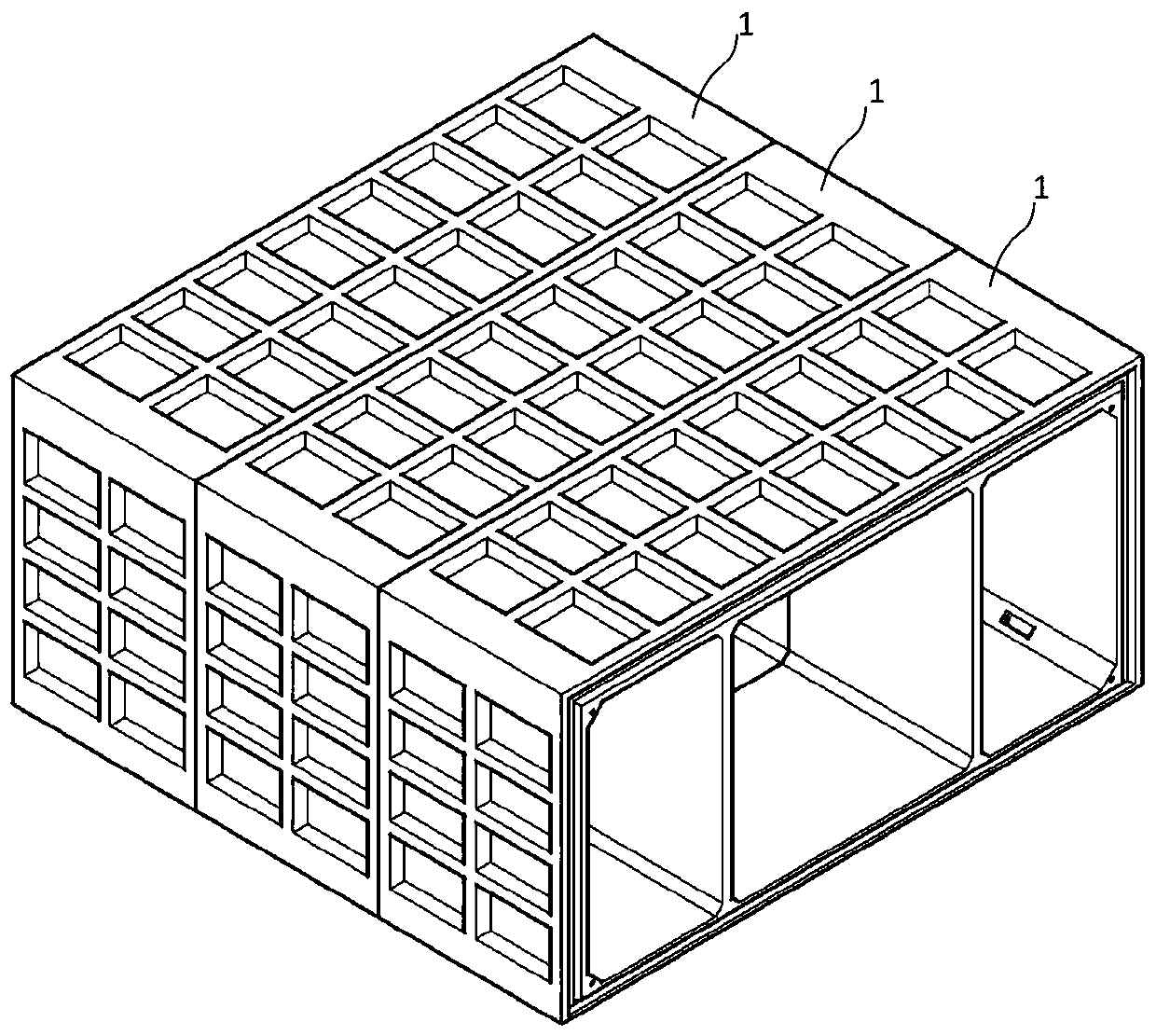

Very-high performance concrete prefabricated assembled pipe gallery and construction method

PendingCN107859065AReduce dosageLose weightArtificial islandsUnderwater structuresPre stressArchitectural engineering

The invention discloses a very-high performance concrete prefabricated assembled pipe gallery and a construction method. The pipe gallery is formed by inserting and splicing a plurality of concrete rectangular culvert monomers which are integrally formed front and back; each of the rectangular culvert monomers comprises a side plate, a bottom plate, a top plate and a partition plate; reinforcing rib structures are arranged on the outer side surfaces of the side plate and the top plate; axil angles are arranged at the connections of the side plate and the bottom plate and the side plate and thetop plate; prestress locking devices are arranged at the axil angles; inserting structures which are matched are arranged at the front and back ends of each of rectangular culvert monomers; and the inserting structures are waterproof devices. The construction method comprises the following steps: 1) preparation of the prefabricated rectangular culvert monomers; 2) excavation and support of foundation pits; 3) foundation treatment and cushion ply paving; 4) hoisting of the prefabricated rectangular culvert monomer sections; 5) penetrating and tensioning of the prestress ribs in position; 6) waterproof experiment of the pipe gallery; and 7) soil mass backfilling. The pipe gallery material dosage is reduced greatly, the self weight is reduced greatly, and the very-high performance concrete prefabricated assembled pipe gallery is convenient to transport and hoist, few in step, short in construction period and good in waterproofness and durability.

Owner:HUNAN UNIV

Outer-wall tongue groove capable of preventing water seepage of window and construction method of outer-wall tongue groove

InactiveCN104153485AReduce the probability of occurrenceReduce plaster thicknessWallsJoints tightening/coveringRebarWater seepage

Owner:TIANJIN 20 CONSTR

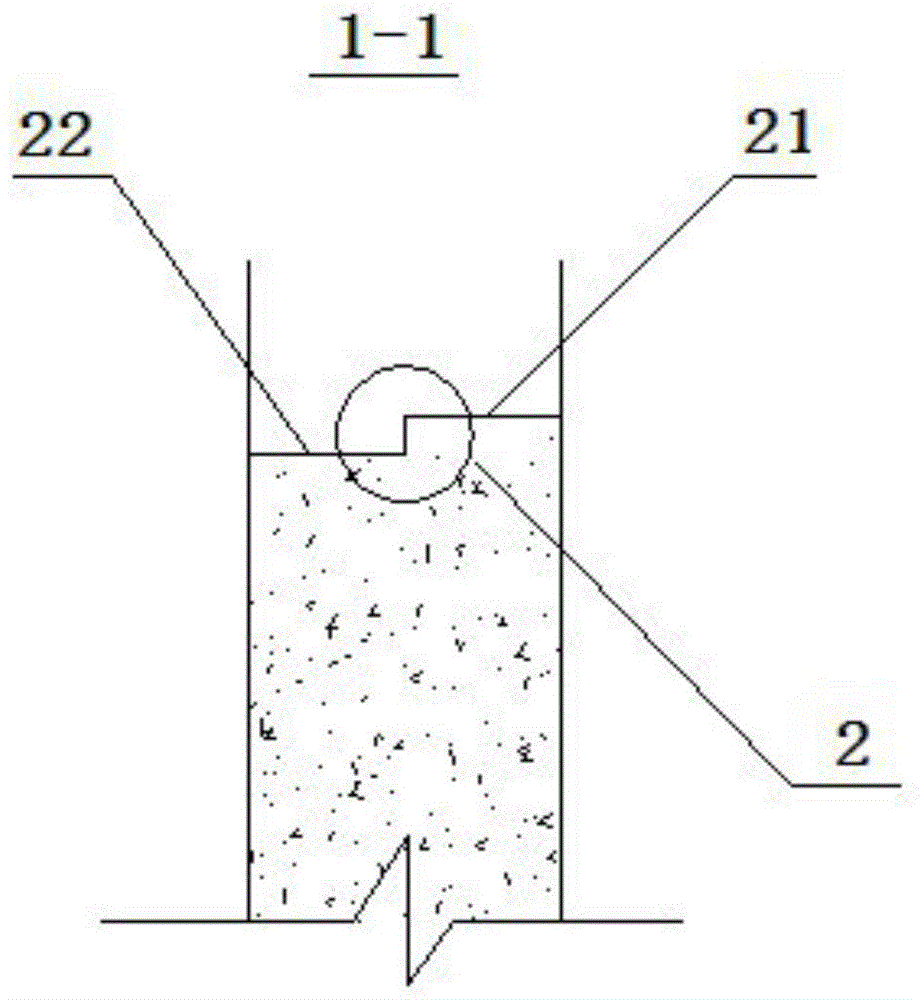

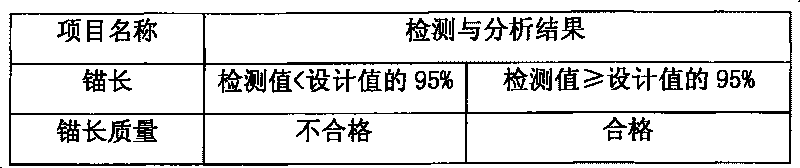

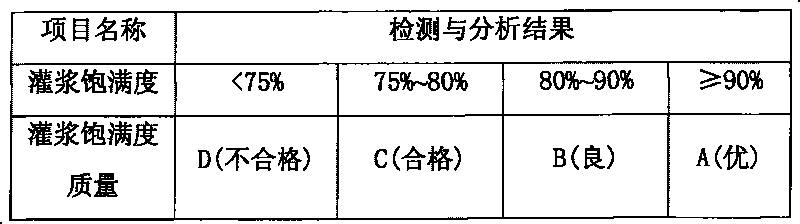

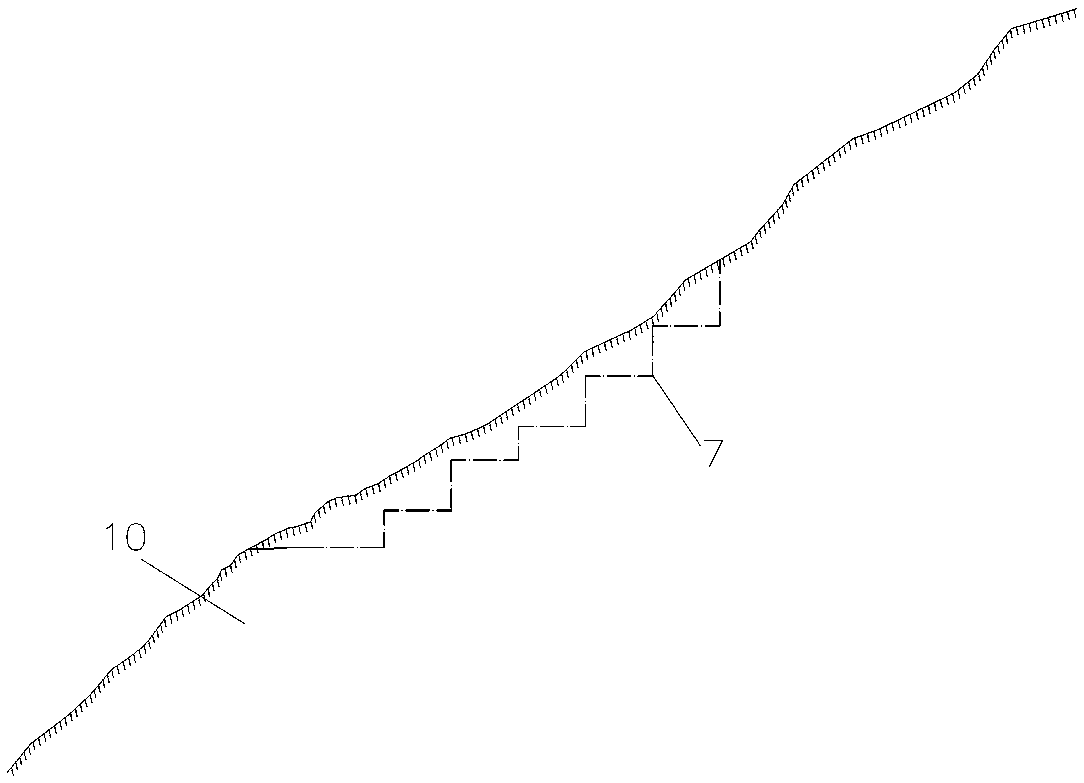

Comprehensive detection method of anchoring status of prestress anchor cable

InactiveCN101694101AControl construction qualityMaster the quality of anchoringFoundation testingPre stressEngineering

The invention discloses a comprehensive detection method of anchoring status of a prestress anchor cable. By detecting the anchor length, grouting plumpness, prestress and corrosive degree of the prestress anchor cable, the method conducts the contrastive analysis and comprehensive analysis of a single index and consequently analyzes the anchorage quality and safety performance of the prestress anchor cable. The detection method has great significance to control the construction quality of newly built anchoring engineering and grasp the operating status and safety of the existing anchoring engineering.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

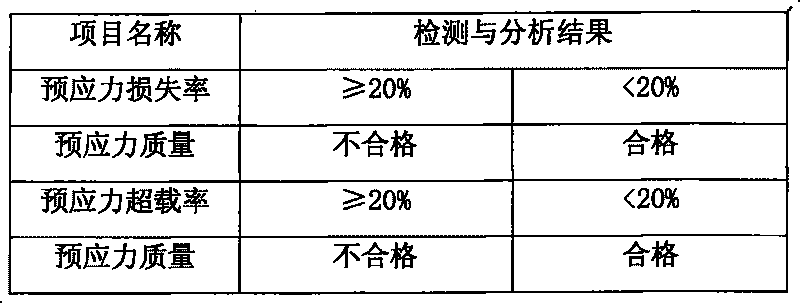

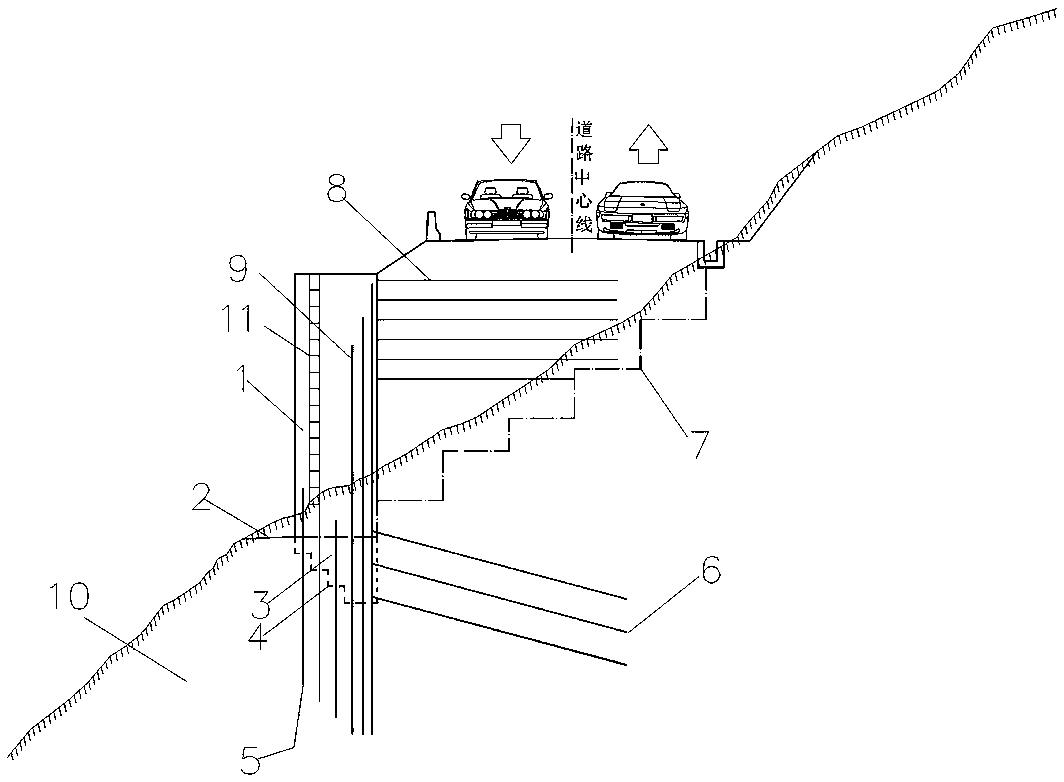

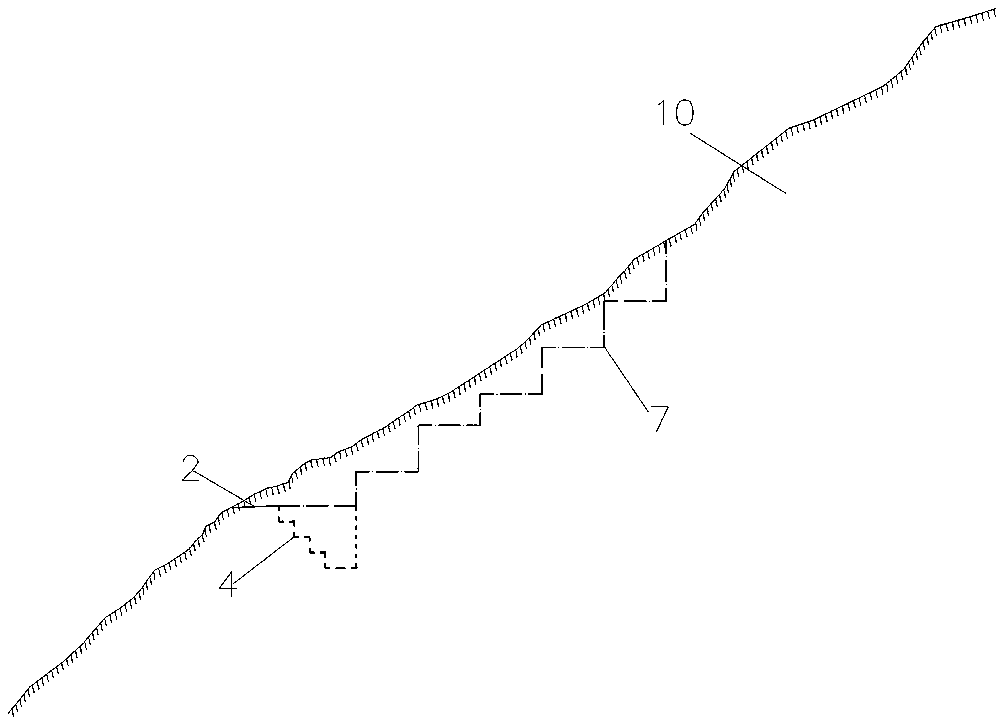

Anti-slide pile supporting structure for anchor bolt foundation of highway hard-rock steep slope embankment

PendingCN108086352AAvoid clutterReduce construction difficultyArtificial islandsRoadwaysEngineeringSteep slope

The invention belongs to the technical field of highway subgrade engineering and particularly discloses an anti-slide pile supporting structure for an anchor bolt foundation of a highway hard-rock steep slope embankment. The anti-slide pile supporting structure comprises an anti-slide pile cantilever segment, an anti-slide pile foundation, a foundation anchor bolt system, a basal stepped foundation, and a pile post-backfill soil geogrid system. The anti-slide pile cantilever segment is designed in a rectangular shape with flanges according to specific conditions. The foundation anchor bolt system includes a transverse anchor bolt system and a vertical anchor bolt system, made with HRB400 rebars phi 32 in diameter. The anti-slide pile supporting structure has the advantages that construction difficulty is relieved, engineering construction cost is reduced, construction period is shortened, and environmental influence due to engineering is reduced.

Owner:云南新创新交通建设股份有限公司

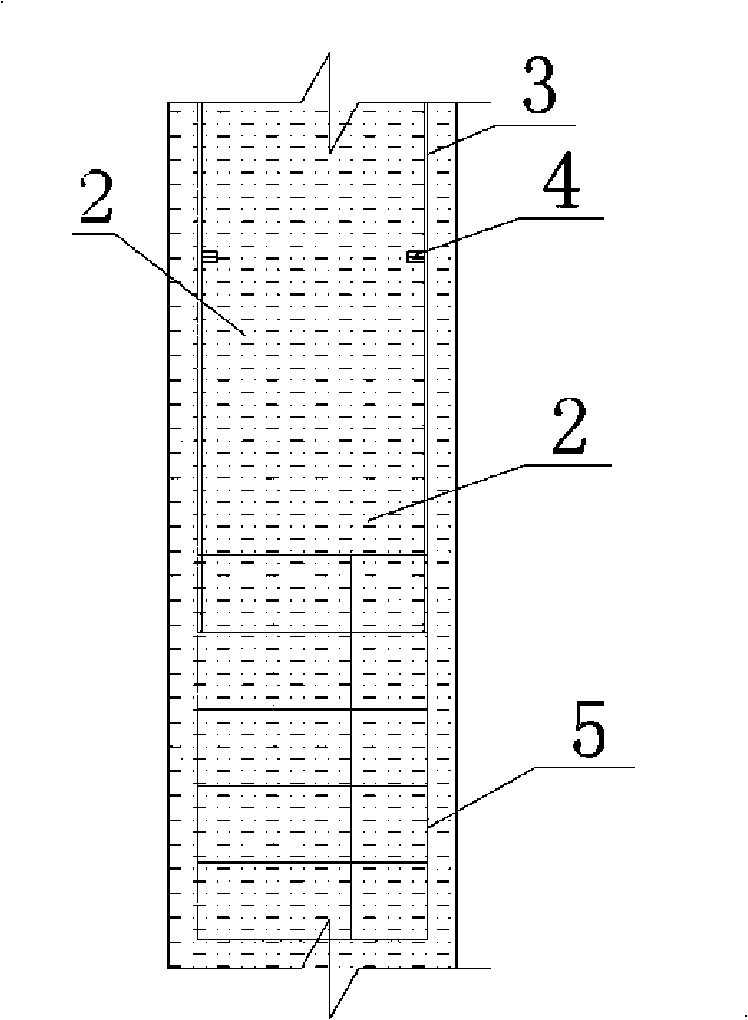

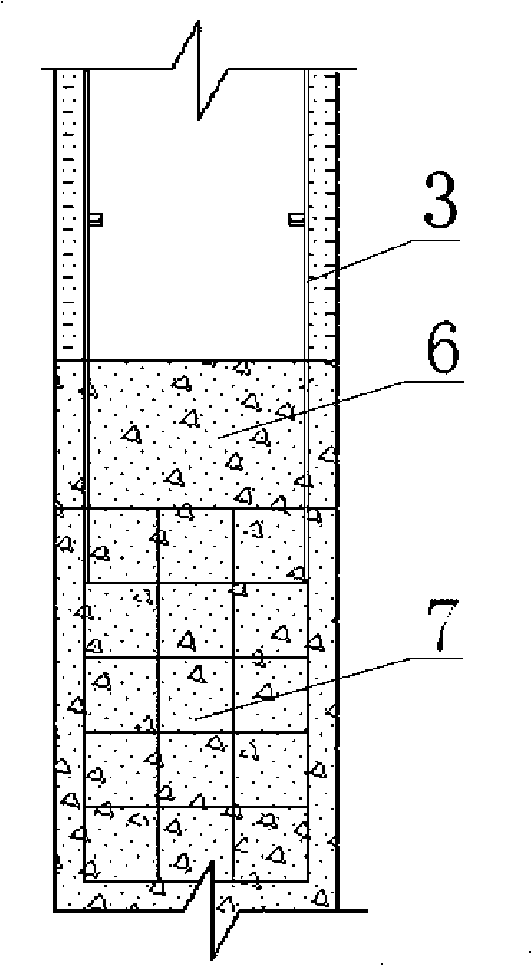

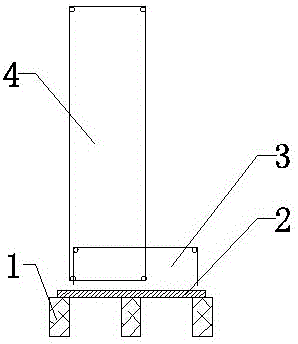

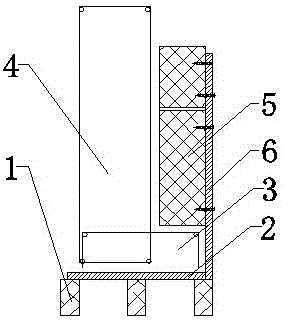

In-situ casting construction method of reinforced concrete structural system using phosphogypsum as wall material

The invention discloses a cast-in-situ construction method for a reinforced concrete structural system taking phosphogypsum as a wall body material. When construction is performed on a reinforced concrete structural system building, the phosphogypsum is used as the wall body material, the reinforced concrete structural system and phosphogypsum wall bodies are cast in situ. When the reinforced concrete structural system and the phosphogypsum wall bodies are cast in situ, the reinforced concrete structural system is cast in four sections according to floor layers; the height of each section is controlled within 600 to 1,300 millimeters; the cast-in-situ construction is performed in layers and sections from the top to bottom; the reinforced concrete structural system is cast first at each section; and then the phosphogypsum wall body part is cast. The construction method has the advantages of easy construction, fast construction progress, good construction quality and low construction cost. In addition, the integrity and strength of buildings completed by the construction method are improved.

Owner:GUIZHOU UNIV +1

Ultra-high-performance concrete prefabricating and splicing integration pipe gallery system and construction method

ActiveCN107842035AIncrease stiffnessImprove bearing capacityArtificial islandsUnderwater structuresArchitectural engineeringPipe

The invention provides an ultra-high-performance concrete prefabricating and splicing integration pipe gallery system which is formed by splicing a plurality of prefabricated sections. Each prefabricated section is prepared through ultra-high-performance concrete. Each prefabricated section is composed of a side plate, a bottom plate, a top plate and a partition plate. Each partition plate is fixed between the corresponding bottom plate and the corresponding top plate. The adjacent prefabricated sections are overlapped through ultra-high-performance concrete patches. The invention further discloses a construction method of the pipe gallery system. According to the integration pipe gallery system, the prefabricated sections of the integration pipe gallery system are made of materials like the ultra-high-performance concrete with high strength, high tenacity and high durability, the structure of the ultra-high-performance concrete patches and the like is combined, rigidity, bearing capacity and waterproof performance of a pipe gallery are improved, the wall thickness of the prefabricated sections is reduced compared with that of a traditional pipe gallery system, the dead weight of the pipe gallery is reduced remarkably, and transporting and hoisting are convenient. The material use amount of the pipe gallery is low to be 50% of that of the traditional pipe gallery system, the comprehensive production cost is reduced by 10-50% correspondingly, rigidity is large, the system is suitable for regions with poor foundation geologic conditions, the construction period of the pipe gallery system is short, and the influence on the construction environment is small.

Owner:HUNAN UNIV

C-C type interlocking steel pipe pile cofferdam and construction method

The invention discloses a C-C type interlocking steel pipe pile cofferdam and a construction method. The cofferdam is encircled by a plurality of C-C type interlocking steel pipe piles which are closely connected in sequence, wherein each C-C type interlocking steel pipe pile comprises a vertical steel pipe as well as a male lock catch and a female lock catch which are distributed at the outer side of the vertical steel pipe, and each two adjacent vertical steel pipes are connected through an interlocking structure composed of the corresponding male lock catch and female lock catch; and each interlocking structure is internally densely filled with an interlocking filling structure, and each interlocking filling structure comprises a cloth bag, heating resistance wires distributed in the cloth bag, and a mortar filling structure formed by sulphur mortar filled in the cloth bag. The construction method comprises the following steps: 1. surveying and setting out; 2. steel pipe pile inserting piling and closure construction; 3. interlocking structure filling; 4. cofferdam construction completion; and 5. cofferdam removal. The cofferdam disclosed by the invention is reasonable in design, simple and convenient to disassemble and assemble, safe and reliable, good in water-stopping effect, and capable of effectively achieving the engineering purposes of interlocking connection, water-stopping and rapid removal of the steel pipe pile cofferdam.

Owner:CHINA RAILWAY FIRST GRP CO LTD

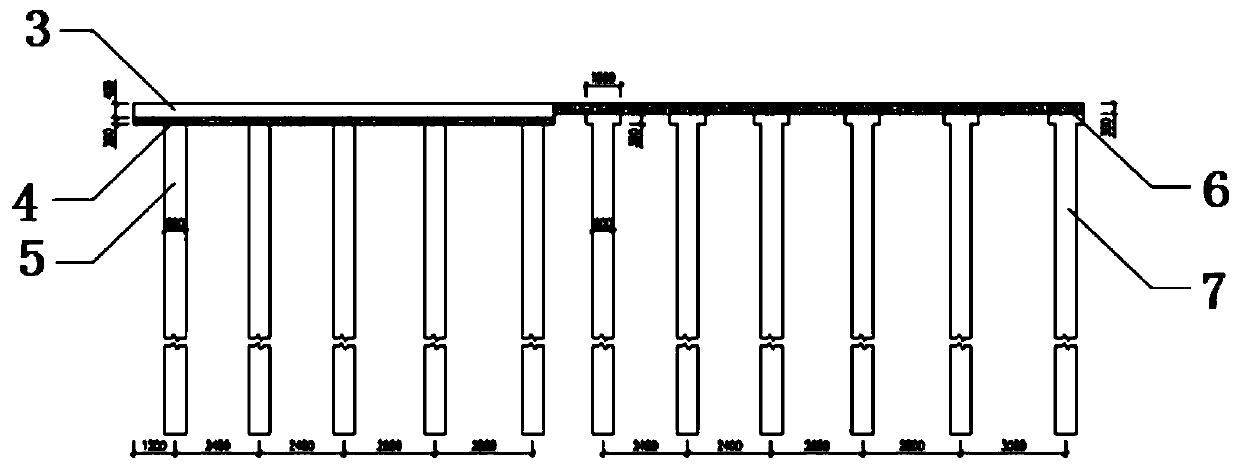

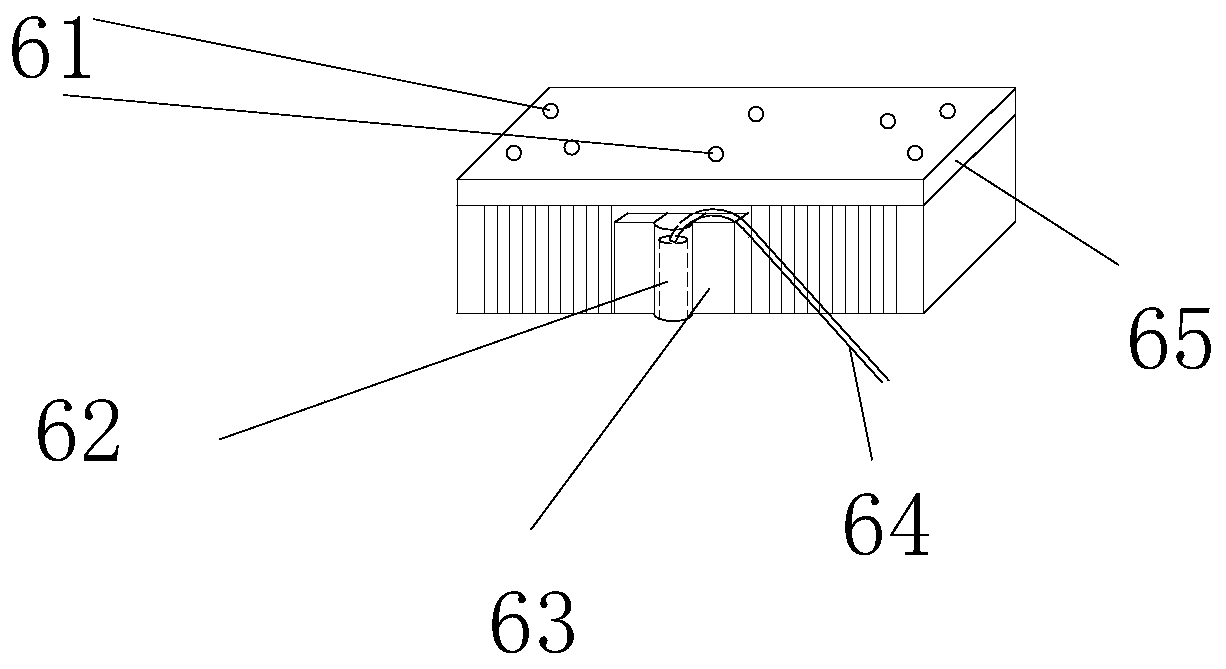

Assembly type integral installation device for building electromechanical engineering

InactiveCN109058681AEasy to adjustReduce working at heightsStands/trestlesGear wheelArchitectural engineering

The invention discloses an assembly type integral installation device for building electromechanical engineering. The assembly type integral installation device for building electromechanical engineering comprises an installation seat, wherein a groove is formed in the top part of the installation seat; a rotating groove is formed in the inner wall of the bottom part of the groove; a rotating column is rotatably arranged in the rotating groove; a first conical gear fixedly sleeves on the outer side of the rotating column; a threaded groove is formed in the top end of the rotating column; a screw rod is in threaded connection into the threaded groove; a first sliding chute is formed in one side of the installation seat and communicates with the groove; and a first sliding block is fixedly arranged on one side of the screw rod and is slidably connected with the first sliding chute. The assembly type integral installation device for building electromechanical engineering provided by the invention is simple in structure and convenient to operate, the height of a main body of the installation device can be quickly and conveniently adjusted, the construction efficiency and the construction quality are improved, the construction period is shortened, the aerial work of workers is reduced, the safety of the construction process is improved, and the demands of the workers are met.

Owner:CHINA CONSTR SENVENTH ENG BUREAU INSTALLATION ENG

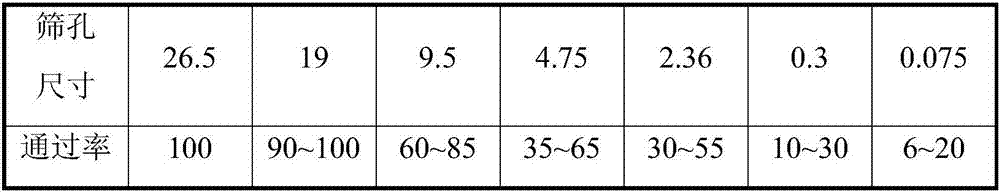

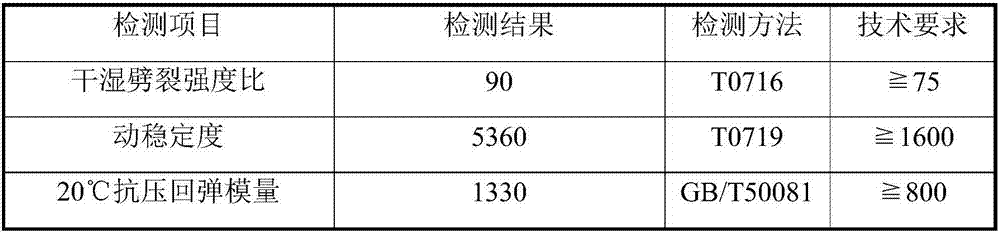

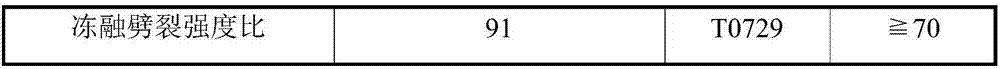

Construction method and construction system for on-site cold regeneration

InactiveCN106988188AReduce dosageReduce engineering costsIn situ pavingsRoads maintainenceSlagCrushed stone

The invention discloses a construction method and a construction system for in-situ cold regeneration. The construction method uses cold recycled materials including foamed asphalt, pre-mixed active filler, crushed stone and old RAP materials for in-situ cold regeneration; the pre-mixed active filler includes 60-80wt% cement and 20-40wt% pulverized coal Ash and / or blast furnace slag powder. The invention also provides a construction system for in-situ cold regeneration of foam, which saves the amount of asphalt, has a simple and clear construction process, improves the construction efficiency of in-situ cold regeneration of foam asphalt, and enables the construction quality to be controlled.

Owner:江苏北极星交通产业集团有限公司

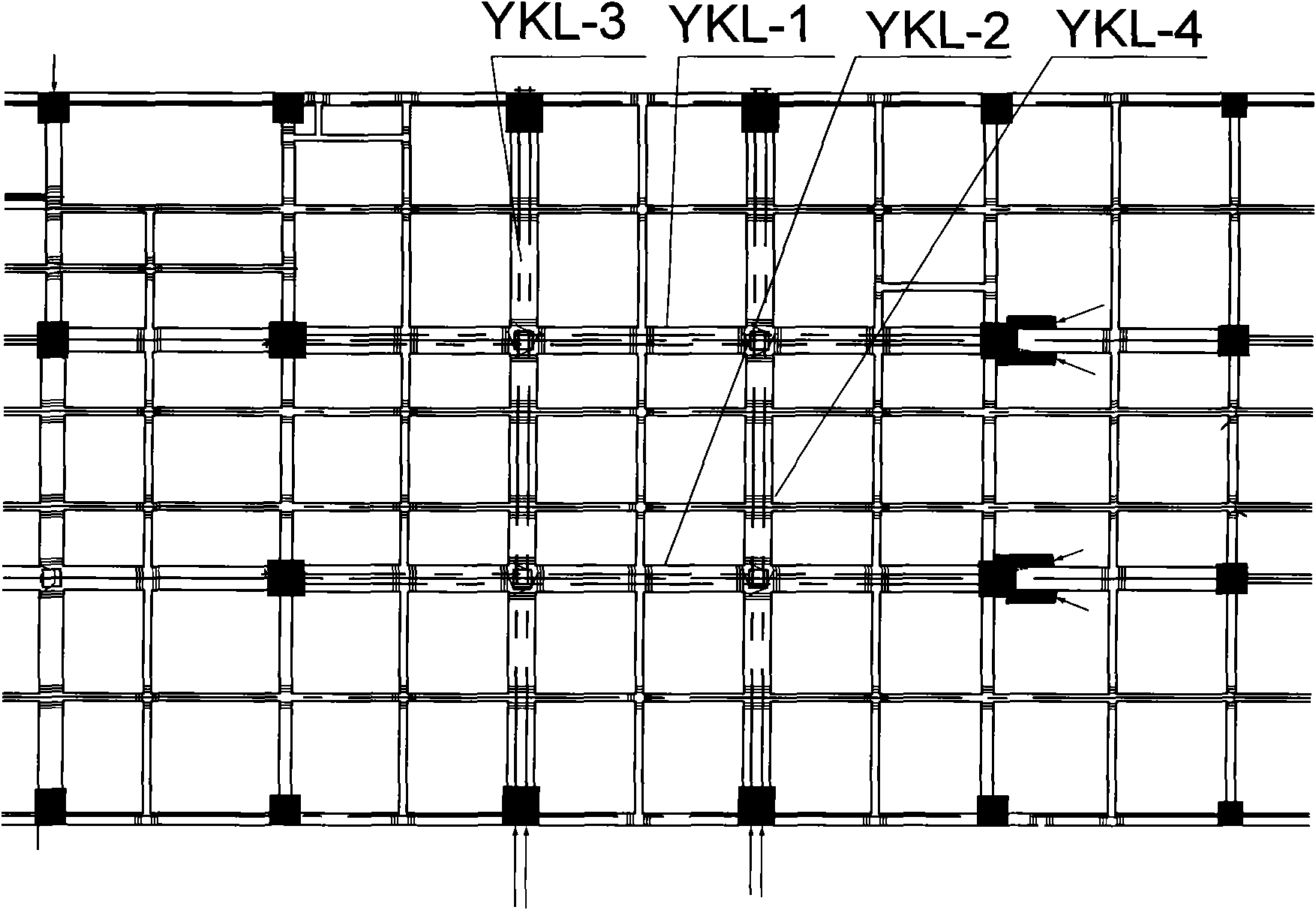

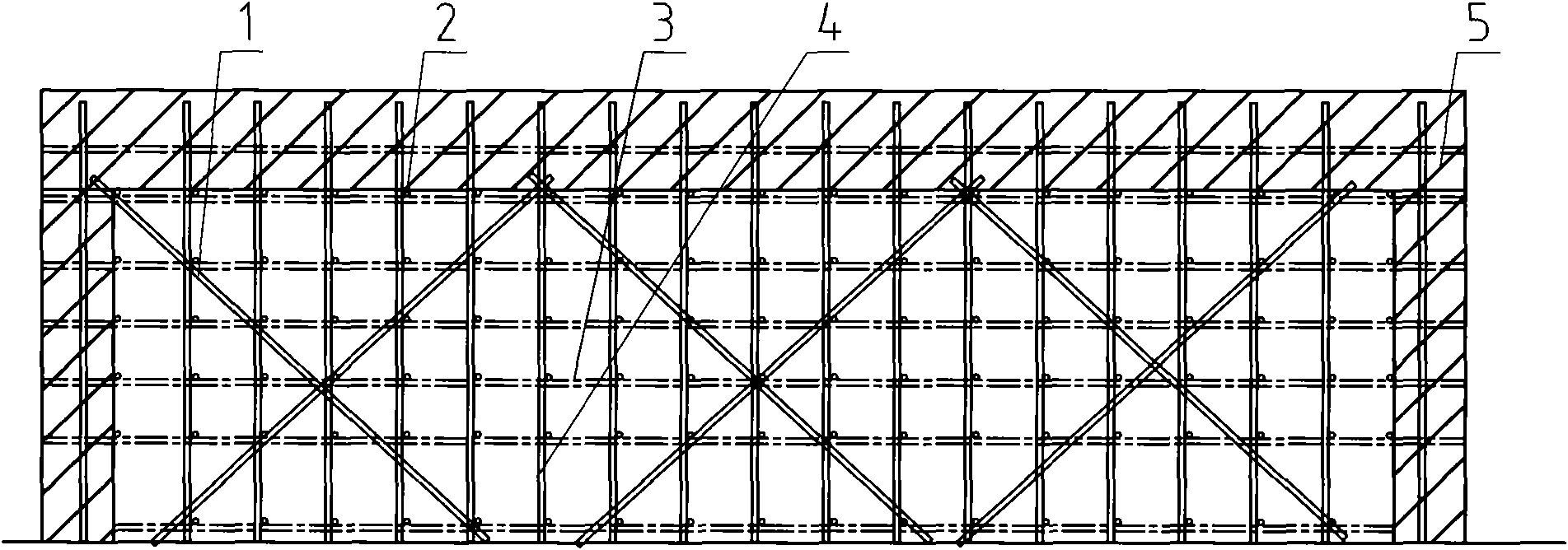

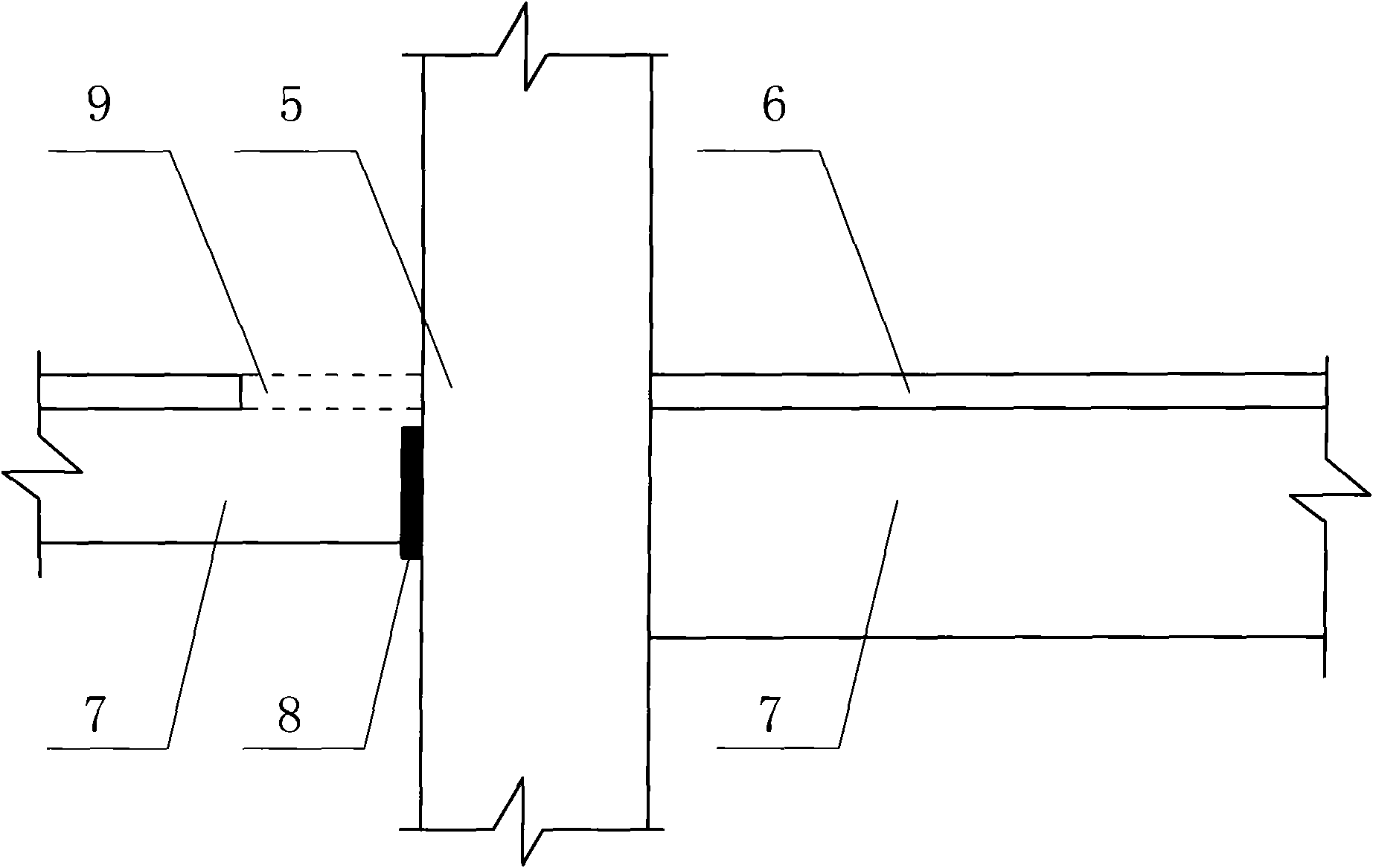

Construction method of large-span post-tensioned prestressed longitudinal and transverse frame beams

InactiveCN101550724AReduce the overall heightReduce the number of entryBuilding material handlingLine tubingReinforced concrete

The invention discloses a construction method of large-span post-tensioned prestressed longitudinal and transverse frame beams, which comprises the steps of erecting a supporting body, producing a template, arranging a base template and a unilateral template, rolling longitudinal main reinforcements, installing a corrugated tube, rolling hoop reinforcements, embedding utility pipelines, mounting prestressing steel wires, mounting an anchor backing plate, closing a lateral templates, filling concrete grouts, pretensioning and grouting pore canals; in the pretensioning, the prestressing tendons of beams are stretched according to the following steps: (1) firstly, the frame beams at the top layer are stretched and then frame beams at the following layers are stretched; (2) the short spans of the longitudinal and transverse frame beams at the same layer are stretched first, and then the long spans thereof are stretched; (3) the upper prestressing tendon of a building unit is stretched first, and then the lower prestressing tendon thereof are stretched; and the left line and the right line of prestressing tendons are stretched symmetrically and separately. The construction method adopts a stretching order from the upper layer to the lower layer and can construct the prestressed frame beams in accordance with an ordinary reinforced concrete structure layer by layer, thereby being capable of reducing the influence of concrete curing on the construction period and accelerating work progress.

Owner:RAILWAY NO 10 ENG GRP CO LTD

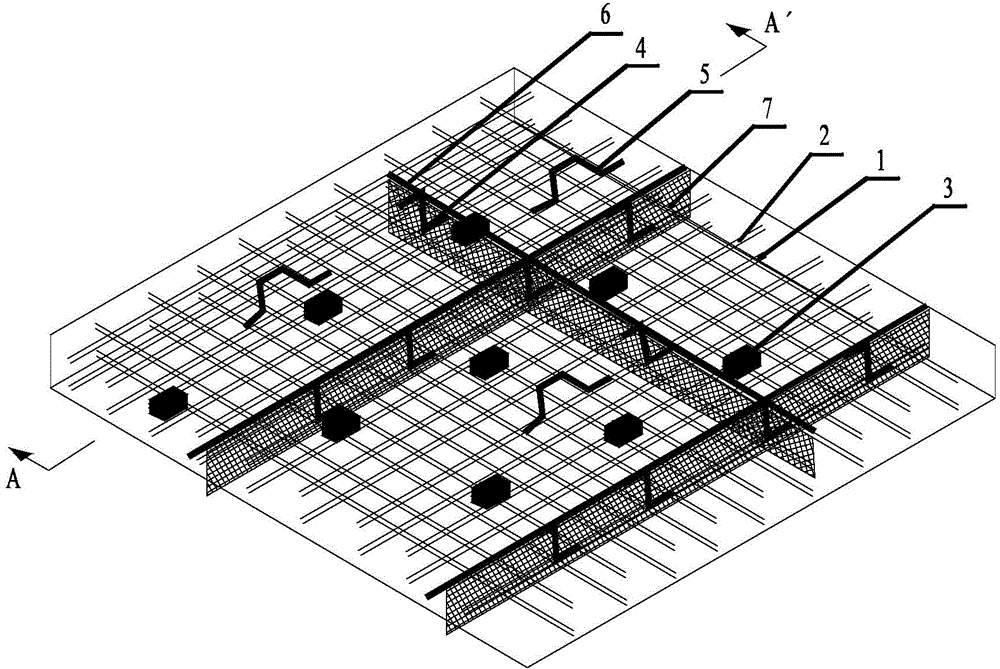

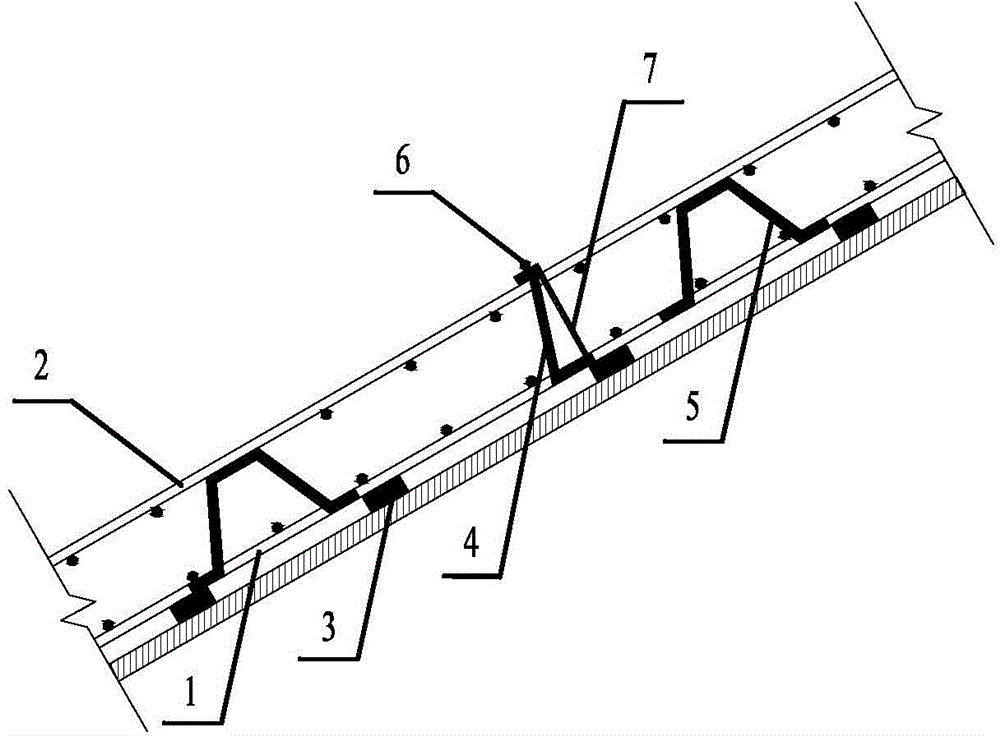

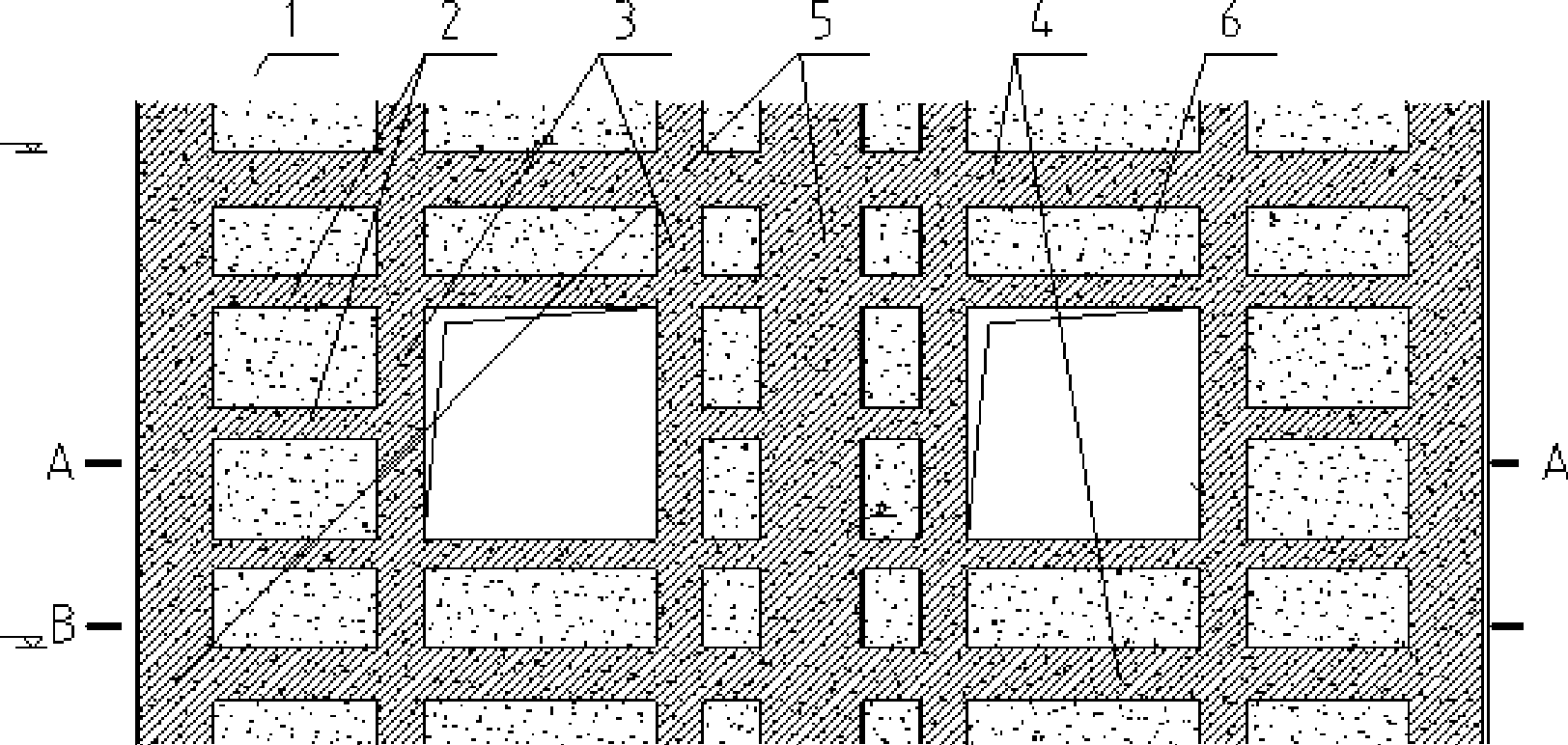

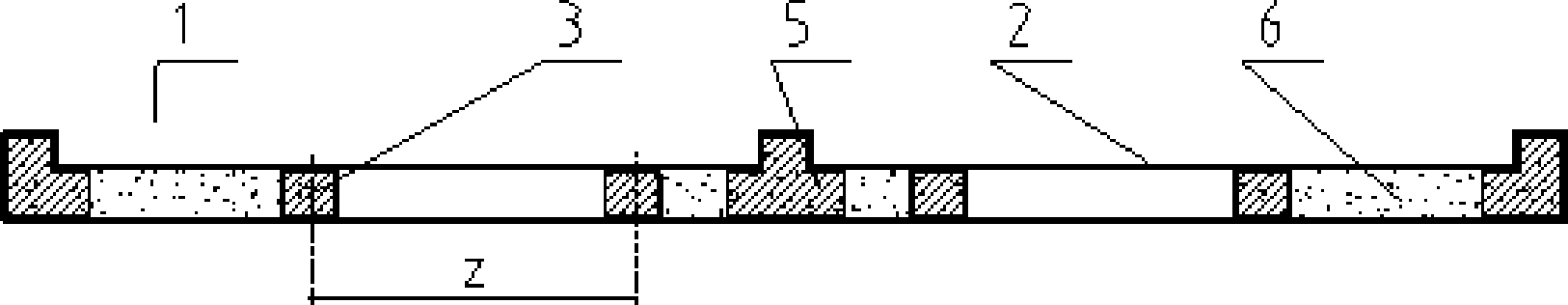

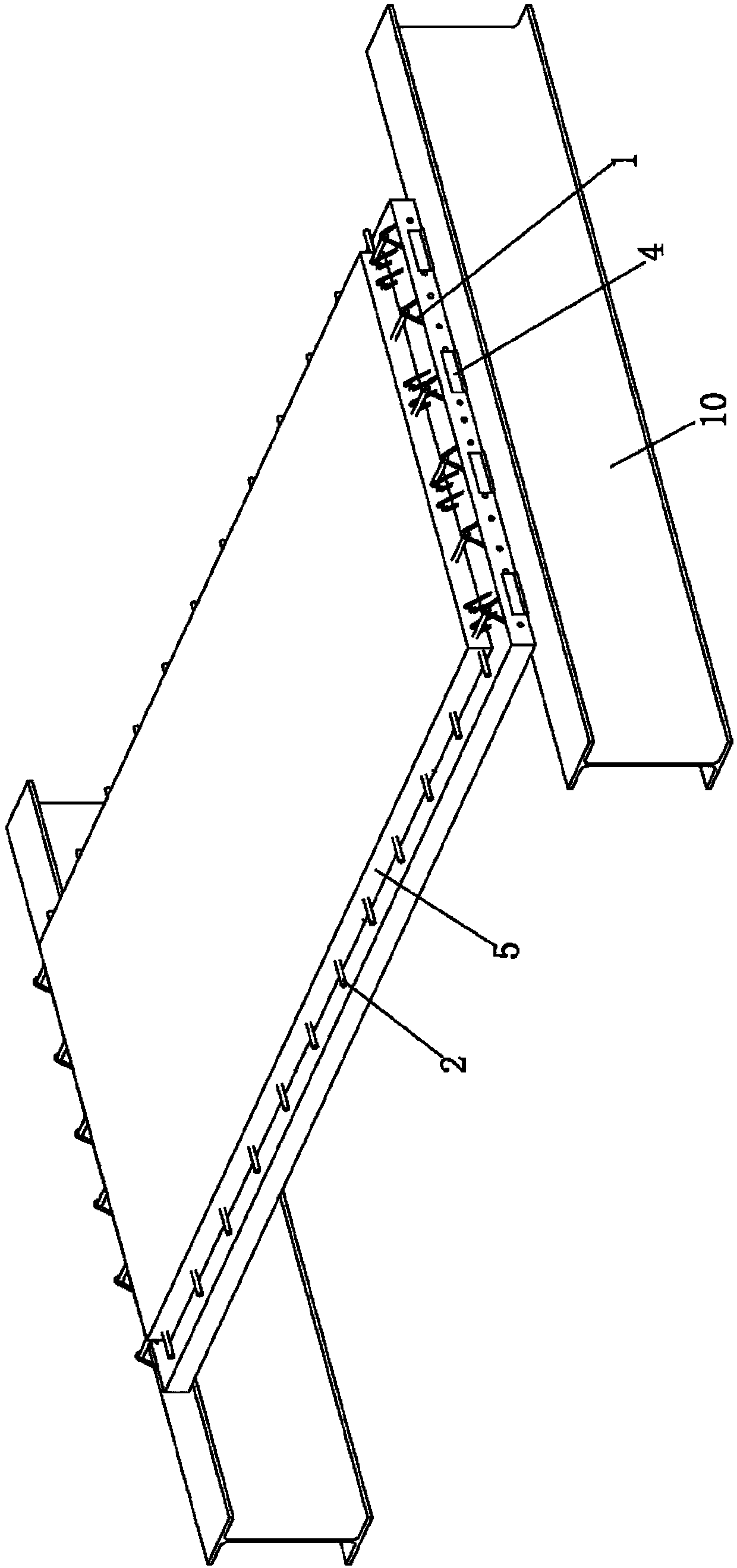

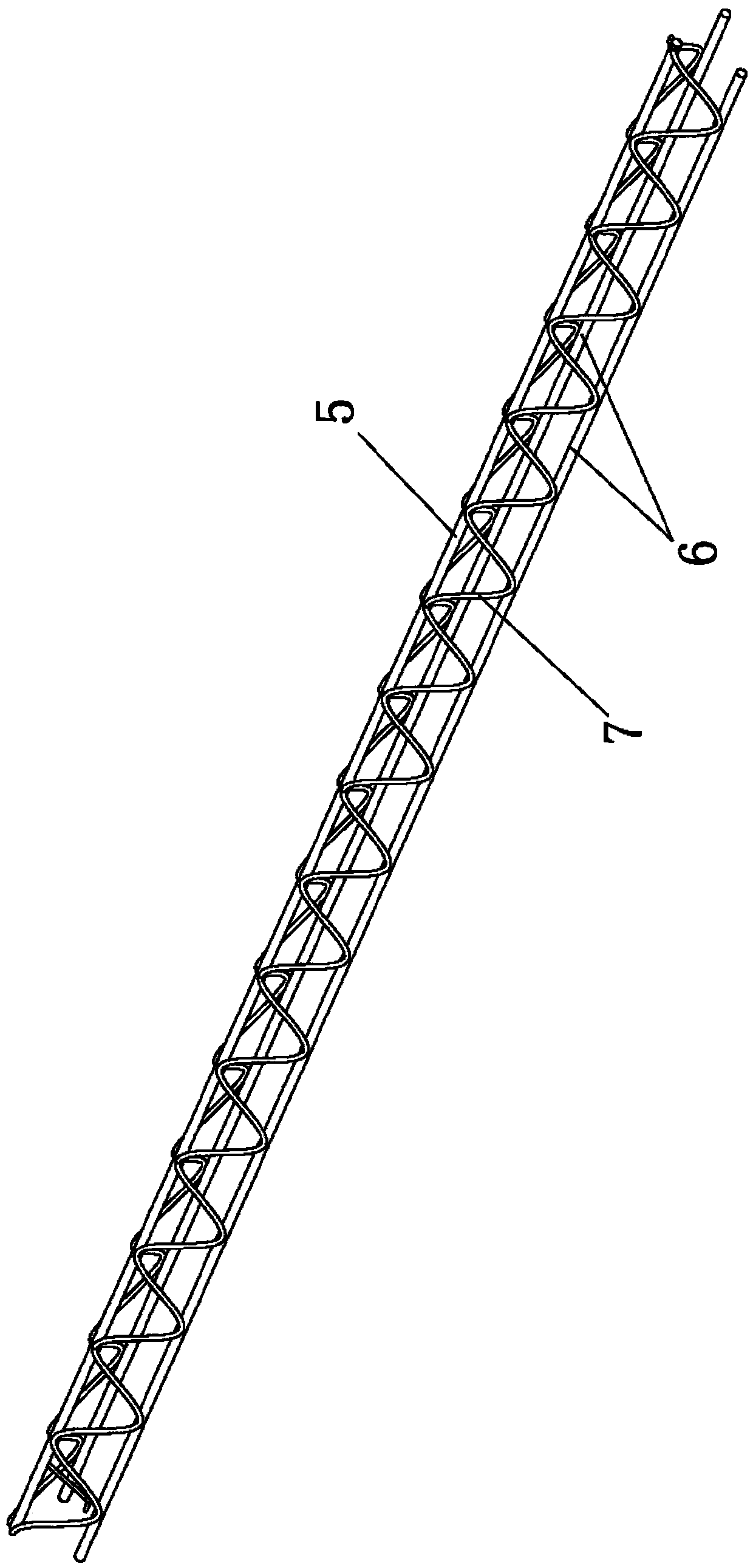

Full-prefabricated floor special for fabricated steel structure

The invention relates to a full-prefabricated floor special for a fabricated steel structure. The full-prefabricated floor is arranged on a steel beam and comprises a steel bar truss, surface bars, bottom bars, an embedded part and a prefabricated concrete layer. The steel bar truss comprises upper string steel bars, lower string steel bars and erecting bars. The upper string steel bars and the lower string steel bars are arranged in parallel and welded to the upper ends and the lower ends of the erecting bars correspondingly. The erecting bars are arranged at equal intervals, and the surfacebars and the upper string steel bars of the steel bar truss are bound together. The bottom bars and the lower string steel bars of the steel bar truss are bound together, and the steel bar truss, thesurface bars, the bottom bars and the embedded part are pre-embedded in the prefabricated concrete layer. The embedded part is connected with the steel beam. According to the full-prefabricated floor,through effective connection with a steel structure main body, the structural integrality and shock resistance are improved, meanwhile, only a joint laminated layer needs to be cast in situ, and thefabricated efficiency is greatly improved, so that the full-prefabricated floor can play a significant role in the fabricated steel structure field.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

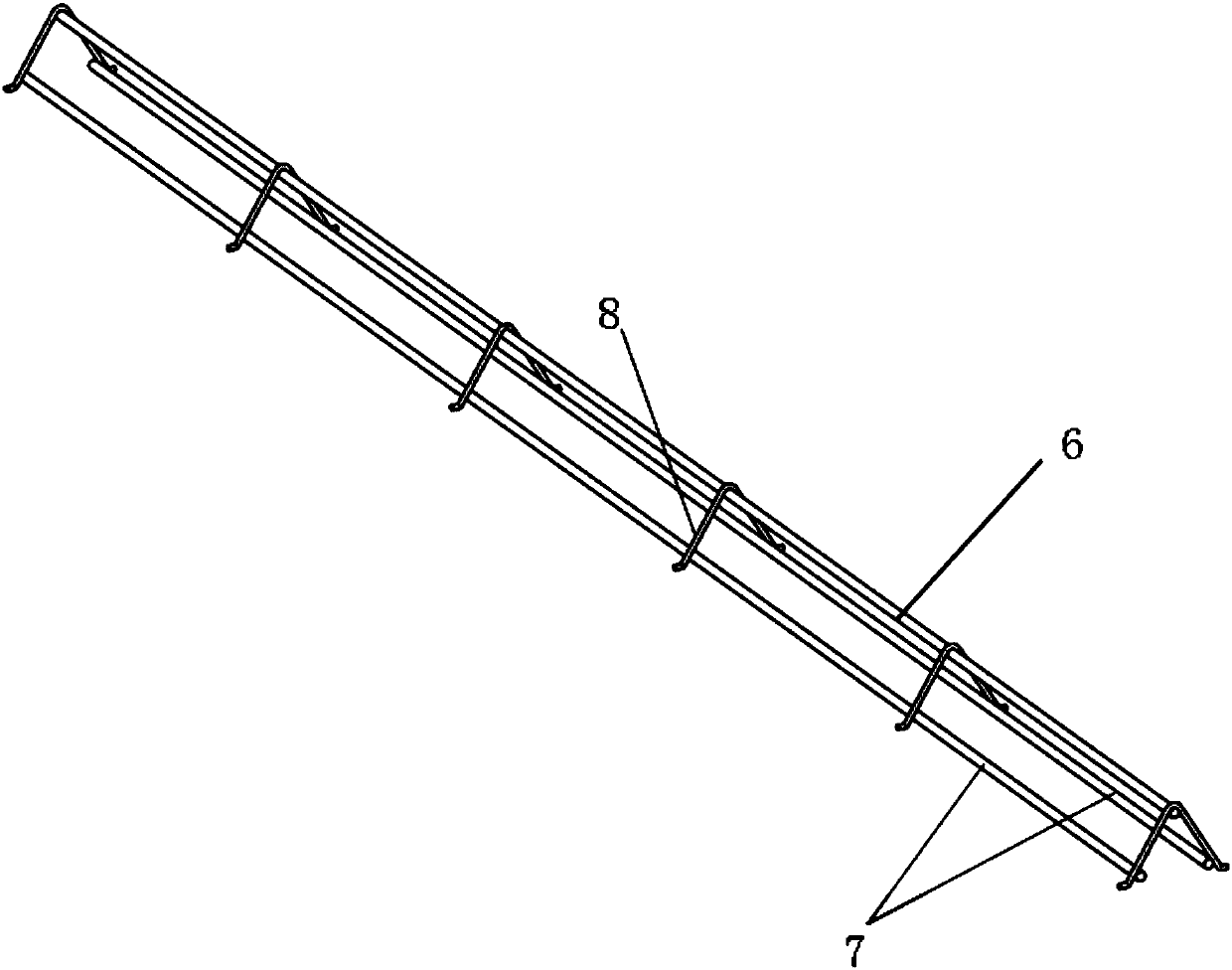

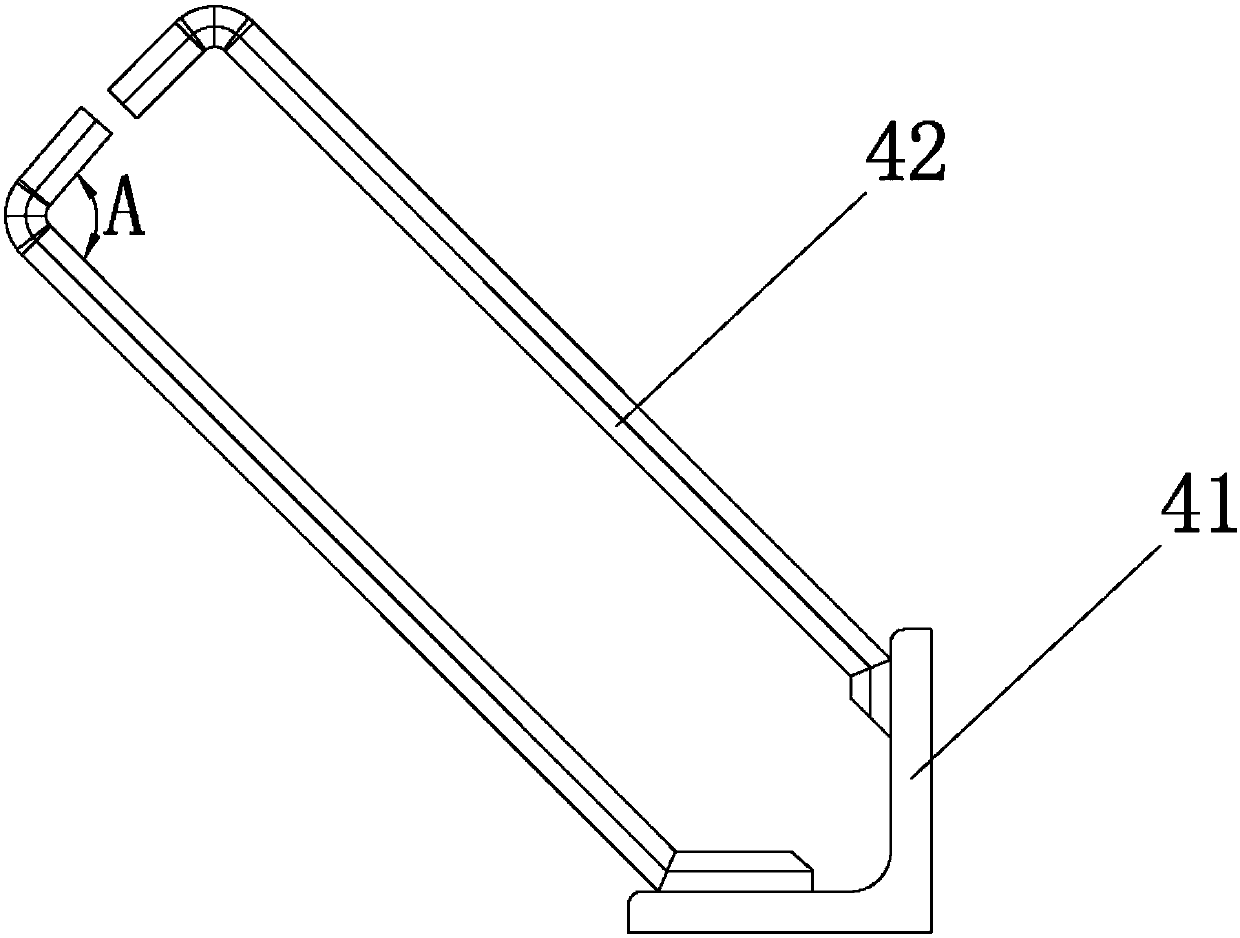

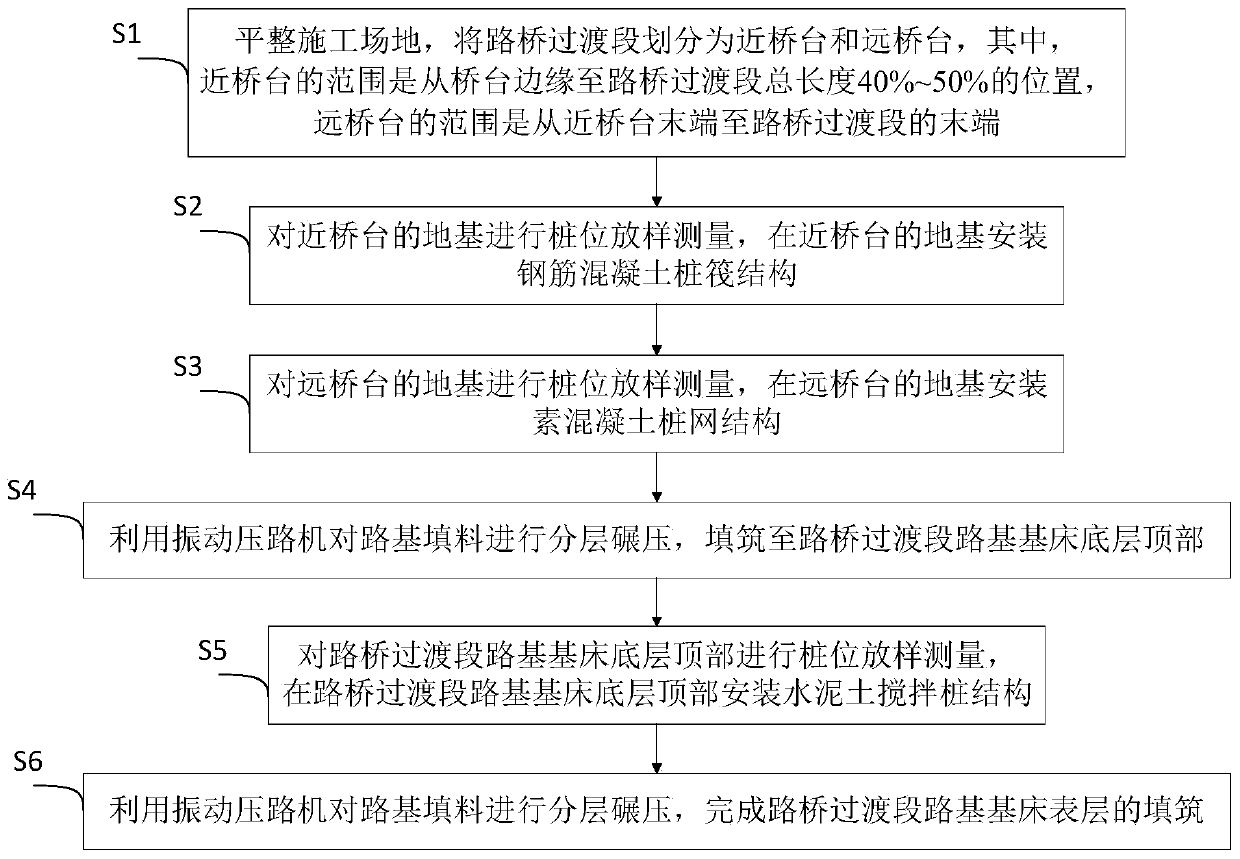

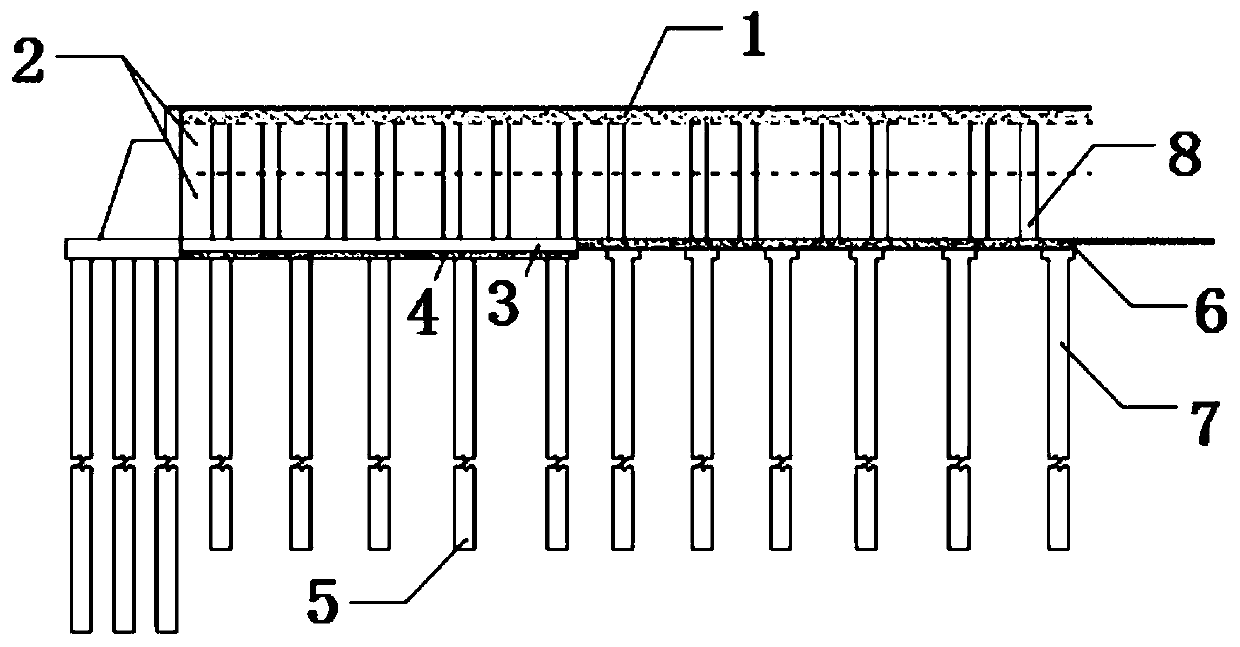

Pile composite structure construction method for controlling differential settlement of high-speed railway bridge transition section

InactiveCN110952389AControl uneven settlementImprove ride comfortRailway tracksBulkheads/pilesReinforced concreteSoil cement

The invention relates to a pile composite structure construction method for controlling differential settlement of a high-speed railway bridge transition section, which comprises the following steps:S1, leveling a construction site, and dividing the high-speed railway bridge transition section into a near abutment and a far abutment; s2, installing a reinforced concrete piled raft structure on the foundation close to the bridge abutment; s3, installing a plain concrete pile net structure on the foundation far away from the bridge abutment; s4, rolling the roadbed filler layer by layer, and filling the filler to the top of the roadbed bed bottom layer of the road and bridge transition section; s5, mounting a cement mixing pile structure at the top of the bottom layer of the roadbed bed ofthe road and bridge transition section; and S6, completing the filling of the roadbed surface layer of the road and bridge transition section. Compared with the prior art, the cement mixing piles on the roadbed are combined with the reinforced concrete piled raft structure and the plain concrete piled net structure on the foundation treatment; by combining the longitudinal pile spacing with transition change, longitudinal differential settlement of the road and bridge transition section can be effectively controlled, rigid transition can be realized without filling of a forward trapezoidal roadbed and an inverted trapezoidal roadbed, and the construction quality is ensured.

Owner:TONGJI UNIV

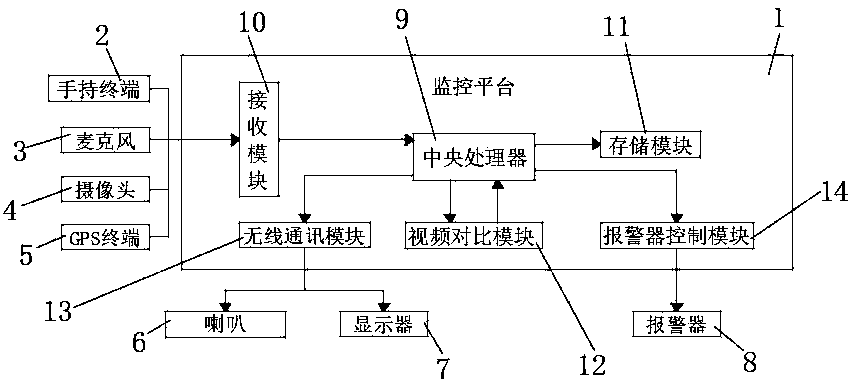

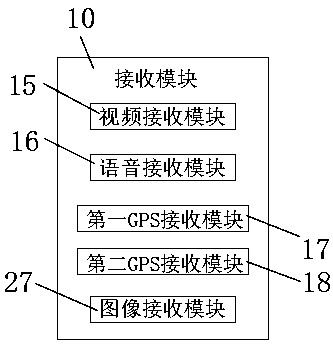

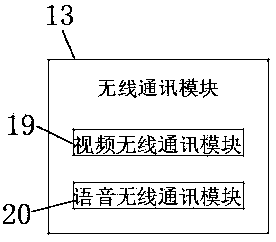

Electric power cross-system interactive quality monitoring platform based on visualization technology

InactiveCN110022464AControl construction qualityCircuit arrangementsClosed circuit television systemsElectric power systemComputer module

The invention discloses an electric power cross-system interactive quality monitoring platform based on a visualization technology. The invention relates to the related technical field of power systems. The platform comprises a monitoring center, a handheld terminal, a microphone, a camera, a GPS terminal, a loudspeaker, a display screen and an alarm. A central processing unit, a receiving module,a storage module, a video comparison module, a wireless communication module and an alarm control module are arranged in the monitoring center, and the input end of the central processing unit is electrically connected with the output end of the receiving module. According to the invention, conditions of a construction site can be transmitted to the display screen in real time through the camera;through the video comparison module and the monitoring personnel, whether the video on the display screen meets the construction standard or not can be compared; the monitoring personnel can be reminded of the problem of on-site construction through the alarm, meanwhile, through the cooperative arrangement of the microphone and the loudspeaker, the monitoring personnel can call and stop illegal construction on the construction site in real time, and the construction quality problem caused by illegal construction can be avoided.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD NANTONG POWER SUPPLY BRANCH

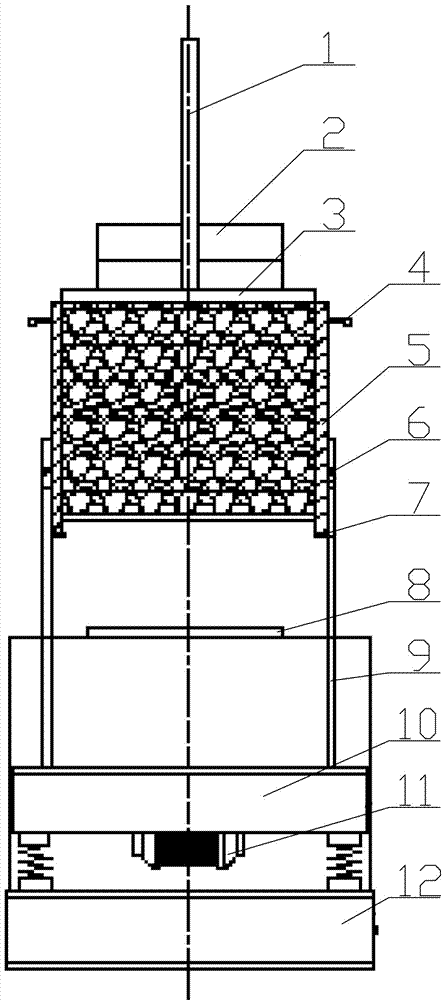

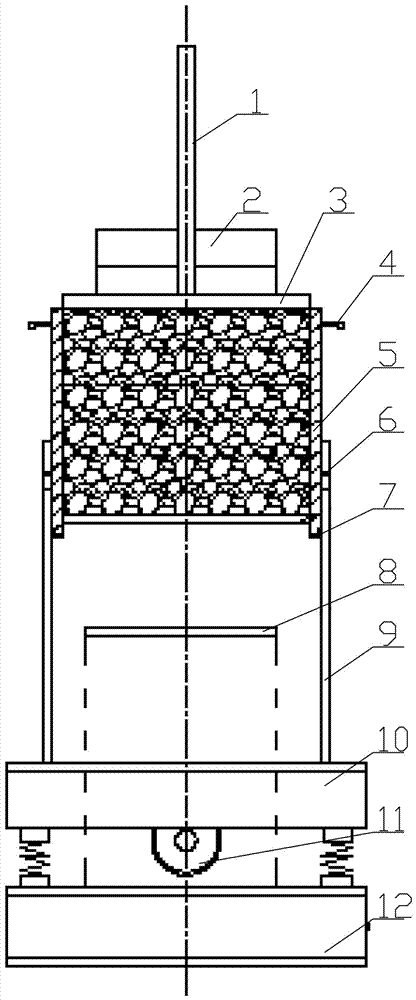

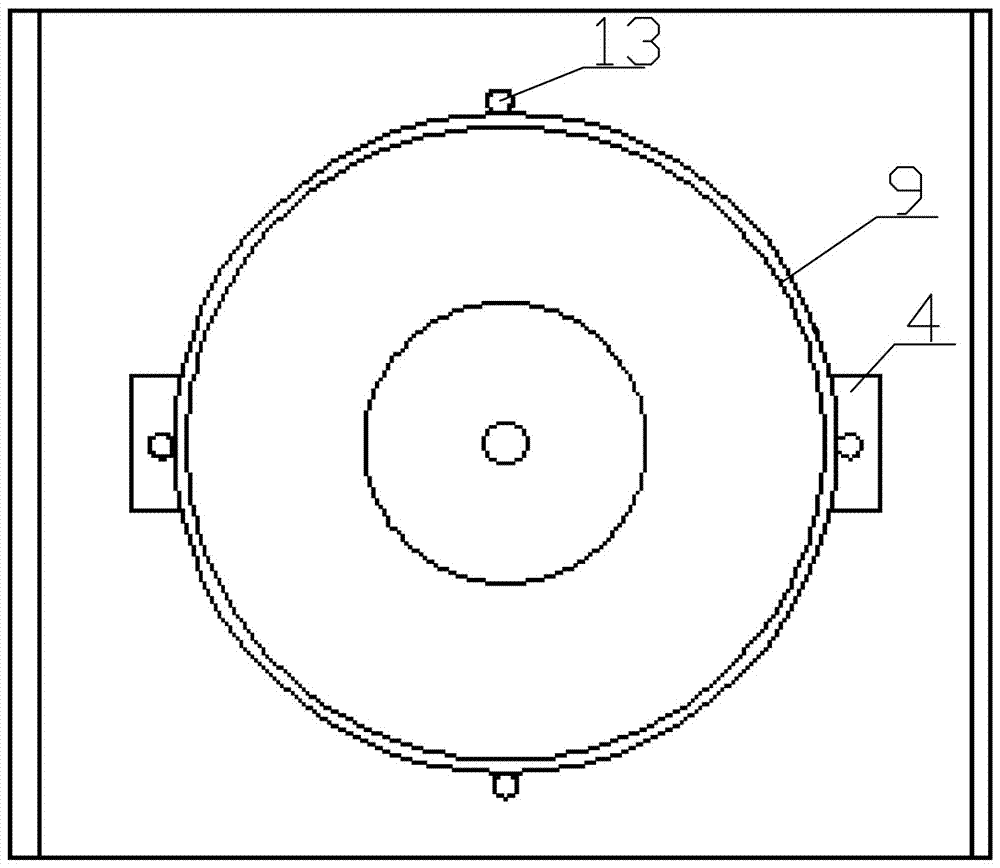

Device and method of measuring working performance of pervious concrete

The invention discloses a device and a method of measuring the working performance of pervious concrete. The device comprises an upper part and a lower part in detachable assembly, wherein the upper part comprises a test detection barrel; the test detection barrel is detachably mounted at the top of a fixing frame; a transparent disc is arranged at the top of the test detection barrel; a counter weight device is mounted at the top of the transparent disc; the lower part comprises a base; a vibrating table is mounted on the base; a vibrating motor is mounted at the bottom of the vibrating table; a reflector is arranged below the test detection barrel and is fixed on the base. The method can be used for quantitatively evaluating the working performance of pervious concrete so as to ensure good working performance of the pervious concrete in different working conditions and improve the construction quality.

Owner:CHINA GEZHOUBA GRP SURVEY DESIGN CO LTD

External wallboard block of industrial building and mounting method thereof

InactiveCN101748856ARealize energy saving and environmental protectionReduced parts countWallsArchitectural engineeringMoisture

The invention relates to an external wallboard block of an industrial building and a mounting method thereof, which belong to the field of building materials. The external wallboard block of the industrial building comprises a wallboard frame block in which a heat preservation material is embedded, wherein the massive heat preservation material, moisture permeable and waterproof paper, an air layer and an external wall decorative hanging plate are orderly fixed on the part, facing the exterior of a room, of the wallboard frame block; rough grounds and interior wall decorative sheets are orderly fixed on the part, facing the interior of the room, of the wallboard frame block; at least two hoisting holes are formed on the upper end face of a frame at the top of the wallboard frame block; a plurality of first hole positions are arranged on the lower end face of the frame at the bottom of the wallboard frame block; and the lateral surface of the frame at the top of the wallboard frame block facing the interior of the room is provided with a plurality of second hole positions. In the method of the invention, the external wallboard blocks can be arranged on a beam frame of the building to form an external wall, so the number of building material parts can be reduced and working days for field construction also can be reduced, which can realize good construction with shortened construction duration and the like. In addition, the external wallboard block can be subjected to standardized production in a factory beforehand, so the quality of the external wallboard block can be ensured, simultaneously cost is reduced and the external wall with stable quality and stable properties can be manufactured with relatively fixed cost.

Owner:宝业集团浙江建设产业研究院有限公司

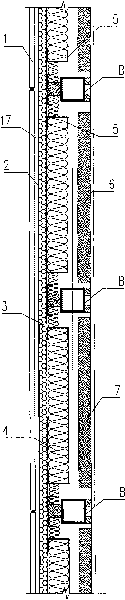

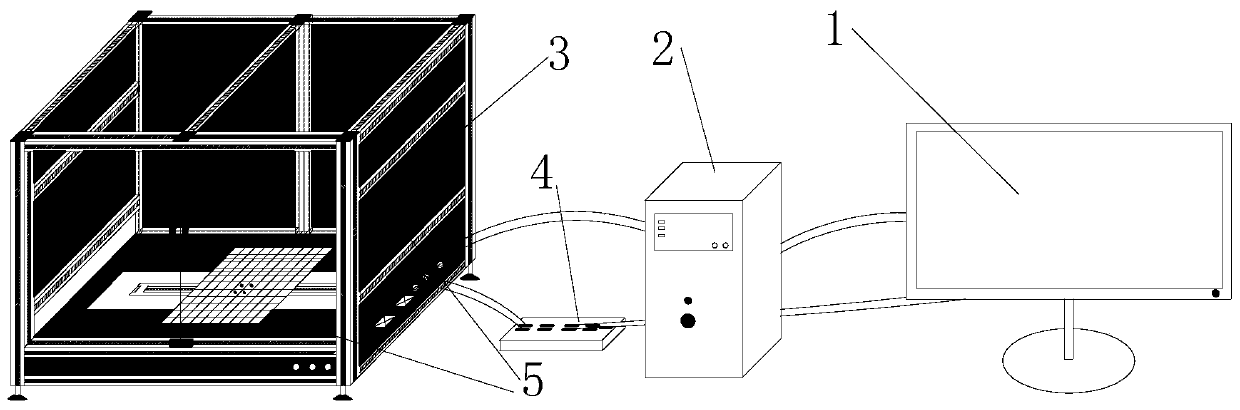

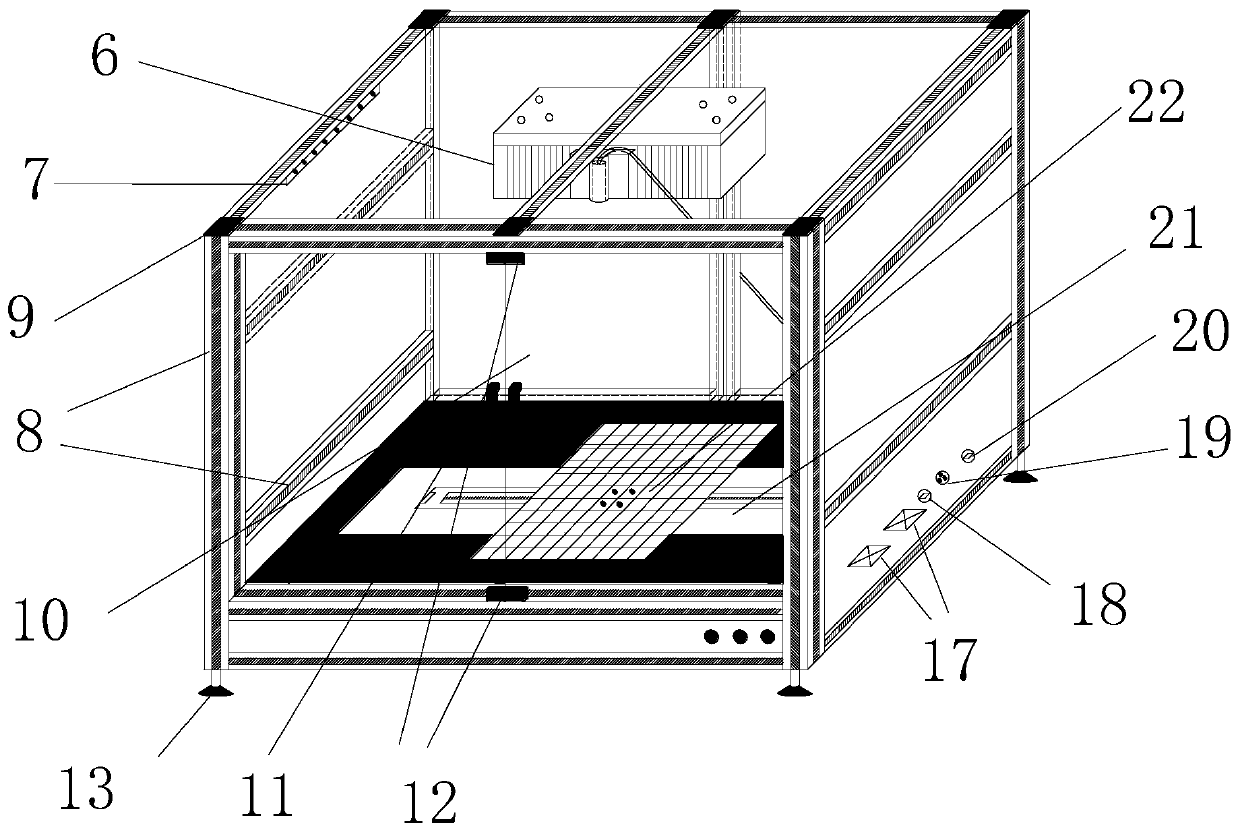

Aggregate morphological characteristic detection system and method based on 3D point cloud data

InactiveCN110907457ATest results are stableHigh precisionInvestigating moving fluids/granular solidsEngineeringEnvironmental geology

The invention belongs to the field of road engineering material detection equipment, and relates to an aggregate morphological characteristic detection system and method based on 3D point cloud data.The system comprises an acquisition mechanism, a processing mechanism and a display unit. The display unit is used for displaying and inputting the acquisition parameters of a set aggregate, the acquisition mechanism is used for placing the aggregate, acquiring the 3D point cloud coordinate information of the aggregate and transmitting the acquired 3D point cloud coordinate information to the processing mechanism, and the processing mechanism is used for receiving the 3D point cloud coordinate information transmitted by the acquisition mechanism and the acquisition parameters inputted by the display unit, extracting and calculating the morphological characteristic parameters of the aggregate from the 3D point cloud coordinate information, carrying out index evaluation on the morphologicalcharacteristic parameters according to the acquisition parameters, and displaying the morphological characteristic parameters through the display unit. The system and the method of the present invention can carry out 3D detection on each aggregate, are not influenced by the light, are stable in test result and high in precision, can carry out the batch detection, can evaluate and optimize the aggregate quality rapidly, and can control the construction quality effectively.

Owner:CHANGAN UNIV

Balcony beam slab inner side filling wall body and main body structure integral casting construction method

ActiveCN105064500AEasy to makeEasy to disassembleBuilding material handlingFalseworkEconomic benefits

The invention relates to a balcony beam slab inner side filling wall body and main body structure integral casting construction method. According to the construction method, the twice structure casting is put forward before the casting step; and a cast filling wall is arranged in grooves formed in the inner side of a beam steel bar and the inner side of a flange steel bar, and is integrally cast with a main body structure. The construction method has the advantages that the manufacturing of a formwork is simple; the reinforcement is convenient; a hollow mold is omitted; the supporting and the dismounting are convenient; building body materials used by a secondary structure are used in advance; the filling wall building work amount of the secondary structure is reduced; meanwhile, the work procedure clearance time is reduced; the integral economic benefits are good; the construction quality is high; the number of times of using a scaffold during the later-stage building is reduced; and the problems of construction quality and construction loss due to aerated concrete block cutting during the later-stage building are avoided.

Owner:中如建工集团有限公司 +1

Composite floor slab special for assembled steel structure

The invention relates to a composite floor slab special for an assembled steel structure. The composite floor slab is arranged on a steel beam and comprises a rebar truss, bottom rebars, embedded members and a prefabricated layer, the rebar truss comprises upper-chord rebars, lower-chord rebars and web member rebars, the upper-chord rebars and the lower-chord rebars are arranged parallelly to eachother and are in isosceles triangle distribution, and the web member rebars are welded between the upper-chord rebars and the lower-chord rebars; the bottom rebars are bound together with the lower-chord rebars of the rebar truss and are perpendicular to the same, the rebar truss, the bottom rebars and the embedded members are embedded in the prefabricated layer, and the embedded members are connected with the steel beam. By the composite floor slab, the problem in connection between conventional composite floor slabs and steel structures is solved; through effective connection with a steel structure body, integrity and aseismicity of the structure are improved, so that the composite floor slab can play a great role in the field of the assembled steel structure.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

Earth-excavating device and earth-excavating method for earth pressure balance shield or pipe-jacking construction

The invention provides an earth-excavating device and earth-excavating method for earth pressure balance shield or pipe-jacking construction. The earth-excavating device comprises a mud pressing pumpconnected to a shield or a screw conveyor earth discharge mouth of a jacking pipe; a booster pump located in the shield or a last-section frame of the jacking pipe and connected with the mud pressingpump through a first pumping pipeline; a wellhead pump located at a tunnel wellhead and connected with the booster pump through a telescopic pipeline; a ground earth collecting pit connected with thewellhead pump through a second pumping pipeline. The earth-excavating device is specially used for tunnel construction by means of a shield or jacking pipe method. By means of the mud pressing pump arranged at the screw conveyor earth discharge mouth, the booster pump arranged in the shield or the last-section frame of the jacking pipe, and the wellhead pump arranged in the tunnel wellhead, the screw conveyor excavated earth generated from the shield or the jacking pipe during the excavation process is continuously and rapidly pumped until the earth is pumped into the ground earth collecting pit, the booster pump is connected with the screw conveyor earth discharge mouth in a sealed mode, and the screw conveyor excavated earth is extruded into pumps in a sealed mode and then into pumping lines, so that the pumping efficiency is higher.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

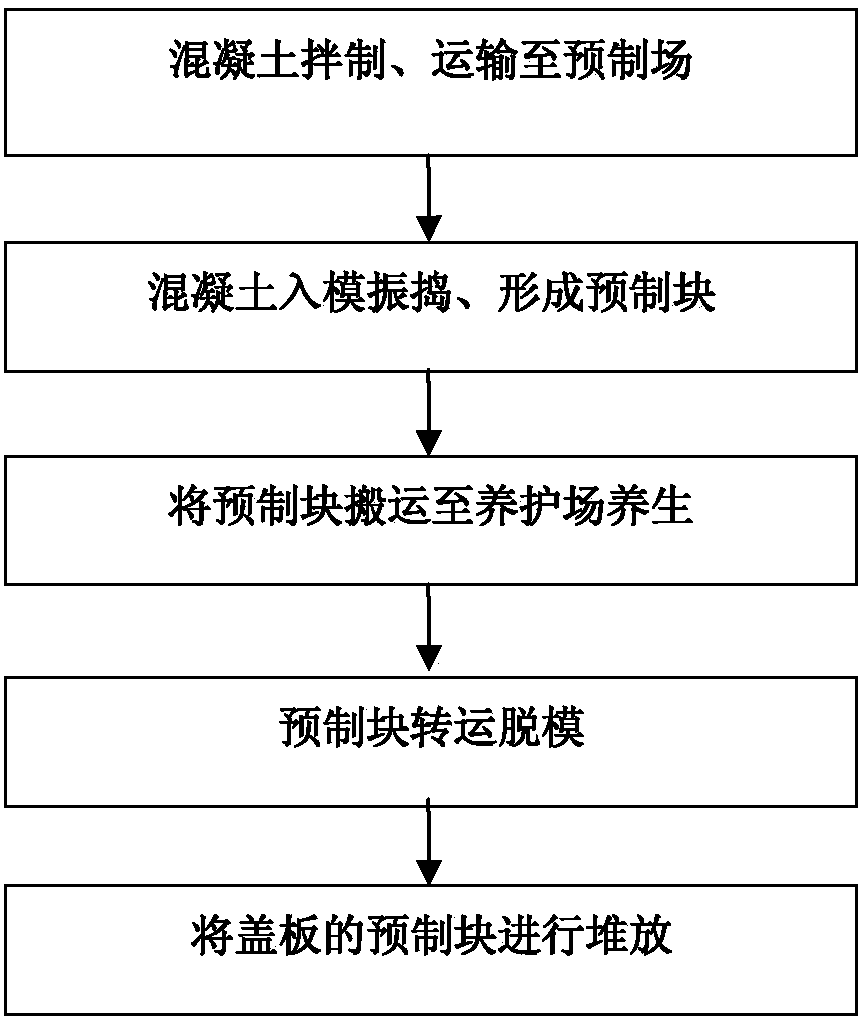

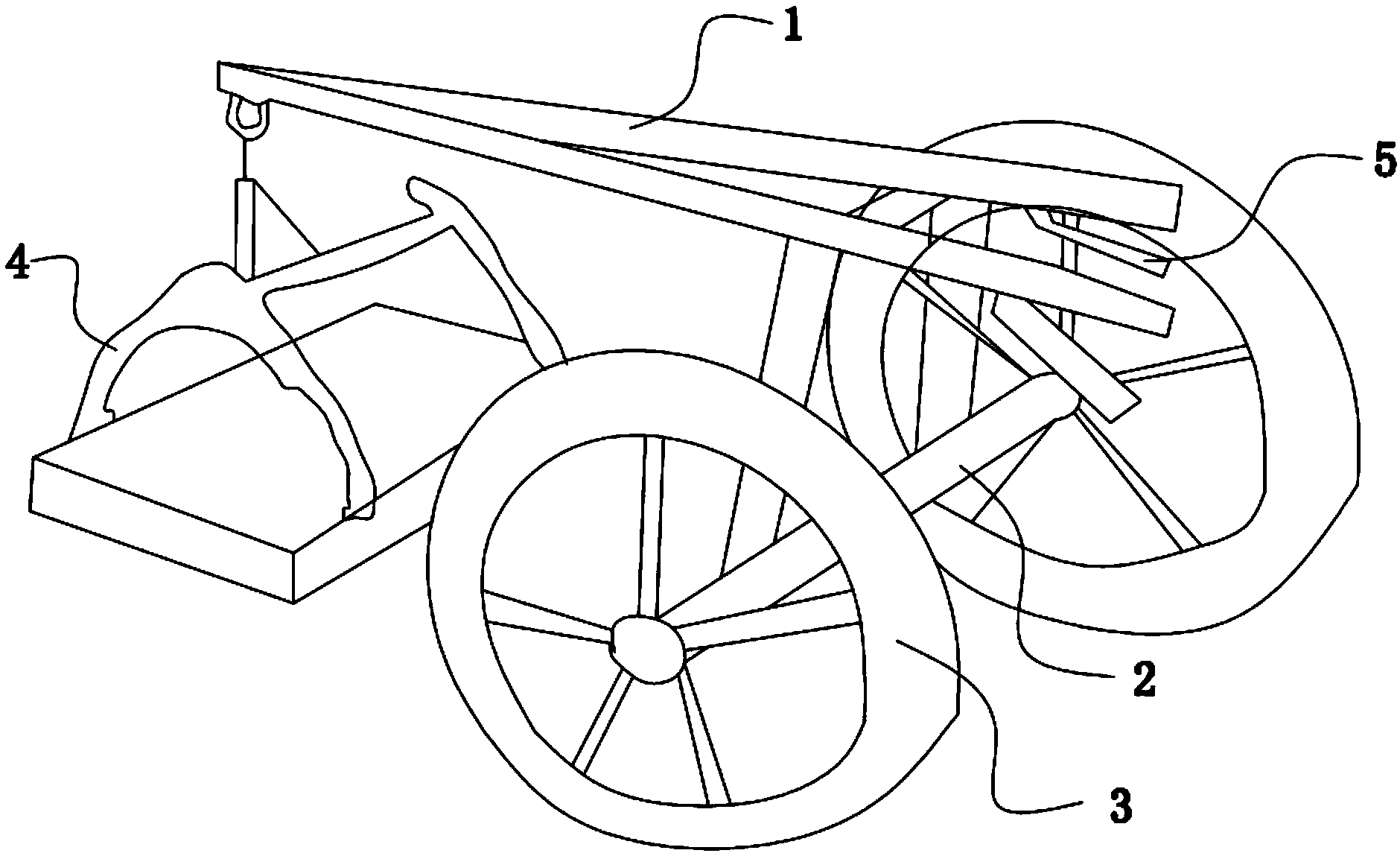

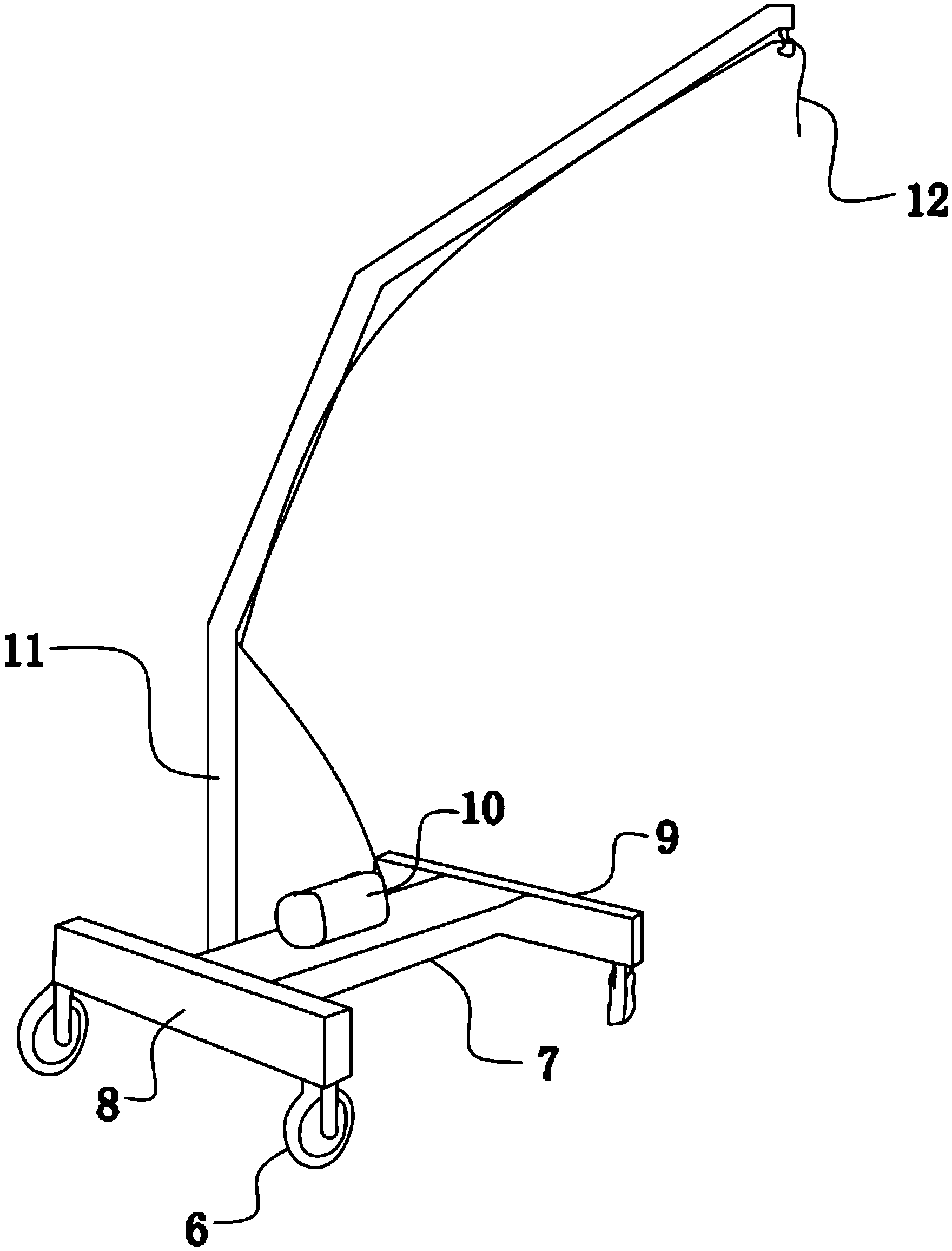

Pre-casting construction method for tunnel groove cover plate

ActiveCN103448131ASmall footprintControl construction qualityCeramic shaping apparatusYardUltimate tensile strength

The invention discloses a pre-casting construction method for a tunnel groove cover plate. The method comprises the following steps of: (a), mixing concrete, and transporting the concrete to a pre-casting yard; (b), vibrating the concrete in a mold to form precast blocks; (c), transporting the precast blocks to a maintenance yard for maintenance; (d), transferring and de-molding the precast blocks; (e), stacking the precast blocks of the cover plate. By the adoption of the method, the construction quality of the precast blocks can be ensured. By the adoption of transporting, transferring and hoisting equipment in cooperation with manual operation, the labor intensity is greatly reduced, the construction progress is accelerated, and the cost is saved.

Owner:CHINA RAILWAY ERJU 1ST ENG +1

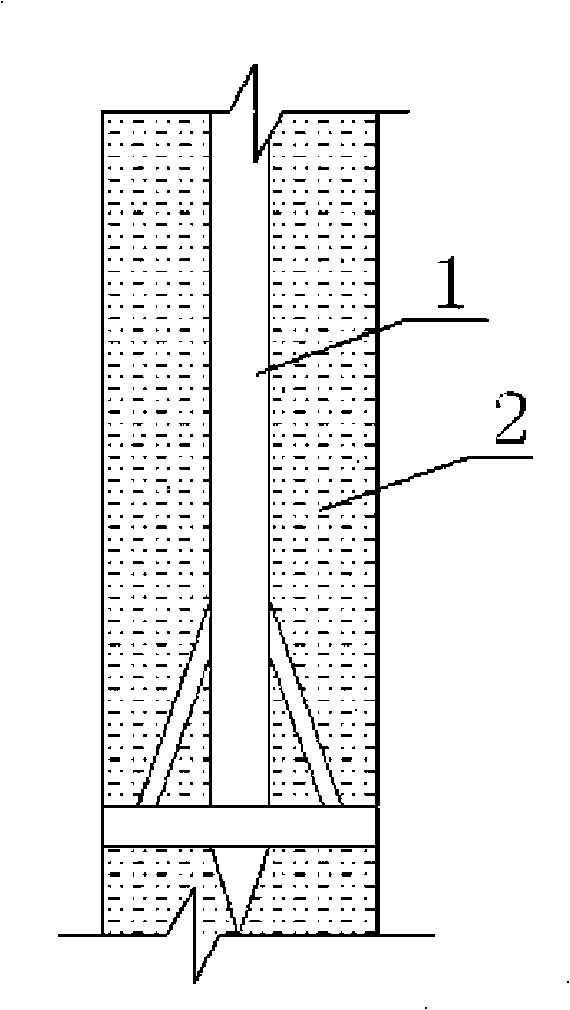

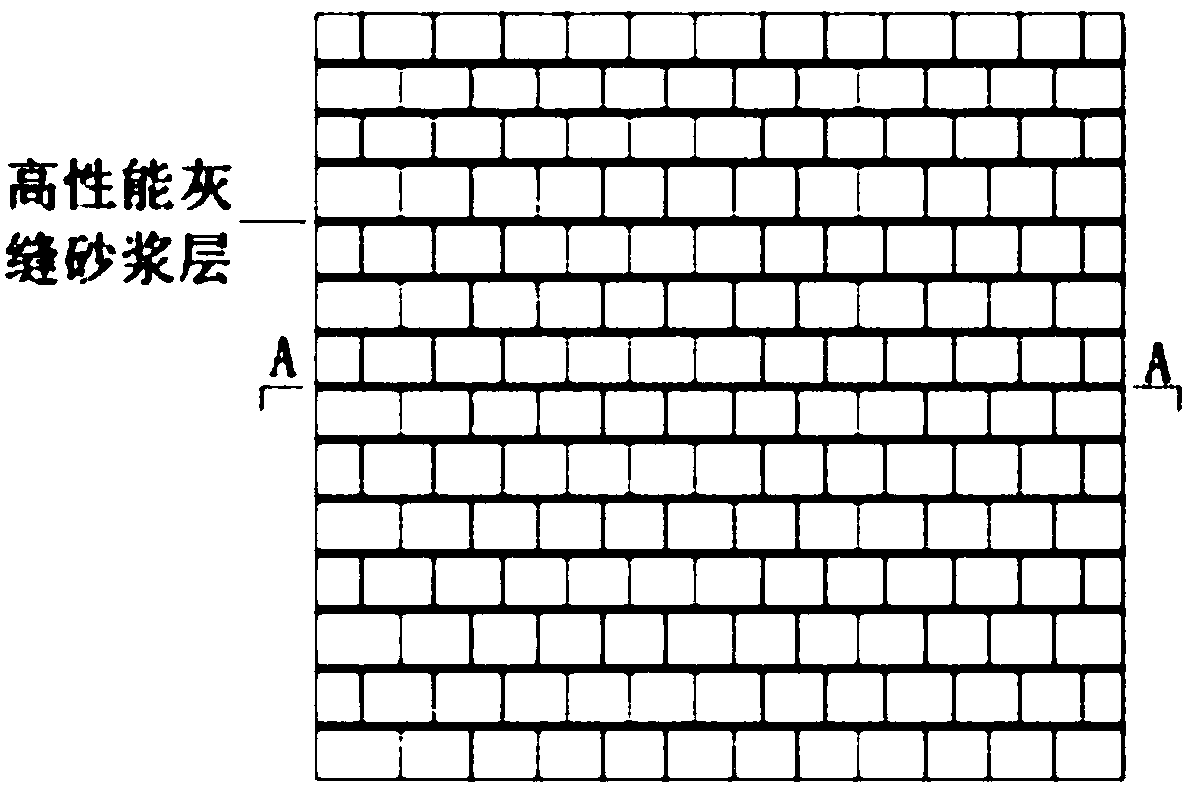

Construction method for high-ductility masonry wall with reinforced mortar-joint mortar layer

InactiveCN108301619AImproved brittle failure characteristicsImproves ductility and integritySolid waste managementWallsMortar jointDuctility

The invention discloses a construction method for a high-ductility masonry wall with a reinforced mortar joint mortar layer, and belongs to a construction method of a high-ductility masonry wall. Theconstruction method comprises the steps that (1) building blocks used for building a wall body are wetted in advance; (2) high-performance mortar-joint mortar with the thickness being 3-5 mm is smeared on first-layer building blocks along the cross section of the wall body according to the size of a cross section of the wall body; (3) a piece of geogrid mesh or a steel wire mesh is laid on the high-performance mortar joint mortar, high-performance mortar-joint mortar with the thickness being 3-5 mm is smeared on the geogrid mesh or the steel wire mesh, and second-layer building blocks are built on the high-performance mortar-joint mortar layer; and (4) the step (2) and the step (3) are repeated, wall body building is completed according to the designed height of the masonry wall. The construction method for the high-ductility masonry wall with the reinforced mortar joint mortar layer has the advantages that (1) the stress property of the whole masonry wall is improved; (2) transfer andexpansion of a crack in the mortar-joint mortar layer are effectively controlled, and ductility and integrity of the masonry wall are improved; and (3) the transfer path of cutting off the crack is effectively obstructed, the anti-shear property of the masonry wall is improved, and the aseismic performance of the newly-built masonry wall is improved accordingly.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com