Main structure for metro long-span station and pillar arching construction method thereof

A main structure and long-span technology, applied in the direction of earth drilling, underground chambers, mining equipment, etc., can solve problems such as multiple processes, weak support system, affecting structural force and appearance quality, and achieve simple construction steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

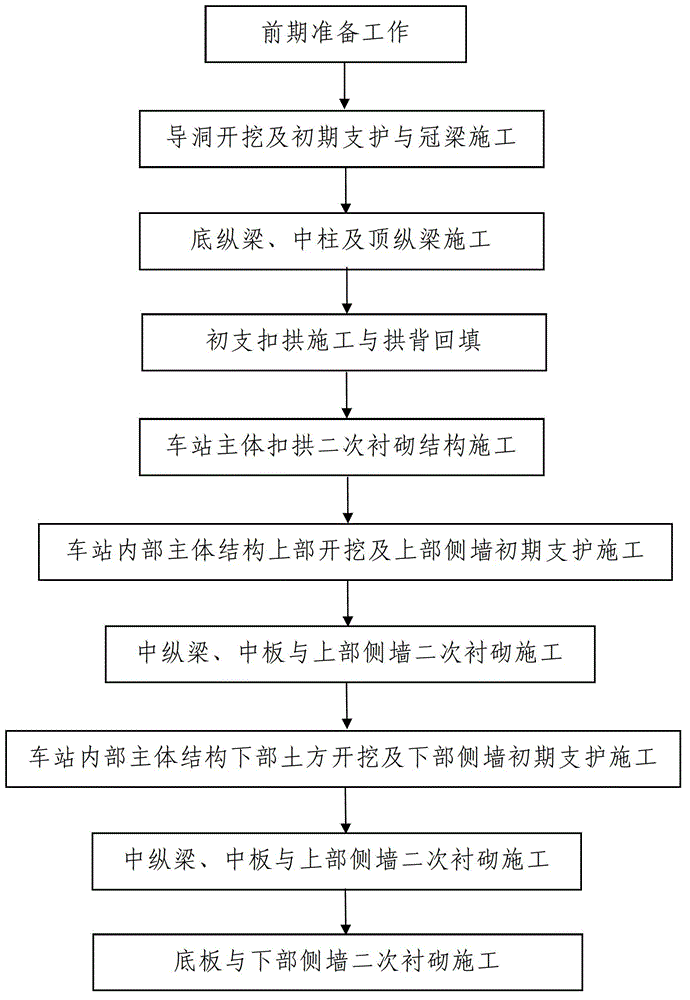

Method used

Image

Examples

Embodiment Construction

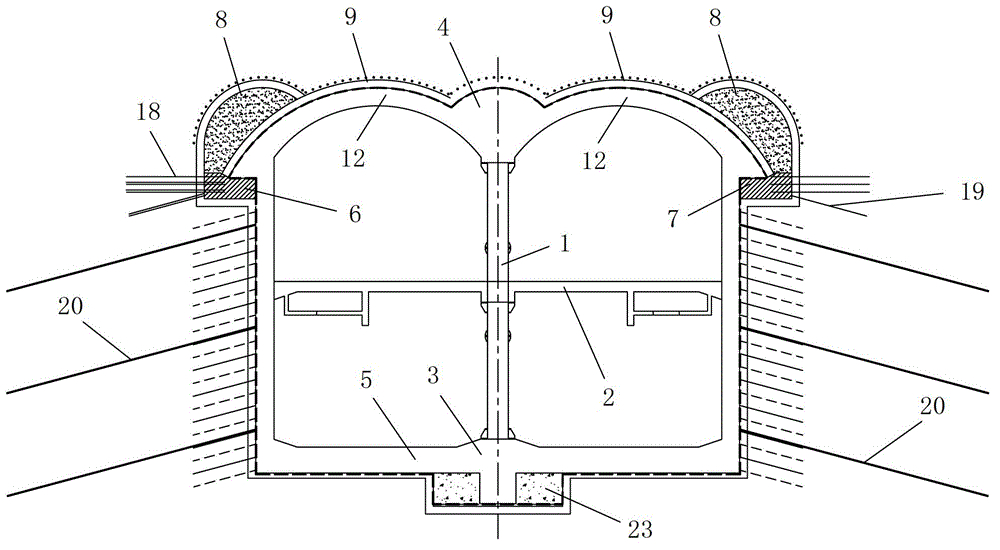

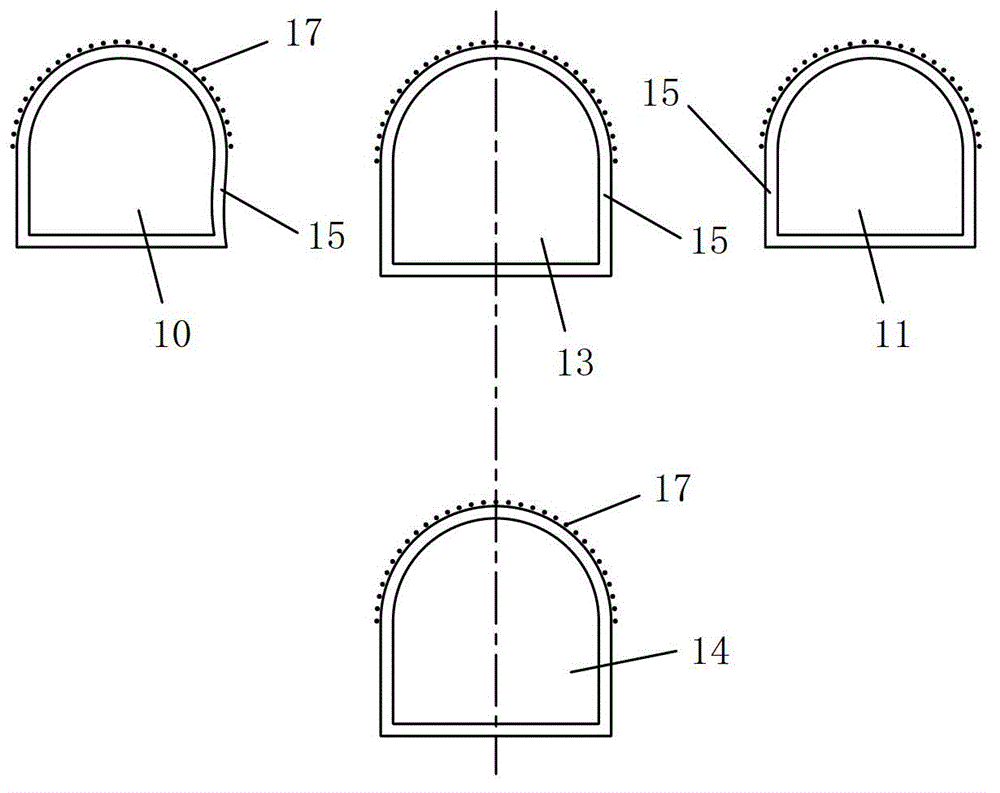

[0066] Such as figure 2The main structure of a long-span subway station is shown, including the main structure inside the station formed by excavation, and a plurality of center columns 1 arranged vertically on the longitudinal centerline of the main structure inside the station from front to back. , the middle plate 2 erected in the middle of the central column 1 and arranged horizontally and the main arch portion arranged directly above the internal main structure of the station, and a bottom longitudinal beam is arranged on the bottom longitudinal center line of the internal main structure of the station 3, and a top longitudinal beam 4 is arranged on the longitudinal center line of the arch of the main body, and the top longitudinal beam 4 is arranged in parallel with the bottom longitudinal beam 3 and is located directly above the bottom longitudinal beam 3 . The bottoms of the plurality of central pillars 1 are all supported on the bottom longitudinal beam 3 , and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com