Patents

Literature

2037 results about "Long span" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Long span structures. 2. LONG SPAN STRUCTURE’S Structures with span larger than 15-20 meters are regarded to as Long Span Structures. For Such structures span is unable to be achieved with ordinary R.C.C. construction. Generally long spans result in flexible, column-free internal spaces, reduces substructure costs and time to erect the structure.

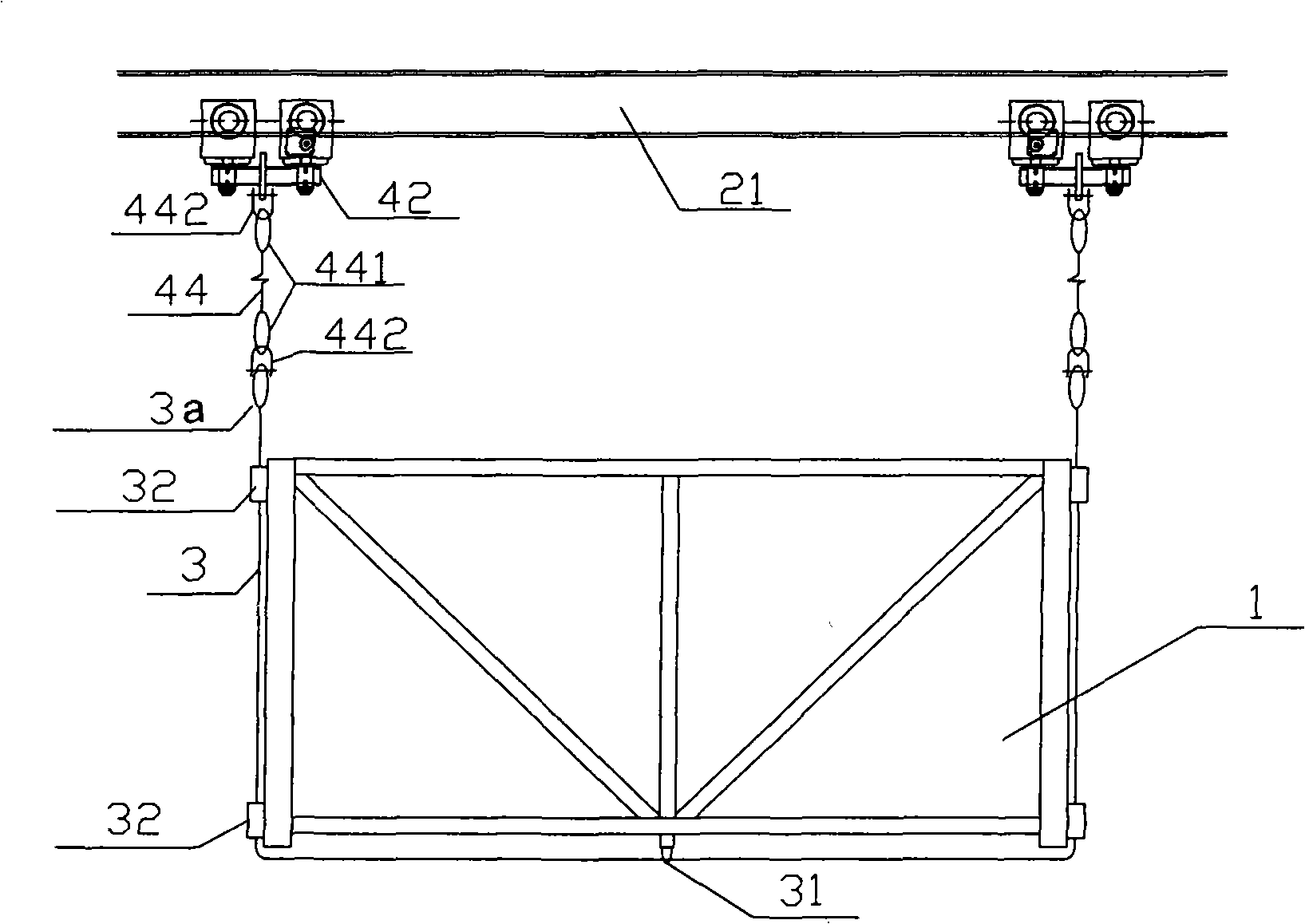

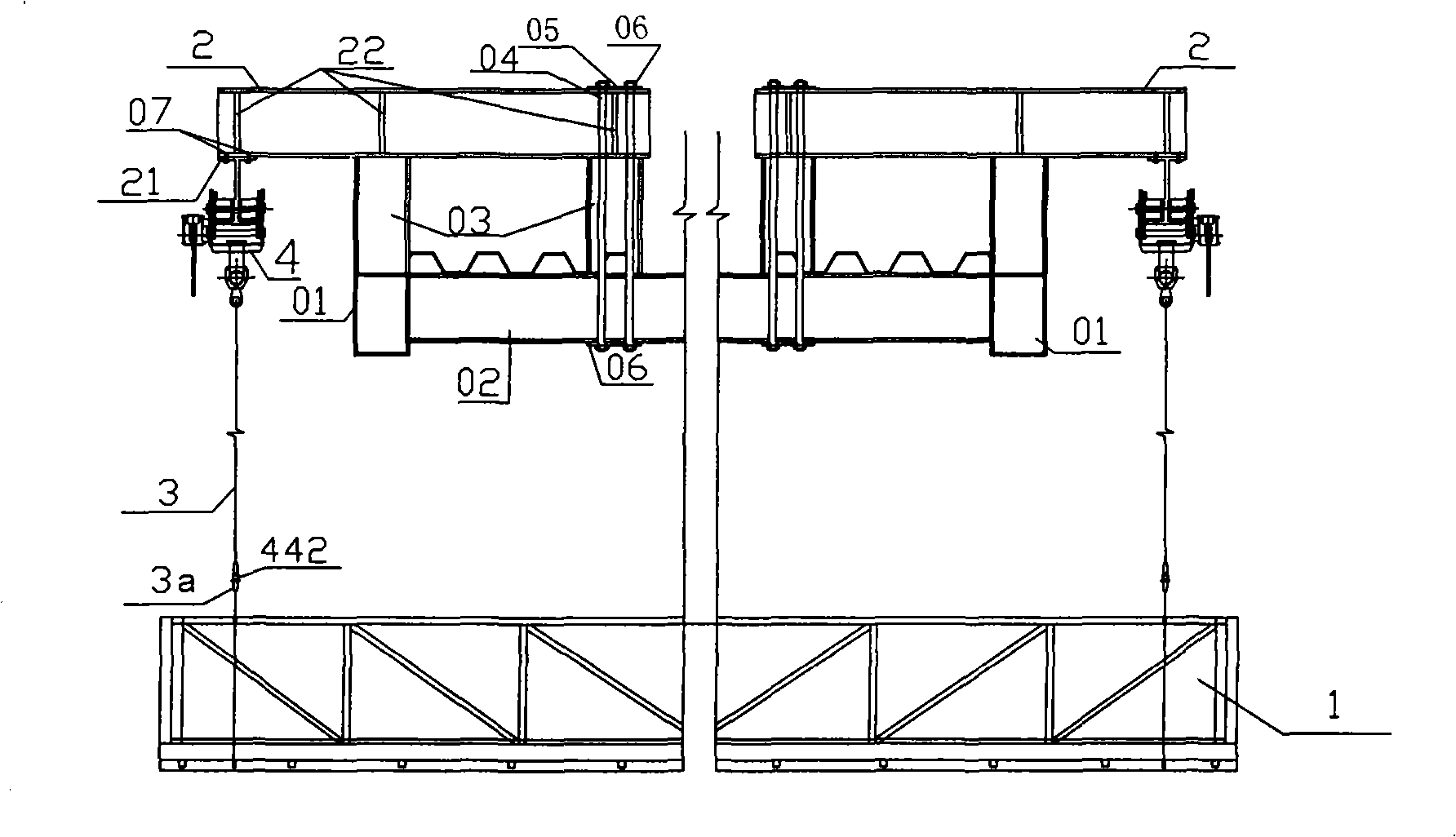

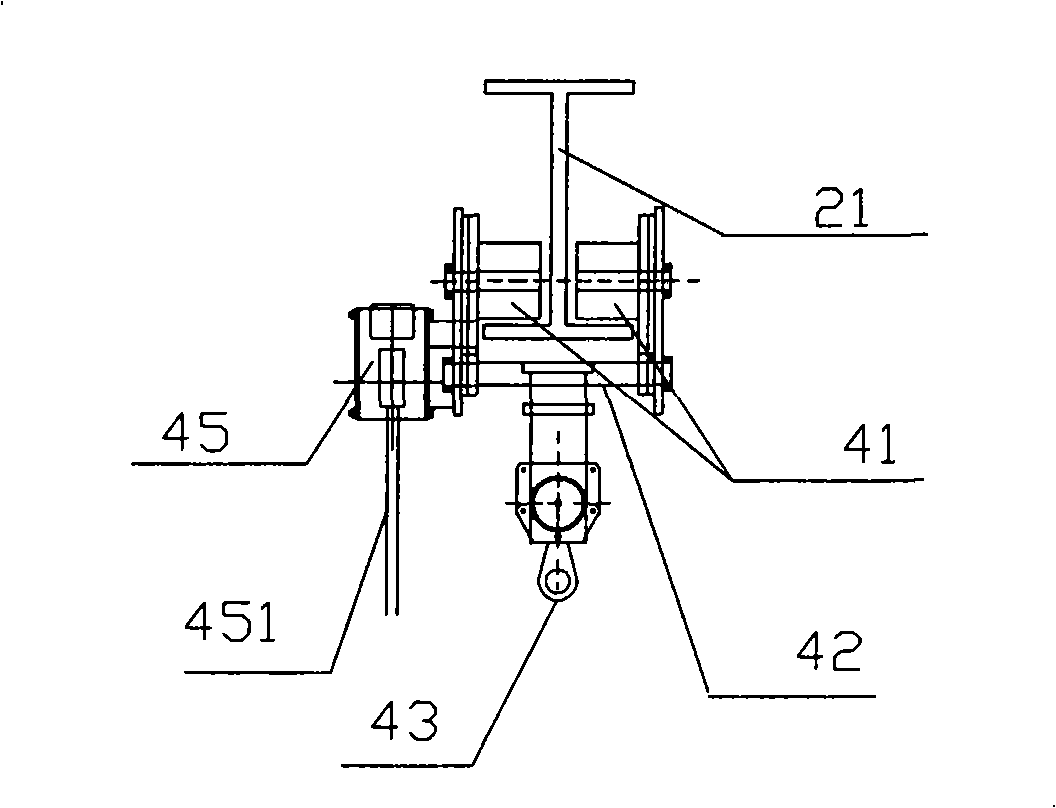

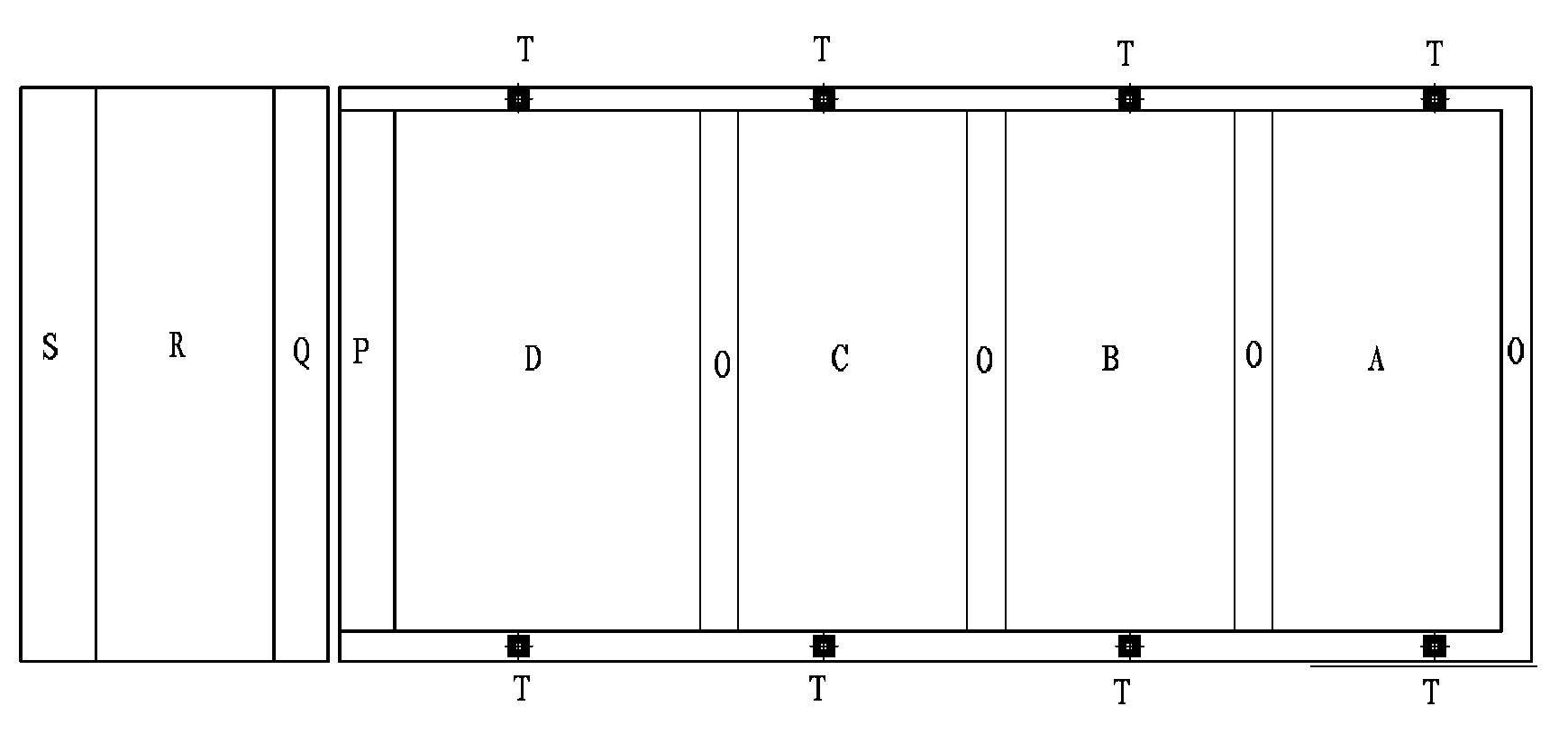

Hanger rail type electric hanging boat and high-rise long span house, bridge building construction method and use thereof

ActiveCN101514586AFirmly connectedImprove securityBridge erection/assemblyBuilding material handlingArchitectural engineeringLong span

The invention provides a hanger rail type electric hanging boat, comprising an overhung hanger rail fixed on a building main component, a construction operation hanging boat, a hanging boat horizontal walking system and a hanging boat lifting system, wherein the overhung hanger rail is fixed on the building main component, the hanging boat is fixed on the hanger rail via a walking device, and a detachable fixedly connecting structure is formed between the hanging boat and a hanger rod via the hanger rod. The invention further provides a method for high-rise building outside wall construction by the hanger rail type electric hanging boat, including a mounting method and a demolishing method. The use of the hanger rail type electric hanging boat and the construction method is further provided. The invention provides the safe and practical hanging boat with reasonable structure, thereby solving the problem that the hanging boat cannot move horizontally in the prior art, and facilitating outside wall ceiling construction of various special buildings such as long span vestibule.

Owner:JANGHO GRP

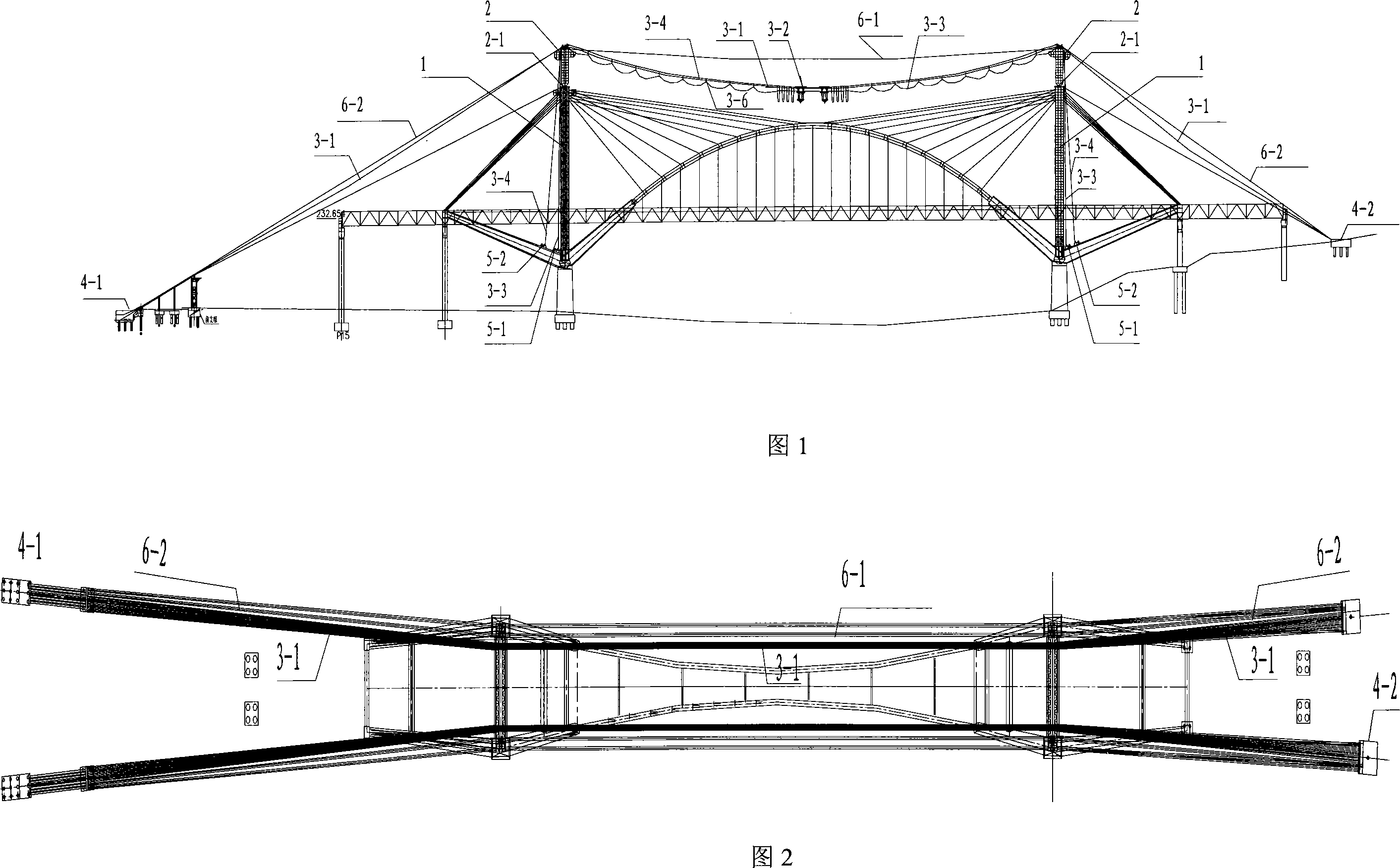

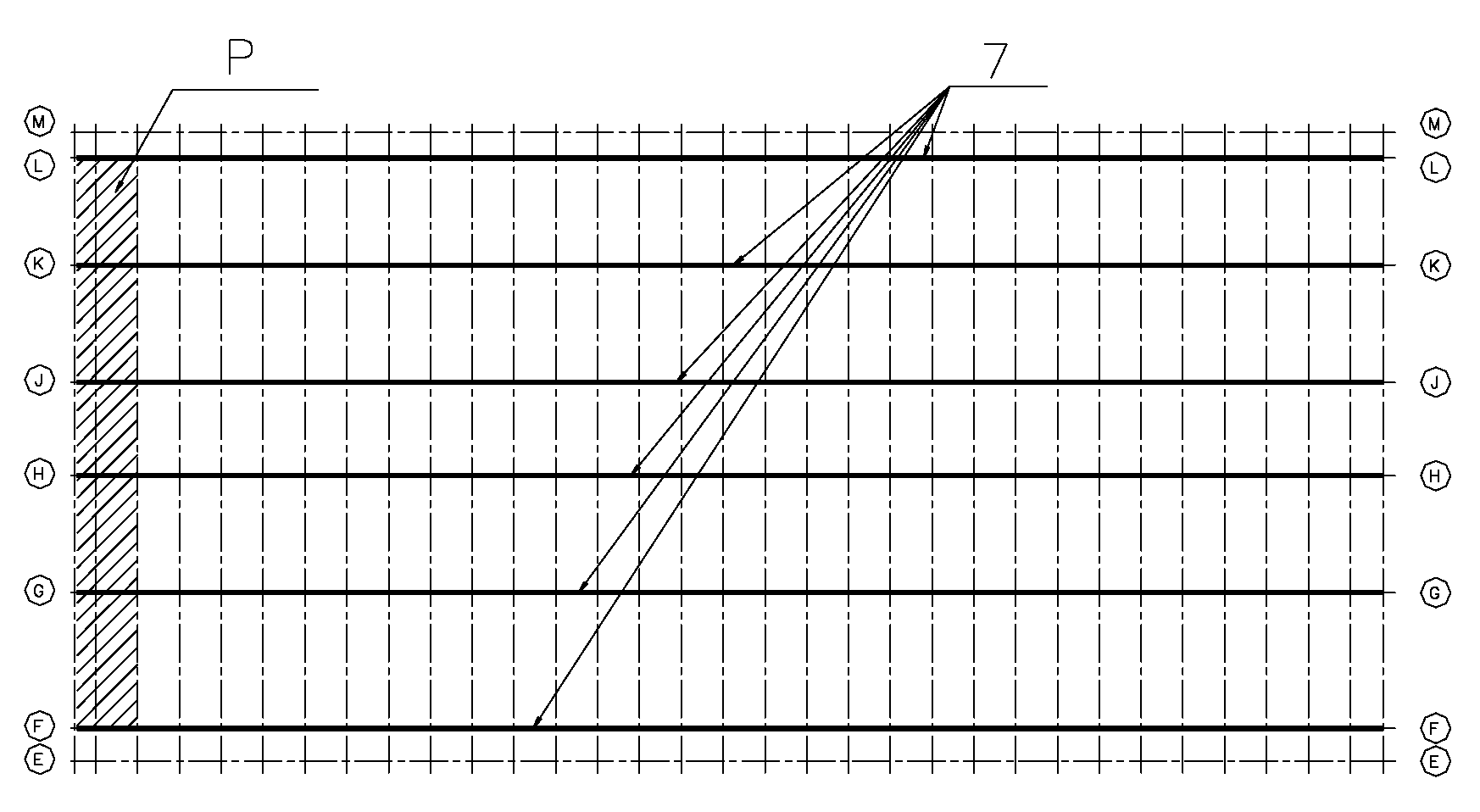

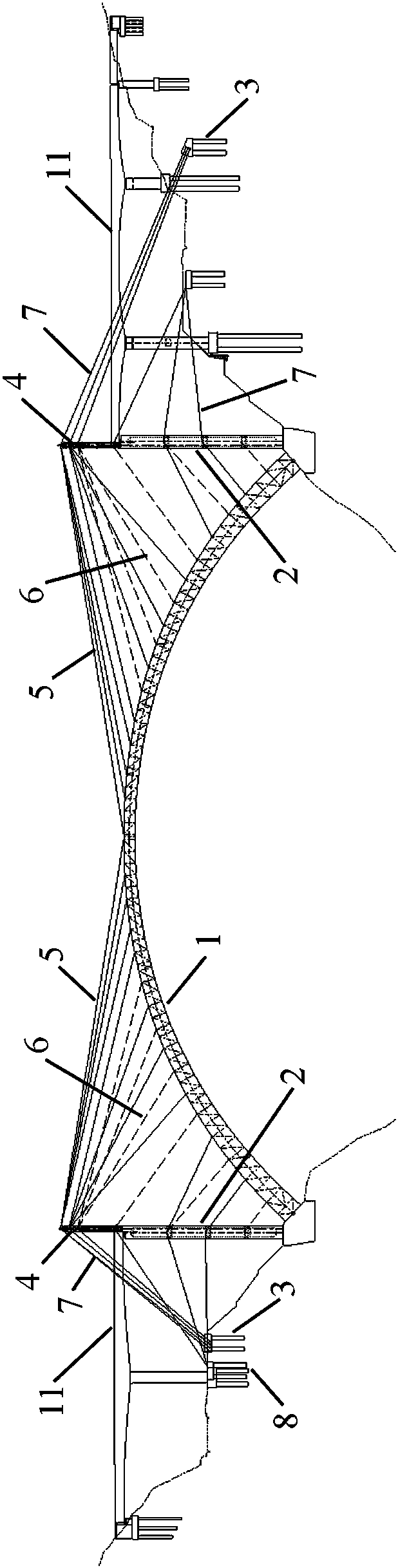

Long-span load-carrying cable lifting machine and mounting method therefor

InactiveCN101224856AReduce the impactReduce misalignmentBridge erection/assemblyCable carsHorizontal forceTraction system

The invention provides a long-span over loading cable crane and an installation method thereof which relates to a cable crane used in bridge construction and consists of a guy rope tower 1, a cable tower 2, a main cable and a hoisting traction system 3, an anchoring system 4, an electromechanical system 5 and a wind cable system 6. The tower of the cable crane consists of the guy rope tower 1 and the cable tower 2 which is hinged on the top of the guy rope tower 1 and fixedly connected with the bottom of the guy rope tower 1. The invention adopts the techniques of the parallel bearing of a plurality of main cables, the wind cables connected in series, the joint construction of the cable towel and the guy rope tower, etc., thereby greatly improving the loading capability of the long-span cable crane and lowering the manufacturing cost as much as possible. The invention can reduce the influence of the unbalanced horizontal force on the top of the cable tower 2 on the guy rope tower 1 and greatly save the construction cost of the guy rope tower 1. The loading cable crane has strong load-carrying capability, wide loading range and high economic performance.

Owner:CHINA MAJOR BRIDGE ENG

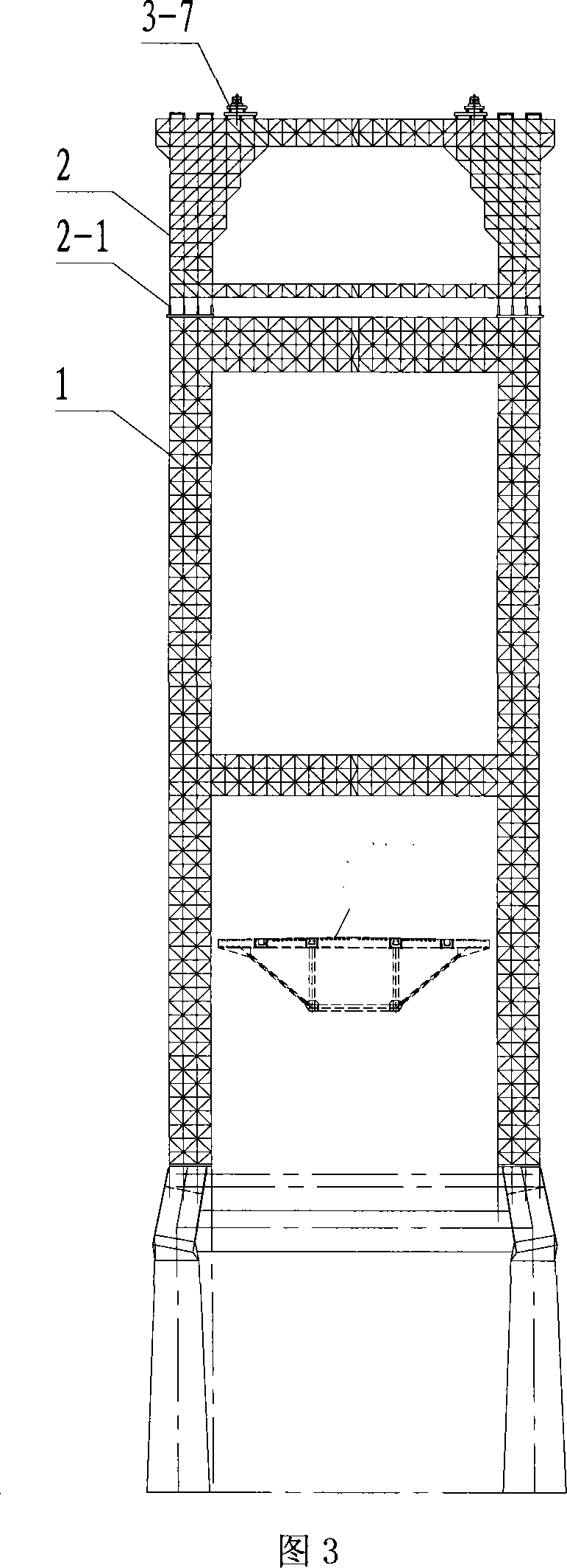

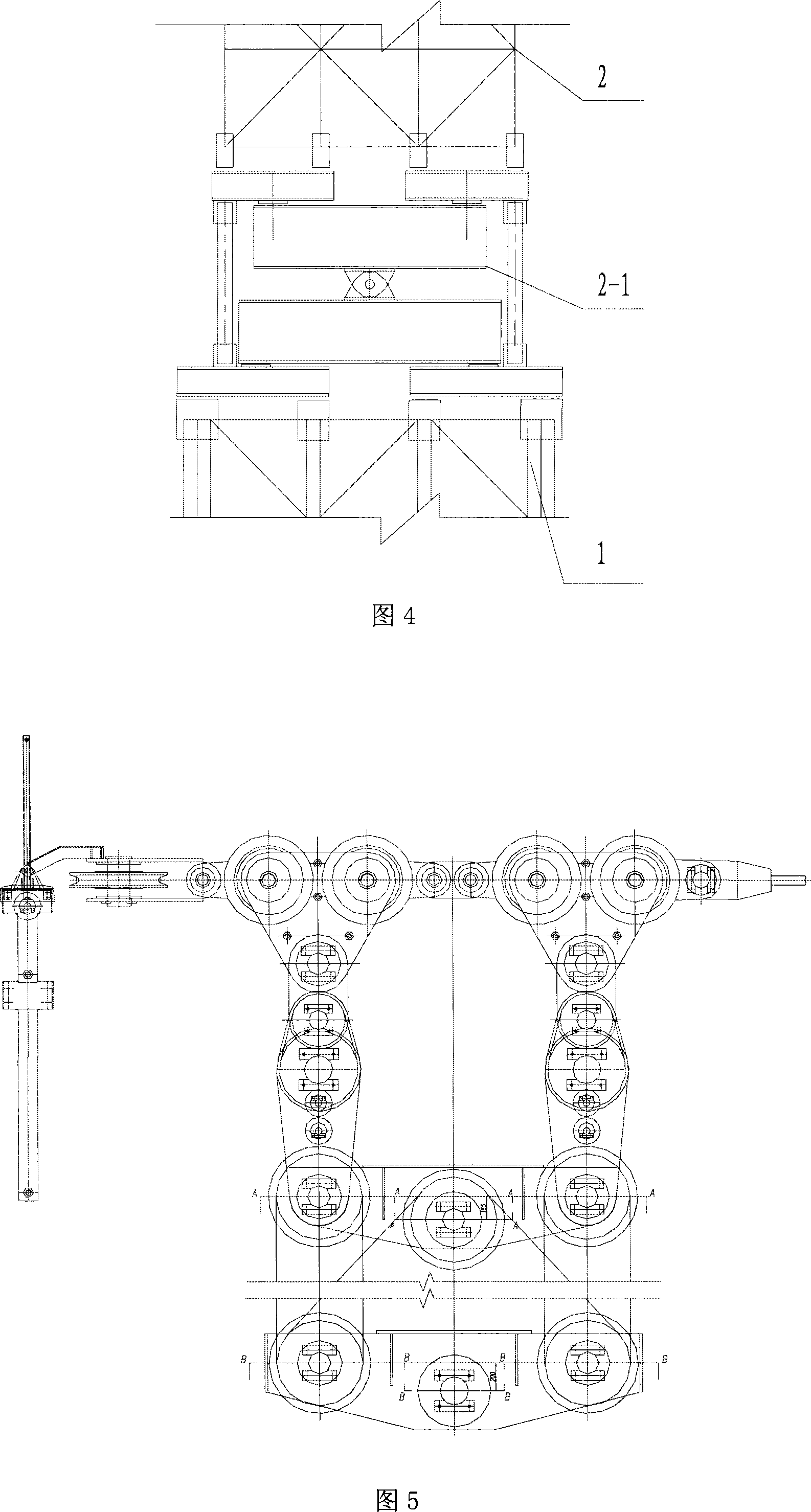

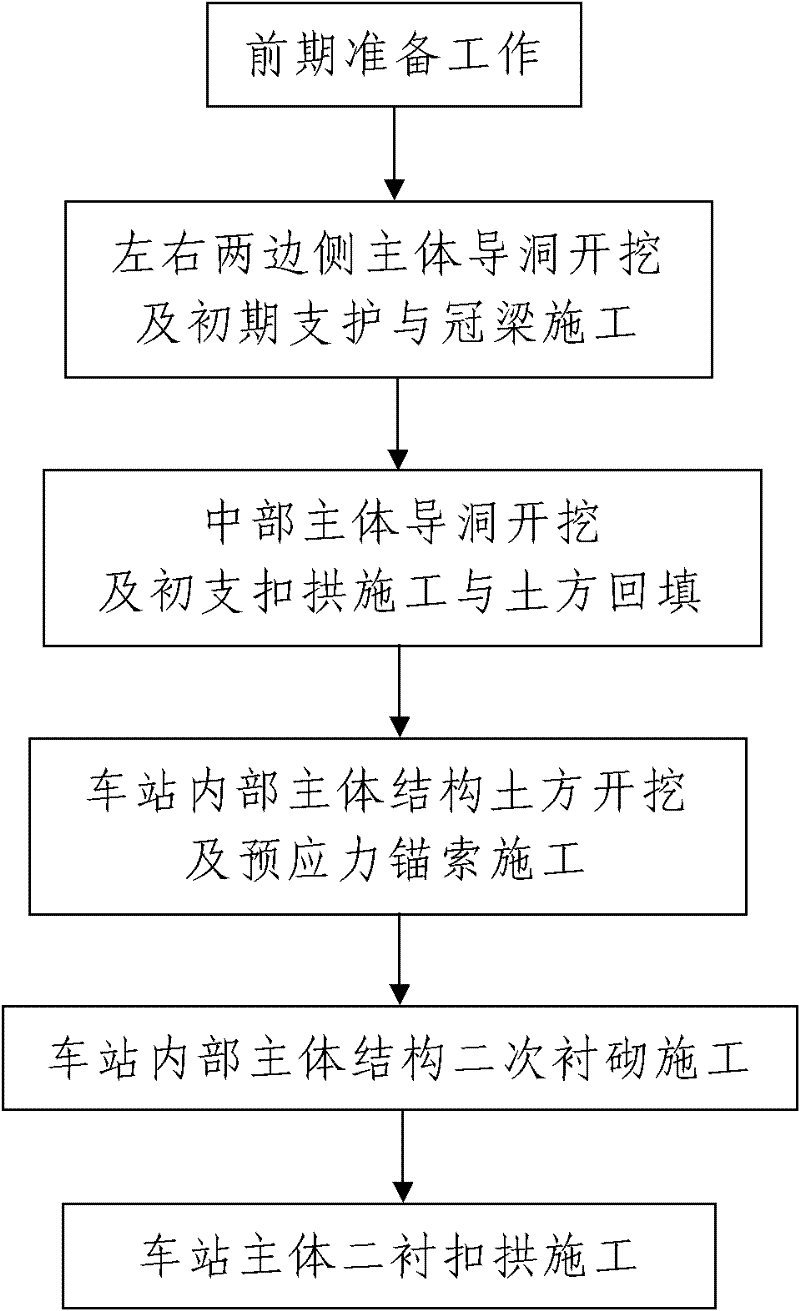

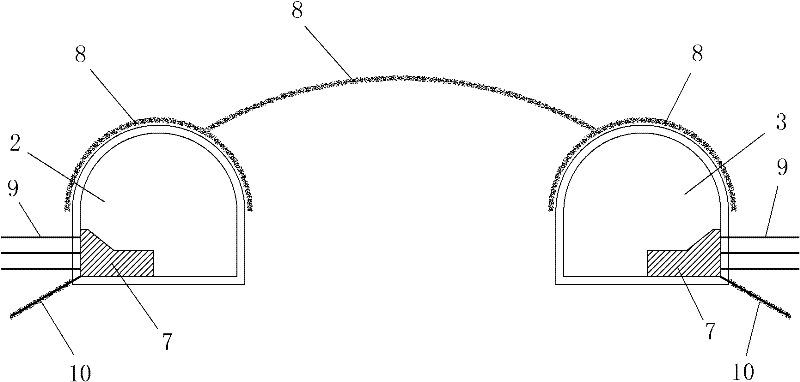

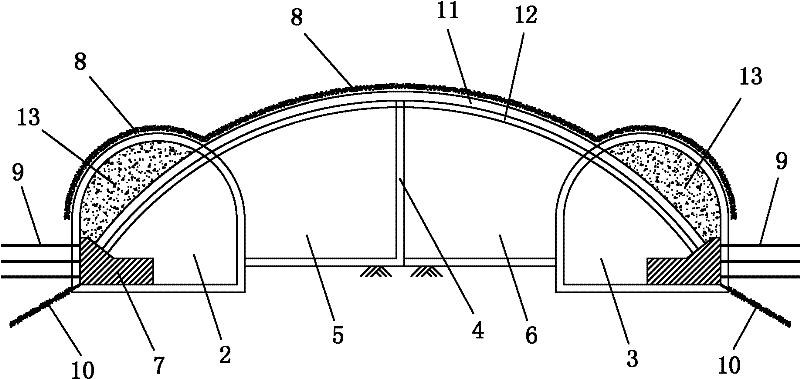

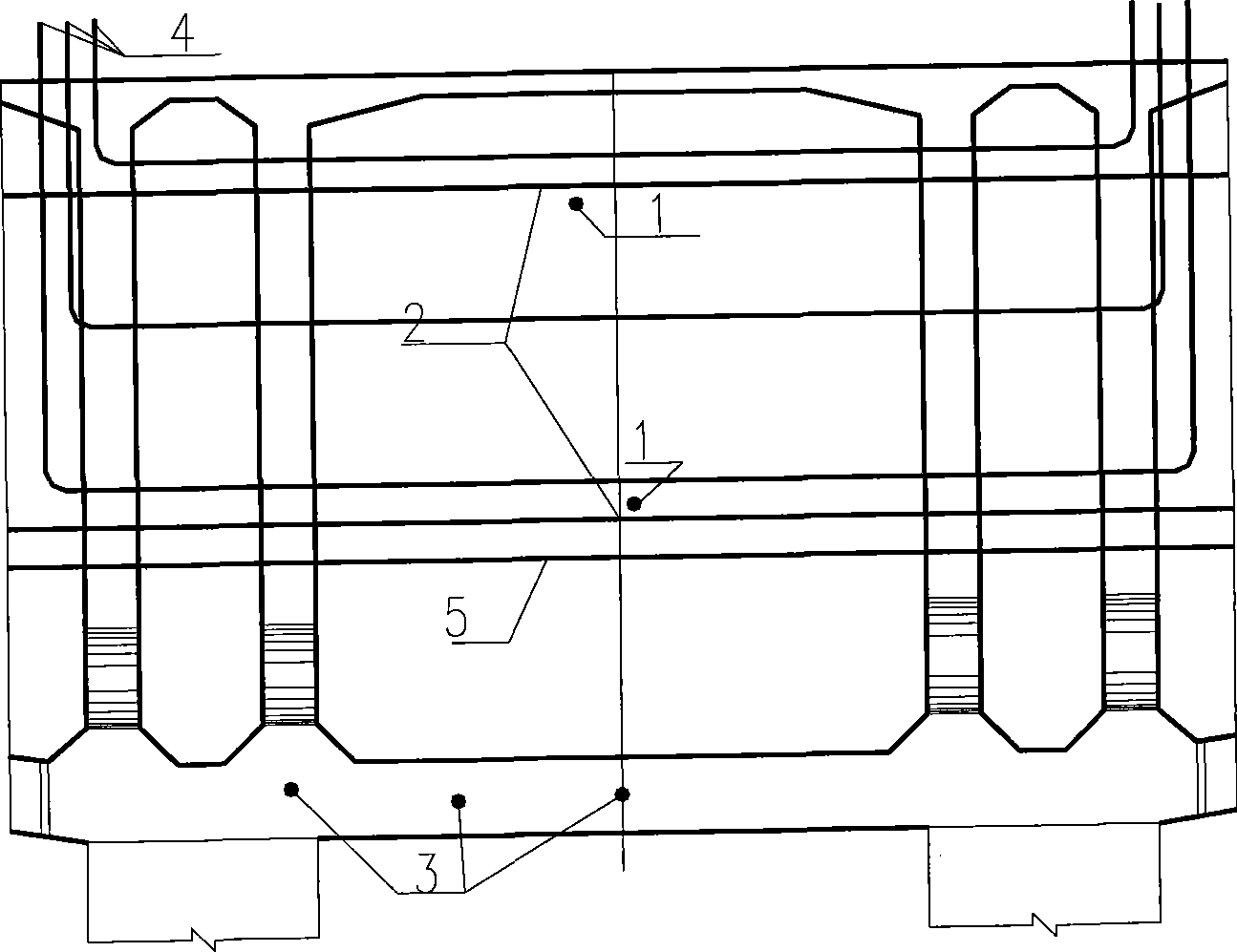

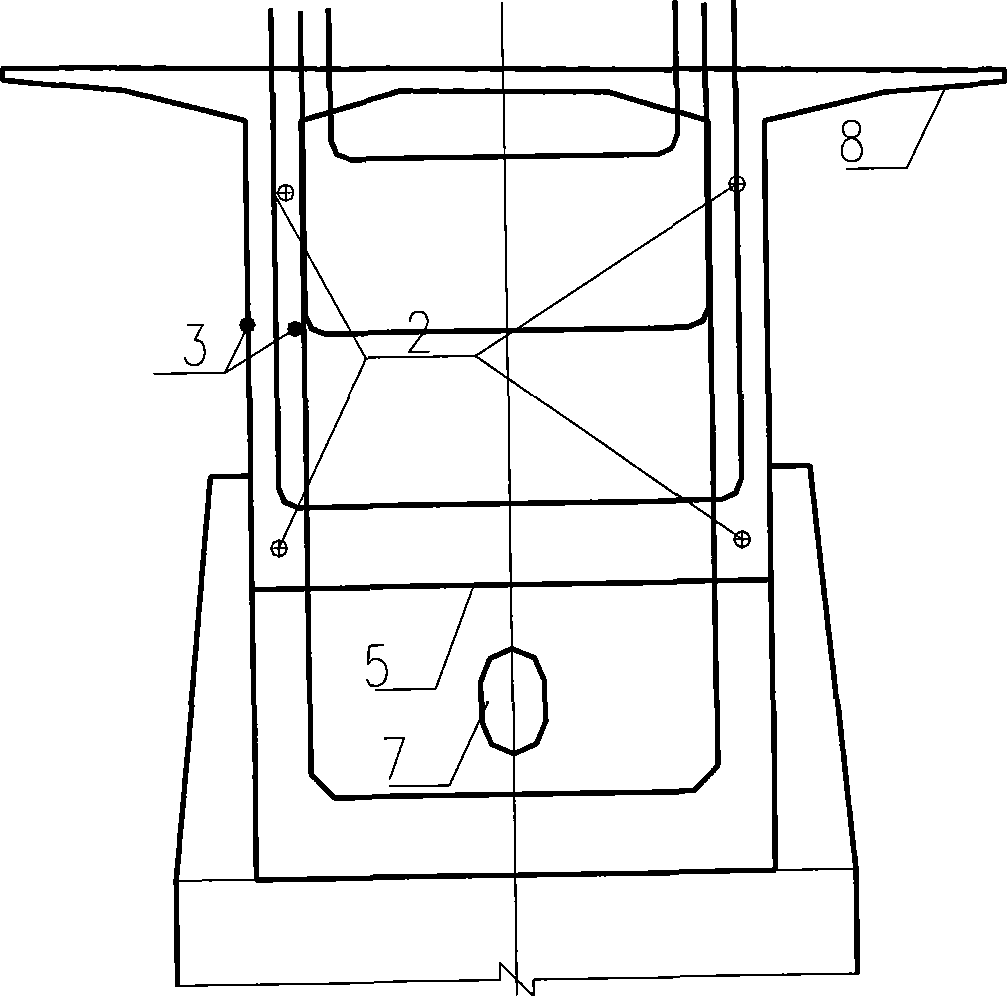

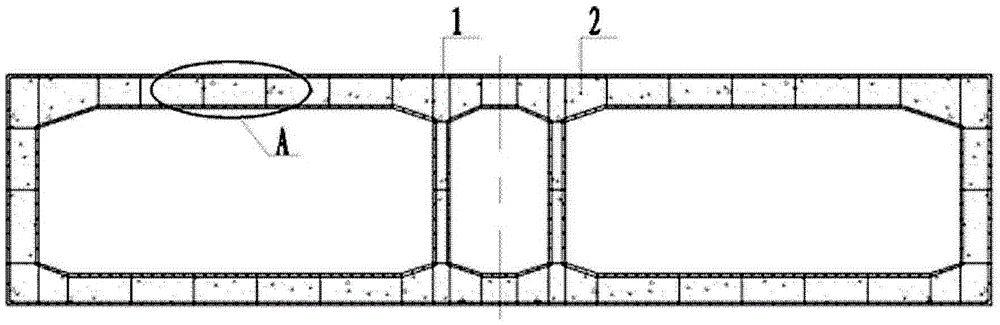

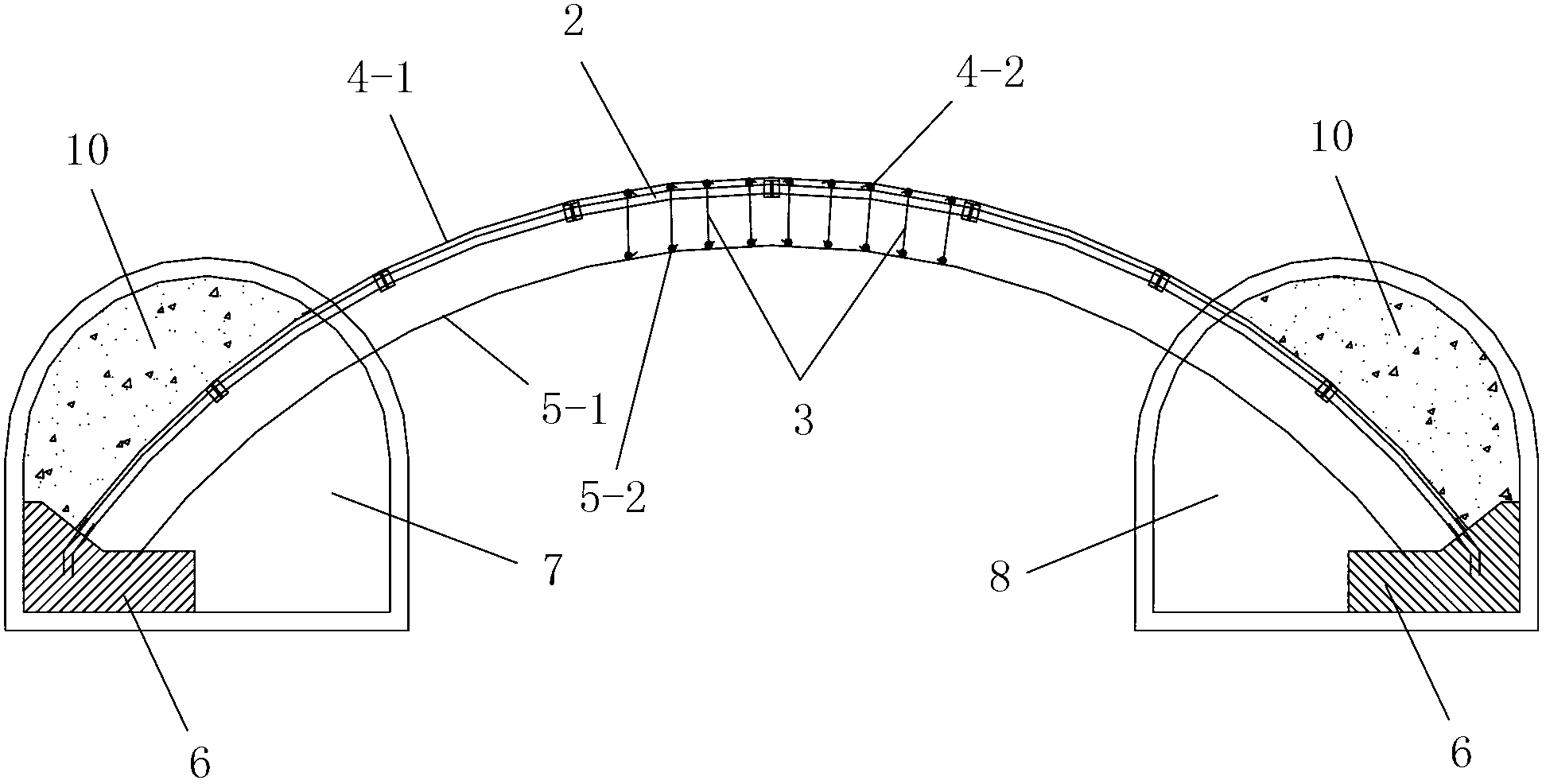

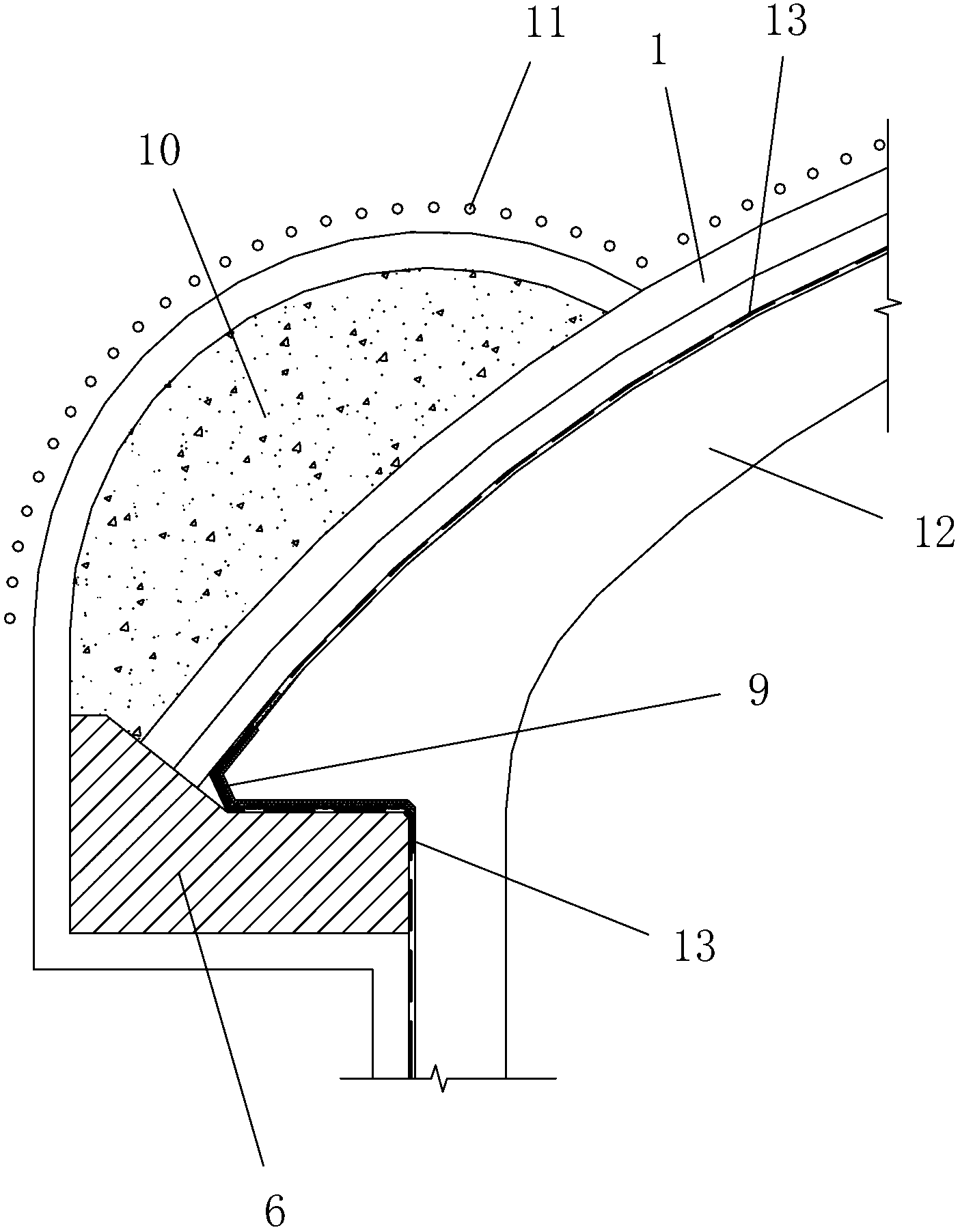

Construction method of large-span subway station main body by using arched cover method and station main body structure

ActiveCN102226403ASimplify construction stepsEasy constructionUnderground chambersSupporting systemArchitectural engineering

The invention discloses a construction method of a large-span subway station main body by using an arched cover method and a station main body structure. The construction method comprises the following steps: 1. making first-phase preparations; 2. excavating main body pilot tunnels at the left side and the right side, and carrying out primary support and top beam construction; 3. excavating a middle-part main body pilot tunnel, carrying out primary support and arch buckling construction, and refilling the earthwork; 4. carrying out earthwork excavation on a main body structure in the station, and prestressing force anchor cable construction; 5. carrying out secondary lining construction on the main body structure in the station; and 6. carrying out secondary lining and arch buckling construction on the station main body. The station main body structure comprises the main body structure in the station, a central post, a central plate and a main body arch part, wherein, the main body arch part comprises a middle arch fragment and two side arch fragments respectively arranged in the two side main body pilot tunnels formed by excavation in advance; and the main body arch part comprises a primary support system and a station main body arch buckling secondary lining structure from the outside to the inside. The station main body structure provided by the invention has reasonable design, simple construction steps, convenience in realization, small construction difficulty and rapid construction speed; the subway station formed by the construction method has a stable structure and a good use effect.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

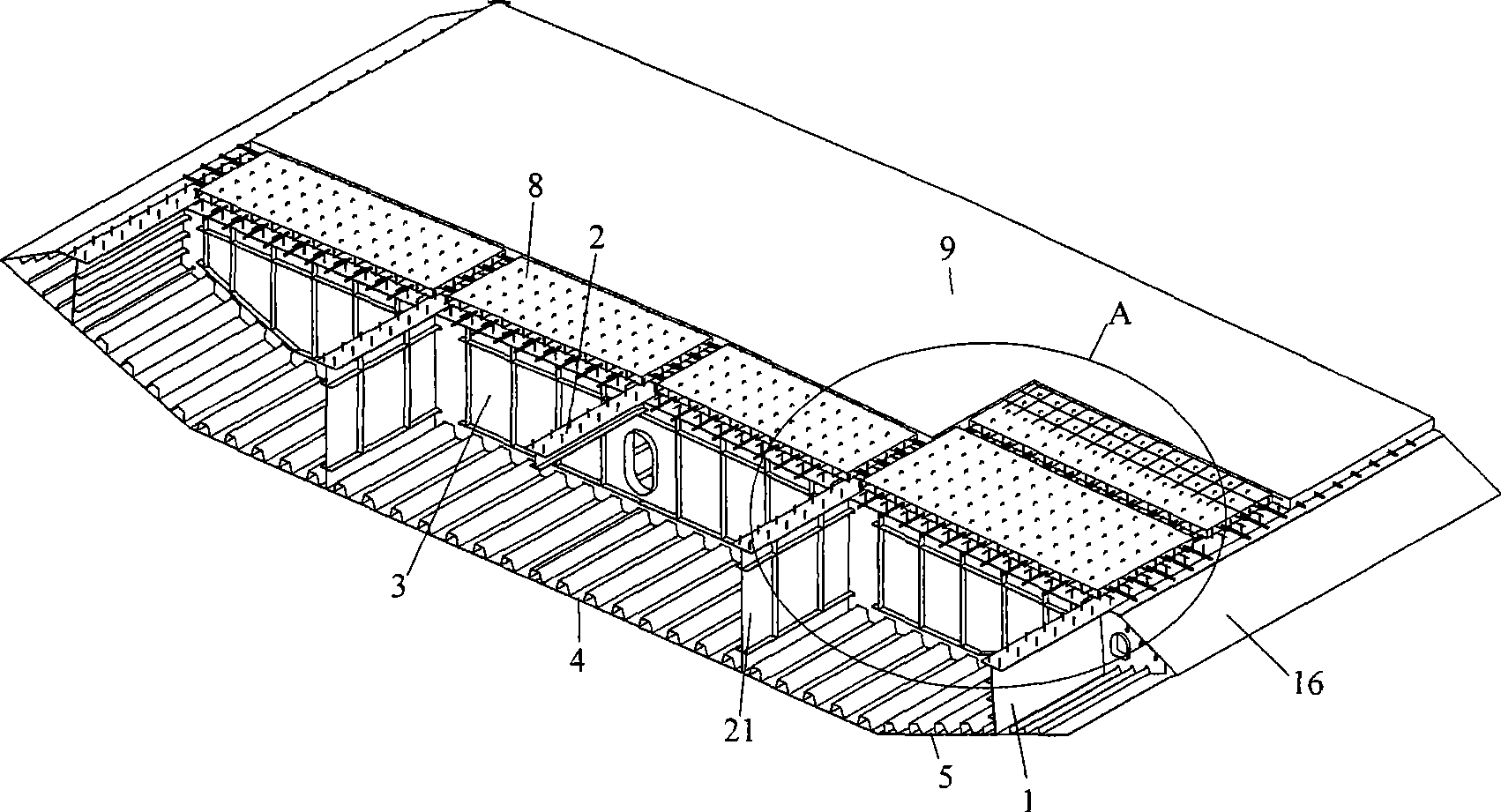

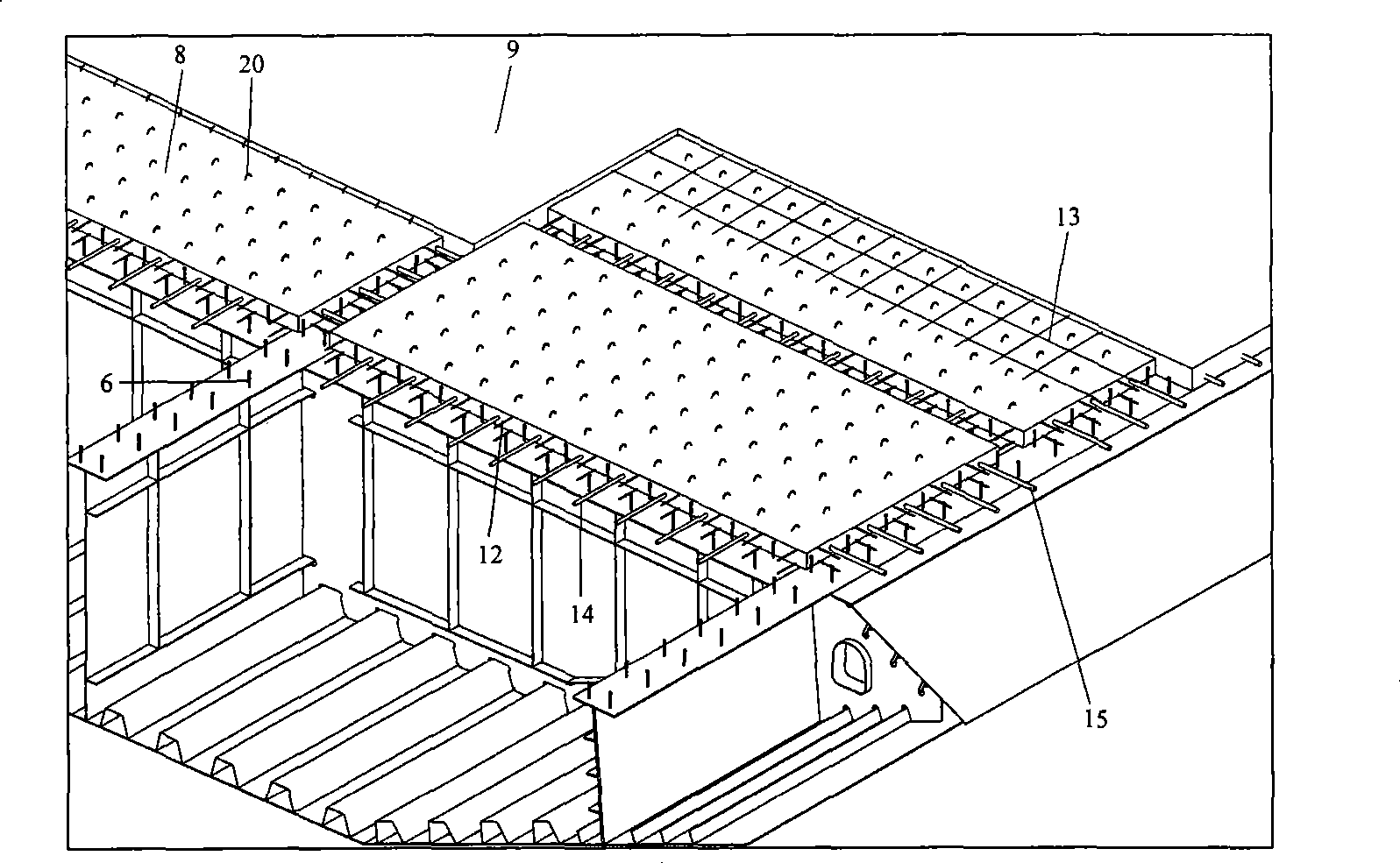

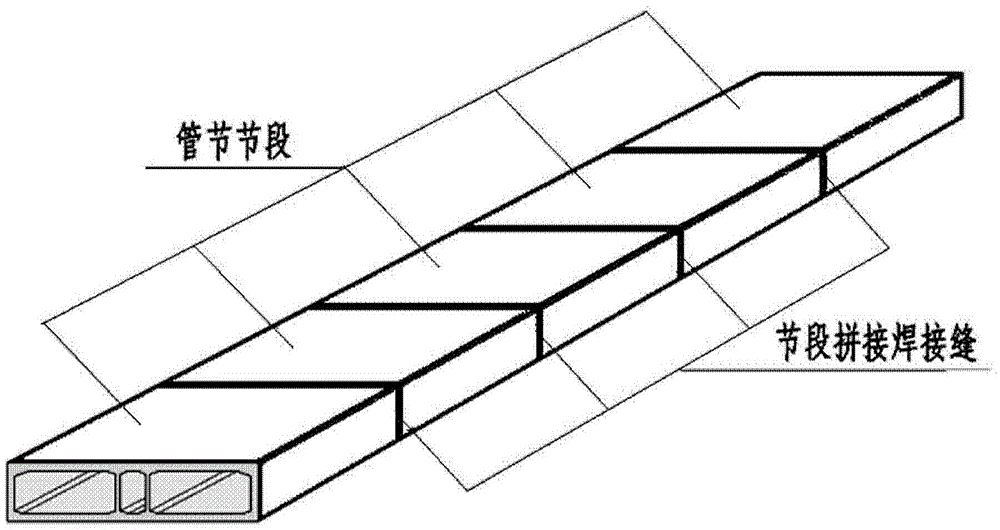

Three-truss main girder structure of highway and railway bi-purpose cable-stayed bridge and installation method thereof

ActiveCN101603288AImprove installation efficiencySave installation timeBridge erection/assemblyLoad-engaging elementsButt jointCable stayed

The invention relates to a three-truss main girder structure of a highway and railway bi-purpose cable-stayed bridge and an installation method thereof, relating to the technologies of designing and constructing a heavy load and long span highway and railway bi-purpose cable-stayed bridge. The structure of three main trusses comprises a middle truss piece and side truss pieces arranged on both sides of the middle truss piece, wherein an orthotropic slab and a transverse bracing truss are arranged between the upper edges of the middle truss piece and each side truss piece, and a railroad transverse girder, a railroad longitudinal girder and a horizontal bracing cross bridging are arranged between the lower edges of the middle truss piece and each side truss piece; and the invention provides the installation method adopting adaptive pre-splicing of multiple truss-sections, arrangement of temporary constructional rod pieces, integral lifting of each truss section and multi-node simultaneous alignment. The invention has the beneficial effects of: 1. pushing the highway and railway bi-purpose cable-stayed bridge to develop towards the direction of large span and heavy loading, 2. improving the installation efficiency and quality, 3. reducing the quantity of welding lines of construction sites, 4. innovatively practicing the multi-point simultaneous butt joint technology, 5. adopting the temporary rod pieces for solving the problems of unstability and large deformation in the processes of delivering and lifting the truss sections, 6. strengthening the adaptability of adjacent truss sections, and 7. solving the problems of inconsistent deformation of the middle and the side trusses and inconsistent centre-of-gravity positions of the truss sections.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD +1

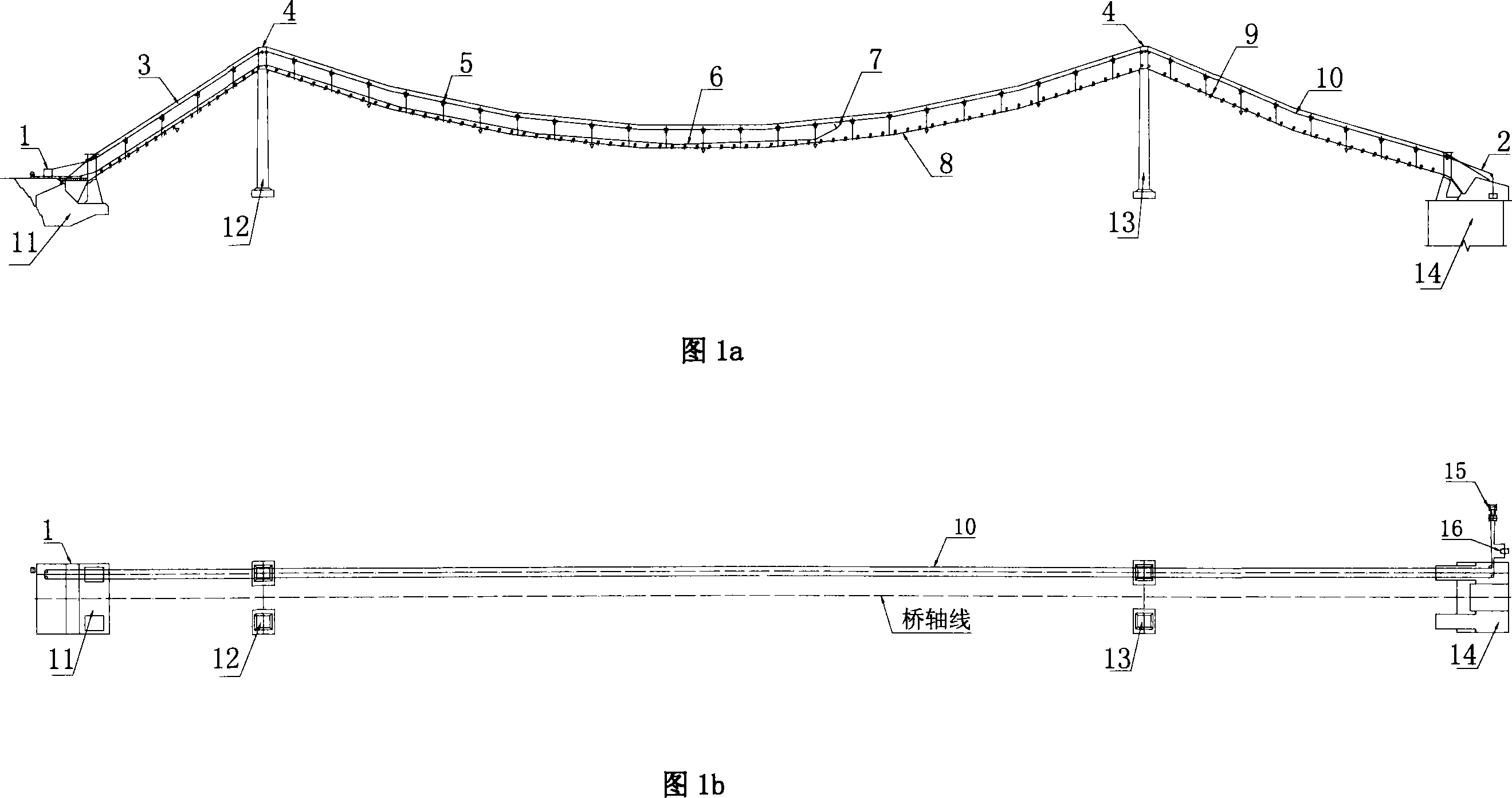

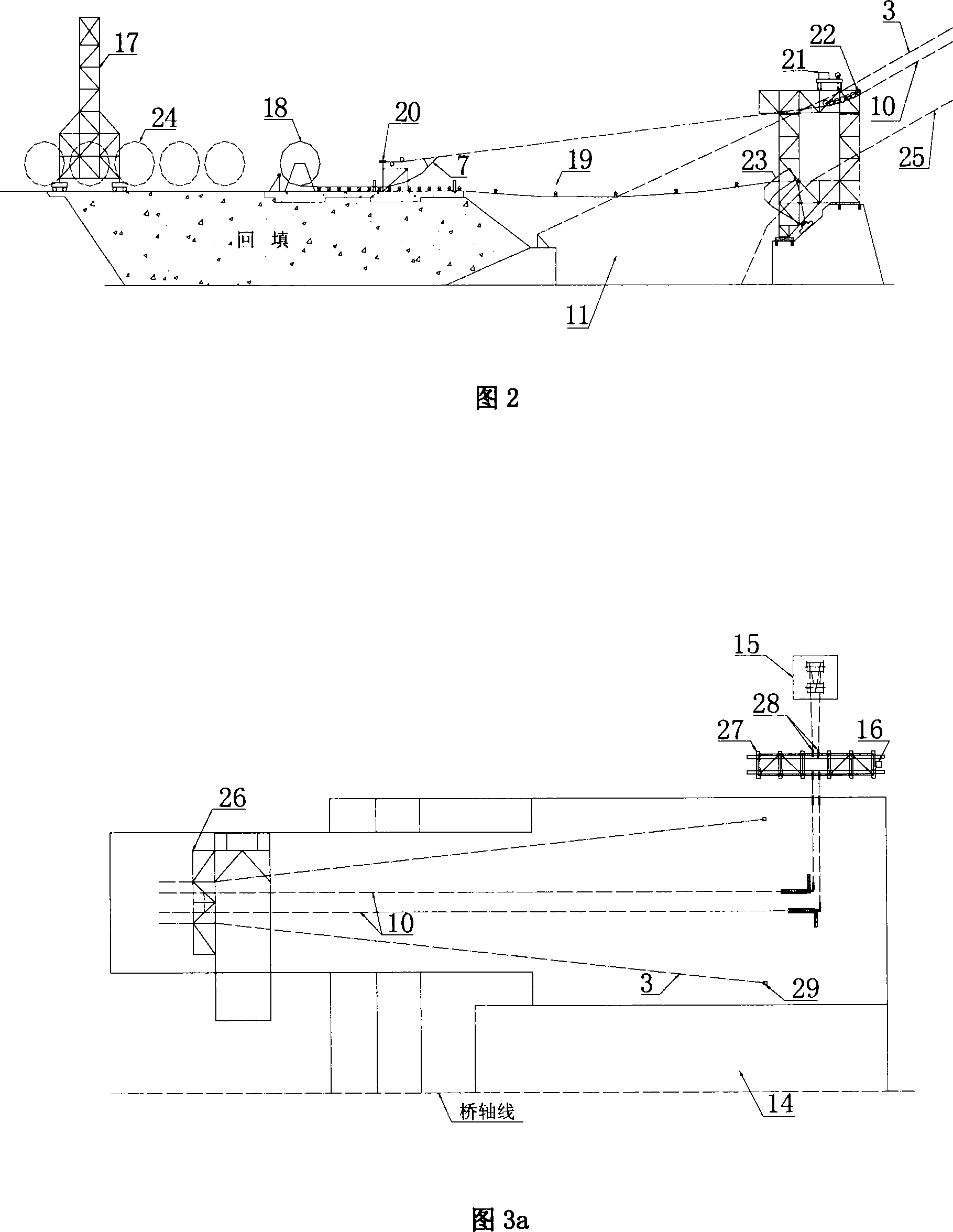

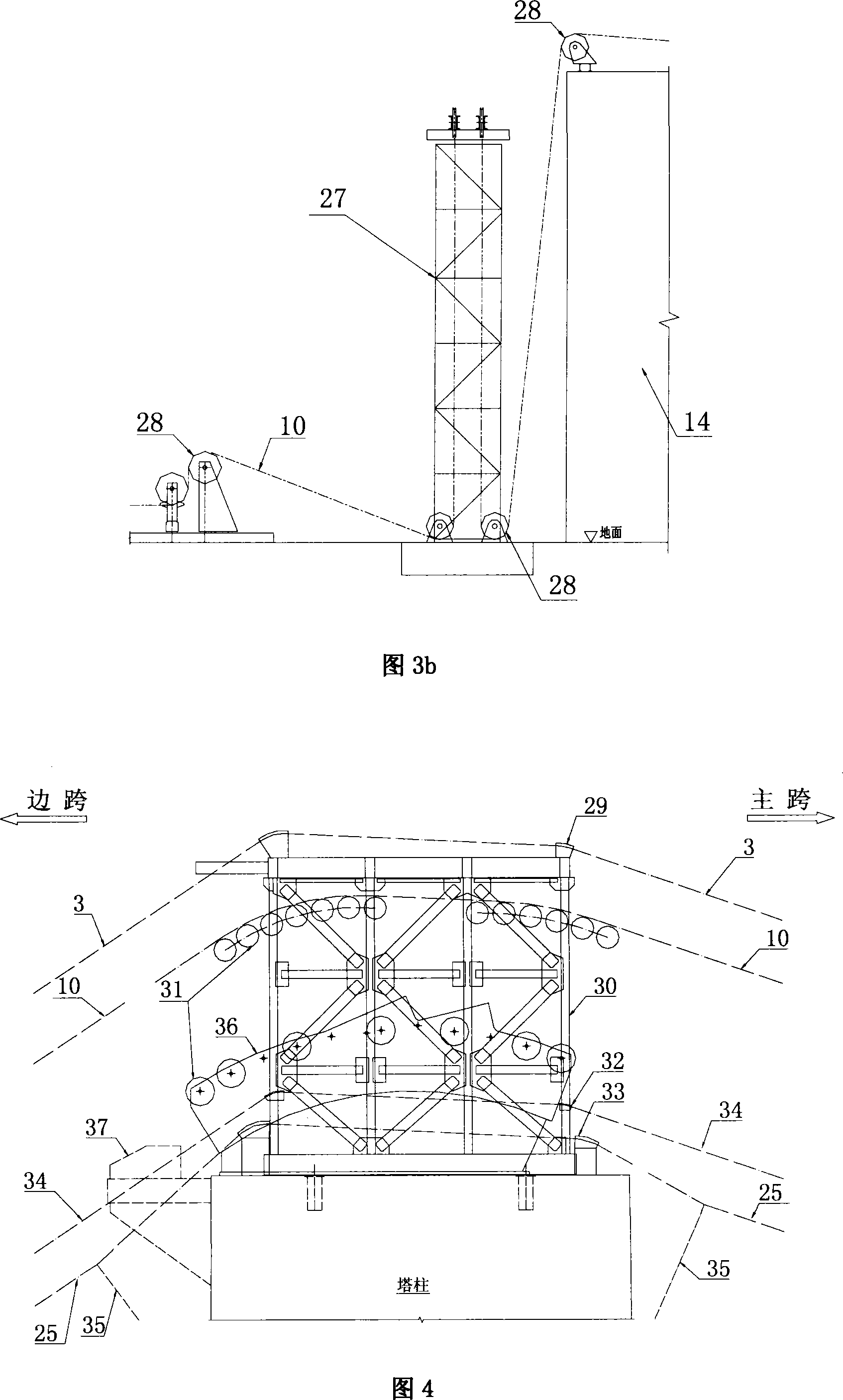

Erection of gantry type small-cycle traction system on large-span suspension bridge main cable

ActiveCN101177931AStable tractionImprove erection qualityBridge erection/assemblyTraction systemTraveling block

The utility model relates to a gantry type small circulation traction system for a main cable erection of a large-span suspension bridge, which belongs to the technical field of bridge superstructure construction. Set up a cable storage area behind the A anchorage, and install a 60-ton gantry crane and a cable-laying bracket; set up a traction cable revolving wheel behind this anchorage; set up a 25-ton main traction hoist and a balance weight bracket on the side of the B anchorage. The traction cable is connected by a puller at Anchor Anchor, bypasses the hoist drum at B Anchor Anchor, and is inserted through the balance weight bracket and each steering block to form a ring-shaped endless cable. Make a horizontal circular motion to form an independent small circular traction system. The small circulation system has the advantages of high power, large traction force, high construction efficiency and low cost.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

Streamline steel-concrete folding case beam

InactiveCN101413247AIncreased torsional stiffnessImprove wind resistanceBridge materialsBridge engineeringCable stayed

The invention discloses a streamlined steel-concrete superimposed box girder, which relates to the technical field of bridge engineering and is used for a long-span bridge girder. Two sides of the superimposed box girder are provided with tuyere structures, and a bridge panel adopts a superimposed structure consisting of prefabricated concrete slabs and a post-poured concrete layer. When the box girder is in use, the superimposed box girder is a streamlined single-box single-chamber or single-box multi-chamber cross section; the tuyere structures are polygonal open thin-walled structures; and longitudinal-transverse prestress is applied in the superimposed bridge panel. The box girder effectively improves the torsional rigidity and wind-resistant stability of the section of the girder, remarkably improves the integrity and durability of the bridge panel, and expands the application of superimposed girders in cable-stayed bridges and other long-span bridges.

Owner:CCCC HIGHWAY CONSULTANTS

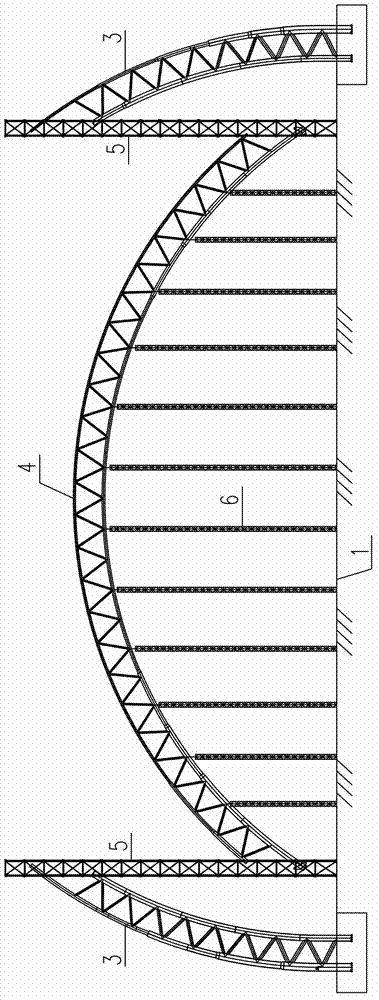

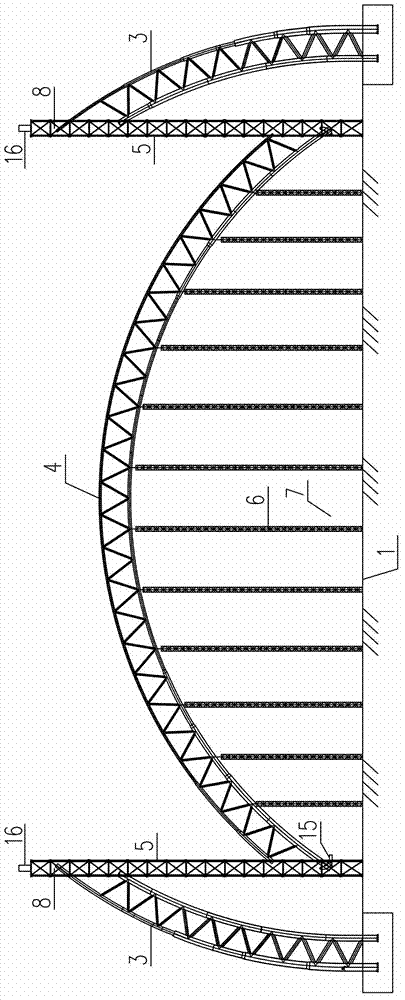

Construction method for lifting arch structure in zero-deformation state

ActiveCN102777043AReduce or even eliminate horizontal thrustHigh precisionArched structuresVaulted structuresButt jointArchitectural engineering

The invention discloses a construction method for lifting an arch structure in a zero-deformation state. The construction method specifically comprises the following steps: 1, sectioning a large-span arch structure into floor arch structures and a lifting construction unit; 2, building up a support bed jig, splicing and assembling the lifting construction unit in situ and simultaneously installing the floor arch structures; 3, installing horizontal steel strands, horizontal jacks and tensioning the horizontal jacks to tension the horizontal steel strands; 4, building up lifting frames, installing lifting jacks and vertical lifting steel strands; 5, alternately tensioning the horizontal steel strands and the vertical lifting steel strands level by level so that the lifting construction unit is separated from the support bed jig; 6, lifting the lifting construction unit to a preset height to be in butt joint with the floor arch structures at two sides, thus forming the large-span arch structure; and 7, unloading and disassembling the horizontal jacks, the horizontal steel strands, the lifting jacks, the vertical lifting steel strands and the lifting frames level by level to finish the construction. The construction method has the advantages of high construction accuracy, high quality, reliable safety and low-cost construction measures.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

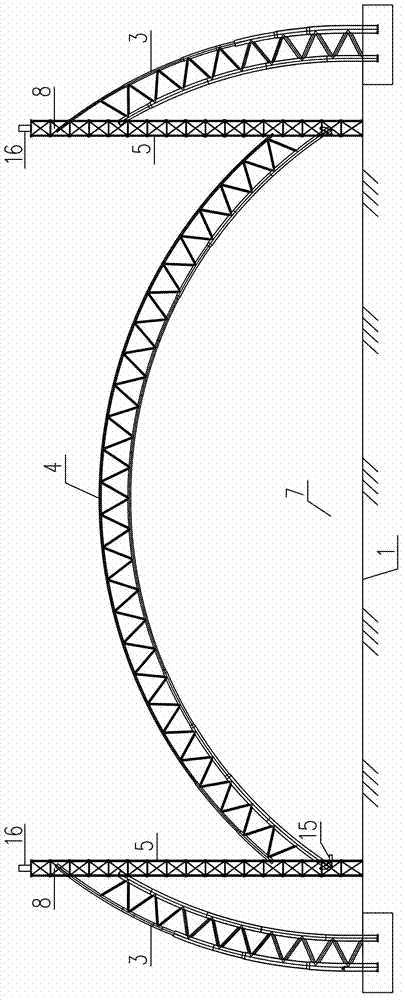

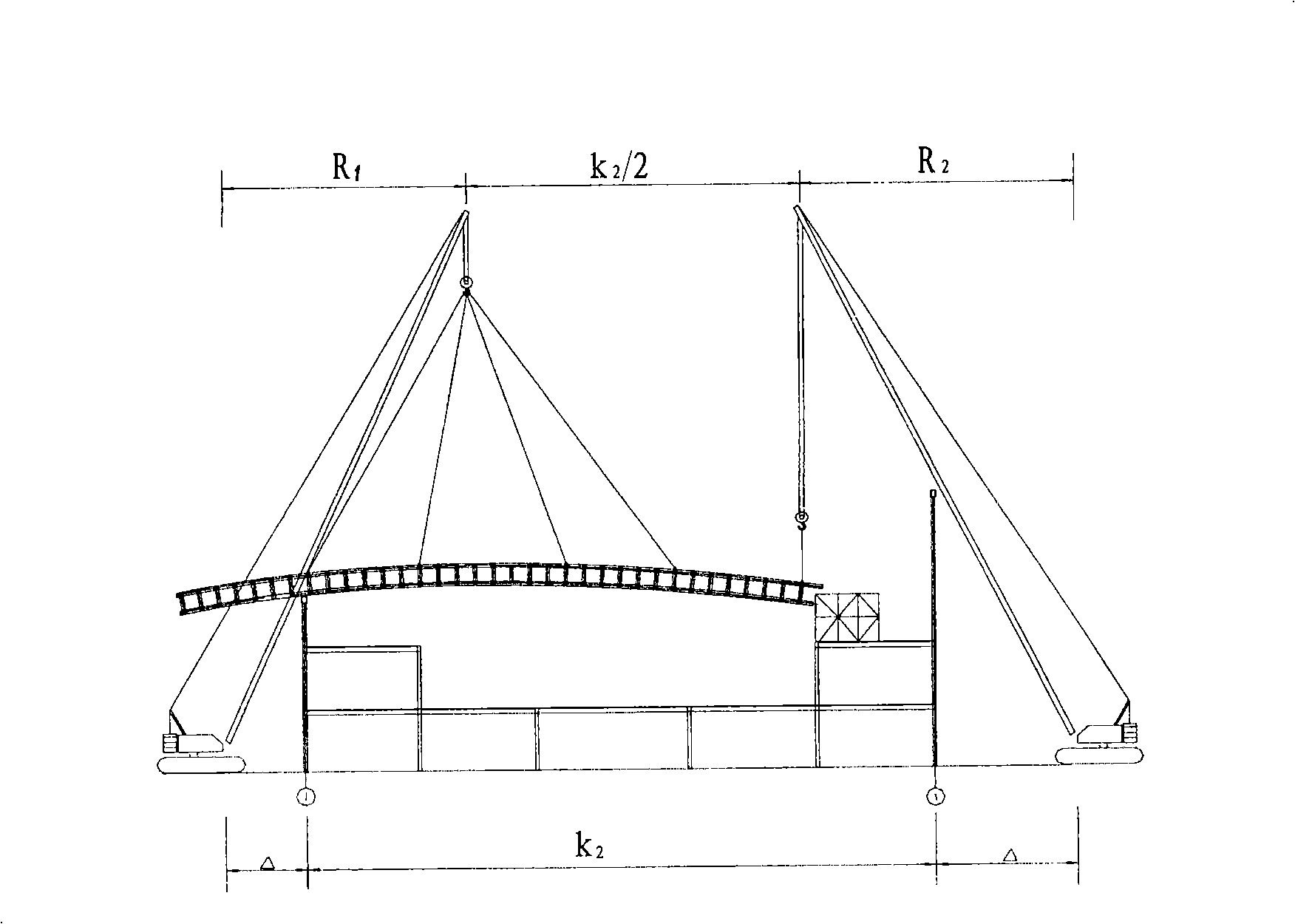

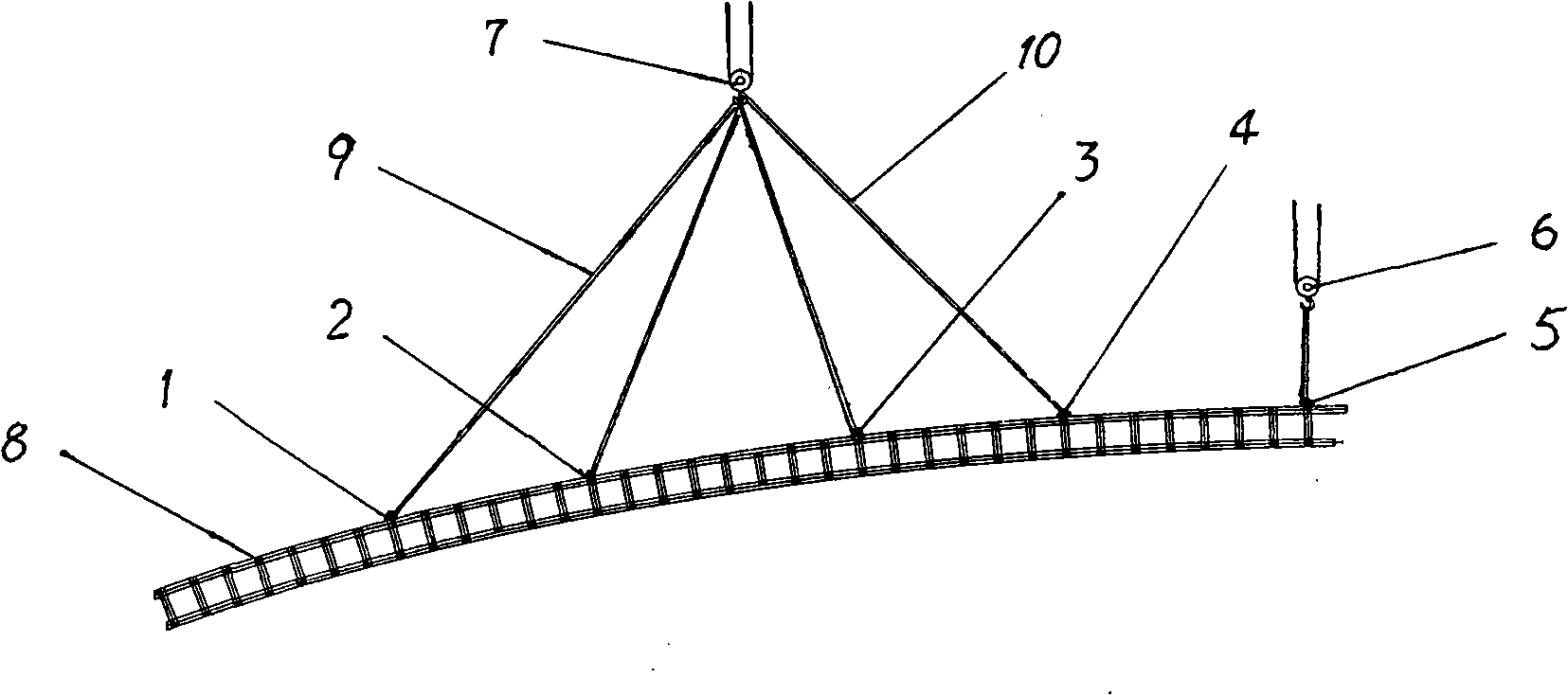

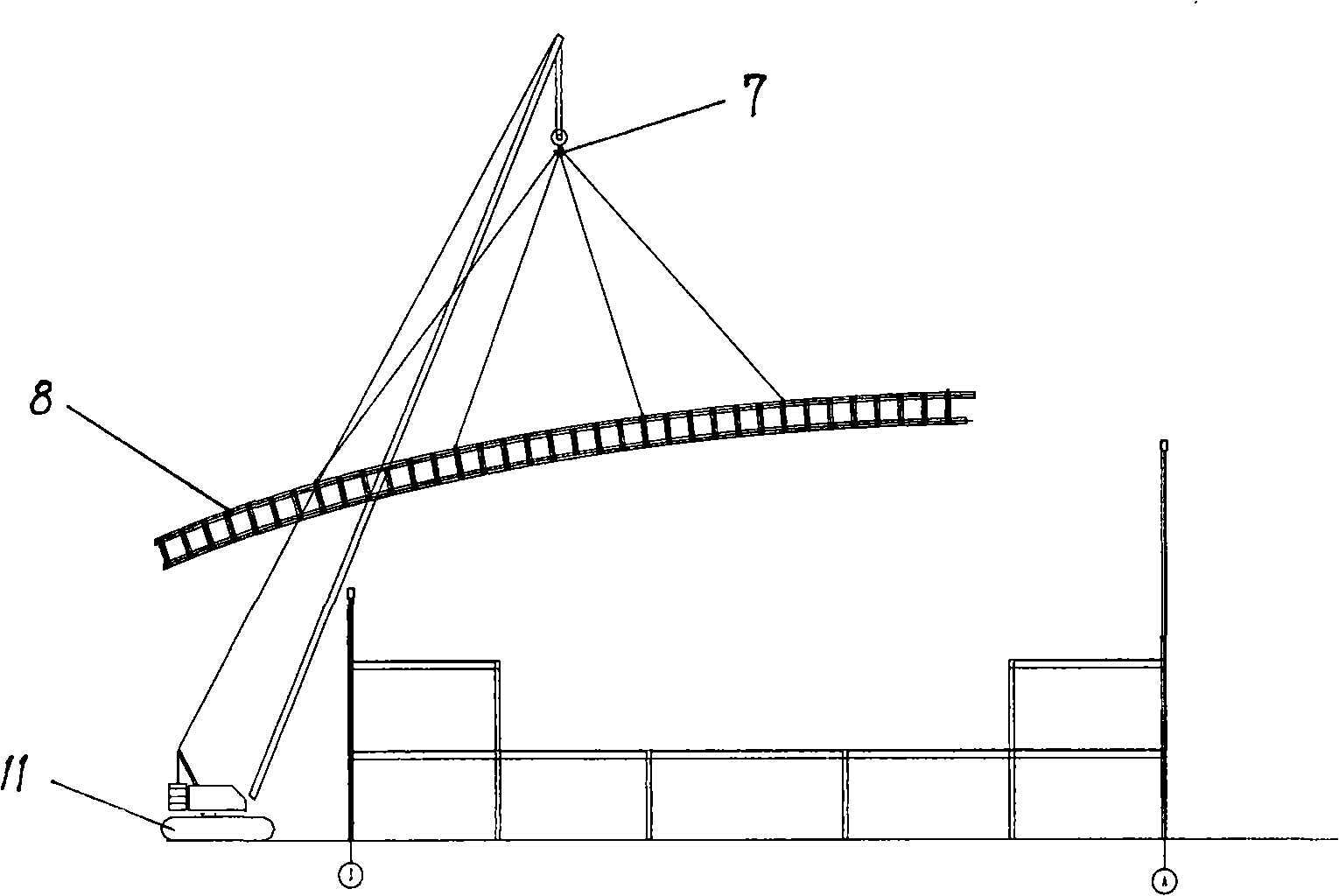

Construction method for hanging wide span arcuated open-web beam

InactiveCN101324146ASolve lifting problemsIncrease spanBuilding material handlingSpandrelStructural component

The invention relates to a large-span arc laced beam hoisting construction method used for constructing an ellipsoid roof. The method comprises the steps that a main crane hoists in a stand-alone way at one side beyond the span and delivers the laced beam to be within the span, one end of the laced beam is hoisted by an assistant crane beyond the span at the other side of a building, and dual-machine lifting and hoisting is formed by hoisting point shifting on the laced beam so as to jointly hoist and position the laced beam. The invention is a brand new dual-machine delivering lifting and hoisting construction method, and solves the hoisting problem of the large-span steel structure laced beam under special conditions that a construction field can not be provided within the span of the building, the dual-machine lifting and hoisting can not be carried out due to the obstruction of the running line of the cranes at the two sides of the building, and a gliding method can not be used for hoisting, etc., and the span of a hoisting structural component can be greatly improved, thus improving construction safety, guaranteeing construction quality and shortening construction period.

Owner:HEBEI CONSTR GRP

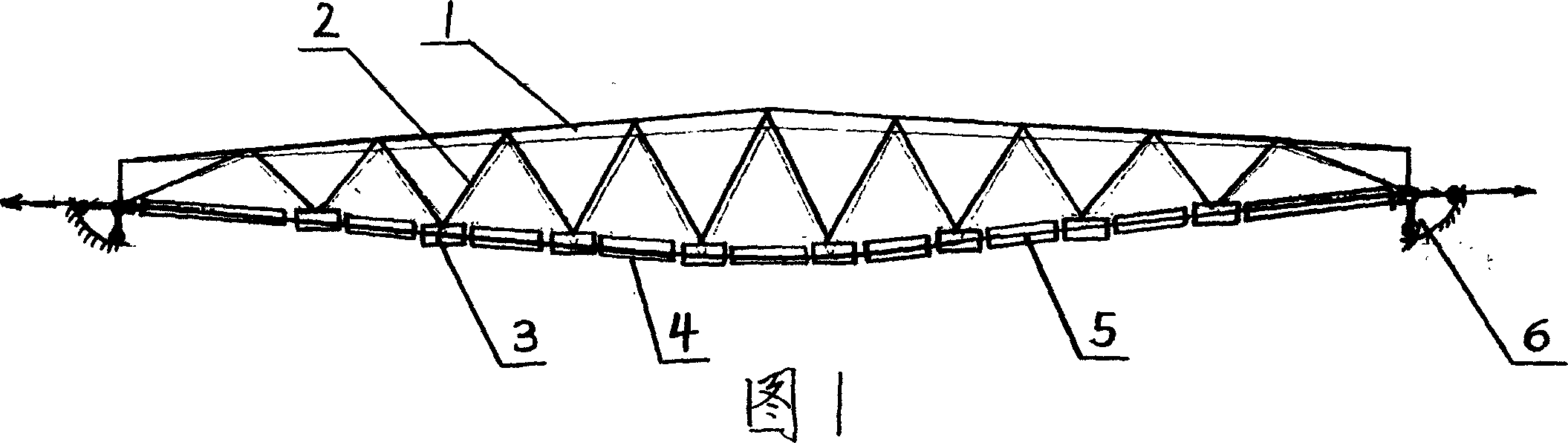

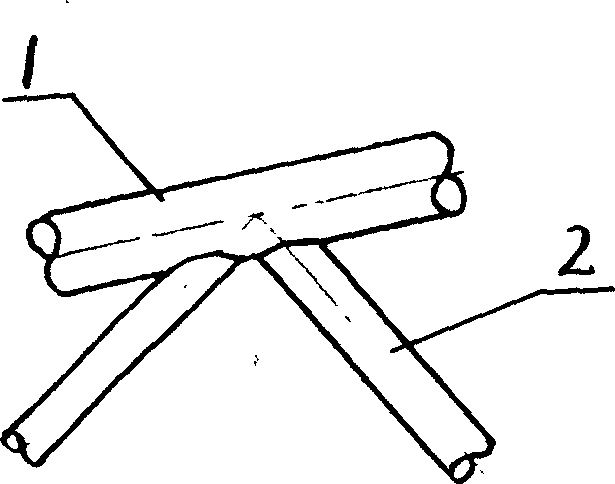

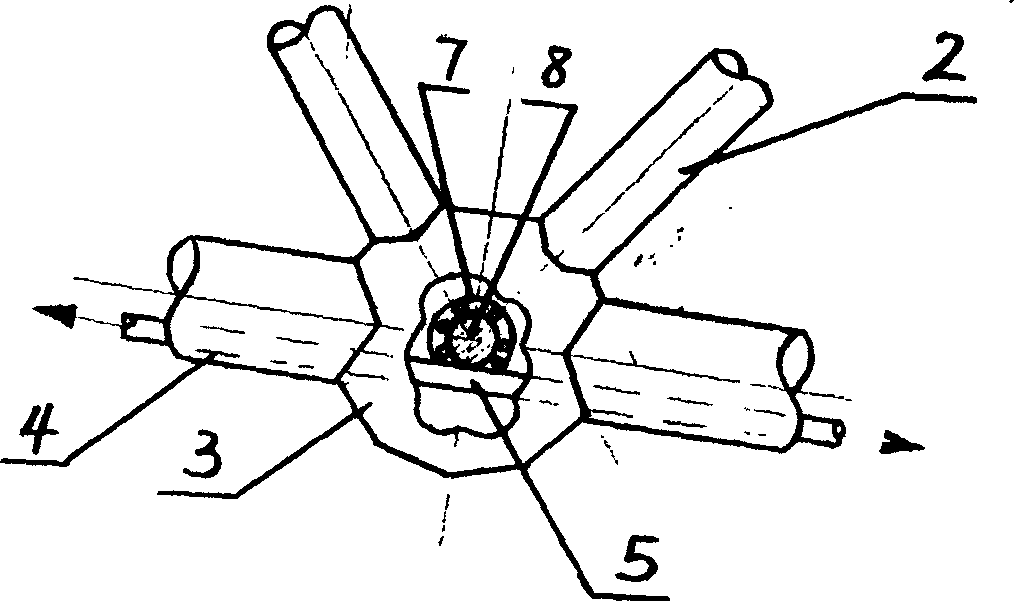

Method for fabricating new type tension chord truss frame in large span

InactiveCN1563626ARelieve pressureReduce the amount of structural steel usedGirdersJoistsArchitectural engineeringLong span

This is a method used to produce long span spread chord truss. It contains: To weld the belly rod on the upper spread chord rod, put the formed upper chord rod on the wording platform, fix the two ends of this chord rod on the fixed seat, then connect lower end of the belly rod with cover joint pipe, and between two cover pipes beforehand put a lower chord steel pipe. The steel rope pierce through every joint cover pipe and every lower chord steel pipe, then to spread out the steel rope, on the steel rope at the spreading straight, state weld every lower steel pipe with every joint cover pipe, keep the steel rope spread out straightly, then loose the two ends of the upper chord rod from platform, then long span spread chord truss is finished.

Owner:GUIZHOU UNIV

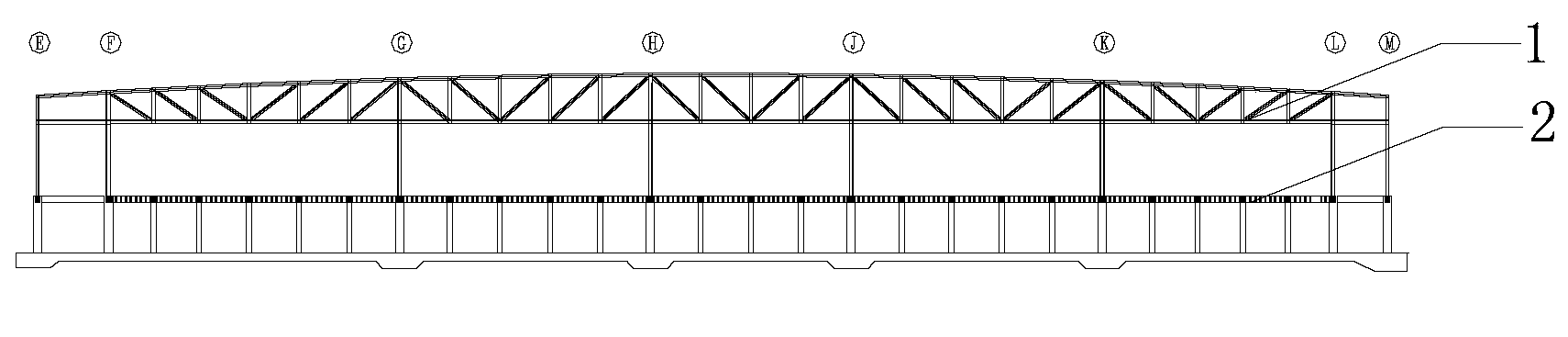

Whole high-cleanliness electronic plant steel structure slippage and detachment method

ActiveCN103806658AImprove construction efficiencyImprove construction safetyBuilding material handlingSynchronous controlEngineering

The invention discloses a whole high-cleanliness electronic plant steel structure slippage and detachment method. A construction route of the ground assembly of a single truss, the aerial assembly and accumulative slippage of a slippage unit, the whole slippage of the slippage unit, and the synchronous detachment of the slippage unit is adopted, a long-span and large plant steel structure is mounted in high altitude above two layers of wafer boards. The method is characterized by comprising the following steps of a, the confirmation of a slippage and detachment scheme and the simulating calculation of the slippage and the detachment of the slippage unit; b, the accumulative slippage and the whole slippage construction of the slippage unit; c, the synchronous detachment and construction of the slippage unit in batches and in levels; d, the synchronous control on the whole slippage and detachment of the steel structure. By using the whole high-cleanliness electronic plant steel structure slippage and detachment method, the problems that a large-size crane cannot enter a hoisting field and reserved holes of wafer board floors, and the circumjacent construction plant of the field is limited are solved, the construction efficiency is greatly improved, the construction safety is ensured, and the engineering construction cost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

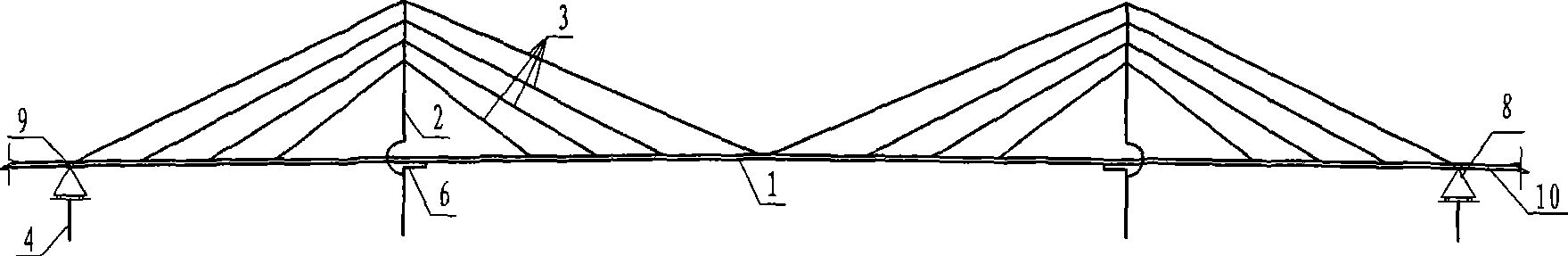

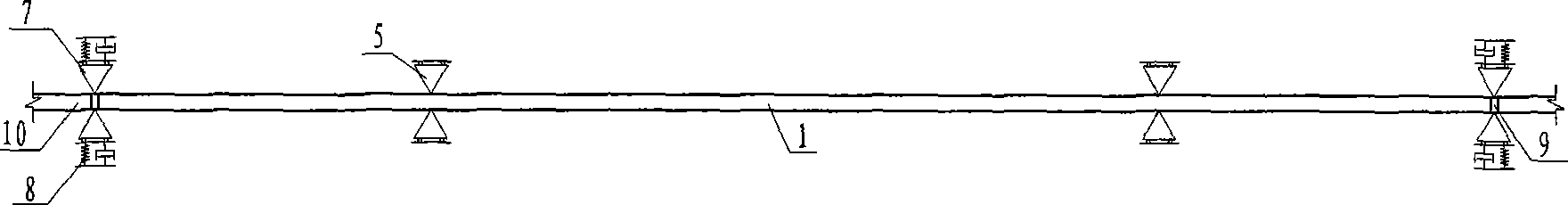

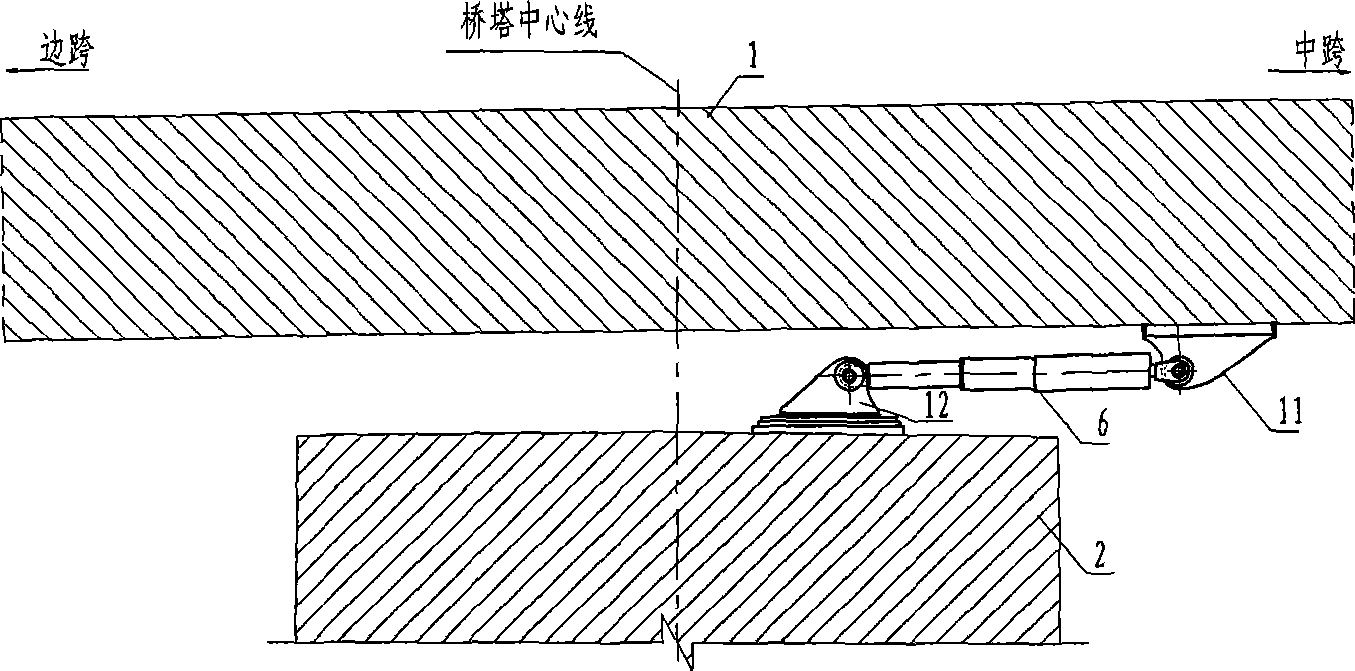

Supporting system of long span stayed-cable bridge

InactiveCN101424071AReduce beam end displacementReduce bending momentCable-stayed bridgeBridge engineeringSupporting system

The invention discloses a support system for a long-span cable-stayed bridge, which relates to the technical field of bridge engineering. The support system consists of nine parts including main girders, bridge towers, stay cables, transitional piers, transverse wind resisting bearings, longitudinal viscous dampers with limiting function, longitudinal sliding bearings with limited transverse rigidity, transverse dampers, and telescopic devices. Compared with the prior support system for the long-span cable-stayed bridge, the support system of the invention has the characteristics that the longitudinal viscous dampers with limiting function are arranged between the main girders and the bridge towers; and the longitudinal sliding bearings with limited transverse rigidity and the transverse dampers are arranged between the main girders and the transitional piers. The support system provides effective rigidity and damping for the long-span cable-stayed bridge to ensure that the static force and the dynamic force responses of the bridge are controlled in an acceptable scope; the structural stress is definite; and the applicability is strong.

Owner:CCCC HIGHWAY CONSULTANTS

Thermal treatment wire rod for 2000MPa-grade cable steel wire and production method

ActiveCN107299280AImprove mechanical propertiesImprove uniformityQuenching agentsWire rodSpecial design

The invention provides a thermal treatment wire rod for a 2000MPa-grade cable steel wire and a production method. The thermal treatment wire rod is prepared from the following components in percentage by weight: 0.85 to 1.0 percent of C, 0.80 to 1.5 percent of Si, 0.30 to 0.80 percent of Mn, 0.20 to 0.80 percent of Cr, less than or equal to 0.015 percent of P, less than or equal to 0.010 percent of S, 0.01 to 0.08 percent of Al, and the balance of Fe and inevitable impurities. According to the thermal treatment wire rod for the 2000MPa-grade cable steel wire and the production method disclosed by the invention, through special design of the components, the wire rod is produced through processes of smelting, continuous casting, blank casting and grinding, steel rolling and off-line thermal treatment, and the sorbitizing rate of the wire rod is greater than 95 percent, tissues are homogenized, and quenching tissues such as network carbide and martensite are avoided. After the wire rod is subjected to drawing, zinc (aluminum) plating, and stabilization treatment, the strength of the steel wire is greater than or equal to 2000MPa, so that the wire rod can be used for producing the 2000MPa-grade cable zinc (aluminum) plating steel wire for bridges, and is applied to bridges requiring extra long-span and ultrahigh strength.

Owner:QINGDAO SPECIAL STEEL CO LTD

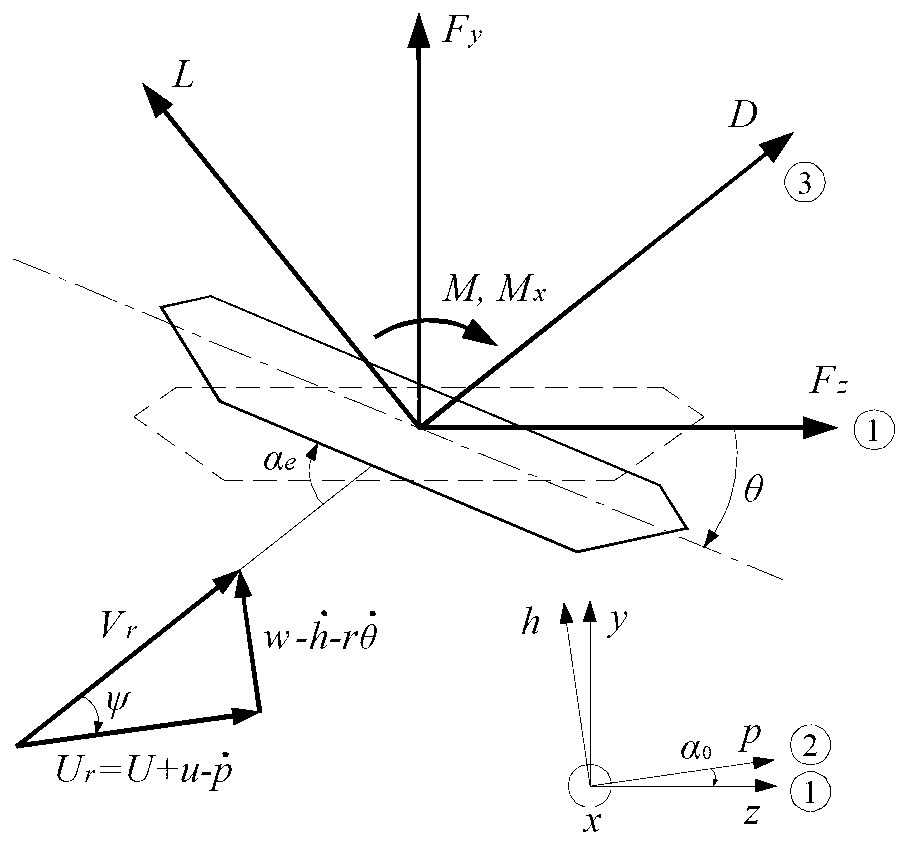

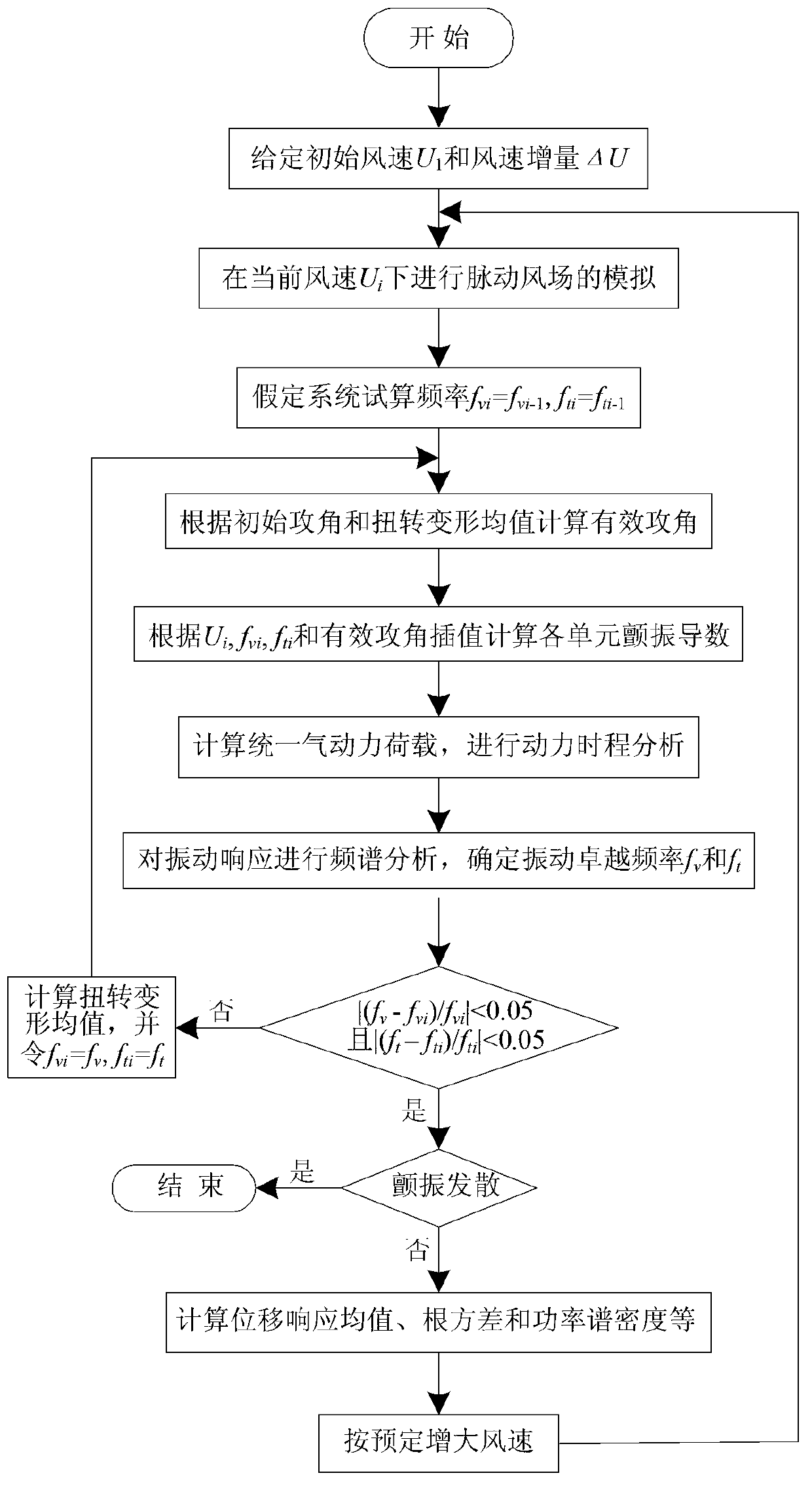

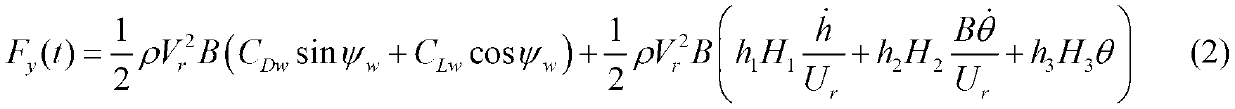

Simulation method of wind-induced disaster whole process of long-span bridge

ActiveCN103218481AColumnar is simple and intuitiveHigh precisionSpecial data processing applicationsElement modelSelf excited

The invention provides a simulation method of a wind-induced disaster whole process of a long-span bridge. The simulation method comprises the steps of making the aerostatic coefficients, an effective instant wind attack angle and the relative wind speed integrally working on an aerodynamic force of a main beam, and then carrying out unsteady correction on self-excited force components in the aerostatic coefficients, the effective instant wind attack angle and the relative wind speed; applying aerodynamic force load to a finite element model for carrying out dynamic-history calculation, and carrying out iteration of torsion base frequency and vertical-curve base frequency in different wind speeds; and judging the steady state of a bridge structure under a certain wind speed according to displacement response. According to the simulation method provided by the invention, the integrated calculation of calm-wind instability, buffering and flutter is realized, the defect of independent calculation in traditional wind vibration calculation is overcome, and the accuracy of bridge wind vibration calculation is increased.

Owner:SOUTHEAST UNIV

0 type block anti-cracking construction method of high pier large across creeping formwork

InactiveCN101413251AControl temperature stressAvoid it happening againBridge erection/assemblyTemperature controlTemperature stress

The invention discloses a No. 0 block anti-cracking construction method for high-pier long-span continuous rigid frame bridges. Concrete is poured twice on a pier top platform, wherein the concrete is poured to a height between 0.3 and 0.6 time that of a web plate in a first step; the rest concrete is poured in a second step; and the age of two layers of concrete is controlled within 15 days. The construction method comprises the following steps of: a. preparing for construction; b. installing a cooling water pipe and a temperature sensor; c. setting up a heat preservation shed; d. pouring the concrete, providing the poured concrete with water for temperature reduction through the cooling water pipe, controlling the temperature of the heat preservation shed to preserve heat and pouring low-heat cement; and e. stretching a temporary prestressing tendon. When a second bin of concrete is poured, the temporary prestressing tendon is arranged. The construction method adopting the combined use of temperature control and the temporary prestressing tendon can effectively control temperature stress in the concrete, and can prevent harmful cracks from being produced.

Owner:CHINA GEZHOUBA GROUP CO LTD +1

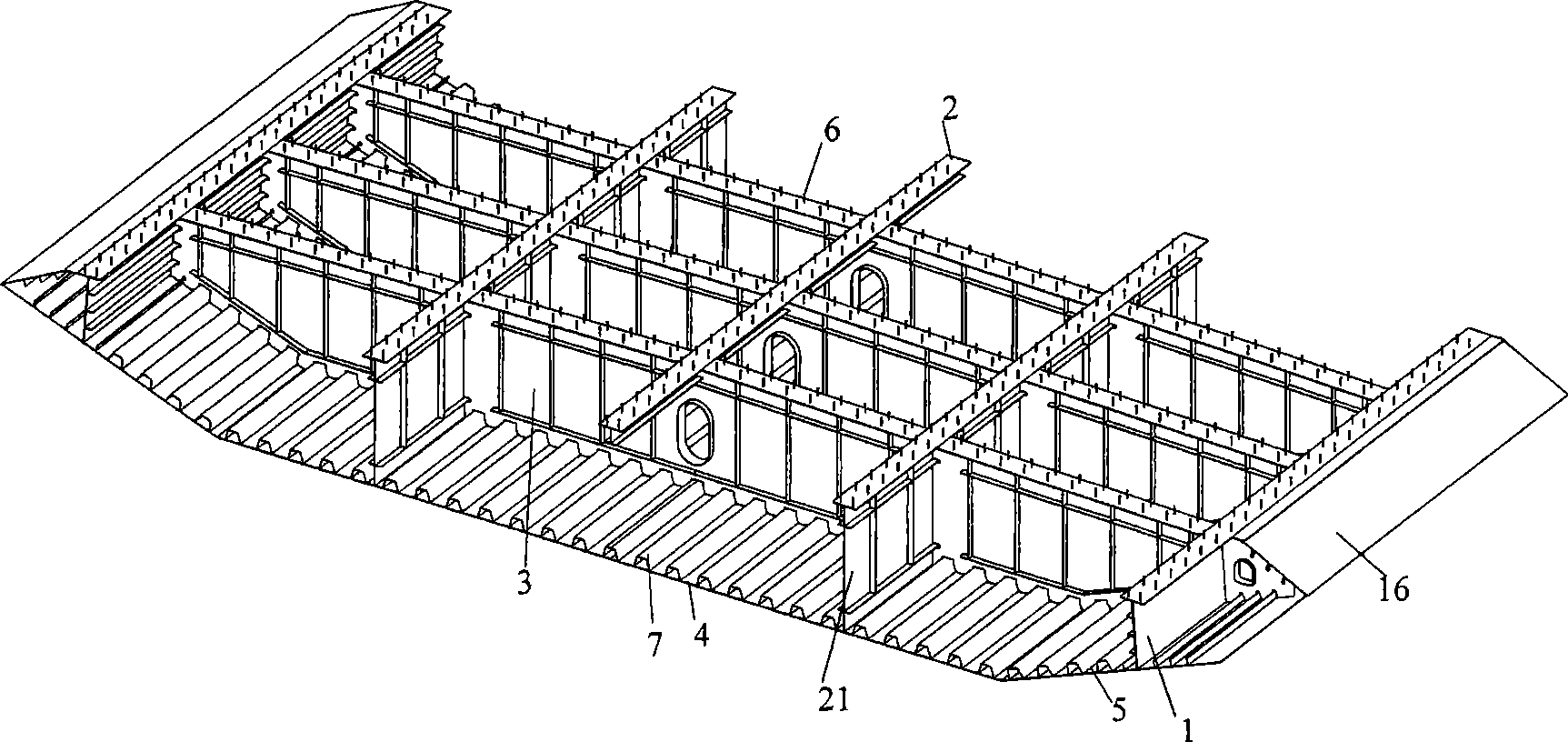

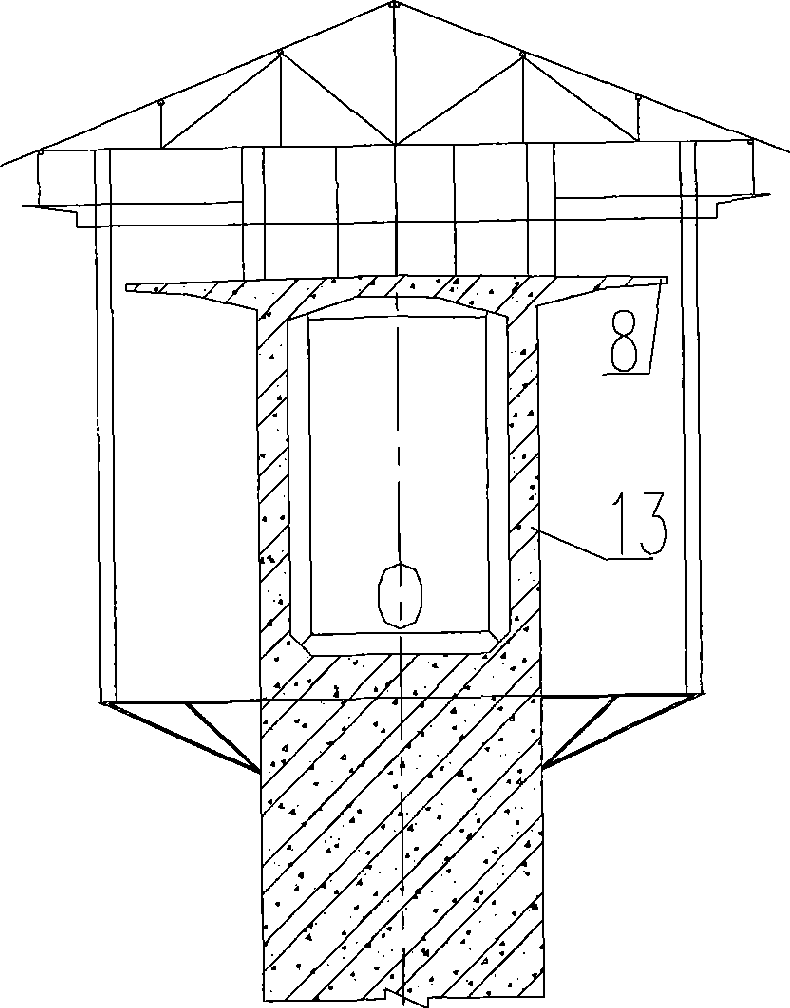

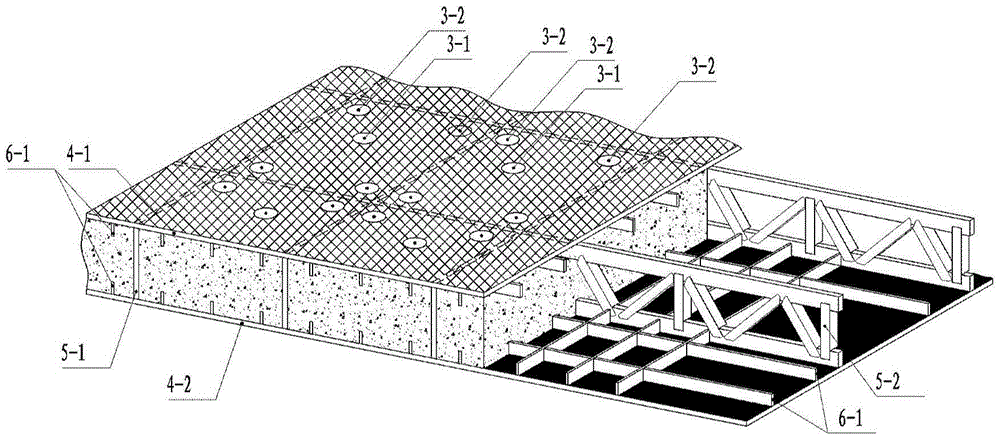

Pipe-joint steel shell and concrete combined structure for immersed tunnel and manufacturing method thereof

ActiveCN105544608AHigh strengthIncrease stiffnessArtificial islandsUnderwater structuresSheet steelShock resistance

A pipe-joint steel shell and concrete combined structure for an immersed tunnel comprises a steel shell structure (a cavity) and concrete. The steel shell structure is filled with the concrete and composed of an inner side steel plate and an outer side steel plate. Transverse and longitudinal reinforced ribbed plates are welded to the surface of an inner cavity of the inner side steel plate and the surface of an inner cavity of the outer side steel plate so that the strength and rigidity of the shell can be enhanced. Transverse and longitudinal steel partition plates or steel trusses are connected with the inner and outer side steel plates so that the inner and outer side steel plates can be of an integrated structure. The shell is filled with the concrete so as to improve the overall rigidity and strength of the pipe joint structure. The invention further discloses a manufacturing method of the pipe-joint steel shell and concrete combined structure for the immersed tunnel. By means of the combined structure of the external steel shell and the concrete arranged in the steel shell in a filling mode, the overall rigidity, strength, waterproofness, durability and shock resistance of the pipe joint structure can be improved, and the pipe-joint steel shell and concrete combined structure is applicable to long-span immersed pipe joint structures on the conditions with high water pressure and large embedding depth and immersed pipe joint structures under other special demands.

Owner:CCCC HIGHWAY CONSULTANTS

Strengthening concrete frame structure and construction method thereof

InactiveCN101845850AImprove fire performanceImprove mechanical performanceBuilding material handlingReinforced concreteSteel bar

The invention relates to a strengthening concrete frame structure. A frame column is formed by integrally pouring a stem steel rib and peripheral column reinforced concretes, wherein the concrete is poured inside the stem steel rib; studs which are vertical to the steel rib are arranged on the periphery of the stem steel rib; the stem steel rib is embedded in the column reinforced concrete structure; the reinforced steel bar in the column reinforced concrete structure comprises a stud, a column stirrup and a drag hook; the beam tendons at the upper part of a beam column joint are a main penetration tendon and a column winding tendon; when the upper column winding tendon passes by the stem steel rib in the frame column, the column winding tendon is bent outwards at a gradient of 1: 6; and when the upper main penetration tendon penetrates a reserved hole on the stem steel rib in the frame column, one end of a lower beam tendon is anchored in the column reinforced concrete structure or is bent upwards. The invention solves the problems that the reinforcing steel bar in the steel rib-concrete structure beam column joint areas is difficult to penetrate the stem steel rib, the concrete is inconvenient to pour and vibrate and the pouring effect is inferior. The structure of the invention can be widely applied to a long span high-rise frame structure.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

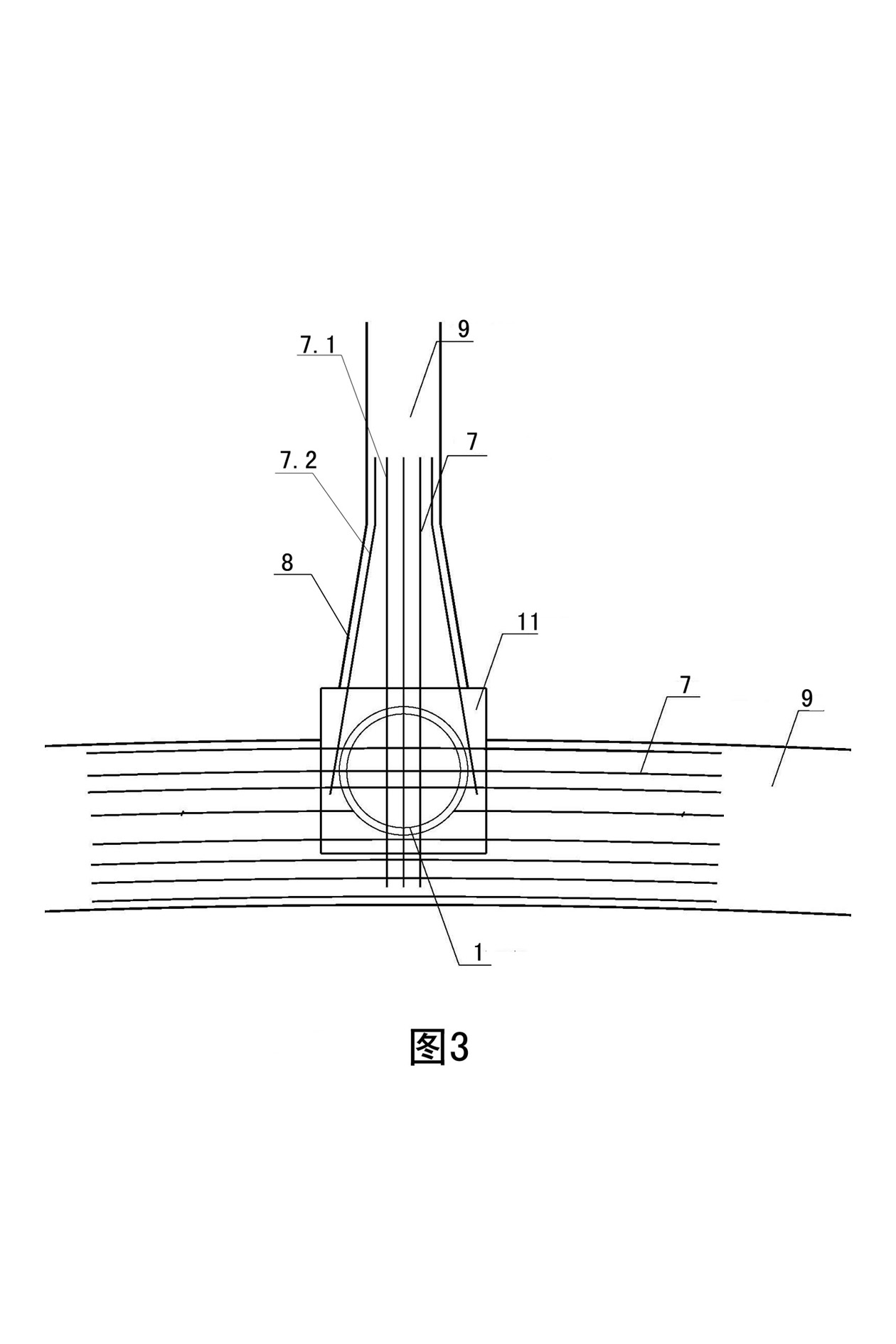

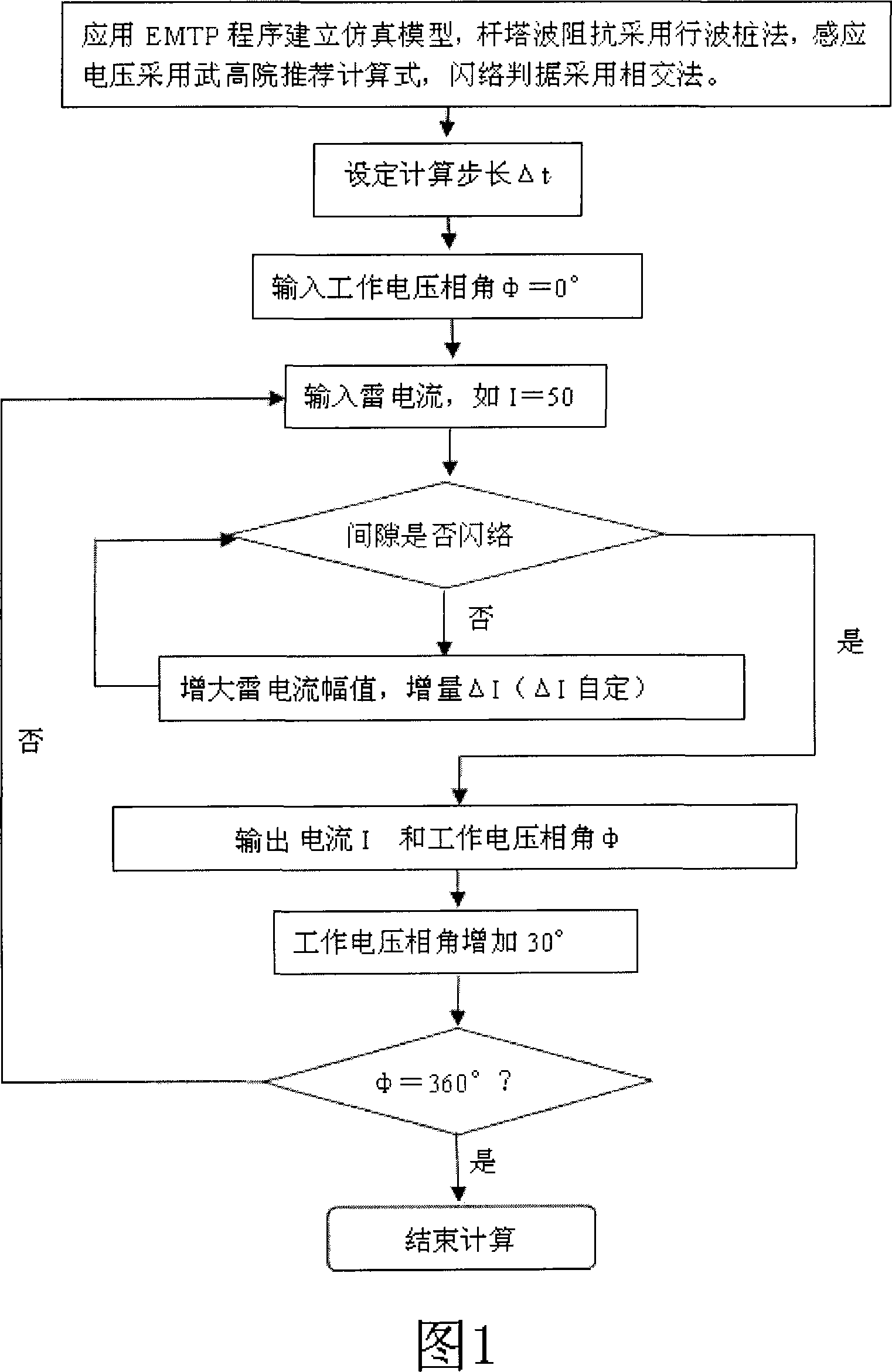

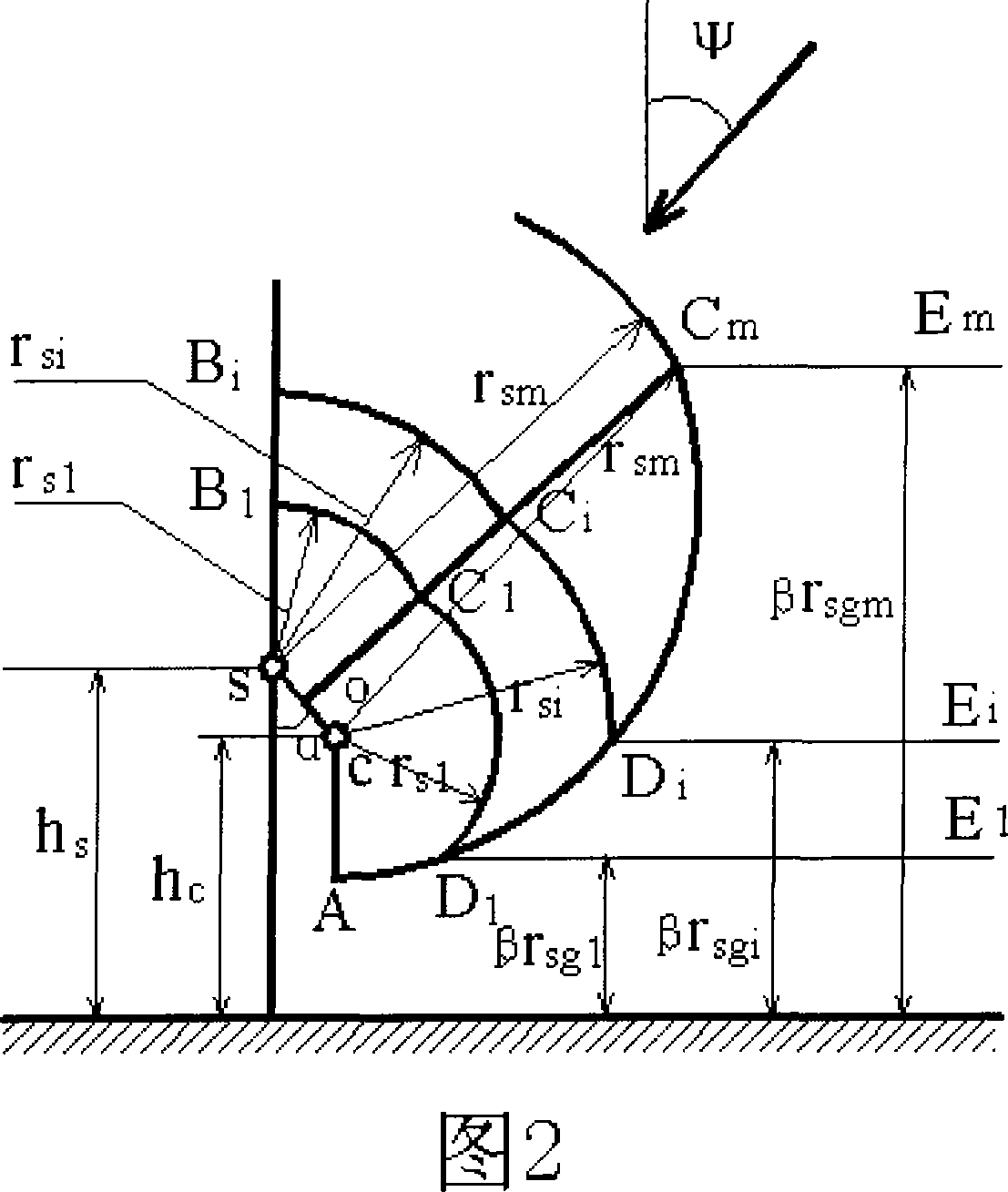

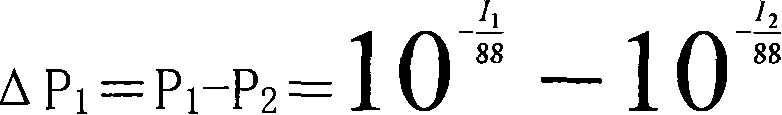

Large cross line total lighting strike tripping rate emulated computation method

InactiveCN101216864AAccurate calculationAccurate calculation of total lightning tripping rateSpecial data processing applicationsLightning strokesTower

The invention relates to a simulation calculation method of total lightning stroke trip rate, in particular to the simulation calculation method of the total lightning stroke trip rate of a long-span circuit. The simulation calculation method of the total lightning stroke trip rate of the long-span circuit is based on a formula that: N is equal to N counter plus N shield; wherein, the N is the total lightning stroke trip rate of the long-span circuit, the N counter is the countering trip rate of the long-span circuit, and the N shield is the shielding failure trip rate of the long-span circuit, that is, the invention includes the simulation calculation method of the countering trip rate of the long-span circuit and the simulation calculation method of the shielding failure trip rate of the long-span circuit, the calculation method of the countering trip rate of the long-span circuit is based on an EMTP procedure, and the invention provides a complete simulation method by taking into consideration of the impacts of various factors such as pole tower wave impedance and wave speed, induction voltage component, air clearance flashover criterion, working voltage phase and ground line arc altitude.

Owner:STATE GRID ELECTRIC POWER RES INST

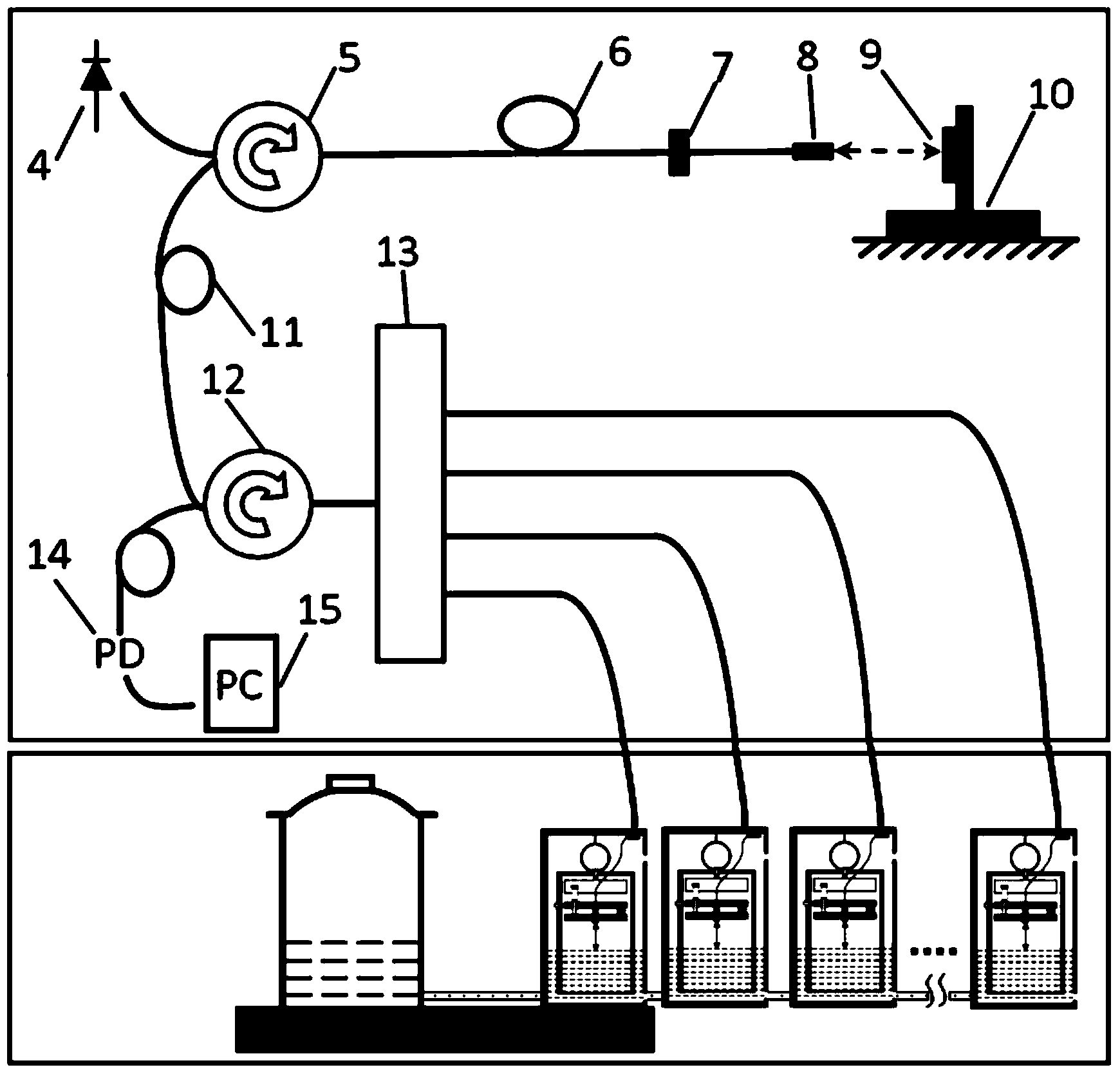

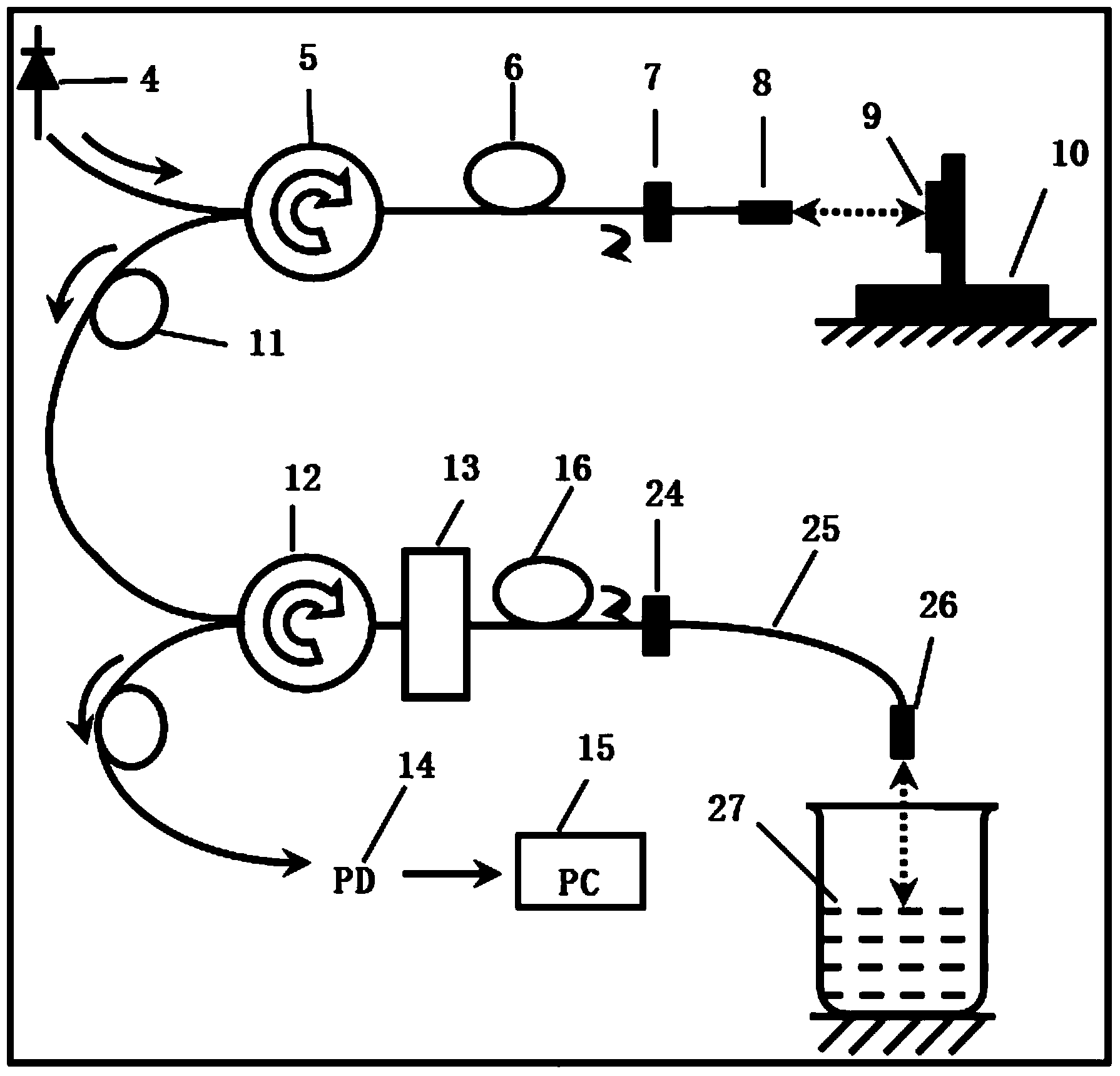

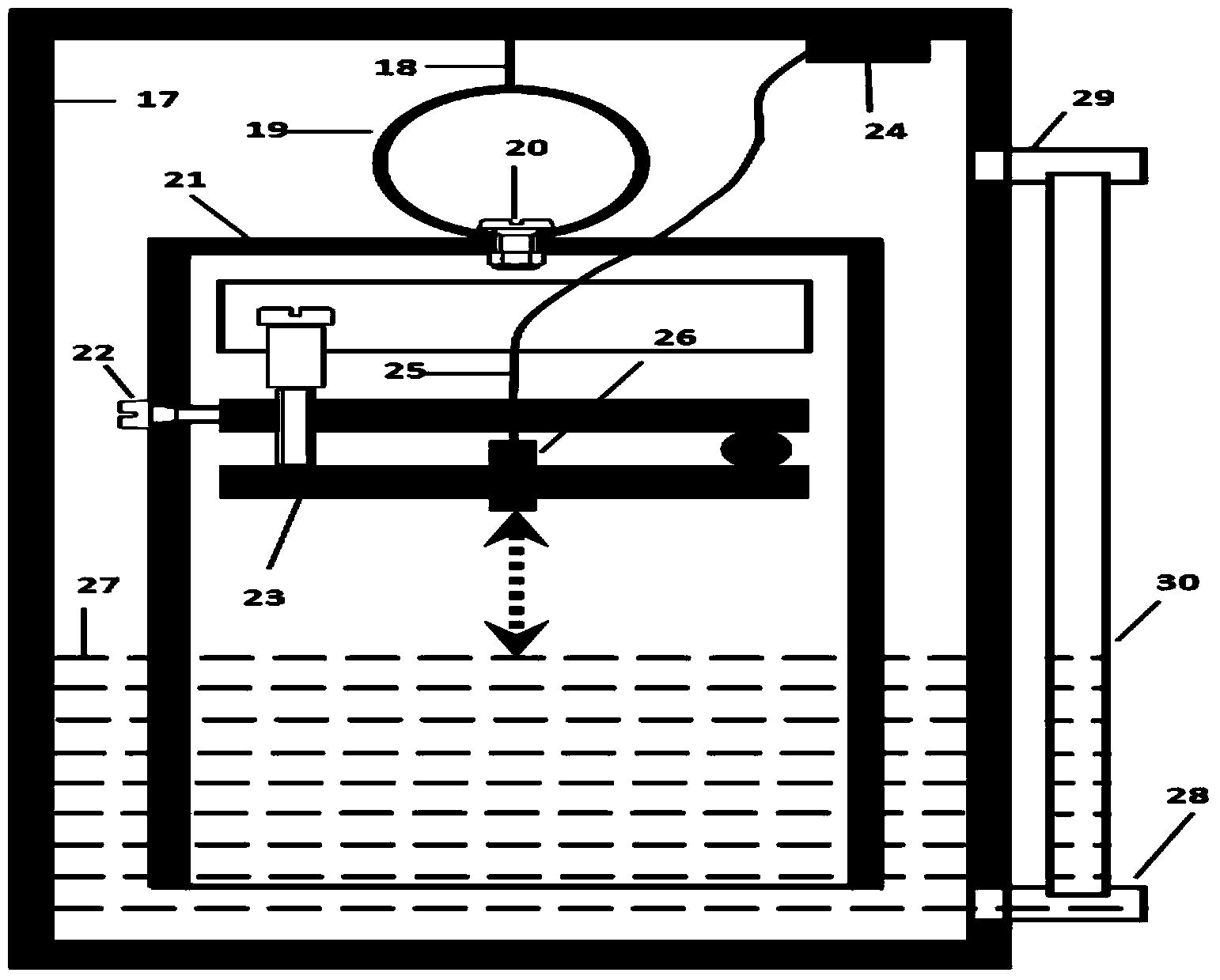

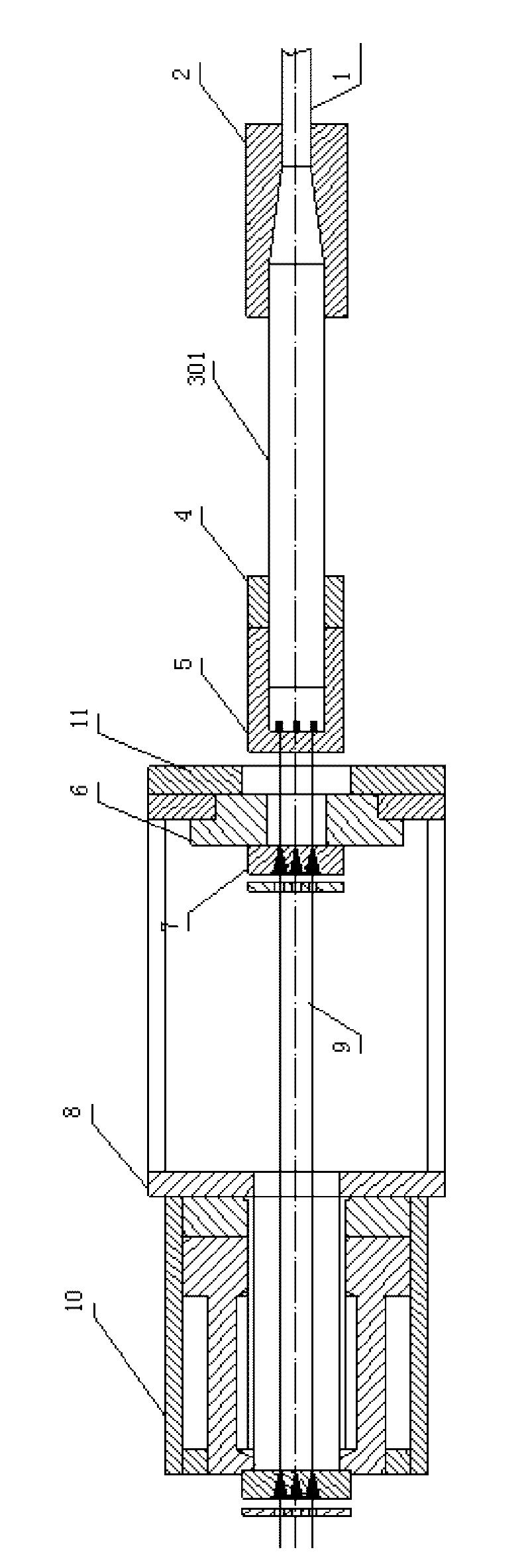

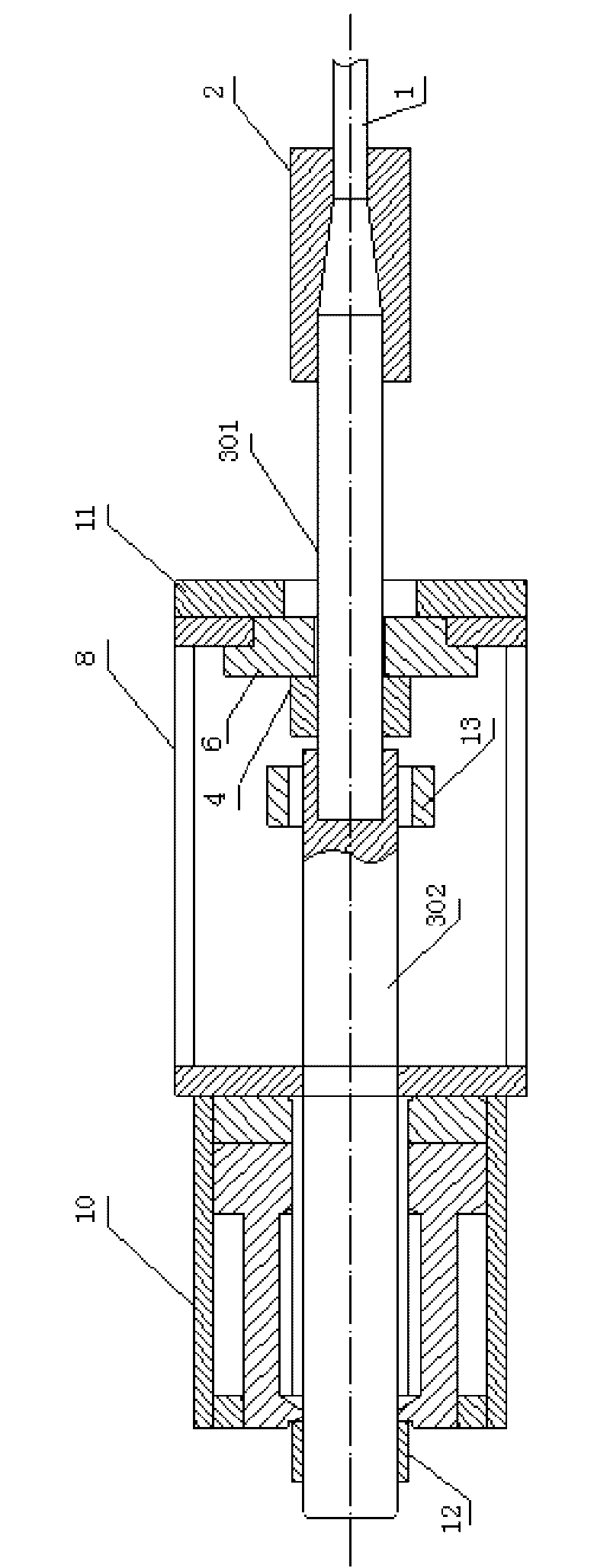

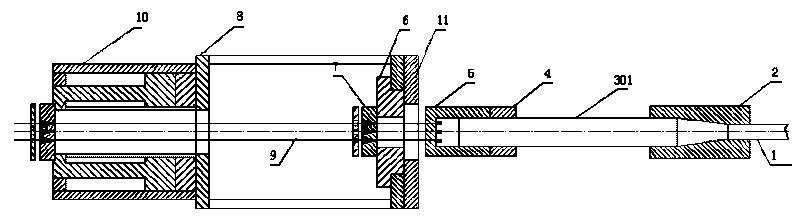

Low coherence optical monitoring system and method for micron settlement of long-span foundation of high speed railway

ActiveCN103968804ASplit ratio controlImprove performanceLevel indicatorsHydrostatic levellingEnvironment effectMonitoring system

The invention relates to a low coherence optical monitoring system and method for micron settlement of the long-span foundation of a high speed railway, and belongs to the technical field of photo-electro-mechanical integration measurement. A central liquid storage tank and a reference liquid storage tank are arranged on the foundation of a non-settlement area; a plurality of testing liquid storage tanks are arranged on the foundation of a settlement area; the upper half parts of the liquid storage tanks are filled with gas; the bottom ends of the liquid storage tanks are communicated with one another through a liquid connecting pipeline; the upper ends of the liquid storage tanks are communicated with one another through a gas connecting pipeline; the liquid connecting pipeline for communicating the liquid storage tanks is communicated with the gas connecting pipeline for communicating the liquid storage tanks through a vertical observation pipeline; low coherence optical sensors are mounted inside the testing liquid storage tanks. A signal transmission system converts the measured optical information into an electric signal to be input into a computer, and the settlement is displayed in real time. The low coherence optical monitoring system is stable in performance and is not influenced by severe environments such as a tunnel, and the low coherence optical monitoring method is a novel optical fiber settlement monitoring method suitable for existing structures and new structures.

Owner:DALIAN UNIV OF TECH

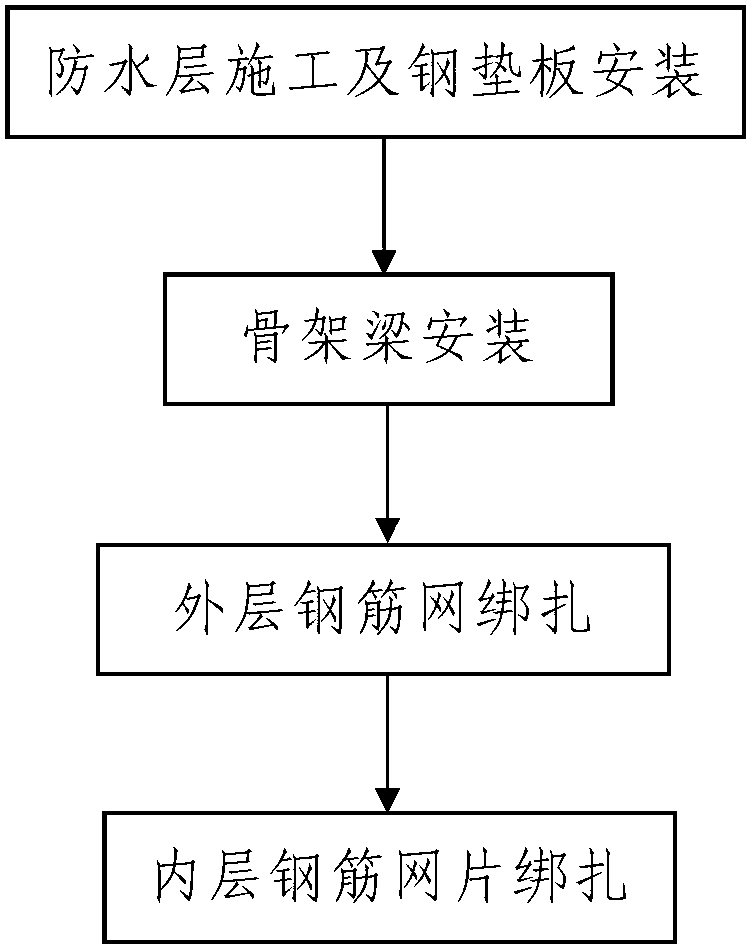

Large-span tunnel arch secondary lining steel bar binding construction method based on skeleton beams

The invention discloses a large-span tunnel arch secondary lining steel bar binding construction method based on skeleton beams. A bound tunnel arch secondary lining steel bar comprises an outer layer reinforcement mat, an inner layer reinforcement mat and a vertical connecting bar for connecting the outer layer reinforcement mat with the inner layer reinforcement mat. The construction method comprises the following steps of: arranging skeleton beam: arranging a plurality of skeleton beams below a tunnel arch primary supporting structure from front to back, wherein the skeleton beams are arch-shaped beams of which the radiuses are the same as that of the outer layer reinforcement mat, and the plurality of skeleton beams construct a load bearing structure of a tunnel arch secondary lining steel bar; and II, binding the tunnel arch secondary lining steel bar: binding the outer layer reinforcement mat on the upper parts of the plurality of skeleton beams, and suspending the inner layer reinforcement mat on the outer layer reinforcement mat through the vertical connecting bar. The method has the advantages of simple construction process, convenience in constructing, good use effect, high practical value, no damage to a paved waterproof structure and easiness and convenience in controlling the deflection of a large-span station arch secondary lining steel bar.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

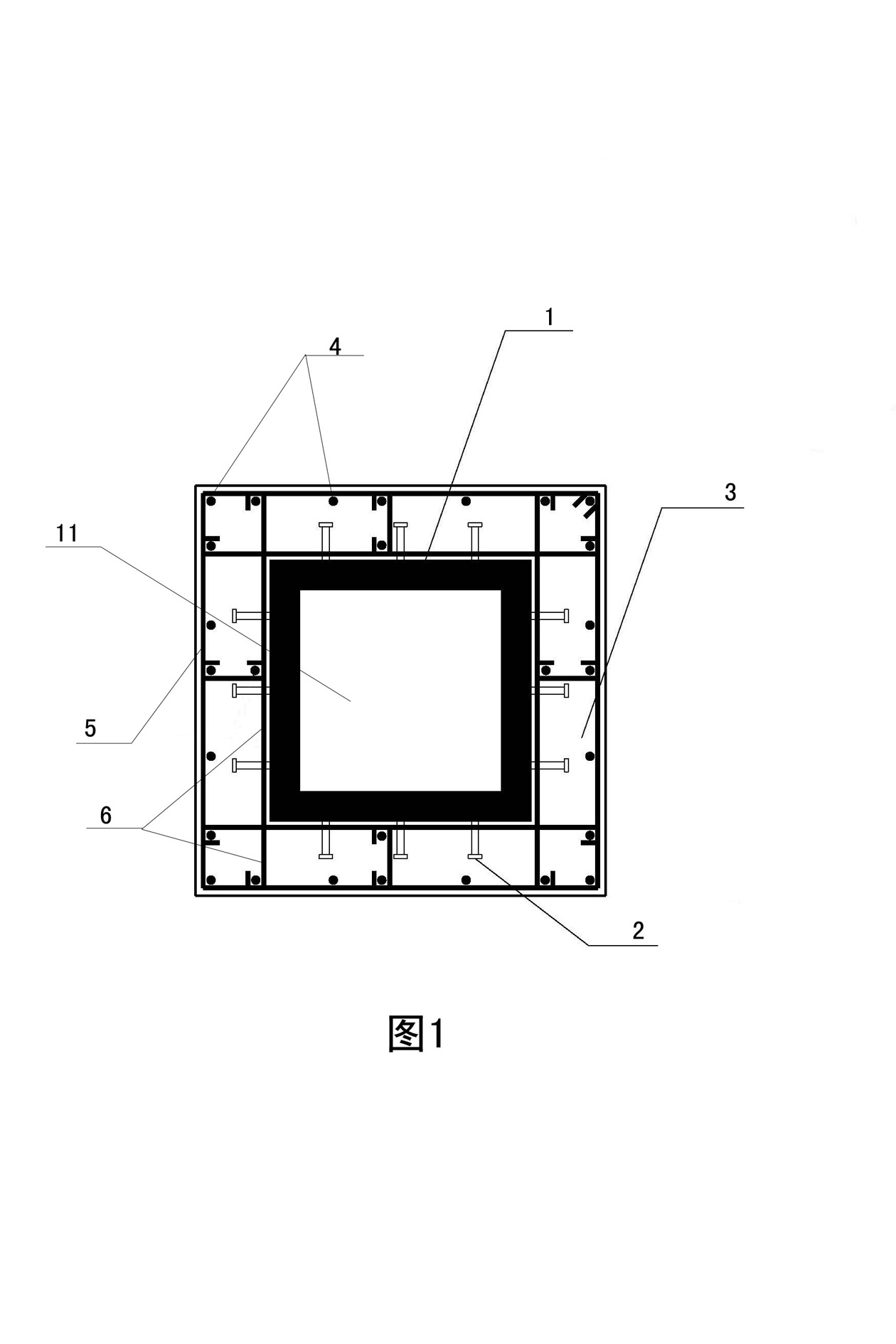

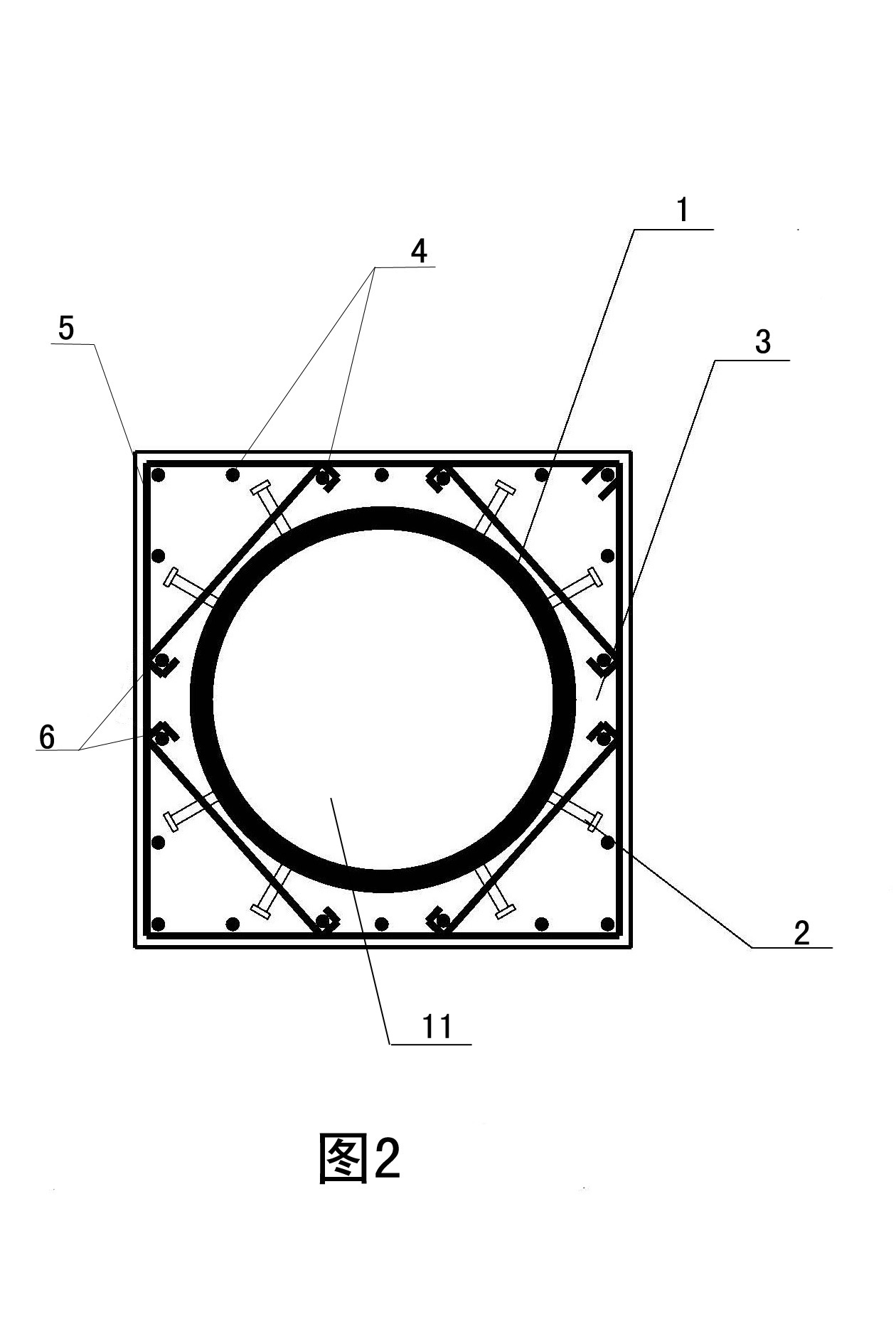

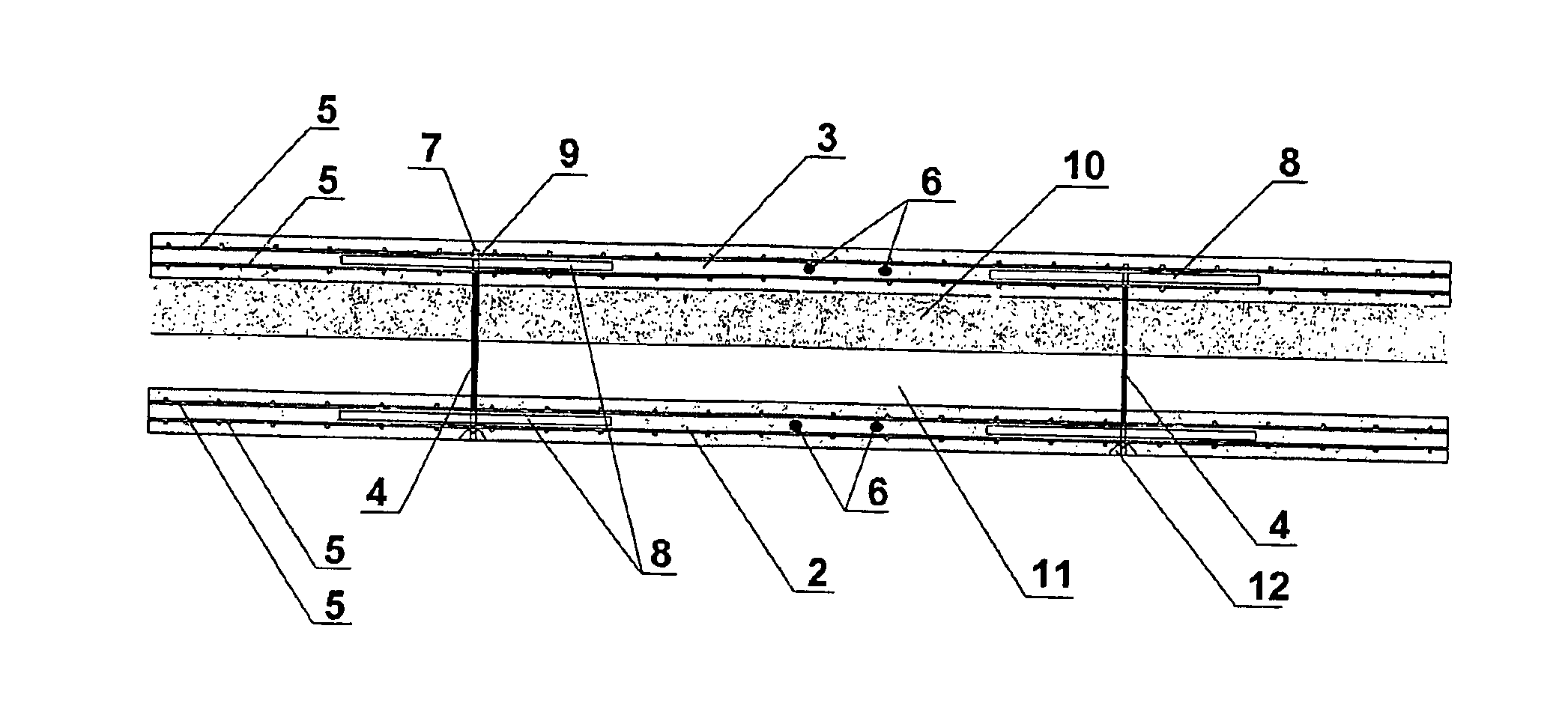

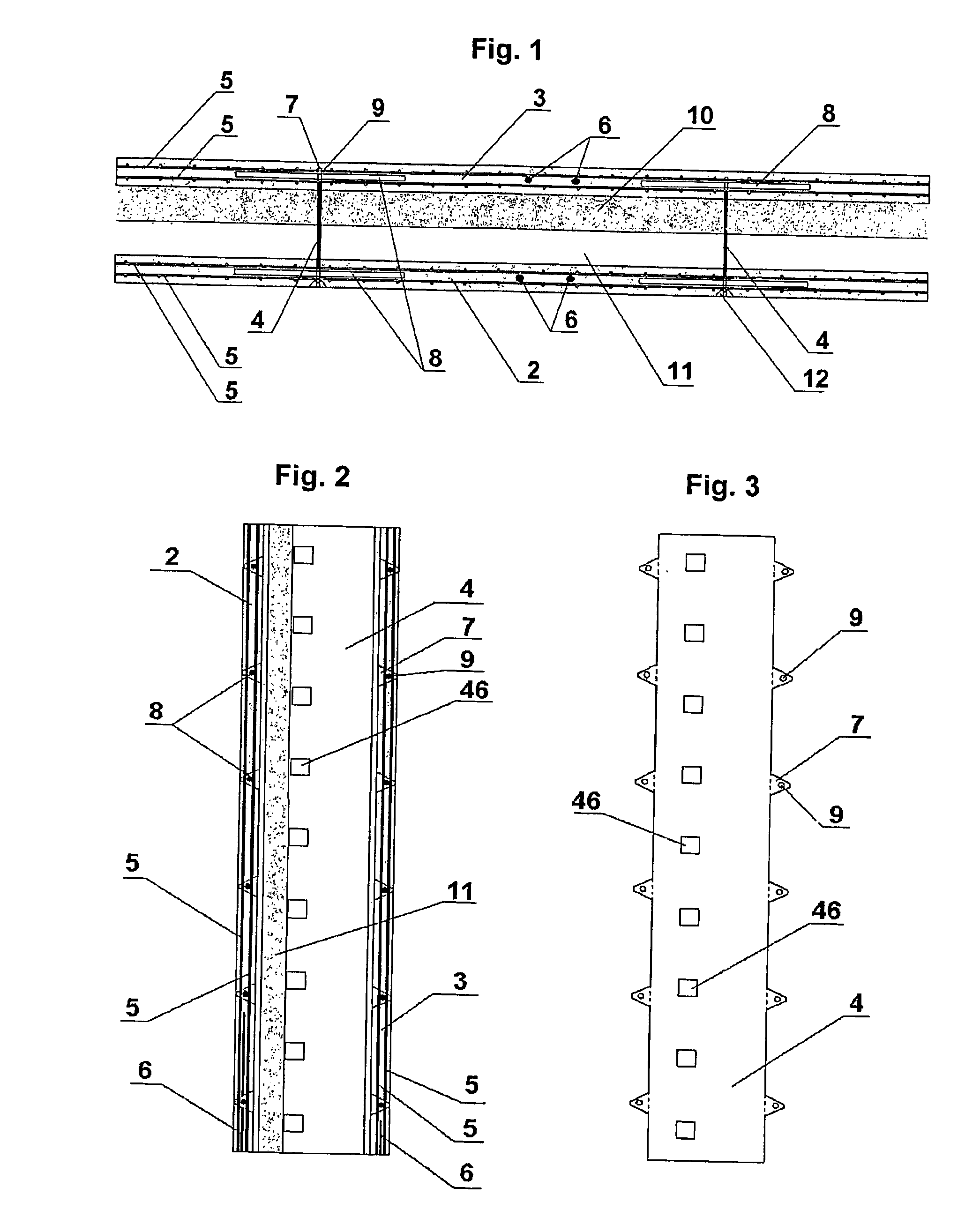

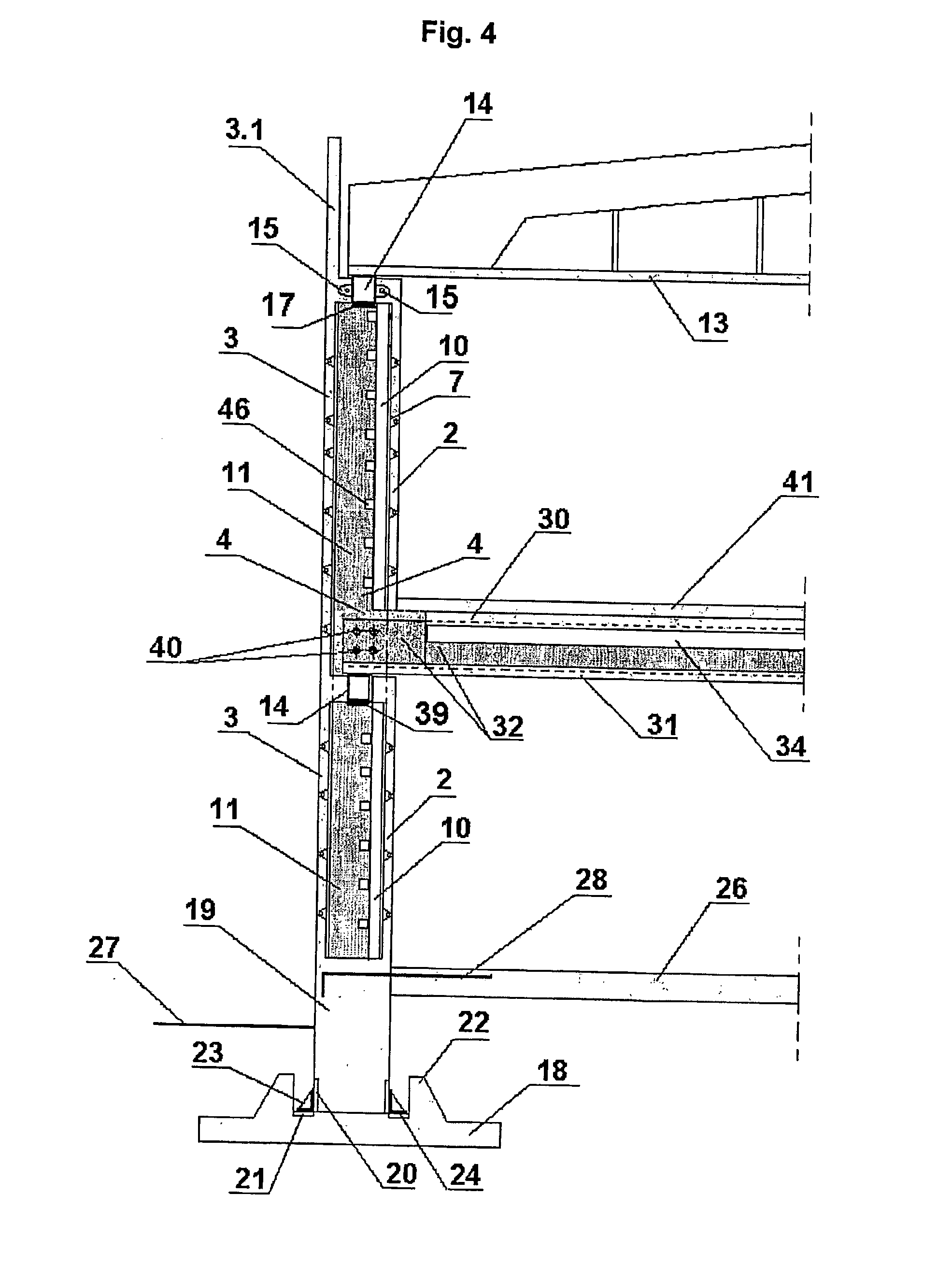

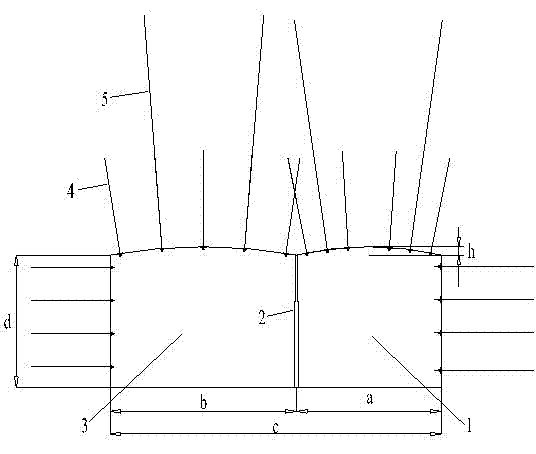

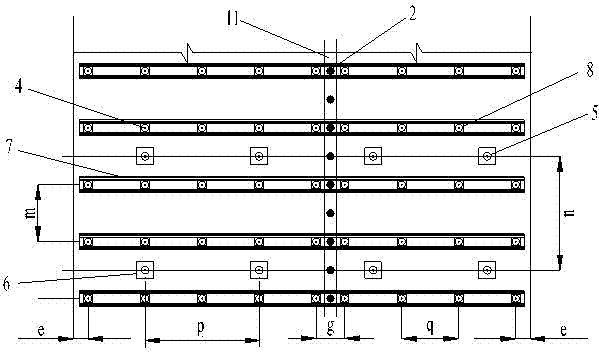

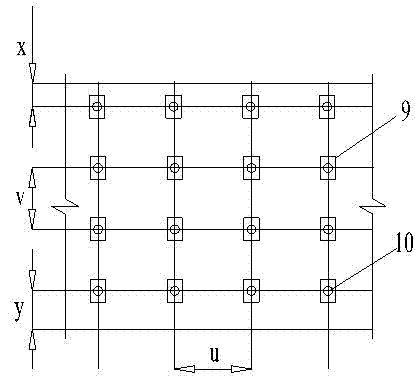

Constructing the large-span self-braced buildings of composite load-bearing wall-panels and floors

InactiveUS20060230706A1Increase heightSimple materialArched girdersConstruction materialFloor slabVertical load

The large span buildings comprising no ordinary beams and columns are formed of vertical load-bearing composite wall-panels and composite floors, both comprising two concrete layers interconnected by steel strip webs. The stiff horizontal plane formed of assembled roof / ceiling units, supported by wall-panels, connected to both gables restrains transversal movement of longitudinally arranged wall-panels attached tops, bracing them simultaneously against sideway and lessening their buckling lengths. Floors, if any applied, being rigidly connected to the vertical panels additionally improve stability of the global structure. Hereby invented composite wall-panel and floor are adapted to the same purpose. The global structure, being braced in that way, behaves as a rigid box made of slender panels.

Owner:MARA INST D O O

Support method for span reduction with double micro-arches in large-span cut-outs

InactiveCN102268998ASolve the problem of difficult to control the stability of the roofImprove top control effectTunnelsMine roof capsLong spanMonomer

The invention discloses a span-reducing support method with double micro-arches for large-span cutouts, which is suitable for span-reduction support in areas with complex structures and deep composite roofs with large-span cutouts. The secondary roadway is used instead of the first roadway, and the double micro-arch cutout is used to replace the traditional one-time long-span rectangular cutout, and the prestressed anchor / cable is used to strengthen the surrounding rock of the cutout. The distribution law of the plastic zone of the surrounding rock of the micro-arch cutout, select reasonable support parameters, give full play to the support function of the prestressed anchor rod / cable, add a row of single pillars and top beams to reduce the span support in the double micro-arch cutout protection, the top control effect is obvious. For large-span cutouts, the span reduction support method of secondary roadway formation + double micro-arch sections + anchor net cables + single pillars and hinged roof beams was adopted to solve the problem of difficult control of the roof of long-span rectangular cutouts and realize The large-span cutting eye is fast, safe and economical to construct, and its method is simple and easy to implement, with low support cost and good support effect.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

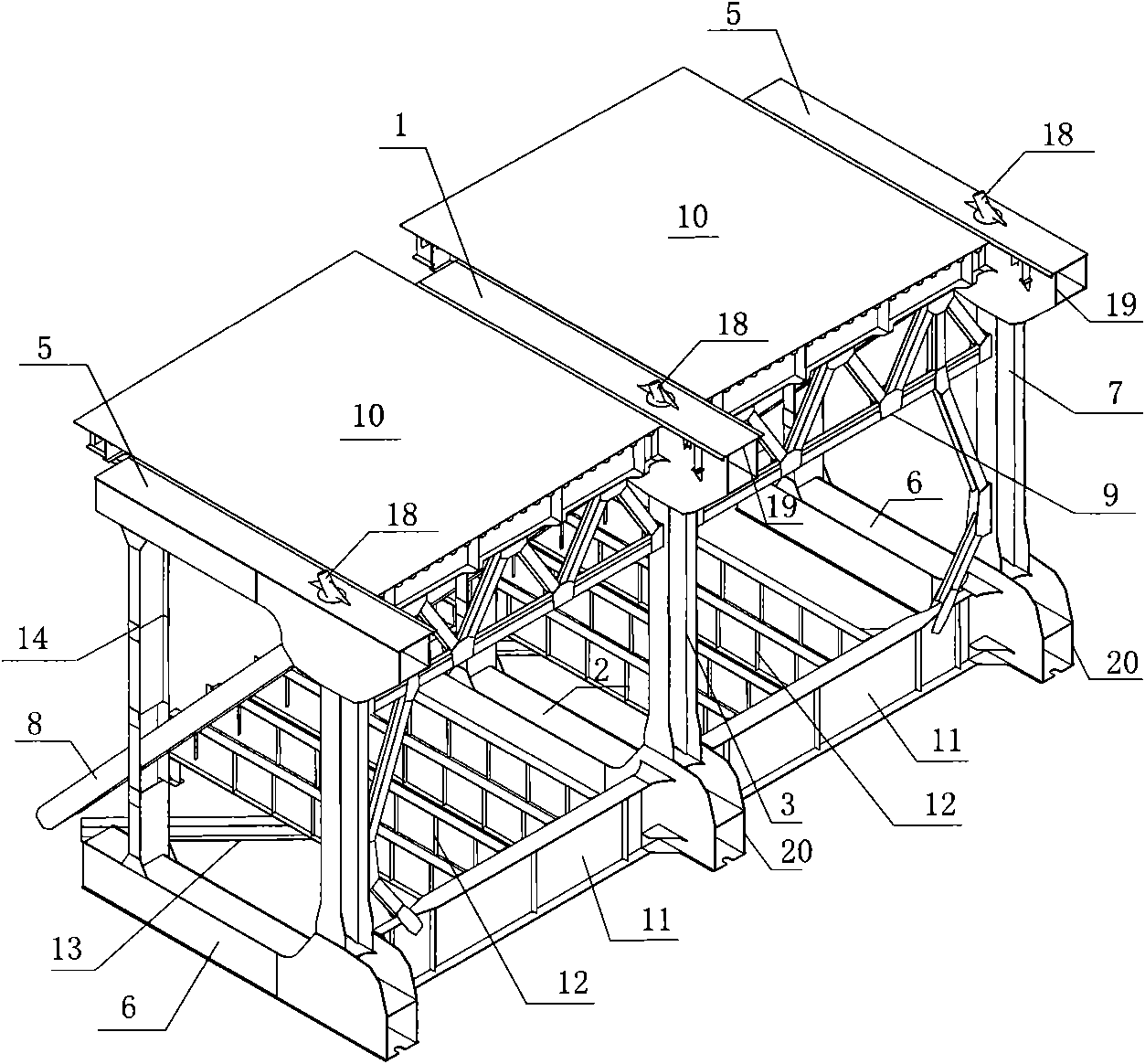

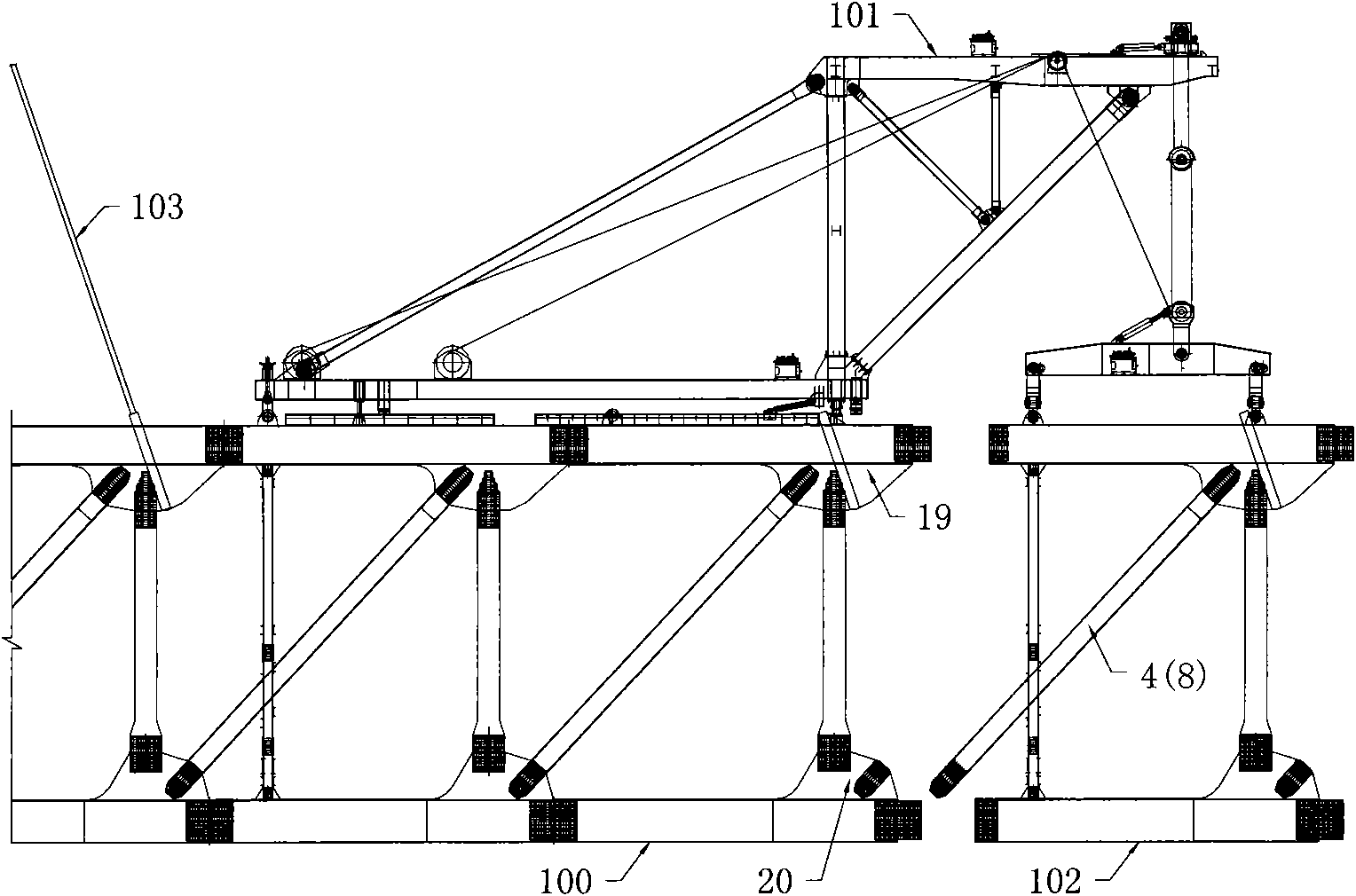

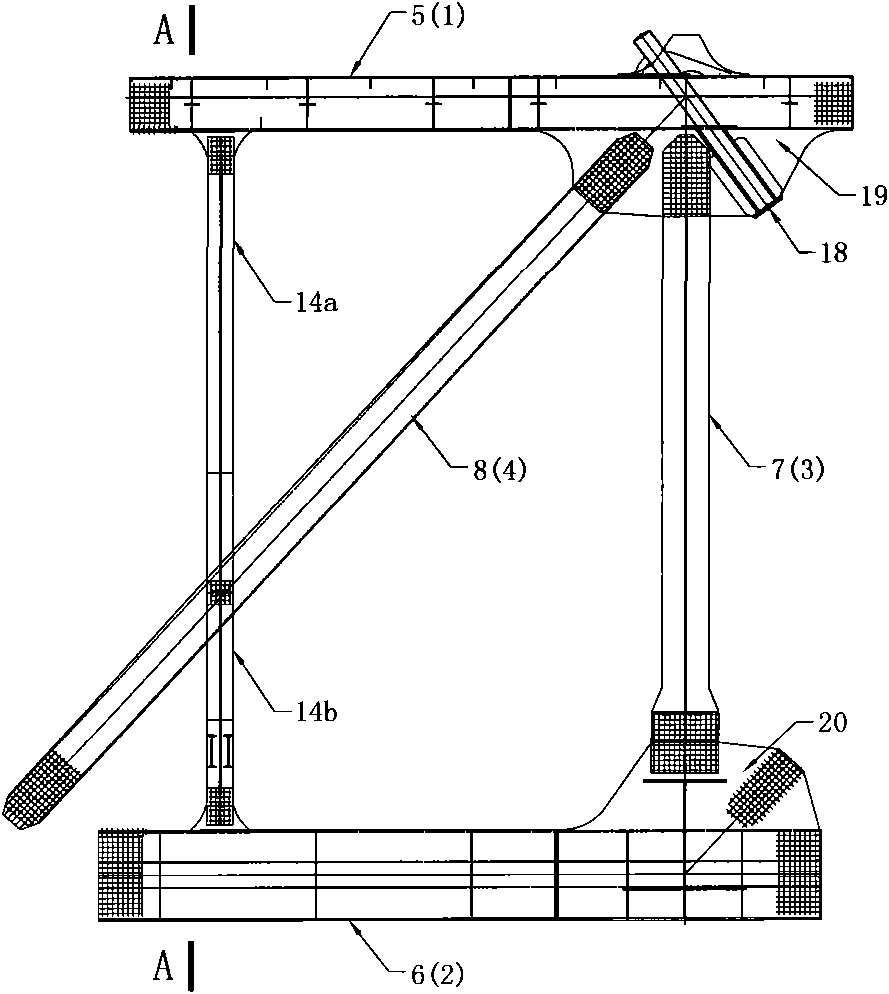

Liftable self-propelled continuous pushing system for large-span steel box beam and construction method thereof

ActiveCN107151980AReduced midline deviationReduced quality damageHydro energy generationBridge erection/assemblyAuto regulationControl system

The invention discloses a liftable self-propelled continuous pushing system for a large-span steel box beam. The liftable self-propelled continuous pushing system for the large-span steel box beam comprises a automatically-positioning continuous pushing device, an automatic pier top slideway elevation adjusting device and a horizontal limiting and correcting device. By virtue of a highly automated control system, precise positioning and synchronous pushing are achieved, damage to the quality of a steel box structure is minimized, and a relatively good quality control effect is ensured. The invention further discloses a pushing construction method. Through arrangement of the automatically-positioning continuous pushing device and the automatic pier top slideway elevation adjusting device in a pushing construction technology, self-propelled advancement and precise positioning of the pushing device are achieved, lifting and mounting and dismounting operation procedures of mechanical equipment are saved, the operation of the construction technology is simplified, the technical difficulty is reduced, the on-site controllability is substantially improved, the construction time is shortened, the safety risks are reduced, and popularization and application are easy.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP OF THE FIFTH ENG +1

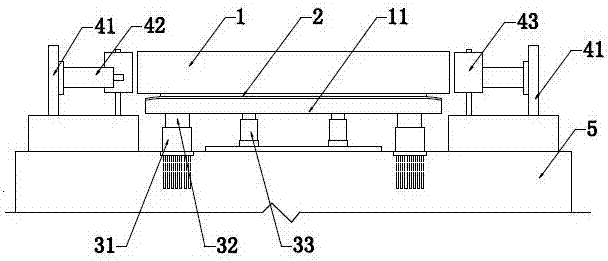

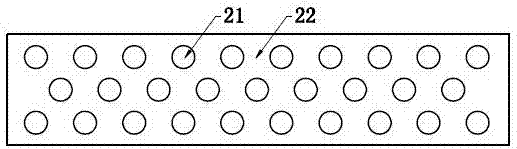

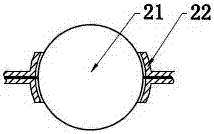

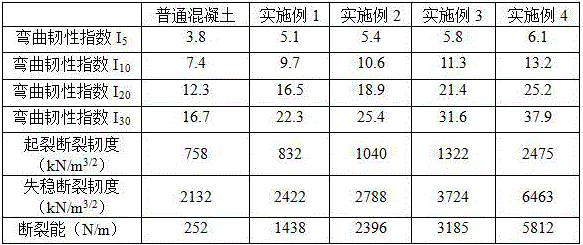

High-toughness hybrid fiber reinforced concrete and a preparing method thereof

The objective of the invention is to provide high-toughness hybrid fiber reinforced concrete and a preparing method thereof. Nanometer silica and hybrid fiber are added into the concrete. Flexural toughness and fracture toughness are significantly improved. The hybrid fiber reinforced concrete can be used for long-span and high-layer building structure projects having high toughness requirements.

Owner:ZHENGZHOU UNIV

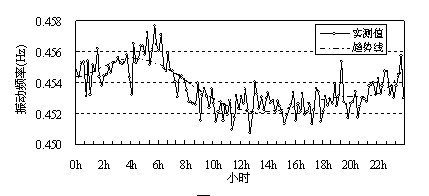

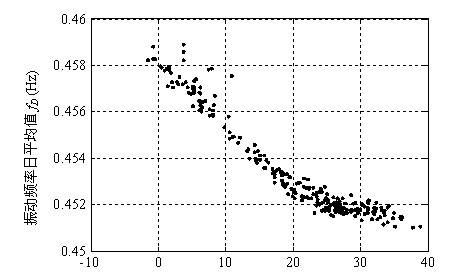

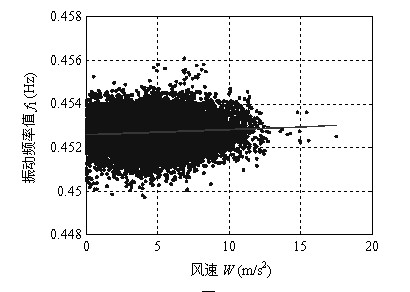

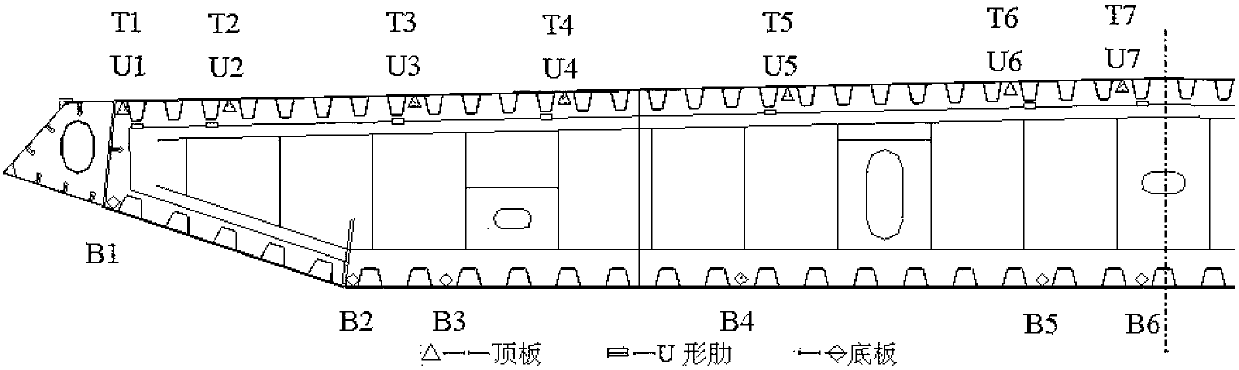

Method for carrying out early warning on damage to steel box girder of long span bridge in operation state

InactiveCN102565194AReduce in quantitySimple methodAnalysing solids using sonic/ultrasonic/infrasonic wavesTransducerLong span

The invention relates to a method for carrying out early warning on the damage to a steel box girder of a long span bridge in an operation state. The method comprises the following steps of: a step 1 of arranging steel box girder sensors, i.e. arranging a vertical acceleration transducer, a temperature sensors and an anemoscope at the midspan positions of the steel box girder for respectively monitoring the vertical acceleration of the steel box girder, the temperature of the steel box girder and the wind speed of a region where the steel box girder is positioned, which are caused by a vehicle load; a step 2 of processing monitoring data; a step 3 of establishing a mathematical correlation model of the vibrating frequency of the steel box girder and operation factors in a good state; a step 4 of determining the significance level of a control chart; and a step 5 of carrying out early warning on the damage to the steel box girder. According to the invention, various factors influencing the variation of the vibrating frequency of the steel box girder in the operation state are comprehensively considered, the real-time performance and accuracy of carrying out early warning on the damage to the steel box girder are effectively improved, and the method is necessarily and widely applied and popularized.

Owner:SOUTHEAST UNIV

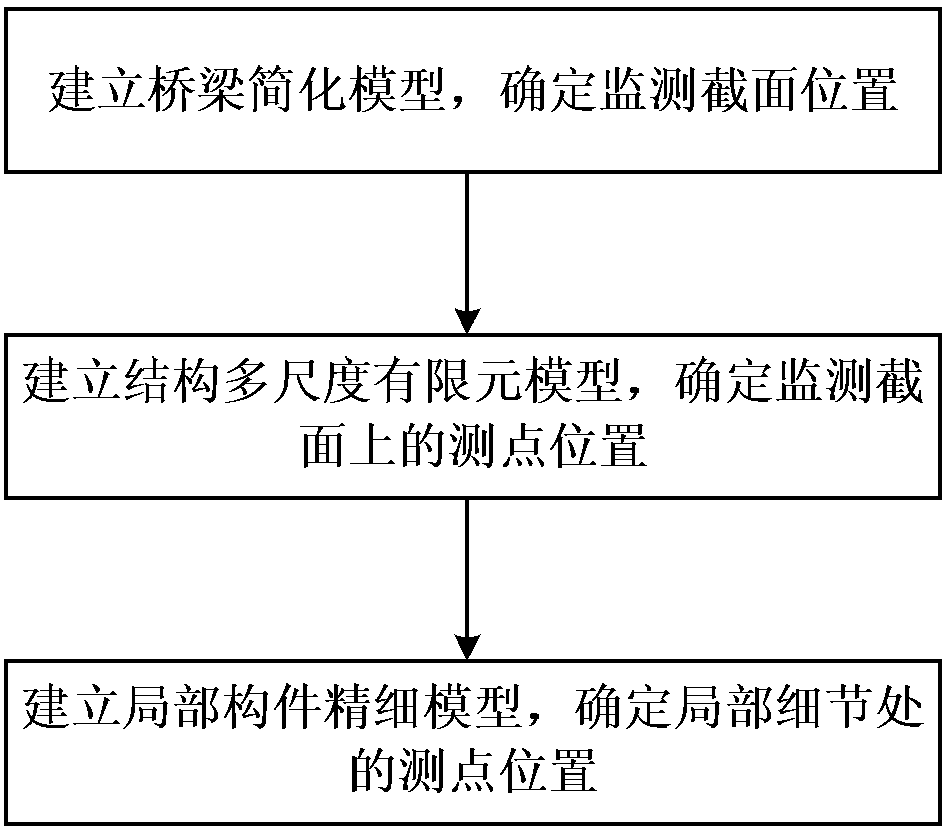

Method for optimized arrangement of strain sensor

InactiveCN103279611AOptimize layoutImprove health monitoringSpecial data processing applicationsReduced modelElement model

The invention discloses a method for optimized arrangement of a strain sensor. The method comprises the following steps of building a simplified bridge model, confirming a monitoring cross section needing to be provided with the strain sensor, building a structural multi-scale finite element model on a bridge section including the monitoring cross section, obtaining the position which is located on the monitoring cross section, is stressed adversely and needs to be provided with the strain sensor, building a mesoscopic model of a local detail of a critical element on the monitoring cross section, carrying out hot spot stress analysis, and confirming the spot distribution position of the local detail. By the help of a multi-scale finite element modeling strategy, the method provides an optimized scheme of the strain sensor in a health monitoring system of a bridge, especially a long-span bridge by different levels, can obtain the comprehensive information of structural critical positions with few strain sensors, and is both safe and economical.

Owner:SOUTHEAST UNIV

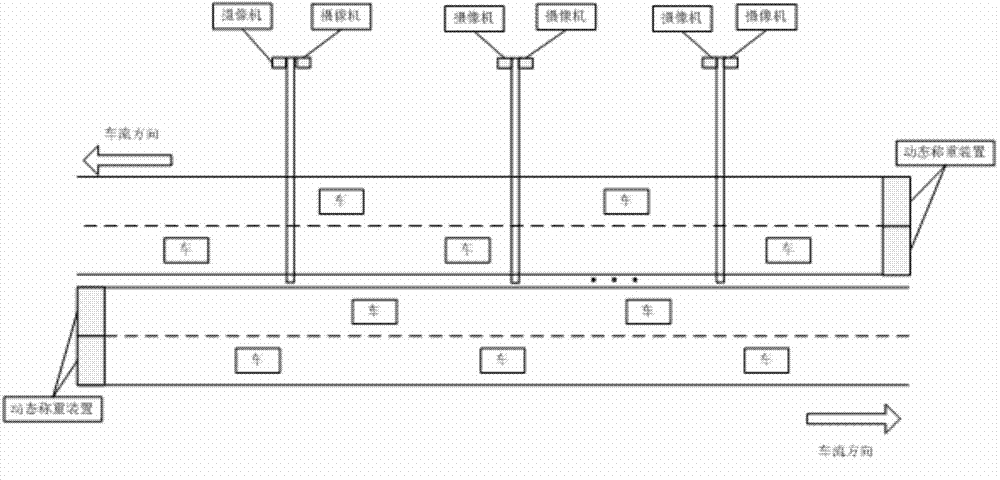

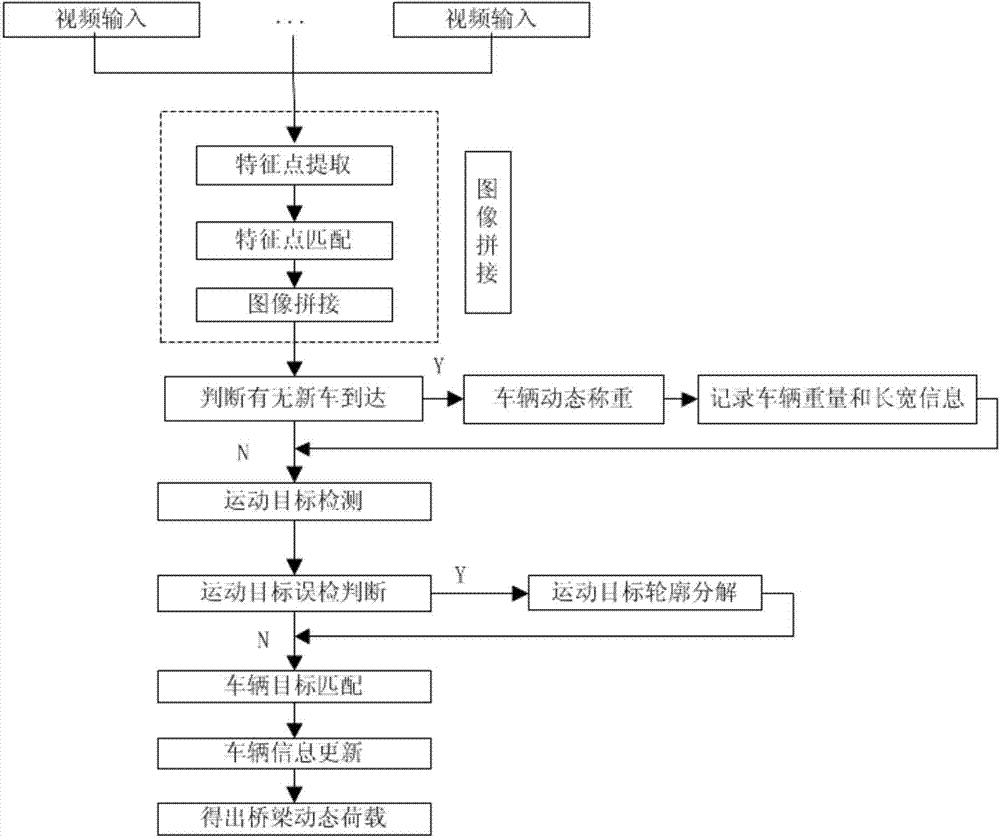

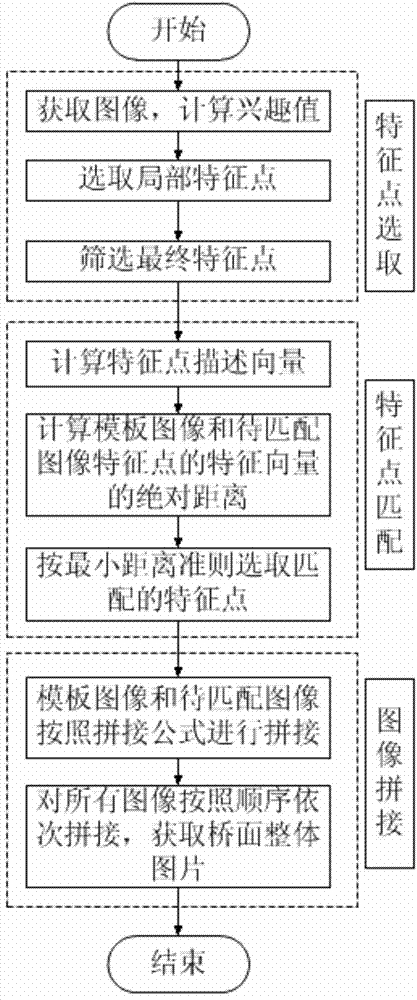

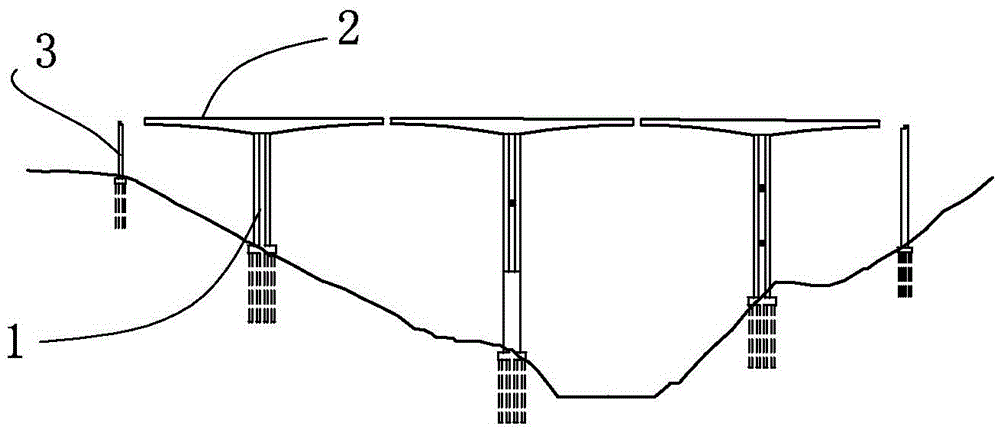

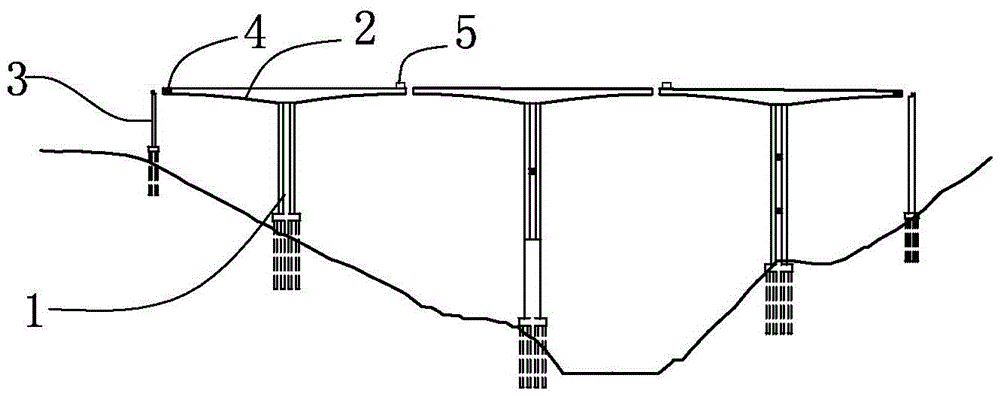

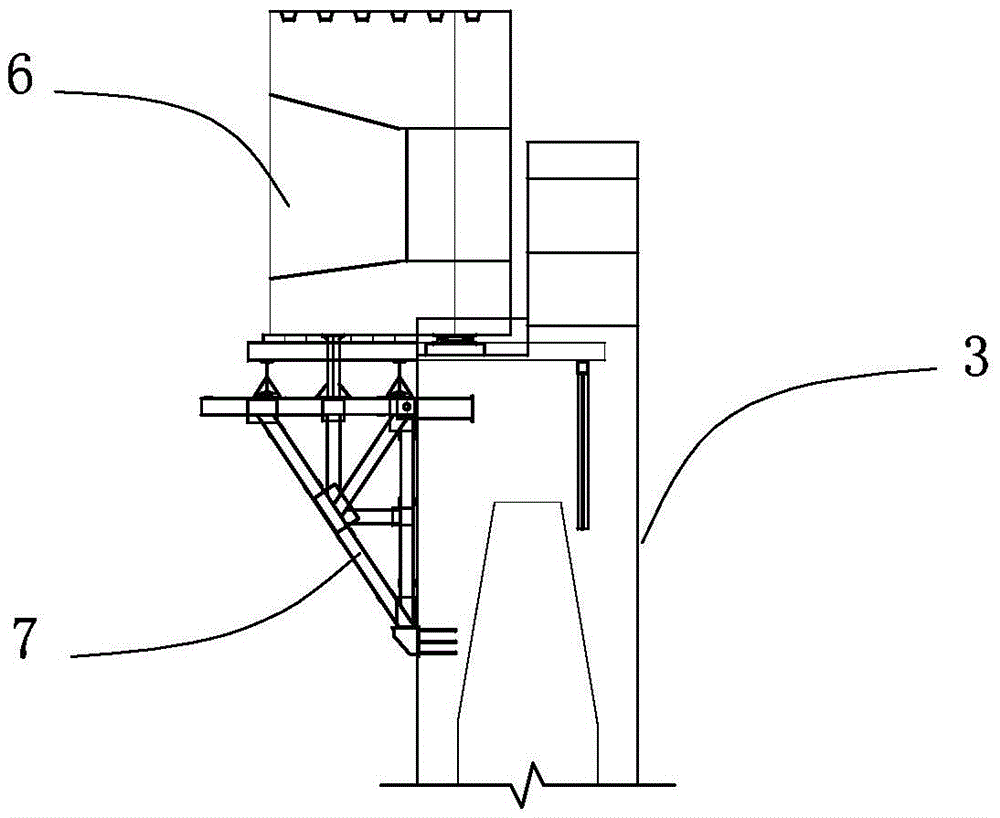

Long-span bridge vehicle dynamic load distribution detection method

ActiveCN103593678AImprove integrityImprove object trackingImage enhancementImage analysisVehicle dynamicsReal time analysis

The invention provides a long-span bridge vehicle dynamic load distribution detection method. According to the method, a dynamic weighing device is used, image stitching and multi-vehicle detection are adopted, real-time collection, real-time processing and real-tine analysis of long-span bridge load data are achieved, and bases are provided for management and maintenance of a bridge. In the splicing process, an image stitching algorithm based on the Harris operator is utilized to remove image overlapping parts. After real-time panoramic images of a bridge floor are obtained, a multi-vehicle detection algorithm is used for tracking vehicles, and vehicle positions are obtained. At last, according to vehicle weights obtained through the dynamic weighing device and the vehicle positions obtained through the multi-vehicle detection algorithm, real-time loads of the bridge are calculated by combining bridge design parameters.

Owner:CHANGAN UNIV

Asymmetrical casting construction method of side span of rigid frame bridge with extra high piers and long span length

InactiveCN105484158AIncrease the lengthShorten the lengthBridge erection/assemblyHanging basketEngineering

The invention provides an asymmetrical casting construction method of a side span of a rigid frame bridge with extra high piers and a long span length. The asymmetrical casting construction method comprises the following steps that after each T-shaped structure of each main pier is symmetrically cast to have largest cantilevered ends in a suspended manner, a hanging basket on one side of the side span of each main pier is continuously moved forward, and an asymmetrical suspended casting segment is cast on the side of the side span in a suspended manner; when the asymmetrical suspended casting segments are constructed, cantilever brackets for 0# block construction of transition piers are directly adopted as side span cast-in-place brackets for constructing side span cast-in-place segments; after the casting of the side span cast-in-place segments is completed, the hanging baskets for constructing the asymmetrical suspended casting segments are put down and moved forward, front cross beams of bottom baskets of the hanging baskets are placed on the side span cast-in-place brackets, rear cross beams of the bottom baskets of the hanging baskets are suspended and hung on baseplates and flange plates of tank beams to be used as side span closing hanging baskets, and the casting construction of side span closing segments is performed; after the side span closing segments meet design requirements, the side span closing hanging baskets are detached, and the side span construction is completed.

Owner:ROAD & BRIDGE INT +1

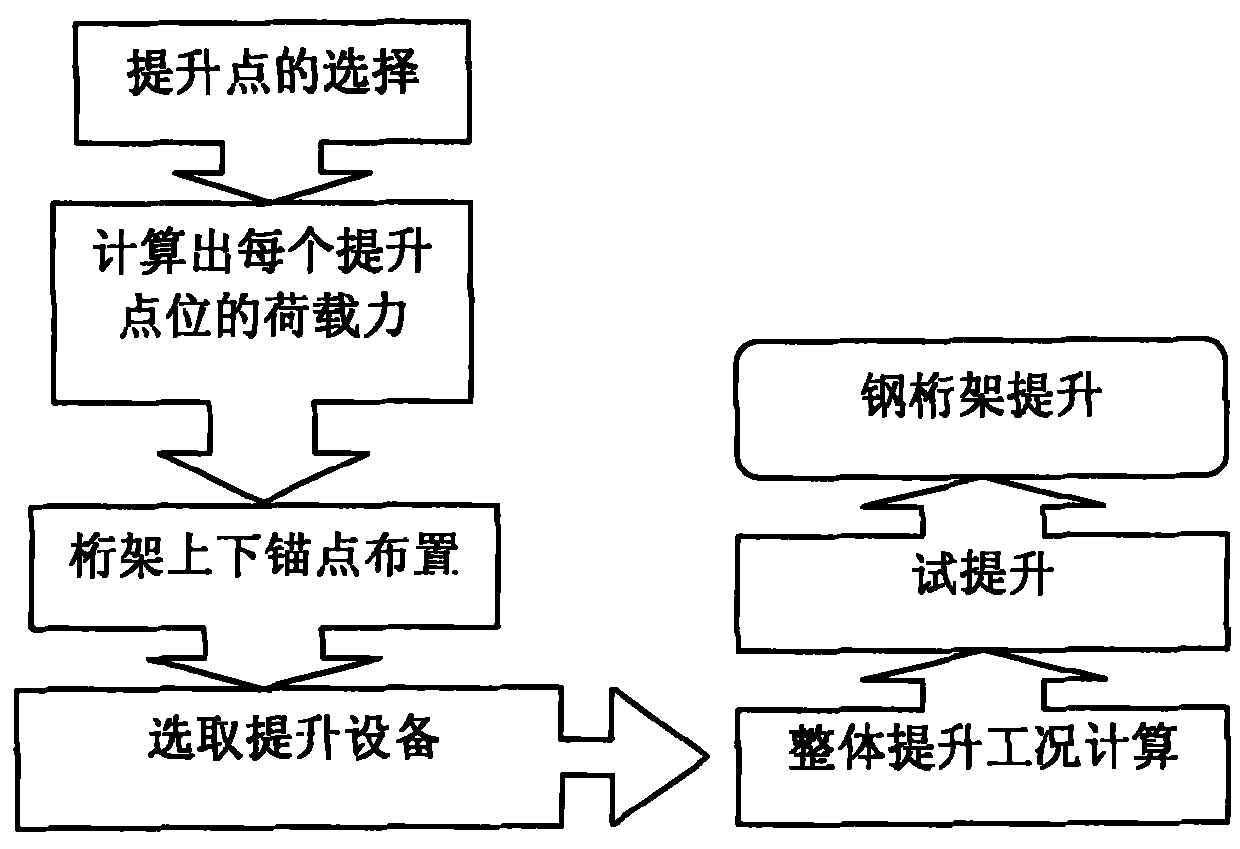

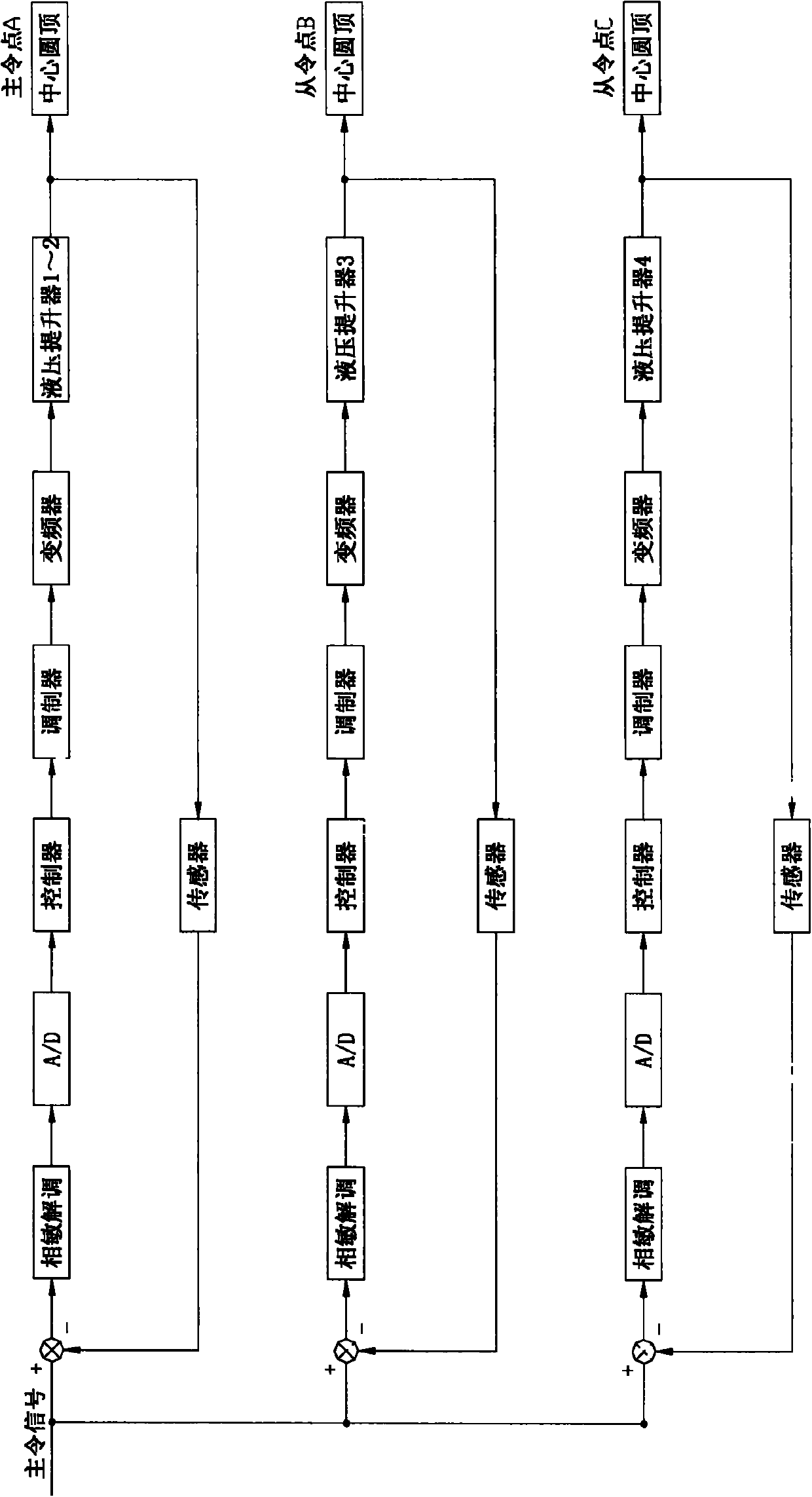

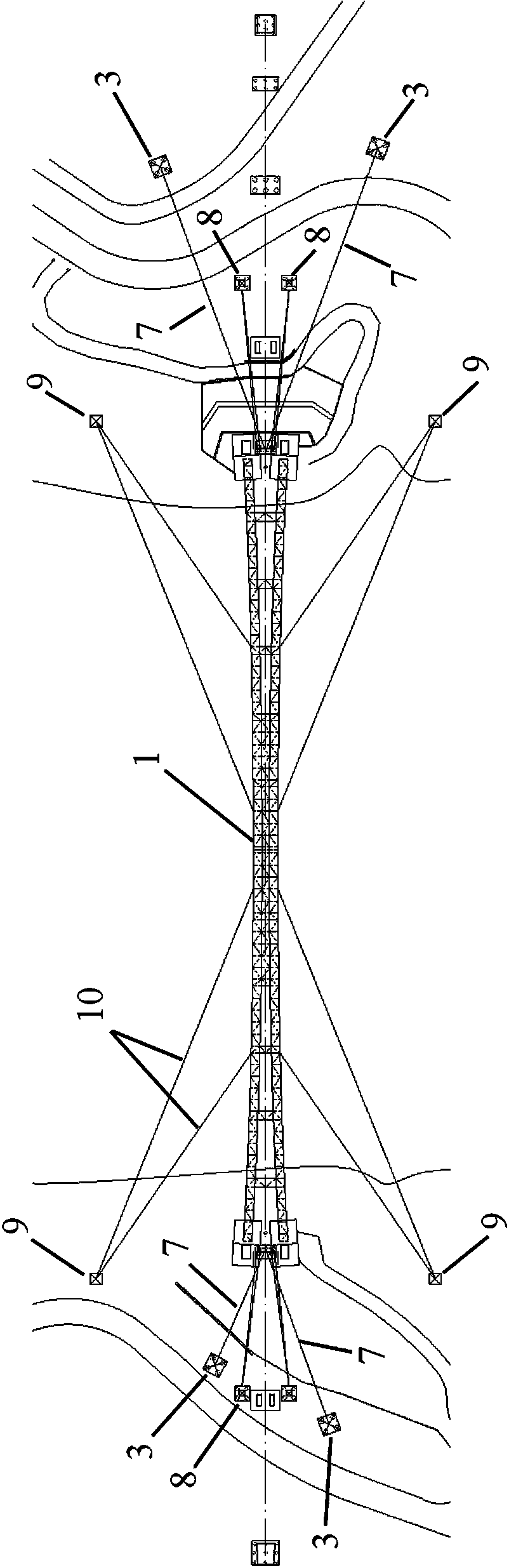

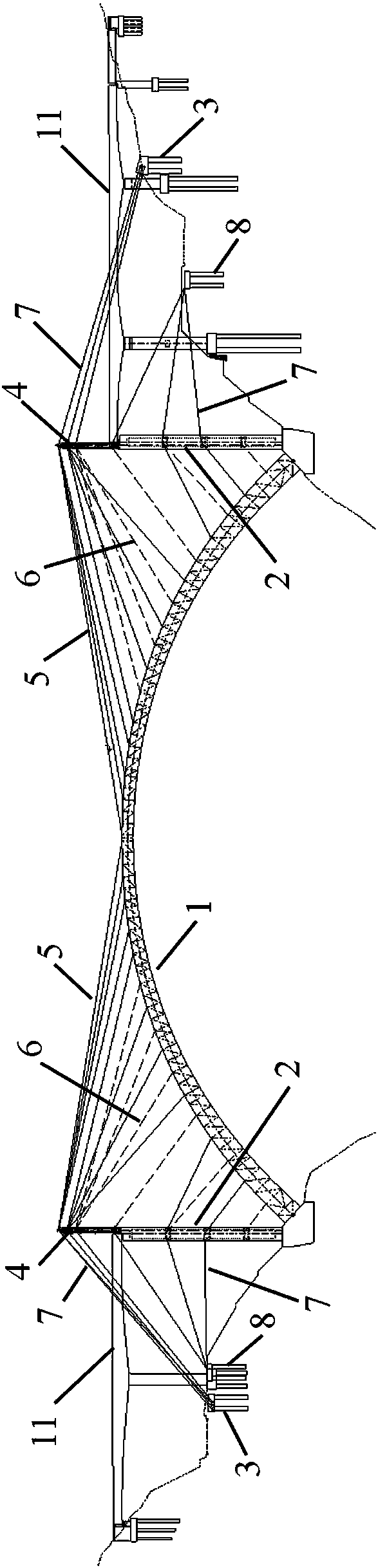

Large-span truss hydraulic multi-point synchronous lifting construction method

InactiveCN103790234AReduce distortionReduce the amount of work at heightBuilding constructionsLong spanControl theory

Disclosed is a large-span truss hydraulic multi-point synchronous lifting construction method. The construction method includes the steps of lifting point selection, calculation of load power of each lifting point position, upper and lower anchor point arrangement of a truss, lifting device selection, calculation of overall lifting conditions, lifting trial and steel truss lifting. Deformation caused by truss lifting can be reduced by adopting the flexible steel strand hydraulic synchronous lifting technology, reasonably selecting lifting point positions and utilizing an original structure to serve as upper and lower anchor points for lifting as much as possible; after assembled on the ground, components are integrally lifted to a preset position to be assembled in place; the large-span components can be synchronously integrally lifted at ultra-high altitude, high-altitude operating quantity can be reduced, quality can be improved, workload can be reduced, labor is saved, convenience in mounting and demounting is achieved, stress bearing is unaffected, cost is lowered, funds are saved, duration of work is shortened, and difficulty of safety protection is remarkably reduced.

Owner:YONGSHENG CONSTR GRP

Construction method for long-span handle-basket arch bridge steel arch rib fastening and hanging system in high speed railway

InactiveCN108374347AReduce investmentLow terrain requirementsBridge structural detailsBridge erection/assemblyCable stayedOperability

The invention discloses a construction method for a long-span handle-basket arch bridge steel arch rib fastening and hanging system in a high speed railway. The construction method is used for assisting in mounting long-span steel arch ribs and linear adjustment, the fastening and hanging system mainly comprises a fastening anchorage cable, a cable tower, an anchor cable and anchorage, a side wind-cable and anchorage and a fastening and hanging anchoring structure. Long-span steel arch ribs are hoisted through a segmental mode, each segment adopts a fastening cable to be hung and fastened, theupper end of the cable tower is aslant anchored to an anchor eye of a tension platform on the top of the cable tower, the cable tower and the corresponding anchor cable are simultaneously and symmetrically stretched and drawn, and the anchor cable is anchored to the anchor cable and anchorage in advance. The steel arch rib is hoisted through the segmental mode, each segment is fastened and hung with one set of fastening cable. The construction method for the long-span basket handle arch bridge steel arch rib fastening and hanging system in the high speed railway has the advantages that the steel arch rib segments are installed by adopting the cable-stayed fastening and hanging system, the technical problem of the long-span arch bridge construction under complex topography conditions suchas mountain areas, river valleys and the like is overcome, it is achieved that an arch bridge can be built without supports in mid-span, the dependence of bridge construction on topography and landform is reduced, the adjustment of installation linearis is convenient, the operability is strong, the overall structure layout is reasonable, safe and reliable, and the construction method for the long-span basket handle arch bridge steel arch rib fastening and hanging system in the high speed railway has popularization and application value.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

Soft and hard combined traction method for long-cable installation of cable-stayed bridge

InactiveCN101761035AEasy dockingEasy to operateCable-stayed bridgeBridge erection/assemblyCable stayedSelf locking

The invention relates to a long-span cable-stayed bridge, in particular to a soft and hard combined traction method for long-cable installation of a cable-stayed bridge. The long-span cable-stayed bridge is characterized by at least comprising stayed cables, a cable-stayed anchor head, a thin tensioned pull rod, a rough tensioned pull rod, a soft drawing head, an auxiliary anchoring base plate, a soft traction self-locking tool anchor, a supporting lug, a soft traction steel strand, a lifting jack, a stayed-cable anchoring base plate and a stayed-cable anchoring nut. The bottom end of the thin tensioned pull rod passes through the auxiliary anchoring base plate and the soft traction self-locking tool anchor through the soft traction steel strand to be fixed with the bottom of the lifting jack; the lifting jack is started and draws the soft traction steel strand to perform reciprocating traction; the lifting jack is drained back and the rough tensioned pull rod replaces the soft traction steel strand for hard traction again; and when the cable-stayed anchor head enters a preserved anchoring port of the tower body, the tool nut is screwed and the stayed cable is anchored on the tower body to finish long-cable installation. The invention solves the difficult problems of large traction force, long traction distance and the like of long-cable installation.

Owner:CCCC SECOND HIGHWAY ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com