Large-span tunnel arch secondary lining steel bar binding construction method based on skeleton beams

A technology of secondary lining and steel bar binding, applied in tunnel lining, tunnel, shaft lining, etc., can solve the problems of inability to meet and ensure construction requirements, inability to guarantee the waterproof quality of tunnels, and inconvenient on-site construction operations, etc. The effect of convenient processing, production and assembly, and convenient binding construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

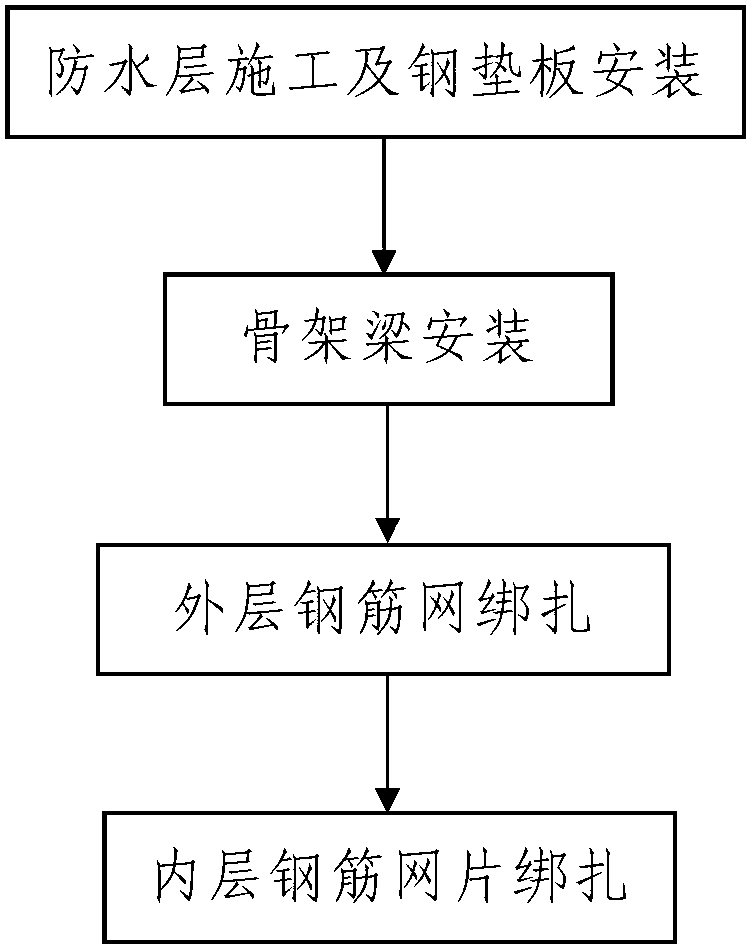

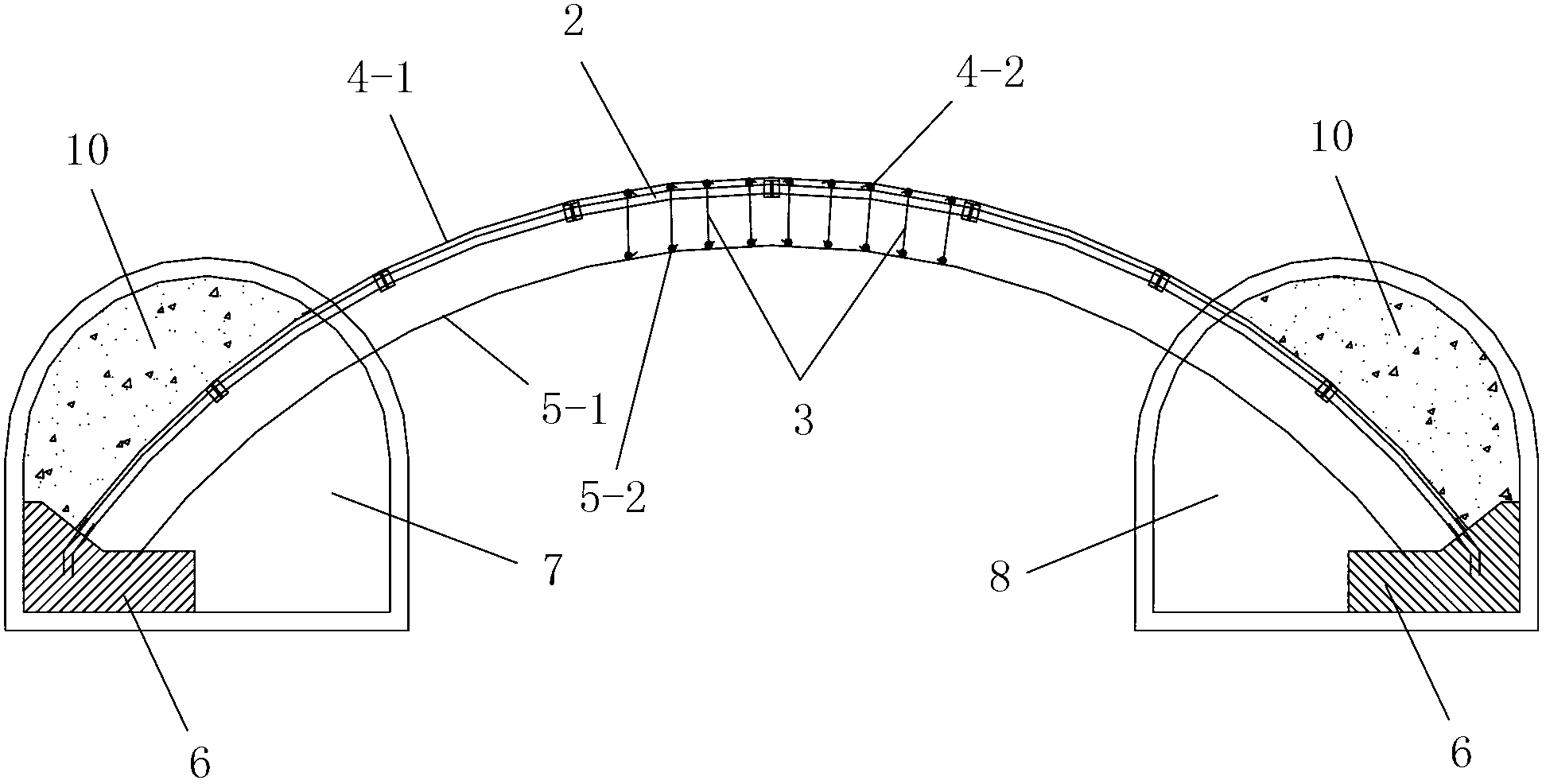

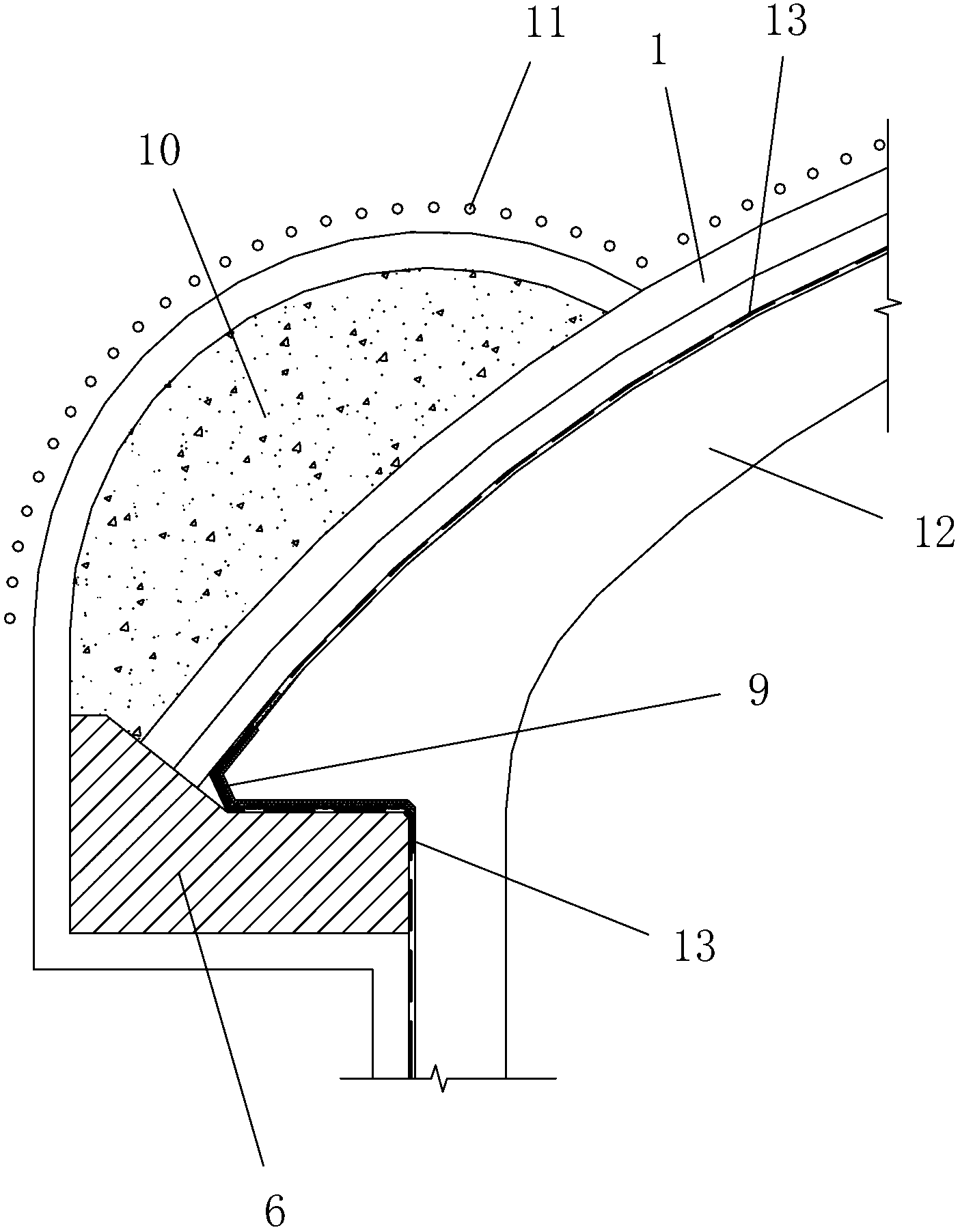

[0038] like figure 1Shown is a construction method for binding secondary lining steel bars in the arch of a large-span tunnel based on skeleton beams. The secondary lining steel bars in the arch of the tunnel to be bound include an outer layer of reinforcement mesh, an inner layer of reinforcement mesh located below the outer layer of reinforcement mesh And the vertical connecting bars connecting the outer layer steel mesh and the inner layer steel mesh, the outer layer steel mesh is arranged under the initial support structure 1 of the tunnel arch, and its construction status is detailed in figure 2 . During actual construction, the construction method for binding steel bars for the secondary lining of the arch of a large-span tunnel based on skeleton beams used in the present invention comprises the following steps:

[0039] Step 1. Skeleton beam installation: install a plurality of skeleton beams 2 under the initial support structure 1 of the tunnel arch from front to bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com