Liftable self-propelled continuous pushing system for large-span steel box beam and construction method thereof

A technology of jacking construction and steel box girder, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., which can solve problems such as dependence on hoisting equipment, large labor demand, and long cantilever time, so as to save hoisting and dismantling costs The effects of operating procedures, reducing safety risks, and shortening construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

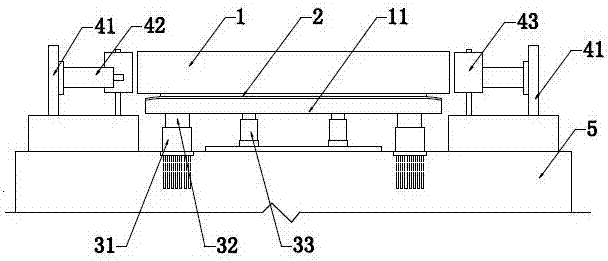

[0055] In this example, if Figure 1-Figure 8 As shown, the large-span steel box girder liftable self-propelled continuous jacking system is installed based on the pier body 5 and used for the jacking construction of the steel box girder 1, including the automatic adjustment device for the elevation of the pier top slideway, the automatic positioning continuous jacking device, The horizontal limit and deviation correction device and the pre-buried steel plate longitudinally on the top of the pier body 5 during the concrete construction of the pier body 5, the automatic adjustment device for the elevation of the pier top slideway and the lateral limit and deviation correction device are all fixedly installed on the preset steel plate;

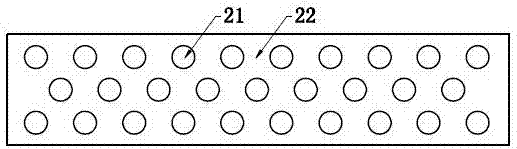

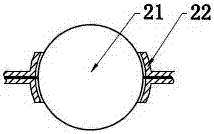

[0056] The automatic adjustment device for the elevation of the pier top slideway is provided with two parallel pier top slideways 11, and the tops of the two pier top slideways 11 are freely placed between the top surface of the pier top slidewa...

Embodiment 2

[0066] In this example, if Figure 9 As shown, the self-propelled continuous jacking construction method of the long-span steel box girder is suitable for all long-span jacking constructions on high-speed railways, ordinary railways, highways, rivers, deep valleys and other construction obstacles. In the process, the automatic positioning continuous jacking device, the automatic adjustment device for the elevation of the pier top slideway, and the lateral limit and deviation correction device are used together to form a large-span, liftable, self-propelled continuous jacking, and no offset. Steel box girder 1 top push construction method.

[0067] The self-propelled continuous jacking construction method of the large-span steel box girder specifically includes the following steps:

[0068] Step S1: Measurement and positioning. According to the design line direction, accurately measure the position of the center line of the steel box girder 1 and whether the setting direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com