Patents

Literature

3249results about How to "Save installation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

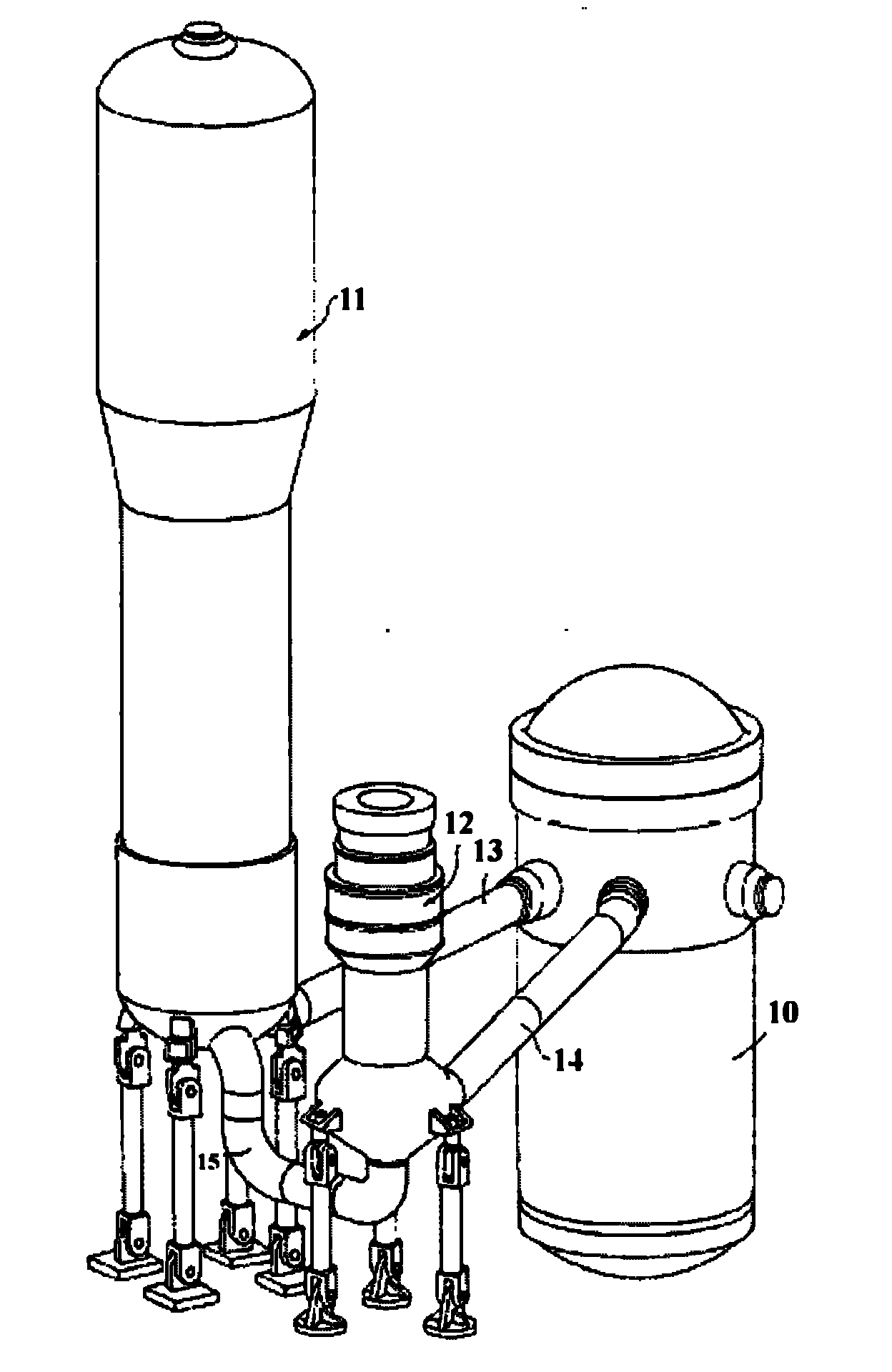

System used for providing mobile power

PendingCN110159432ASave installation timeEasy to transportEngine fuctionsGas turbine plantsAutomotive engineeringRoad transport

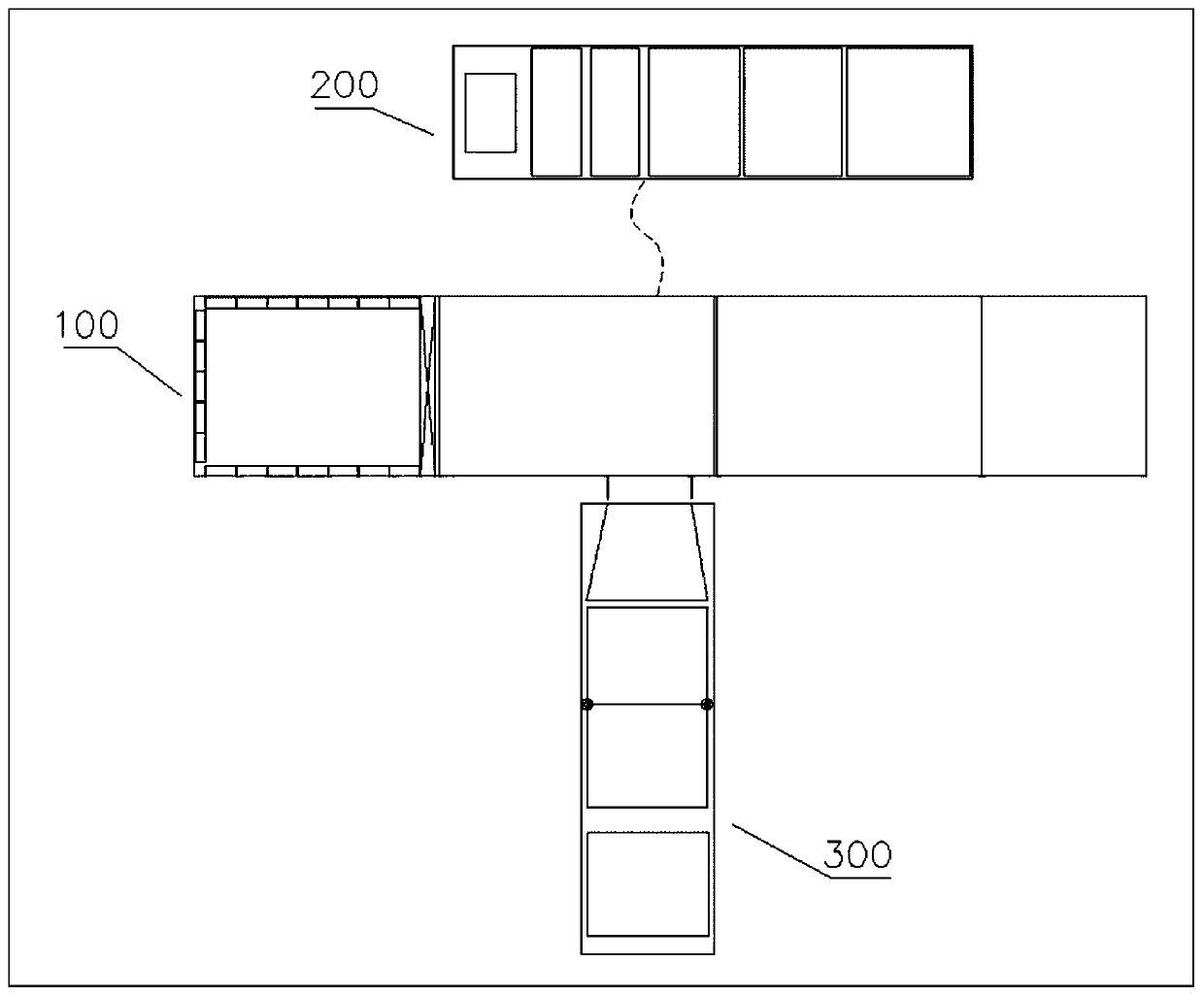

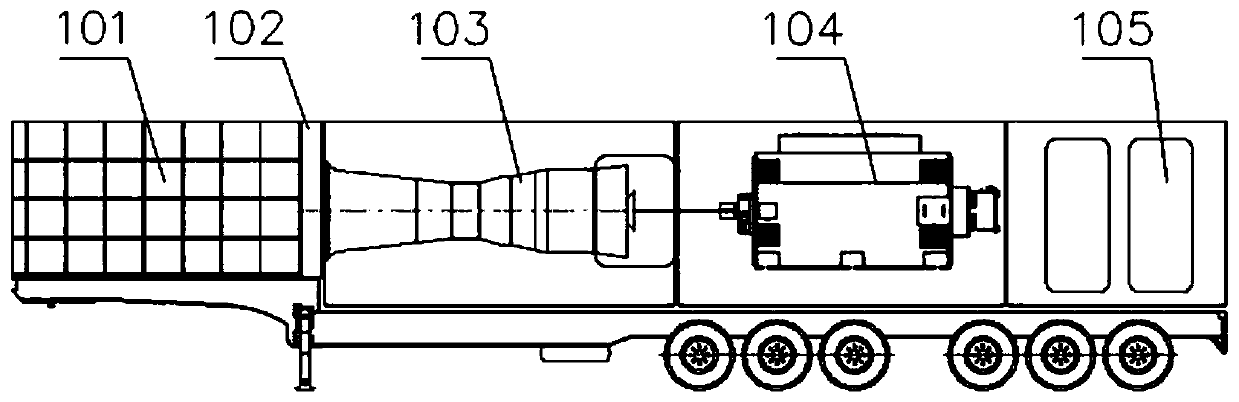

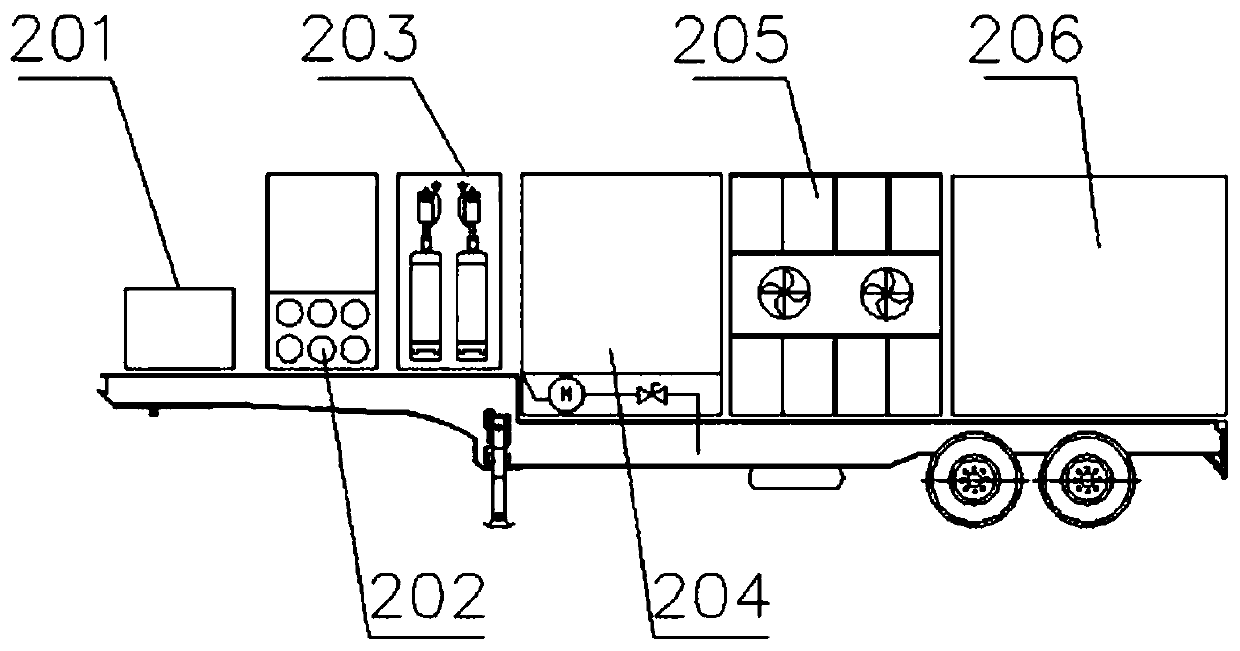

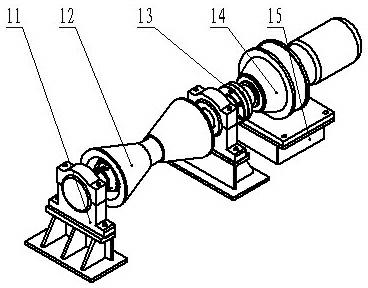

The invention discloses a system used for providing mobile power. Through reasonable integrating of a device needed by a fracture site power supply system, a connection cable and a connection hose, the system is divided into three transport carriers for moving and effective connection, on the first transport tool, an air inlet assembly and a turbine power generation system are combined together, mounted and directly transported to the customer site, and the mounting time of the air inlet assembly and the turbine power generation system on the user site is saved. An exhaust chimney and an exhaust silencer are designed on two different positions, and the waste gas exhaust need during work can be met while the road transport need is met.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

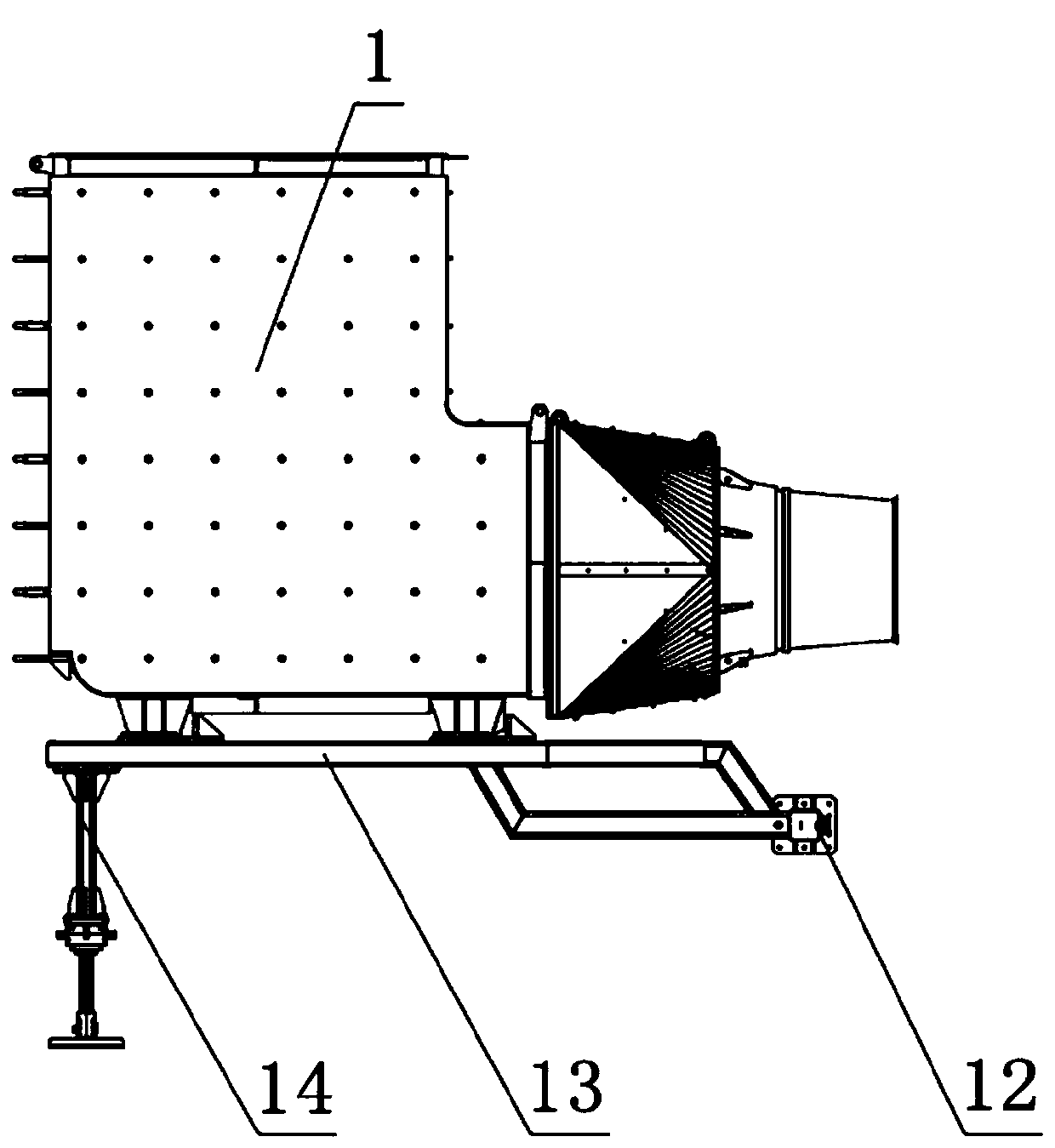

Vehicle-mounted type gas turbine generator set

PendingCN111412064ASave installation timeImprove shock absorptionVehicle fittings for liftingGas turbine plantsAutomotive engineeringElectric generator

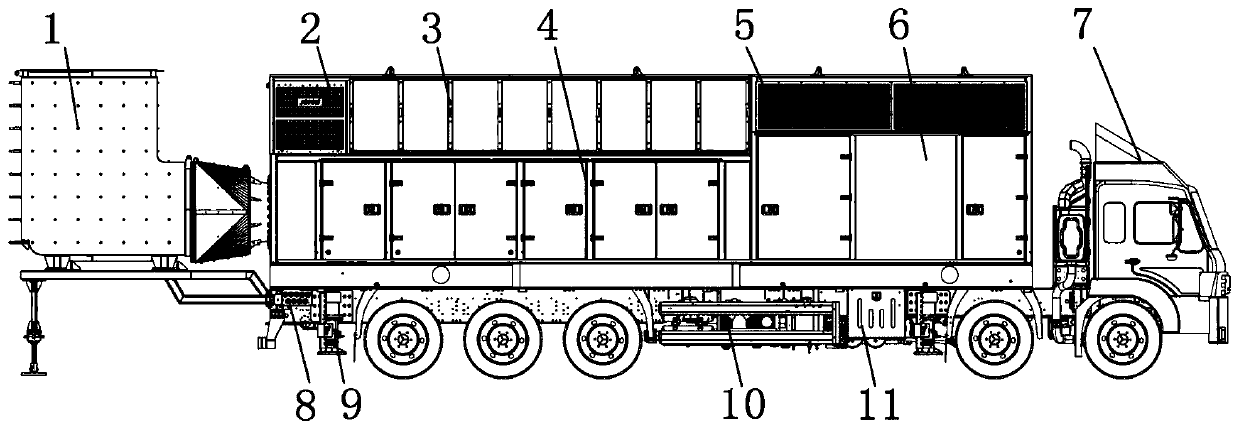

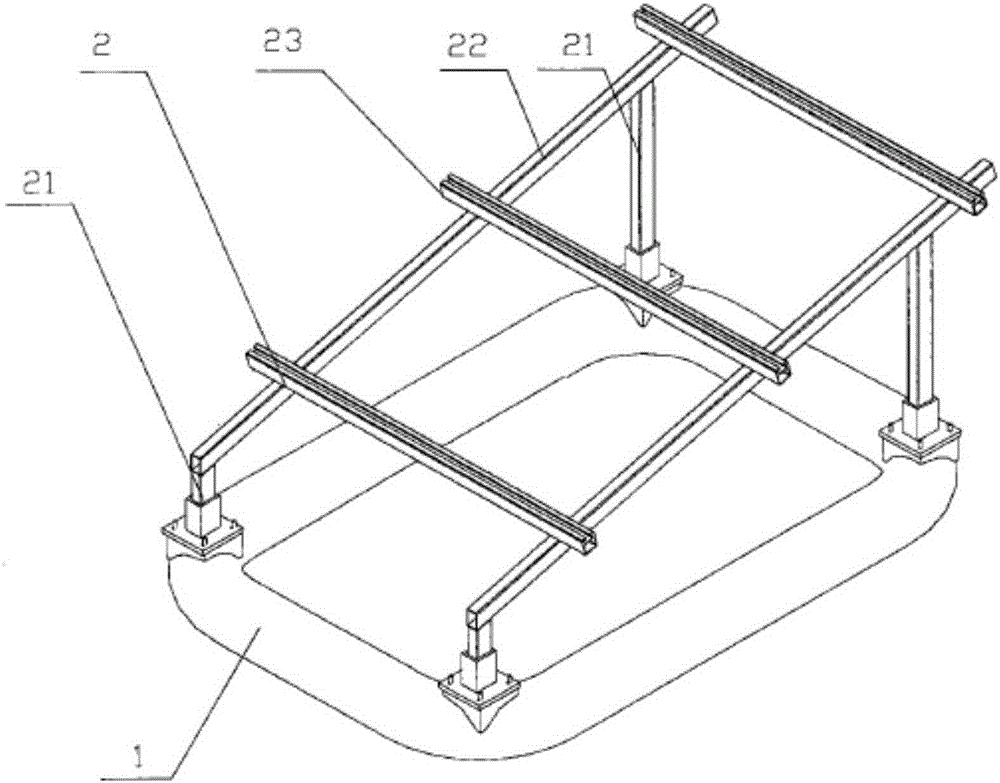

The invention discloses a vehicle-mounted type gas turbine generator set which comprises a chassis, a power bin, an electrical bin, a gas inlet filtering system, a ventilation filtering system and hydraulic leveling systems. The power bin, the electrical bin, the gas inlet filtering system and the ventilation filtering system are arranged on the chassis. The hydraulic leveling systems are arrangedon the two sides of the lower portion of the chassis. The power bin and the electrical bin are arranged at the two ends of the chassis correspondingly. The gas inlet filtering system is arranged on the top of the power bin. The ventilation filtering system is arranged on the top of the electrical bin. A gas turbine, a generator, a gearbox and a start motor are installed in the power bin. The vehicle-mounted type gas turbine generator set has the advantages that by selecting the chassis with proper bearing capacity and excellent damping performance and integrating the high-power generator seton the chassis through reasonable space optimized layout, the vehicle-mounted type gas turbine generator set is high in output power, convenient to transport and move, quick to install on site and high in adaptability.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

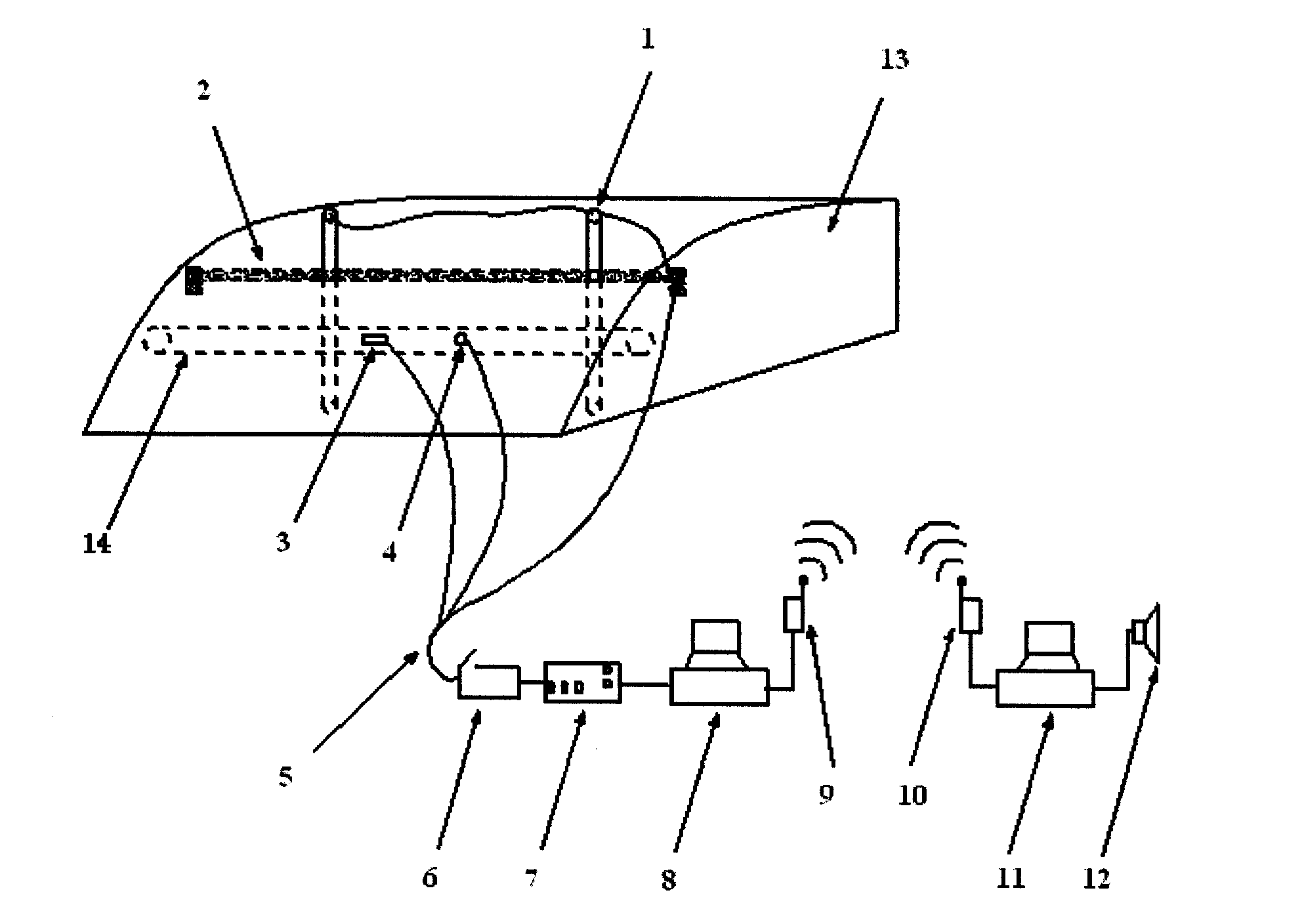

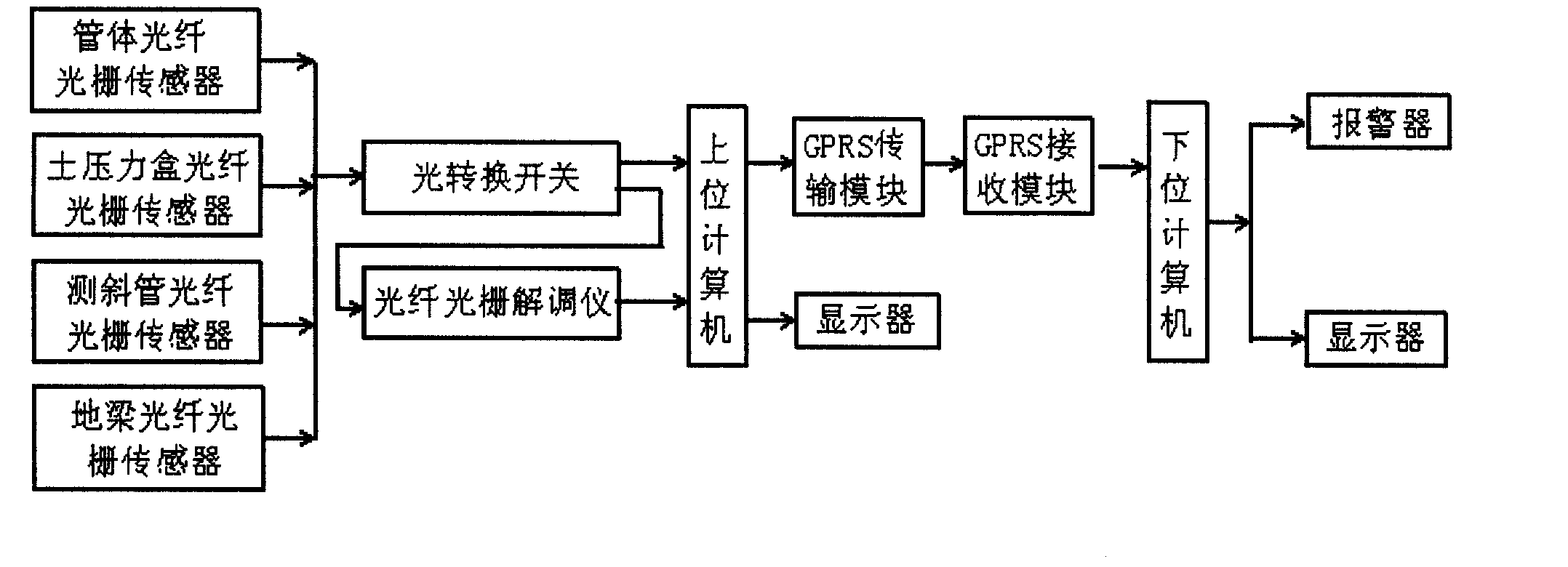

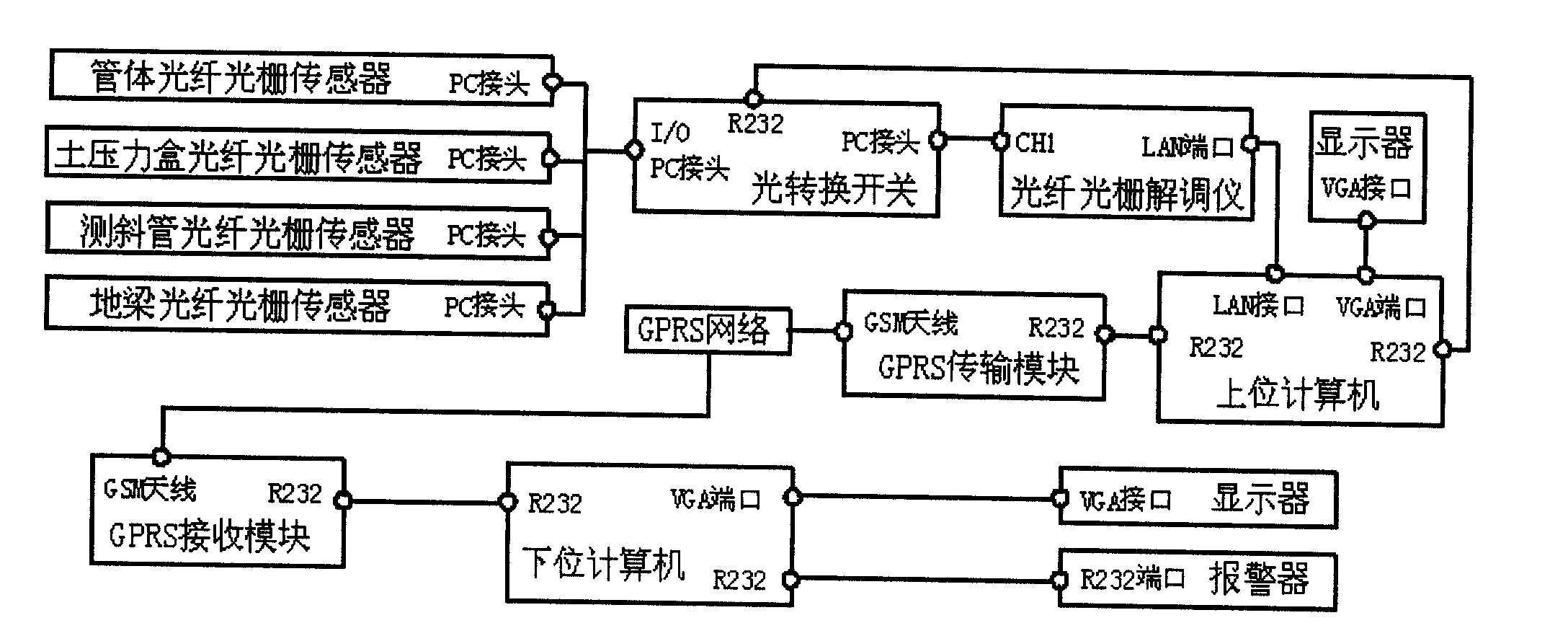

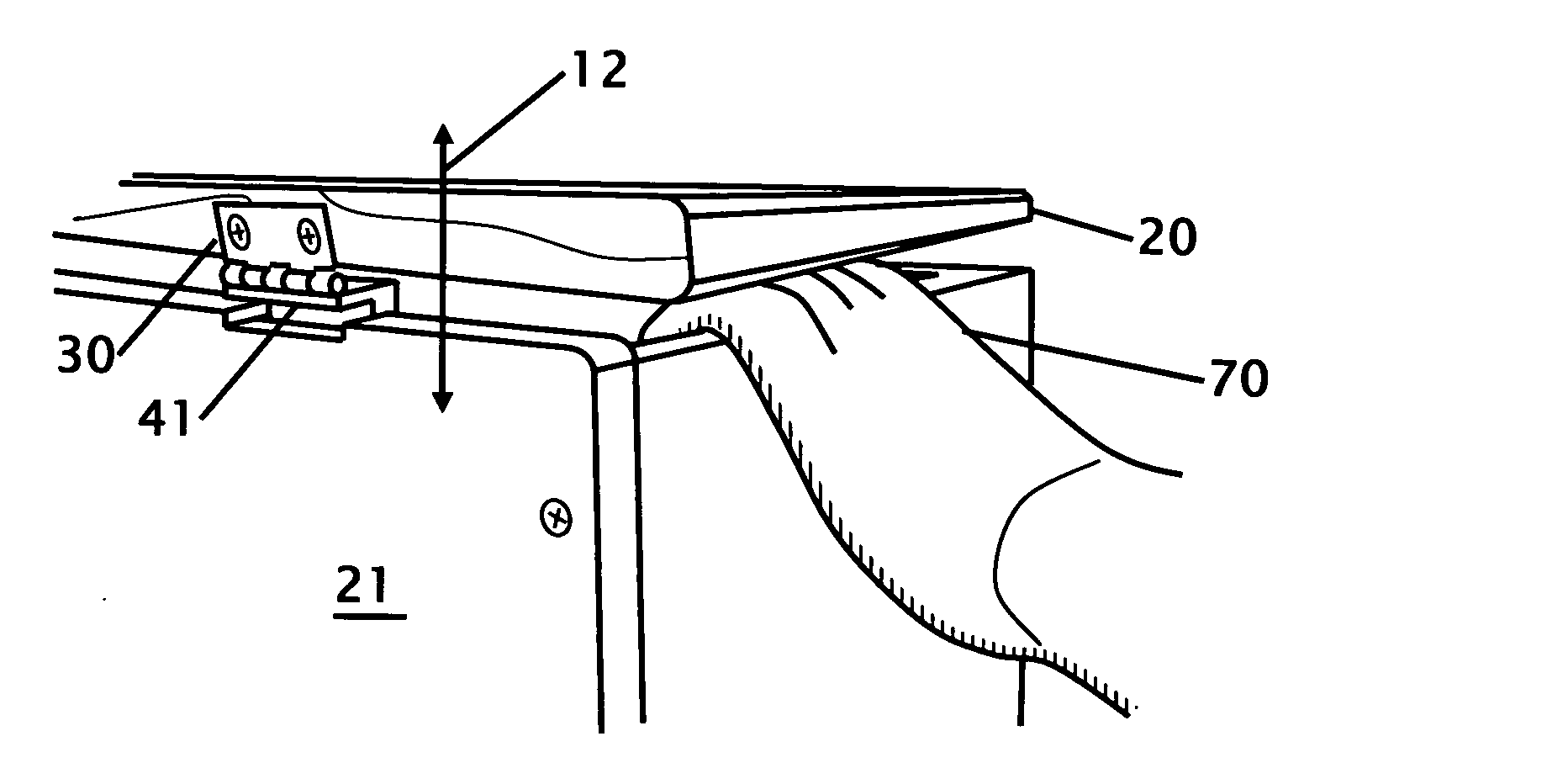

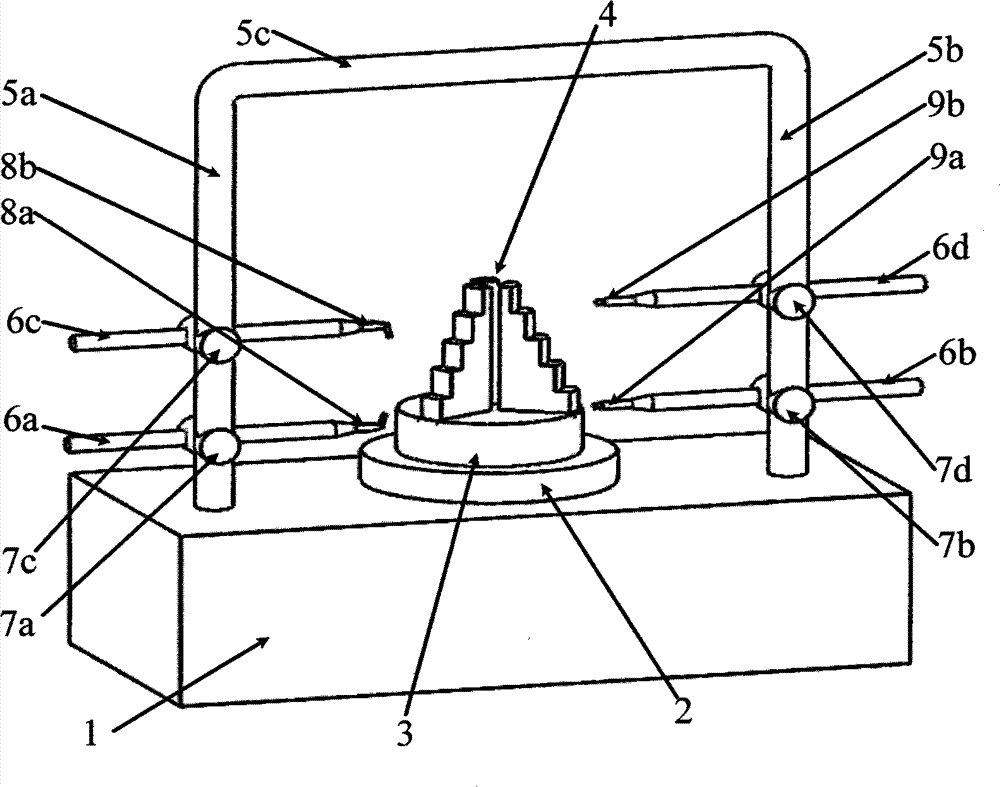

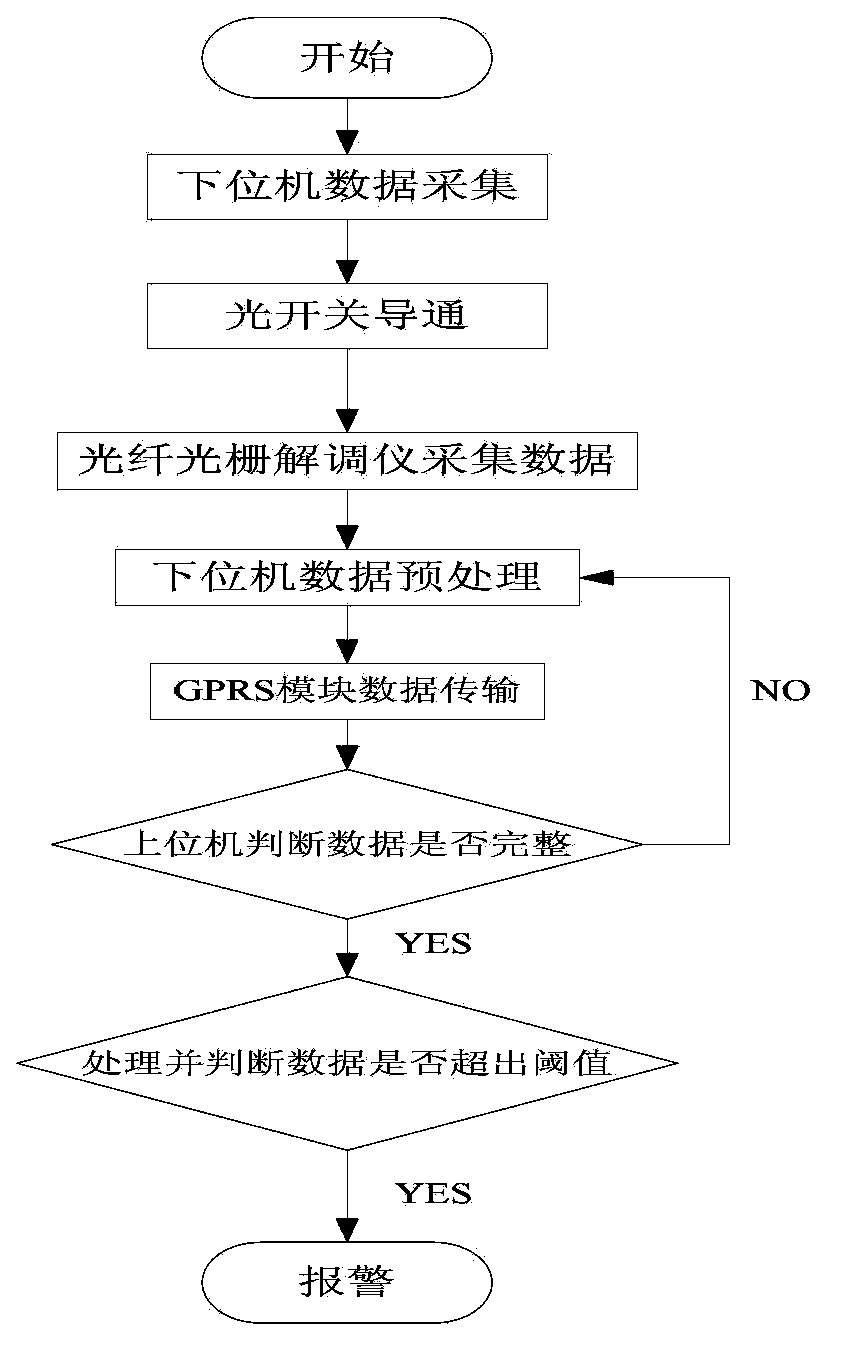

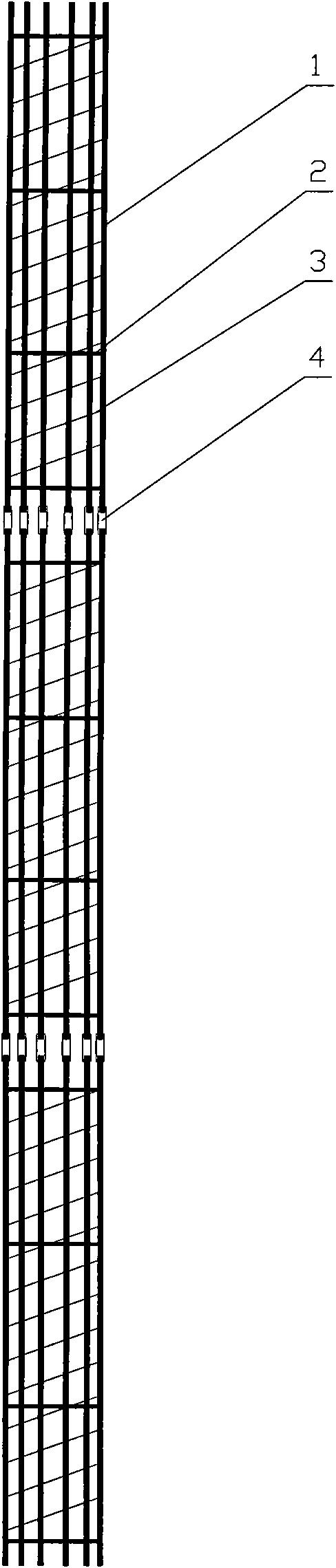

Method and system for monitoring and warning pipeline landslide and method for constructing system

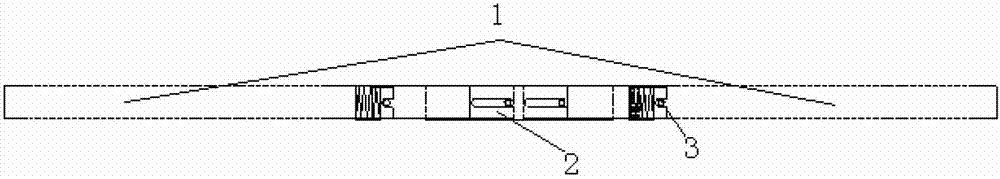

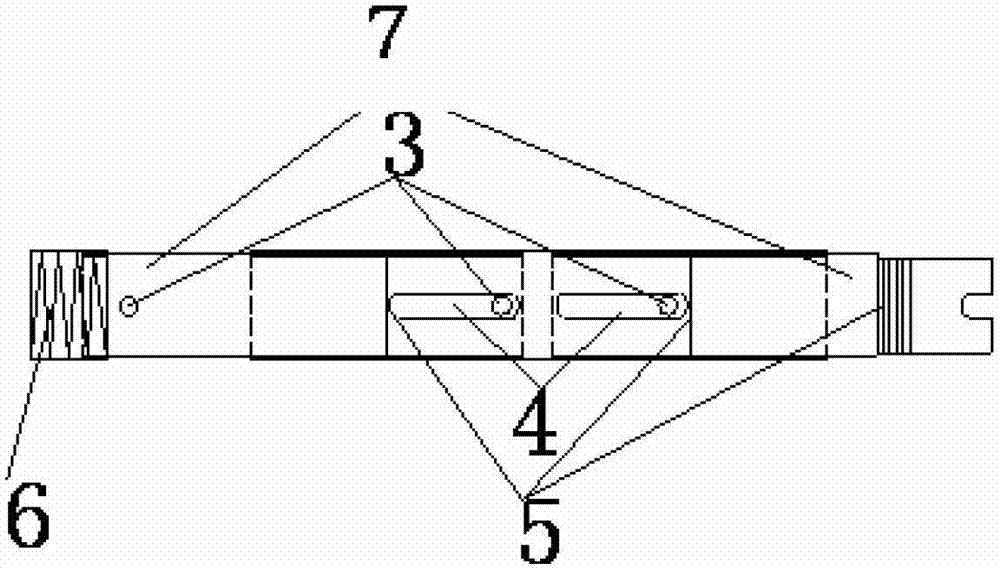

ActiveCN101667324ASimple structureReduce volumeForce measurement by measuring optical property variationUsing optical meansFiberGrating

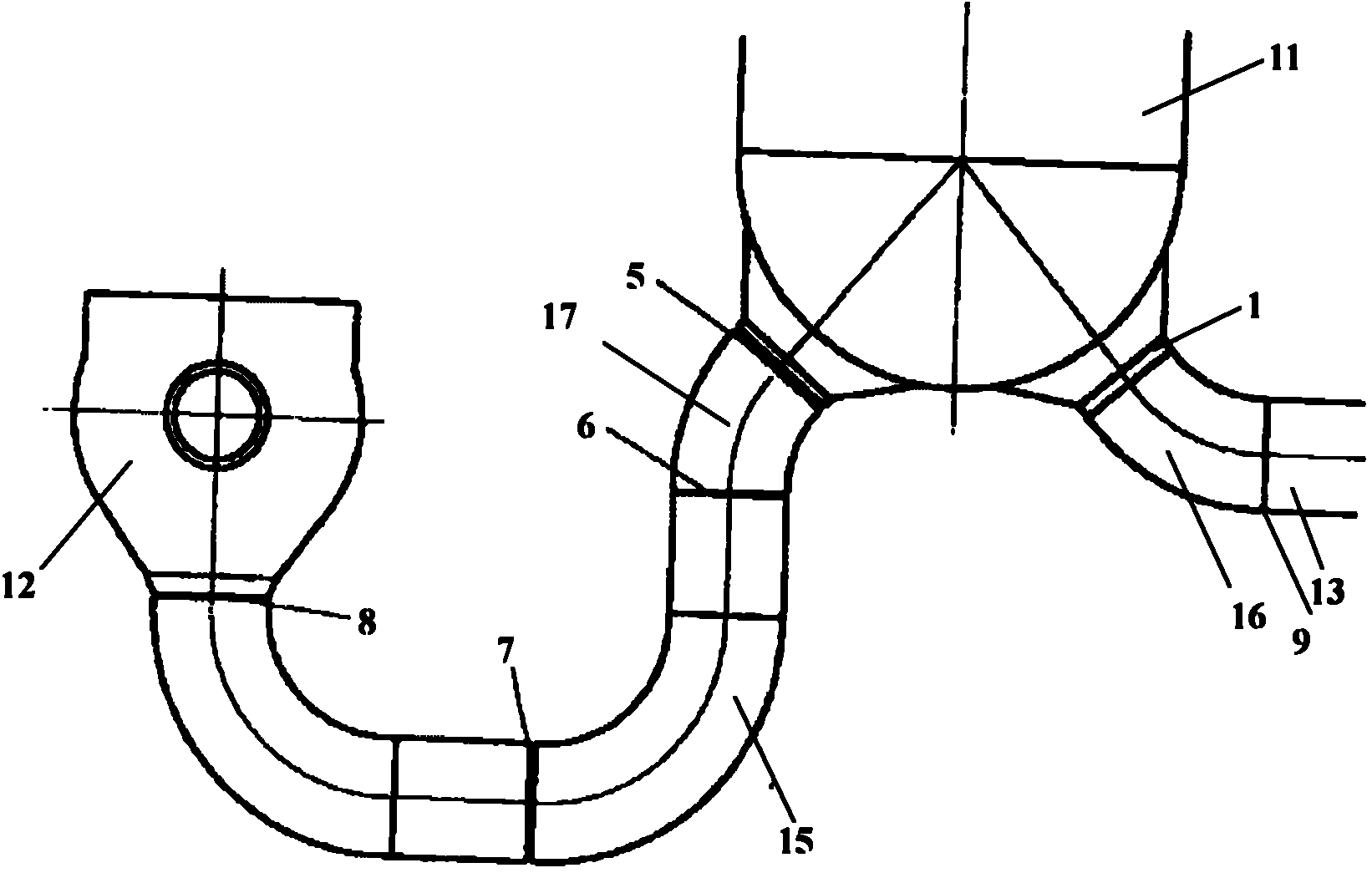

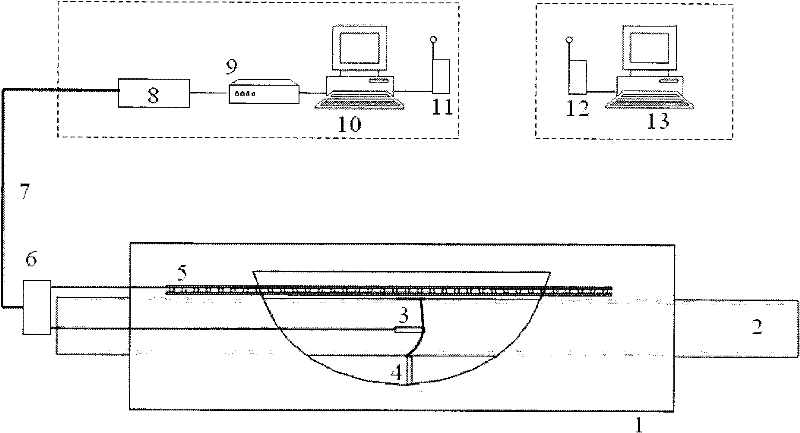

The invention relates to a method and a system for monitoring and warning a pipeline landslide based on a fiber Bragg grating and a method for constructing the system. The monitoring is performed on four parts including landslide depth displacement, landslide surface displacement, thrust of landslide on a pipeline and pipeline strain, and comprises the steps of: firstly, inserting an inclinometerpipe (1) pasted with a fiber Bragg grating sensor from the landslide (13) to all potential sliding surfaces (15); secondly, embedding a slender concrete ground beam (2) of which two ends are fixedly restrained and the axial direction of a central reinforced bar (17) is stuck to a ground beam fiber Bragg grating sensor (20) in a direction vertical to the deformation direction of the landslide (13)below the surface of the landslide (13); thirdly, measuring the thrust of the landslide (13) on the pipeline by using an earth pressure cell fiber Bragg grating sensor (4) fixed on the pipeline (14);and fourthly, arranging monitoring sections on edges on two sides and the pipeline (14) in the center of the landslide (13), and uniformly arranging three pipe strain fiber Bragg grating sensors (3) on each monitoring section to monitor the axial strain of the pipeline (14).

Owner:PIPECHINA SOUTH CHINA CO

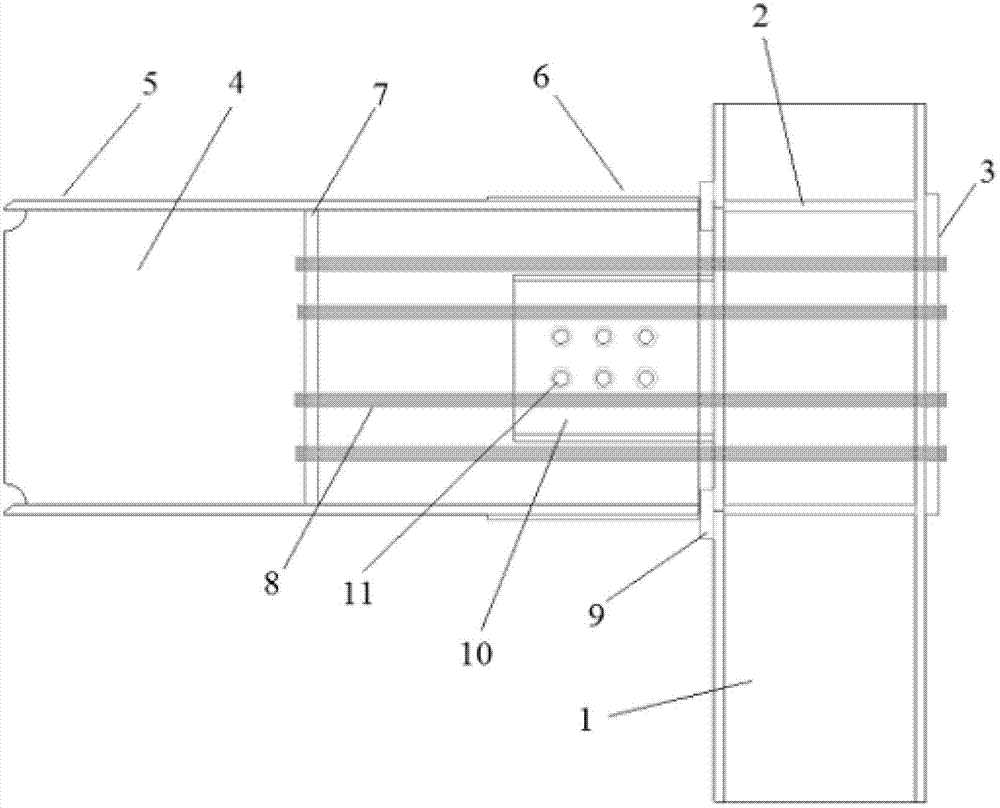

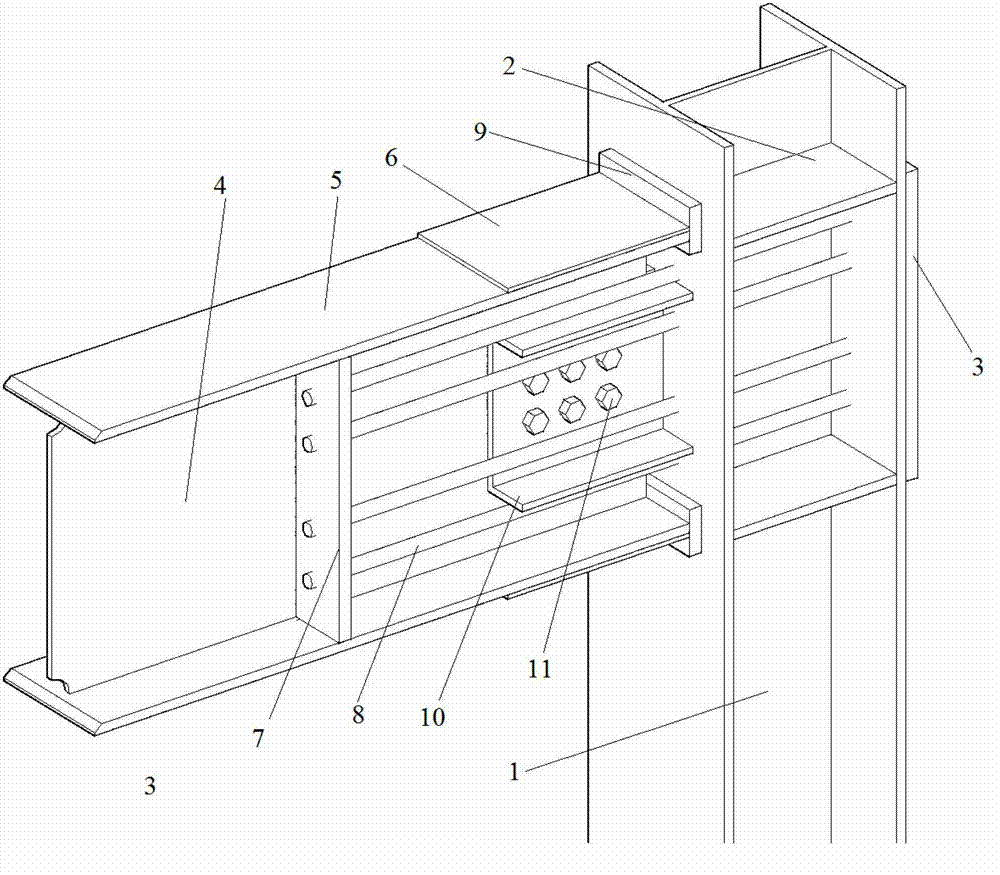

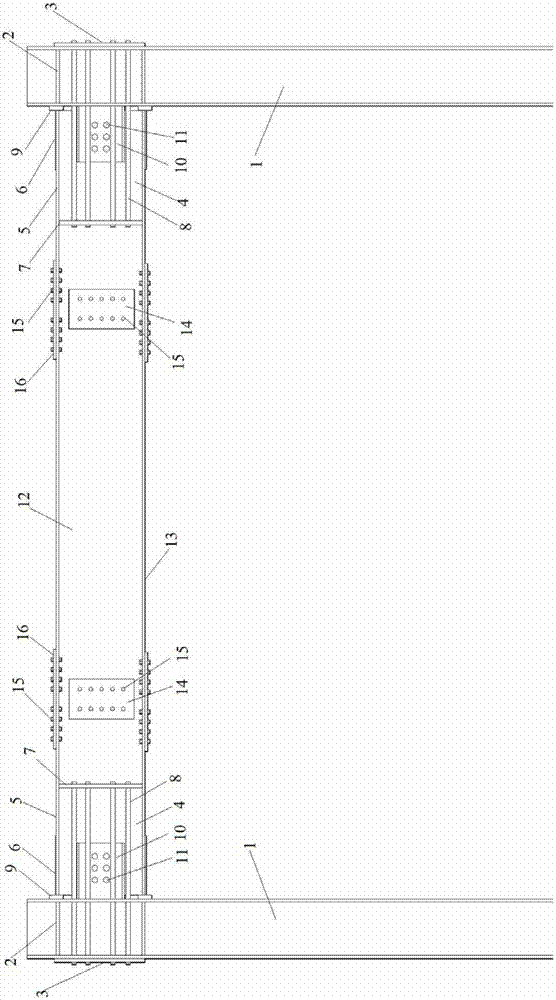

Steel frame precast prestressed beam column joint with post-earthquake recovering function

InactiveCN102817413AEasy constructionImprove construction qualityBuilding material handlingShock proofingPre stressSteel frame

The invention relates to a steel frame precast prestressed beam column joint with a post-earthquake recovering function. The joint comprises a steel frame column, a short beam section, a beam column connection device and an energy consumption device, wherein the steel frame column comprises a steel column, a column reinforced rib and a column reinforced plate; the short beam section comprises a short beam section web, a short beam section flange and a short beam section flange reinforced plate; the beam column connection device comprises a short beam section web reinforced rib, a prestressed cable and a beam end top plate; the energy consumption device comprises two channel steels and a high-strength bolt; and the two short beams are integrally connected with the column in a factory through a tension prestressed cable and two short beam section web reinforced ribs. When the earthquake action achieves a certain degree, the contact surface of the beam and the column is opened; the high-strength bolt is in friction energy dissipation so as to avoid destroying main components, such as beams and columns After the earthquake, the beams can be recovered to the former vertical position under the action of the prestress.

Owner:BEIJING UNIV OF TECH +1

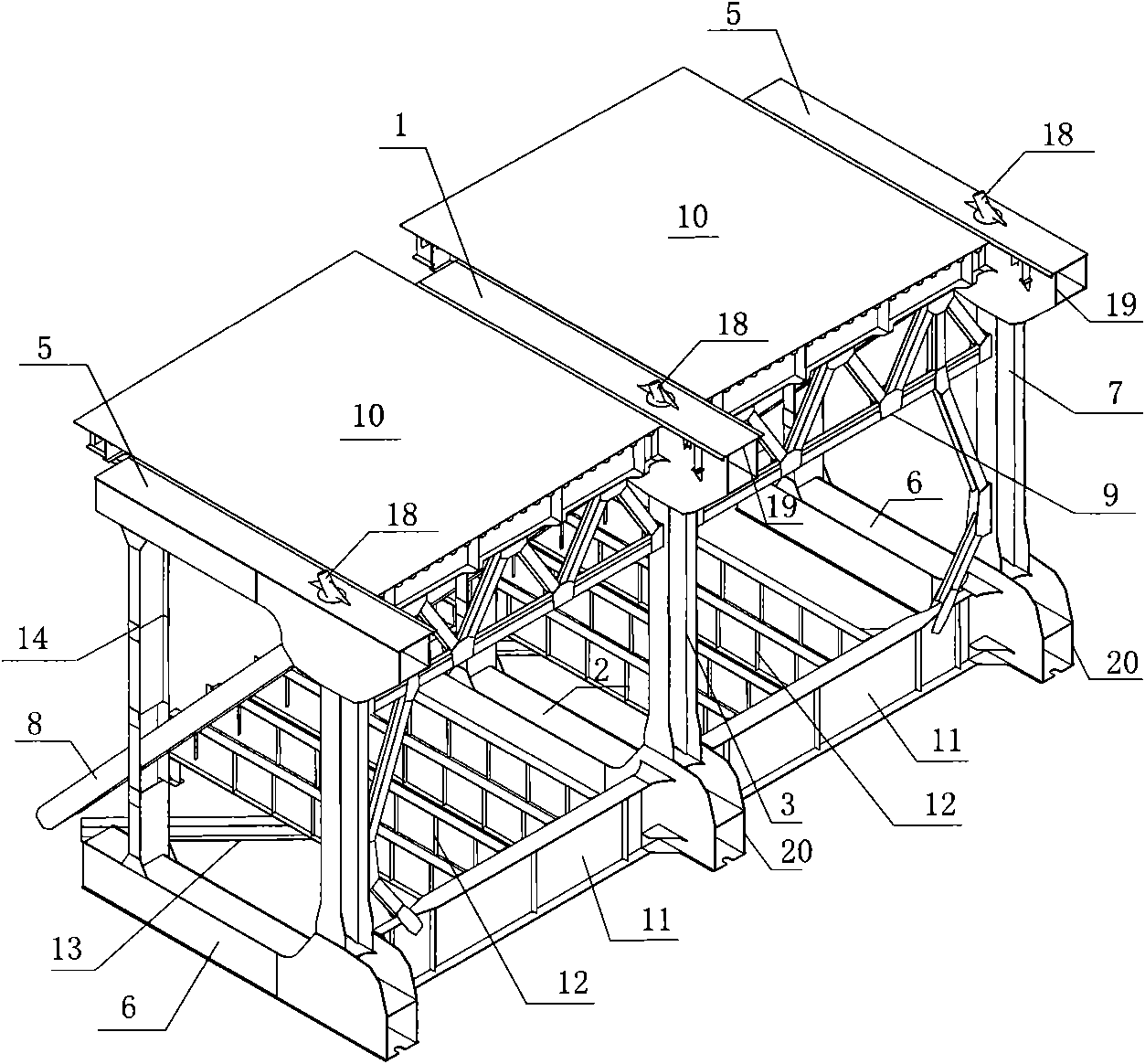

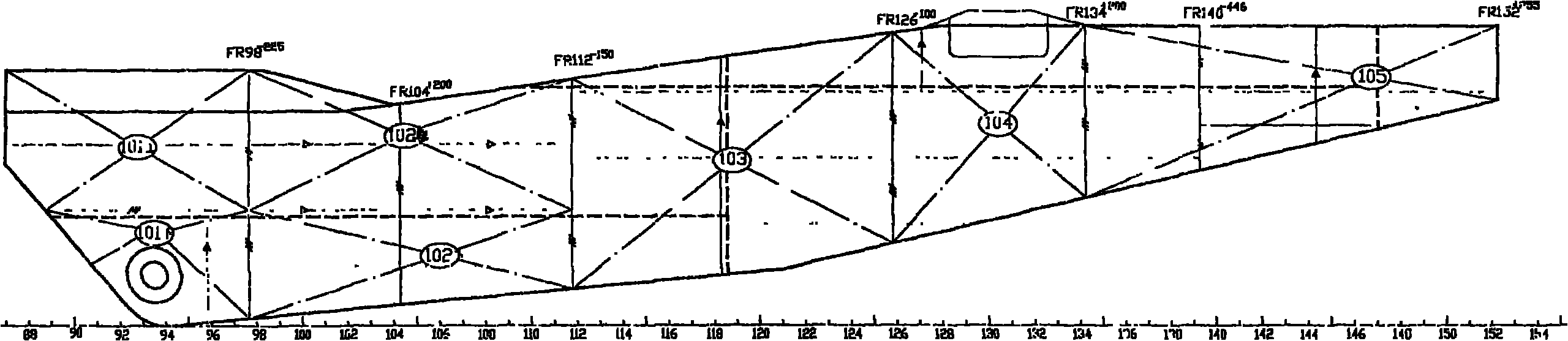

Three-truss main girder structure of highway and railway bi-purpose cable-stayed bridge and installation method thereof

ActiveCN101603288AImprove installation efficiencySave installation timeBridge erection/assemblyLoad-engaging elementsButt jointCable stayed

The invention relates to a three-truss main girder structure of a highway and railway bi-purpose cable-stayed bridge and an installation method thereof, relating to the technologies of designing and constructing a heavy load and long span highway and railway bi-purpose cable-stayed bridge. The structure of three main trusses comprises a middle truss piece and side truss pieces arranged on both sides of the middle truss piece, wherein an orthotropic slab and a transverse bracing truss are arranged between the upper edges of the middle truss piece and each side truss piece, and a railroad transverse girder, a railroad longitudinal girder and a horizontal bracing cross bridging are arranged between the lower edges of the middle truss piece and each side truss piece; and the invention provides the installation method adopting adaptive pre-splicing of multiple truss-sections, arrangement of temporary constructional rod pieces, integral lifting of each truss section and multi-node simultaneous alignment. The invention has the beneficial effects of: 1. pushing the highway and railway bi-purpose cable-stayed bridge to develop towards the direction of large span and heavy loading, 2. improving the installation efficiency and quality, 3. reducing the quantity of welding lines of construction sites, 4. innovatively practicing the multi-point simultaneous butt joint technology, 5. adopting the temporary rod pieces for solving the problems of unstability and large deformation in the processes of delivering and lifting the truss sections, 6. strengthening the adaptability of adjacent truss sections, and 7. solving the problems of inconsistent deformation of the middle and the side trusses and inconsistent centre-of-gravity positions of the truss sections.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD +1

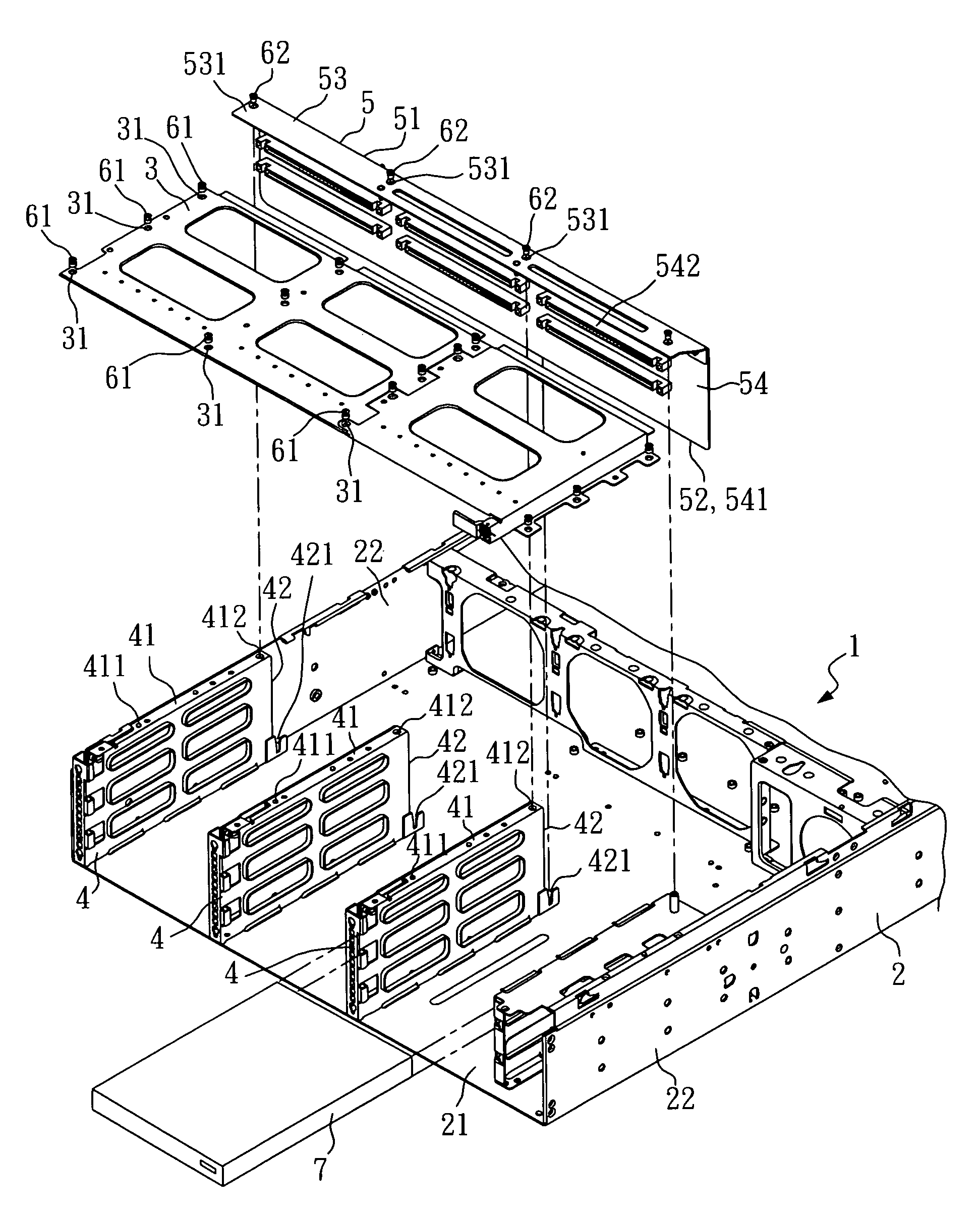

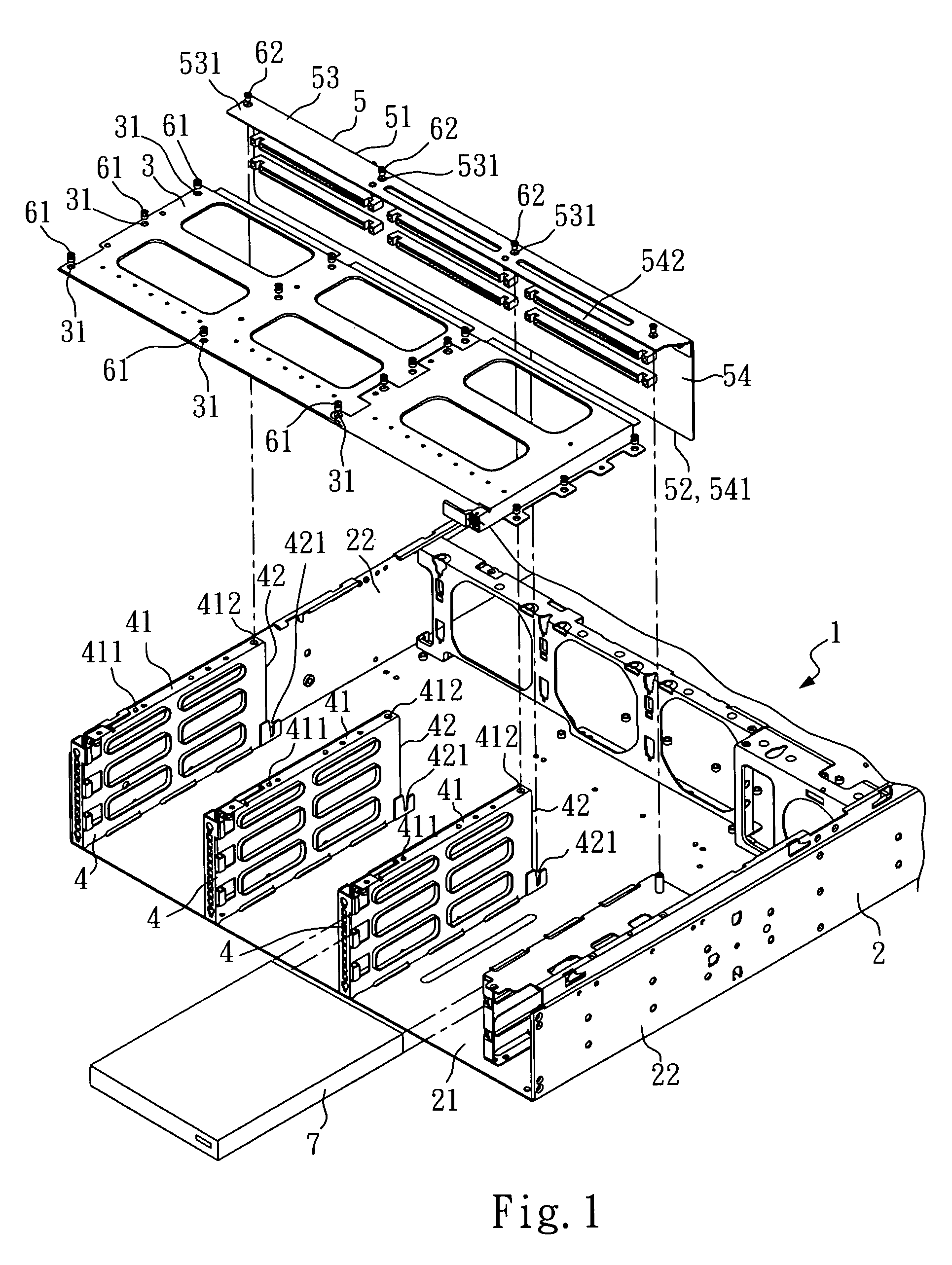

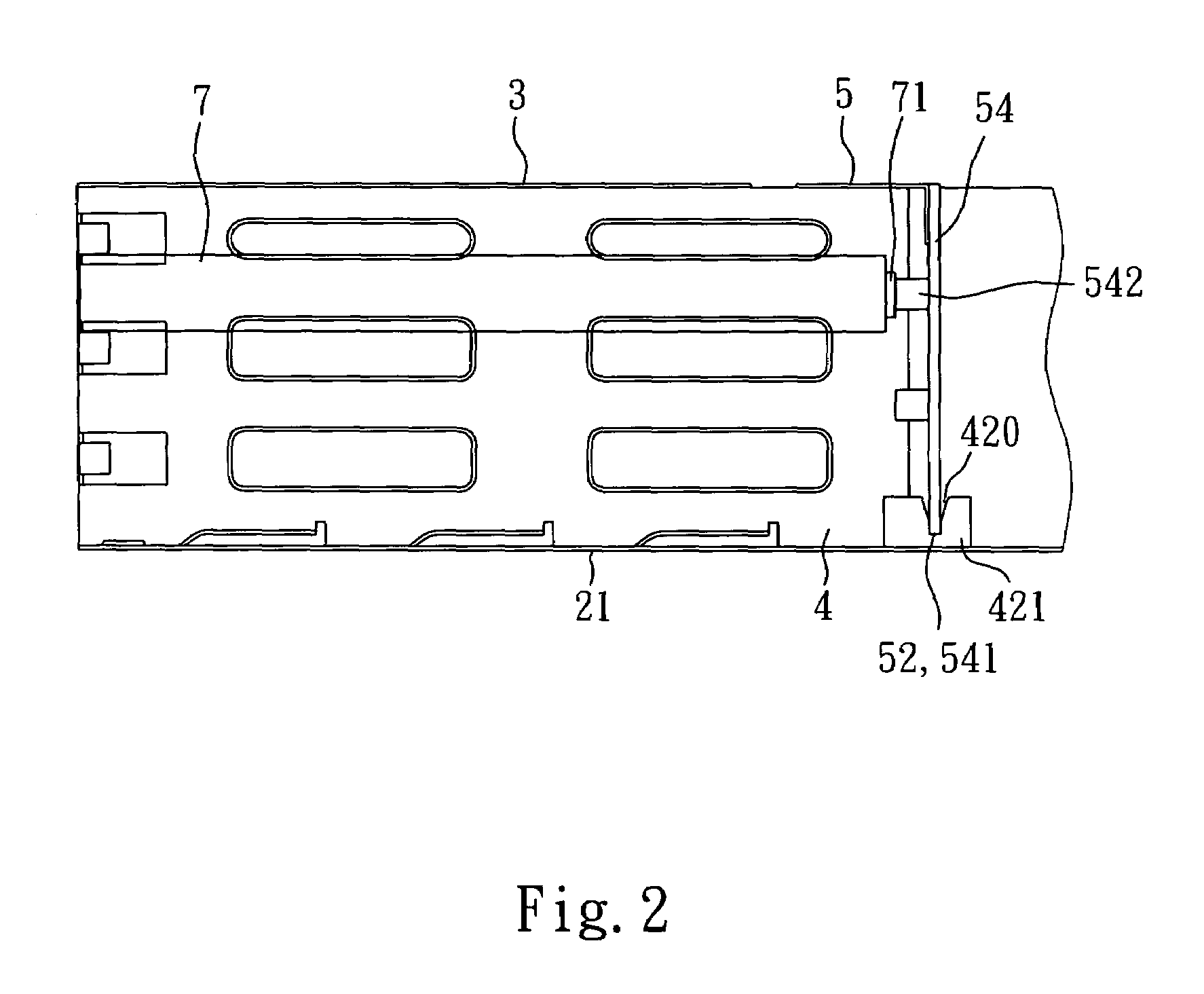

Support frame structure

InactiveUS6999319B2Quickly and accurately be set into positionHighly detachableSubstation/switching arrangement detailsSemiconductor/solid-state device detailsComputerized systemEngineering

A support frame structure mounted inside the housing of a computer system for supporting electronic drives is disclosed to include a plurality of upright partition plates affixed to the bottom panel between two upright side panels of the housing, a cover plate fastened to the upright side panels of the housing and covered on the upright partition plates, and a detachable upright back panel, which has a bottom side engaged into notched locating strips at the back side of each upright partition plate and a top side terminating in a forwardly extended bend, which is covered on a rear part of the top of each upright partition plate and affixed thereto with a screw.

Owner:TATUNG COMPANY

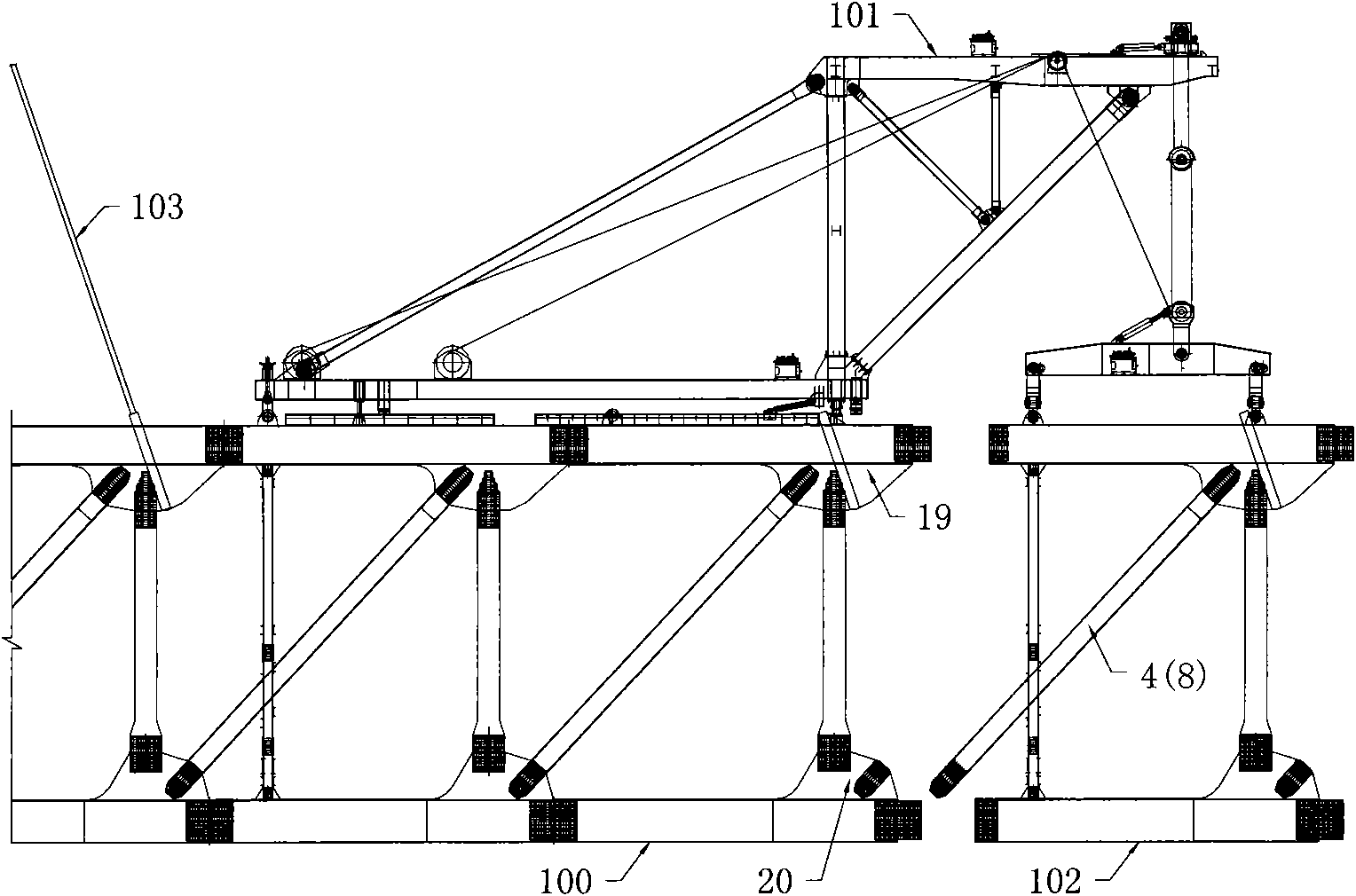

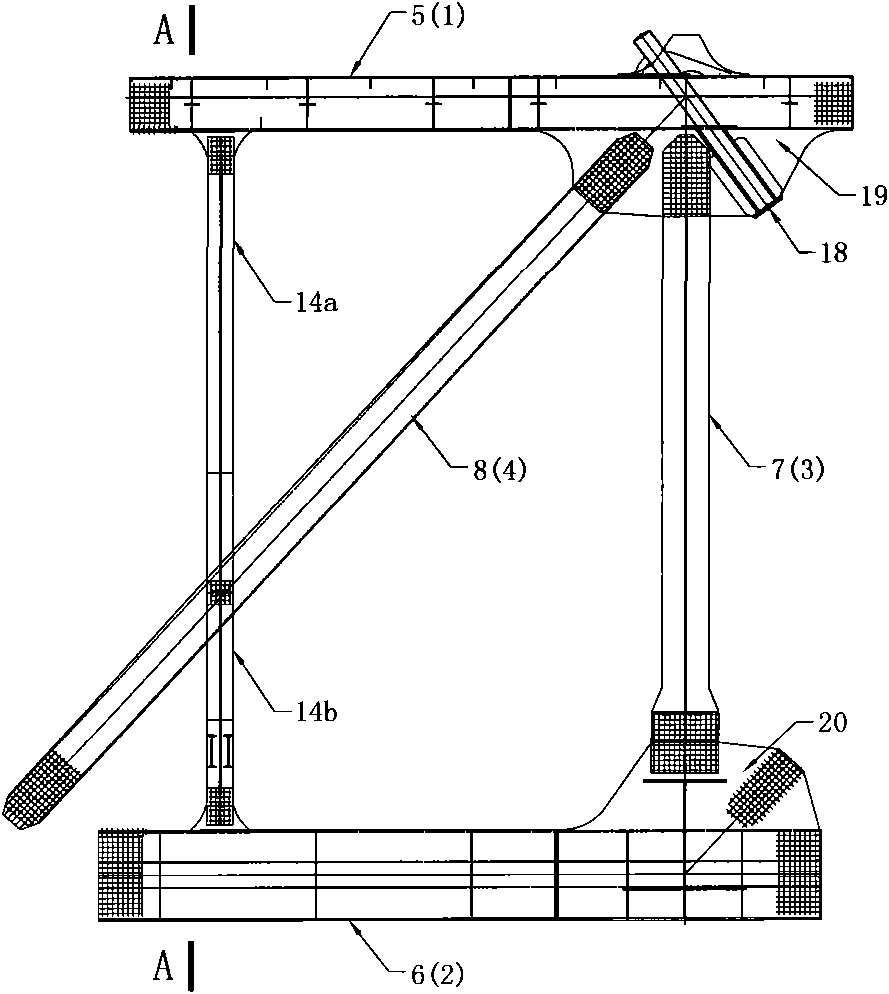

Preparation and on-board installation process of crane span of cutter suction dredger

InactiveCN101811553ASave installation timeShorten the manufacturing cycleVessel partsOn boardEngineering

The invention discloses a preparation and on-board installation process of crane span of cutter suction dredger. The process comprises the following steps: preparing the jig of a crane span, performing sectionalized assembly of the crane span, performing wire-drawing to the trunnion of the crane span, performing wire-drawing to the trunnion of a hull, closing shipways, fixing the crane span, installing bolts, etc. The process of the invention has the advantages of convenient construction and good construction effect; and the installation time of the crane span is fully reduced, and the total cycle time for the preparation of ships is shortened.

Owner:南通港闸船舶制造有限公司

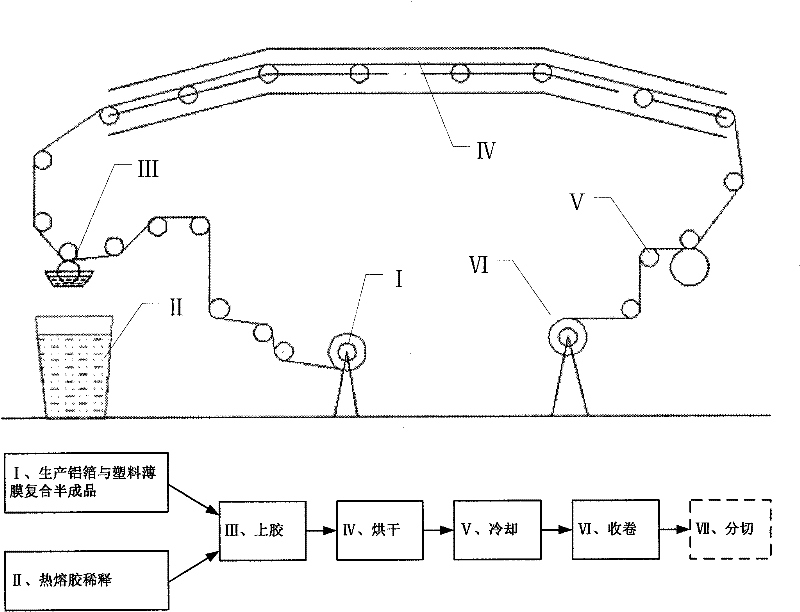

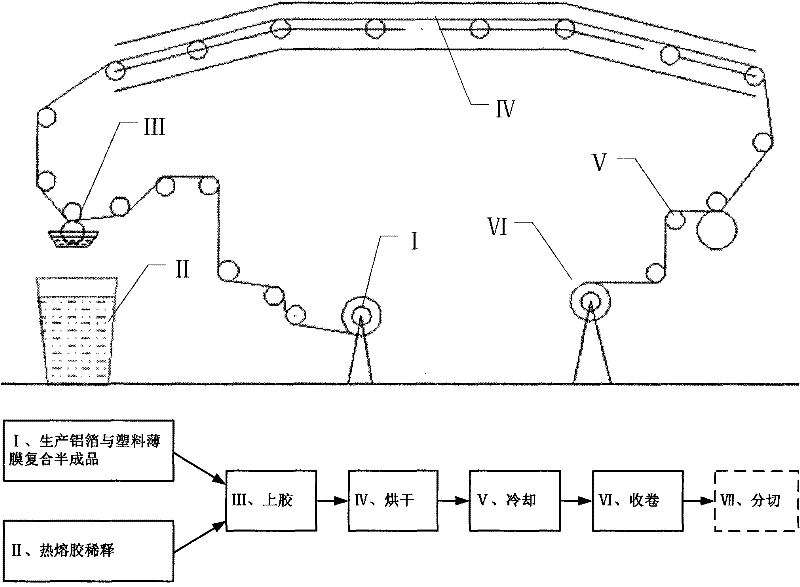

Method for producing hot-melt-adhesive aluminum-plastic composite tape

ActiveCN102250557AGood adhesionThe test effect is goodFilm/foil adhesivesLaminationProduction lineWork in process

The invention discloses a method for producing a hot-melt-adhesive aluminum-plastic composite tape. The method provided by the invention comprises the following steps of: manufacturing a composite semi-finished product of aluminum foil and plastic thin film, preparing a hot melt adhesive, coating the hot melt adhesive, drying the hot melt adhesive, cooling, coiling, and cutting. On the productionline of a PVC (Poly Vinyl Chloride) cable sheath, the hot-melt-adhesive aluminum-plastic composite tape and the sheath material can be bonded together by utilizing the temperature of the sheath when the PVC cable sheath material is extruded; the adhesive force is strong and the testing performance is good; and when a user strips the cable PVC sheath, the hot-melt-adhesive aluminum-plastic composite tape can be easily stripped so that the procedure of stripping two times is omitted, the mounting time is greatly saved and the damage on the cable is reduced. The hot-melt-adhesive aluminum-plastic composite tape manufactured with the method can be widely applied to a communication cable industry, and can propel the application reformation of the communication cable industry on the hot-melt-adhesive aluminum-plastic composite tape and also exploit a new application market of the hot melt adhesive.

Owner:FLY DRAGON PRECISION TECH SUZHOU CO LTD

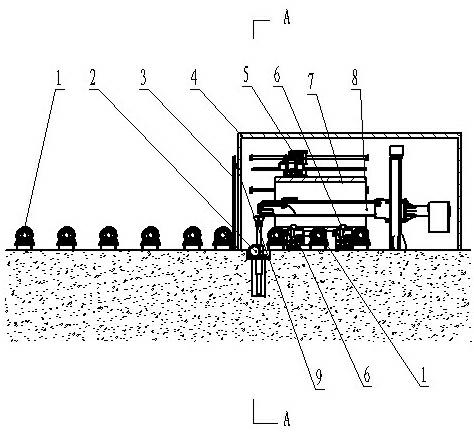

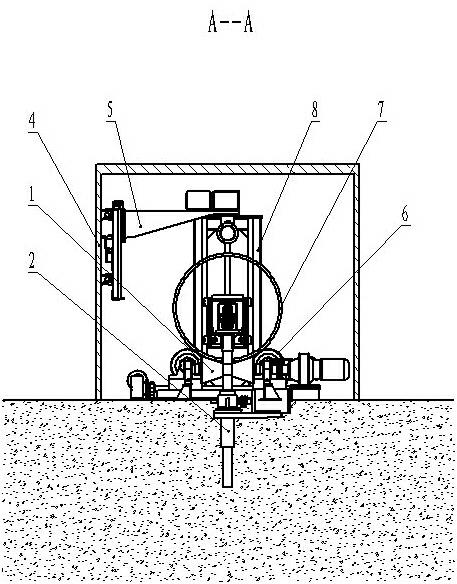

Detection device for steel tube weld seams through X-ray real-time imaging

ActiveCN102608140AShorten the lengthSave installation timeMaterial analysis by transmitting radiationSoft x rayX-ray

The invention relates to a detection device for steel tube weld seams through X-ray real-time imaging. The detection device comprises a steel tube detection conveyor line formed by conveyor roller joined parts fixed on mill floor foundation and a detection protection chamber which is arranged at the conveyor roller joined parts at the tail end of the steel tube detection conveyor line, is connected with the steel tube detection conveyor line and is in a same floor foundation with the steel tube detection conveyor line; the conveyor roller joined parts used for bearing workpieces to be detected are arranged in the detection protection chamber; lifting rotating wheel joined parts are arranged between the conveyor roller joined parts; and the detection protection chamber is internally provided with an X-ray receiver joined part, an arm jack joined part and an X-ray pipe support joined part. The detection device provided by the invention can be used for substituting the existing workpiecedetecting car in detecting the steel tube weld seams through the X-ray real-time imaging, so as to meet the requirements on detecting circumferential weld seams, straight weld seams and spiral weld seams of tubular objects. The detection device occupies a small area, is low in energy consumption and high in detection efficiency and is convenient for installing, so that a large amount of money andenergy is saved for users and the cost is reduced.

Owner:DONGDAN AOLONG RADIATIVE INSTR GRP

Floating member used for waterborne photovoltaic power station and connection method thereof

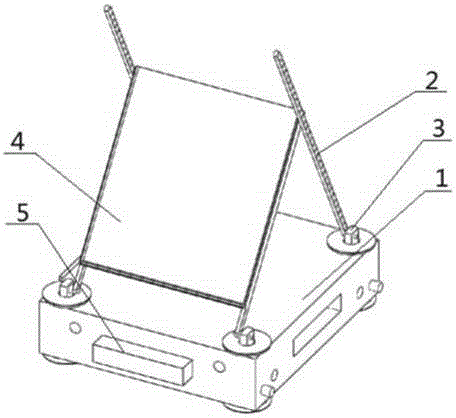

InactiveCN105186968ASimplify the installation processImprove stabilityPV power plantsPhotovoltaic energy generationPhotovoltaic power stationSurface level

The invention discloses a floating member used for a waterborne photovoltaic power station and a connection method thereof. The floating member at least comprises a floating member body which can be floated on water. The floating member body comprises a first end part and a second end part. Height of the upper surface of the first end part is lower than that of the upper surface of the second end part. The upper surface of the floating member body, which is close to the first end part, is provided with a first connection structure which is used for being detachably connected with the first connection piece of the back surface of a photovoltaic panel. The upper surface of the floating member body, which is close to the second end part, is provided with a second connection structure which is used for being detachably connected with the second connection piece of the back surface of the photovoltaic panel. Height of the upper surface of the first end part of the floating member body is set to be higher than that of the upper surface of the second end part, and the connection structures connected with the photovoltaic panel are directly arranged on the upper surface of the floating member body so that the installing technology of the photovoltaic power station can be greatly simplified, installing time can be saved and installing cost can be reduced.

Owner:SHANGHAI QIHUA WHARF ENG CO LTD

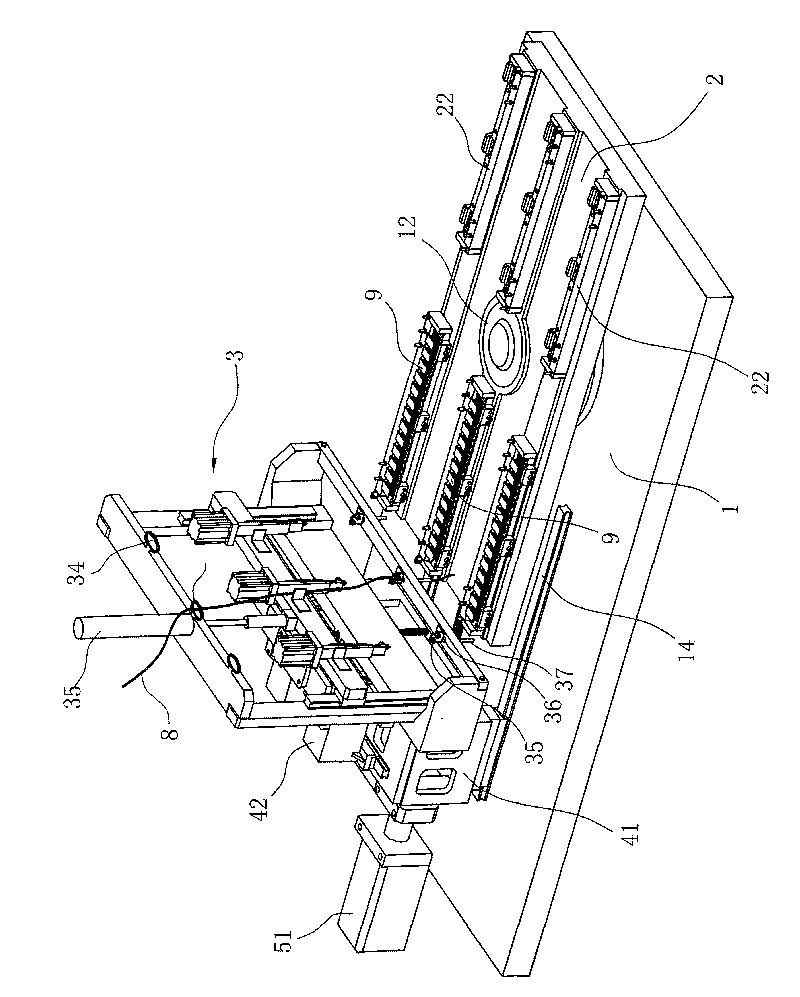

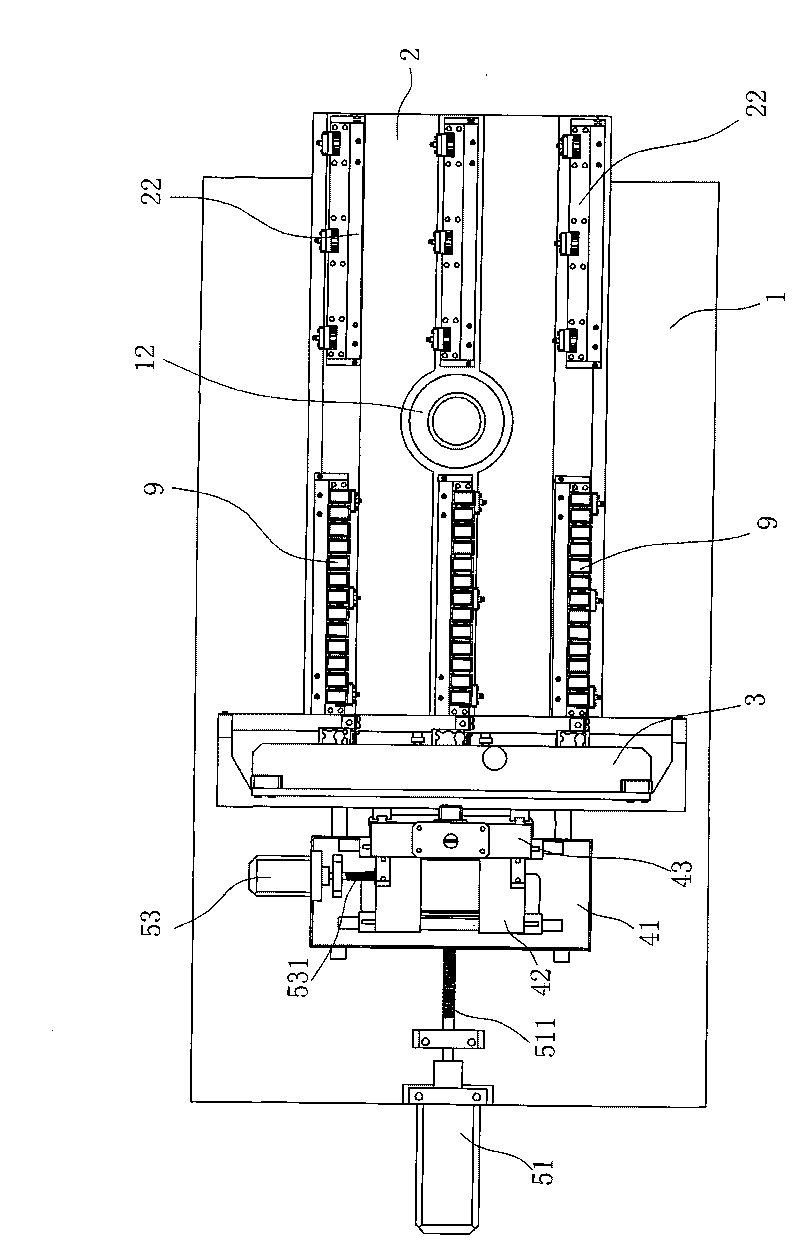

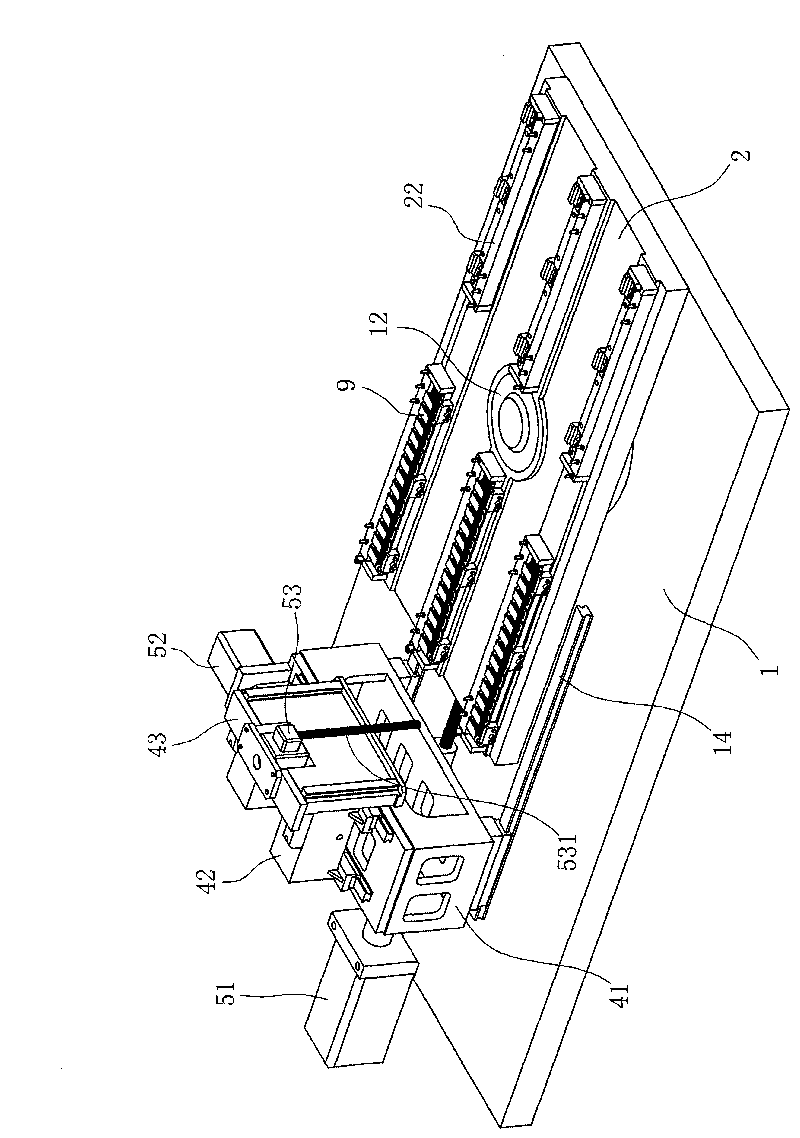

Automatic winding machine of motor iron core

ActiveCN101752966AShorten the timeImprove efficiencyManufacturing dynamo-electric machinesWinding machineEngineering

The invention discloses an automatic winding machine of a motor iron core, which comprises a machine frame and a guide roller. The automatic winding machine of the motor iron core is characterized by also comprising a base, a workbench, a winding device and a driving device, wherein the workbench is rotationally connected with the base; a plurality of clamps which are used for clamping in-line or block type iron cores are arranged at the two opposite ends of the workbench; the winding device draws an enameled wire led out by the guide roller and the enameled wire is wound on the in-line or block type iron cores; and the driving device is arranged on the winding device and can perform three-dimensional movement relative to the base so as to control the winding trace of the winding device. Compared with the prior art, the automatic winding machine of the motor iron core adopts the multistage rotary workbench, saves time for mounting workpieces and improves the winding efficiency; and the driving device and the winding device of the automatic winding machine form a three-dimensional movement mechanism to flexibly adjust the coordinates of the thread end of the enameled wire along an X-axis direction, a Y-axis direction and a Z-axis direction, so the winding of coils is easier.

Owner:BOSCH NINGBO E SCOOTER MOTOR

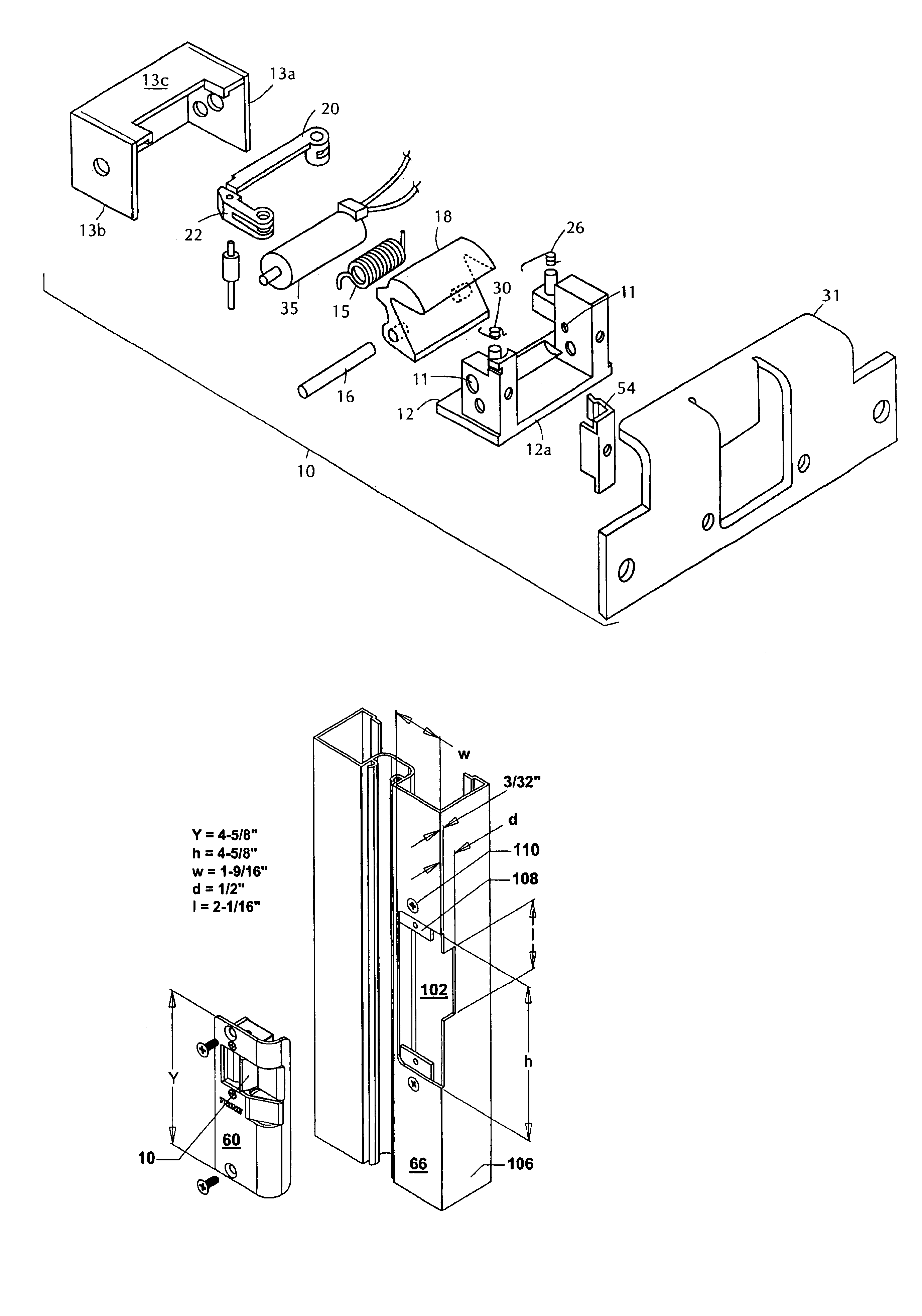

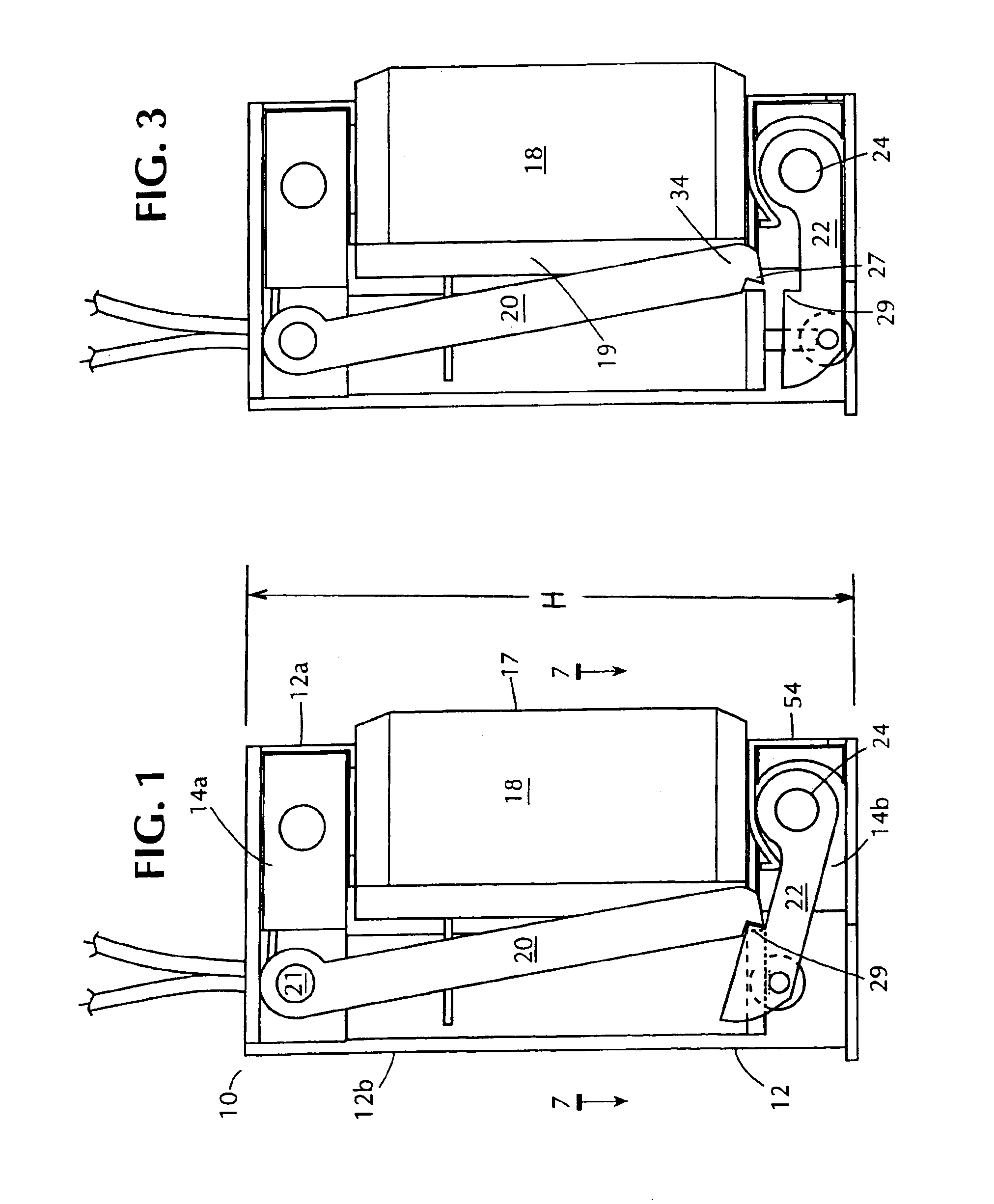

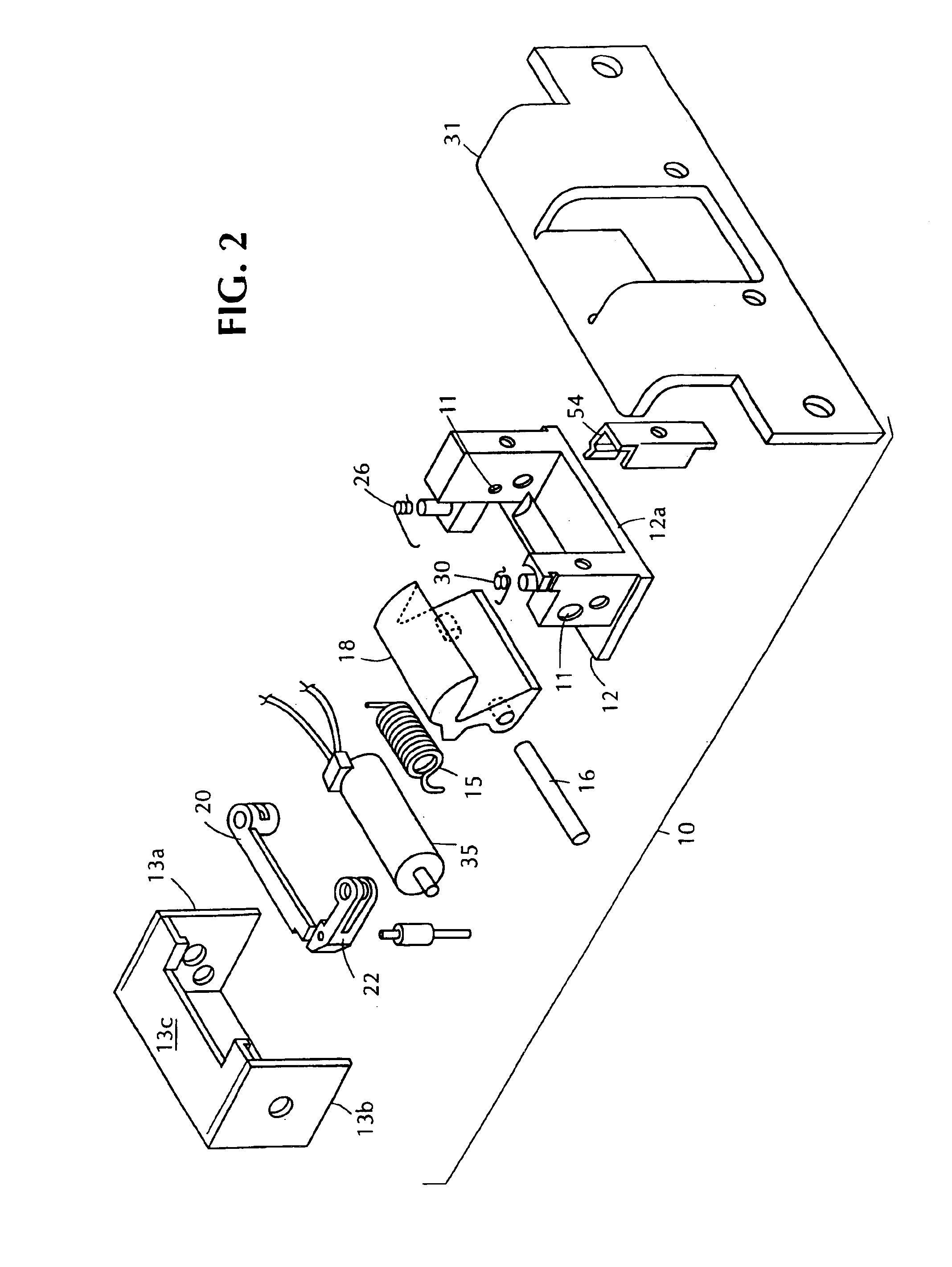

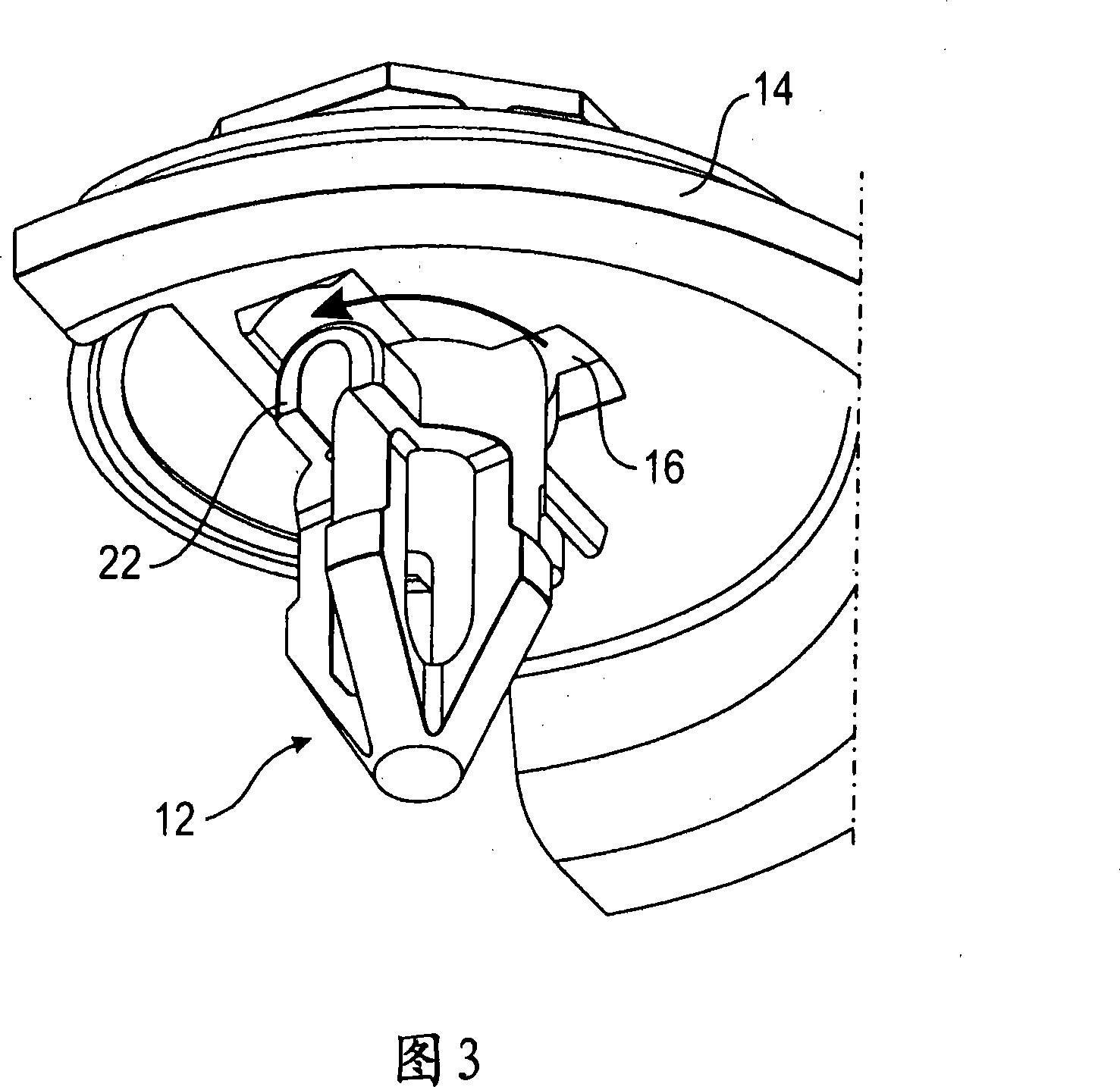

Electronically-operable door strike with guard clip, springless solenoid and face plate

InactiveUS6935663B2Reduce amountProblem can be overcomeNon-mechanical controlsBuilding repairsEngineeringMagnetism

An electronically-operable door strike employing a guard clip for deterring picking of the locking mechanism therein, a springless solenoid designed to avoid the undesirable build-up of residual magnetism and which incorporates air gaps for dissipating heat, thus prolonging the useful life of the solenoid, and a face plate for mounting the strike into a door jamb.

Owner:TRINE ACCESS TECH

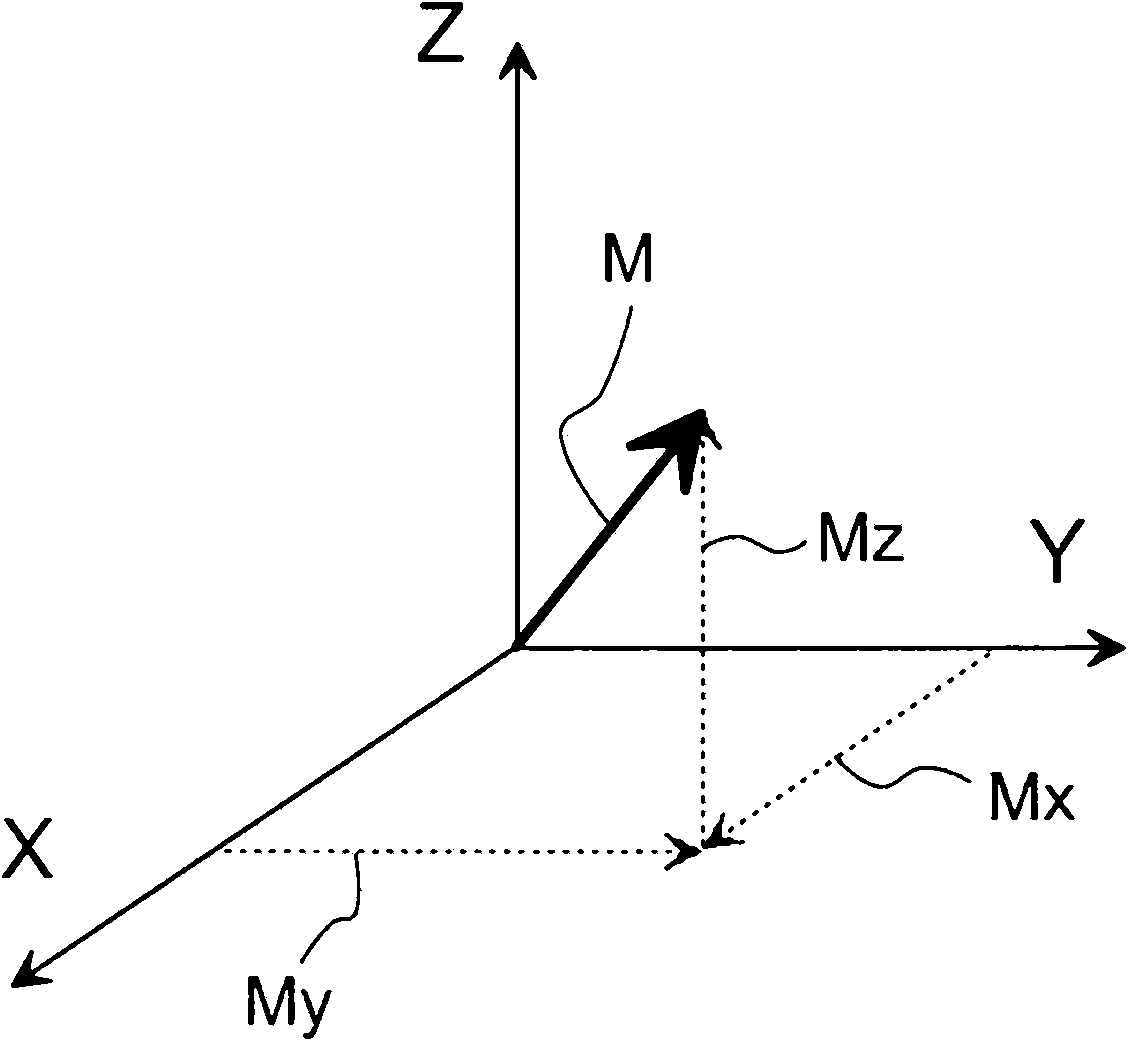

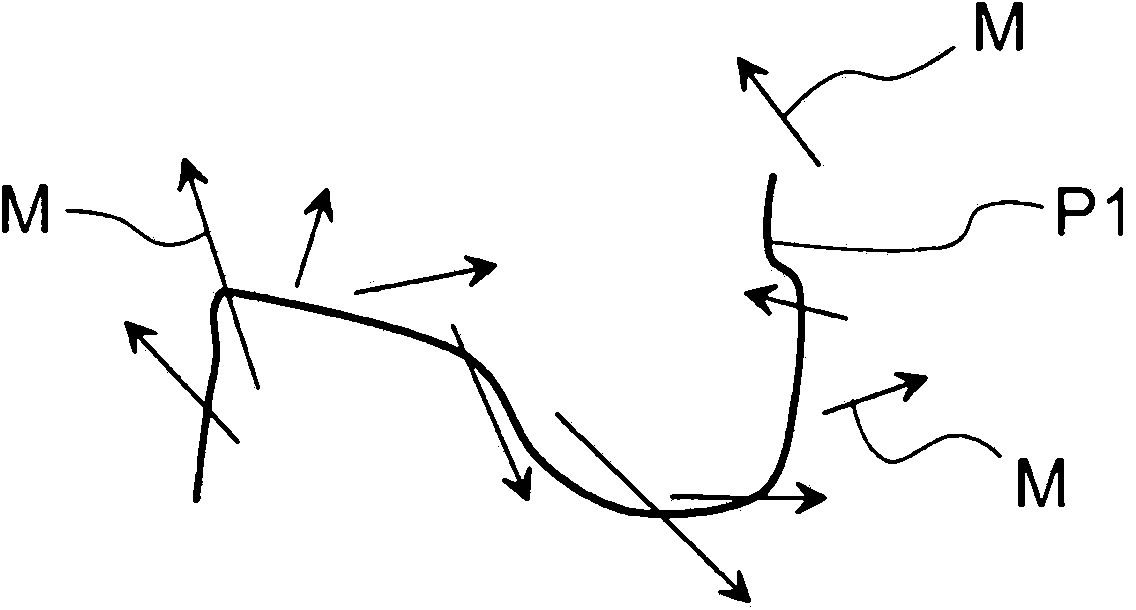

Method and arrangement for determining location and/or speed of a moving object and use of the arrangement

ActiveCN104145172AModern and cost-effectiveReduce installation costsNavigational calculation instrumentsElevatorsMeasurement deviceClassical mechanics

A method and an arrangement is provided for determining the location and / or speed of an object configured to move along a controlled trajectory, in connection with which object is fitted a measuring device measuring at least the magnetic field acting on the object in its different locations, which measuring device comprises a device configured to measure the magnetic field, from the measuring data received from which device a magnetic footprint describing the magnetic field acting on the object in its different locations is formed, which magnetic footprint is recorded in connection with a teaching run, or with self-learning, for later use. The location of the object after a teaching run is determined by measuring in essentially real-time in the direction of the three coordinates X, Y, Z of the magnetic field acting on the object moving along a controlled trajectory and by comparing the measurement results to a magnetic footprint recorded in advance and also by deducing as a result of the comparison the exact location of the object on its path of travel.

Owner:KONE CORP

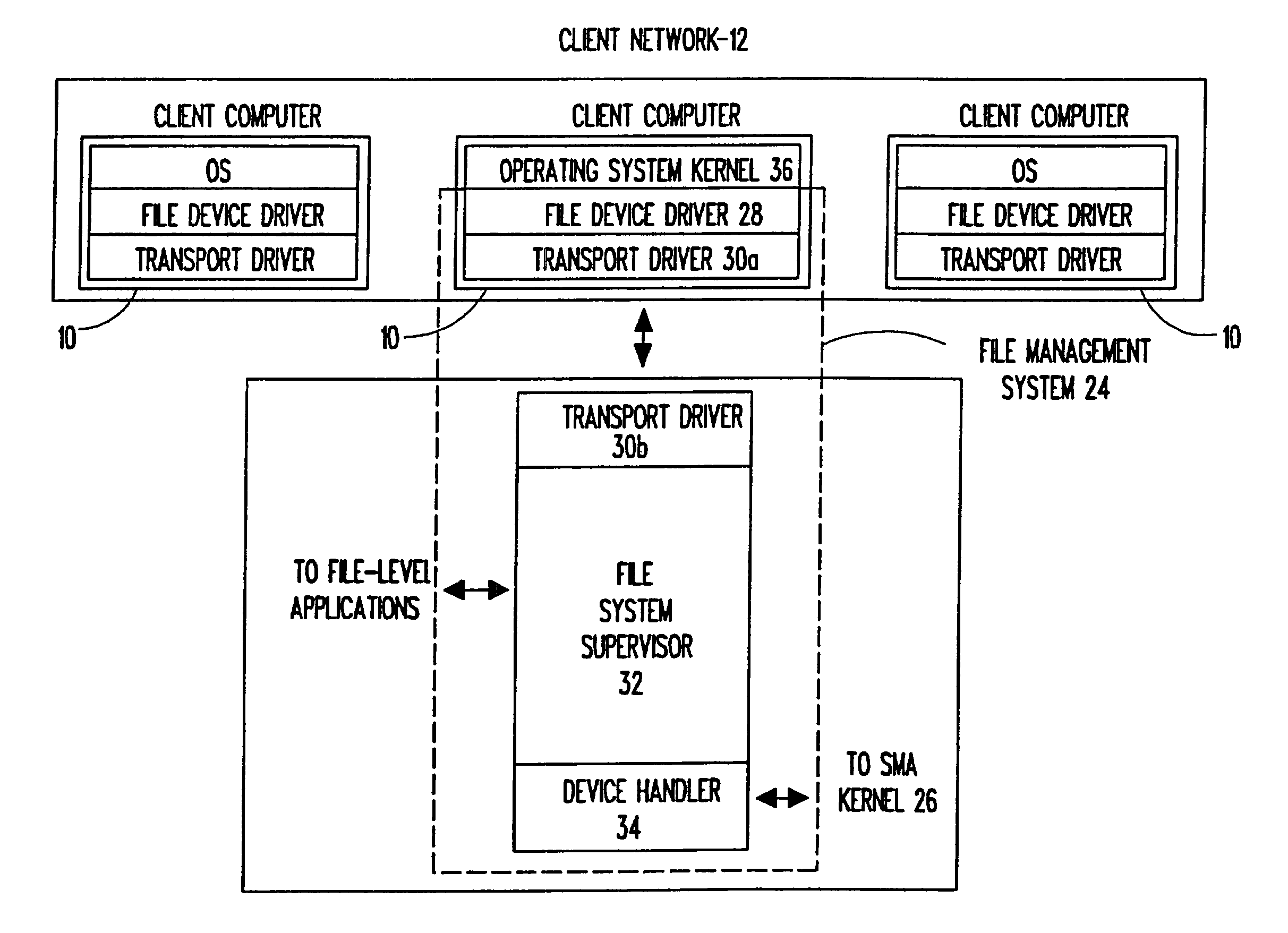

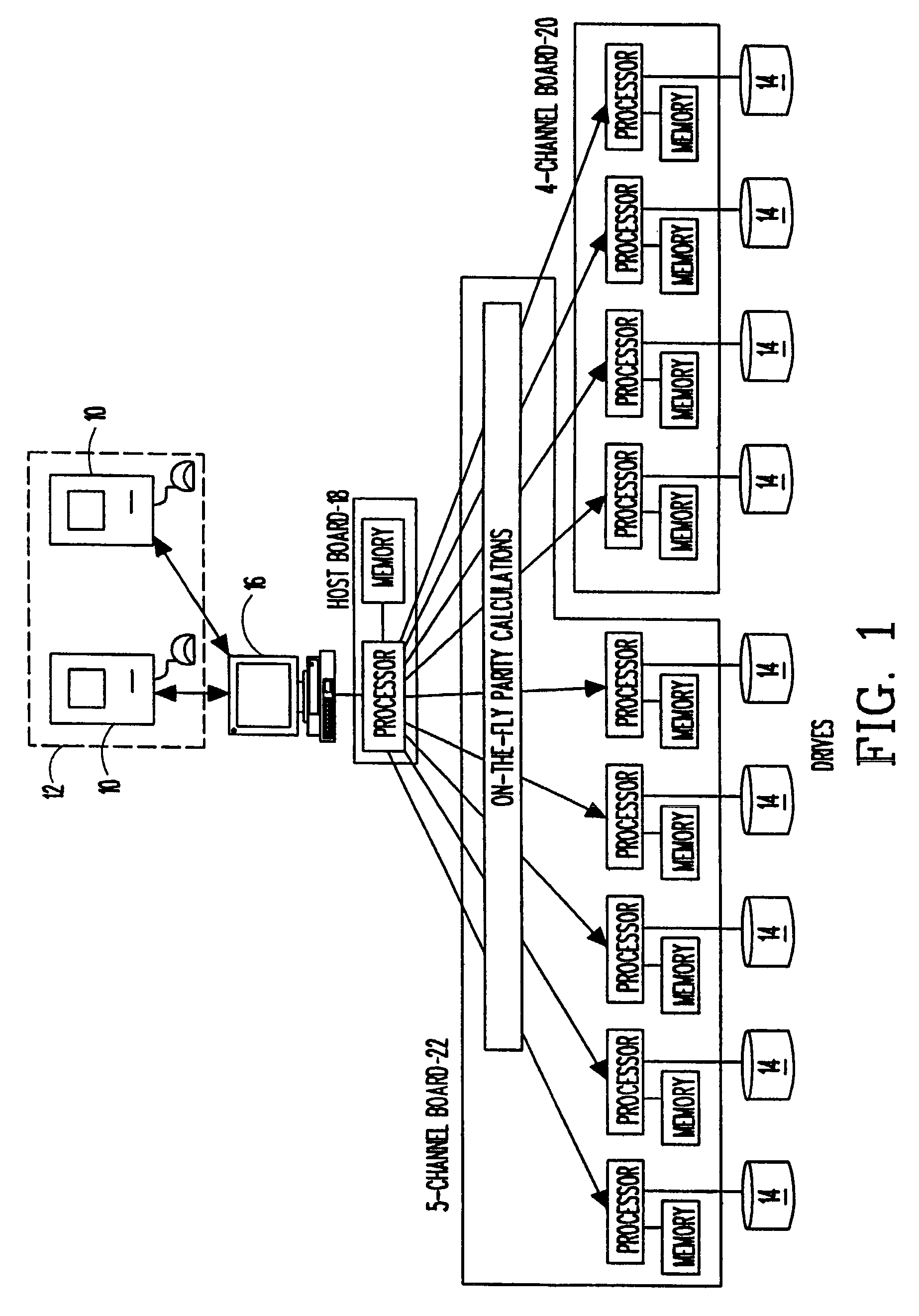

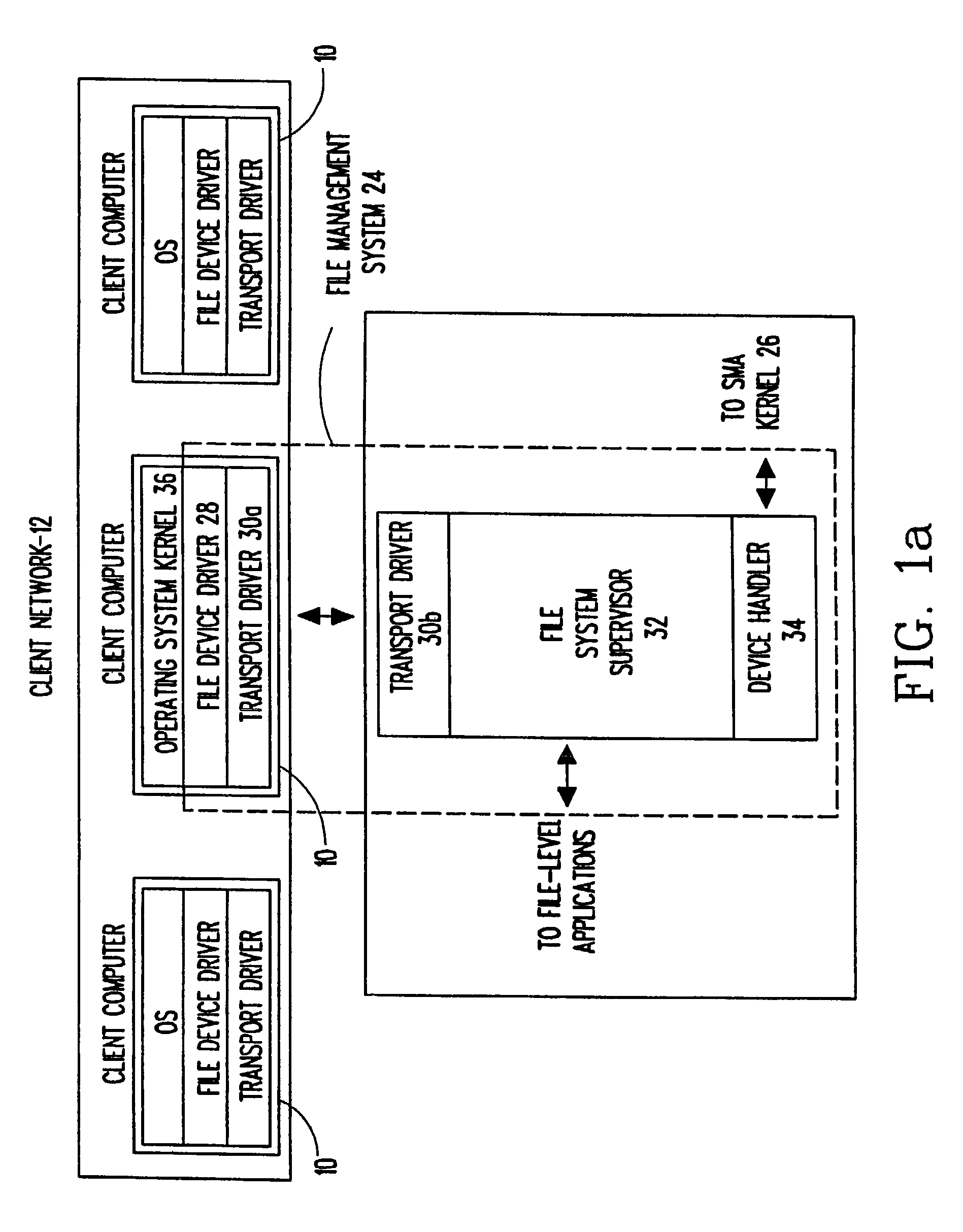

Universal storage management system

InactiveUSRE42860E1Save installation timeReduce overheadInput/output to record carriersDigital data processing detailsComputer hardwareInterconnection

A universal storage management system which facilitates storage of data from a client computer and computer network is disclosed. The universal storage management system functions as an interface between the client computer and at least one storage device, and facilitates reading and writing of data by handling I / O operations. I / O operation overhead in the client computer is reduced by translating I / O commands from the client computer into high level commands which are employed by the storage management system to carry out I / O operations. The storage management system also enables interconnection of a normally incompatible storage device and client computer by translating I / O requests into an intermediate common format which is employed to generate commands which are compatible with the storage device receiving the request. Files, error messages and other information from the storage device are similarly translated and provided to the client computer.

Owner:VELEZ MCCASKEY RICARDO E +1

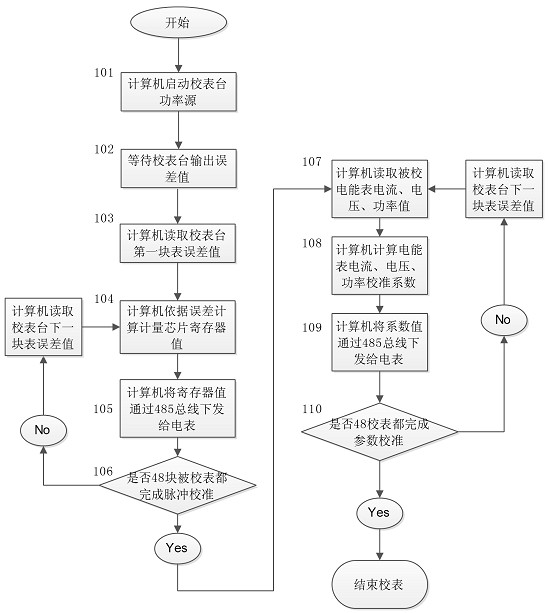

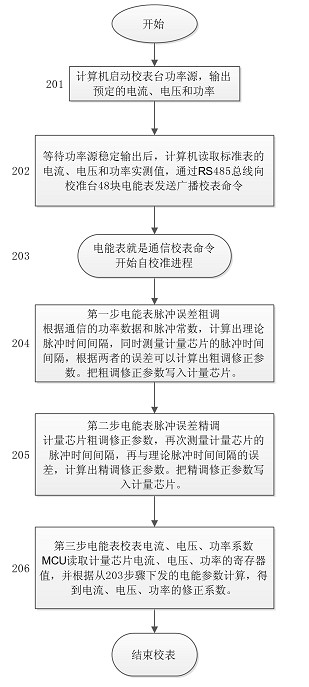

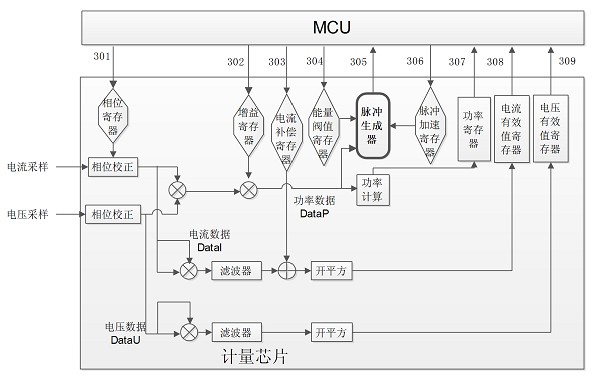

Single-phase intelligent energy meter distributed correction method

ActiveCN102590784AHigh precisionImprove consistencyElectrical measurementsSmart meterCorrection method

The invention provides a single-phase intelligent energy meter distributed correction method, and relates to a correction method for energy meters. The invention realizes the distributed correction method by utilizing software and hardware resources of intelligent energy meters, each correction point is only required to be communicated with a corrected energy meter once, and the specific pulse acceleration technique in the intelligent energy meters is used; a master control computer is not required to acquire the pulse input of each energy meter, and a high-precision crystal oscillator inside the energy meter is used as a clock reference during the error detection, so that the output pulse interval of a metering chip can be accurately caught; through the correction of rough adjustment and fine adjustment, the error of each correction point is within plus or minus 0.1%, and the correction precision and consistency are remarkably improved; and an error detection line is not required to be connected in the correction process, so that the time for mounting each energy meter is saved, and the labor intensity is lowered.

Owner:北方智能装备有限公司

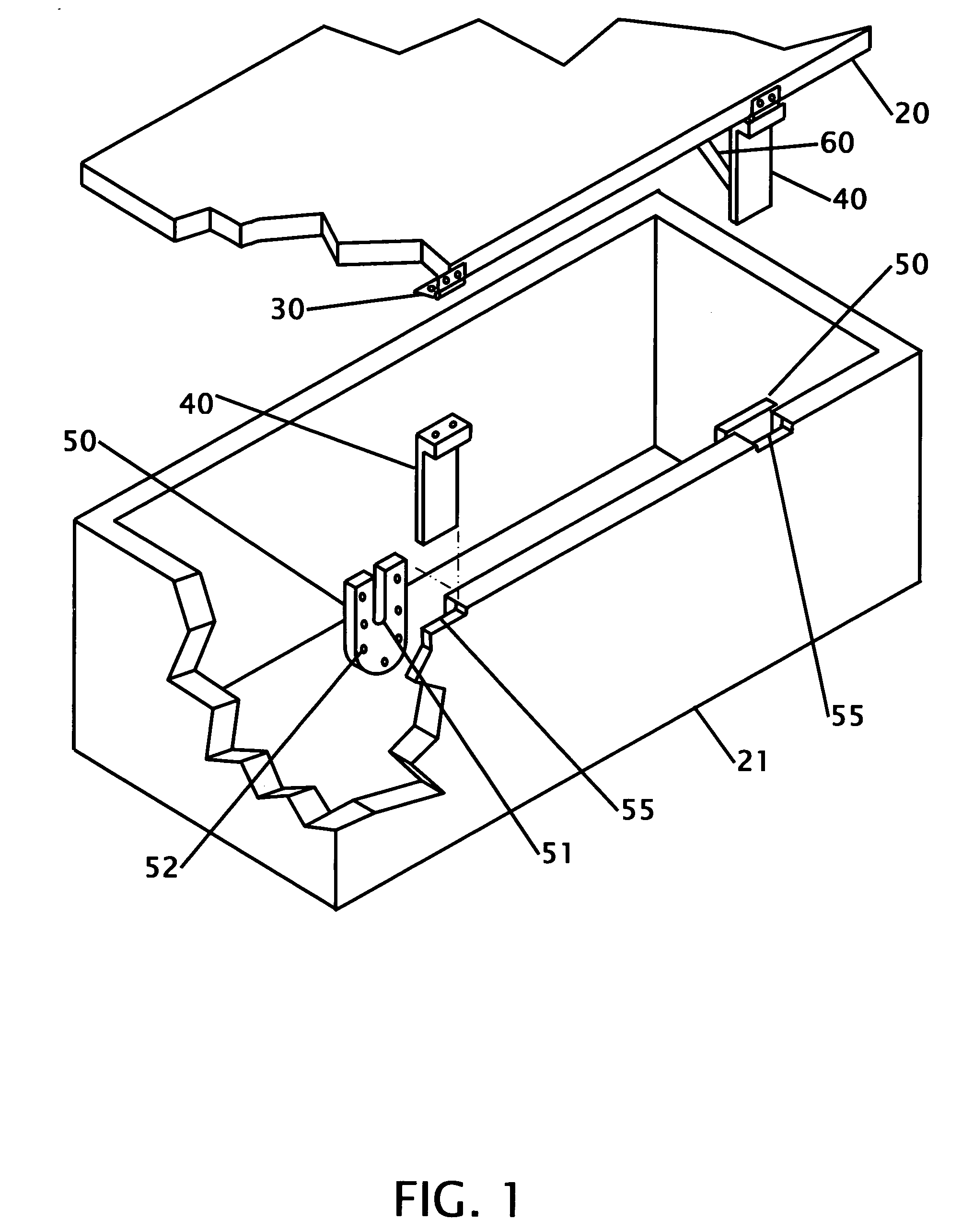

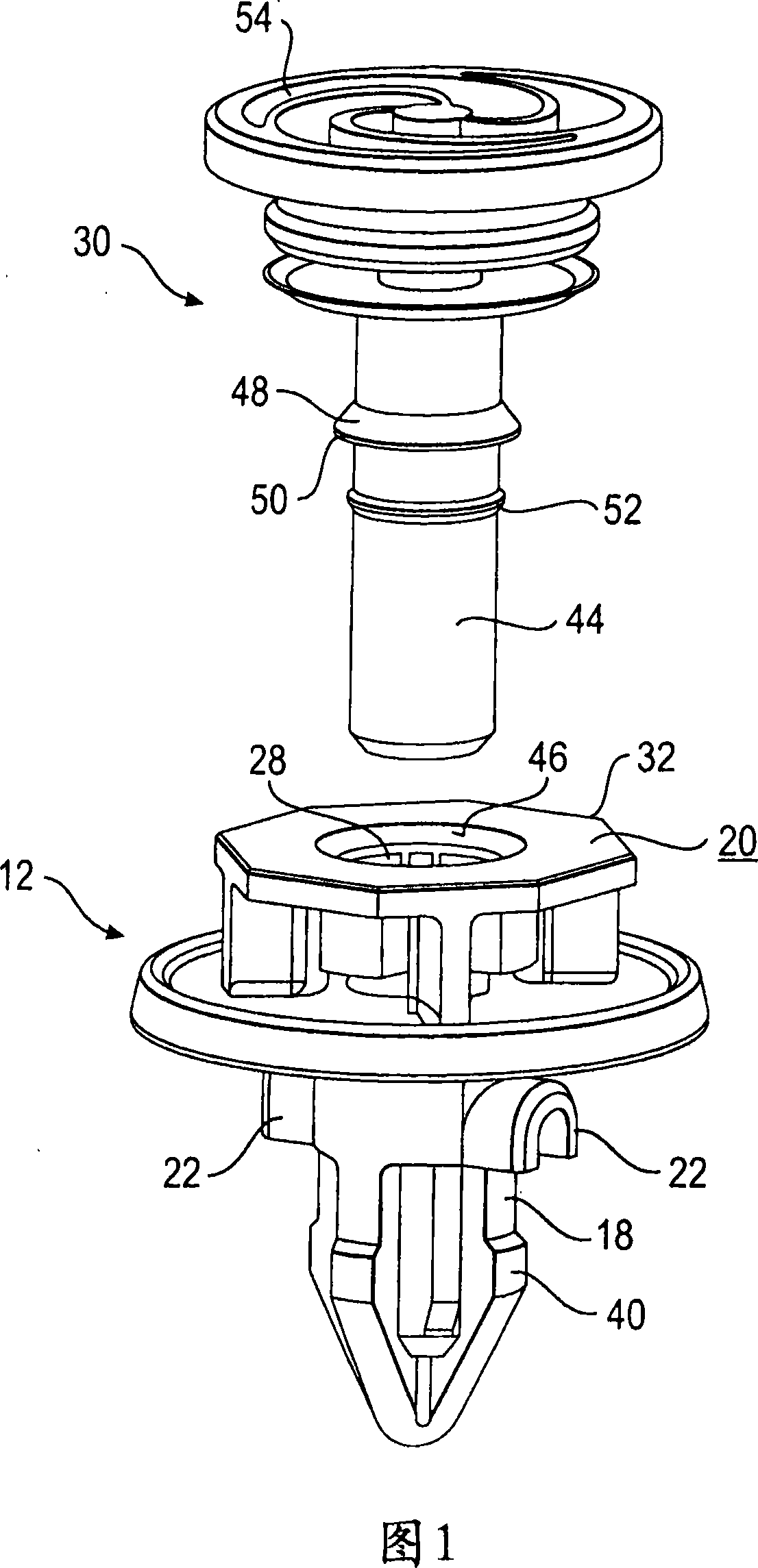

Sliding safety hinge assembly for lid of box

InactiveUS20080237252A1Minimize resultant forceSaving install time & complexityLidsPin hingesHinge angleEngineering

The Sliding Safety Hinge Assembly (SSHA) minimizes the degree of personal injury or discomfort that could result from accidental closure of the lid of a box, i.e. “toy box”, by pinching a finger between the lid and box, particularly as the obstruction approaches the side or rear of the box near the hinge. A traditional hinge attached to the lid and rear of box carcass provides a fixed pivot point such that a severe pinch point exists due to the leverage of the lid. The SSHA reduces this potential by a sliding design such that the hinge element normally fastened to the rear of the box is rather installed on a slide assembly allowing free sliding motion in the vertical plane at the rear of the box. The SSHA assembly would include a slide, pivot and counter weight device to reduce the weight of the lid.

Owner:ELEFANTE DENNIS JAMES

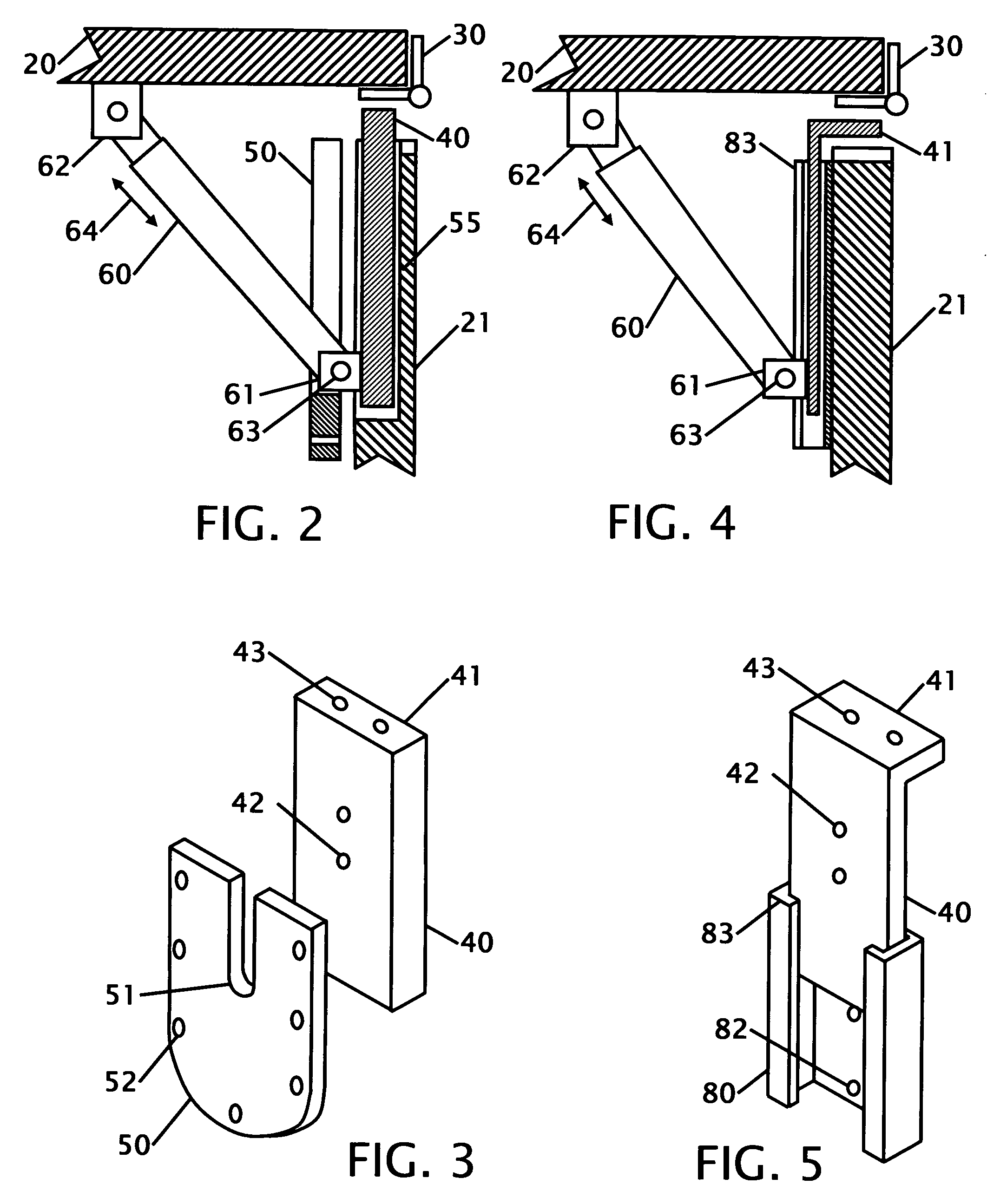

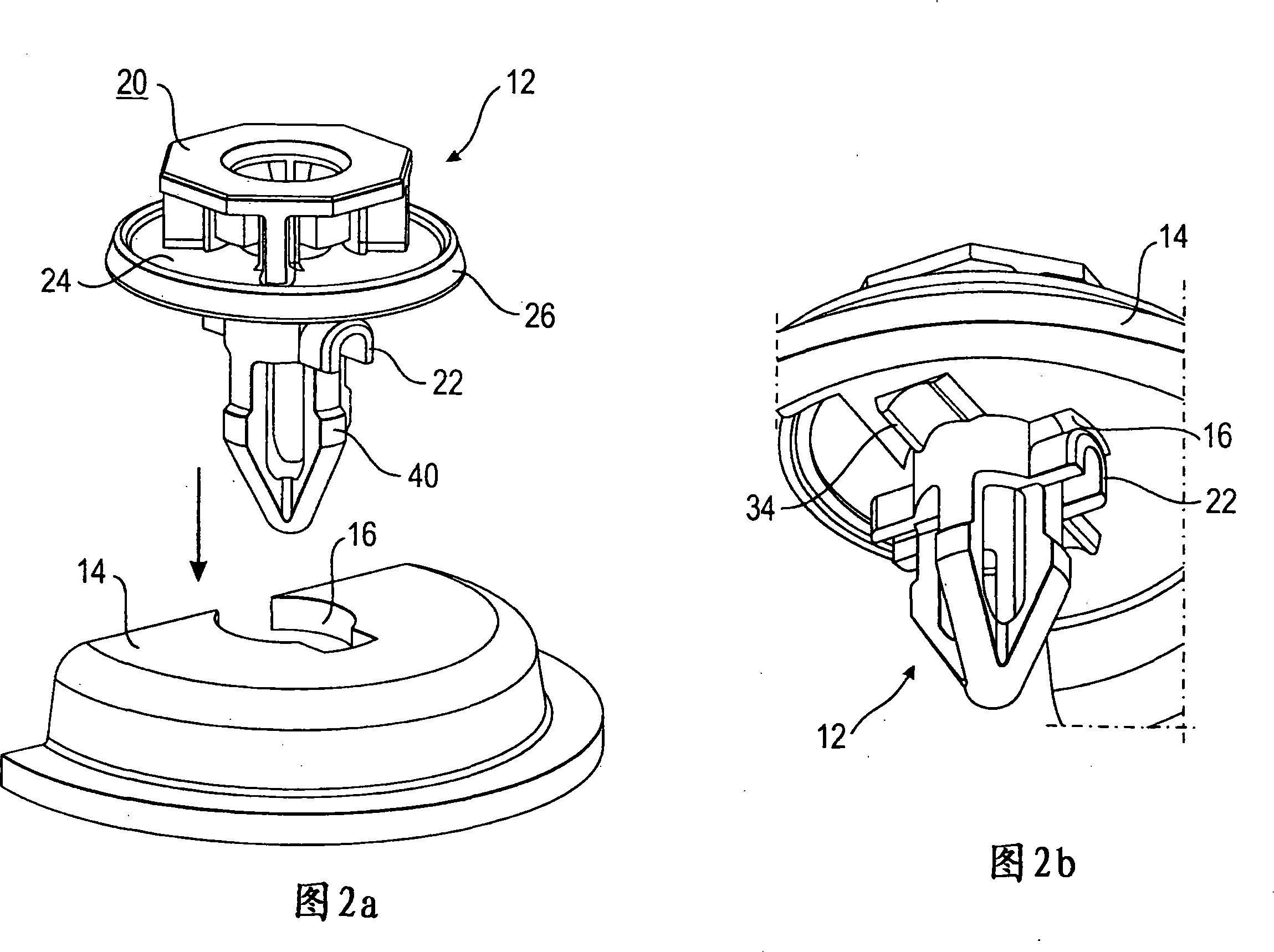

Fastening devcie

InactiveCN101251142ASimplify work stepsSave installation timeSheet joiningScrewsMobile vehicleEngineering

Owner:ILLINOIS TOOL WORKS INC

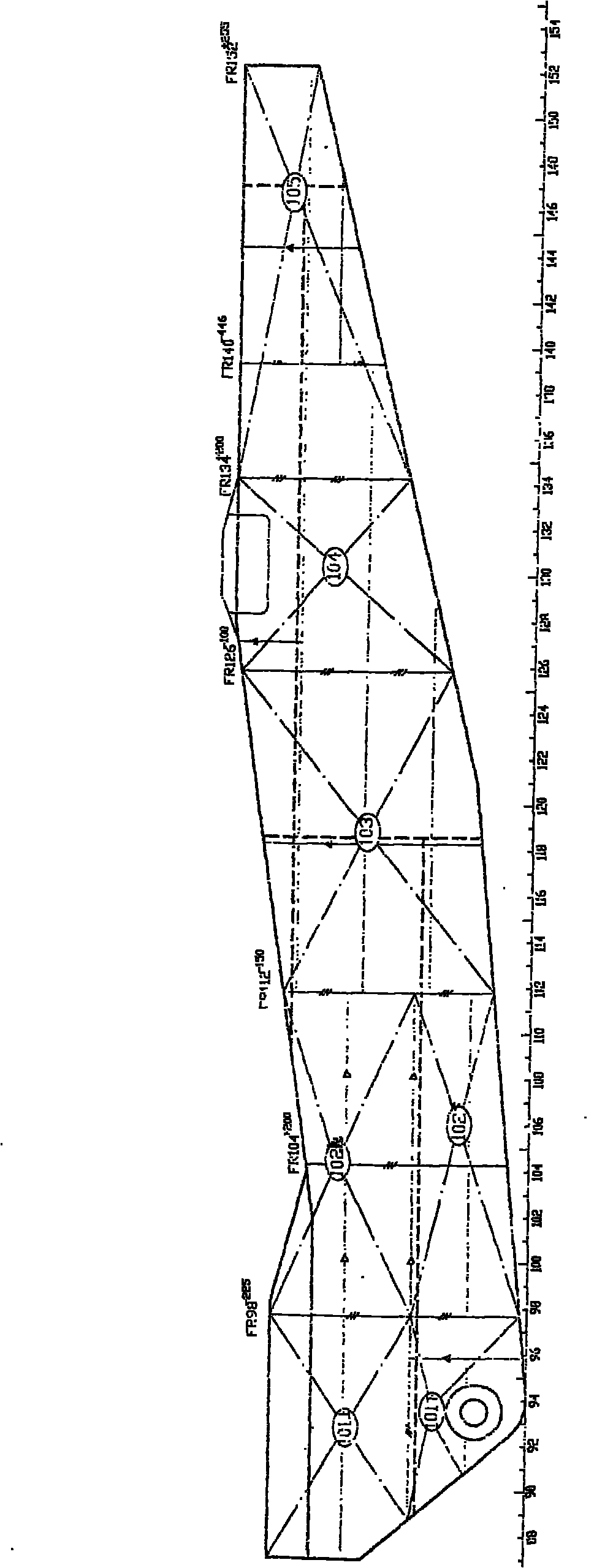

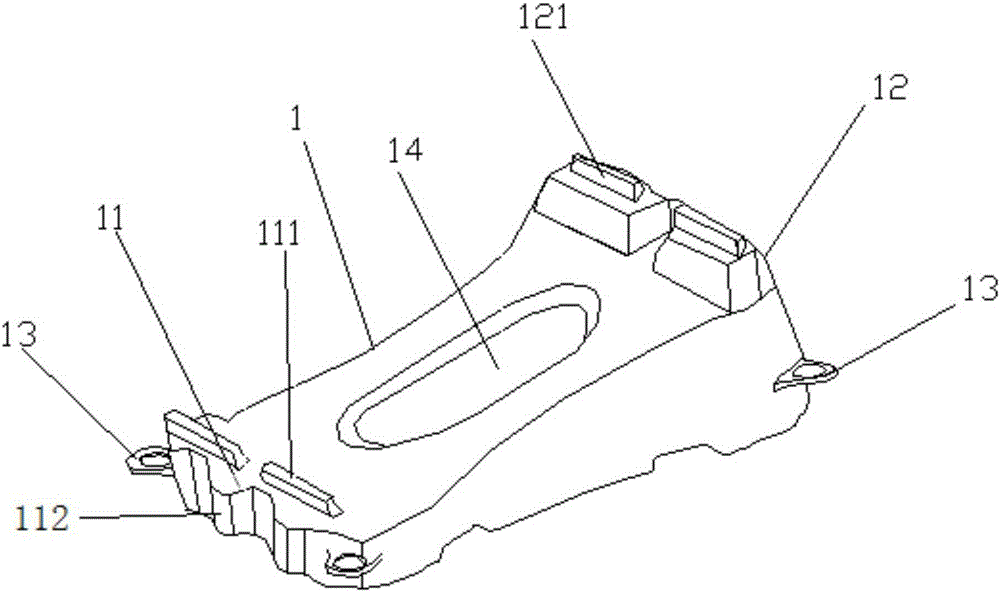

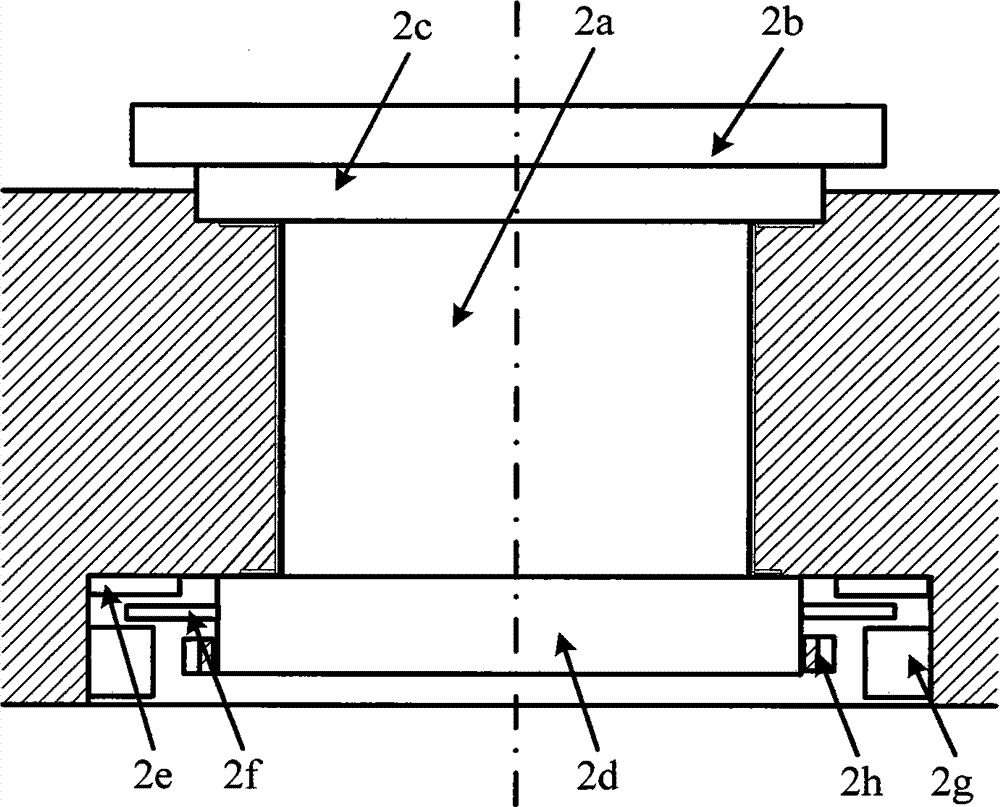

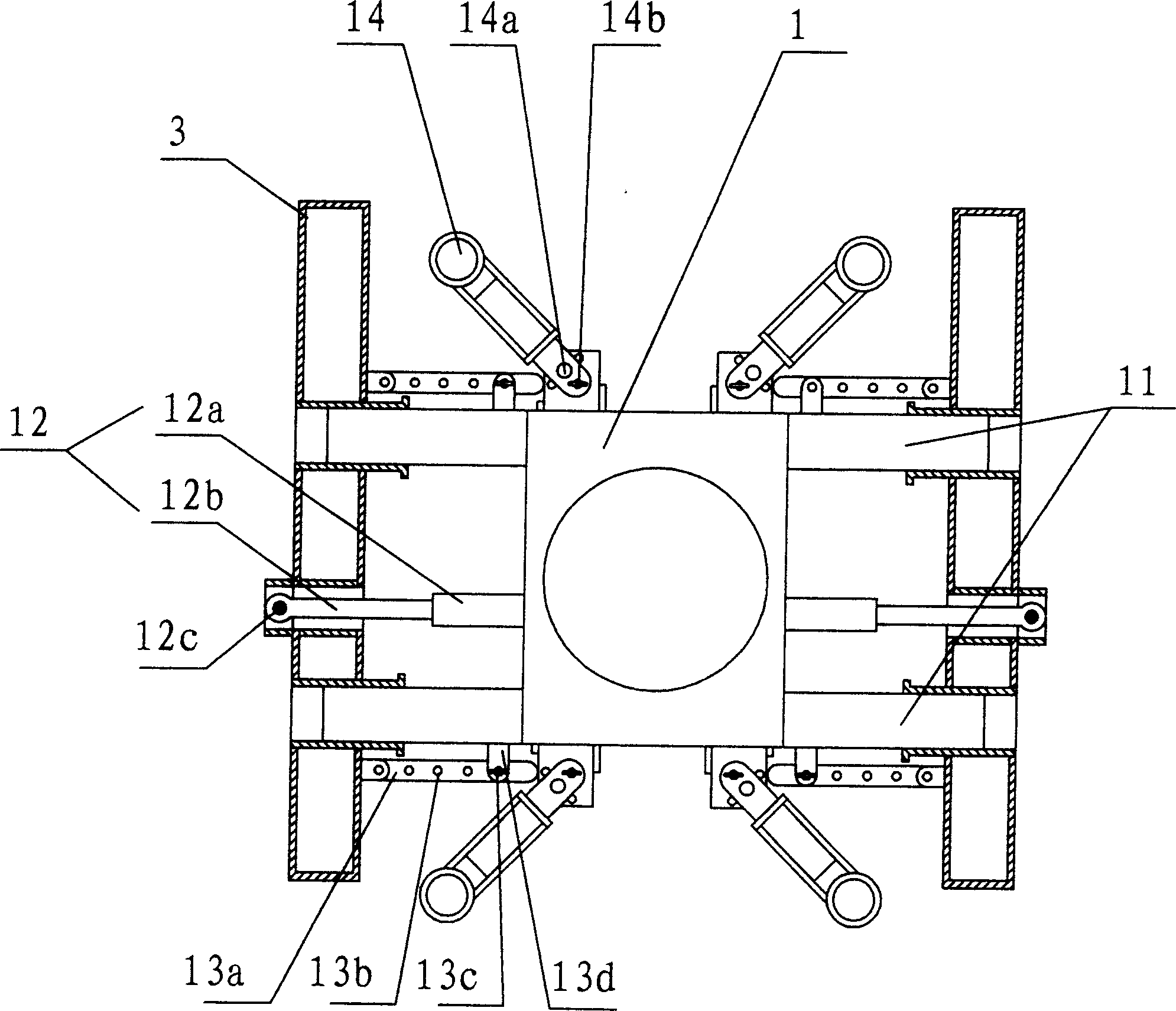

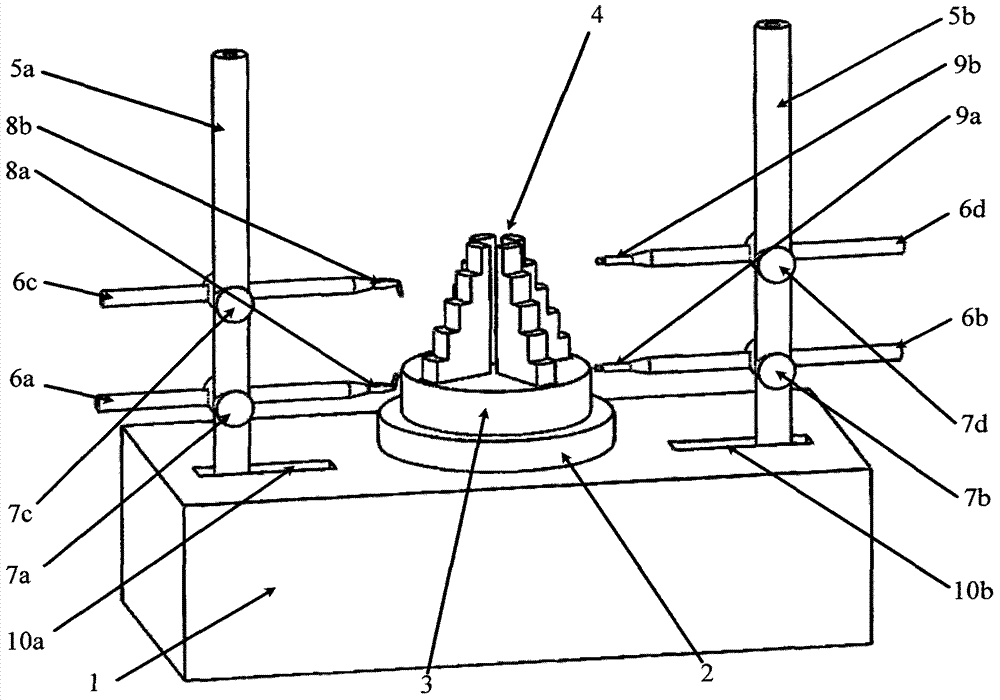

Hydraulic capturing and clamping type aircraft engine rotor assembling method and device based on inductance sensing

InactiveCN103790647AReduce consumptionImprove stabilityMachines/enginesSafety/regulatory devicesAviationRadial error

The invention relates to a hydraulic capturing and clamping type aircraft engine rotor assembling method and device based on inductance sensing, and belongs to the machine assembling technology. According to the hydraulic capturing and clamping type aircraft engine rotor assembling method and device, a rotation standard is determined based on an air floating rotation shaft system; angle location of a rotary table is determined according to an inductive synchronizer; based on a four-measuring-head measuring device, radial errors of a rotor radial assembly face and slant errors of an axial assembly face are extracted, and the influence weights of rotors on the rotor coaxiality after the rotors are assembled are obtained; all the rotors required to be assembled are respectively measured, and the influence weights of the rotors on the rotor coaxiality after the rotors are assembled are obtained; vector optimizing is carried out on the weights of the rotors, and the assembling angles of the rotors are obtained. According to the hydraulic capturing and clamping type aircraft engine rotor assembling method and device, the problem that the coaxiality is low after the aircraft engine rotors are assembled is solved, and after the rotors are assembled, the hydraulic capturing and clamping type aircraft engine rotor assembling method and device have the advantages of being high in coaxiality, reducing vibration, being easy to install and high in flexibility, and improving the engine performance.

Owner:HARBIN INST OF TECH

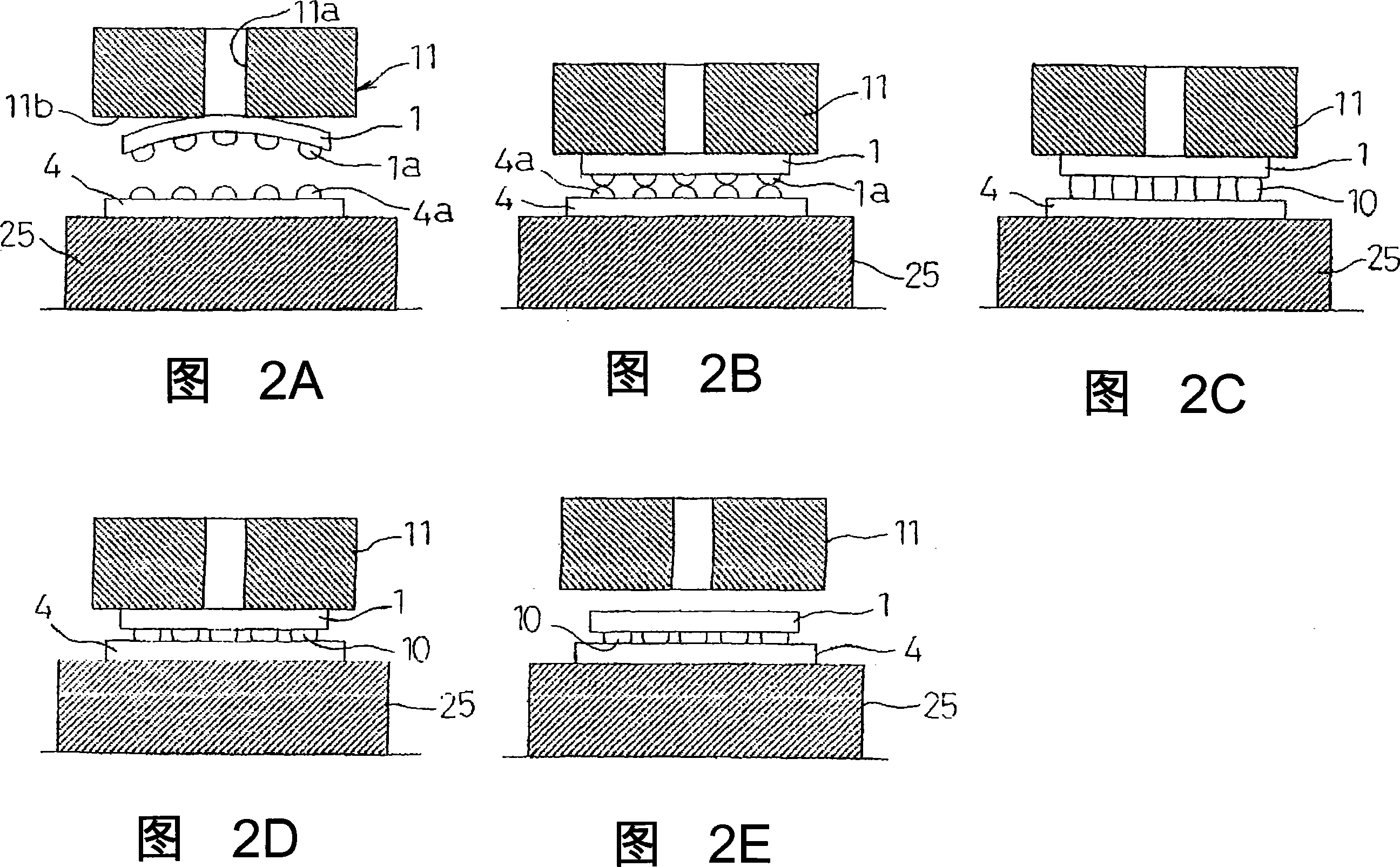

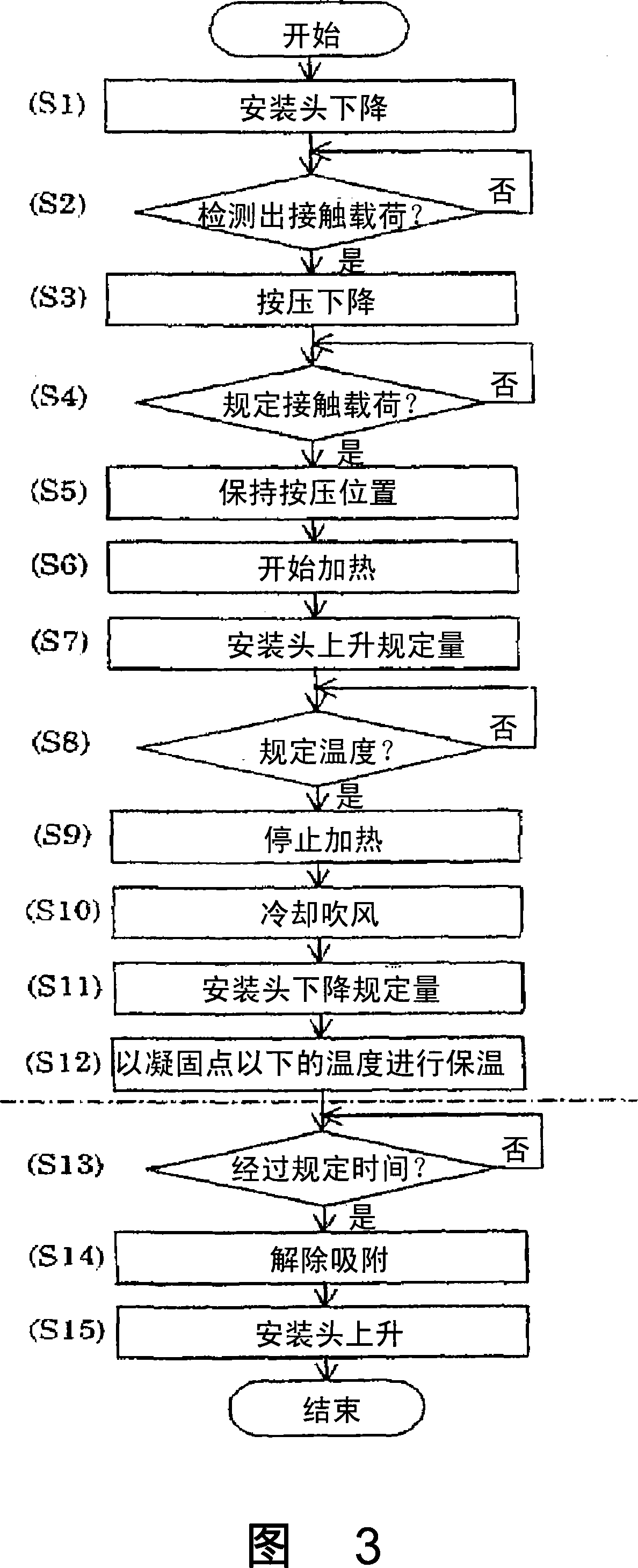

Component mounting method and component mounting apparatus

InactiveCN1965401AAvoid strippingRelative interval increasePrinted circuit assemblingFinal product manufactureEngineeringThermal expansion

There has been a possibility of deteriorating planarity of a thin IC chip due to process distortion and deformation generated when sucking the IC chip by a suction nozzle. The deformation is corrected by pressing the thin IC chip on a board (4) with a prescribed load by a suction nozzle (11) having a suction plane (11b) formed flat. A reduction of a prescribed opposing interval between the IC chip and the board (4), due to thermal expansion caused by heat applied for melting a solder bump (1a) formed on an electrode, is corrected by controlling rising of the suction nozzle (11). A peeling action of the melting part, due to a part which has heat- expanded and contracted by cooling, is corrected by controlling descending of the suction nozzle (11). Thus, an electronic component mounting method and an electronic component mounting apparatus are provided for correctly mounting even the electronic components, such as the thin IC chip easily deformed and the IC chip wherein a multitude of electrodes are formed at a narrow pitch.

Owner:PANASONIC CORP

Method for mounting main pipeline and main loop of pressurized water reactor nuclear power station steam generator

ActiveCN101839467AAvoid inconvenienceEasy to controlNuclear energy generationContainmentNuclear engineeringPressurized water reactor

The invention discloses a method for mounting a main return loop of a nuclear power station pressurized water reactor coolant system, which is characterized in that: a main pipeline heat section bend (16) and a main pipeline transition section bend (17) are welded at a loop nozzle of a lower seal end of the used steam generator (1); during mounting, a welding line (9) between a main pipeline heat section (13) and the main pipeline heat section bend (16) on the lower part of the steam generator (11) and a welding line (2) between the main pipeline heat section (13) and a reactor pressure container (10) can be assembled and welded simultaneously. In addition, the working amount for a welding line (5) is reduced during mounting. The mounting method can better control and guarantee the assembling and welding quality, improve the working efficiency, reduce the mounting time, and shorten the construction period.

Owner:CHINA NUCLEAR POWER ENG CO LTD

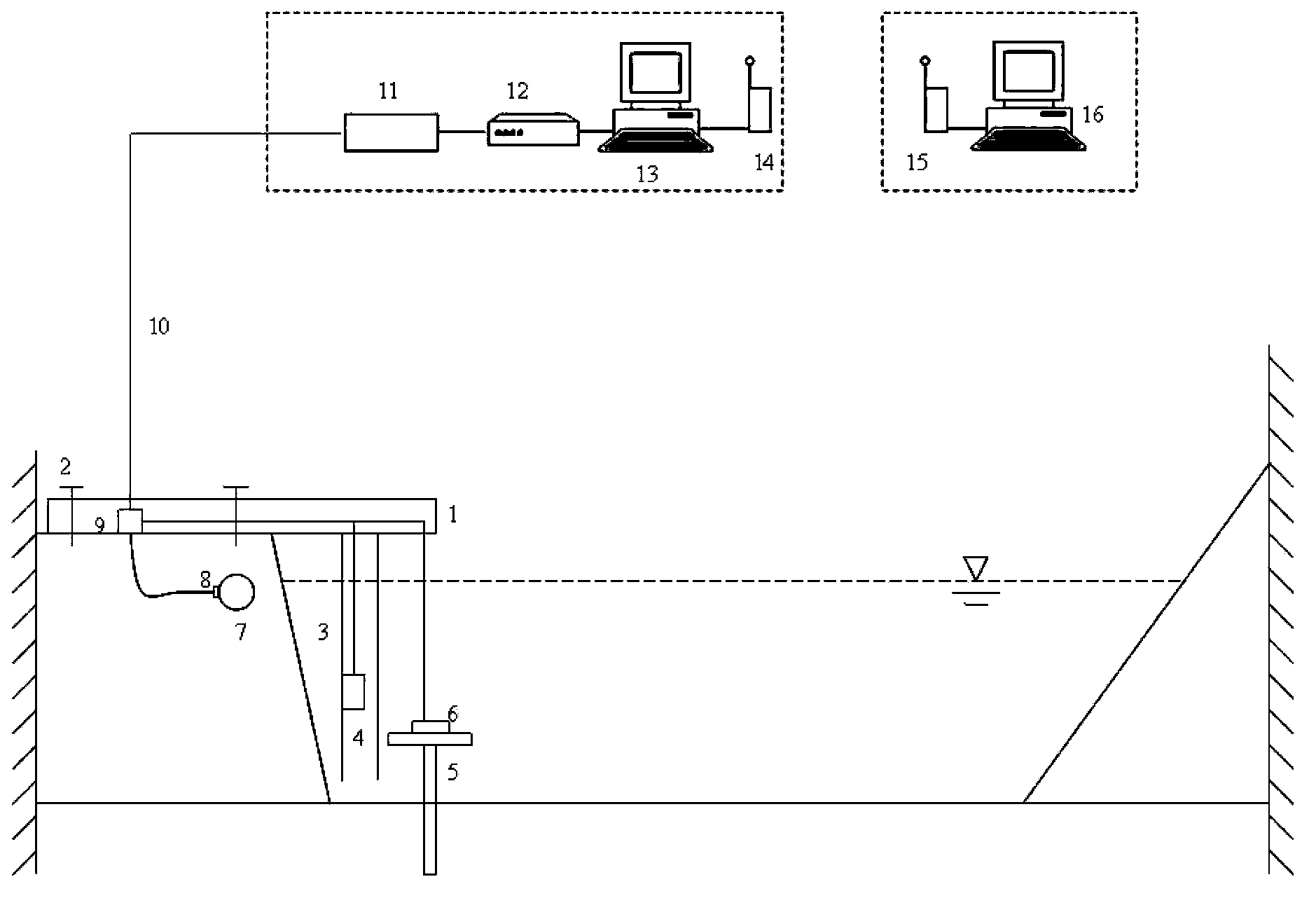

Method and system for monitoring oil-gas pipeline in mining subsidence area and system constructing method

InactiveCN102345793AReveal Security WarningReveal collapse featuresPipeline systemsUsing optical meansRelative displacementGas pipeline

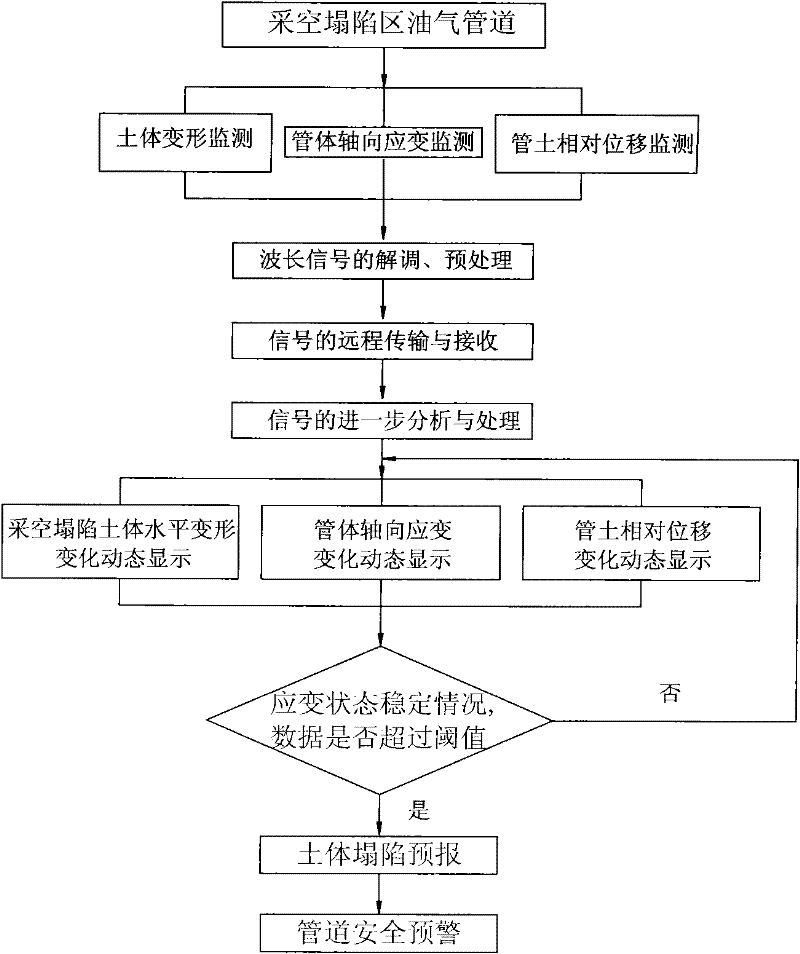

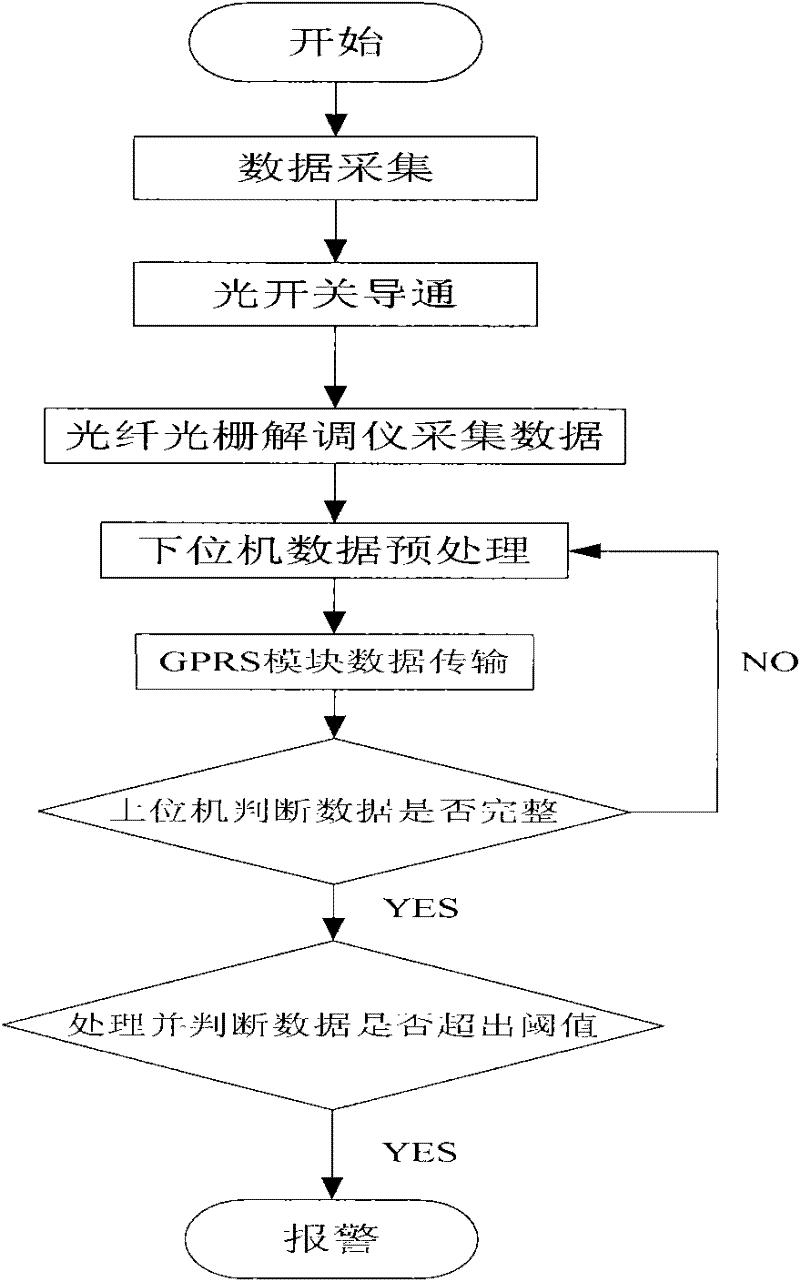

The invention discloses a method and a system for monitoring an oil-gas pipeline in a mining subsidence area and a system constructing method. The method comprises the following steps of: monitoring axial strain of a pipe body with a fiber grating strain sensor, monitoring pipe-soil relative replacement with a fiber grating displacement sensor, and monitoring horizontal deformation of a soil body with a fiber grating sensor; demodulating and preprocessing signals acquired by the sensors, and transmitting the signals to a remote monitoring center; further analyzing and processing data in the monitoring center, and computing horizontal deformation change of a soil body on the top of the pipe in the mining subsidence area, axial strain change of the pipe body and pipe-soil relative displacement change; judging the state stabilities of the pipe body strain change and the soil body strain change, and judging whether the data surpass threshold values; when three parameter values are smaller than respective threshold values, judging that the pipeline is in a safe state; and when the axial strain of the pipe body reaches 70 percent of a pipe body limit strain value, or a pipe-soil relative displacement value reaches a threshold value and keeps constant, or a horizontal deformation curve of the soil body changes suddenly, performing pipeline safety joint early-warning.

Owner:PETROCHINA CO LTD

Extensible settlement and incline measuring pipe for measuring settlement and horizontal displacement and mounting method thereof

ActiveCN103195043AEasy to installEasy to processFoundation testingIn situ soil foundationEngineeringSediment

An extensible settlement and incline measuring pipe for measuring settlement and horizontal displacement is composed of a settlement measuring pipe, an incline measuring pipe, a bottom cover and a joint pipe and is characterized in that the joint pipe is an freely-extensible connection sleeve pipe which is composed of two secondary pipes and a main pipe, the external walls of the two secondary pipes are provided with sliding grooves, and fixing pins arranged on the internal wall of the main pipe are snapped with the sliding grooves of the secondary pipes; and both ends of each secondary pipe are respectively connected with the screws of the settlement measuring pipe and the incline measuring pipe through locating pins. The extensible settlement and inline measuring pipe for measuring the settlement and the horizontal displacement can guarantee the settlement measuring pipe and the inline measuring pipe not to be deformed along with a large-displacement deformation of a soil body, thereby reducing the interaction force between the settlement measuring pipe of the inline measuring pipe and the surrounding soil body and reducing the probability of pipe blocking or pipe breaking; sediment and water can be effectively prevented from entering among every parts; and the freely-extensible joint pipe, the settlement measuring pipe and the incline measuring pipe can be mounted through direct screwing. Therefore, the extensible settlement and inline measuring pipe for measuring the settlement and the horizontal displacement is convenient to build in and mount, has low technical requirements for mounting personnel, can largely reduce the mounting time, and is easy to process and achieve.

Owner:NANJING HYDRAULIC RES INST +1

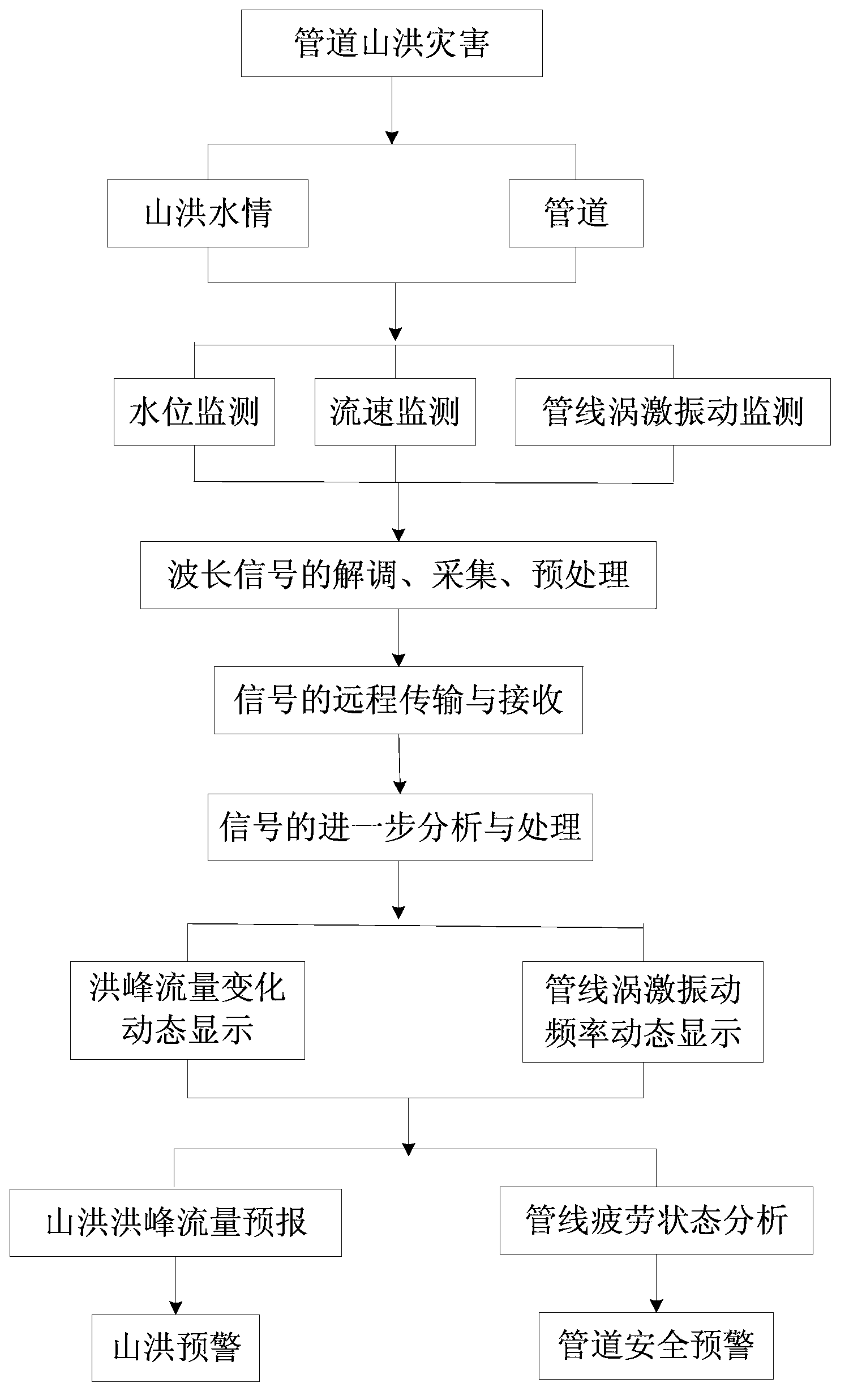

Oil-gas pipeline torrential flood disaster monitoring method

ActiveCN103700221ASimple networkingEasy to realize automatic real-time online monitoringHuman health protectionAlarmsGratingDisaster monitoring

The invention discloses an oil-gas pipeline torrential flood disaster monitoring method based on an optical fiber grating sensing technology, and relates to the technical field of linear velocity measurement, liquid level measurement, mechanical vibration measurement, common safety devices, and pipeline systems. The method comprises the following processes: performing water level monitoring, flow speed monitoring and pipeline vortex-induced vibration monitoring on torrential flood water and a pipeline; demodulating, acquiring and preprocessing wavelength signals; remotely transmitting and receiving signals; further analyzing and processing the signals; dynamically displaying flood peak flow change and dynamically displaying pipeline vortex-induced vibration frequency; predicting torrential flood peak flow and analyzing the pipeline fatigue state; performing torrential flood forecasting and pipeline safety pre-warning. The method is high is spatial resolution, low in cost, safe and effective.

Owner:PIPECHINA SOUTH CHINA CO

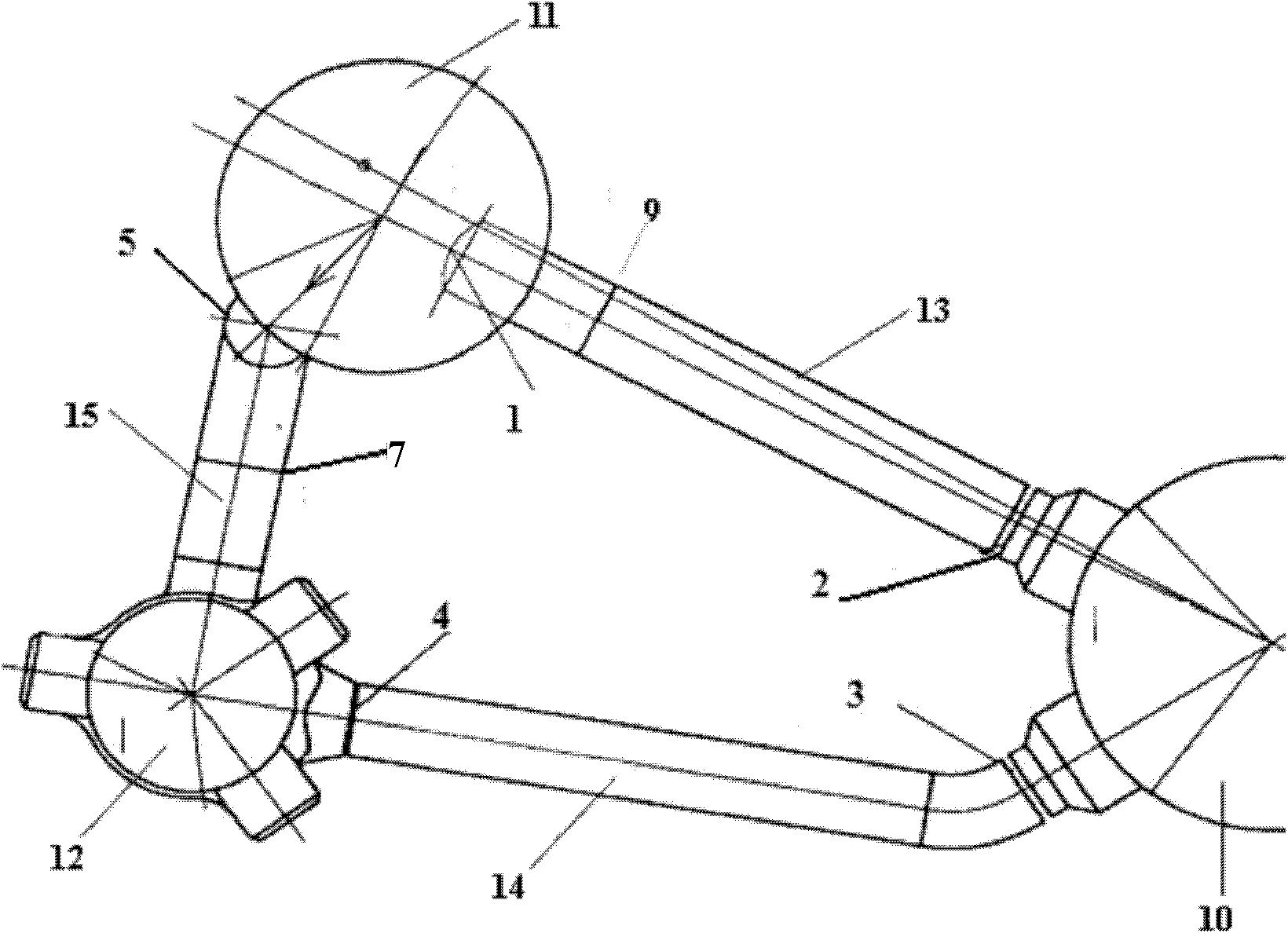

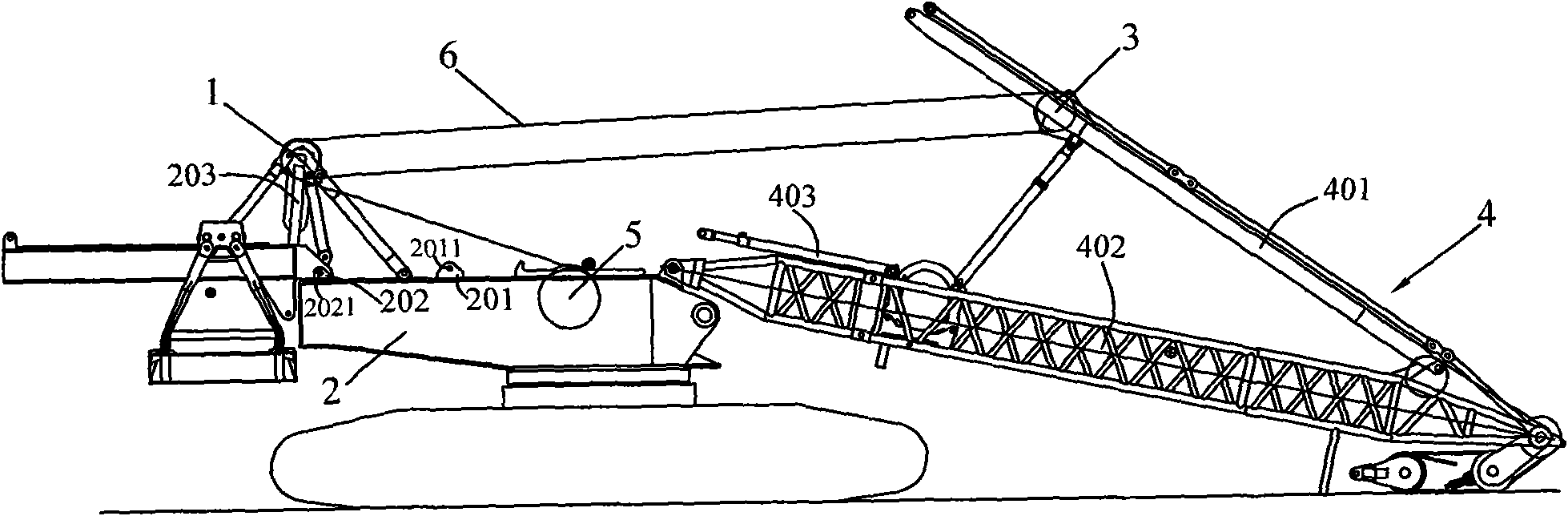

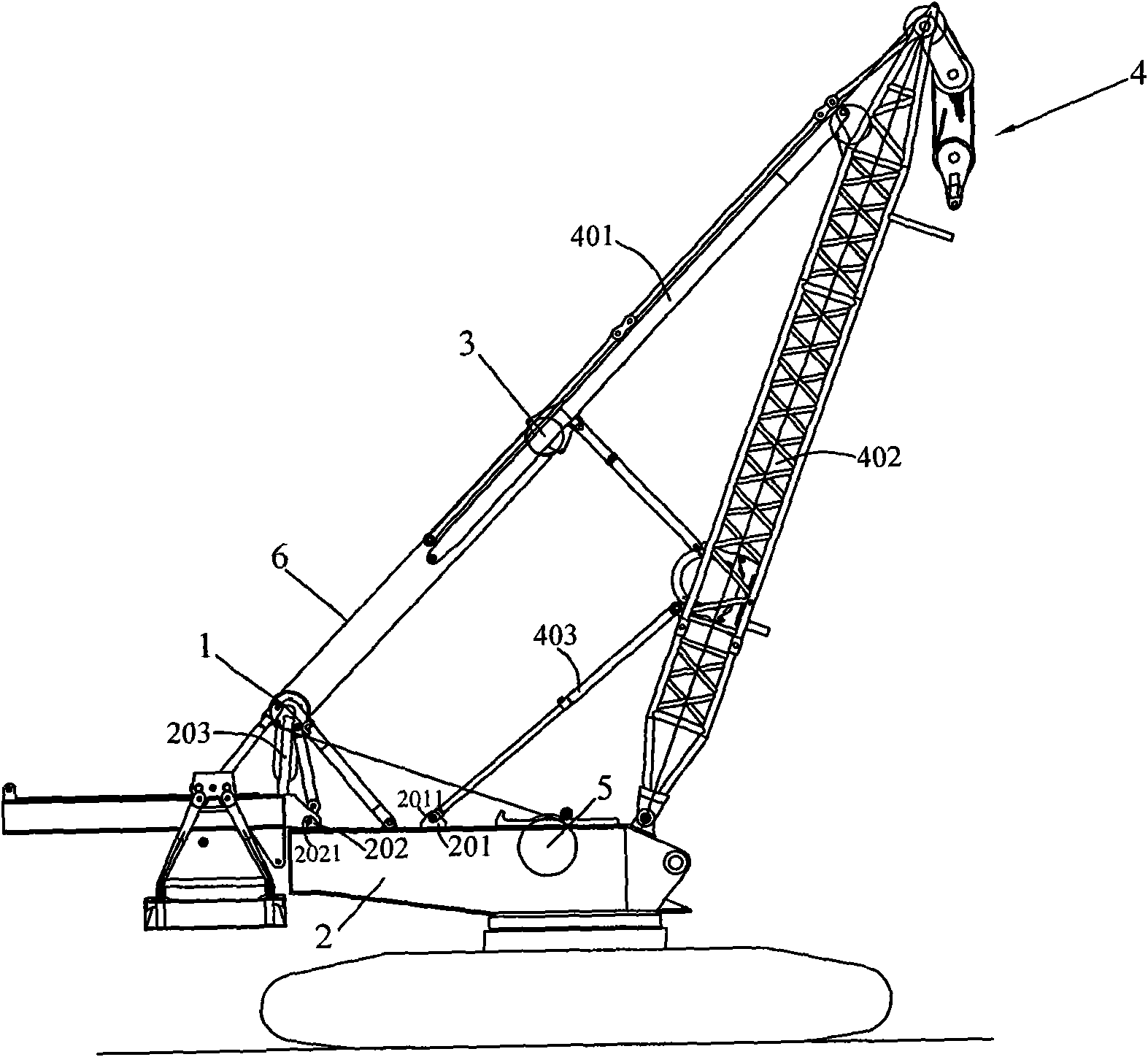

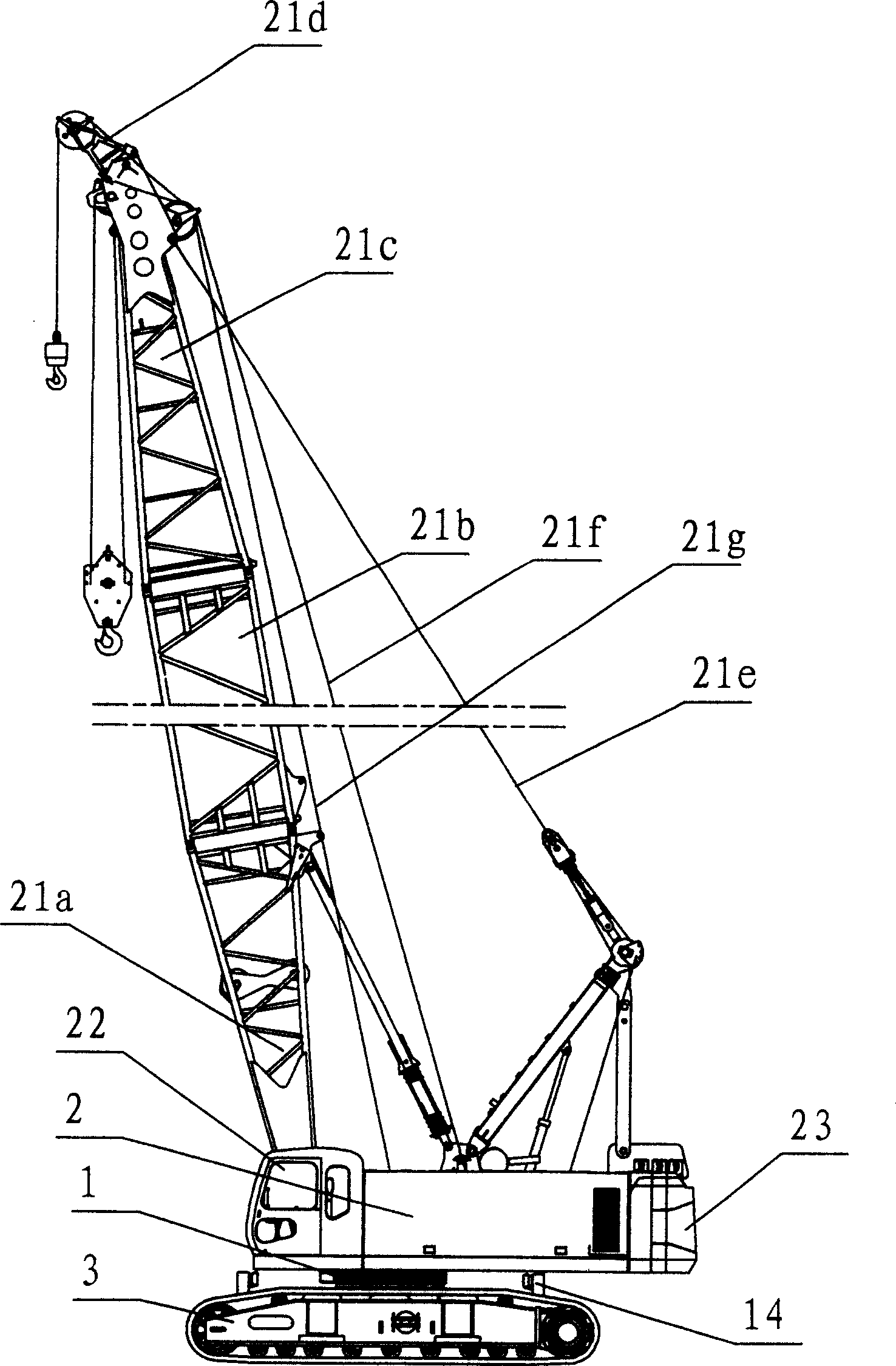

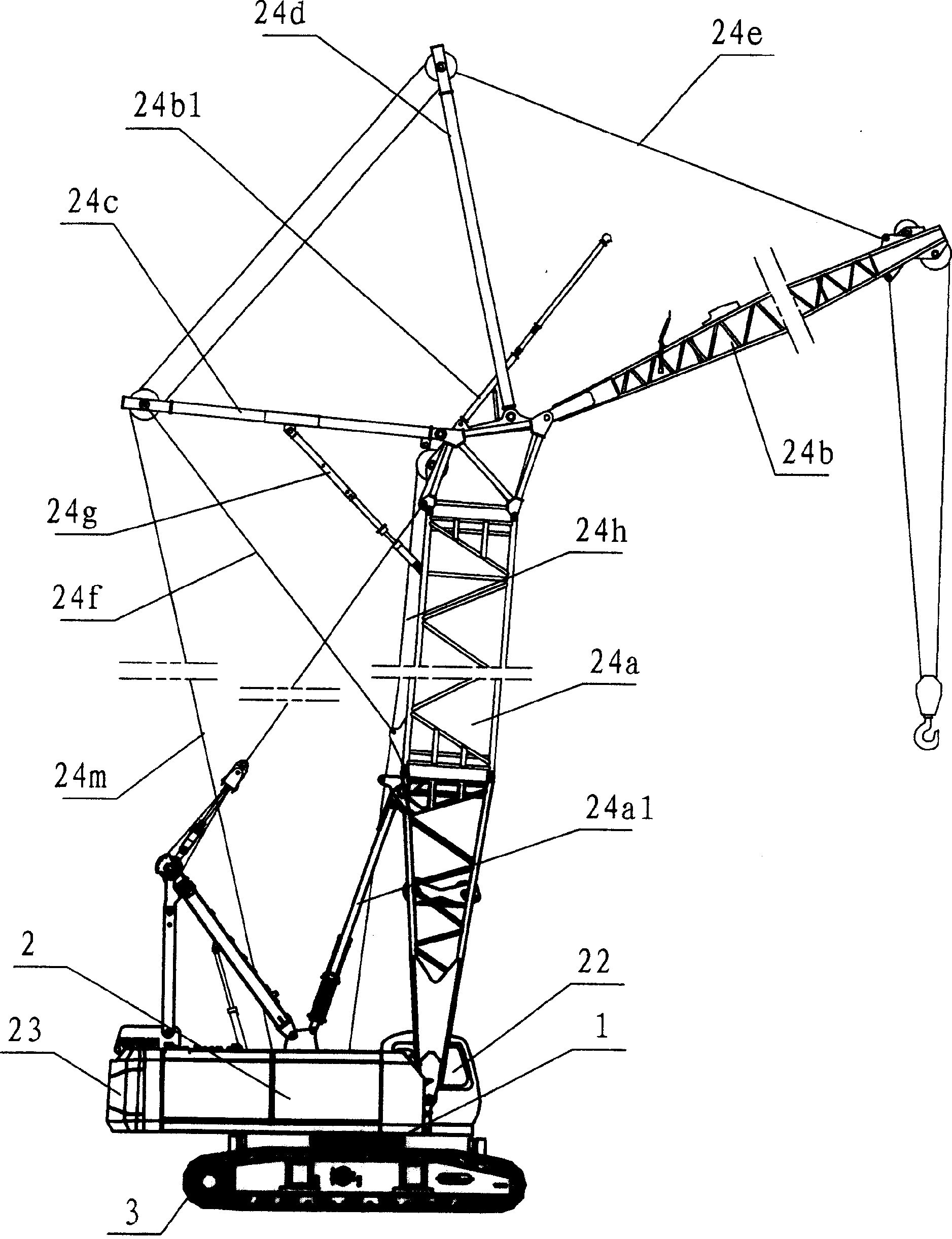

Installation method and device of caterpillar crane mast

The invention relates to an installation method and a device of caterpillar crane mast. The installation method comprises the following steps: connecting the bottom end of a mast with the pivot of a crane platform; respectively installing a standing block and a running block on the crane platform and the mast; arranging a hoister on the platform; fixedly connecting the hoister with one end of a steel wire, and fixedly connecting the other end of the steel wire with the platform by orderly winding around the standing block and the running block; pulling the mast up around the pivot by the hoister through the driving of the standing block and the running block, and successively fixing an anti-slantwise oil cylinder and a mast bracket on the mast at installation positions on the platform during the process of pulling so as to finish mast installation. The invention has the advantages of rapid and effective installation, no need of the hoisting operation of a crane, safe and controllable operation and time saving.

Owner:ZHEJIANG SANY EQUIP

All hydraulic caterpillar cranes

A fully-hydraulic caterpillar hoister is composed of a central body, hydraulic supporting legs for raising the hoister from ground, a caterpiller assemblage, a push-pull system for driving caterpillers, and locating-locking system. It features its self-detaching function.

Owner:山东拓能重机制造有限公司

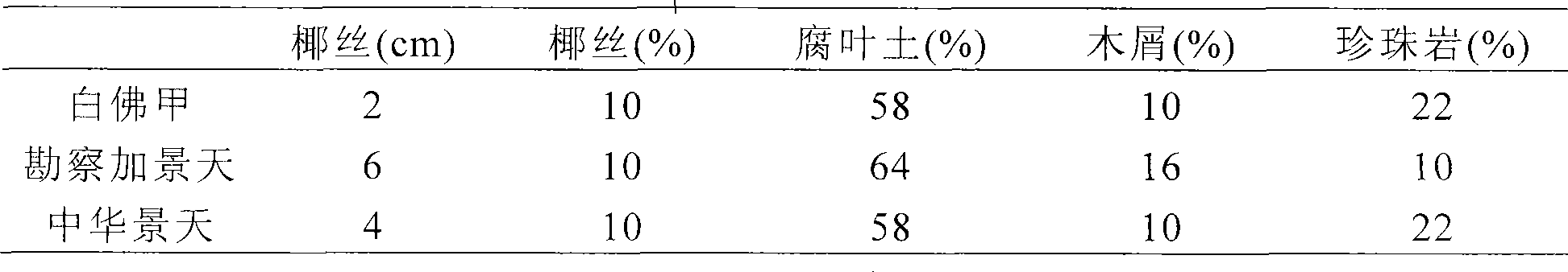

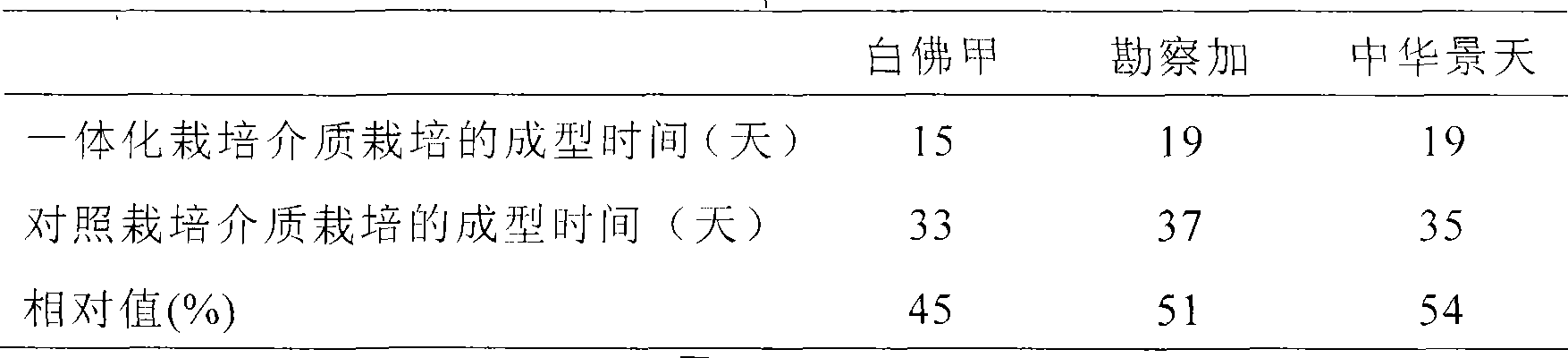

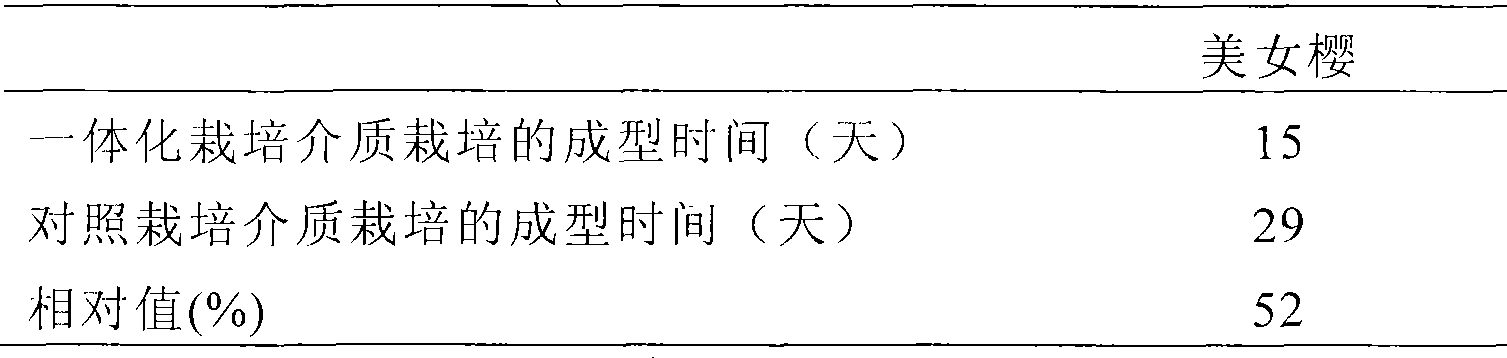

Cultivation medium of integrated molding gardening plant

InactiveCN101411302AHigh exchange energyImprove buffering effectCultivating equipmentsSoilless cultivationFiberDisease

The invention discloses a cultivation medium for integrally molded horticultural plants, which comprises plant fiber, yellow soil and rotten leaf soil, wherein the length of the plant fiber is 2 to 10 centimeters. In addition, the cultivation medium comprises ventilating gap regulation matter as well. The technical proposal of the invention overcomes the deficiencies that the prior plant cultivation medium is large in volume weight and is easy to loosen, fall off and cause diseases and insect pests, and the like, so as to form a lightweight environment-friendly integral plant cultivation medium with excellent physicochemical property. The convenient simple operability of the cultivation medium during transport or plant replacement not only is favorable for saving mounting time, but also can avoid injury to plant root systems, landscape destruction and even environmental pollution which are caused by the falling-off of the cultivation medium when plant materials are replaced.

Owner:上海植物园管理处

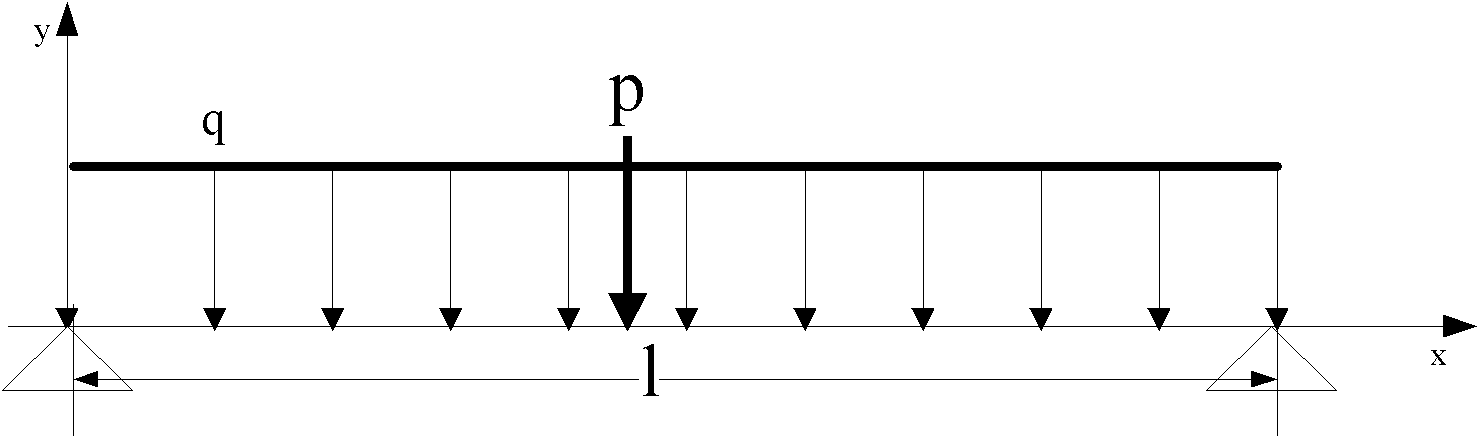

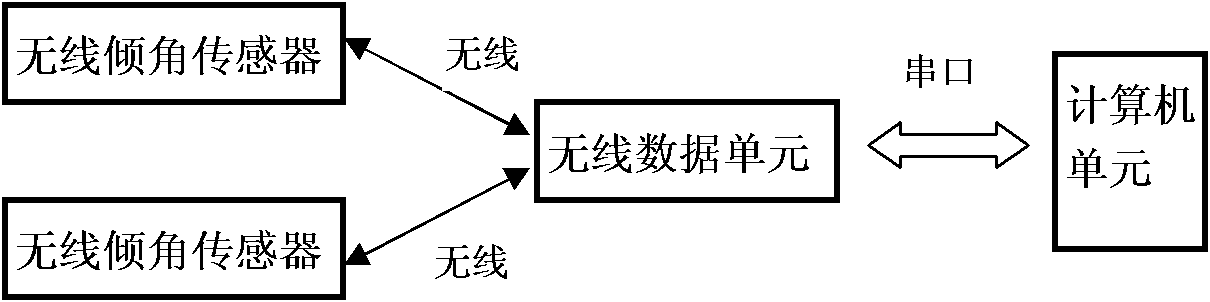

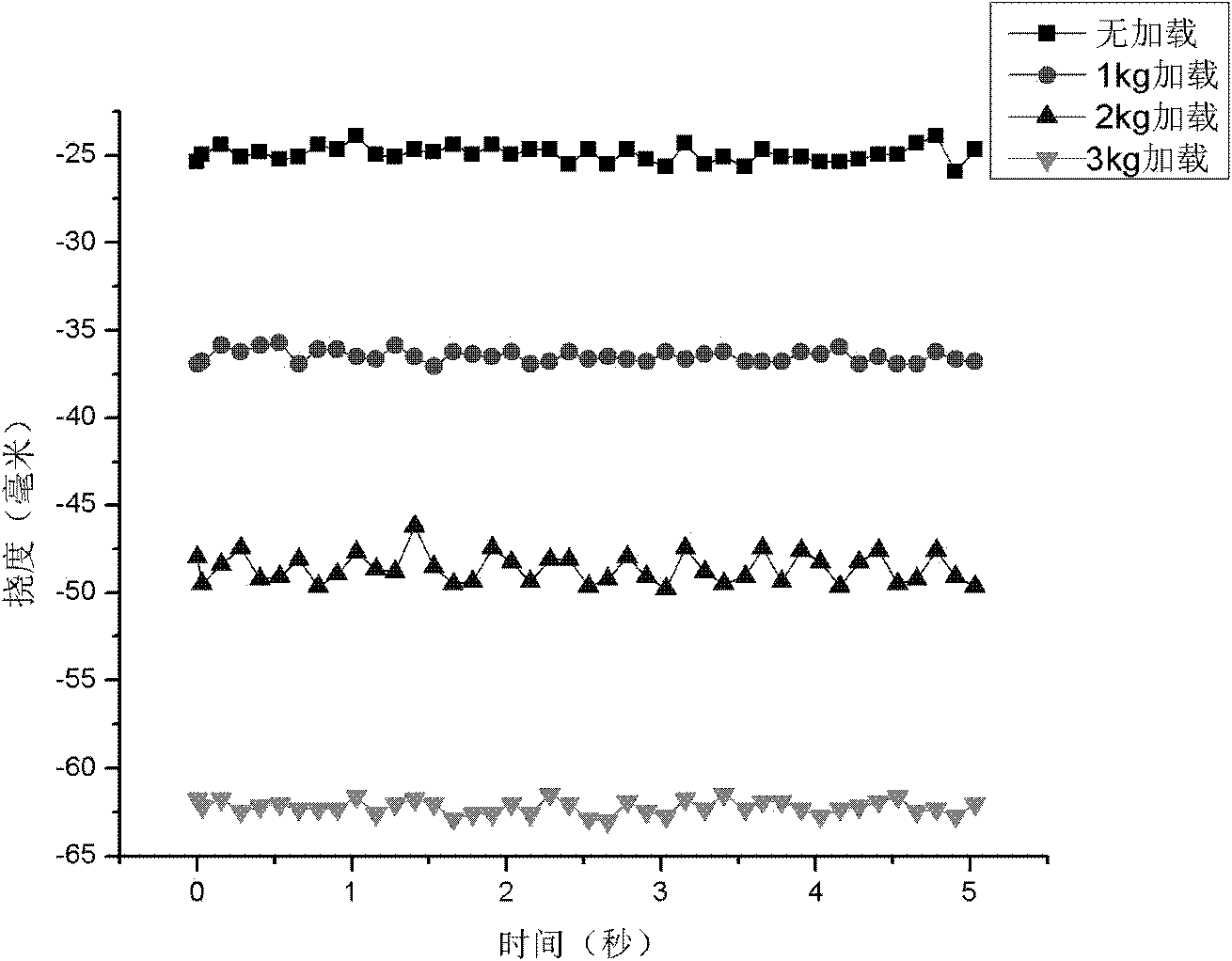

System and method for measuring deflection of bridge structure based on wireless tilt

InactiveCN101915650AEasy to install and removeLow costTransmission systemsUsing electrical meansWireless dataPersonal computer

The invention discloses a system and method for measuring deflection of a bridge structure based on wireless tilt, belonging to the technical field of bridge structure measurement. The invention is characterized in that the system is jointly formed by two wireless tilt sensors, a wireless data unit and a personal computer (PC), wherein the wireless data unit is connected with the PC via a serial port; and each wireless tilt sensor is jointly formed by a micro electro mechanical system (MEMS) technology based tilt unit, a tilt acquisition unit, a wireless transceiving unit and an energy module. The method is characterized by building the bridge deflection curve formula in consideration of the joint action of the deal weight of the bridge structure and the external load, deriving the deflection formula to obtain the tilt formula, computing the unknown parameters according to the actually measured tilt and further obtaining the deflection. The invention overcomes the defects existing in the traditional wired measuring systems and methods, the system has the characteristics of high testing precision, good stability, strong real-time property, accurate computation, etc, and the method is suitable for measuring deflection of similar bridge structures and has good application prospect.

Owner:DALIAN UNIV OF TECH

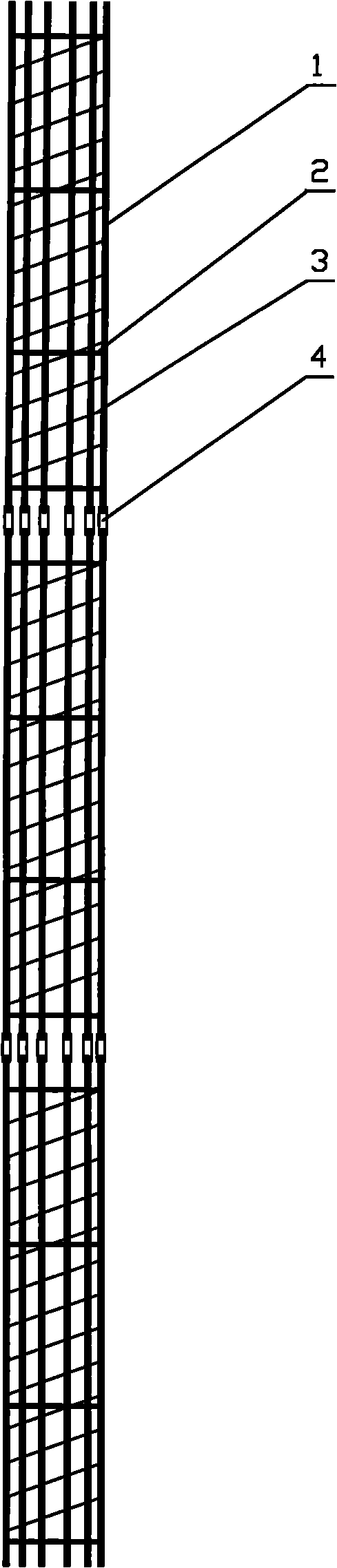

Reinforcement cage and manufacturing method thereof

InactiveCN101967825AQuality improvementImprove machining accuracyBuilding reinforcementsBulkheads/pilesEngineeringRebar

The invention relates to a reinforcement cage and a manufacturing method thereof. The reinforcement cage comprises main reinforcements; the reinforcement cage is divided into a plurality of sections; the main reinforcements, an inner locating stirrup and an outer locating stirrup are arranged in each section of reinforcement cage; the length of the main reinforcements is the same; one ends of the main reinforcements are half wires, and one ends of the reinforcements are full wires; a main reinforcement joint between each section of reinforcement cage is provided with straight thread connectors; and the main reinforcements in each section of reinforcement cage are connected in one-to-one correspondence. The manufacturing method comprises the following steps of: blanking the reinforcements; performing thread rolling on the reinforcement cages; processing the reinforcement cages; storing and delivering the reinforcement cages; splicing the reinforcement cages, preassembling on a spot, putting the processed reinforcement cages end to end according to the sequence of the divided sections into a straight line, sequentially splicing from one end to another end, screwing the connectors one by one, and sequentially arranging the rest reinforcement cages; splicing orifices; and detecting. The invention solves the problem that the reinforcement cage needs to be divided into a plurality of sections for processing and splicing due to the limitation of construction condition. The invention has the characteristics that: the manufacturing method is simple to operate, and the reinforcement cage has high precision and installation rate.

Owner:THE FIFTH ENG CO LTD OF CHINA TIESIJU CIVIL ENG GRP

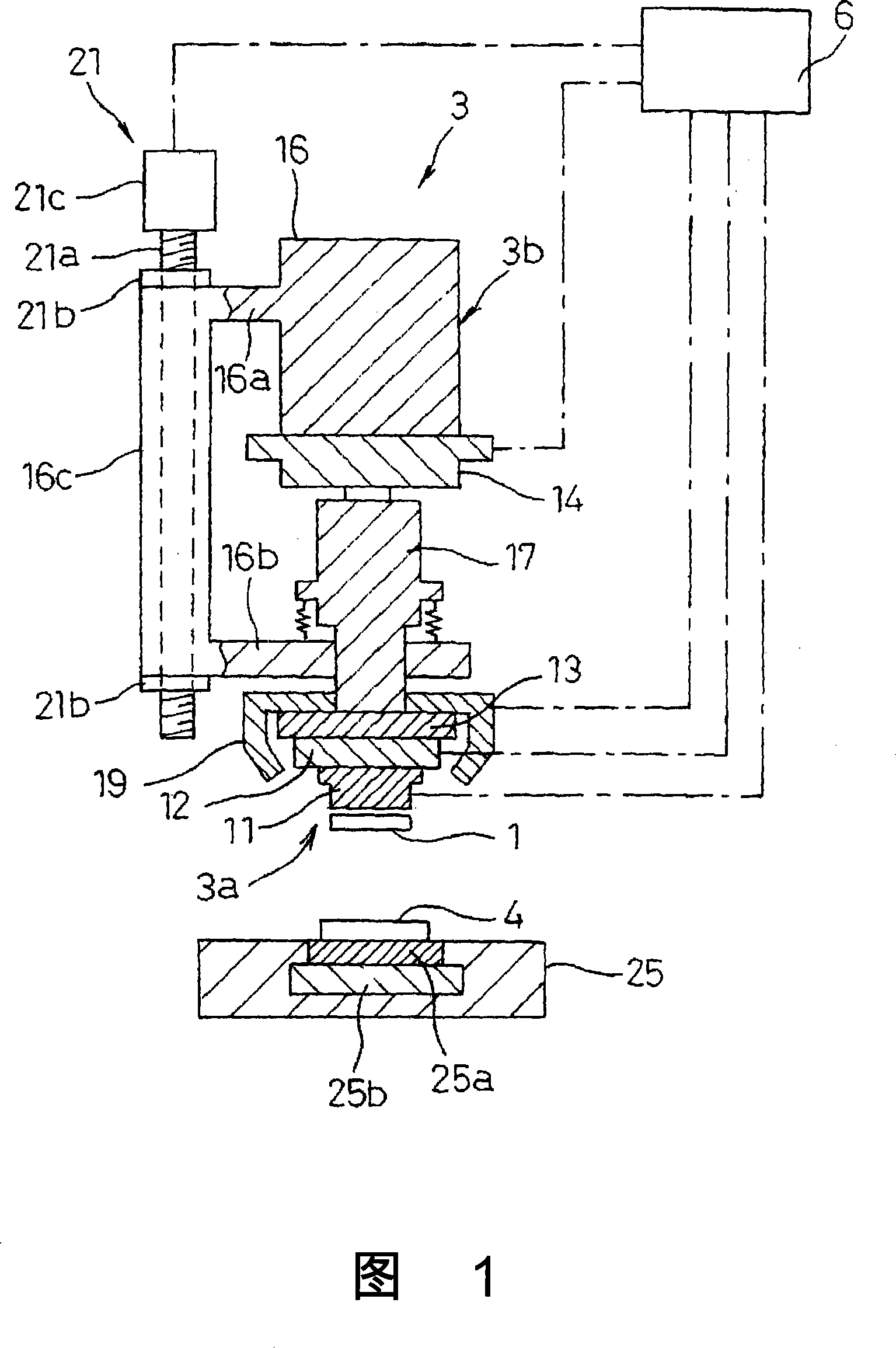

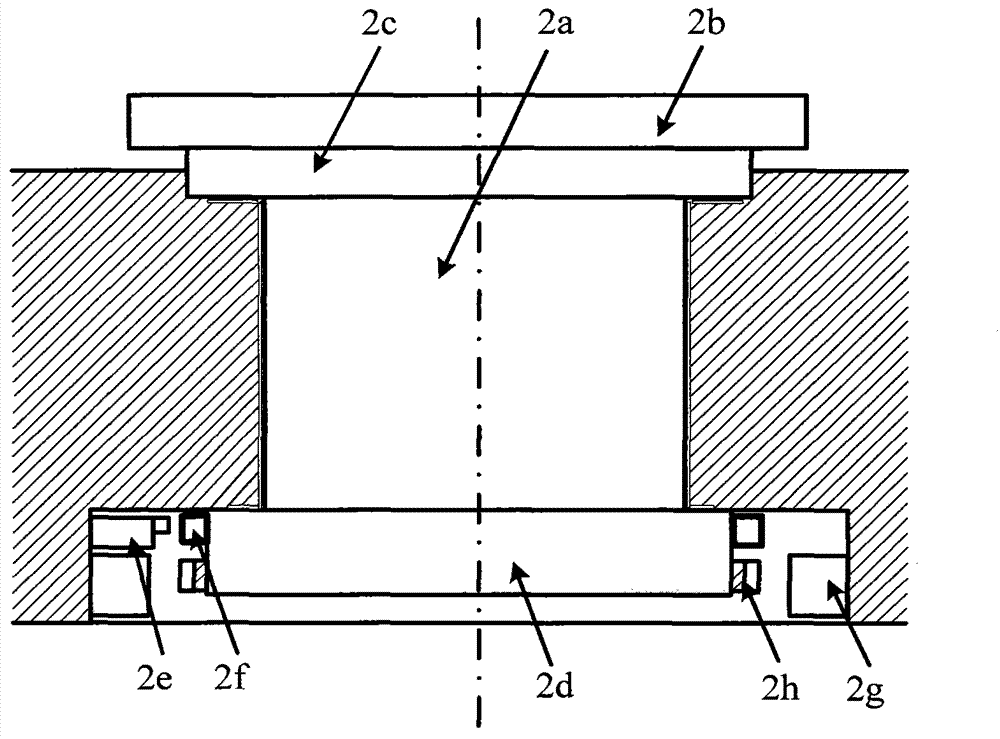

Aero-engine rotor stack-assembling method and device

InactiveCN103899367AReduce consumptionImprove stabilityMachines/enginesSafety/regulatory devicesElectricityAviation

The invention discloses an aero-engine rotor stack-assembling method and device and belongs to the technical field of mechanical assembly. The method comprises the steps of determining a rotary standard based on an air floatation rotary shaft system, determining angle location of a rotary table through an optical-electricity encoder, extracting the radial error of a rotor radial assembly surface and the oblique error of a rotor axial assembly surface through a four-measuring-head measurement device to obtain the influence weight of a rotor on the coaxiality of assembled rotors, measuring all the rotors needed by assembly to obtain the influence weight of each rotor on the coaxiality of the assembled rotors, and conducting vector optimization on the weight of each rotor to obtain the assembly angle of each rotor. The method and device can effectively solve the problem that coaxiality of aero-engine rotors is low after assembly and has the advantages that coaxiality of the rotors is high after assembly, vibration is reduced, installation is easy to achieve, flexibility is high, and the performance of an engine is improved.

Owner:HARBIN INST OF TECH

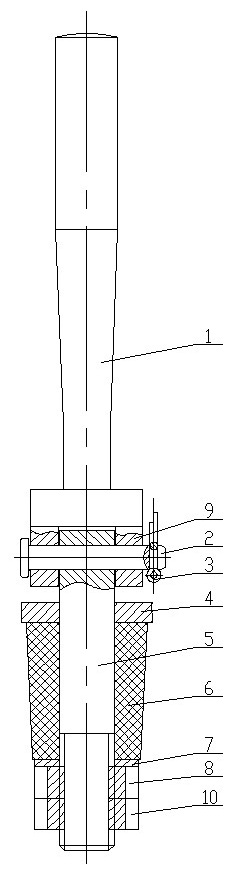

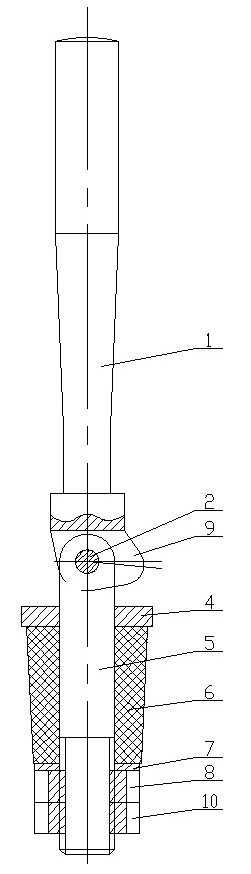

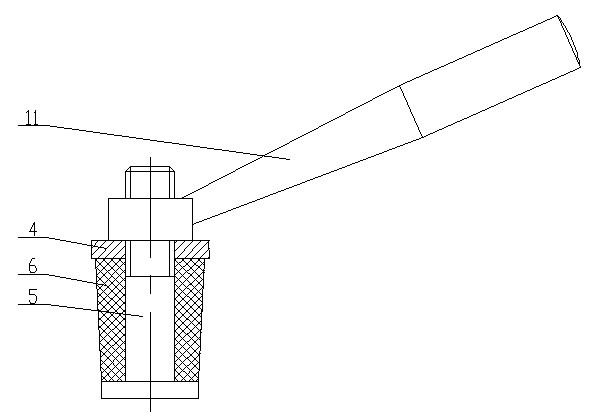

Engine airtight detection rapid plugging head

InactiveCN101986120ASmall turning radiusSave installation timeEngine sealsPipe elementsEngineeringCam

The invention discloses an engine airtight detection rapid plugging head, comprising a cam handle, a cam, a pull rod, an upper gasket, a rubber sleeve, a lower gasket and a nut; wherein the pull rod is sheathed with the upper gasket and the rubber sleeve, the upper gasket is arranged above the rubber sleeve, the bottom of the rubber sleeve is adhered with the lower gasket, the lower gasket is limited by the nut sheathed on the pull rod; the cam is arranged above the upper gasket, the cam is arranged at the bottom of the cam handle, and the cam is hinged with the upper end of the pull rod. The invention can effectively reduce mounting time of plugging head, plugging efficiency is improved, the semidiameter of the cam handle rotating downward is small, the plugging head can be used in narrow space, and the plugging head has the characteristics of simple structure, easy and rapid operation and wide application range.

Owner:力帆科技(集团)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com