Method for producing hot-melt-adhesive aluminum-plastic composite tape

A technology of aluminum-plastic composite tape and production method, which is applied to chemical instruments and methods, adhesives, layered products, etc., can solve the problems of time-consuming peeling of aluminum-plastic composite tape, easy damage to cables, etc., and achieves strong adhesive force and saves installation. time, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

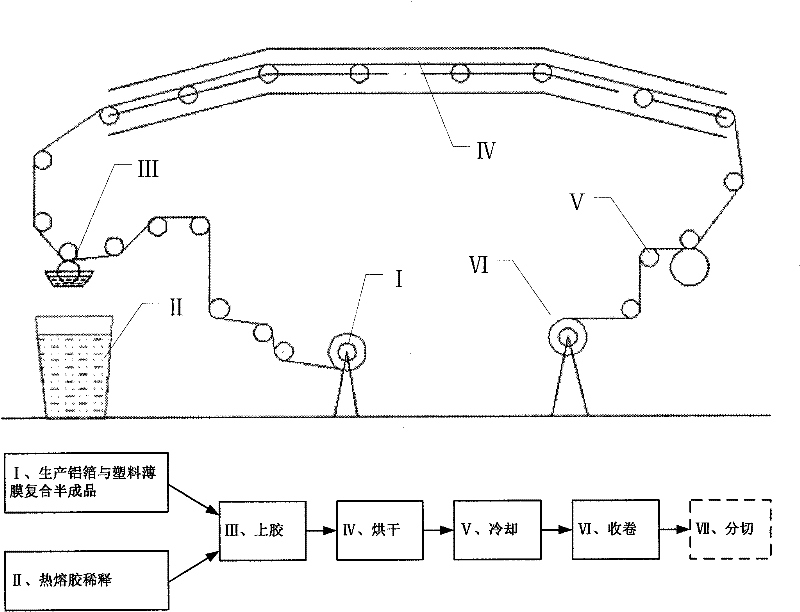

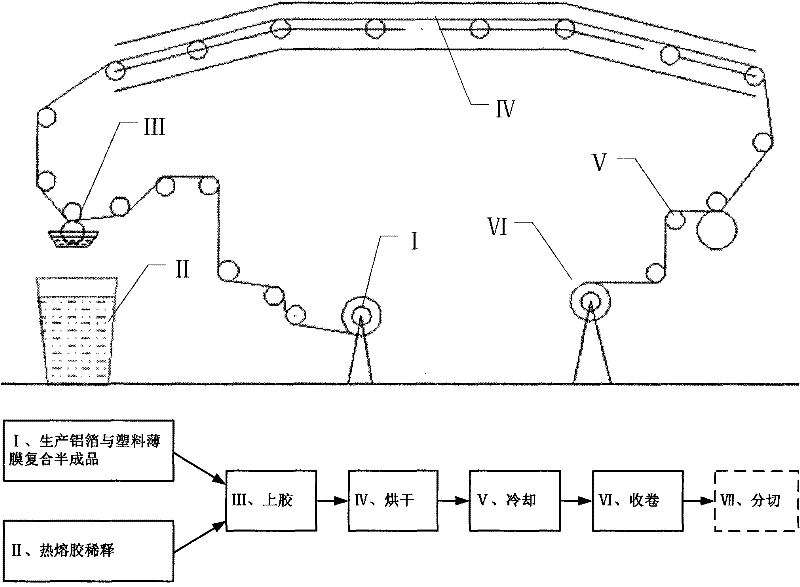

[0022] A method for producing a hot-melt adhesive aluminum-plastic composite tape of 9 μmA1 / 23 μm plastic film / 9 μmA1 / Green HC specification, the processing steps are as follows:

[0023] 1) Aluminum foil and plastic film compound semi-finished product: on a dry compound machine, use polyurethane glue to compound 9μm aluminum foil and 23μm plastic film together, put it in the curing room for 12-72 hours, and then cool it at room temperature for more than 24 hours , that is to complete the aluminum foil and plastic film composite semi-finished product.

[0024] 2) Dilution of hot melt adhesive: hot melt adhesive refers to a viscous liquid made of polyester, ethyl acetate, butyl acetate, butanone, etc., which are reacted in a chemical reaction furnace according to a certain proportion, and the solid content is 5- 80%, the viscosity is 10-5000mPa.S. Hot melt adhesive has good adhesion to PVC and plastic film, and the peel strength is ≥10N / 20mm. The hot melt adhesive has a high ...

Embodiment 2

[0036] A method for producing a 9μmA1 / 23μm plastic film / 9μmA1HC hot-melt adhesive hot-melt aluminum-plastic composite tape, the processing steps of which are as follows:

[0037] 1) Aluminum foil and plastic film compound semi-finished product: on a dry compound machine, use polyurethane glue to compound 9μm aluminum foil and 23μm plastic film together, put it in the curing room for 12-72 hours, and then cool it at room temperature for more than 24 hours , that is to complete the aluminum foil and plastic film composite semi-finished product.

[0038] 2) Preparation of hot melt adhesive: The hot melt adhesive has a high concentration and needs to be diluted with a thinner before it can be used on a dry compound machine. The thinner can use ethyl acetate, toluene, xylene, butyl acetate, butanone, etc. The weight ratio of hot melt adhesive and diluent is 1:0.1~10, weighed and stirred evenly.

[0039] 3) Hot melt adhesive gluing: Pour the prepared hot melt adhesive into the glue...

Embodiment 3

[0050] A method for producing a 25 μm A1 / 23 μm plastic film / Green HC standard hot-melt adhesive aluminum-plastic composite tape, the processing steps of which are as follows:

[0051] 1) Aluminum foil and plastic film compound semi-finished product: on a dry compound machine, use polyurethane glue to compound 25 μm aluminum foil and 23 μm plastic film together, and put it into the curing room for 100 hours of curing at a curing temperature of 10-100 ° C, and then put it at room temperature After cooling down for more than 24 hours, the composite semi-finished product of aluminum foil and plastic film is completed.

[0052] 2) Preparation of hot melt adhesive: The hot melt adhesive has a high concentration and needs to be diluted with a thinner before it can be used on a dry compound machine. The thinner can use ethyl acetate, toluene, xylene, butyl acetate, butanone, etc. The weight ratio of hot melt adhesive and diluent is 10:5-15, and the green ink is optional. After weighin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com