Patents

Literature

92results about How to "Enough carrying capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

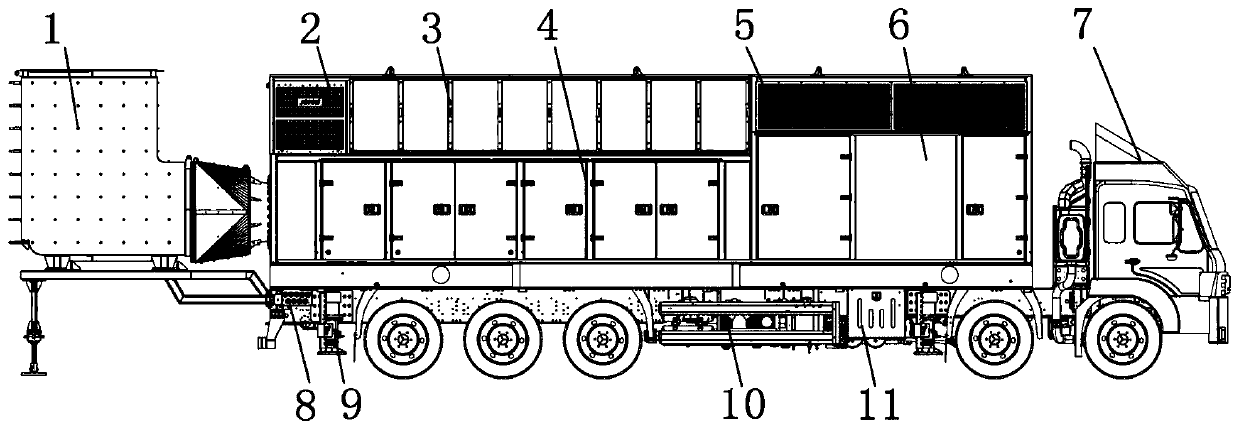

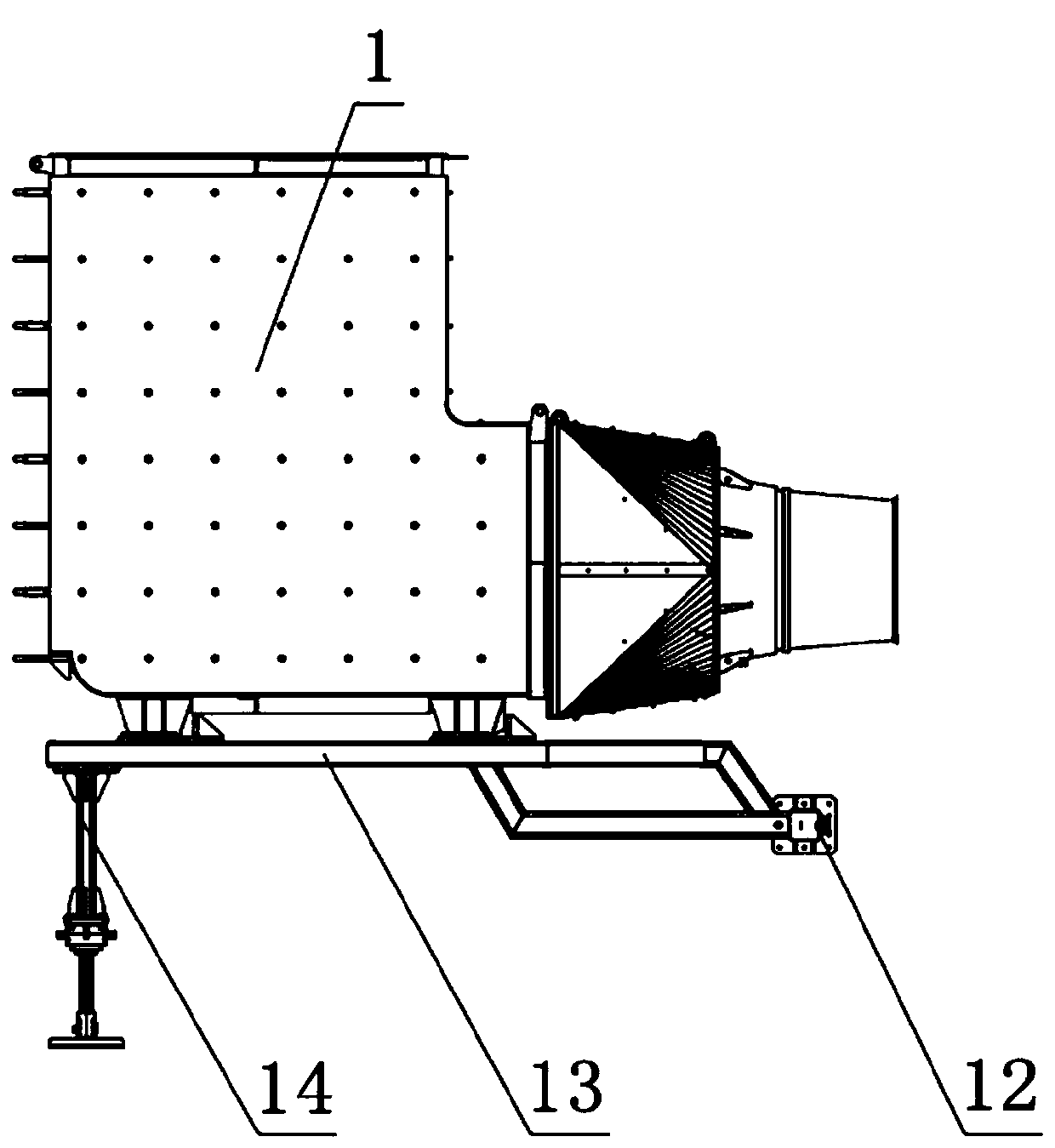

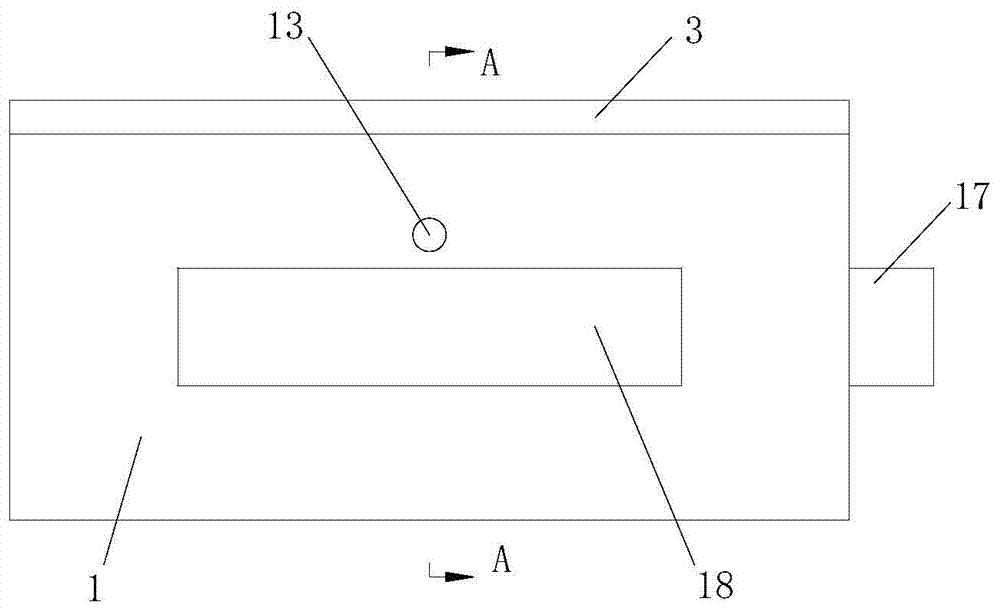

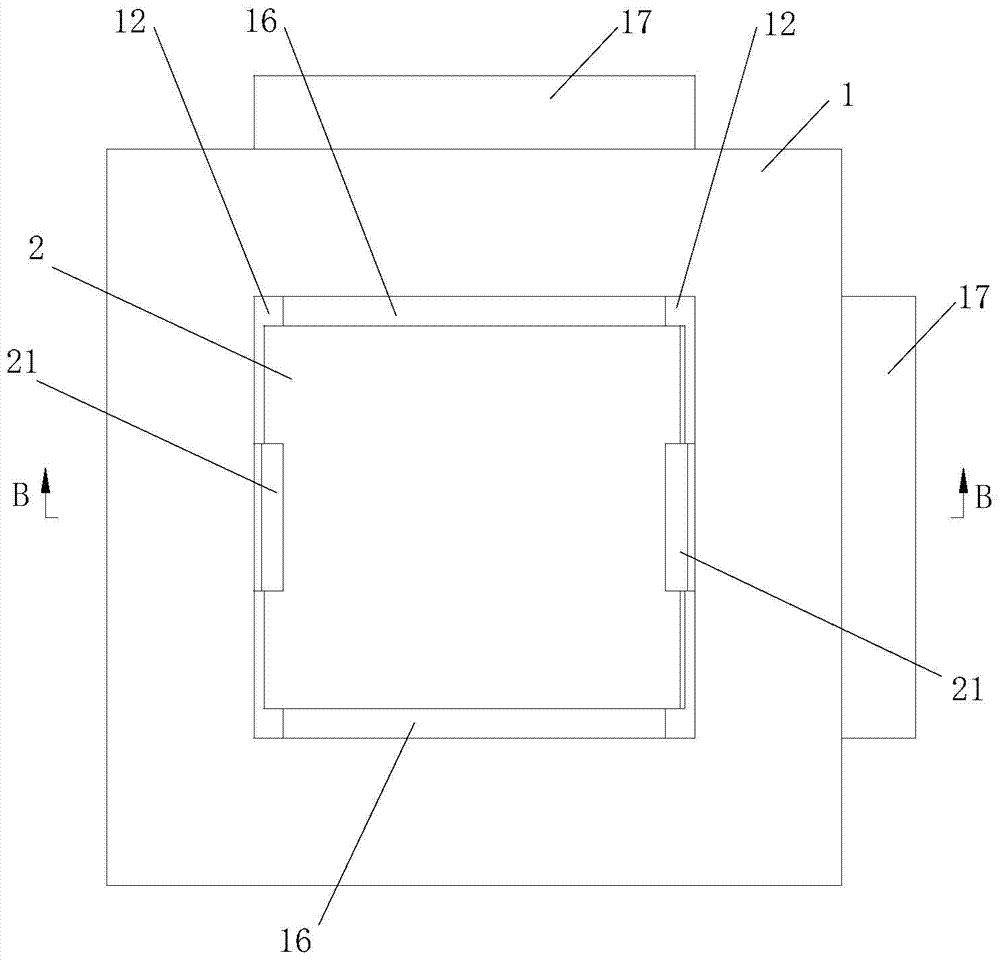

Vehicle-mounted type gas turbine generator set

PendingCN111412064ASave installation timeImprove shock absorptionVehicle fittings for liftingGas turbine plantsAutomotive engineeringElectric generator

The invention discloses a vehicle-mounted type gas turbine generator set which comprises a chassis, a power bin, an electrical bin, a gas inlet filtering system, a ventilation filtering system and hydraulic leveling systems. The power bin, the electrical bin, the gas inlet filtering system and the ventilation filtering system are arranged on the chassis. The hydraulic leveling systems are arrangedon the two sides of the lower portion of the chassis. The power bin and the electrical bin are arranged at the two ends of the chassis correspondingly. The gas inlet filtering system is arranged on the top of the power bin. The ventilation filtering system is arranged on the top of the electrical bin. A gas turbine, a generator, a gearbox and a start motor are installed in the power bin. The vehicle-mounted type gas turbine generator set has the advantages that by selecting the chassis with proper bearing capacity and excellent damping performance and integrating the high-power generator seton the chassis through reasonable space optimized layout, the vehicle-mounted type gas turbine generator set is high in output power, convenient to transport and move, quick to install on site and high in adaptability.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

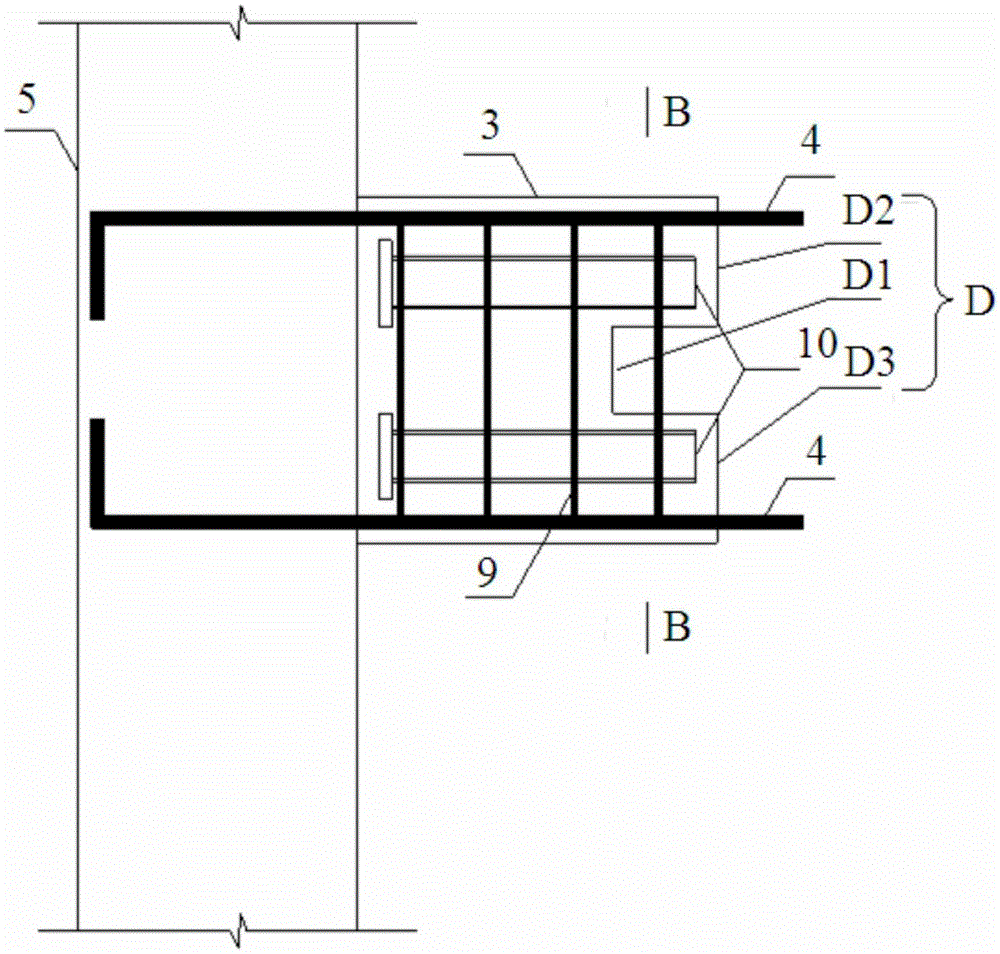

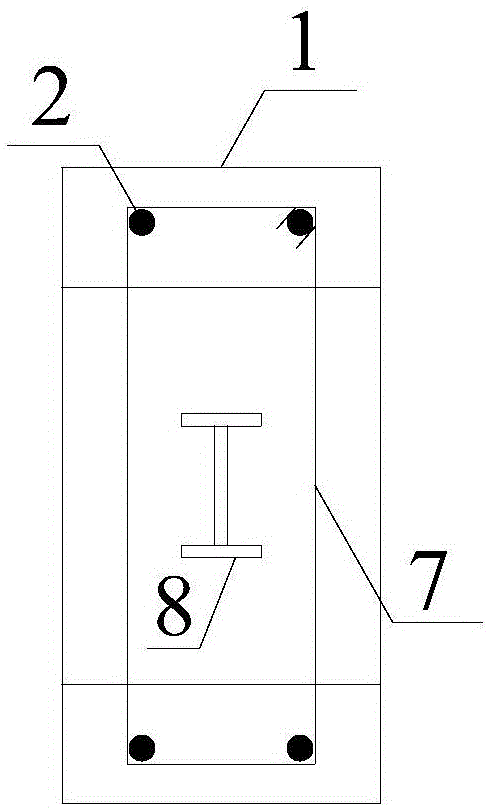

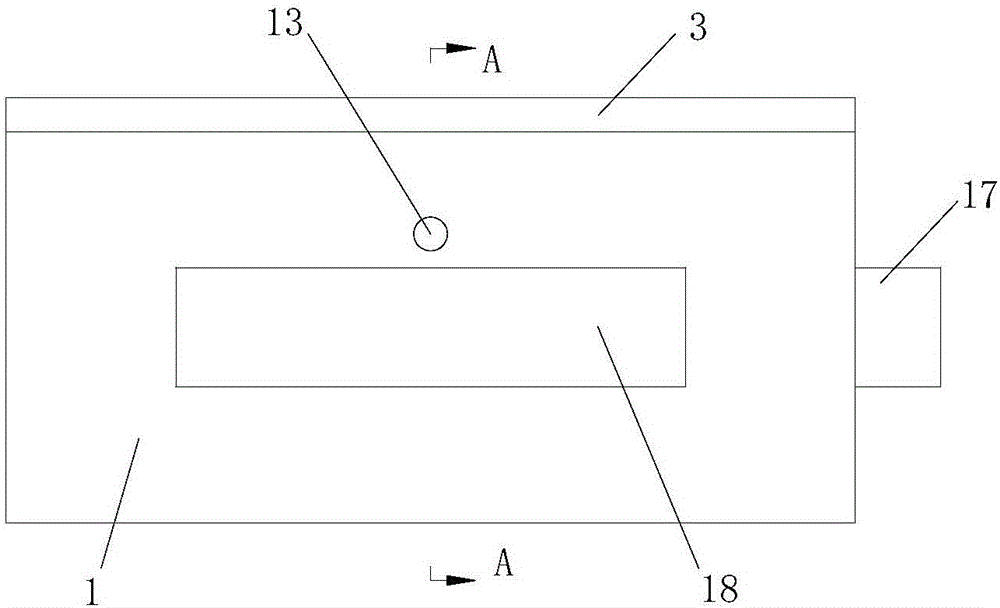

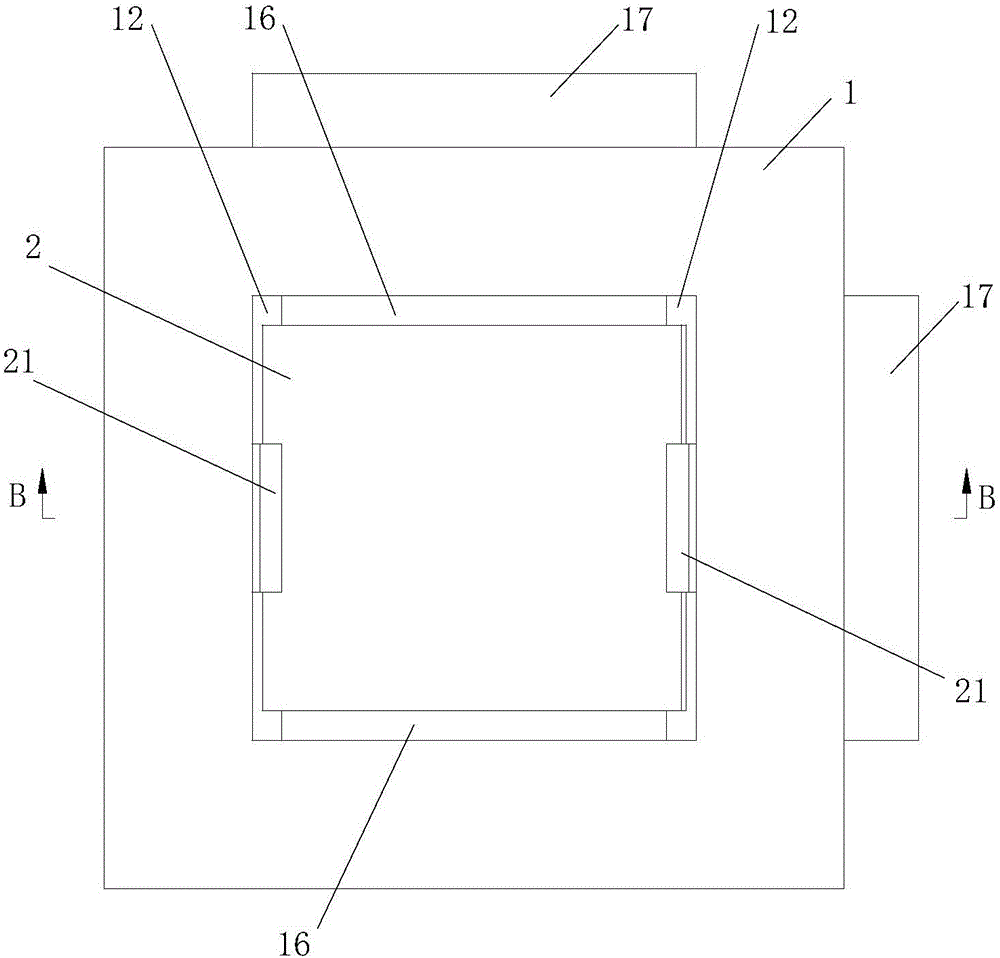

Photovoltaic solar energy pavement structure unit, power generation system and manufacturing method of pavement structure unit

ActiveCN103929119ASave land costReduce the cost of photovoltaic power generationPhotovoltaic supportsSolar heating energyAutomotive engineeringStructural unit

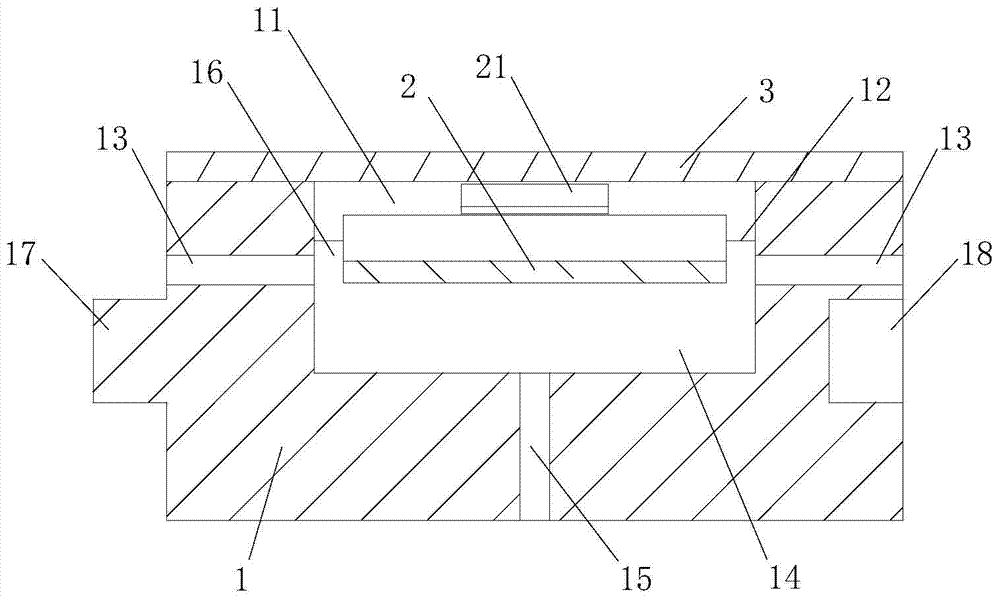

The invention relates to a photovoltaic solar energy pavement structure unit, a power generation system and a manufacturing method of the pavement structure unit. The pavement structure unit comprises a concrete base, a photovoltaic solar cell panel and a PMMA light-transmitting protective plate, a sinking part is arranged in the center of the concrete base, the PMMA light-transmitting protective plate is arranged on the concrete base in a covering mode to define a closed space, and the photovoltaic solar cell panel is packaged in the closed space. The power generation system comprises a solar energy storage battery controller, a storage battery and multiple photovoltaic solar energy pavement structure units, the photovoltaic solar energy pavement structure units are laid to form a pavement and connected in parallel or series to the solar energy storage battery controller, the solar energy storage battery controller is connected with the storage battery, and the output end of the storage battery or the output end of the solar energy storage battery controller is connected with an electric load. The manufacturing method includes the steps that S1, the concrete base is prefabricated; S2, the photovoltaic solar cell panel is installed; S3, the PMMA light-transmitting protective plate is arranged on the concrete base in a packaging mode and receives penetrating light irradiation.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

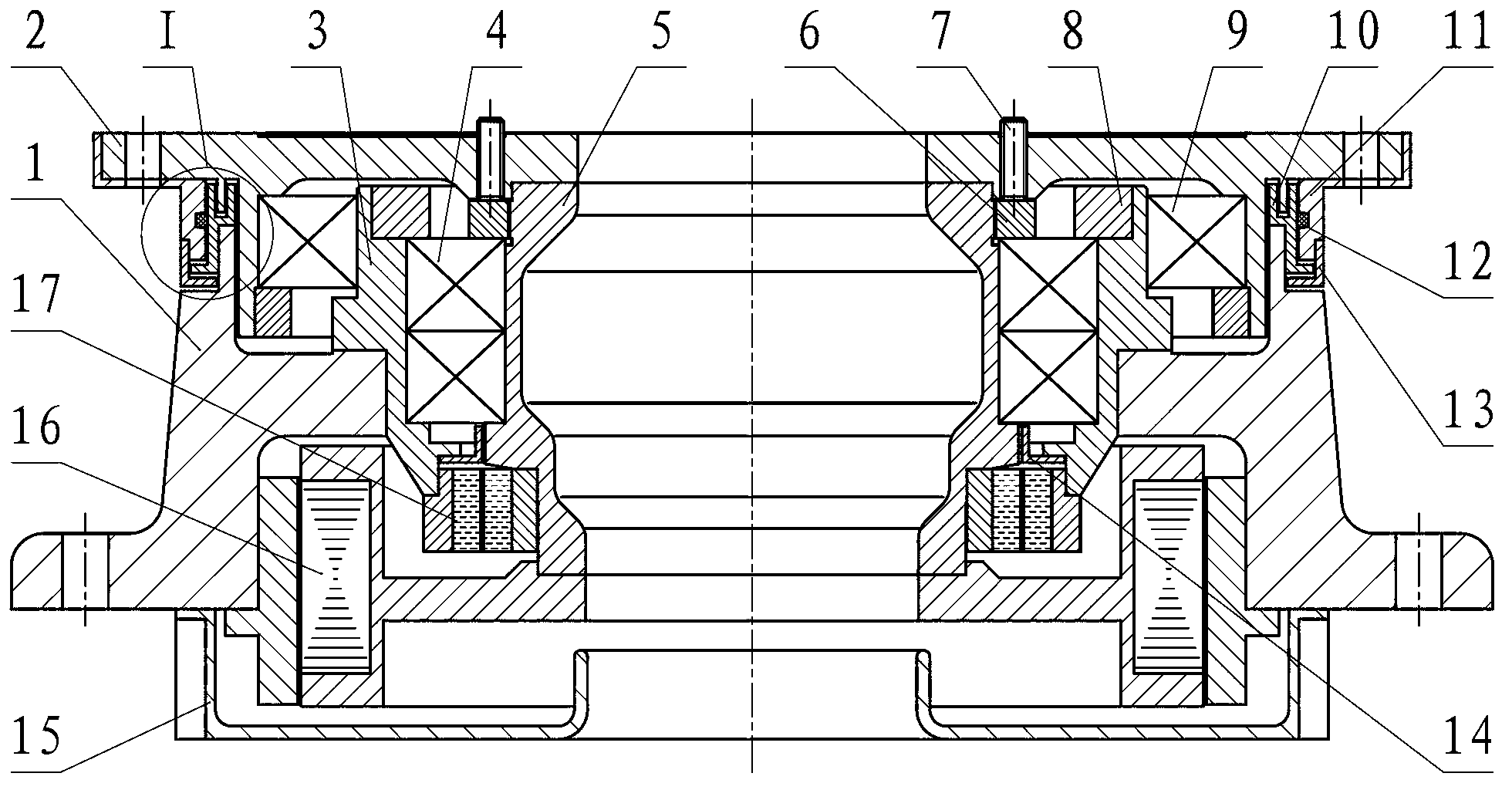

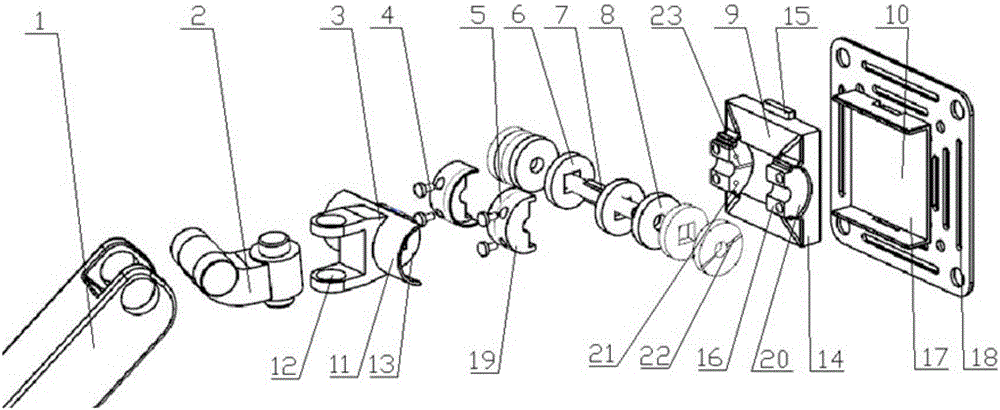

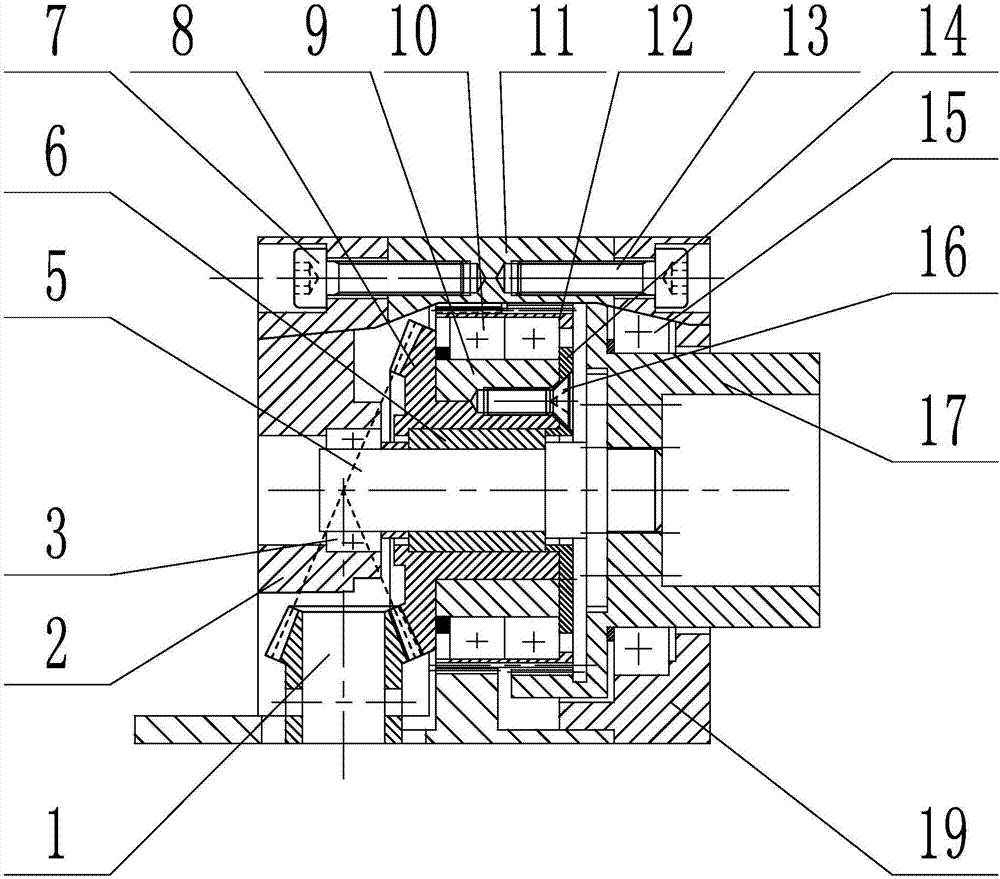

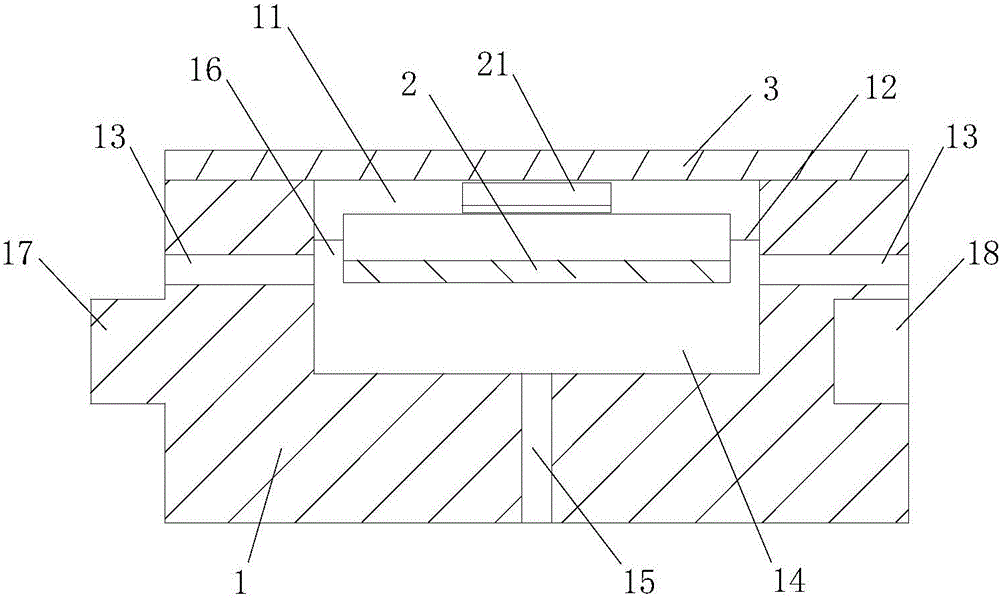

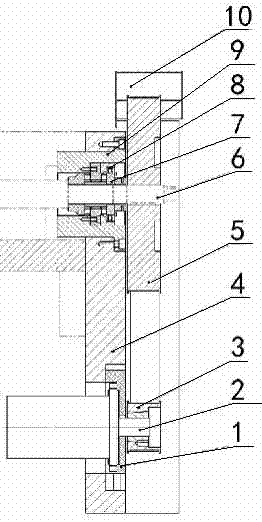

Azimuth device applicable to vehicular photoelectric turntable

ActiveCN103294066AAchieving a modular designImprove maintainabilityPosition/direction controlBiaxial loadMaintainability

The invention discloses an azimuth device applicable to a vehicular photoelectric turntable. The azimuth device comprises a revolving shaft system, an azimuth shell, a rotary transformer and a torque motor. The revolving shaft system comprises an azimuth dead shaft, an azimuth moving shaft, an azimuth rotating adaptor disc and two groups of bearings, the azimuth dead shaft is connected with the azimuth moving shaft and the azimuth rotating adaptor disc respectively via a first bearing and a second bearing, the first bearing bears biaxial loads, the second bearing is larger in diameter and bears radial and tipping loads, and thereby the rotating disc type revolving shaft system borne by the internal and external bearings is formed. The revolving shaft system as well as the rotary transformer and the torque motor are respectively positioned on an upper side and a lower side of an annular transverse plate in the middle of the azimuth shell and are independent to one another. Furthermore, a comprehensive labyrinth felt collar sealing structure is adopted. The azimuth device has the advantages of simple structure, low height, light weight, good maintainability, excellent expansibility, strong environmental suitability and the like, mechanical characteristics and capabilities of resisting shock, vibration and large-angle inclination of the photoelectric turntable are effectively improved, and tracking precision of photoelectric tracking equipment is guaranteed.

Owner:西安应用光学研究所

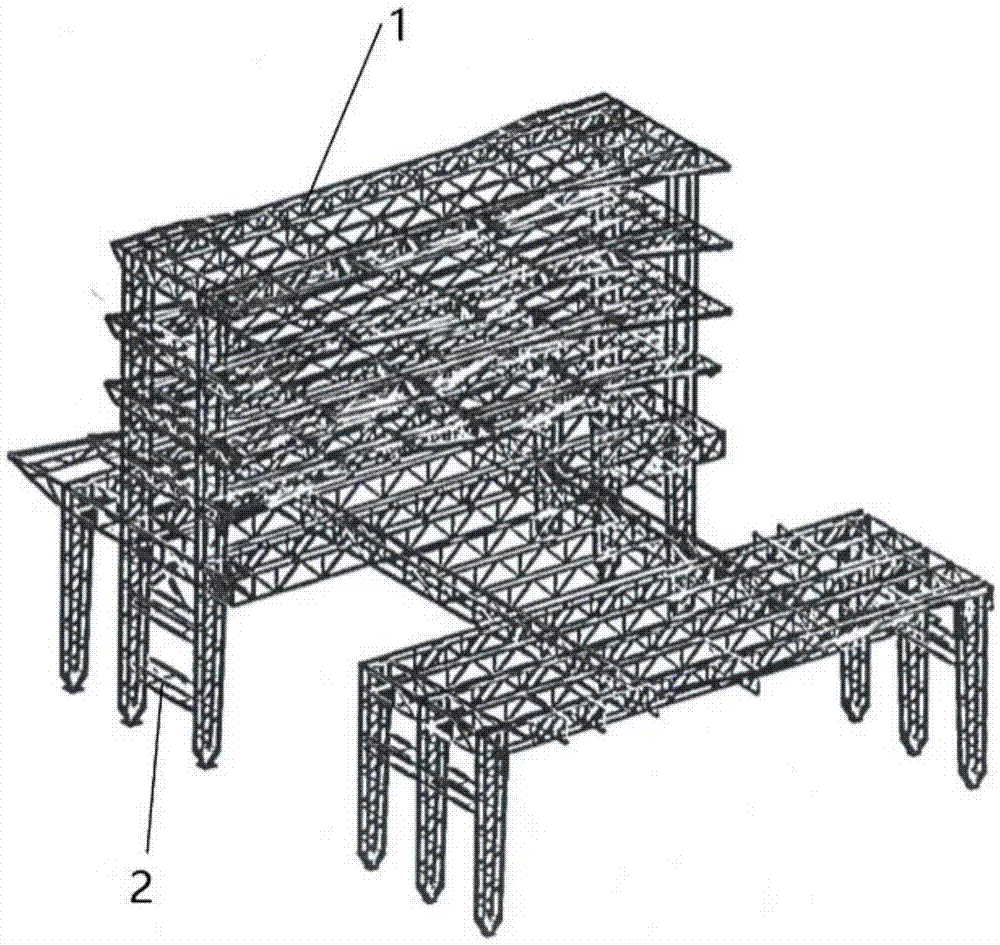

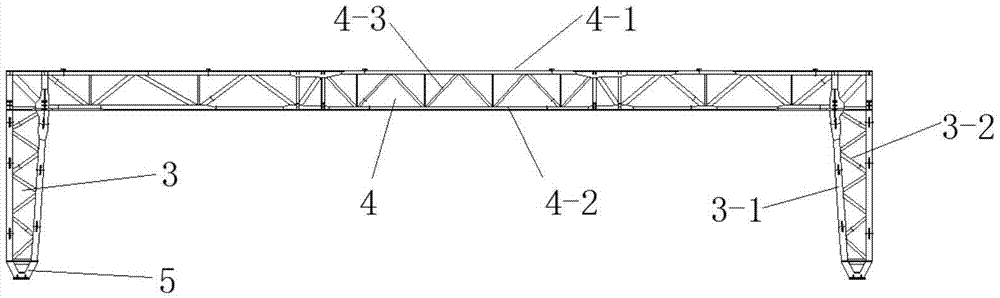

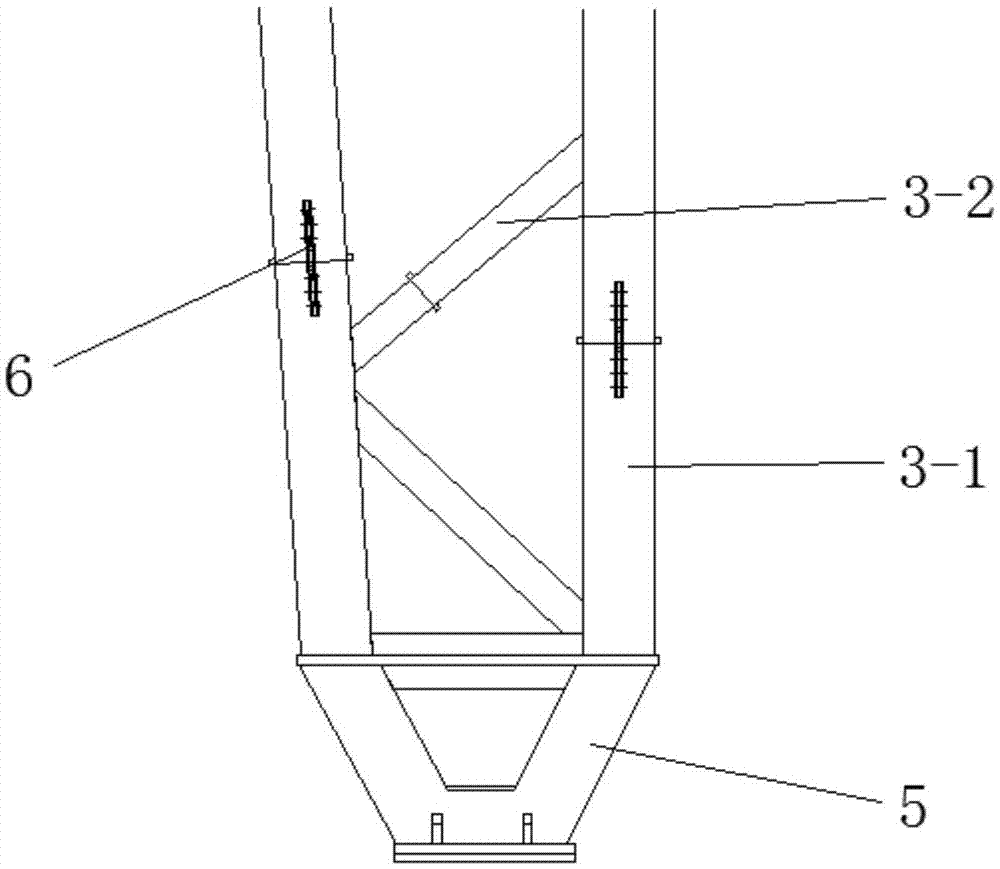

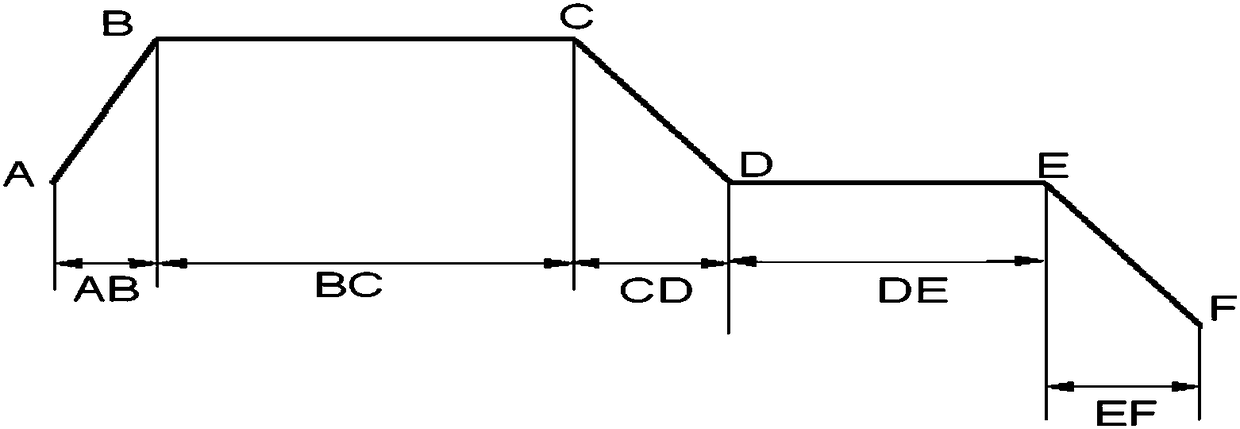

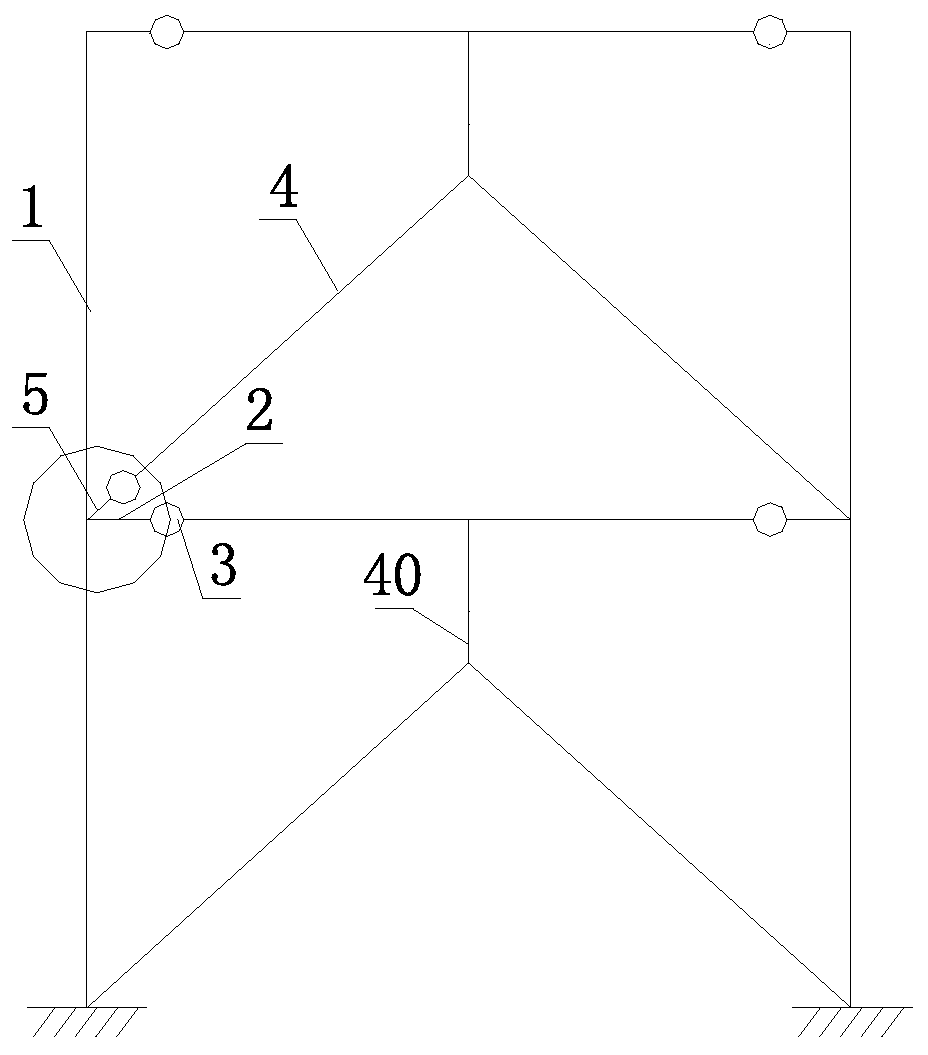

Large-span steel truss structure and installation method thereof

The invention discloses a large-span steel truss structure and an installation method thereof. The large-span steel truss structure comprises one group of steel frames and secondary trusses which are located between the adjacent steel frames and are vertically connected with the steel frames; each steel frame adopts a double-truss combined truss and comprises two supporting columns and a main truss located at the tops of the supporting columns; column pins are arranged at the lower parts of the supporting columns; each supporting column comprises one group of steel columns and reinforcing ribs which are alternatively distributed between the steel columns; each main truss comprises one group of upper chord plates, one group of lower chord plates and webs located between the upper chord plates and the lower chord plates. According to the installation method provided by the invention, a long slippage rail is paved at the lower part and a lot of labor force is alleviated; the whole structure can be divided into different construction regions according to different structures so that the construction is more convenient and rapid.

Owner:JIANGSU HUNING STEEL MECHANISM

Detachable concrete component constructing method

ActiveCN105155773AGuaranteed shear capacityGuaranteed local shear capacityBridge structural detailsGirdersConcrete beamsEngineering

The invention provides a detachable concrete component. The detachable concrete component comprises a concrete frame column section, a first concrete beam section, a second concrete beam section and a longitudinal bar intersection region, wherein one end of the second concrete beam section is perpendicularly connected with the concrete frame column section integrally; the other end of the second concrete beam section is spliced with a tenon type connecting joint at one end of the first concrete beam section through a mortise type connecting joint; and a plurality of first longitudinal bars arranged on the upper side and the lower side of the inside of the first concrete beam section and a plurality of second longitudinal bars arranged on the upper side and the lower side of the inside of the second concrete beam section outwards extend to the longitudinal bar intersection region and then are connected to one another. The invention further provides a constructing method and application of the detachable concrete component. The manufactured first concrete beam section can be detached and then assembled again, the amount of post-poured concrete is small, the detachable concrete component is convenient to mount and detach, the shearing force bearing capability and the repeated bending moment capability of the detachable concrete component are the same with those of an integrally cast concrete beam, and the structure is safe.

Owner:TONGJI UNIV

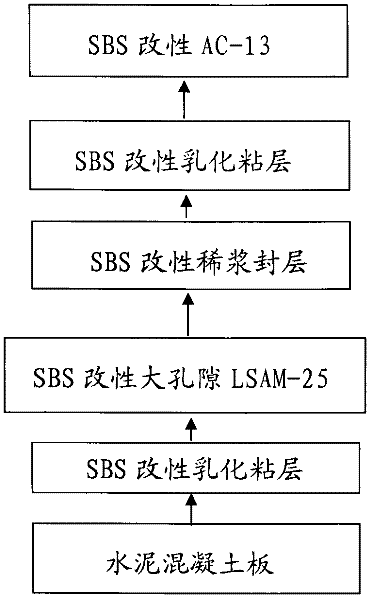

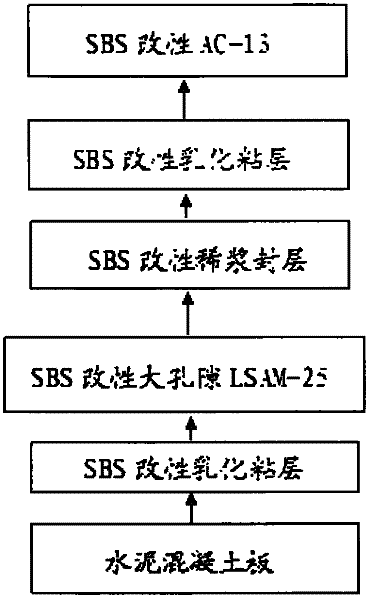

Thin-layer asphalt pavement overlaid with old cement concrete suitable for heavy-duty coal transportation traffic

The invention relates to a thin-layer asphalt pavement overlaid with old cement concrete suitable for heavy-duty coal transportation. The cement concrete slab is provided with a rubber mastic high elastic stress absorption belt and a rubber mastic high elastic stress absorption belt. SBS modified macroporous LSAM-25 with a thickness of 6-8 mm is arranged on the top, and a SBS modified slurry seal layer with a thickness of 1 cm is arranged on the top of the SBS modified macroporous LSAM-25, and the top of the SBS modified slurry seal layer SBS modified AC-13 with a thickness of 4cm is set, and SBS is passed between SBS modified AC-13 and SBS modified slurry seal layer, SBS modified macroporous LSAM-25 and rubber mastic high elastic stress absorption belt The porosity of the modified emulsified adhesive layer connected with SBS modified macroporous LSAM-25 ranges from 18% to 22%. The pavement has excellent bearing capacity and high temperature stability, good anti-reflective cracking effect, long service life of the pavement, and can meet the needs of heavy-duty traffic such as coal transportation.

Owner:SHANXI PROVINCIAL RES INST OF COMM

Double-zero aluminum foil for alloying high-performance aseptic packaging material and production process of double-zero aluminum foil

InactiveCN108165832AShort processIncrease productivityMetal rolling arrangementsChemical compositionAluminum foil

The invention relates to a double-zero aluminum foil for an alloying high-performance aseptic packaging material. The double-zero aluminum foil is characterized by comprising chemical compositions including, by mass, 0.48%-0.55% of Si, 0.58%-0.66% of Fe, 0.005%-0.01% of Cu, 0.0015%-0.005% of Mn, 0.0015%-0.005% of Ni, less than 0.001% of Zn, 0.02%-0.05% of Ti, less than 0.0003% of Zr and the balance aluminum. The double-zero aluminum foil for the alloying high-performance aseptic packaging material and the production process of the double-zero aluminum foil are high in production efficiency, high in finished product rate, low in cost, good in plate shape and stable in quality.

Owner:JIANGSU ZHONGJI LAMINATION MATERIALS

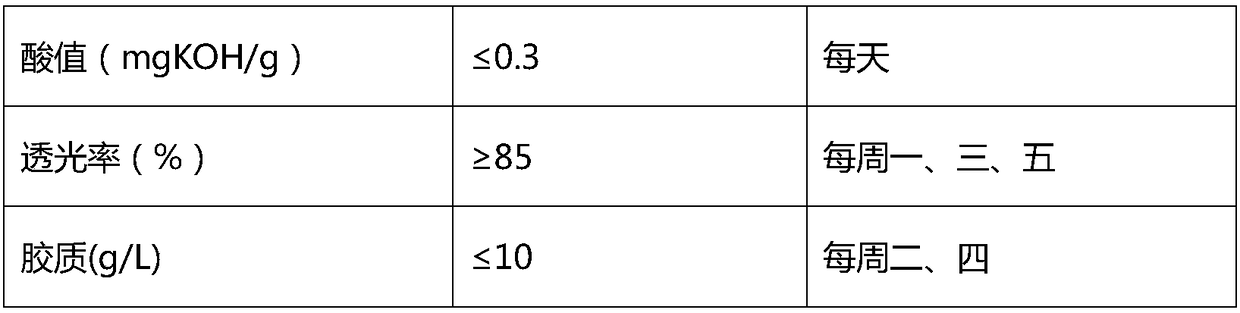

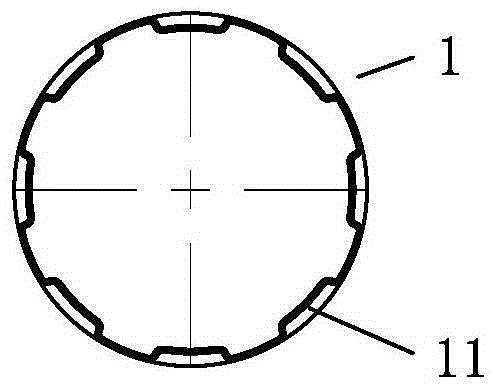

Anti-loosening bracket joint device with multiple friction plates

ActiveCN106499933AEnough carrying capacityAchieve brake locking effectStands/trestlesPivotal connectionsEngineeringSacroiliac joint

The invention discloses an anti-loosening bracket joint device with multiple friction plates. The anti-loosening bracket joint device comprises a rotary base, an adapter crankshaft, an adapter block, a locking bolt, a locking cover, a first friction plate, a rotary shaft, a second friction plate (number of friction plates can be increased), a rotary head rotation block and a hanging plate assembly, wherein the rotary base is fixedly arranged on parts such as a desktop and a wall through connection or other joints; the adapter crankshaft, the rotary base and the adapter block form a rotary pair; the locking cover is blocked with the rotary head rotation block through the locking bolt; the rotary shaft penetrates through the center of the first friction plate, the center of the second friction plate and the center of a square hole bearing, and is positioned in a cavity which is formed by fixedly connecting the locking cover and the rotary head rotation block; and the rotary head rotation block is connected with the hanging plate assembly through a blocking pin. According to the anti-loosening bracket joint device disclosed by the invention, multiple friction plates are adopted, so that friction surfaces and axial pressing are increased, and therefore, greater friction force can be obtained. The anti-loosening bracket joint device is reasonable in design, is simple in structure, and is suitable for the optimized design of the anti-loosening bracket joint device.

Owner:苏州济和精密传动系统有限公司

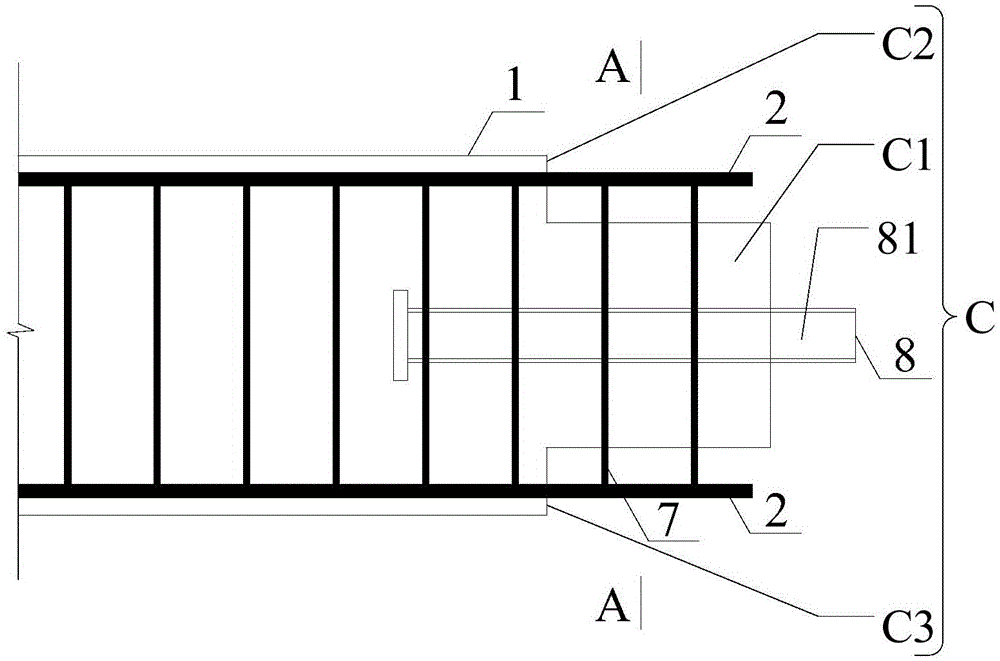

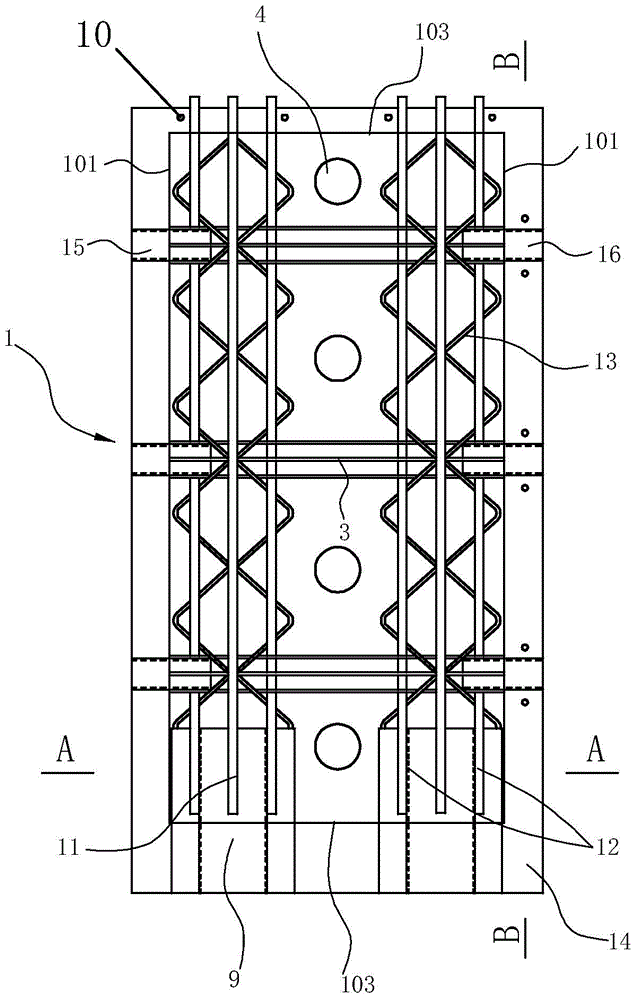

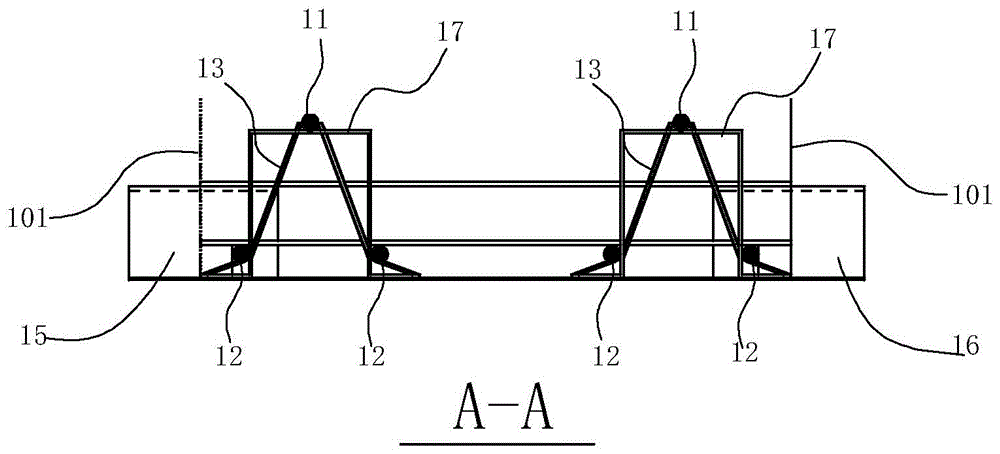

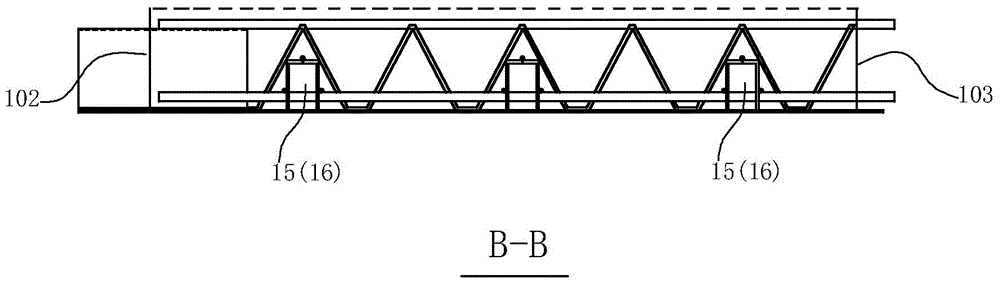

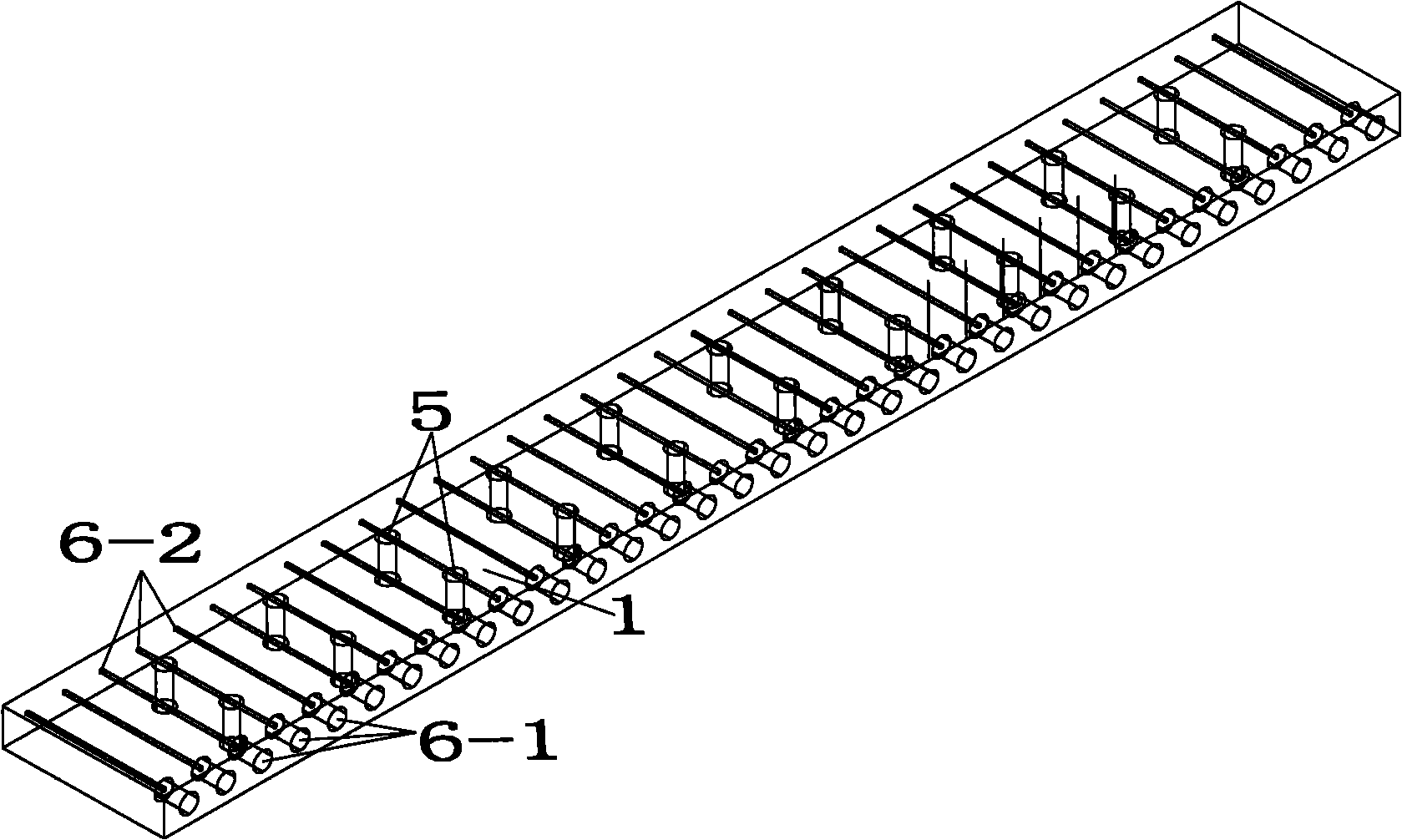

Prefabricated steel bar truss combined floor and splicing method thereof

InactiveCN104947837AImprove performanceShorten the construction periodFloorsCarrying capacityFloor slab

The invention relates to a prefabricated steel bar truss combined floor and a splicing method thereof. The prefabricated steel bar truss combined floor is characterized by comprising a bottom board and poured layers, wherein the bottom board is formed by assembling prefabricated boards, the poured layers are poured on the bottom board and in gaps between prefabricated board splicing seams, and prefabricated boards I or prefabricated boards II are adopted as the prefabricated boards. Compared with the prior art, the prefabricated steel bar truss combined floor has the advantages that the prefabricated steel bar truss combined floor comprises the bottom board formed by assembling the prefabricated boards and the poured layers poured on the bottom board and in the gaps between the prefabricated board splicing seams, and light-weight aggregate concrete can be adopted as poured concrete, so that the weight of the overall structure is reduced, the foundation construction cost is lowered, the seismic performance of a building structure is improved, and high carrying capacity is achieved; prefabricated construction can be achieved, so that the construction period is greatly shortened, and construction is convenient; bottom steel plates of the prefabricated boards are completely wrapped in the concrete in the prefabrication process, so that secondary treatment on the bottom steel plates is not needed.

Owner:NINGBO UNIV

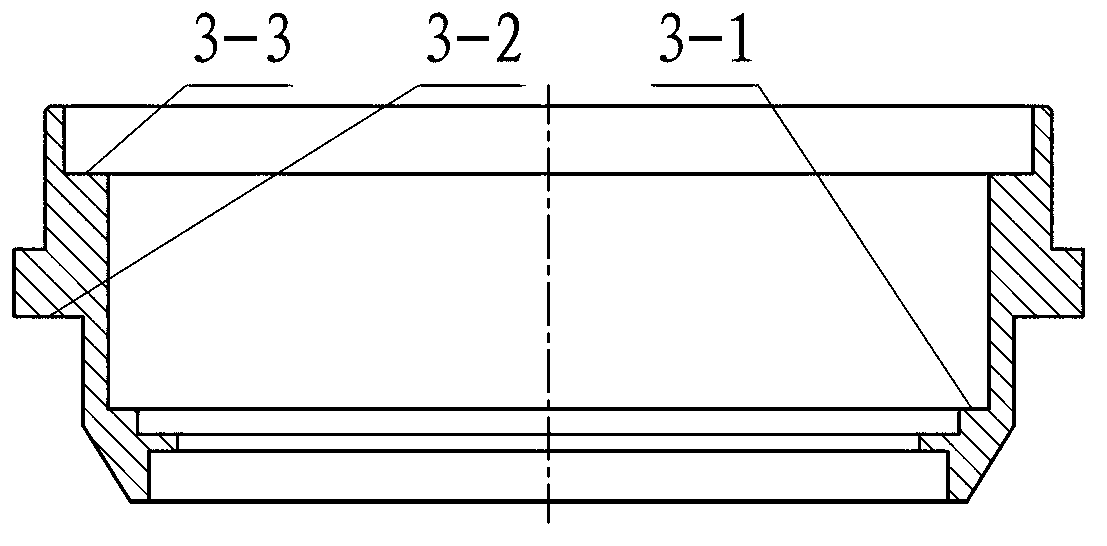

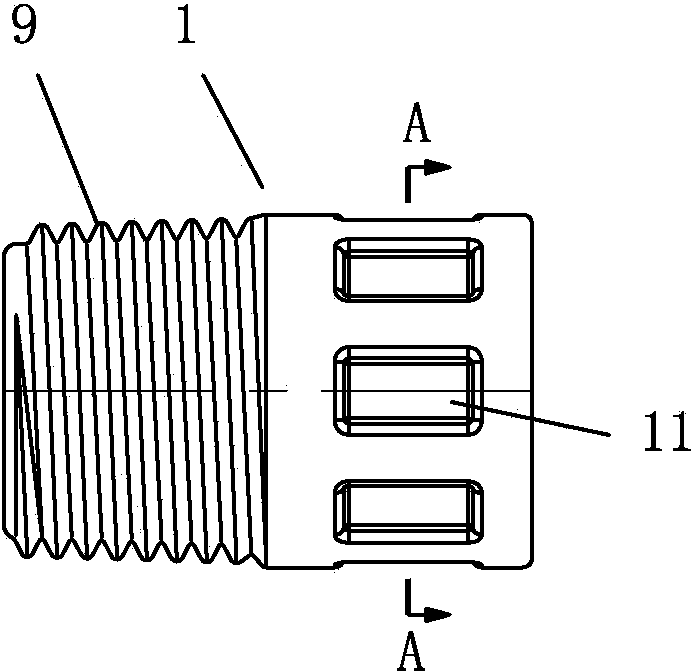

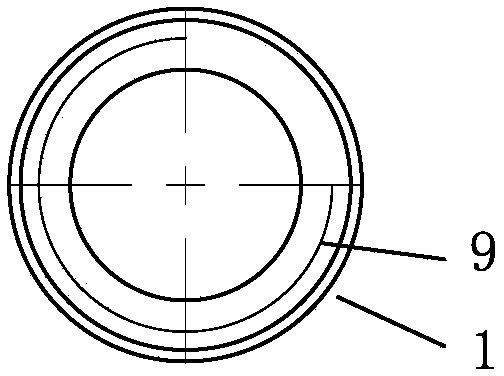

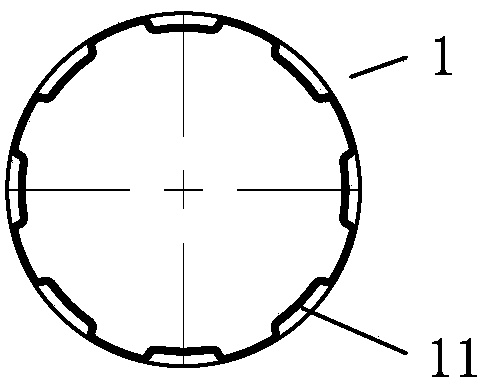

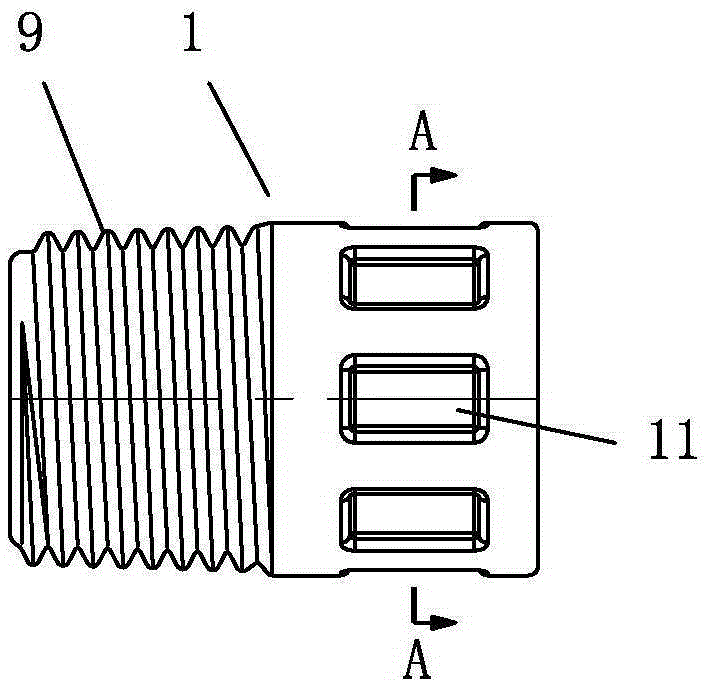

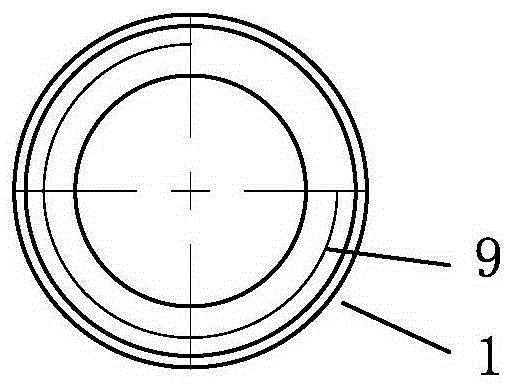

Plastic fitting with plastic-steel composite reinforced thread insert and production process of plastic fitting

InactiveCN103759091AEasy to useSolution to short lifePipe connection arrangementsEngineeringInjection moulding

The invention belongs to the technical field of plastic fittings, and particularly relates to a plastic fitting with a plastic-steel composite reinforced thread insert and a production process of the plastic fitting. The plastic fitting comprises an internal thread bushing or an external thread bushing, a plastic-coated reinforced bushing is formed outside the internal thread sleeve to form a composite reinforced internal thread insert, or a plastic-filled reinforced bushing is formed in the external thread bushing to form a composite reinforced external thread insert, and a fitting connecting portion is arranged on one side of the internal thread insert or the external thread insert by injection molding to form the plastic fitting. The plastic fitting is long in service life, environment friendly, safe and reliable, and production cost is reduced.

Owner:徐胜

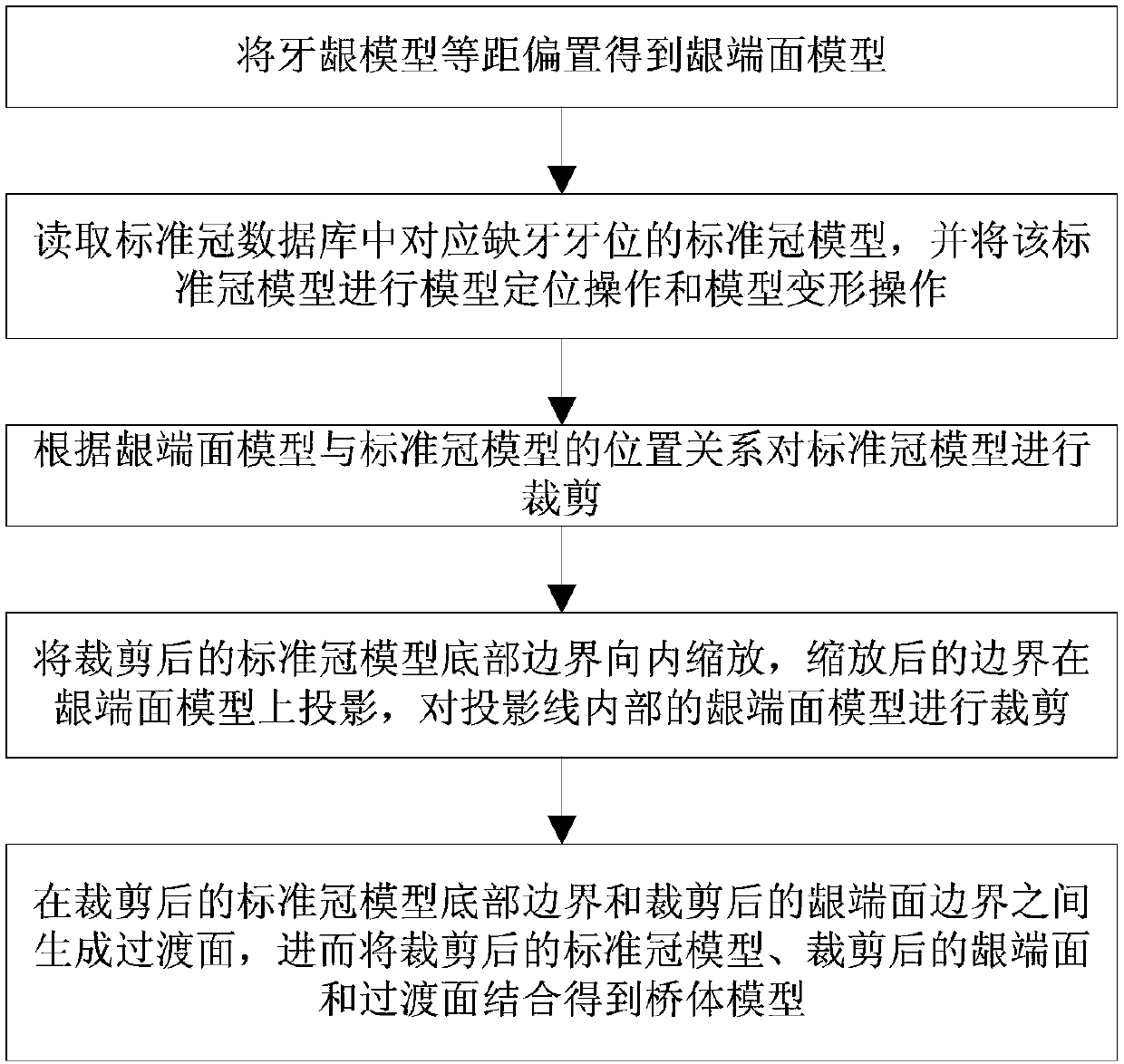

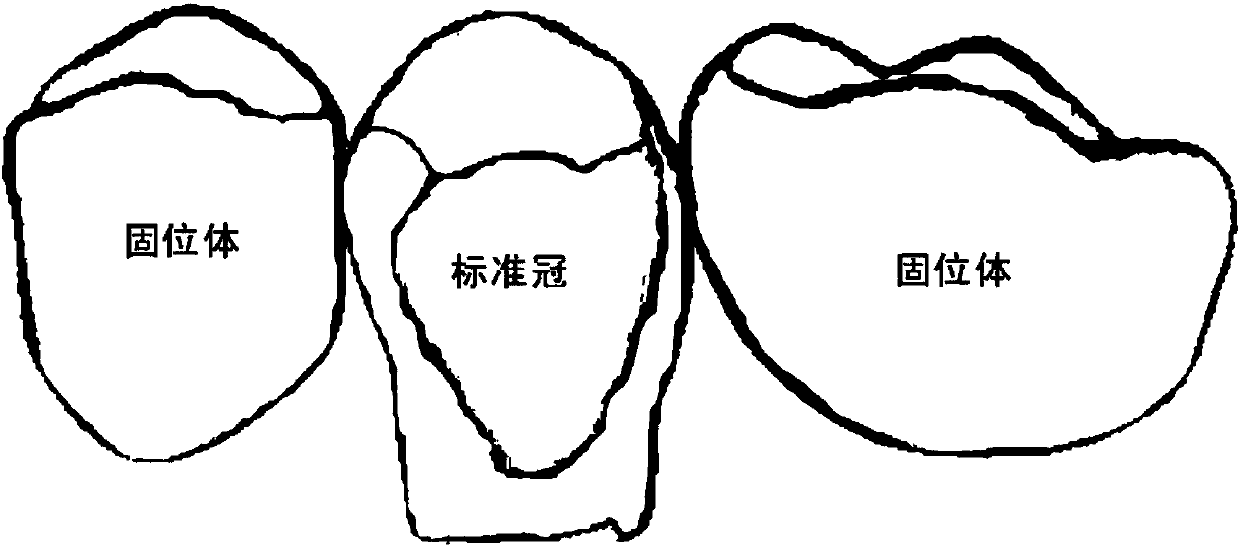

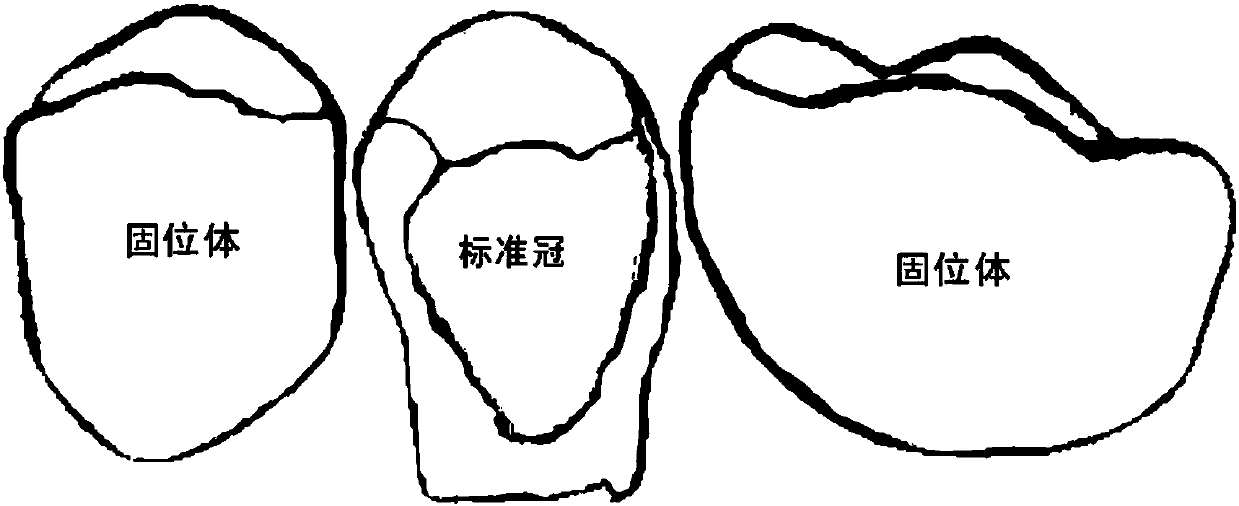

Digitalized generation method for pontic of full crown bridge

ActiveCN107689077AImprove smoothnessEnough carrying capacityImage generation3D modellingWrinkle skinEngineering

The invention discloses a digitalized generation method for pontic of a full crown bridge. According to a gingival model, a gingival end surface model obtained by utilizing implicit surface isometricoffset based on radial basis function has extremely high smoothness, and no wrinkles or local self-intersection occurs. A proper transition gap is arranged between the pontic and the gingiva, so thatit is avoided that food is stuck in teeth and it is also guaranteed that the pontic has a sufficient bearing capacity. According to the position relationship between a standard crown and a gingival end surface, the standard crown is dynamically cut to create a good boundary position relation for transition between the standard crown and the gingival end surface, and the generation quality of transition surfaces is significantly improved. Meanwhile, according to a whole set of standard crowns with regular forms, the method of transition surface generation based on skin subdivision is adopted incombination with particular forms of the standard crowns, the generation efficiency of the transition surfaces is greatly improved, the real-time effect of the pontic can be shown in the edit state,which is beneficial for editing operation in the next step. The digitalized generation method for the pontic of the full crown bridge can be widely used in the field of dental prosthesis.

Owner:FOSHAN NUOWEI TECH

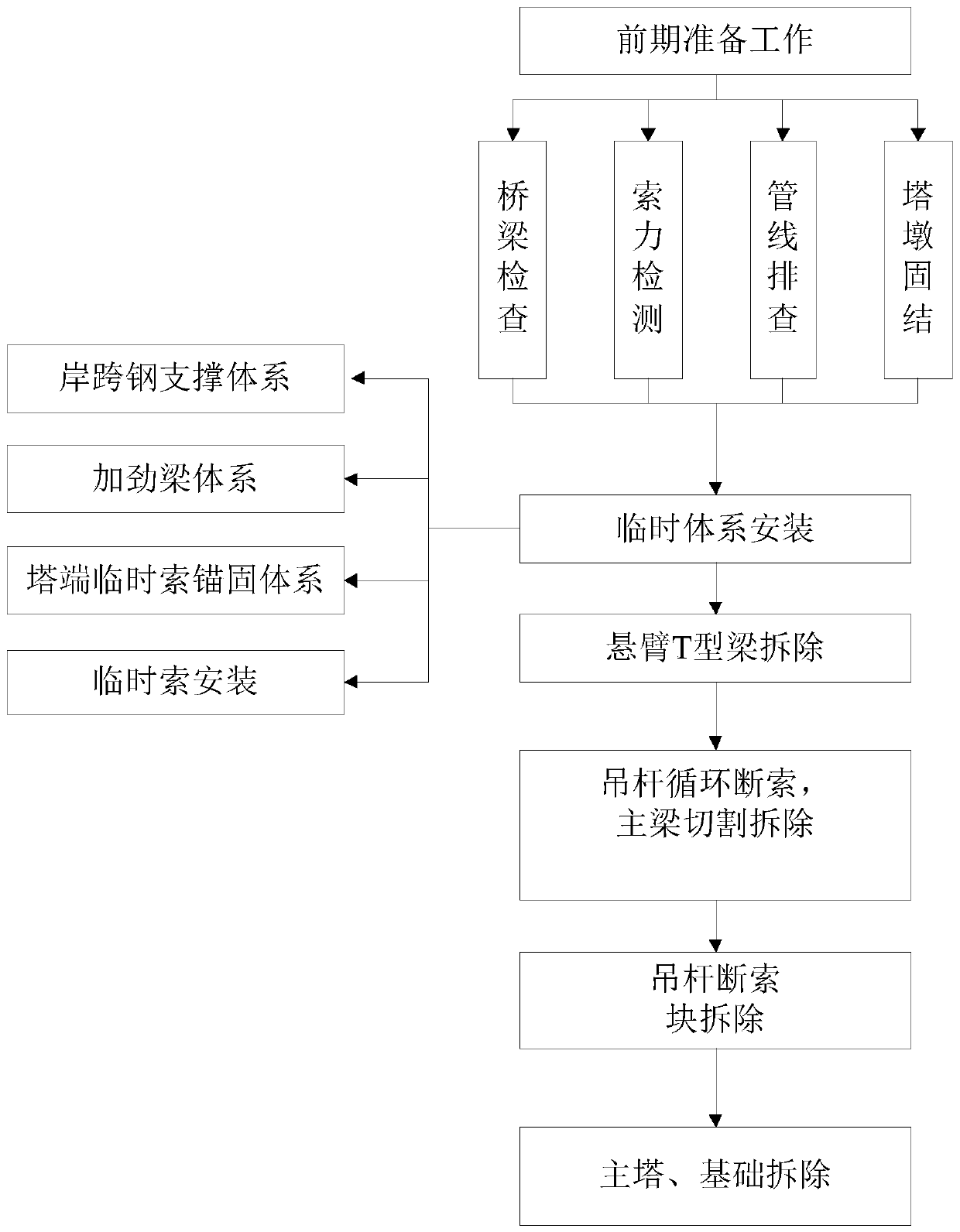

Construction method for cable-stayed bridge dismantling

ActiveCN110552296AImprove anti-overturn performanceSmooth demolitionCable-stayed bridgeBuilding repairsCable stayedAbutment

The invention discloses a construction method for cable-stayed bridge dismantling. The method is characterized in comprising the following steps that: S1, carrying out early-stage detecting and troubleshooting work: reinforcing and solidifying a tower pier; S2, installing a temporary reinforcement system on a main girder: adding a stiffening girder on the main girder, and adding a temporary stay cable between the stiffening girder and a main tower; S3: dismounting the stay cable after the stay cable is tensioned: replacing an old stay cable through a temporary stay cable, carrying out tensioning, gradually cutting off the replaced old stay cable, and dismounting the old stay cable; S4, carrying out segmented cutting and main girder hoisting: through the stiffening girder, carrying out segmented cutting on the main girder, and hoisting the cut main girder; S5, repeating S4 to S5 until the old stay cable and the main girder are dismounted by segments; S6, dismounting the main tower; andS7, dismounting an approach bridge and a bridge abutment. The construction method for the cable-stayed bridge dismantling has a core that the stiffening girder and the temporary stay cable are added to form the temporary reinforcement system, and the old stay cable and the main girder of a bridge surface are gradually dismounted by the way. The way is unique and novel, is convenient and efficientin construction, is low in cost and conforms to modernized construction requirements.

Owner:SHANGHAI PUDONG NEW DISTRICT ROAD CONSTR DEV

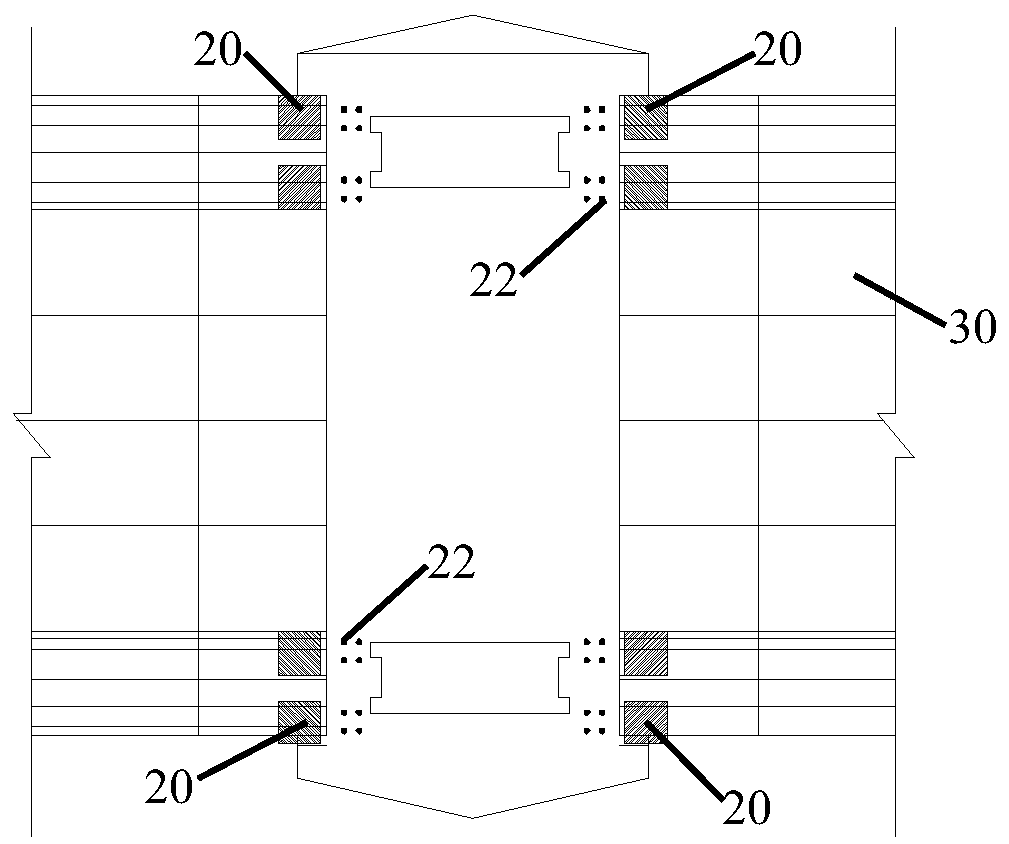

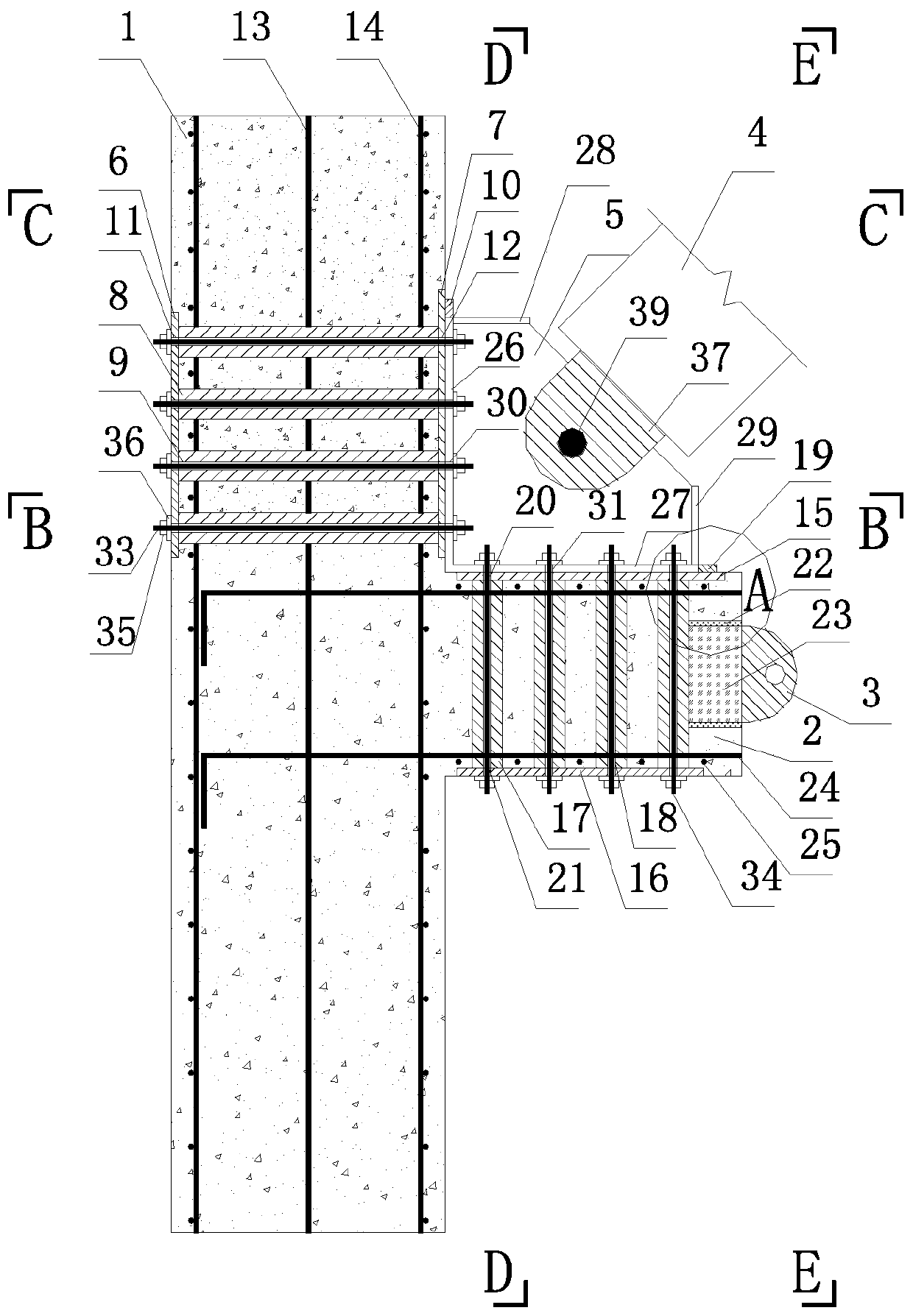

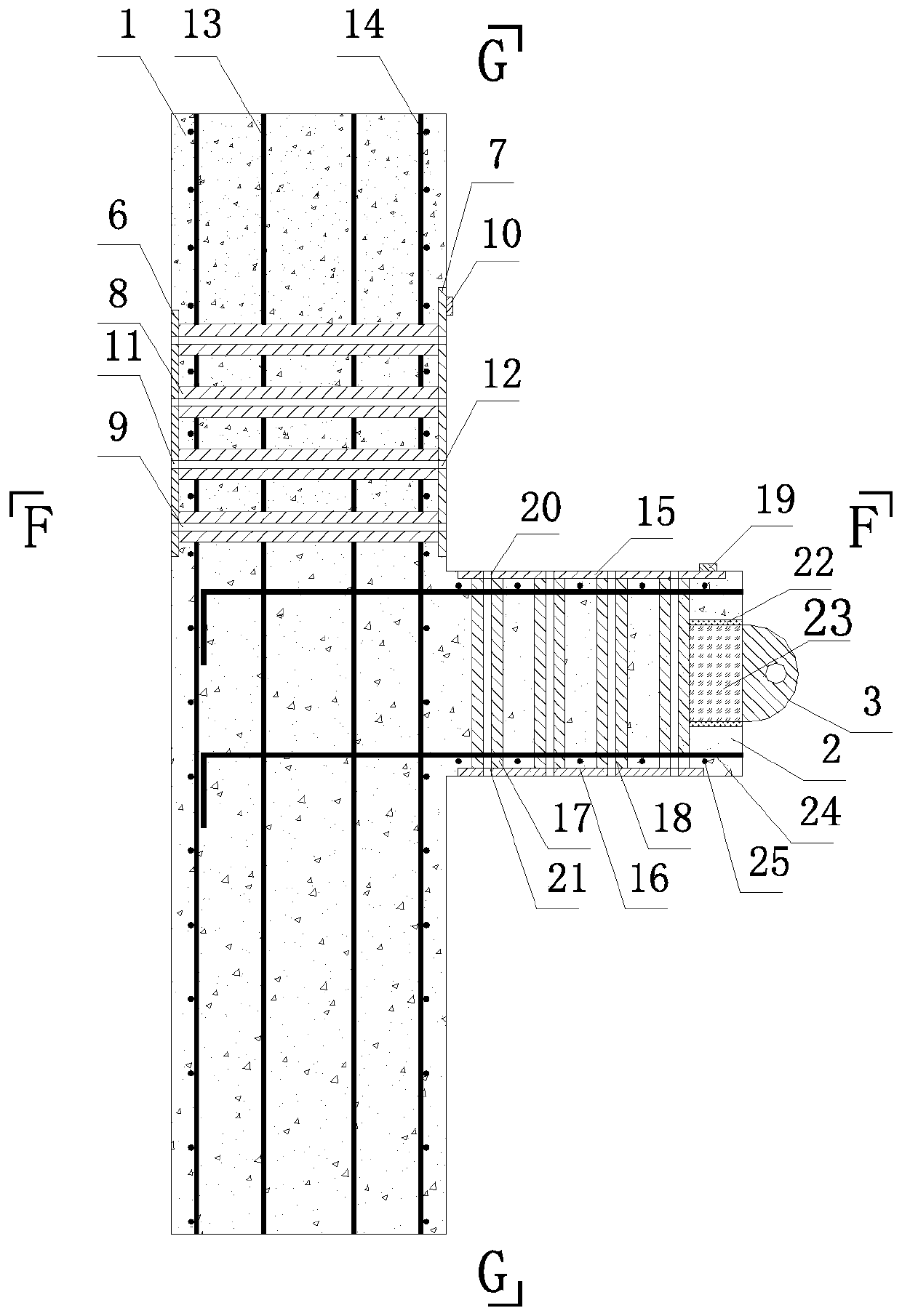

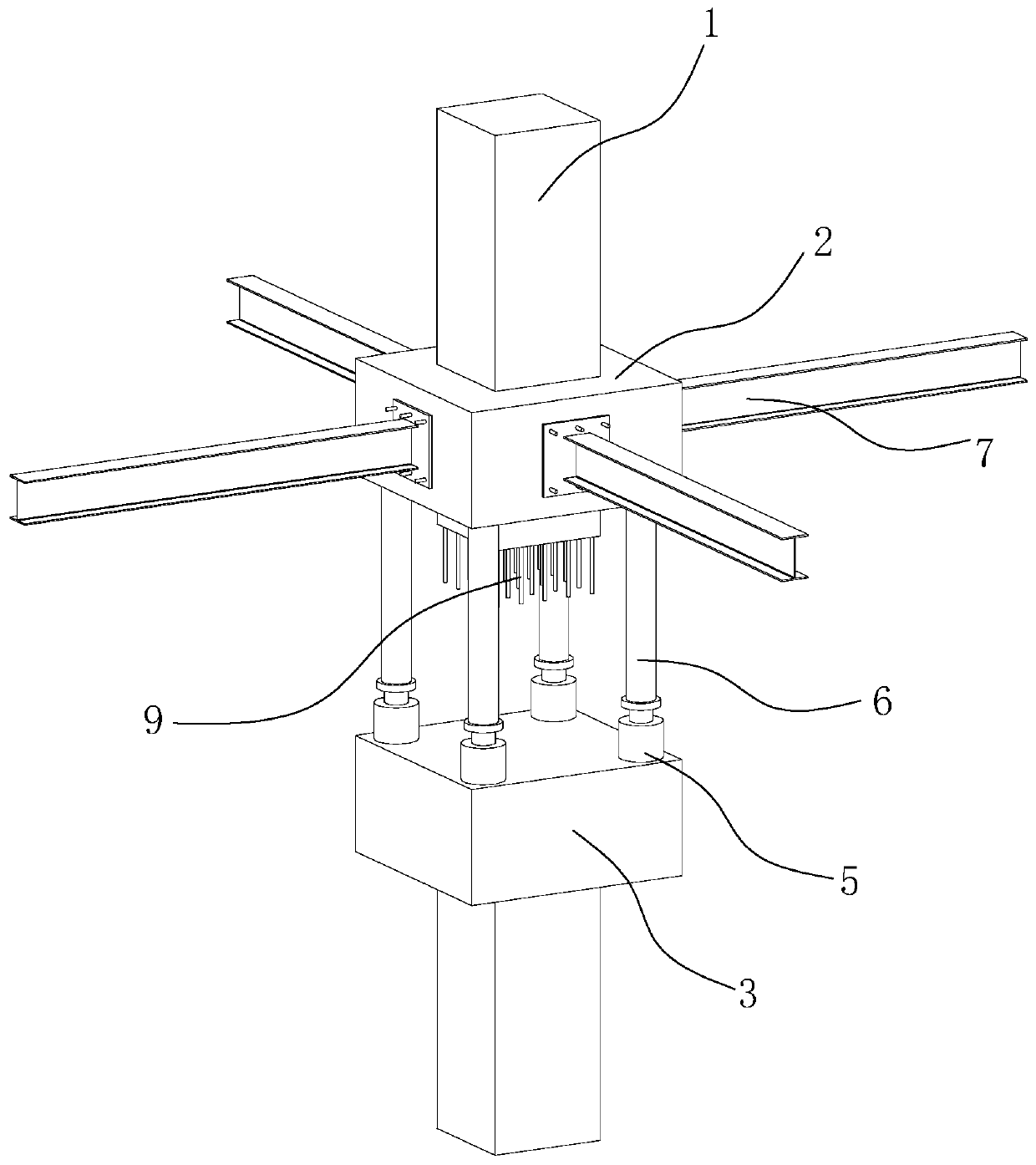

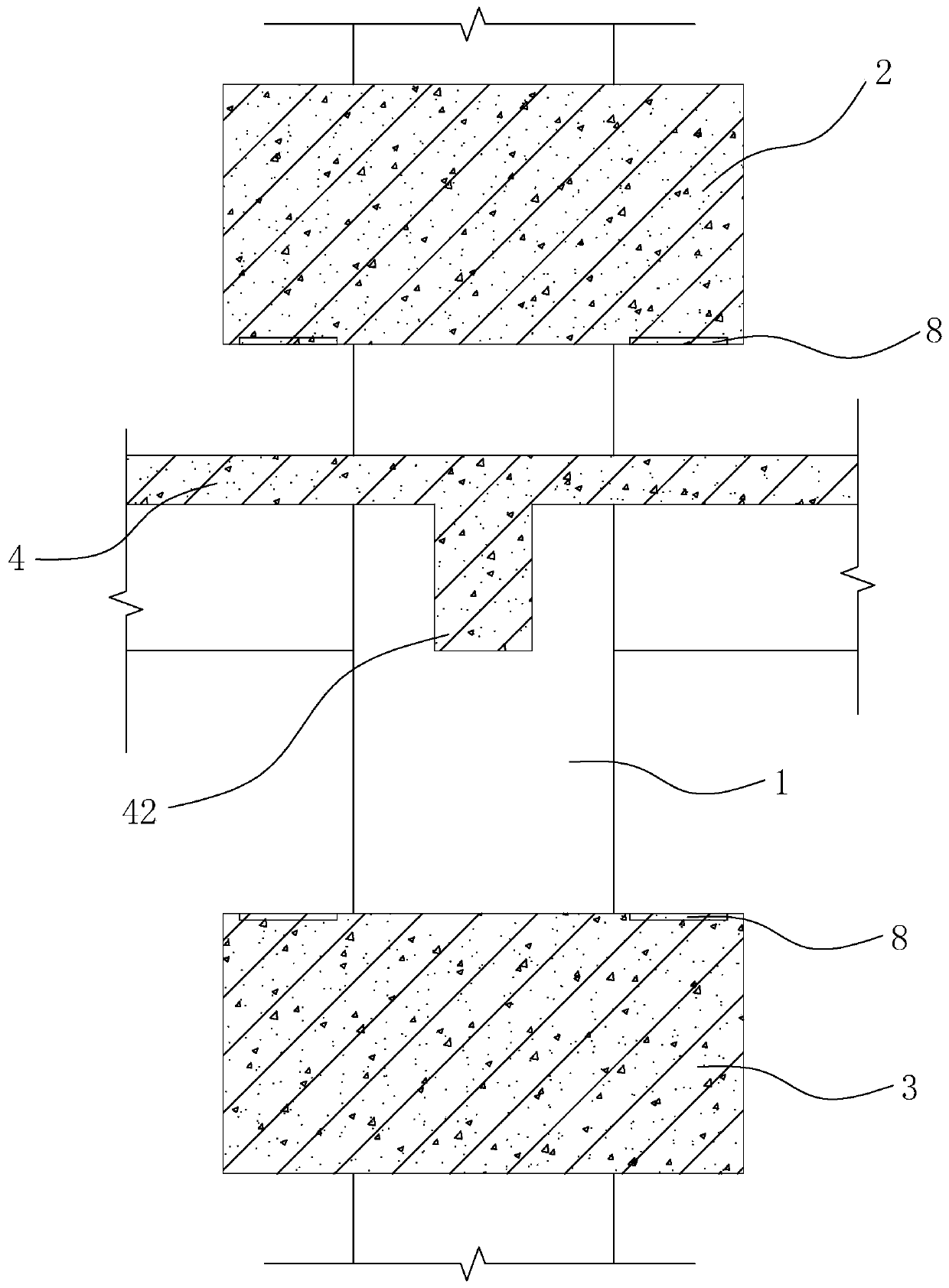

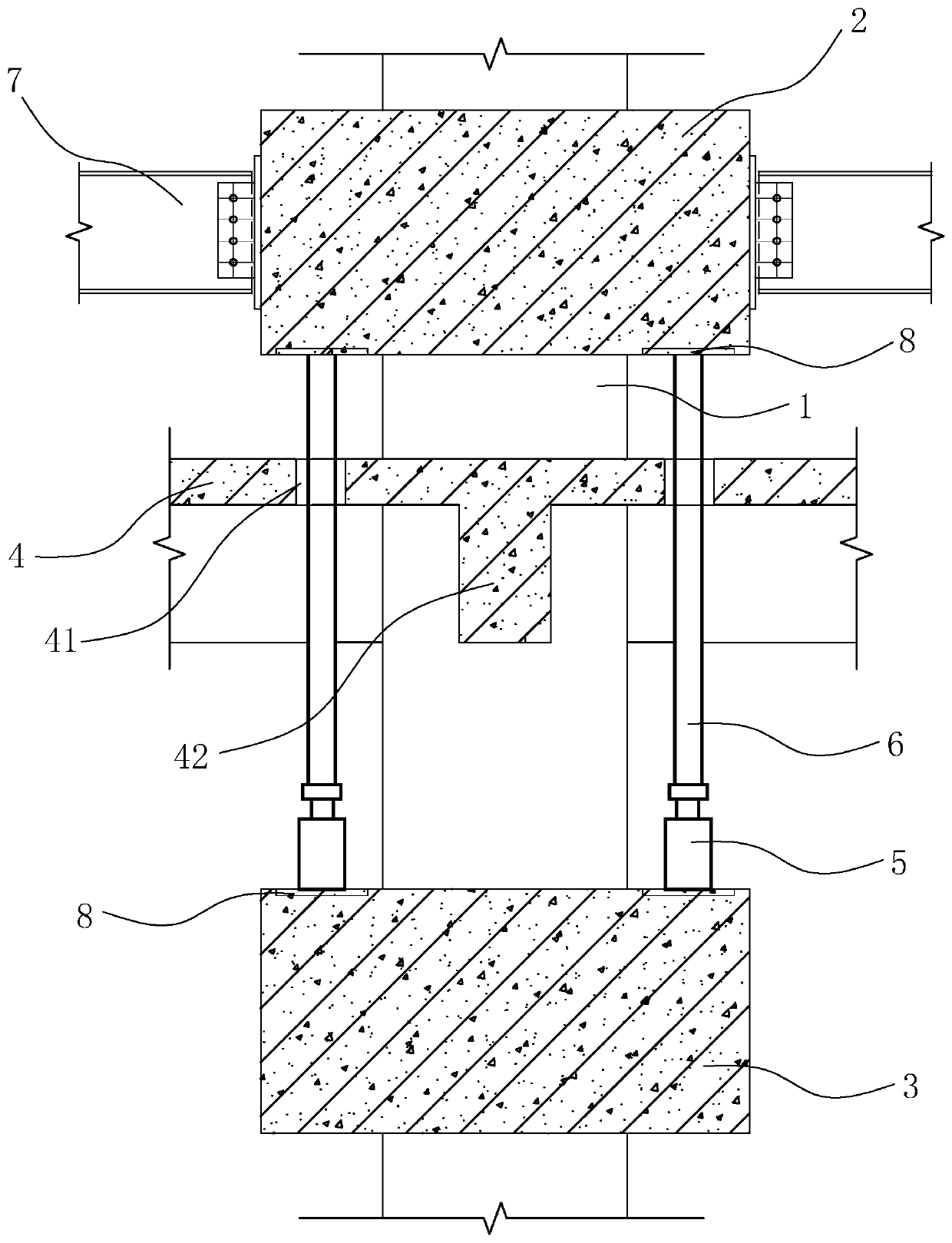

Fully fabricated concrete beam-concrete column-steel support combination connection node

PendingCN110258786AGuaranteed reliabilityAvoid damageProtective buildings/sheltersShock proofingConcrete beamsBearing capacity

The invention discloses a fully fabricated concrete beam-concretecolumn-steel support combination connection node. The fully fabricated concrete beam-concrete column-steel support combination connection node comprisesfabricated concrete columns, fabricated concretebeams, a hinged connection plate and a square steel support, the fabricated concrete columns comprisevertical embedded parts, vertical longitudinal reinforcements and vertical stirrups, the fabricated concretebeams comprise horizontalembedded parts, horizontallongitudinal reinforcements and horizontalstirrups, two support end plates are arranged at the end portions of the square steel support, and the support end plates are connected with steel support connectors through a shaft pin, the steel support connectorsand the fabricated concrete columns are connected by vertical pair of threaded screws, the steel support connectors and the fabricated concrete beams are connected by horizontal through screws. The combination connection nodecan improve the seismic resistance of a composite node and reduce the damage of components, so that the combination connection node cannot be damaged in an earthquake and has sufficient bearing capacity,the combination connection node has the advantages of good seismic performance, post-earthquake function recovery, high assembly efficiency and simple construction.

Owner:ZHONGHENG CONSTR GRP +1

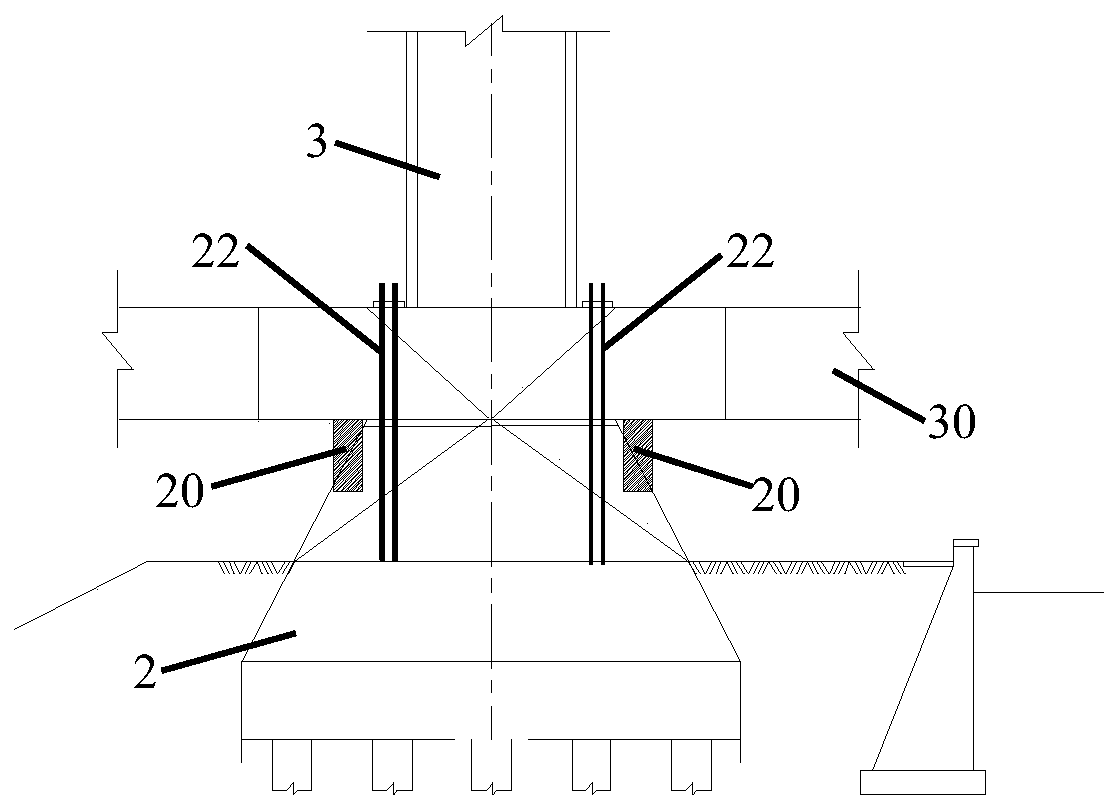

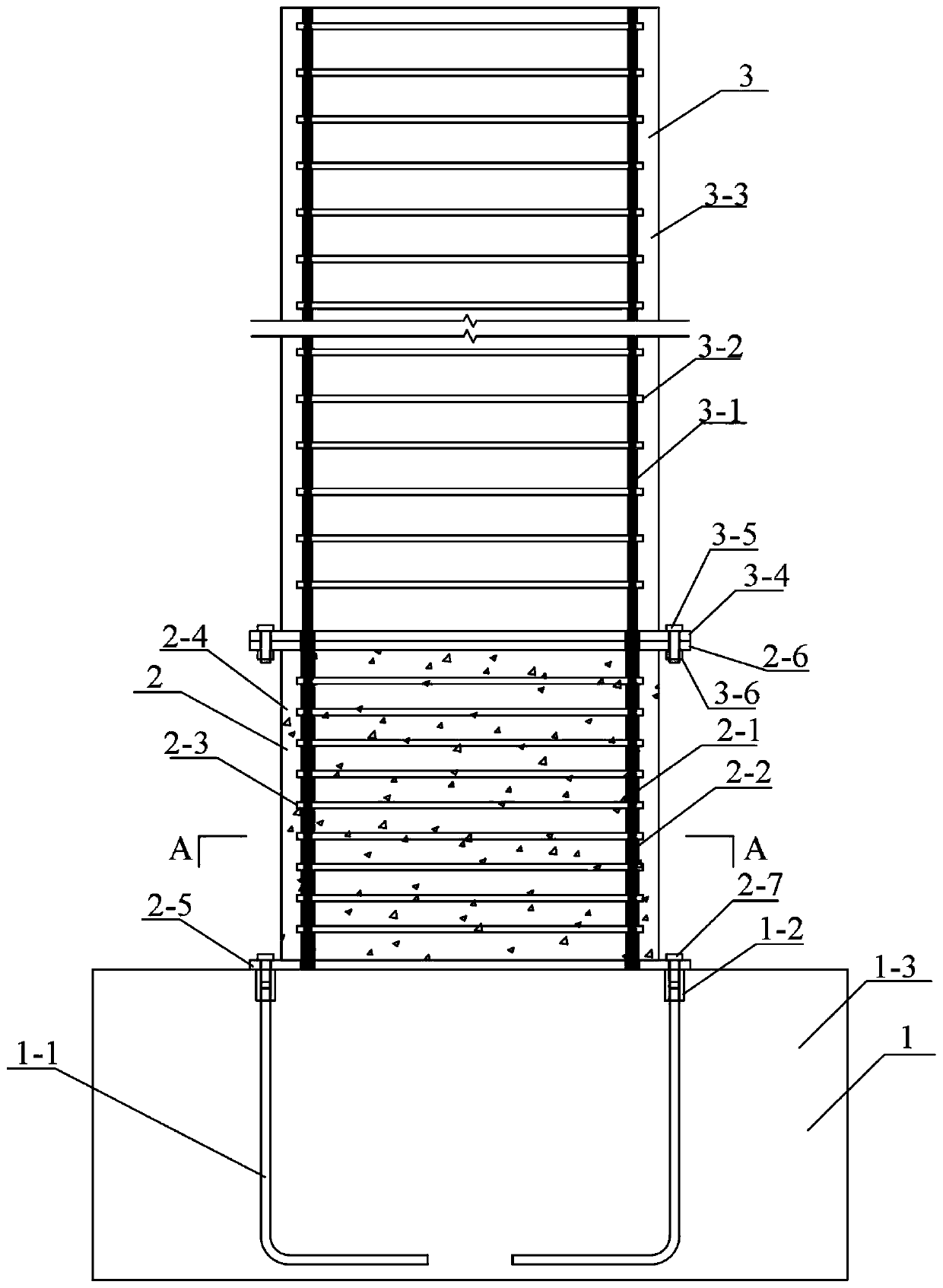

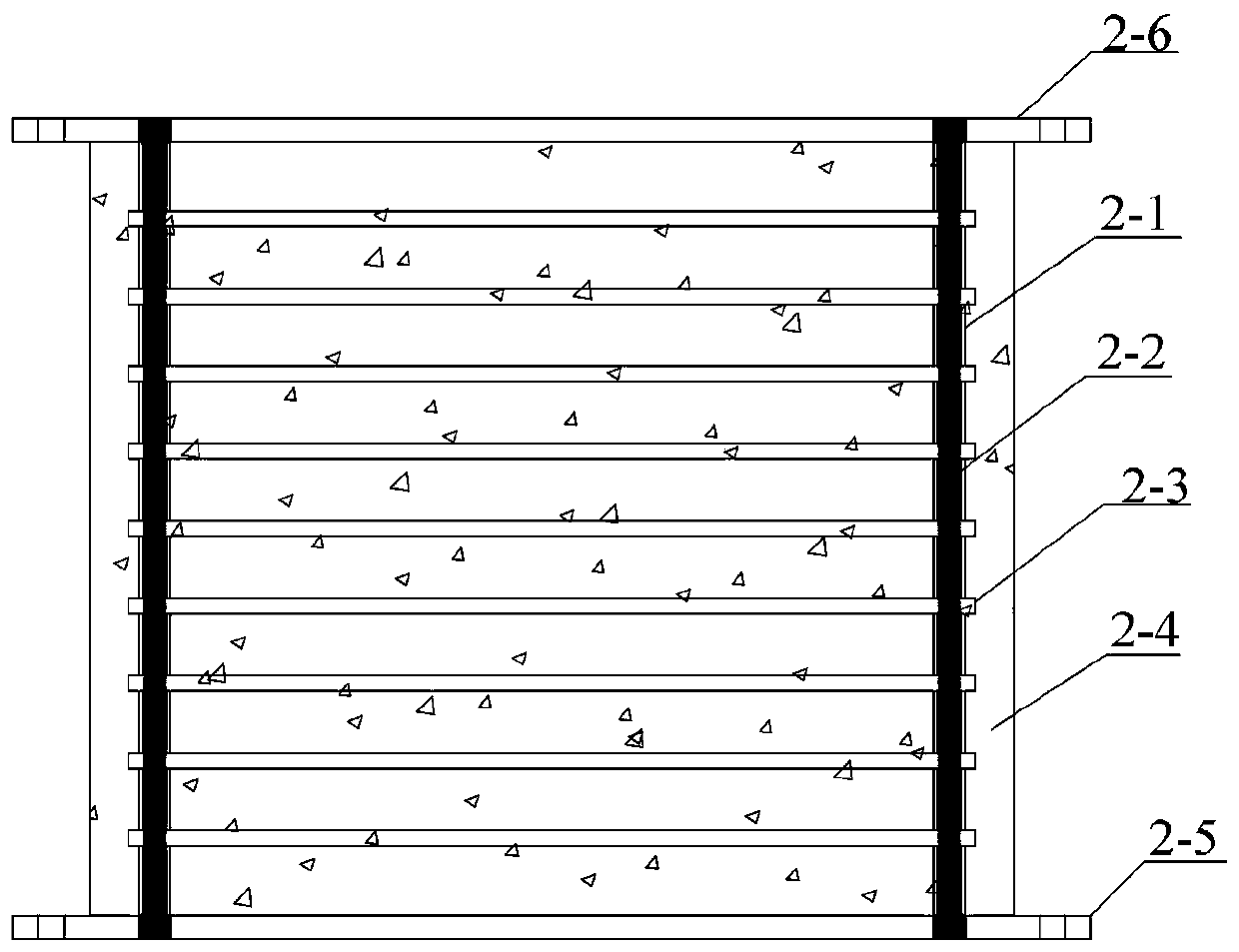

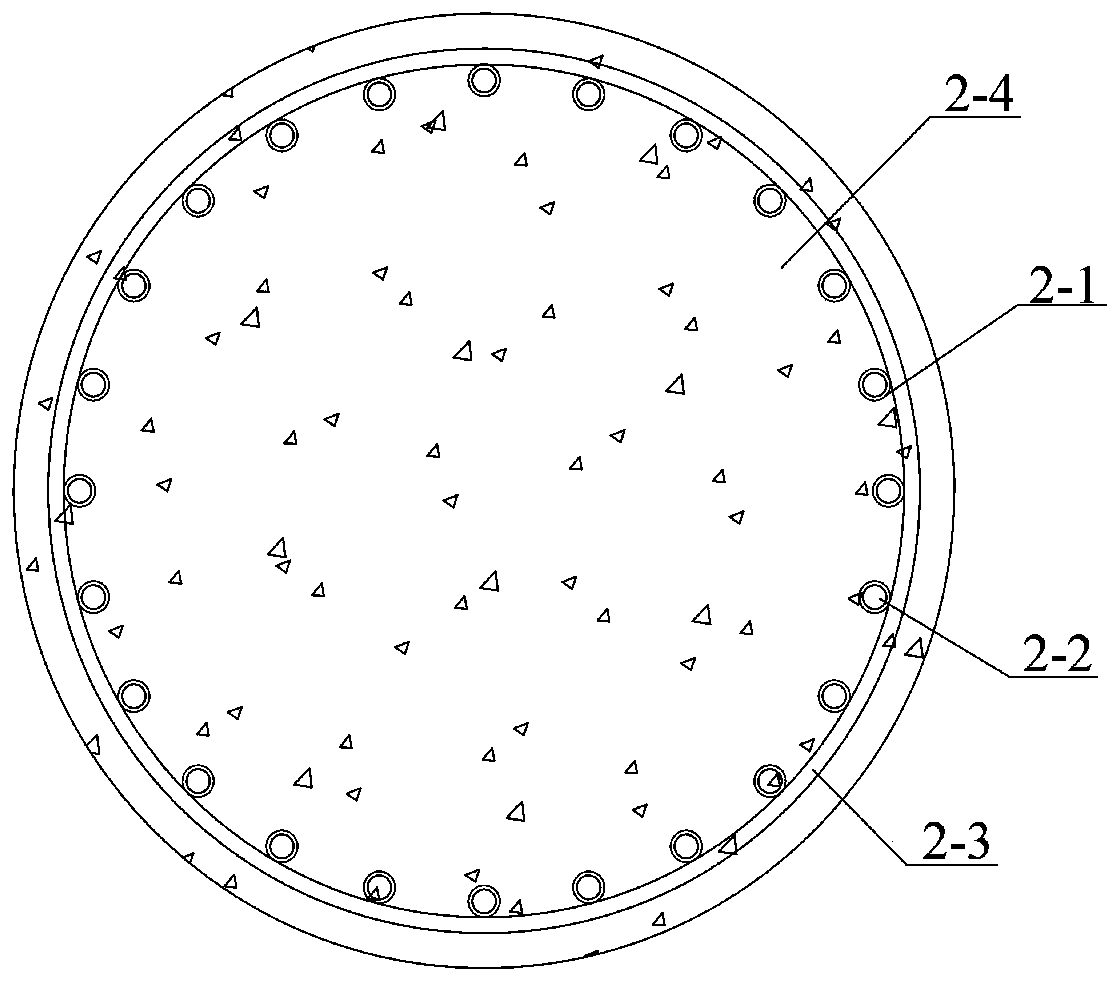

High performance aseismatic bridge pier structure system with replaceable plastic hinge

The invention discloses a high performance aseismatic bridge pier structure system with replaceable plastic hinge and belongs to the field of bridge engineering. The high performance aseismatic bridgepier structure system comprises a bearing platform, a replaceable plastic hinge section, a reinforced concrete bridge pier section and the like. A anchor bar and a connecting sleeve are pre-embeddedin the bearing platform; the replaceable plastic hinge section comprises a PVC pipe, a SMA bar and a high-strength steel bar, a stirrup, a high-ductility concrete, a lower connecting plate, an upper connecting plate and the like; and the reinforced concrete bridge pier section comprise a longitudinal bar, a stirrup, an ordinary concrete, a bottom connecting plate and the like. The bearing platformis connected with the lower connecting plate of the replaceable plastic hinge section through a high-strength bolt, and the upper connecting plate of the replaceable plastic hinge section is connected with the bottom connecting plate of the reinforced concrete bridge pier section through the high-strength bolt. The high performance aseismatic bridge pier structure system with replaceable plastichinge has better bending rigidity, bearing capacity and energy consumption capacity under normal use conditions and earthquake. The replaceable plastic hinge section can be easily replaced and repaired after the earthquake.

Owner:BEIJING UNIV OF TECH

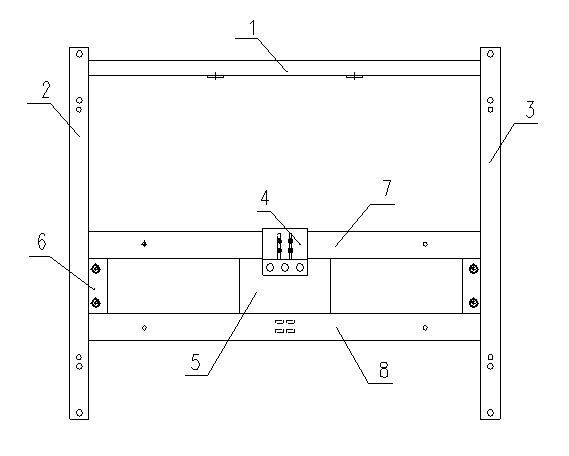

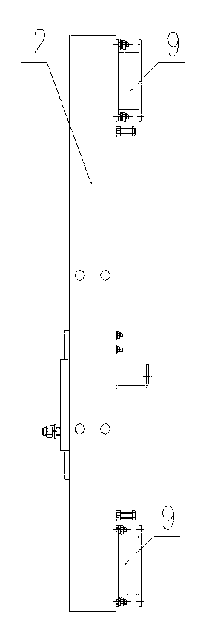

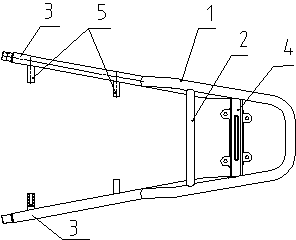

Elevator lifting car bracket

InactiveCN103274278ASimple structureEasy to produceNon-rotating vibration suppressionBuilding liftsEngineeringTransverse beam

The invention relates to an elevator lifting car bracket, relates to a novel lifting car bracket, and belongs to the technical field of elevators. The elevator lifting car bracket comprises a back beam, a left beam, a right beam, a weighing device, a buffer collision plate, safety tong mounting plates, a first transverse beam, a second transverse beam and damping devices, wherein the upper end of the left beam and the upper end of the right beam are connected with the two ends of the back beam respectively, the middle of the left beam and the middle of the right beam are provided with the first transverse beam and the second transverse beam respectively, the first transverse beam and the second transverse beam are vertically parallel, the weighing device is arranged on the first transverse beam on the upper portion, the buffer collision plate is arranged between the weighing device and the second transverse beam located on the lower portion, the at least two sets of safety tong mounting plates are arranged between the first transverse beam and the second transverse beam, and the at least two sets of damping devices are arranged on the left beam and the right beam respectively. The elevator lifting car bracket achieves the purposes of meeting bearing requirements, meanwhile, simplifying a structure, enabling production and assembly to be convenient, reducing the weight of a whole elevator, and reducing manufacturing cost.

Owner:CANNY ELEVATOR

Heavy load single waveform generator harmonic reducer with ultrashort designed life

InactiveCN107882949AReduce axial sizeIncreased torsional stiffnessPortable liftingToothed gearingsGear wheelHarmonic

The invention discloses a heavy load single waveform generator harmonic reducer with ultrashort designed life, relates to the technical field of aerospace, and aims to solve the problems that the existing harmonic reducer is large in size and obviously redundant in service life to reduce the effective load of an aerospace vehicle. The heavy load single waveform generator harmonic reducer comprisesa bevel pinion, a left shell, a resetting shaft, a bevel gear wheel, a wave generator, a fixed steel wheel, a flexible gear, an output shaft and a right end cover, wherein the rear end of the resetting shaft is fixedly connected with the output shaft horizontally; the bevel gear wheel is mounted on the outer side of the resetting shaft in a sleeving manner and is meshed with the bevel pinion; thewave generator is mounted on the outer side of the bevel gear wheel in a sleeving manner and is an eccentric circular ring; the flexible gear is mounted on the outer side of the wave generator in a sleeving manner; and the outer gear of the flexible gear is meshed with the inner gear of the fixed steel wheel and the inner gear of the output shaft. The heavy load single waveform generator harmonicreducer is used for aerospace drive.

Owner:HARBIN INST OF TECH

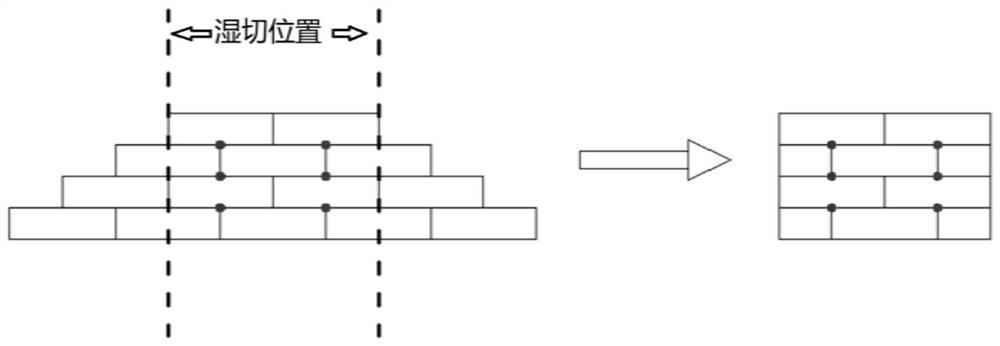

Printing and reinforcement method for 3D printing concrete member

PendingCN114132047AReduce the effect of anisotropyIntegrity guaranteedAdditive manufacturing apparatusBuilding reinforcements3d printArchitectural engineering

The invention relates to a printing and reinforcement method of a 3D printing concrete member, which comprises the following steps: (1) determining a mix proportion: preparing concrete suitable for a 3D printing structure, fully mixing, testing related printing performance, and meeting various performance requirements, otherwise, adjusting or repreparing until the requirements are met; (2) according to design requirements, relevant parameters of components, relevant parameters of equipment and relevant parameters of reinforcing bars are determined; and (3) after single-layer concrete is printed, rib grids are laid, concrete layer printing and rib grid laying are repeated till a complete spliced rib cage is formed, and finally concrete is covered to form a complete component. According to the method, the influence of 3D printing anisotropy on the 3D printing concrete structure is relieved through the staggered joint printing method, meanwhile, the reinforcing bars integrating the tensile longitudinal bars, the erection bars and the stirrups are configured, the assembled bar cage is formed, and the stress performance of the 3D printing concrete structure is improved.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

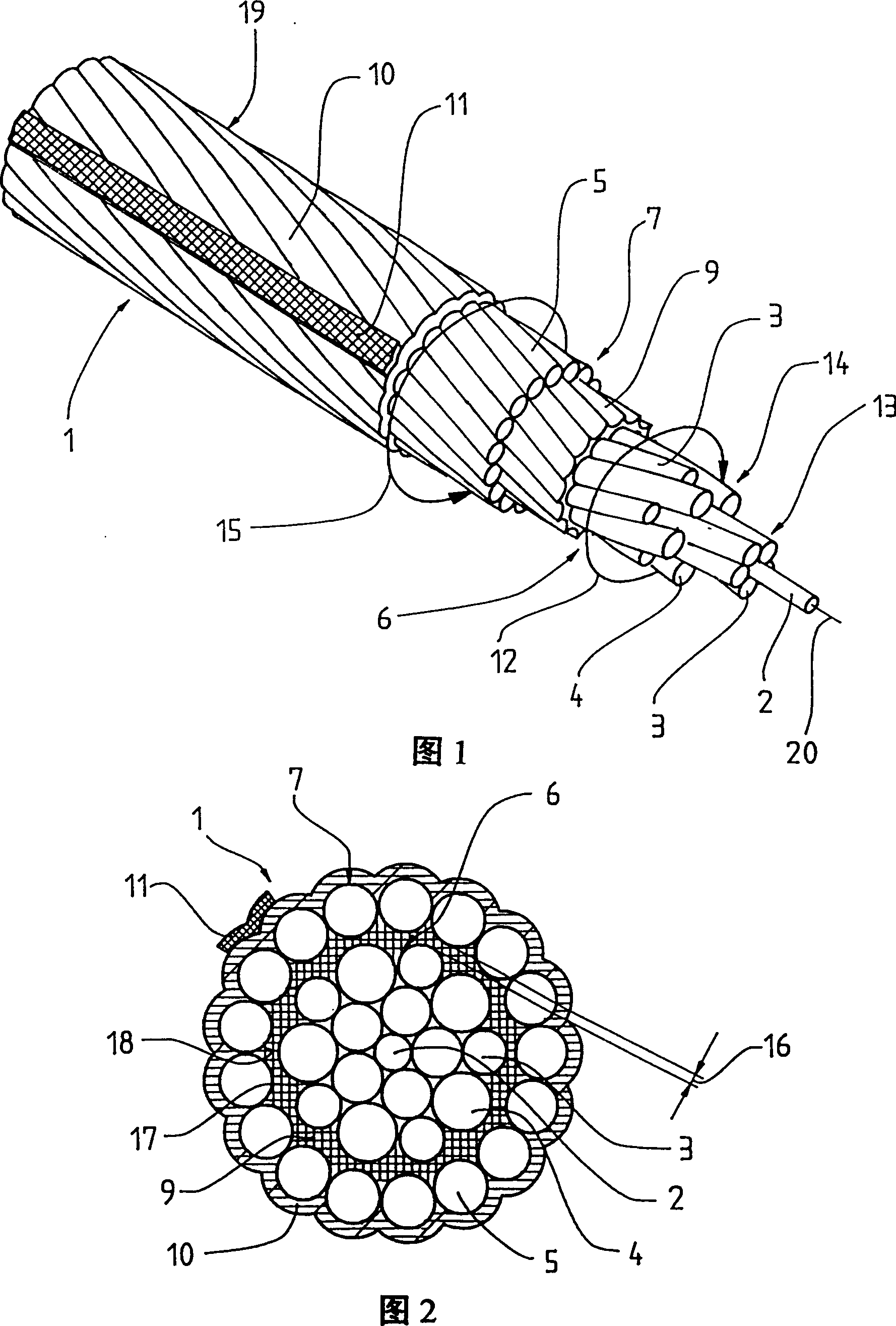

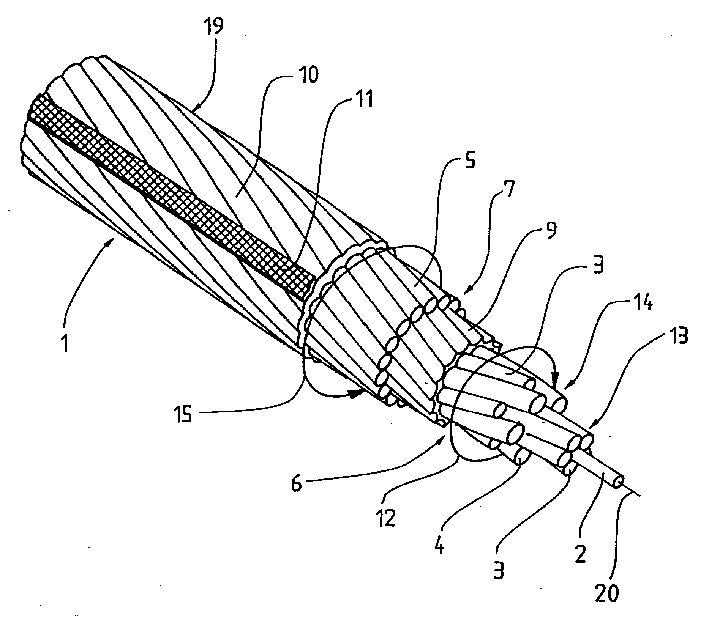

Device for detemining requiring or not to charge synthetic fibre rope

InactiveCN1108519CReduce frictionEnough carrying capacityMarking textilesTextile cablesAramidesVisual inspection

To identify the need for replacement of stranded synthetic fiber ropes, preferably ropes of aramide fiber, a torsionally neutral rope construction of load-bearing fiber strands is obtained by having at least two layers of strands laid together in opposite directions so that the torsional forces in the layers of strands compensate each other. If the layers of the strands become weakened by unequal amounts due to wear or external influences, when the rope is under load and running operationally it begins to twist about its longitudinal axis. The twisting of the rope can be made visible by a colored mark or strip extending along the length of the rope to indicate twisting of the rope thereby providing visual identification of the need for replacement of the rope.

Owner:DE REGT GERMANY

Method for changing floor frame column to on-beam column structure

The invention discloses a method for changing a floor frame column to an on-beam column structure, and belongs to the technical field of house structural transformation. Aiming at solving the problemthat an existing method has difficulty in improving a load-bearing structure, according to the following adopted technical scheme, the method for changing the floor frame column to the on-beam columnstructure comprises the following steps: 1, an upper encircling column holder and a lower encircling column holder are mounted; 2, a tie structure is mounted; 3, a to-be-cut part is removed; 4, a newfixing structure is manufactured, specifically, a new floor and a new supporting beam are manufactured; and 5, other structures are removed. According to the method, the floor frame column is changedto the on-beam column structure, the established tie structure shares the bearing weight of the floor frame column, and thus the structure keeps stable in the demolition process; and the new floor andthe new supporting beam which are connected with anchoring steel bars into a whole are established to become a new load-bearing structure, the original floor frame column below a floor is removed, thus the lower part of the floor has a large space, and the structure keeps stable all the time in all the operating steps.

Owner:HANGZHOU TONGDA GRP

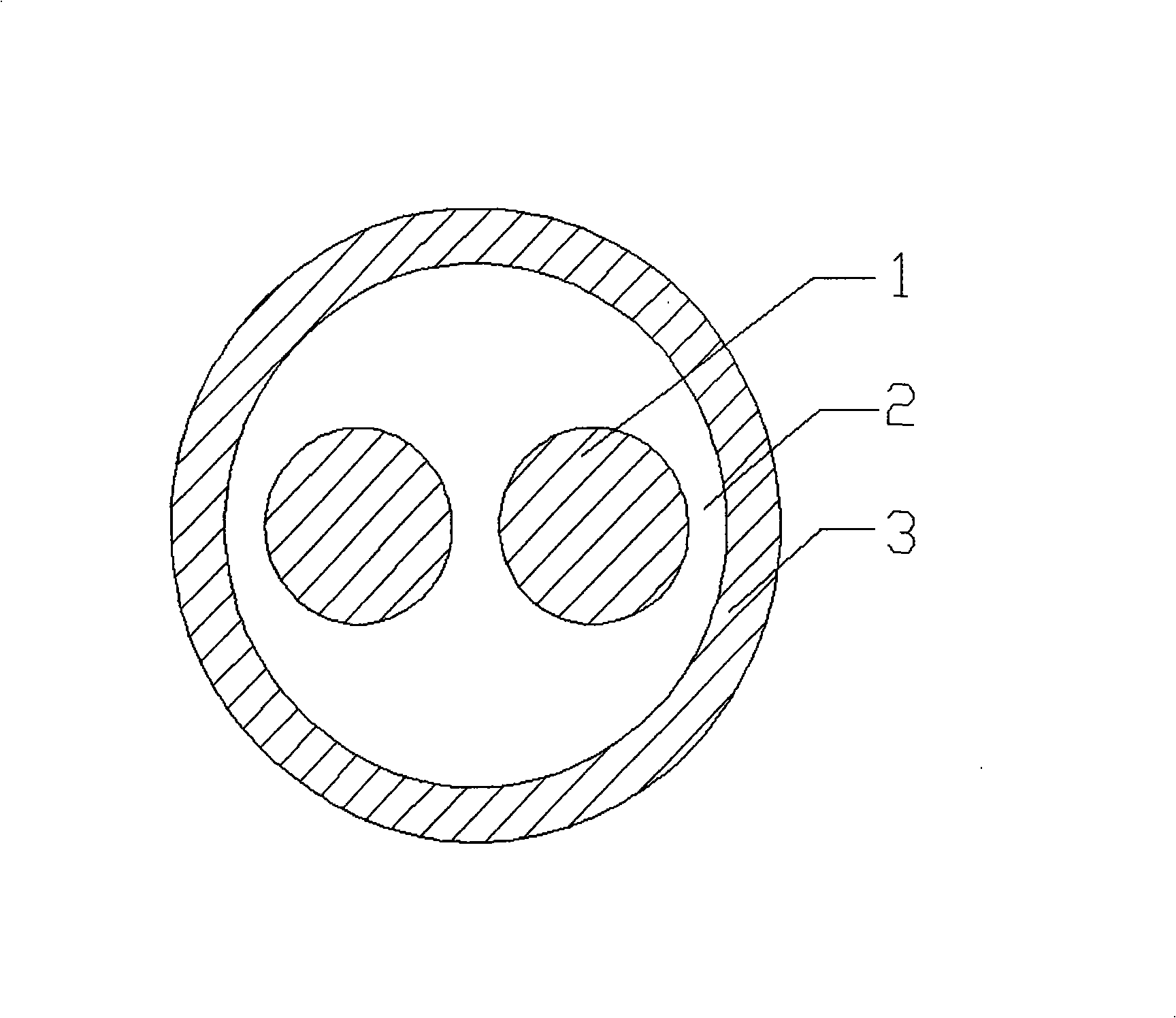

Mineral insulated cable of large length

InactiveCN101339826AImprove thermal conductivityImproved resistance to overloadInsulated cablesMetallic oxidesCopper conductorExplosion protection

The invention relates to a cable, in particular to a long mineral insulation fireproof cable, which solves the problem that the organic insulating cable has poor high temperature resistance and flame resistance (taking fire and burning) and low electric insulating property. The technical proposal of the invention is as follows: the long mineral insulation fireproof cable consists of a copper conductor, an insulating layer and a copper sheath; the conductor is coated by the insulating layer, and the copper sheath is coated outside the insulating layer. The long mineral insulation fireproof cable is characterized in that the insulating layer is a compact magnesia powder filling layer; and the copper sheath is an argon arc longitudinal seam welding sheath formed by wrapping a copper strip. The long mineral insulation fireproof cable can be widely applied to explosion protection systems and devices, the hazardous fire areas (petrochemical industry, nuclear power stations, etc.), high temperature places (metallurgical industry, power plants, etc.), underground lines (metro, tunnel, mine, etc.) and the areas requiring specially safe facilities (public places, dense population areas, high-rise buildings, etc.), and also can be used for distributing and transmitting electric energy or electrical control and connection.

Owner:SHANGHAI MORN ELECTRIC EQUIPMENT CO LTD

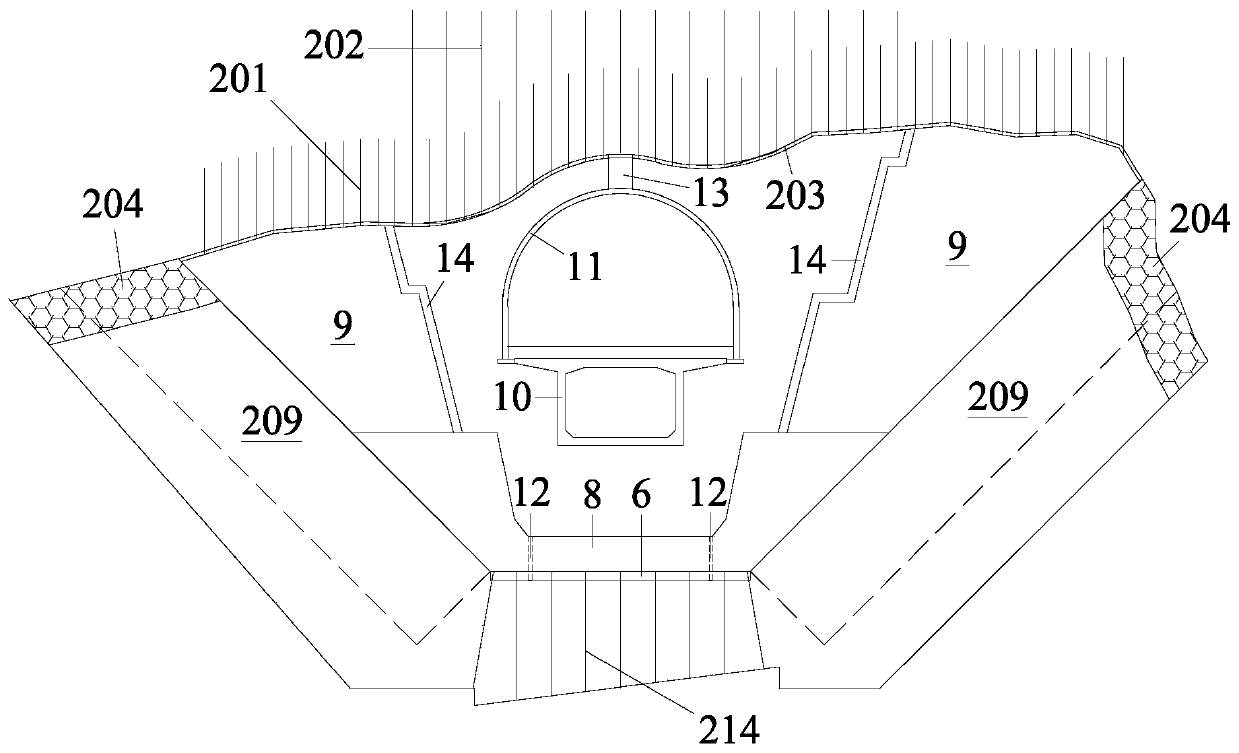

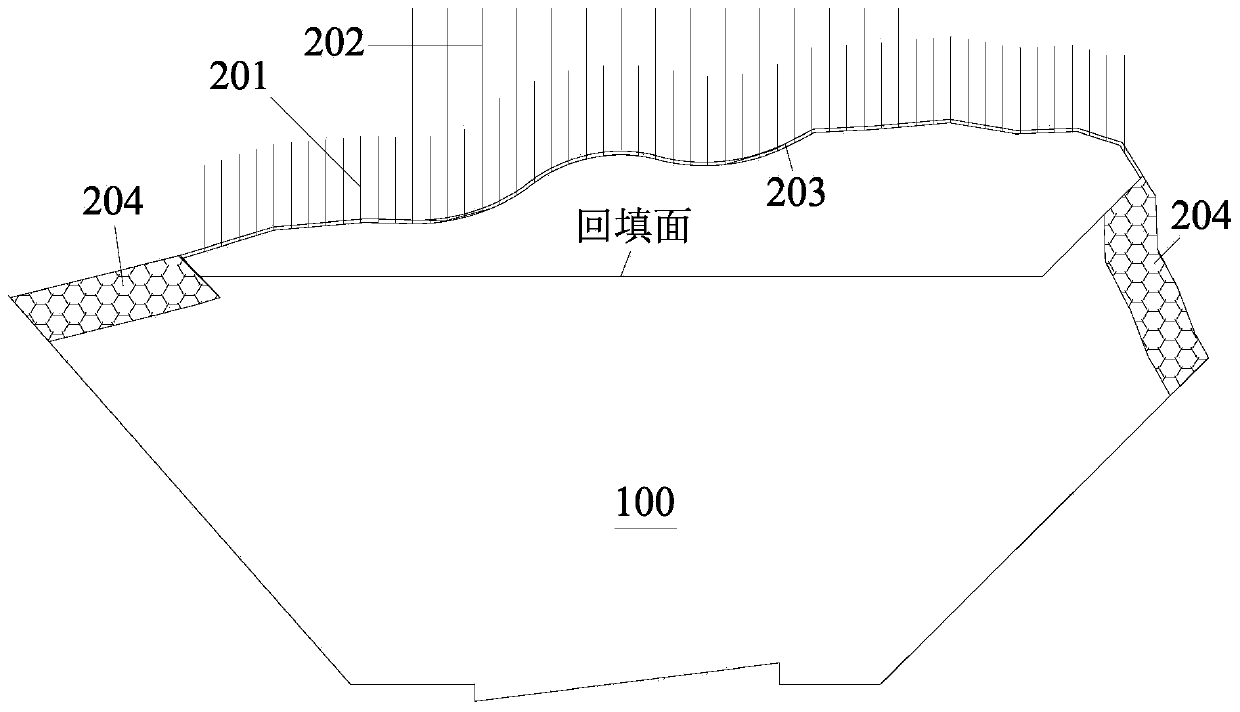

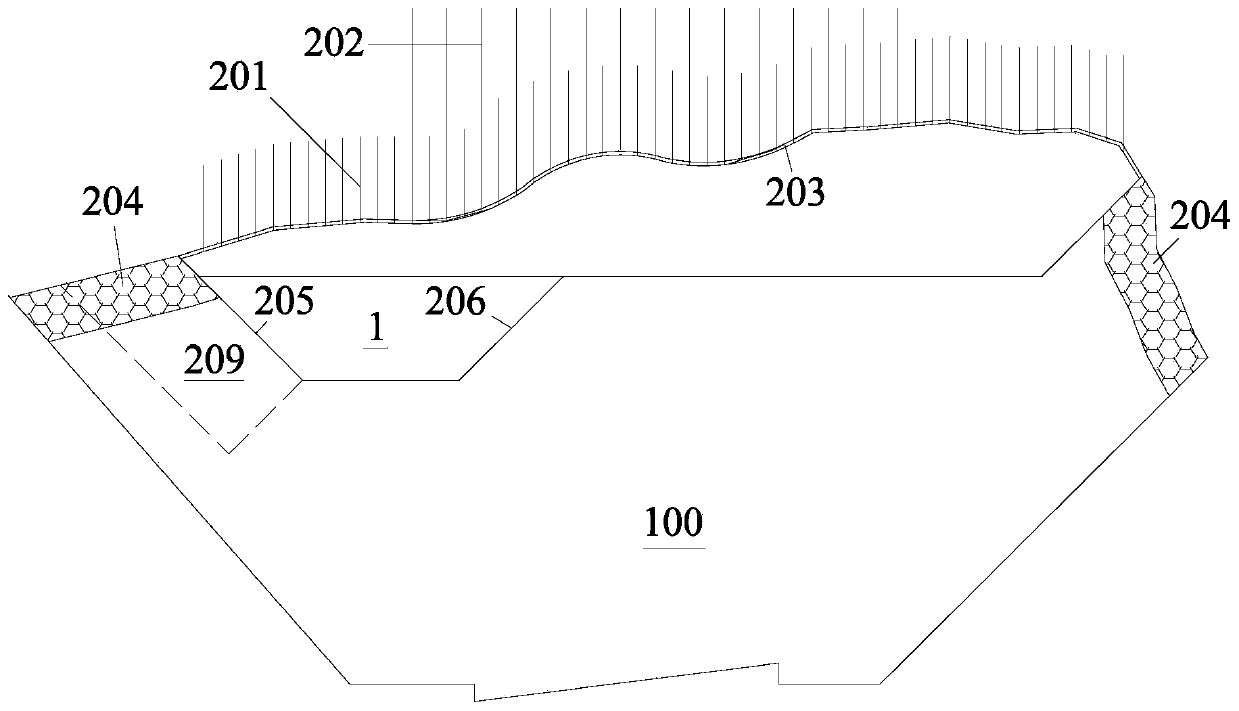

Integrated structural system penetrating through giant karst cave and construction method of integrated structural system

PendingCN111411992AEnsure supportEnsure stabilityUnderground chambersMaterial fill-upSlagArchitectural engineering

The invention discloses an integrated structural system penetrating through a giant karst cave and a construction method of the integrated structural system. The integrated structural system comprisesa top reinforcing structure, a base reinforcing structure, a guarding structure, a bridge structure and a light steel shed tunnel structure; the top reinforcing structure is used for reinforcing thetop of a karst cave hall; the base reinforcing structure is used for reinforcing an excavation base of a waste slag backfilling body of the karst cave hall; the guarding structure is arranged on the waste slag backfilling body and connected to the top of the karst cave hall, and vertical grouting channels are formed in the bottom of the guarding structure at intervals in the line direction, and extend into the waste slag backfilling body where the base reinforcing structure is located; the bridge structure is arranged with the range between the guarding structure and the rock wall of the top of the karst cave hall and is a train and track bed load bearing structure; and the two ends of the bottom of the light steel shed tunnel structure are supported on the bridge structure. All the structures are clearly stressed, loads are transmitted separately, uneven settlement of the structures is avoided, and the safety during operation is guaranteed.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

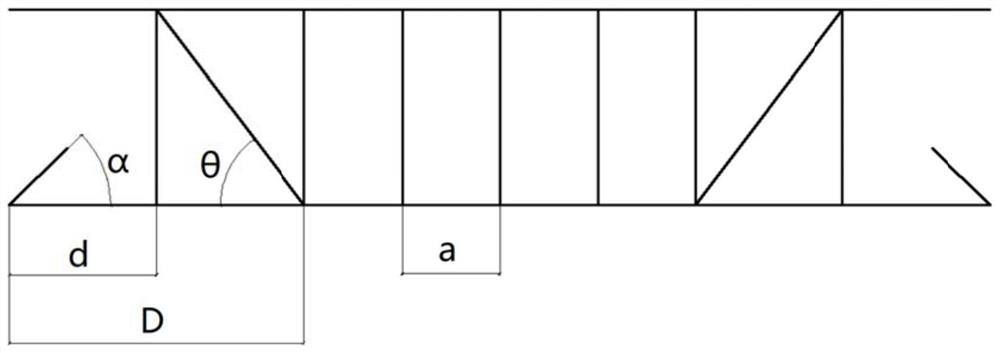

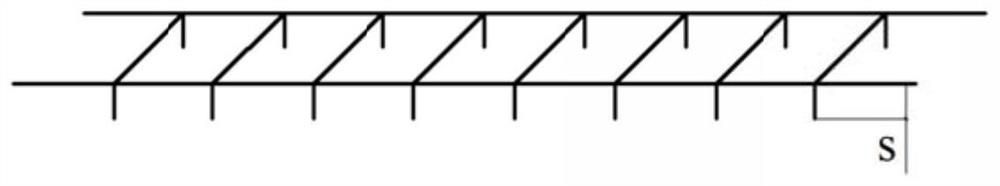

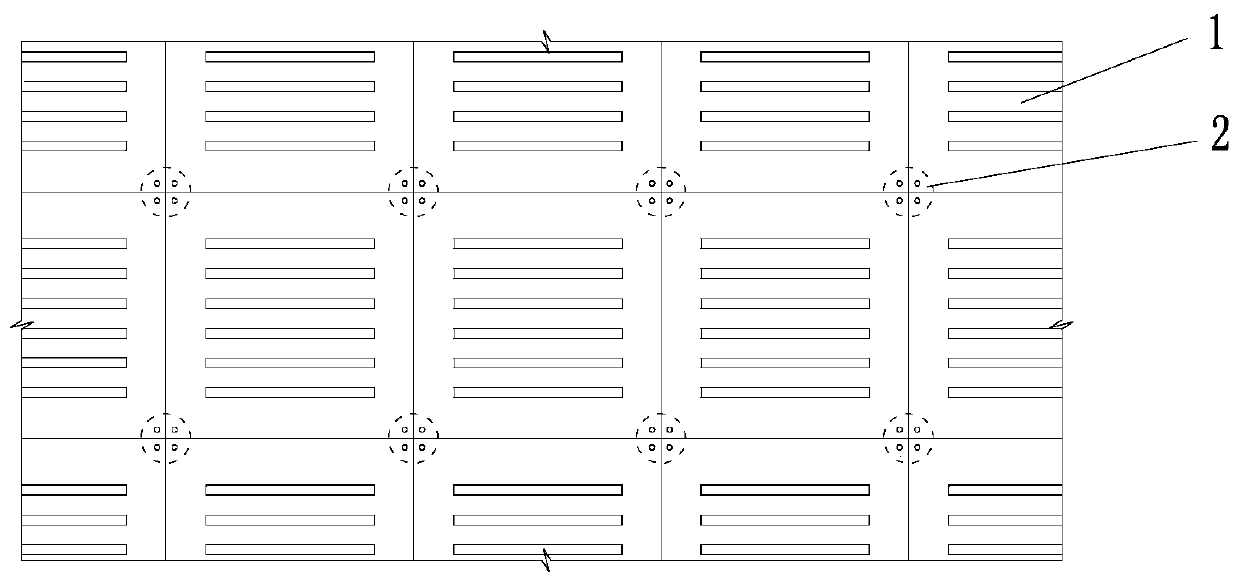

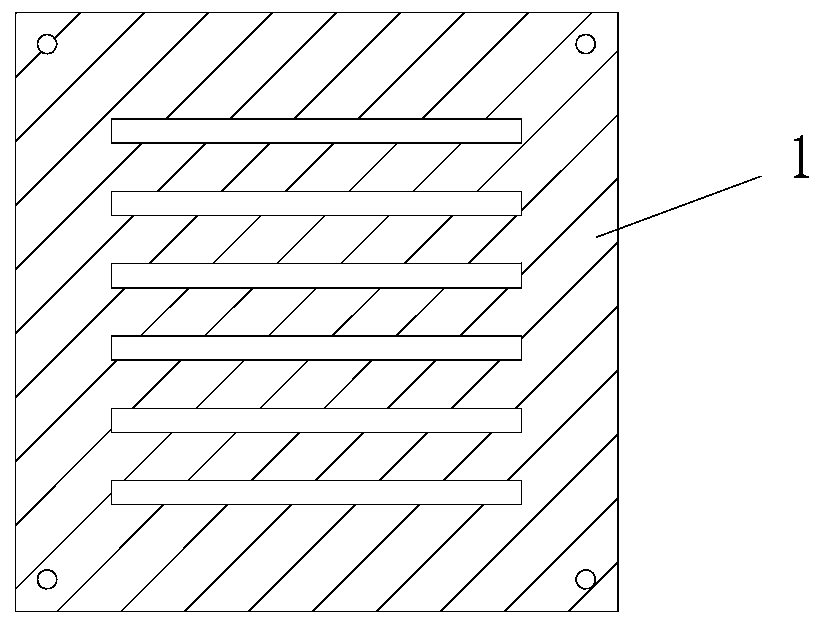

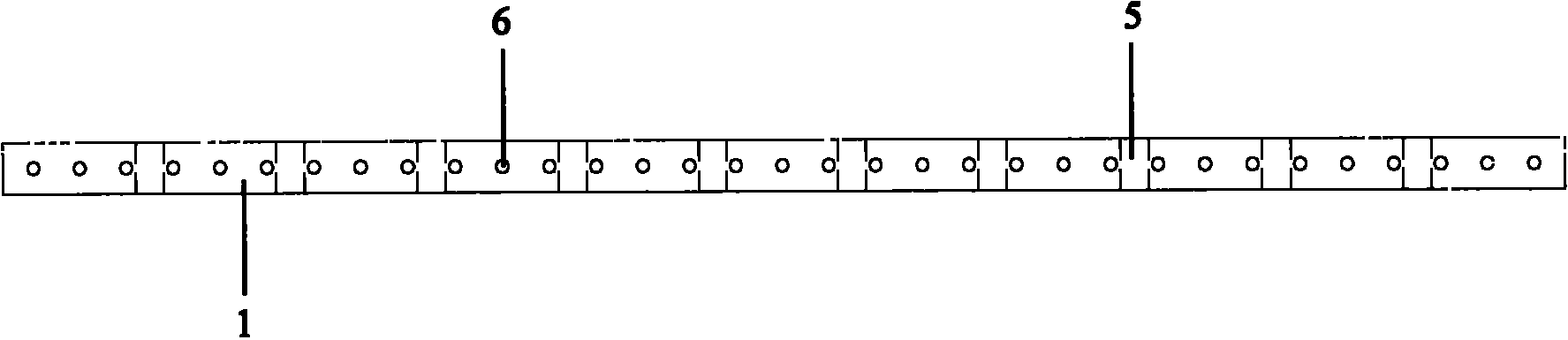

Photovoltaic solar pavement structural unit, power generation system and manufacturing method of structural unit

ActiveCN103929119BEnough carrying capacityMeet load requirementsPhotovoltaic supportsSolar heating energyPhotovoltaic solar energySolar energy storage

The invention relates to a photovoltaic solar energy pavement structure unit, a power generation system and a manufacturing method of the pavement structure unit. The pavement structure unit comprises a concrete base, a photovoltaic solar cell panel and a PMMA light-transmitting protective plate, a sinking part is arranged in the center of the concrete base, the PMMA light-transmitting protective plate is arranged on the concrete base in a covering mode to define a closed space, and the photovoltaic solar cell panel is packaged in the closed space. The power generation system comprises a solar energy storage battery controller, a storage battery and multiple photovoltaic solar energy pavement structure units, the photovoltaic solar energy pavement structure units are laid to form a pavement and connected in parallel or series to the solar energy storage battery controller, the solar energy storage battery controller is connected with the storage battery, and the output end of the storage battery or the output end of the solar energy storage battery controller is connected with an electric load. The manufacturing method includes the steps that S1, the concrete base is prefabricated; S2, the photovoltaic solar cell panel is installed; S3, the PMMA light-transmitting protective plate is arranged on the concrete base in a packaging mode and receives penetrating light irradiation.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

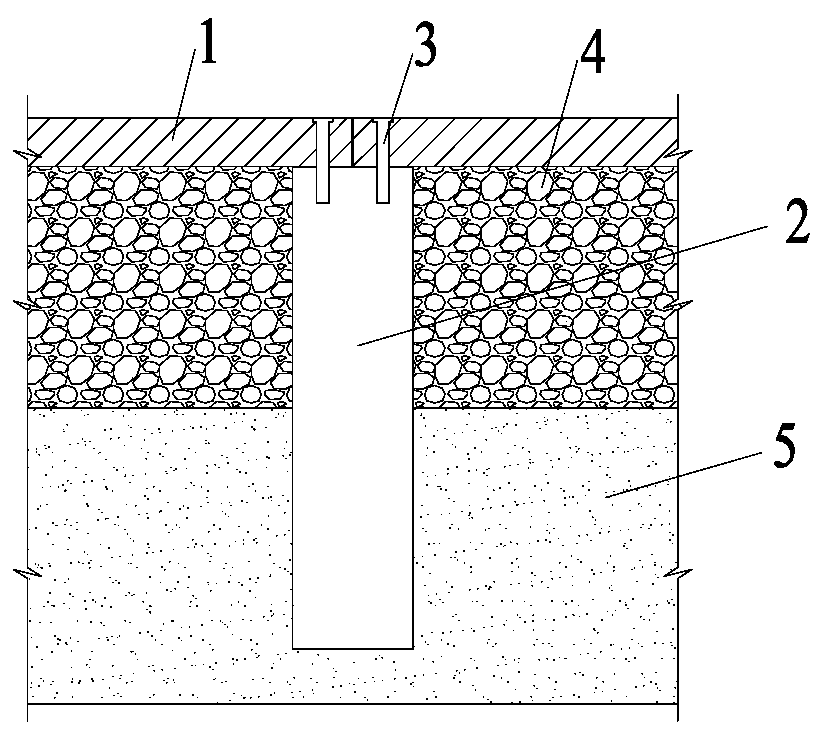

Permeable pavement structure and construction method thereof

ActiveCN109763392AGuaranteed flatnessReduce Waterlogging ProblemsSingle unit pavingsPaving gutters/kerbsWater storageCarrying capacity

The invention belongs to the technical field of road engineering, in particular to a permeable pavement structure and a construction method thereof. The permeable pavement structure comprises cover plates, columns, connecting pieces and gravel layers; wherein the gravel layers are laid on the soil foundation; the cover plates are laid on the gravel layers; permeable slots are formed at the middleparts of the cover plates; through holes are formed at the edges of the cover plates; the columns are inserted in the gravel layers and the soil foundation in the connecting positions of the cover plates; the upper end faces of the columns are flush with the upper surfaces of the gravel layers; a plurality of connecting holes are formed in the upper end faces of the columns; and the connecting pieces pass through the through holes for being inserted into the connecting holes and used for locating the cover plates. The invention has the advantages that the pavement flatness is ensured, and enough carrying capacity is provided, thereby being safe and comfortable for pedestrians to pass; rainwater can be quickly drained to the place beneath the pavement, thereby reducing the gathered water onthe pavement; and the gravel layers not only play the water storage function, but also provide support force for the cover plates, so that the rainwater in the gravel layers can gradually permeate into the soil foundation, thereby replenishing groundwater.

Owner:WUXI MUNICIPAL DESIGN INST

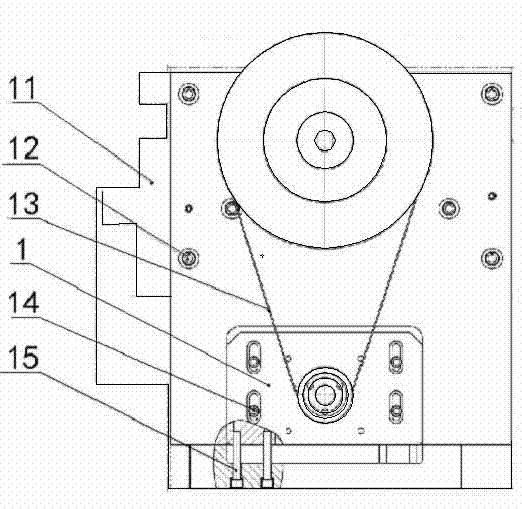

Horizontal feeding device of numerical control vertical lathe with maximum machining diameter of 2.5m

InactiveCN102773753AEnough carrying capacitySimple structureFeeding apparatusNumerical controlToothed belt

Owner:中传重型机床有限公司

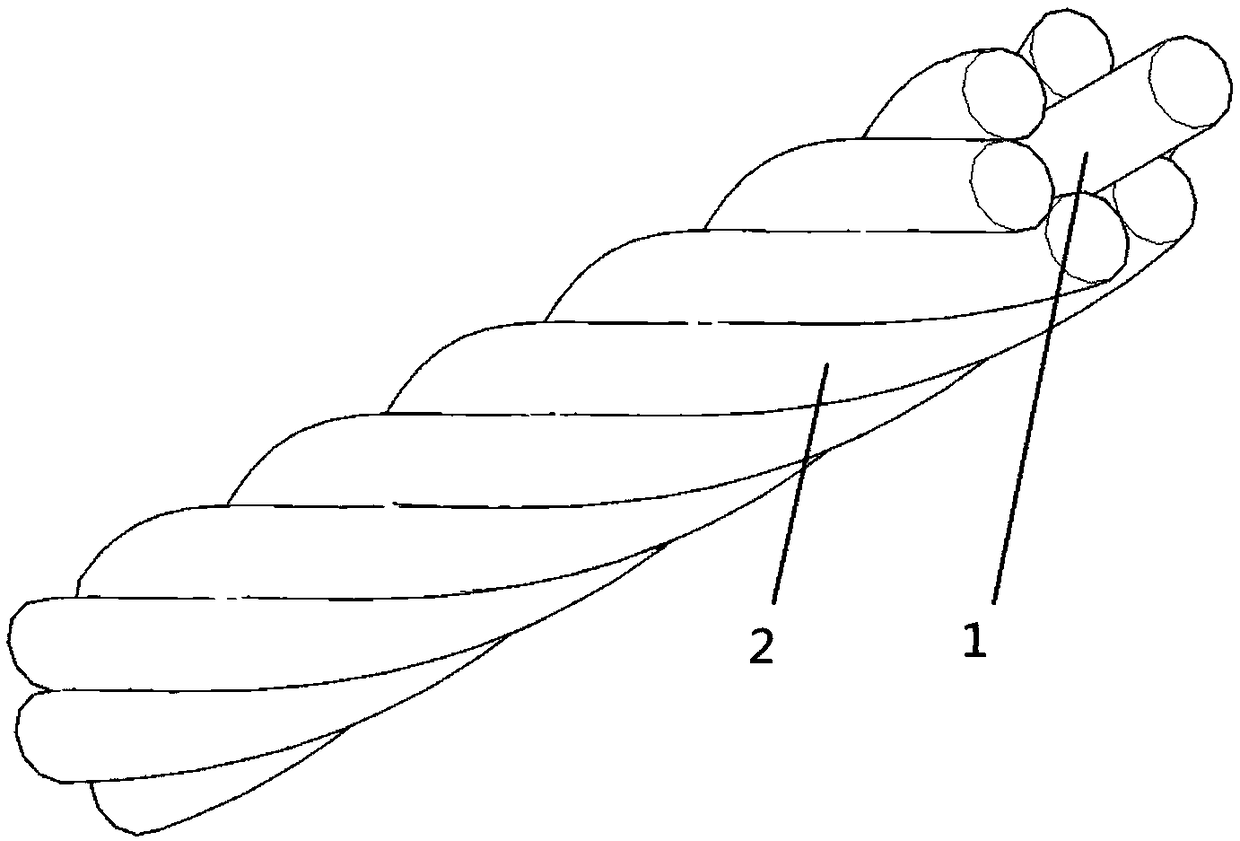

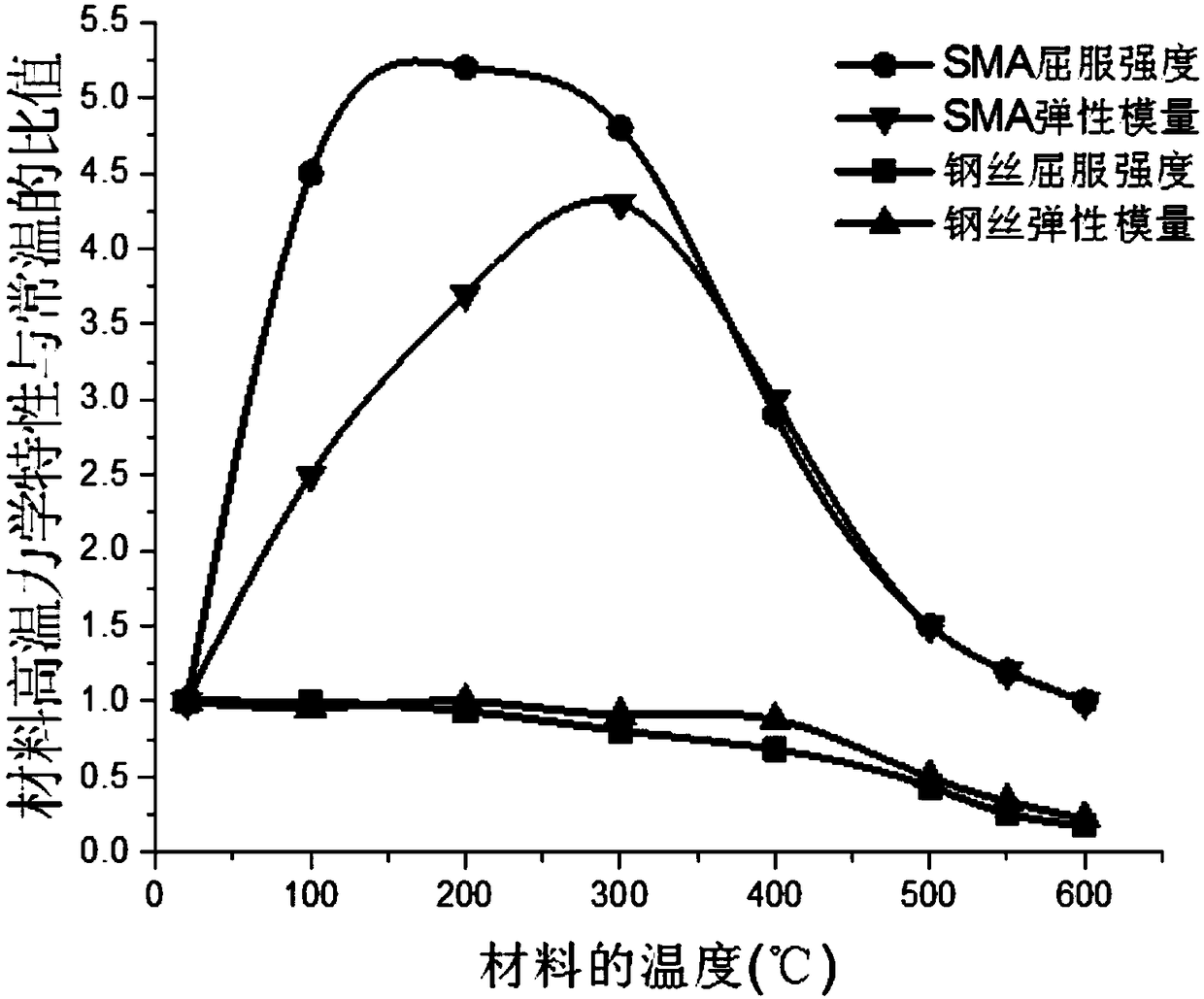

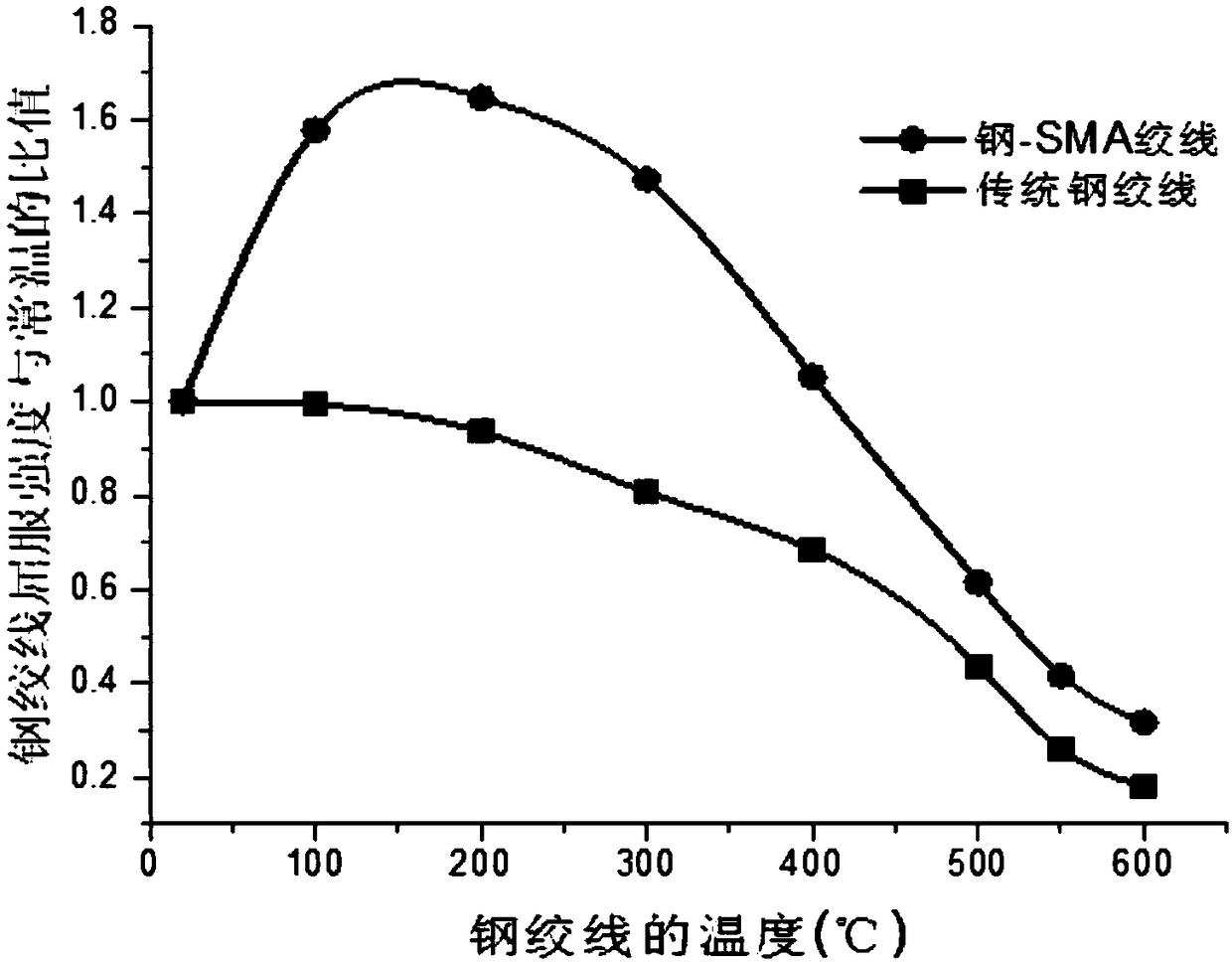

High-temperature resistant prestressed steel stranded wire

ActiveCN108716150ADoes not reduce bond stressGood mechanical propertiesTextile cablesPre stressShape-memory alloy

The invention relates to a high-temperature resistant prestressed steel stranded wire comprises an inner core and a plurality of stands of stranded wires wound around the outer side of the inner core.The inner core is made from a shape memory alloy (SMA) material, and the stranded wires are spirally wound around the outer side of the inner core. Compared with the prior art, the inner core made from the SMA material is used, the SMA is converted from a martensitic phase to an austenite phase under high-temperature induction, is restored to an initial state and produces a prestressing force under a constraint effect, considerable resilience is produced, and accordingly the prestressing force of the steel stranded wire is not too low or even is improved somewhat.

Owner:TONGJI UNIV

Motorcycle goods shelf

InactiveCN103171668AEasy to modifyHigh strengthLuggage carriersUltimate tensile strengthTransport engineering

The invention discloses a motorcycle goods shelf. The motorcycle goods shelf comprises a goods shelf main tube. The goods shelf main tube is a U-shaped bending tube. A goods shelf cross member tube is fixedly connected in a U-shaped opening of the goods shelf main tube. The goods shelf cross member tube is vertical to the U-shaped opening of the goods shelf main tube. Two tail ends of the goods shelf main tube are provided with goods shelf supporting tubes. The goods shelf supporting tubes are L-shaped bending tubes. The tail ends of the goods shelf supporting tubes are connected with the middle portion of the goods shelf main tube. A goods shelf supporting plate is arranged in the U-shaped opening of the goods shelf main tube. The goods shelf supporting plate is placed at the back of the goods shelf cross member tube and is fixed with the goods shelf main tube in a welding mode. The goods shelf supporting plate is a rectangular stamping plate. An inner flanging structure is arranged in the middle portion of the goods shelf supporting plate. Outer flanging structures are arranged on two sides of the goods shelf supporting plate. The goods shelf supporting tubes are provided with two goods shelf front-back installation double-screw bolts. Welding between stamping parts and the goods shelf is utilized, the motorcycle goods shelf is designed to be the inner flanging structure, rigidity of the supporting plate is increased, and strength of the goods shelf is greatly improved. The motorcycle goods shelf is impact resistant, simple in structure, low in production cost, easy to form, stable in performance, and capable of guaranteeing enough bearing capacity of the goods shelf.

Owner:万李

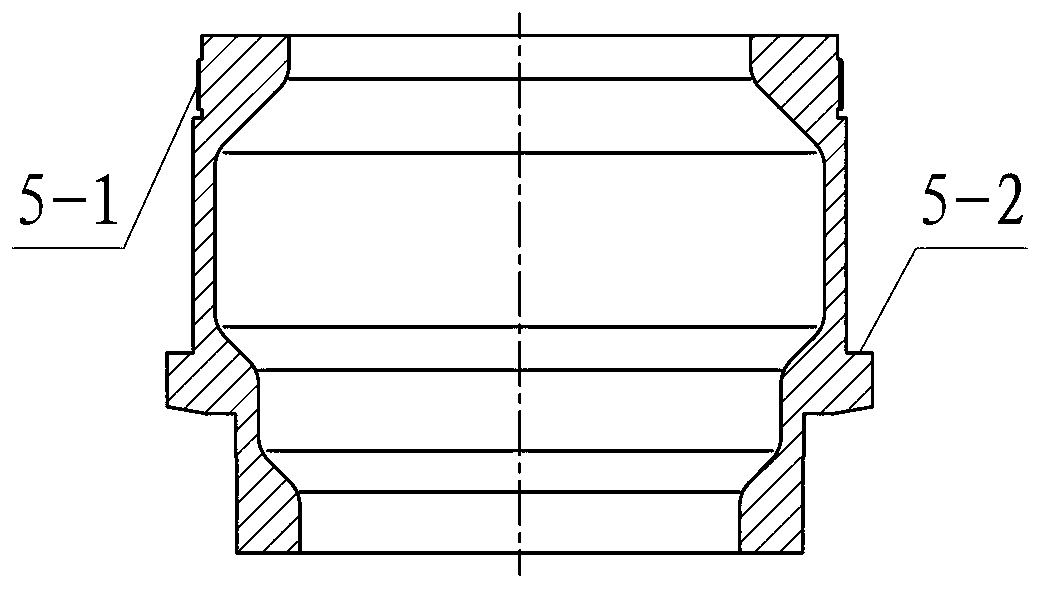

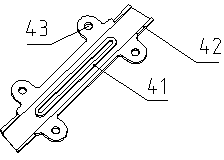

Prestressed high-strength steel wire mesh anchorage device

InactiveCN101942902AReduce pressure peaksUniform stressBridge erection/assemblyBuilding material handlingPre stressSteel bar

The invention discloses a prestressed high-strength steel wire mesh anchorage device. The prestressed high-strength steel wire mesh anchorage device provided by the invention is characterized by comprising an anchoring part (1), a bolt (2), a screw (3) and a clamping sheet (4), wherein the bolt is arranged in a through hole of the anchoring part; the screw and the clamping sheet are arranged in a through hole of the bolt and are connected with each other; and the conical angle of the clamping sheet is bigger than that of the through hole of the bolt and the difference between the two conical angles is 0.05 to 0.5 degree. The prestressed high-strength steel wire mesh anchorage device has the advantages of reliable anchoring property, sufficiency bearing capacity, durability, simple and convenient construction, capacity of instant tensioning after assembling, convenient centering process, high interchangeability, high adaptability to environments, small flat anchor capable of anchoring a plurality of high-strength steel wires at the same time and capacities of completely exerting the strength of prestressed reinforcing steel bar and realizing tensioning operation safely.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

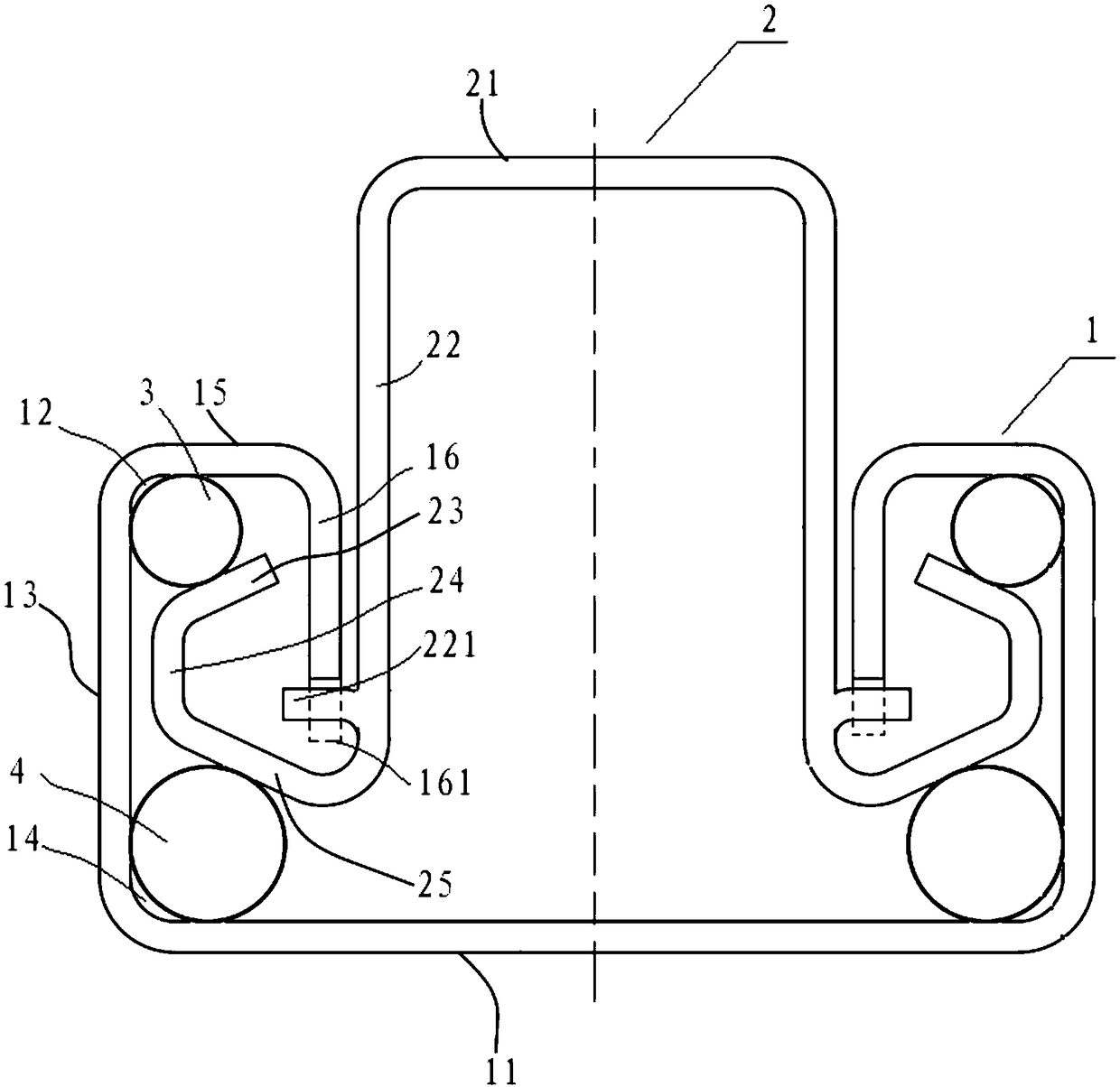

Automobile and sliding rail assembly of seat thereof

The invention discloses an automobile and a sliding rail assembly of a seat thereof. The sliding rail assembly is bilaterally symmetric and comprises an upper sliding rail and a lower sliding rail extending in the front-back direction and an upper ball and a lower ball arranged between the upper sliding rail and the lower sliding rail; the lower sliding rail comprises a horizontal base plate, a first vertical side plate connected to the upper portion of the left edge of the horizontal base plate, and a first horizontal top plate connected to the right side of the upper edge of the first vertical side plate; the upper sliding rail comprises a first inclined plate and a second inclined plate; the extension line of the first inclined plate, the first vertical side plate and the extension lineof the first horizontal top plate are tossed to form an upper triangular region; the upper ball is arranged at the upper triangular region and makes point contact with the first inclined plate, the first vertical side plate and the first horizontal top plate, and the extension line of the second inclined plate, the horizontal base plate and the first vertical side plate are crossed to form a lower triangular region. The lower ball is located at the lower triangular region and makes point contact with the second inclined plate, the horizontal base plate and the first vertical side plate. The sliding rail assembly solves the problem that the seat vibrates when adjusted, and has the enough bearing capability.

Owner:HUBEI AVIATION PRECISION MASCH TECH CO LTD

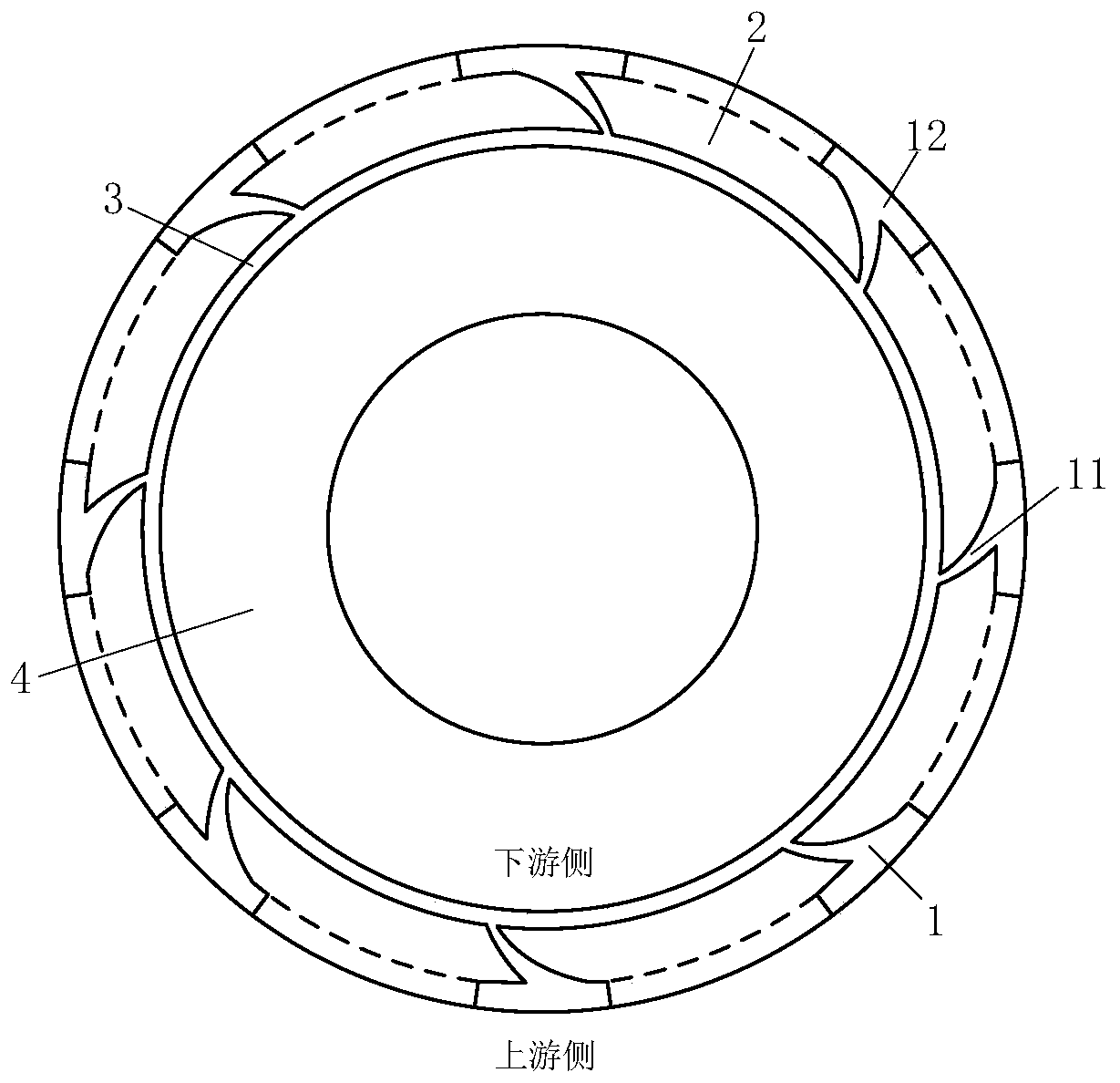

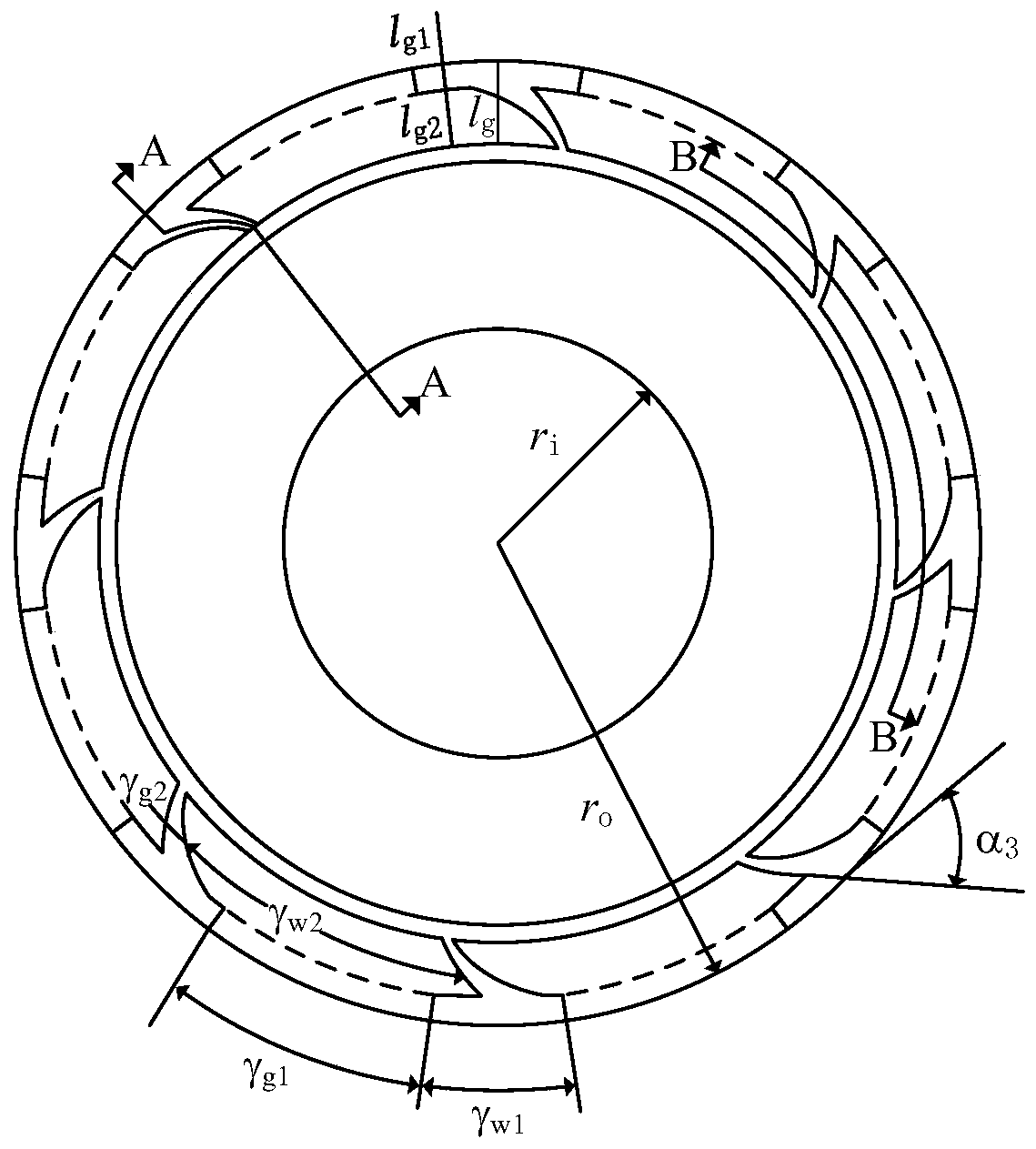

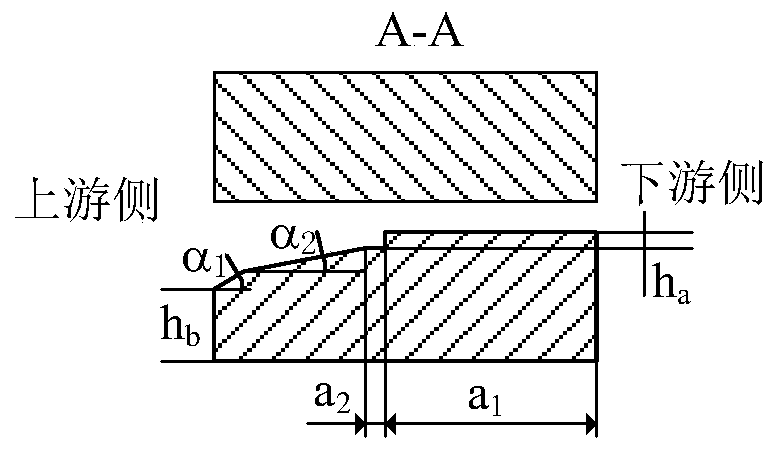

Mechanical seal end face structure of variable-depth spiral T-shaped groove

ActiveCN110410504AEnhance the dynamic pressure effectImprove work performanceEngine sealsEngine lubricationSolid particleEngineering

The invention discloses a mechanical seal end face structure of a variable-depth spiral T-shaped groove. The structure comprises a mechanical seal movable ring and a mechanical seal static ring, wherein one side of the end face of the movable ring or the static ring is provide with a high-pressure side, namely an upstream side, and the other side of the end face of the movable ring or the static ring is provide with a low-pressure side, namely a downstream side; variable-depth spiral T-shaped grooves are formed in the end face of the movable ring, seal weirs are arranged among the variable-depth spiral T-shaped grooves, the variable-depth spiral T-shaped grooves communicate with a circumferential annular groove, and a seal dam is arranged between the circumferential annular groove and thedownstream side; and the number of the variable-depth spiral T-shaped grooves is an even number in 8 - 24, and the radial width of the whole variable-depth spiral T-shaped grooves accounts for less than one third of the radial width of the whole seal end face. According to the mechanical seal end face structure of the variable-depth spiral T-shaped groove, the fluid dynamic pressure effect is effectively improved, the working efficiency of mechanical seal is improved, and the sealing performance of the mechanical seal in a static state is ensured; and solid particles and the like can be timely discharged out of the seal end face, so that the friction between end surfaces is reduced, the temperature distribution is improved, and the problems of deformation and even mechanical seal end surface cracking caused by uneven heating of a seal ring are avoided.

Owner:BEIHANG UNIV

Plastic pipe fitting with plastic-steel composite reinforced threaded insert and its production process

InactiveCN103759091BEasy to useSolution to short lifePipe connection arrangementsPipe fittingEngineering

The invention belongs to the technical field of plastic fittings, and particularly relates to a plastic fitting with a plastic-steel composite reinforced thread insert and a production process of the plastic fitting. The plastic fitting comprises an internal thread bushing or an external thread bushing, a plastic-coated reinforced bushing is formed outside the internal thread sleeve to form a composite reinforced internal thread insert, or a plastic-filled reinforced bushing is formed in the external thread bushing to form a composite reinforced external thread insert, and a fitting connecting portion is arranged on one side of the internal thread insert or the external thread insert by injection molding to form the plastic fitting. The plastic fitting is long in service life, environment friendly, safe and reliable, and production cost is reduced.

Owner:徐胜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com