Integrated structural system penetrating through giant karst cave and construction method of integrated structural system

A construction method and karst cave technology, which are applied to the integrated structural system passing through giant karst caves and its construction field, can solve the problems of high cost, uneven stress on the tunnel structure, affecting the safety of tunnel engineering operations, and achieve clear structural stress, The effect of avoiding uneven settlement and ensuring the safety of train operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

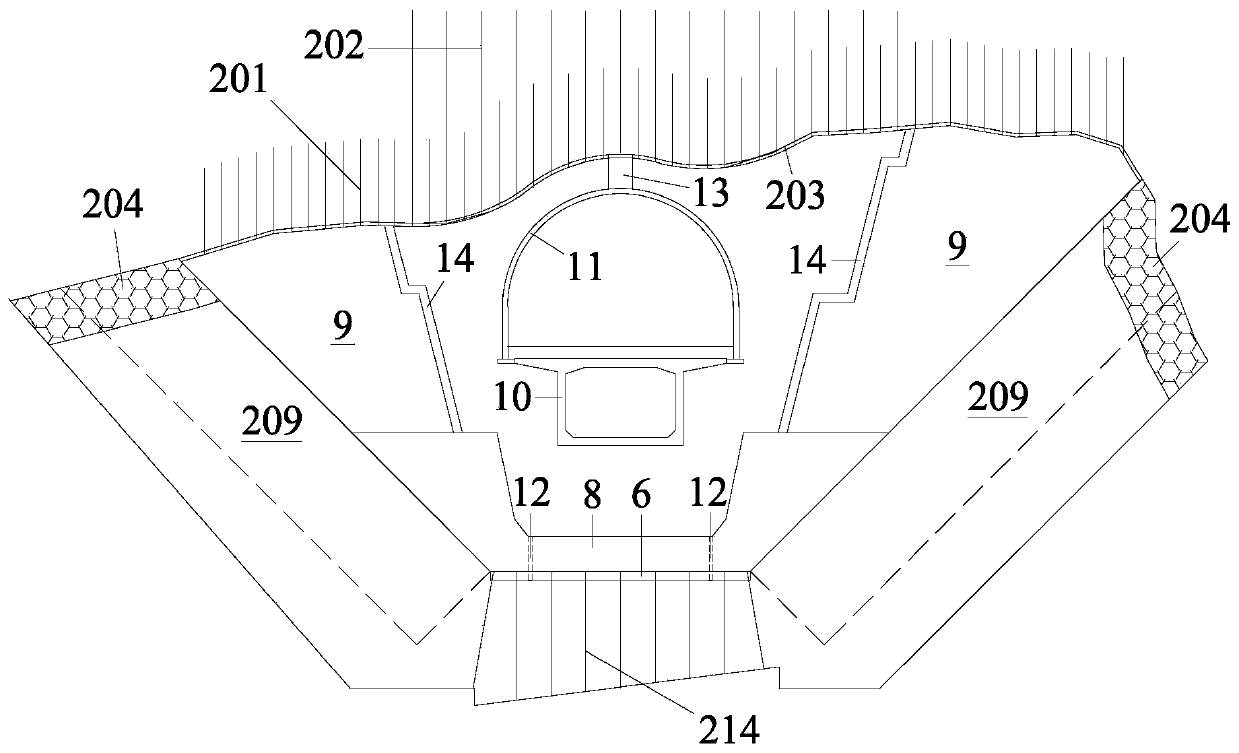

[0066] like Figure 1-12 As shown, an integrated structural system for crossing a giant cave according to the present invention includes a top reinforcement structure, a base reinforcement structure 214 , a retaining structure, a bridge structure 10 and a light steel shed tunnel structure 11 .

[0067] The top reinforcement structure is used to reinforce the top of the karst cave hall; specifically, the top reinforcement structure includes an anchor rod 201 and an anchor cable 202 extending into the top of the karst cave hall, and a roof anchor net that is connected to cover the top surface of the karst cave hall The sprayed layer 203, the stone backfill structure 204 is arranged on both sides of the roof anchor net sprayed layer 203.

[0068] The base reinforcement structure 214 is used to reinforce the excavation base of the spoil slag backfill body 100 in the karst cave hall; specifically, the base reinforcement structure 214 includes a grouting structure, a steel pipe pile...

Embodiment 2

[0073] like Figure 1-12 As shown, a kind of construction method of the integrated structural system passing through the giant karst cave as described in Embodiment 1 of the present invention includes the following steps:

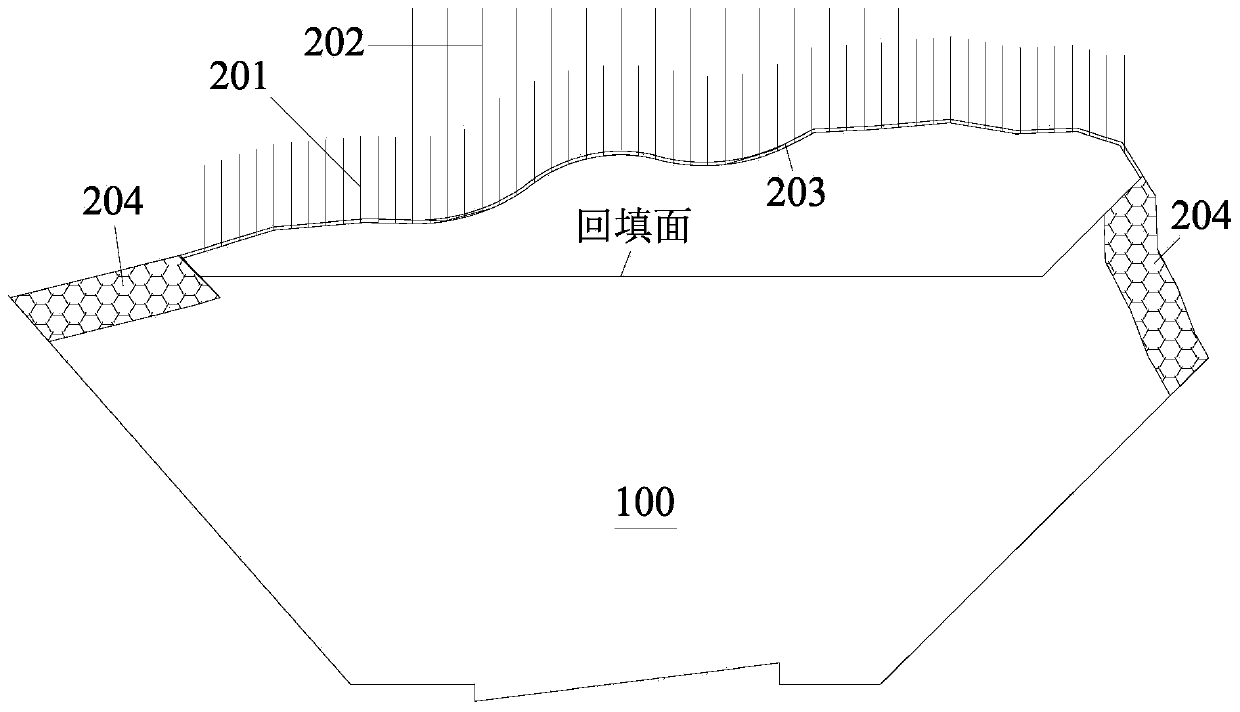

[0074] ① if figure 2 As shown, the karst cave hall is backfilled with spoil to a distance of 6m-10m from the top, and the top reinforcement structure is applied on the top of the karst cave hall; specifically, the top reinforcement structure includes The anchor rod 201 and the anchor cable 202 at the top, and the roof anchor net sprayed layer 203 connected to cover the top surface of the cave hall, and the rock backfill structures 204 are arranged on both sides of the roof anchor net spray layer 203;

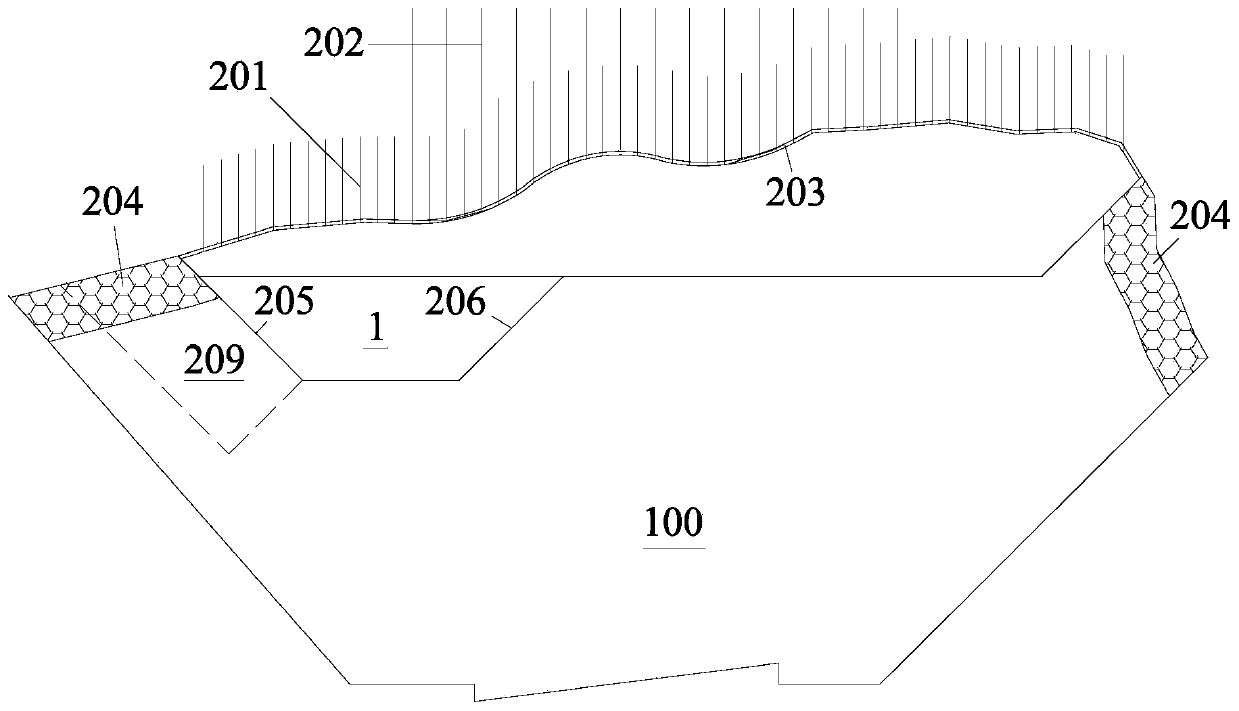

[0075] ② if image 3 As shown, the upper left core soil 1 is excavated, and the first temporary slope spray net protection 205 and the second temporary slope spray net protection 206 on both sides of the upper left core soil 1 are applied after excavation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com