Patents

Literature

39results about How to "Minimize play" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

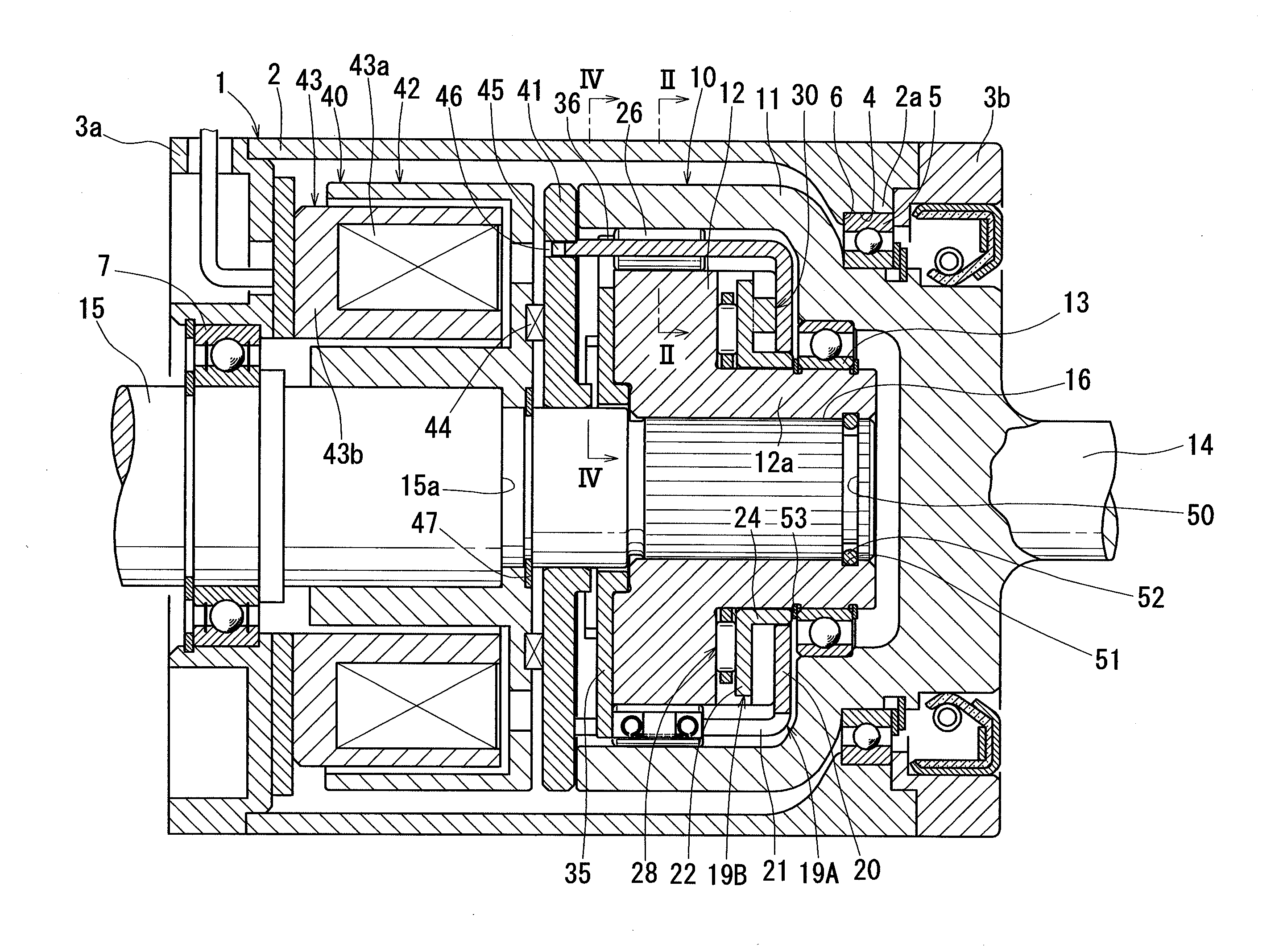

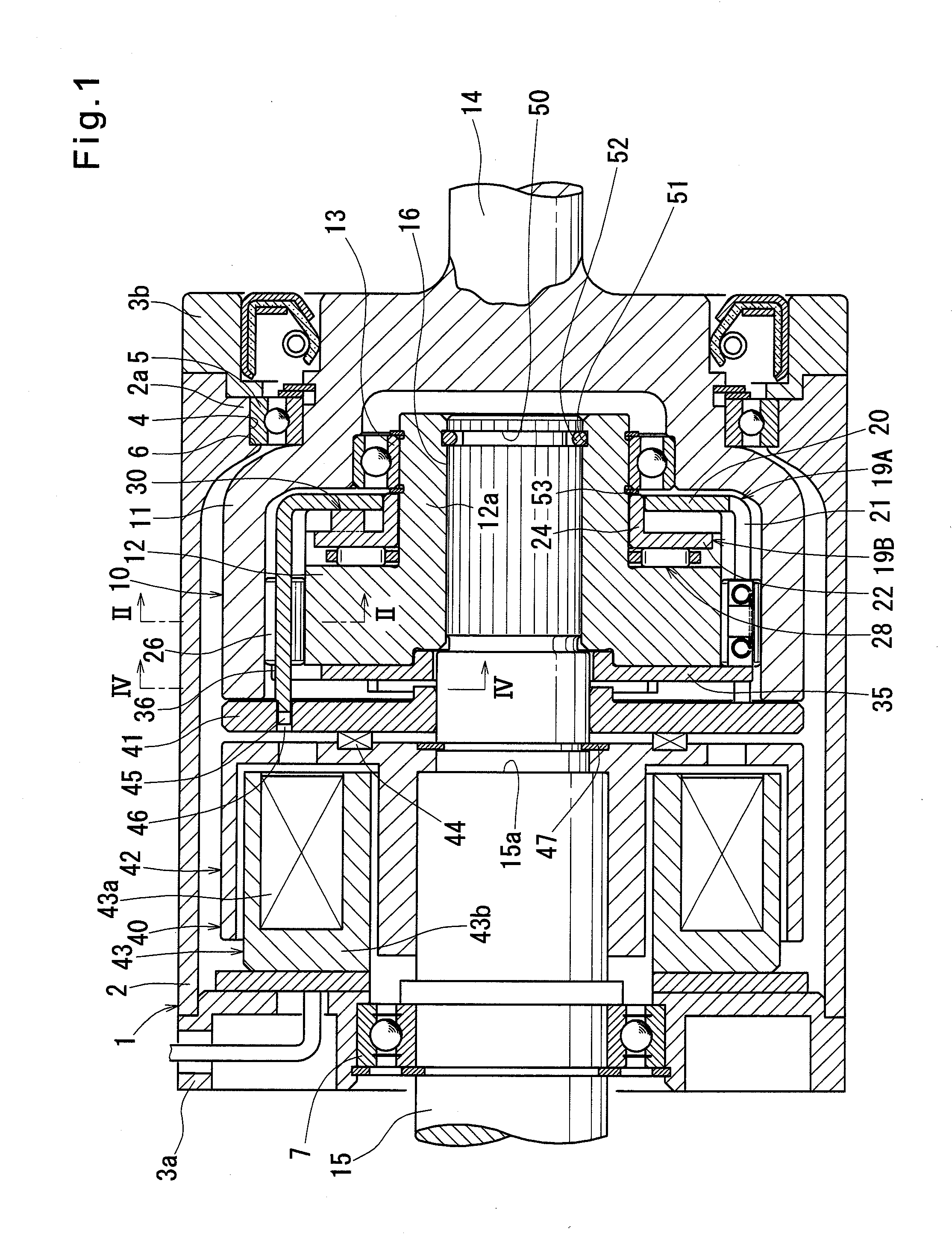

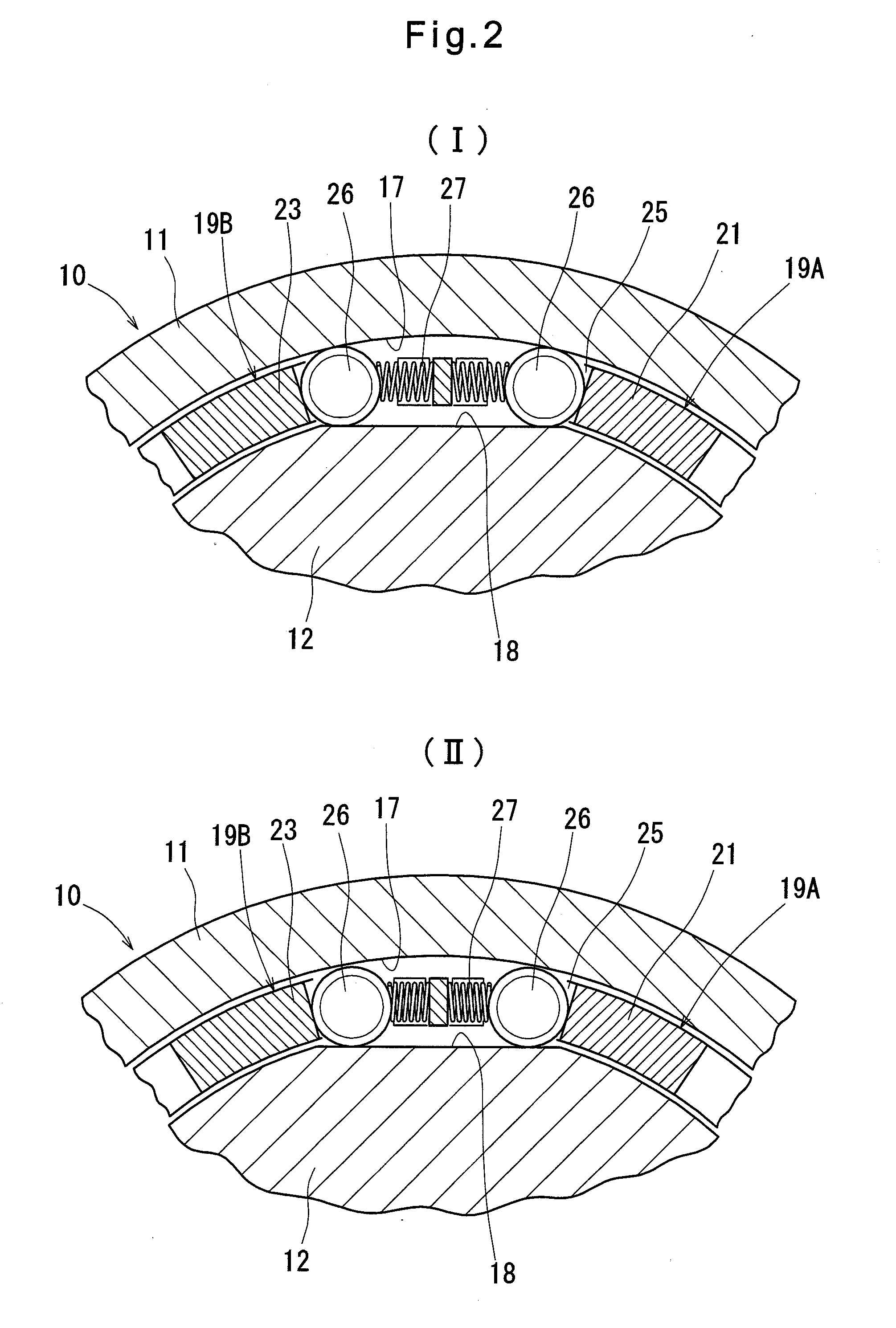

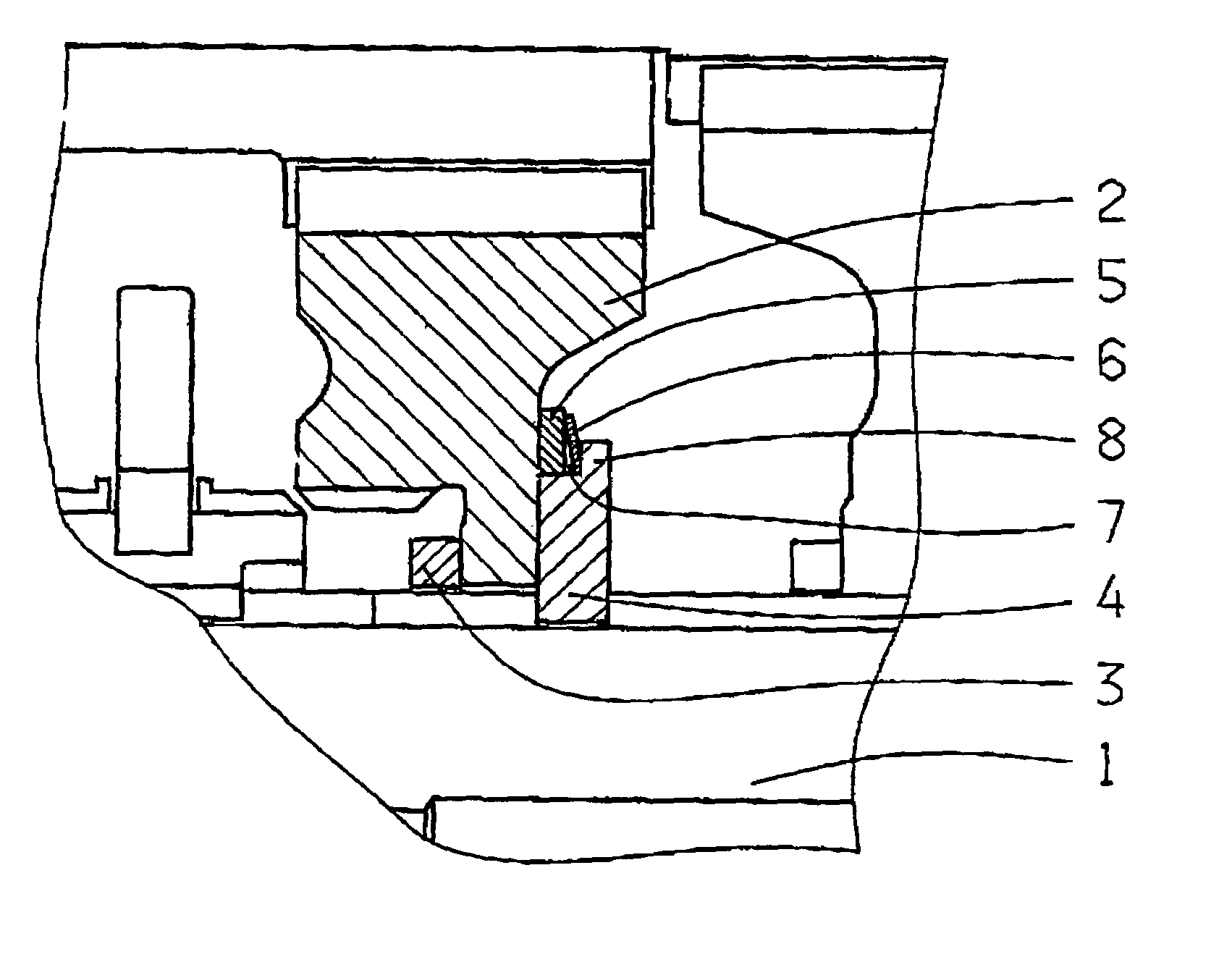

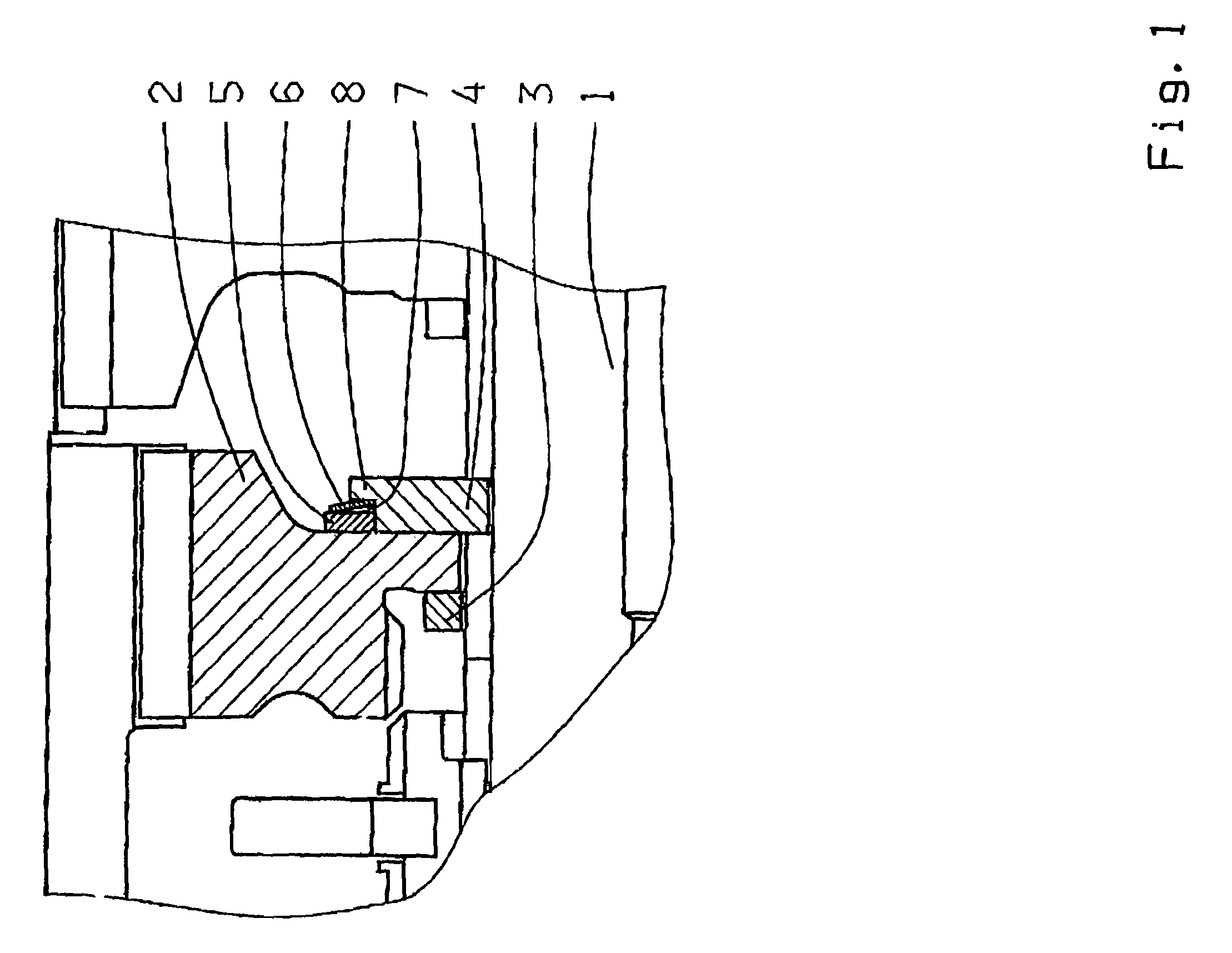

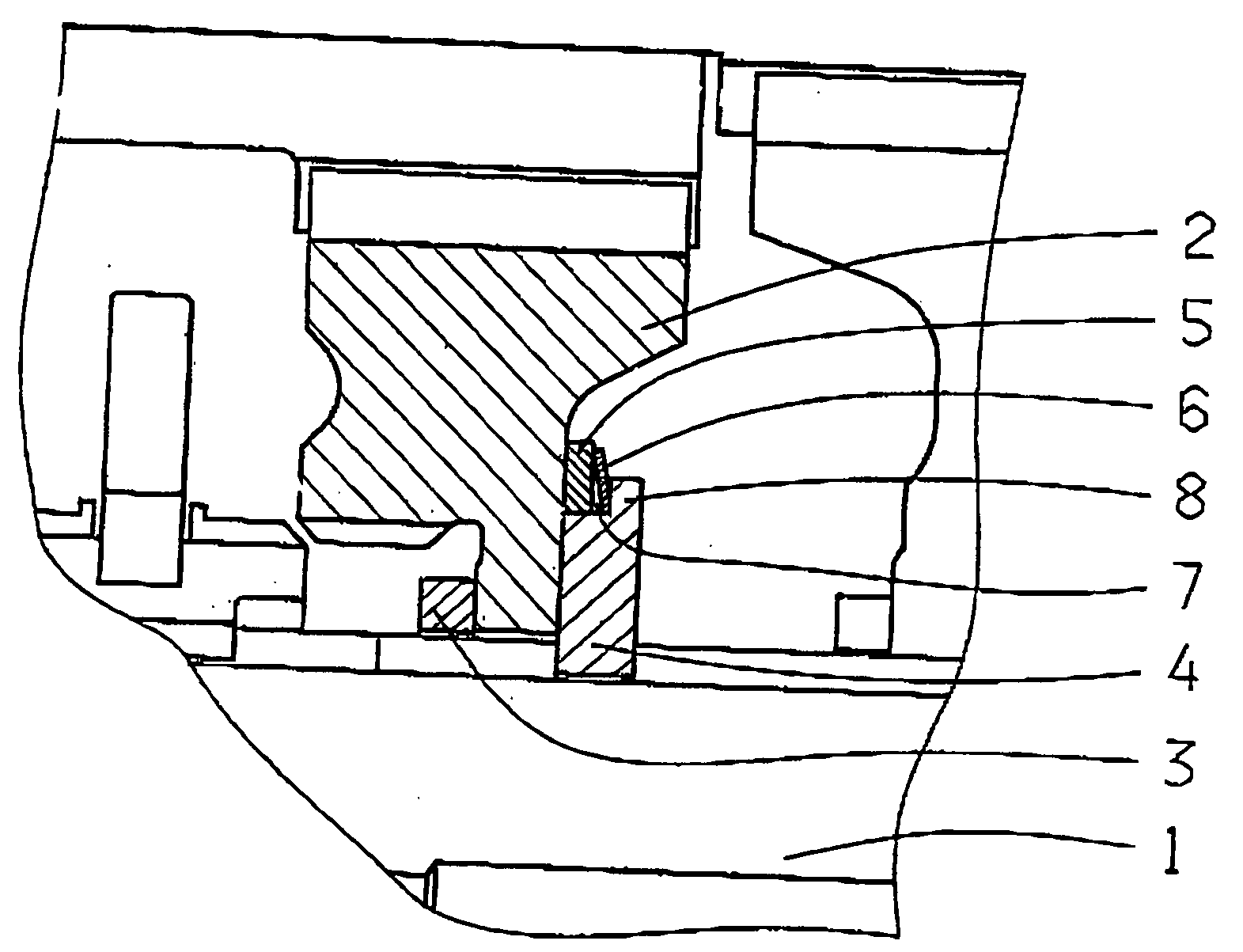

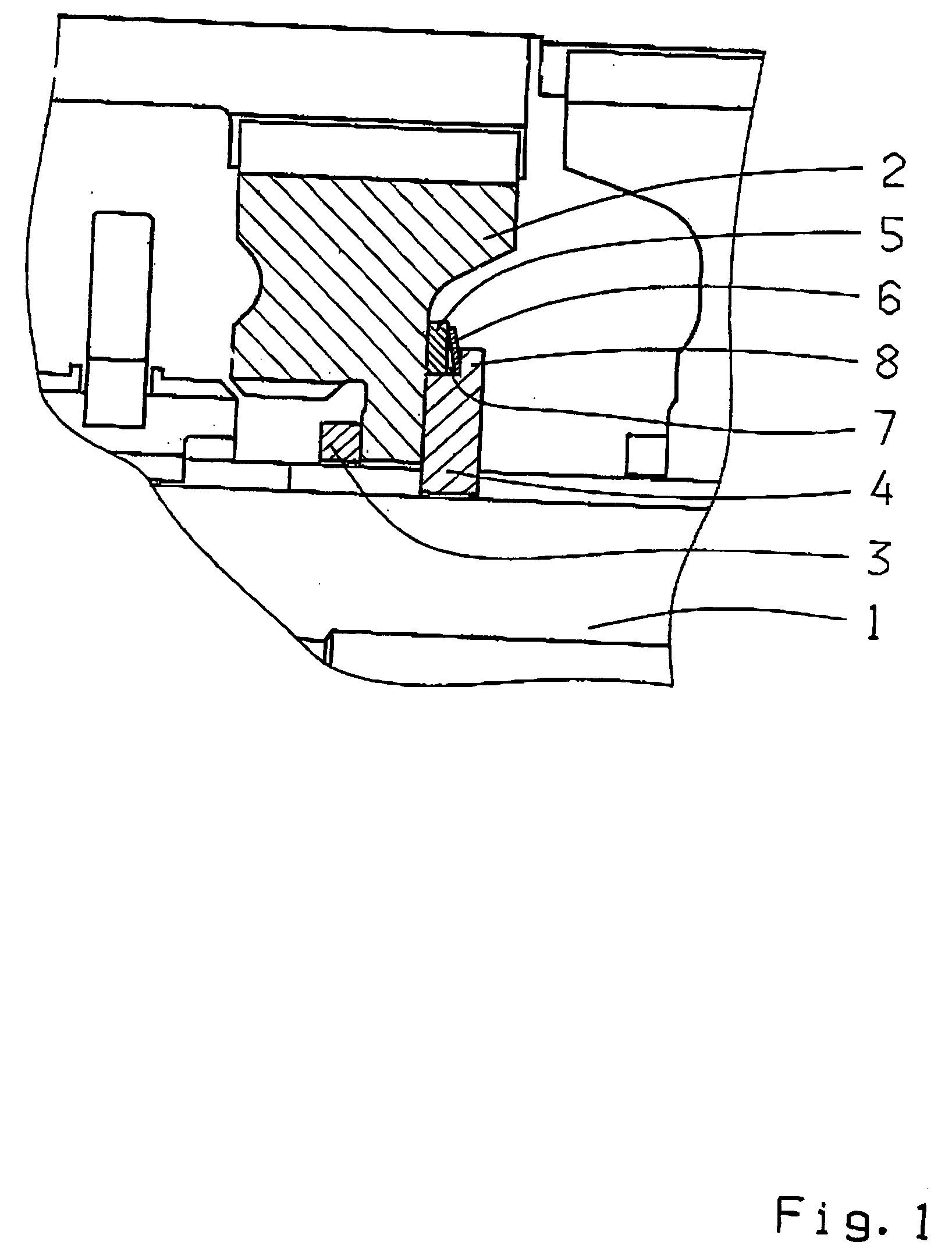

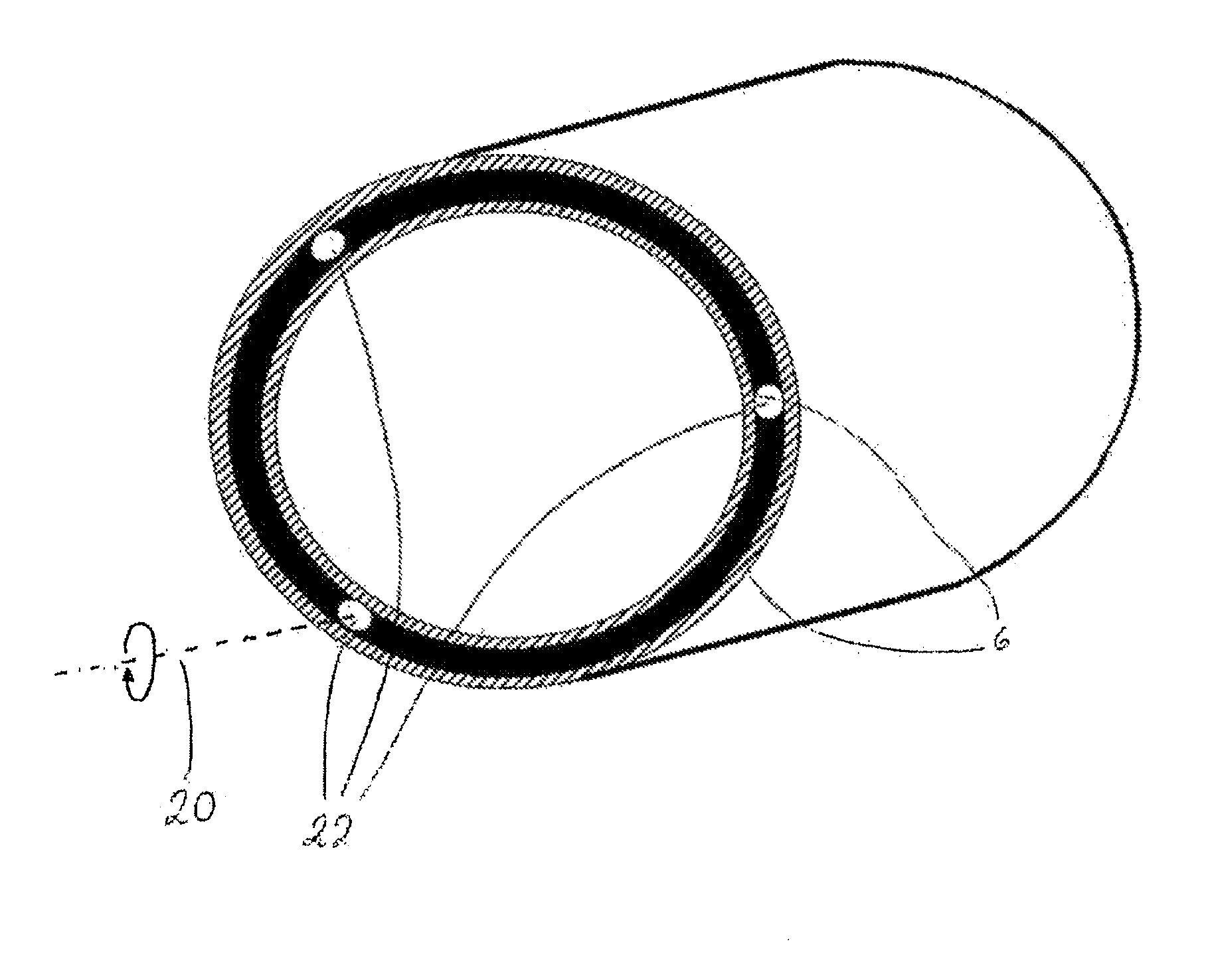

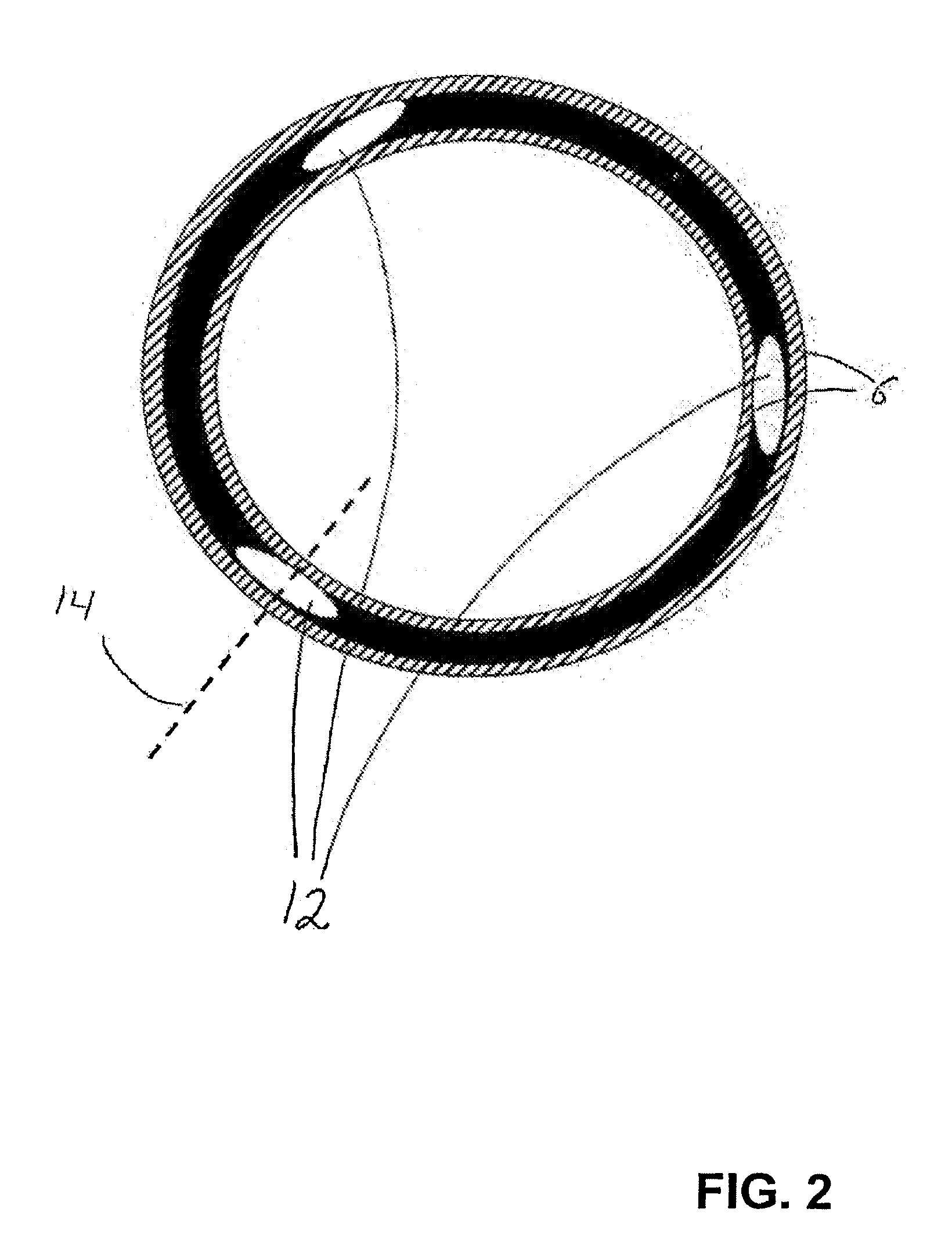

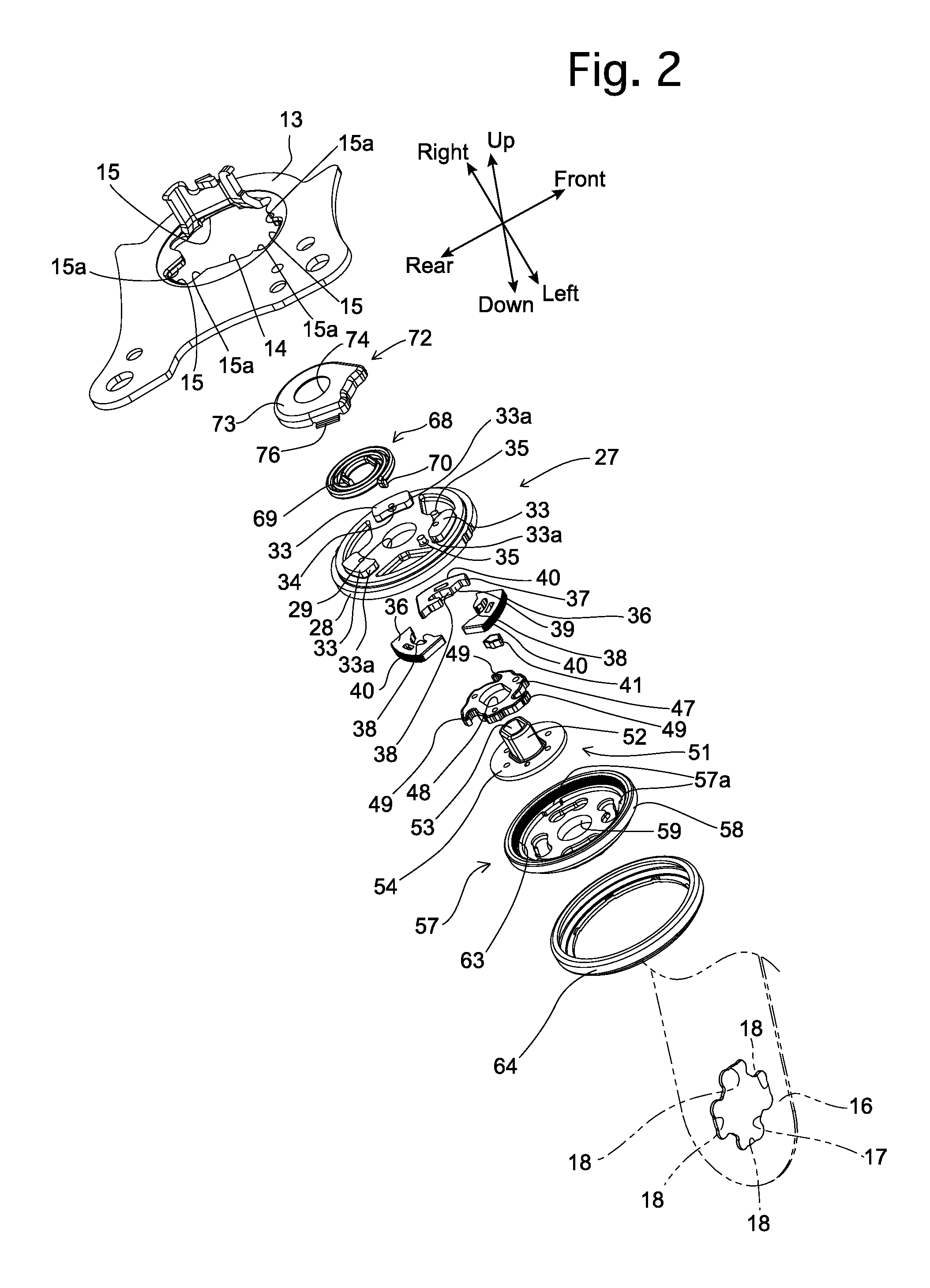

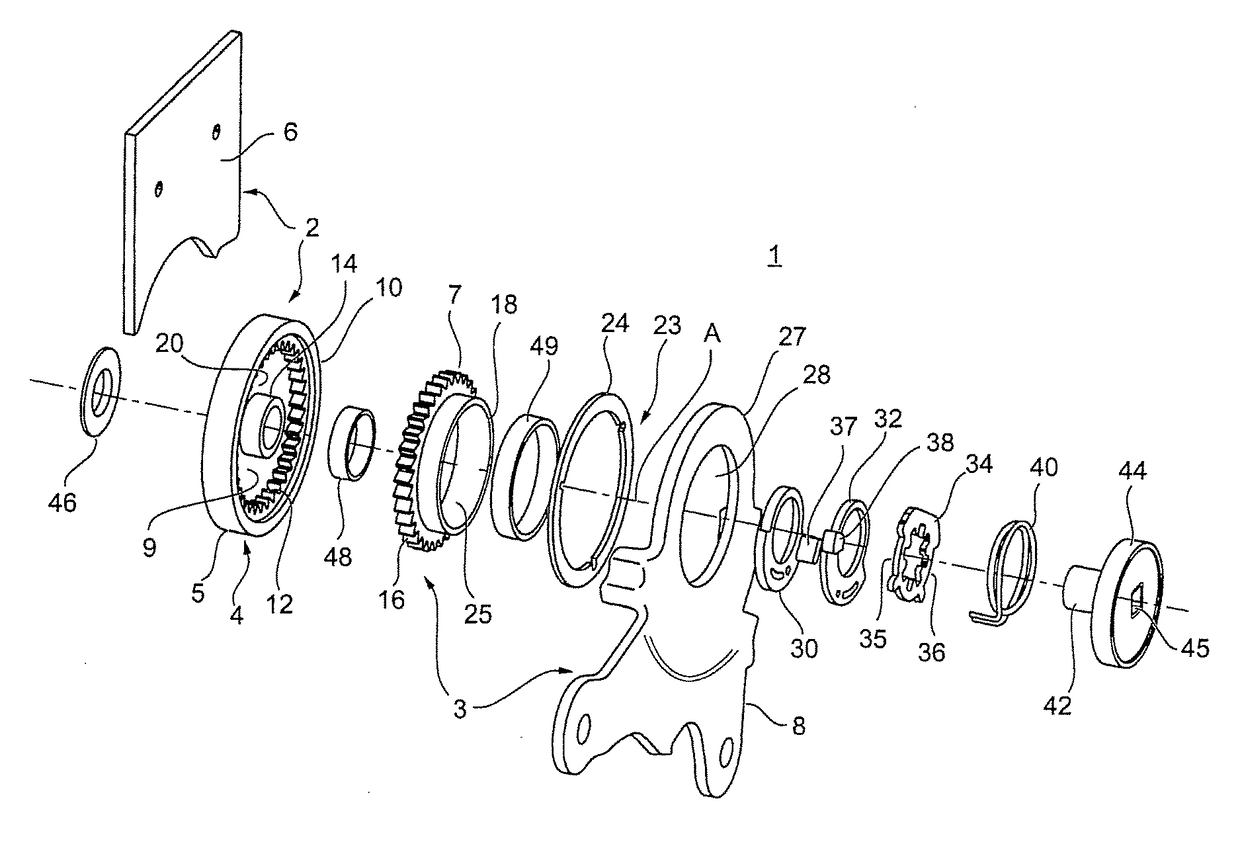

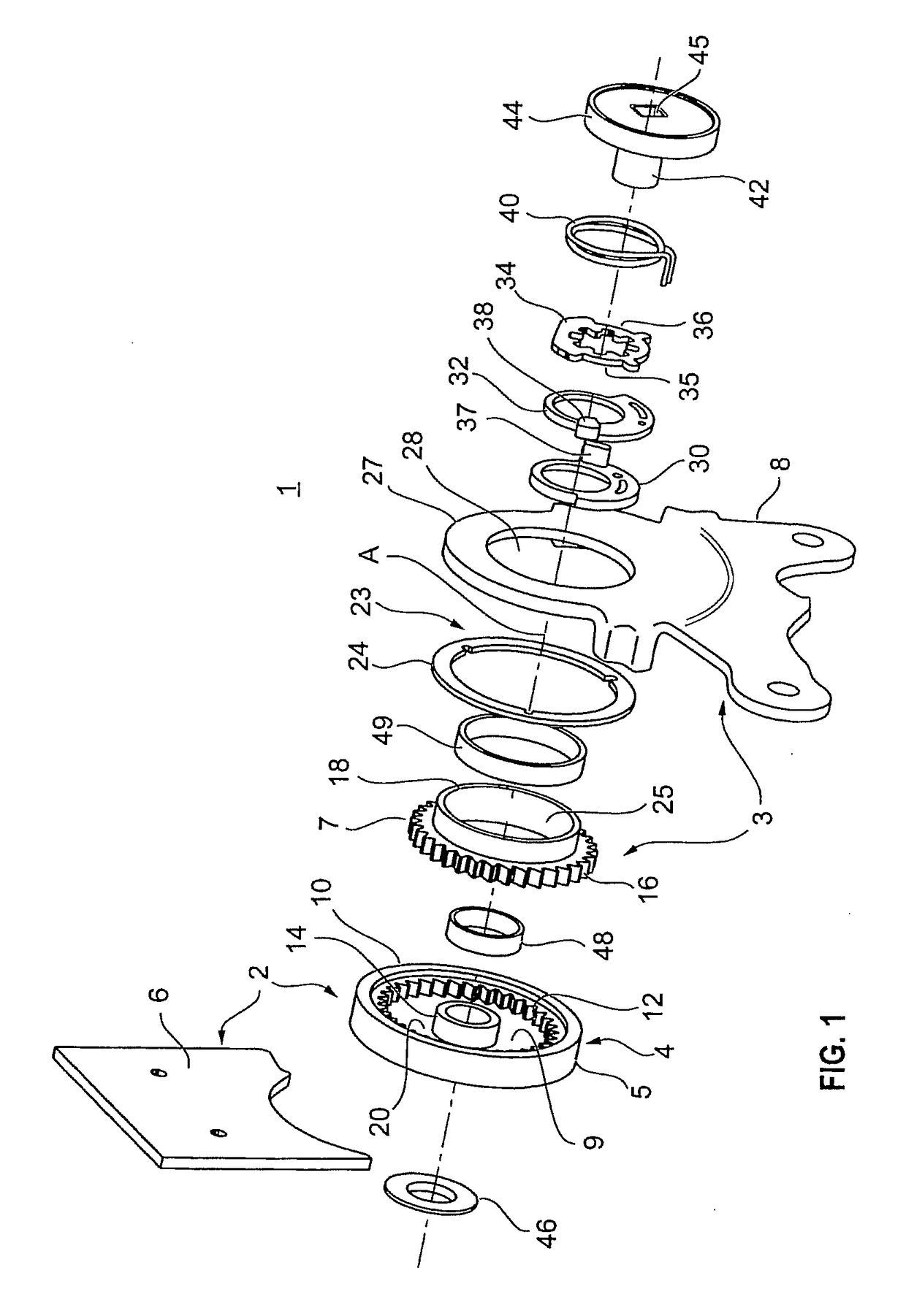

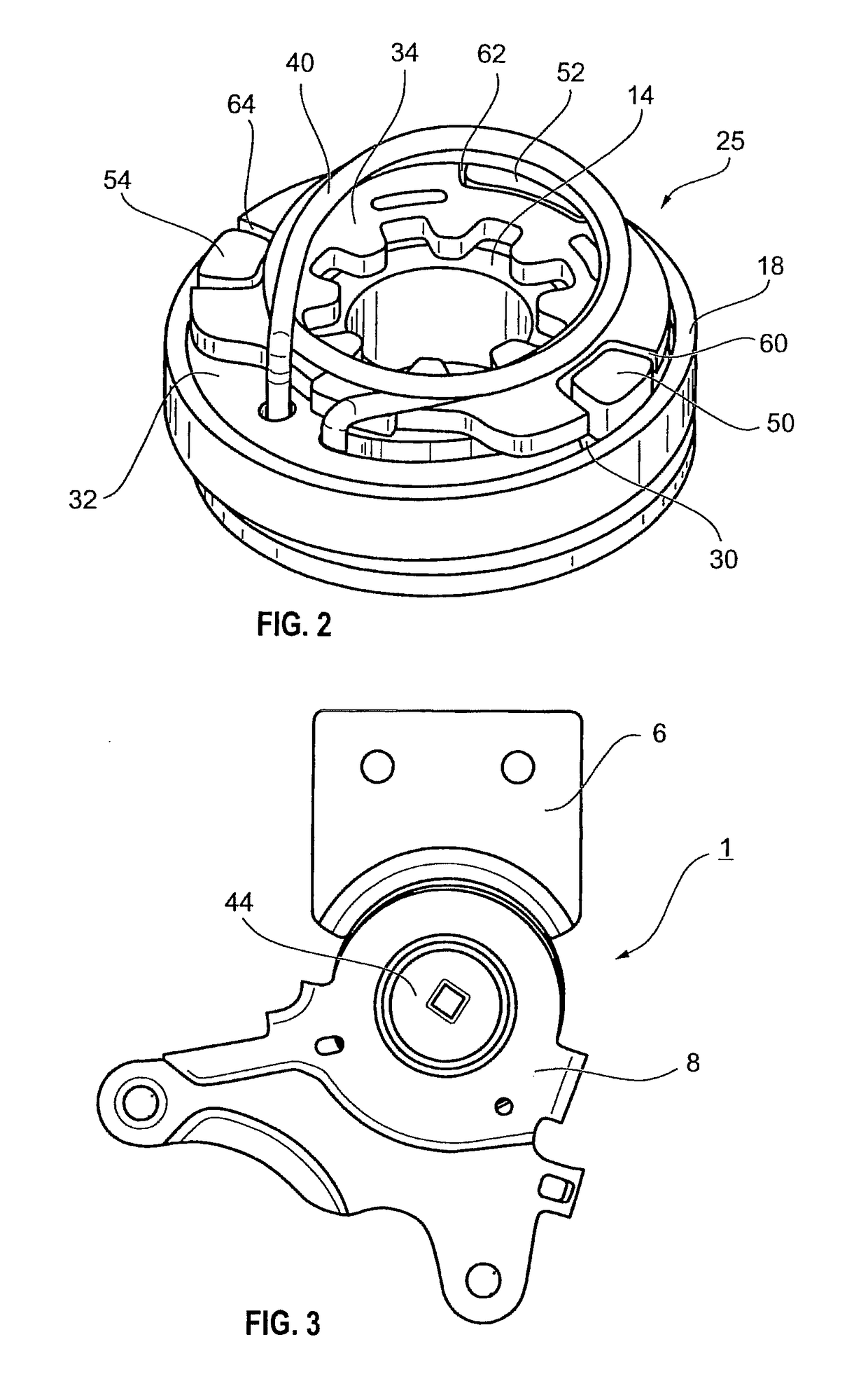

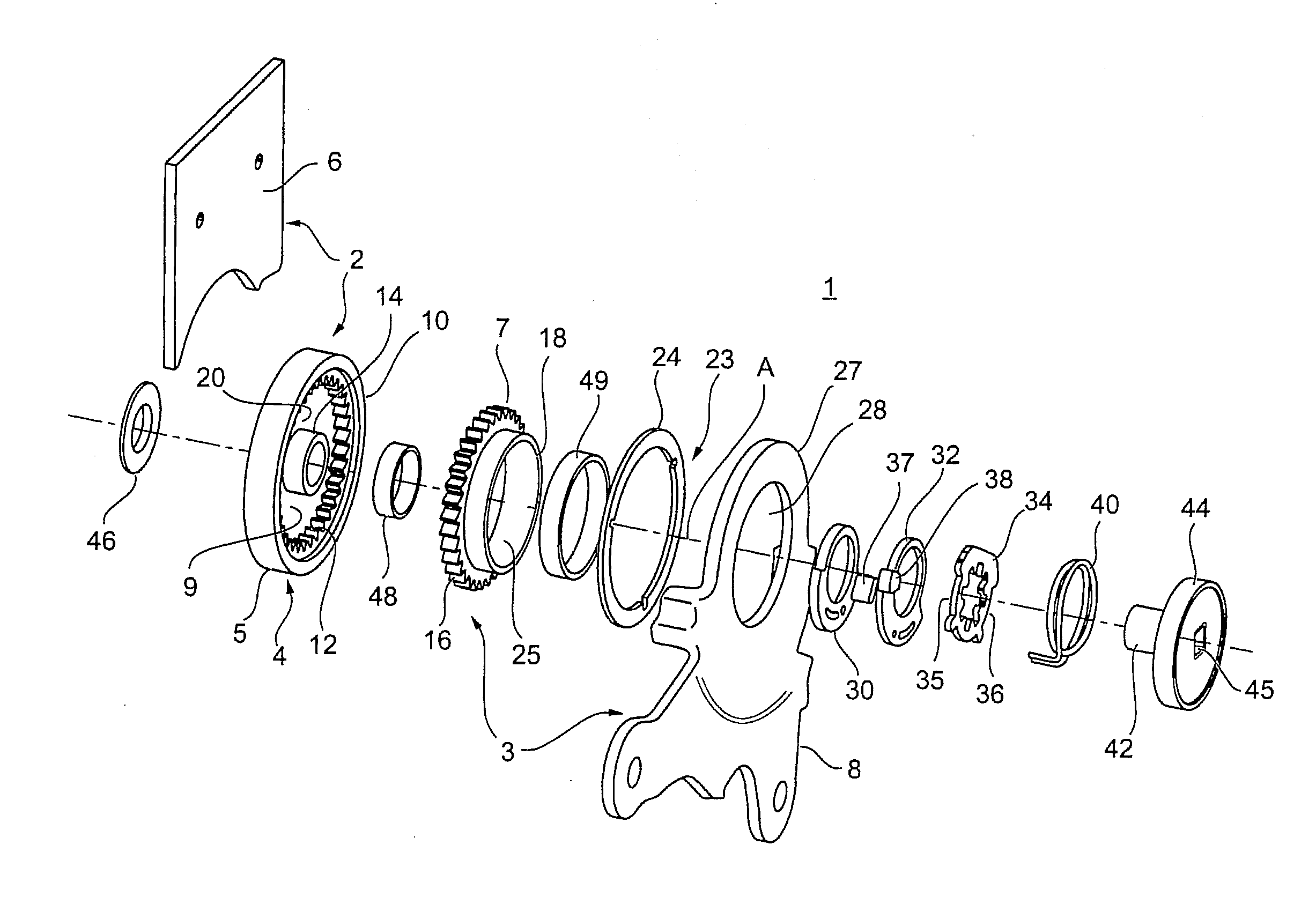

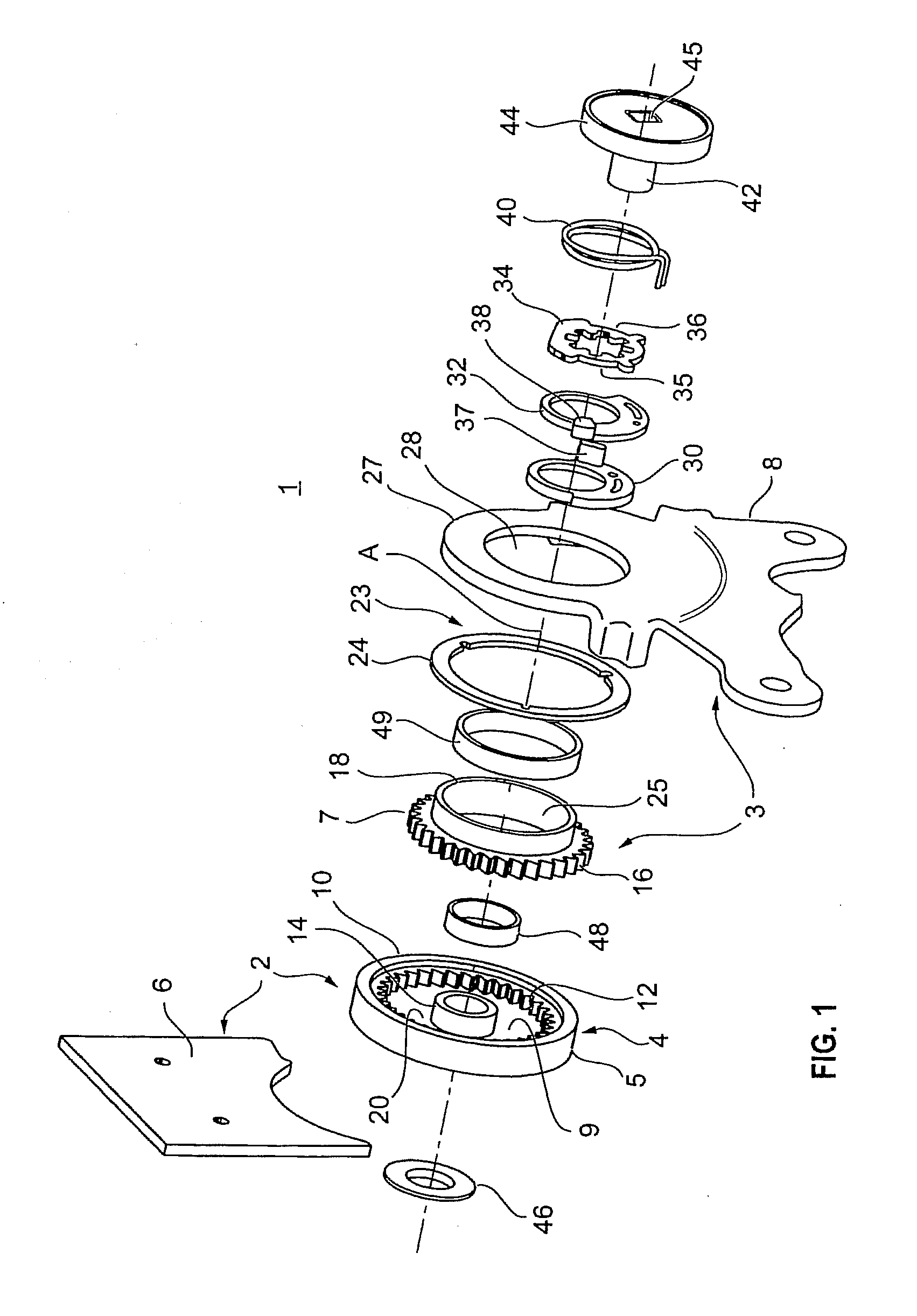

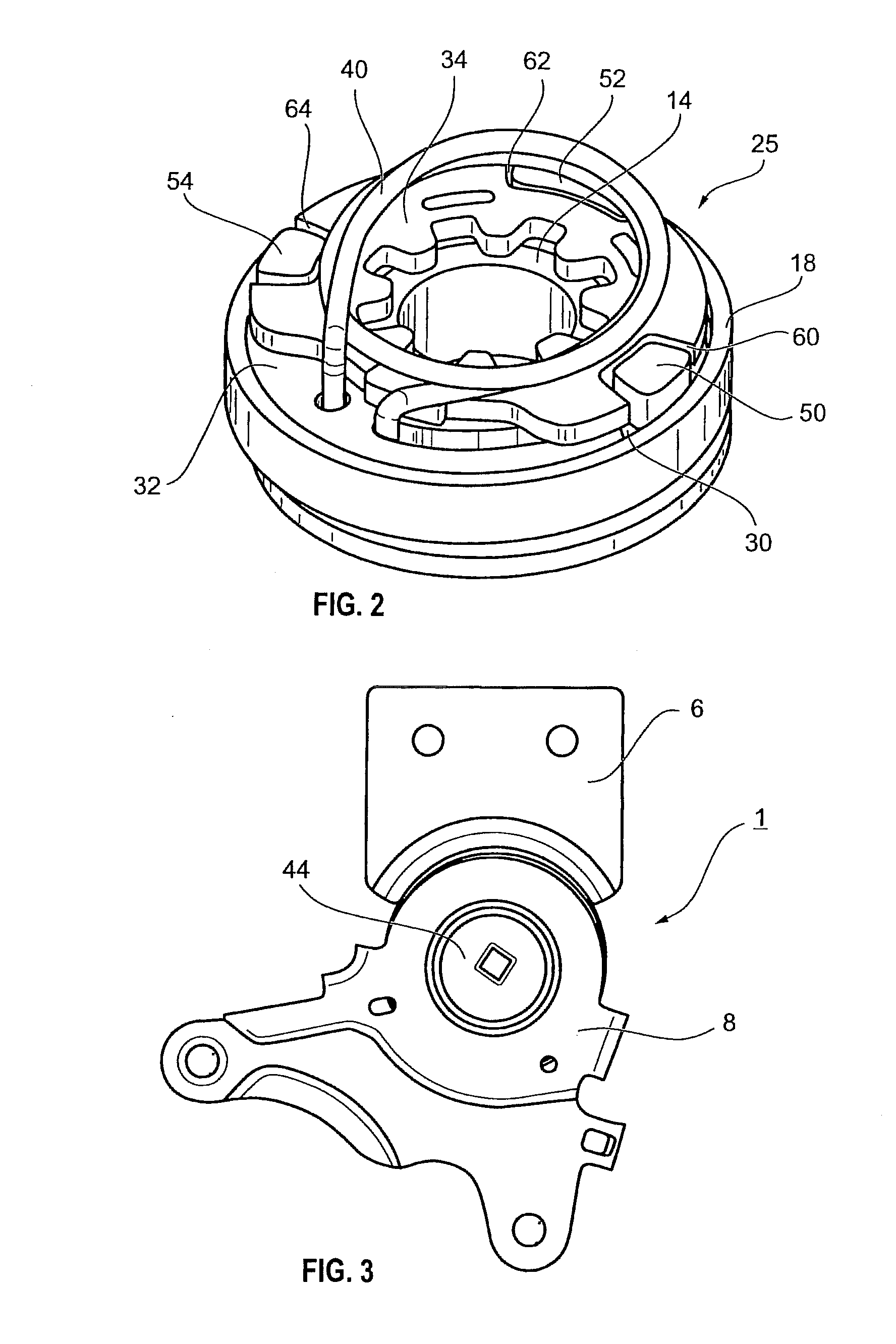

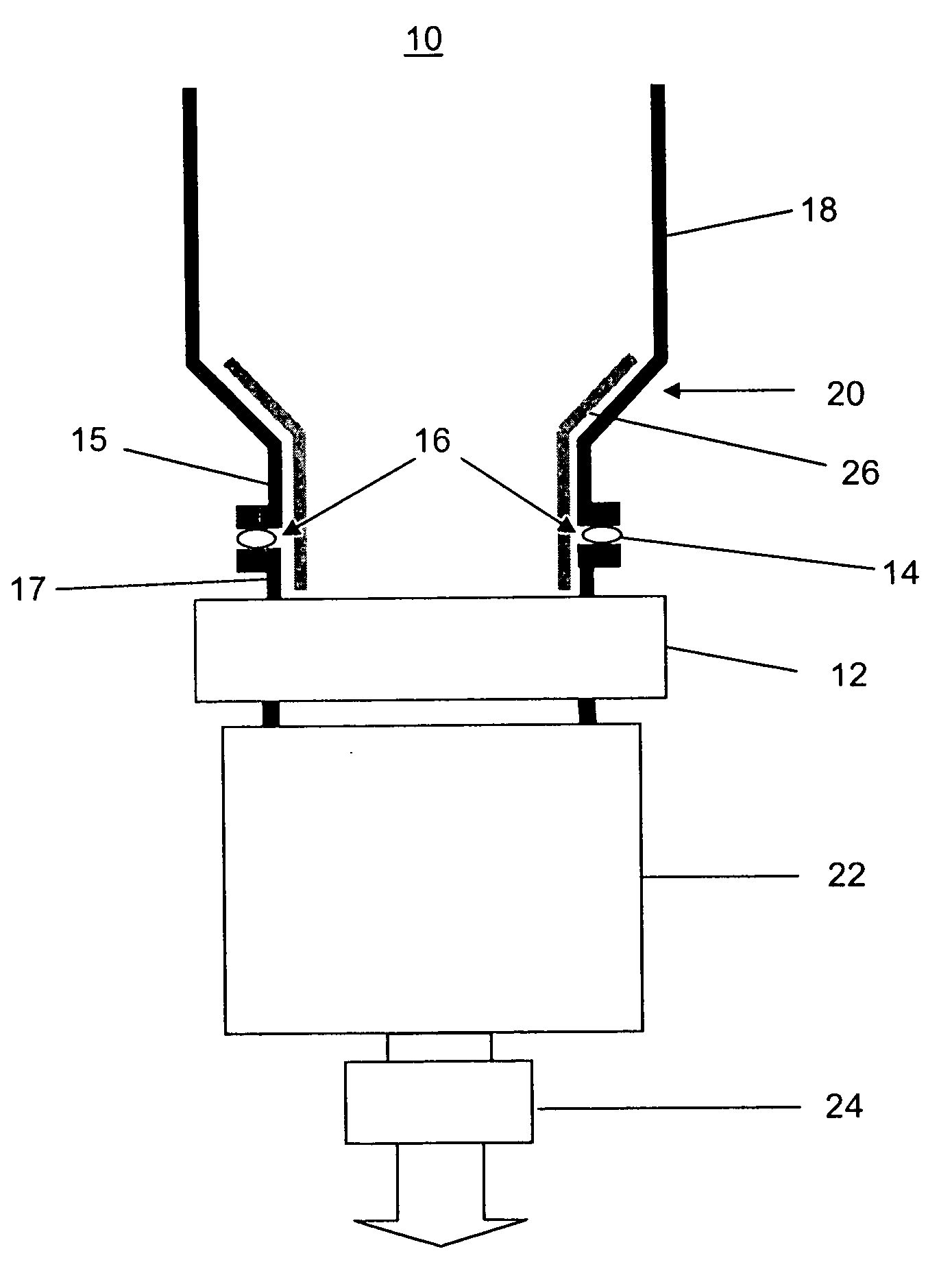

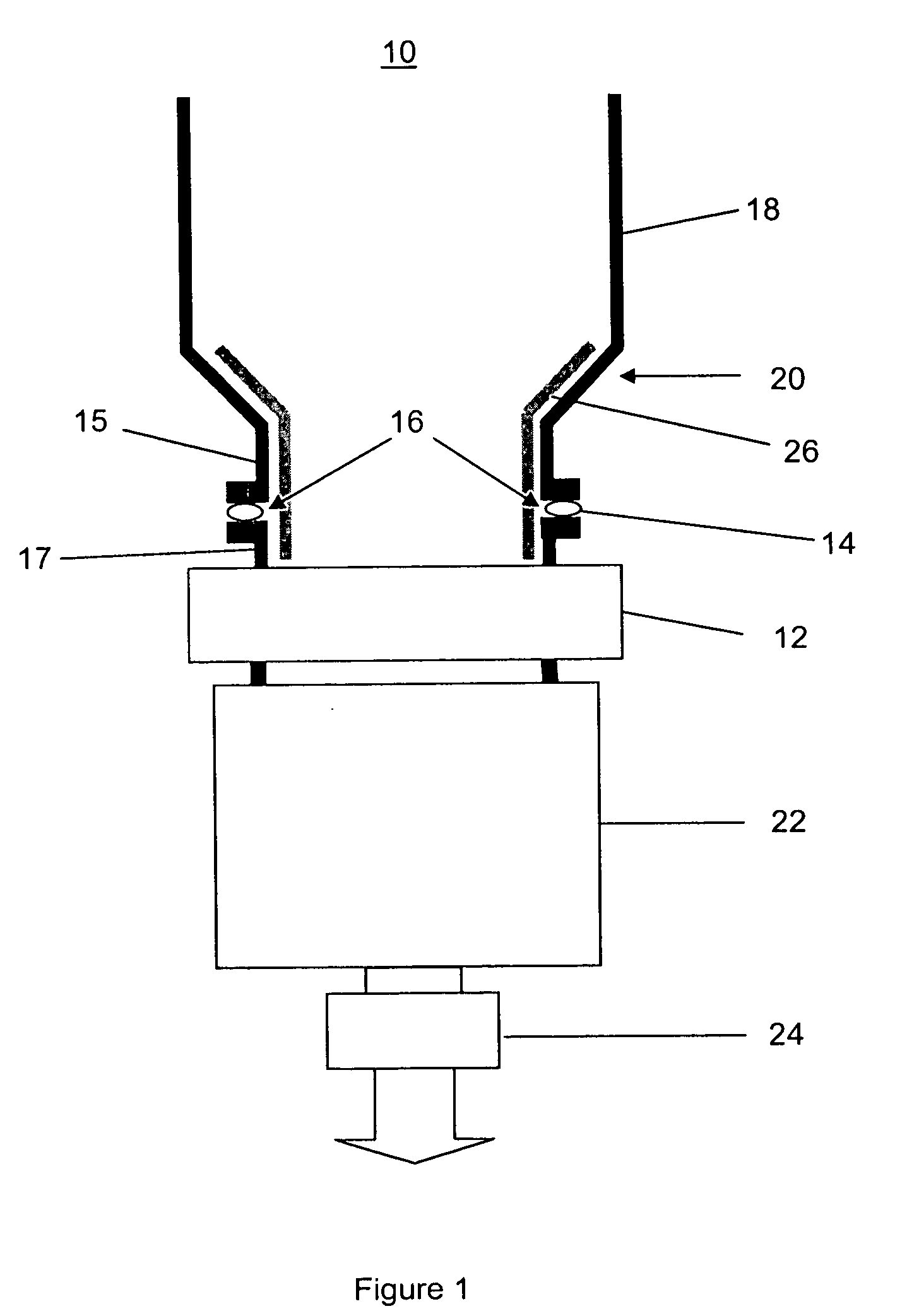

Rotation transmission device

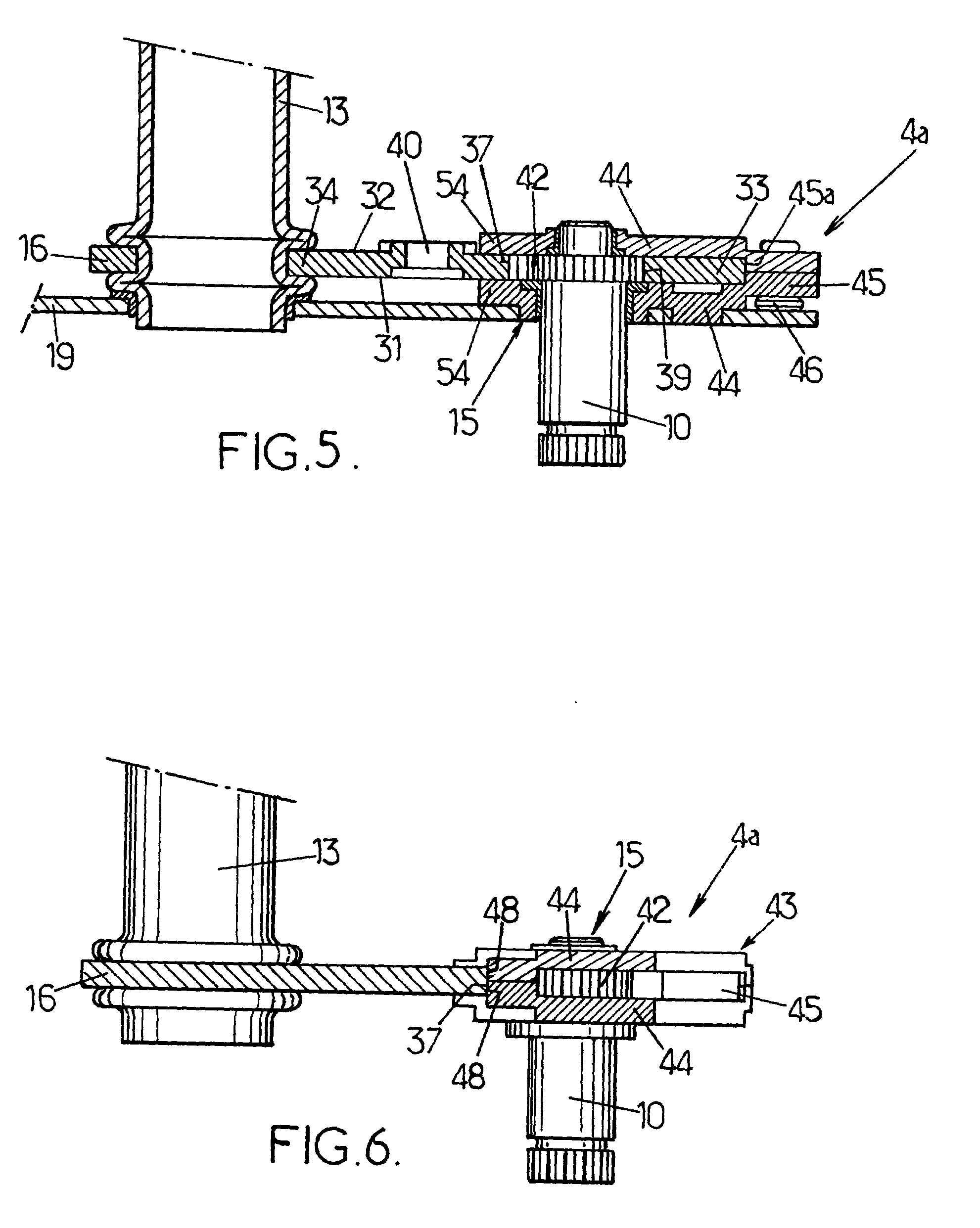

InactiveUS20100314212A1Increase circumferential widthMinimize playBearing assemblyShaft assemblyCamFlange

A rotation transmission device is provided which is small in play in the rotational direction, can be idled with high reliability and is high in torque capacity.An axially movable control retainer 19A and a rotatable rotary retainer 19B are mounted between an outer ring 11 having a cylindrical surface 17 on its inner periphery and an inner ring 12 having cam surfaces on its outer periphery. An opposed pair of rollers 26 and a coil spring 27 for biasing the pair of rollers 26 away from each other are received in each pocket 25 defined between bridges 21 and 23 of the respective retainers 19A and 19B. A torque cam 30 is provided between flanges 20 and 22 of the control retainer 19A and the rotary retainer 19B, respectively. An armature 41 is coupled to the bridges 21 of the control retainer 19A. An electromagnet 43 is provided to face a rotor 42 that axially faces the armature 41 so that when the electromagnet 43 is energized, the control retainer 19A moves toward the rotor 42, and the control retainer 19A and the rotary retainer 19B rotate relative to each other in the direction to reduce the circumferential width of the pockets 25, thereby disengaging the opposed pairs of rollers 26. When the electromagnet 43 is deenergized, the control retainer 19A moves away from the rotor 42 under the biasing force of the separation spring 44, and the control retainer 19A and the rotary retainer 19B rotate relative to each other in the direction to increase the circumferential width of the pockets 25, thereby engaging the opposed pairs of rollers 26.

Owner:NTN CORP

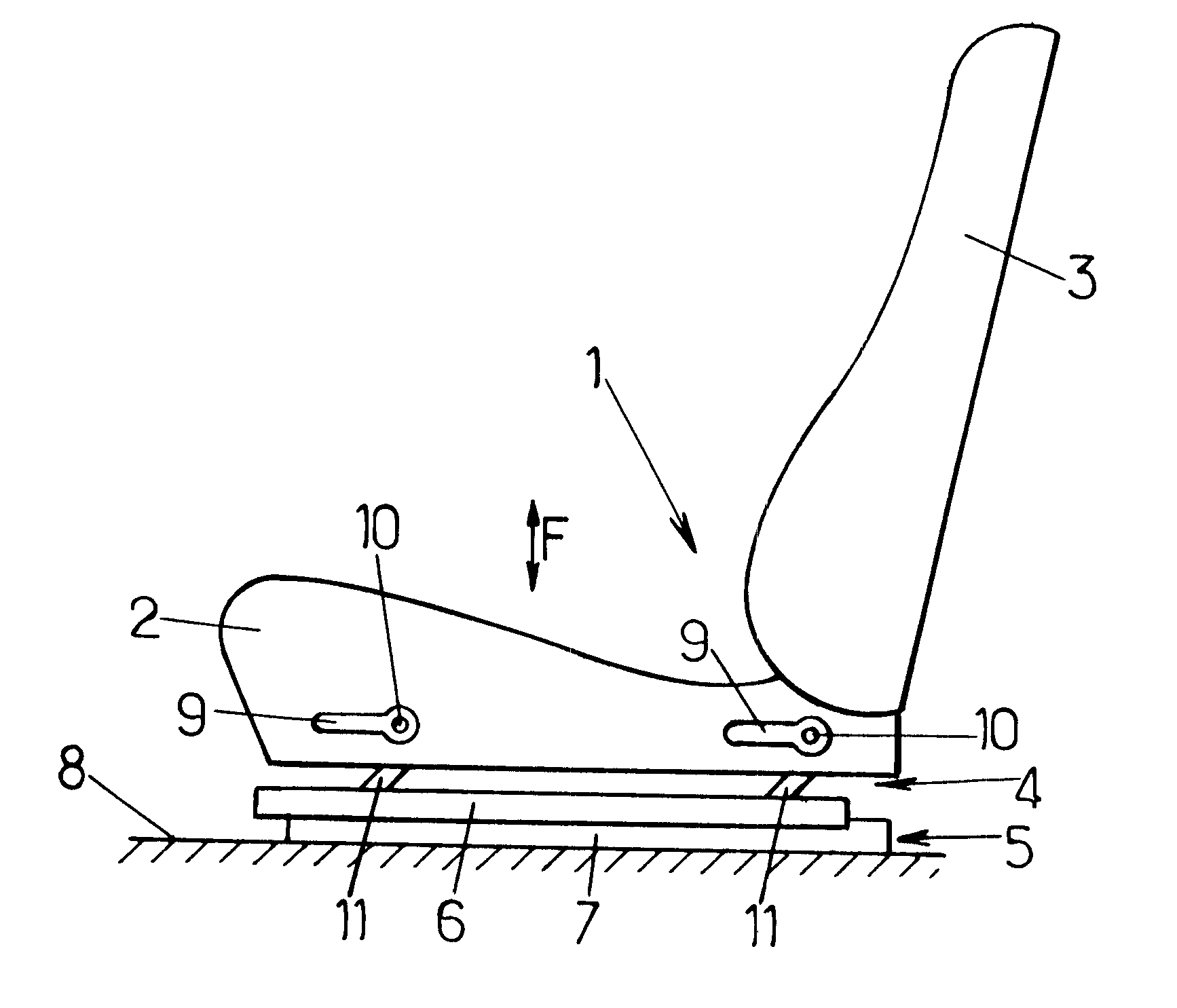

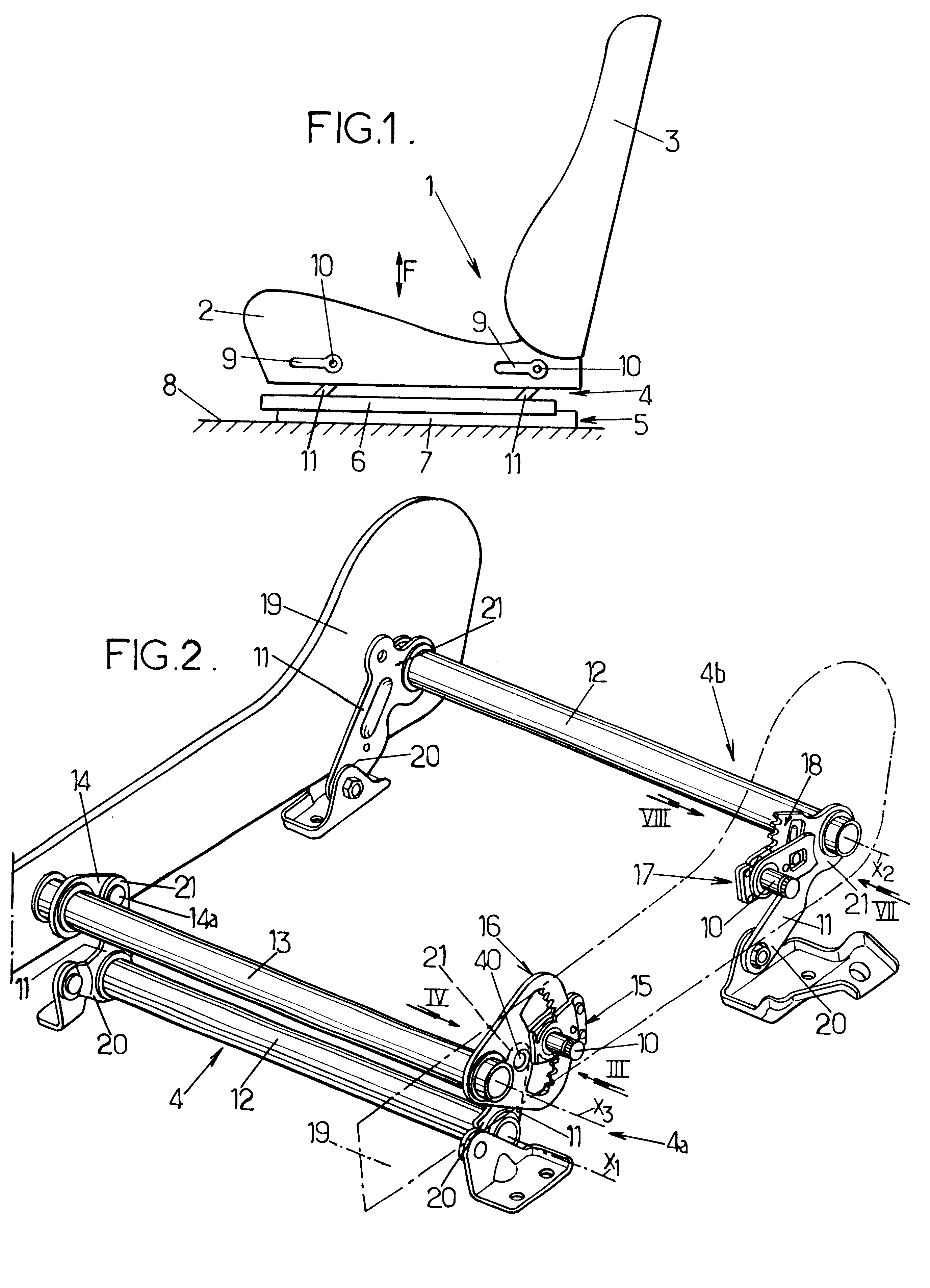

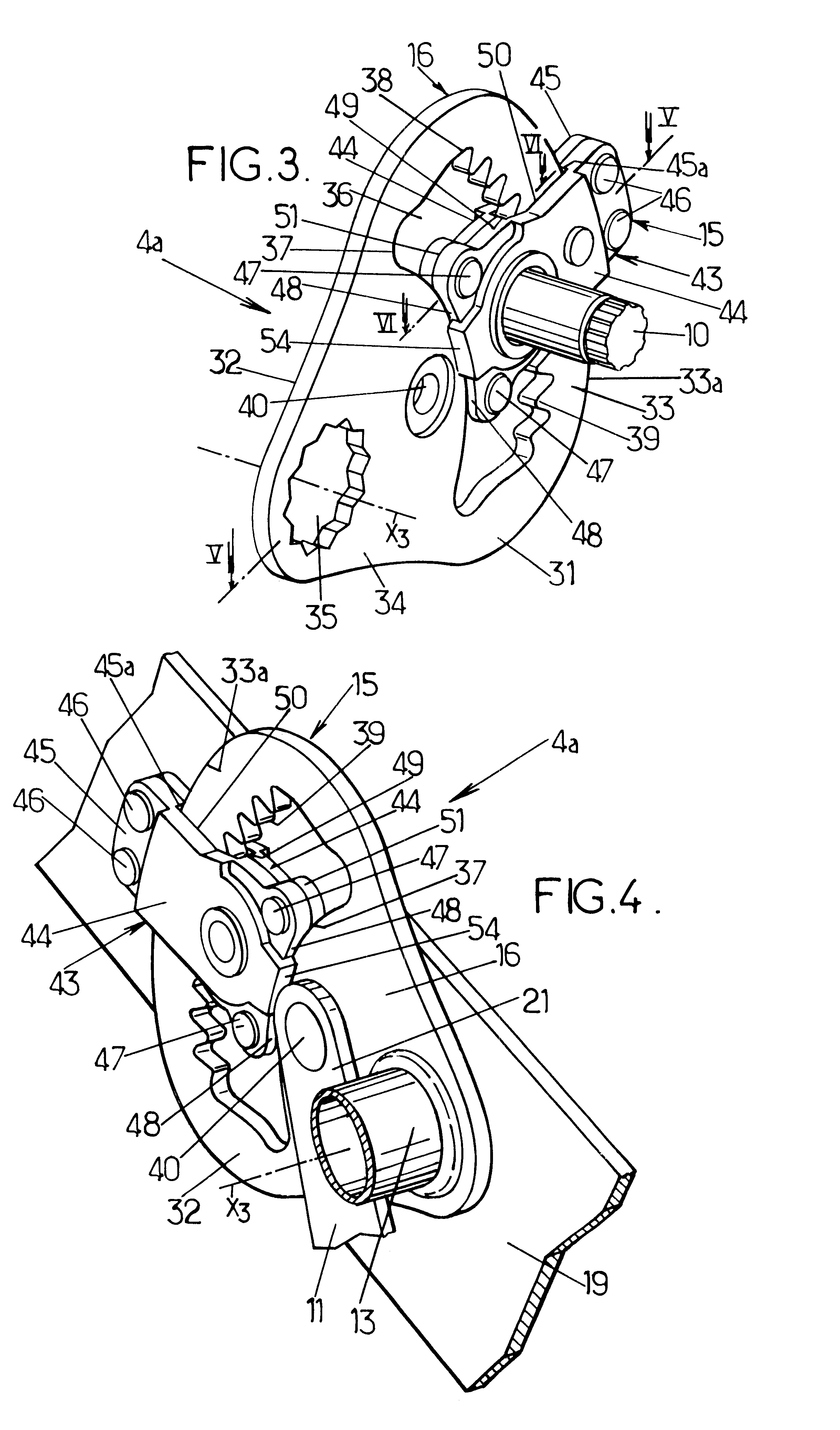

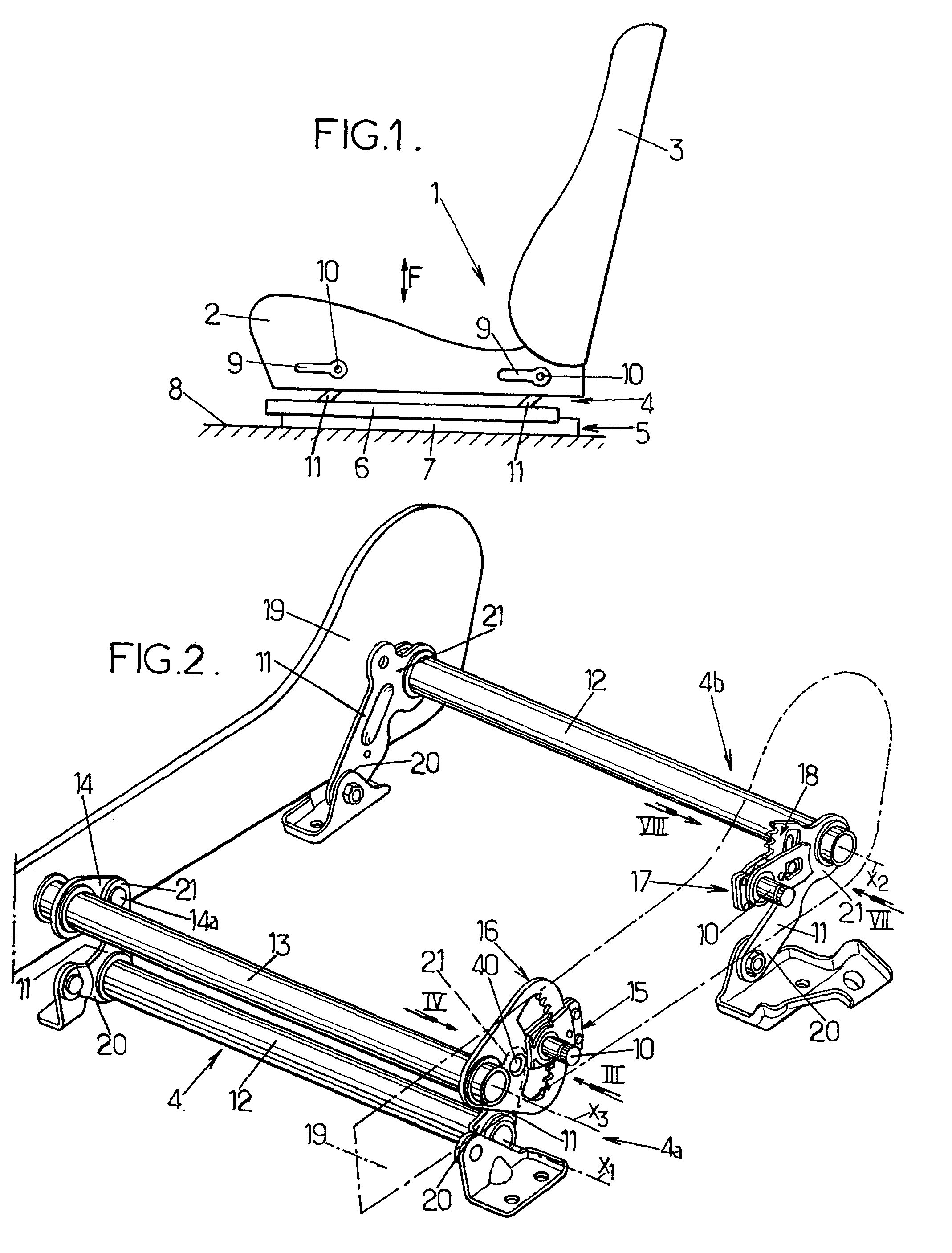

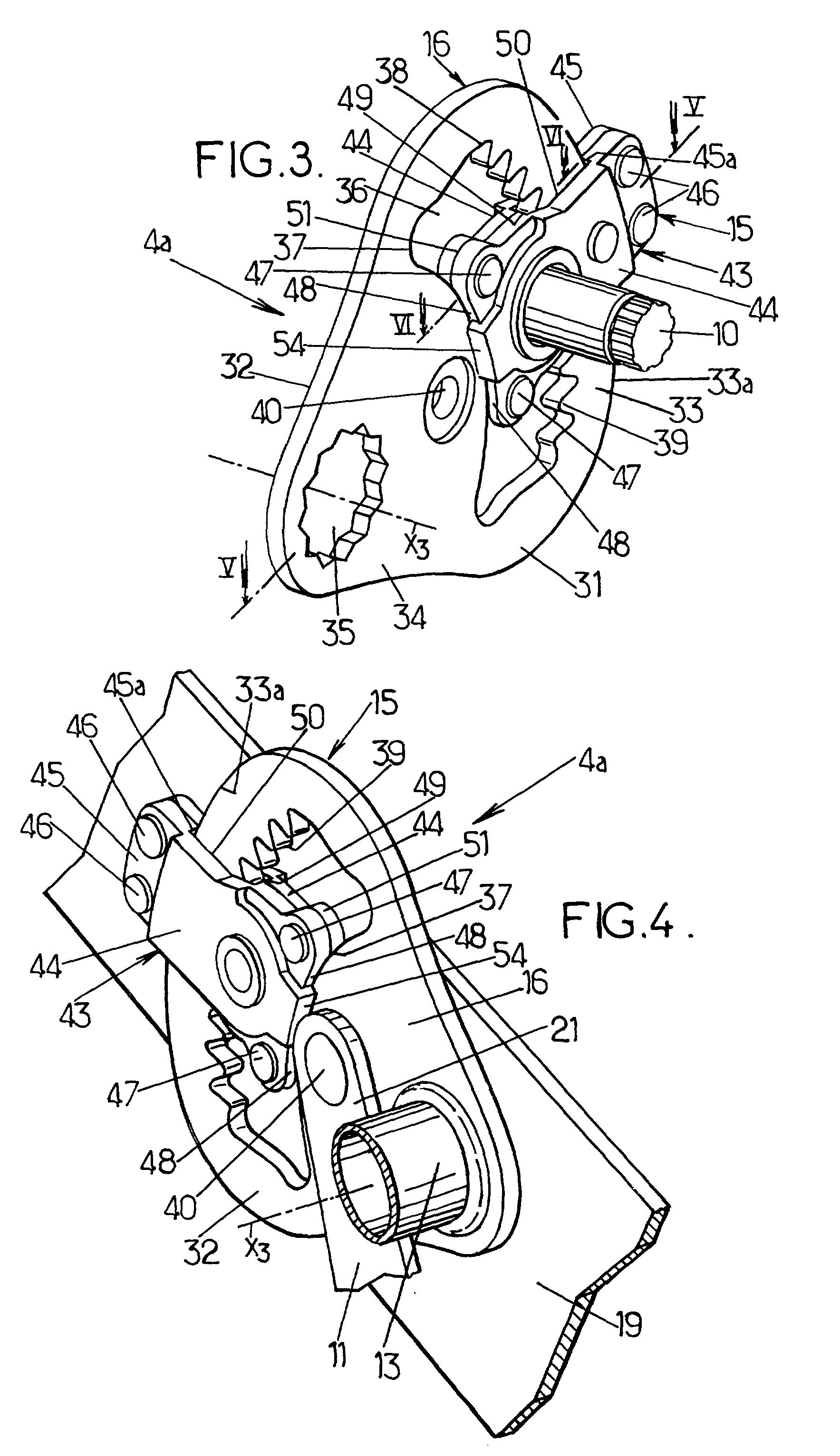

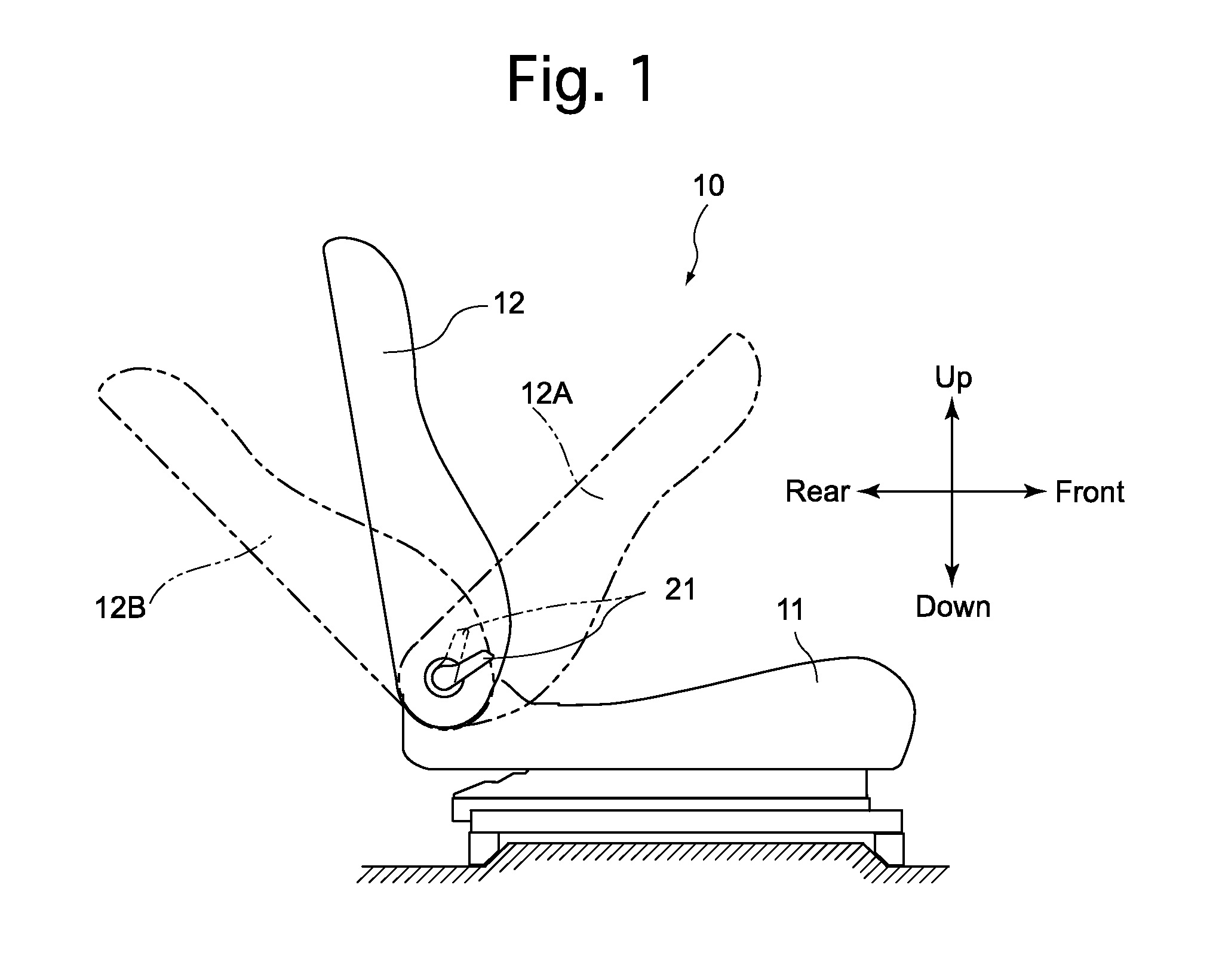

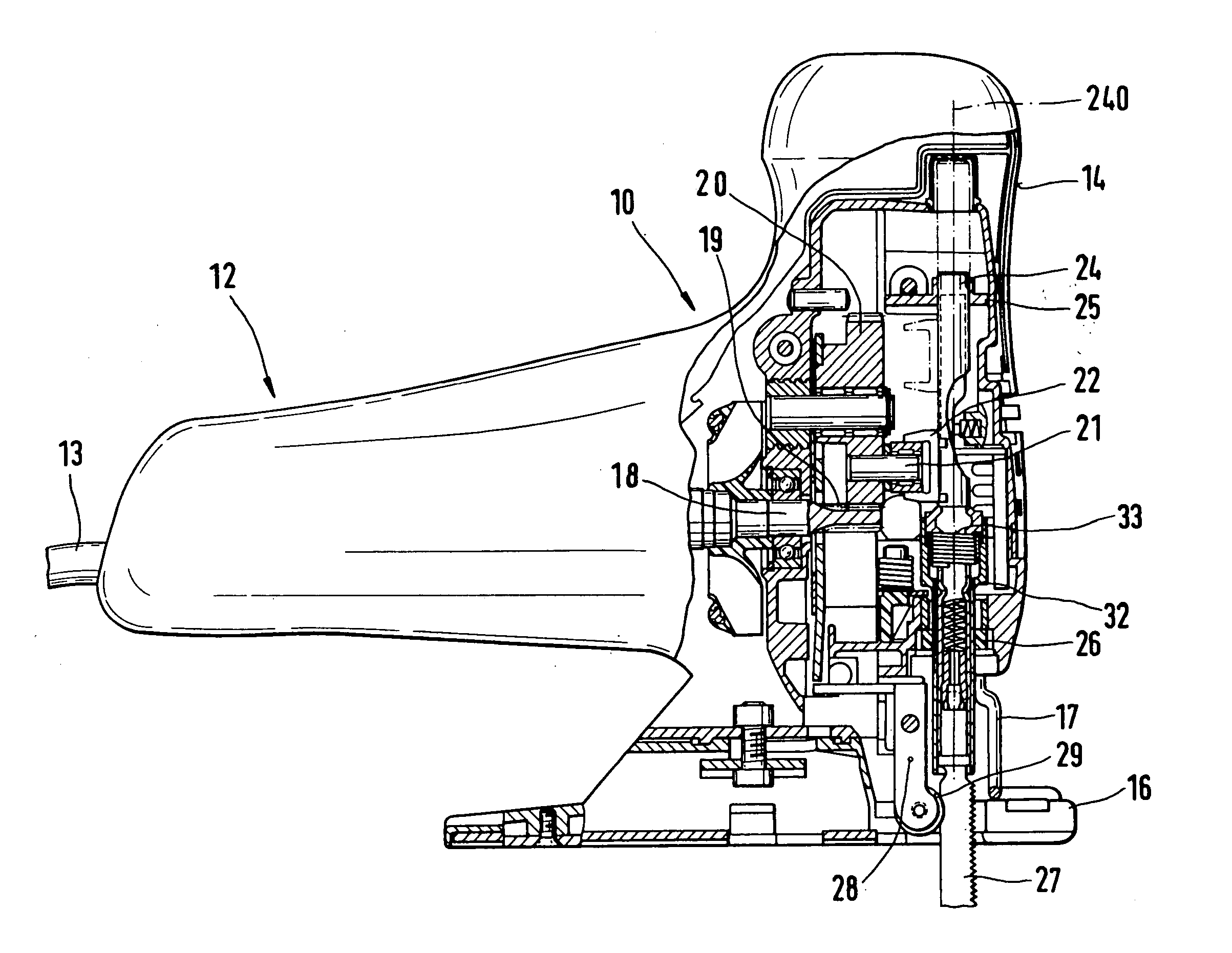

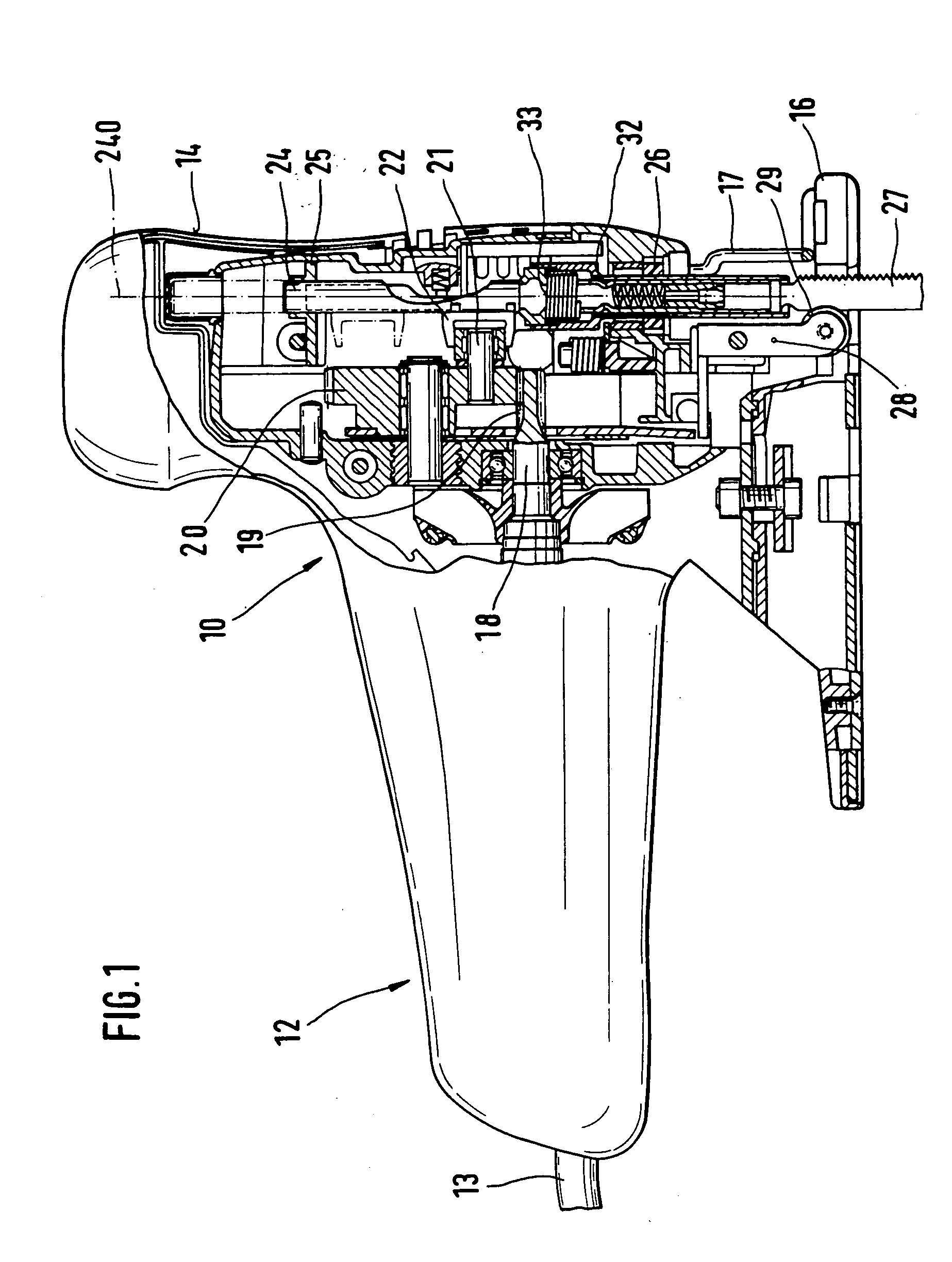

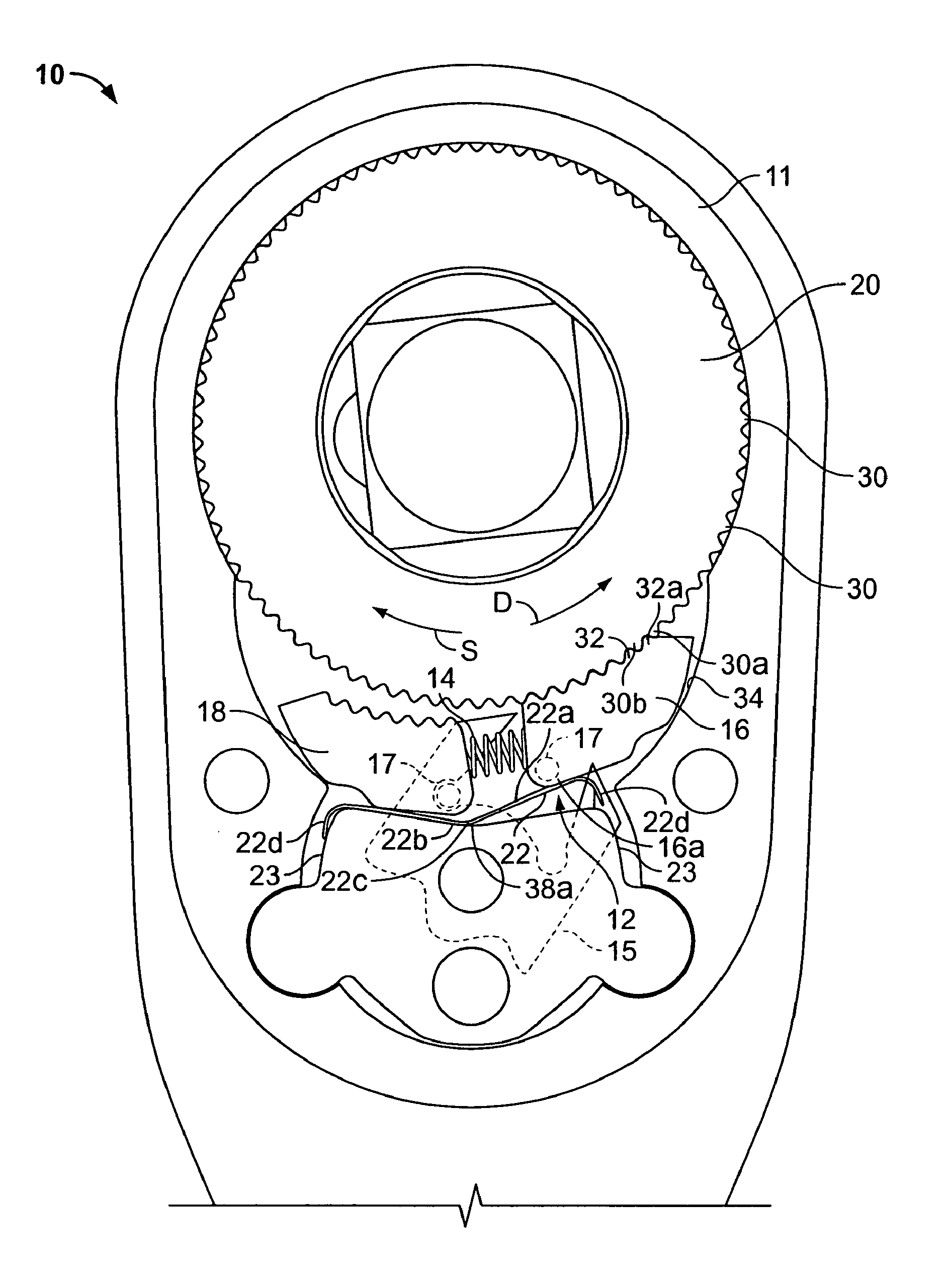

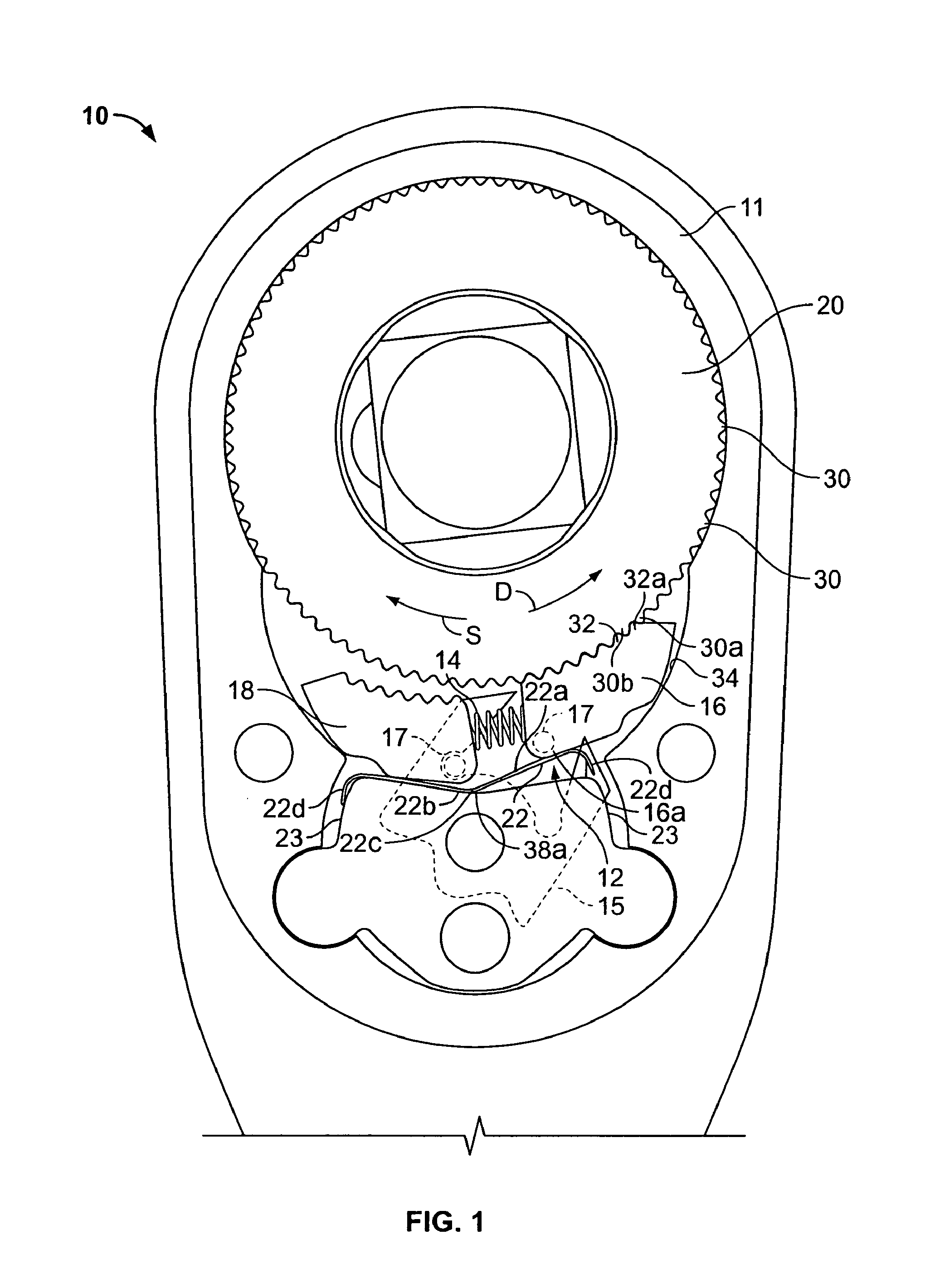

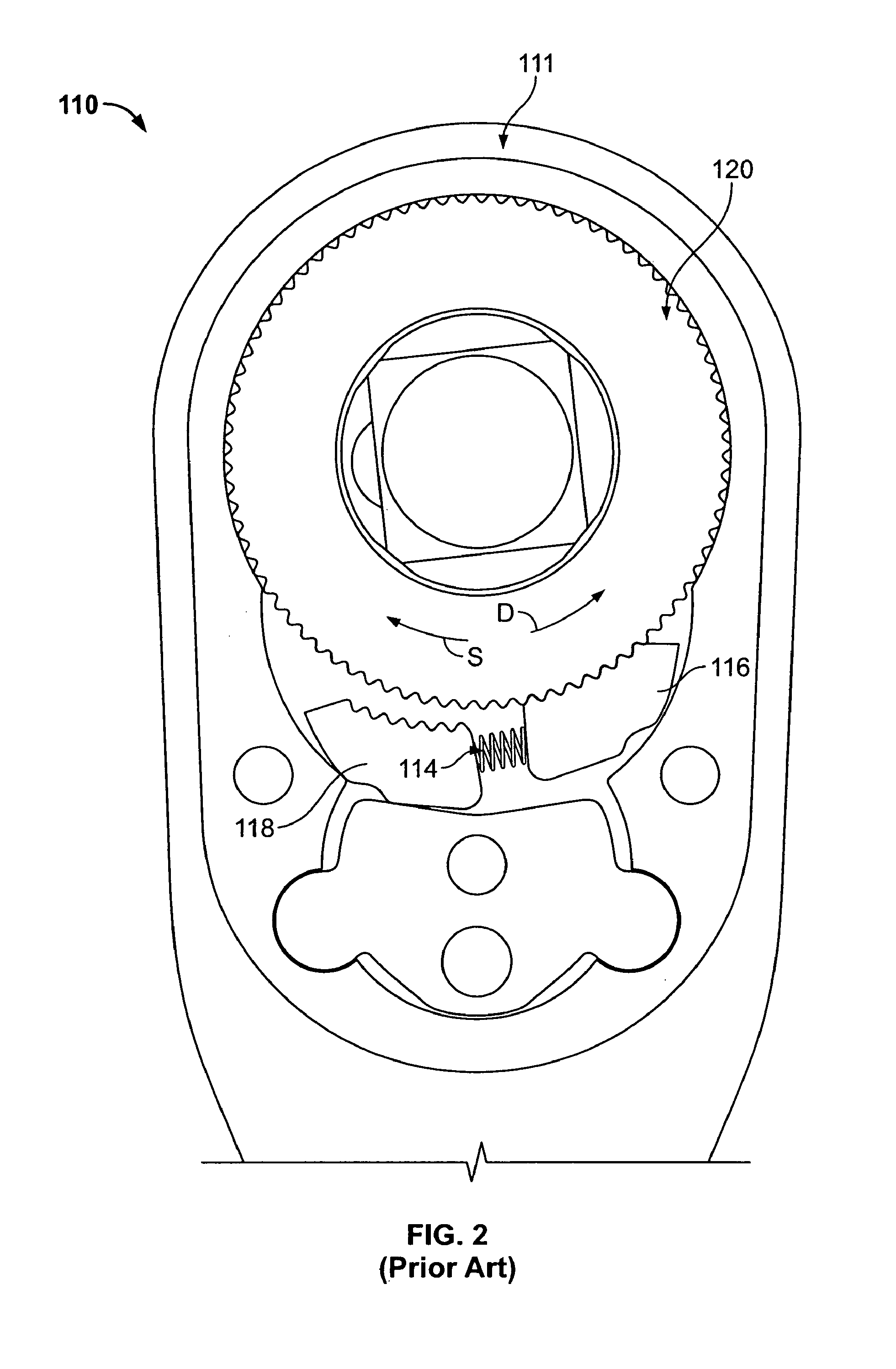

Vehicle seat comprising a height-adjusting mechanism, and a control device for such a seat

InactiveUS6502799B2Weight controlLow mechanical strengthOperating chairsDental chairsEngineeringPinion

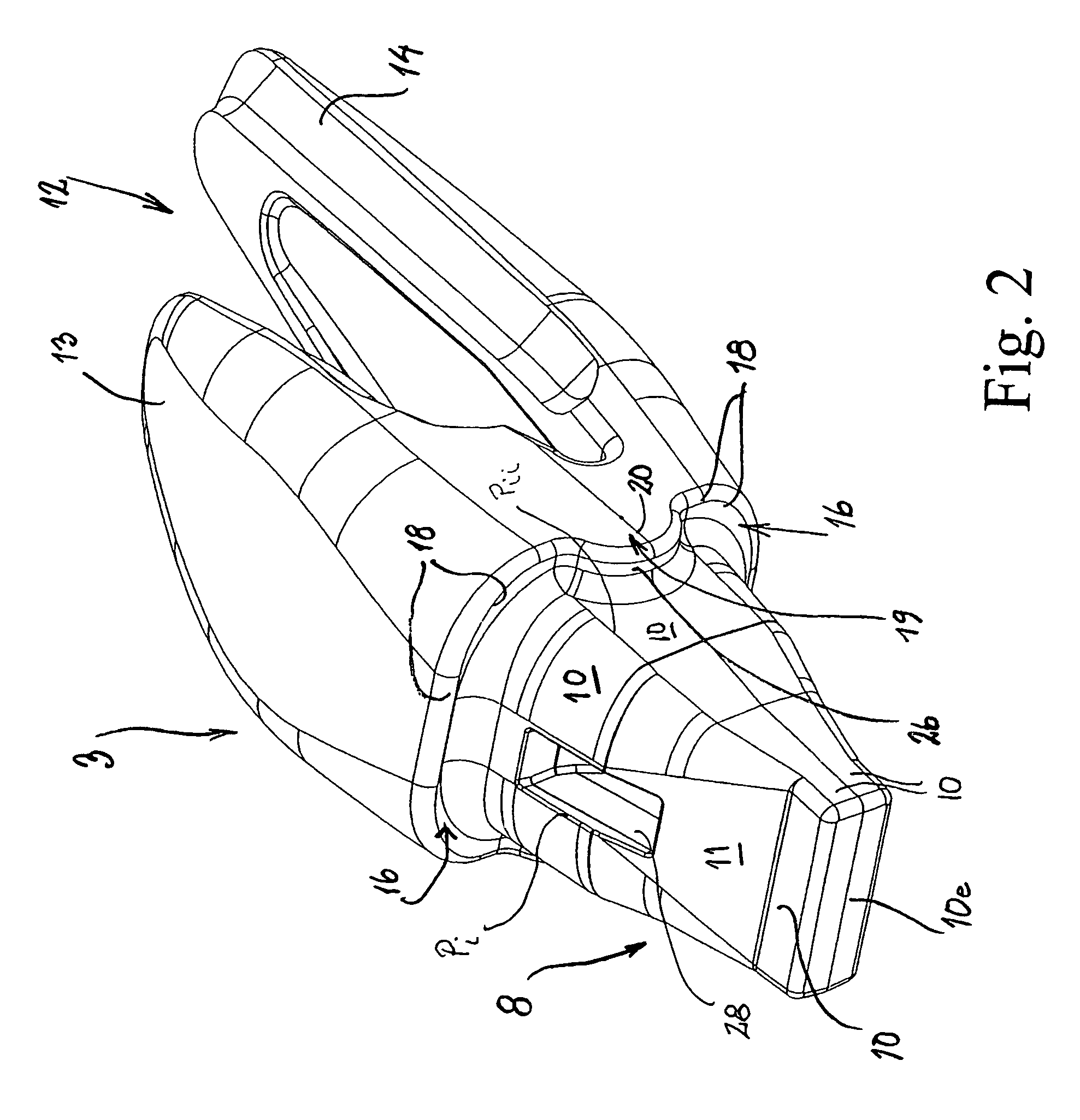

Vehicle seat provided with a height-adjusting mechanism comprising a link connected to a rack which is pivotally mounted to the seat cushion and has a circular toothed section meshing with a pinion mounted to the cushion by means of a rigid yoke the plates of which are guided without free play by arcuate guides formed by the rack, a part of the yoke engaging in an arcuate slot formed in the rack.

Owner:FAURECIA

Vehicle seat comprising a height-adjusting mechanism, and a control device for such a seat

InactiveUS20010035673A1Mitigate disadvantageWeight controlOperating chairsDental chairsCushionEngineering

Vehicle seat provided with a height-adjusting mechanism comprising a link connected to a rack which is pivotally mounted to the seat cushion and has a circular toothed section meshing with a pinion mounted to the cushion by means of a rigid yoke the plates of which are guided without free play by arcuate guides formed by the rack, a part of the yoke engaging in an arcuate slot formed in the rack.

Owner:FAURECIA

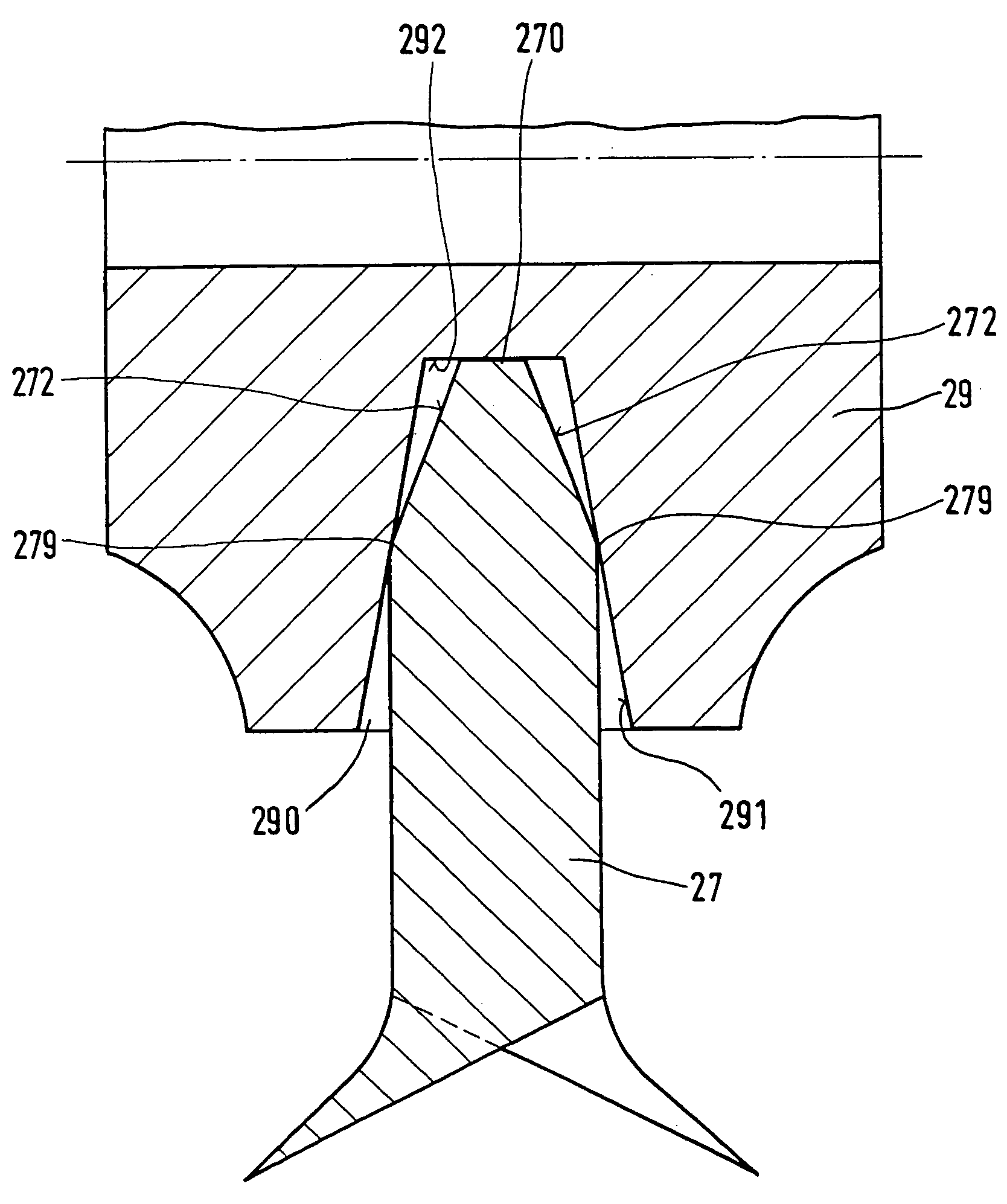

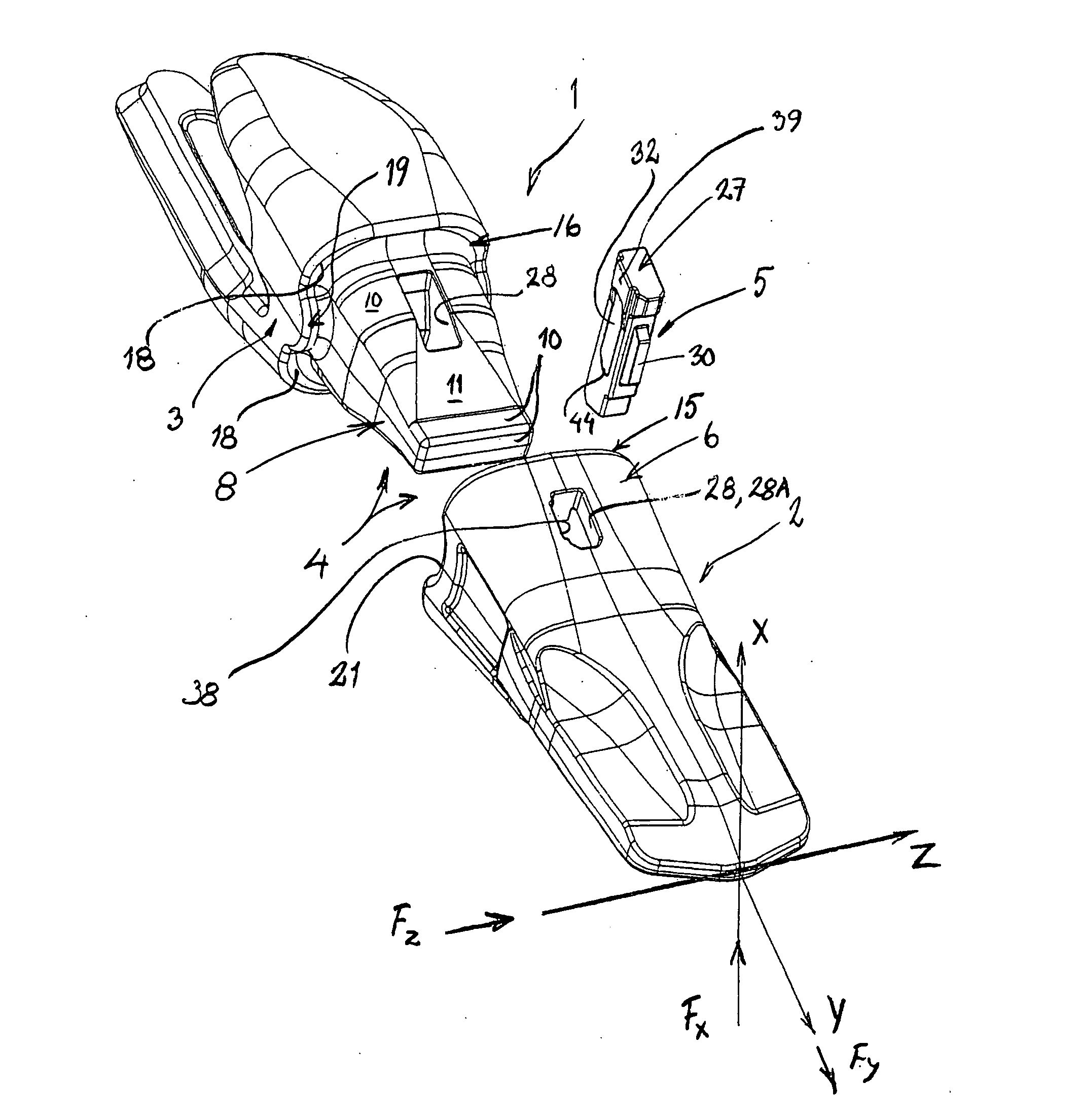

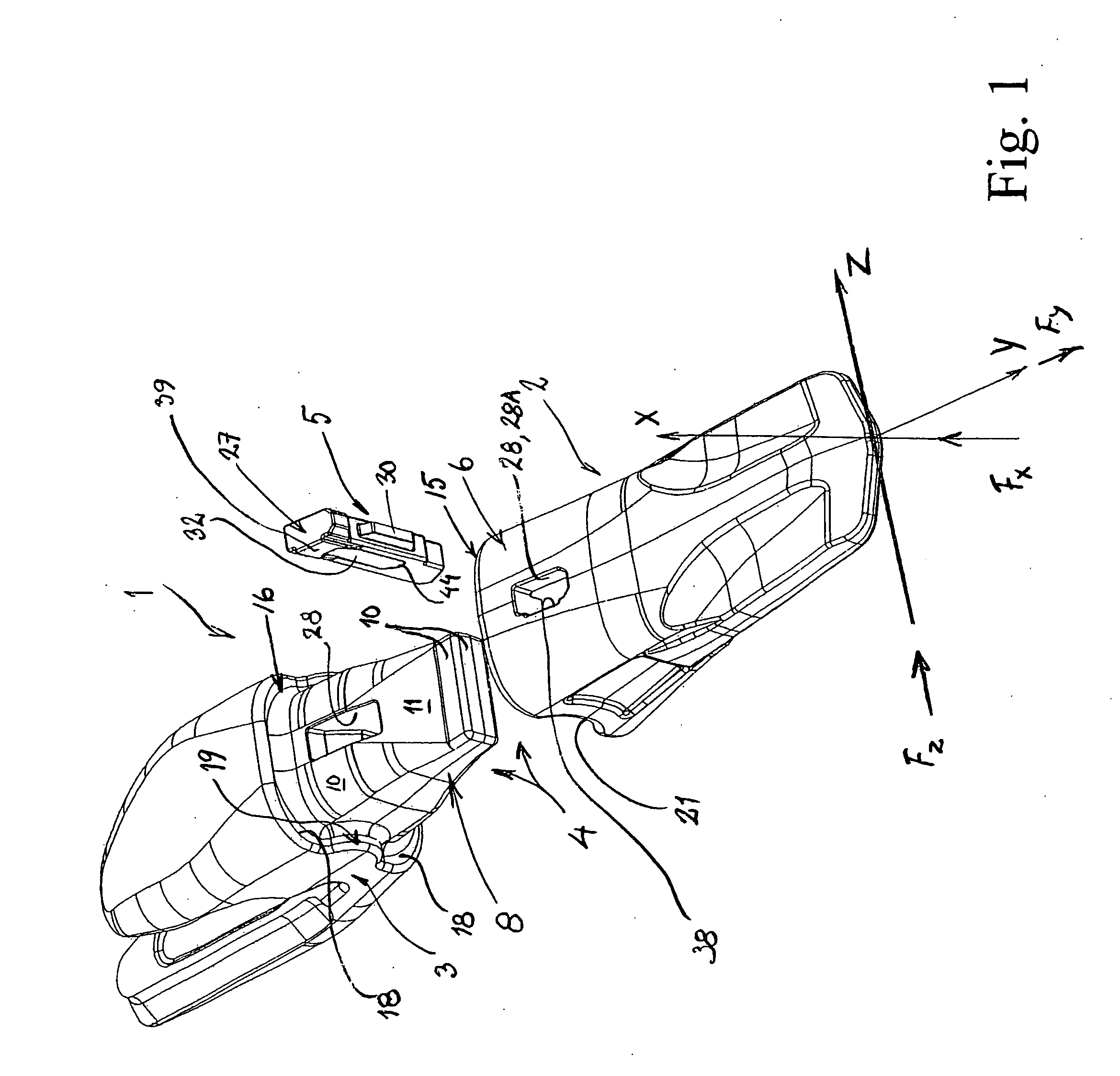

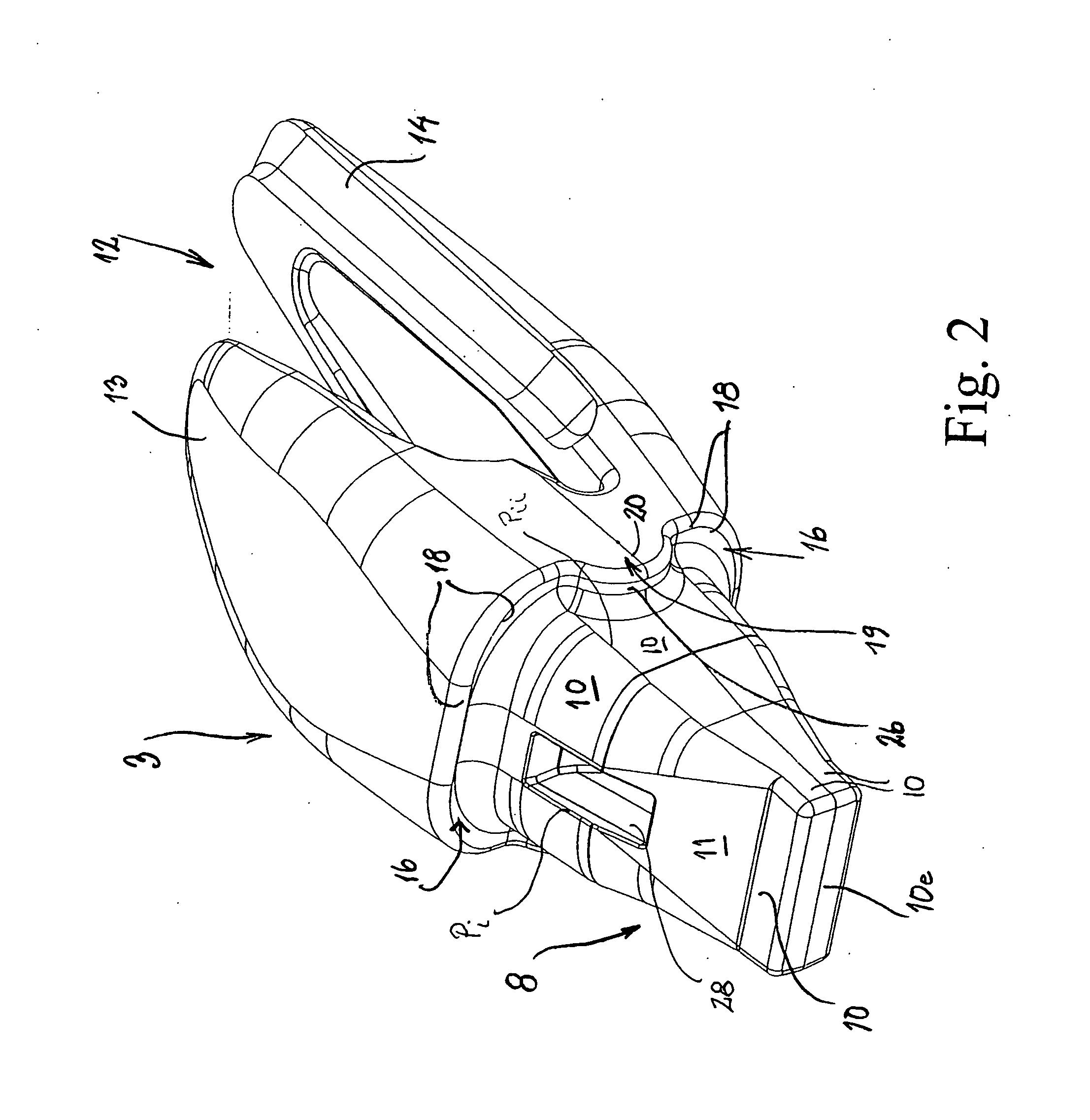

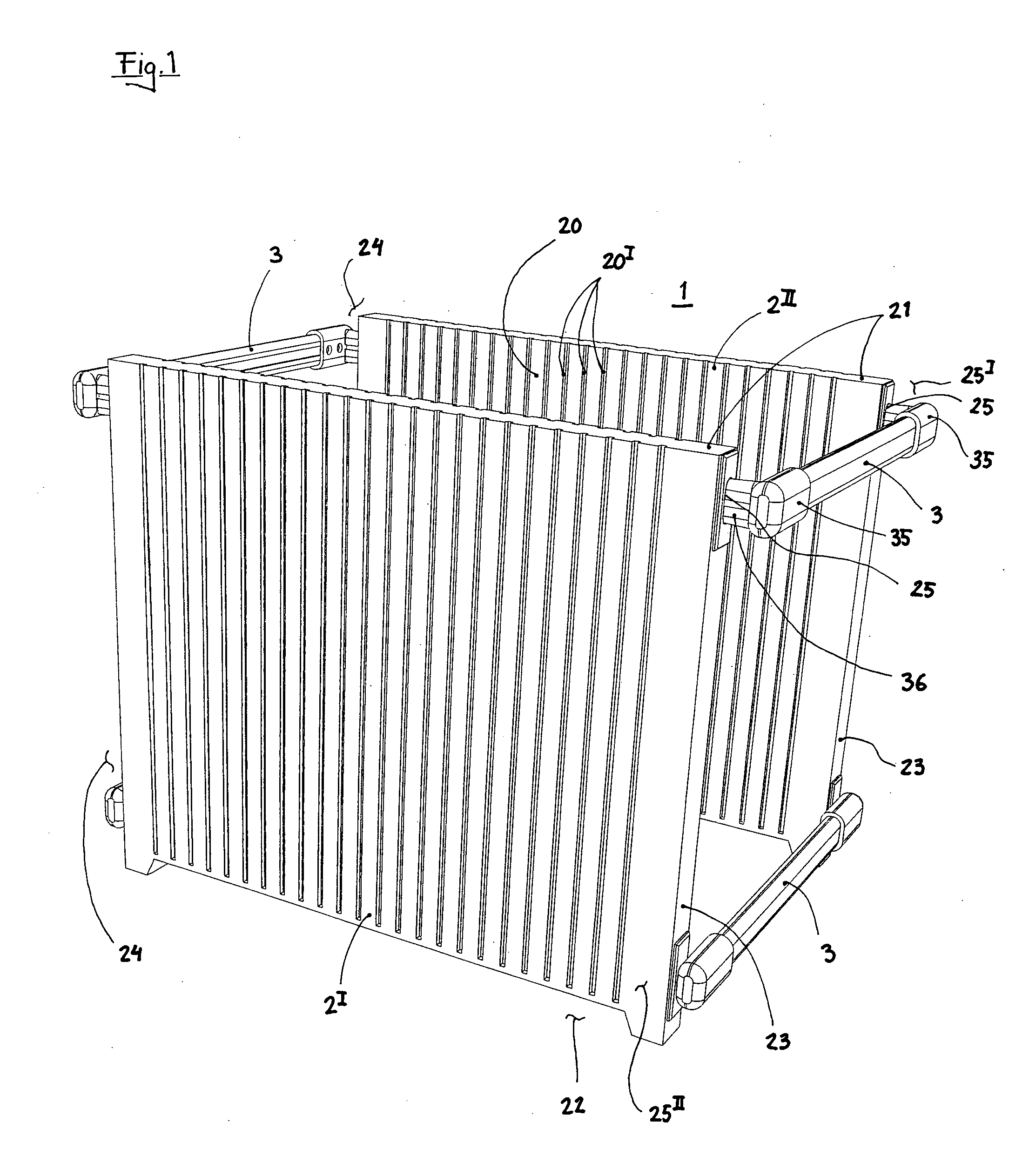

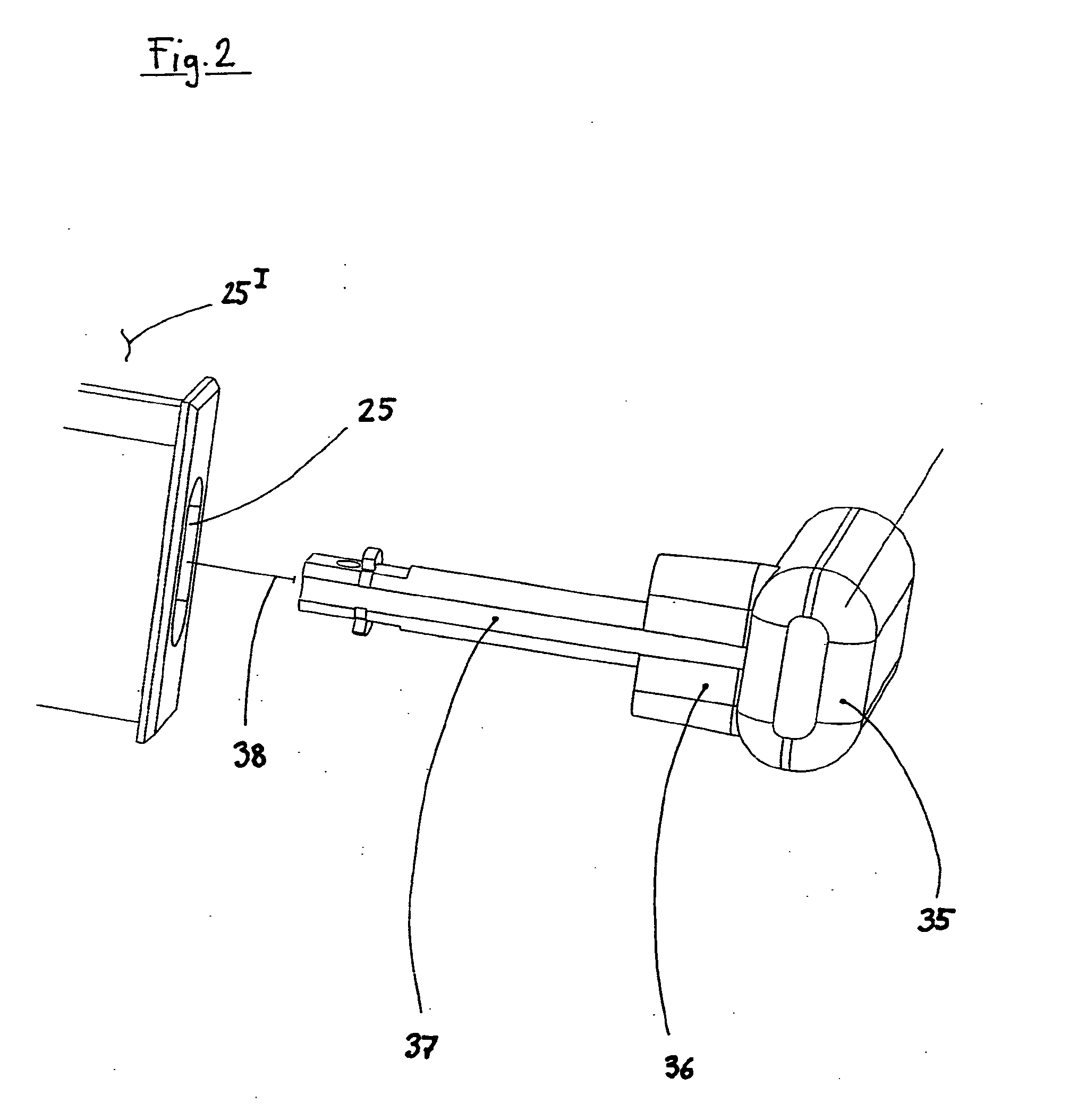

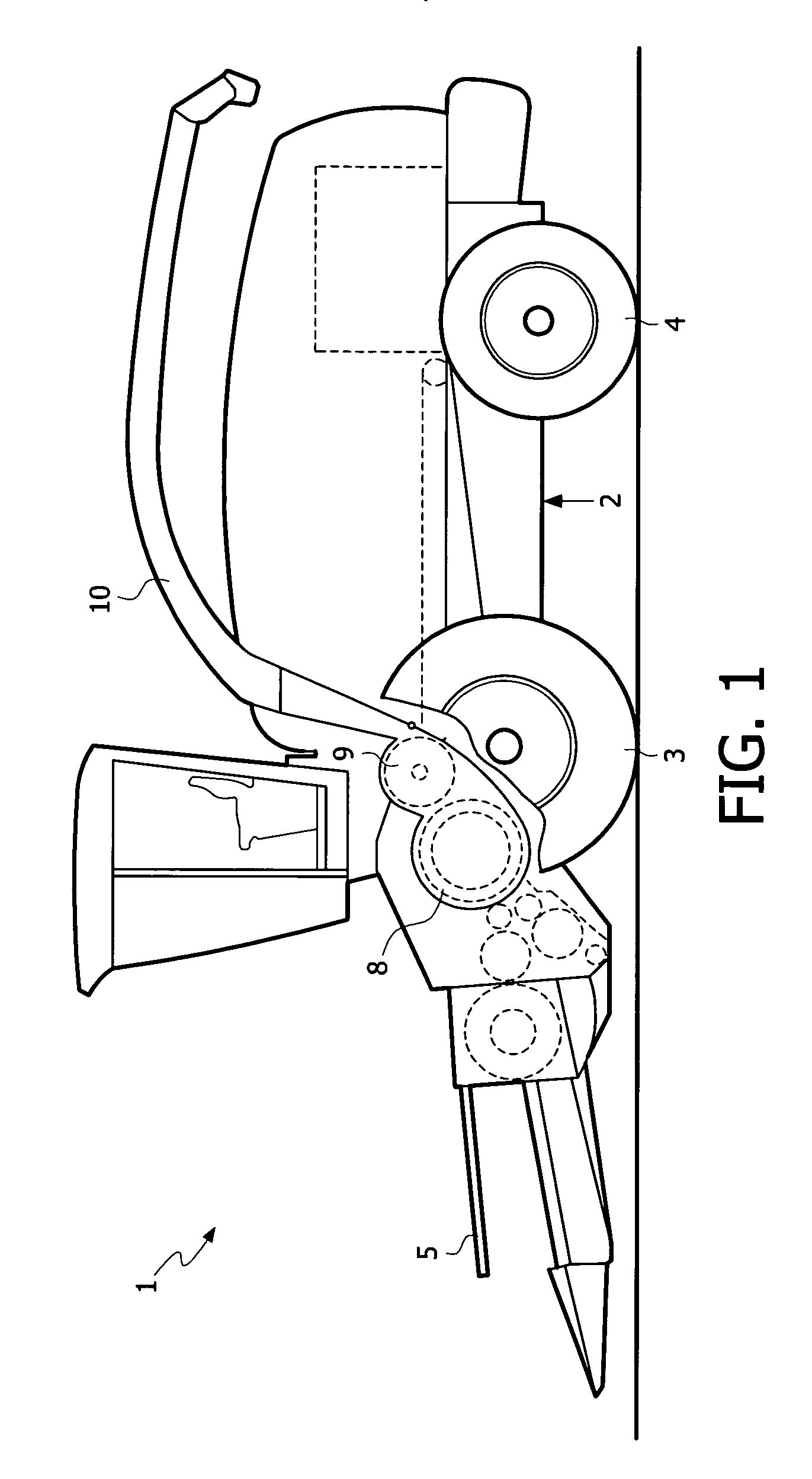

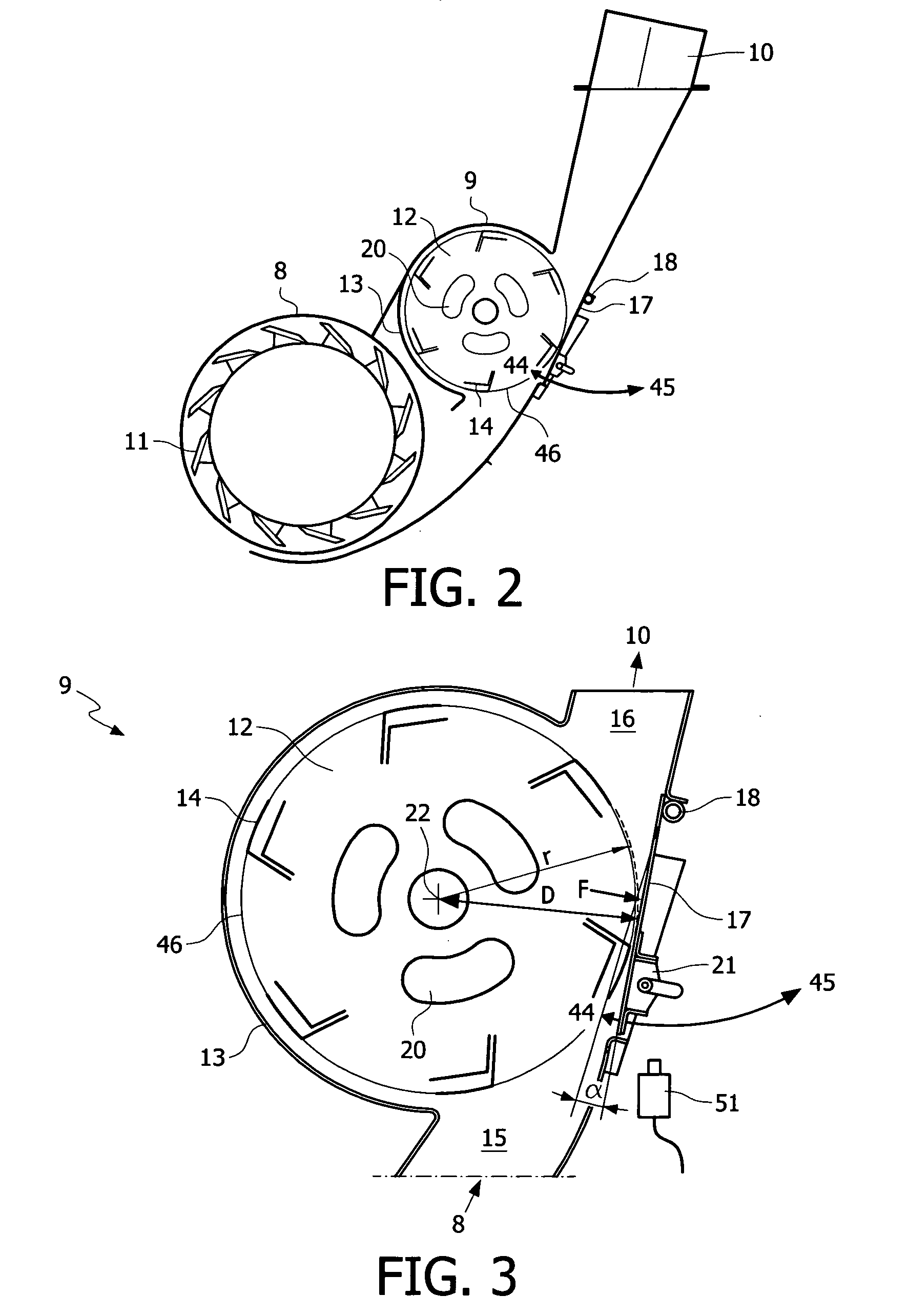

Wearing parts system for detachable fitting of wearing parts for the tool of a cultivating machine

ActiveUS7703224B2Effective strikeImprove stabilitySoil-shifting machines/dredgersEngineeringMechanical engineering

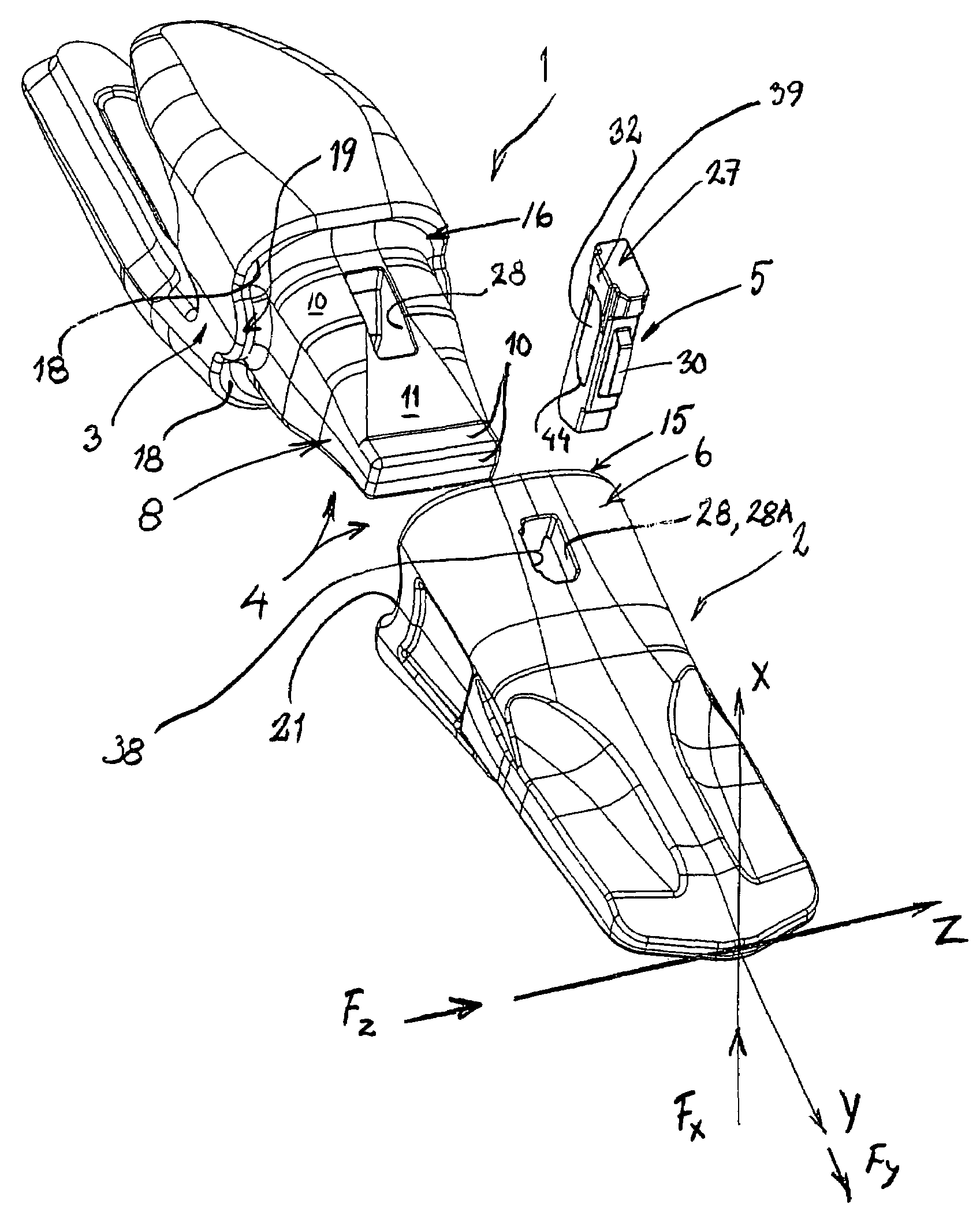

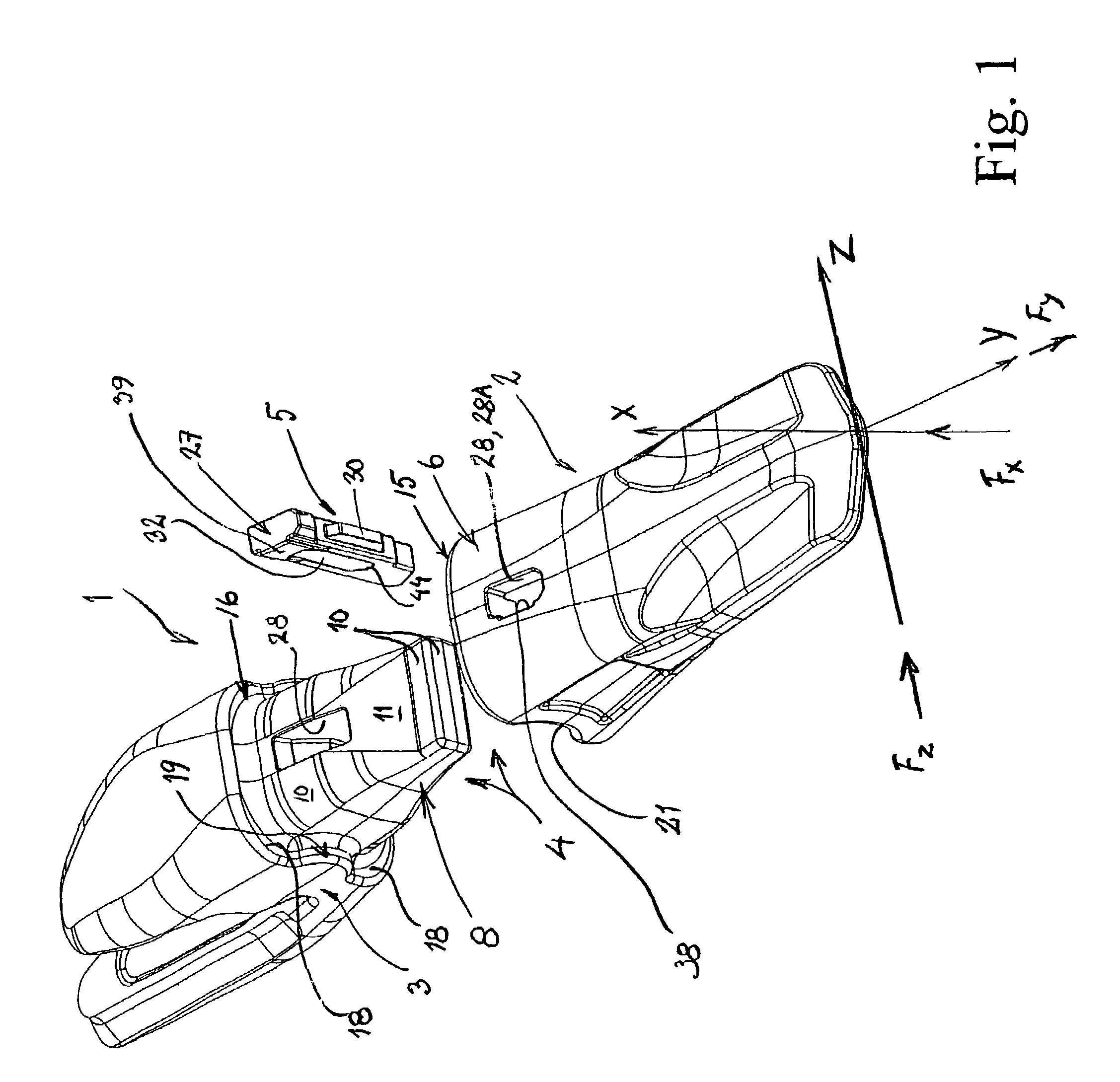

The invention relates to a wearing parts system (1) intended for the tool of a tilling machine of the type which comprises a holder part (3), having a front end part (8), and an exchangeable wearing and / or replacement part (2), arranged over this end part and comprising a hood-shaped (6) hollow (7) which, when the wearing part (2) is fitted in place, is designed to grip over the end part and is fixed thereto by means of at least one locking device (27) placed through interacting openings (28), the end part and the hollow having front, rear and collateral contact zones (9, 22, 23), each comprising contact faces (10, 25, 26), disposed one on the holder part and one on the wearing part, for the absorption of acting vertical, horizontal and collateral forces Fx, Fy and Fz. The contact faces (25, 26) are designed to interact so as, on the one hand, to limit the pushing-on of the wearing part over the holder part and, on the other hand, to ensure that the contact between the contact faces will be made, primarily, at the common centre M0, of the two radii (of a recess and a projection) essentially in the horizontal plane YZ and secondarily, as the wear has progressed, symmetrically about this mid contact point as an increasingly large contact zone (22′, 23′).

Owner:COMBI WEAR PARTS AB

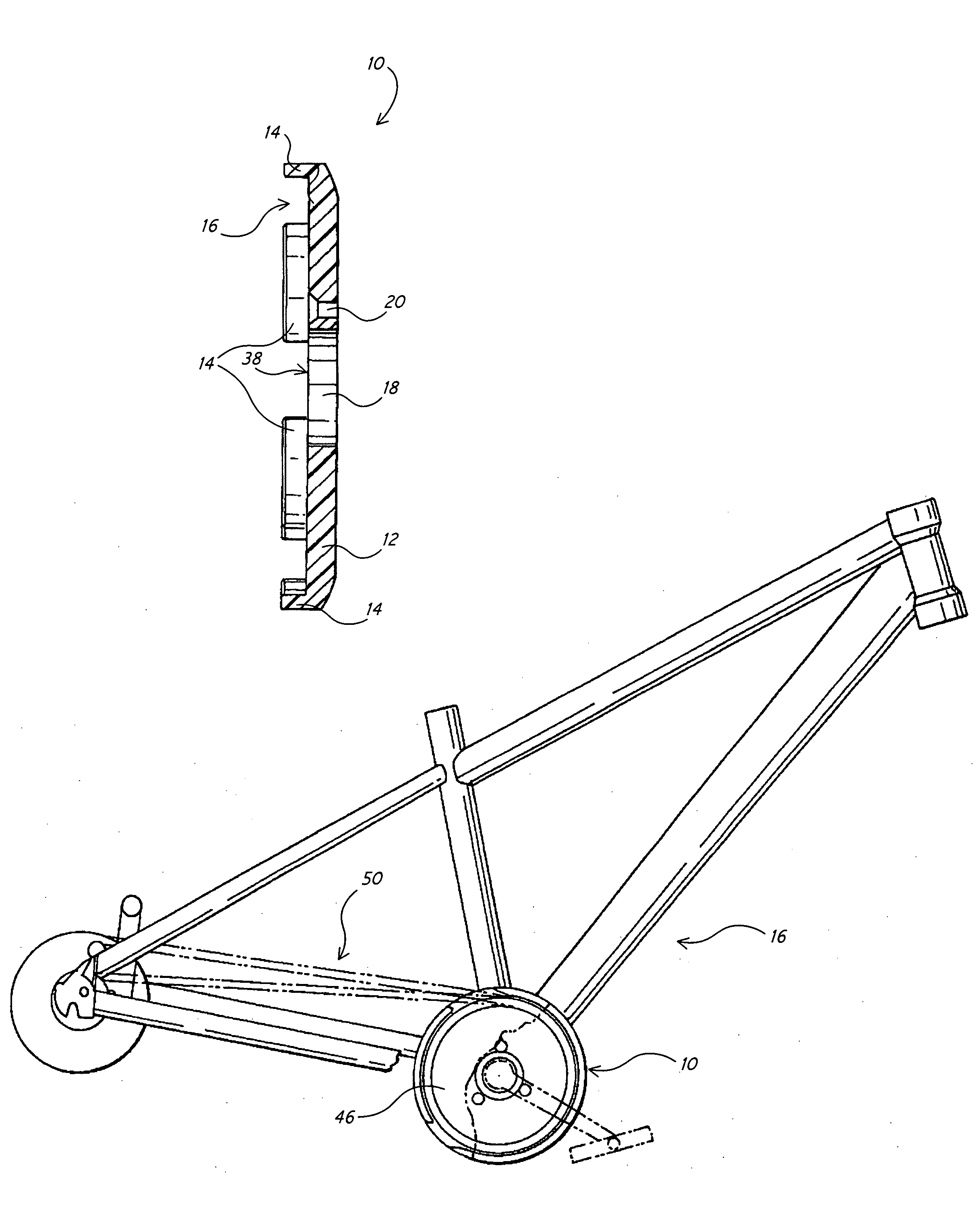

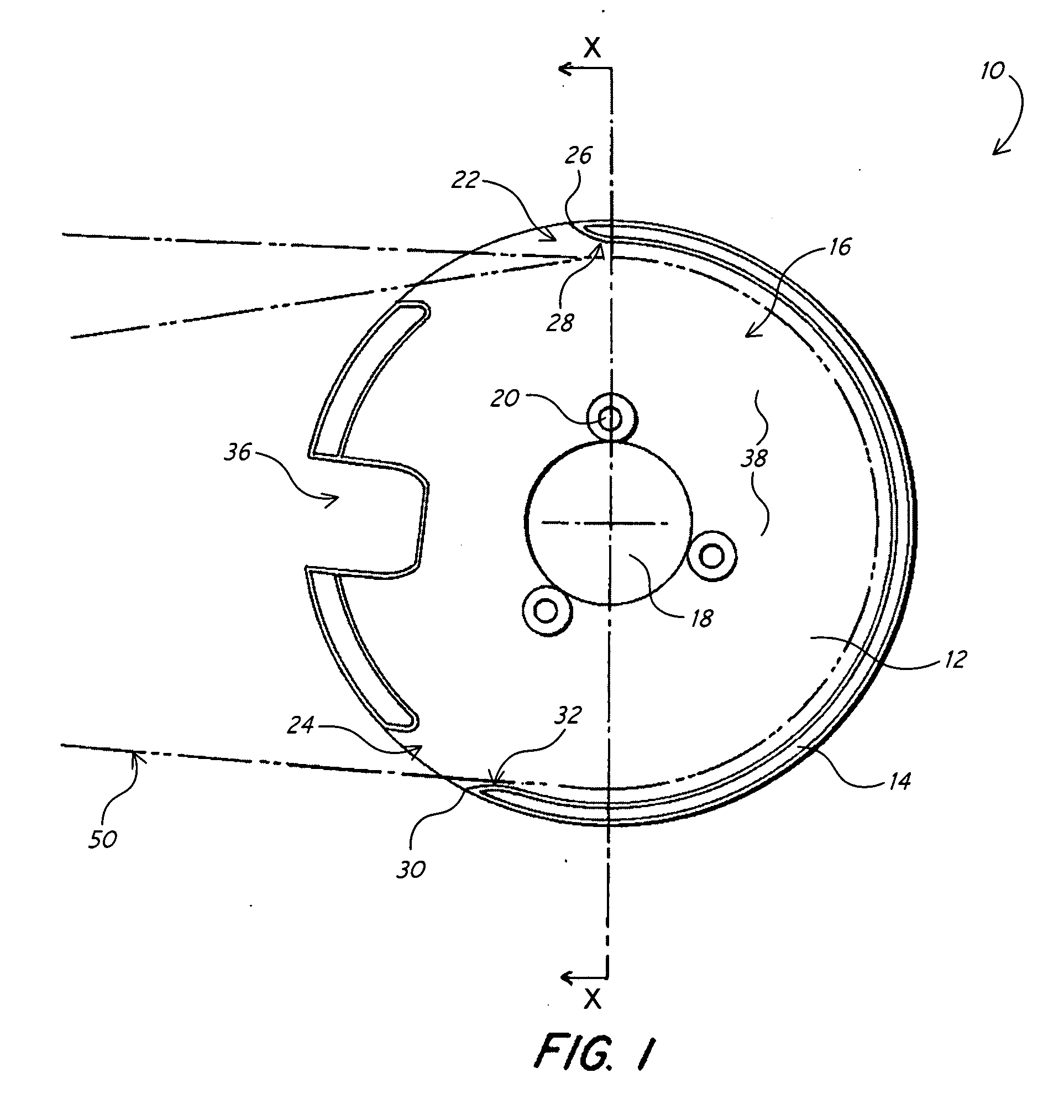

Chain guide

InactiveUS20060199690A1Play of the chain is minimizedMinimize playGearboxesGearingSprocketEngineering

Owner:CANNONDALE BICYCLE CORPORATION

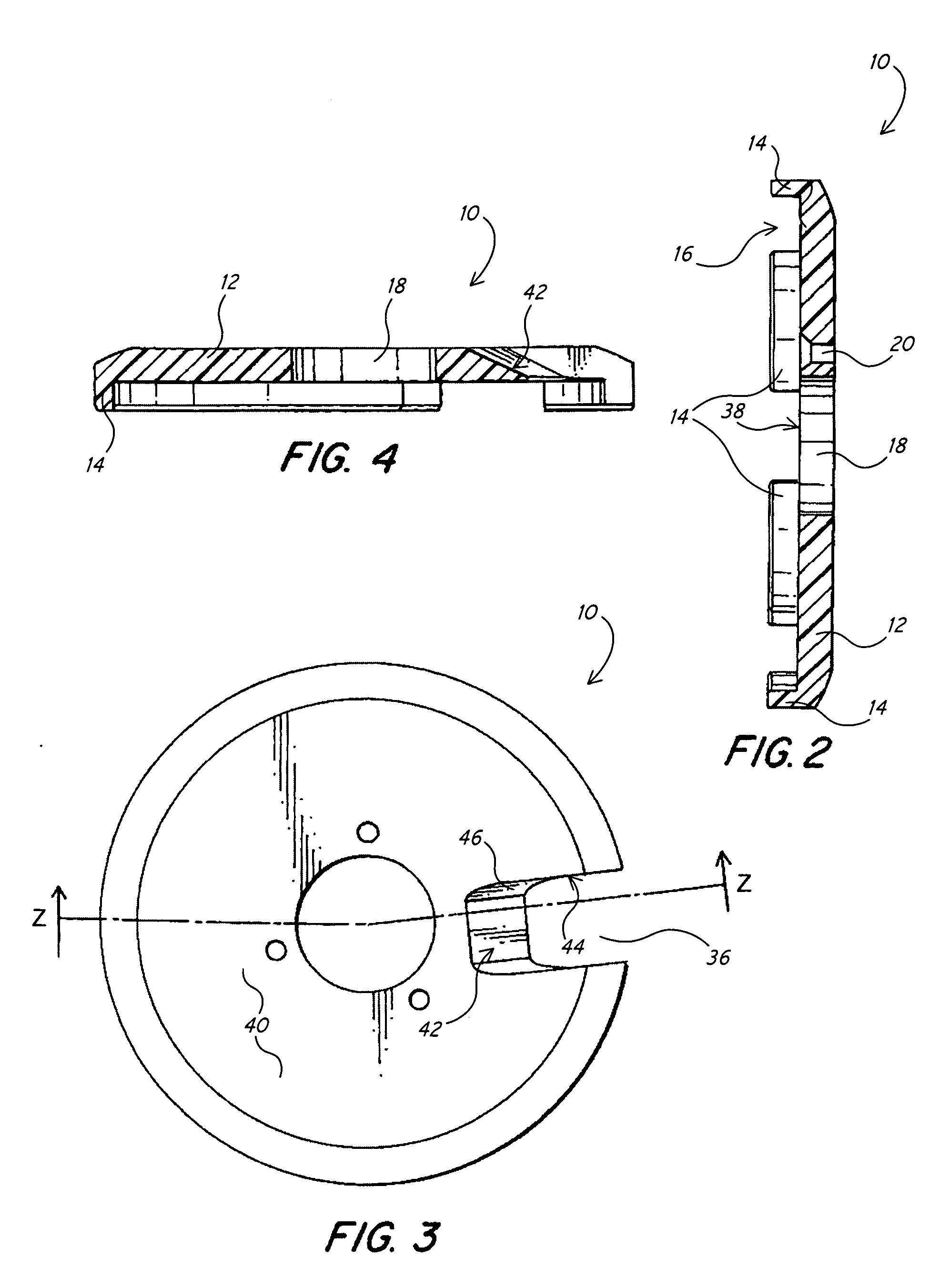

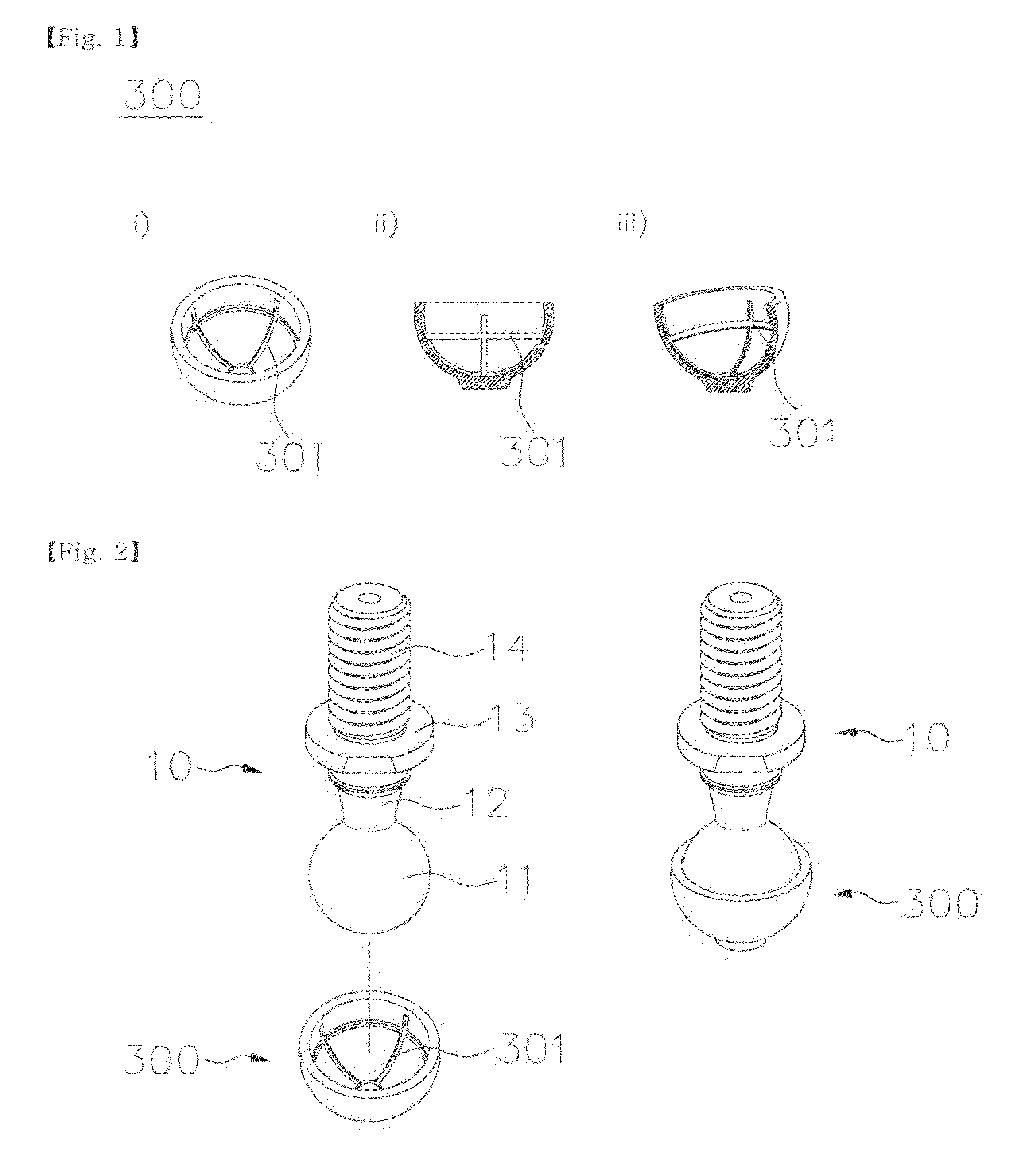

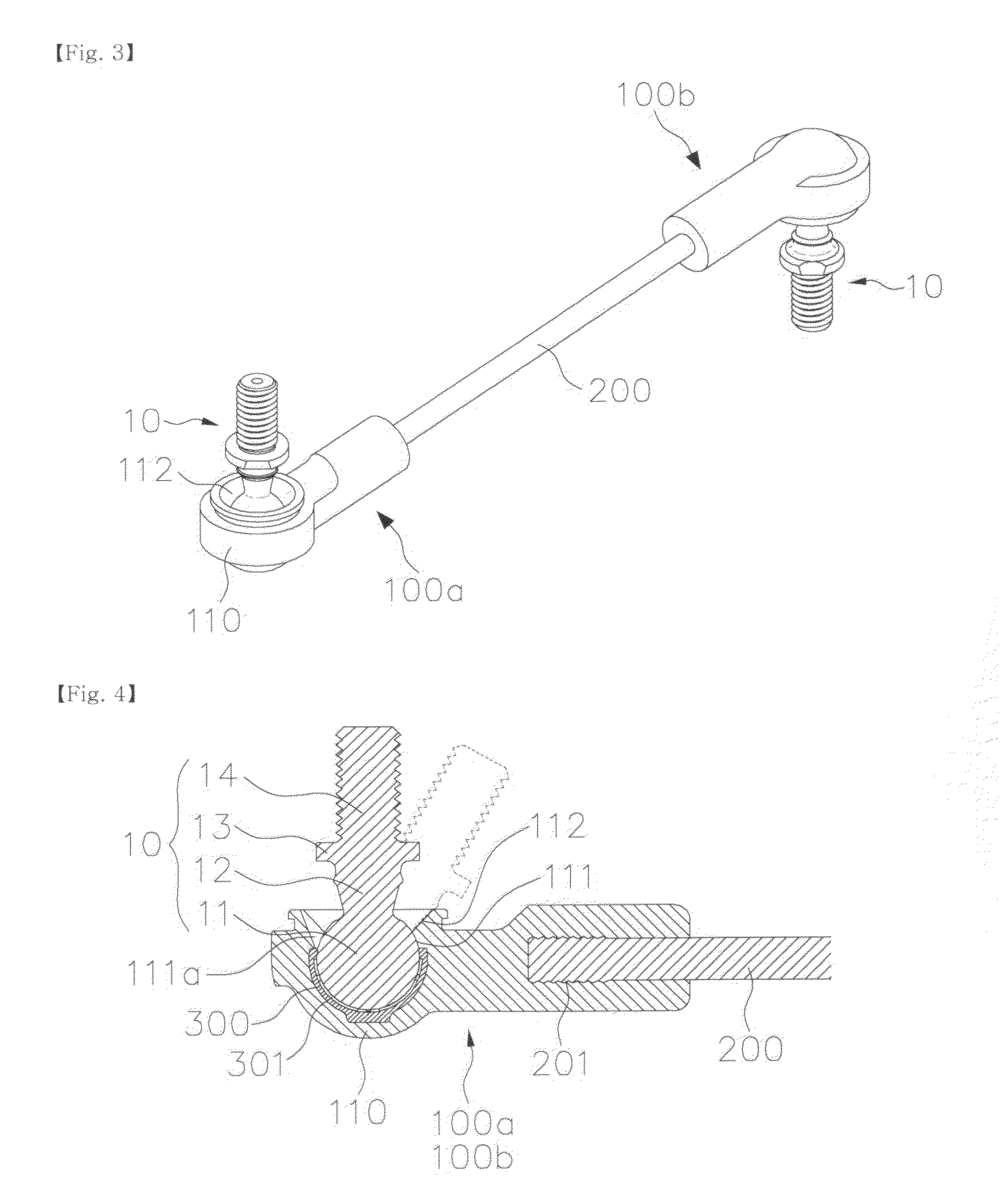

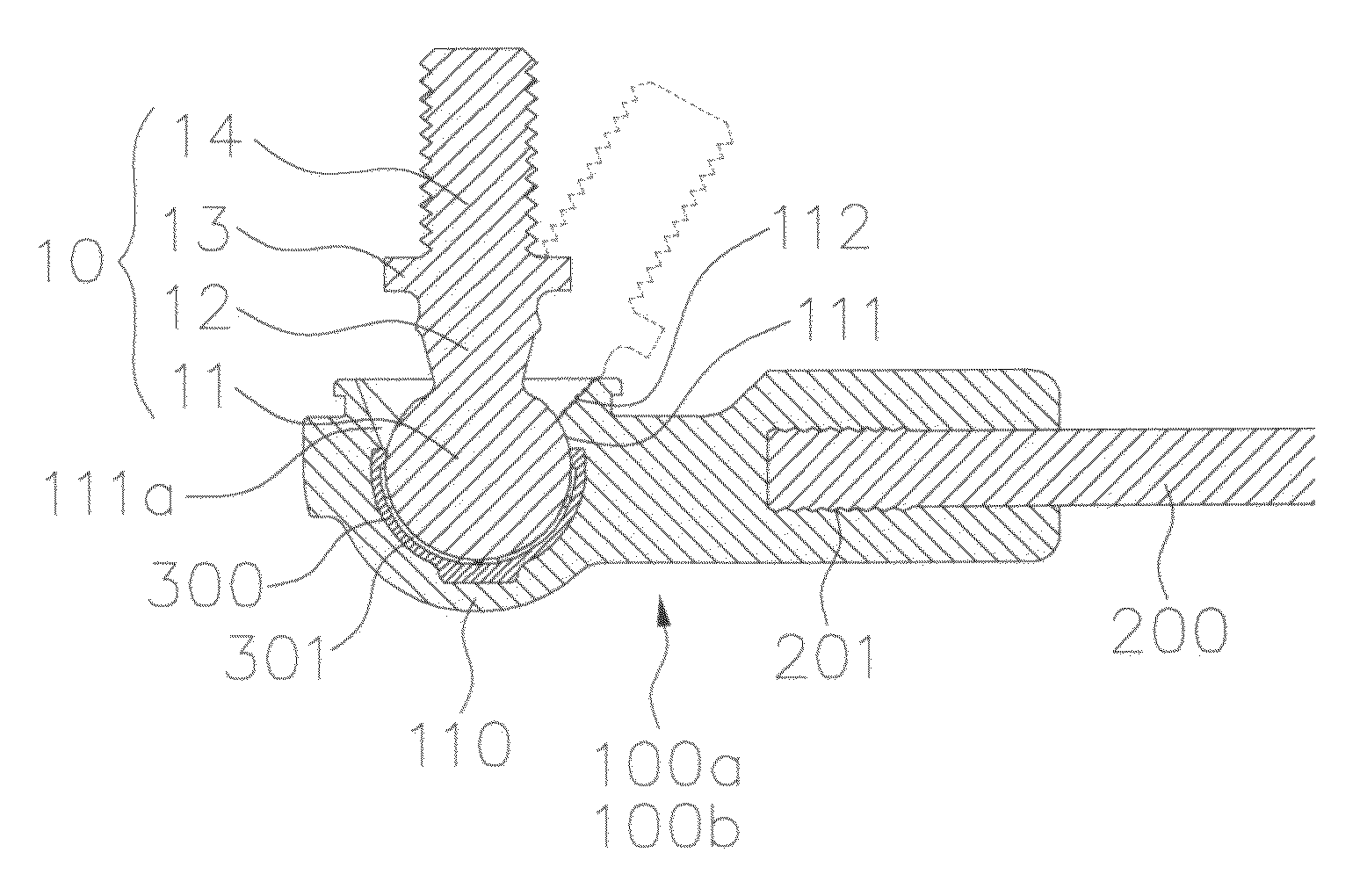

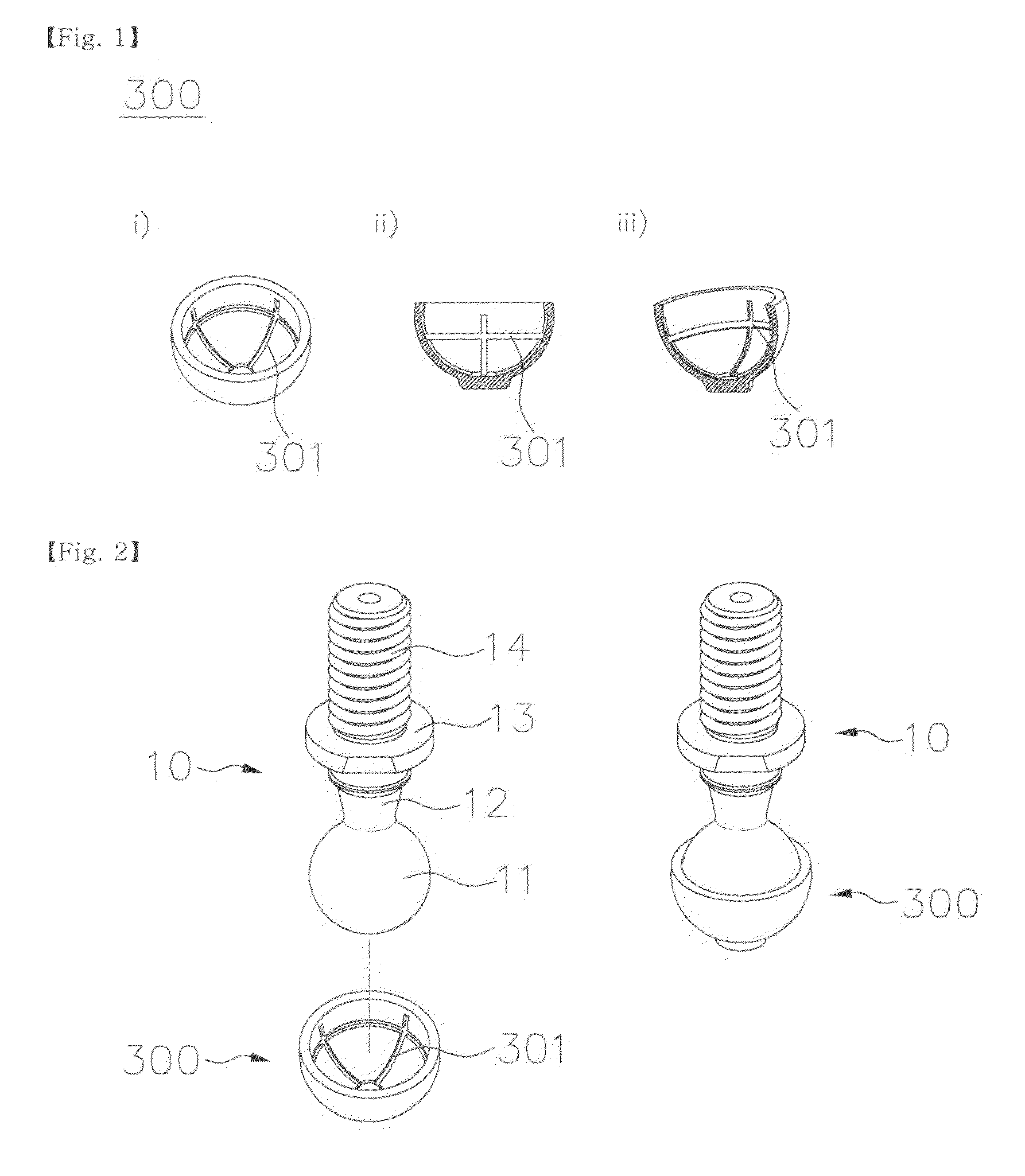

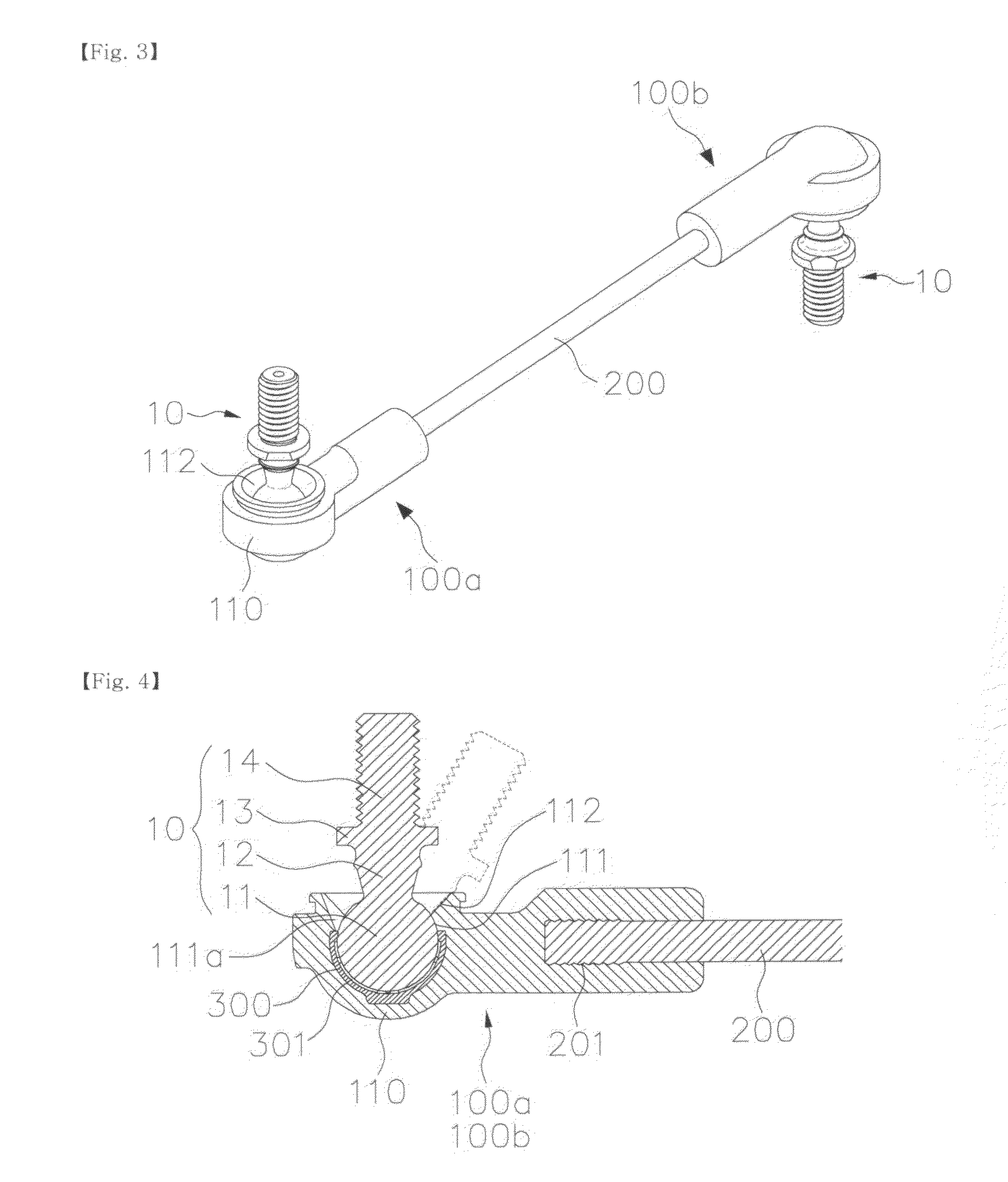

Insert-molded ball joint

InactiveUS8061921B2Increased pull-out strengthPlay of the ball stud is minimizedSuspensionsCouplings for rigid shaftsEngineeringBall joint

Disclosed herein is an insert-molded ball joint which is configured such that rotational frictional torque of a ball stud is kept below the appropriate level, pull-out strength of the ball stud is increased, and play of the ball stud is minimized. The ball stud has a spherical head. The spherical head of the ball stud is rotatably inserted into the ball seat. The housing covers the ball seat and a portion of the spherical head that is exposed from the ball seat. The upper end of the ball seat is disposed higher than the center of the spherical head. The housing includes a head support which covers the spherical head. A ball seat grease groove is formed in the inner surface of the ball seat. Housing grease grooves are formed in the head support in a vertical direction and meet the upper end of the ball seat.

Owner:CENT LTS +3

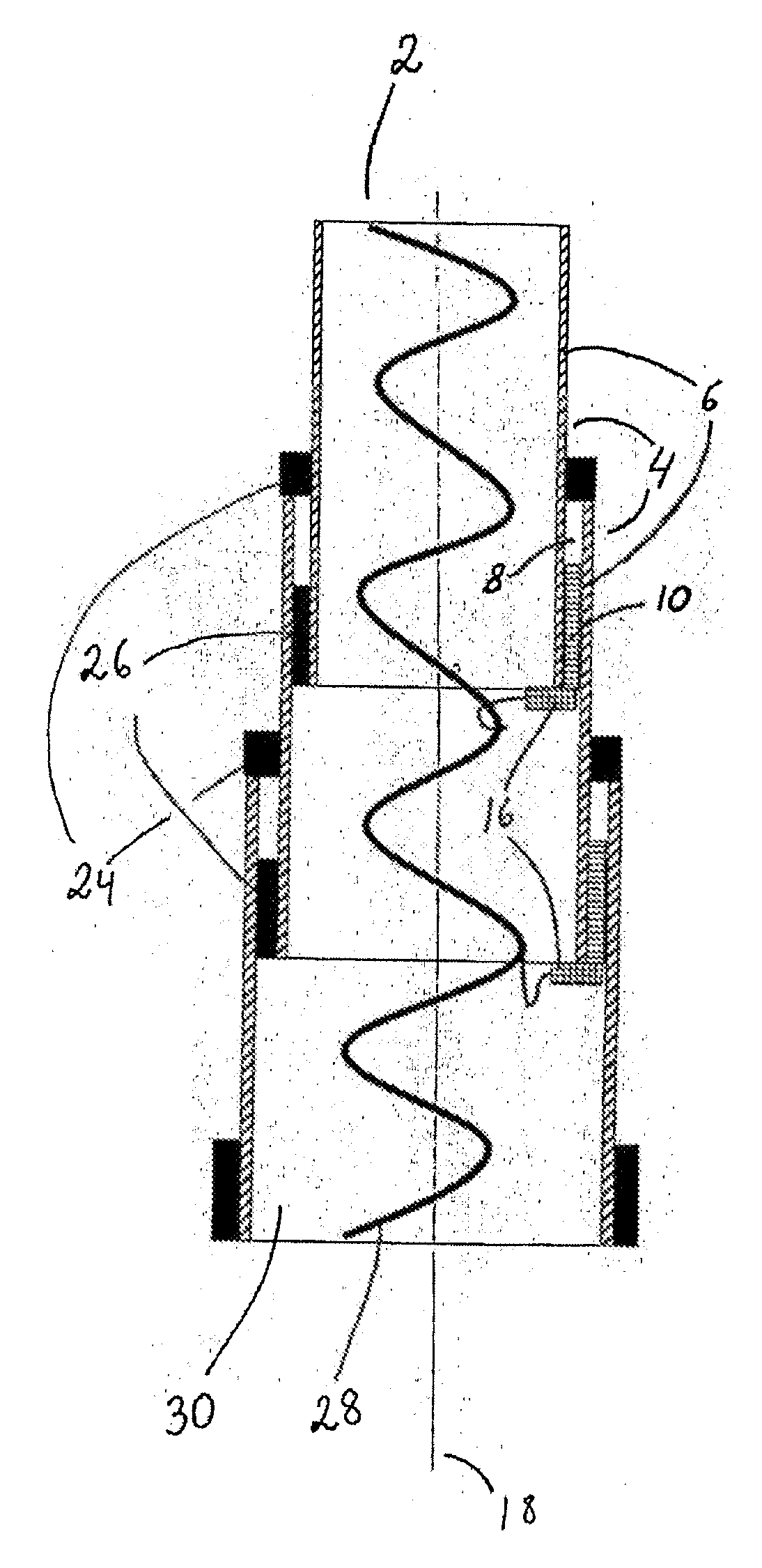

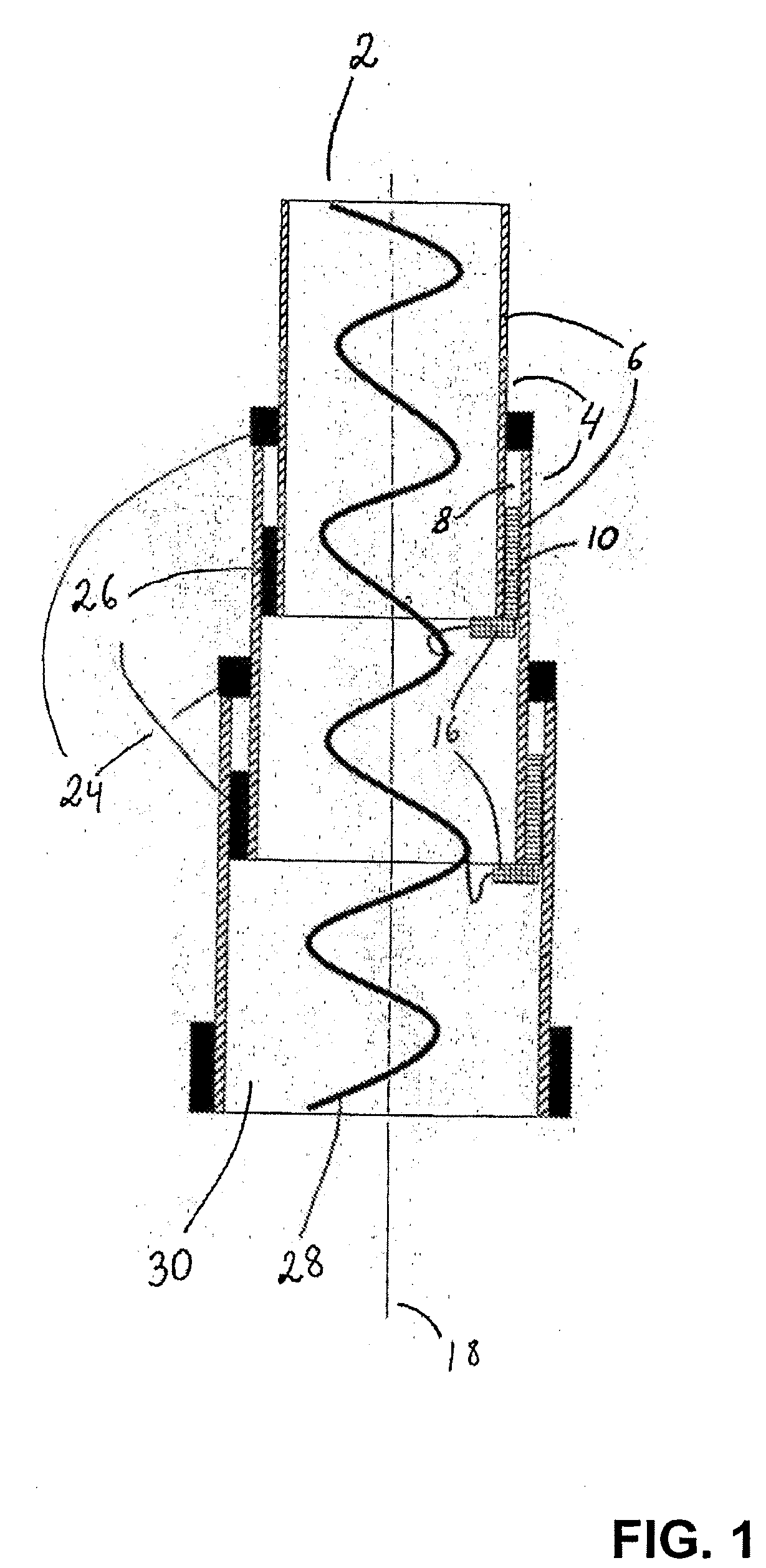

Telescopic mast having reduced play

There is disclosed a telescopic mast (2) including two or more cylindric telescoping sections (4) with parallel walls (6), where the distal one of two adjacent telescoping sections (4) is narrower than the proximal one of the two adjacent telescoping sections (4), so that the distal telescoping section (4) can be moved into and out of the proximal telescoping section (4), respectively. In the interspace (8) between two adjacent telescoping section (4) there is provided at least one means (10) interacting with an actuator (16) and pressing the adjacent walls (6) away from each other. Hereby play is eliminated or minimised.

Owner:DRS SUSTAINMENT SYST

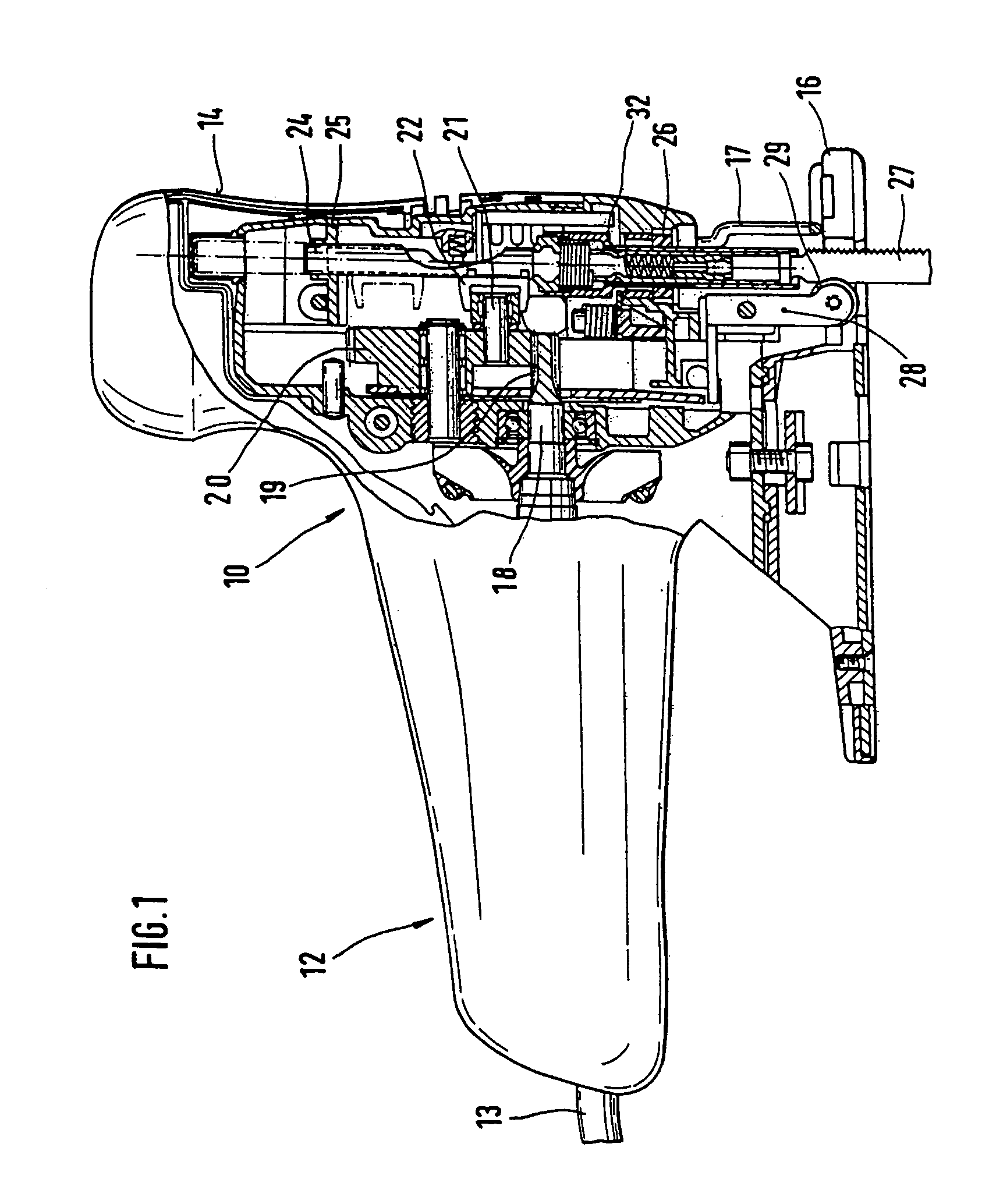

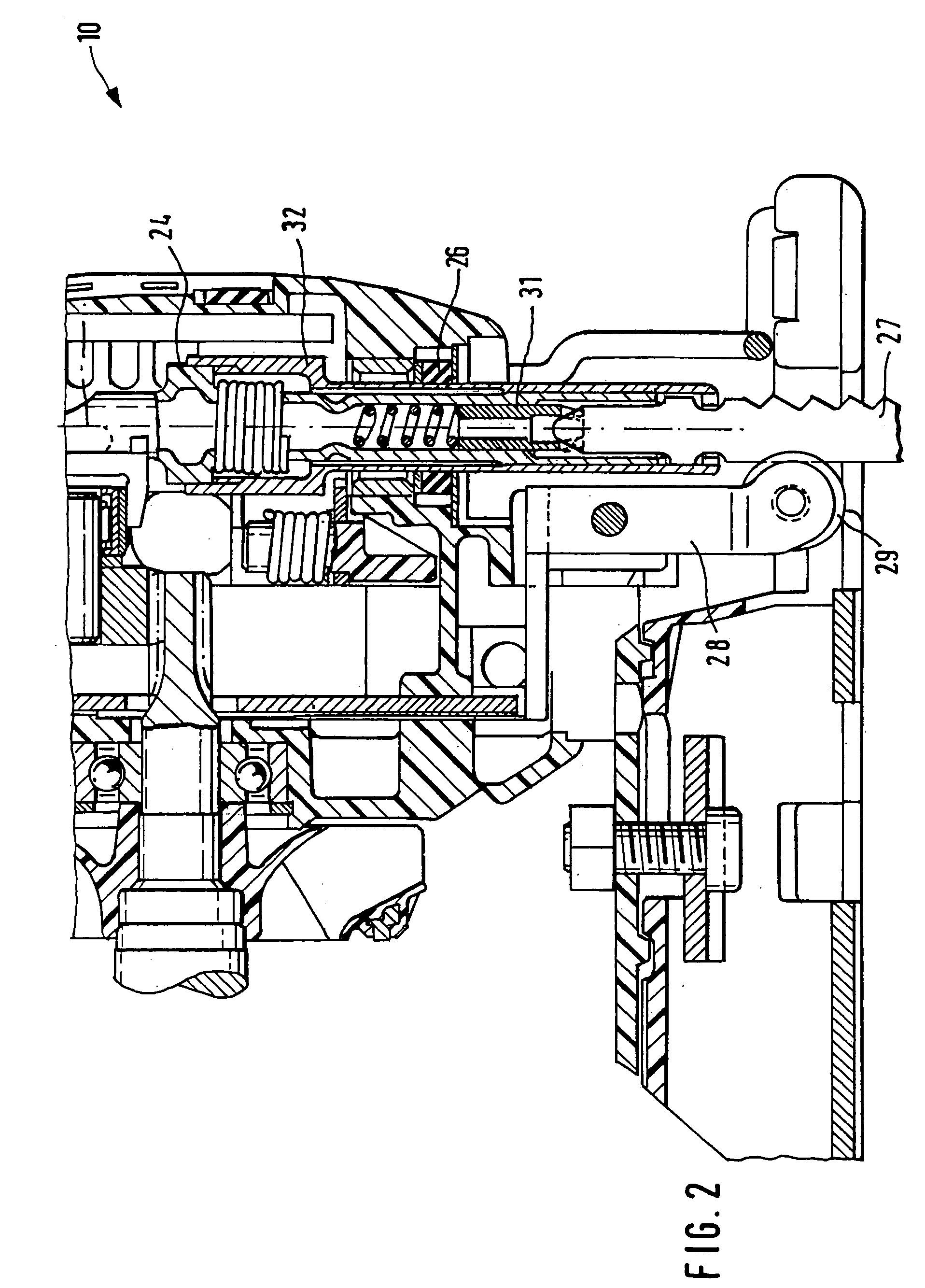

Hand-held compass saw

InactiveUS7047651B2Minimize playMinimizing any tendencyMetal sawing devicesTurning machine accessoriesHand heldEngineering

A power compass saw with a housing that accommodates a lifting rod for the up and down movement of a longitudinal saw blade attached thereto, has a toothed side and a saw blade back and with a guide roller which supports the saw blade back and has a central groove into which the saw blade extends with its saw blade back and is guided therein, the central circumferential groove has tapered groove sides with a 5° taper, the saw blade back has a straight portion and an end beveled portion with beveled edges having a 7° taper at both sides, the saw blade back has diametrically opposed edges provided at a transition from the straight portion to the beveled portion, and the saw blade back has a width which is measured between the diametrically opposed edges and is greater than a width of a bottom of the circumferential groove.

Owner:SCINTILLA AKTIENGES

Wearing parts system for detachable fitting of wearing parts for the tool of a cultivating machine

ActiveUS20060143953A1Reduce wearGood stabilitySoil-shifting machines/dredgersEngineeringMechanical engineering

The invention relates to a wearing parts system (1) intended for the tool of a tilling machine of the type which comprises a holder part (3), having a front end part (8), and an exchangeable wearing and / or replacement part (2), arranged over this end part and comprising a hood-shaped (6) hollow (7) which, when the wearing part (2) is fitted in place, is designed to grip over the end part and is fixed thereto by means of at least one locking device (27) placed through interacting openings (28), the end part and the hollow having front, rear and collateral contact zones (9, 22, 23), each comprising contact faces (10, 25, 26), disposed one on the holder part and one on the wearing part, for the absorption of acting vertical, horizontal and collateral forces Fx, Fy and Fz. The contact faces (25, 26) are designed to interact so as, on the one hand, to limit the pushing-on of the wearing part over the holder part and, on the other hand, to ensure that the contact between the contact faces will be made, primarily, at the common centre M0, of the two radii (of a recess and a projection) essentially in the horizontal plane YZ and secondarily, as the wear has progressed, symmetrically about this mid contact point as an increasingly large contact zone (22′, 23′).

Owner:COMBI WEAR PARTS AB

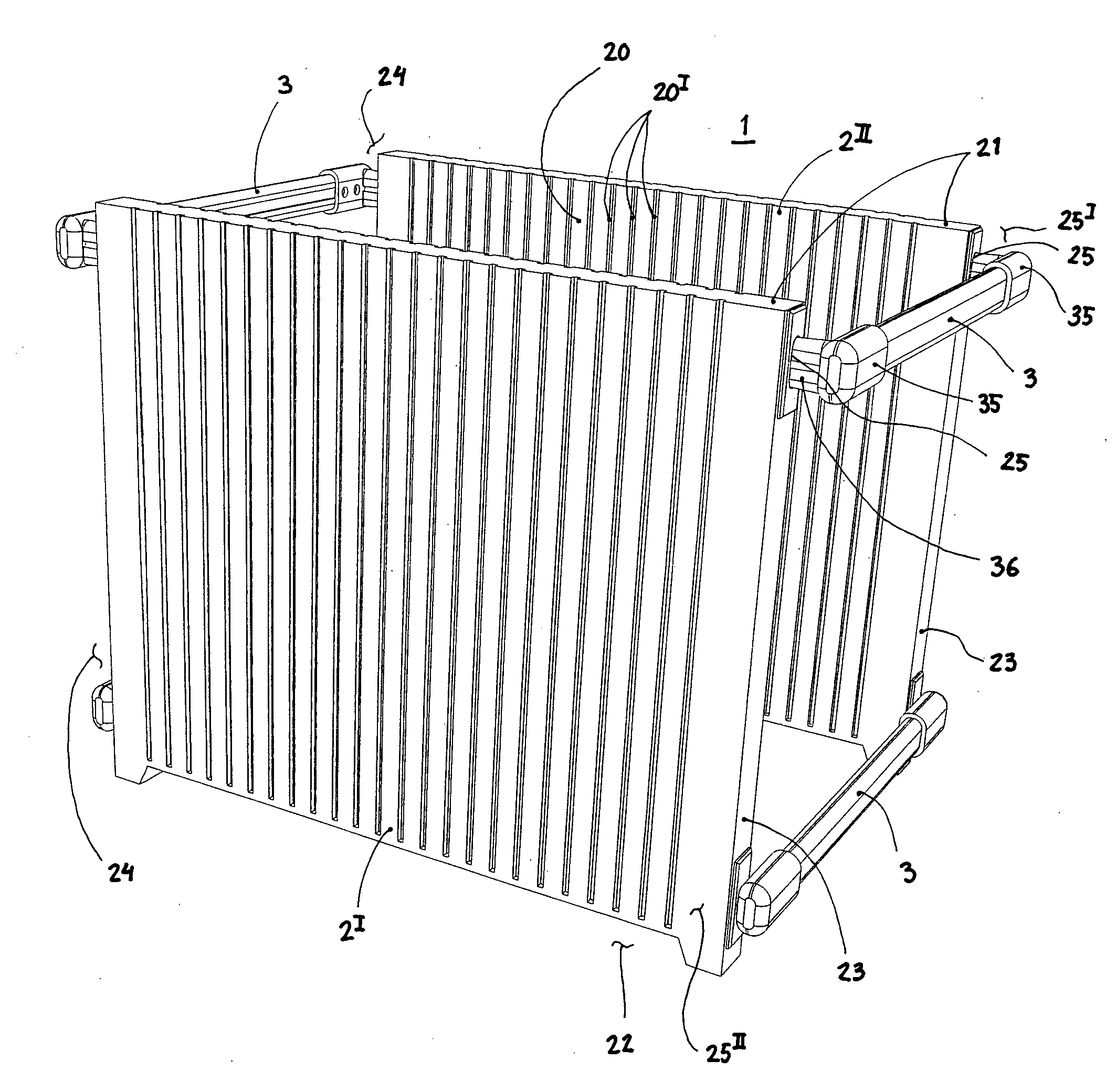

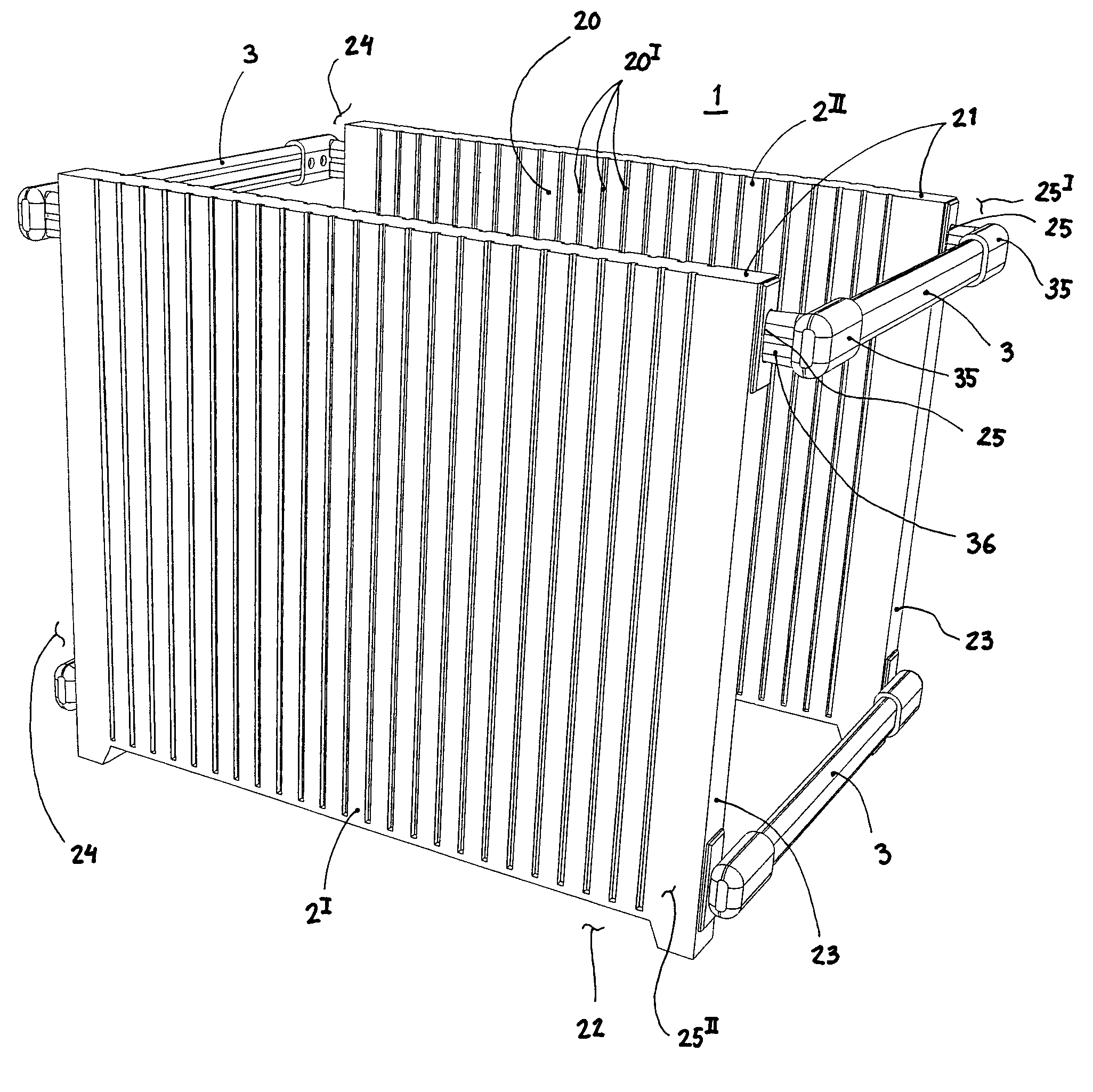

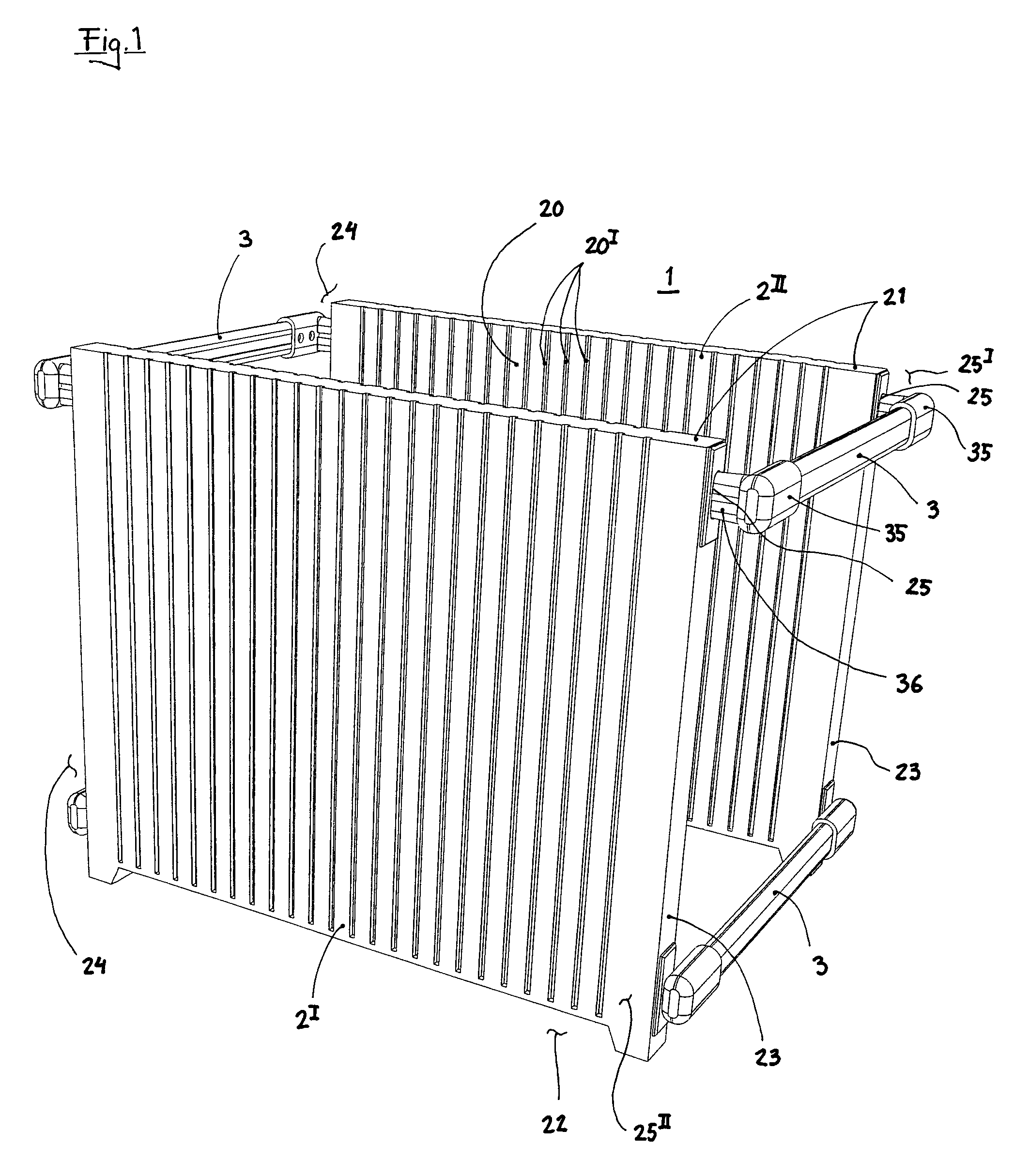

Rack for transport and storage

InactiveUS20100038331A1Minimize the numberCost effectiveFolding cabinetsDismountable cabinetsCouplingEngineering

A collapsible rack for transport and storage, includes a first and a second panel and a plurality of distance bars. The first and second panel include a groove side including at least one groove. A first and a second edge is arranged on opposite sides and adjacent to these, a third and a fourth edge. The third and fourth edges each include at least one hole that extends parallel to the first and second edges. The hole has a non-circular shape. The distance bars at each of their ends includes a hole coupling mechanism. The hole coupling mechanism extends perpendicular to the extension of the bar. The hole coupling mechanisms include clutching sections that match the hole, wherein pivoting between the bars and the first and second panel is prevented where the hole coupling mechanism and hole are fully mated.

Owner:SCHOELLER ARCA SYST

Device for reduction of axial movement of the main shaft gears in a transmission with at least two countershafts

InactiveUS7334493B2Reduce exerciseMinimize playRoller bearingsGear vibration/noise dampingEngineeringMechanical engineering

A device for the reduction of axial movement of the main shaft gears (2) in a transmission containing at least two countershafts. The main shaft gears (2) are held axially by two washer discs (3, 4) which is designed to be a pressing device (5, 6) on the main shaft (1) for at least one of the main shaft gears (2) against the washer disc (3) holding the main shaft gear (2) axially.

Owner:ZF FRIEDRICHSHAFEN AG

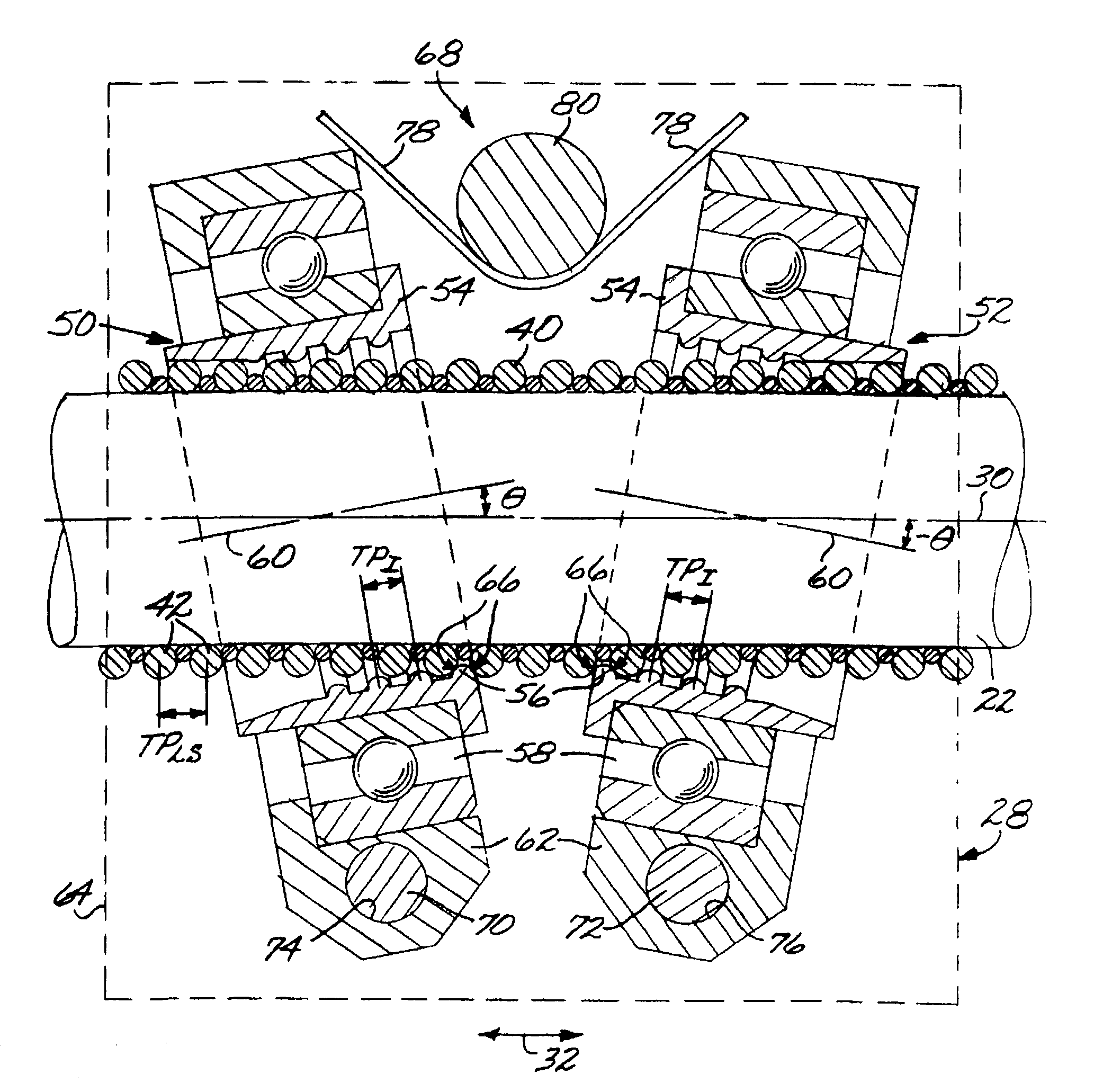

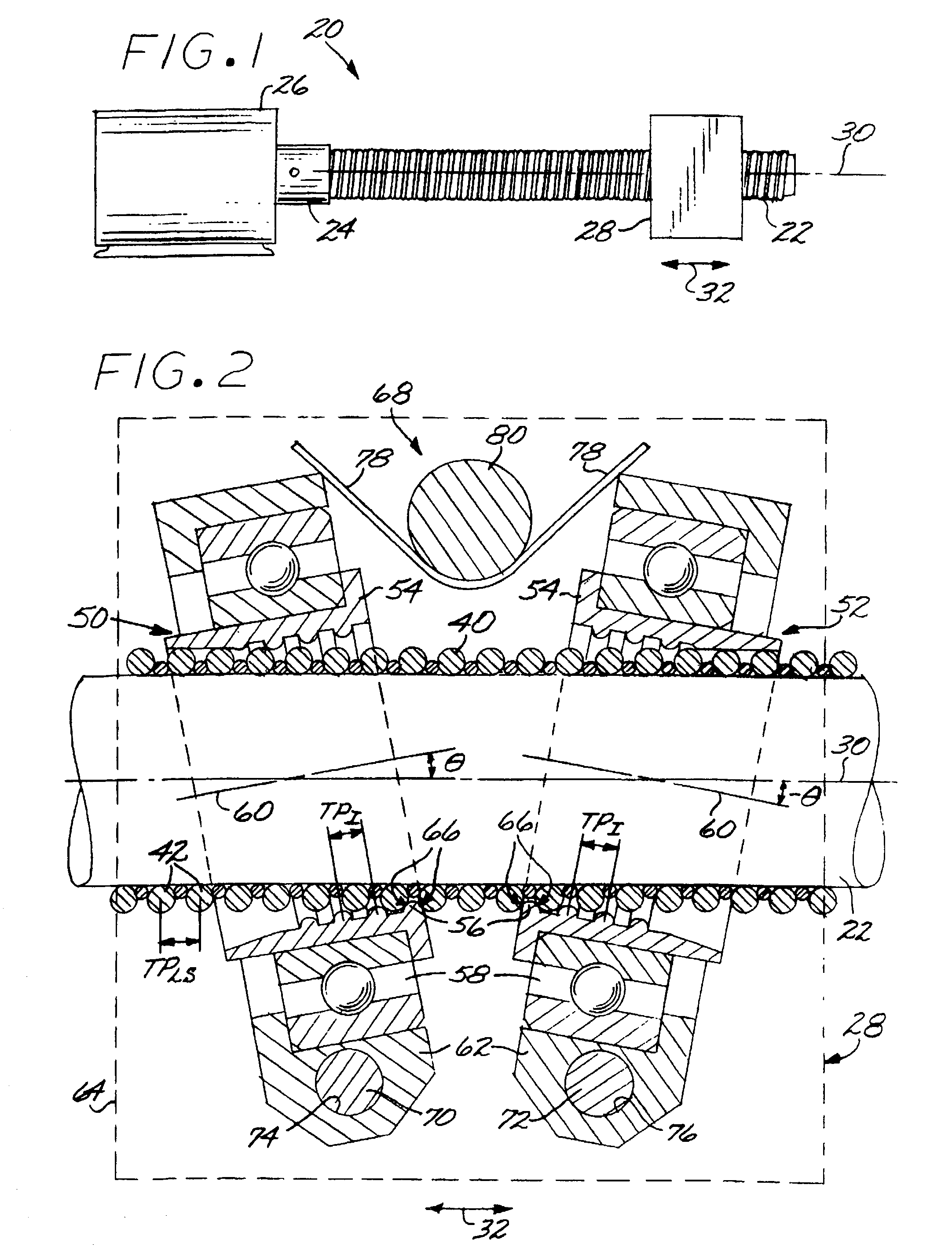

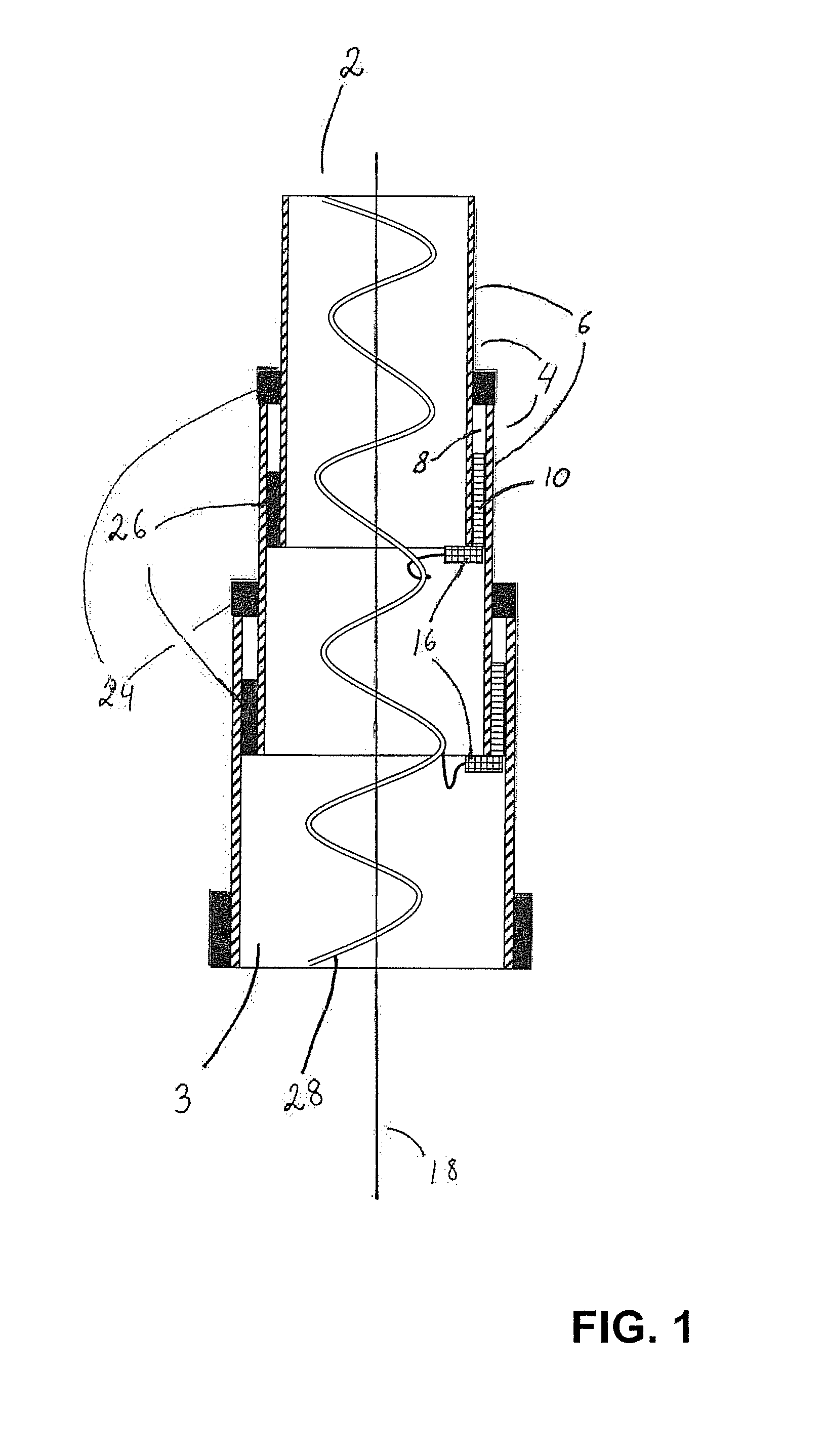

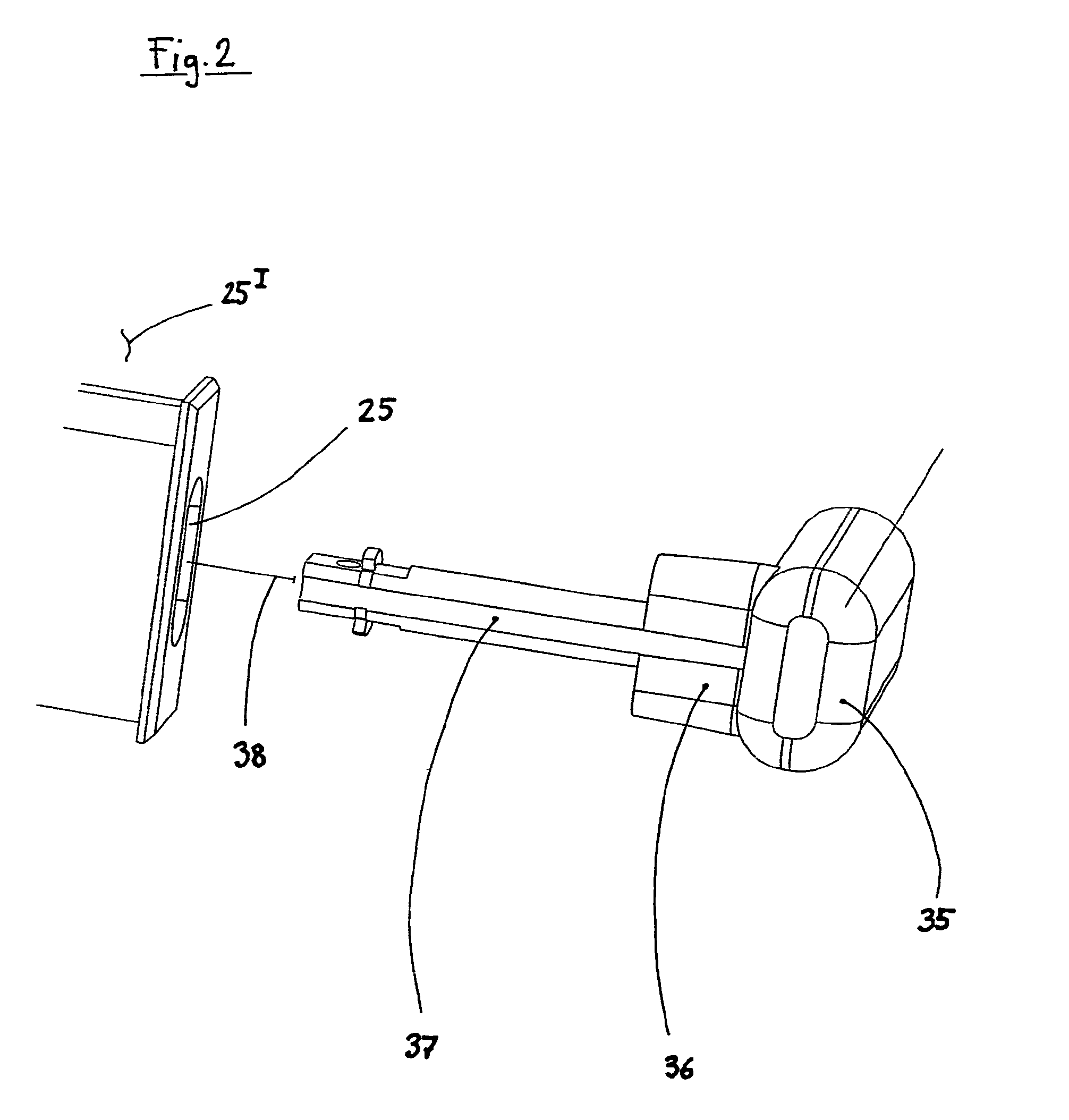

Leadscrew mechanical drive with differential leadscrew follower structure

InactiveUS6931960B1Small linear movement rateThe implementation process is simplePortable liftingToothed gearingsEngineeringMechanical drive

A leadscrew mechanical drive includes a leadscrew having a leadscrew axis and a leadscrew thread with a nonzero leadscrew thread pitch. A leadscrew follower structure preferably having two leadscrew followers is engaged to the leadscrew. Each leadscrew follower includes a threaded insert having an insert thread with a nonzero insert thread pitch different front the leadscrew thread pitch. The insert thread is engaged to the leadscrew thread over a circumferential distance of less than one-half turn of the insert thread. Each leadscrew follower further includes a bearing in which the threaded insert is received and which permits the threaded insert to rotate about an insert axis that is inclined to the leadscrew axis by an angle θ for the first leadscrew follower and −θ for the second leadscrew follower, and a bearing support in which the bearing is received. A preload structure biases each of the leadscrew followers against the leadscrew.

Owner:RAYTHEON CANADA LTD

Device for reduction of axial movement of the main shaft gears in a transmission with at least two countershafts

InactiveUS20060112778A1Increased leverageReduce exerciseRoller bearingsGear vibration/noise dampingGear wheelClassical mechanics

A device for the reduction of axial movement of the main shaft gears (2) in a transmission containing at least two countershafts. The main shaft gears (2) are held axially by two washer discs (3, 4) which is designed to be a pressing device (5, 6) on the main shaft (1) for at least one of the main shaft gears (2) against the washer disc (3) holding the main shaft gear (2) axially.

Owner:ZF FRIEDRICHSHAFEN AG

Insert-molded ball joint

InactiveUS20110103883A1Increased pull-out strengthMinimize playSuspensionsCouplings for rigid shaftsEngineeringSpherical shaped

Disclosed herein is an insert-molded ball joint which is configured such that rotational frictional torque of a ball stud is kept below the appropriate level, pull-out strength of the ball stud is increased, and play of the ball stud is minimized. The ball stud has a spherical head. The spherical head of the ball stud is rotatably inserted into the ball seat. The housing covers the ball seat and a portion of the spherical head that is exposed from the ball seat. The upper end of the ball seat is disposed higher than the center of the spherical head. The housing includes a head support which covers the spherical head. A ball seat grease groove is formed in the inner surface of the ball seat. Housing grease grooves are formed in the head support in a vertical direction and meet the upper end of the ball seat.

Owner:CENT LTS +3

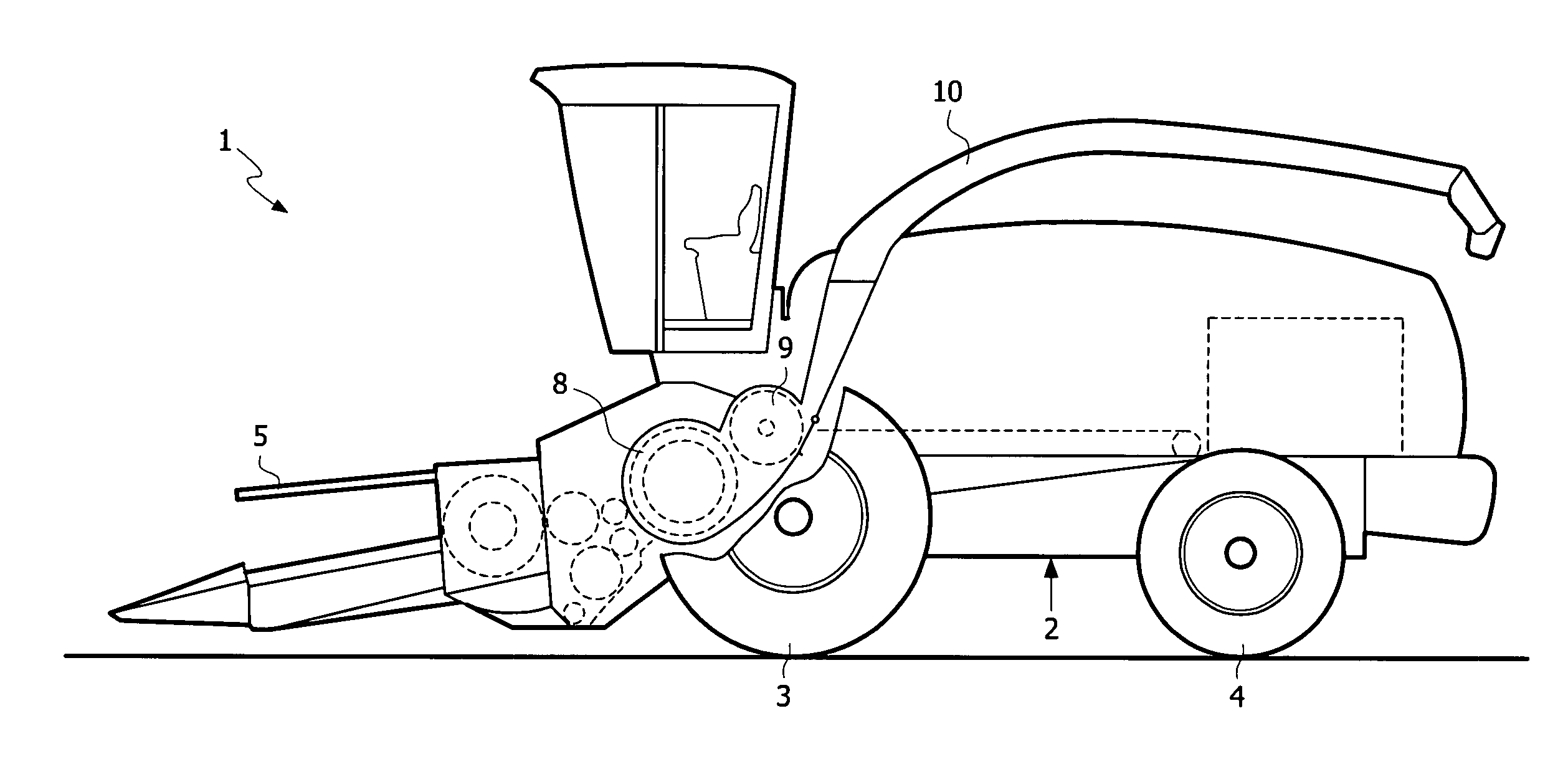

Forage harvester blower

The present invention relates to a forage harvester blower including a blower rotor having a plurality of generally radially extending rotor paddles which operate in a corresponding substantially cylindrical housing, characterised in that said housing is provided with adjustment mechanism for at least locally adjusting the diameter of the housing. The present invention further relates to a method for optimising the operation of a forage harvester blower and to a method for preventing damage to a forage harvester blower during operation.

Owner:BLUE LEAF I P INC

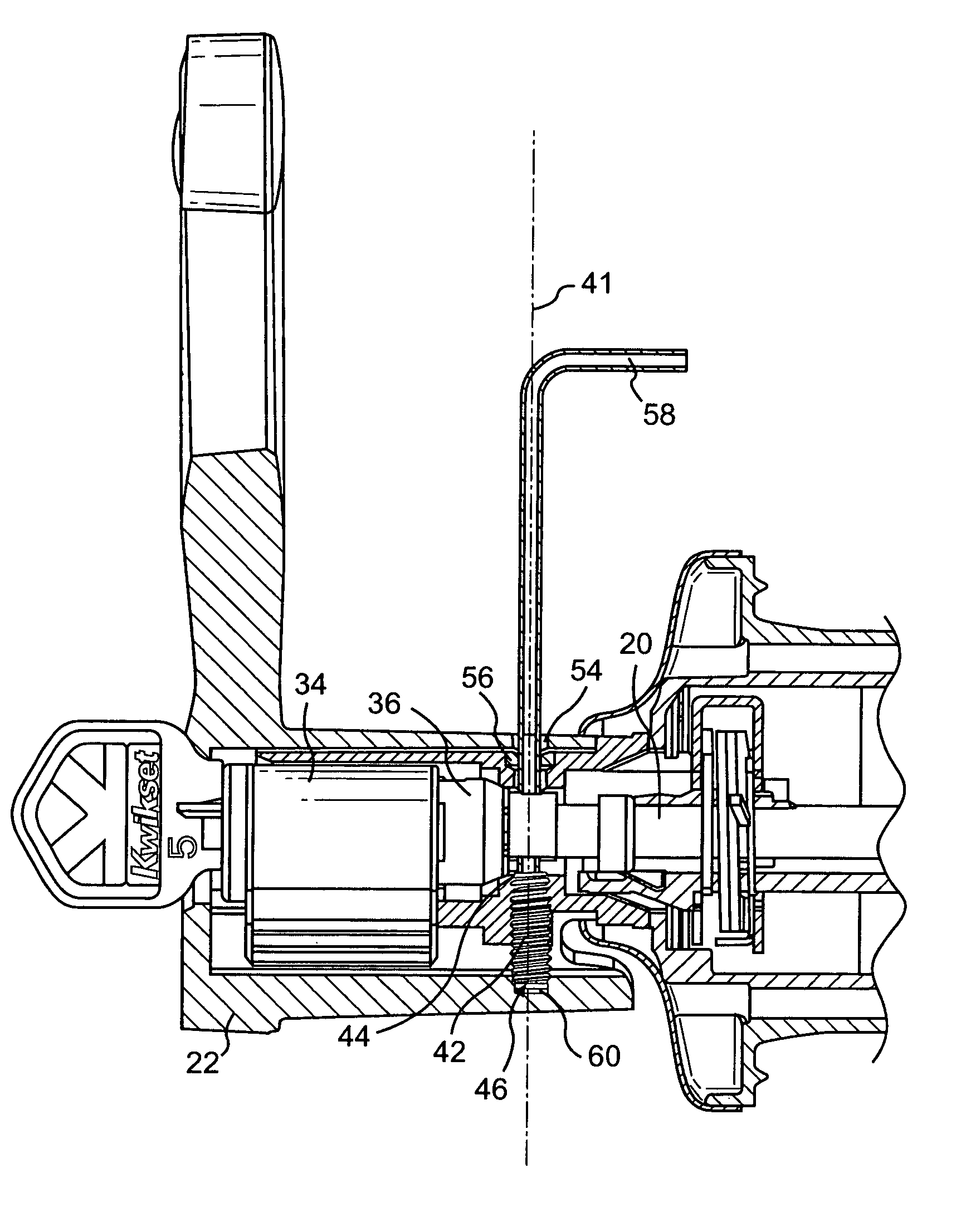

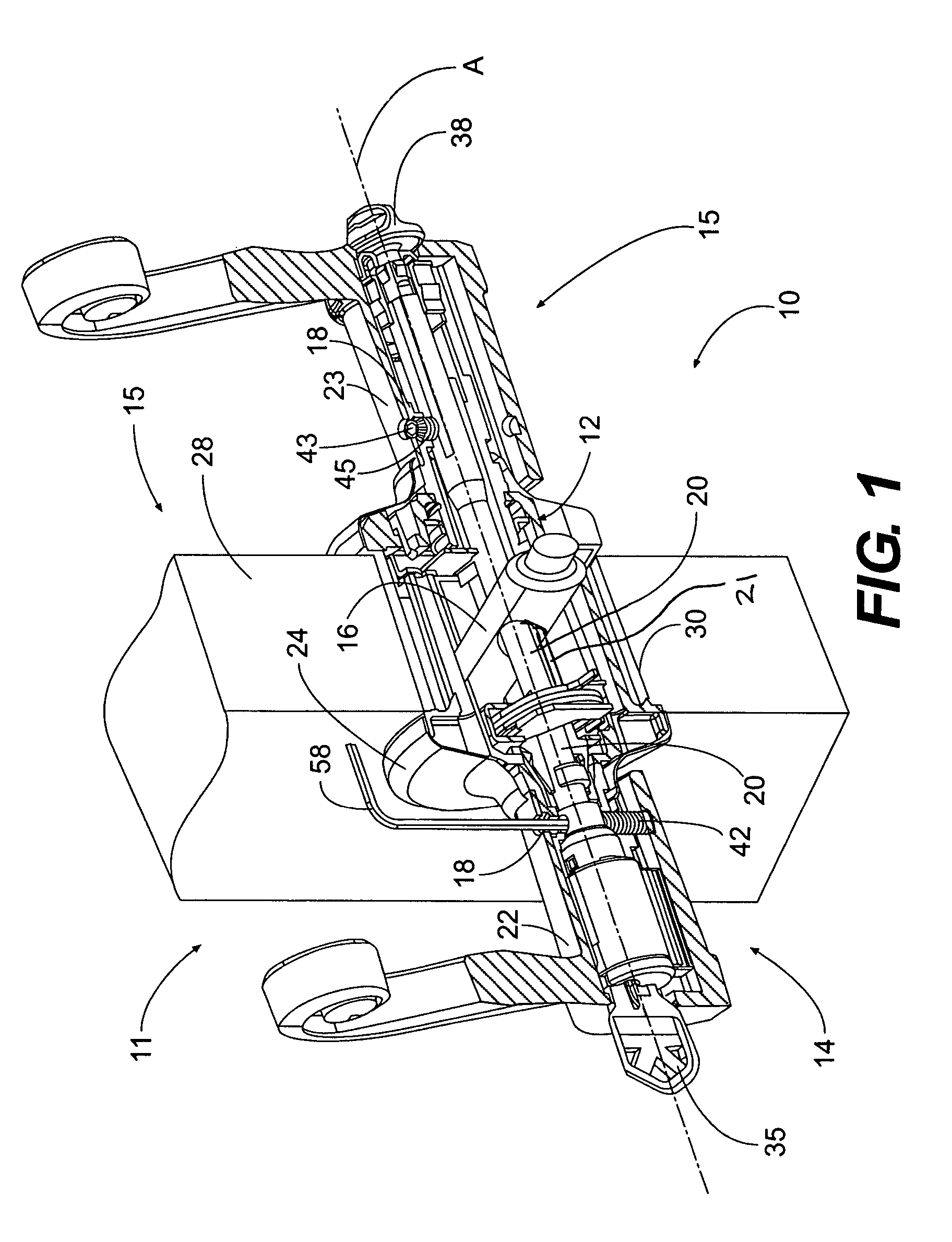

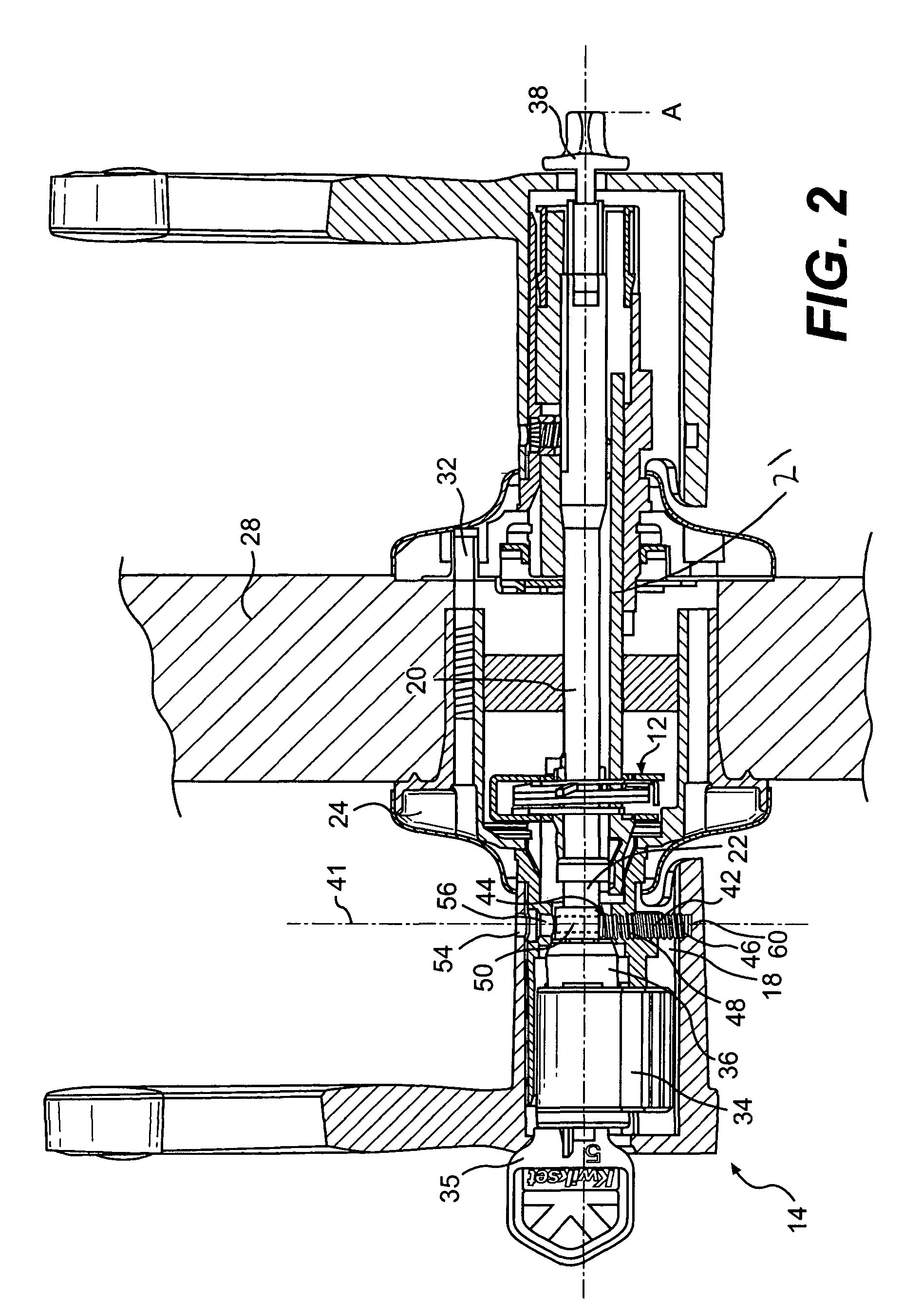

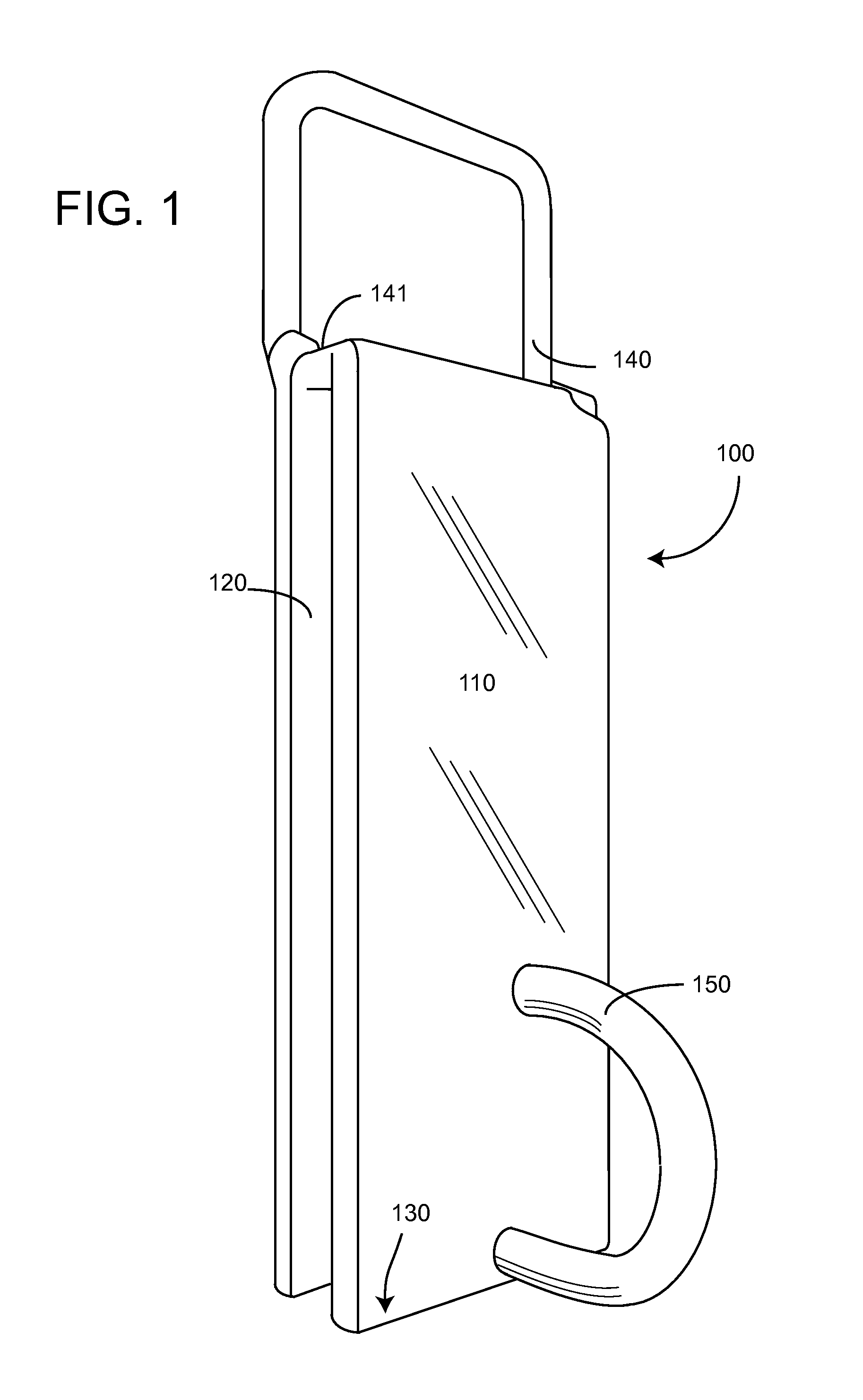

Door handle retainer system

ActiveUS8201307B2Easy to assembleMinimize playTravelling carriersWing handlesEngineeringThreaded fastener

A door handle assembly providing an entry function includes a sleeve, a spindle and a handle that fits over the sleeve. Gap and play between the handle and the sleeve is eliminated by tightening of a threaded fastener against an inner surface of the handle. A tool is selectively received through an opening in the spindle for tightening the threaded fastener. The opening in the spindle is alignable with an aperture in the handle when in an unlocked condition. The tool is then permitted to extend through the aperture and the opening in the spindle to engage the threaded fastener. A second end of the threaded fastener abuts the inner surface of the handle, securing the handle to the sleeve. Another door handle assembly according to this invention provides a privacy function and includes a threaded fastener that contacts an inner surface of a door handle assembly.

Owner:RAYOVAC CORP

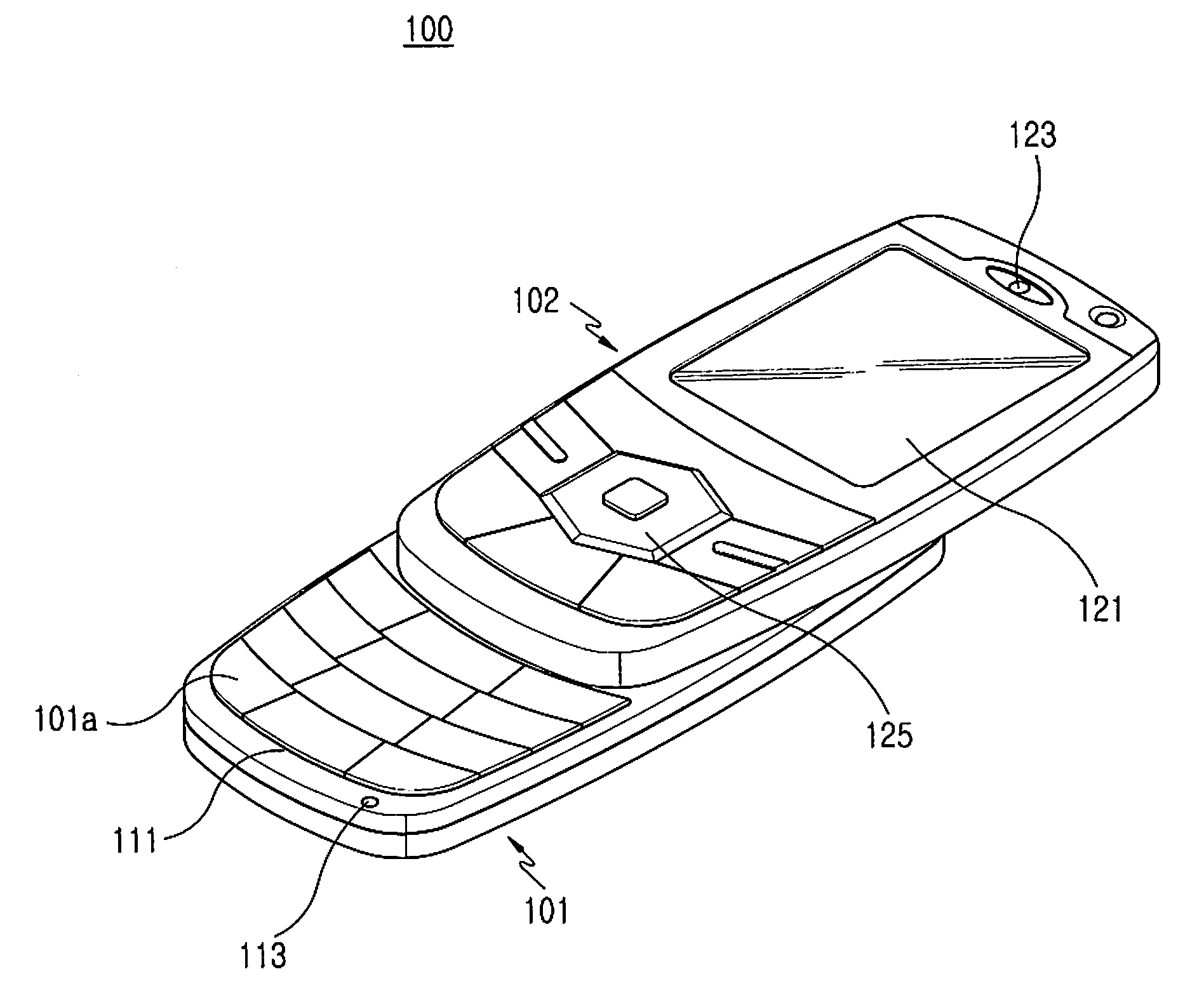

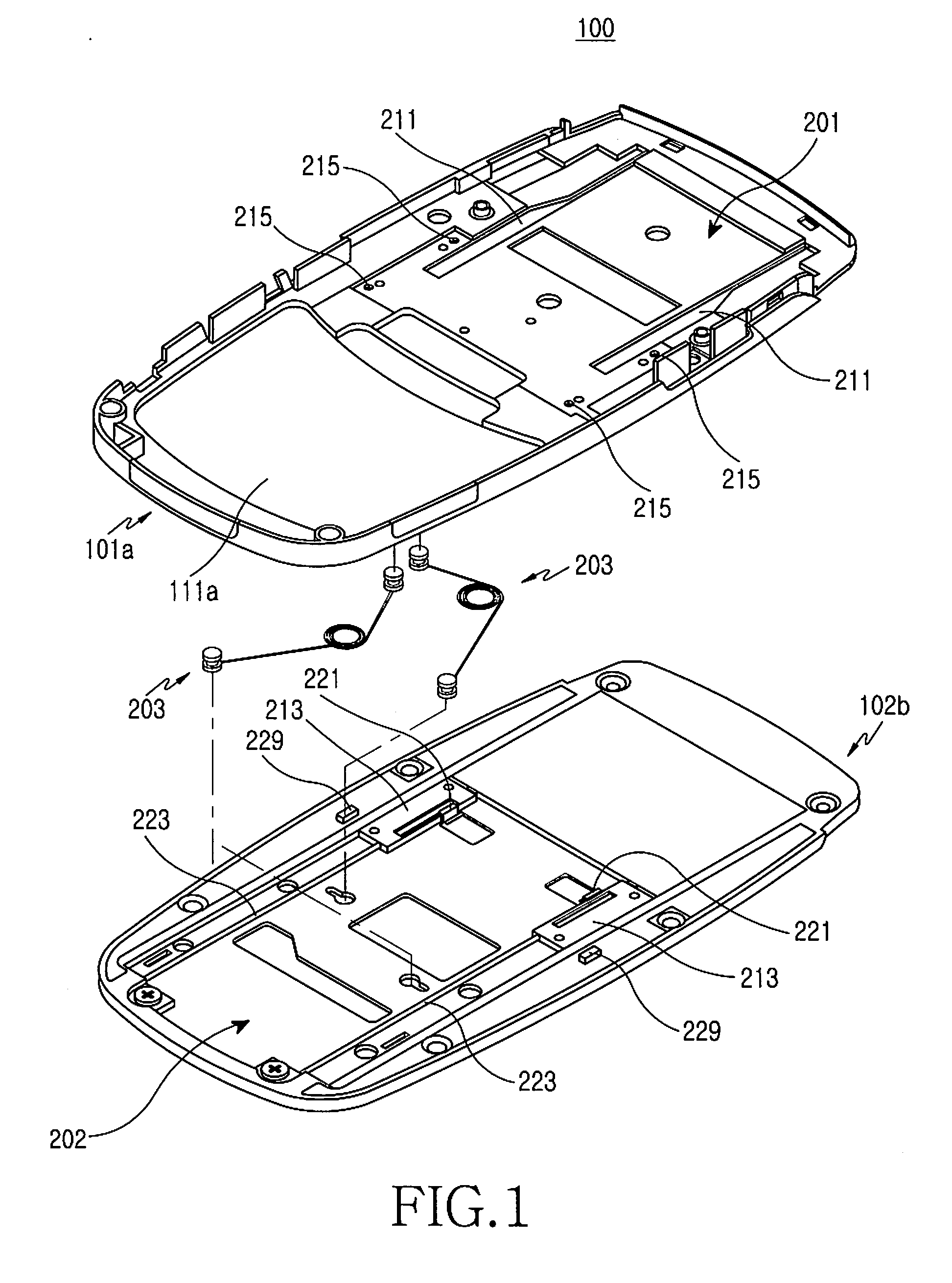

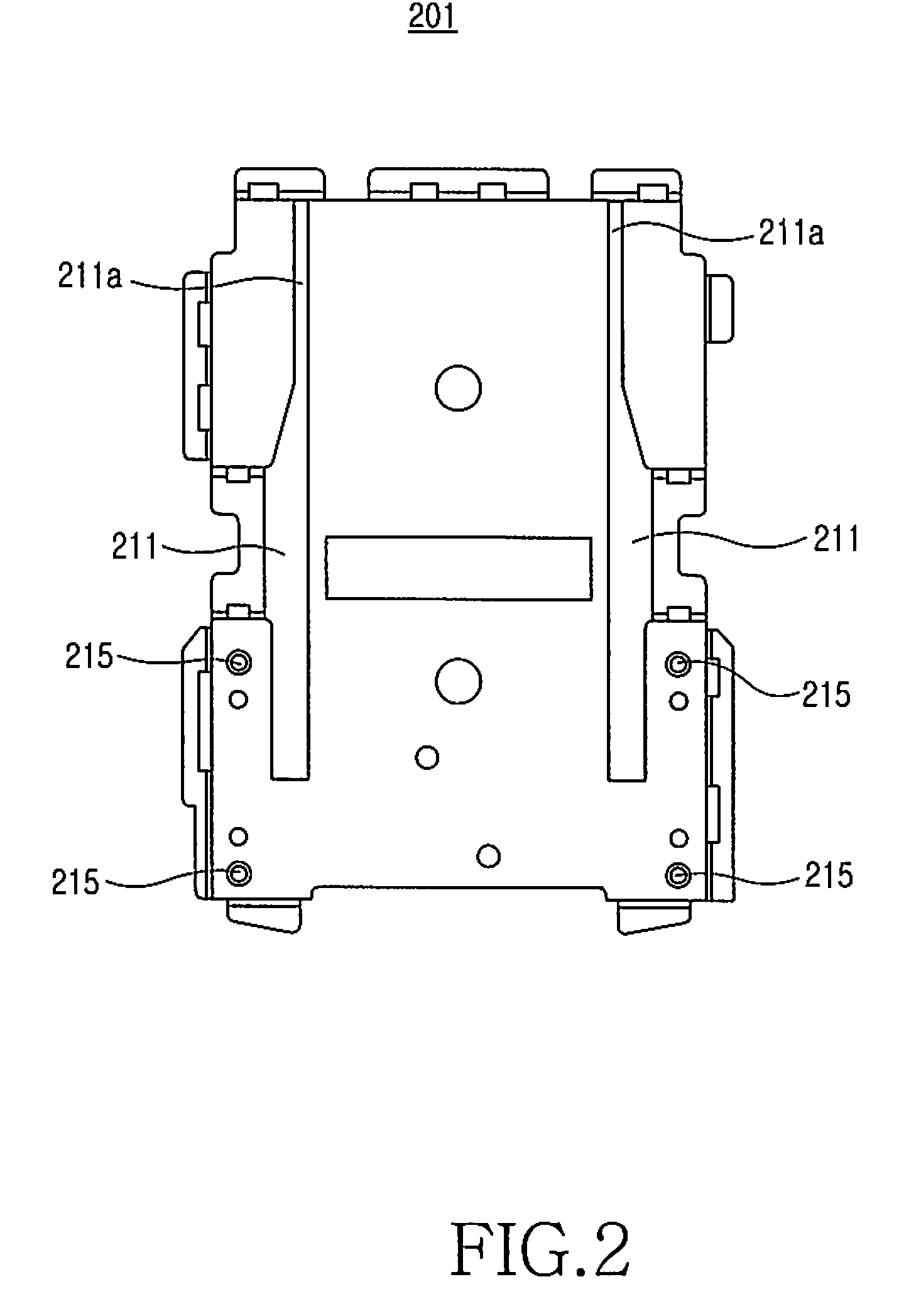

Sliding-type portable terminal

Disclosed is a sliding-type portable terminal including a first housing; a second housing coupled to the first housing so as to slide while facing the first housing; and a sliding module for slidably coupling the first and second housings to each other. The sliding module includes a sliding guide mounted on the first housing, the sliding guide having at least one slit extending in a longitudinal direction; a sliding plate mounted on the second housing, the sliding plate being slidably coupled to the sliding guide and facing the sliding guide; and a hook extending from the sliding plate so as to slide in the slit, the hook extending into the first housing via the slit, an end of the hook being bent so as to face an inner surface of the sliding guide.

Owner:SAMSUNG ELECTRONICS CO LTD

Telescopic mast having reduced play

There is disclosed a telescopic mast (2) including two or more cylindric telescoping sections (4) with parallel walls (6), where the distal one of two adjacent telescoping sections (4) is narrower than the proximal one of the two adjacent telescoping sections (4), so that the distal telescoping section (4) can be moved into and out of the proximal telescoping section (4), respectively. In the interspace (8) between two adjacent telescoping sections (4) there is provided at least one device (10) interacting with an actuator (16) and pressing the adjacent walls (6) away from each other. Hereby play is eliminated or minimized.

Owner:DRS SUSTAINMENT SYST

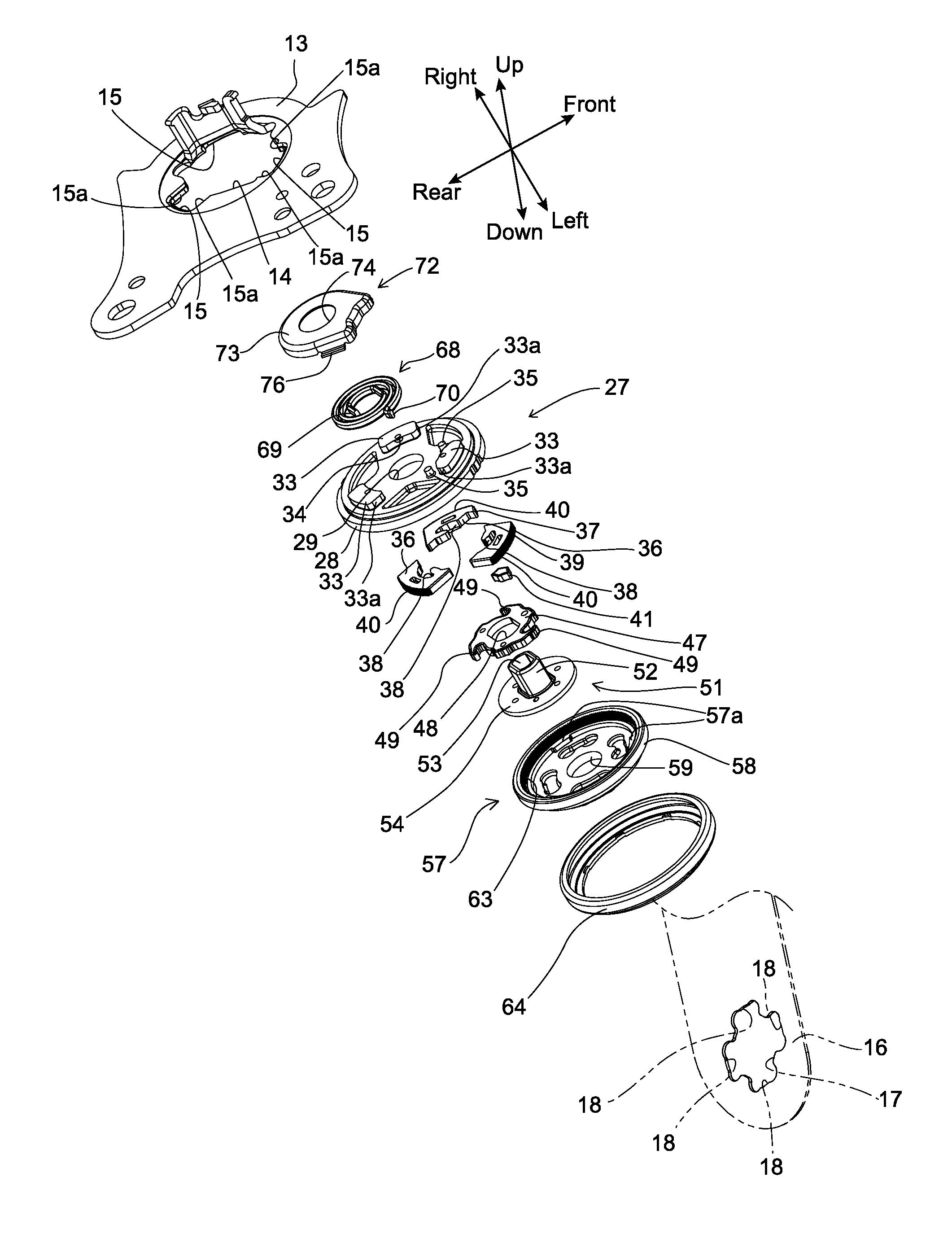

Seat reclining apparatus

A seat reclining apparatus includes a base plate, a ratchet plate, guide grooves formed on the base plate including an internal gear, lock members installed in the guide grooves and each having an outer toothed portion, and an operating member for moving the lock members between engaged and disengaged positions in which an outer toothed portion is engaged and disengaged with the internal gear, respectively. One of the lock members constitutes a small-clearance lock member which is smaller in play in a circumferential direction relative to a guide groove than the remaining lock members when in the engaged position. The small-clearance lock member is provided at the smallest distance between an engagement central position, at which the outer toothed portion and the internal gear are centered about, and an upper end of the seatback side frame.

Owner:TOYOTA BOSHOKU KK

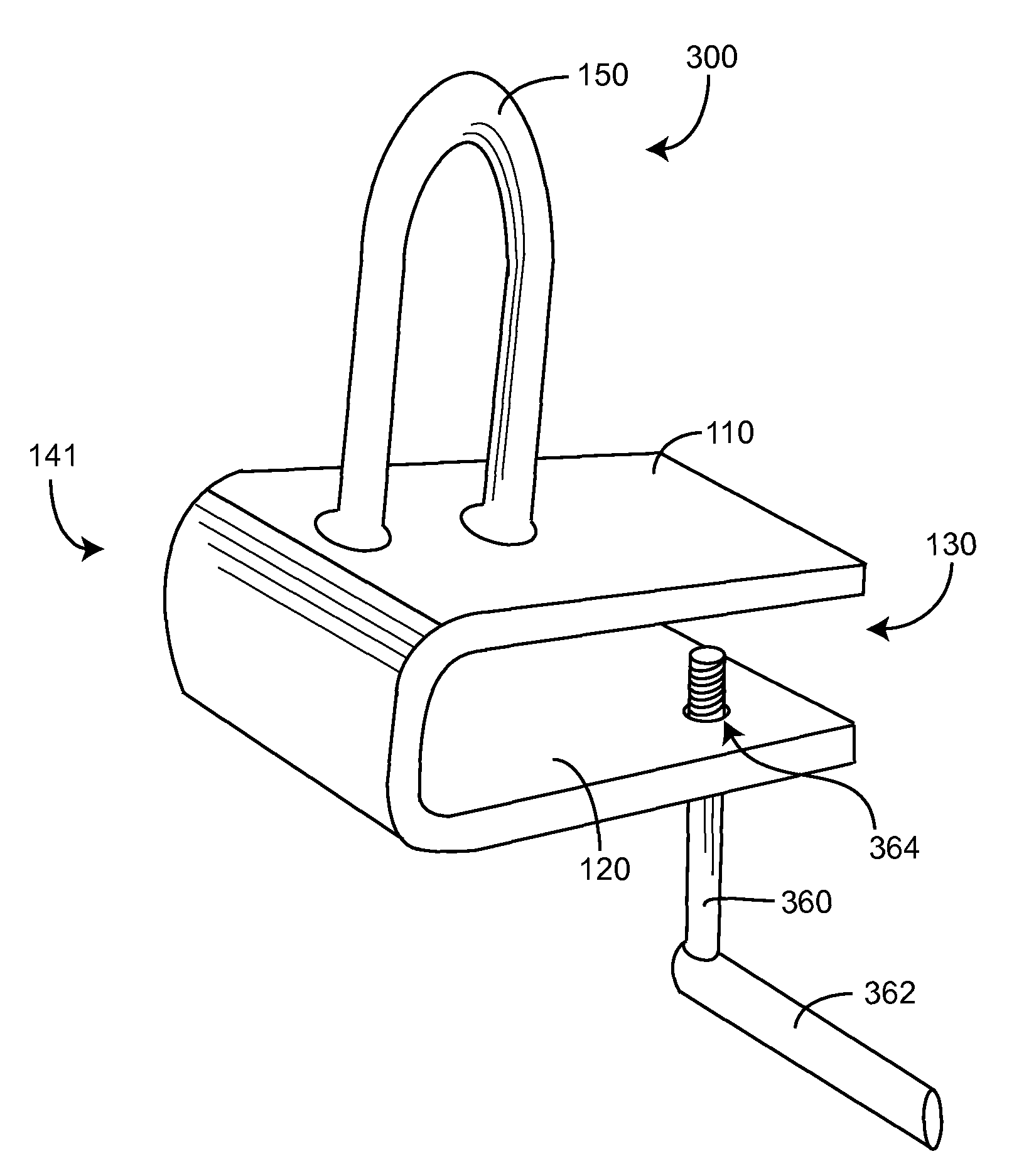

Bucket lift ring for loader and backhoe buckets

InactiveUS8985934B1Shorten the timeLow costMechanical machines/dredgersLifting devicesParallel plateMechanical engineering

A removable bucket ring attachment configured to slide over a terminal bottom front end of a bucket on a loader or a backhoe; where the bucket ring attachment has a pair of parallel plates closed at one end and open at an opposing end.

Owner:SR&D

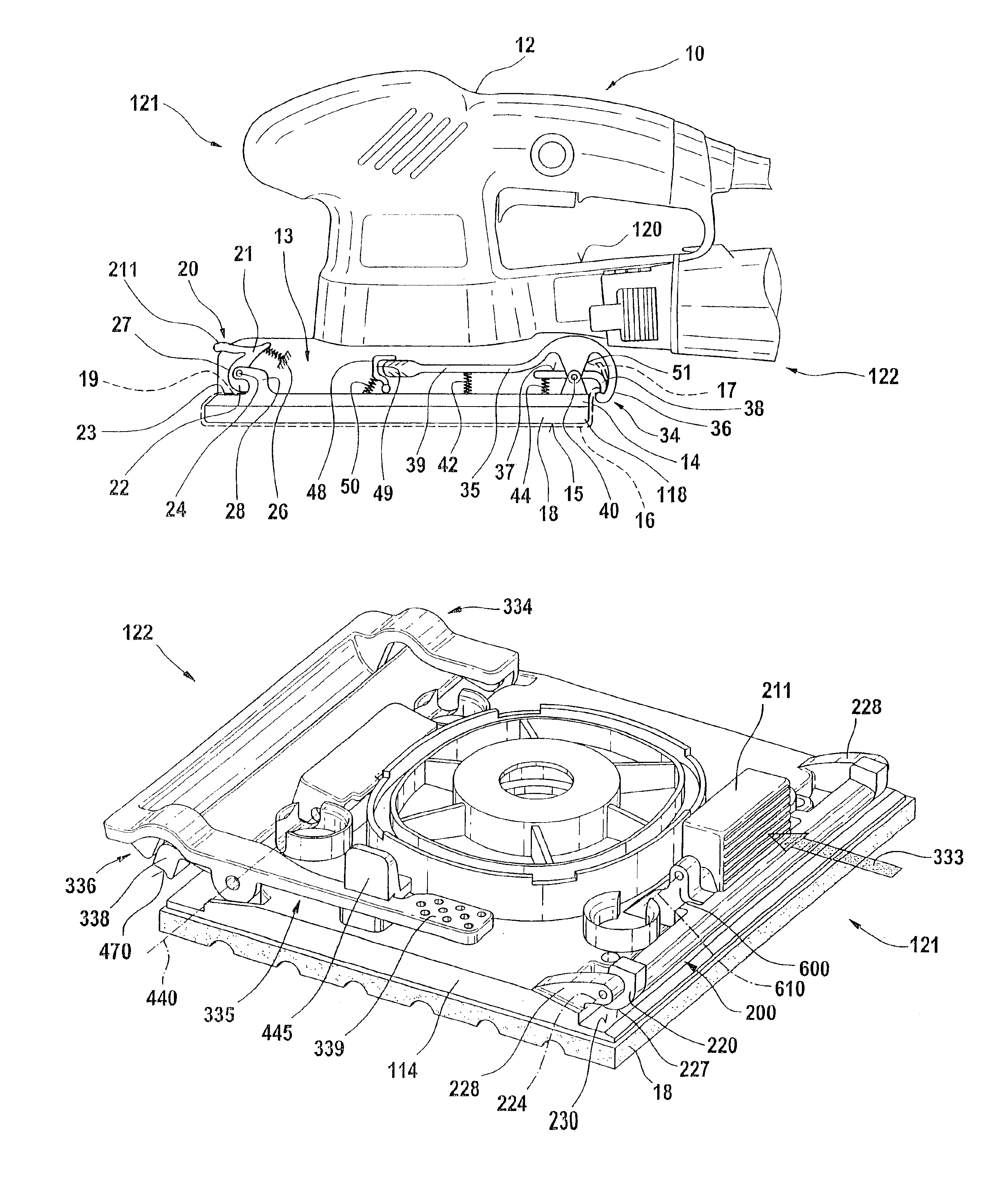

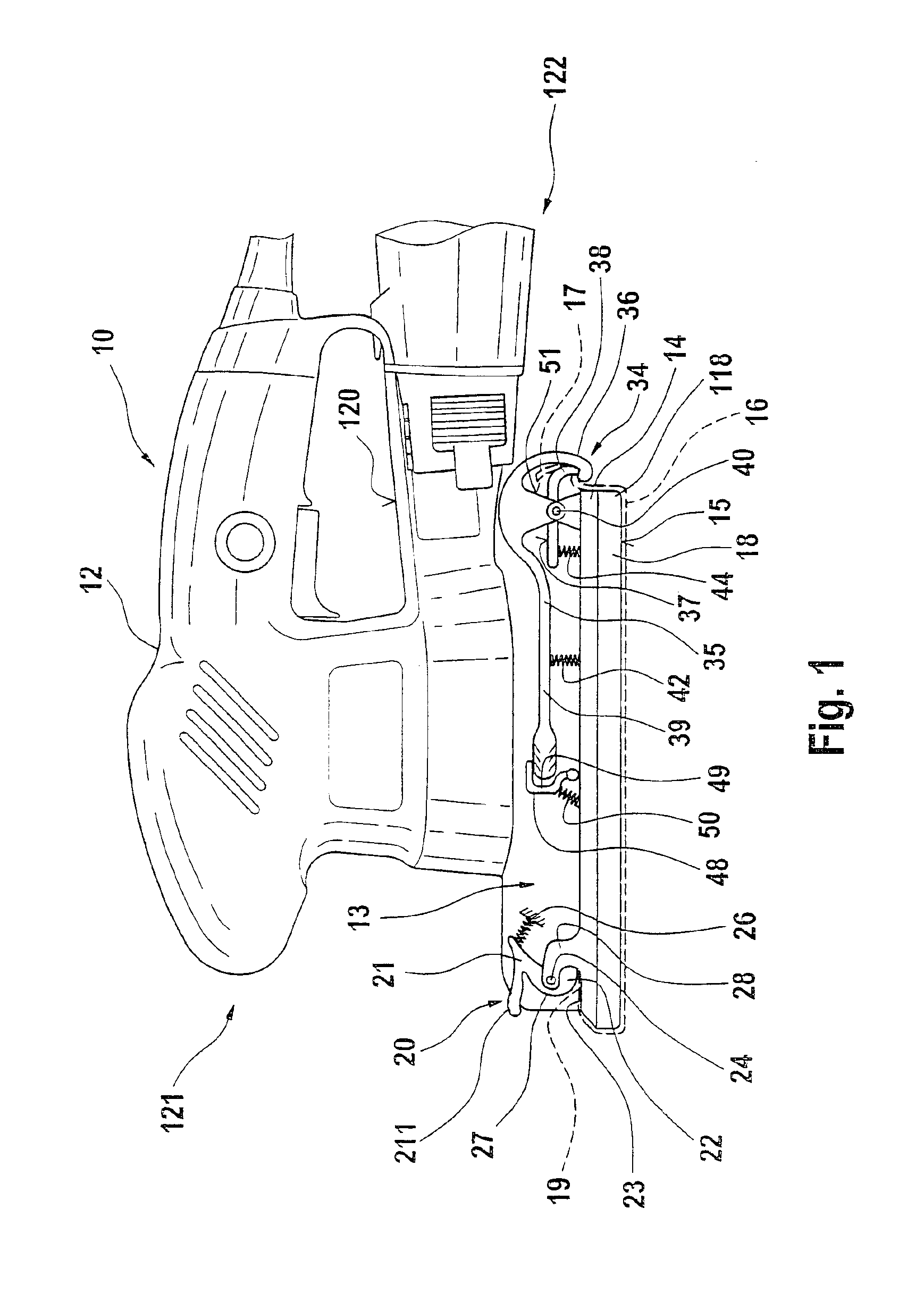

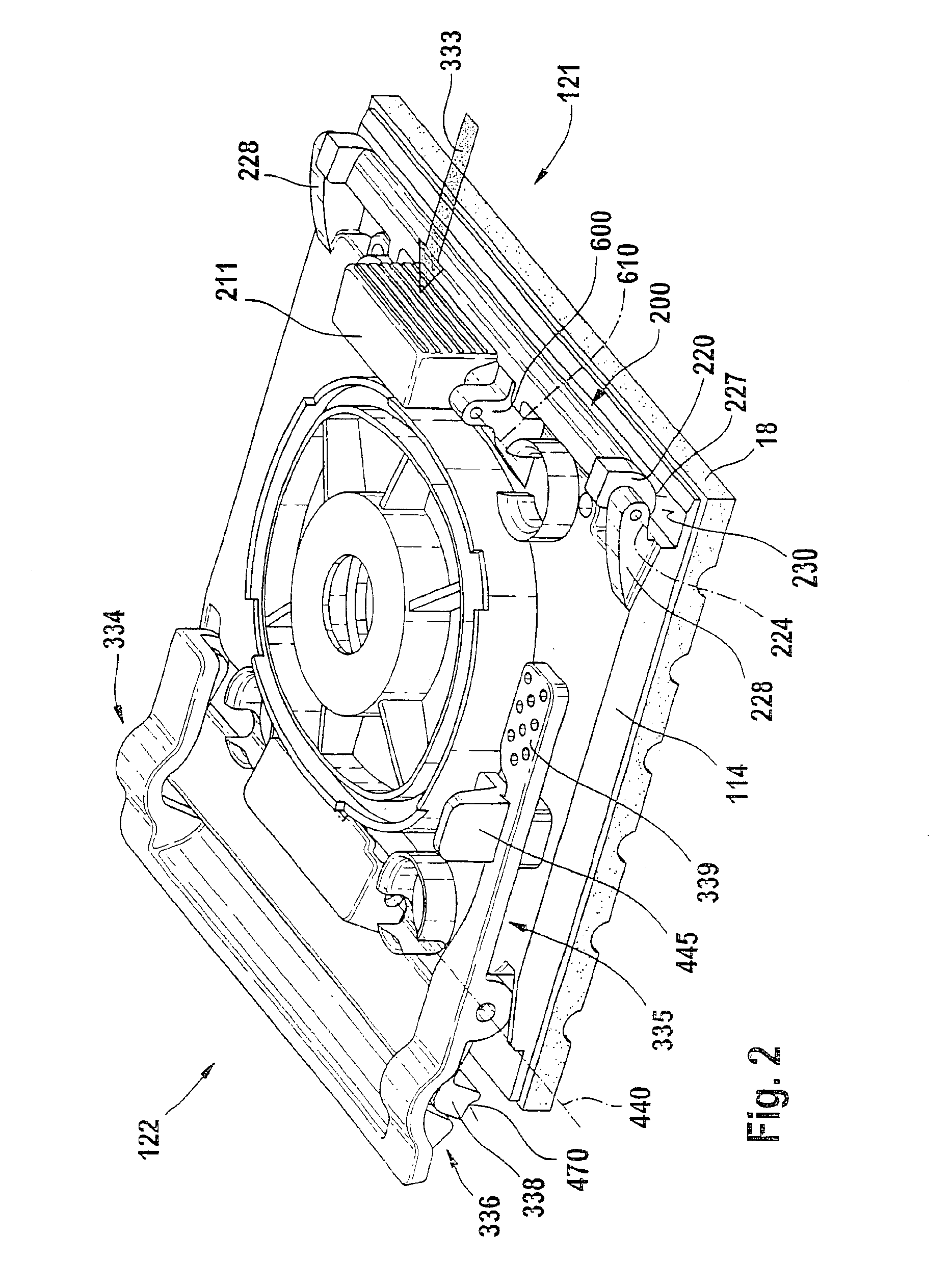

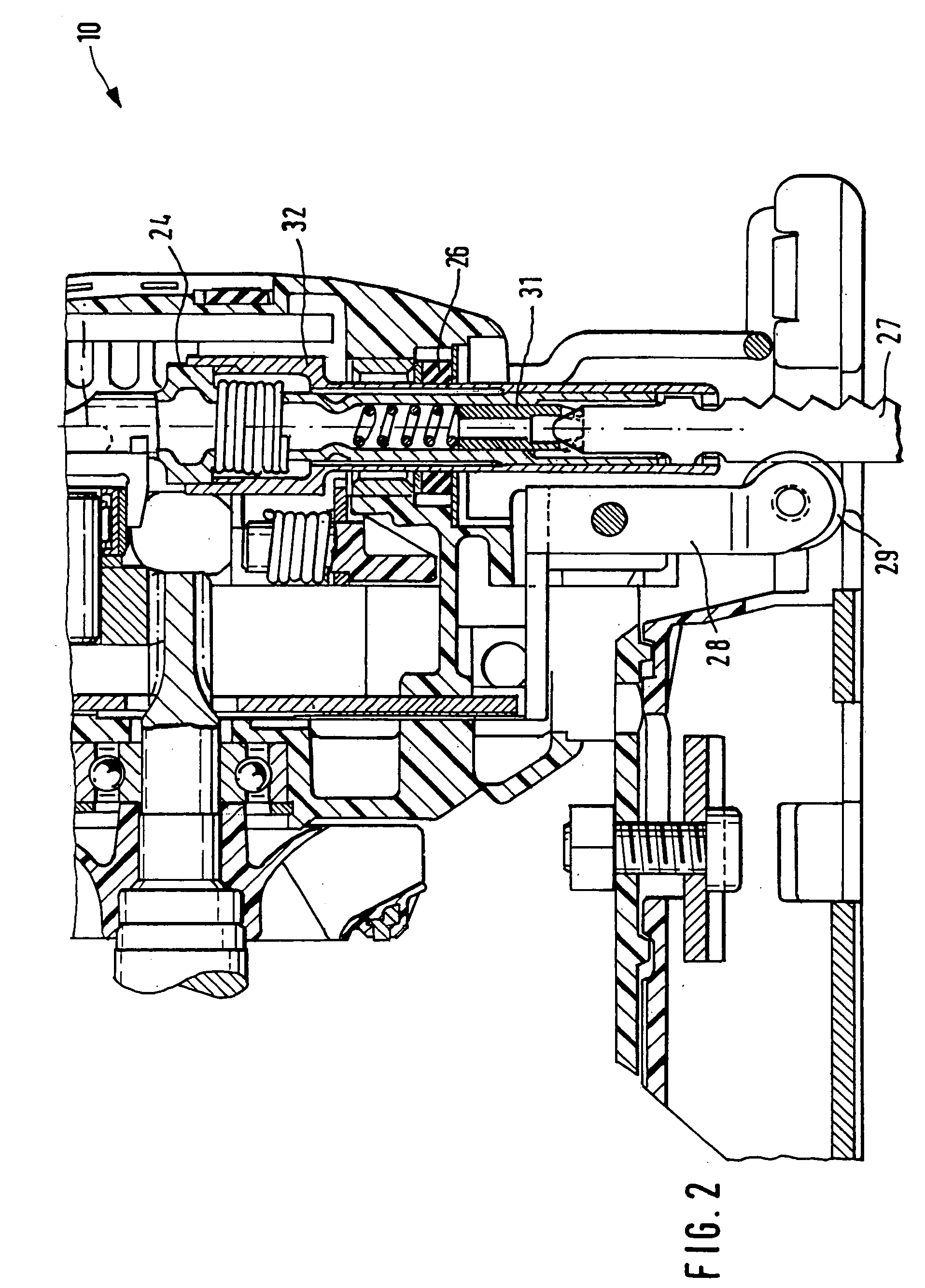

Sanding machine tool

InactiveUS6855041B2Increase clamping forceConvenient to accommodatePortable grinding machinesGrinding/polishing hand toolsEngineeringMachine tool

Owner:ROBERT BOSCH GMBH

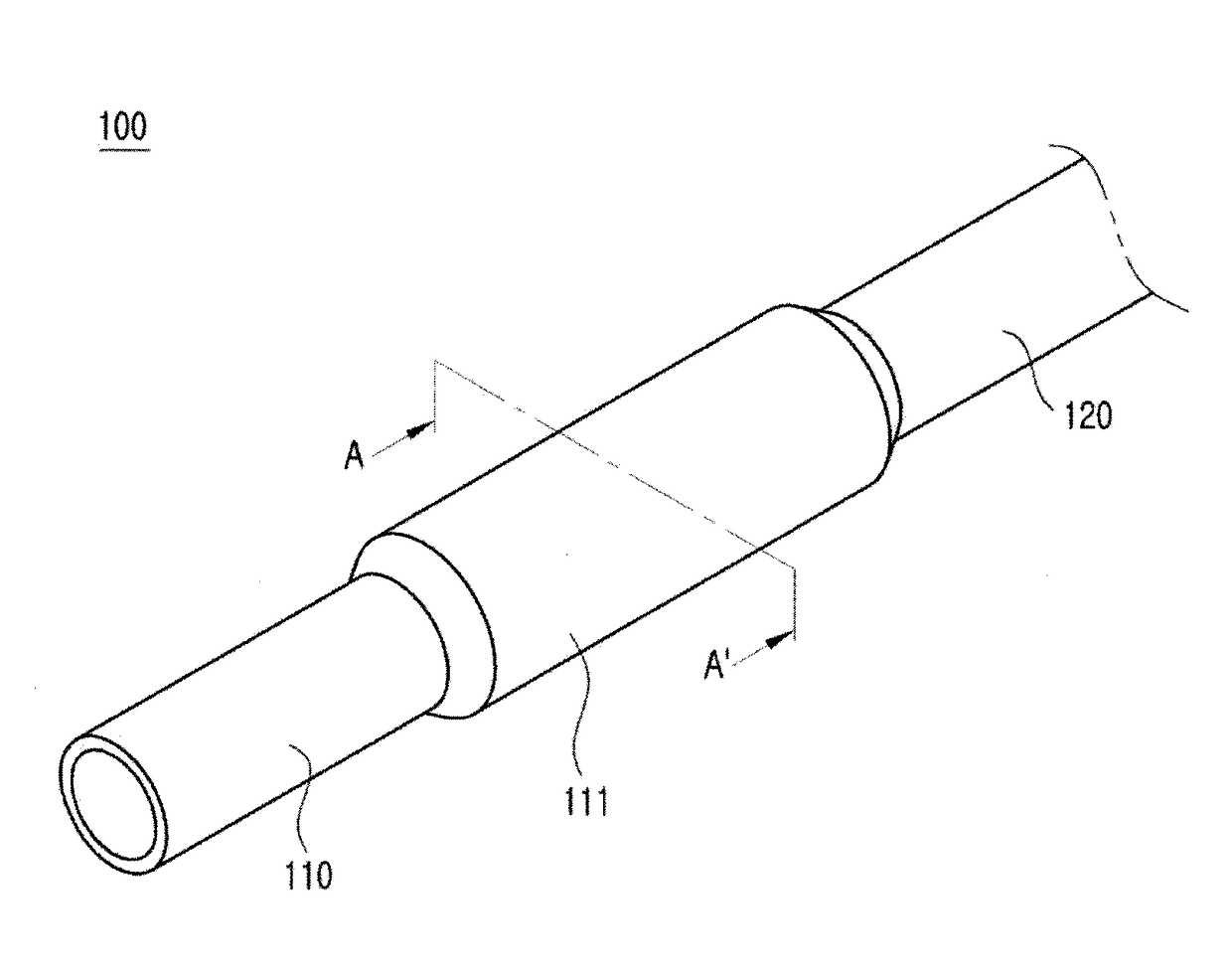

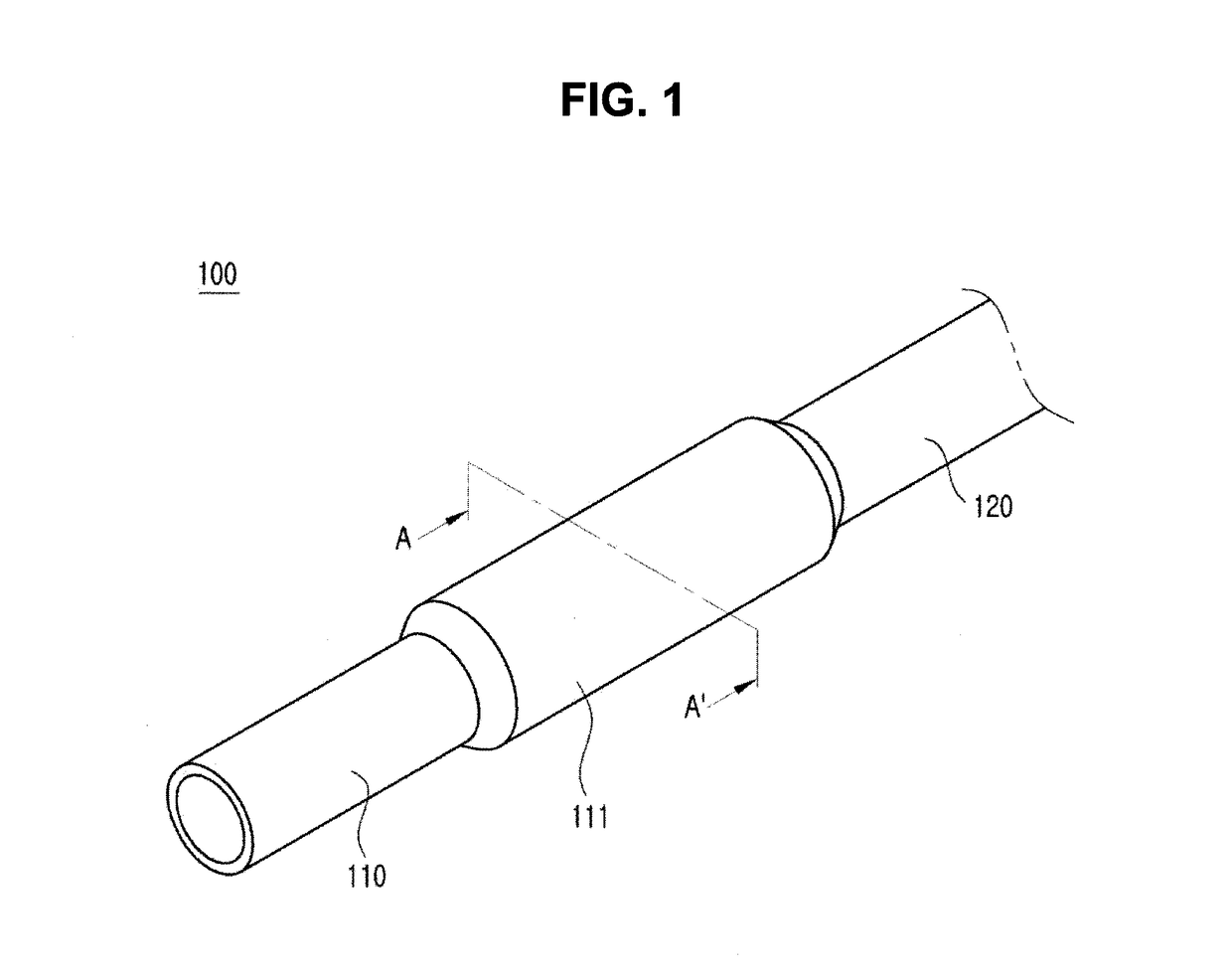

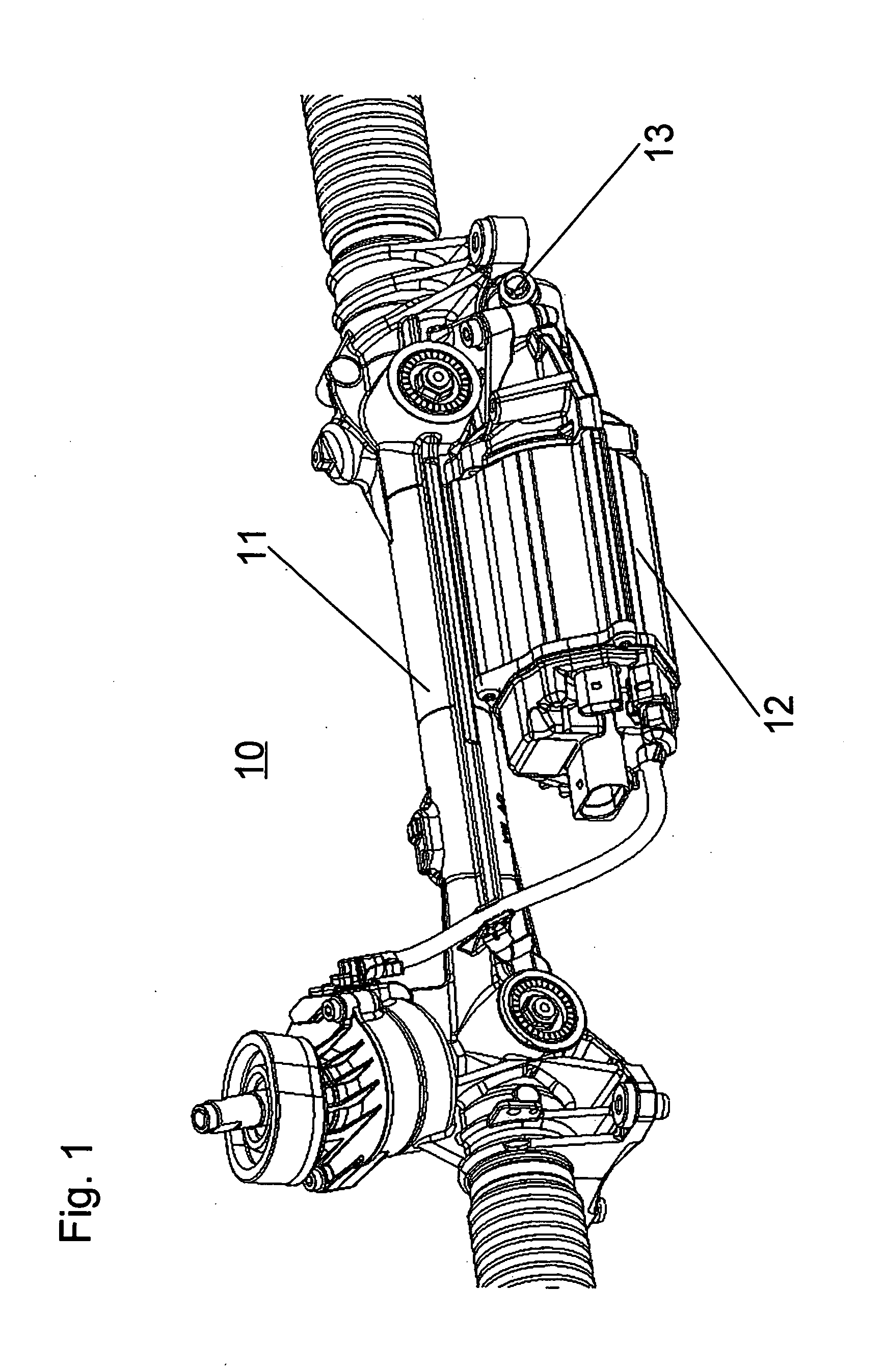

Telescopic shaft

Owner:KOREA FLANGE

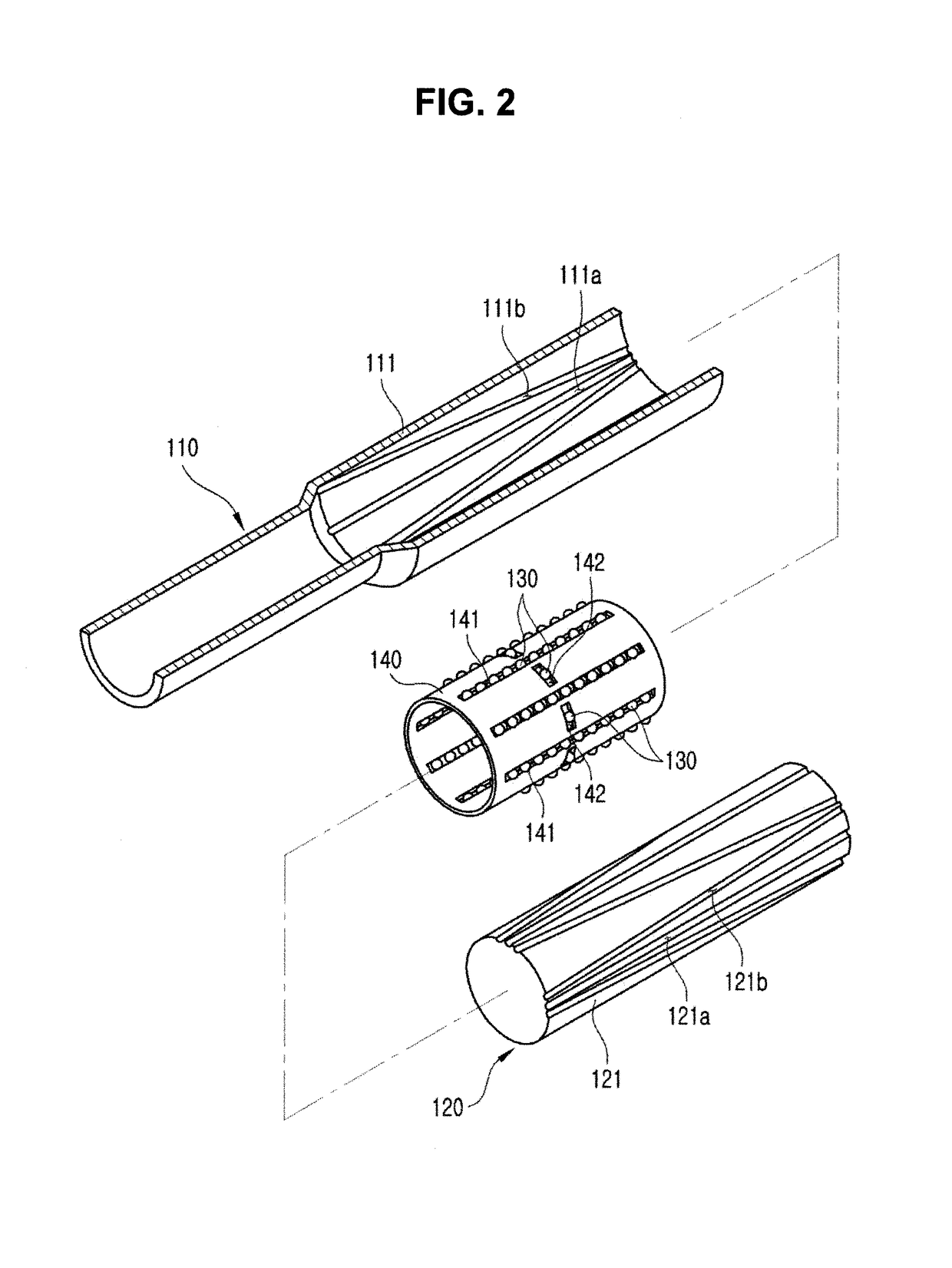

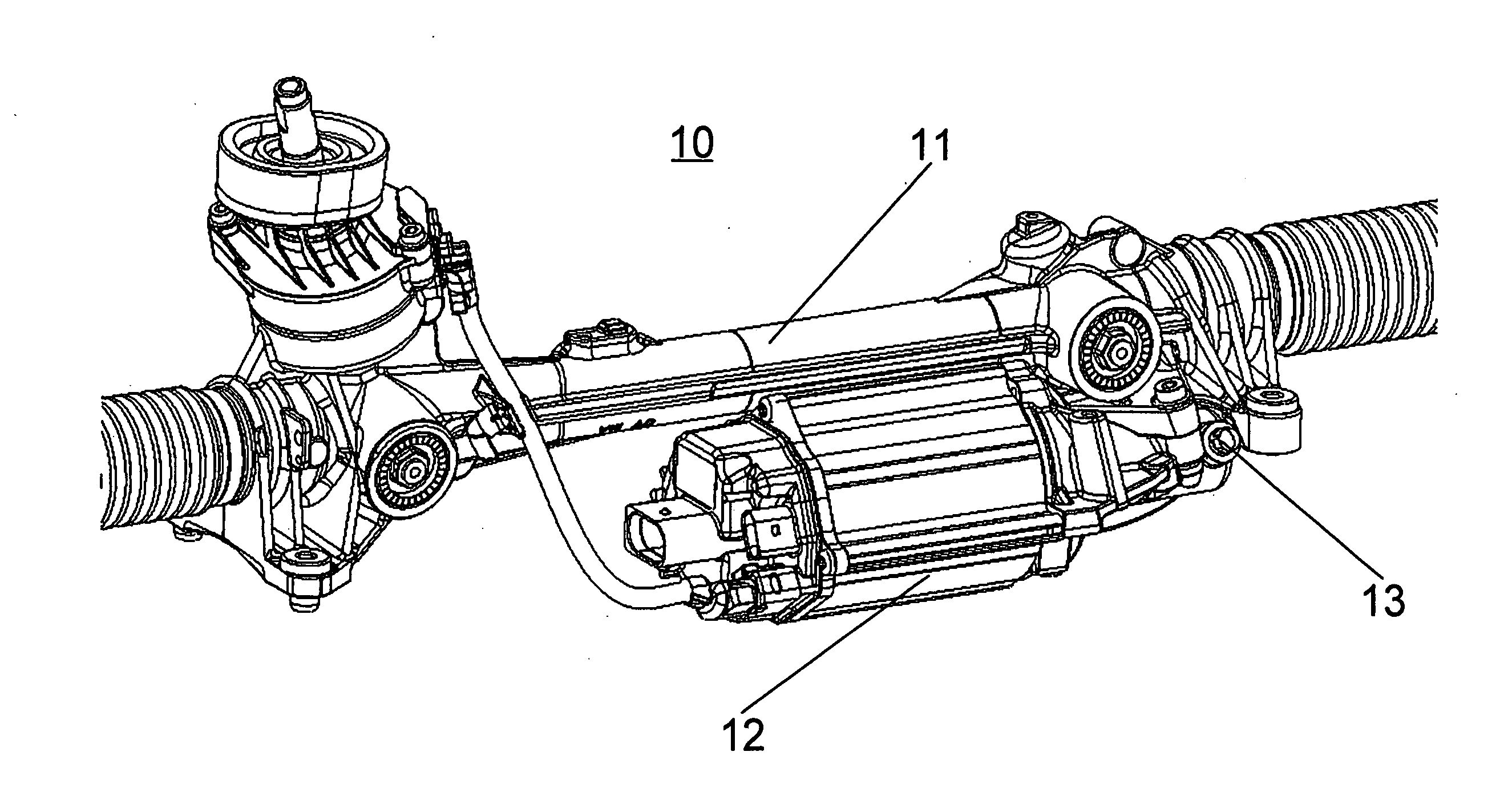

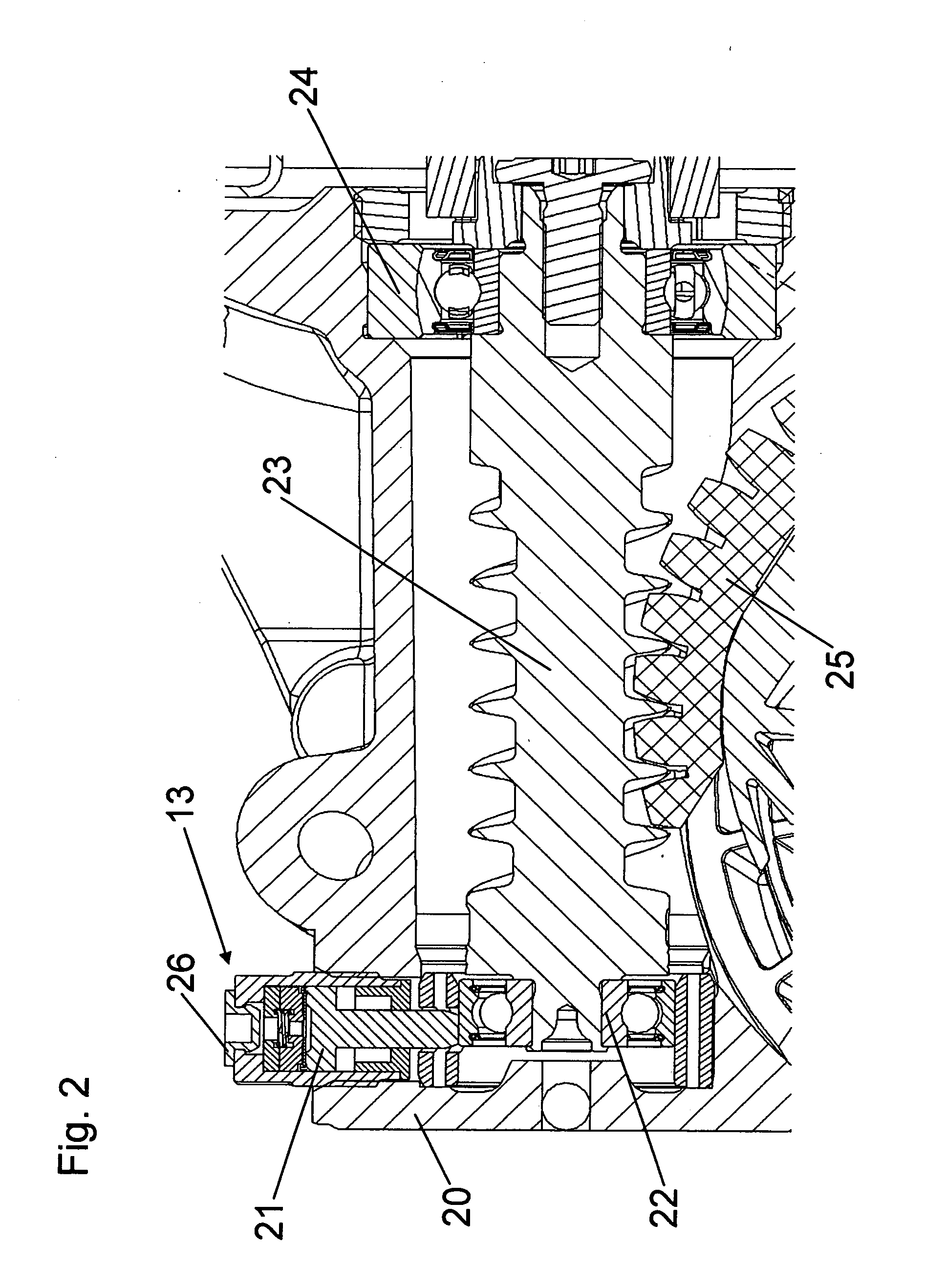

Device for pressing a transfer element

InactiveUS20120186378A1Reduces undesirable noiseReduce noiseGearingGearing detailsEngineeringMotorized vehicle

Described is a device for pressing a first transmission element onto a second transmission element engaging with the first transmission element, in particular for a steering system of a motor vehicle, comprising a pressure piece which can be loaded in the direction of the first transmission element and is displaceably guided in a housing. The devices known from the prior art can cause undesirable noise during driving operations. The device according to the invention thus comprises an adjustment unit for minimizing play occurring between the first transmission element and the second transmission element.

Owner:ZF LENKSYST

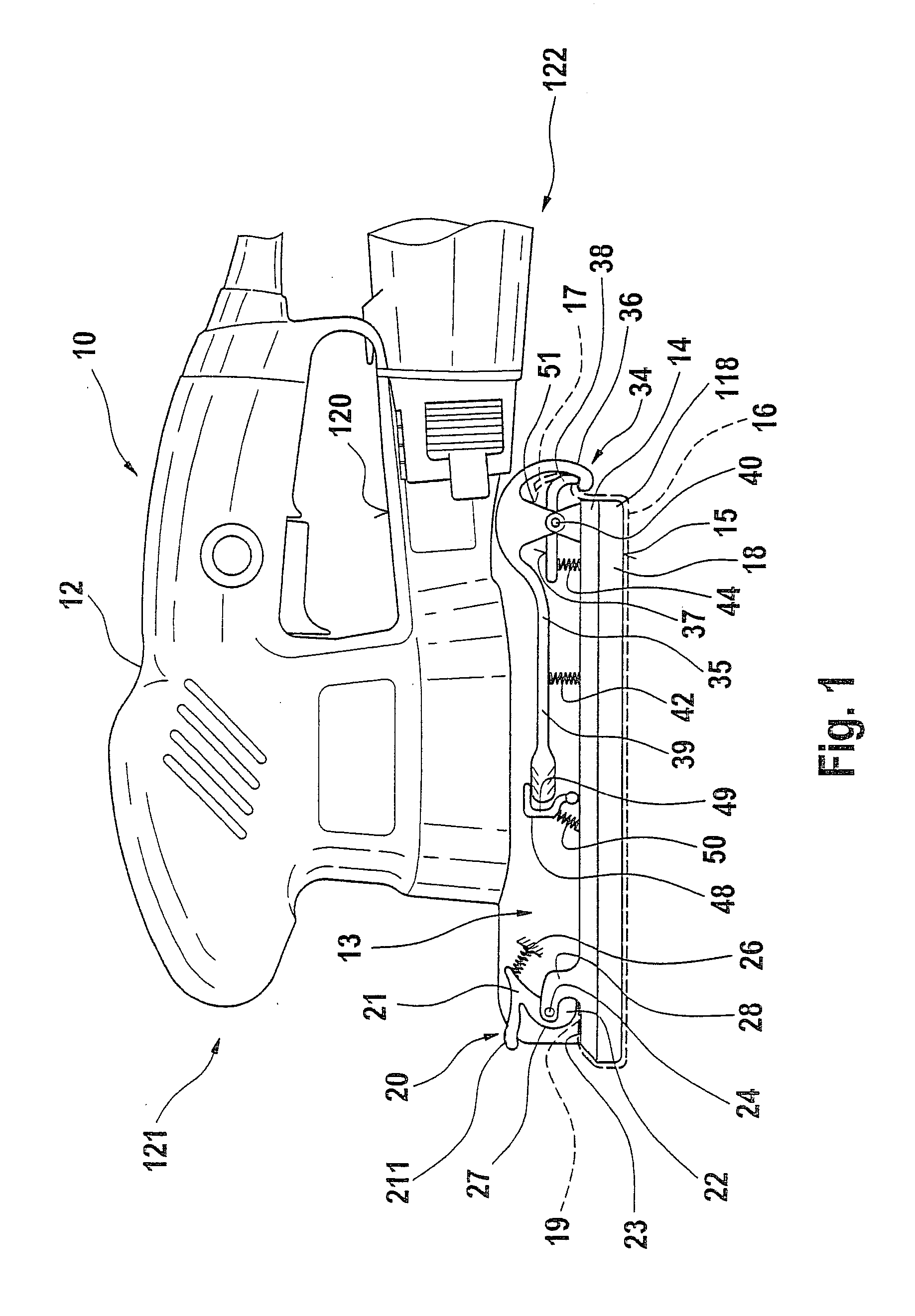

Hand-held compass saw

InactiveUS20050076509A1Minimize playMinimizing any tendencyMetal sawing devicesMetal sawing accessoriesHand heldEngineering

A power compass saw (10) with a housing (12) that accommodates a lifting rod for the up and down movement of a longitudinal saw blade (27) attached thereto, the saw blade having a toothed side and a saw blade back (270), and with a guide roller (29) which supports the saw blade back (270) and has a central circumferential groove (290) into which the saw blade extends with its saw blade back (270) and is guided therein, whereby the sides of the circumferential groove (290) are tapered, the power compass saw functioning particularly precisely and efficiently due to the fact that the saw blade back (270) of the saw blade (27) is designed with a 7° conical configuration and / or taper on both sides, so that it tapers toward the saw blade back (270) and is capable of being supported in two dimensions in the circumferential groove (290), the groove sides (291) of which have a 5° taper.

Owner:SCINTILLA AKTIENGES

Bias assembly for ratchet tools

ActiveUSRE44655E1Quantity minimizationMinimal amount of wasted motionSpannersWrenchesEngineeringCounter rotation

A ratcheting tool such as a reversible dual-pawl ratchet wrench is disclosed that minimizes wasted motion during ratchet slip or counter-rotation. The ratchet wrench includes a bias assembly that biases the pawls apart to bias a first, selected pawl for a selected drive direction towards engagement with a ratchet gear, and that the biases the selected pawl into a concentric alignment with the ratchet gear. In this manner, non-ratcheting initial rotation of the pawl due to counter-rotation prior to the pawl camming out of engagement with the ratchet gear is eliminated, thus eliminating wasted motion and maximizing the available angular sweep for the wrench.

Owner:SNAP ON INC

Method for manufacturing an adjustment fitting

ActiveUS9663003B2Quality improvementImprove operational reliabilityToothed gearingsMeasurement/indication equipmentsRotational axisEngineering

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG

Method for manufacturing an adjustment fitting

ActiveUS20110154925A1Quality improvementImprove operational reliabilityToothed gearingsMeasurement/indication equipmentsRotational axisSpite

A method for producing an adjustment fitting, particularly for a vehicle seat is provided, whereby an outer wheel is associated with a first fitting part, the wheel having inner toothing, and having an inner wheel that can be associated with a second fitting part, the wheel having outer toothing, wherein the inner wheel having the outer toothing is inserted into the outer wheel having the inner toothing eccentrically to a rotational axis in the manner of a wobble mechanism, wherein partial eccentric elements are inserted rotatably with respect to each other in an eccentric receiving chamber formed between the rotational axis and the inner wheel so as to produce variable eccentricity, wherein a transmission element having an engagement element for actuating the partial eccentric element is inserted such that the engagement elements interacts with a catch of the partial eccentric element. In spite of the production tolerances of the components, overall higher quality and higher operational safety of the produced adjustment fitting are to be achieved. For this purpose, the geometry of the partial eccentric element is measured, and the geometry of the transmission element is individually adapted according to the data of the measurement before inserting the transmission element.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG

Rack for transport and storage

A collapsible rack for transport and storage, includes a first and a second panel and a plurality of distance bars. The first and second panel include a groove side including at least one groove. A first and a second edge is arranged on opposite sides and adjacent to these, a third and a fourth edge. The third and fourth edges each include at least one hole that extends parallel to the first and second edges. The hole has a non-circular shape. The distance bars at each of their ends includes a hole coupling mechanism. The hole coupling mechanism extends perpendicular to the extension of the bar. The hole coupling mechanisms include clutching sections that match the hole, wherein pivoting between the bars and the first and second panel is prevented where the hole coupling mechanism and hole are fully mated.

Owner:SCHOELLER ARCA SYST

Etch chamber

InactiveUS20070163714A1Reduce refluxMinimize playElectric discharge tubesDecorative surface effectsEngineeringFlange

An etch chamber and a method of reducing back flow of particles in an etch chamber having a valve connected thereto. The etch chamber comprises a valve connected to the etch chamber; and a liner a liner disposed to cover an internal gap between a flange portion of the valve and a flange portion of the etch chamber.

Owner:SYST ON SILICON MFG PTE

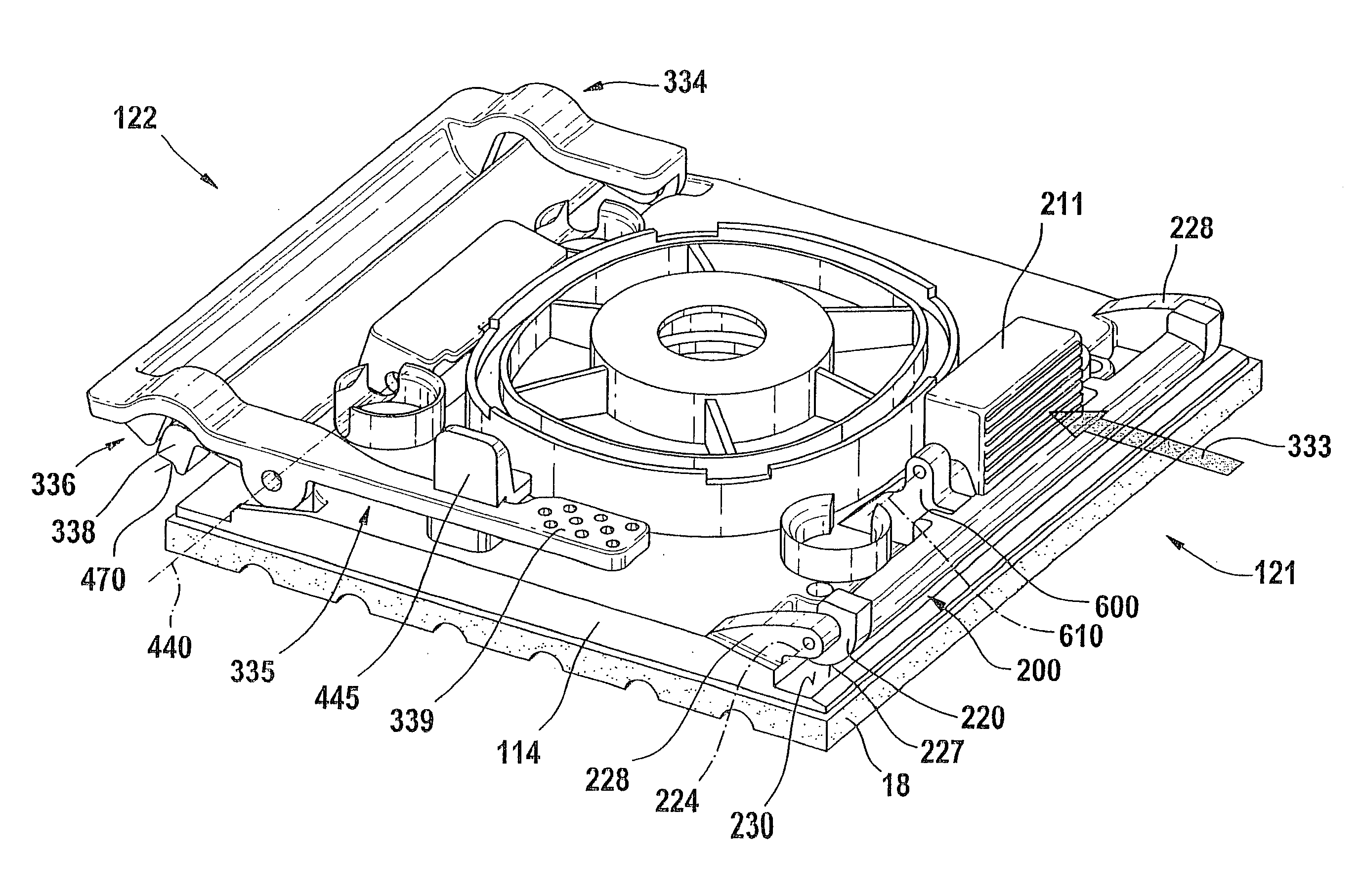

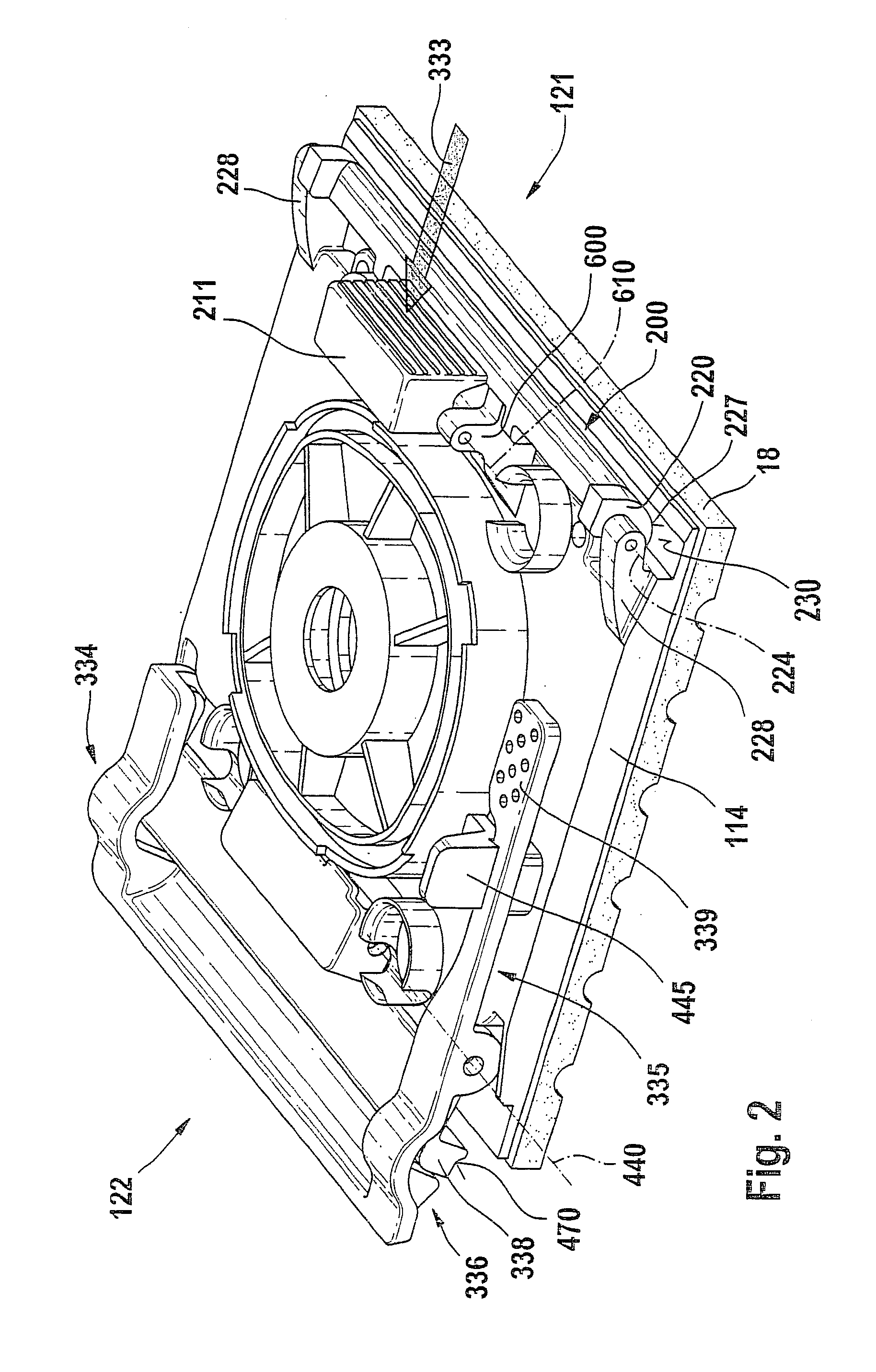

Sanding machine tool

InactiveUS20040002295A1Increase clamping forceConvenient to accommodatePortable grinding machinesGrinding/polishing hand toolsEngineeringMachine tool

An oscillating grinder (10) with a housing (12) a grinding sheet holder (14) having clamping means (20, 23; 200, 230; 334) for receiving a grinding sheet (16), whose grinding sheet ends (17, 19) can be clamped firmly to the grinding sheet holder (14), and in which the clamping means (20, 23; 200, 230; 334, 1334) are levers with a pivot axis (24; 224; 40; 440; 1440) supported on the grinding sheet holder side and clamping jaws (22; 220; 1222; 336, 338) that clamp the grinding sheet (16) on one end, preferably manually actuatable on the other end, can be equipped faster, more conveniently and more securely with a grinding sheet (16) by providing that one of the grinding sheet ends (19) for one-handed operation can be clamped solely by insertion between first clamping means (20, 23; 200, 230; 334; 1334), and the other grinding sheet end (17), likewise for one-handed operation, can be clamped after being placed in second clamping means (34; 334; 1334) and after their actuation; the grinding sheet (16) can be tensed tautly by its subsequent motion, together with the clamped grinding sheet end (17), in particular pivoting, away from the first clamping means (20, 23; 200, 230; 334; 1334).

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com