Patents

Literature

175 results about "Forage harvester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A forage harvester (also known as a silage harvester, forager or chopper) is a farm implement that harvests forage plants to make silage. Silage is grass, corn or other plant that has been chopped into small pieces, and compacted together in a storage silo, silage bunker, or in silage bags. The silage is then fermented to provide feed for livestock. Haylage is a similar process to silage but using grass which has dried.

Agricultural working machine

InactiveUS20090044505A1Improving visibility conditionIncrease awarenessMowersPicking devicesAgricultural scienceForage harvester

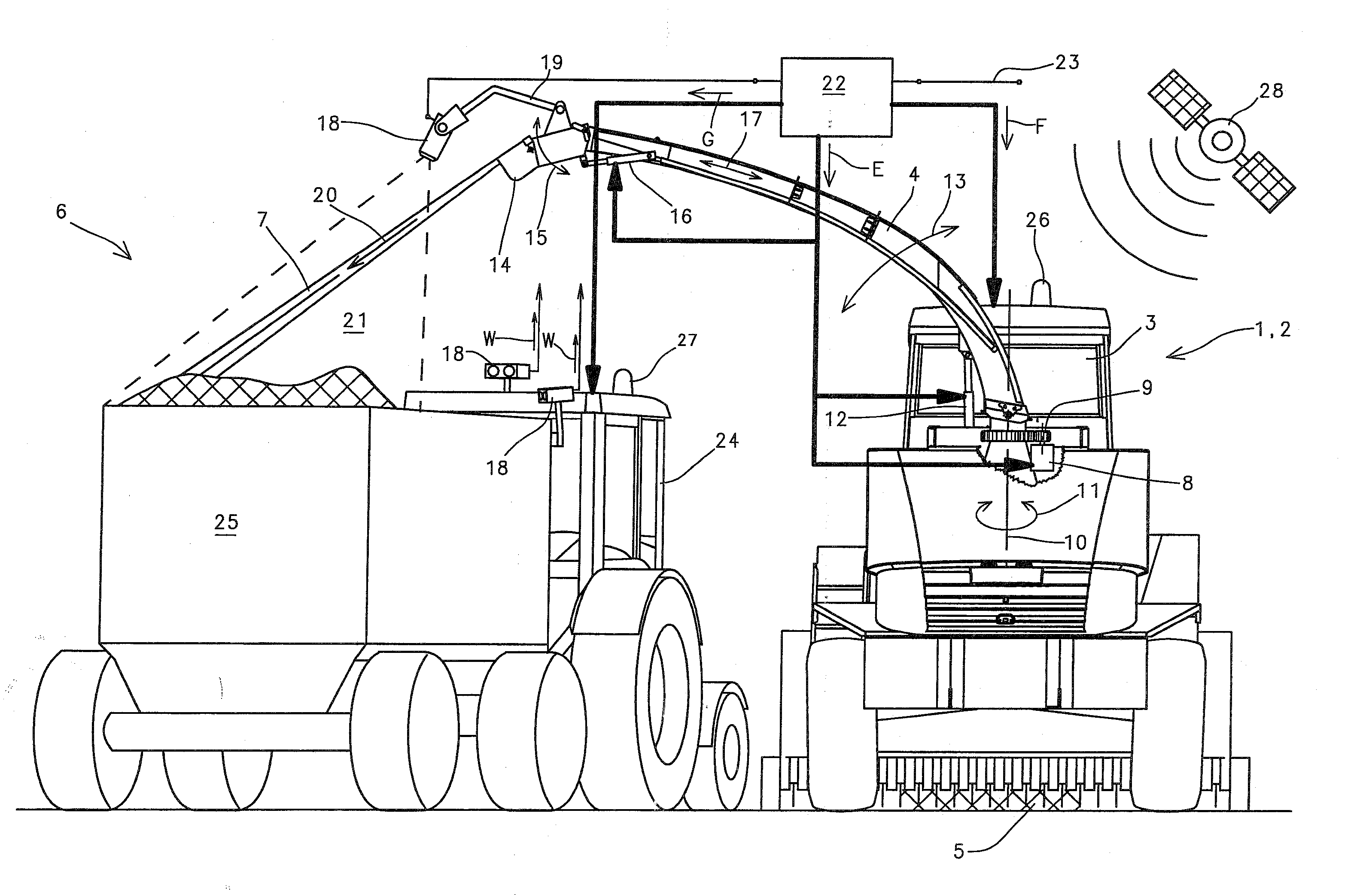

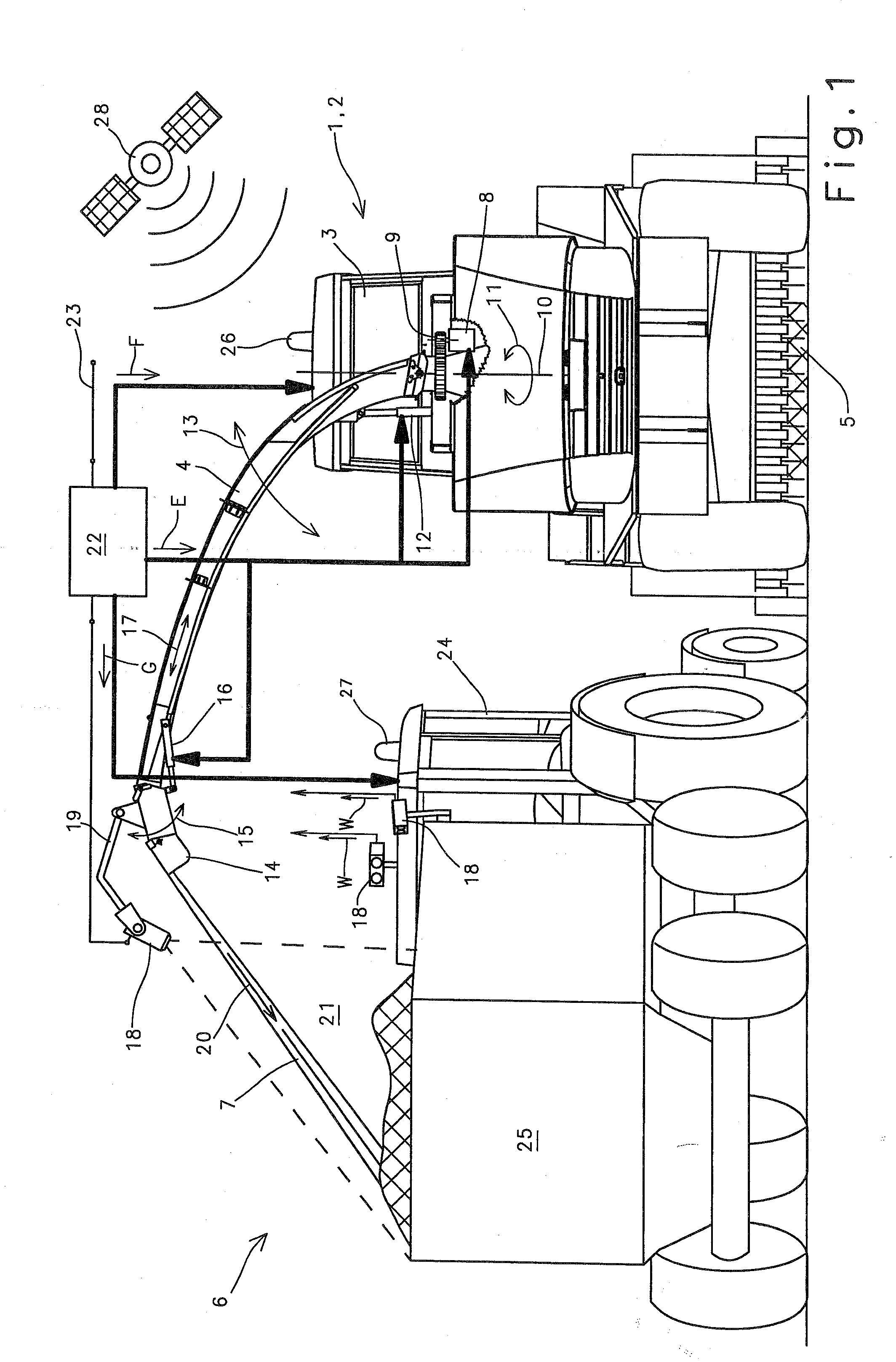

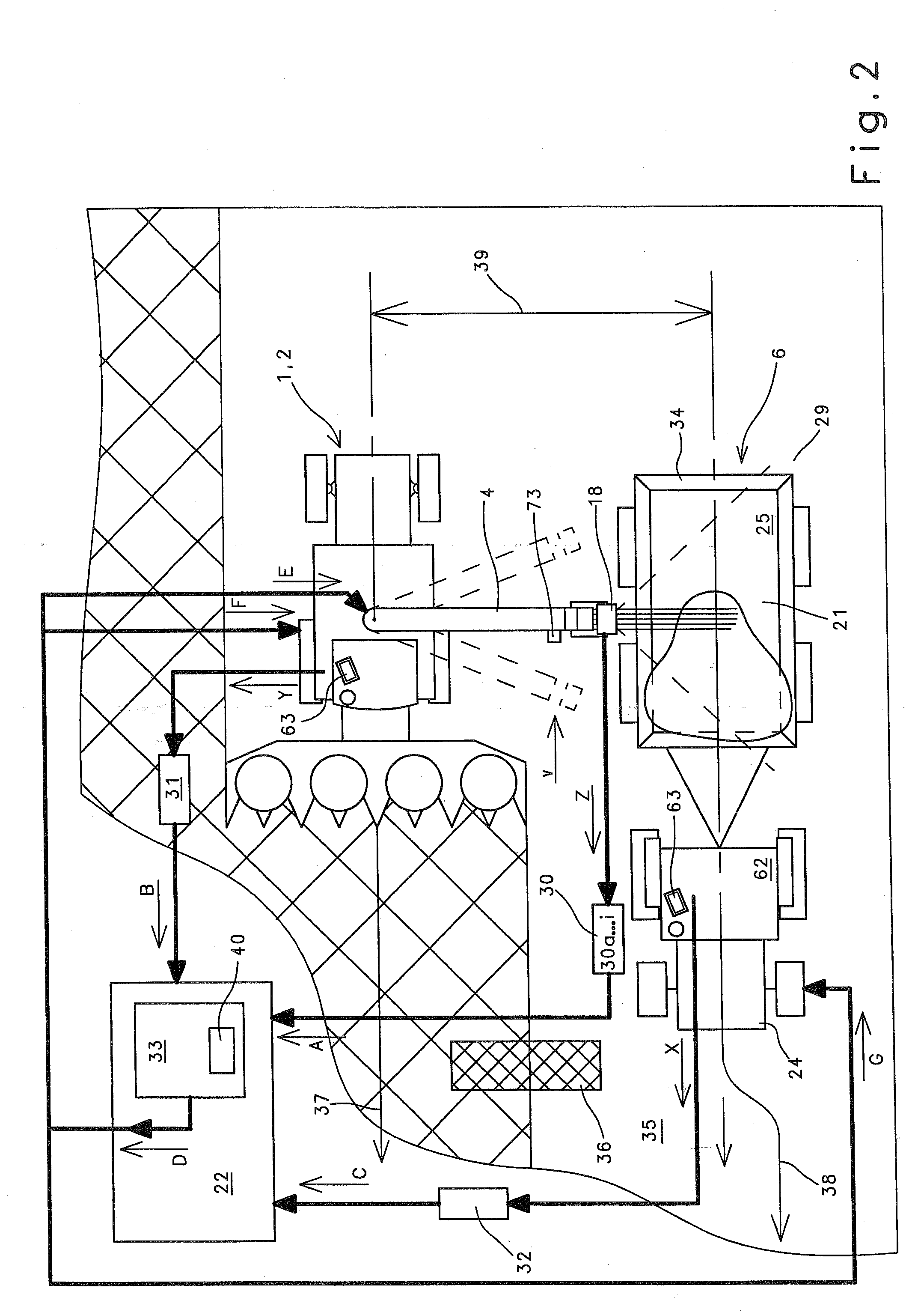

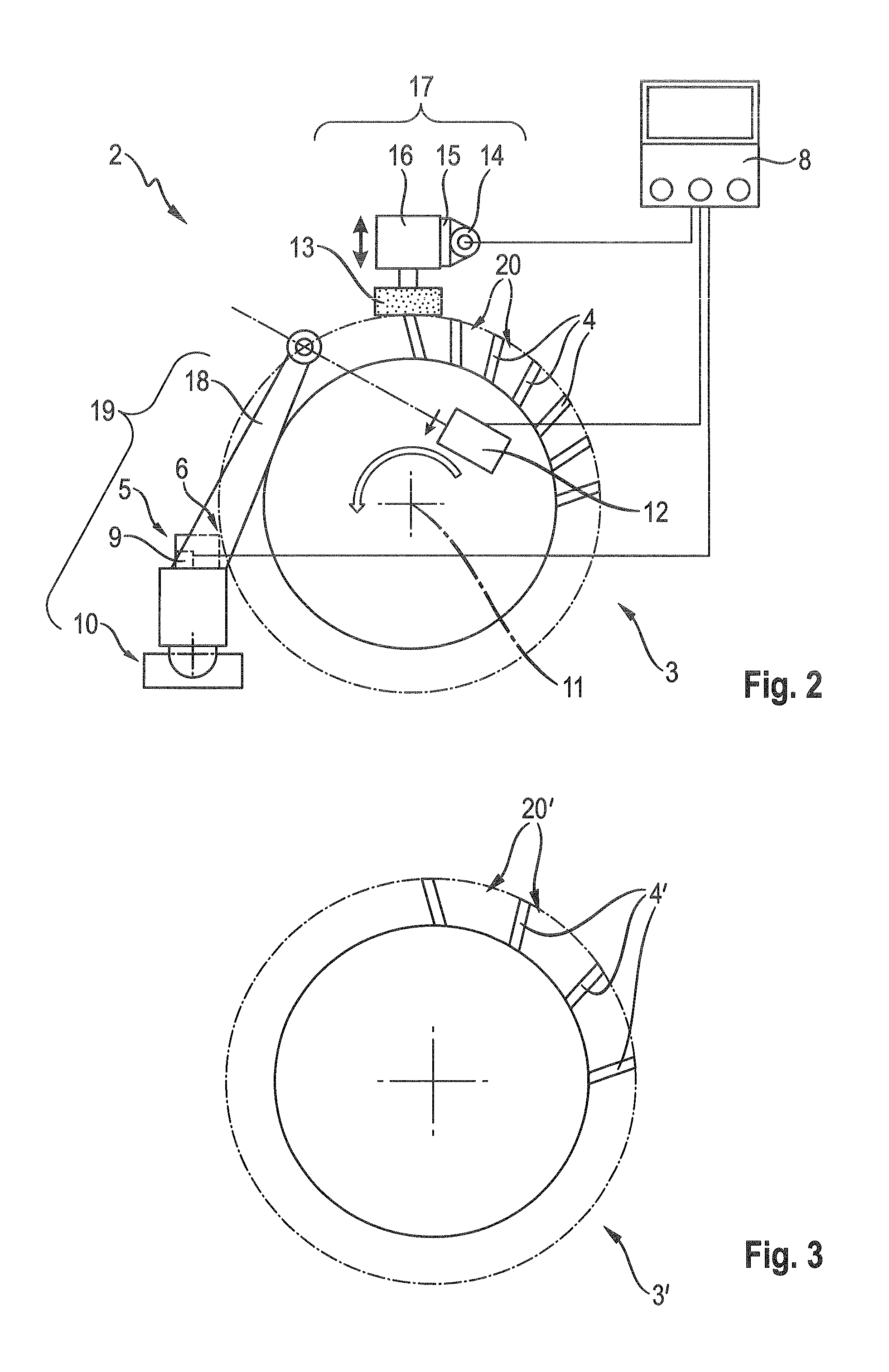

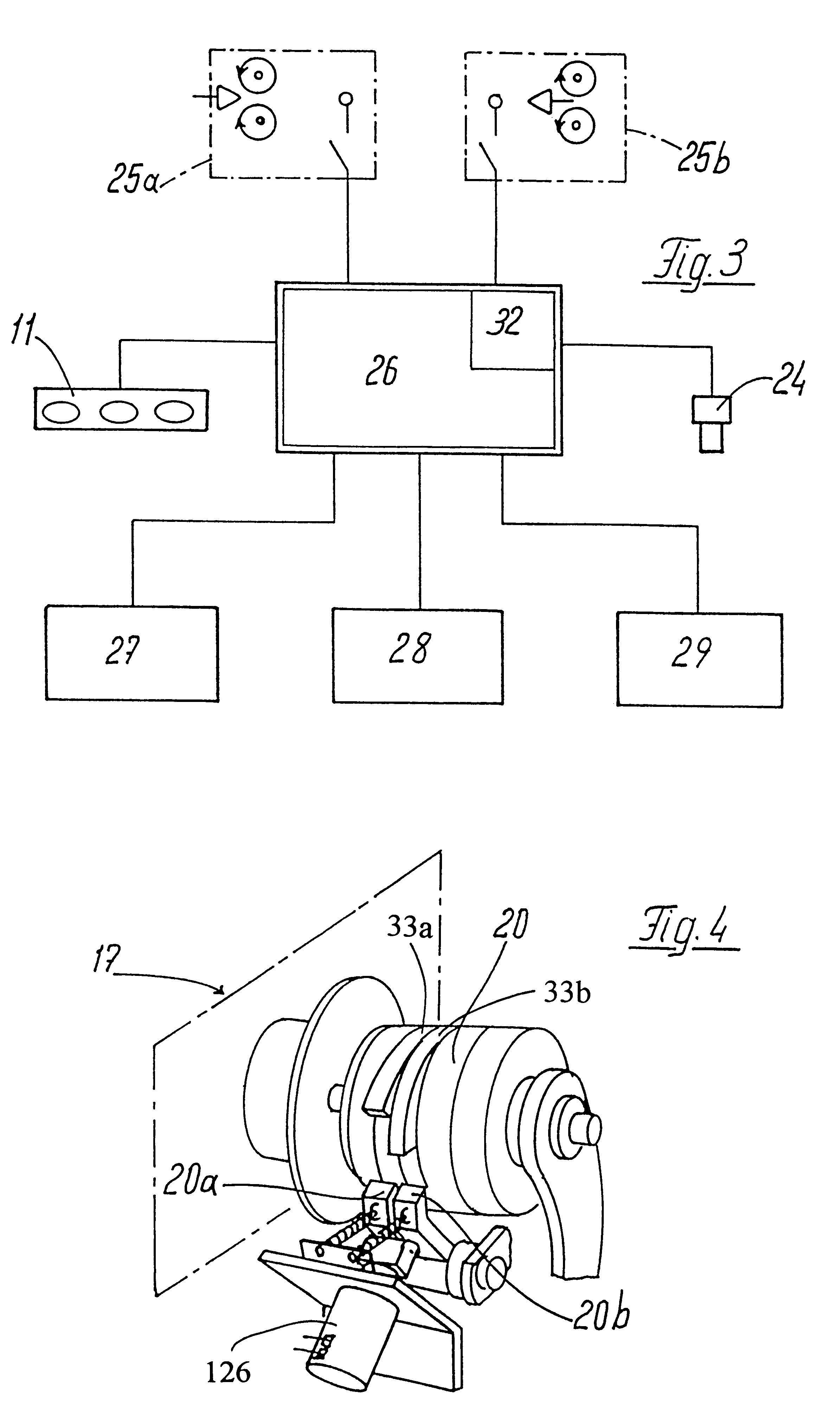

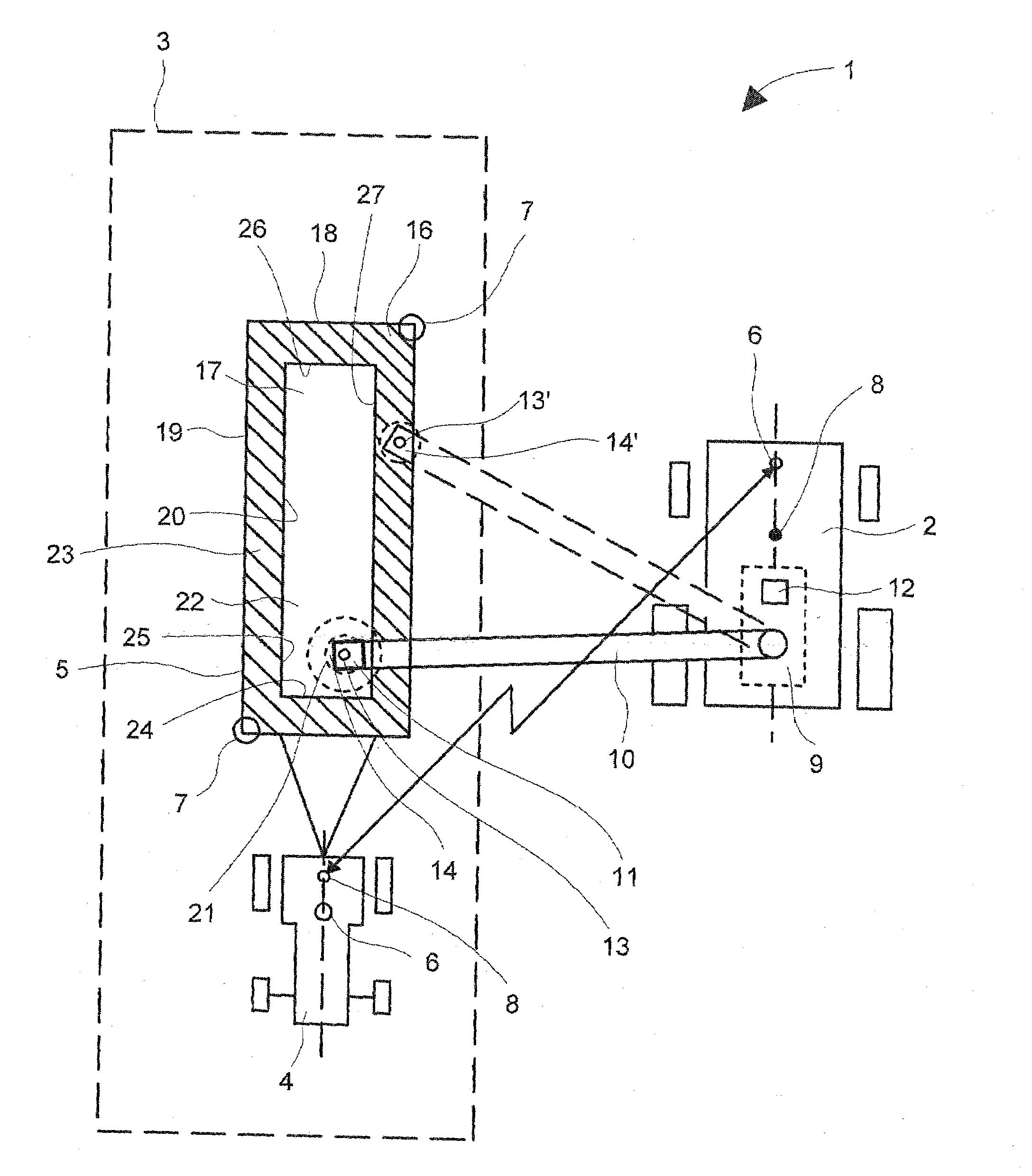

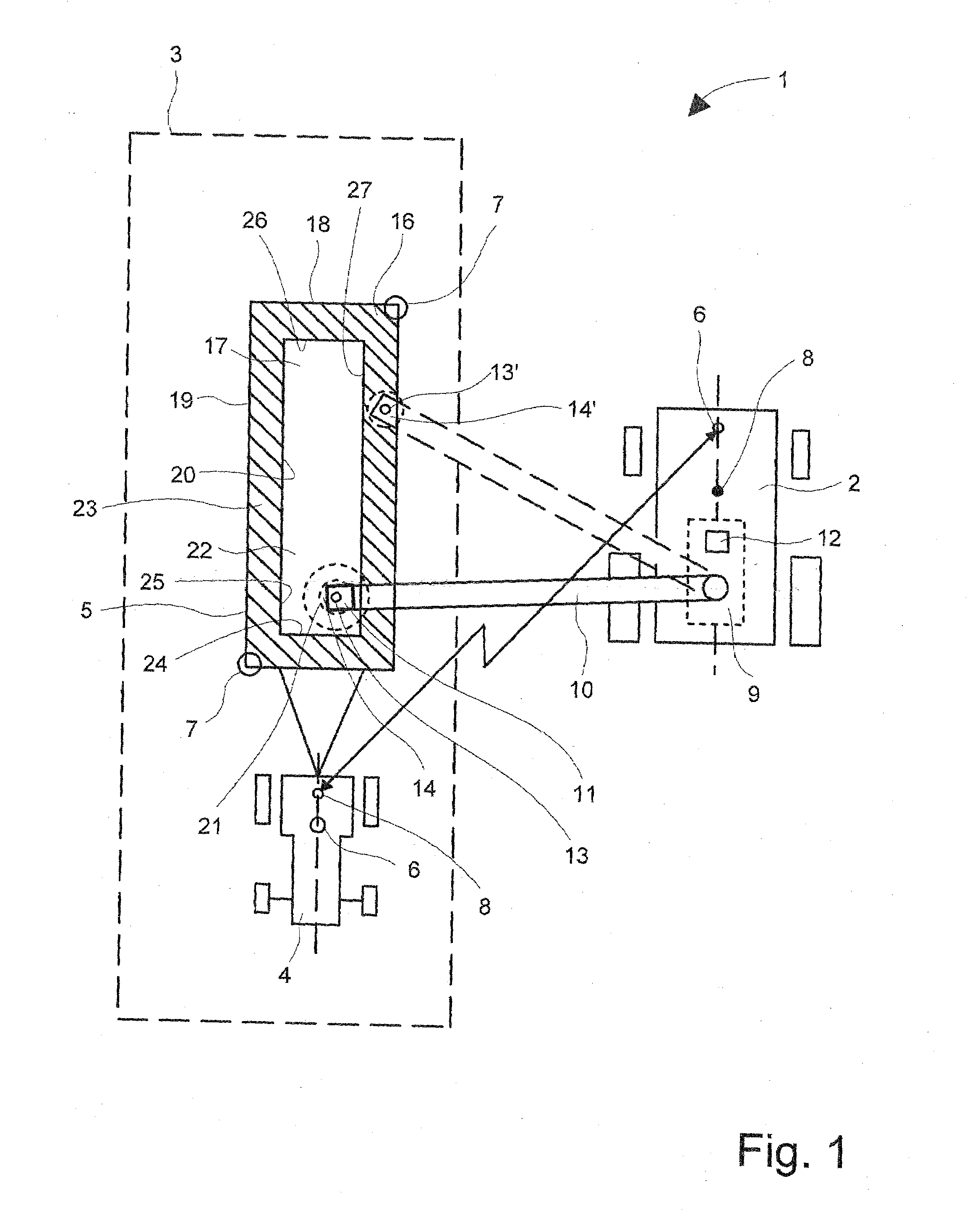

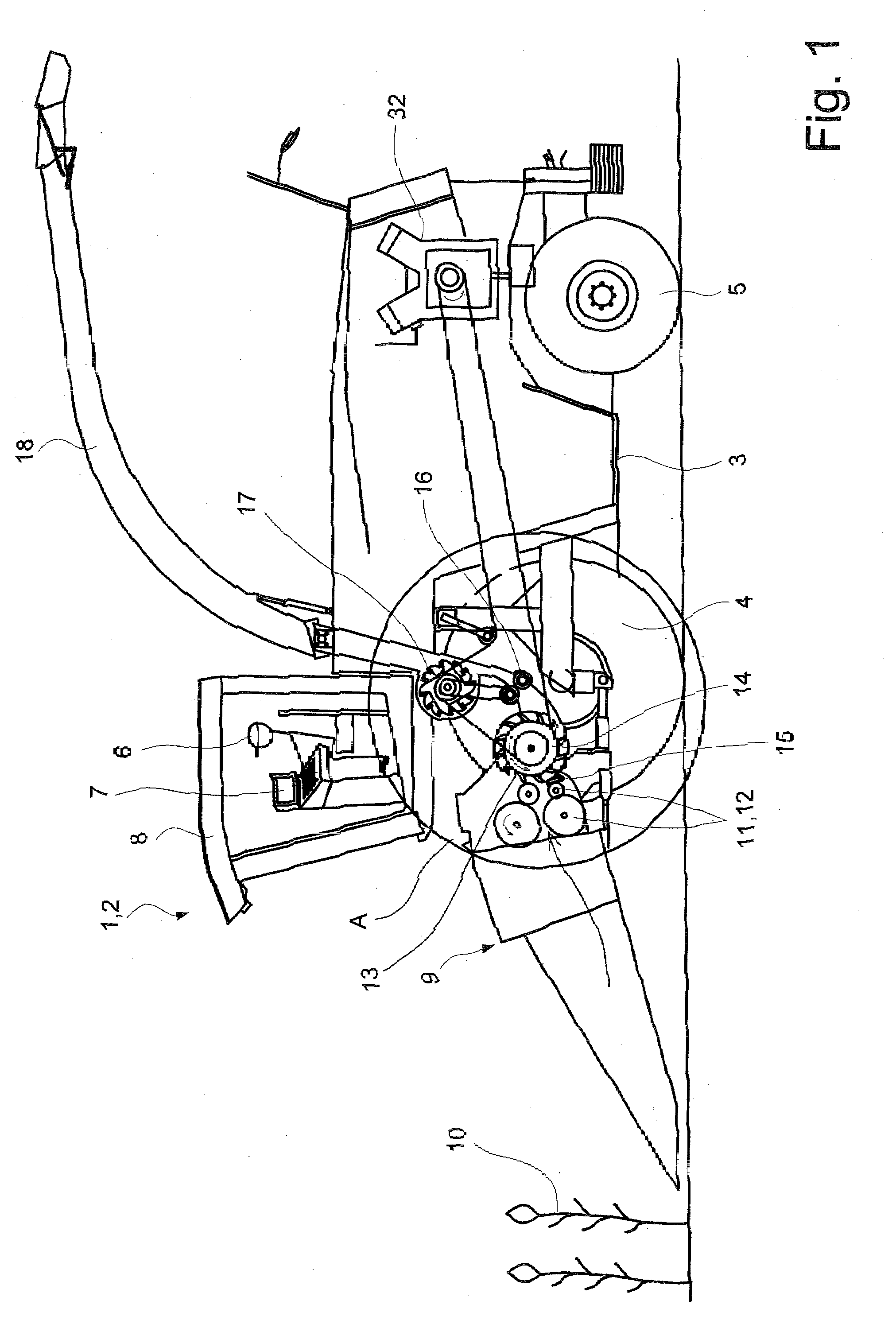

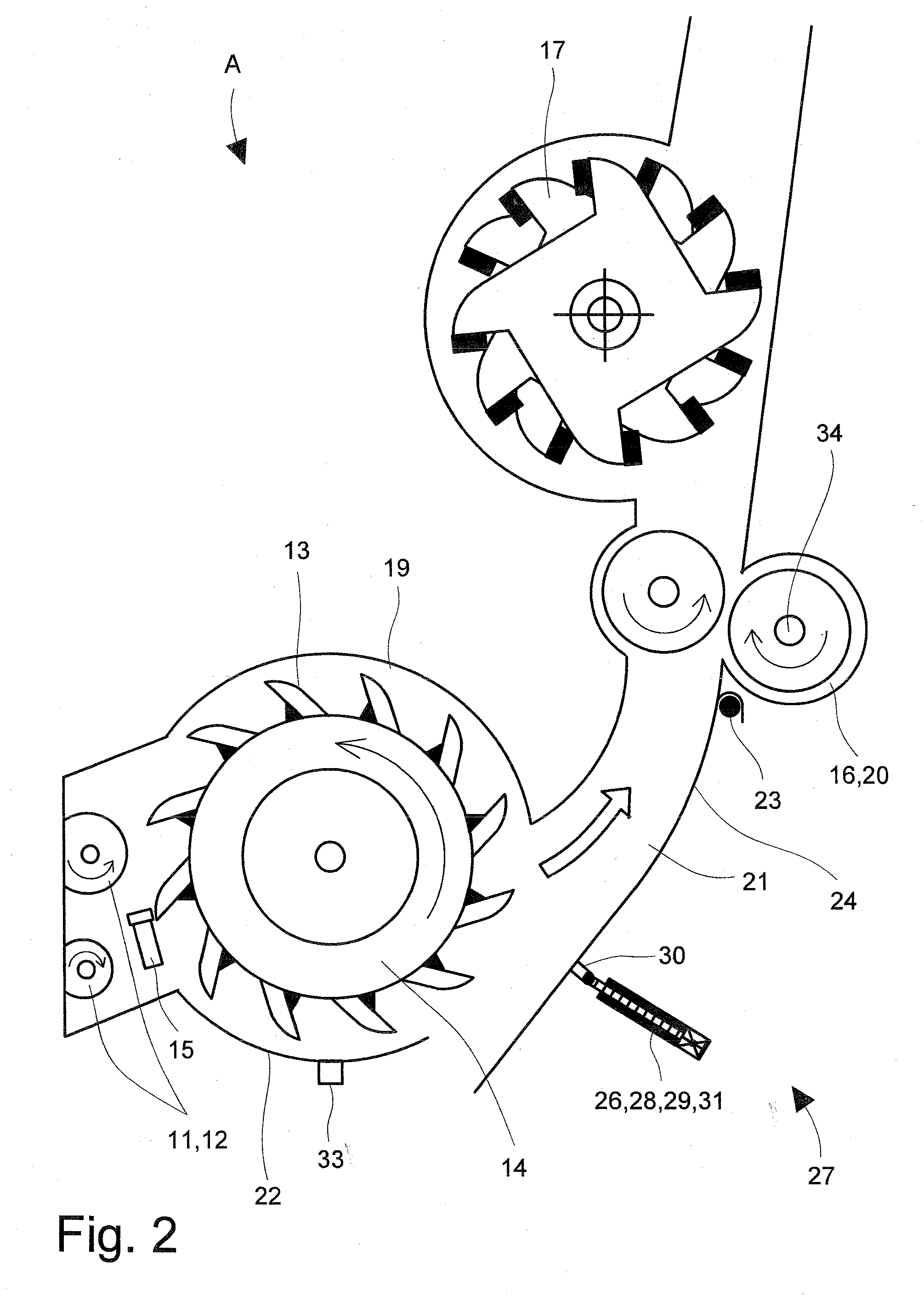

The invention relates to an agricultural working machine (1), in particular a forage harvester (2), with at least one spout (4) for conveying received and processed crop (7) to a transport vehicle (6, 25), wherein an electro-optical device (18) is provided for the direction control of the spout (4) at least during the process of conveying to the transport vehicle (6, 25), and wherein the electro-optical device (18) detects characteristic parameters (30) of the spout (4) and characteristic parameters (30) of the transport vehicle (6) and / or the agricultural working machine (1). This ensures that a control of a spout (4) of agricultural working machines (1, 2) is provided which almost completely relieves the operator of the agricultural working machine (1, 2) of the task of monitoring the spout.

Owner:AGROCOM & AGRARSYST

Detection arrangement for the detection of a crop jam in a harvesting machine

A self-propelled forage harvester includes an overload clutch inserted into the driveline of a crop conveying element of crop pick-up arrangement of the harvesting machine. The overload clutch generates acoustic and / or mechanical vibrations when a defined torque is exceeded, and a knock sensor is provided for sensing when the overload clutch is operating in an overloaded condition. The knock sensor sends a signal to a control arrangement including a signal processor which recognizes a vibration pattern representative of an overload, and in response to such a pattern, sends a control signal for shutting off the drive to various driven components of the harvester.

Owner:DEERE & CO

Agricultural harvesting machine

An agricultural harvesting machine embodying a forage harvester includes a comminution assembly with a drum equipped with a plurality of knives. The drum is set into rotation opposite a stationary shear bar in order to comminute crop fed in a region of a cutting gap formed by knives and the shear bar during the harvesting operation. A device controls a rotational speed (n) of the drum at least during a maintenance procedure of the comminution assembly, depending on a property of the drum.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

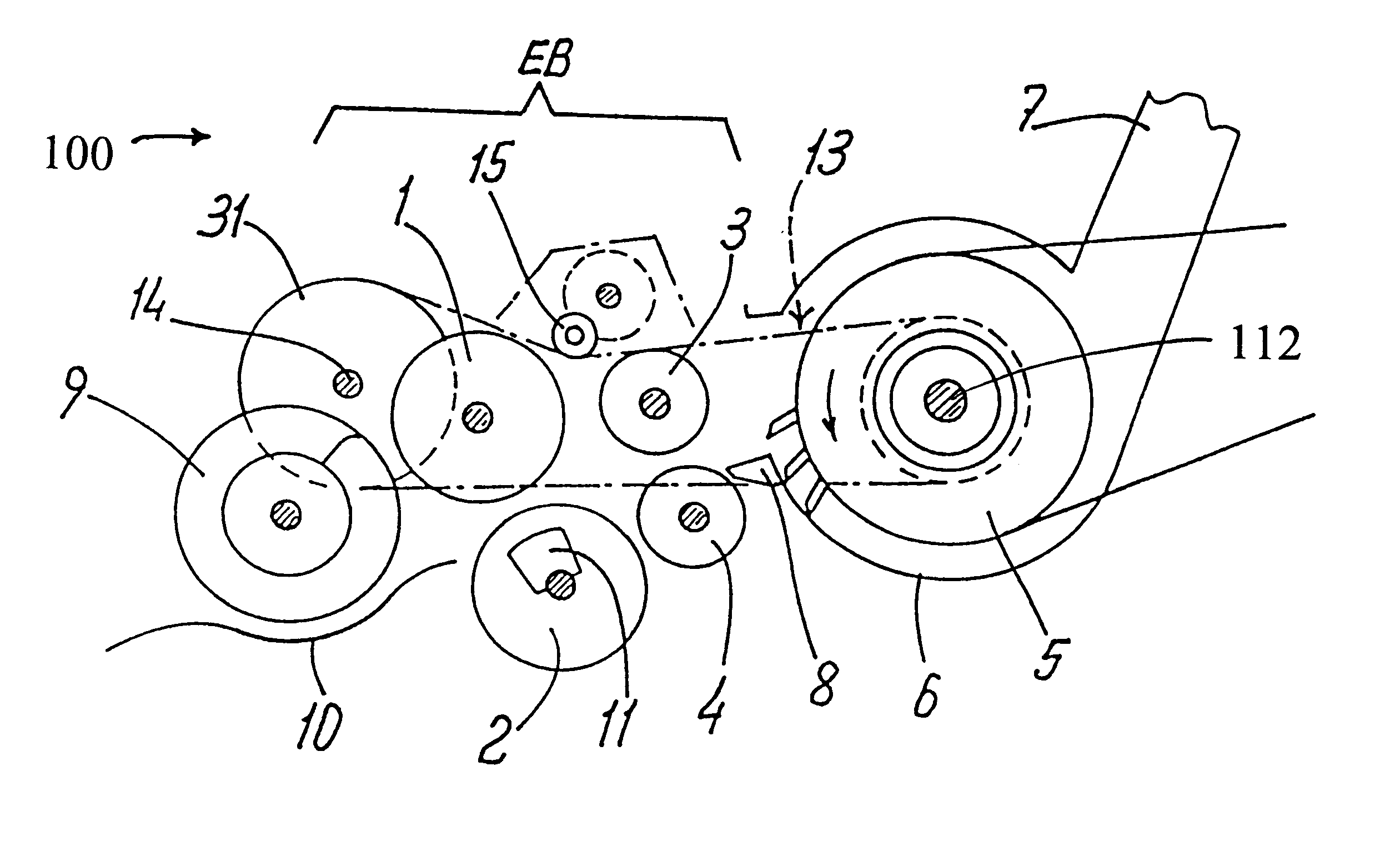

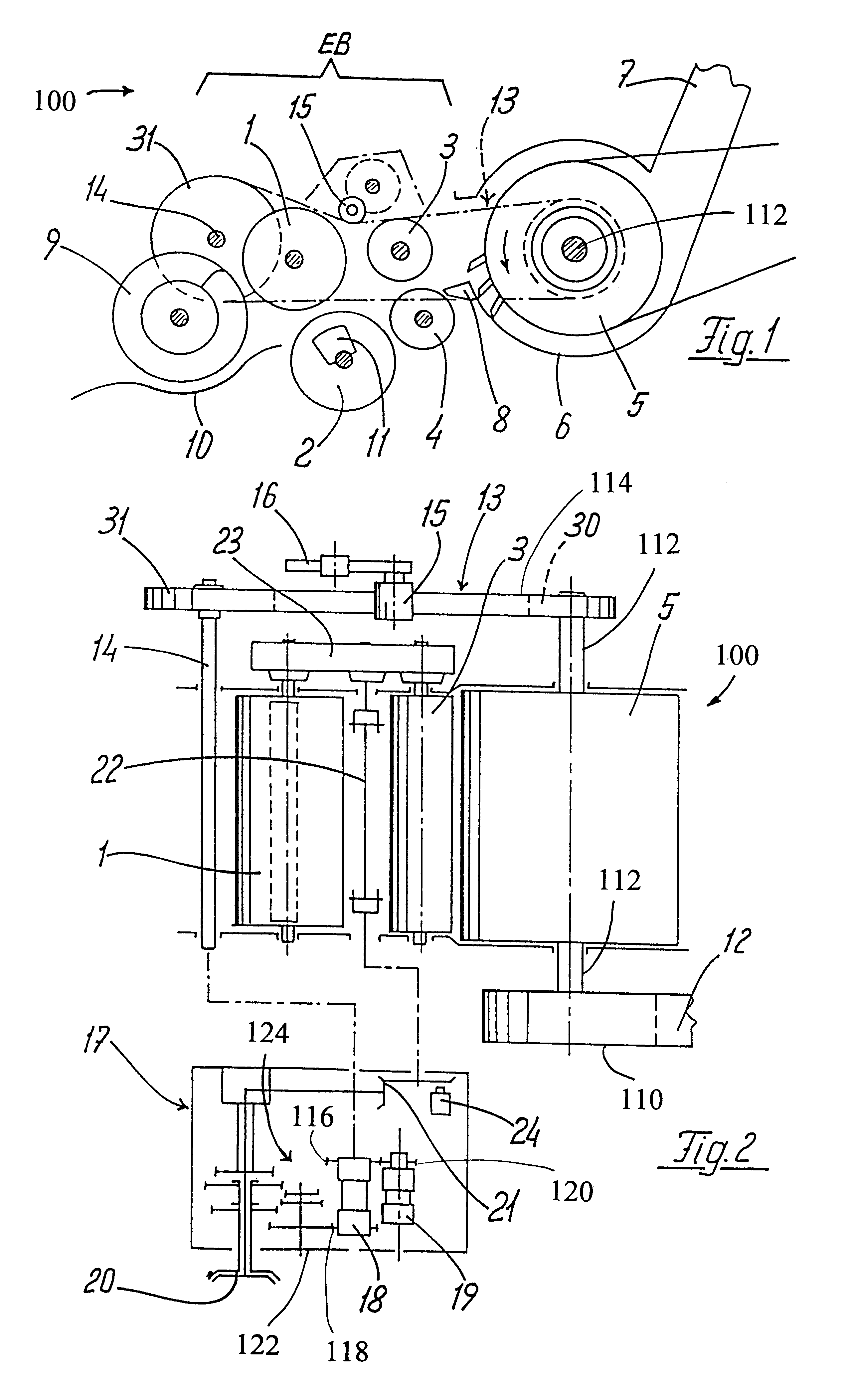

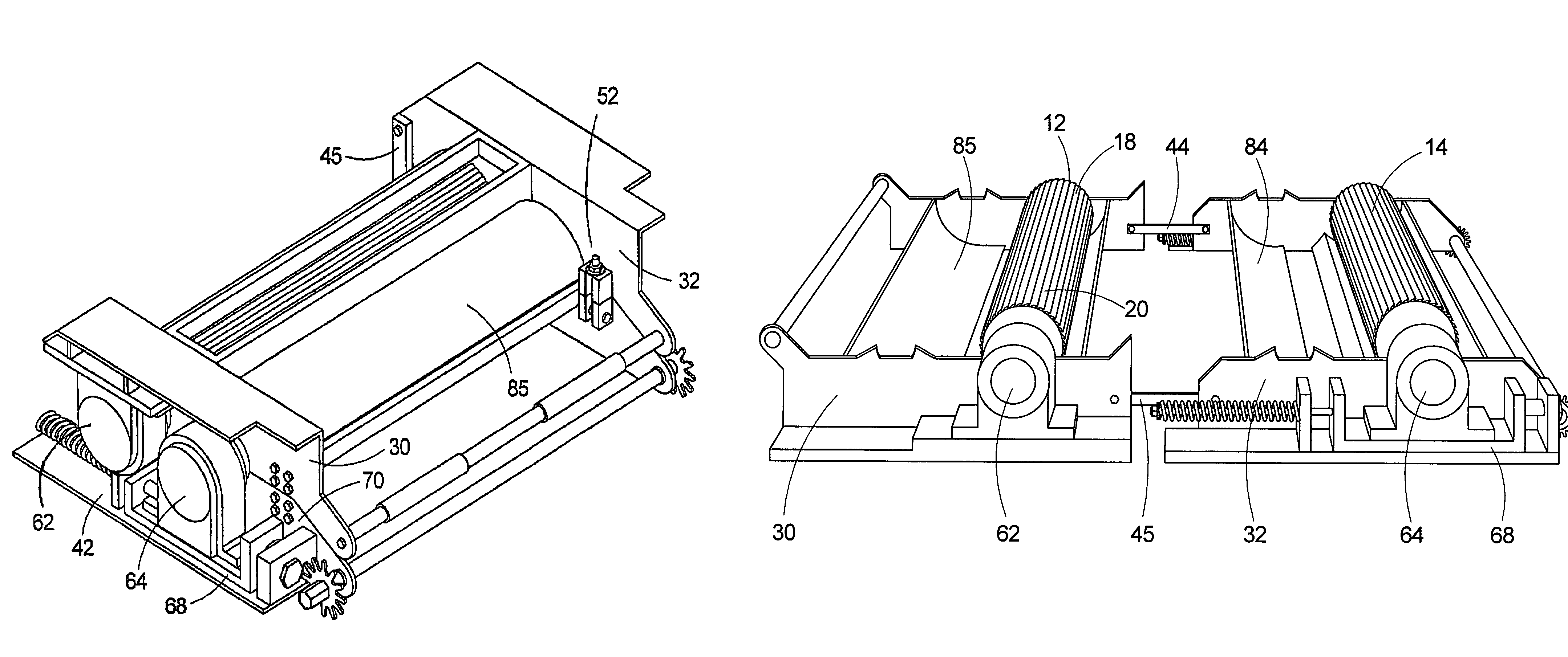

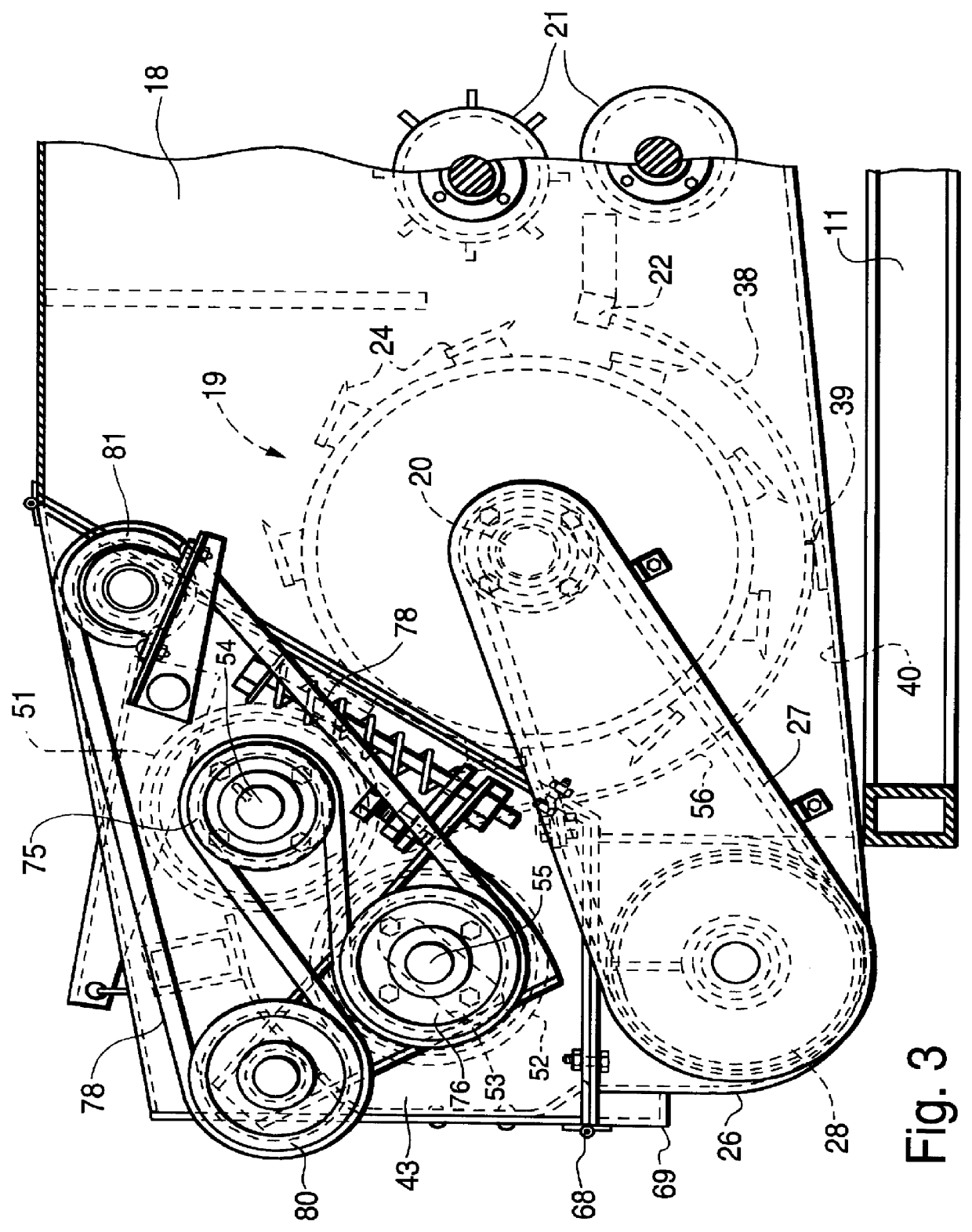

Crop processor roll arrangement for a forage harvester

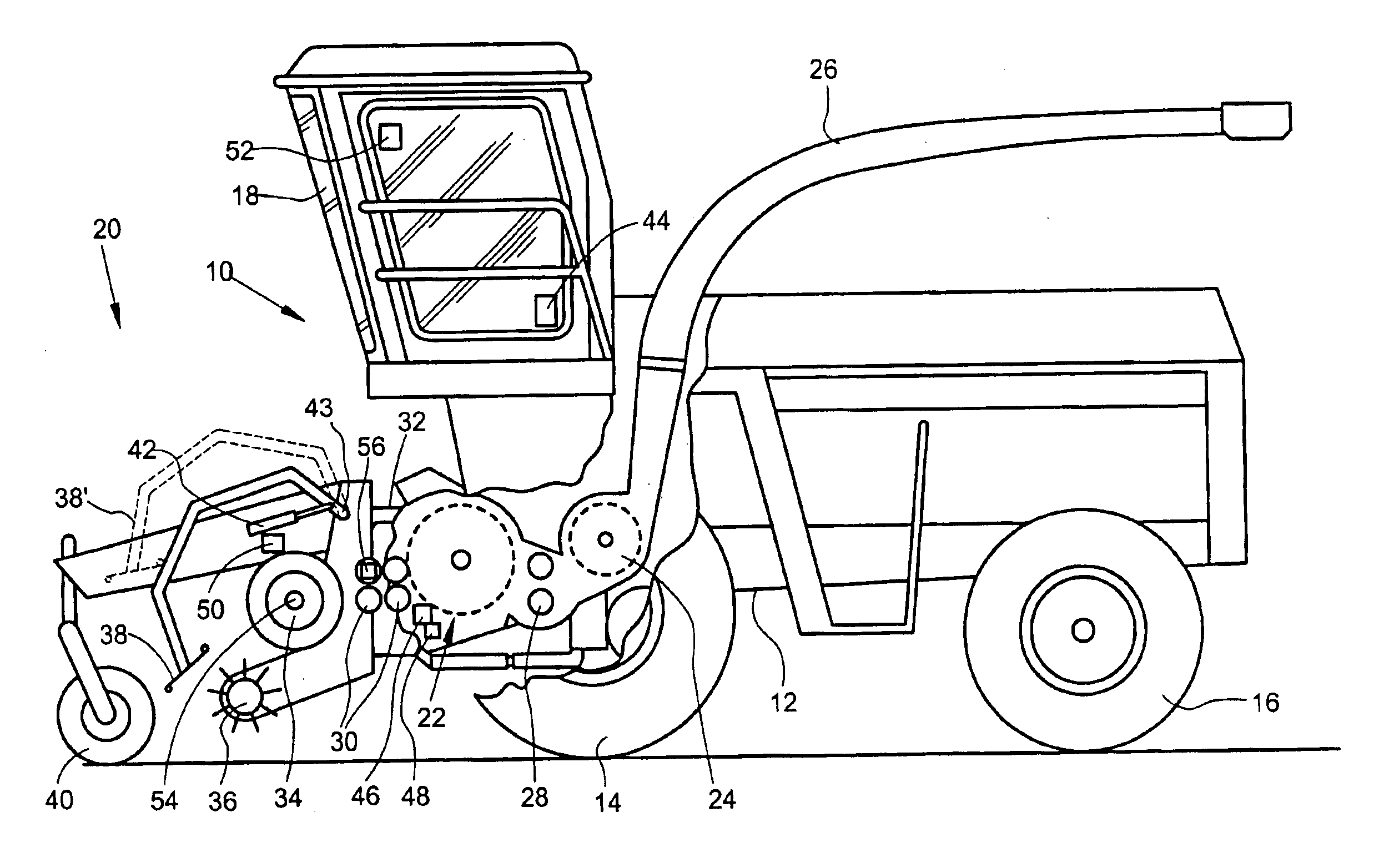

A forage harvester and a method of operating the same which comprises a crop processor unit located in a crop flow between a cutterhead and a blower rotor, the crop processor unit being for handling crop material including kernels, the crop processor comprising a pair of counter-rotating processor rolls arranged to crack kernels between the rolls when the rolls are in a first position, both processor rolls being movable away from each other to move each roll substantially out of the crop flow into a second position. A cover plate is preferably arranged to move and cover the lower roll when the rolls are in a second position and to isolate the lower roll from the crop flow. The processor rolls are preferably driven by independent drives. One of the drives can be a hydraulic motor supplied with pressure from a hydraulic pump which can also work as a motor. When used as a motor the cutterhead may be driven in the reverse direction for maintenance purposes.

Owner:BLUE LEAF I P INC +1

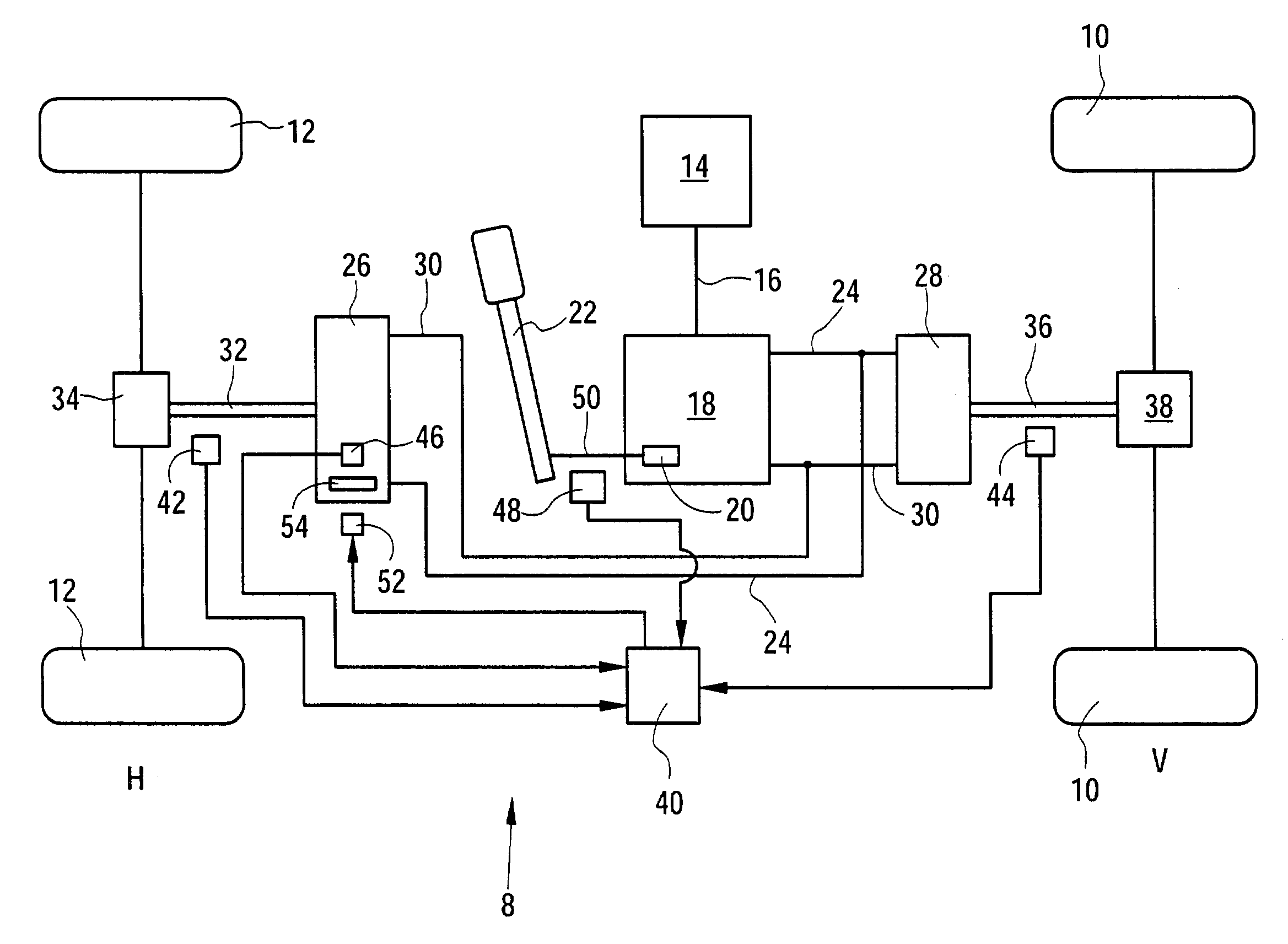

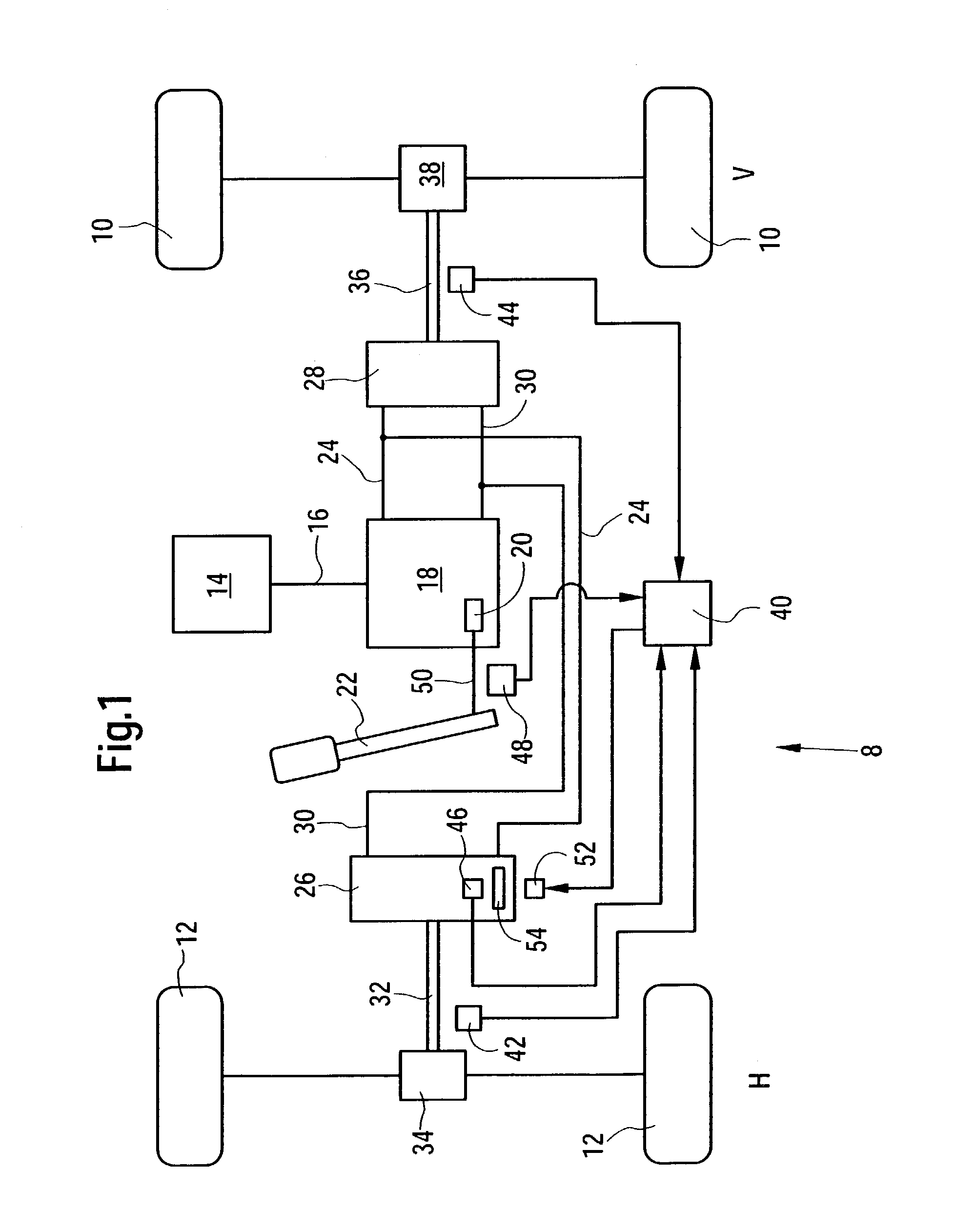

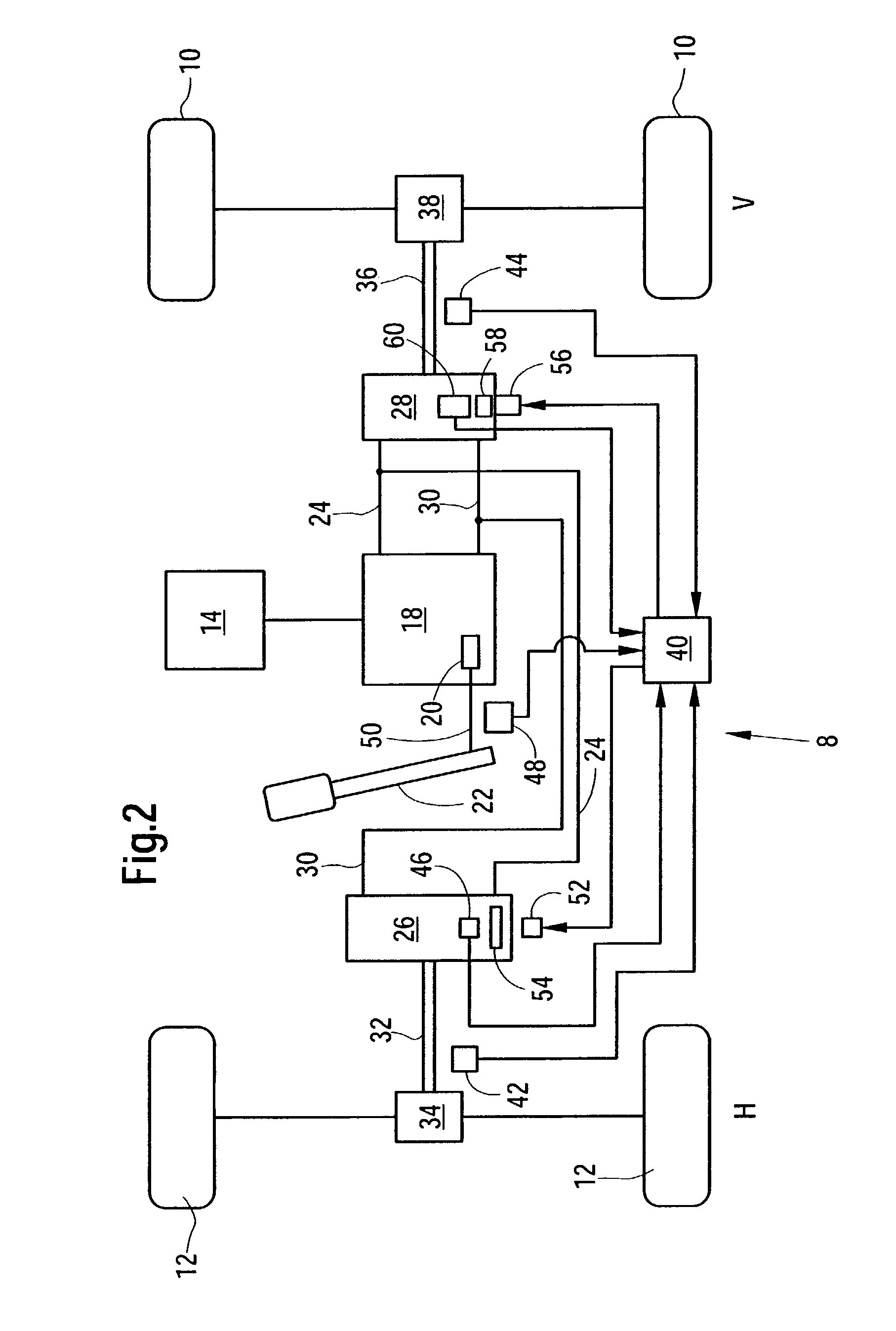

Drive system of a utility vehicle

InactiveUS7044257B2Avoid drivingPrevent reversalGearing controlMotor depositionControl signalEngineering

A drive system for use in utility vehicles, such as agricultural forage harvesters and combines, includes a hydrostatic transmission having a pump driven by a main engine of the vehicle and having first and second motors respectively coupled to front and rear axles of the vehicle by way of first and second differential gear sets. The pump and one or both of the motors have a variable displacement determined by positioning respective swash plates through the agency of a lever, in the case of the pump, and by electronic devices, in the case of the motors, the electronic devices acting in response to control signals sent by a control arrangement, which in turn, operates in response to signals produced by pressure sensors associated with the motors and by signals produced by speed sensors associated with output shafts of the hydraulic motors. The control arrangement has a memory for storage of data, such as maximum legal ground speed and the ratio of the speeds of the axles as results from a given wheel size, and uses this information for controlling the hydrostatic transmission such that the vehicle does not exceed the speed, and the front and rear axles are driven so as to produce the same ground speed.

Owner:DEERE & CO

Crop conditioning roller flute shape

ActiveUS7322175B2Improved shape and arrangementImprove actionCrop conditionersHarvestersFluteForage harvester

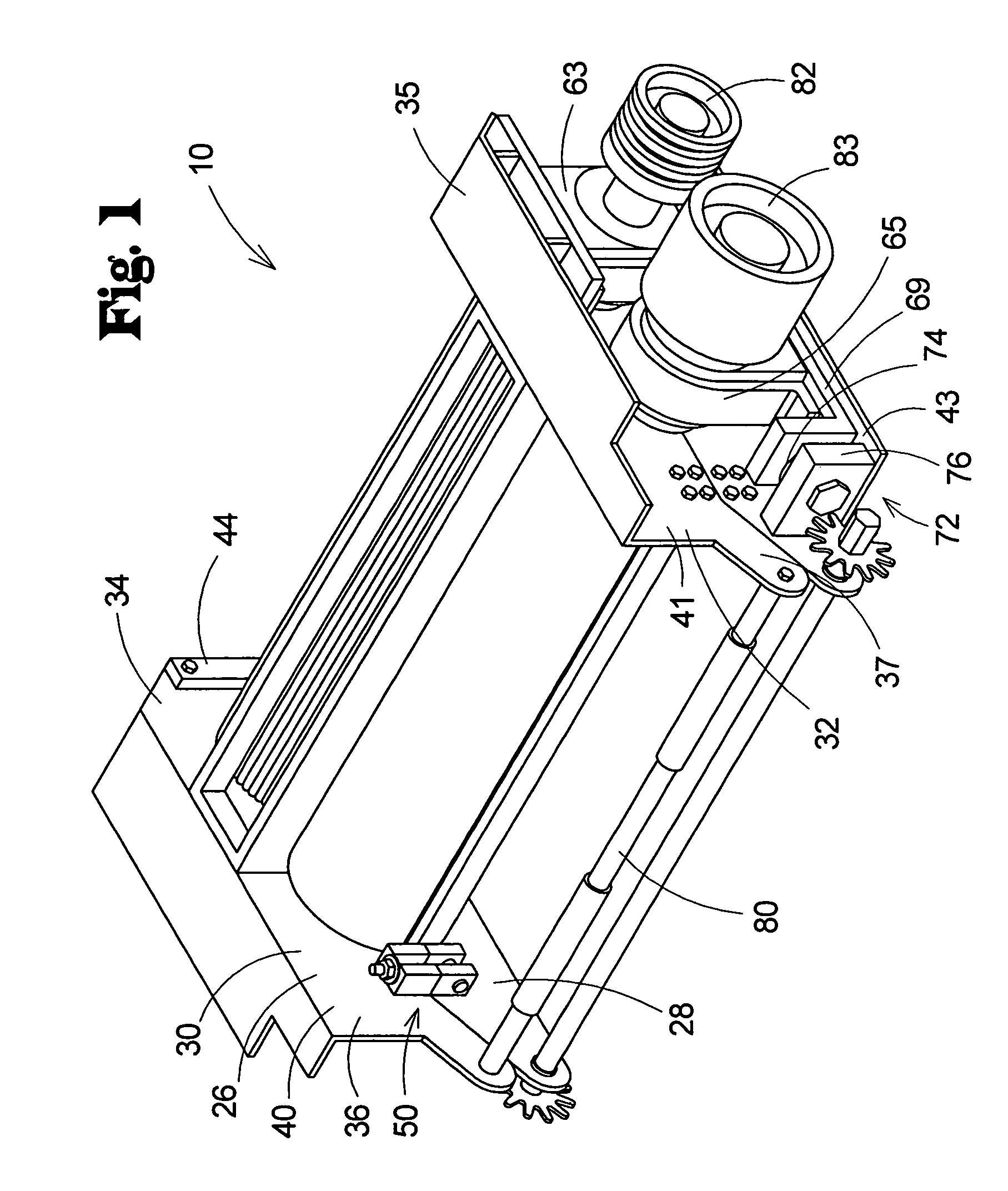

A forage conditioner for conditioning cut crop material from a forage harvester includes a fixed bottom fluted roller carried in end housings and a top fluted roller which is pivotally mounted on the housings by a linkage pivotal relative to the housing about an axis lying in a plane at right angles to the roller axes so that the top roller is liftable from crushing position against the bias of a spring extending along the top roller. Flutes on the rollers are arranged with a first surface on one side which extends substantially radially outwardly to an apex and a second surface which has a first portion parallel to a tangent of the roller and a second portion inclined inwardly to the roller surface at an angle significantly less than 90 degrees. The bottom roller is arranged with the first surfaces leading to carry the crop into the area between the rollers and the top roller is arranged with the first surface trailing. Thus the first surface of intermeshing flutes pass through a condition in which the first surfaces are substantially parallel and on opposite sides of a line joining the centers of the rollers to provide an effecting conditioning action on the crop.

Owner:MACDON INDS

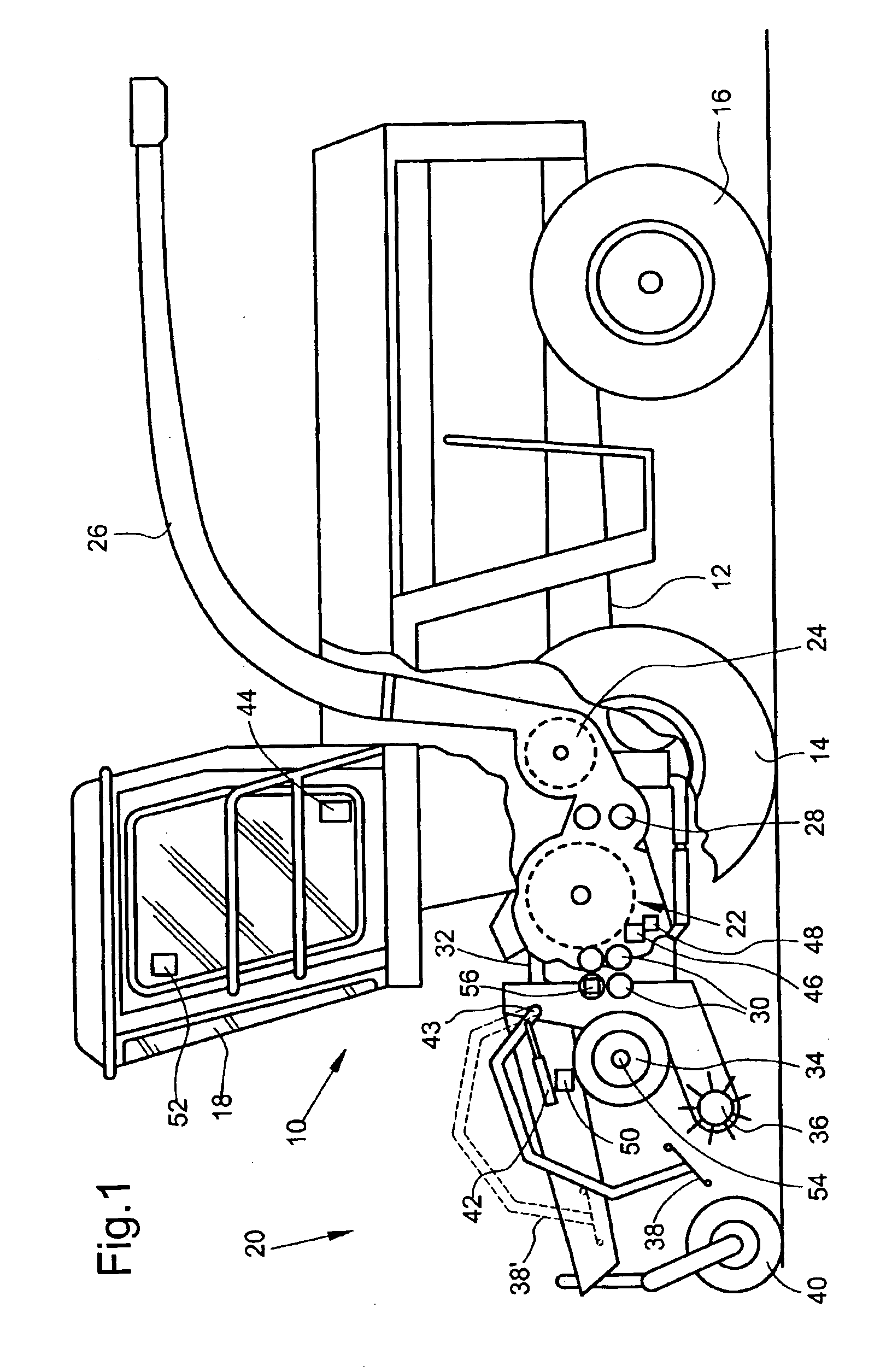

Device for monitoring the intake subassembly of an agricultural harvesting machine

An intake subassembly for an agricultural harvesting machine, in particular a self-propelled forage harvester for corn, grass and the like, including a cutting cylinder, feed rollers, and compression rollers, has a cut-out clutch for bringing the feed rollers and the compression rollers to a sudden stop. The machine may have a monitor system for detecting and processing information relating to the status and motion of the components of the subassembly and generating a signal to interrupt and brake the detected motion, for example, in response to the presence of foreign objects or overloads in the subassembly.

Owner:CLAAS SAULGAU

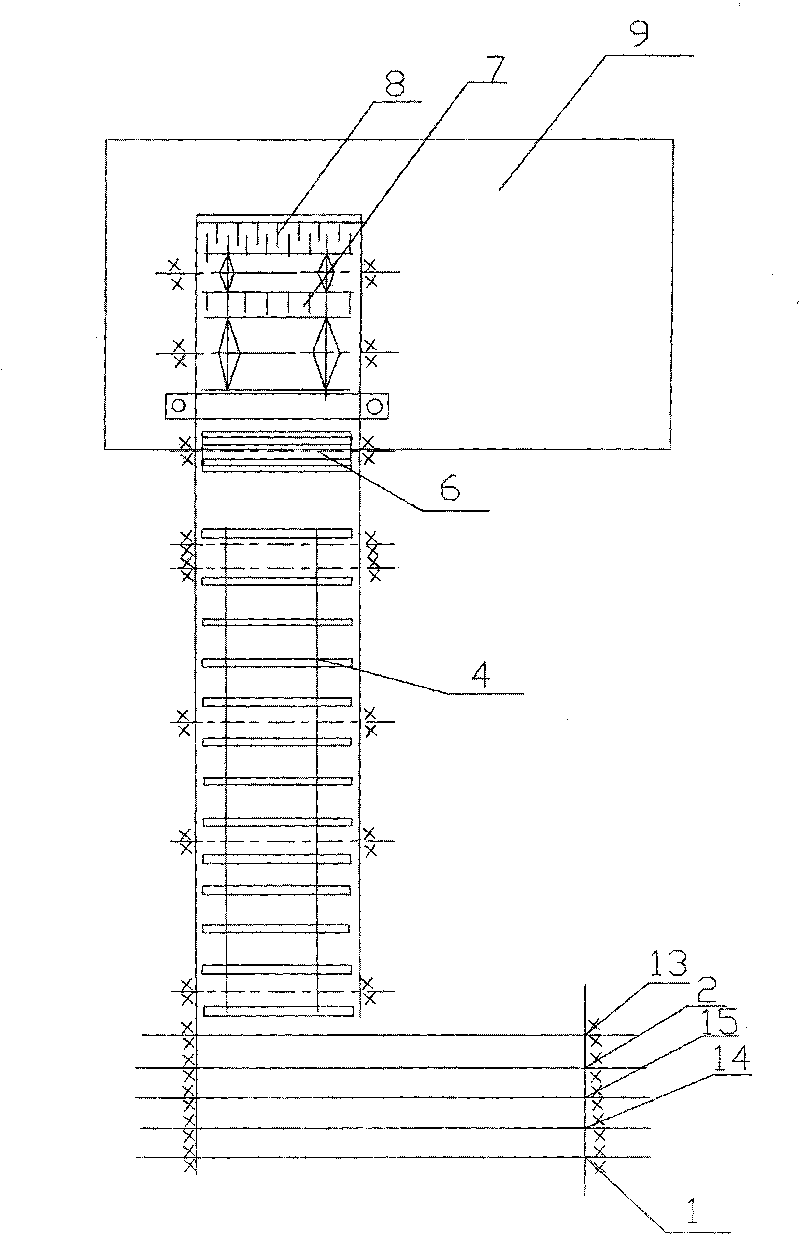

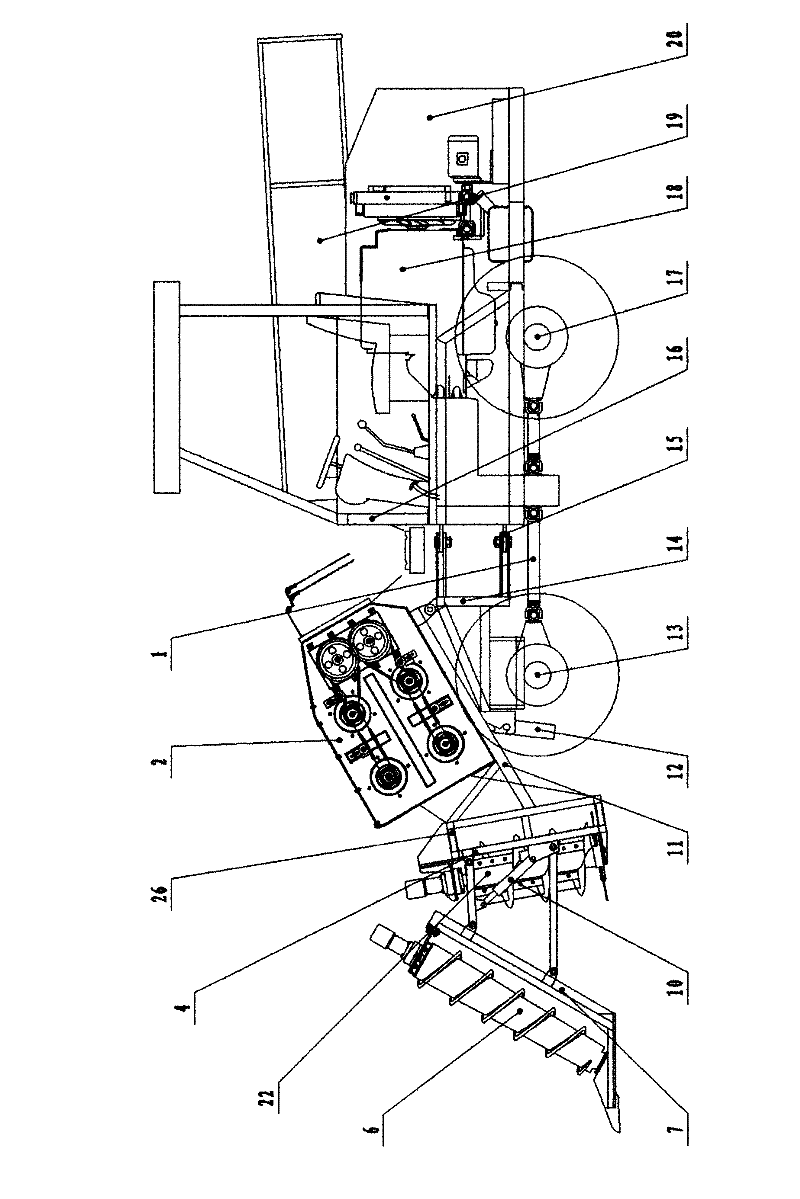

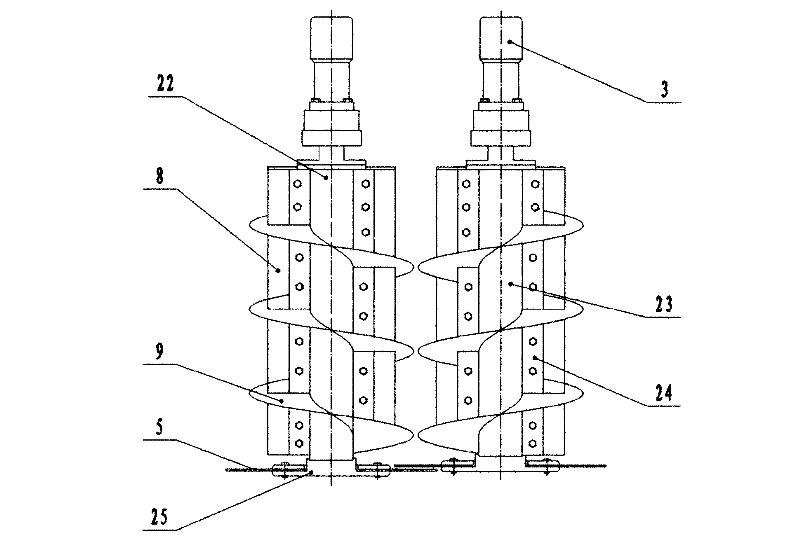

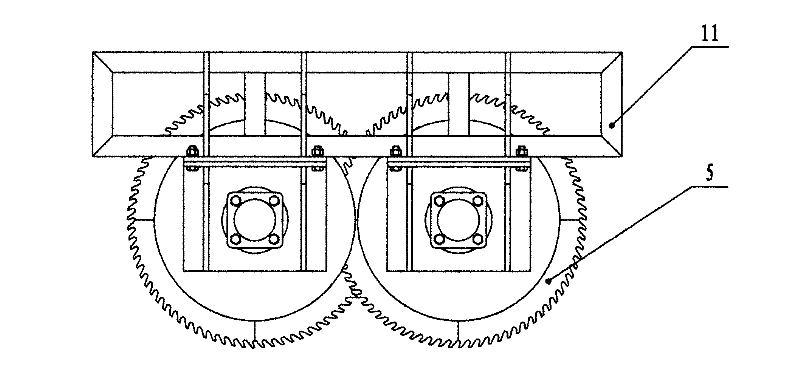

Multifunction straw chopping ensilage machine

InactiveCN101720600ASmall loadReduce energy consumptionCrop conditionersMowersEngineeringForage harvester

The invention discloses agricultural machinery and in particular discloses a multifunction straw chopping ensilage machine. The ensilage machine comprises a support frame which is provided with a feed device and a crushing device. The ensilage machine is characterized in that the front end of the support frame is provided with a straw cutting rotary blade for cutting the straws; the feed device comprises an upper feed roll and a lower feed roll which have opposite rotation directions; a certain gap is arranged between the upper feed roll and the lower feed roll; a conveyer chain is arranged on the right upper part of the gap between the two feed rolls; a certain distance exists between the conveyer chain and the upper end of the support frame; the crushing device is arranged at the tail end of the conveyer chain and a collection device is arranged at the lower end of the crushing device. The invention has the beneficial effects of realizing one-off completion of corn straw cutting, straw feeding, straw conveying, straw chopping, secondary straw crushing, stubble ploughing and soil moisture preserving, straw collection and ensilage and aftercrop of residual corn ears, and having light load, low energy consumption and high efficiency.

Owner:袁东明

Self-propelled agricultural harvesting machine with controllable transfer device

Vehicles, in particular self-propelled agricultural harvesting machines such as forage harvesters or combine harvesters designed to pick up and process crops, include transfer devices that transfer all of the harvested crop material to a hauling vehicle or an attached hauling container. The discharge device is equipped with a control device for performing automatic or manual adjustments, and the self-propelled agricultural harvesting machine is equipped with a navigation system for determining the positions of the vehicles involved. To transfer the crop material to the hauling vehicle without loss, the crop discharge flow is directed only to a defined permissible tolerance region on the hauling container. The tolerance region is located within the hauling container contour and is bounded by edge zones, which are “keep-out” zones for the transfer.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

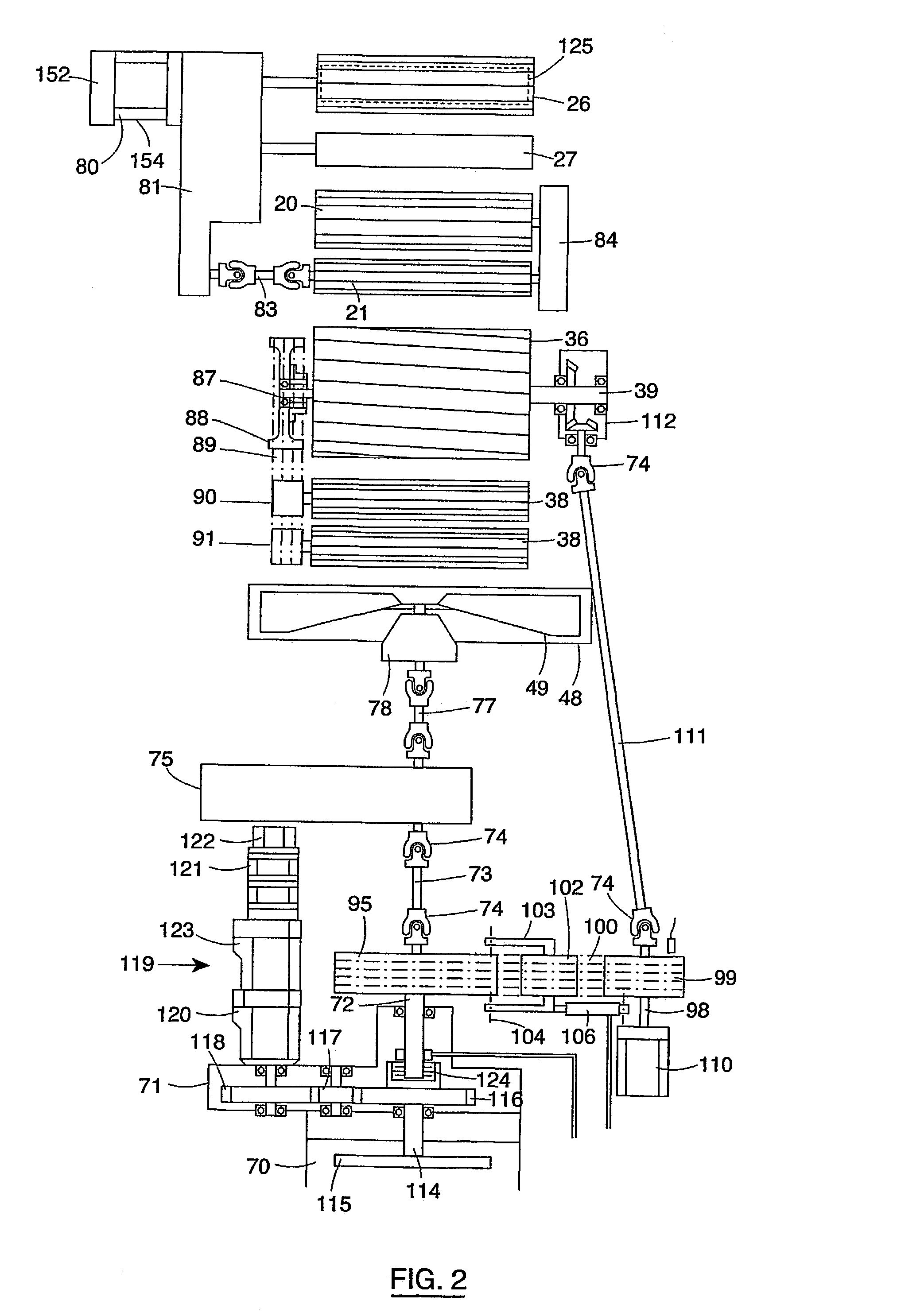

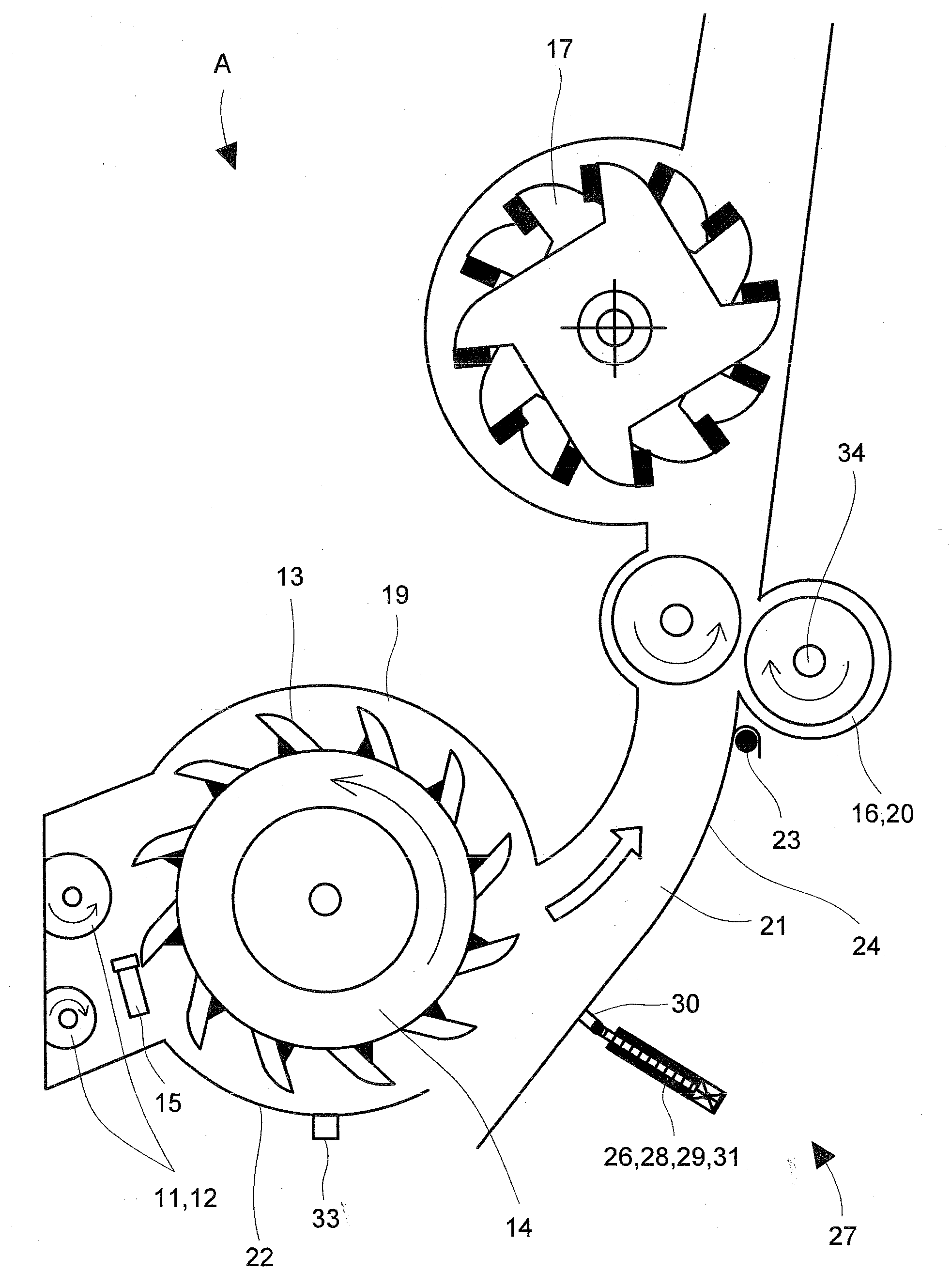

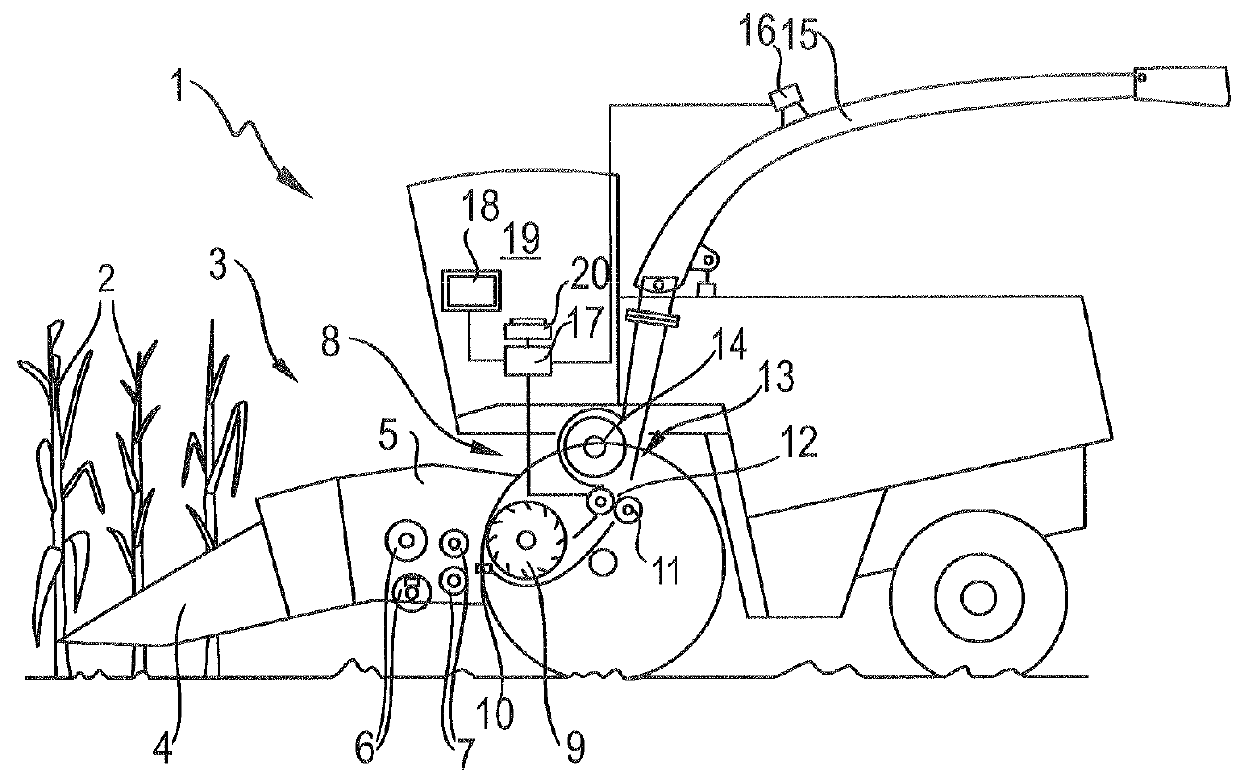

Harvesting machine combination for the utilization of plant remains

A harvesting machine combination for the utilization of harvested plant remains is provided and includes a combine with an outlet for harvested crop remains, a self propelled forage harvester that includes a conveyor to take over the harvested crop remains from the outlet of the combine, a discharge arrangement for the harvested crop remains, an engine for the drive of the conveyor and a container to take up the harvested crop remains delivered by the discharge arrangement. The combine is equipped with a transmitting arrangement for the transmission of position data and / or operation direction and speed data of the combine. The forage harvester is equipped with a receiving arrangement that interacts with an automatic steering and speed input arrangement of the forage harvester that can be operated on the basis of the data received by the receiving arrangement in order to permit the forage harvester to follow the combine automatically.

Owner:DEERE & CO

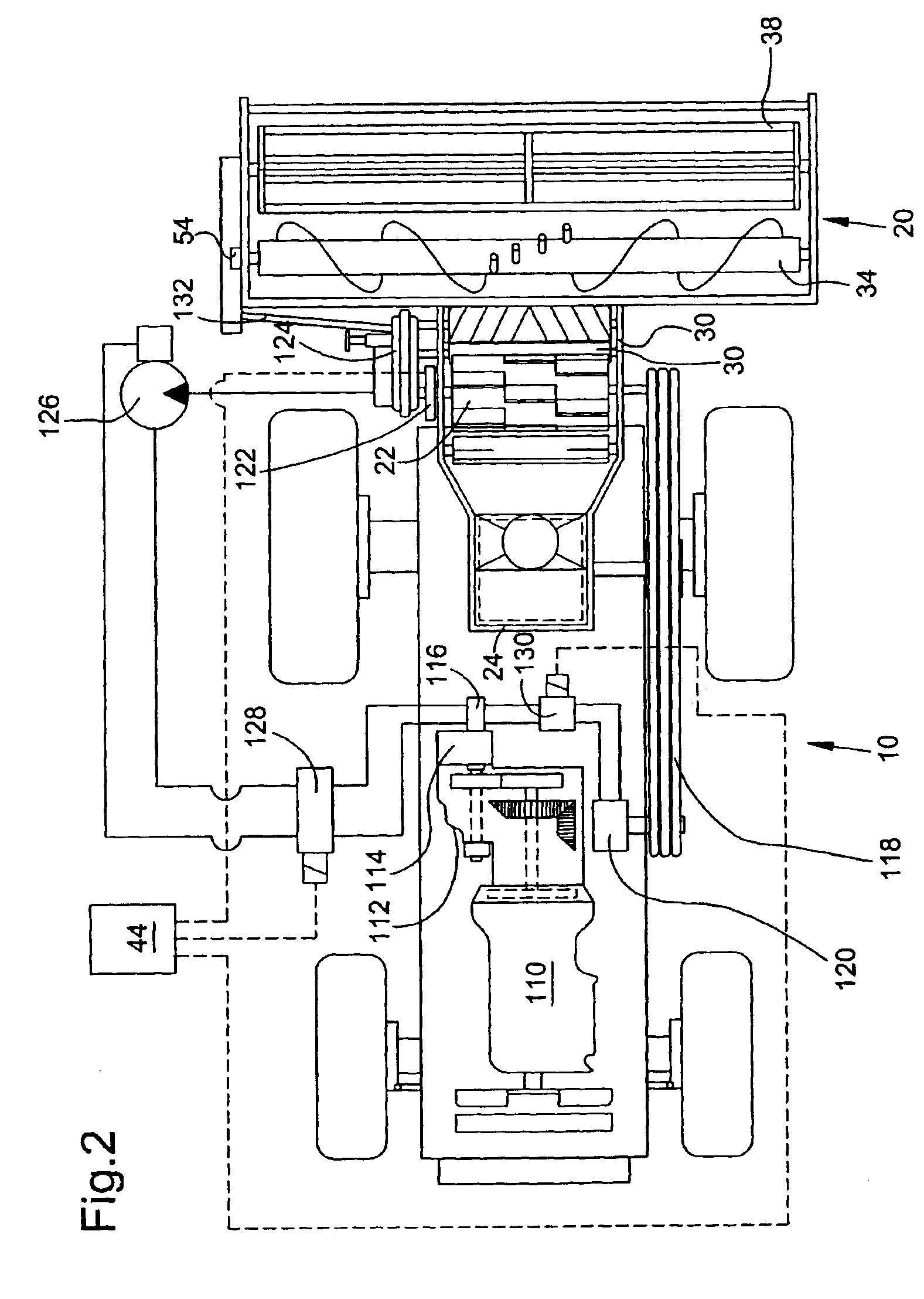

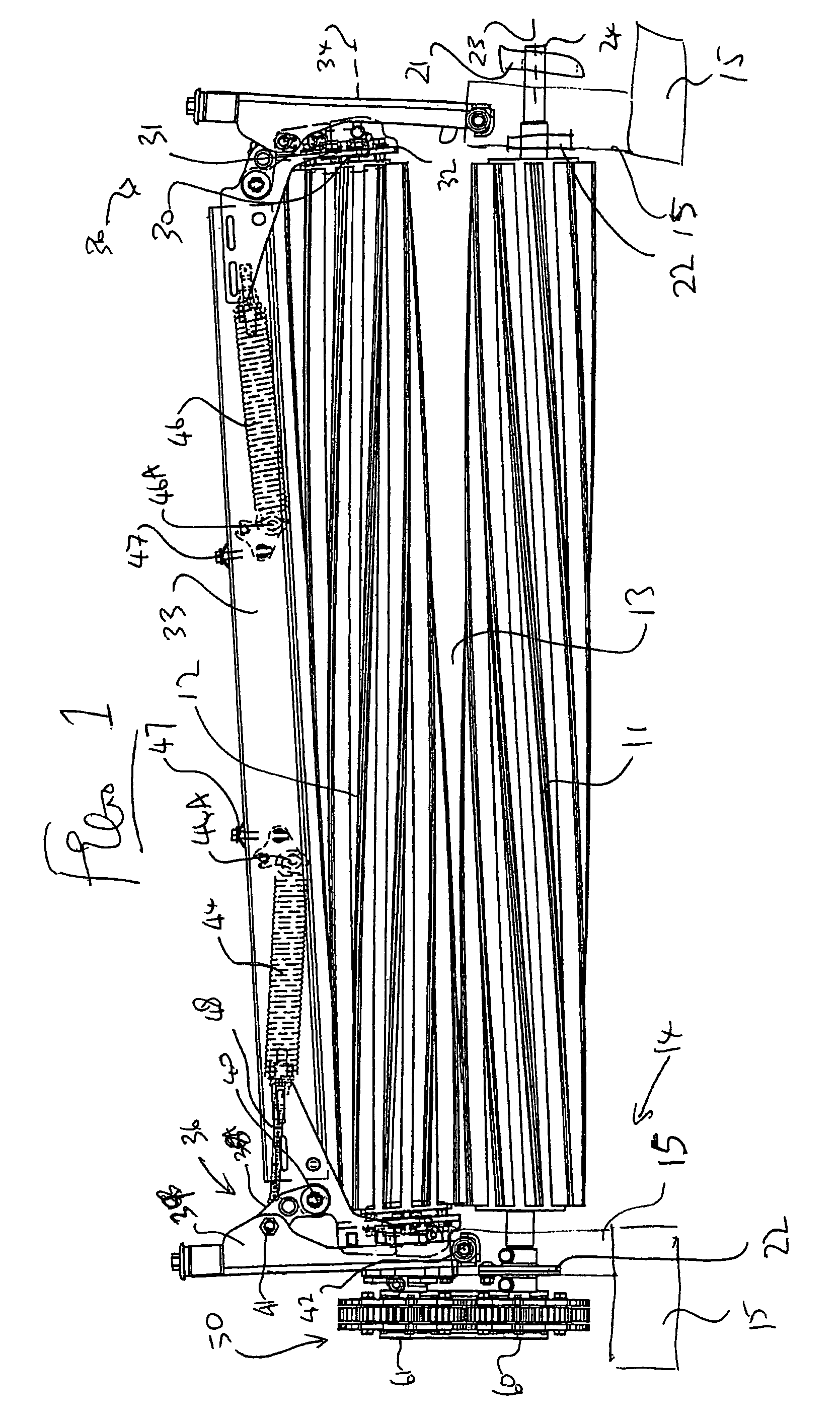

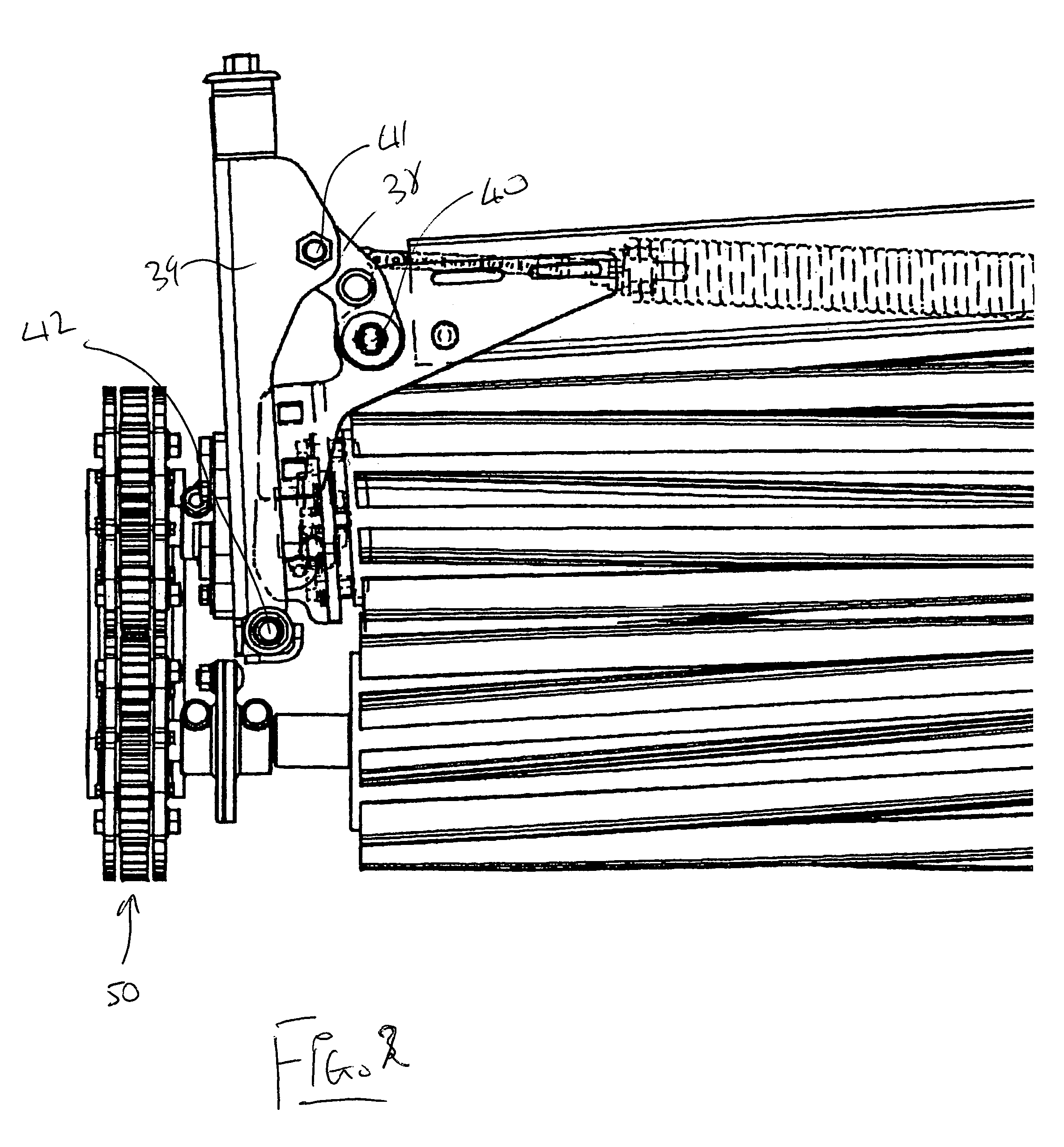

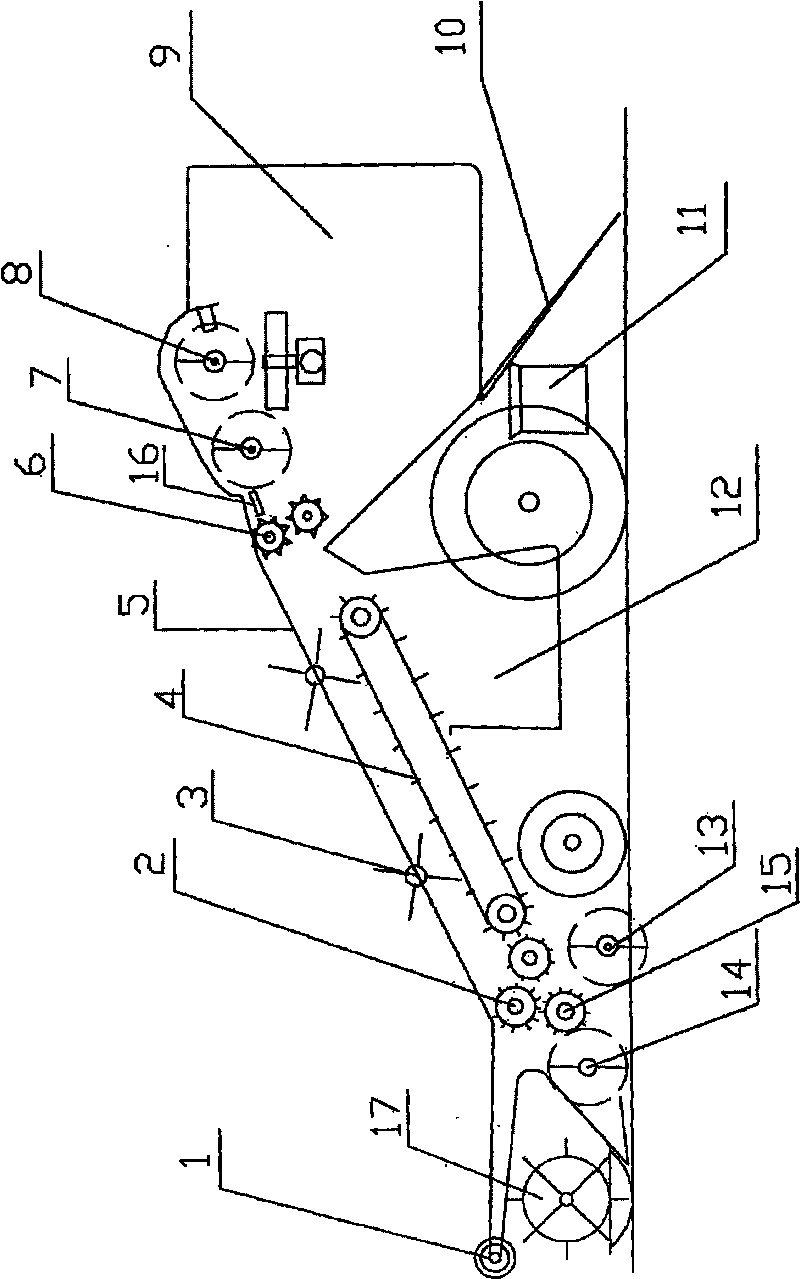

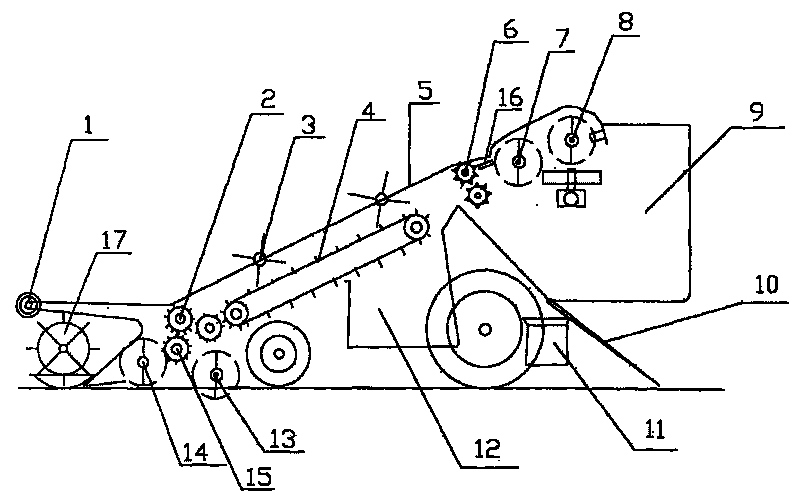

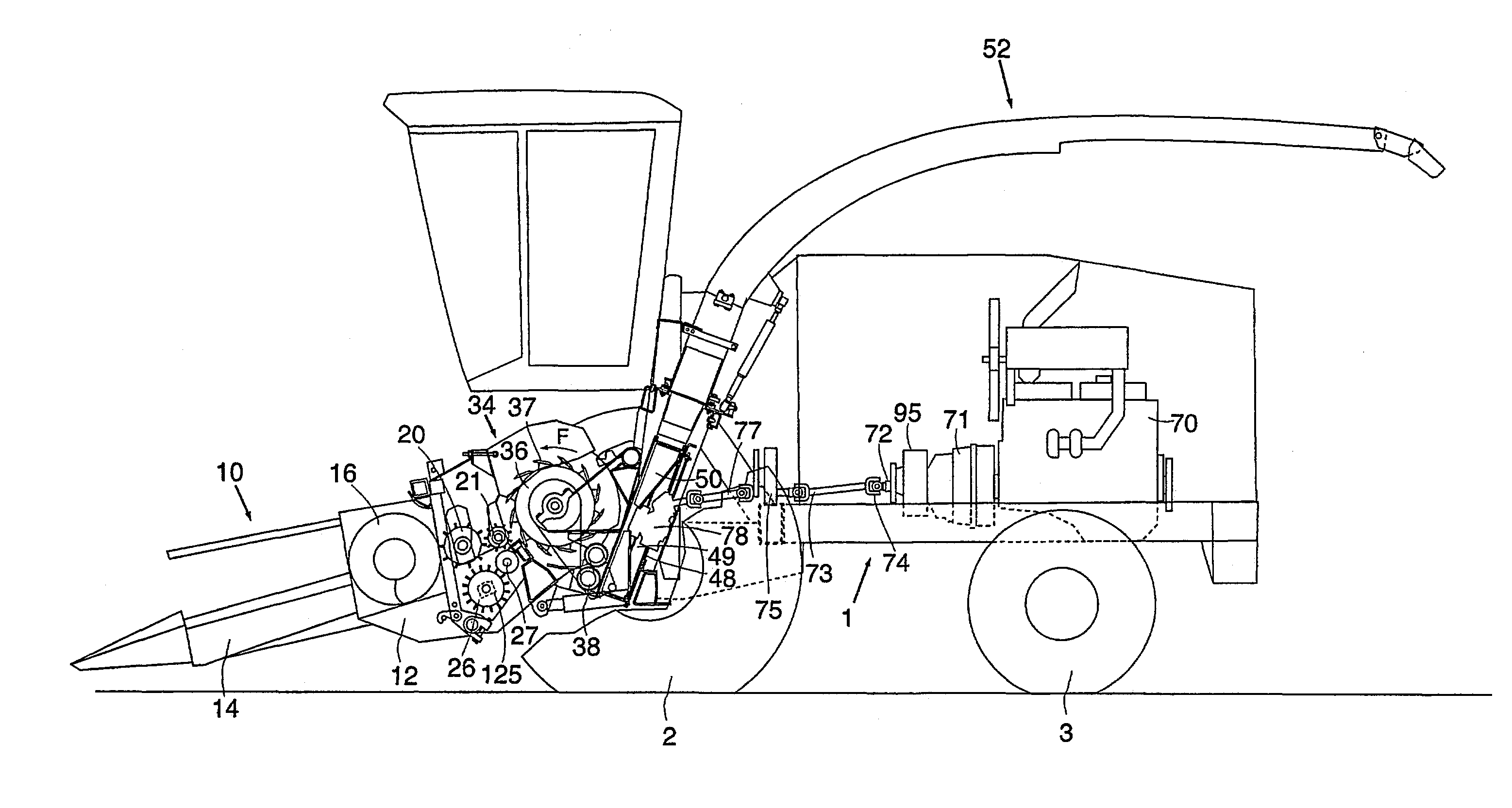

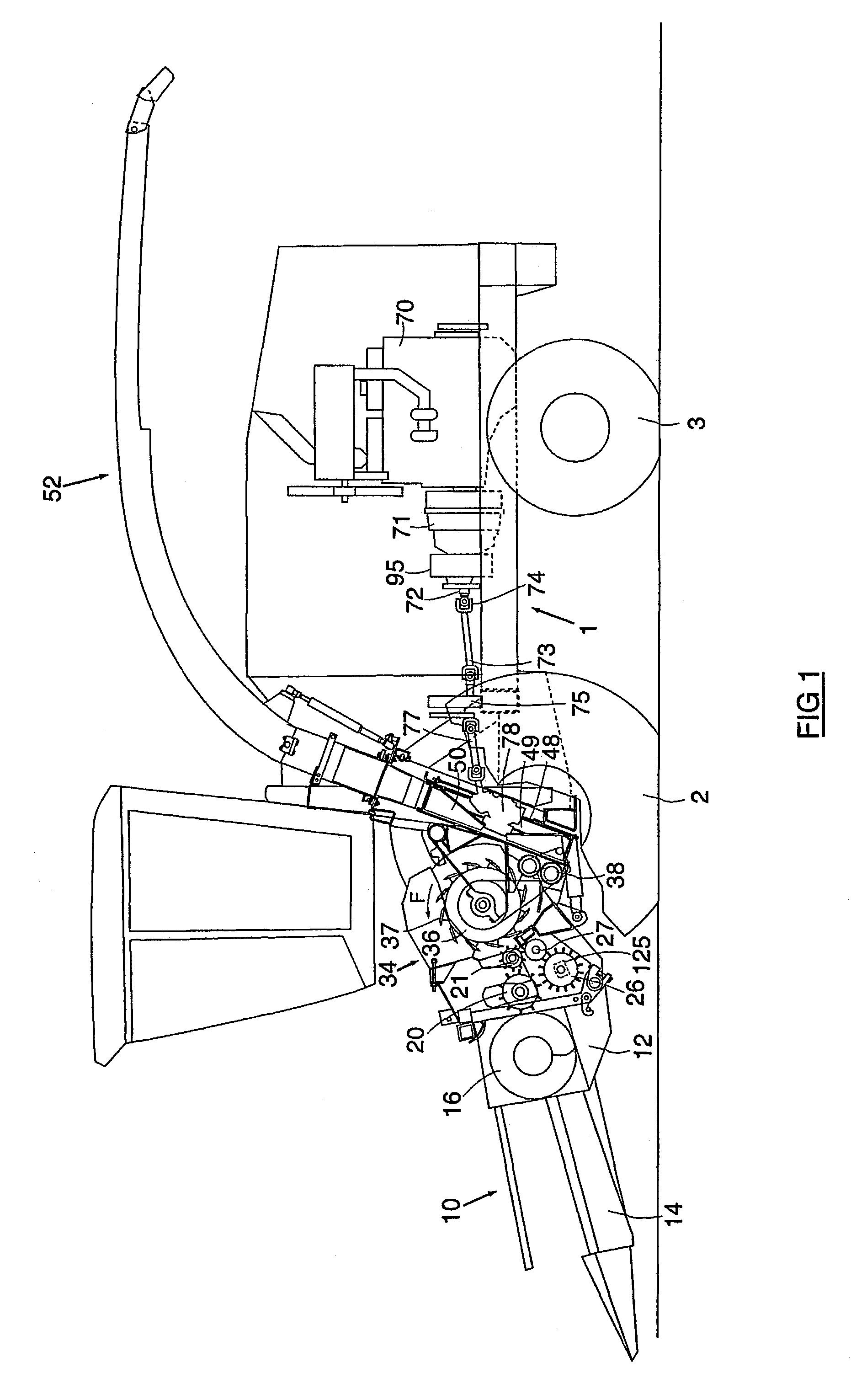

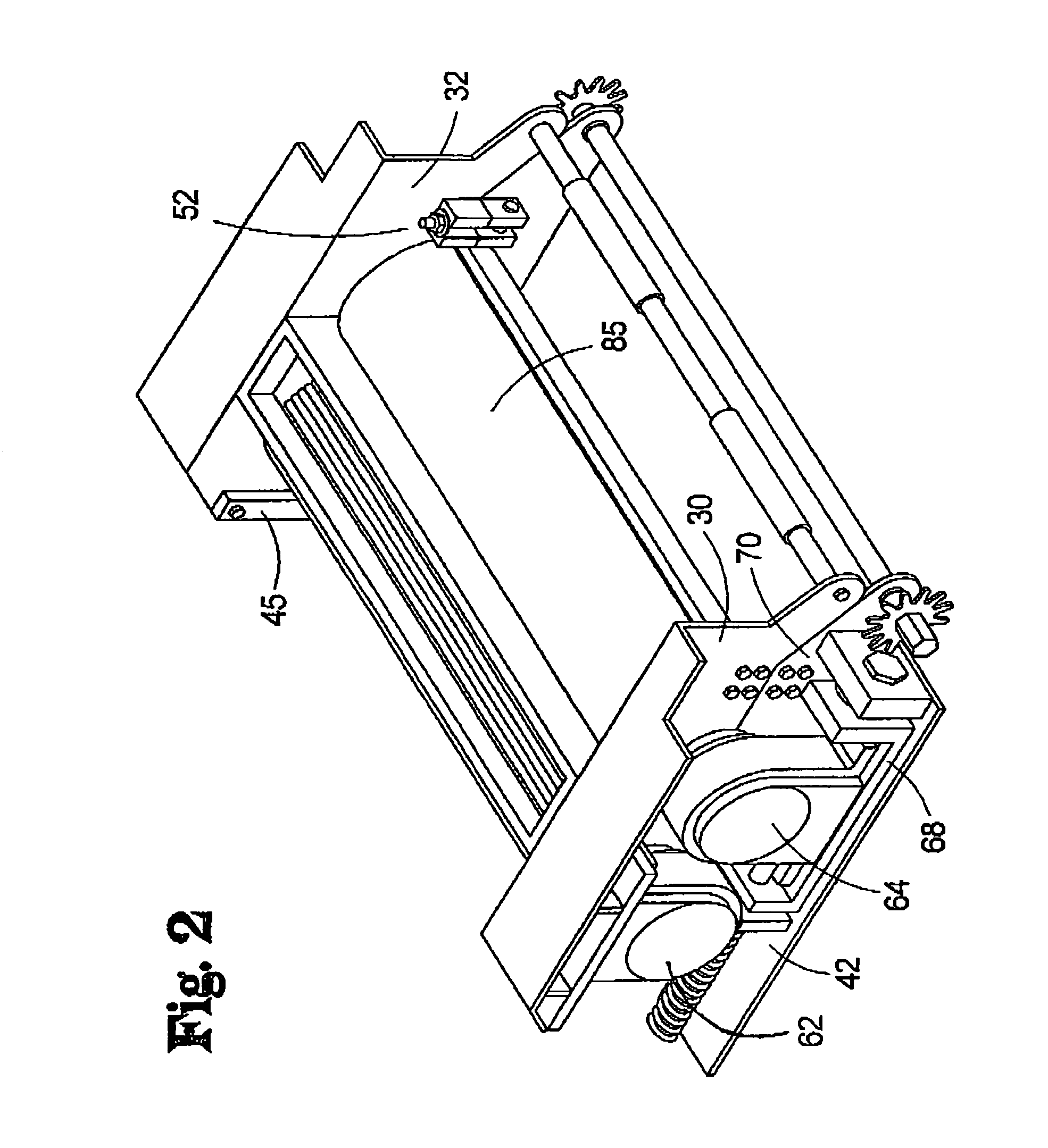

Feeder controls for a forage harvester

InactiveUS7140169B2Improve reaction speedVolume of oilHarvestersGearing controlForeign matterForage harvester

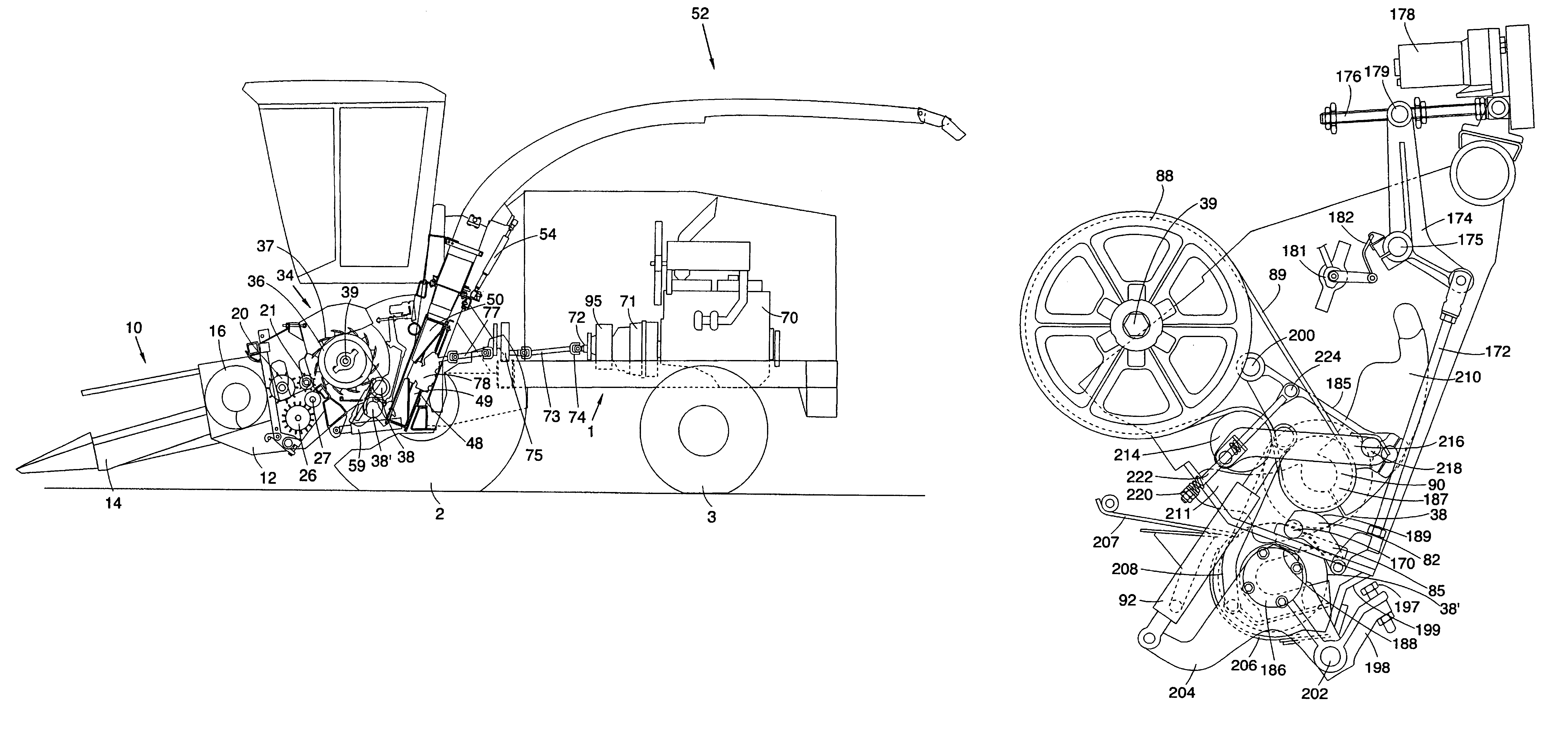

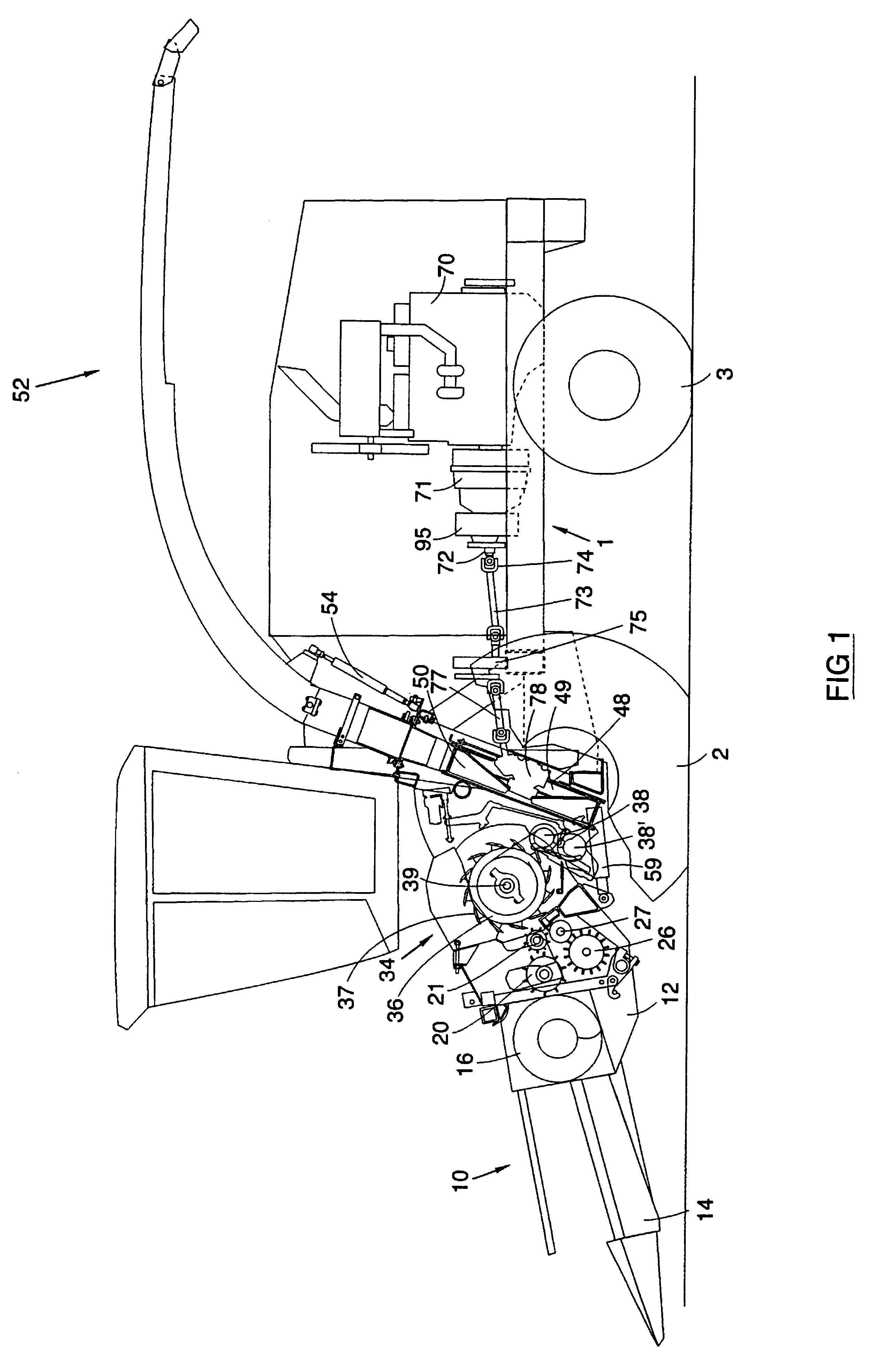

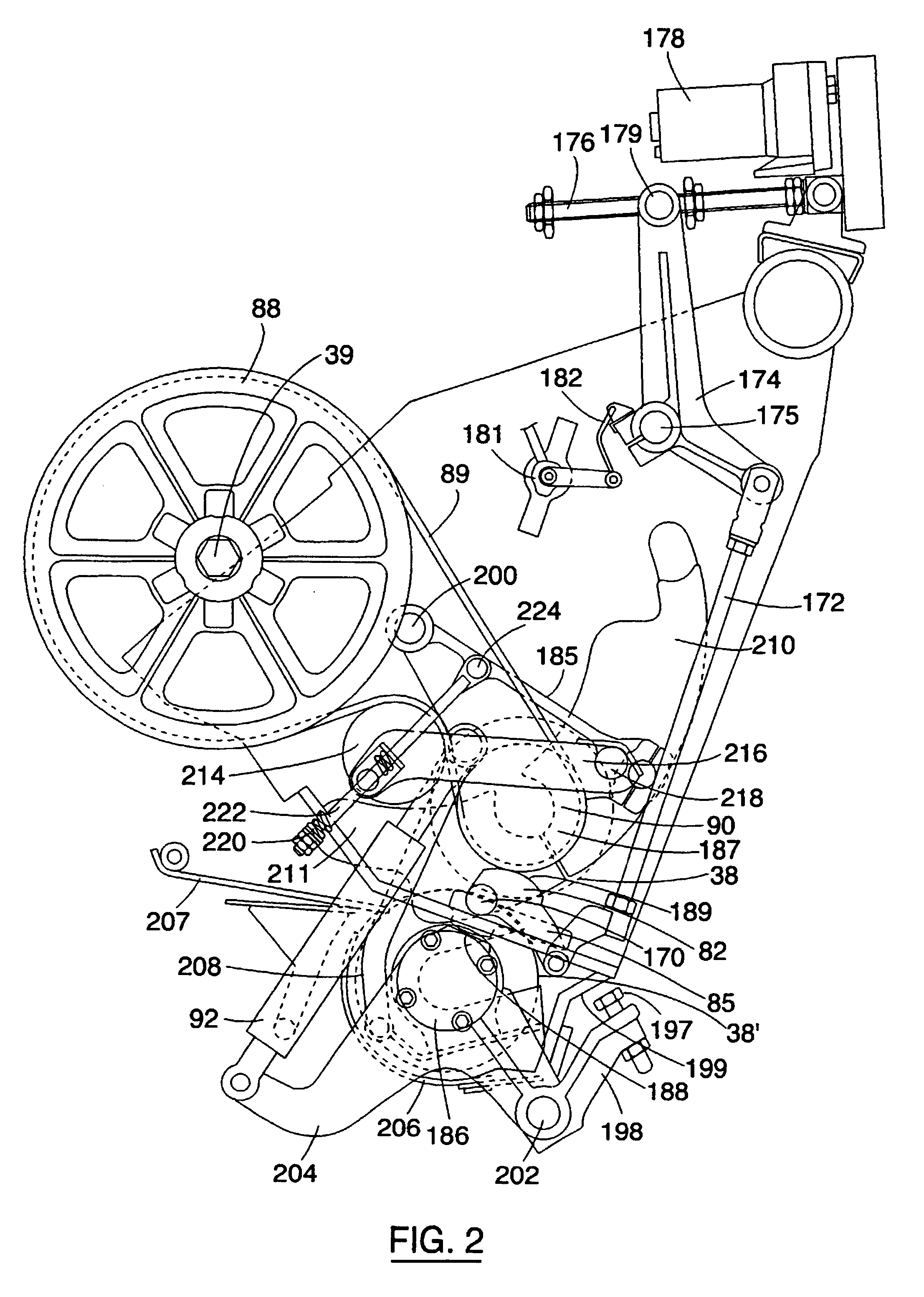

An agricultural harvesting machine, such as a forage harvester comprises a set of feedrolls (20, 21, 26, 27) for feeding harvested crop material to a rotating cutterhead (36). The feedrolls are driven by a hydraulic drive means comprising a hydrostatic pump (123) coupled to the engine (70) of the harvesting machine, a hydrostatic motor (80) coupled to said feeder means (20, 21, 26, 27) and hydraulic circuitry (142, 143, 152) interconnecting the pump and the motor. The circuitry comprises a feeder arrest valve (165) which is operable to interrupt the oil flow from said hydrostatic motor (80), thereby arresting said feedrolls (20, 21, 26, 27). The hydrostatic motor (80) is provided with a flushing valve (156) for diverting part of the oil flow in said circuitry through said motor for lubricating and cooling the latter. The arrest valve (165) is provided in said circuitry (142, 143, 152) between the hydrostatic motor (80) and the flushing valve (156). This arrangement allows for an immediate and efficacious arresting of the feedrolls upon detection of a foreign object in the harvested crop.

Owner:BLUE LEAF I P INC +1

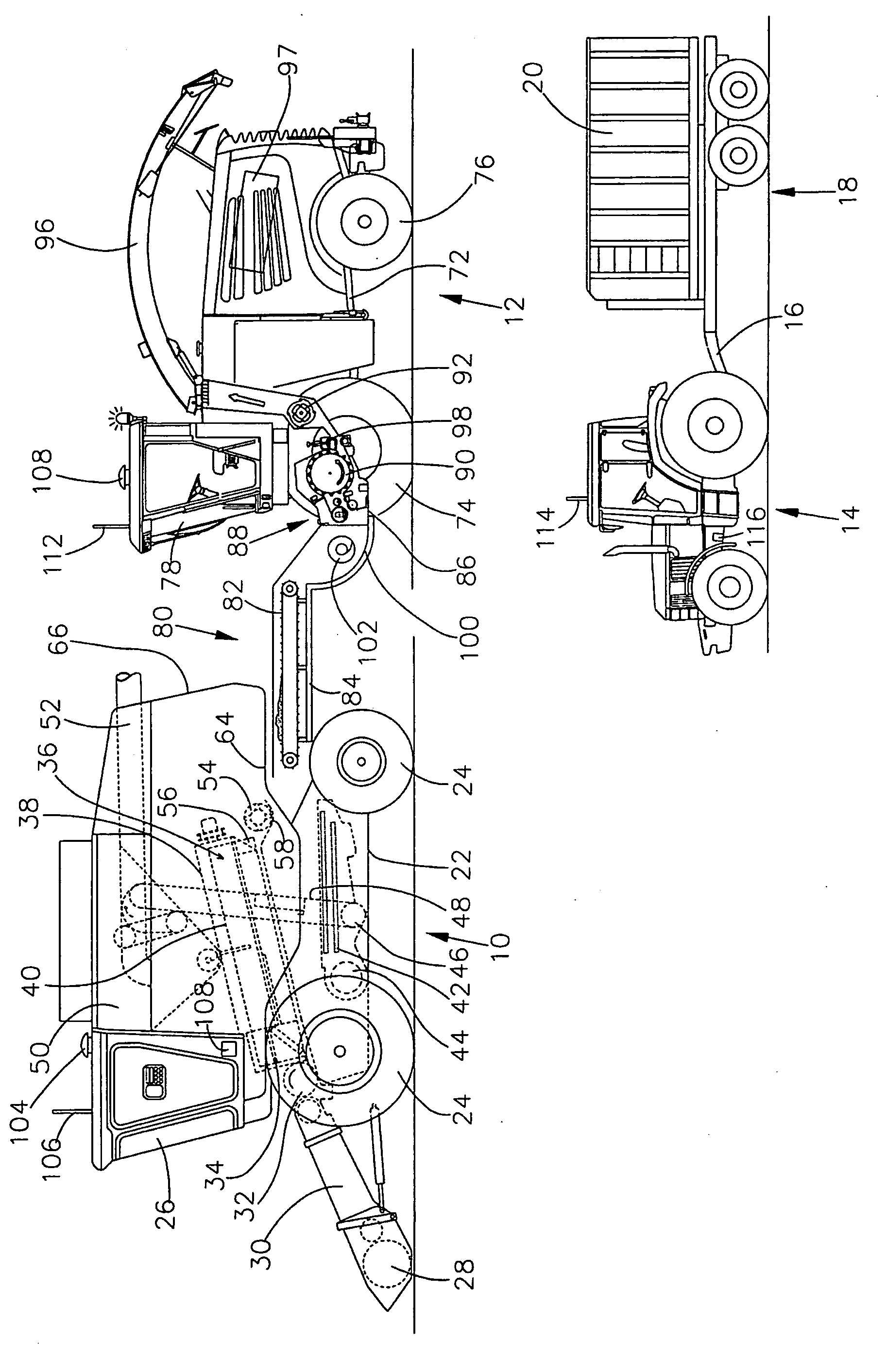

Harvesting Machine Combination For The Utilization Of Plant Remains

ActiveUS20090193777A1Not fatigueAnalogue computers for trafficLoadersAutomatic steeringForage harvester

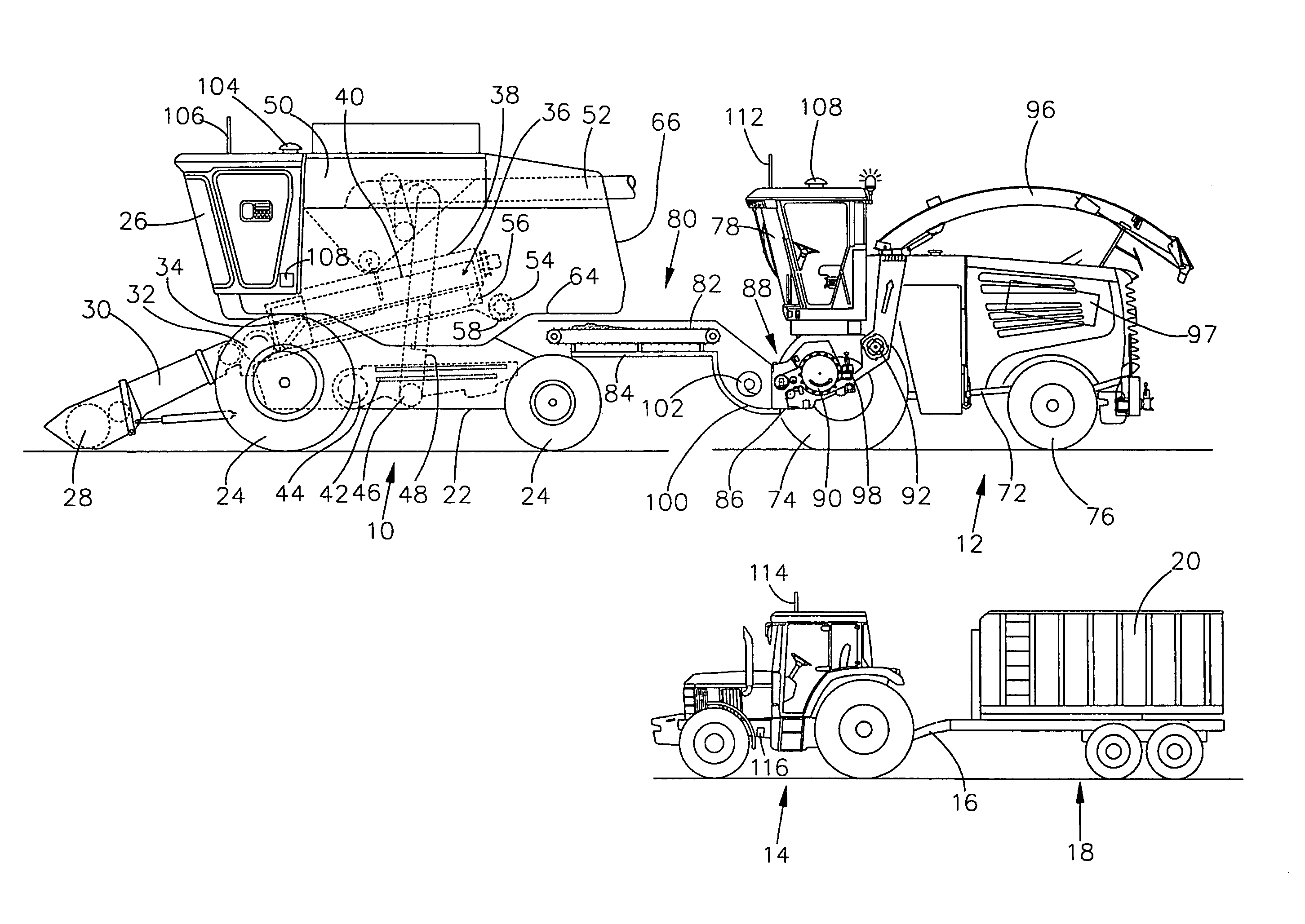

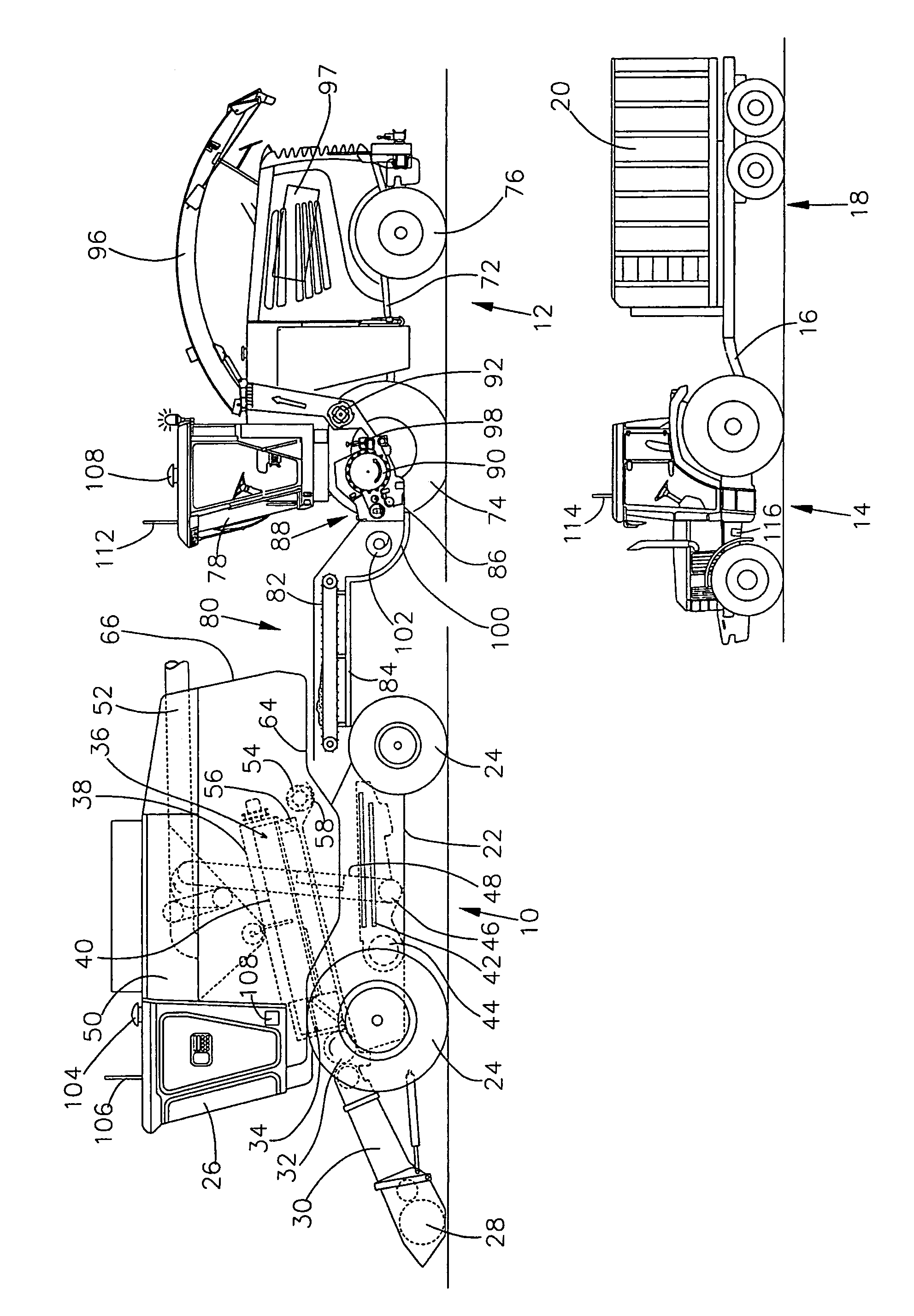

A harvesting machine combination for the utilization of harvested plant remains is provided and includes a combine with an outlet for harvested crop remains, a self propelled forage harvester that includes a conveyor to take over the harvested crop remains from the outlet of the combine, a discharge arrangement for the harvested crop remains, an engine for the drive of the conveyor and a container to take up the harvested crop remains delivered by the discharge arrangement. The combine is equipped with a transmitting arrangement for the transmission of position data and / or operation direction and speed data of the combine. The forage harvester is equipped with a receiving arrangement that interacts with an automatic steering and speed input arrangement of the forage harvester that can be operated on the basis of the data received by the receiving arrangement in order to permit the forage harvester to follow the combine automatically.

Owner:DEERE & CO

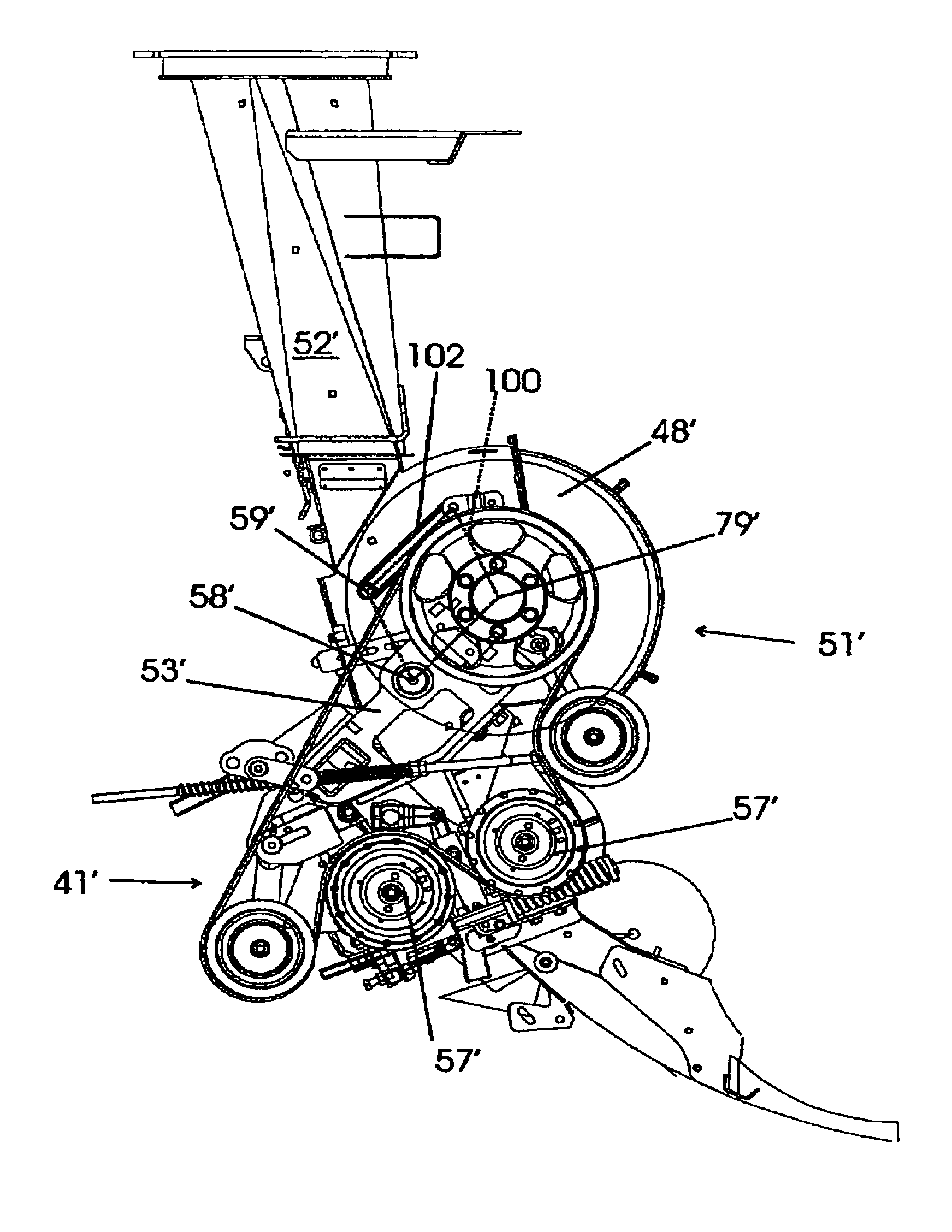

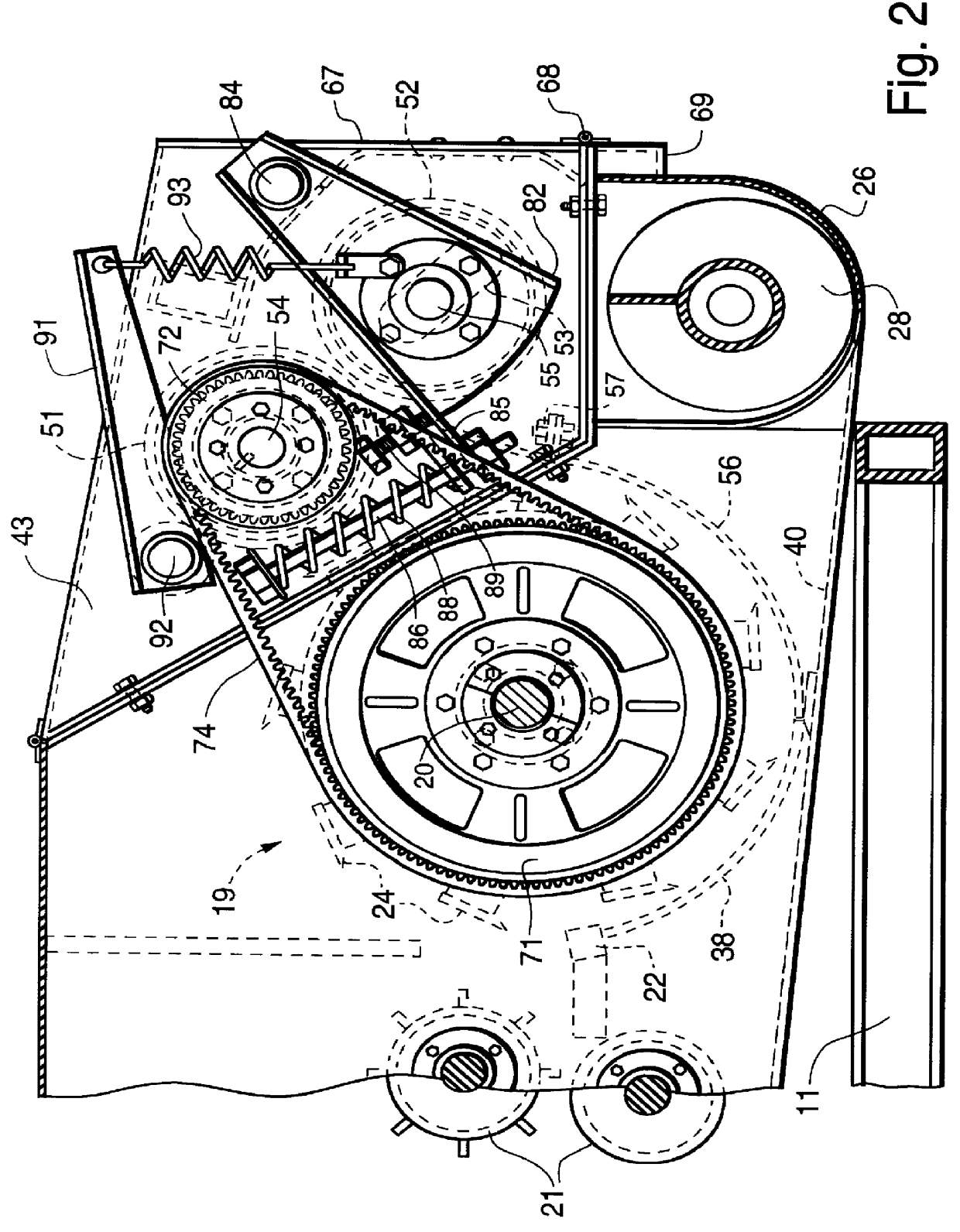

Accelerator and crop processor movement

In a forage harvester having a cutter for chopping gathered crop material, a unit is arranged downstream of the cutter, the unit including an accelerator arranged in the path of crop flow for propelling the crop towards a discharge spout, and a crop processor for cracking kernels which is selectively movable into and out of the crop flow path at a location between the cutter and the accelerator. The accelerator comprises a rotor and housing which are together movable towards the cutter when the crop processor is withdrawn from the crop flow path.

Owner:BLUE LEAF I P INC +1

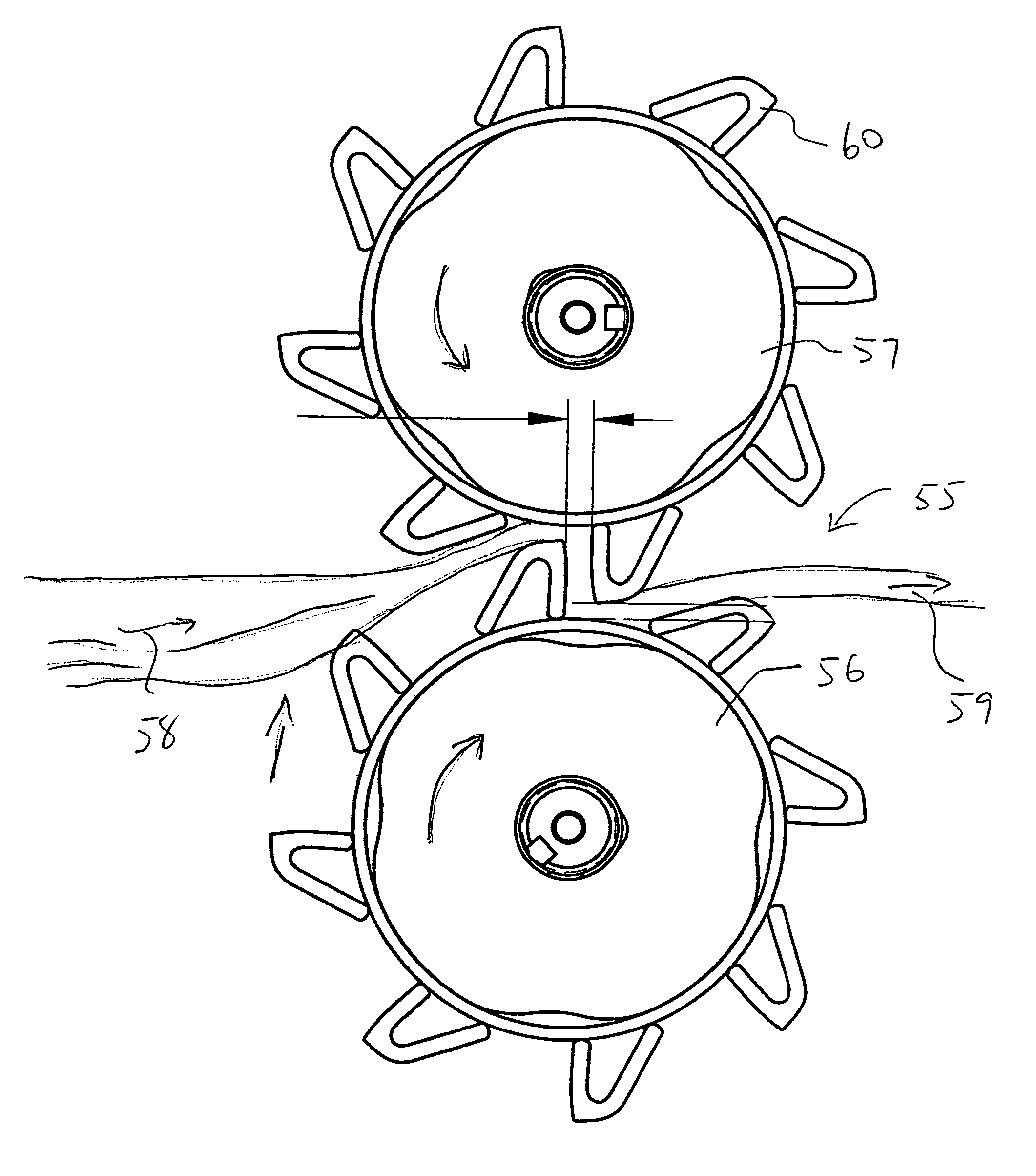

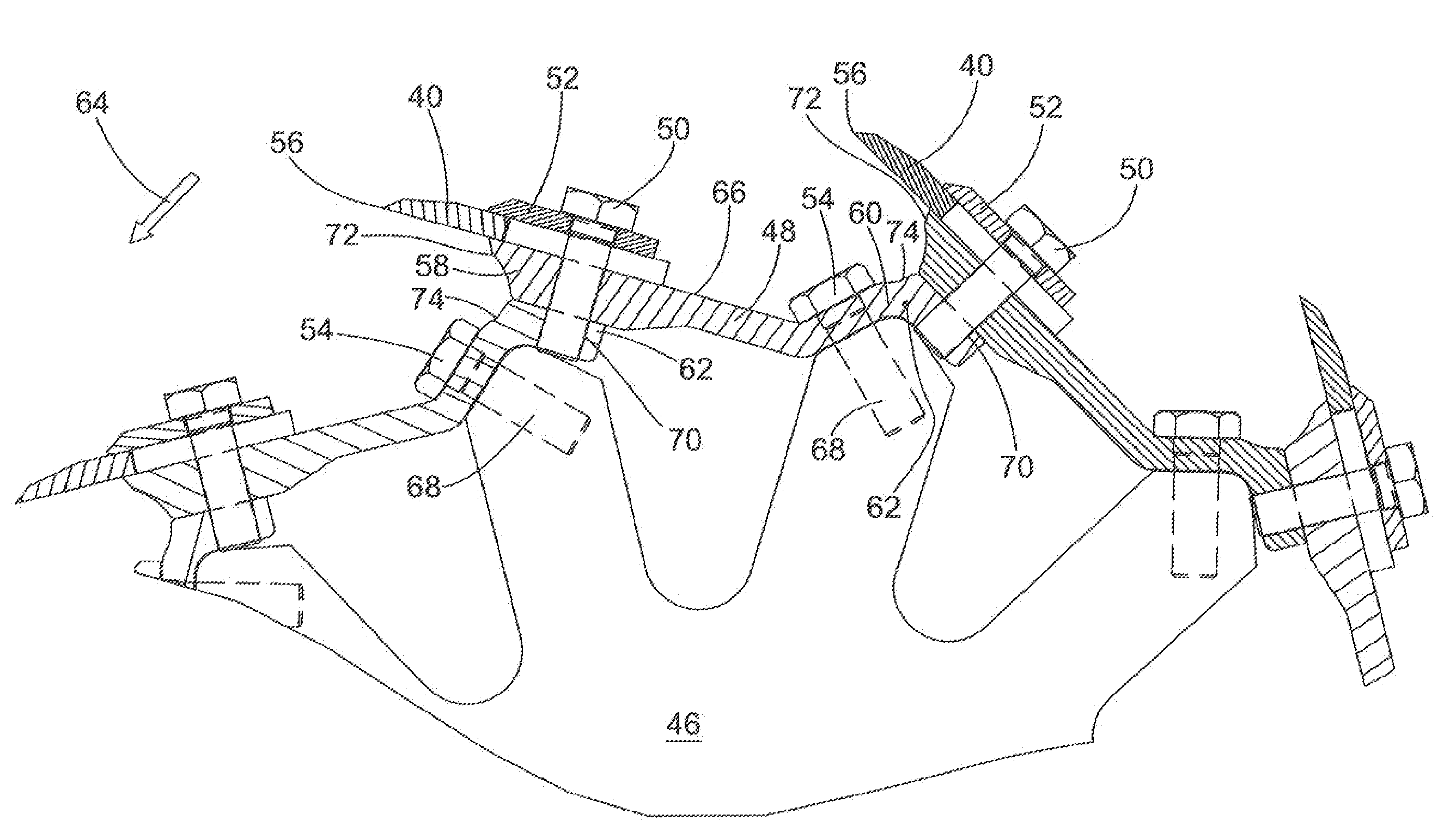

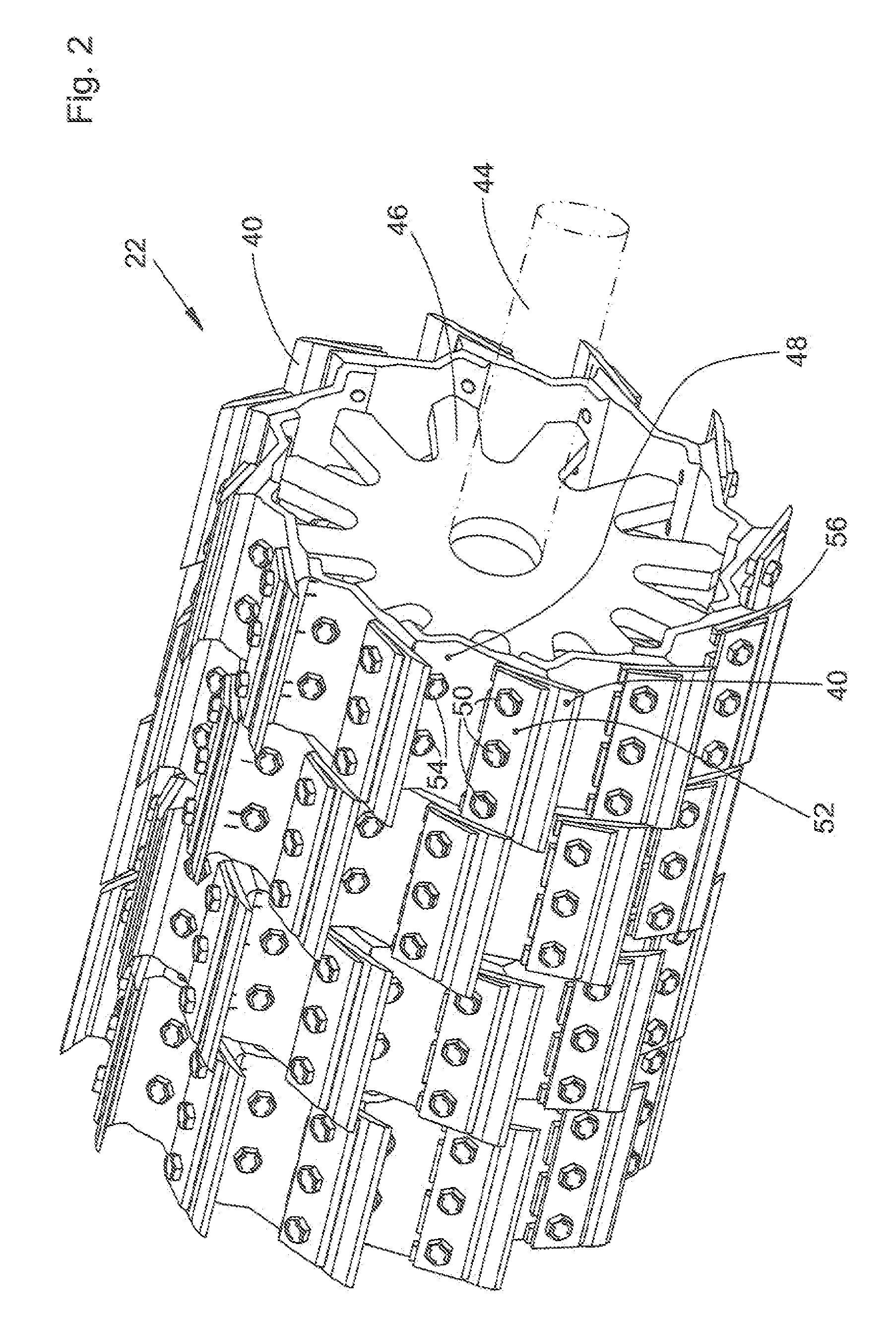

Apparatus for processing crop materials in a forage harvester

An apparatus is disclosed for processing crop materials in a forage harvester. The apparatus may comprise a pair of rotatable rollers for cutting crop materials passed between the rollers, and a bifurcated frame supporting the rollers in a proximate condition to each other. The bifurcated frame includes a first frame portion and a second frame portion, with a first one of the rollers being mounted on the first frame portion for moving with the first portion and a second one of the rollers being mounted on the second frame portion. The first frame portion may be movable with respect to the second frame portion to move the first roller laterally away from the second roller.

Owner:SCHERER BOB A

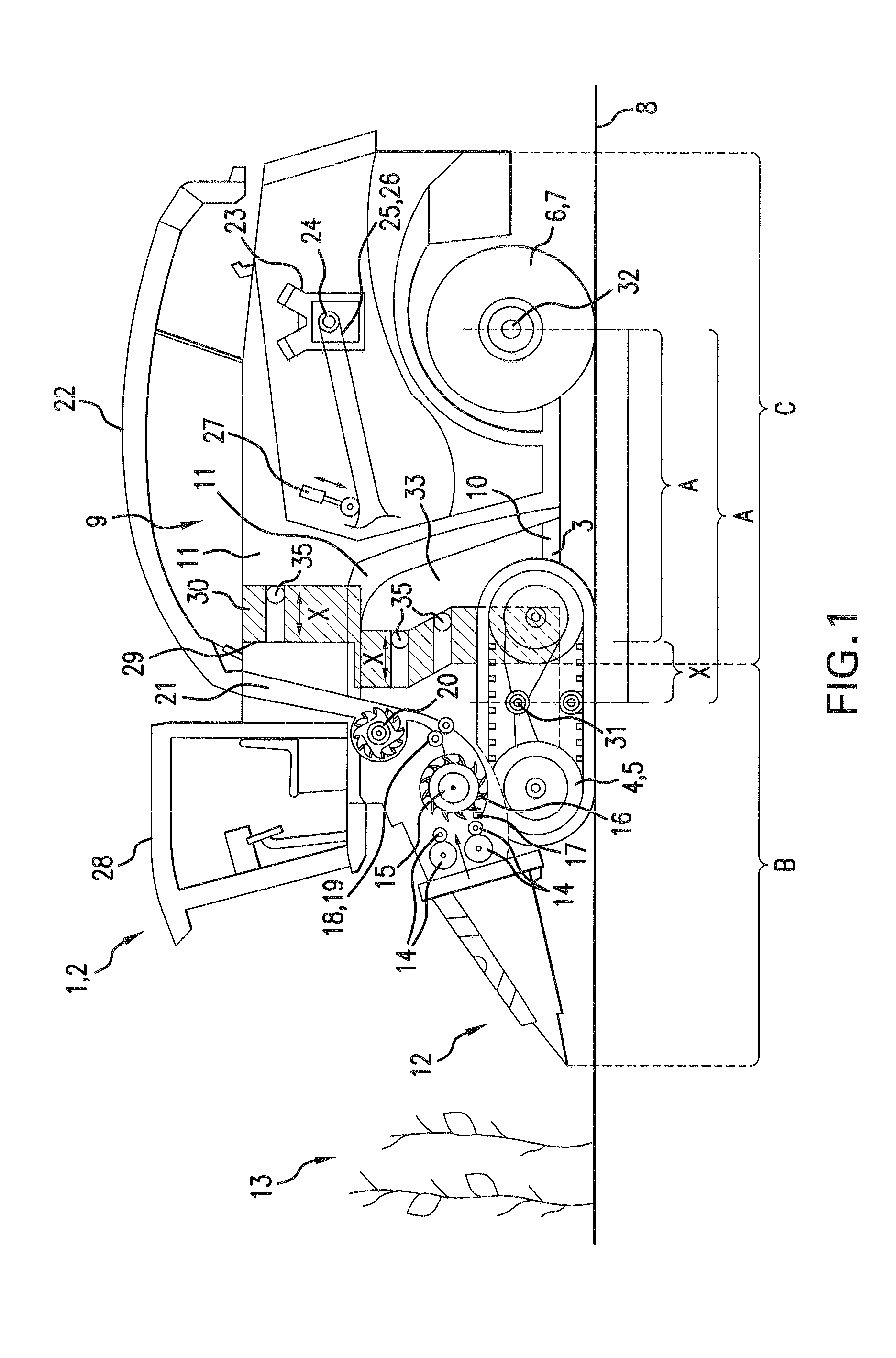

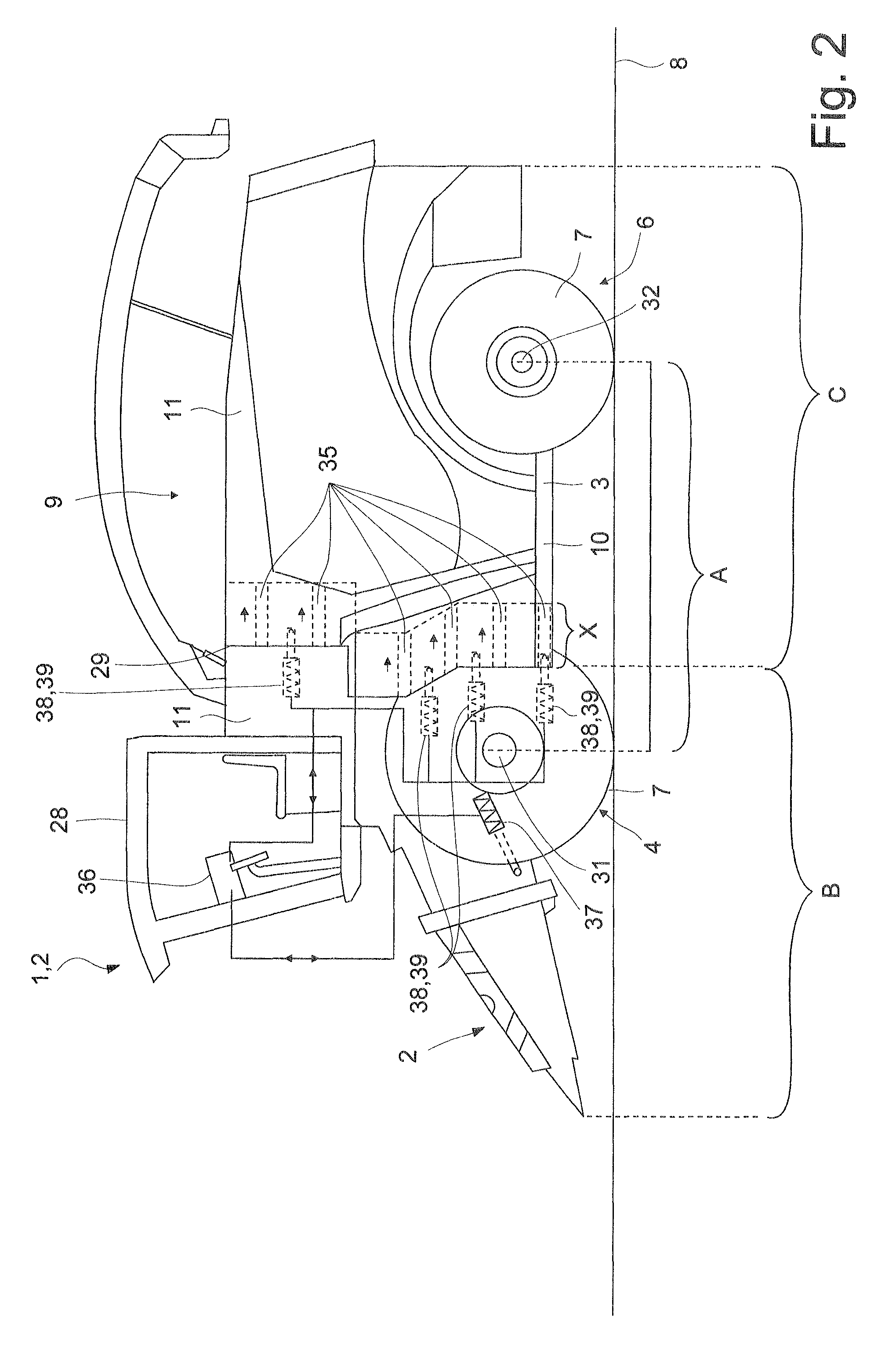

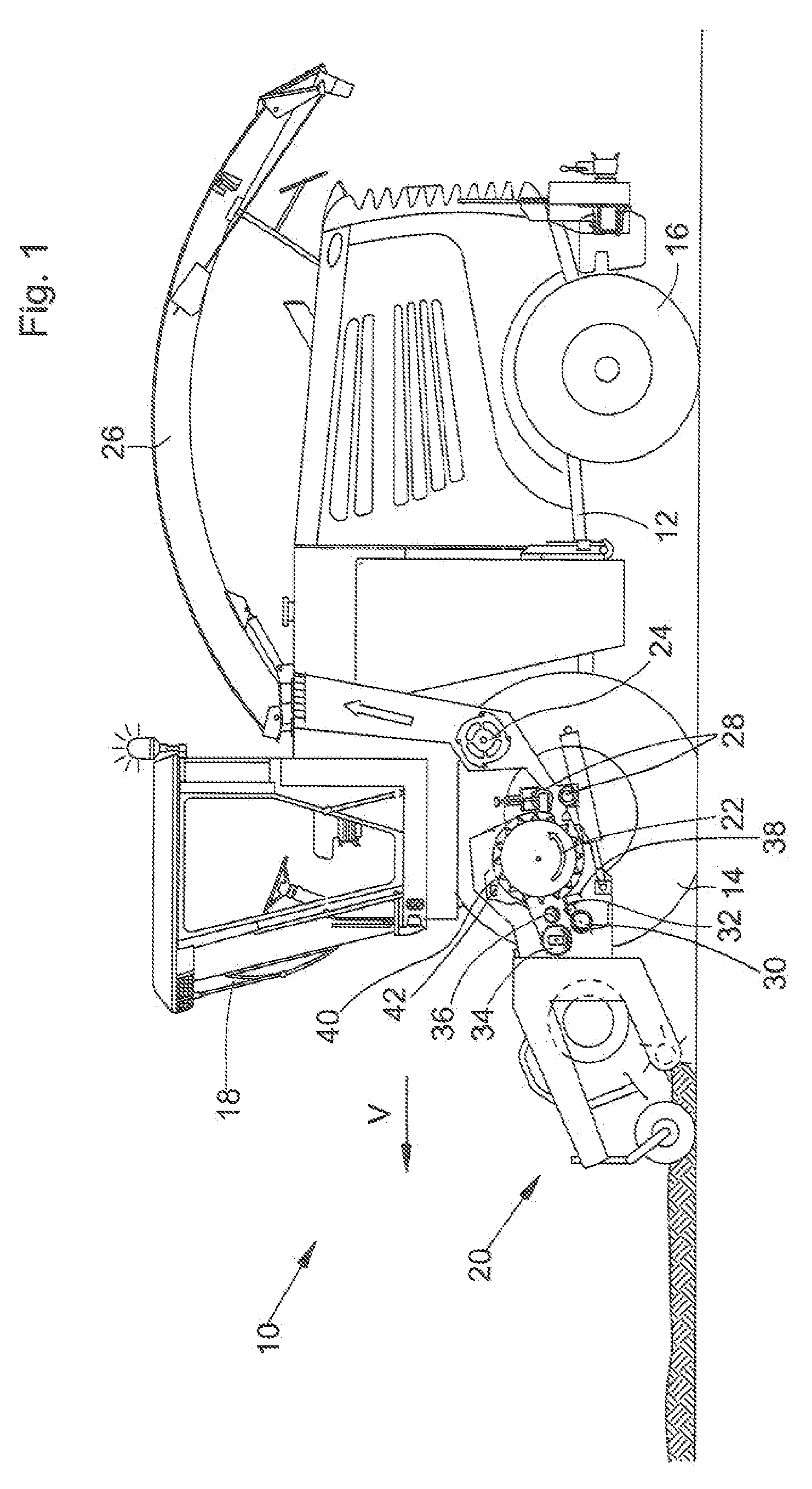

Agricultural harvesting machine

An agricultural harvesting machine, in particular a forage harvester, has a frame, with a drive unit, an intake conveyor mechanism that directs the crop material to a downstream chopper drum, and a post-fragmentation device located downstream of the chopper drum. A bottom plate that encloses a portion of the chopper drum and is located adjacent to the guide plate in the crop material conveying chute is assigned to the chopper drum. The guide plate, which is located on the bottom of the crop material conveying chute in the region between the chopper drum and the downstream post-fragmentation device is capable of being swiveled vertically around a horizontal pivot axis from a closed position into an open position, and vice versa.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

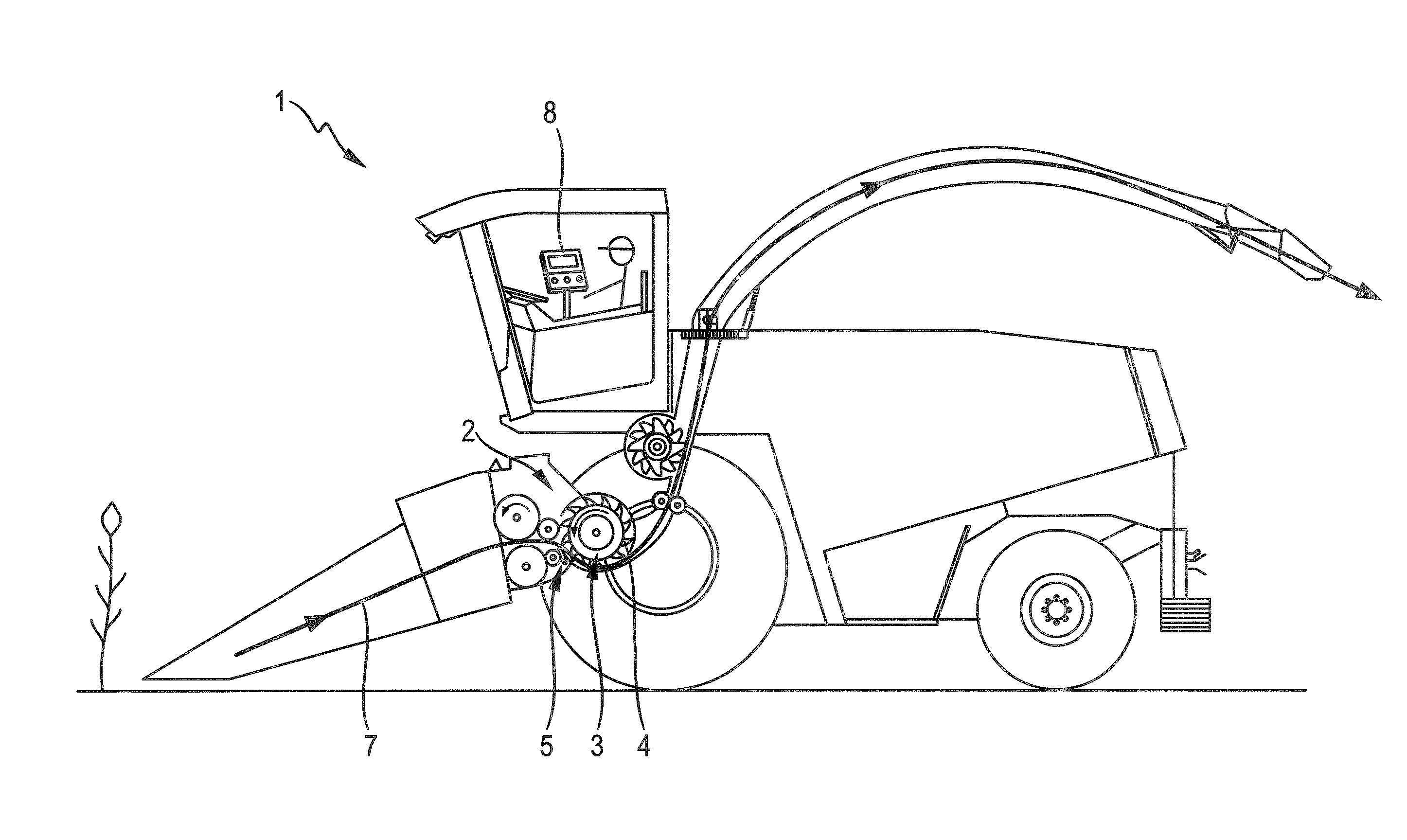

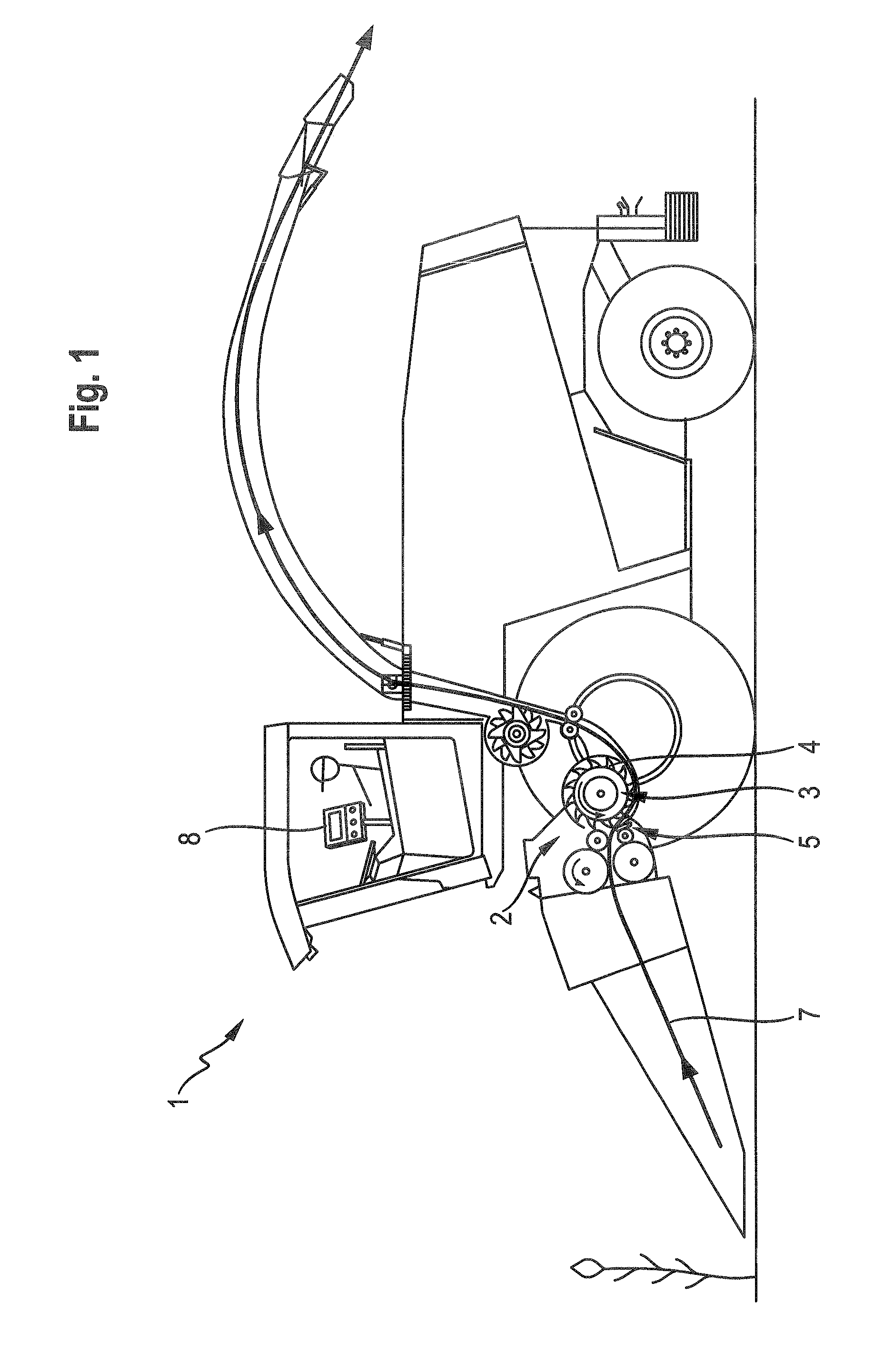

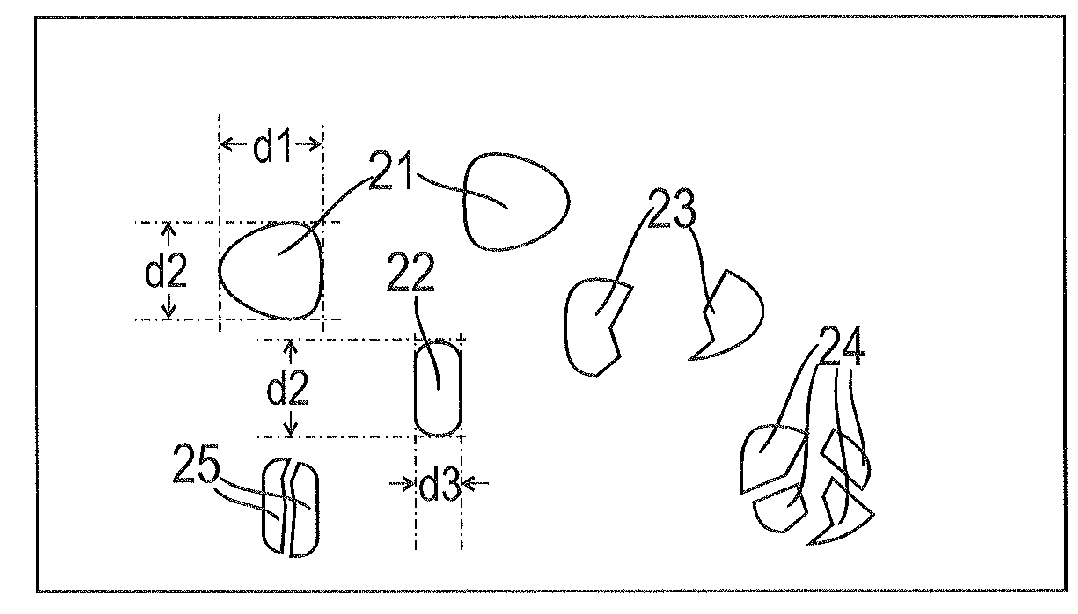

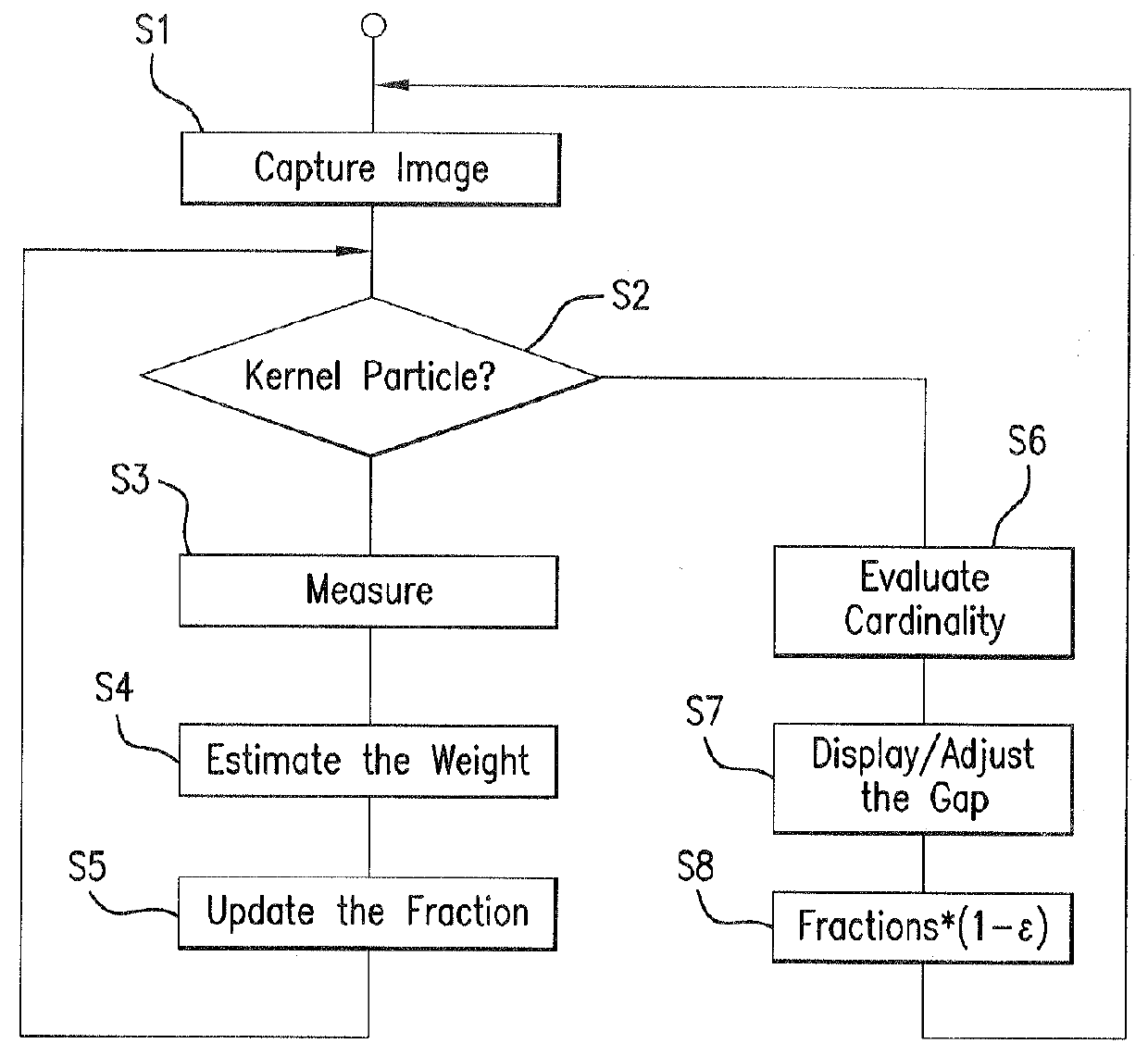

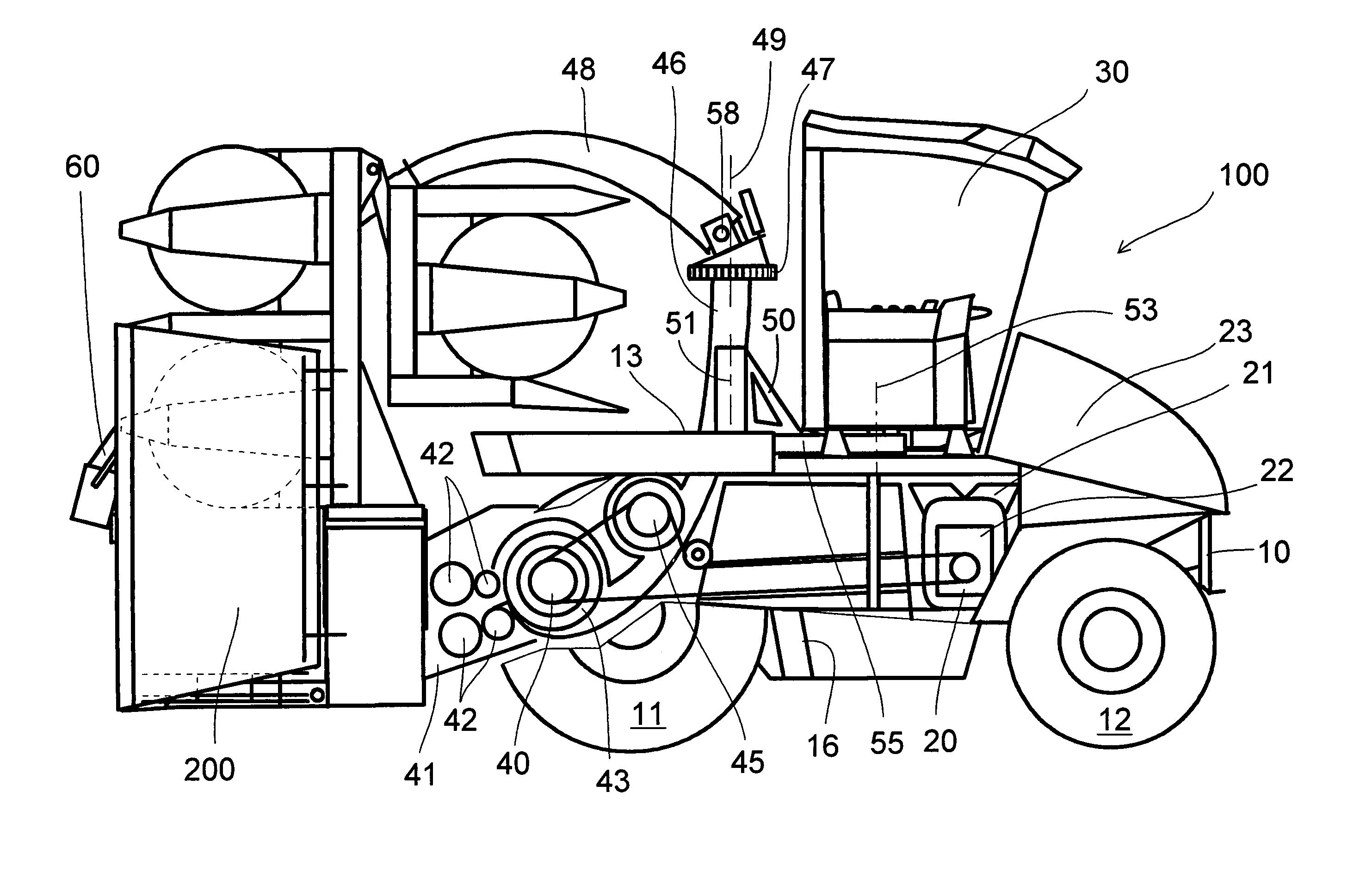

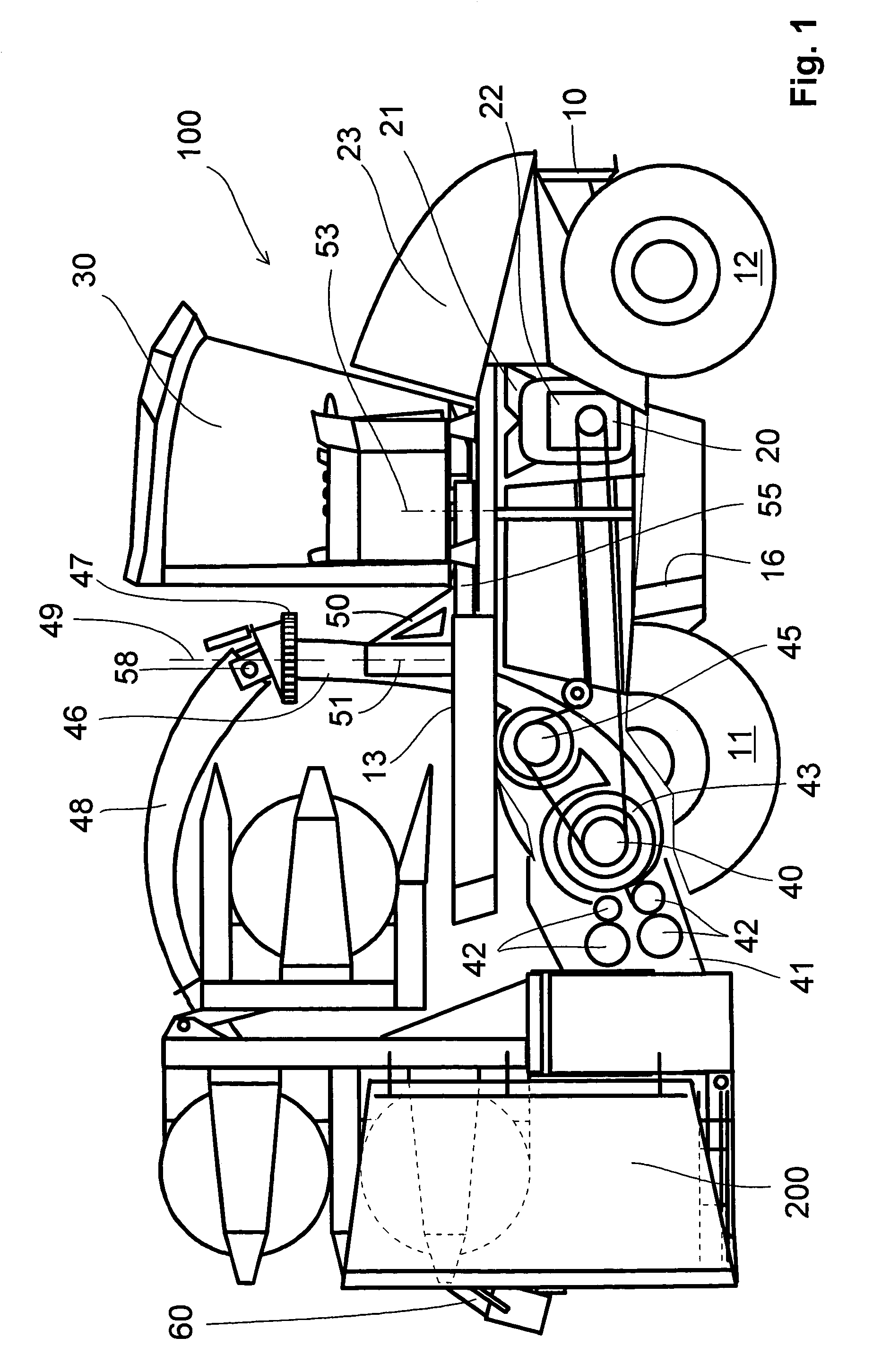

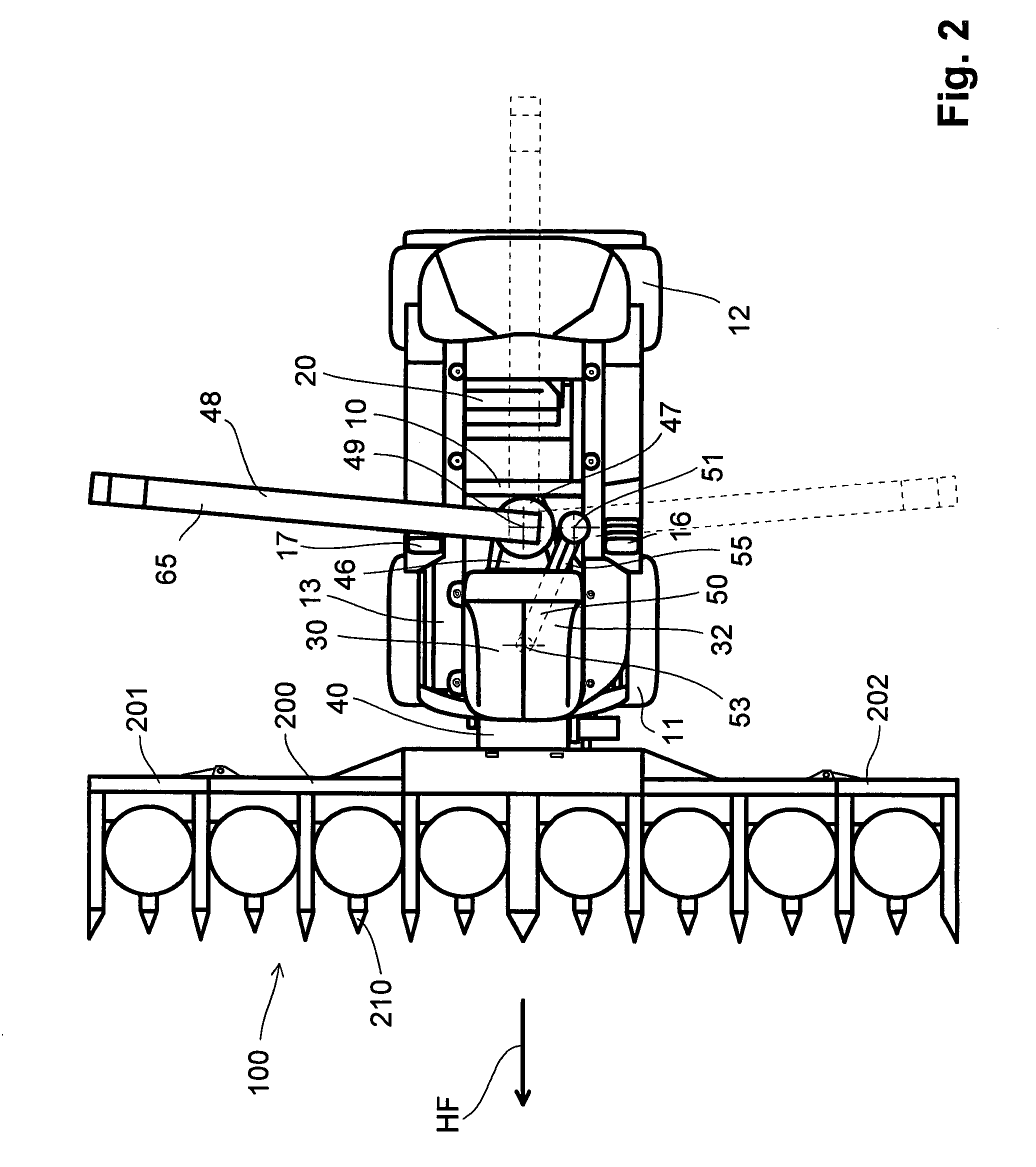

Forage harvester and operating method therefor

InactiveUS20160029561A1More interferenceGrain huskingImage enhancementForage harvesterComputer science

A method for operating a forage harvester includes steps of capturing images of chopped material produced in the forage harvester using a camera, identifying images of kernel-type particles in the images, sorting the images of the kernel-type particles into at least two size fractions and determining a cardinality of the size fractions.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

Forage harvester with positionable operator's cabin

A self-propelled forage harvester has a chassis, an operator's cabin arranged on the chassis, a chopper drum, an ascending lower discharge chute extending from the chopper drum inside the chassis to a level above the chassis, and a working element arrangement, the operator's cabin being movable from a street operating position into at least one chopper operating position and vice versa and the cabin embracing the at least one working element arrangement during movements between the positions.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

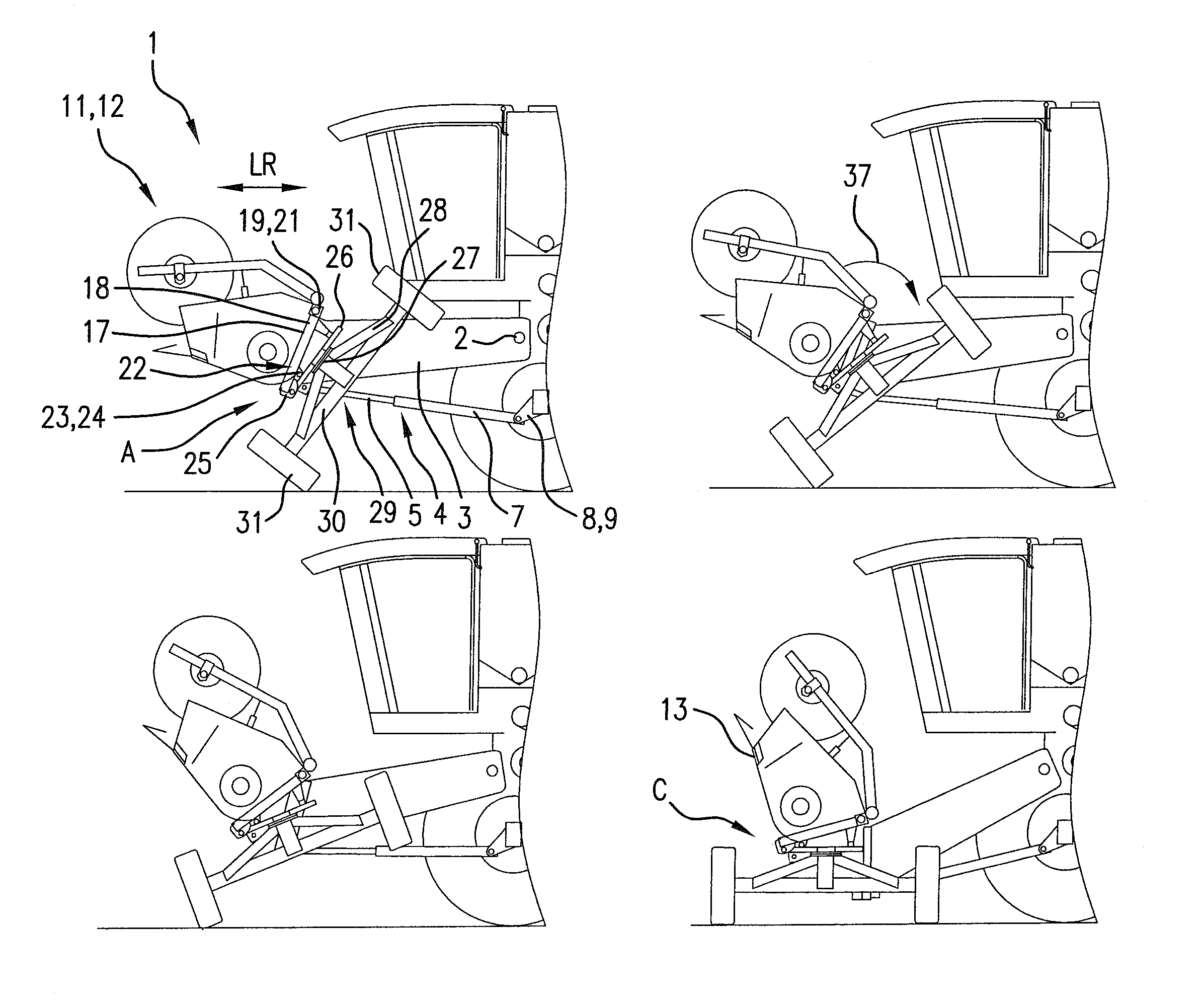

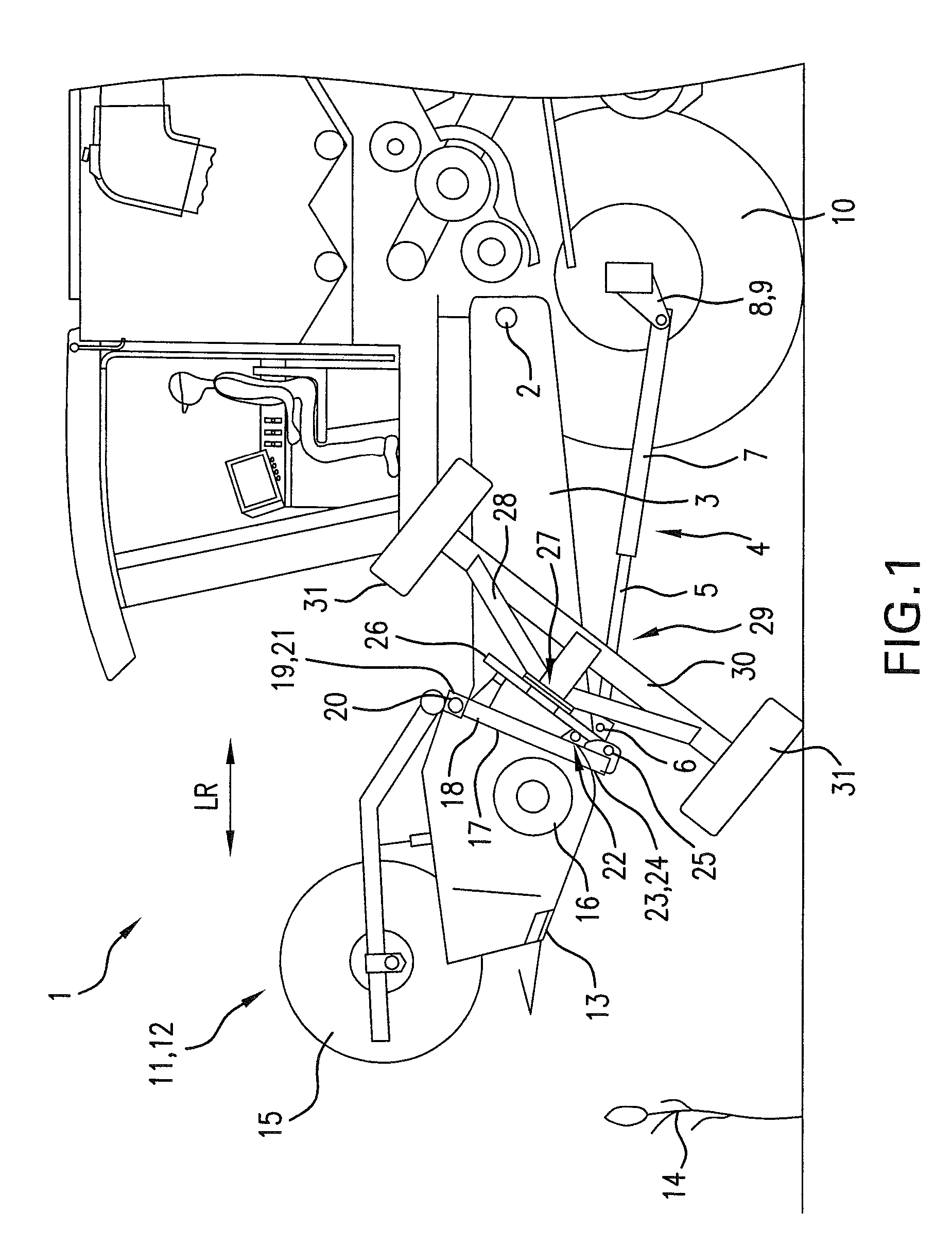

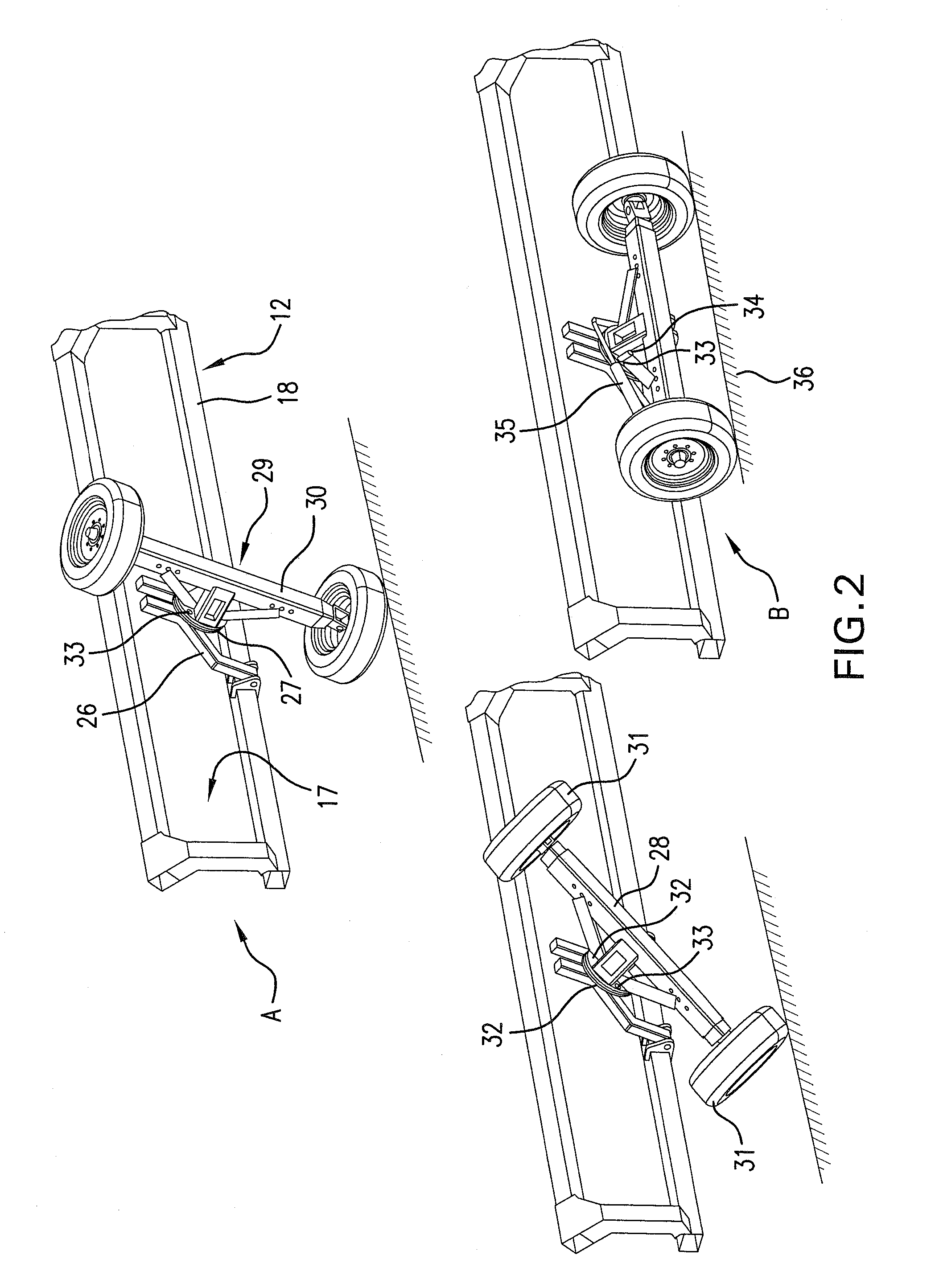

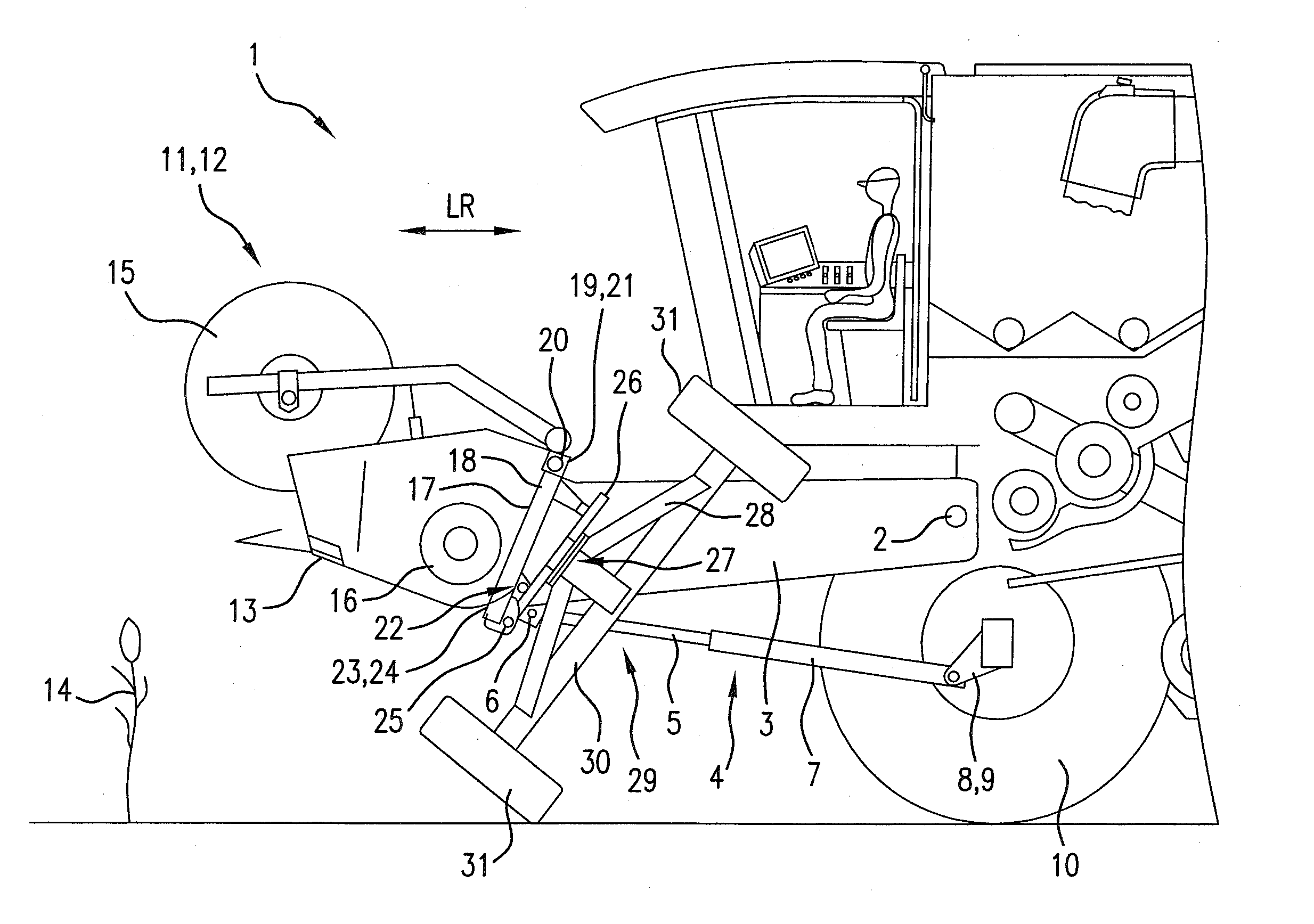

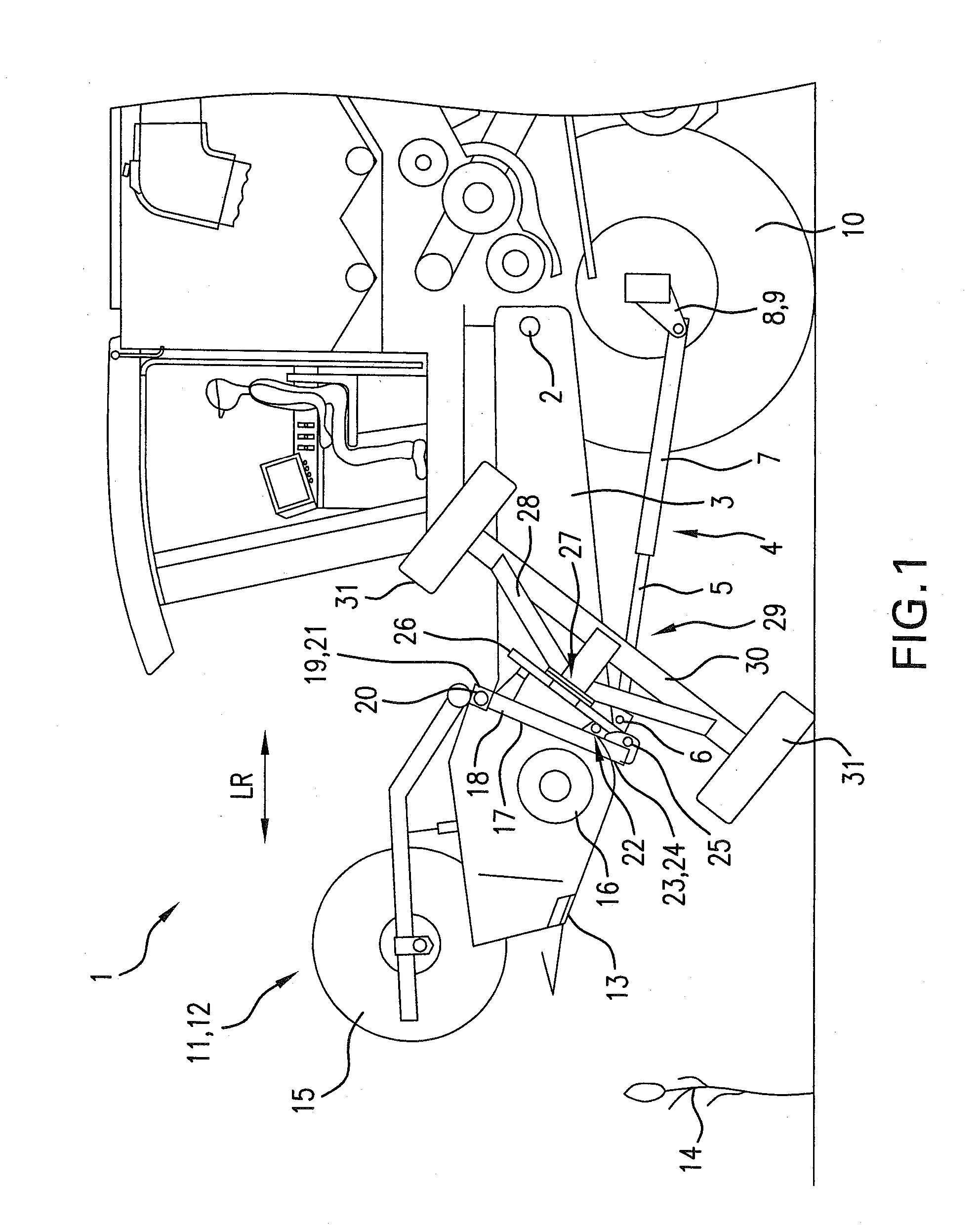

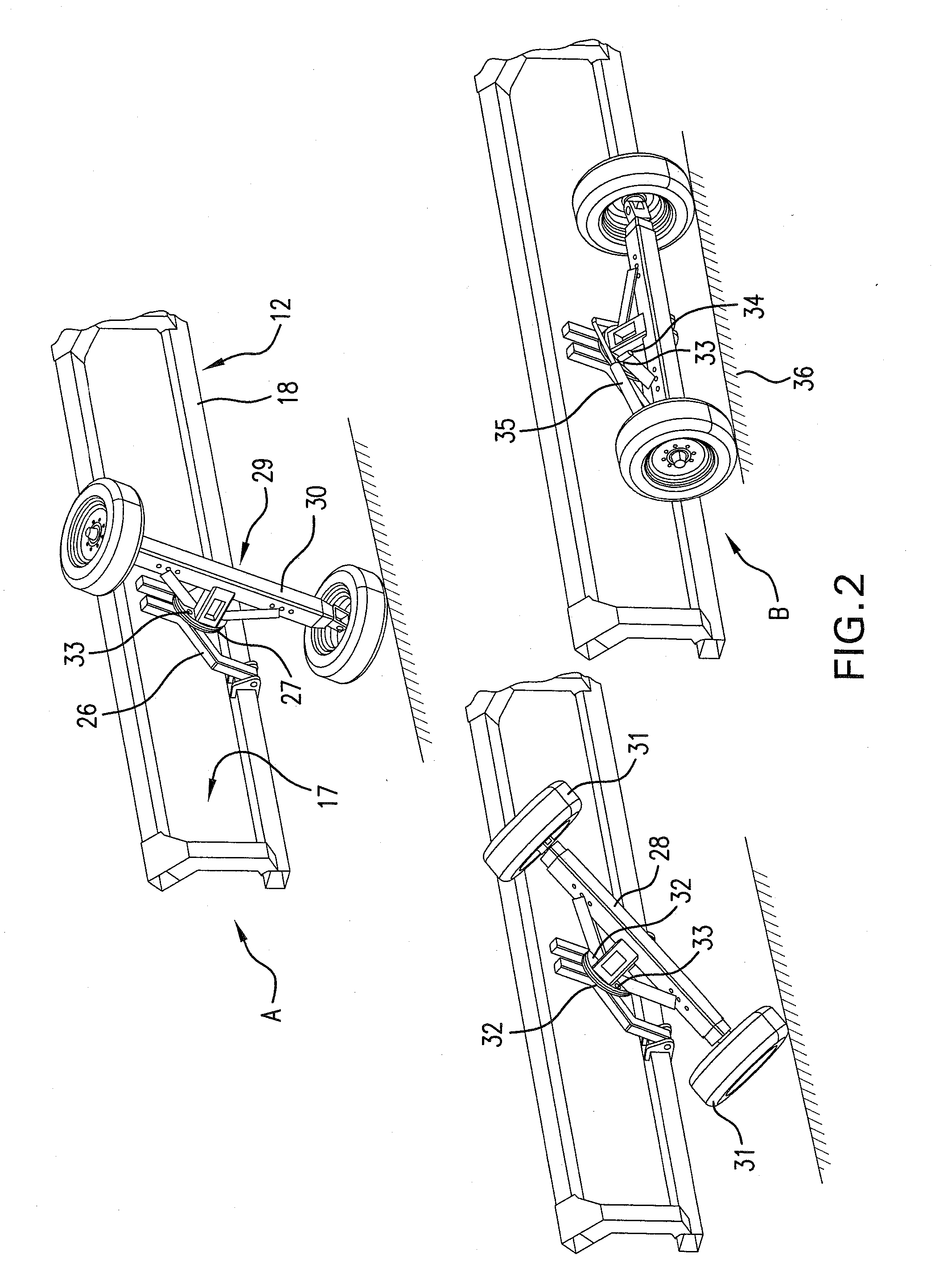

Agricultural working machine header support between transport and working positions

An agricultural working machine, such as a combine harvester or forage harvester, has a feeding assembly arranged on the front for accommodating a header attachment which is designated to harvest and convey a harvested crop, and at least one gauge wheel attachment comprising at least one support wheel associated with the header attachment on one or both sides of the feeding assembly, wherein the header attachment is arranged pivotally about a rotation axis extending transversely to the longitudinal direction of the agricultural working machine on the feeding assembly in such a manner that the header attachment can be automatically rotated from a working position into a transport position when the feeding assembly is lowered, and at least one support wheel of at least one gauge wheel attachment supports the header attachment on the ground in the transport position. This ensures that the use of a separate header trailer is not necessary. At the same time such a rotating mechanism enables support wheel arrangements to be brought quickly from a working to a non-working position without heavy physical work being required for that alteration.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

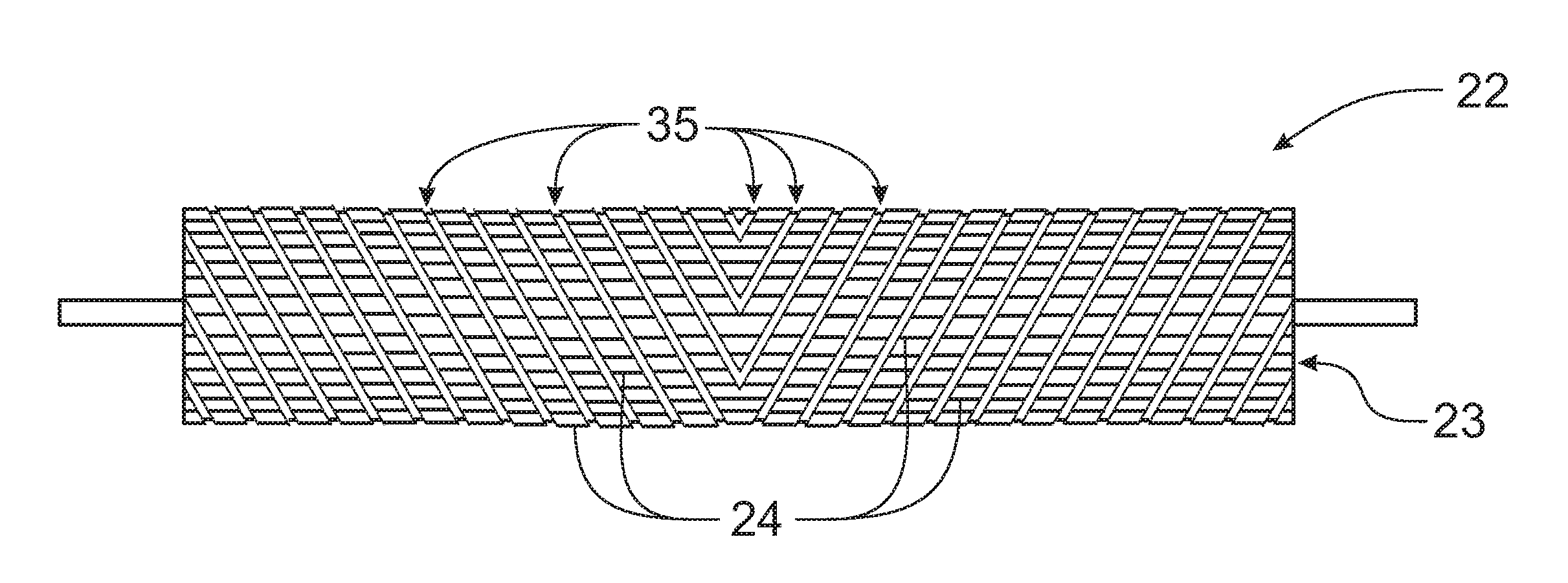

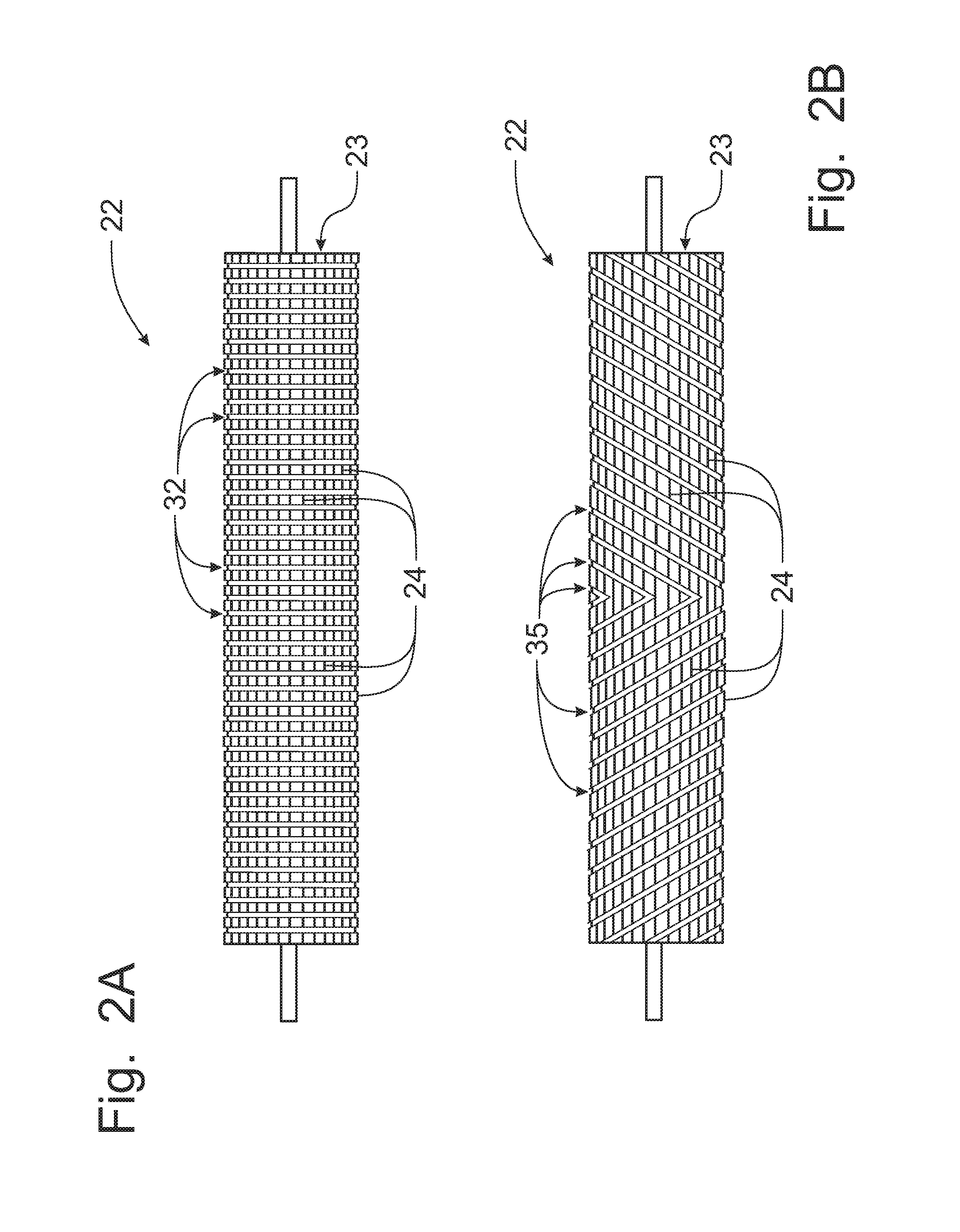

Corn Processing Roll with Chevron Grooves

ActiveUS20170000031A1Increased operating lifeEqual operating livesCrop conditionersMowersEngineeringForage harvester

Crop processing rolls are provided for operative use in forage harvesters wherein the crop processing rolls are formed with spiraled grooves that are oriented in opposing slopes extending from the opposite ends of the crop processing roll toward the center of the roll. The formation of these spiraled grooves defines teeth from the ridges created with the formation of horizontal grooves into the circumferential surface of the crop processing roll. In one configuration, the spiraled grooves meet at the center of the crop processing roll in a V-shaped intersection to provide a chevron shape to the spiraled grooves. In a second configuration, the spiraled grooves do not intersect at the center and form a semi-chevron pattern that does not form a short tooth that the chevron configuration creates at the V-shaped intersection.

Owner:HORNING MFG LLC

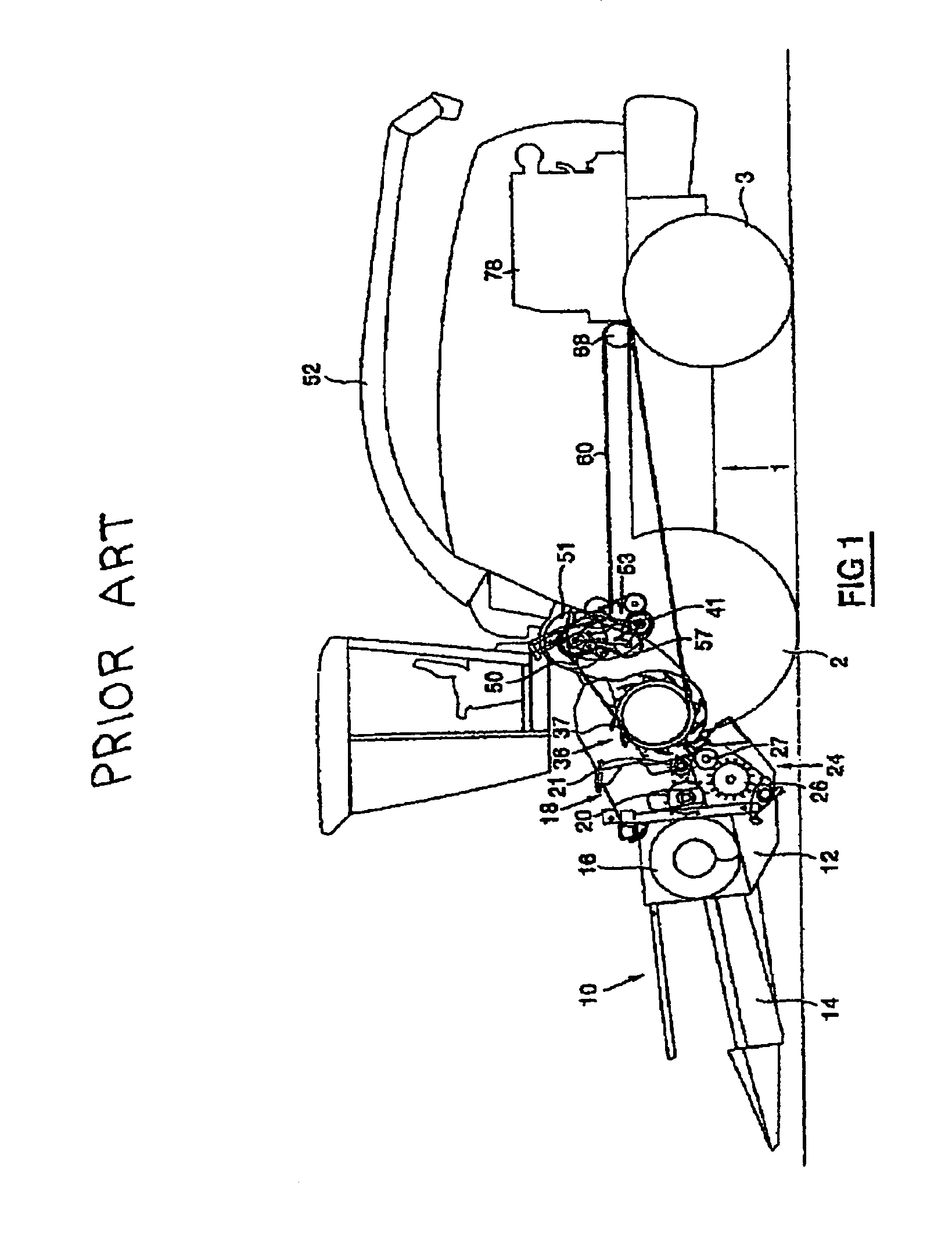

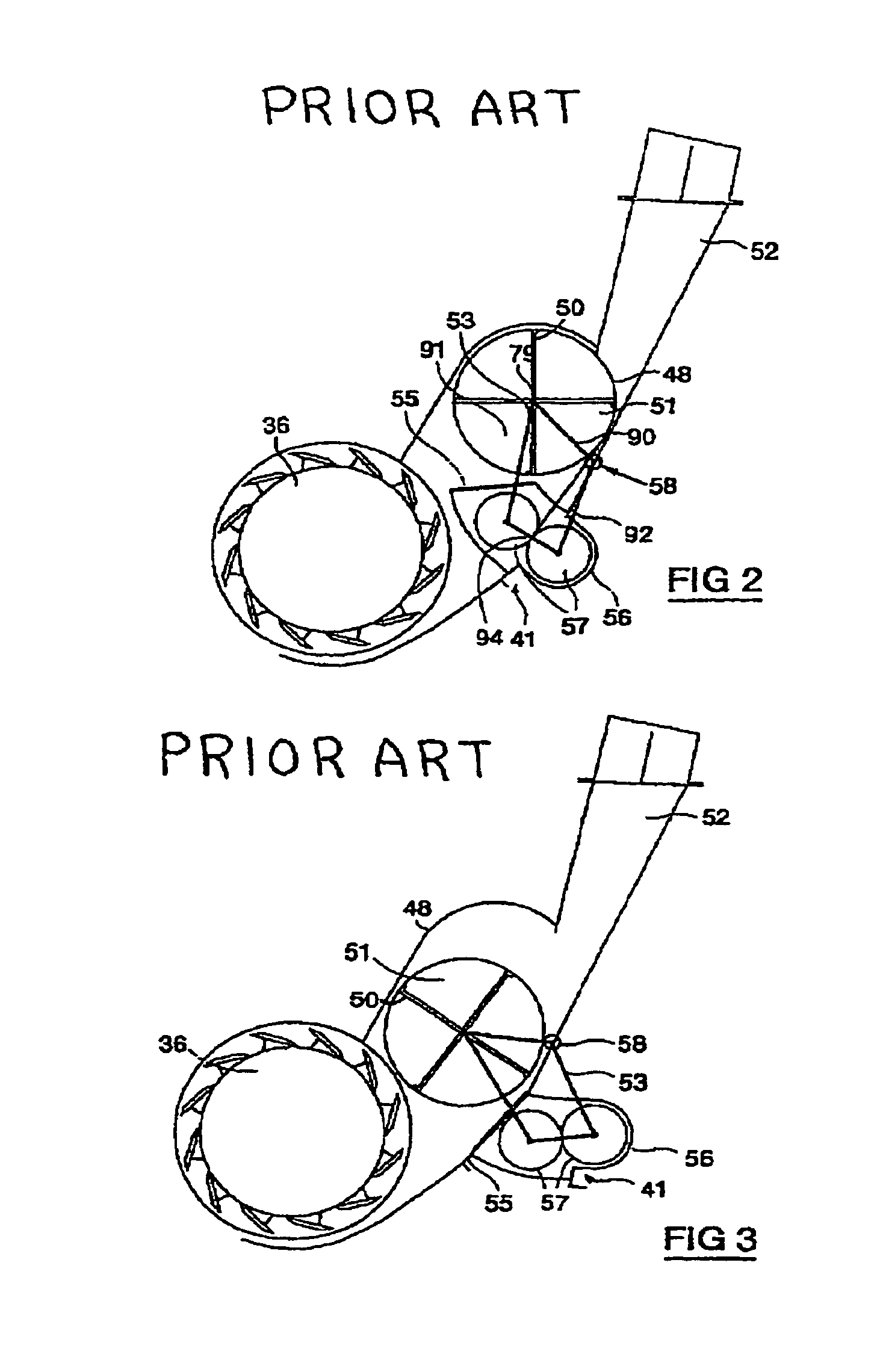

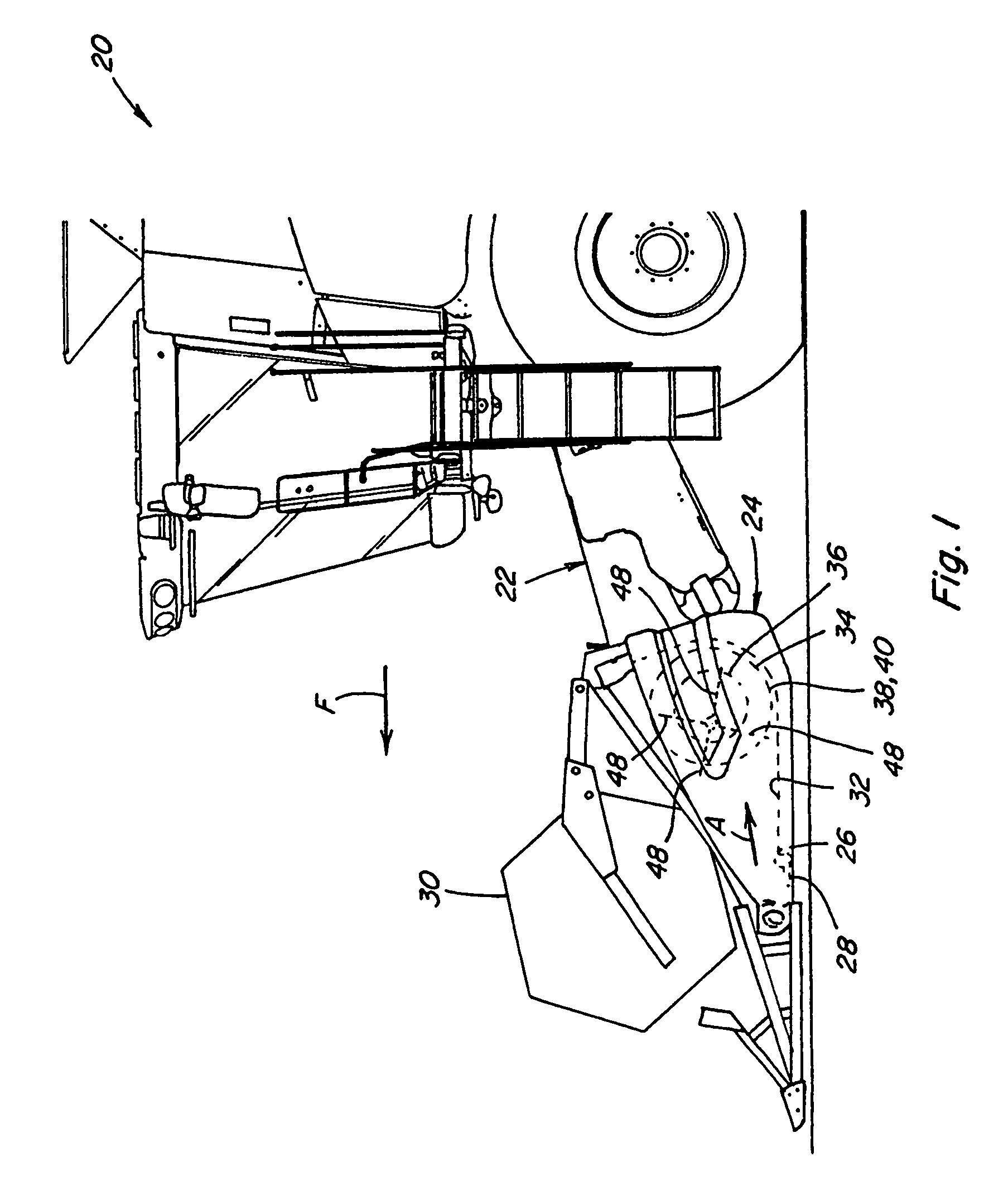

Corn processor for forage harvester

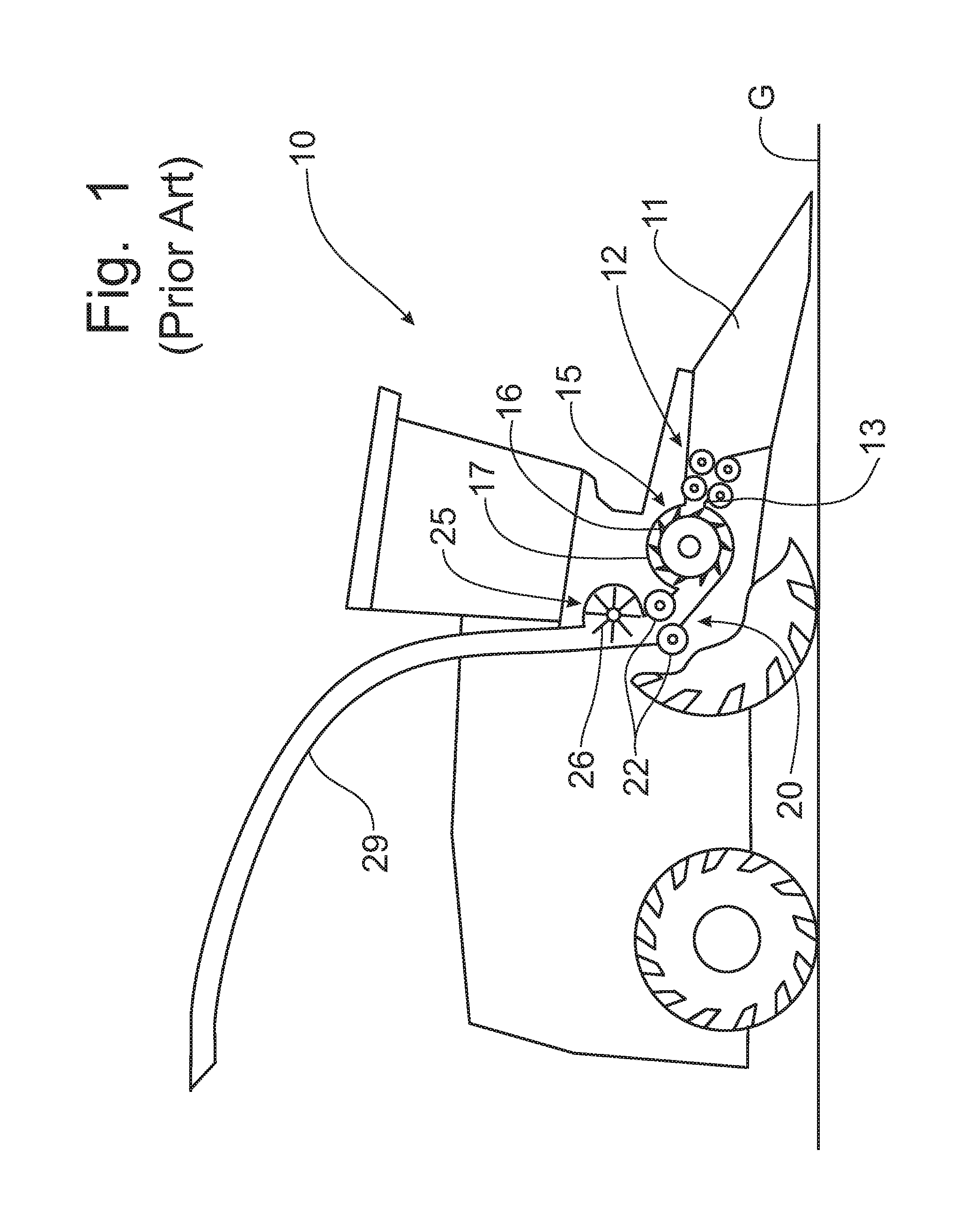

In a pull type forage harvester which travels forwardly in a field to pick up crop material and feed it into a housing having a cutterhead with knives rotatable around a transverse axes. The cutterhead chops the crop material and deposits it in a transverse trough having an auger which carries the crop to a lateral discharge location. The improvement comprises a corn processor adapter to which chopped corn is conveyed over a floor to an upper and a lower roll rotatable on axes parallel to the cutterhead. The rolls form a bite to receive the corn and pass it between them to crush the kernels therein. The upper roll is positioned close to the cutterhead knives and in crop stripping relation thereto. The lower roll is positioned over the auger to hold down chopped corn thrown upwardly out of the trough.

Owner:FISHER JR GIDEON A +1

Agricultural working machine

An agricultural working machine, such as a combine harvester or forage harvester, has a feeding assembly arranged on the front for accommodating a header attachment which is designated to harvest and convey a harvested crop, and a gauge wheel attachment comprising at least support wheel associated with the header attachment on one or both sides of the feeding assembly, wherein the header attachment is arranged pivotally about a rotation axis extending transversely to the longitudinal direction of the agricultural working machine on the feeding assembly in such a manner that the header attachment can be automatically rotated from a working position into a transport position when the feeding assembly is lowered, and at least one support wheel of at least one gauge wheel attachment supports the header attachment on the ground in the transport position. This ensures that the use of a separate header trailer is not necessary. At the same time such a rotating mechanism enables support wheel arrangements to be brought quickly from a working to a non-working position without heavy physical work being required for that alteration.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

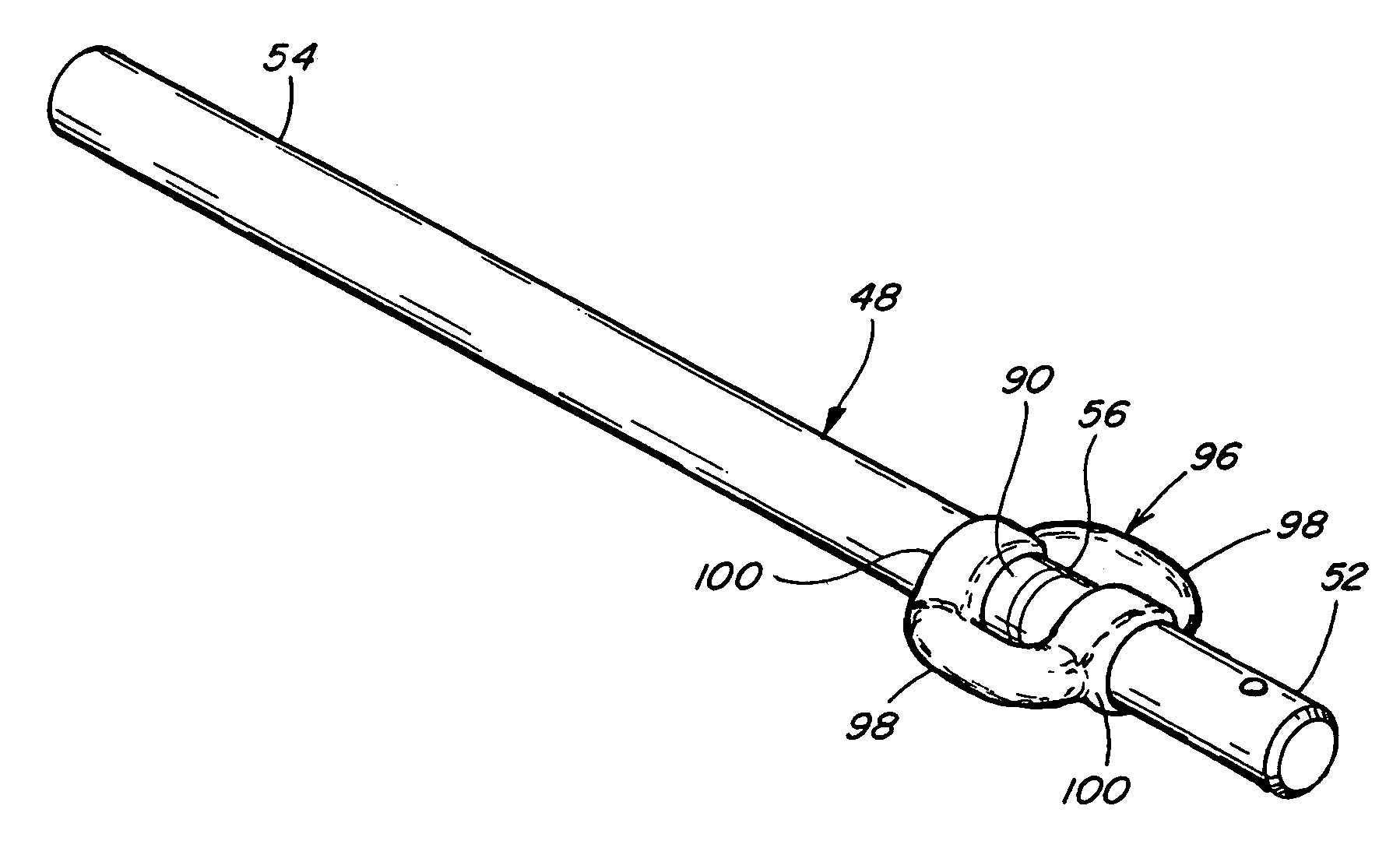

Auger finger with resilient elastomeric retainer retractor at breaking point

A finger for a crop gathering auger of a grain header for an agricultural combine, a forage harvester, or the like, the finger including a resilient elastomeric retainer retractor which spans a failure region of the finger and will retain a free end of the finger in connection with a mounting end thereof when the failure region is broken, and which is configured and operable for automatically retracting the broken off free end into an auger drum and retaining it therein during subsequent rotation of the drum for limiting potential damage from the broken end and preventing entry of the broken end into crop handling equipment of the combine or other machine.

Owner:BLUE LEAF I P INC

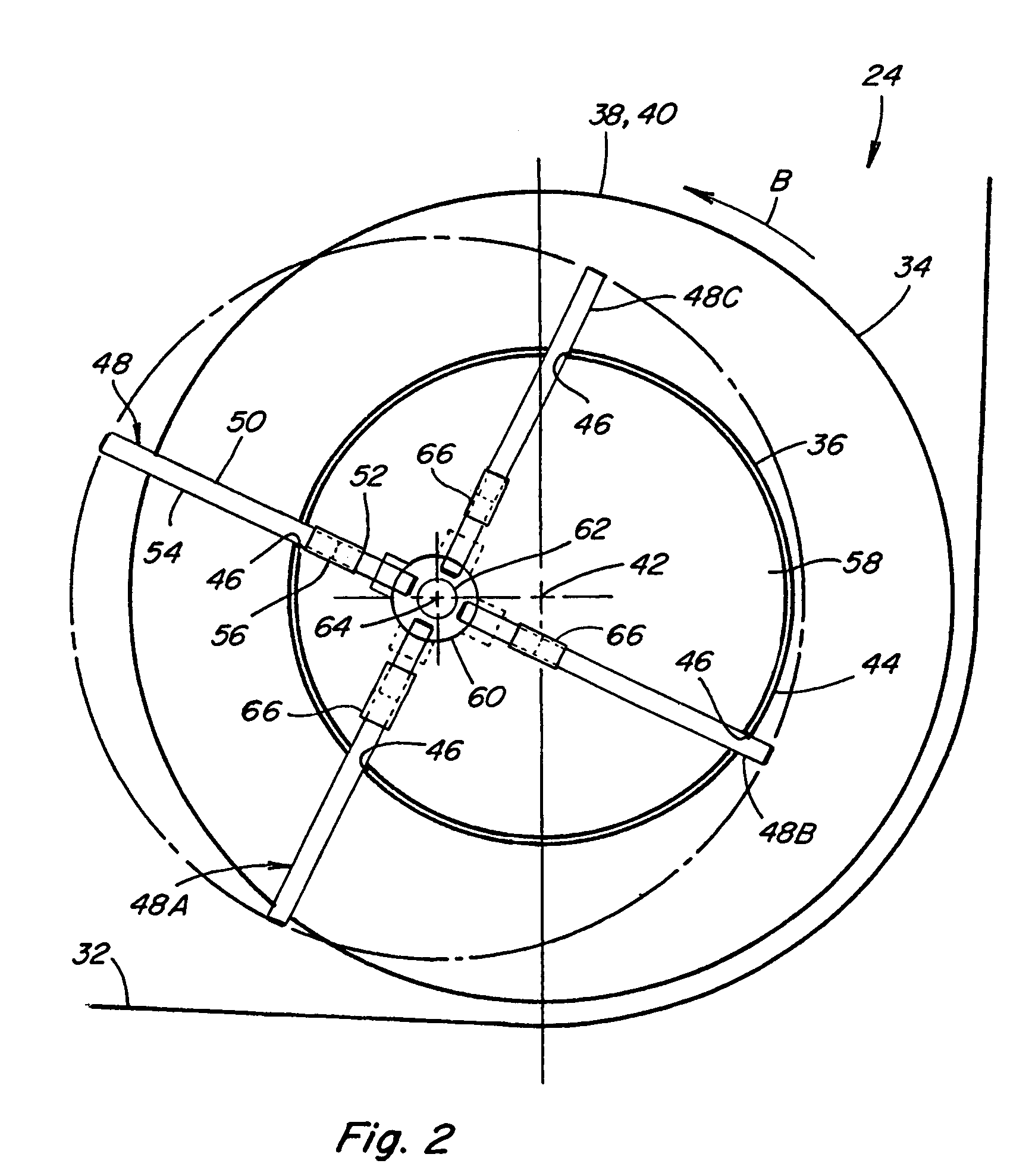

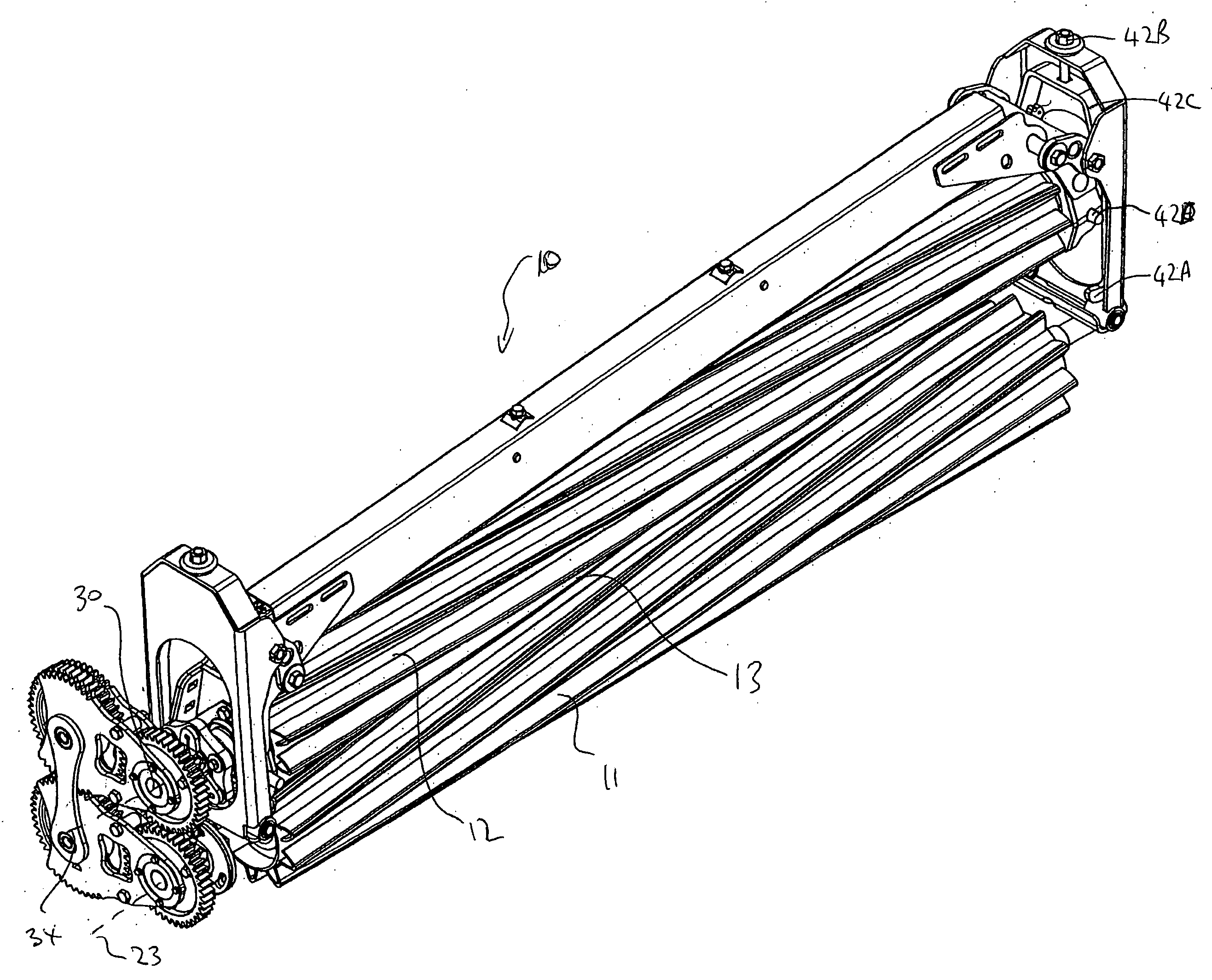

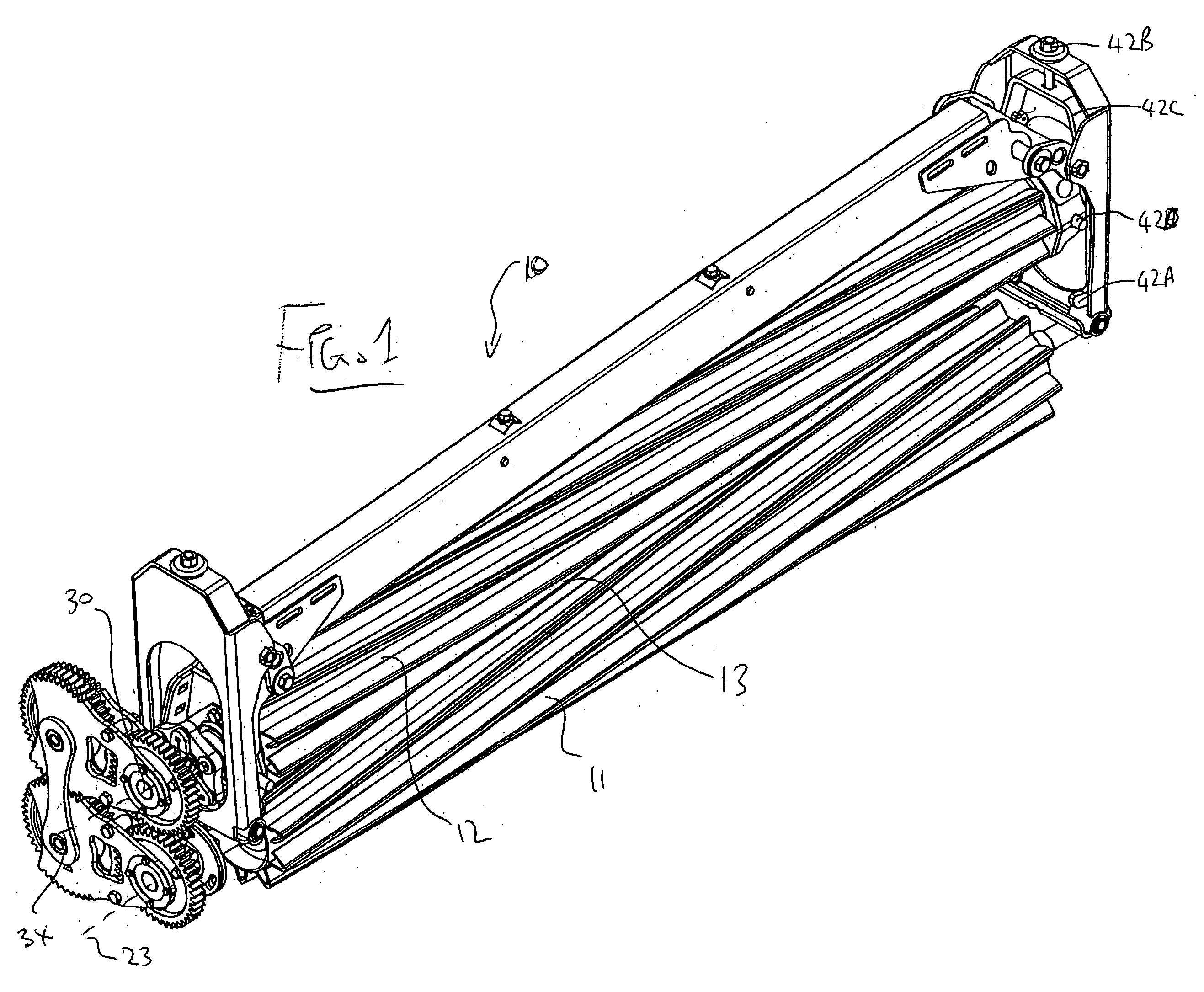

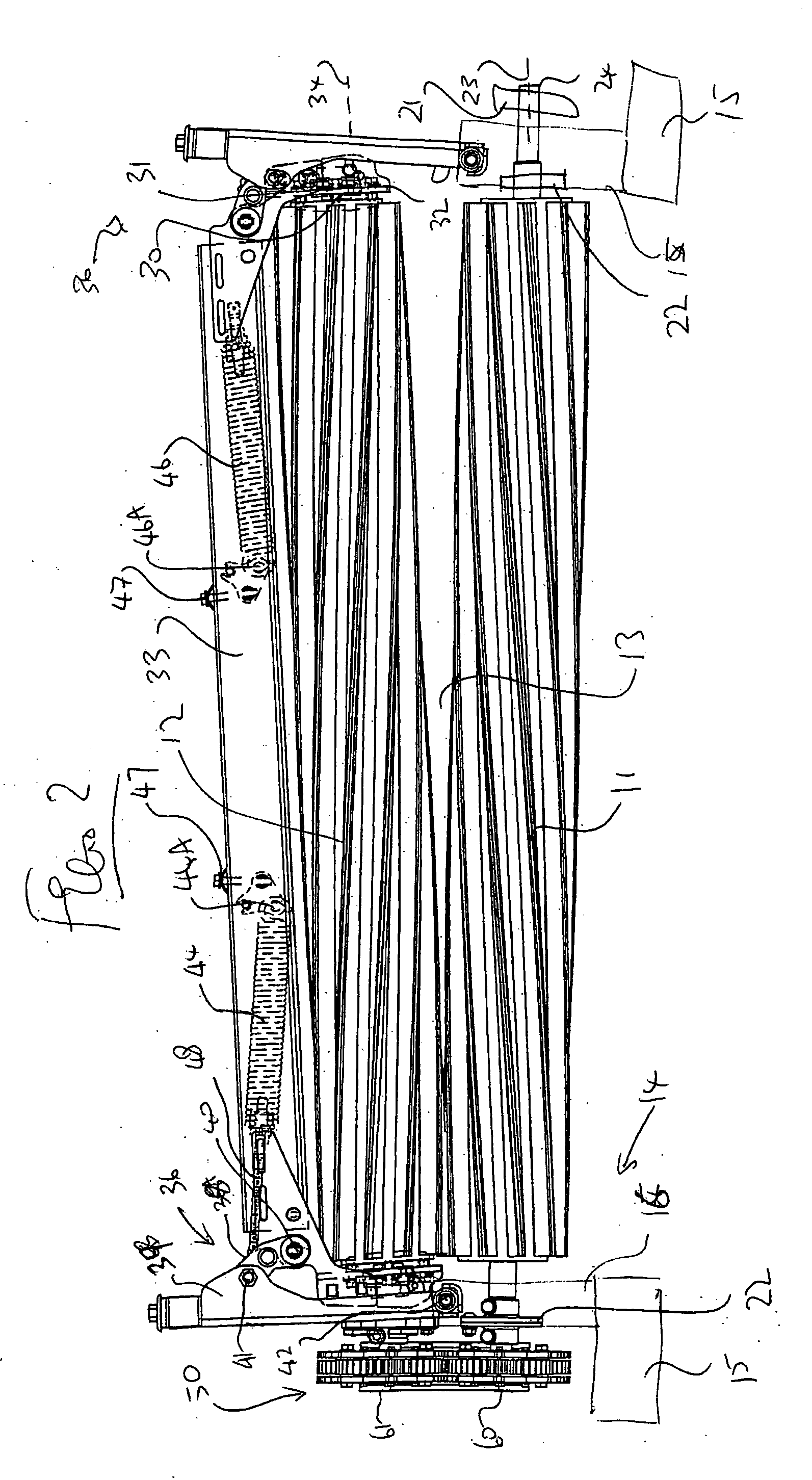

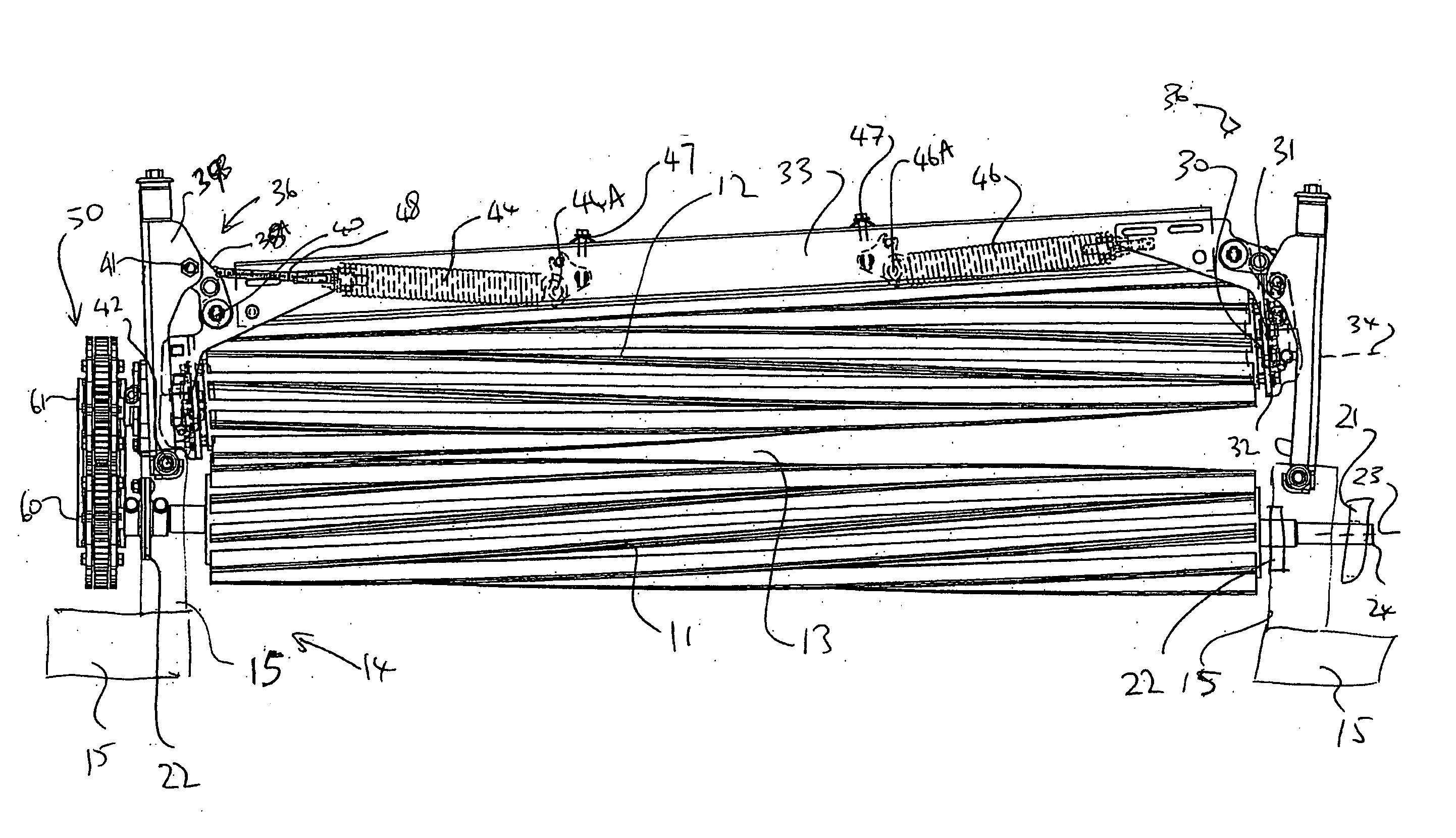

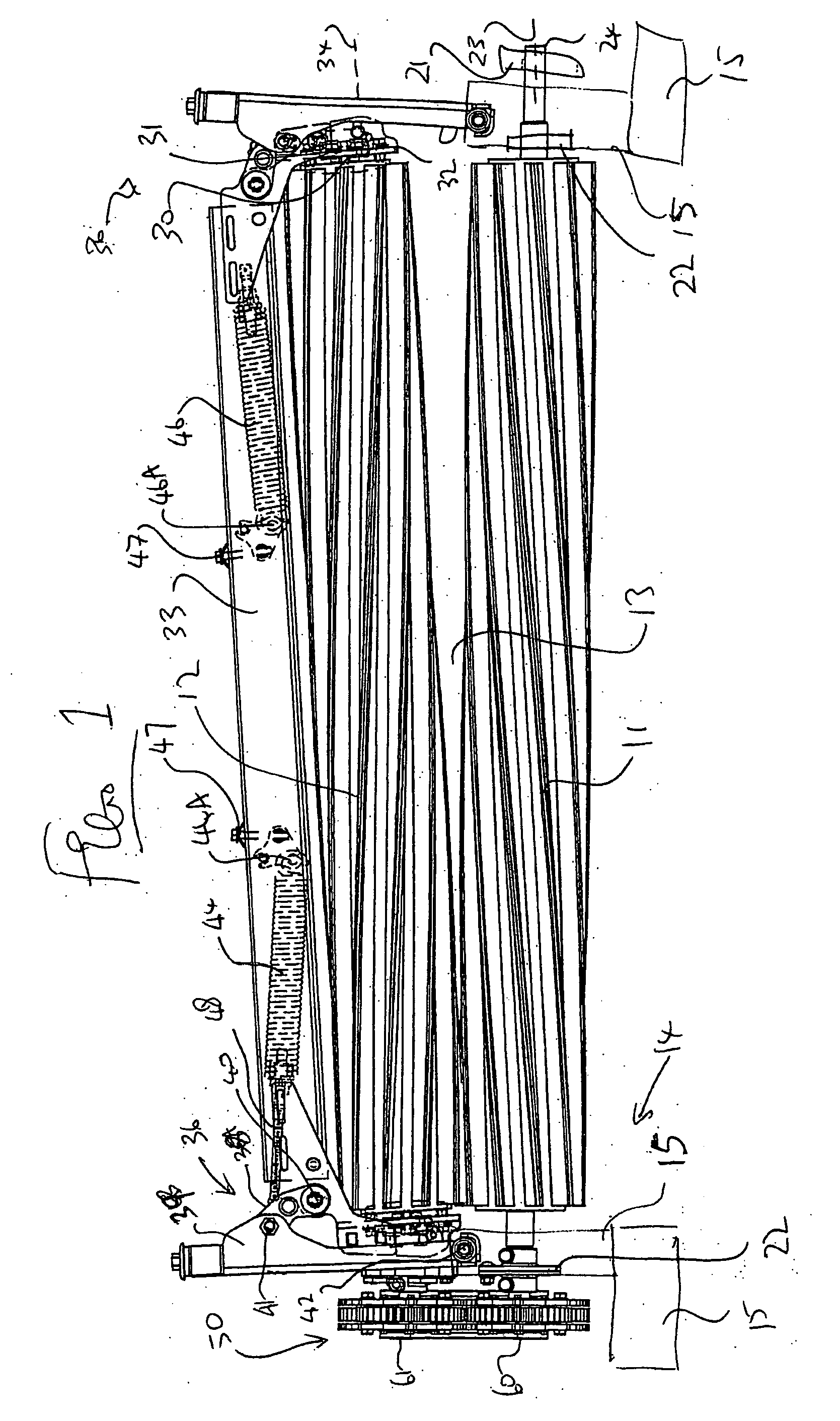

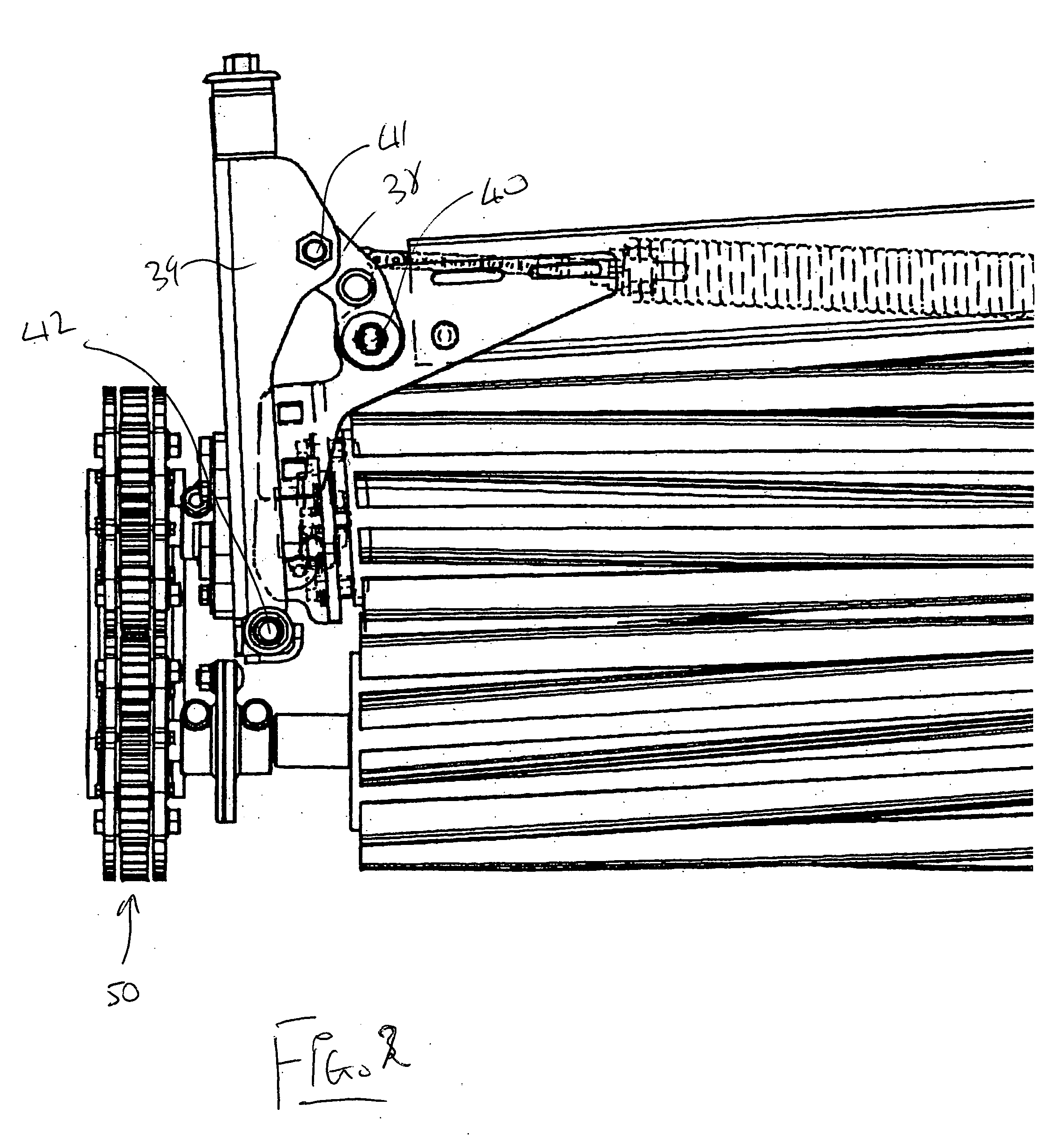

Conditioning roller drive

ActiveUS20060123759A1Accurate angular timingAccurate timingCrop conditionersHarvestersForage harvesterEngineering

A forage conditioner for conditioning cut crop material from a forage harvester includes a fixed bottom fluted roller carried in end housings and a top fluted roller which is pivotally mounted on the housings by a linkage pivotal relative to the housing about an axis lying in a plane at right angles to the roller axes so that the top roller is liftable from crushing position against the bias of a spring extending along the top roller. Rotation of the bottom roller is transferred to the top roller through a gear train which includes two idler gears each mounted on a respective arm with the arms constrained to move symmetrically relative to the rollers by intermeshing teeth on the arms so as to control the angular timing of the rollers to ensure accurate intermeshing of the flutes.

Owner:MACDON INDS

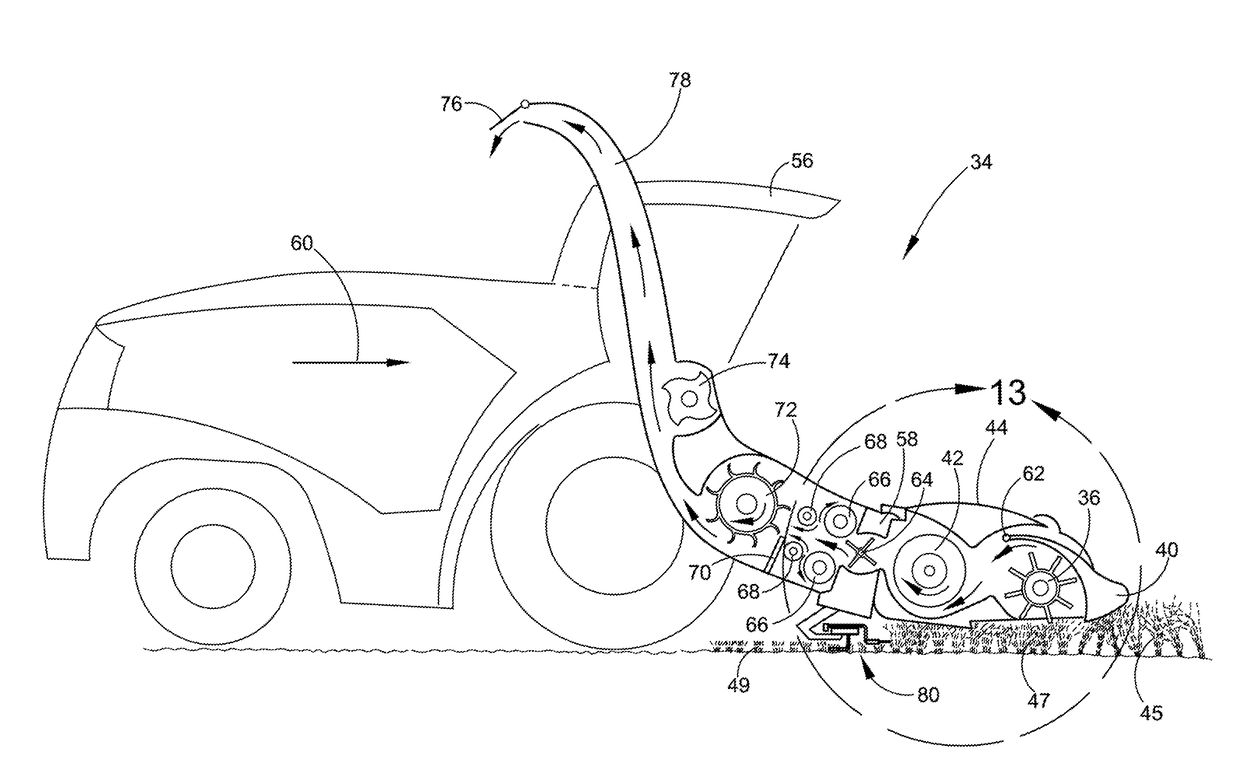

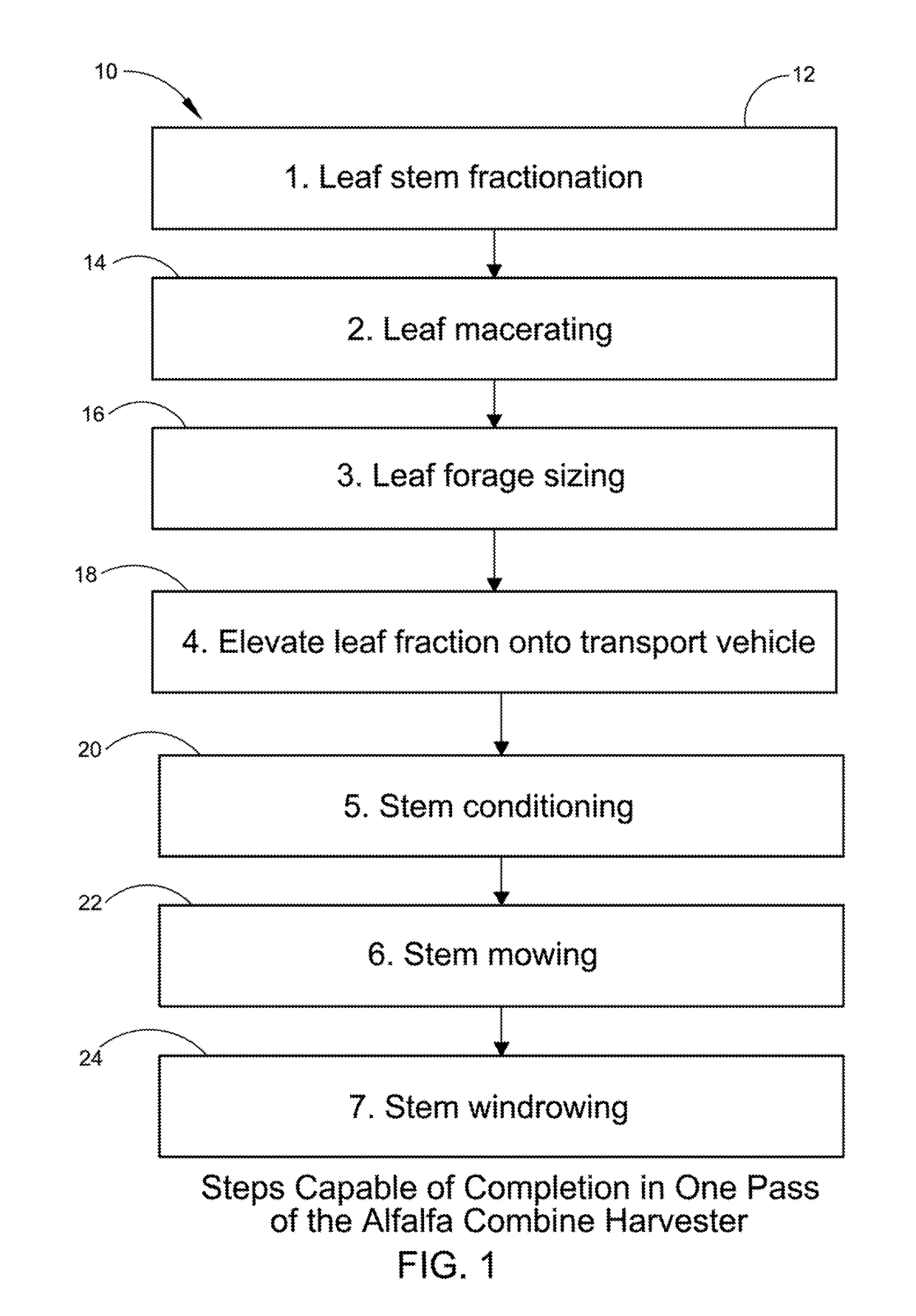

Multipurpose leaf crop harvesting apparatus and processing method

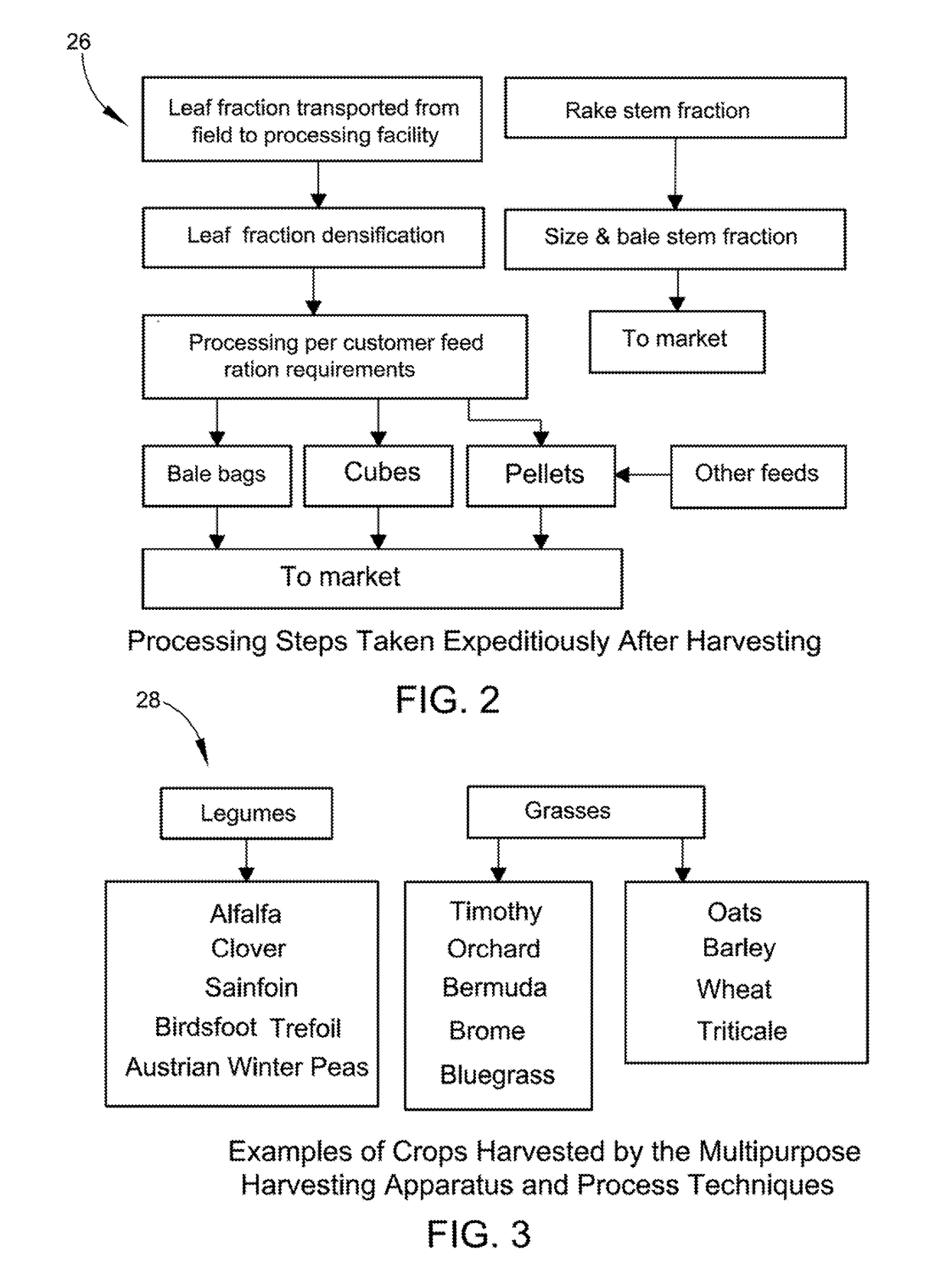

The Multipurpose Leaf Crop Harvesting Apparatus and Processing Method will accomplish seven steps in one pass of the combine harvester. This apparatus and processing method harvests leaf crops and is configured to perform multiple processing operations, including fractionation of the leaf crop, leaf maceration, leaf sizing, elevating the leaf fraction to a transport vehicle, and stem conditioning, cutting and windrowing, in a single pass through the crop field. These steps are accomplished using a header unit, an adapter feeder macerator and a forage harvester vehicle, expeditiously removing the leaf fraction from the field. Following leaf fraction harvesting, the leaf fraction is processed by densification into forage feed products. The processed leaf fraction can be combined with other feeds to make up customized feed rations. The stem fraction is also processed. The present invention can also be used to harvest grass crops.

Owner:GREEN GOLD DEV LLC

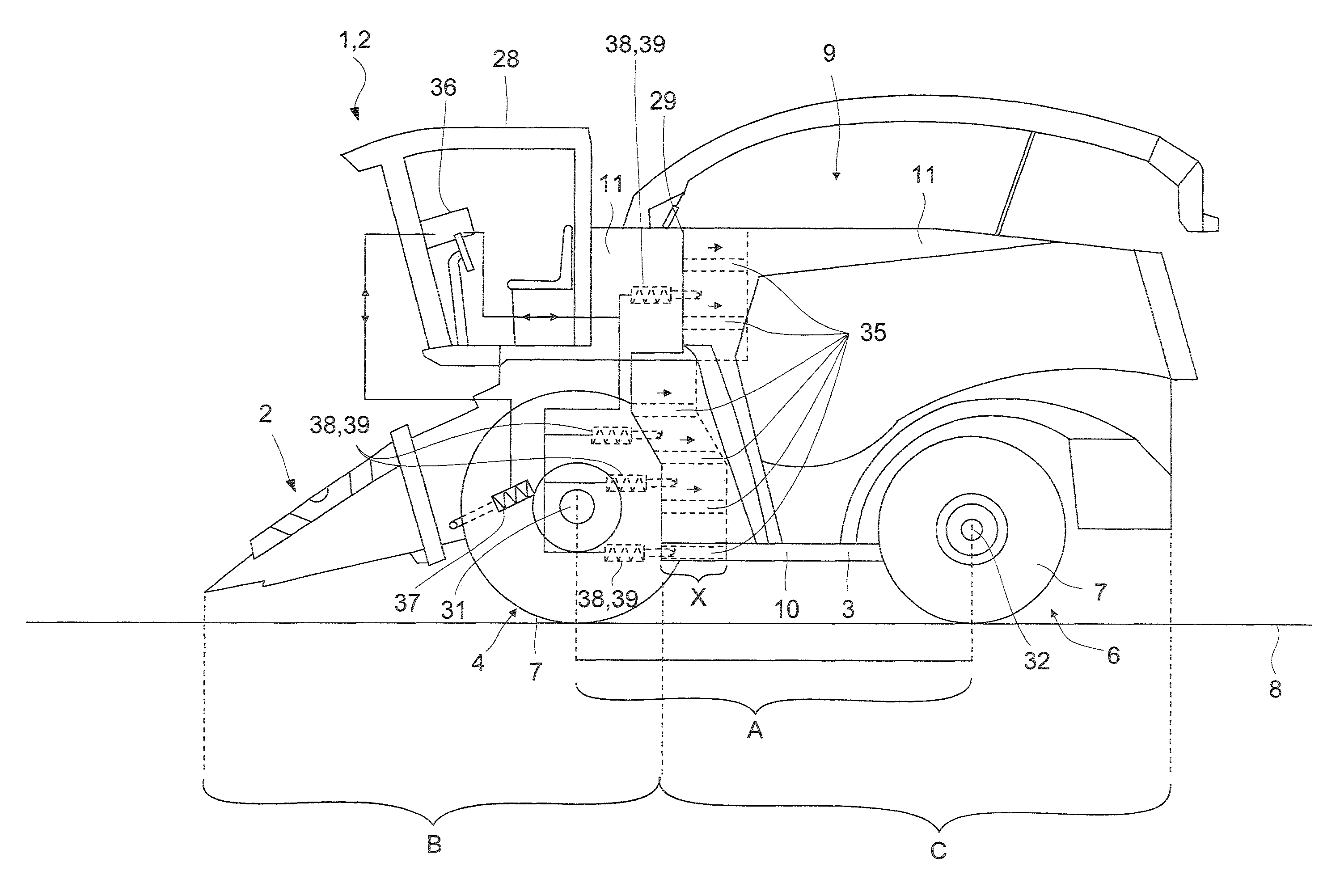

Agricultural harvesting machine

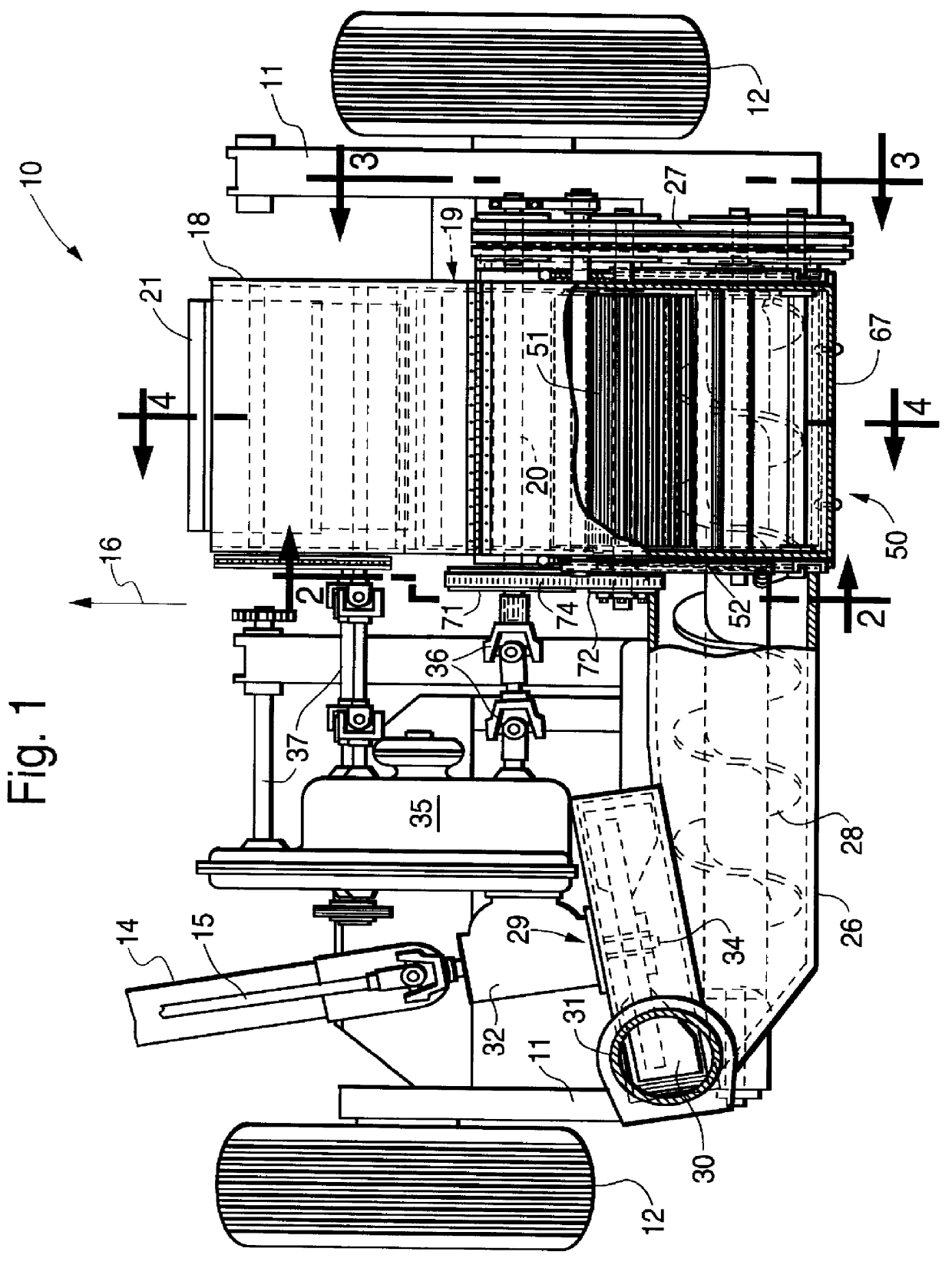

An agricultural harvesting machine, in particular a self-propelled forage harvester, has a body which includes frame parts and parts of the outer shell, a chassis having at least two drive axles which form the ground drive, and various working units and drive units, and the harvesting machine is separatable into at least one front module and one rear module which are displaceable relative to one another.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

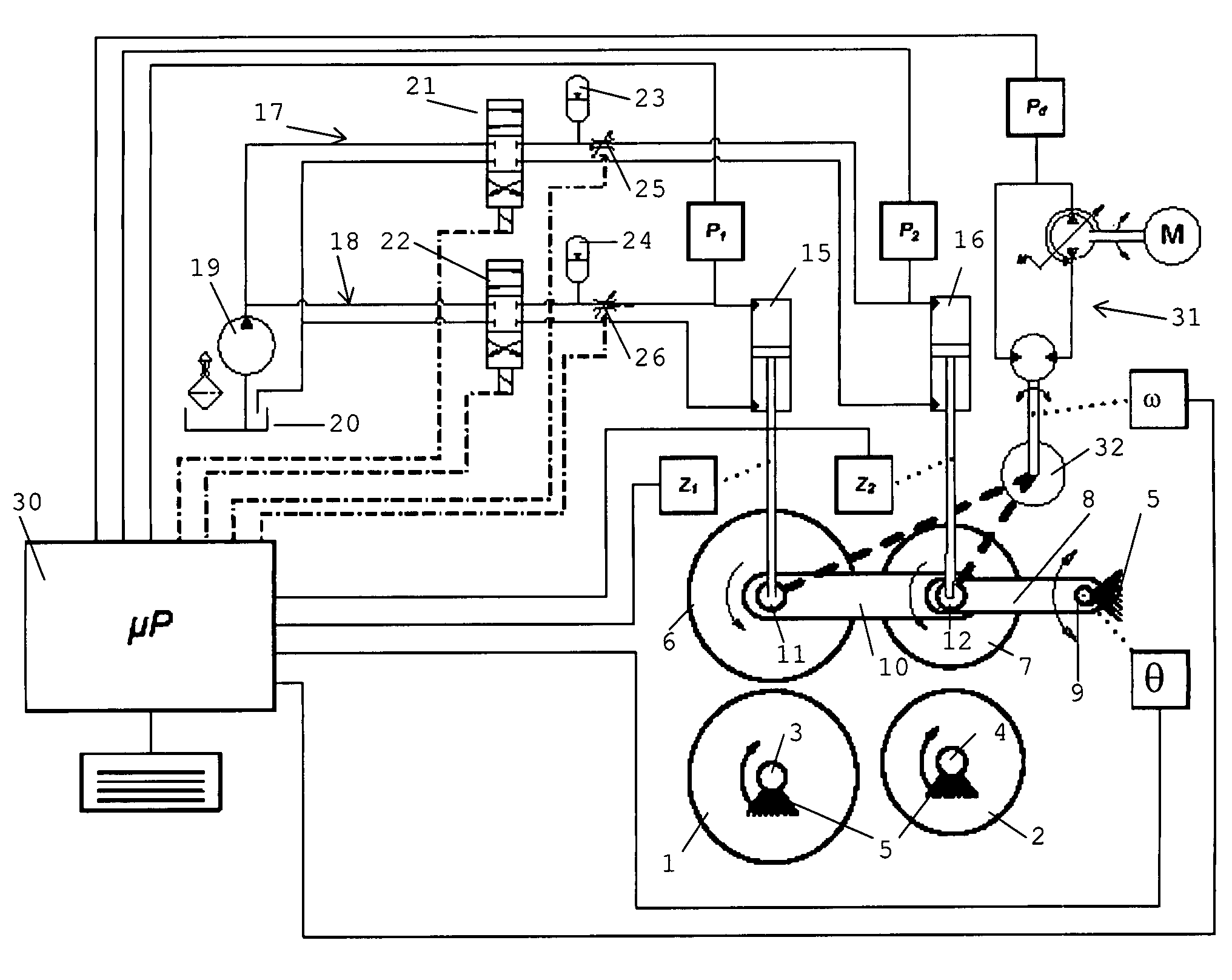

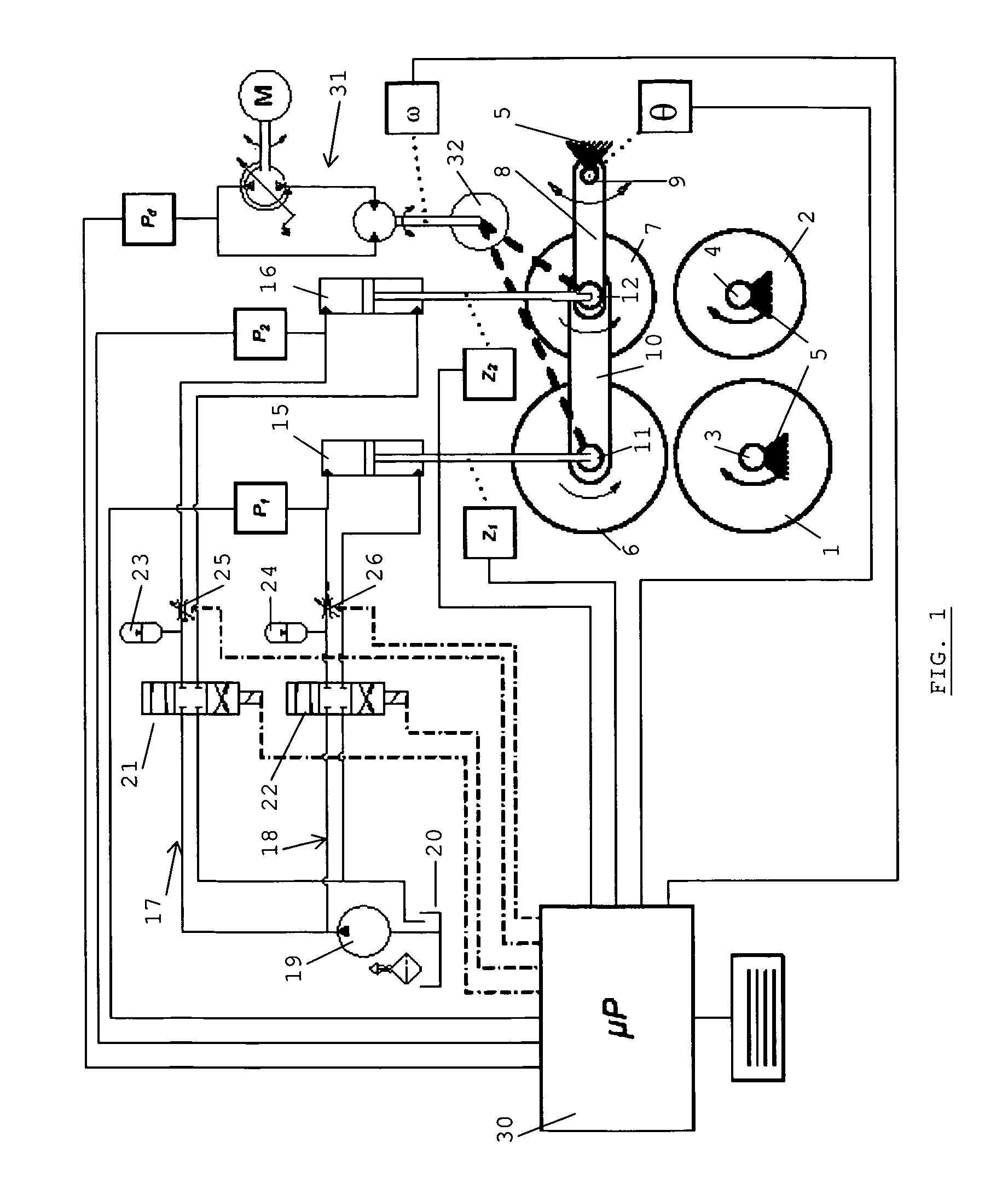

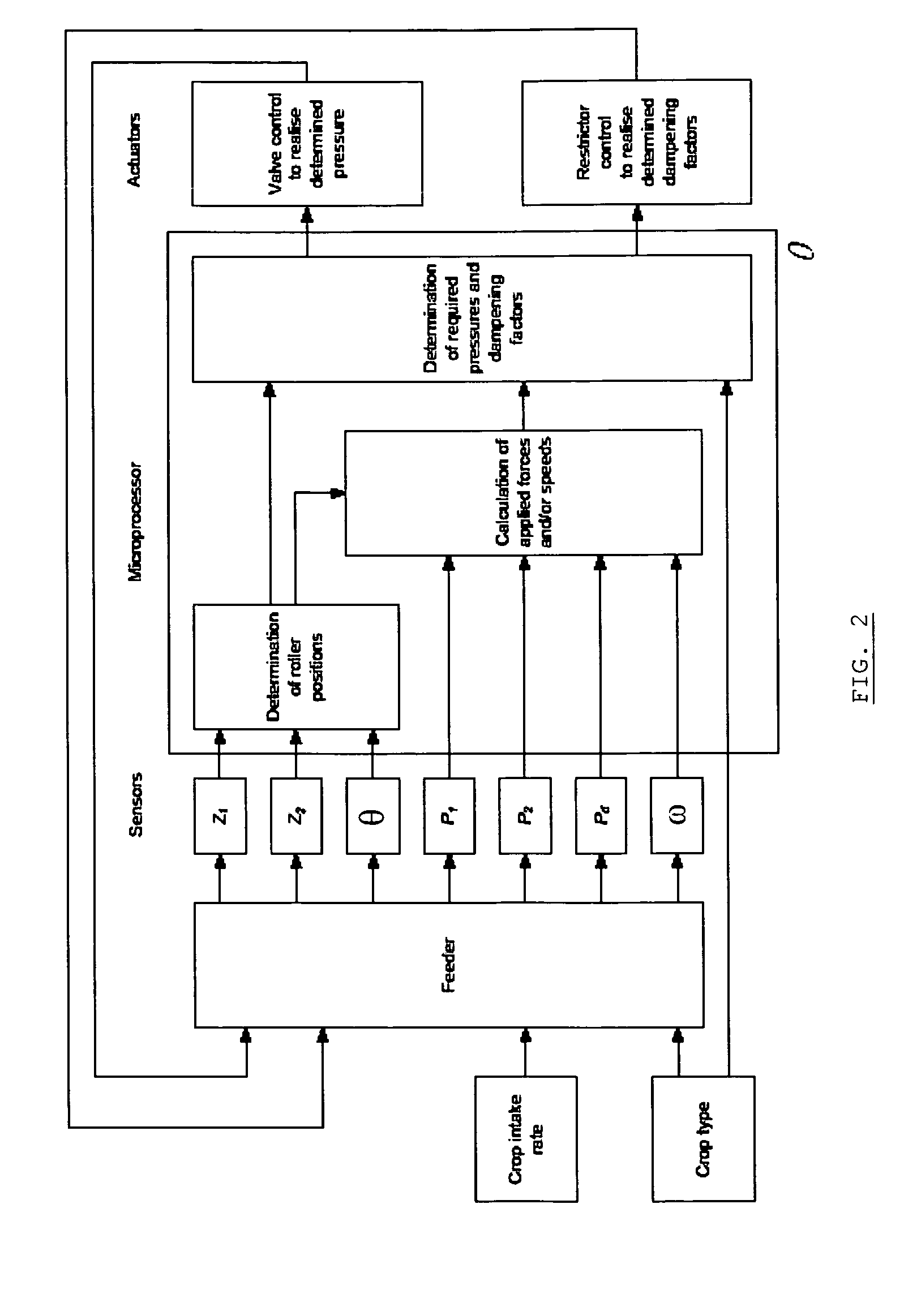

Feed roll control system for a forage harvester

A system to control the position of one or more feed rolls in a forage harvester. The system includes at least one fixed feed roll arranged to rotate around a rotation axis which is fixed with respect to a chassis of the harvester, and in cooperation with the at least one fixed feed roll, a movable feed roll arranged to rotate around a rotation axis which is movable towards or away from the corresponding fixed roll. The system determines various parameters, including input data for the driving force exerted on the rolls, position of the movable feed roll, and rotational speed of the drive shaft, and inputs the data to a control unit, which provides commands to one or more valves and to one or more throttles to control the movable feed roll via the hydraulic piston / cylinder arrangements.

Owner:BLUE LEAF I P INC

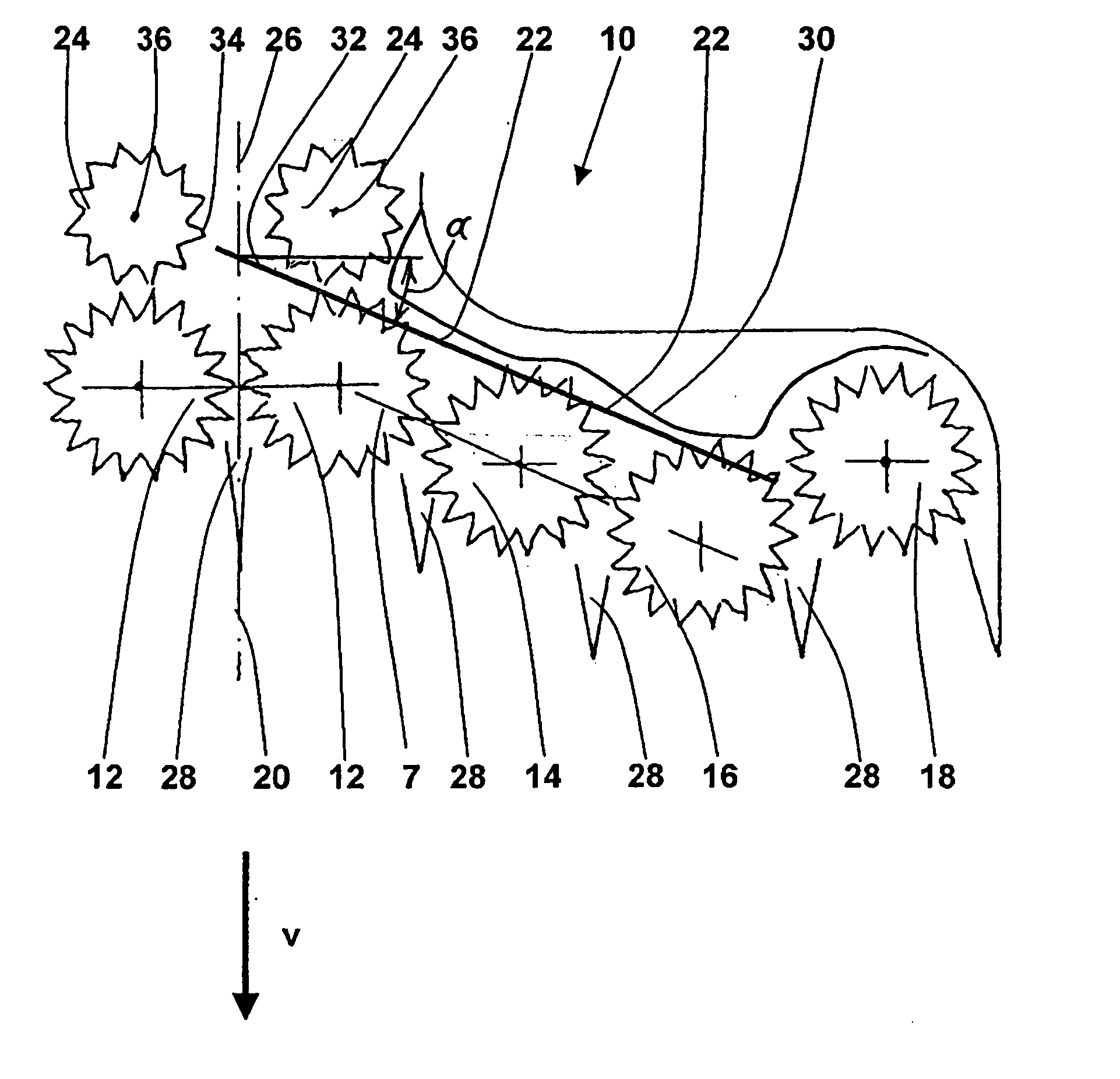

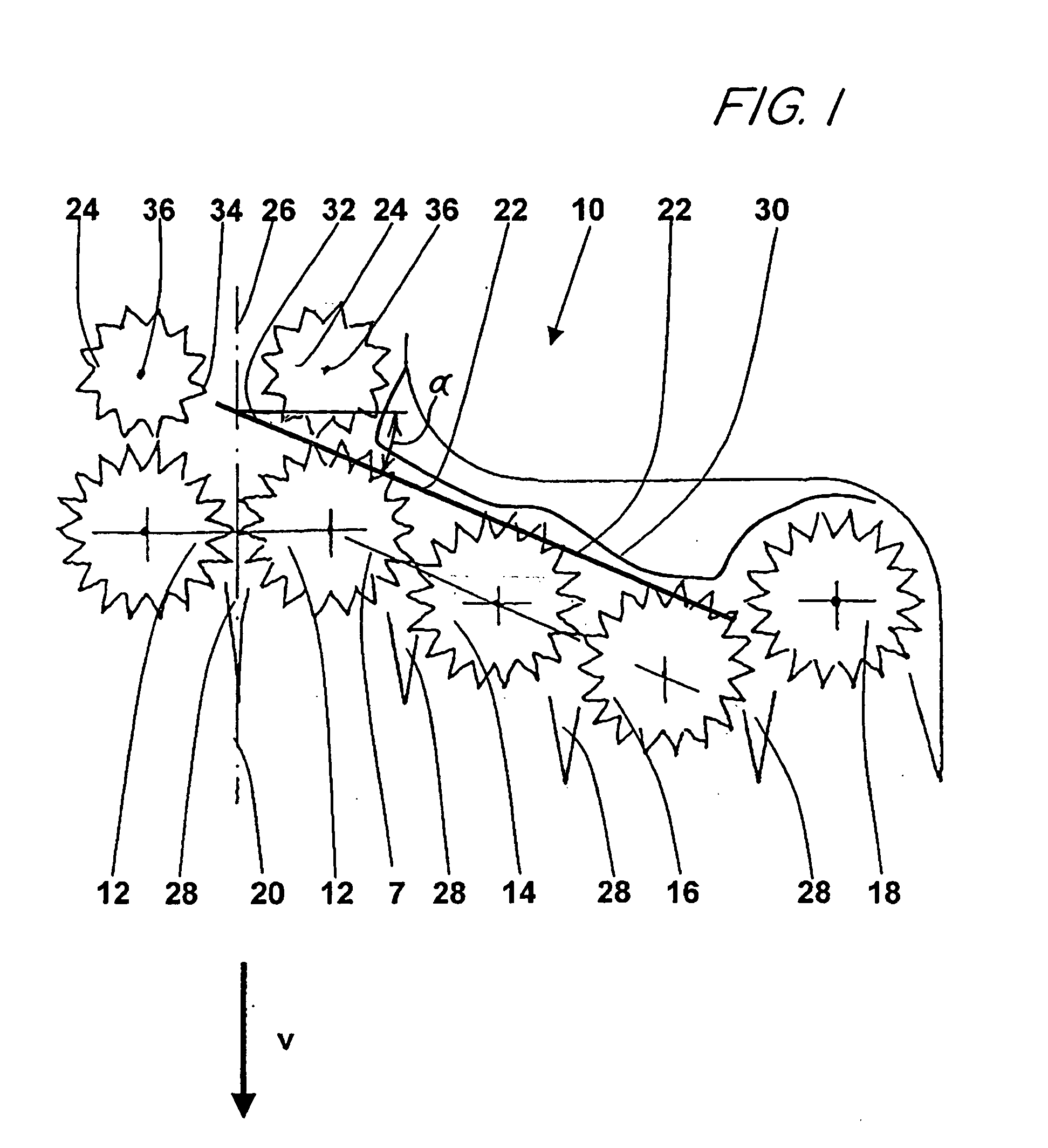

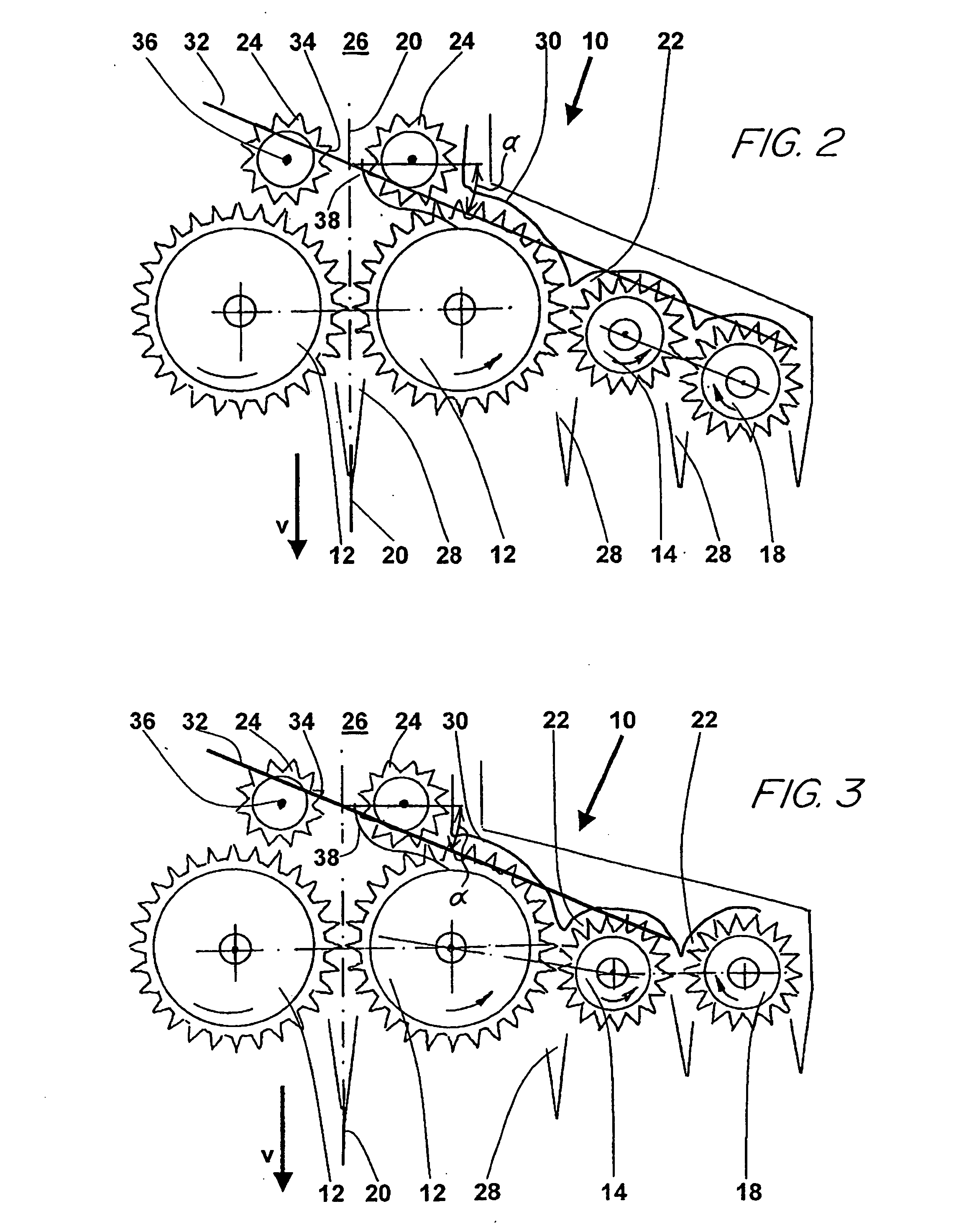

Header having an angled transverse feeding channel

InactiveUS20050132688A1Increase deflectionBlockage of the crops can be preventedMowersEngineeringForage harvester

A header for mowing stalk crops is equipped with several mowing and feed devices which are disposed on both sides of the longitudinal mid-plane of the header. Along the backs of the mowing and feed devices at each side of the header there is a transverse conveyor channel through which plants, harvested by the mowing and feed devices, are conveyed to the center of the header. At the center of the header deflecting conveying elements are disposed on both sides in front of a feed channel of a forage harvester and operate to deflect the plants to the rear so as to transfer them to the feed channel. The transverse conveying channels are disposed at an angle relative to the transverse direction. Preferably, an extension of an imaginary line lying along the transverse conveying channel at each side of the header intersects the opposite deflecting conveying elements at or behind a point where the deflecting conveying elements move to a greater extent rearward than toward the longitudinal mid-plane of the header.

Owner:MASCHFAB KEMPER

Chopping drum for a forage harvester

A chopping drum for a forage harvester has a shaft. Supporting rings are mounted on the shaft one next to the other in the axial direction and extending in the radial direction. Blade holders are distributed around the outer periphery of the supporting rings, and chopping blades are mounted on the blade holders by first screws. The first screws produce a connection between blade holders one following the other in the peripheral direction.

Owner:DEERE & CO

Crop conditioning roller flute shape

ActiveUS20070022726A1Easy to shapeImproved arrangementCrop conditionersHarvestersFluteAnimal Foraging

A forage conditioner for conditioning cut crop material from a forage harvester includes a fixed bottom fluted roller carried in end housings and a top fluted roller which is pivotally mounted on the housings by a linkage pivotal relative to the housing about an axis lying in a plane at right angles to the roller axes so that the top roller is liftable from crushing position against the bias of a spring extending along the top roller. Flutes on the rollers are arranged with a first surface on one side which extends substantially radially outwardly to an apex and a second surface which has a first portion parallel to a tangent of the roller and a second portion inclined inwardly to the roller surface at an angle significantly less than 90 degrees. The bottom roller is arranged with the first surfaces leading to carry the crop into the area between the rollers and the top roller is arranged with the first surface trailing. Thus the first surface of intermeshing flutes pass through a condition in which the first surfaces are substantially parallel and on opposite sides of a line joining the centers of the rollers to provide an effecting conditioning action on the crop.

Owner:MACDON INDS

Cane harvester

InactiveCN102550210AReduce the rate of broken headsCompact structureHarvestersEngineeringForage harvester

The invention discloses a cane harvester, which comprises a cab assembly, a cane collecting hopper assembly, a frame chassis assembly, a cane supporting assembly, a header assembly, a leave stripping and tip removing assembly, a T-shaped lifting support frame assembly and a hydraulic system assembly. The cane harvester has the advantages of compact structure of the whole machine, light weight, small turning radius, and simple operation, is suitable for complicated, winding and narrow cane fields, and reduces the broken rate after the roots of canes are cut off.

Owner:南宁五菱桂花车辆有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com