Patents

Literature

257 results about "Size fractions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Particle size fractions. The physical and chemical properties of soil are strongly influenced by the particle size distribution of soil particles. Although the particle size distribution is a continuum, it is conveniently broken down into size classes. Particle sizes range from less than 0.002 mm (e.g. clay) to greater than 2 mm (e.g. fine gravel).

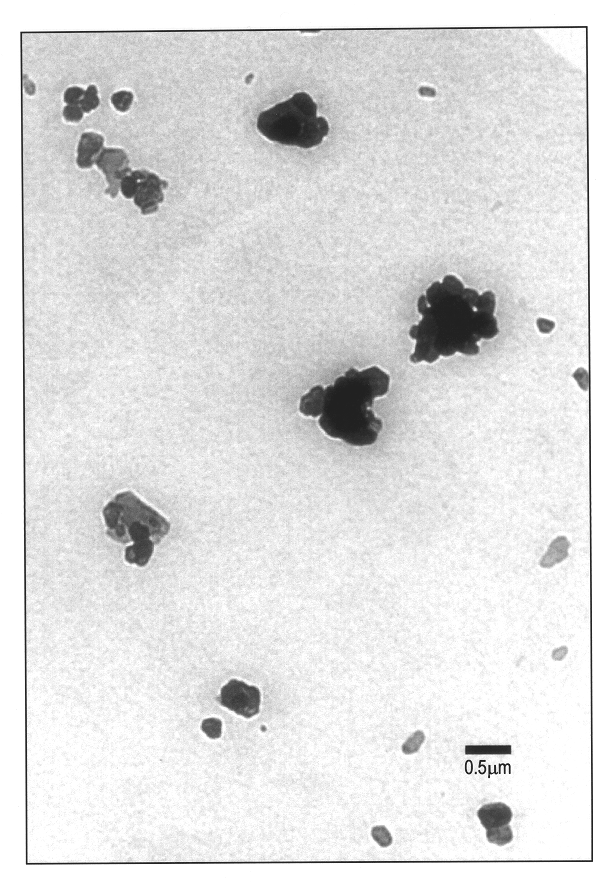

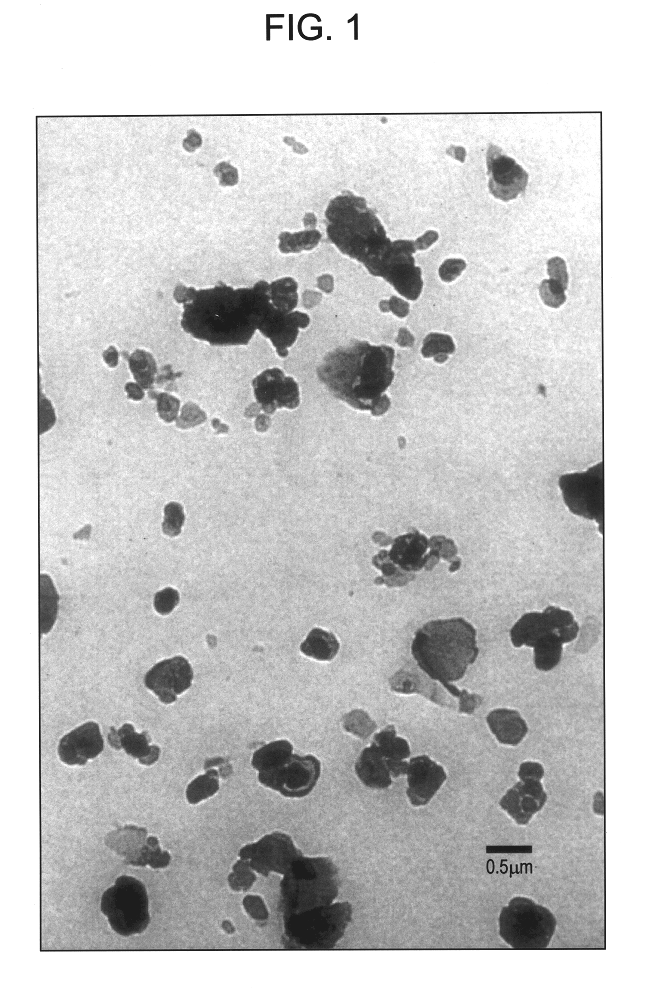

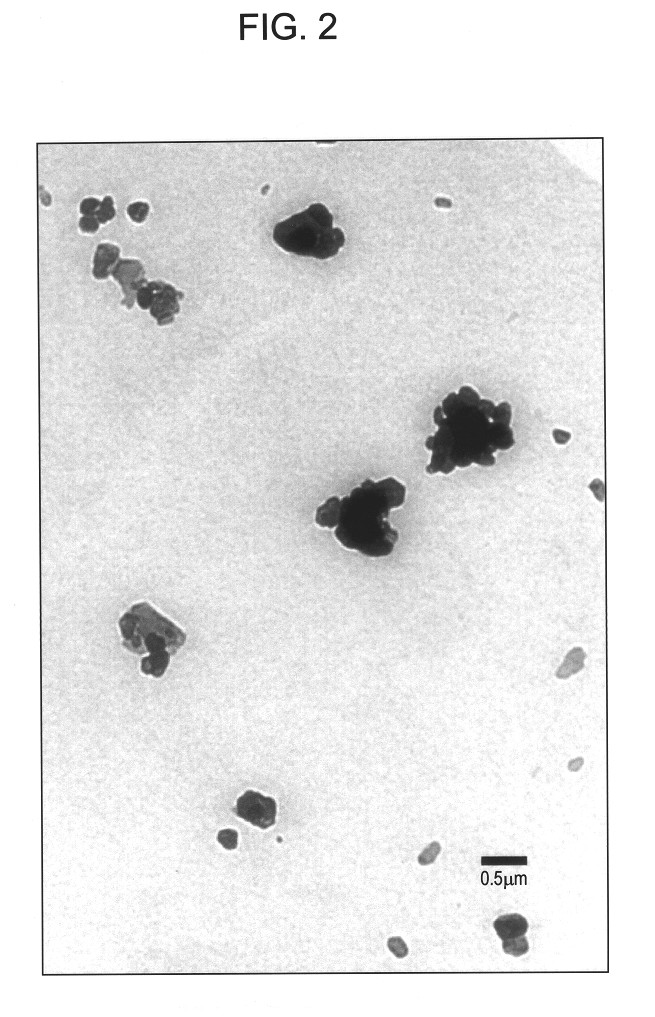

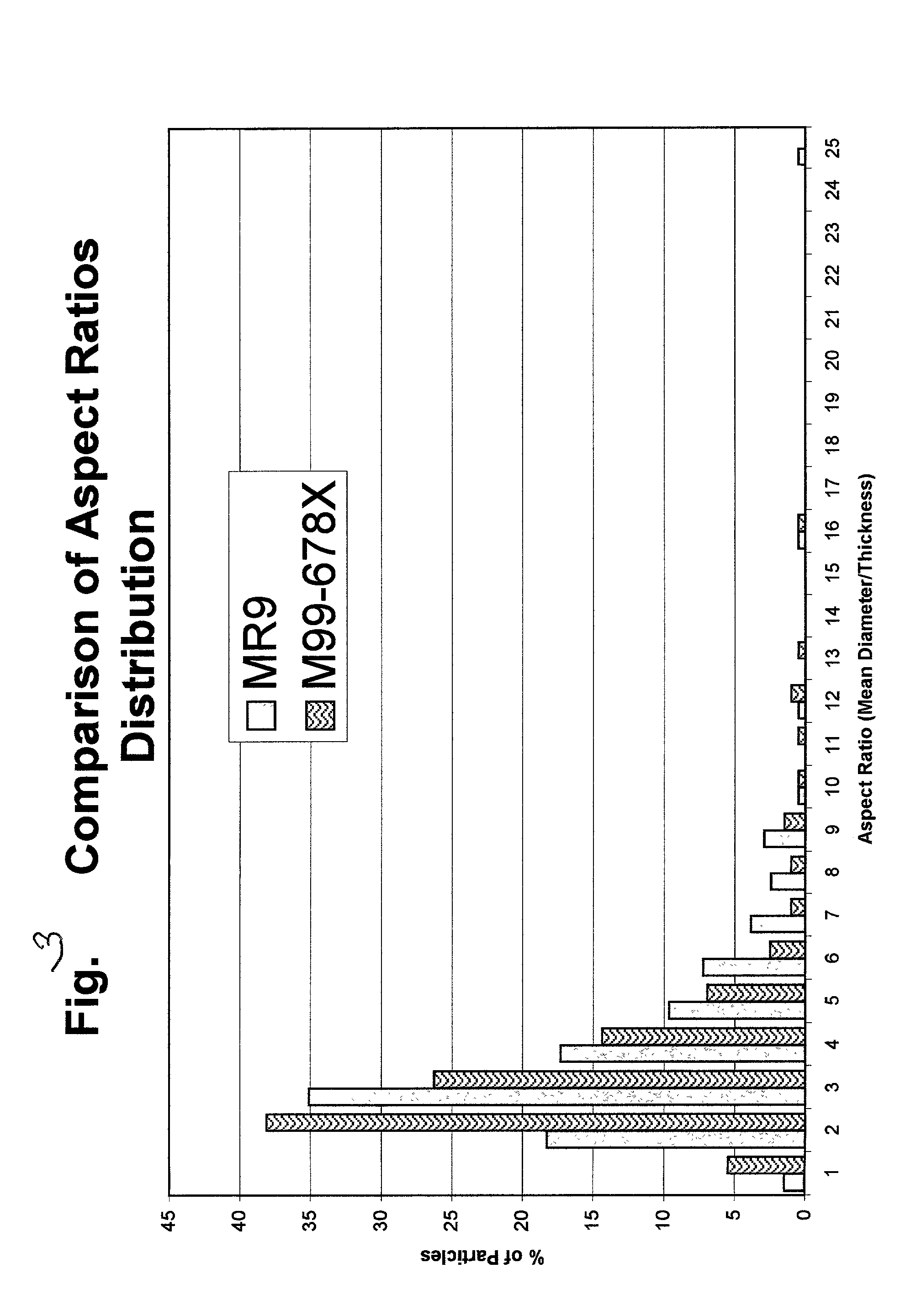

Kaolin clay glossing pigment and preparation thereof

Novel nanosized kaolin clay particles are prepared by agitating a fine particle size fraction of kaolin clay in a Netzsch mill until the particle size is reduced, aspect ratio is decreased and surface area is increased. The ultrafine kaolin particles are especially useful as a pigment to provide high surface gloss to ink jet printing papers.

Owner:IMERYS USA INC

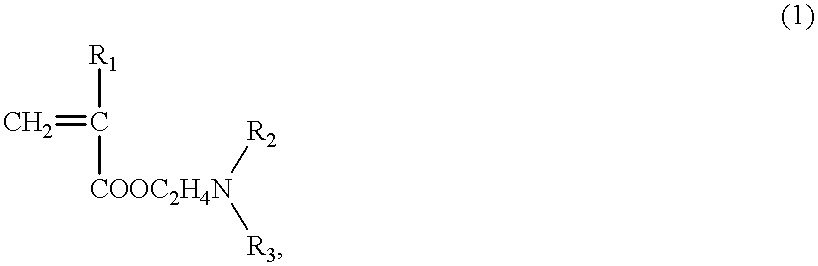

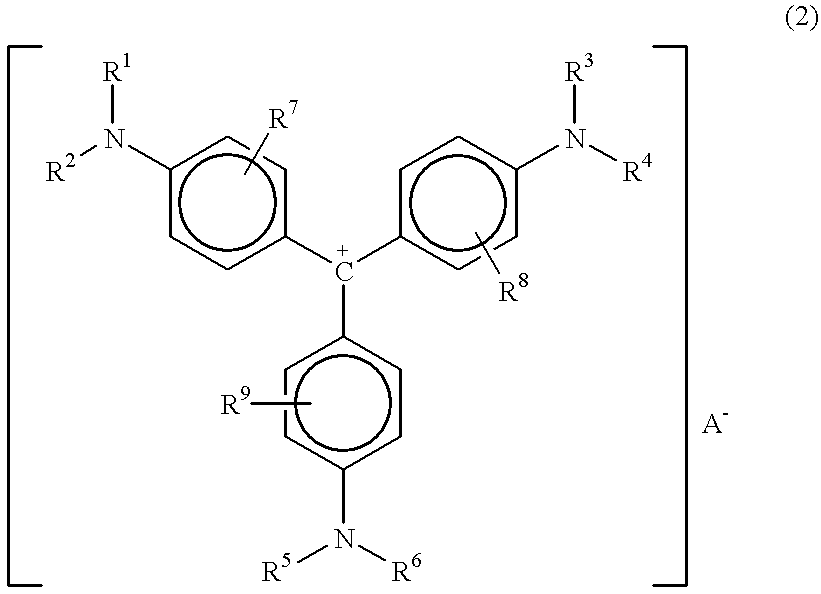

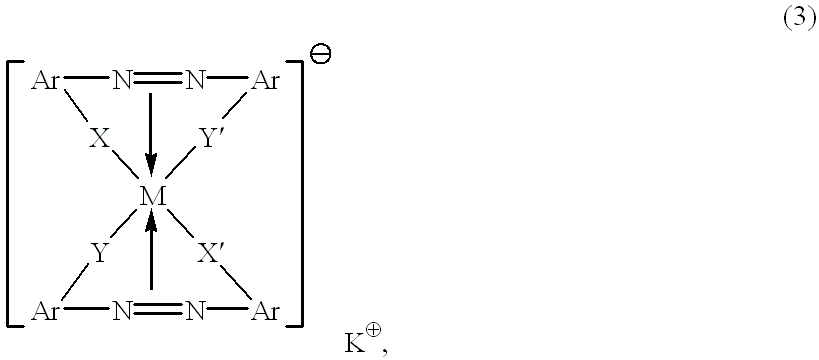

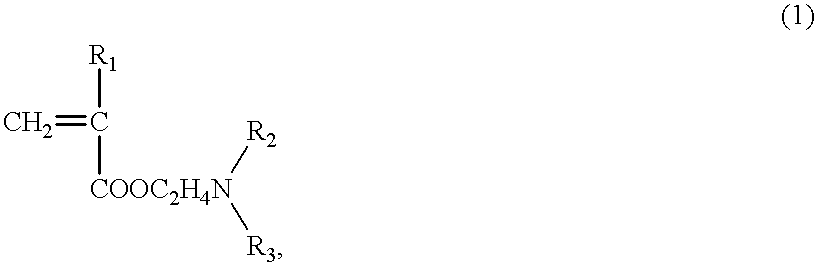

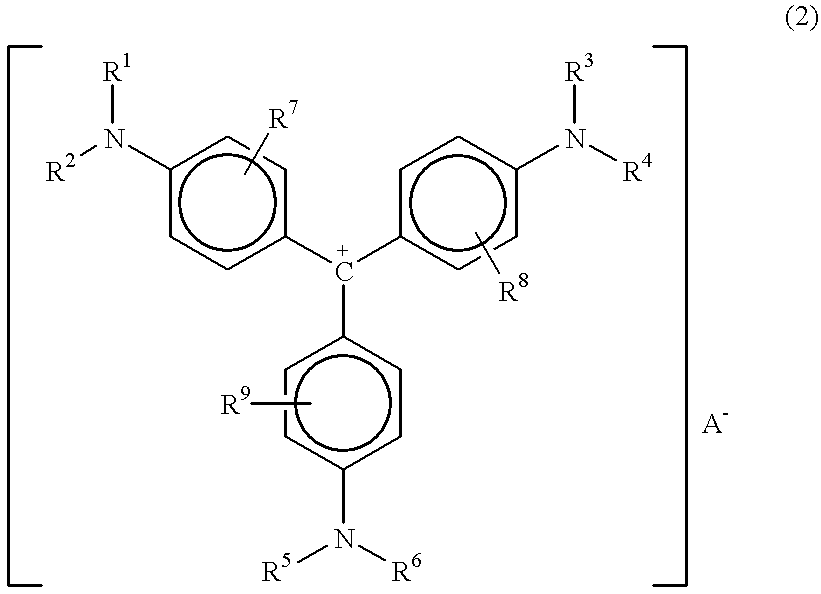

Developer, image-forming method, and process cartridge

InactiveUS20010031414A1DevelopersElectrographic processes using charge patternLower limitLatent image

A developer for developing an electrostatic latent image is formed from toner particles each comprising a binder resin and a colorant, inorganic fine powder having a number-average particle size of 4-80 nm based on primary particles, and electroconductive fine powder. The developer is characterized by having a number-basis particle size distribution in the range of 0.60-159.21 mum including 15-60% by number of particles in the range of 1.00-2.00 mum, and 15-70% by number of particles in the range of 3.00-8.96 mum, each particle size range including its lower limit and excluding its upper limit. As a result of inclusion an appropriate amount of the electroconductive fine powder represented by the particle size fraction of 1.00-2.00 mum, the developer is suitably used in an image forming method including a contact charging step of charging the image-bearing member based on the direct injection charging mechanism and also in an image forming method including a developing-cleaning step of developing the electrostatic latent image and recovering the developer remaining on the image-bearing member after the transfer step.

Owner:CANON KK

Porous cement concrete using regenerative concrete aggregate

InactiveCN101407390AReduce the amount of miningEasy to useSolid waste managementPerformance indexWater circulation

The invention relates to water permeable cement concrete using recycled concrete as the aggregate, which has the raw material compositions with the weight parts of 250-400 parts of cement, 1500-2000 parts of recycled concrete aggregate, 25-40 parts of inorganic plastering agent and 2.5-5 parts of synthetic fiber, wherein, the recycled concrete aggregate has 5-12mm of unitary size fraction and 25 percent or smaller of crushing value. The ecological water permeable concrete has the advantages of increasing the service means of the high added value of waste concrete, reducing the mining quantityof natural aggregates, lowering the cost for confecting water permeable materials, improving the traffic safety factors of the road, improving the water circulation function of the environment and having the performance indexes meeting the requirements of the set mechanical performance and other technical indexes.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Nanometer composite silicon brick and preparation method thereof

The invention relates to a nano-sized composite silica brick and a production method thereof. The invention is characterized in that: raw materials and binder of the silica brick are as follows: silica granules and fine powders, waste silica brick granules, calcium carbonate nanoparticles, iron oxide nanoparticles, silicon dioxide nanoparticles, fluorite powders, lime and sulfite pulp wastes. The production method is based on the existing production process of the silica brick, and introduces compound nanopowders in optimal proportions in the production process of the silica brick after high-efficiency dispersion, to produce nano-sized composite silica bricks. With the addition of nanopowders, the performance of silica brick is significantly improved, and manifested as follows: 1) the particle size fraction is more reasonable, the accumulation is compact and the texture is uniform; 2) the slurry has good plasticity and moldability and the production efficiency is improved; 3) the burning temperature is decreased to 20 DEG C, thus realizing energy conservation and discharge reduction; 4) the tridymite is superior in crystallization conversion and has low content of quartz residues; 5) the number of closed pores is increased, the number of opened pores are reduced, the porosity is reduced, and the strength and refractoriness under load are increased; and 6) the final product has good appearance, smooth end surface and good bonding property, and the rate of qualified products is increased.

Owner:ZHENGZHOU UNIV +1

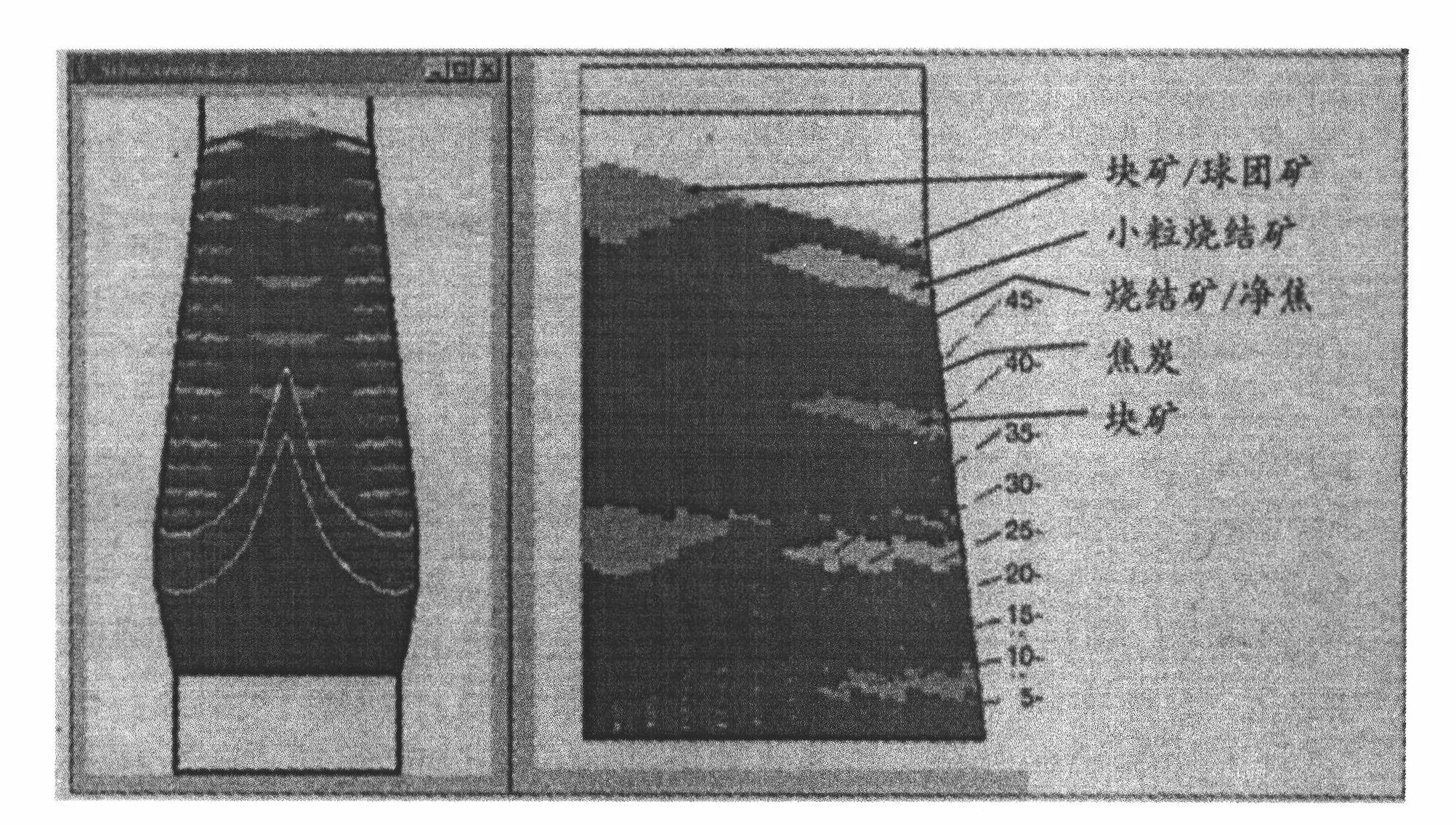

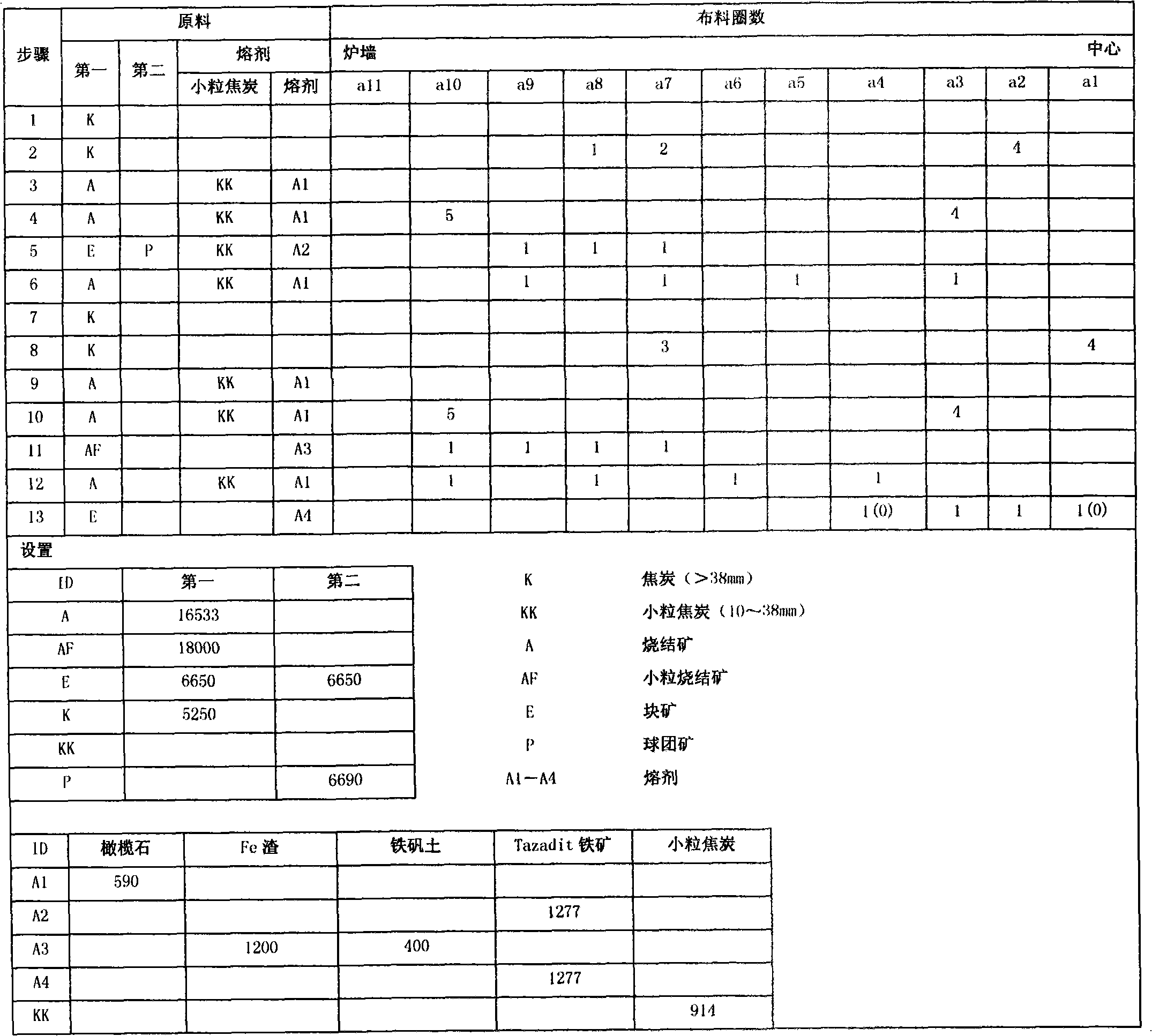

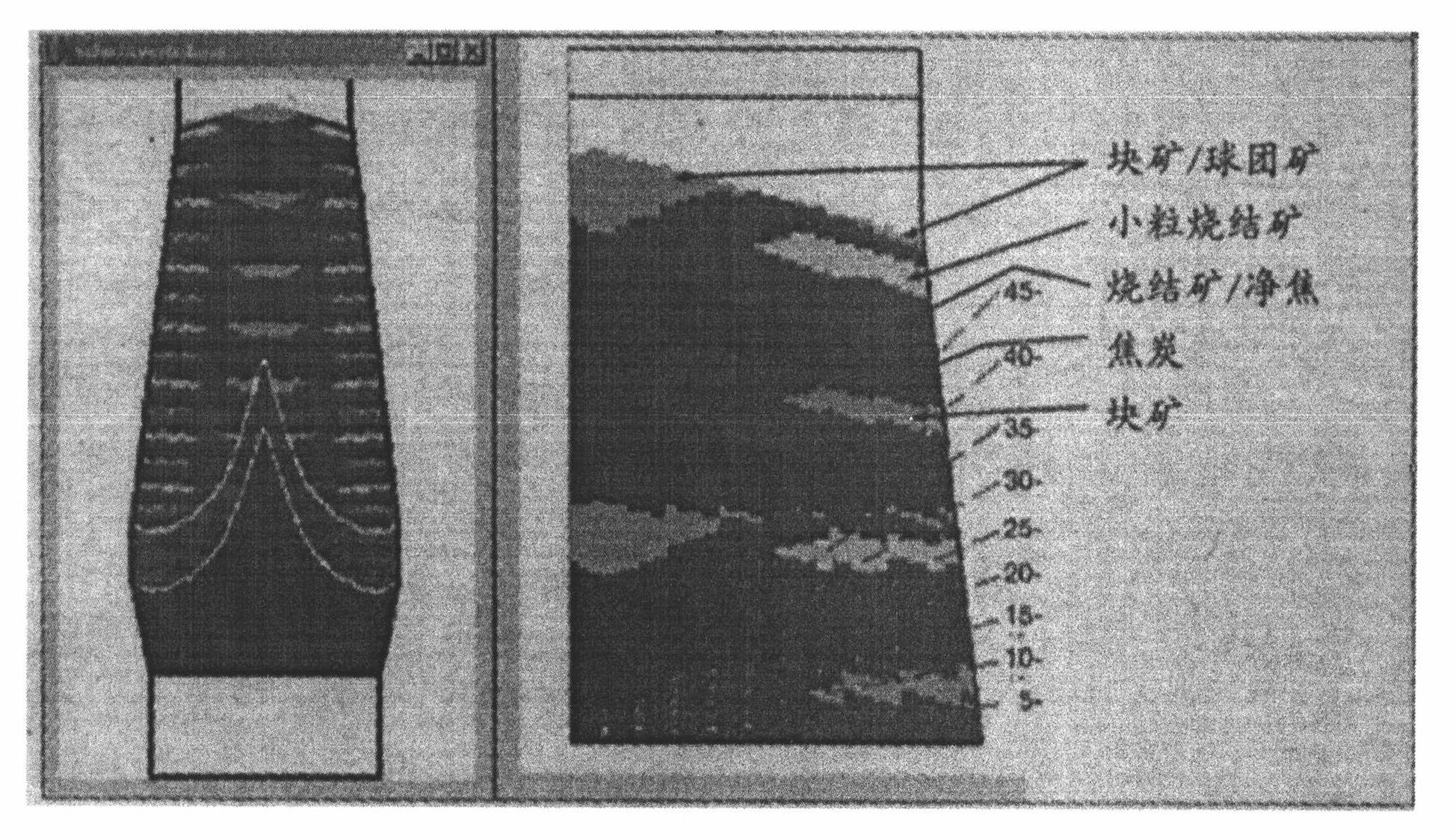

Bell-less top multi-ring matrix burden distribution central coke charging method of blast furnace

ActiveCN101880739AFirm edgesFurnace condition is stableBlast furnace componentsBlast furnace detailsDistribution methodMaterials science

The invention relates to a bell-less top multi-ring matrix burden distribution central coke charging method of a blast furnace, which belongs to the technical field of blast furnace burden distribution. The method comprises the following steps of: on the basis of a multi-ring matrix burden distribution method, firstly, distributing more than 50 percent of coke amount in the central area of a furnace throat so that the thickness of central coke is greater than that of edge coke and the burden surface of the furnace throat forms a steamed bread shape; removing a central mixture layer of the furnace throat to accurately control radial ore to coke ratio because the center of the burden surface is high while the edge is low. The invention has the advantages of being adapted to the fluctuation of coke quality, facilitating the use of ore with ultra-small size fraction, maintaining steady and smooth furnace conditions and realizing the aim of opening the center, stabilizing the edge so as to reduce production cost. The furnace top thermal imaging edge temperature is 120+ / -50 DEG C, and the center temperature is 450+ / -150 DEG C.

Owner:SHOUGANG CORPORATION

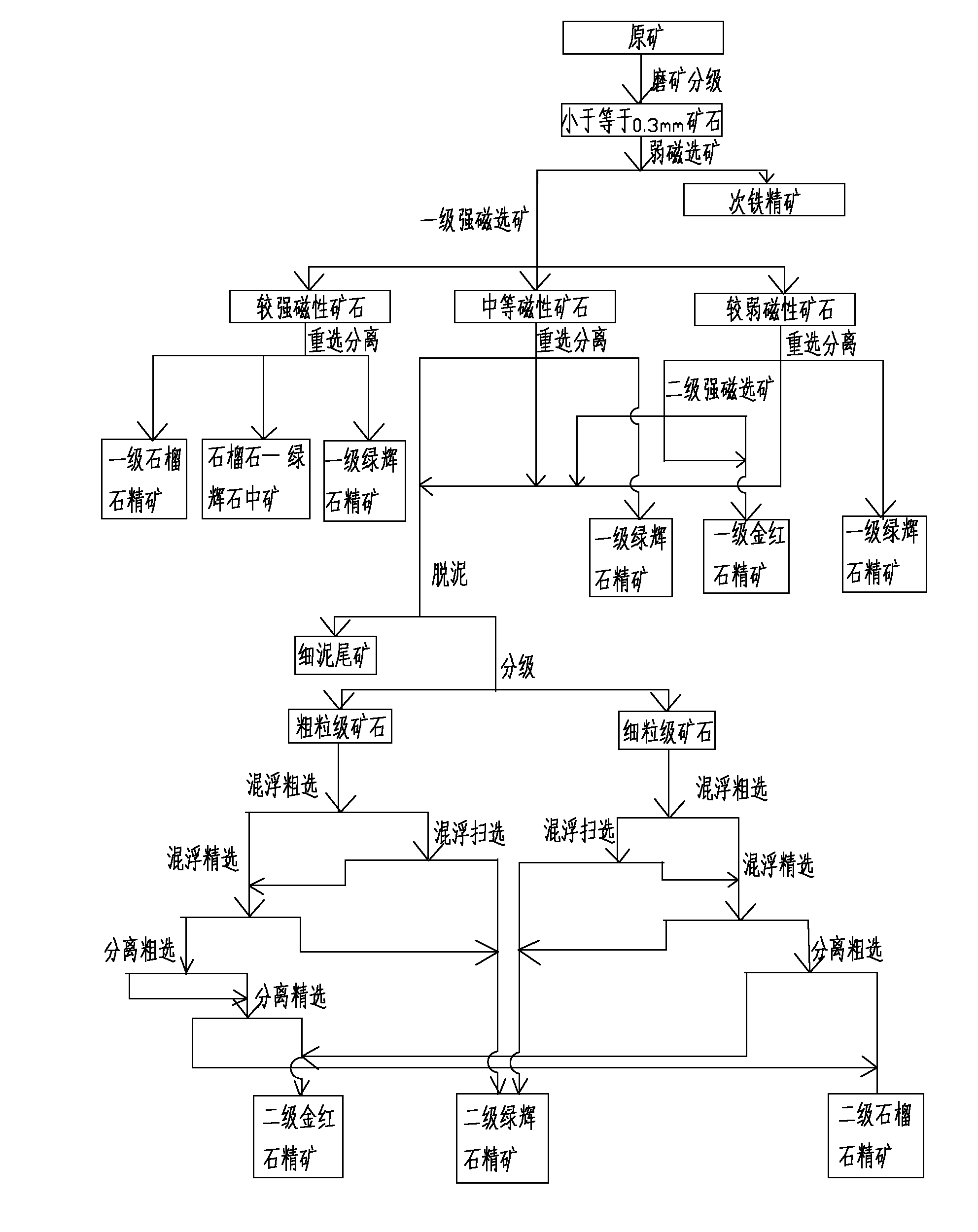

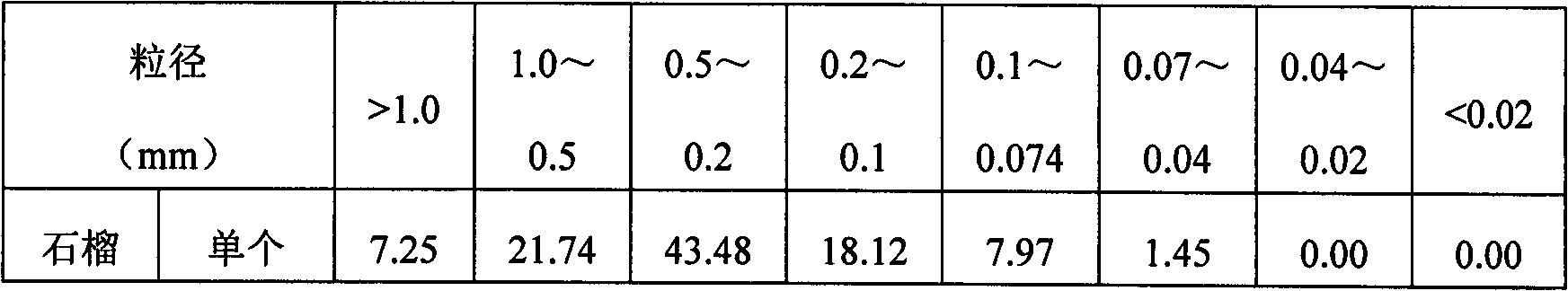

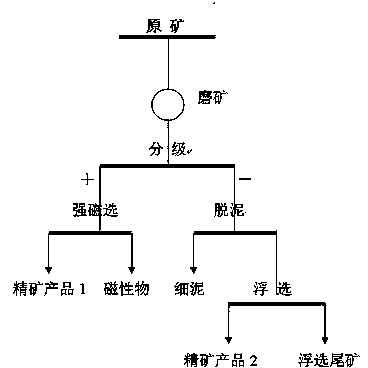

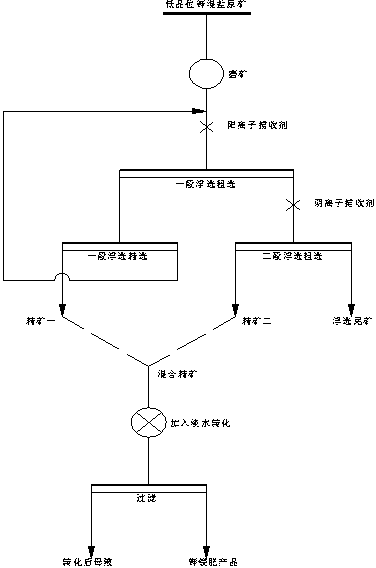

Rutile ore part size fraction benefication joint production process

InactiveCN102728451AReasonable useReduce the cost of beneficiationFlotationMagnetic separationMaceralRutile

The invention relates to a rutile ore part size fraction benefication joint production process. The joint production process comprises the steps of part size fraction magnetic separation, reselection, magnetic separation, desliming and grading, and flotation in sequence, so that the limit of only recovering rutile or comprehensively recovering garnet and rutile can be broken, and three main minerals including rutile, garnet and omphacite in the ore can be recovered comprehensively. By adopting the process, the rutile concentrate with TiO2 being in 90% grade and garnet and omphacite concentrate with purity being 88% can be obtained, the recovery rates of TiO2, the rutile, garnet and omphacite are 67.44%, 77.95%, 81.50 and 71.18%. Test results show that the main mineral resources in raw ores can be reasonably and effectively utilized with low flotation cost.

Owner:新沂市经济信息中心

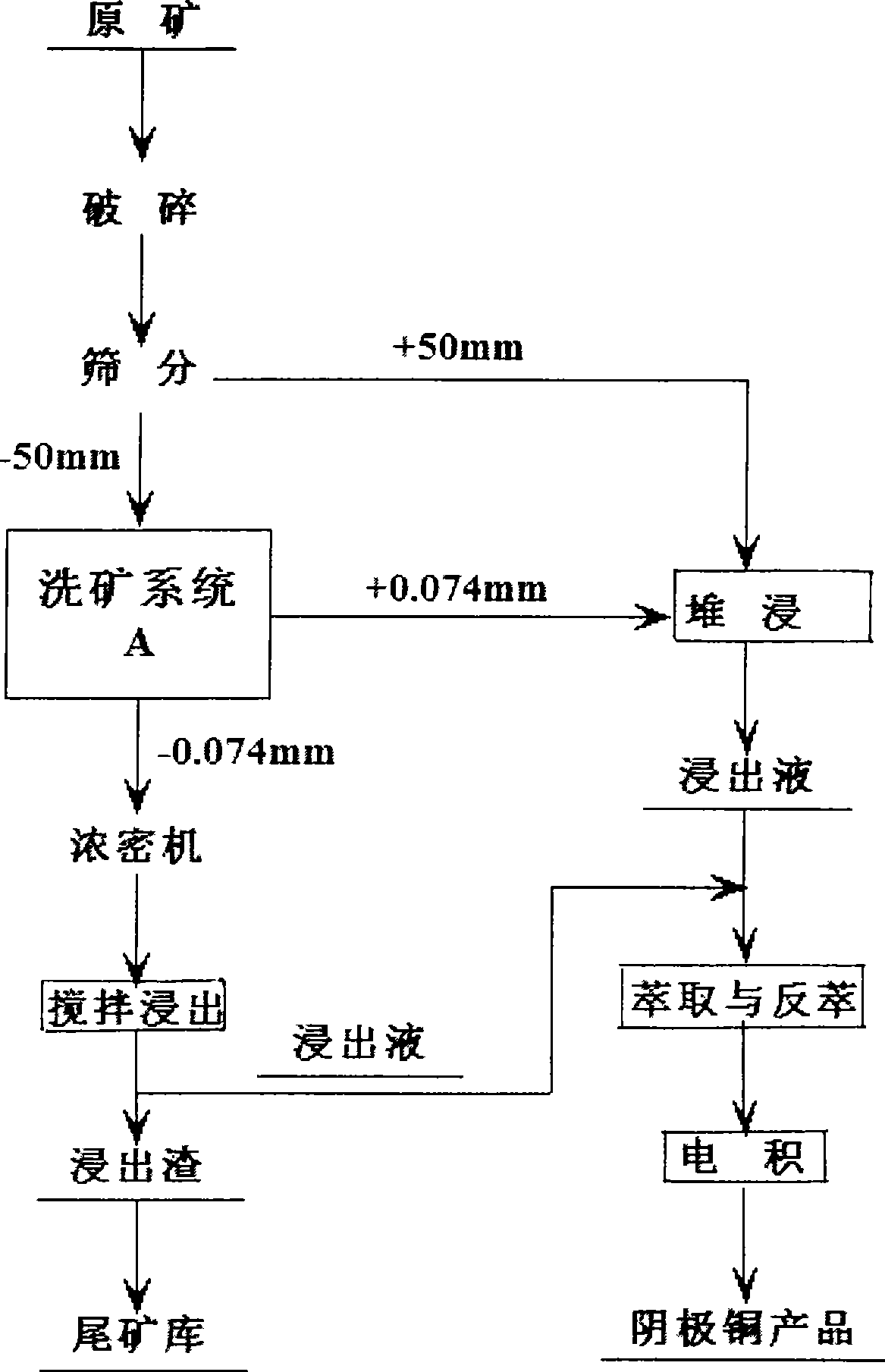

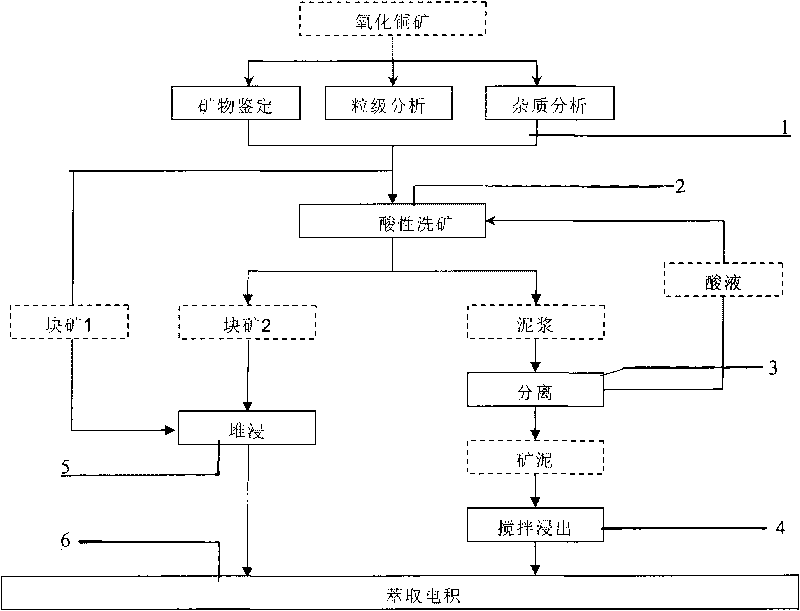

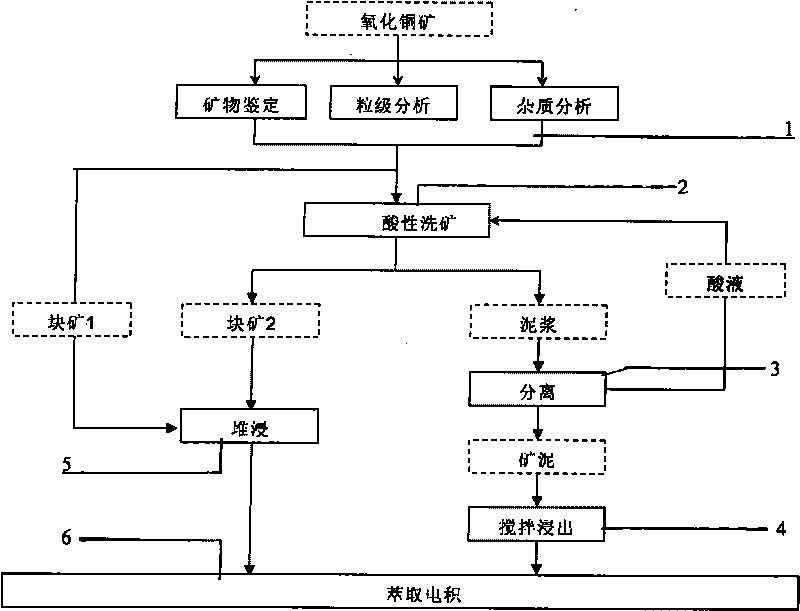

Wet processing process of high mud cupric oxide mine at high-cold area

InactiveCN101457299ASolve permeabilitySolve the problem of low copper leaching ratePhotography auxillary processesProcess efficiency improvementSlagCopper oxide

The invention provides a wet copper extraction process used in high mud-content copper oxide ores of cold areas. The process comprises the following steps: crude ores are crushed and sieved, coarse fraction ores are sent to a storage yard for piling, fine fraction ores are sent to an ore washing system for washing and grading; placer ores are sent to the storage yard for the piling after washing the ores, and mud ores are sent to an agitation tank for agitation leaching; leaching solution which is obtained from heap leaching and agitation leaching processes is sent for extraction and stripping; stripping concentration solution is sent to an electrodeposition process, and a qualified cathode copper product is obtained; leached slag from the agitation leaching is neutralized and sent to a tailings reservoir for piling. The process has good permeability, fast copper leaching rate, and greatly improved copper leaching rate and leached copper yield per day by the grading and the heap leaching of the coarse fraction ores; and the copper leaching rate is improved and the ore utilization rate is greatly improved by the agitation leaching of minus 0.074mm size fraction ores. The method is applicable to the development and the application in the wet copper extraction process used in the high mud-content copper oxide ores of the cold areas, solves the difficult technical problems of poor bing permeability and slow copper leaching rate, widens the use range of copper ore resources and improves the comprehensive utilization rate of the copper.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

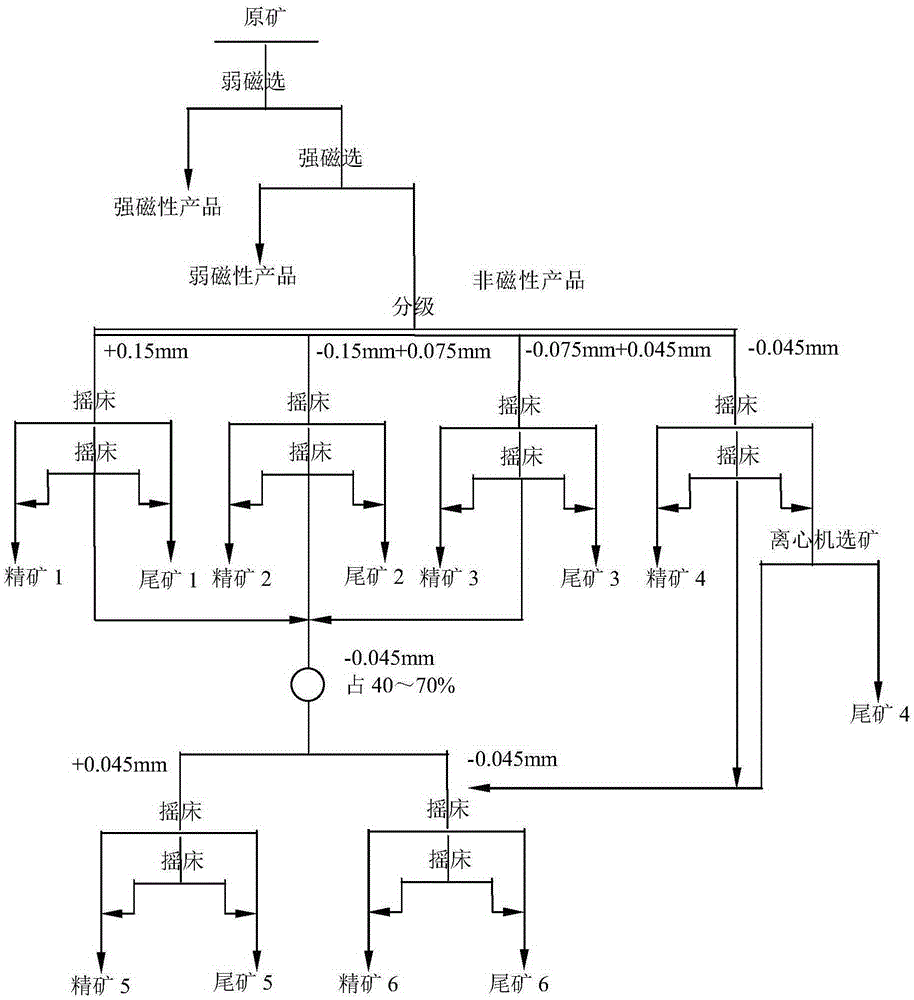

Mineral separation and enrichment method suitable for associated scheelite in molybdenite floatation tailings

InactiveCN105312148AReduce processingImprove sorting efficiencyMechanical material recoveryWet separationEnrichment methodsNon magnetic

The invention provides a mineral separation and enrichment method suitable for associated scheelite in molybdenite floatation tailings. The method includes the steps of low-intensity magnetic separation, high-intensity magnetic separation, non-magnetic ore pulp material size fraction grading, gravity separation, middling regrinding, regrading gravity separation and the like. A high-grade and high-recovery scheelite concentrate product is obtained, the associated low-grade scheelite resource in Cu-Mo polymetallic mixed associated ore is effectively and comprehensively recovered and used. The method can be widely applied to the field of recovering and using the associated low-grade scheelite resource.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

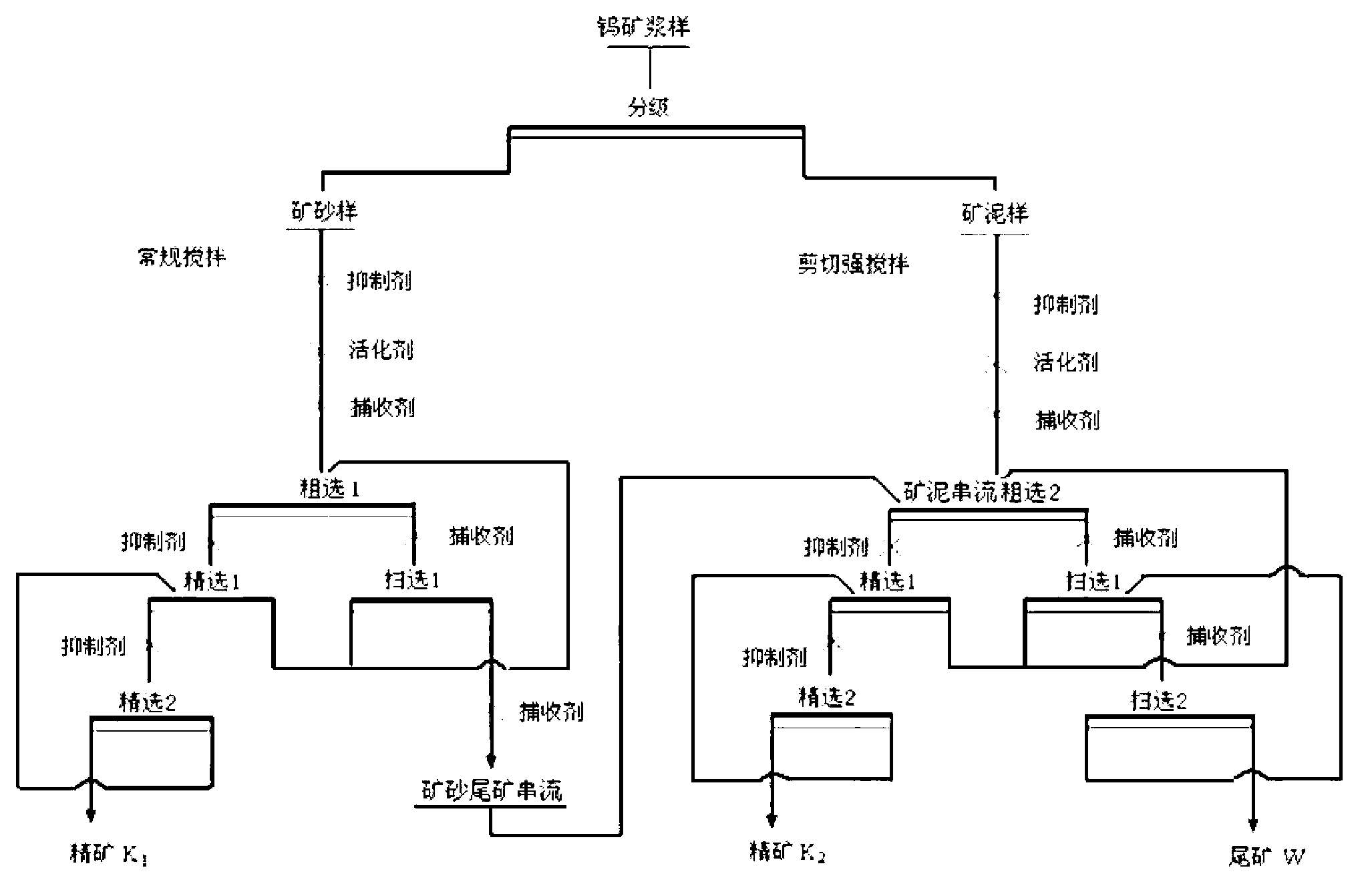

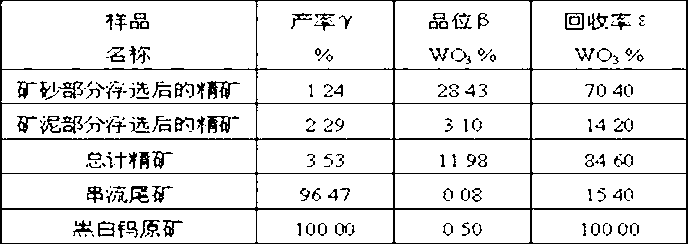

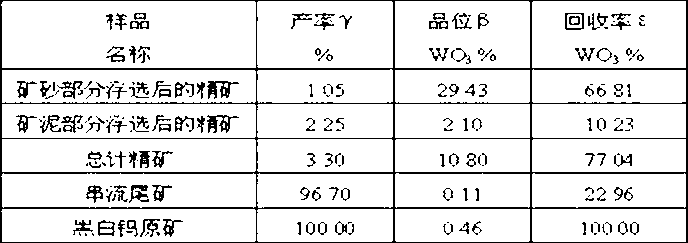

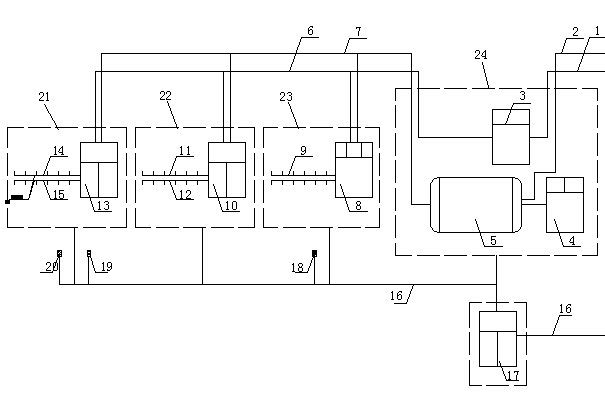

Grading and branching streaming flotation method of tungsten ore

ActiveCN103301946AImprove flotation technical indicatorsImprove sorting indexFlotationRed mudLower grade

The invention discloses a grading and branching streaming flotation method of tungsten ore. The grading and branching streaming flotation method of the tungsten ore comprises the following steps: firstly, finely grinding the tungsten ore; secondly, grading ore pulp of the ground tungsten ore into an ore sand part with a high flotation speed and an ore mud part with a low flotation speed by using grading equipment; thirdly, floating the ore sand part to obtain medium-grade tungsten concentrate and ore sand tailing; and finally, streaming the ore sand tailing to the ore mud part for floating, and obtaining low-grade tungsten concentrate and streamed tailing. By the grading and branching streaming flotation method of the tungsten ore, the size fraction for floating the ore pulp can be improved and the flotation performance and flotation indexes of the ore mud part can be improved.

Owner:中钨共享服务(湖南)有限公司

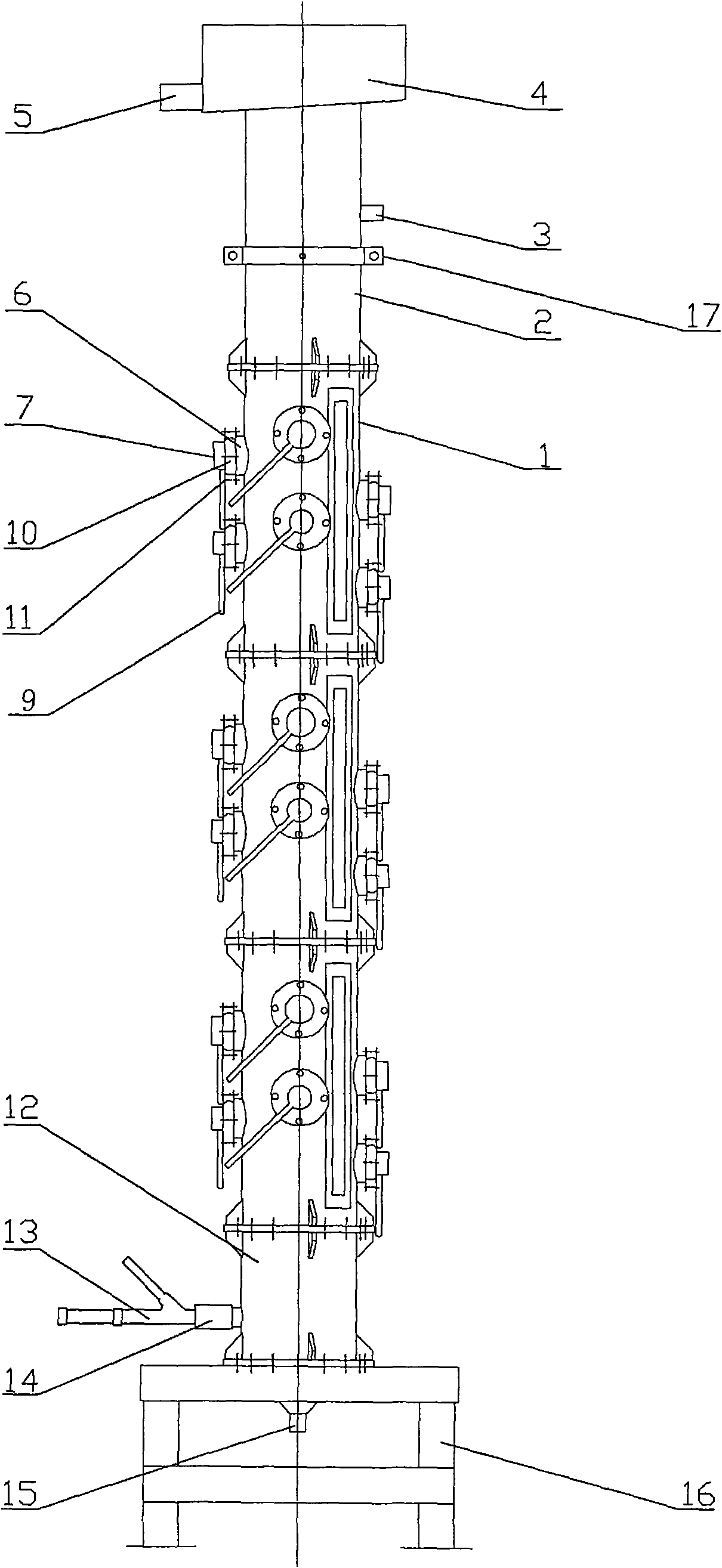

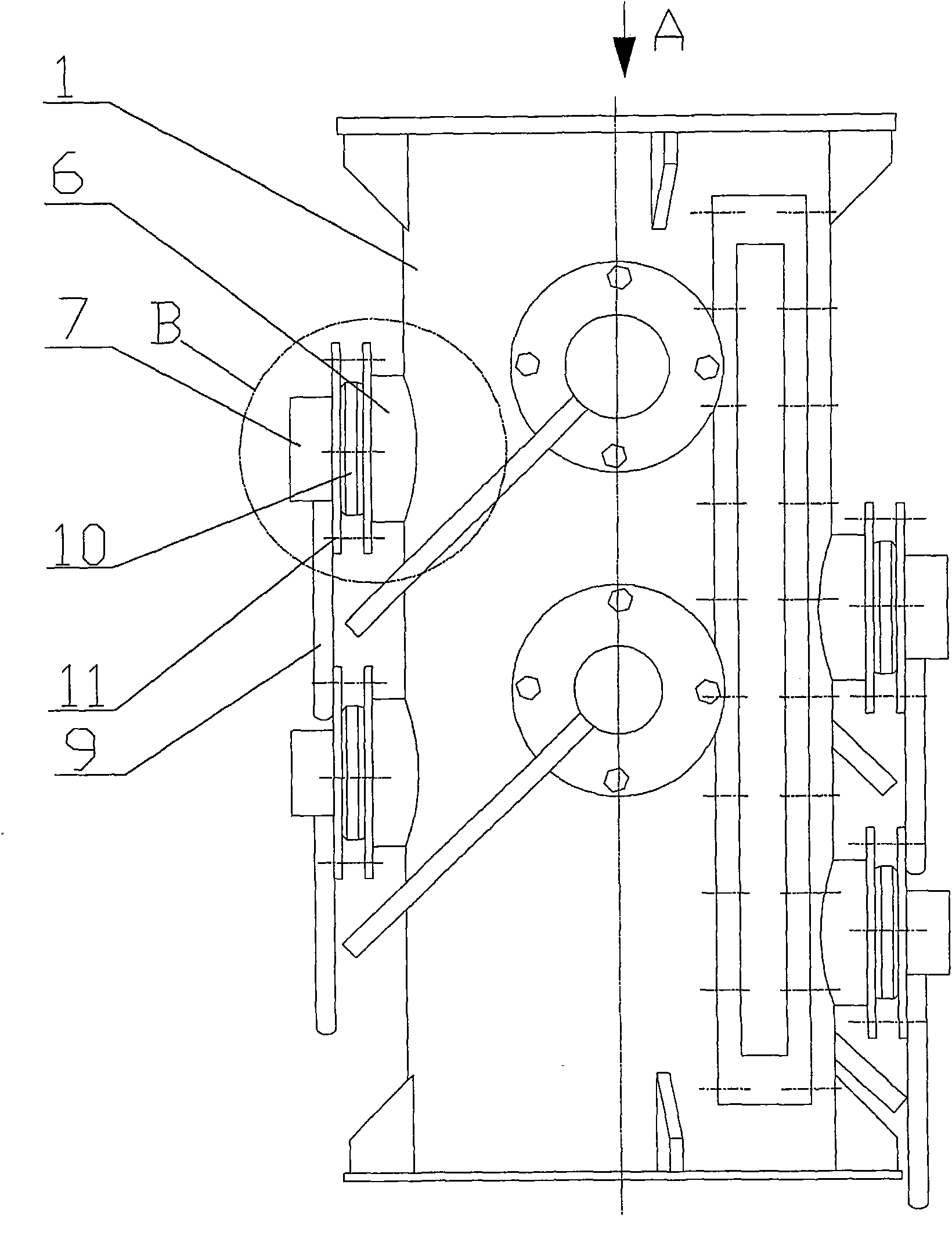

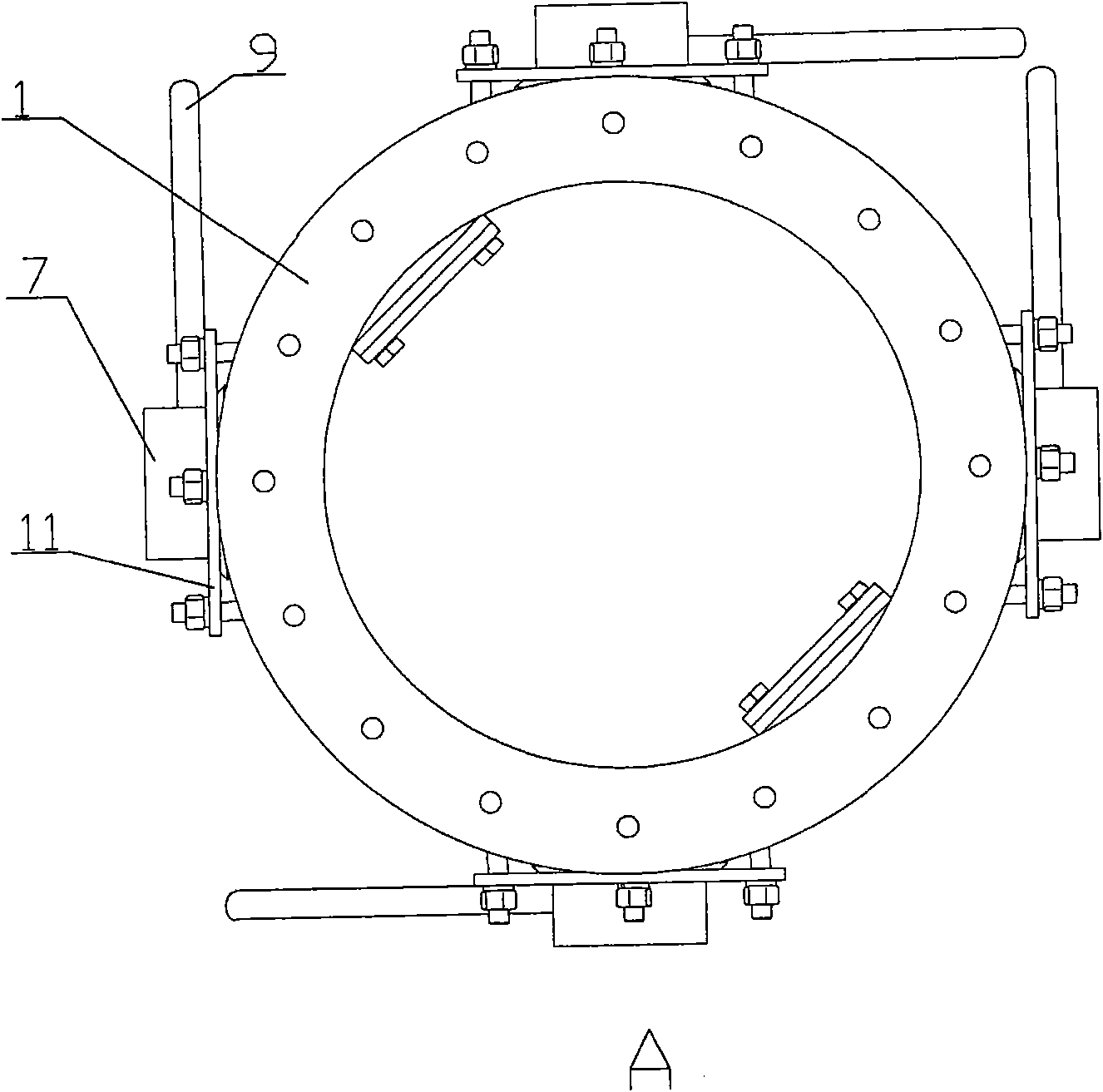

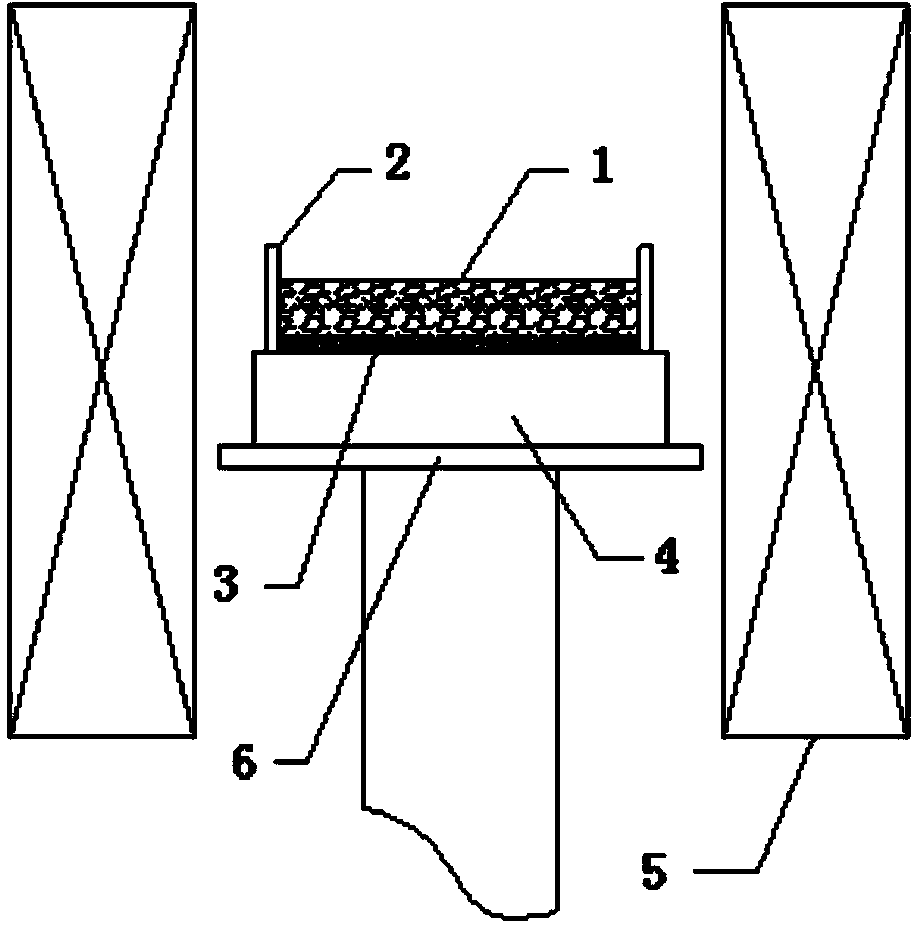

Mineral floatation column

ActiveCN101642732AHigh recovery rateAchieve emulsification and dispersionFlotationLiquid mediumCavitation

The invention relates to a mineral floatation column, in particular to a columnar floatation device for separating minerals in a liquid medium. The columnar floatation device is characterized by structurally comprising a floatation column body, an ultrasonic generating device and a mounting base, wherein the mounting base is fixedly connected to a circular through-hole formed on the lateral wall of the floatation column body; and the ultrasonic generating device is mounted on the mounting base. By taking the unique advantages of the existing floatation column and introducing the ultrasonic technology into the floatation column, materials passing through the floatation column are subject to hydrodynamic force, gravity force, surface chemical force, interaction force among particles, and cavitation and ultrasonic direct-inflow effects generated by ultrasonic waves, so that the invention can strengthen the separation process of materials, extend the size fraction range for the materials of the floatation column to select, stimulate the recycling of coarse-particle materials and improve the separation precision, and meanwhile, the invention can improve the recovery rate of operations and reduce the cost of separation operations. The floatation column is applicable to various separation fields, such as mineral separation, wastewater treatment, petroleum, chemical engineering, environmental protection and the like.

Owner:BGRIMM MACHINERY & AUTOMATION TECH CO LTD

Ultrahigh heat-conduction diamond/aluminum composite material and preparation method of ultrahigh heat-conduction diamond/aluminum composite material

ActiveCN104313385ASolve the strength problemSolve the problem of forming special-shaped componentsMaterials preparationThermal diffusivity

Owner:HARBIN INST OF TECH

Composite sodium salt for producing sodium stannate from cassiterite concentrate and application of composite sodium salt

The invention discloses a composite sodium salt for producing sodium stannate from cassiterite concentrate and an application of the composite sodium salt. The composite sodium salt consists of 70%-90% of sodium carbonate, 5%-20% of sodium bicarbonate, 2.5%-5% of sodium borate and 2.5%-5% of sodium humate by mass. When the composite sodium salt is used, the composite sodium salt is ground to the particles with the size fraction of minus 0.1mm being no less than 90% by mass, the cassiterite concentrate of the fine fraction and the composite sodium salt are mixed according to the mass ratio of 1:(0.5-2), pelletized and dried, coke powder or anthracite is taken as a reducing agent, the mixture is calcined for 30 minutes-90minutes at the temperature of 800 DEG C-950 DEG C, and the cooled calcined product is ground, leached, filtered, purified, concentrated and crystallized, so that the sodium stannate product is obtained. The adopted composite sodium salt is reasonable in component, can be widely obtained, is low in price, is easy to obtain and does not cause pollution to the environment. With the composite sodium salt, the stable crystal structure of the cassiterite concentrate can be obviously damaged, and the composite sodium salt can be widely applied to various cassiterite concentrates so as to directly produce sodium stannate.

Owner:CENT SOUTH UNIV

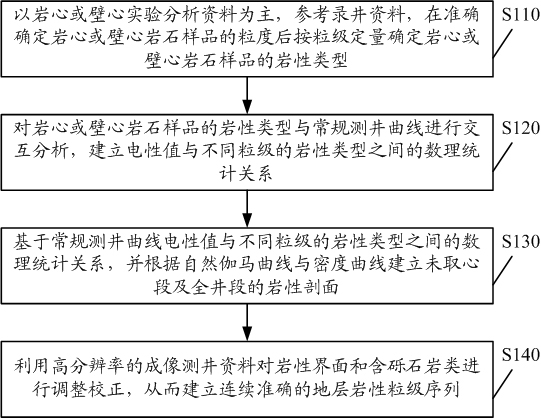

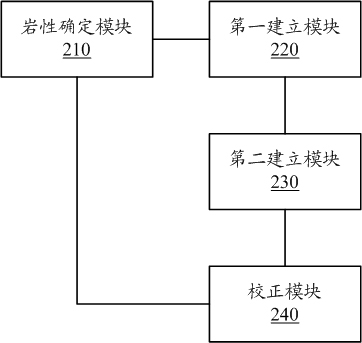

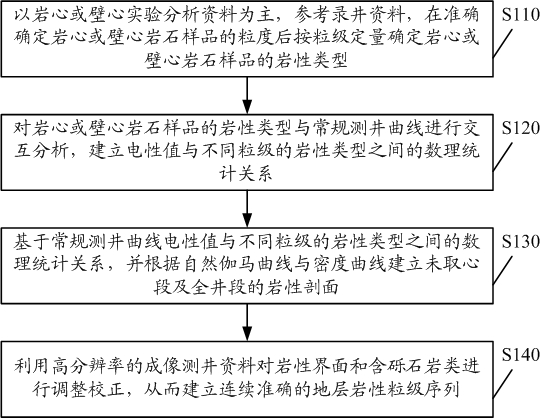

Method and system for identifying fragmental rock lithological characters

ActiveCN102606150AFine and reliable profileReflect changing characteristicsBorehole/well accessoriesLithologyAnalysis data

The invention discloses a method and a system for identifying fragmental rock lithological characters, which aim to overcome the defect of incapability of accurately and continuously identifying the lithological characters of strata. The method includes the steps: determining lithological character types of rock samples of rock cores or wall cores in terms of size fractions according to experimental analysis data and logging data of the rock cores or the wall cores; performing interaction analysis for the lithological character types of the rock samples of the rock cores or wall cores and regular logging curves, and establishing mathematical statistic relation among electrical property values of the regular logging curves and the lithological character types of different size fractions; establishing lithological profiles of core unsampled sections and whole well intervals according to the regular logging curves based on the mathematical statistic relation among the electrical property values of the regular logging curves and the lithological character types of different size fractions; and correcting thicknesses of different lithological characters and rocks containing gravels in the lithological profiles by means of image logging data, and establishing the continuous stratum lithological character size fraction sequence. The method can accurately reflect change characteristics of stratum deposition, so as to provide reliable basis for meticulously evaluating reservoir physical properties and sedimentology research.

Owner:CHINA NAT OFFSHORE OIL CORP +1

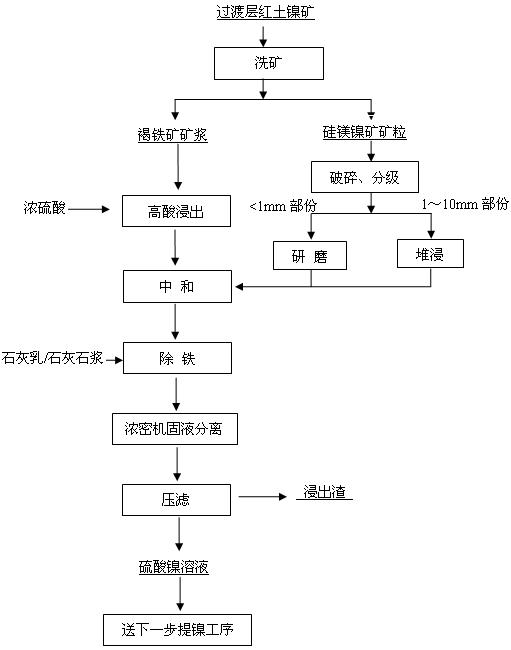

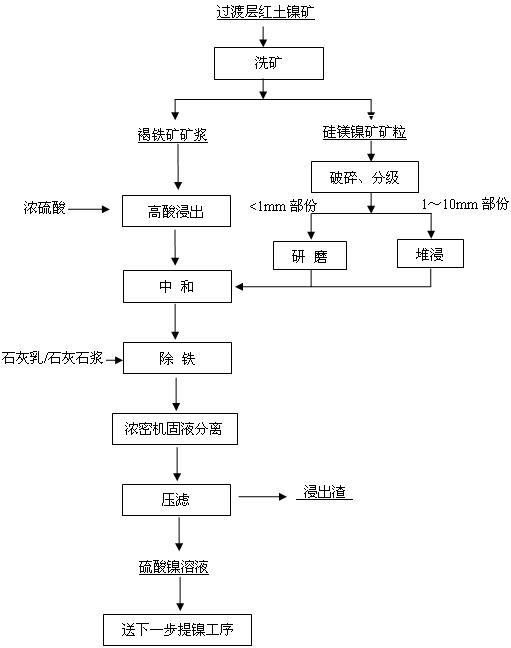

Method for wet-leaching lateritic-nickel ore at transition layer

ActiveCN102212684AImprove leaching rateReduce consumptionProcess efficiency improvementSlurryImpurity

The invention discloses a method for wet-leaching lateritic-nickel ore at a transition layer. The method comprises the following steps: firstly washing lateritic-nickel ore at a transition layer so as to separate out limonite type lateritic-nickel ore and garnierite type lateritic-nickel ore; crushing and grading garnierite, sorting out ore with size fraction of 1-10mm for heap leaching to lixiviate metallic nickel, and mechanically grinding ore with particle size of less than 1mm into garnierite pulp with particle size of -100 meshes; adding concentrated sulfuric acid to limonite pulp for high-acid leaching under normal pressure; adding the garnierite pulp and nickel-containing solution subjected to heap leaching to the high-acid leaching pulp so as to neutralize residual acid; adding lime milk or limestone slurry for removing iron; and carrying out preliminary solid-liquid separation on the slurry without iron by utilizing a thickener, then finely filtering the slurry by utilizing apress filter, and further treating the obtained nickel-containing solution. The method has the advantages of simple flow, no need of ore pretreatment, the adoption of conventional leaching equipment,low acid consumption, good impurity removal effect, high nickel recovery rate and the like.

Owner:广西银亿新材料有限公司

Developer, image-forming method, and process cartridge

A developer for developing an electrostatic latent image is formed from toner particles each comprising a binder resin and a colorant, inorganic fine powder having a number-average particle size of 4-80 nm based on primary particles, and electroconductive fine powder. The developer is characterized by having a number-basis particle size distribution in the range of 0.60-159.21 mum including 15-60% by number of particles in the range of 1.00-2.00 mum, and 15-70% by number of particles in the range of 3.00-8.96 mum, each particle size range including its lower limit and excluding its upper limit. As a result of inclusion an appropriate amount of the electroconductive fine powder represented by the particle size fraction of 1.00-2.00 mum, the developer is suitably used in an image forming method including a contact charging step of charging the image-bearing member based on the direct injection charging mechanism and also in an image forming method including a developing-cleaning step of developing the electrostatic latent image and recovering the developer remaining on the image-bearing member after the transfer step.

Owner:CANON KK

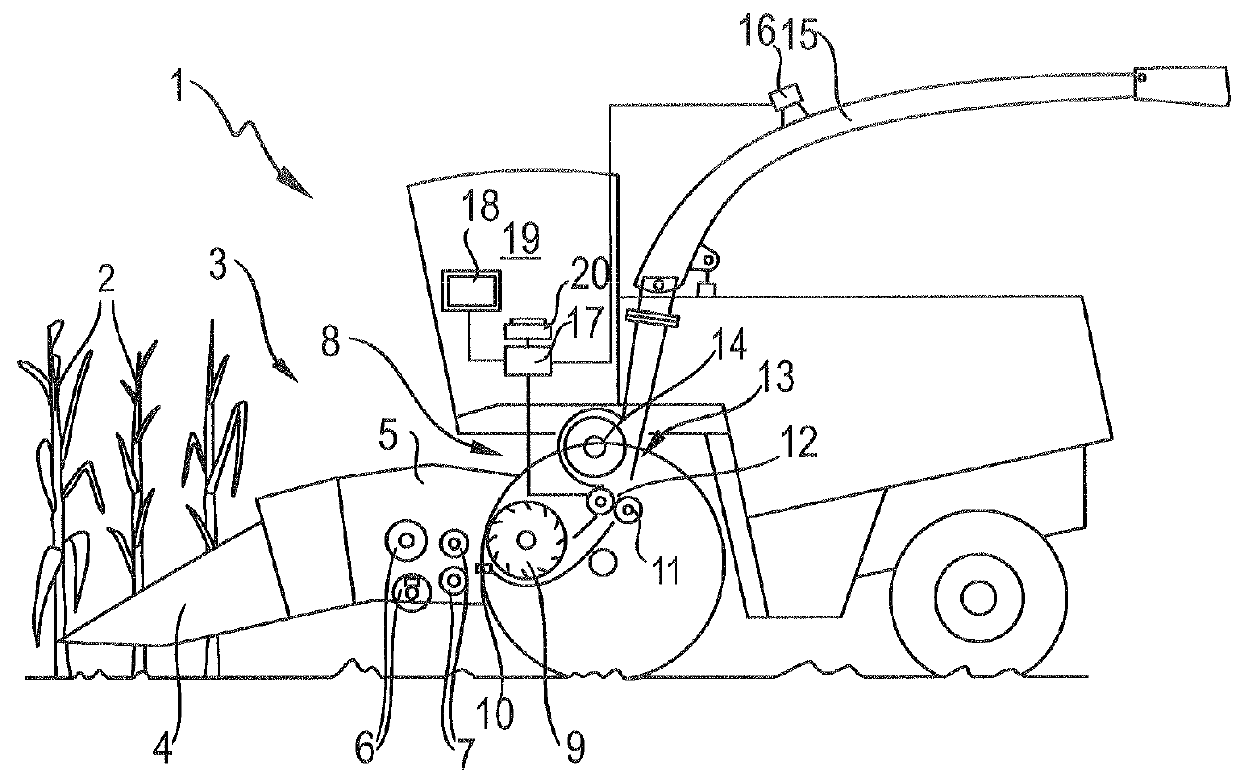

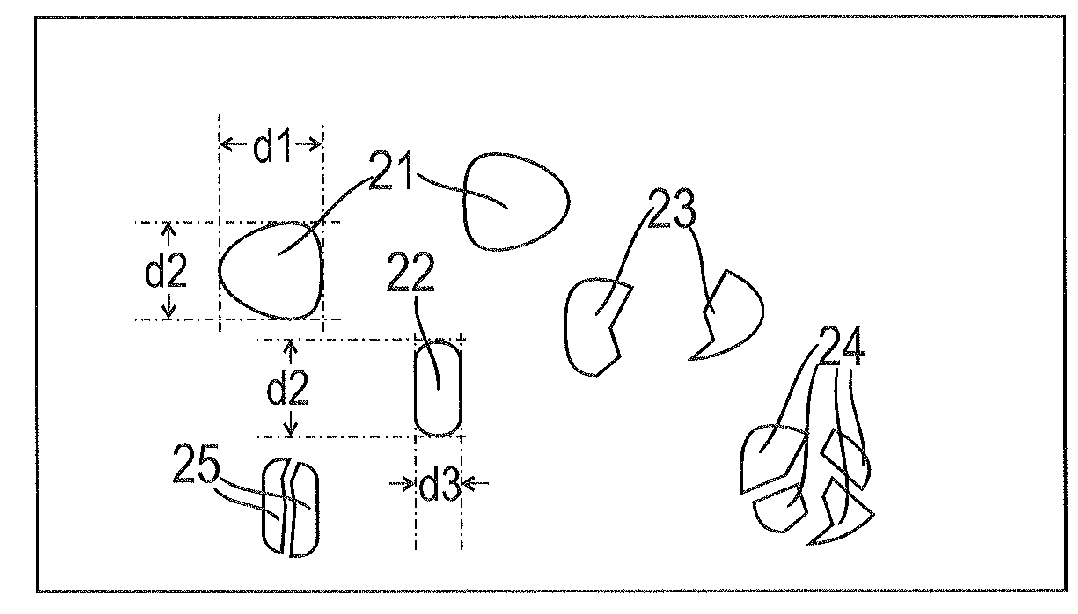

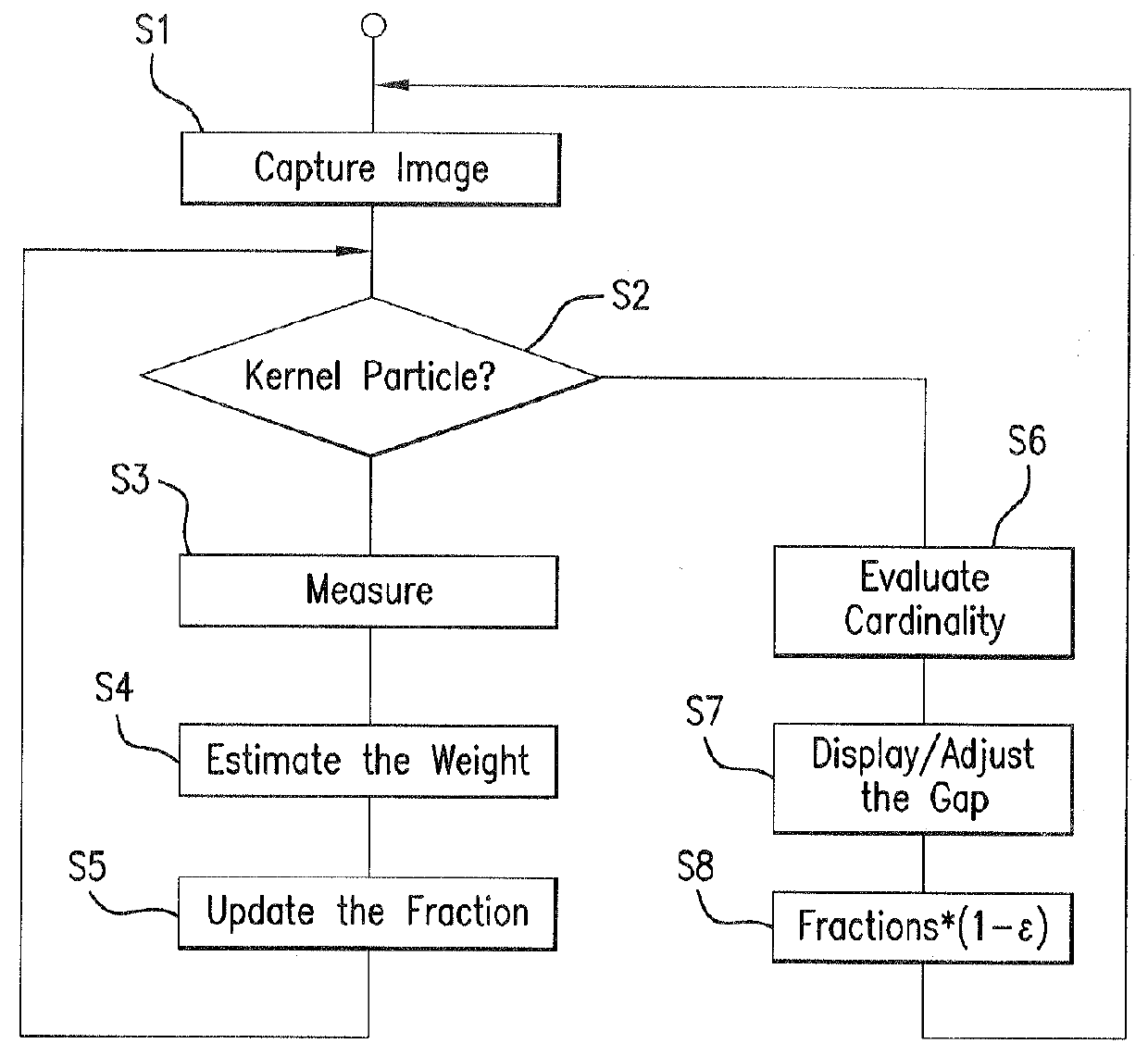

Forage harvester and operating method therefor

InactiveUS20160029561A1More interferenceGrain huskingImage enhancementForage harvesterComputer science

A method for operating a forage harvester includes steps of capturing images of chopped material produced in the forage harvester using a camera, identifying images of kernel-type particles in the images, sorting the images of the kernel-type particles into at least two size fractions and determining a cardinality of the size fractions.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

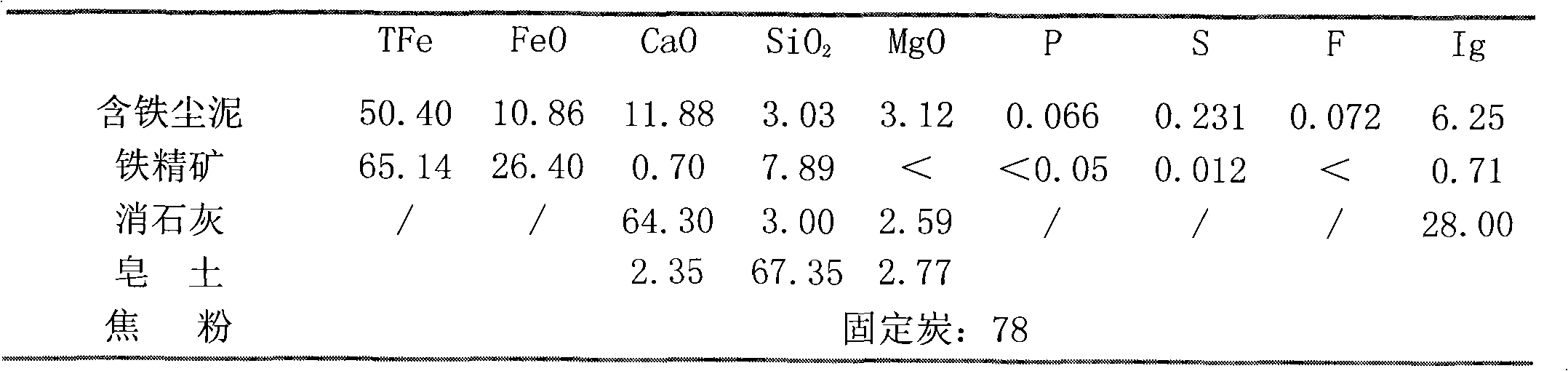

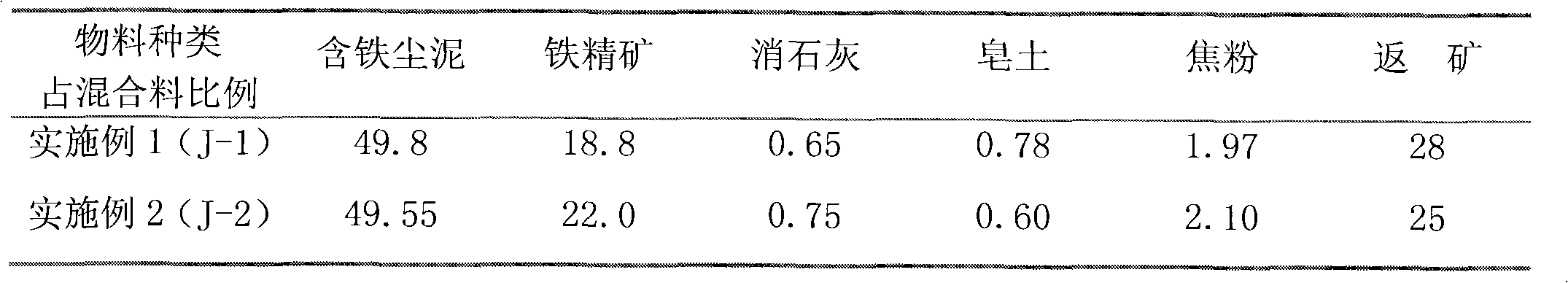

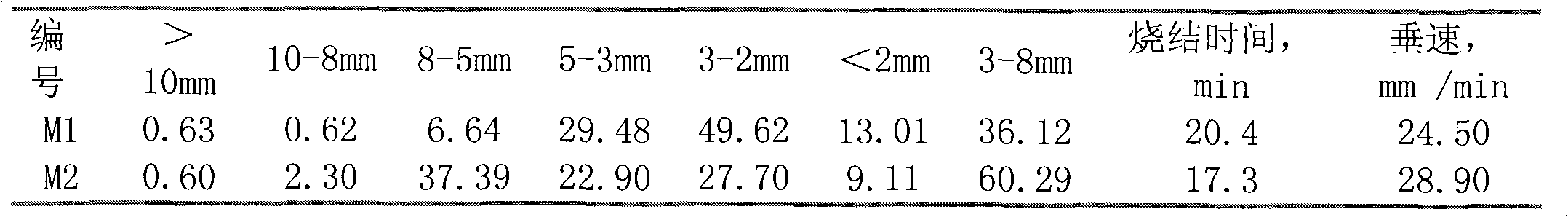

Method for applying ferric dust in sintering

The invention discloses a method for applying ferric dust in sintering, which relates to a recycling method of metallurgical wastes and belongs to the technical field of black metallurgy sintering. The method comprises the following steps: uniformly mixing 45-50 % ferric dust, 17-22 % of iron ore concentrate, 0.6-0.8 % of hydrated lime, 0.6-0.8 % of bentonite, 1.9-2.1 % of coke powder, 25-30 % ofreturn fines, wherein the particle size of the return fines is below 5mm; pelletizing the mixed material with a pelletizing disc, wherein the pelletizing particle size is 3-8 mm, the size fraction of3-8 mm accounts for 70-80 %, the pelletizing time is 2-3 min, and the moisture of mini pellets is controlled to 10-11 %; and finally sintering the material pelletized by the pelletizing disc, whereinthe sintering technological parameters comprise an igniting time of 1.5-2 min, an igniting negative pressure of 4900 Pa, a sintering suction pressure of 6860 Pa, and a material layer thickness of 500mm. According to the invention, a sinter obtained by the method has an alkalinity of 1.80-1.90, and MgO is controlled to 2.3-2.5 %; after igniting, the mixed material is sintered from top to bottom, and a finished sintering ore product is used by a blast furnace. By directly using the ferric dust as the mixed material for sintering, and directly using the sinter with the dust for blast furnace production, the process flow is simple and convenient, new devices are not needed, and the investment is low.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

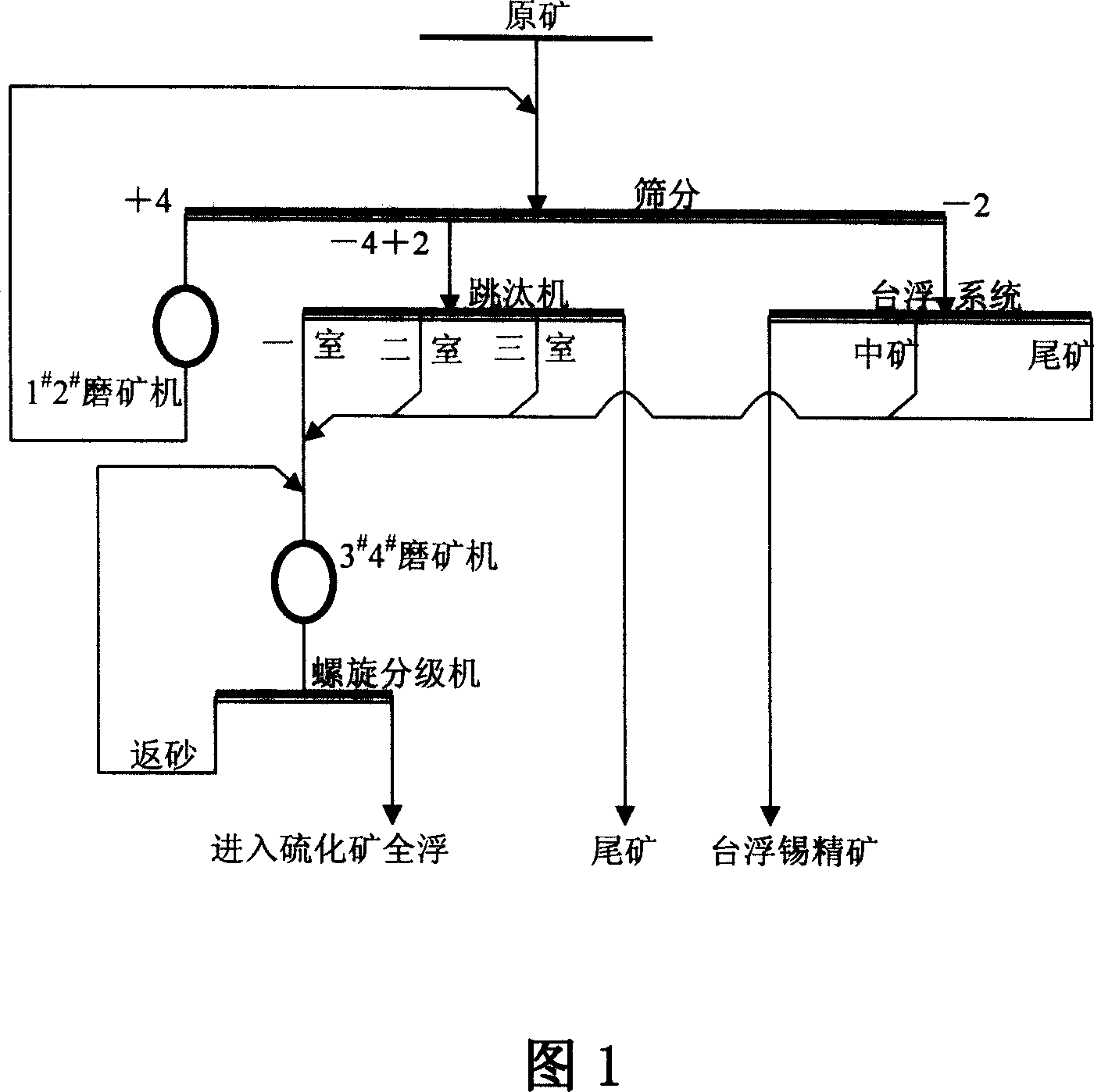

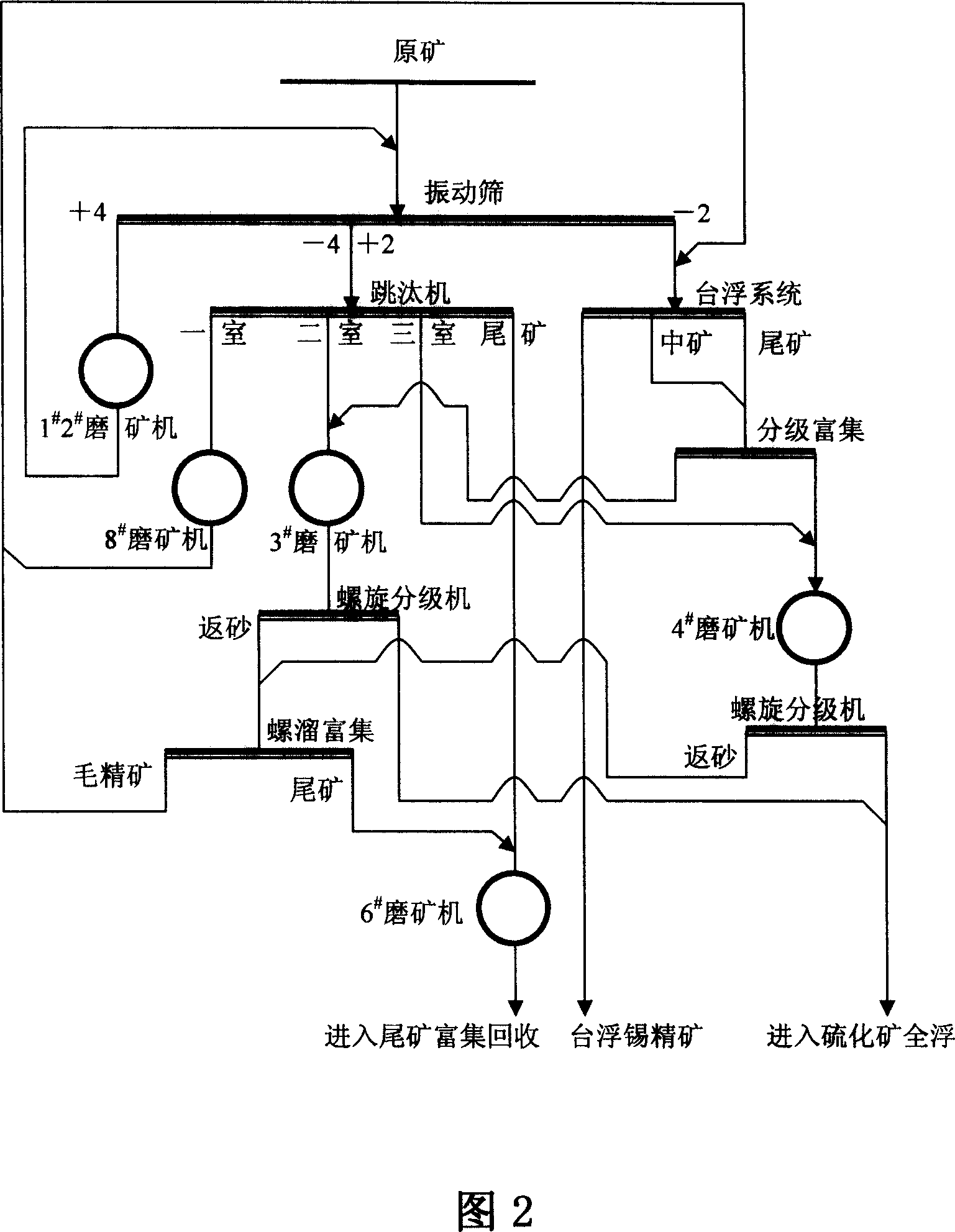

Step branched ore milling and milling and dressing circular new technology

InactiveCN1943869ASolve the powderSolve the contradiction of under-grinding of sulfide oreWet separationSlagNonferrous metal

The present invention relates to the non-ferrous ore milling and separating process. The process includes sieving the crude ore into three size fractions, including 4 mm over fraction to the ore mill for milling to 3 mm below size, 2-4 mm fraction to the jigger for enriching and 2 mm below fraction to the screw chute system for enriching and to the table floating system for separating; milling crude ore in the crude ore mill; enriching in the jigger; grading after milling; separating in the table floating system and the screw chute system to obtain ore concentrate; and milling the concentrated tailings to recover target metals before draining ore slag. The present invention has sufficient milling and high metal recovering rate.

Owner:广西华锡集团股份有限公司

Method for selecting zinc oxide from muddy zinc oxide fine ore grains

The invention provides a method for selecting zinc oxide from muddy zinc oxide fine ore grains. Muddy zinc oxide ore is ground into ore pulp after being crushed and then is classified, then the ore pulp with size fraction smaller than 0.125mm is mixed, ore pulp gangue dispersing agent, siliceous gangue activating agent and granular zinc oxide ore agglomeration agent are respectively added in the ore pulp and then are stirred to obtain ore pulp, the ore pulp is conveyed to an ore distributor of a conventional table concentrator to realize table concentrator sorting, and then zinc oxide fine ore with the granularity smaller than 0.125mm is sorted. The method is simple and easy in operation, equipment includes a conventional crusher, an ore grinder and the table concentrator and investment is saved, particularly, zinc oxide recovery rate can be effectively improved, problems that low-grade lead-zinc oxide ore is difficult to be sorted in the prior art and then is accumulated, resources are waste and environments and water are polluted are solved, resources are recycled, and the method brings rich economical benefit for mine enterprises.

Owner:兰坪县矿产三废回收厂

Differential separation and upgrading method for feldspar minerals

The invention provides a sorting method for differential feldspar ore separation and purification of feldspar minerals. According to the sorting method, raw feldspar ore is divided into two size fractions in a coarse grinding state according to the natural feature that the dissemination granularity of the feldspar minerals is uneven, the two size fractions are different in quality, the coarse fraction raw feldspar ore is low in iron content, the high-quality fine fraction raw feldspar ore is high in iron content, the fine fraction raw feldspar ore is sorted to obtain high-quality concentrates through a simple and practical method, slurry is removed from the low-quality coarse fraction raw feldspar ore, and the coarse fraction raw feldspar ore is sorted to obtain low-quality feldspar concentrates through a flotation method suitable for fine fraction purification. The sorting method for differential feldspar ore separation and purification of the feldspar minerals has the advantages that the process is simple, the product quality is good, the product value is high, the recovery rate is high, environmental pollution is low, and energy conservation and consumption reduction are realized, thereby being suitable for purification of feldspar ore with high ion content and coarse feldspar mineral dissemination granularity.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Novel kaolin clay glossing pigment and preparation thereof

InactiveUS20020129741A1Improve productivityFacilitates required penetration of inkPigmenting treatmentNon-fibrous pulp additionKaolin clayHigh surface

Novel nanosized kaolin clay particles are prepared by agitating a fine particle size fraction of kaolin clay in a Netzsch mill until the particle size is reduced, aspect ratio is decreased and surface area is increased. The ultrafine kaolin particles are especially useful as a pigment to provide high surface gloss to ink jet printing papers.

Owner:IMERYS USA INC

Acid washed ore leaching process for low-grade copper oxide ores with high mud content

InactiveCN101736152AReduce pollutionLow permeabilityProcess efficiency improvementCopper oxideDissolution

The invention provides an acid washed ore leaching process for low-grade copper oxide ores with high mud content, which comprises the following steps: after the raw ores are crushed and sieved, conveying the ores of +50mm size fraction to a storage yard for stacking, and carrying out acid washed ore treatment on the ores of -50mm size fraction; by adding sulfuric acid into the washing liquid, rewashing the ores to remove partial basic gangue; after the washing liquid is separated and deposited, recycling the acid liquid; after the ores are treated by an acid washed ore system, conveying the sand ores of +0.074mm size fraction to the storage yard for stacking, and stirring and leaching the mud ores of -0.074mm size fraction; after the leaching liquid generated by stirring and the leaching liquid generated by heap leaching are mixed, carrying out extracting and electrodepositing processes; and finally, obtaining cathode copper products. The process of the invention has the advantages of short procedures, simple equipment, small investment, low cost and little pollution to the environment, further solves the problems of poor heap leaching penetrability, low copper leaching rate and the like caused by existence of mud ores and dissolution and deposition of basic gangue, improves the recovery rate of copper, and comprehensively utilizes the mineral resources of the low-grade copper oxide with high mud content.

Owner:有研资源环境技术研究院(北京)有限公司

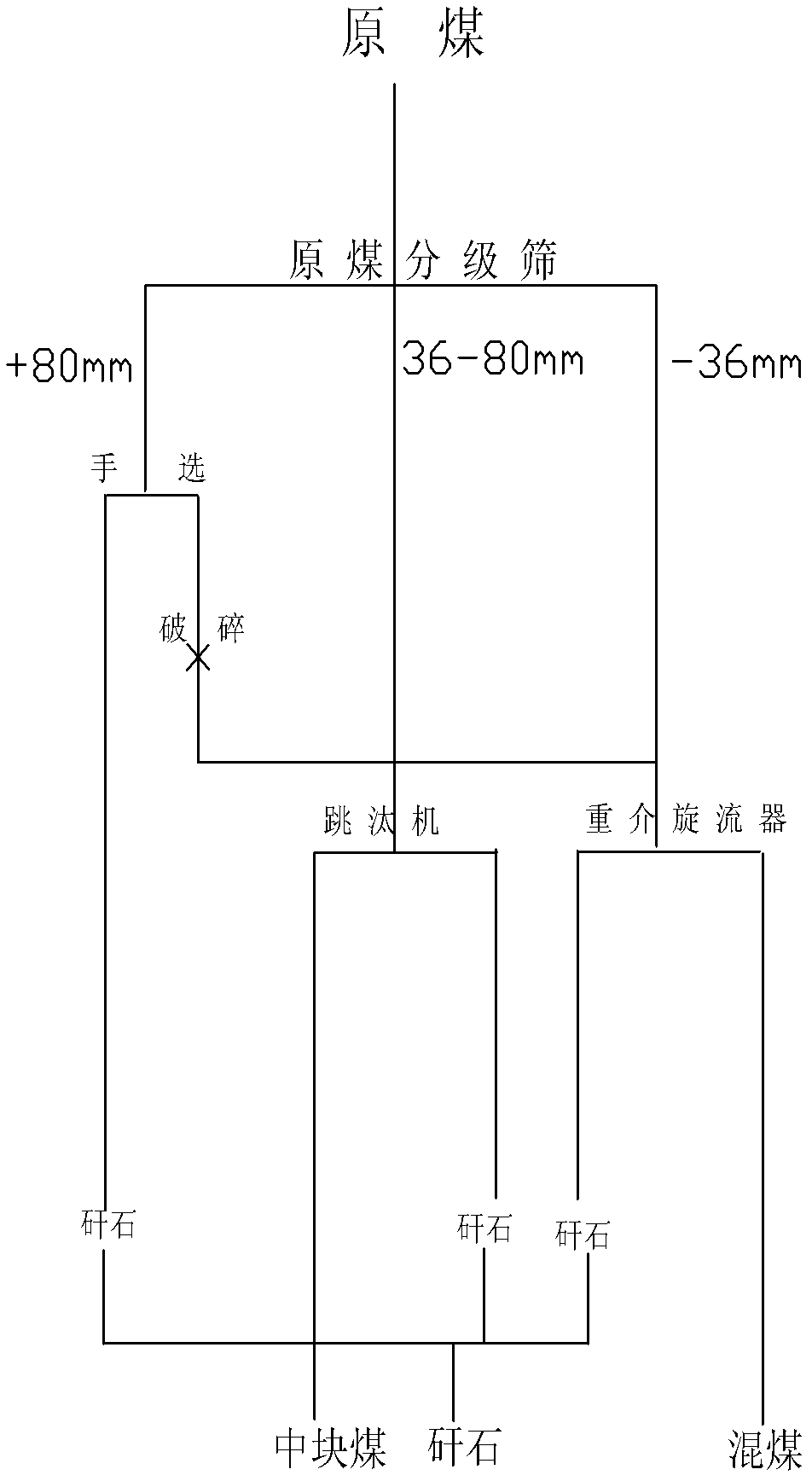

Graded washing process for raw coal

The invention relates a graded washing process for raw coal, which comprises the following steps of: dividing the raw coal into different size fractions according to coal quality: raw coal larger than 80 mm, raw coal from 36 mm to 80 mm and raw coal smaller than 36 mm; sorting different size fractions of raw coal by different sorting devices, sorting the raw coal from 36 mm to 80 mm by a raw coalwash box, and sorting raw coal smaller than 36 mm by a dense medium cyclone. The advantages of the two sorting devices are combined to increase the sorting accuracy of single sorting device, so that the recovery rate of commercial coal is maximized, resource loss and wastage are reduced, the production cost is reduced, expense is saved, consumption is lowered, and meanwhile, the processing ability of the whole set of system is improved.

Owner:山东新矿赵官能源有限责任公司

Testing method of iron mine powder sintering and assimilating flux amount and speed

ActiveCN104359934AImprove accuracyThe test method is simple and reliableMaterial weighingInvestigating phase/state changeCoalSize fractions

Owner:武汉钢铁有限公司

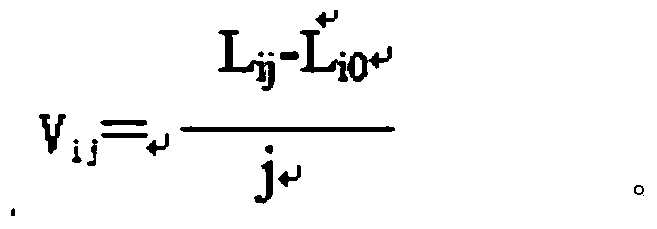

Two-stage flotation process for low-grade mixed potassium salt

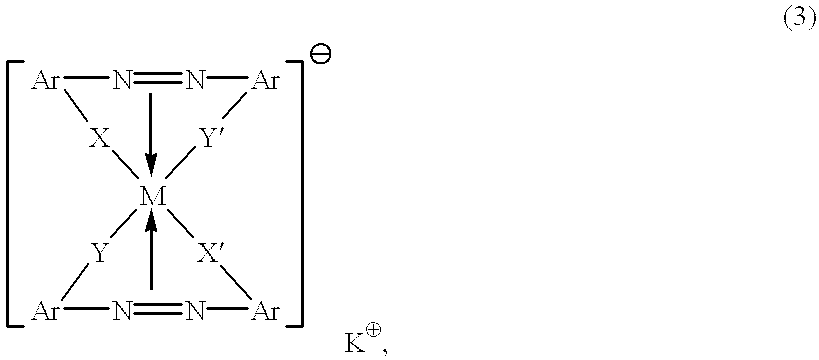

The invention discloses a two-stage flotation process for low-grade mixed potassium salt. The process comprises the following steps: (1) grinding low-grade mixed potassium salt until content of the salt with size fraction of -0.15mm is no less than 64.90% by mass; (2) transferring ore pulp obtained from the step (1) to a flotation machine for the first stage of flotation; (3) adding an anionic collector to coarse ore pulp obtained from the step (2) for the second stage of flotation; (4) totally combining potassium chloride concentrate obtained from the step (2) with the second stage of flotation concentrate obtained from the step (3), adding fresh water at a mass ratio of the concentrate to the fresh water of 1: (0.65-0.80), stirring at normal temperature and conducting a conversion reaction fore 1-2h, filtering and drying to obtain a finished potassium sulfate fertilizer product. The process disclosed by the invention has such advantages as simple process, low energy consumption, easy implementation of operation and high K<+> recovery rate, and is suitable for recovering a potassium resource from some low-grade mixed potassium salt complex in potassium mineral composition through flotation.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

Mine dust grading combined dust fall method and device

InactiveCN103758557AAchieve dust reductionAchieve explosion-proofDust removalFire preventionDrizzleAutomatic control

The invention discloses a mine dust grading combined dust fall device. A primary dust fall system is formed by an inner spraying device and an outer spraying device which are arranged in a coal cutter or a heading machine. The mine dust grading combined dust fall device comprises a secondary haze transform system formed by an ultrasonic wave dry haze generator and a tertiary drizzle wall haze fall system formed by a drizzle generating device. By means of the mine dust grading combined dust fall method and device, conventional instantaneous point dust fall is changed into segmental process dust fall, mine dust different size fraction can be inhibited and reduced by forming water mist particles or gas water mist particles different in particle diameter, and particle diameter grading, segmental inhibition and reduction and process transformation of mine dust in wind current of mining ports are achieved. The mine dust grading combined dust fall device can move along with pushing of the mining points and has functions of automatic control and rain stopping when people go out, dust fall efficiency is high, and dust inhibition, dust fall, explosion protection, fire protection, temperature reduction and drag reduction of return current are achieved by humidifying dirty wind. Compared with the conventional dust fall method, dust fall effect is obvious.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

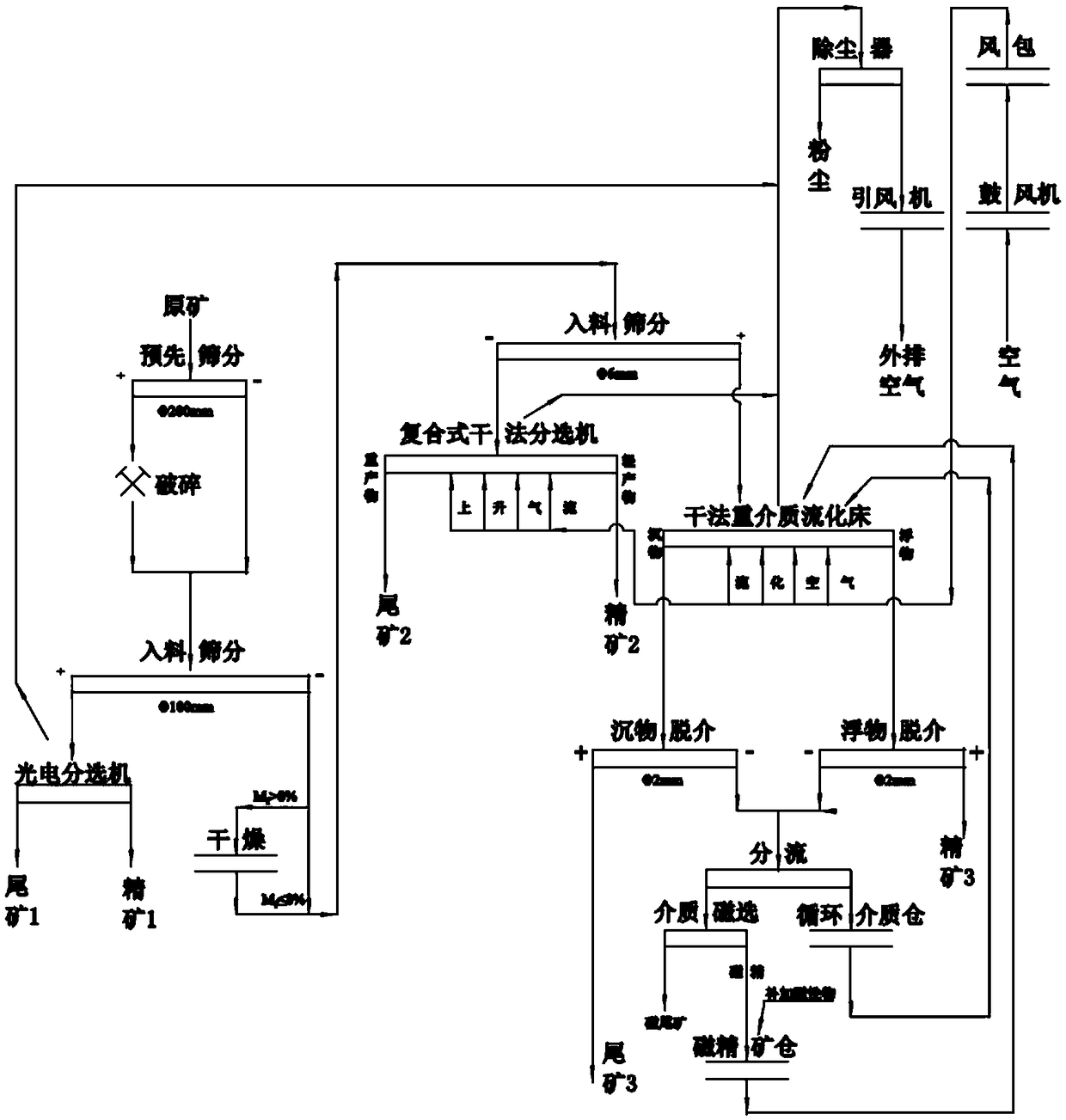

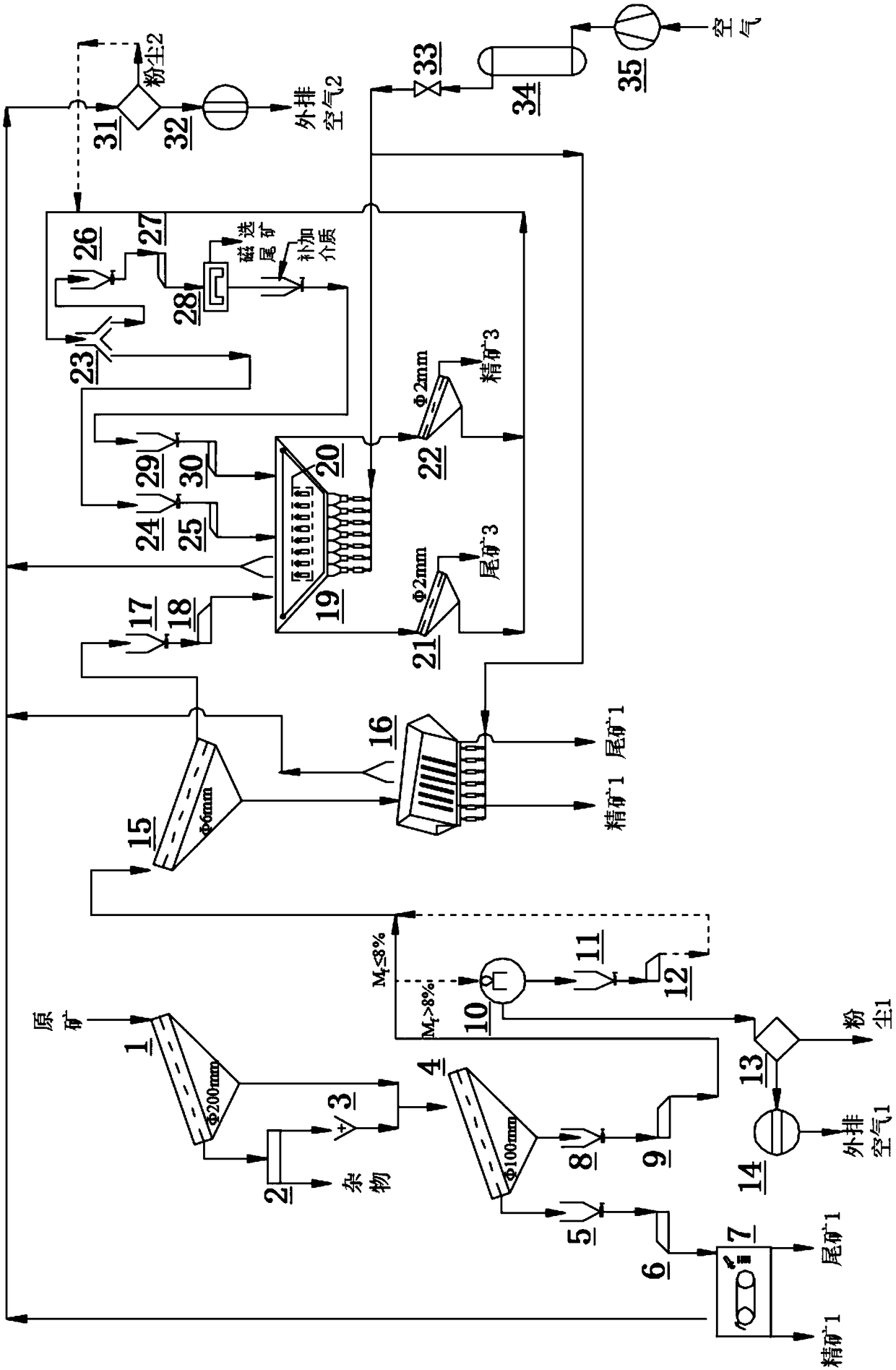

Full-size-fraction dry separation clean process and system for coal-series coexisting and associated mineral resources

InactiveCN109331987AOvercome limitationsOvercoming the Difficulty of Efficient and Clean UtilizationWet separationFluidized bedMaterial removal

The invention discloses a full-size-fraction dry separation clean process and system for coal-series coexisting and associated mineral resources. According to the process, after to-be-separated raw ore is broken and screened, oversize products enter a photoelectric separation machine to be subjected to tailing removal, products of two size fractions are obtained by further screening undersize products after drying, the undersize products enter a compound dry separation machine and a dry dense medium fluidized bed separation machine correspondingly to be subjected to separation, and concentrateand tailing are obtained; after medium solid brought out by the products is removed through a medium draining screen, one part of the medium solid enters a magnetic separation machine to be subjectedto non-magnetic material removal, magnetic material concentrate is then obtained and flows back to enter the separation machines, and the other part of the medium solid is directly recycled. The system comprises a raw ore preparation and drying part, a separation part and a medium purification circulation and density control part. By means of the full-size-fraction dry separation clean process and system, the coal-series coexisting and associated mineral of different large, medium and small particle sizes can be efficiently separated at the same time, and the problems that at present, in thedry separation field, the number of separated products is small, the concentrate quality is poor, the medium utilization rate is low and dust is excessively discharged are solved.

Owner:CHINA UNIV OF MINING & TECH

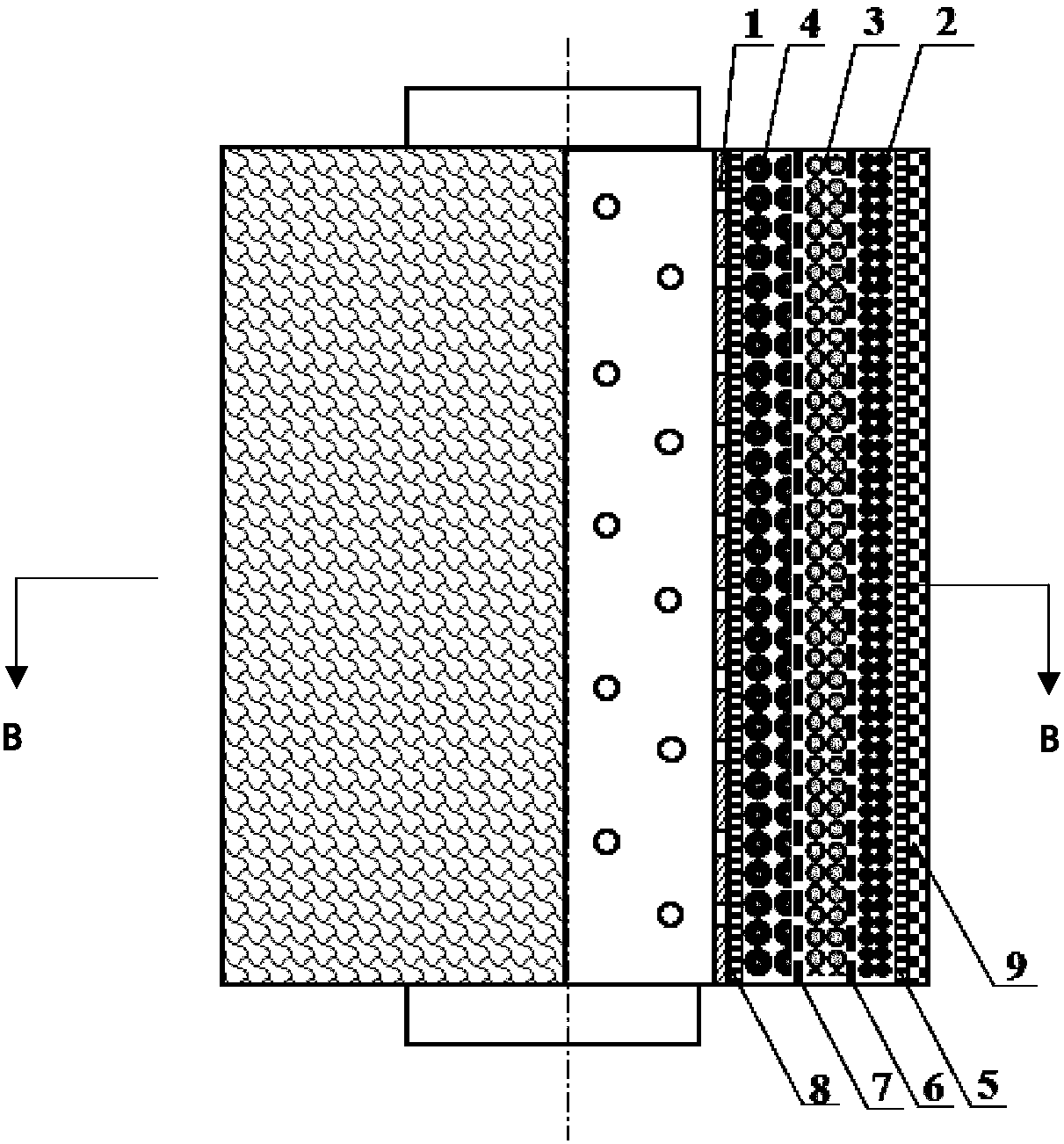

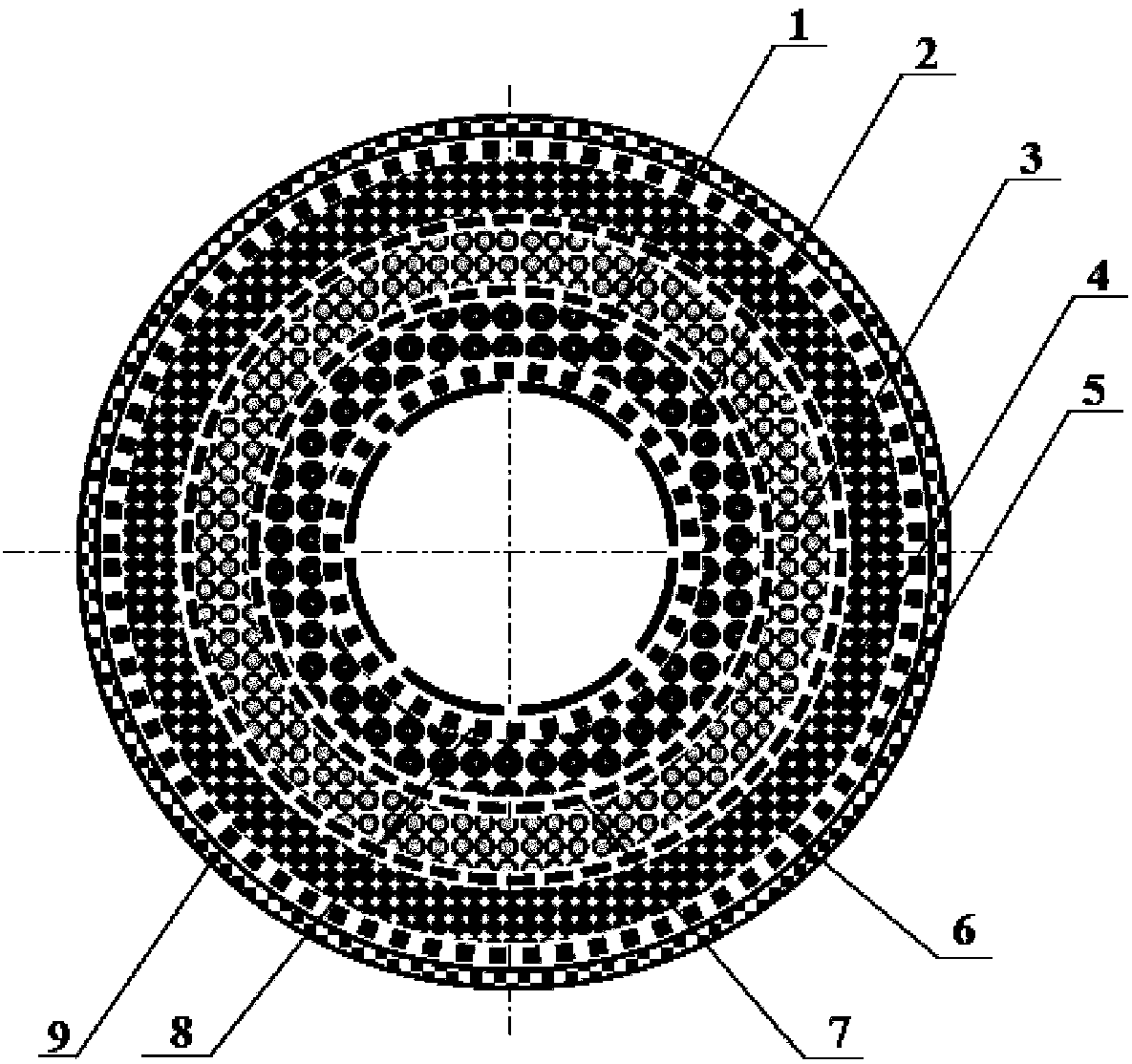

Multi-layer multi-size fraction composite prefilling sieve tube suitable for sand prevention of silty-fine sand

The invention relates to a multi-layer multi-size fraction composite prefilling sieve tube suitable for sand prevention of silty-fine sand. The multi-size fraction composite prefilling sieve tube suitable for the sand prevention of the silty-fine sand comprises a base tube, an internal wire winding layer, a multi-size fraction composite filling layer, an external wire winding layer and an externalprotection cover in sequence from inside to outside, wherein the outer surface of the base tube is sleeved with the internal wire winding layer, the outer portion of the internal wire winding layer is sleeved with the multi-size fraction composite filling layer, the multi-size fraction composite filling layer is composed of three layers, gravels fill the gaps between the layers, the thickness ofeach layer is different from that of other layers, and the grain sizes of the gravels of different gaps between different layers are different; the outer portion of the multi-size fraction composite filling layer is sleeved with the external wire winding layer, and the external protection cover serves as the outermost layer. Compared with existing methods of gavel filling sand prevention and mechanical sieve tube sand prevention, the multi-layer multi-size fraction composite prefilling sieve tube has the advantages that the sand prevention layer is thick, the useful life is long, the sand prevention layer function and the circulation function can both provided, and the sand prevention effect and oil-gas well high yield are kept. The multi-layer multi-size fraction composite prefilling sieve tube suitable for the sand prevention of the silty-fine sand is suitable for the sand prevention of petroleum, natural gas and natural gas hydrate silty-fine sand.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

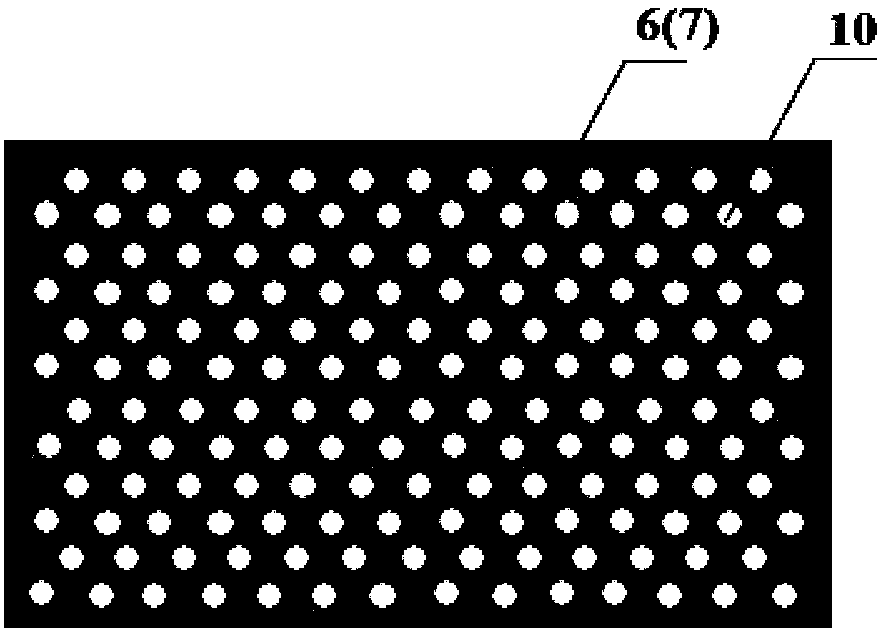

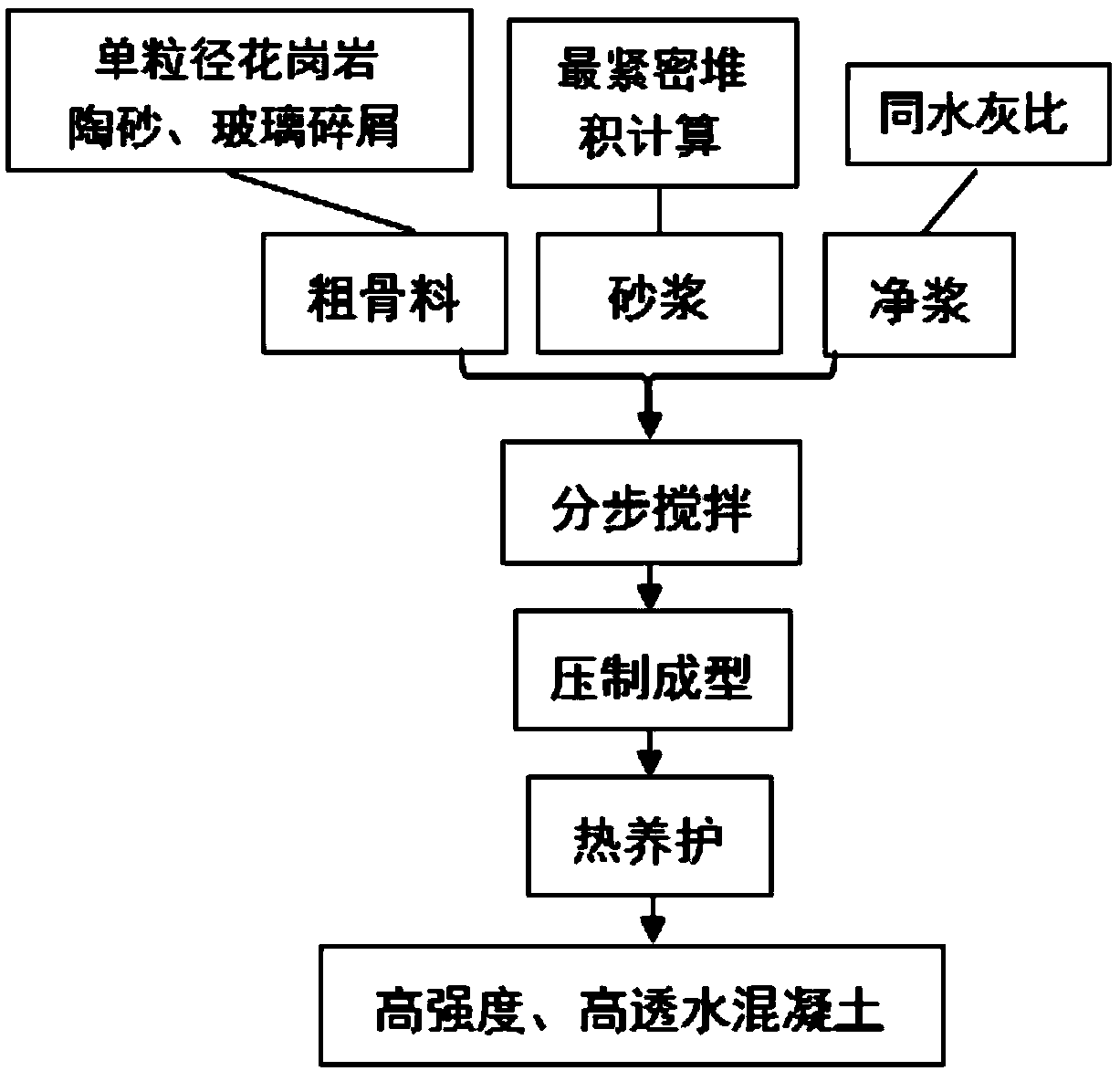

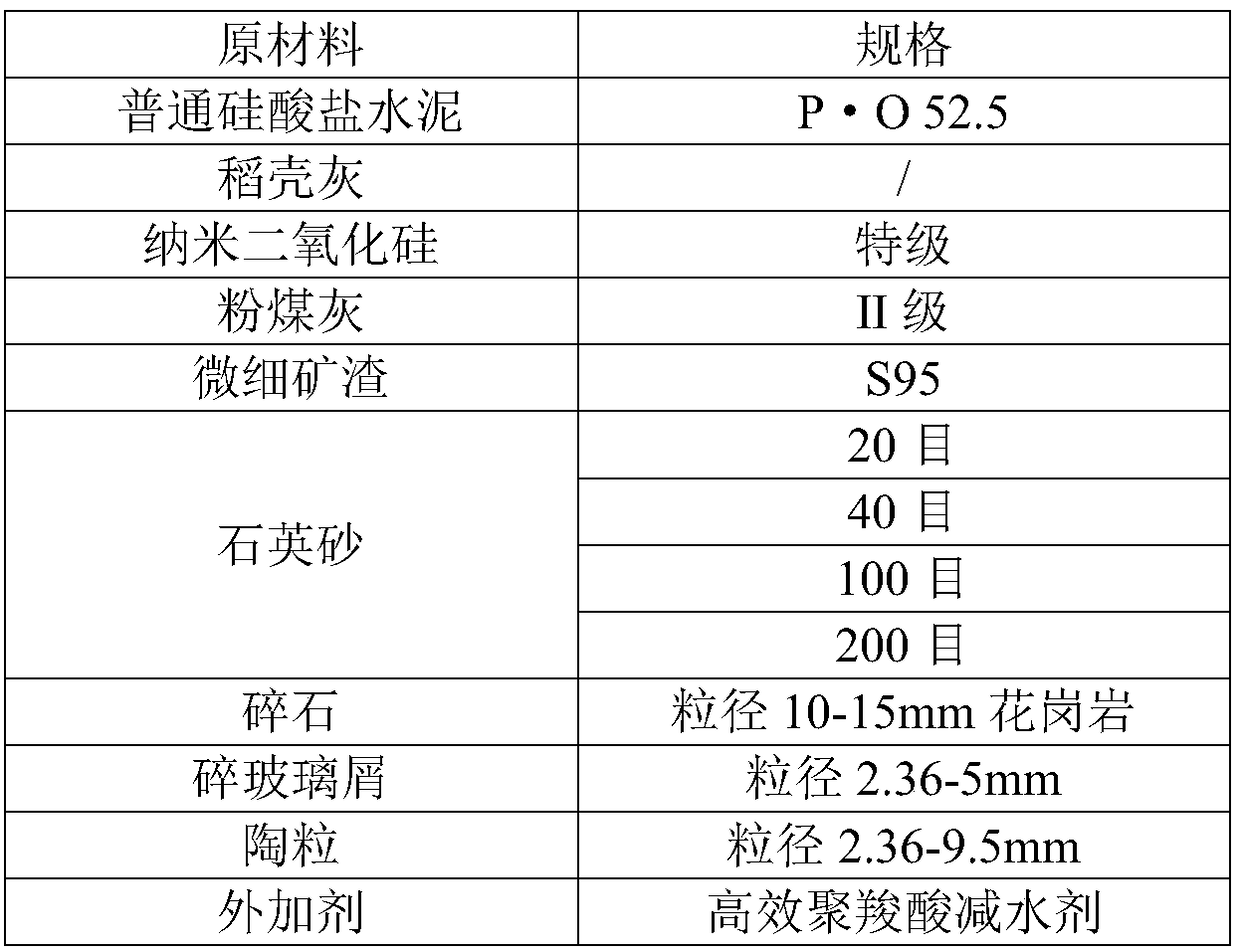

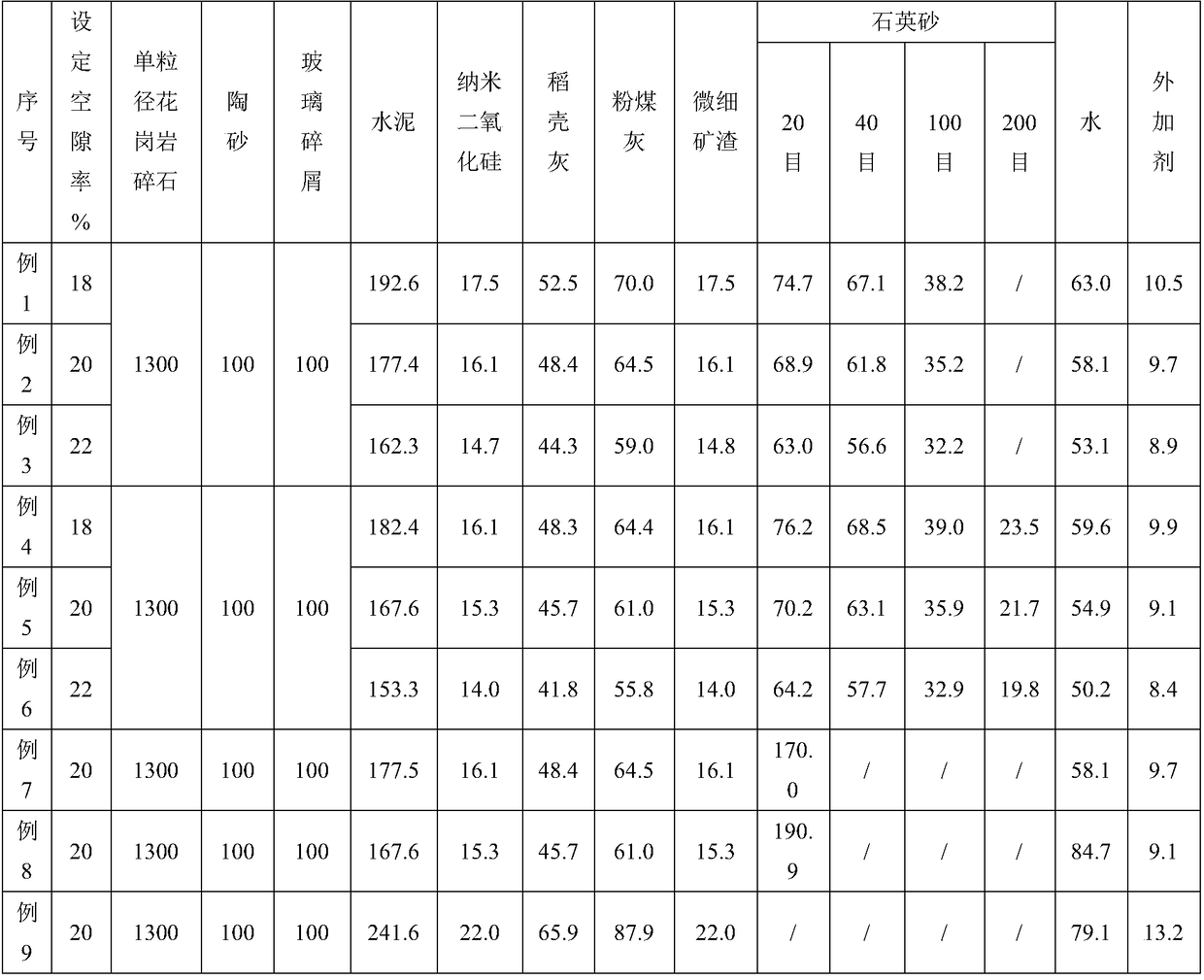

Preparation method for high-strength high-permeability concrete

The invention relates to a preparation method for high-strength high-permeability concrete, and belongs to the technical field of road laying materials. The high-strength high-permeability concrete comprises the following raw materials in parts by weight: 1400-1600 parts of coarse aggregate, 150-210 parts of cement, 40-50 parts of rice hull ash, 10-20 parts of nano silicon dioxide, 50-70 parts ofcoal ash, 10-20 parts of fine slag, 150-210 parts of continuous grain size quartz sand, 45-65 parts of water, and 8-11 parts of a high-efficient water reducing agent, wherein the composition of the coarse aggregate is as follows: a proportion of single-grain-size granite gravels which have the framework support effect is 80%-90%, ceramsite with 2.36-9.5 mm of a size fraction which is capable of improving an internal maintenance environment is 5%-10%, and 2.36-4.75 mm of glass chips which are capable of increasing a bridging number between permeable concrete gravel bonding points are 5%-10%. After most compact slurry is formed, a mix proportion design for the permeable concrete is performed with the coarse aggregate under the guidance of an extra coefficient, so 28d compressive strength ofa prepared permeable concrete finished product is greater than 30 MPa on the basis of guaranteeing large permeability performance. The prepared permeable concrete has the excellent performance, and has the considerable economical and practical effect and promotional value.

Owner:CENT SOUTH UNIV +1

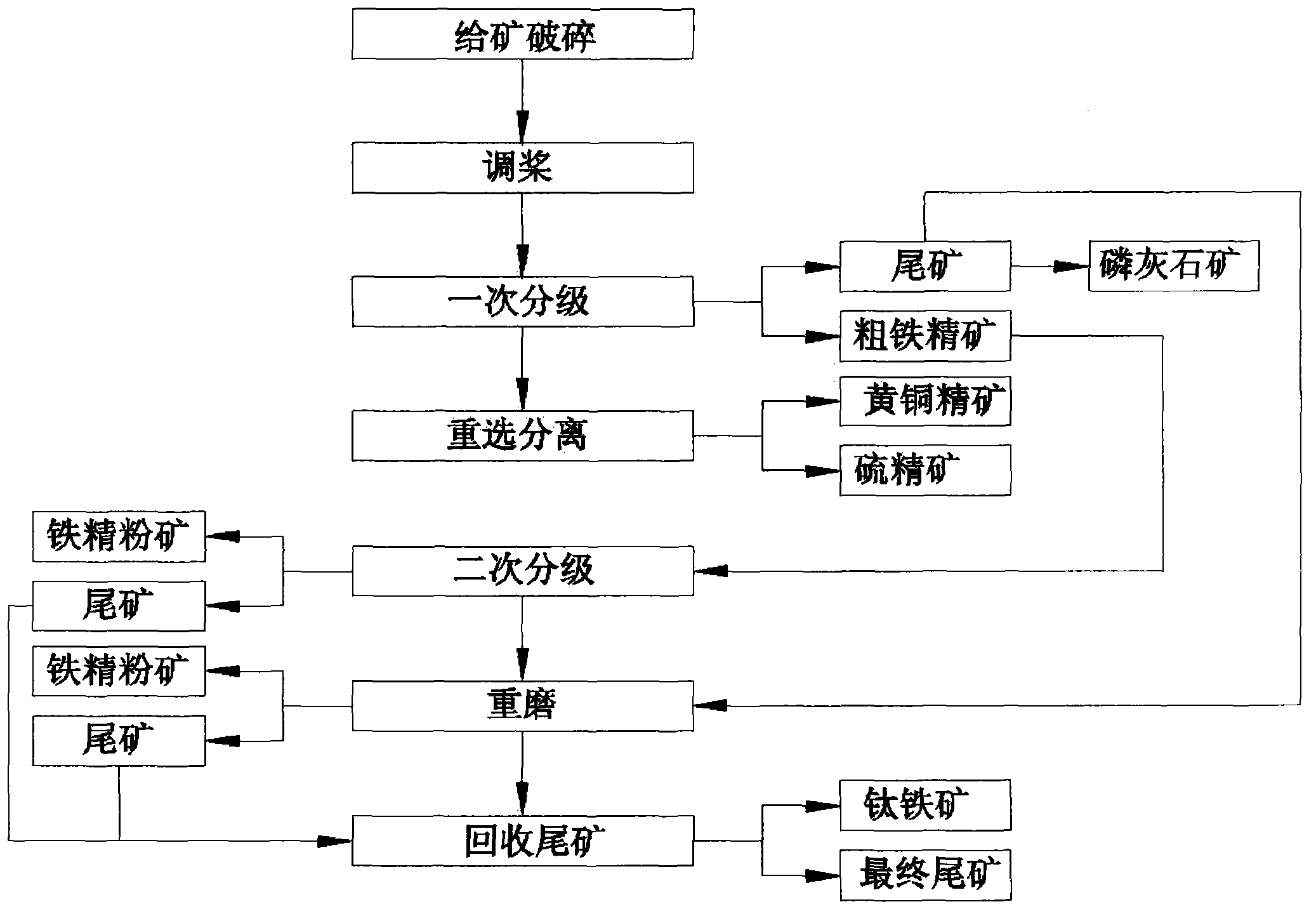

Novel mineral separation process for gravity separation of useful minerals such as magnetite, apatite, ilmenite and sulfide minerals and product

The invention discloses a novel mineral separation process for gravity separation of useful minerals such as magnetite, apatite, ilmenite and sulfide minerals and a product obtained by implementing the process. The product comprises powdered iron minerals, apatite concentrate, the ilmenite, brass concentrate and sulfur concentrate. The mineral separation process is simple, easy to implement, fine in mineral separation effect and high in working efficiency, sufficiently takes the advantage that the sulfide minerals can be sorted by recovering apatite agents, and the drawback of no recovery of the sulfide minerals in a traditional process is eliminated. The comprehensive utilization rate of resources is increased, useful resources are maximally recovered, the magnet grain size of ultra-low-grade magnetite is non-uniform, qualified concentrate can be separated according to gravity and timely extracted, energy waste due to the fact that qualified concentrate is outputted only when all materials are grinded to below a certain size fraction in the past is avoided, process flow is simplified, cost is reduced, the advantages of various devices are maximally taken, the resources are sufficiently used, and wide popularization and application are facilitated.

Owner:北京华夏建龙矿业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com