Full-size-fraction dry separation clean process and system for coal-series coexisting and associated mineral resources

A technology of mineral resources and full-grain classification, which is applied in the direction of wet separation, solid separation, chemical instruments and methods, etc., can solve the problems of deteriorating mineral interface properties, difficulty of sorting and purification, affecting product application efficiency, and increasing product moisture. Achieve promotion and application, significant social and environmental benefits, and solve the effect of less selected products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following, the present invention will be further described in detail by taking the coal series kaolin separation and purification process as an example in conjunction with the accompanying drawings and specific embodiments.

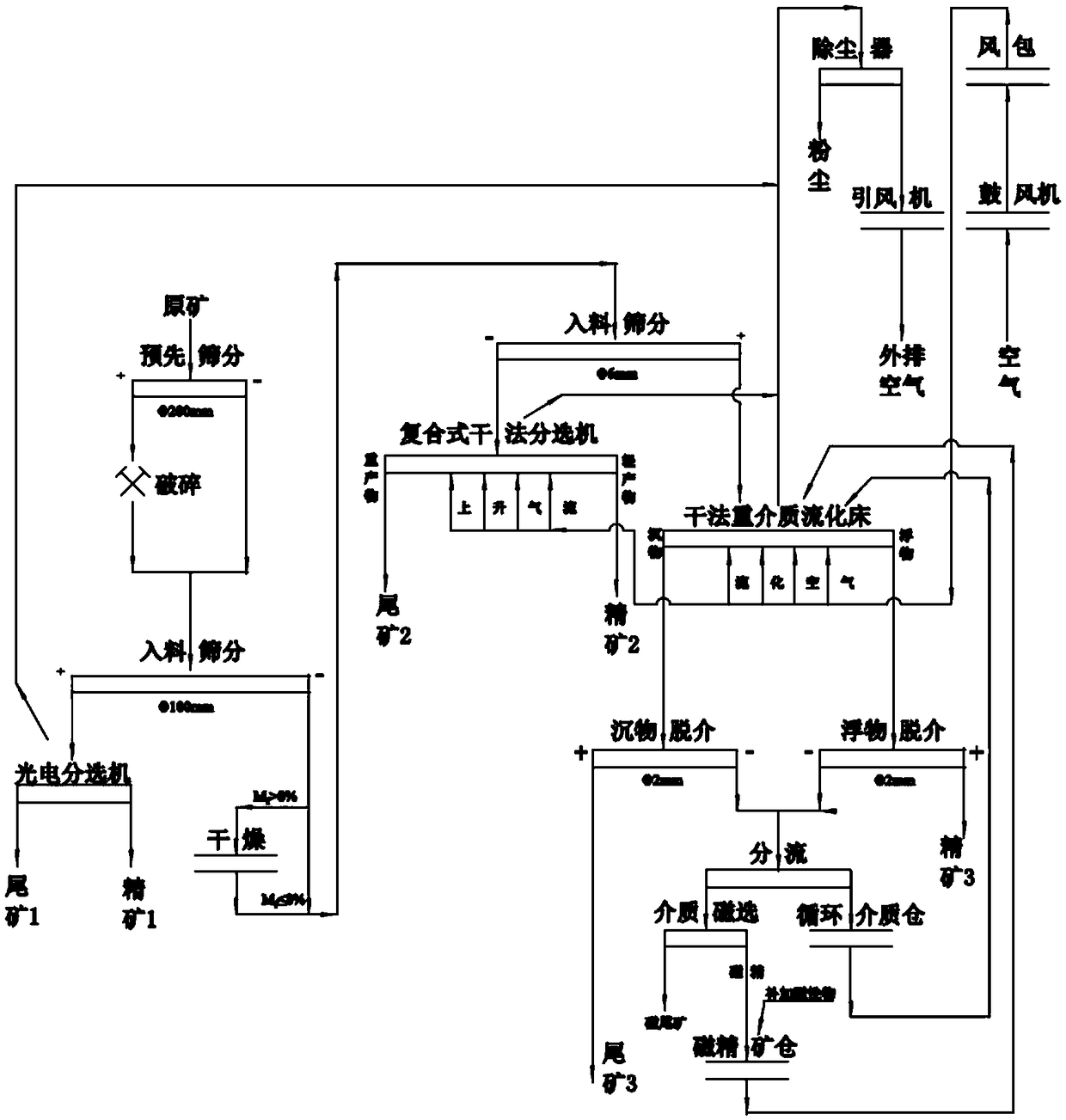

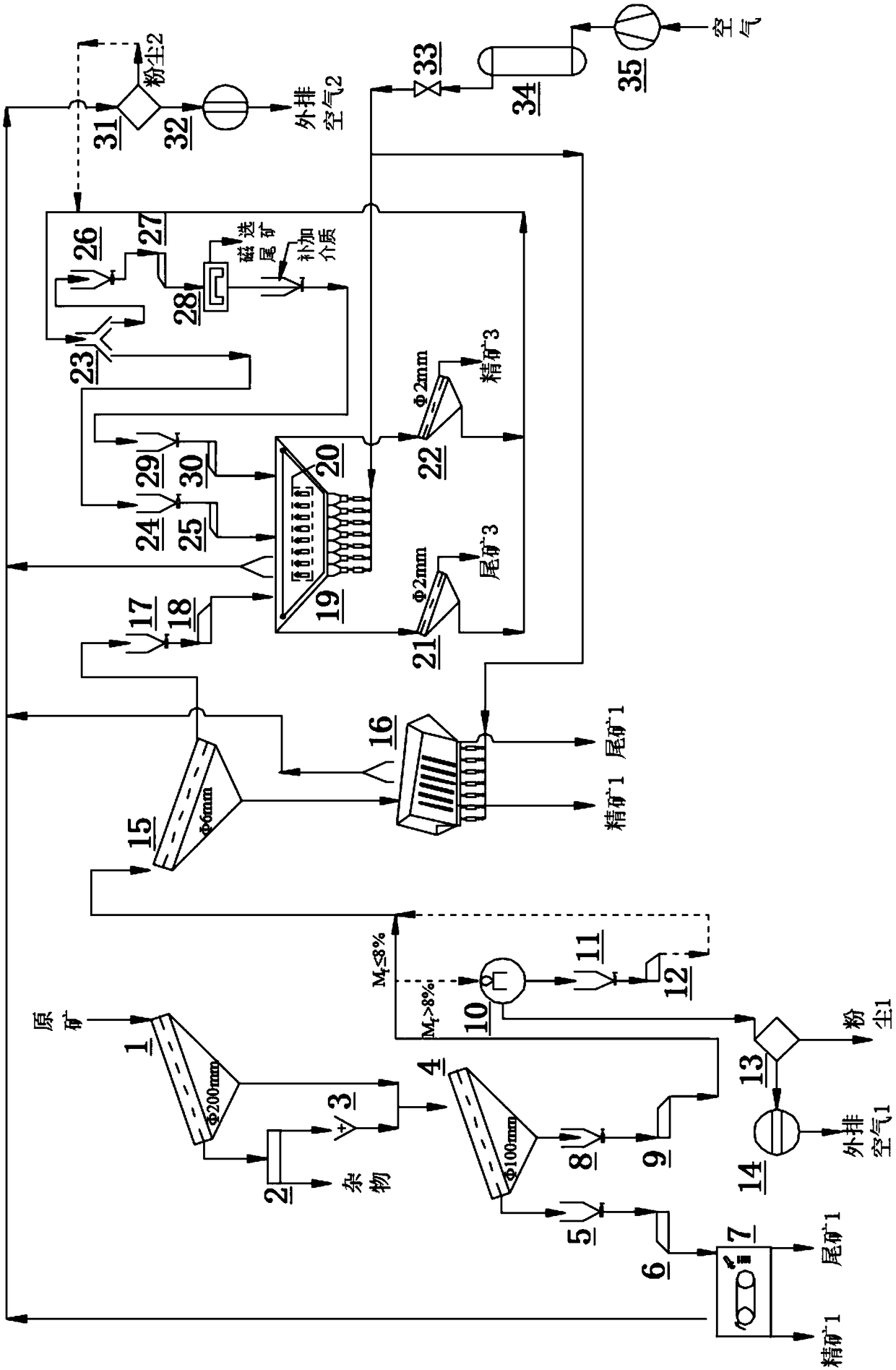

[0037] Such as figure 1 As shown, a kind of coal system associated mineral resources full-grain dry separation cleaning process of the present invention comprises the following steps:

[0038] (1) Raw ore preparation and drying: Coal-based kaolin raw ore transported from mines or storage yards is first graded through a grading sieve with an aperture of 200mm. 200mm kaolin raw ore is mixed and screened by a grading sieve with an aperture of 100mm; the oversized kaolin raw ore of 100-200mm is sent to a photoelectric separator for sorting, and the kaolin concentrate product 1 and kaolin tailings with a particle size of 100-200mm are discharged Mineral product 1; the undersieve is -100mm kaolin raw ore external moisture M f If it is higher tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com