Two-stage flotation process for low-grade mixed potassium salt

A potassium mixed salt, low-grade technology, applied in the field of potassium salt flotation, can solve the problem that the processing capacity cannot meet the ore output of potash mixed salt ore in salt fields, turn into langbeinite and anhydrous langbeinite, and potassium mixed salt flotation Solve problems such as separation difficulties, achieve the effect of improving process adaptability and reliability, good product quality, and improving K+ recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

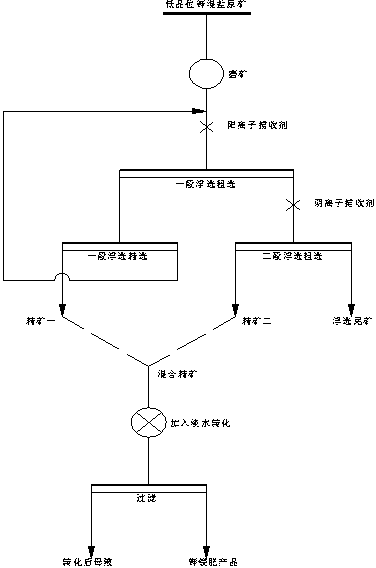

Image

Examples

Embodiment 1

[0021] This embodiment includes the following steps:

[0022] (1) will be composed as K + 4.23%, Na + 22.08%, Mg 2+ 3.57%, SO 4 2- 14.32%, Cl - 37.71% low-grade potash mixed salt raw ore, ground to -0.15mm particle size accounted for 64.90% of the mass content, to obtain pulp;

[0023] (2) Transfer the ore slurry obtained in step (1) to a flotation machine for one-stage flotation. The target minerals of the one-stage flotation are potassium chloride and kainite. The process flow is one rough and one fine. Collector CB-805 [3-hexadecyloxypropylamine hydrochloride, the molecular formula is C 16 h 33 —O—(CH 2 ) 3 NH 2 ·HCl] for pulping, the agent dosage is 120g / t raw ore, and the flotation time is 8min to obtain potassium chloride roughing concentrate (including kainite) and roughing pulp, and the obtained potassium chloride roughing concentrate (including potassium magnesia) and then selected, selected without adding drugs, flotation time 6min, to obtain potassiu...

Embodiment 2

[0029] This embodiment includes the following steps:

[0030] (1) will be composed as K + 4.23%, Na + 22.08%, Mg 2+ 3.57%, SO 4 2- 14.32%, Cl - The mass content of 37.71% low-grade potassium mixed salt grinding to -0.15mm particle size accounted for 65.87%, and the ore pulp was obtained;

[0031] (2) Transfer the ore slurry obtained in step (1) to a flotation machine for one-stage flotation. The target minerals of the one-stage flotation are potassium chloride and kainite. The process flow is one rough and one fine. Collector CB-805 [3-hexadecyloxypropylamine hydrochloride, the molecular formula is C 16 h 33 —O—(CH 2 ) 3 NH 2 ·HCl] for pulping, the agent dosage is 140g / t raw ore, and the flotation time is 7min to obtain potassium chloride roughing concentrate (including kainite) and roughing pulp, and the obtained potassium chloride roughing concentrate (including potassium magnesia) and then selected, selected without adding drugs, flotation time 5min, to obta...

Embodiment 3

[0037] This embodiment includes the following steps:

[0038] (1) will be composed as K + 4.23%, Na + 22.08%, Mg 2+ 3.57%, SO 4 2- 14.32%, Cl - 37.71% of the low-grade potassium mixed-salt raw ore was ground to -0.15mm particle size, accounting for 67.44%, and the pulp was obtained;

[0039] (2) Transfer the ore slurry obtained in step (1) to a flotation machine for one-stage flotation. The target minerals of the one-stage flotation are potassium chloride and kainite. The process flow is one rough and one fine. Collector CB-805 [3-hexadecyloxypropylamine hydrochloride, the molecular formula is C 16 h 33 —O—(CH 2 ) 3 NH 2 ·HCl] for pulping, the agent dosage is 160g / t raw ore, and the flotation time is 6min to obtain potassium chloride roughing concentrate (including kainite) and roughing pulp, and the obtained potassium chloride roughing concentrate (including potassium gallinite) and then selected, selected without adding drugs, flotation time 4min, to obtain p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com