Efficient beneficiation method for low-grade titanic magnetite hard to select and smelt

A technology of titanomagnetite and ore dressing method, which is applied in the field of high-efficiency ore dressing of low-grade refractory titanomagnetite, which can solve the problems of large iron metal loss, loss, and less tailings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

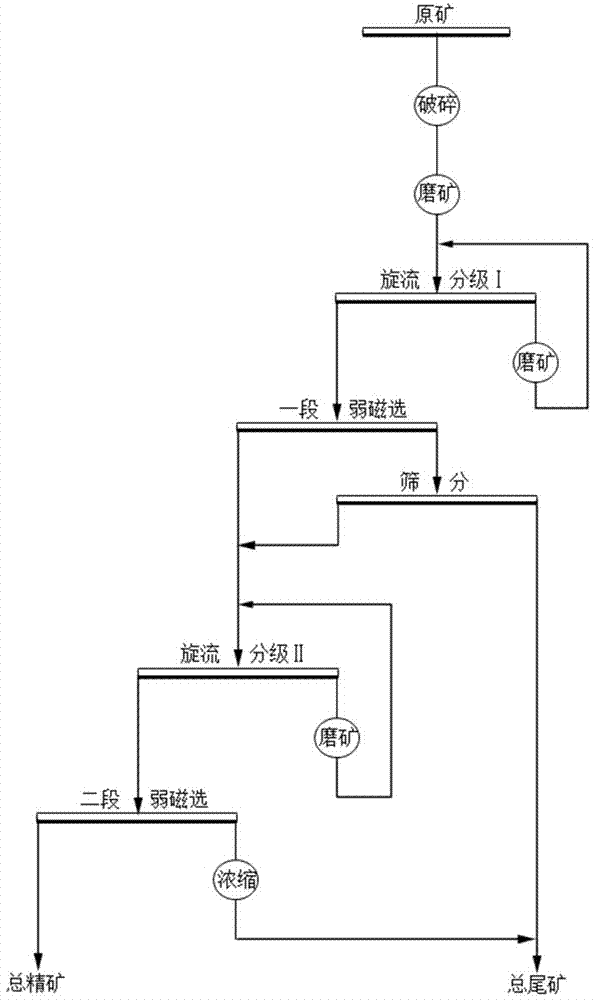

[0043] like figure 1 As shown, the raw ore iron grade of Yuhezhai Iron Mine is 19.29%, TiO 2 The grade is 5.03%, and the moisture content of the raw ore is 3.3%. The above-mentioned raw ore is selected according to the following steps:

[0044] S100: Crushing the raw ore above through a PE900×1200 jaw crusher to a particle size of -10mm;

[0045] S200: Put the crushed raw ore through φ5.5×1.8 semi-automatic closed-circuit wet grinding to obtain pulp with a fineness of -200 mesh accounting for more than 70% and a concentration of 30.5%. The pulp is classified by a φ350 hydrocyclone I to obtain a concentration For 17.4% fine grain overflow Ⅰ and coarse grain pulp Ⅰ, the coarse grain pulp Ⅰ is wet re-grinded by φ3.2×5.4 ball mill and then returned to φ350 hydrocyclone Ⅰ for classification;

[0046] S300: Pass fine particle overflow I through weak magnetic separation I with a magnetic induction intensity of 200mT to obtain iron concentrate slurry I and tailings slurry I with a ...

Embodiment 2

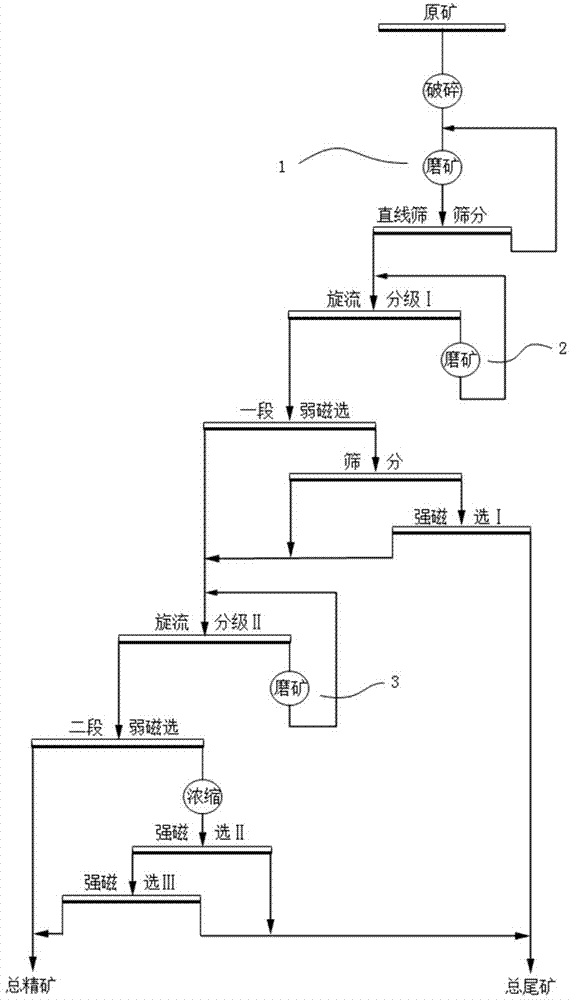

[0052] like figure 2 As shown, the raw ore iron grade of Yuhezhai Iron Mine is 21.37%, TiO 2 The grade is 4.95%, and the moisture content of the raw ore is 3.5%. The above-mentioned raw ore is selected according to the following steps:

[0053] S100: Crushing the raw ore above through a PE900×1200 jaw crusher to a particle size of -10mm;

[0054] S200: Put the crushed raw ore through φ5.5×1.8 semi-automatic closed-circuit wet grinding to obtain pulp with a fineness of -200 mesh accounting for more than 70% and a concentration of 32.8%. The pulp is classified by a φ350 hydrocyclone I to obtain a concentration For 18.3% fine grain overflow Ⅰ and coarse grain pulp Ⅰ, the coarse grain pulp Ⅰ is wet re-grinded by φ3.2×5.4 ball mill and then returned to φ350 hydrocyclone Ⅰ for classification;

[0055] S300: Pass fine particle overflow I through weak magnetic separation I with a magnetic induction intensity of 150mT to obtain iron concentrate slurry I and tailings slurry I with a...

Embodiment 3

[0062] like figure 2 As shown, the raw ore iron grade of Yuhezhai Iron Mine is 18.86%, TiO 2 The grade is 5.11%, and the moisture content of the raw ore is 3.2%. The above-mentioned raw ore is selected according to the following steps:

[0063] S100: Crushing the raw ore above through a PE900×1200 jaw crusher to a particle size of -10mm;

[0064] S210: Put the crushed raw ore through a φ5.5×1.8 semi-automatic closed-circuit wet grinding to obtain a pulp with a fineness of -200 mesh accounting for more than 50%;

[0065] S220: The ore pulp obtained by S210 grinding is screened by a linear sieve to obtain under-sieve pulp and over-sieve coarse ore with a fineness of -200 mesh accounting for more than 70% and a concentration of 29.34%. 1.8 Semi-automatic closed circuit wet regrinding;

[0066] S230: Classify the under-screen pulp through φ350 hydrocyclone I to obtain fine particle overflow I and coarse pulp I with a concentration of 17.06%, and return the coarse pulp I to φ3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com