Patents

Literature

174results about How to "Improve beneficiation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

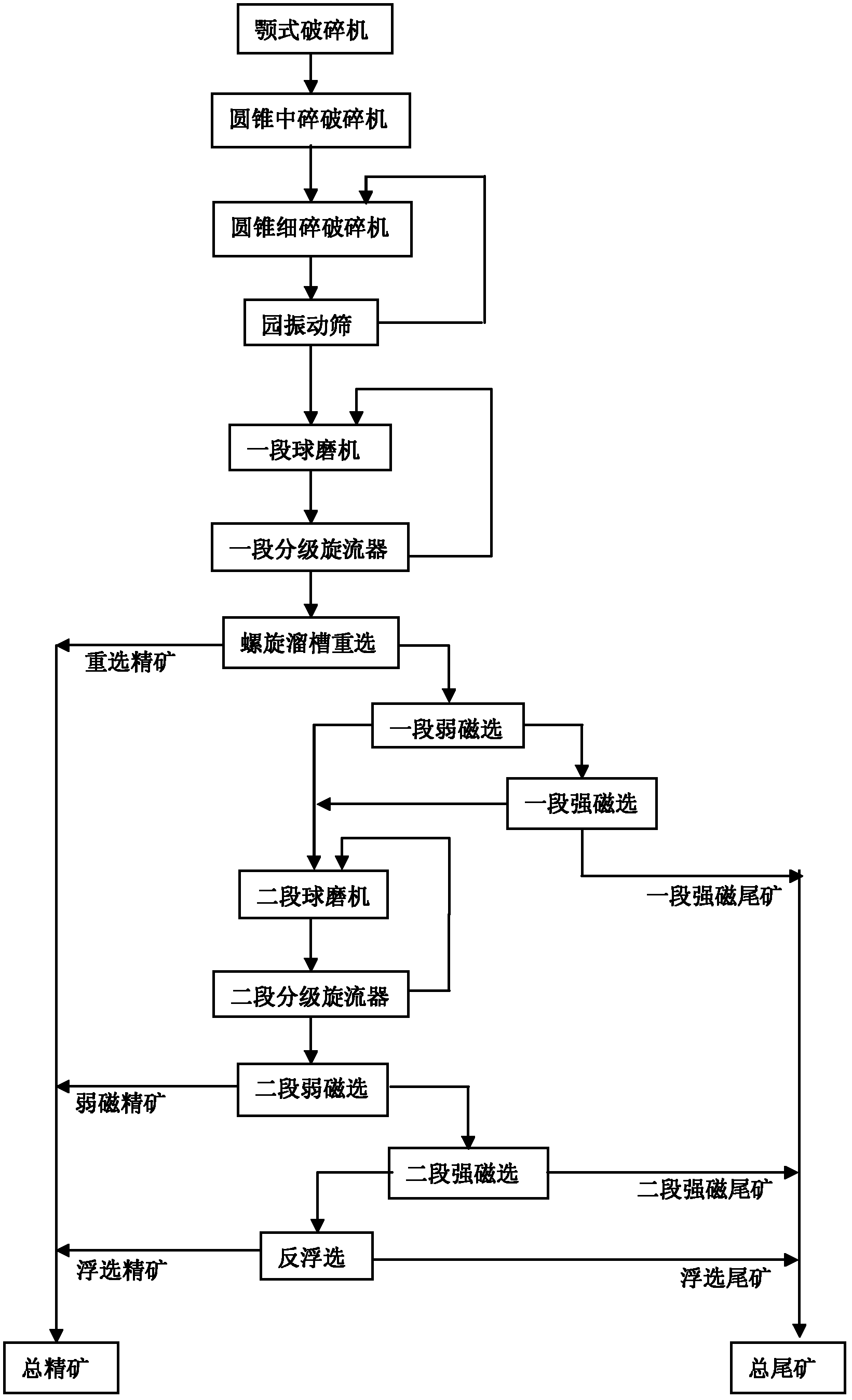

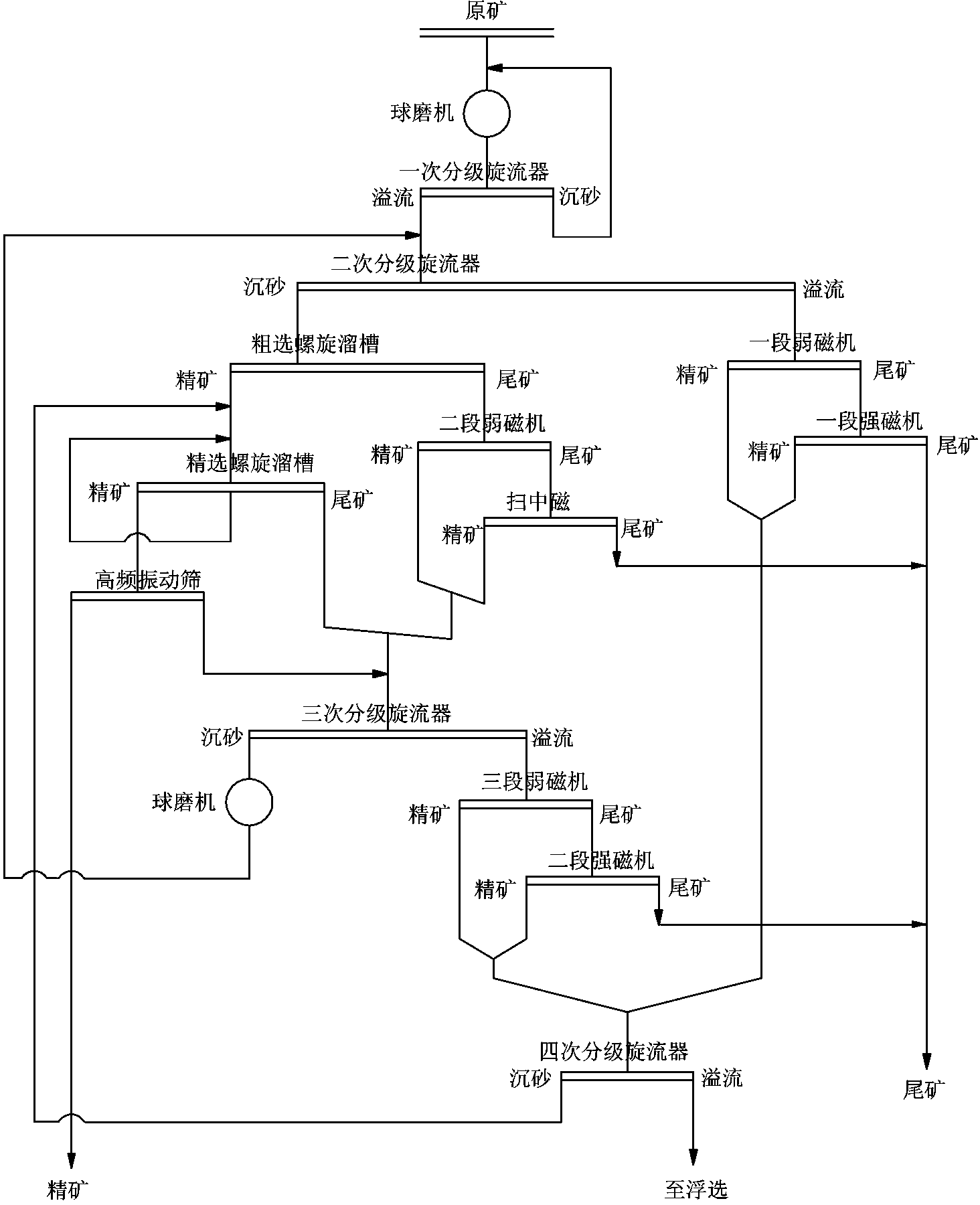

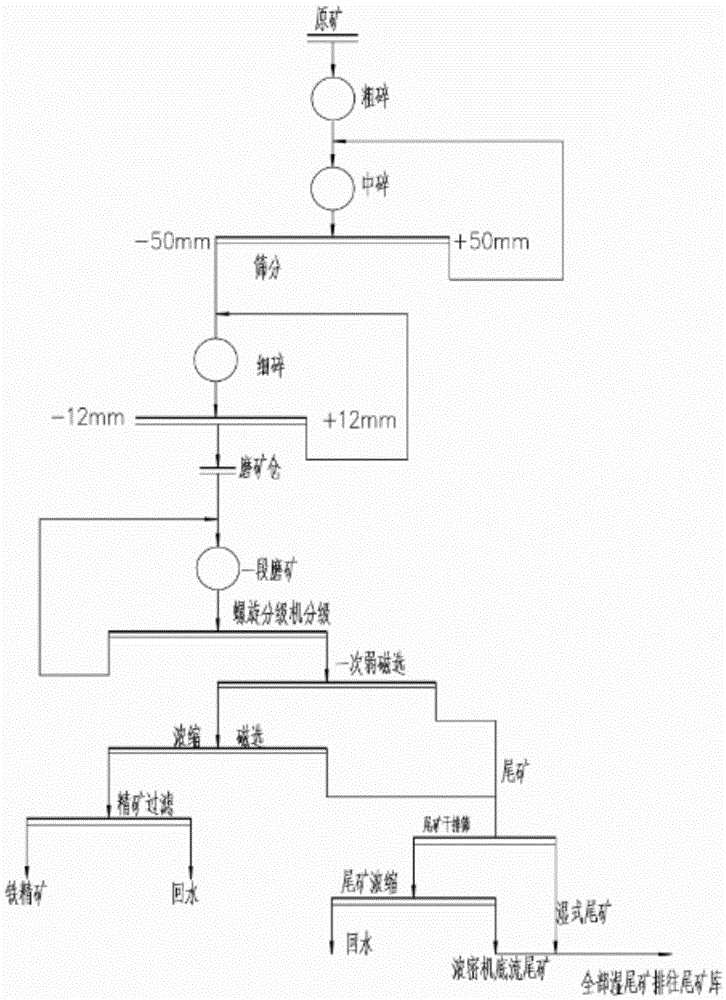

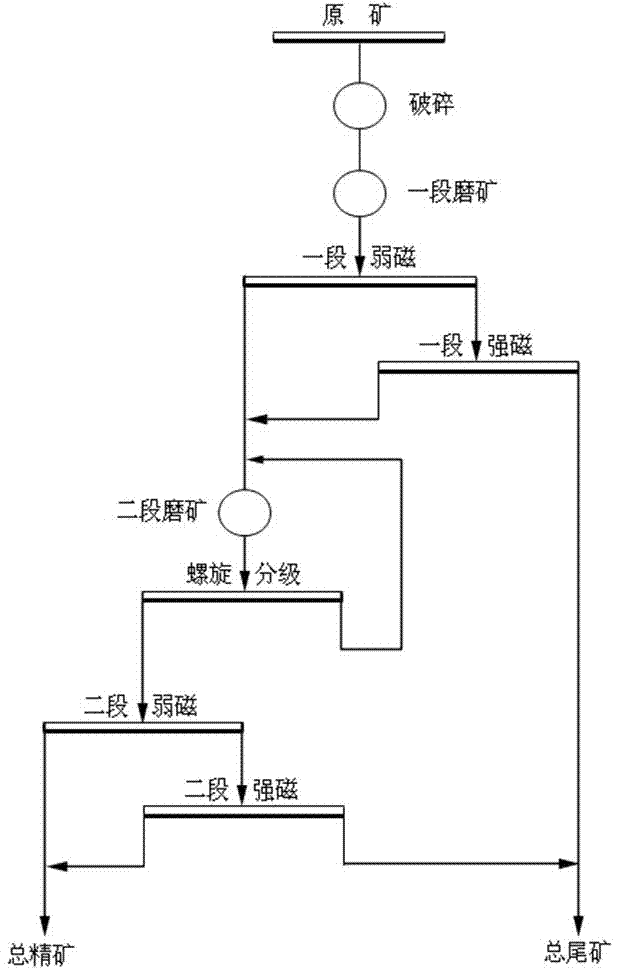

Beneficiation process of low-grade magnetite and specularite mixed ore

ActiveCN102205273AReduce loadReduce energy consumptionMagnetic separationMining engineeringMagnetite

The invention relates to the technical field of black metal ore exploitation and beneficiation, in particular to a beneficiation process of low-grade magnetite and specularite mixed ore, which is especially suitable for associated magnetite and specularite mixed ore of Zhouyoufang iron ore. The novel beneficiation process is realized according to an operation procedure and the process proceduressuch as ore crushing, one-stage grinding and grading, reselecting, one-stage weak magnetic separation, one-stage strong magnetic separation, two-stage grinding and grading (crude concentrate re-grinding), two-stage weak magnetic separation, two-stage strong magnetic separation, reverse floating and the like. The iron ore is comprehensively recycled, and a high-quality iron concentrate product is produced. The process has the characteristics of energy saving, high beneficiation efficiency and low beneficiation cost.

Owner:ANHUI JINRISHENG MINING

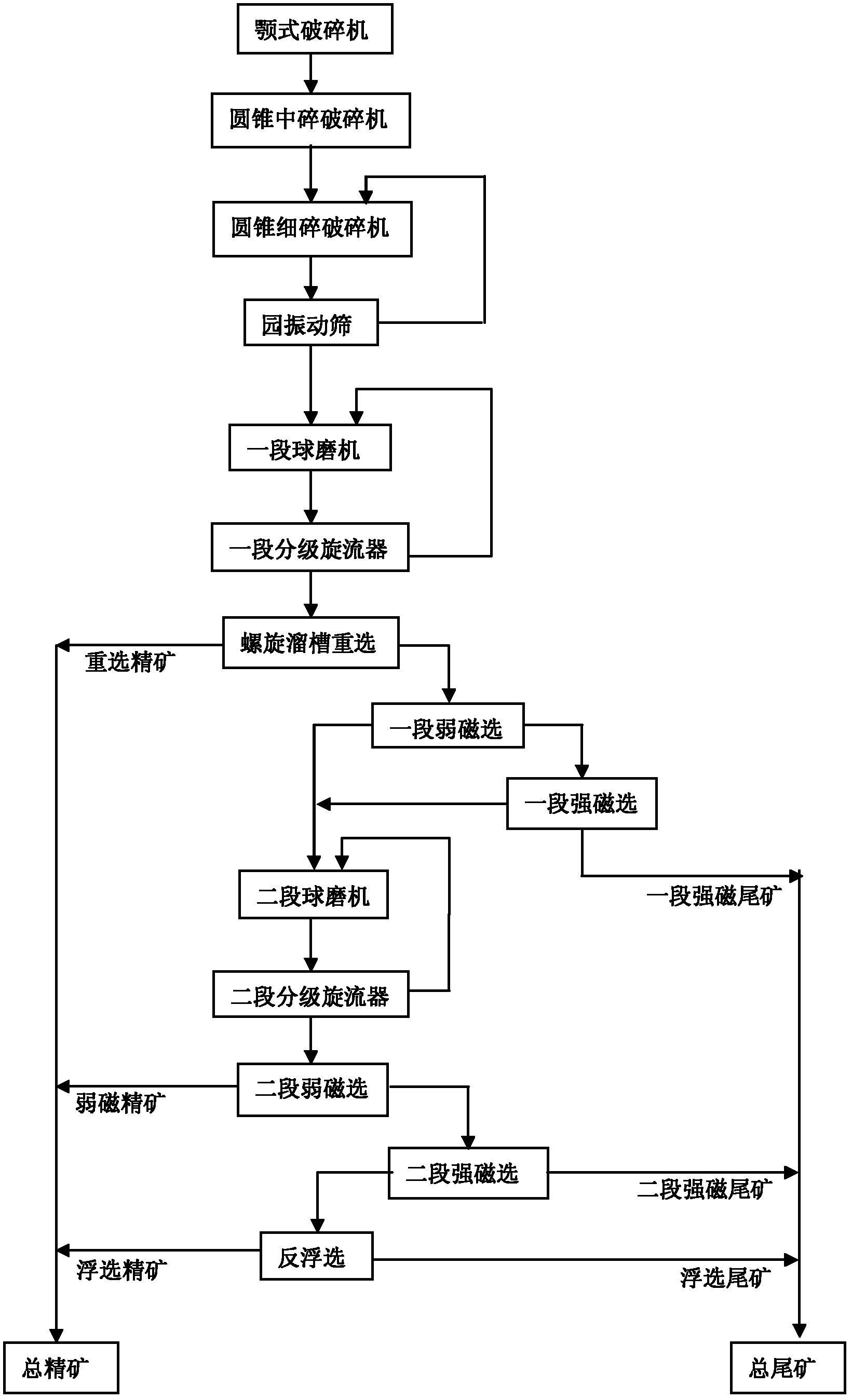

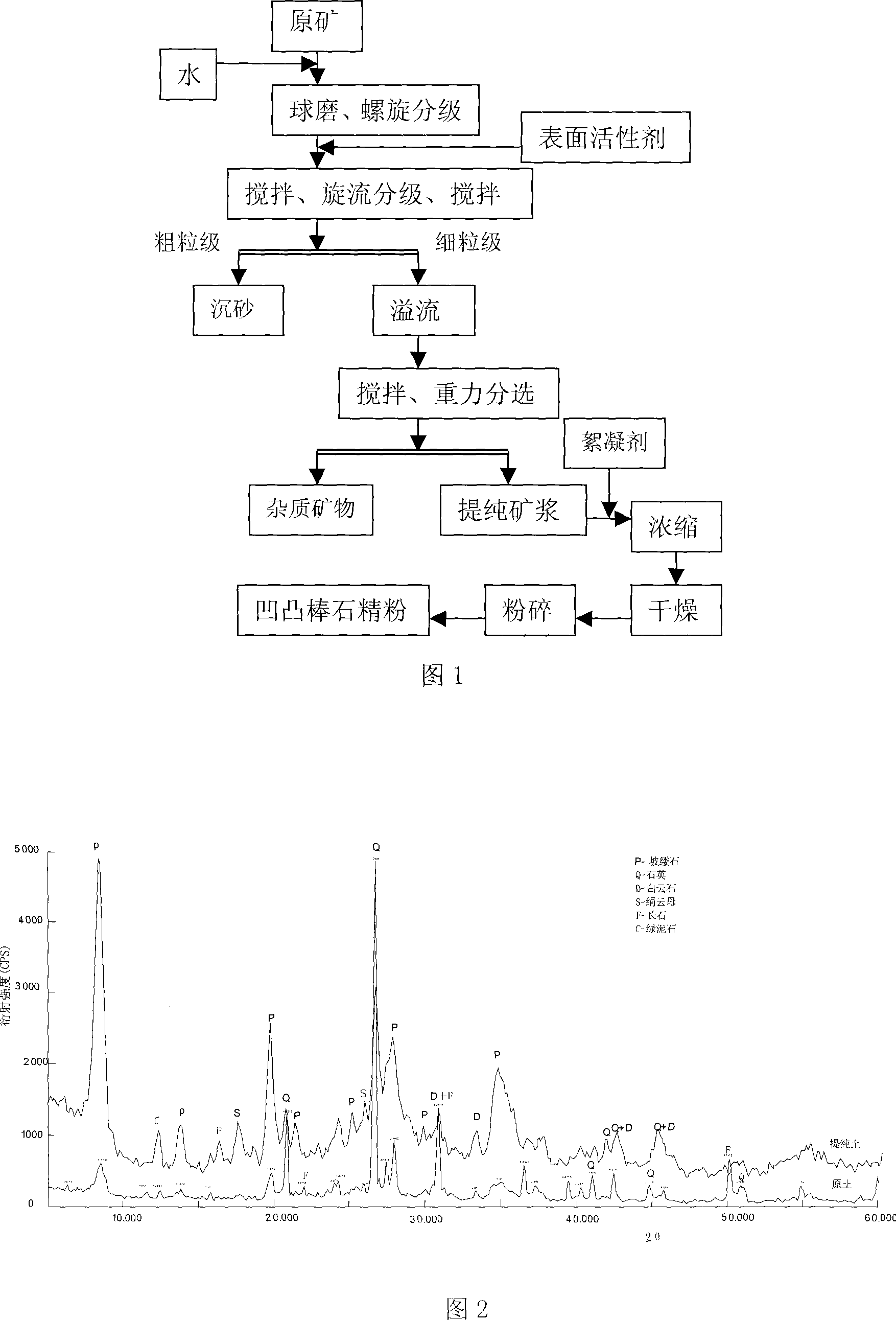

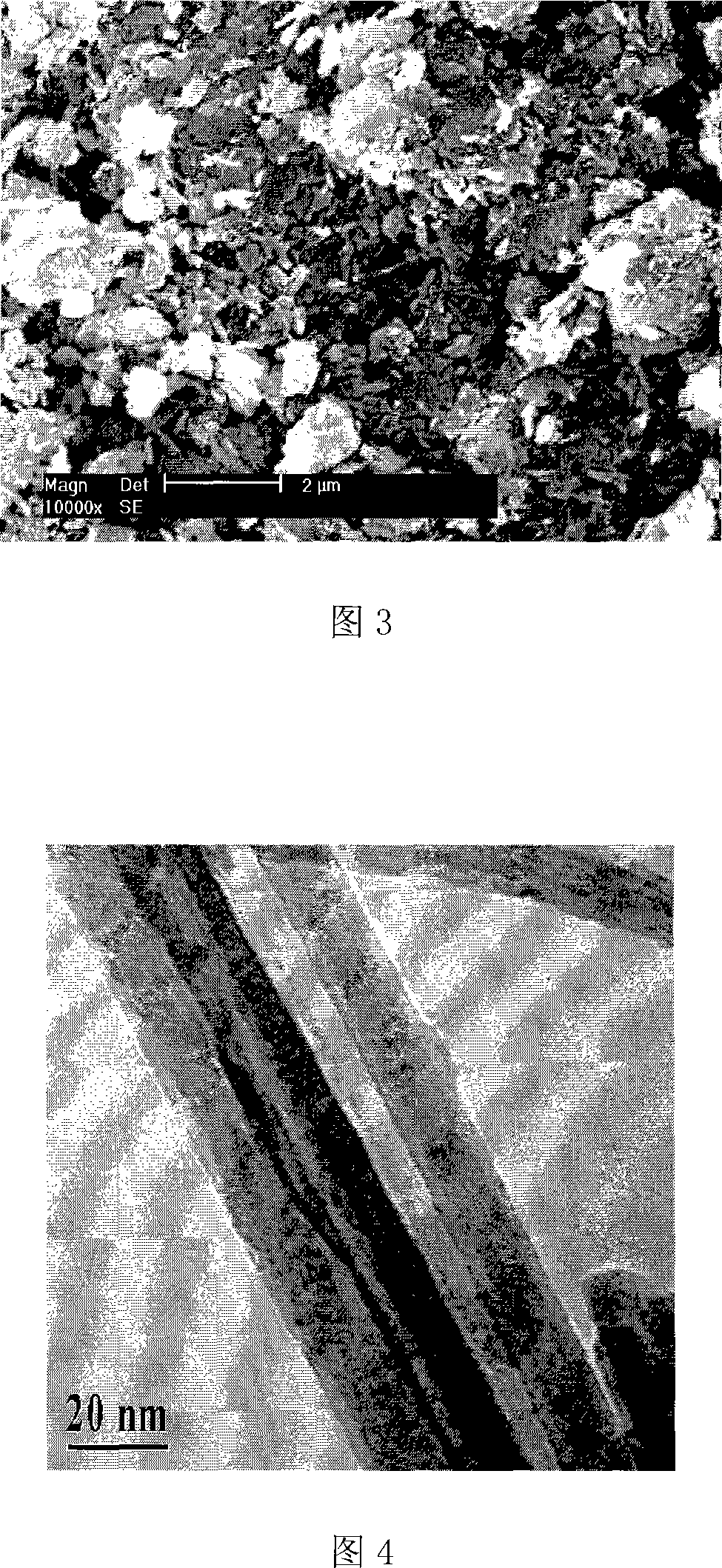

Method for purifying and processing attapulgite clay mineral

InactiveCN101214968AMeet the needs of industrial mineral processing and purificationEase of industrial productionEnergy inputSilicon compoundsSeparation factorClay minerals

The invention relates to a purifying and processing method of attapulgite clay minerals, which belongs to the technical field of the wet separating technique of minerals. The specific steps comprise utilizing spiral classifier for primary purification, utilizing cyclone classifier for secondary purification, employing gravity separation equipment for three-stage purification, concentration, drying and disintegration, thereby preparing ultrafine powders of the purified attapulgite clay minerals with the average particle size of 0.93-2.0 micron, and particle size of the largest particle is 3.5-5.0 micron. The method employs spiral classifier to remove the partly impure minerals with bigger particles in raw ores in advance, reinforcing the dispersion effect and the difference of suspension property of the attapulgites and impure minerals by means of surfactants, increasing separation factor, utilizing gravity separation equipment to separate the impure minerals and the attapulgite clay minerals efficiently, thereby overcoming the shortcomings that the prior art is difficult to achieve industrial production and obtain qualified purification products.

Owner:HEBEI UNIV OF TECH

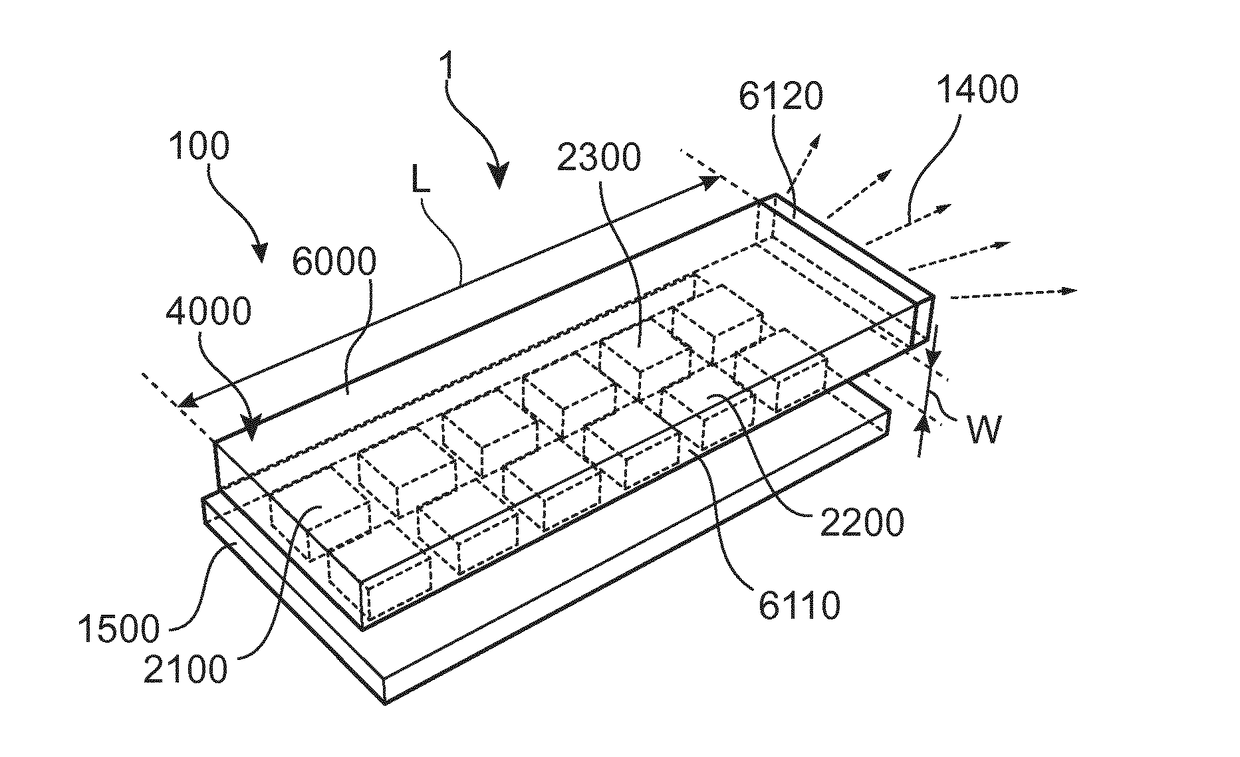

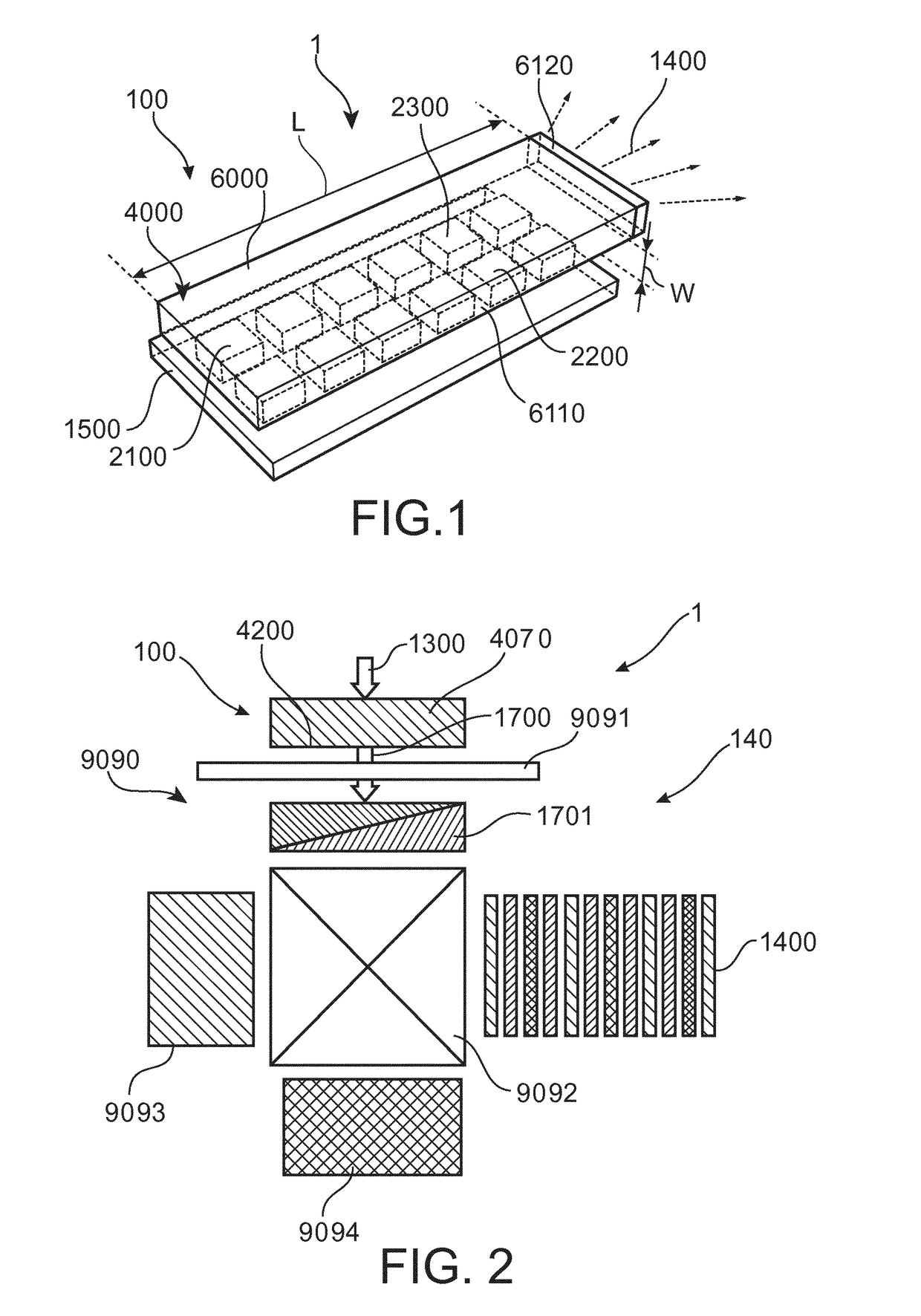

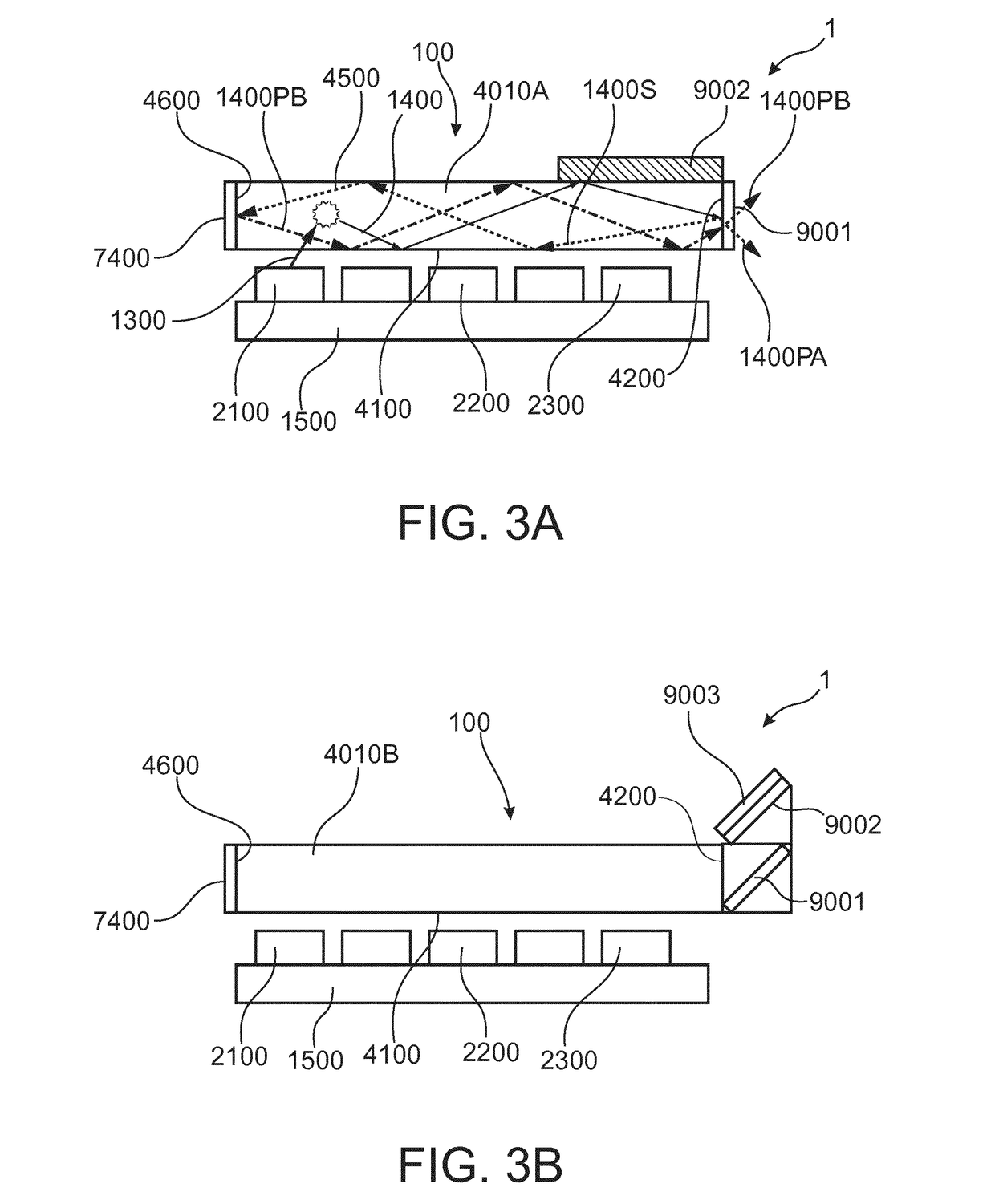

Luminescence concentrator with increased efficiency

ActiveUS20170139113A1Improve beneficiation efficiencyImprove efficiencyMechanical apparatusVehicle headlampsWaveguideLuminescence

The invention provides a device (1) comprising (i) a luminescent concentrator (100), the luminescent concentrator (100) comprising a waveguide (4000) having a radiation input face (4100), a radiation exit face (4200), and a width (W) defined by the radiation input face (4100) and an opposite face (4500), the waveguide (4000) comprising a radiation converter element (20) distributed in the waveguide (4000) with a converter concentration; (ii) a solid state light source (10) configured to irradiate the radiation input face (4100) of the waveguide (4000) with solid state light source radiation (11); wherein the radiation converter element (20) is configured to absorb at least part of the light source radiation (11) and to convert into radiation converter element radiation (21), and wherein the converter concentration is at least three times higher than necessary to absorb 98% of the light source radiation (11) over the width (W) of the waveguide (4000).

Owner:SIGNIFY HLDG BV

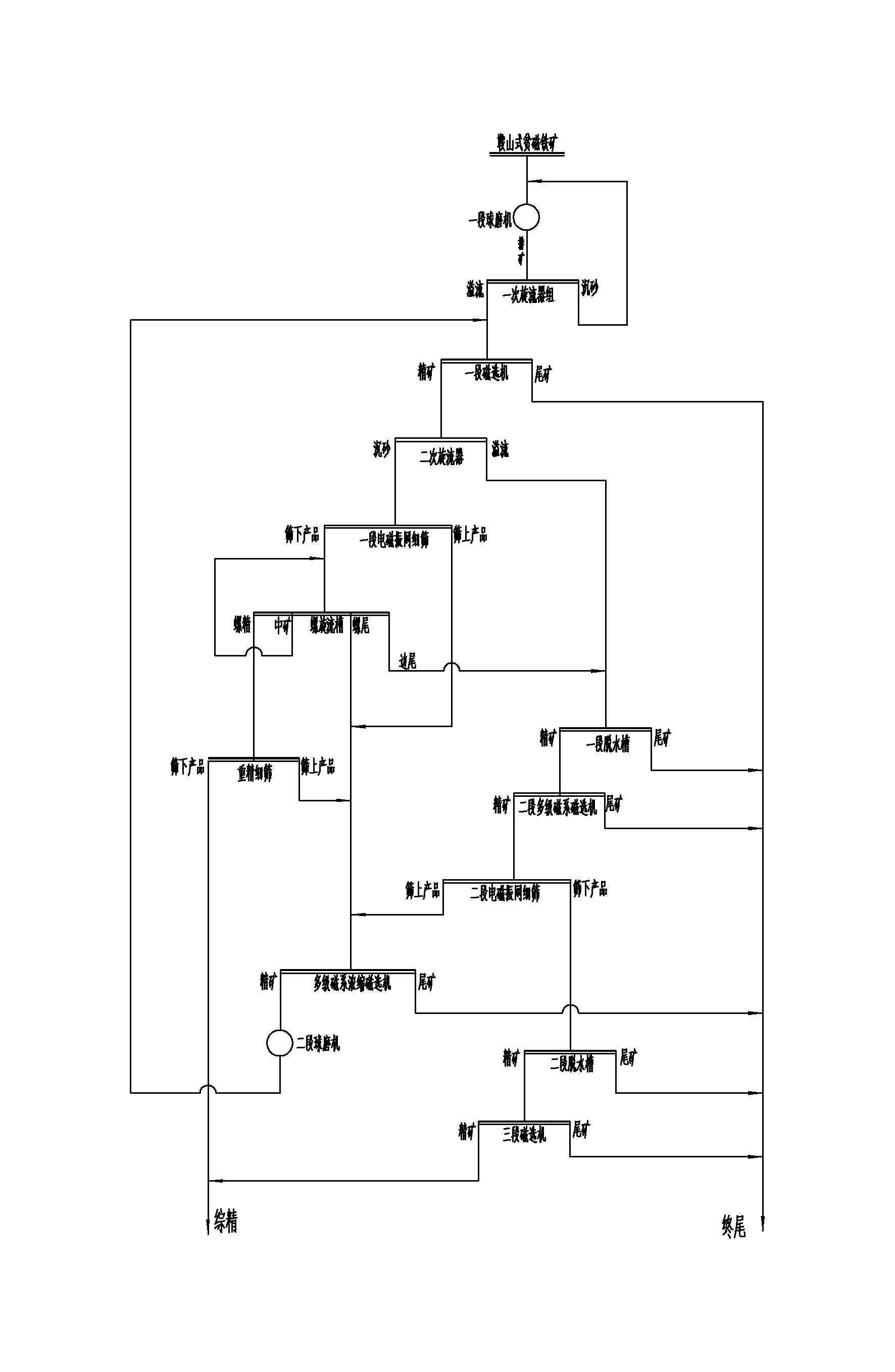

Magnetic-gravity separation technology for Anshan type lean magnetite

ActiveCN103272694AImprove mineral processing technical indicatorsGuaranteed GranularityMagnetic separationMagnetiteEngineering

The invention relates to a magnetic-gravity separation technology for Anshan type lean magnetite, which comprises the following steps: after adoption of a first-stage ball mill for ore grinding, a primary cyclone, a first-stage magnetic separator and a secondary cyclone for classification, settled sand is subjected to first-stage sieve screening, an screened product is fed into a spiral chute, concentrate in the spiral chute is fed into a gravity fine sieve, and a screened product by the gravity fine sieve is qualified concentrate; after overflow of the secondary cyclone and the edge tail of the spiral chute are merged, the concentrate is fed into a second-stage sieve after separation by a first-stage dehydration tank and a second-stage magnetic separator; products on the first-stage sieve, the second-stage sieve and the gravity fine sieve as well as mineral tailings in the spiral chute are merged and fed into a concentration magnetic separator, the mixture is fed into a second-stage ball mill for ore grinding after concentration, then the products return to the first-stage magnetic separator, and after separation by a second-stage dehydration tank and a third-stage magnetic separator, the screened product of the second-stage sieve is merged with the screened product of the gravity fine sieve into the final concentrate. The magnetic-gravity separation technology has the advantages that mineral processing technical indexes for the Anshan type lean magnetite are improved, the mineral processing efficiency is improved, and the production cost is reduced.

Owner:ANSTEEL GRP MINING CO LTD

Dry separation method of manganese carbonate ore

ActiveCN103639027AHigh recovery rateIdeal beneficiation technical indicatorsSievingScreeningBrickEconomic benefits

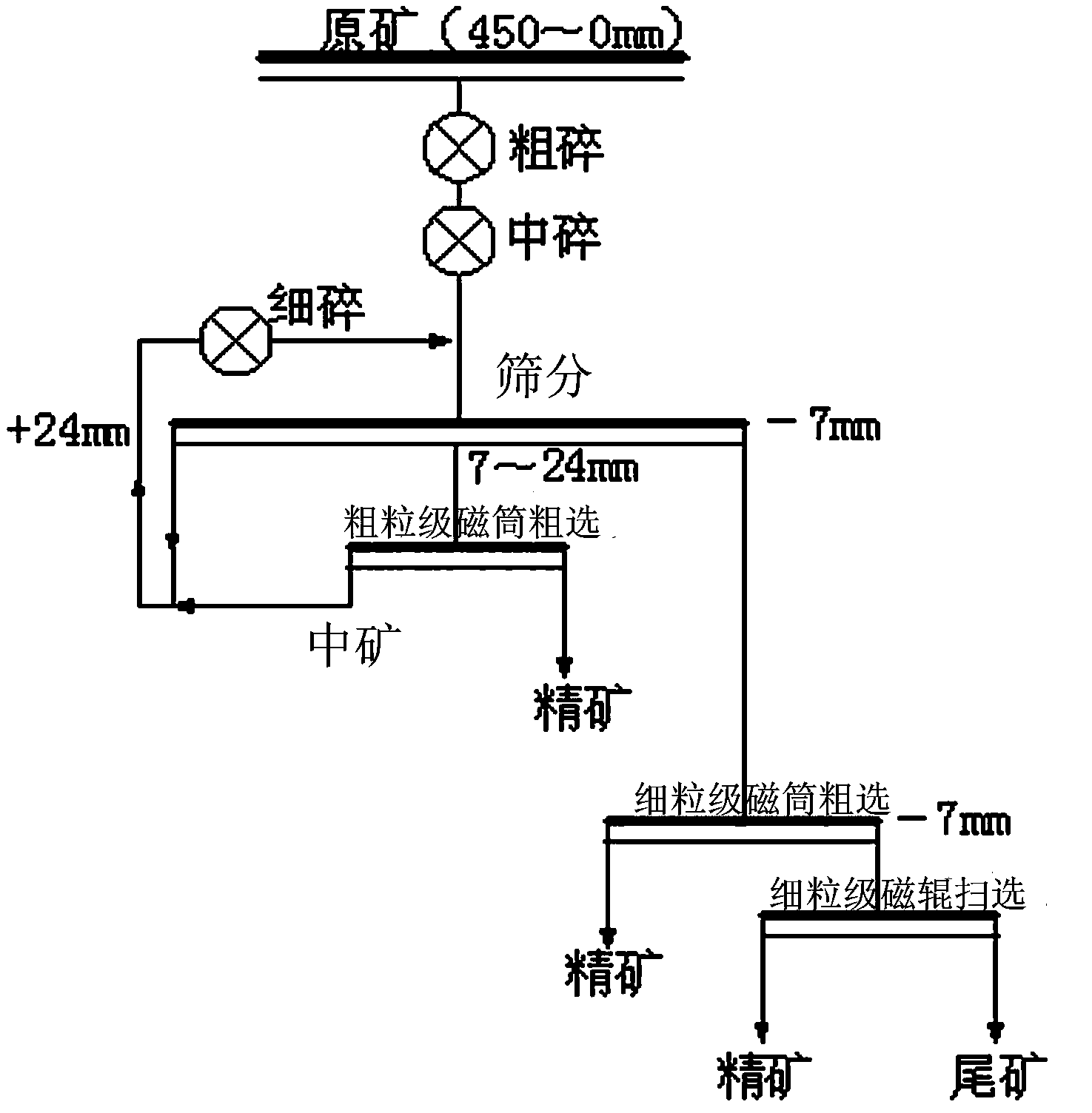

The invention discloses a dry separation method of manganese carbonate ore. The dry separation method comprises the following steps: feeding raw manganese carbonate ore into a crushing system for crushing; screening the crushed ore through a double-layer dry-type screening system; according to the screen hole size of the screening system, performing coarse-fraction magnetic separation on the screened ore through a coarse-fraction dry-type magnetic separation system to obtain coarse-fraction concentrate and middling, and performing fine-fraction magnetic separation on the screened ore through a fine-fraction dry-type magnetic separation system to obtain fine-fraction concentrate and tailings, wherein the obtained middling is returned to the crushing system. The dry separation method has the beneficial effects that (1) the process flow is simplified, the ore separation efficiency is improved, and the recovery rate of manganese ore is improved; (2) on the basis of cost reduction, the grading index of concentrate grade is not reduced; (3) energy is saved, consumption is reduced, clean production is realized, and economic benefits are improved; (4) overflowing is avoided, the storage capacity pressure of a tailings pond can be released fundamentally, and meanwhile, final manganese carbonate tailings (waste sands) can be applied to paving or brick-making after being treated.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

Method for recycling metal iron from steel slag of converter

ActiveCN102688804AHigh recovery rateImprove product qualityRecycling and recovery technologiesMagnetic separationSlagIron industry

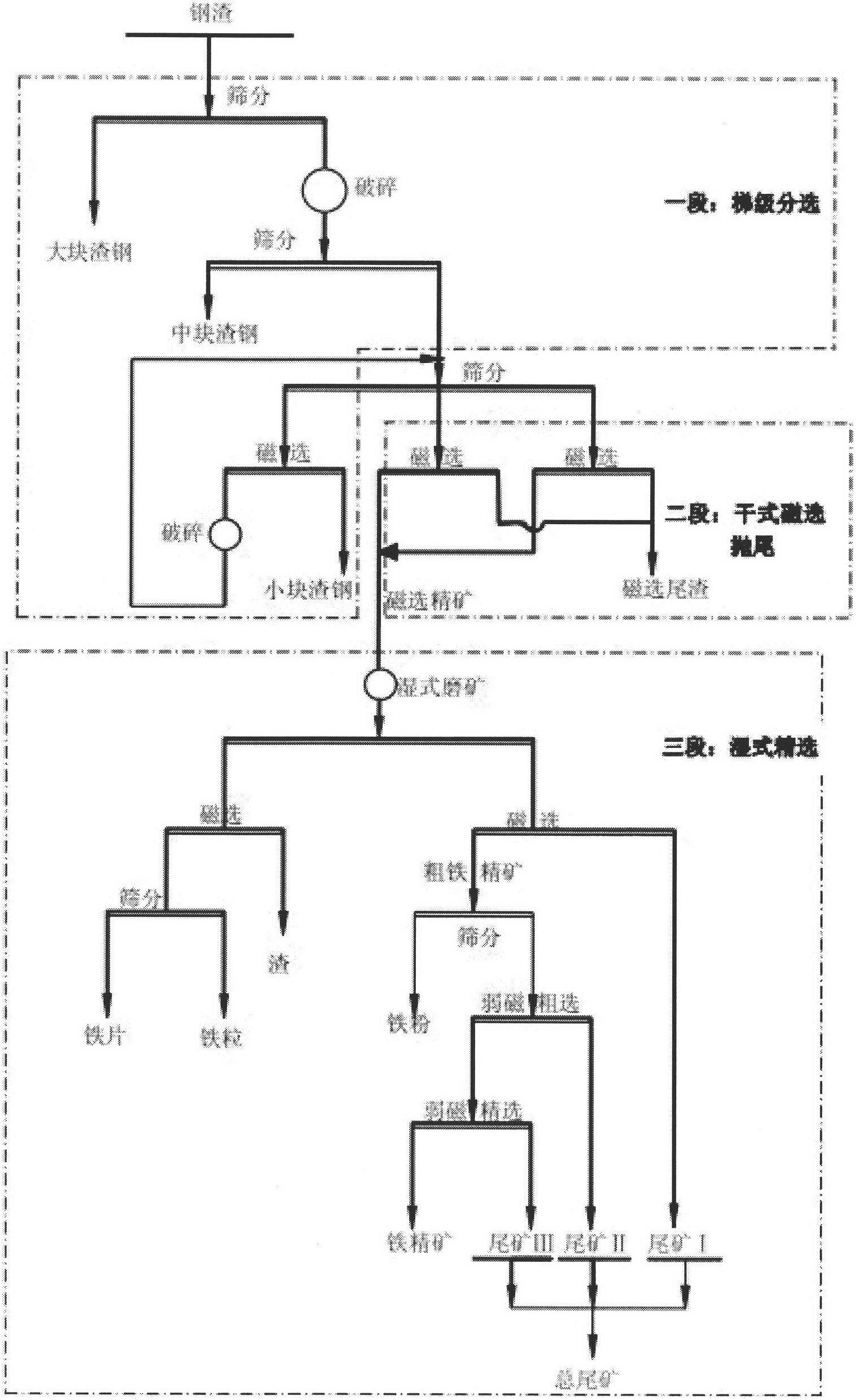

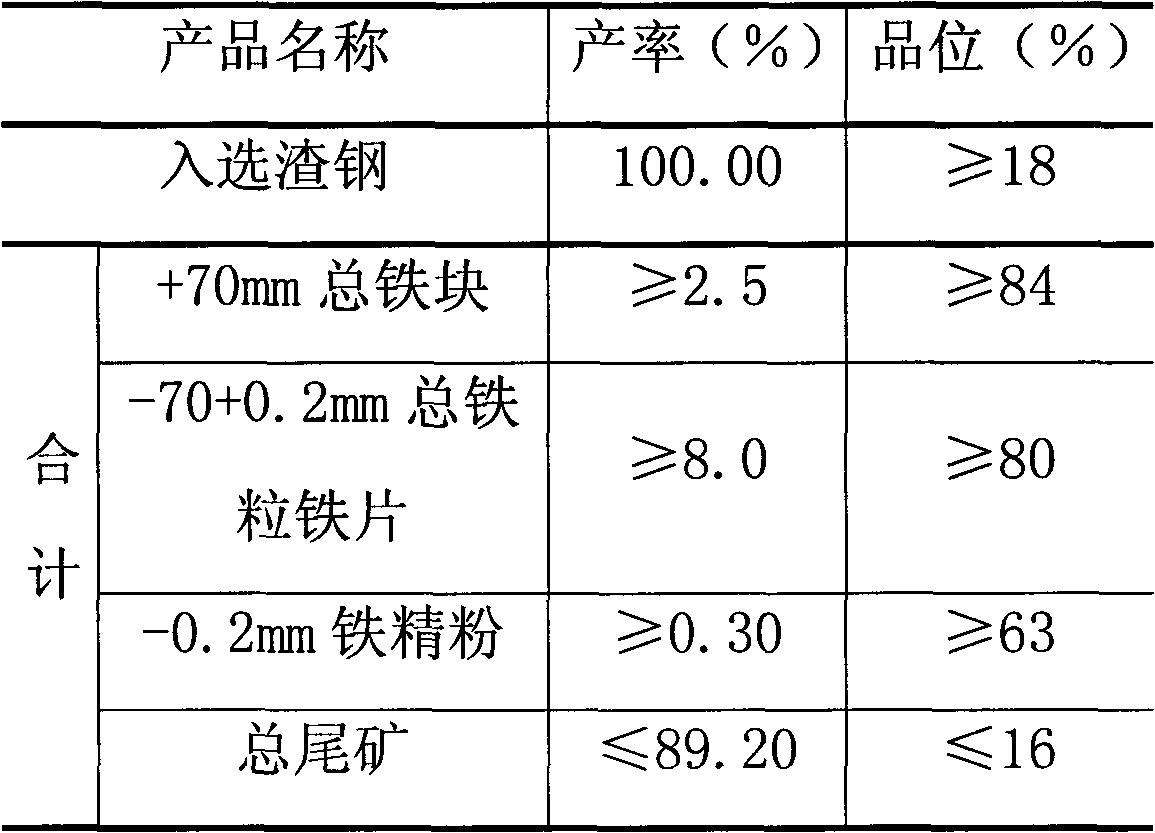

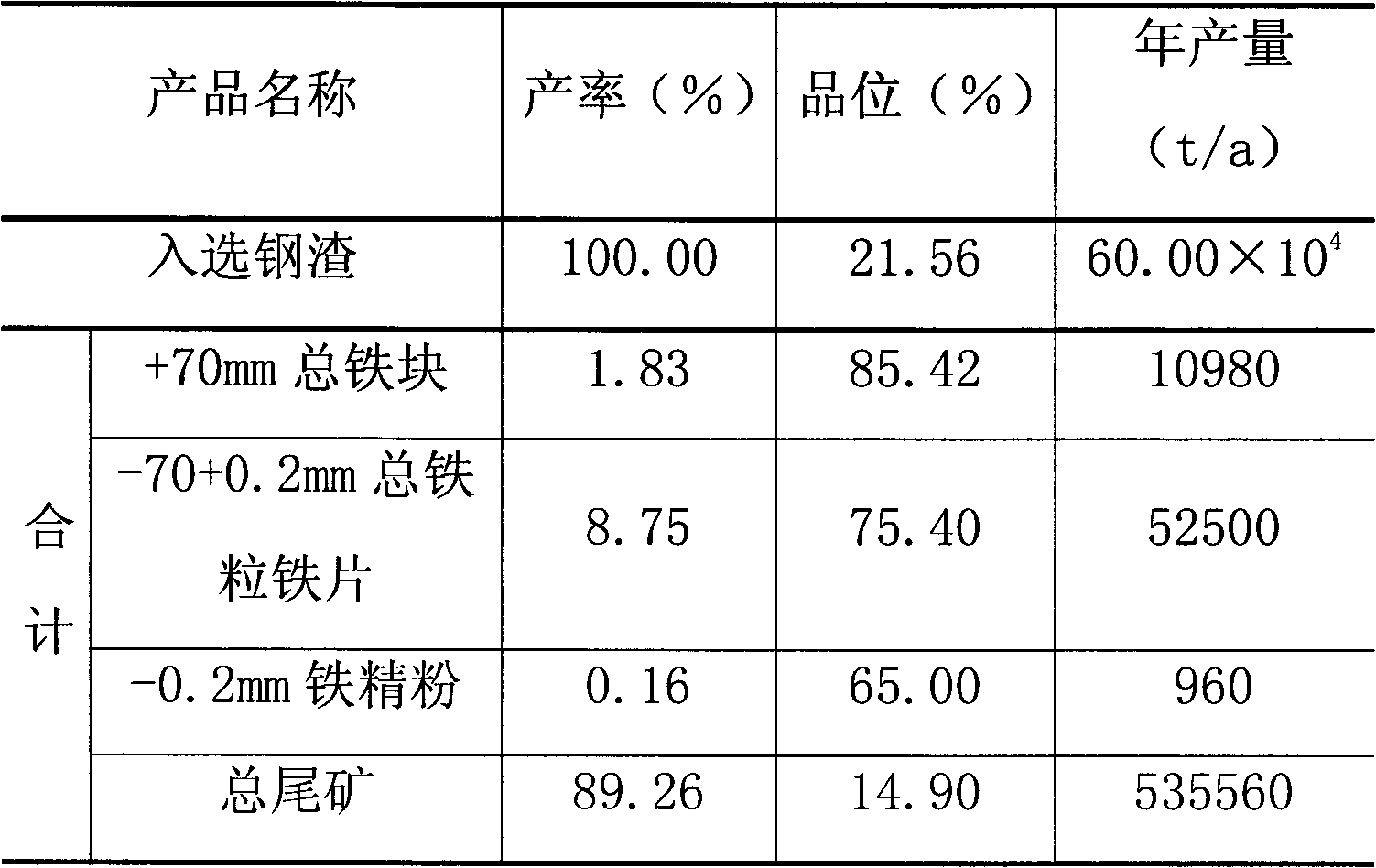

The invention relates to a method for recycling metal iron resources from waste residues of the iron and steel industry, particularly relates to a method for recycling metal iron from steel slag of a converter, and belongs to the technical field of benefication and comprehensive utilization of resources. The method includes recycling the metal iron from the slag of the converter by a cascade separation technological method, a dry magnetic separation technological method for discarding tailings and a wet concentration technological method, and is characterized in that +70mm large high-grade steel slag of the steel slag of the converter is in cascade separation and recycling, -70mm large high-grade steel slag is in classification dry magnetic separation for discarding tailings, rough concentration is further in full-grain wet ore grinding for separating slag from iron, cascade screening and cascade magnetic separation, and finally the metal iron with different grain sizes and magnetic iron concentration are obtained. The method has the advantages of high recycling rate and the grade of the metal iron, simplicity in technological process, simplicity and convenience in operation, low production cost, applicability to processing different types of steel slag of converters, and the like.

Owner:KUNMING METALLURGY INST

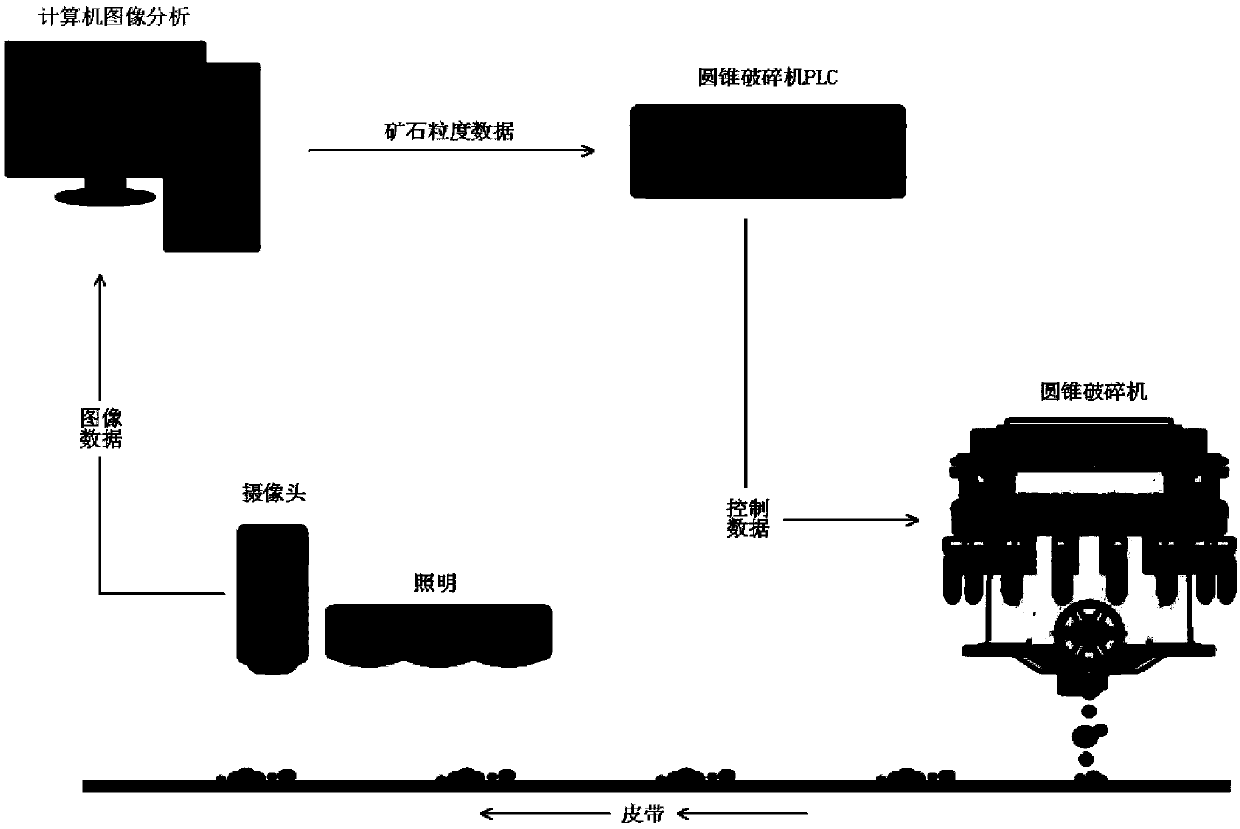

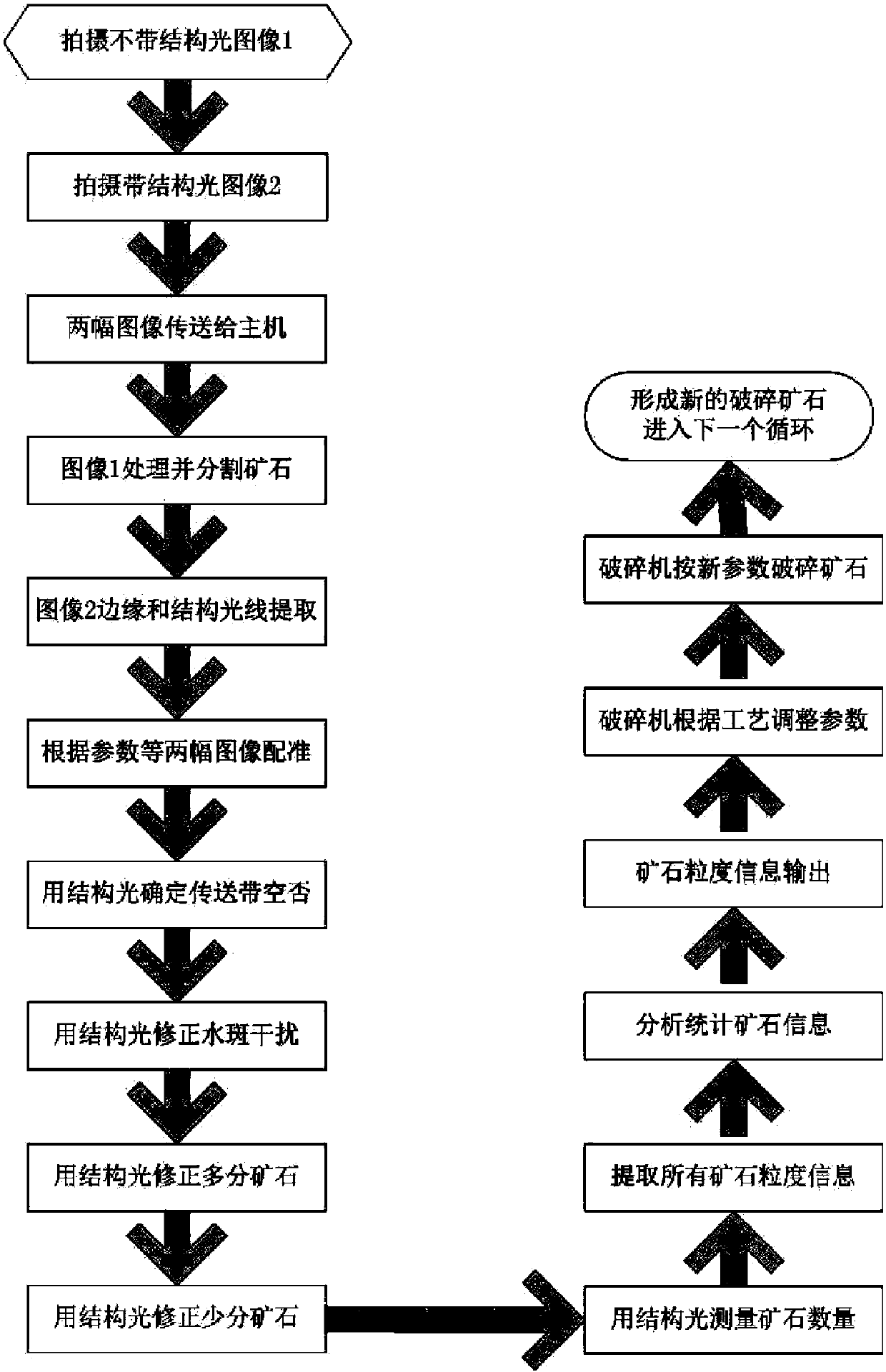

Smarter-vision-based high-performance ore granularity visual inspection system

InactiveCN107894379ASolve the problem of inaccurate detection and analysisImprove analytical accuracyParticle size analysisGrain treatmentsGranularityVision based

The invention relates to a smarter-vision-based high-performance ore granularity visual inspection system. Detection steps are as follows: a high-speed and high-definition camera is installed above anore conveyor belt; an ordinary image and an image with structured light of broken ore on the ore conveyor belt can be taken by the camera; information of the ordinary image and the image with the structured light is transmitted to a system host for detection, ore particles are cut, ore granularity information is extracted for statistics and analysis, and the ore granularity information is outputted to a main controller of an ore crusher; the main controller adjusts various control parameters of the ore crusher according to the requirements of the production process, and the ore crusher operates according to new control parameters; after the ore crusher operates according to the new control parameters, the broken ore again appears in the image of the camera, and the closed-loop control ofthe ore crusher is realized. The smarter-vision-based high-performance ore granularity visual inspection system can effectively solve the problems that an ordinary camera can only collect two-dimensional image information, and an ore particle size analyzer cannot distinguish an damaged or water-stained empty conveyor belt from a conveyor belt scattered with the ore, so that the ore granularity information detection and analysis are inaccurate.

Owner:沈阳聚德视频技术有限公司

Process method for hematite dressing to increase gravity concentrate yield

InactiveCN103611623AIncrease productionReduce consumptionWet separationThermodynamicsProcess engineering

Owner:ANSTEEL GRP MINING CO LTD

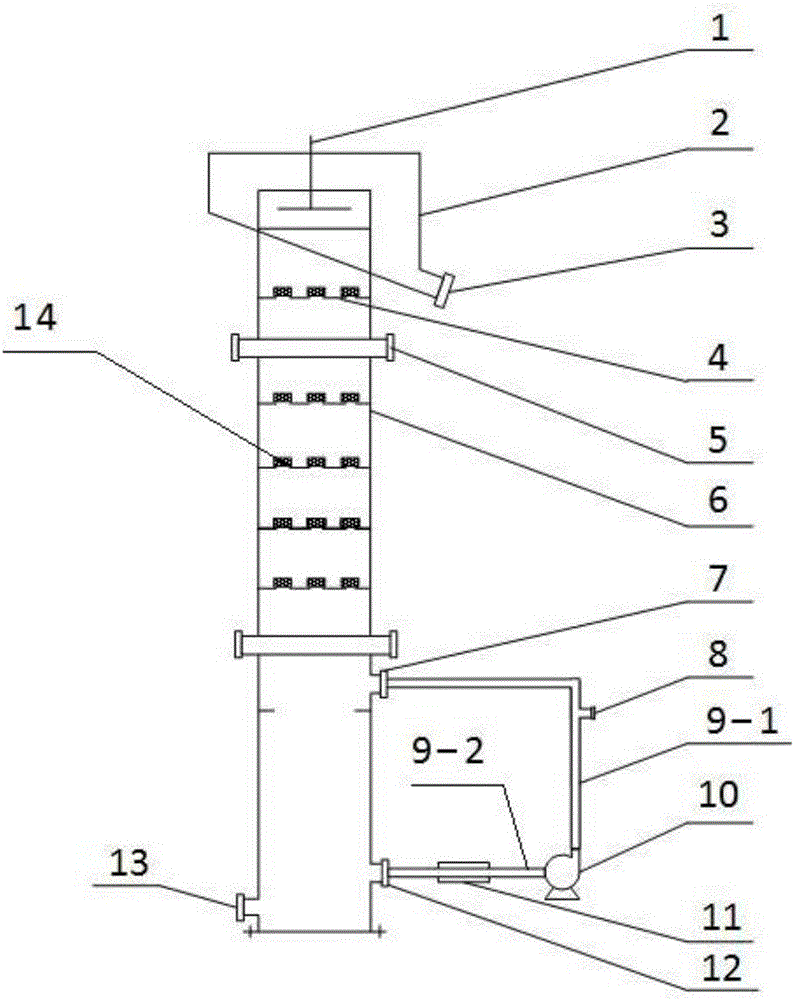

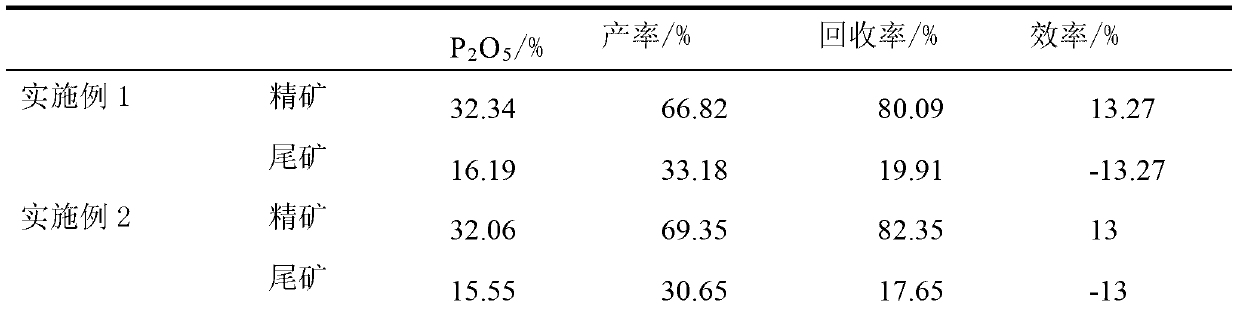

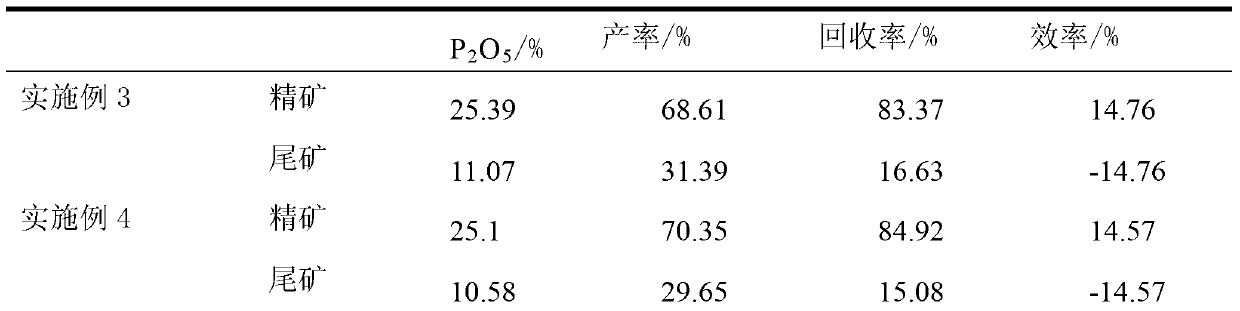

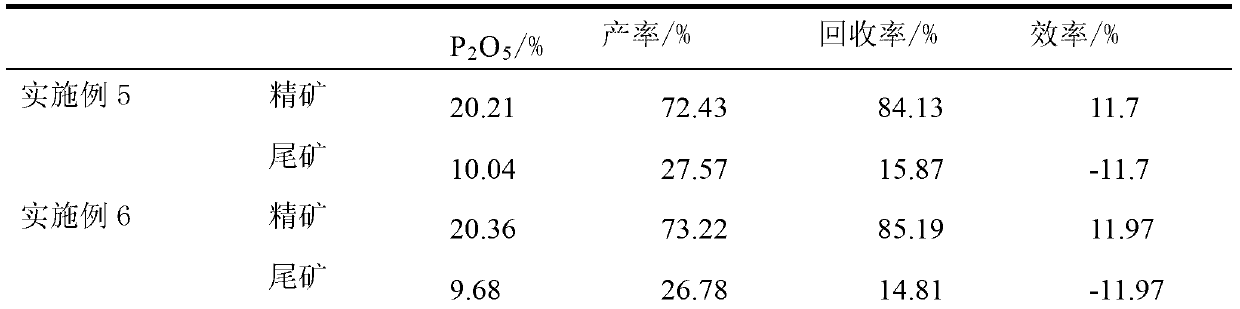

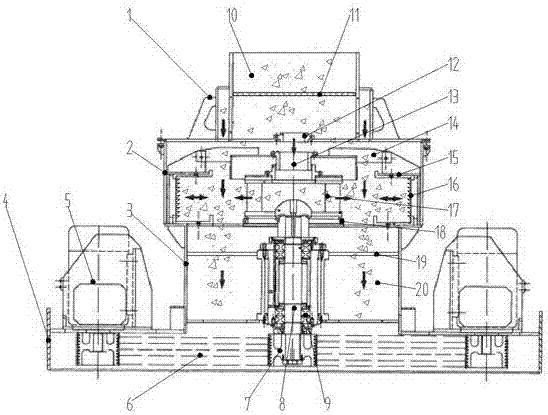

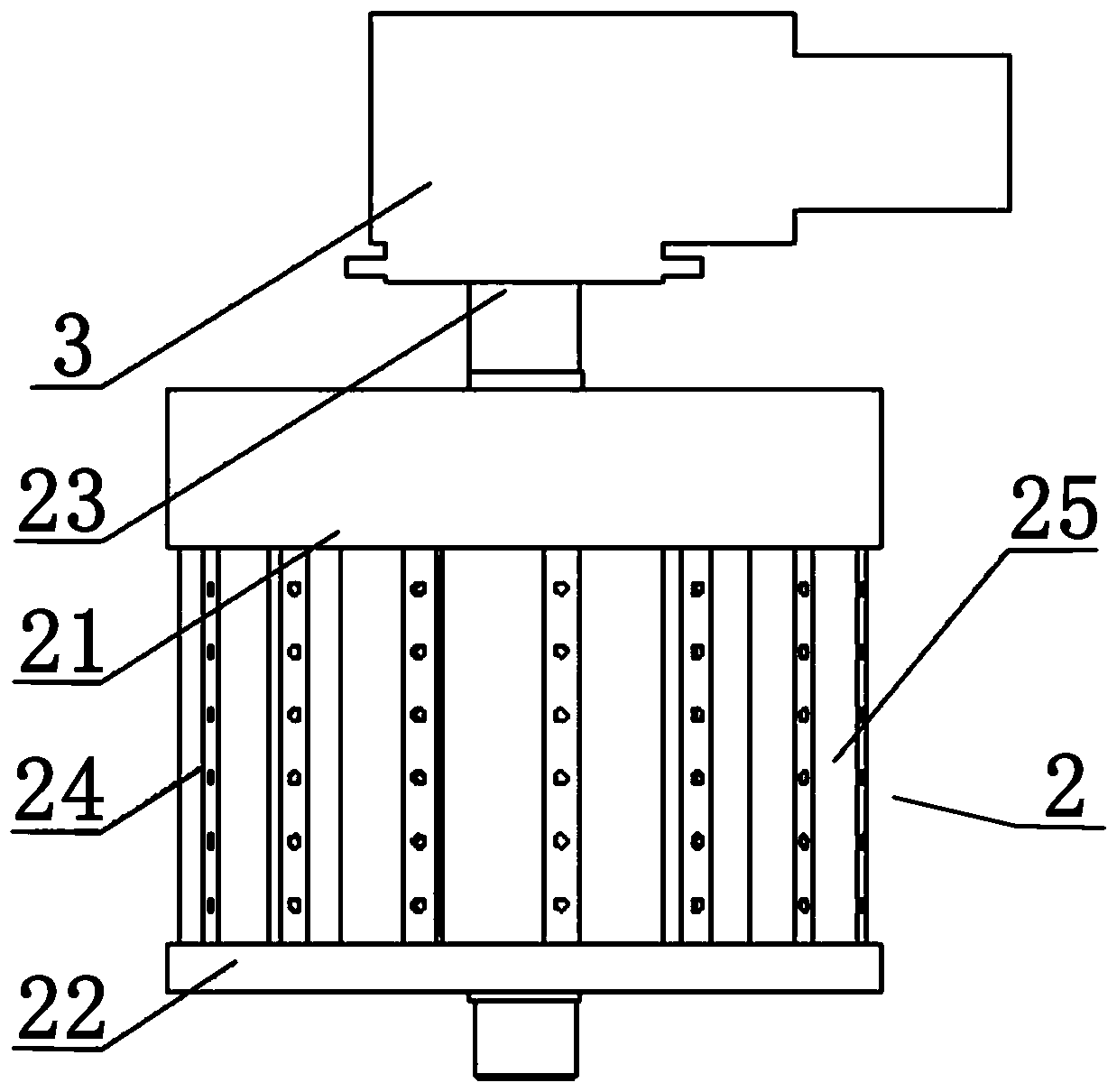

Flotation column separation equipment and separation method

The invention discloses flotation column separation equipment. The flotation column separation equipment comprises a hollow column body. A foam collecting tank, a spraying device and a tailing pipeline are arranged at the top of the column body. A plurality of sieve plates are arranged on the middle-upper portion in the column body. A middling circulating device is arranged on the lower portion of the column body. The middling circulating device comprises a circulating ore pulp outlet, and the circulating ore pulp outlet is sequentially connected with a chemical feeding tank, a middling circulating ore pulp pump, a bubble generator and a circulating ore pulp inlet. A feeding pipe is arranged on the upper portion of the column body. A concentrate pipe is arranged on the lower portion of the column body, and the concentrate pipe is lower than the circulating ore pulp outlet. The invention further provides an ore separation method. According to the flotation column separation equipment and the separation method, the trinity mineralization mode integrating raw ore reverse flow mineralization, middling pipe flow mineralization and middling fluid impact mineralization is adopted, efficient separation of phosphorus ore can be achieved, the production cost is low, and the energy consumption is low.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Reverse flotation collecting agent of cellophane and preparation method thereof

InactiveCN103357509AEfficient removalImprove complexation abilityFlotationCellophaneReverse flotation

The invention relates to a reverse flotation collecting agent of collophane, and particularly to the collecting agent manufactured by the compounding and combination of modified fatty acid, strong alkali solution, and fatty acid, and a preparation method thereof. The method comprises the following steps: mixing raw materials of 1-5 parts of Alpha-hydroxy oleinic acid, 0.2-1.5 parts of strong alkali A, 0-1 parts of oleinic acid, and 1 parts of saturated higher fatty acid in parts by weight, wherein the temperature is controlled between 60-95 DEG C, and the mechanical stirring is 2-5 hours, so as to obtain basic materials; when in use, adding water to preparing 2 wt%-50 wt% water solution. The combination collecting agent obtained by the compounding of Alpha-hydroxy oleinic acid, strong alkali, oleinic acid, and saturated higher fatty acid has the advantages that the ordinary temperature selectivity is strong, the dispersivity is good, the medicine dosage is small, the cost is low, the beneficiation overall efficiency is obviously improved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

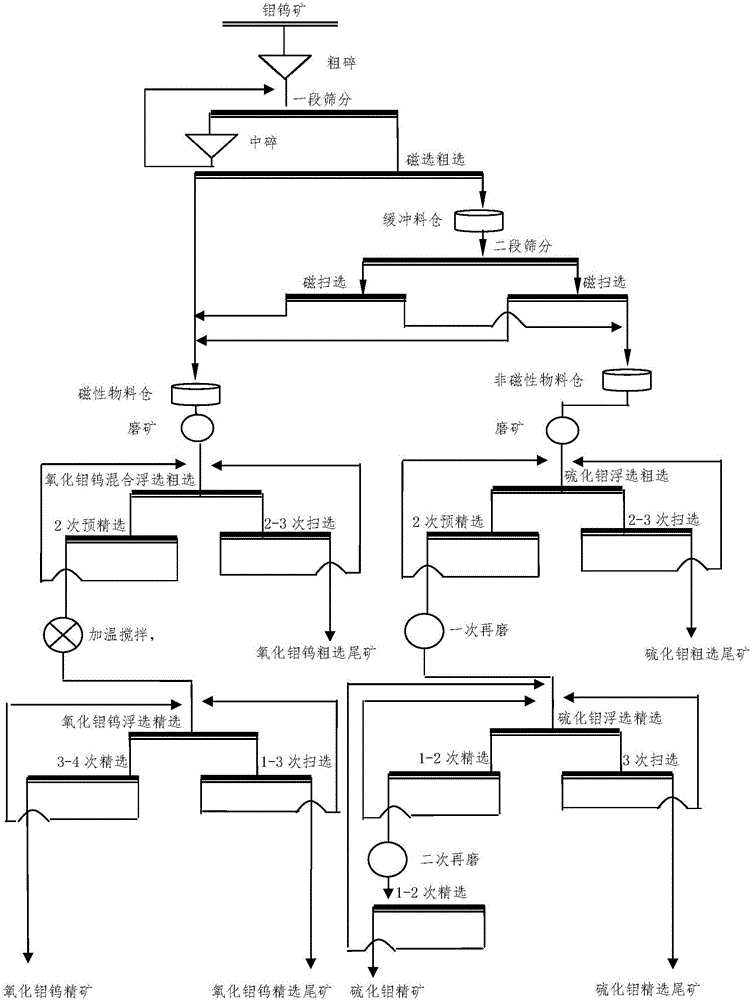

Beneficiation method for separating molybdenum-tungsten oxide ore and molybdenum sulfide ore from molybdenum tungsten ore

InactiveCN106076590AEliminate the need for deslimingThe beneficiation process is simpleFlotationMagnetic separationNon magneticMagnetic characteristic

The invention relates to a beneficiation method for separating molybdenum-tungsten oxide ore and molybdenum sulfide ore from molybdenum tungsten ore. The beneficiation method comprises the steps that magnetic separation is conducted on raw separation molybdenum sulfide ore at least twice, so that the raw separation molybdenum sulfide ore subjected to magnetic separation is divided into magnetic ore containing molybdenum-tungsten oxide and non-magnetic ore containing molybdenum sulfide; and a molybdenum-tungsten oxide flotation process is conducted on the magnetic ore, and a molybdenum sulfide flotation process is conducted on the non-magnetic ore, so that molybdenum-tungsten oxide concentrate and molybdenum sulfide concentrate are obtained. According to the beneficiation method for separating the molybdenum-tungsten oxide ore and the molybdenum sulfide ore from the molybdenum tungsten ore, the magnetic ore containing molybdenum-tungsten oxide and the non-magnetic ore containing molybdenum sulfide are separated out before ore grinding by means of the magnetic characteristic of iron-bearing ore in skarn in a magnetic separation and flotation combined way, so that the floatability of the ore is improved, the beneficiation feed grades of the molybdenum sulfide ore and the and molybdenum-tungsten oxide ore subjected to flotation are increased, and a subsequent flotation technological process is simplified; and in addition, grading index fluctuation caused by the change of the characteristics of the ore is reduced, and the mine production cost can be reduced easily.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

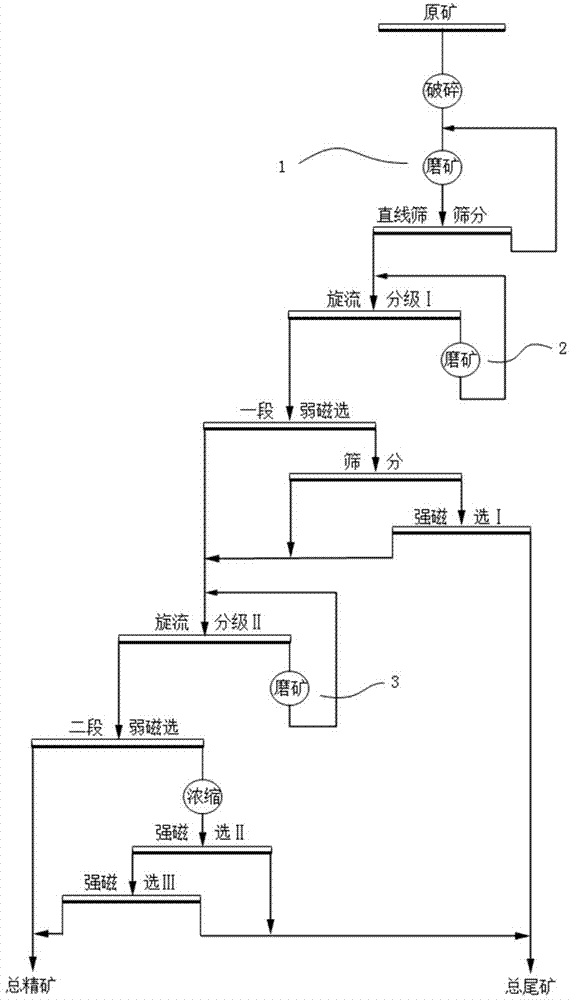

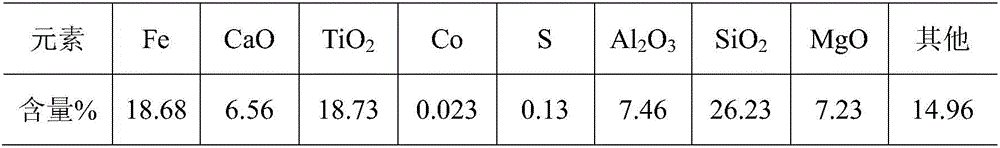

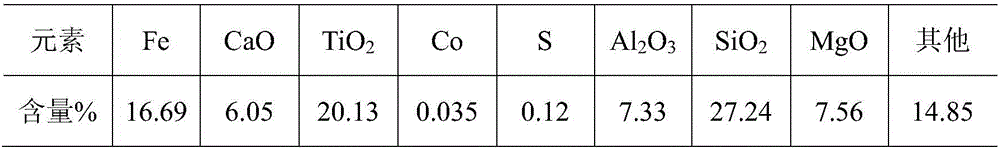

Efficient beneficiation method for low-grade titanic magnetite hard to select and smelt

ActiveCN107335535AHigh recovery rateWeakening of magnetic agglomerationWet separationMagnetiteRotational flow

The invention discloses an efficient beneficiation method for low-grade titanic magnetite hard to select and smelt. The method comprises the steps that in the crushing step, the low-grade titanic magnetite hard to select and smelt is crushed; in the first section ore grinding classification step, the titanic magnetite obtained after crushing is ground, first rotational flow classification is conducted, first fine particle overflow and first coarse grain pulp are obtained, and the first coarse grain pulp is subjected to first grinding again to return,; in the one-section low intensity magnetic separation step, the first fine particle overflow is subjected to first low intensity magnetic separation, and first iron concentrate pulp and first tailings pulp are obtained; in the screening classification step, the first iron concentrate pulp I is screened, and plus sieve coarse ore and minus sieve fine pulp are obtained; and in the second-section ore grinding classification step, the first iron concentrate pulp and the plus sieve coarse ore are combined and subjected to second rotational flow classification, second fine particle overflow and second coarse grain pulp II are obtained, and the second coarse particle pulp is subjected to second grinding to return to second rotational flow classification. For the low-grade titanic magnetite hard to select and smelt, the iron and titanium recycling rate is increased in combination of rotational flow classification and low intensity magnetic separation, and the method has the beneficial effects of being simple in technology, easy to operate and high in beneficiation efficiency.

Owner:YUXI DAHONGSHAN MINING

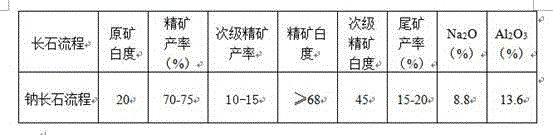

Method for efficiently preparing feldspar glazes for ceramics

The invention discloses a method for efficiently preparing feldspar glazes for ceramics. The method comprises the following specific steps: after raw feldspar ores are crushed, grinding the raw feldspar ores by a high-alumina ball grinding mill, classifying the raw feldspar ores in a spiral manner by a spiral classifier, and screening the raw feldspar ores by a high-frequency classifying screen, so that the sufficient dissociation of feldspar mines and the controlling the granularity can be ensured, the feeding granularity of the fed feldspar mines can be ensured, and conditions for the following magnetic separation and the classifying processes of a cyclone are created; separating and effectively removing magnetic impurities of the raw feldspar ores by the magnetic separation with various intensity in a classifying and multi-section manner of the granularity, increasing the kinds of products, and increasing the recovery of resources. Through the use of the technologies, such as the classification of the cyclone, the permanent magnet iron removal of a drum magnetic separator, the iron removal of a vertical ring pulsating high-gradient strong magnetic separator and the like, the adaptability and the reliability are greatly improved, the quality of the concentrates is effectively ensured and stabilized, the risk due to fluctuation of the impurity content is reduced, the separating efficiency and the comprehensive utilization of resources are improved, and the efficiently comprehensive utilization of the feldspar resources is realized.

Owner:赣州金环磁选科技装备股份有限公司

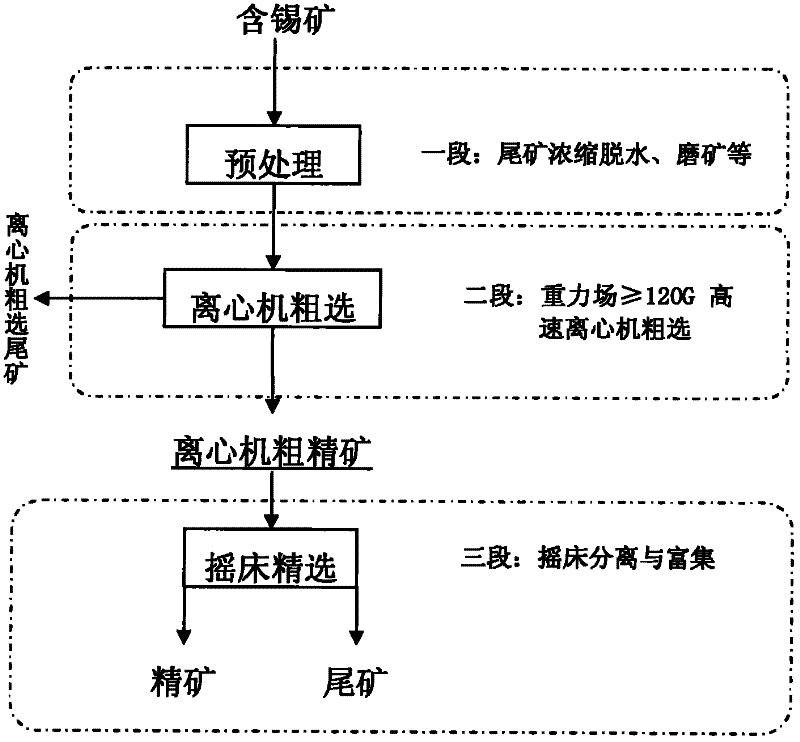

Method for recovering tin by centrifugal concentration

InactiveCN102172560ARaise the gradeHigh process recovery rateWet separationEconomic benefitsResource efficiency

The invention discloses a method for recovering tin by centrifugal concentration, belonging to the technical field of metal ore concentration. The method comprises the following steps of: recovering and enriching a tin resource from a tin-containing ore by using a high-speed centrifugal concentrator together with a shaking table; performing pretreatment or not performing treatment according to the milling characteristic of a tin ore; entering the high-speed centrifugal concentrator for rough gravity concentration; enriching to obtain a tin rough ore concentrate; removing tailings; and selecting the tin rough ore concentrate by using the shaking table to obtain a tin ore concentrate. The method has the advantages of high process specificity, high resource efficiency, remarkable economic benefit, small investment, small floor area and the like.

Owner:KUNMING METALLURGY INST

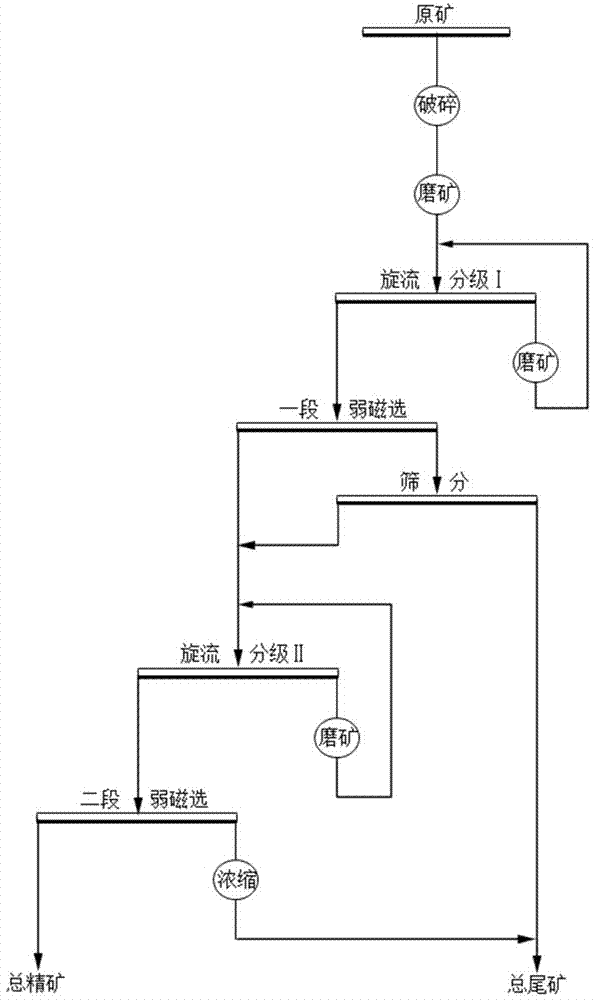

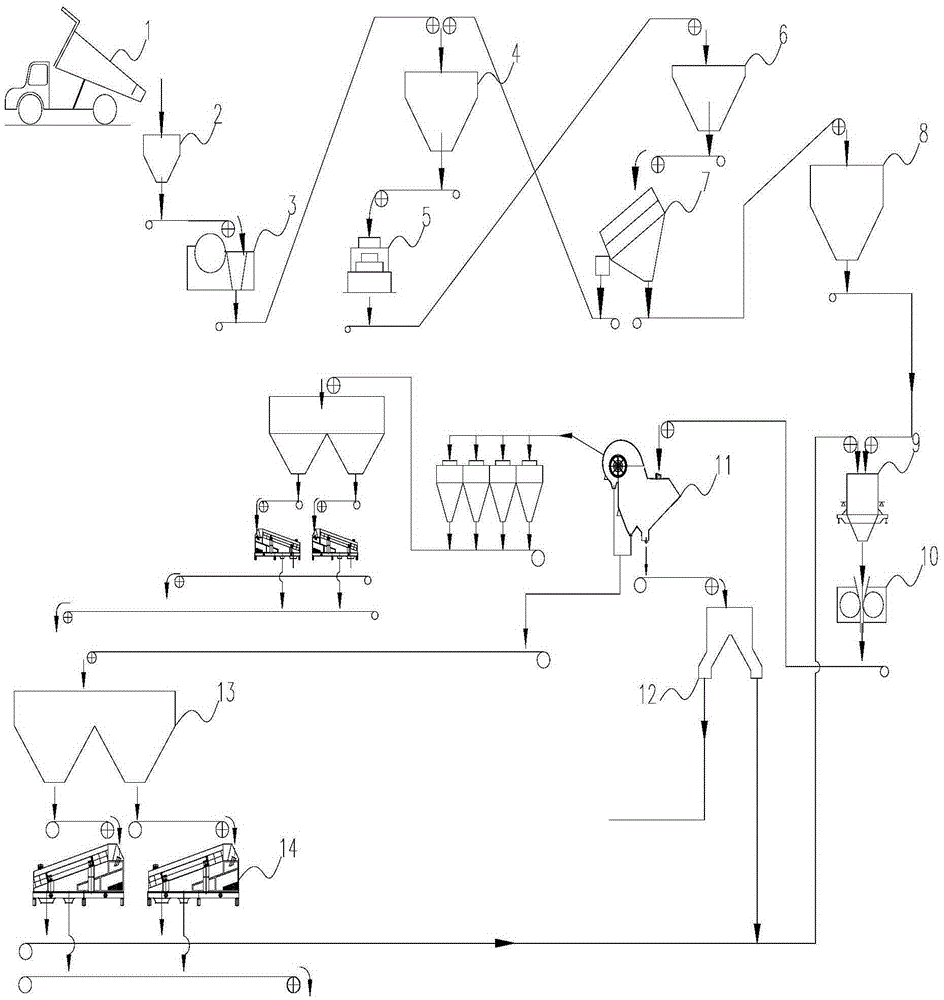

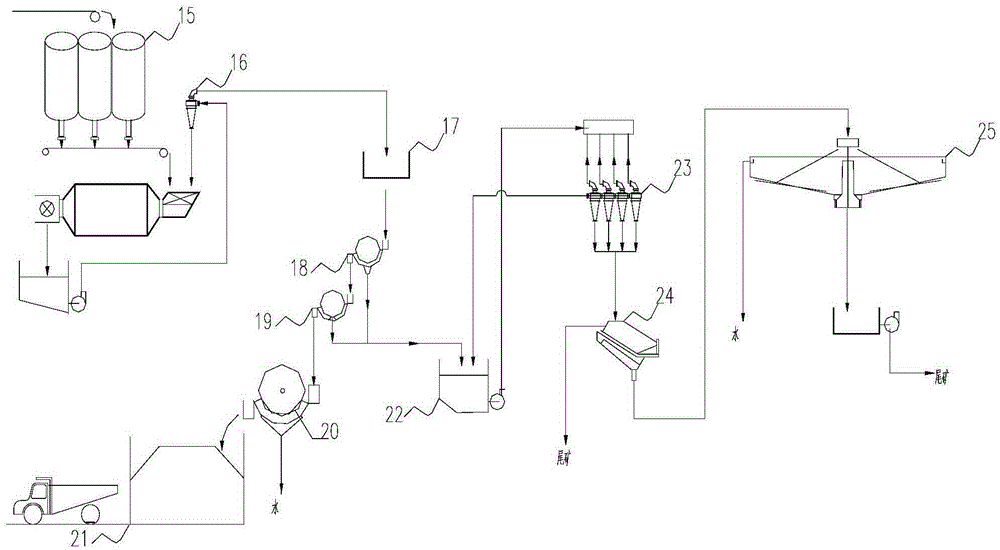

Mineral separation process and system for ultra-lean magnetite ore

ActiveCN105413842AReduce the cost of beneficiationReduce total beneficiation costMagnetic separationGrain treatmentsMagnetiteWet grinding

The invention provides a mineral separation process and system for an ultra-lean magnetite ore. The mineral separation process for the ultra-lean magnetite ore comprises the following steps of sequentially carrying out coarse crushing, intermediate crushing and fine crushing on a raw magnetite ore to obtain a fine-particle ore; carrying out dry magnetic separation on the fine-particle ore, and throwing tailings to obtain a dry concentrate; and carrying out wet grinding and separation on the dry concentrate. The dry pre-separation step is additionally arranged in the mineral separation process, so that the technical problems of high ore grinding and magnetic separation energy consumption, high cost, high mineral separation water consumption, tailing pond construction and the like are solved.

Owner:中冶沈勘工程技术有限公司

Cellophane direct flotation collecting agent and method for preparing same

The invention relates to a cellophane direct flotation collecting agent and a method for preparing the cellophane direct flotation collecting agent, in particular to a novel cellophane direct flotation collecting agent which is formed by modification and compounding of fatty acid and the like. The method for preparing the cellophane direct flotation collecting agent comprises the steps that by weight, 20%-80% of cotton oil residues and 10%-60% of higher fatty acid are respectively added to a reaction still, strong base solution with any concentration is slowly added to the reaction still, the use amount of strong base is 5%-20% within the temperature of 60DEG C-150DEG C, the solution in the reaction still is well stirred at the speed of 500-2500rad / min, is cooled to the temperature of 60DEG C or so, then 0-20% of chlorinated fatty citric acid acids ester is added to the solution and the solution is well stirred, and accordingly the cellophane direct flotation collecting agent is obtained. The cellophane direct flotation collecting agent is high in selectivity and cellophane-carrying capability, has good sorting effect under a normal temperature, and can reach an excellent flotation index.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Combined type vibrating sand making machine

The invention discloses a composite vibrating sand making machine, which comprises an upper machine case, a lower machine case, a discharge box and a frame, which respectively correspond to a material inlet, a crushing cavity and a material discharge port, and the three are in the order of axes from top to bottom connection, the connection is connected with the lower frame as a whole; the drive motor is connected to the frame, and the drive motor is connected to the rotating main shaft inside the sand making machine through the transmission mechanism, and the upper end is connected to the impeller; the main shaft of the rotating shaft is also connected with The vibrating mechanism cooperates with the impeller; the vibrating screening is combined with the crushing structure of the sand making machine, which can screen the materials with uneven particle size to a certain extent and perform corresponding crushing. There is also a material distribution component. It can realize the switching of various crushing forms and has a wide range of applications. Through the above structure, the problems of unsmooth discharge, low crushing efficiency of sand making machine and insufficient crushing of materials in the prior art can be effectively solved, and the crushing efficiency of materials is greatly improved. The quality and beneficiation efficiency of the beneficiation process.

Owner:尹国祥

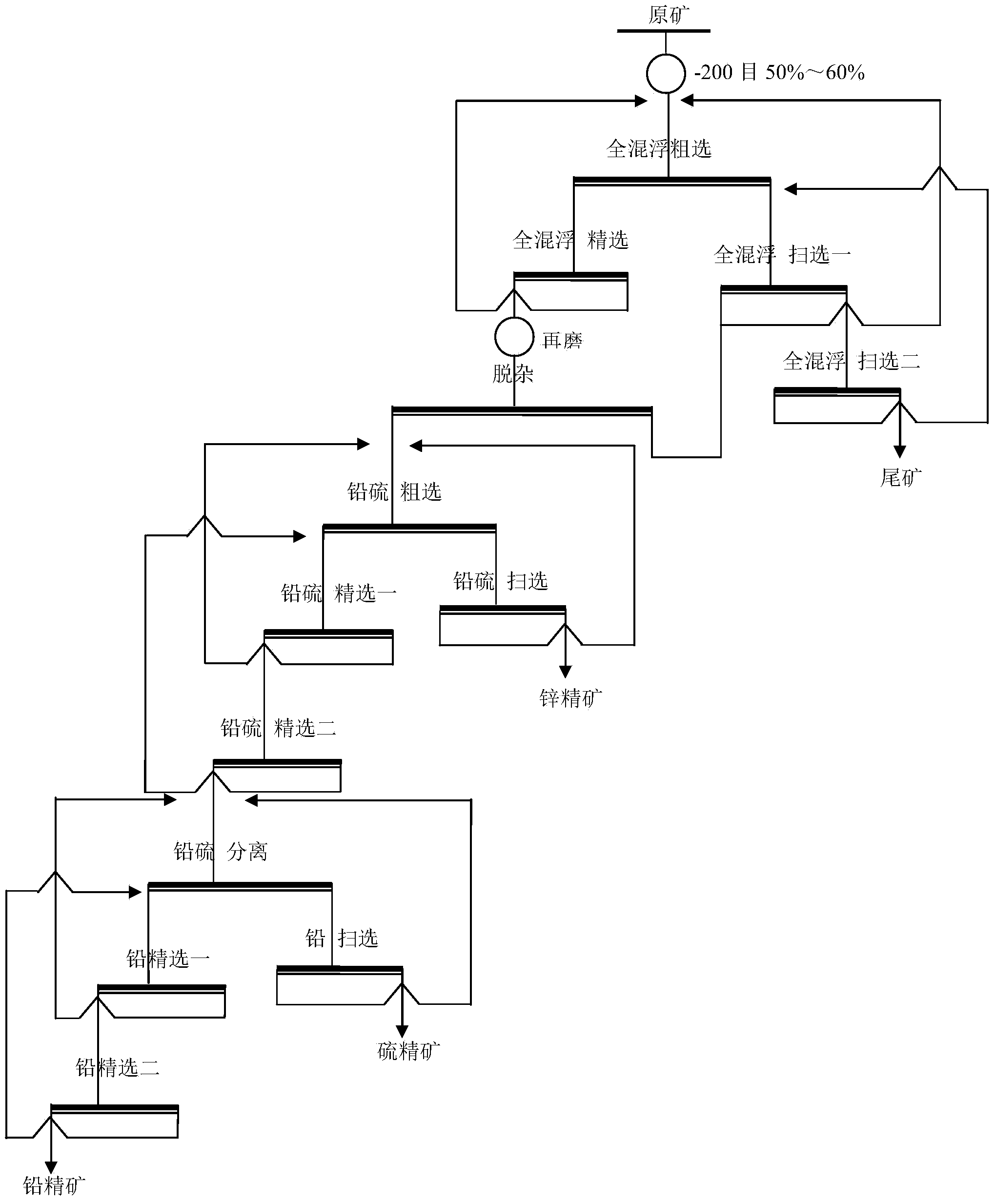

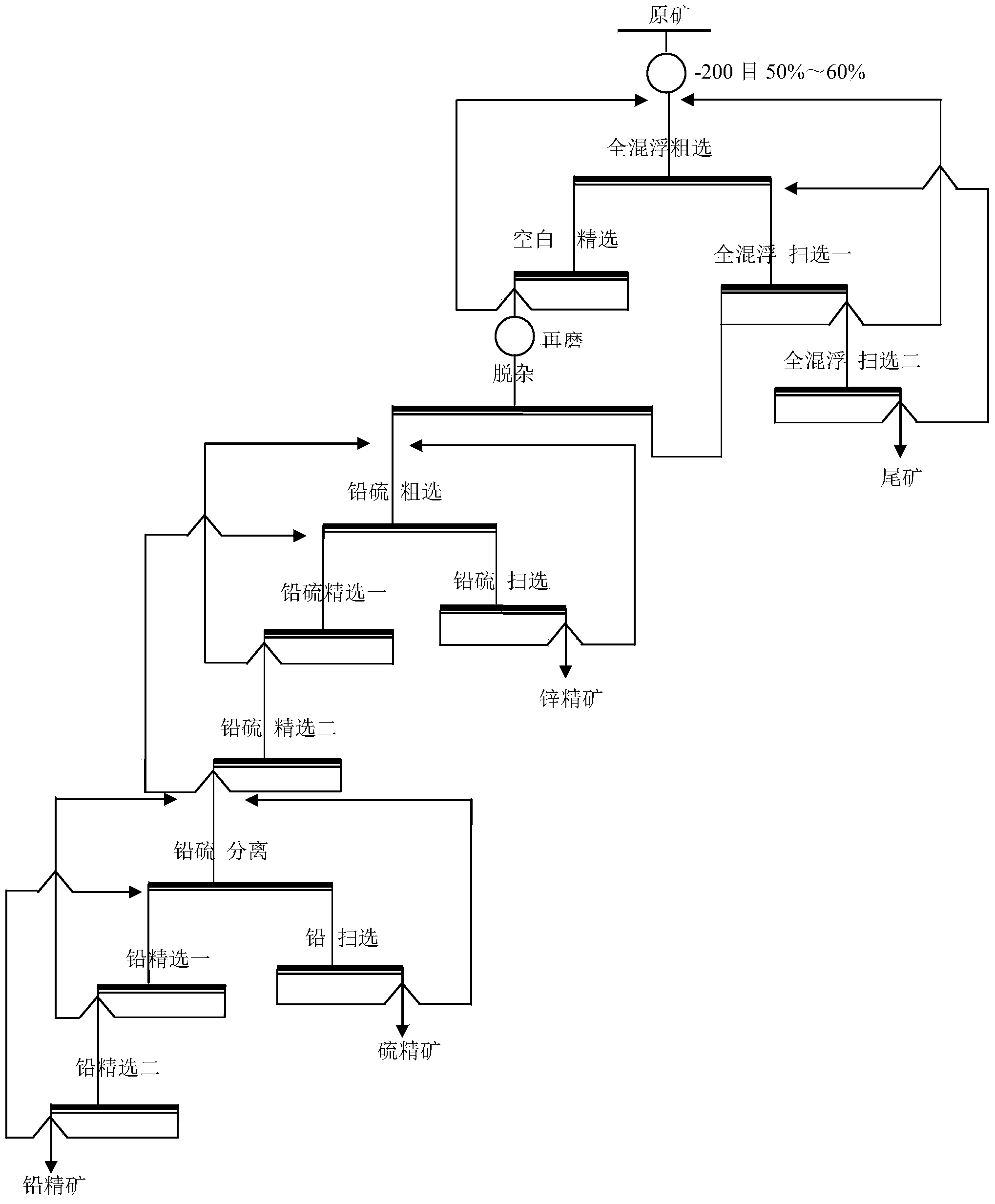

Method for obtaining valuable ores from multi-metal sulfide ores containing lead and zinc through flotation separation

ActiveCN104001626AReduce grinding energy consumptionImprove beneficiation efficiencyFlotationZincMaceral

The invention discloses a method for obtaining valuable ores from multi-metal sulfide ores containing lead and zinc through flotation separation. The method comprises the steps of firstly performing ore grinding on raw ores; then adding a combined flotation agent to perform complete-mixing rough flotation treatment on the raw ores subjected to the ore grinding; continuing to perform fine flotation on rough concentrates subjected to the rough flotation, and continuing to add the combined flotation agent to perform scavenging on tailings subjected to the rough flotation; re-grinding lead-zinc-sulfur mixed rough concentrates subjected to the fine flotation; adding the combined flotation agent into the grinded lead-zinc-sulfur mixed rough concentrates to perform impurity removal treatment, and performing scavenging on the tailings subjected to the impurity removal. On the basis of the method, lead-sulfur rough flotation, lead-sulfur fine flotation and lead-sulfur separation can be additionally performed to obtain lead concentrates, the tailings subjected to the flotation separation is subjected to lead scavenging, and finally sulfur concentrates are obtained. The method has the advantages of being simple and convenient to operate, reasonable in technological process, small in agent dosage, low in energy consumption, long in service life, good in separation effect and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

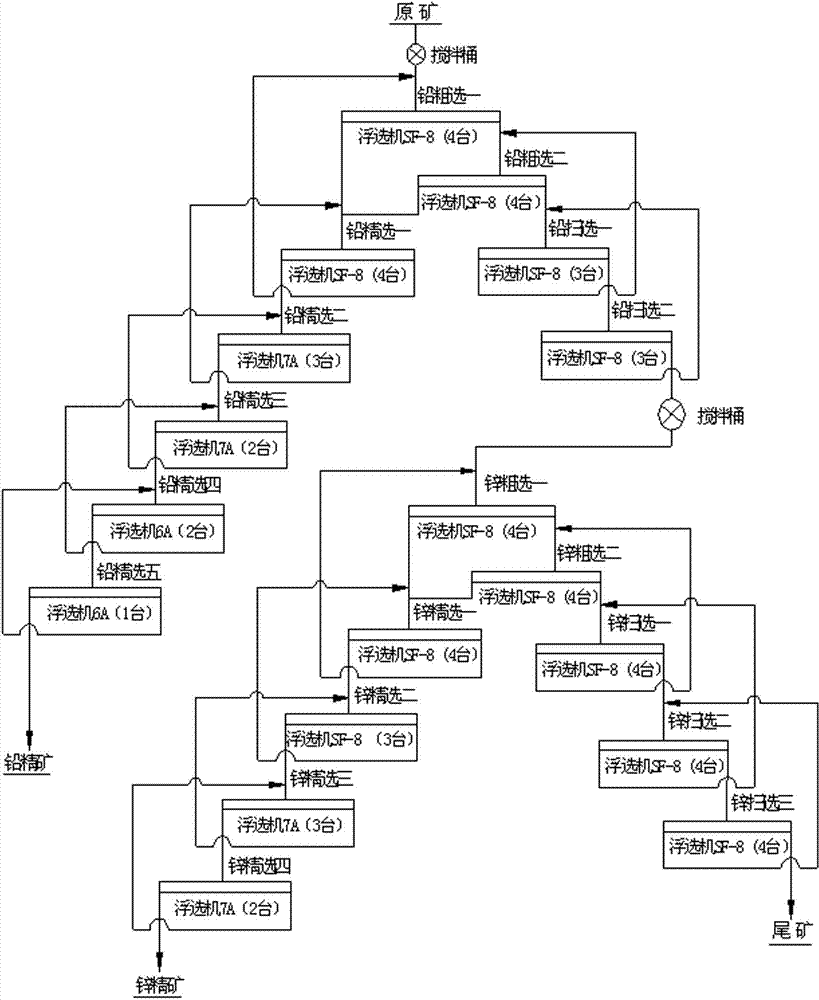

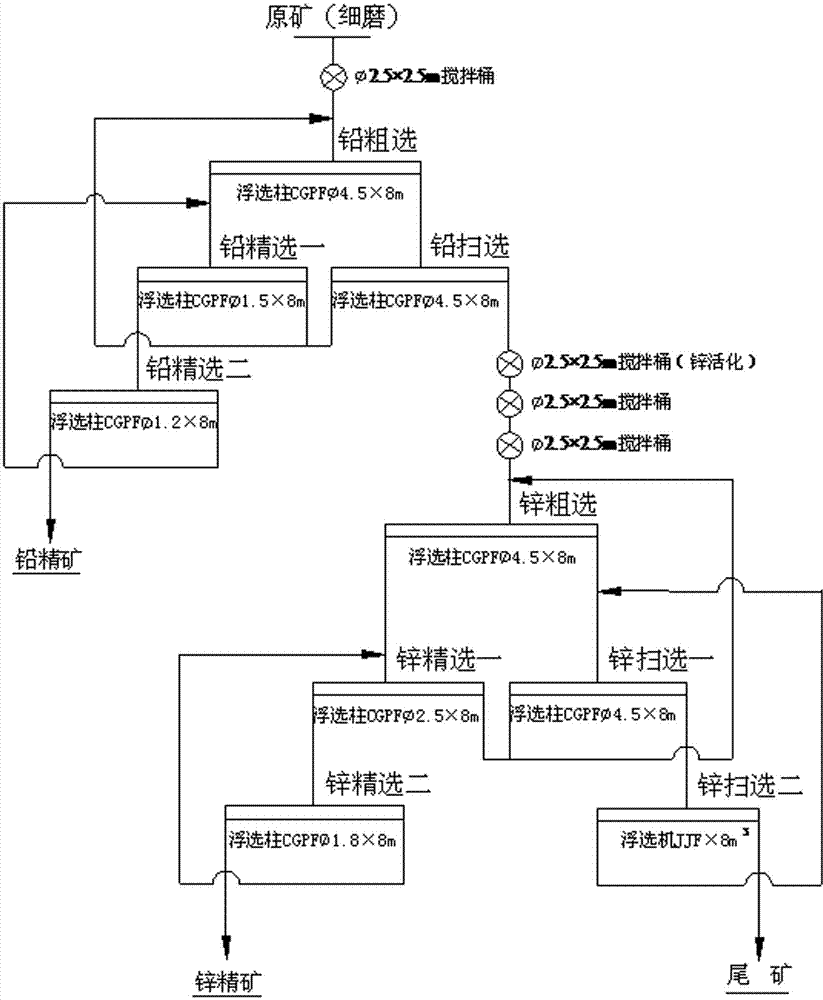

Technology for flotation of lead and zinc sulfide ores through inflatable floatation columns

ActiveCN103934117AImprove beneficiation efficiencyHigh enrichment ratioFlotationMineralogyMining engineering

The invention discloses a technology for floatation of lead and zinc sulfide ores through inflatable floatation columns. The floatation columns are fully utilized, and the method includes the steps of ore grinding, mixing of ore pulp and flotation reagents, rougher flotation operation, concentration operation, scavenging operation and the like. The method is based on the flotation column three-phase flow mechanics theory, through process mineralogy research and technological process research of low-grade, complex and refractory lead and zinc sulfide ores of mines and research and improvement on an inflatable flotation column device, the flotation columns are successfully applied to the flotation technology of low-grade, complex and refractory lead and zinc sulfide ores, and the technological process that the floatation columns are adopted in all the flotation operations of rougher flotation, concentration and scavenging of lead and zinc sulfide ores is achieved. The technology has the advantages that the automation degree is high, labor intensity of workers is low, ore flotation efficiency is high, the technological process is simple, production indexes are stable, maintenance is convenient, building investment and production cost are low, consumption of the reagents is saved by about 10%, electricity consumption is saved by about 20 %, and water consumption is saved by about 20 %.

Owner:GUANGXI ZHONGJIN LINGNAN MINING CO LTD

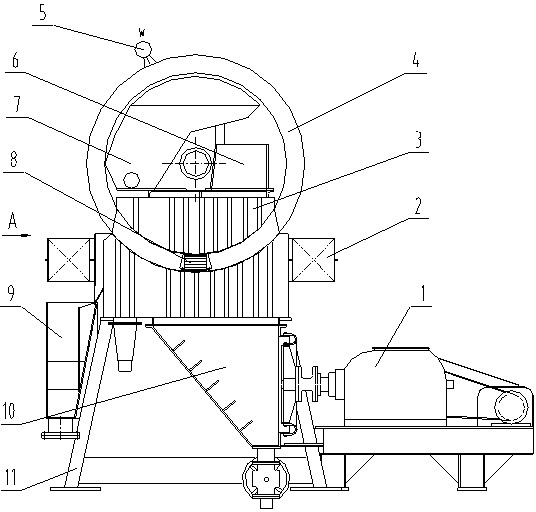

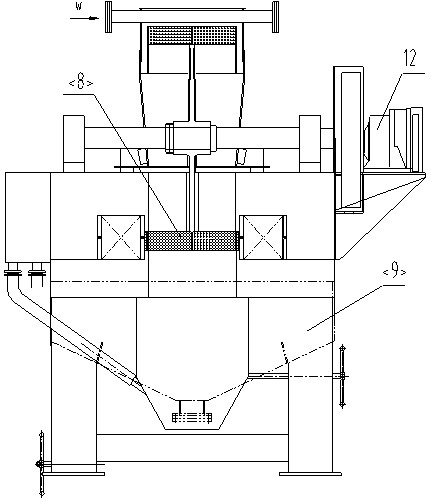

Large-particle vertical ring pulsation high-gradient magnetic separator

ActiveCN102614983AHigh enrichment ratioMeet the requirements of the sorting channelHigh gradient magnetic separatorsMagnetic mediaMagnetic separator

The invention discloses a large-particle vertical ring pulsation high-gradient magnetic separator. The large-particle vertical ring pulsation high-gradient magnetic separator comprises a machine frame, wherein magnetic yokes, excitation coils, a swivel, a concentrate bucket, a concentrate collecting tank and a tailing bucket are arranged on the machine frame; the swivel is provided with a magnetic medium pile; the tailing bucket is connected with a pulsation drive mechanism; the magnetic medium pile consists of thin stainless steel plates and medium rods inserted in the stainless steel plates; the high gradient of magnetic fields is ensured by selecting the diameters and the spatial arrangement ways of the medium rods under the condition that 2 to 5mm of material particles can smoothly pass; the outer side wall, the front side wall and the rear side wall of the concentrate bucket are arranged in a manner of inclining to a bottom discharge port, and a discharge pipe connected with the discharge port is arranged in a manner of inclining downwards; and the bottom wall of the concentrate collecting tank and the inclined side wall of the tailing bucket are horizontally provided with material baffle plates. Due to a series of improvement on the conventional magnetic separator, the vertical ring pulsation high-gradient magnetic separator can directly separate 2 to 5mm of large-particle materials and provides reliable technical guarantee for the exploitation and utilization of lean ore resources.

Owner:赣州金环磁选科技装备股份有限公司

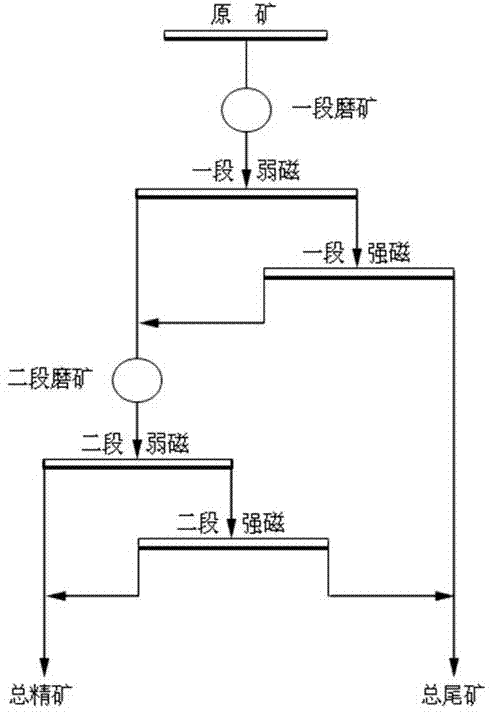

Beneficiation method of efficiently recovering fine-grain low-grade magnetite

The invention discloses a mineral processing method for efficiently recovering fine-grained low-grade magnetite. Iron concentrate I and tailings I can be obtained by weak magnetic separation with a magnetic induction intensity of 1100-1300Oe; iron concentrate II and tailings II can be obtained from tailings I by strong magnetic separation with a magnetic induction intensity of 0.9-1T; iron concentrate I and iron Concentrate II is combined and ground to -0.045mm, accounting for 75-85% to obtain fine-grained ore II; fine-grained ore II is subjected to weak magnetic separation with a magnetic induction intensity of 1000-1200Oe to obtain iron concentrate III and tailings III; Iron concentrate IV and tailings IV are obtained by strong magnetic separation with a magnetic induction intensity of 0.560-0.783T, and iron concentrate III and iron concentrate IV are combined to obtain a total concentrate, and tailings II and tailings IV are combined to throw tailings. The invention has the characteristics of short process flow, less grinding amount, high beneficiation efficiency, iron recovery rate and high concentrate grade.

Owner:YUXI DAHONGSHAN MINING

Chelate collector for floatation of iron mineral

The invention provides a chelate collector for flotation of iron mineral, which is characterized in that alpha-hydroxyl-13-fatty acid and carbon chain alpha-hydroxyl-fatty acids having carbon chain lower than that of the alpha-hydroxyl-13-fatty acid account for 18 to 21 percent of the total content of the alpha-hydroxyl-fatty acid; alpha-hydroxyl-17-fatty acid and carbon chain alpha-hydroxyl-fatty acid having carbon chain higher than the alpha-hydroxyl-17-fatty acid account for 18 to 21 percent of the total content of the alpha-hydroxyl-fatty acid; and alpha-hydroxyl-14-fatty acid, alpha-hydroxyl-15-fatty acid and alpha-hydroxyl-16-fatty acid account for 58 to 62 percent of the total content of the alpha-hydroxyl-fatty acid. Compared with the prior chelate collector for flotation, the chelate collector has the advantages of high mineral processing efficiency, few species of used reagents and simple preparation.

Owner:ANSTEEL GRP MINING CO LTD

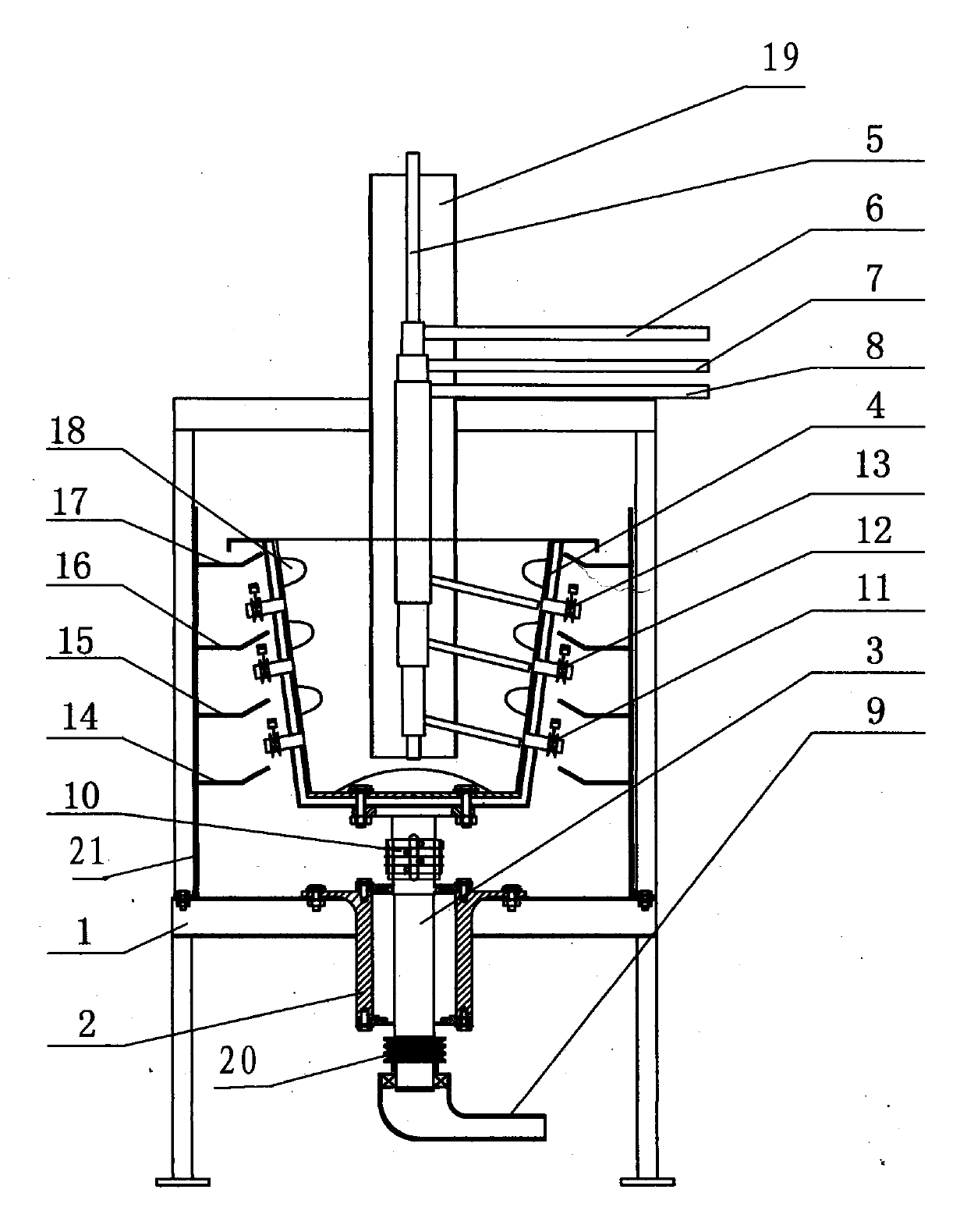

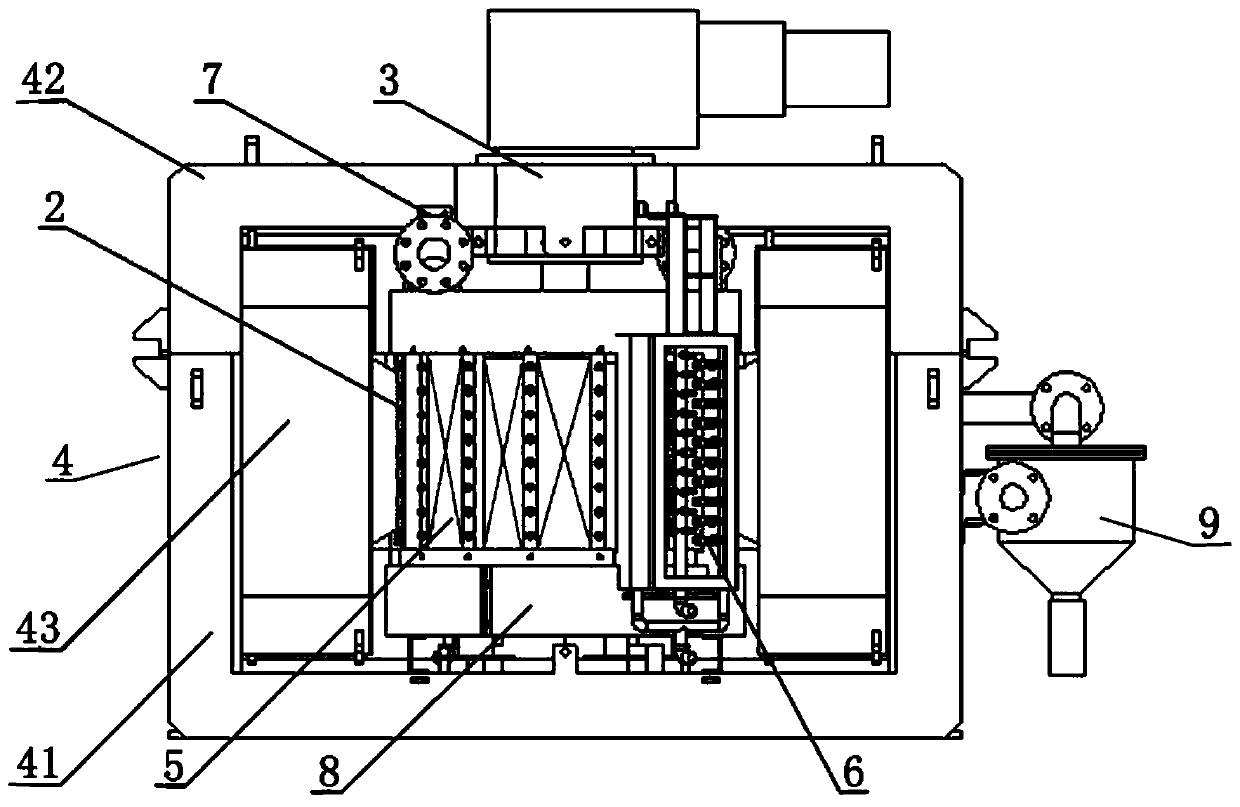

Multifunctional electromagnetic centrifugal continuous concentrating machine

ActiveCN104190532AImprove beneficiation efficiencyLarge amount of processingMagnetic separationWet separationHigh densityMedium density

The invention discloses a multifunctional electromagnetic centrifugal continuous concentrating machine comprising a main frame, an ore collecting barrel on the upper portion of the main frame, a sorting cone inside, an ore feeding tube, a bearing holder on the lower portion of the main frame, a hollow spindle connected to the bearing holder, a transmission wheel, a reverse water flushing pipe, a collecting ring mounted on the hollow spindle, a high-density ore sucking pipe and a medium-density ore sucking pipe and a low-density ore sucking pipe which are mounted on the main frame, weak-magnetic annular material collecting grooves, medium-magnetic annular material collecting grooves, strong-magnetic annular material collecting grooves, a waste collecting annular grooves, 3 to 5 rows of ribs welded to the circumference of the inner wall of the sorting cone, weak, medium and strong magnetic electromagnets mounted on the circumference of the inner wall of the sorting cone, and reverse water flushing holes; the weak-magnetic annular material collecting grooves, the medium-magnetic annular material collecting grooves, the strong-magnetic annular material collecting grooves and the waste collecting annular grooves are mounted on the inner wall of the ore collecting barrel sequentially, and the reverse water flushing holes are adjacent to the electromagnets and are formed in the inner wall of the sorting cone. The multifunctional electromagnetic centrifugal continuous concentrating machine can be applied to magnetic material concentrating and non-magnetic material concentrating, the concentrating efficiency is high, the processing quantity is large, the machine is adaptive to large-scale line production, the machine has the advantages of low power, fine concentrating effect and low cost, energy is saved, and the consumption is reduced.

Owner:刘克俭

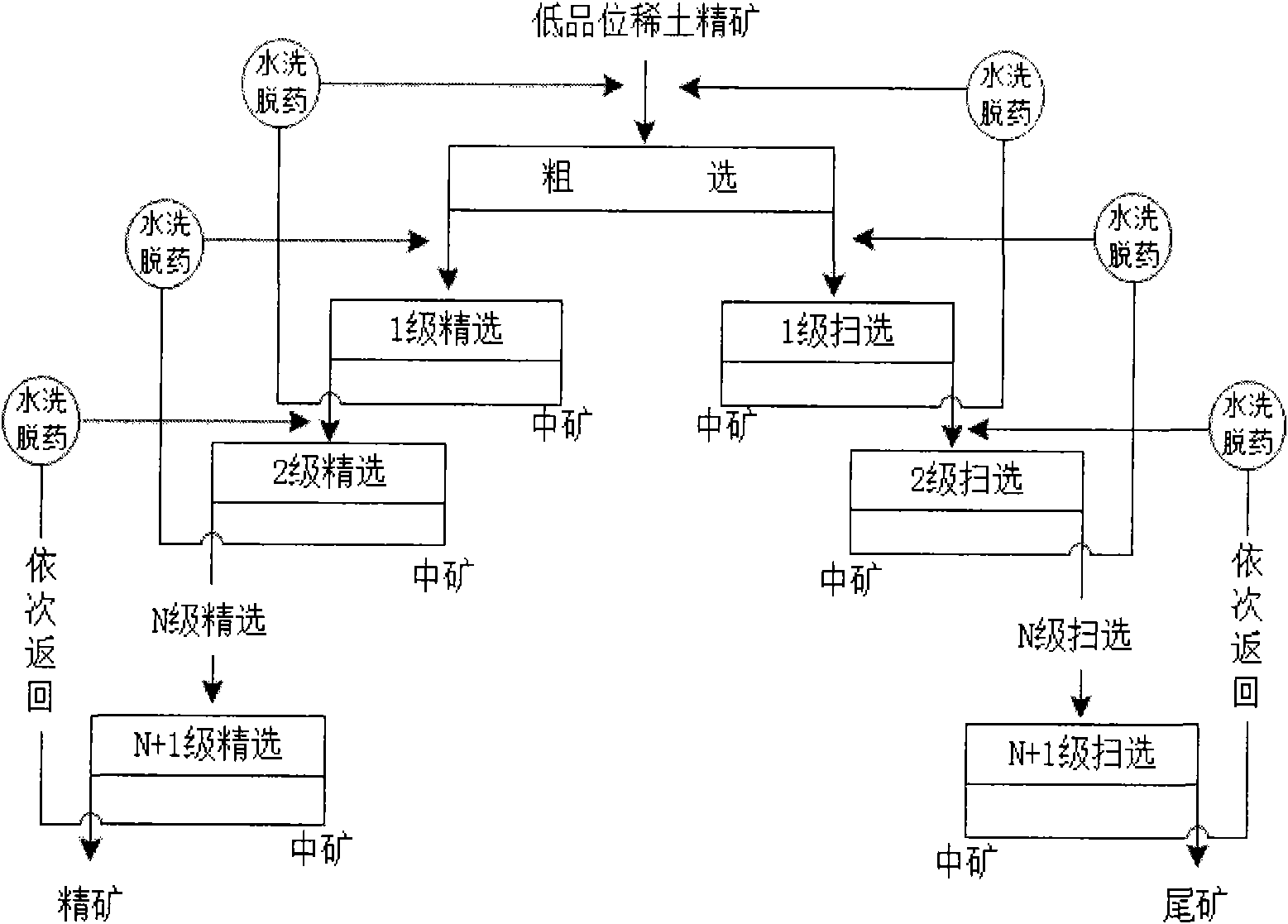

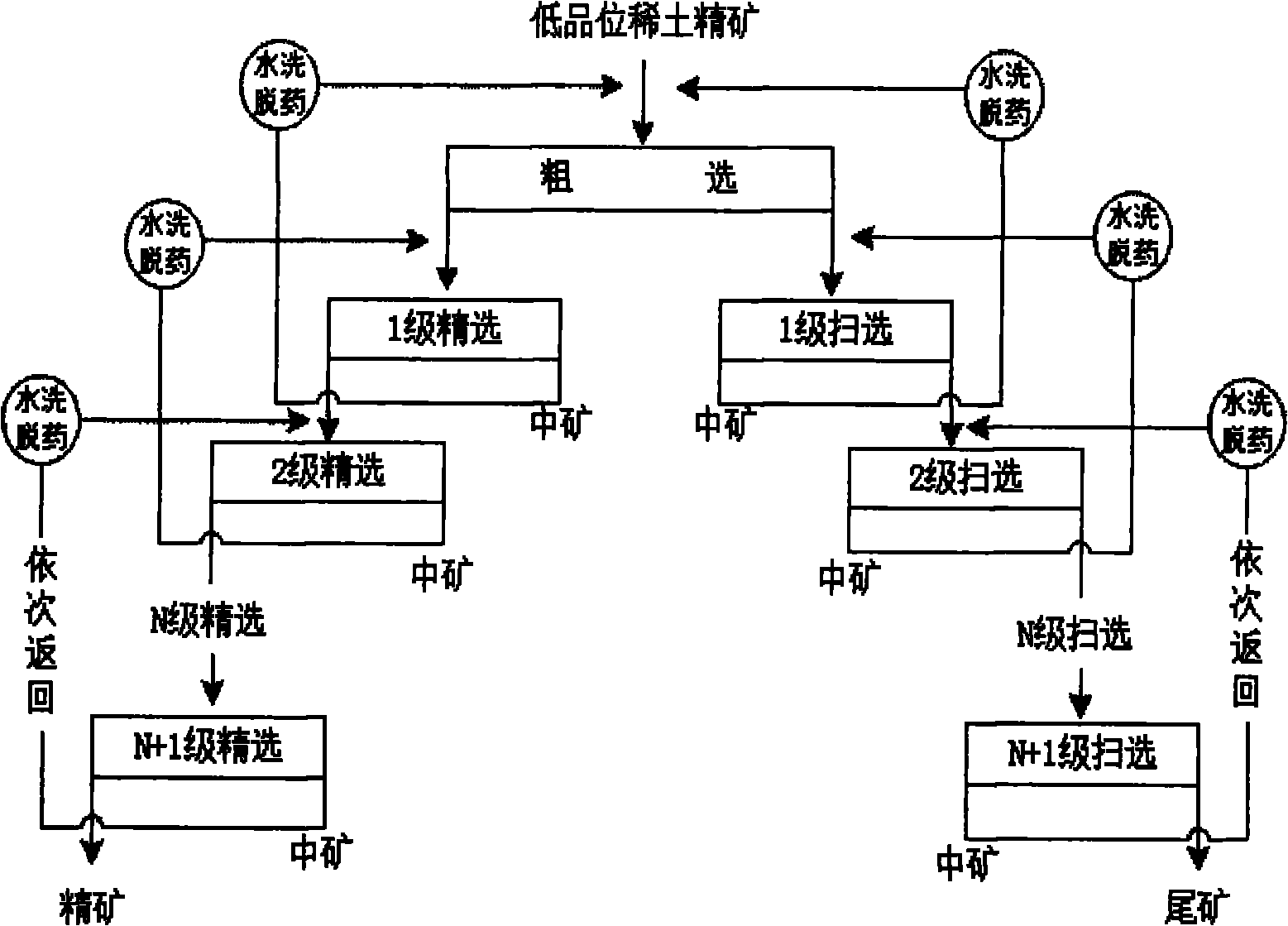

Beneficiation method for improving rare earth grade of rare earth ore

The invention relates to a beneficiation method for improving rare earth grade of rare earth ore, and belongs to the technical field of beneficiation technologies. The method is a beneficiation method by using low-grade rare earth ore concentrate to prepare high-grade rare earth ore concentrate and is characterized in that: the low-grade rare earth ore concentrate of which rare earth ore (REO) grade is below 60 percent and which is widely used in conventional production is used as a raw material; a washing reagent removal process which is never used in the traditional rare earth beneficiationis adopted in a beneficiation technology; and the whole flotation process adopts a mode of closed cycle beneficiation, so middling ore cannot be produced, and the grade and the recovery rate of the ore concentrate are improved. The invention has the remarkable characteristics that: the high-grade rare earth ore concentrate of which the REO grade is more than or equal to 65 percent and the recovery rate is more than or equal to 95 percent are produced, and high-quality raw materials are provided for effective improvement of the traditional rare earth smelting technology.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

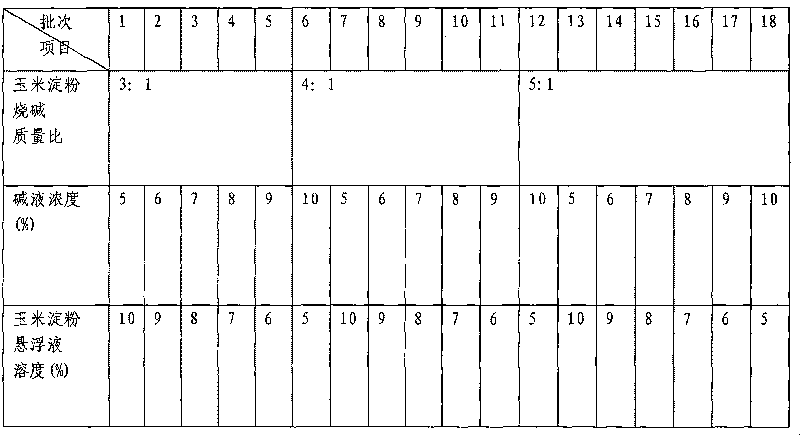

Corn starch pasting method

The invention discloses a conventional corn starch pasting method, which comprises the following steps: weighing raw materials in a mass ratio of corn starch to sodium hudroxide being 3-5:1; preparing the sodium hudroxide into 5 to 10 percent suspended alkali liquor; preparing the corn starch into 5 to 10 percent suspension; adding the sodium hudroxide solution into the corn starch suspension with stirring, standing for 3 to 10 minutes to prepare alkalified starch colloid, and diluting to required concentration when the alkalified starch colloid is used. The corn starch pasting method overcomes the defects of high energy consumption, low utilization rate and poor depression effect of the conventional method, and has low energy consumption, high utilization rate of the corn starch, and good suppression effect selectivity.

Owner:湖南省铸万有实业有限公司 +1

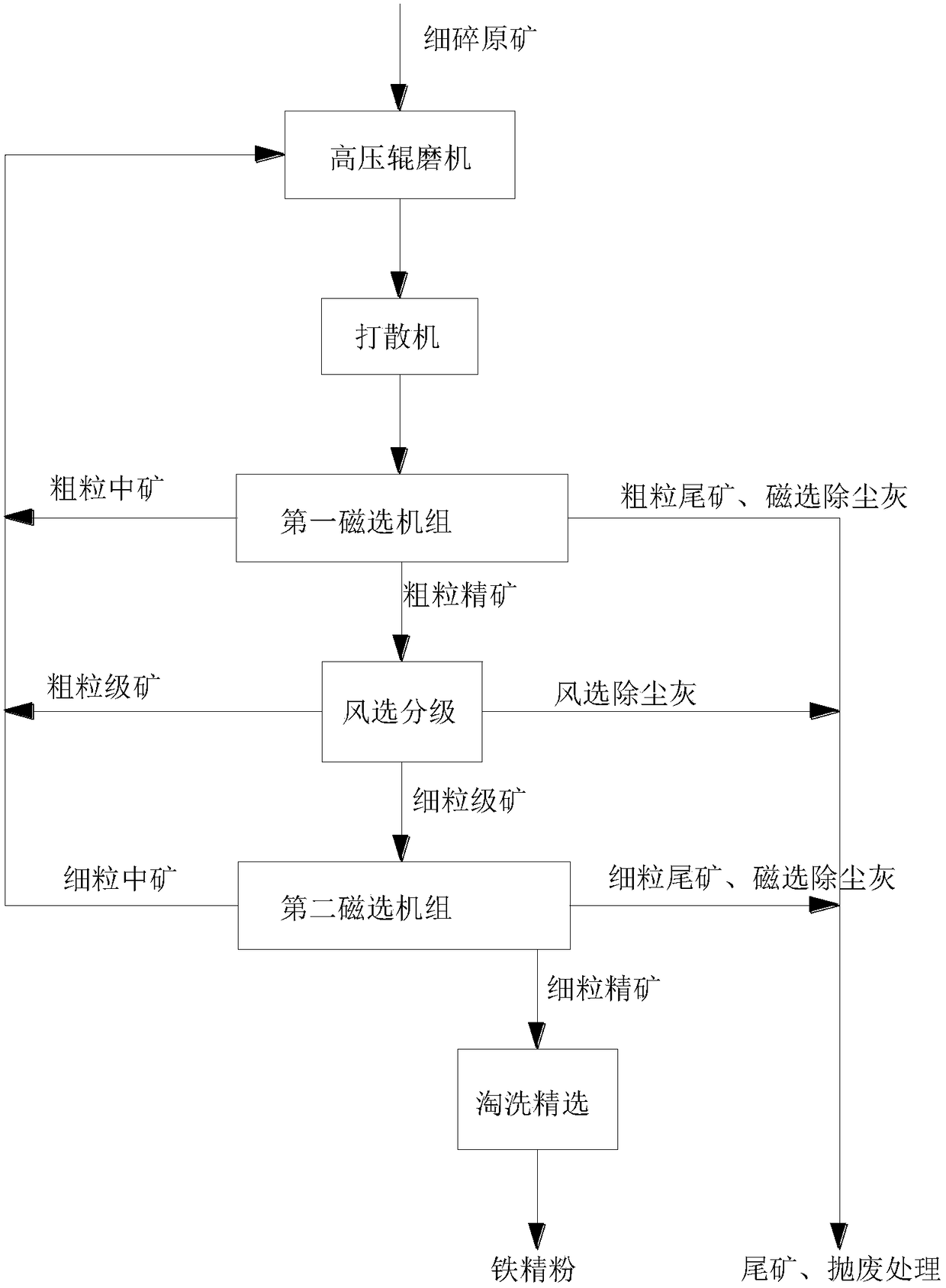

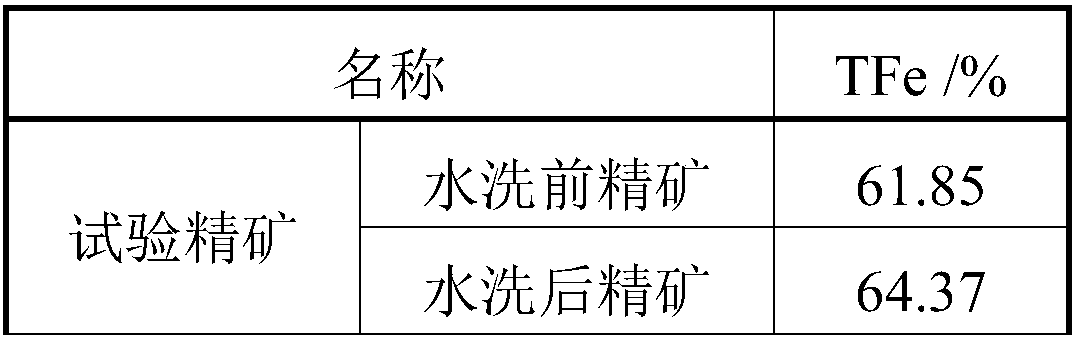

Fine product dry type separation iron fine powder technology

InactiveCN108380380AGreat tasteReduce processing loadGrain treatmentsWet separationIron powderMagnetic separator

The invention relates to the technical field of beneficiation in the metallurgical industry, and relates specially to a fine product dry type separation iron fine powder technology. The fine product dry type separation iron fine powder technology comprises the following steps that (1) a crushed raw ore is extruded into a material cake through a high-pressure grinding roller, the material cake is broken and merged into a magnetic separator unit to carry out magnetic separation, and coarse-size tailings separation and coarse-size middlings are obtained and returned to the high-pressure grindingroller; (2) coarse-size concentrates obtained in step (1) are subjected to winnowing classification to obtain coarse-size ore and fine-size ore, the coarse-size ore is returned to the high-pressure grinding roller in the step (1), the fine-size ore is subjected to the magnetic separation by the magnetic separator unit to obtain fine powder concentrates, fine powder middling concentrates and fine powder tailings; and the fine powder middling concentrates are returned to the high-pressure grinding roller; and (3) the fine powder concentrates obtained in the step (2) is subjected to elutriation and concentration to obtain the iron fine powder. According to the technology, through cooperation with the reasonable cooperation with magnetic separation and the winnowing, impurities which are useless are thrown away as early as possible; and meanwhile, double magnetic separation treatments are carried out, so that the grade of the final iron fine powder is improved, and the ore dressing efficiency of equipment is improved.

Owner:安徽马钢张庄矿业有限责任公司

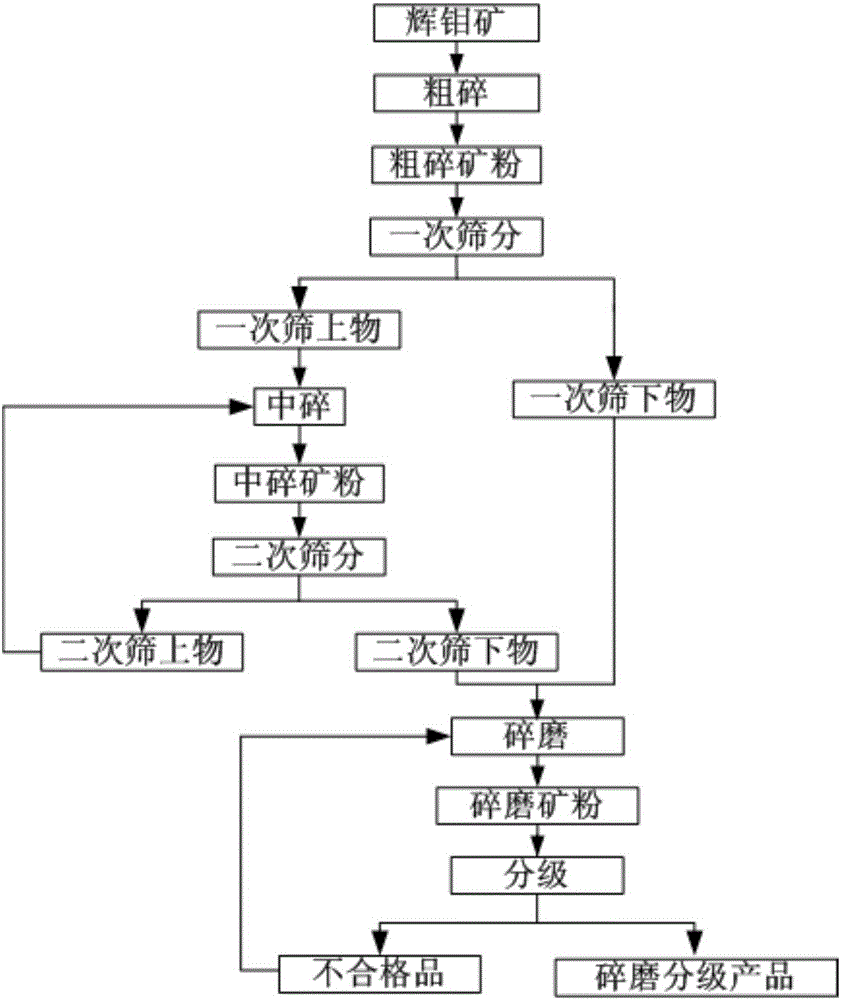

Smashing and classifying technology for molybdenite

The invention provides a smashing and classifying technology for molybdenite. The technology comprises the following steps that first, a gyratory crusher is used for conducting coarse crushing treatment on the molybdenite, so that coarsely-crushed mineral powder is obtained; then primary screening is carried out, and accordingly primary oversize products and primary screen underflow are obtained; second, a cone crusher is used for conducting intermediate crushing treatment on the primary oversize products, so that intermediately-crushed mineral powder is obtained; then secondary screening is carried out, and accordingly secondary oversize products and secondary screen underflow are obtained; third, the primary screen underflow and the secondary screen underflow are evenly mixed and then added into a high-pressure grinding roller to be smashed, so that smashed mineral powder is obtained; and fourth, the smashed mineral powder is classified, and hence smashed and classified products with the granularity D55 being smaller than or equal to 0.074 mm are obtained. By the adoption of the smashing and classifying technology, the technical problems that the process is long, the number of devices is large, smashing and classifying production cost is high, classification efficiency is low, easy-to-select size fraction content of the mineral is low, and the molybdenum selection recovery rate is affected in the prior art are effectively solved. The application prospect is broad.

Owner:JINDUICHENG MOLYBDENUM CO LTD

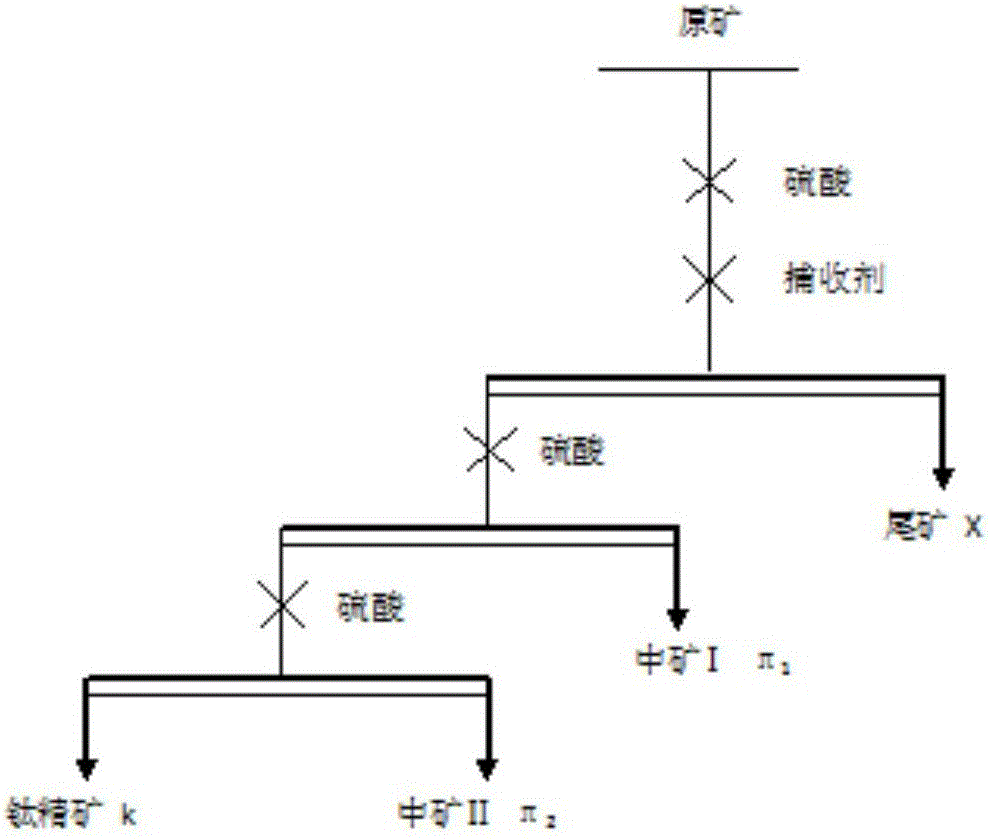

Ilmenite floatation collecting agent, and preparation method and application thereof

InactiveCN106238219ASimple preparation processEasy to operateFlotationHigh pressureCoordination complex

The invention relates to an ilmenite floatation collecting agent, and a preparation method and application thereof. The collecting agent is prepared by performing reaction on cottonseed oil waste, mixed fatty acid, triethylene-tetramine hexmethanephonic acid, higher fatty hydroximic acid and strong alkali in a high-pressure reaction kettle for 2 to 5 hours at the temperature of 140 to 180 DEG C, wherein the weight ratio of the cottonseed oil waste, the mixed fatty acid, the triethylene-tetramine hexmethanephonic acid, the higher fatty hydroximic acid and the strong alkali is (2-4.5):(3-5):(0.2-0.5):(0.2-0.5):(1-2). When the collecting agent provided by the invention is used for floatation, rough floatation is conducted at first and then concentration is conducted twice. The higher fatty hydroximic acid, which is one of the raw materials, is a good metal complexing agent and enhances the complexing ability with Ti4+ plasma to enable the Ti4+ plasma to form a stable complex, so that ilmenite ore can be floated effectively; in addition, the mixed fatty acid has high foamability after being chemically modified, so an extra foaming agent is not needed. The collecting agent provided by the invention has the advantages of high normal-temperature selectivity, high dispersibility, small reagent dosage, high mineral separation comprehensive efficiency and the like, is suitable for floatation production of various kinds of ilmenite, and has very important significance to promote the development of ilmenite beneficiation.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

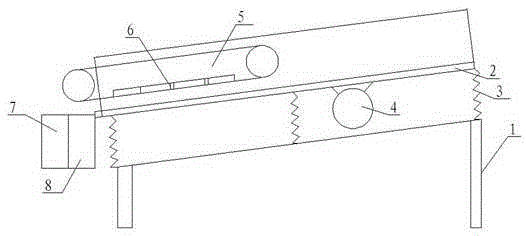

Vibration type magnetic separator for mine

ActiveCN105344470ASmall footprintImprove adaptabilityMagnetic separationMagnetic separatorEngineering

The invention discloses a vibration type magnetic separator for a mine, and belongs to the technical field of mine machinery. The vibration type magnetic separator for the mine comprises a frame, wherein the frame is provided with an inclined vibration flowing plate; the vibration flowing plate is arranged on the frame through a vibration spring; a vibration exciter is arranged on the bottom surface of the vibration flowing plate; magnetic separation equipment is arranged above the lower end of the vibration flowing plate; a nonmagnetic ore port and a magnetic ore port are formed in the tail end of the vibration flowing plate; and the magnetic ore port is aligned to an ore polishing place of the magnetic separation equipment. The vibration type magnetic separator for the mine is simple and compact, and is small in floor area; and the vibration plate and the magnetic separation equipment are combined, so that a magnetic material in a mineral is exposed on the surface and absorbed by a magnetic system, and the absorptivity of the magnetic material in the mineral is greatly improved.

Owner:盐城市锐金磨料磨具有限公司

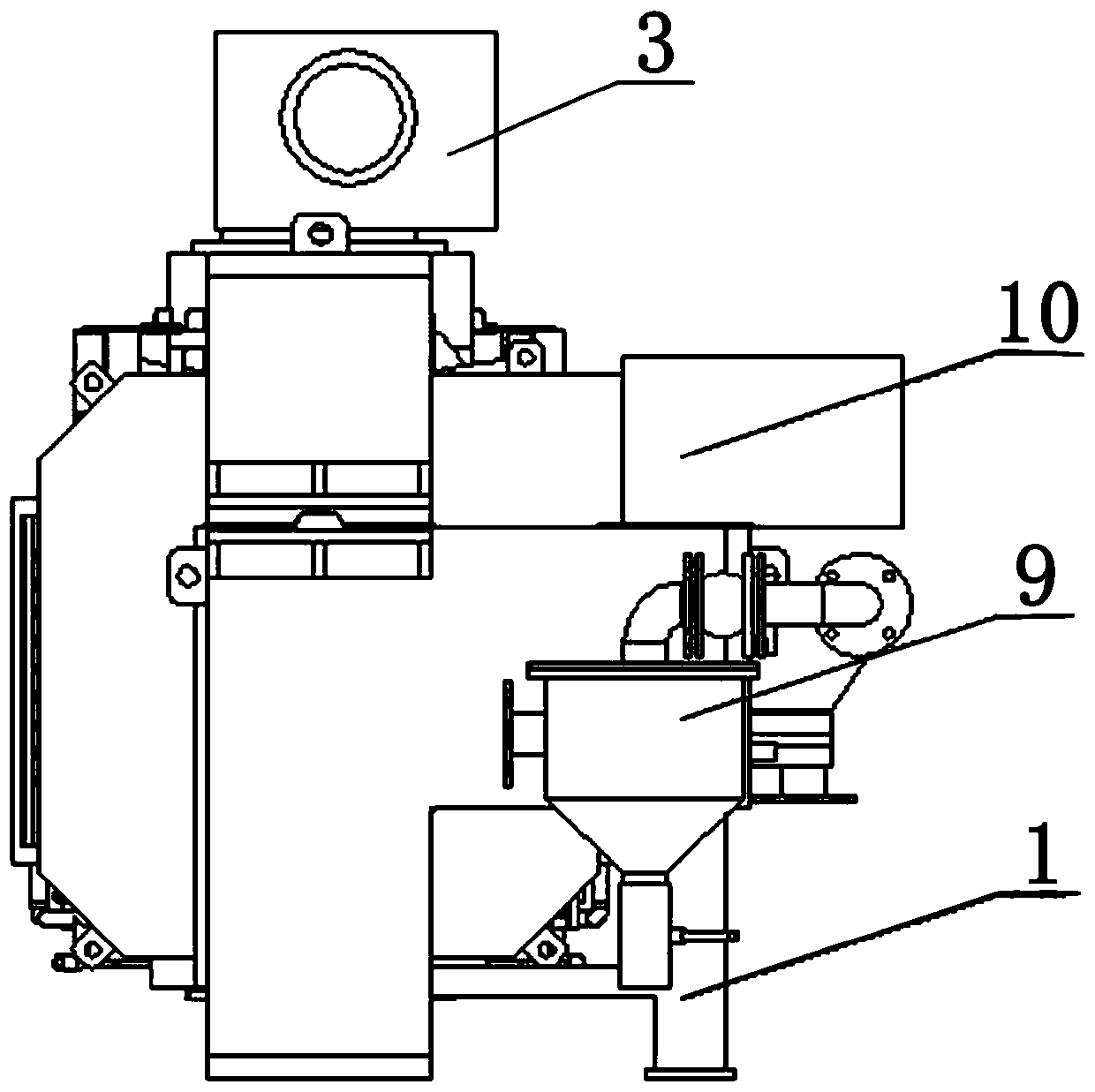

Magnetic separator

PendingCN107552225AIncrease the magnetic field strengthImprove beneficiation efficiencyHigh gradient magnetic separatorsMagnetic separatorContinuous operation

Disclosed is a magnetic separator. The magnetic separator comprises a machine frame, a rotating ring, a horizontal rotating drive mechanism and an exciting device which is arranged on the machine frame and used for generating a horizontal separation magnetic field. A medium mixing box is arranged on the rotating ring. A water-vapor combined washing device used for washing and discharging the medium mixing box from the side face is arranged beside the rotating ring. Materials are fed from the upper end face of the rotating ring and are further discharged out of the lower end face of the rotating ring after separation. The feeding and discharging direction is perpendicular to the washing and discharging direction. By adoption of the structure that the feeding and discharging direction is perpendicular to the washing and discharging direction, as long as the thickness (washing and discharging depth) of the medium is unchanged, the sorting height of the medium box can be designed accordingto the magnetic property requirements of sorted substances without affecting the washing and discharging effect of the medium box, stable and continuous operation of equipment is guaranteed, and blocking can be avoided; the sorting gradient is increased by using the medium mixing box, and the grading effect is effectively improved; and the moisture content of the discharged substances is effectively lowered through the water-vapor combined washing device on the side face, the follow-up treatment difficulty is lowered, and reliable and practical technical equipment is provided for sorting weakly magnetic substances.

Owner:广东省资源综合利用研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com