Method for recycling metal iron from steel slag of converter

A technology for converter steel slag and metal iron, which is applied in the field of recycling metal iron resources and metal iron from converter steel slag, can solve the problems of restricting the popularization and application of recycling technology, low iron recovery rate, and low metal iron recovery rate, so as to reduce construction costs. Investment costs and subsequent beneficiation costs, effects of improved quality, high ferrous metal recovery and product grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

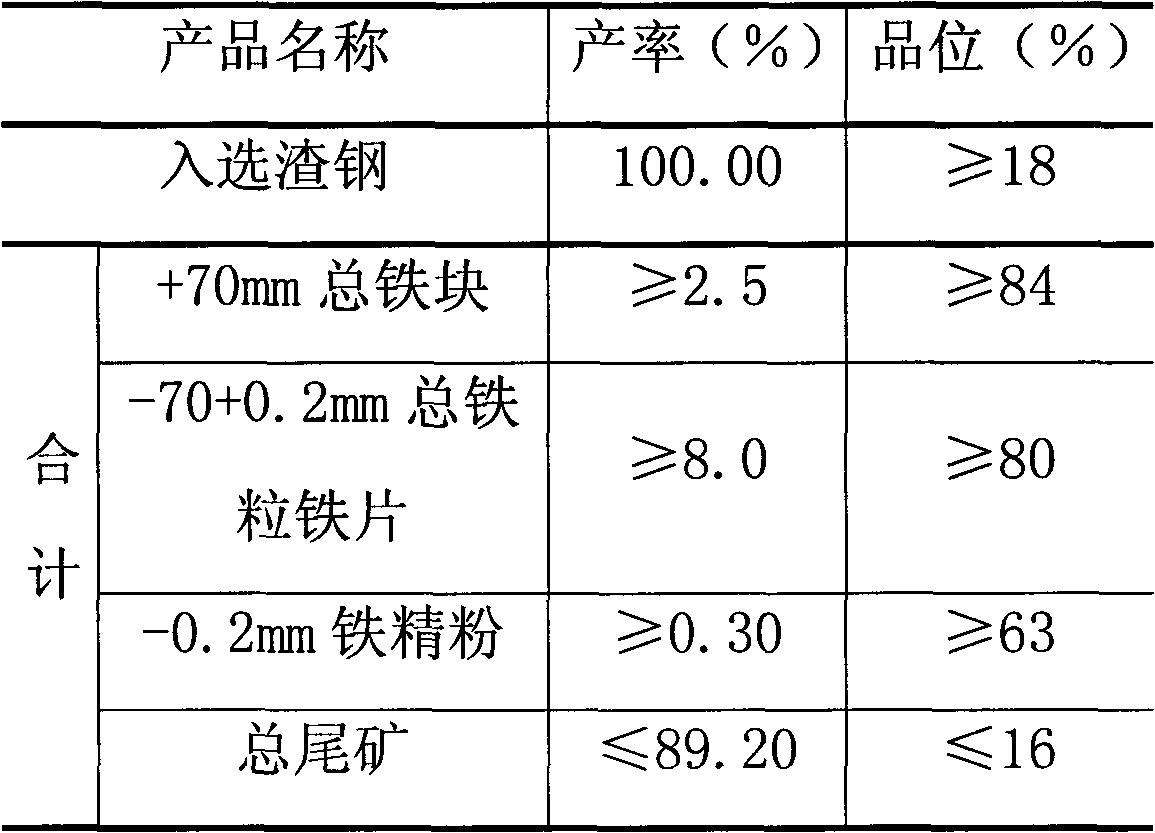

[0021] In a pilot test, the daily processing capacity is 20t / d, and the steel slag grade is 17.67%.

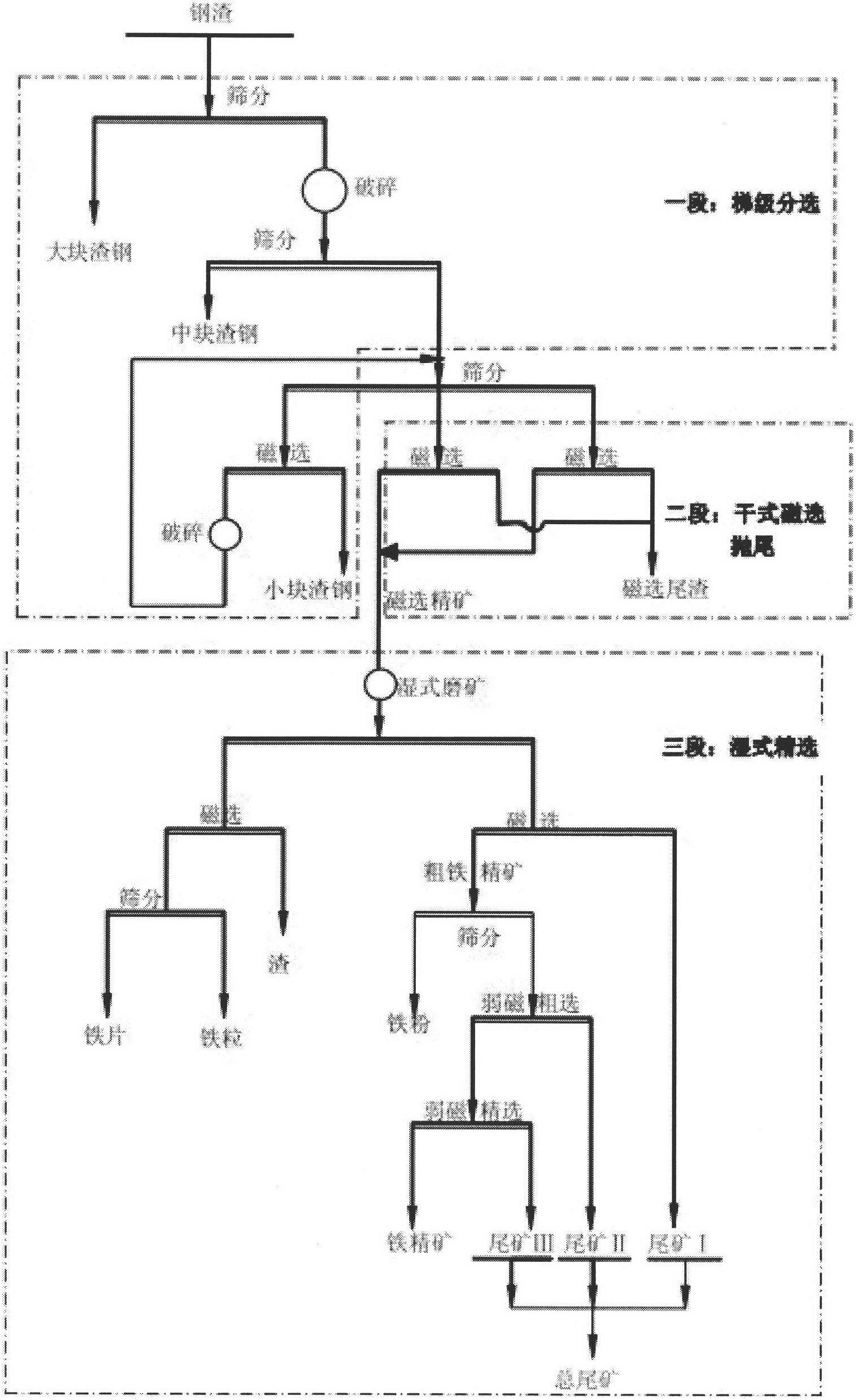

[0022] The metal iron in the converter steel slag is recovered by the method shown in the attached figure. The converter steel slag is firstly recovered by a rod screen to recover the large slag steel of +300mm. Bar sieve screening and manual selection are used to select -300+130mm large slag steel, and the +130mm large steel slag is returned to the jaw crusher for crushing; -130mm steel slag is screened by a grading 70mm sieving machine into -130+70mm And -70mm two grades; -130+70mm steel slag is sorted with a magnetic pulley (magnetic field strength of 800Oe) to select the medium-130+70mm high-grade slag steel, and the -130+70mm tailings are crushed with a jaw crusher Return to 70mm sieving machine screening; -70mm steel slag is classified into -70mm+25mm sieving and -25mm two particle sizes for dry magnetic separation (magnetic drum) throwing, the magnetic field strength is...

Embodiment 2

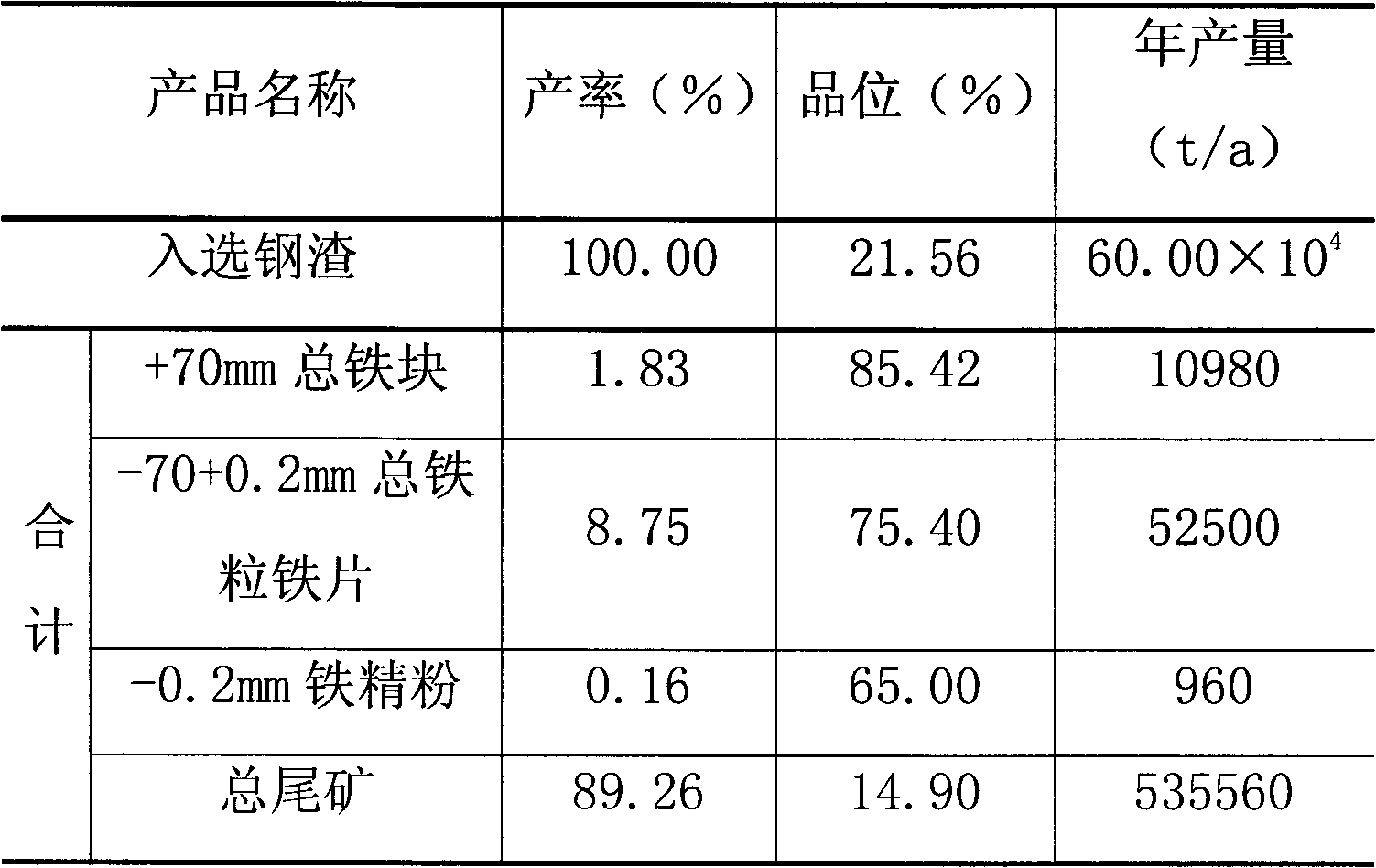

[0027] The annual output of converter steel slag in a large-scale steelmaking enterprise in Yunnan is 600,000t / a (2000t / d), and the grade of steel slag is 21.56.

[0028] The metal iron in the converter steel slag is recovered by the method shown in the attached figure. The converter steel slag is firstly recovered by a rod screen to recover the large slag steel of +300mm. The large slag steel of -300+130mm and the steel slag of -130+70mm grain size are screened out by the bar sieve, which is further crushed by the jaw crusher and then passed through the sorting method of vibrating screen + magnetic pulley (magnetic field strength is 1000Oe) to select the middle block High-grade slag steel; -70mm coarse concentrate is wet-type full-size grinding with a rod mill (grinding time 15min), and the pulp after grinding is screened with a +1mm drum sieve, and the +1mm particle size obtained after screening After dry magnetic separation (1500Oe magnetic drum) to remove slag, then use +1...

Embodiment 3

[0033] The annual output of converter steel slag in a steelmaking enterprise in Yunnan is 260,000t / a, and the grade of steel slag is 20.98.

[0034] The metal iron in the converter steel slag is recovered by the method shown in the attached figure. The converter steel slag is firstly recovered by a rod sieve to recover the large slag steel of +300mm. The large slag steel of -300+130mm and the steel slag of -130+70mm grain size are screened out by the bar sieve, which is further crushed by the jaw crusher and then passed through the sorting method of vibrating screen + magnetic pulley (magnetic field strength is 1800Oe) to select the middle block High-grade slag steel; -70mm coarse concentrate is wet-type full-size grinding with a rod mill (grinding time 20min), and the pulp after grinding is screened with a +1mm drum sieve, and the +1mm particle size obtained after screening After dry magnetic separation (2000Oe magnetic drum) to remove slag, then use +10mm vibrating screen to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com