Patents

Literature

230results about How to "Reduce construction investment costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

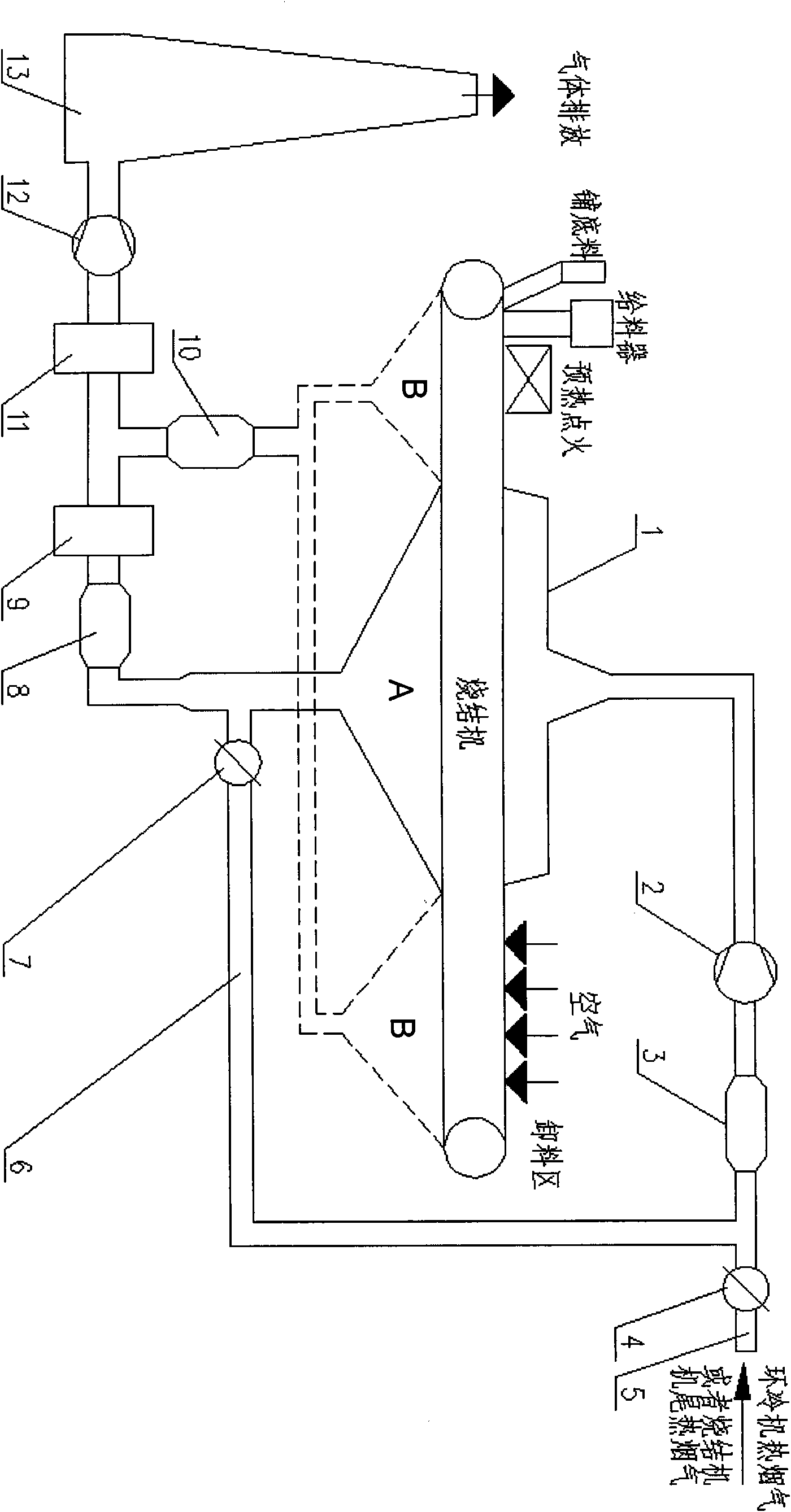

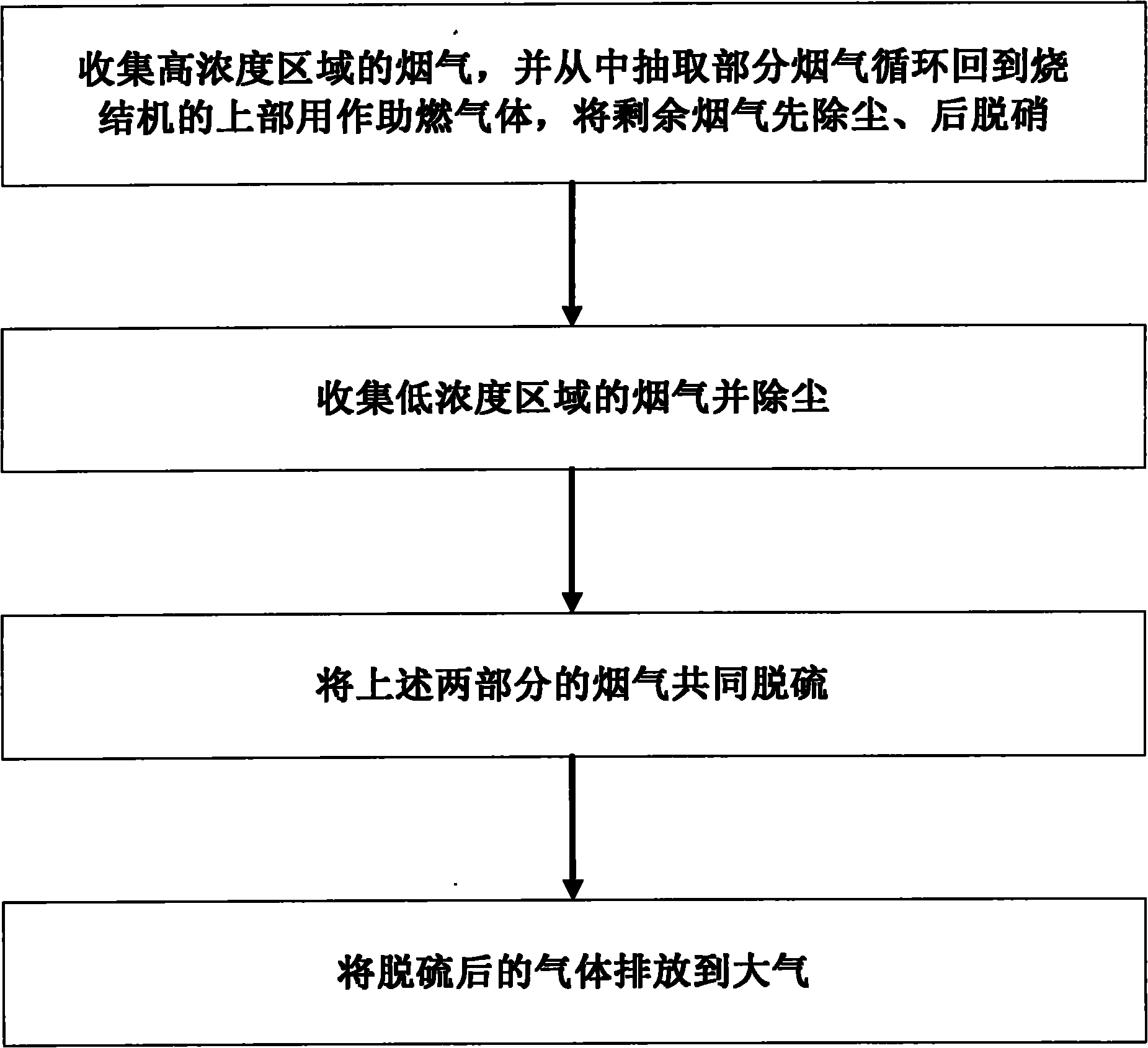

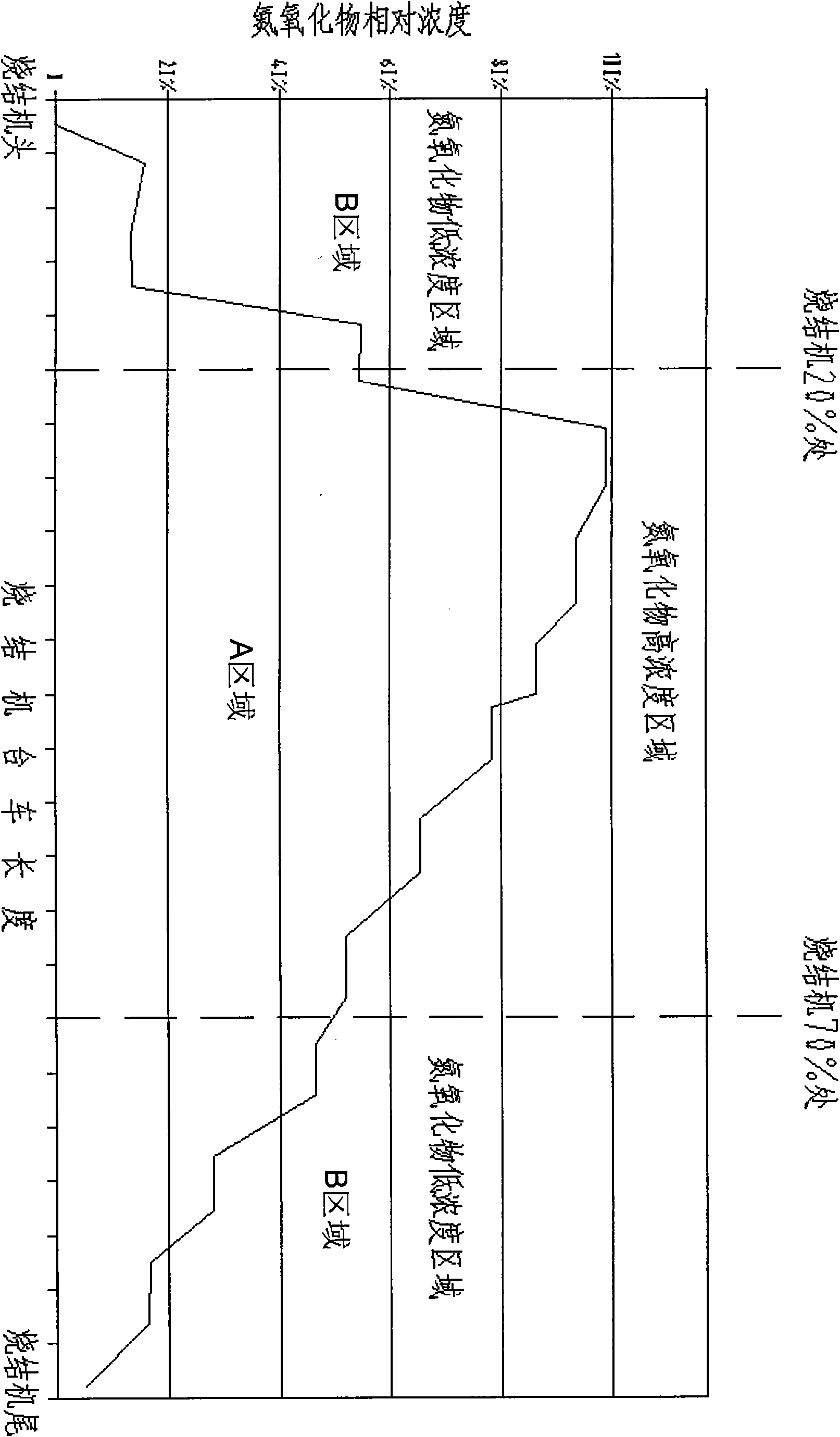

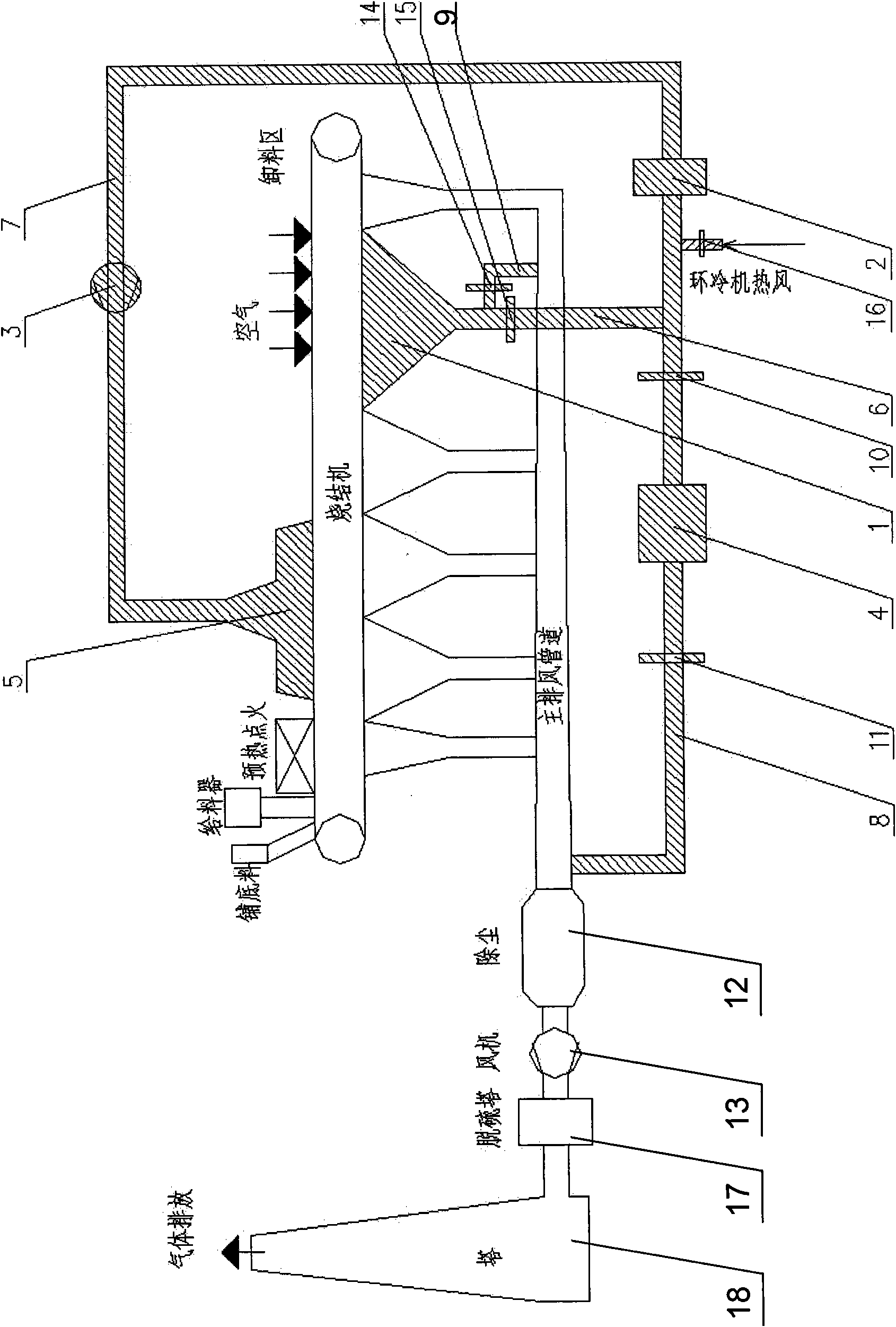

Emission reduction system of sintered fume nitric oxide with low energy consumption and method thereof

InactiveCN101829481ASimple systemSimple operation management and maintenanceDispersed particle separationNitric oxideHigh concentration

The invention relates to an emission reduction system of sintered fume nitric oxide with low energy consumption and a method thereof. The system comprises a nitric oxide high-concentration region air bellow A, a nitric oxide low-concentration region air bellow B, a denitration dust remover, a denitration device, a dust remover, a desulfuration device, a main exhaust fan, an emission chimney and a circulation loop. The denitration dust remover is connected with the air bellow A to collect the fume in the air bellow; the denitration dust remover is sequentially connected with the denitration device and the desulfuration device; and the fume subjected to dust removal and denitration is guided into the desulfuration device. The dust remover is connected with the nitric oxide low-concentration region air bellow B to collect the fume; the dust remover is connected with the desulfuration device; and the fume subjected to dust removal is guided into the desulfuration device. The desulfuration device is sequentially connected with the main exhaust fan and the emission chimney so as to desulfur the fume and discharge into the atmosphere. The circulation loop at least comprises a circulation fume hood, a circulation blower, a circulation fume dust remover and a circulation pipeline. The method comprises the following steps of collecting fume, removing dust, denitrating, desulfuring, discharging fume into the atmosphere and the like. The whole system is relatively simple and has obvious effects of energy saving and emission reduction.

Owner:BAOSTEEL ENG & TECH GRP

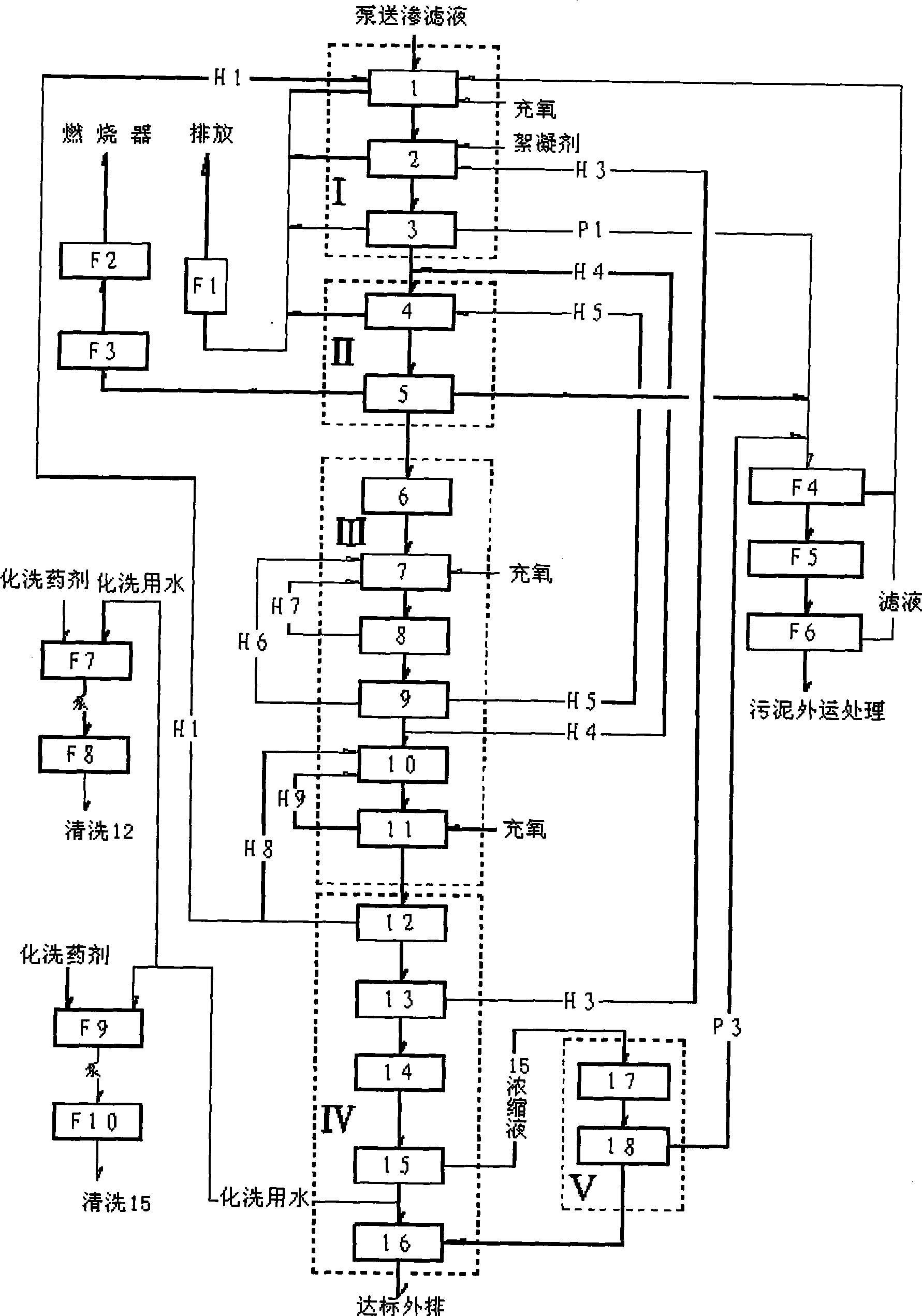

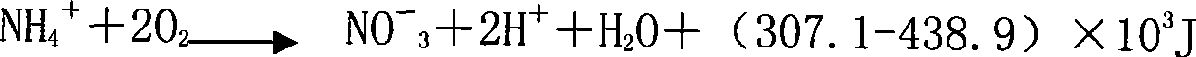

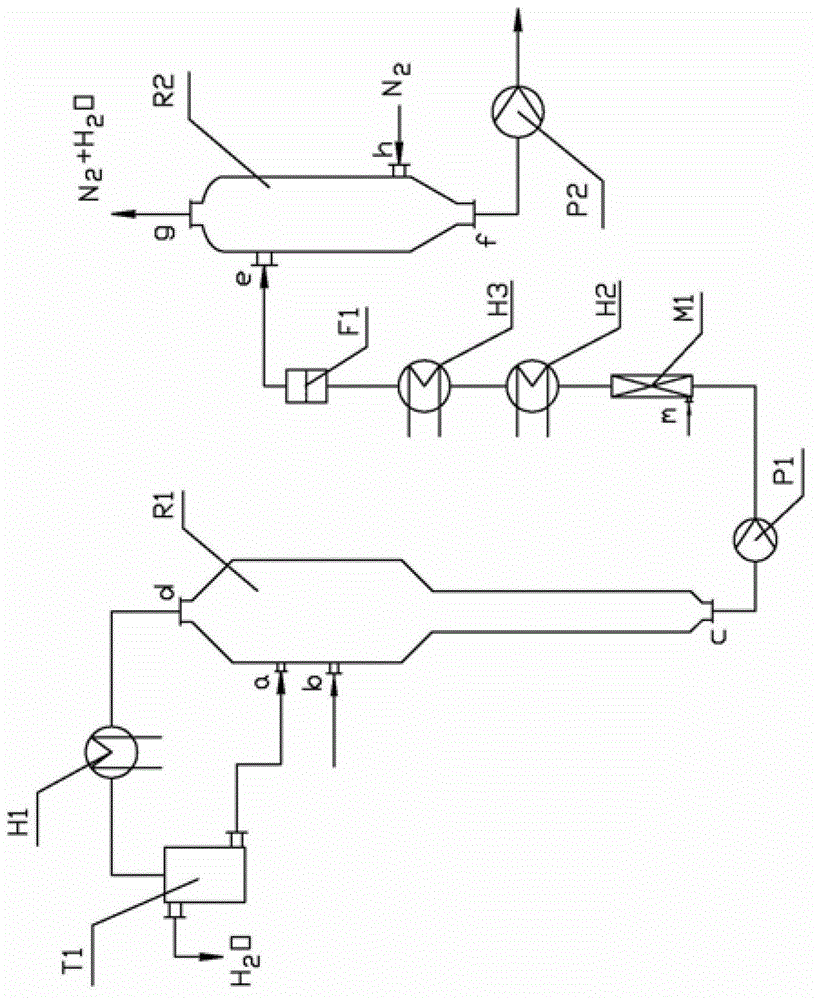

Treatment process for garbage leachate

ActiveCN101428938AImprove biodegradabilityPrevent rancidityTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisFlocculationHydrolysis

The invention discloses a method for treating landfill leachate, which orderly comprises flocculation precipitation pretreatment, hydrolysis pre-acidification treatment, anaerobic treatment, aerobic treatment comprising shortcut nitrification-denitrification and secondary nitrification-denitrification, membrane separation treatment and oxidation flocculation treatment. The method has the advantages of having higher removal rate of ammonia nitrogen and lower energy consumption, realizing the up-to-standard discharge of leachate concentrated solution, ensuring sound operation of the whole system, greatly lowering the oxidation-reduction potential in the anaerobic reaction, and improving the anaerobic treatment effect, thereby making the landfill leachate fully meet the first-level discharge standard of the Integrated Wastewater Discharge Standard.

Owner:浙江永峰环保科技股份有限公司 +1

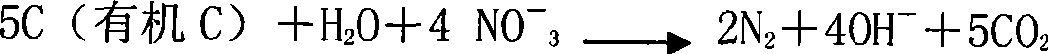

Environmental-protection and energy-conservation treatment technology of sintering flue gas

ActiveCN105509491AIncrease concentrationLow investment costGas treatmentDispersed particle separationCombustionMetallurgy

The invention discloses an environmental-protection and energy-conservation treatment technology of sintering flue gas, and belongs to the technical field of energy conservation and environmental protection. Flue gas having high SO2 concentration and very low NOx concentration at a sintering head is subjected to dust removal, and is mixed with hot flue gas in a flue gas hood at a second cooling section of a cooling machine to form circulating hot flue gas, and then flue gas circulating sintering is carried out; flue gas having high SO2 concentration and high NOx concentration at a sintering middle part is subjected to the dust removal and then flue gas desulfurization, the desulfurized flue gas is sintered and cooled by a flue gas heat exchanger, undergoes preheating temperature-rising, then undergoes pipeline complementary combustion temperature-rising to meet the requirement on SCR (Selective Catalytic Reduction) denitration temperature, flue gas denitration is carried out, and the denitrified flue gas is discharged; flue gas having low SO2 concentration and low NOx concentration at a sintering tail is subjected to the dust removal, and is mixed with hot flue gas in the flue gas hood at a first cooling section of the cooling machine to form high-temperature mixed flue gas, the high-temperature mixed flue gas is subjected to heat exchange by the flue gas heat exchanger, the flue gas after being subjected to heat exchange and cooled is directly discharged. According to the treatment technology, the effects of sectional desulfurization and denitration of sintering flue gas, and reduction in flue gas emission are realized; waste heat of the flue gas is used, so that the denitrified flue gas heating consumption is reduced; the construction investment and production running cost are reduced integrally; and the treatment technology corresponds with the running mode of energy conservation, environmental protection, emission reduction, consumption reduction, effect increasing and circular economy.

Owner:安庆沐尔环保科技有限公司

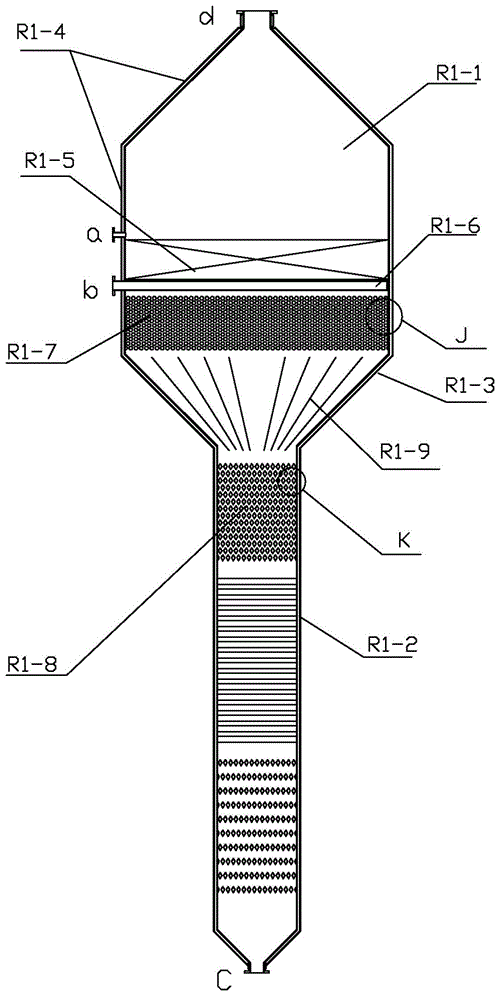

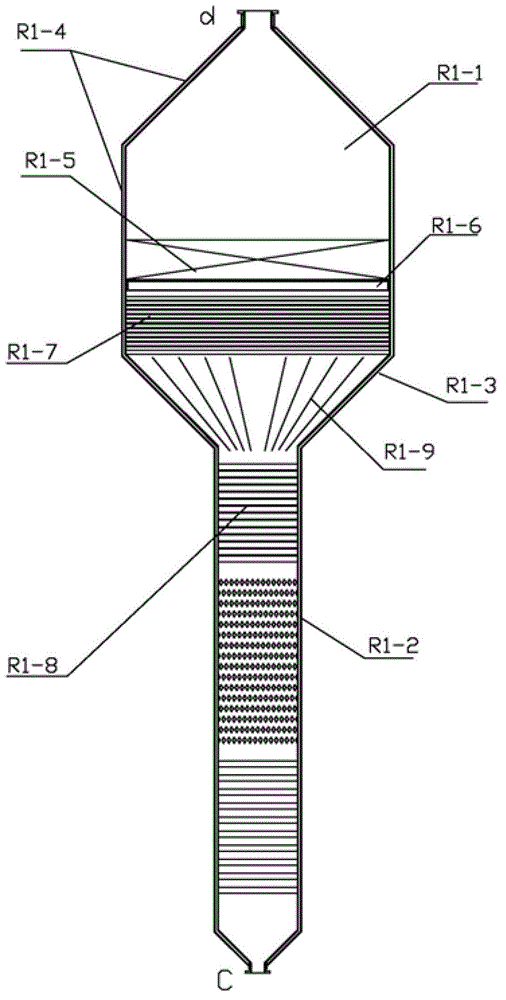

Method for continuously polymerizing nylon from bi-component monomer serving as raw material

The invention discloses a method for continuously polymerizing nylon from a bi-component monomer serving as a raw material. The method comprises the following steps of: reacting and rectifying a nylon salt aqueous solution serving as a raw material in a pre-condensing tower in which a liquid phase is a continuous phase, a gas phase is a dispersed phase and falling liquid and rising bubbles keep flat push flow respectively under a low pressure to generate a prepolymer of which the polymerization degree 5-50 (preferably 20-40) and a terminal carboxyl group, a terminal amino group and the like are of equal molar amounts; and pre-heating the pre-polymer to generate a polymer of which the polymerization degree reaches process indexes in the pre-condensing tower. In the pre-condensing tower, a film falling or strip falling method is adopted, so that evaporation of condensed water is accelerated, the reaction temperature is lowered, reaction time is shortened, and gel is reduced; and a kettle wall is coated with a falling liquid film, so that kettle wall scars are avoided. The method has the advantages of short flow, large mono-line scale, saving in investment, low running cost, good product quality, long continuous running period, environment friendliness and suitability for continually polymerizing nylon 66, nylon 56 and other nylon made of bi-component monomers serving as raw materials.

Owner:XCEED CHEMTECH

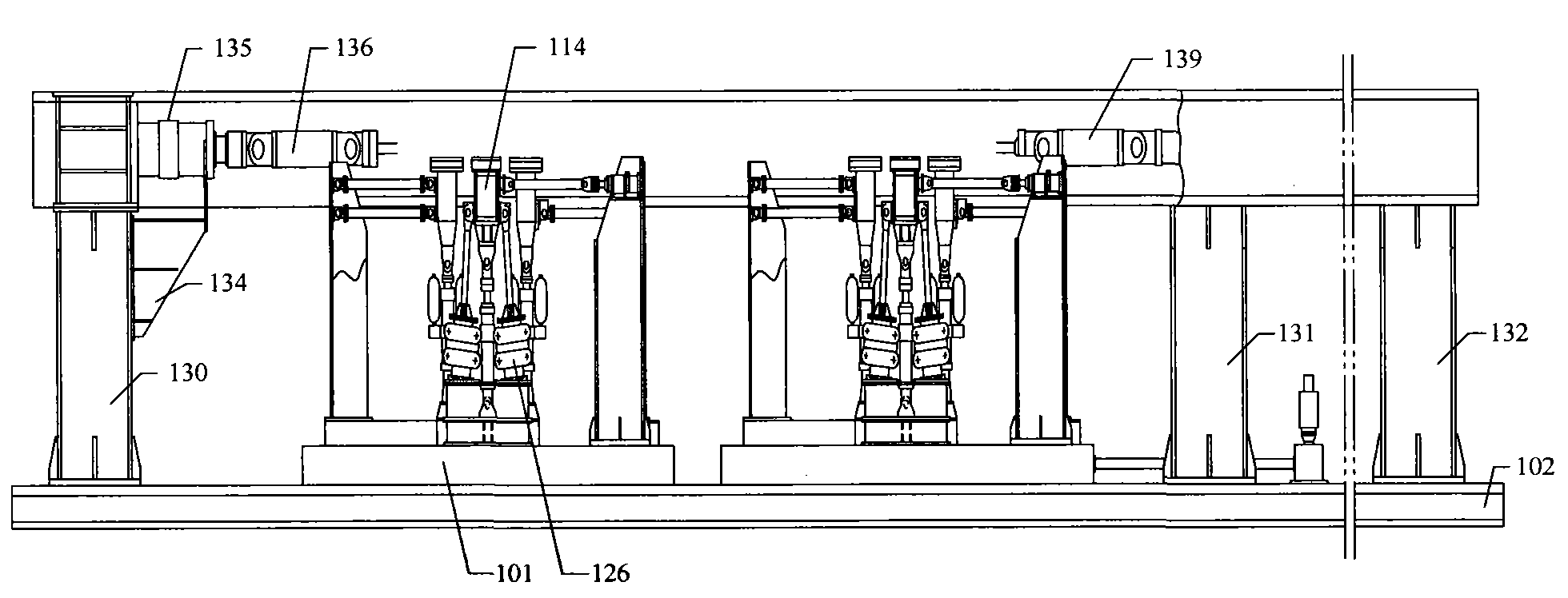

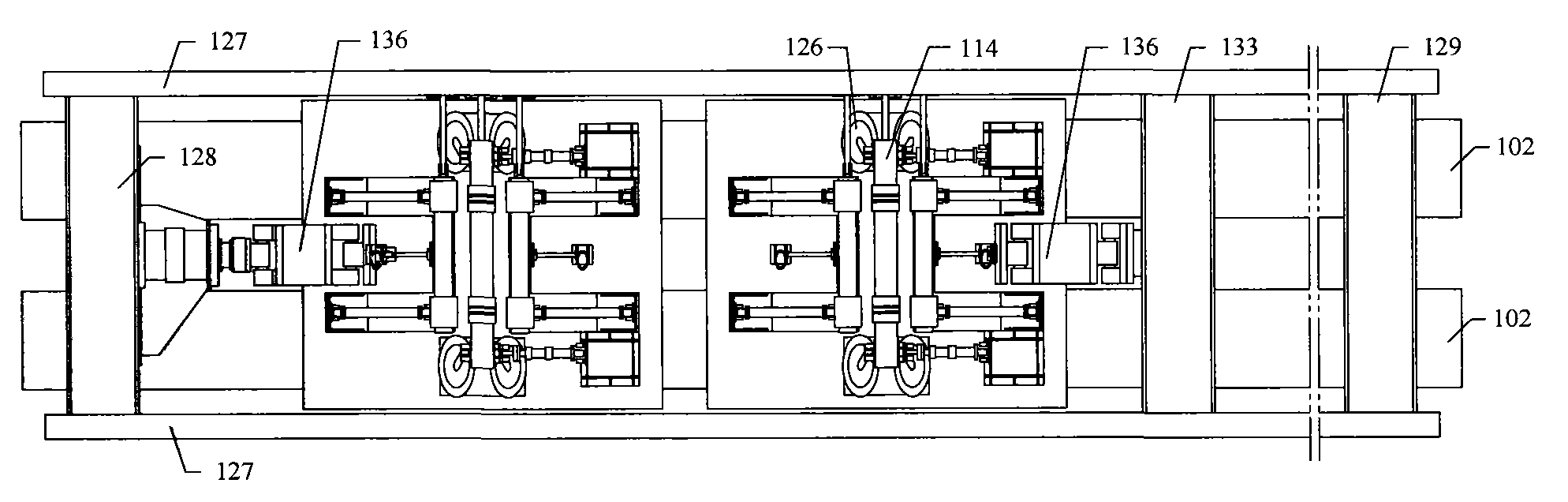

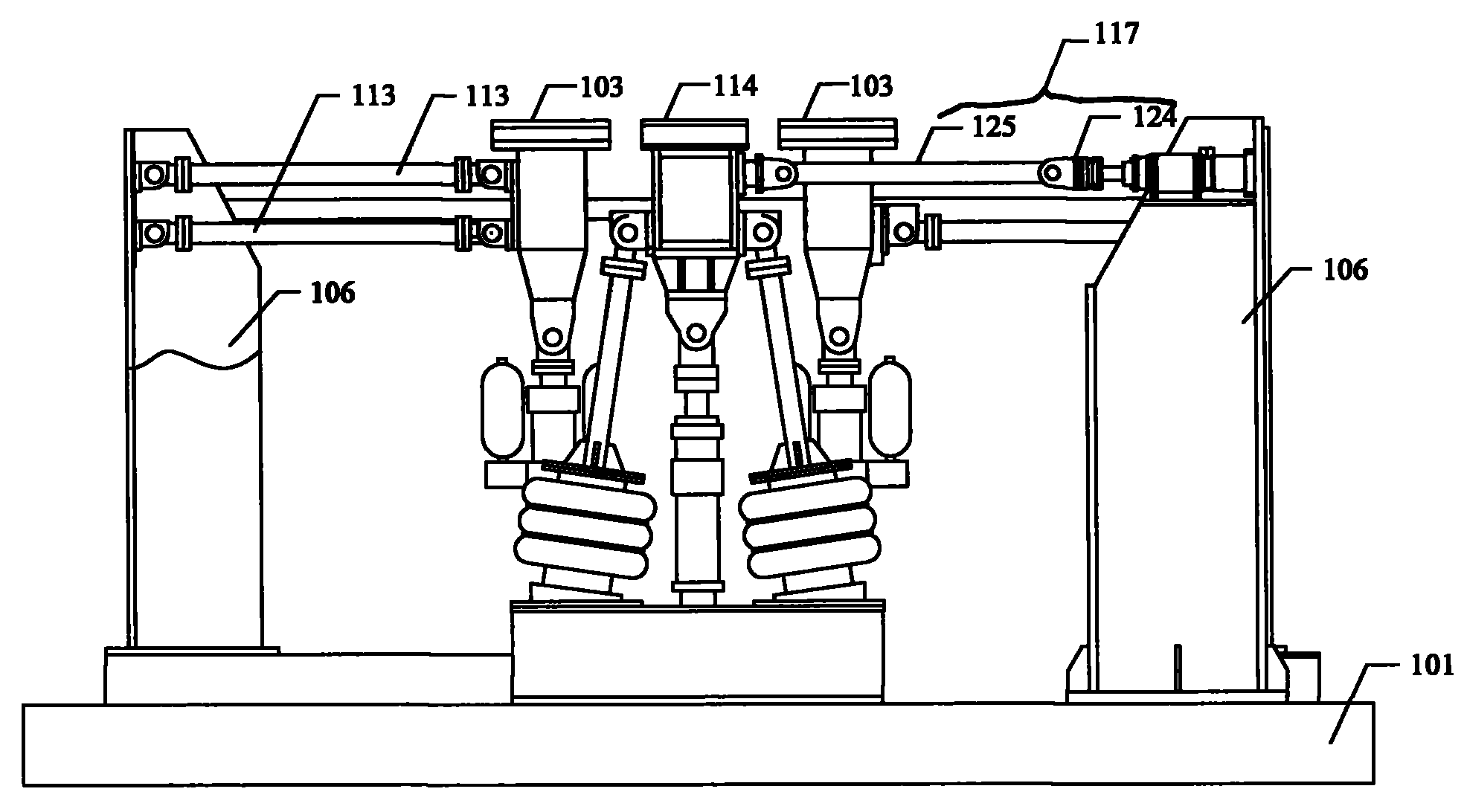

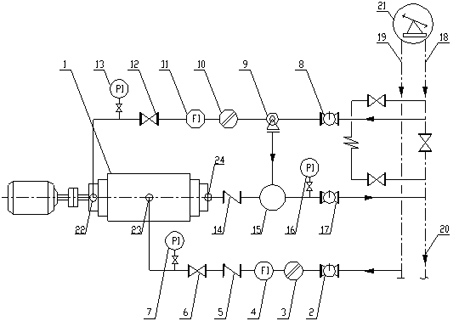

Fatigue and vibration experiment table and system

InactiveCN101788392ASolve the costSolution areaRailway vehicle testingVibration testingEngineeringSmall footprint

The invention provides a fatigue and vibration experiment table and a fatigue and vibration experiment system. The fatigue and vibration experiment table comprises two fatigue and vibration experiment modules, a longitudinal platform, a longitudinal loading framework and a longitudinal loading device, wherein each fatigue and vibration experiment module comprises two vibration units, a fatigue unit and a bearing platform; the two vibration units are arranged on the bearing platform in a sliding way; the fatigue unit is fixedly arranged on the bearing platform and is positioned between the two vibration units; and the bearing platform is arranged on the longitudinal platform in a sliding mode and slides in a frame body of the longitudinal loading framework. The technical scheme of the invention solves problem that separate fatigue experiment table and vibration experiment table are used to complete fatigue experiments and vibration experiments in the prior art, so the two experiment tables have high building and investment cost and large occupied area, fulfills the aim of integrating the fatigue experiment table and the vibration experiment table, and has the characteristics of low building and investment cost and small occupied area.

Owner:CRRC QIQIHAR ROLLING CO LTD

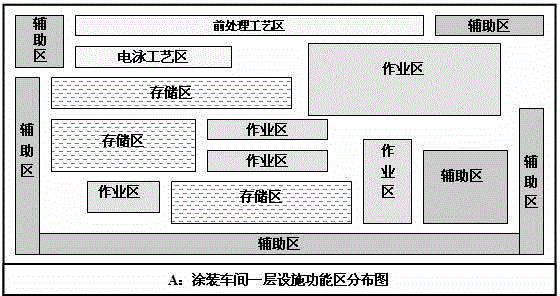

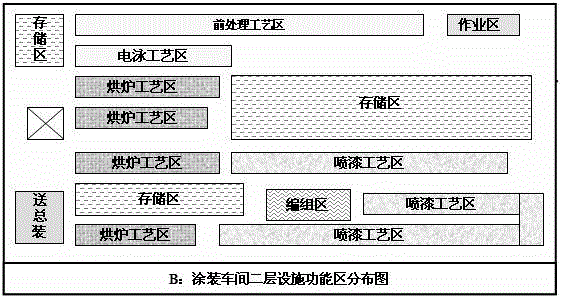

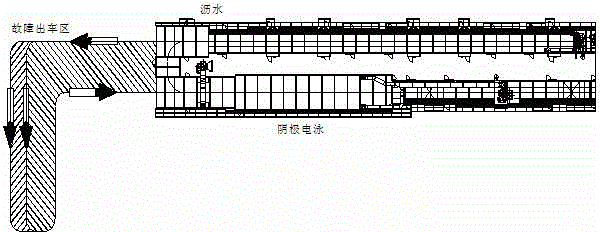

Implementation method for mixed routing production of different types of vehicles in vehicle coating line

InactiveCN103949380AReduce construction investment costsCompact process layoutLiquid surface applicatorsElectrophoretic coatingsIn vehicleTruck

The invention discloses an implementation method for mixed routing production of different types of vehicles in a vehicle coating line. The method comprises the following steps: (1) determining the types of the vehicles needing to be subjected to mixed routing production and a coating production process for each vehicle, and during mixed routing layout, only arranging a set of production equipment corresponding to the procedure on the vehicle coating line for the vehicles with the same procedure, so that all the vehicles with the procedure share the set of equipment, and the procedure operation is carried out; and (2) performing mixed routing production, namely when a vehicle body in white enters the vehicle coating line, identifying the type of the vehicle, transmitting the type of the vehicle to a control system, controlling the vehicle body to automatically operate by the control system according to a designed process route, and then performing corresponding treatment in each procedure. According to the method, the mixed routing production of different large-span types of vehicles such as economy cars, MPV (multi-purpose vehicles), minibuses and mini-trucks can be realized, so that the investment cost is greatly lowered, the production efficiency is improved, and the site occupation is reduced.

Owner:重庆同乘工程咨询设计有限责任公司

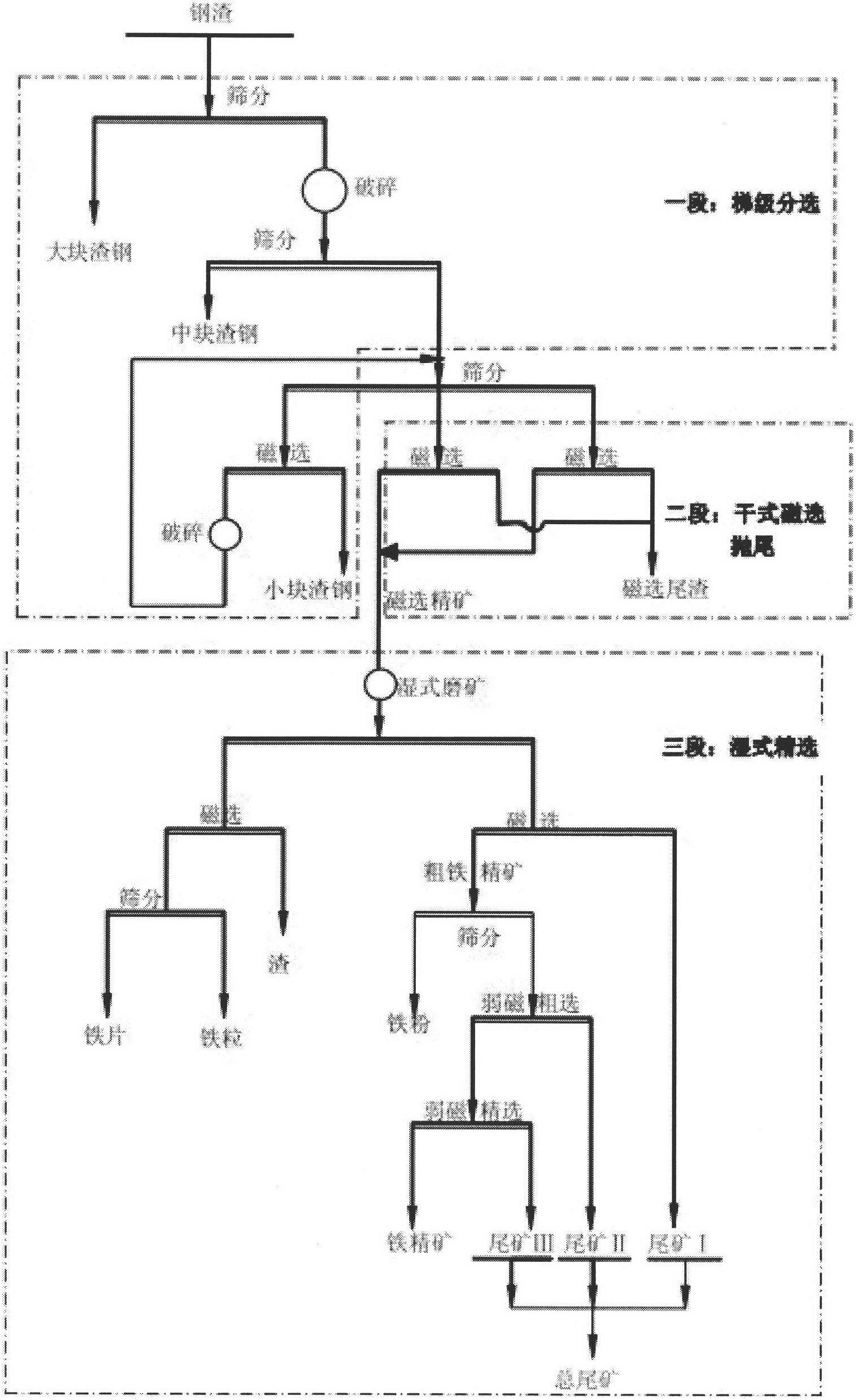

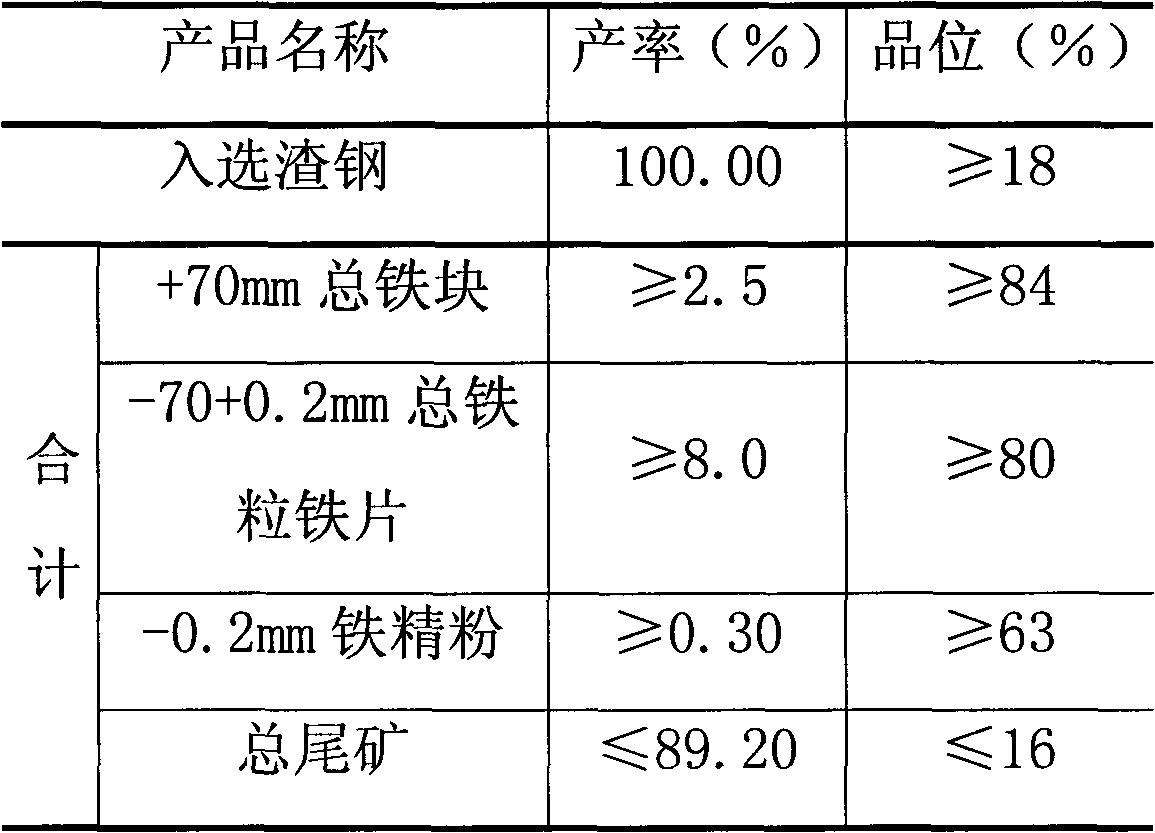

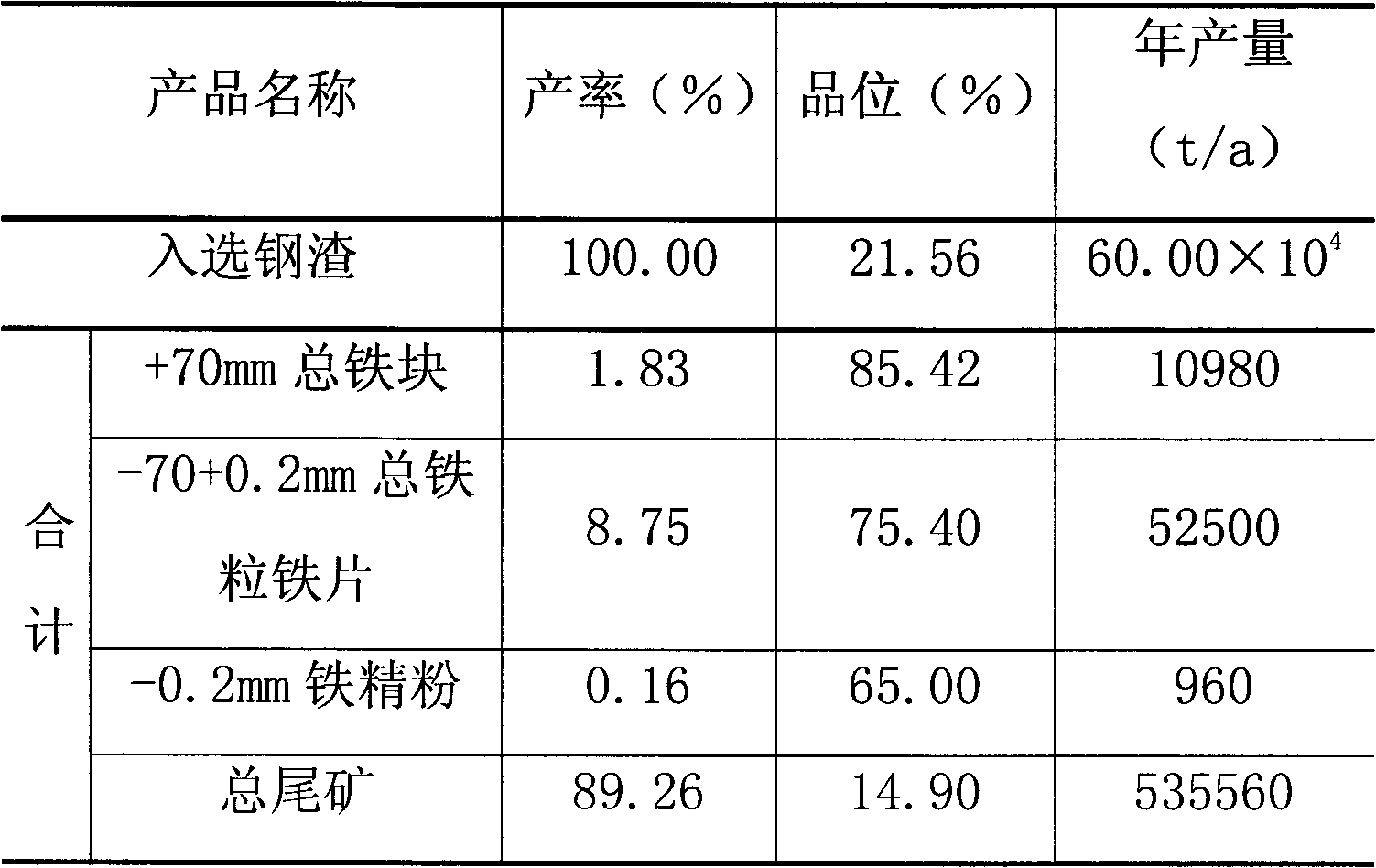

Method for recycling metal iron from steel slag of converter

ActiveCN102688804AHigh recovery rateImprove product qualityRecycling and recovery technologiesMagnetic separationSlagIron industry

The invention relates to a method for recycling metal iron resources from waste residues of the iron and steel industry, particularly relates to a method for recycling metal iron from steel slag of a converter, and belongs to the technical field of benefication and comprehensive utilization of resources. The method includes recycling the metal iron from the slag of the converter by a cascade separation technological method, a dry magnetic separation technological method for discarding tailings and a wet concentration technological method, and is characterized in that +70mm large high-grade steel slag of the steel slag of the converter is in cascade separation and recycling, -70mm large high-grade steel slag is in classification dry magnetic separation for discarding tailings, rough concentration is further in full-grain wet ore grinding for separating slag from iron, cascade screening and cascade magnetic separation, and finally the metal iron with different grain sizes and magnetic iron concentration are obtained. The method has the advantages of high recycling rate and the grade of the metal iron, simplicity in technological process, simplicity and convenience in operation, low production cost, applicability to processing different types of steel slag of converters, and the like.

Owner:KUNMING METALLURGY INST

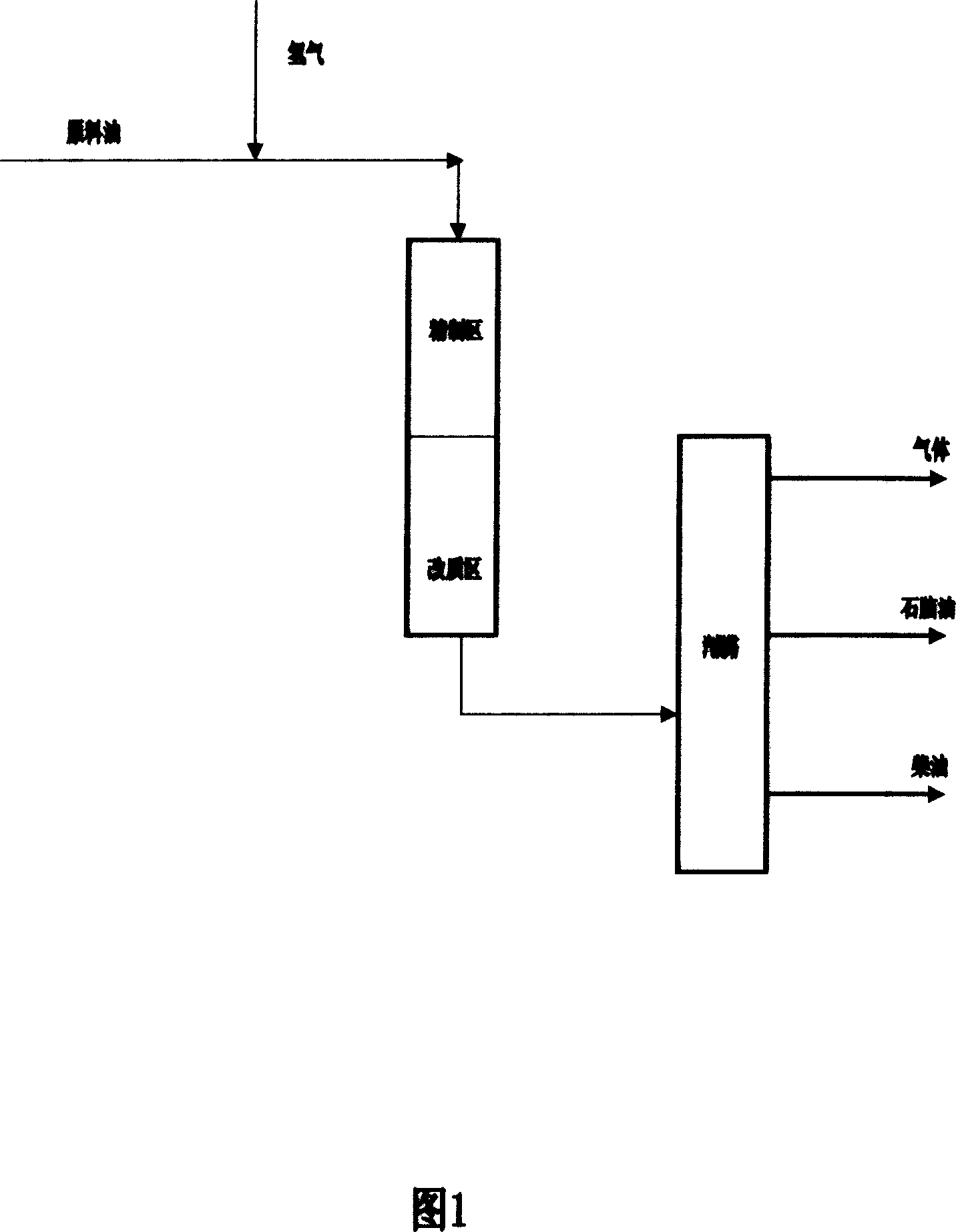

Diesel oil fraction upgrading and pour point reducing process

ActiveCN101089135AReduce usageReduce contentRefining to eliminate hetero atomsHydrogenOxidation stability

The diesel oil fraction upgrading and pour point reducing process has the mixture of diesel oil material and hydrogen passing through the hydroupgrading reaction region to result in diesel oil with low solidification point through reaction under certain condition. The catalyst in the hydroupgrading reaction region includes at least one kind of bulk phase catalyst comprising complex oxide NixWyOz and oxide MoO3 in the weight ratio 0.1-10 and accounting for 40-100 wt% of total catalyst, and at least one kind of upgrading catalyst containing beta-zeolite. The present invention can lower the solidification point, 95 vol% point temperature and sulfur content of diesel oil, and raise cetane number and oxidation stability under mild condition.

Owner:CHINA PETROLEUM & CHEM CORP +1

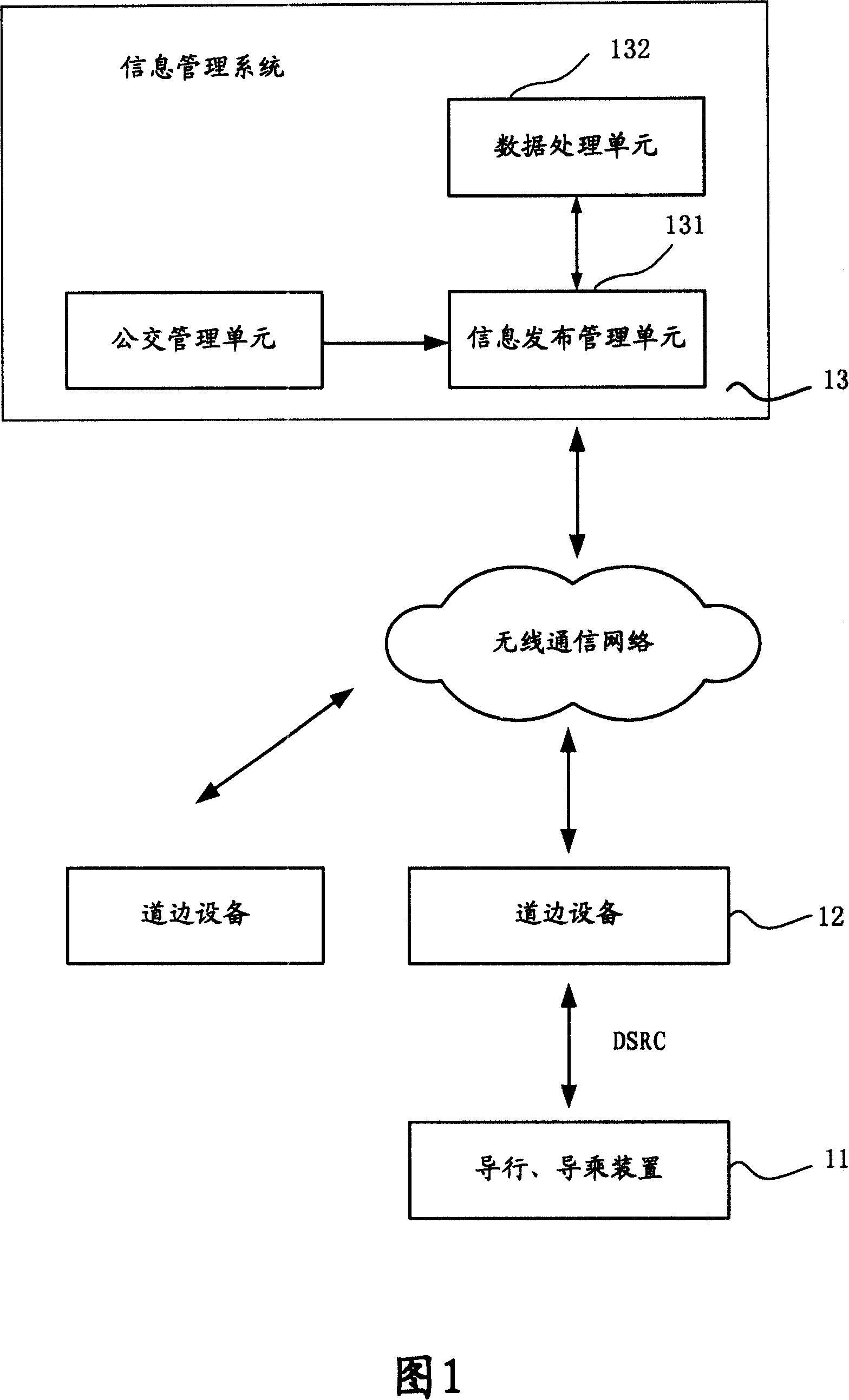

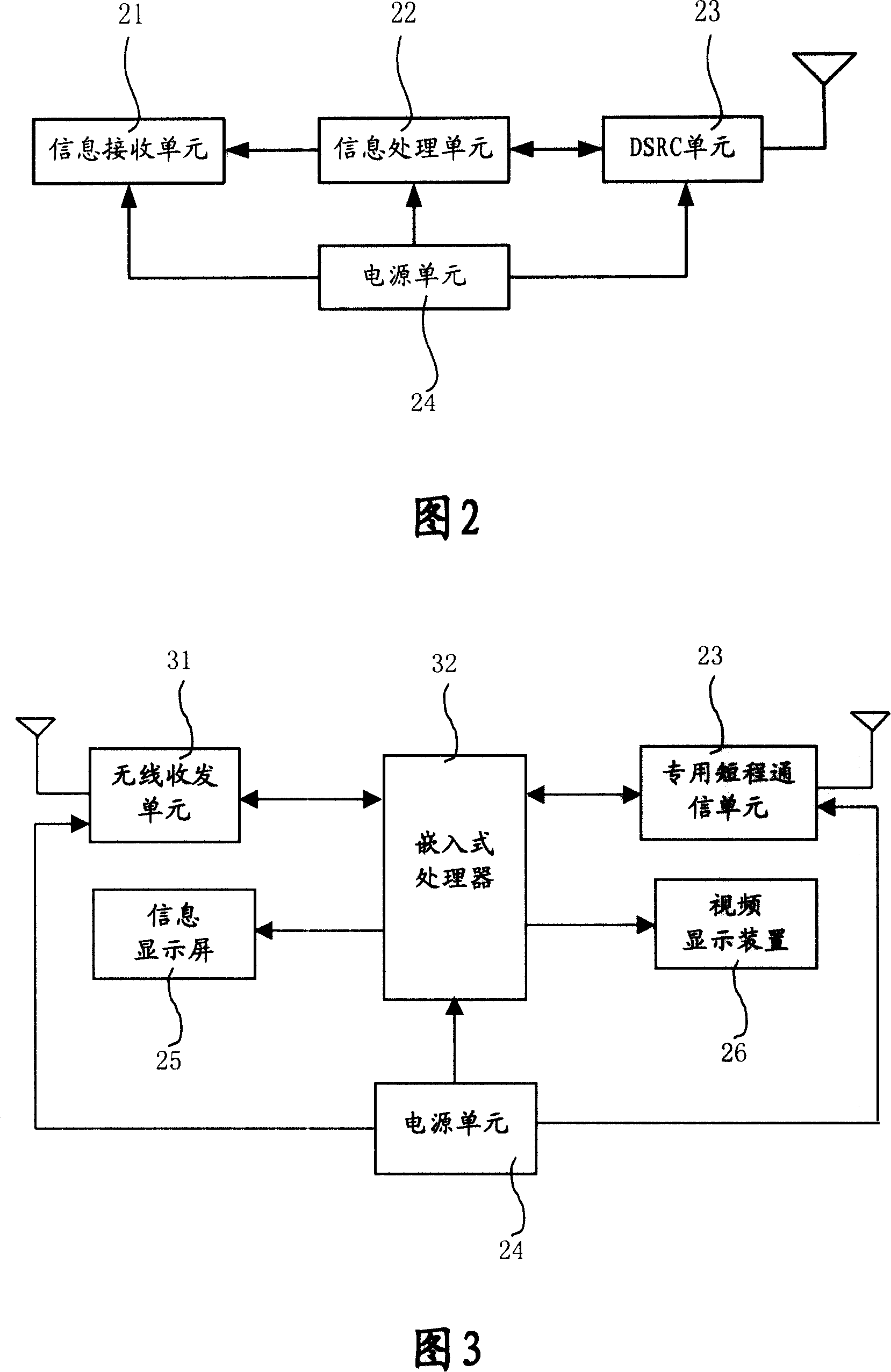

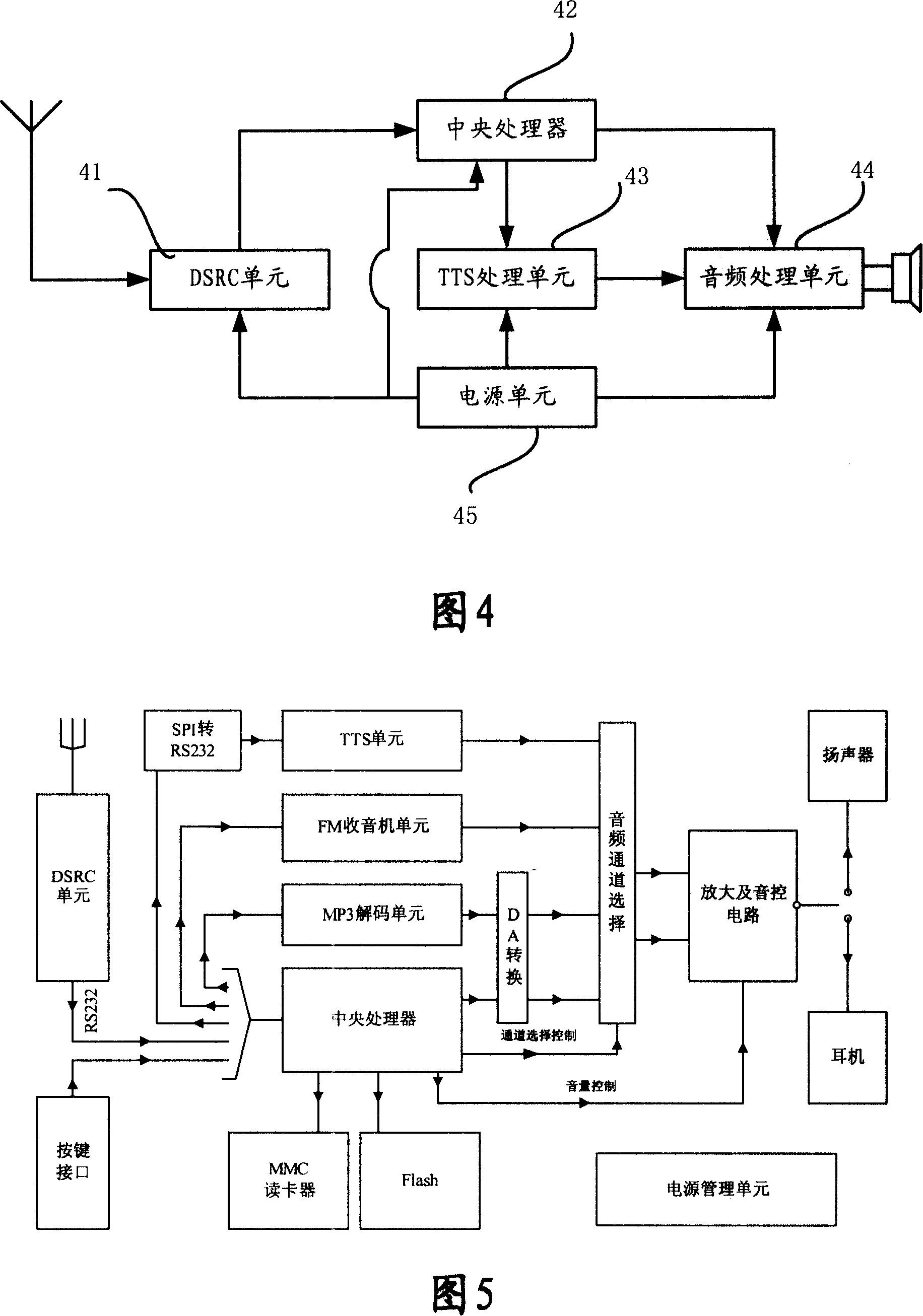

A voice walking and taking guidance and its working method

InactiveCN101123037AEfficient acquisitionLow costControl with pedestrian guidance indicatorWorking setService information

The invention provides a speech walking guide and car-taking guide system and a working method of the system. The system comprises at least one portable walking guide and car-taking guide device, at least one roadside device and an information managing system, wherein the information managing system is used for collecting various information, processing the collected information, communicating with the roadside device, receiving the information sent by the roadside device, sending the information to be broadcasted and transmitting the information to the roadside device; the roadside device is used for receiving the to-be-broadcasted information sent by the information managing system, processing the information and sending the processed information to the portable walking guide and car-taking guide device; and the portable walking guide and car-taking guide device is used for interchanging information with the roadside device, receiving the to-be-broadcasted information sent by the roadside device, converting the information to speech signal, and outputting the signal. The invention provides great convenience to travelers, in particular blind people on effectively acquiring public service information necessary for travelling.

Owner:新世界(中国)科技传媒有限公司

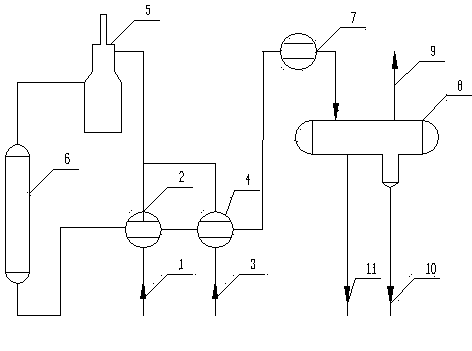

Oil field well casing gas recovery device and process

ActiveCN101915074ASimplify the gathering and transportation processIncrease gathering radiusFluid removalOil fieldEnergy consumption

The invention relates to an associated gas recovery process in the oil field oil extraction process, in particular to an oil field well casing gas recovery device and an oil field well casing gas recovery process. The process is characterized in that: when a part of oil from a well mouth is connected with an inlet port pipeline of a synchronal rotary compressor through a first-path pipeline with a throttle valve, a ball valve and a filter, the part of the oil from the well mouth of the first-path pipeline enters the synchronal rotary compressor to seal, lubricate and cool the synchronal rotary compressor, the other part of the oil is transported to a downstream pipeline under the action of an oil extractor, and the casing gas of a second-path pipeline is pressurized by the synchronal rotary compressor and is pressed into an oil pipe for transport so as to pressurize and recover the casing gas. The invention provides the oil field well casing gas recovery device and the oil field well casing gas recovery process which can effectively reduce the return pressure of the well mouth, improve oil extraction working conditions and reduce the energy consumption of the oil extractor.

Owner:XIAN CHANGQING TECH ENG

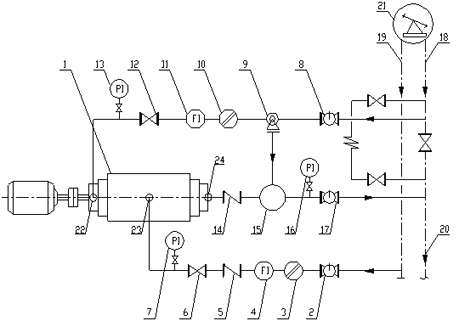

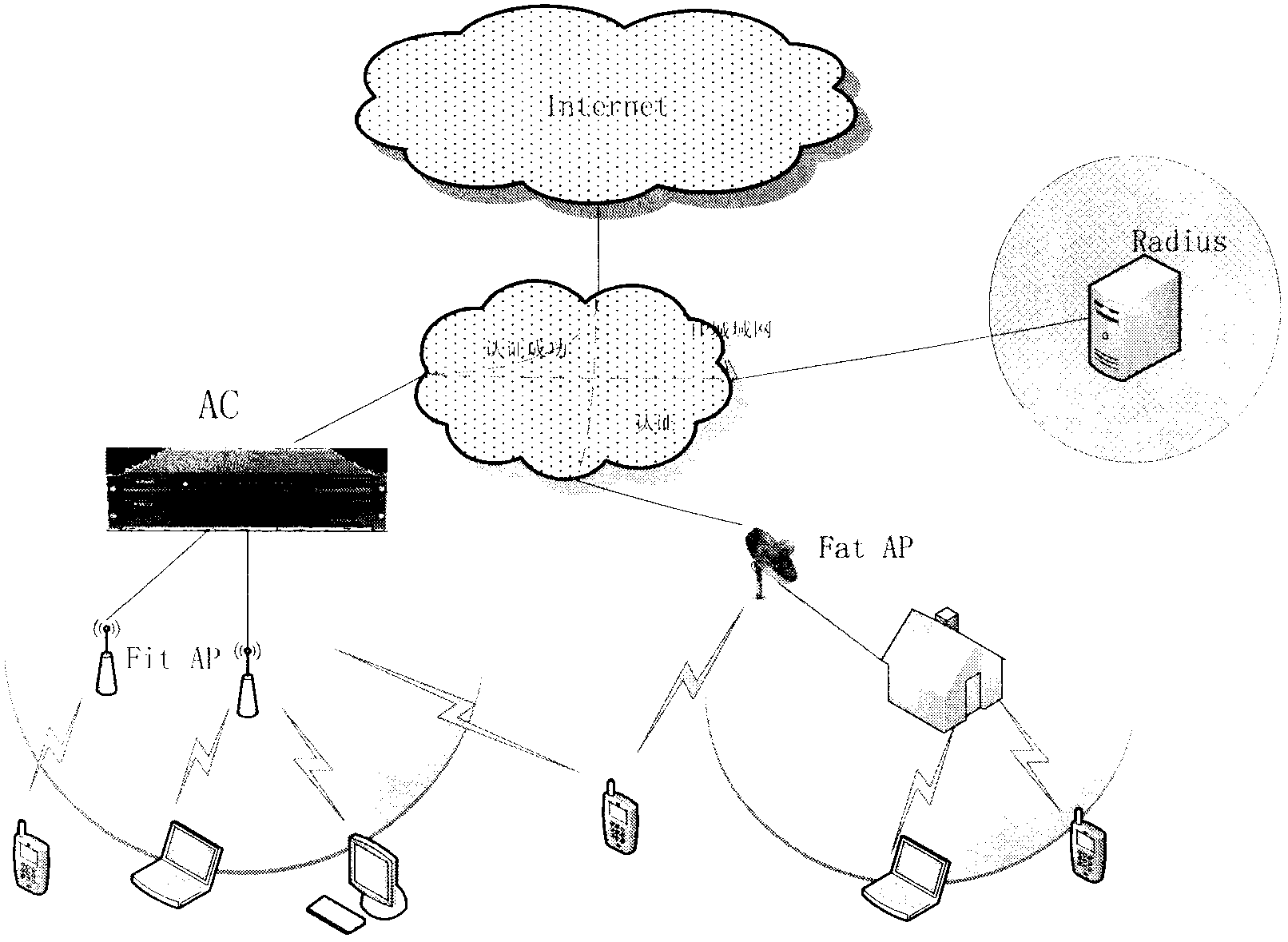

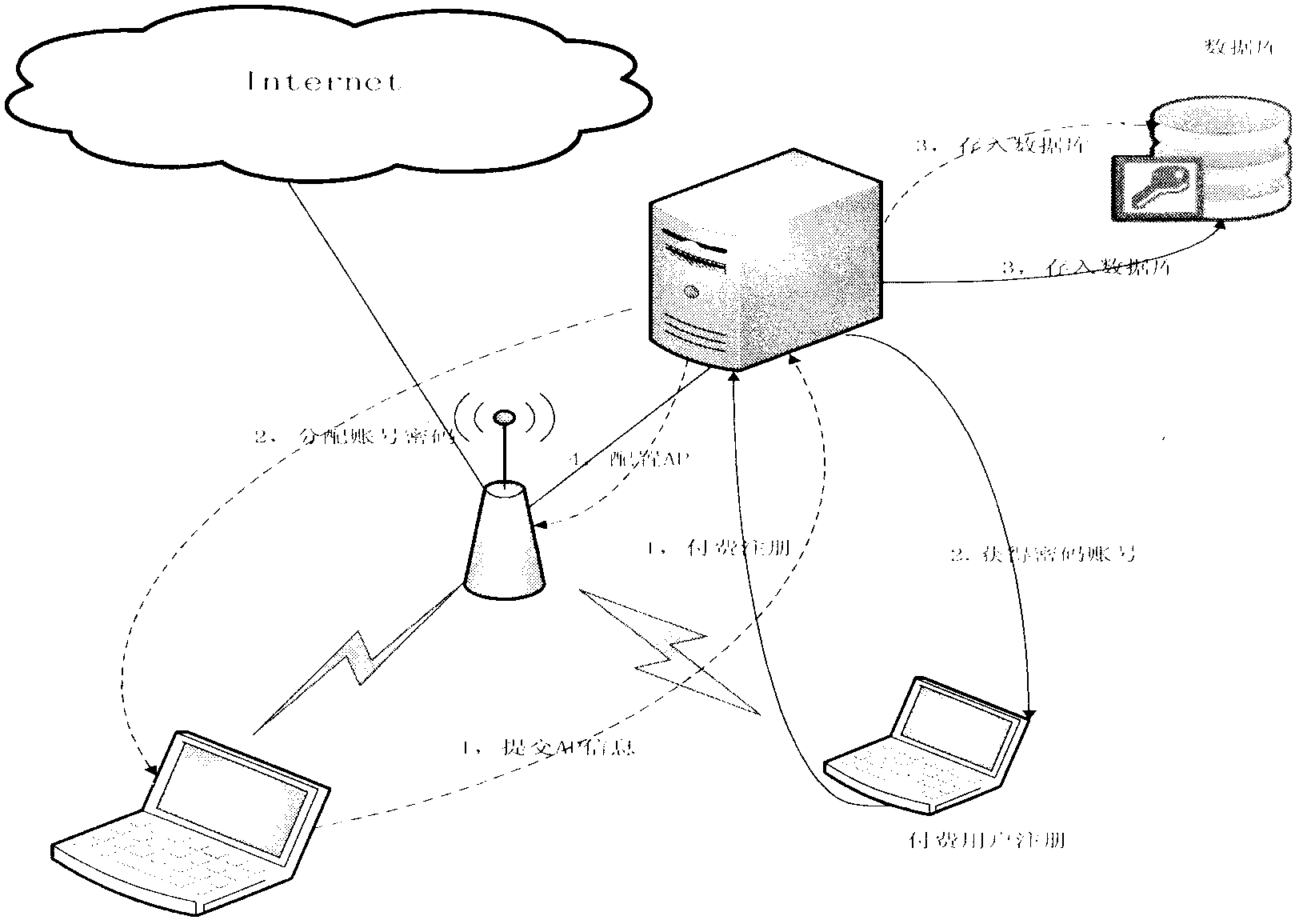

Intelligent WIFI (Wireless Fidelity) sharing system

InactiveCN102710634AAchieve sharingReduce construction investment costsTransmissionWorld Wide WebSoftware

The invention discloses an intelligent WIFI (Wireless Fidelity) sharing system. A method comprises the steps that 1) a family user who has fat-AP becomes a member of a Wifi league and registers to join in the league by carrying the self own fat AP; 2) the registering for an AC+fit AP type user only needs a simple inheritance, namely, all the user data of AC+fit AP is loaded on a server of the league; and 3) a user who does not have AP registers to be as the member in the league by a paying manner. According to the method provided by the invention, the Wifi resource sharing is realized by software based on an existing AP device without any change on the hardware. Compared with the Wifi sharing mode supported by hardware, the method has the advantages of wider promotion and wider promotion space, as well as more convenient application.

Owner:刘乃安

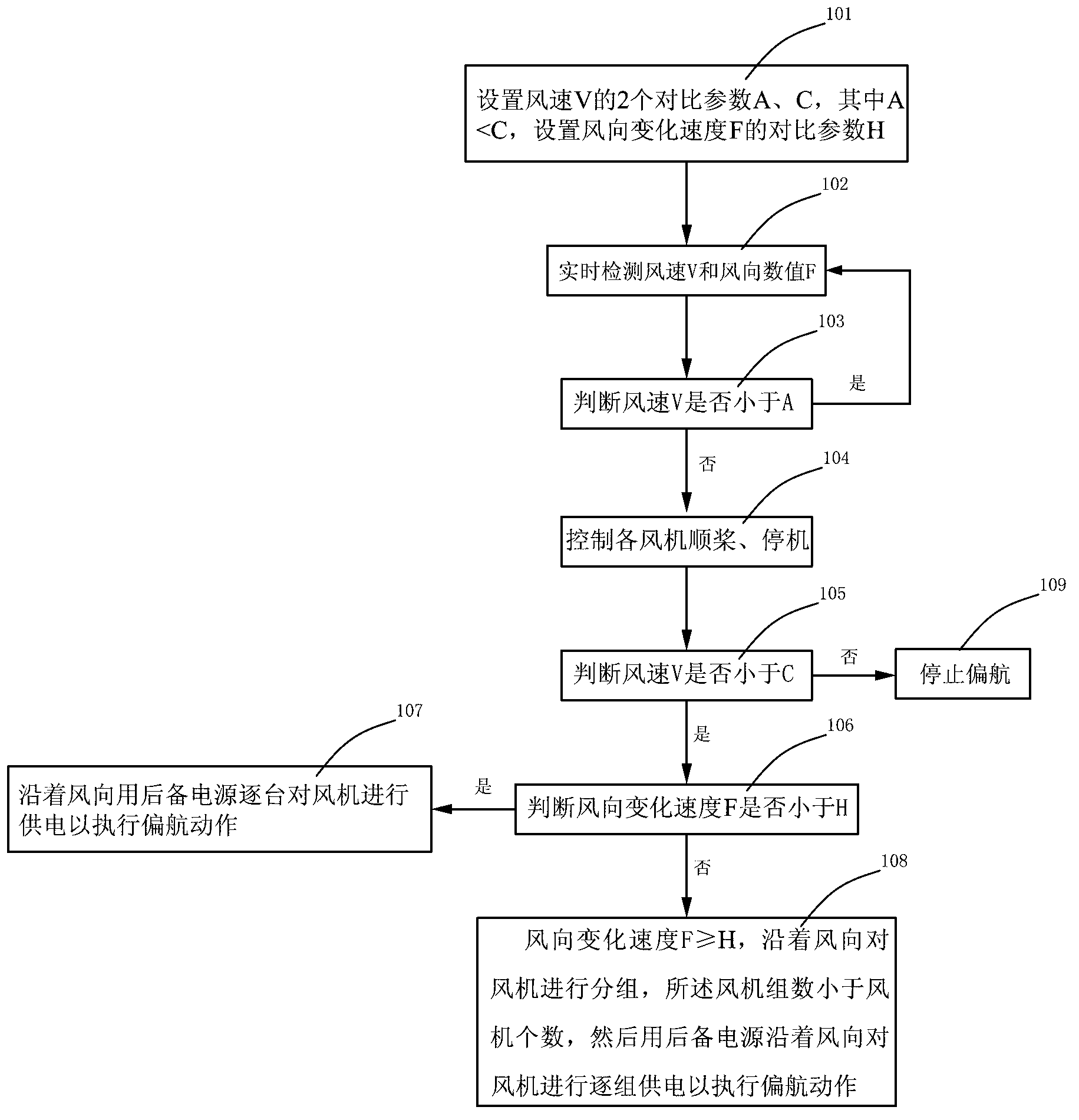

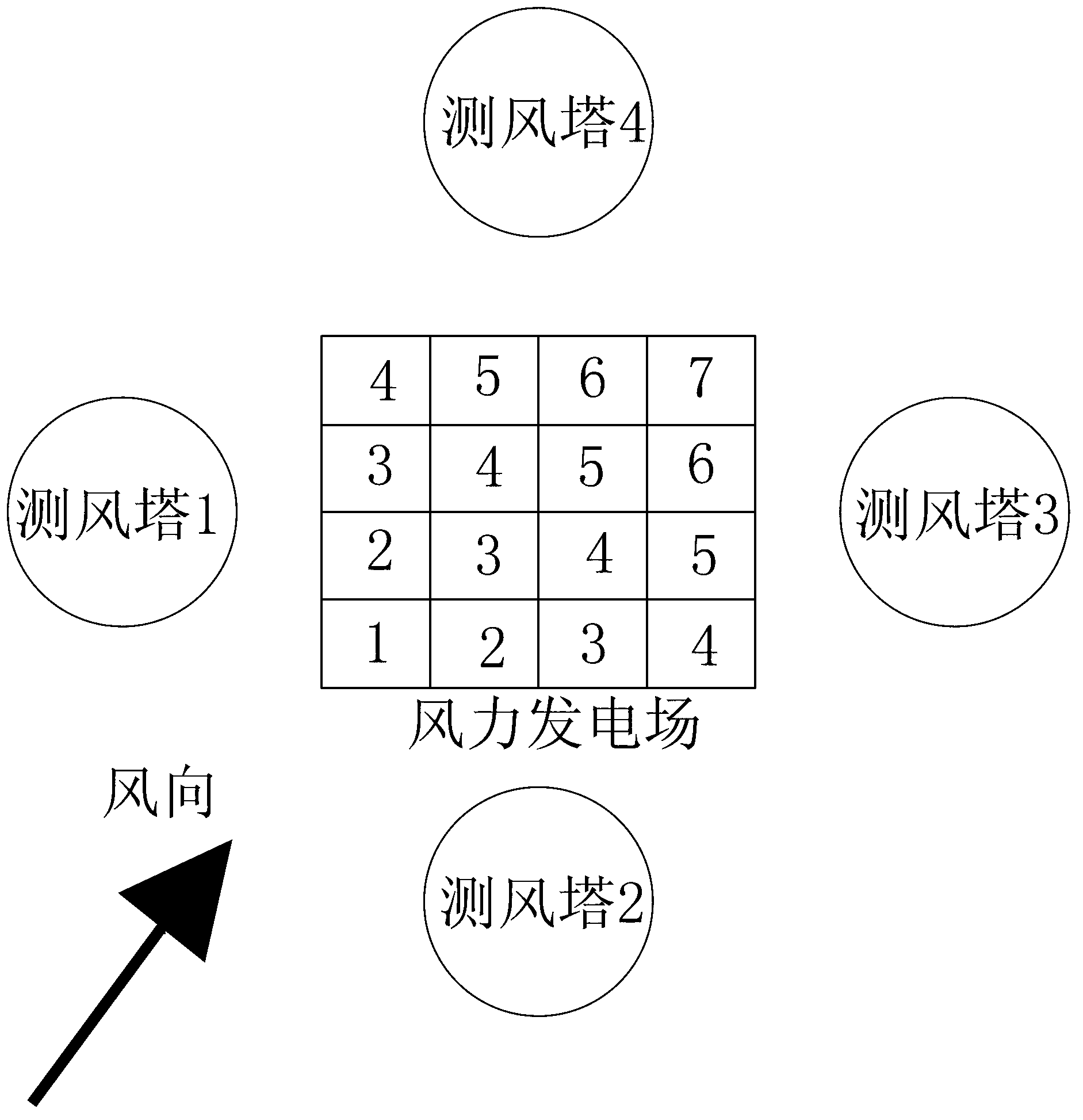

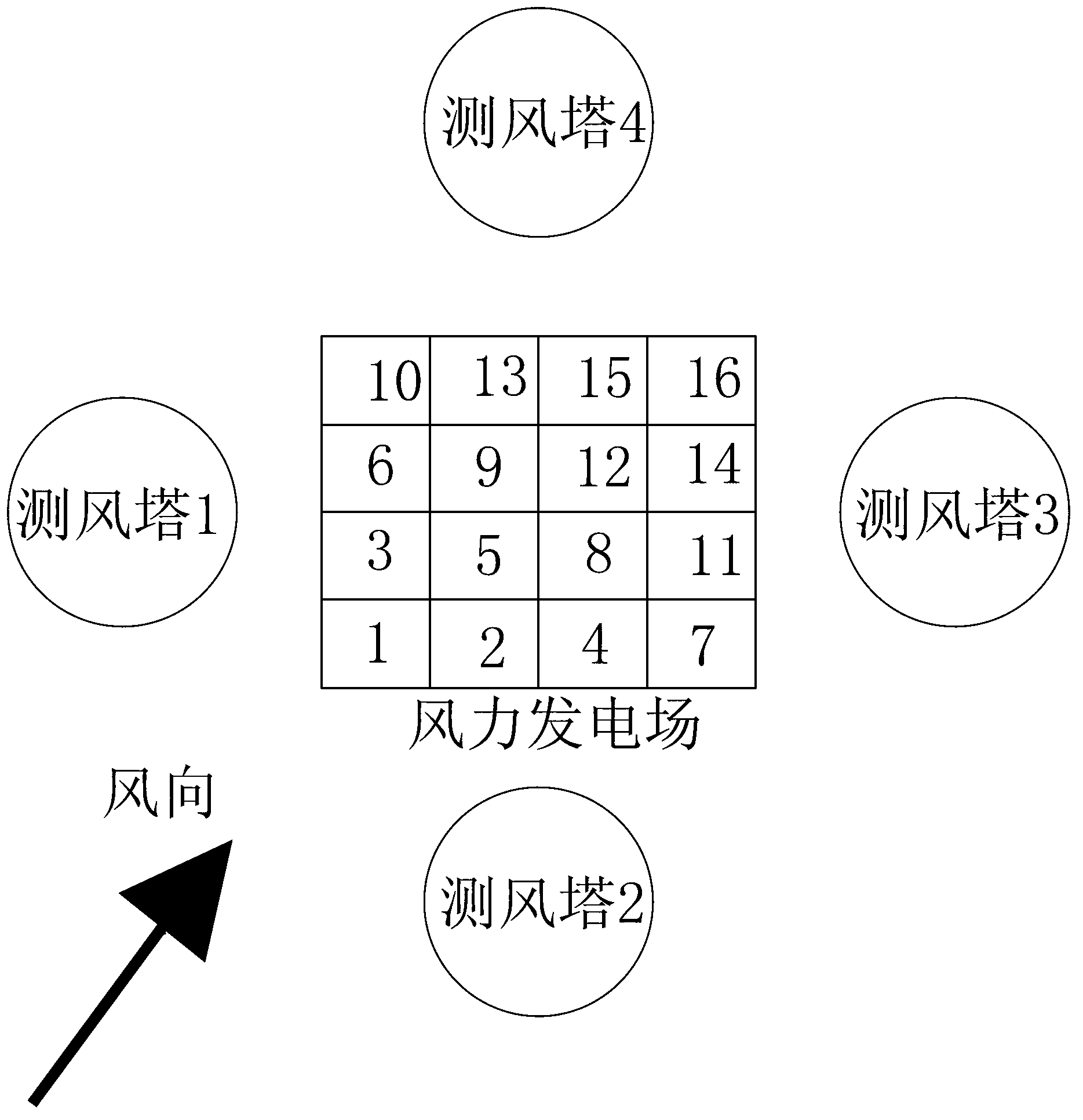

Anti-typhoon control method for wind power plant

ActiveCN103321840AReduce construction investment costsSufficient reaction timeWind motor controlMachines/enginesControl mannerTyphoon

The invention discloses an anti-typhoon control method for a wind power plant. Different yawing power supply is performed according to wind speed levels so as to perform yawing motions and effectively cope with typhoon. When A<=wind speed V<C and F<=H, a standby power supply is utilized to supply power to fans one by one along the wind direction so as to perform the yawing motions, the implementation process can be achieved by utilizing the standby power supply small in capacity, and construction investment cost in adopting a high-capacity standby power supply is reduced in the control mode. When A<=wind speed V<C and F>=H, the fans are divided into groups along the wind direction, output power of the adopted standby power supply in the yawing power supply mode does not need to be designed to provide power needed for simultaneous yawing of all the fans in the wind power plant in one time, the output power of the standby power supply only needs to meet the power needed for the group with the maximum fan number so that the control process can be achieved, the capacity of the standby power supply can be effectively reduced, and the construction investment cost is reduced.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

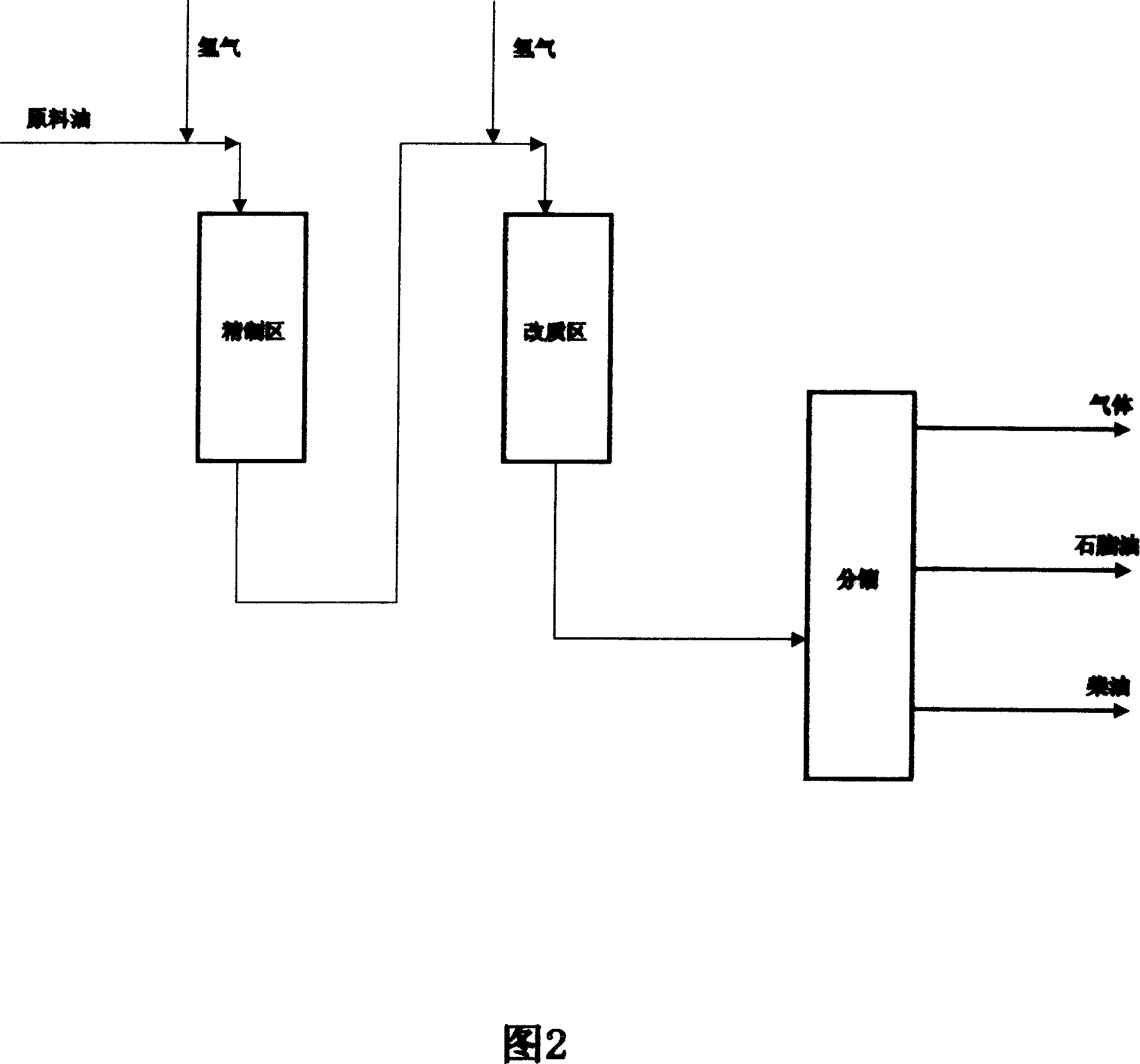

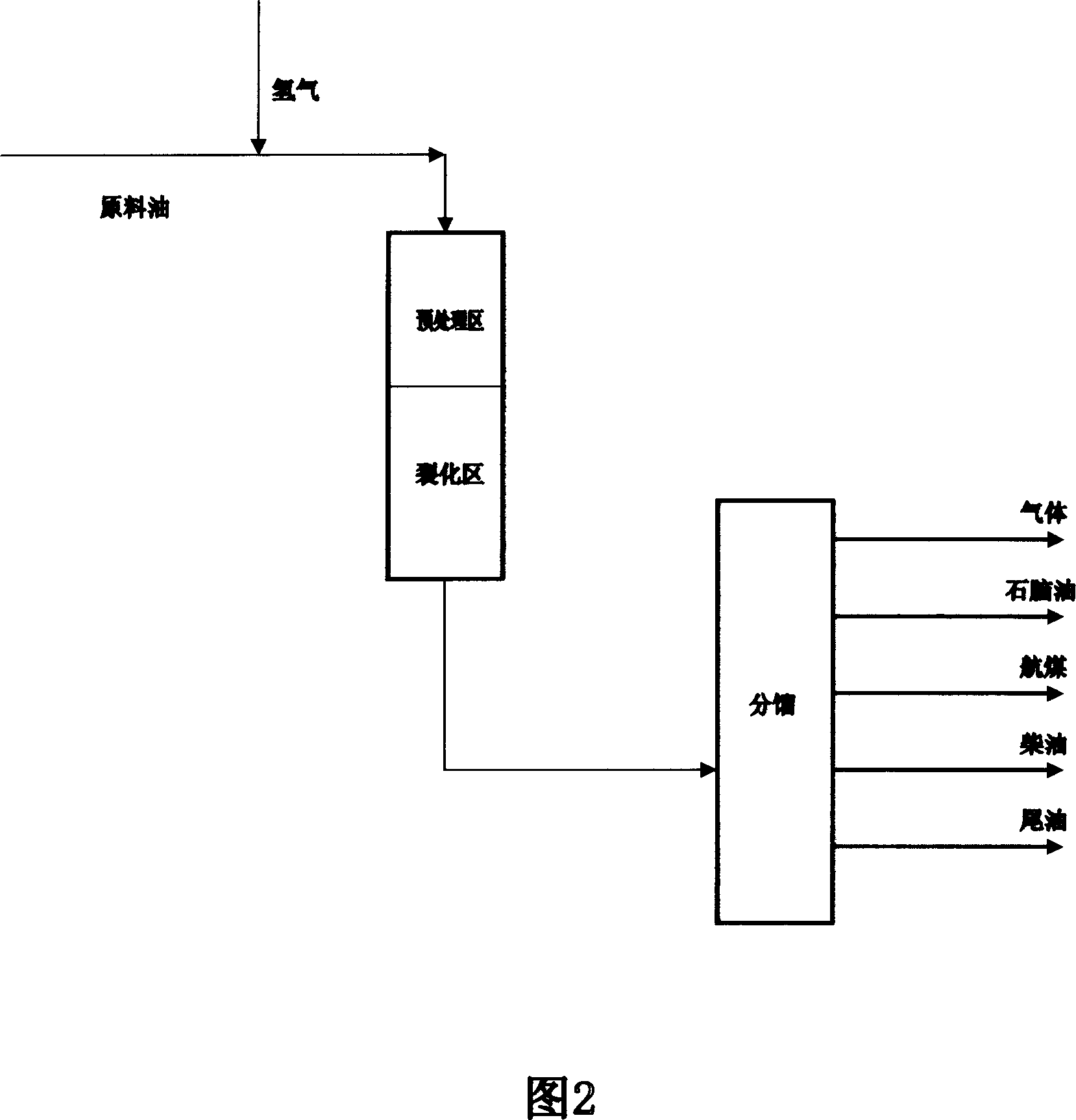

Moderate hydrocracking process

ActiveCN101089137AReduce usageIncreased refining depthHydrocarbon oils refiningComplex oxideChemistry

The moderate hydrocracking process has the inferior diesel oil fraction, VGO or other heavy fraction oil as the material oil hydrocracked under moderate condition to result in high quality products, especially high quality hydrocracked tail oil. The catalyst in the hydrocracking reaction region includes at least one kind of bulk phase catalyst comprising complex oxide NixWyOz and oxide MoO3 in the weight ratio 0.1-10 and accounting for 40-100 wt% of total catalyst. The present invention facilitates the hydrocracking operation, increases the treating capacity of the apparatus, increases the service life of the catalyst and raises the quality of the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

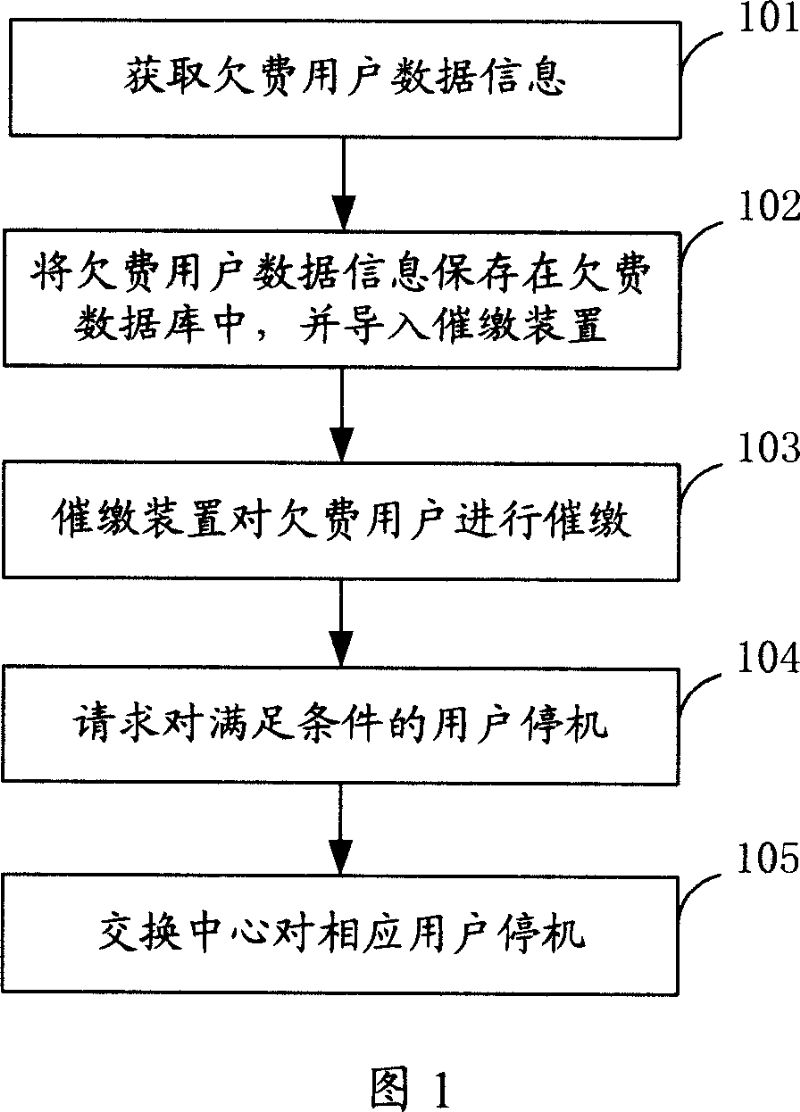

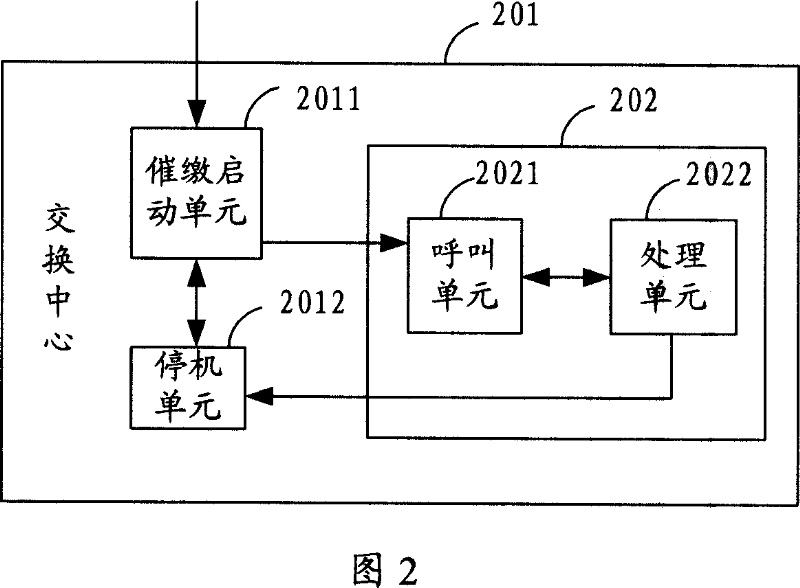

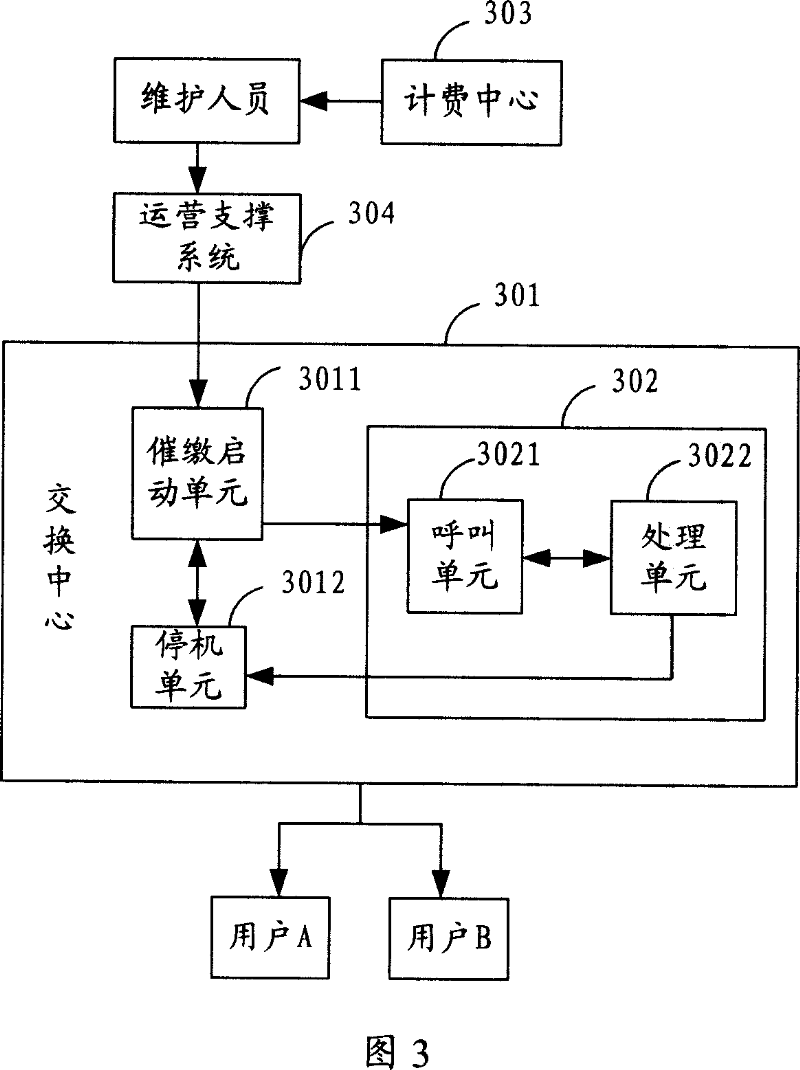

Method and system for shutdown and calling up user owing due and pursuing device

InactiveCN101039351AAutomatic downtimeReduce construction investment costsTelemetry/telecontrol selection arrangementsMetering/charging/biilling arrangementsComputer science

The present invention relates to the communication field disclosing a calling-up and shutdown method and system for an arrearage user, and a calling-up device thereof. The disclosed method comprises following steps: sending arrearage calling-up order to an exchanging center; after receiving the order, the exchanging center starting the calling-up process; after completion of the calling-up, the user who satisfied the preset qualifications being shut down. The disclosed calling-up device is arranged within the exchanging center for executing the calling-up according to the calling-up order from the center. With the technical scheme in this invention, the calling-up device is unnecessary to be arranged solely; after calling-up, shutdown of the user is automatically realized; and the investment and construction cost are saved, and the efficiency is also improved.

Owner:HUAWEI TECH CO LTD

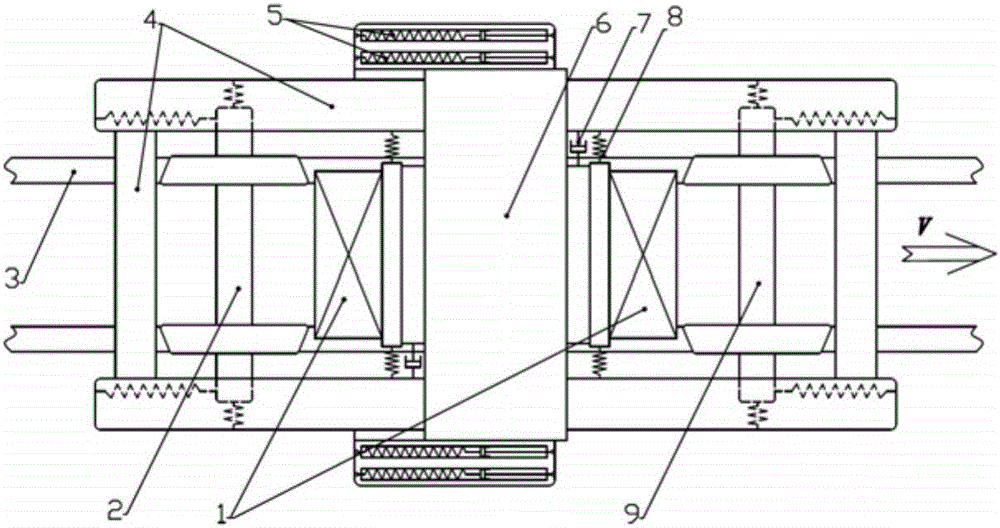

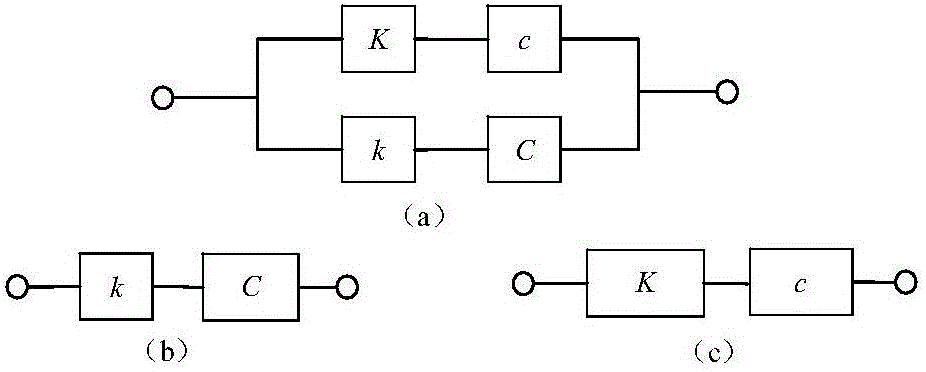

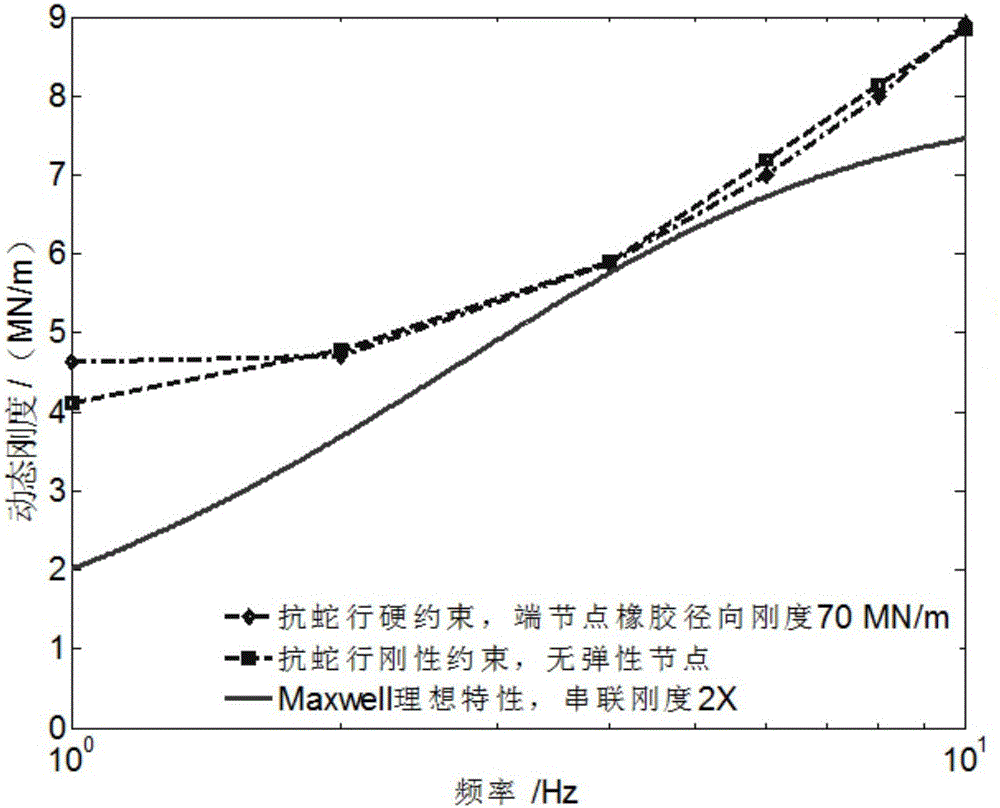

Method for achieving anti-snaking broadband energy absorption mechanism and optimal configuration method for parameters of bogie

ActiveCN105109510AOvercome constraintsMeet the technical requirements of cross-line applicationBogiesBogieEnergy absorption

The invention discloses a method for achieving an anti-snaking broadband energy absorption mechanism and an optimal configuration method for the parameters of a bogie. According to the method and the optimal configuration method, a dynamic design method is mainly applied, and lead-lag correction of unstable snaking oscillation phenomena of the bogie is achieved in a self-adaptive control manner; an anti-snaking redundant design form of an ICE3 prototype is borrowed, the anti-snaking broadband energy absorption mechanism is achieved through combination application of novel anti-snaking vibration reducers, and the method and the optimal configuration method are simple and applicable; and an anti-snaking soft constraint or anti-blocking technology is borrowed, the hydraulic rigidity is properly reduced, and rheology nonlinear influences are avoided. By means of the method and the optimal configuration method, the design defects of the ICE3 bogie prototype are overcome, a high-speed-rail passenger-dedicated development manner is gradually changed, and then the rate of return on investment is increased; in addition, the adaptability and the friendliness to track lines are improved, and the railway construction investment cost can be saved; and meanwhile the robustness of perturbation or disturbance of natural factors is improved, and particularly when the method and the optimal configuration method are used for mountain lines, and the structural technical service cost can be obviously reduced.

Owner:DALIAN JIAOTONG UNIVERSITY

Method and equipment for separating diolefin component in oil cracking ethylene byproduct carbon-5 fraction

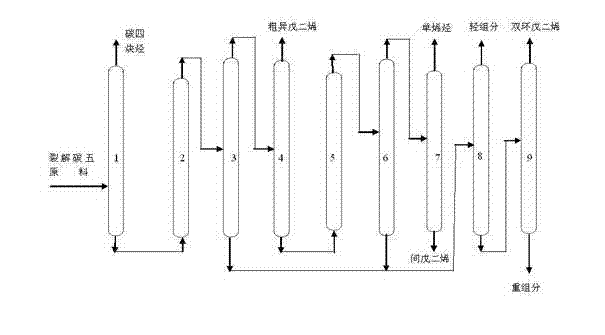

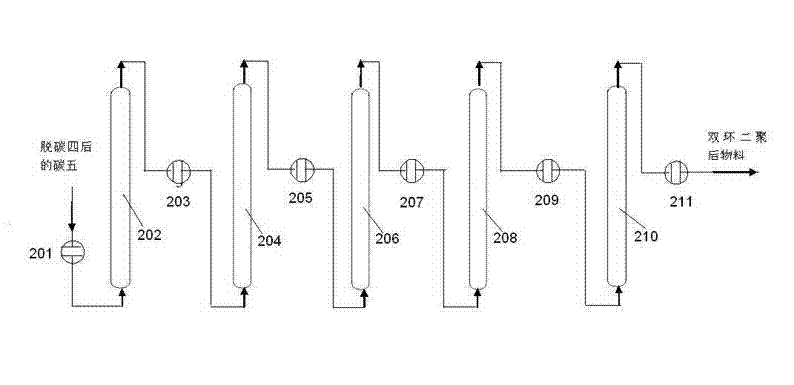

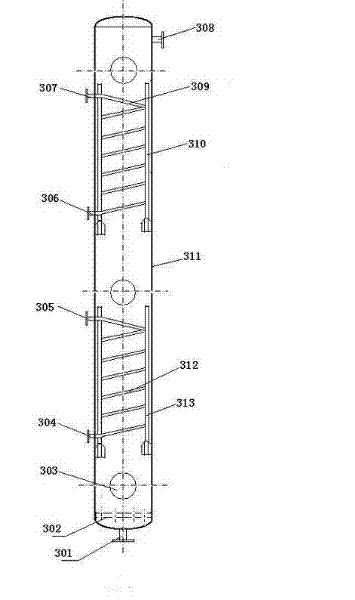

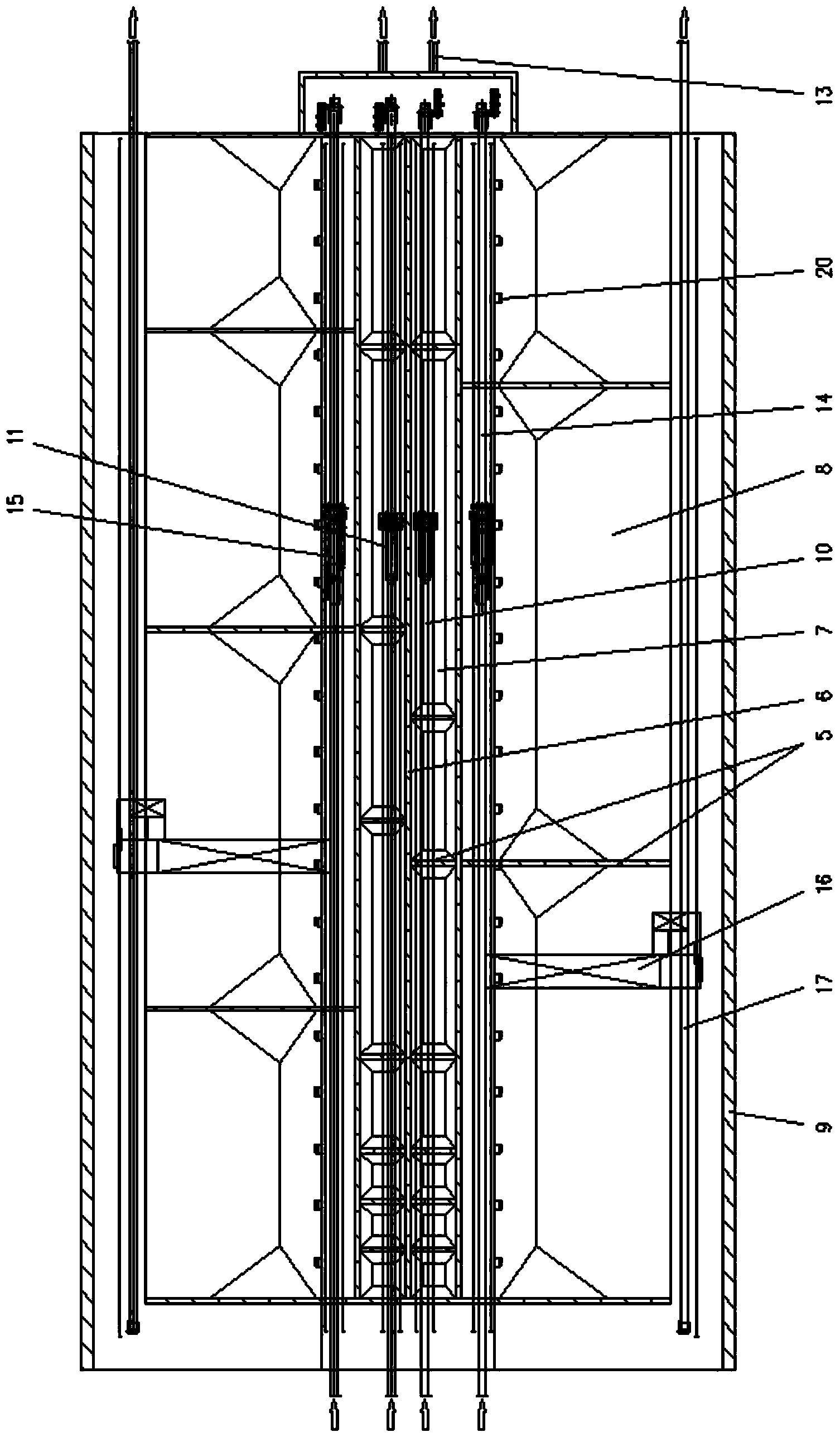

ActiveCN102516010ADimerization reaction conditions are mildThe reaction is easy and stable to controlDistillation purification/separationHydrocarbons from unsaturated hydrocarbon additionPiperyleneChemistry

The invention provides a separation method of diolefin in carbon-5 aiming at the problem of high content of cyclopentadiene in isoprene when the diolefin in carbon-5 is separated by utilizing the post-heating dimerization method. The method comprises the following steps of: carrying out thermal dimerization reaction for two times, carrying out heavy removal for two times and removing the cyclopentadiene in the carbon-5 by using a special thermal dipolymer reactor. The content of the cyclopentadiene in the isoprene prepared by adopting the method is below 1 percent (weight), and meanwhile, thecontent of cyclopentadiene in produced piperylene is less than 1 percent (weight); and the content of an isoprene autopolymer or an isoprene copolymer in dicyclopentadiene can reach the level of a post-heating dimerization carbon-5 separation technology. The invention also discloses equipment for implementing the separation method at the same time.

Owner:DAQING HUAKE

Material storage device of storage yard and closed storage yard

ActiveCN103640832AIncrease storage capacityImprove space utilizationLoading/unloadingStorage devicesEngineeringYard

The invention discloses a material storage device of a storage yard. The material storage device comprises a material storage bearing bottom plate and two retaining walls, wherein a material storage bin is formed between the two retaining walls, and material storage lattices are arranged on two longitudinal sides or one side of the material storage bin. The invention further discloses a closed storage yard which comprises a material storage shed and the material storage device arranged in the material storage shed. According to the invention, the material storage bin can eliminate V-shaped space at the top of the material, then the space utilization rate is increased, and the occupied area as well as energy consumption for ventilation, heating, lighting and the like of the storage yard are reduced; more independent unit storage bins and unit material lattices are provided, and the variety adaptability of the storage yard is higher; an across bulkhead can support the retaining walls, the rigidity and pressure bearing performance of the retaining walls can be improved greatly, the thickness of each retaining wall is smaller, and the construction investment cost is lower; size of the material exposed in the air in the material storage bin is smaller, raising amount of dust in feeding and discharging processes is smaller, so that the material with high environmental protection requirement can be stored in the material storage bin, and the environmental protection performance is better.

Owner:CISDI ENG CO LTD

Method for producing ultra-low sulfur diesel

ActiveCN101280216AImprove hydrogenation performanceLow operating temperatureTreatment with hydrotreatment processesRefining to eliminate hetero atomsUltra-low-sulfur dieselComposite oxide

The invention relates to a method of producing ultra-low sulfur diesel. The diesel distillate is used as raw oil; the single stage or a stage of series process flow is adopted; the feed stock is mixed with hydrogen to pass the hydrogenation reaction area; under the operating condition of hydrorefining, the quality of diesel is improved greatly; wherein, at least one of the catalysts in the hydrogenation reaction area is bulk phase catalyst; the bulk phase catalyst is composed of composite oxide NixWyO z and oxide MoO3 with the weight ratio of 1:10-10:1; the composite oxide NixWyO z and oxide MoO3 account for 40%-100% of the total weight of the catalyst combination. Compared with the prior art, the method of producing ultra-low sulfur diesel in the invention can reduce the operation severity of the hydrorefining reaction area effectively, improve the processing load of the device, prolong the service life of the catalyst or produce the ultra-low sulfur diesel directly.

Owner:CHINA PETROLEUM & CHEM CORP +1

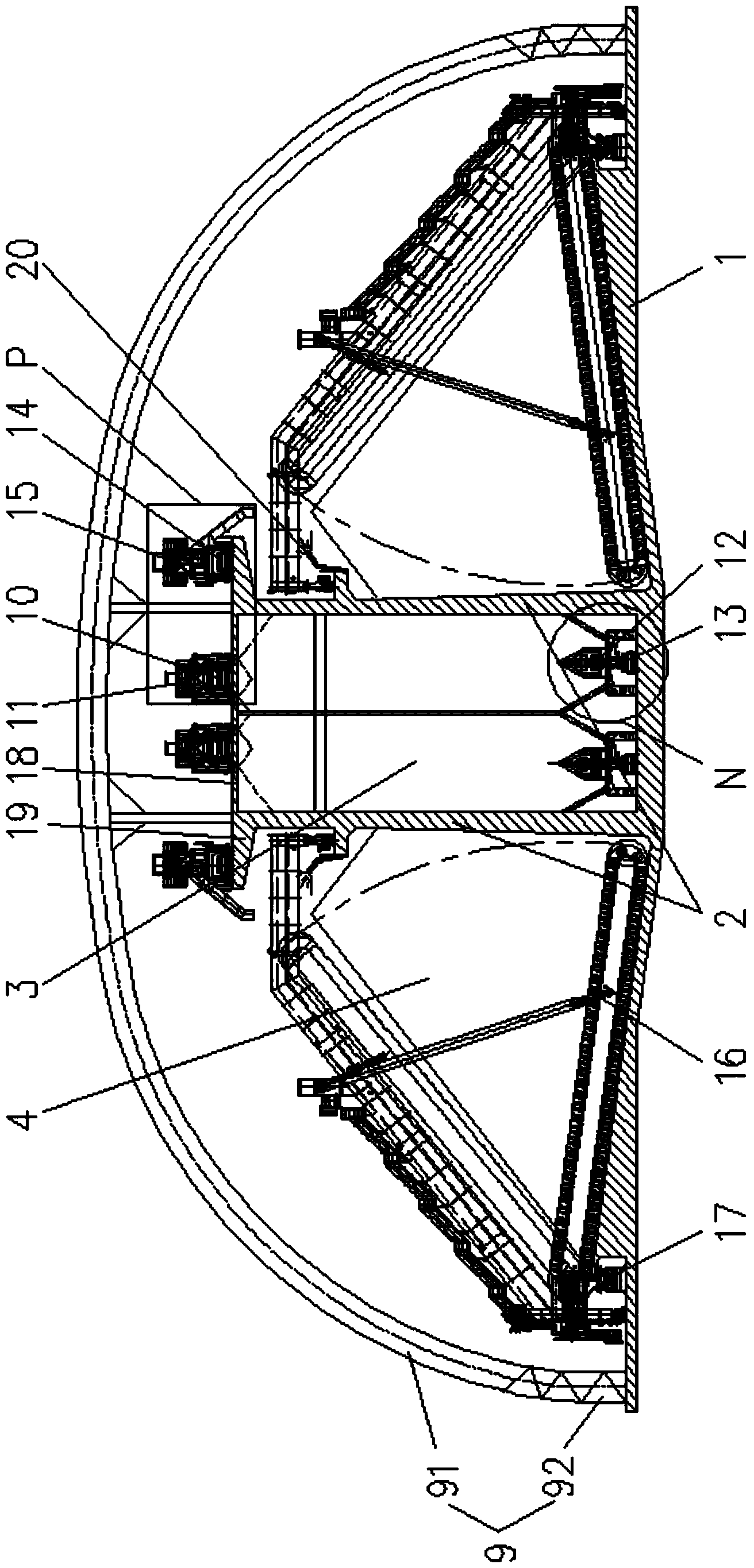

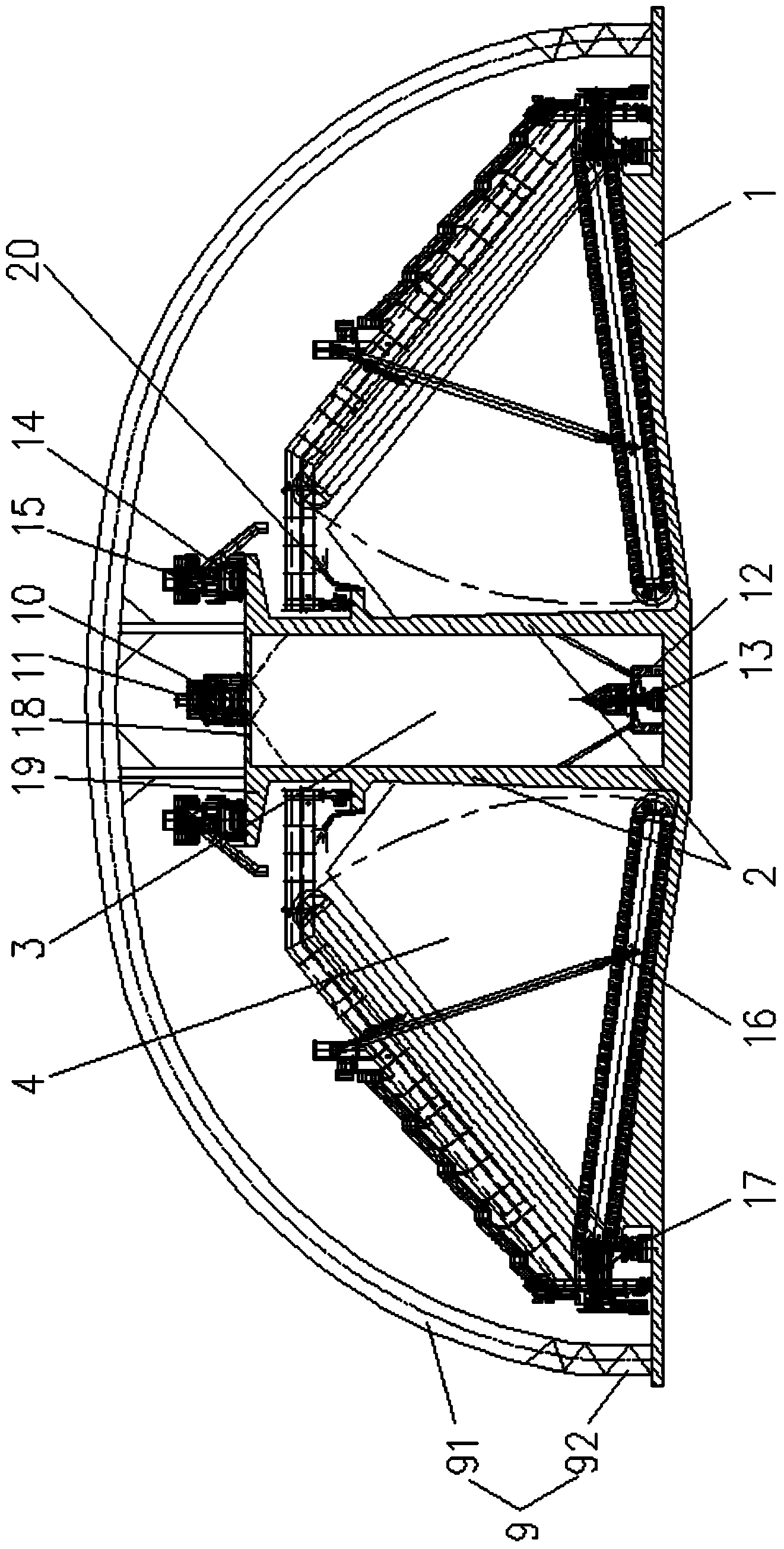

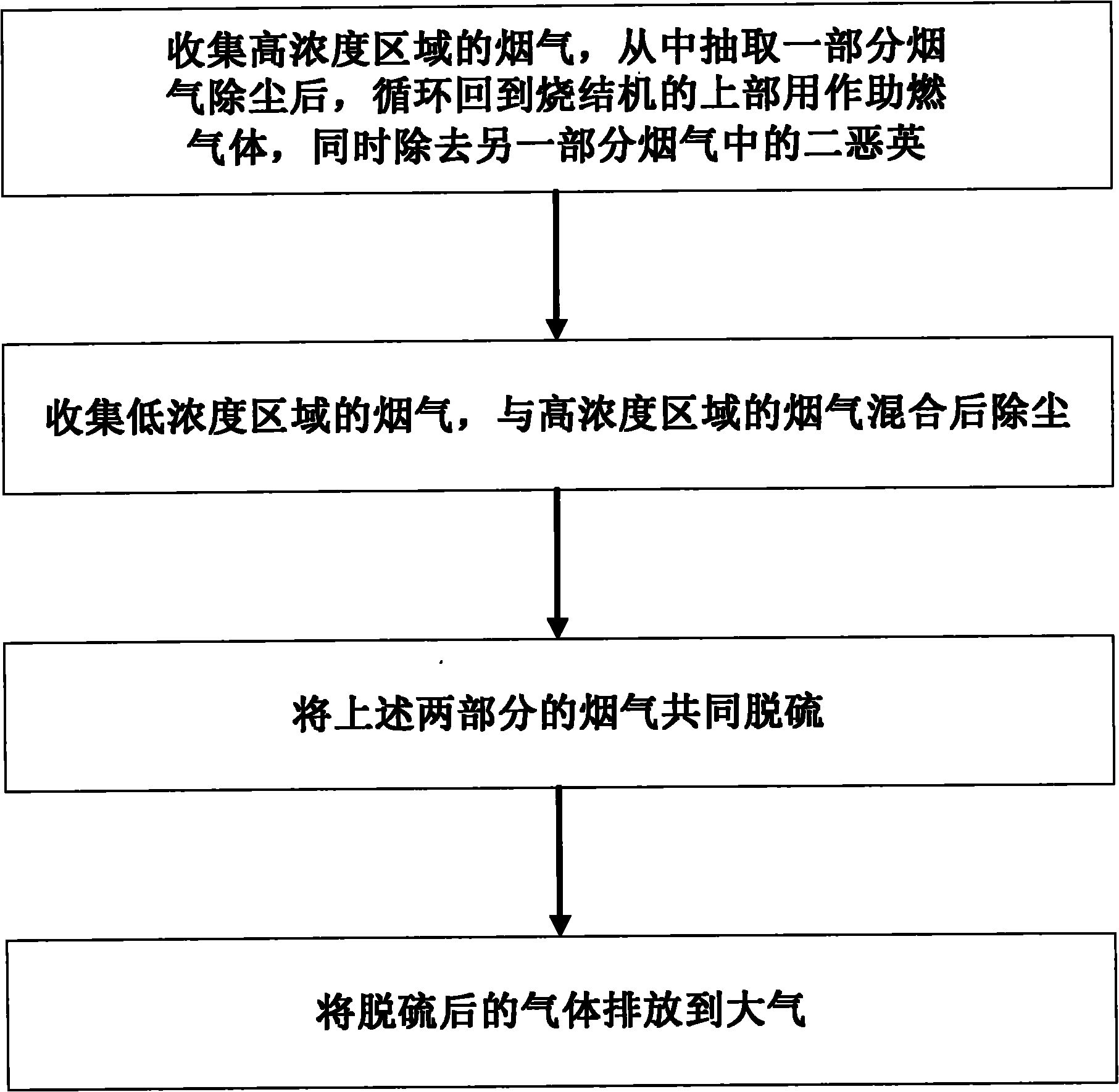

Low energy consumption sintering flue gas dioxin emission-reducing system and method thereof

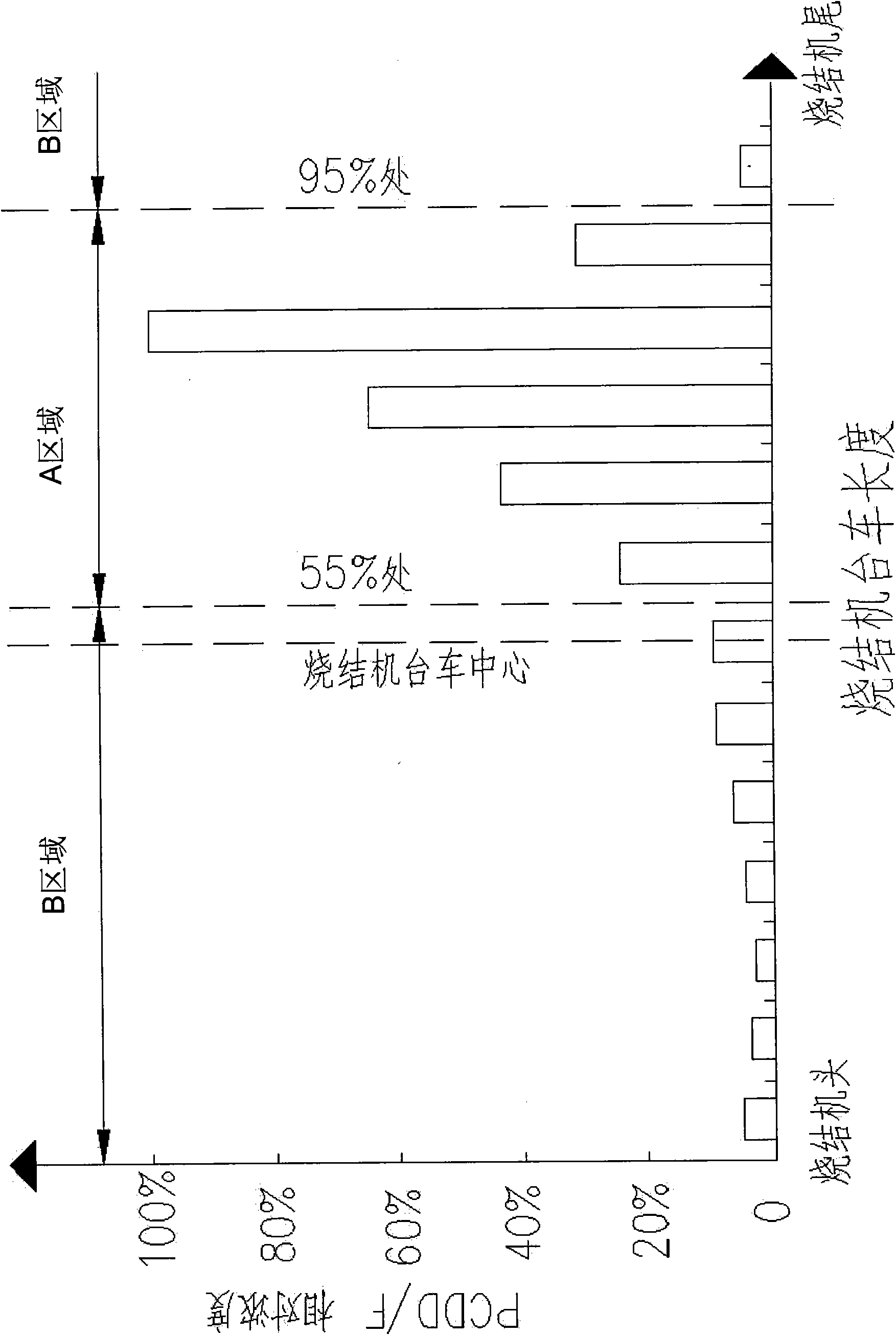

InactiveCN101822946AConducive to emission reductionEmission reductionDispersed particle separationHigh concentrationAtmospheric air

The invention relates to a low energy consumption sintering flue gas dioxin emission-reducing system and a method thereof. The system comprises a main flue exhaust pipeline, a main dust remover, an air blower, a dioxin desorption system, a closed gas hood, a high dioxin compound flue gas flue, a circulating air pipeline, a dioxin compound desorption flue, a bypass flue, a dust remover, the other air blower, a desulfurizing tower and a chimney. A low-concentration area exhaust box is connected with the main flue exhaust pipeline, passes through the main dust remover, the air blower and the desulfurizing tower in sequence to reach the chimney, and then the flue gas is exhausted to the air. The closed gas hood covers above a sintering machine board trolley; one end of the high dioxin compound flue gas flue is connected with a high-concentration area exhaust box; and the other end of the high dioxin compound flue gas flue is connected with the dioxin compound desorption flue and the main dust remover of the main flue exhaust pipeline. The method comprises the steps of collecting flue gas, removing dioxin in the flue gas, removing dust, desulfurizing, exhausting to the air and the like. The invention greatly reduces the flue gas to be purified and treated, reduces the construction investment and the operation cost, and is beneficial to reducing the emission of various pollutants in sintering flue gas.

Owner:BAOSTEEL ENG & TECH GRP

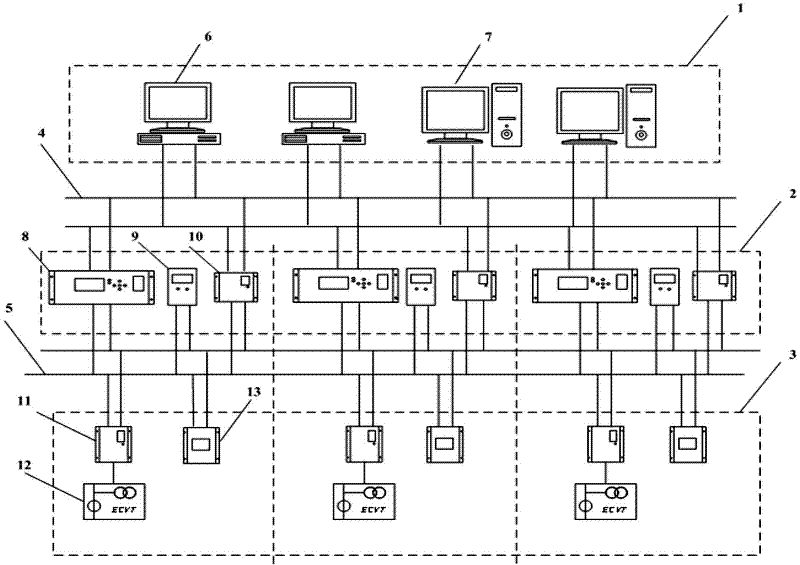

Basic automation control system for tandem cold rolling unit with five frames

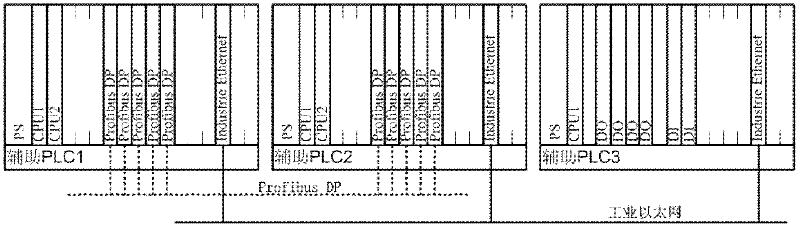

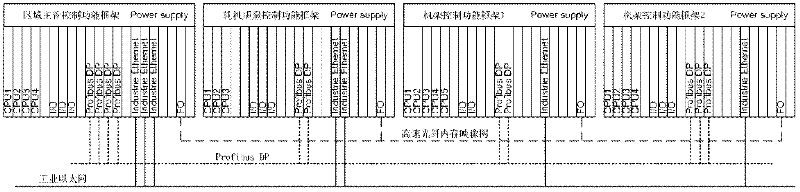

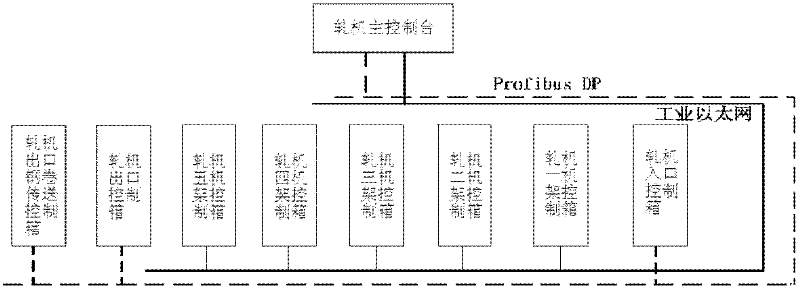

InactiveCN102553937AImplement functional requirementsRealize automatic roll change functionRoll mill control devicesMetal rolling arrangementsLoop controlPerformance computing

The invention provides a basic automation control system for a tandem cold rolling unit with five frames, which comprises a PLC (programmable logic controller ) cluster, an HPC (high performance computing ) controller cluster, a field rolling mill control console, a real-time data acquisition system, a developing and debugging system and a system communication network. By the basic automation control system, automatic roll changing can be realized, roll changing time is shortened, production and maintenance can be carried out easily, and building investment and maintenance cost are reduced greatly. Since a high-speed closed-loop control function is realized, continuously high-speed production on sites is guaranteed. Since a high-speed data acquisition function is realized, the basic automation control system is capable of running safely and efficiently and meeting the requirements to millisecond-level monitoring data during fault analysis of the high-speed closed-loop control system of the tandem cold rolling unit. Since functional units are debugged and controlled to run successfully, structural uniformity of the basic automation control system after modification of programs is guaranteed. The high-speed optical fiber memory map net serves as the communication network, high-speed data exchange is realized by data caching among functional units of the HPC controller cluster, and accordingly high-speed data acquisition of the real-time data acquisition system is realized.

Owner:ANGANG STEEL CO LTD

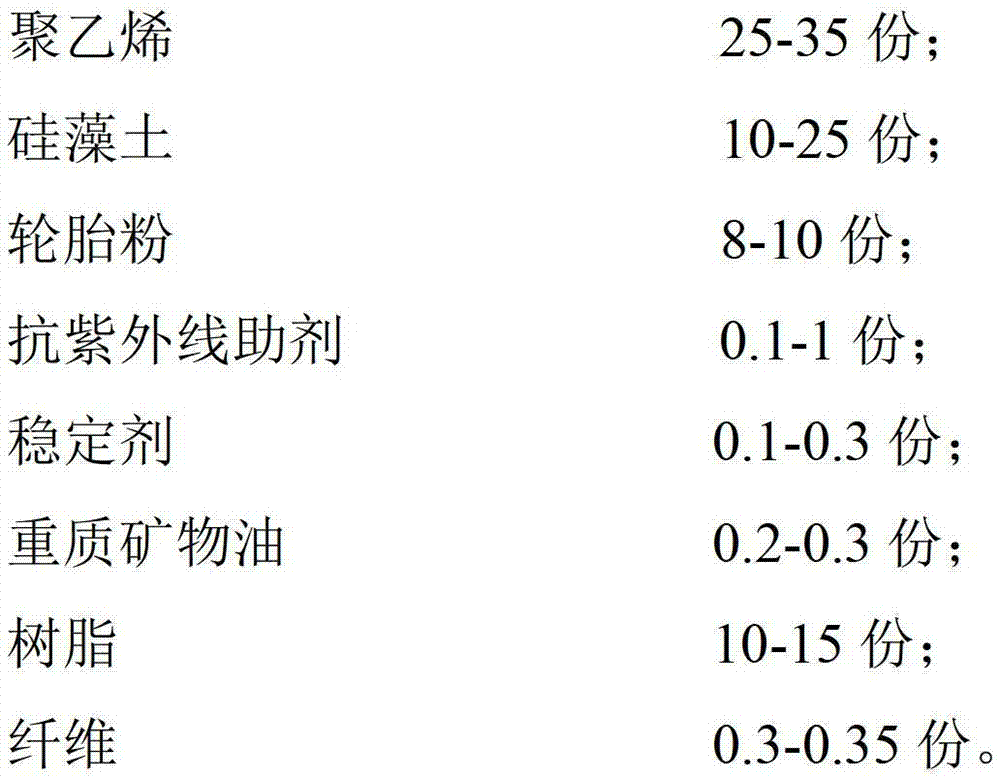

Old asphalt concrete regenerant and preparation method thereof

The invention relates to an old asphalt concrete regenerant and a preparation method thereof. The old asphalt concrete regenerant is prepared by using the following raw materials in parts by weight: 25-35 parts of polyethylene, 10-25 parts of kieselguhr, 8-10 parts of tire powder, 0.1-1 part of an uvioresistant additive, 0.1-0.3 part of a stabilizing agent, 0.2-0.3 part of heavy mineral oil, 10-15 parts of resins, and 0.3-0.35 part of fibers. The old asphalt concrete regenerant provided by the invention not only solves the problem of 100% recycling of old asphalt concrete, but also improves the compatibility and adhesion of recycled asphalt concrete, new aggregates, asphalt and mineral aggregates, so that each pavement performance of newly combined asphalt concrete is far higher than national high-grade pavement specifications and standard requirements and energy conservation and environmental protection requirements; and meanwhile, the pavement construction investment cost is reduced, and the construction speed of old road reconstruction is increased, therefore, the old asphalt concrete regenerant has extremely high economic values and social benefits.

Owner:深圳市天坤元环保科技有限公司

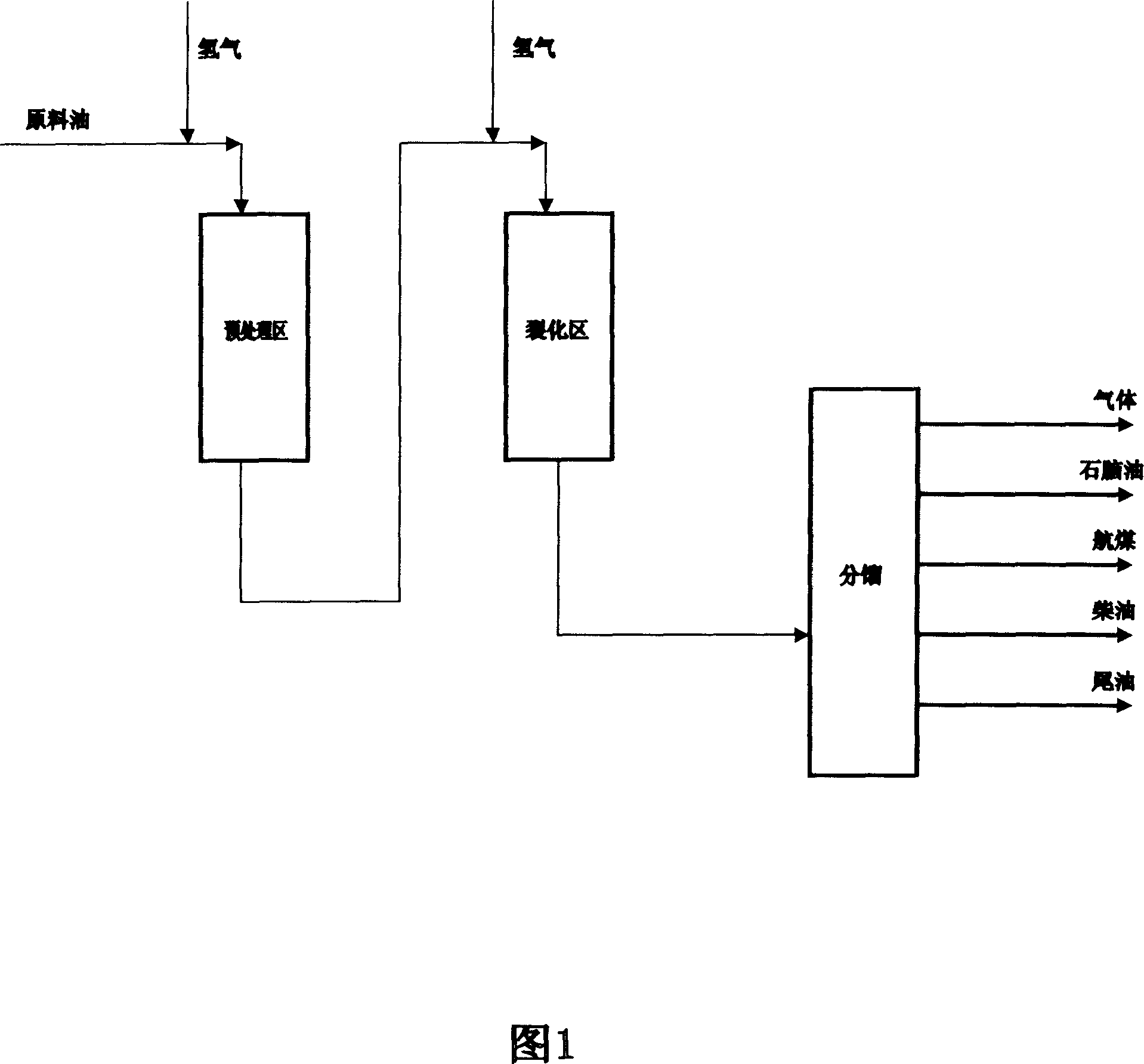

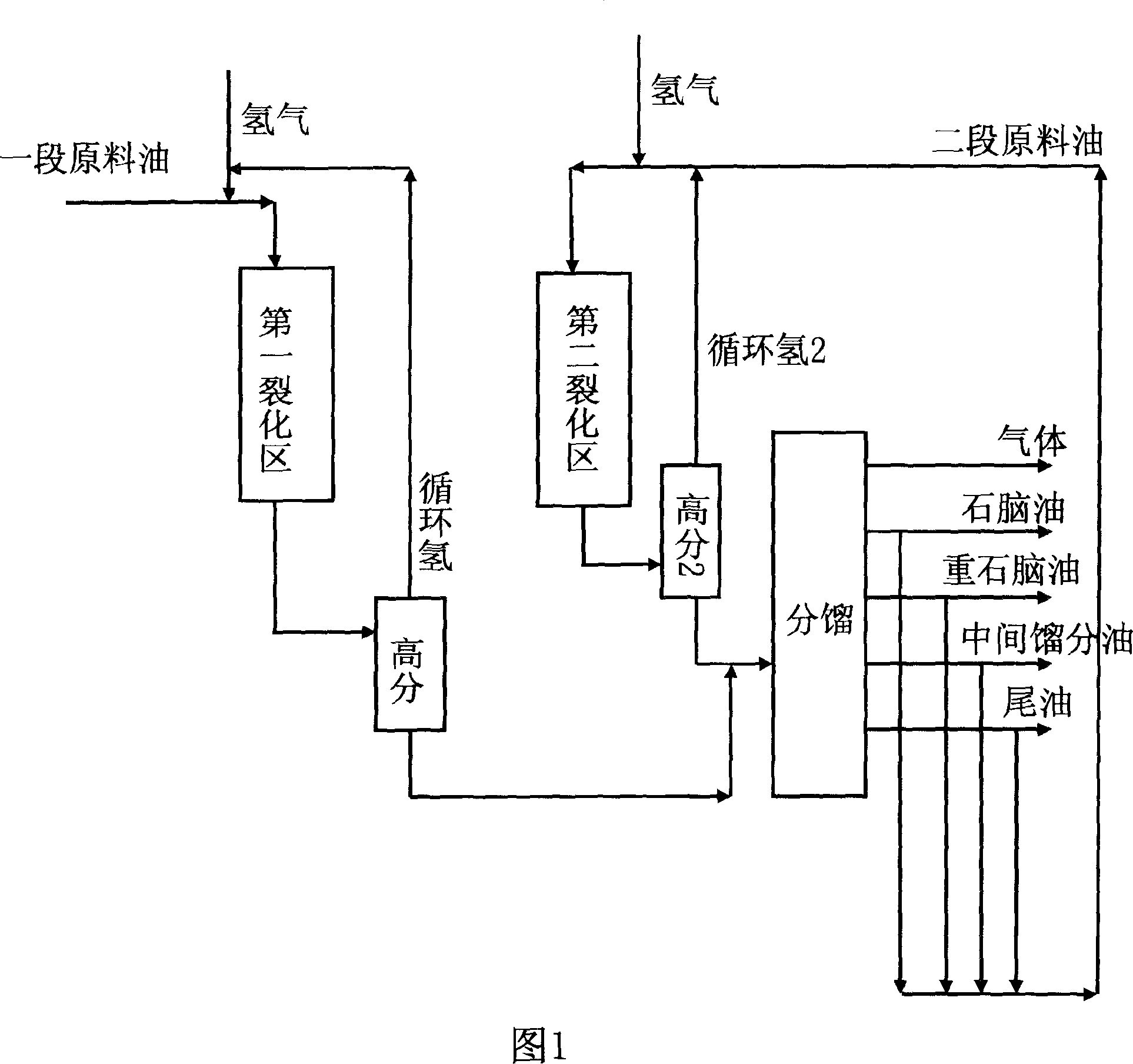

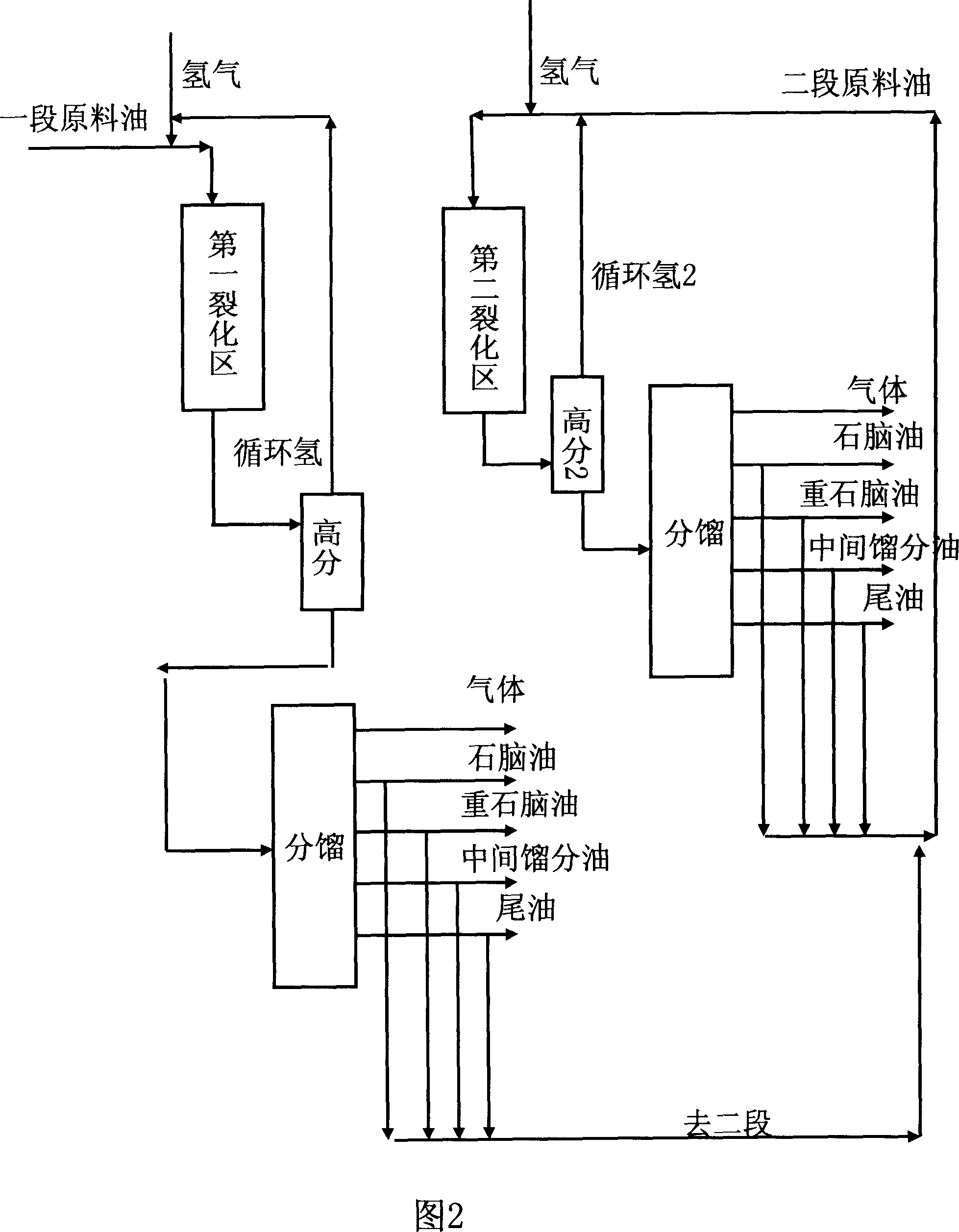

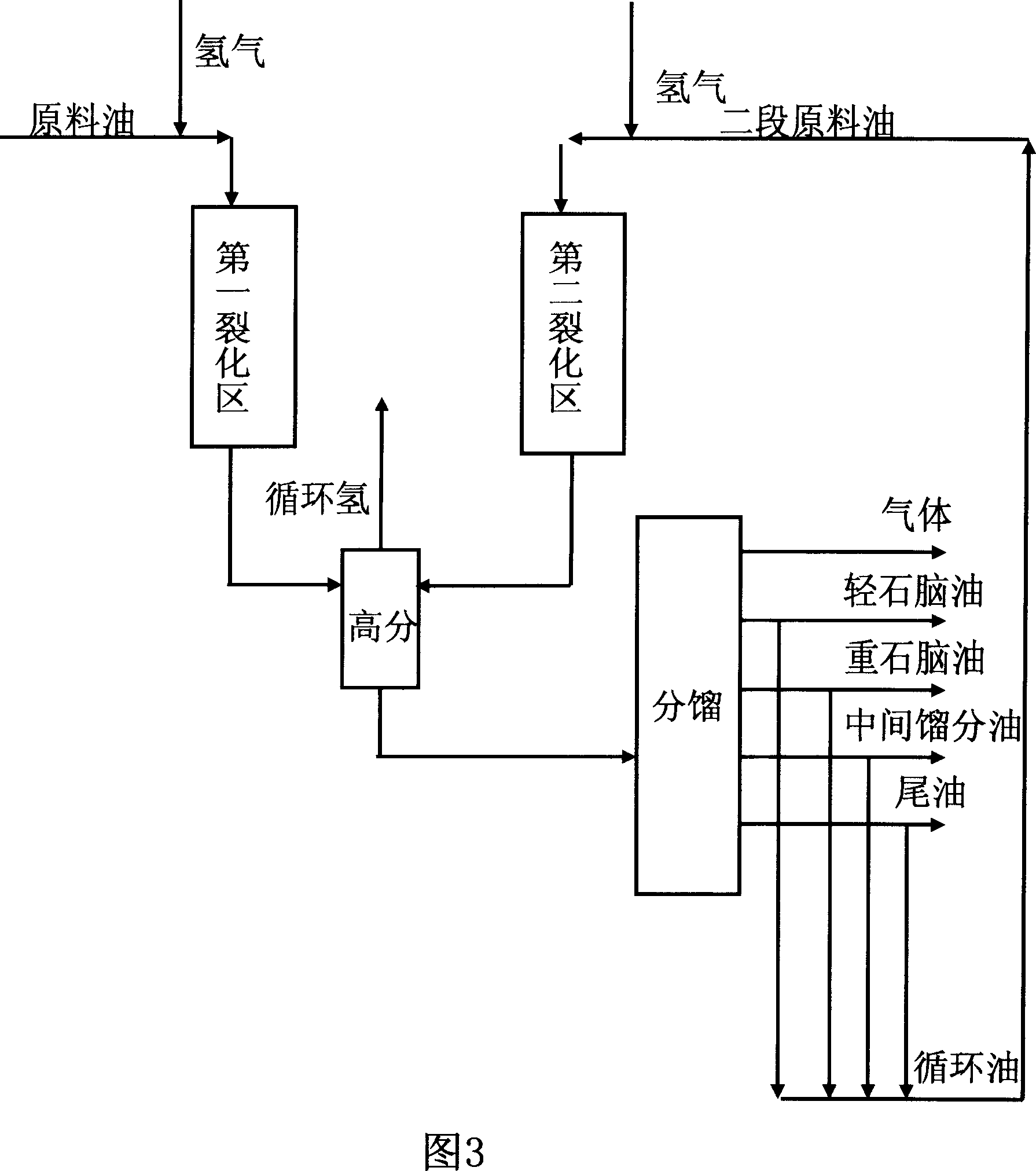

Two-stage hydrocracking process

ActiveCN101089140AReduce usageReduce the content of organic nitrogenTreatment with hydrotreatment processesPre treatmentComplex oxide

The two-stage hydrocracking process has the VGO and / or other heavy fraction oil as the material oil hydrocracked under certain condition to obtain high quality clean oil and / or high quality chemical material. The catalyst in the first stage of pre-treatment includes at least one kind of bulk phase catalyst comprising complex oxide NixWyOz and oxide MoO3 in the weight ratio 0.1-10 and accounting for 40-100 wt% of total catalyst. The present invention facilitates the hydrocracking operation, increases the treating capacity of the apparatus, increases the service life of the catalyst and raises the quality of the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

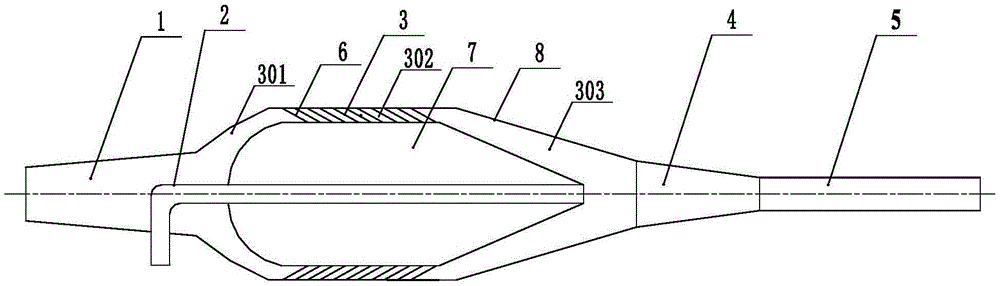

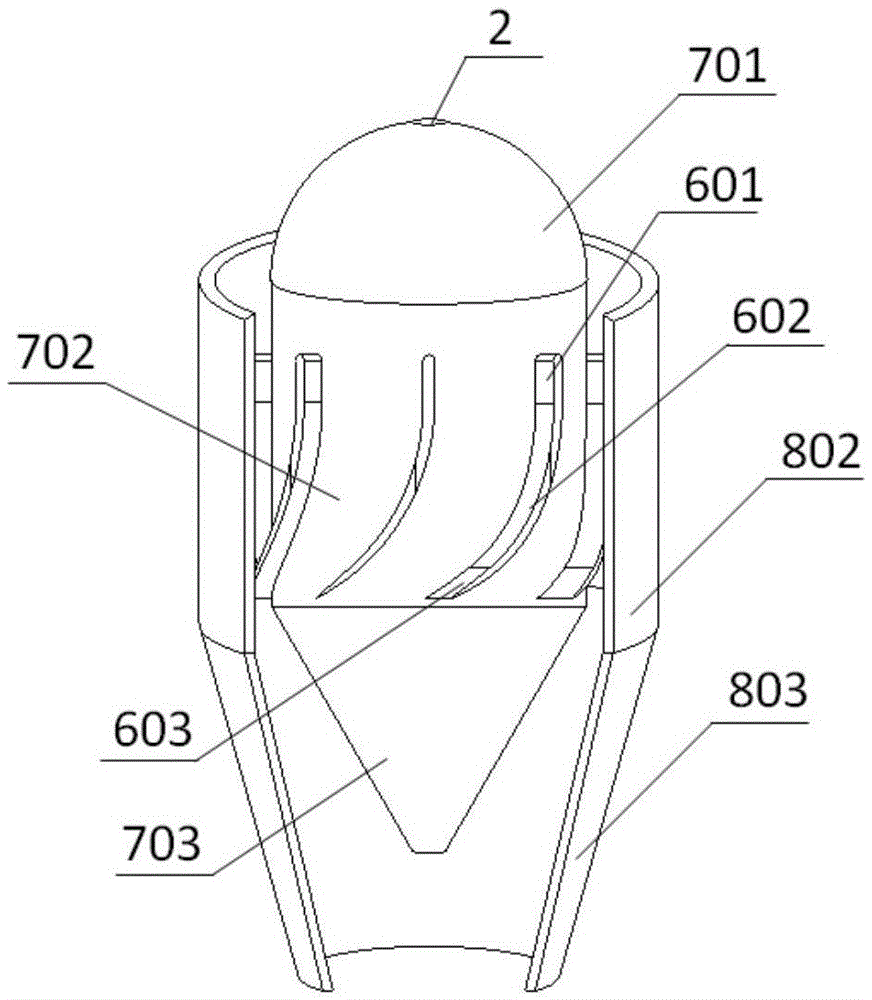

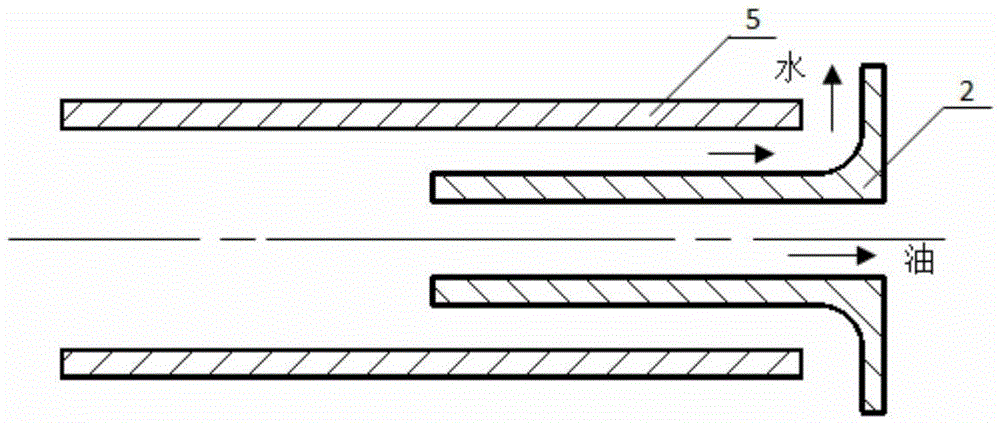

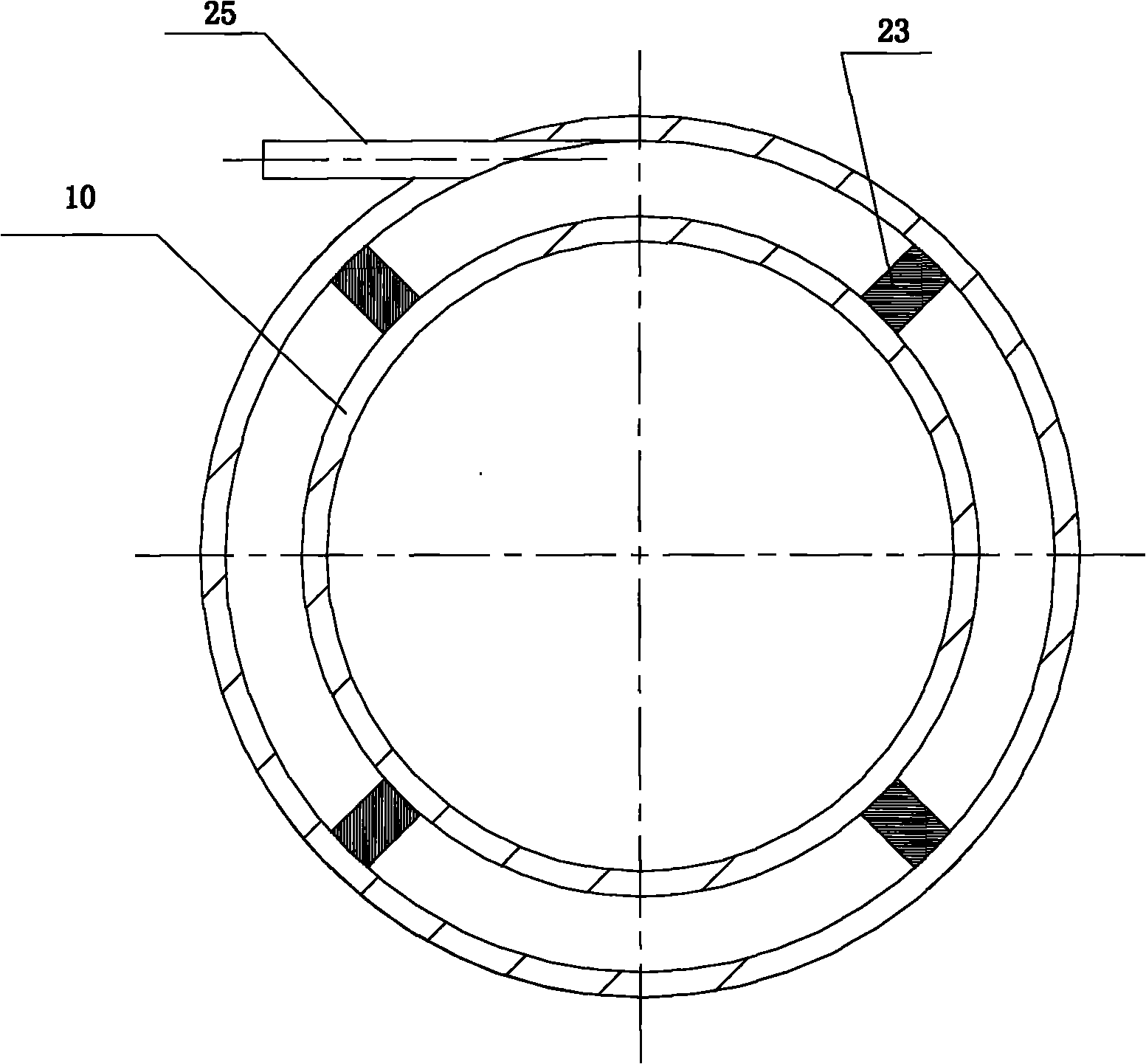

Tubular oil-water cyclone separation equipment

The invention discloses tubular oil-water cyclone separation equipment. The equipment mainly comprises a liquid inlet pipe, a swirler, a separating cavity and a liquid discharge pipe. The overall equipment adopts a tubular structure, and space occupied by the cyclone separation equipment can be saved to a larger extent; a rotary flow field is generated by the aid of streamline blades, the inlet pressure and the operating pressure are far smaller than those of a conventional tangential inlet type hydrocyclone, and the treatment capability is far higher than that of the conventional tangential inlet type hydrocyclone; with the adoption of an axial flow tubular structure, the equipment has the advantages of compact structure, high treatment capacity, small resistance loss, high oil-water separation efficiency and the like, can be used for the oil-water separation process in the petroleum and chemical industry and is particularly suitable for an offshore platform. Multitube skid-mounting is easy to realize, and the problem that the conventional tangential inlet type hydrocyclone occupies large space is solved.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

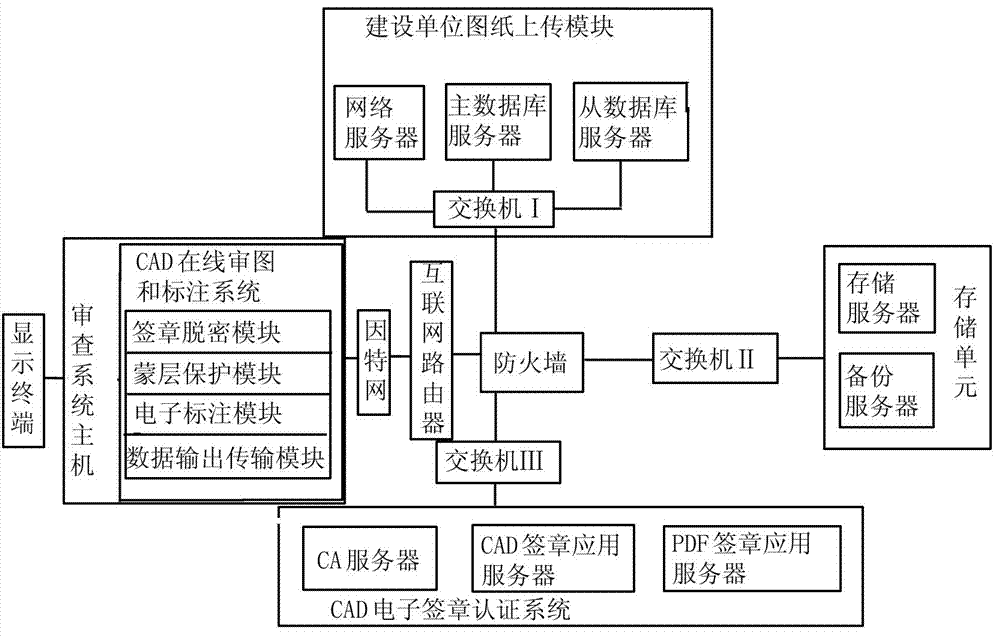

Big data O2O drawing reviewing cloud platform management system used for construction project construction drawing reviewing

PendingCN107451737AAchieve separationImprove access speedResourcesTransmissionNetwork servicePaperless office

The invention discloses a big data O2O drawing reviewing cloud platform management system used for construction project construction drawing reviewing. A construction organization drawing paper upload module comprises a network server and a database server assembly. A construction unit data terminal is connected with the input end of the network server. The data output end of the network server is connected with the database server assembly. A firewall is connected on the port of the database server assembly through a switch I. The firewall is divided into three paths to be connected with a reviewing organization drawing reviewing management terminal, a storage unit and a CAD electronic signature authentication system. The whole course of paperless drawing reviewing of construction drawing reviewing can be realized, the drawing reviewing efficiency and the installation performance can be enhanced, and the cost can be greatly saved and the project period can be shortened.

Owner:泰州市抗震办公室 +1

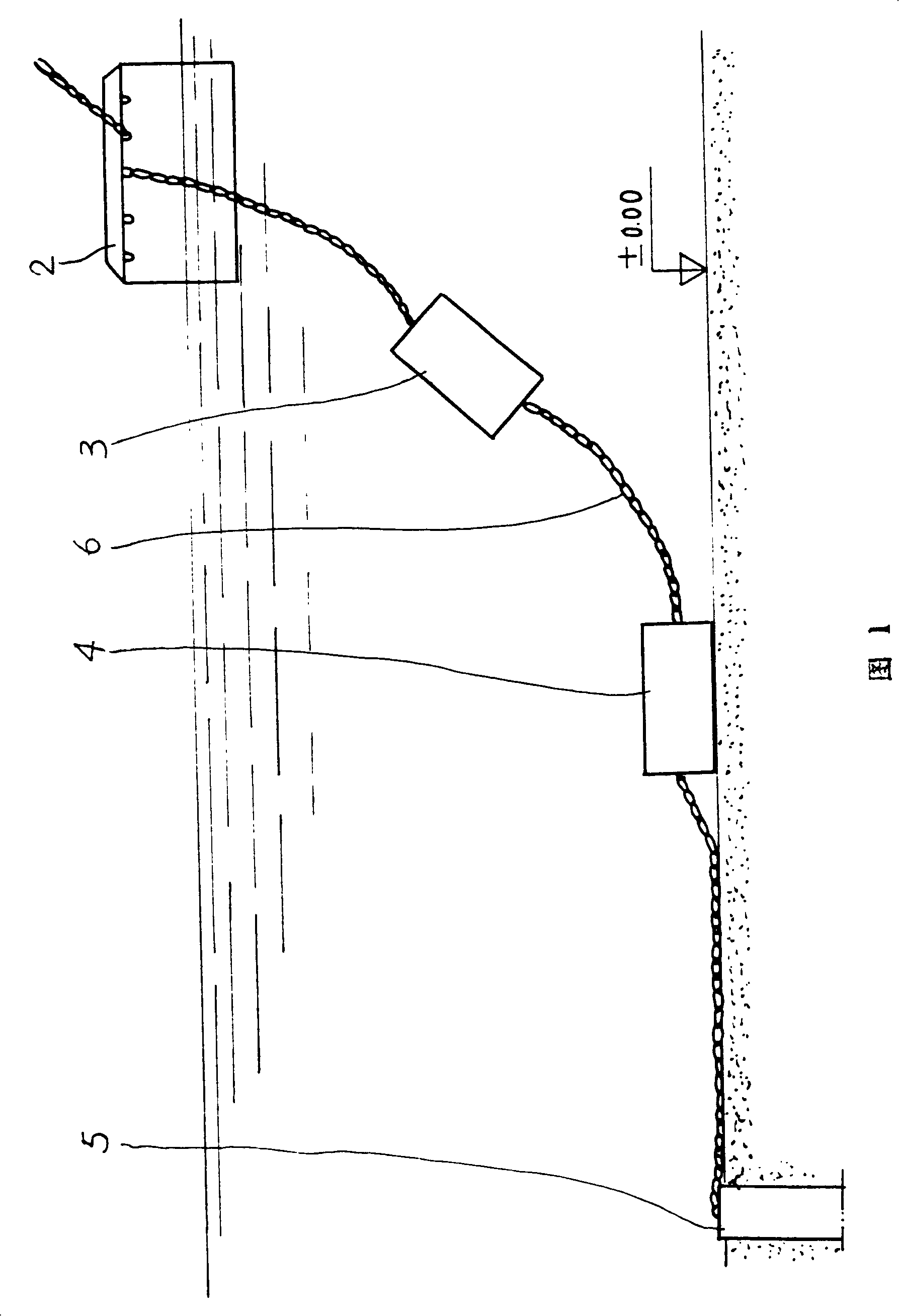

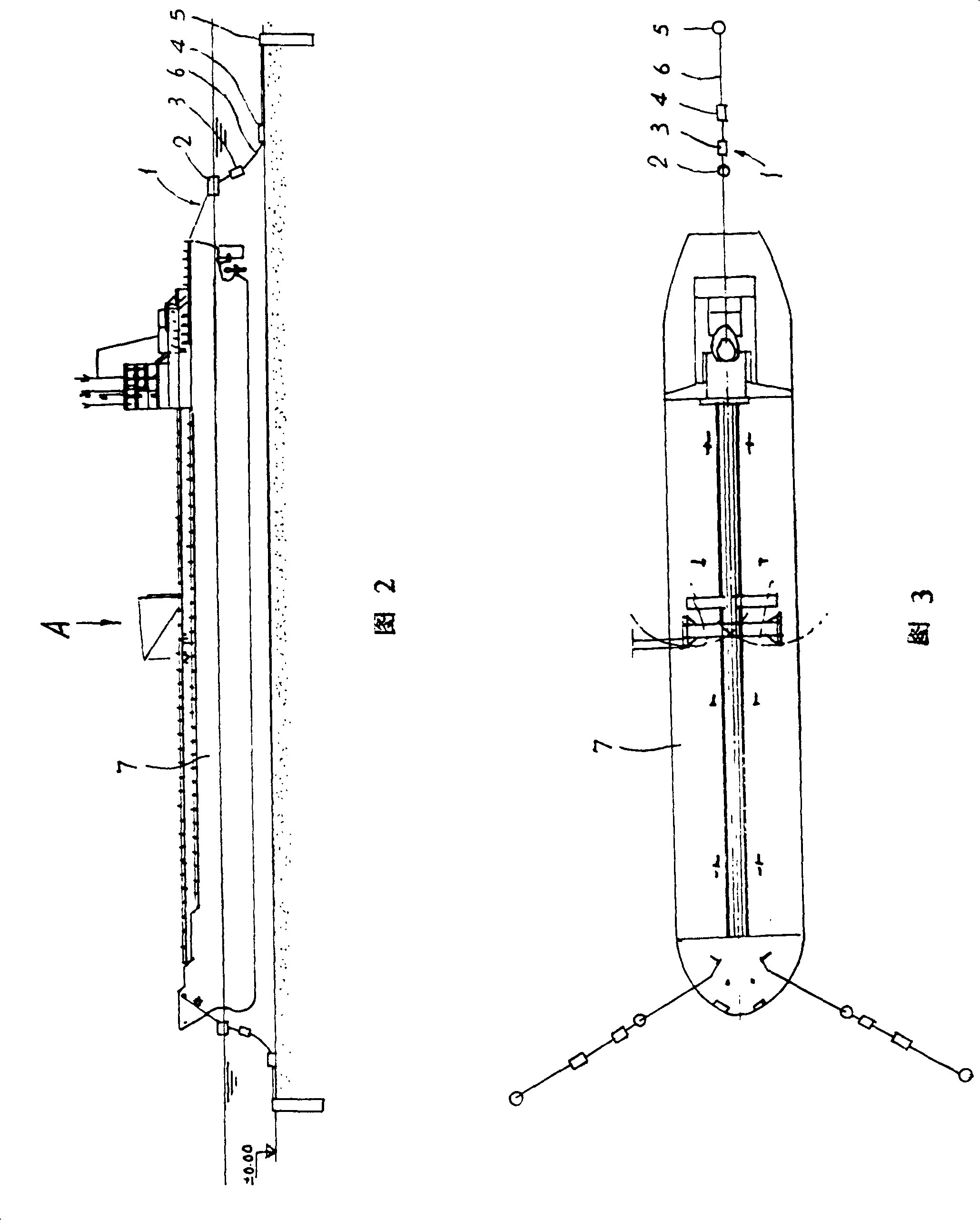

Off land loading and unloading anchoring system and anchoring method for liquid bulk cargo carrier

InactiveCN101157378AIncreased vertical downward forceImprove stabilityAnchorsBulk cargoMooring system

The invention relates to an offshore loading, unloading and mooring system for liquid bulk carriers as well as a mooring method, and the invention is characterized in that the mooring system consists of three sets of mooring device; the mooring device is formed by using connecting components to connect a buoy, a suspension bullback-weight, a chassis bullbacke weight and a anchoring base one by one; when in mooring, each set of mooring device connects the buoy and a carrier together by connecting components, wherein, two sets of mooring device are connected with the head of the liquid bulk carrier; another set of the mooring device is connected with the stern of the liquid bulk carrier; the three sets of mooring device are in Y-shaped arrangement; the mooring system can anchor the liquid bulk carrier in an off-shore sea area to load or unload materials; compared with the prior art, the invention has the advantages of small occupation sea area, low investment, short construction cycle, convenient operation, safety and reliability. Moreover, the invention does not take up shore-line resources, and is easy to be recovered and ruled, as well as especially suitable for the loading and unloading of the liquid bulk carriers.

Owner:陈杰诚

Technology for preparing high-cleanliness and high-octane gasoline from methanol through one-step catalysis method

InactiveCN104130796AEasy to adjustPrecise temperature controlLiquid hydrocarbon mixture productionBio-feedstockGas compressorComponents of crude oil

The invention relates to a technology for preparing high-cleanliness and high-octane gasoline from methanol through a one-step catalysis method. The process of preparing gasoline from methanol is a strong heat release process, and existing technologies for preparing gasoline from methanol at home and abroad all adopt recycle gas (which mainly contains mixed methane, ethane, hydrogen, propane, butane, pentane, carbon monoxide, carbon dioxide and the like) as a heat taking medium to take away heat generated in a reactor, so as to control the outlet temperature of the reactor; liquefied gas (mainly containing propane and butane) produced by a device per se is adopted in the technology to substitute the recycle gas and enters the reactor to serve as a heat removal medium, and the liquefied gas rarely participates in reaction under the same reaction condition, the reaction product is basically unchanged. The technology has the advantages that a recycle gas compressor is not needed, the equipment investment is greatly reduced, the running power consumption of the device is reduced, the heat exchange flow of the device is optimized, the device is simple, stable and reliable in operation, and meanwhile, the public engineering grade is also reduced, so that the technology has significant practicability, huge economic benefits and wide application prospect.

Owner:张永魁

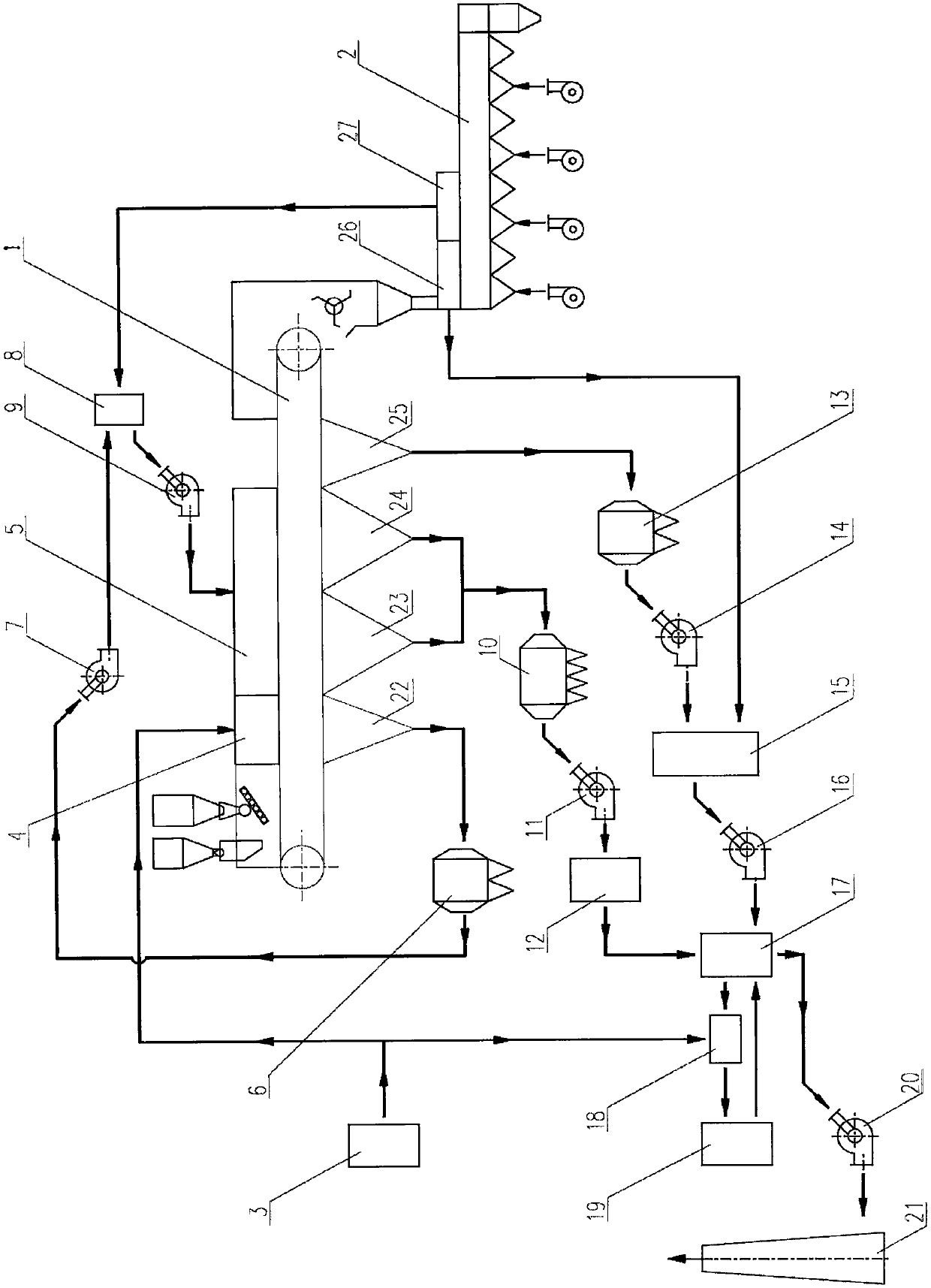

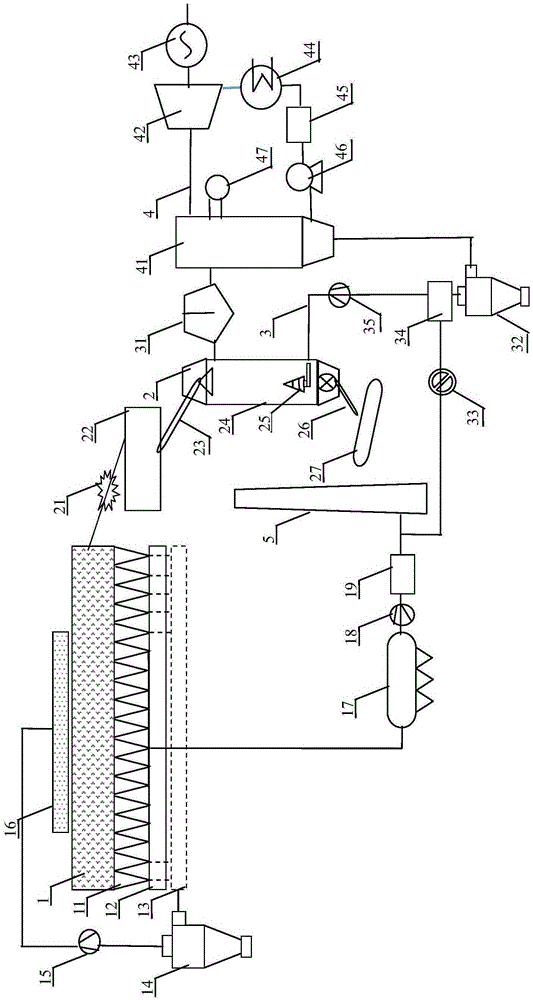

Sintering flue gas reduction and waste heat comprehensive utilization method and device

ActiveCN106610230AEmission reductionQuick breakdownIncreasing energy efficiencyHandling discharged materialCounter flowMixed gas

A sintering flue gas reduction and waste heat comprehensive utilization process is composed of flue gas circulating sintering, sinter vertical cooling, circulating air cooling, waste heat power generation and the like. The process comprises the following specific steps that part of sintering flue gas is guided out from a sintering trolley head and tail bellows branch pipes, and after dedusting and boosting, the flue gas is circulated to the surface of a middle material layer of a sintering trolley; sintering waste gas in the middle of the sintering machine trolley is guided out and subjected to dedusting and purification, most of the purified waste gas is emitted, and a small amount of waste gas takes participation in high-temperature sinter vertical cooling; the sinter at the tail end of the sintering trolley is crushed and then enters a vertical cooling furnace, counter flow cooling is conducted on the crushed sinter and circulating air blown from the bottom, and the sinter is discharged; the circulating cold air enters a waste heat power generation system after being subjected to heat exchange and primary dedusting; and the circulating air flowing through the waste heat power generation system is subjected to secondary dedusting and is mixed with part of purified sintering waste gas, boosting is conducted, and then the mixed gas enters the vertical furnace for hot ore circulating air cooling. According to the sintering flue gas reduction and waste heat comprehensive utilization process, the sintering flue gas and sinter sensible heat can be utilized effectively, the flue gas emission is cut down, pollutants such as dust, SO2, NOx and dioxin can be removed at the same time, the occupied space is small, and the investment is small.

Owner:BAOSHAN IRON & STEEL CO LTD

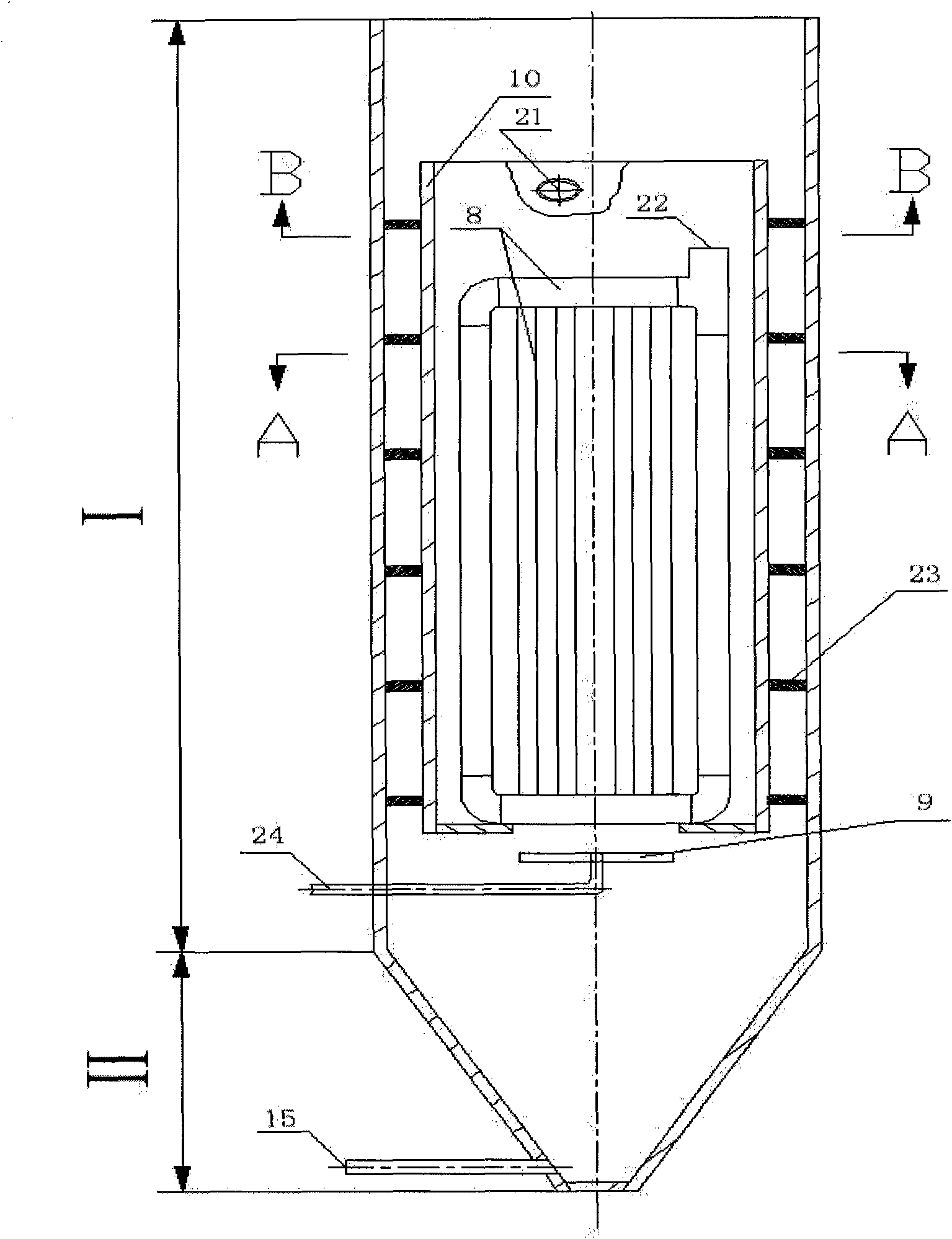

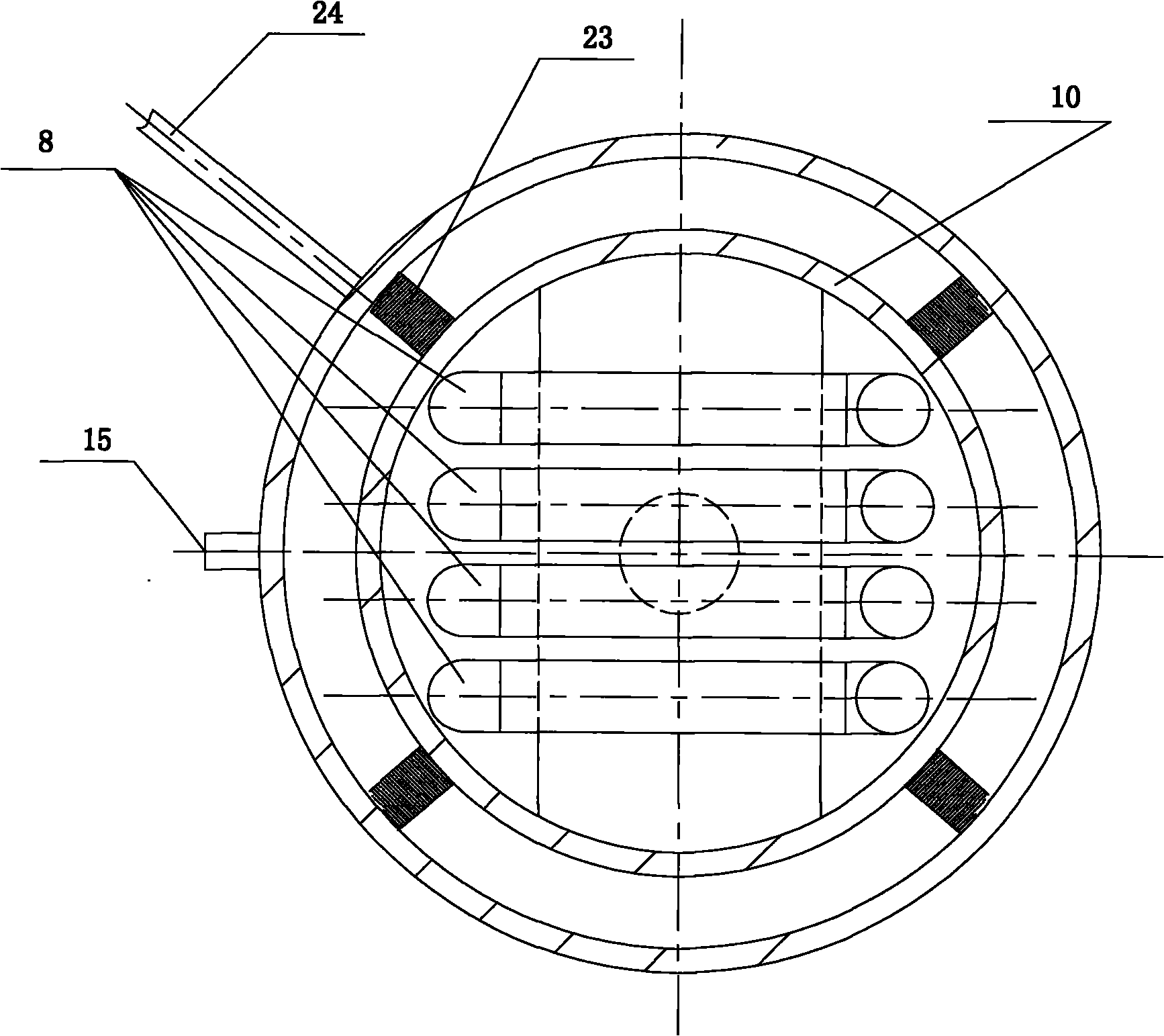

Immersed water treatment device of inner circulating membrane coagulation reactor

ActiveCN102050529ASmall footprintReduce construction investment costsWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentSmall footprintPollution

The invention discloses an immersed water treatment device of an inner circulating membrane coagulation reactor, belonging to the field of water treatment. The immersed water treatment device of the inner circulating membrane coagulation reactor comprises an inner circulating membrane coagulation reactor, wherein the main body of the inner circulating membrane coagulation reactor is a reaction tank divided into an upper part and a lower part; the upper part is internally provided with an inner circulating cylinder of which the upper end and the lower end are opened; the inner circulating cylinder is internally provided with a membrane assembly on which a water outlet is arranged; an aeration pipe or an aeration disk is arranged below the membrane assembly; and the upper part of the reaction tank is provided with a turbulent flow member arranged between the inner wall of the reaction tank and the cylinder wall of the inner circulating cylinder. The water treatment device can be used for efficiently relieving pollution of the membrane in the water treatment device and removing pollutants in water and also has the advantages of small occupation area and low construction investment and running cost.

Owner:ENVIRONMENTAL PROTECTION RES INST OF LIGHT IND

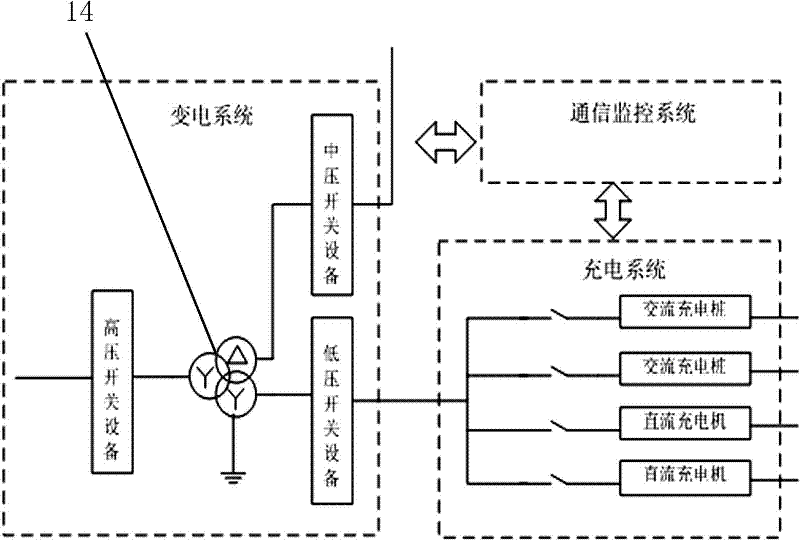

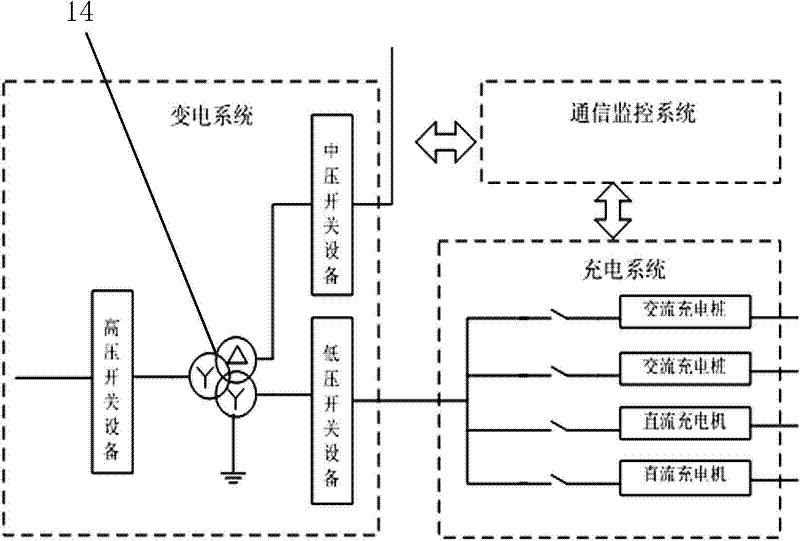

Multifunctional intelligent station integrating transformation, charging and conversion

InactiveCN102394506AReduce construction investment costsSave construction investmentBatteries circuit arrangementsStar/tree networksLand acquisitionInformatization

The invention belongs to the electric power equipment technology field and especially relates to a multifunctional intelligent station integrating transformation, charging and conversion. And specifically, the invention relates to an intelligent transformer station and an electric automobile charging station, and the integrated multifunctional intelligent station possessing transformation, charging and conversion functions. The multifunctional intelligent station of the invention mainly comprises: a transformer substation system, a charging system and a communication monitoring system. The transformer substation system is connected with the charging system. The communication monitoring system constructs Ethernet through a fiber to realize communication with the transformer substation system and the charging system and monitoring the transformer substation system and the charging system. By using the multifunctional intelligent station of the invention, construction and investment costs of an electric automobile charging station distribution transformer can be directly saved. The construction and investment costs are small. A whole construction area of the transformer station and the electric automobile charging station can be directly reduced. Building land acquisition demands can be directly reduced. Information sharing in the intelligent station can be realized. Levels of automation, informatization and intellectualization of the intelligent station are high. The multifunctional intelligent station is suitable for dense population areas in cities and the areas where land expropriation is difficult, and has a good application prospect.

Owner:NORTHEAST POWER SCI RES INSTITUTION +3

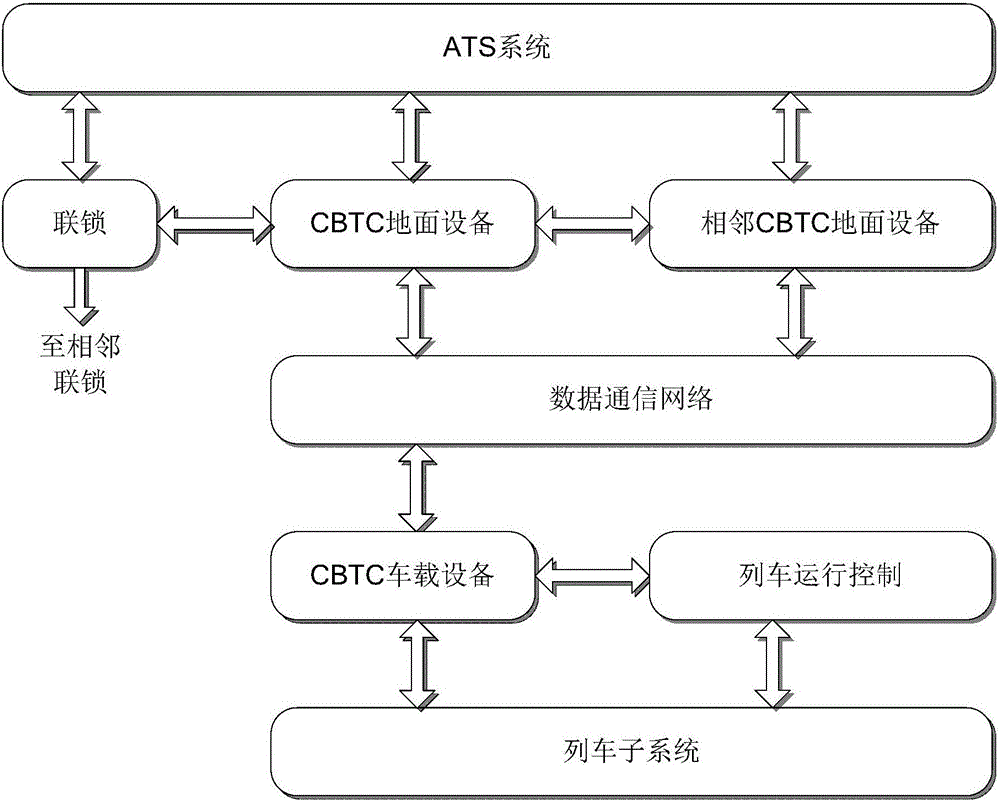

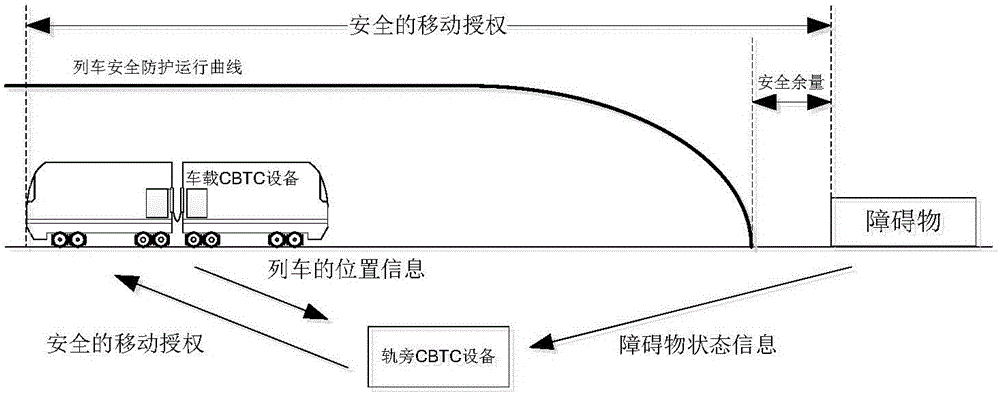

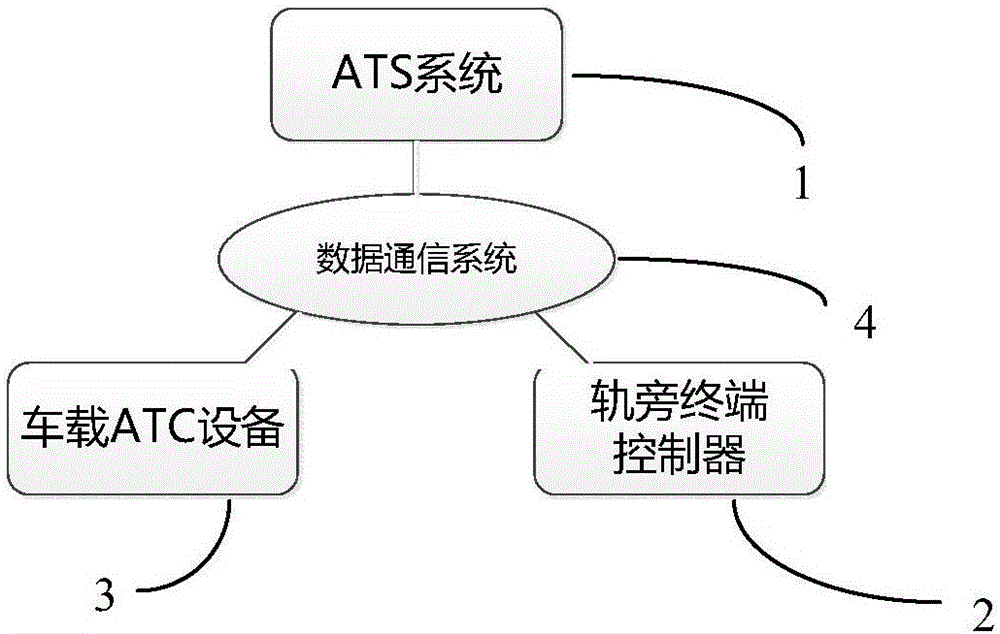

Distributed train running control system based on communication

ActiveCN106809253ASimplify complexityReduce loadRailway traffic control systemsCommunications systemHigh density

The invention discloses a distributed train running control system based on communication. In combination with existing computer control technology and digit communication technology that are developing in high speed, increasing demand like high density and long transportation is satisfied. The technical scheme is that the system comprises a train automatic supervise system (ATS), a trackside terminal controller (TDC), a vehicle ATC apparatus and a data communication system. The running control system can realize train path calculation and train running path dangerous obstacle protection.

Owner:HUNAN CRRC TIMES SIGNAL & COMM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com