Low energy consumption sintering flue gas dioxin emission-reducing system and method thereof

A technology for reducing emissions of sintering flue gas and dioxins, applied in the metallurgical field, can solve problems such as no control measures, achieve obvious investment advantages and operating cost advantages, improve dust removal efficiency, and be easily accepted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

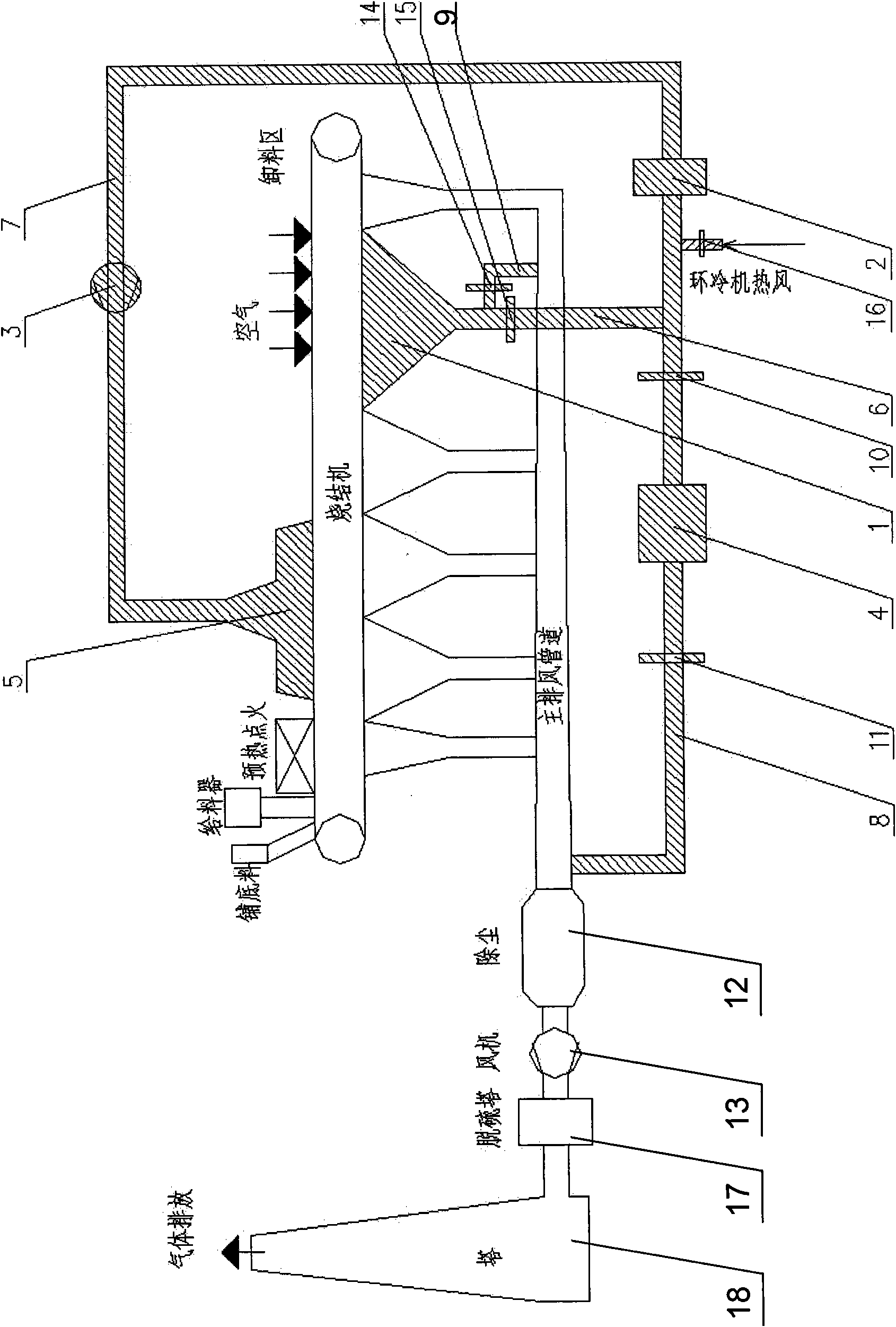

[0043] see figure 1 , a low-energy sintering flue gas dioxin emission reduction system of the present invention is mainly composed of a high-concentration area exhaust box 1, a dust collector 2, a fan 3, a dioxin removal system 4, a closed gas hood 5, and a high-density dioxin Compound flue gas flue 6, circulating air duct 7, dioxin-like compound removal flue 8, bypass flue 9, valve 10, valve 11, main dust collector 12, fan 13, valve 14, valve 15, valve 16. Composed of a desulfurization tower 17 and a chimney 18.

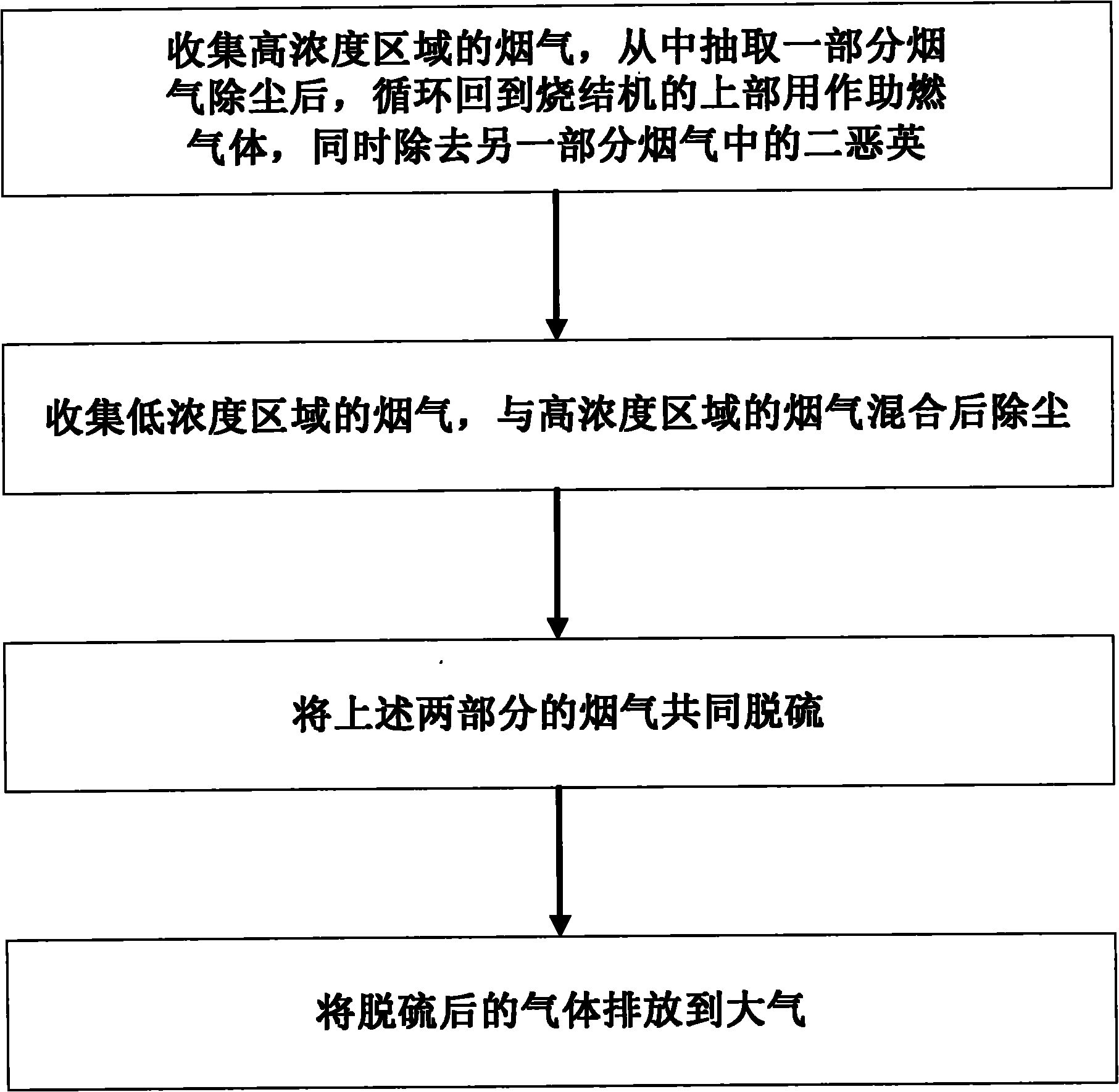

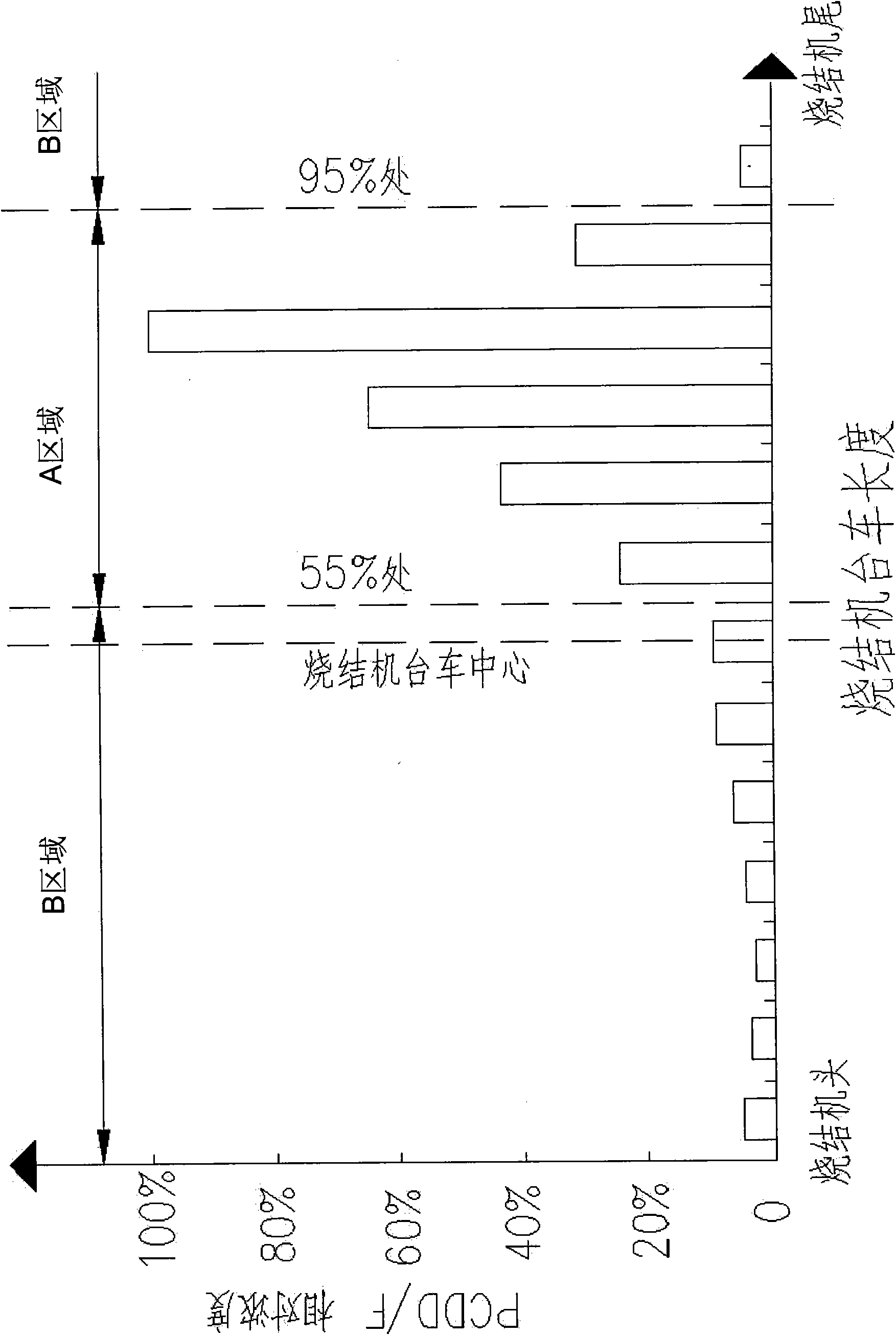

[0044] According to the level of dioxin concentration in the area, all the exhaust boxes at the lower part of the sintering machine trolley are divided into high-concentration area exhaust box 1 and low-concentration area exhaust box. The exhaust box in the low-concentration area is connected to the main smoke exhaust pipe, and then passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com