Patents

Literature

70results about How to "Simple crafting system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Classified-desliming pressurized-feeding three-product dense medium cyclone coal preparation process

InactiveCN103350027AImprove sorting efficiencyFlexible structureWet separationThermodynamicsMagnetic separator

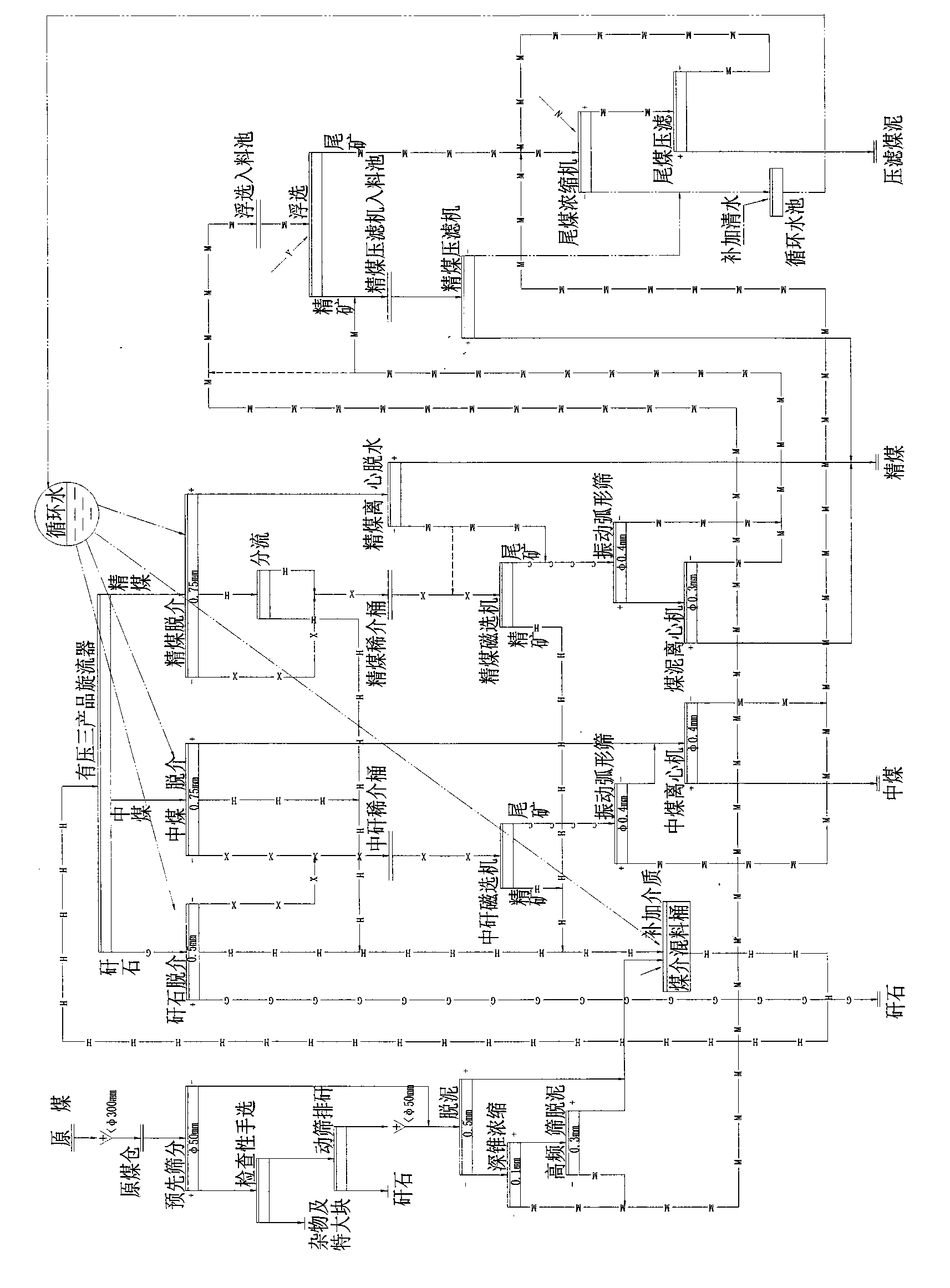

Provided is a classified-desliming pressurized-feeding three-product dense medium cyclone coal preparation process. The process comprises the steps that wet classification and primary desliming are carried out on raw coal after prescreening, gangue predischarging and breaking are carried out on the raw coal, secondary desliming is carried out on the screen underflow of the raw coal after the screen underflow is concentrated, the oversize products of the secondary desliming and the screen underflow of the primary desliming are together fed in a pressurized three-product cyclone, three products are obtained after separation, and clean coal, middle coal and gangue are obtained after medium separation and dehydration are carried out on the three products. Part of qualified suspension liquid and dilute suspension liquid are obtained when the medium separation is carried out on the three products, magnetic concentrate is obtained after the dilute suspension liquid is recovered by a magnetic separator, and the magnetic concentrate and the qualified suspension liquid are directly fed in a medium blending barrel. The magnetic tailings of the dilute suspension liquid and the undersize mixtures of pre-desliming, the overflow of concentration classifying equipment and a secondary desliming screen enter a coal slime recovery processing system together. The process is high in separation efficiency, flexible in product structure, low in producing and operating cost and prone to achieving the large-scale single system, the modularization and the integrating intellectualization of plant layout.

Owner:煤炭科学研究总院唐山研究院

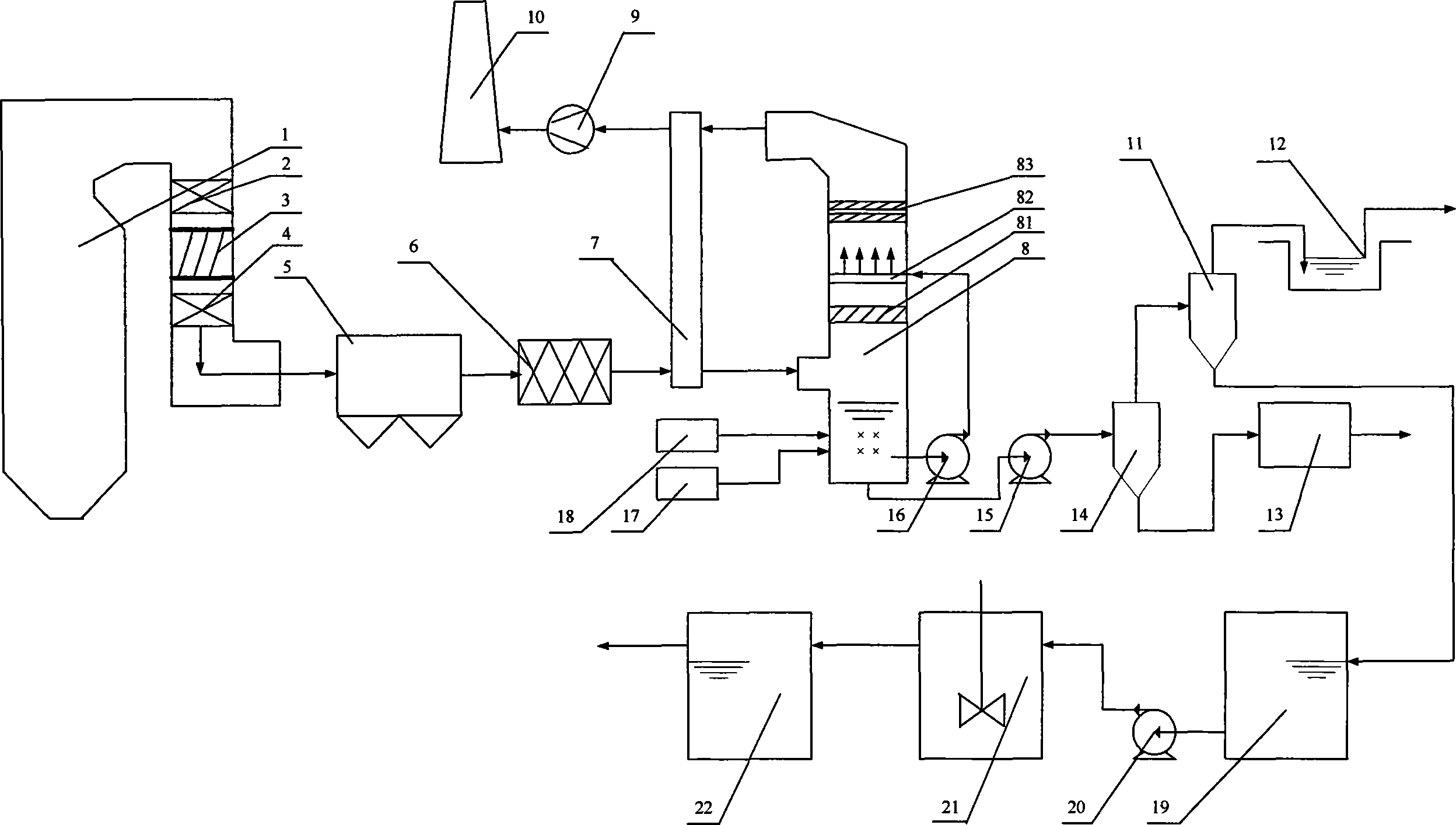

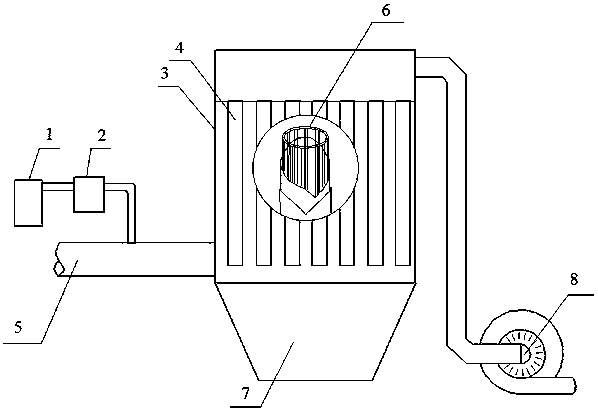

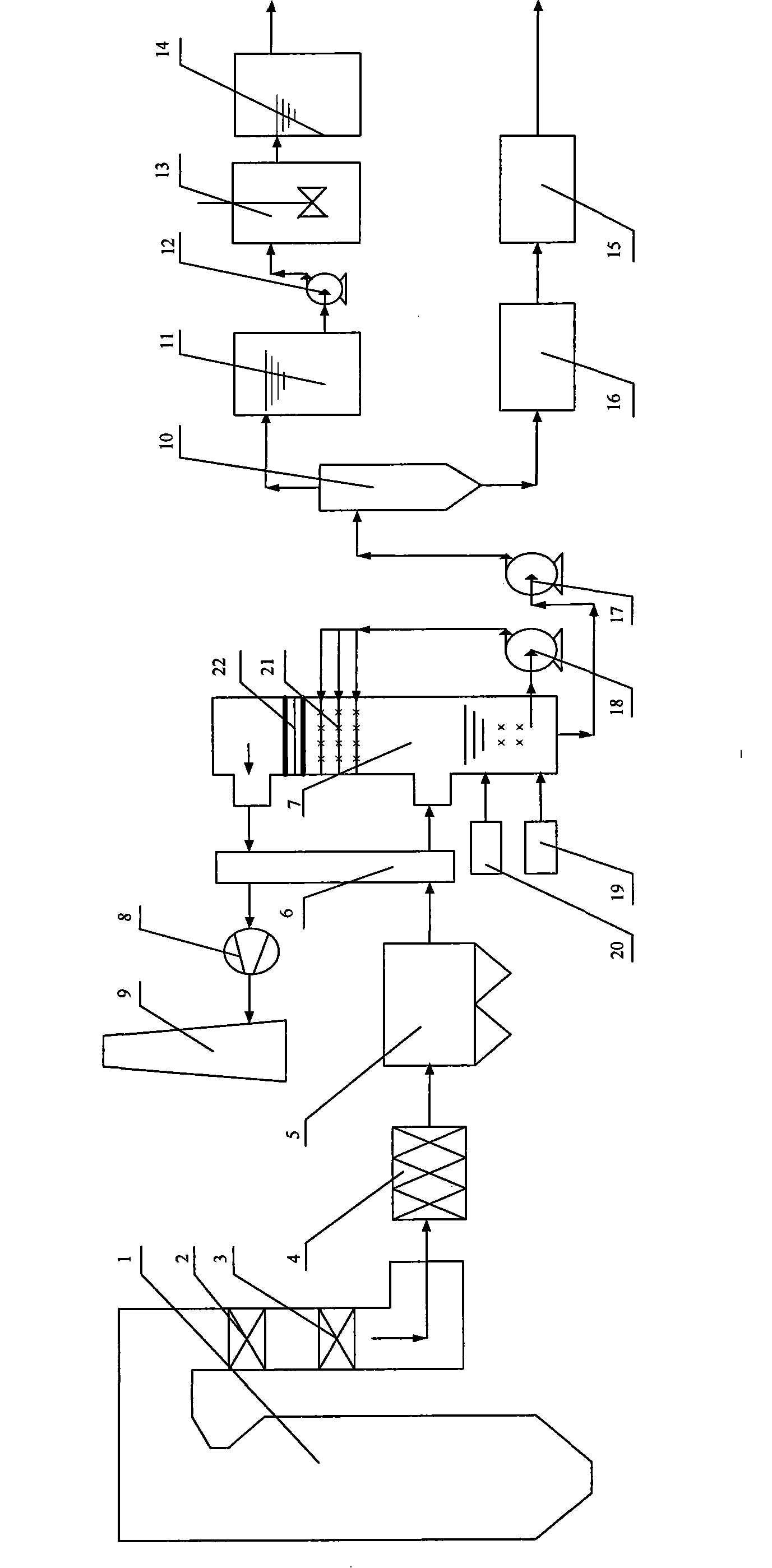

Wet-type ammonia process flue gas purifying technique for jointly removing multipollutant and system thereof

InactiveCN101108303ASimple processSmall footprintDispersed particle separationAir quality improvementChemistryProcess systems

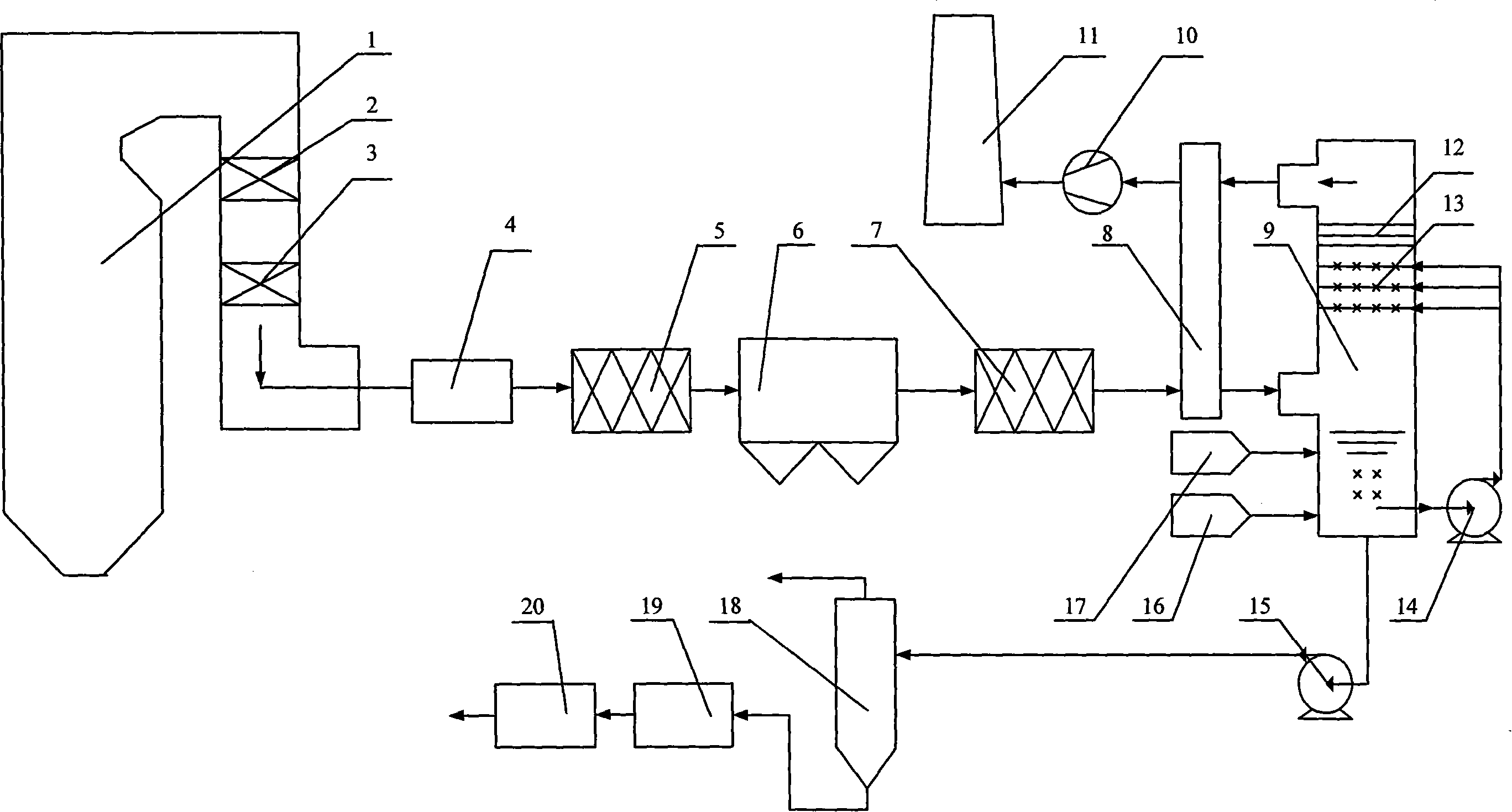

A damp ammonia smoke and gas purifying techniques and system which deprives plurality kinds of infectant is provided. The technique uses the dual functions of high gradient magnetic field and grain conglobation accelerator firstly, which makes small grains in smoke and gas reunite large grains. Then deprives the reunited large grains by a static dedusting device, adopts oxydol to proceed oxidation on nitric oxide in the smoke and gas to convert to nitrogen dioxide, finally adsorbs sulfur dioxide and nitrogen dioxide in smoke and gas by damp ammonia smoke and gas purifying techniques. The system is composed of a high gradient magnetic field generator, a grains conglobation accelerator spaying device, a static dust catcher, an oxidant spaying device and a reaction adsorption tower which are laid in series one by one. A draining opening of the reaction adsorption tower can be connected with an outgrowth process system which is composed of a rotary stream separator, an evaporator and a desiccator. The invention can improve the utilization rate of absorbent effectively, deprives the respirable grains, oxysulfide and nitrogen oxides in smoke and gas, and has simple technics, simplified system and low investment and operating cost.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

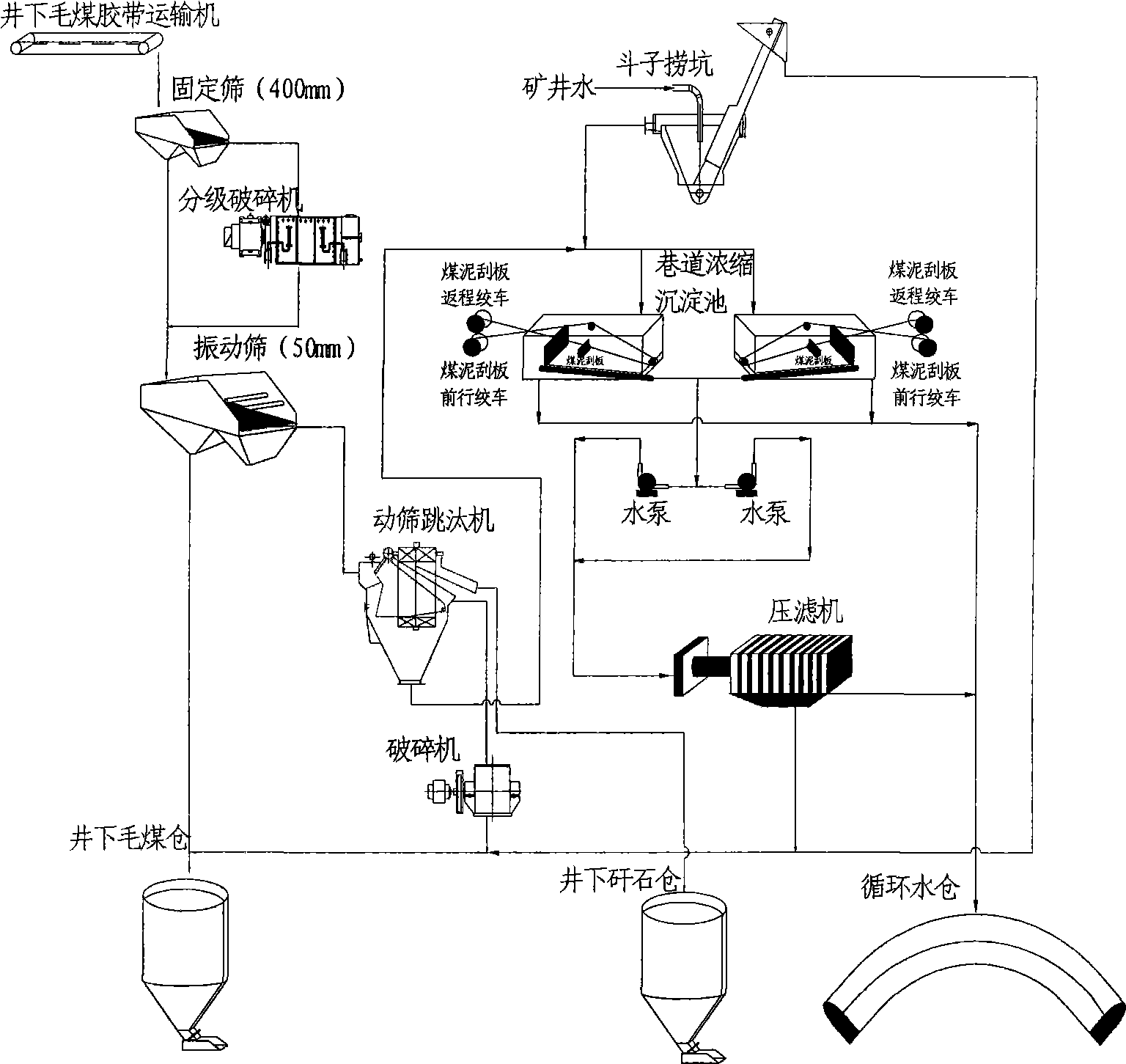

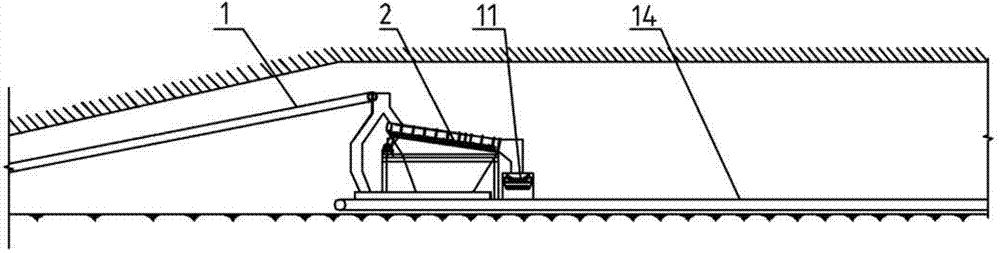

Down-hole gross coal dirt-discharging and mine water treating combined process

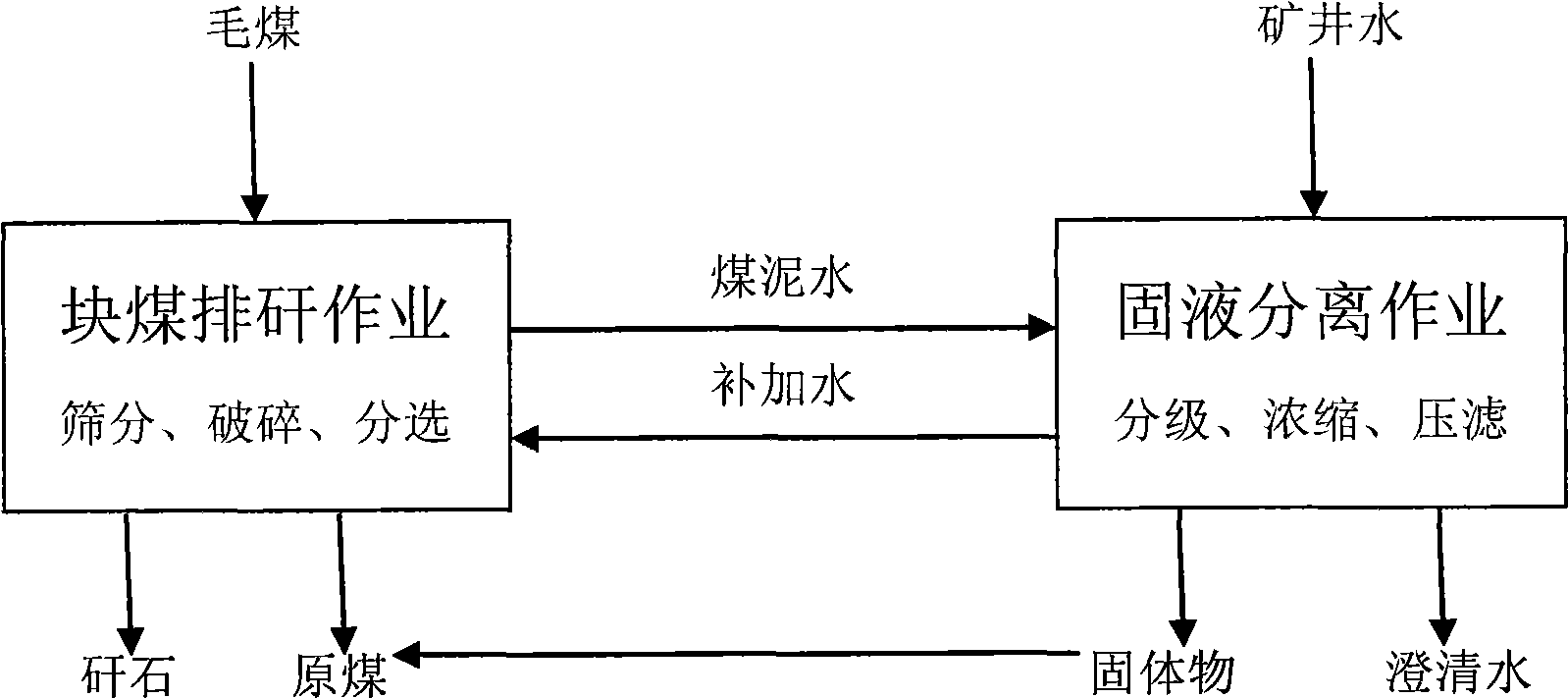

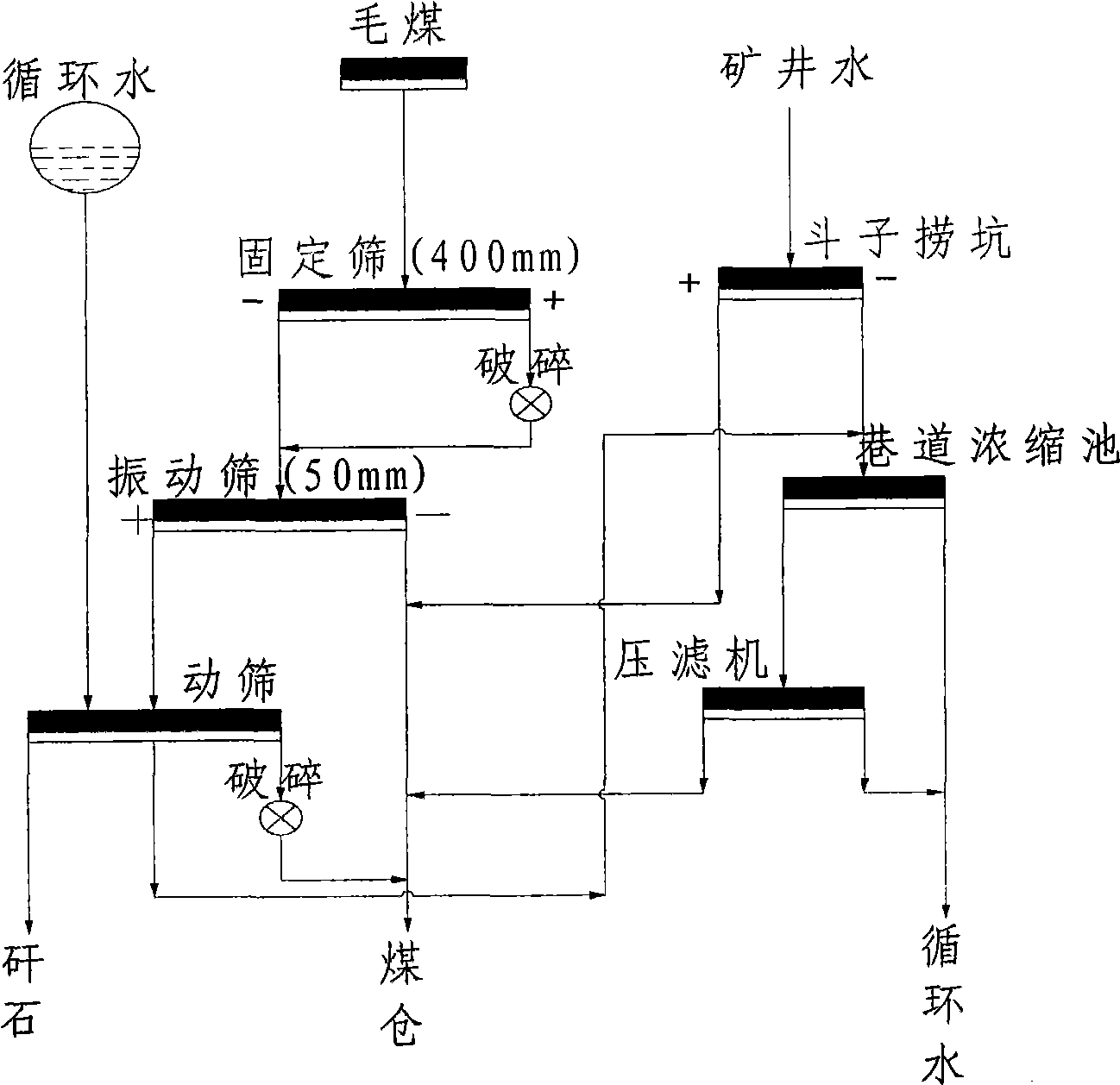

An underground gross coal gangue removal and mine water treatment combined process is characterized in that the process comprises two parts: gangue removal operation from lump coal and mine water solid-liquid separation operation, wherein, the gangue removal operation from lump coal comprises screening, crushing and separation steps, and the mine water solid-liquid separation operation comprises hydraulic classification, concentration and pressure filtration steps; by the gangue removal operation from lump coal, chunks of gangues in the gross coal are removed, and simultaneously the large particles thereof are crushed into appropriate size; by the mine water solid-liquid separation operation, the solid substances in the mine water are recycled to a coal streamline, and simultaneously the clear overflow water is delivered to a underground water sump; the coal muddy water generated by the gangue removal operation from lump coal is delivered to a mine water solid-liquid separation system for treatment and the mine water solid-liquid separation system provides water for washing and selection for the gangue removal operation from lump coal, so the coal muddy water and the water for washing and selection are combined into an organic whole.

Owner:HENAN POLYTECHNIC UNIV

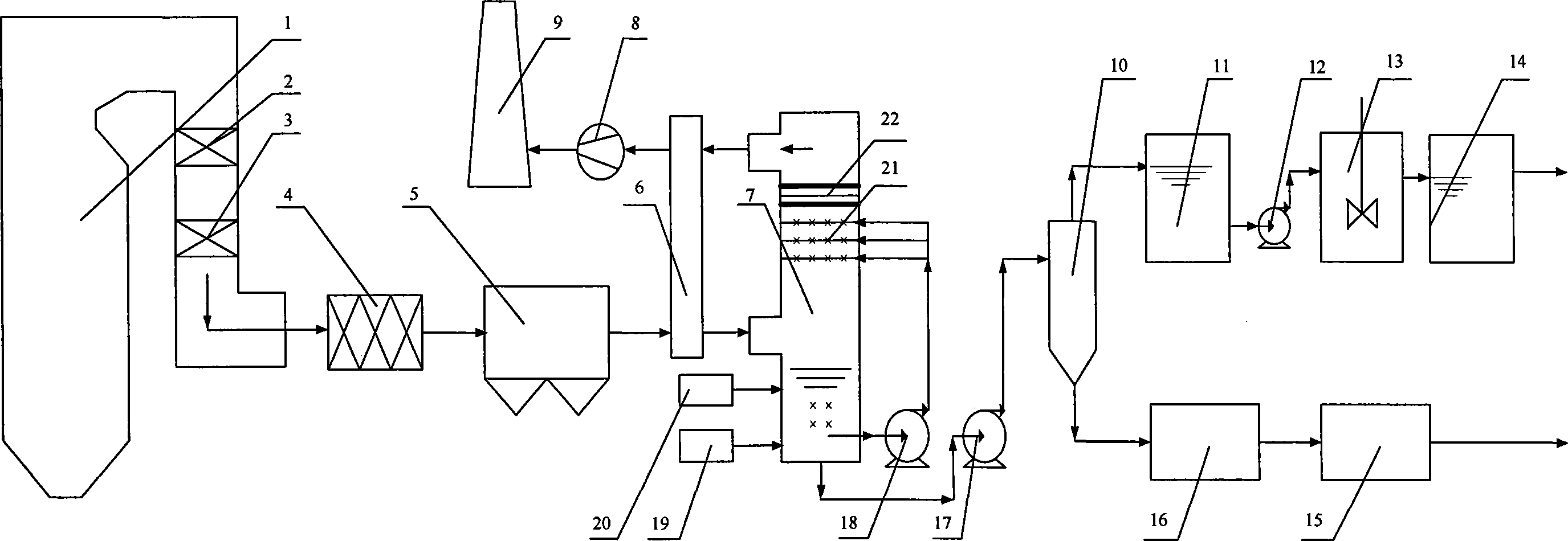

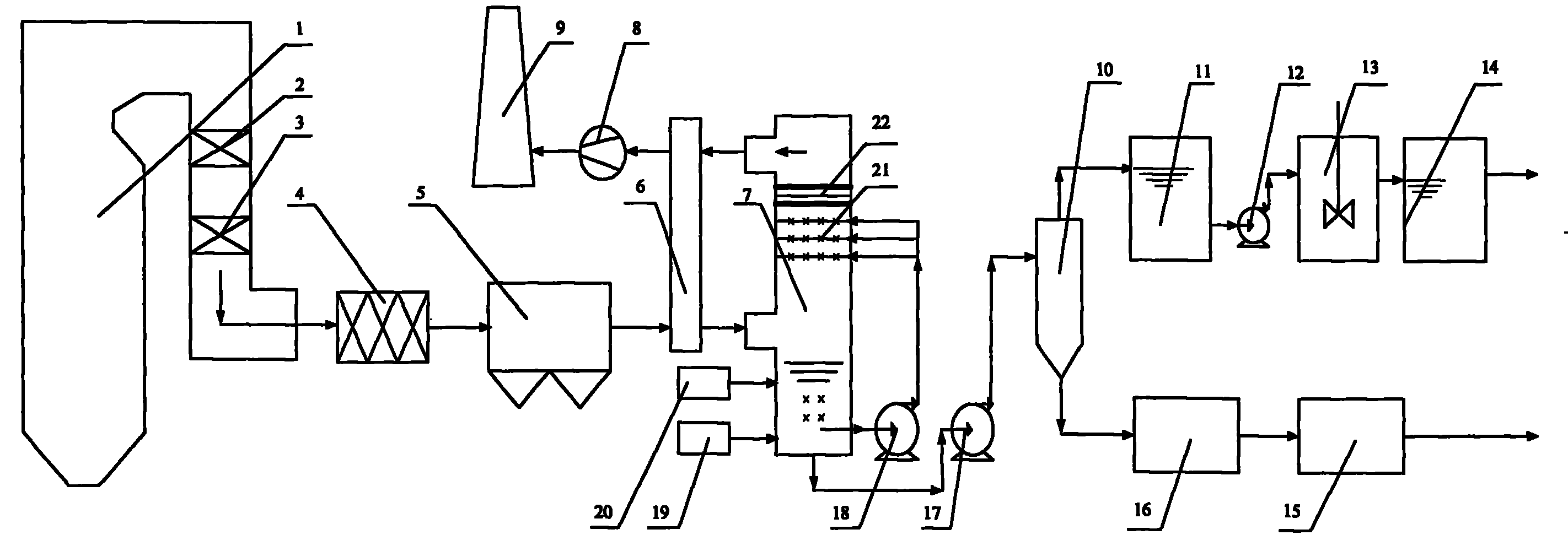

Wet flue gas desulfurizing and hydrargyrum-removing technology based on two-stage oxidation reaction and system thereof

A wet flue gas desulfurization and demercuration process and a system thereof based on two-stage oxidizing reaction. The process does two-stage oxidizing treatment to the simple substance HgO in flue gas utilizing to ultraviolet radiation and oxidant of halogen series, transmutes the gas phase divalent ion Hg2+ therein to liquid phase divalent ion Hg2+ using the modified limestone-gesso wet desulfurization process, and then transmutes the liquid phase divalent ion Hg2+ to the stable mercuric sulfide-HgS deposition via stabilizer of liquid phase divalent ion Hg2+. The system comprises desulfurization and demercuration equipments such as an ultraviolet irradiator, an electrical precipitator, an oxidant spraying unit and a reaction absorber etc, gesso treatment equipments of desulfurization byproduct, and a treating equipment for mercuric sulfide-HgS deposition. The process and the system thereof can raise the oxidation rate of simple substance Hg in the flue gas effectively, and at the same time effectively overcome the reduction release of divalent ion Hg2+ to avoid secondary pollution and be capable of raise desulfurization and demercuration efficiency of limestone-gesso wet desulfurization system.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

Wet-type ammonia flue gas spiritualization technics of associated desulfuration demercuration

The invention relates to a wet ammonia flue gas purification process for the combined sulfur and mercury removing and the system thereof. The process adopts chlorine gas as oxidizing agent to completely oxidize elemental mercury in the flue gas, and gas phase divalent mercuric ion after being oxidized is converted into liquid phase divalent mercuric ion through the improved wet ammonia desulphurization process, and further the liquid phase divalent mercuric ion is converted into stable mercuric sulfide sendimentation through liquid phase divalent mercuric ion stabilizing agent. The system comprises a flue gas oxidizing demercuration preprocessing system composed of an oxidizing agent injection device and an electrostatic precipitator, a wet ammonia flue gas sulfur and mercury removing system composed of a reaction absorbing tower, a sulfur removing accessory substance processing system composed of a cyclone cleaner, a dewaterer, and a dryer, and a mercuric sulfide HgS sendimentation processing system composed of a wastewater buffer pool, a liquid phase mercuric ion reaction chamber, and a settling pond. The process and the system can effectively improve the oxidation rate of the elemental mercury in the flue gas, overcome the defaults that the divalent mercuric ion is easy to be reduced and released and the secondary pollution problem is caused by excess oxidizing agent, and greatly improve the efficiency of sulfur removing and mercury removing.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

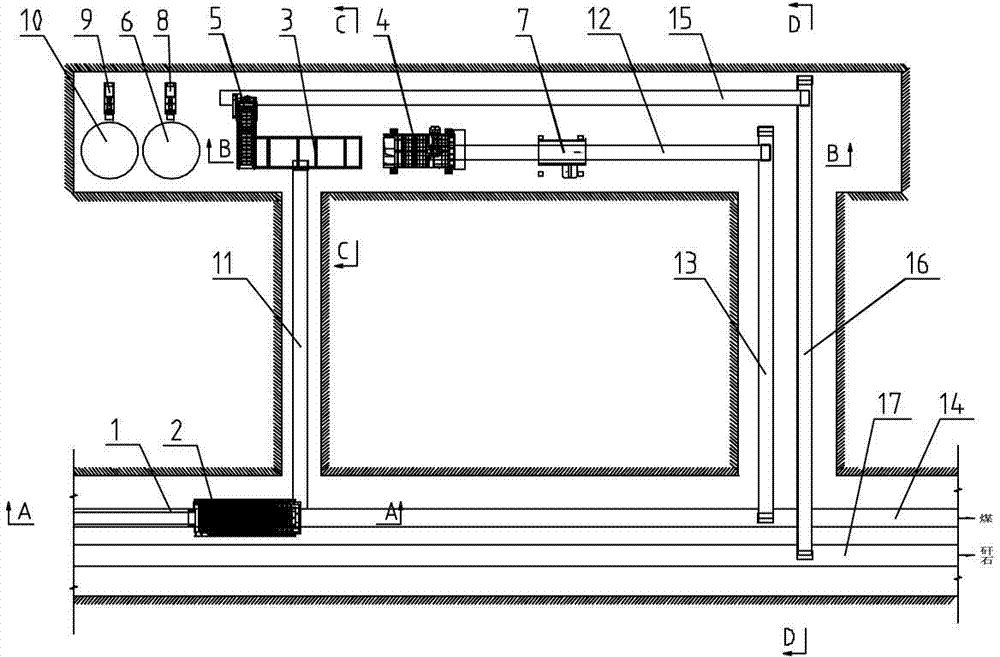

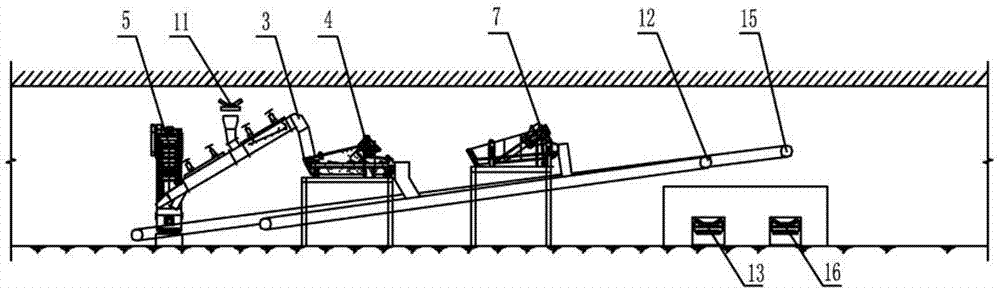

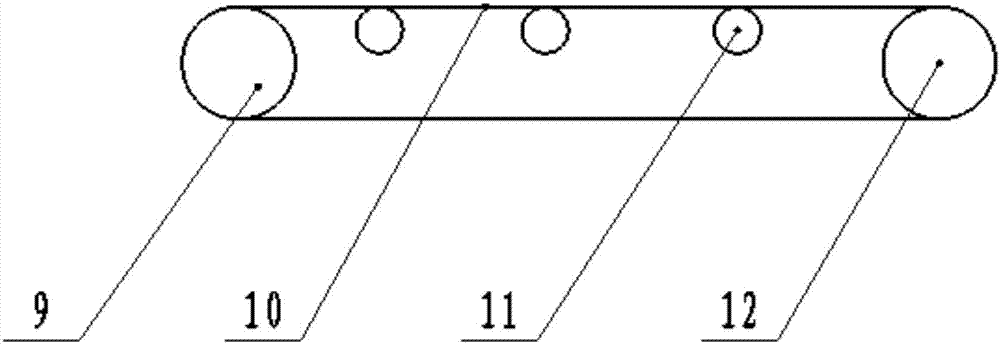

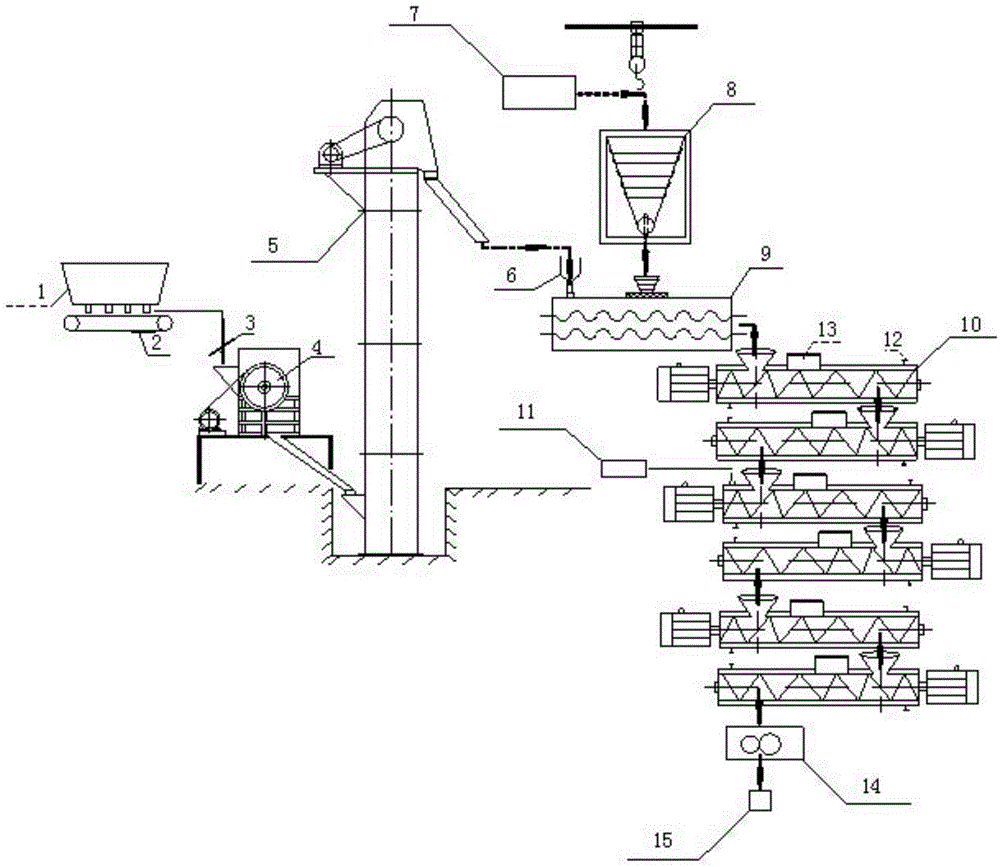

Flowing current separation process coal mine underground gangue dumping system

ActiveCN103480482AIncrease production capacityImprove efficiencyWet separationEngineeringBucket elevator

The invention relates to a flowing current separation process coal mine underground gangue dumping system. The technical scheme includes that a run-of-mine coal conveyor is mounted on one side of a feeding end of a roller screen, two ends of an on-screen selected raw material coal conveyor are connected with a front-screen chute of the roller screen and a feeding port of a flowing current separation machine respectively, a block coal of the flowing current separation machine is connected with a dewatering screen, an oversize material discharging end of the dewatering screen is sequentially connected with a block coal conveyor, a block coal transferring conveyor and a pulverized coal conveyor, a high frequency screen is mounted in the middle of the block coal conveyor, under-screen water of the dewatering screen is connected with a concentration tank through a pipeline, the concentration tank is connected with the high frequency screen, a gangue outlet of the flowing current separation machine is connected with a bucket elevator, a discharging end of the bucket elevator is sequentially connected with a gangue conveyor, a gangue transferring conveyor and a gangue warehousing conveyor, under-screen water of the high frequency screen and overflow of the concentration tank are connected with a circulating water tank through pipelines respectively, and the circulating water tank is connected with a water inlet of the flowing current separation machine through a circulating water pump and a pipeline. The flowing current separation process coal mine underground gangue dumping system is simple in process, good in separation effect, low in power consumption and low in operating cost.

Owner:沈阳科迪通达工程技术有限公司

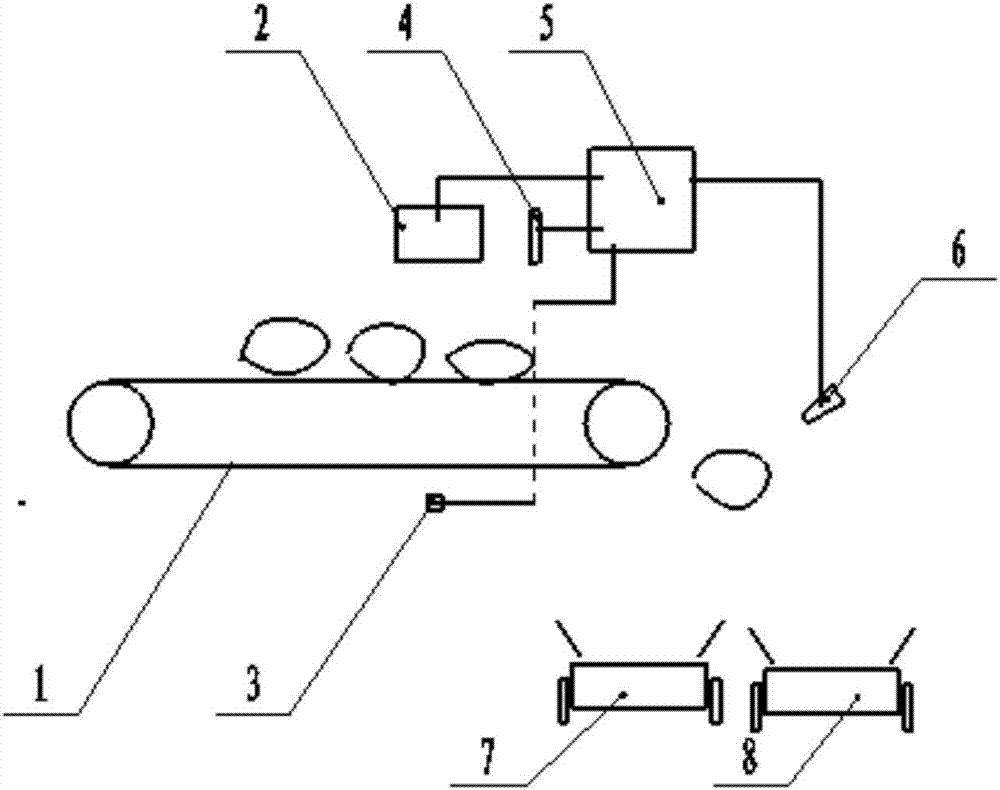

Intelligent dry method gangue discharge system and method applied to underground coal mine

InactiveCN106862103ASolve production practice problemsNot affected by particle sizeSortingX-rayKinetic energy

The invention provides an intelligent dry method gangue discharge system and method applied to an underground coal mine. The intelligent dry method gangue discharge system and method are suitable for preferential separation of underground coal gangue, on-line identification of coal and the coal gangue and sorting based on different densities of the coal and the coal gangue through the synergistic effect of an X-ray and lattice detector and an ultrasonic ranging device. The intelligent dry method gangue discharge system and method are simple in process, high in intelligent level, good in separation effect and small in investment. With the adoption of the intelligent dry method gangue discharge system and method, the gangue can be discharged underground directly on the spot and does not need to be conveyed to the ground. Kinetic energy consumption and transport cost are reduced, due to the fact that the gangue is not lifted out of a well, ineffective transport can be canceled, transport expense is reduced, and transport cost is reduced.

Owner:TANGSHAN SHENZHOU MFG

Low energy consumption sintering flue gas dioxin emission-reducing system and method thereof

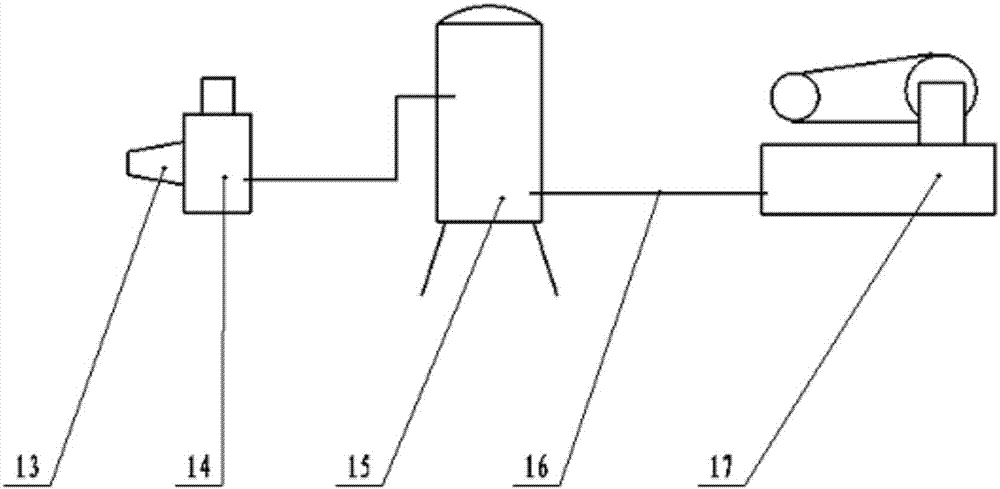

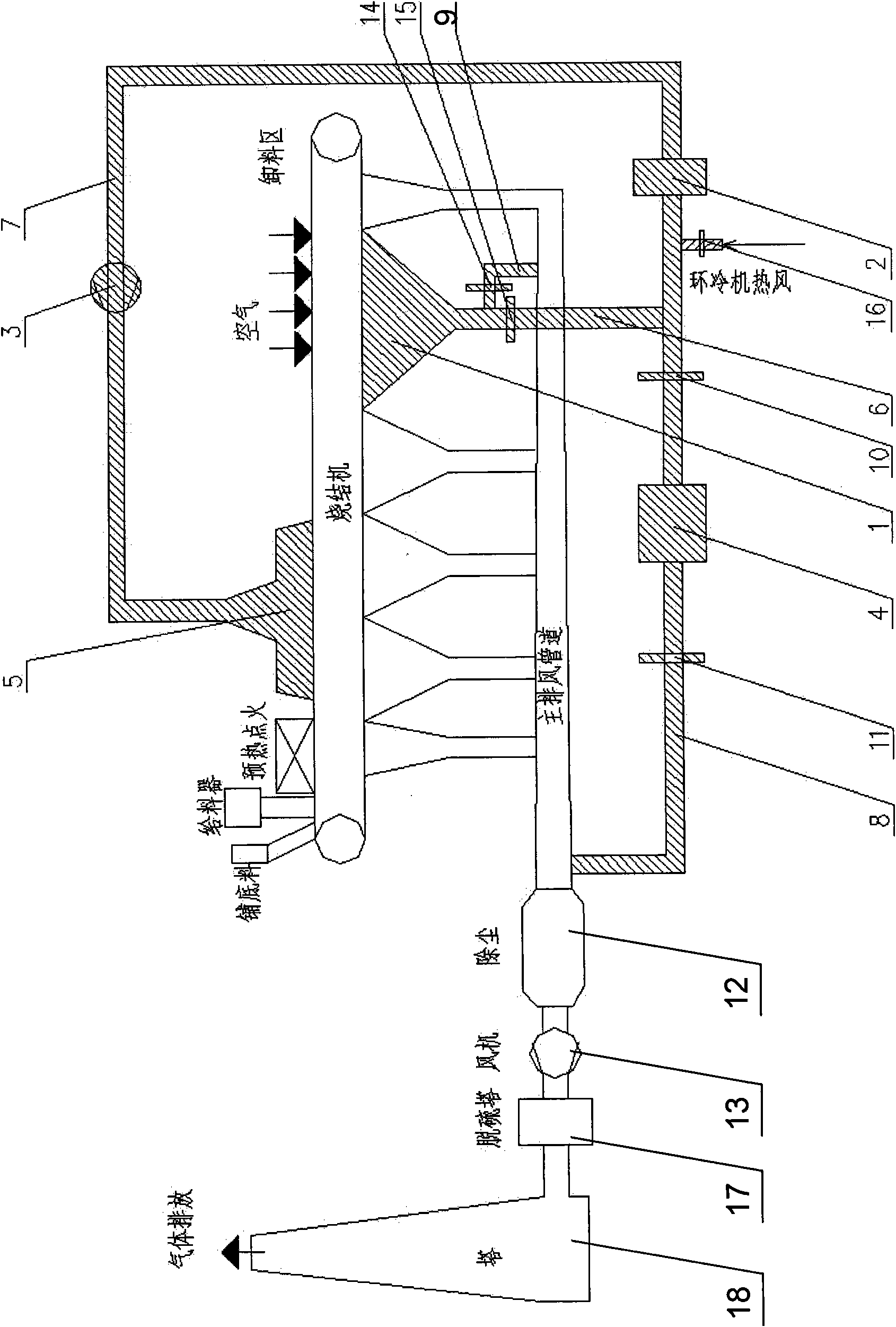

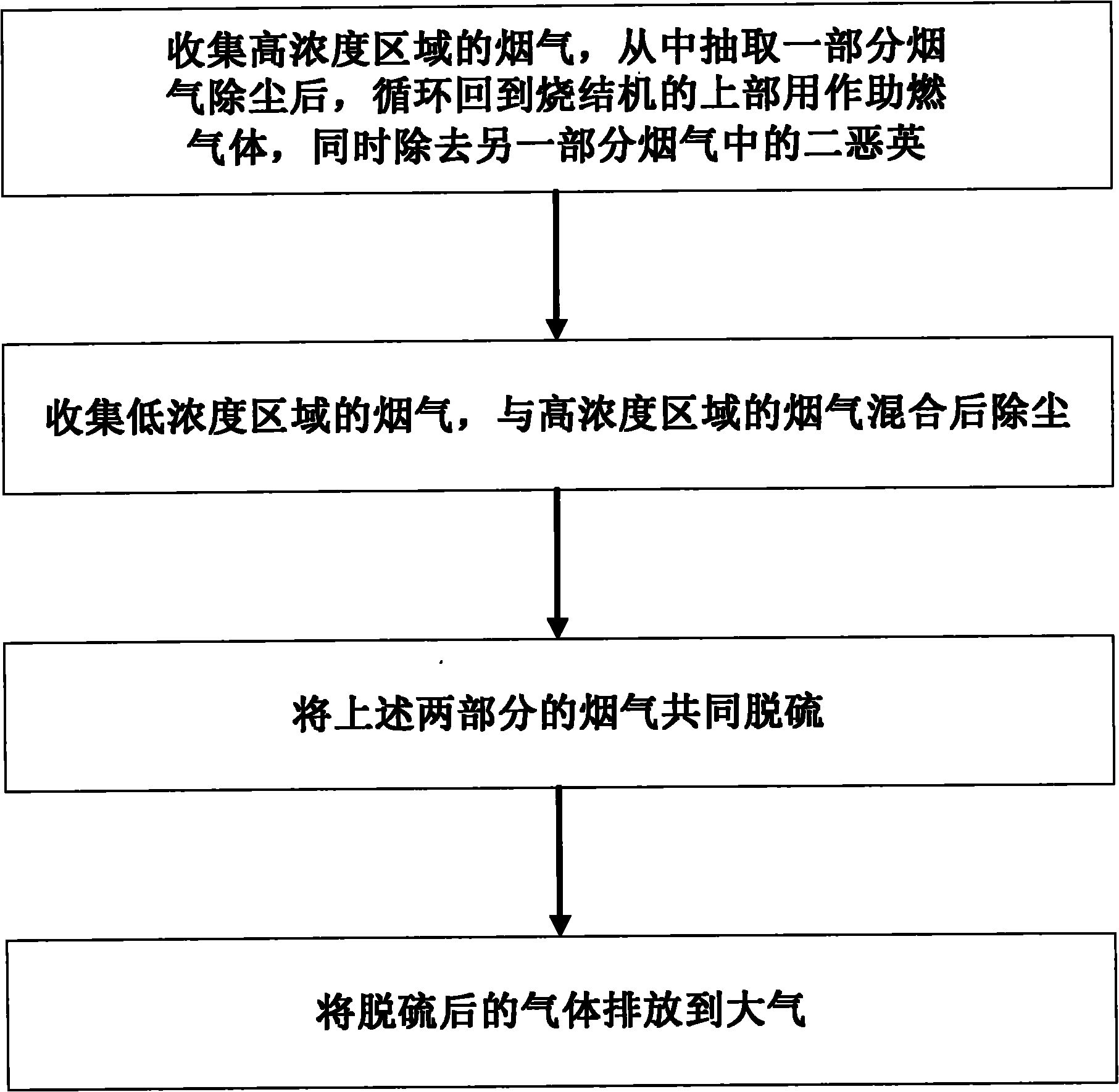

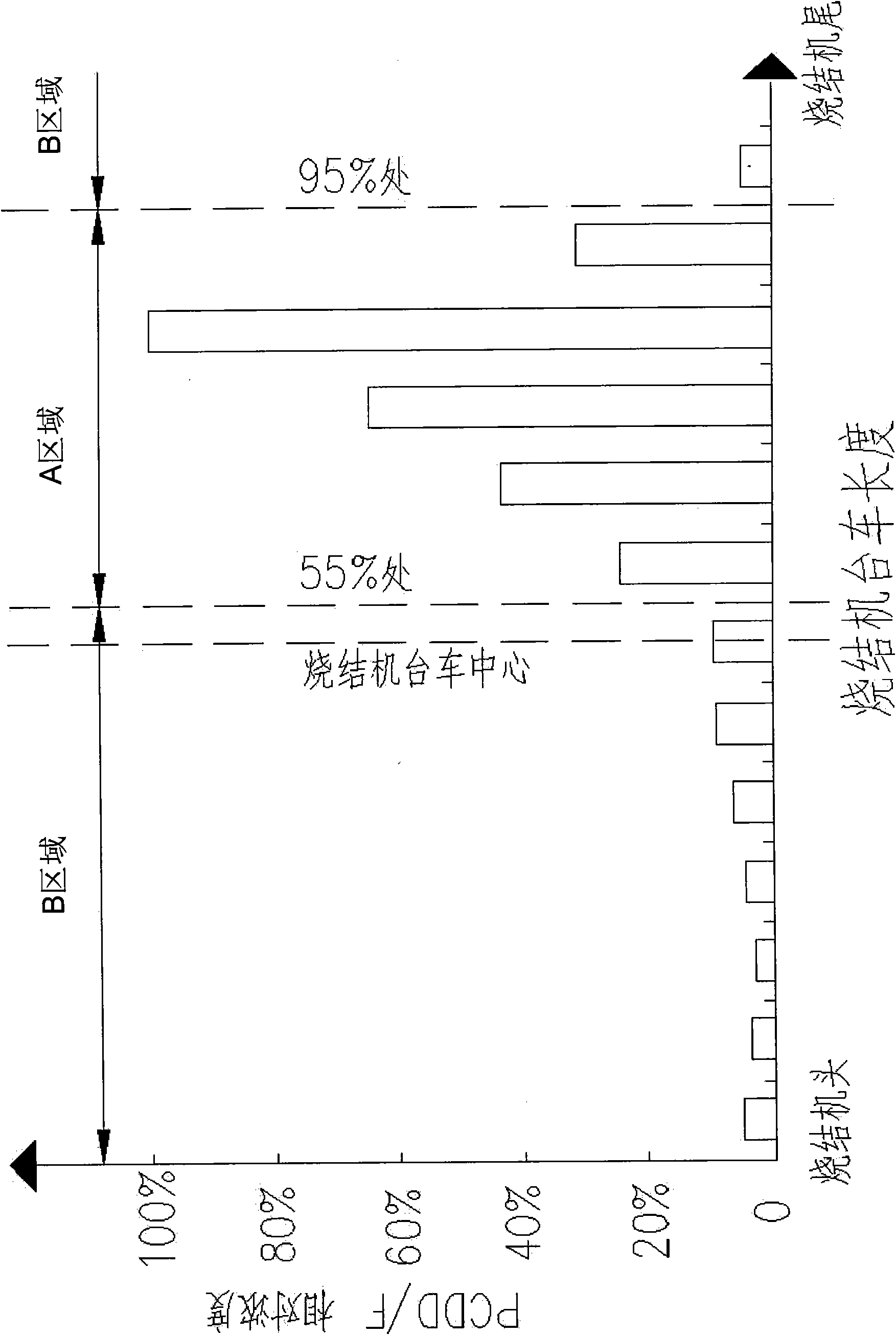

InactiveCN101822946AConducive to emission reductionEmission reductionDispersed particle separationHigh concentrationAtmospheric air

The invention relates to a low energy consumption sintering flue gas dioxin emission-reducing system and a method thereof. The system comprises a main flue exhaust pipeline, a main dust remover, an air blower, a dioxin desorption system, a closed gas hood, a high dioxin compound flue gas flue, a circulating air pipeline, a dioxin compound desorption flue, a bypass flue, a dust remover, the other air blower, a desulfurizing tower and a chimney. A low-concentration area exhaust box is connected with the main flue exhaust pipeline, passes through the main dust remover, the air blower and the desulfurizing tower in sequence to reach the chimney, and then the flue gas is exhausted to the air. The closed gas hood covers above a sintering machine board trolley; one end of the high dioxin compound flue gas flue is connected with a high-concentration area exhaust box; and the other end of the high dioxin compound flue gas flue is connected with the dioxin compound desorption flue and the main dust remover of the main flue exhaust pipeline. The method comprises the steps of collecting flue gas, removing dioxin in the flue gas, removing dust, desulfurizing, exhausting to the air and the like. The invention greatly reduces the flue gas to be purified and treated, reduces the construction investment and the operation cost, and is beneficial to reducing the emission of various pollutants in sintering flue gas.

Owner:BAOSTEEL ENG & TECH GRP

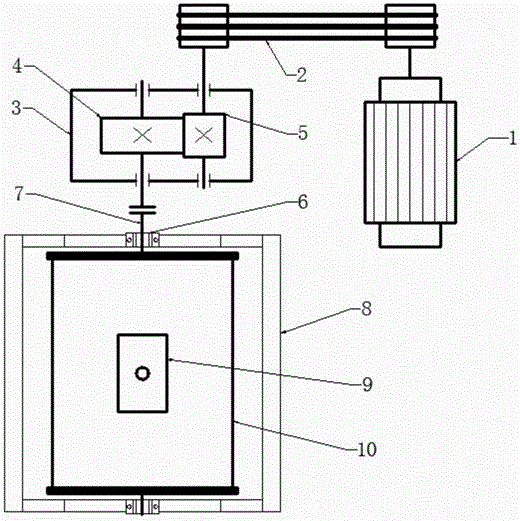

SCR (Selective Catalytic Reduction) denitration method and device with urea pyrolysis pipes in boiler

ActiveCN104226109ASimple crafting systemLow investment costLighting and heating apparatusDispersed particle separationUreaChemistry

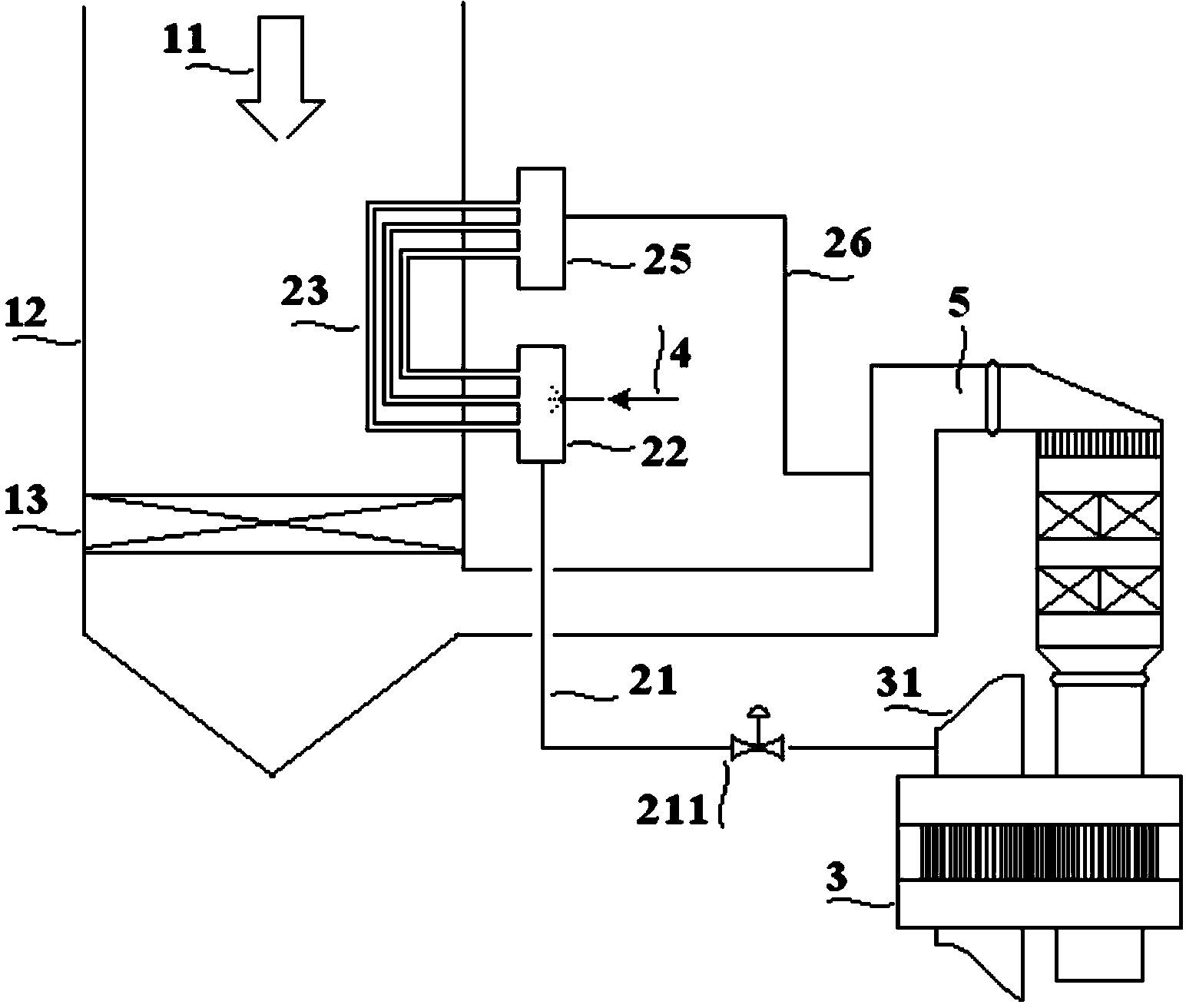

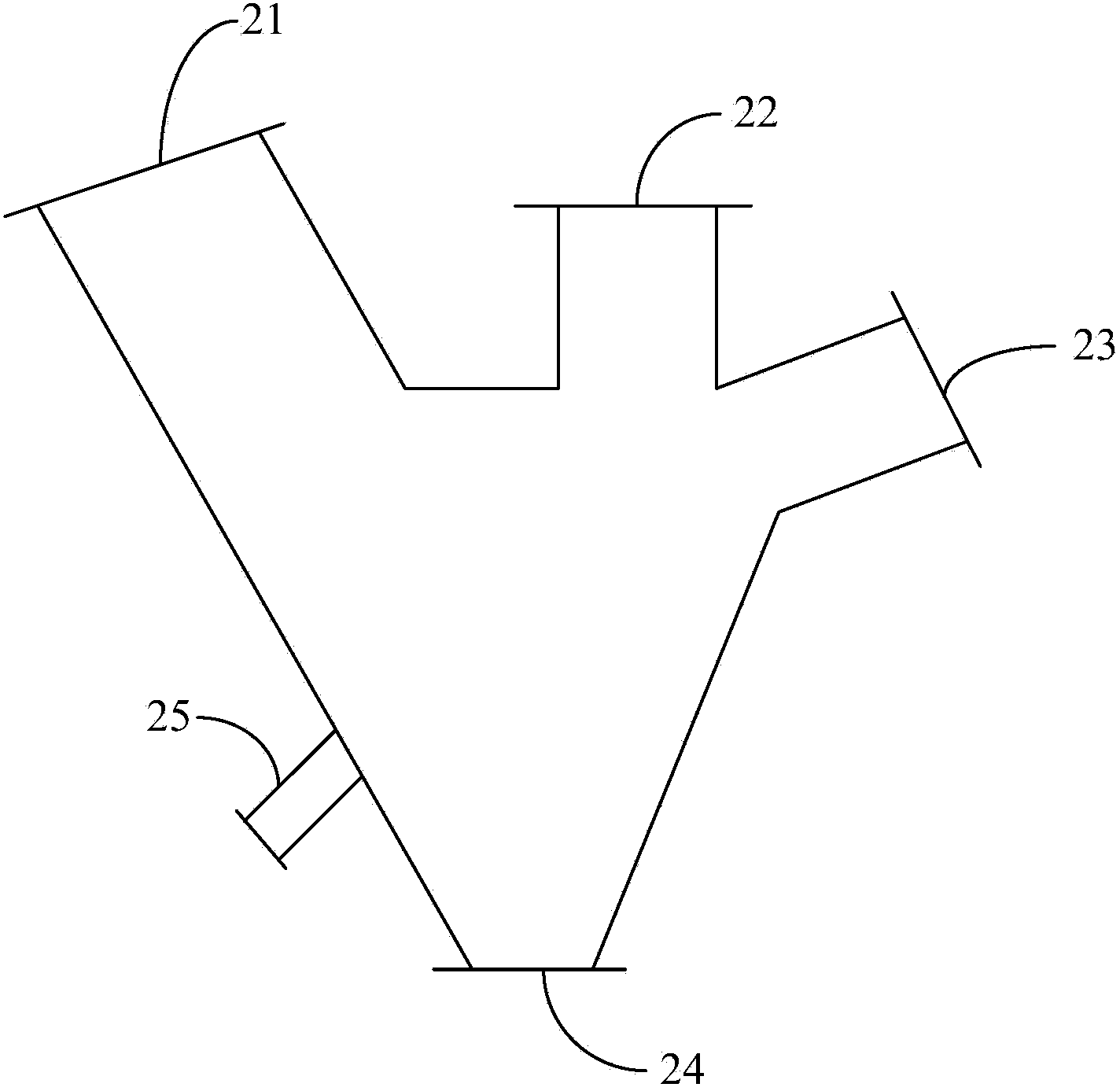

The invention discloses an SCR (Selective Catalytic Reduction) denitration method and device with urea pyrolysis pipes in a boiler and belongs to the field of boiler denitration. According to the denitration method, boiler flue gas in a corresponding region is used for heating a urea solution in a urea pyrolysis pipe bundle to decompose the urea solution into mixed gas containing NH3, and NH3 is used as a reducing agent of a downstream SCR flue gas denitration chemical reaction. The device comprises the urea pyrolysis pipe bundle; the inlet of the urea pyrolysis pipe bundle is communicated with primary air or secondary air of an air pre-heater by a urea pyrolysis pipe bundle inlet distribution pipe and a urea pyrolysis air supplying pipe; the outlet of the urea pyrolysis pipe bundle is communicated with an SCR denitration reaction device or an upstream thereof by a urea pyrolysis product collection pipe and a urea pyrolysis product supplying pipe; the urea pyrolysis pipe bundle inlet distribution pipe is further provided with an atomization device which is communicated with a urea solution supplying pipe. By virtue of the SCR denitration method and device, the investment cost of an SCR denitration reducing agent urea pyrolysis process can be greatly reduced, the operation energy consumption of urea pyrolysis is reduced and the operation cost is saved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

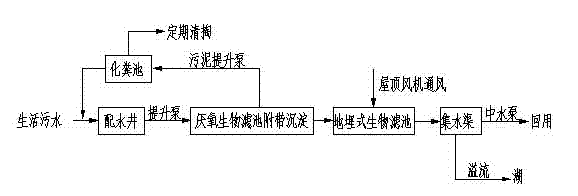

Production method of superfine slag powder

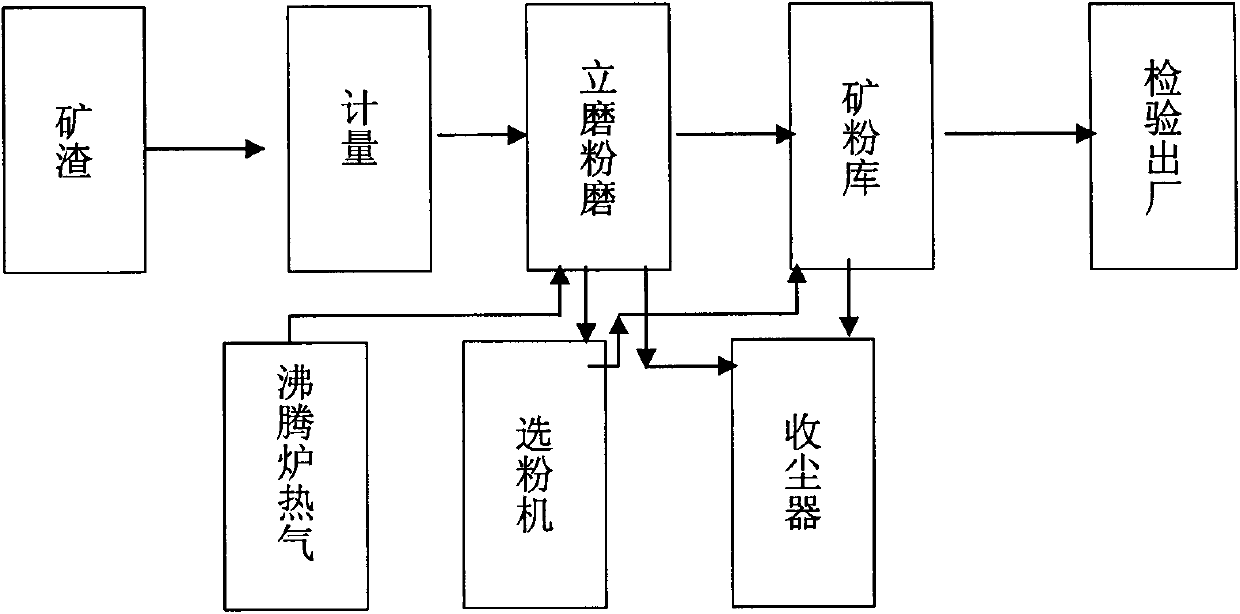

The invention discloses a production method of superfine slag powder. The production method is characterized in that slag is grinded by a vertical grinding machine and simultaneously hot gas is fed into the vertical grinding machine, wherein the slag is crushed by pressure rollers of the vertical grinding machine and is continuously driven by a centrifugal force to move towards the outer edge of a grinding disc and the slag separated from the grinding disc contacts with the hot gas in the vertical grinding machine, rises with the hot gas, passes through a middle housing of the vertical grinding machine and enters into a separator, and in the above process, the slag and the hot gas undergo heat exchange, water is fast evaporated, only the particles which can be carried by air can reach the separator at the upper part, the particles are screened by a screener, the superfine slag powder having a specific surface area greater than or equal to 400m<2> / Kg enter into a slag powder warehouse and the undesirable coarse slag powder is grinded sequentially. The production method has the advantages of high production efficiency, low energy consumption, high qualified rate and stable quality.

Owner:NANTONG WANHAO BUILDING MATERIAL SCI & TECH

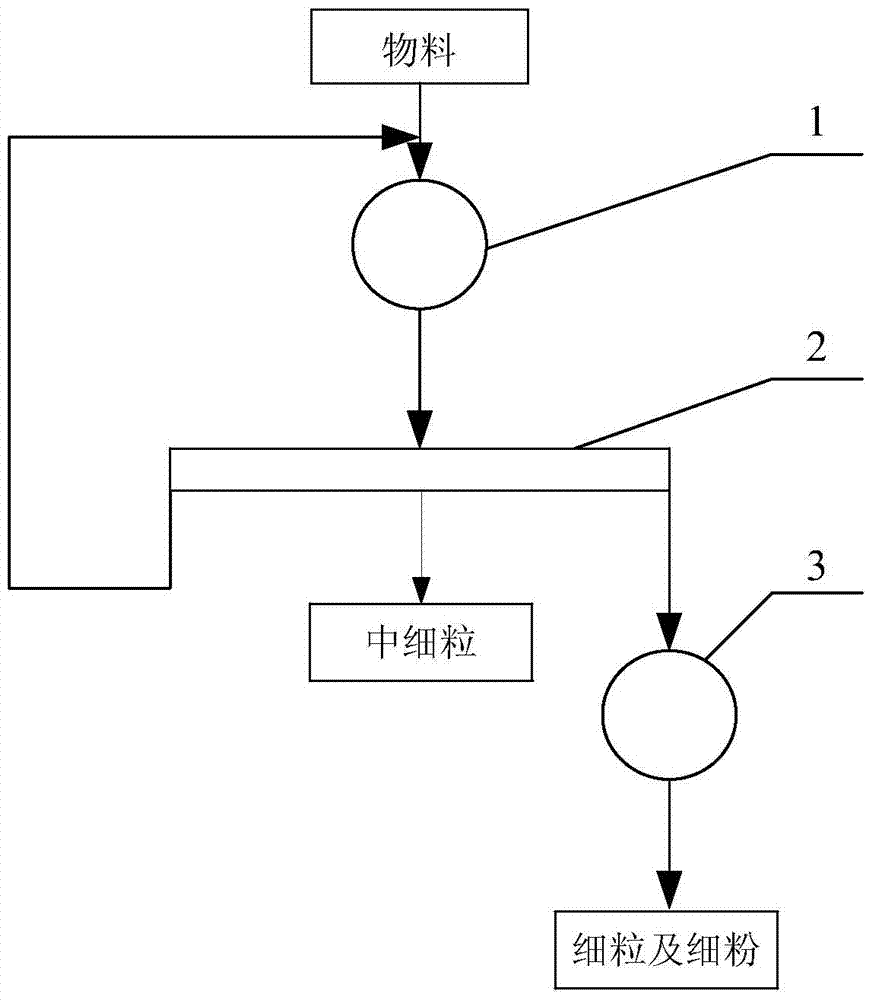

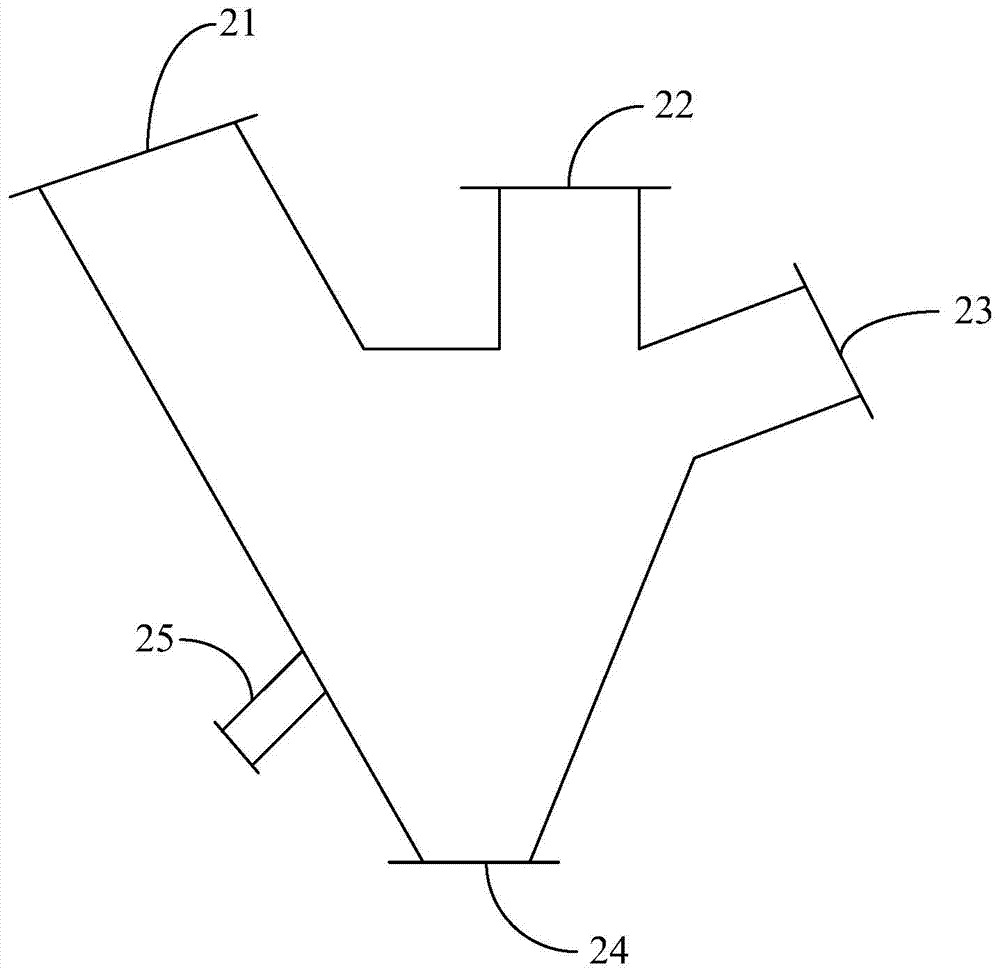

Smashing and two-stage sorting process and system

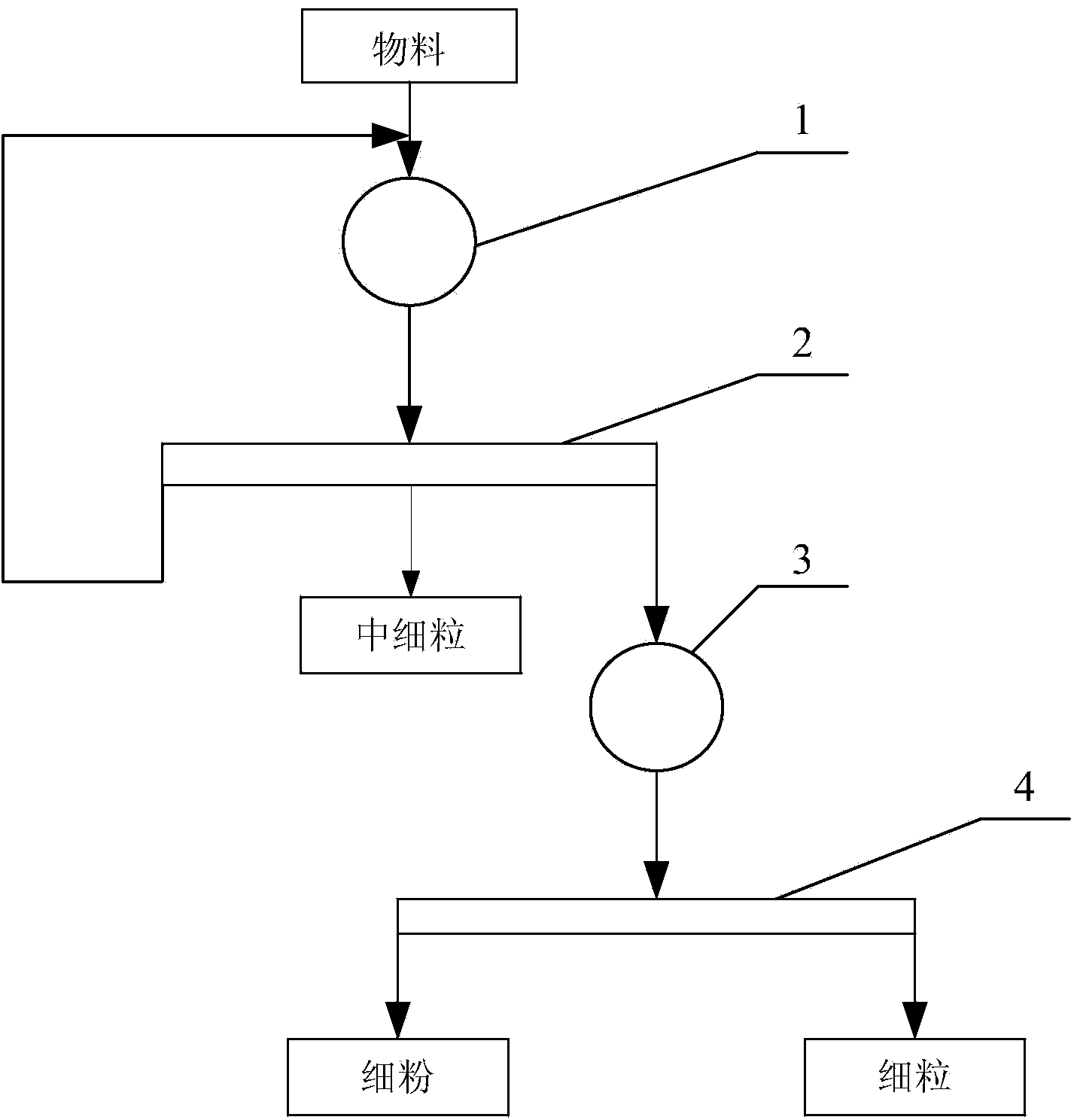

The invention discloses a smashing and two-stage sorting process which comprises steps as follows: (1), a smashed material is fed into a cascade flow type powder concentrator, a mixture of fine grains and fine powder are sorted; (2), the fine grains and the fine powder are fed into a dust collector with gas of the cascade flow type powder concentrator, and the gas is separated from the fine grains and the fine powder; and (3) the mixture of the fine grains and the fine powder is fed into a fine powder concentrator, and the fine grains and the fine powder are sorted. According to the smashing and two-stage sorting process, the cascade flow type powder concentrator and the fine powder concentrator are adopted in the technological process for separating the fine grains and the fine powder, so that the problems of high power consumption and steel consumption, low yield and high fault rate during production of a prior art are solved. The invention further discloses a smashing and two-stage sorting system.

Owner:CHANGSHA SHENXIANG UNIVERSAL MACHINE

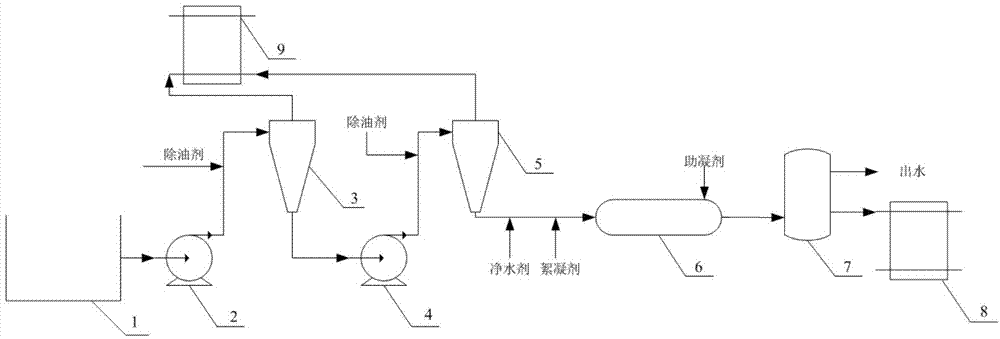

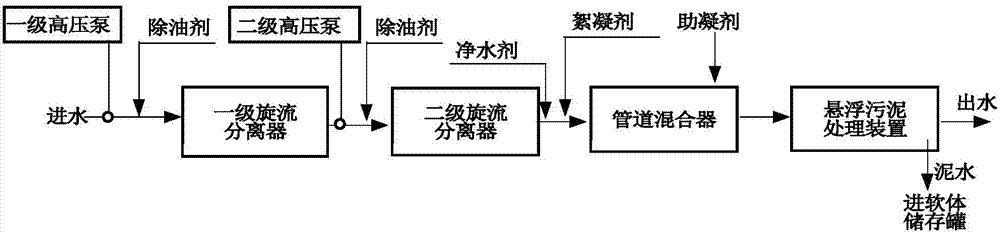

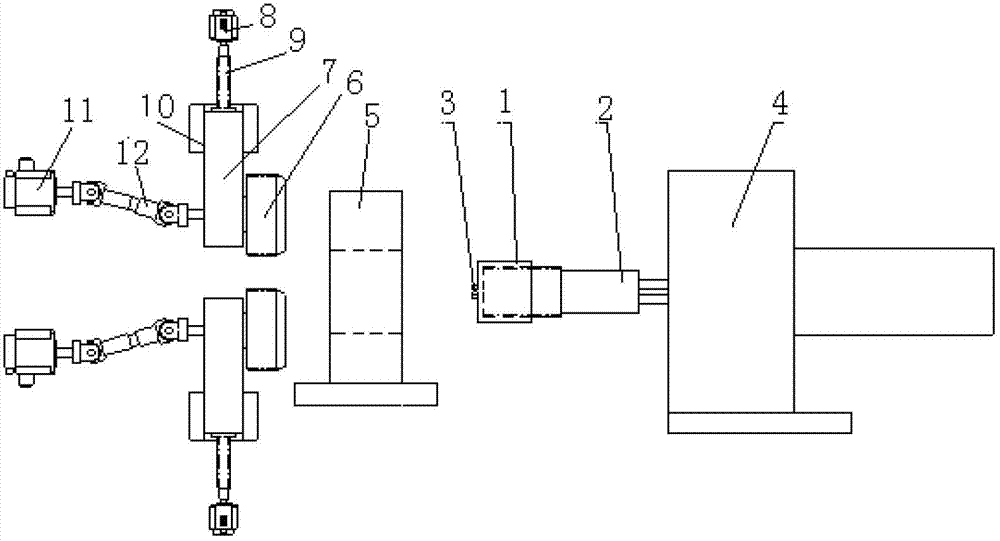

Skid-mounted lightweight oily sewage treatment device and treatment technology thereof

The invention provides a skid-mounted lightweight oily sewage treatment device and a treatment technology of the device. The device sequentially comprises a primary pressure pump (2), a primary cyclone separator (3), a secondary pressure pump (4), a secondary cyclone separator (5), a pipeline mixer (6), a suspension sludge treatment device (7) and a storage tank. The technology employs a physicochemical method, and sewage continues to enter the suspension sludge equipment for coagulation, settling and filtration after an agent and water are intensively mixed by the cyclone separators. According to the device and the method, the agent and the water are mixed ingeniously to achieve the purpose of oil and suspended matter removal; a technology system is simple; high oily sewage in an oil field is treated stably; the operating cost is lower; filling replacement is not required; the equipment maintenance cost is low; operation immediately after shutdown can be achieved according to field requirements; equipment transportation is convenient; the floor area is small; and station construction treatment for a field is not required.

Owner:BEIJING OTC ENERGY & ENVIRONMENT ENGINEERING PUBLIC LIMITED COMPANY

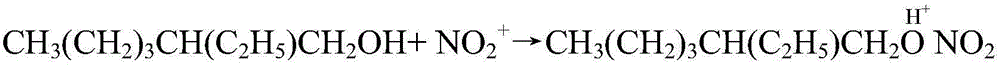

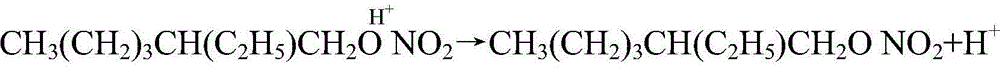

Synthetic method of isooctyl nitrate

InactiveCN103980125ASimple crafting systemReduce manufacturing costNitric acid ester preparationProcess systemsNitrate

The invention provides a synthetic method of isooctyl nitrate. The method includes preparing a mixed acid solution and keeping for further use, wherein a concentrated sulfuric acid solution having a mass concentration of 90% and a concentrated nitric acid solution having a mass concentration of 98% are mixed to obtain the mixed acid solution, and the mole ratio of the sulfuric acid to the nitric acid in the mixed acid solution is 1.5-2.5:1. The synthetic method achieves efficient utilization of resources by a waste acid circulating system. The reaction temperature is low and the application zone is wide. The method can be widely used in cities in northern China. In low-temperature reactions, the selectivity of reactants is good and byproducts are less, thus facilitating waste water treatment in the later period and easily meeting the state standard of second level for discharging. The yield of a finished product of the isooctyl nitrate is high, the process system is simple, and the production cost is low, so that the synthetic method is prone to achievement.

Owner:CHANGZHOU UNIV

Smashing and sorting technology as well as smashing and sorting system

InactiveCN103495482AImprove sorting efficiencyIncrease productionGrain treatmentsProduct gasMaterials science

The invention discloses a smashing and sorting technology. The smashing and sorting technology comprises the following steps of (1) feeding a material after smashing into a waterfall stream powder selecting machine, and sorting a mixing body of fine grains and fine powder; and (2) feeding the fine grains and the fine powder along the gas of the waterfall stream powder selecting machine into a dust collector, separating the gas from the fine grains and the fine powder, and obtaining the fine grains and the fine powder. The smashing and sorting technology provided by the invention adopts a technological process of a smashing machine and the waterfall stream powder selecting machine, and solves the problems that the power dissipation is large, the steel consumption is large, the yield is low, and the fault ratio is high in the existing technology. The invention also discloses a smashing and sorting system.

Owner:CHANGSHA SHENXIANG UNIVERSAL MACHINE

Device for restoration of persistent organic pollutant-polluted soil and use method thereof

ActiveCN103978023AReduce energy consumptionReduce speedContaminated soil reclamationPollution soilPersistent organic pollutant

The invention relates to the technical field of mechanical-chemical process-based harmless treatment on persistent organic pollutants and provides a device for restoration of persistent organic pollutant-polluted soil and a use method thereof. The device comprises a motor, a belt transmission device, a transmission gear set, a horizontal ball milling roller and a roller support. The use method comprises the following steps of adding polluted soil, an additive and grinding balls into the horizontal ball milling roller together, and after the polluted soil in the horizontal ball milling roller is subjected to pollutant-polluted soil restoration, and pouring the polluted soil, the additive and the grinding balls from the horizontal ball milling roller. At a rotation rate less than a critical rotation rate, the device greatly saves energy consumption, can be simply and reliably operated and can continuously work in dozens of hours. The device has a simple system, less initial investment, simple processes, less wearing and a low maintenance cost and is especially suitable for restoration of soil in the developing countries and the remote areas.

Owner:ZHEJIANG UNIV

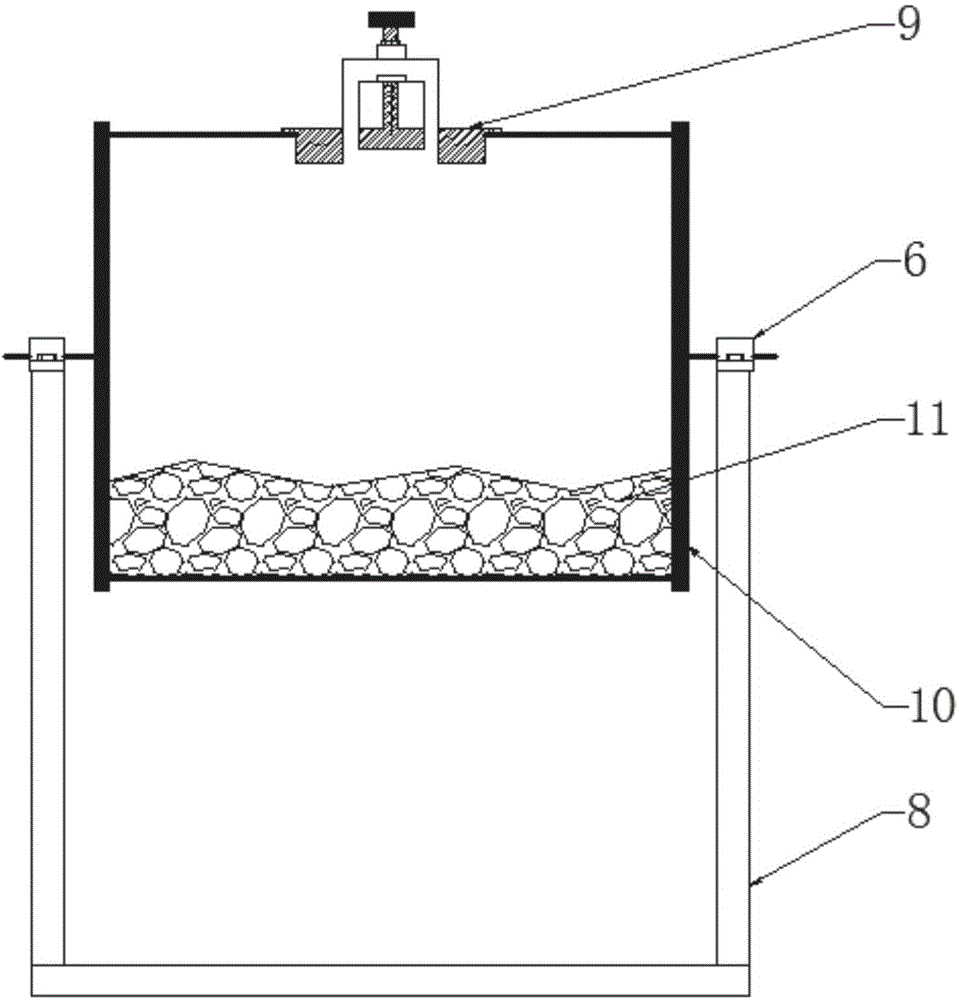

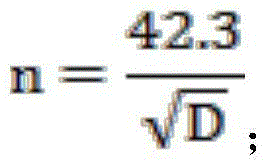

Preparation device and method of first-stage reverse osmosis after chemical desalt optimization pure water

InactiveCN1955119ASimple crafting systemLow investment costGeneral water supply conservationWater/sewage treatment by ion-exchangeIon exchangeReverse osmosis

An optimized apparatus for preparing purified water by reverse osmosis and chemical desalting has a strong alkaline anionic exchanger unit and a cation and anion mixed exchanger unit. Its preparing process is also disclosed.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

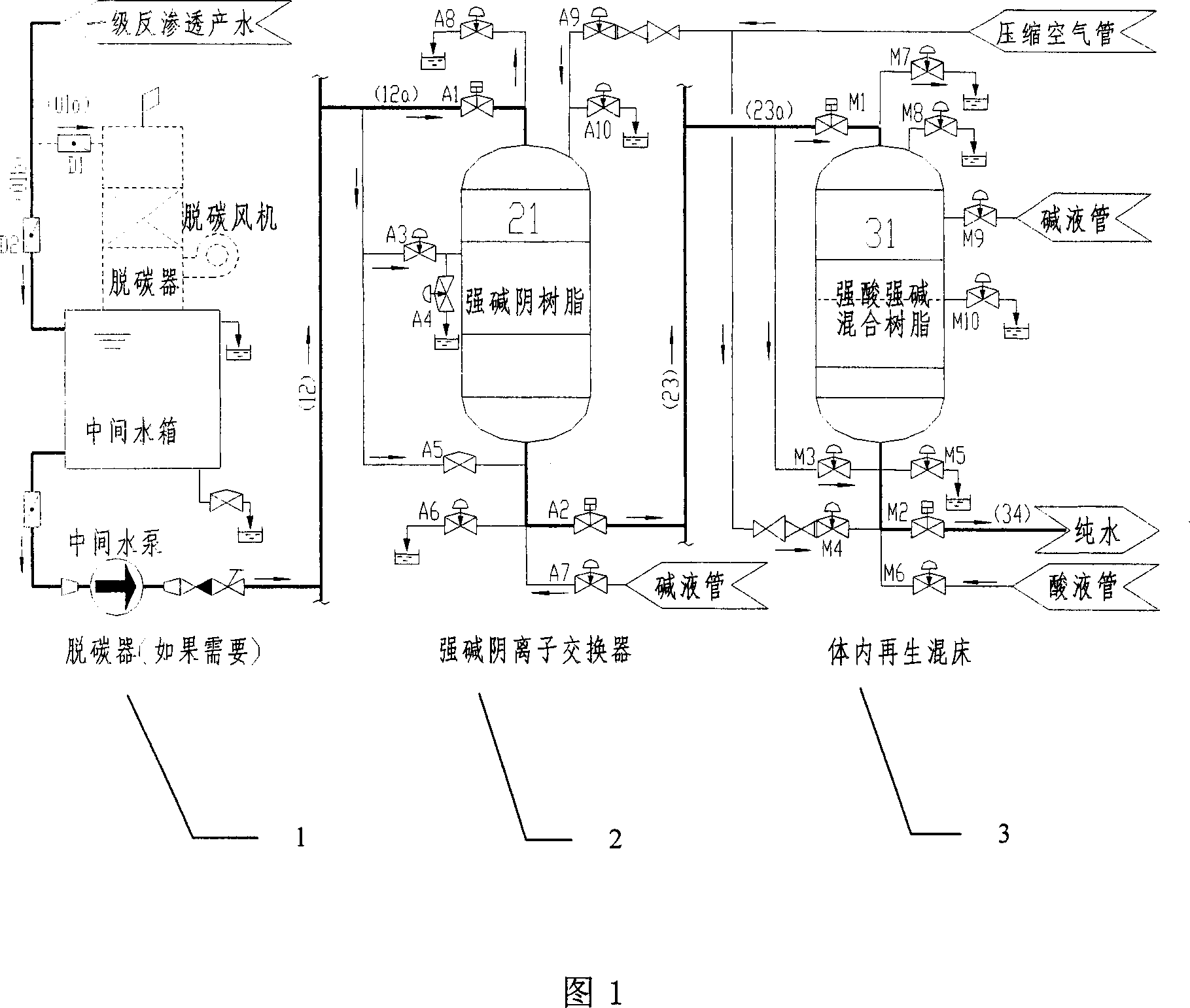

Sequencing batch limestone slurry wet desulfurization technique

InactiveCN101327395ASimple crafting systemLow by-product disposal requirementsDispersed particle separationSlagPH decrease

The present invention provides an order-batch-mode limestone mortar wet desulphurization process, in particular relates to a high-efficient limestone desulphurization process that adopts the limestone mortar as the desulphurization agent, and adopts the order-batch alternative absorption reaction, and adopts the high-efficient desulphurization tower as the desulphurization device, and adopts lower pH value, lower liquid-gas ratio and economical desulphurization rate, and adopts the desulphurization waste slag as the byproduct. Smoke enters into the high-efficient desulphurization device, and a group of limestone mortar is adopted as absorption agent for the smoke to be desulphurized, until the pH value is decreased to a pre-determined value, and the smoke is temporarily withdrawn and the absorption is stopped; the absorption solution is continued to be reacted with the tiny particle of CaCO3, until the pH value is returned to the original value, and then another group of limestone mortar is filled to be desulphurized until the pH decreases to the pre-determined value; the mortar is filled at one group by another group for alternative absorption and after the mortar is reacted with the CaCO3, a new group of limestone mortar is replaced; the waste mortar is discharged after being processed; the waste slag is processed after being dehydrated. The order-batch-mode limestone mortar wet desulphurization process saves the investment, and has low operation expense, and is simple to be operated and managed, and has wide application, and resolves the scale formation problem of the tower and pool.

Owner:贡有成

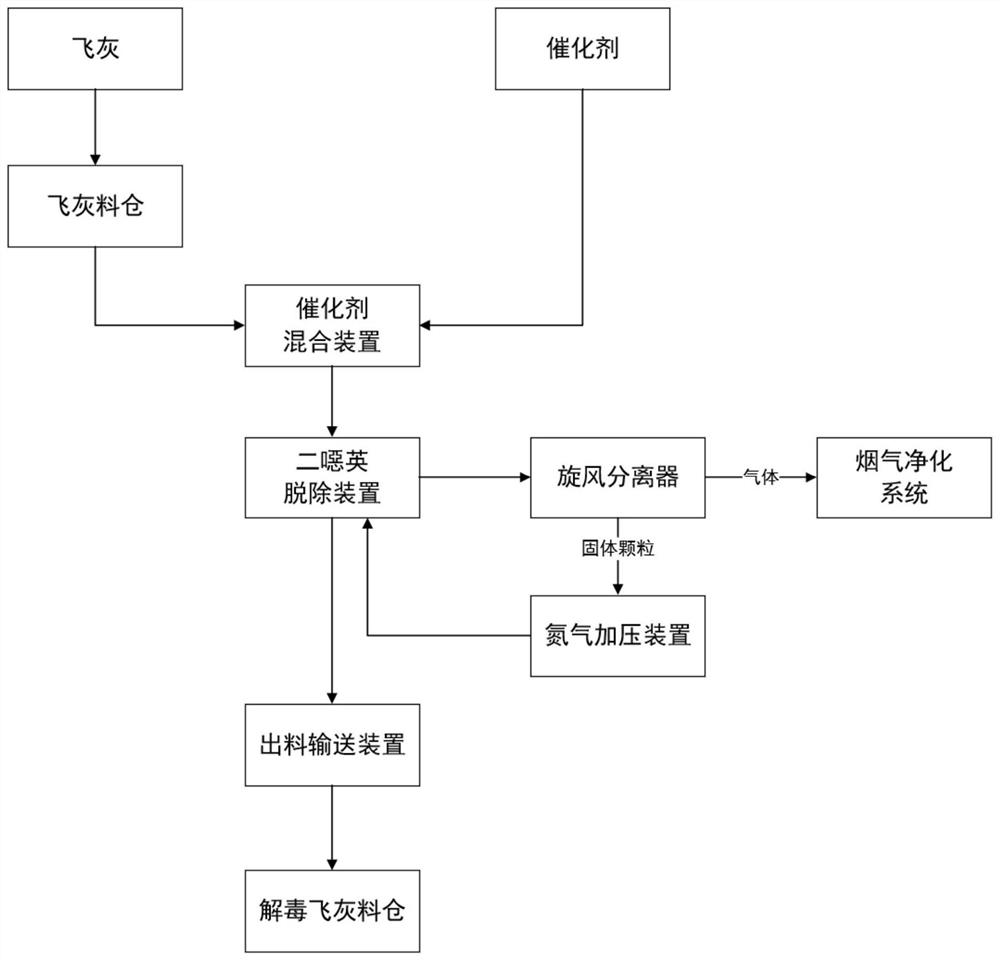

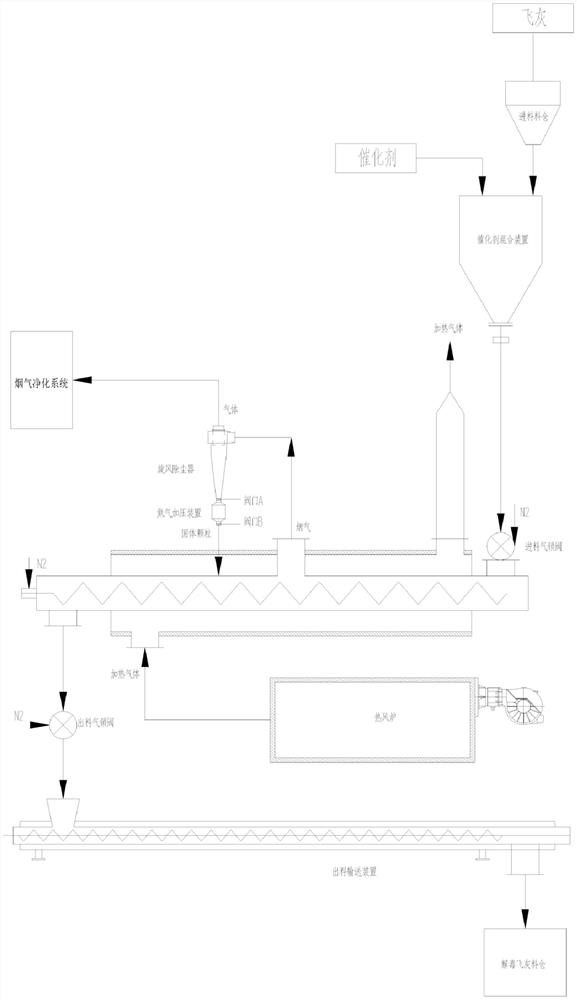

System and method for removing dioxin from fly ash

InactiveCN112775156AEfficient low temperature pyrolysisFulfillment of Removal RequirementsCombination devicesGas treatmentPtru catalystEnvironmental engineering

The invention discloses a system and method for removing dioxin from fly ash, and relates to the technical field of household garbage incineration fly ash treatment. The system for removing dioxin from fly ash comprises a fly ash bin, a dioxin removing device, a discharging and conveying device and a detoxification fly ash bin which are sequentially connected and further comprises a catalyst mixing device, the catalyst mixing device is arranged between the fly ash bin and the dioxin removing device, and a catalyst in the catalyst mixing device comprises a Ca-containing compound and a transition metal oxide. According to the system and method for removing dioxin from fly ash, the fly ash and the catalyst are mixed and can be subjected to high-efficiency low-temperature pyrolysis, and detoxified fly ash is obtained; the process system is simple and efficient, the number of devices is small, and the requirement for removing the dioxin in the incinerated fly ash can be met with low cost; and reaction environment is anaerobic, and the efficiency of removing the dioxin in the fly ash is effectively improved.

Owner:四川深蓝环保科技有限公司 +1

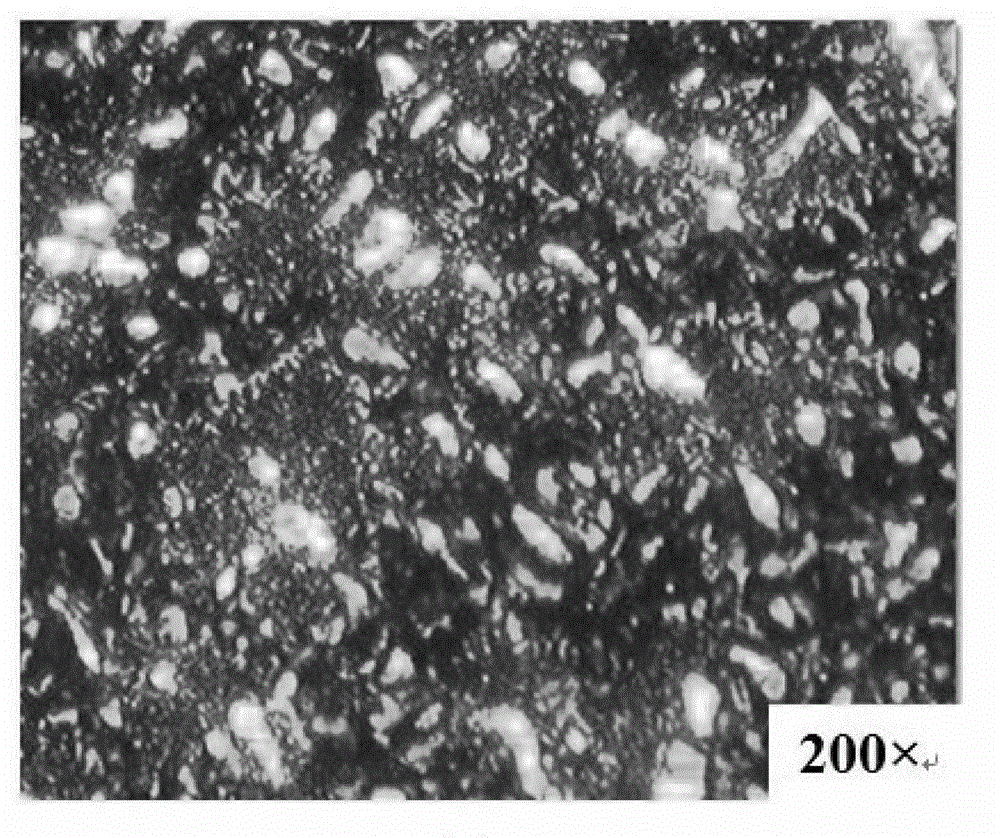

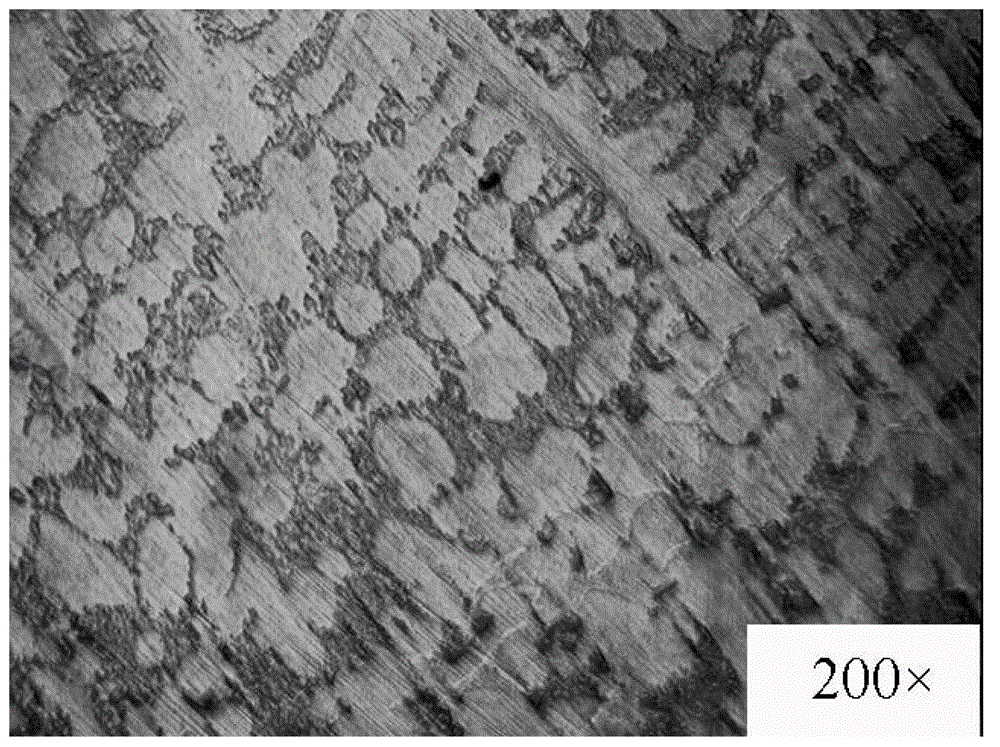

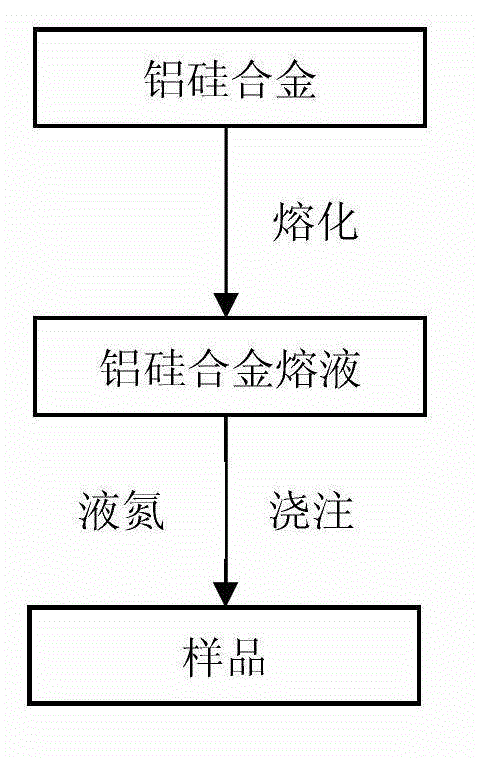

Method for refining hypo eutectic aluminum-silicon alloy structure

The invention discloses a method for refining a hypo eutectic aluminum-silicon alloy structure. The method comprises the steps of: firstly melting down an aluminum-silicon alloy; then casting rapidly, solidifying and shaping the melt aluminum-silicon alloy in a liquid nitrogen environment. The method for refining the hypo eutectic aluminum-silicon alloy structure has the advantages of being simple in operation, safe and environment-friendly, obvious in refining effects and fast to prepare. A relatively large number of eutectic structures which are distributed uniformly, have compact and fine organization and have low cutting function for a basal body can be obtained after the AC4B aluminum-silicon alloy is cooled by liquid nitrogen, so that the hardness of the aluminum alloy is up to 148 HBS. The AC4B aluminum-silicon alloy which is obtained by being cooled rapidly in the liquid nitrogen environment has a size of about 3 microns to 15 microns. The crystal particle structure is fine; and the edges and corners of the crystal particles are passivated and smooth.

Owner:ANHUI RUNXIN TAIDA INTELLIGENT SYST ENGCO

Tar slag machining process and system

InactiveCN104531182ANo secondary pollutionSimple crafting systemWorking-up pitch/asphalt/bitumen by distillationLiquid hydrocarbon mixture productionDistillationSlag

The invention provides a tar slag machining process and system, and belongs to a tar slag cleaning machining utilization process and system. According to the process, after tar slag is added to crushed coal according to proportion, the tar slag and the crushed coal are fully mixed in a double-spiral mixer and then sent to multi-stage spiral dry distillation and conveying integrated machines to be subjected to dry distillation devolatilization, pitch prepared by coal tar in a distillation mode is added into a one-level spiral dry distillation and conveying machine of the multi-stage spiral dry distillation and conveying integrated machines, three materials are fully distillated and mixed through the dry distillation and conveying machines, and a product model block formed by final mixed materials for gas making of a gas station is obtained. The system includes the four steps that 1, binder pitch is obtained through tar machining; 2, fine coal is crushed to be power coal; 3, tar slag fine coal is mixed and subjected to distillation devolatilization; 4, the binder pitch and the tar slag coal generated after dry distillation is conducted are mixed to form and manufacture the gasified model block.

Owner:CHINA UNIV OF MINING & TECH

Composite filter bag, dedusting and denitrification integrated device, and flue gas short-process dedusting and denitrification purifying method

PendingCN108970269ARealize short-range dust removal and denitrification purificationLow costHuman health protectionGas treatmentLiquid storage tankEngineering

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

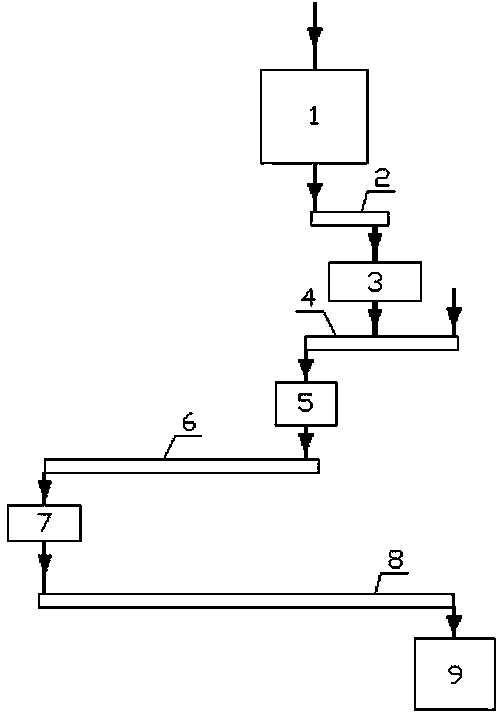

Preparation method for mixed desulfurizing agent for circulating fluidized bed boiler

InactiveCN104208989ASimple crafting systemLess investmentDispersed particle separationFluidized bedEngineering

The invention discloses a preparation method for a mixed desulfurizing agent for a circulating fluidized bed boiler, and relates to a desulfurizing technology in the circulating fluidized bed boiler. The preparation method solves the problems of low utilization rate of conventional limestone flour serving as a desulfurizing agent, high equipment loss and high power consumption. The preparation method comprises the technical steps of (1) conveying limestone fine-powder materials into a limestone powder bin; (2) stirring the limestone fine-powder materials by a star wheel feeder and a differential turbine so as to enable the limestone fine-powder materials to fall to a coal slime conveying belt; (3) adding coal slime into the conveying belt so as to be mixed with the limestone fine-powder materials; (4) stirring the coal slime and the limestone fine-powder material mixture in a double-shaft stirring machine, and then conveying to a briquette forming machine; (5) pressing the stirred coal slime and limestone fine-powder material mixture to form the spherical mixed desulfurizing agent; and (6) conveying the spherical mixed desulfurizing agent into a finished product bin for later use through a mixed desulfurizing agent conveying belt. The mixed desulfurizing agent prepared by the preparation method is used for realizing desulfurization in the circulating fluidized bed boiler and has the advantages of simple system, low investment, high desulfurizing agent utilization rate, low equipment loss and low power consumption.

Owner:山西平朔煤矸石发电有限责任公司

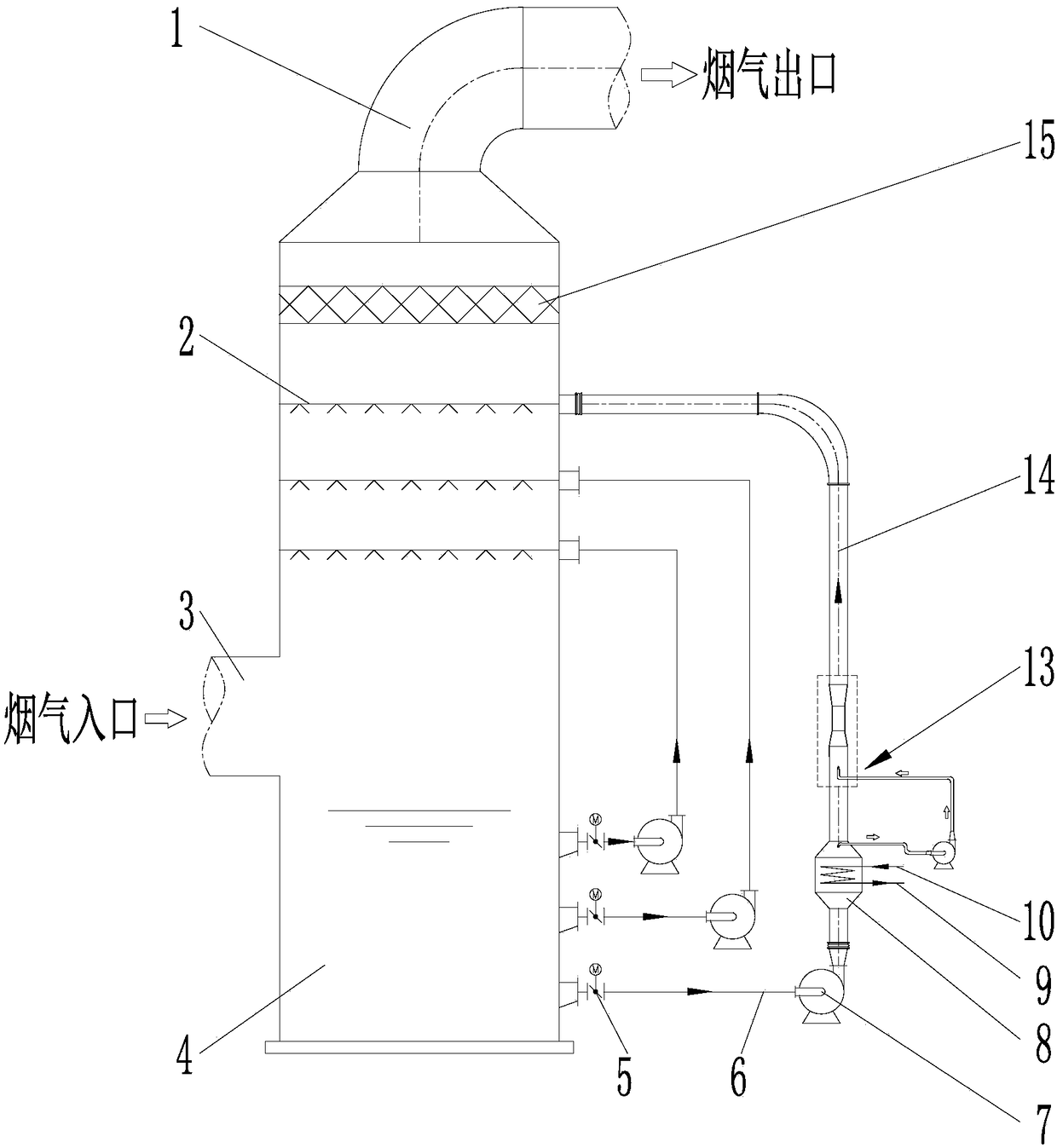

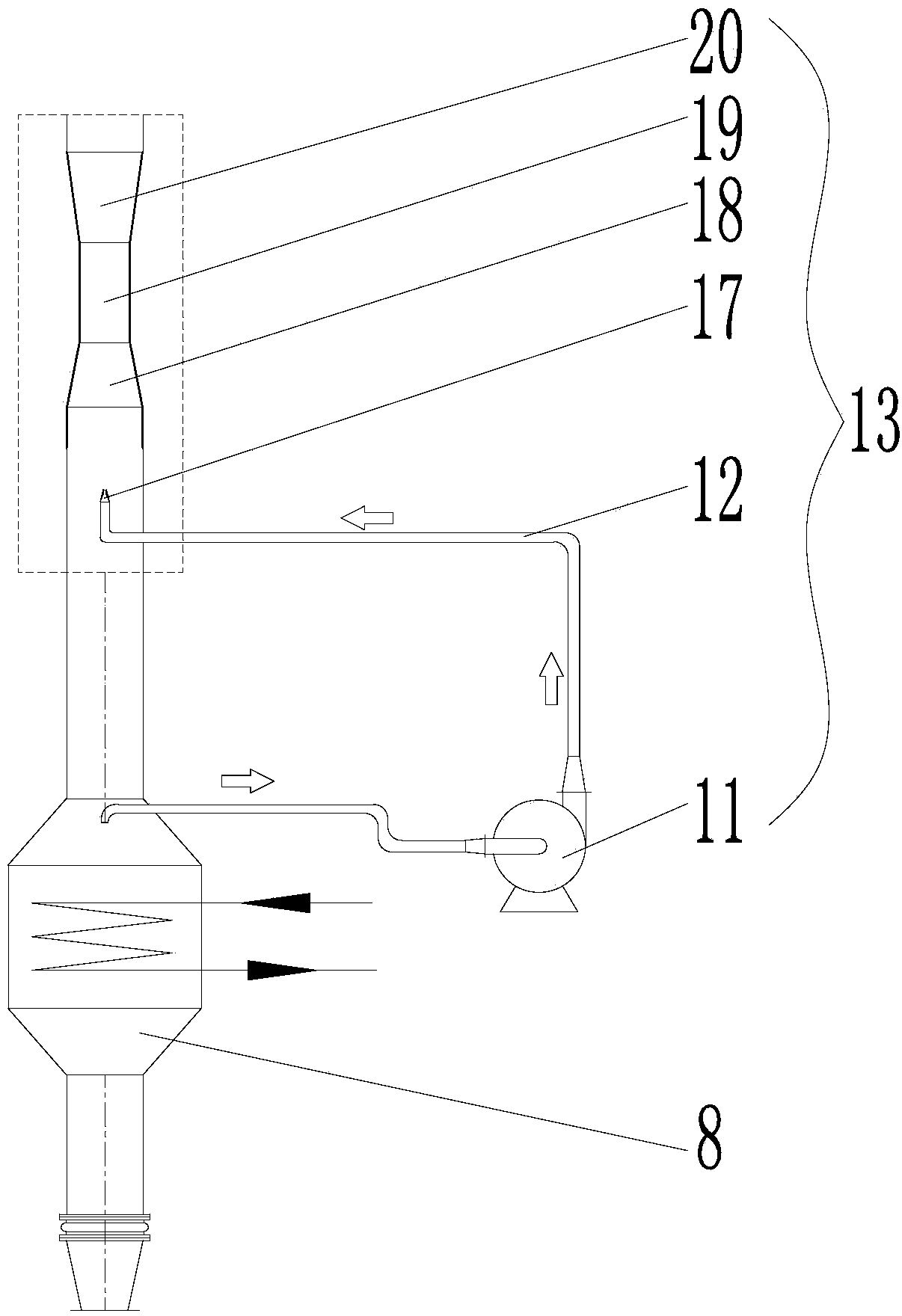

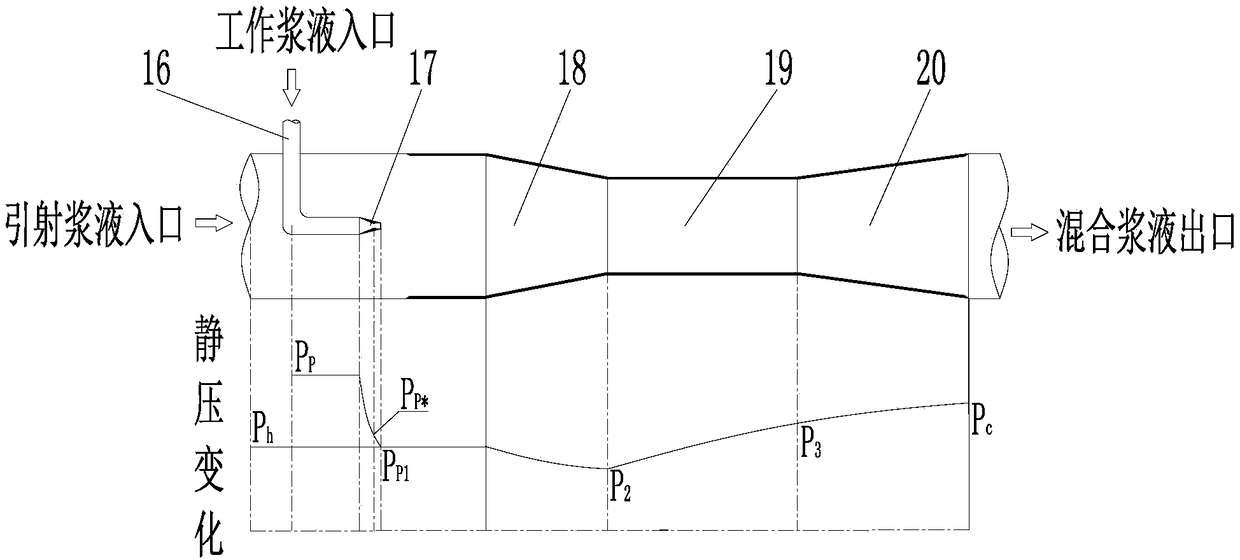

Cooling and white smoke eliminating device and method for circulating slurry for desulfurizing tower of thermal power plant

ActiveCN108295633ASimple crafting systemShort transformation periodUsing liquid separation agentCombustion technology mitigationSlurryButterfly valve

The invention discloses cooling and white smoke eliminating device and method for circulating slurry for a desulfurizing tower of a thermal power plant, and belongs the fields of the flue gas purification and the white smoke elimination of utility boilers and metallurgical coking and relevant industrial boilers, and the like. The side surface of the bottom of the desulfurizing tower in the deviceis provided with electric butterfly valves; the electric butterfly valves, slurry circulating pump inlet pipes, slurry circulating pumps, a slurry cooler, a slurry jetting and boosting device, a slurry circulating pump outlet pipe and top-layer spray layers are connected in sequence. The device can be used for reducing the water replenishing amount of the desulfurizing tower, is used for decreasing the moisture content of flue gas, and is used for further eliminating white smoke. Meanwhile, the invention also provides the cooling and white smoke eliminating method for the circulating slurry for the desulfurizing tower of the thermal power plant. The latent heat of vaporization in the flue gas is recovered; the heat loss of the smoke exhausted from a boiler is further decreased; the moisture carried in the flue gas is reduced; the water resource is saved, and the white smoke from a chimney outlet is eliminated.

Owner:CHINA HUADIAN ENG +1

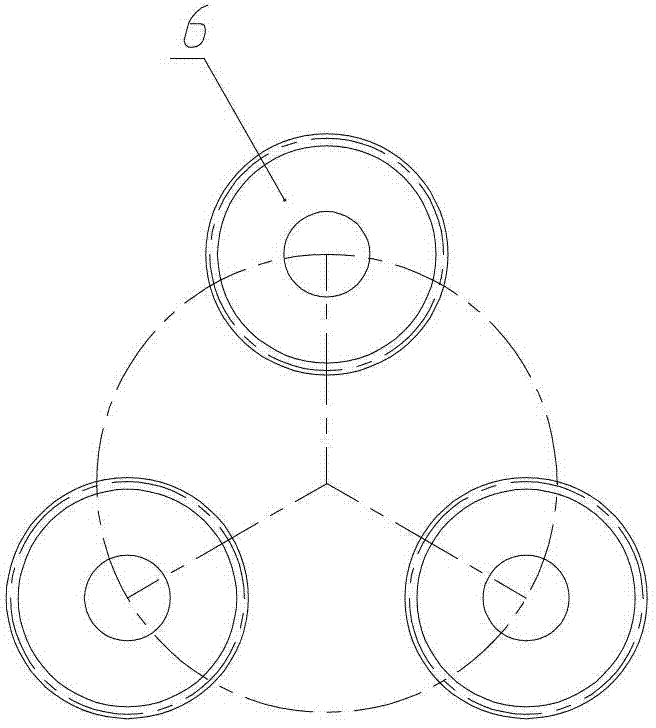

Servo direct-drive type incremental rolling forming process for cylindrical piece with teeth inside and outside

The invention relates to a servo direct-drive type incremental rolling forming process for a cylindrical piece with teeth inside and outside. The process comprises the following steps: sleeving the blank of the cylindrical piece on a core mold; axially feeding to a high-frequency induction heater under driving of a composite alternating current servo motor and heating quickly; continuously and axially feeding to the rolling position of 3 to 6 rolling molds which are circumferentially and uniformly distributed along the axis of the blank, wherein the rolling molds are driven by an adjusting alternating current servo motor to radially feed and driven by a main power alternating servo motor, and the blank and the core mold are driven by the composite alternating current servo motor simultaneously; gradually finishing incremental rolling forming of the cylindrical piece with teeth inside and outside under the action of the rolling molds; withdrawing the blank reversely; and unloading. The process has the advantages of simple process system, high control precision, small forming force, high forming quality, wide processing range and the like.

Owner:XI AN JIAOTONG UNIV

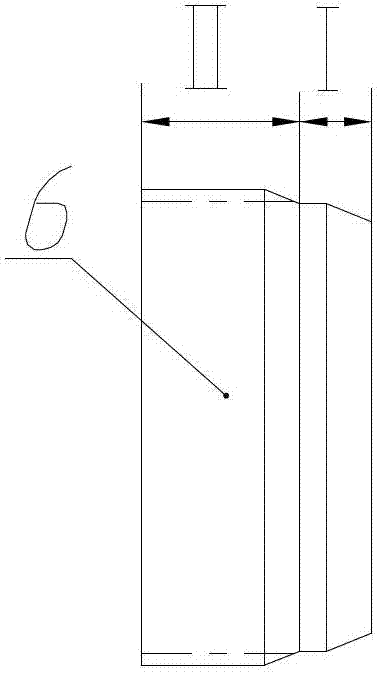

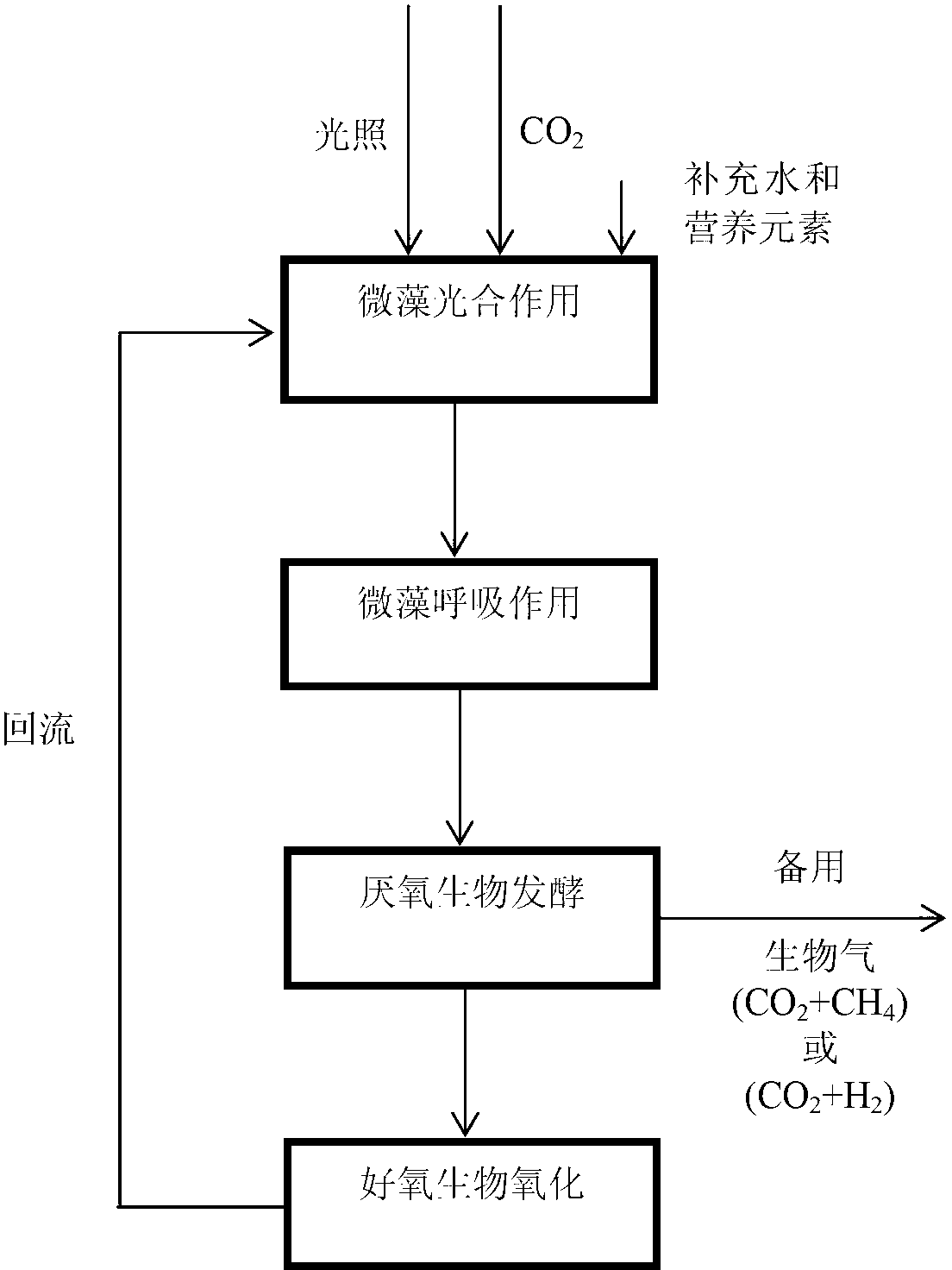

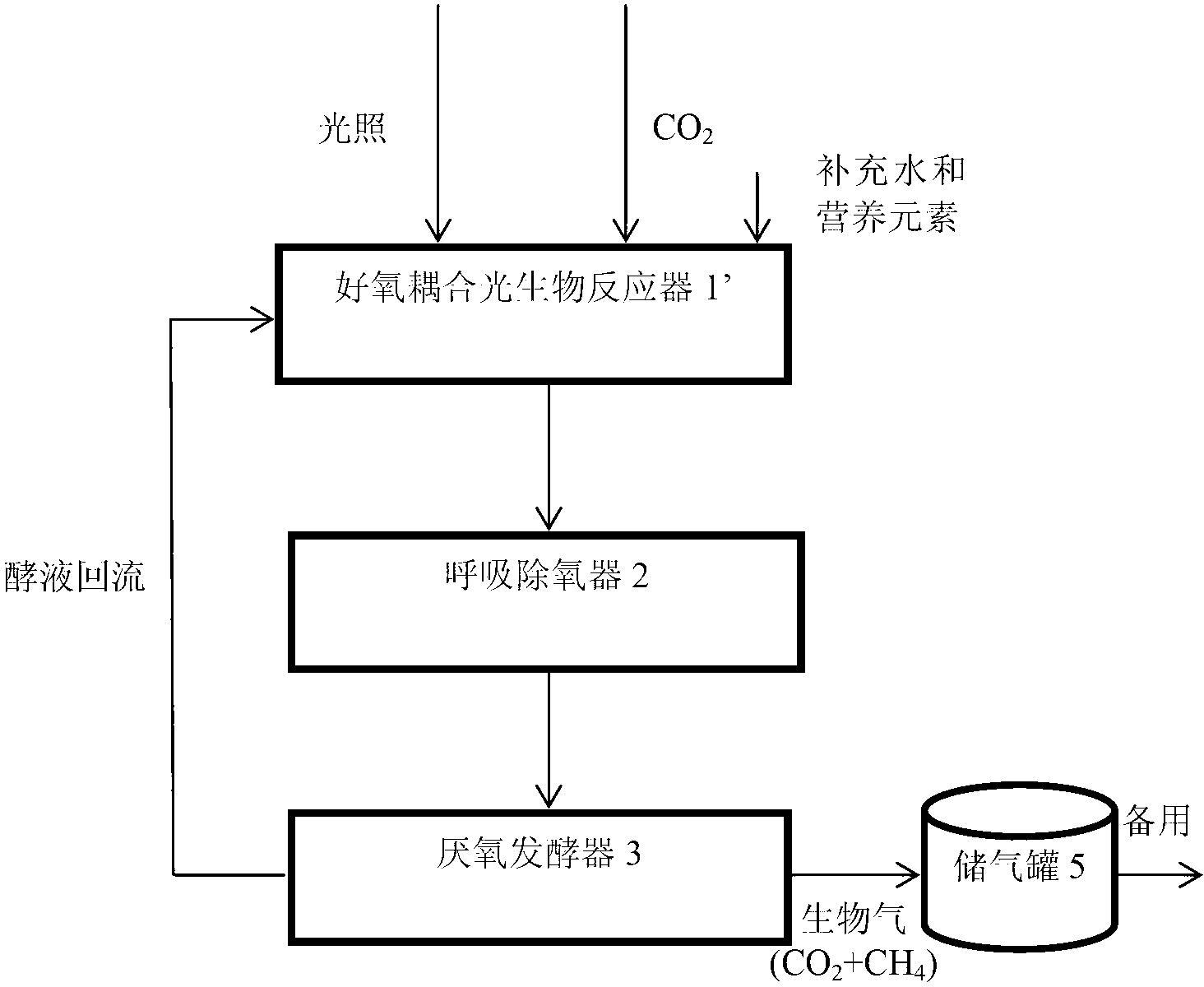

Biochemical novel technology capable of realizing solar energy utilization

ActiveCN103290059ASimple crafting systemLow manufacturing costEnergy inputWaste based fuelNutrientChemistry

The invention relates to a biochemical novel technology capable of realizing solar energy utilization. The method comprise the following steps: (1) microalgae in water synthesizes organic matters of the microalgae from inorganic substances of carbon dioxide, water and nutrient elements under a condition of sunlight radiation by photosynthesis, and a microalgae-containing suspension is obtained; (2) dissolved oxygen in water of the microalgae-containing suspension is removed by respiration of the microalgae in the absence of light, and a microalgae suspension without the dissolved oxygen is obtained; (3) the microalgae suspension is directly subjected to anaerobic fermentation without a separation process, and a combustible biogas is obtained, which is gathered and stored to keep in reserve as an energy source; (4) the fermentation liquor after anaerobic fermentation is subjected to aerobic biological oxidation, and the obtained product is recycled by returning to step (1). Compared with the prior art, the biochemical novel technology helps to realize efficient utilization of solar energy, the technology system is extremely simple, and the cost is extremely low.

Owner:SHANGHAI JIAO TONG UNIV

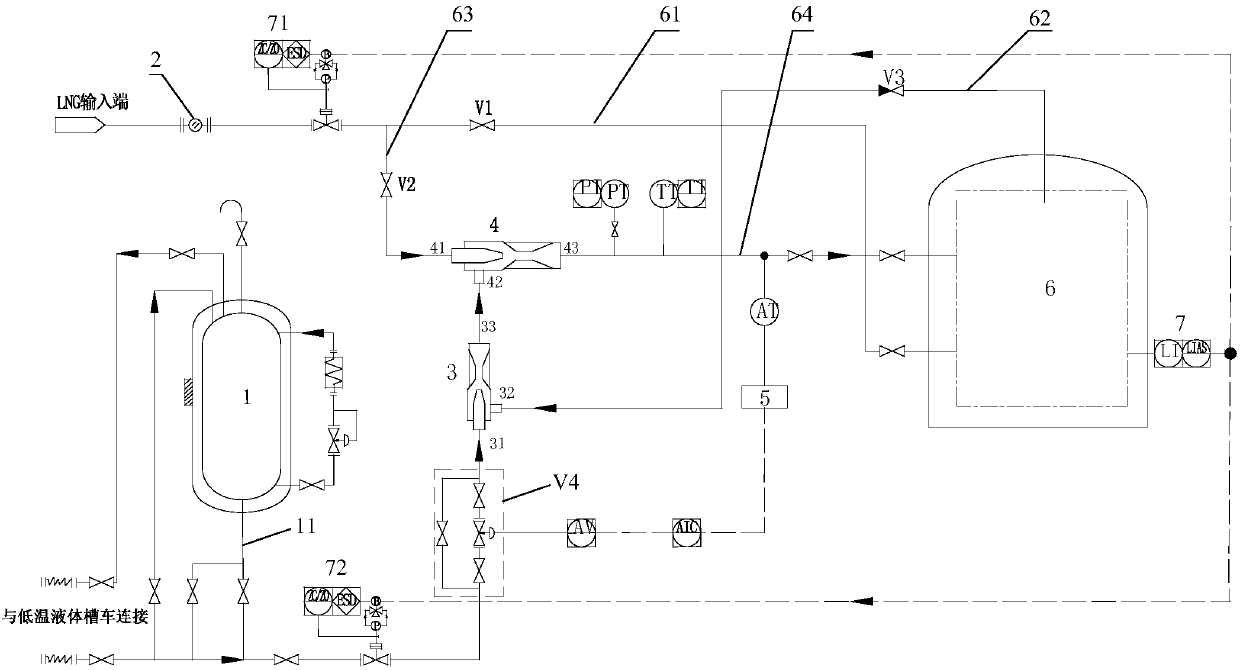

BOG liquefaction recycling system for liquefied natural gas

InactiveCN107726045ALow investment costLow operating and maintenance costsContainer filling methodsPressure vesselsProcess systemsControl system

The invention discloses a BOG liquefaction recycling system for liquefied natural gas. The BOG liquefaction recycling system comprises a low-temperature liquid storage tank, an LNG filter, a primary jet mixer, a secondary jet mixer, an LNG storage tank, a BOG pressure monitoring device and a DCS control system. When the DCS control system judges that a BOG pressure value exceeds a preset value, afirst stop valve is closed, a second stop value, a drain valve and a check value are opened, and gaseous BOG generated in the LNG storage tank and low-temperature liquid in the low-temperature liquidstorage tank are led into the primary jet mixer together for primary cooling liquefaction; then, cooling liquid output by the primary jet mixer and LNG of an LNG input end are led into the secondary jet mixer together for secondary cooling; finally, BOG is completely liquefied and flows back into the LNG storage tank. Thus, BOG liquefaction recycling is realized, and therefore BOG zero emission isreached. The BOG liquefaction recycling system does not need equipping a compressor and a pump and has the advantages of low cost of investment, simple process system and low operational and maintenance cost.

Owner:SHENZHEN GAS CORP +1

Resourceful treatment method and system of lithium battery cathode material production wastewater

ActiveCN104628207AReduce consumptionFully dephosphorizedMultistage water/sewage treatmentNature of treatment waterCalcium biphosphatePhysical chemistry

The invention discloses a resourceful treatment method and system of lithium battery cathode material production wastewater. According to the method, phosphate radicals are precipitated by virtue of mainly using lime milk and the addition of lime milk is controlled so that phosphate radicals are completely precipitated and meanwhile, the pH of the reaction liquid is kept to be alkaline, the reduction in the addition of lye required in the subsequent ammonia removal is achieved, the low-cost dephosphorization and ammonia recovery are truly realized, the obtained calcium phosphate and high-purity concentrated ammonia water can be recycled, the process is stable and is basically free of fouling.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

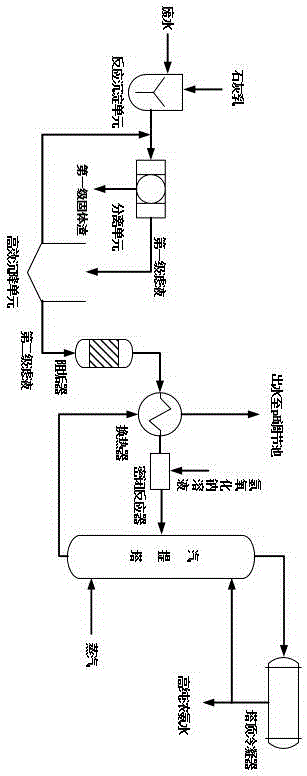

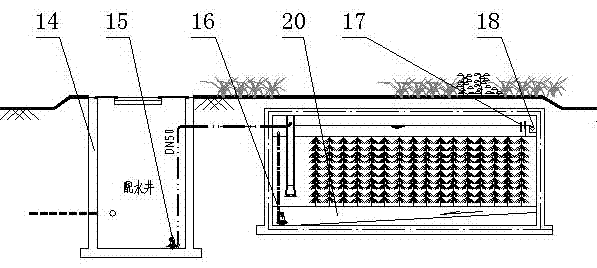

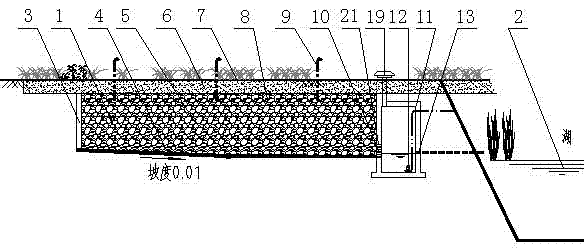

Technology and system suitable for country and dispersive type sanitary sewage purification

InactiveCN102229457ASimple crafting systemEasy maintenance managementMultistage water/sewage treatmentSludgeMaintenance management

The invention provides a technology and system suitable for country and dispersive type sanitary sewage purification. The technical scheme of the technology and the system is as follows: for the technology and the system suitable for country and dispersive type sanitary sewage purification, the system comprises a water distributing well; sanitary sewage is collected to the water distributing well; the sanitary sewage in the water distributing well is pumped to an anaerobic biological filter through an elevator pump for being carried out first-step purification as well as sedimentation; a sludge elevator pump is arranged inside the anaerobic biological filter and is used for elevating biochemical sludge to a septic tank; water subjected to the first-step purification is pumped to a buried biological filter for being carried out second-step purification; and water subjected to the second purification can be reused. The technology and the system have the advantages of simple maintenance, convenience for management and little influence on over-ground cultivation although large areas are occupied.

Owner:SHANDONG JIANZHU UNIV

Wet-type ammonia flue gas purification technics for associated desulfuration demercuration and system

InactiveCN101157003BSimple processSmall footprintDispersed particle separationMercuric ionFluid phase

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

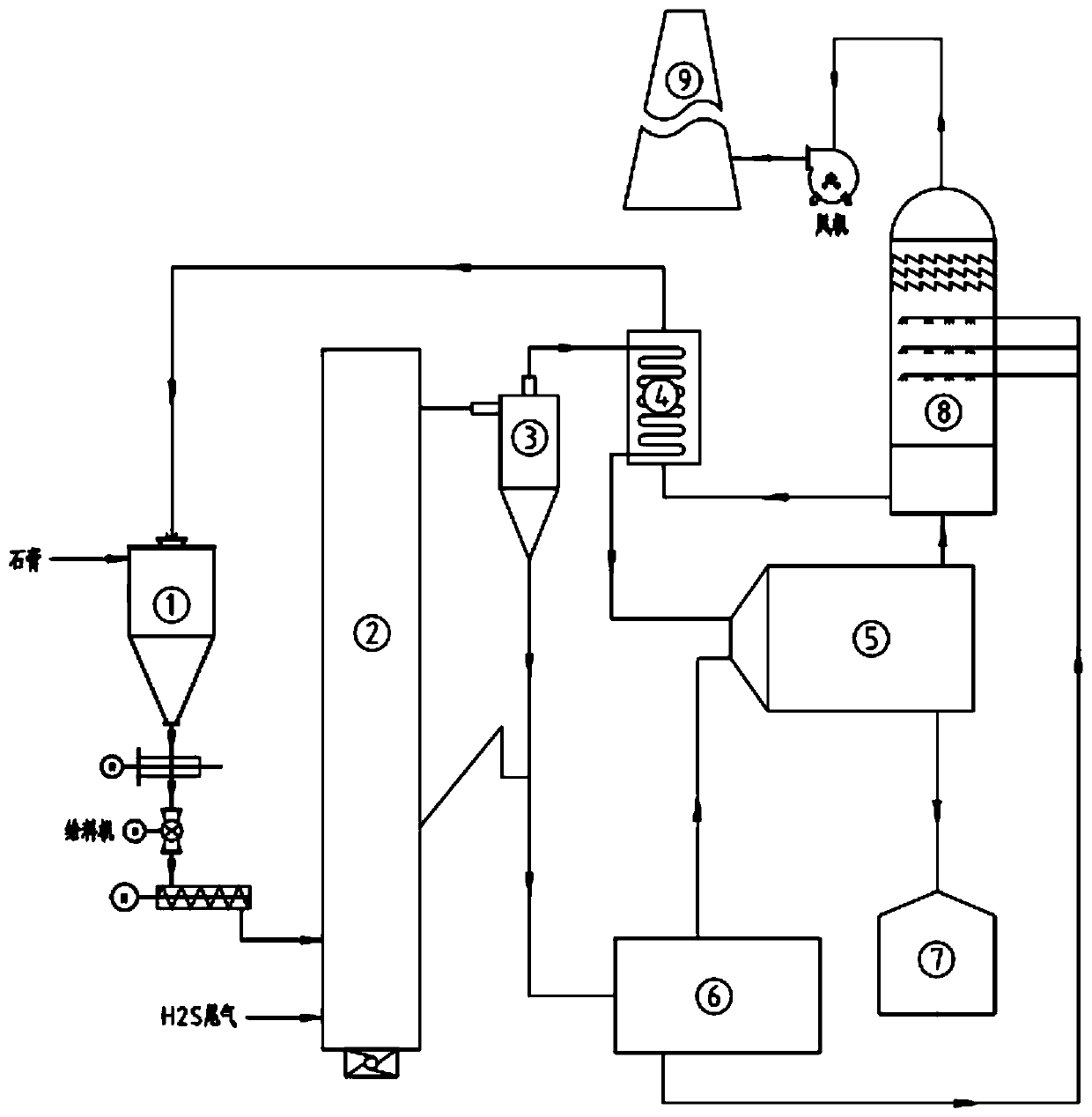

System and method for removing hydrogen sulfide and co-producing calcium carbonate and sulfur from gypsum

InactiveCN111573710AImprove decomposition rateIncrease profitCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesPtru catalystChemistry

The invention discloses a system and a method for removing hydrogen sulfide and co-producing calcium carbonate and sulfur from gypsum. The system comprises a reduction calcining furnace which is respectively connected with a gypsum source and an H2S source, a high-temperature separator which is arranged at an outlet of the reduction calcining furnace and is used for carrying out gas-solid separation on a reaction product in the reduction calcining furnace, an H2O-CO2 processor which is used for providing a space for a mixture of calcium sulfide and calcium oxide to react with water and carbondioxide, and a Claus reactor of which the inlet end is respectively communicated with the gas outlet of the high-temperature separator and the gas outlet of the H2O-CO2 processor. According to the process, industrial by-product gypsum difficult to treat and H2S-containing industrial tail gas are subjected to resource synergistic utilization to produce high-value sulfur and calcium carbonate, calcium carbonate can replace limestone to serve as a desulfurization and denitrification agent and can also serve as a catalyst of a coal gasification process, sulfur serves as an important industrial rawmaterial, and both calcium carbonate and sulfur have high utilization value.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com