Patents

Literature

543results about How to "Stabilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

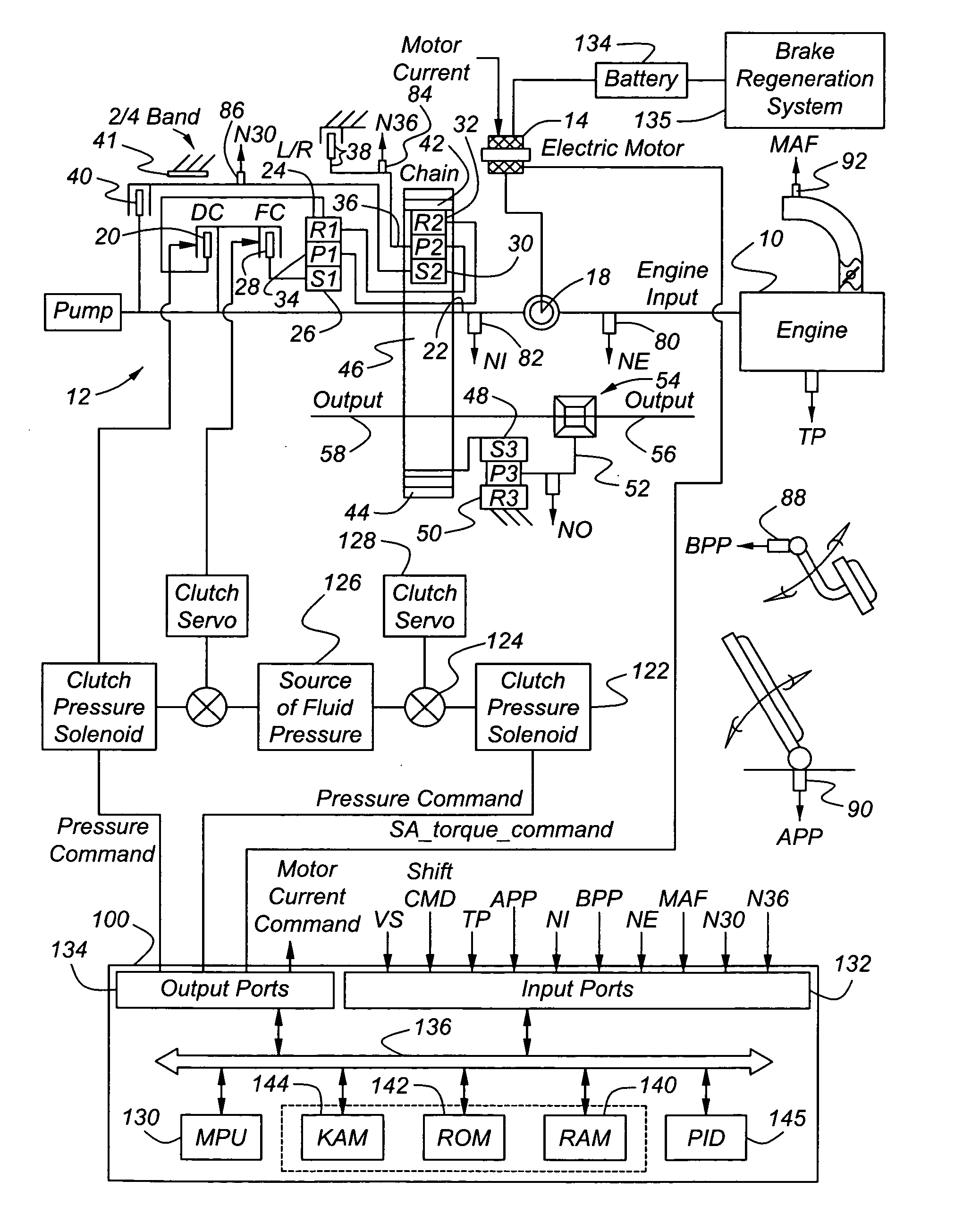

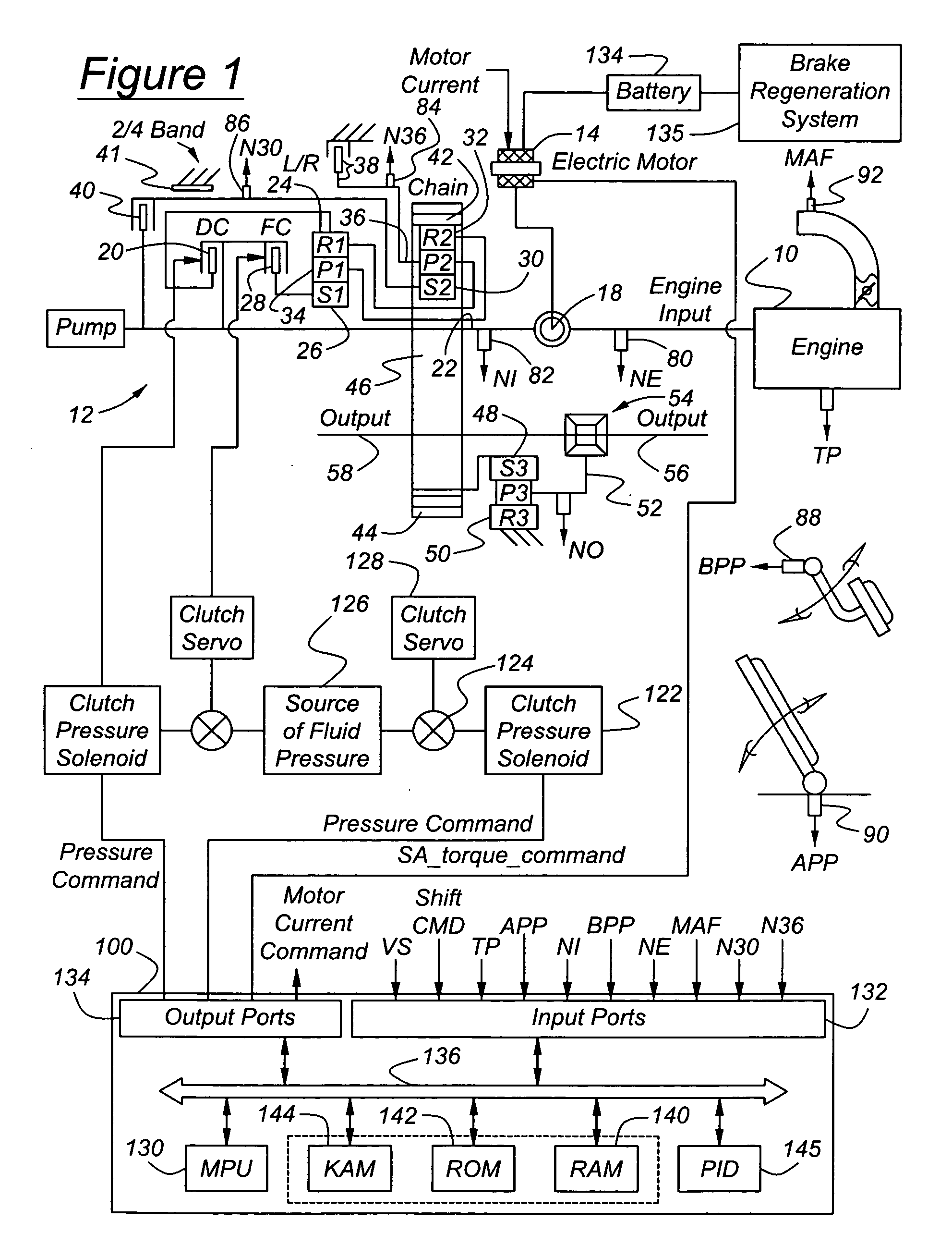

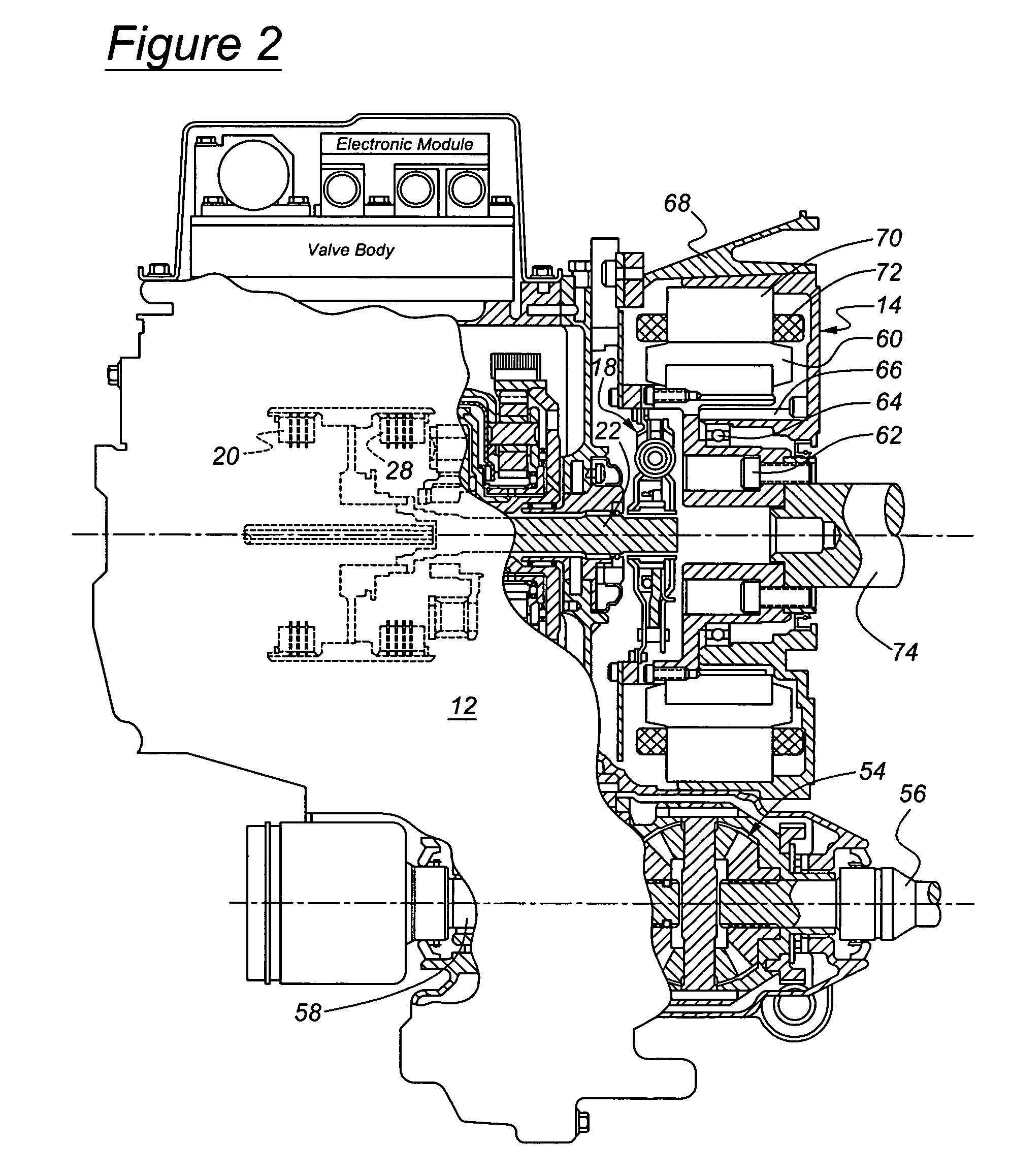

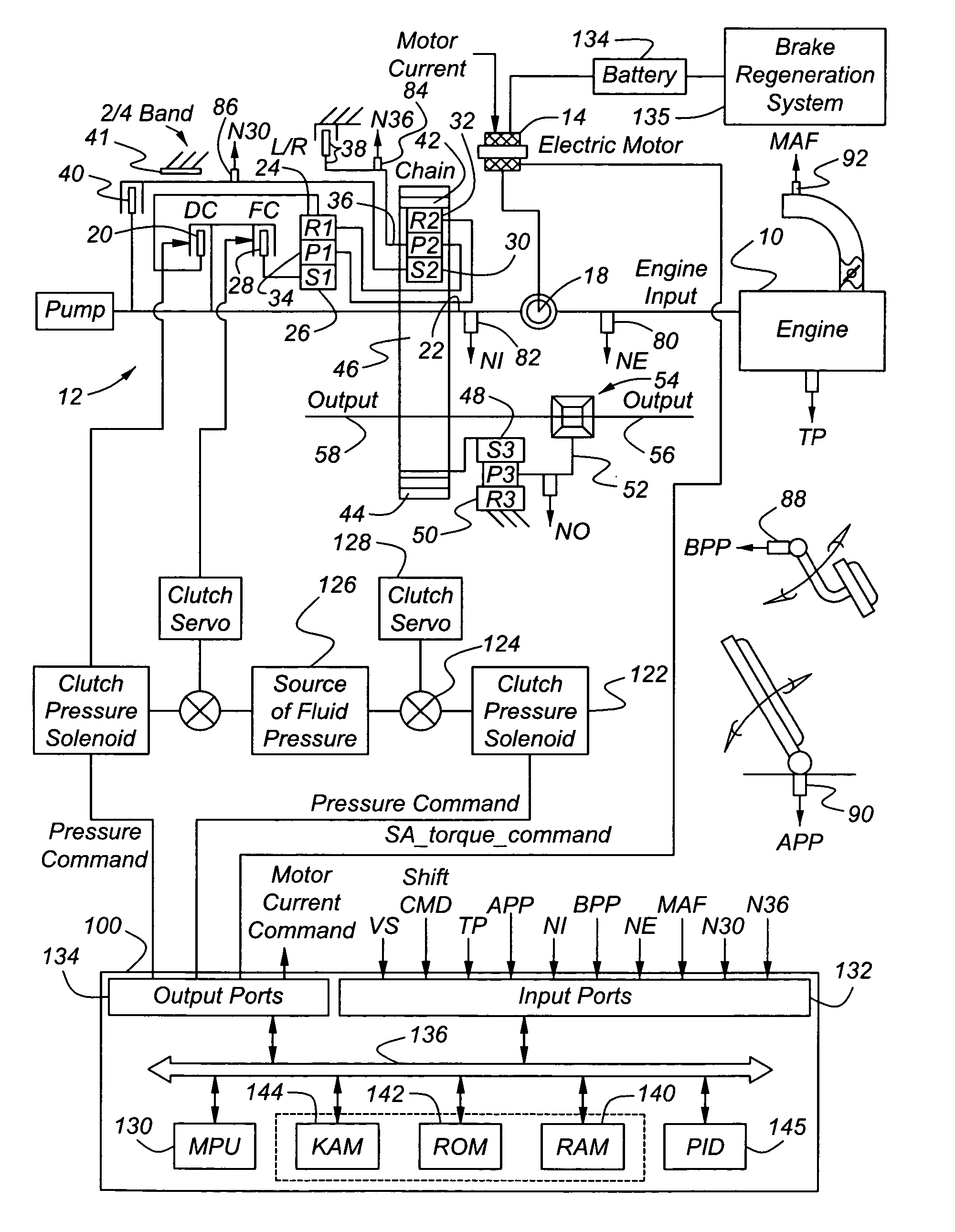

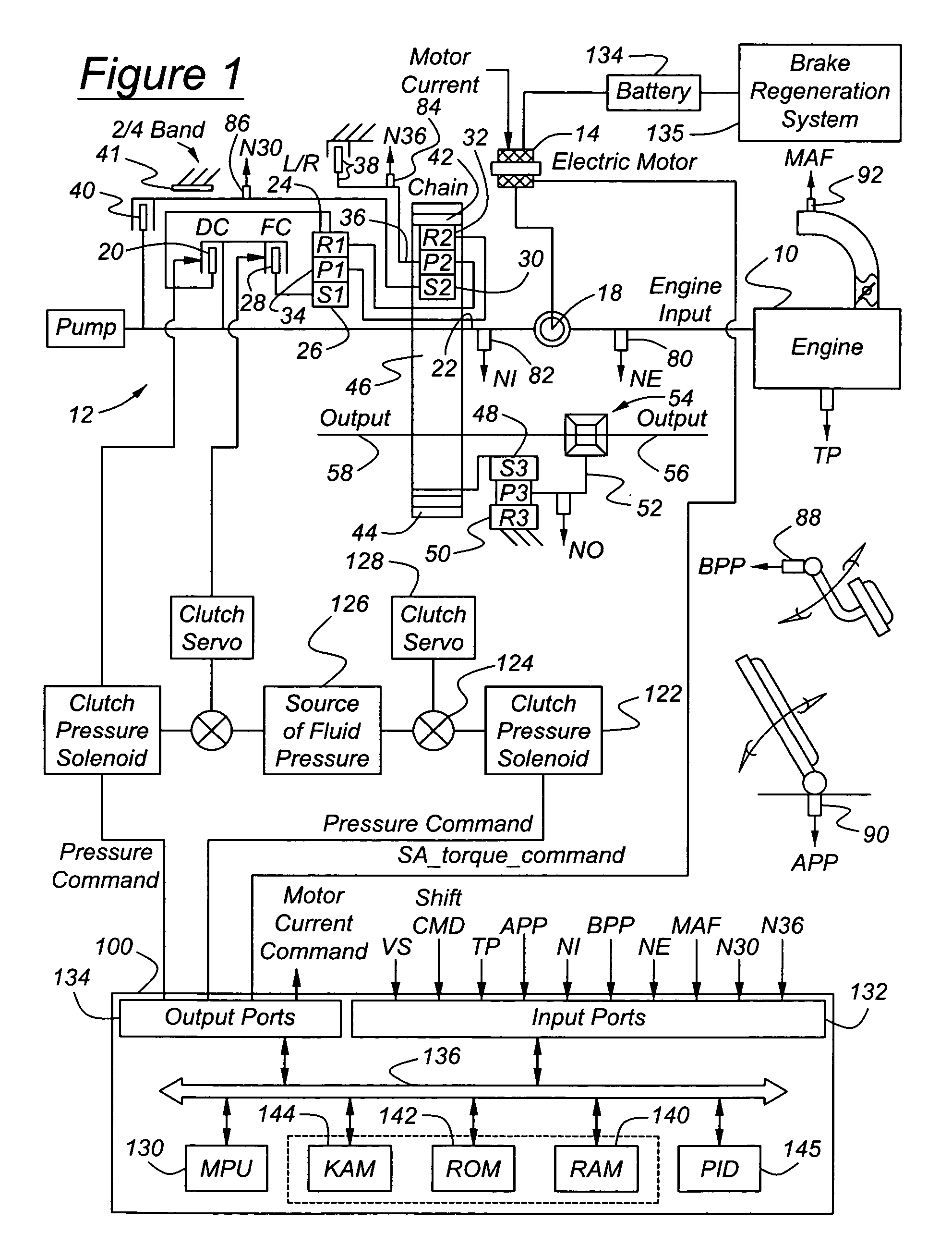

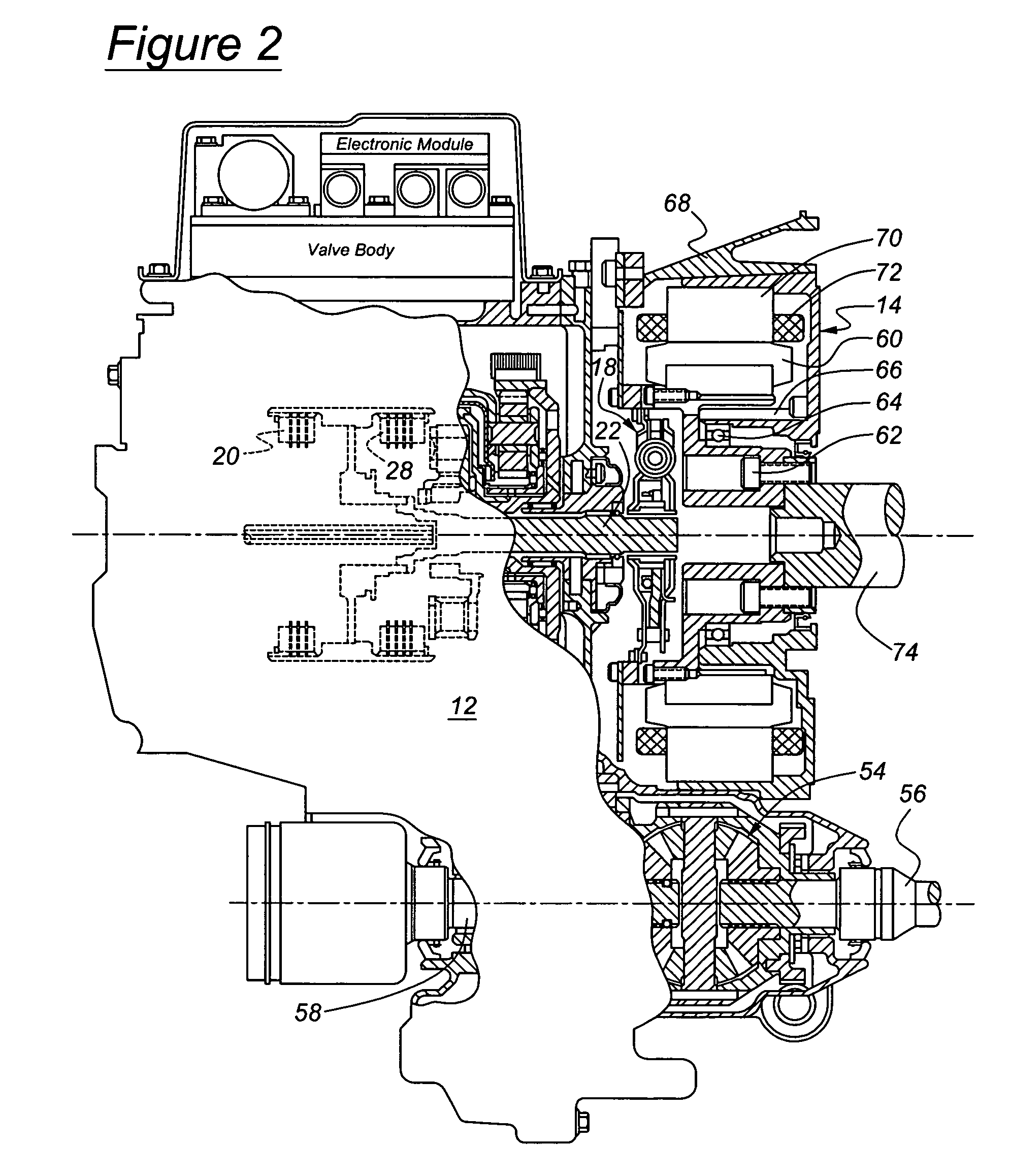

Torsional isolation of a convertless automatic transmission through slip control of friction clutch

ActiveUS20050250618A1StabilizationMechanical actuated clutchesDigital data processing detailsMobile vehicleThrottle control

An automotive vehicle driveline includes an internal combustion engine for transmitting input torque to a hydraulically-actuated input clutch, and having a throttle controlled by a displaceable accelerator pedal. A transmission produces multiple gear ratios between the clutch and an output. A method for controlling operation of the clutch includes determining a magnitude of clutch pressure that would produce a torque capacity of the input clutch equal to the current magnitude of input torque; if no transient condition occurs, pressurizing the clutch at a magnitude of pressure that produces a predetermined slip of the input clutch at the current magnitude of input torque; and if a transient condition occurs, holding and / or reducing the determined input clutch pressure such that slip occurs at the input clutch.

Owner:FORD GLOBAL TECH LLC

Torsional isolation of a convertless automatic transmission through slip control of friction clutch

ActiveUS6991585B2StabilizationMechanical actuated clutchesDigital data processing detailsThrottle controlAutomatic transmission

An automotive vehicle driveline includes an internal combustion engine for transmitting input torque to a hydraulically-actuated input clutch, and having a throttle controlled by a displaceable accelerator pedal. A transmission produces multiple gear ratios between the clutch and an output. A method for controlling operation of the clutch includes determining a magnitude of clutch pressure that would produce a torque capacity of the input clutch equal to the current magnitude of input torque; if no transient condition occurs, pressurizing the clutch at a magnitude of pressure that produces a predetermined slip of the input clutch at the current magnitude of input torque; and if a transient condition occurs, holding and / or reducing the determined input clutch pressure such that slip occurs at the input clutch.

Owner:FORD GLOBAL TECH LLC

Chemical cleaning method of ultrafiltration membrane

The invention discloses an ultrafiltration membrane chemical cleaning method and aims at an ultrafiltration membrane that is used for processing purified PTA waste water. The invention uses an acid lotion prepared by citric acid and sodium bisulfite for dissolving and eluting inorganic pollutants that are formed by cobalt and manganese ion hydroxide, deposited and absorbed on the surface of the ultrafiltration membrane, and uses an alkaline oxidative lotion that contains sodium hypochlorite for dissolving and eluting organic colloid pollutants that are deposited and absorbed on the surface of the ultrafiltration membrane. The ultrafiltration membrane chemical cleaning method can effectively elute the pollutants, recover the running flux and running pressure of the ultrafiltration membrane, and ensure stable running of the purified PTA waste water in an ultrafiltration process.

Owner:CHINA PETROLEUM & CHEM CORP +1

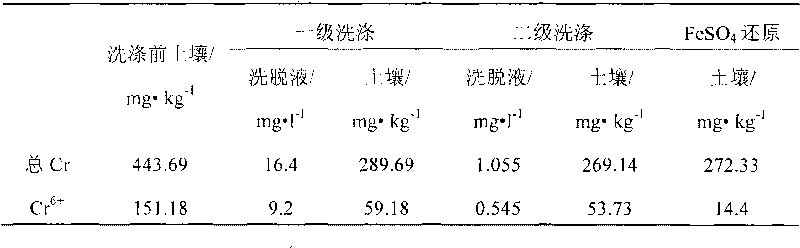

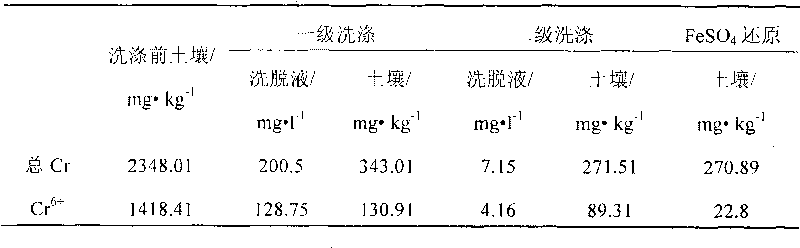

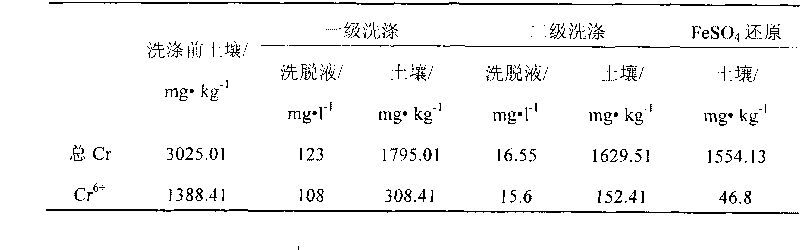

Two-stage countercurrent washing medicament addition stabilization combined restoration method of chromium polluted soil

InactiveCN101708501AAchieve recyclingReduce loadContaminated soil reclamationWater treatment systemRestoration method

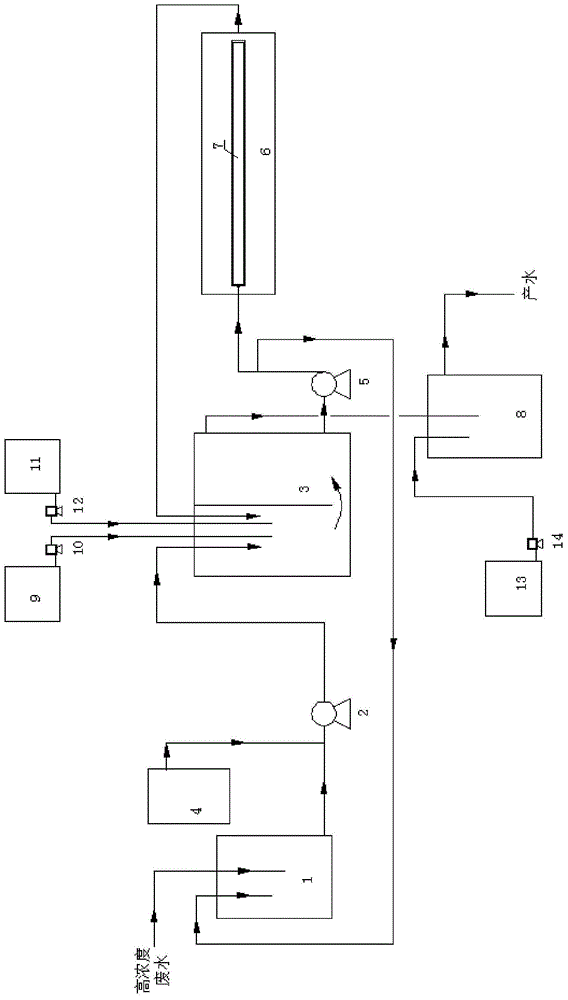

The invention relates to a two-stage countercurrent washing medicament addition stabilization combined restoration method of chromium polluted soil, comprising the following steps of: (1) pouring polluted soil into fist-stage washing equipment, stirring and washing the soil with a liquid-to-solid ratio of 10:1 and then carrying out solid-liquid separation; filling separated waste water into a water treatment system, and pouring dewatered soil into second-stage washing equipment; (2) using clearing water which is treated by the water treatment system and reaches the standard as the water of the second-stage washing equipment, stirring and washing the dewatered soil with a liquid-to-solid ratio of 10:1 and then carrying out solid-liquid separation; sending separated washing liquid to the first-stage washing equipment for recycling; (3) adding FeSO4 to the soil after second-stage washing to carry out stabilization treatment, wherein the addition quantity of the FeSO4 is 1-5 percent of the soil to further reduce the content of Cr6 in the soil and reduce the pH to 6-9 meanwhile; and (4) directly backfilling the stabilized soil. The invention has the advantages of thorough elimination of hexavalent chromium pollution, low price and easy obtain of medicaments, environmental security, use function recovery of restored soil, and the like.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

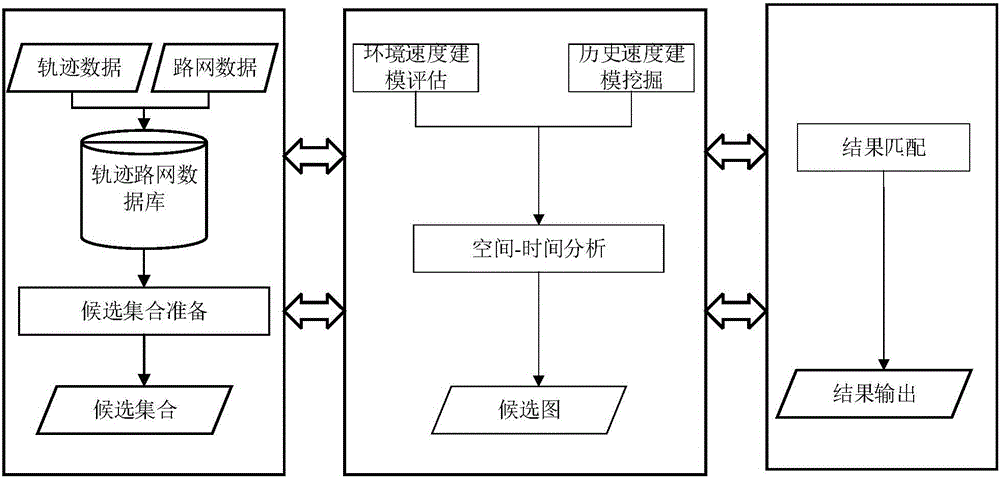

Track data road network precise matching method based on multi-information fusion

The invention discloses a track data road network precise matching method based on multi-information fusion, and belongs to the technical field of road network matching. The track data road network precise matching method is characterized in that based on input track data and road network data, corresponding candidate points are determined for each sampling point, and the road network sections where the candidate points are arranged are candidate sections; then, candidate probability weights of adjacent candidate sections are determined from time and space; and finally, in a result matching process, one maximum weighted path is searched for in a plurality of candidate path and is used as result output, and the corresponding candidate points are simultaneously used as updated sample point coordinates. According to the invention, the track data can be precisely matched with the road network, thereby conjecturing matching points and a driving track. Even under the conditions that the sampling frequency of the track data is unstable, the road network condition is complex and data loss exists, the processing of the invention is still stable, and the time complexity is low.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

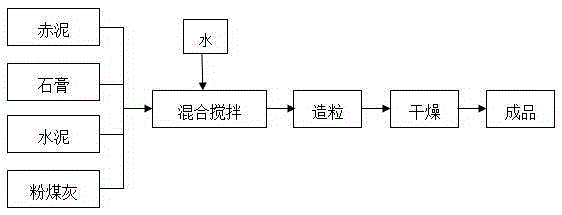

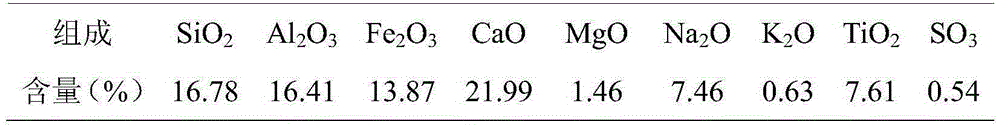

Red mud particle soil repairing adhesives and preparation method thereof

The invention discloses red mud particle soil repairing adhesives and a preparation method and application thereof. The red mud particle soil repairing adhesives are prepared through a series of steps of water adding, mixing, ball forming, room-temperature drying and solidifying by using red mud as the raw material, mixing gypsum into the red mud and using binding material Portland cement and powdered coal in a compound mode to achieve the synergistic interaction result and remarkably improve the red mud gelling property. Red mud powder is granulated and prepared at a room temperature, the obtained red mud particle soil repairing adhesives have certain mechanical strength and quite good heavy metal stabile solidifying performance, soil or mud polluted by heavy metal can be effectively treated, and meanwhile OH radical ions can be slowly released; the pH of soil is kept between 6.7 and 8.1 after soil is repaired through the repairing adhesives, the problems that when soil is repaired through red mud powder, the pH of soil rises too fast and plant growth is not facilitated can be effectively solved, and high application value and environment benefits are achieved.

Owner:国家电投集团山西铝业有限公司 +1

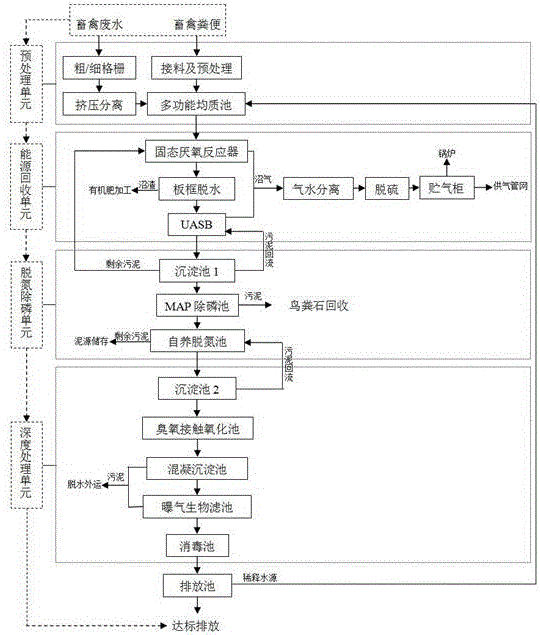

Recycling treatment method for feces and wastewater in large-scale livestock and poultry breeding farm

InactiveCN106242162ANo need to addReduce aerationSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesAnimal fecesEnergy recovery

A recycling treatment method for feces and wastewater in a large-scale livestock and poultry breeding farm includes the following steps: (1) pre-treating the feces and wastewater in the large-scale livestock and poultry breeding farm in a pretreatment unit to form slurry; (2) feeding the slurry into an energy recovery unit, and performing solid anaerobic digestion in a solid anaerobic reactor to obtain an energy gas, methane; (3) performing solid-liquid separation to the digested slurry to generate wastewater, which is then fed into a UASB reactor to perform further anaerobic fermentation to remove organic pollutants from the wastewater; (4) feeding the treated wastewater into a nitrogen and phosphorus removal unit to perform nitrogen and phosphorus removal treatment; (5) separating and purifying a precipitate, which is generated in the nitrogen and phosphorus removal unit and mainly includes magnesium ammonium phosphate, to obtain an organic fertilizer additive, wherein the nitrogen removal process is autotrophic nitrogen removal and can reduce aeration quantity by 62.5% without addition of any carbon sources, thus saving large quantity of operation cost; and (6) feeding the treated wastewater into a deep-treatment unit to remove bio-refractory substances and disinfect the wastewater so as to finally reach emission and recovery standards of wastewater.

Owner:SOUTH VENTURE TIANJIN TECH DEV CO LTD

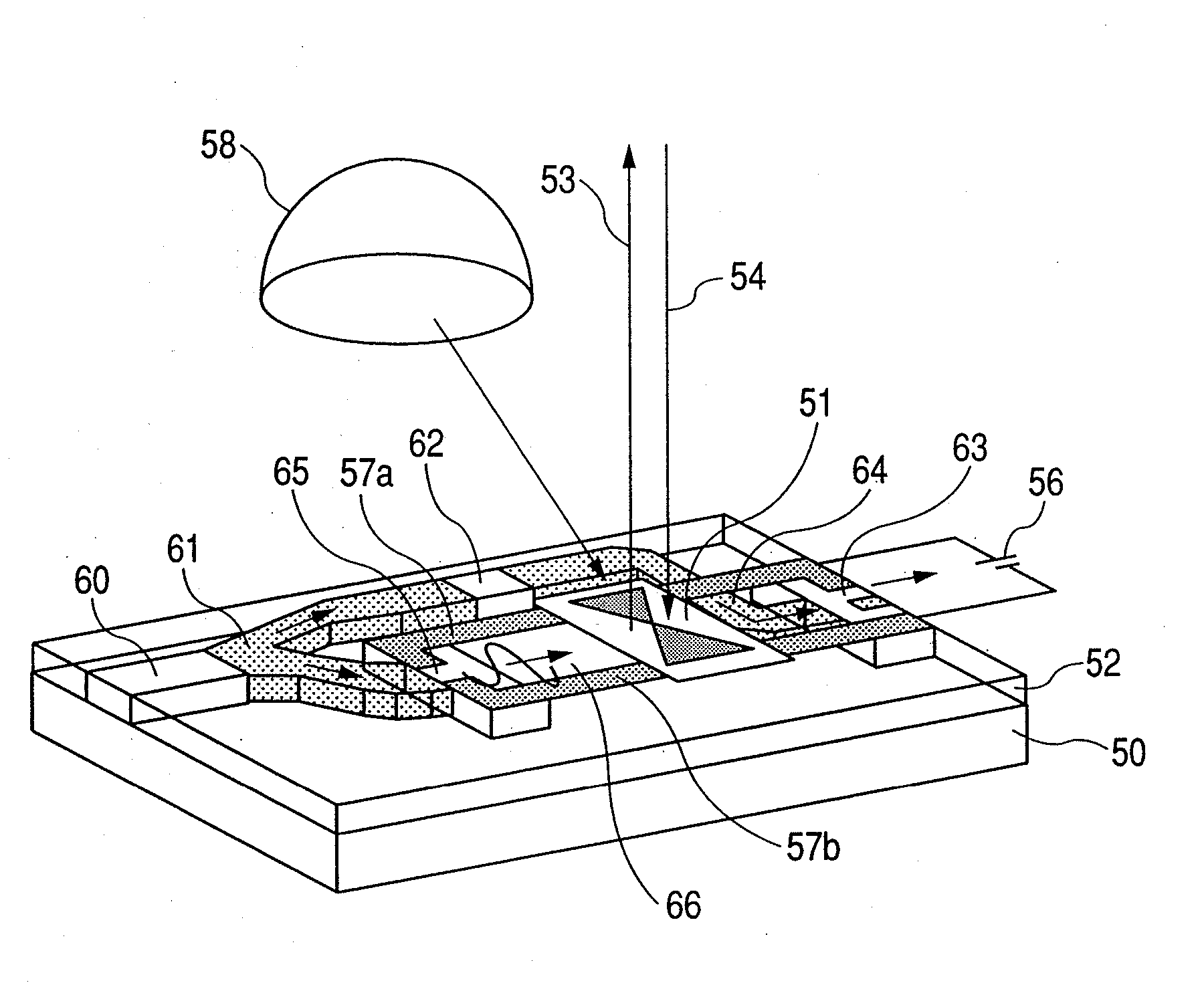

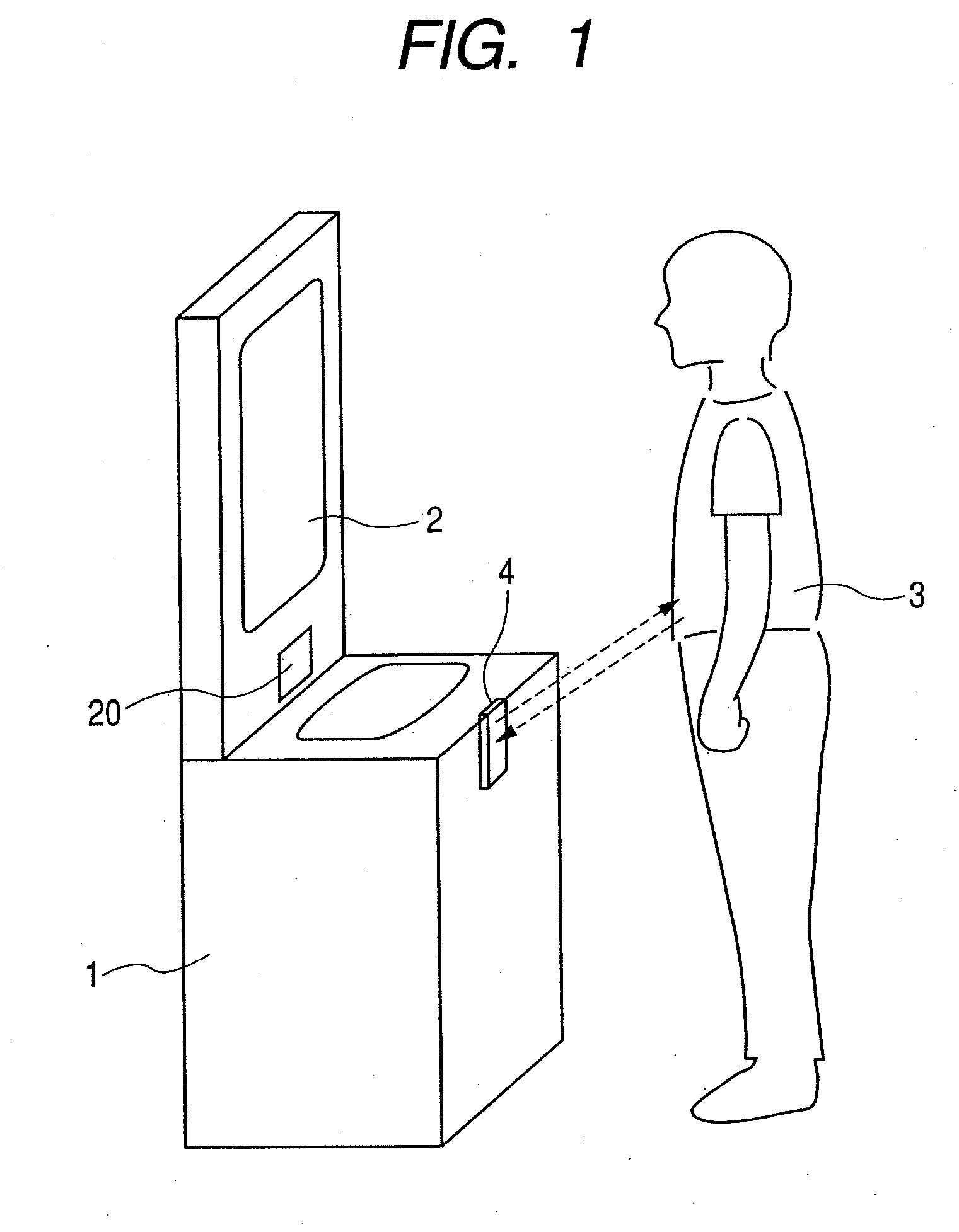

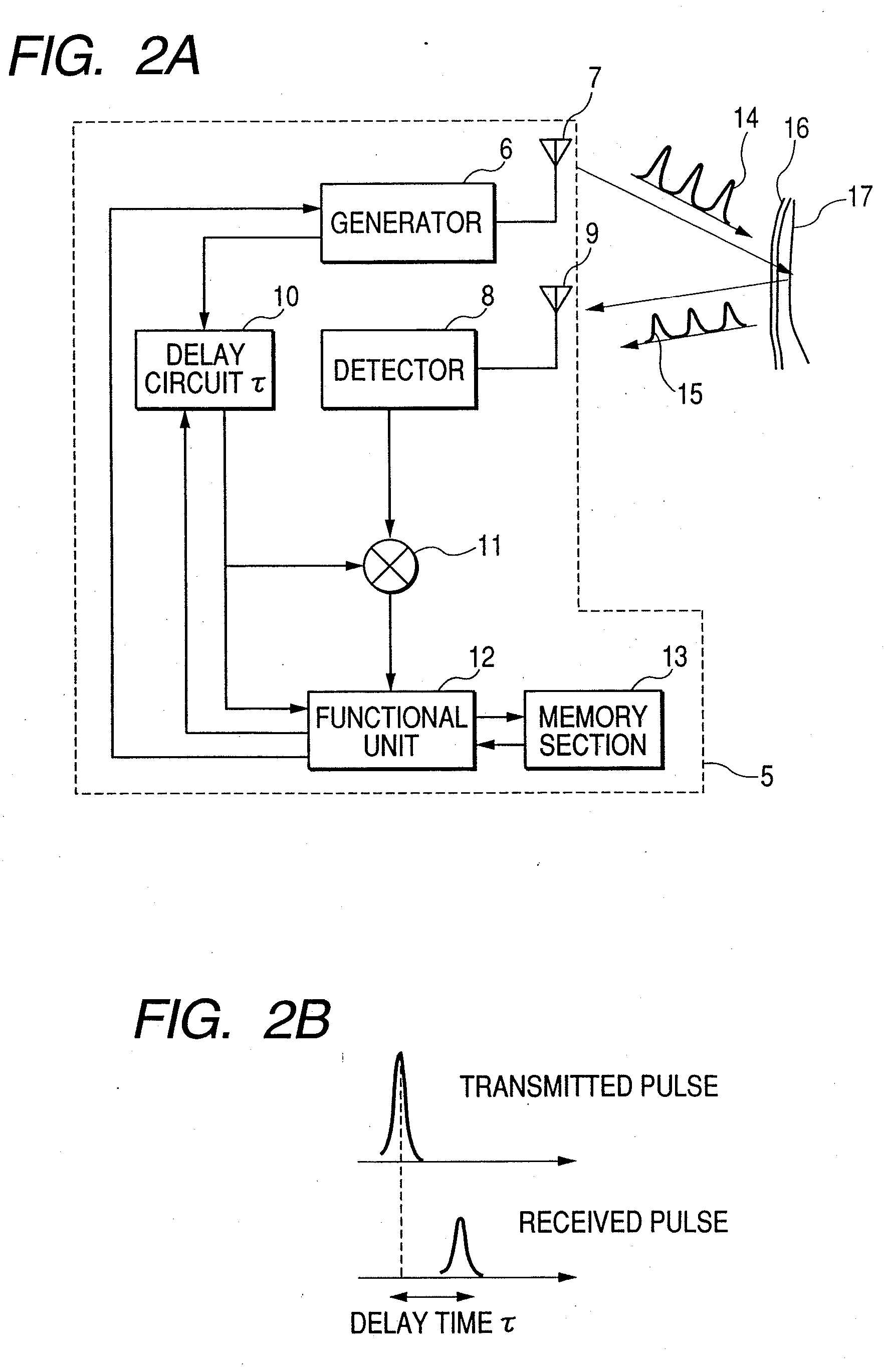

Biological information monitoring apparatus

InactiveUS20080234568A1Life supportEasy to useEvaluation of blood vesselsCatheterBiological bodyElectromagnetic electron wave

A biological information monitoring apparatus highly precisely observes a clothed subject who is taking any desired posture. The apparatus acquires information on positional displacements of the surface of a living body, by generating a high-frequency electromagnetic wave to radiate it into air, detecting the electromagnetic wave scattered by the surface of the living body, computationally determining the changes with time of the positional displacements of the surface of the living body from the state of propagation of said electromagnetic wave and computationally determining characteristic quantities of vibrations of the living body such as the pulse or the respiration from the changes with time as biological information.

Owner:CANON KK

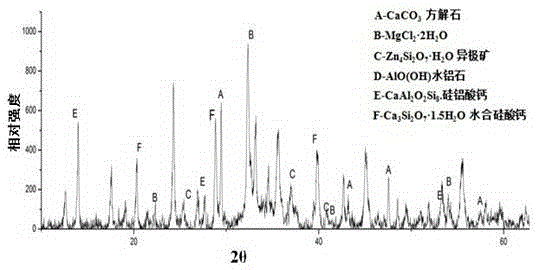

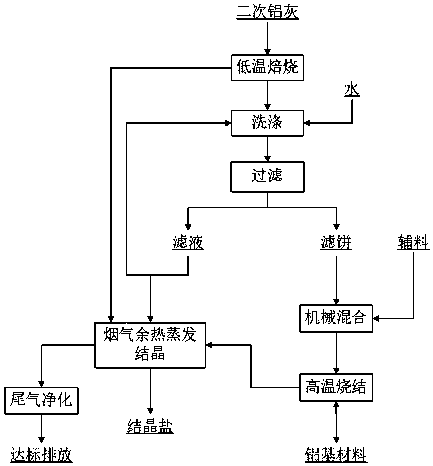

High-efficiency clean resource utilization method for quadratic aluminum dust

ActiveCN109179464AClean and efficient treatmentRealize high-value utilizationHuman health protectionCalcium aluminatesResource utilizationPotassium

The invention discloses a high-efficiency clean resource utilization method for quadratic aluminum dust. The method comprises the following steps: performing low-temperature roasting treatment on quadratic aluminum dust, removing harmful elements such as nitrogen, carbon and fluorine, pulping, washing, desalting and dehydrating the quadratic aluminum dust, removing sodium salt, potassium salt andother impurity components, washing brine and evaporating and crystallizing by utilizing flue gas waste heat. The purified quadratic aluminum dust can serve as a raw material to be directly utilized, and after the quadratic aluminum dust is mechanically mixed with auxiliary materials (calcium-based, silicon-based and magnesium-based), an aluminum based inorganic material is prepared at a high temperature, and the sintering exhaust gas realizes up-to-standard discharge by virtue of dust removal and dry defluorinated purification. According to the technology in the invention, the quadratic aluminum dust can be safely, cleanly and efficiently treated and converted into the high-value aluminum based inorganic material to the greatest degree, and environmental-friendly treatment and high-value resource utilization of the quadratic aluminum dust can be realized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

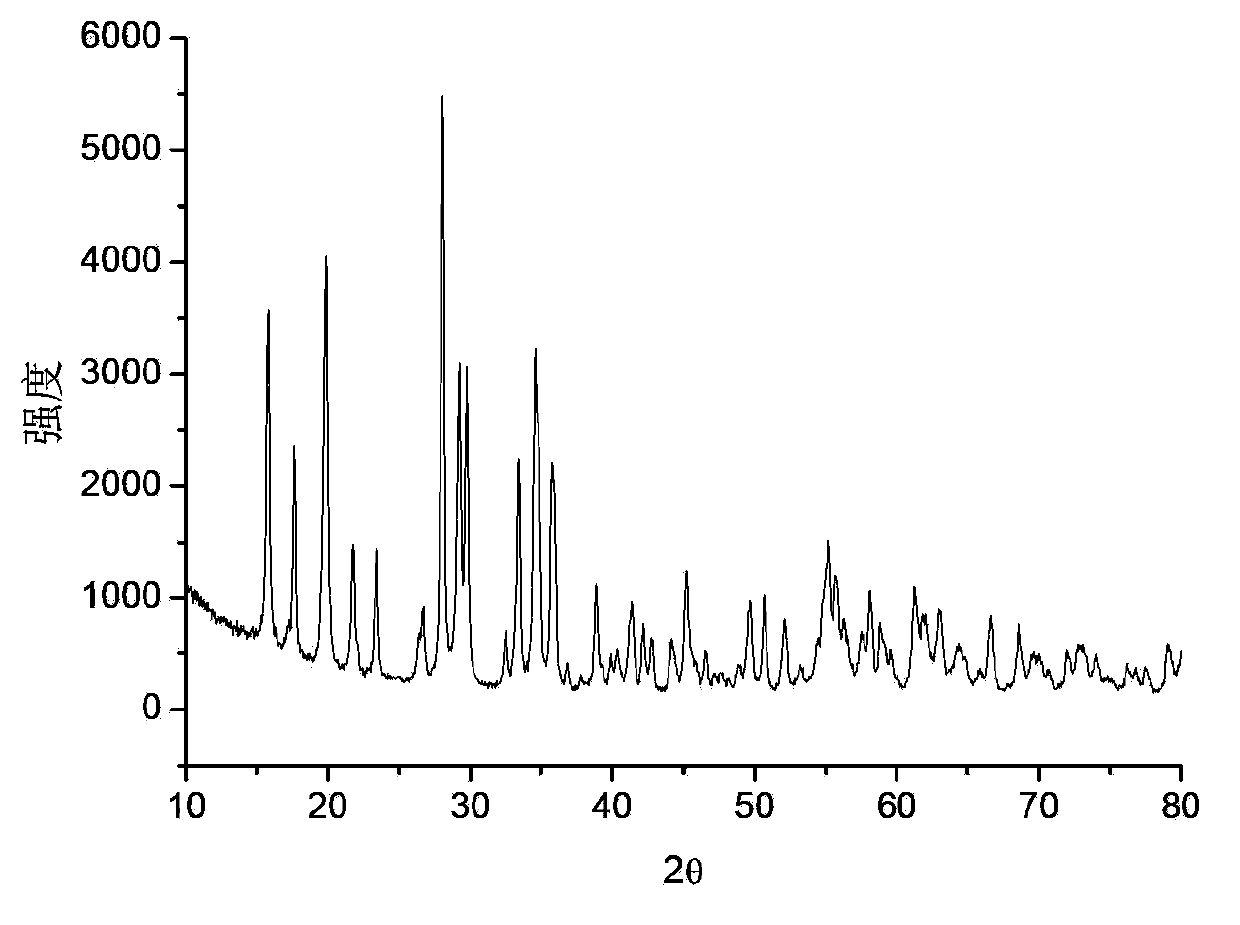

Method for treating arsenic-containing industrial wastewater

ActiveCN103964601AReduce productionReduce the risk of secondary pollutionMultistage water/sewage treatmentEnvironmental resistanceWastewater

The invention belongs to the wet metallurgy and environmental protection technical fields, and particularly, discloses a method for treating arsenic in arsenic-containing industrial wastewater. Under a condition of high temperature, an iron solution is slowly added into the arsenic-containing industrial wastewater, arsenic in the wastewater forms a stable scorodite crystal (FeAsO4.2H2O), and thus arsenic in the wastewater is removed. The method is simple in process, can obtain the stable arsenic-containing solid waste, and reduces secondary pollution caused to the environment.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

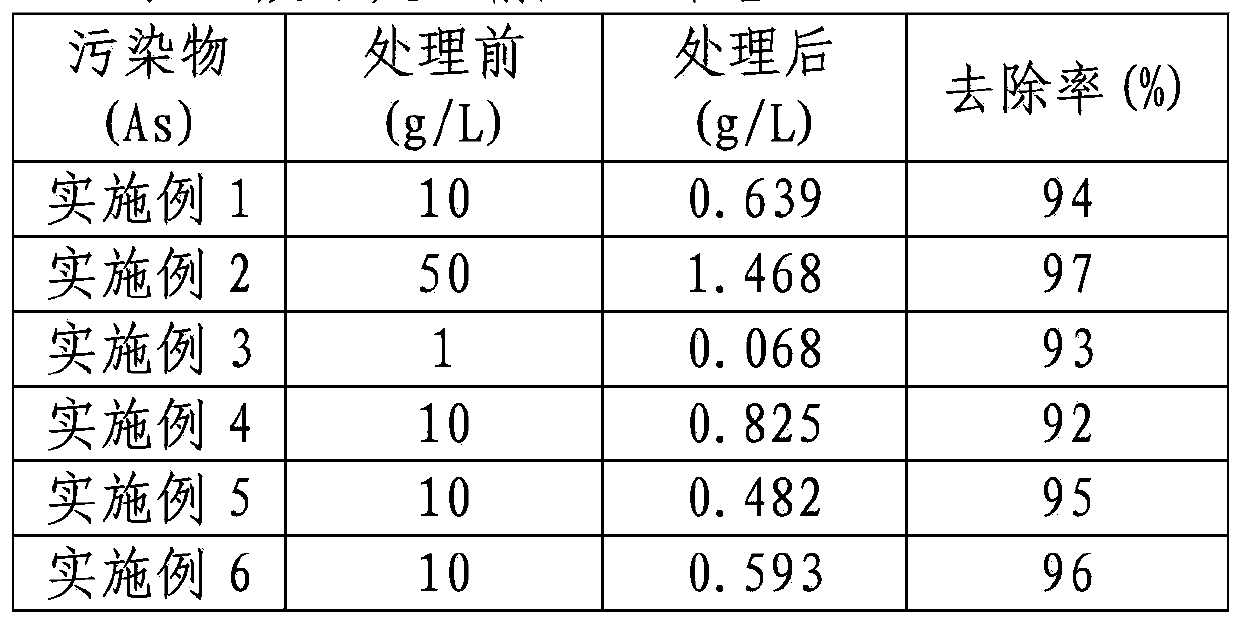

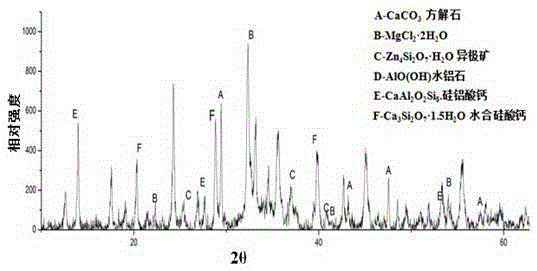

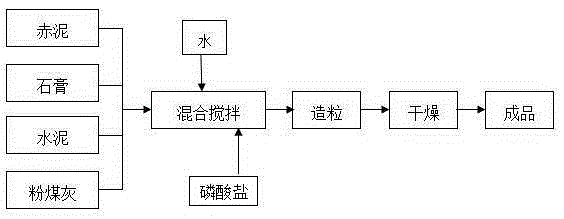

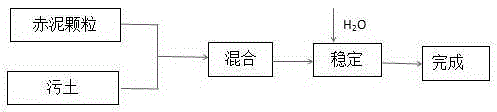

Method for repairing heavy metal-polluted soil by using red mud granular material

The invention discloses a red mud granular material and an application thereof. A red mud particle soil repairing agent takes red mud powder, gypsum, cement and fly ash as main materials, phosphate is doped as an activation material, thereby, gelling capability of red the mud powder and capability for fixing heavy metal ions in a stable mode can be increased, a series of processes of mixing by adding water, balling, and drying solidification at normal temperature can be carried out, so that the spherical particle soil repairing agent can be obtained by composite moulding of the red mud raw ore powder material. The method realizes preparation of the red mud powder with granulation at normal temperature, the obtained red mud particle soil repairing agent has certain mechanical strength and good heavy metal stable solidification performance, the heavy metal-polluted soil or sludge can be effectively processed, OH radical ions can be slowly released simultaneously, a pH value of the soil after restoration by the repairing agent is basically stabilized below 7.5, problems of fast increase of the pH value of the soil and poor growth condition for plants during a soil restoration process by the red mud powder can be effectively overcome, and the method has high application value and environment benefit.

Owner:SUN YAT SEN UNIV

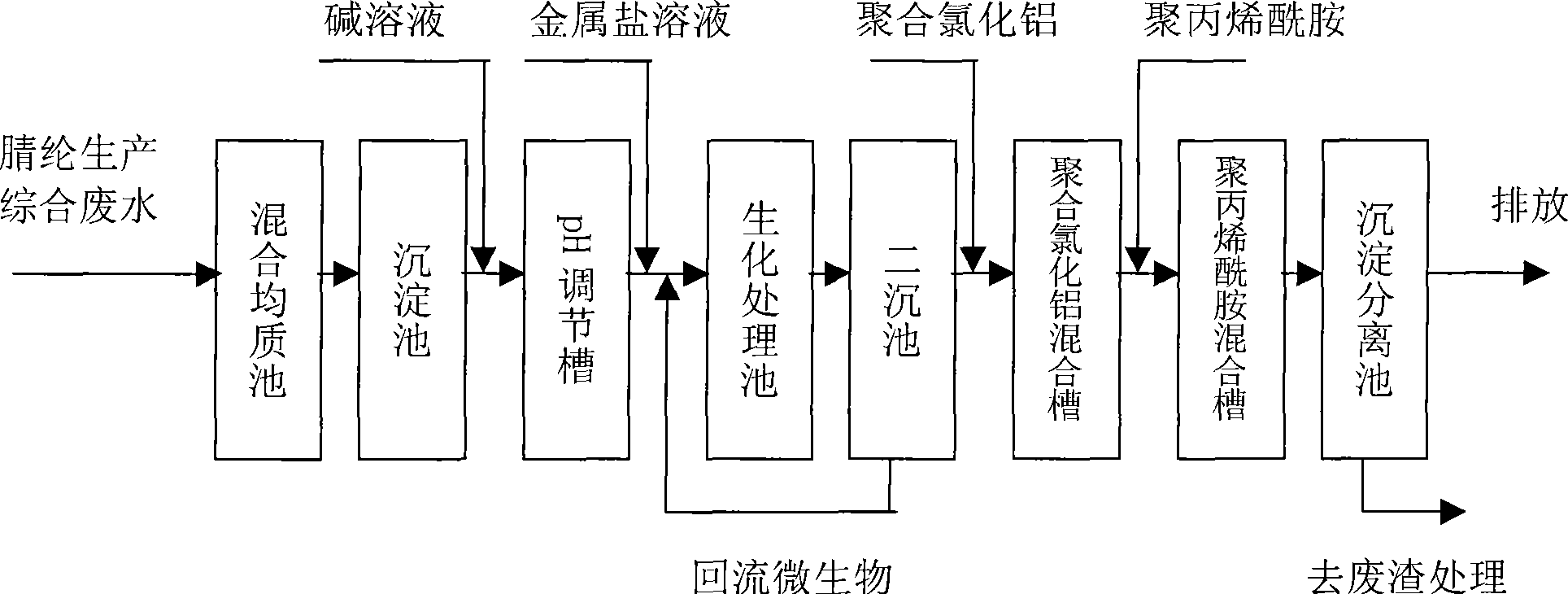

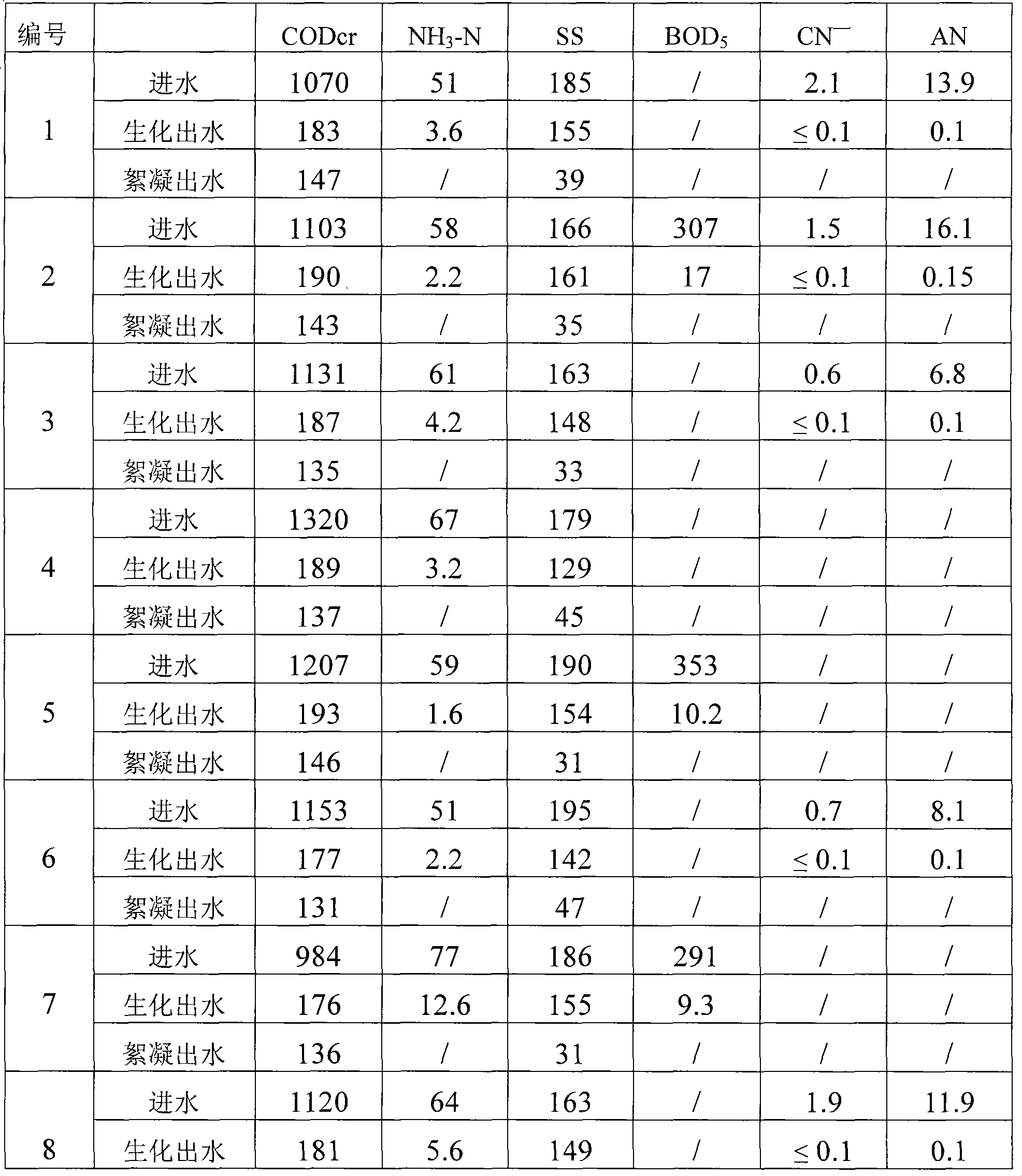

Acrylon production waste water treatment method

ActiveCN101423312ASolve the problem of chelation poisoningEasy to handleMultistage water/sewage treatmentSustainable biological treatmentAcrylonitrileTherapeutic effect

The method discloses a method for treating wastewater generated during the production of acrylic fibers. The method is to treat comprehensive wastewater generated during the production of acrylic fibers taking acrylonitrile as a first monomer by steps of uniform settlement, pH value adjustment, aerobic biochemical treatment and flocculation precipitation. The method adds iron ions, magnesian ion, calcium ion and other metallic ions during the biochemical treatment to react the ions with cyanogens, nitrile, amine and other substances in the wastewater to form chelate complexs, thereby preventing the substances form damaging enzymes of microorganisms, solving the problem of chelating poisoning of microorganisms during water treatment, improving activities of microorganisms and wastewater treatment effect, shortening treatment process, reducing treatment cost and having the characteristics of simpleness, practicality, stable treatment effect, high removal efficiency and wide application range, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

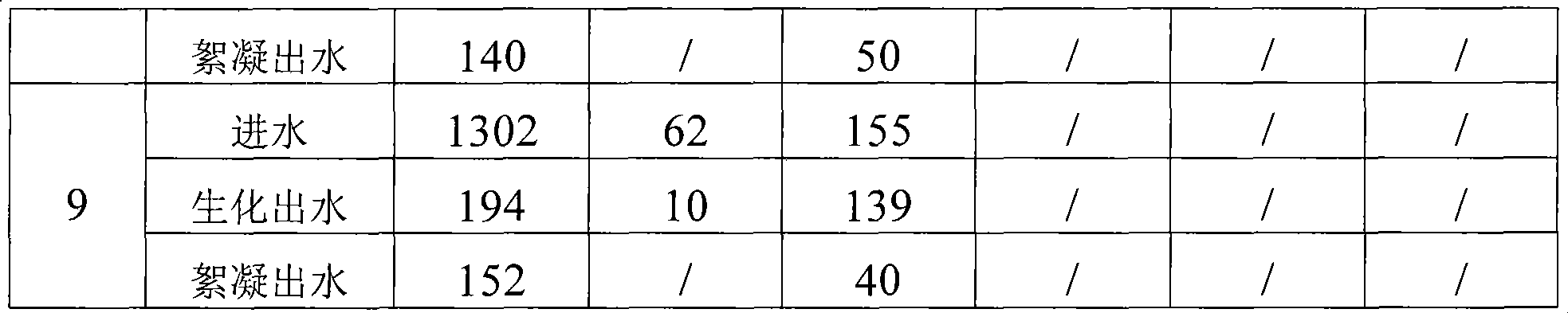

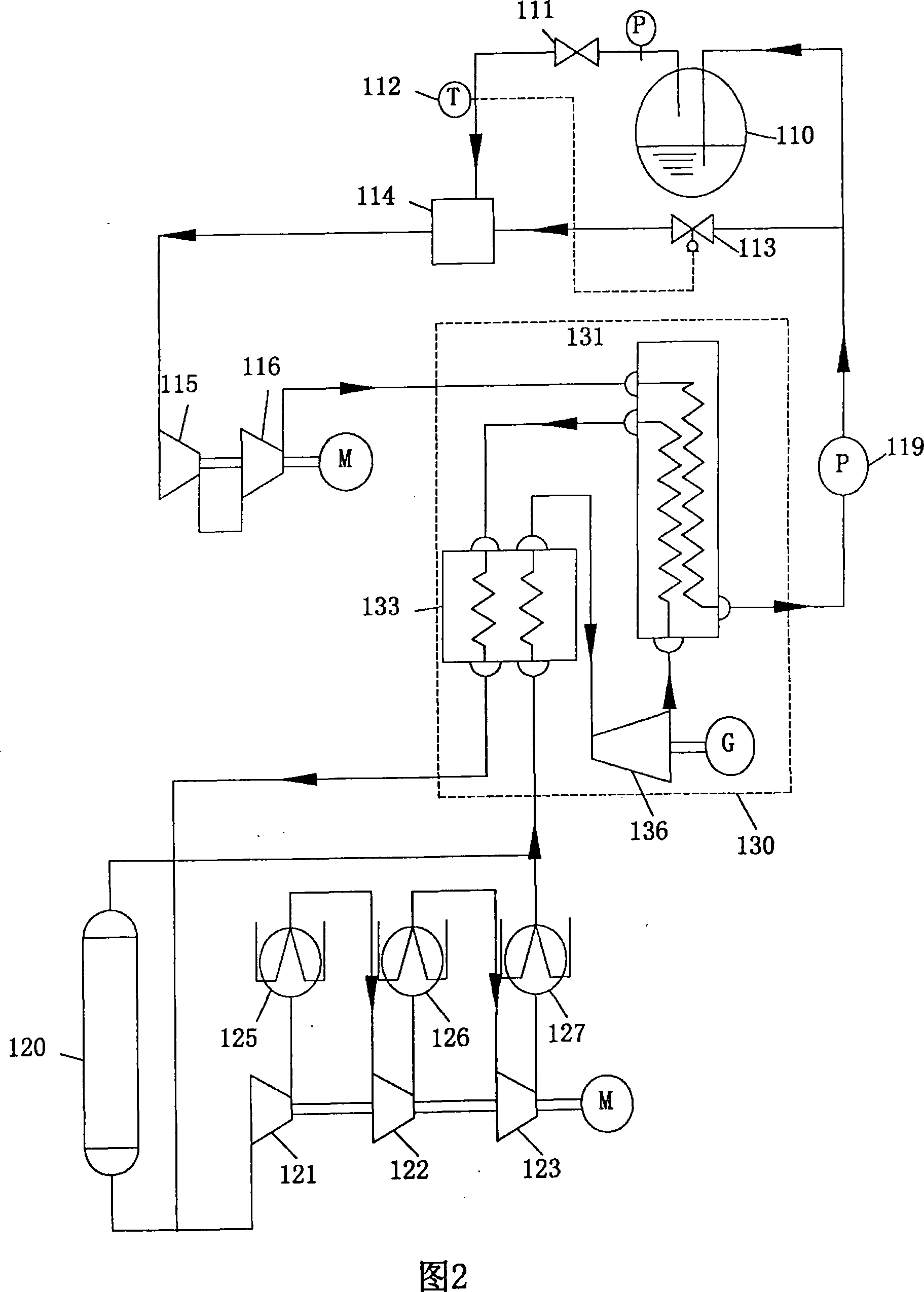

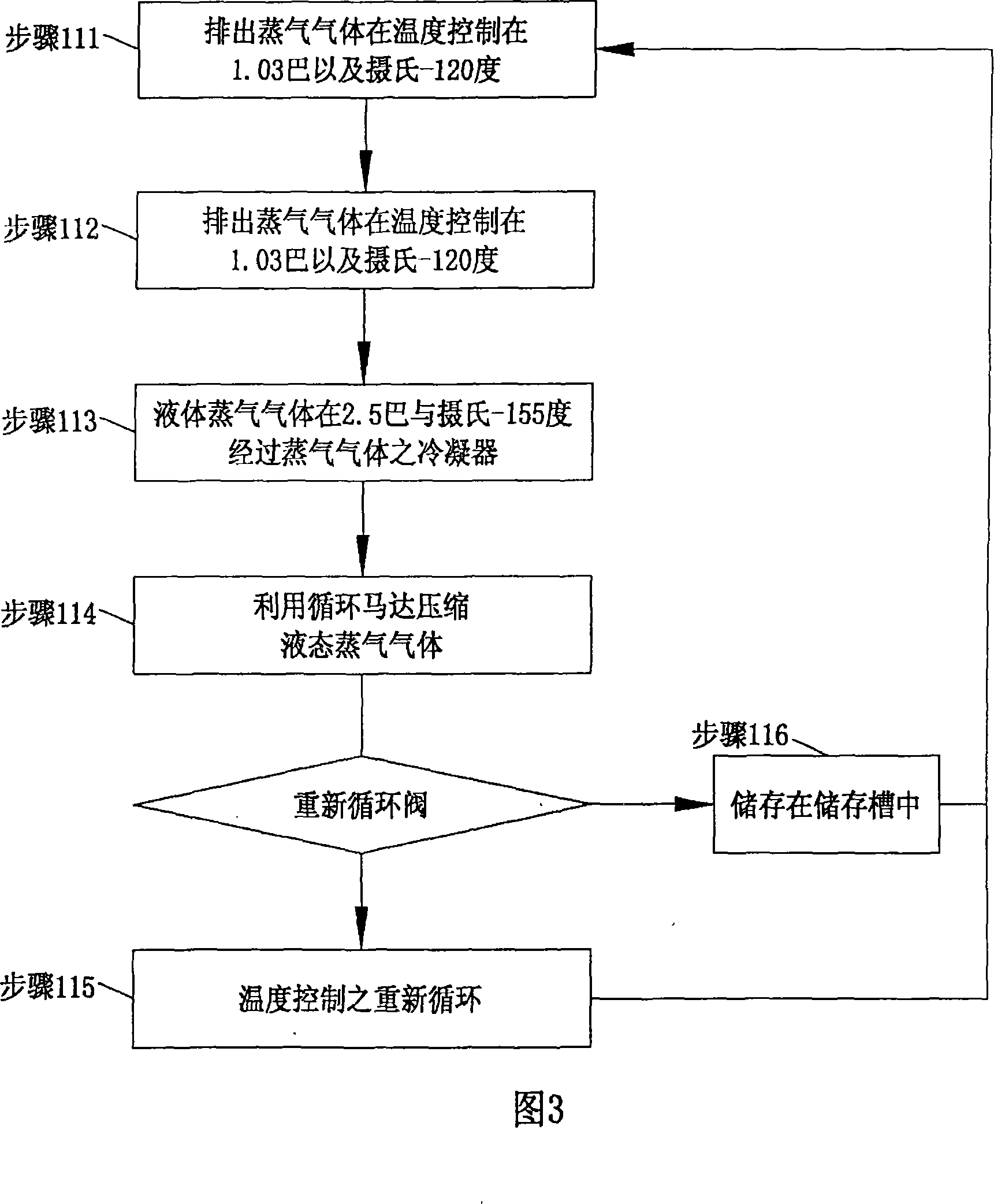

Lng bog reliquefaction apparatus

The invention provides a low-temperature liquefied natural gas (liquefied natural gas) in a boil-off gas (boil-off gas, BOG) transport storage tank. Apparatus for reliquefaction of liquefied natural gas vapors, comprising a compressor for compressing methane in a storage tank for liquefied natural gas, a condenser for at least partial condensing of the methane compressed by the compressor, and nitrogen cycle equipment to supply heat and cold to the compressor from condensation The reliquefied vapor is returned from the compressor to the storage tank, and the vapor gas is compressed by the compressor in the pre-cooled condenser, so the advantage is that the temperature of the reliquefied vapor is maintained within a preset range even if the quantity or temperature of the reliquefied vapor changes. Further, the present invention incorporates a cooling device constituting a low temperature section in the device for reliquefied LNG in order to reduce the size of the device for reliquefied LNG and stably process a low temperature range of nitrogen gas without cold heat loss.

Owner:SHINYOUNG HEAVY IND

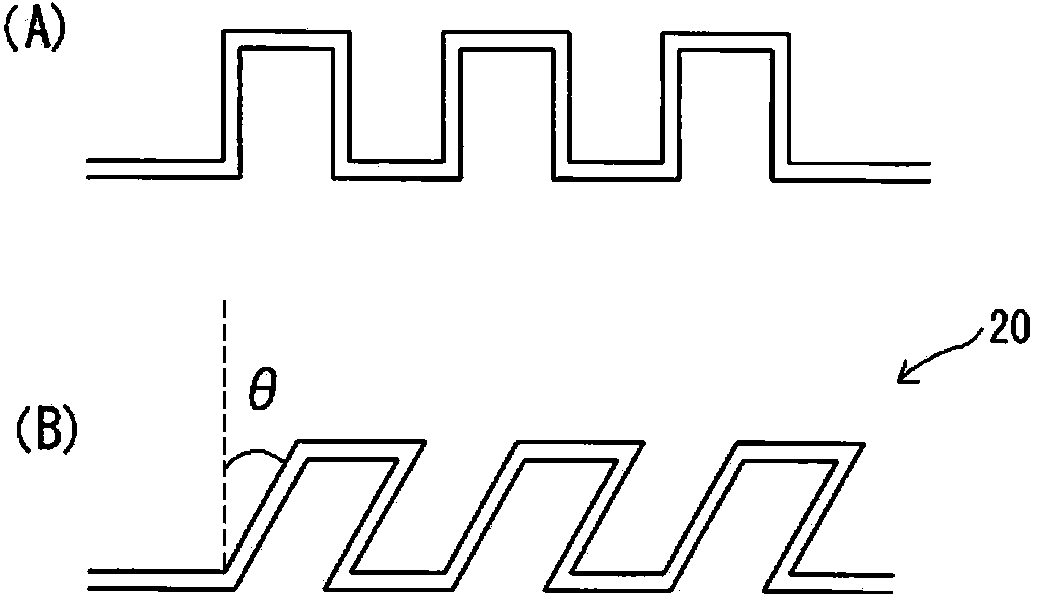

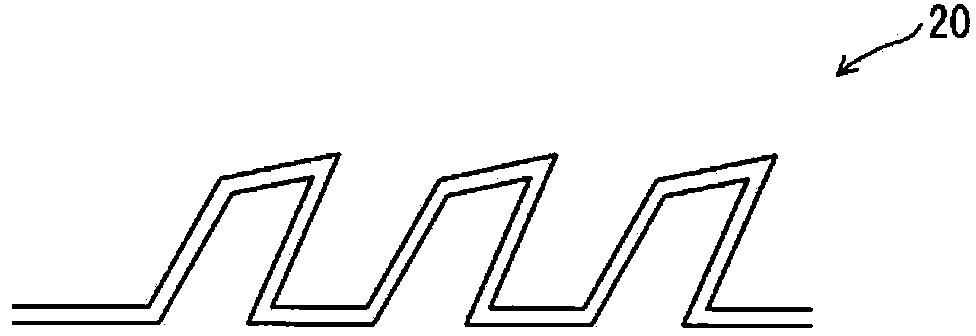

Heater, and fixing device and drying device provided with same

ActiveCN103931271AReduce widthAvoid temperature riseHeating element materialsElectrical resistance and conductanceEngineering

This heater is provided with: a long base section (11); a resistance heating wiring section (15) formed on the surface of the base section (11) or inside the base section (11), and formed in a state of electrical insulation from said base section, said resistance heating wiring section (15) having multiple parallel wires that electrically heat; and at least two power supply terminal sections (17) that, to supply power to the resistance heating wiring section (15), electrically connect one terminal section (17) and the other terminal section (17) via the resistance heating wiring section (15). The resistance heating wiring section (15) contains a material with a temperature coefficient of resistance of between 500 and 4,400 ppm / DEG C, and the parallel wires contain a sloping rectangular pattern.

Owner:MISUZU IND

Ferro-manganese composite oxide catalyst and preparation method thereof

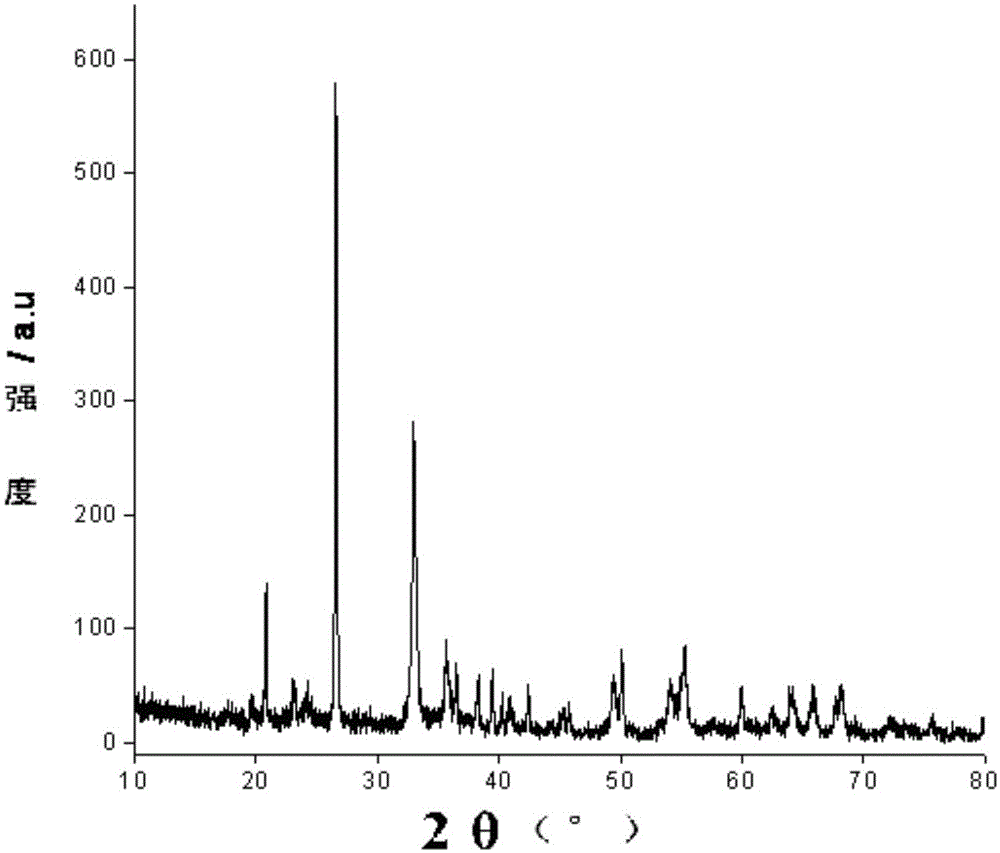

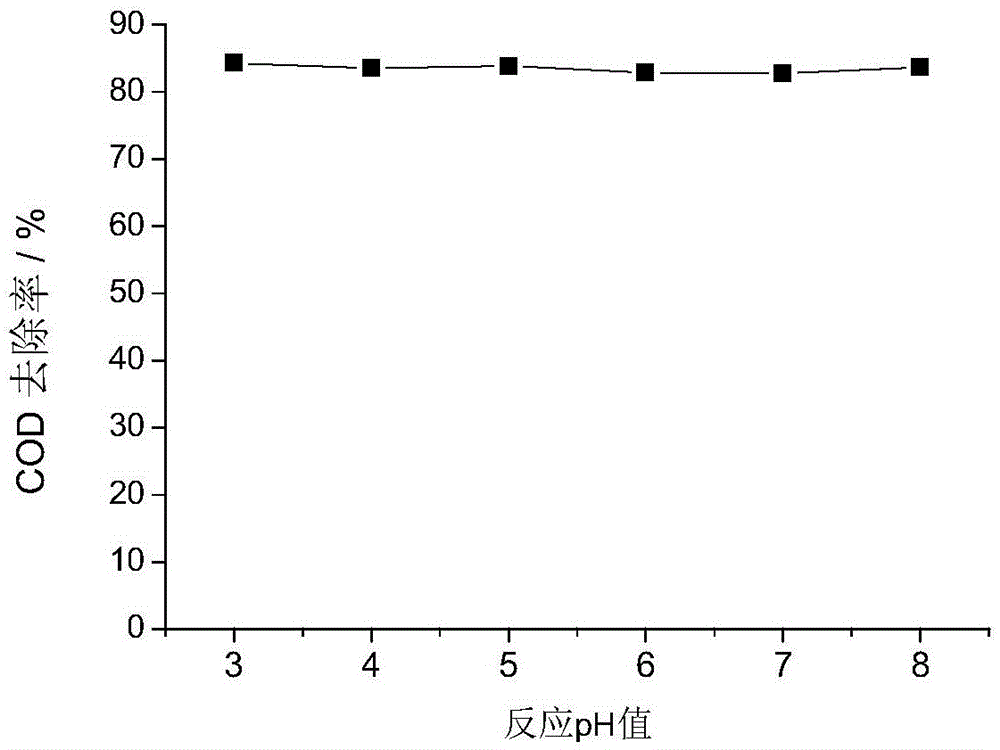

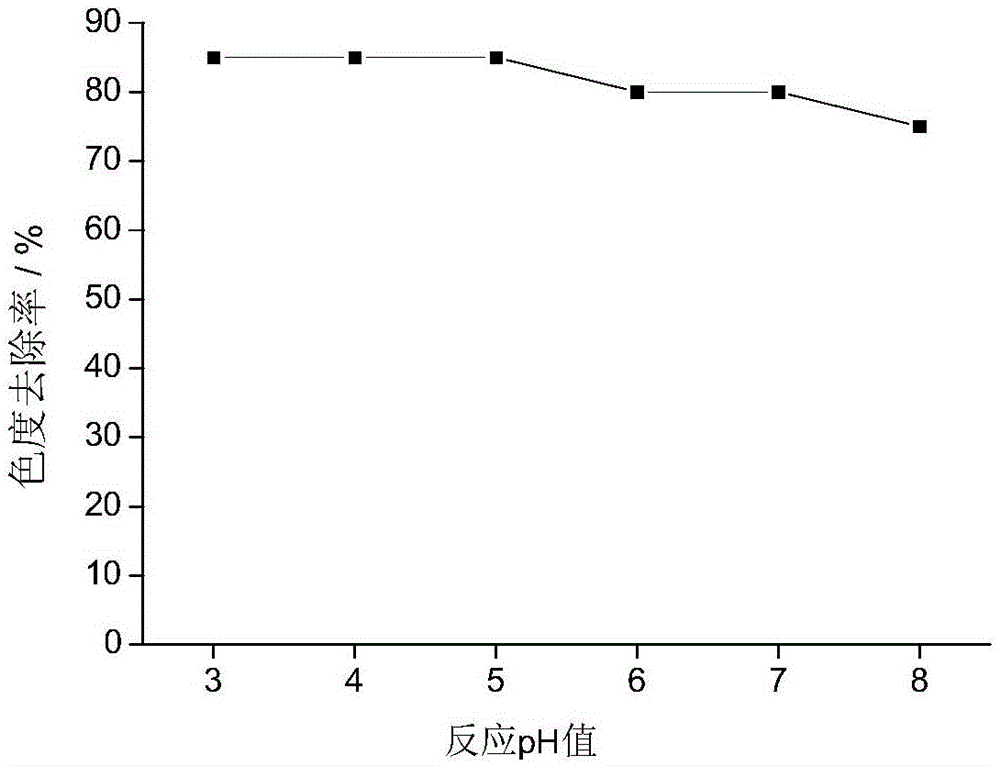

ActiveCN105107522APromote degradationLow costWaste water treatment from plant processingMetal/metal-oxides/metal-hydroxide catalystsPolyvinyl alcoholSludge

The invention relates to a ferro-manganese composite oxide catalyst and a preparation method thereof. The ferro-manganese composite oxide catalyst is granular and is prepared by calcining polyvinyl alcohol, sodium dodecyl benzene sulfonate (SDBS), ferrous sulfate, sodium carbonate and natural ferro-manganese ore after reaction. The catalyst can be used for advanced degradation of papermaking wastewater after biochemical treatment. The catalyst disclosed by the invention is changed to ferro-manganese composite oxide particles from conventional ferrous sulfate, can be reused after calcination, is low in chemical sludge output, can save sludge treatment cost, can reduce production of secondary pollution, and can easily realize solid-liquid separation.

Owner:W STARTECH BEIJING ENVIRONMENTAL TECH

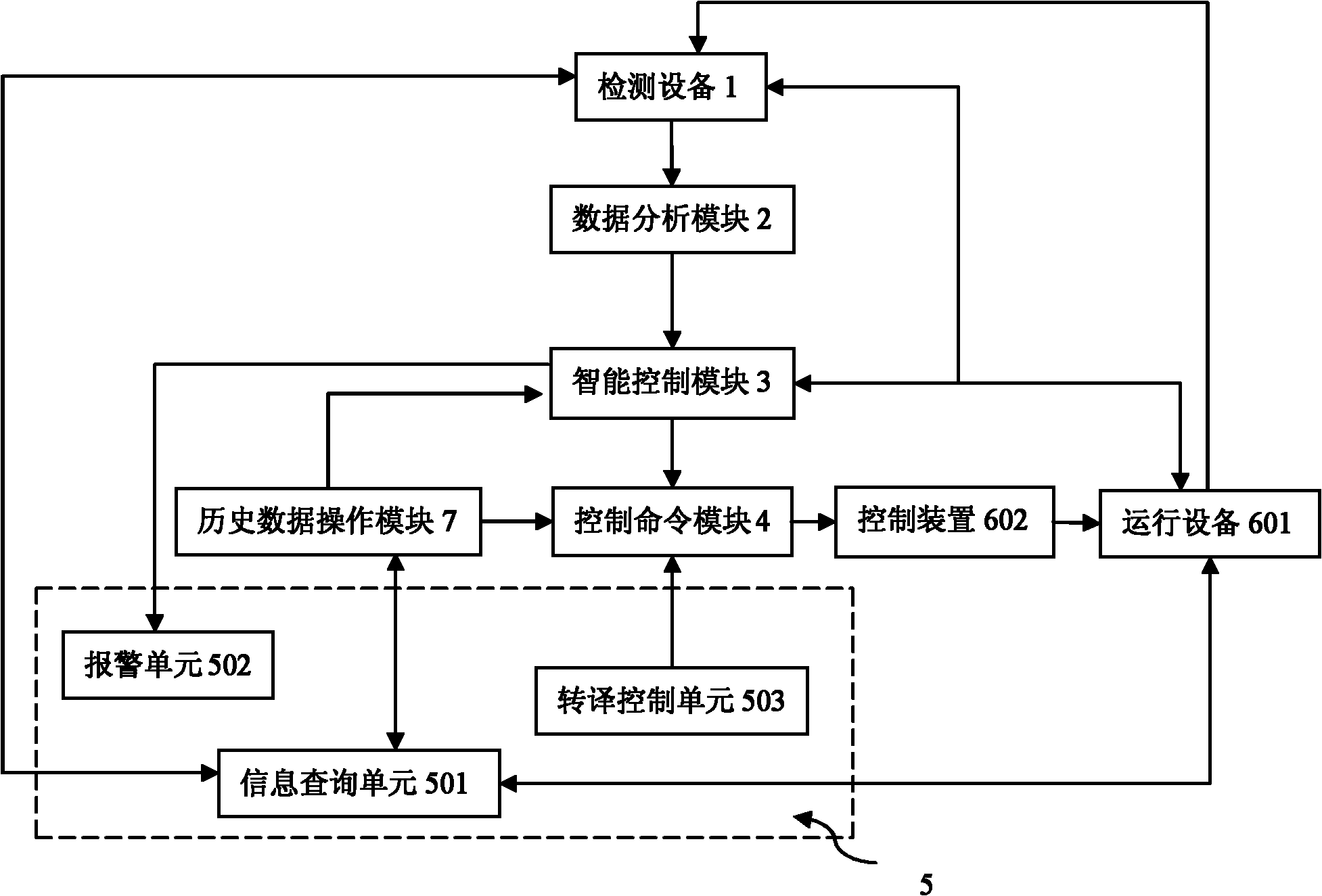

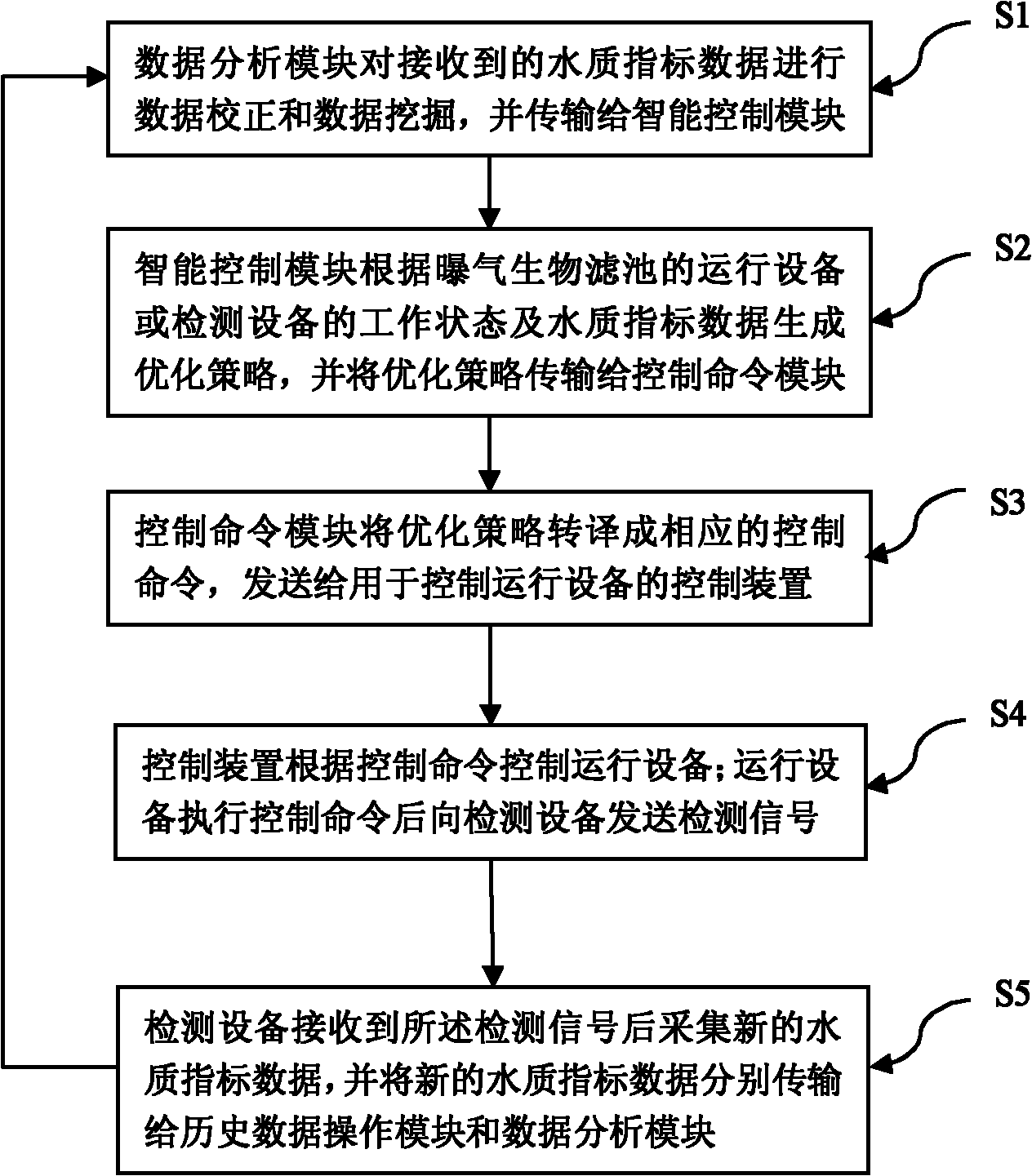

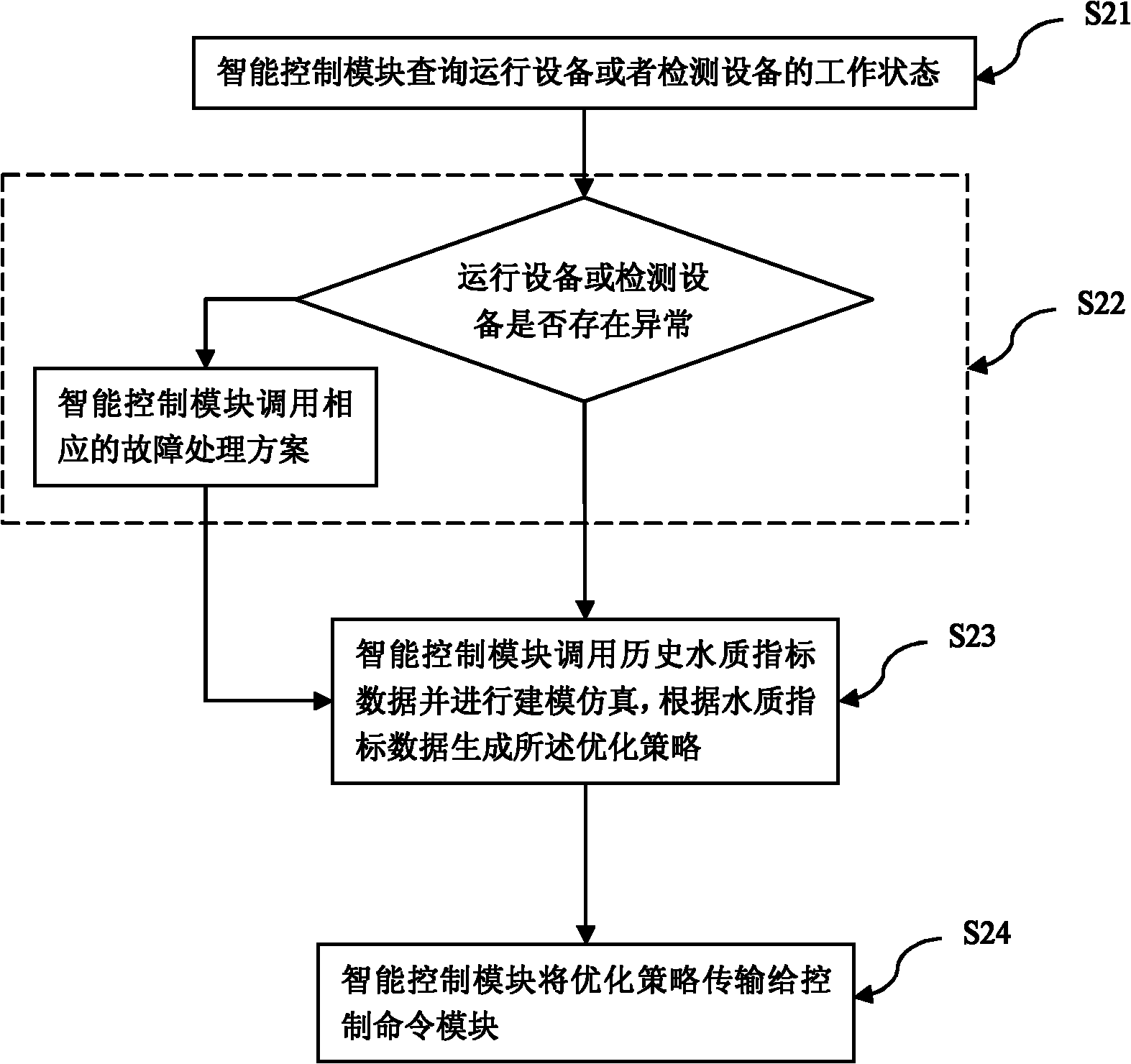

Method and system for controlling aeration biofilter of sewage treatment plant

InactiveCN102491506AStabilizationAvoid control operationsSustainable biological treatmentTotal factory controlWater qualitySewage treatment

The invention discloses a method for controlling an aeration biofilter of a sewage treatment plant. The method comprises the following steps of: S1, after performing data reconciliation and data mining on water quality index data by a data analysis module, transmitting the data to an intelligent control module; S2, generating an optimizing strategy by the intelligent control module, and transmitting the optimizing strategy to a control command module; S3, translating to form a control command by the control command module, and sending the control command to a control device; S4, controlling running equipment by the control device, and sending a detection signal to detection equipment by the running equipment; and S5, acquiring new water quality index data by the detection equipment, transmitting the new water quality index data to a historical data operating module and a data analysis module, and returning the step S1. The invention also discloses a system for implementing the method for controlling the aeration biofilter of the sewage treatment plant. The method and the system for controlling the aeration biofilter of the sewage treatment plant are regulated according to requirements, have a stable process, save energy and reduce consumption and are low in manual control cost.

Owner:SHENZHEN DAS INTELLITECH CO LTD

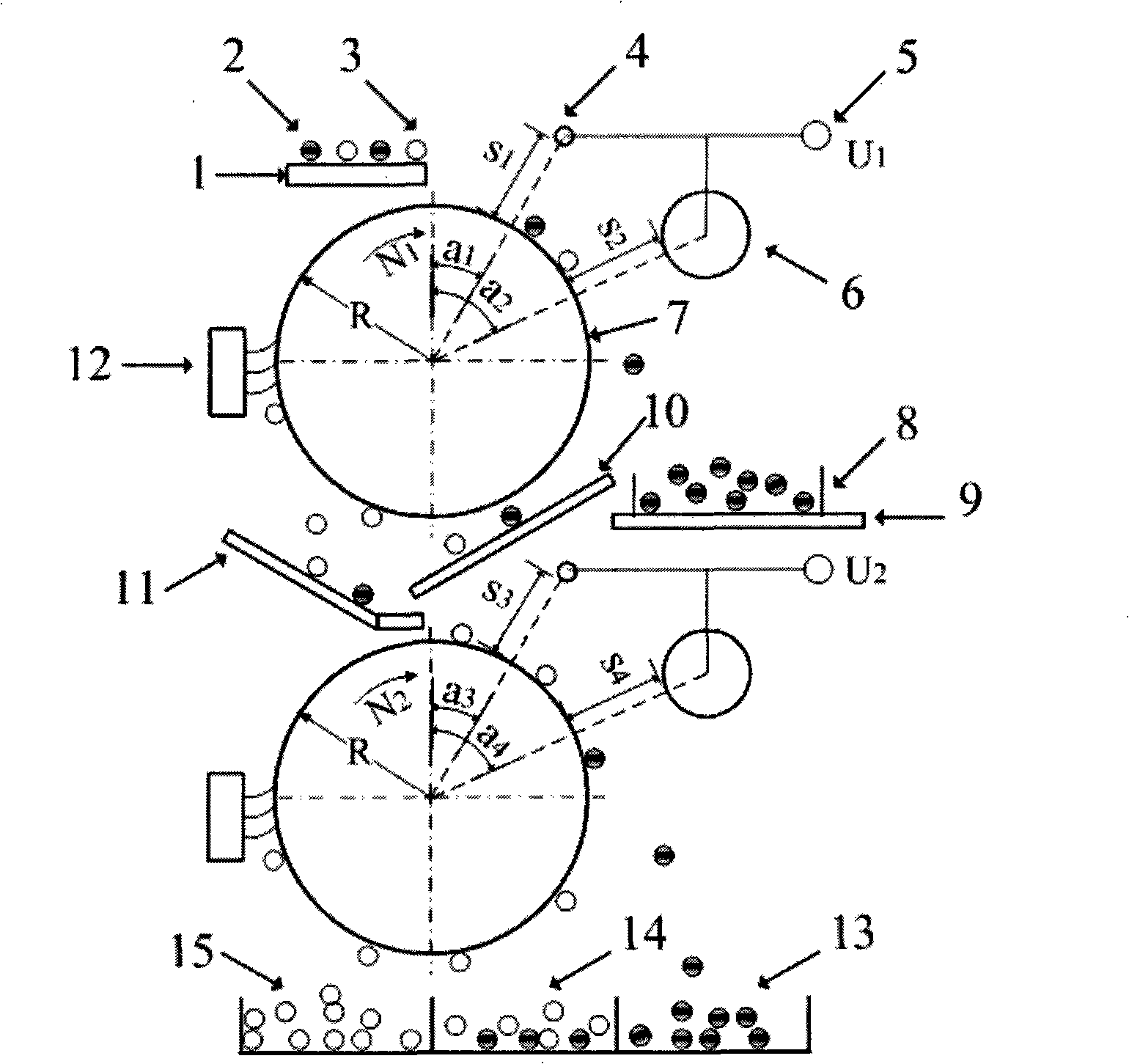

Multiple-roller type high-pressure electrostatic separation method for recovering waste and old printed circuit boards

InactiveCN101406861AHigh recovery rateStabilizationElectrostatic separationElectrostatic separationEngineering

The invention relates to a method in multi-roll type high-voltage electrostatic separation for recycling a worn-out printed circuit board, which belongs to the technical field of environmental protection. The method comprises the following steps: at least two roll type separation devices with the same structure are arranged in the vertical direction to form an array; materials are fed into a primary separation device to carry out primary separation; an intermediate product and the like which are generated after separation are collected and transported to a secondary separation device to carry out secondary separation; and then products can enter a tertiary separation device, a quaternary separation device and the like in sequence according to requirement, until the recycling of the worn-out printed circuit board is completed. The problems of intermediate products, stability and treatment capacity can be solved by multistep separation, so as to realize optimization to electrostatic separation. Compared with the prior roll type high-voltage electrostatic separator, the method has higher recovery ratio of metal and non metal and more stable processing process, and greatly improves the processing efficiency.

Owner:SHANGHAI JIAO TONG UNIV

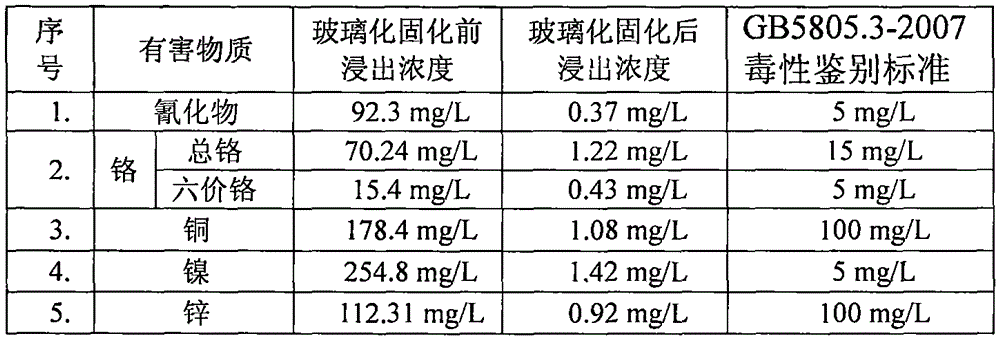

Sludge vitrifaction curing treatment process

InactiveCN105621843AReduce moisture contentMeet environmental protection requirementsSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisHazardous substanceSolid particle

The invention relates to the field of sludge treatment, and in particular to a sludge vitrifaction curing treatment process which comprises the following steps: dehydrating and drying sludge in sequence so as to reduce the water content of sludge; crushing and grinding the dried sludge till the crushed sludge can pass through the 100-mesh screen; sufficiently mixing the grinded sludge with silicate powder according to a mass ratio of 1:0.5 at the temperature of 25-50 DEG C at the rotation speed of 2400 r / min, so as to obtain mixed powder; performing high-temperature calcination on the mixed powder at 1700 DEG C to completely carbonize and decompose organisms in the sludge, and finally molding the residual inorganic substances into glass solid granules. By the adoption of the sludge vitrifaction curing treatment process, harmful substances such as heavy metals and arsenide which are hard to carbonize or decompose can be fixed in the glass solid granules. The result of a toxicity leaching test on a glass solid granule sample according to GB5805.3-2007 shows that the national environment-friendly requirements can be met, and the glass solid granule sample can be directly buried. The process provided by the invention requires lowly on sources of sludge and components of pollutant in the sludge, and is applicable to various types of sludge; harmlessness, reduction and stabilization treatment on sludge can be achieved.

Owner:江苏沃奇环保工程有限公司

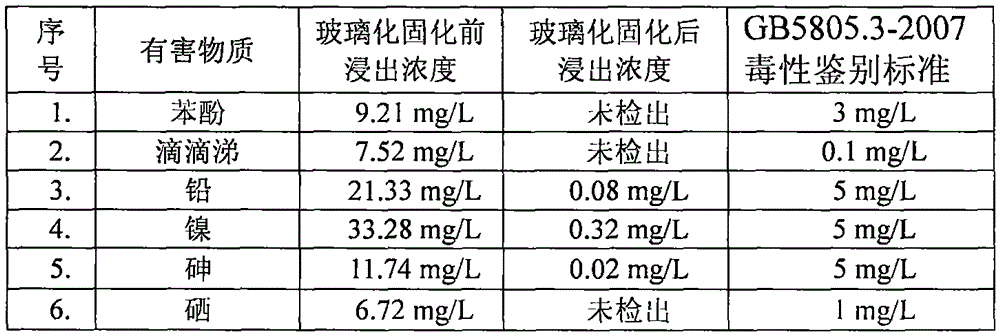

Washing softening technology for MSWI (Municipal Solid Waste Incineration) fly ash

ActiveCN104803537ASolving Excessive Chlorine ProblemsGuaranteed qualityWater/sewage treatment by centrifugal separationSludge treatmentWater qualityTherapeutic effect

The invention discloses a washing softening technology for MSWI (Municipal Solid Waste Incineration) fly ash. The technology comprises the following steps of performing primary washing on the fly ash; performing primary centrifugal dewatering on the washed fly ash after the washing operation is completed; adding a PAM (Polyacrylamide) solution into the separated filter liquor and uniformly blending; feeding the mixture into a first-level centrifugal machine B for performing secondary centrifugal dewatering; feeding the filter liquor separated from the first-level centrifugal machine B into a decalcified centrifugal machine for centrifuging after the filter liquor is subjected to hardness coarse-adjustment and heavy metal removal treatment; finely adjusting the hardness of the filter liquor separated from the decalcified centrifugal machine, sequentially precipitating and filtering the filter liquor, and adjusting the PH value of the filter liquor to be 7-8; finally feeding the filter liquor to an MVR (Mechanical vapor recompression) evaporator. According to the washing softening technology for the MSWI (Municipal Solid Waste Incineration) fly ash, the washing treatment effect is good, and the effluent quality is stable; a filter cake separated from the decalcified centrifugal machine is mixed with the filter liquor discharged by a second-level centrifugal machine A, and then the mixture is subjected to subsequent treatment, so that the mixture can be washed twice again, therefore the content of chloride ions in the filter cake is smaller than 0.5%, and the problem of high chlorine content in the filter cake is solved, and the cement quality is guaranteed.

Owner:BEIJING ZKGR ENVIRONMENTAL PROTECTION TECH CO LTD

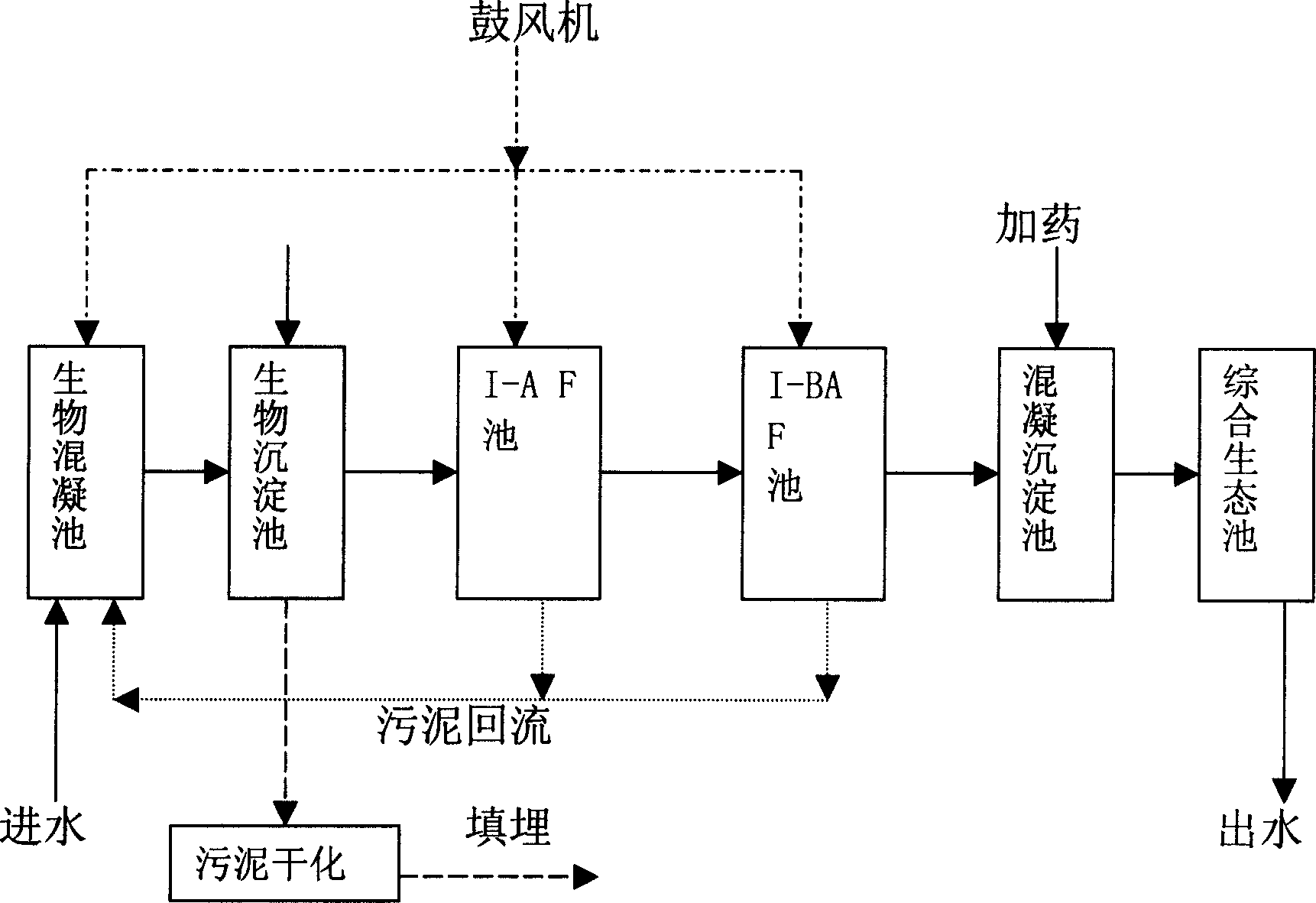

Combined treatment method and system for landfill leachate

InactiveCN1631820AEasy to handleStabilizationTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentFiltrationWater quality

Disclosed are a method for processing rubbish percolating water and its system. The processing technique realizes the procession by combining the procession, biological processing technology and ecological procession. The system mainly comprises of adjusting pool, biological coagulation pool, high effective biological filtration pool, comprehensive ecological pool and so on. Compared with the present technology, it has rapid processing speed, high quality of water processed which can reach the first-class drainage standard, and can realize naugh drainage of waste water in rubbish processing factory.

Owner:PEKING UNIV

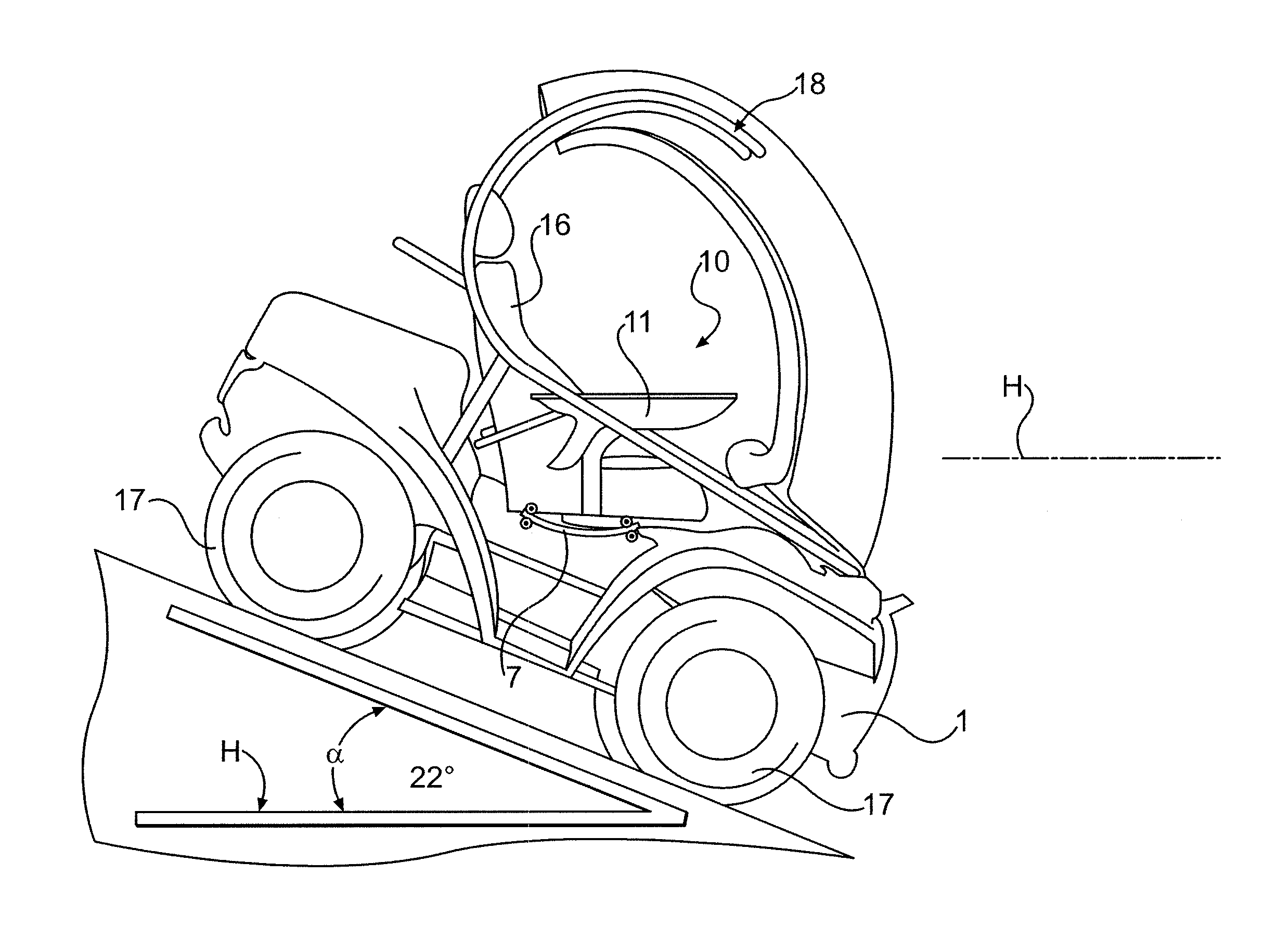

Vehicle with driver's seat with adjustable inclination

ActiveUS8061755B2Improve comfortStabilizationOperating chairsWheelchairs/patient conveyanceWheelchairEngineering

A vehicle, in particular electric wheelchair, having a chassis and a driver's seat which is fastened thereto and can be set in its inclination with respect to the chassis. The vehicle includes an inclination sensor which determines the angular position (α) of the seat surface of the driver's seat with respect to the horizontal (H), an adjusting device which is connected to the chassis and to the driver's seat, and a control and regulating device which is operatively connected to the inclination sensor and the adjusting device and via which the driver's seat can be pivoted by the adjusting device in such a manner that its seat surface is always situated essentially parallel to the horizontal (H).

Owner:OTTOBOCK SE & CO KGAA

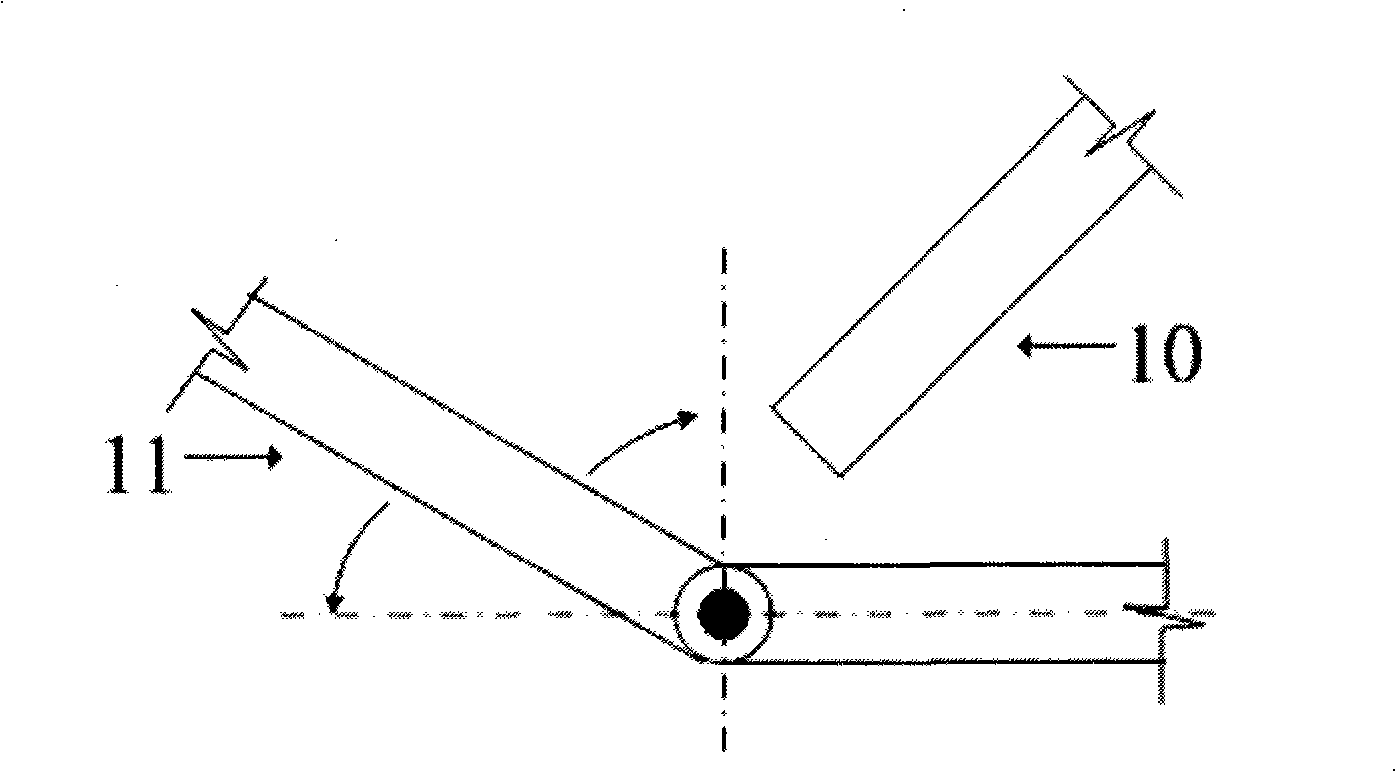

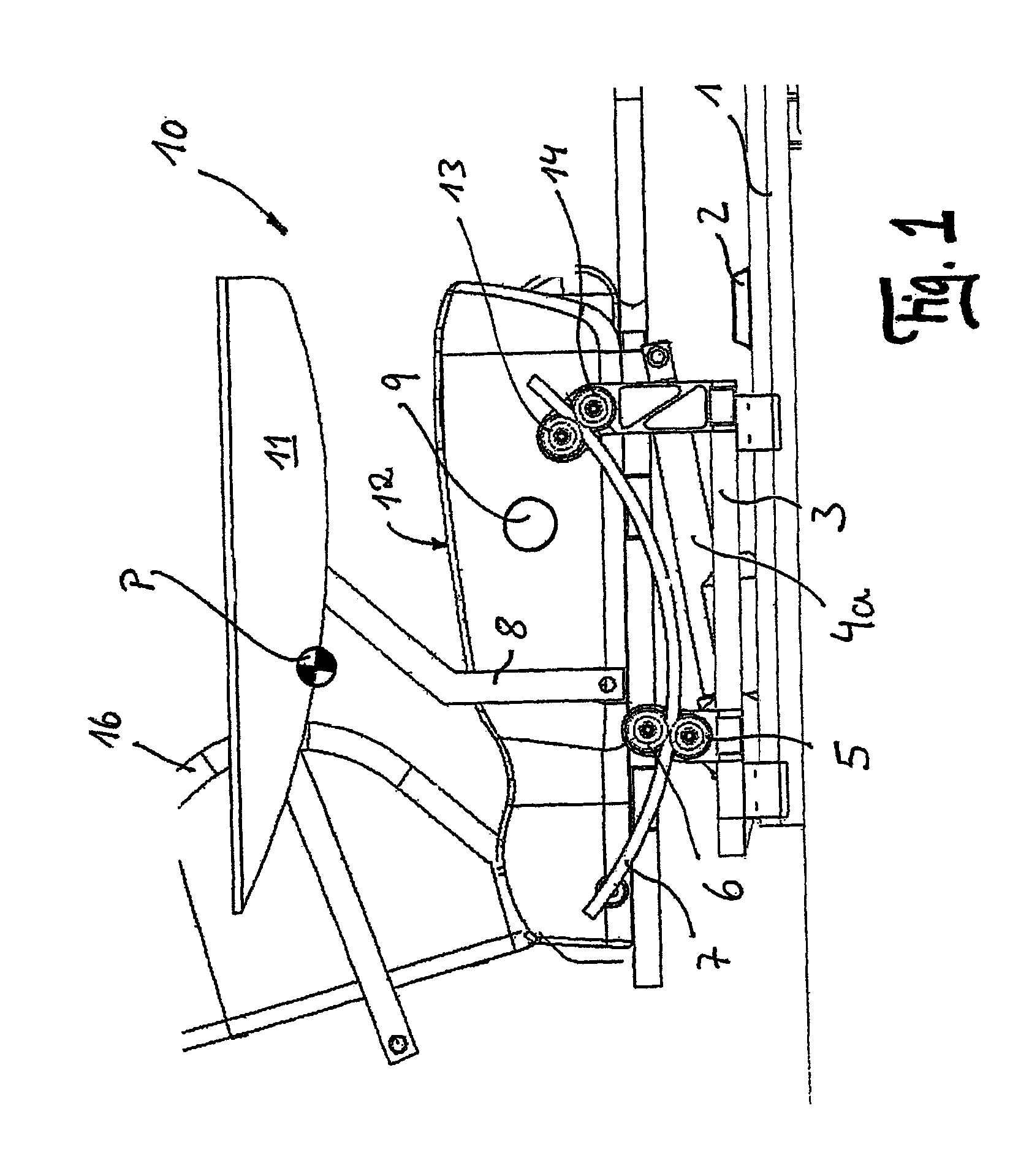

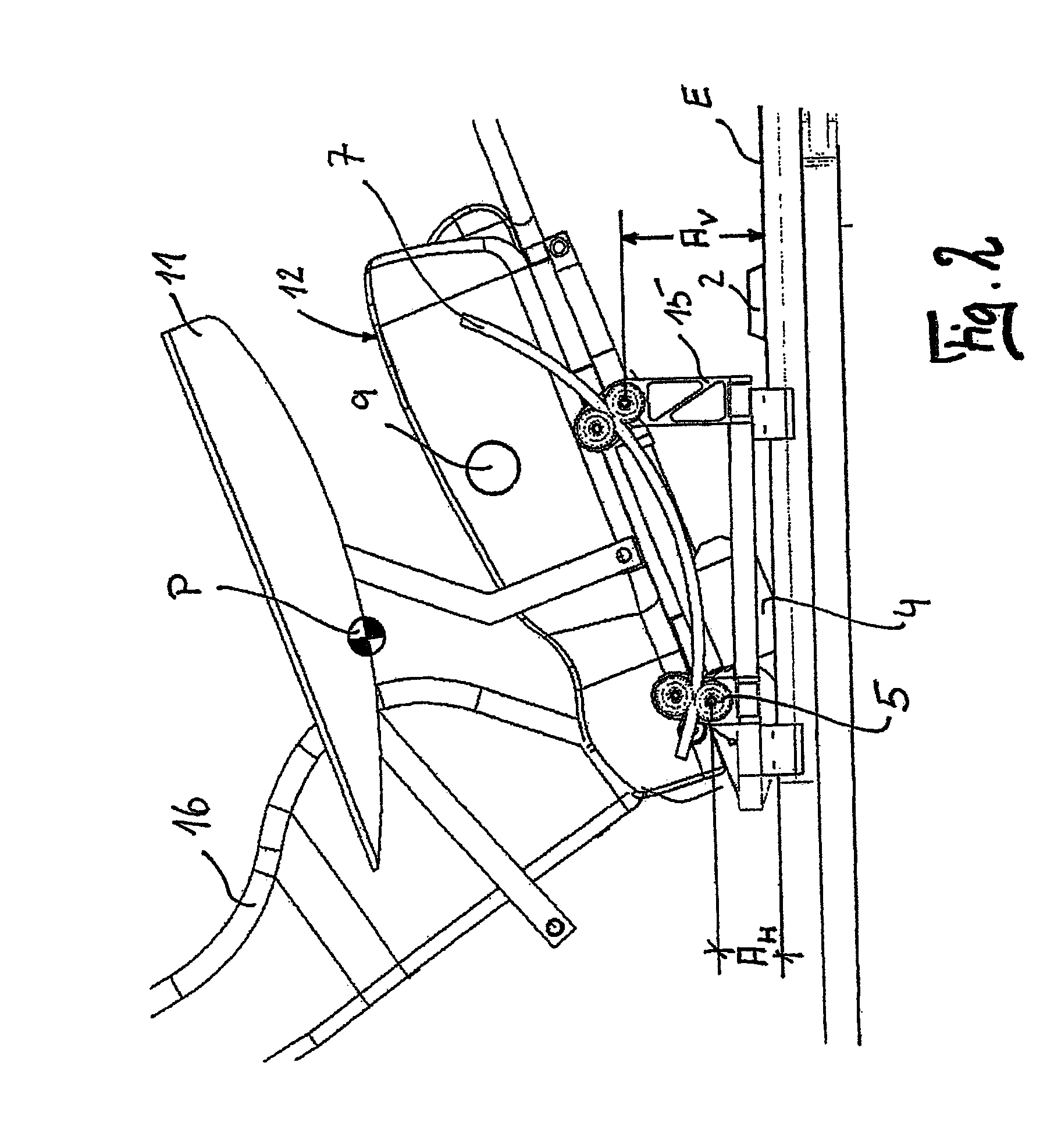

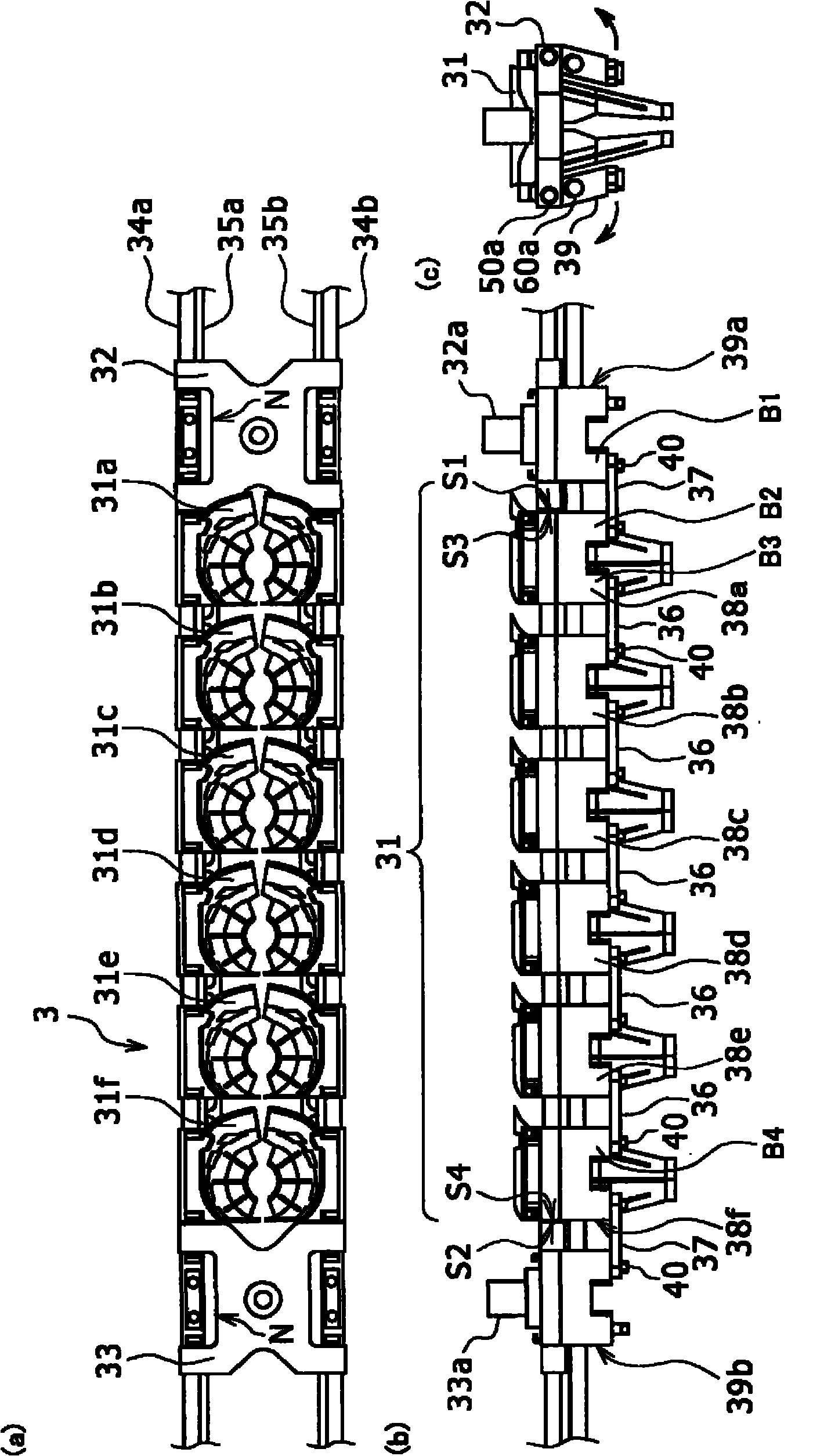

Apparatus and method processing material by ultrasonic apparatus

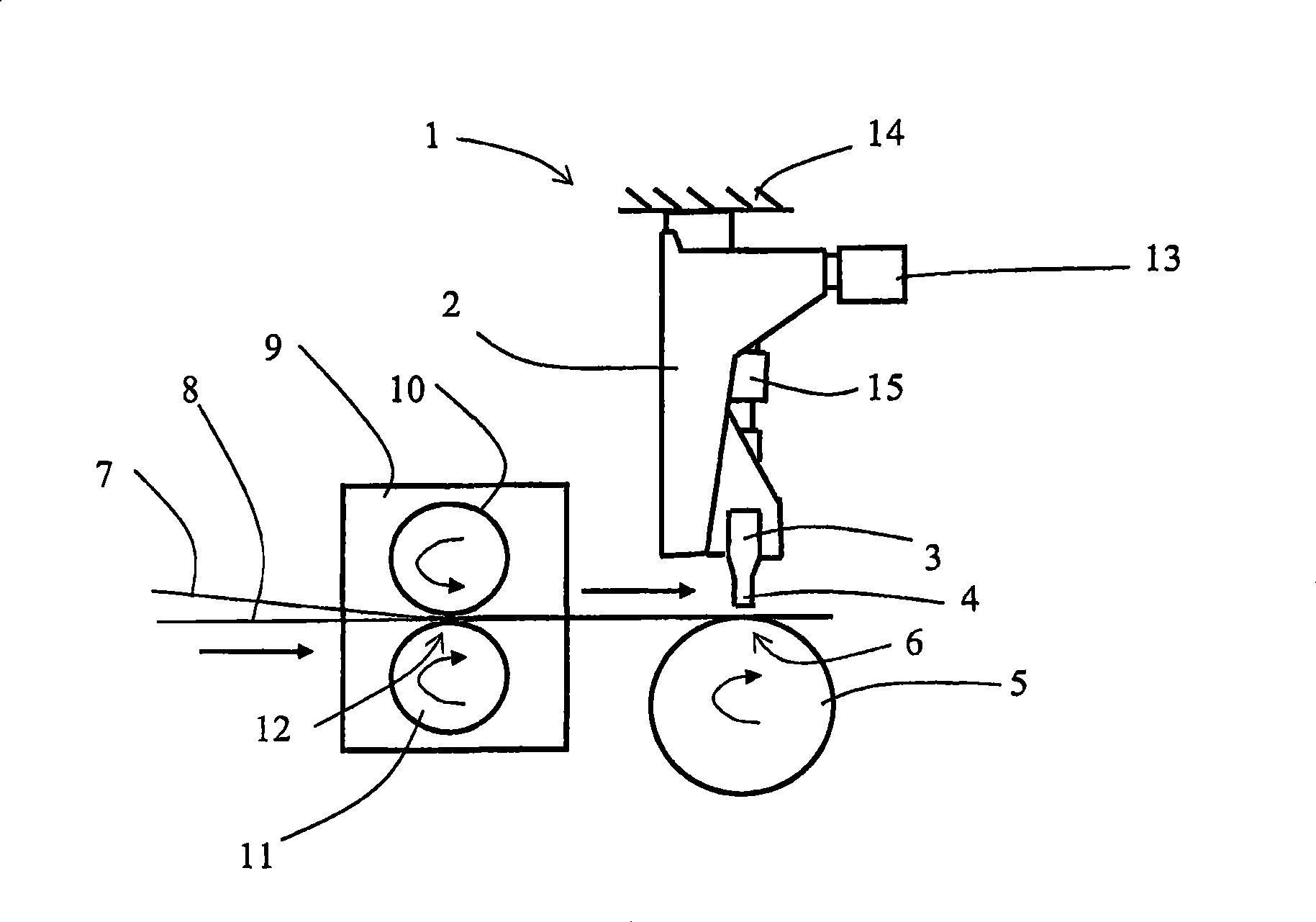

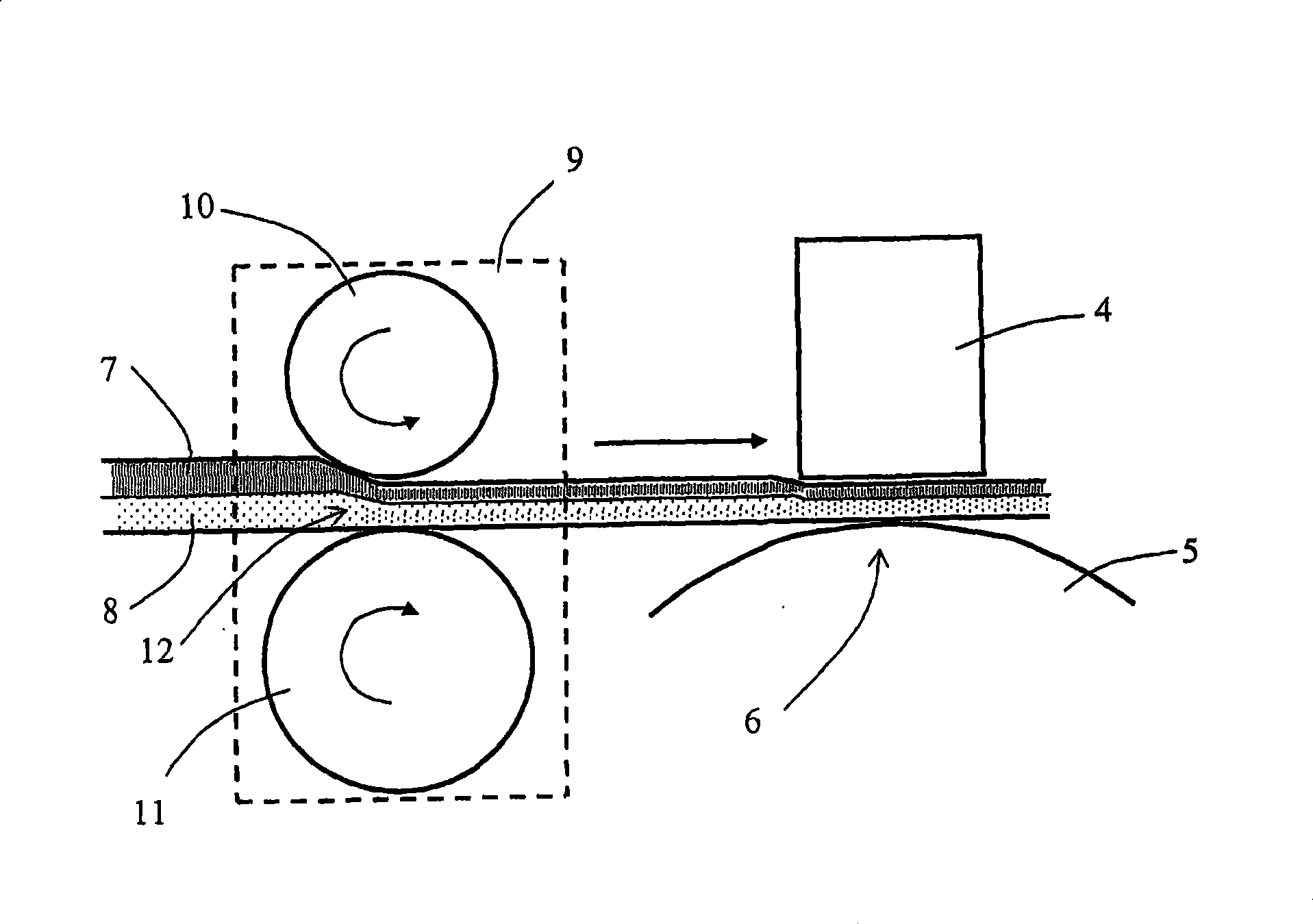

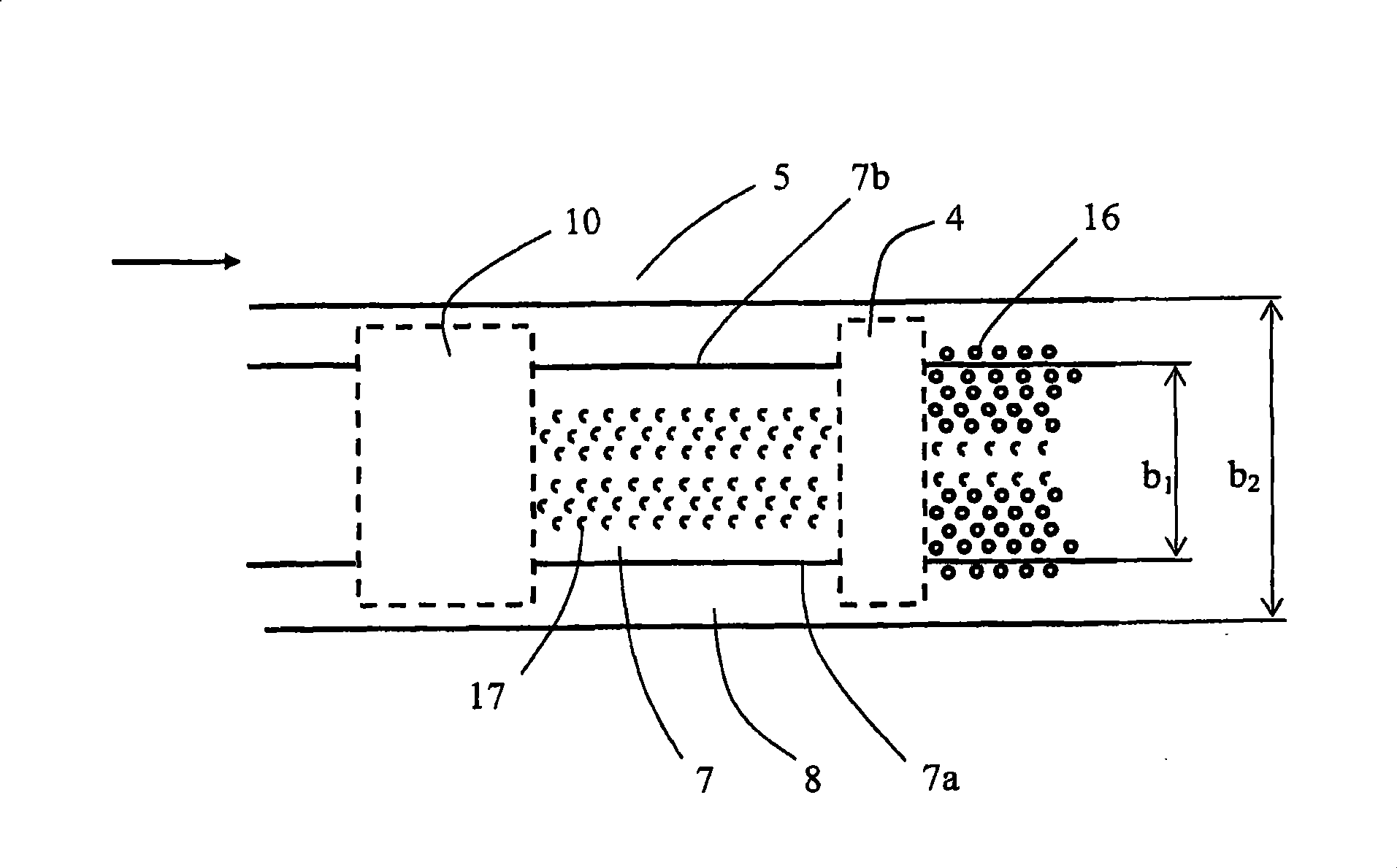

InactiveCN101365577AGood effectStabilizationLamination ancillary operationsLayered product treatmentEngineeringAcoustics

The present invention relates to an arrangement (1 ) for processing of a material (7, 8) comprising at least one layer of material by means of an ultrasonic device (2) consisting of an ultrasound horn (3) arranged adjacent to an abutment (5; 5'), in conjunction with which a gap is defined between the aforementioned ultrasound horn (3) and the aforementioned abutment (5; 51), in conjunction with which the aforementioned ultrasonic device (2) is arranged for the purpose of feeding the aforementioned material (7, 8) through the aforementioned gap (6). In accordance with the invention, the arrangement (1 ) includes a pre-compression unit (9; 9') for the mechanical compression of the aforementioned material (7, 8) before it is fed through the aforementioned gap (6). The invention also relates to a method for processing of the aforementioned kind.

Owner:SCA HYGIENE PROD AB

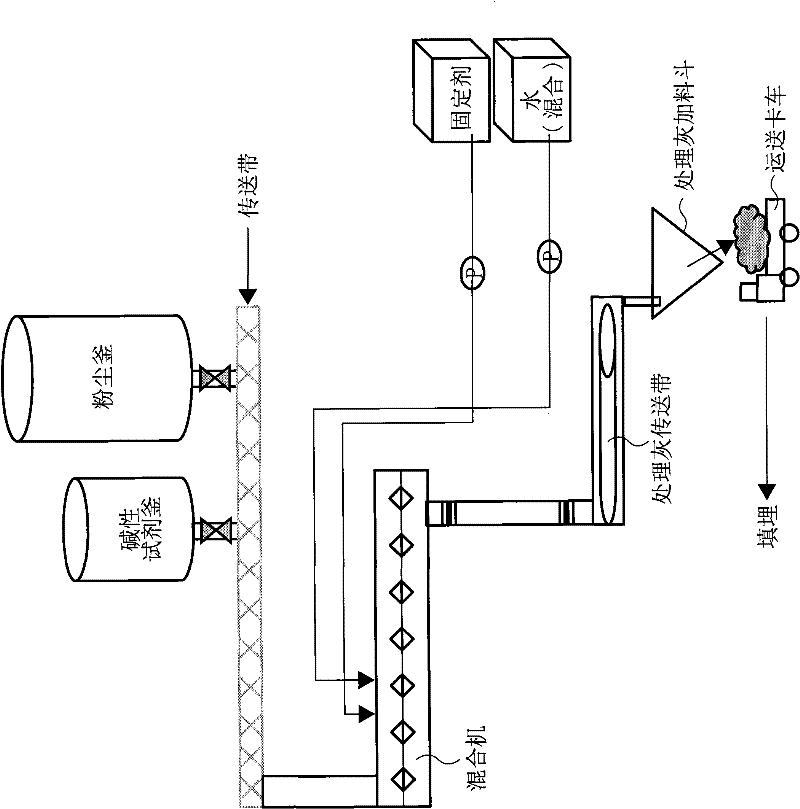

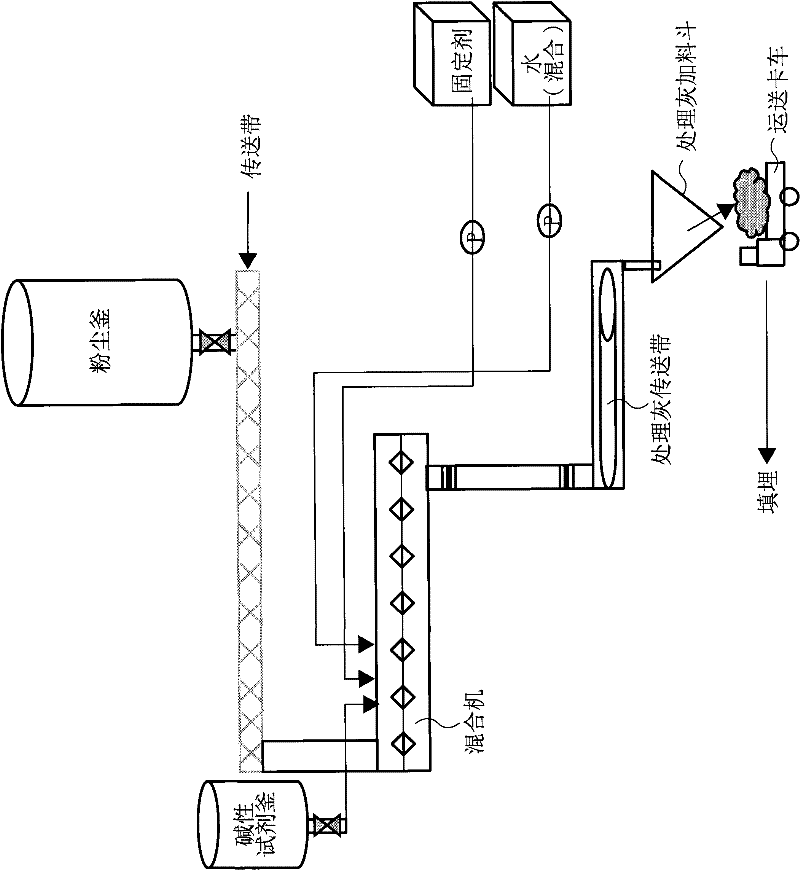

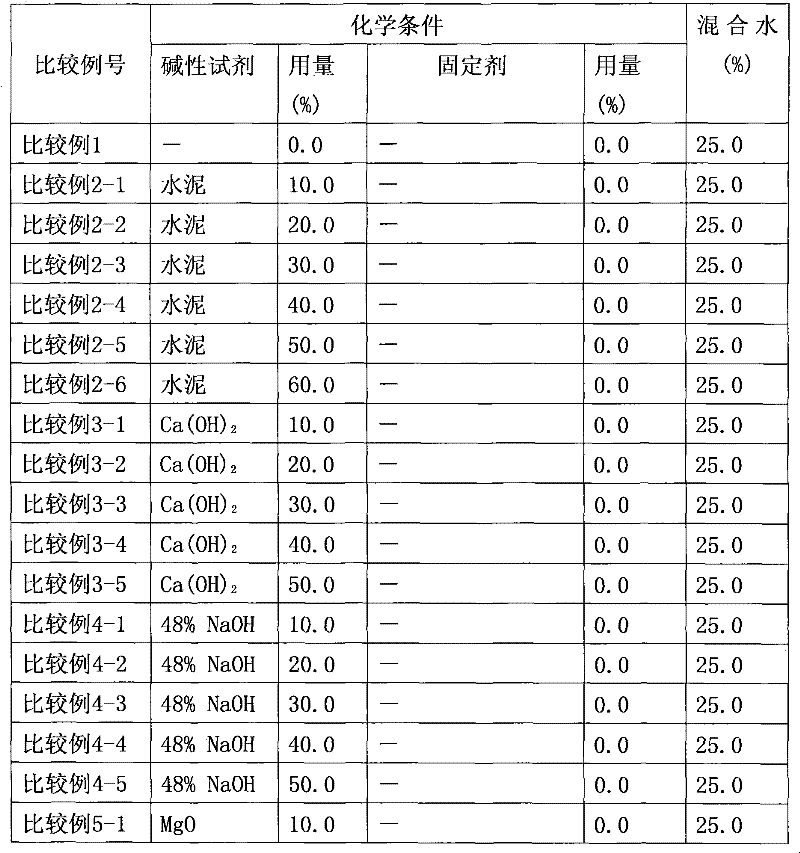

Heavy metal stabilization treatment method for heavy metal dust

The invention relates to a stabilization treatment method for heavy metal, in particular to a P-alkalinity displaying stabilization treatment method for heavy metal containing heavy metal dust. Alkaline reagents and heavy metal fixing agents are added and mixed. The invention provides a stable and long-term treatment method for heavy metal containing heavy metal dust; in a test method of an acetic acid buffer solution method according to a People's Republic of China (PRC) HJT 300-2007 solid waste leaching toxicity leaching method, a standard value of household refuse landfill pollution control standard GB16889-2008 can be stably reached, the cost is low, and the environmental load can be lightened.

Owner:KURITA WATER INDUSTRIES LTD

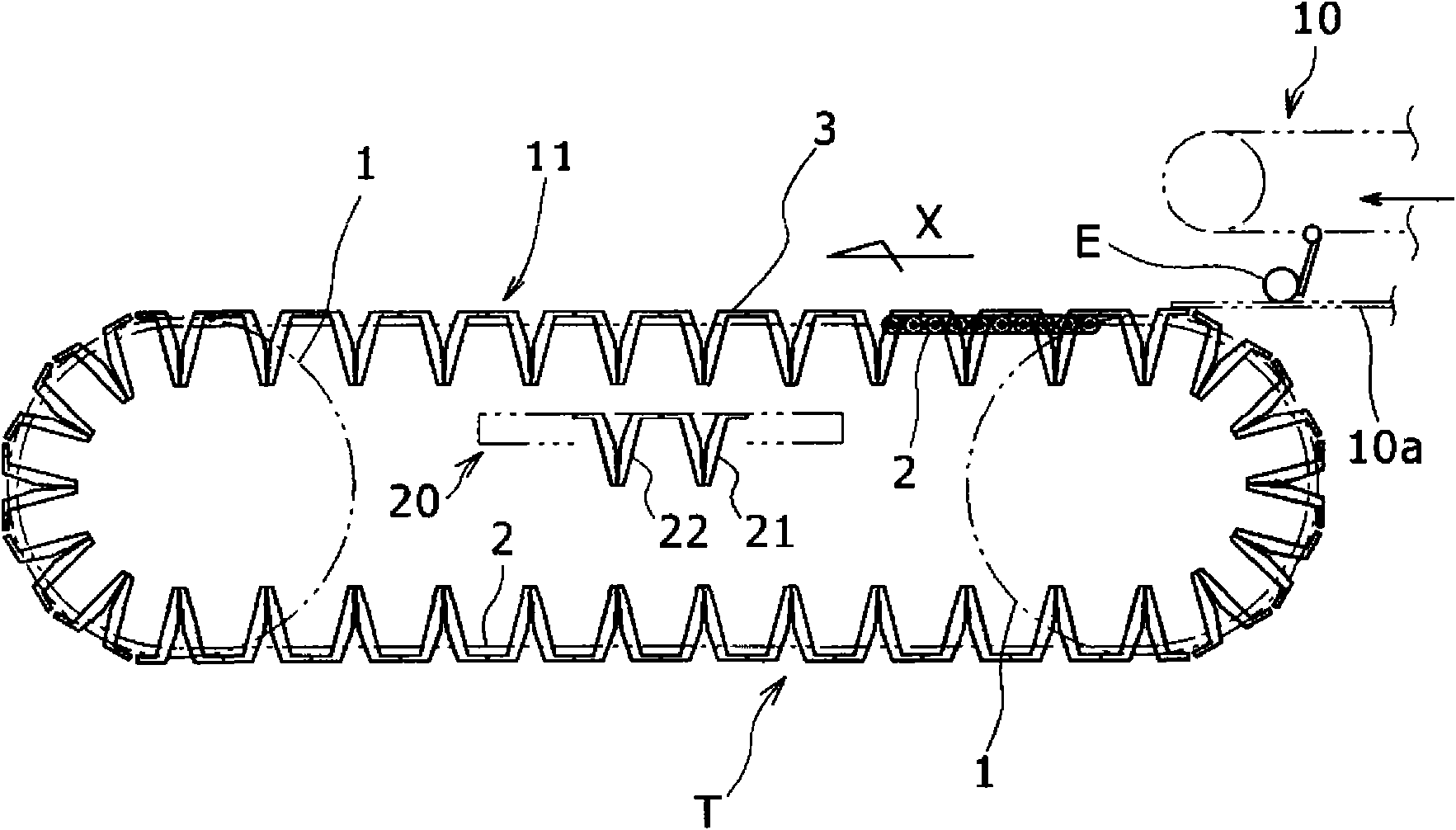

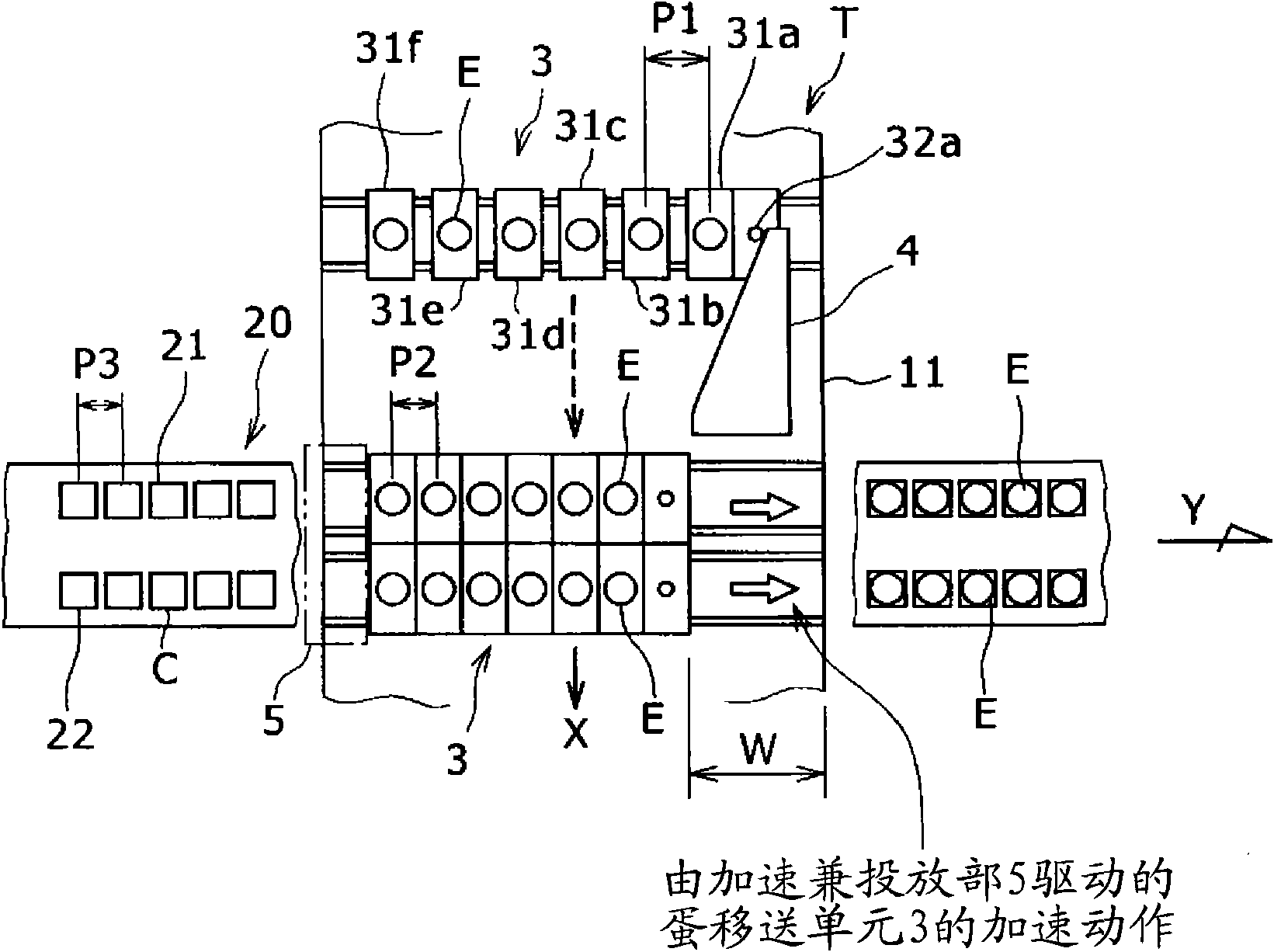

Device for transferring eggs

ActiveCN101772464AHigh speed processingStabilizationPackaging eggsConveyor partsEngineeringElectrical and Electronics engineering

A device for transferring eggs comprises a regulation board (4) for limiting the containing seat pitch of an egg transfer unit (3) to a pitch substantially equal to the containing seat pitch in the line direction of a next position conveyor (20) in a process for carrying the egg transfer unit (3) having a predetermined number of containing seats slidable in the carrying width direction respectively, and an accelerating / discharging section (5) for urging the egg transfer unit (3) in the same direction as the carrying direction of the next position conveyor (20) and synchronizing the moving speed of the egg transfer unit (3) in the urging direction substantially with the carrying speed of the next position conveyor (20) when the egg transfer unit (3) having a pitch limited substantially equal to the containing seat pitch in the line direction of a next position conveyor (20) by the regulation board (4) arrives above the next position conveyor (20), and discharging the eggs (E) containedin the egg transfer unit (3) collectively to the containing seats of the next position conveyor (20).

Owner:股份公司南备尔

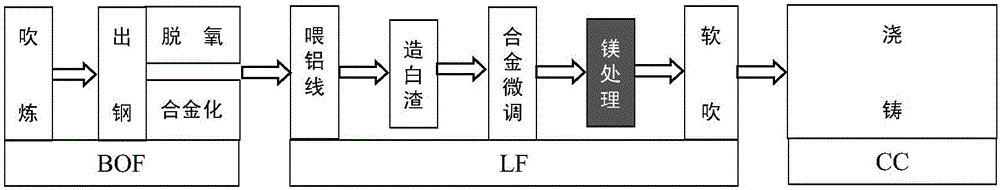

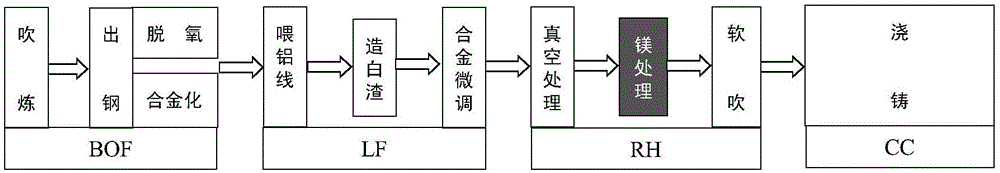

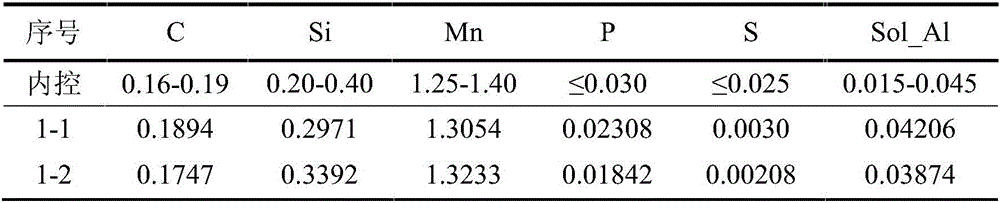

Liquid steel magnesium treatment process for ship plate steel

The invention discloses a liquid steel magnesium treatment process for ship plate steel and belongs to the field of clean steel smelting. The process comprises the following steps that firstly, the station and time for magnesium treatment are determined, wherein Mg-Al-Fe alloy core-spun yarn is added after an LF procedure alloy is slightly adjusted or after RH procedure vacuum treatment is carried out; secondly, according to the content of acid dissolved aluminum in steel, on the premise of guaranteeing the magnesium treatment effect of the Mg-Al-Fe alloy core-spun yarn, the aluminum feeding amount and the magnesium treatment wire feeding amount are coordinately configured; and next, magnesium treatment is carried out, wherein in the LF or RH procedure, a core-spun yarn feeding method is adopted to add the Mg-Al-Fe alloy core-spun yarn into liquid steel of the ship plate steel, and finally, the finished product liquid steel is obtained. The liquid steel magnesium treatment process for the ship plate aluminum deoxidizing steel is applied to the ship plate steel refining process, and the cleanliness of the ship plate steel and the ingredients, number, particle size and distribution of inclusions in the steel can be controlled; and by means of the method, the cleanliness of the ship plate steel and the control level of nonmetallic inclusions are improved, and therefore the mechanical performance and the stability of the ship plate steel are improved.

Owner:NORTHEASTERN UNIV

Method and device for pretreating high-concentration wastewater through ultraviolet-ozone co-oxidation

ActiveCN104944656AImprove solubilityImprove oxidation efficiencyMultistage water/sewage treatmentHigh concentrationUltraviolet

The invention provides a method and device for pretreating high-concentration wastewater through ultraviolet-ozone co-oxidation. The method comprises the steps that high-concentration wastewater in a raw water tank and ozone are mixed to obtain milk white effluent water with ozone microbubbles, the milk white effluent water flows into a reaction tank provided with a vertical partition board, the vertical partition board divides the reaction tank into a water inlet side and a water outlet side, sulfuric acid and hydrogen peroxide are added into the water inlet side of the reaction tank, and organic pollutants are degraded under the joint action of the ozone and the hydrogen peroxide; one part of effluent water from the lower portion of the water outlet side of the reaction tank cyclically flows to the raw water tank to be subjected to another reaction, the other part of effluent water flows into an intensified reactor to be subjected to a photochemical reaction, the organic pollutants are degraded through synergistic effect of the effluent water subjected to the photochemical reaction and ozone produced subsequently, and the effluent water returns to the water inlet side of the reaction tank for a continuous reaction; produced water overflows into a produced water tank from the upper portion of the water outlet side of the reaction tank,and the subsequent biochemical treatment process is conducted after the pH value of the produced water is adjusted to range from 6 to 9. By means of the method, the treatment efficiency is high, and the treatment effect is good; the device can operate stably and is less in investment and low in operating cost.

Owner:CHINA NAT OFFSHORE OIL CORP +3

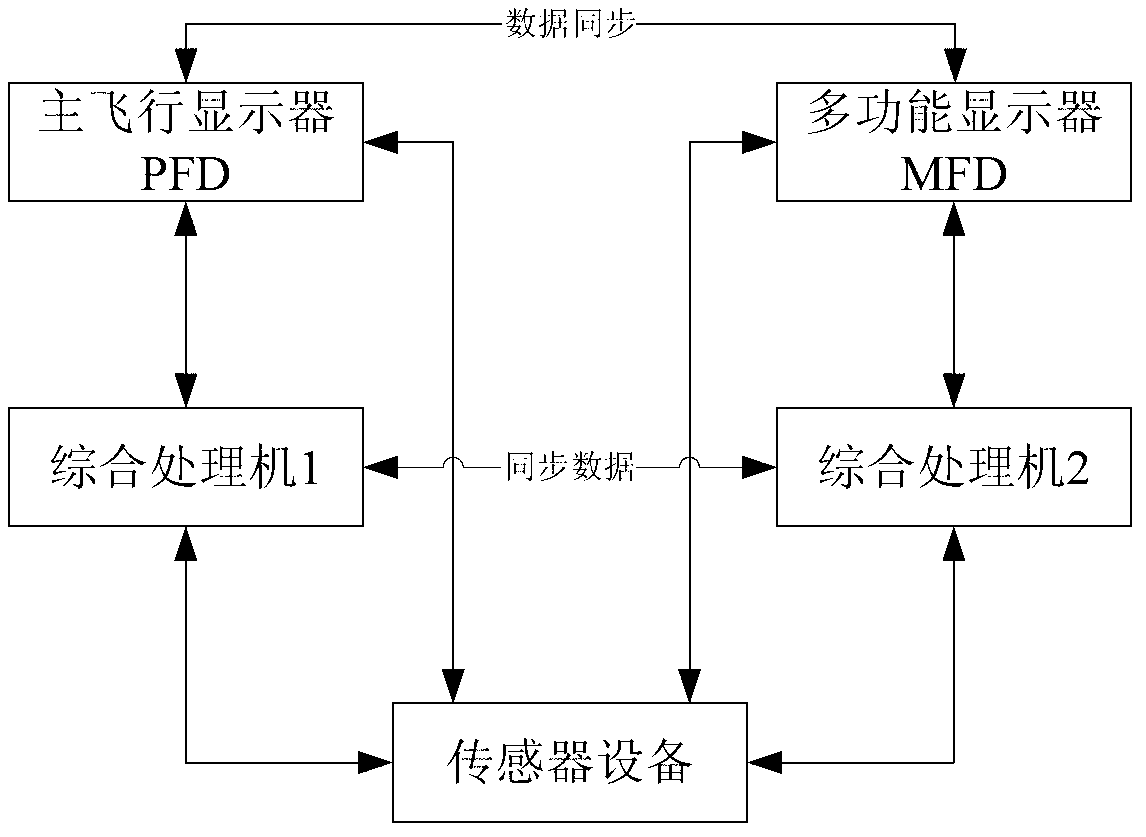

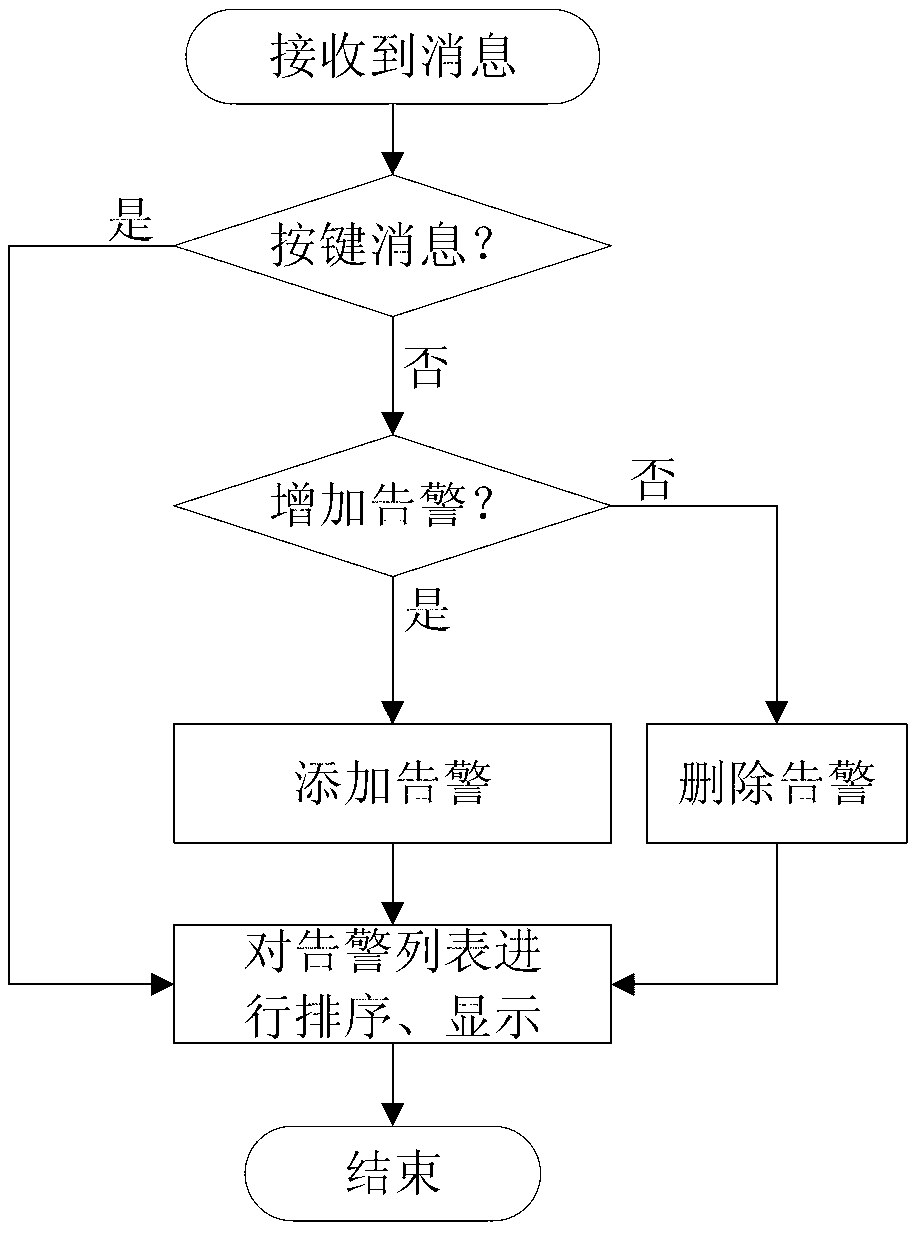

Method for processing aviation electronic system warning information for general-purpose aircraft

The invention provides a method for processing aviation electronic system warning information, which is suitable for a general-purpose aircraft. The method comprises the steps of: (1) dividing equipment information required to be monitored in a general-purpose aircraft aviation electronic system into four classes, setting a warning information list on an airborne display, and respectively establishing corresponding warning processing tasks for the four classes of equipment information; (2) receiving messages sent by the warning processing tasks, judging whether the messages are key messages firstly, if so, directly turning to a step (4), otherwise, carrying out a next step; (3) judging whether the messages are adding warning messages, and if so, adding corresponding warning information into the warning information list, otherwise, indicating the messages to be deleting warning messages, and deleting corresponding warning information from the warning information list; and (4) sequencing and displaying the warning information list. The method has the advantages of simplicity, stability, real time, strong testability and expandability, and the like.

Owner:AVIC NO 631 RES INST

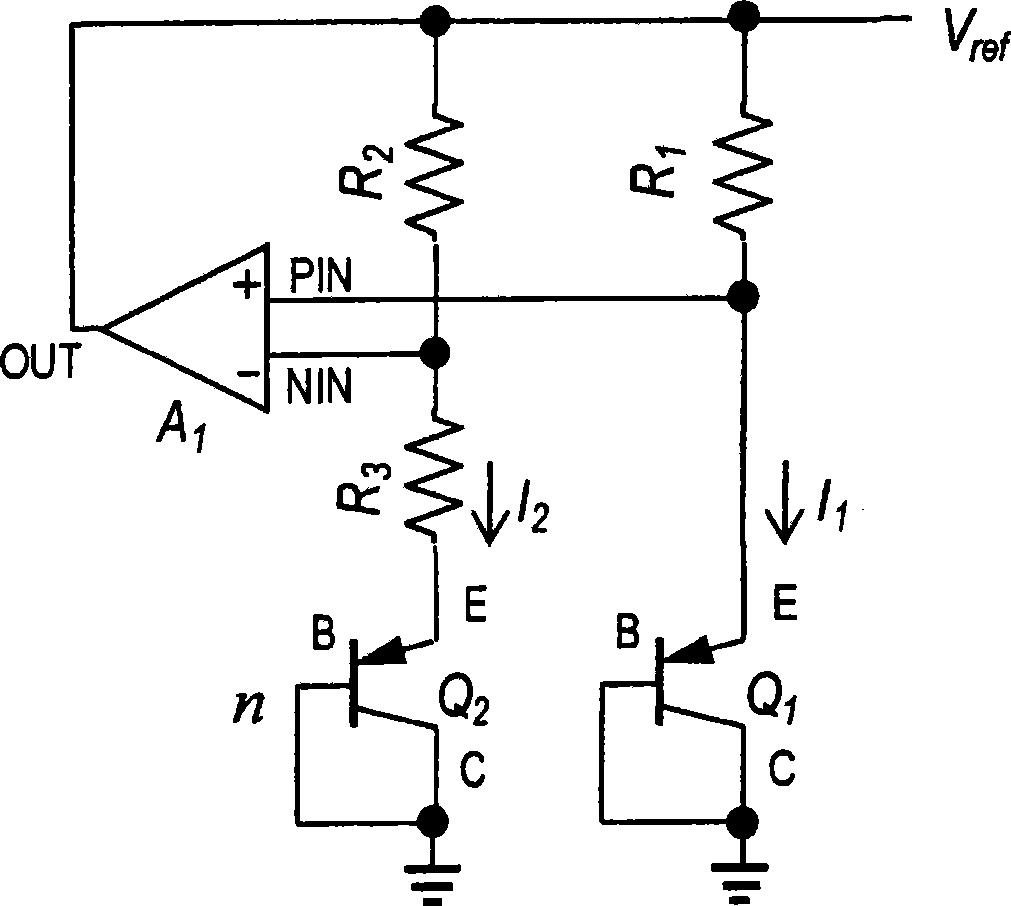

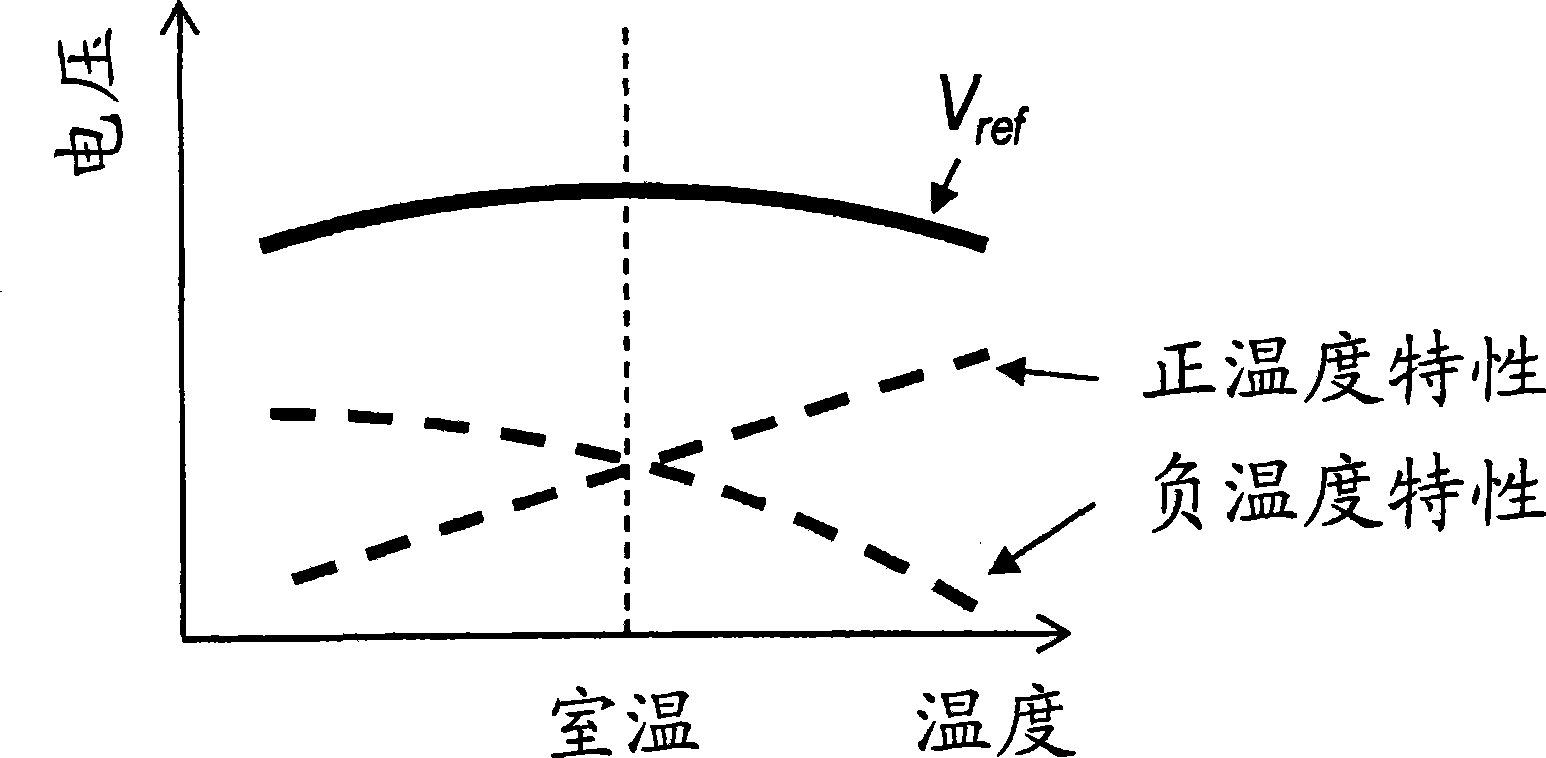

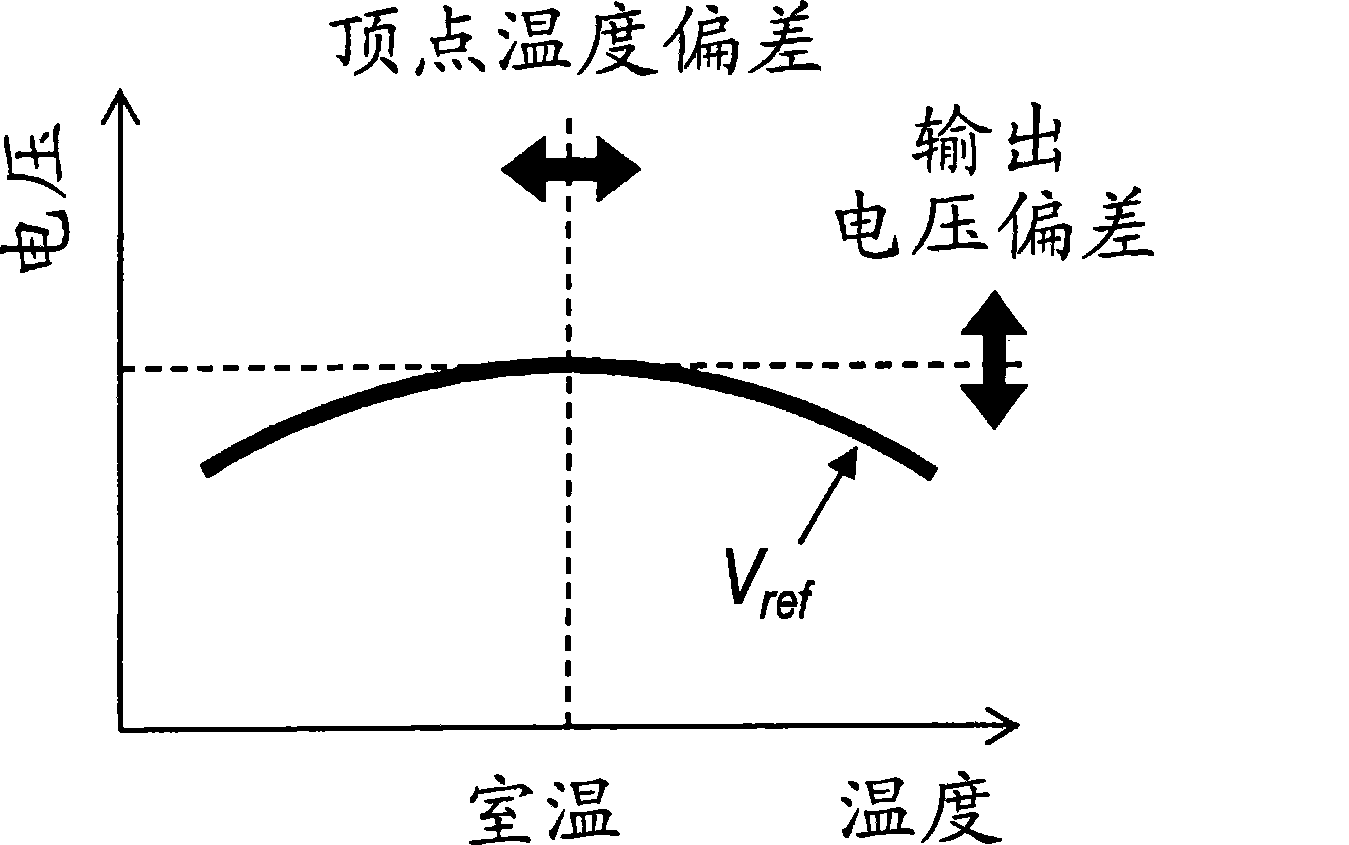

Reference voltage generating circuit, integrated circuit device, and signal processing apparatus

InactiveCN101510108AControl Temperature CharacteristicsStabilizationElectric variable regulationAdjustable resistorsElectrical resistance and conductanceSignal processing

Owner:SEIKO EPSON CORP

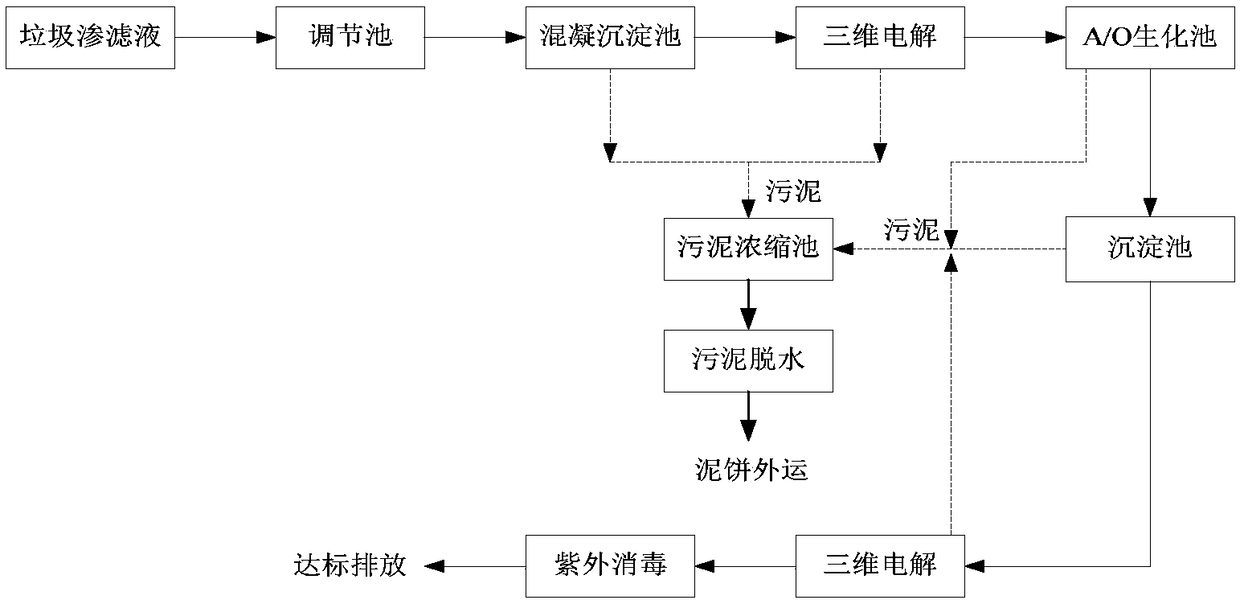

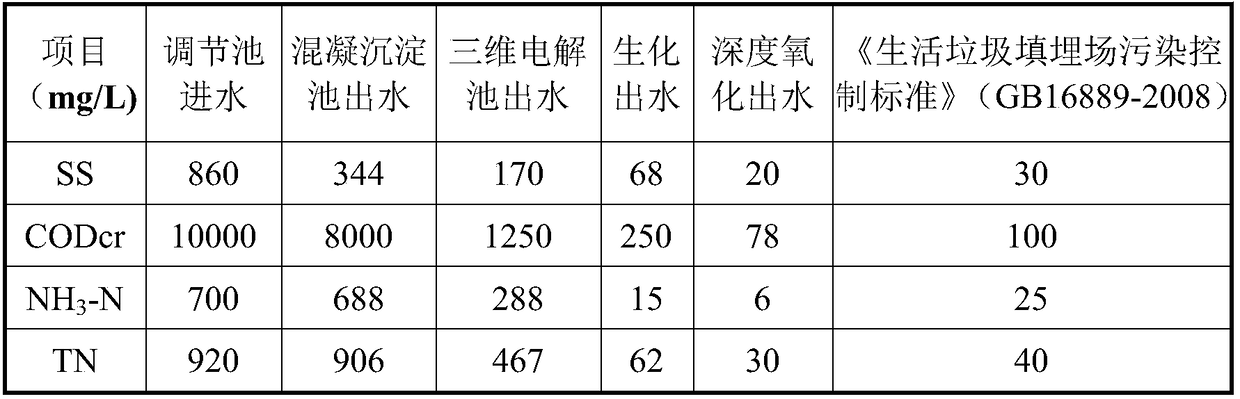

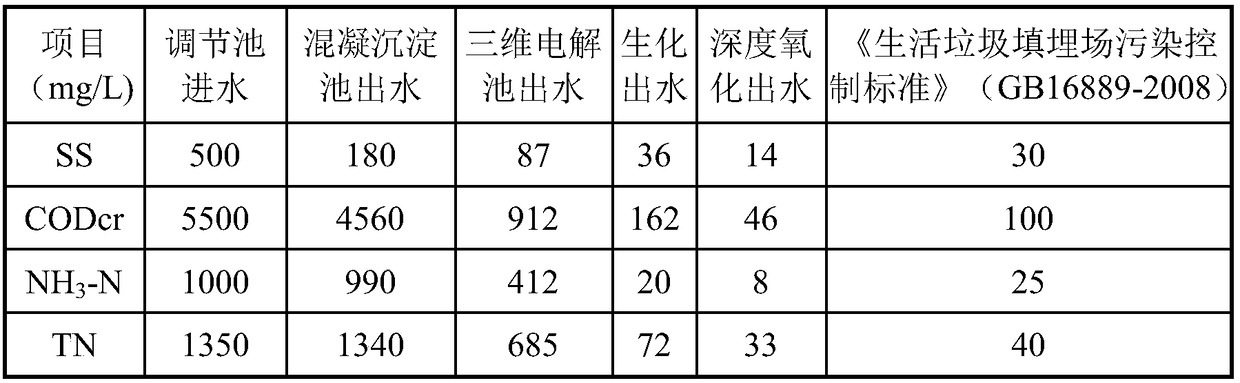

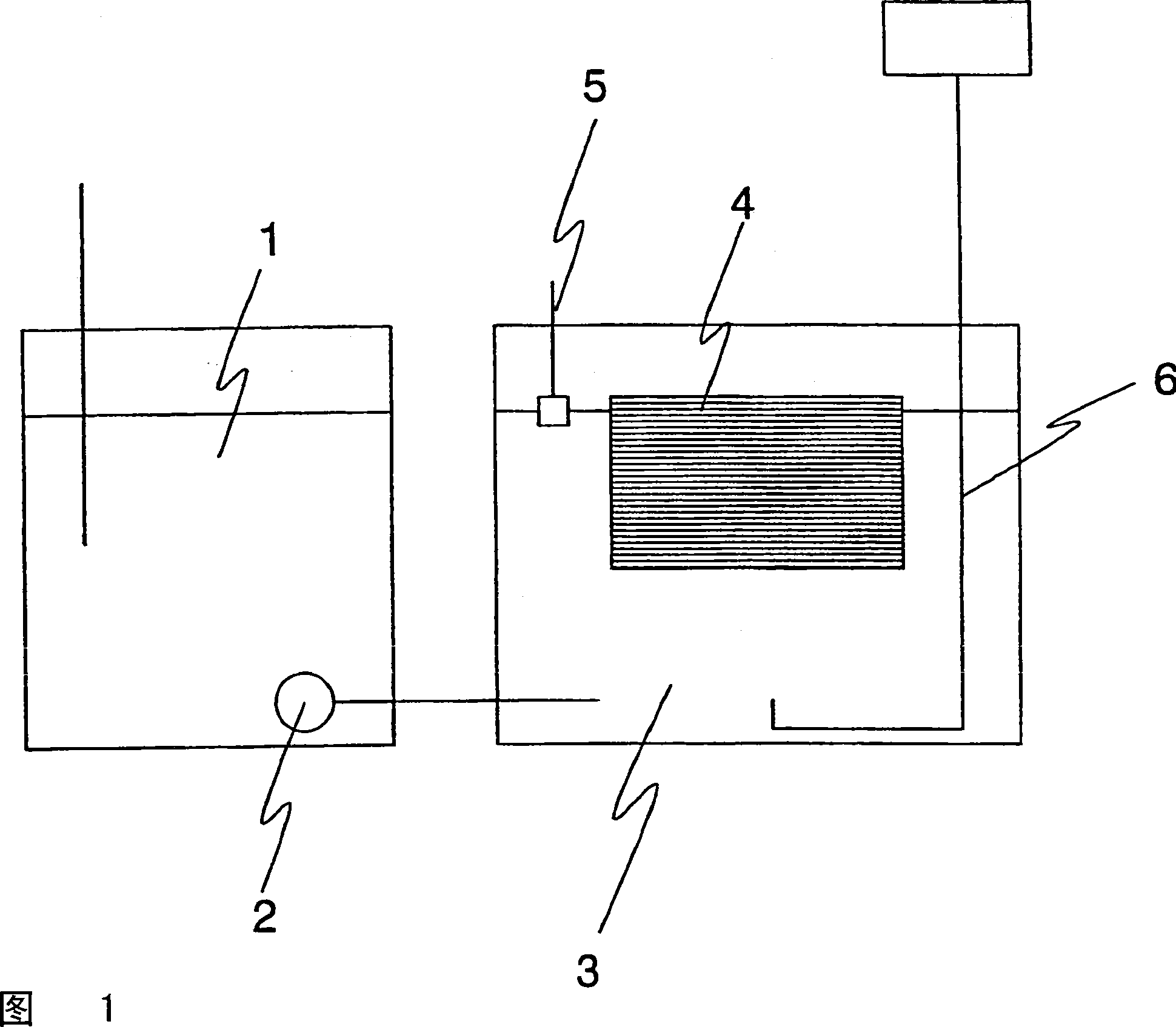

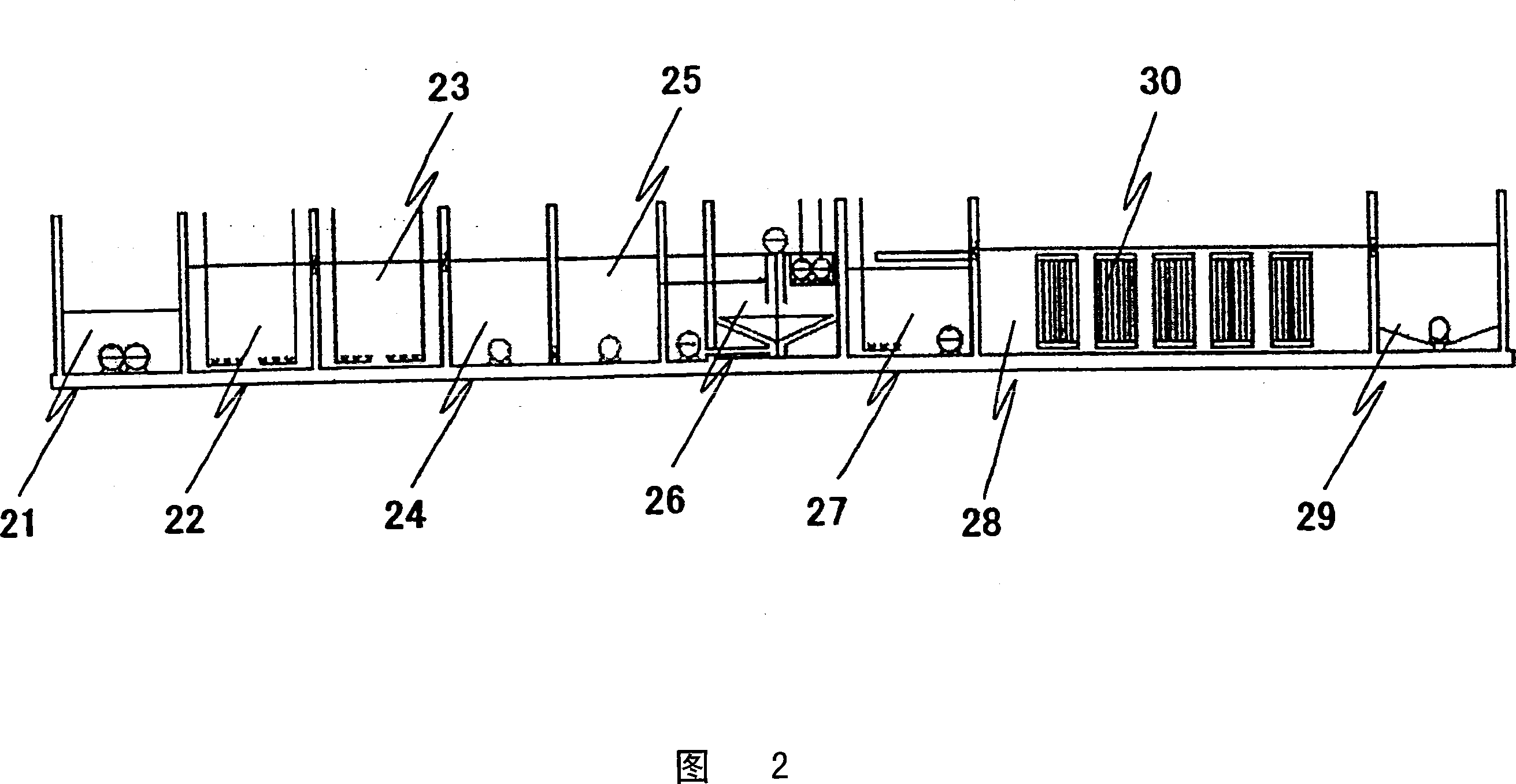

Landfill leachate treatment process system and method

InactiveCN109133522AGood coagulation effectAchieve biodegradabilityWater treatment parameter controlWater/sewage treatment by irradiationElectrolysisHydrogen

The invention discloses a landfill leachate treatment process system and method. The method includes the process steps: (1) enabling landfill leachate to automatically flow into a regulating tank andhomogenizing water in the regulating tank; (2) enabling waste water in the regulating tank to automatically flow into a coagulative precipitation tank; (3) enabling coagulative precipitation effluentto automatically flow into a three-dimensional electrolytic tank and performing oxidizing reaction on organic pollutants in the waste water; (4) adjusting the pH (potential of hydrogen) value of the waste water to be 6.8-7.2, enabling the waste water to be suitable for biochemical treatment, and then enabling the waste water to automatically flow into an A / O biochemical system; (5) setting three-dimensional electrolysis behind a biochemical system to take deep treatment measures. After the effluent is subjected to ultraviolet disinfection, various indexes can reach discharge standards. The system and the method have the advantages of high efficiency, economical efficiency, easiness in operation management and the like.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

Method of treating wastewater containing organic compound

InactiveCN101031637AImprove efficiencyGood effectBacteriaSustainable biological treatmentActivated sludgeLiquid waste

The present invention provides a method for treating waste liquid containing organic substances, which can treat waste liquid containing organic substances at high efficiency and high speed, produce not odor during the treatment, and obtain waste liquid containing organic substances that has water quality at least suitable for discharging to sewage system or public water areas; the present invention further provides a waste liquid treatment device, an additive for treatment of waste liquid containing organic substances, and bacteria that can decompose waste liquid containing organic substances. The method and device for treating waste liquid containing organic substances are characterized in: they can force activated sludge containing specific bacteria to contact with the waste liquid containing organic substances. The present invention further provides an additive that can be added to the active sludge in a treatment pond where specific bacteria exist to treat waste liquid containing organic substances, and specific bacteria that can decompose waste liquid containing organic substances.

Owner:IBIDEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com