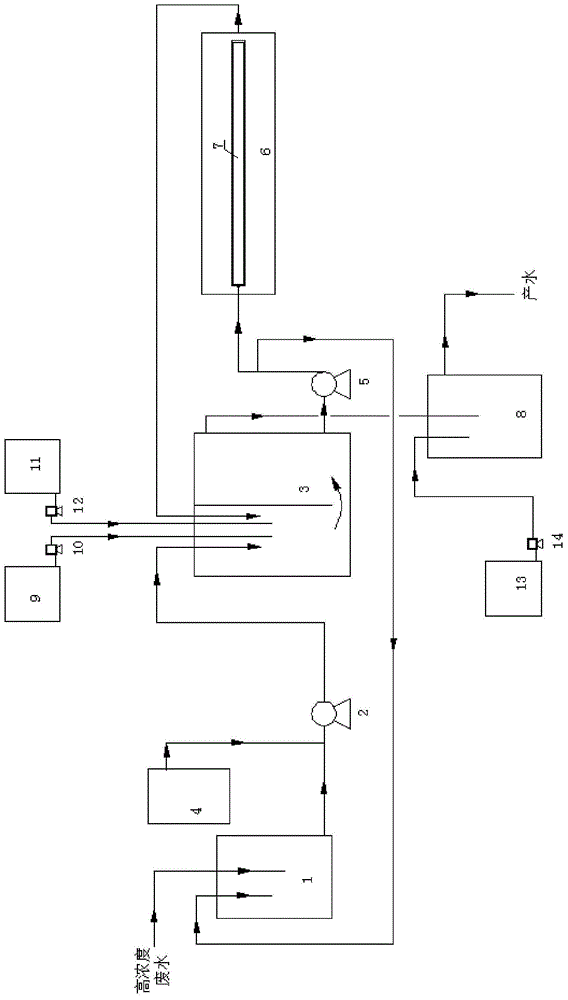

Method and device for pretreating high-concentration wastewater through ultraviolet-ozone co-oxidation

A high-concentration wastewater and synergistic oxidation technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of low ozone dissolution efficiency, destructive impact of biological treatment systems, pollution It can meet the requirements of subsequent biochemical inflow, reduce the pressure of biochemical treatment, and achieve high treatment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A refinery in Guangdong handles 600m of refinery wastewater per day 3 , in order to achieve the standard discharge of wastewater after treatment, investigate and investigate to find a suitable treatment process. On-site pilot test is carried out by adopting the process method of forced circulation ultraviolet-ozone synergistic oxidation pretreatment of high-concentration wastewater of the present invention, and the processing capacity of the device is 10m 3 / h, when the ozone gas concentration is 150mg / L, the dosage of 30% hydrogen peroxide is 55g / L, the pH in the reaction tank is adjusted to 3.0, and the circulation pump flow rate is 100m 3 / h, the COD drops from 21000mg / L to 4500mg / L, and the COD removal rate of the device is 78.57%, which meets the water requirements of the subsequent biochemical and advanced oxidation treatment system. After the subsequent biochemical and advanced oxidation treatment system is treated, the effluent can reach the discharge standard ...

Embodiment 2

[0023] A refinery in Shandong, daily treatment of refinery wastewater 1000m 3 , COD is still as high as 12000mg / L after degreasing, flocculation and sedimentation, and the load of the biochemical system is relatively heavy. The process method of forced circulation UV-ozone synergistic oxidation pretreatment of high-concentration wastewater of the present invention is used to carry out on-site pilot test, and the processing capacity of the device is 15m 3 / h, the concentration of ozone gas is 125mg / L, the dosage of 30% hydrogen peroxide is 24g / L, the pH in the reaction tank is adjusted to 4.5, and the circulation pump flow rate is 150m 3 / h, the COD drops from 12000mg / L to 3200mg / L, and the effluent meets the influent requirements of the subsequent biochemical treatment, reducing its treatment load.

Embodiment 3

[0025] A knitting factory in Shandong, daily treatment of printing and dyeing wastewater 800m 3 , COD between 13000-16000mg / L, dark brown. On-site pilot test is carried out by adopting the process method of forced circulation ultraviolet-ozone synergistic oxidation pretreatment of high-concentration wastewater of the present invention, and the processing capacity of the device is 10m 3 / h, the concentration of ozone gas is 100mg / L, the dosage of 30% hydrogen peroxide is 31.2g / L, the pH in the reaction tank is adjusted at about 2.5, and the flow rate of the circulating pump is 120m 3 / h, the COD drops from 15000mg / L to 4200mg / L, and the effluent is basically colorless, meeting the requirements for subsequent treatment of influent water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com