Patents

Literature

1717results about How to "Achieve cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of biodiesel oil using high acid ralue animal and vegetable grease

InactiveCN1556174AAchieve cycleAchieve recyclingBiofuelsLiquid hydrocarbon mixture productionOil and greaseAlcohol

A process for preparing the biological diesel oil from the animal fat or vegetative oil with high acid number includes esterifying by glycerine under existance of strong acid catalyst, distilling in azeotropic solvent for removing water, mixing with methanol, transesterifying reacting to remove glycerine, water washing, and low-temp treating for removing high-smelting-point substances to obtain methyl ester of fatty acid, which is just the biological diesel oil.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

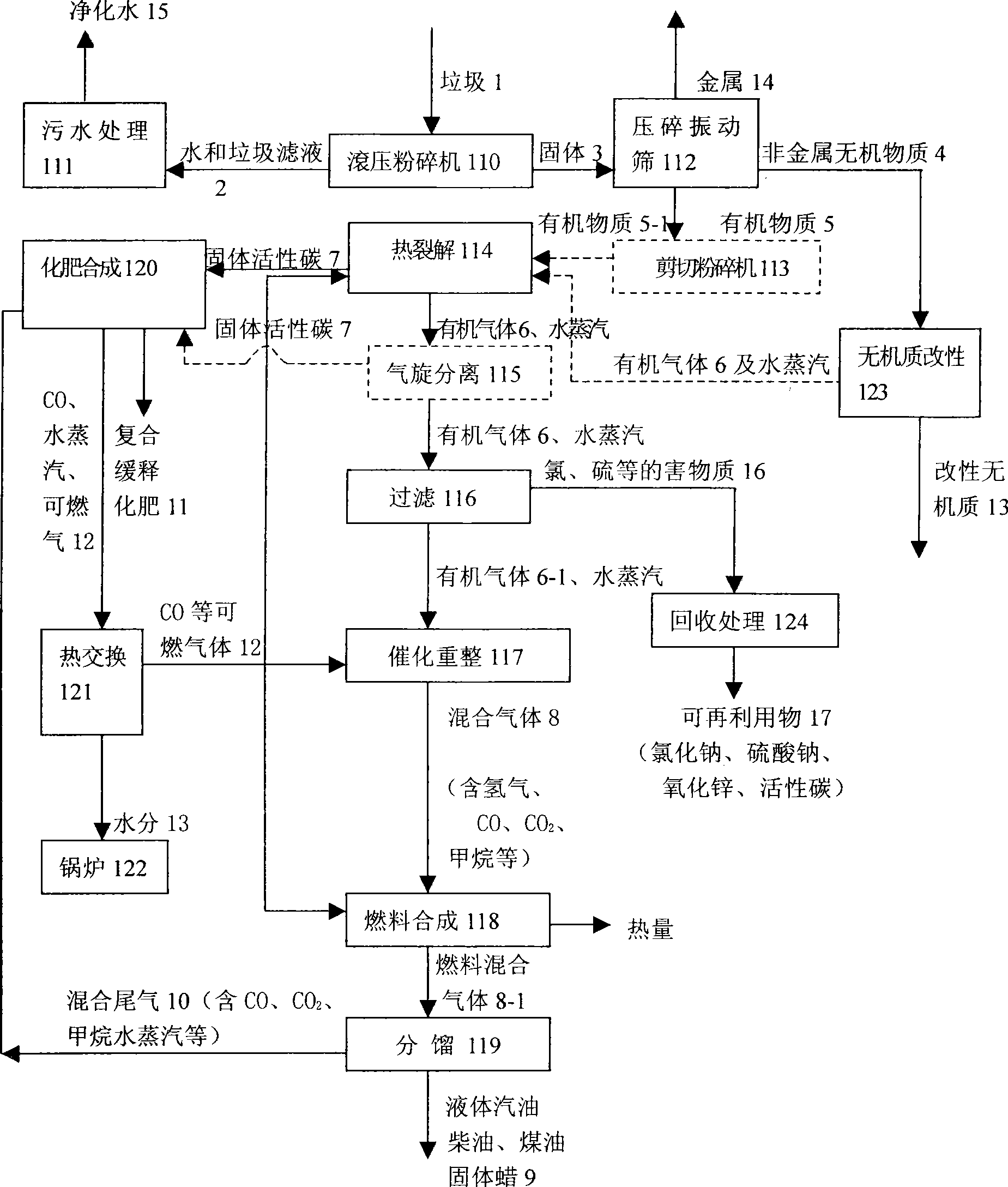

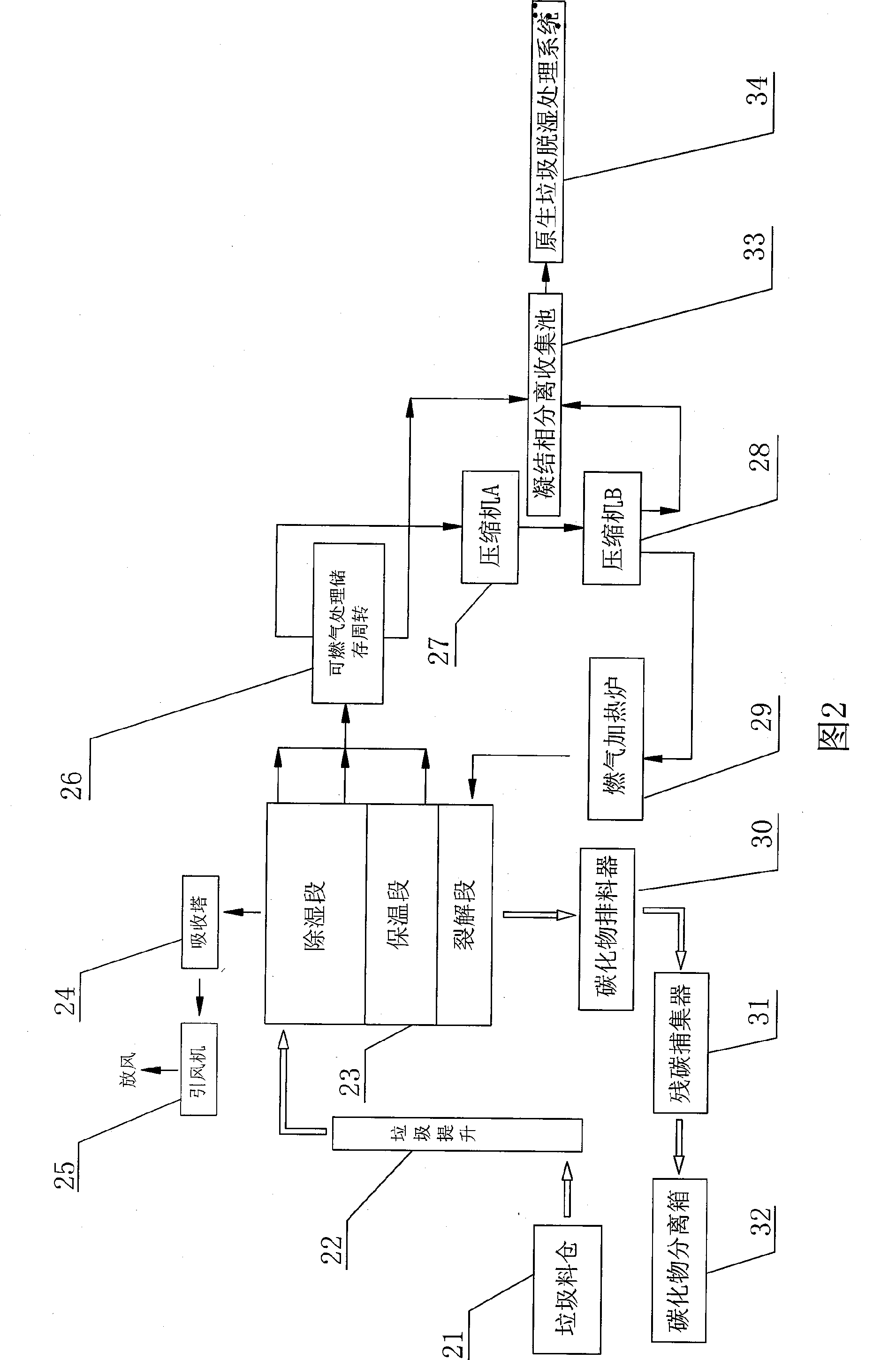

Energy sources regeneration of urban domestic garbage and non-waste comprehensive utilization processing technique

InactiveCN101433904AEffective generationAchieve conversionWaste processingSolid waste disposalFiltrationFuel oil

The invention relates to a manufacturing technique for energy regeneration and non-waste comprehensive utilization of municipal domestic waste, which is characterized by comprising the steps of waste classification, pretreatment and treatment of nonmetallic inorganic substances, schizolysis, filtration and reforming of organic substances, synthesis of fuel oil and treatment of organic substance byproducts. The manufacturing technique completely treats waste, has no secondary pollution during the whole treatment, and really realizes complete conversion and utilization of the waste. When the technology is used for treating organic substance waste and so on, including organic substance parts of the municipal domestic waste and various animal and plant waste, not only the environmental problem caused by the municipal domestic waste and the waste problem of the waste can be solved but also energy and slow release fertilizer which returns to earth can be efficiently generated, so that green circulation of renewable energy resources is realized. The applied proposal has reasonable energy consumption in the whole process, has no pollution, has controllable products, high output value and stable and reliable sources of raw materials, and realizes sustainable development.

Owner:深圳开普蓝生能源环保有限公司

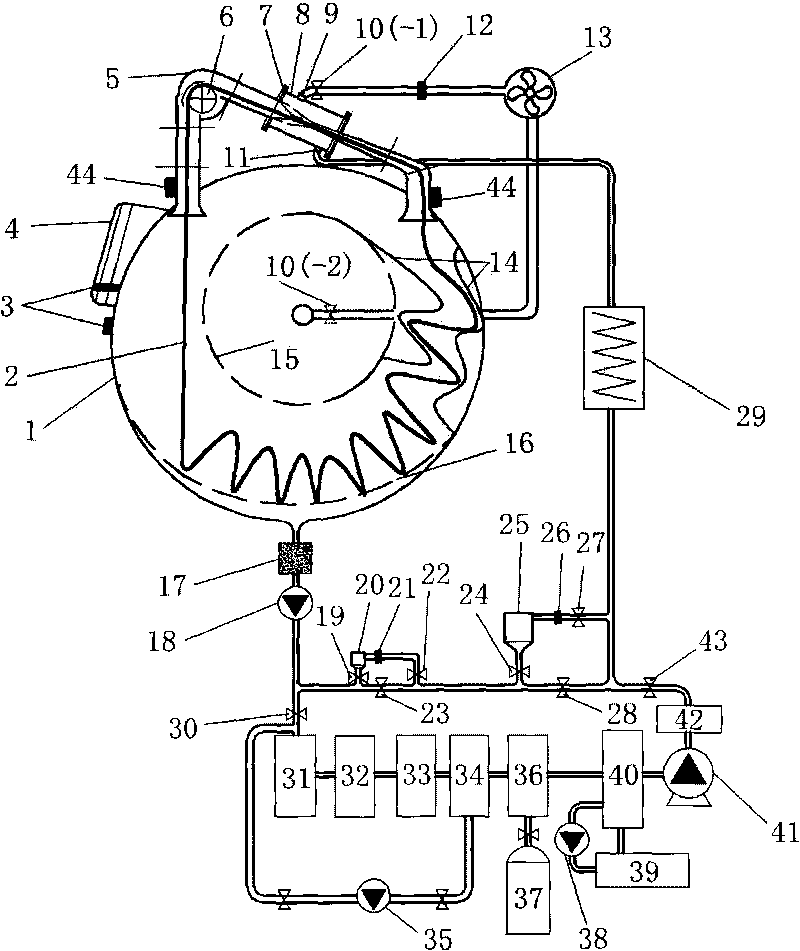

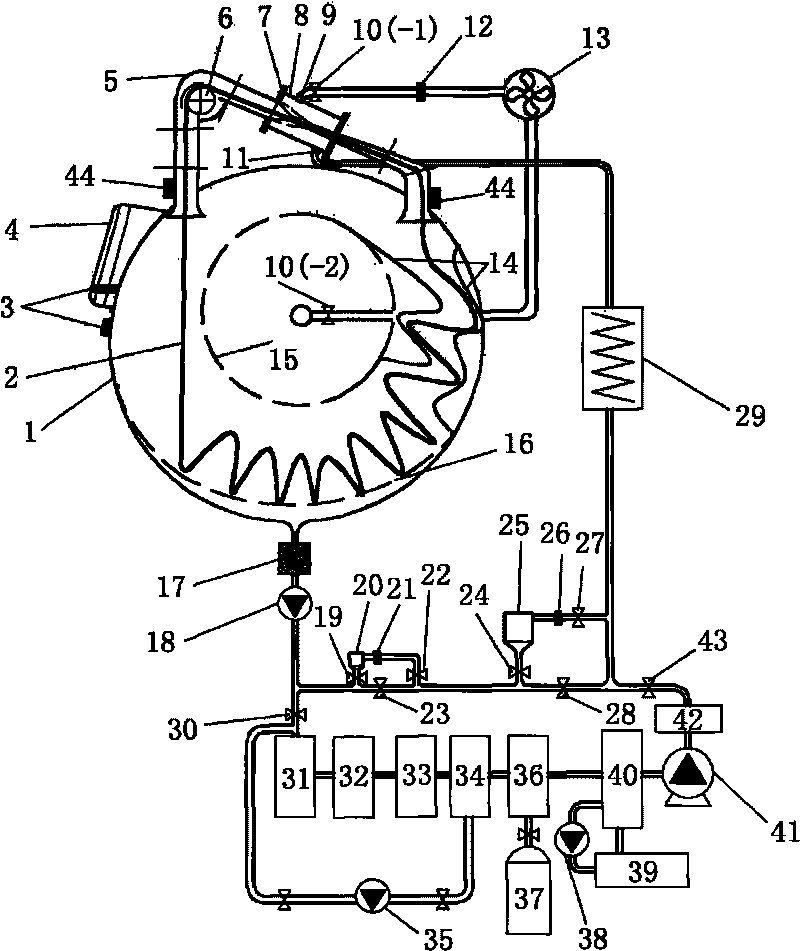

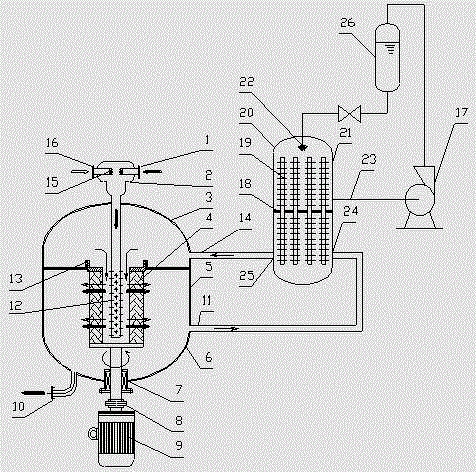

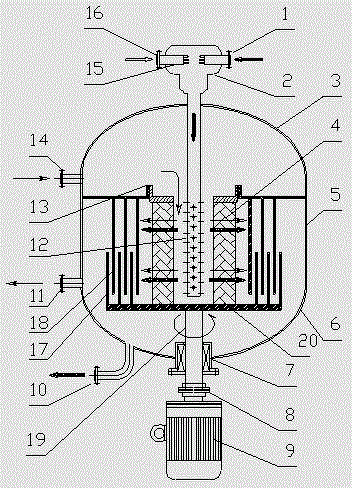

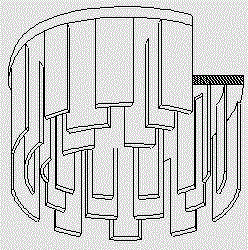

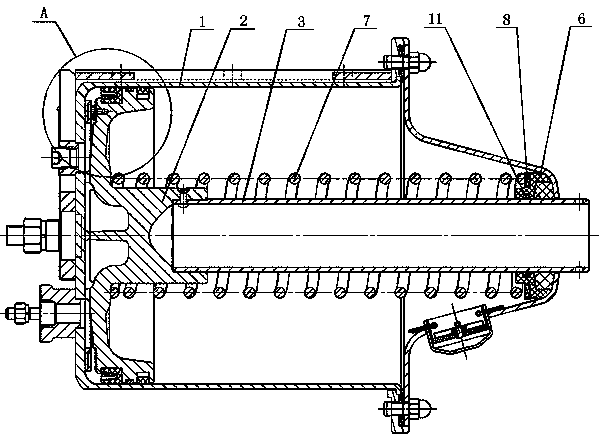

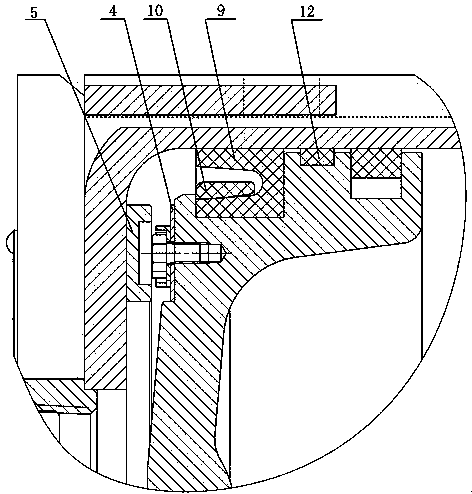

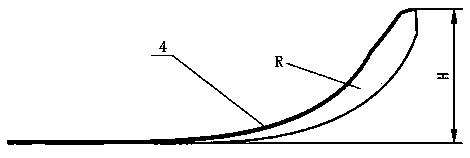

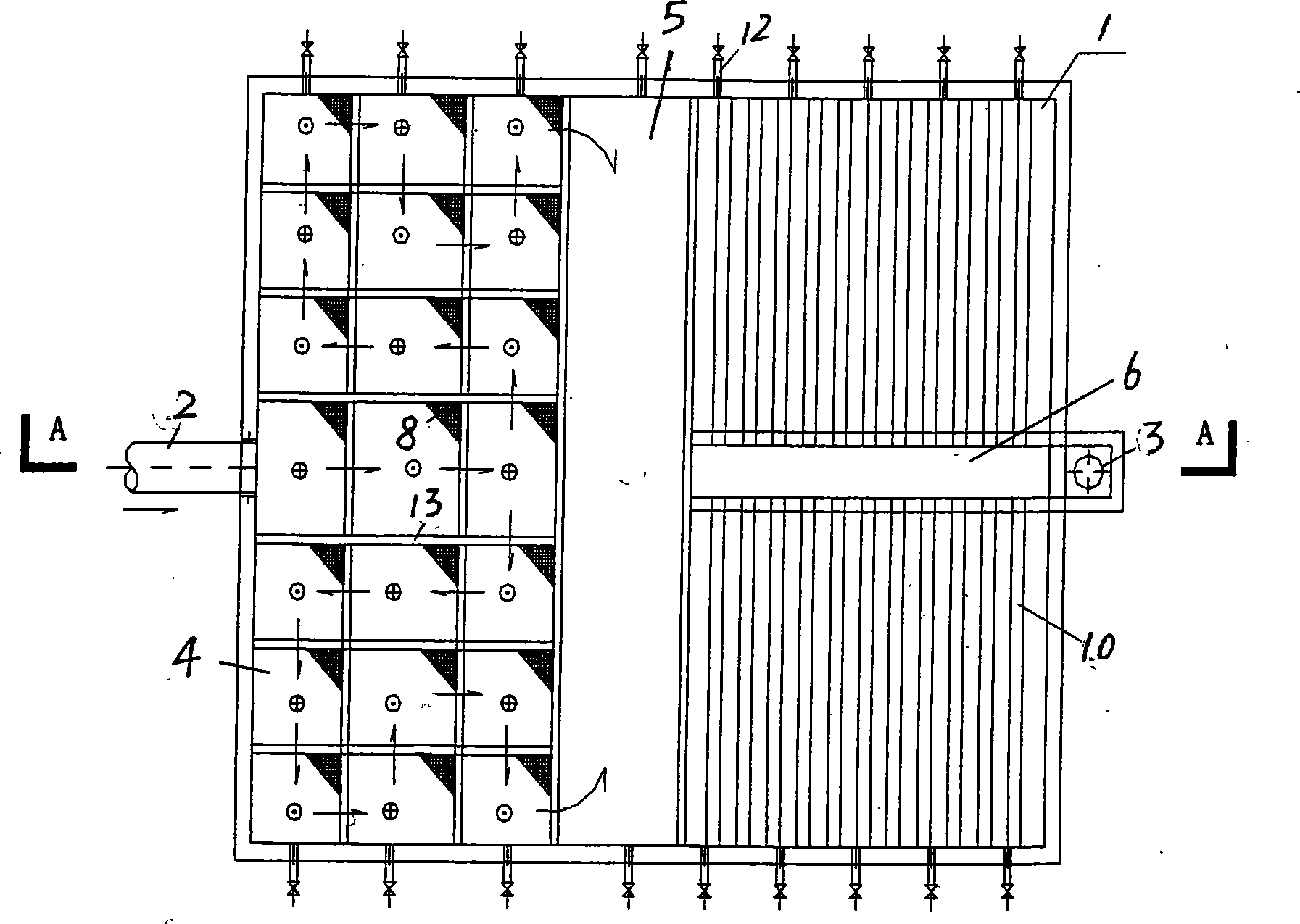

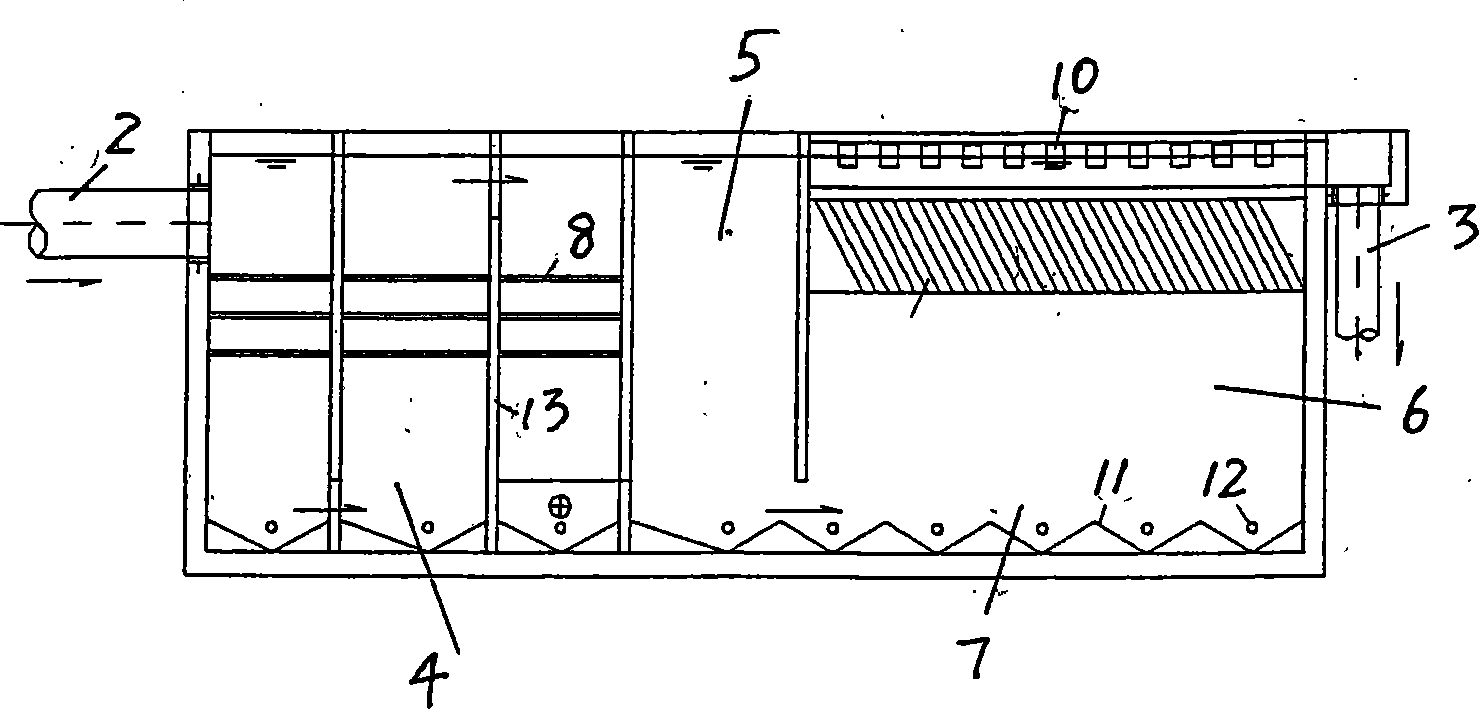

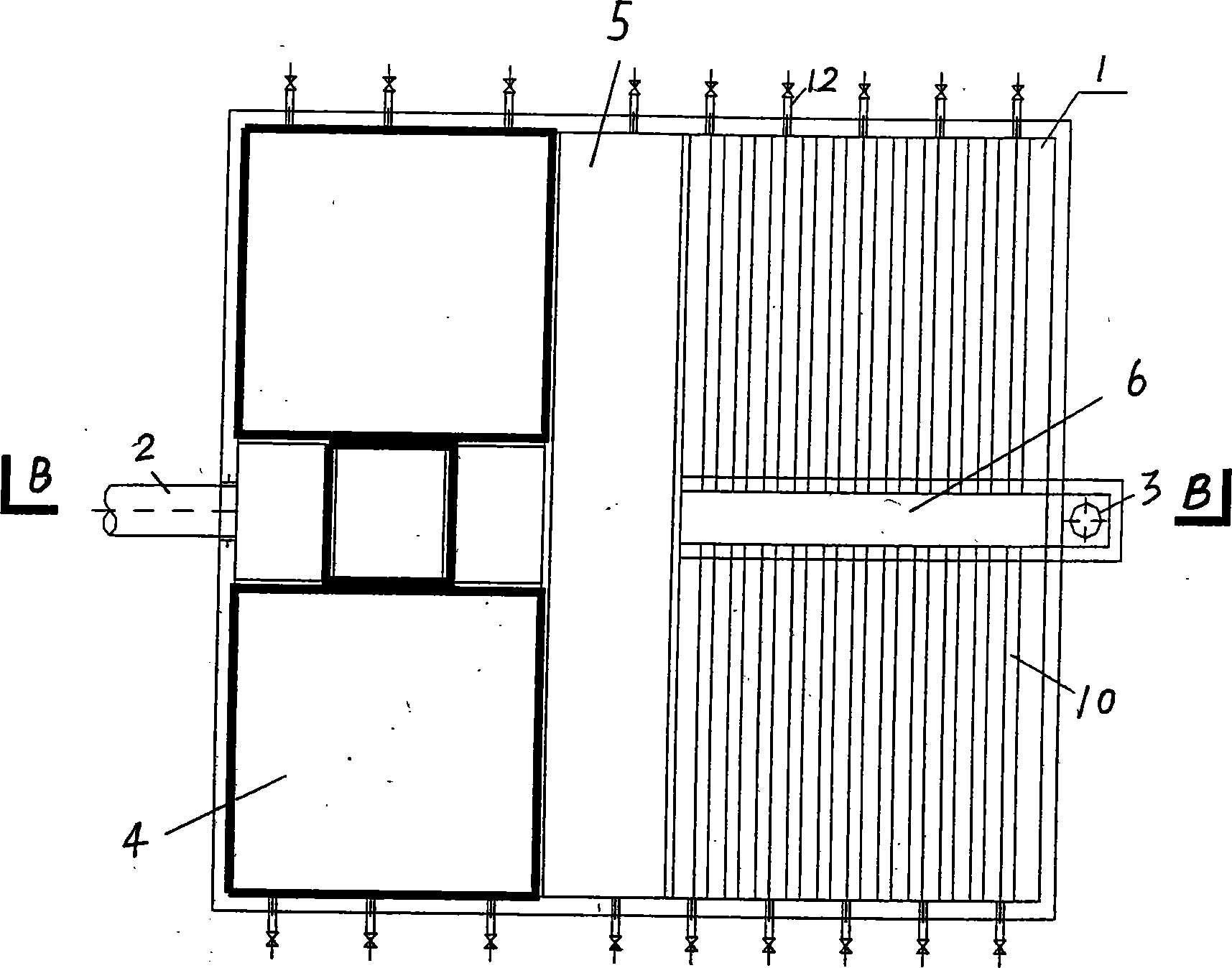

Supercritical fluid dyeing machine

ActiveCN101760914ASave powerLower average tensionTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsWave shapeFree state

The invention discloses a supercritical fluid dyeing machine. A horizontal type cylindrical dyeing kettle, a magnetomotive cloth lifting wheel, a spray cavity, a wave-shaped cloth guide passage in the dyeing kettle, a heat exchanger, a dye kettle or / and an entrainer kettle and a circulating pump are used as main components to form a dyeing circulation system; and both ends of a fan are respectively connected with fluid outlets under the spray cavity and the dyeing kettle and form a cloth feeding system together with the magnetomotive cloth lifting wheel, the spray cavity and an operating opening. A rope-shaped fabric realizes circulated dyeing under the common action of the fluid in the magnetomotive cloth lifting wheel and the spray cavity, and the fluid in the dyeing kettle carries out forced circulation by the circulating pump. The dye and the fluid can realize recycling by a separating and recycling system after dyeing, and the whole dyeing circulation system and the separating and recycling system are clean to achieve the requirement during color changing and dyeing. The supercritical fluid dyeing machine can realize anhydrous dyeing processing on the fabric in a loosening type tension-free state without the production and discharge of pollutants, and has the characteristics of ecology, environmental pollution, wide adaptability of fabric variety, and the like.

Owner:SUZHOU UNIV +2

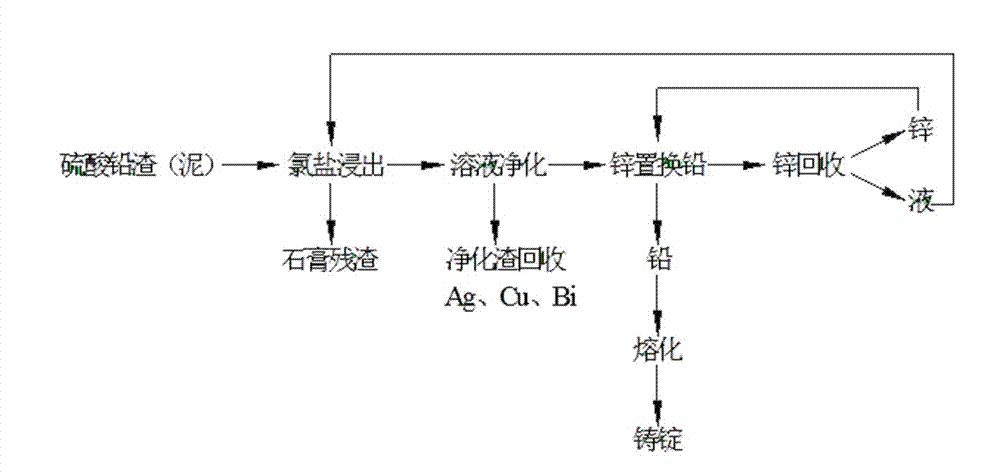

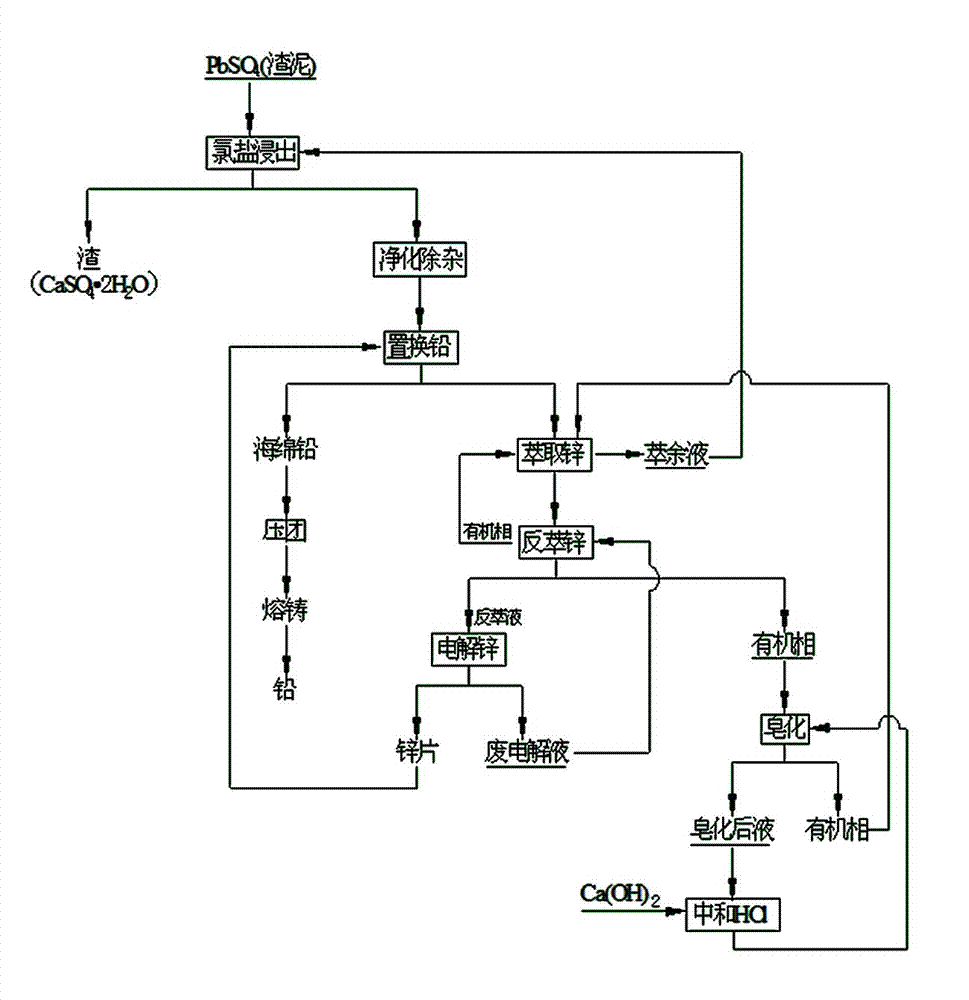

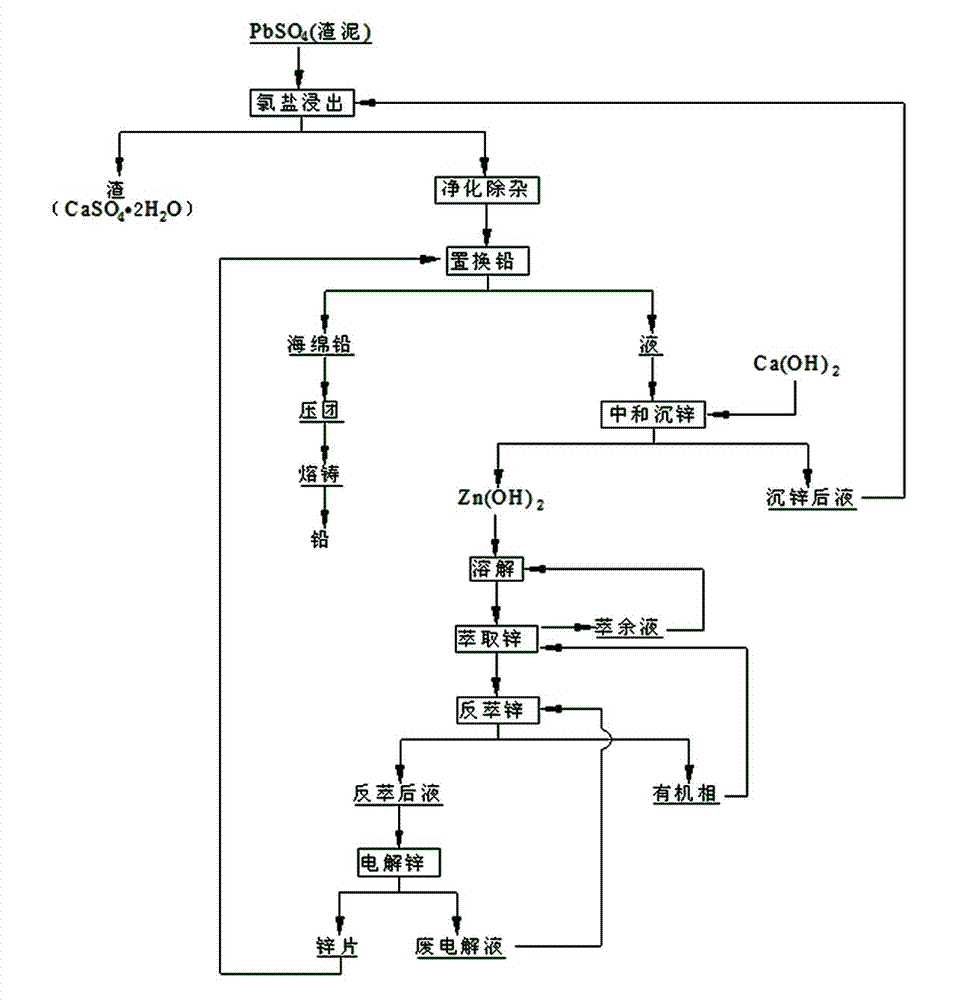

Lead hydrometallurgical technology through utilizing lead sulfate

The invention discloses a lead hydrometallurgical technology through utilizing lead sulfate, belongs to a hydrometallurgical technology, and relates to a technology which adopts a full-hydrometallurgical technology to produce lead through lead sulfate residuals or lead storage battery lead slime which is additionally produced in a zinc hydrometallurgical process. The method comprises steps of: with CaCl2 and NaCl as a leaching solvent; leaching high leaching residuals generated by zinc hydrometallurgy and containing lead sulfate, lead skims generated by leaching zinc out of lead-containing zinc oxides or the lead slimes generated by dismantling lead-acid storage batteries; using zinc to replace lead in the leaching solution; recovering zinc from the replacing solution; returning the recovered zinc to a lead replacement process; and circulating a Cl<->-containing liquid after zinc recovery to a lead sulfate chloride leaching process. The technology has the characteristics of low energy consumption, low cost and easiness in popularization and application; and smoke pollutions such as lead fume, lead dust and SO2 are thoroughly eliminated by utilizing the technology.

Owner:YUNNAN XIANGYUNFEILONG RESOURCES RECYCLING TECH CO LTD

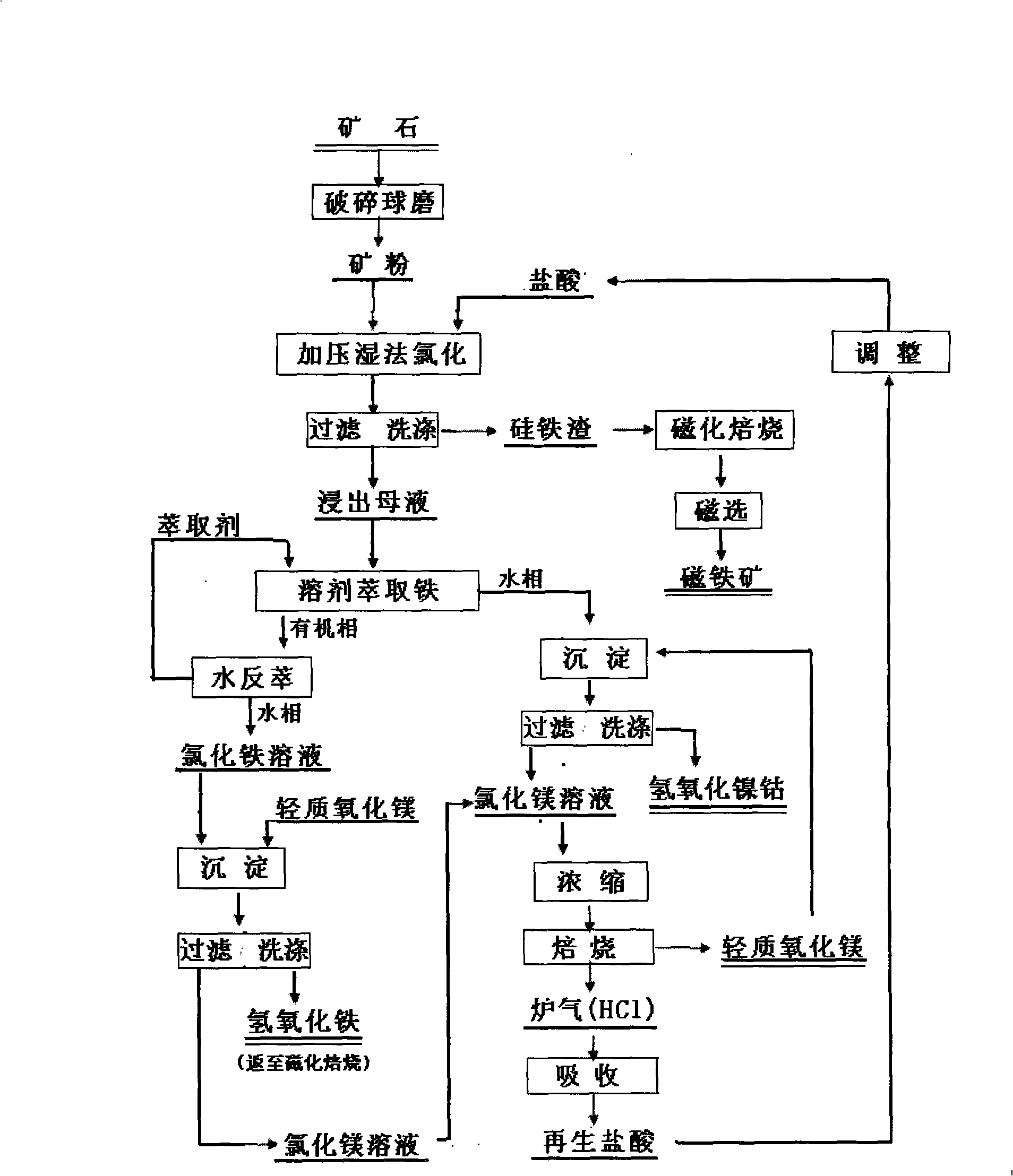

Process for comprehensively developing and utilizing nickel, cobalt, iron and magnesium from laterite-nickel ore

The invention relates to a method for compressively developing and utilizing nickel and cobalt in a lateritic nickel ore. The lateritic nickel ore is used as the raw material; the technical flows of mining, defibrination and ore preparation, pressurizing and wet chlorinating extraction, separating the nickel (cobalt) and iron by extraction, hydrolyzing magnesium chloride with a high temperature, magnetizing and roasting the extracted slag, magnetically separating, etc., and the like, are adopted to extract the middle product of the nickel and cobalt, recycle the light magnesium chloride and the materials used for pudding. The invention is mainly characterized in that the nickel and cobalt in the lateritic nickel ore is firstly and selectively dissolved and extracted by using the pressurized muriatic acid; a depositing method is used on the nickel and cobalt in a liquid to obtain the middle product; the mother liquid after the nickel is deposited is hydrolyzed by high temperature to obtain the light magnesium chloride and the chlorine hydride is recycled to obtain the muriatic acid; a material used for pudding is obtained after the extracted slag is reduced, magnetized, roasted and weakly separated in a magnetic way; the recycling muriatic acid enters the working period of extraction, thereby leading the muriatic acid to closely circulate. The method of the invention comprehensively recycles nickel and cobalt, magnesium and iron and has the advantages of high nickel and cobalt extraction rate, low cost, less investment and closed muriatic acid circulation. The whole technique is simple, clean, environmental friendly and is applicable for industrial production with large scale in particular.

Owner:CENT SOUTH UNIV

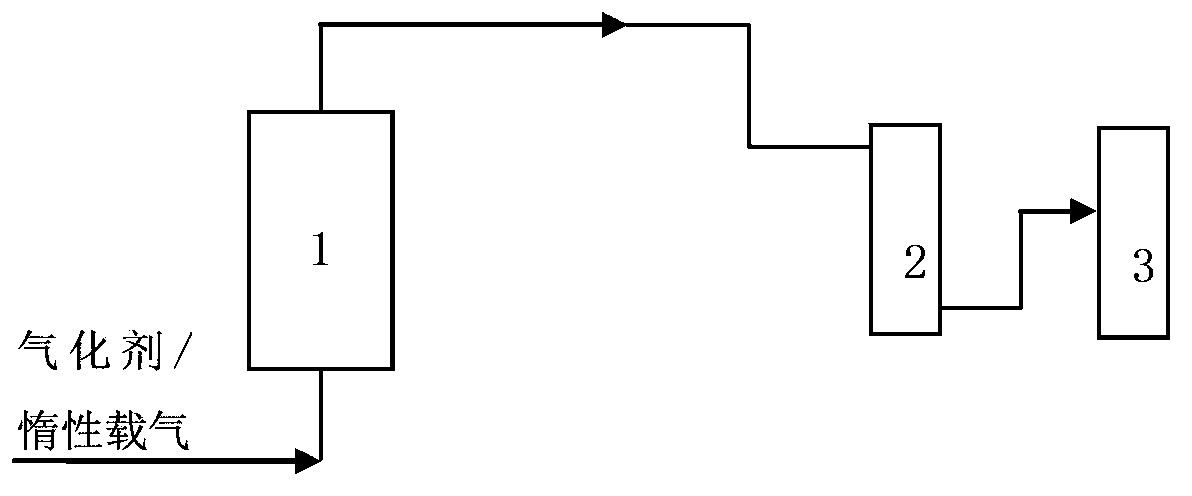

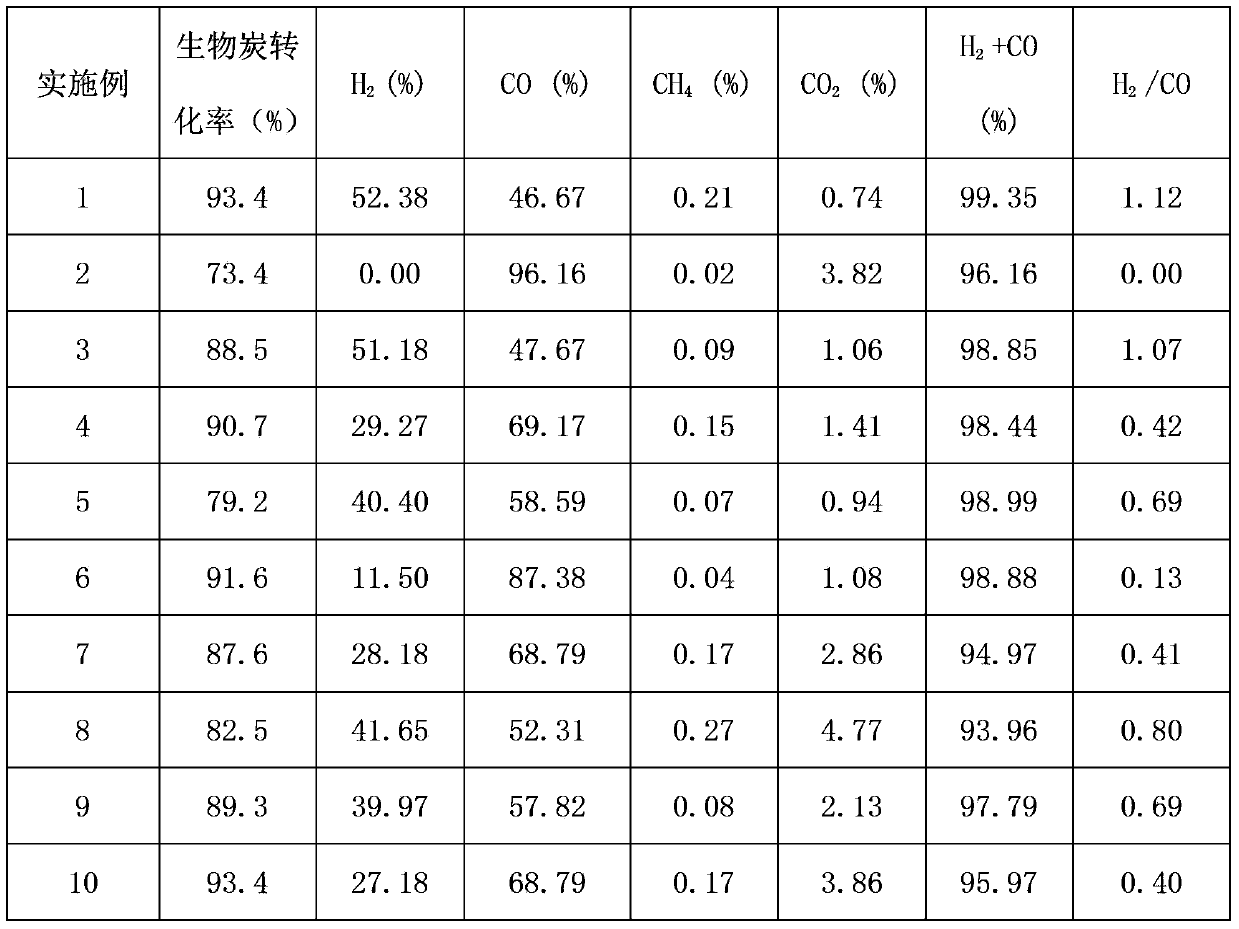

Method for producing synthesis gas by microwave gasification of biochar

The invention discloses a method for producing synthesis gas by microwave gasification of biochar. The method comprises the following steps of: 1) fully pyrolyzing a biomass raw material to obtain the biochar, mechanically mixing with a catalyst, crushing, and then filling into a gasification reactor; 2) taking microwaves as a heat source, heating a mixture in the step 1) to the required gasification temperature in an inert gas atmosphere, and fully removing volatile matters in the biochar; and 3) switching inert gas to a gasification agent, performing gasification reaction, generating gas, and cooling to obtain a synthesis gas product. According to the method disclosed by the invention, the biochar with extensive sources and low price is taken as the raw material, the microwaves are taken as the heat source, and then the synthesis gas is prepared by gasification reaction, so that the production efficiency and quality of the synthesis gas are improved, the emission of CO2 is reduced, and the energy consumption and the production cost are reduced.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

Method for fully recovering silicon dioxide in waste SCR (Selective Catalyst Reduction) catalyst

The invention relates to the field of smoke denitration, in particular to a method for fully recovering silicon dioxide in a waste SCR (Selective Catalyst Reduction) catalyst. The method comprises the following steps: soaking the pulverized waste SCR catalyst with three to four times of water to remove impurities, leaching powder from which the impurities are removed with excessive thick alkaline solution with the concentration of 60-80wt%, filtering to obtain a Na2TiO3 solid, adding sulfuric acid into filtrate, regulating pH to 11.5-12.5 at a temperature of 70-90 DEG C, leaving the mixture to stand for 0.5-1h, filtering, and discarding filter cakes; adding sulfuric acid into the filtrate until the pH is regulated to 9-10 to obtain the silicate filter cakes, heating and stirring the silicate filter cakes in mixed acid of dilute sulfuric acid and oxalic acid at a temperature of 40-60 DEG C for 1-2h, filtering, washing the filter cakes with deionized water, washing off acid radical ions in the solid, and obtaining high-purity silicon dioxide through heating and decomposition. Therefore, the recovery of the silicon dioxide in the waste SCR catalyst can be realized without a roasting process.

Owner:沈阳远大固废处理有限公司

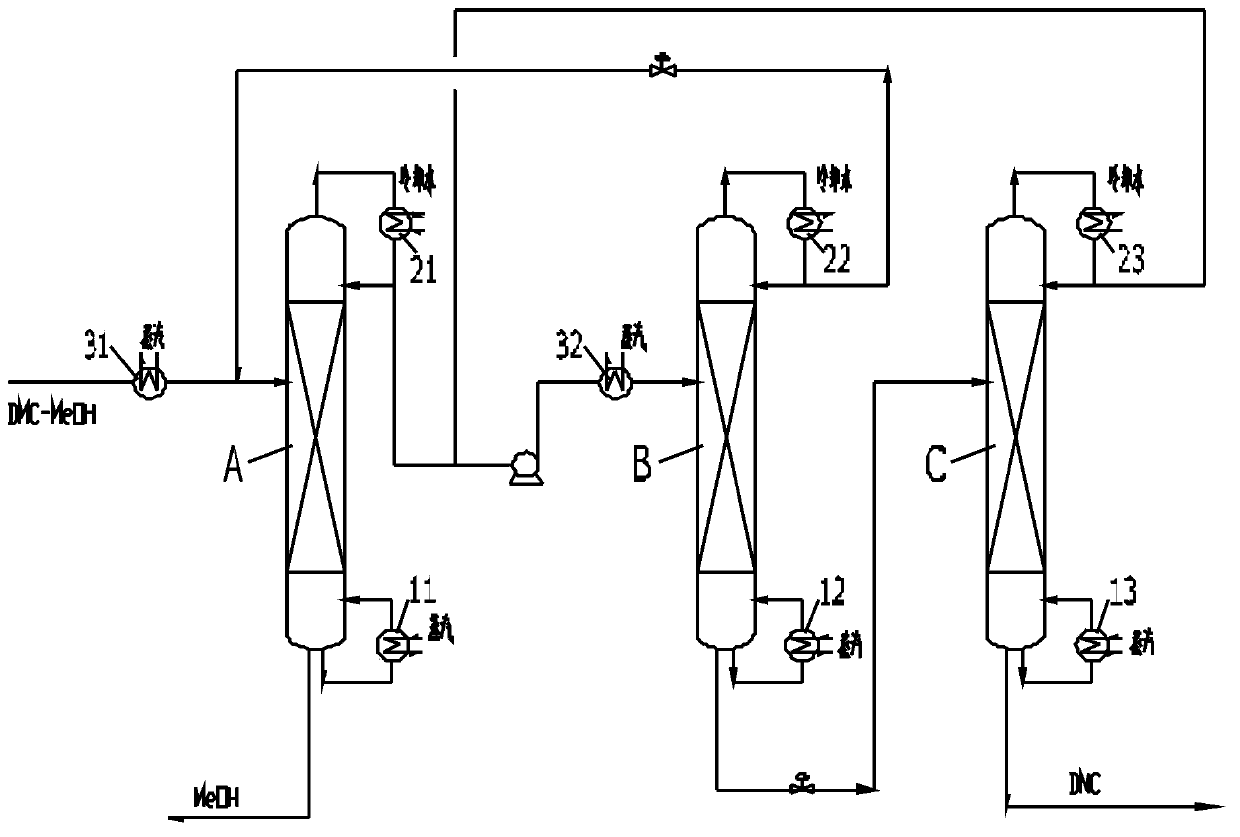

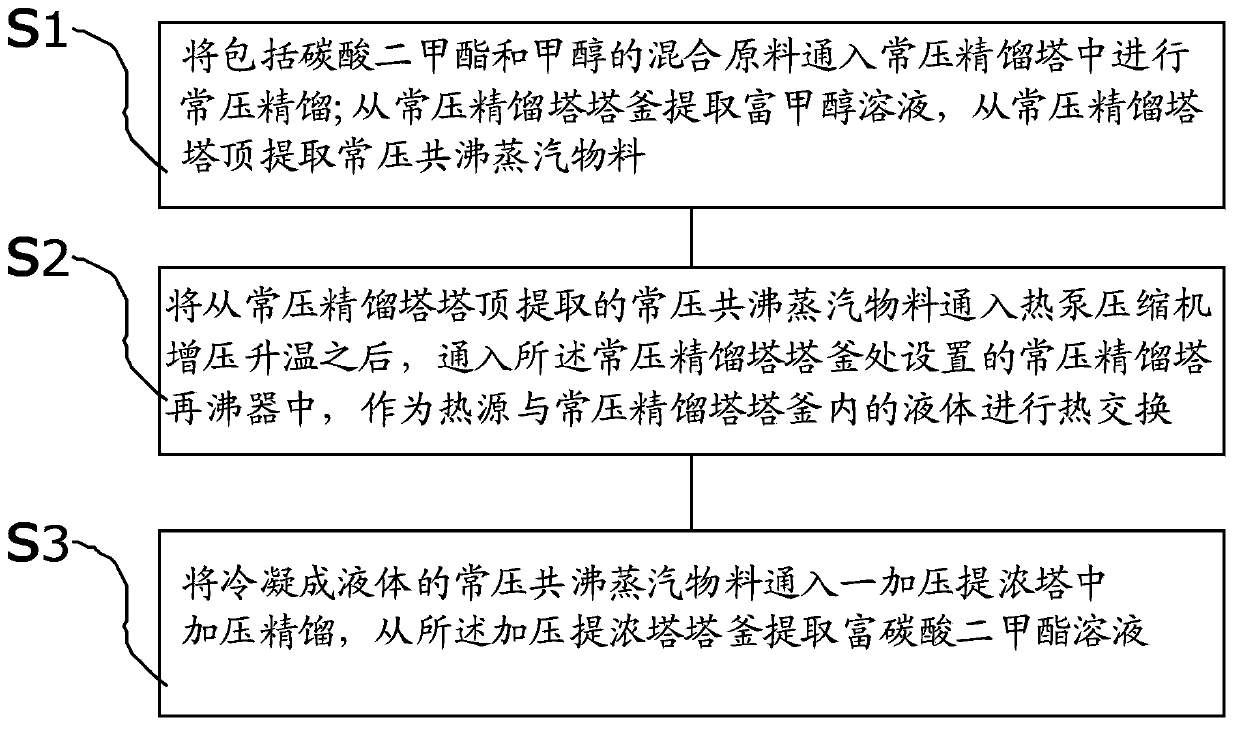

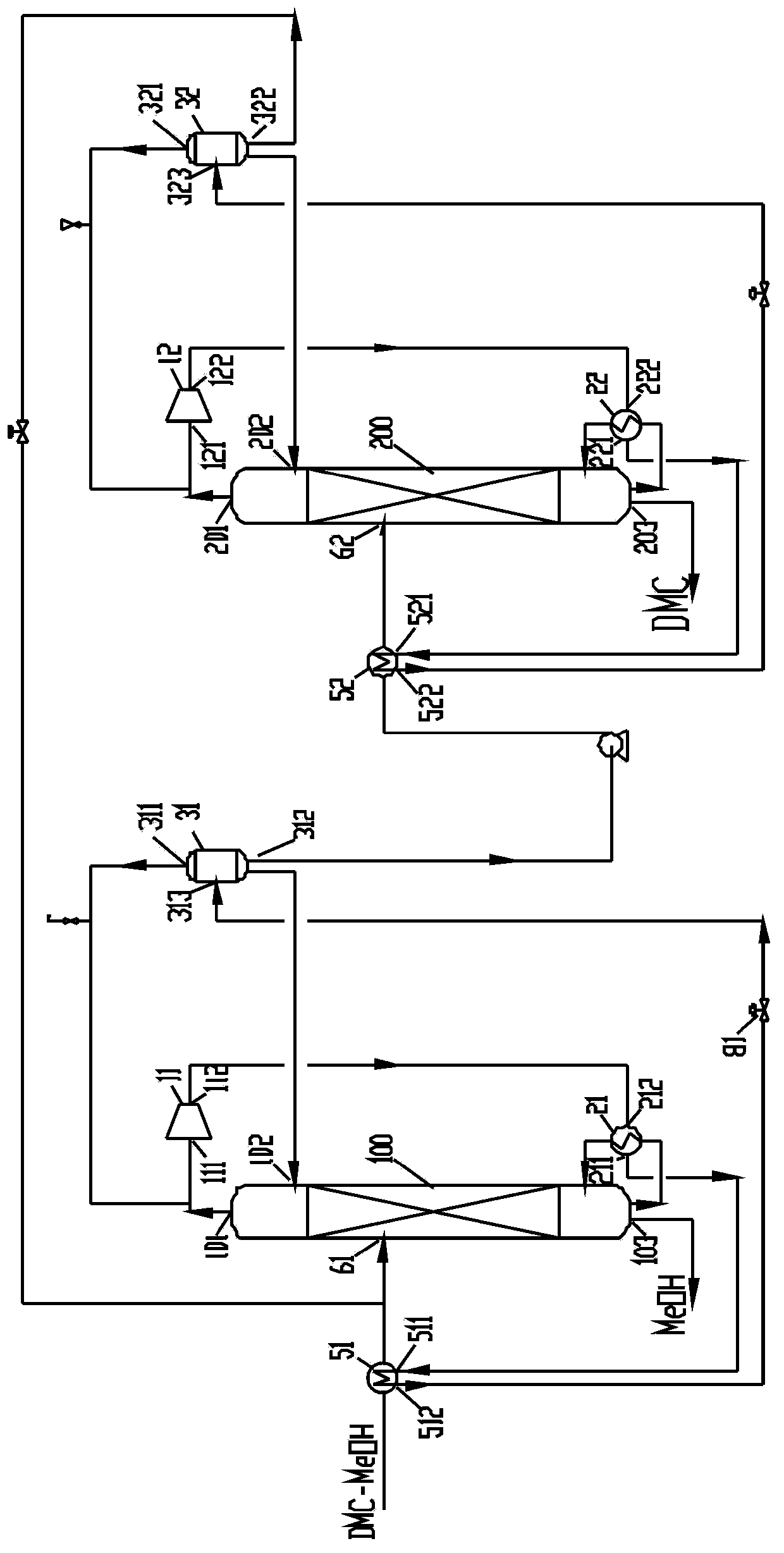

Method for separating dimethyl carbonate and methanol through pressure-swing distillation of heat pump, and apparatus thereof

InactiveCN103626656AReduce energy consumptionLow costCarbamic acid derivatives preparationOrganic compound preparationReboilerSelf-condensation

The invention provides a method for separating dimethyl carbonate and methanol through pressure-swing distillation of heat pump, and an apparatus thereof. In the dimethyl carbonate and methanol through pressure-swing distillation of the heat pump, an atmospheric azeotropic steam material obtained from the top of an atmospheric rectification tower is supercharged and heated by a heat pump compressor, and is introduced to a reboiler at the bottom of the atmospheric rectification tower as a heat source, so a liquid in the atmospheric rectification tower is heated, and the self-condensation of the atmospheric azeotropic steam material is completed. Compared with traditional atmospheric azeotropic steam material condensation through using cooling water and kettle liquid heating realized through an extra external heat source, the method in the invention properly improves the temperature and the pressure of an atmospheric azeotropic steam through the heat pump compressor to make the atmospheric azeotropic steam realize the kettle liquid heating and the reasonable and effective energy cycle as a heat source; and the cost generated by the pump heat compressor is far lower than the cost of traditional cooling water and the external heat source, so a good economic benefit is generated.

Owner:YASHENTECH CORP

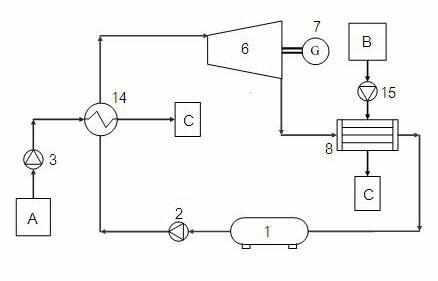

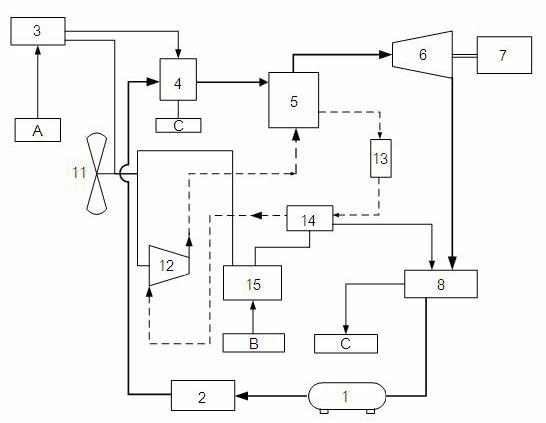

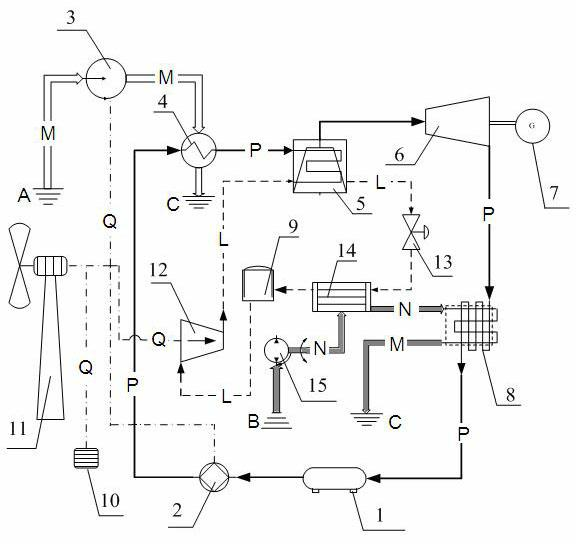

Ocean thermal energy conversion method and ocean thermal energy conversion device

ActiveCN102213199ALarge temperature differenceIncreased efficiency of closed loopsMachines/enginesMechanical power devicesThermal energyOcean thermal energy conversion

The invention provides an ocean thermal energy conversion method and an ocean thermal energy conversion device. The method comprises the following steps of: heating a low-boiling-point working medium by using hot seawater on a surface of ocean; evaporating the low-boiling-point working medium; feeding into a turbine to push a turbo generator set to work for power generation; condensing working medium gas which is exhausted from the turbine into liquid by using cold seawater on a deep layer of the ocean; heating by using the hot seawater; feeding into the turbine to make the working medium gasevaporated; pushing the turbo generator set to work for the power generation; cyclically executing the steps; and continuously carrying out power generation. Power is generated by using ocean surfacewind power, a heat pump device is driven by the power, the temperature of the working medium is further raised by using a medium of the heat pump device, and the volume expansion ratio of the workingmedium is improved; and the temperature of the cold seawater is further reduced by using the medium of the heat pump device, the working medium exhausted gas is condensed by using the low-temperatureseawater, and a condensing effect of the working medium exhausted gas is improved. The method and the device improve the efficiency of closed cycle generation of ocean thermal energy conversion, realize the comprehensive utilization of ocean thermal energy and wind energy, have an important practical value, provide environment-friendly energy sources, and are easy to use and promote in large scale.

Owner:DONGFANG TURBINE CO LTD +2

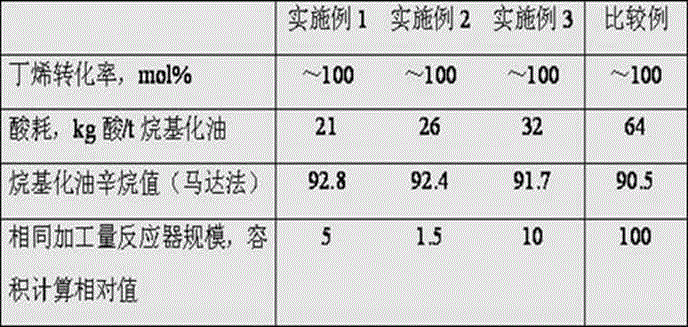

Alkylation reactor and alkylation process method

The invention discloses an alkylation reactor and an alkylation process method. The reactor comprises a reactor tube body, closure heads, a revolving bed, a charging pipe, a charge distribution pipe, a discharging opening, a circulating cooling gas inlet, a circulating cooling gas refrigeration system and a circulating cooling gas outlet, wherein a closed reactor shell body is formed by the reactor tube body and the closure heads, and the revolving bed is vertically located at the internal middle part of the shell body; a sealing member is arranged between the upper part of the revolving bed and the reactor shell body, the upper part of the revolving bed and the sealing member are of rotatable connection, the circulating cooling gas inlet and the circulating cooling gas outlet are respectively formed in the shell body at the upper and lower sides of the sealing member, and the circulating cooling gas refrigeration system is located between the circulating cooling gas inlet and the circulating cooling gas outlet. According to the alkylation method disclosed by the invention, alkylation reaction is carried out by taking concentrated sulfuric acid as a catalyst and taking isobutane and alkene as raw materials. According to the alkylation reactor and the alkylation process method, the alkylation reaction can be carried out at low temperature, the acid consumption is low, and the equipment scale is small.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multi-dimensional and parallel-swing sea wave power generation device

InactiveCN103306881AWon't be corrodedImprove sealingMachines/enginesEngine componentsHydraulic cylinderHydraulic motor

The invention discloses a multi-dimensional and parallel-swing sea wave power generation device. A top cover is fixedly connected with the top wall of a buoyancy box, one end of a three-degree-of-freedom movement pair is fixedly connected with the top cover, the other end of the three-degree-of-freedom movement pair is engaged with a swing rod, one end of the swing rod penetrates through the top wall of the buoyancy box and is fixedly connected with an outside device, the other end of the swing rod is fixedly arranged on an upper platform through the support of rib plates, a spring is fixedly connected with a shaft shoulder of the swing rod, six parallel hydraulic cylinders are arranged between the upper platform and a lower platform, piston rods of the six parallel hydraulic cylinders are hinged to the upper platform, cylinder bodies of the six parallel hydraulic cylinders are hinged to the lower platform, the lower platform is fixedly arranged on an oil mixture tank, the oil mixture tank is fixedly connected with the side wall of the buoyancy box, the oil mixture tank is connected with a hydraulic motor through a separating pipe and a return pipe, a generator is connected with the hydraulic motor, the generator and the hydraulic motor are arranged at the bottom of the buoyancy box, and an energy accumulator is connected with the hydraulic motor. The device has the characteristics that the service life is long, and the pollution is little; and while the energy of the sea wave in the transverse swinging is absorbed, the energy of the sea wave in the vertical direction can also be absorbed.

Owner:SHANGHAI JIAO TONG UNIV

A comprehensive utilization method of red mud

ActiveCN104340995AEfficient separationAchieve cycleChlorine/hydrogen-chlorideSolid waste disposalFerric hydroxideAluminium hydroxide

The invention relates to a comprehensive utilization method of bauxite and particularly relates to a comprehensive utilization method of red mud. The method includes: a step of mixing the red mud with hydrochloric acid, adding the mixture into a hydrochloric acid-resistant reactor, and reacting; a step of cooling after the reaction is finished, performing solid liquid separation and washing; a step of adding the obtained solution into a sodium hydroxide solution to obtain an aluminium hydroxide precipitate, an iron hydroxide precipitate and a sodium chloride solution, performing solid liquid separation, and washing; a step of preparing the aluminium hydroxide and iron hydroxide solid into metallurgy-level aluminum oxide and high-iron slag through a simple Bayer process; a step of subjecting the sodium chloride solution to electrolysis by an ionic exchange membrane electrolytic cell to obtain hydrogen, chlorine and a sodium hydroxide solution; a step of returning the sodium hydroxide solution discharged from an ionic membrane cathode zone and recycling; and a step of returning and recycling the obtained hydrogen and the obtained chlorine. The method is obvious in environment protection effects, effectively separates aluminum, iron and silicon in the red mud, and recovers the aluminum, the iron, sodium and other useful elements, thus achieving comprehensive utilization.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

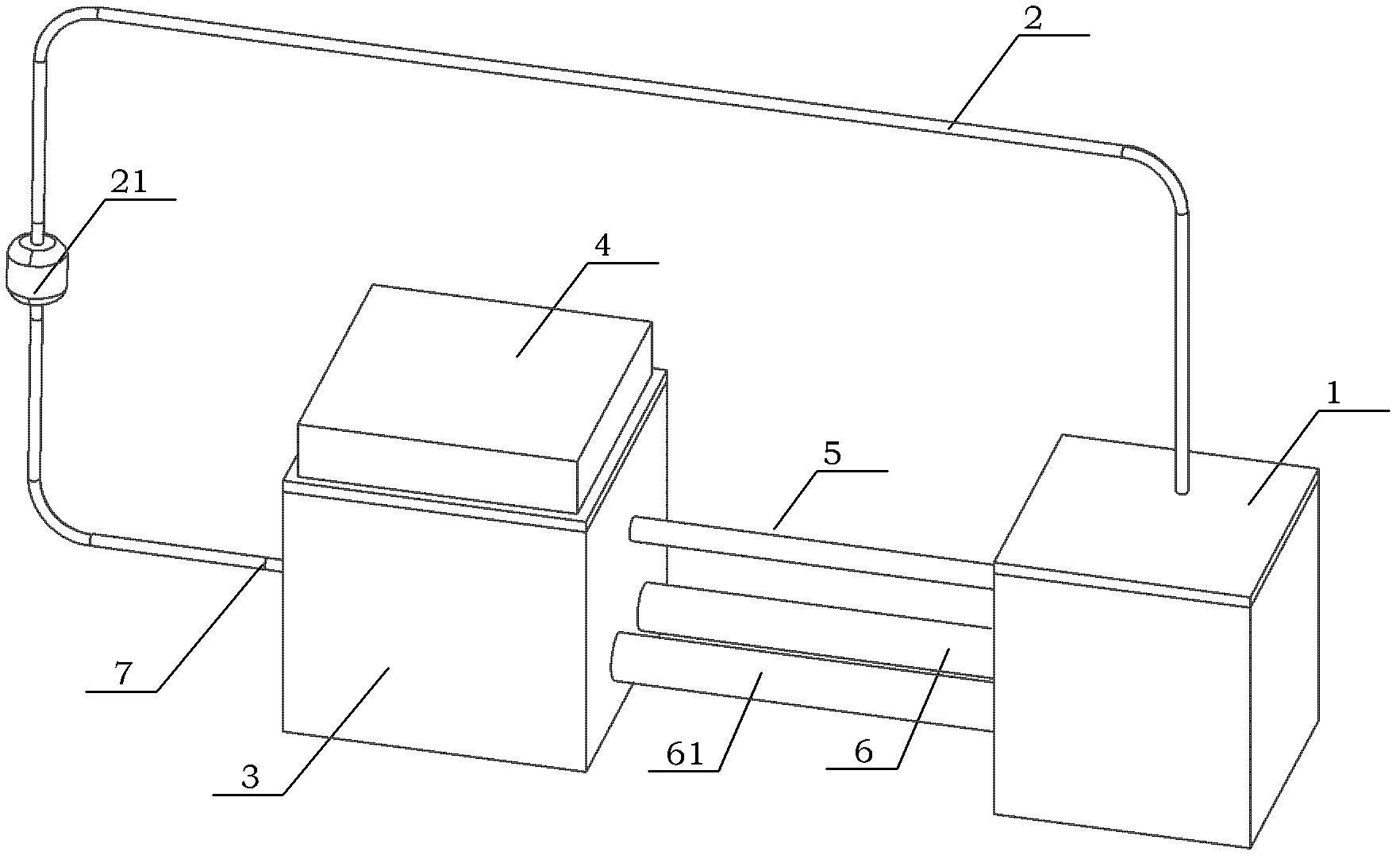

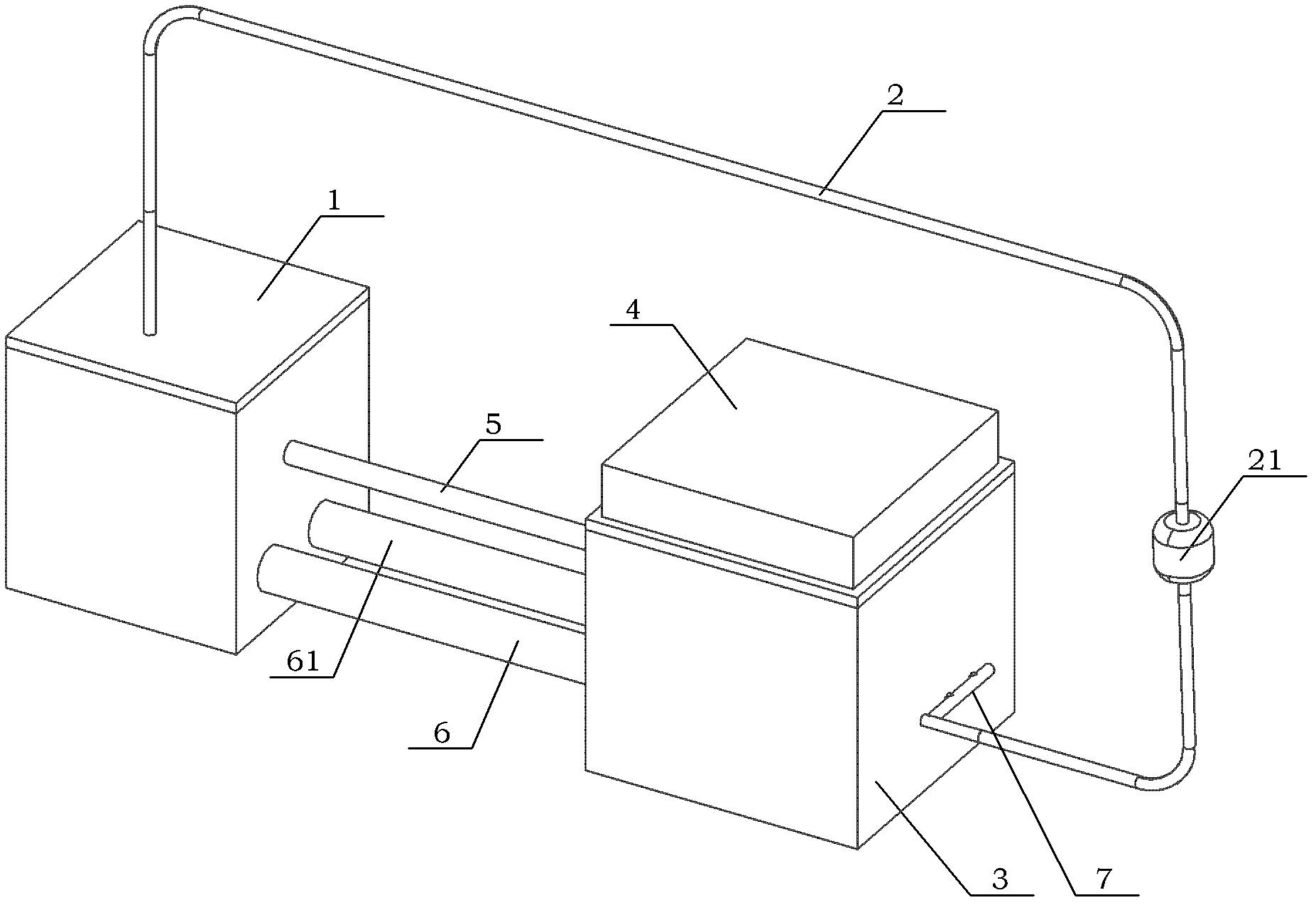

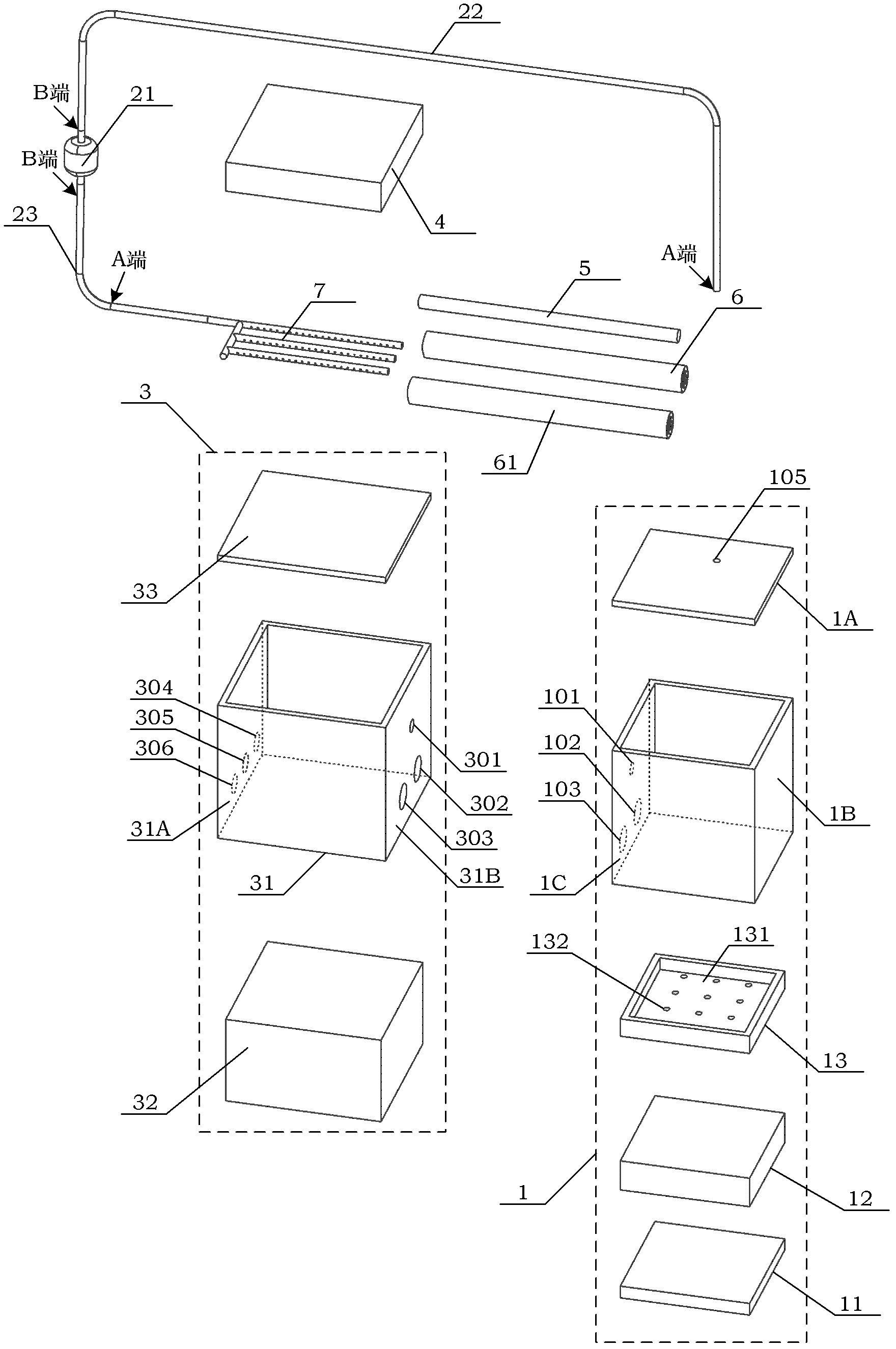

Microgravity environment-based spray cooling loop device

InactiveCN102514733ARealize the collectionAchieve cycleCosmonautic vehiclesCosmonautic partsDiaphragm pumpEvaporation

The invention discloses a microgravity environment-based spray cooling loop device. According to the device, a heat sink is arranged on a liquid storage component; a hydraulic driving pipeline is provided with a micro high pressure diaphragm pump; two ends of the hydraulic driving pipe are communicated with a liquid collector and a spray component respectively; three hole drain pipes of the liquid collector are inserted into a second capillary core of the liquid storage component; and the spray component and the liquid storage component are connected through a steam collecting pipeline, a first liquid collecting pipeline and a second liquid collecting pipeline. The device generates high-speed atomized liquid drops under high pressure impact, and the high speed atomized liquid drops impact the surface of the first capillary core connected with a heat source to take away heat generated by the heat source in heat transfer modes such as forced convection, boiling, evaporation phase change and the like. By the capillary characteristics of the capillary core, the device collects and circulates the liquid under microgravity environment; and moreover, a steam collector, a steam condenser and the liquid collector are integrated into a unit, so the volume is reduced.

Owner:BEIHANG UNIV

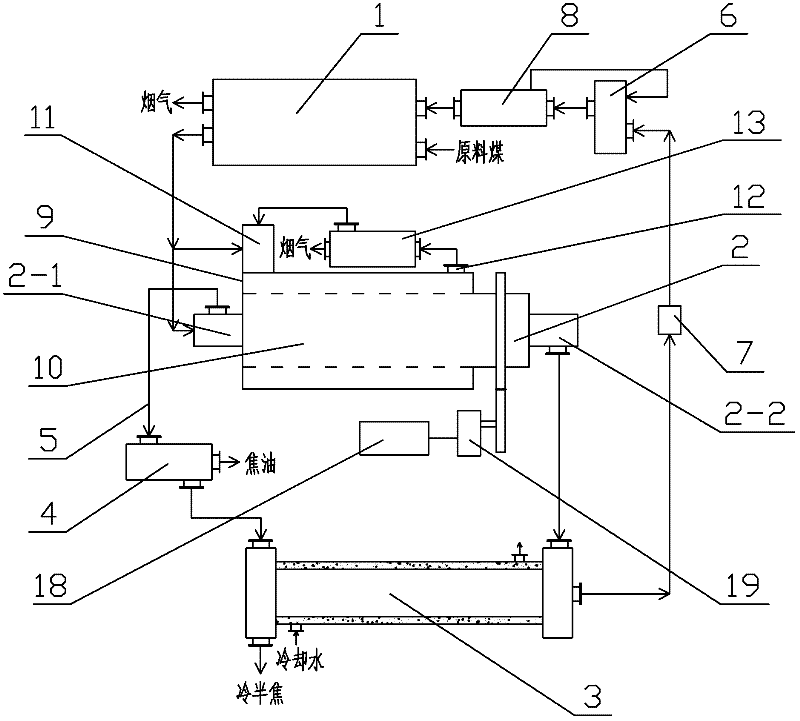

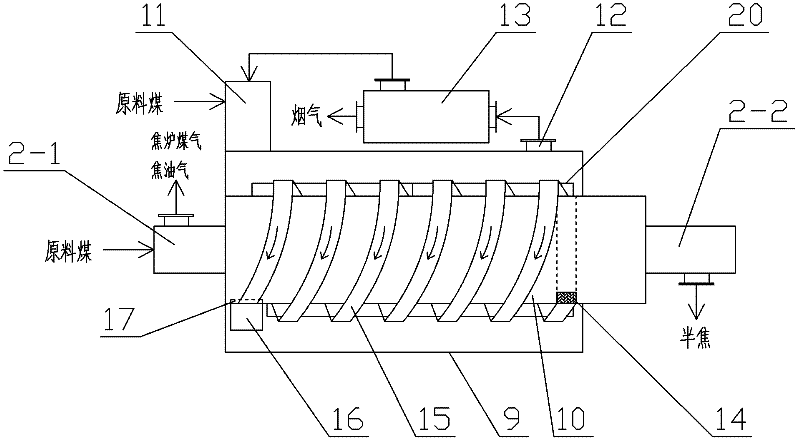

Coal horizontal rotation dry distillation process and equipment

InactiveCN102504848AAchieve cycleGuaranteed uptimeCoke quenchingInternal combustion piston enginesTarCoke oven gas

The invention discloses coal horizontal rotation dry distillation equipment, which comprises a dryer and a horizontal rotation gas retort, wherein the dryer is used for drying and preheating the coal; the horizontal rotation gas retort is communicated with the discharge hole of the dryer and is used for performing dry distillation and thermolysis on the coal; the horizontal rotation gas retort comprises a feeding section, a dry distillation section and discharge section; the discharge hole of the discharge section is communicated with a feeding hole arranged at one end of a carbocoal cooler; and a light pipeline which is used for performing cracking on coke-oven gas and tar gas and is filled with a catalyst is arranged between an exhaust port which is arranged on the feeding section and is used for discharging the coke-oven gas and the tar gas which are generated by dry distillation themolysis and the suction port of a coal gas desulfuration filter. Moreover, the invention also provides a process for performing horizontal dry distillation on the coal by utilizing the equipment. In the process, the waste heat of generated gas fume and carbocoal is reasonably utilized, and the heat use ratio is high. Compared with carbocoal produced by a traditional method, the carbocoal produced by the process does not contain water and has high quality and wide application, and the produced tar has high yield and high quality.

Owner:CHANGAN UNIV

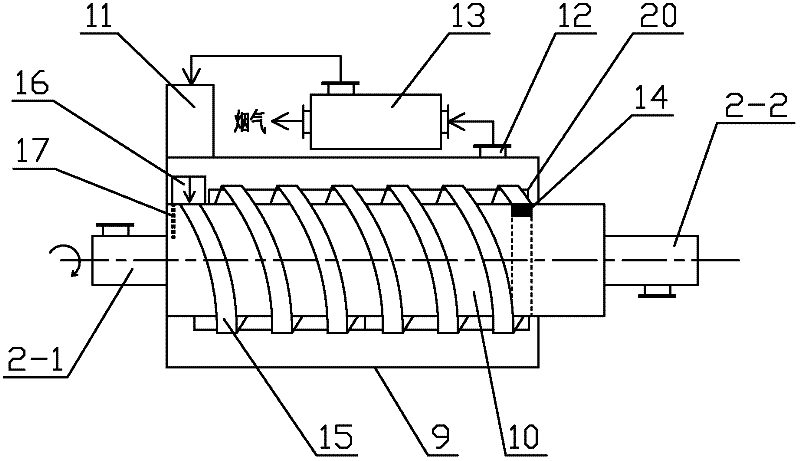

Method for preparing aluminum oxide through treatment of coal ashes with hydrochloric acid

ActiveCN103663511AEffective leachingAchieve cycleAluminium oxides/hydroxidesAluminium chlorideSteelmaking

The invention discloses a method for producing aluminum oxide through treatment and utilization of industrial solid wastes and particularly relates to a method for preparing aluminum oxide through treatment of coal ashes with hydrochloric acid. The method comprises the following steps: activating coal ashes; mixing the activated coal ashes with 15%-36% hydrochloric acid, wherein a molar ratio of HCl in the hydrochloric acid to aluminum oxide and iron oxide in the coal ashes is 4-9; feeding mixed serous fluid into a reactor, heating to 90 DEG C-230 DEG C, wherein reaction time is 1 hour-8 hours; carrying out solid-liquid separation after reacting and cooling to obtain aluminum chloride liquid and high-silicon residue, and evaporating, concentrating or drying to obtain crystallized aluminum chloride; decomposing the crystallize aluminum chloride to obtain crude gamma-Al2O3 and a hydrogen chloride gas; and preparing metallurgical-level aluminum oxide by gamma-Al2O3 through a Bayer process, wherein the residue is high-iron residue and can be used as a steelmaking material. According to the method, any auxiliary agent is not added, so that aluminum oxide in the coal ashes can be effectively leached out, and the leaching rate of the aluminum oxide can reach over 85%.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Method for efficient and comprehensive utilization of high-iron bauxite

ActiveCN102515223AAchieve cycleEffective leachingAluminium oxides/hydroxidesAluminium chlorideAluminium hydroxide

The invention relates to a method for efficient and comprehensive utilization of high-iron bauxite. The method provided by the invention comprises the following steps that 1, high-iron bauxite and hydrochloric acid are mixed, then are added into a hydrochloric acid-resistant medium-pressure reactor and undergo a heating reaction; 2, after cooling, the reaction products are subjected to solid-liquid separation so that high-silicon dregs and a solution containing aluminum chloride and ferric chloride are obtained; 3, the solution containing aluminum chloride and ferric chloride is added with an excess amount of a sodium hydroxide alkaline solution so that a sodium aluminate solution and high-iron dregs are obtained; and the sodium aluminate solution is electrolyzed to produce chlorine, hydrogen, a sodium hydroxide solution and a pure sodium aluminate solution; 4, the pure sodium aluminate solution is introduced into a crystal seed precipitation tank, is subjected to precipitation and then is subjected to solid-liquid separation so that aluminum hydroxide products and a mother liquor are obtained by the precipitation; and 5, the aluminum hydroxide products are graded, wherein the aluminum hydroxide products having small granularity are utilized as crystal seeds for precipitation and the aluminum hydroxide products having big granularity are washed and then are subjected to high-temperature calcination to form metallurgical-grade alumina products. The method provided by the invention can realize effective precipitation of alumina and iron of high-iron bauxite, has low energy consumption in a whole flow, avoids waste production, realizes full green production and is conducive to industrialization.

Owner:SHENYANG POLYTECHNIC UNIV

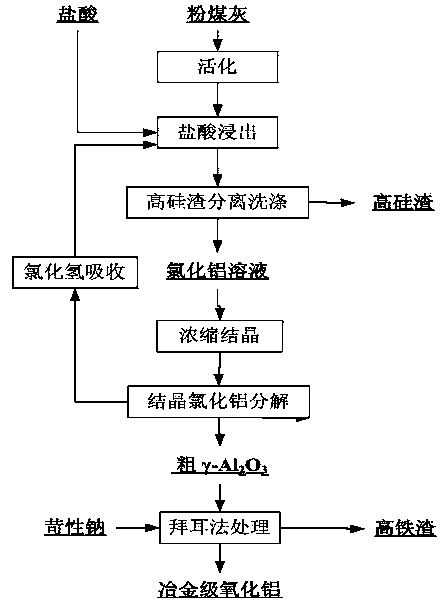

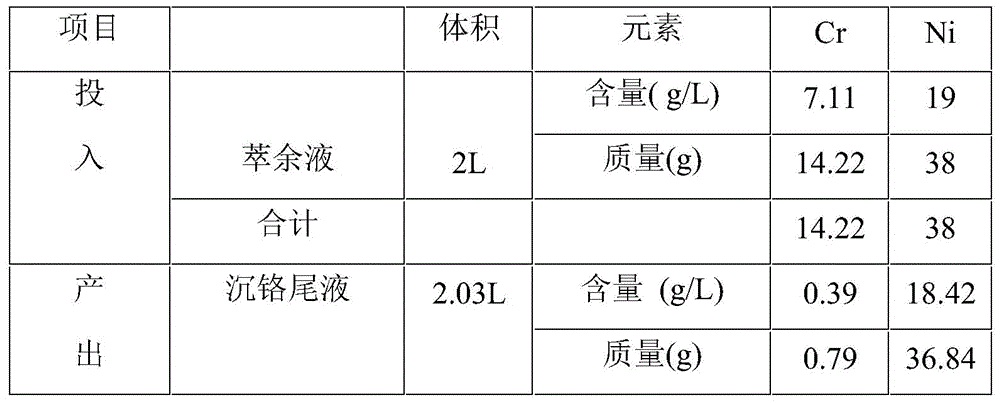

Harmless disposal and resource utilization method for electroplating sludge

InactiveCN105734294ADetoxify thoroughlyAdaptableProcess efficiency improvementResource utilizationSludge

The invention provides a harmless disposal and resource utilization new technology for electroplating sludge and particularly for complex electroplating sludge rich in copper, iron, nickel, zinc and chromium. Selected microorganisms are high in adaptation to the electroplating sludge and good in leaching performance; one-step extraction is adopted to extract copper, iron and zinc, follow-up nickel and chromium separation and purification are facilitated, in the whole technology, the iron cannot form any solid phase, and the problem that according to an existing reported technology, during iron separation, entrainment is serious or iron precipitation is not thorough is solved; a metallurgical method is adopted to carry out separating and recycling on extraction raffinate, the separation effect is good, and an obtained product is high in purity; and according to the technological process, cleaning and efficient high-value recycling of valuable metal in the electroplating sludge are achieved, the method is high in adaptation to various kinds of electroplating sludge, the electroplating sludge meets the harmless requirement, and the method extremely has the industrialized utilization value.

Owner:HUNAN AIGE ENVIRONMENTAL PROTECTION TECH CO LTD

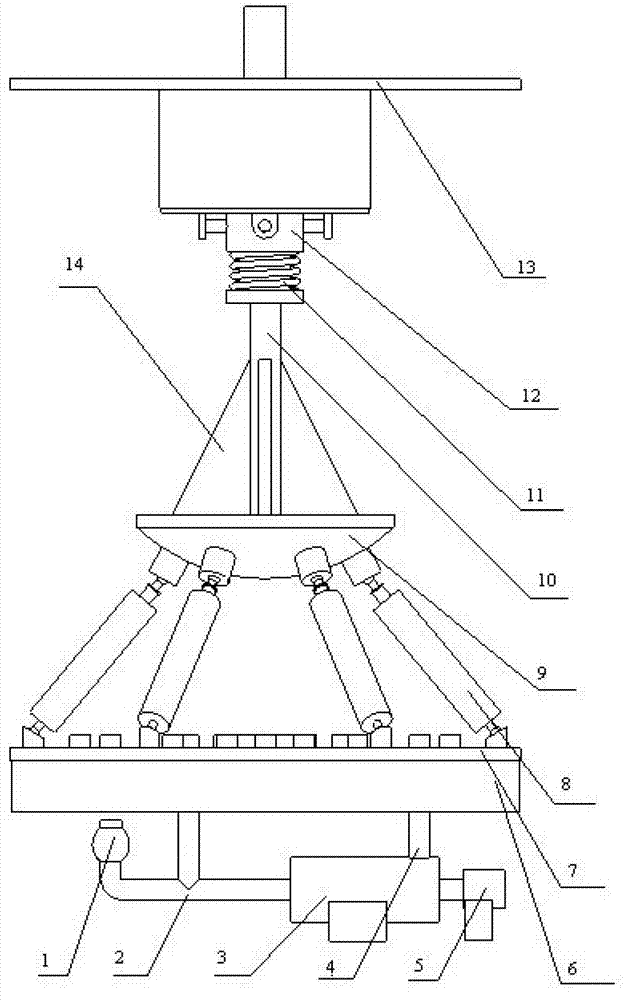

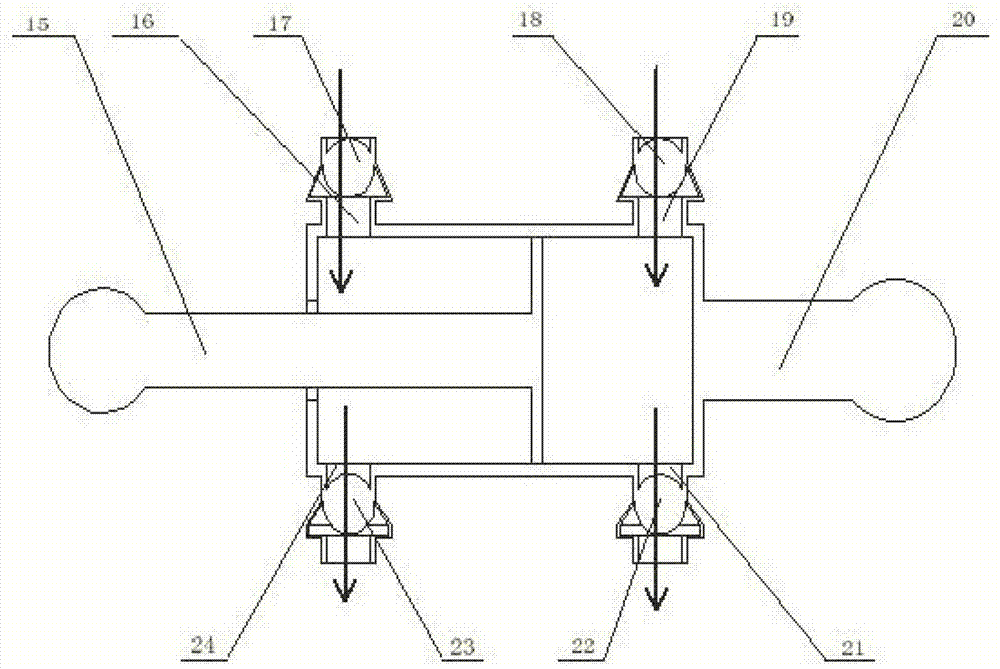

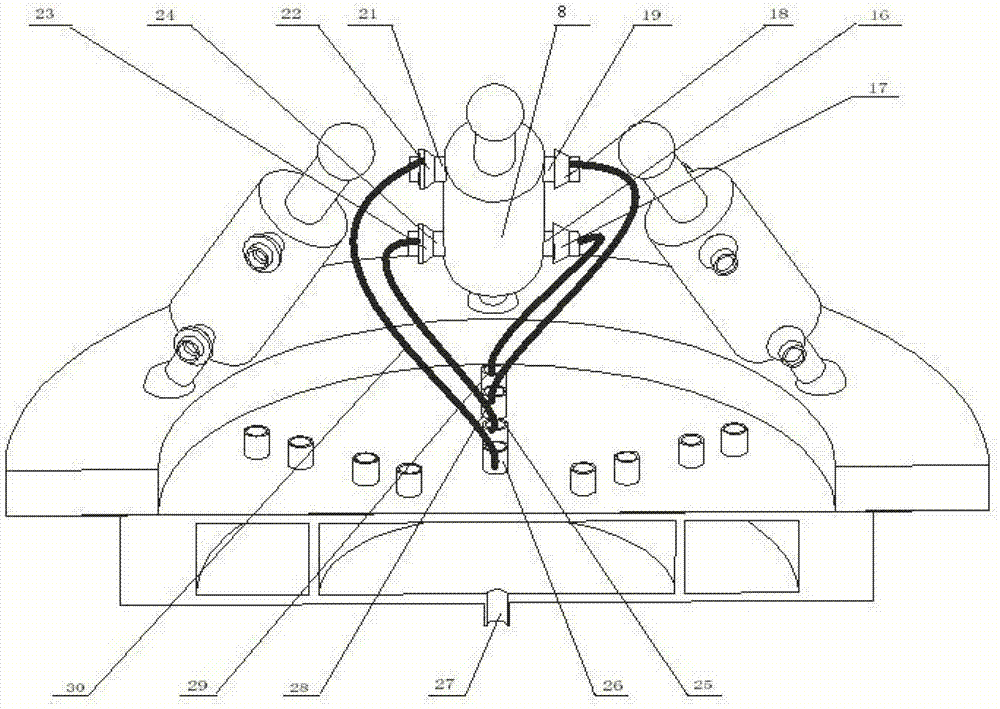

Alkylation reactor and alkylation reaction method

ActiveCN104549110ALow powerFully dispersedLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical nozzle-type rreactorsPtru catalystProcess engineering

The invention discloses an alkylation reactor and an alkylation reaction method. The reactor comprises a reactor tube body, closure heads, a revolving bed, a charging pipe, a charge distribution pipe, a discharging opening, a circulating cooling gas inlet, a circulating cooling gas outlet and a circulating cooling gas refrigeration system, wherein a shell body is formed by the reactor tube body and the closure heads, the revolving bed is arranged at the internal middle part of the shell body and is connected with a driving device through a revolving shaft, the charge distribution pipe is arranged in a hollow tube structure of the center of the revolving bed and is communicated with the charging pipe, the discharging opening is formed in the lower part of the shell body of the reactor, a sealing member is arranged between the upper part of the revolving bed and the shell body, static components and revolving components are sequentially arranged at the radial outer side of the revolving bed, and the circulating cooling gas refrigeration system is located between the circulating cooling gas inlet and the circulating cooling gas outlet. According to the alkylation reaction method disclosed by the invention, alkylation reaction is carried out by taking concentrated sulfuric acid as a catalyst and taking isobutane and alkene as raw materials. According to the alkylation reactor and the alkylation reaction method, the alkylation reaction can be carried out at relatively low temperature, the acid consumption is low, the quality of products is high, and the equipment scale is small.

Owner:CHINA PETROLEUM & CHEM CORP +1

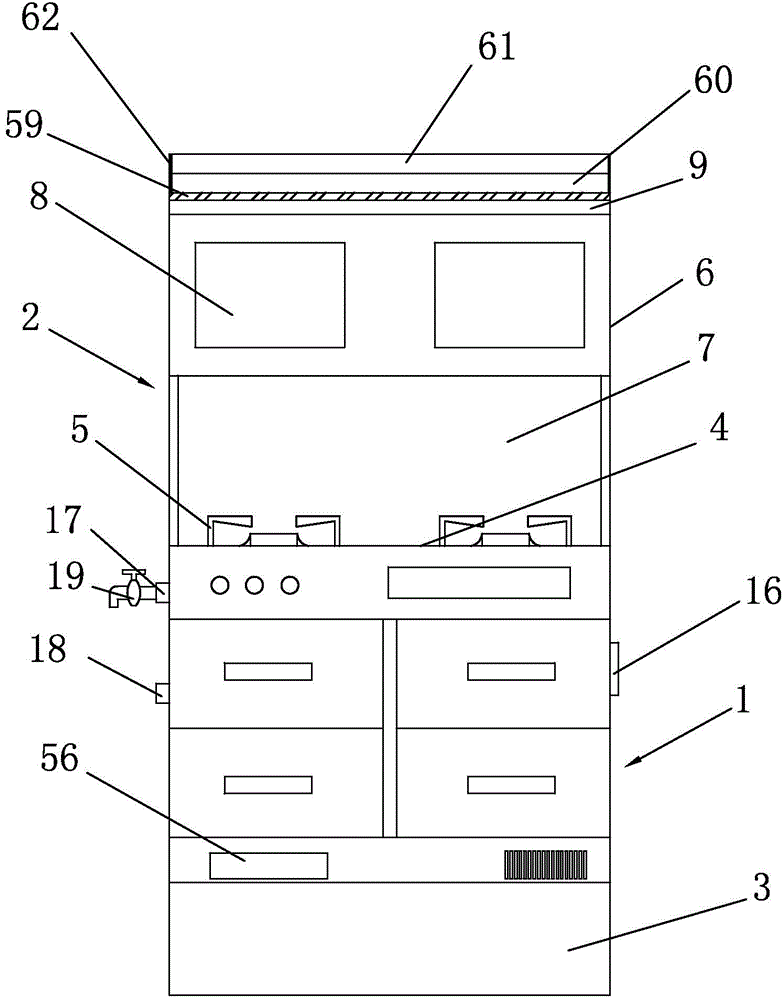

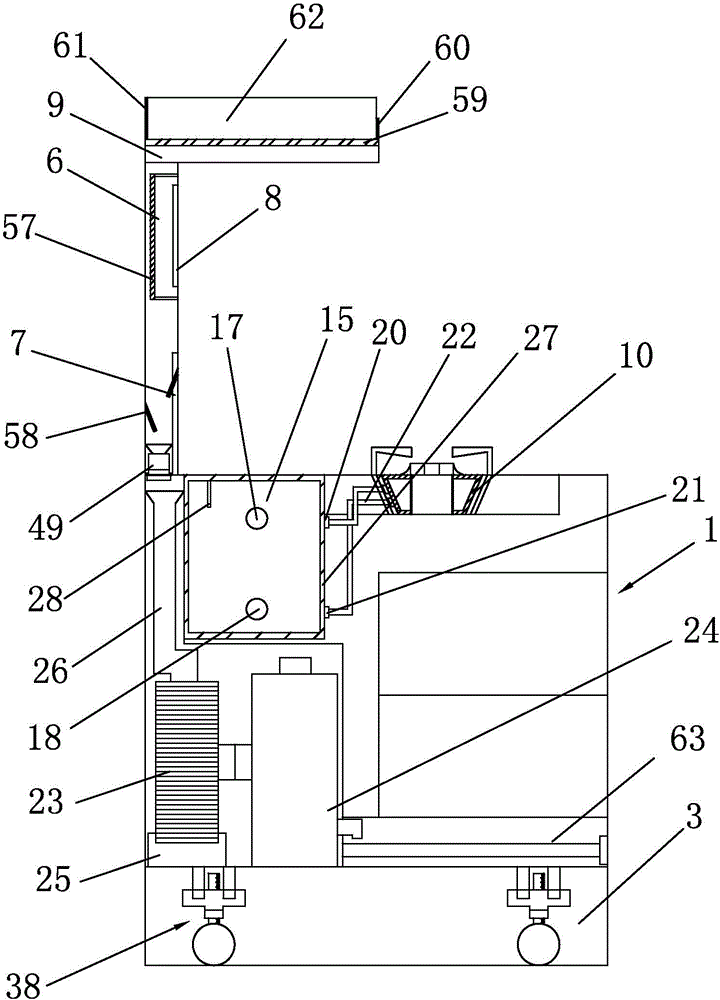

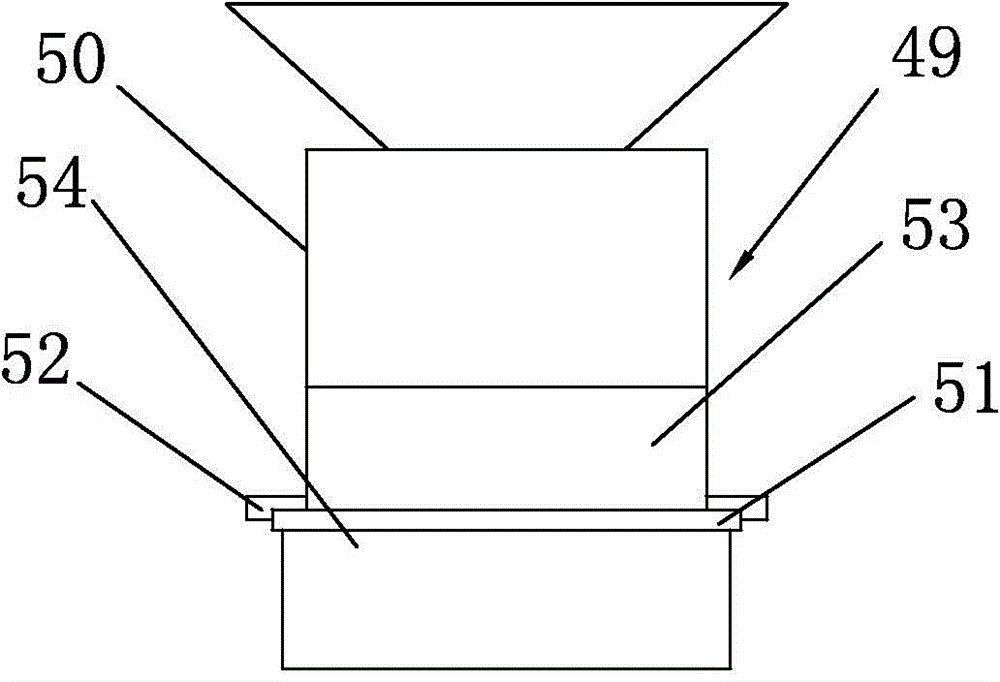

Multifunctional integrated cooker with waste heat collection devices

ActiveCN104633731AExtended service lifeTake advantage ofStoves/ranges foundationsLighting and heating apparatusHearthPollution

The invention discloses a multifunctional integrated cooker with waste heat collection devices. The multifunctional integrated cooker comprises a body, an exhaust fume collecting hood and a protective plate, wherein a cooking bench is arranged on the top surface of the body; at least two cookers are arranged on the cooking bench; the exhaust fume collecting hood comprises a side plate, a smoke guide plate, an air door and a smoke stop cover; the waste heat collection devices are arranged in the hearths of the cookers; at least four height adjusting devices are arranged at the bottom of the body; the height adjusting devices comprise rollers, screw rods, limiting nuts, lifting seats and supporting rods; and the protective plate is positioned below the body and is connected with the body. The multifunctional integrated cooker disclosed by the invention is simple in structure and high in practicality, and due to the waste heat collection devices, the heat energy utilization rate during fuel gas combustion is improved, and the energy consumption is reduced. Moreover, cold water can be heated by virtue of heat, the water can be drunk and can be used for cleaning the cookers, and the cookers are convenient to use; and due to the design of an anti-counter-flow device, the condition that pollution of a kitchen environment is caused due to smoke recirculation in the flue is avoided, the cooker is safe to use, and the comprehensive utilization efficiency is improved.

Owner:绍兴吾家电器有限公司

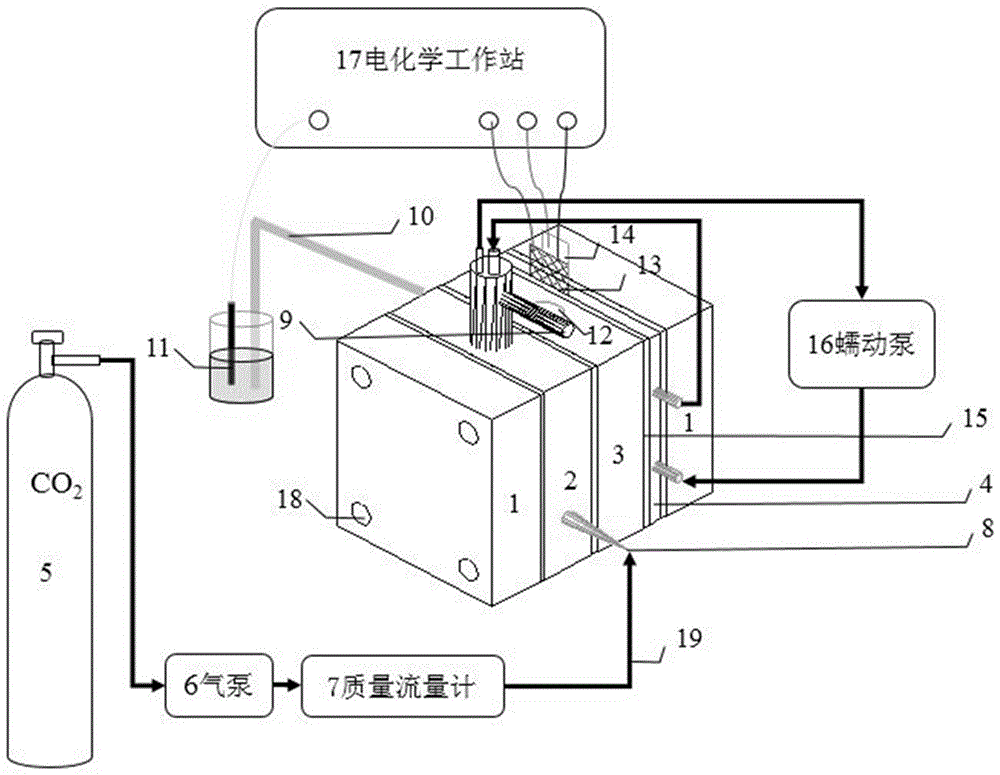

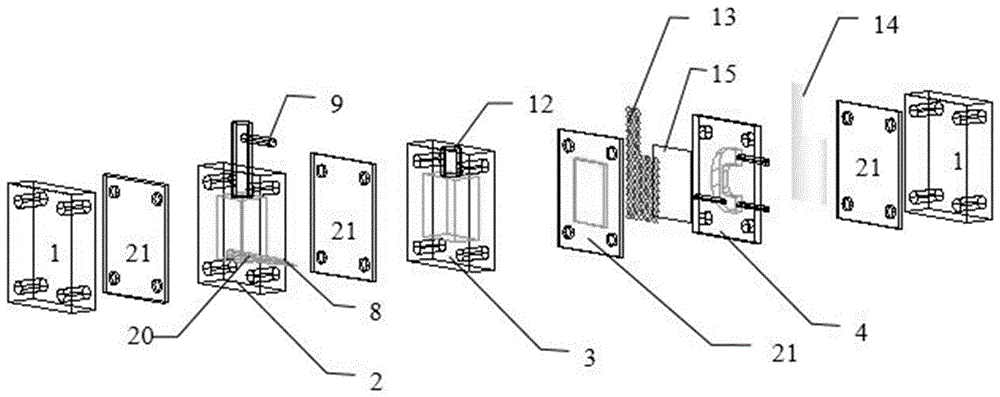

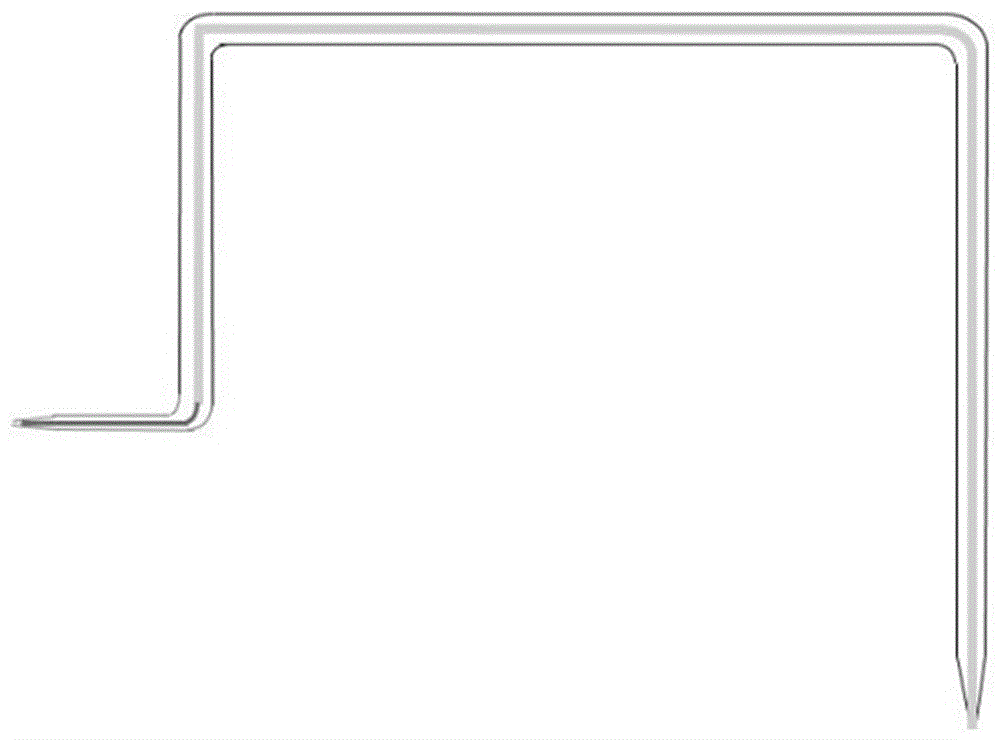

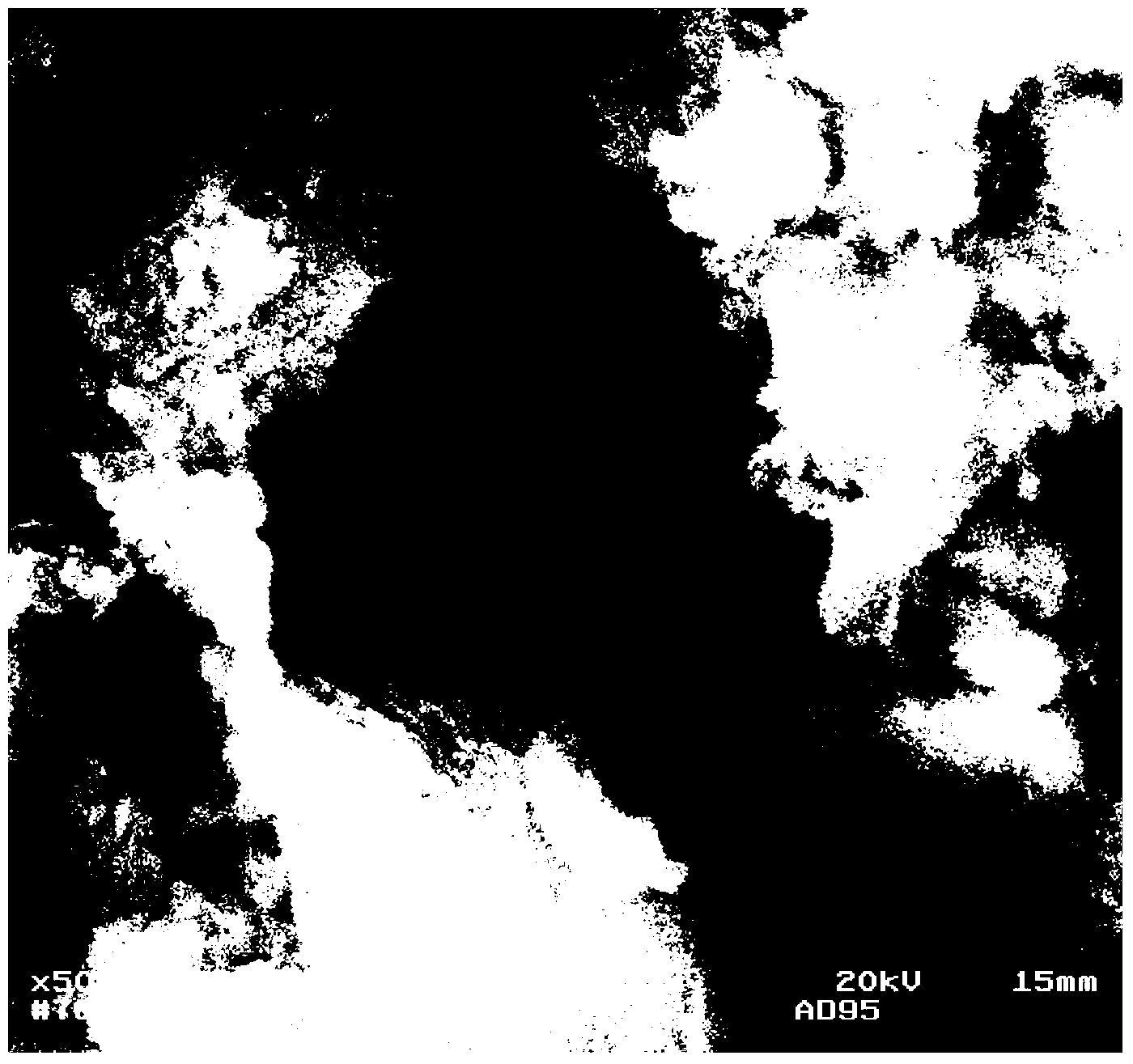

Flow-rate-adjustable electrolytic tank reaction device for electrically reducing carbon dioxide

InactiveCN106521541AAchieve dissolutionAchieve cycleCellsElectrolytic organic productionLiquid productPeristaltic pump

The invention discloses a flow-rate-adjustable electrolytic tank reaction device for electrically reducing carbon dioxide. The electrolytic tank reaction device comprises two end plates (1), an aeration liquid storage chamber (2), an anode chamber (3) and a cathode chamber (4), wherein the cathode chamber (4) is provided with an S-shaped flow channel; an ion exchange membrane (15) is spaced between the anode chamber (3) and the cathode chamber (4); two electrodes are located at two sides of the cathode chamber (4) respectively; a feeding and discharging opening is formed in the side of the cathode chamber (4); a solution is fed from the bottom and is discharged from the top; circulation of the solution in the cathode chamber is realized by a peristaltic pump (16); an aeration head is arranged at the bottom of the aeration liquid storage chamber (2); meanwhile, the circulation of a cathode solution is completed at the top of the aeration liquid storage chamber while products can be collected. The device is simple in structure and stable in performance, and is capable of carrying out real-time sampling analysis on gaseous products and liquid products, stably realizing circulation of the cathode solution and accurately controlling the flow rate of the liquid flowing through the surface of a catalyst so as to improve the selectivity of reduced products obtained by electrically reducing carbon dioxide.

Owner:山东金奥环保科技有限公司

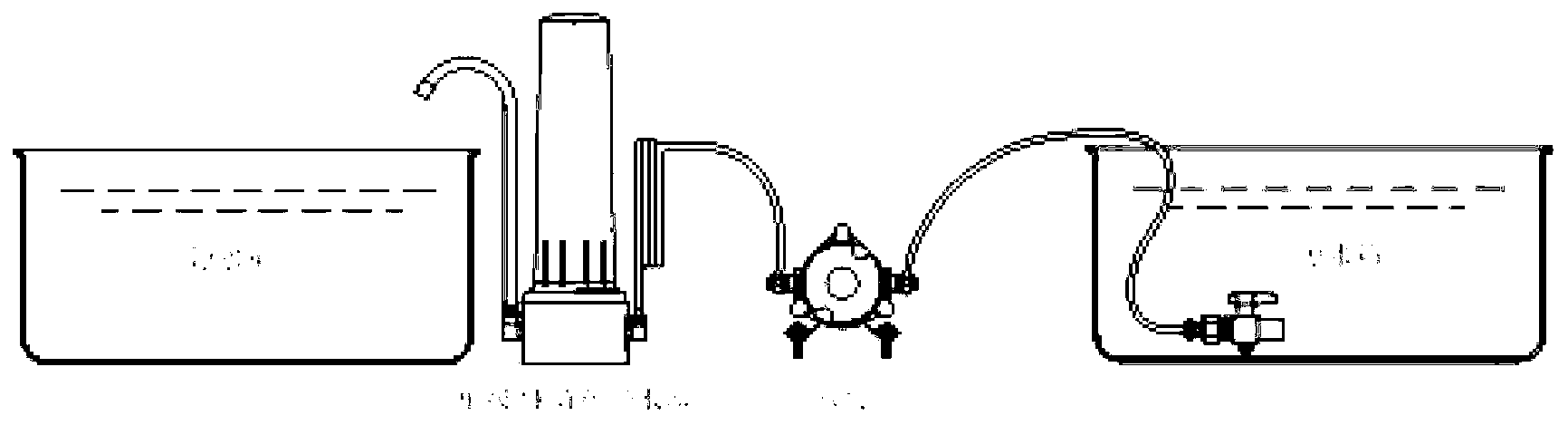

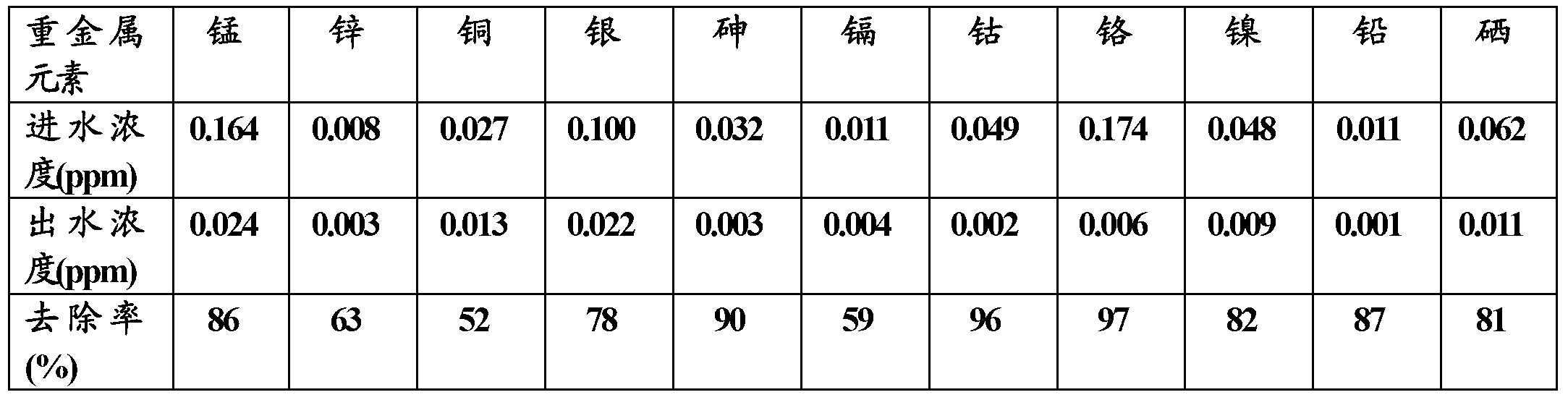

Wastewater treatment filtering material, and preparation method and use thereof

ActiveCN103316544AHigh adsorption and fixation functionStable weak alkalineOther chemical processesFiltration separationWater qualityZerovalent iron

The invention relates to a wastewater treatment filtering material, and a preparation method and a use thereof. The filtering material is formed by a porous ceramic matrix having an amount of porosity of 35-85% and nanometer zerovalent iron particles in-situ generated in the porous ceramic matrix, the micropore size of the porous ceramic matrix is 2-10mum, a fuzzy amorphous silicon-iron-carbon structure is formed in the micropore and can form an adsorbing film after absorbing water, and the material of the porous ceramic matrix is composed of 55-65 parts by weight of diatomite, 12-15 parts by weight of calcium-based bentonite, 7-12 parts by weight of carbon powder, 2-3 parts by weight of starch, and 4-6 parts by weight of kaolin. The filtering material obtained in the invention forms a nose-like porous fluffy filtering structure in the microstructure and generates the adsorbing film, so the absorbing efficiency is greatly improved, and the filtering material can be adapted to the chemical environment change of water. The shedding or heavy metal precipitation of the used filtering material does not appear, and the use safety of the filtering material is good.

Owner:SUZHOU MICRO CERAMICS HEAVY METAL FILTER TECH

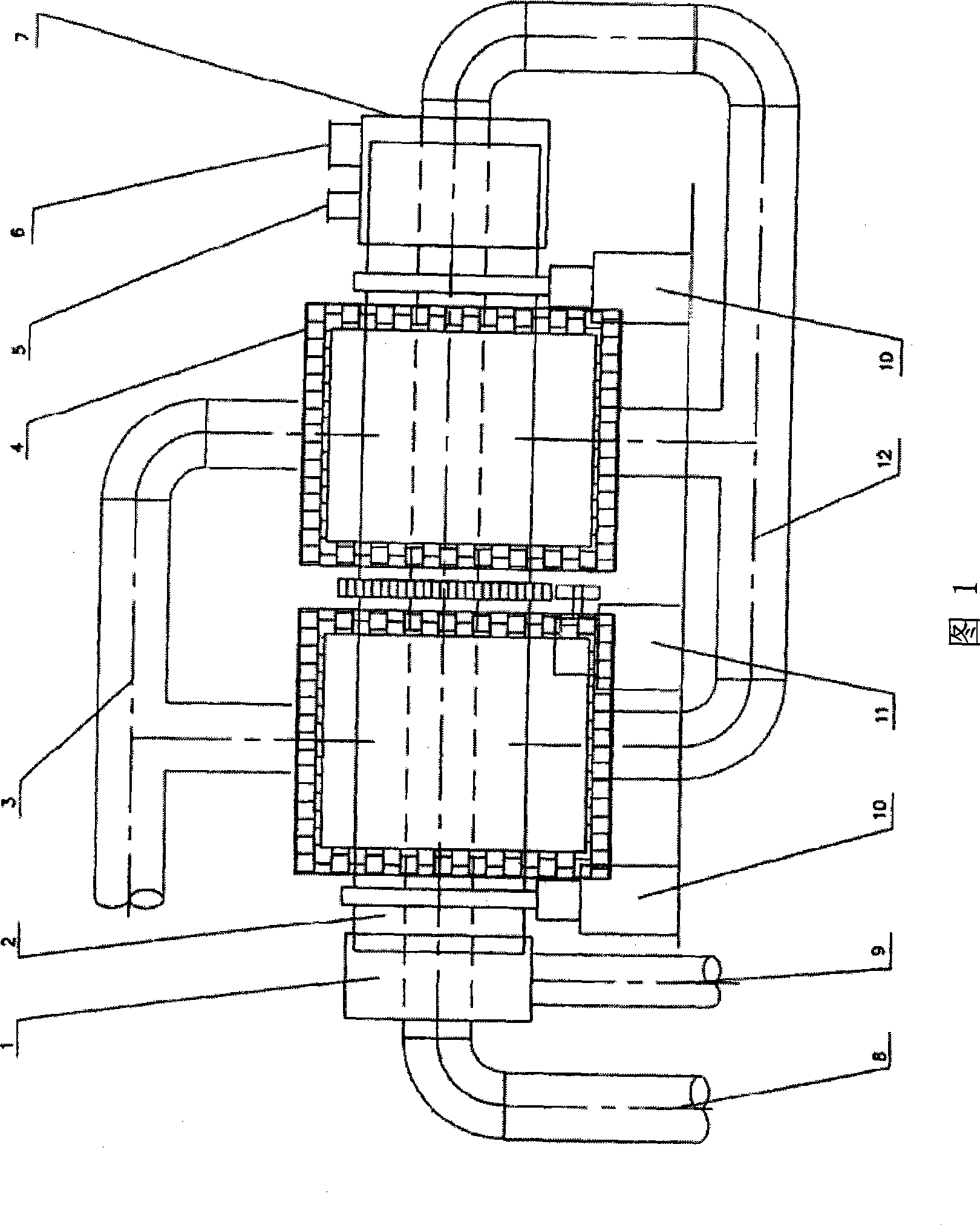

No-oxygen pyrolysis gasification processing device of urban domestic garbage and technique thereof

The present invention discloses a city domestic rubbish anaerobic schizolysis gasification processing apparatus and technical skill thereof, wherein the apparatus is composed by a rubbish storage hopper, a converting kiln, a compressor, an organic matter converting kiln and a sewage disposal system etc. The technical skill includes no exogenous source low energy consumption dispose and system secondary pollution control technique etc. Technical problems like system oxygen exhaust technology, domestic rubbish dehumidifying technology, flowing technology of solid material inside the system, heating technology during the process etc. are solved through the invention. Harmlessness and zero discharge, energy self-supply and basic energy source and substance recirculation in the process of production, social low cost input and facilitating operation of rubbish treatment, and every saving, exhaust reducing and material cycle in natural world can be realized.

Owner:SHANGHAI SHENGONG ENVIRONMENTAL PROTECTION CO LTD

Railway wagon brake cylinder

InactiveCN103352942AAchieve cycleActive lubrication achievesRailway hydrostatic brakesRailway hydrodynamic brakesEngineeringCylinder block

The invention discloses a railway wagon brake cylinder which comprises a cylinder body, a piston assembly and a piston rod. The piston assembly and the piston rod are arranged in the cylinder body. A drive lubrication mechanism used for enabling the piston assembly to rotate in the process of brake release is arranged in the cylinder body. The drive lubrication mechanism comprises a plurality of leaf springs arranged at the bottom of the piston assembly, a gear ring base arranged at the bottom in the cylinder body, a spring seat arranged at the front end in the cylinder body and a release spring sleeved on the piston rod. The leaf springs are matched with the gear ring base to form a ratchet wheel structure. One end of the release spring abuts against the inner side end face of the piston assembly, the other end of the release spring abuts against the end face of the spring seat, and the release spring is in a compressed state continuously. When brake release is conducted on the piston assembly, the piston assembly can rotate under the action of the drive lubrication mechanism, so that grease naturally flowing to the lower portion of the brake cylinder is guided to the upper portion of the brake cylinder through the rotation of the piston, the grease of the brake cylinder circulates in the brake cylinder, and the function of driving lubrication is achieved.

Owner:MEISHAN CRRC BRAKE SCI & TECH CO LTD

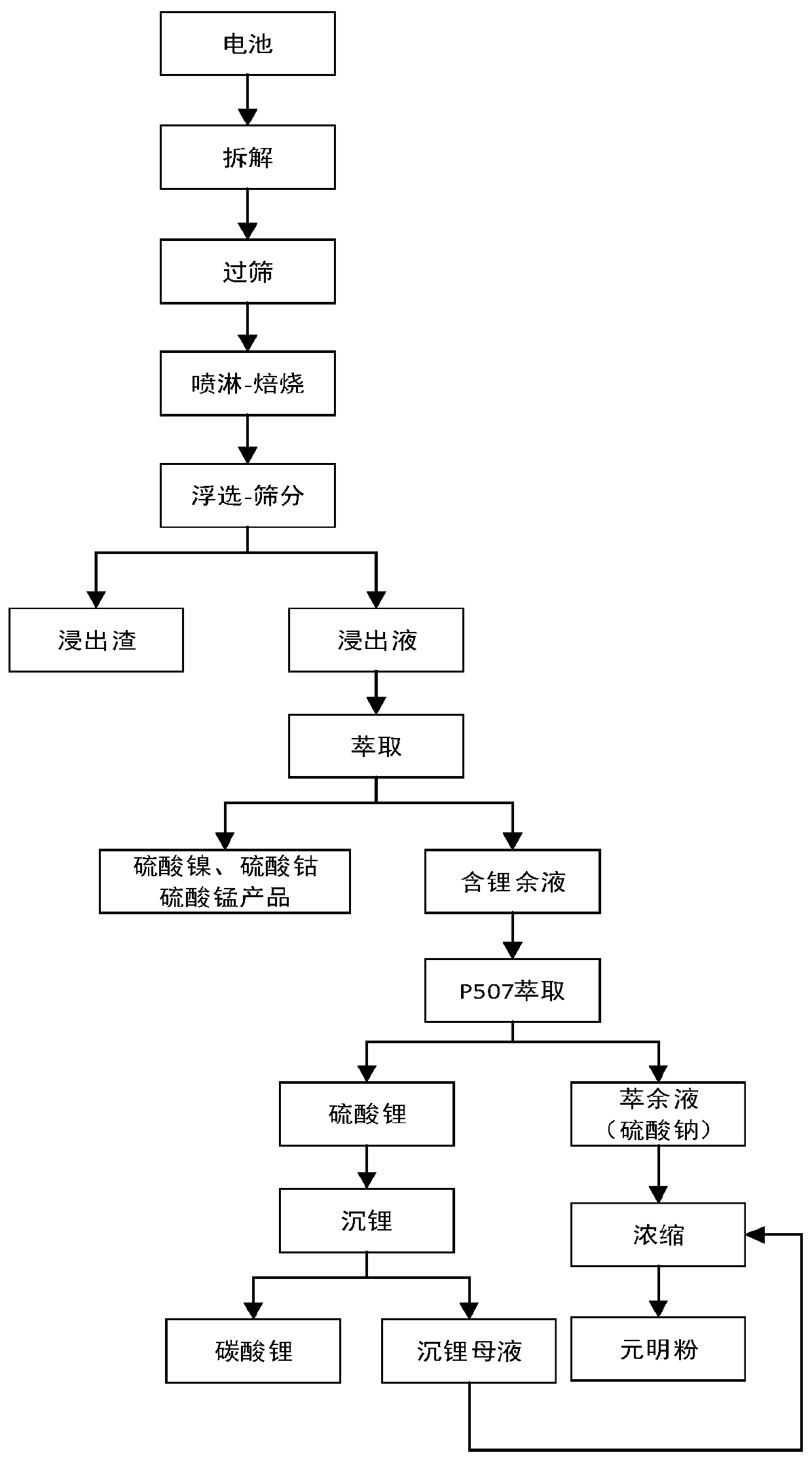

Power lithium ion battery all metal recycling and cyclic utilizing method

ActiveCN110616331AAchieve recyclingShort processCobalt sulfatesWaste accumulators reclaimingElectrical batteryLithium carbonate

The invention discloses a power lithium ion battery all metal recycling and cyclic utilizing method. Waste lithium ion batteries serve as raw materials, the disassembling-screening and roasting procedures are adopted for separating battery pole powder from other parts in the batteries, then, acid leaching is conducted, and leaching liquid containing cobalt, nickel, manganese and lithium is obtained; through extraction, separation and purification of cobalt, nickel, manganese and lithium are achieved, battery-level cobaltous sulfate, nickel sulfate and manganese sulfate are obtained, then, lithium-sodium separation is conducted, and lithium carbonate and sodium sulfate products are obtained through lithium deposition and concentration. The power lithium ion battery all metal recycling and cyclic utilizing method is green and efficient, danger waste generation is avoided, and large-scale production can be achieved. Various valuable metals are systematically recycled from the waste powerlithium batteries, according to the recycling rates, Co is larger than 95%, Ni is larger than 95%, Mn is larger than 98%, Li is larger than or equal to 94%, and the water cyclic utilization rate is larger than 95%. Nickel sulfate liquid, cobaltous sulfate liquid, manganese sulfate liquid and lithium carbonate obtained through the power lithium ion battery all metal recycling and cyclic utilizing method meet the battery level product standard.

Owner:衢州华友资源再生科技有限公司

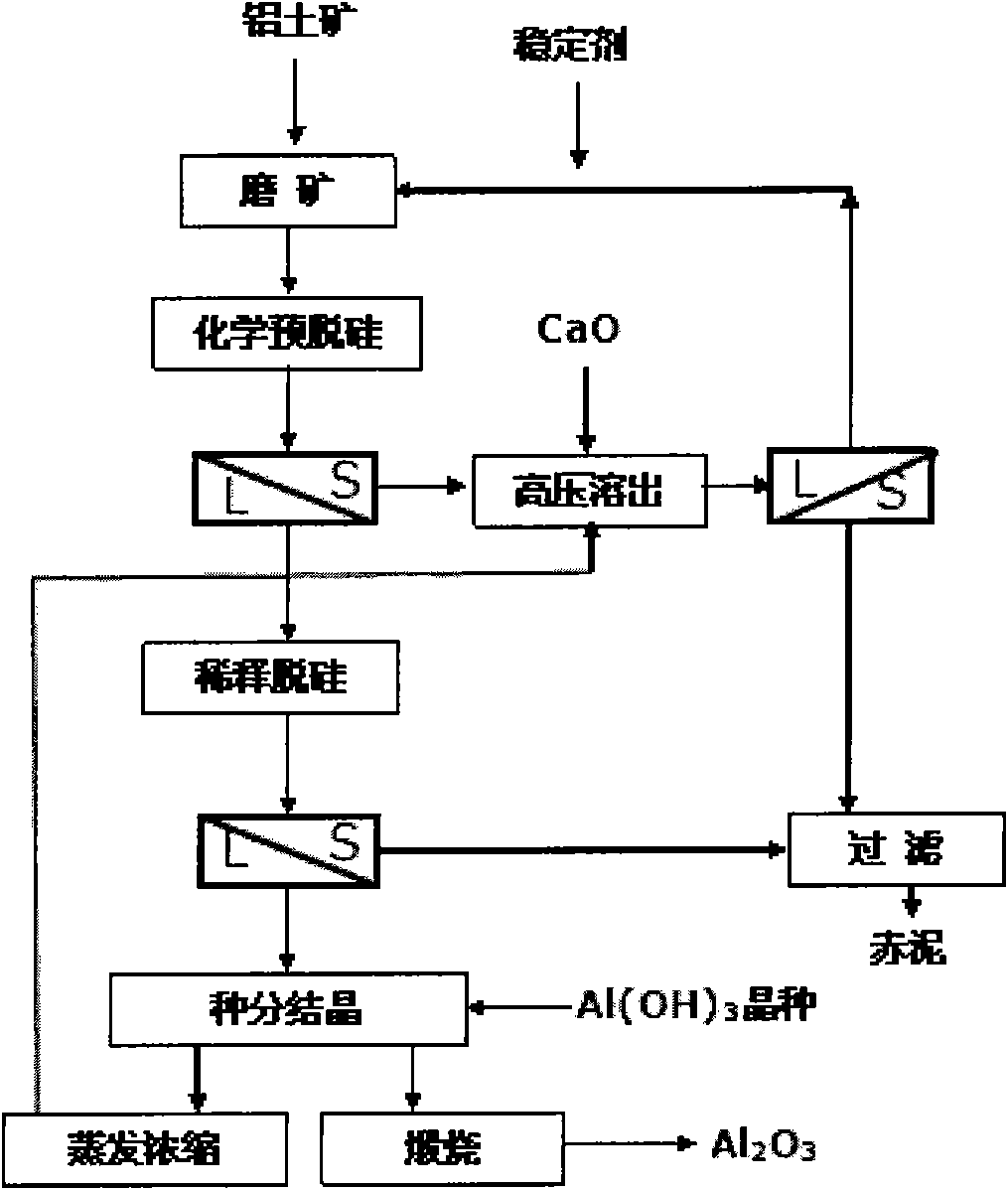

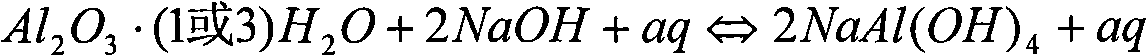

Method for modifying Bayer process, processing low-grade diaspore bauxite and producing alumina

The invention provides a method for modifying a Bayer process, processing low-grade diaspore bauxite and producing alumina. The method comprises steps that: (1) silicon is chemically pre-removed, wherein the low-grade bauxite is immersed into a sodium aluminate solution containing a stabilizing agent, such that a slurry containing dissolved silica is obtained; (2) obtained high-silicon sodium aluminate solution is processed through desilication, wherein desilication crystal seeds are added to the slurry processed through filtration, such that desilication is carried out; (3) the sodium aluminate solution is processed through seed precipitation, wherein aluminum hydroxide crystal seeds are added to the sodium aluminate solution processed through desilication, such that seed precipitation is carried out; (4) the obtained aluminum hydroxide product is baked, such that an alumina product is obtained; (5) a high-pressure dissolution process is carried out, wherein the obtained seed precipitation mother liquor is processed through evaporation and alkali supplementation, and is used in high-pressure dissolution of a concentrate obtained in the step (2); a stabilizing agent is added to the obtained sodium aluminate solution, the sodium aluminate solution is then used for processing the next batch of bauxite, and the steps (1) to (4) are repeated. The method provided by the invention is suitable to be used for processing low-grade diaspore bauxite. With the method, a silicon scaling problem in alumina industries can be effectively solved, energy consumption can be substantially improved, and the quality of the finished product alumina can be improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

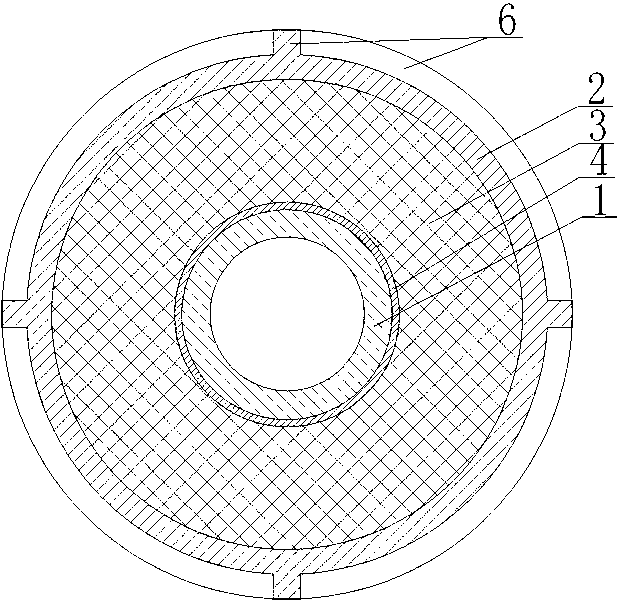

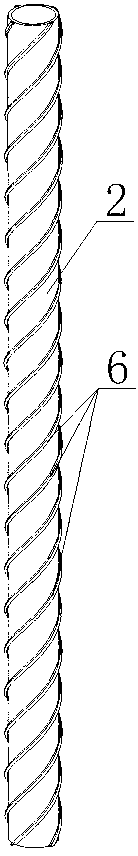

Improved annular fuel element of supercritical water reactor and fuel component consisting of fuel element

ActiveCN103106929AGood for controlling heat conductionPrecise control of heat conductionFuel elementsNuclear energy generationFully developedNuclear engineering

The invention discloses an improved annular fuel element of a supercritical water reactor and a fuel component consisting of the fuel element. The improved annular fuel element comprises an inner wrapping shell and an outer wrapping shell coaxial with the inner wrapping shell, wherein granular fuel is filled between the inner wrapping shell and the outer wrapping shell; and a heat isolation coating layer is also arranged between the granular fuel and the inner wrapping shell. The fuel component consists of the annular fuel element, an upper heat isolation plate, a lower heat isolation plate, an upper flow guide plate and a lower flow guide plate which are matched with one another; a moderator on the inner side of the annular element and a coolant which is arranged on the outer side and flows in an opposite direction can be effectively shunted; no special control stick guide pipe is arranged in the component, so that the structural design of the component is simplified, the using amount of structural materials is reduced, and the economical property is improved; the advantages of uniformity in moderation of the annular fuel element, heat transmission on both sides, low fuel temperature and the like are fully developed; the engineering application feasibility is greatly improved; and therefore, the supercritical water reactor with relatively high economical property and safety can be designed.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

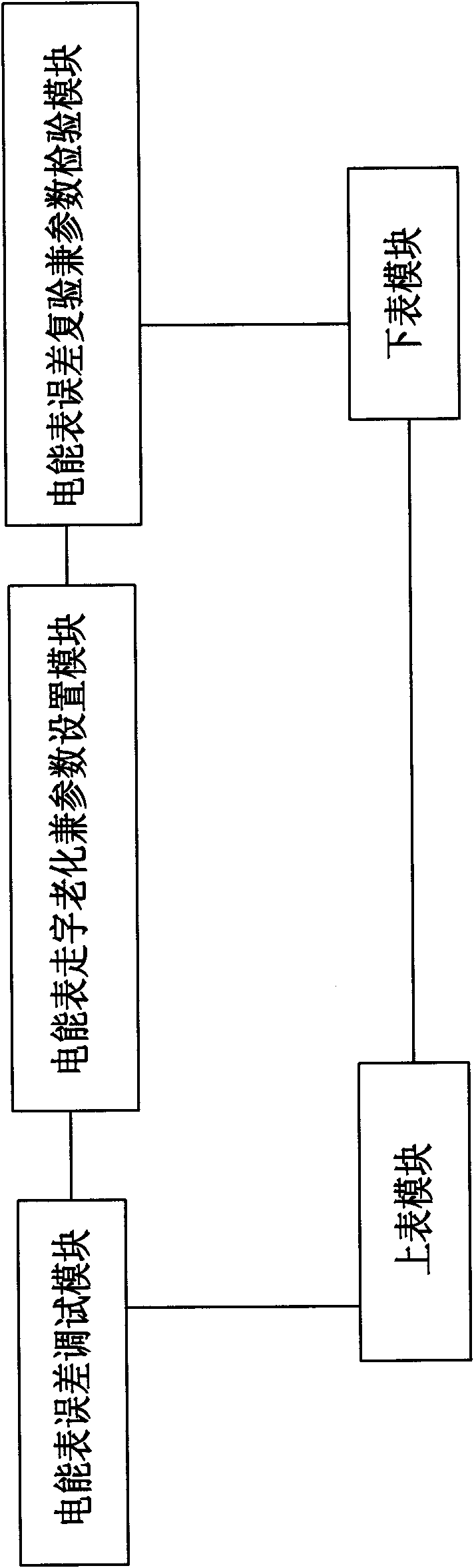

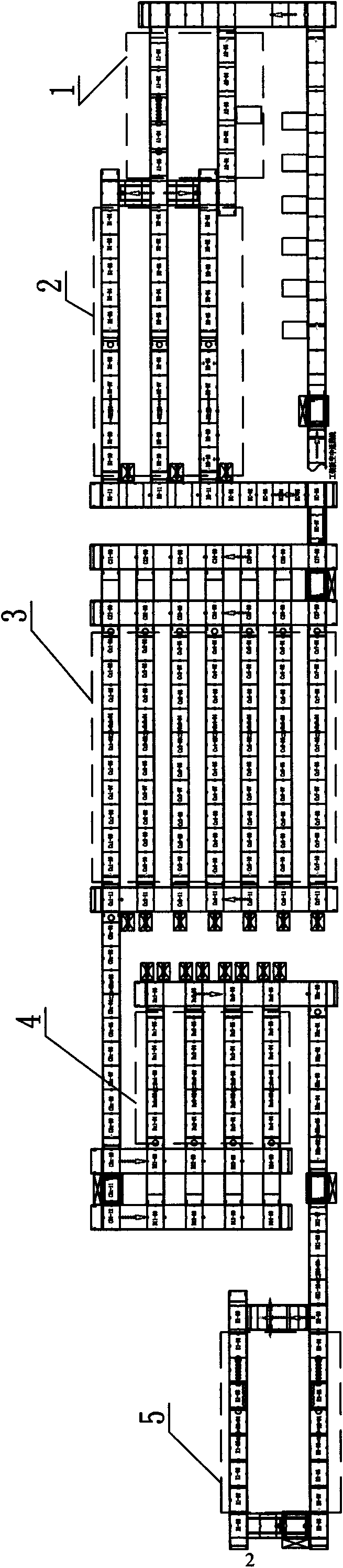

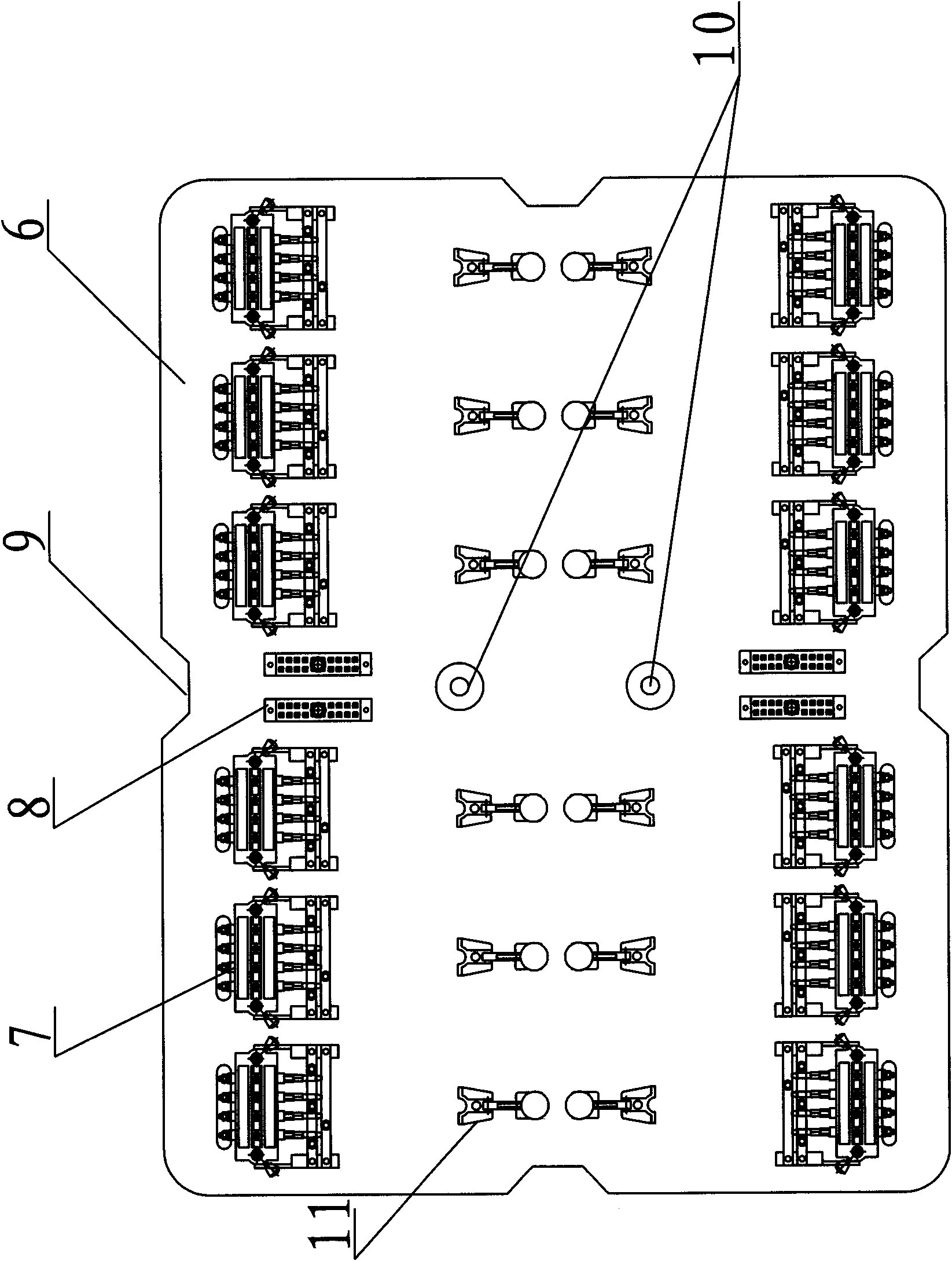

Detecting and setting device on production line of electric energy meters

ActiveCN101819266AHigh degree of automationImprove work efficiencyElectrical measurementsElectric energyTransmission line

The invention discloses a detecting and setting device with high degree of automation, working efficiency and reliability on a production line of electric energy meters. The detecting and setting device on a production line of electric energy meters comprises an upper meter module (1), an electric energy meter error adjusting module (2), an electric energy meter motion aging and parameter setting module (3), an electric energy meter error re-detecting and parameter detecting module (4) and a lower meter module (5), wherein transmission lines are arranged between adjacent modules and between the upper meter module (1) and the lower meter module (5), at least one transmission line is arranged in each module and connected with an adjacent transmission line between the modules, each transmission line is provided with a tray, a position sensor and a limit unit, the transmission line in each module is provided with an automatic crimping unit, the upper meter module (1) and the lower meter module (5) are also internally provided with scanning units, and the motor control modules, the position sensors and the limit units of the transmission lines, the scanning units and the automatic crimping units are electrically connected with a central control unit on the production line of electric energy meters.

Owner:NINGBO SANXING INTELLIGENT ELECTRIC

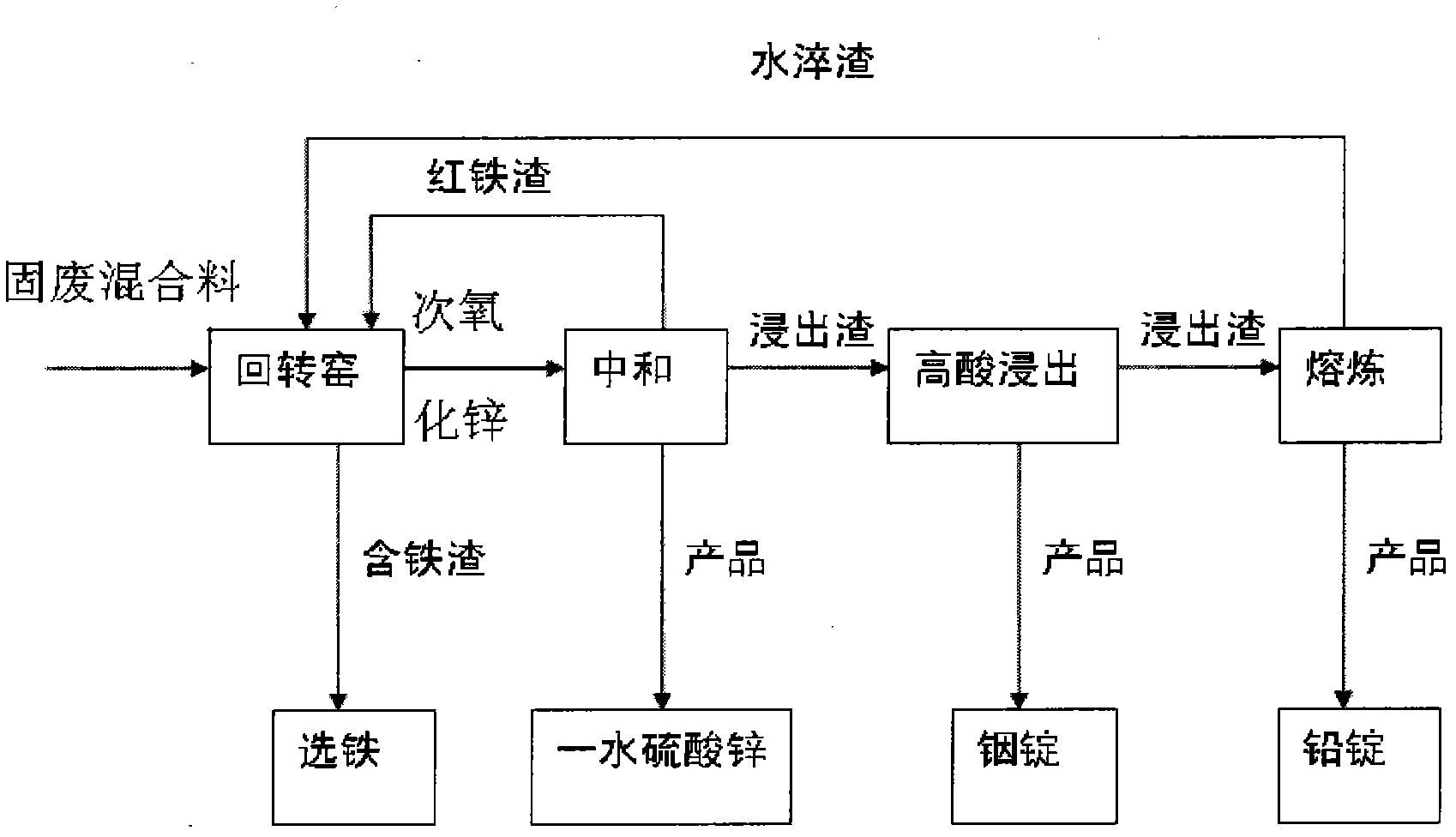

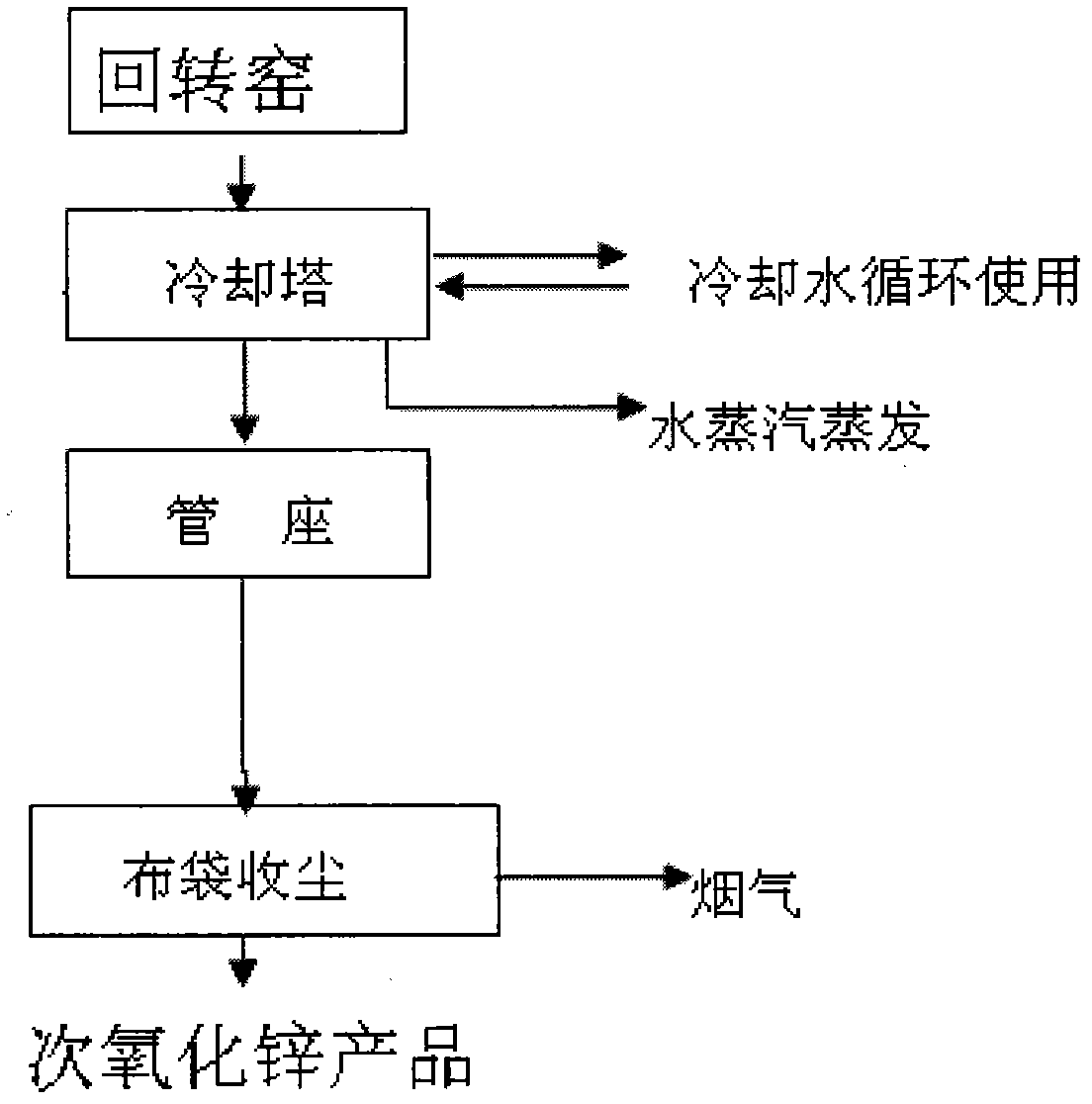

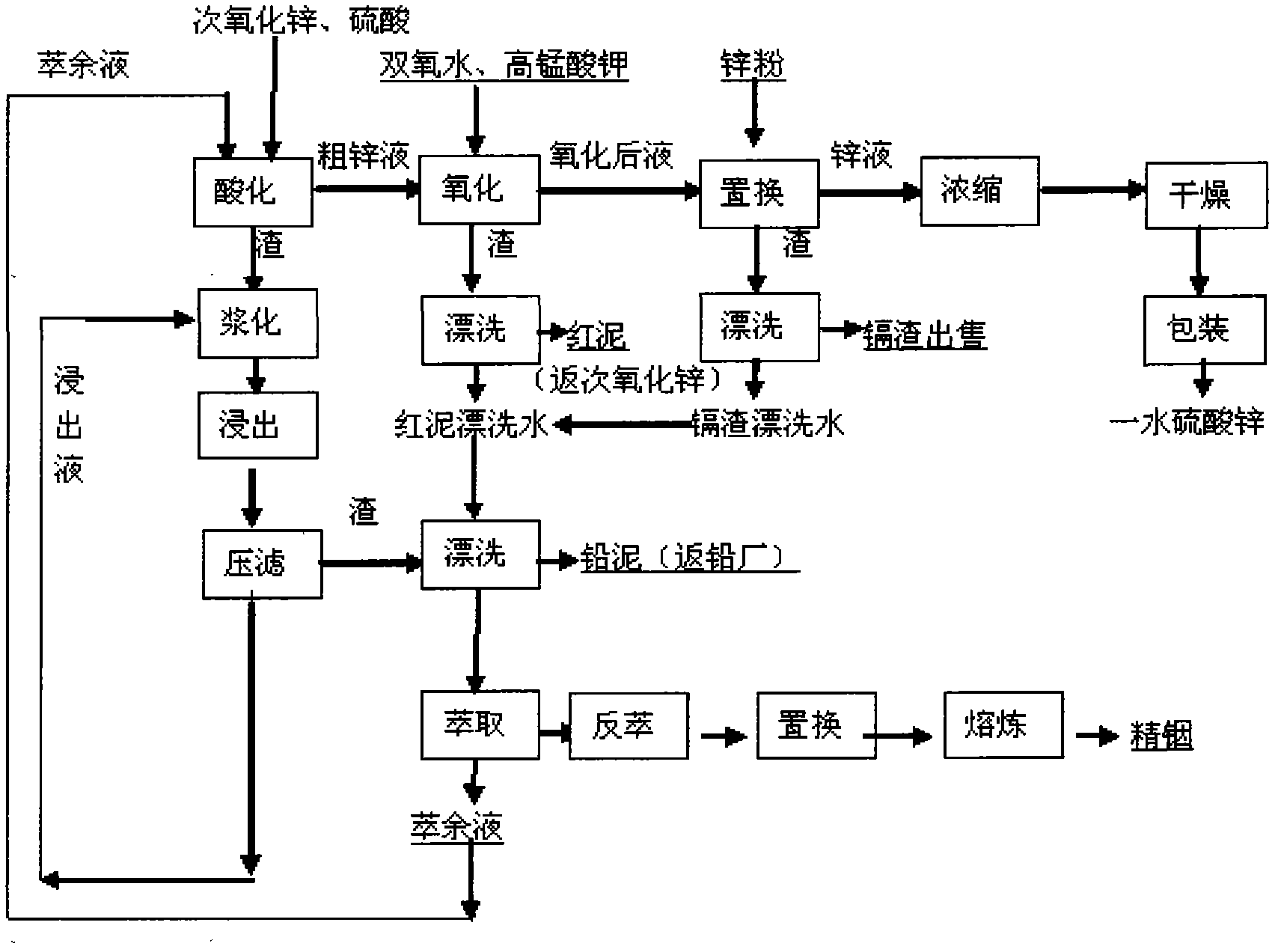

Treatment method for harmless reclamation of solid waste of heavy metal

ActiveCN102560124ABurn fullyReduce maintenance costsProcess efficiency improvementSlagZinc sulfate monohydrate

The invention discloses a treatment method for harmless reclamation of solid waste of heavy metal, comprising the following steps: adding coal-free solid waste mixture with low heat value to a rotary kiln for harmless reclamation of solid waste of heavy metal; combusting the solid waste mixture at a high temperature in the rotary kiln to produce zinc hypoxide and gather other valued metals; producing iron powders from the iron-containing slag that is generated in the rotary kiln as iron screening raw material; using zinc hypoxide as raw material to conduct acid leaching for neutralization to produce zinc sulfate monohydrate, then using the red iron slag that produces zinc sulfate monohydrate as the raw material for zinc hypoxide and leaching the leached slag that produces zinc sulfate monohydrate with high acid to reclaim indium ingot; after reclamation of the indium ingot, smelting the leached slag as raw material of lead to produce lead ingot; and recovering the water-hardening slag that produces lead ingot as the raw material for zinc hypoxide. The treatment method of the invention realizes zero discharge of waste water and slag, which not only saves the energy, but also realizes reclamation and comprehensive utilization of the resources and greatly lowers the production cost of the companies so as to create a core competence of the company.

Owner:唐锡中

Sludge return sedimentation pool improved from pipe chute sedimentation pool and improving method thereby

The present invention provides a return sludge settler changed by an inclined tube settler, characterized in that the upper reation region is set with a mixing region and a promoting flocculation zone, a blender is set in the mixing region, a promoting mixer and an attachable stainless steel cylinder are set in the promoting flocculation zone, a baffle system is set between a filtering zone and a inclined tube water outlet, a mud zone sets a plug concentrating mud scraper, the mud pipe is connected with a mud runback to water inlet, the mud runback is set with a mud reflux pump, the mud runback is connected with exterior, and a medical feeding point is set in the water inlet and the main settler. The advantages of the invention is that giving full play impact to index such as biological degradation organic matter, nitrogen and phosphorus etc nu changing traditional inclined tube settler, enhancing coagulation efficiency by high effect mixing and mud return, thus the effluent effect is improved, and the solid ratio of the drainable sludge is enhanced, meeting the direct dehydration condition.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

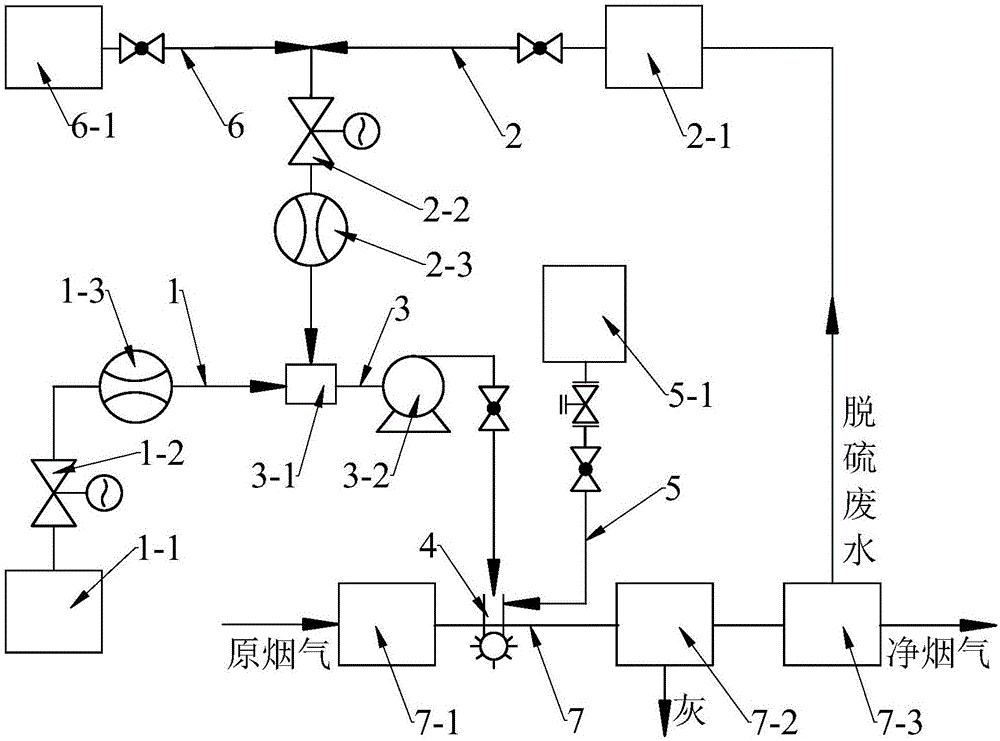

Desulfurization wastewater zero-emission system using coal-fired flue gas semidry method to remove fluorine and chlorine

InactiveCN106076100AEmission reductionAchieve emissionsDispersed particle separationHigh concentrationAir preheater

The invention discloses a desulfurization wastewater zero-emission system using a coal-fired flue gas semidry method to remove fluorine and chlorine. The desulfurization wastewater zero-emission system comprises a high-concentration alkali liquor pipeline, a desulfurization wastewater pipeline, a diluted alkali liquor pipeline, an alkali liquor atomizing device, a compressed air pipeline, a process water pipeline and a flue. The flow of high-concentration alkali liquor is controlled according to unit load and the HCl concentration in flue gas, the high-concentration alkali liquor is mixed with desulfurization wastewater to obtain diluted alkali liquor, the diluted alkali liquor is sprayed into the flue between an air preheater and a dust remover through the alkali liquor atomizing device with multiple nozzles in grid arrangement, the diluted alkali liquor is sufficiently evenly mixed with the flue gas to solidify most of gas such as HCl, HF. SO3 and the like in the flue gas into fly ash, the emission quantity of the desulfurization wastewater is reduced greatly, the desulfurization wastewater can be sprayed into the flue as the base solvent, and zero emission of the desulfurization wastewater is achieved. The desulfurization wastewater zero-emission system has the advantages that the system is low in influence on smoke temperature, the tail flue and equipment, the tendency of fouling corrosion of the tail low-temperature flue and the equipment can be reduced effectively, the desulfurization efficiency is increased, and the system is simple, low in investment and low in operation cost.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com