Desulfurization wastewater zero-emission system using coal-fired flue gas semidry method to remove fluorine and chlorine

A technology for desulfurization wastewater and coal-fired flue gas, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of difficult removal of sediment, large drop in smoke temperature, and high operating costs, and achieve low operating costs. , reduced emissions, simple system effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

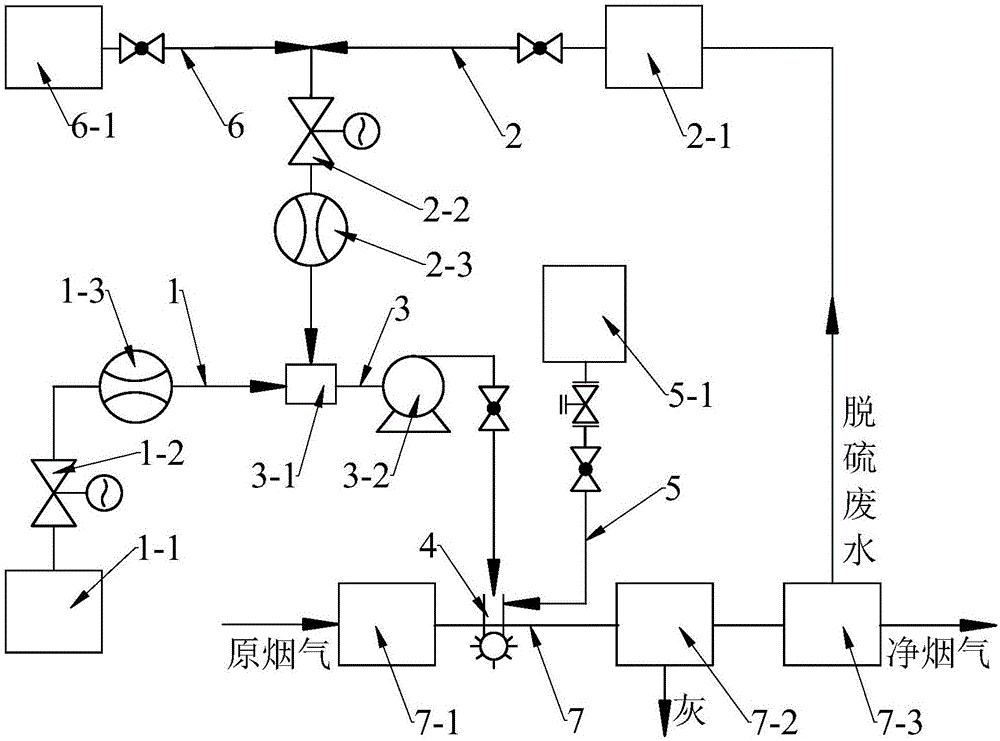

[0021] Such as figure 1 As shown, a desulfurization wastewater zero discharge system for the semi-dry removal of fluorine and chlorine from coal-fired flue gas, including a high-concentration lye pipeline 1, a desulfurization wastewater pipeline 2, a diluted lye pipeline 3, and an lye atomization device 4. Compressed air pipeline 5, process water pipeline 6 and flue 7.

[0022] The high-concentration lye pipeline 1 includes a high-concentration lye storage tank 1-1, a high-concentration lye regulating valve 1-2, and a high-concentration lye flowmeter 1-3.

[0023] The desulfurization wastewater pipeline 2 includes a desulfurization wastewater clarification tank 2-1, a desulfurization wastewater regulating valve 2-2, and a desulfurization wastewater flow meter 2-3.

[0024] The diluted lye pipeline 3 includes an lye dilution mixer 3-1 and a high-pressure pump 3-2.

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com