Patents

Literature

2502results about How to "Improve desulfurization efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Energy-saving and high-quality ammonia desulphurization process for ammonia sulfate recovery

InactiveCN101579602ALow recycling comprehensive operating costConsiderable "positive benefit"Dispersed particle separationThermal energySulfate

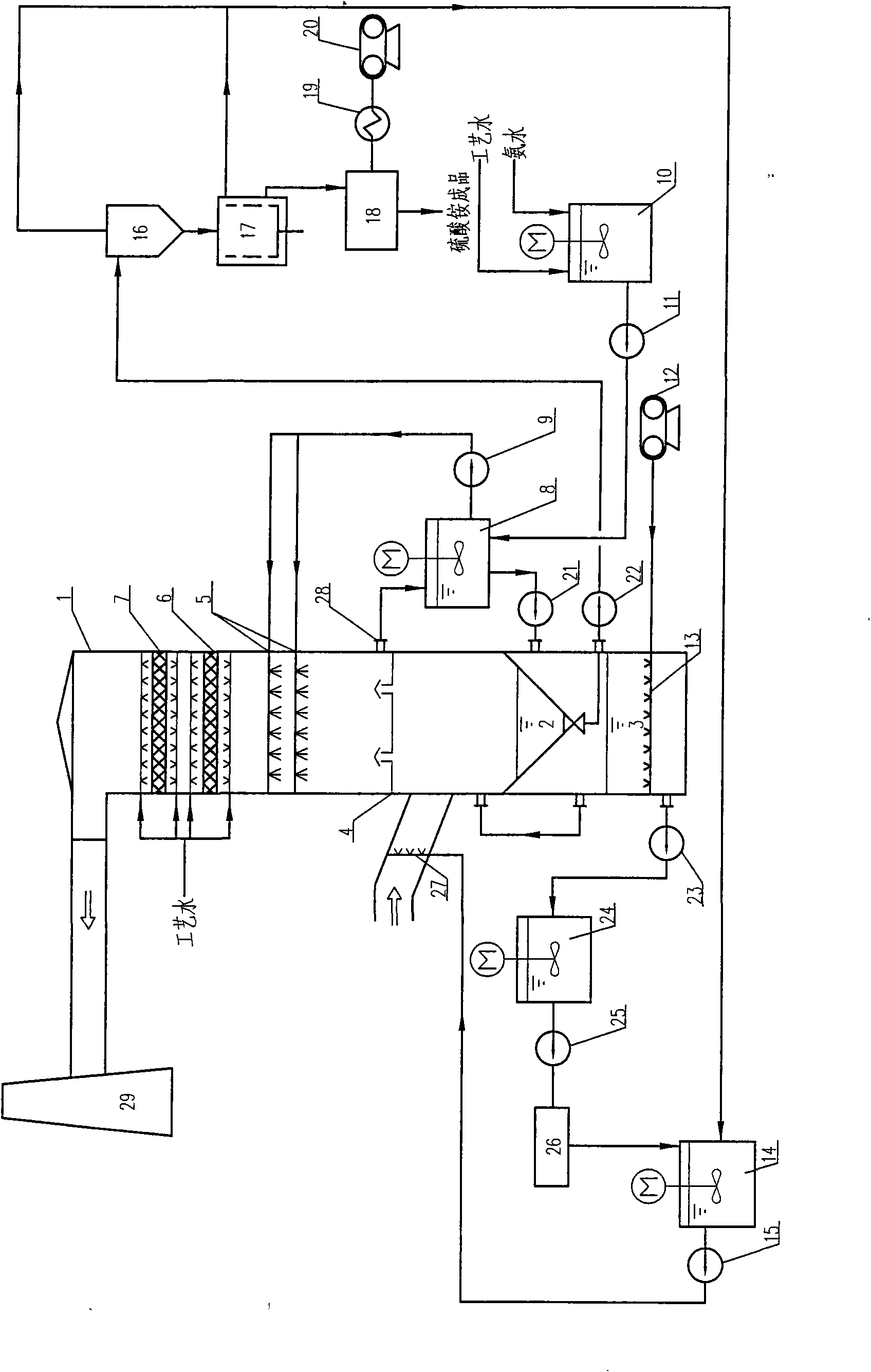

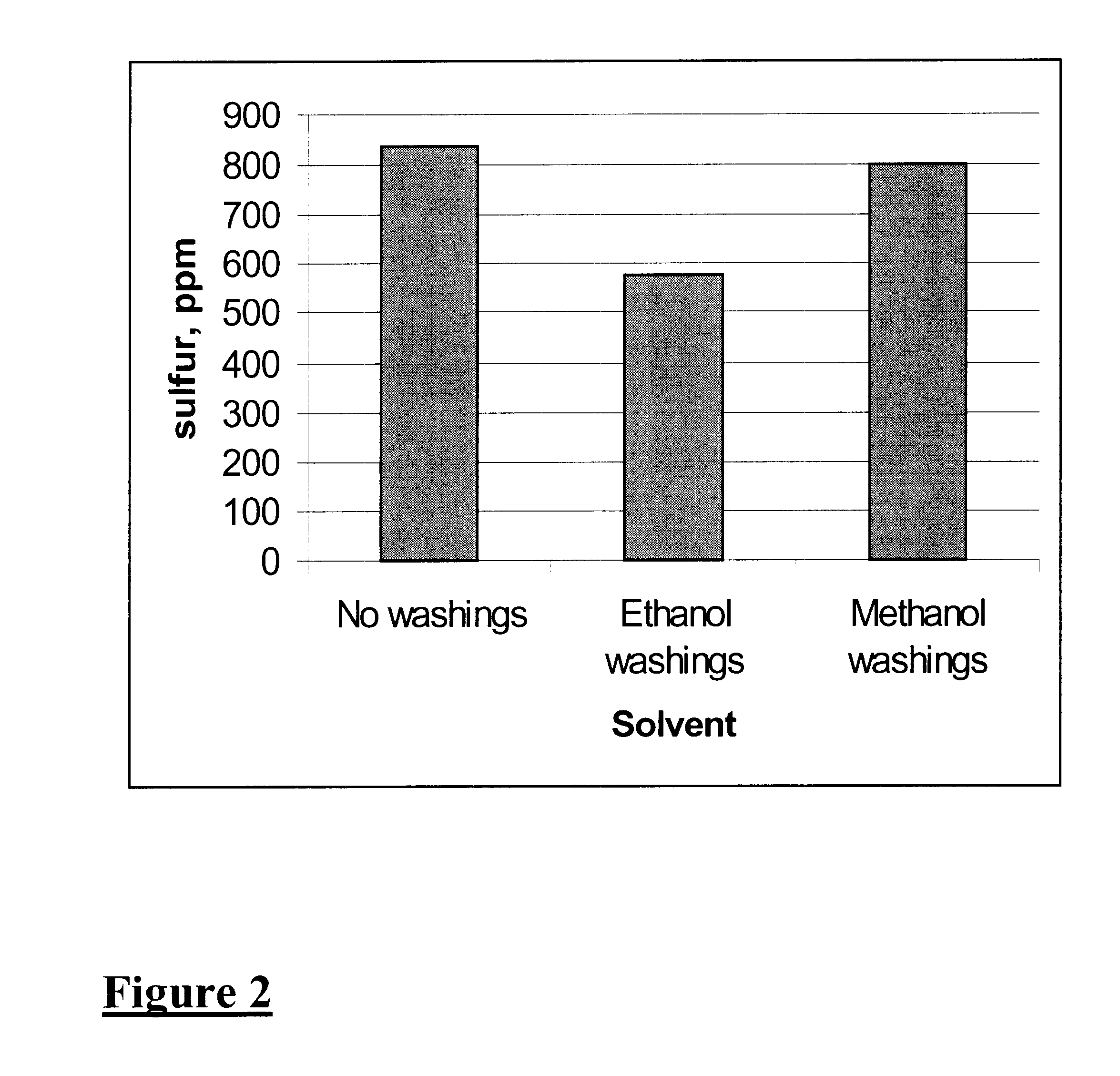

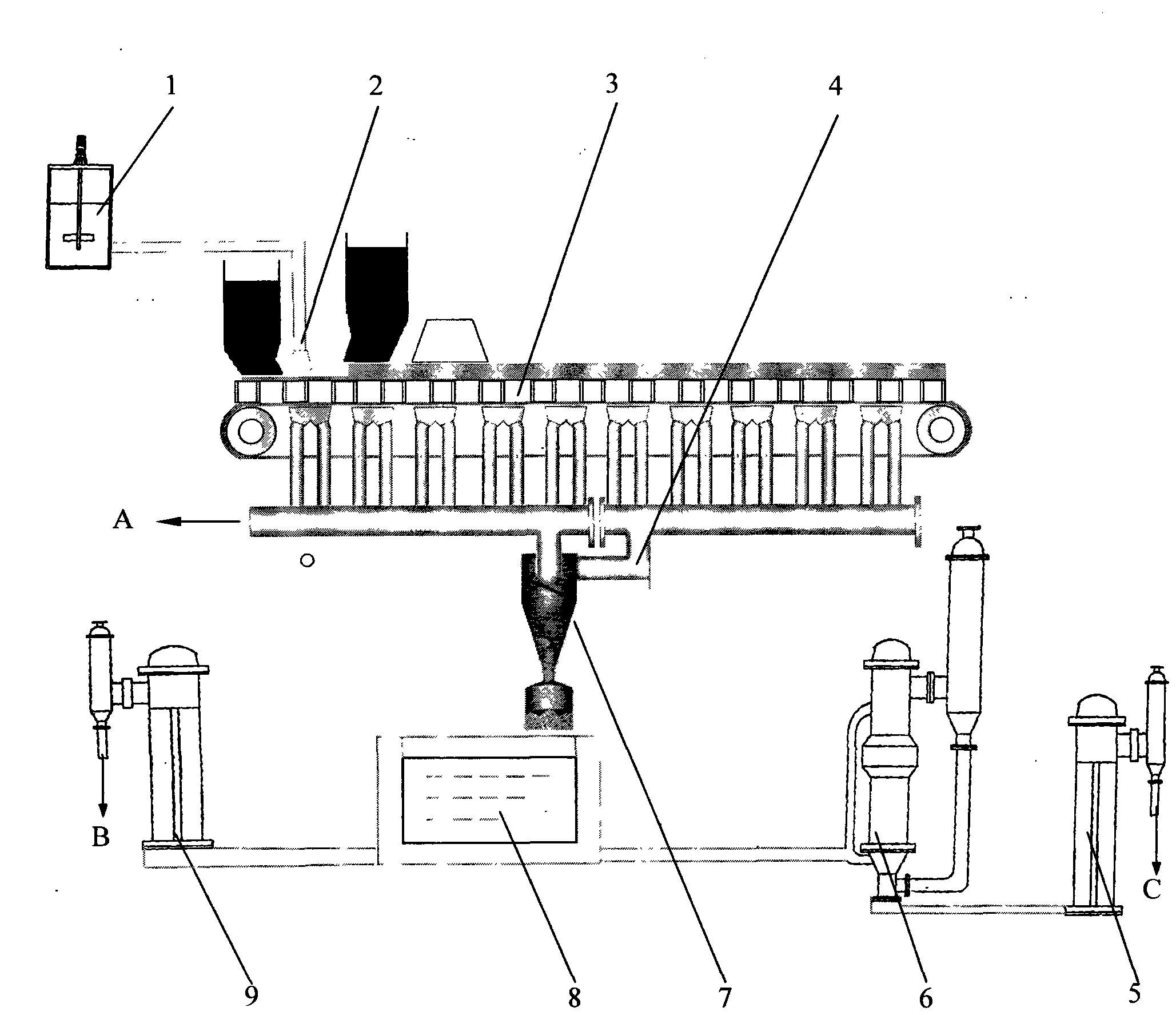

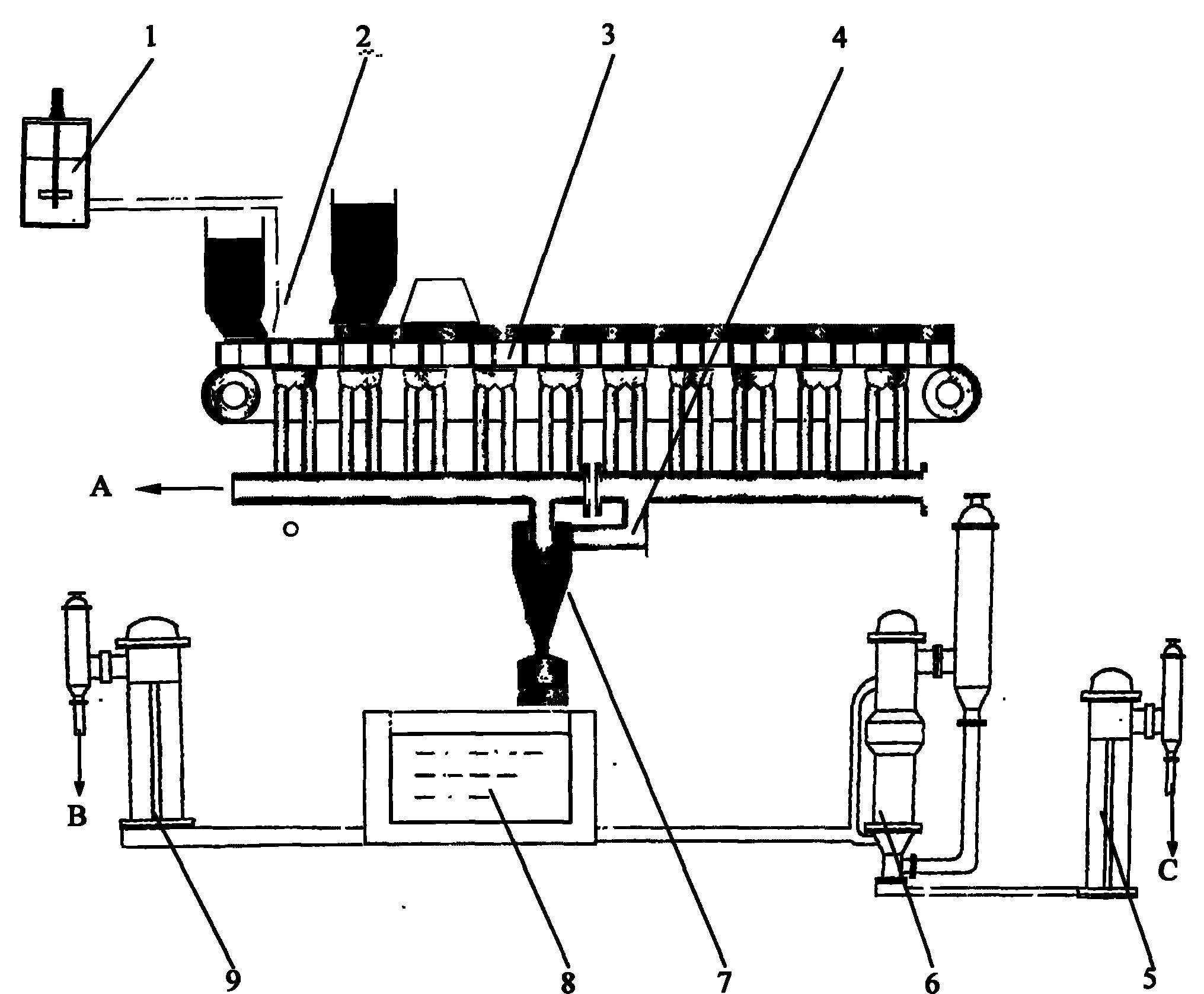

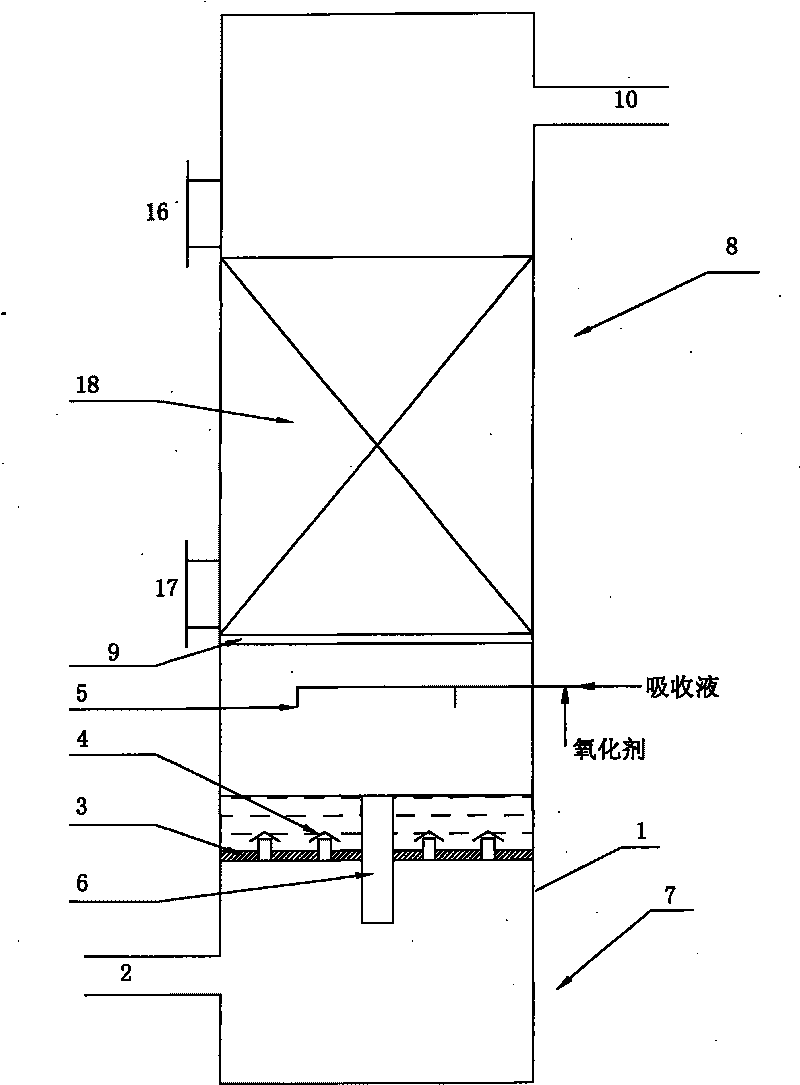

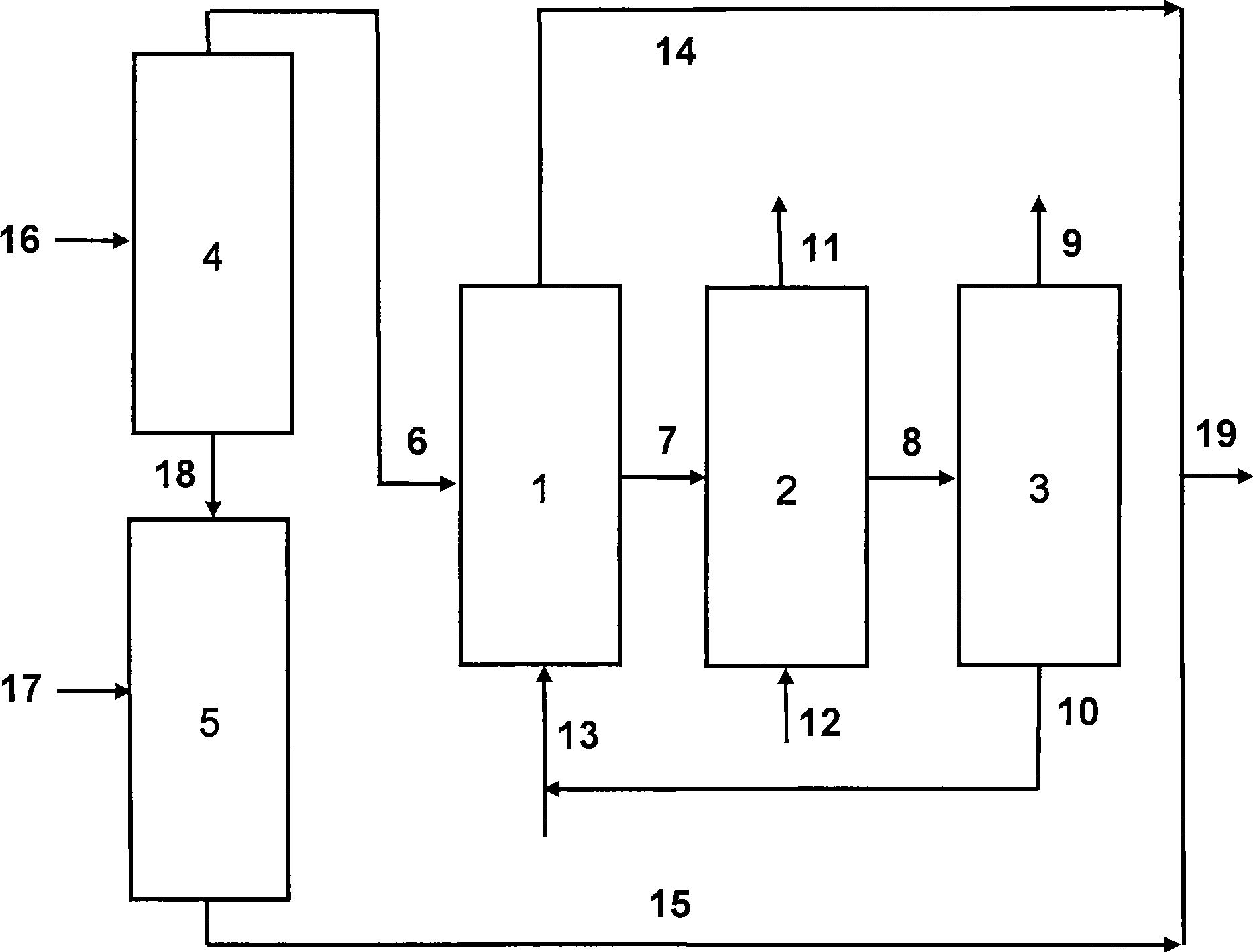

The invention belongs to flue gas desulphurization technology of the environmental protection field. To solve the problems of large energy consumption, lower product quality and large investment in recovering ammonia sulfate by an ammonia desulphurization technique, the invention provides an energy-saving and high-quality ammonia desulphurization process for ammonia sulfate recovery. The process adopts ammonia water as a desulfurizer, ammonium sulfite is produced after the ammonia water and flue gas are decarbolized completely, and ammonia sulfate is produced after the ammonium sulfite is forcibly oxidized in a tower; impurities in the ammonia sulfate solution is removed by filtering, the filtrate is contacted with high-temperature flue gas in a desulfurizing tower for heat exchange, and when flue gas is cooled, the ammonia sulfate solution is heated and saturated; and then after crystallization of the saturated ammonia sulfate solution for a period of time, high-quality ammonia sulfate is produced after centrifugal drying. By adopting the technical proposal of the invention, not only thermal energy of an ammonia sulfate product which is produced by drying process can be greatly saved, high-quality ammonia sulfate fertilizer can be recovered, occupation area can be reduced and investment can be save, but also flue gas emission can meet the standard, without resulting in secondary pollution such as waste water and the like.

Owner:山西晋丰节能环保工程设计有限公司

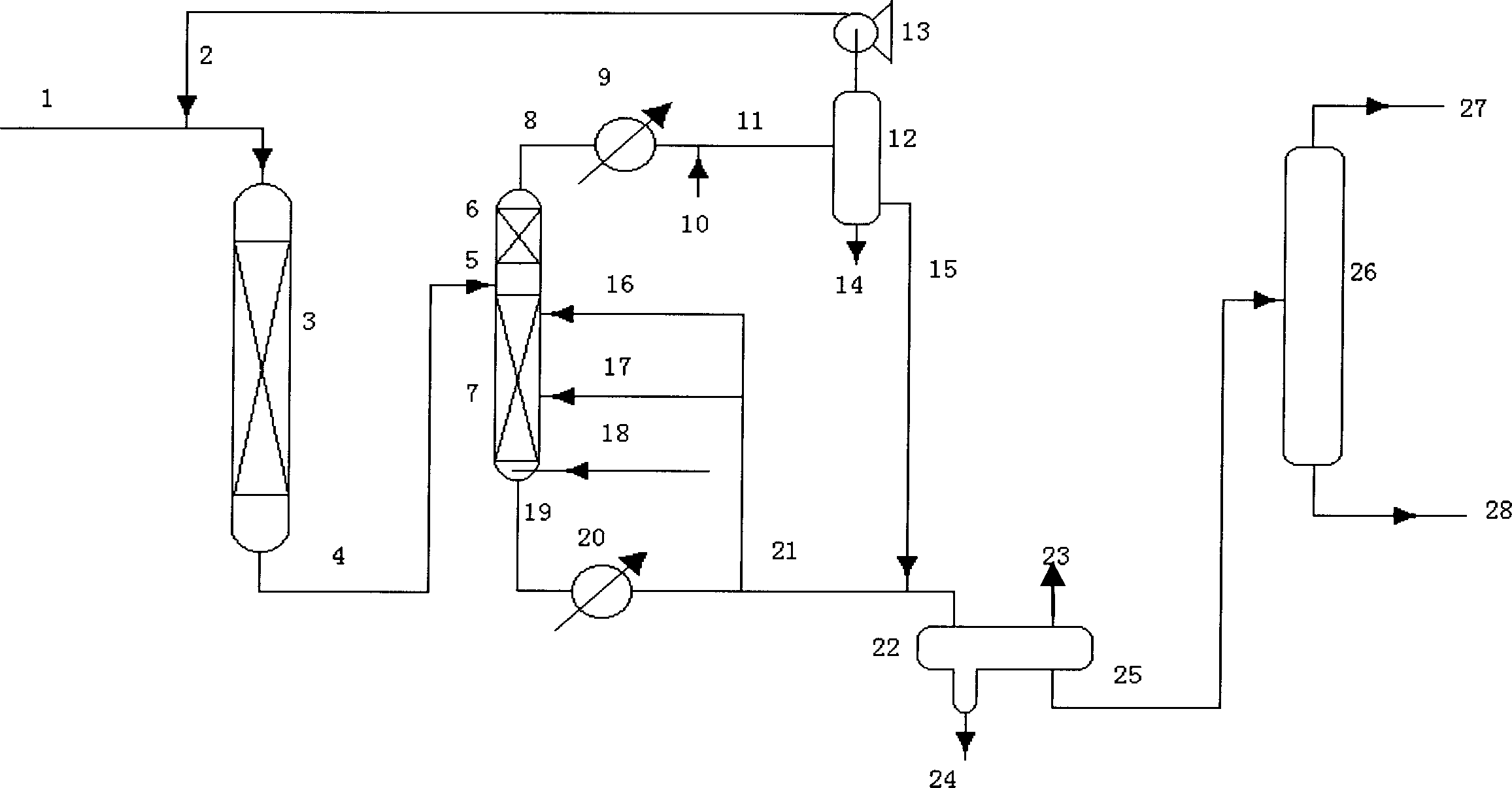

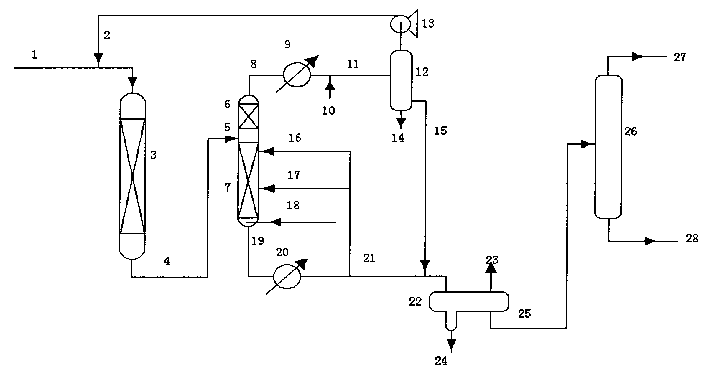

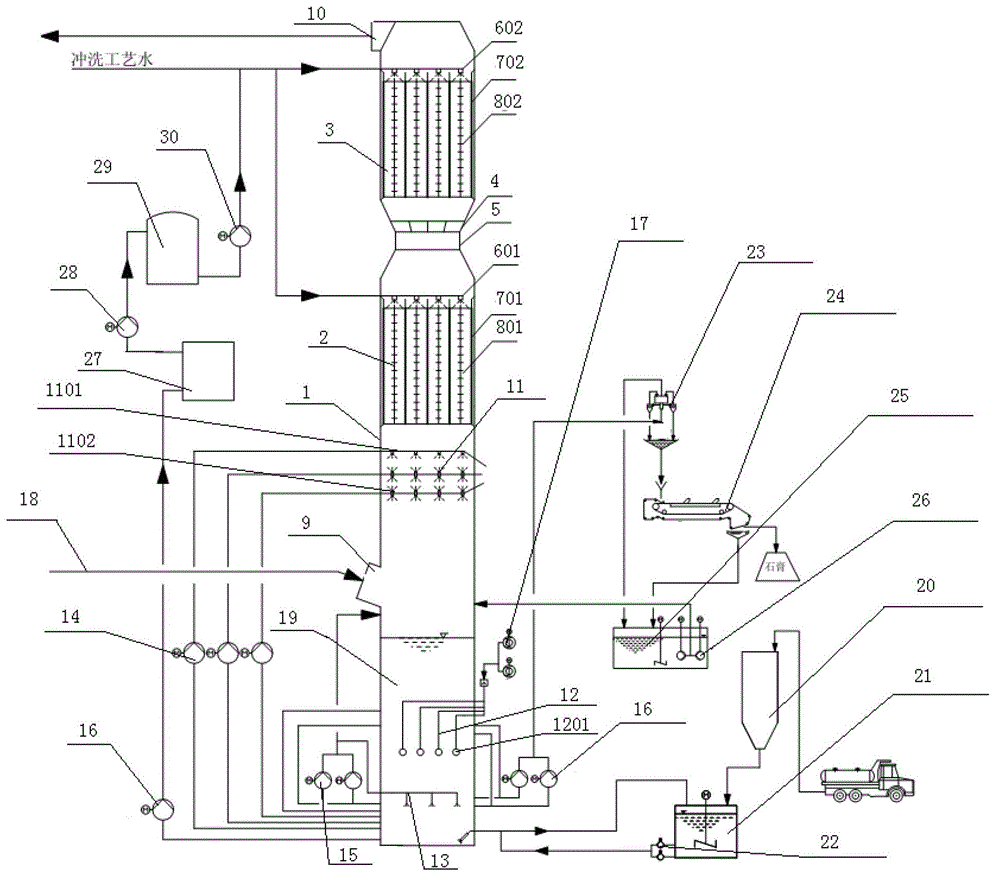

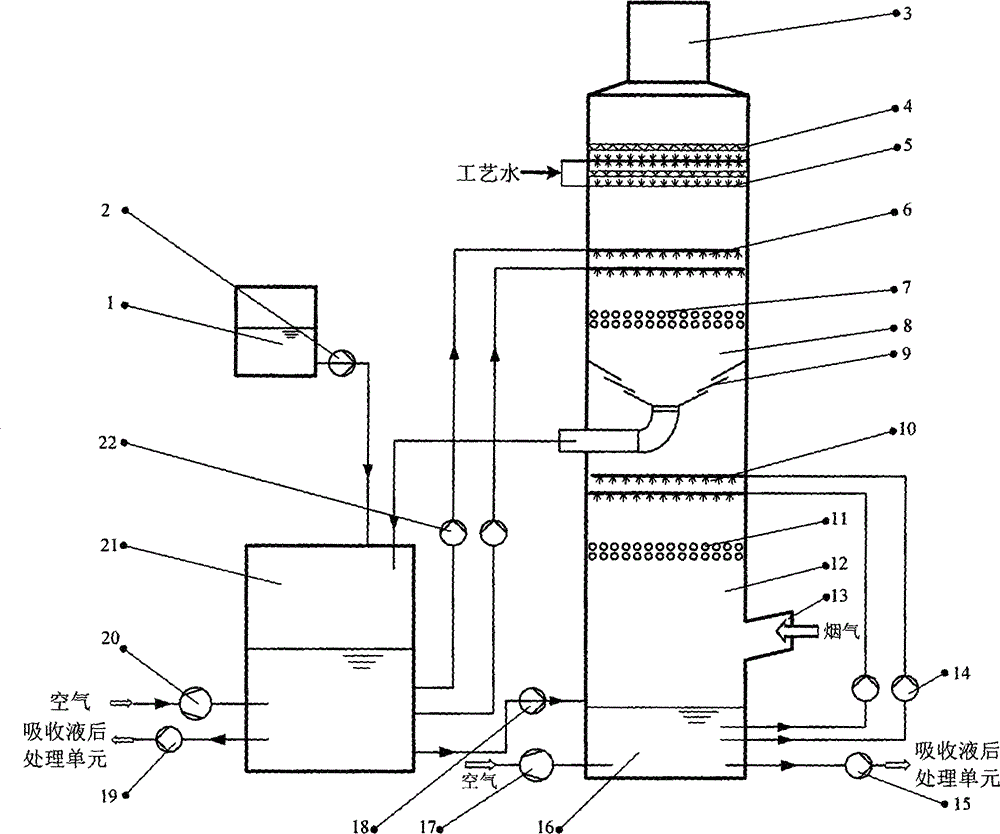

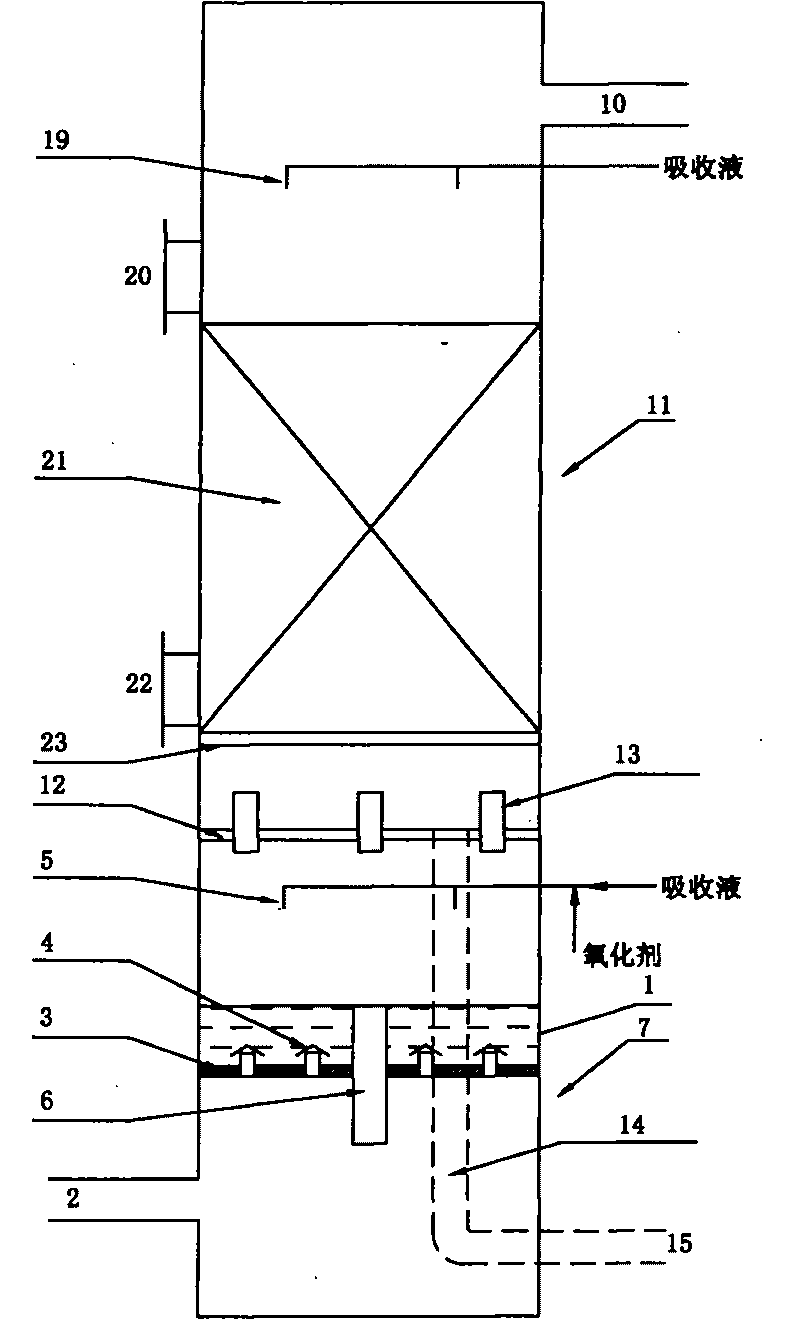

Ammonia process flue gas treatment method for acidic tail gas and device

ActiveCN103223292AIncreased self-concentrationGood desulfurization absorptionDispersed particle separationAmmonium sulfatesEnvironmental resistanceAmmonia storage

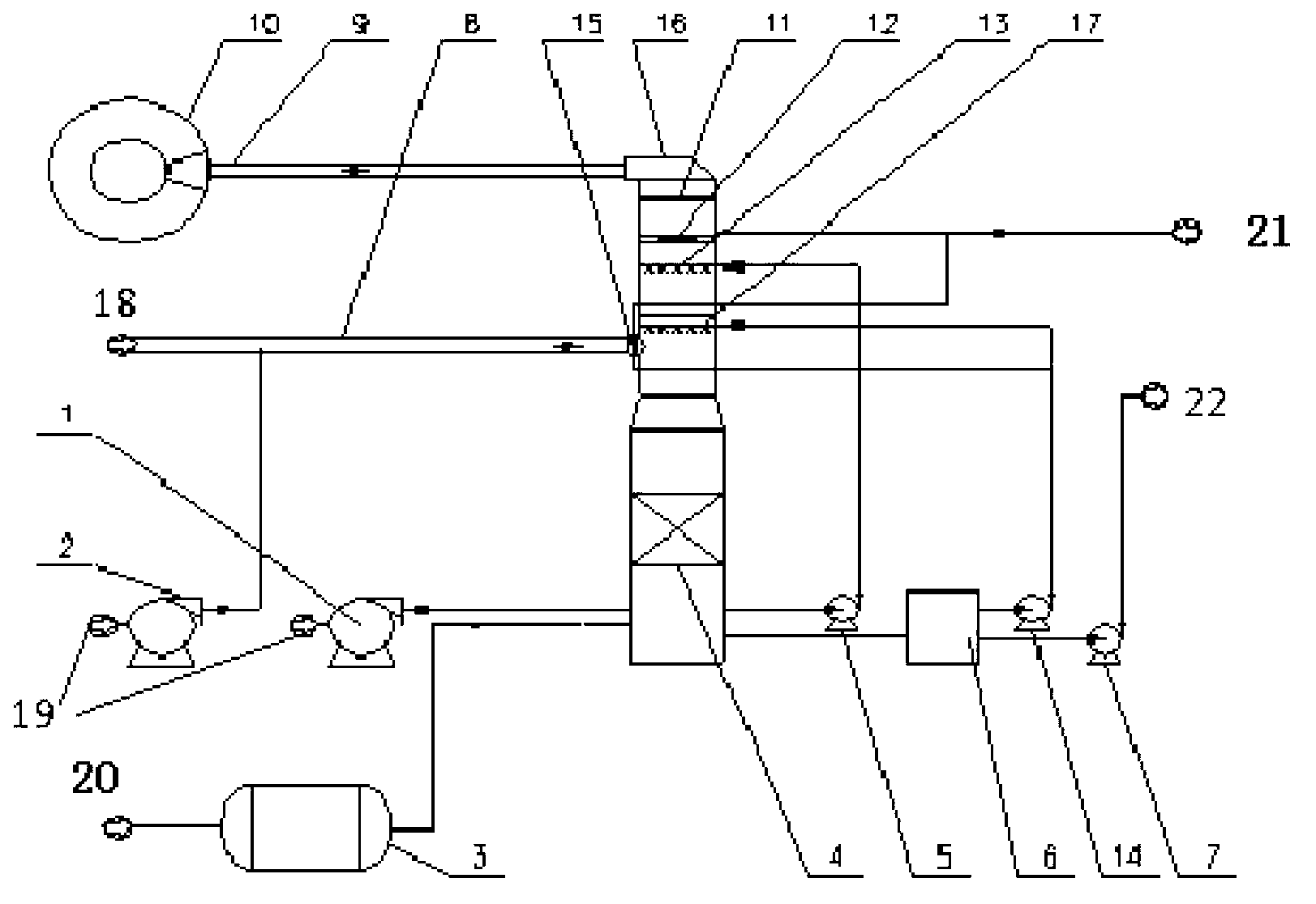

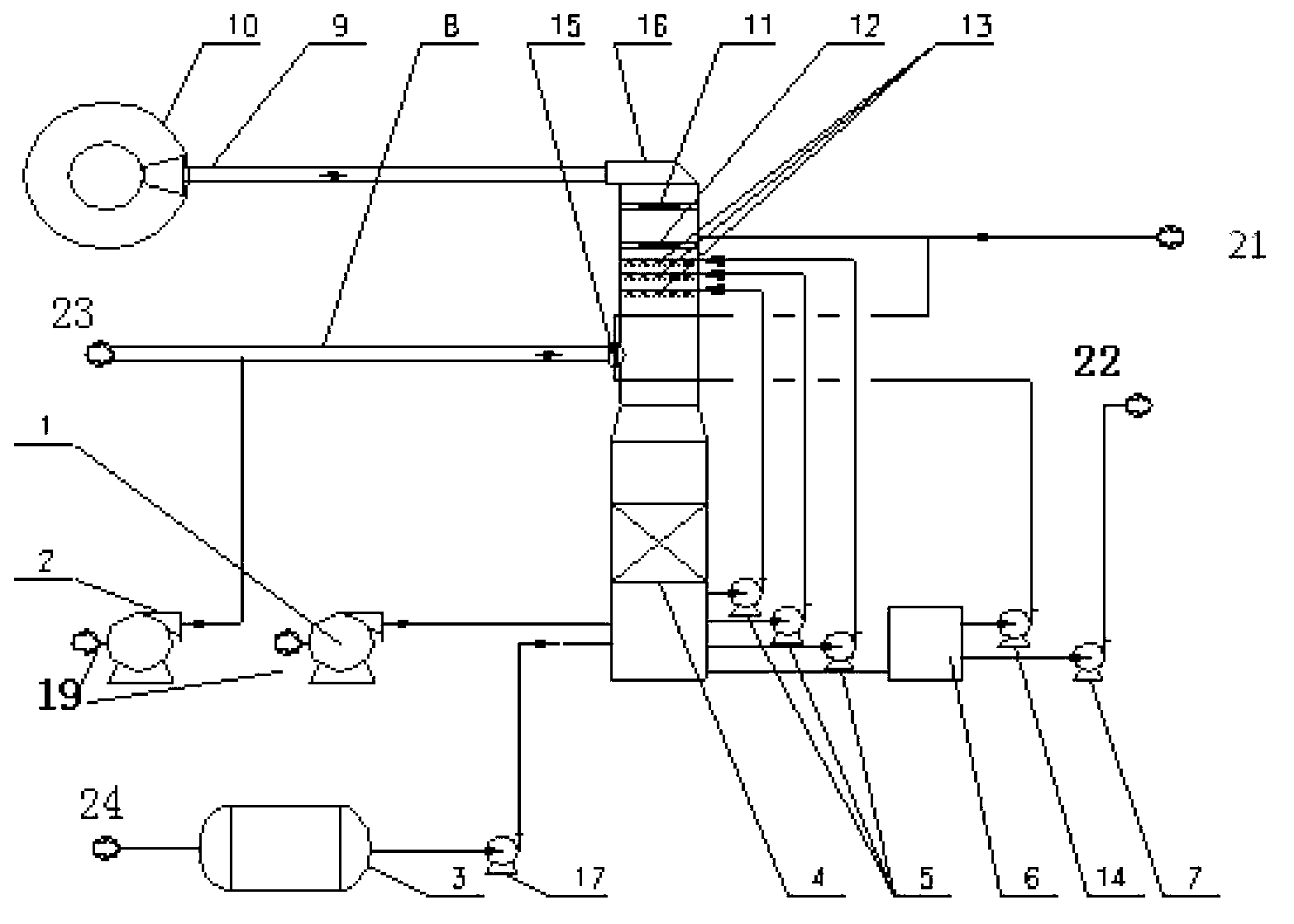

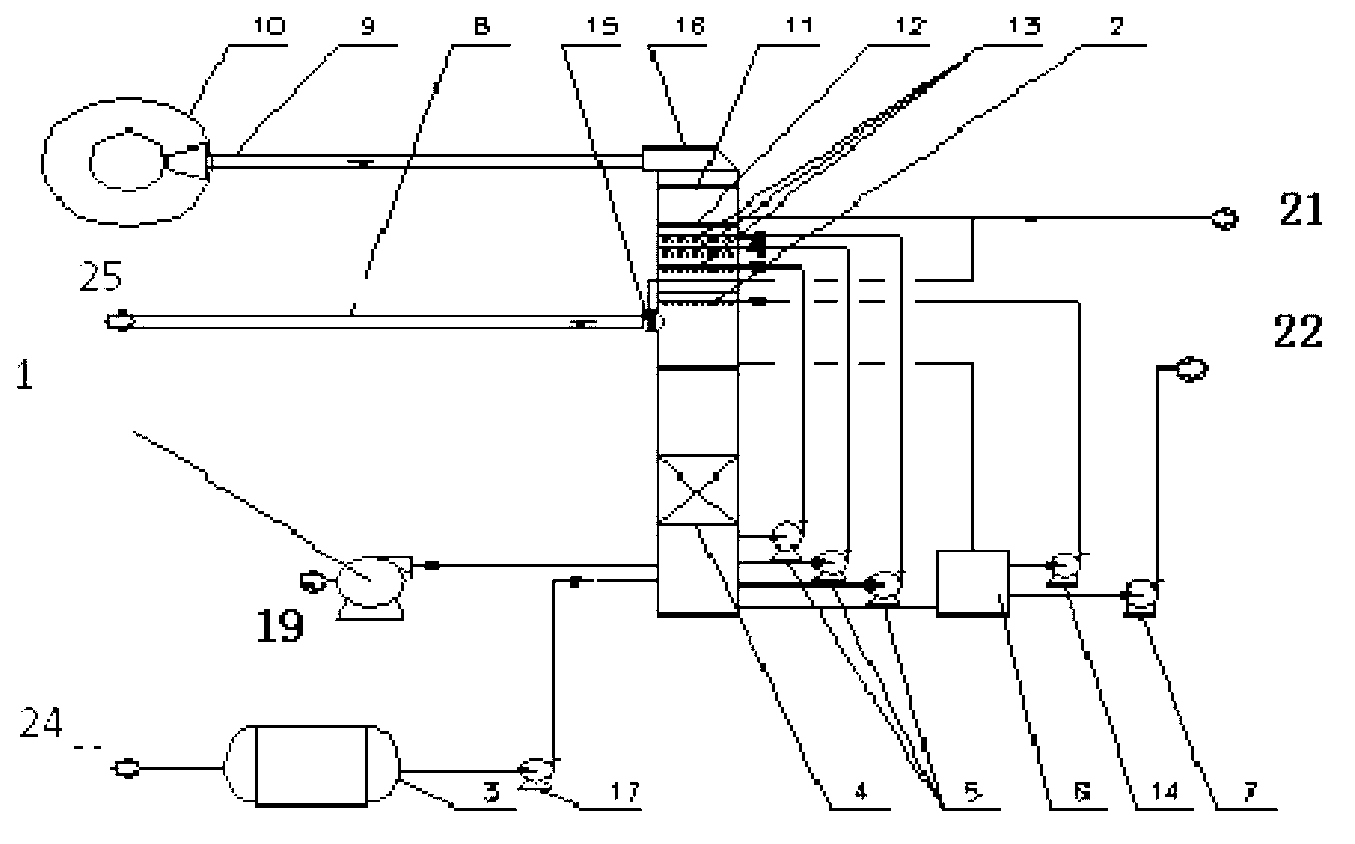

The invention relates to an ammonia process flue gas treatment method for acidic tail gas. The method includes the steps of: 1) controlling the sulfur dioxide concentration of tail gas entering an absorption tower at a level of less than or equal to 30000mg / Nm<3>; 2) arranging process water in an absorption tower entrance flue or in the absorption tower or cooperating with a ammonium sulphate solution to perform spray cooling; 3) disposing an oxidation section in the absorption tower, setting an oxidation distributor at the oxidation section to achieve oxidation of a desulfurized absorption liquid; 4) arranging an absorption section in the absorption tower, utilizing an absorption liquid distributor in the absorption section to realize desulfurization spray absorption by an ammonia-containing absorption liquid, which is fed through an ammonia storage groove; 5) arranging a water washing layer at an absorption section upper part in the absorption tower, washing the absorption liquid in the tail gas by the water washing layer and reducing the absorption liquid escape; and 6) setting a demister at the upper part of the water washing layer in the absorption tower to control the mist drop content in the purified tail gas. Employment of the Claus sulfur recovery and ammonia process desulfurization integrated desulfurization technology in the coal chemical industry can reduce the investment cost of after-treatment, the process can be simpler, and factory environmental protection treatment can form an intensive advantage.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

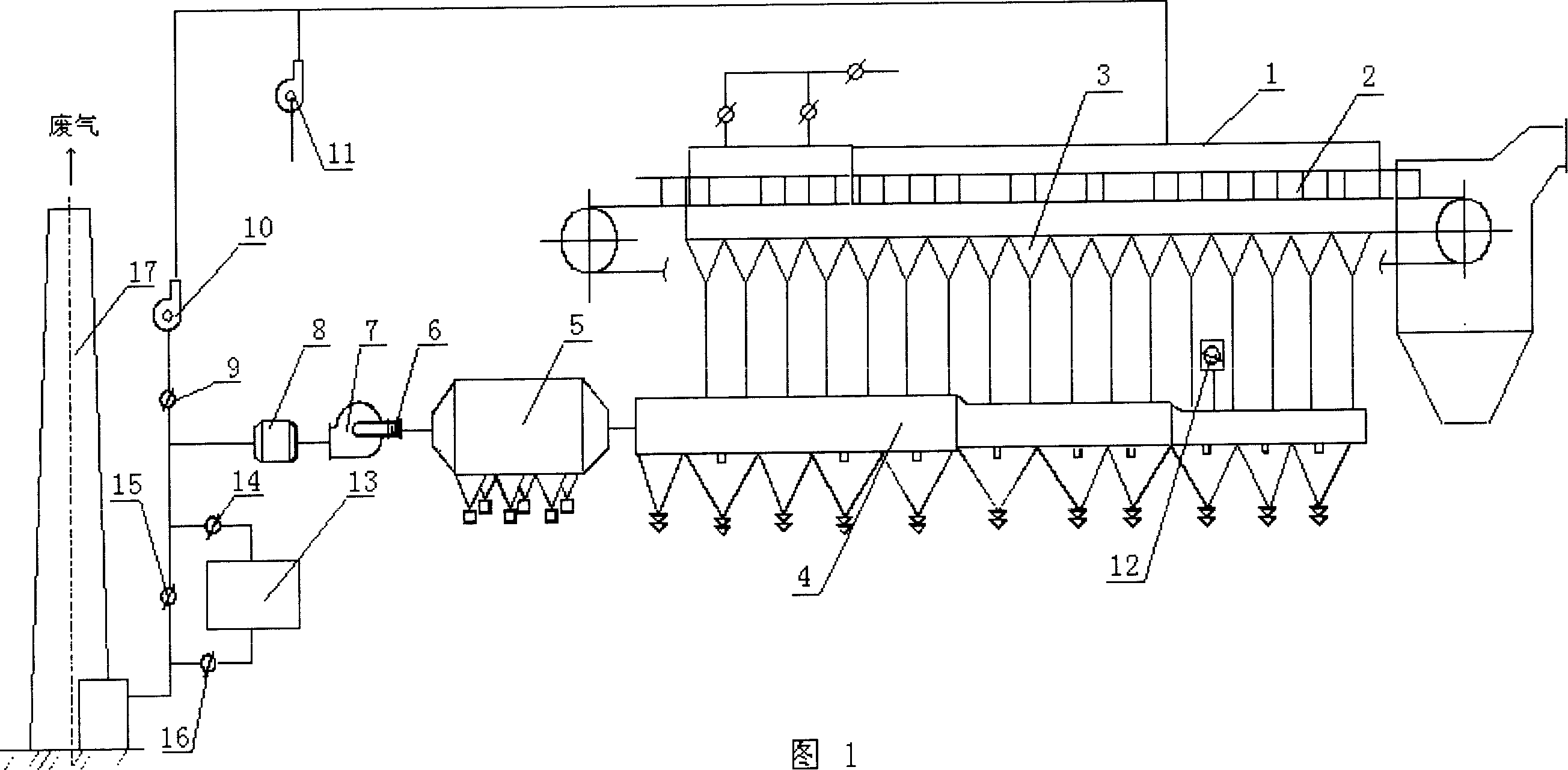

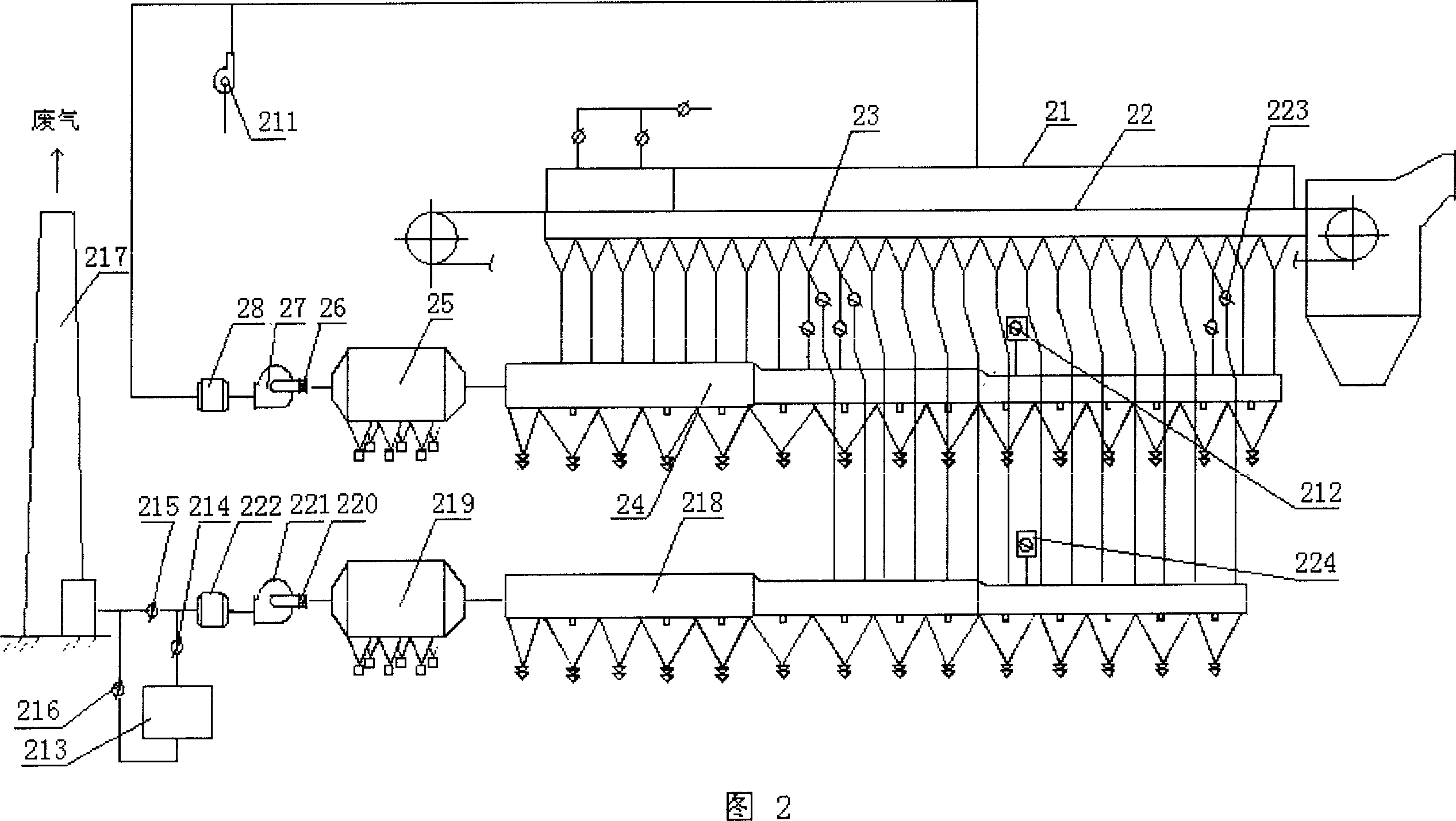

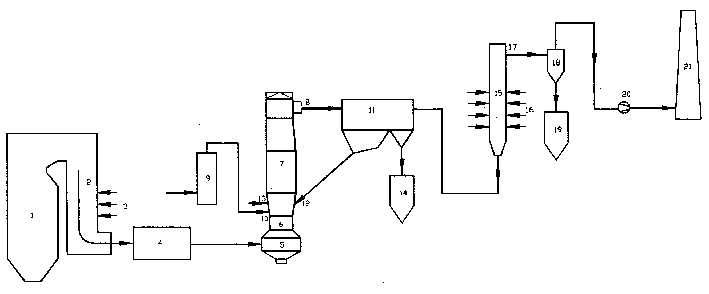

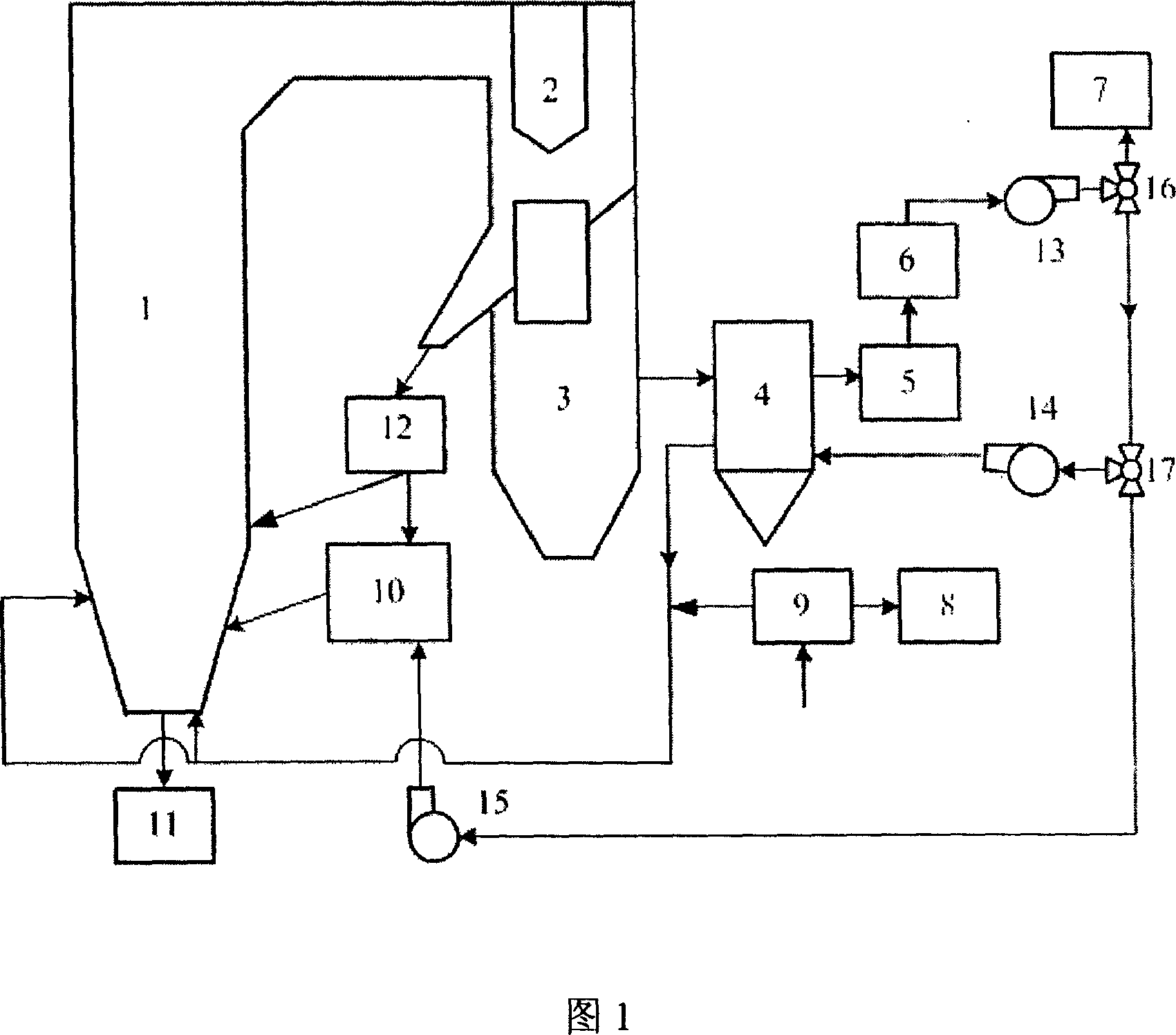

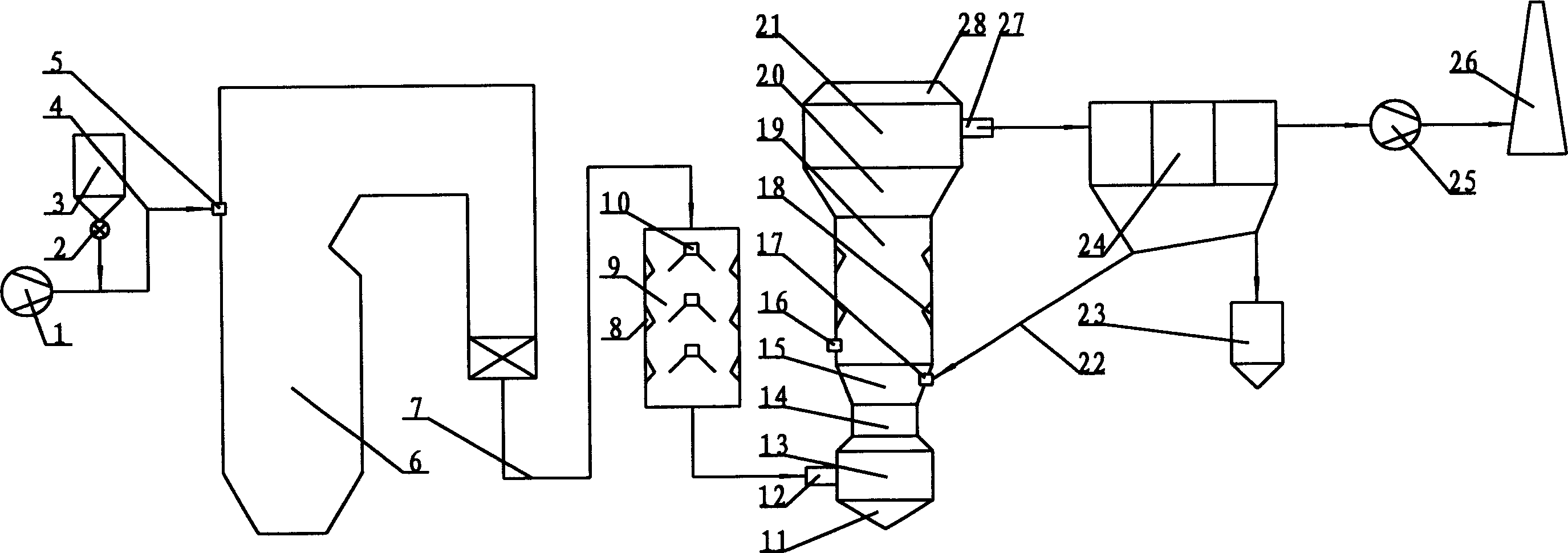

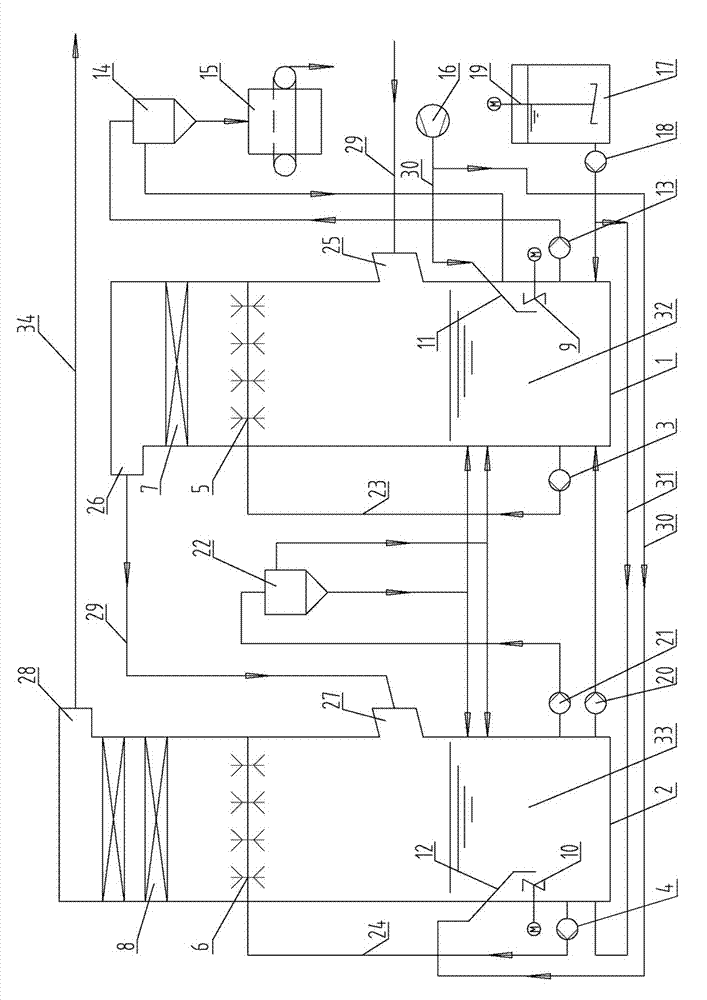

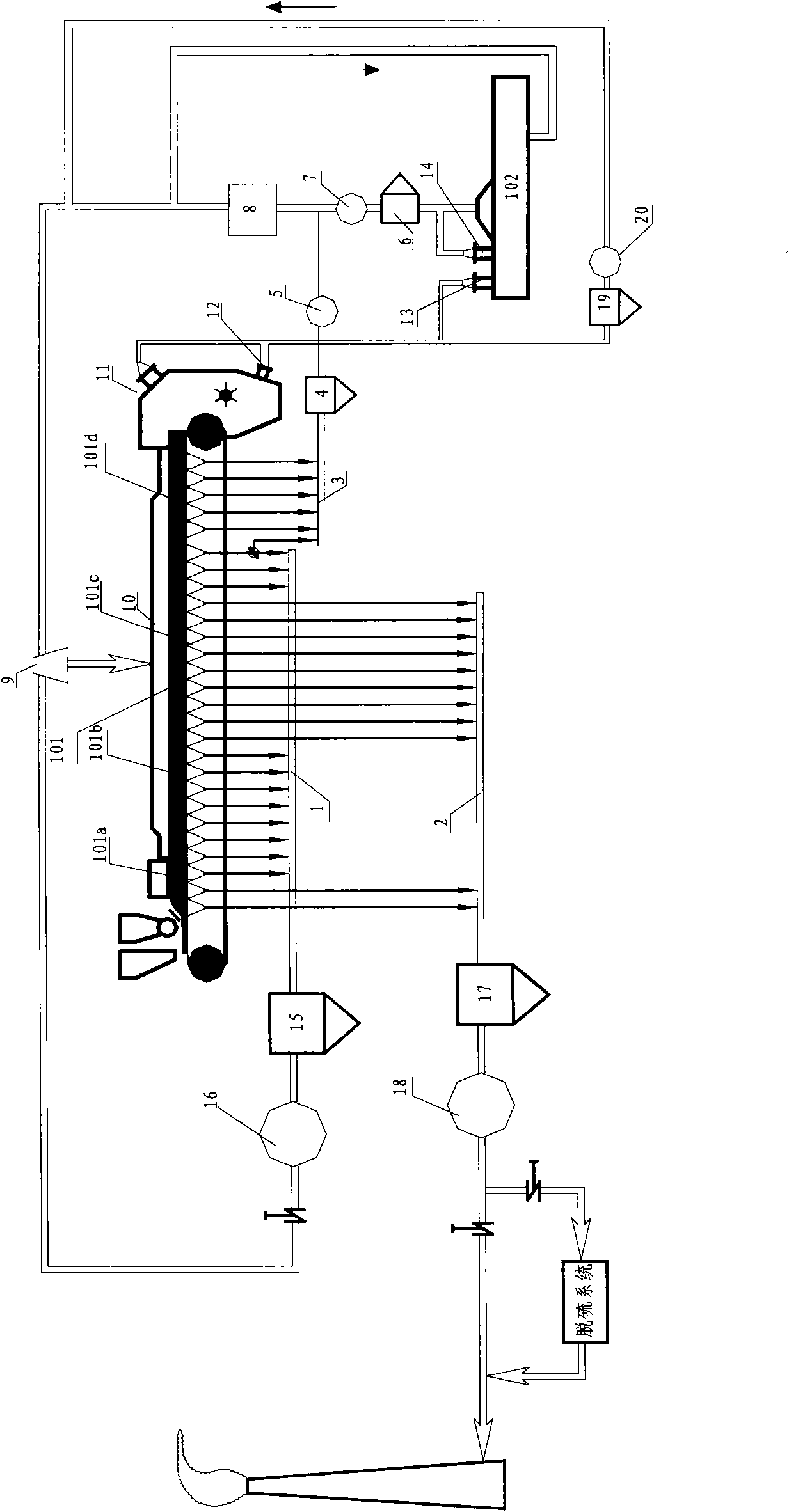

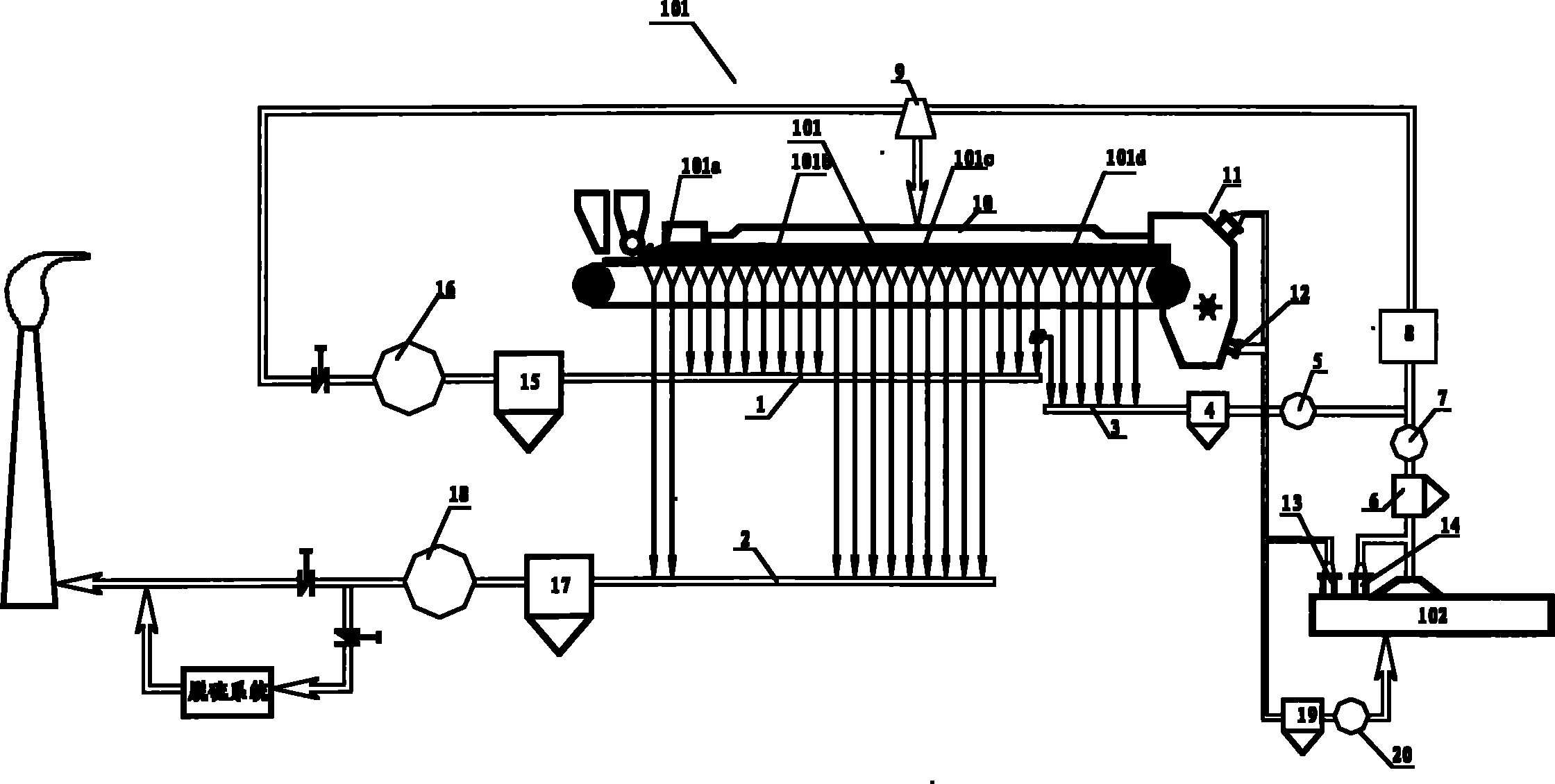

Sinter-smoke circulation collected desulfurizing method and apparatus

InactiveCN101024143AEmission reductionReduce effluxDispersed particle separationFurnace typesFlue gasEnrichment methods

The invention discloses a sintering flue gas desulfurization cycle enrichment methods and device, the described method from the sintering machine take part gas return to the top of sintering machine sealed enclosures within cycle, while complementing sintering machine burning need oxygen, the remaining part of the flue gas discharge after desulfurization. In devices, including dedusting device of flue gases between the chimney and flue, in the road before the desulfurization setup a branch pipeline to connect sintering machine sealed enclosures, in the branches of pipe setup cycle fan and supplement device. This invention due to sintered exhaust gas partly return to the seal trolley of sintering machine to reduce the displacement of gas, thereby reducing the total of dust and exhaust gas, while the SO2 of the sintering process play a enrichment role, to increase desulfurization efficiency, and reduce release total of burning exhaust gas, reducing the processing load of desulfurization device.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

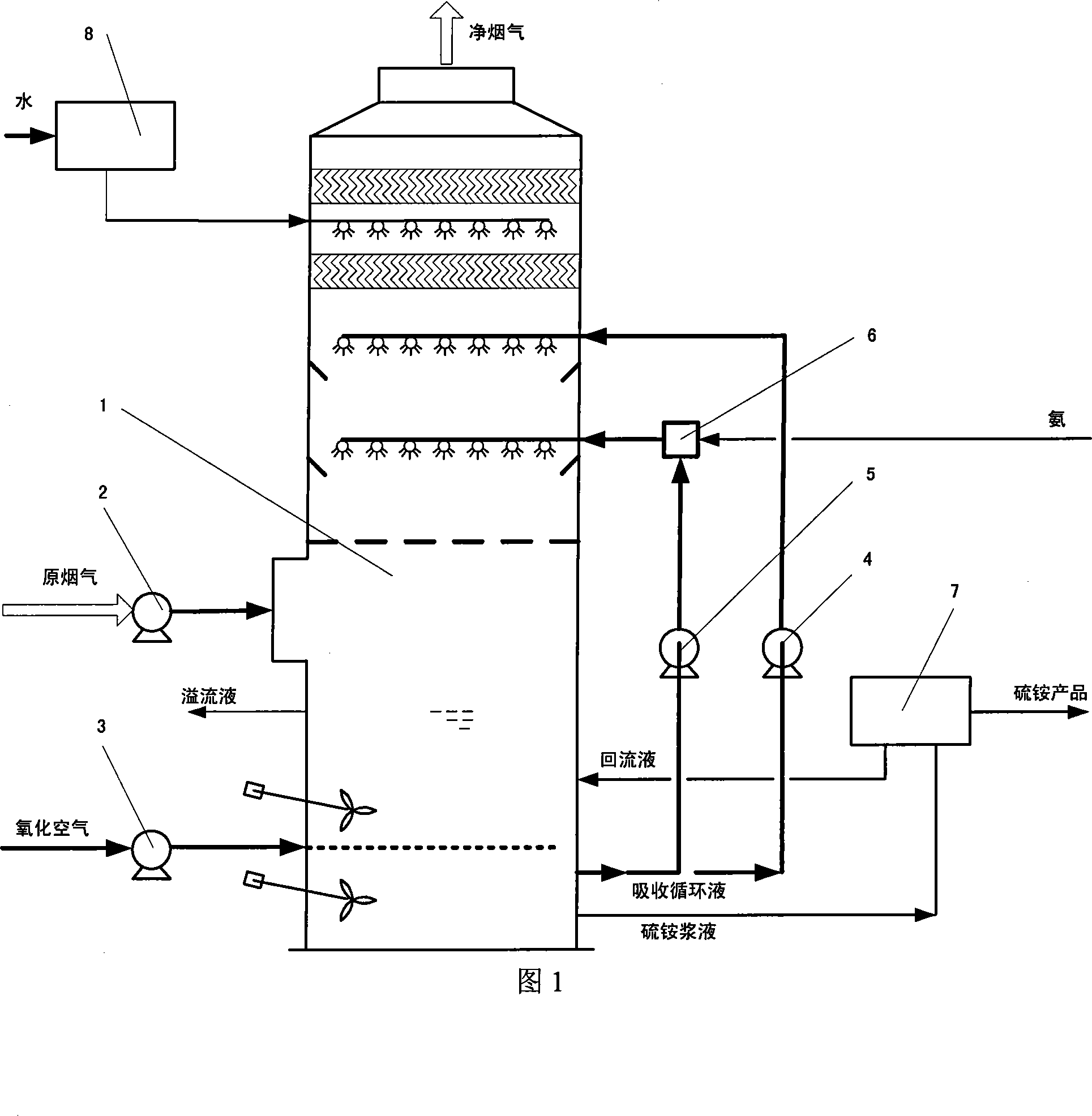

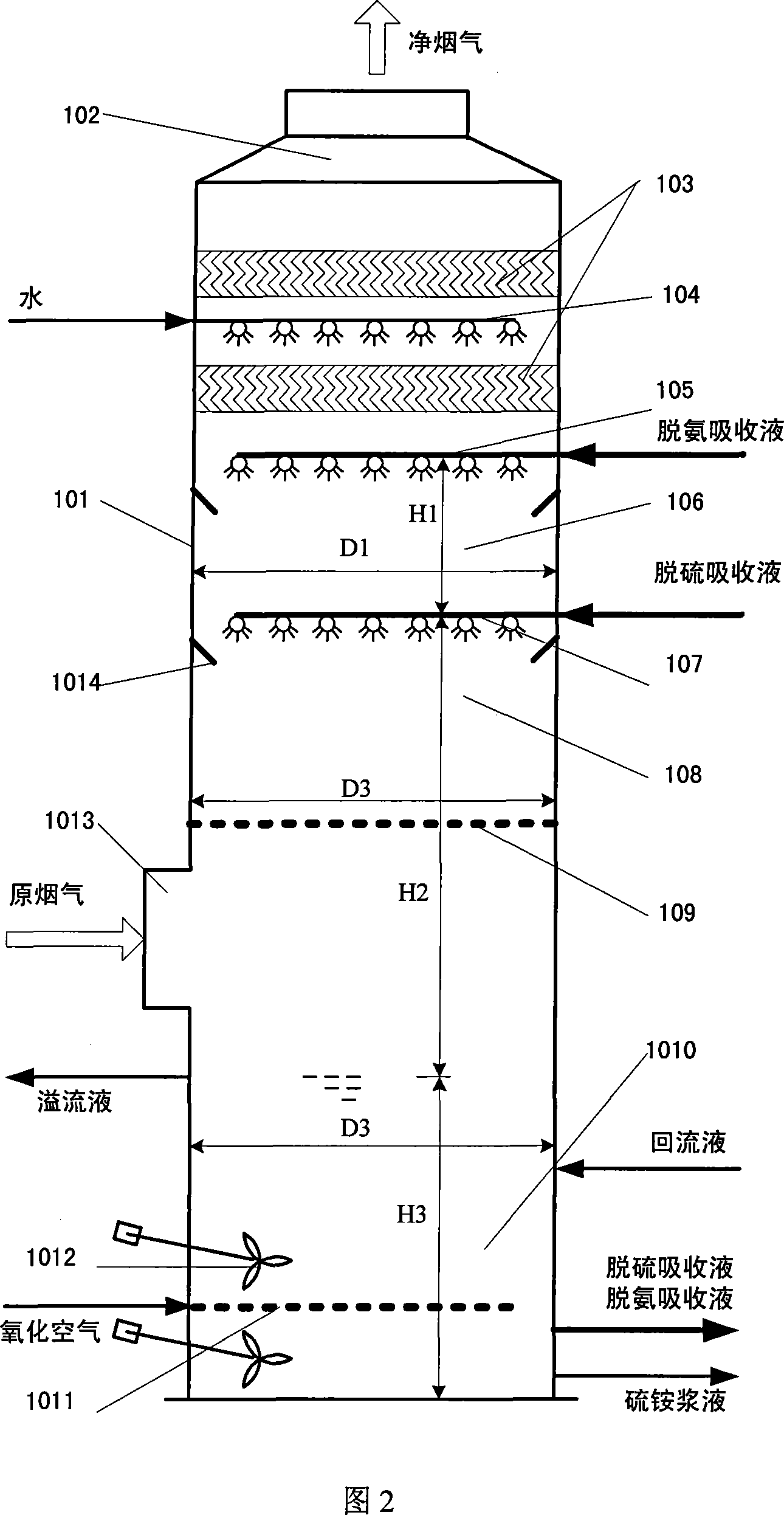

Method and device for reclaiming sulfur dioxide from countercurrent flue gas

InactiveCN101085410AAvoid short circuitImprove efficiencyDispersed particle separationSulfur compoundsSulfur dioxideFlue gas

The invention relates to the new SO2 absorption device with three function areas, namely deamination zone, desulfuration zone and oxidization zone. It has purification air exhaust at the top of the SO2 absorption device, top of the inside of the tower composed of water and liquid separator of the flush water distributor, deamination circulation absorbing distributor connected to its inlet under the air and liquid separation component, under the deamination zone set with desulfuration circulation absorbing outlet connected liquid absorbing distributor, under which set the desulfuration zone, with absorbent liquid overflow outlet on the tower, and oxidization crystallization zone under the overflow outlet. It is low in investment, small in energy consumption, strong in gas treatment ability, high in efficiency, applicable for mass mode industrial application.

Owner:娄爱娟

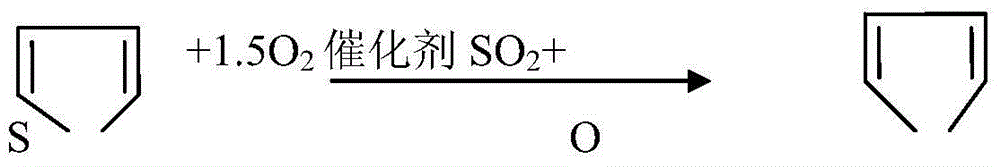

Method for the production of hydrocarbon fuels with ultra-low sulfur content

InactiveUS6673236B2Efficient oxidationReduce sulfur contentRefining with oxygen compoundsCatalytic naphtha reformingAlcoholCatalytic oxidation

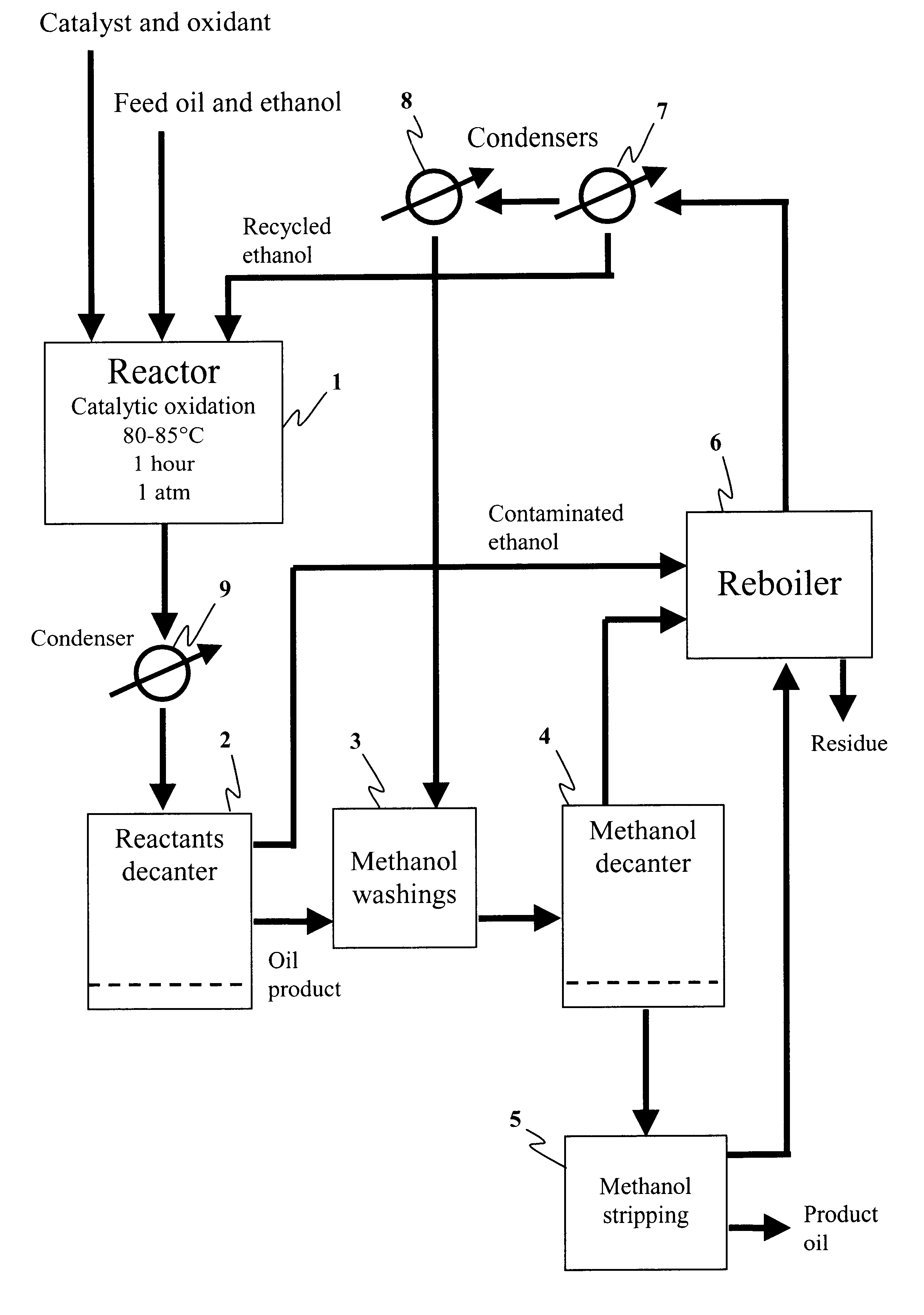

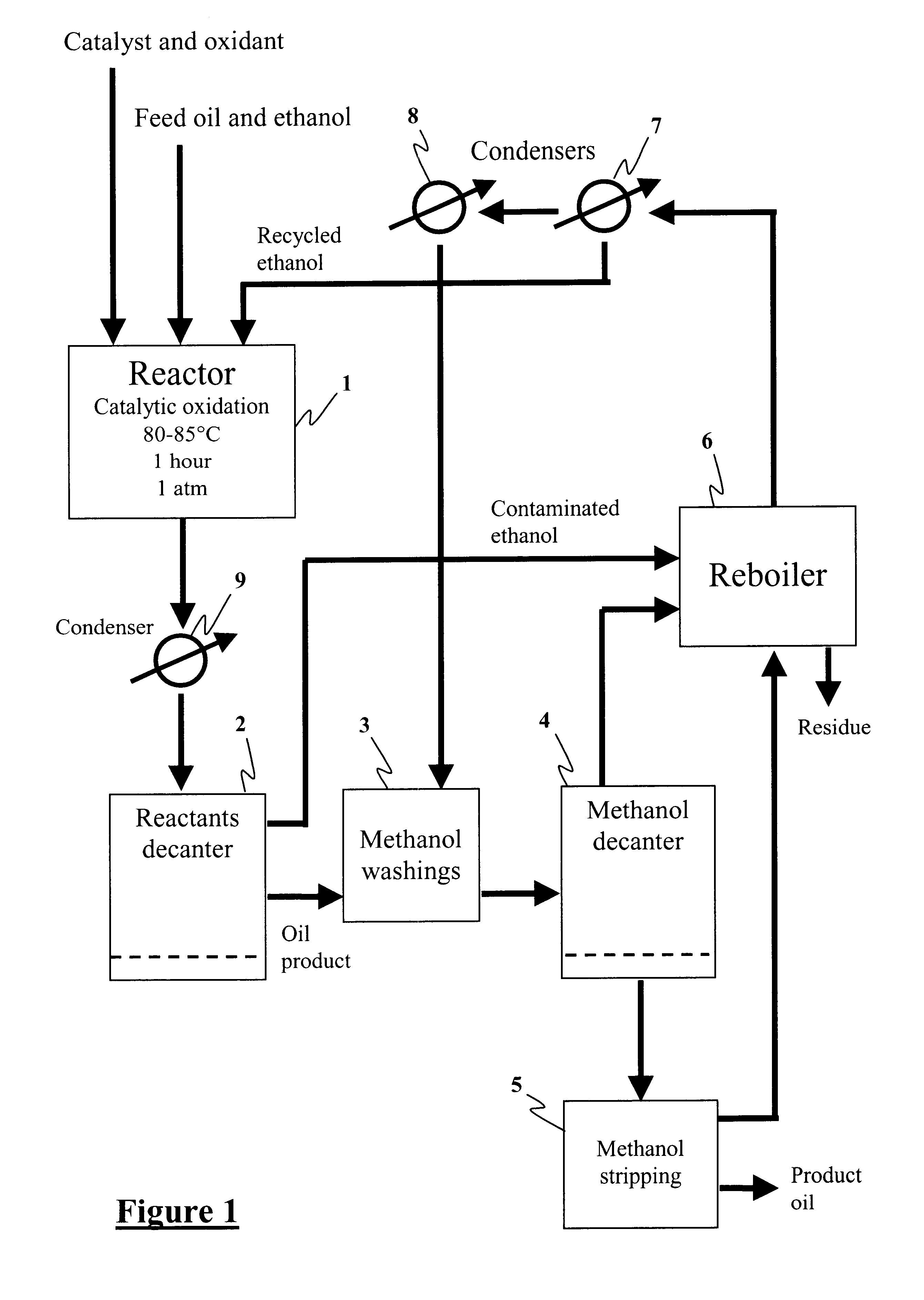

The present invention provides a method for producing hydrocarbon fuels with ultra-low levels of sulfur. The method involves catalytic oxidation of the sulfurous compounds within the hydrocarbon fuel, followed by extraction of the oxidized (and polarized) sulfurous compounds using a polar solvent. The present invention teaches the involvement of ethanol during catalytic oxidation. In this way, the oxidation catalyst has a dual-role in the oxidation process: firstly the catalyst directly oxidizes the sulfurous compounds, and secondly the oxidation catalyst converts of a small portion of the alcohol to the corresponding peroxy acid, which also helps to drive the oxidation process.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

Dry smoke cleaning process for desulfurizing and denitrating simultaneously and its system

InactiveCN1589954ASimplify stand-alone removal systemsSimple processDispersed particle separationSprayerNitric oxide

A dry method for simultaneously desulfurizing and denitrating fume includes using H2O2 or methanol to convert the NO in fume to NO2, using Ca-base particles as desulfurizing agent to react with SO2 to obtain calcium sulfate, and using ammonia water or urea as denitrating agent to react with NO2 to obtain ammonium nitrate and clean fume. Its apparatus is composed of additive sprayer, desulfurizing system and denitrating system.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

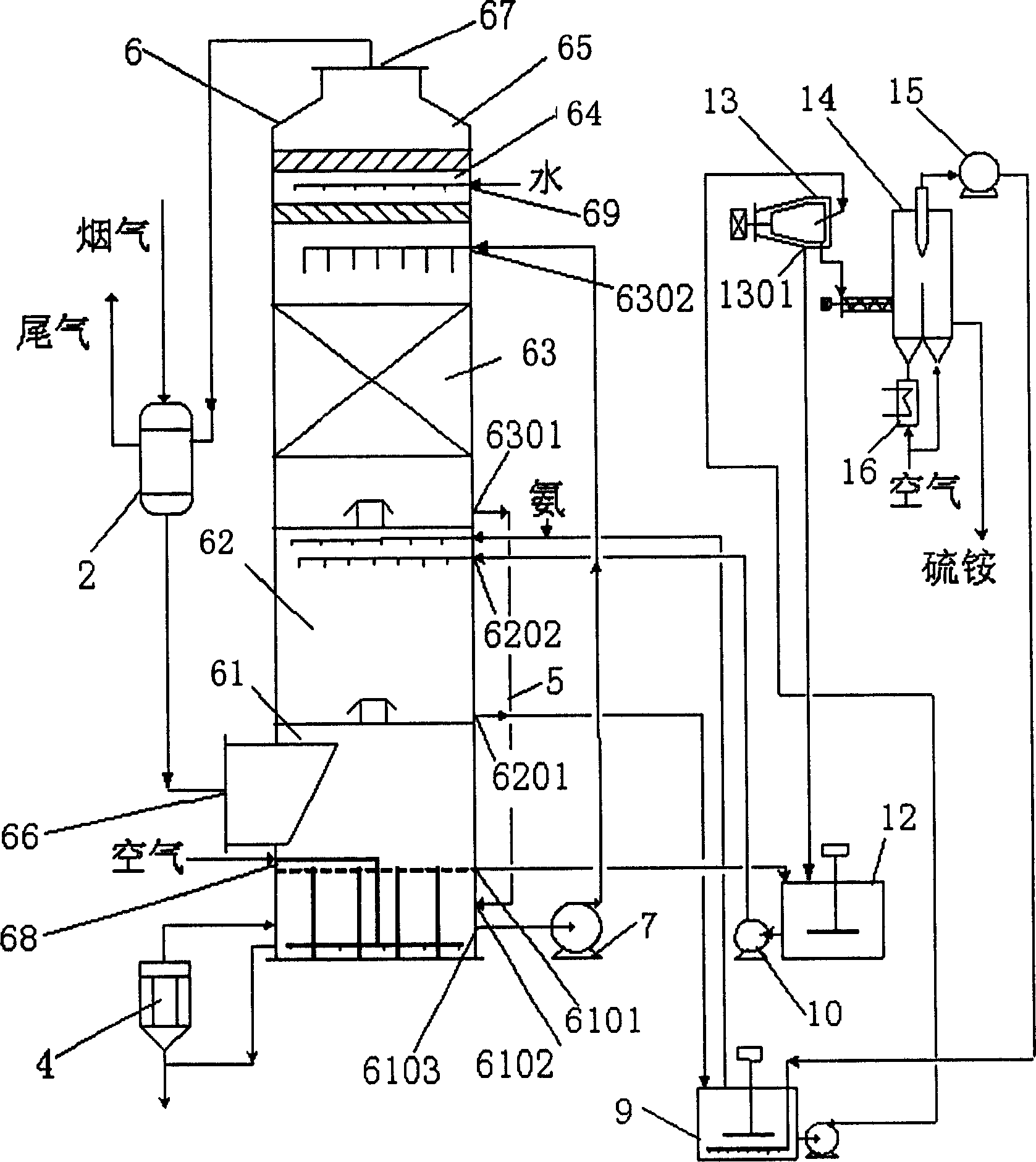

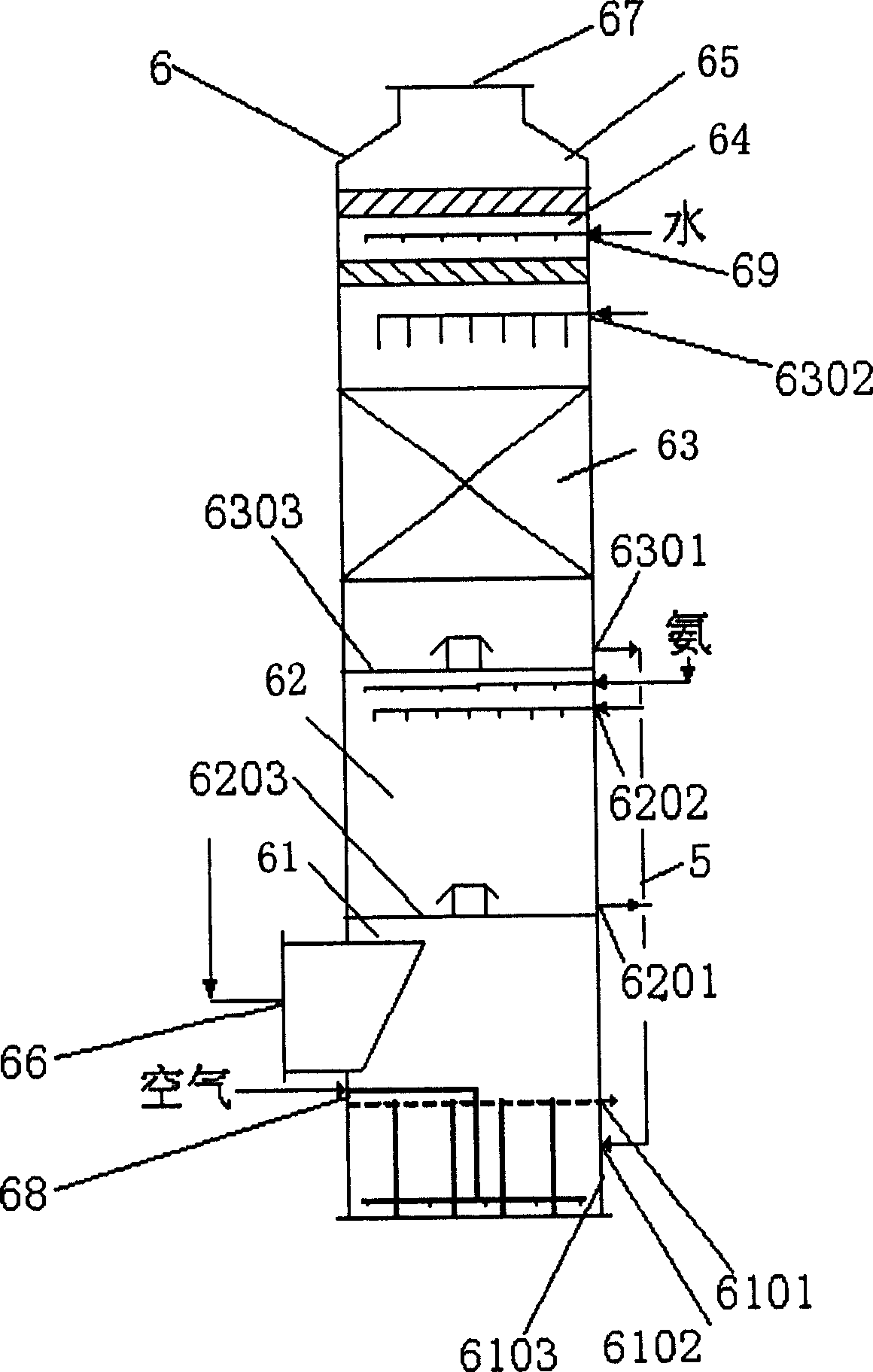

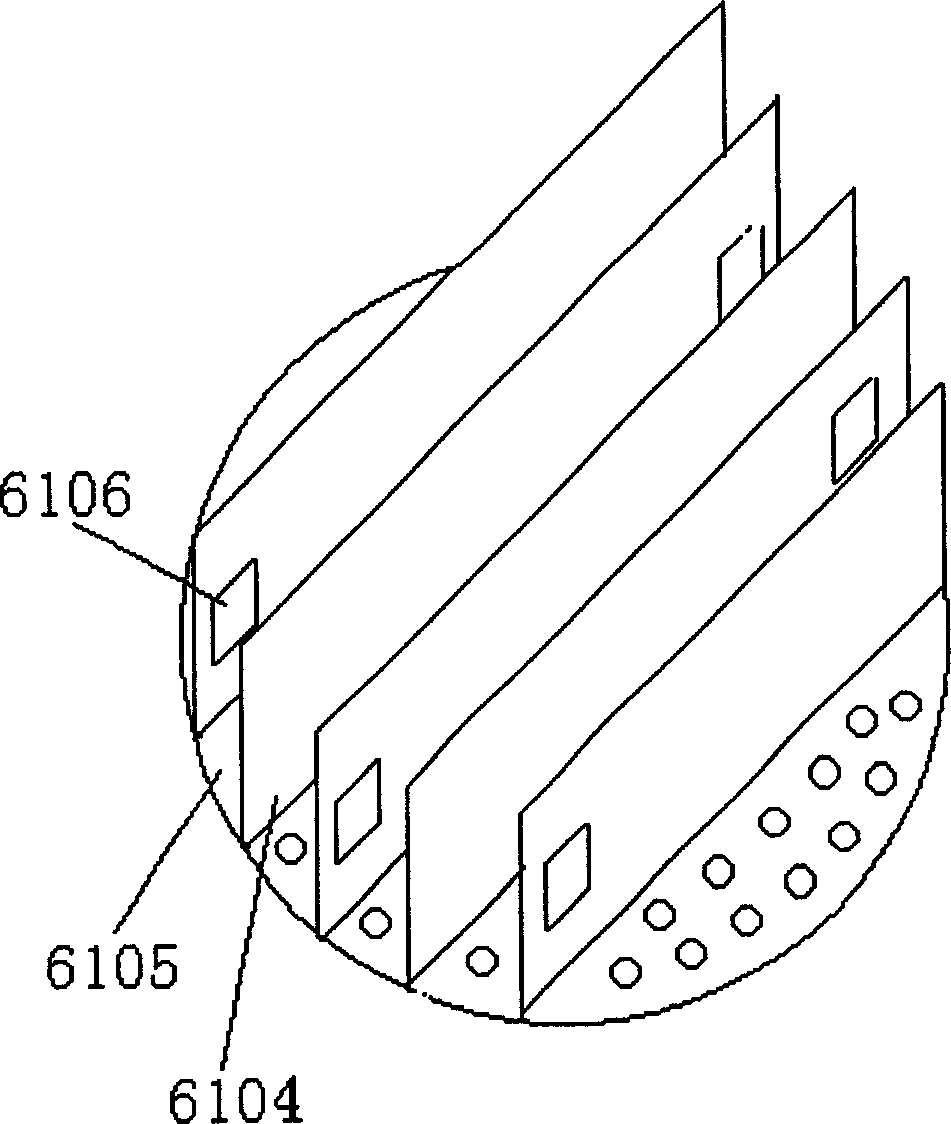

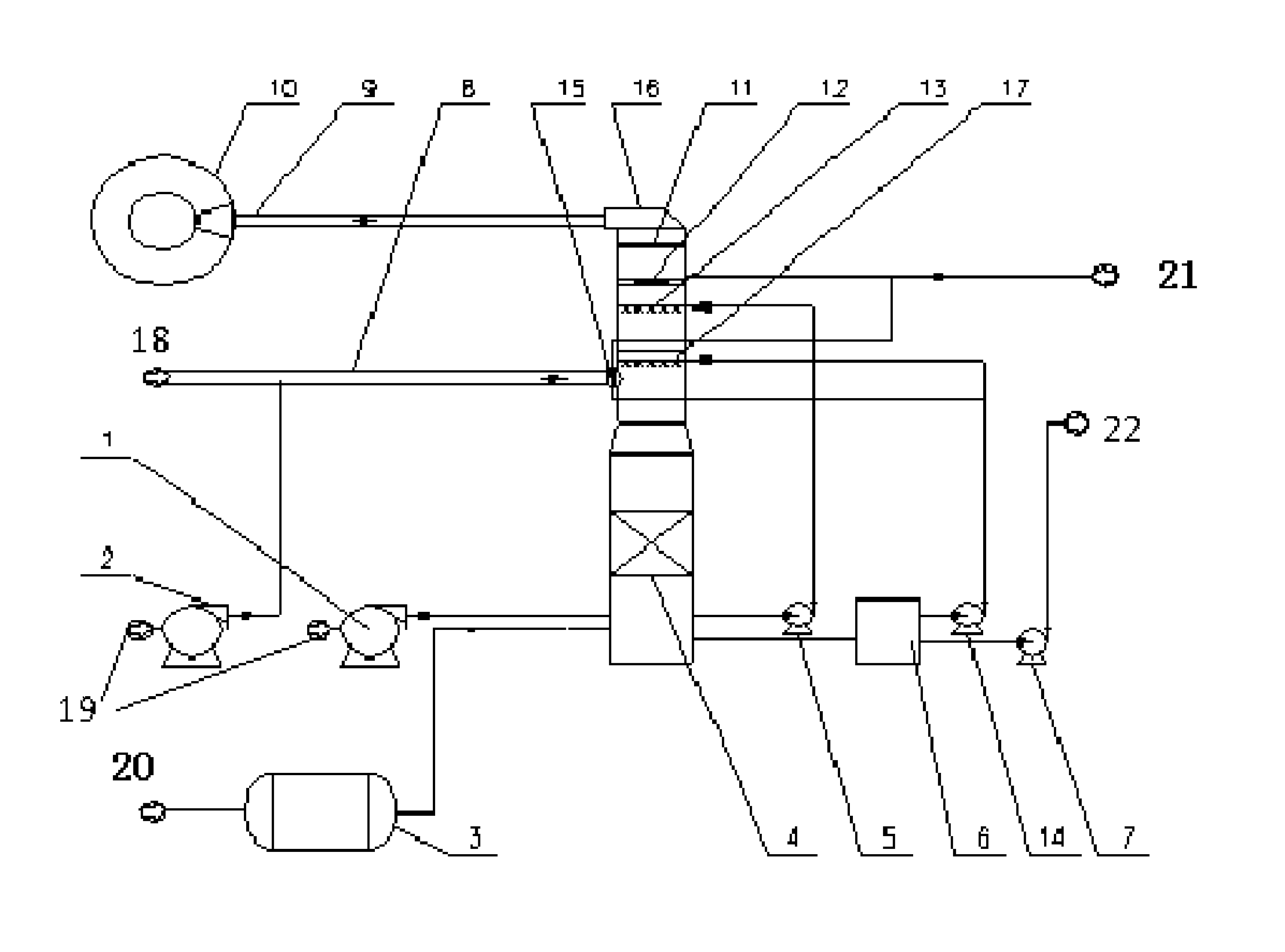

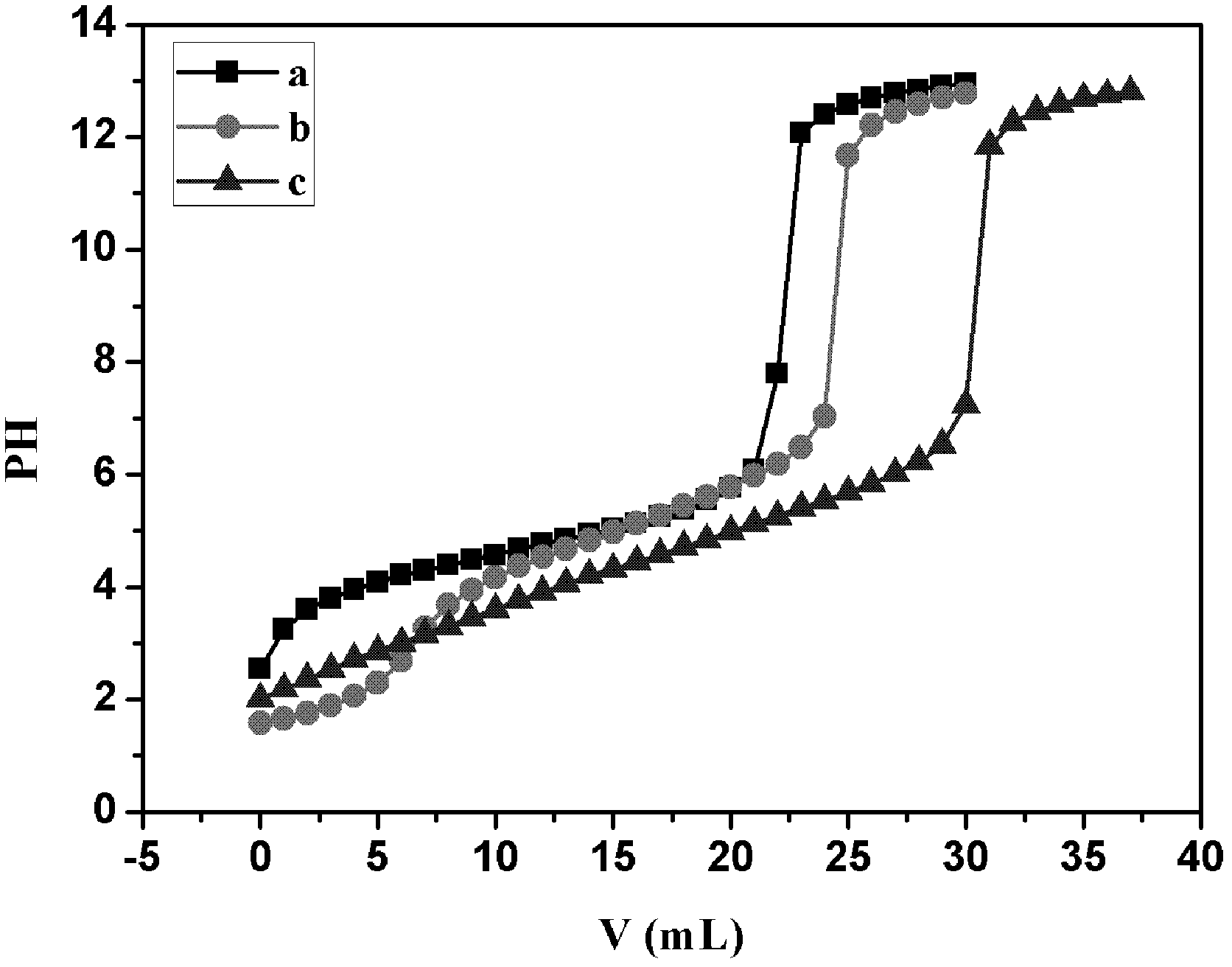

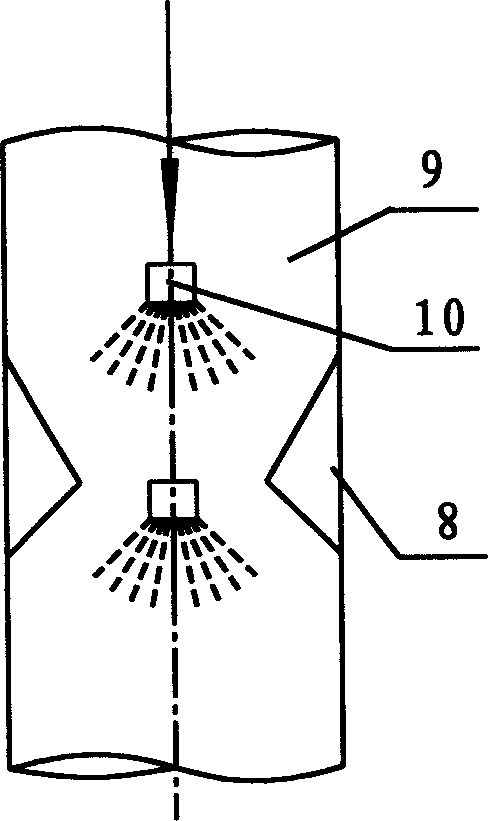

Removing and recovering process and device for SO2 in flue gas

InactiveCN1178735CReduce consumptionEasy to operateDispersed particle separationAmmonium sulfatesSulfateEnvironmental engineering

The present invention provides a method and apparatus for eliminating and recovering S02 from fume, including the following steps: l ) firstly, the fume containing low sulphur reacts with aqueous solution of ammonia, producing ammonia sulfite solution, ammonia / sulphur=1.3-1.8 (molar ratio), gas / liquid=2000-5000 (volume ratio); 2) the oxidizing reaction between the ammonium sulfite and air produces ammonia sulfate solution; 3) the ammonia sulfate solution is contacted heat fume, then the water-vaporized ammonia sulfate solution is delivered to crystallizer to be processed into ammonia sulfate fertilizer. The apparatus includes a desulphurizing tower, the desulphurizing tower includes S02 adsorption section, ammonia sulfite oxidizing section, ammonia sulfate solution condensing section, scrubbing section and demisting section. The apparatus can be operated easily. The cost can be reduced 10-30%.The vapor consumption can be reduced 90%. The concentration of S02 of fume can be reduced less than 10-100ppm. The quality of ammonia sulfate meets national standard.

Owner:EAST CHINA UNIV OF SCI & TECH

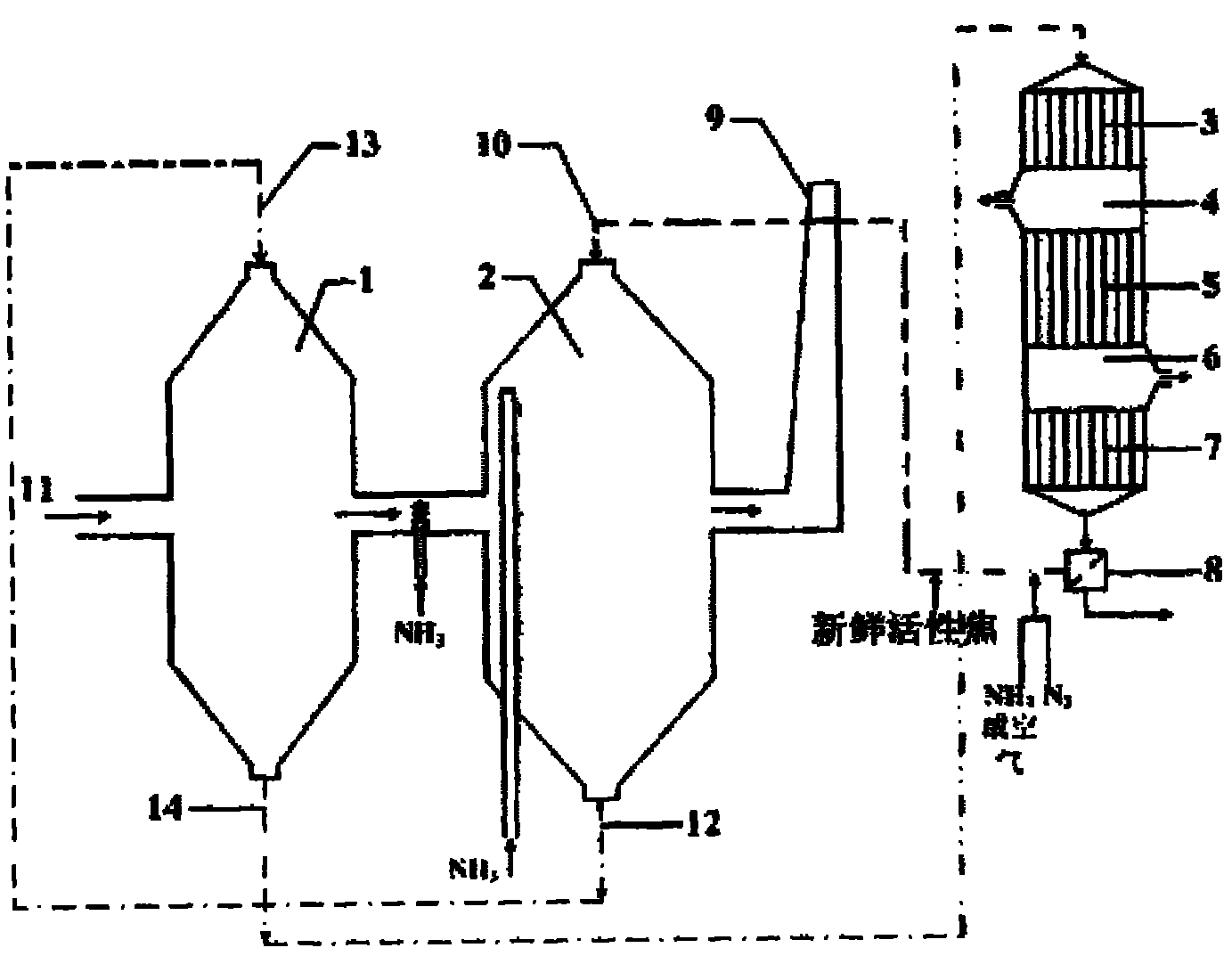

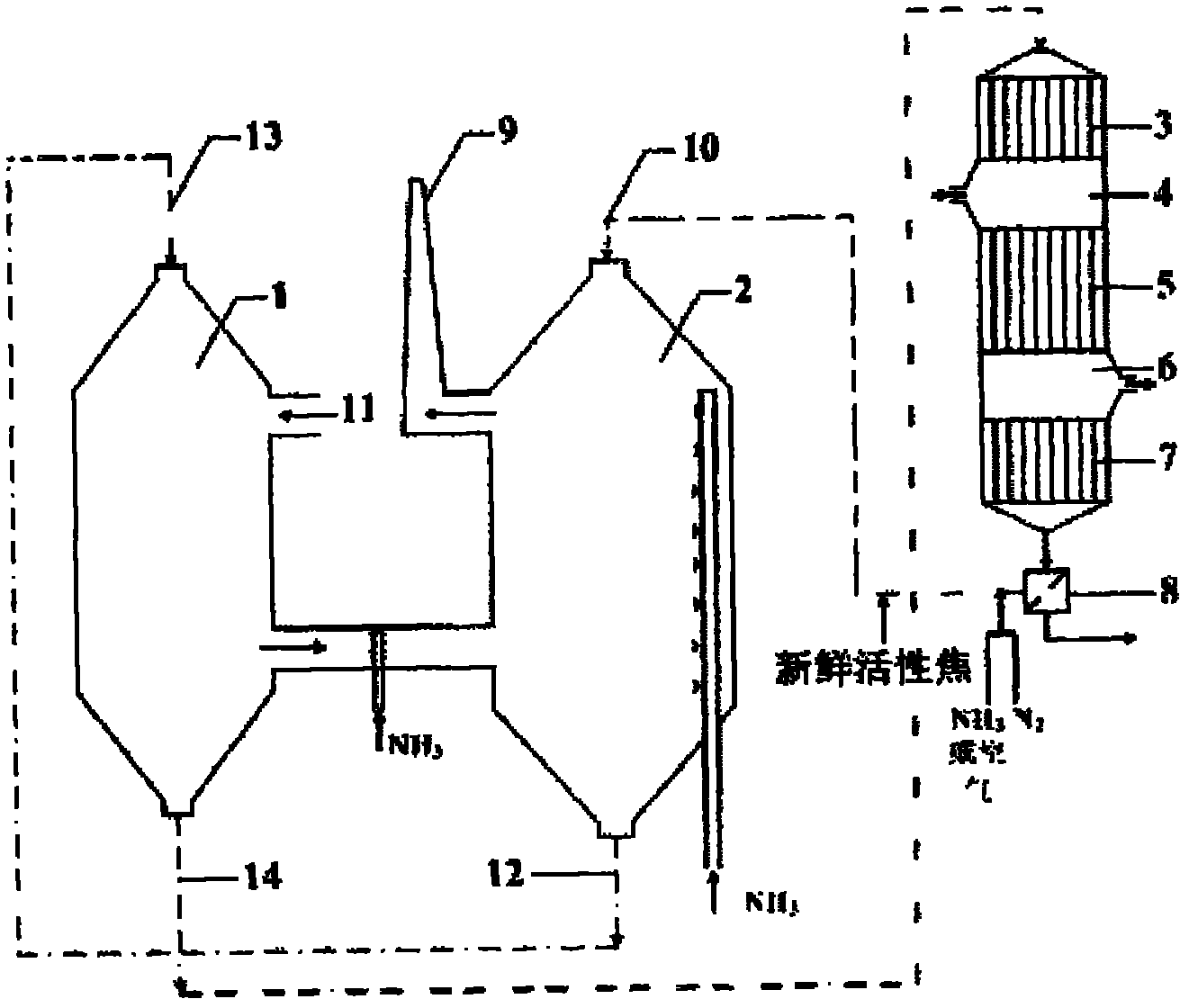

Flue gas-treating method and apparatus for treating acidic tail gas by using ammonia process

ActiveUS9370745B2Improve desulfurization efficiencyEffectively control the ammonia slip and the aerosol generationGas treatmentDispersed particle separationFlue gasAmmonia storage

Owner:JIANGNAN ENVIRONMENTAL PROTECTION GRP INC

Method for desulfurizing acid gas containing hydrogen sulfide and recycling sulfur

ActiveCN104208992AHigh activityReduce energy consumptionDispersed particle separationSulfur preparation/purificationCombustionLiquid state

The invention discloses a method for desulfurizing acid gas containing hydrogen sulfide and recycling sulfur. The method for desulfurizing acid gas containing hydrogen sulfide and recycling sulfur sequentially comprises the following steps: introducing the acid gas into a combustion furnace to be mixed with air introduced by the other pipeline so as to carry out a combustion reaction; introducing the gas reacted in the combustion furnace into a cooler to be cooled to 230-250 DEG C, after cooling, separating the cooled liquid sulfur at a liquid outlet, introducing mixed gas in the combustion furnace into a catalyst reactor, enabling hydrogen sulfide to react with sulfur dioxide in the catalyst reactor so as to generate sulfur and water, and separating the generated liquid sulfur at the liquid outlet of the catalyst reactor; introducing the mixed gas in the catalyst reactor into a hydrogenation reactor and enabling the sulfur dioxide to react with hydrogen in the hydrogenation reactor; introducing the gas in the hydrogenation reactor into a hydrogen sulfide absorption device and preparing the hydrogen sulfide into elemental sulfur under the action of an alkaline solution, a complex catalyst and the introduced air. The method for desulfurizing acid gas containing hydrogen sulfide and recycling sulfur has the advantages of short process route, high quality of produced sulfur and low energy consumption, is capable of fully removing SO2 gas and is green and environmentally friendly.

Owner:NINGBO RES & DESIGN INST OF CHEM IND

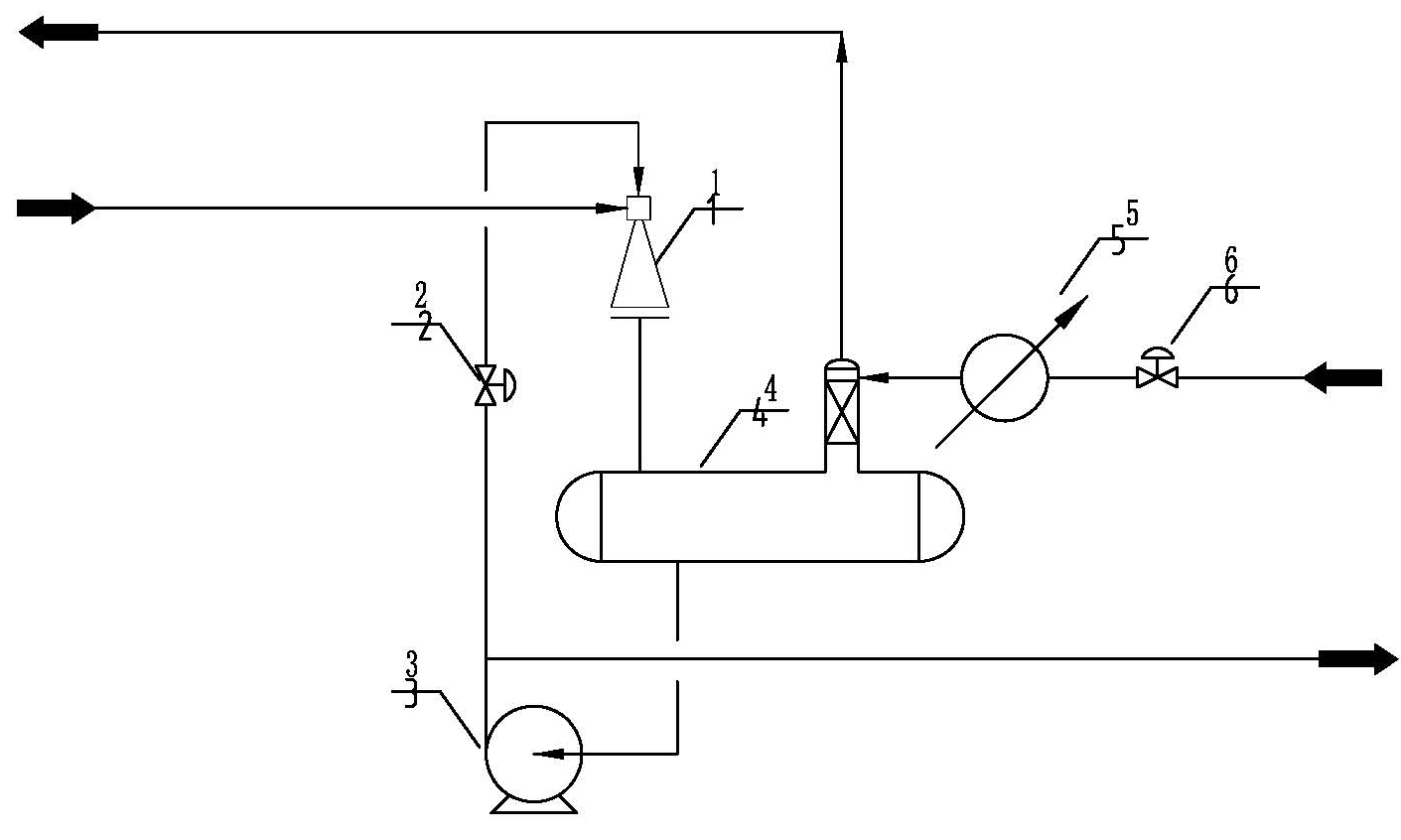

Boiler system of circulating fluid bed burning in oxygen enrichment

InactiveCN1959208AOvercome the problem of difficult temperature controlIncrease concentrationFluidized bed combustionIndirect carbon-dioxide mitigationHigh concentrationFluidized bed

A circulation fluidized-bed boiler of rich-oxygen combustion type is prepared as utilizing circulation fluidized-bed boiler with external fluidized bed heat exchanger to carry out combustion in mode of mixing mixture gas of high concentration oxygen from air separate and recirculation smoke from boiler tail with fuel, controlling load and firepot temperature of said boiler by regulating flow rate of fly ash particles entering into external fluidized bed heat exchanger.

Owner:HUAZHONG UNIV OF SCI & TECH

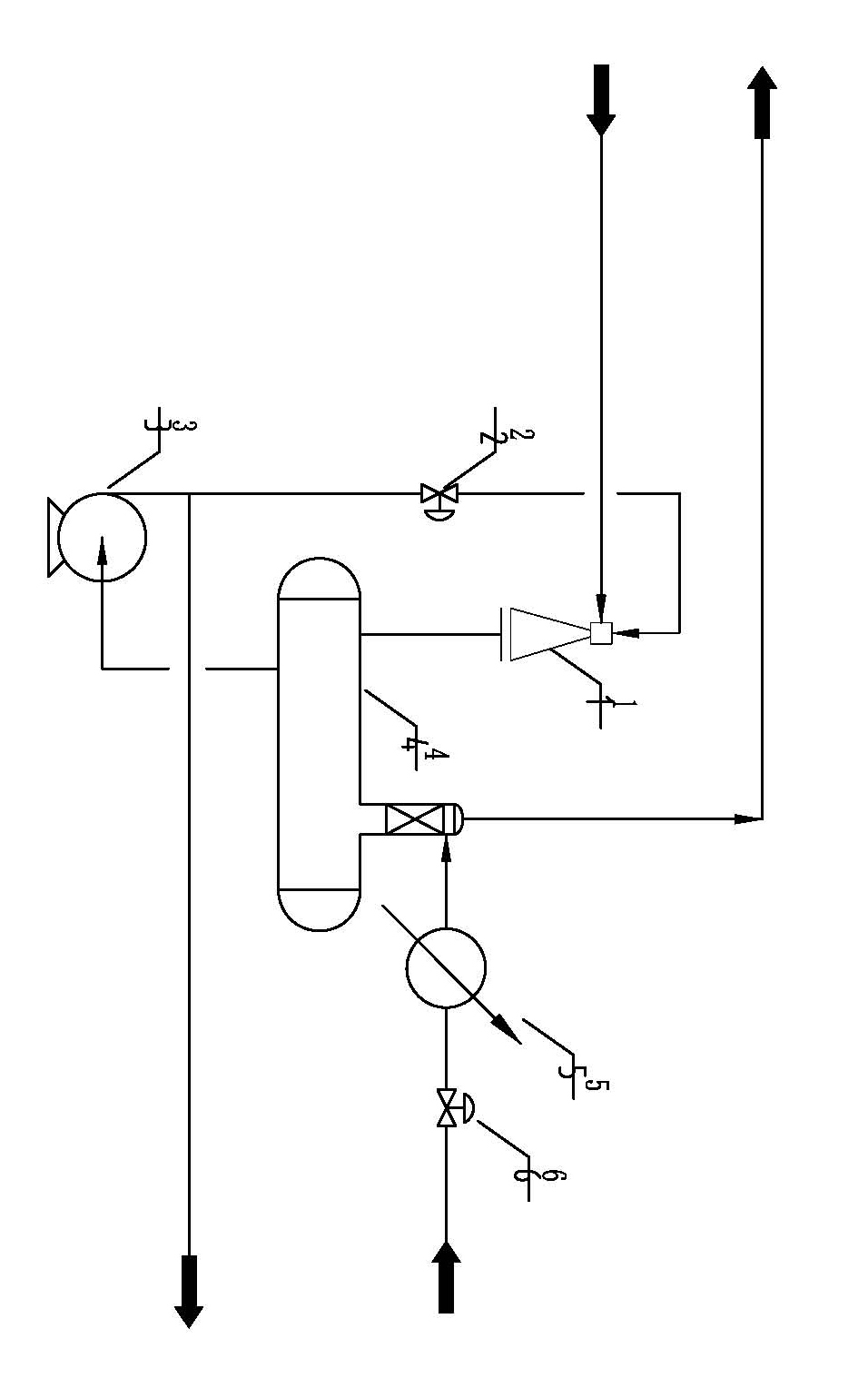

Pressure reduction gas desulfurization method

The invention relates to a pressure reduction gas desulfurization method which belongs to the technical field of chemical technology. The pressure reduction gas desulfurization method comprises the following steps of: firstly, performing injection desulfurization with an absorbent; secondly, performing absorption desulfurization with an absorbent in a recycling tank; and then performing absorption again with absorbing structured packing after absorption desulfurization. In the specific operations of the vacuum gas desulfurization method, the absorbent is recycled through a circulation line; a circulating pump and the recycling tank are connected to the circulation line; an injector is connected to an upstream circulation line of the recycling tank; sulfur-contained gas is connected to the injector; and the top of the recycling tank is provided with a clean gas outlet. The pressure reduction gas desulfurization method has the advantages of simple process, convenience of operation, low construction investment and low failure rate. Moreover, the content of hydrogen sulfide after gas desulfurization can be reduced to be less than 500ppm, thus the desulfurization and purification effects are good and the desulfurization efficiency is high.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

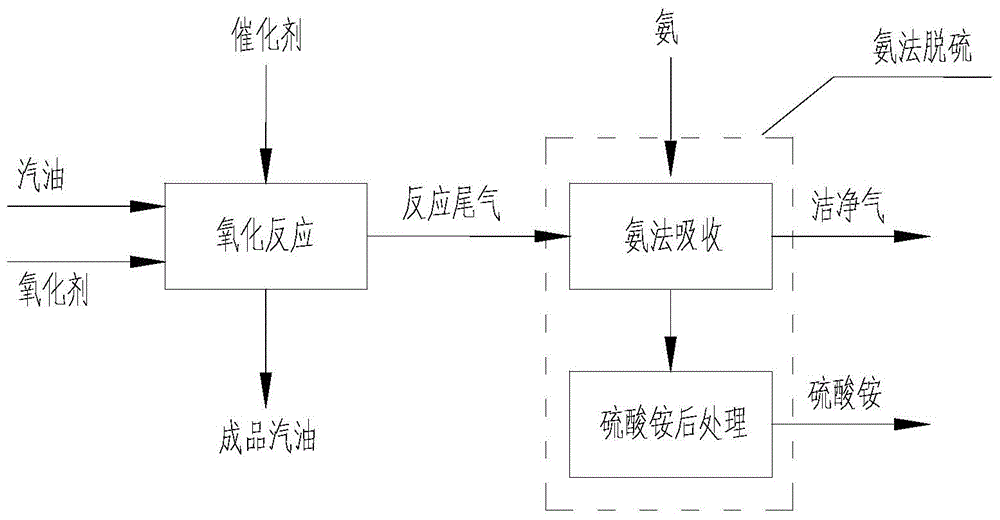

Gasoline-oxidation ammonia-process desulfurization method

InactiveCN104946296ARealize recycling of resourcesImprove desulfurization efficiencyRefining with oxygen compoundsDispersed particle separationGasolineComponents of crude oil

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Method for producing the clean diean diesel oil with low sulfur and low arene

InactiveCN1415706AExpand sourceImprove adaptabilityTreatment with hydrotreatment processesSulfurImpurity

A process for preparing low-sulfur low-arylhydrocarbon clean diesel oil includes such steps as hydrorefining / hydrocracking raw hydrocarbon to obtain intermediate fraction oil, catalytic stripping to separate light fraction from heavy fraction, hydrorefining the light fraction to remove residual S and impurities, and catalytic stripping of heavy fraction for removing sulfure and arylhydrocarbon to obtain final product. Its advantage is cyclic use of two reactino segments for low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Additive for strengthening wet flue gas desulfurization technology

InactiveCN102580514AImprove qualityAchieve reuseCalcium/strontium/barium sulfatesDispersed particle separationOrganic acidAdipic acid

The invention belongs to the technical field of a limestone / gypsum wet flue gas desulfurization technology, and particularly relates to an additive for strengthening a wet flue gas desulfurization technology, which comprises the following components in percentage by mass: 35-45% of mixed organic acid, 5-10% of organic acid salt, 6-9% of surfactant, 1-6% of heavy metal salt and 35-45% of dirt dispersion agent; and the mixed organic acid comprises adipic acid, wherein the percentage of mass of the adipic acid in the mixed organic acid is not less than 50%. The additive can be added and used for strengthening the wet flue gas desulfurization technology, improve the desulfurization efficiency of a system, reduce the energy consumption, strengthen oxidization, improve the limestone quality and restrain system scaling, and accordingly, the purposes of energy conservation, consumption reduction and waste recycling are realized.

Owner:SCI GREEN SHANDONG ENVIRONMENT TECH CO LTD

Inhibitor addition-based desulfurizing method in iron ore sintering process

ActiveCN102068887AConcentrated emission concentration is highImprove desulfurization efficiencyDispersed particle separationIronstoneFiltration

The invention discloses an inhibitor addition-based desulfurizing method in the iron ore sintering process, and aims to provide a desulfurizing method in the iron ore sintering process, which has the advantages of low investment cost, low operation cost and high desulfurization efficiency. In the method, an ammonia-containing compound is added into a bedding material layer at the bottom of a sintered material layer, ammonium sulfate generated in the reaction of ammonia which is decomposed from the ammonia-containing compound and sulfur oxide in the sintering process is adsorbed to dust and taken away by flue gas; ammonium sulfate-containing dust in the flue gas of an air bellows on the rear half part of a sintering machine is collected by a cyclone dust separator; and the collected dust is washed, filtered and dried to form dry dust, and the filtrate after filtration is concentrated, crystallized and dried to form ammonium sulfate.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

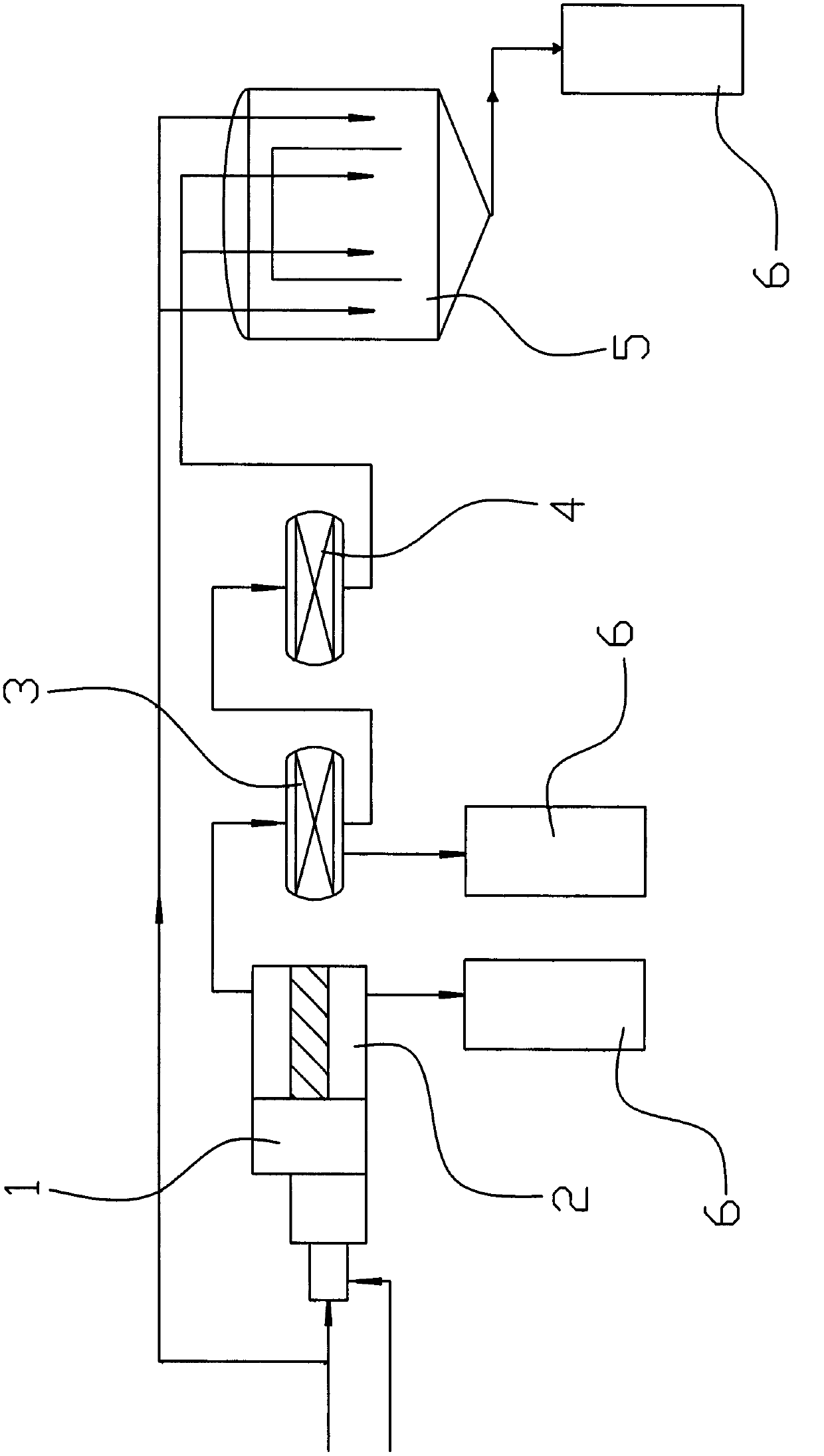

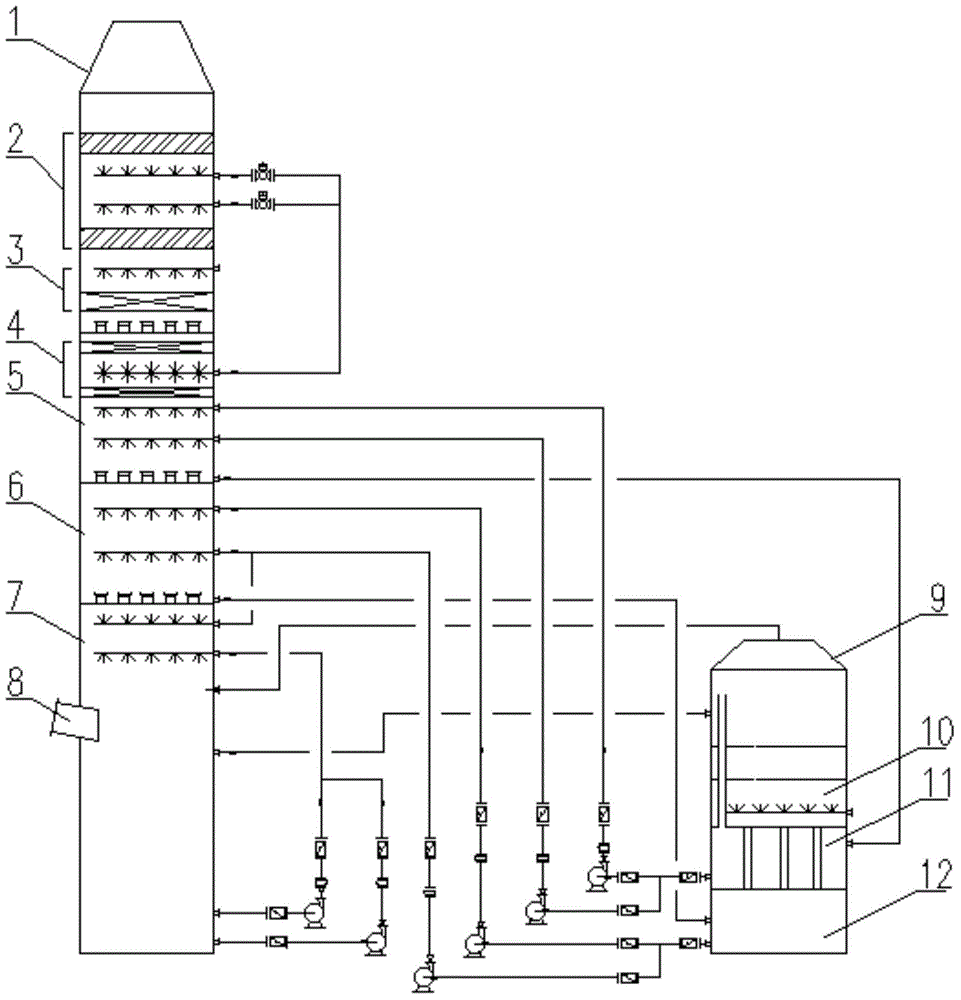

Modularized integrated smoke purification system and method for removing plurality of pollutants

ActiveCN102974185ALow running costLower stoichiometric ratioCombination devicesElectricityMulti pollutant

The invention discloses a modularized integrated smoke purification system and method for removing a plurality of pollutants. The system comprises an absorption tower, wherein a smoke inlet is arranged in the lower end of the absorption tower; the absorption tower is internally provided with a spraying device which is located above the smoke inlet and is used for spraying an absorbent, a first wet-type electric precipitation device located above the spraying device, and a second wet-type electric precipitation device located above the outer side of the absorption tower; and a smoke uniform distributor is arranged between the first wet-type electric precipitation device and the second wet-type electric precipitation device. The invention further discloses a method for carrying out smoke purification by using the system; the pollutants existing in an aerosol form, including SO2, NOX, superfine smoke dust, SO3 acid fog, mercury and the like in the smoke, can be intensively removed; gypsum rain is prevented and an environment is protected; and the smoke purification efficiency is improved.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

Coke oven flue gas desulfurization and denitrification purification process and device

InactiveCN105107349AGuaranteed negative pressureGuaranteed desulfurizationDispersed particle filtrationUsing liquid separation agentParticulatesFlue gas

The invention relates to a coke oven flue gas desulfurization and denitrification purification process and a device, wherein flue gas is effectively desulfurated at low temperature through a rotating spray semi-dry method before denitrating, then is denitrated by utilizing a selective catalytic reduction method and utilizing an ammonia gas which is obtained by evaporating surplus ammonia water in a coking plant steamed ammonia section as a reducing agent, a denitration process is completed in a dust removal denitration integration device, dust in flue gas is removed and particulate matter is filtered out before denitrating, and the particulate matters in flue gas which is filtered and reactants which are generated through desulfurization are conveyed into a circulating ash solution preparation unit which is arranged in a desulfurization system through a desulfurization ash collecting transportation device, and are conveyed to the top portion of a desulfurization tower through a solution transportation unit to participate in the flue gas desulfurization process after being prepared to be a circulating ash solution, thereby enabling unreacted desulfurizer to be fully utilized. The coke oven flue gas desulfurization and denitrification purification process and the device combine rotating spray drying desulfurization method and a low temperature selective catalytic reduction (SCR) denitrification, achieve efficient desulfurization and denitrification of coke oven flue gas, and are simple in technological process, small in floor space and less in equipment investment.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

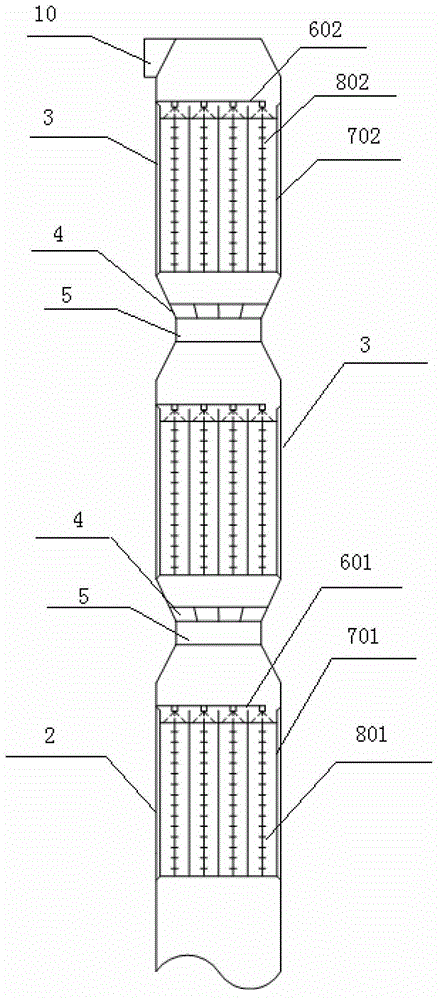

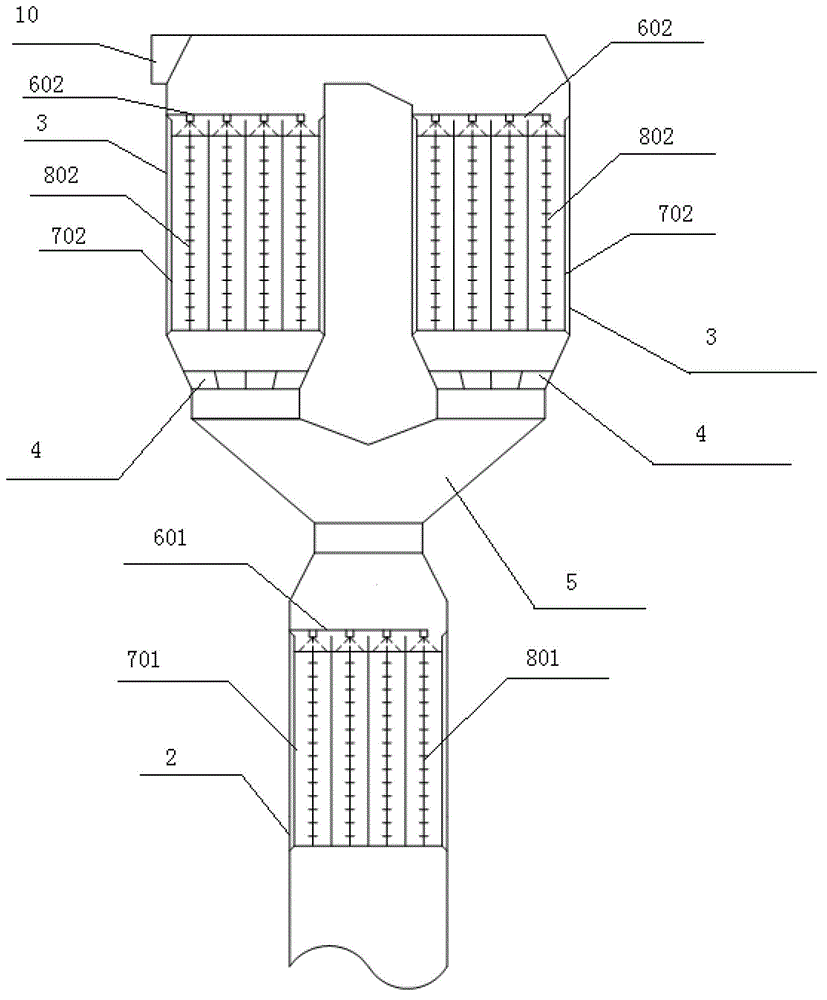

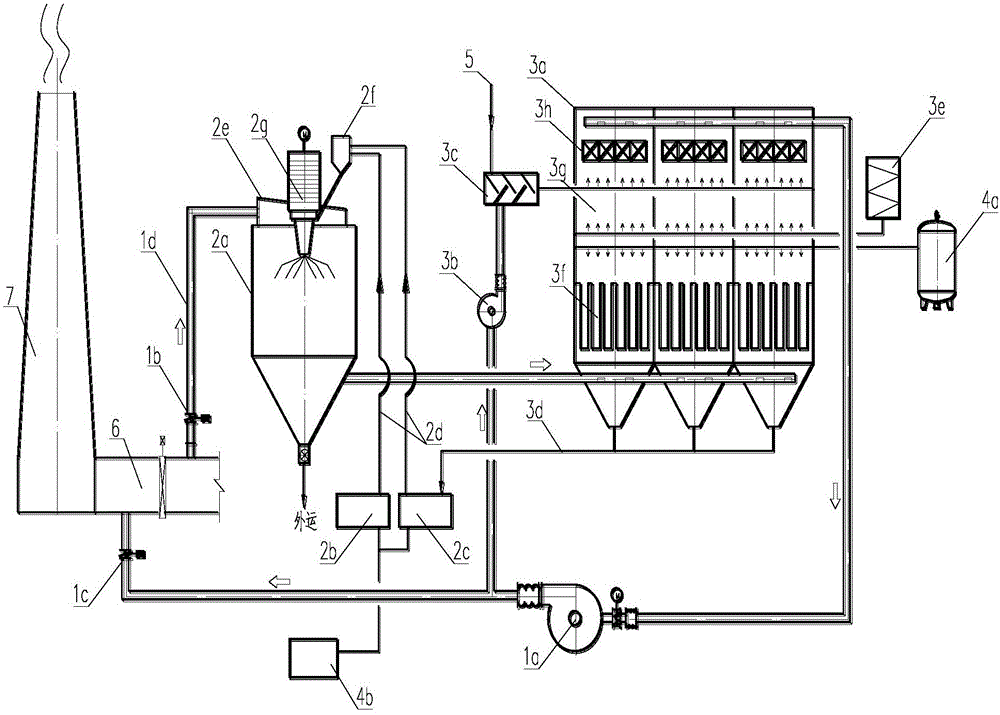

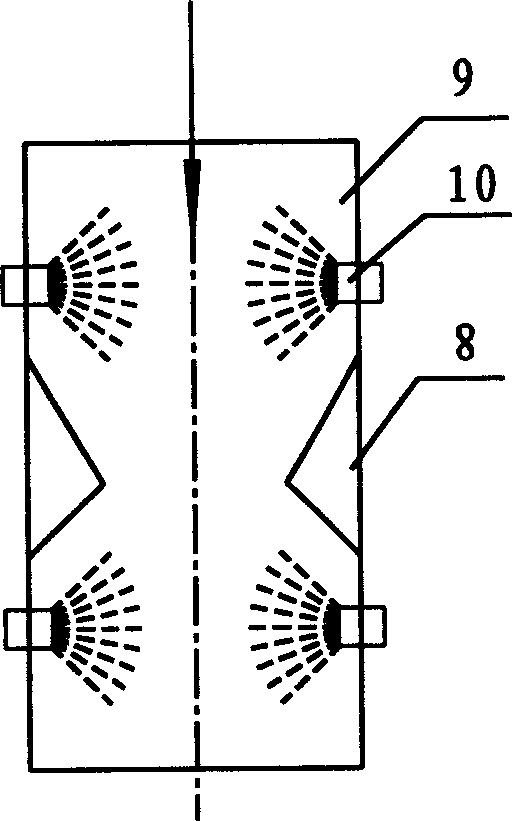

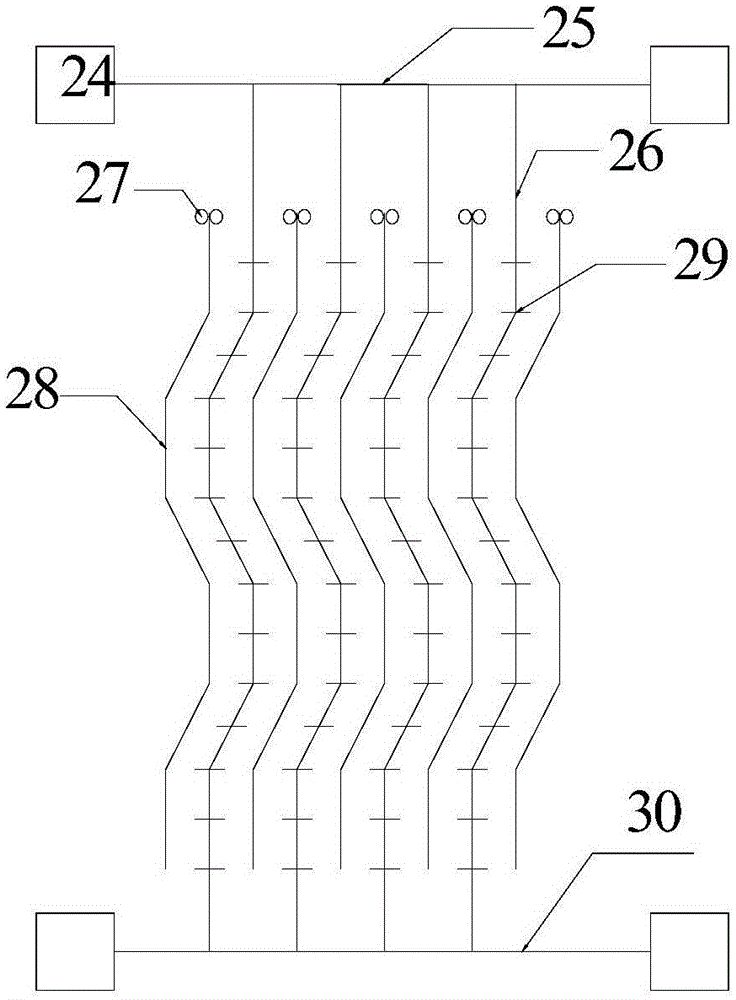

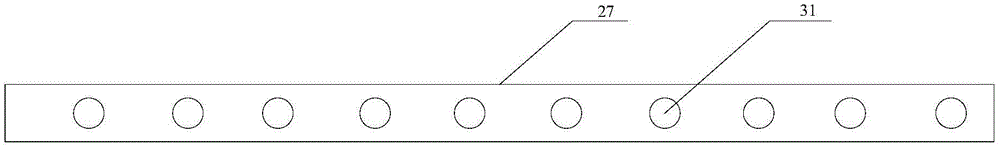

Flue gas dust removal desulphurization system of double-circulation Venturi rod tower

The invention belongs to the field of environment protection, and discloses a wet-method flue gas dust removal desulphurization system of a double-circulation Venturi rod tower. The system comprises an adsorption-liquid supplying unit, a flue-gas purification unit and an adsorption-liquid postprocessing unit. The flue-gas purification unit comprises an upper Venturi rod tower section, a lower Venturi rod tower section, a shutter-type separation cone separating the upper Venturi rod tower section and the lower Venturi rod tower section, an upper circulation liquid pool, a lower circulation liquid pool, upper circulation-liquid sprayers, lower circulation-liquid sprayers, and demisters. Flue gas in the upper tower section and flue gas in the lower tower section are in series connection. A circulation-liquid spraying system is operated independently. Dust removal and desulphurization are separately optimized and performed. The "homogenization" gas flow distribution, "gas in liquid" efficient mass transfer, highly-turbulent "self-cleaning", and other effects of Venturi rod layers are fully utilized by the system so as to perform efficient cooling, dust removal desulphurization of the flue gas. The system is advantages by high dust removal desulphurization efficiency, low operation liquid gas ratio, small resistance, less scale, small occupation area, low investment, low operation energy consumption, less discharge of high-salt water, and the like, and is suitable for dust removal and desulphurization for various kinds of flue gas, particularly suitable for processing of high-temperature high-dust high-sulfur flue gas such as regenerated flue gas of a petroleum catalytic cracking device.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

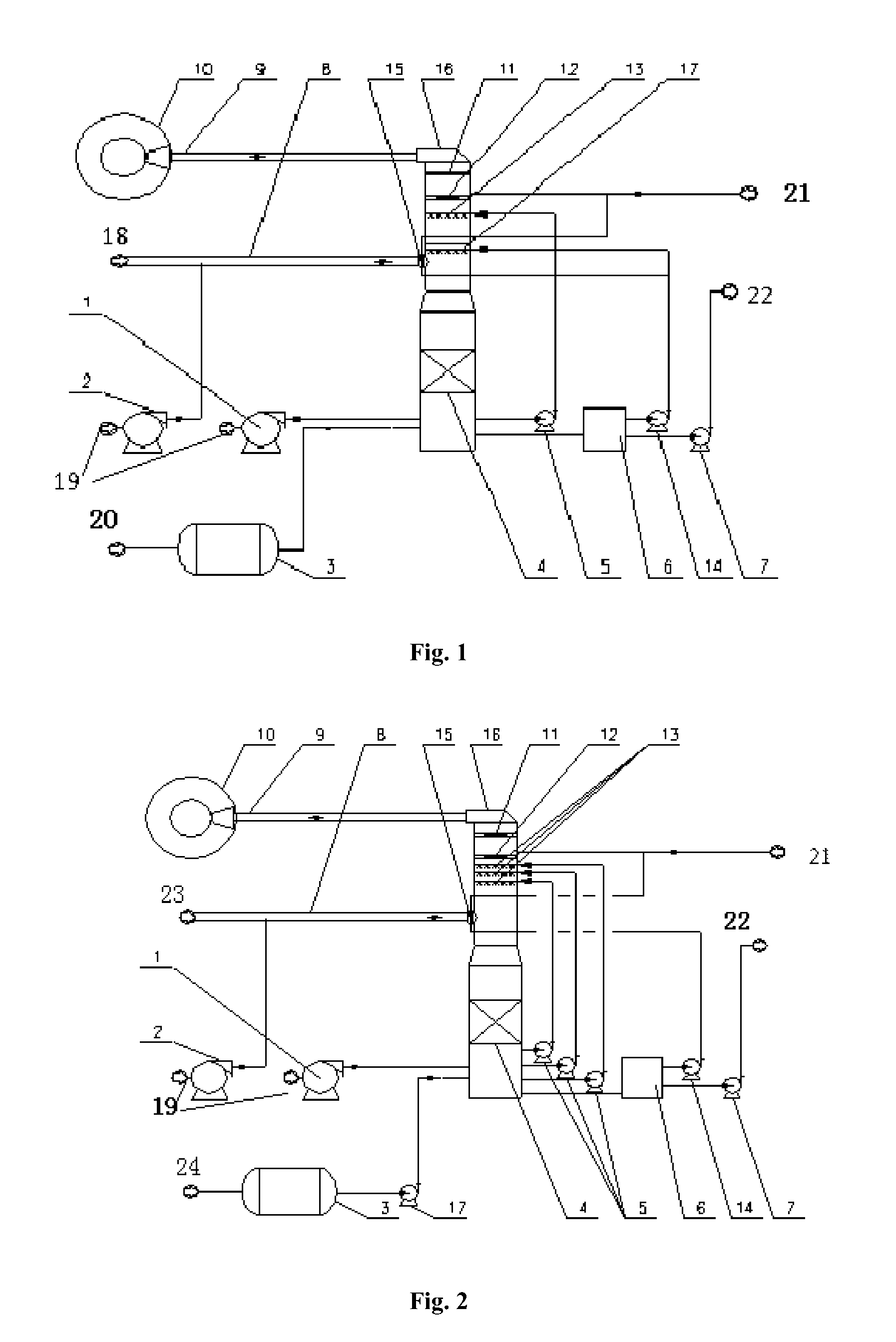

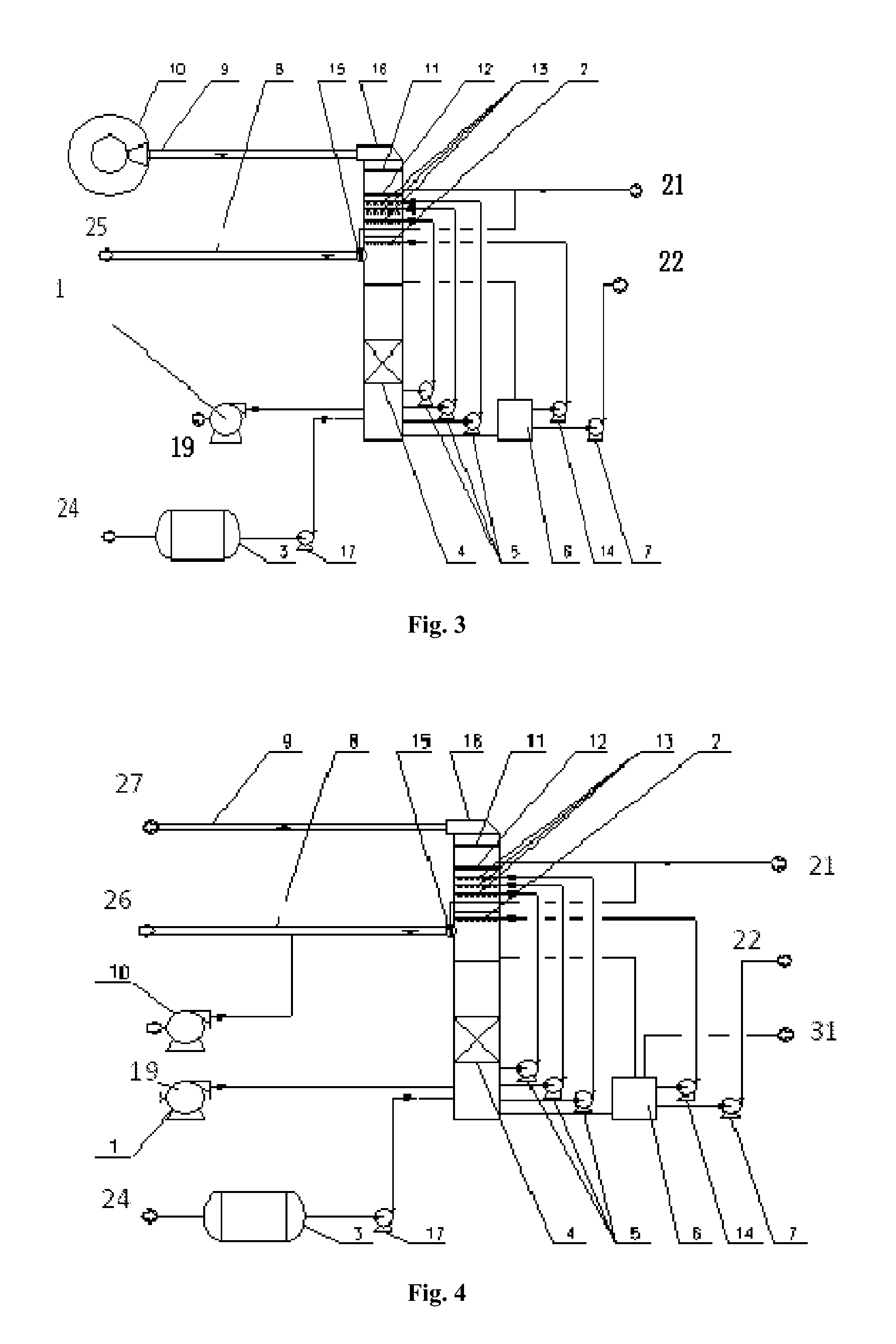

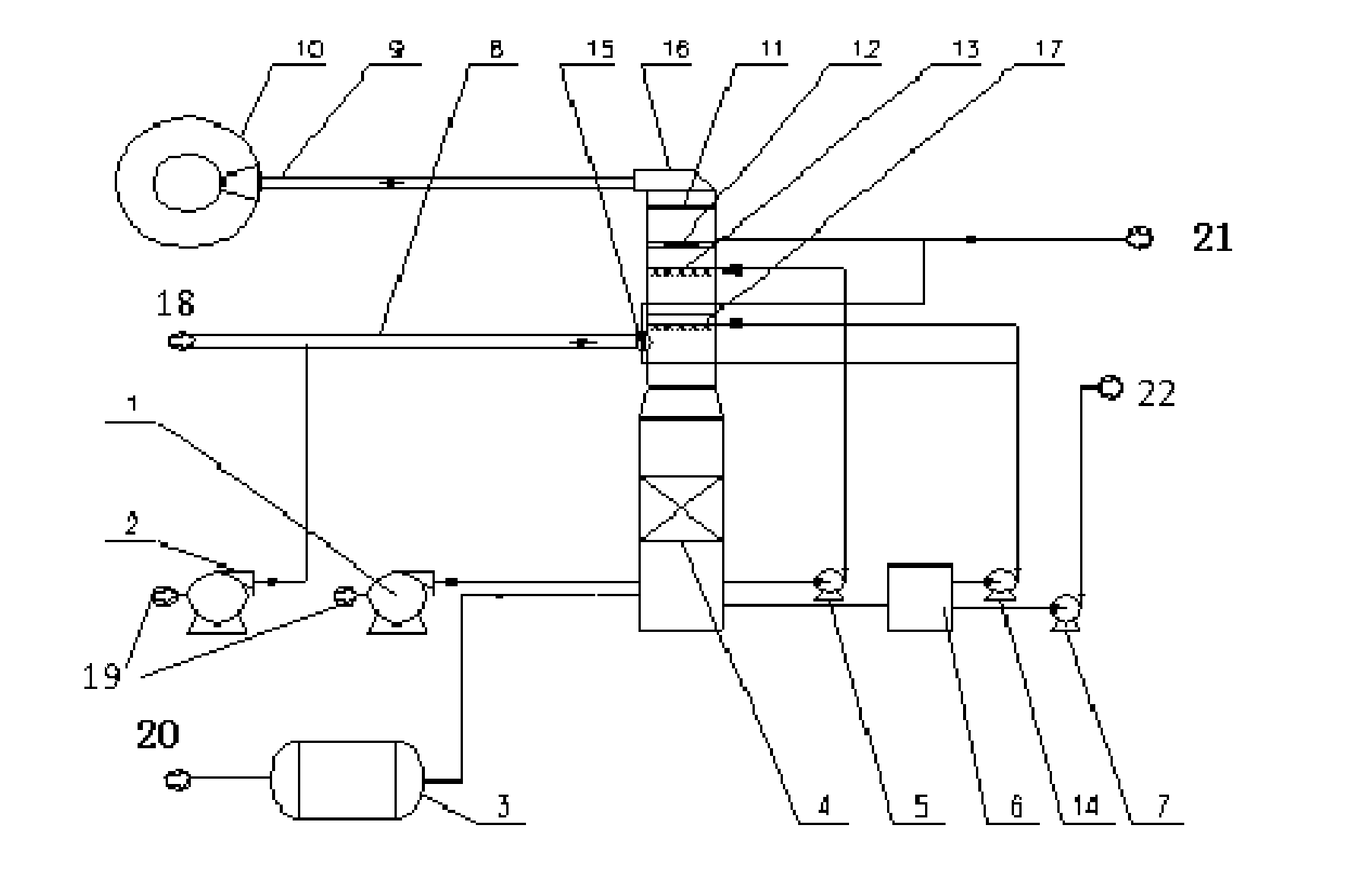

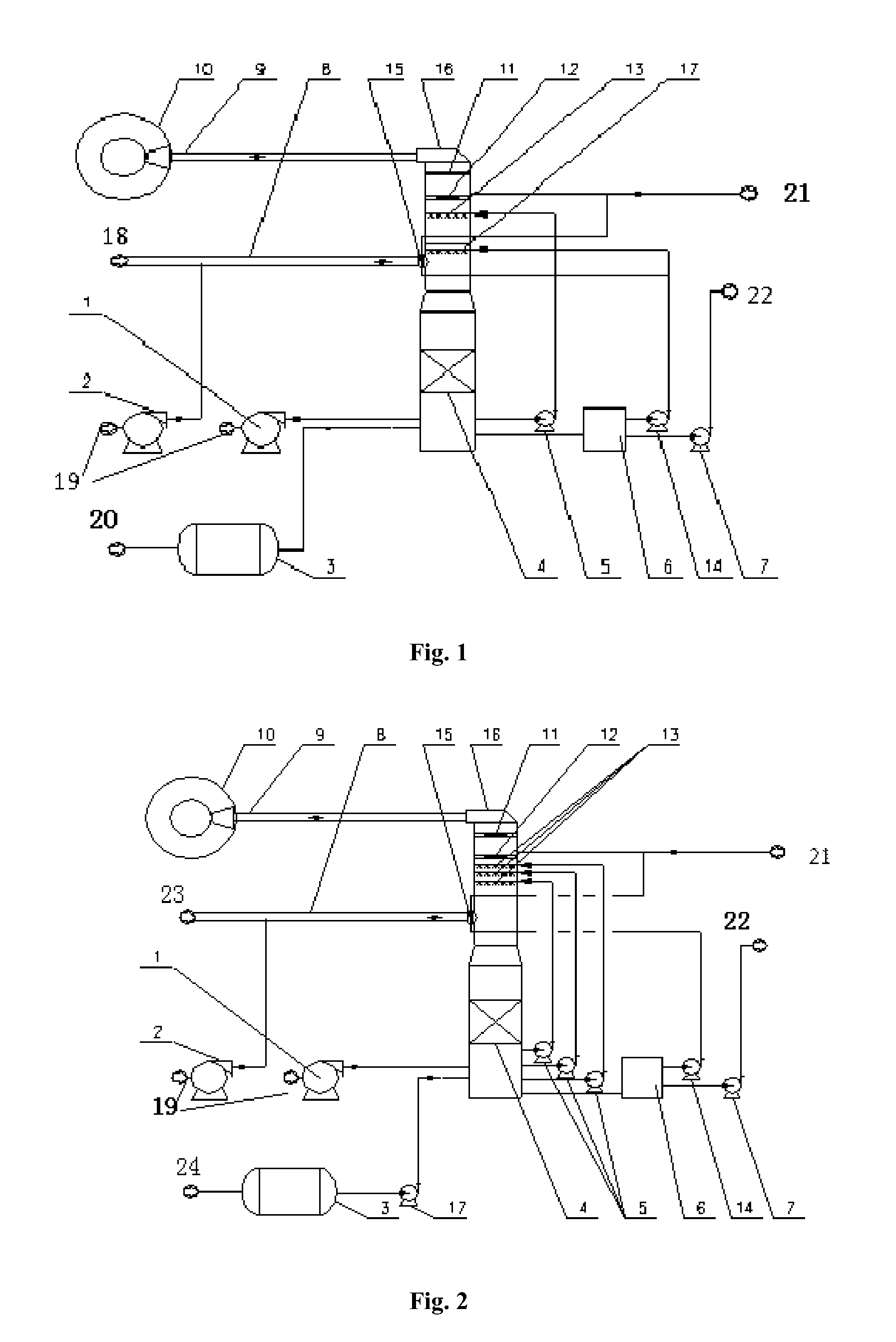

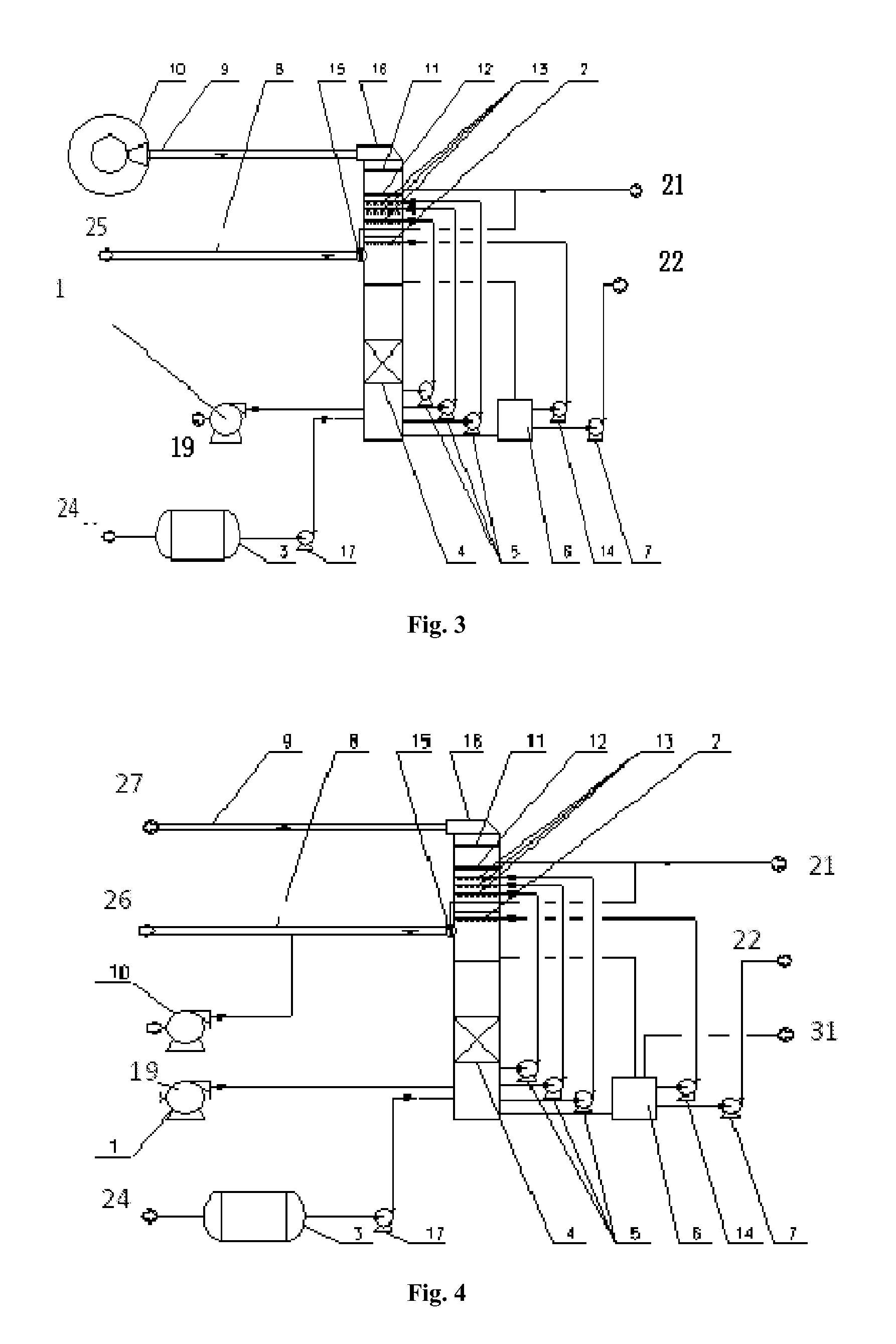

Flue gas-treating method and apparatus for treating acidic tail gas by using ammonia process

ActiveUS20150352486A1Improve efficiencyReduce investmentCombination devicesGas treatmentAmmonia storageFlue gas

A flue gas-treating method for treating acid tail gas by using an ammonia process, comprising the following steps of: 1) controlling the concentration of sulfur dioxide in an acid tail gas entering an absorber to be ≦30,000 mg / Nm3; 2) spraying and cooling with a process water or / and an ammonium sulfate solution in the inlet duct of the absorber or inside the absorber; 3) providing an oxidation section in the absorber, wherein the oxidation section is provided with oxidation distributors for oxidizing the desulfurization absorption solution; 4) providing an absorption section in the absorber wherein the absorption section achieves desulfurization spray absorption by using absorption solution distributors via an absorption solution containing ammonia; the absorption solution containing ammonia is supplied by an ammonia storage tank; 5) providing a water washing layer above the absorption section in the absorber, wherein the water washing layer washes the absorption solution in the tail gas to reduce the slip of the absorption solution; 6) providing a demister above the water washing layer inside the absorber to control the concentration of mist droplets contained in the cleaned tail gas. In the coal chemical industry, the integration of the Claus sulfur recovery process and the ammonia desulfurization technology can reduce the investment of the post-treatment and simplify the operation process, and provide intensive advantages to the environmental control of plants.

Owner:JIANGNAN ENVIRONMENTAL PROTECTION GRP INC

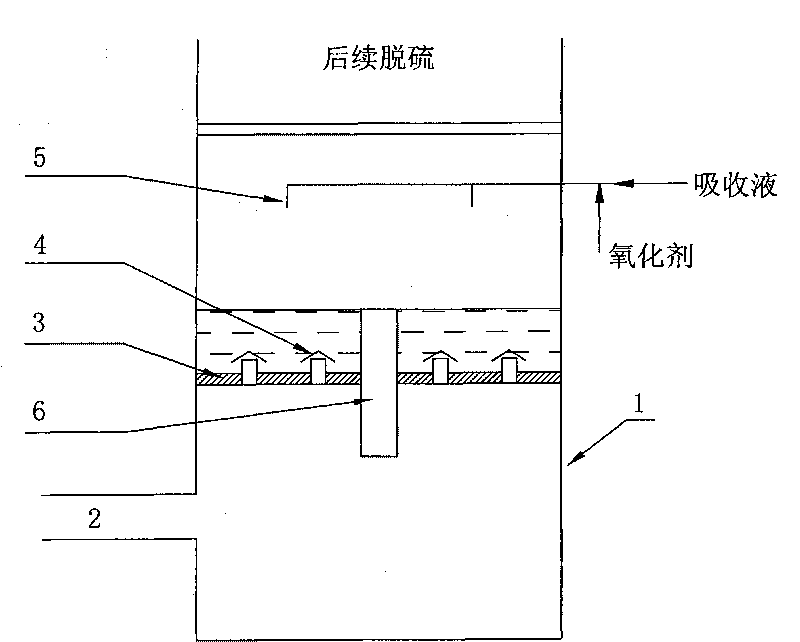

Method for depriving sulfureted hydrogen in biogas and device

The invention provides a method for depriving sulfureted hydrogen in biogas, which is characterized by comprising the following steps: firstly, introducing the biogas into a bubble column plate absorption oxidation device, and absorbing sulfureted hydrogen in the biogas by utilizing sprayed absorption solution containing an oxidant; secondly, controlling the air velocity in a hollow tower of the bubble column plate absorption oxidation device to be 0.2-1.5m / s, wherein the height of the liquid on a plate grid is 0.2-0.8m; and finally sending the biogas absorbed by absorption solution to a subsequent dry-type desulfurizing tower, a wet-type desulfurizing tower or a biological desulfurizing tower for depriving sulfureted hydrogen further. The invention also discloses three devices for depriving sulfureted hydrogen in the biogas by utilizing the combination of the bubble column plate absorption oxidation devices, a desulfuration device using the common dry method and wet method. The invention has simple method, and can effectively and quickly carry out desulfuration at constant pressure.

Owner:NANJING UNIV

Multiple reaction integrated process for desulfuizing from fume by dry method and its system

ActiveCN1537668AImprove surface activityReduce desulfurization costDispersed particle separationPartial oxidationCalcium sulfite

A multiple reactions integrated process for desulfurizing from the fume by dry method includes such steps as spraying limestone powder in high-temp combustion box from its top to decompose calcium carbonate into calcium oxide and CO2, absorbing SO2 from fume by partial calcium oxide to generate calcium sulfate, spraying water to activate calcium oxide to transform partial calcium oxide to calcium hydroxide and absorb SO2 from fume to generate calcium sulfite, and using the residual calcium hydroxide and calcium oxide to desulfurize the fume in desulfurizing tower. Its system is composed of limestone powder sprayer, moistening flue, desulfurizing tower, external electric duster, draught blower and chimney.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

Chelated iron desulfurizer and application method thereof

InactiveCN105233649AImprove desulfurization efficiencyImprove gas-liquid mass transfer efficiencyDispersed particle separationIron saltsOffshore oil and gas

The invention discloses a chelated iron desulfurizer and application method thereof, and belongs to the technical field of gas purification. The chelated iron desulfurizer comprises the following components: soluble iron salt, an iron salt chelating agent, a sulfide absorbent, a stabilizing agent, a composite particle settling agent, and a multifunctional corrosion inhibitor; wherein the mole ratio of Fe<3+> to Fe<2+> in soluble iron salts is 1:3-5:1; the mole ratio of chelating agent to iron salts is 1.2:1-3:1, and the pH value of the solution is 8.0 to 9.5. The chelated iron desulfurizer is used to remove sulfur under the assistance of a hyper-gravity technology; the desulfurization efficiency is high, the work sulfur capacity is high, the performance of the desulfurizer is stable, and the oxidation regeneration performance is good. The hyper-gravity chelated iron desulfurization technology has the advantages that the technology is simple, the mass transfer efficiency between gas and liquid is high, the equipment is small and can be easily assembled or disassembled, and the technology can be used to remove H2S from natural gas or associated gas in an offshore oil and gas platform.

Owner:ZHONGBEI UNIV

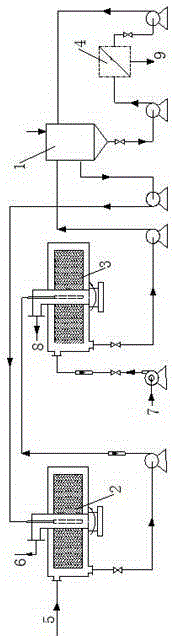

Flue gas-based combined desulfuration and denitration method and special device for method

ActiveCN102019135AImprove distributionImprove denitrification efficiencyDispersed particle separationFlue gasProcess engineering

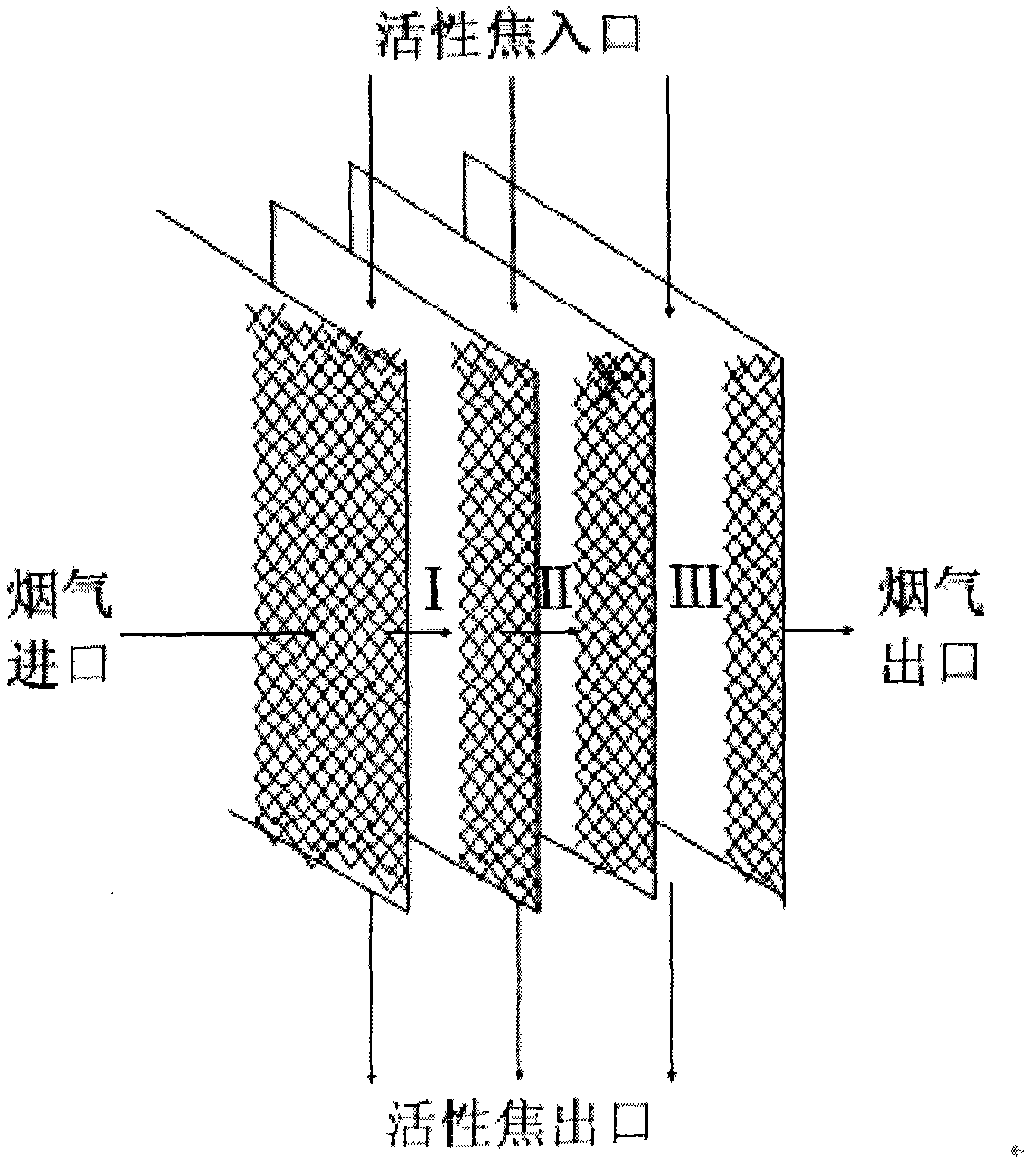

The invention discloses a flue gas-based desulduratoin and denitration method and a special device for the flue gas-based desulduratoin and denitration method. The special device comprises a denitration reactor body and a desulphurization reactor body, wherein the side wall of the desulphurization reactor body is provided with a flue inlet; the desulphurization reactor body and the denitration reactor body are communicated in parallel; the volume of the denitration reactor body is 1-2 times that of the desulphurization reactor body; the communicating position of the desulphurization reactor body and the denitration reactor body is provided with a device for spraying NH3; the top of the denitration reactor body is provided with a denitration reactor inlet for active coke; the bottom of thedenitration reactor is provided with a denitration reactor outlet for the active coke; the top of the desulphurization reactor is provided with a desulphurization reactor inlet for the active coke; the bottom of the desulphurization reactor is provided with a desulphurization reactor outlet for the active coke; and the denitration reactor outlet for the active coke is communicated with a desulphurization reactor inlet for the active coke through a pipeline, and the desulphurization reactor outlet for the active coke is communicated with a regeneration reactor. The invention also provides a method for flue gas desulfurization and denitration by using the device.

Owner:CCTEG CHINA COAL RES INST

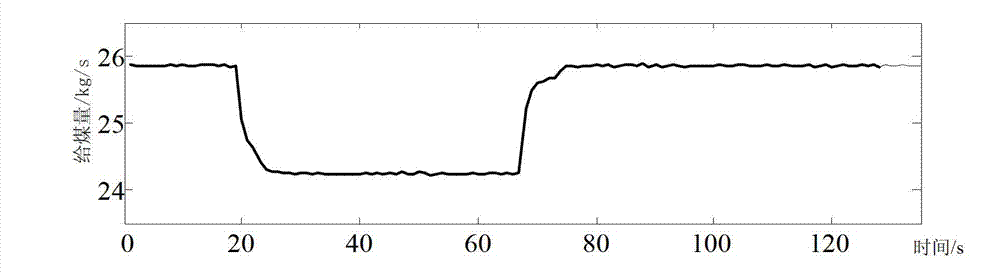

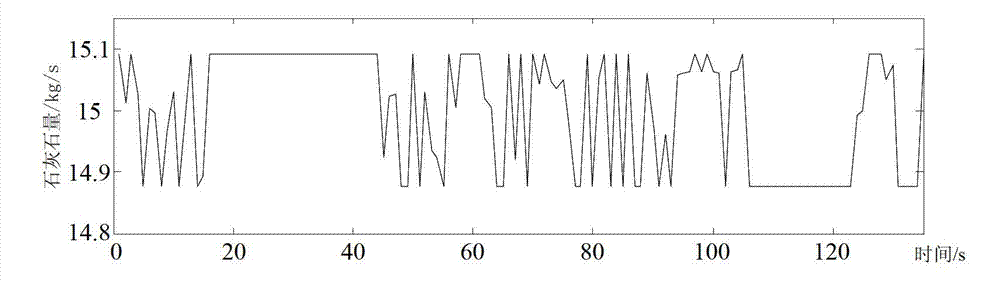

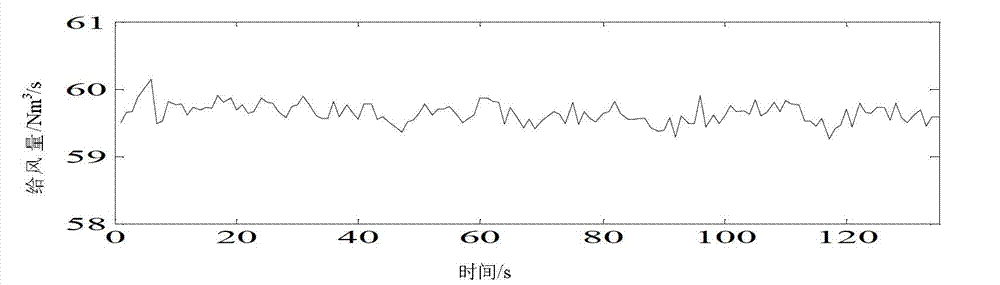

Soft measurement method and optimal control method of sulfur dioxide in circulating fluidized bed boiler smoke

InactiveCN103197549AAdjust the feeding amount in timeFeed rate is stableAdaptive controlFluidized bedOptimal control

The invention discloses a soft measurement method and an optimal control method of sulfur dioxide in circulating fluidized bed boiler smoke. The soft measurement method of the sulfur dioxide in the circulating fluidized bed boiler smoke includes the following steps: (1) collecting operational data of a practical industrial device, and constructing a soft measurement model of activated limestone in a furnace; (2) constructing a soft measurement model of emission concentration of the sulfur dioxide in an outlet of the furnace combining with coal feeding quantity according soft measurement value of the activated limestone in the furnace; and (3) controlling a limestone feeding machine to adjust limestone feeding quantity according feedback of soft measurement value of the emission concentration of the sulfur dioxide in the outlet of the furnace, and guaranteeing that the emission concentration of the sulfur dioxide meets a criterion. Due to the fact that the soft measurement model of the activated limestone in the furnace is established, and the soft measurement model of the emission concentration of the sulfur dioxide in the outlet of the furnace is established according to the soft measurement value of the activated limestone and the coal feeding quantity, the emission concentration of the sulfur dioxide in the outlet of the furnace is forecasted, the limestone feeding quantity can be beforehand feed back and adjusted, and functions of adjustment and control are fundamentally achieved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for reducing sulfur content in gasoline

ActiveCN101376842ALow vapor pressureEasy to recycleTreatment with hydrotreatment processesGasolineDistillation method

The invention discloses a method for reducing the sulfur content in gasoline which includes of cutting fraction oil containing sulfur gasoline into a light fraction and a heavy fraction; a hydrogenation refining method is adopted to desulfurize the heavy fraction gasoline; the method including the following steps is adopted to desulfurize the light fraction gasoline: a) in an extraction unit which takes an ion liquid as an extraction agent and under the extraction condition of the ion liquid, the light fraction gasoline is contacted with the ion liquid, then the light fraction gasoline with reduced sulfur content and the ion liquid rich in sulphocompounds are obtained through separation; b) in an extraction unit which takes water as an extraction agent, the ion liquid of the sulphocompounds obtained in step a is contacted with the water, then the sulphocompounds and the mixture of water and ion liquid are obtained through separation; c) the mixture of the water and the ion liquid are obtained through the separation step b of a distilling method and then a regenerated ion liquid is obtained; d) the heavy fraction gasoline desulfurized through the hydrogenation refining method is mixed with the light fraction gasoline the sulfur content of which is reduced, thus obtaining product oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

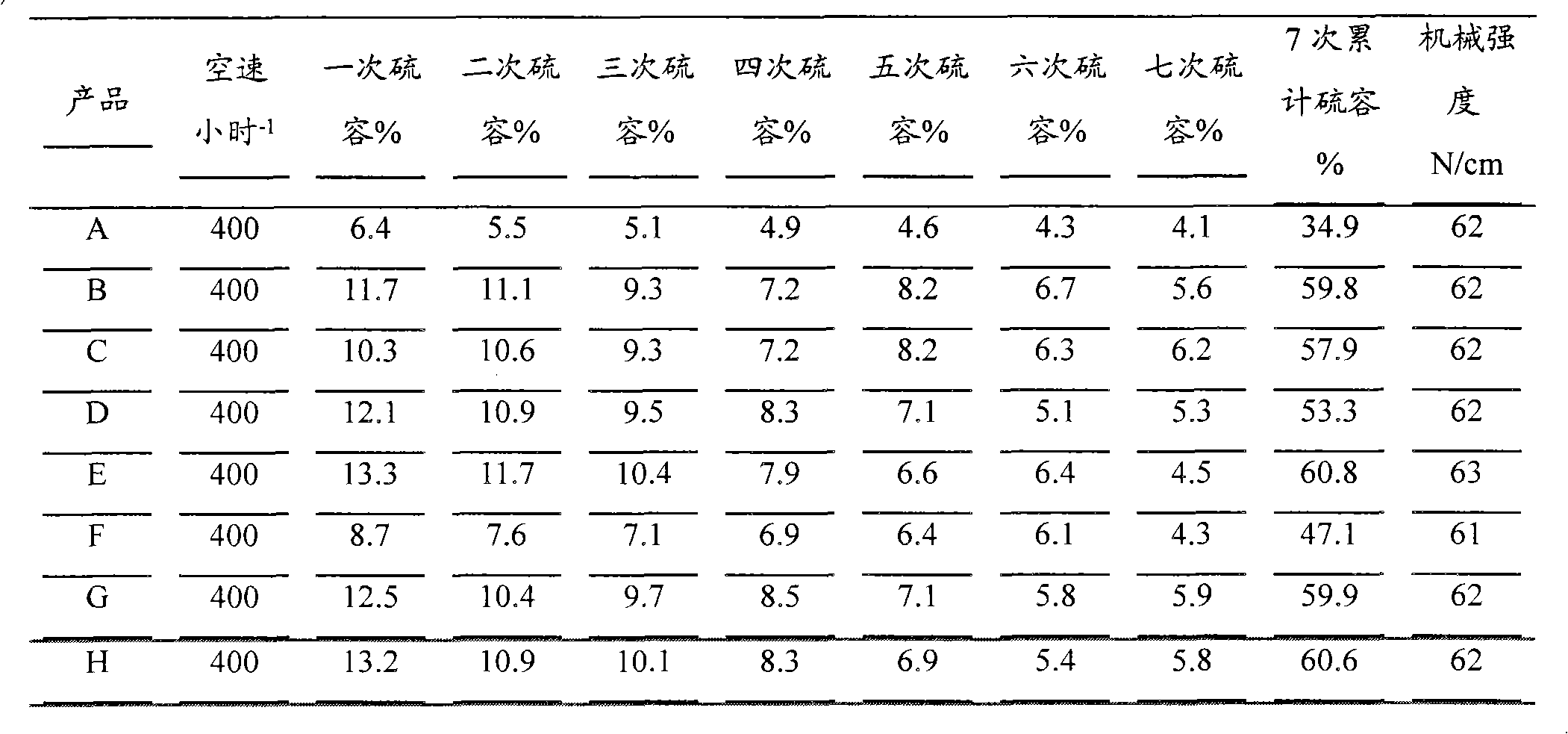

Method for preparing supported iron oxide series desulfurizing agent

ActiveCN102049179AImprove desulfurization efficiencyGuaranteed desulfurization activityDispersed particle separationSulfur preparation/purificationChemical industrySulfur

The invention discloses a method for preparing a supported iron oxide series desulfurizing agent. The preparation method comprises the following steps: a) preparing soluble iron salt solution and alkali solution; b) putting a porous material serving as a carrier into the soluble iron salt solution prepared in the step a), and soaking under the condition that the pressure is less than 3MPa and not equal to normal pressure; c) drying the carrier soaked in the step b) at the temperature of between 30 and 85 DEG C for 1 to 24 hours; d) putting the dried carrier obtained in the step c) into the alkali solution, and soaking under the condition that the pressure is less than 3MPa and not equal to normal pressure; e) drying or draining the carrier obtained in the step c), and eluting the carrier by using water of 20 to 80 DEG C till the eluted water has no negative ions; and f) drying the carrier obtained in the step e) for 1 to 24 hours at the temperature of between 30 and 85 DEG C to obtain the desulfurizing agent. The desulfurizing agent prepared by adopting the method has the advantages of high accumulative sulfur capacity, high mechanical strength, abrasion resistance and the like, is easy to regenerate, and is widely applied in the fine desulfuration process of petroleum industry, chemical industry and the like.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Ammonia process type double-cycle desulfurization and denitrification dust removal system

InactiveCN105195002AAdaptableImprove desulfurization efficiencyDispersed particle separationParticulatesSmall footprint

The invention discloses an ammonia process type double-cycle desulfurization and denitrification dust removal system and belongs to the technical field of environmental protection equipment. The system comprises a cleaning absorbing tower and an oxidation circulation tank, wherein the cleaning absorbing tower sequentially comprises an efficient water mist removal section, a reinforced ammonia mist removal section, an absorption liquid mist removal section, a secondary absorption section, a primary absorption section and a cleaning cooling section; the oxidation circulation tank sequentially comprises an oxidation section, a secondary absorption liquid circulation section and a primary absorption liquid circulation section; the oxidation section is communicated with the cleaning cooling section through a pipeline; the secondary absorption liquid circulation section is communicated with the secondary absorption section through a pipeline; the primary absorption liquid circulation section is communicated with the primary absorption section through a pipeline. The system has the advantages that the desulfurization efficiency is high, generation of ammonia escape, aerosol and particulate matters is reduced from the start and blocked in the process, and the system has high adaptability to coal types and boiler load changes, occupies small area and is compact in arrangement and simple to mount and requires less investment.

Owner:ASIA PACIFIC ENVIRONMENTAL CORP

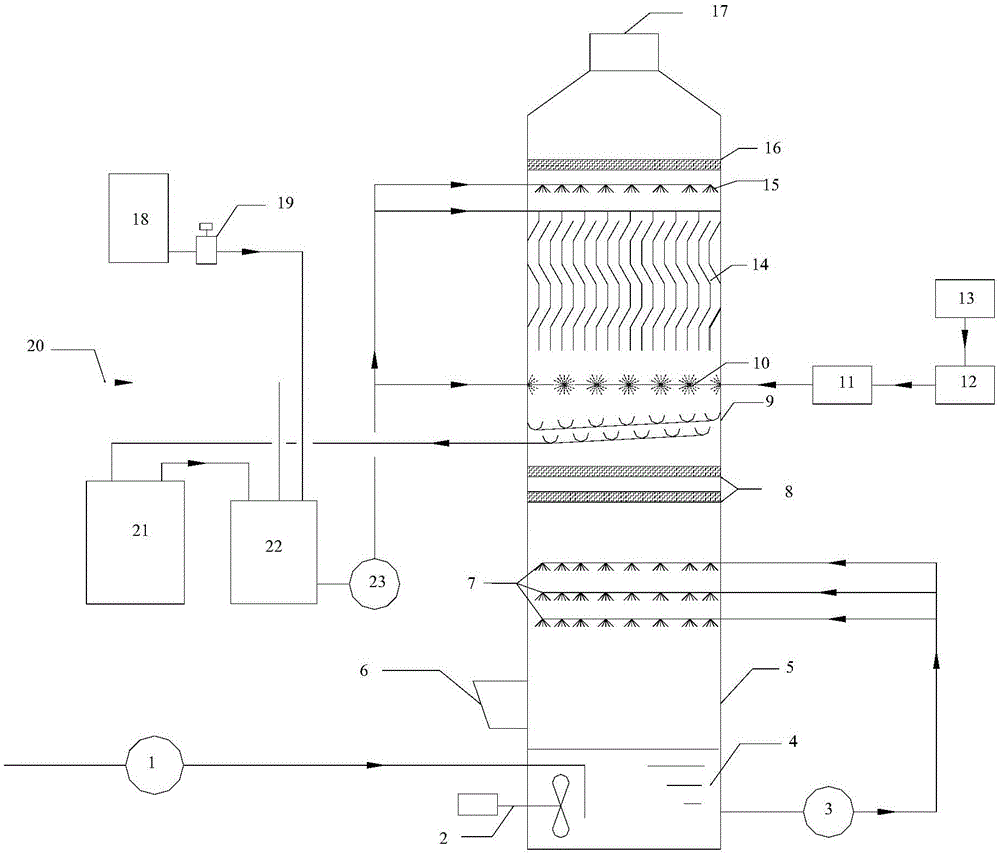

Super-clean exhausting integral tower and treating technology for coal-fired boiler exhaust gas

ActiveCN105080311AWell mixedIncrease profitCombination devicesExternal electric electrostatic seperatorElectricitySlurry

The invention discloses a super-clean exhausting integral tower and treating technology for coal-fired boiler exhaust gas. The treating technology includes the steps that the exhaust gas is fed into an absorption tower through an exhaust gas inlet of the absorption tower and upwards flows, desulfurization spraying and primary demisting are sequentially carried out, ozone oxidation, alkali liquor atomization mixing denitration and wet-type electric precipitation are carried out at the same time, secondary demisting is finally carried out, and then the exhaust gas is exhausted through an exhaust gas outlet in the top of the absorption tower; ozone and denitration absorption liquor are fed into an oxidation and denitration section through an air way and a liquor way respectively and mixed through double-fluid denitration spraying guns to be atomized and sprayed into the exhaust gas; slurry generated by desulfurization spraying falls into a slurry pond, and air is introduced into the slurry pond for oxidation; atomization alkaline liquor is captured through wet-type electric precipitation, and washing water generated in the wet-type electric precipitation process and washing water generated after wet-type electric precipitation are collected through a liquid collecting tank and temporarily stored and filtered outside the absorption tower to be reused as washing water. By means of the super-clean exhausting integral tower and treating technology, the desulfurization efficiency of the absorption tower is improved; meanwhile, denitration, dust removing and demisting can be achieved, and therefore the coal-fired exhaust gas can meet the stricter exhausting standard.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Double-tower double-circulation limestone wet method desulfurization device and method

ActiveCN102921287AImprove adaptabilityAdvanced technologyDispersed particle separationProcess engineeringTower

The invention discloses a double-tower double-circulation limestone wet-method desulfurization device and method. The double-tower double-circulation limestone wet-method desulfurization device comprises a smoke purification part, an absorbent supply part, a slurry oxidization and crystallization part and a gypsum slurry dehydration part, wherein the smoke purification part consists of a first-stage circulation absorption tower and a second-stage circulation absorption tower; the absorbent supply part consists of a gypsum slurry tank, a gypsum slurry pump and a slurry supply pipeline; the slurry oxidization and crystallization part consists of a oxidization fan, a first-stage circulation absorption tower oxidization spraying gun, a second-stage circulation absorption tower oxidization spraying gun and an oxidization air pipeline; and the gypsum slurry dehydration part consists of a first-stage circulation gypsum discharging pump, a gypsum whirlcone and a vacuum dehydration belt conveyer. The desulfurization device is extremely high in desulfurization efficiency, and the aims of reducing the sulfur dioxide and purifying air are fulfilled; and moreover, gypsum with extremely high quality can be obtained.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

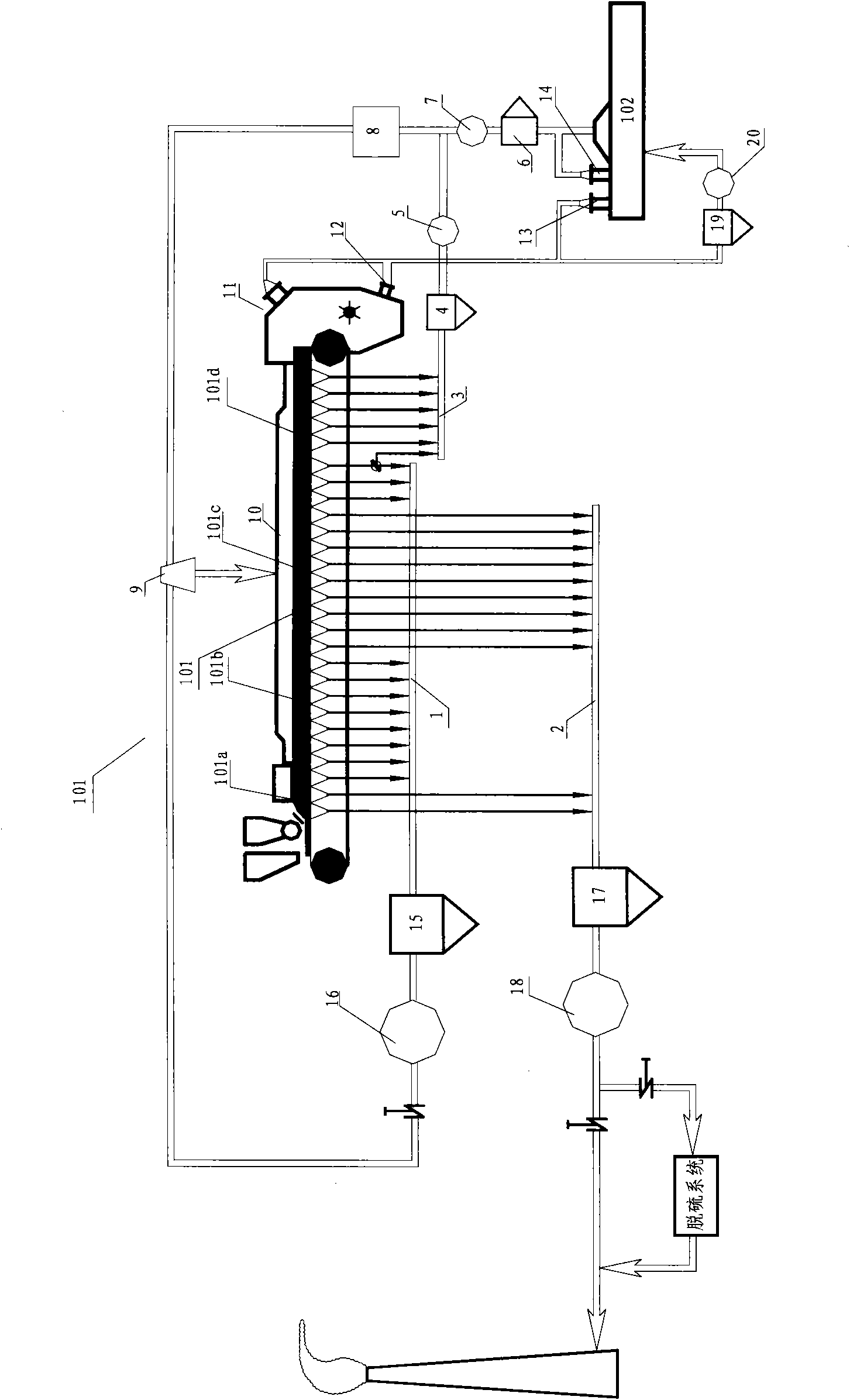

Method for treating smoke generated by sintering ore materials

ActiveCN101949650AImprove working conditionsReduce the amount of exhaust gasIncreasing energy efficiencyWaste heat treatmentSulfurSmoke Emission

The invention provides a method for treating smoke generated by sintering ore materials. The method comprises the following steps of: sintering the ore materials by using a sintering machine to obtain blocky sintered materials; cooling the sintered materials by using a circular cooler to obtain sintered ore; and exhausting the smoke generated by the sintering machine 7 through a flue, wherein thesintering machine is divided into a sintering machine ignition section, a sintering machine low-sulfur section, a sintering machine high-sulfur section and a sintering machine high-temperature section sequentially; the flue comprises a low-sulfur flue, a high-sulfur flue and a high-temperature flue; a machine tail cover is arranged on the tail part of the sintering machine; the circular cooler isdivided into a circular cooler material-distributing section, a circular cooler cooling section and a circular cooler material-discharging section sequentially; and dust-removing wind exhausted from a circular cooler material-distributing hopper is circulated to the circular cooler to serve as a cooling gas source of the circular cooler. Compared with the prior art, the method has the advantages of recycling the smoke of the machine tail part and the smoke generated by circular cooler material-distributing points, the low-sulfur flue and the circular cooler material-distributing hopper, reducing the smoke emission and fully utilizing the afterheat of the smoke.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com