Double-tower double-circulation limestone wet method desulfurization device and method

A technology of wet desulfurization and limestone, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems that desulfurization technology cannot achieve high desulfurization efficiency, long outage time for desulfurization equipment transformation, poor adaptability of coal quality, etc. problems, to achieve the effect of easy optimization and quick adjustment, quick adaptation to coal type changes and load changes, and reliable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

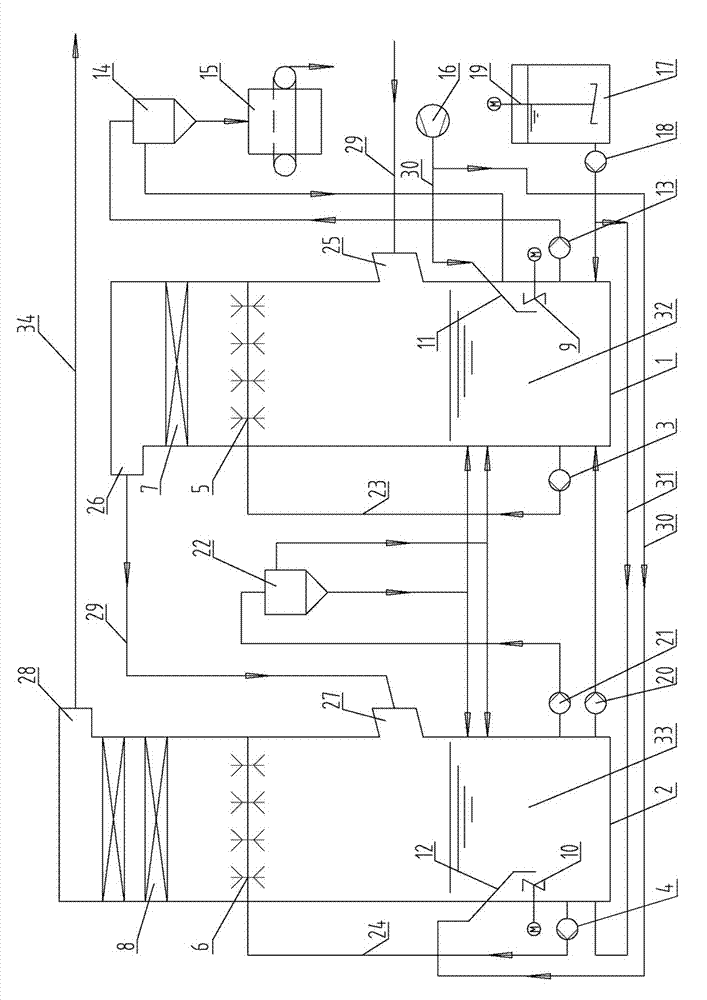

[0037] Examples see figure 1 As shown, this double-tower double-circulation limestone wet desulfurization device includes a flue gas purification part, an absorbent supply part, a slurry oxidation crystallization part and a gypsum slurry dehydration part.

[0038] The flue gas purification part is composed of a primary circulation absorption tower 1 and a secondary circulation absorption tower 2, and the primary circulation flue gas outlet 26 at the top of the primary circulation absorption tower 1 passes through the transmission flue 29 and the secondary circulation absorption tower 2 The secondary circulation flue gas inlet 27 in the middle is connected, and the secondary circulation net flue gas outlet 28 at the top of the secondary circulation absorption tower 2 is communicated with the atmosphere through the exhaust flue 34 .

[0039] The inner lower section of the primary circulation absorption tower 1 has a primary circulation absorption tower slurry pool 32, and the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com