Patents

Literature

272results about How to "Short downtime" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

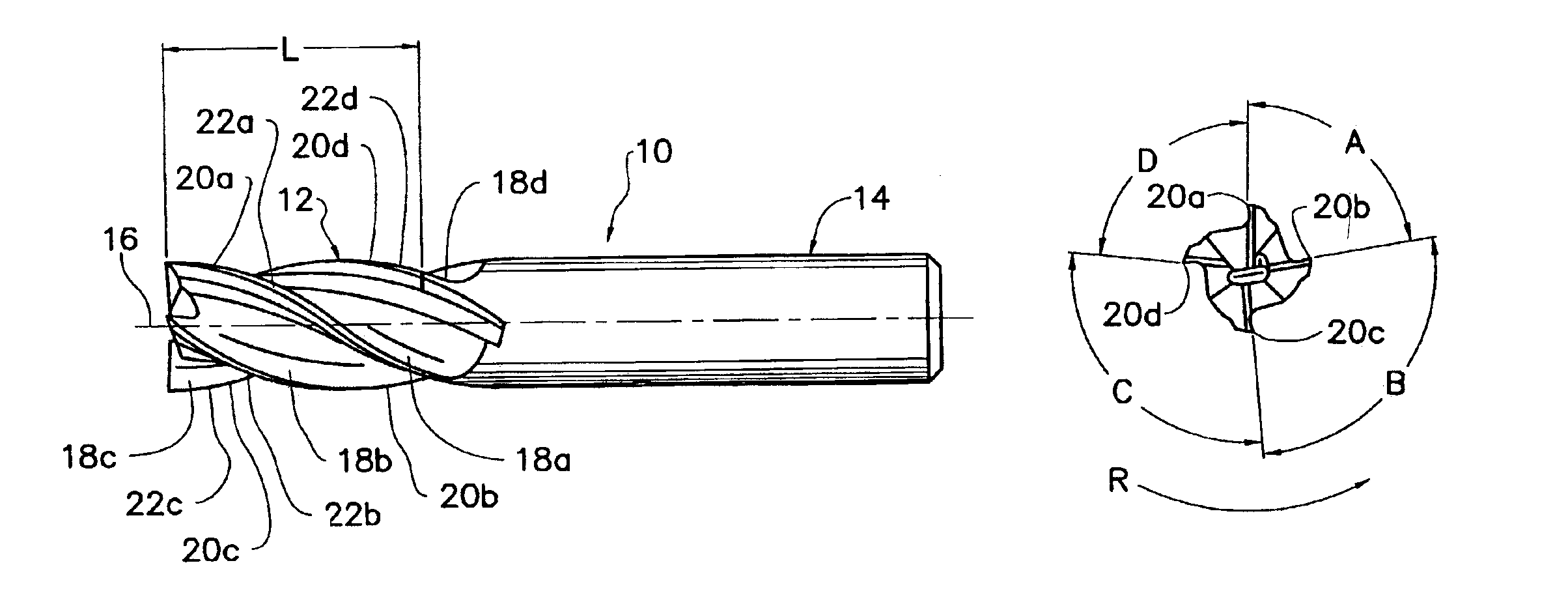

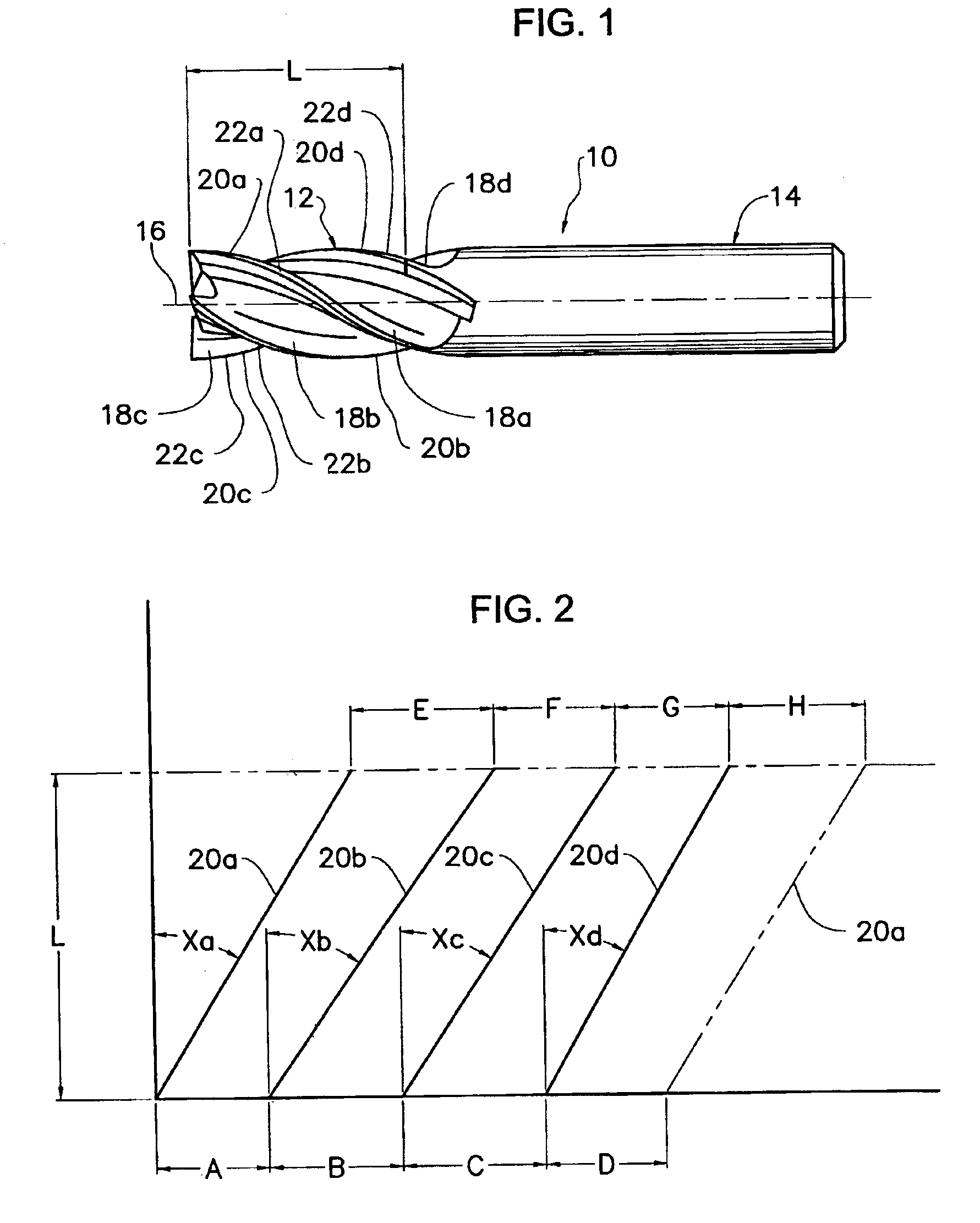

Rotary cutting tool

A rotary cutting tool that includes an elongated tool body, rotatable along a longitudinal axis of rotation is disclosed. It has a fluted cutting end on one end and a shank end on the opposite end of the tool body. The fluted cutting end includes a nose, a periphery and an end surface that extends from the nose to the periphery. A plurality of axial flutes extends from the end surface to the fluted cutting end and combines with a plurality of cutting edges. The cutting edges are unequally spaced along the circumference of the end surface lying in a plane perpendicular to the longitudinal axis of rotation. In addition, all cutting edges are of a different helix from one another and the cutting edge geometries vary from one another to create a different sound pattern. This reduces resonant harmonic vibrations.

Owner:NIAGARA CUTTER LLC

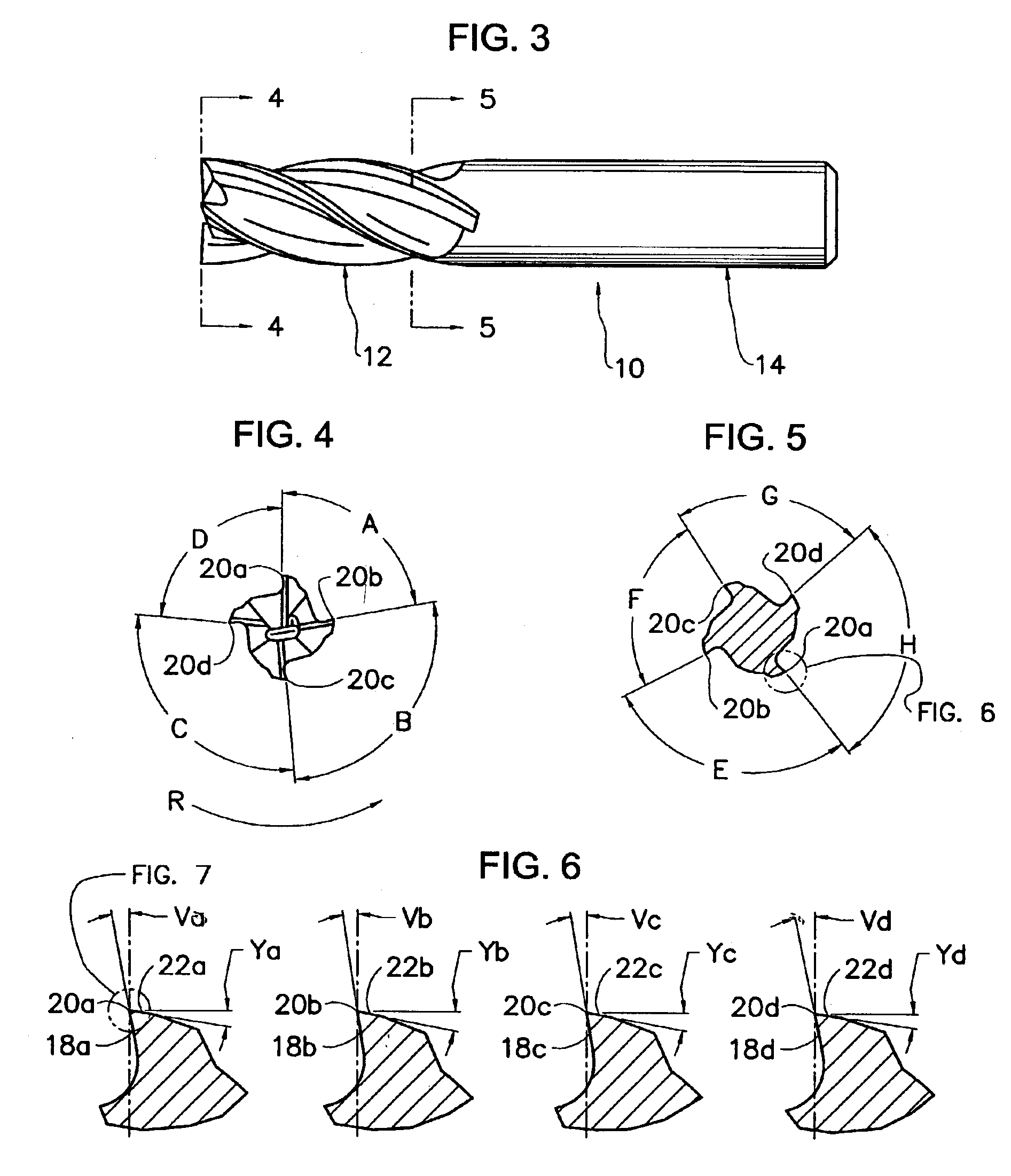

Cleaner cartridge

InactiveUS7051399B2Longer operational runtimeShort downtimeCarpet cleanersMixing methodsCatheterCleansing Agents

A cleaner cartridge includes a container having an interior cavity, in which cleaning agent can be stored. A first end of conduit is fluidically coupled to the interior cavity. A second end of the conduit is connectable to a chemical dispenser.

Owner:TENNANT COMPANY

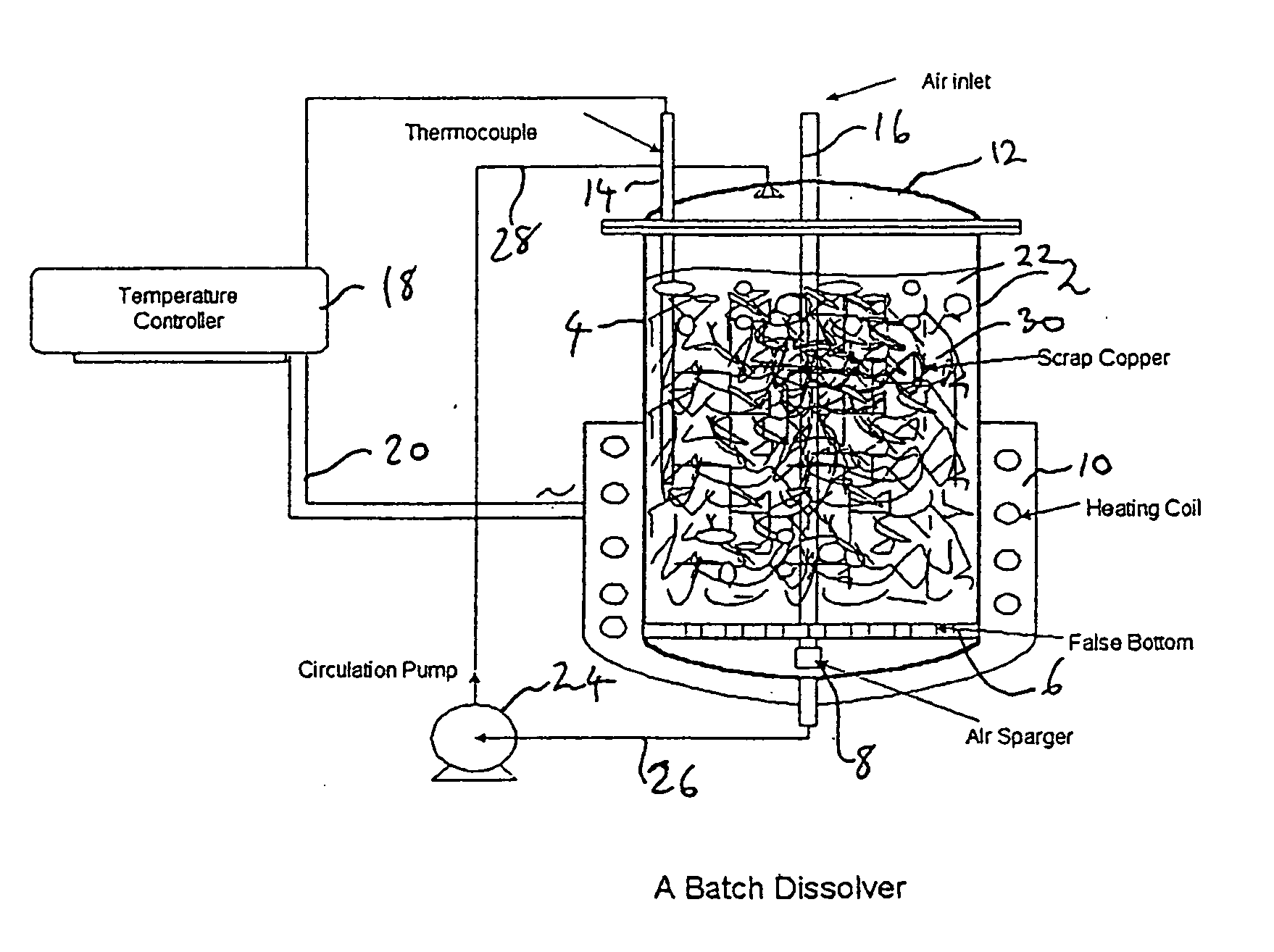

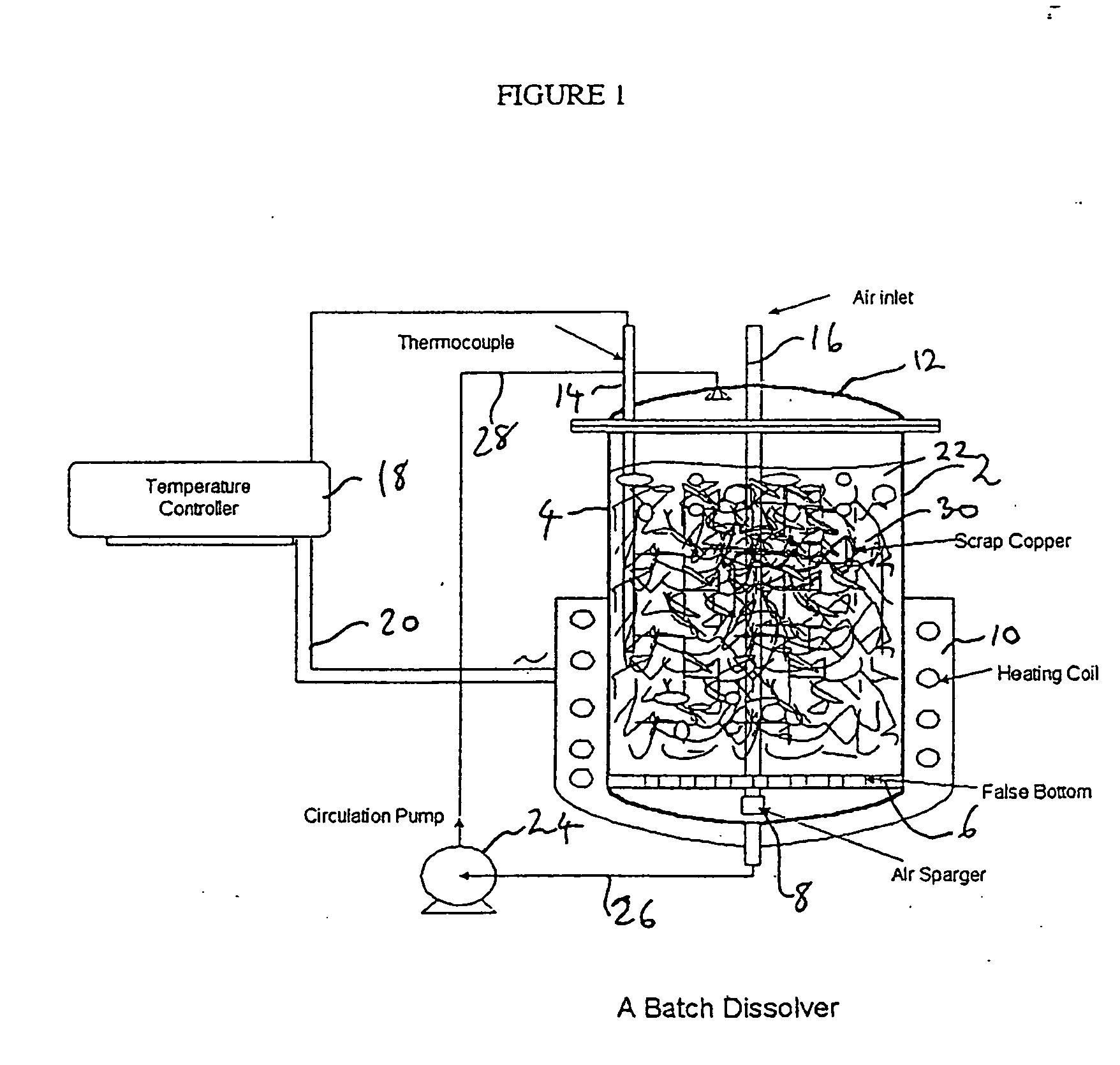

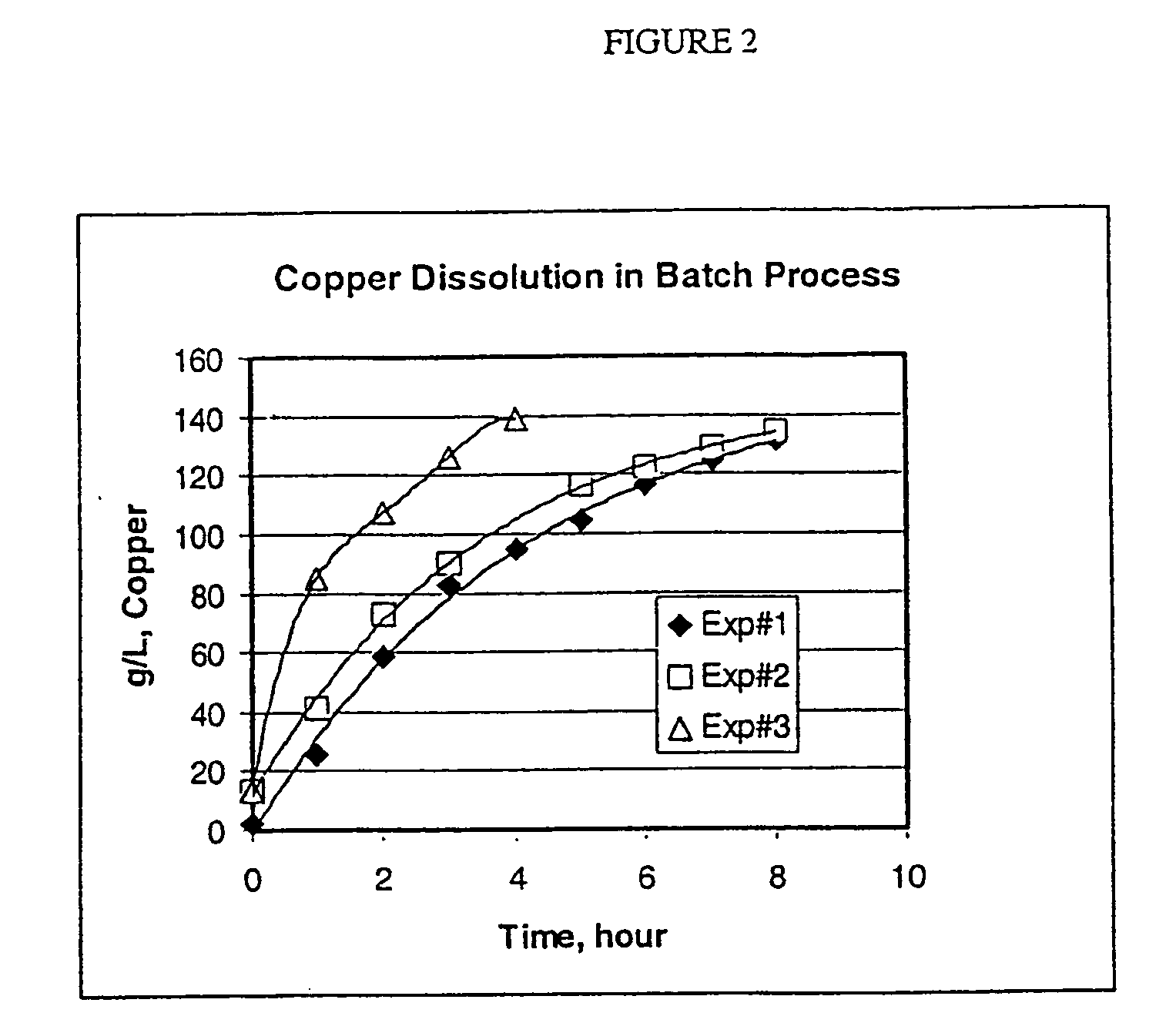

Process for the dissolution of copper metal

ActiveUS20050130866A1High initial dissolution rateShorten the timeGroup 1/11 element organic compoundsSolvent extractionGramEquivalent weight

Process for producing a copper-containing aqueous solution, in which a copper mass is dissolved in the presence of air in an aqueous leach liquor containing monoethanolamine and an acid, wherein the amount of acid equivalents is between 0.05 and about 0.7 times the equivalents of monoethanolamine, and wherein the rate of copper dissolution into the aqueous leach liquor is greater than about 4.3 grams of copper per liter of leach liquor per hour until a product having at least about 80 grams per liter is obtained.

Owner:KOPPERS PERFORMANCE CHEM

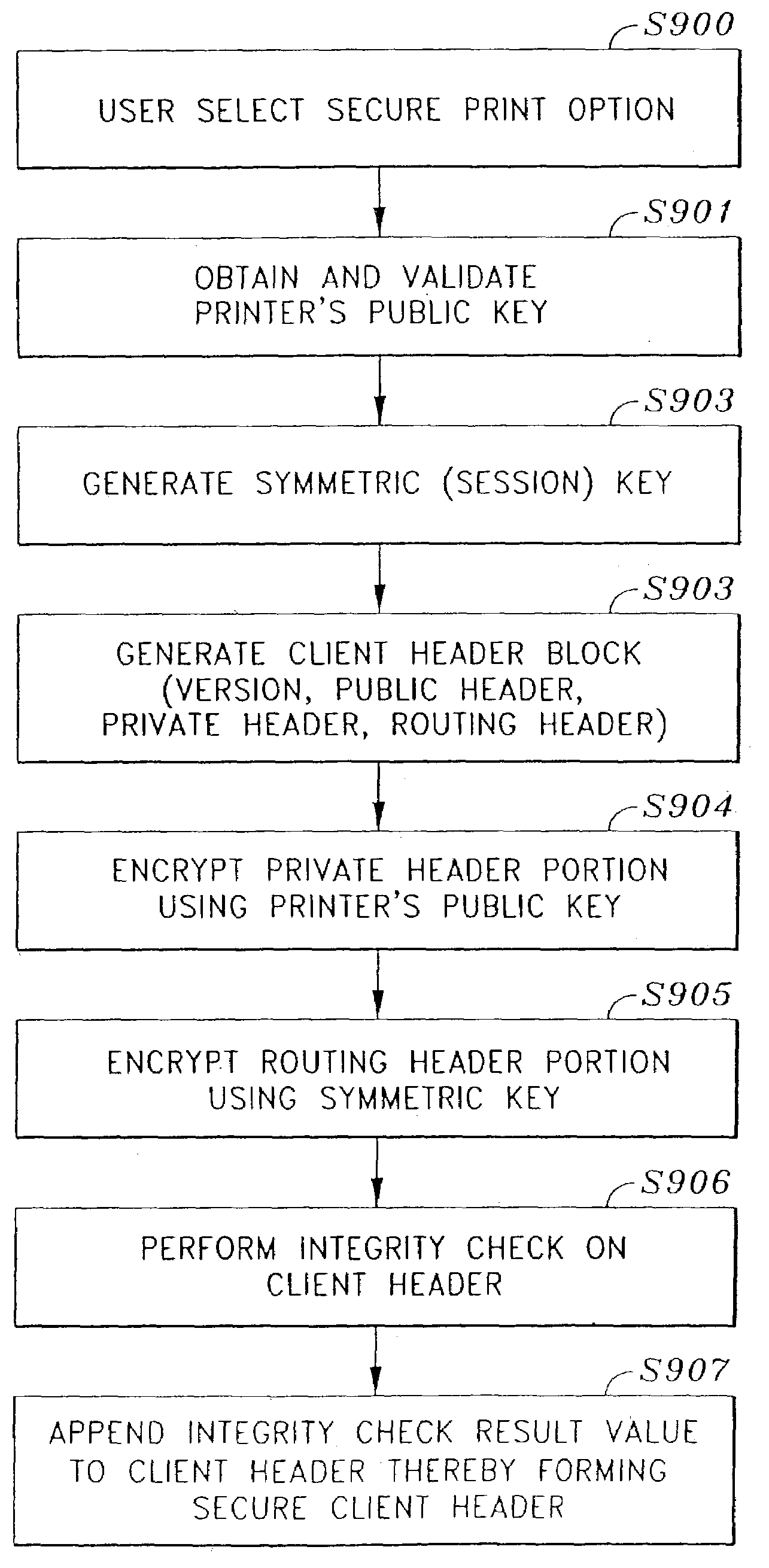

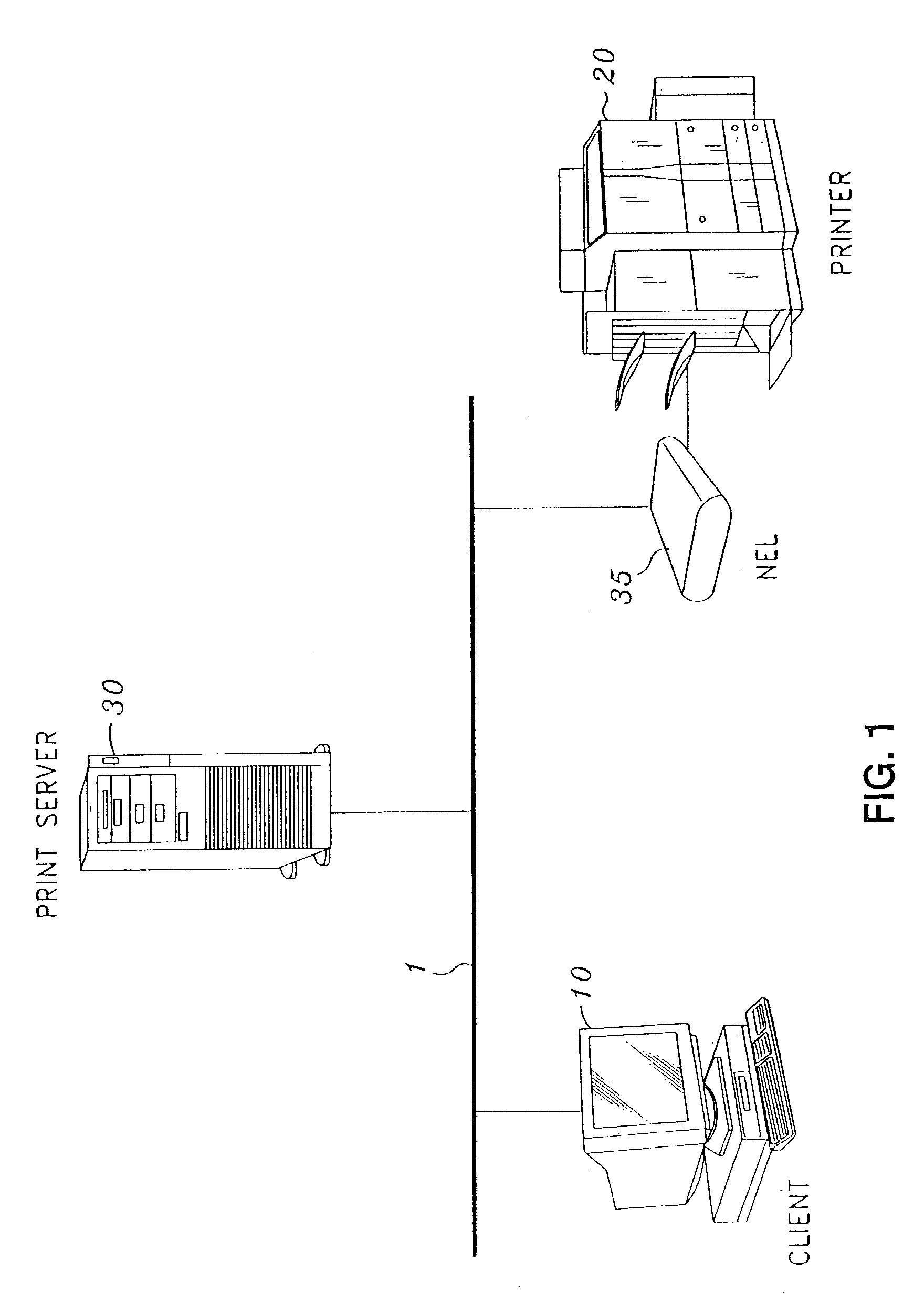

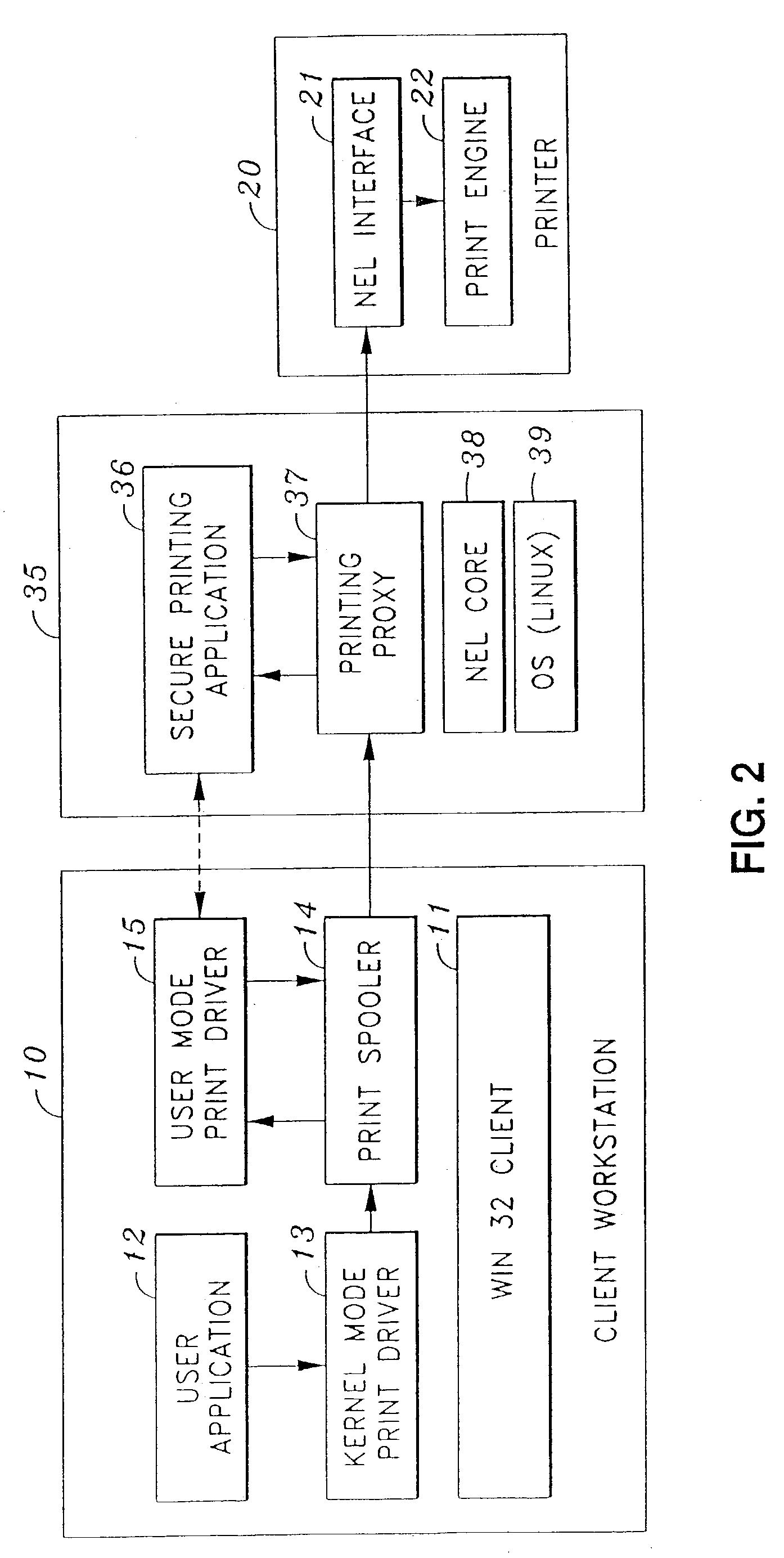

Automatic generation of a new encryption key

InactiveUS7111322B2Easy and successfulShort downtimeKey distribution for secure communicationDigital data processing detailsComputer hardwareSafe operation

A device (such as a printer or a network device that may be connected to the printer) that is connected to a network and which performs secure operations using an existing encryption keypair maintained within the device, generates a new encryption keypair within the device by receiving a request from another device on the network to provide an encryption key of the existing encryption keypair to the another device. In response to the request, the device determines whether an encryption key of the existing encryption keypair within the device is valid. In a case where it is determined that the encryption key of the existing encryption keypair is invalid, the device automatically deletes each key of the existing encryption keypair from the device, generates a new encryption keypair within the device and stores the new encryption keypair in the device. The device then provides a new encryption key corresponding to the requested encryption key of the new encryption keypair to another device.

Owner:CANON KK

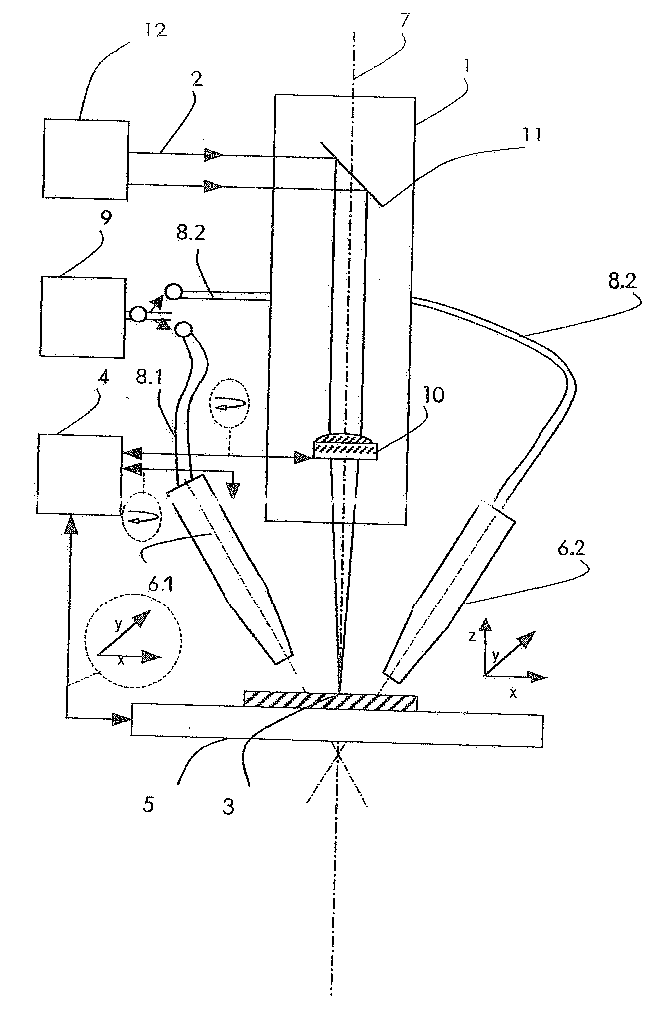

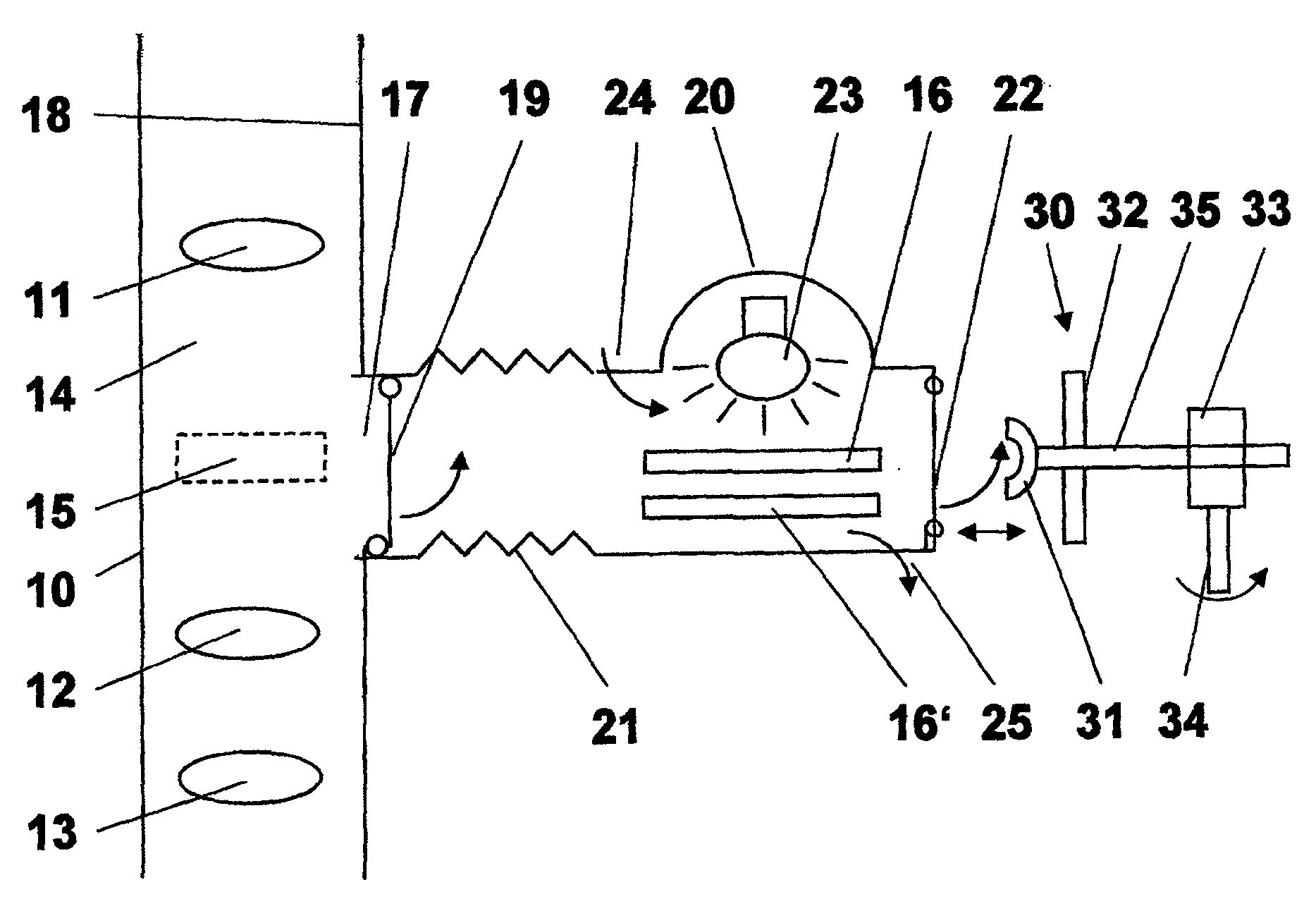

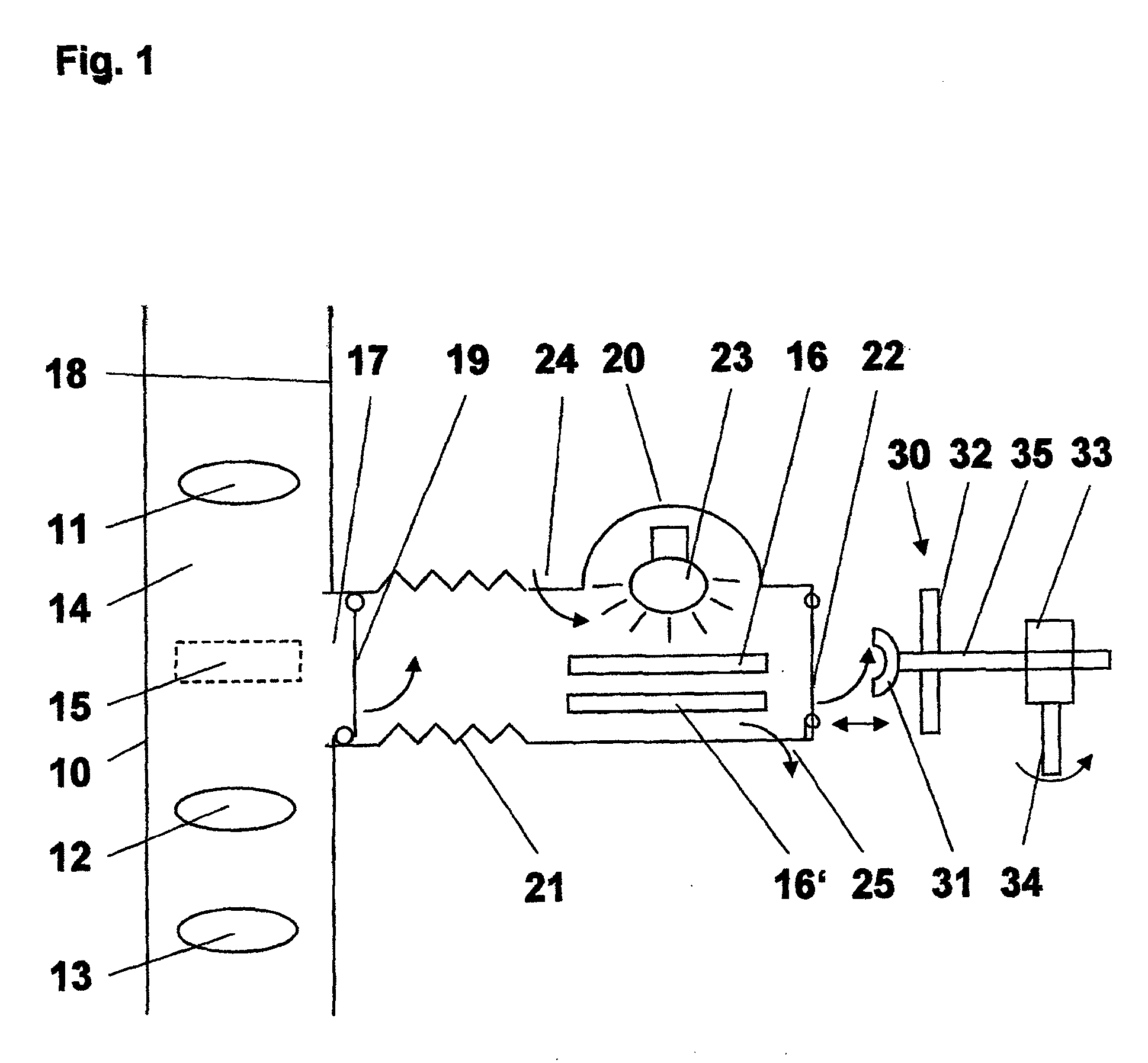

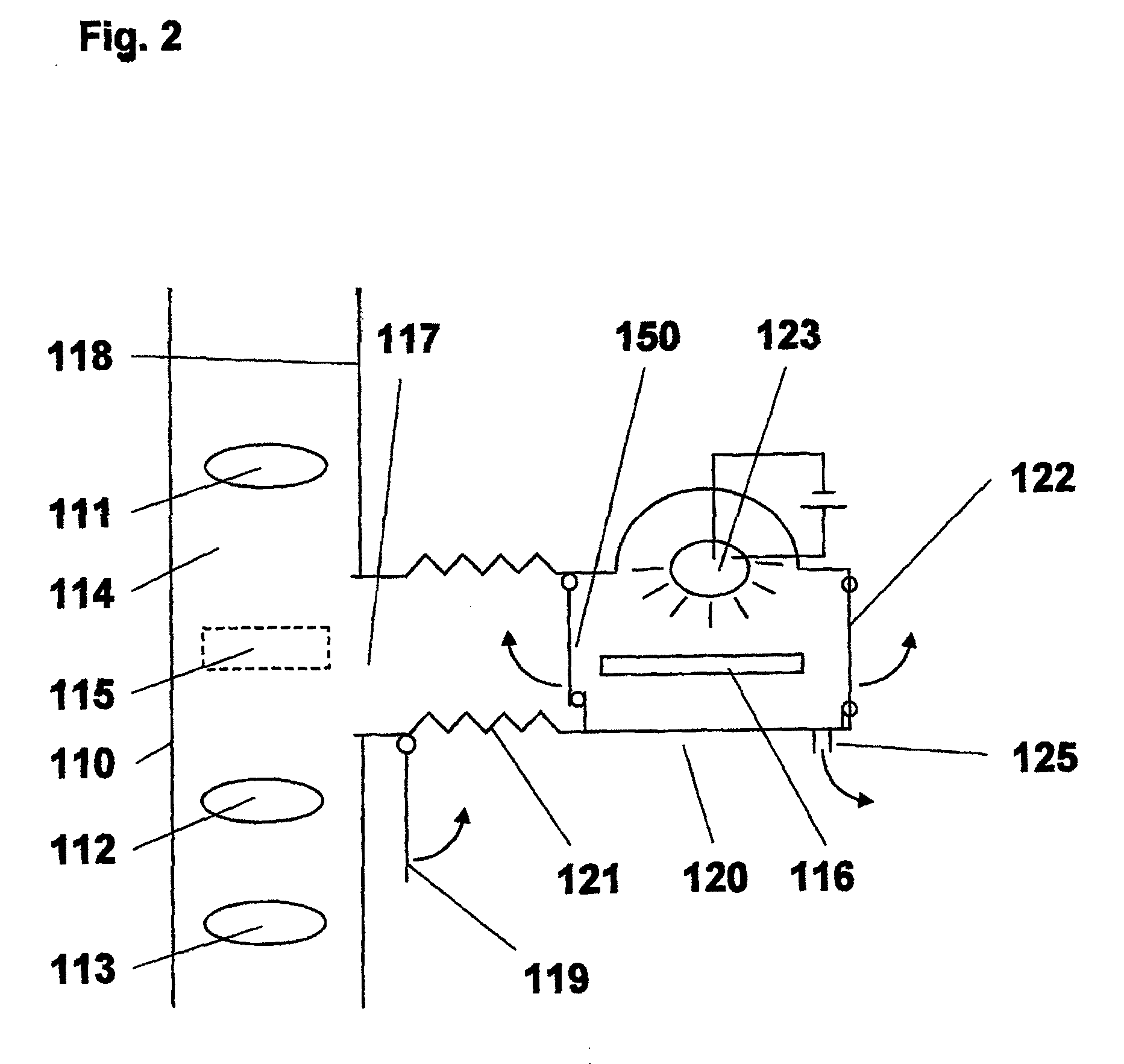

Arrangement for severing a flat workpiece of brittle material multiple times by means of a laser

InactiveUS20060278619A1Short downtimeShortest possible downtimeGlass severing apparatusWelding/soldering/cutting articlesOptoelectronicsLaser beams

Flat workpieces of brittle material be severed in a time-saving manner by an arrangement according to the invention by inducing thermomechanical stresses by laser radiation particularly along severing lines in the same orientation in alternating directions, in that the arrangement has two coolant nozzles which selectively direct coolant to the workpiece and which, preferably coupled with optical means for shaping the laser beams, are mounted so as to be rotatable around the axis of the laser head.

Owner:JENOPTIK AUTOMATISIERUNGSTECHN

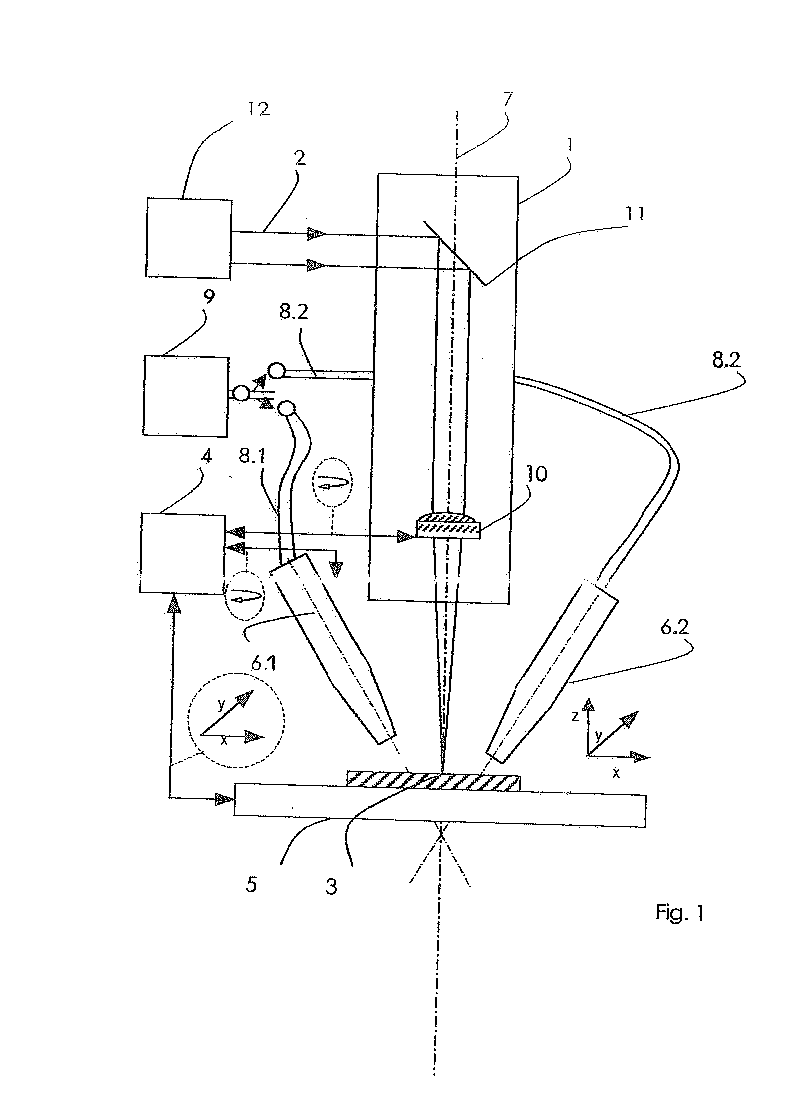

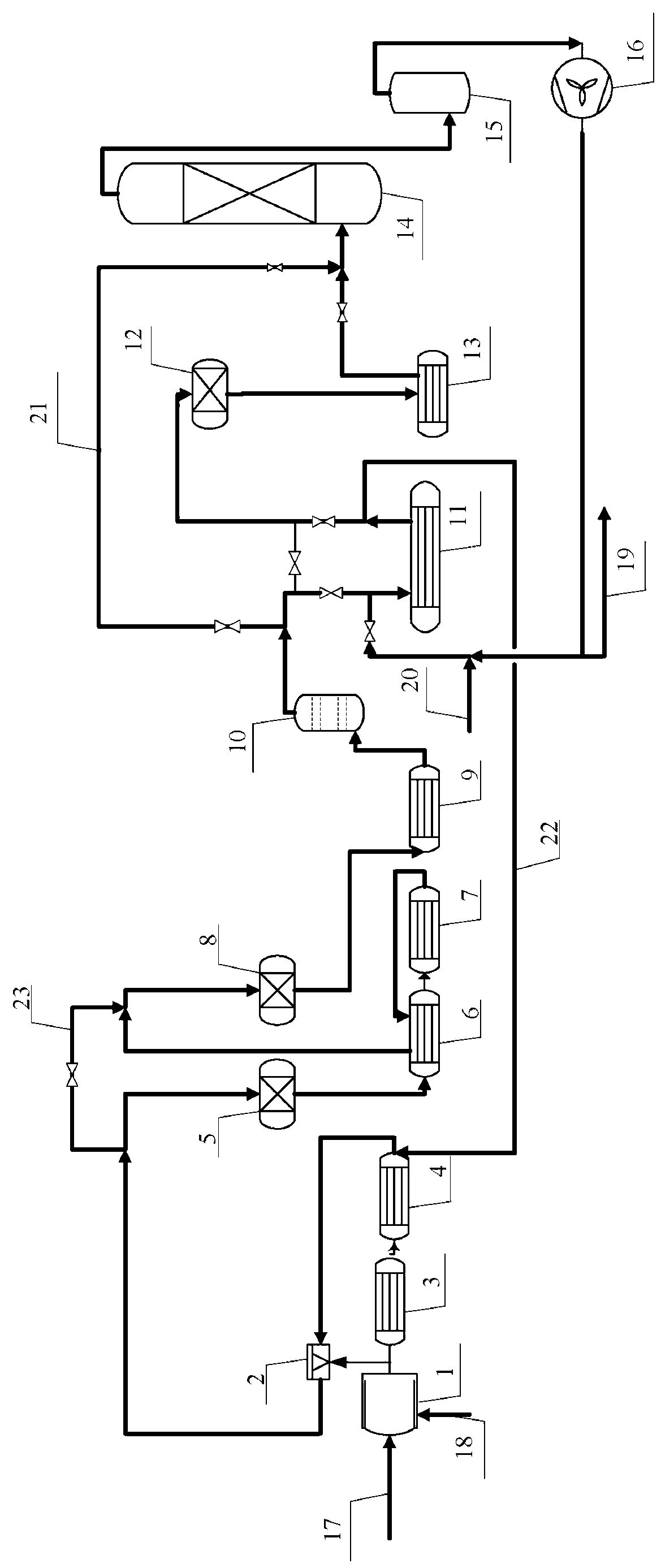

Double-tower double-circulation limestone wet method desulfurization device and method

ActiveCN102921287AImprove adaptabilityAdvanced technologyDispersed particle separationProcess engineeringTower

The invention discloses a double-tower double-circulation limestone wet-method desulfurization device and method. The double-tower double-circulation limestone wet-method desulfurization device comprises a smoke purification part, an absorbent supply part, a slurry oxidization and crystallization part and a gypsum slurry dehydration part, wherein the smoke purification part consists of a first-stage circulation absorption tower and a second-stage circulation absorption tower; the absorbent supply part consists of a gypsum slurry tank, a gypsum slurry pump and a slurry supply pipeline; the slurry oxidization and crystallization part consists of a oxidization fan, a first-stage circulation absorption tower oxidization spraying gun, a second-stage circulation absorption tower oxidization spraying gun and an oxidization air pipeline; and the gypsum slurry dehydration part consists of a first-stage circulation gypsum discharging pump, a gypsum whirlcone and a vacuum dehydration belt conveyer. The desulfurization device is extremely high in desulfurization efficiency, and the aims of reducing the sulfur dioxide and purifying air are fulfilled; and moreover, gypsum with extremely high quality can be obtained.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

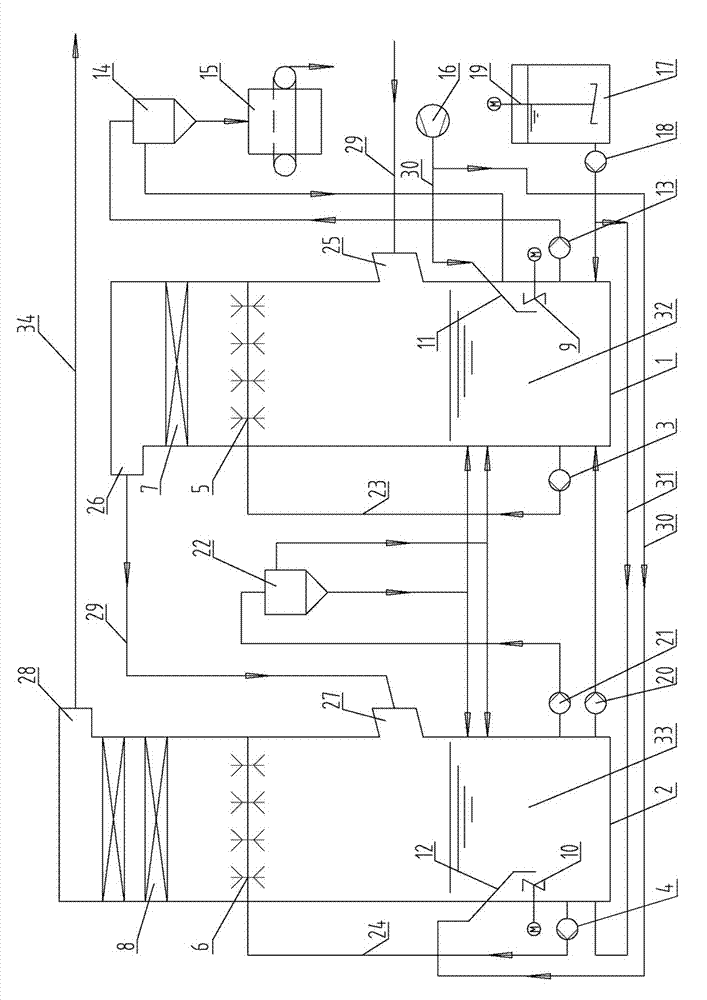

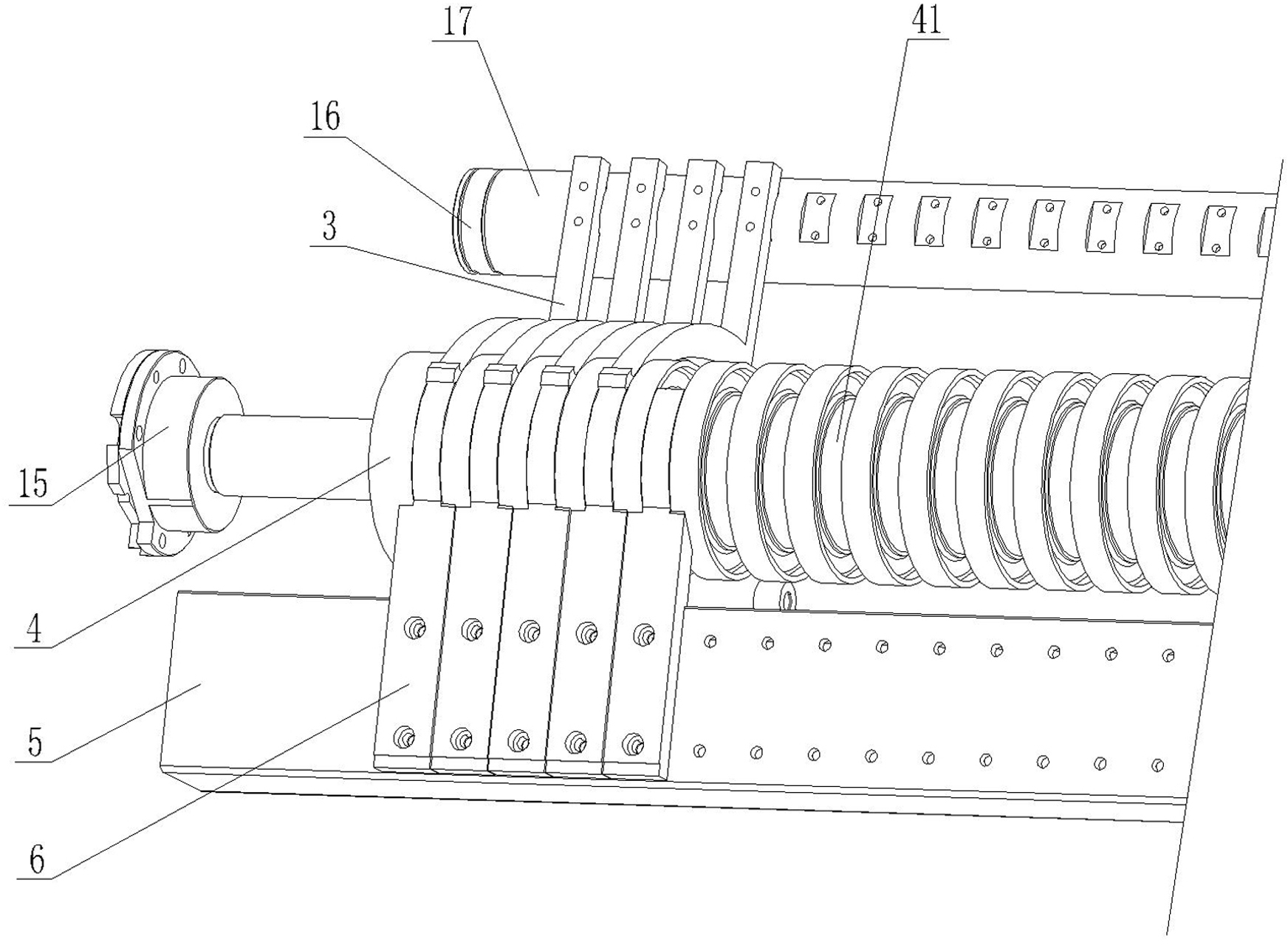

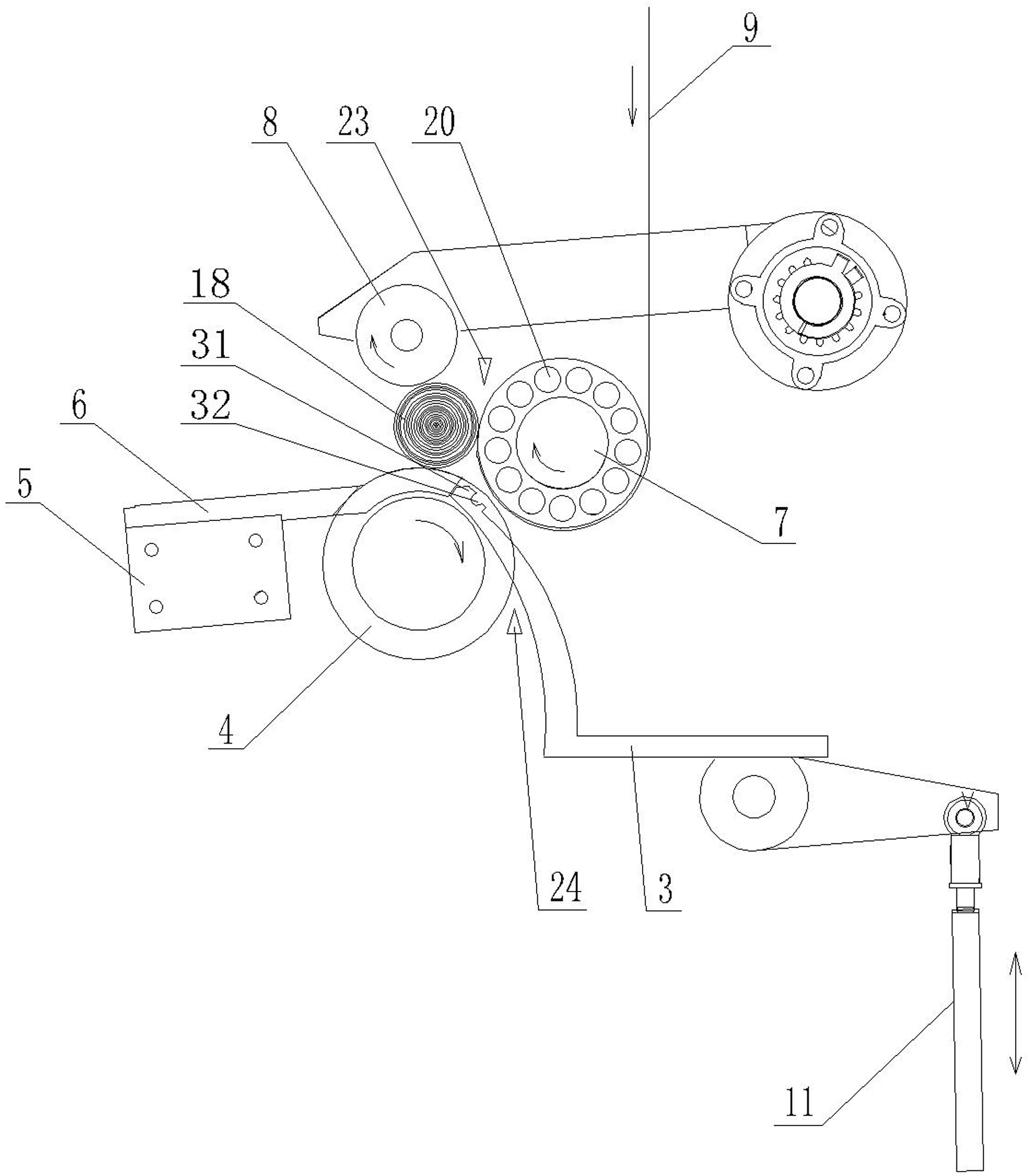

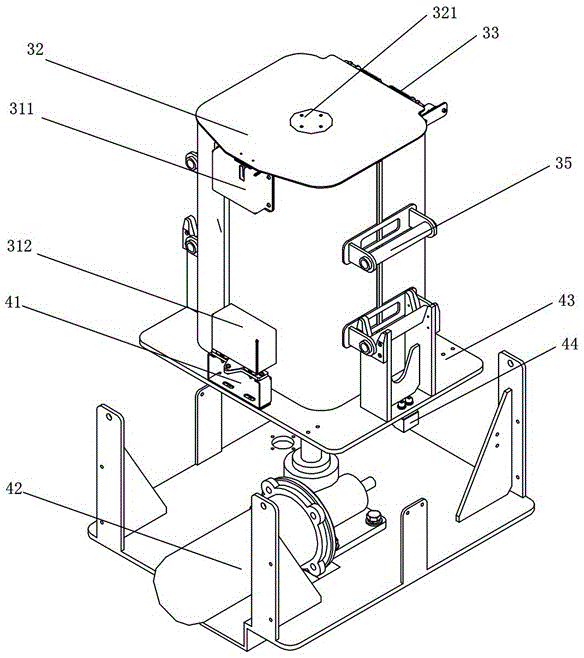

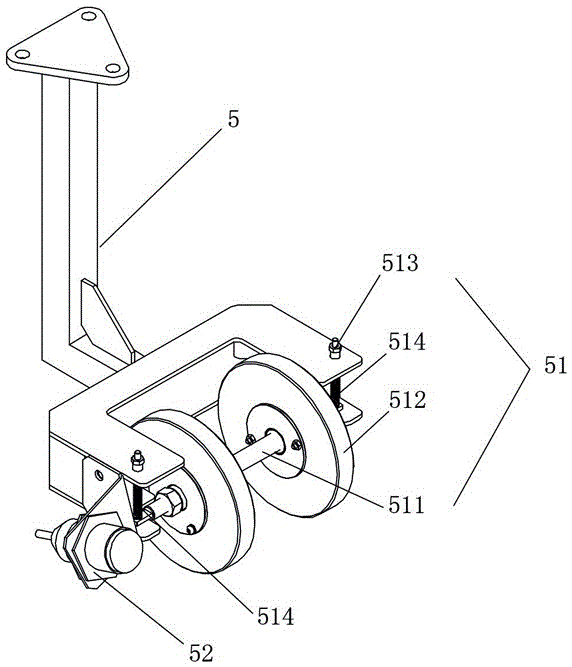

Double-purpose rewinding machine for preparing cored toilet paper and coreless toilet paper and method thereof

The invention provides a double-purpose rewinding machine for preparing cored toilet paper and coreless toilet paper and a method thereof. The rewinding machine comprises an upper rewinding roller, a lower rewinding roller, a rewinding compression roller and a paper tube core feed mechanism, wherein the upper part of the lower rewinding roller is provided with a plurality of double-purpose guide plates; the double-purpose guide plates are used for roll set at the time of winding the coreless toilet paper and leading-in of a paper tube core at the time of winding the cored toilet paper; the lower rewinding roller is provided with a plurality of grooves capable of accommodating the double-purpose guide plates; and the double-purpose guide plates can be lifted properly from the grooves of the lower rewinding roller under the condition of being driven by a second driving mechanism at the time of rewinding the coreless toilet paper, thus peaks at the front ends of the double-purpose guide plates can contact with the surface of the upper rewinding roller. In the invention, a double-purpose guide plate structure is additionally arranged at the upper part of the lower rewinding roller skillfully, and the lifting and descending of the front ends of the double-purpose guide plates in the grooves of the lower rewinding roller are utilized, thus being capable of reliably and fast realizing the rewinding of the two types of toilet paper, improving the production efficiency, producing the cored toilet paper and coreless toilet paper at the same time only by one machine for manufacturers, and reducing the production costs.

Owner:FOSHAN NANHAI DECHANGYU PAPER MASCH MFG CO LTD

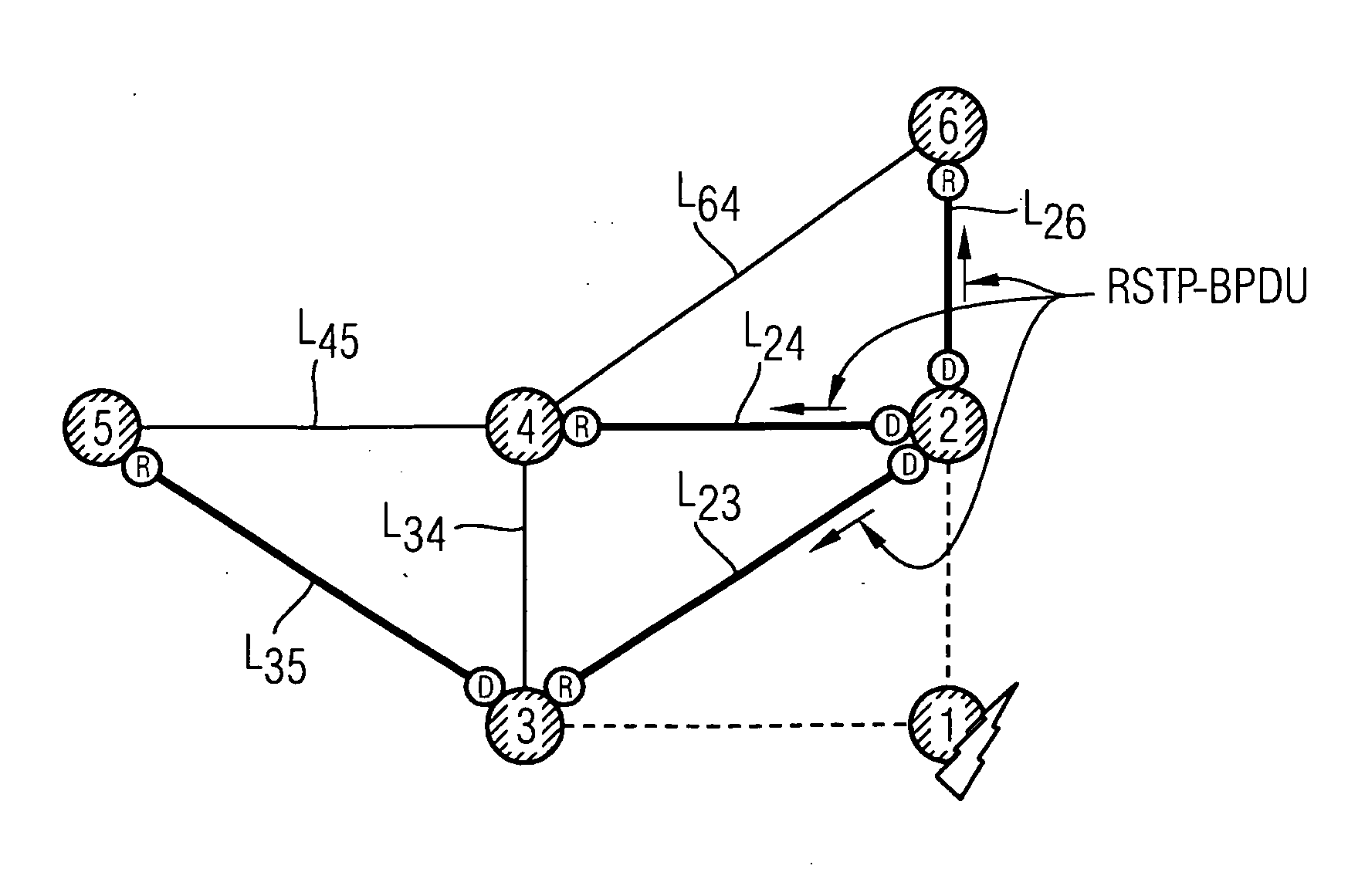

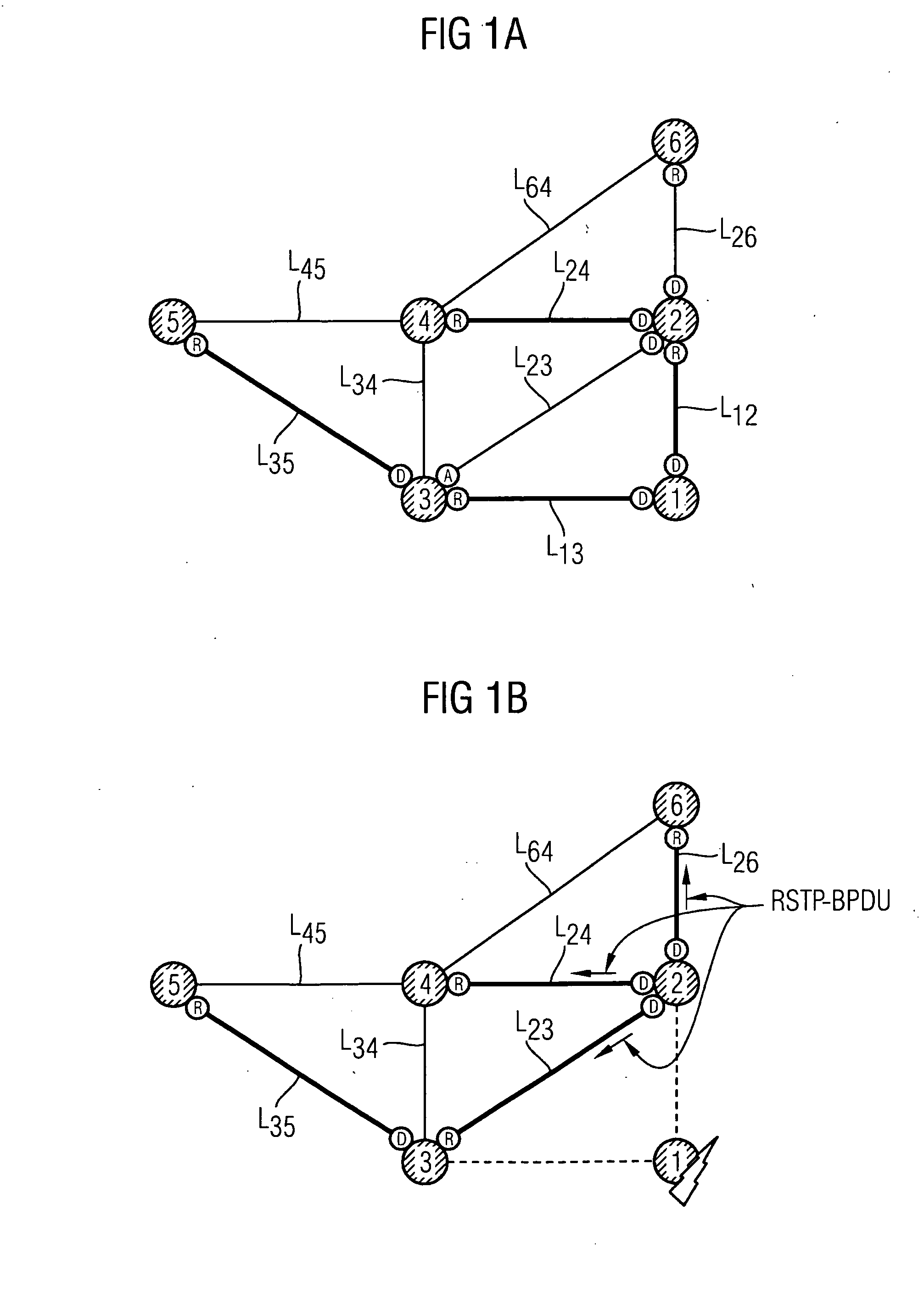

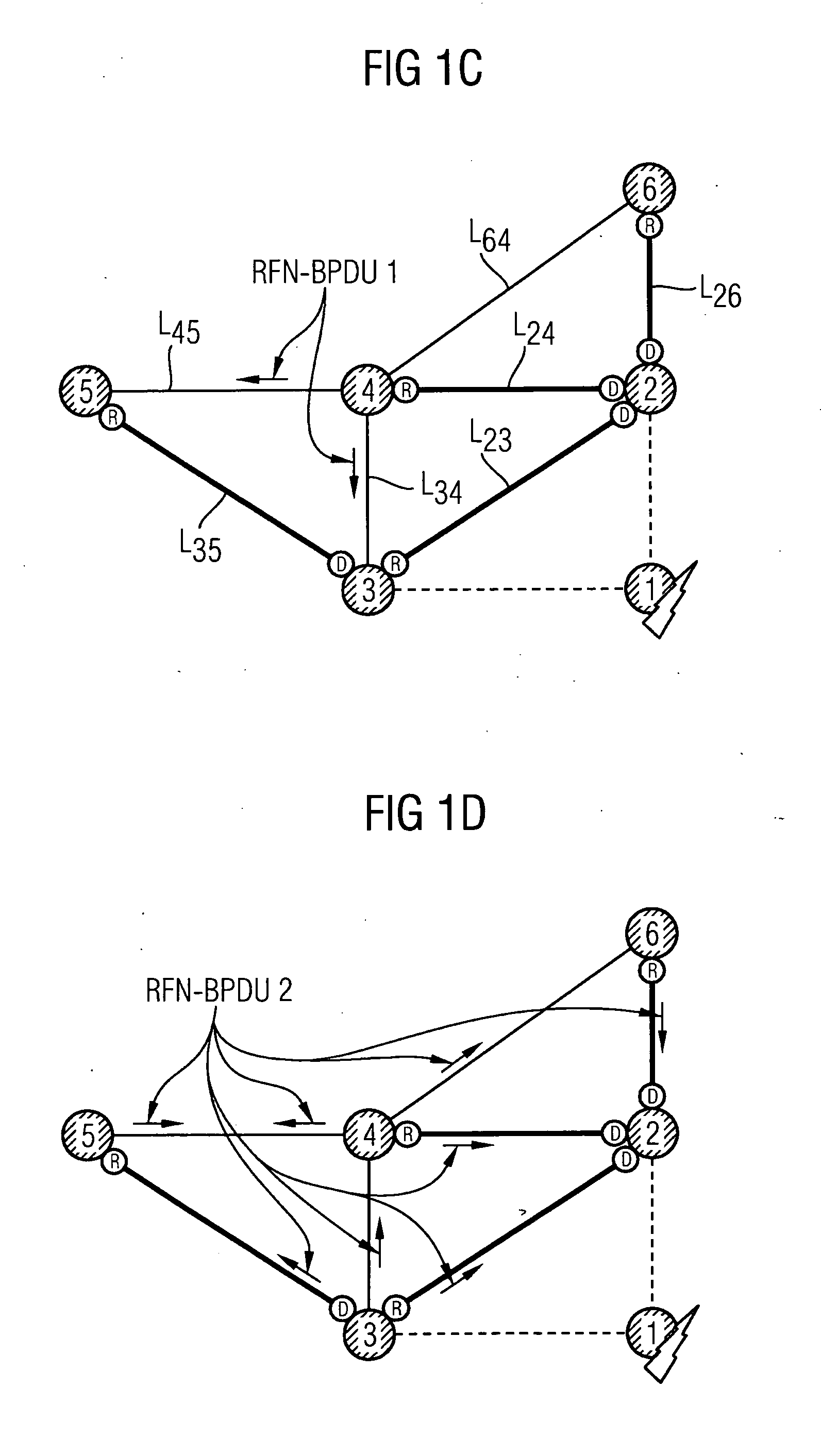

Method for reconfiguring a communication network

ActiveUS20100110880A1Reduce downtimeShort downtimeMetering/charging/biilling arrangementsError preventionNetworking protocolLogical topology

A method for reconfiguring a packet-switched communication network using a network protocol for installing a logic topology of the network formed as a spanning tree is disclosed. The method includes detecting failure of a direct link to a root bridge of the spanning tree by a first bridge; detecting the failure of a direct link to the root bridge by a second bridge; transmitting a first configuration frame generated by the first bridge to other bridges; receiving the first configuration frame by a third bridge and transmitting a second configuration frame, generated by the third bridge, to the other bridges; detecting the first or second configuration frame by the second bridge and transmitting the third configuration frame generated by the second bridge to the other bridges; receiving the third configuration frame by the other bridges of the network and triggering a reconfiguration of the network with detection of a new spanning tree by the network protocol.

Owner:SIEMENS AG

Method for erasing a lithographic printing master

InactiveUS6408755B1Fast and environment-friendly and convenient and simple cleaning stepImprove automationPlate printingThermographyPlasma jetImage recording

A method is disclosed for removing ink accepting areas of a printing surface of a lithographic printing master by treatment with an atmospheric plasma. Preferably, the plasma is directed to the printing surface as a plasma jet while the printing master is mounted on the plate cylinder of a printing press. The method enables to clean a support of a printing master and then reuse the cleaned support for making another printing master. Preferably, all the following steps are performed on-press:(i) making an imaging material by providing a support with an image recording layer; (ii) making a printing master having a printing surface comprising ink accepting areas by image-wise exposing and optionally developing the imaging material; (iii) starting a pressrun; (iv) a cleaning step using an atmospheric plasma and then repeating steps (i) to (iv).

Owner:AGFA NV

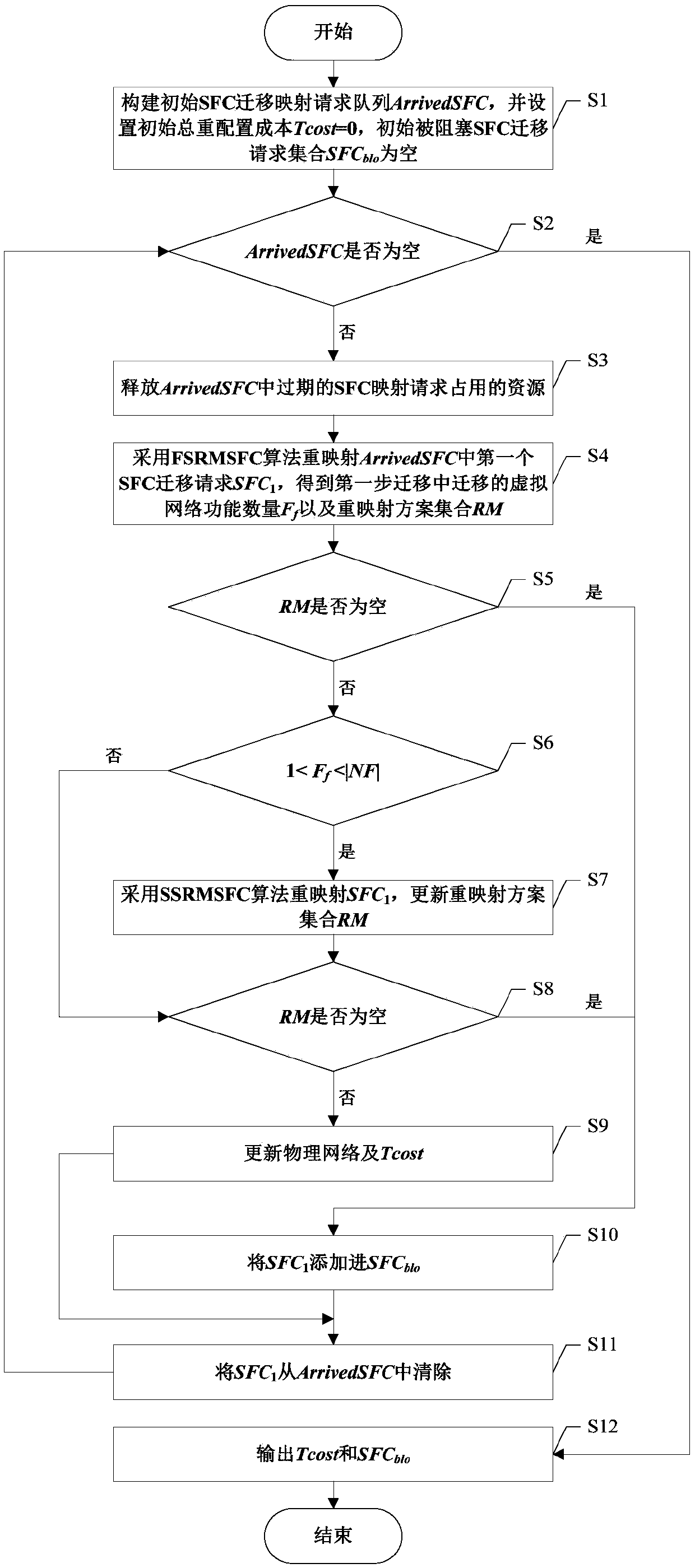

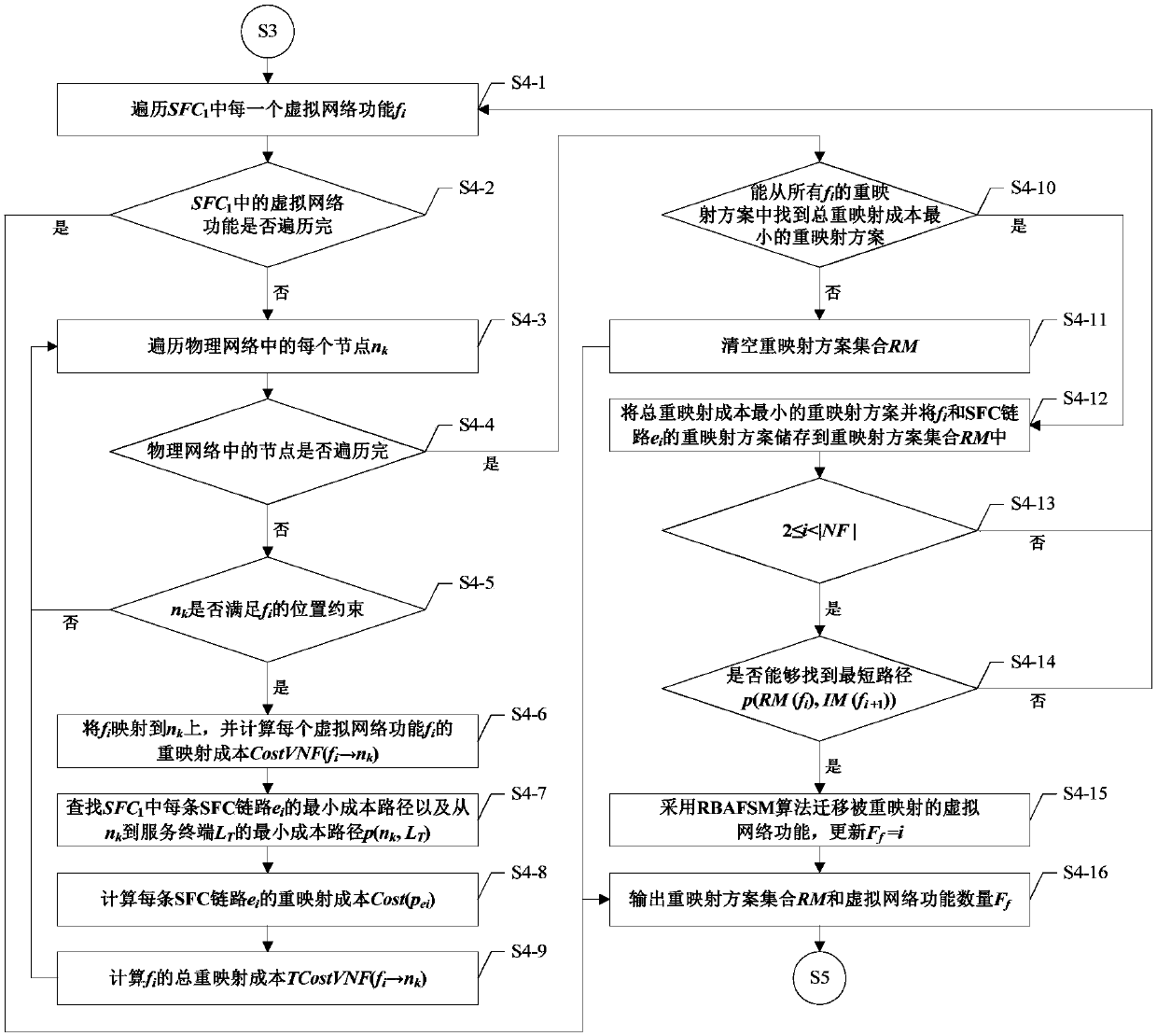

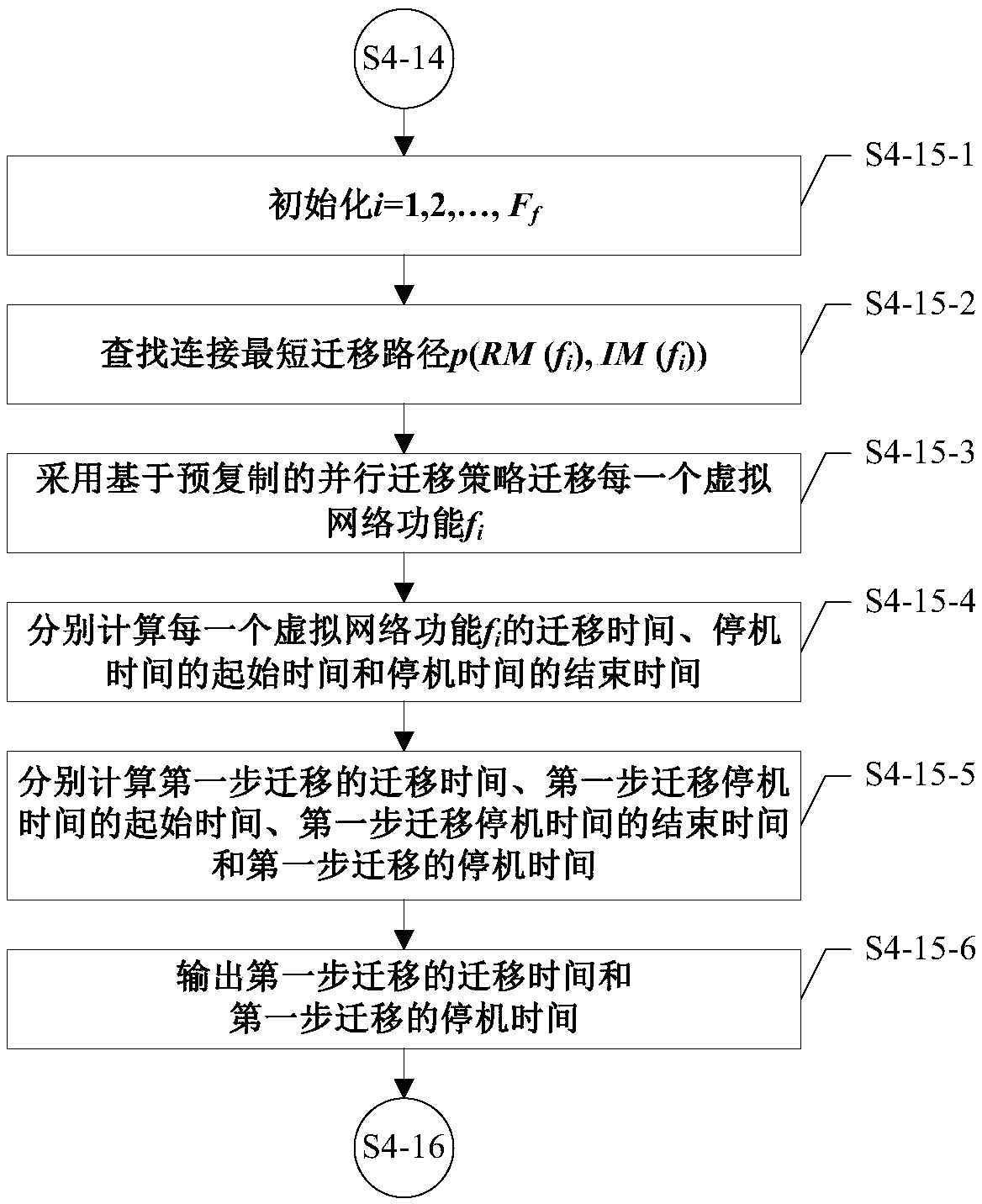

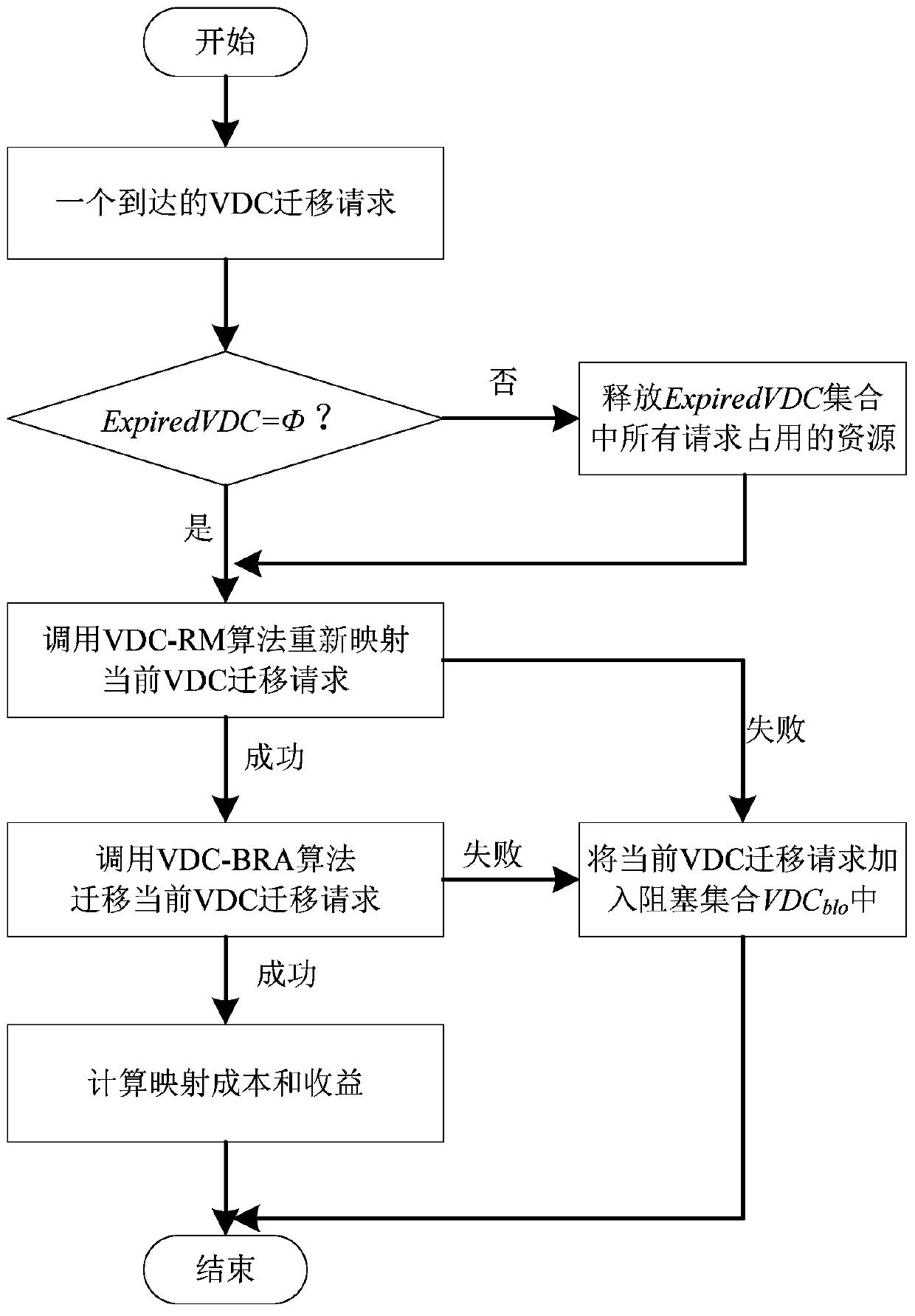

Real-time migration method of service function chain applied to cloud computing network

The invention discloses a real-time migration method of a service function chain applied to a cloud computing network. The method includes the following steps: when remapping and migrating service function chain requests, considering each virtual network function and link connection condition in each service function chain request, and remapping and migrating the service function chain requests with the goal of consuming the minimum server resources and bandwidth resources and reducing the migration time, downtime and blocking rate of the service function chain migration requests in the case of meeting relevant constraint conditions. According to the method disclosed by the invention, the specificity of the service function chain requests is comprehensively considered, the common bandwidthresource requirements and server resource requirements are optimally configured, and the advantages of wide application scope, low remapping cost, short downtime, low mapping blocking rate and the like can be achieved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

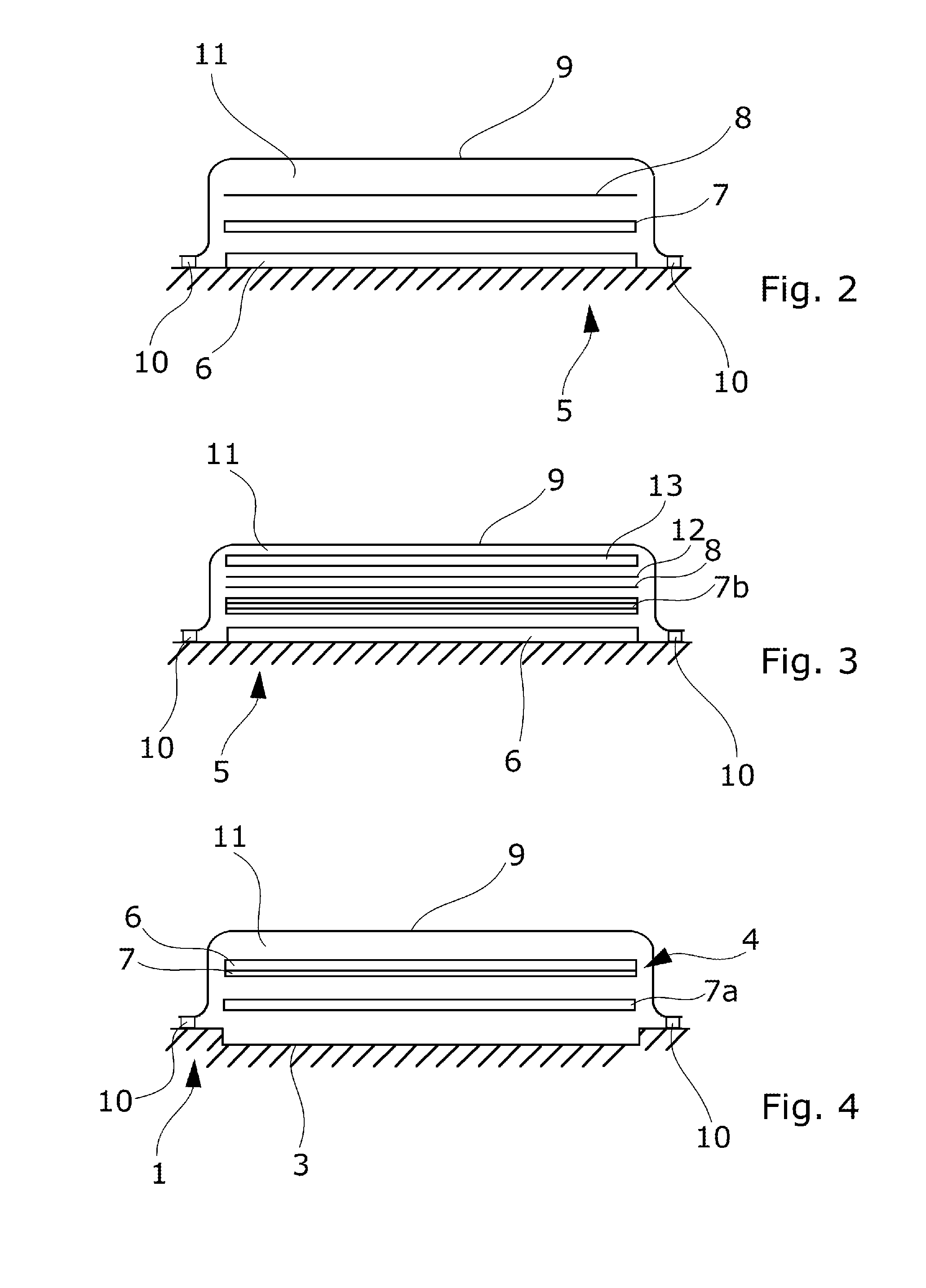

Method of repairing a fibre composite solid member

ActiveUS20110036482A1Short downtimeEfficient executionLayered productsLaminationTurbine bladeEngineering

The present invention relates to a method of repairing a fibre composite solid member having a locally deteriorated surface area, such as having cracks or creases. The solid member may e.g. be a mould for the manufacturing of wind turbine blades or such blades. The method comprises machining a surface section comprising the locally deteriorated surface area in order to obtain a recess having a predefined depth and circumferential shape, placing a repair patch having a predefined thickness and circumferential shape matching the recess in the recess, and fastening the repair patch to the solid member by use of a binder material. At least some of the elastic and thermal properties of the repair patch and the binder material are so that after fastening, the repair patch and the binder material in combination have elastic and thermal properties which are substantially the same as the corresponding properties of the surface section before machining.

Owner:VESTAS WIND SYST AS

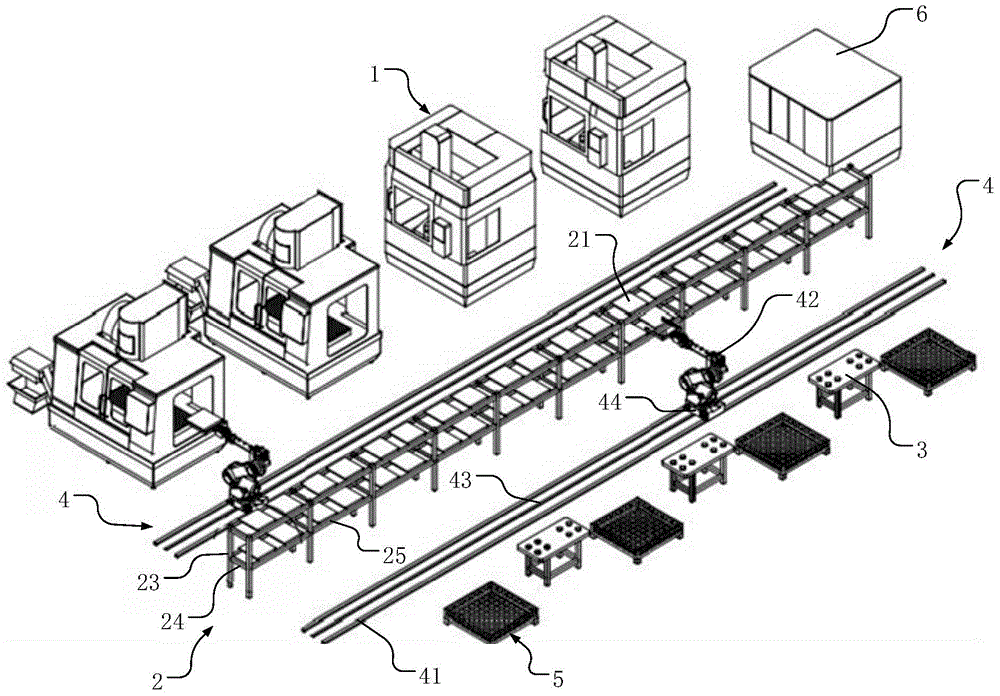

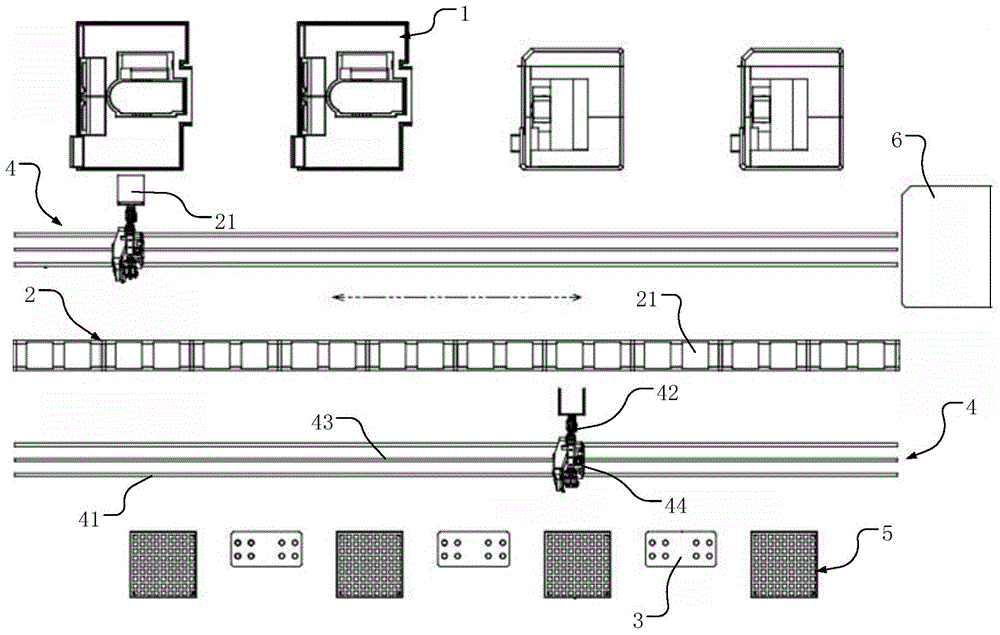

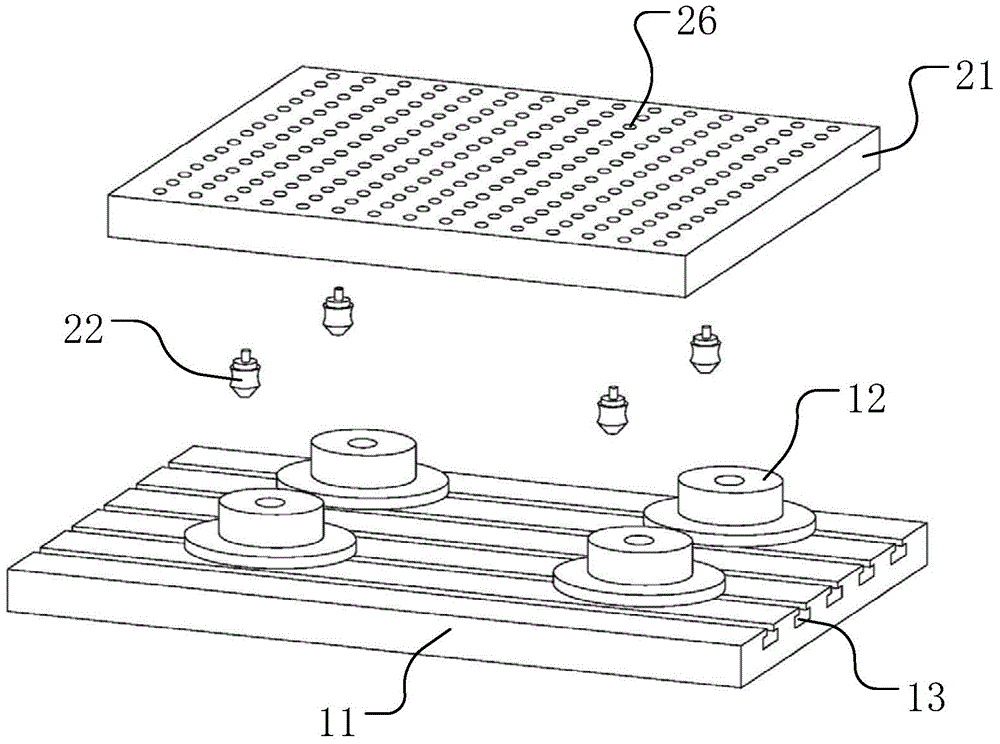

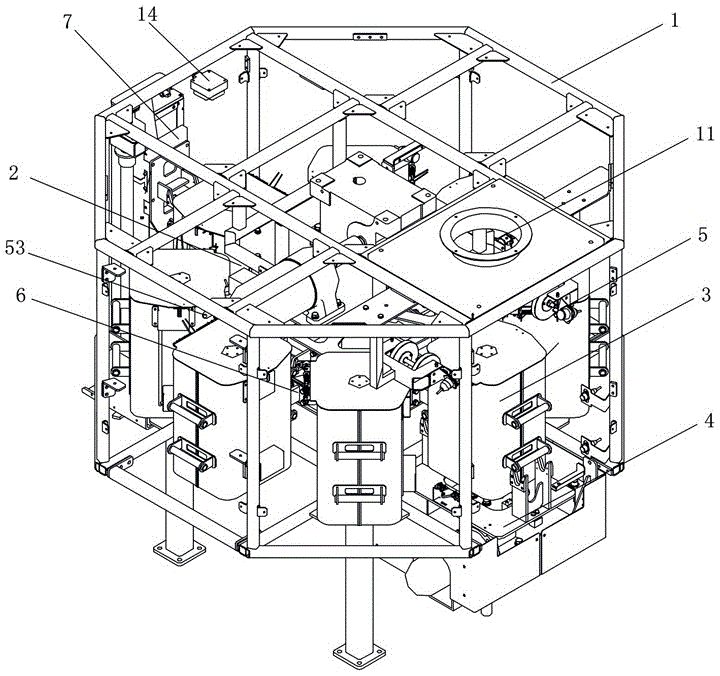

Flexible machining production line based on numerically-controlled machine tools

ActiveCN104816202ALess investmentShort downtimeMetal working apparatusProduction lineNumerical control

A flexible machining production line based on numerically-controlled machine tools comprises the plurality of numerically-controlled machine tools, a tool three-dimensional library, a plurality of workpiece replacing platforms and two groups of transportation units, wherein the plurality of numerically-controlled machine tools and the plurality of workpiece replacing platforms are sequentially arrayed on the two sides of the tool three-dimensional library in sequence; the two groups of transportation units are arranged on the tool three-dimensional library respectively and are arranged between the plurality of numerically-controlled machine tools and the plurality of workpiece replacing platforms; worktables of the plurality of numerically-controlled machine tools are provided with at least two zero-point positioning devices; the tool three-dimensional library is provided with a plurality of supporting frame erecting positions; a tool supporting frame can be erected on each supporting frame erecting position; the bottoms of the tool supporting frames are provided with positioning lock heads with the quantity which is the same as the quantity of the zero-point positioning devices on the worktable of each numerically-controlled machine tool; each of the two groups of transportation units comprises a guide rail and a mechanical arm capable of sliding and moving on the guide rail; the guide rails in the two groups of transportation units are parallel to the long-strip-shaped tool three-dimensional library.

Owner:JIANGXI JUST NUMERICAL CONTROL TECH

Method of migrating a plurality of associated virtual machines among a plurality of data centers

ActiveCN104935628ALow costLow cost of remappingResource allocationTransmissionData centerCloud computing

The present invention provides a method of migrating a plurality of associated virtual machines among a plurality of data centers, and belongs to the cloud computing technology field. The method can be suitable for a whole virtual data center (VDC) migration request, and the plurality of associated virtual machines are in the VDC migration request, can be one virtual machine, and also can be more than two associated virtual machines, so that the application range of the method is wider by being compared with a conventional migration algorithm. According to the present invention, after the successful remapping of the whole VDC migration request, a migration path is found for each virtual machine until the migration paths of all virtual machines are found, and then all virtual machines are migrated by using a uniform parallel migration strategy, so that the shutdown time and the migration time are shorter than migrating the virtual machines one by one and orderly.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

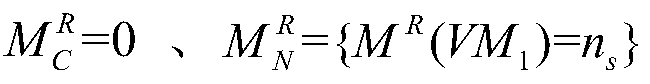

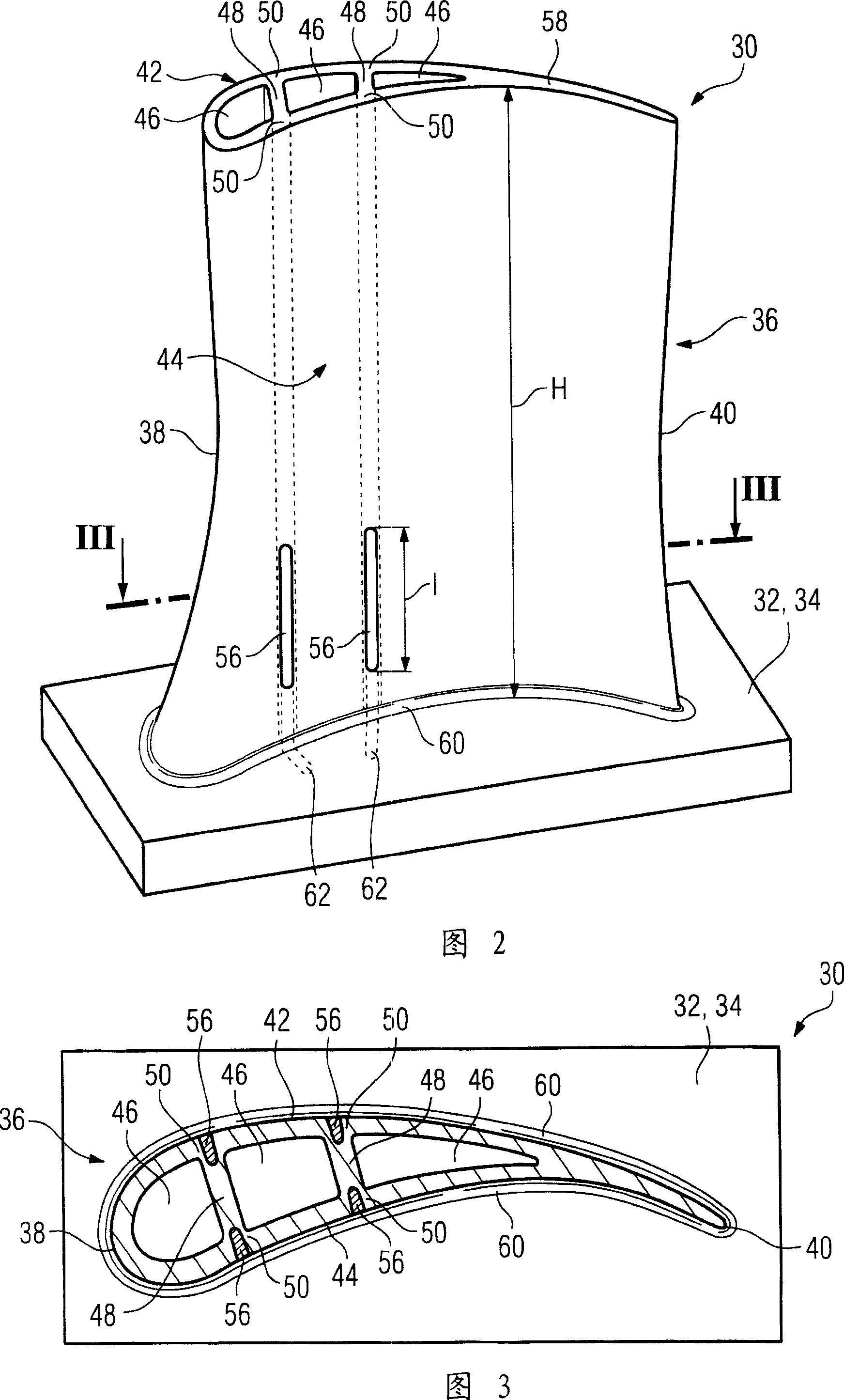

Hollow turbine blade

InactiveCN1936273AReduce the temperatureEasy to crackBlade accessoriesMachines/enginesCombustionTurbine blade

This hollow turbine blade comprises airfoil bodies 36 formed on the rear wall 42 of the blade and the front wall 44 of the blade and washed down by combustion gas 11, at least one partition wall 48 formed inside a turbine blade 30, and the at least one slit 56 formed on the combustion gas side of the blade walls 42, 44 and extending along the blade axis. The airfoil bodies comprise a height H equal to a distance between a blade pedestal 32 and an airfoil body end 58 measured along the blade axis. The partition wall joints the rear wall 42 of the blade to the front wall 44 of the blade at the joined portion 50. The slits 56, 62 are positioned in the blade walls 42, 44 on the combustion gas side to face the joined portion 50 formed of the partition wall 48 and the blade walls 42, 44.

Owner:SIEMENS AG

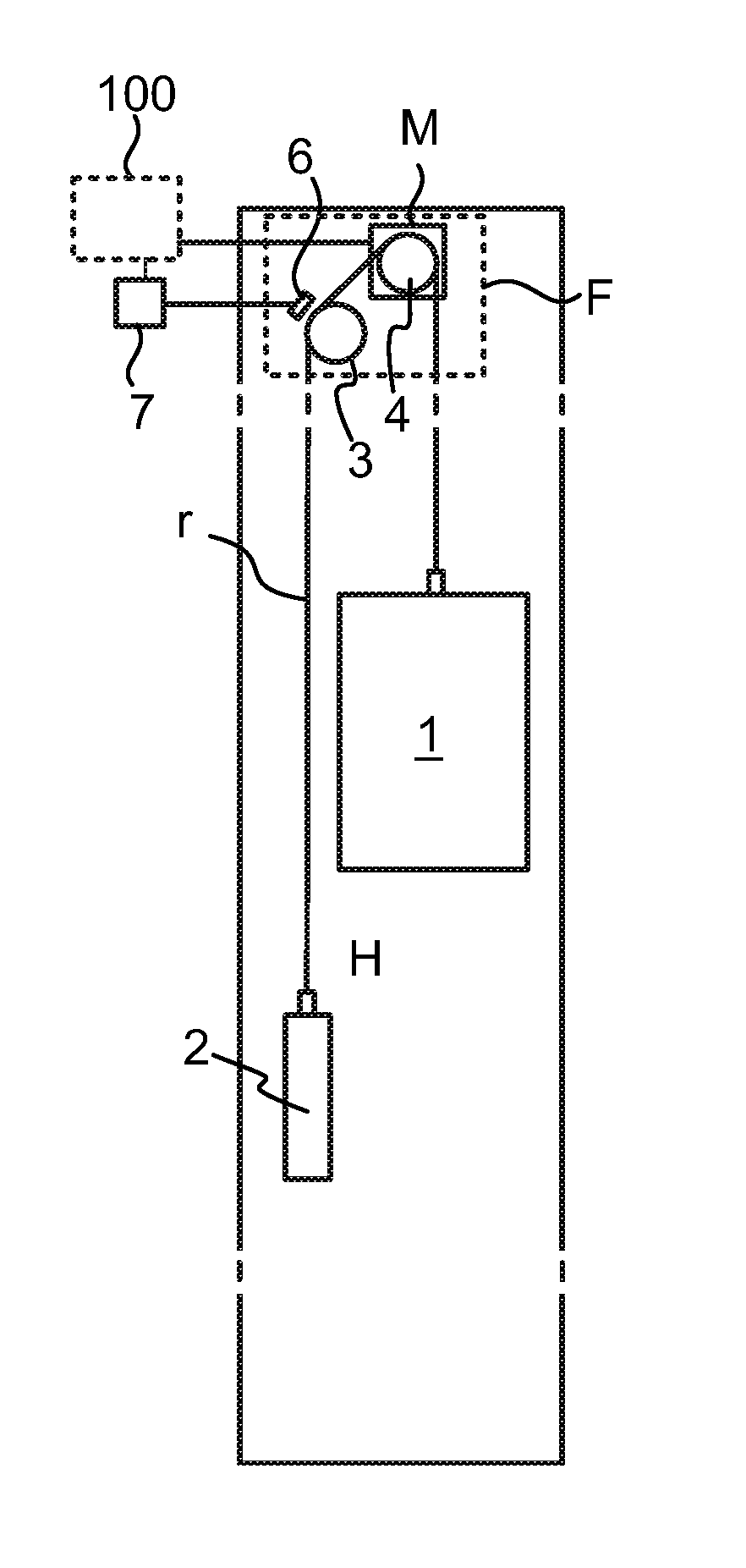

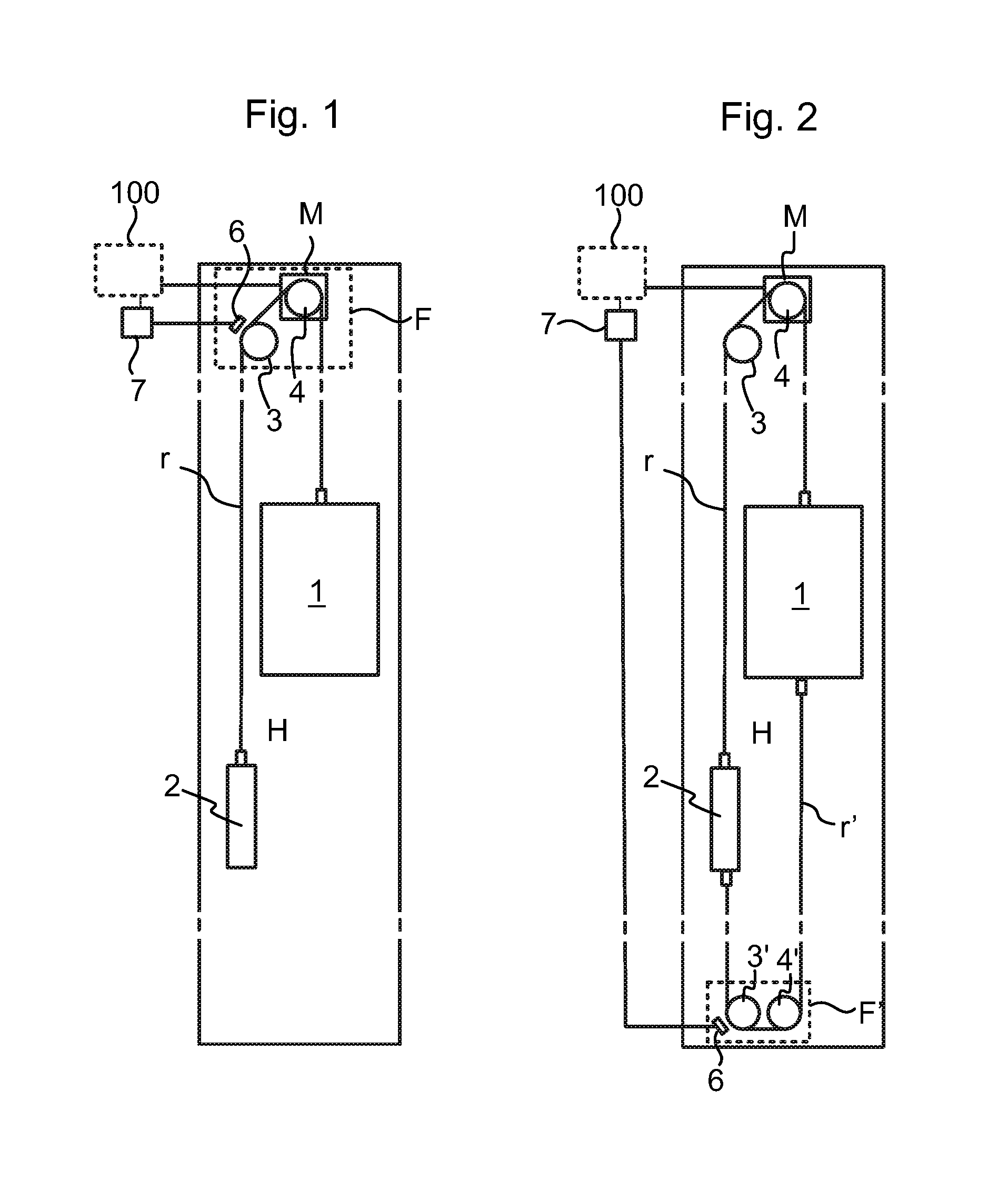

Elevator

ActiveUS20160311649A1Easy to manufactureEasy to checkElevatorsBuilding liftsEmbedded systemMark sense

An elevator includes a hoistway; an elevator car vertically movable in the hoistway; a rope connected to the elevator car movably together with the elevator car; a guide for guiding the rope along a path; and a device for determining position of the elevator car. The device for determining position of the elevator car including an elongated code mark pattern provided on the rope, which elongated code mark pattern comprises code marks distributed along the length of the rope; one or more sensors mounted beside the rope for sensing code marks of the code mark pattern; and an analyzer connected with the at least one sensor. The one or more sensors are arranged to sense code marks of the code mark pattern passing by them when the rope moves along its path, and the analyzer is configured to determine current position of the elevator car based on code marks sensed by the one or more sensors during movement of the rope.

Owner:KONE CORP

Intelligent sample collecting device

ActiveCN105752470ARisks Affecting Mass AccuracyHigh security for collection and transferLidsNon-removalbe lids/coversLocking mechanismEngineering

The invention discloses an intelligent sample collecting device which comprises a machine frame. The machine frame is provided with a feed inlet. A rotatable rotating disc mechanism and multiple sample storage barrels used for collecting samples are arranged in a collecting cavity formed by the machine frame. The sample storage barrels are hung on the rotating disc mechanism. Each sample storage barrel is provided with a hinged barrel cover and an induction locking mechanism used for locking the barrel cover. The hinged position of the barrel cover is provided with an elastic part so that the barrel cover can bounce upwards to be opened when not locked. The feed inlet is provided with a liftable weighing mechanism. The weighing mechanism is provided with an induction unlocking assembly matched with the induction locking mechanism. When the rotating disc mechanism drives the sample storage barrels to rotate to the position below the feed inlet, the weighing mechanism raises to lift up the sample storage barrels, so that the induction locking mechanism induces an unlocking signal of the induction unlocking assembly to open the barrel covers for sample connection and weighing operation. The intelligent sample collecting device has the advantages that the structure is simple and compact, the intelligence degree is high, sample collection and transfer safety is high, sample collection quality precision is high, working efficiency is high, and the production cost is low.

Owner:HUNAN SUNDY SCI & TECH DEV

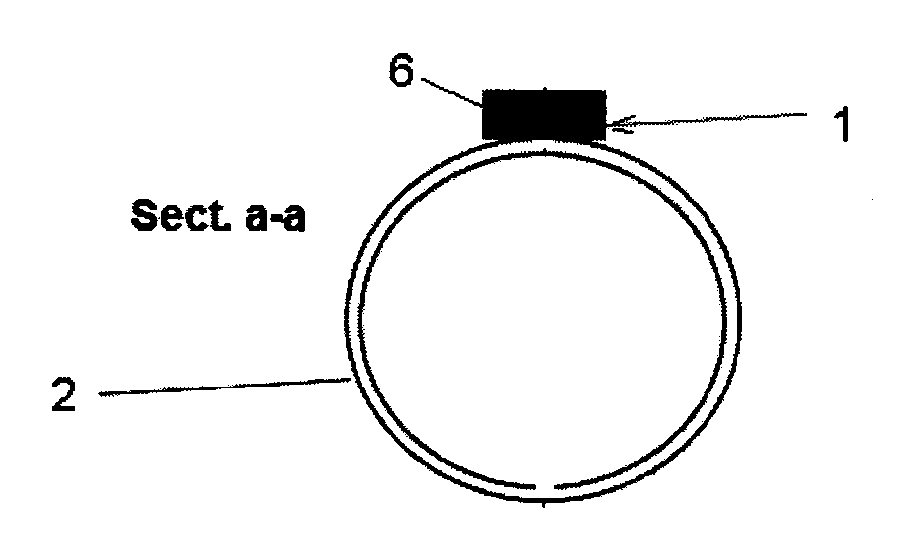

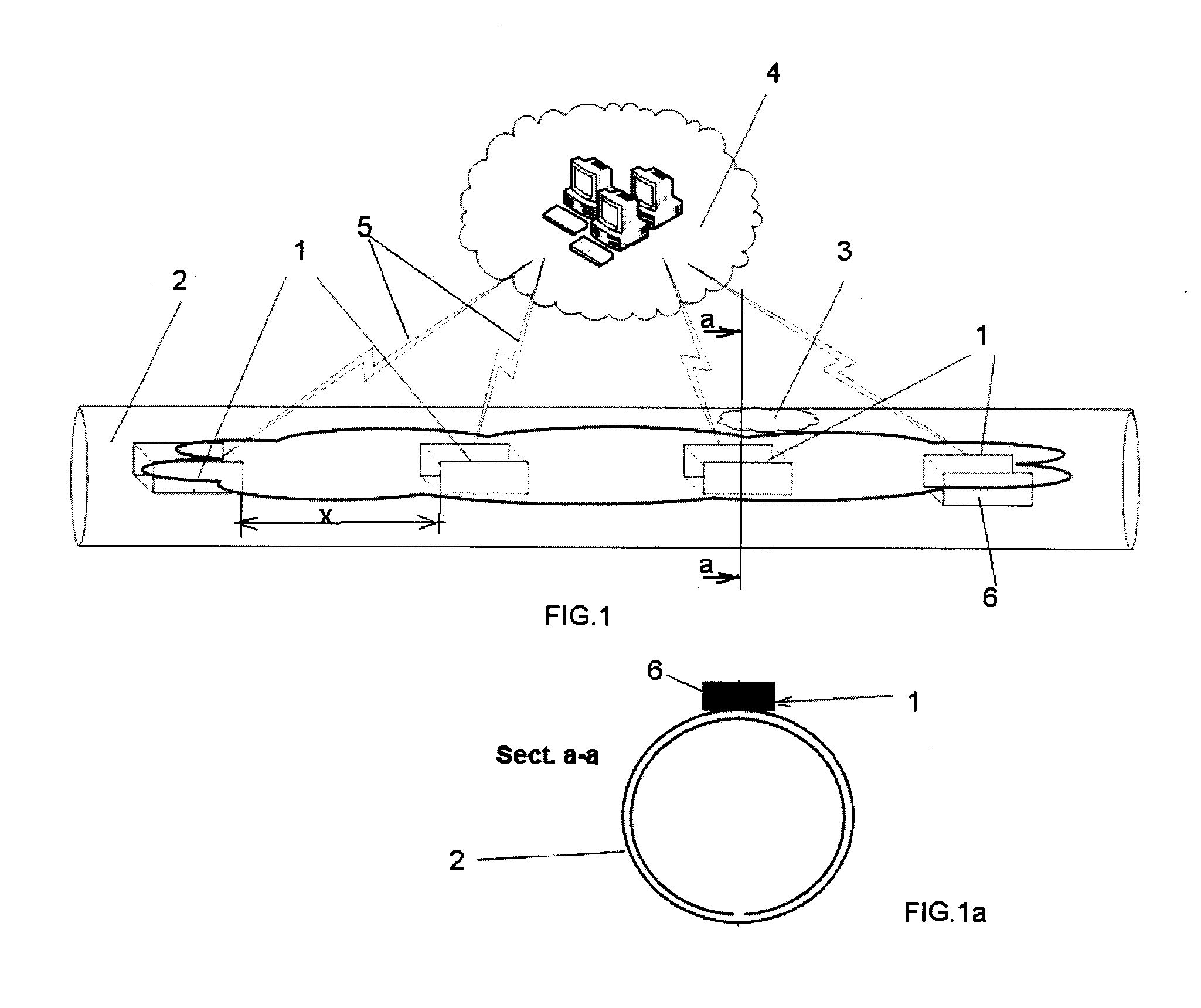

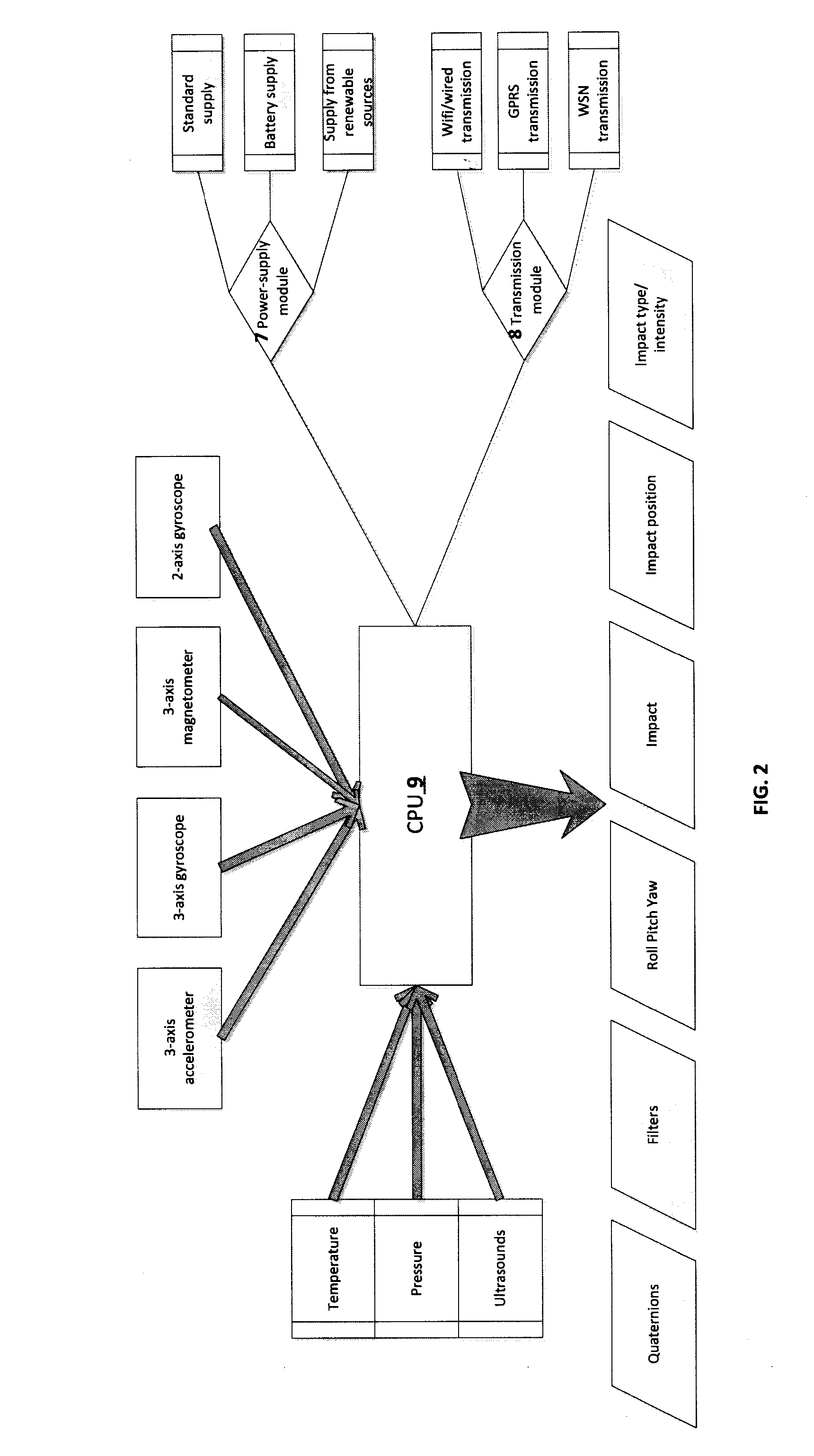

System and method for supervising, managing, and monitoring the structural integrity of a fluid-transportation pipeline network, for locating the leaking point, and for evaluating the extent of the failure

ActiveUS20150308917A1Structural damageConsequent costDetection of fluid at leakage pointMeasurement of fluid loss/gain rateEngineeringNatural gas

A system and method for supervising, managing, and monitoring the structural integrity of a network of metal pipelines for transporting a fluid, for locating the leaking point, and for evaluating the fault or failure, comprising a plurality of detection units (1) positioned on a pipeline (2) for oil or gas at a distance apart by a given value and fixedly applied to the pipeline (2), and a central data-processing unit (4) connected by means of communication lines (5) to said detection units (1) for receiving from the latter detection data, wherein said units (1) comprise sensors capable of measuring one or more physical quantities, wherein said processing unit (4) processes in real time the detection data received from the detection units (1).

Owner:PIPE MONITORING

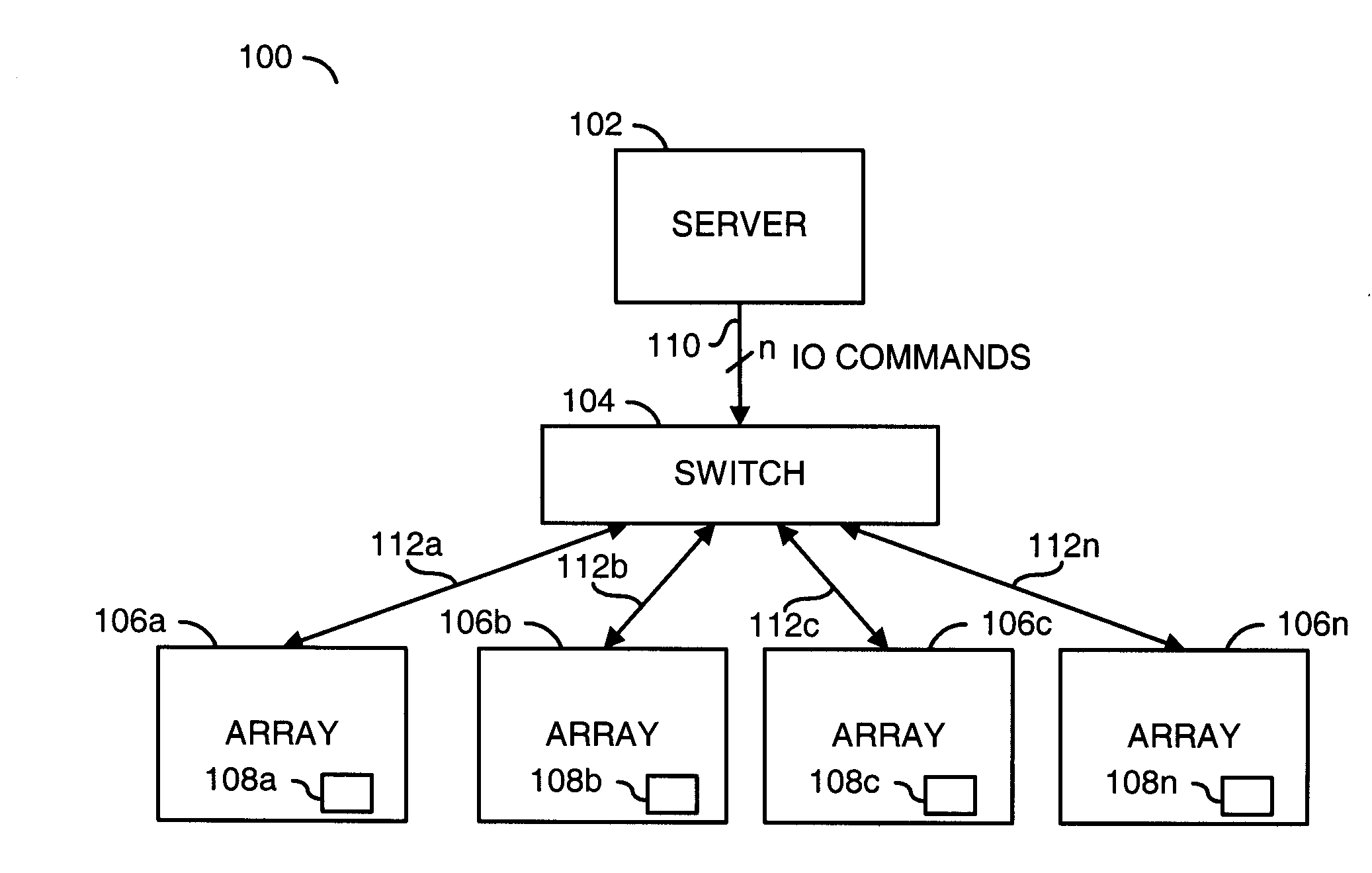

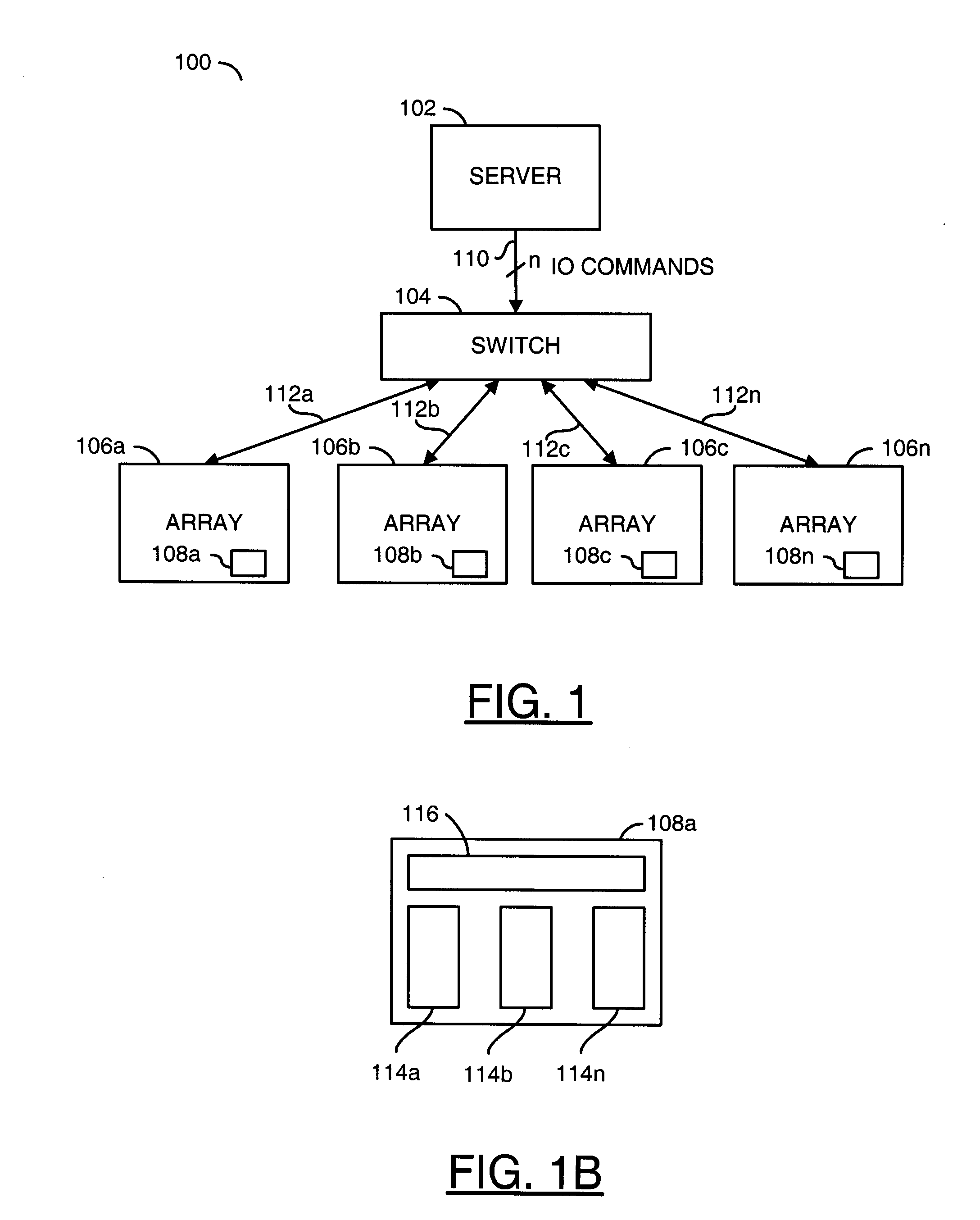

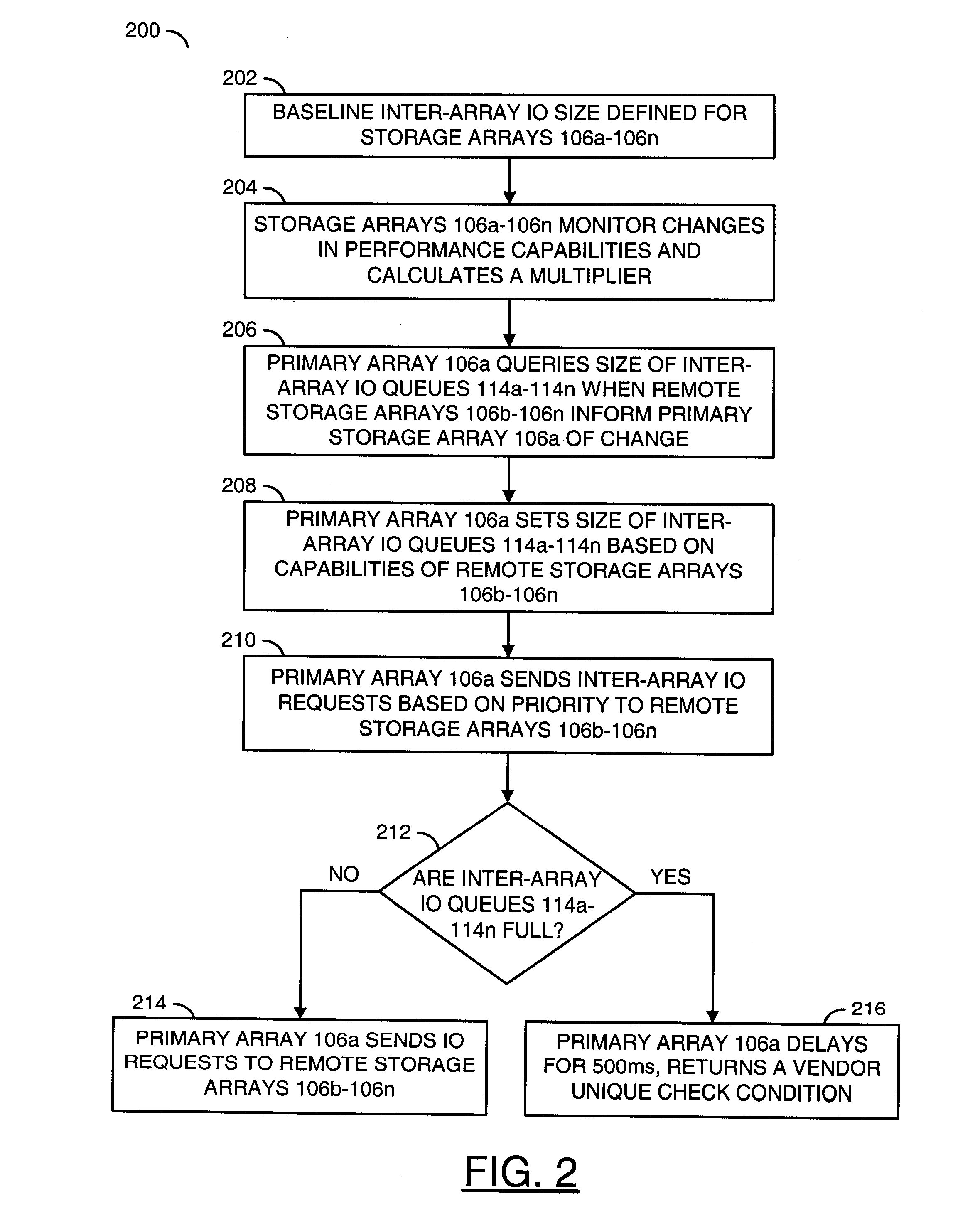

System for handling input/output requests between storage arrays with different performance capabilities

ActiveUS20100223427A1Short downtimeReduced performance capabilityTransmissionMemory systemsComputer hardwareEmbedded system

An apparatus comprising a remote storage array, a primary storage array and a network. The remote storage array may be configured to (i) define a queue size based on a performance capability of the remote storage array, (ii) generate a multiplier based on resources being used by the remote storage array, and (iii) adjust the queue size by the multiplier. The primary storage array may be configured to execute input / output (IO) requests between the remote storage array and the primary storage array based on the adjusted queue size. The network may be configured to connect the remote storage array to the primary storage array.

Owner:NETWORK APPLIANCE INC

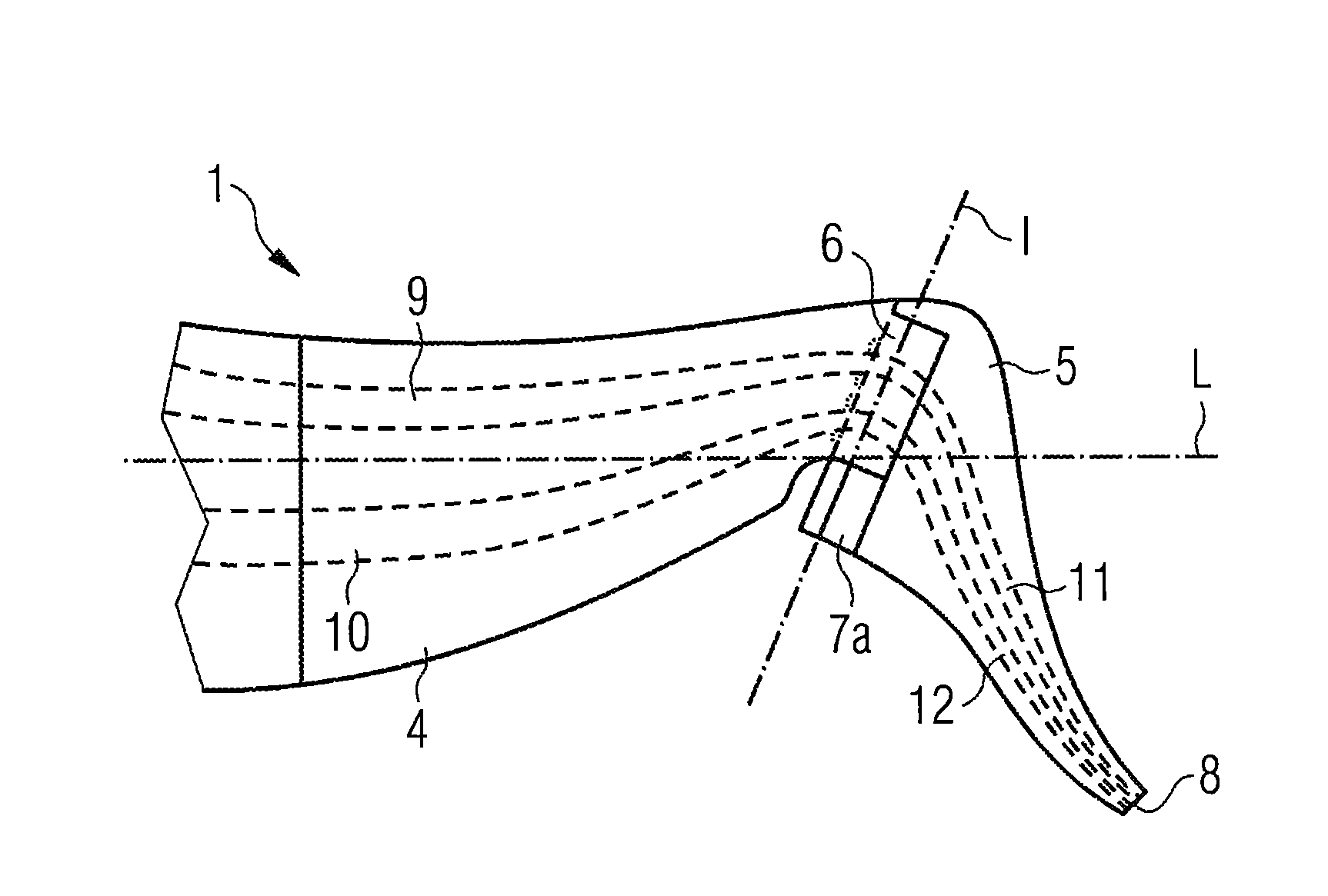

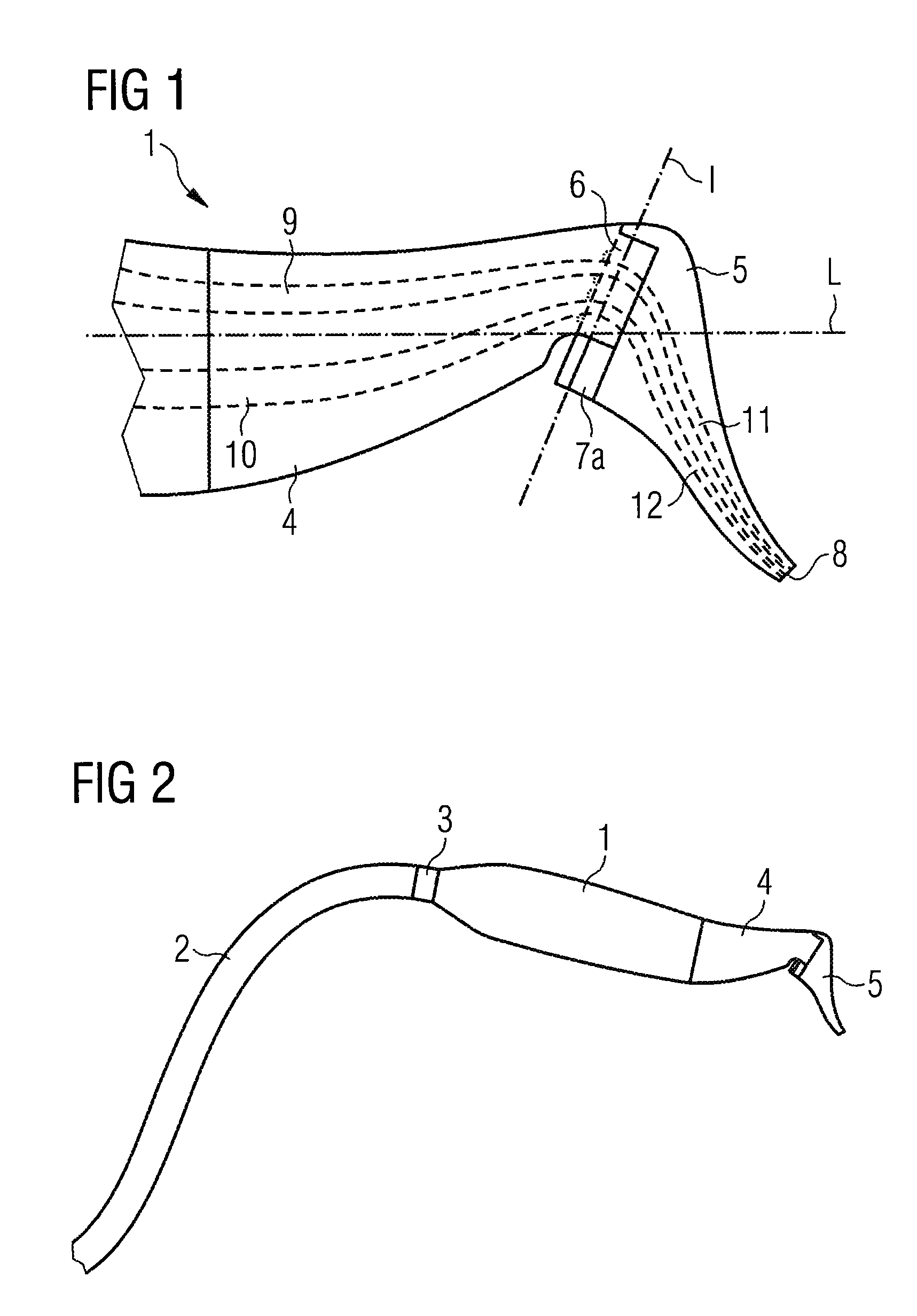

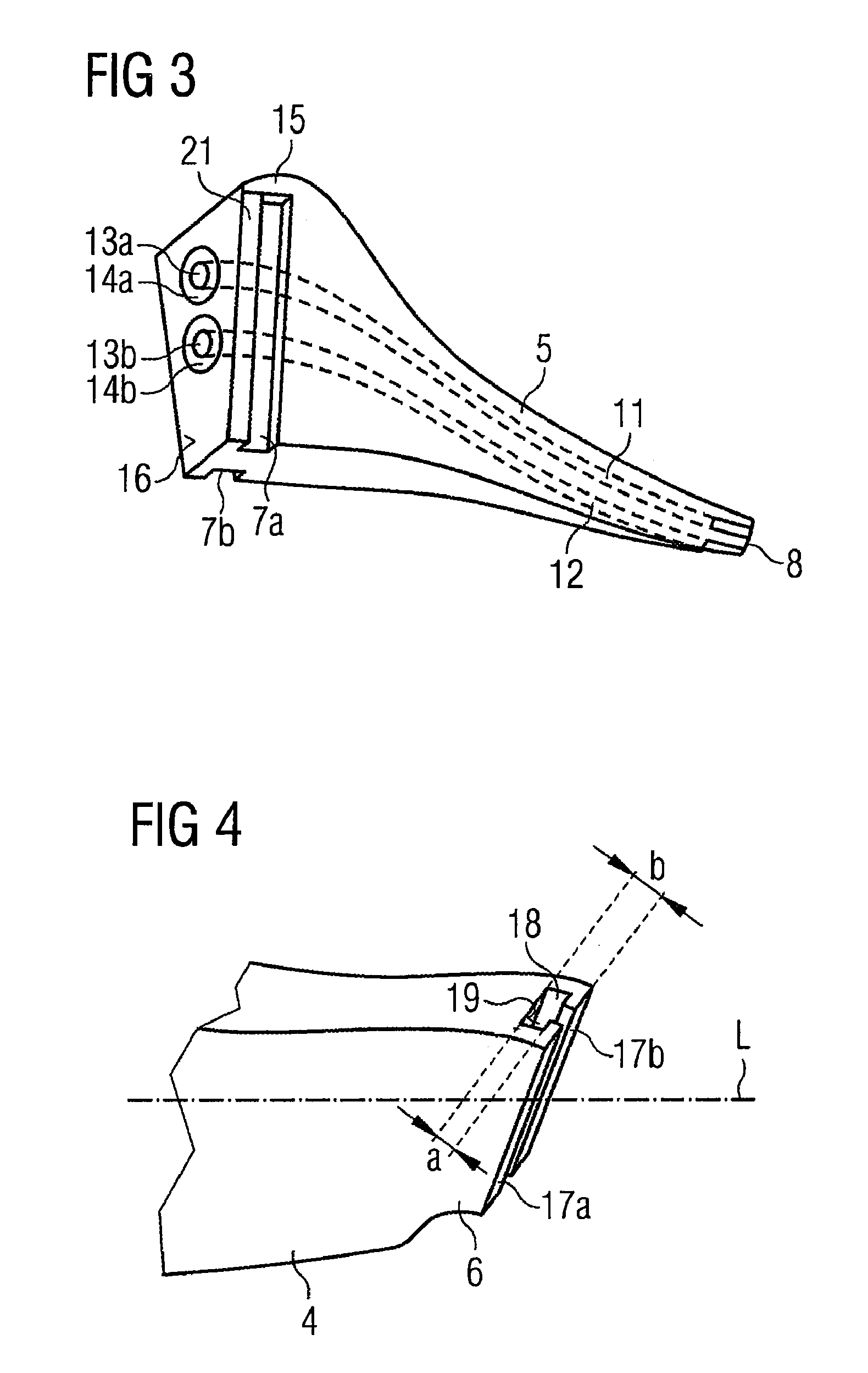

Medical handset and exchangeable nozzle for the same

ActiveUS7762812B2Down timePatients can be treated more quicklyTeeth fillingDental toolsInterference fitPowder mixture

The present invention relates to a medical handset with a nozzle having at least one nozzle line for supplying a medically active medium, such as for example an air-powder mixture and / or a fluid, in particular for the prophylactic treatment of teeth, wherein the handset has a head part with a connecting part on the head for the exchangeable connection of the handset to the nozzle, wherein at least one supply line of the handset is connected to the at least one nozzle line of the nozzle by producing a sealing-tight interference fit of a sealing face on the nozzle with a sealing face on the handle, in particular in that a tongue-and-groove connection is produced between the nozzle and the connecting part, e.g. in that a T-groove on the nozzle is inserted into a T-tongue on the handle, the axis of insertion lying roughly at right angles to the longitudinal axis of the handset.

Owner:FERTON HLDG

Shutdown technique of cleaner production of sulfur recovery and tail gas treatment device

The invention belongs to the technical field of sulfur recovery, and particularly relates to a sulfur recovery and tail gas liquid phase treatment technique. The technique comprises the following steps: heating circulating nitrogen and purging a sulfur recovery unit to generate sulfur-mist-containing gas; directly contacting the sulfur-mist-containing gas with water for cooling, and condensing the sulfur mist to form sulfur powder and removing the sulfur powder for gaseous phase circulation; heating by using the circulating nitrogen containing trace O2 to forge the sulfur recovery and tail gas treatment device to generate SO2-containing gas; and directly contacting the SO2-containing gas with NaOH dilute solution for cooling, and entering the produced industrial wastewater into a sludge treatment device. According to the technique, the shutdown device is treated by using high-temperature nitrogen in place of smoke gas generated from combustion of fuel gas, so that the controllability of the device is greatly improved, the service lives of the equipment and catalyst can be effectively prolonged, the discharge of sulfur dioxide in the shutdown period of the sulfur recovery device is less than 10ppm, and the environmental pollution is greatly reduced.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

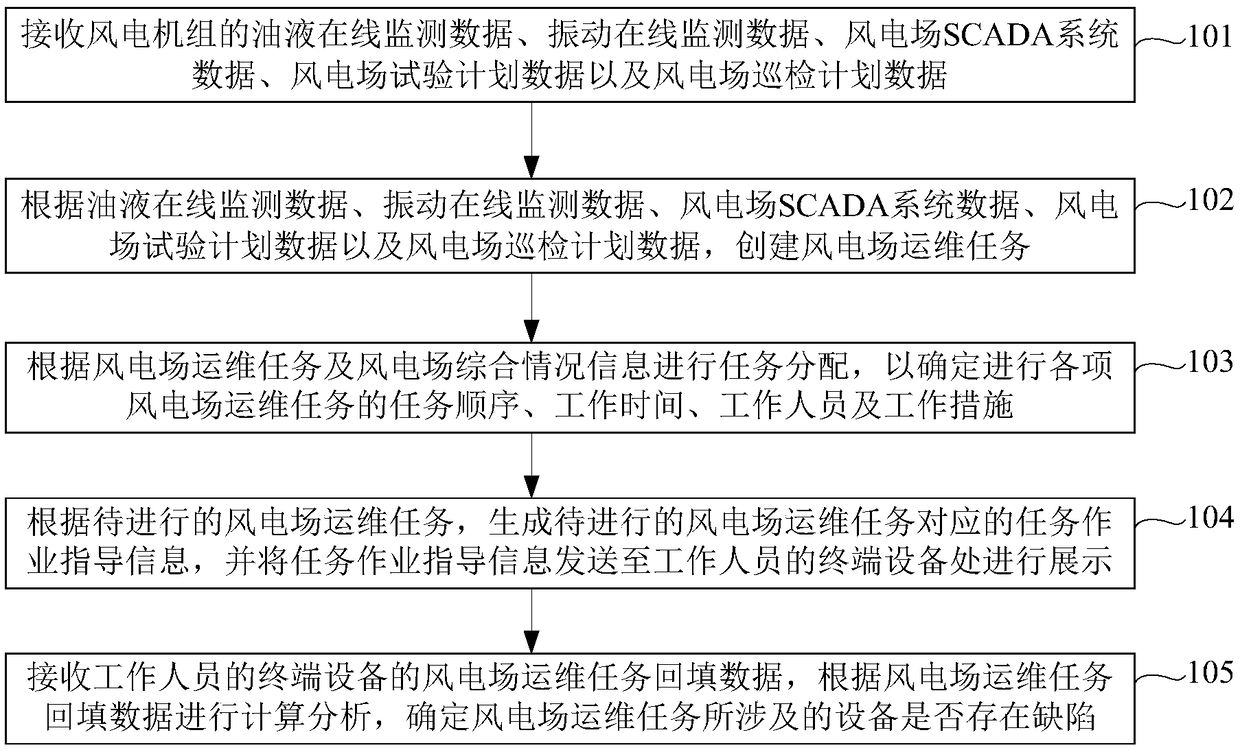

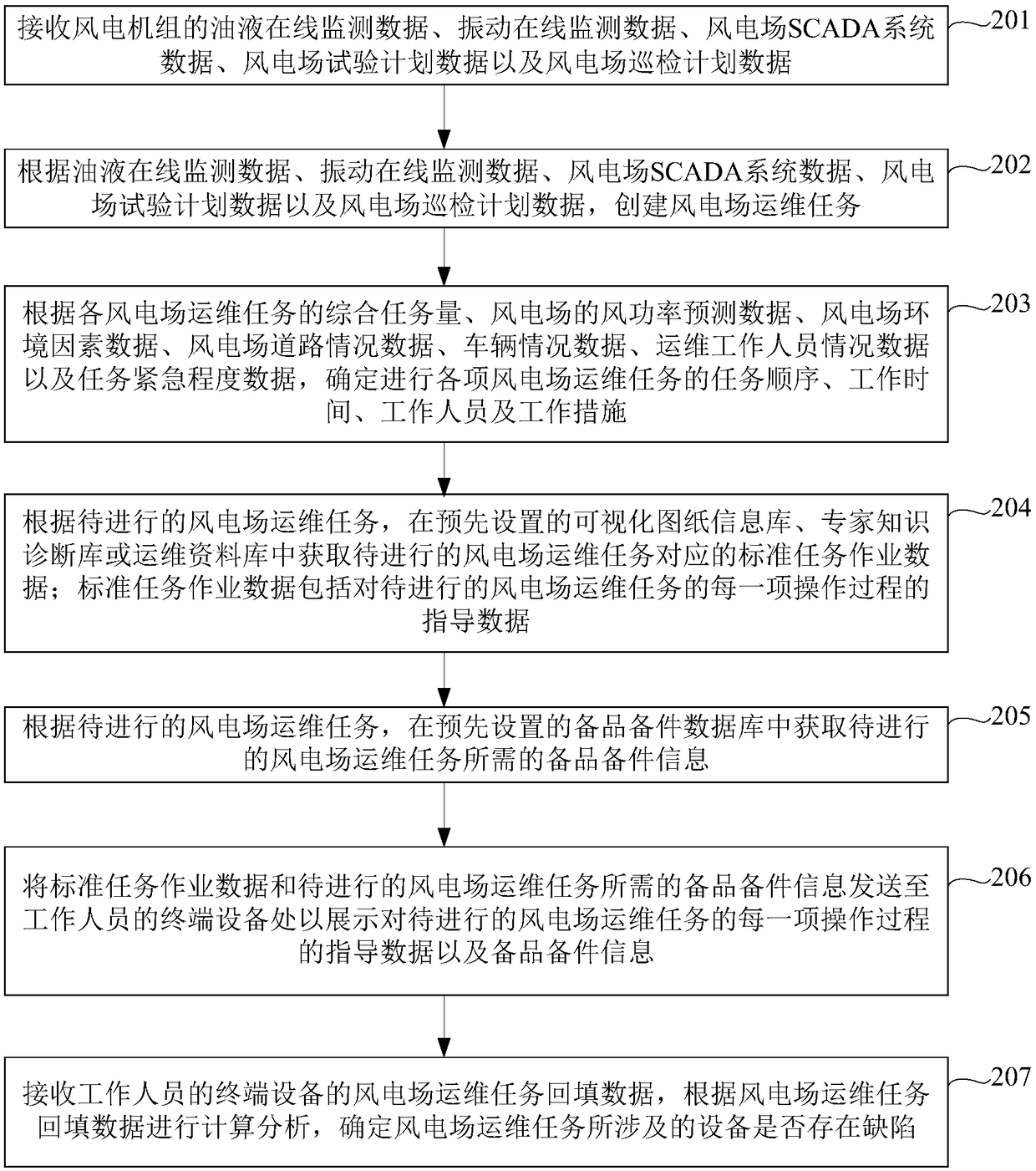

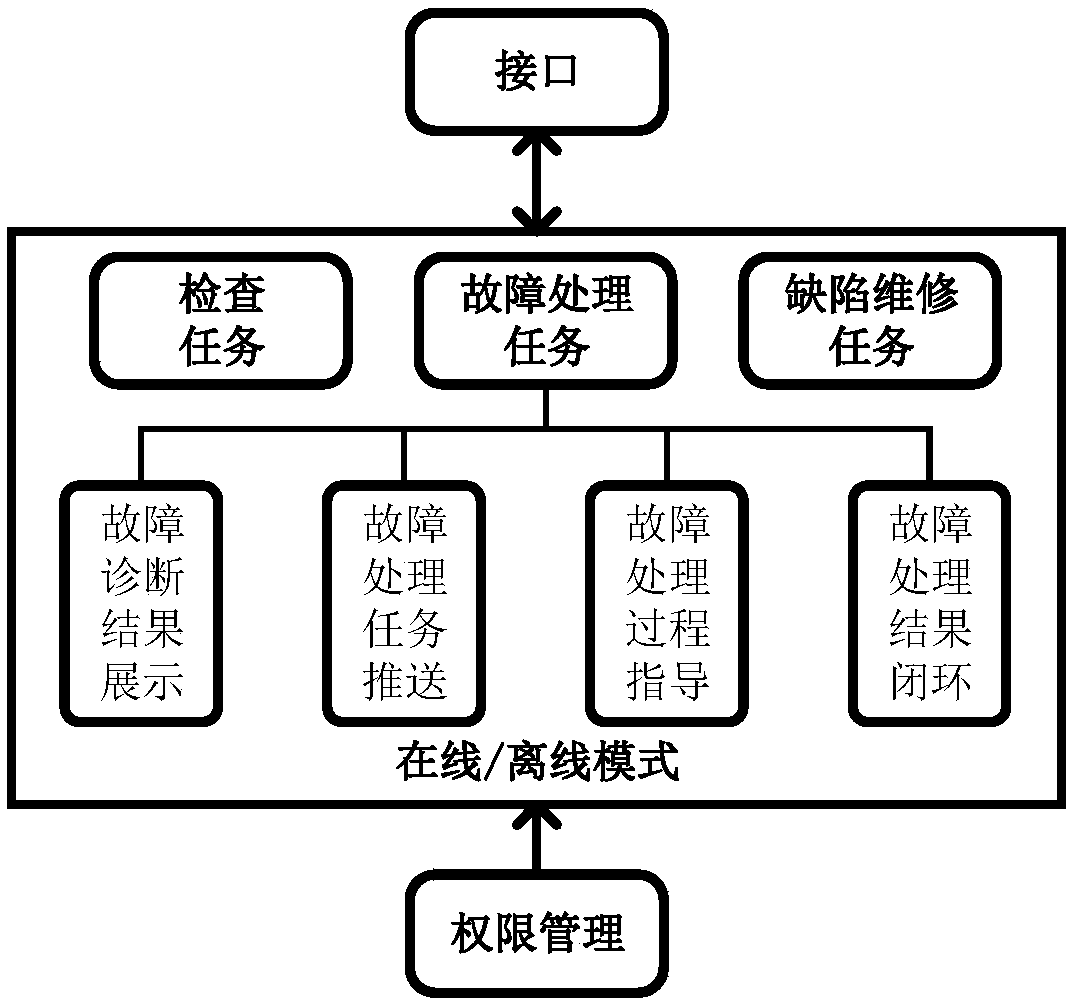

Intelligent operation and maintenance method, device and system of wind power plant

InactiveCN109209782AGuaranteed uptimeEasy maintenanceMachines/enginesWind motor monitoringElectric fieldSCADA

The invention provides an intelligent operation and maintenance method, device and system of a wind power plant. The method comprises the following steps: oil online monitoring data of a wind power unit, vibration online monitoring data, wind power plant SCADA system data, wind power plant test planning data and wind power plant polling planning data are received to build wind power plant operation and maintenance tasks; the tasks are distributed according to the wind power plant operation and maintenance tasks and wind power plant comprehensive condition information to determine the task sequence, the working time, workers and working measures of the wind power plant operation and maintenance tasks; task operation guidance information corresponding to the wind power plant operation and maintenance tasks to be performed is generated according to the wind power plant operation and maintenance tasks to be performed, and the task operation guidance information is sent to terminal equipment of the workers for displaying; wind power plant operation and maintenance task backfill data of the terminal equipment of the workers is received; and the calculation and the analyzed are performedaccording to the wind power plant operation and maintenance task backfill data to determine if equipment related to the wind power plant operation and maintenance tasks is failed.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +2

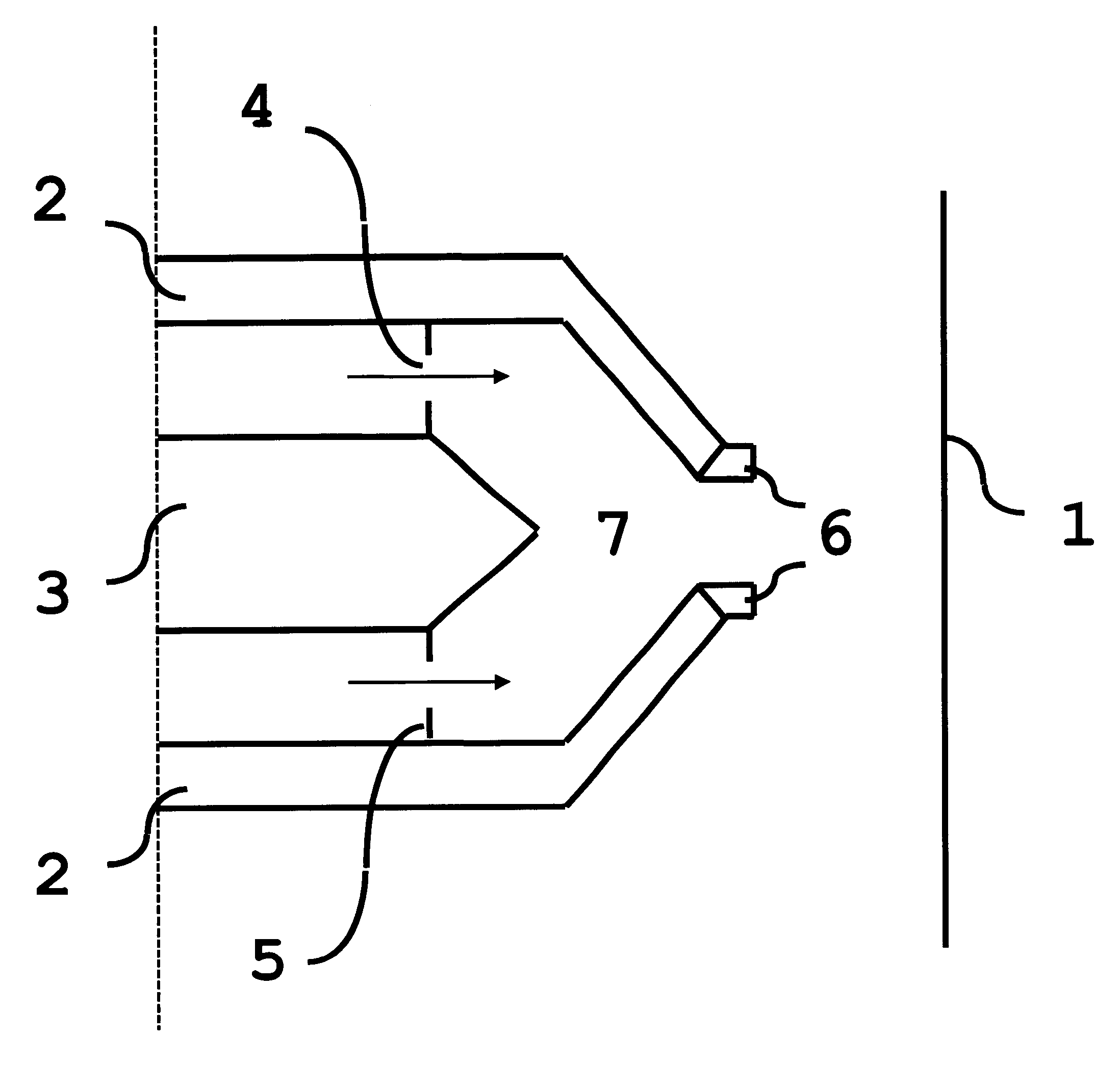

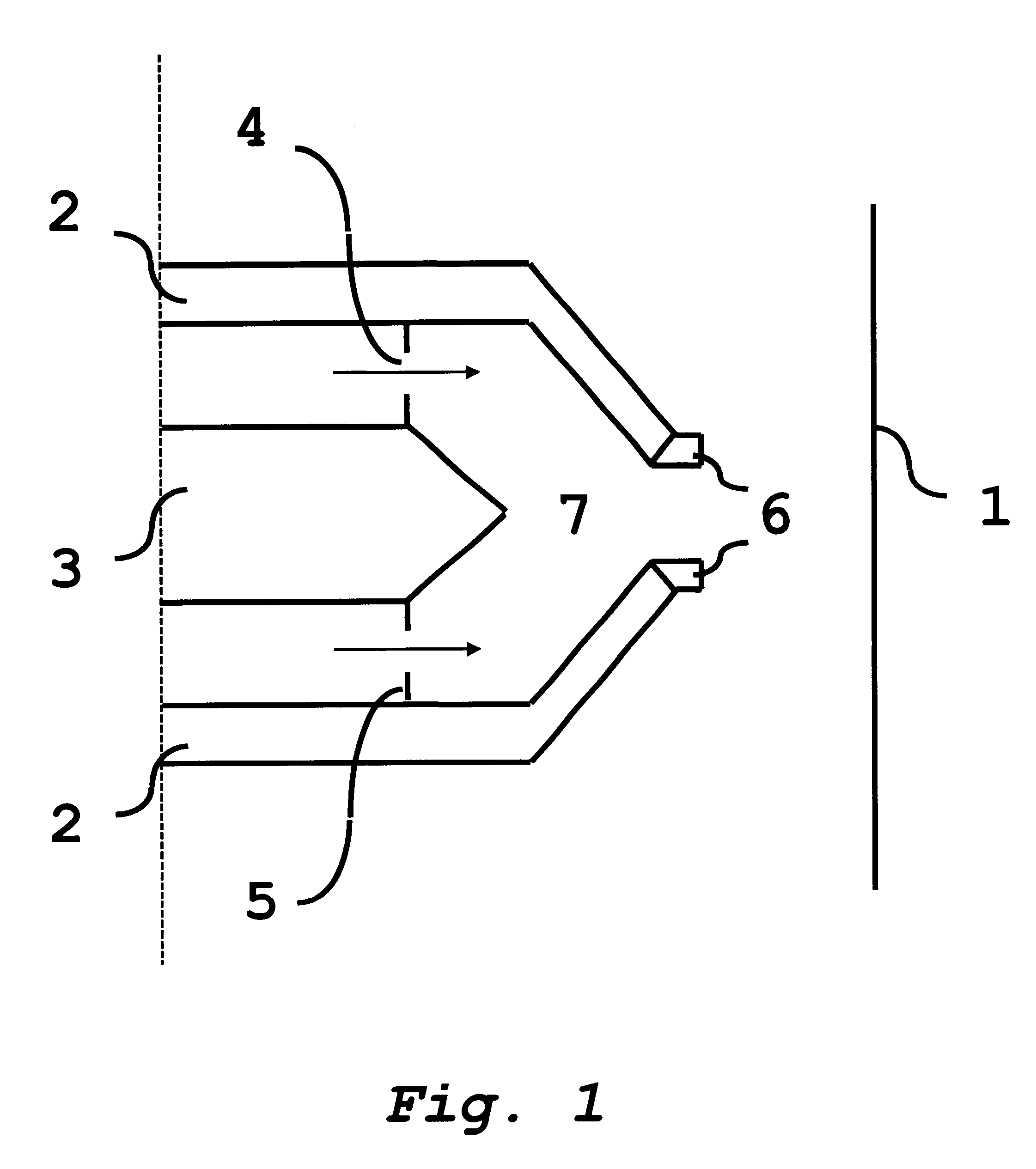

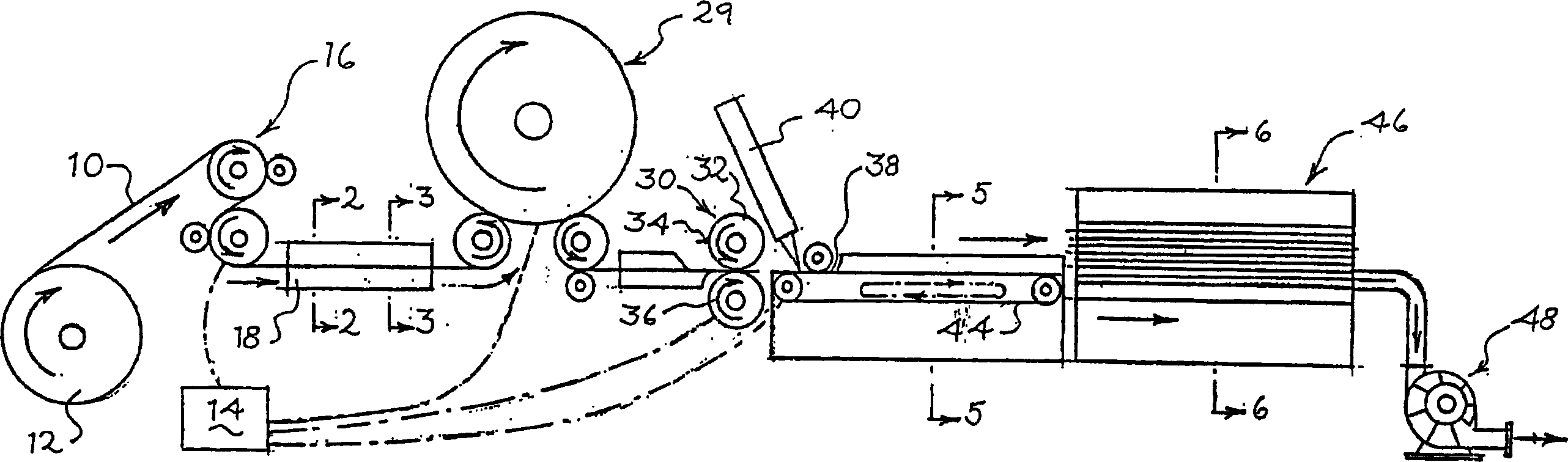

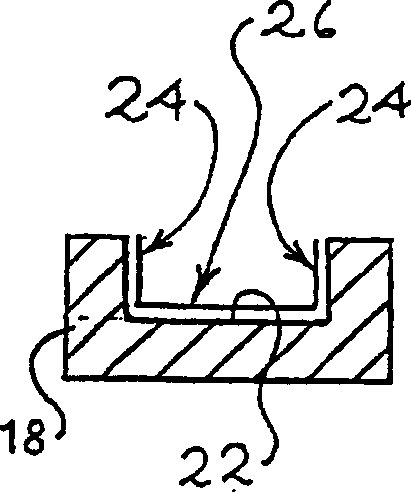

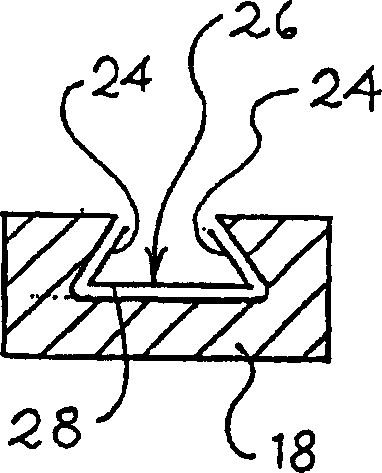

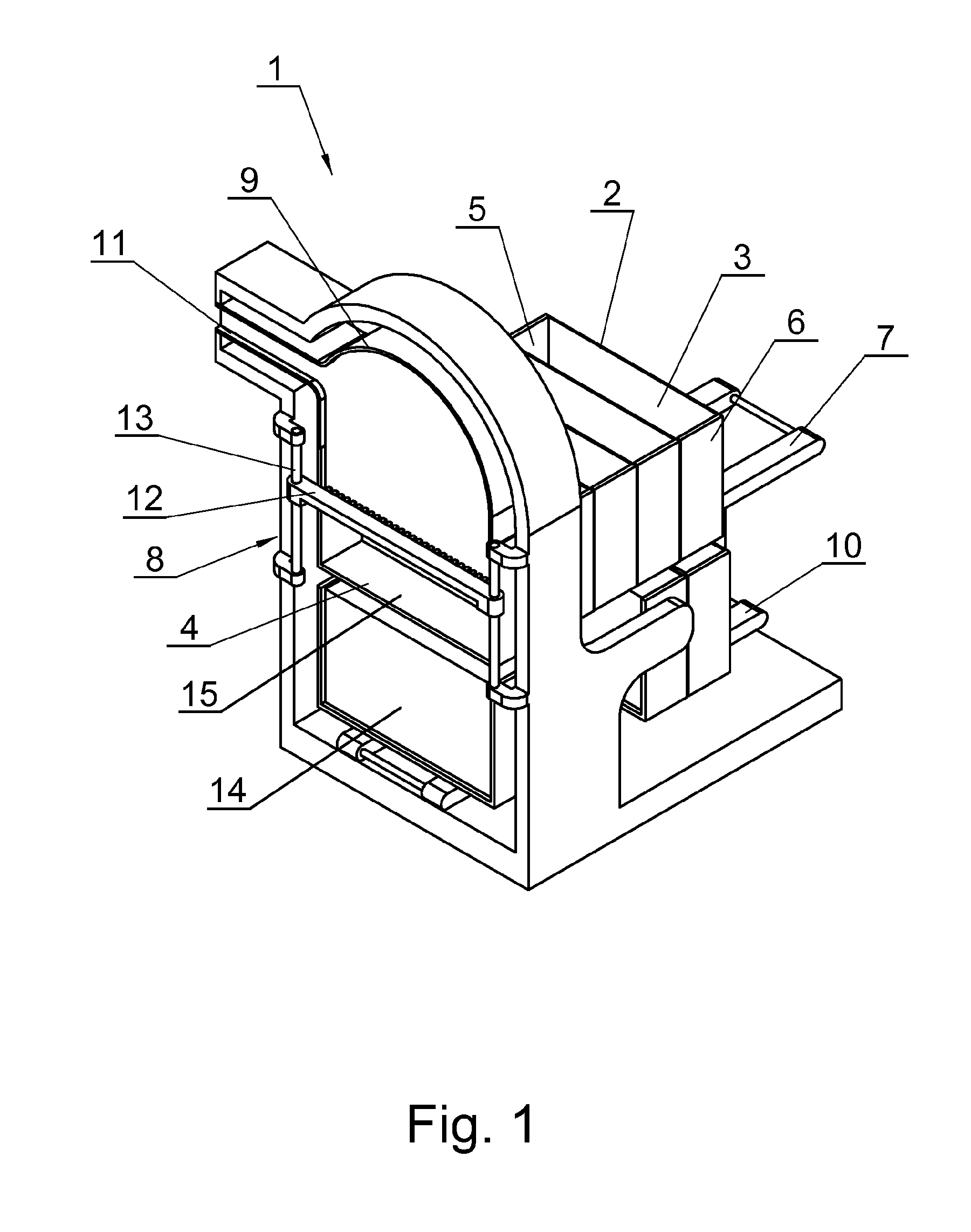

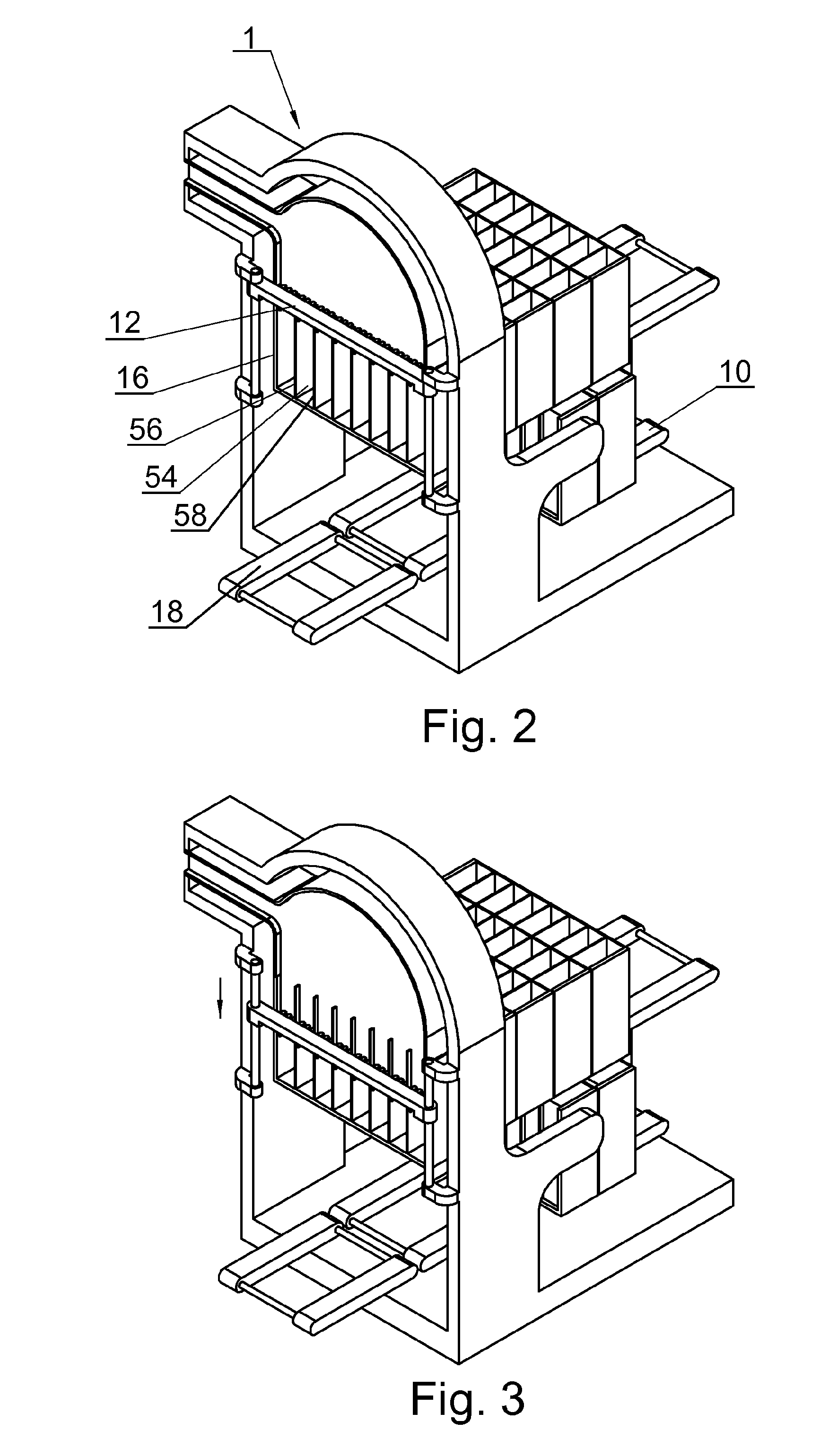

Apparatus and method for making cellular shade material

ActiveCN1824478ALess quantityProcess efficiencyDoor/window protective devicesLamination ancillary operationsEngineering

The invention relates to a device for producing concave cord material, and relative method, wherein said method comprises: supplying one preformed element; transmitting said preformed element along one transmission path; slicing said preformed element into cord plates at the first treating point on the transmission path; coating at least one adhesive line on the cord plate at the second treating point on the transmission path; said second treating point is at the descending of the first treating point; and layering the coated cord plate with other cord plates to form concave structure at the third treating point on the transmission path.

Owner:TEH YOR CO LTD

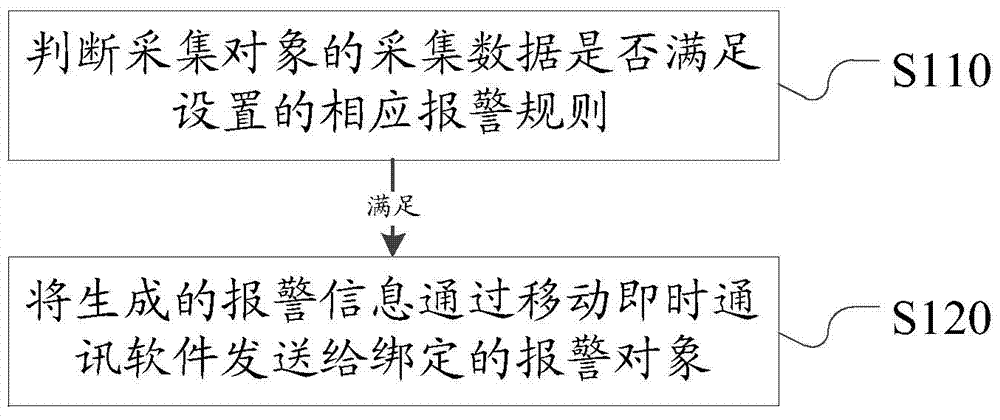

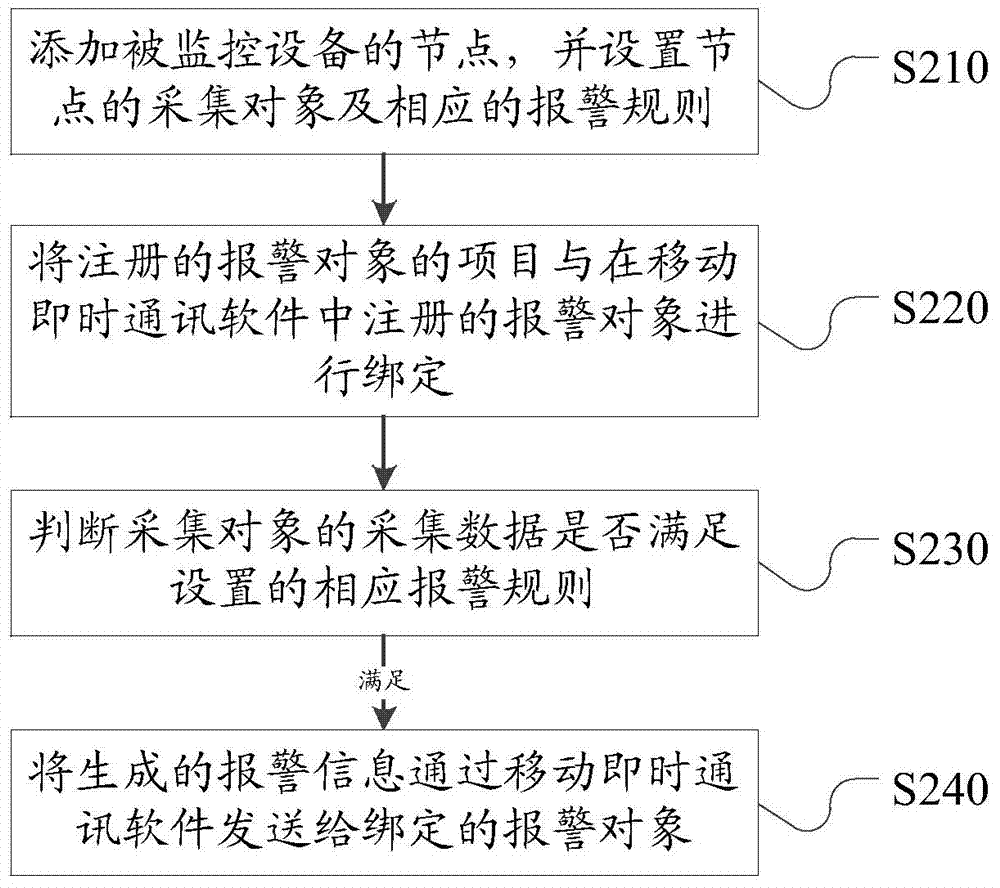

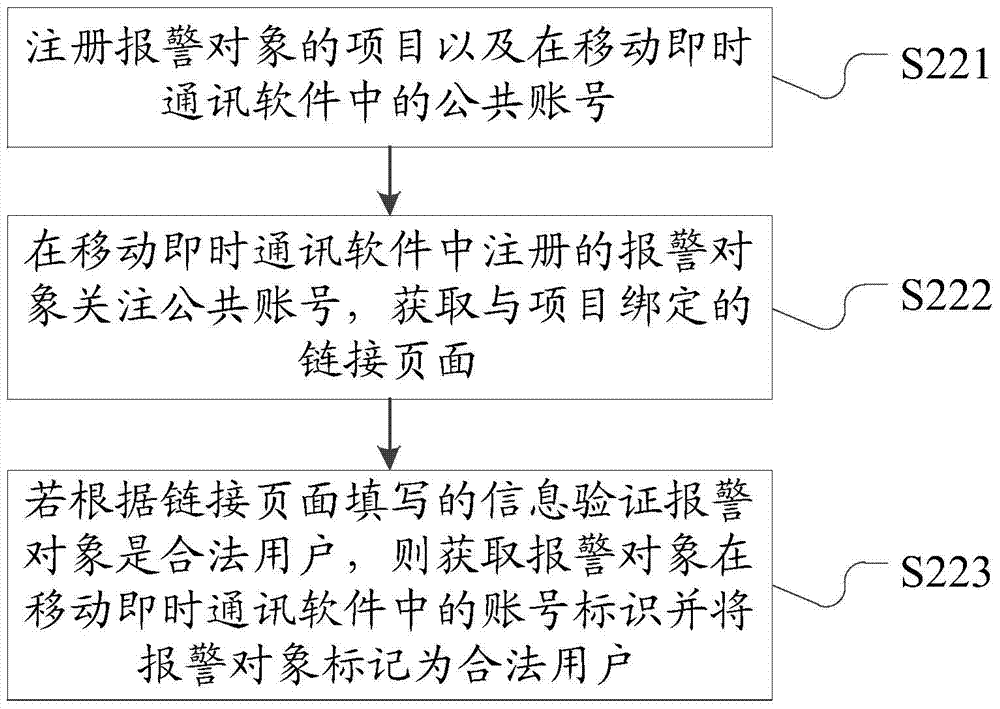

Monitoring alarm method and device

ActiveCN103794033AShort downtimeRealize timely and free notificationAlarmsMonitor equipmentMobile instant messaging

Provided are a monitoring alarm method and device. The method comprises the steps that whether collecting data of a collected object meet set corresponding alarm rules or not is judged, and if the collecting data of the collected object meet the set corresponding alarm rules, generated alarm information is sent to a bound alarm object through mobile instant messaging software; the device comprises an alarm information sending module used for sending the generated alarm information to the bound alarm object through the mobile instant messaging software when the collecting data of the collected object meet the set corresponding alarm rules. According to the monitoring alarm method and device, the alarm information is sent through the mobile instant messaging software, and fault information of monitored equipment can be sent to a system manager in time; timely and free informing of the fault information is achieved through the existing widely-adopted mobile instant messaging software, and development cost is lowered.

Owner:GCI SCI & TECH

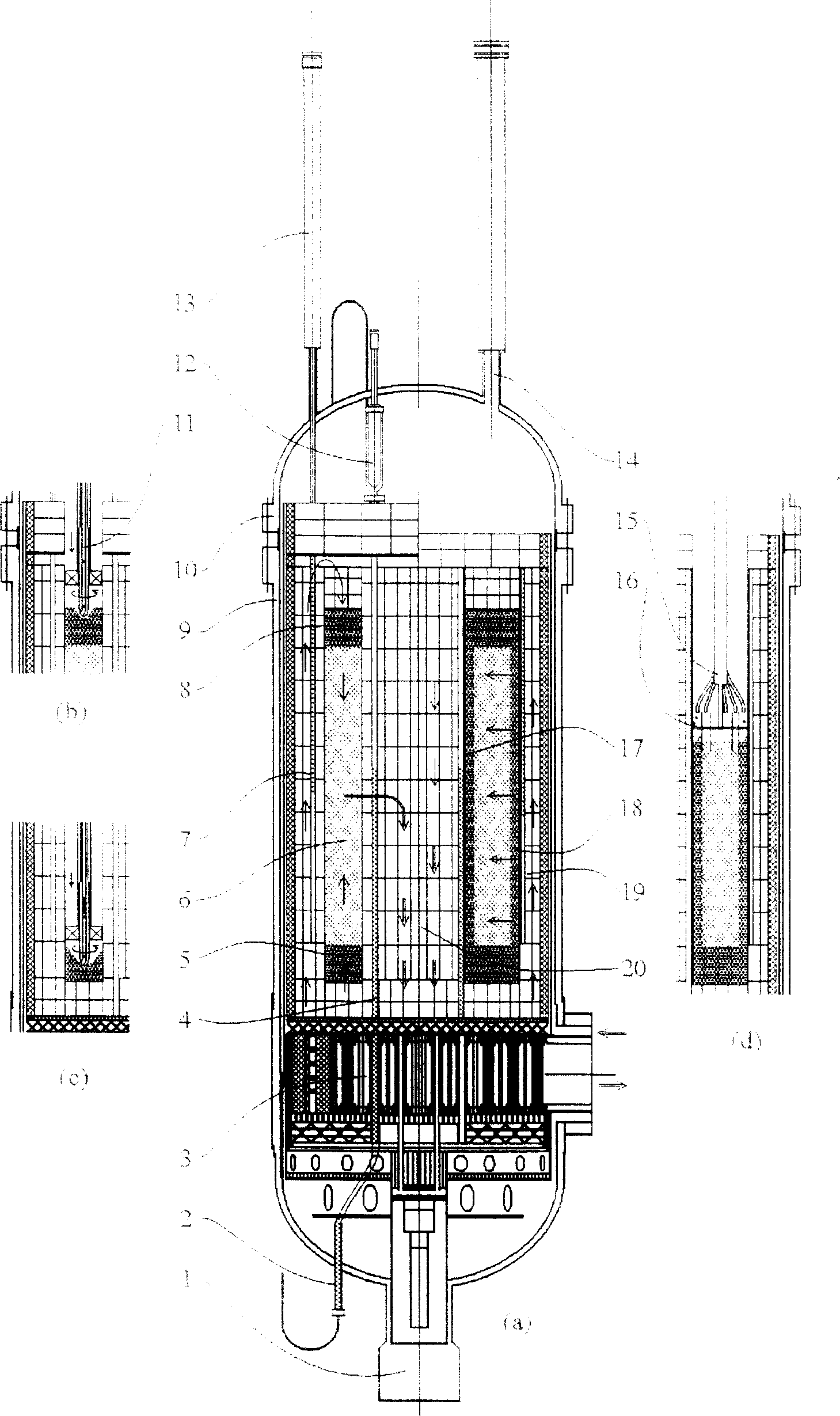

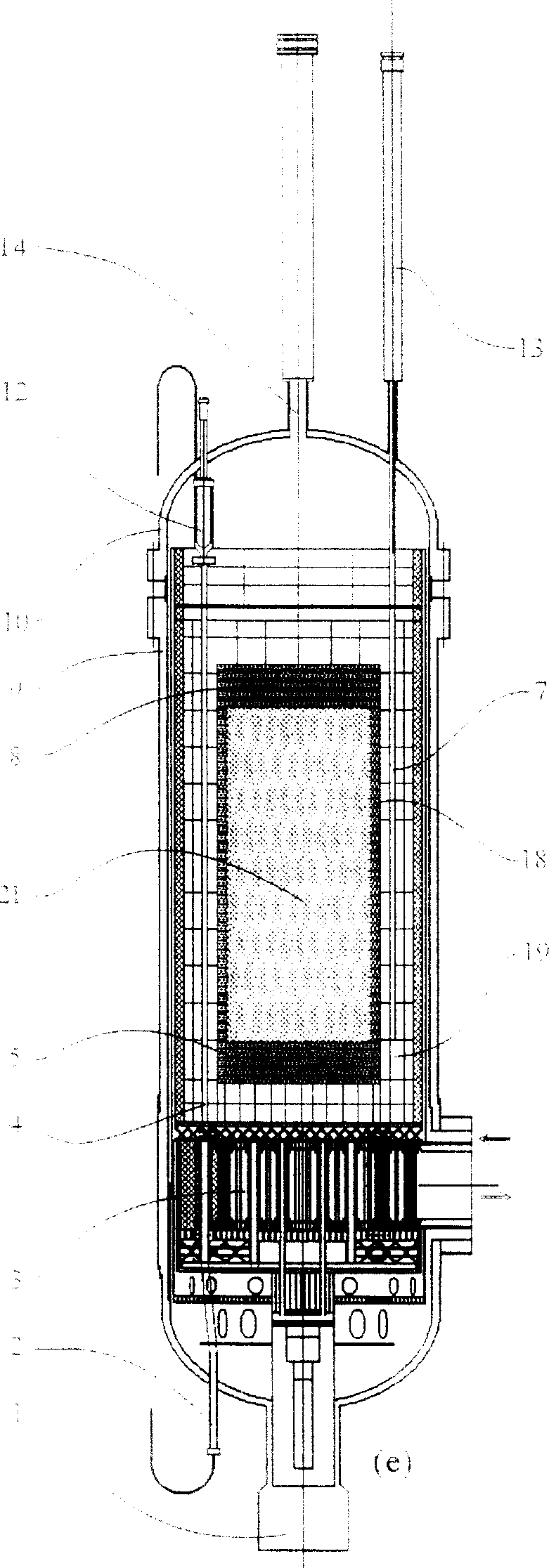

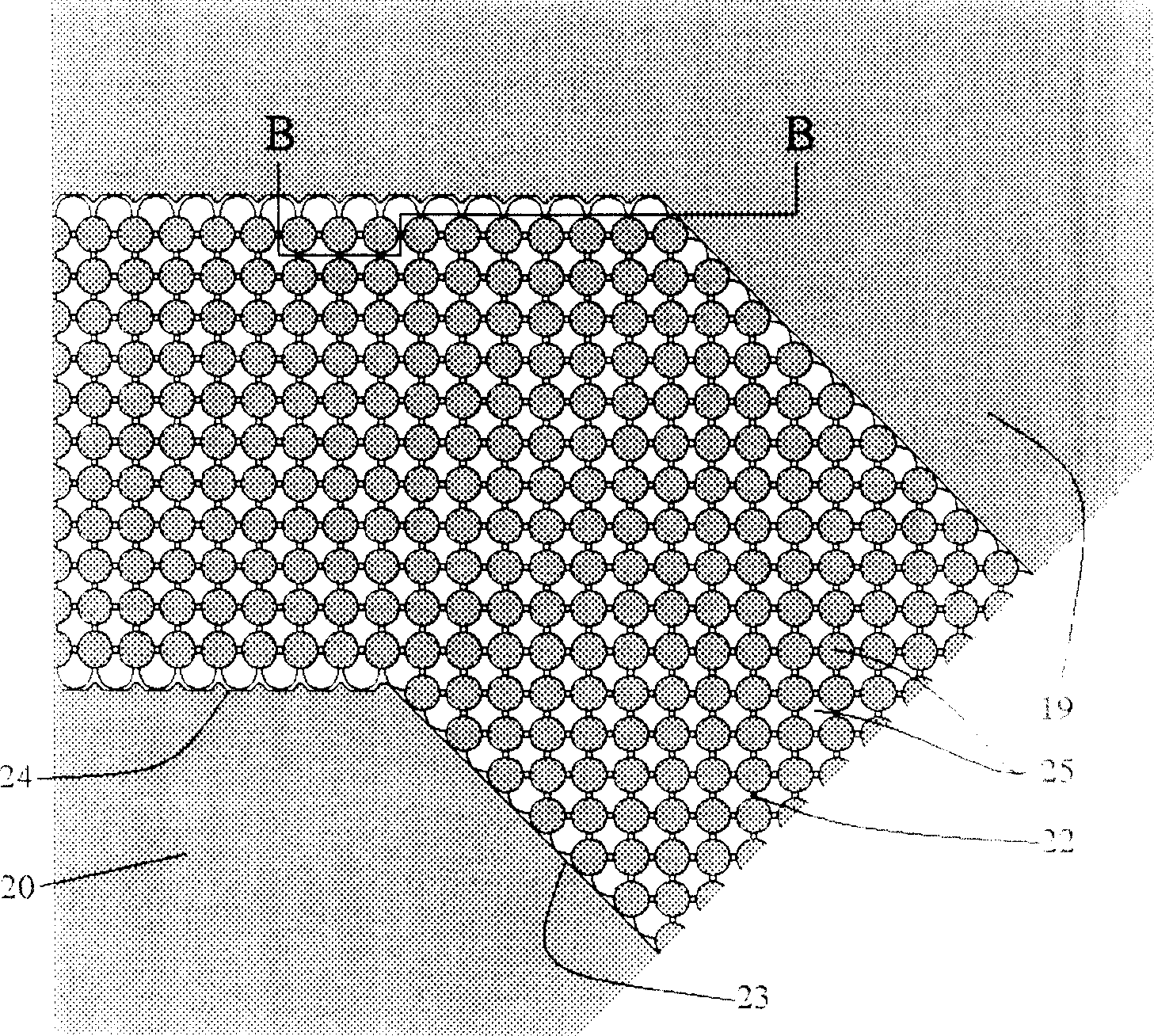

Regular bed modular high temperature gas cooled reactor and its fuel sphere disposal method

InactiveCN1731533AGood powerGood temperatureNuclear energy generationShieldingNuclear reactorGraphite

The invention relates to a rule bed module type high temperature gas-cooled reactor and fuel ball arranging method in the field of nuclear reactor technology. It arranges the helium inside the graphite block reflector. The control rod and the absorbing small ball are position inside the graphite block reflector. The flue ball is quadratic arranged on the level of the graphite block reflector hollow cavity, the center deck of each four balls can be used as the location of the second layer ball so as to form the rule bed with the up end and the down end is graphite block reflector.

Owner:田嘉夫

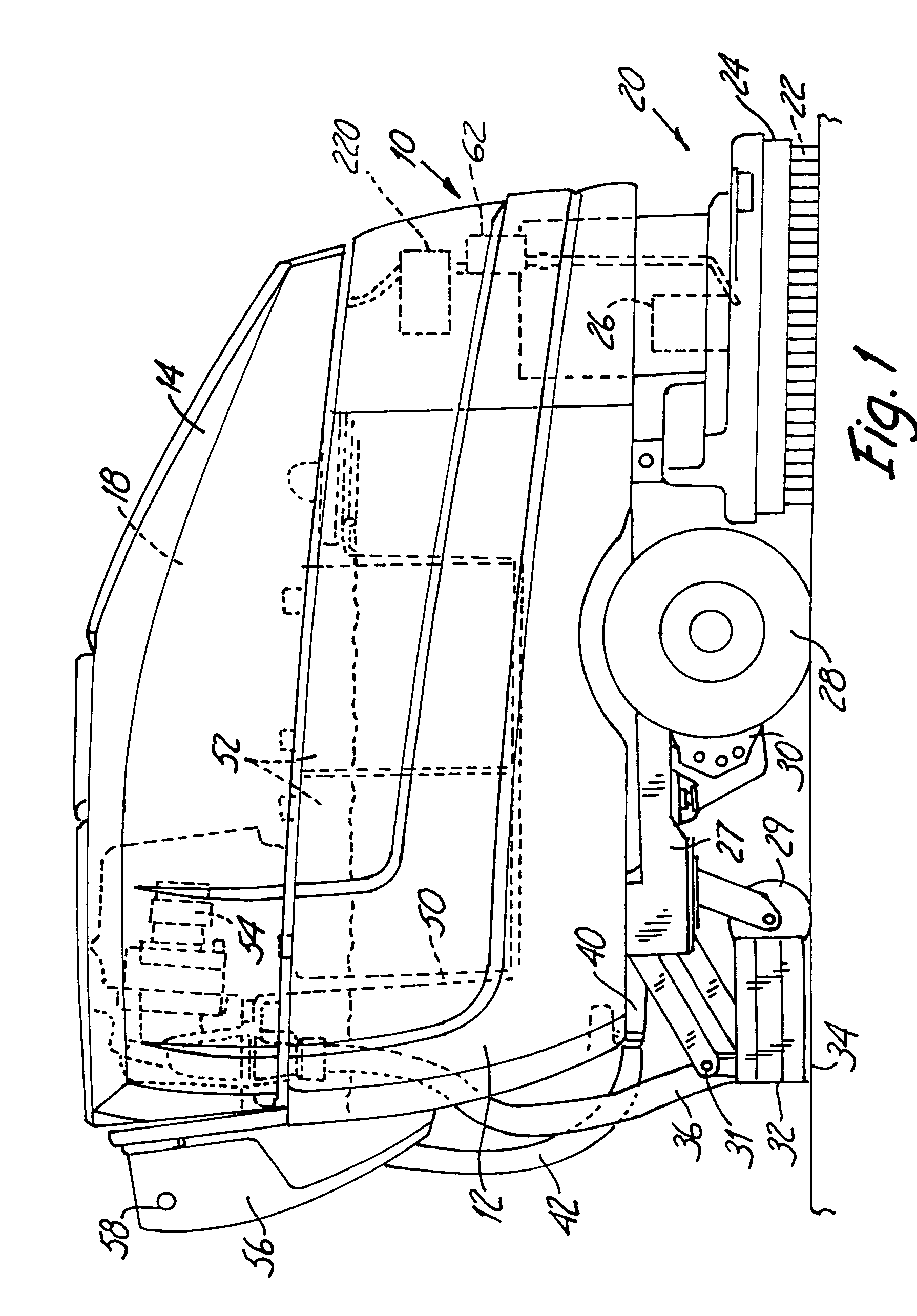

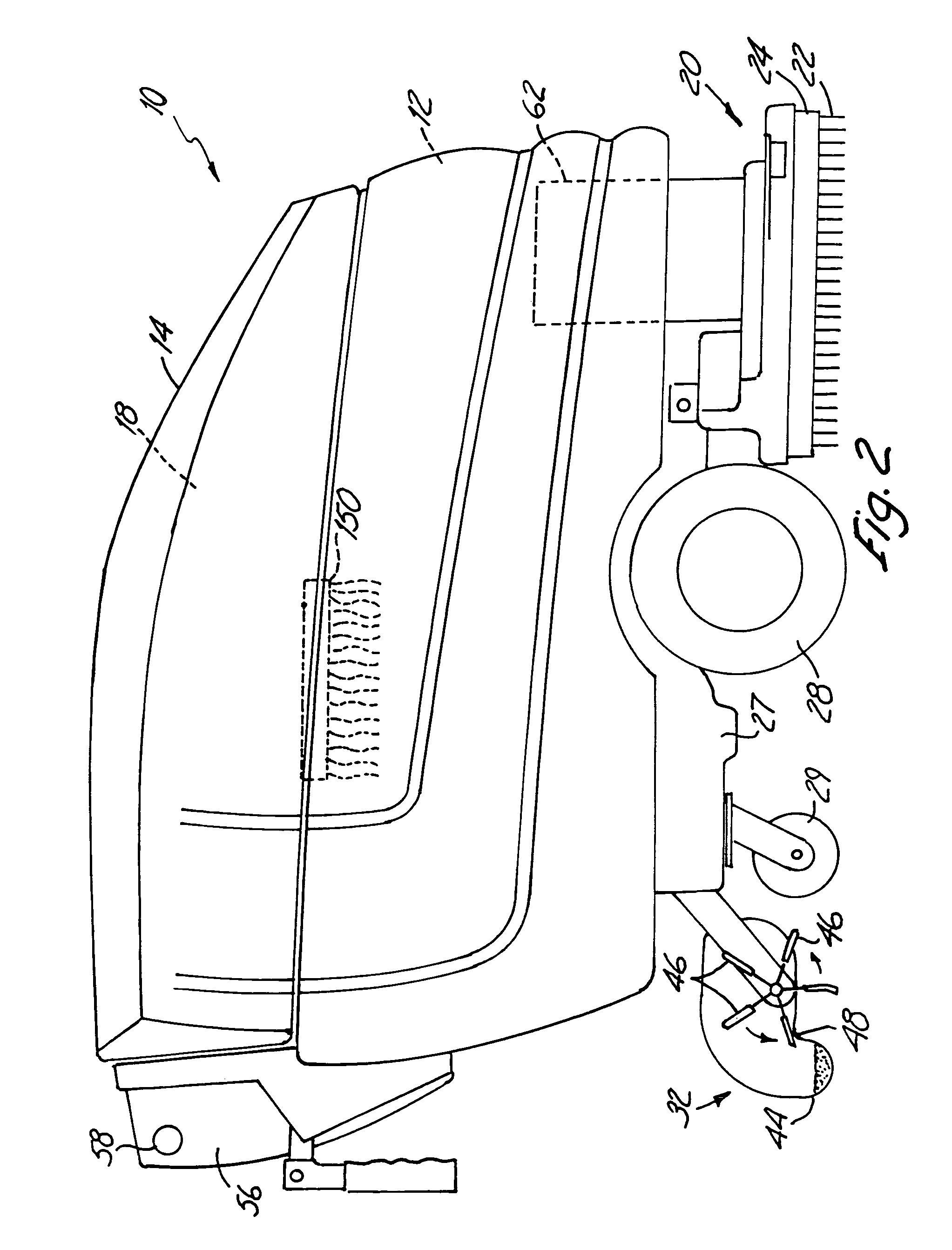

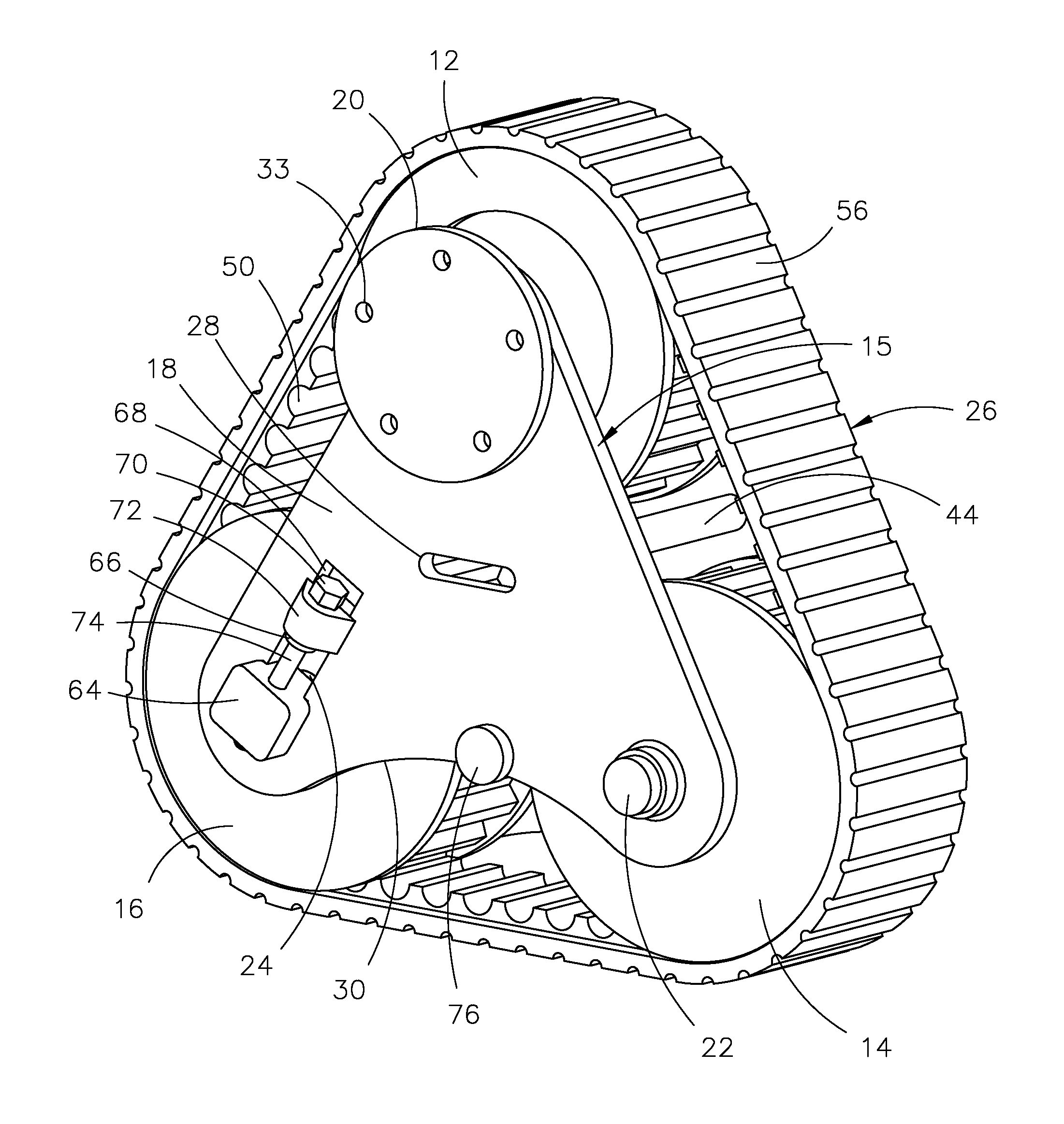

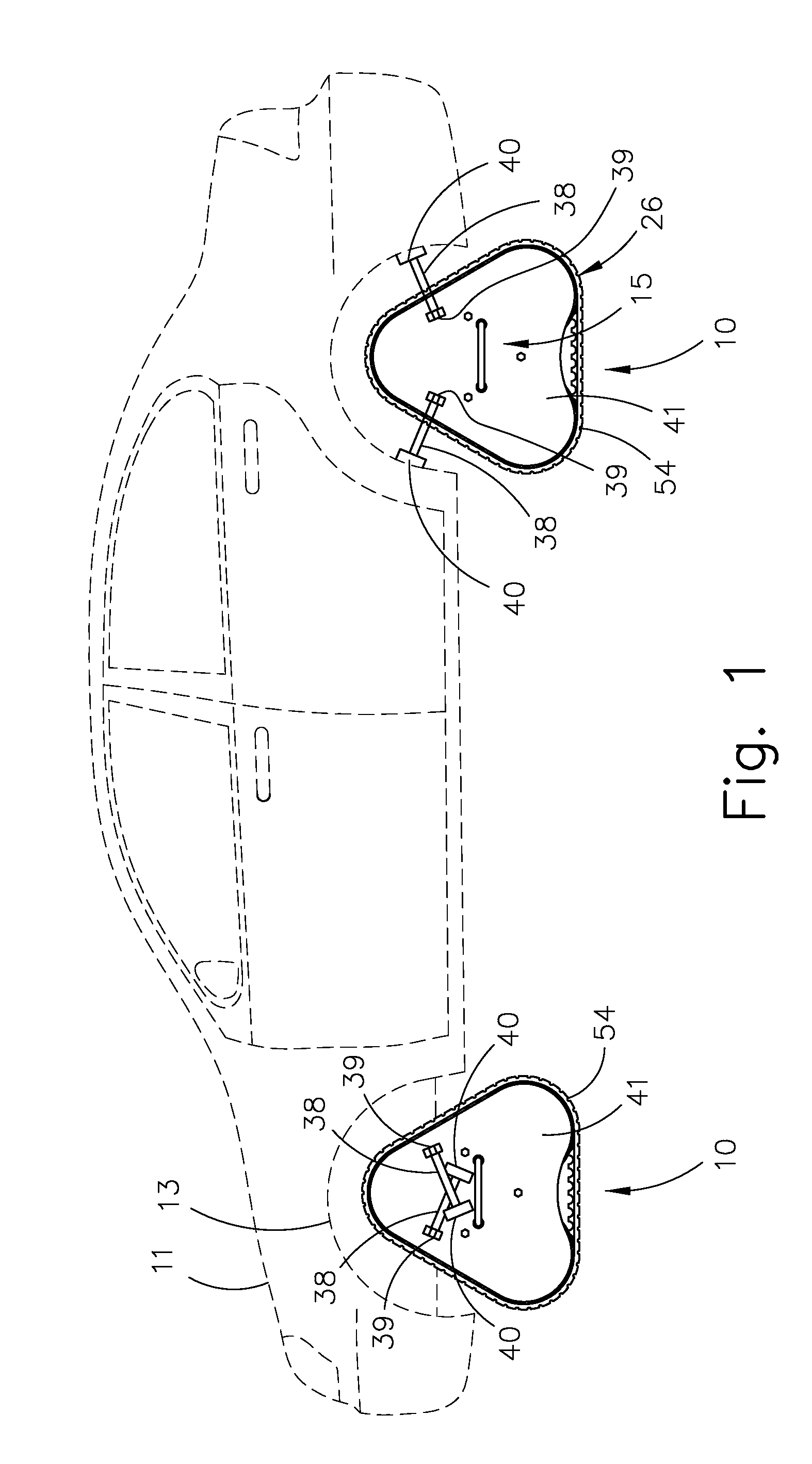

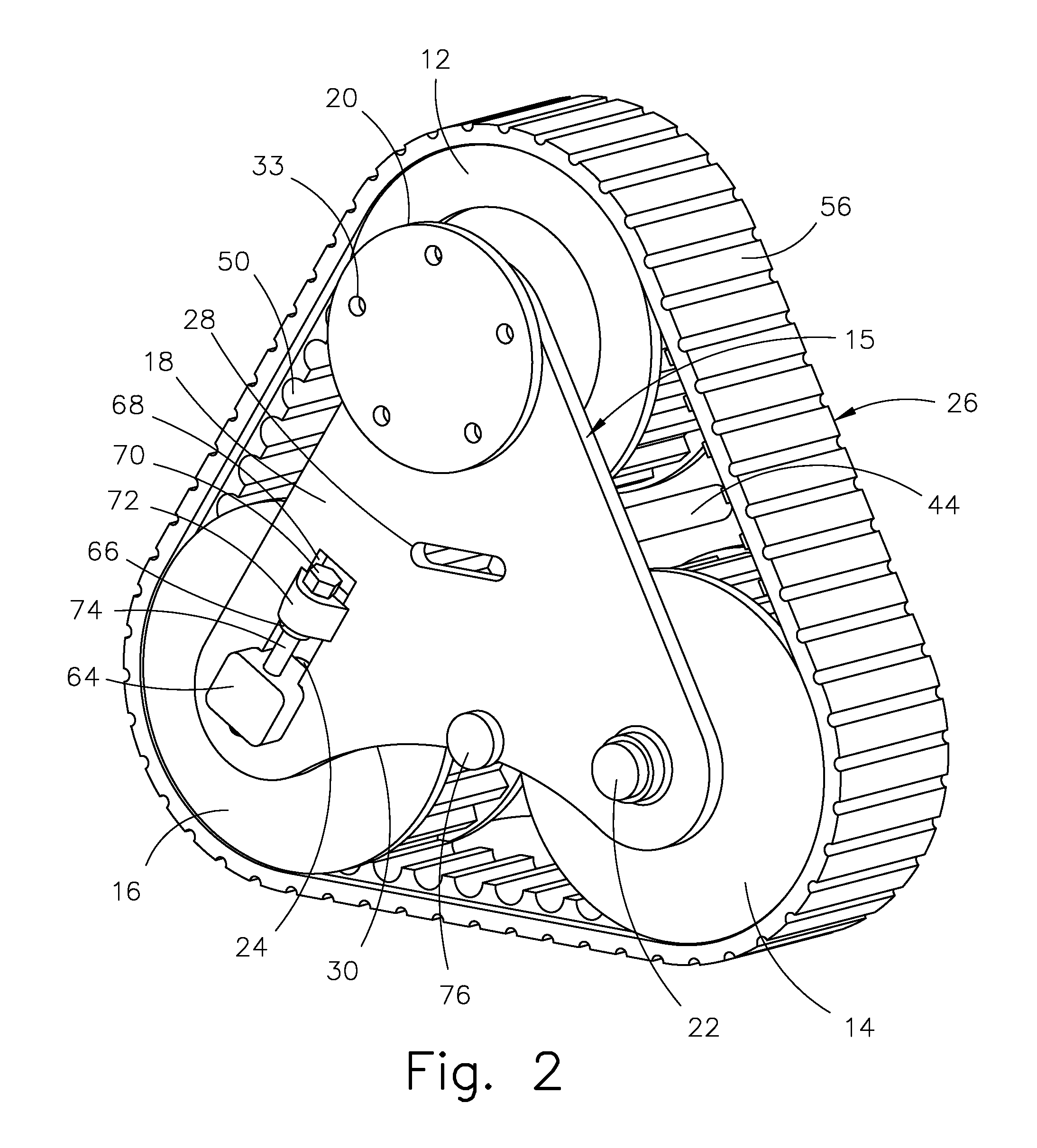

Triangle Track Vehicle Wheel

A triangular continuous track device is disclosed for direct replacement of a conventional tire and wheel combination found commonly on cars, trucks and other vehicles. A hub on the device is provided for direct bolt onto vehicles with a standard wheel bolt pattern. A track tensioning feature allows the track to be installed or repaired without removing the device from the vehicle. Grooves on the wheels are provided that engage with ribs on the inside of the track to efficiently transfer power from a power wheel in direct communication with the vehicle's axle to the two bottom idle wheels. The two idle wheels are centered under the power wheel and are held in ground contact by the weight of the vehicle. Other features as shown and disclosed are also provided.

Owner:AFANADOR ANGELO

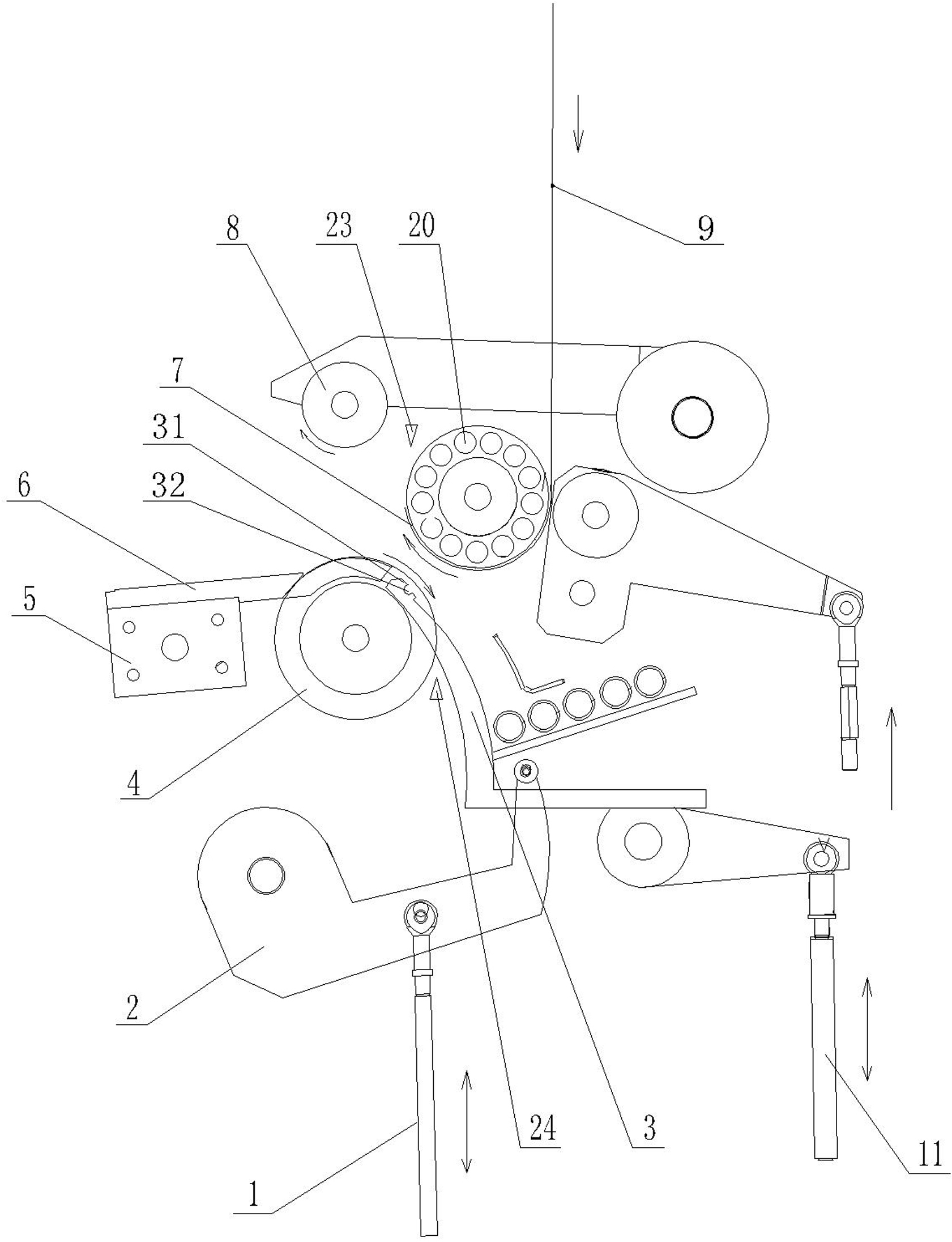

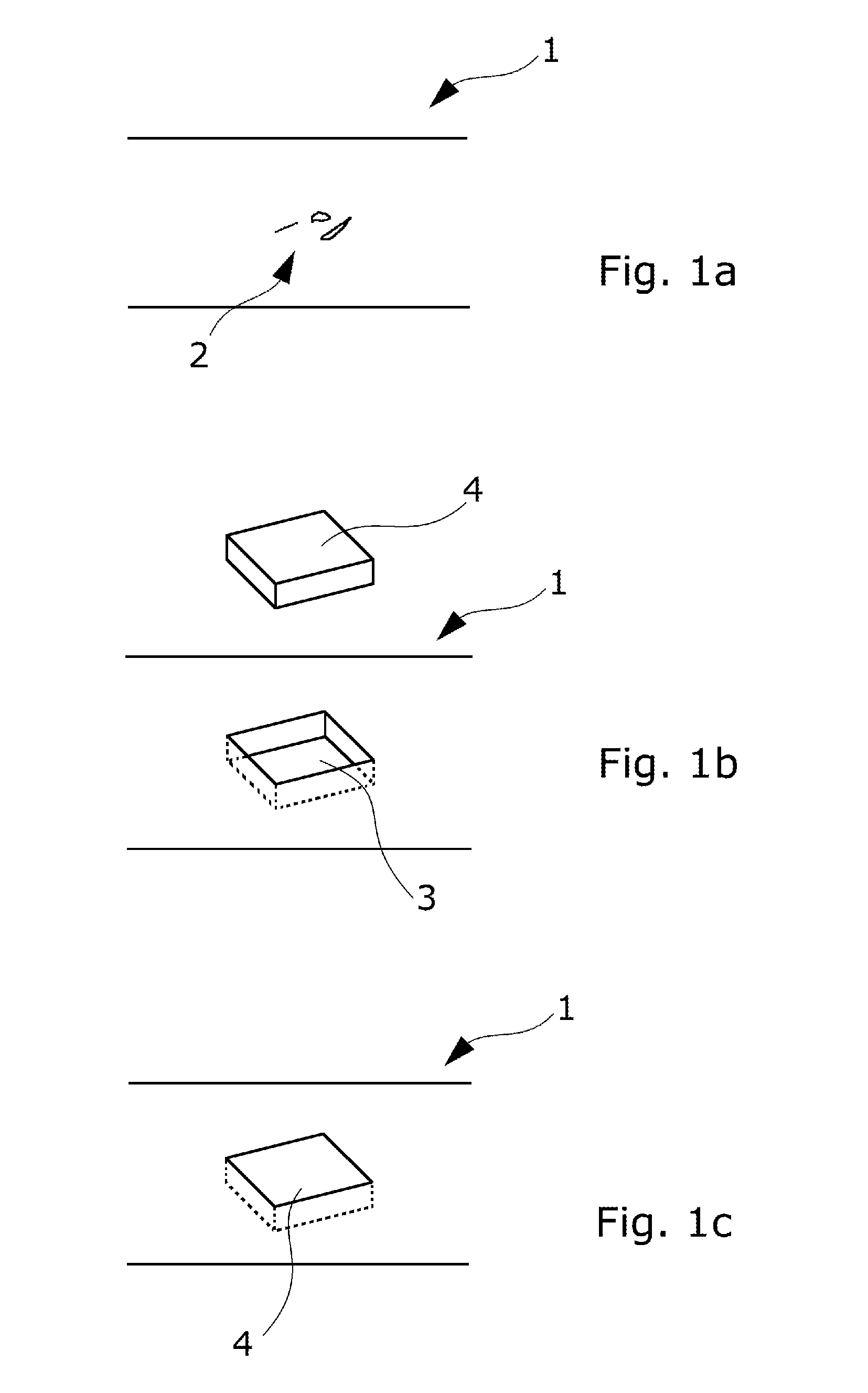

Method and device for replacing objective parts

InactiveUS20090260654A1Short downtimeAvoid introducingPhotomechanical apparatusElectrostatic cleaningIndustrial engineeringAtmosphere

A method and a device for replacing objective parts, especially of a projection or illumination objective for microlithography in which an objective having an objective interior and objective parts provided therein is provided. At least one objective part is replaceably accommodated in the objective. Immediately prior to installation in the objective, the replaceable objective part is cleaned outside the objective interior in at least one cleaning room sealed off from the ambient atmosphere. Immediately after cleaning, the replaceable objective is installed in the objective without contact with the normal ambient atmosphere.

Owner:CARL ZEISS SMT GMBH

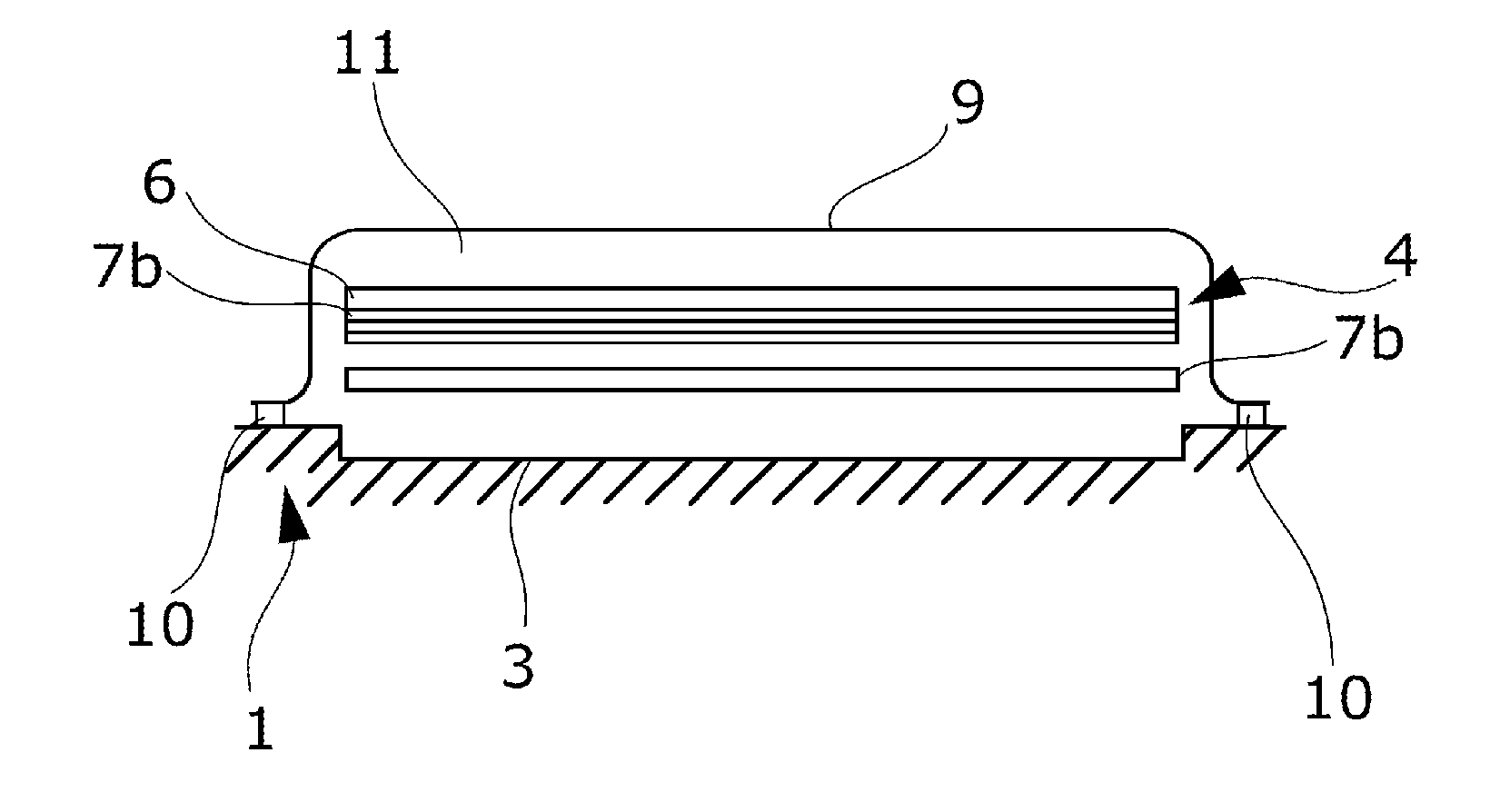

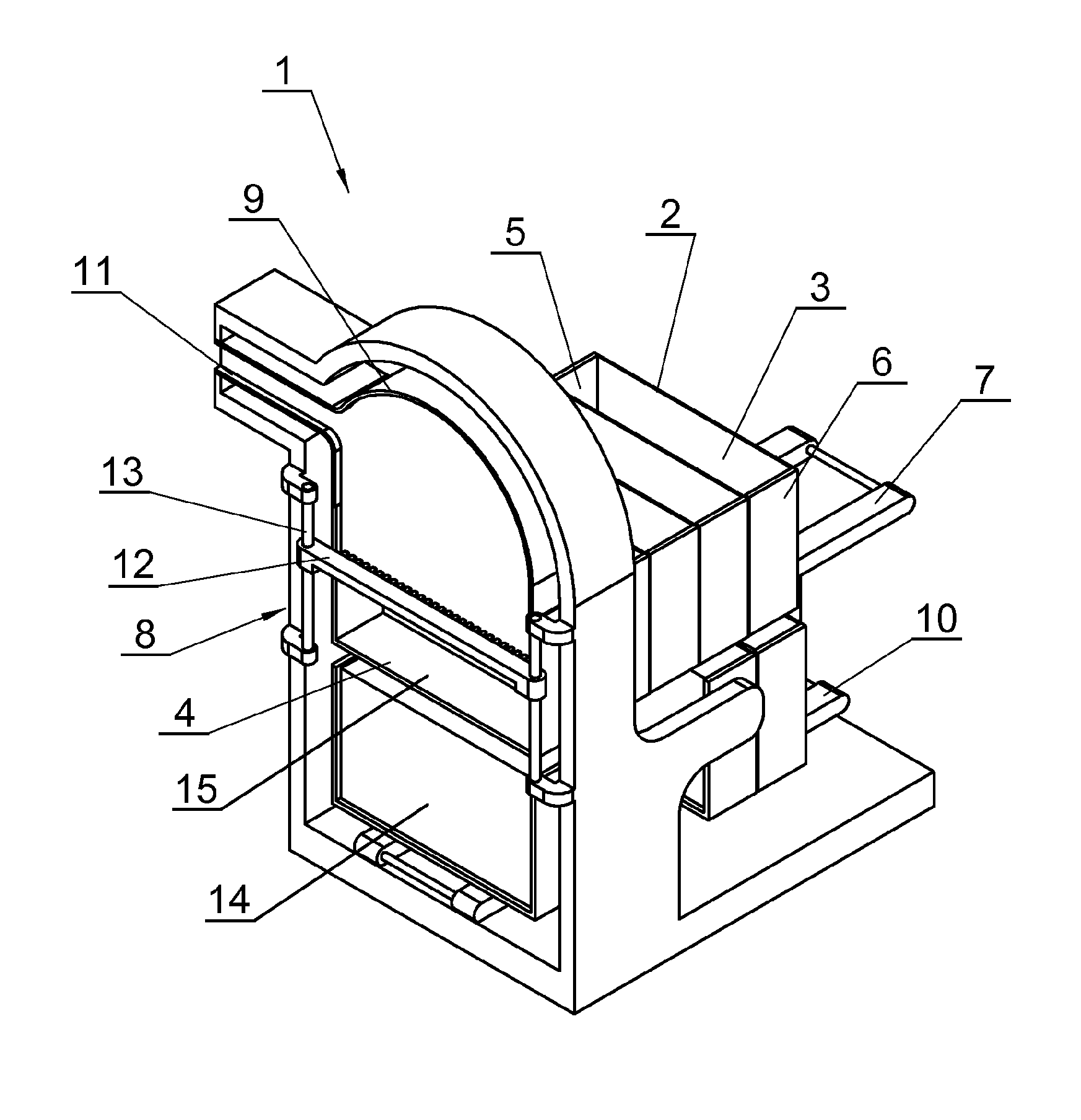

Apparatus for filling a cavity, filling station and method of filling a cavity

InactiveUS8662088B2Minimize the numberSimple mechanical structureTobacco treatmentPackaging cigaretteGravitationFill device

Apparatus and method for filling under gravity from a hopper (9), a storage device (2) for articles that has the form of a columnar cavity between opposed side walls with a mass flow of mutually parallel rod-shaped articles descending from the hopper, a cavity-filling device (12) that alternates in use between a closed configuration that blocks a downward flow of the said articles through the device and an open configuration that allows flow of the articles through the device, the device being movable in translation, in alternate upward and downward strokes within the cavity, being in the closed configuration on the downward stroke and in the open configuration on the upward stroke.

Owner:INT TOBACCO MACHINERY POLAND

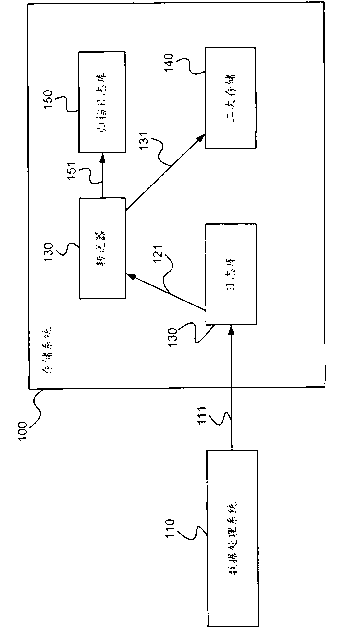

Data storage and backup system and method

InactiveCN102750196AEnhanced write functionImprove performanceRedundant operation error correctionData processing systemDowntime

The invention provides a data storage method for a data processing system. The data storage method comprises the following steps of: defining a local storage of the data processing system as a logging library; storing data in the logging library in a logging way; transmitting the data from the logging library to a forwarder; and transmitting the data to a secondary storage from the forwarder. By the adoption of the system and the method, the write operation function of a low-performance storage device is enhanced by utilizing a logging mechanism. When the system and the method are applied to backup, the performance of the overall system is improved obviously when the system is used for backup, and the backup system extends to another place easily; and moreover, when the storage of a production system fails, the storage system provided by the invention can be switched to a production mode and the service can be provided within a shortest downtime.

Owner:DALIAN ZHAOYANG SOFTWARE TECH

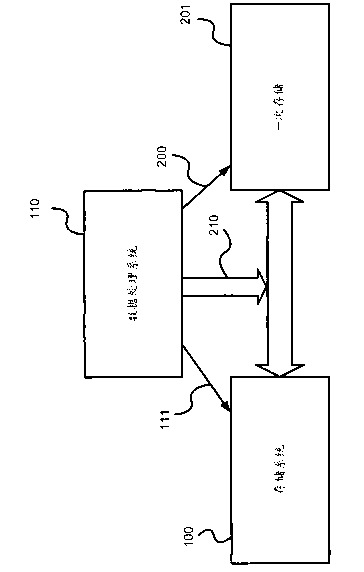

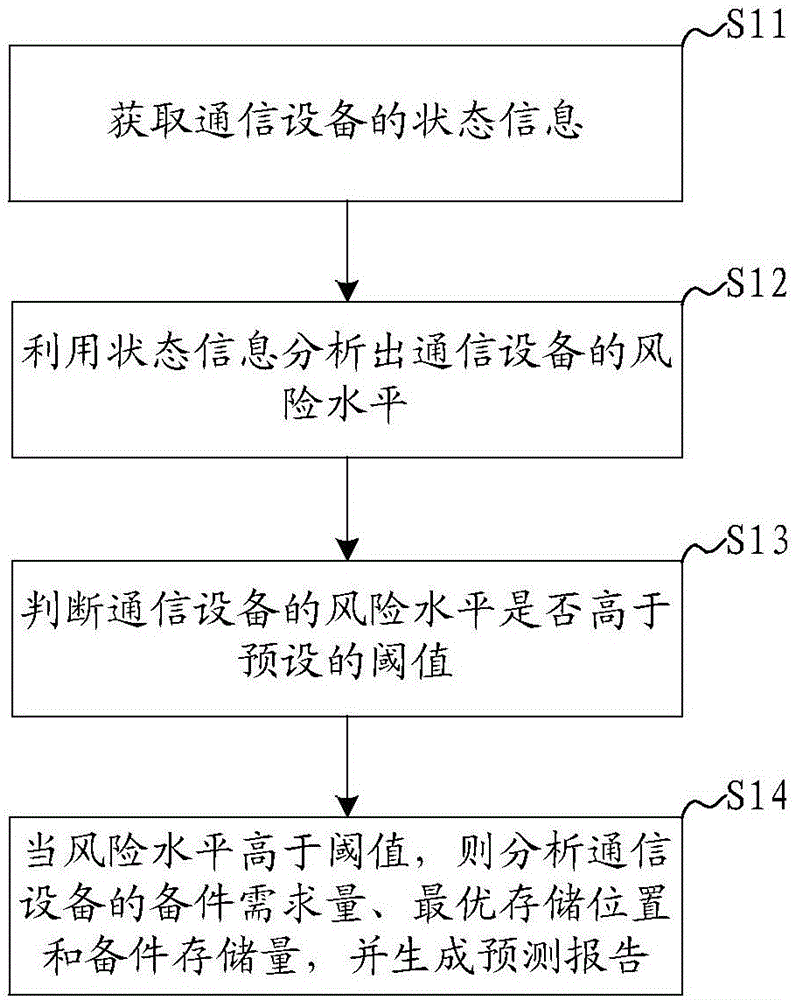

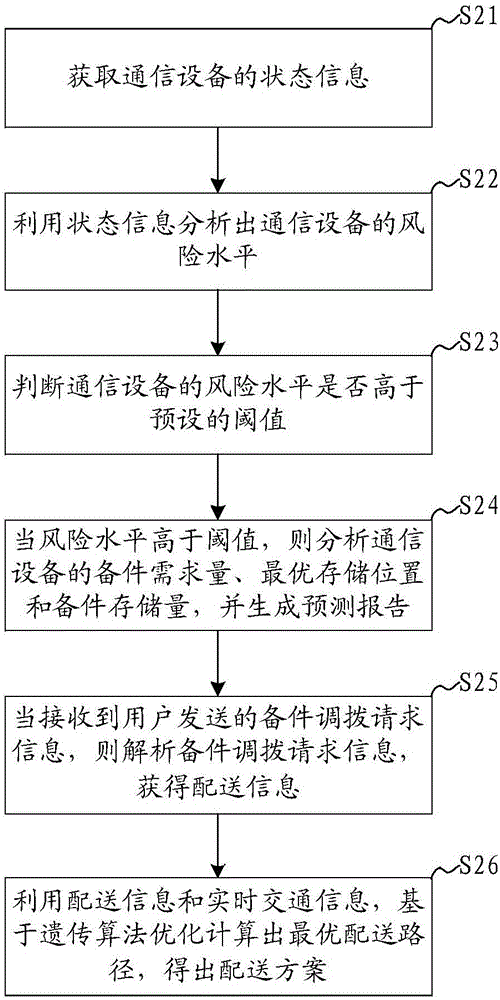

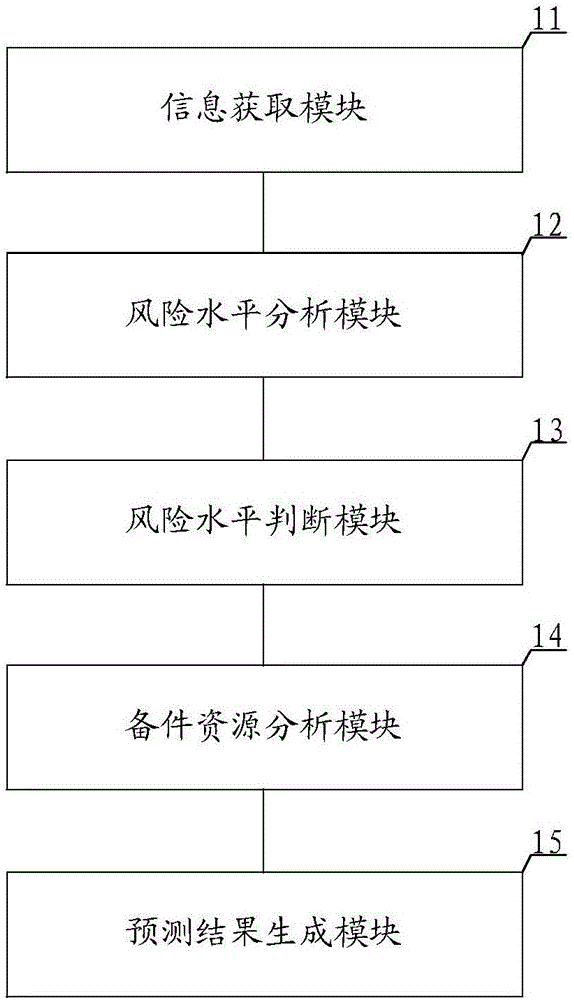

Method and device for whole-network integrative dynamic deployment of electric communication spare part resources

InactiveCN106845678AOperational Risk Level ControlShort downtimeForecastingLogisticsInformation analysisEngineering

The invention discloses a method for whole-network integrative dynamic deployment of electric communication spare part resources. The method comprises the following steps of: obtaining state information of communication equipment; analyzing a risk level of the communication equipment by utilizing the state information; judging whether the risk level is higher than a preset threshold value or not; and when the risk level is higher than the threshold value, analyzing a spare part quantity demanded, an optimal storage position and a spare part storage quantity of the communication equipment, and generating a prediction result. According to the method, the risk level of the communication equipment is previously analyzed by utilizing the state information of the communication equipment before the communication equipment malfunctions, and if the risk level of the communication equipment is higher than the preset threshold value, the prediction result is generated by the communication equipment, so that the users can prepare for the upcoming faults or communication equipment asset returning in time by utilizing the prediction result, and the operation and maintenance loss caused by the faults is lightened. Moreover, the invention correspondingly discloses a device for whole-network integrative dynamic deployment of electric communication spare part resources.

Owner:STATE GRID CORP OF CHINA +1

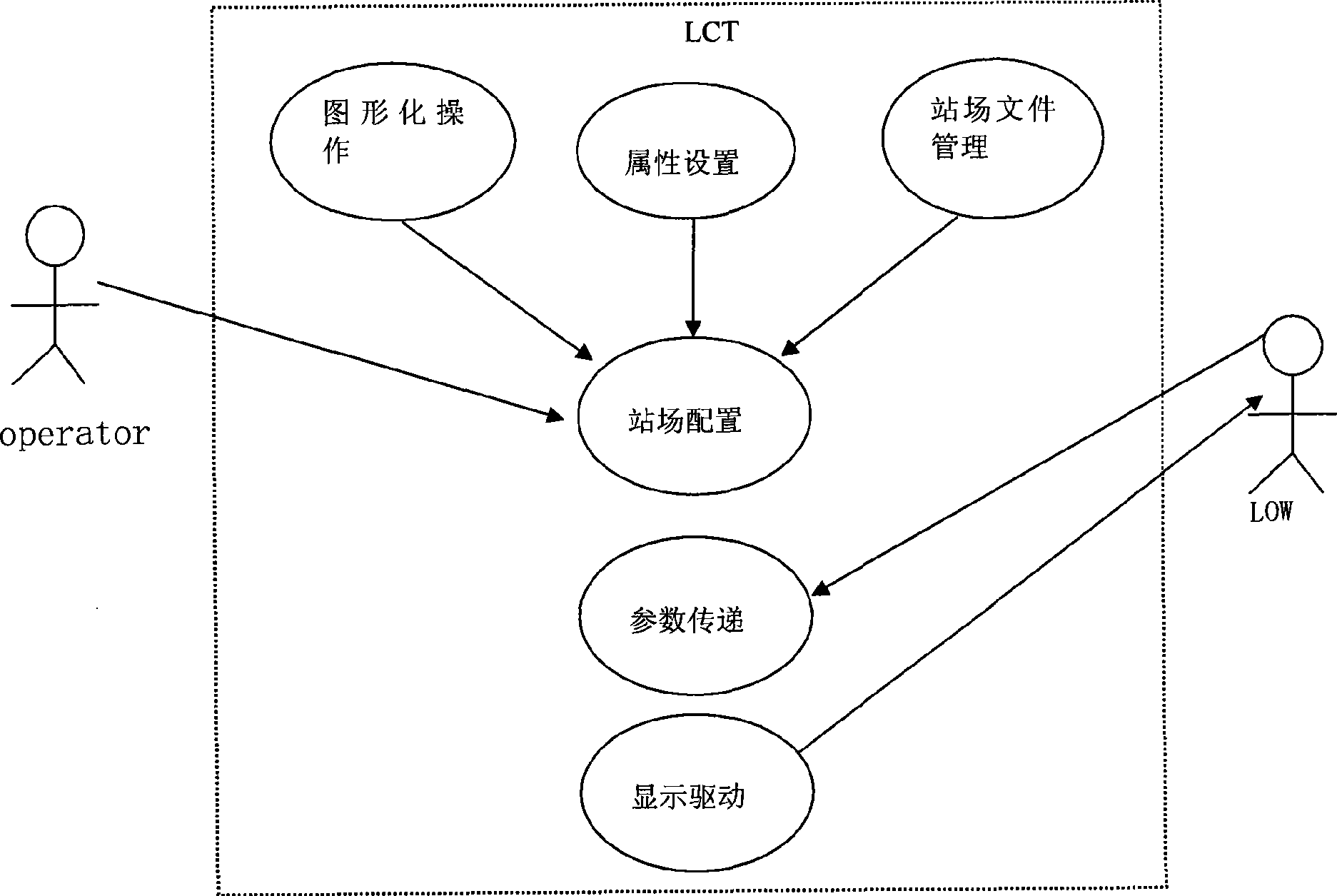

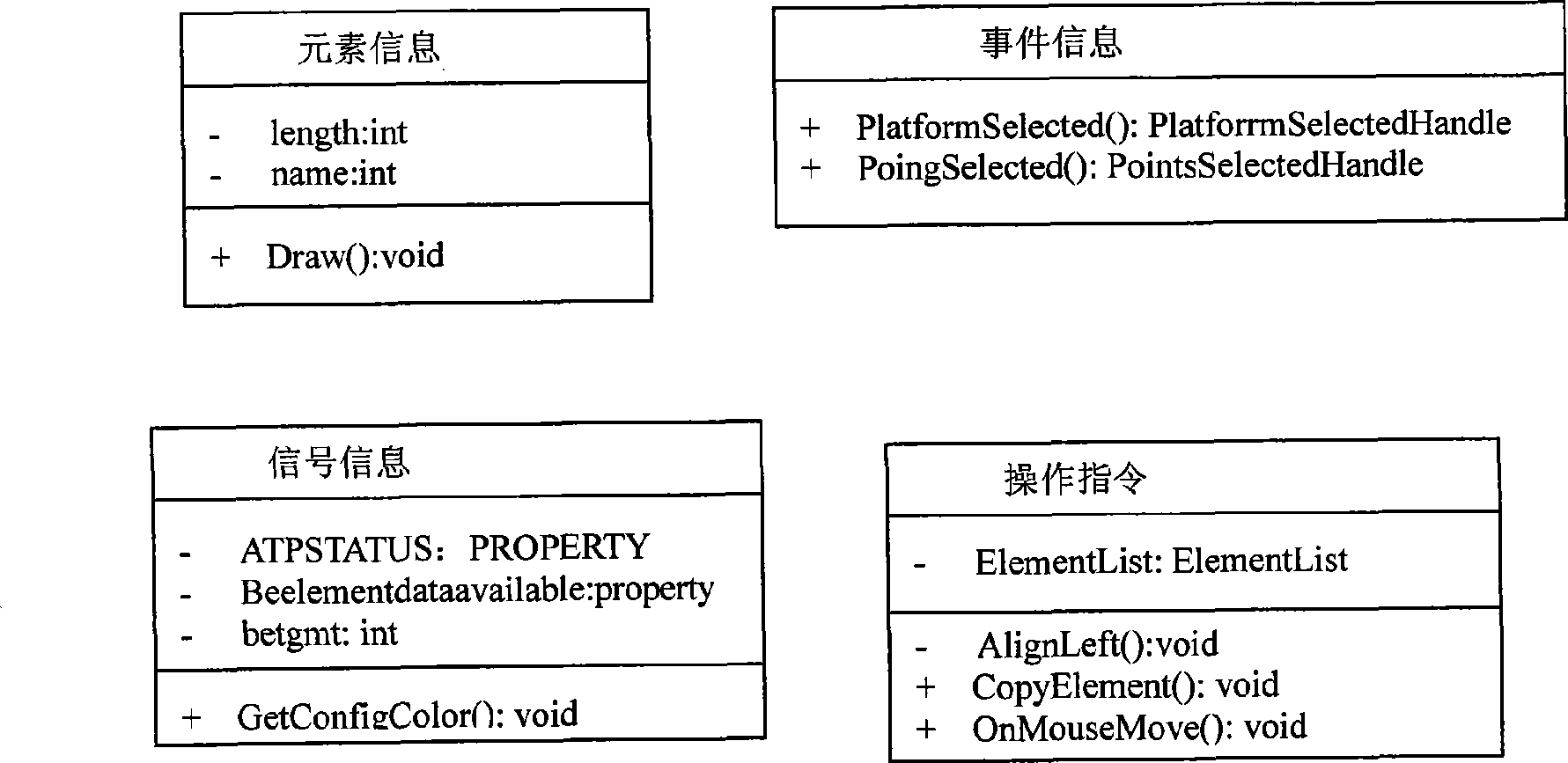

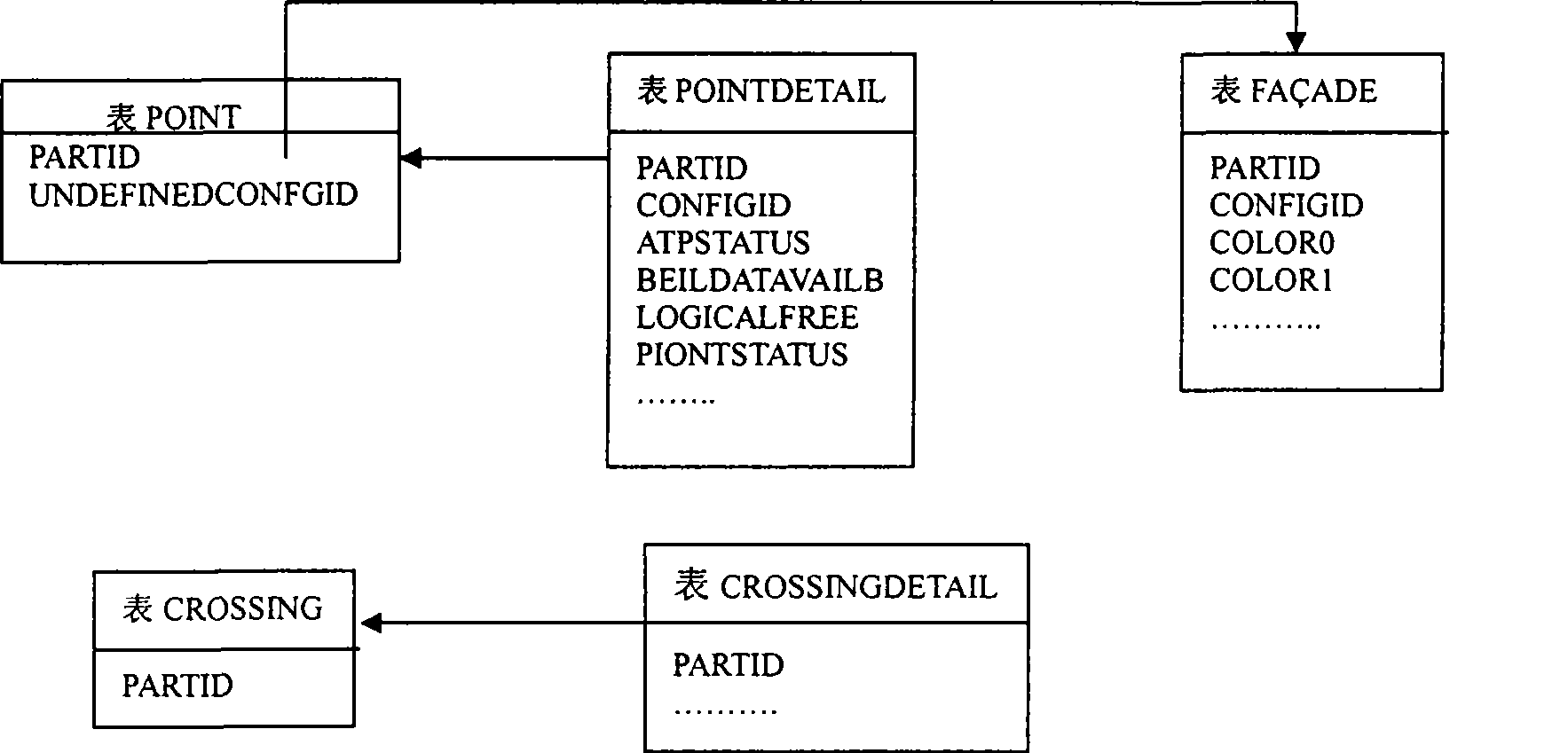

Line allocation tool implementing method based on rail traffic

ActiveCN101441570AFlexible designEasy to installSpecific program execution arrangementsFiltrationSignal element

The invention provides a method for realizing a line configuration tool based on track traffic, which comprises: establishing a database according to signal elements of a station yard and related attributes of the signal elements; establishing color files according to the signal elements of the station yard and the related attributes of the signal elements; designing the station yard according to a station running chart; operating and storing station yard files; and calling and driving the station yard files, wherein a LOW receives the signal attribute transmitted by an interlock system and utilizes the line configuration tool to search color display of corresponding parts, and a color display interface of the LOW displays colors to operators in the station yard. The method for realizing the LCT realizes functions such as loading of the station yard files, display of the station yard, user interaction, amplification and display of the station yard, and display and filtration of the station yard, and achieves the aims of beautiful appearance and conciseness of a display interface. Moreover, due to extensible requirements of the LCT on the signal elements and the display colors, convenience is provided for the LCT to truly reflect the status of field devices in urban track traffic.

Owner:NANJING NRIET IND CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com