Flexible machining production line based on numerically-controlled machine tools

A CNC machine tool and flexible processing technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of being unsuitable for the normal operation of small and medium-sized enterprises, the inability to integrate and utilize CNC machine tools, and the high cost of flexible production lines, so as to shorten the clamping of workpieces Time and tool setting time, machine downtime is short, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

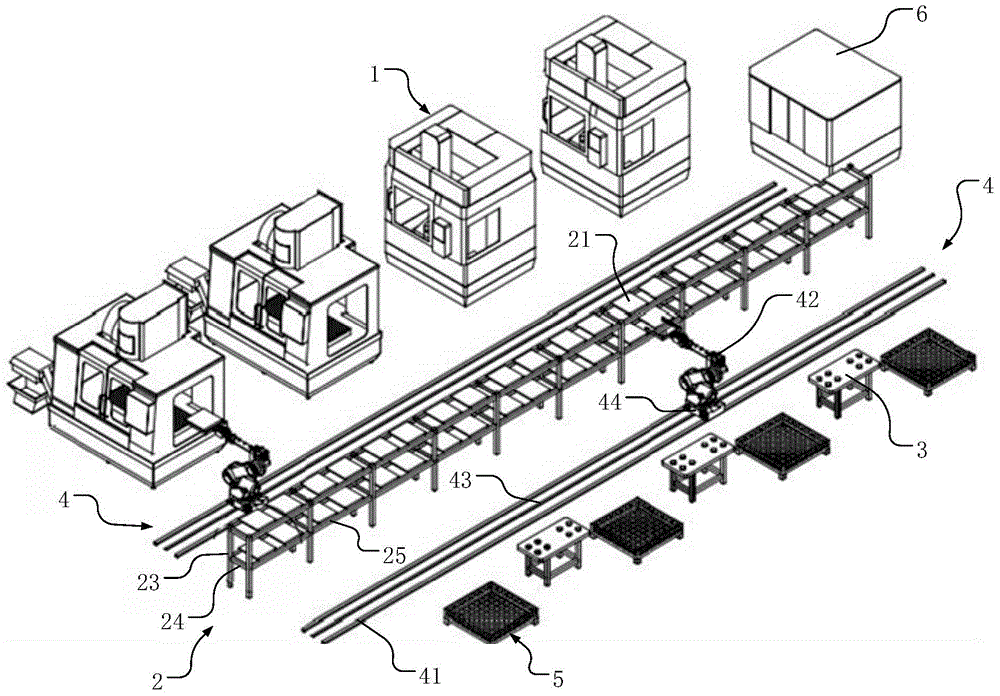

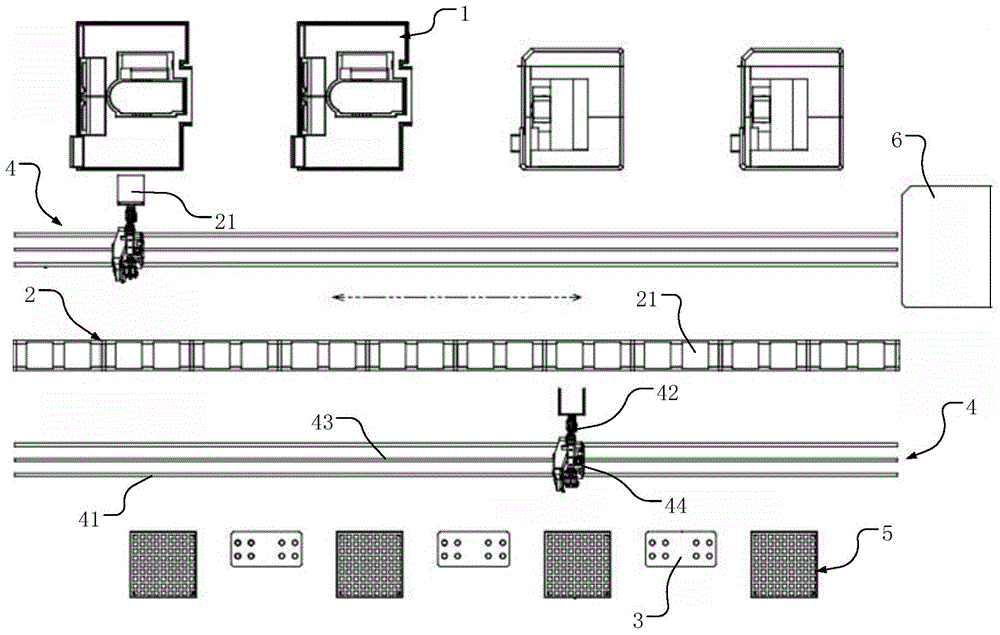

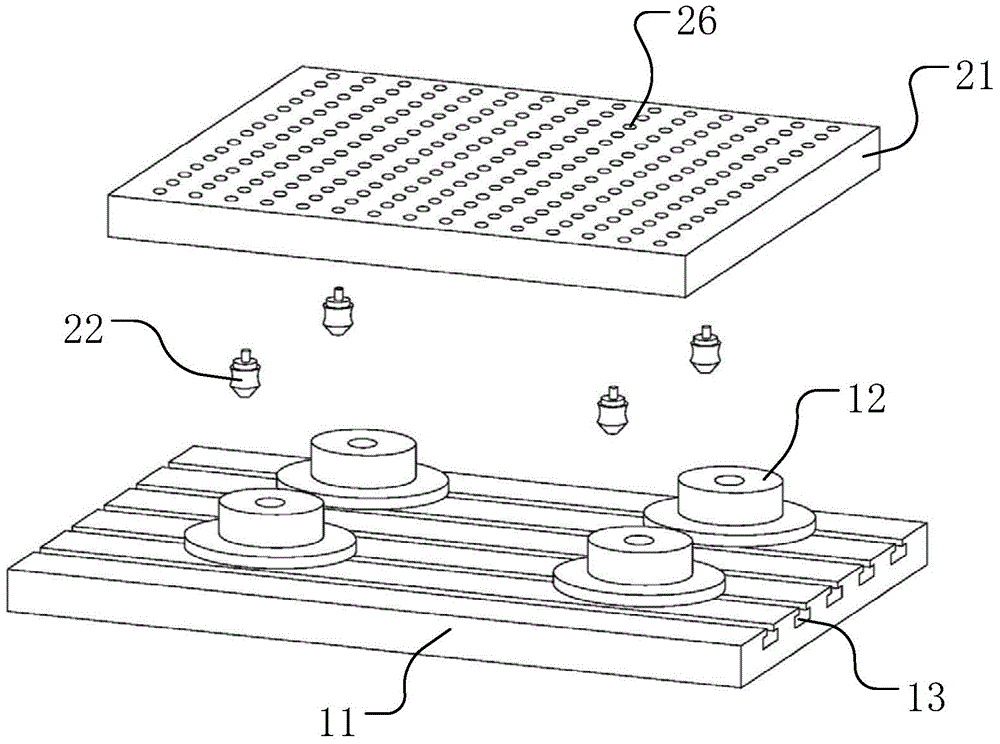

[0022] Embodiment 1: The present invention provides a flexible processing production line based on CNC machine tools, which includes several CNC machine tools 1, a three-dimensional tooling warehouse 2, several workpiece replacement tables 3 and two groups of handling units 4, wherein the several CNC machine tools 1 can be It is any one or several of the vertical machining centers, horizontal machining centers and CNC grinding machines among the existing machine tools of the enterprise. On both sides of the three-dimensional warehouse 2, two groups of the handling units 4 are respectively arranged between the tooling three-dimensional warehouse 2 and the plurality of numerically controlled machine tools 1 and the plurality of workpiece changing stations 3; image 3 As shown, at least two zero point locators 12 are provided on the workbench 11 of the several numerically controlled machine tools 1 (the zero point locators 12 preferably use the link " http: / / www.goepe.com / apollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com