Patents

Literature

1021results about How to "Reduce setup time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

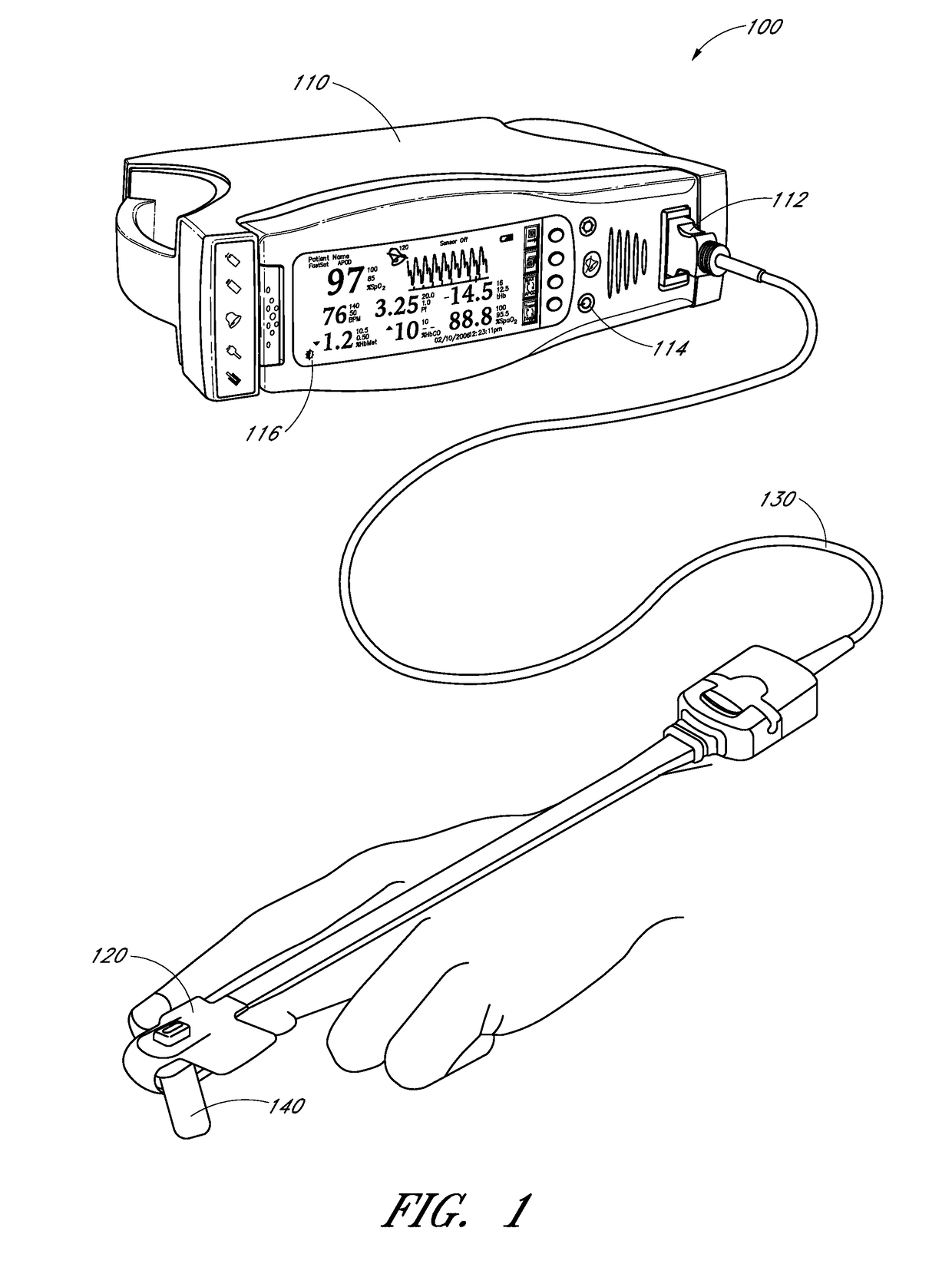

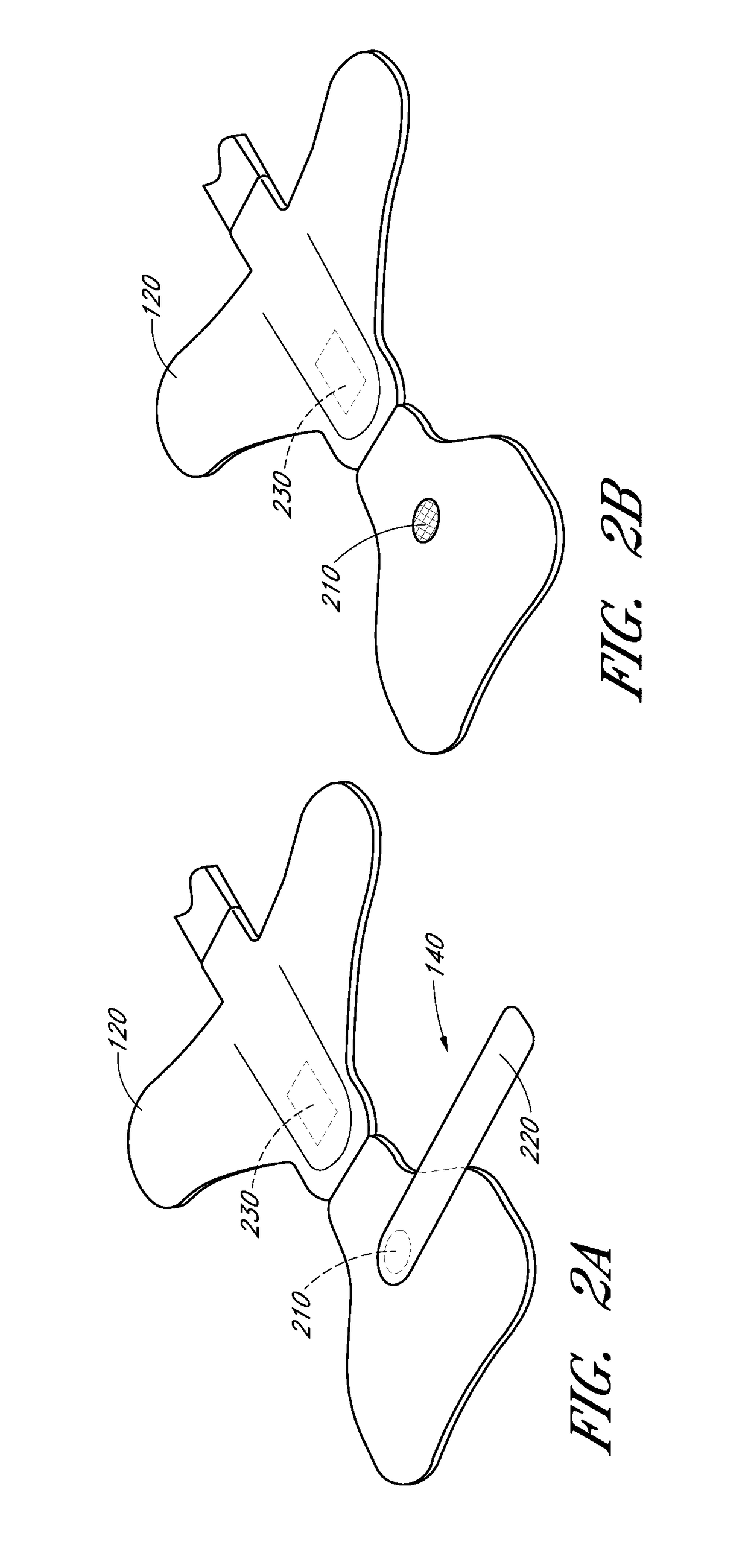

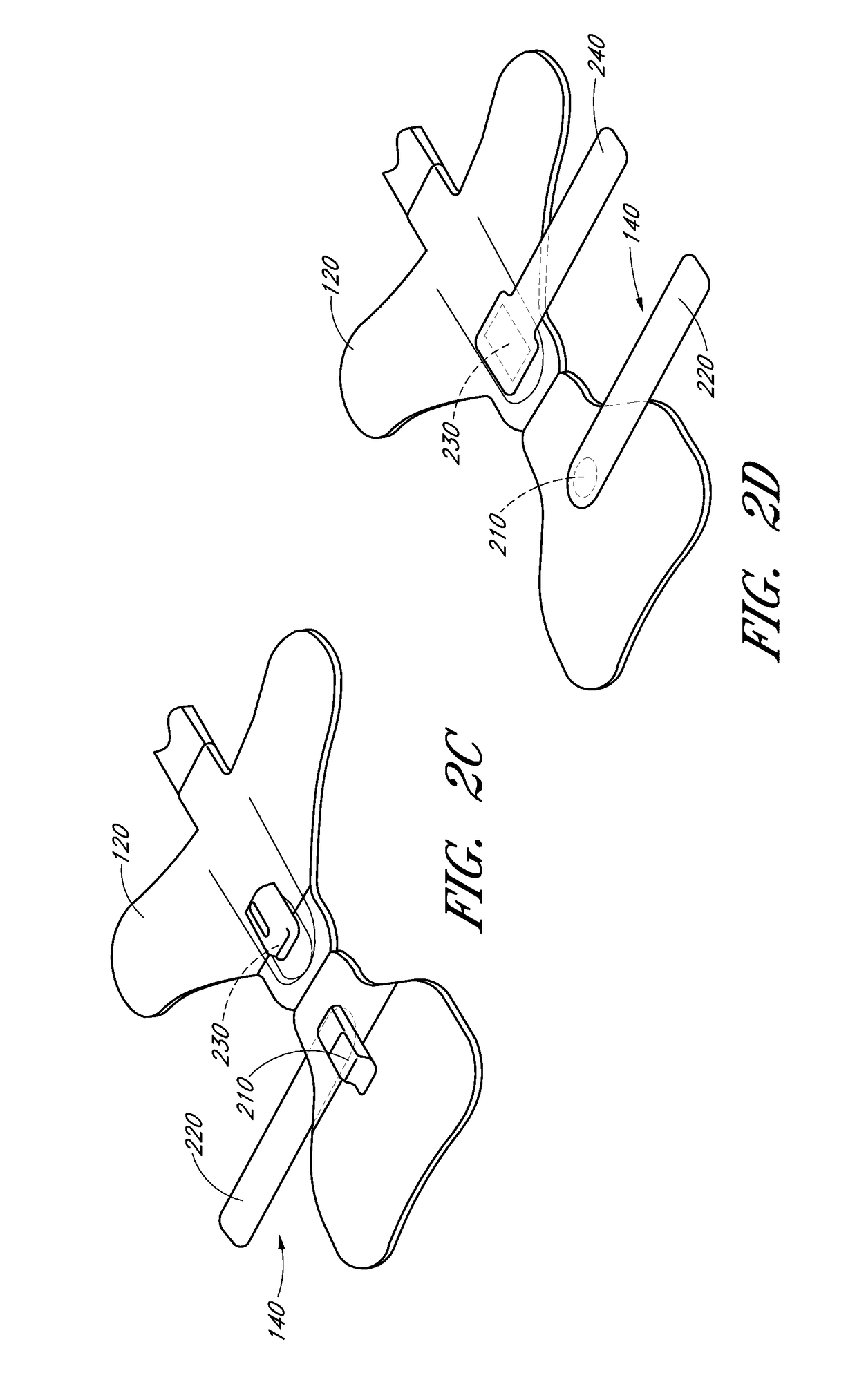

Non-invasive physiological sensor cover

ActiveUS8473020B2Reduce setup timePrevents and reduces false readingCatheterDiagnostic recording/measuringPulse oximetryEngineering

Owner:MASIMO CORP

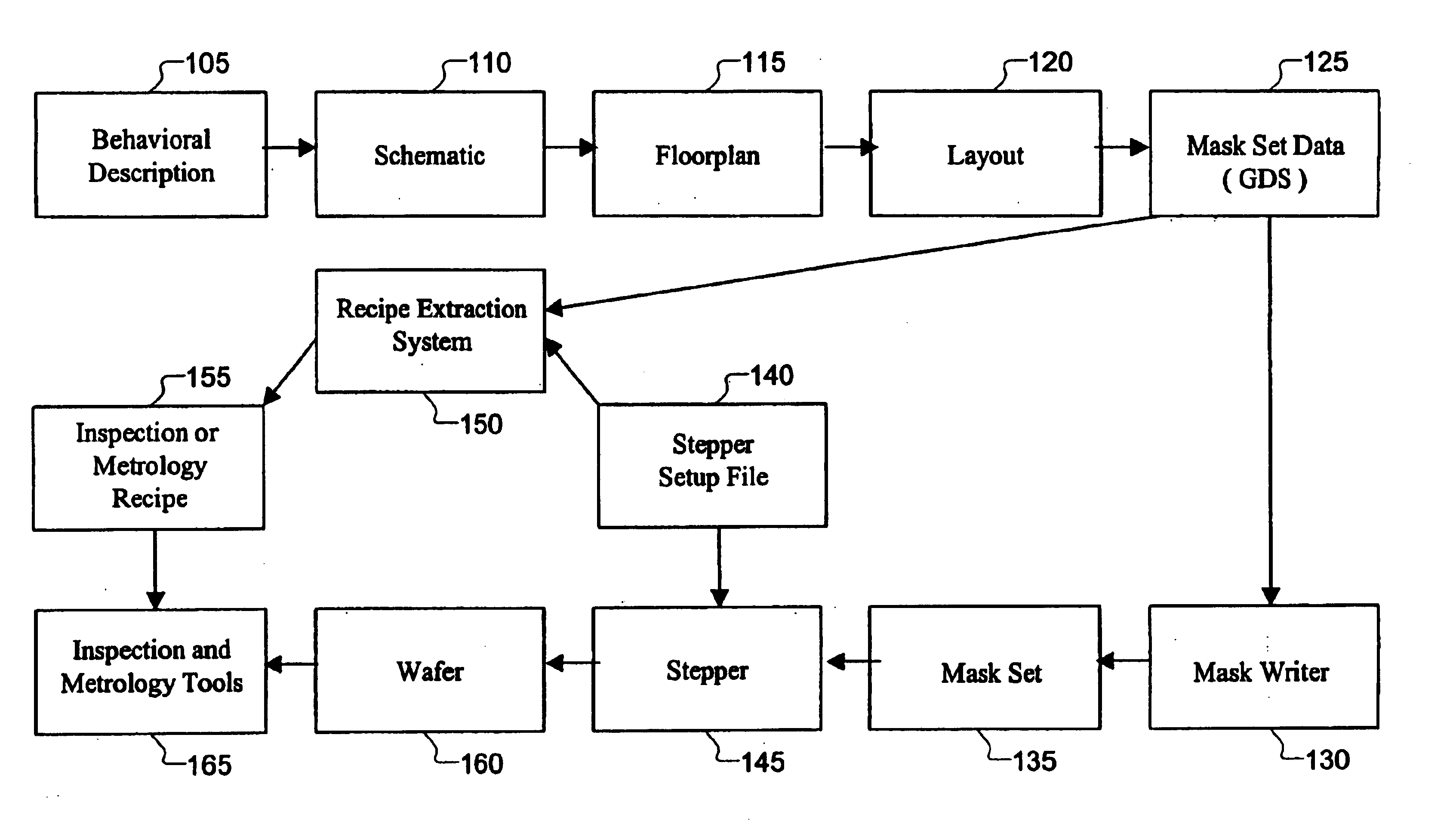

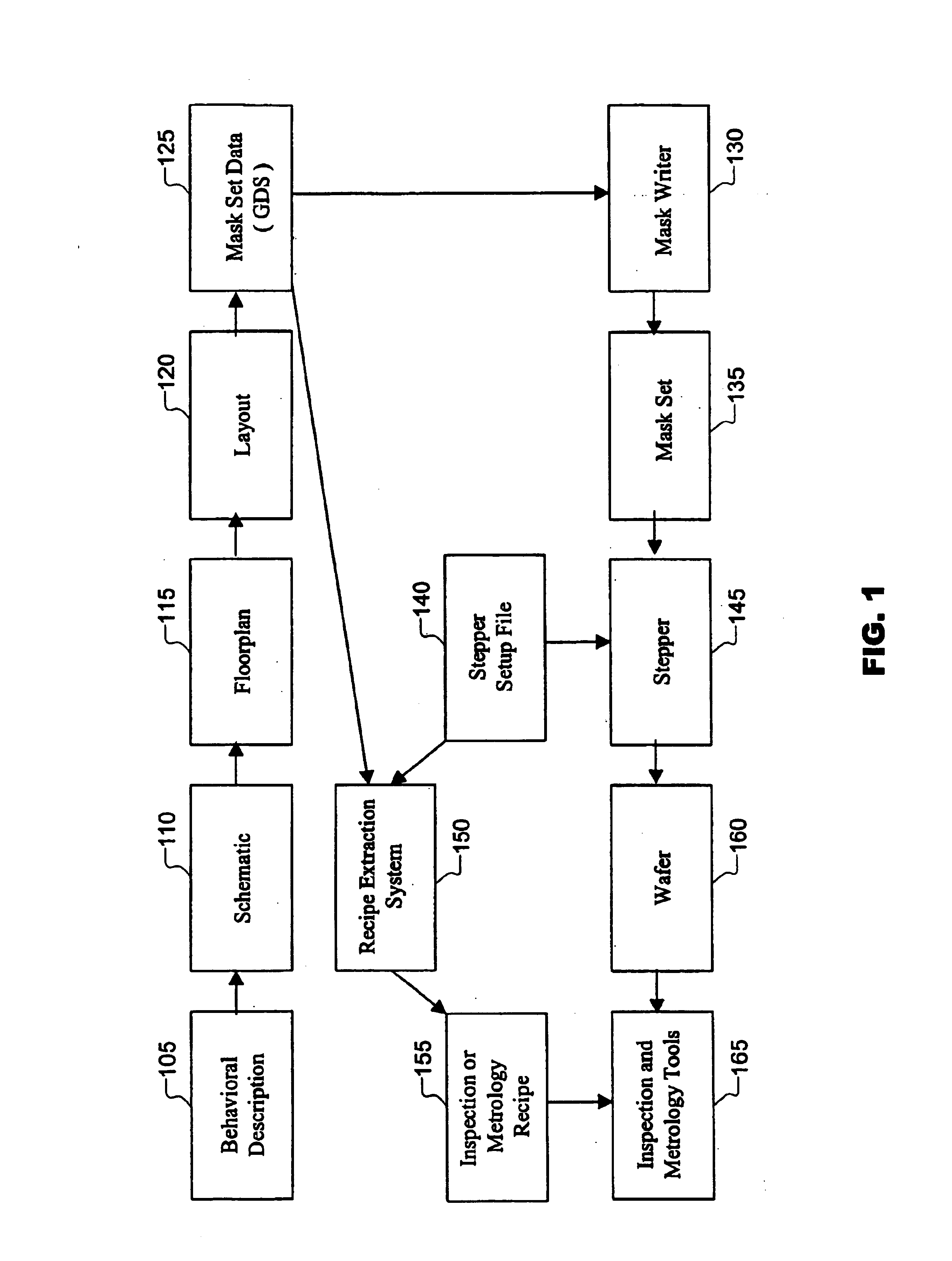

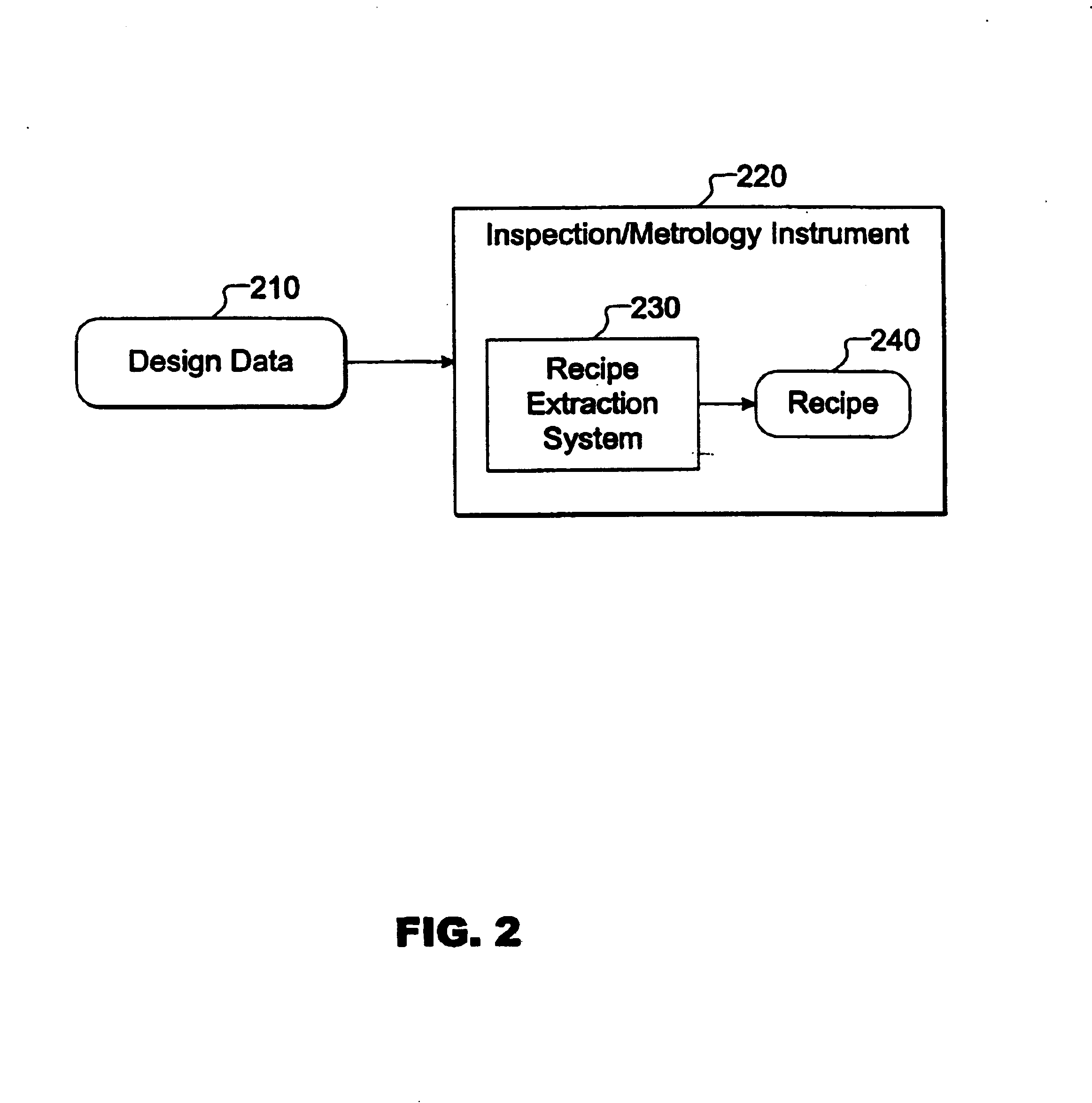

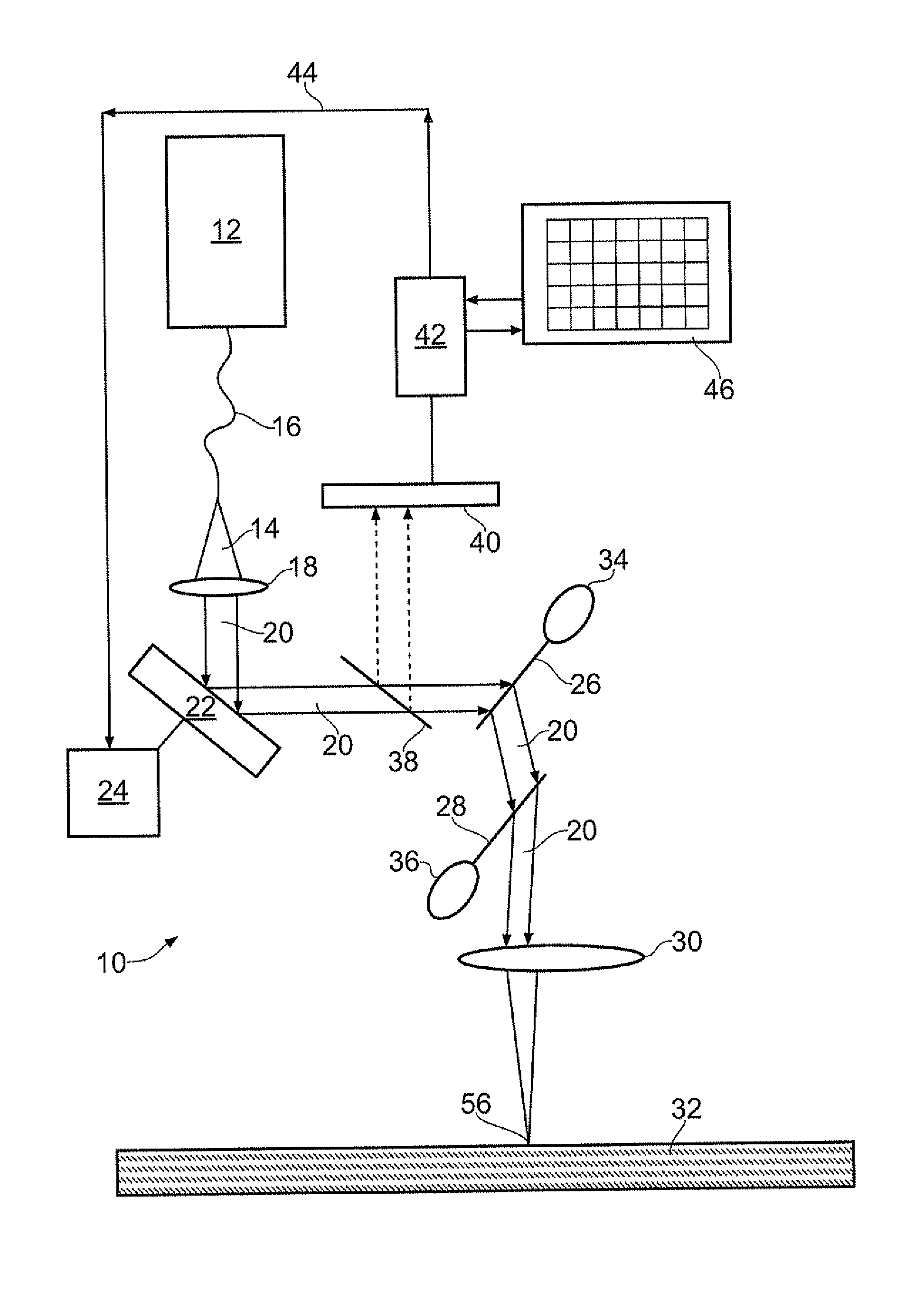

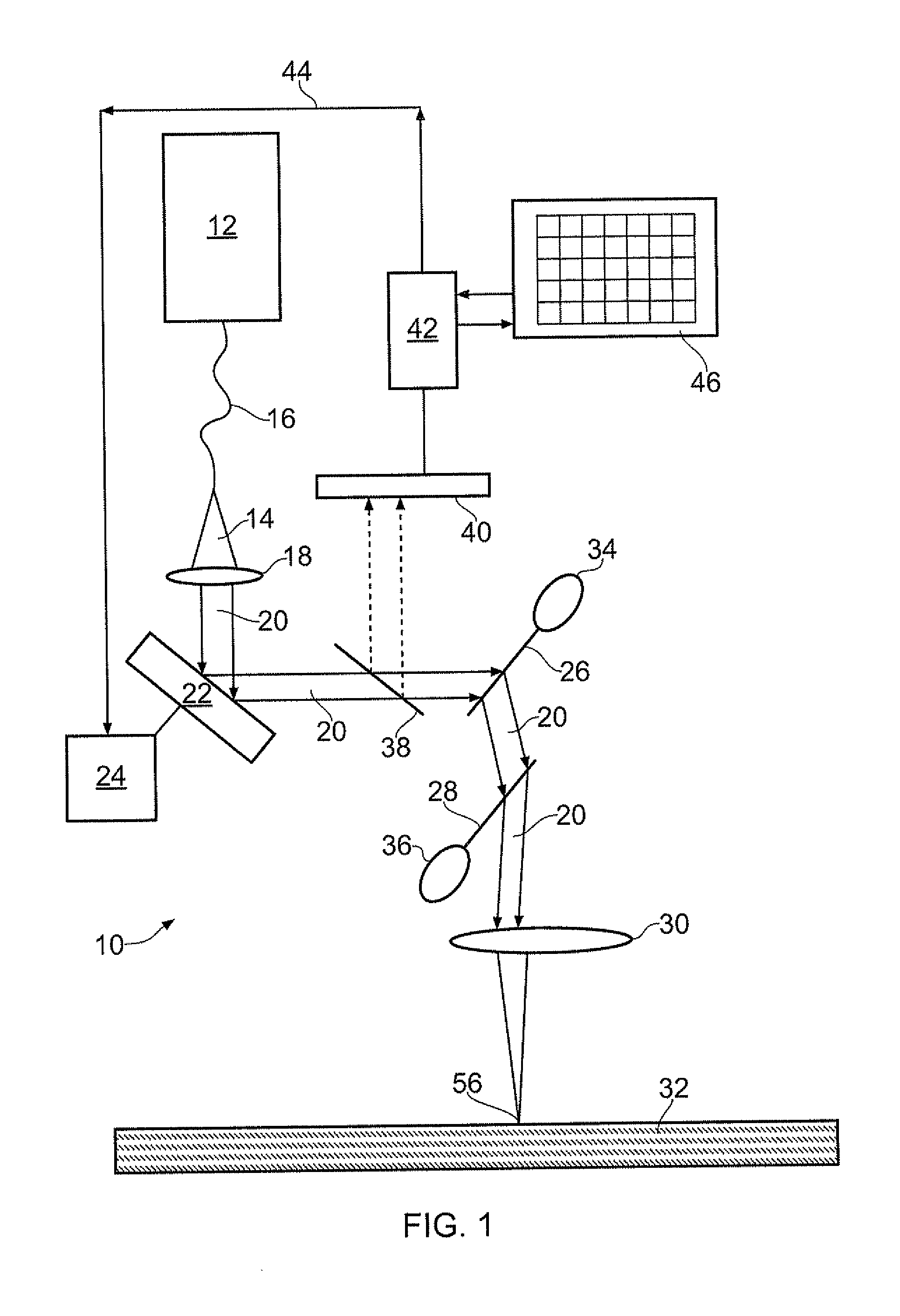

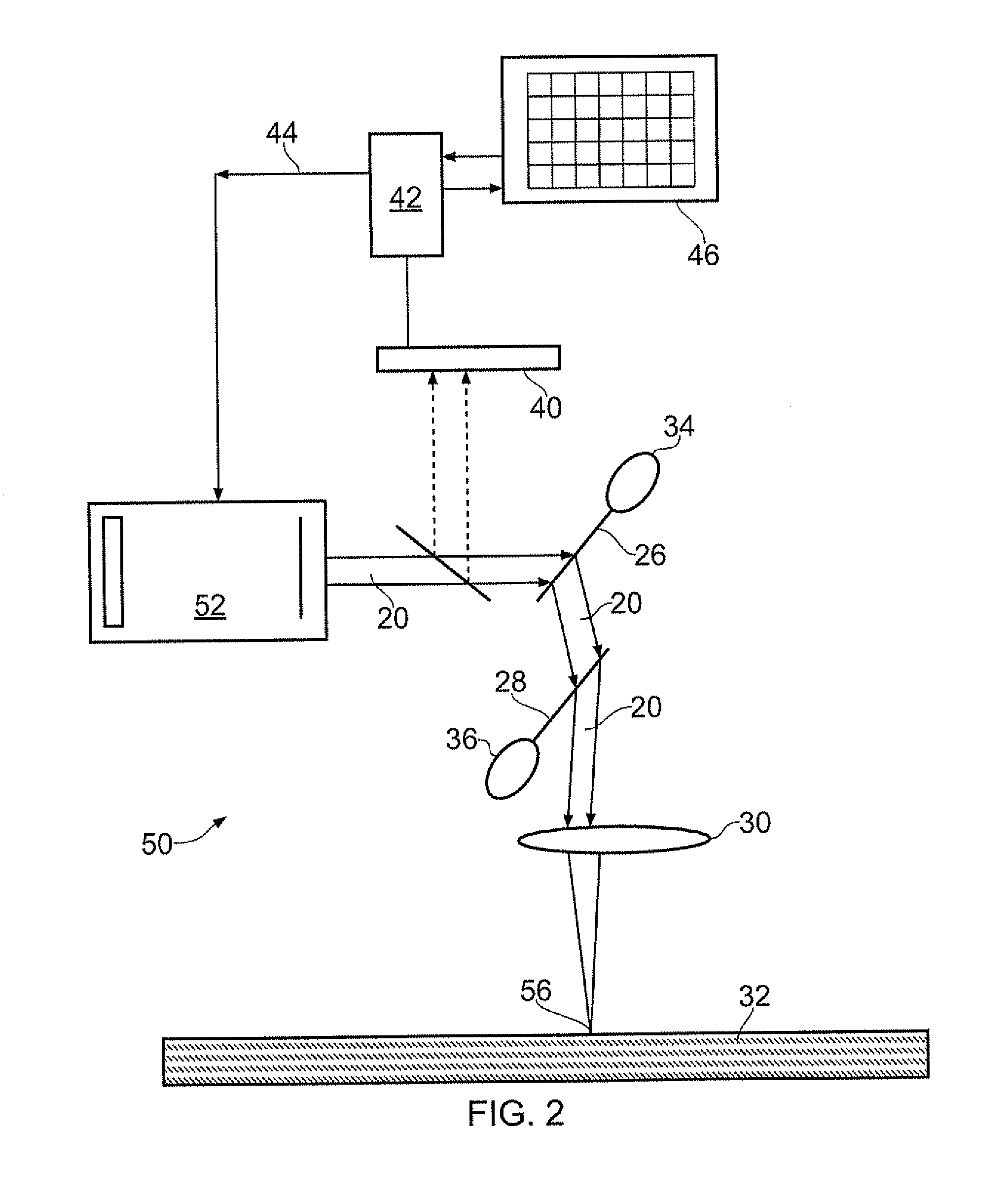

Design driven inspection or measurement for semiconductor using recipe

InactiveUS6886153B1Reduces instrument setup timeReduce setup timeSemiconductor/solid-state device testing/measurementPhotomechanical exposure apparatusMetrologySemiconductor

Design driven inspection / metrology methods and apparatus are provided. A recipe is a set of instructions including wafer processing parameters, inspection parameters, or control parameters for telling an inspection / metrology system how to inspect / measure a wafer. Design data is imported into a recipe extraction system that recognizes instances of target structures and configures recipe parameters accordingly, thereby reducing manual instrument setup time, improving inspection / measurement accuracy, and improving fabrication efficiency.

Owner:KLA TENCOR TECH CORP

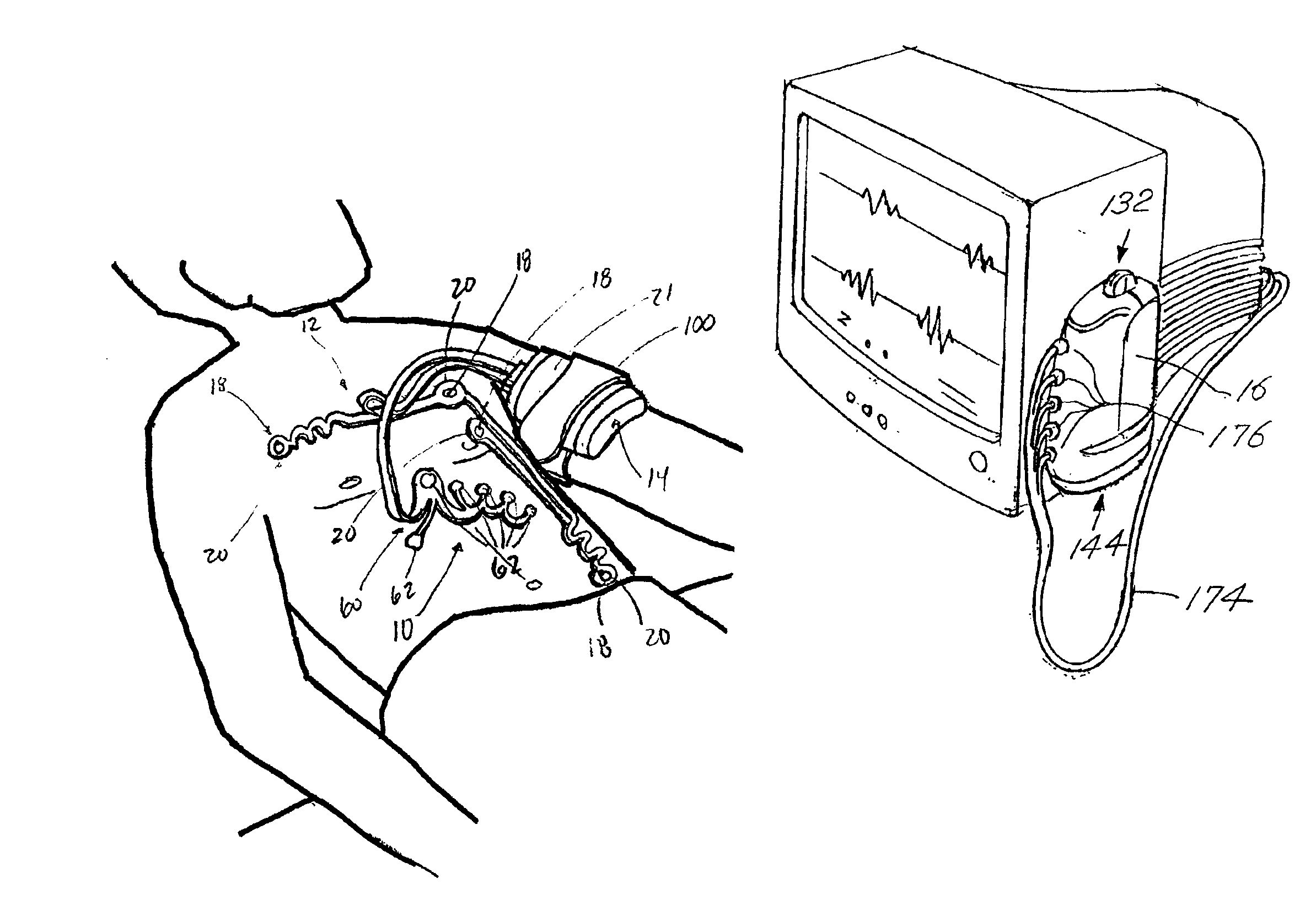

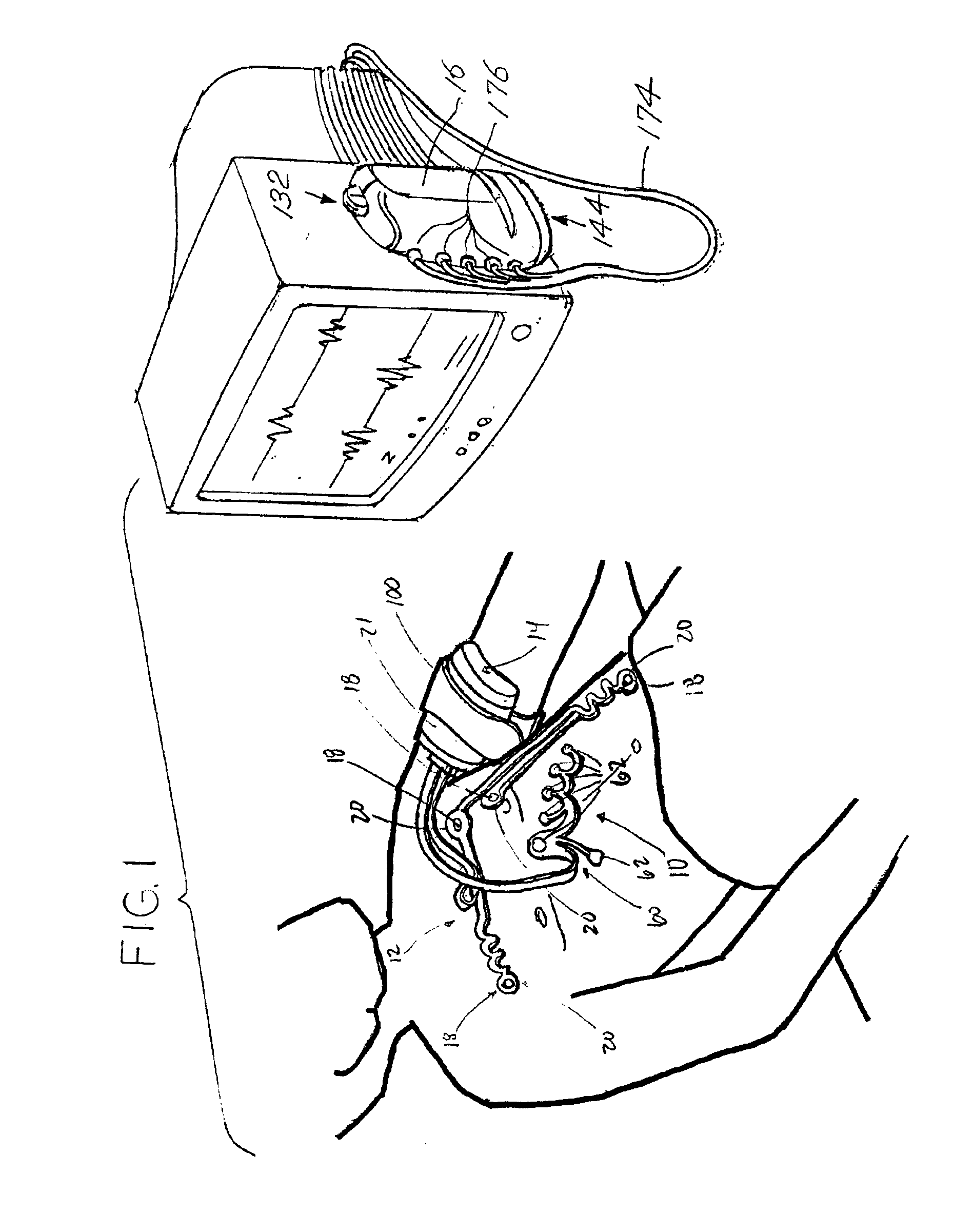

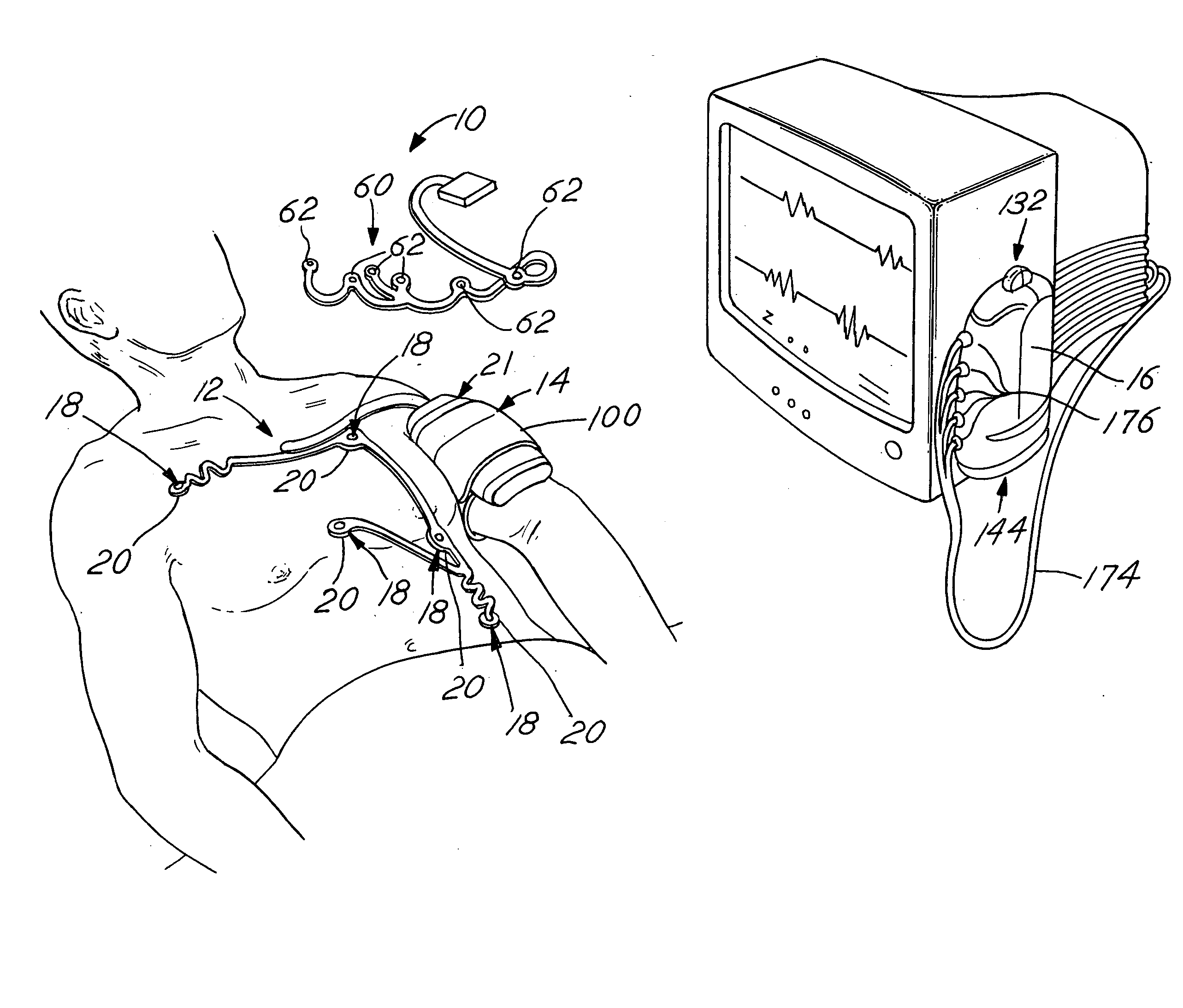

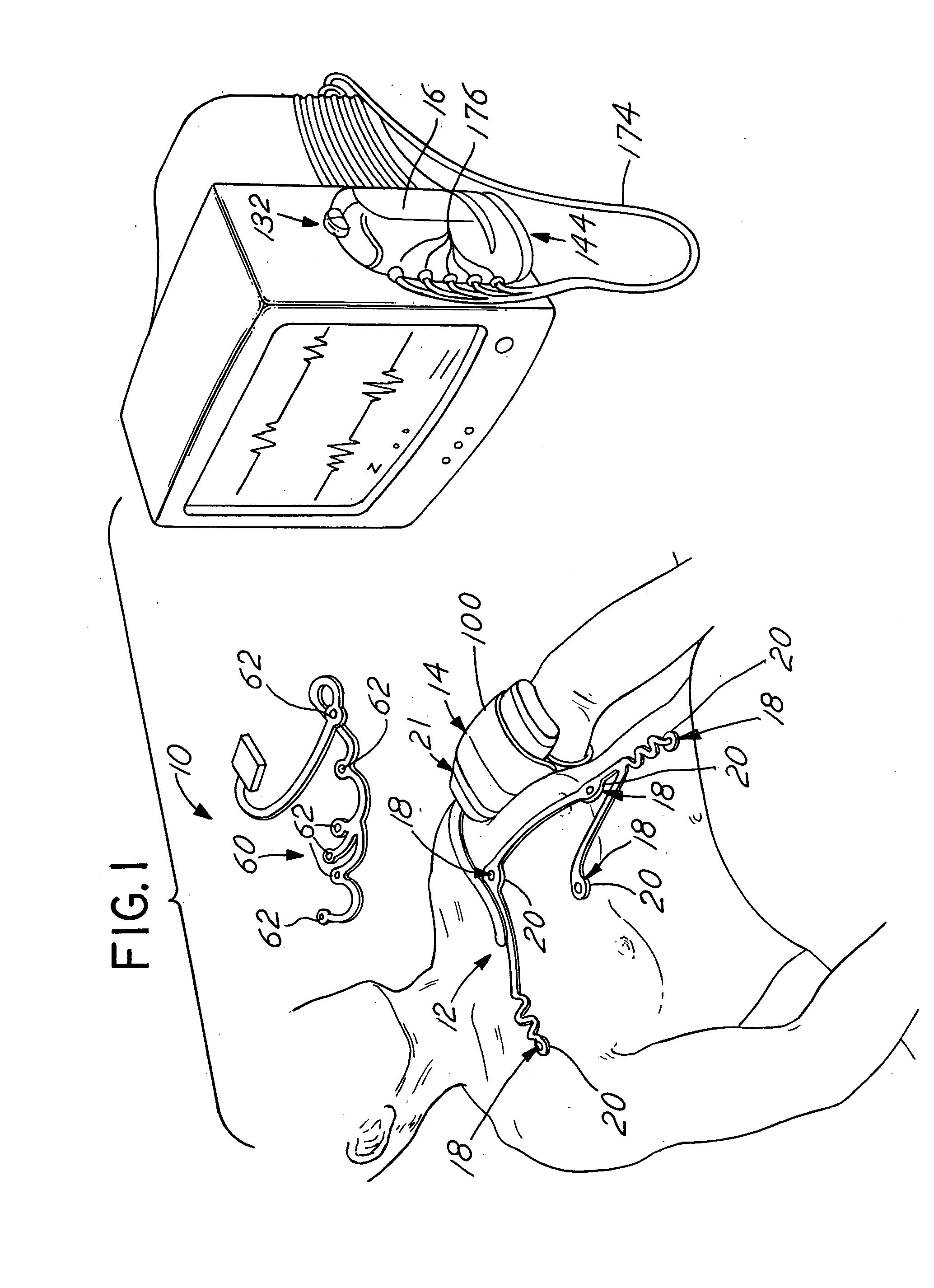

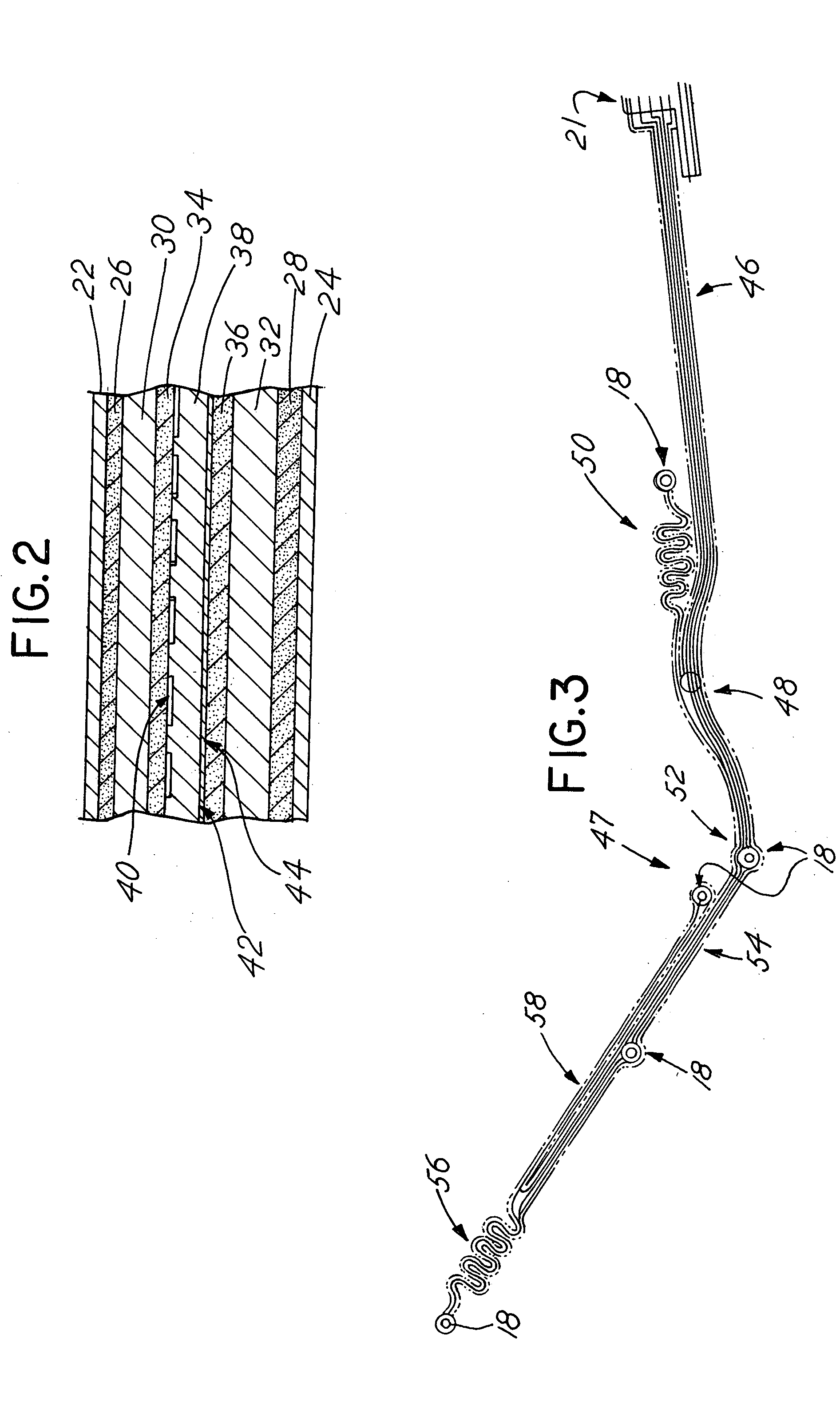

Wireless ECG system

InactiveUS7197357B2Increased comfort and mobilityEasy to useElectrocardiographySensorsCardiac monitoringEngineering

A cardiac monitoring system and, more particularly, a wireless electrocardiograph (ECG) system. The present invention detects electrical signals from a patient's heart and transmits the signals digitally to a remote base station via telemetry. The base station converts the digital signals back to an analog electrical signals that can be read by an ECG monitor.

Owner:LIFESYNC

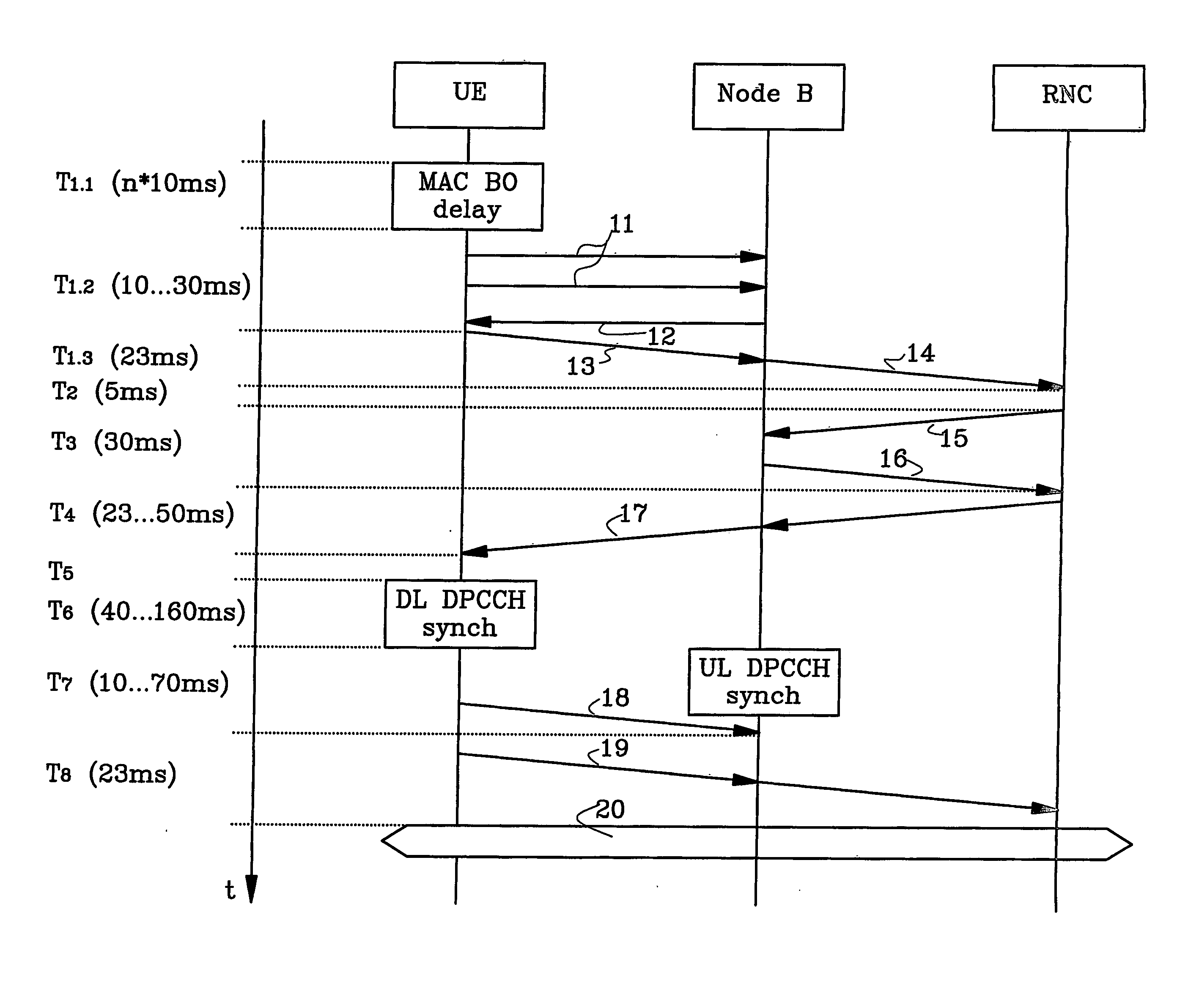

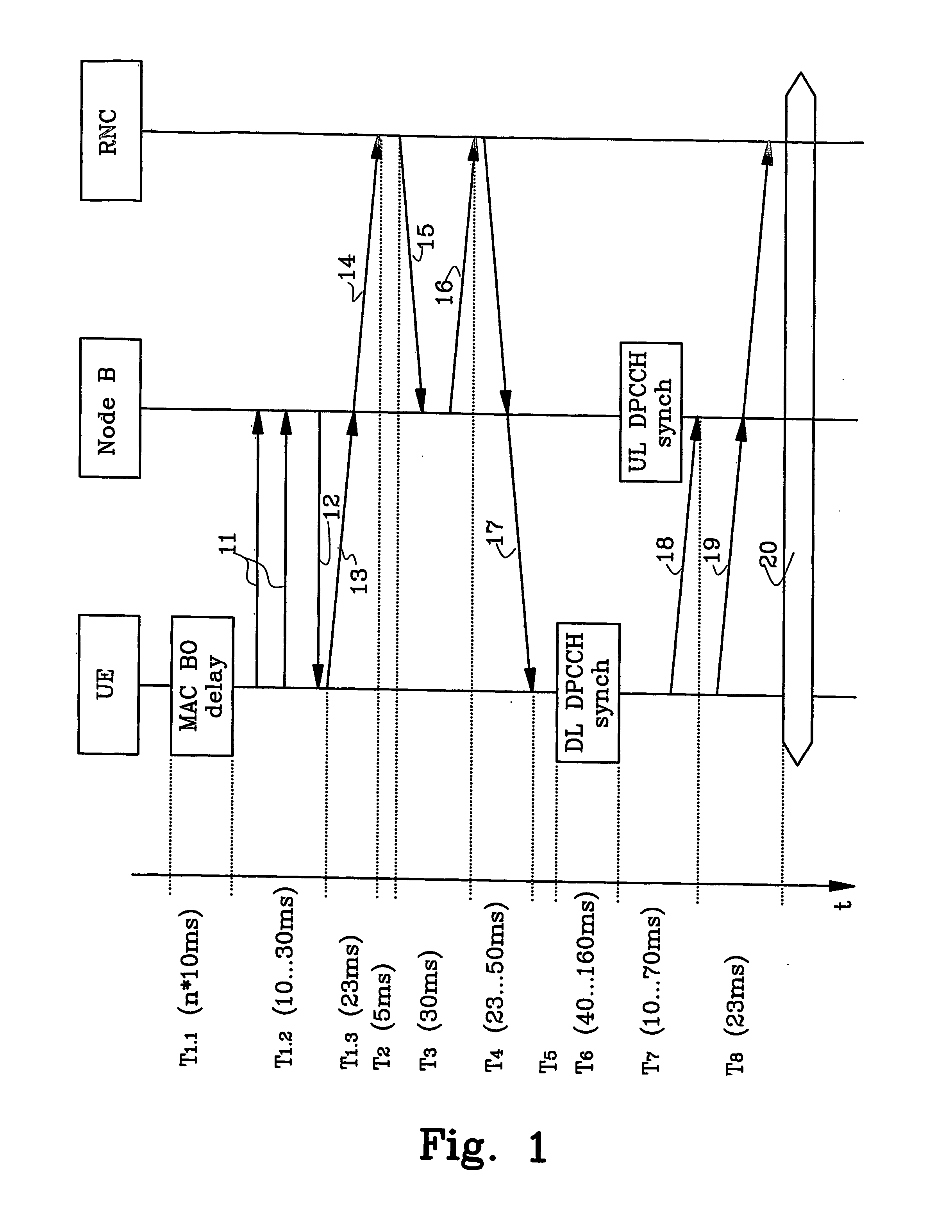

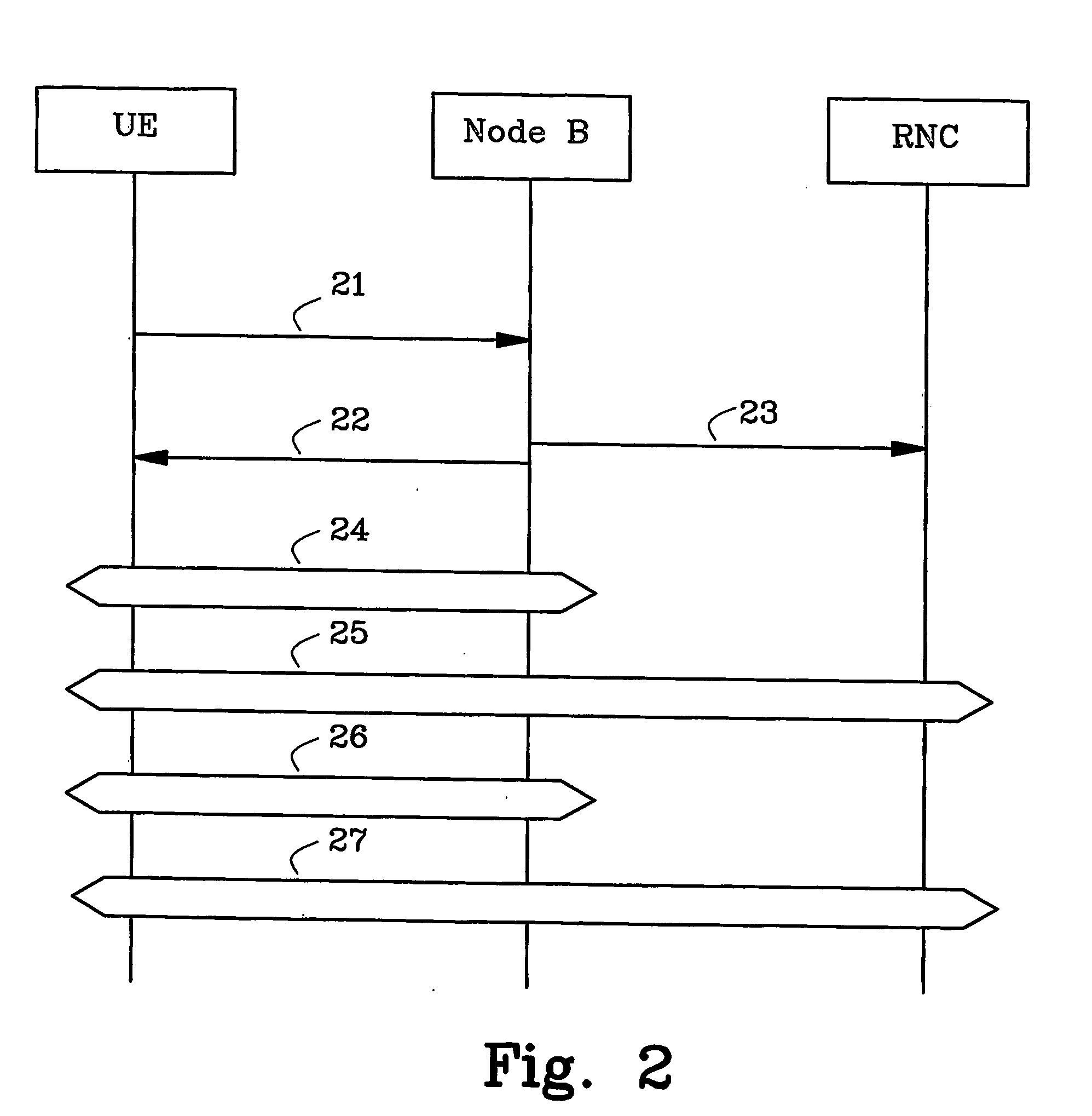

Fast Setup Of Physical Communication Channels

InactiveUS20080123585A1High speed of settingAvoid inefficiencyError preventionNetwork traffic/resource managementTelecommunications networkRadio networks

The present invention relates to improvements for a fast setup of physical communication channels in a CDMA-based communication system. A Node B of a telecommunication network is permitted to manage and assign a certain share of the downlink transmission resources of a radio network controller without inquiry of said radio network controller. On reception of a resource request message from a user equipment, the node B derives and specifies a certain amount of said resources that can be allocated to the user equipment. In a preferred embodiment of the present invention said resources are only assigned temporarily until the ordinary RL setup procedure, which involves the RNC, has been successfully finished.

Owner:TELEFON AB LM ERICSSON (PUBL)

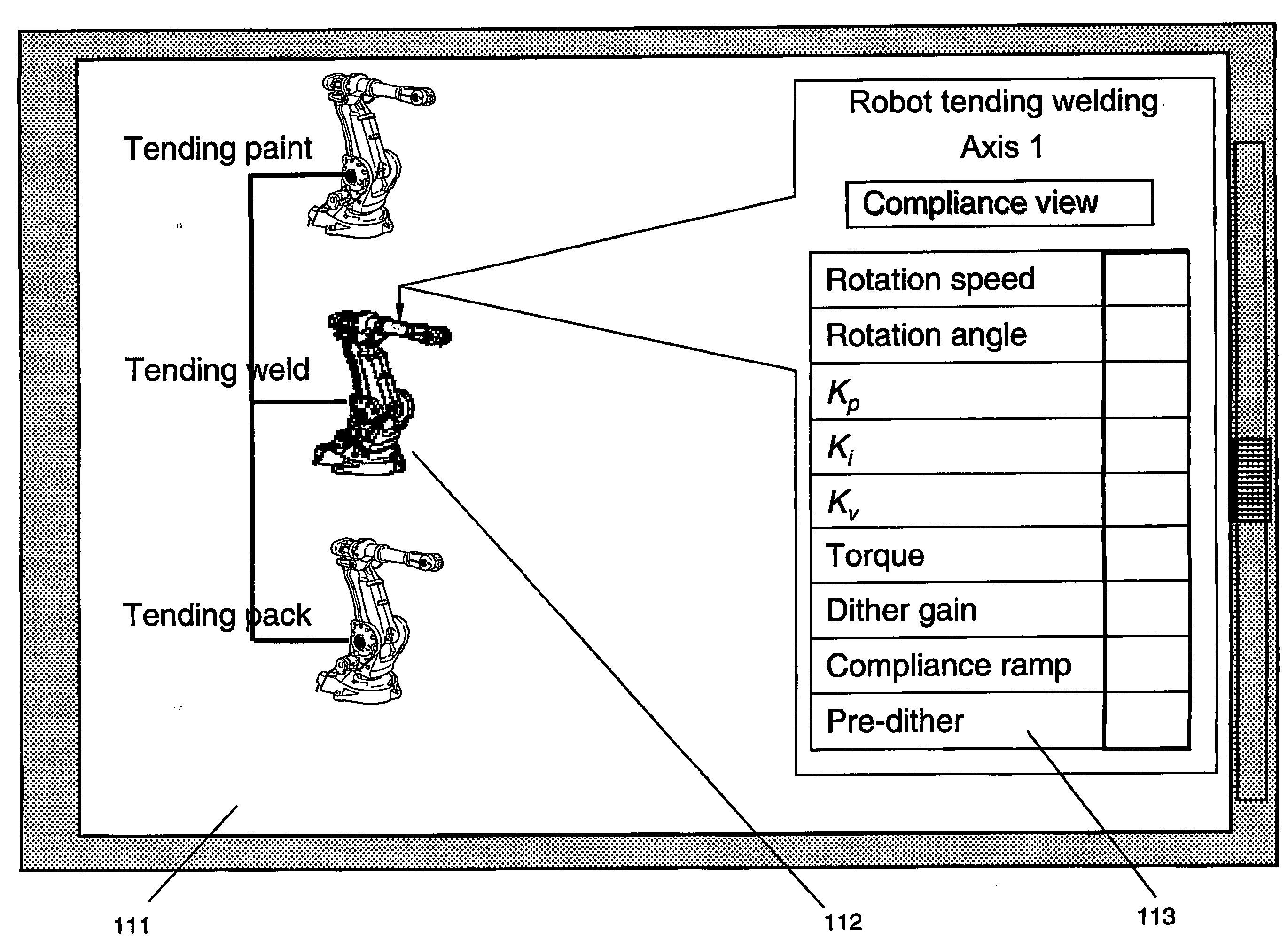

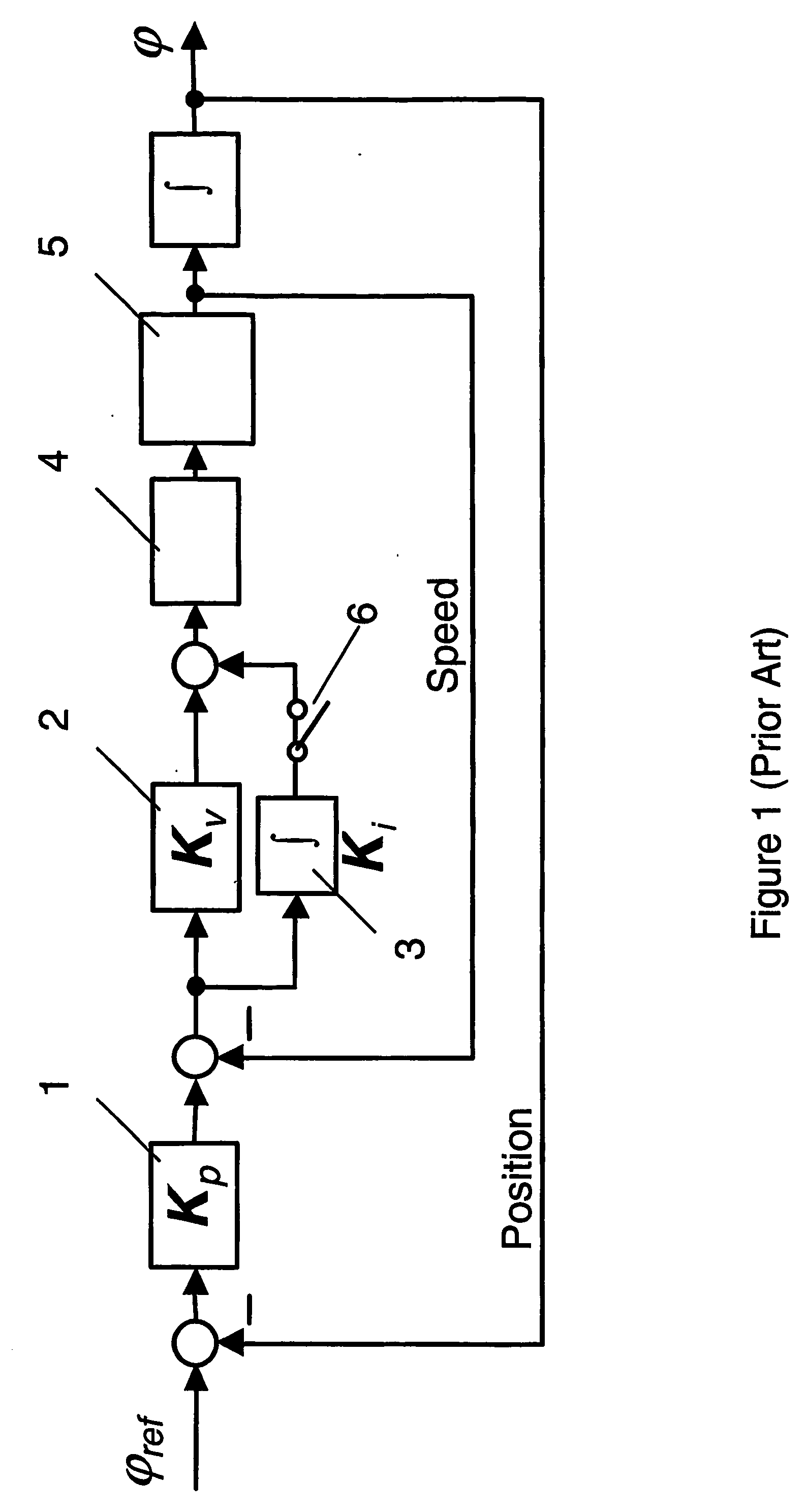

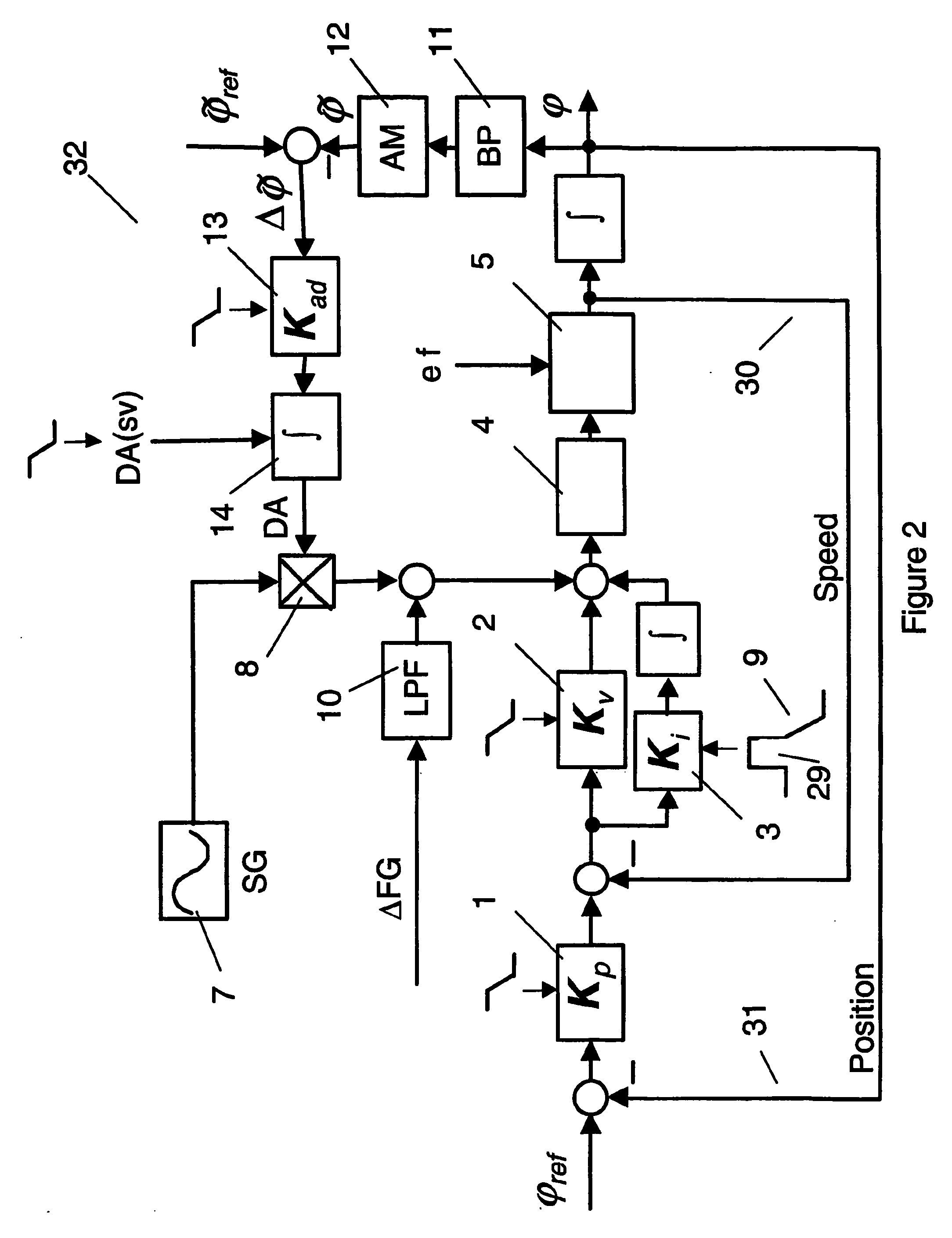

Control Method for a Robot

ActiveUS20070260356A1Reduce the effects of frictionFaster and accurate responseProgramme-controlled manipulatorComputer controlGraphicsGraphical user interface

An apparatus, a method and a control system for controlling an industrial robot with at least one axis of rotation and / or translation. The robot includes at least one actuator or motor at each of the axes for driving a movement of an arm of the robot and at least one sensor at each of the rotatable shafts. A dither-signal generator for generation of a periodic signal is used to provide a varying dither signal to a servo of the actuator. Automatic adaption of the dither signal is provided. A computer program for carrying out the method and a graphical user interface.

Owner:ABB (SCHWEIZ) AG

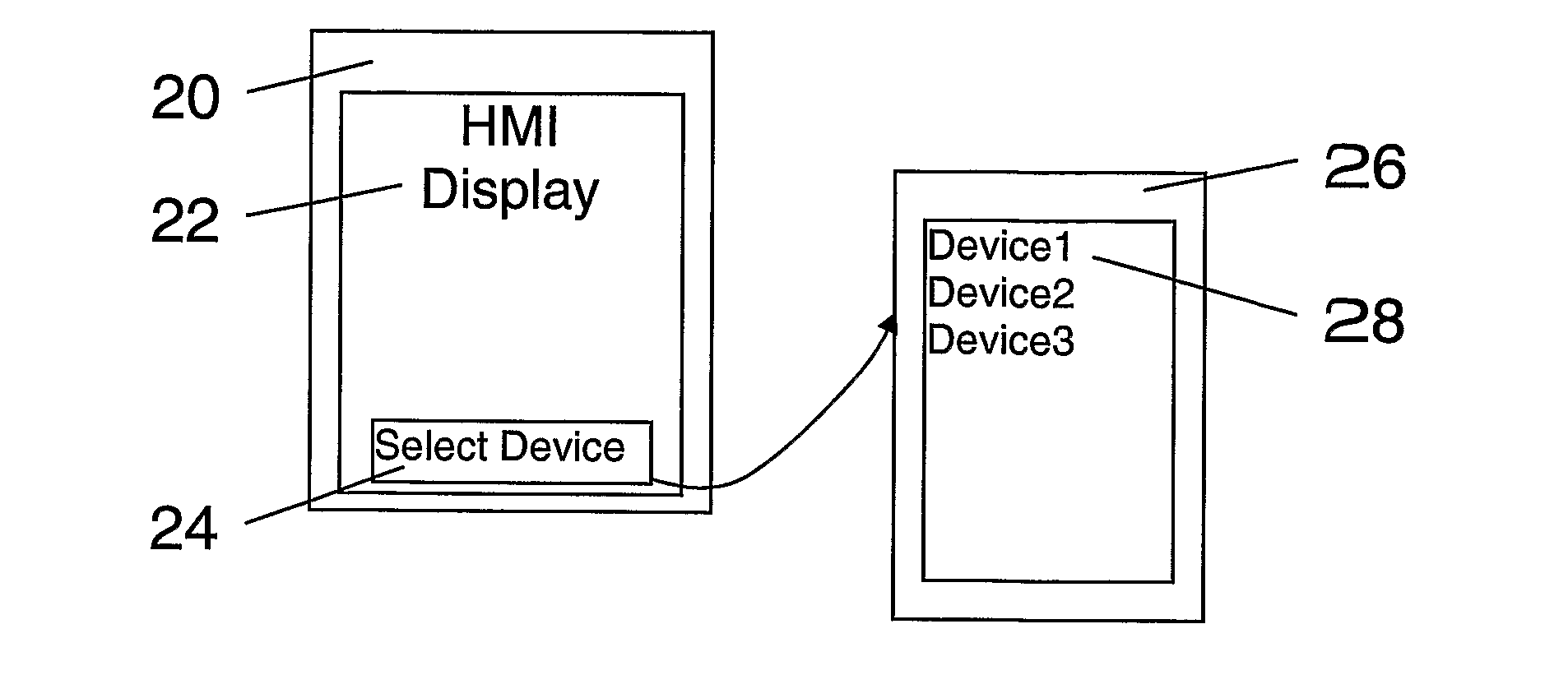

Wireless Communication Method, Device and System for Establishing a Connection

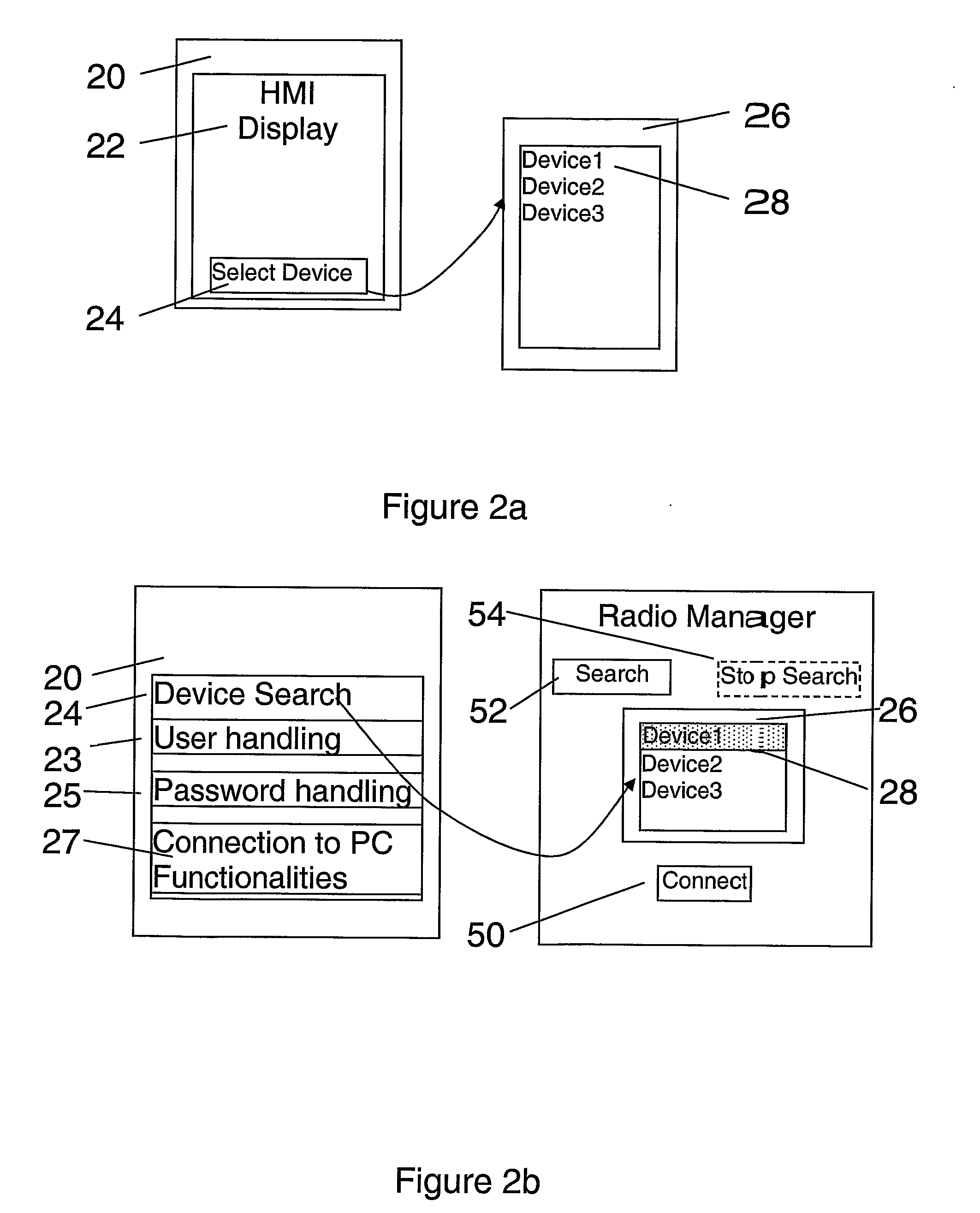

ActiveUS20080139116A1Short timeSimplifying and speeding monitoringElectric testing/monitoringData switching by path configurationGraphicsHuman–machine interface

A method for a user to establish a wireless connection between a wireless portable computing device and a wireless-equipped device in an industrial or electrical power or distribution plant. Actions of the method are carried out by a second computer program that provides information in a graphical user interface display to a user and opens a wireless connection with a selected industrial device. In other aspects a human-machine interface and a system are also described.

Owner:ABB (SCHWEIZ) AG

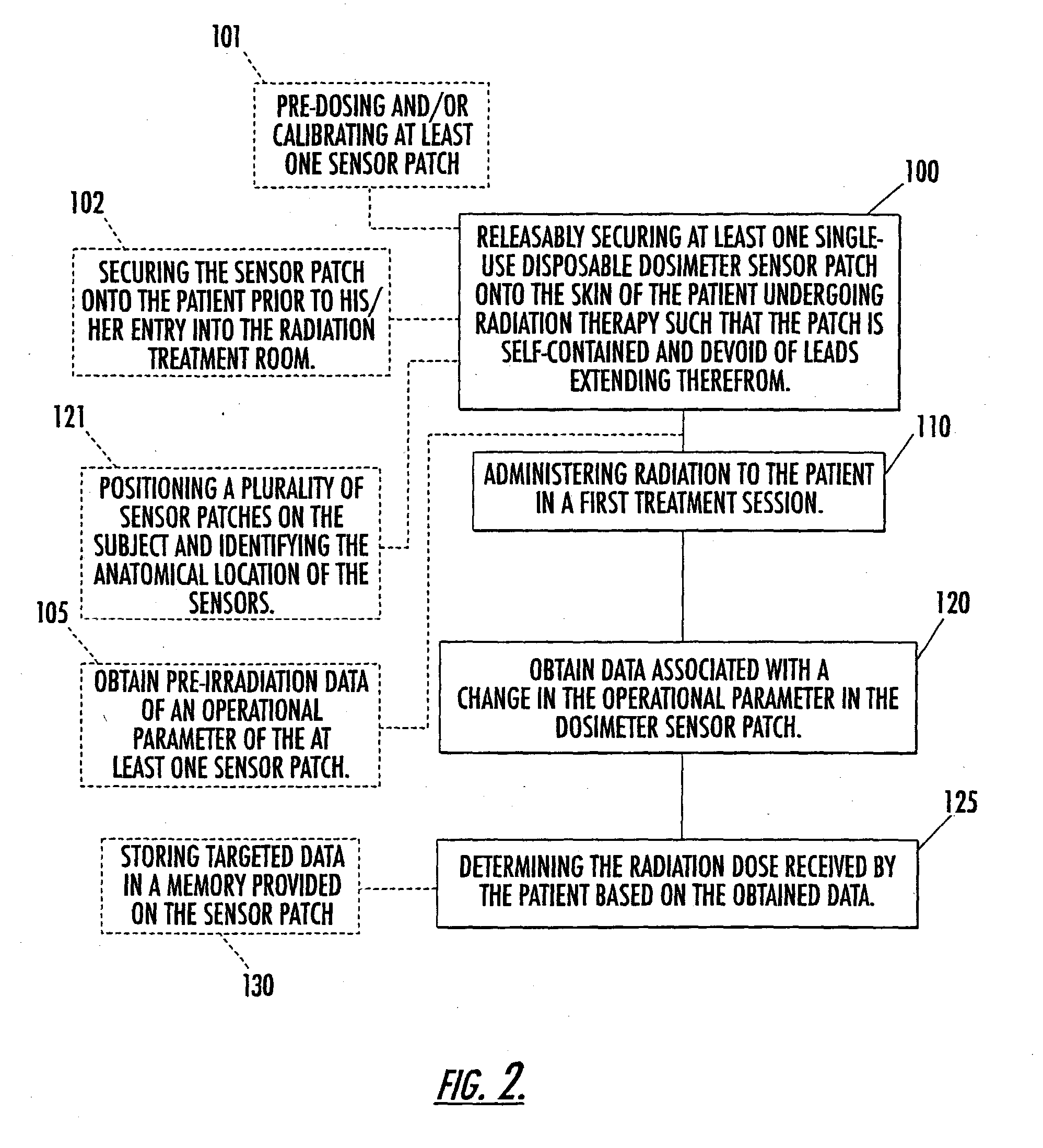

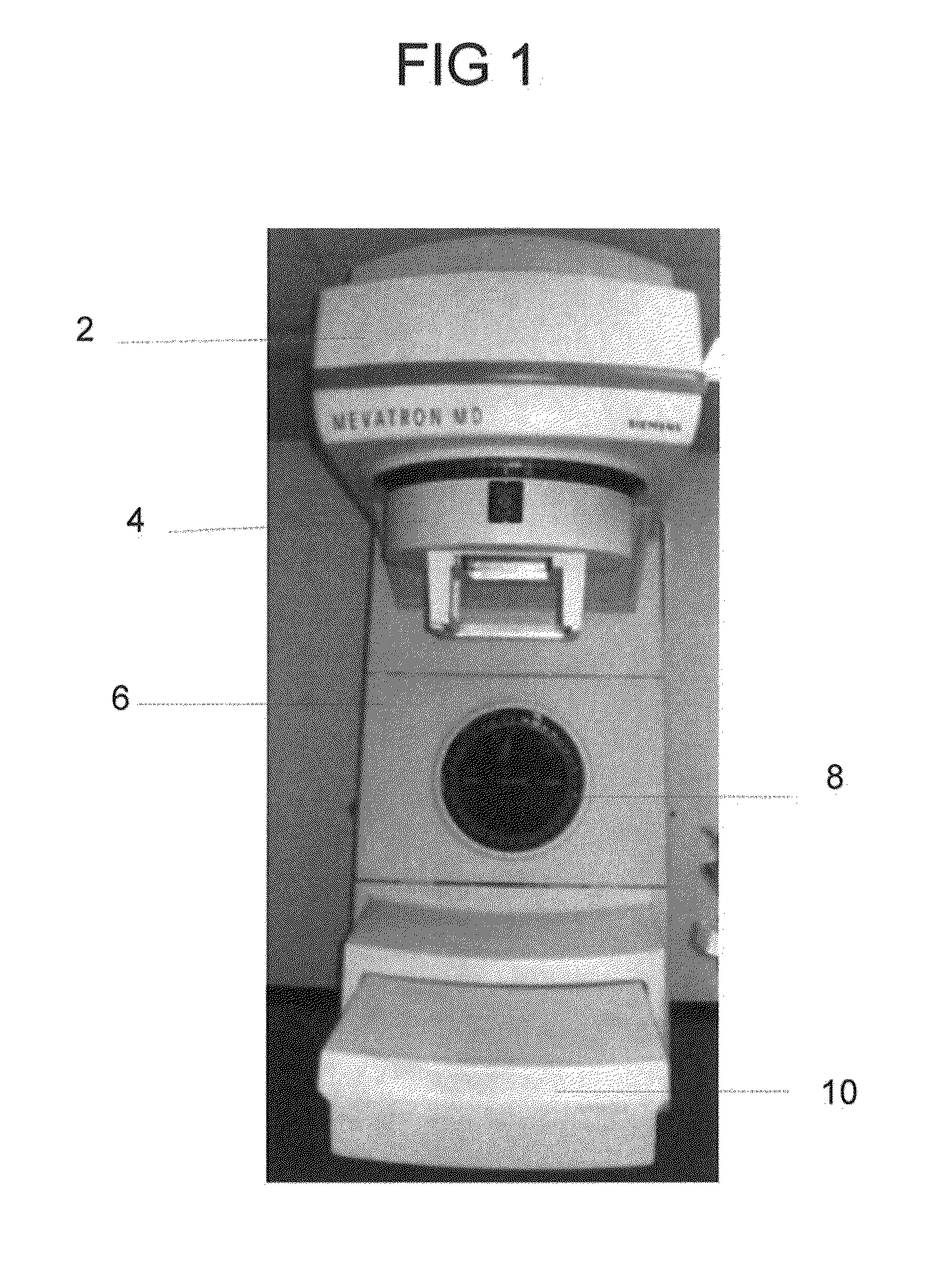

Disposable single-use external dosimeters for use in radiation therapies

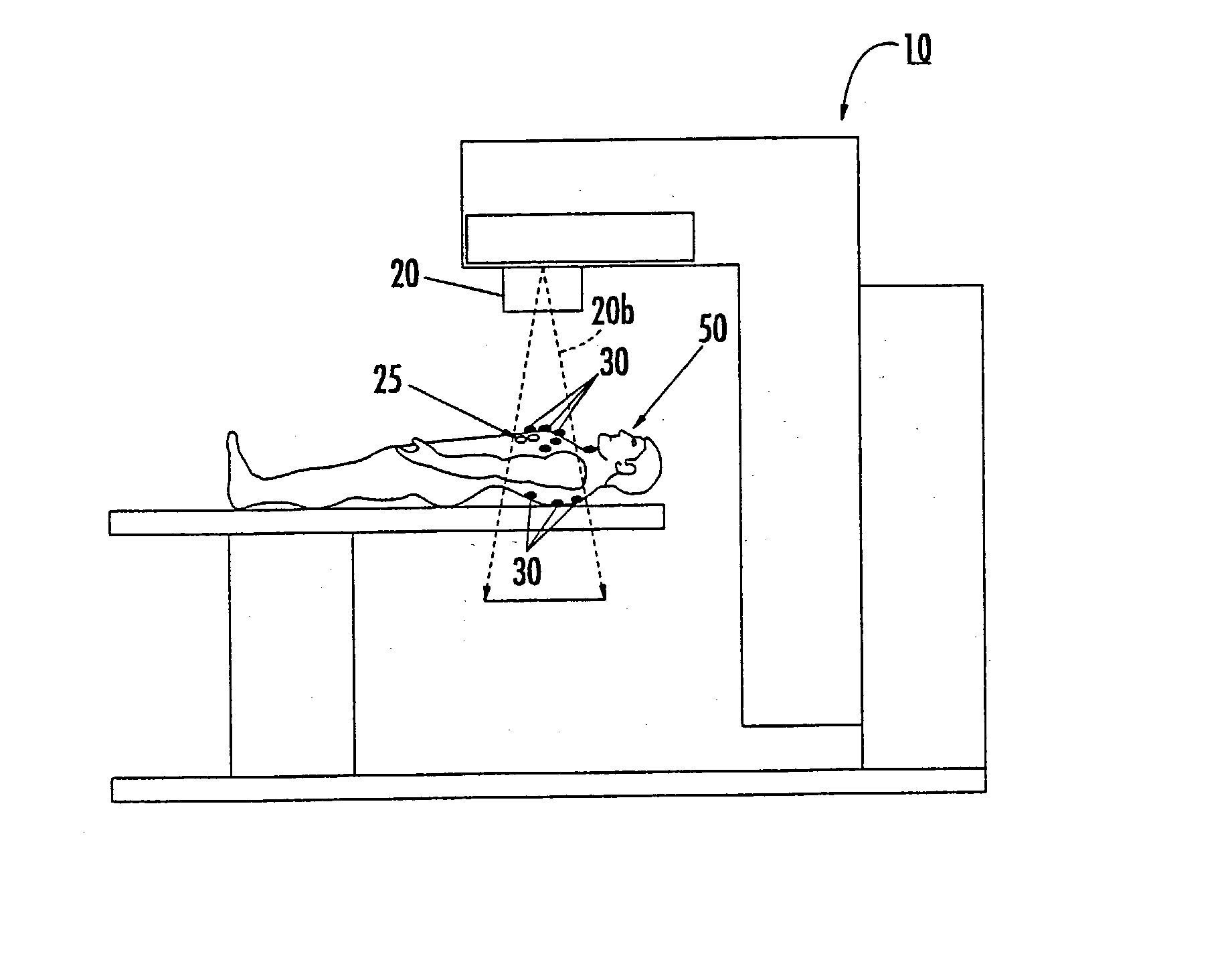

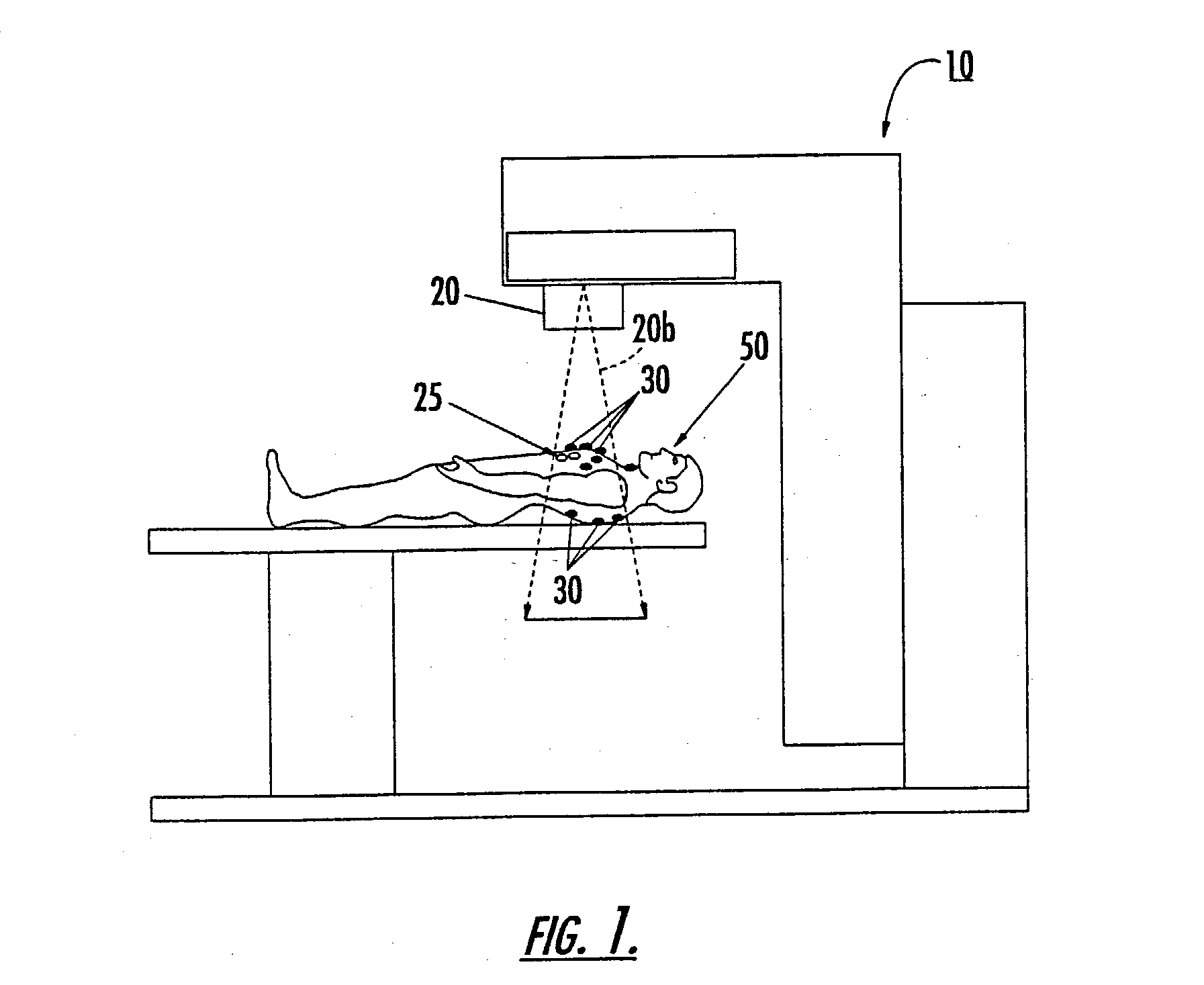

ActiveUS20030125616A1Cost-effectiveReduce labor set-up timeDosimetersDiagnostic recording/measuringDosimeterRadiation sensor

Methods, systems, devices, and computer program products include positioning disposable single-use radiation sensor patches that have adhesive means onto the skin of a patient to evaluate the radiation dose delivered during a treatment session. The sensor patches are configured to be minimally obtrusive and operate without the use of externally extending power chords or lead wires.

Owner:VTQ IP HLDG

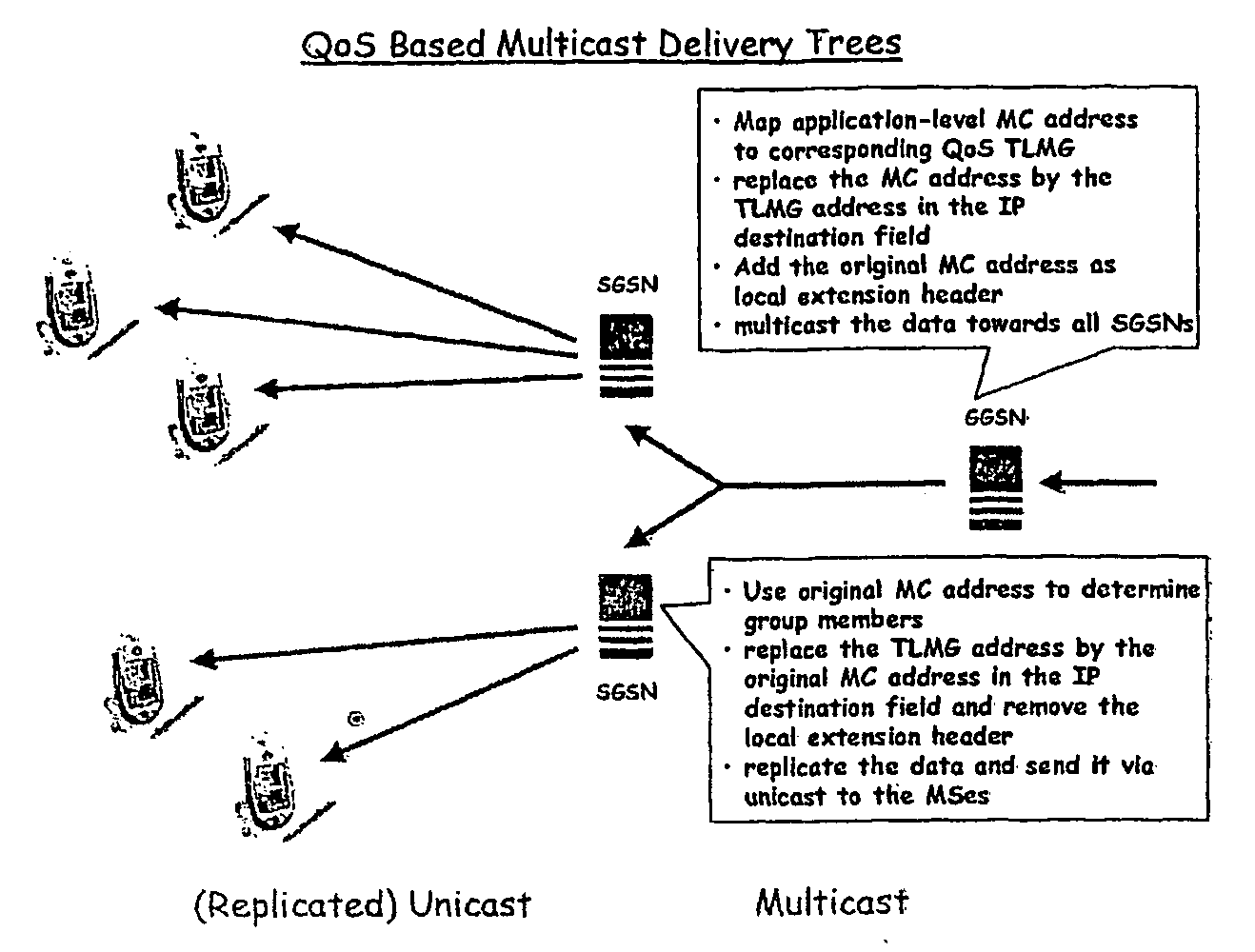

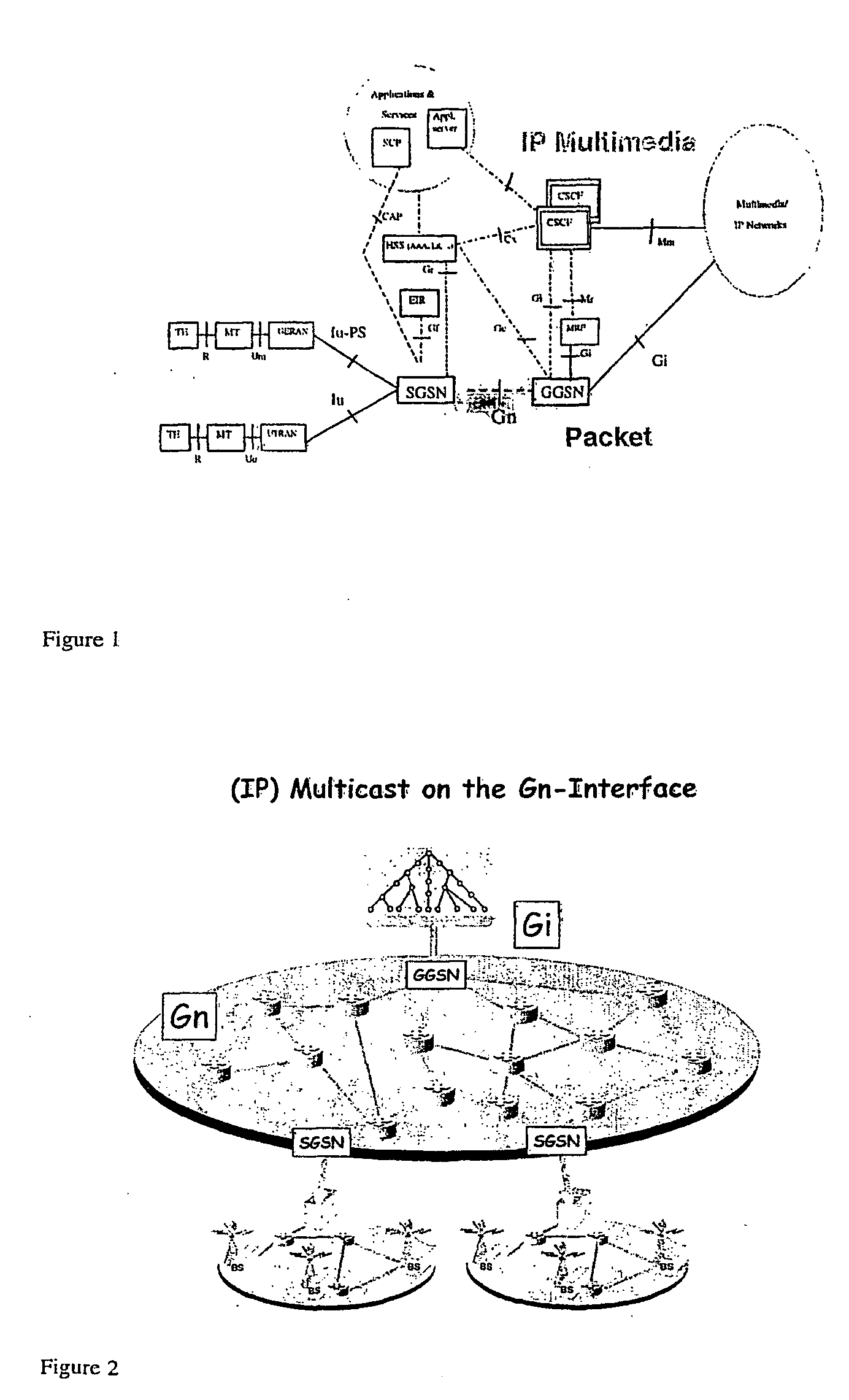

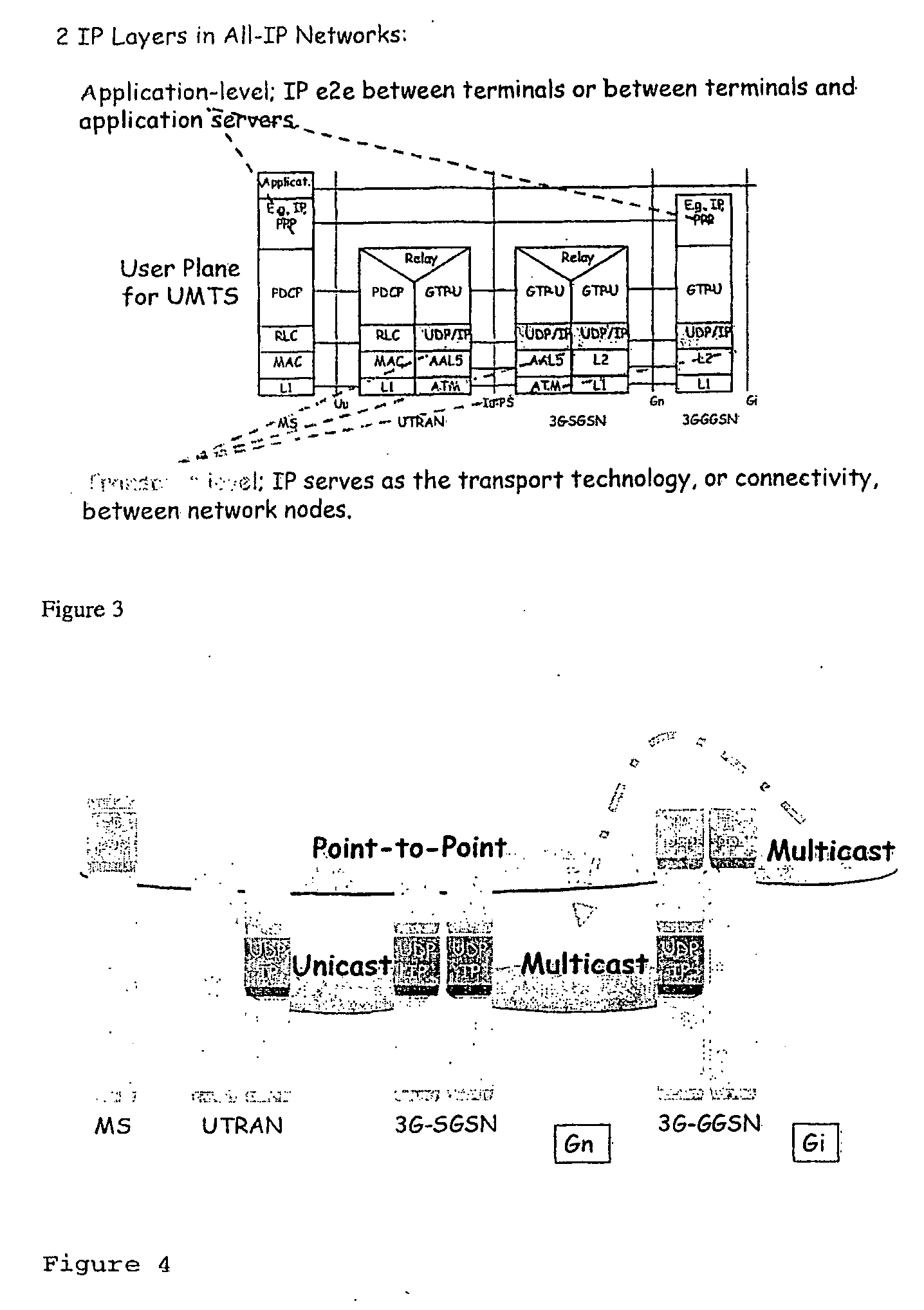

Multicast in point-to-point packet-switched oriented networks

ActiveUS20040233907A1Efficient use ofReducing transmission resourceSpecial service provision for substationData switching by path configurationMultiplexingTelecommunications network

The invention relates to a method, network node, router, serving node and system for performing multicast in a point-to-point packet-switched oriented telecommunication network. The basic idea is to introduce pre-configured multicast transmission for parts of a network. This is done by creating pre-configured transport multicast group tunnels between a router and a serving node in order to transport the multicast data. Further the present invention describes the possibility of multiplexing of the multicast data streams on a pre-configured transport multicast group tunnel. In particular the invention is applicable for multicasting in networks, like UMTS with a scarce number of resources, in the IP network between the SGSN and GGSN for example on the Gn interface.

Owner:TELEFON AB LM ERICSSON (PUBL)

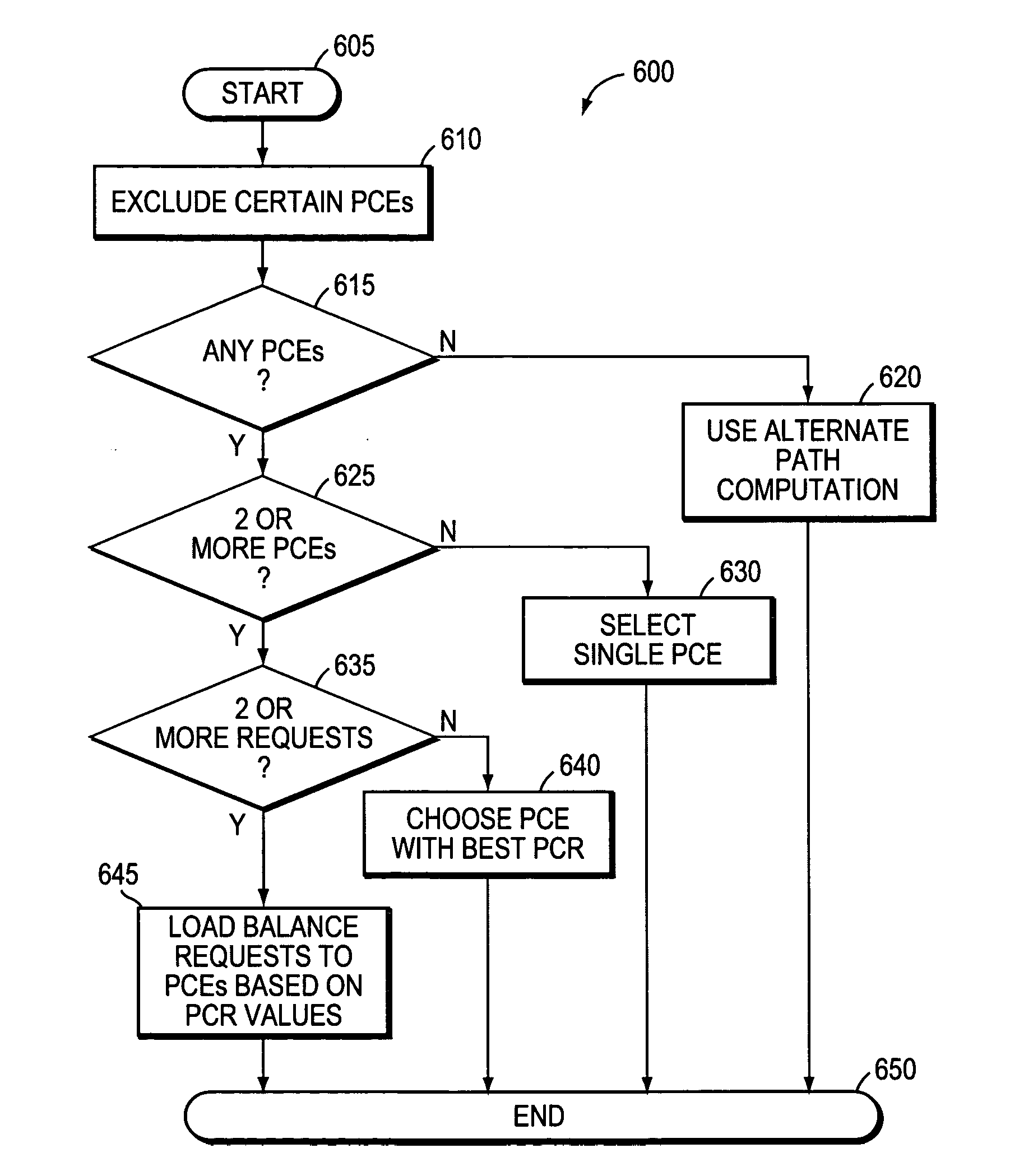

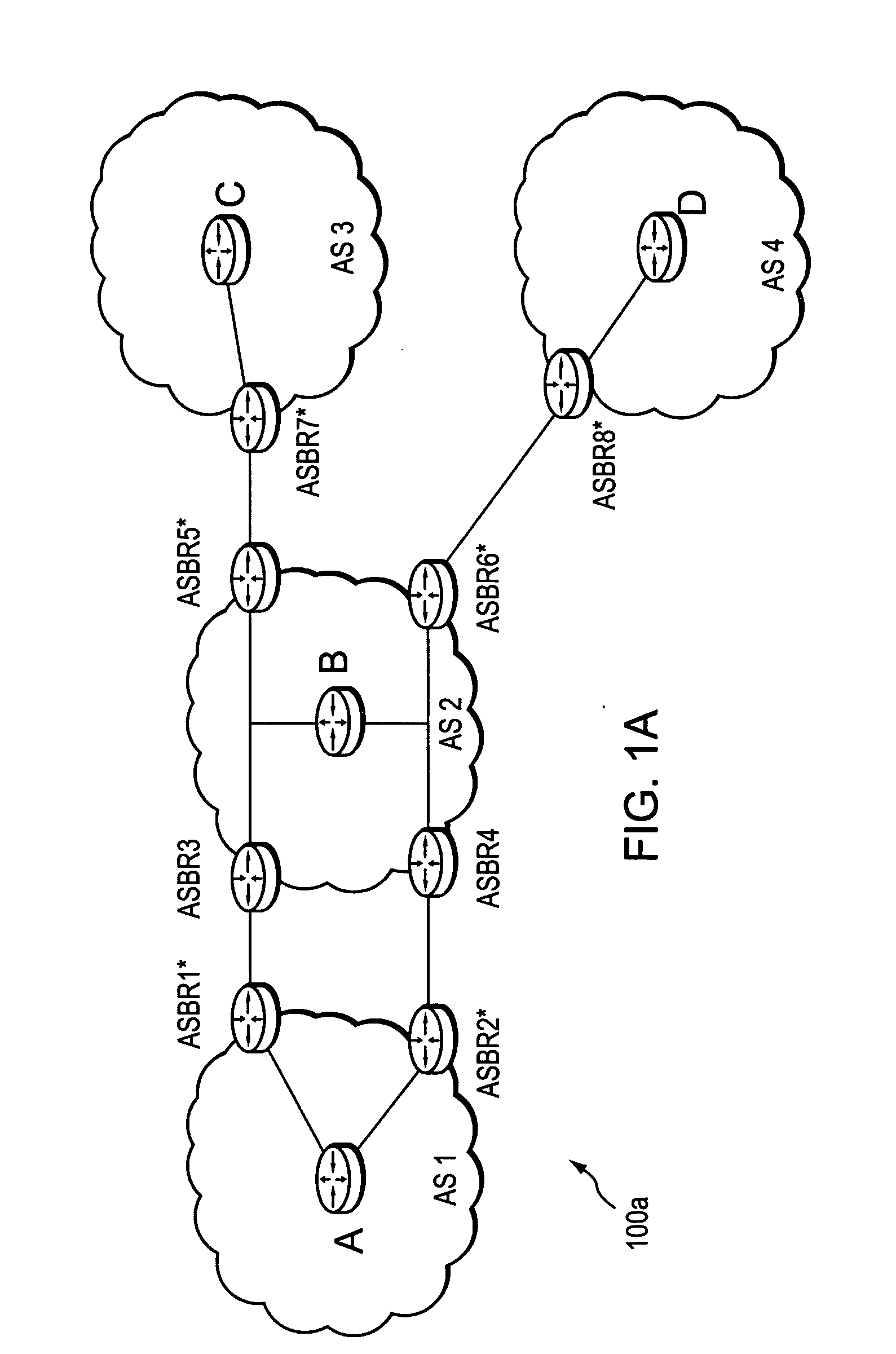

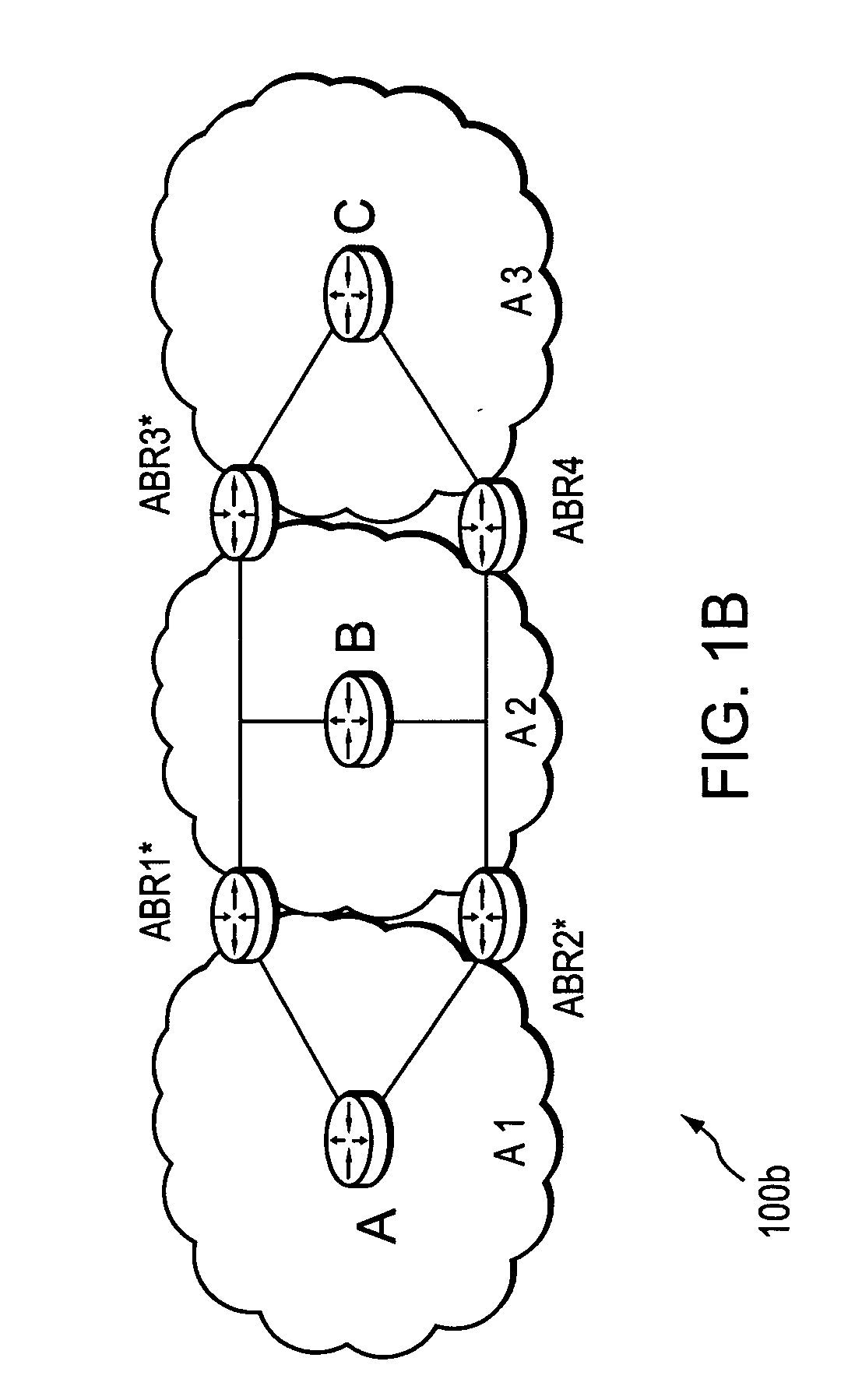

Technique for selecting a path computation element

ActiveUS20060101142A1Valid choiceEfficient load balancingDigital computer detailsTransmissionLow-pass filterPath computation element

A technique efficiently selects a Path Computation Element (PCE) to compute a path between nodes of a computer network. The PCE selection technique is illustratively based on dynamic advertisements of the PCE's available path computation resources, using (i) a low-pass filter algorithm to compute such resources, and (ii) threshold determinations to control distribution of those advertisements. To that end, the novel technique enables one or more PCEs to dynamically send (advertise) their available path computation resources to a Path Computation Client (PCC) by way of the controlled advertisements. In addition, the technique enables the PCC to efficiently select a PCE (or set of PCEs) to service a path computation request based upon those available resources.

Owner:CISCO TECH INC

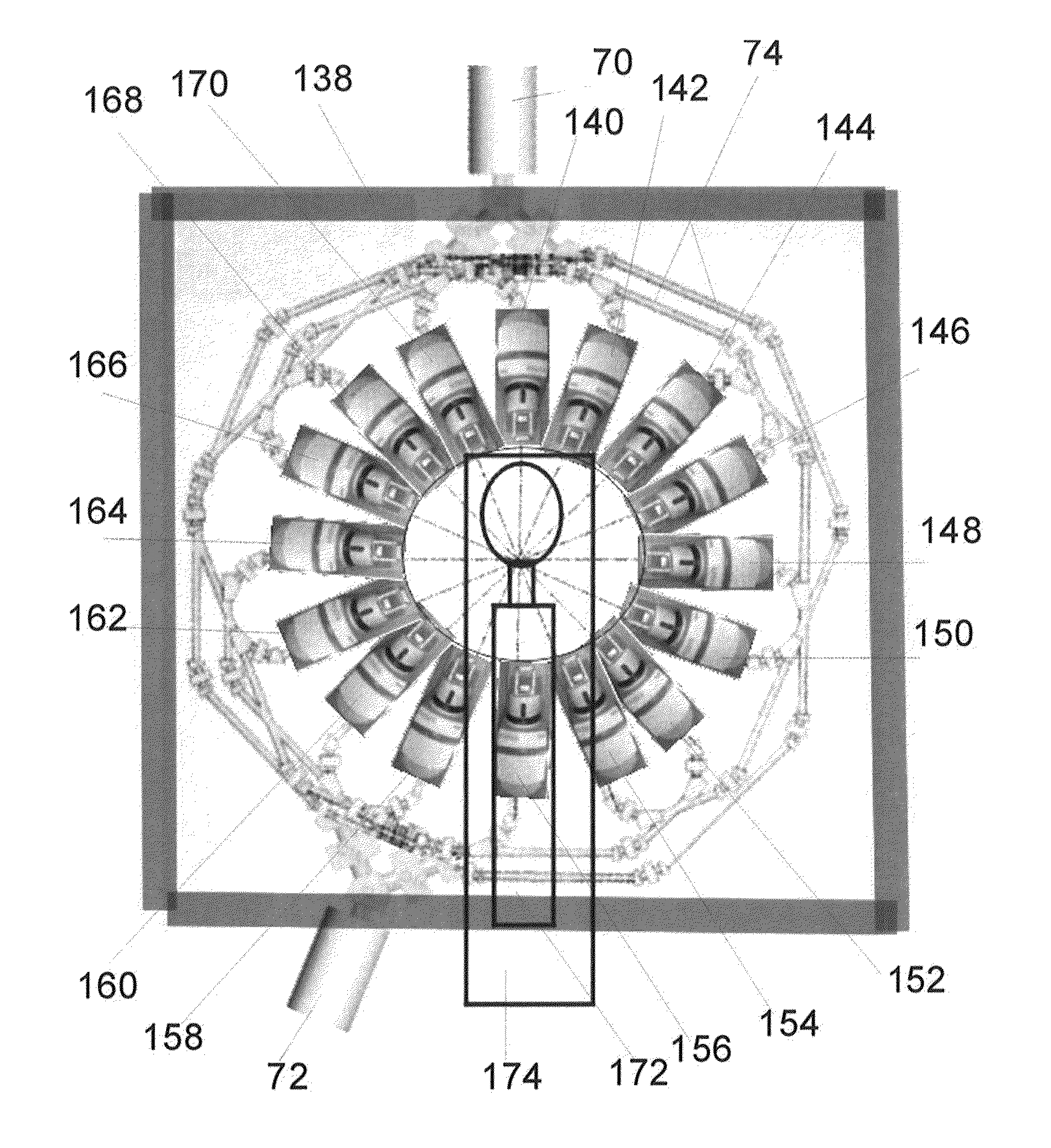

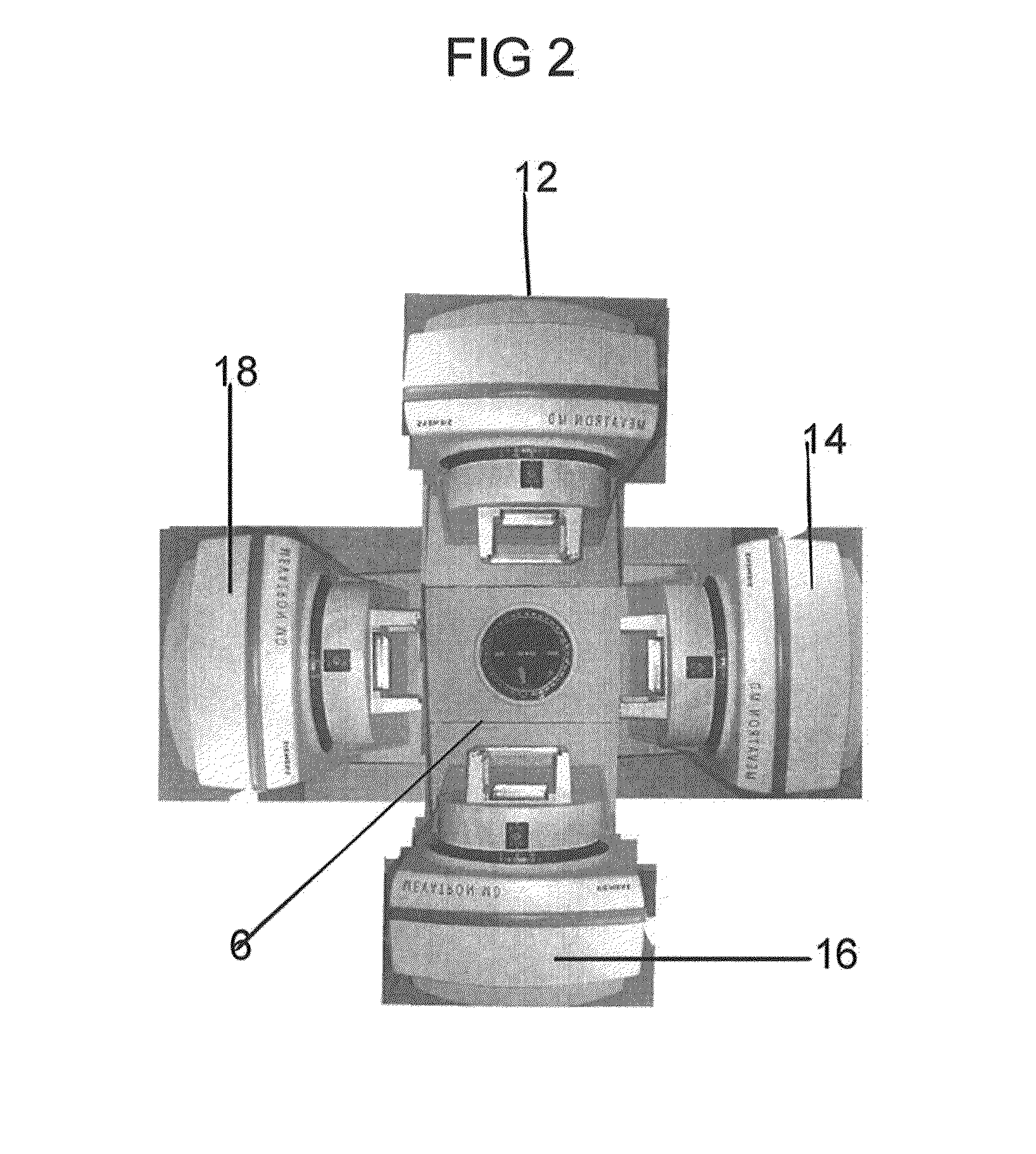

Lethal and sublethal damage repair inhibiting image guided simultaneous all field divergent and pencil beam photon and electron radiation therapy and radiosurgery

InactiveUS7835492B1Improve modulationIncrease radiation intensityIrradiation devicesX-ray/gamma-ray/particle-irradiation therapyRadiosurgeryC banding

A medical accelerator system is provided for simultaneous radiation therapy to all treatment fields. It provides the single dose effect of radiation on cell survival. It eliminates the inter-field interrupted, subfractionated fractionated radiation therapy. Single or four beams S-band, C-band or X-band accelerators are connected to treatment heads through connecting beam lines. It is placed in a radiation shielding vault which minimizes the leakage and scattered radiation and the size and weight of the treatment head. In one version, treatment heads are arranged circularly and connected with the beam line. In another version, a pair of treatment heads is mounted to each ends of narrow gantries and multiple such treatment heads mounted gantries are assembled together. Electron beam is steered to all the treatment heads simultaneously to treat all the fields simultaneously. Radiating beam's intensity in a treatment field is modulated with combined divergent and pencil beam, selective beam's energy, dose rate and weight and not with MLC and similar devices. Since all the treatment fields are treated simultaneously the dose rate at the tumor site is the sum of each of the converging beam's dose rate at depth. It represents the biological dose rate. The dose rate at d-max for a given field is the individual machine dose rate. Its treatment options includes divergent or pencil beam modes. It enables to treat a tumor with lesser radiation toxicities to normal tissue and higher tumor cure and control.

Owner:SAHADEVAN VELAYUDHAN

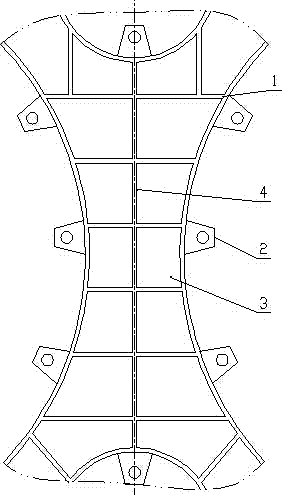

Plane wing titanium alloy thin-wall web efficient numerical control machining technology

A plane wing titanium alloy thin-wall web efficient numerical control machining technology comprises the following steps that (1) blanking is carried out; (2) web outer contour machining is carried out, and an ear piece for locating is machined; (3) a web is clamped, and a cavity on the front face of the web is machined; (4) a web side wall is machined; (5) web quick converting is carried out, and a cavity on the back face of the web is machined; (6) the locating ear piece is removed by milling; and (7) quality testing is carried out. The rigidity of a machining technology system is improved, unstressed machining is achieved, by optimized design of a feed track, the stability of a machining process is improved, machining speed is increased, titanium alloy shallow cutting large feeding milling technology parameters are used, heat deforming during machining is lowered, rectifying processes are omitted, the metal removing rate is improved by 30%-50%, finally, machining efficiency is obviously improved, the clamping time of workpieces is obviously shortened through a quick-reloading technology, the repeated locating accuracy of clamping is guaranteed, and accordingly numerically-controlled machine tool machining efficiency is greatly improved.

Owner:HUANGHE S & T COLLEGE

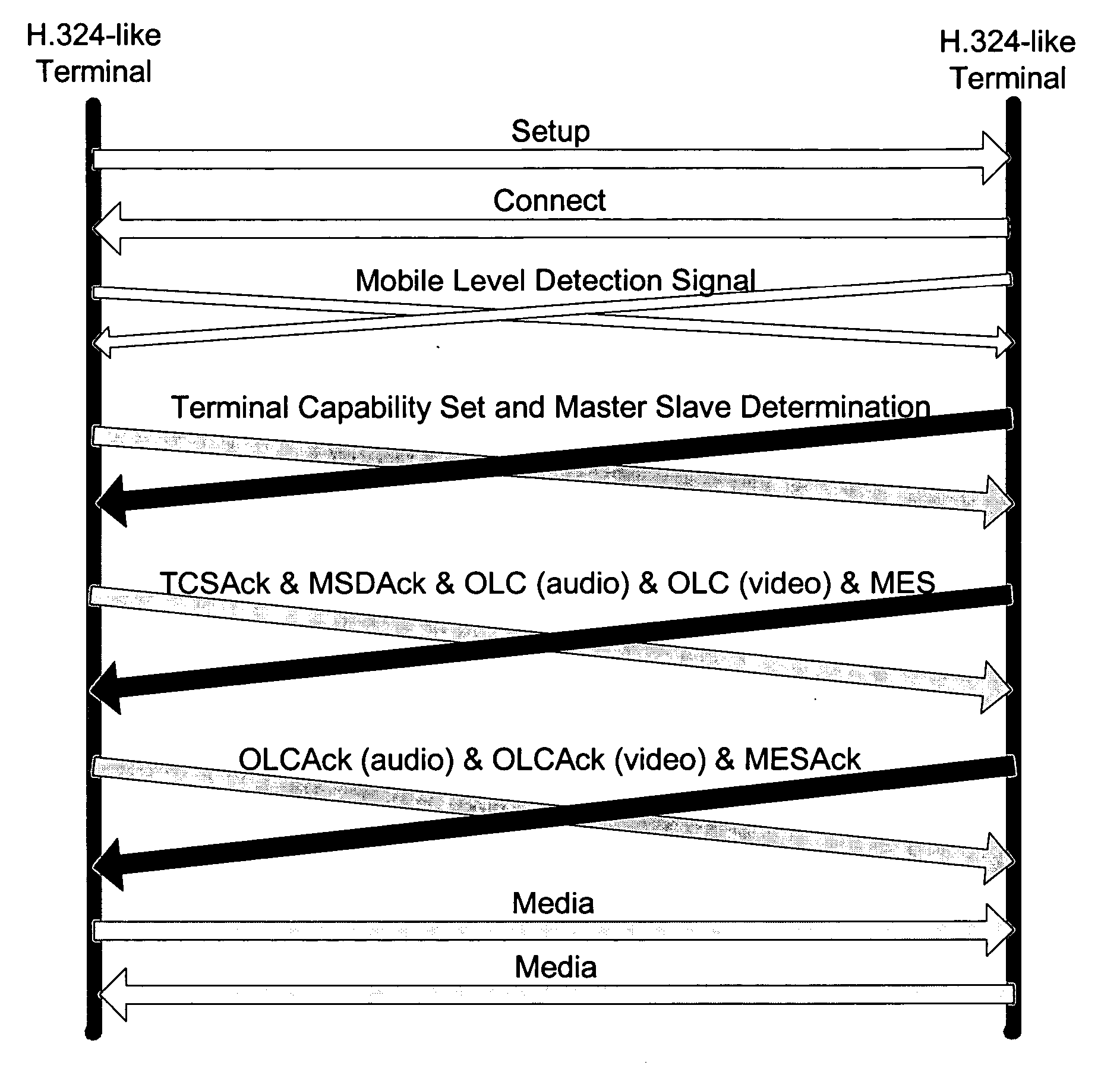

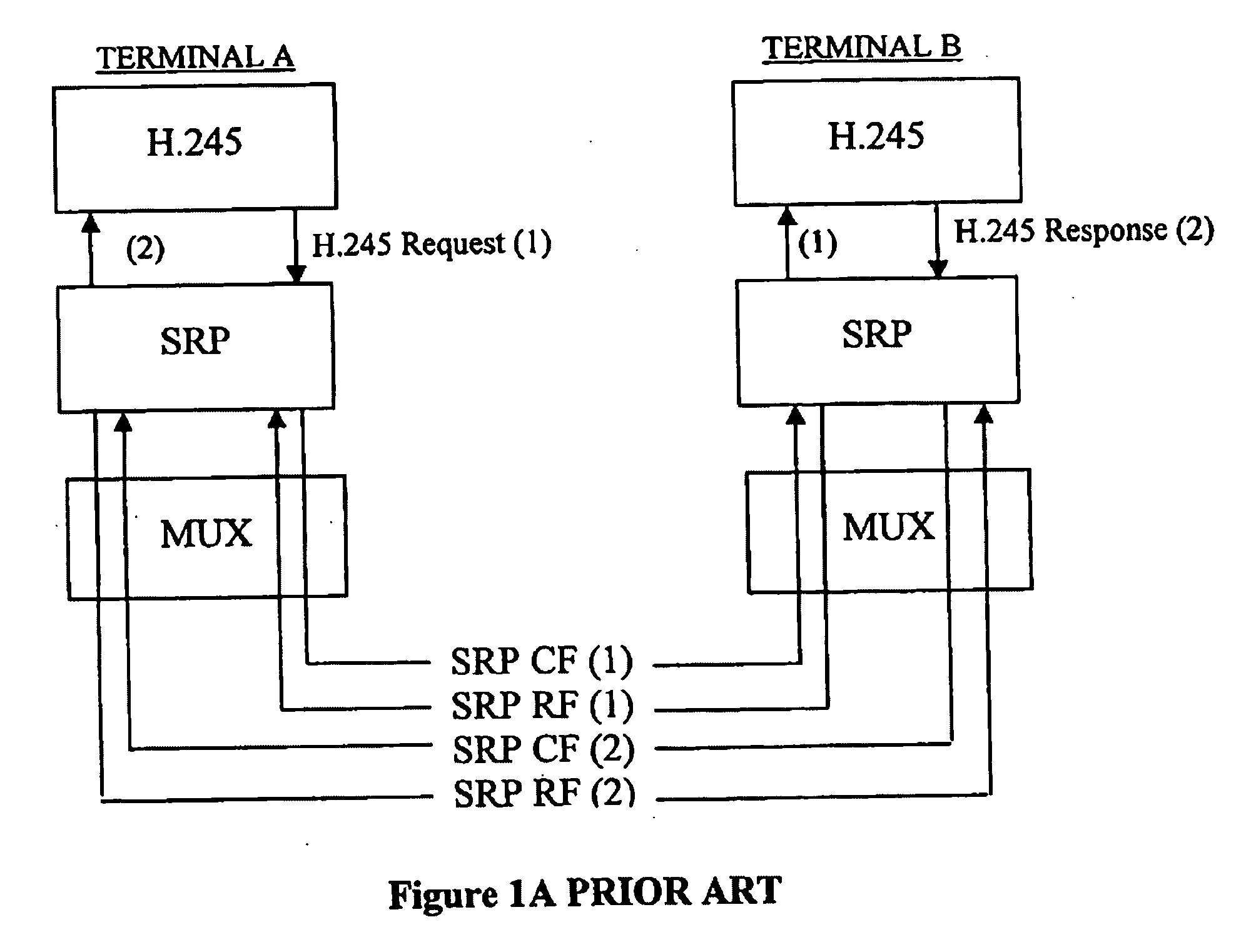

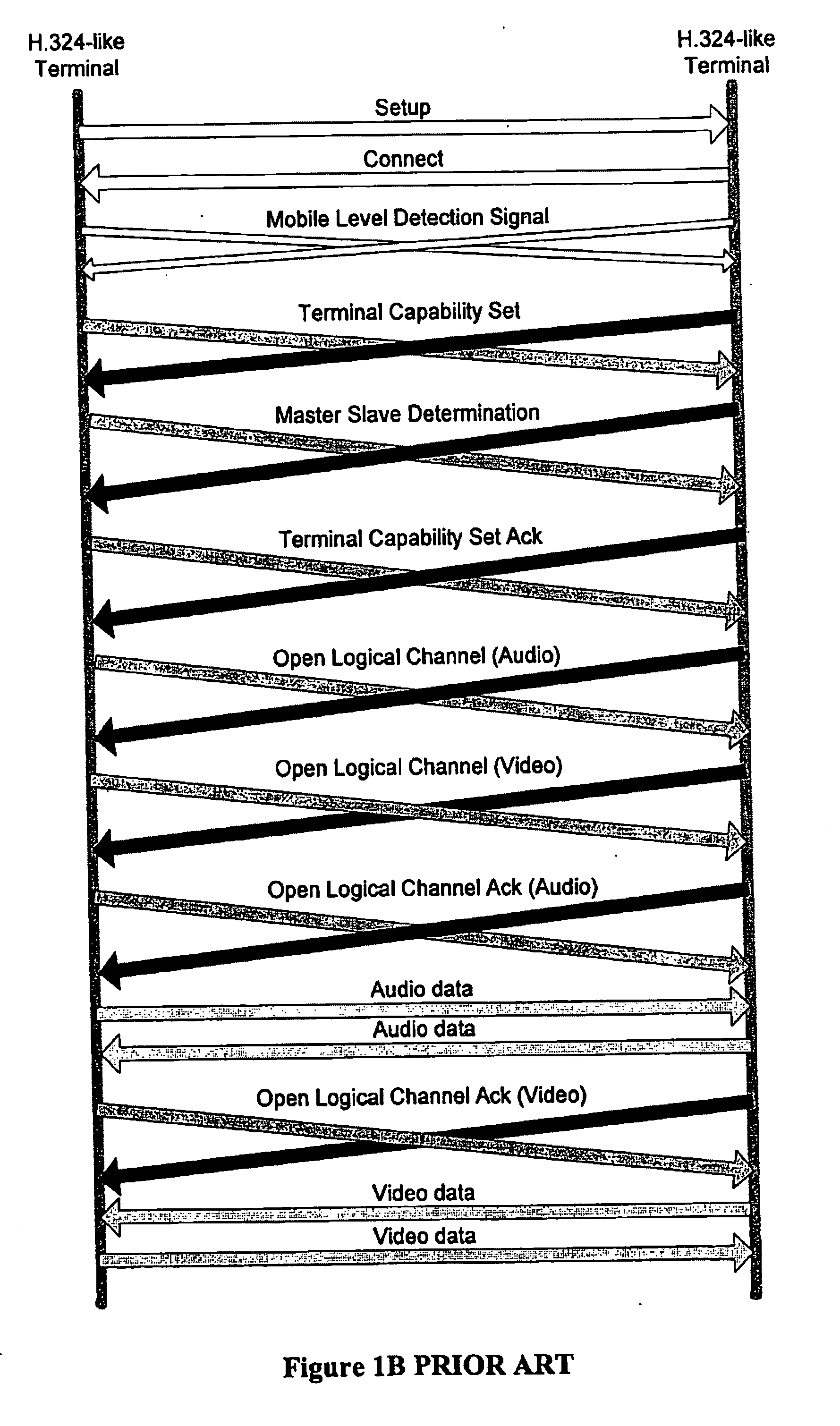

Fast session setup extensions to H.324

InactiveUS20060159037A1Shorten the timeReduce setup timeMultiplex system selection arrangementsConnection managementTelecommunications networkThird generation

A method of initiating a set up process for a call between users with reduced set up times using one or more 3G telecommunication networks. The method includes establishing a bearer channel between a first terminal and a second terminal after a call signaling process and determining, at the first terminal, one or more preferences for a call between the first terminal and the second terminal. The one or more preferences are associated with one or more modes of operation for the call. The method also includes determining a mobile level for operations and interleaving the one or more preferences, the mobile level for operations, and one or more media streams. The method further includes transferring the one or more preferences, the mobile level for operations, and the one or more media streams from the first terminal to the second terminal through a portion of a telecommunication network using the bearer channel.

Owner:ONMOBILE GLOBAL LTD

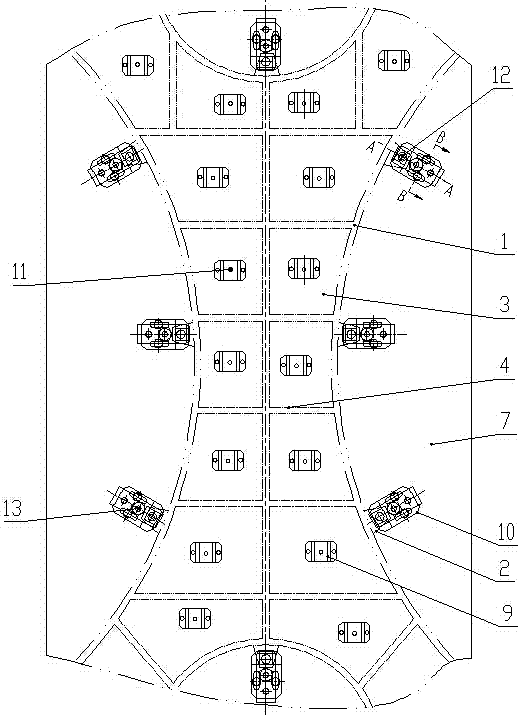

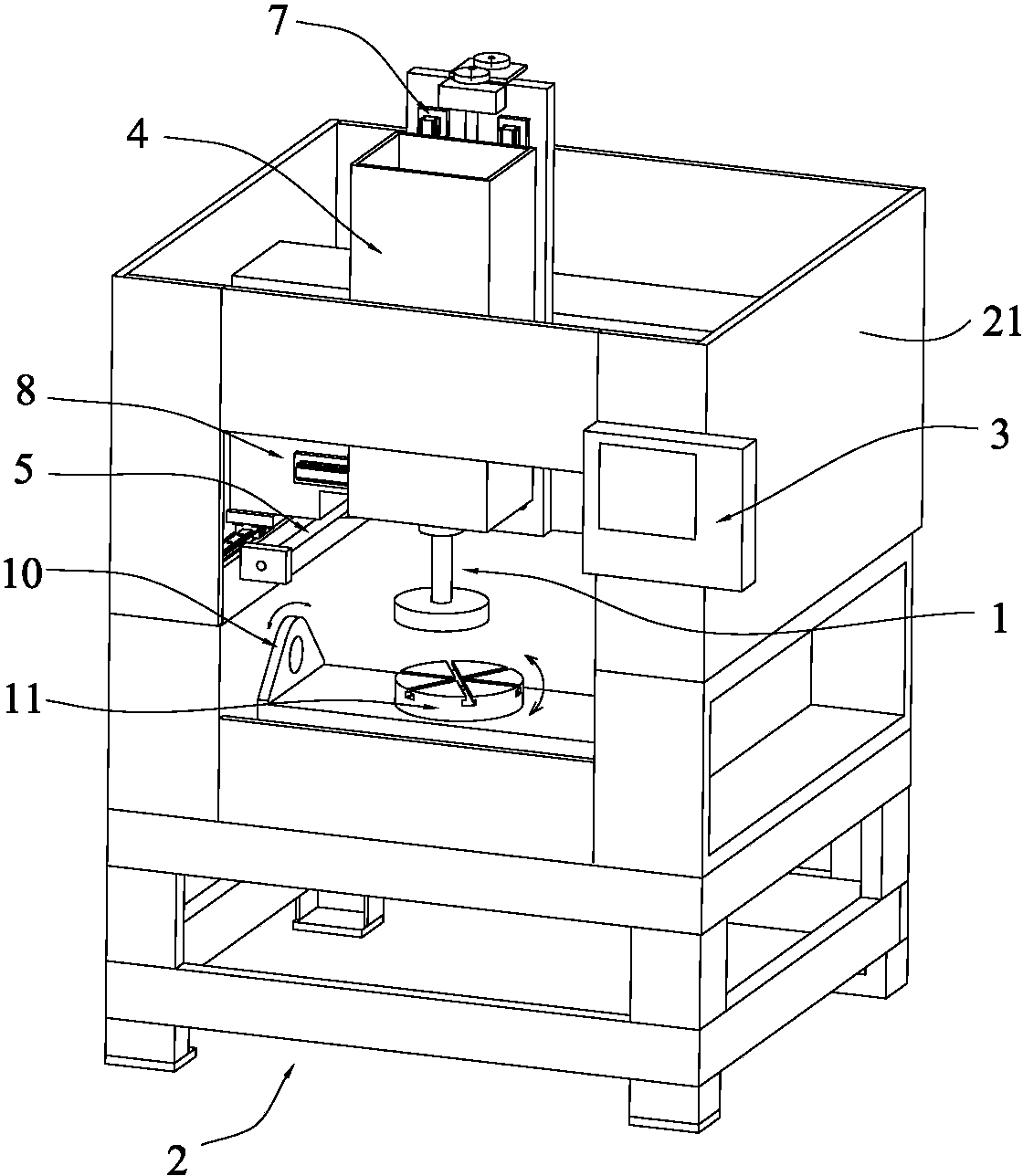

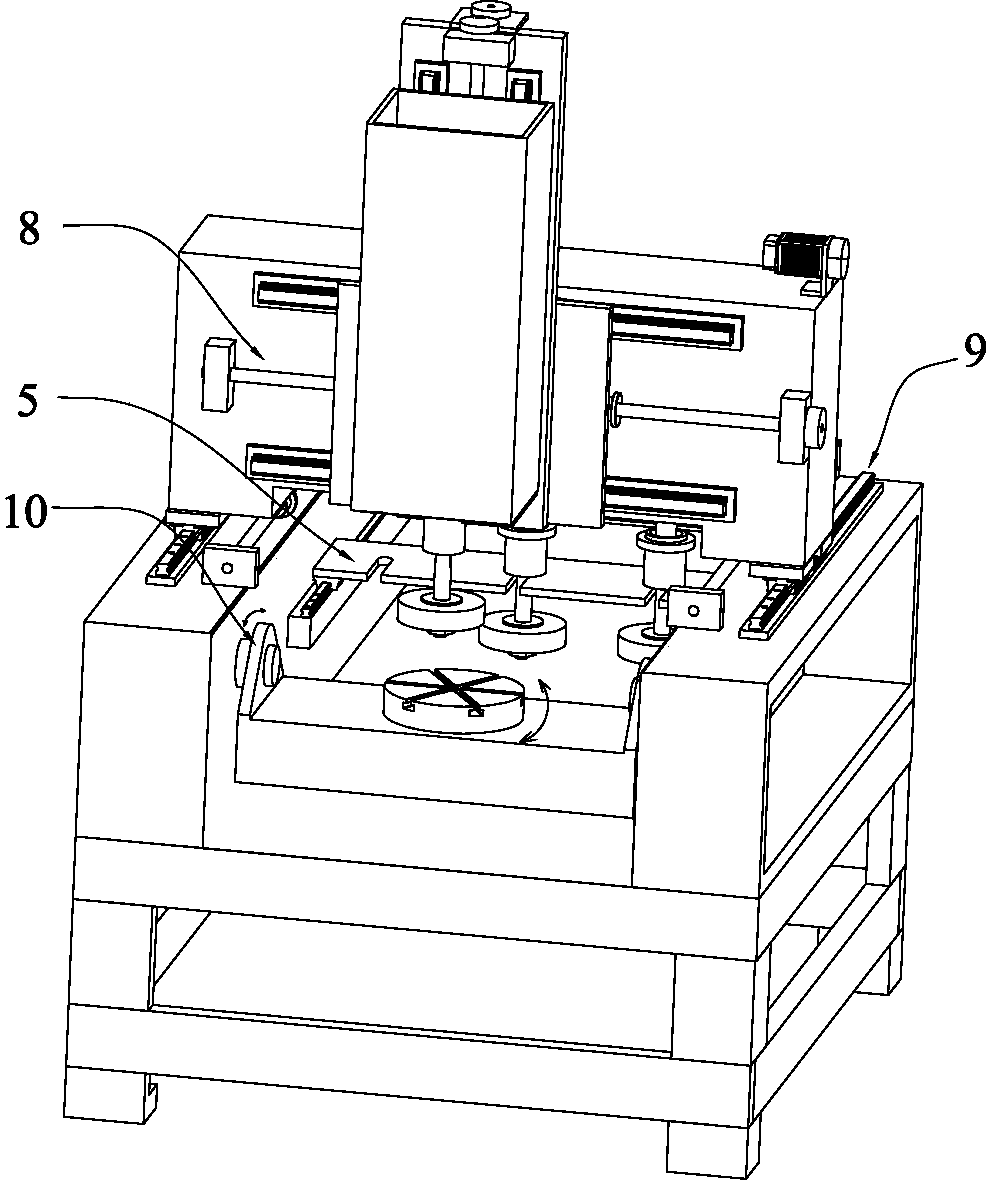

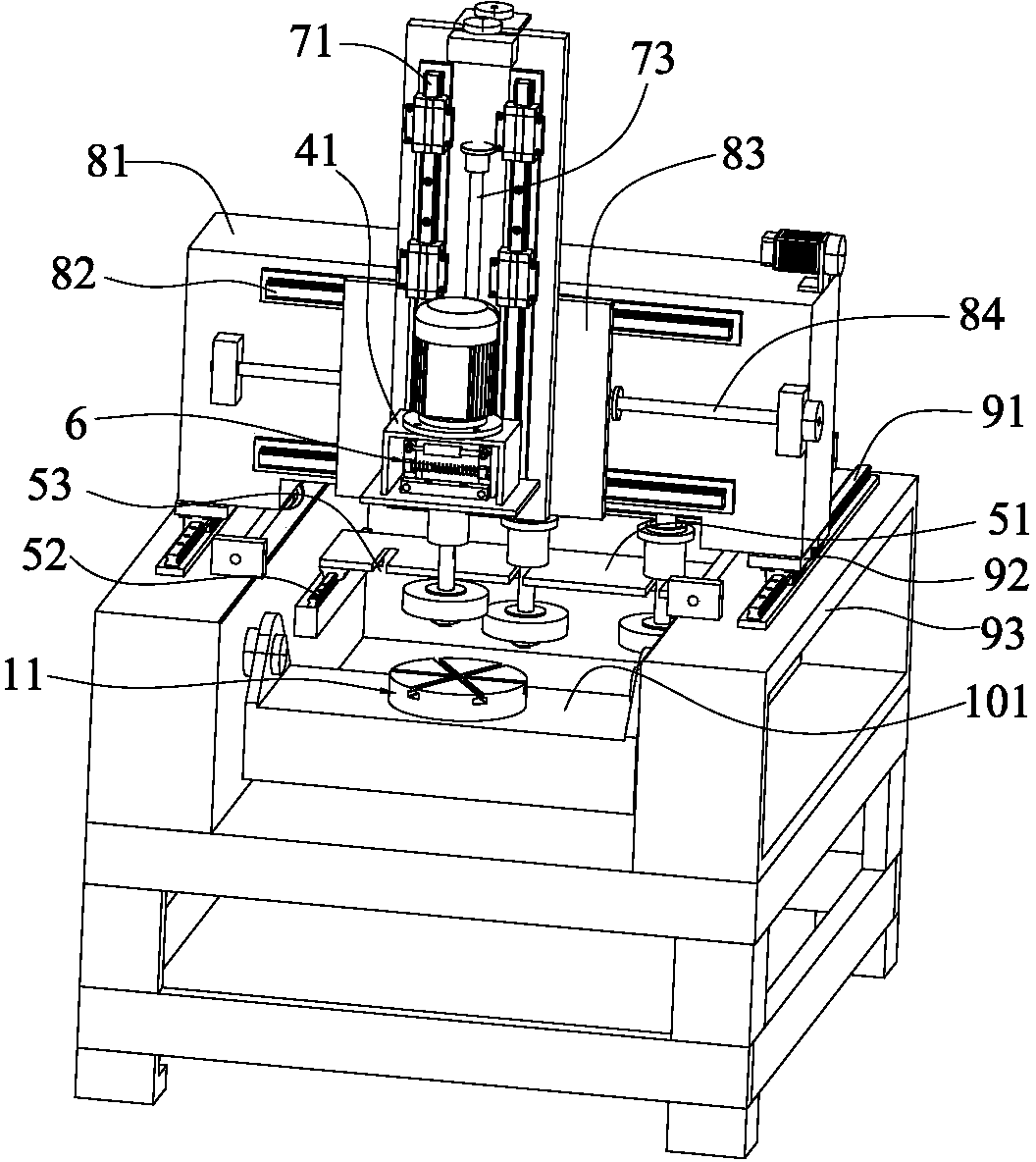

Five-axis numerical control polishing machine capable of changing grinding heads automatically

InactiveCN103465145AAutomatic replacementReduce labor intensityPolishing machinesNumerical controlCurve shape

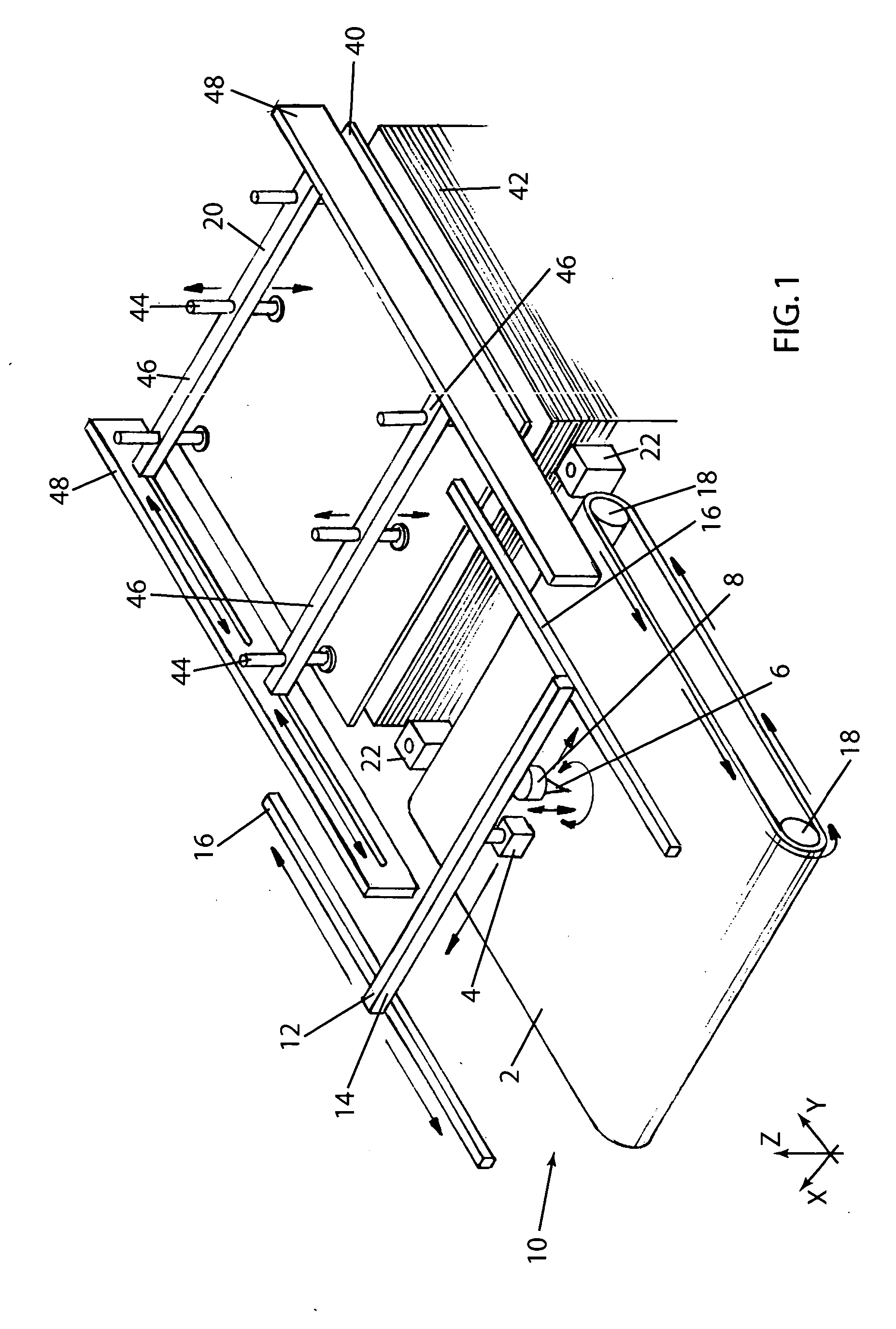

The invention discloses a five-axis numerical control polishing machine capable of changing grinding heads automatically. The five-axis numerical control polishing machine comprises a plurality of semi-axis grinding heads, a machine body frame, a controller, a polishing head, a grinding head supply mechanism, a spindle clamping device, a Z-axis drive mechanism, an X-axis drive mechanism, a Y-axis drive mechanism, an A-axis rotary workbench and a C-axis rotating mechanism. The polishing head, the grinding head supply mechanism, the spindle clamping device, the Z-axis drive mechanism, the X-axis drive mechanism, the Y-axis drive mechanism, the A-axis rotary workbench and the C-axis rotating mechanism are respectively connected with the controlled and controlled by the same. The five-axis numerical control polishing machine capable of changing grinding heads automatically has the advantages that the polishing machine is ingenious and reasonable in structural design, high in automation level, convenient and fast to operate, high in flexibility by the five-axis linkage structure, and widely applicable; multiple polishing procedures such as rough polishing, fine polishing and mirror polishing can be completed at one-step clamping, clamping time is saved, machining efficiency and precision are increased greatly, polishing effect is guaranteed, work efficiency is increased, labor intensity of workers is lowered, enterprise competitiveness is increased effectively, and polishing of surfaces of complex curve shapes can be achieved.

Owner:东莞市钜铧机械有限公司

Method of manufacturing a component

InactiveUS20120267345A1Reduce setup timeShorten production timeElectron beam welding apparatus3D object support structuresEngineeringManufacturing engineering

Apparatus for manufacturing a component and a method of manufacturing a component. The method comprises the steps of directing a beam of energy to heat a working region of a substrate and adjusting the cross sectional shape of the beam to thereby generate a variety of predetermined cross sectional shapes of working region while the beam is being directed onto the substrate. Thus the distribution of energy delivered to the substrate is controlled during the manufacturing process. The cross sectional shape and area of the beam is repeatedly monitored and compared to a library of predetermined cross sectional shape(s) and area(s).

Owner:ROLLS ROYCE PLC

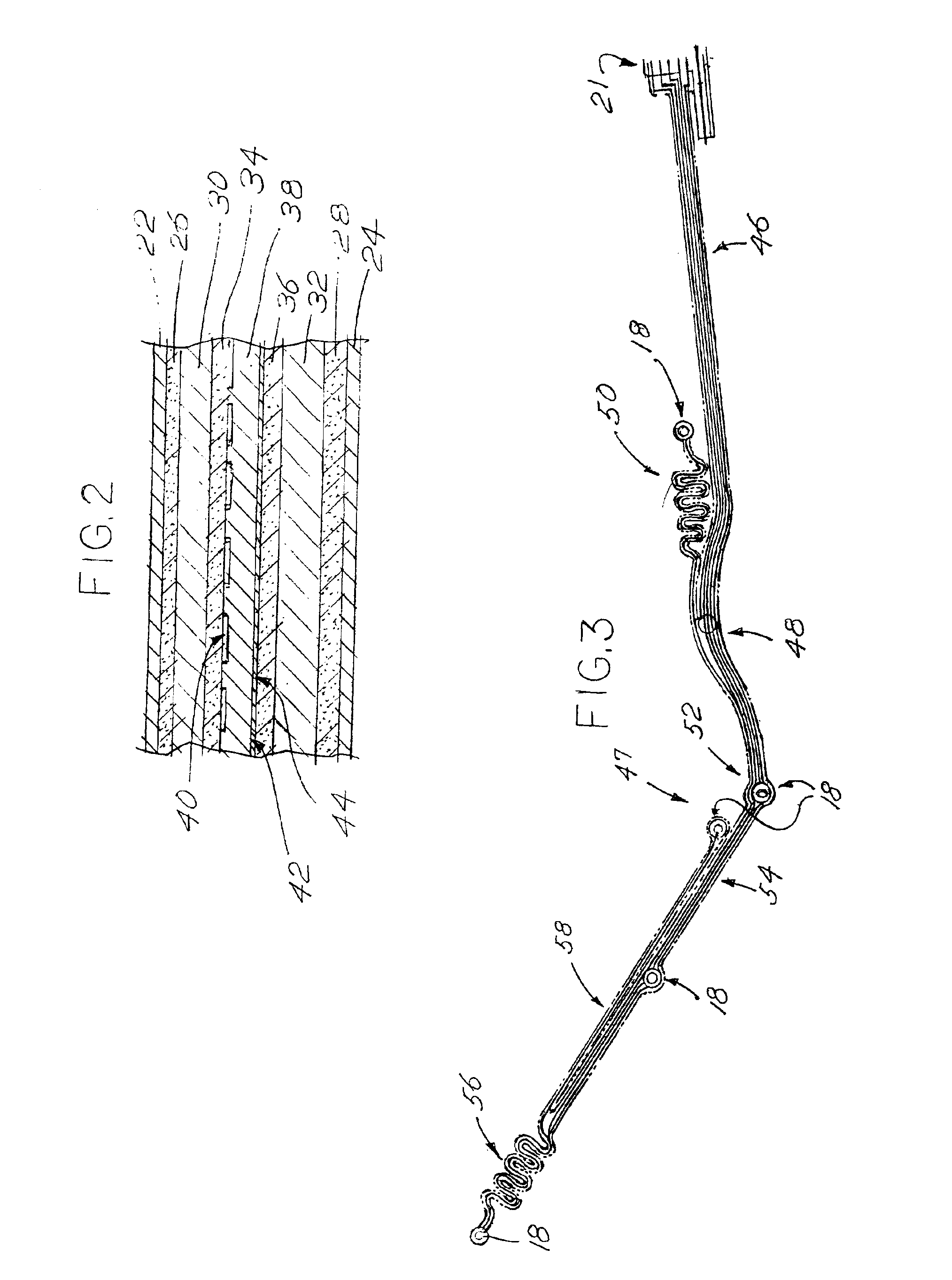

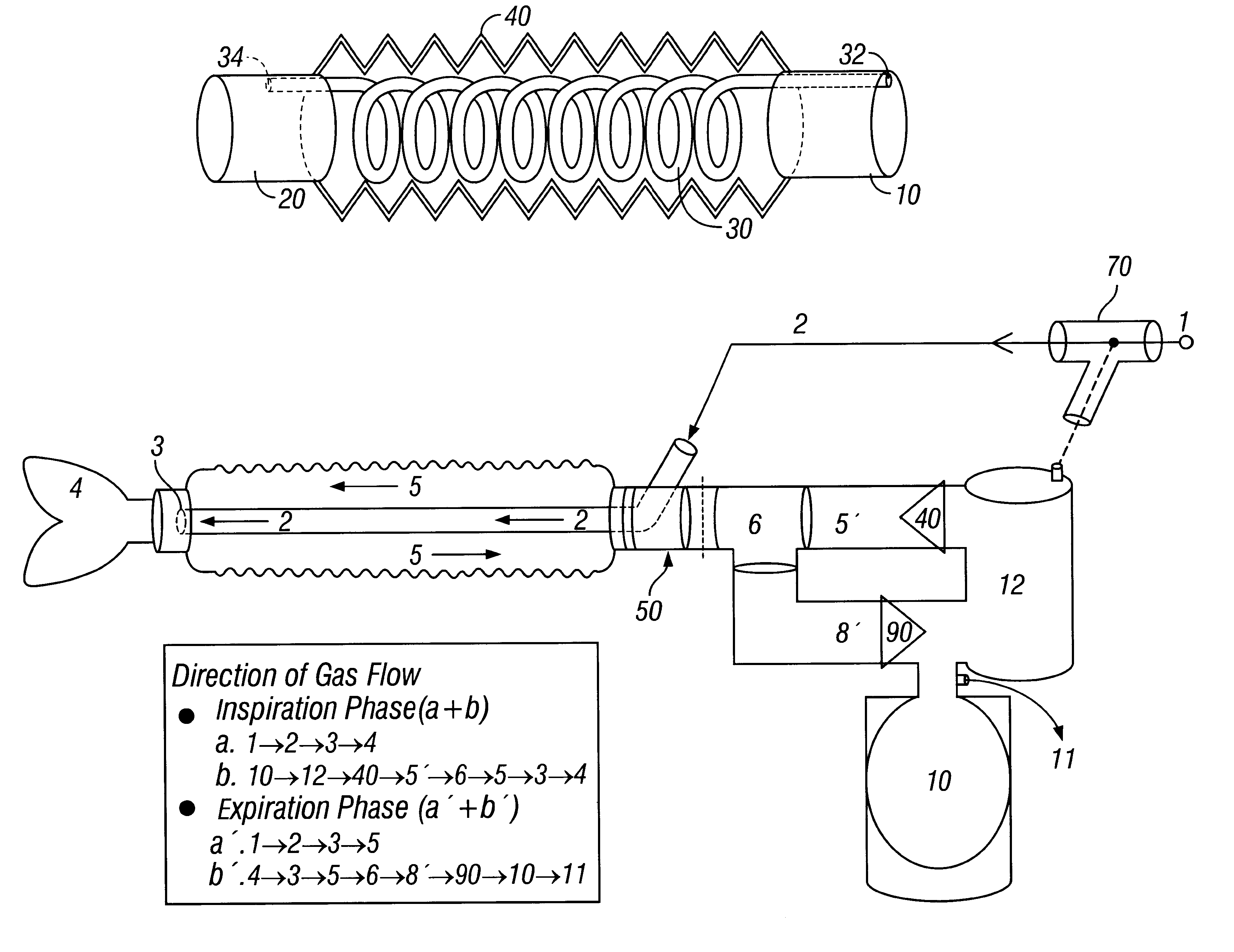

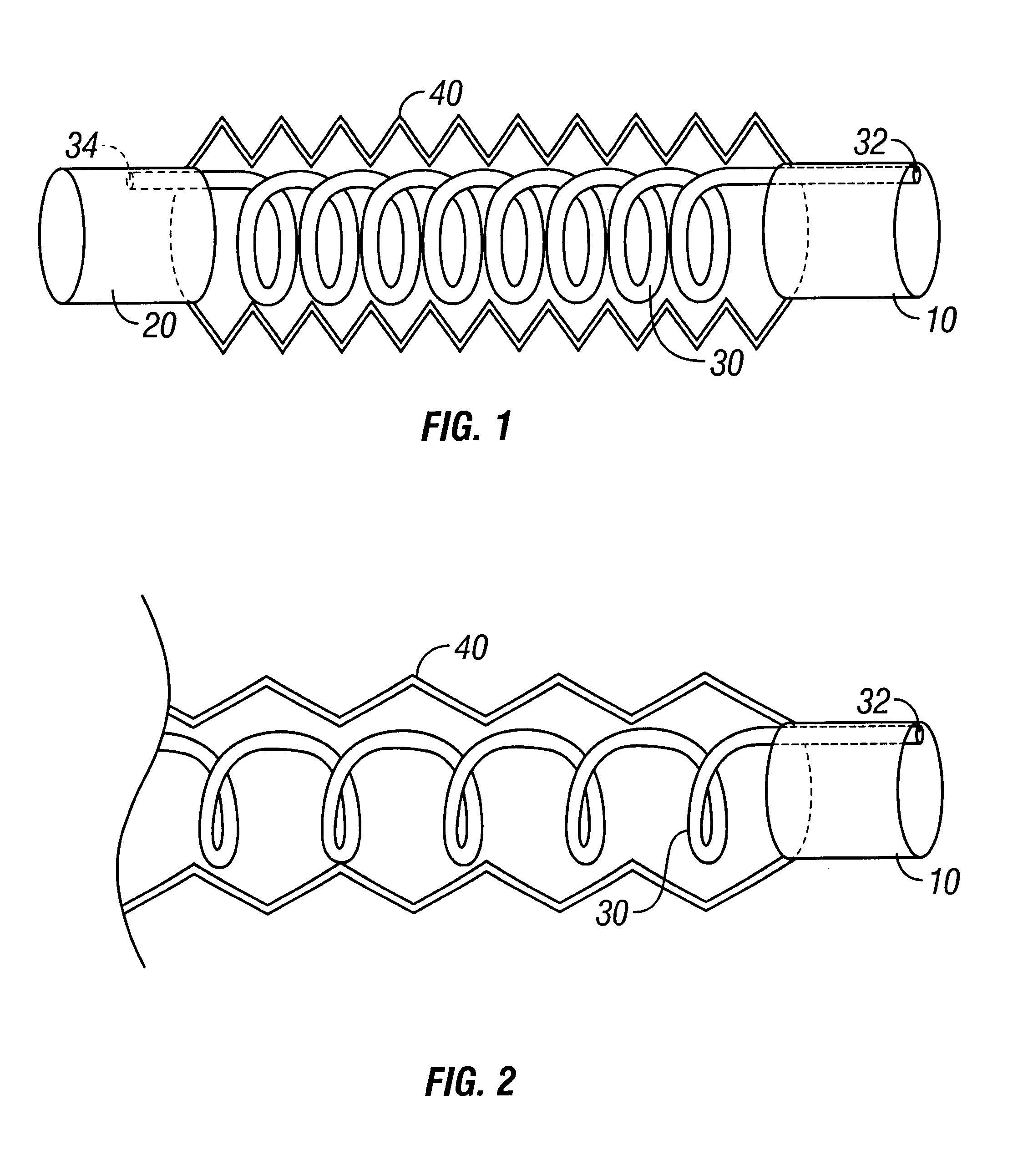

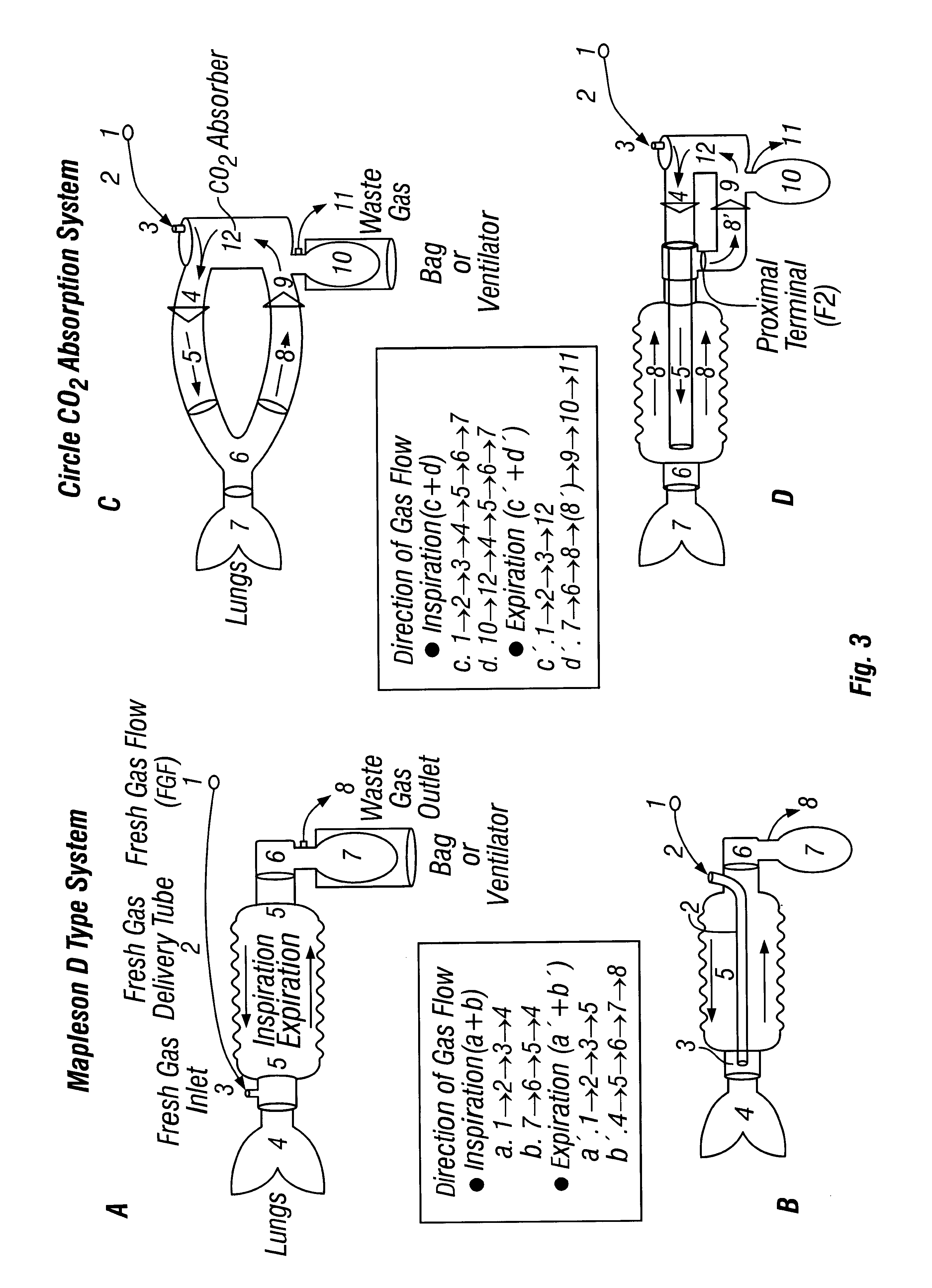

Breathing circuits having unconventional respiratory conduits and systems and methods for optimizing utilization of fresh gases

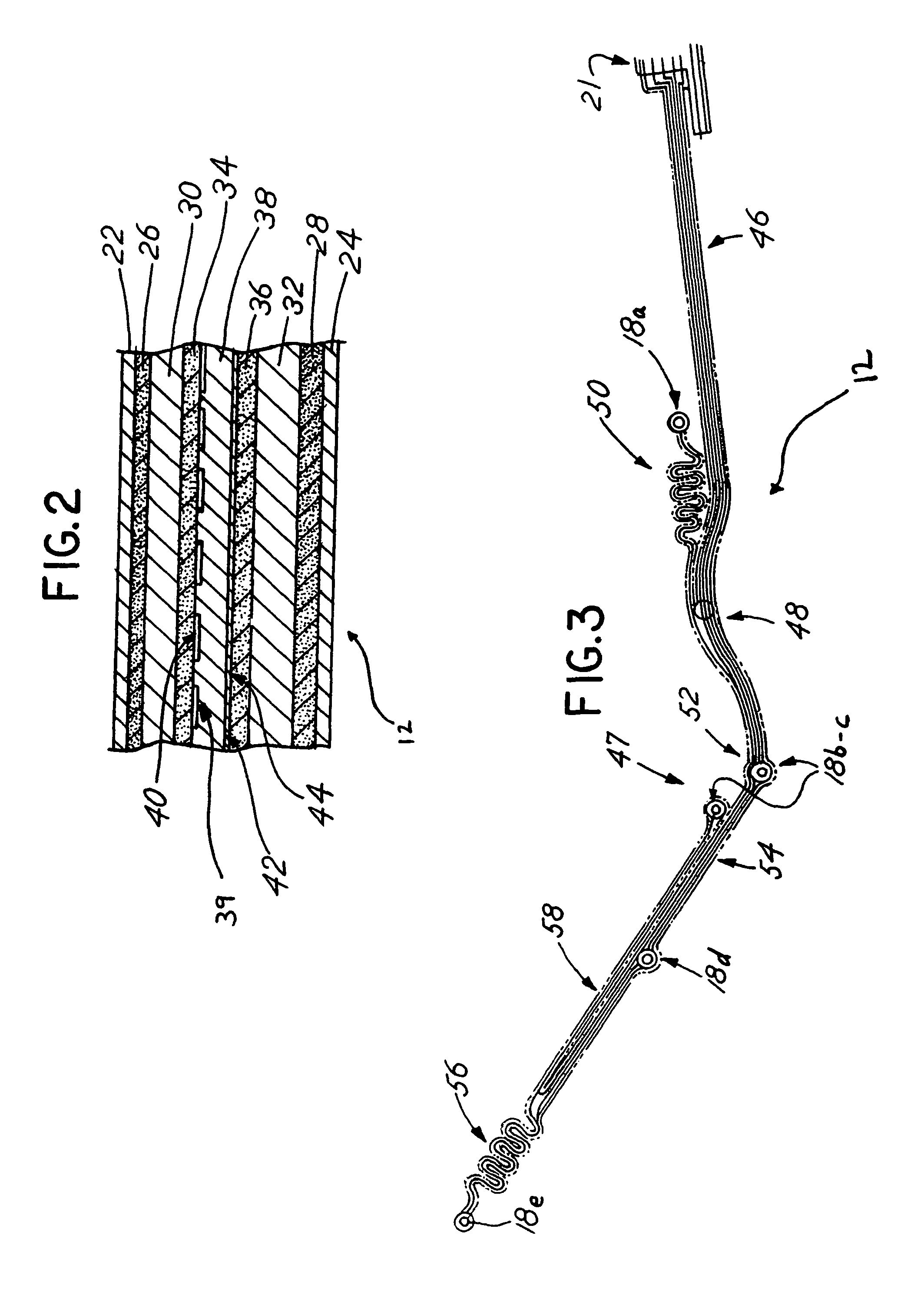

InactiveUS6874500B2Regulate securityOptimizing the utilization of anesthetic gasesRespiratorsSurgeryBreathing gasCatheter

A breathing circuit comprising first and second conduits, wherein at least one of the conduits is a non-conventional conduit. In an embodiment, a multilumen unilimb breathing circuit has first and second conduits, wherein when the proximal ends of said first and second conduits are each connected to an inlet and outlet fitting, respectively, movement of the distal end of the first conduit causes a corresponding movement of the distal end of the second conduit. In an embodiment, at least one of said conduits is coiled. In another embodiment, a coiled conduit is contained within an outer flexible conduit that is axially extendable and compressible, forming a unilimb multilumen respiratory circuit. The outer flexible conduit may be pleated to provide for non-rebounding axial extension and contraction. The multilumen respiratory circuit can provide a variable rebreathing volume. In an embodiment, at least one tube in a multilumen respiratory conduit is radially collapsible and radially expandable to a maximum radius for carrying respiratory gases to and from a patient. The methods and systems can be used to administer anesthesia and for other purposes.

Owner:AMBU AS

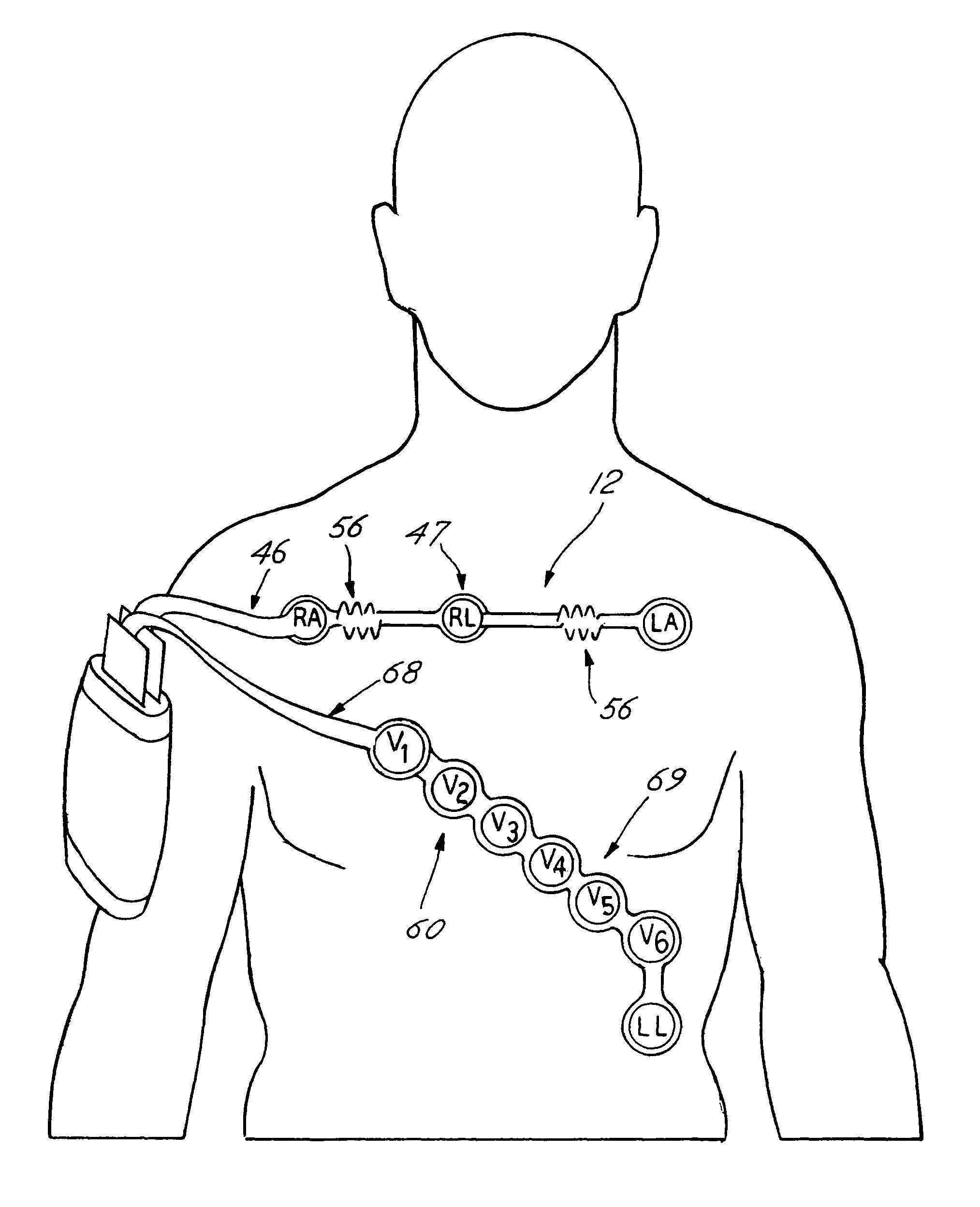

Wireless ECG system

InactiveUS20050177052A1Improve comfortImprove mobilityCoupling device connectionsElectrocardiographyCardiac monitoringEngineering

A cardiac monitoring system and, more particularly, a wireless electrocardiograph (ECG) system. The present invention detects electrical signals from a patient's heart and transmits the signals digitally to a remote base station via telemetry. The base station converts the digital signals back to an analog electrical signals that can be read by an ECG monitor.

Owner:LIFESYNC

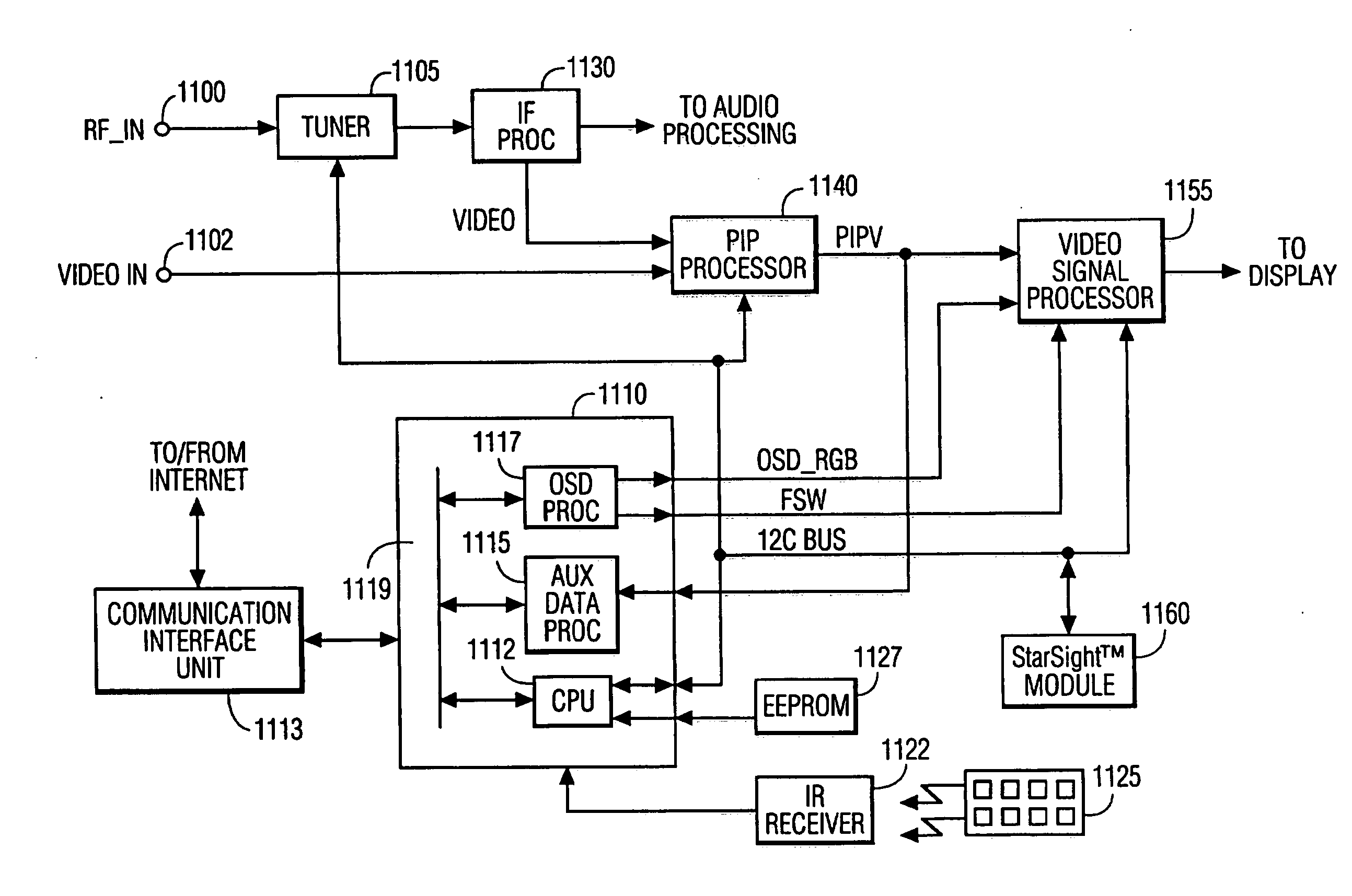

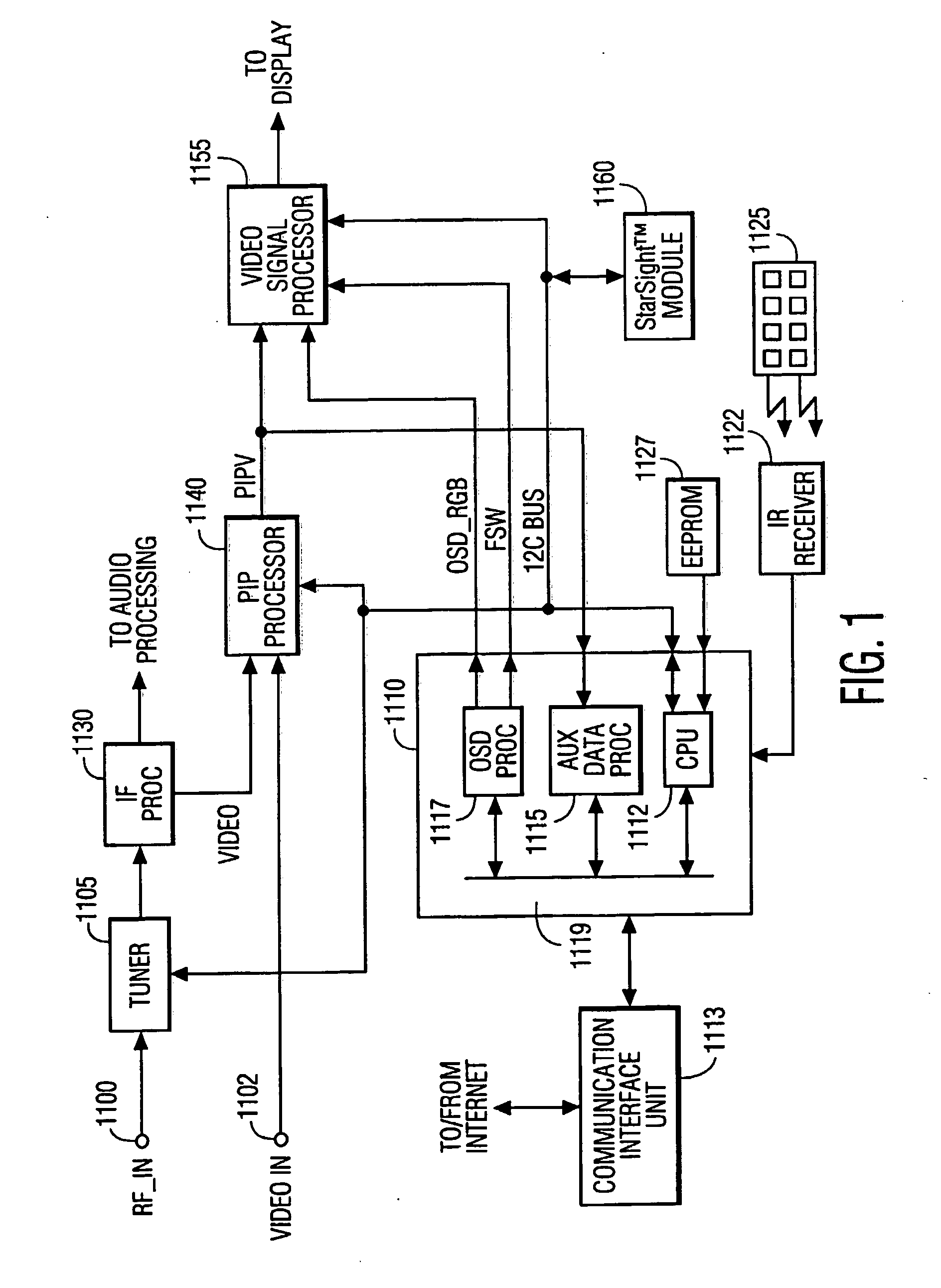

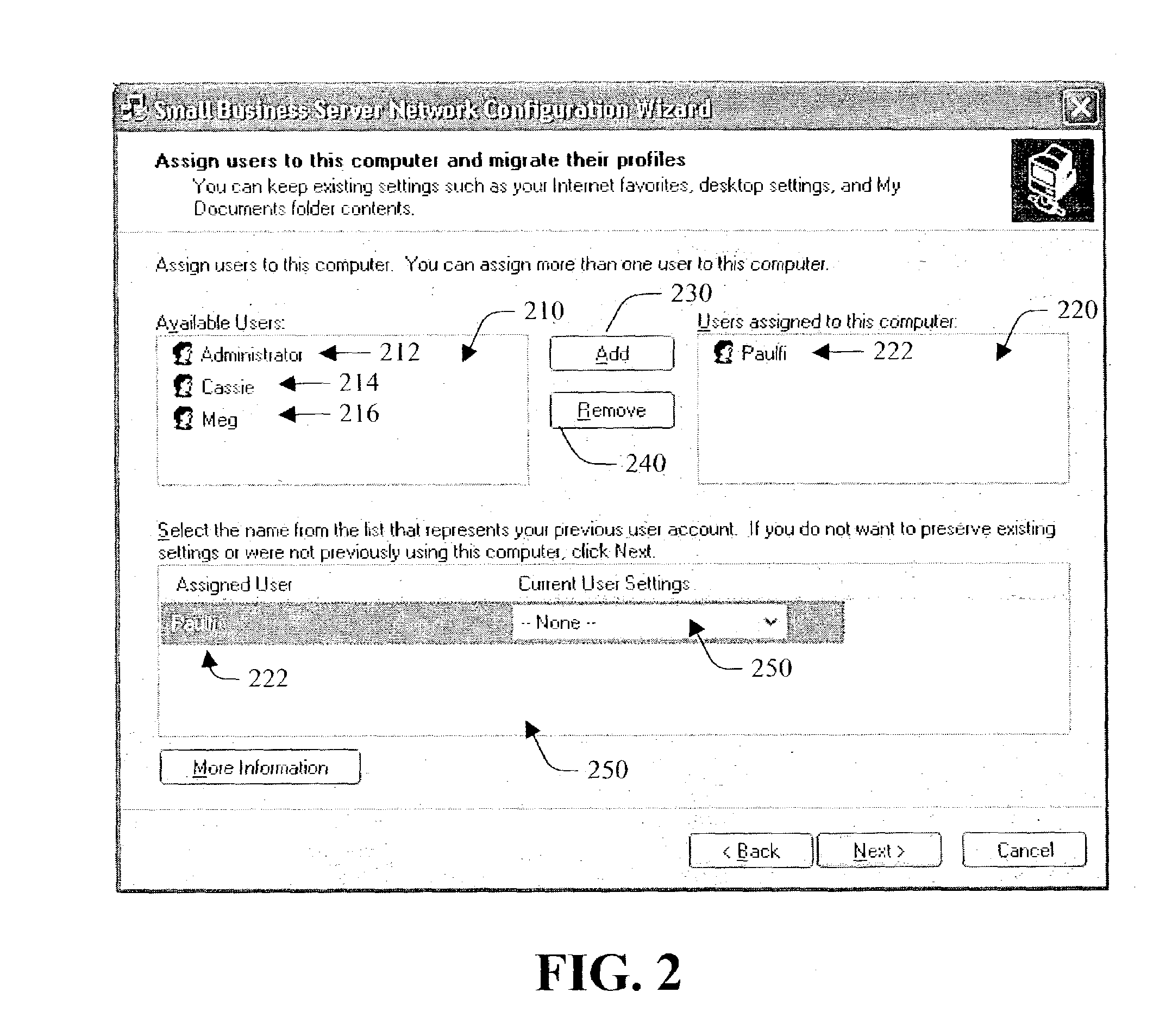

System and method for creating user profiles

InactiveUS20050076367A1Reduce setup timeShorten the lengthTelevision system detailsAnalogue secracy/subscription systemsData entryUser profile

A system and method for creating user profiles in a television system are described. The system comprises a storage medium having storage locations to store user profiles for a plurality of users; a user interface for creating new user profiles having fields for data entry to be stored in the storage medium; the user interface for creating new user profiles comprising a user option to select and copy data from a stored user profile; and means to select a stored user profile, copy selected data from the stored user profile to corresponding fields in the new user profile, and save the new user profile at a storage location.

Owner:THOMSON LICENSING SA

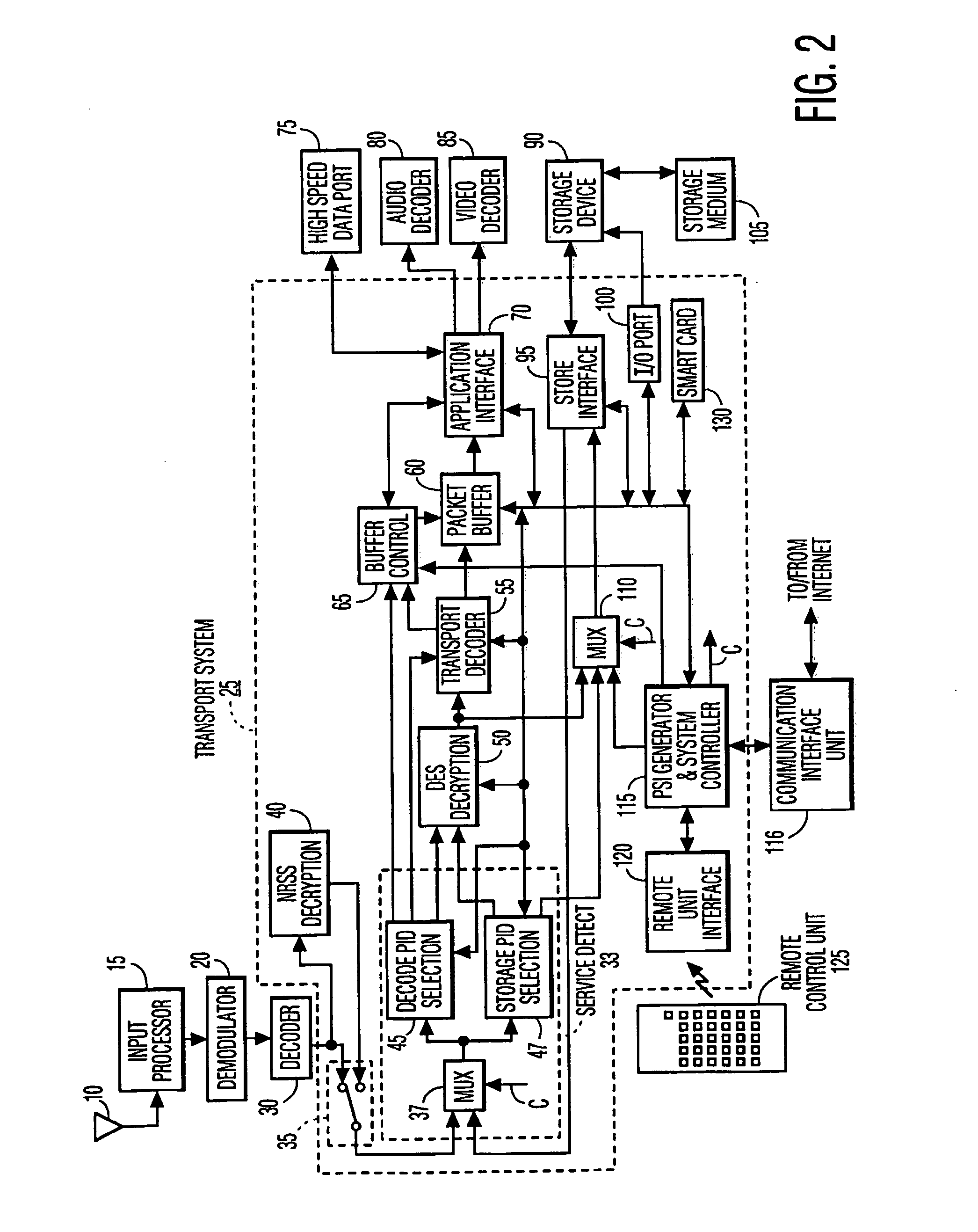

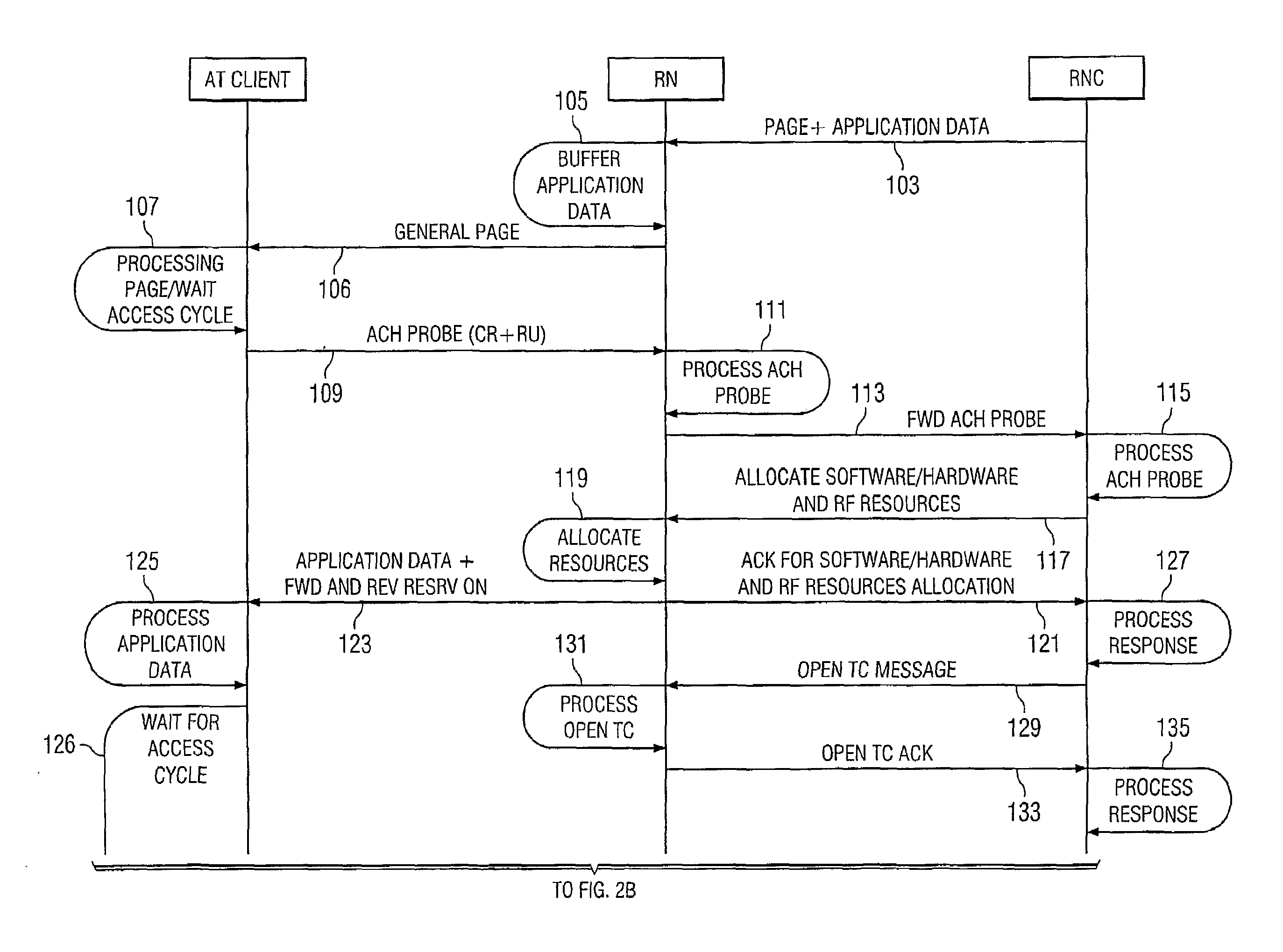

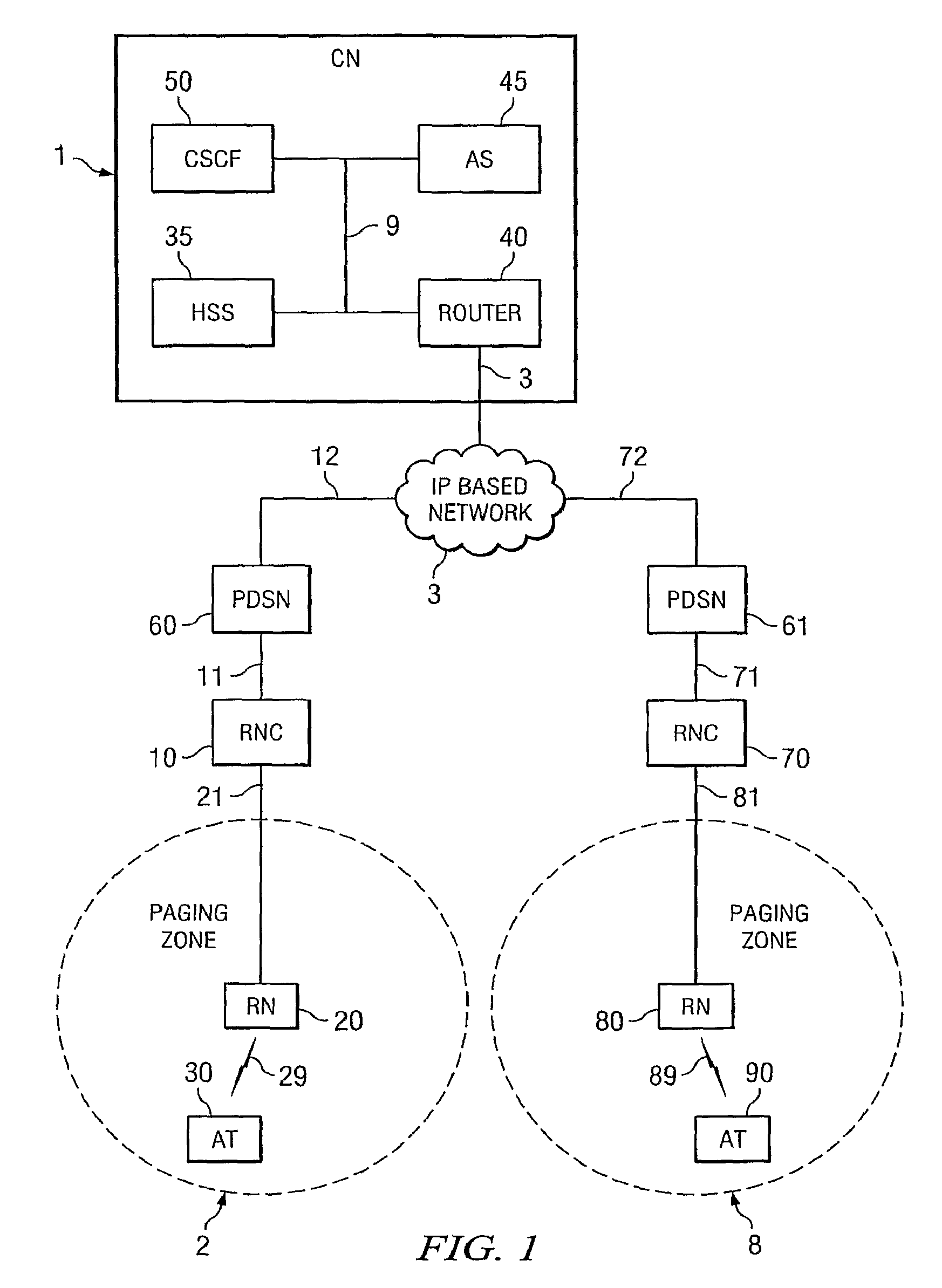

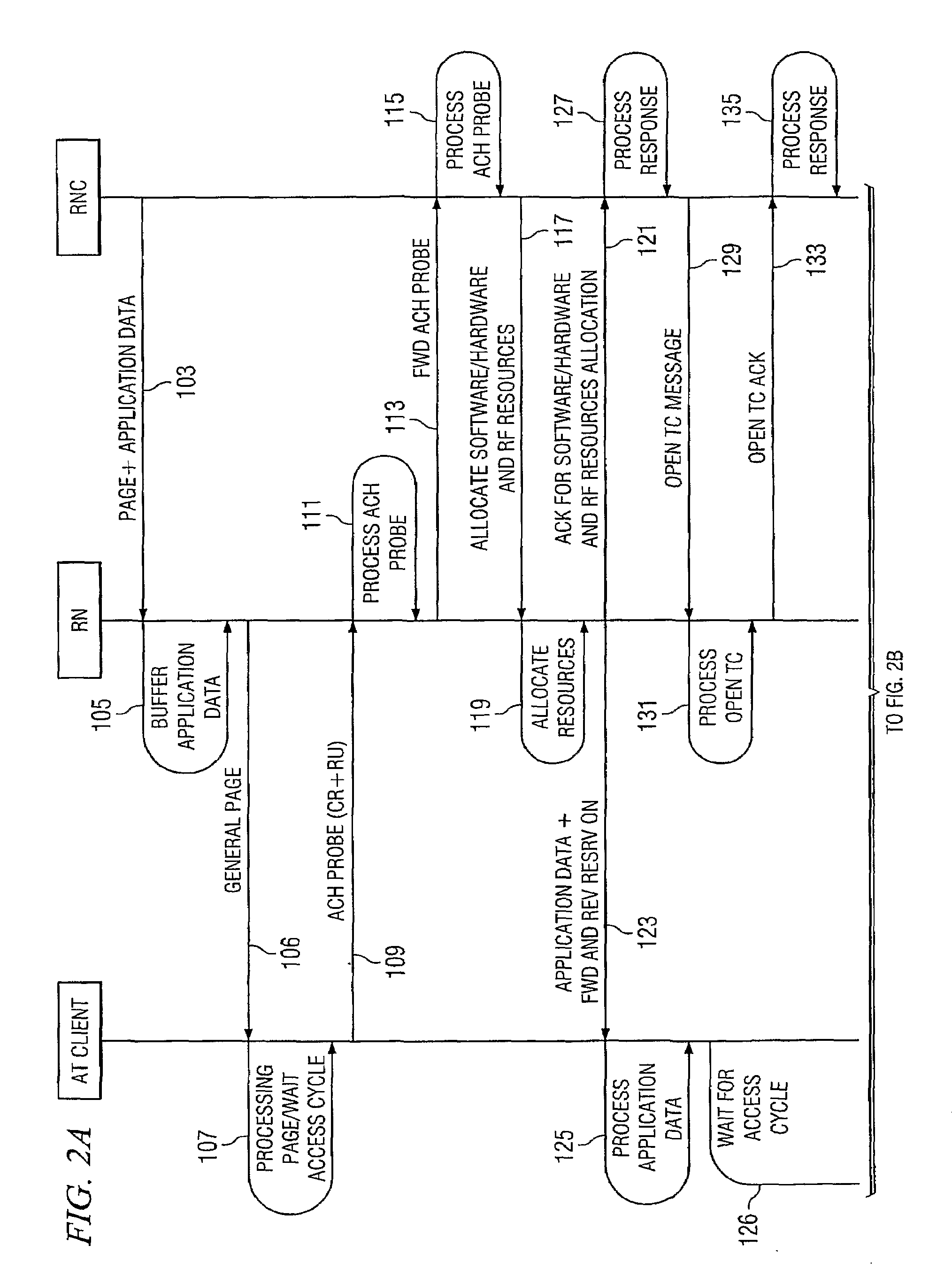

Radio resource reservation for wireless networks

InactiveUS8825070B2Reduce setup timeImprove performanceNetwork traffic/resource managementWireless commuication servicesQuality of serviceRadio networks

The present invention supports a communication protocol on a wireless communication network to allocate network resources. The radio network controller maintains quality of service (QoS) profiles. A serving node determines the type of application in a communication call and determines a QoS policy it transmits to the radio network. The radio network identifies the QoS profile based on the received policy and allocates network resources before announcing the call to an access terminal.

Owner:APPLE INC

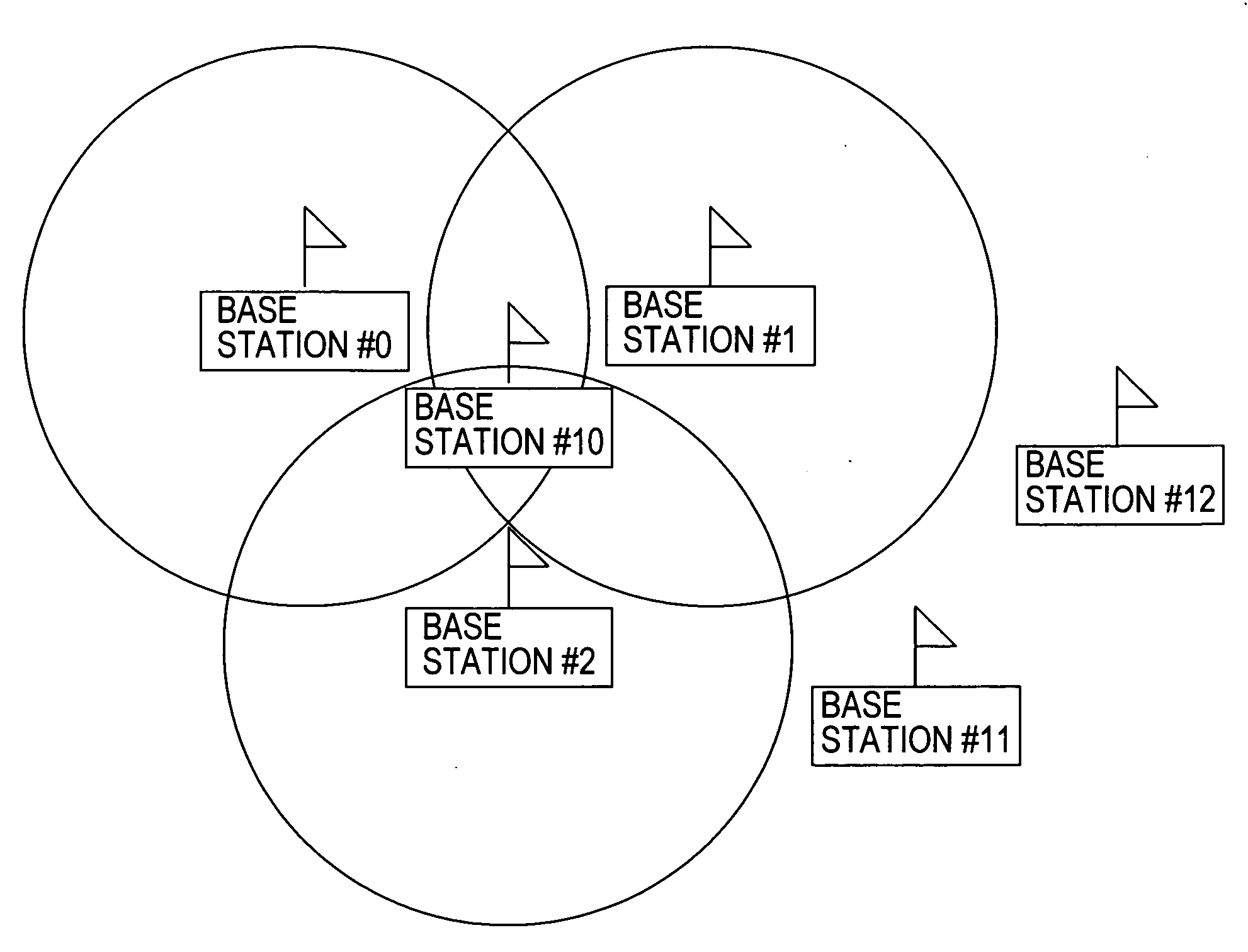

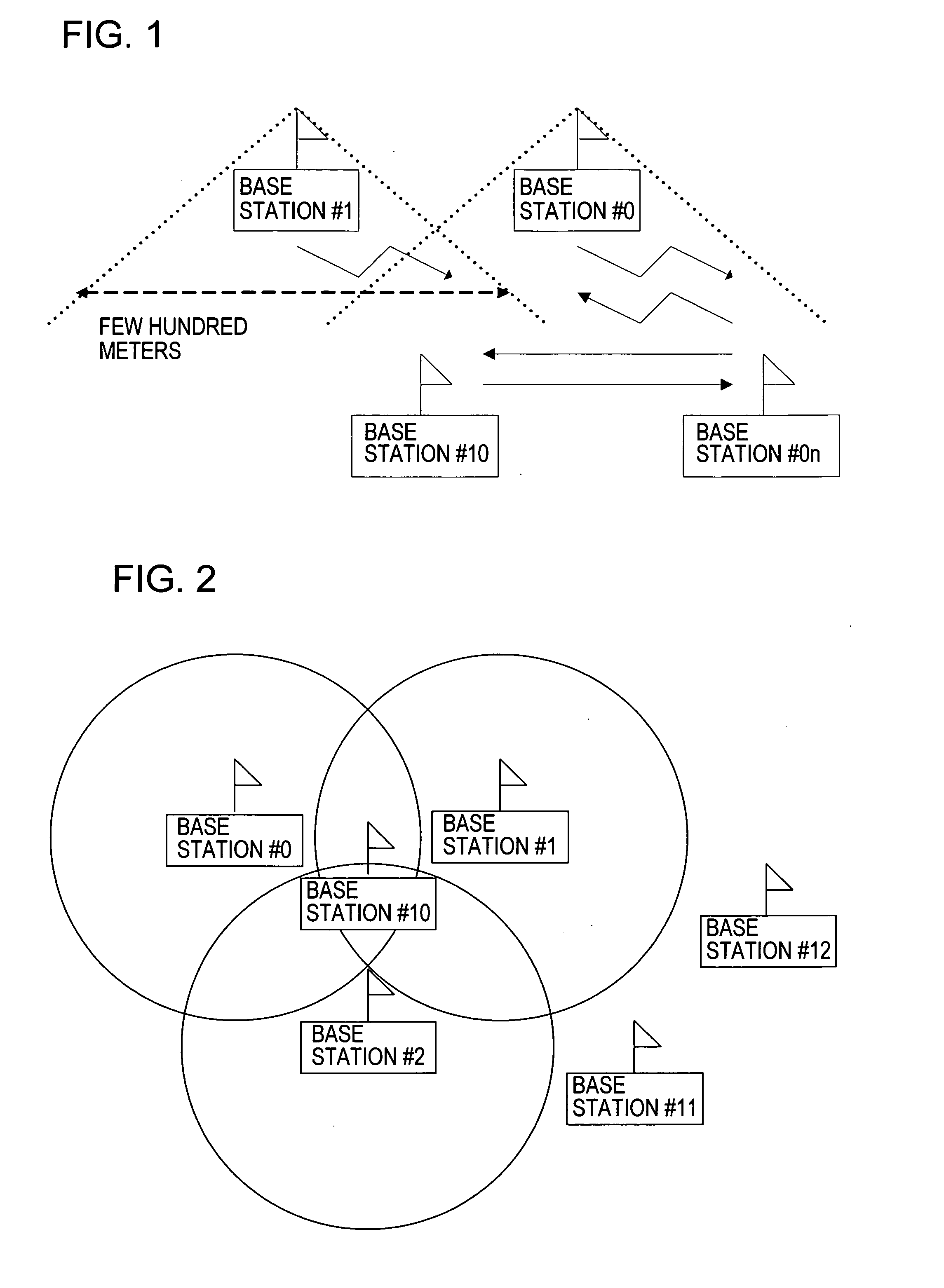

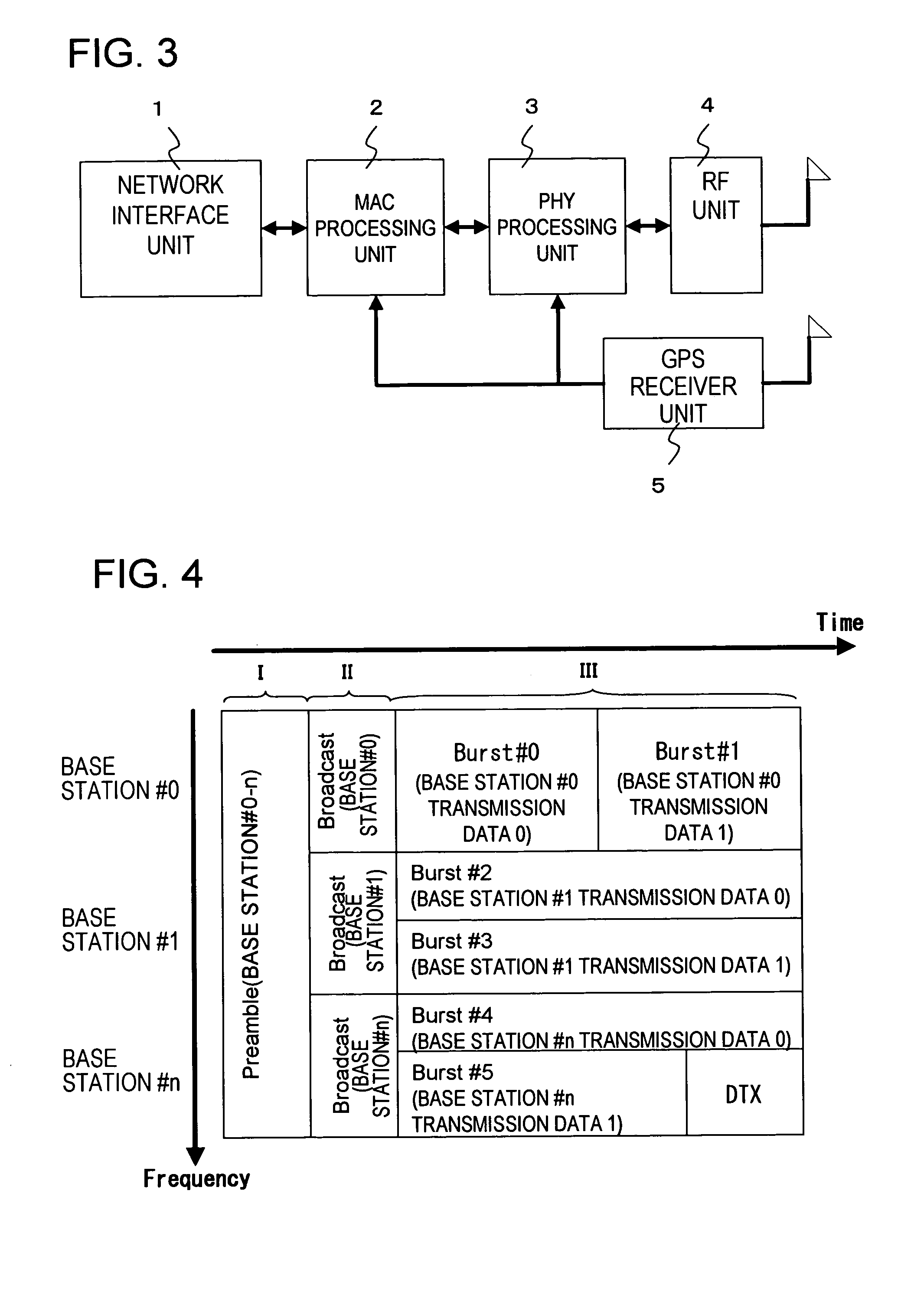

Communication system

InactiveUS20070291713A1Reduce setup timeEnable in small areaSynchronisation arrangementAssess restrictionCommunications systemMaximum level

A communication system forms a frame format such that each of the plurality of the base stations is assigned with one of a plurality of frequency bands, which are orthogonally frequency divided; in accordance with the frame format, the plurality of the base stations transmitting a frame signal including a preamble signal, a broadcast signal that allows the plurality of the terminal apparatuses to commonly recognize information indicating an area of presence of transmission data disposed within the assigned frequency band, and the transmission data disposed within the assigned frequency band, periodically in a downlink frame period; each of the plurality of the terminal apparatuses detecting a path with the maximum level from the preamble signal in the received frame signal to establish synchronization with the base station based on the detected path to acquire the transmission data in the frequency band recognized based on the broadcast signal.

Owner:FUJITSU LTD

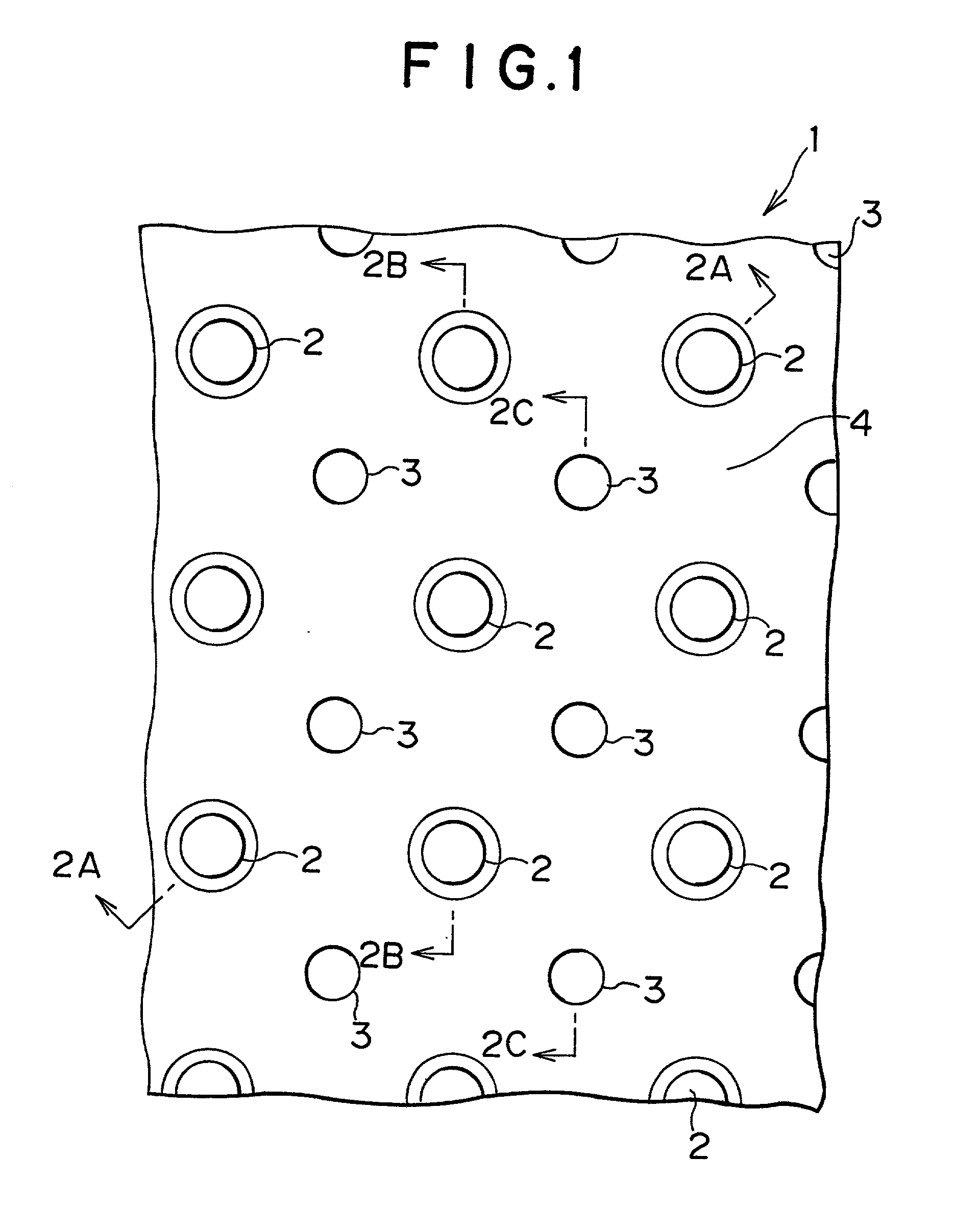

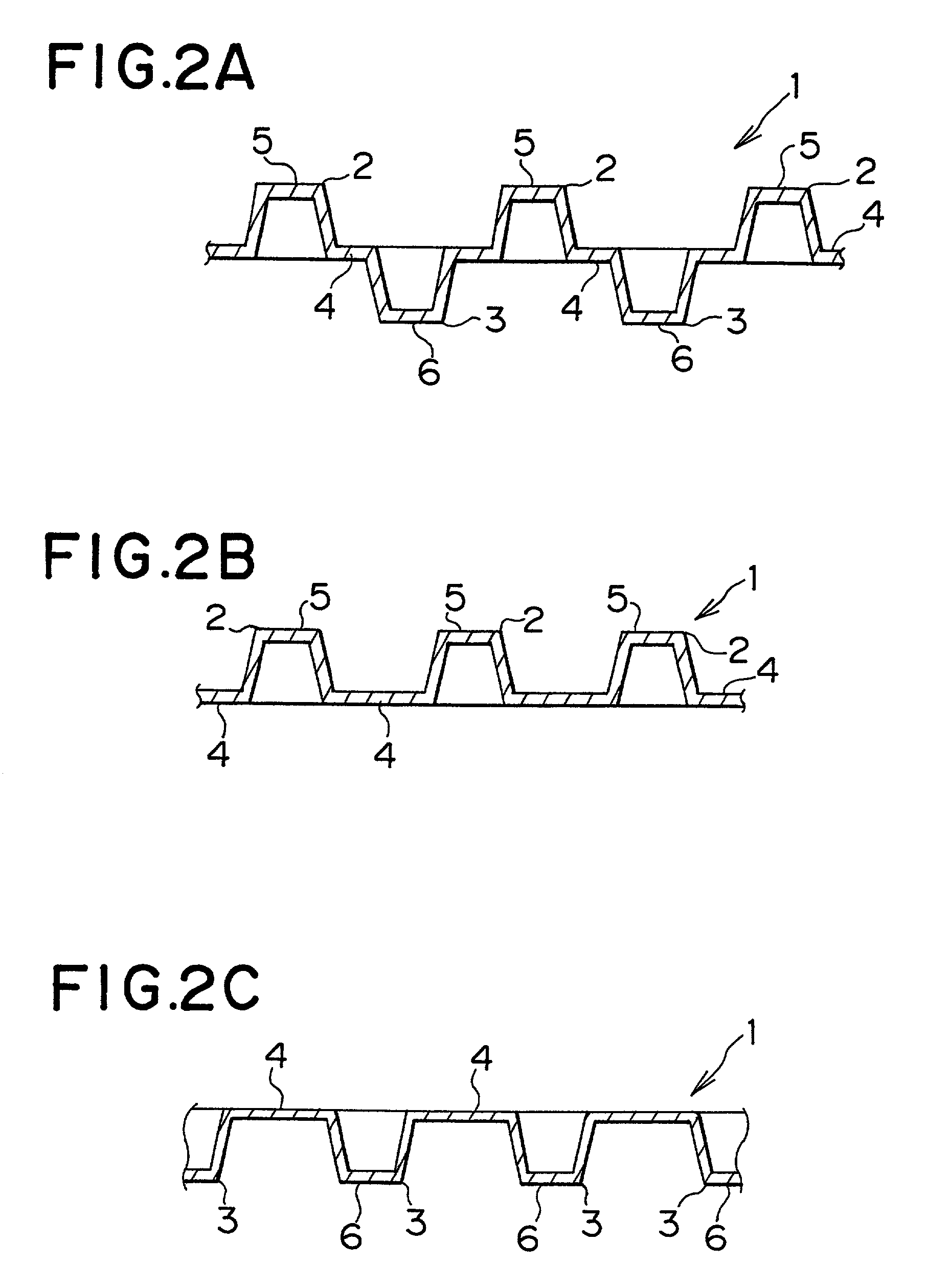

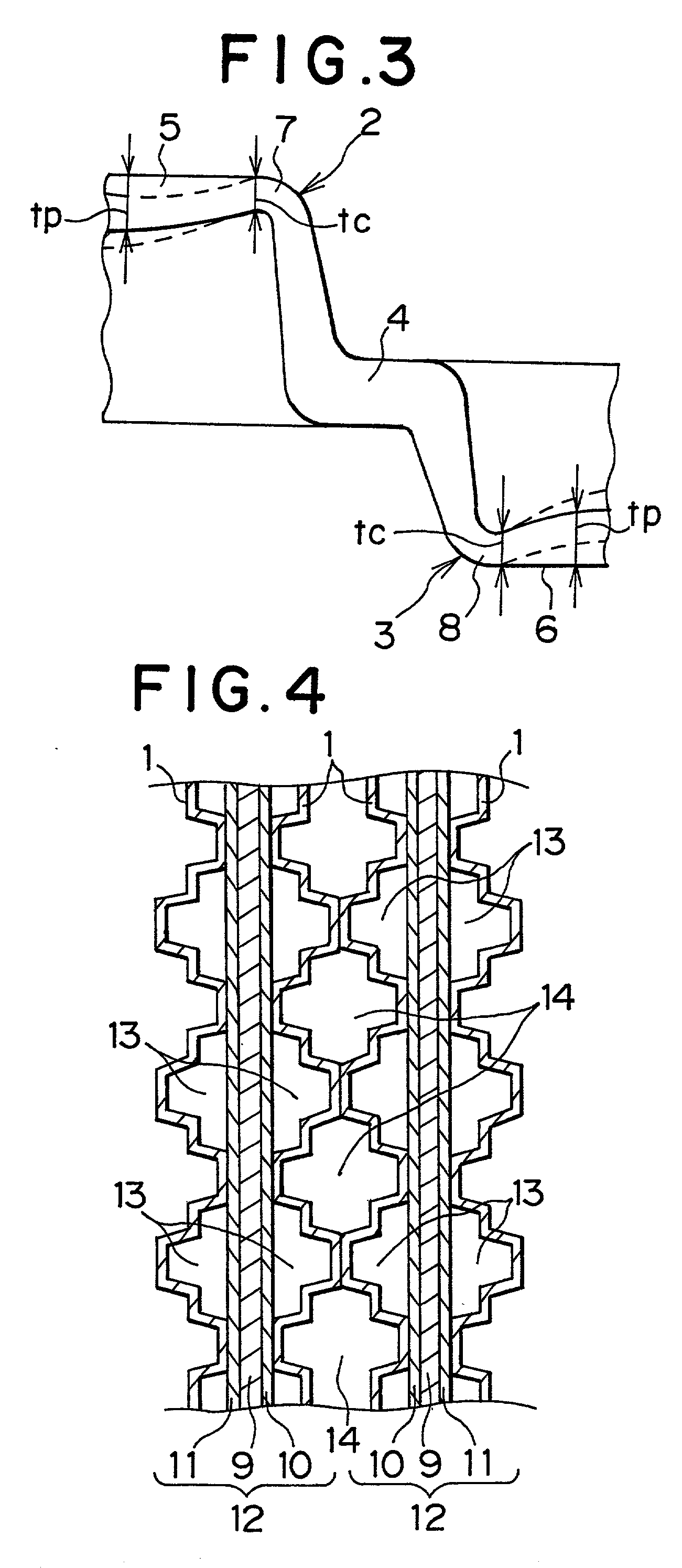

Plate with regular projections, and device and method for forming the plate

InactiveUS20010008719A1Improve rigidityPrecise positioningSolid electrolytesFuel cell auxillariesFuel cellsEngineering

A plate formed with a plurality of regular projections projecting from both faces of the plate can suitably be used as a separator for a fuel cell. Projections on one face of the plate and projections on the opposite face of the plate are alternately and adjacently formed in at least one direction along a plane of a reference plate portion of a metal plate. The reference plate portion has not been deformed. The top face sections of the projections or bottom face sections of the projections are thicker than their peripheral corner portions.

Owner:TOYOTA JIDOSHA KK

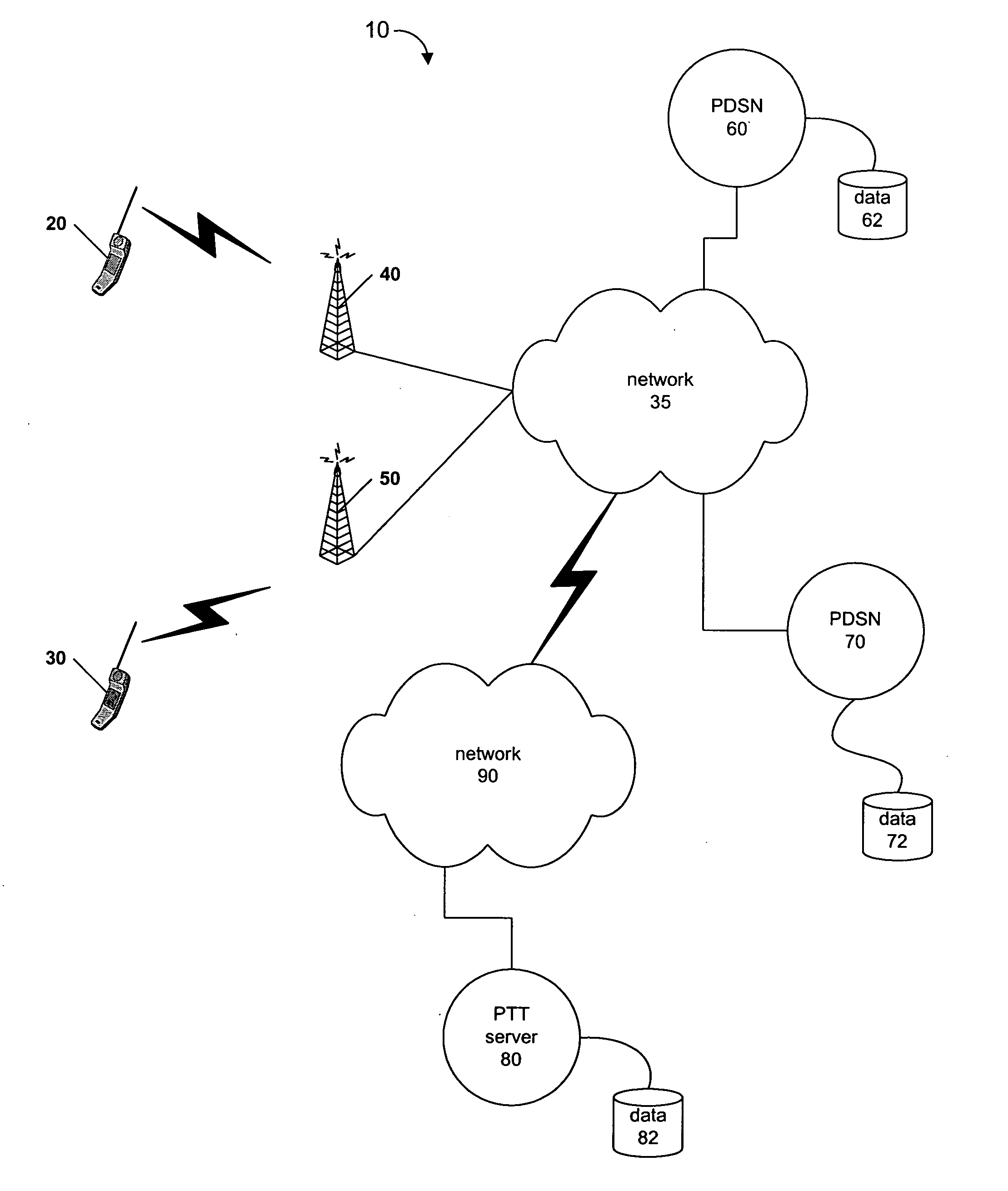

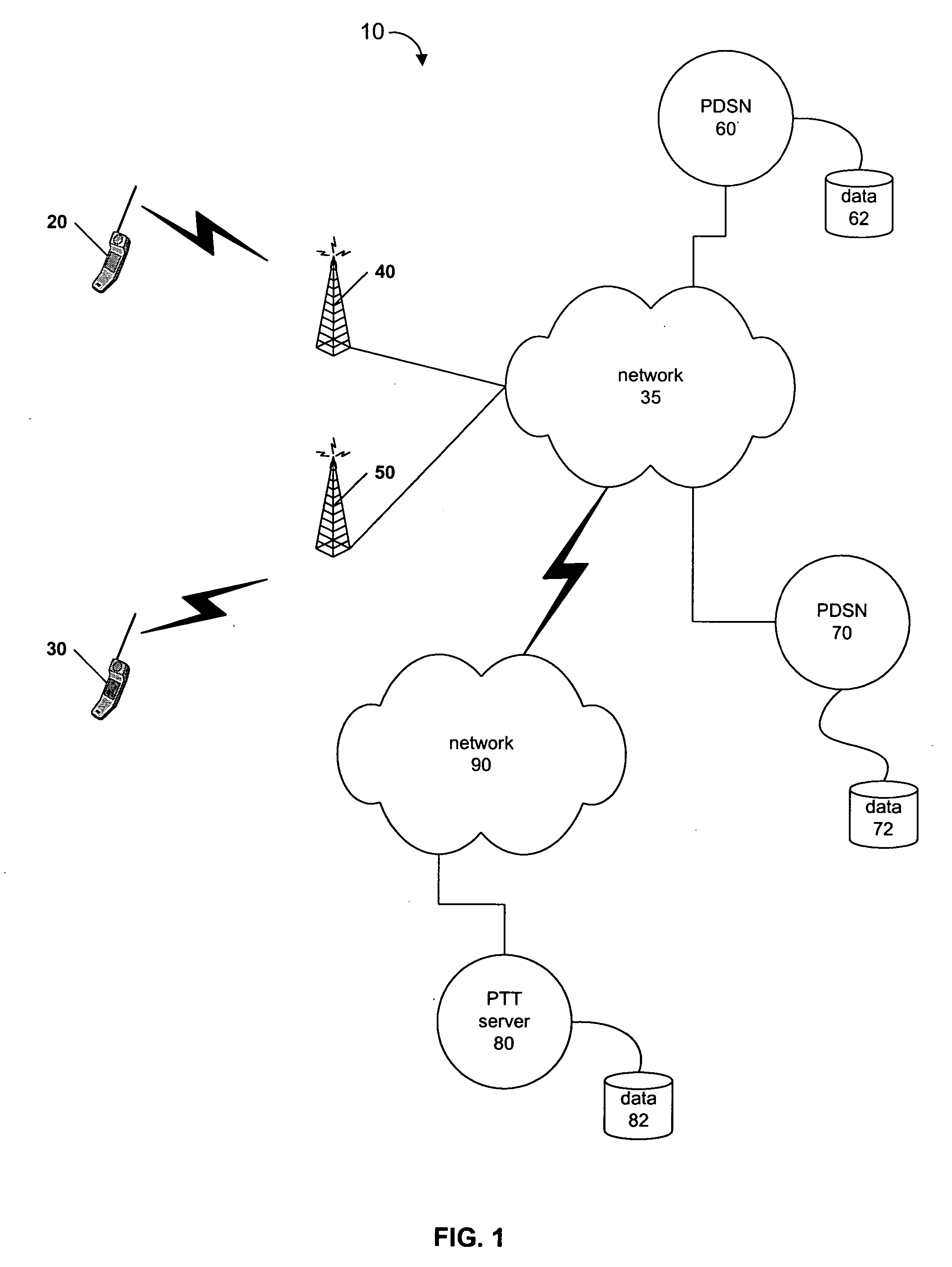

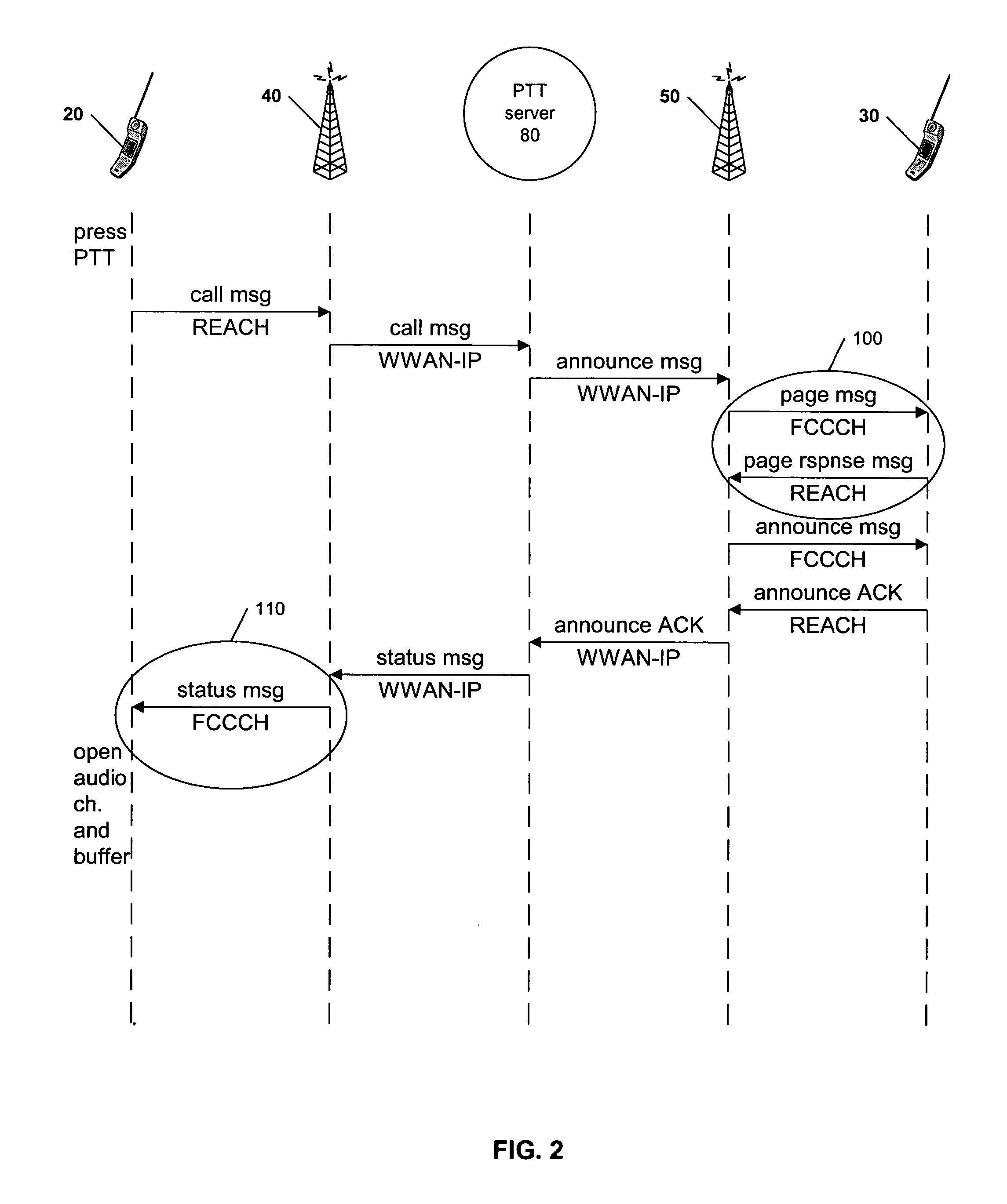

Optimized push-to-talk call setup

InactiveUS20050124367A1Reduce conventional setup timeEliminate delaysSpecial service for subscribersConnection managementPush-to-talkControl channel

A requesting handset in a wireless communication network sends a call message requesting a push-to-talk connection with a target handset. In response, a push-to-talk server sends a connection status message to the requesting handset. The connection status message is sent to the requesting handset in a control channel such as the forward common control channel. The requesting handset indicates to the caller that the connection has been made with the target handset, turns on the audio channel, and buffers any audio received from the caller until the traffic channel has been established. Once the traffic channel is established, any buffered audio is sent over the traffic channel and the push-to-talk call ensues.

Owner:KYOCERA CORP

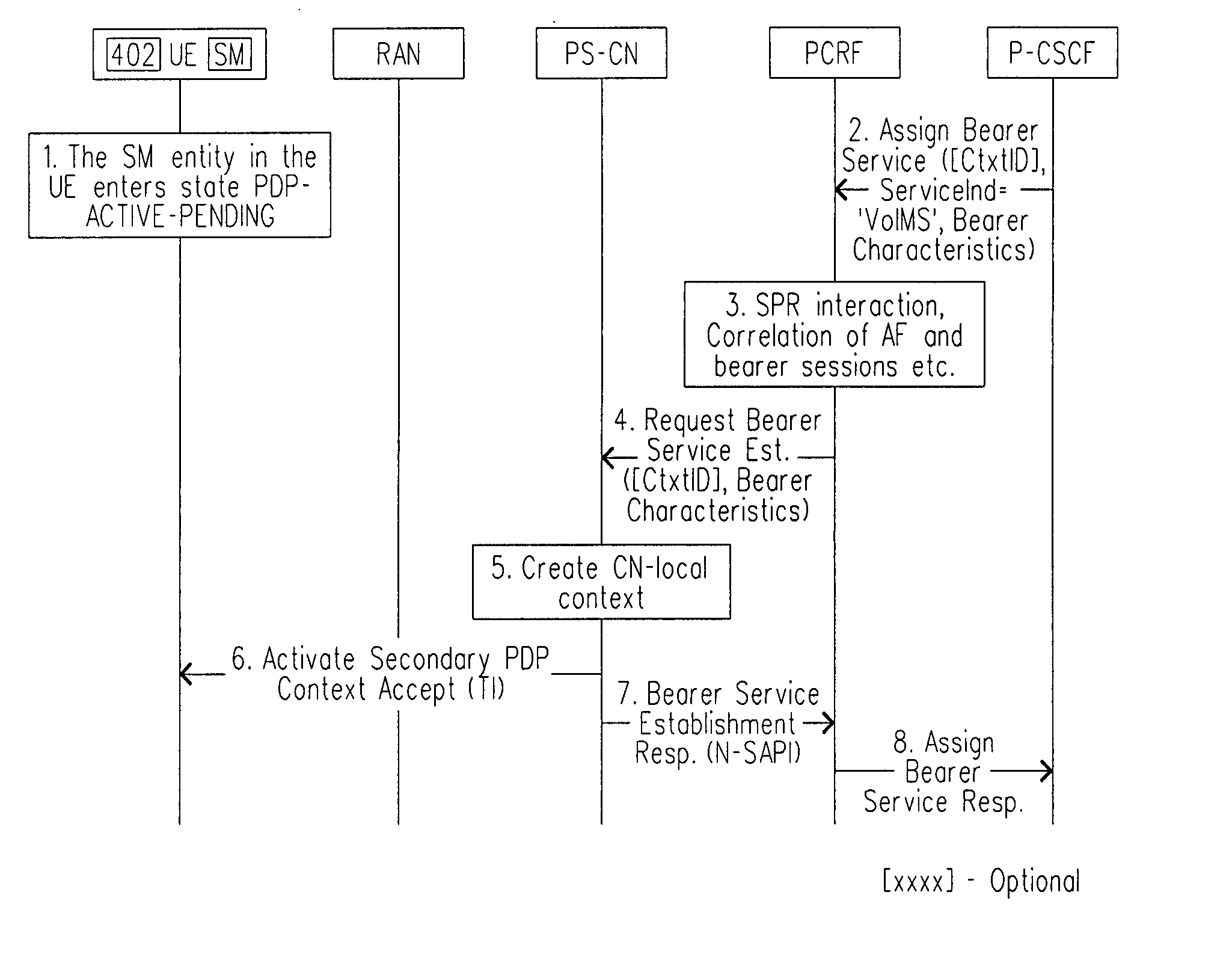

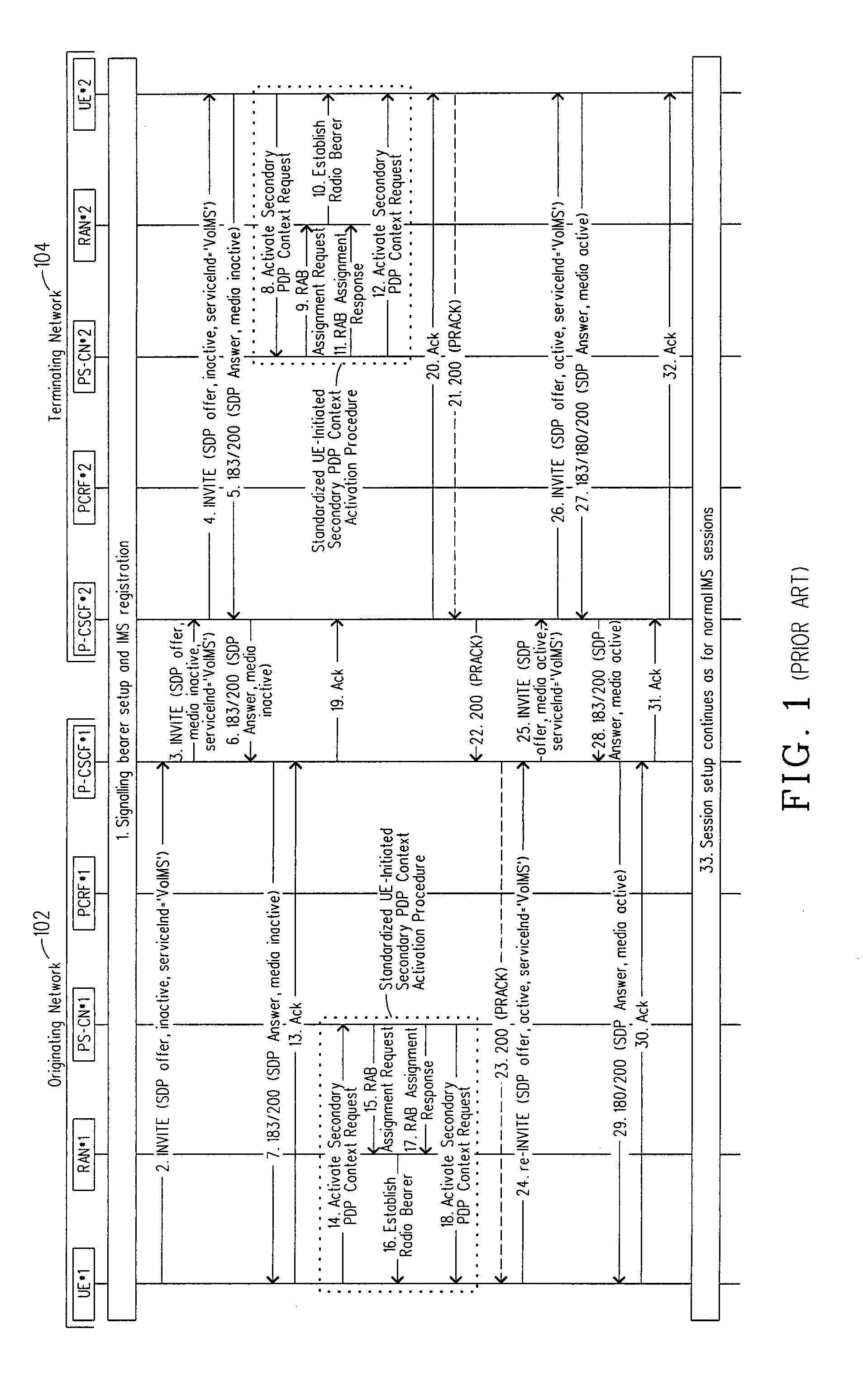

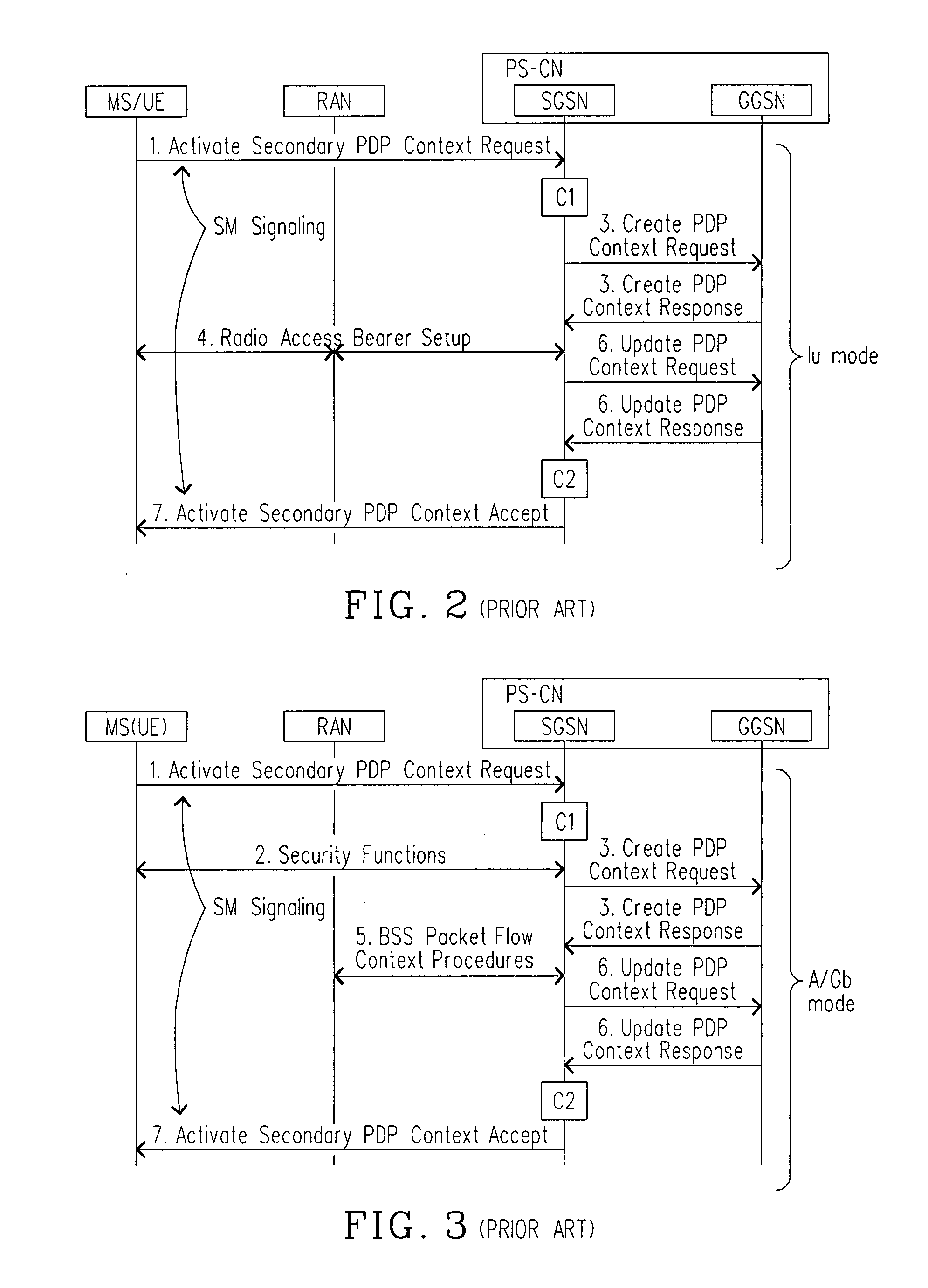

Minimized setup time for IMS multimedia telephony using PRE provisioned resources reserve at answer

InactiveUS20070223450A1Minimize timeReduce setup timeNetwork traffic/resource managementConnection managementSpeech soundVoice communication

Owner:TELEFON AB LM ERICSSON (PUBL)

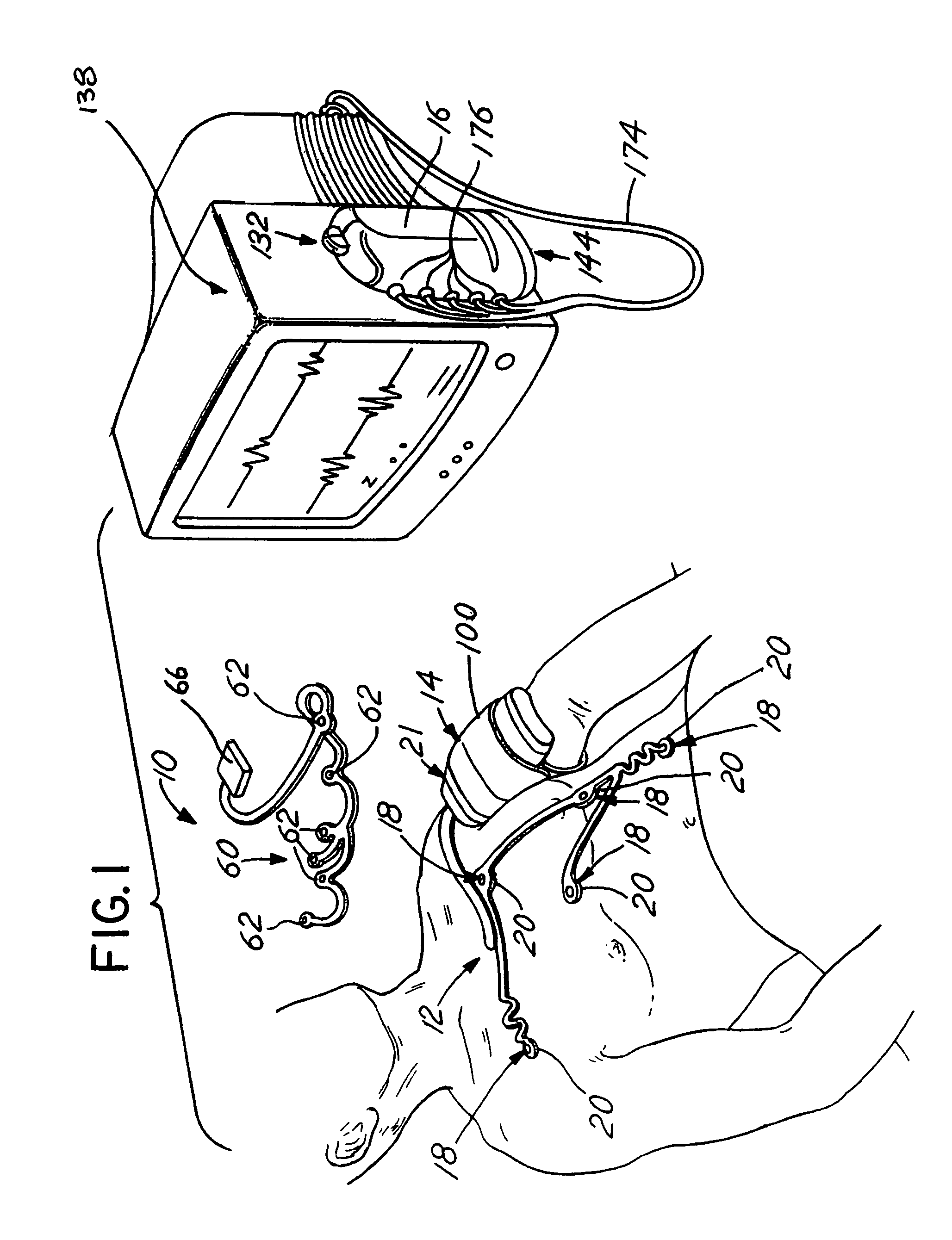

Radiolucent chest assembly

InactiveUS7860557B2Increased comfort and mobilityEasy to useElectrotherapyElectrocardiographyMonitoring systemCardiac activity

A wireless monitoring system and, more particularly, a wireless monitoring system for detecting and transmitting physiological data. The present invention detects physiological data relating to a patients cardiac activity and respiration rate and transmits the data to a remote base station via telemetry. The base station processes the data so that the data can be displayed by an ECG monitor.

Owner:LIFESYNC

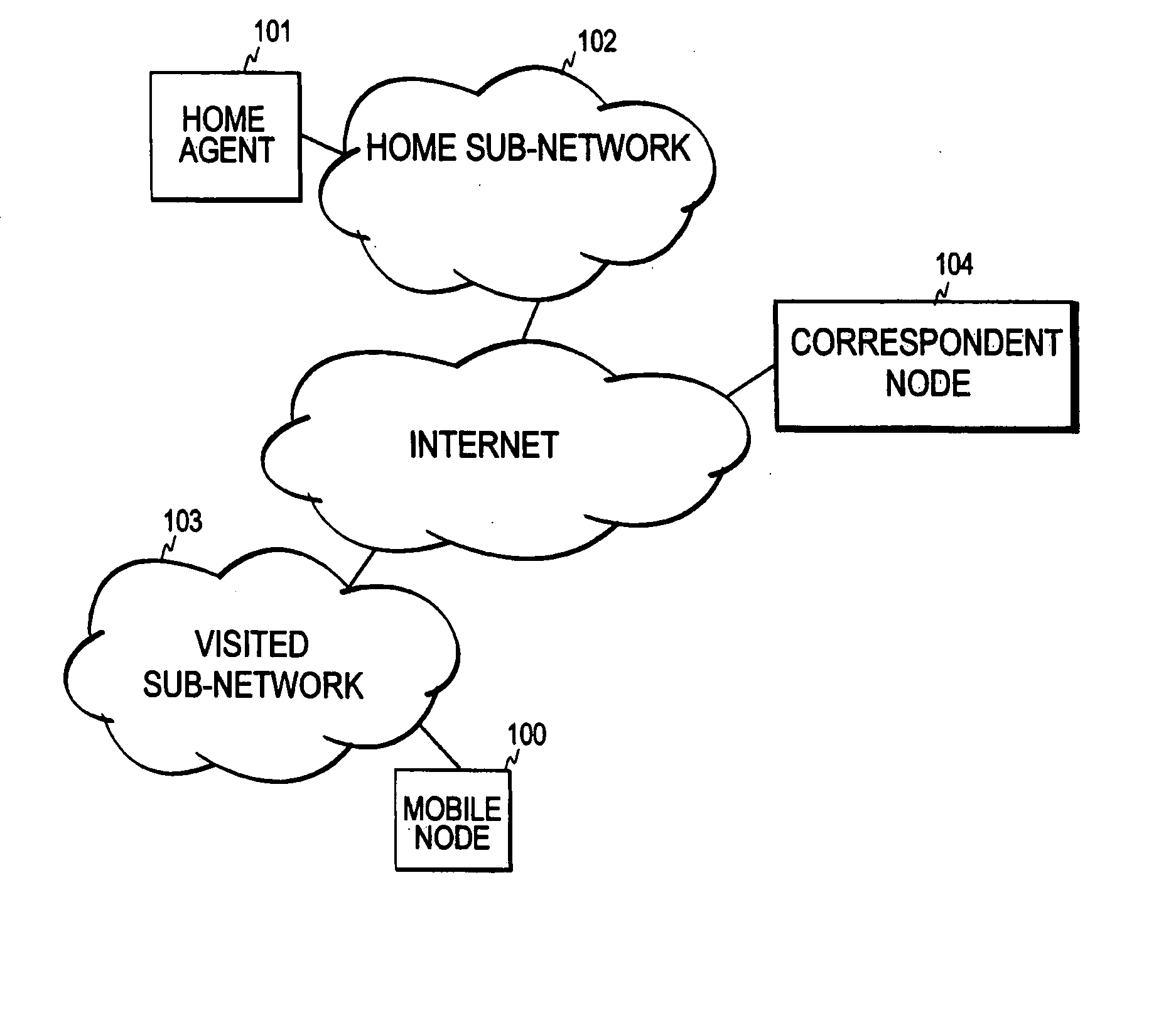

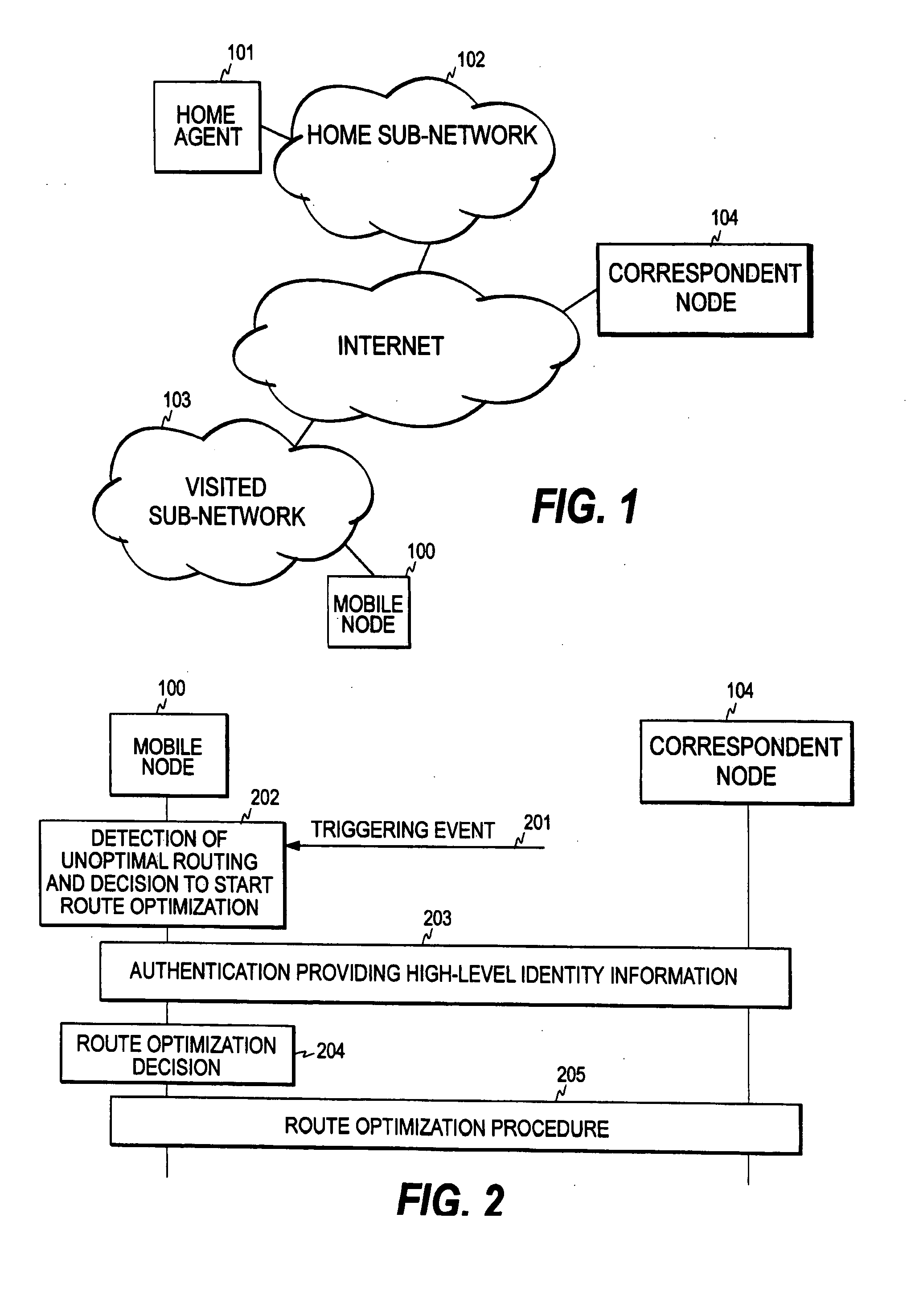

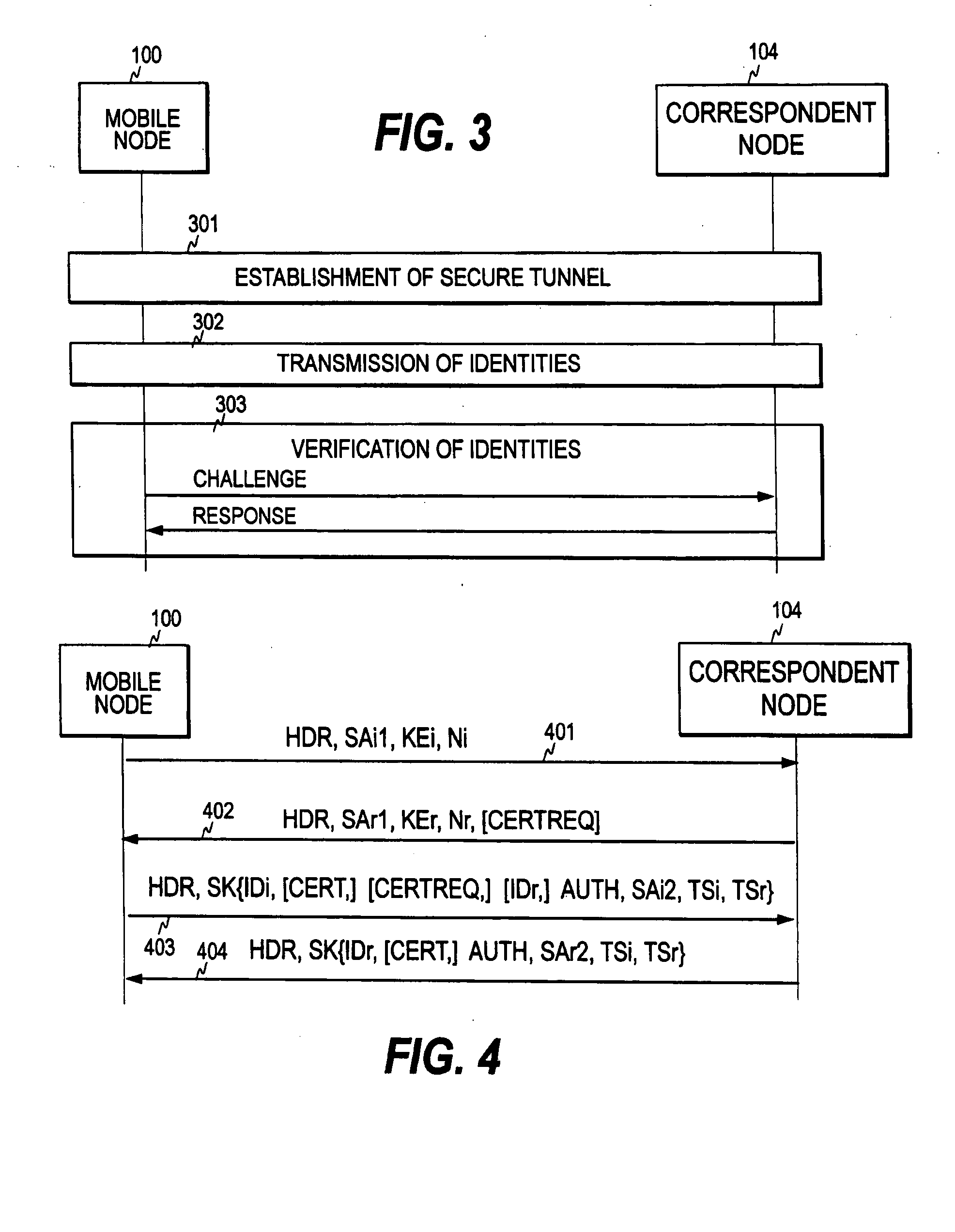

Location privacy in a communication system

InactiveUS20050055576A1Reduce overheadImprove setup timeUnauthorised/fraudulent call preventionDigital data processing detailsCommunications systemAuthentication

A mechanism for providing a mobile node with reliable information for location privacy decisions in connection with an address update process that gives the correspondent node a chance to deduce the location of the mobile node is provided. According to one embodiment of the invention, an indication is given when an address update process needs to be performed for optimizing routing between a mobile node and a correspondent node. In response to the indicating step, the correspondent node may be authenticated, the authentication yielding identity information about the correspondent node. Based on the identity information, a route optimization decision may be made based on whether or not the address update process is to be performed, and the address update process may be carried out depending on the decision.

Owner:NOKIA TECHNOLOGLES OY

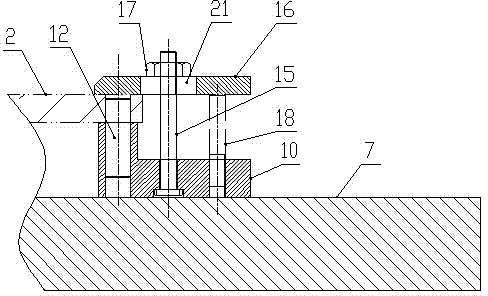

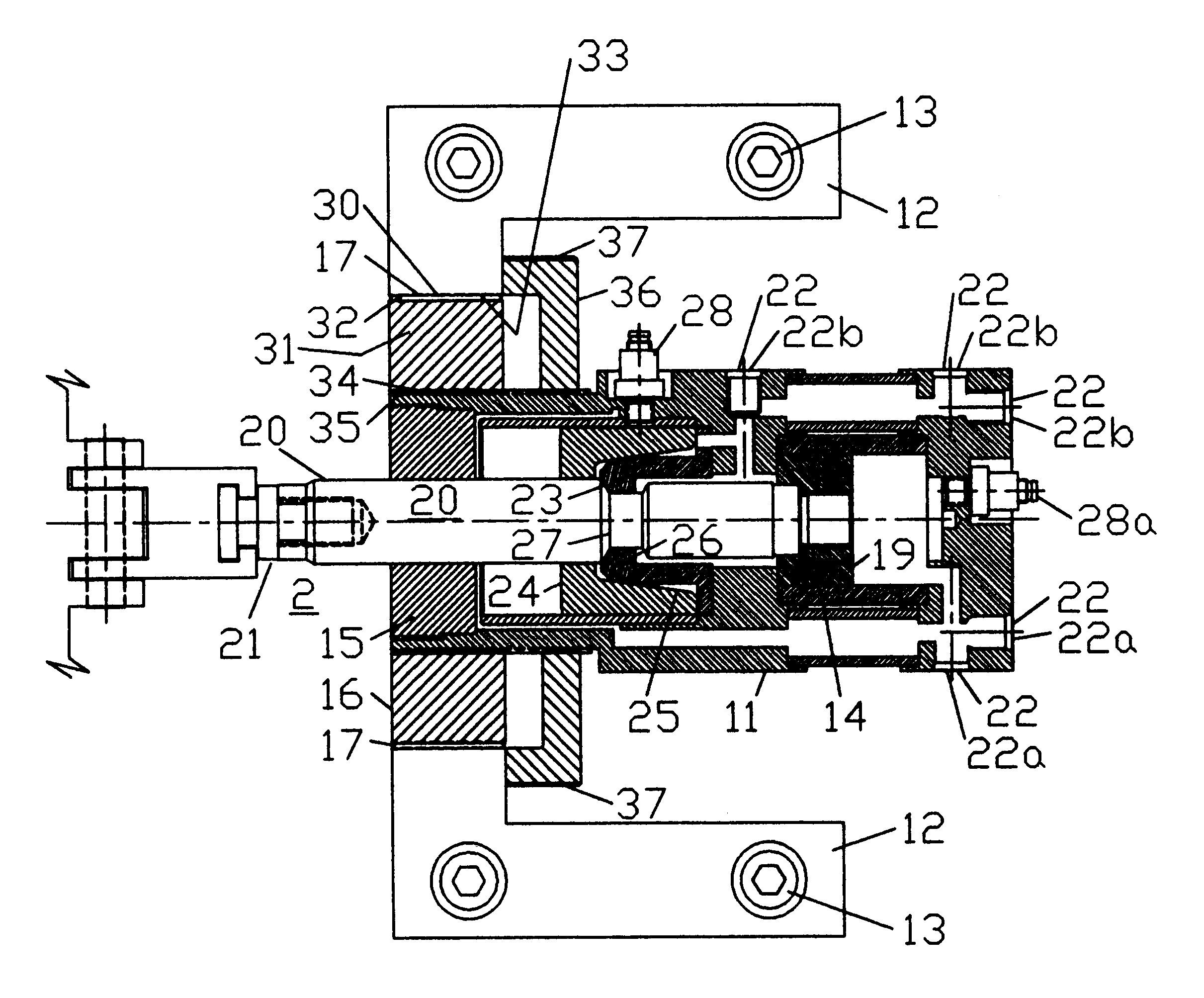

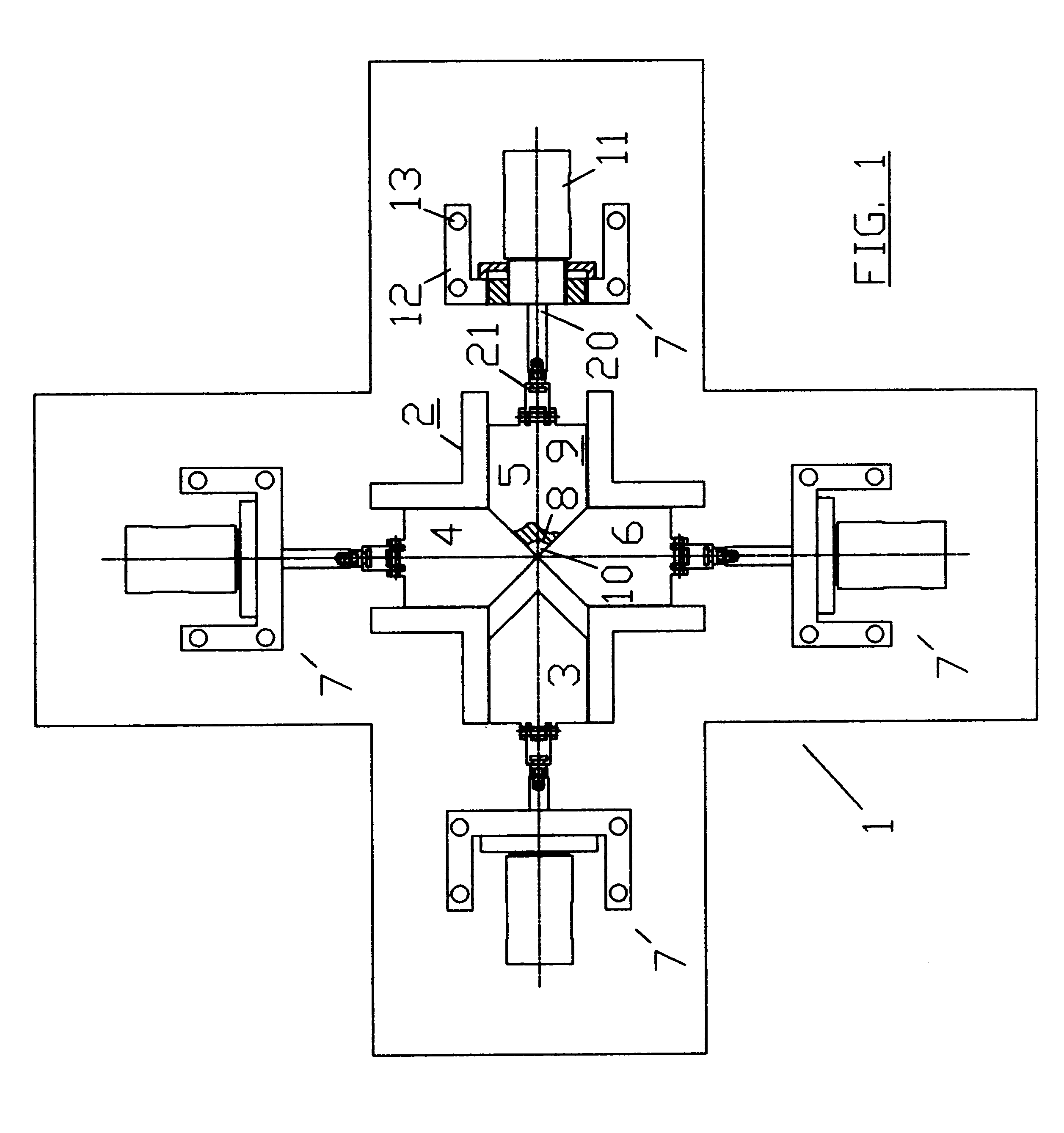

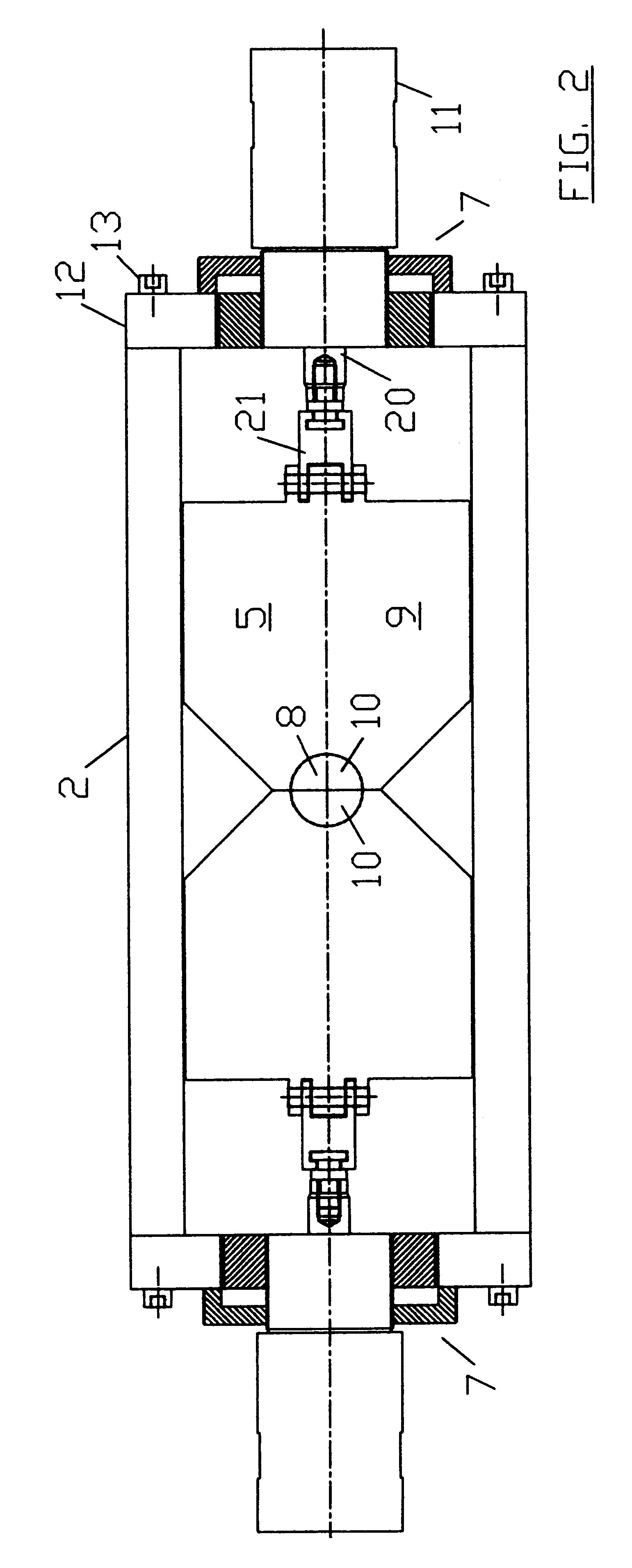

Threaded actuator for positioning structure subjected to intense loads

InactiveUS6186763B1Reduce setup timeAccurate settingConfectionerySweetmeatsHydraulic cylinderEngineering

A threaded actuator is disclosed for positioning a core in a molding apparatus. The threaded actuator includes a hydraulic cylinder unit having a piston rod connected to the core for positioning thereof. The core is subjected to intense force during the molding process and this force is transmitted onto the piston rod and hydraulic cylinder unit and its support. The hydraulic cylinder has a threaded nose which is secured within a threaded opening in a support. A rotatable threaded connecting member is threaded between the threaded nose and the threaded opening of the support structure. The outer and inner threaded connections of the rotatable threaded connecting member are of different thread configurations to form a differential thread assembly. The configurations may differ either in pitch and / or in the handedness of the threads. The differential threaded assembly provides for relative positioning of the hydraulic cylinder unit and core relative to the mold. A preload system includes a wall on the cylinder and a wall on the rod for preloading of the locked rod and the supporting components. The hydraulic cylinder and the piston rod are formed with stop wall members which provide for controlled extension of the piston rod for preloading of the piston rod and the supporting structure. A locking unit provides for locking of the rod in an extended position.

Owner:PFA

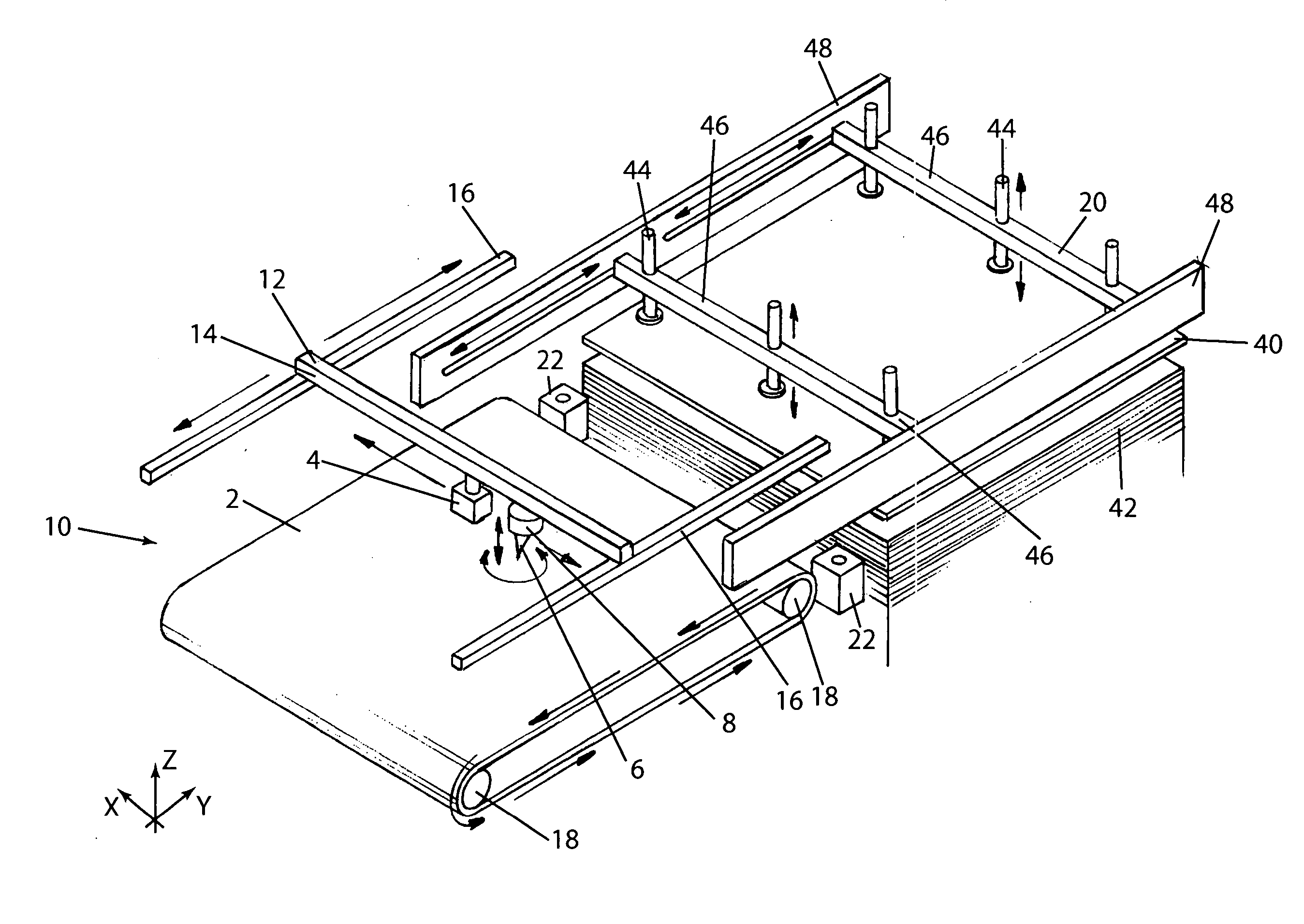

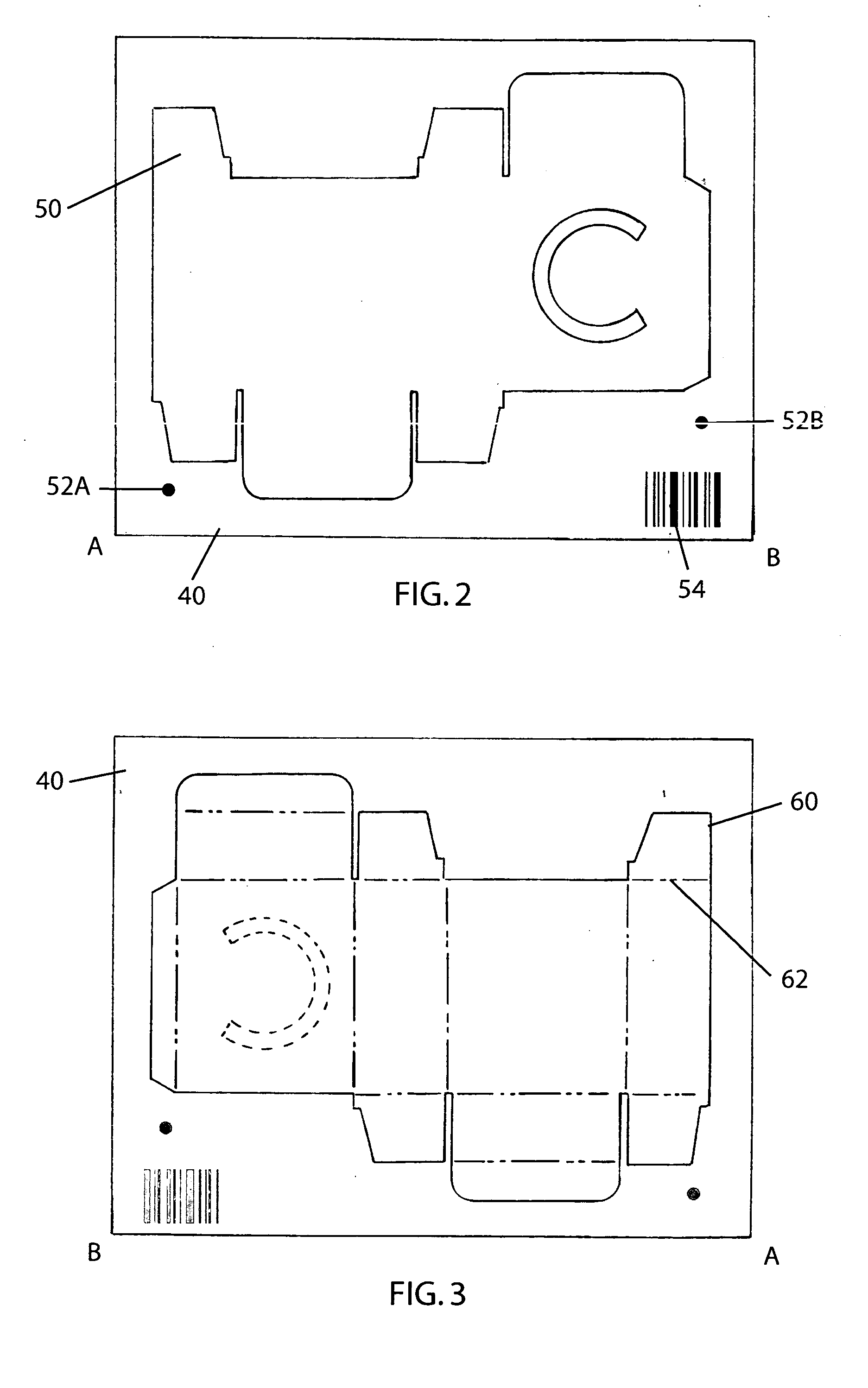

Automated method and apparatus for vision registration of graphics areas operating from the unprinted side

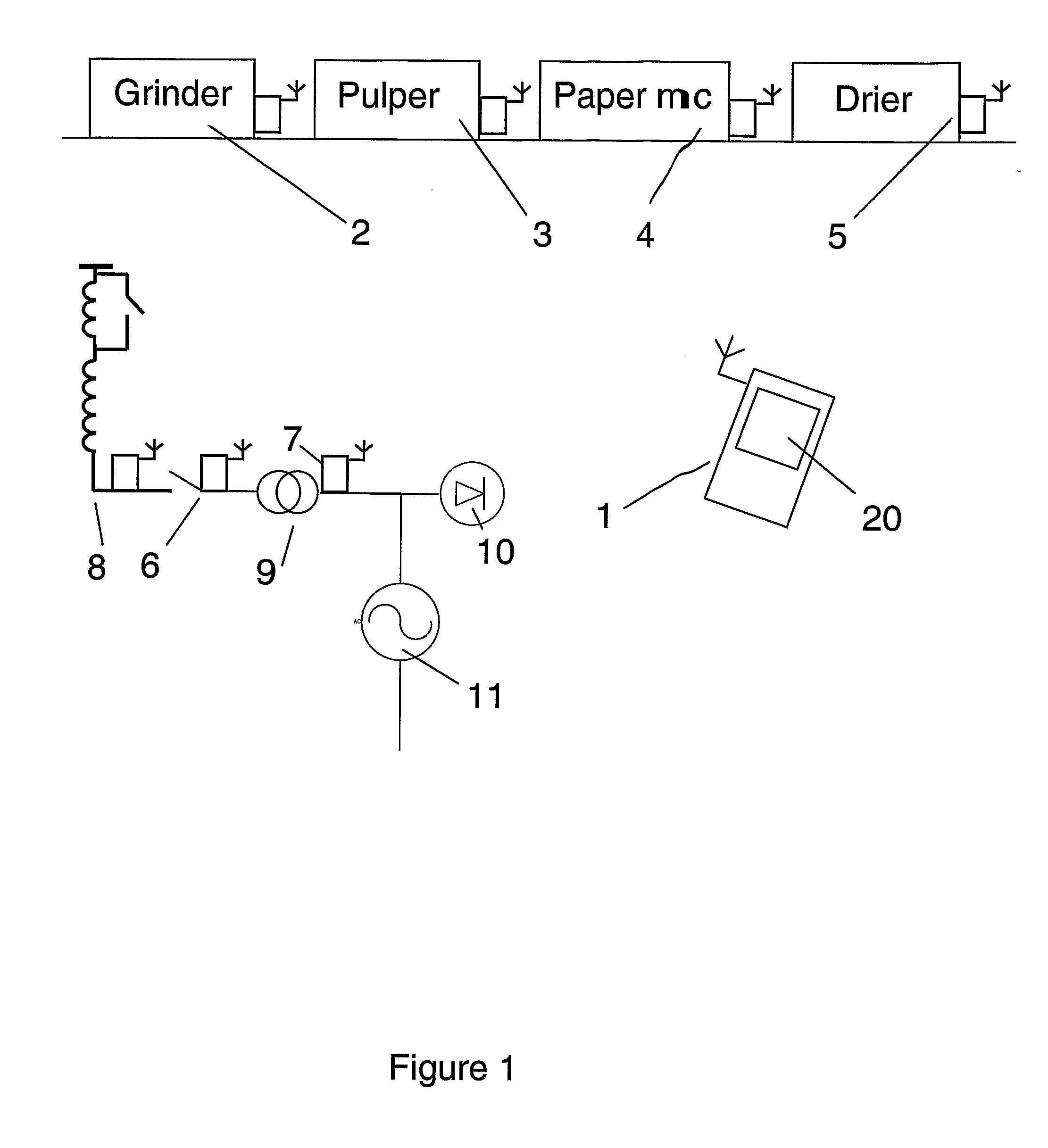

ActiveUS20050247173A1Increase speedReduce the amount requiredBox making operationsPaper-makingGraphicsPoint registration

A method and apparatus are disclosed for performing finishing operations on at least one graphics area on a graphics sheet, the graphics sheet having a graphics side, an opposite process side, and reference features, the graphics side bearing the graphics area(s) and registration marks in predetermined positions with respect to the graphics area(s). The method comprises positioning the graphics sheet on a sheet-receiving surface, sensing from the graphics side the positions of the registration marks, determining the coordinates of the graphics area(s) with respect to the sheet-receiving surface as if viewable from the process side, and performing finishing operations on the process side of the graphics sheet based on such determination, whereby such process-side finishing operations compensate for variations of the graphics area(s).

Owner:ESKO GRAPHICS KONGSBERG

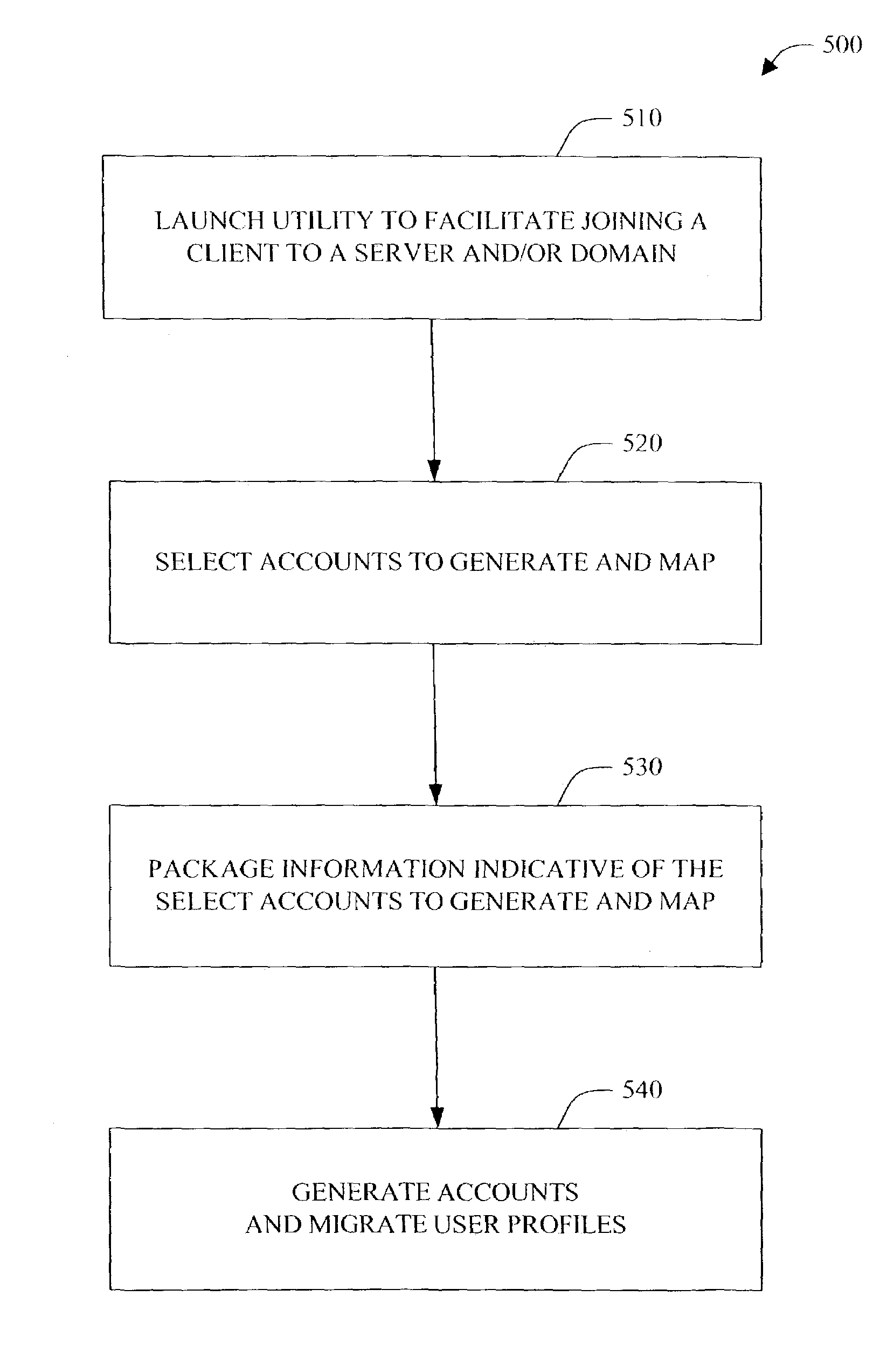

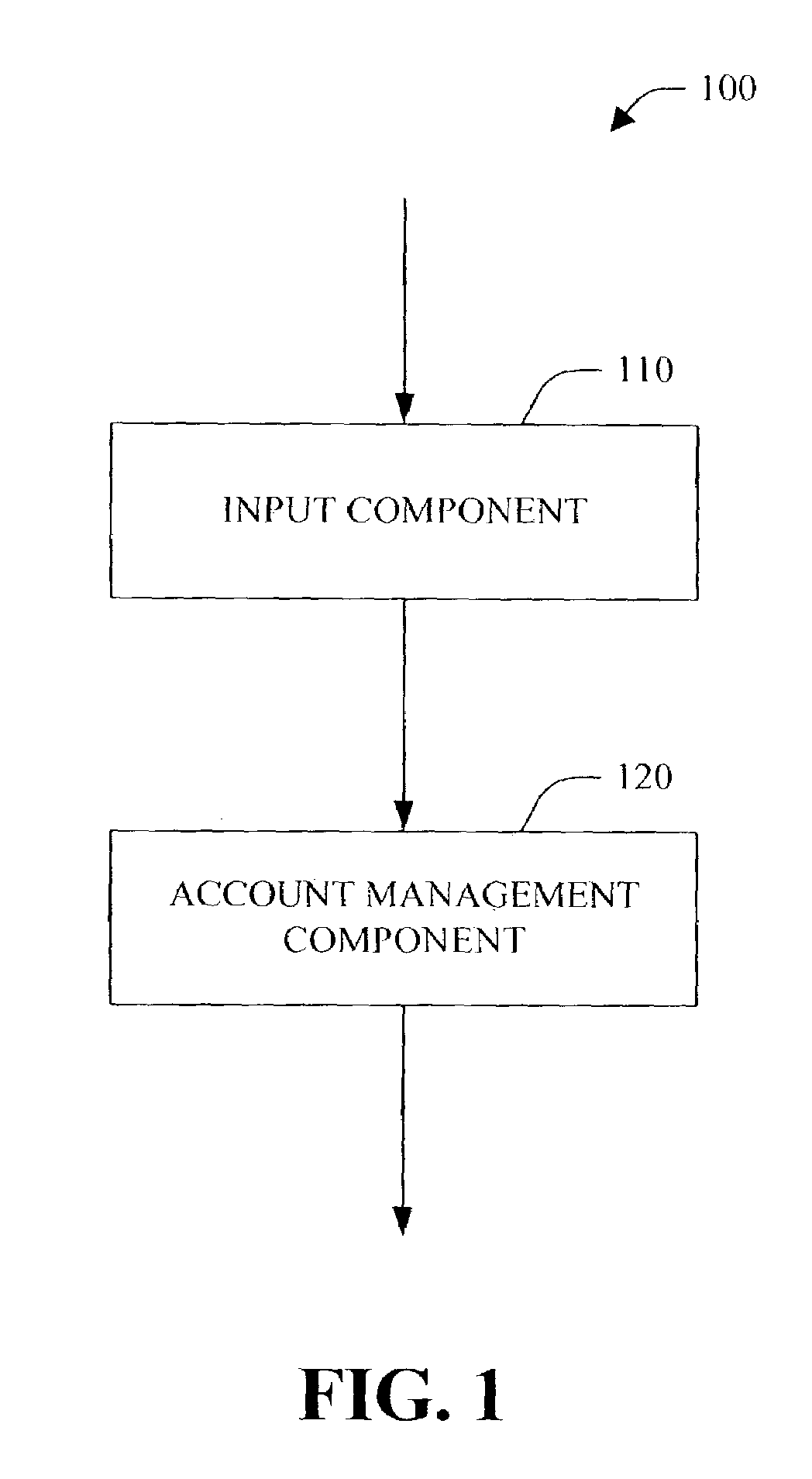

Systems and methods to migrate a user profile when joining a client to a server and/or domain

ActiveUS7320068B2Save customizationReduce setup timeDigital data processing detailsMultiple digital computer combinationsInternet privacyA domain

The present invention relates to systems and methods to generate accounts on a client when joining the client to a domain while preserving user profiles that were generated prior to joining the client. In general, a user with an account on a client can customize the account, wherein the customization can be saved in an associated profile. The client can employ the user profile when the user logs on in order to return the customization to the user. The present invention provides a novel approach to retain a user's existing user profile when joining the client via mapping the user's existing account to the account that will be generated, and then automatically migrating the user's profile to the generated account during joining the client. The foregoing can provide reduced client setup time, improved setup efficiency, reduced setup cost, and mitigation of severing customization from a user's account.

Owner:MICROSOFT TECH LICENSING LLC

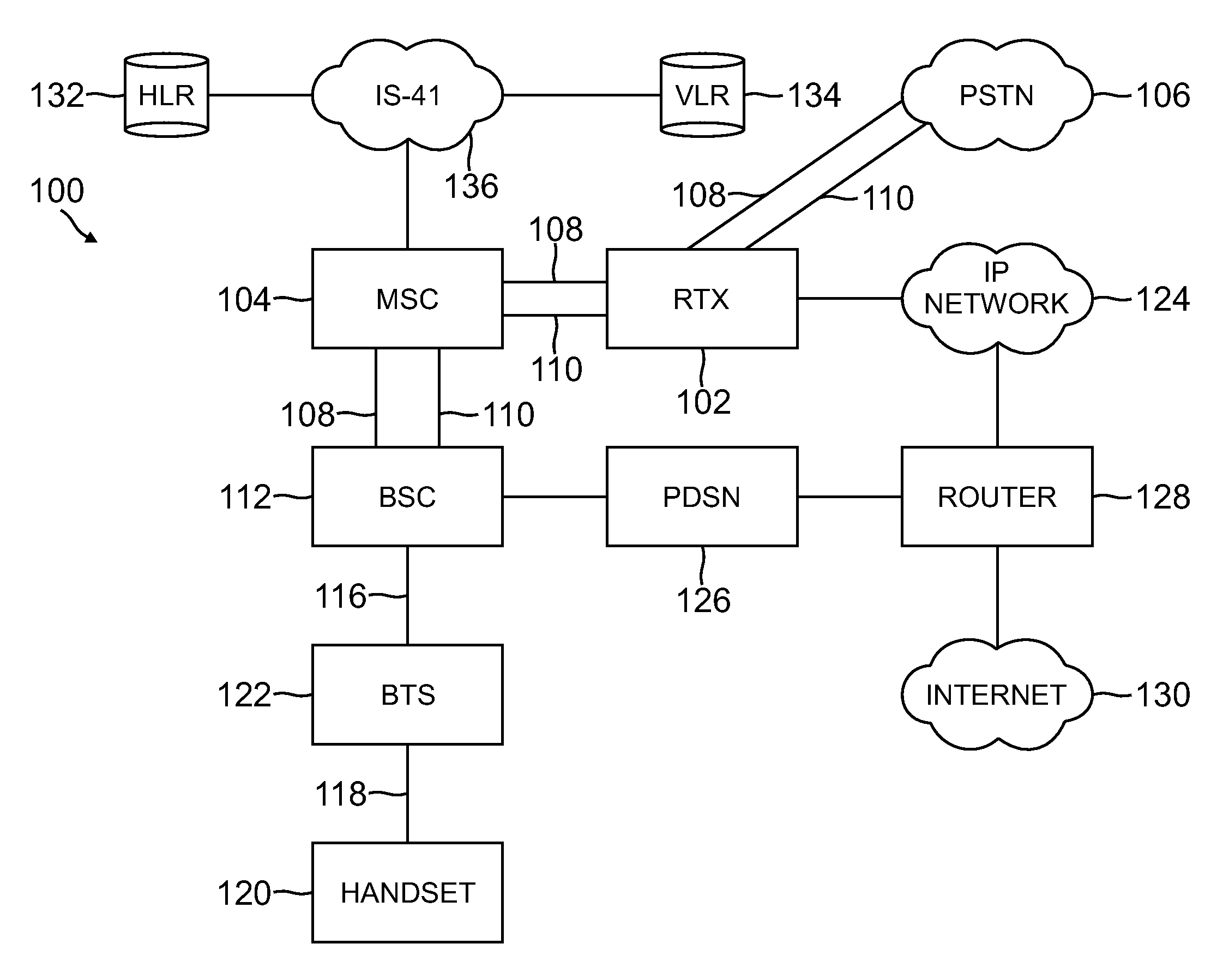

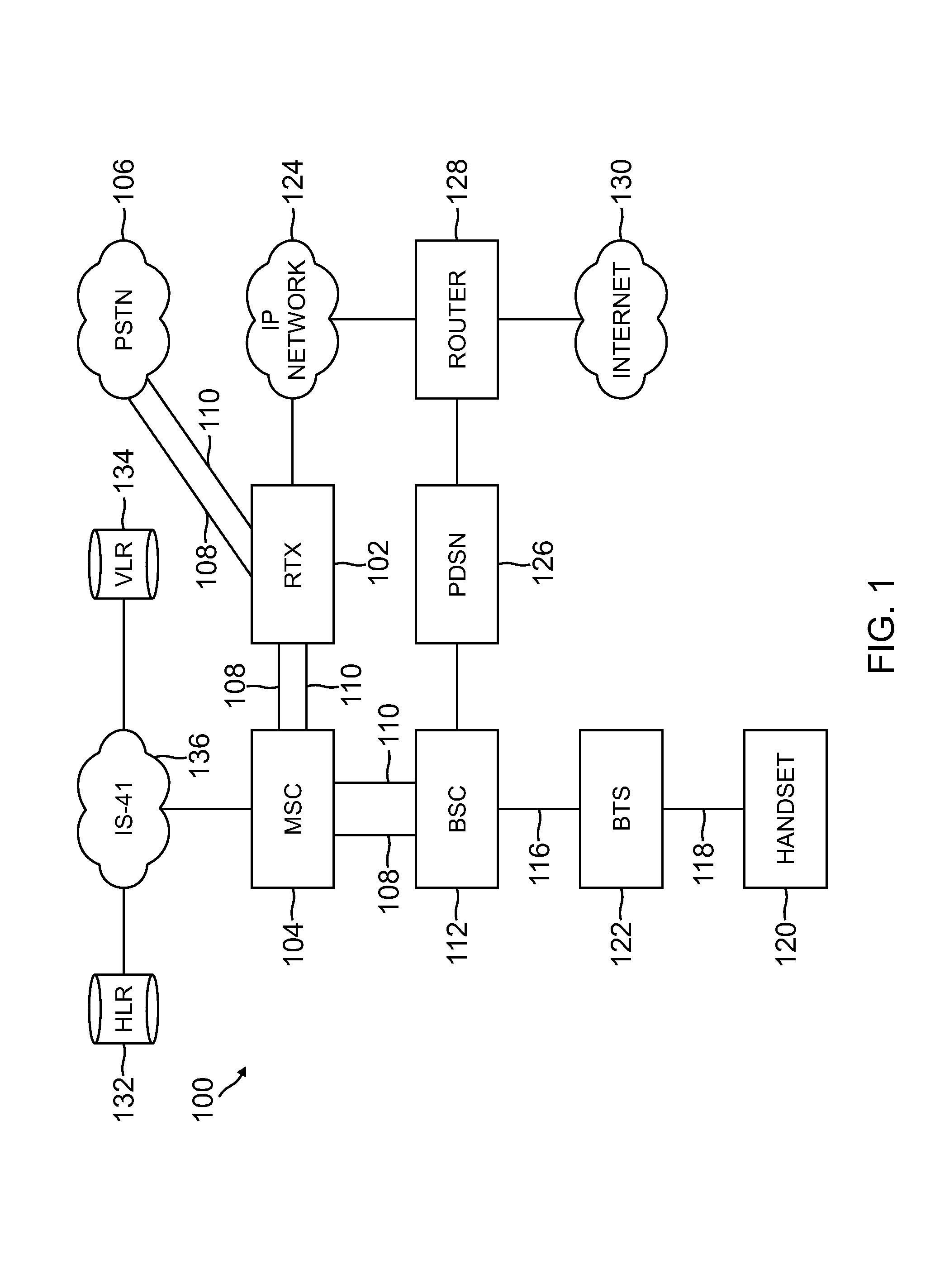

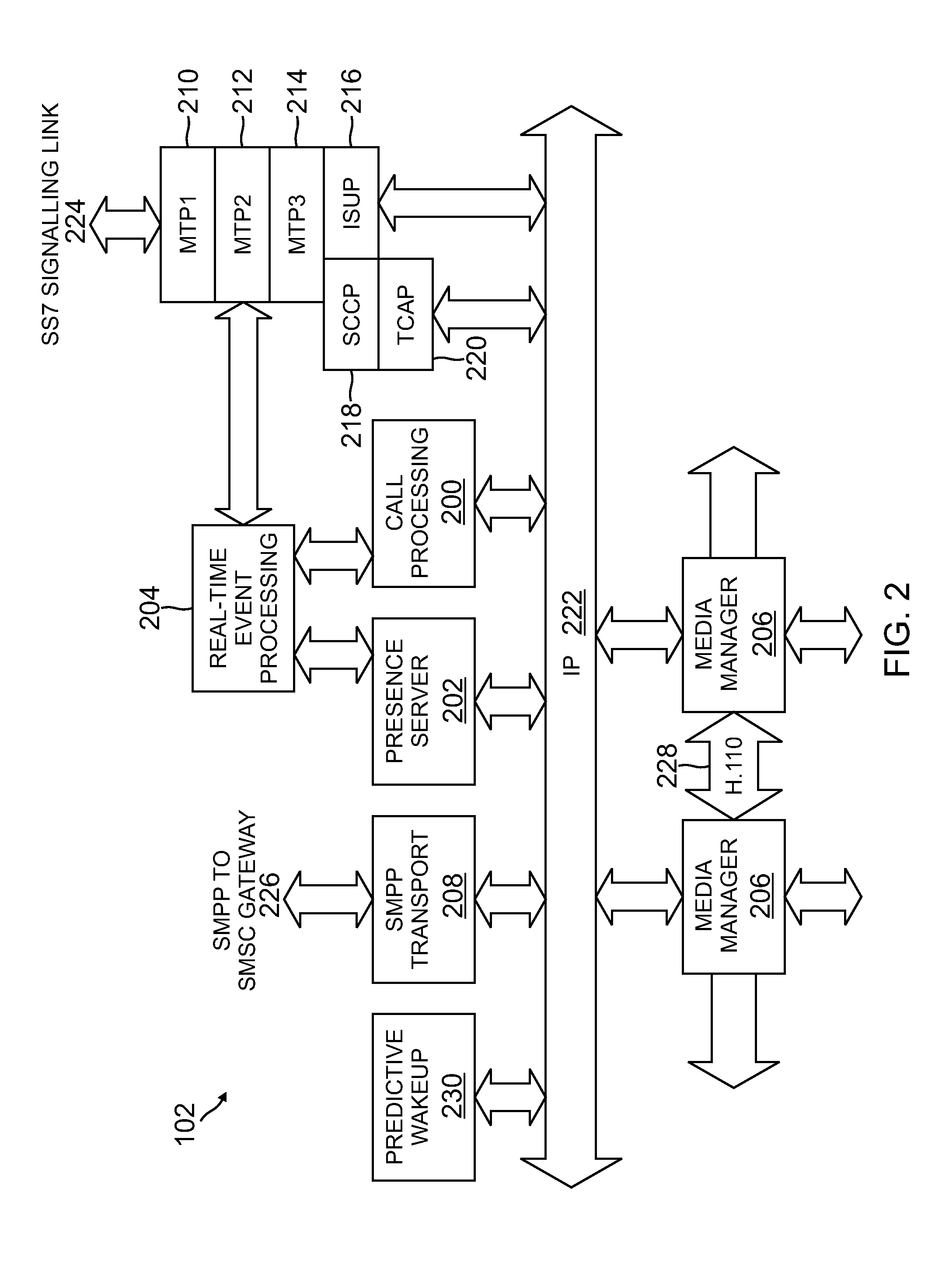

Predictive wakeup for push-to-talk-over-cellular (POC) call setup optimizations

ActiveUS8478261B2Reduce settingsReduce setup timePower managementConnection managementHeuristicPush-to-talk

Owner:KODIAK NETWORKS

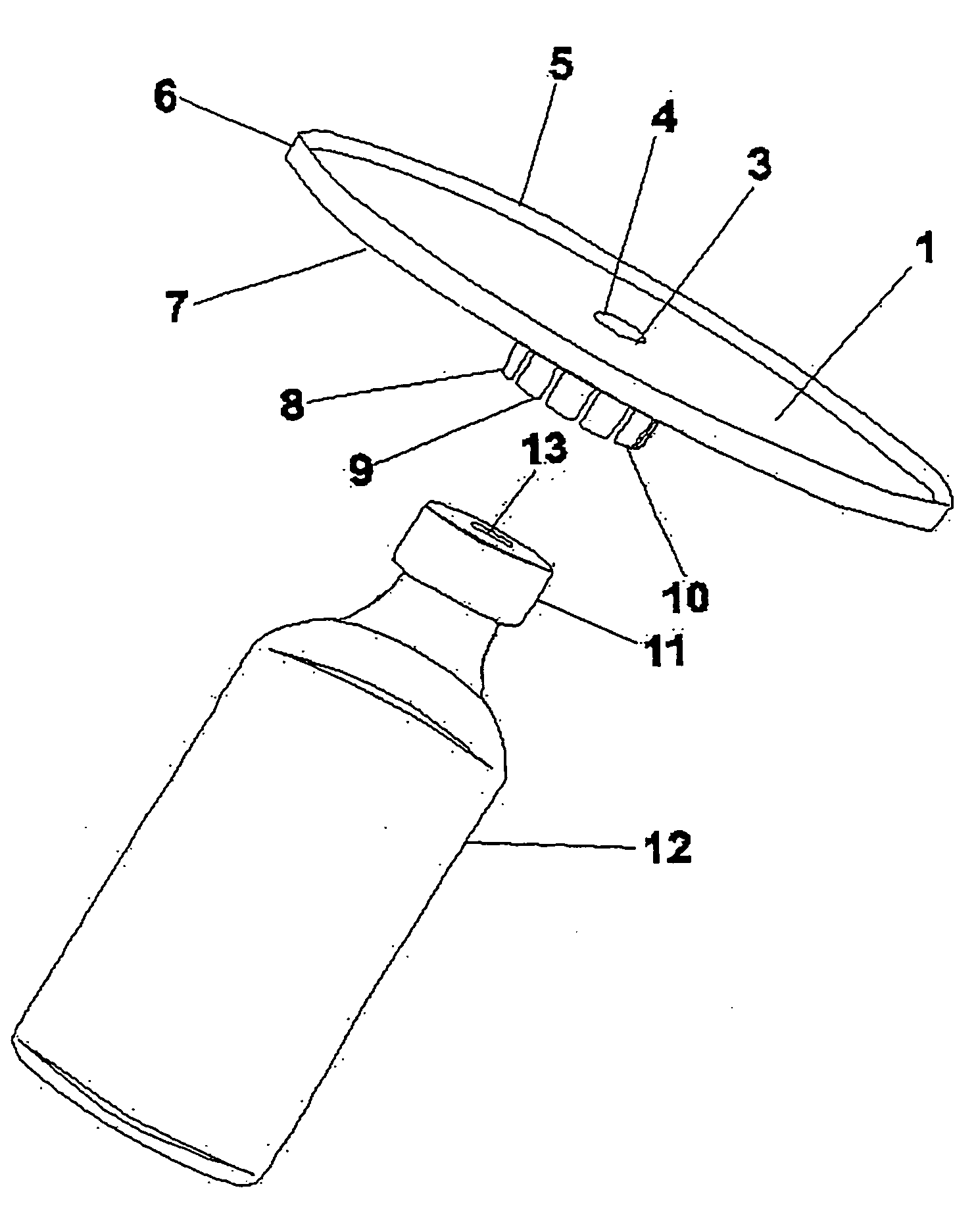

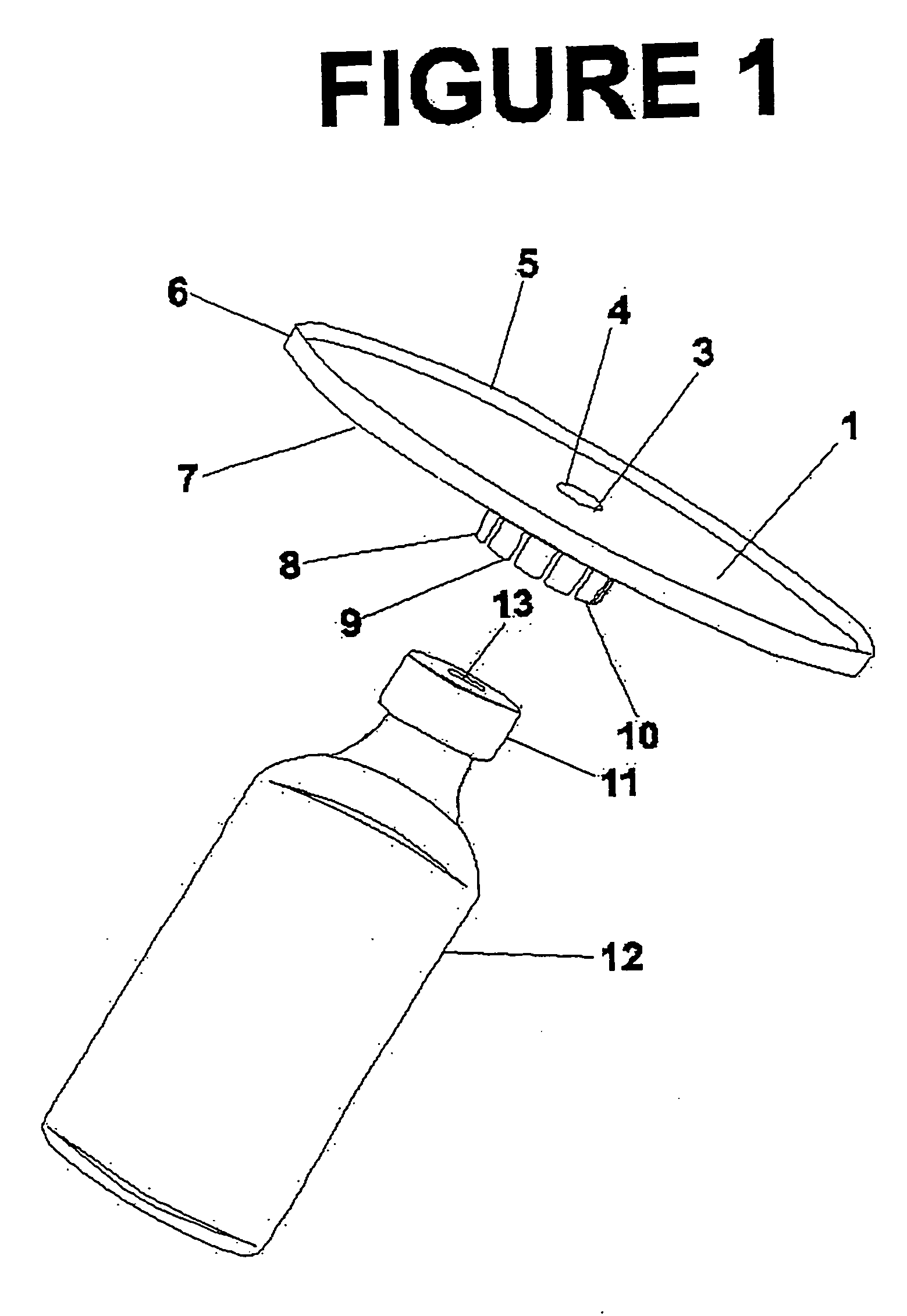

Vial attachment to prevent needle sticks

InactiveUS20060108319A1Easy to produceNot time-consume to putSmall article dispensingBottlesEngineeringBiomedical engineering

A clear protective disc shield that attaches to vial that protect medical personnel hand from being injured and contamination of the needle. The protective disc shield has a circular orifice that effectuates attachment of the disc shield to a vial for the dispensing of medicine or other material. The disc shield is designed so that any contact between the needle and the upper surface of the shield will guide the needle to the circular orifice and further prevents the needle from slipping of the disc shield. The disc shield further has a smooth underside and edges to prevent scratching and other injuries to the user.

Owner:MEITTUNEN ERIC JOHN

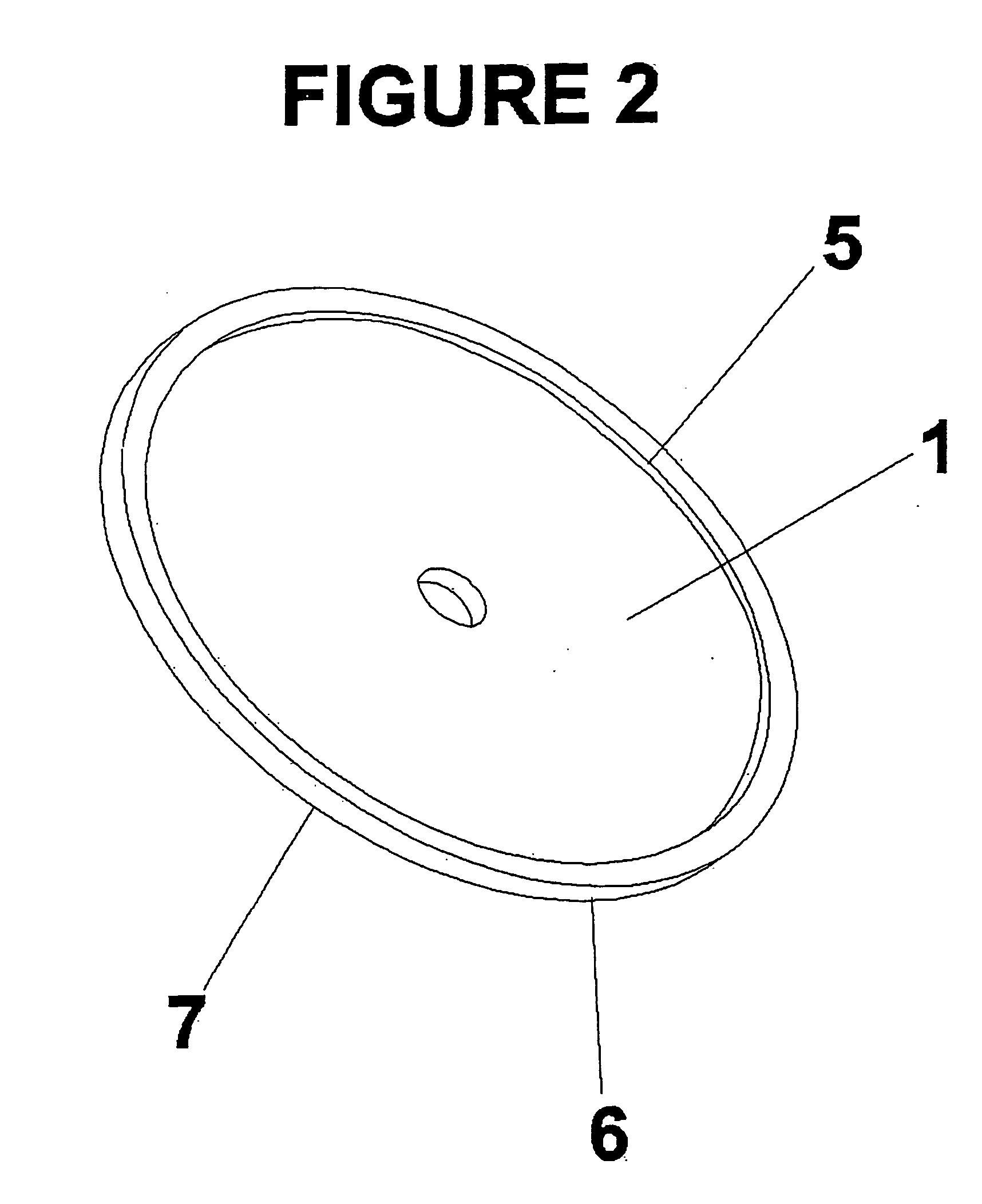

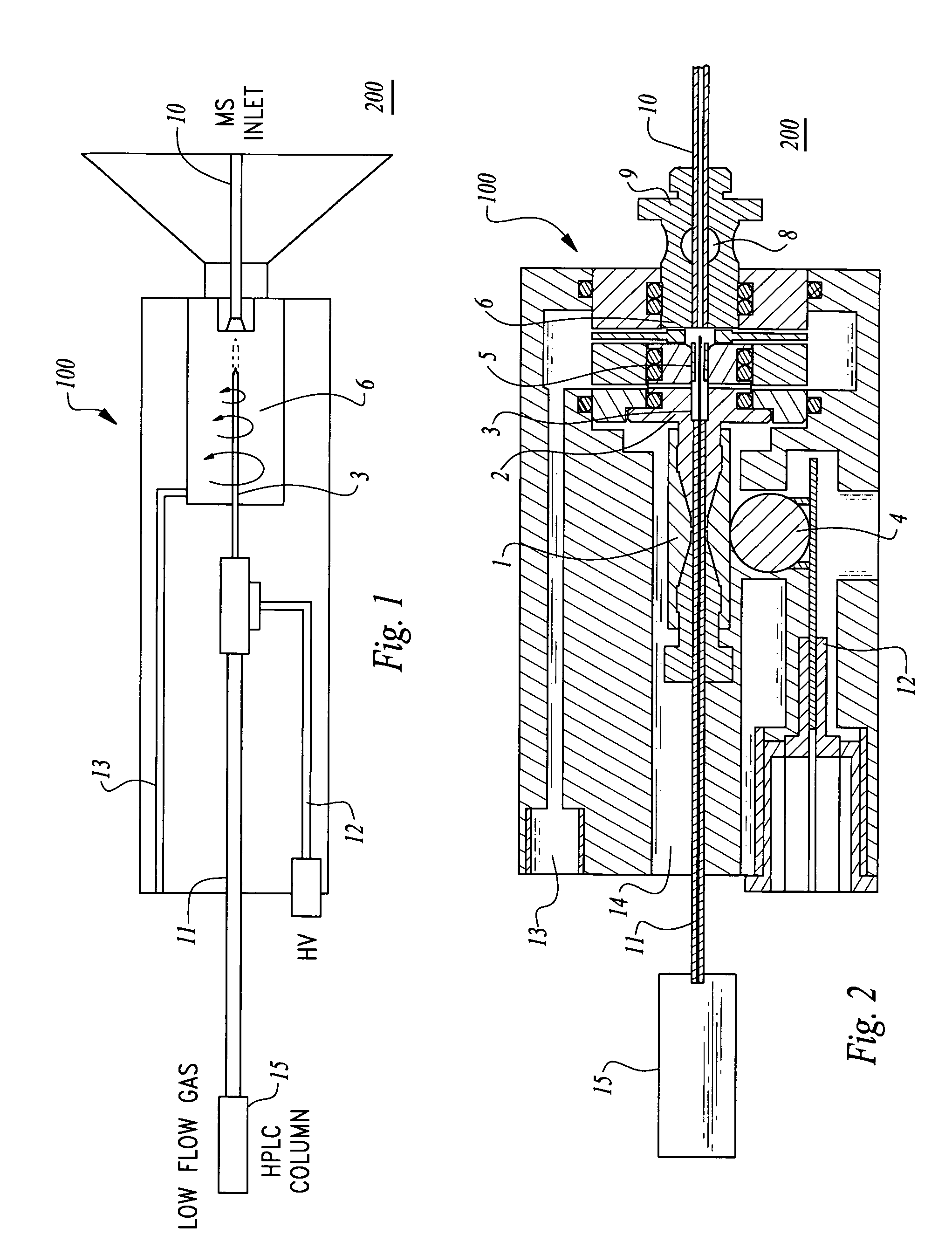

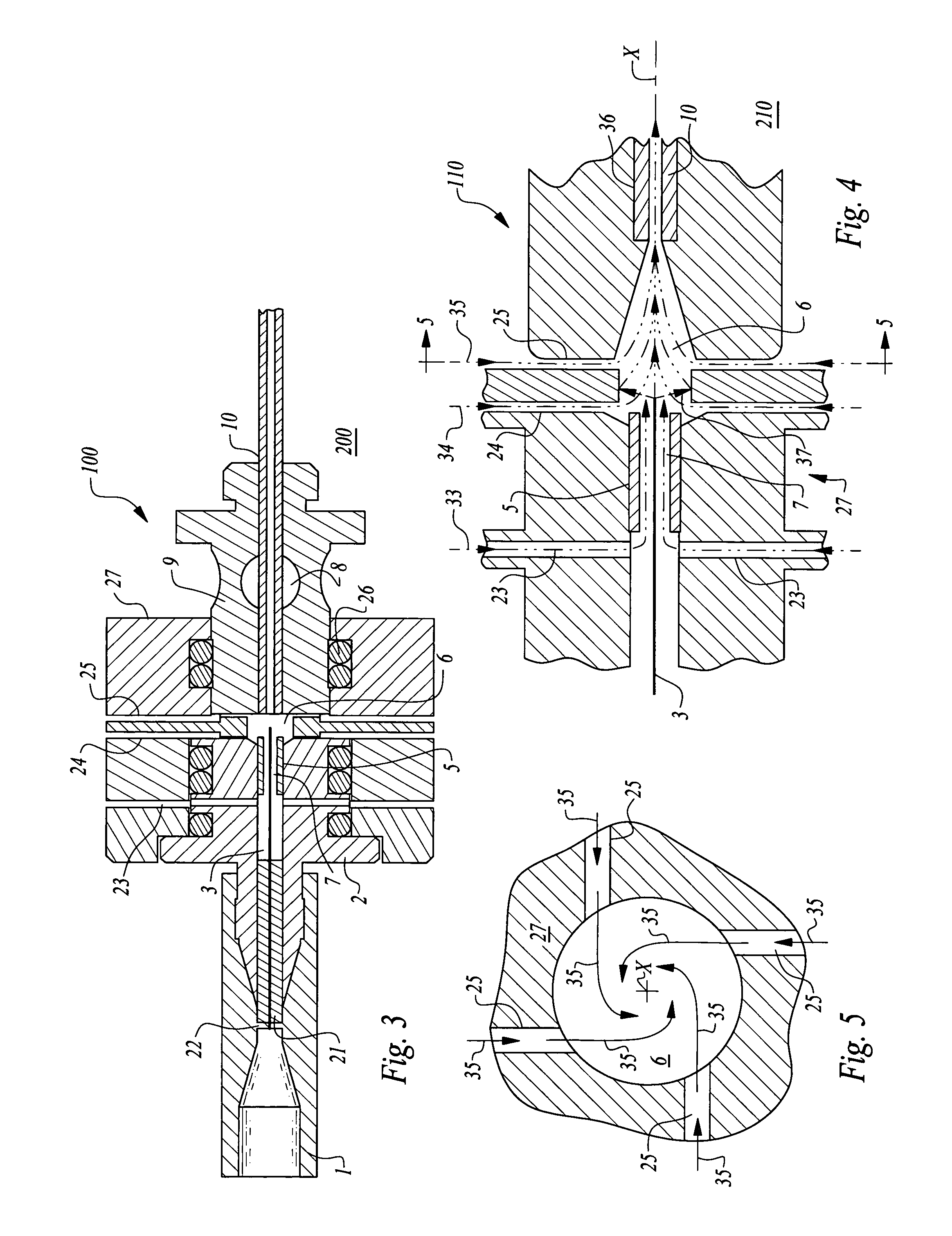

Method and apparatus for nano-capillary/micro electrospray for use in liquid chromatography-mass spectrometry

ActiveUS8227750B1Good adhesionReduce setup timeParticle separator tubesComponent separationAtmospheric airEngineering

An ion injection spray apparatus and method are provided for coupling a liquid chromatograph or other liquid flow device to a mass spectrometer. The ion injection spray assembly is composed in part of a chamber for voltage and gas input, a metal union for a liquid voltage junction, a gas distribution assembly, a vacuum seal and an ion spray needle. The position of the ion spray needle within this assembly is directly coupled to the outlet of the upstream liquid flow device through the metal union. The vacuum of the mass spectrometer pulls gas at atmospheric pressure though the gas distribution assembly to focus the sample liquid at the spray needle outlet and create a centrifugal gas funnel which helps to desolvate the sample ions and sweep them into the mass spectrometer over a wide range of flow rates.

Owner:BRUKER SCI LLC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com