Patents

Literature

654 results about "Dose rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dose Rate The dose rate is a measure of how fast a radiation dose is being received. Knowing the dose rate, allows the dose to be calculated for a period of time. Fore example, if the dose rate is found to be 0.8rem/hour, then a person working in this field for two hours would receive a 1.6rem dose.

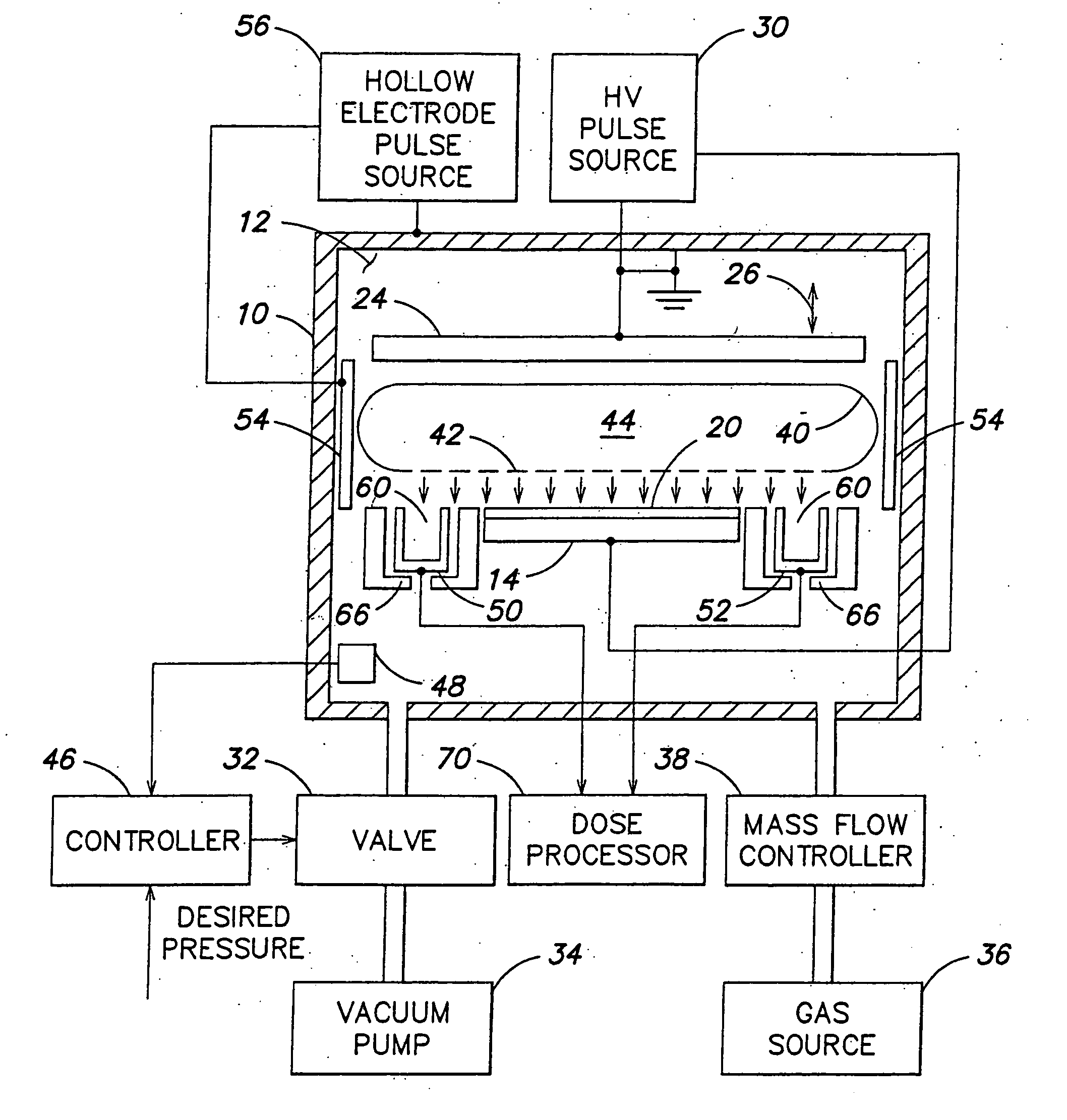

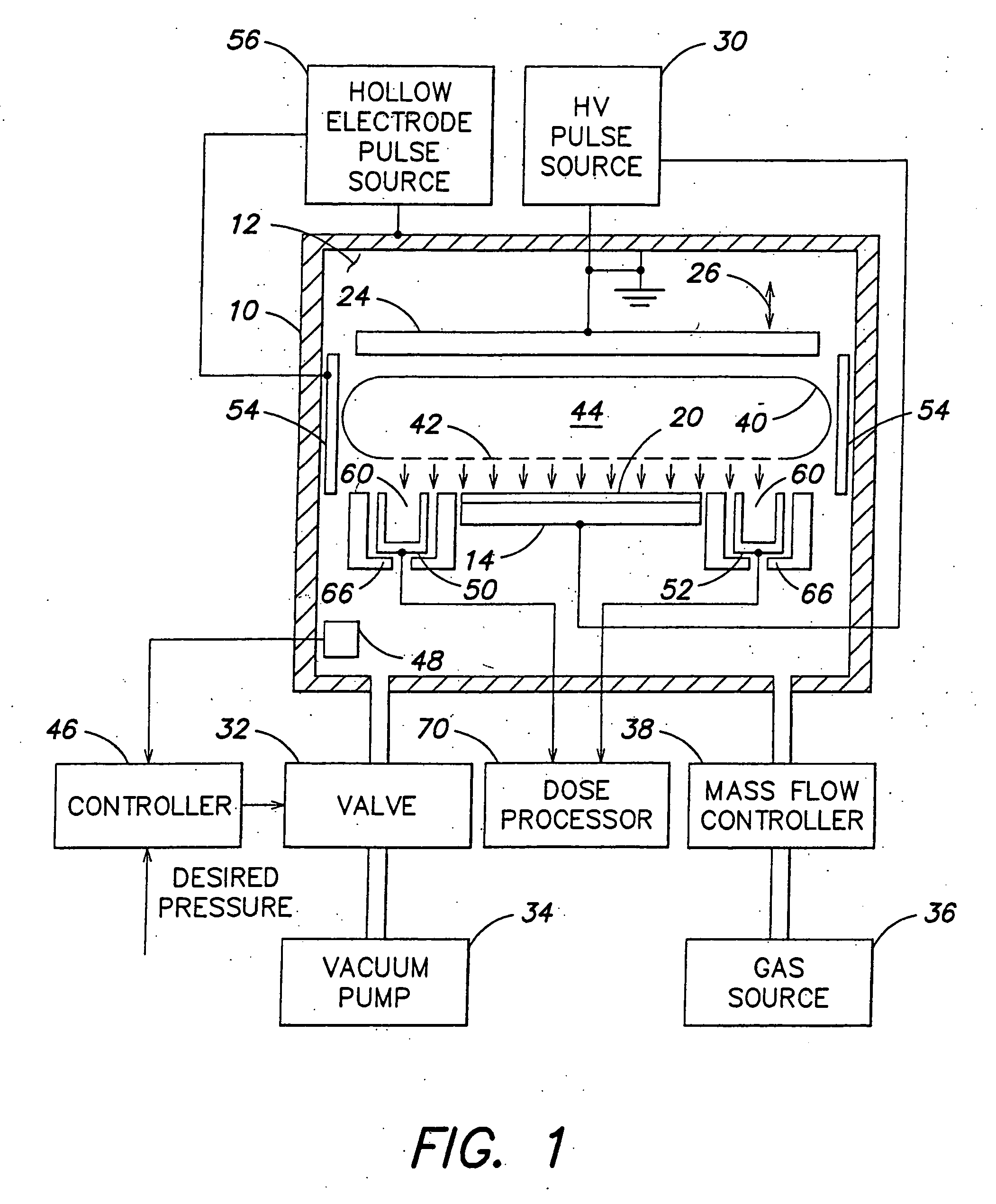

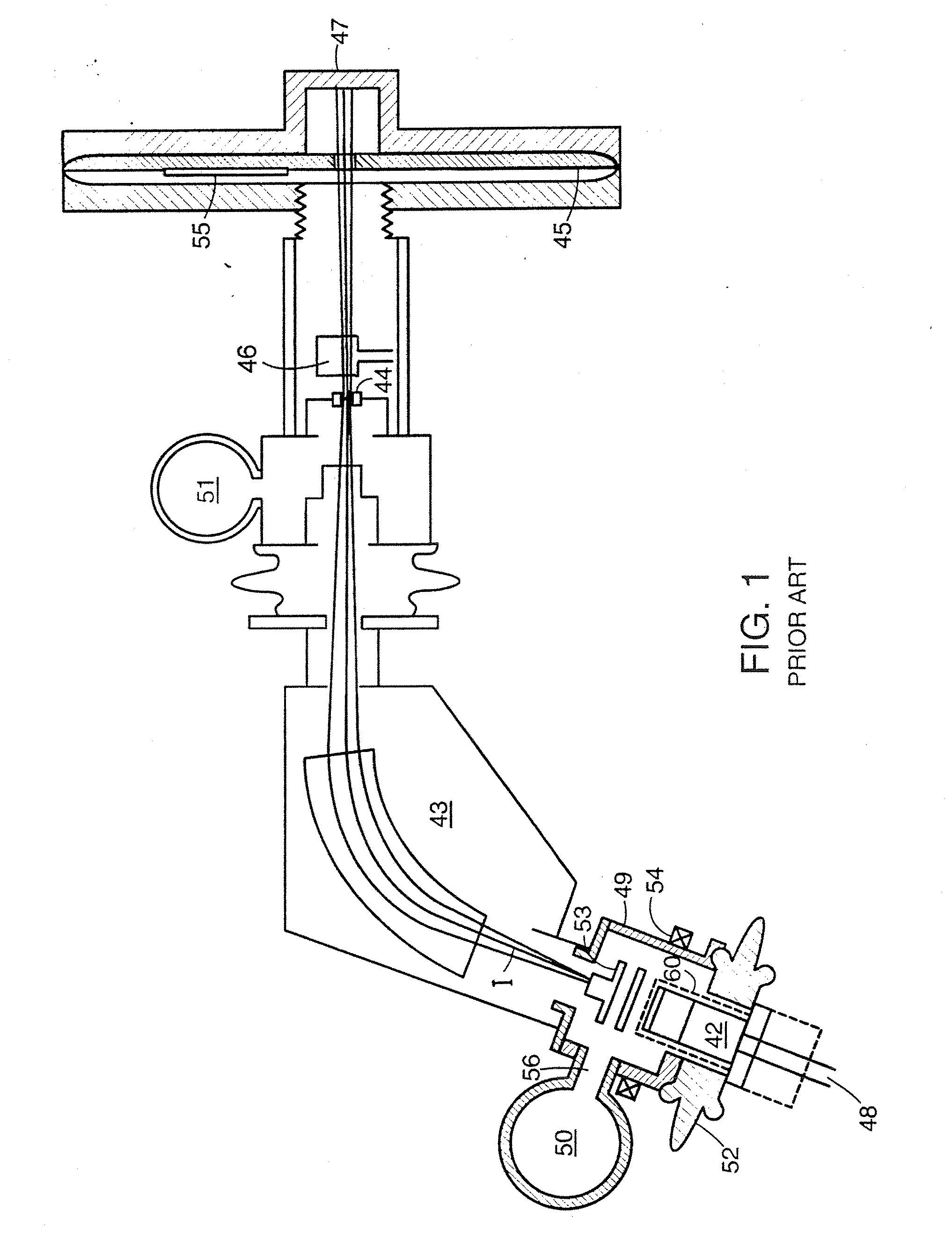

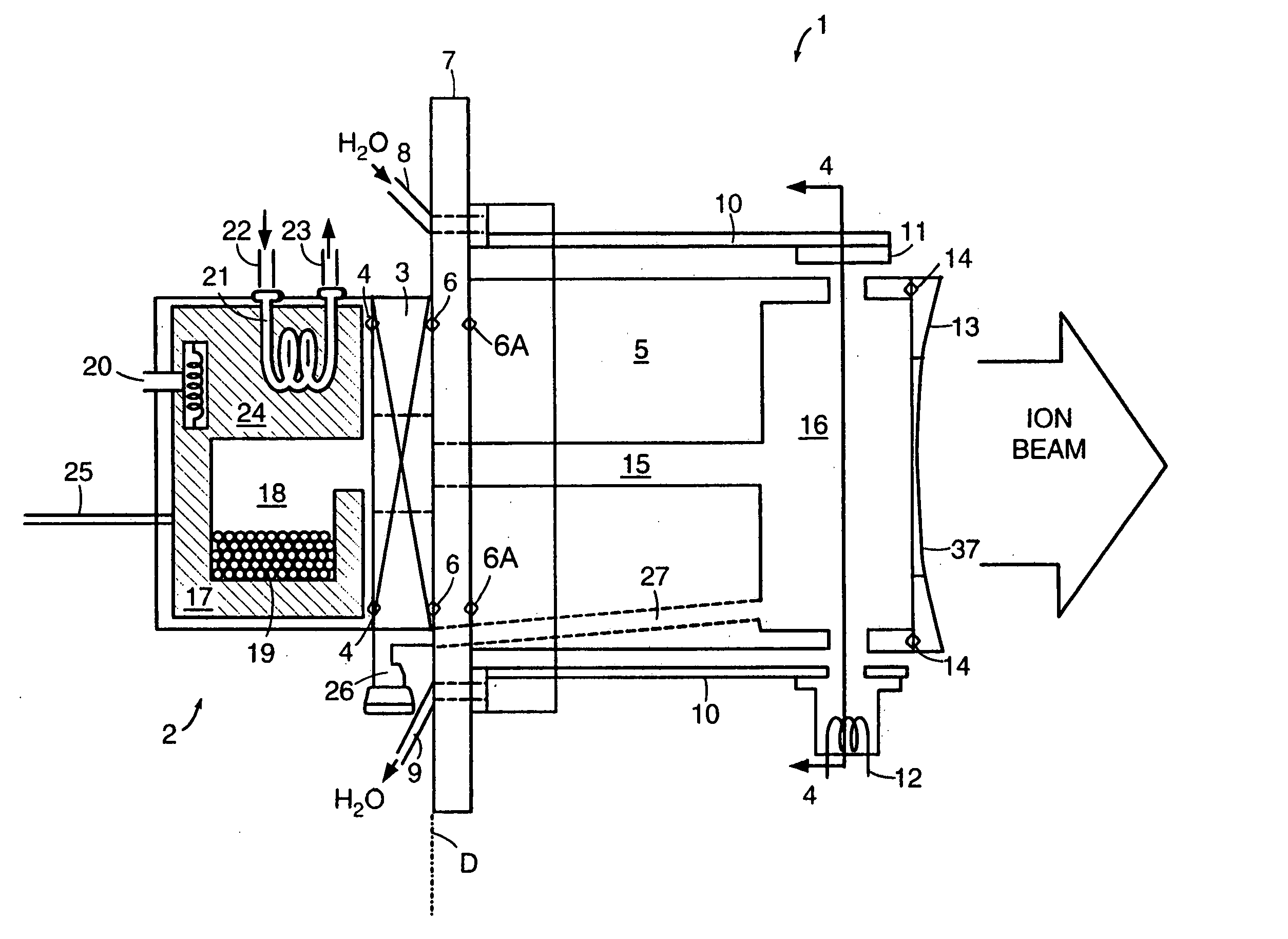

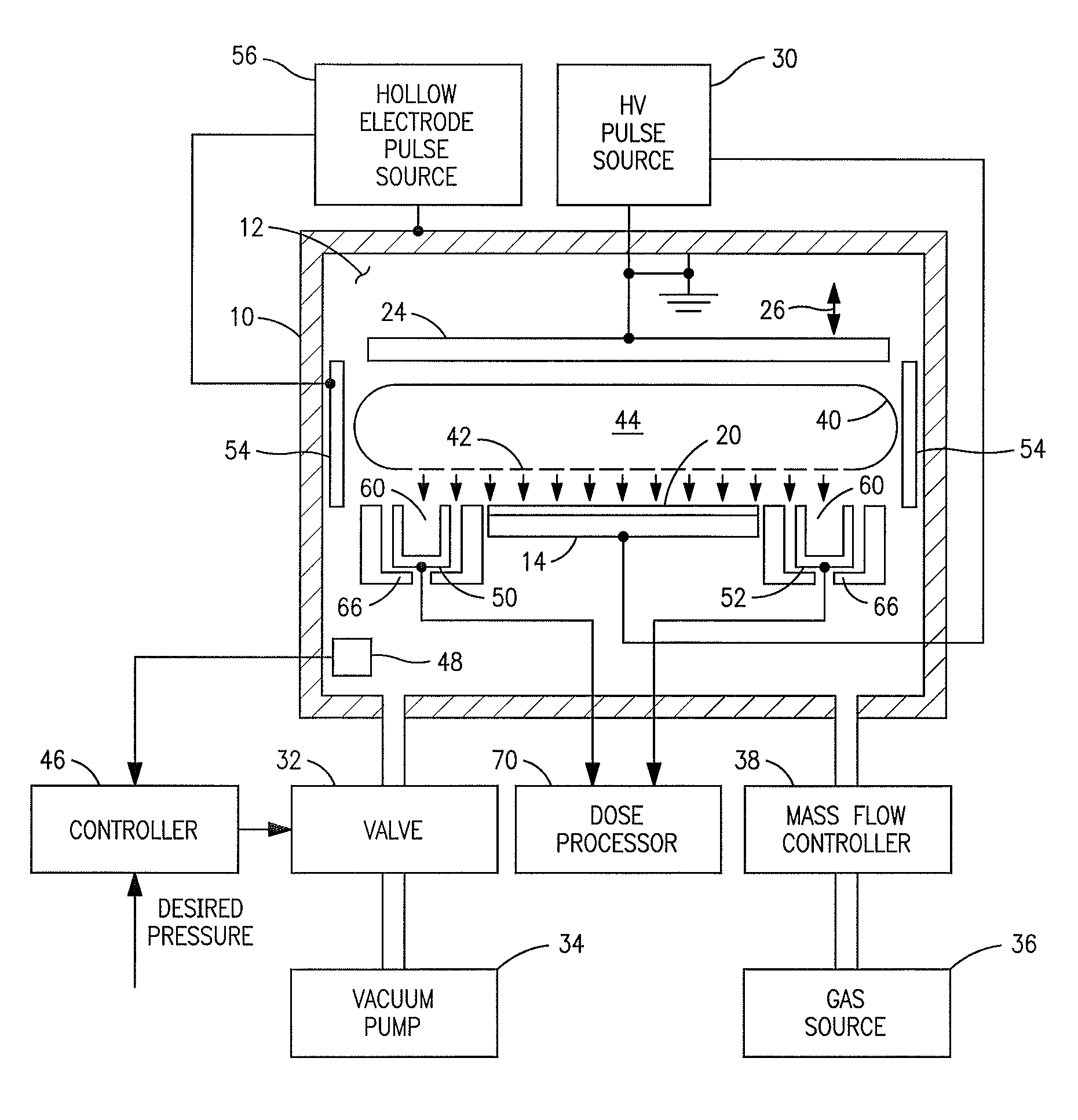

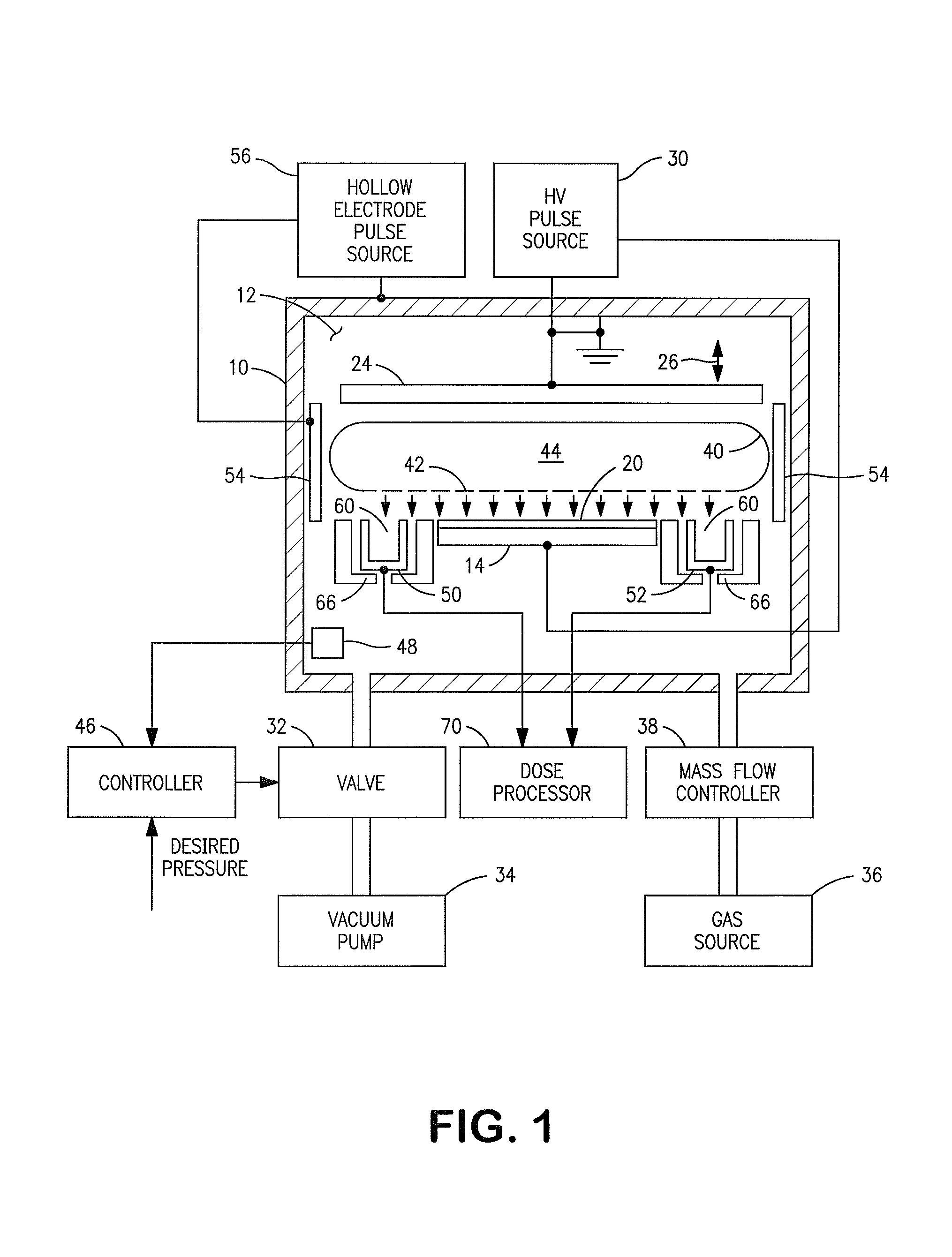

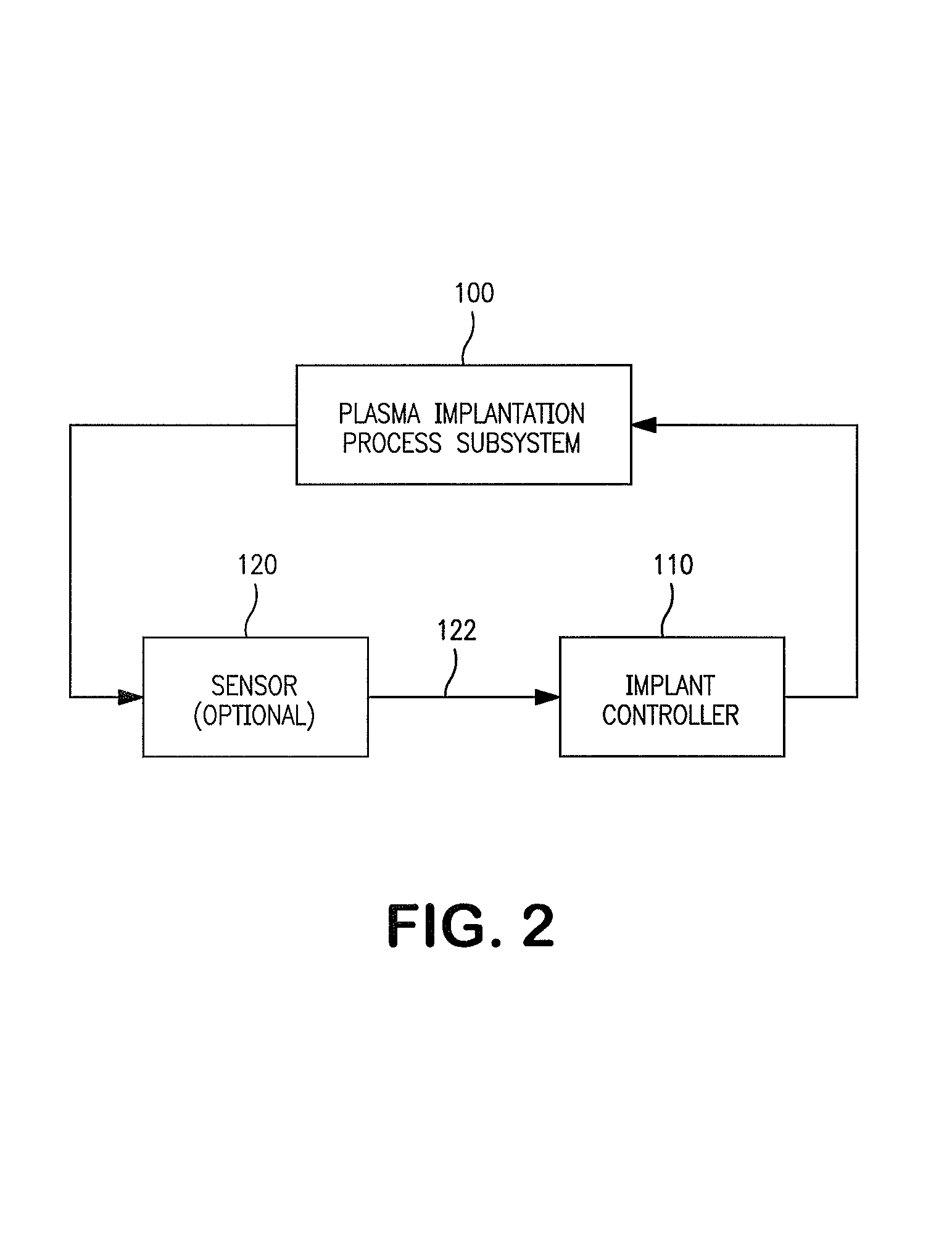

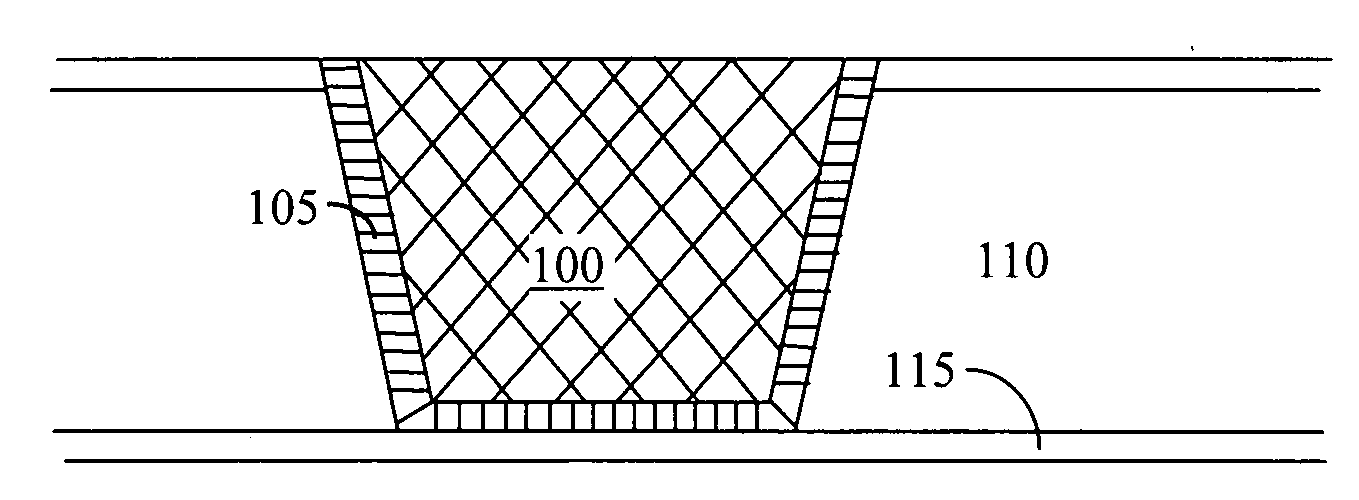

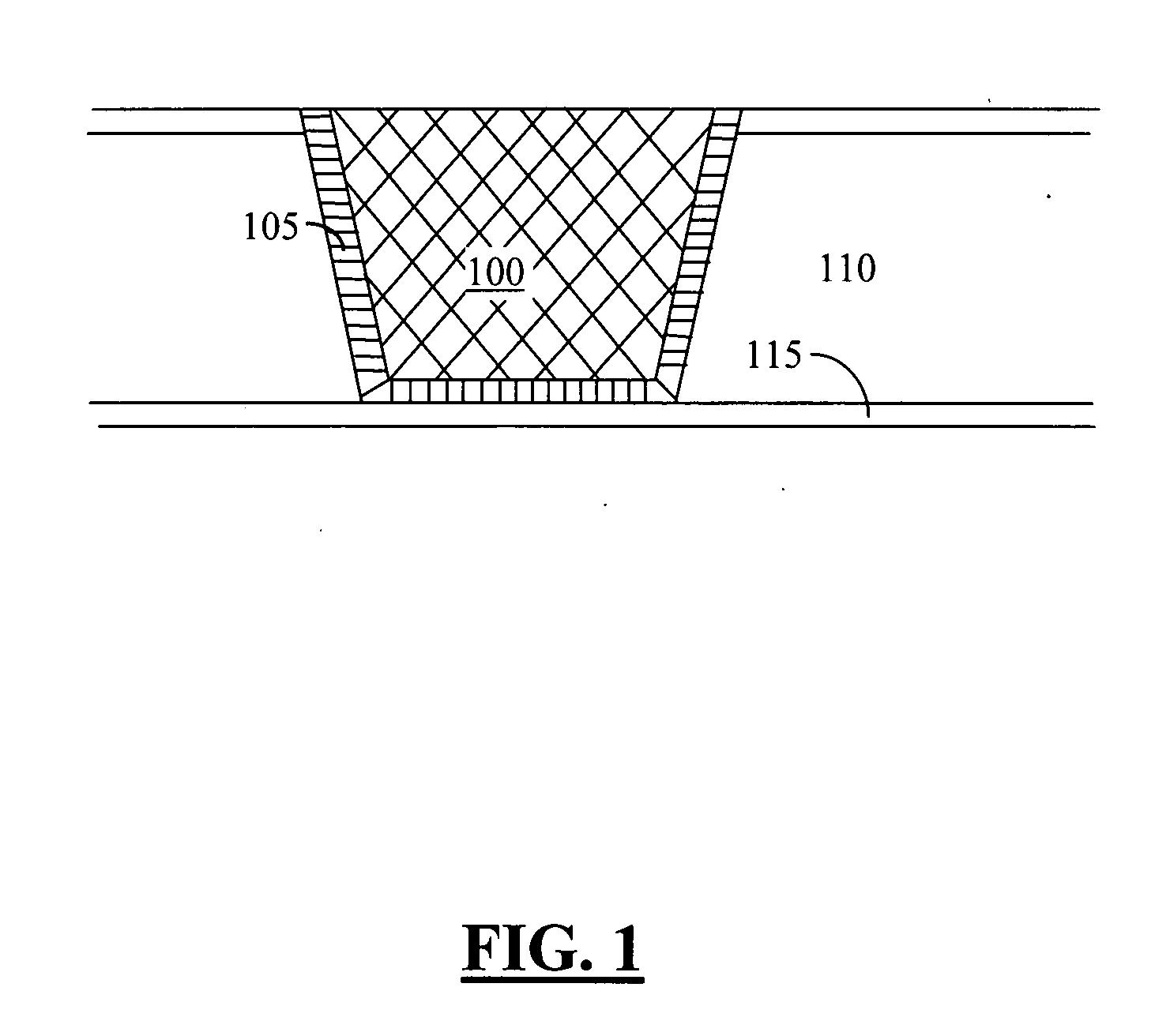

Methods for stable and repeatable ion implantation

A method for plasma ion implantation of a substrate includes providing a plasma ion implantation system having a process chamber, a source for producing a plasma in the process chamber, a platen for holding a substrate in the process chamber, an anode spaced from the platen, and a pulse source for generating implant pulses for accelerating ions from the plasma into the substrate. In one aspect, a parameter of an implant process is varied to at least partially compensate for undesired effects of interaction between ions being implanted and the substrate. For example, dose rate, ion energy, or both may be varied during the implant process. In another aspect, a pretreatment step includes accelerating ions from the plasma to the anode to cause emission of secondary electrons from the anode, and accelerating the secondary electrons from the anode to a substrate for pretreatment of the substrate.

Owner:VARIAN SEMICON EQUIP ASSOC INC

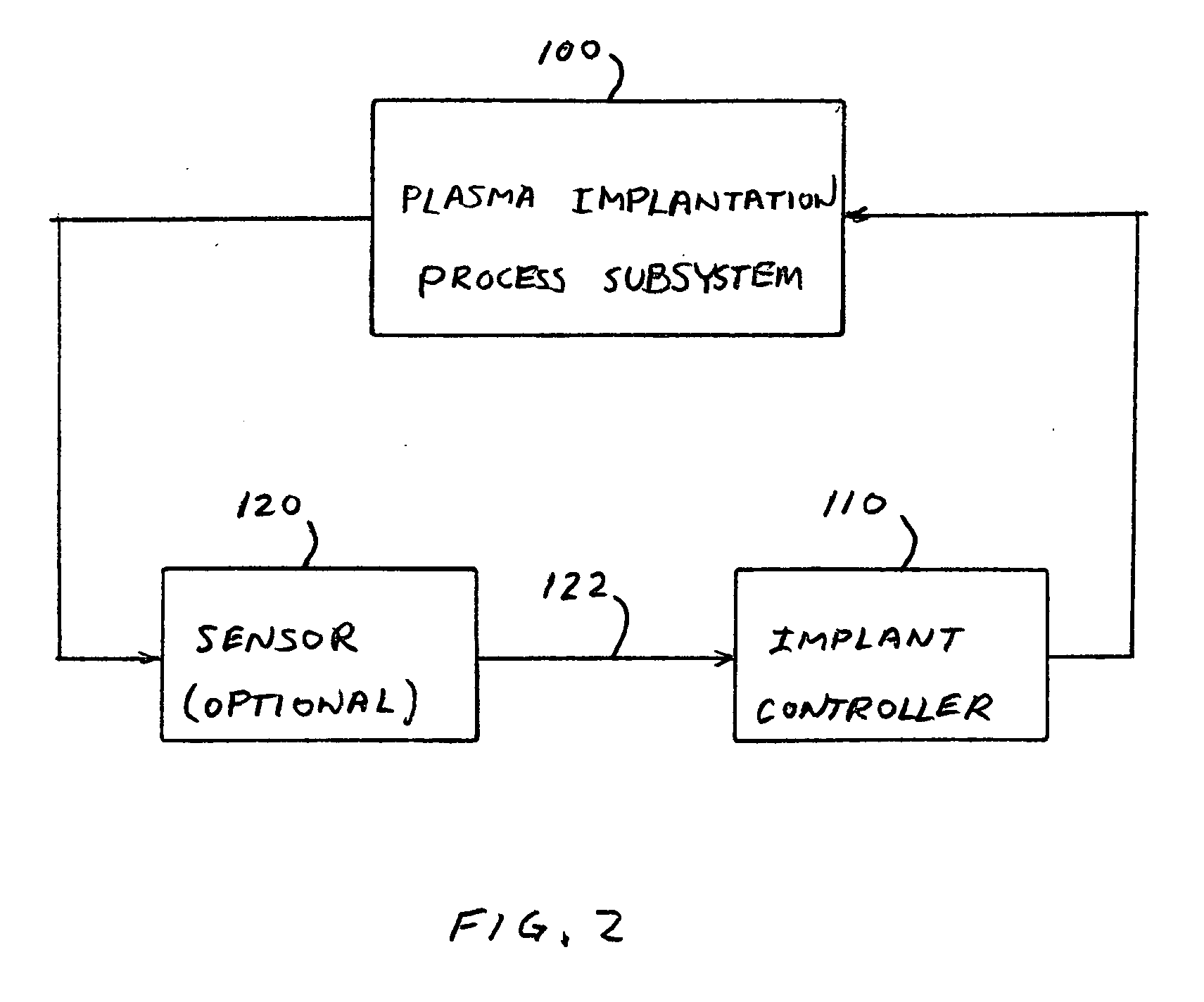

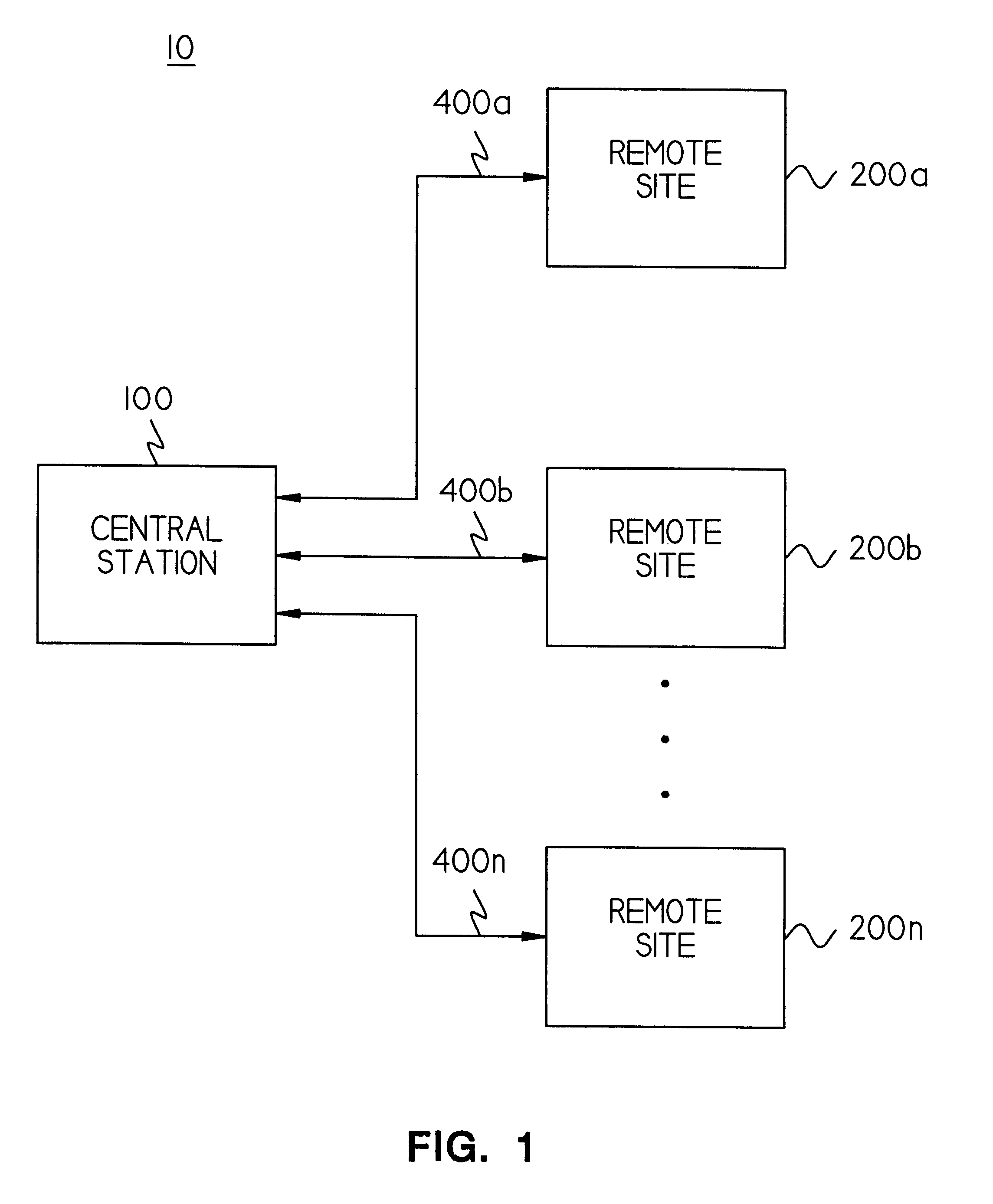

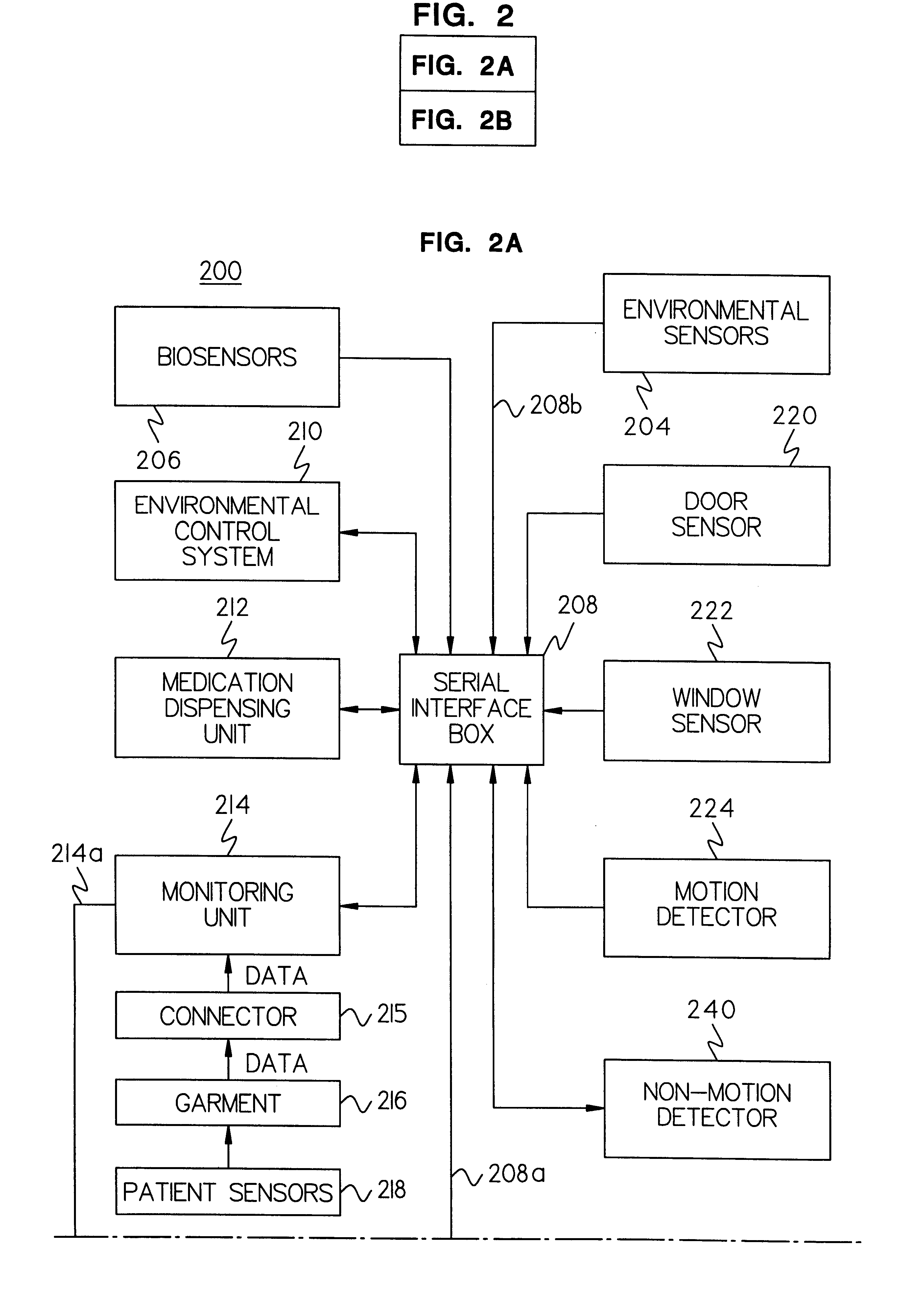

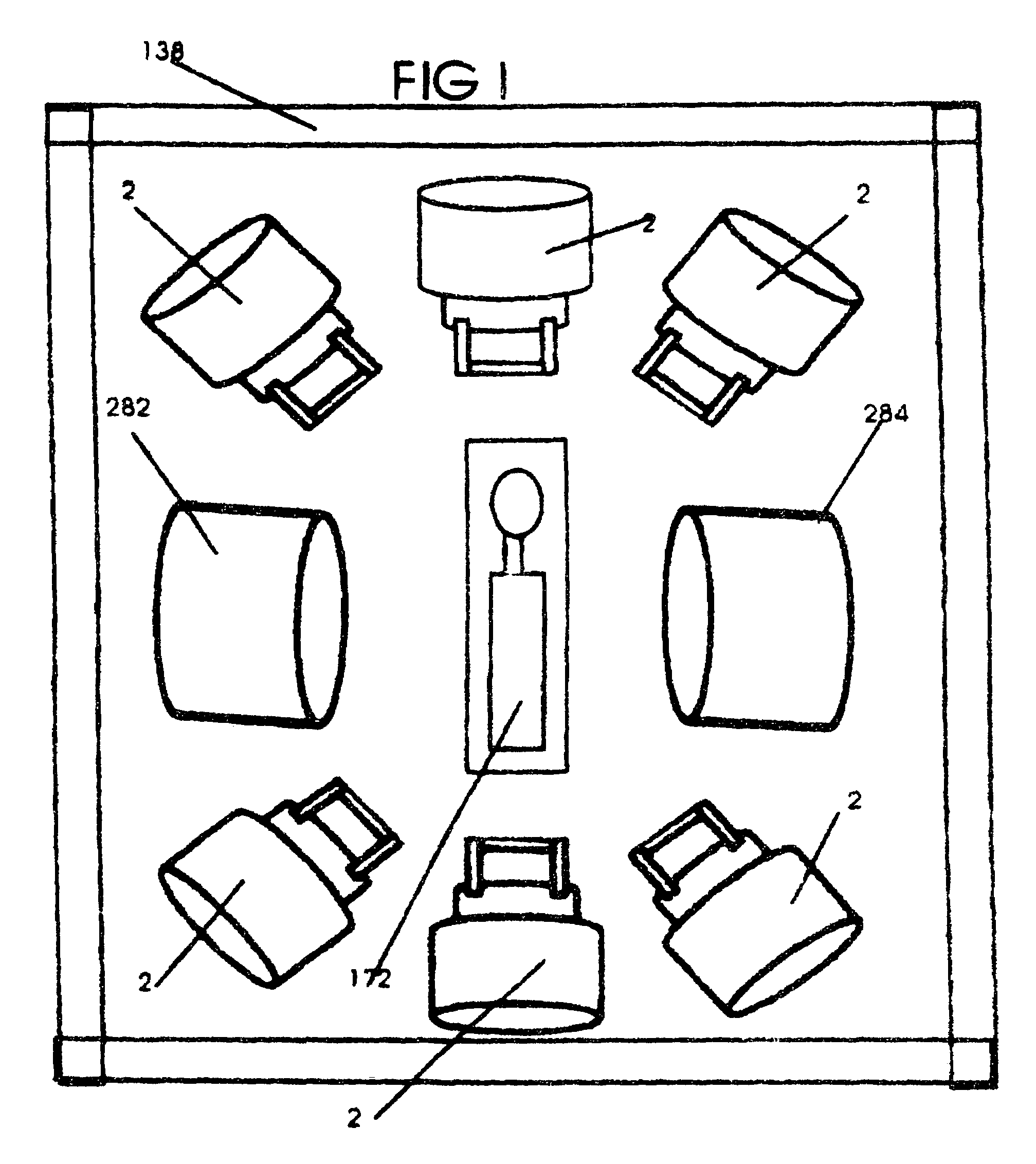

Automated medication dispenser with remote patient monitoring system

InactiveUS6304797B1Drug and medicationsRespiratory organ evaluationMicrocontrollerMedication Dispenser

A medication dispensing unit comprising a carousel defining a plurality of compartments, each of the compartments adapted to store a dose of medication is disclosed. The dispensing unit also comprises a housing that has a surface adapted to receive the carousel. The housing defines a receptacle and an access aperture that communicates between the receptacle and the surface that is adapted to receive the carousel. One of the compartments is positioned to communicate with the receptacle through the access aperture. The unit also comprises a dosing drawer that is positioned within the receptacle and communicates with the access aperture to receive a dose of medication from the compartment through the access aperture. The dosing drawer includes a normally closed trap door that, when opened, allows a dose of medication in the drawer to drop out of the dosing drawer. The dispensing unit comprises a recovery drawer that is positioned within the receptacle and communicates with the dosing drawer through the trap door, and receives a dose of medication from the dosing drawer when the trap door is opened. The medication dispensing unit also comprises means for rotating the carousel and a microcontroller that defines dosing period, determines that the patient has accessed the dosing drawer within a dosing period, and locks the recovery drawer.

Owner:RAPID PATIENT MONITORING

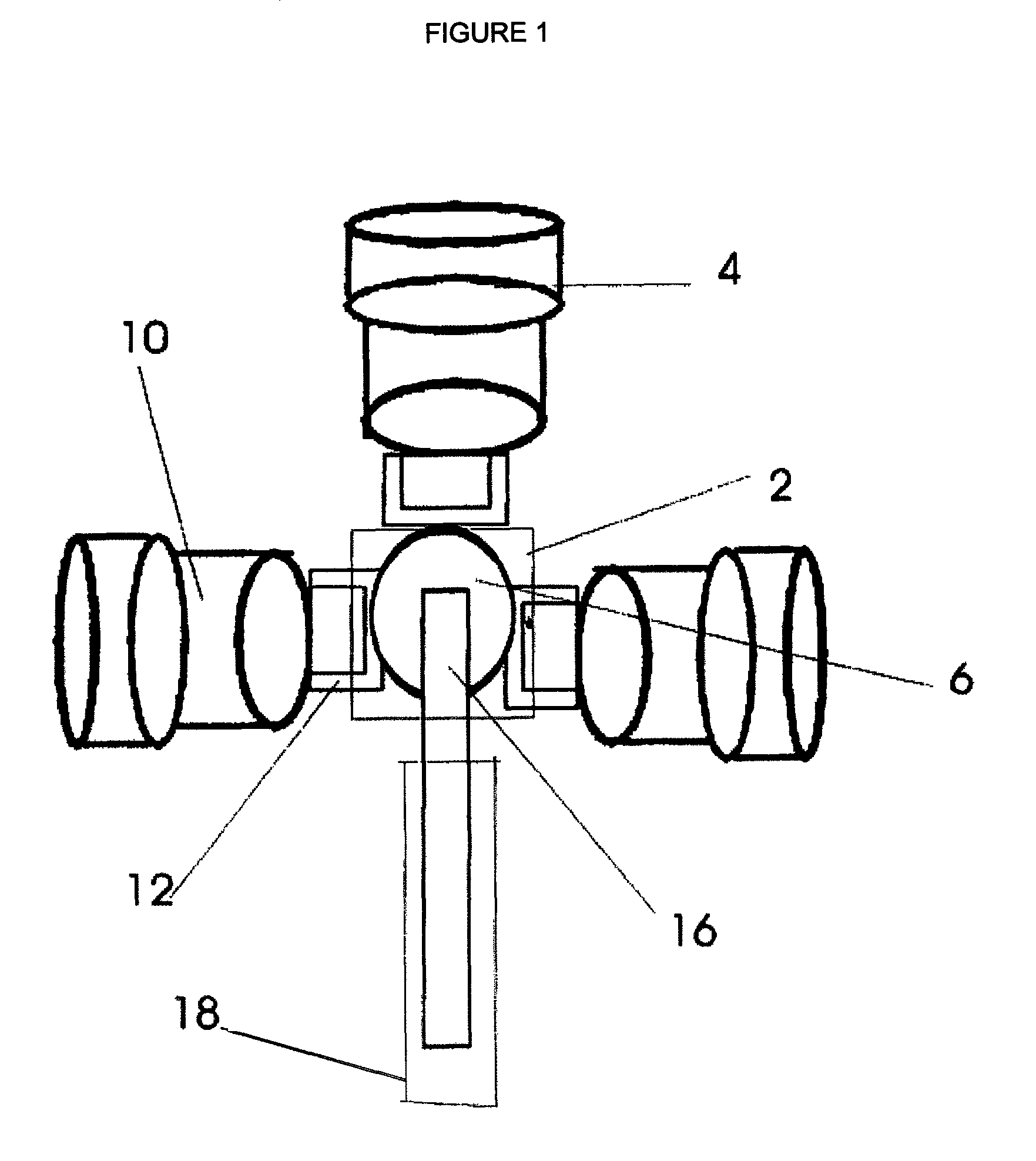

Aerosol processing and inhalation method and system for high dose rate aerosol drug delivery

ActiveUS20070144514A1Increase dose rateRisk minimizationRespiratorsLiquid surface applicatorsSolvent vaporCounter flow

A method and system is disclosed which is capable of delivering at a high dose rate, respirable solid aerosols derived from aqueous- or nonaqueous-based solutions containing the desired therapeutic agent(s). The method and system comprises the integration of an aerosol generator, an aerosol evaporator, an aerosol concentrator, and an aerosol flow regulator. The aerosol generator generates 10-30 μm droplets, with a narrow size distribution. The aerosol jet is arrested by a coaxial counter-flow heated air jet, and evaporated rapidly by annular swirling heated air. Most of the air, together with the unwanted solvent vapor, is removed from the aerosol stream during the process of aerosol concentration. The output aerosol carries the dry particles to be inhaled by the patient. The respiratory-governed control of aerosol fluid generation system delivers fluid containing the test agent of interest (drug or toxin) to the aerosol generator throughout inhalation.

Owner:KAER BIOTHERAPEUTICS CORP

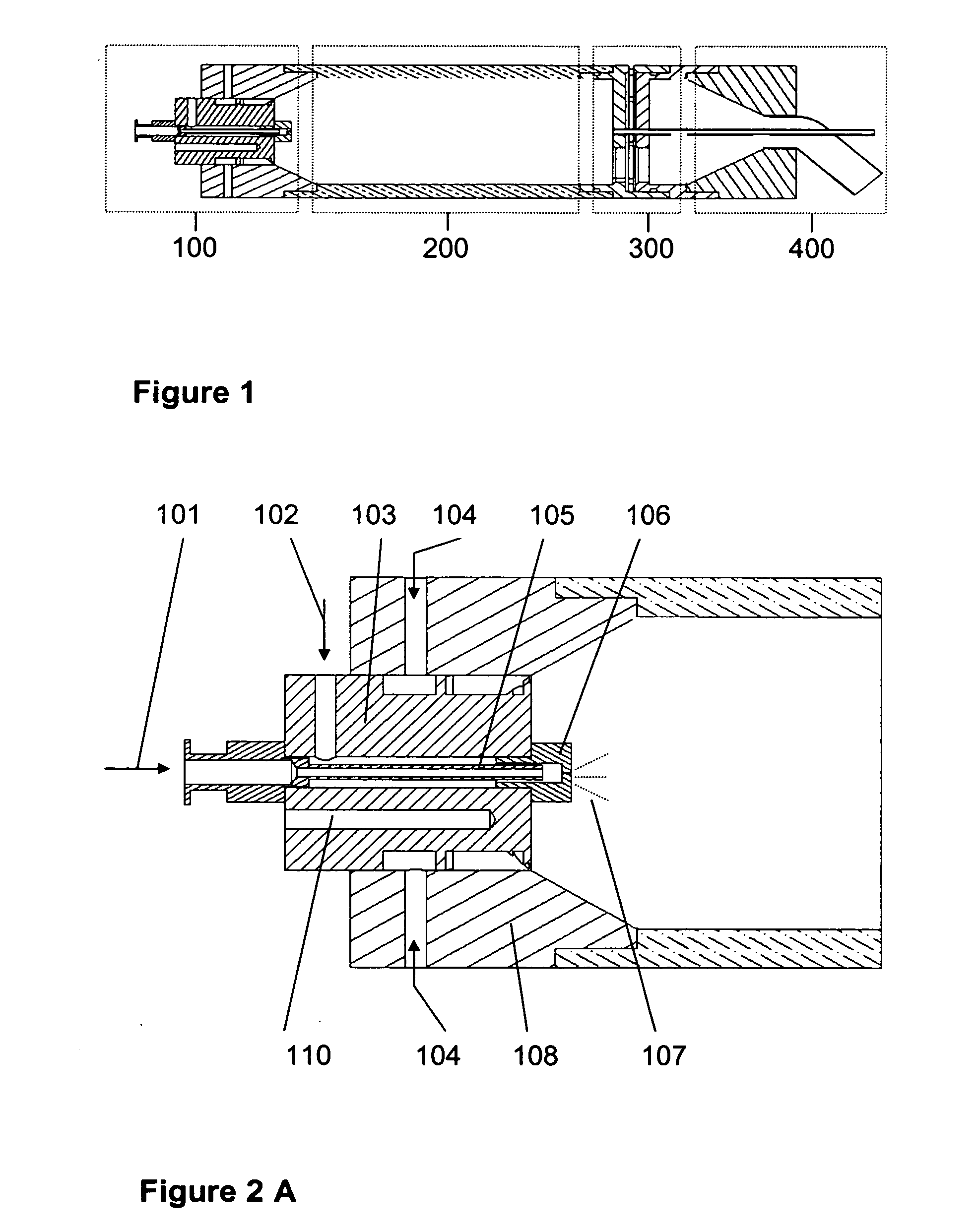

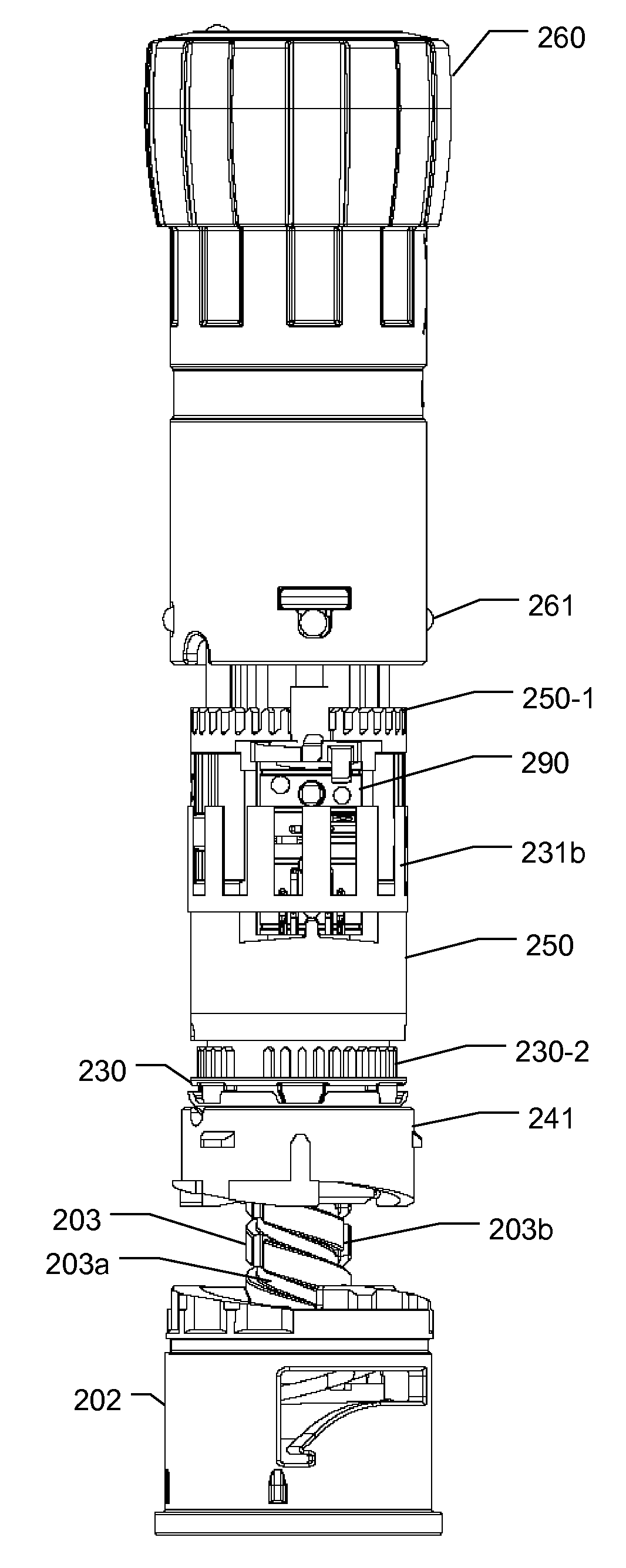

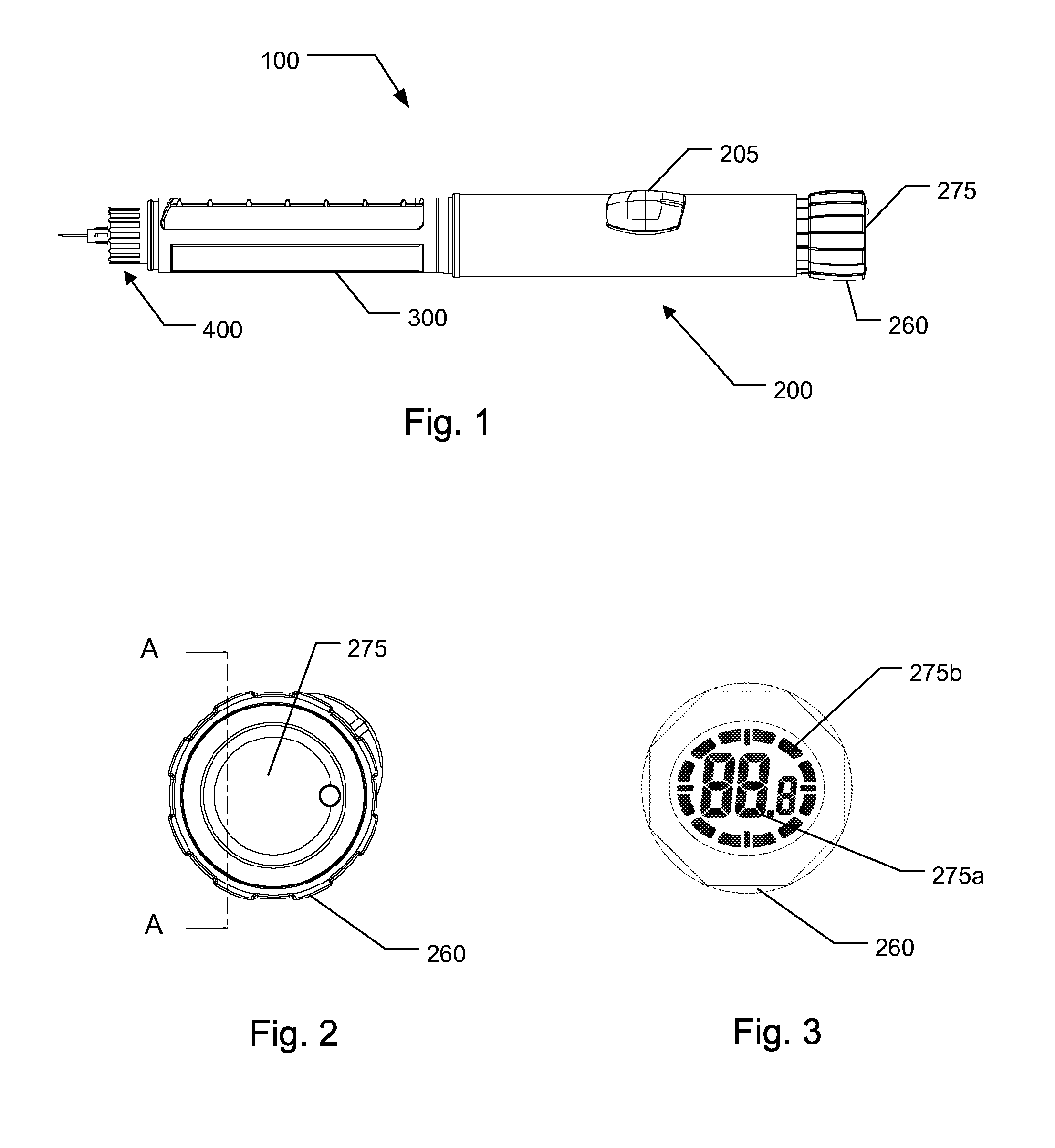

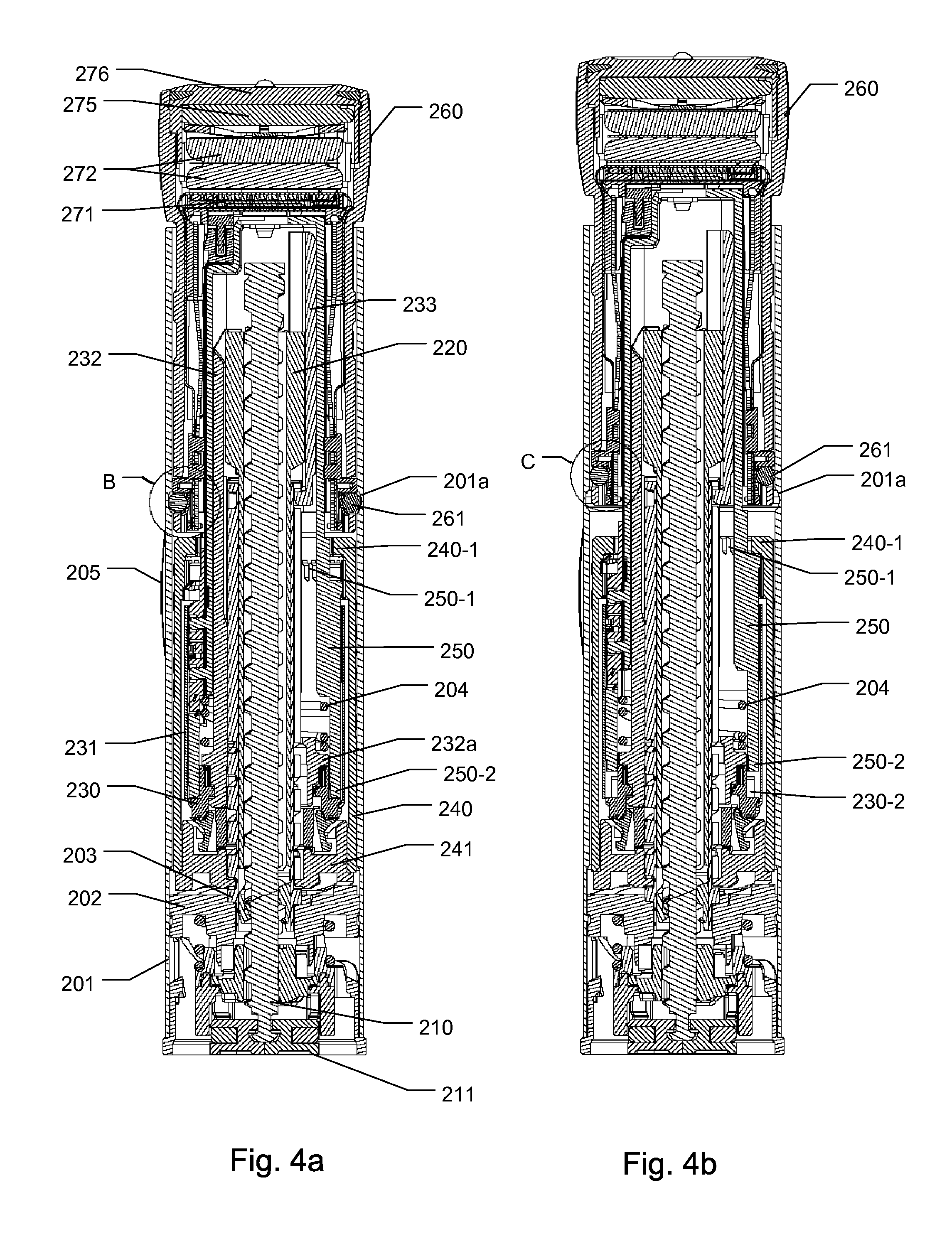

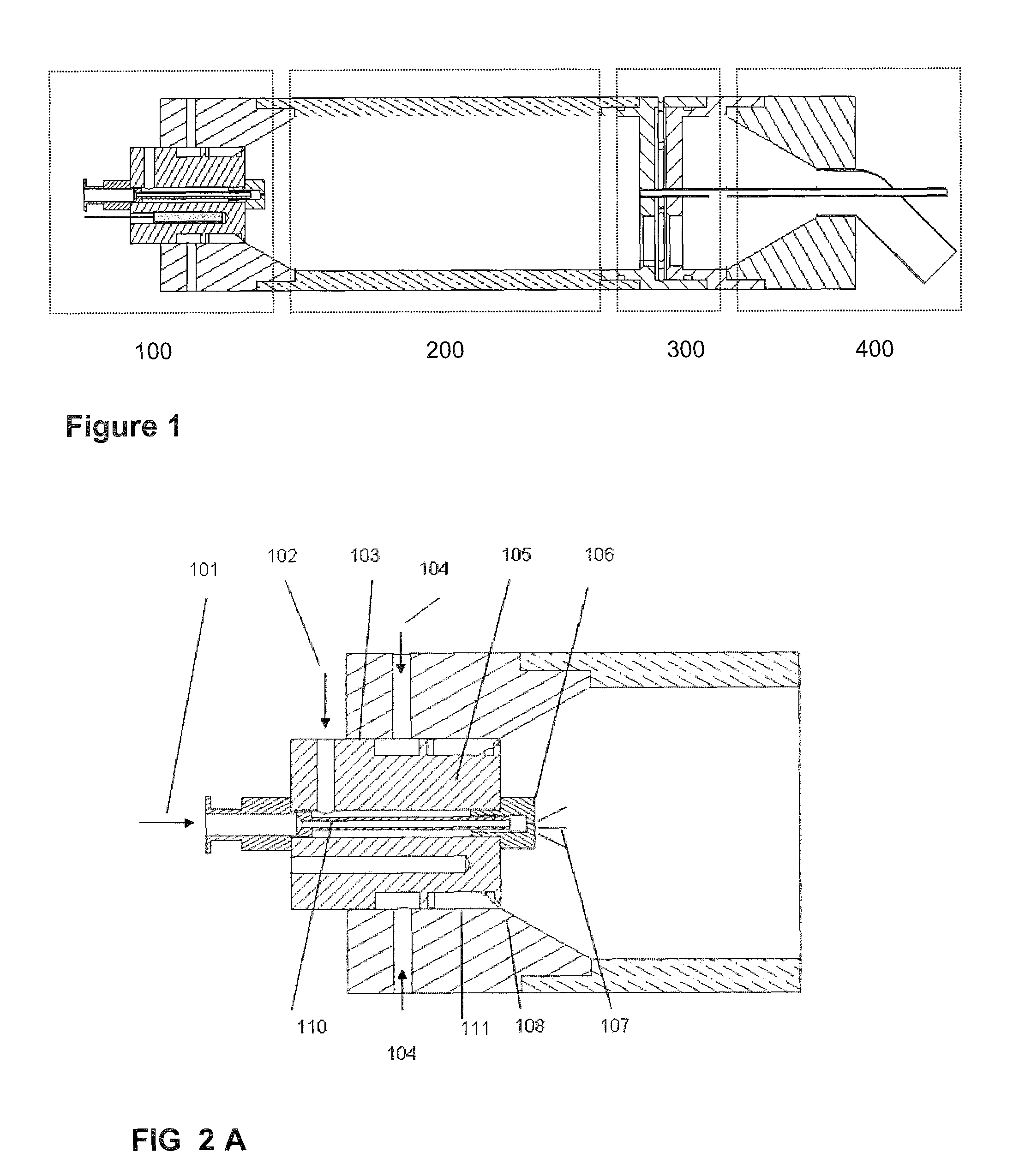

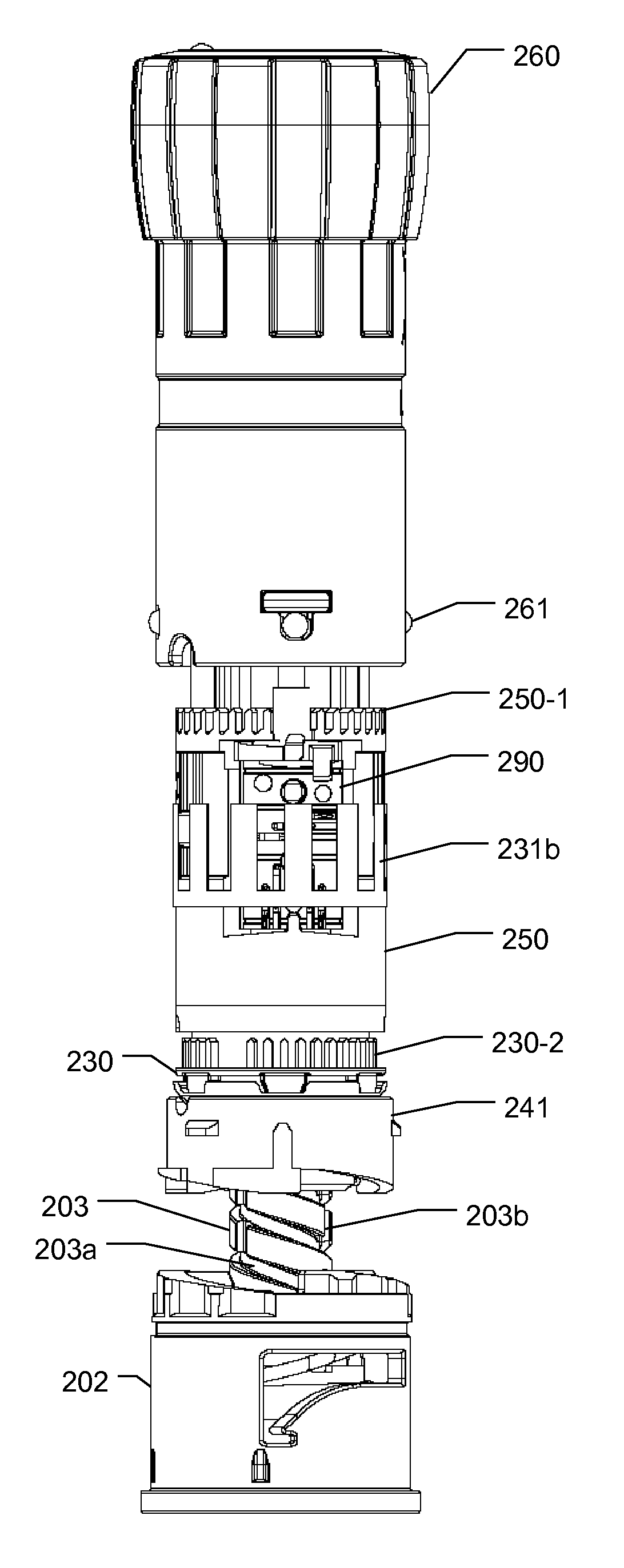

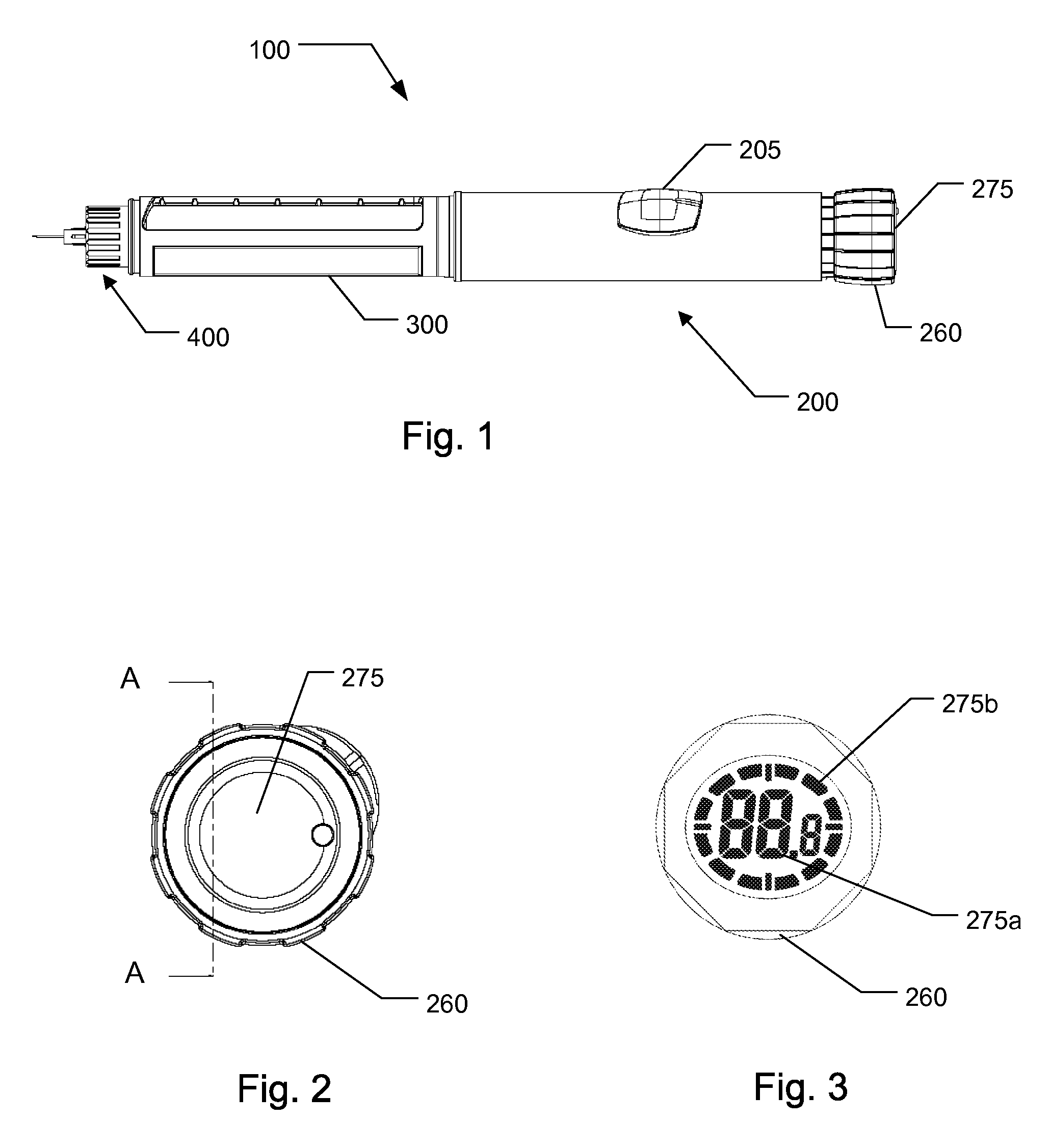

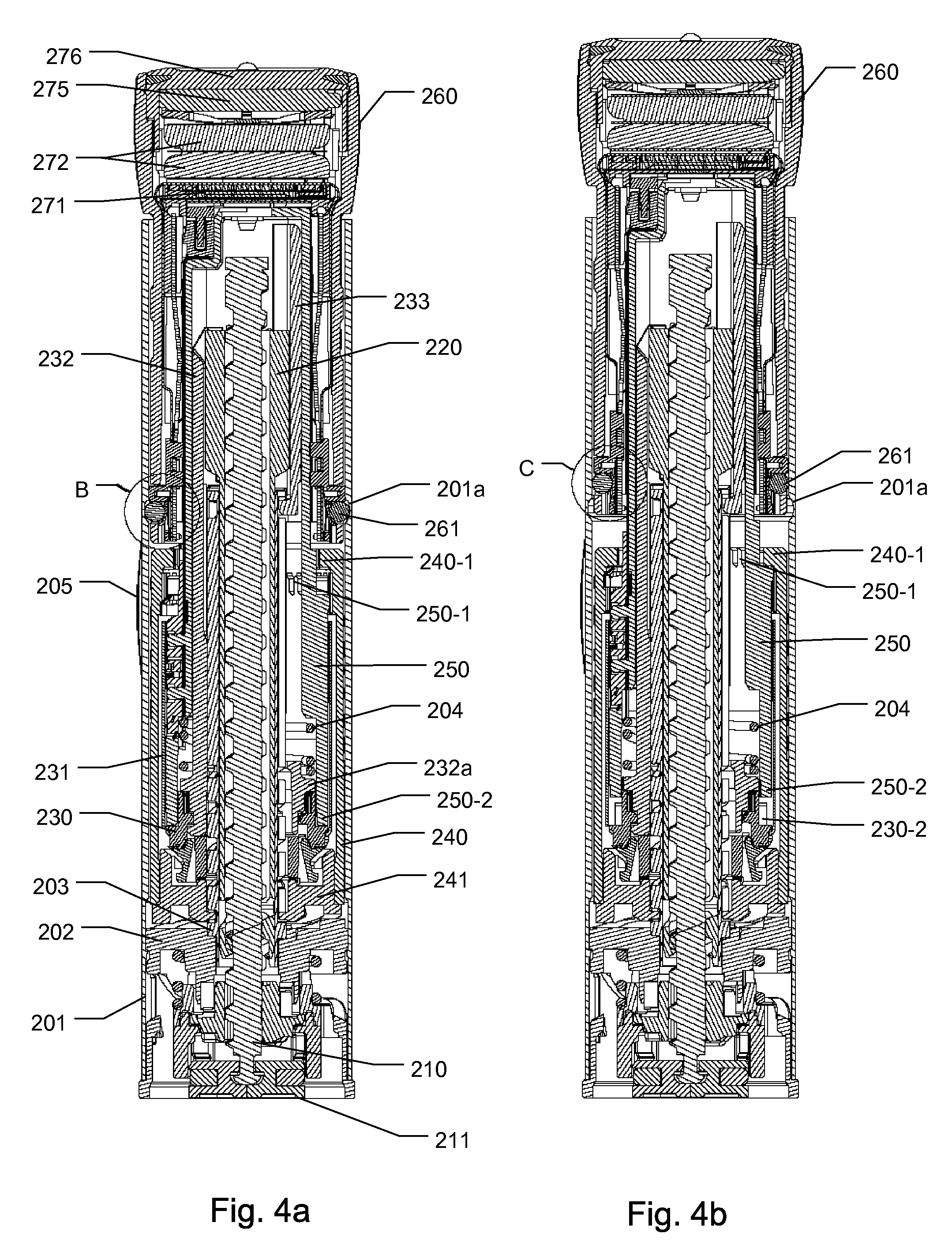

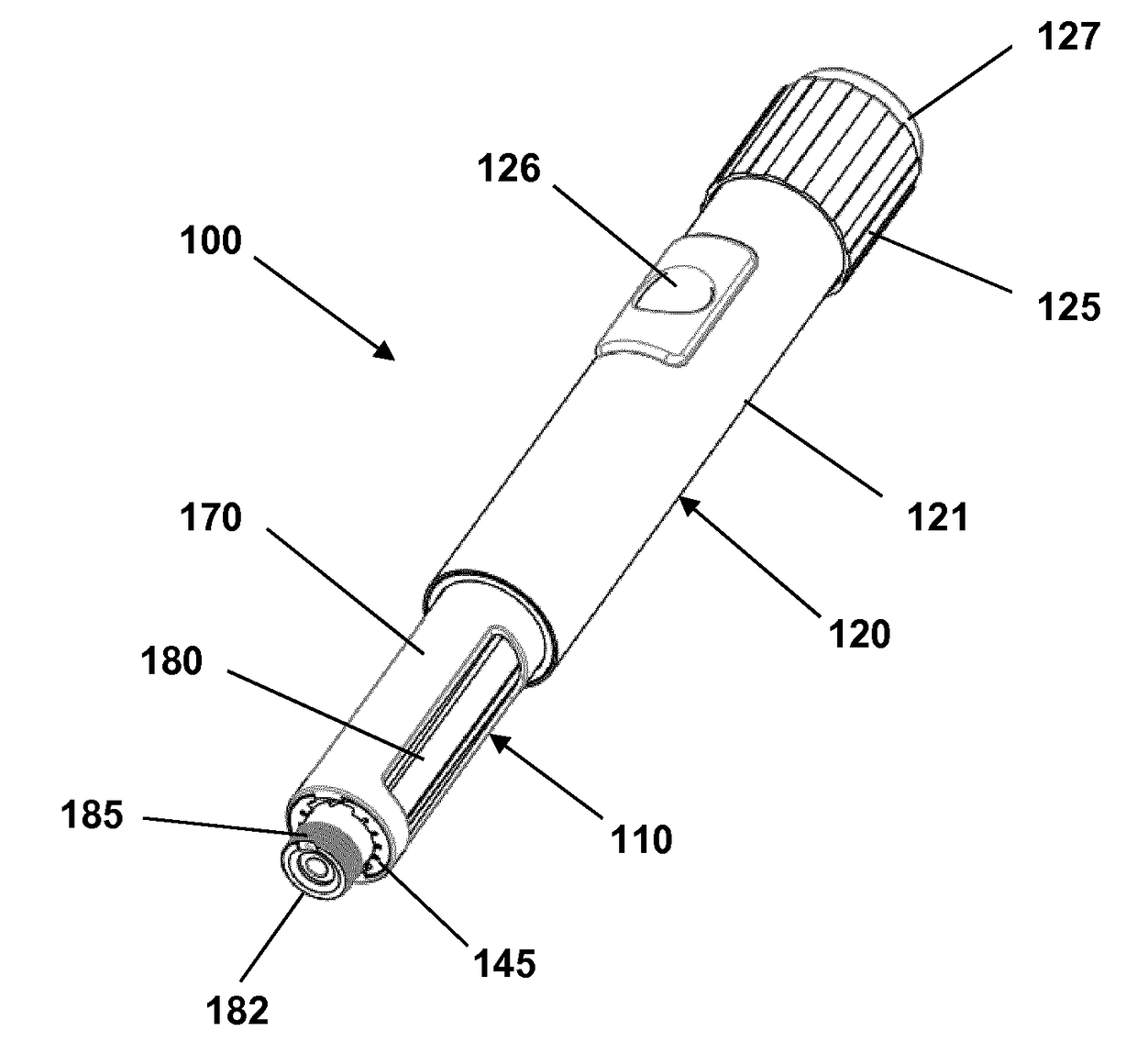

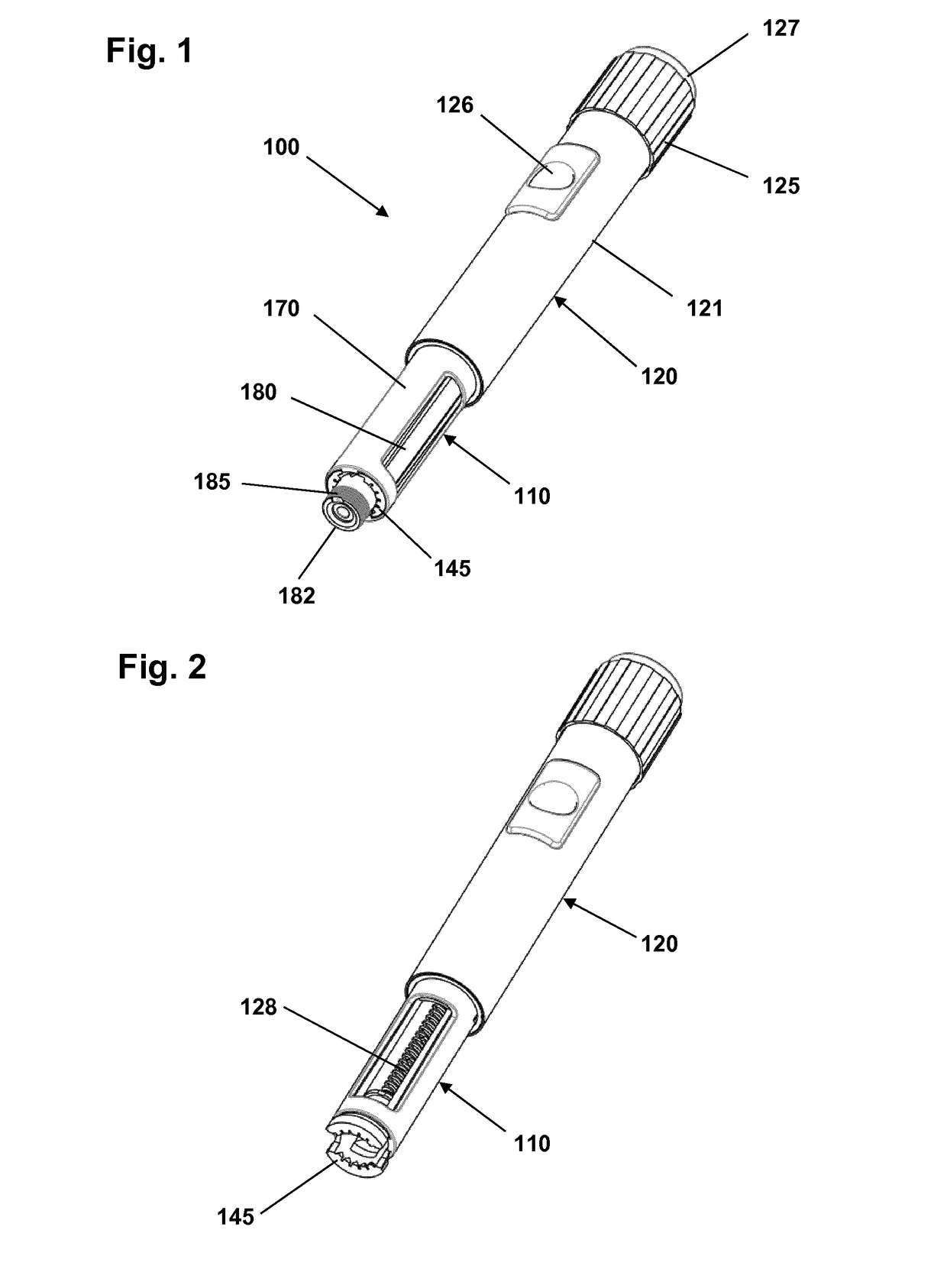

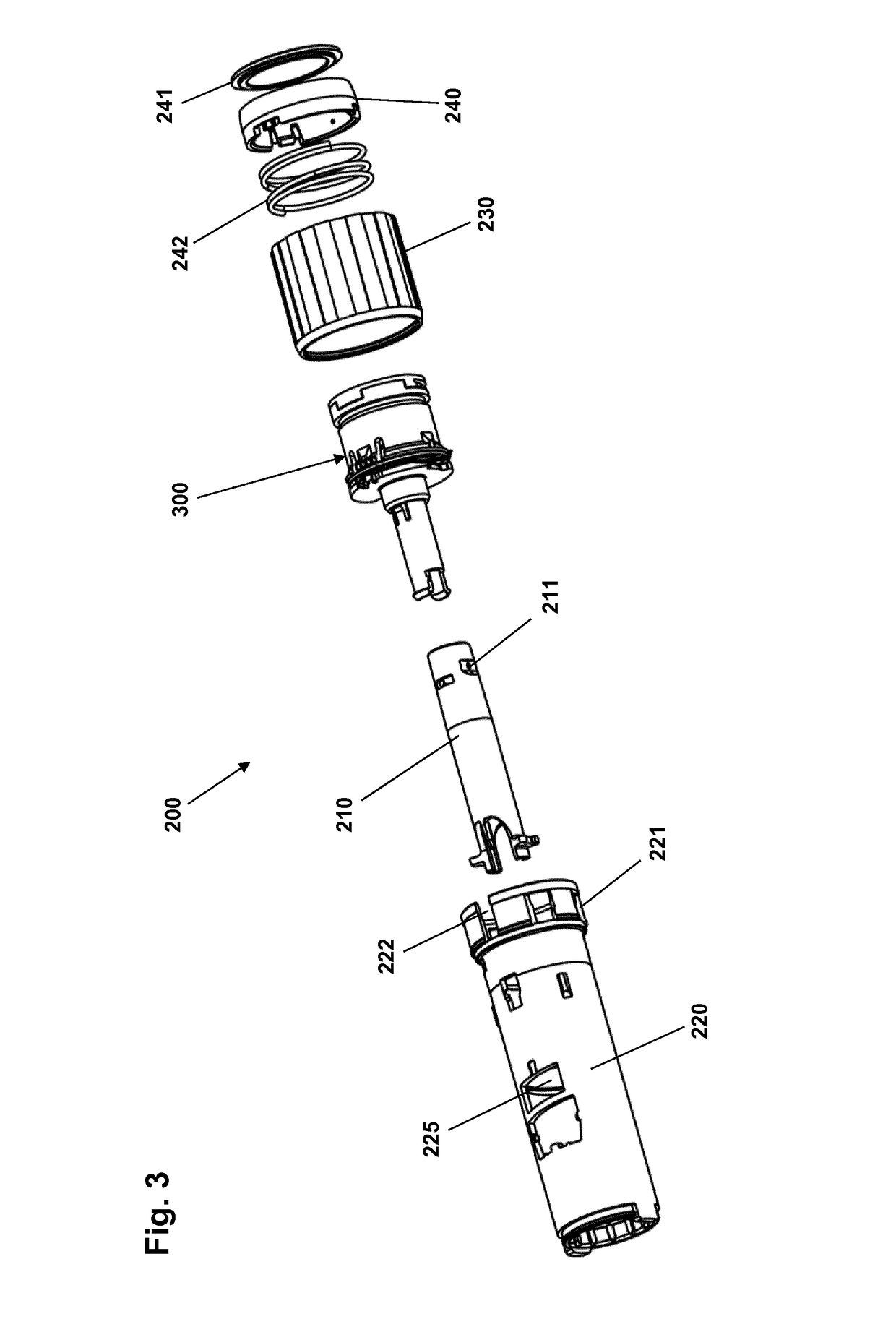

Electronically assisted drug delivery device

The present invention relates to electronically assisted drug delivery devices (100). The drug delivery device may include a Gray code type detector for sensing dosage data, wherein the detector comprises a code track consisting of a sequence of alternating markings and a plurality of detectors that are mutually spaced in a direction extending along the code track. The drug delivery device may also include a dosage selector (260) which is moved in a proximal direction upon dose setting and in a distal direction upon dose injection, where the dosage selector is latched in the end of dose position by a latching element, the latching element actuating an end of dose switch for signalling the end of dose state. The drug delivery device may also incorporate power-management arrangements which effectively minimizes power consumption for the incorporated electronic circuitry.

Owner:NOVO NORDISK AS

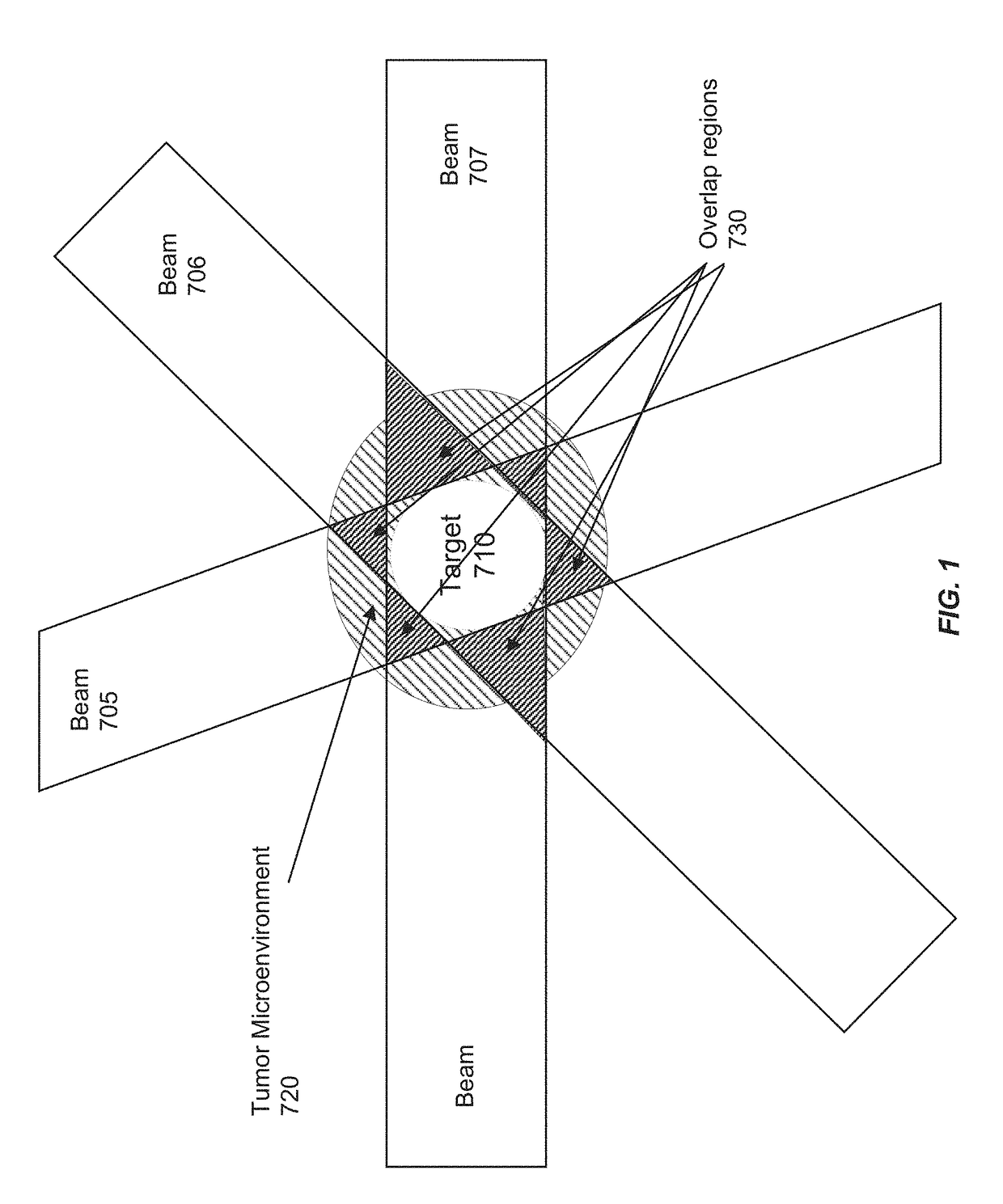

Few seconds beam on time, breathing synchronized image guided all fields simultaneous radiation therapy combined with hyperthermia

This invention relates to single session image guided all field simultaneous radiation therapy combined with hyperthermia. Hyperthermia renders the radiation resistant cells as more radiation sensitive cells. The high and super-high dose rate radiation greatly improves the RBE of the photon radiation. It also minimizes photon radiation therapy's OER and cell cycle dependent tumor cell kill by minimizing the repair capacity of cell after photon radiation. Single session hyperthermia and radiation therapy overcomes the thermotolerance-associated inefficiency of hyperthermia treatment as it is when hyperthermia is combined with fractionated, lower dose rate radiation. The synergetic effects of sublethal damage repair inhibiting single session hyperthermia-combined with high dose and dose rate single session radiation therapy, and combined chemotherapy brings the photon radiation therapy's tumor cure and control capabilities closer to high LET radiation therapy.

Owner:SAHADEVAN VELAYUDHAN

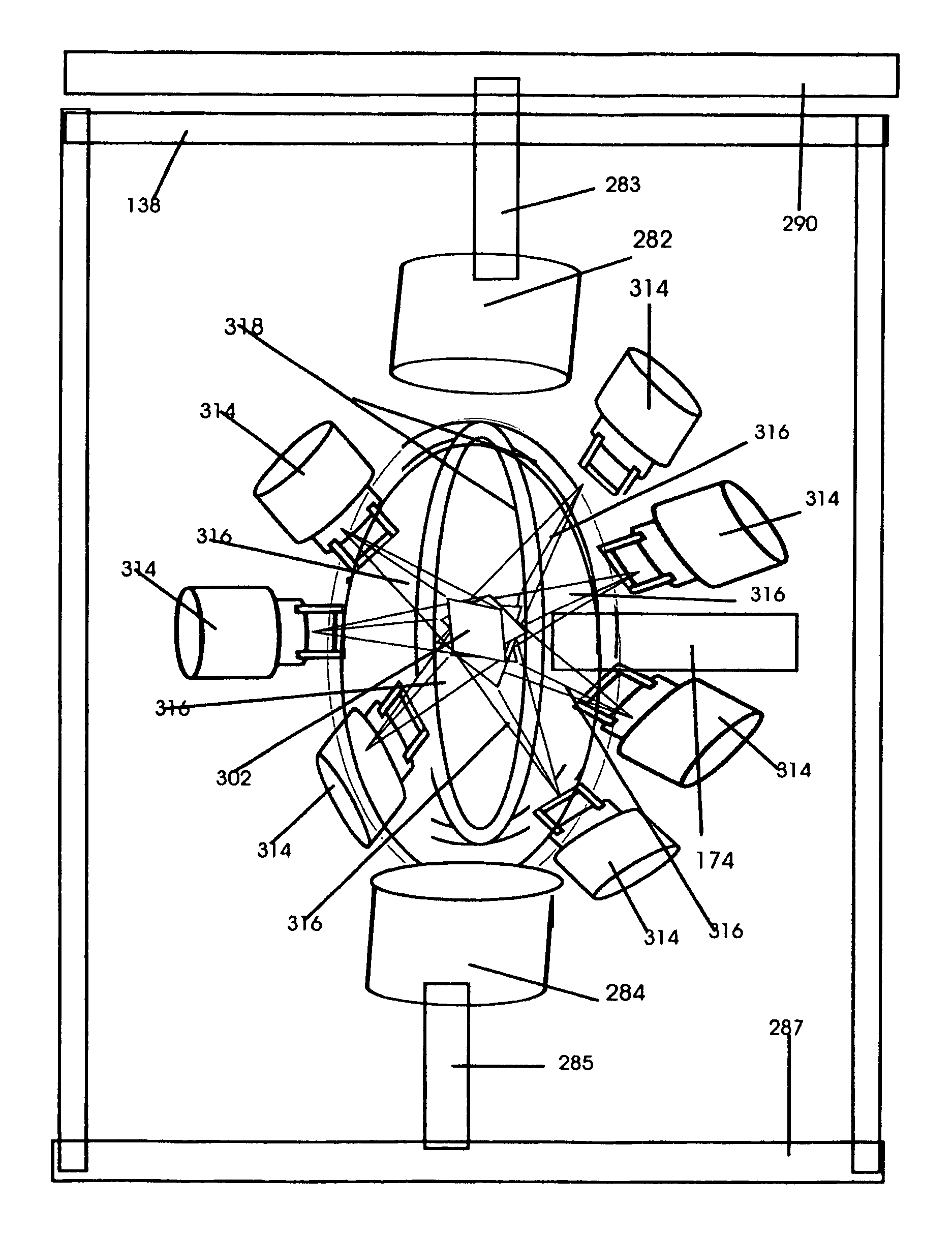

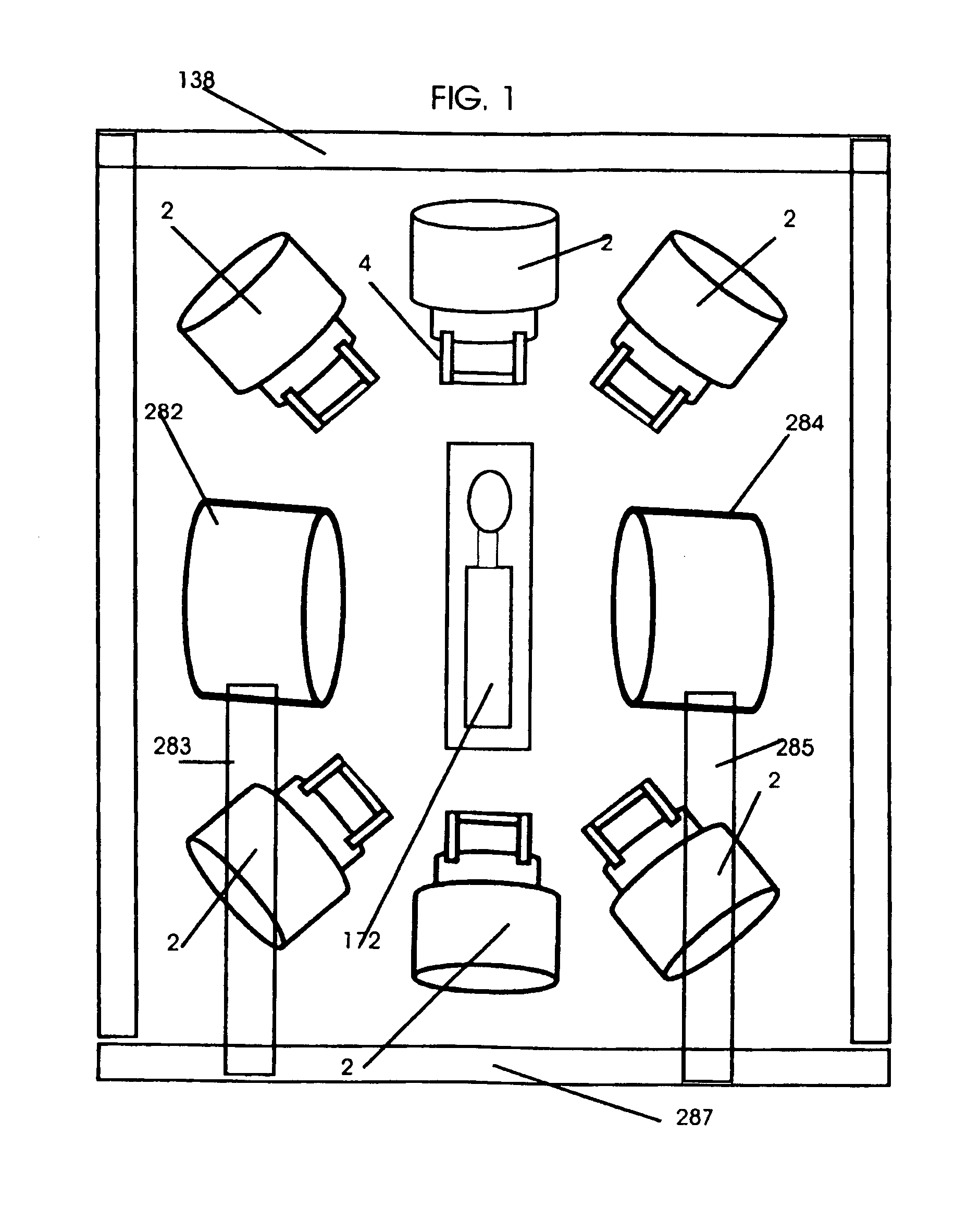

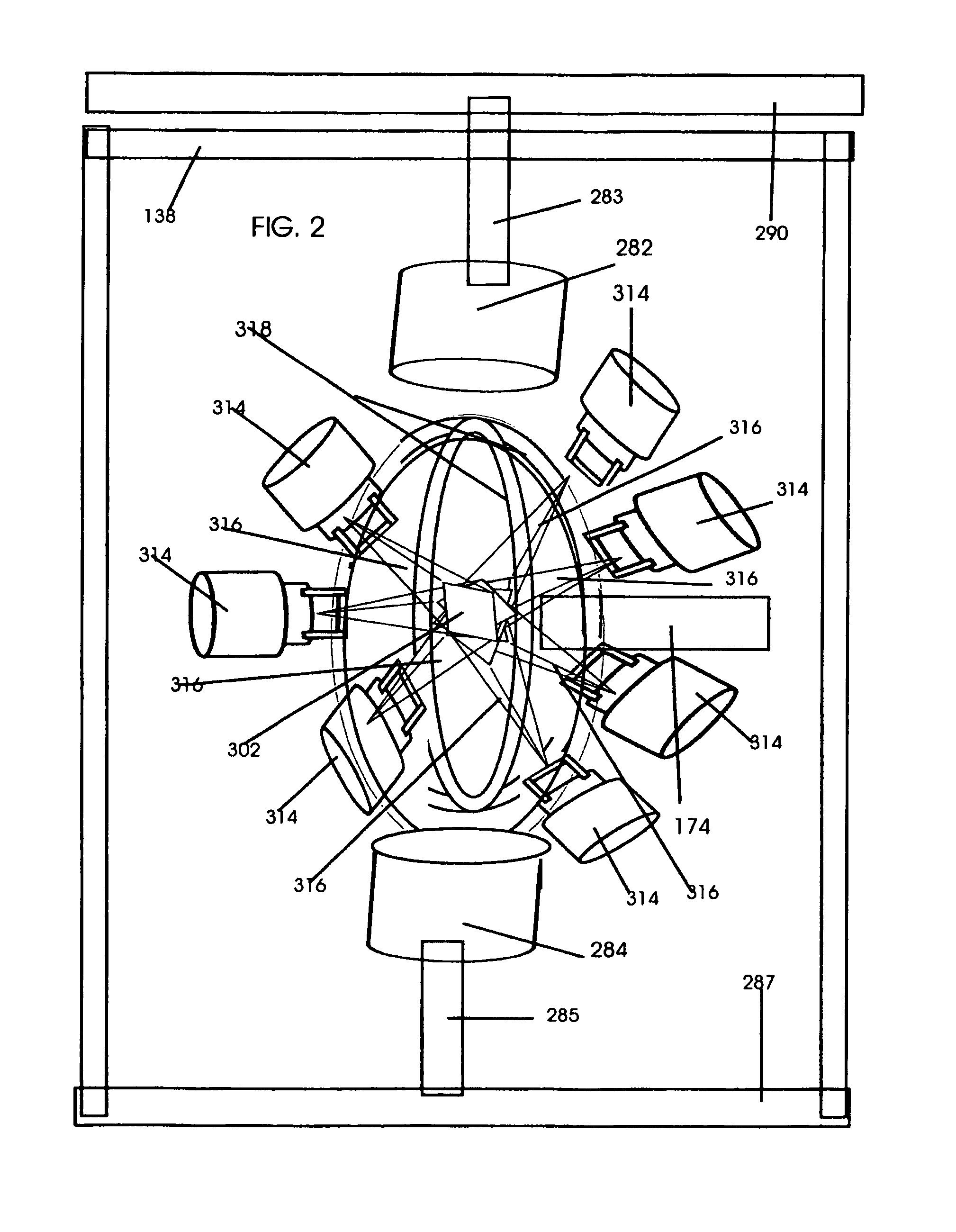

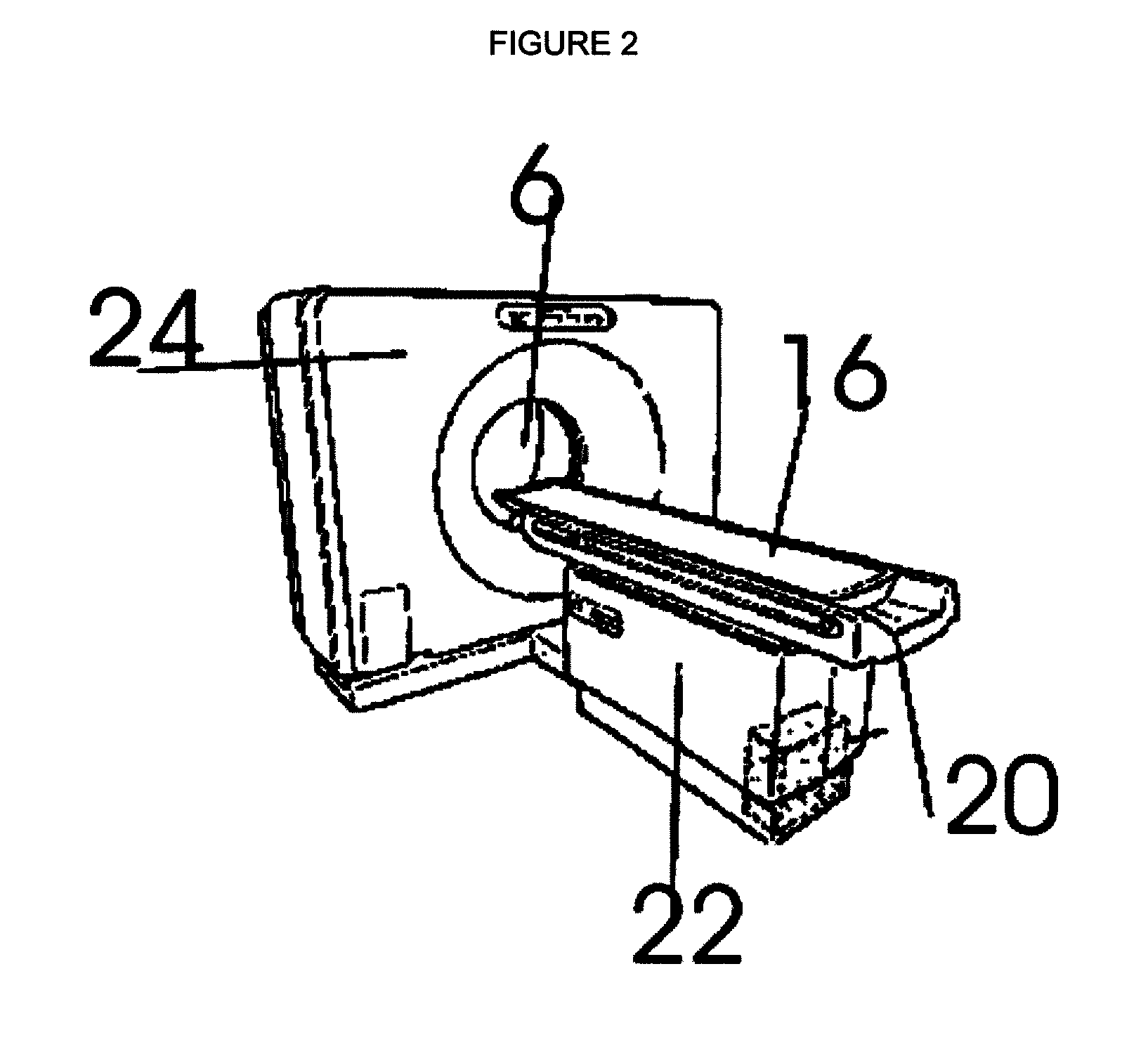

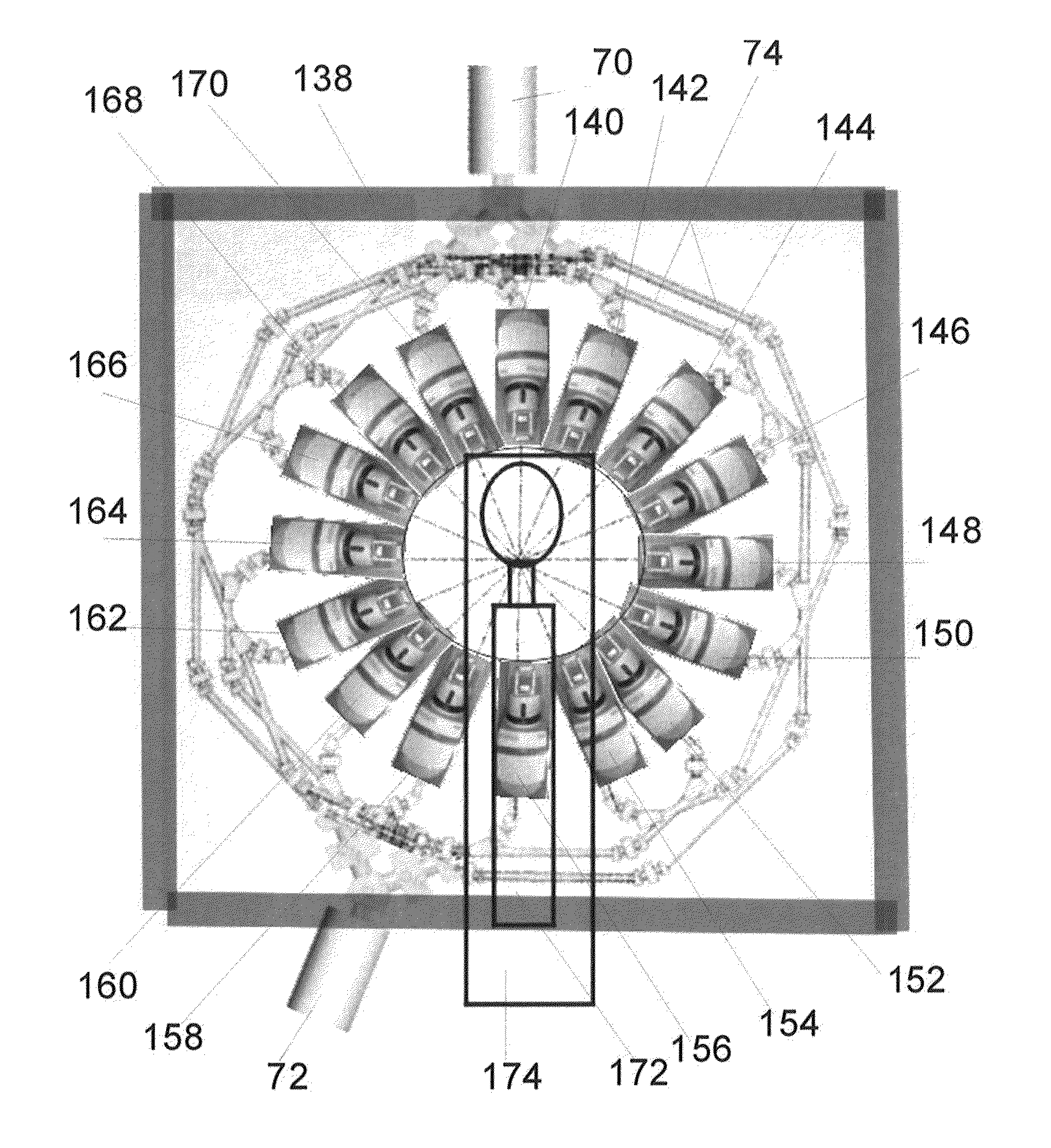

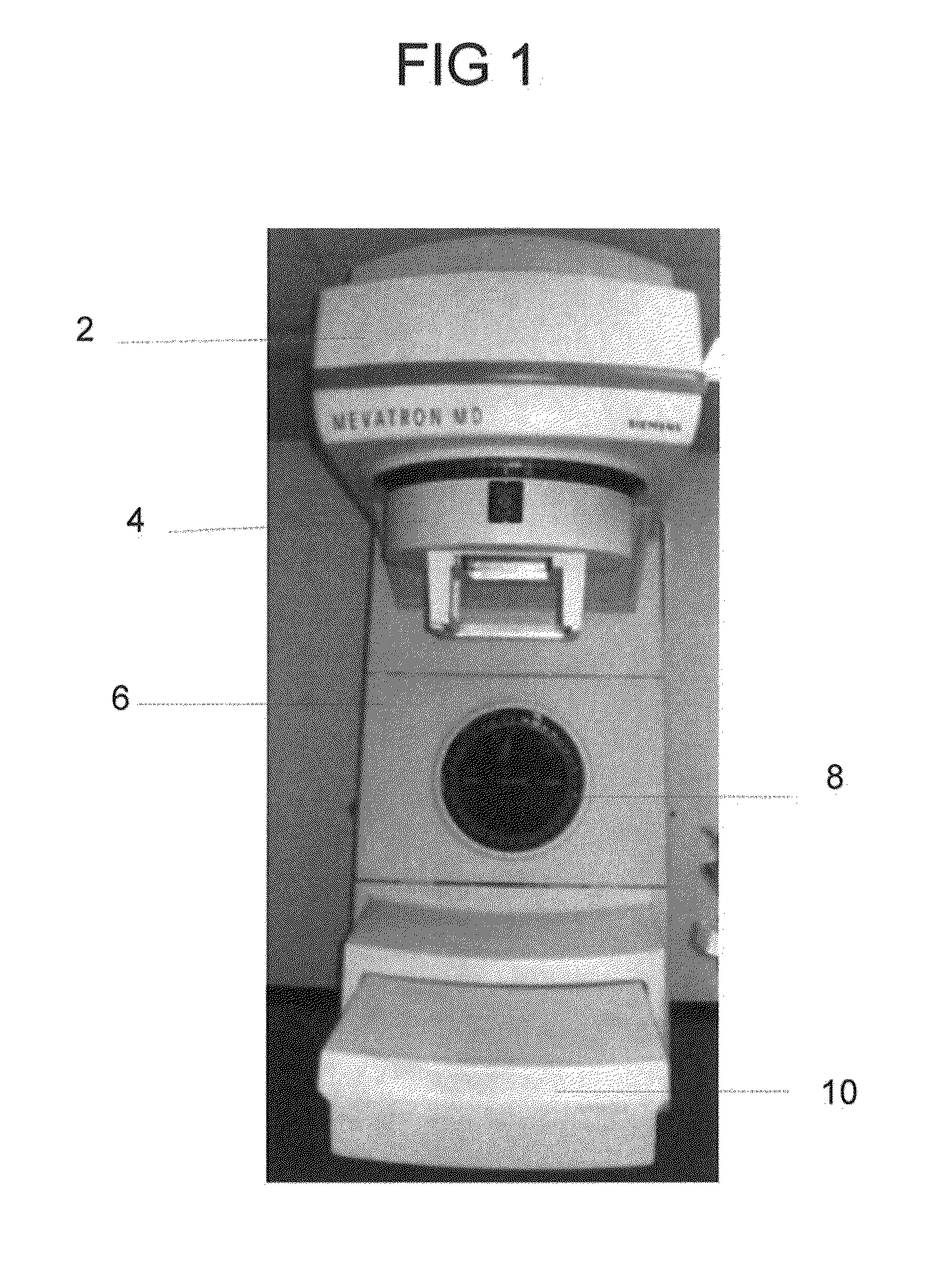

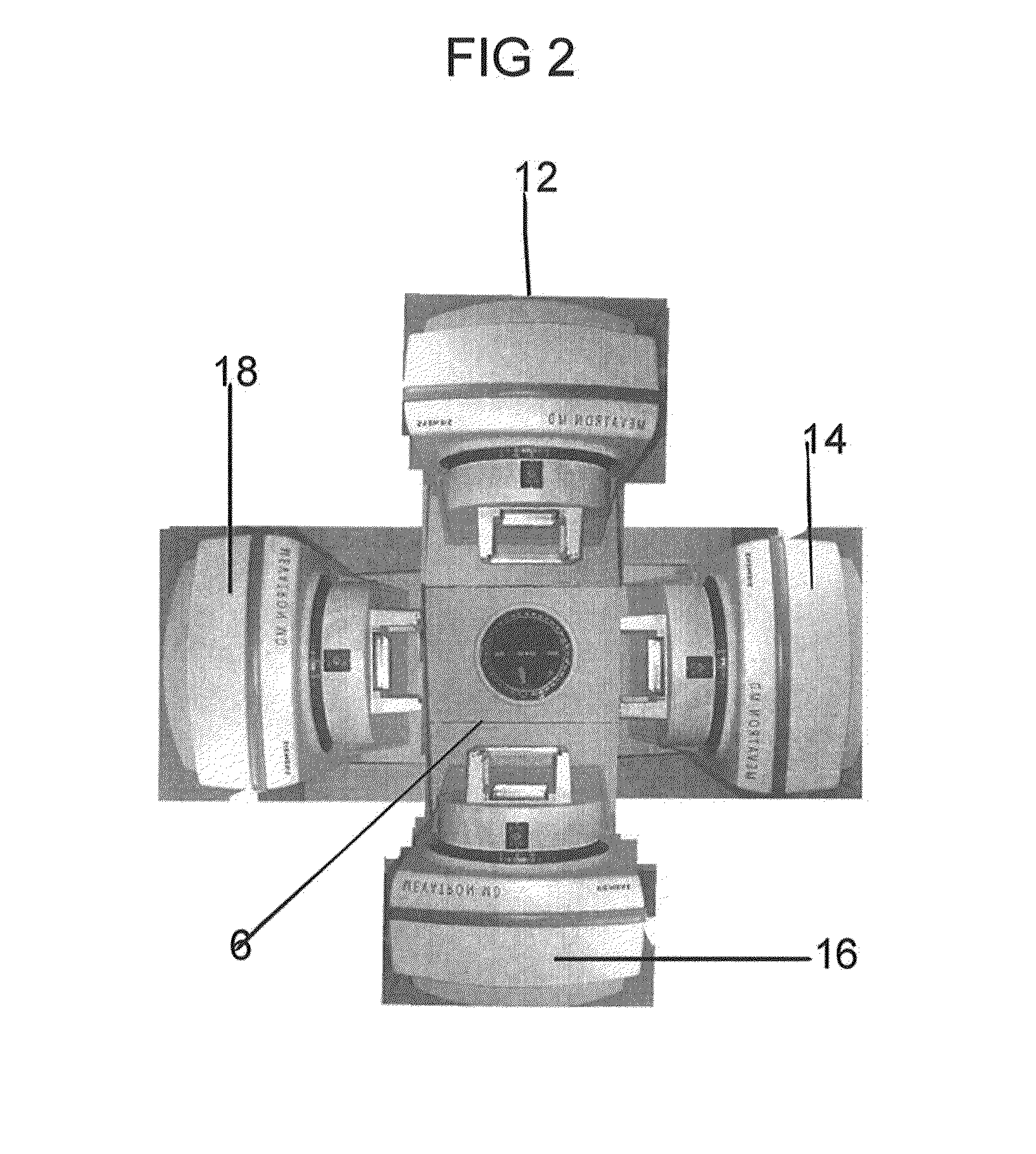

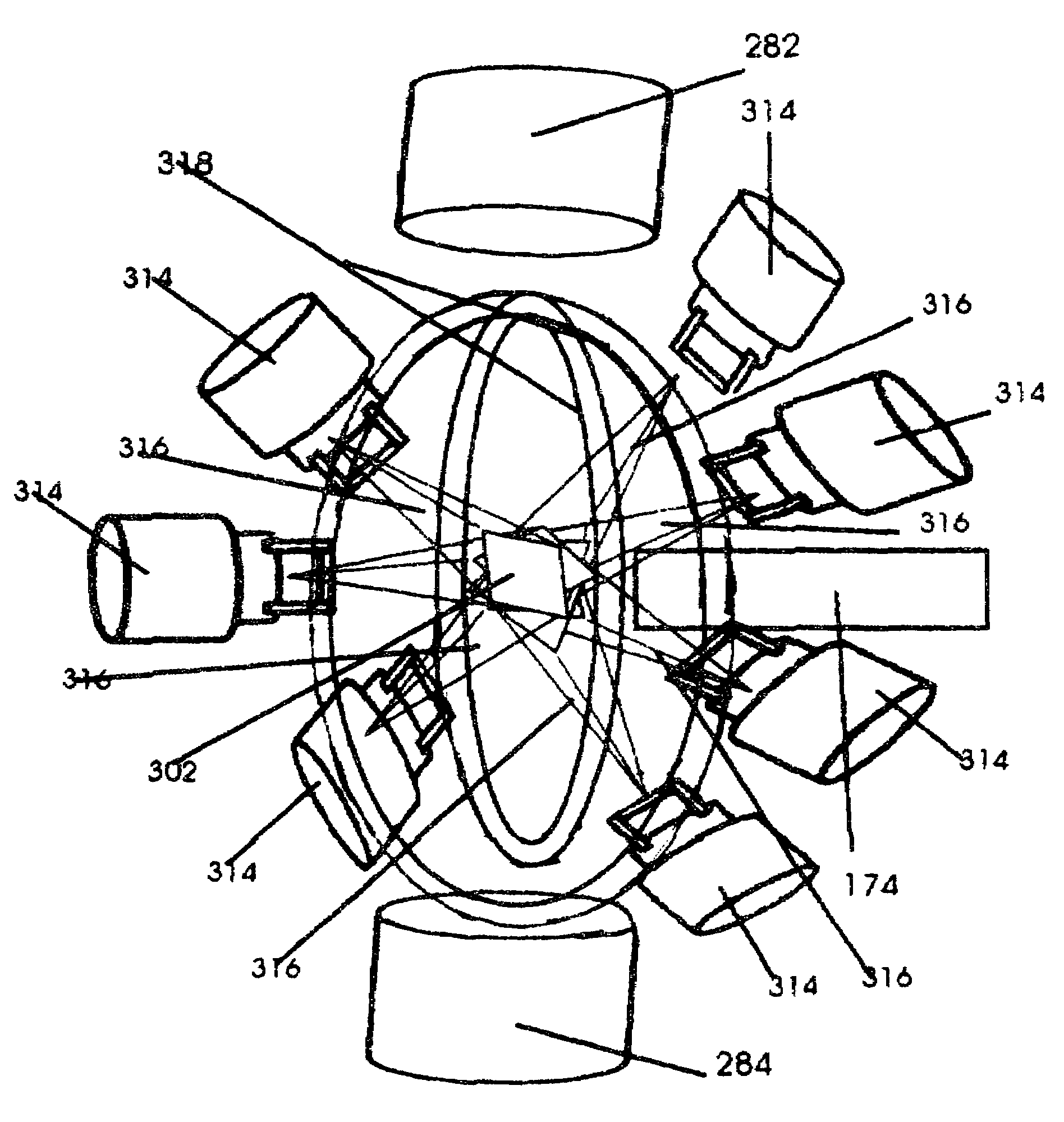

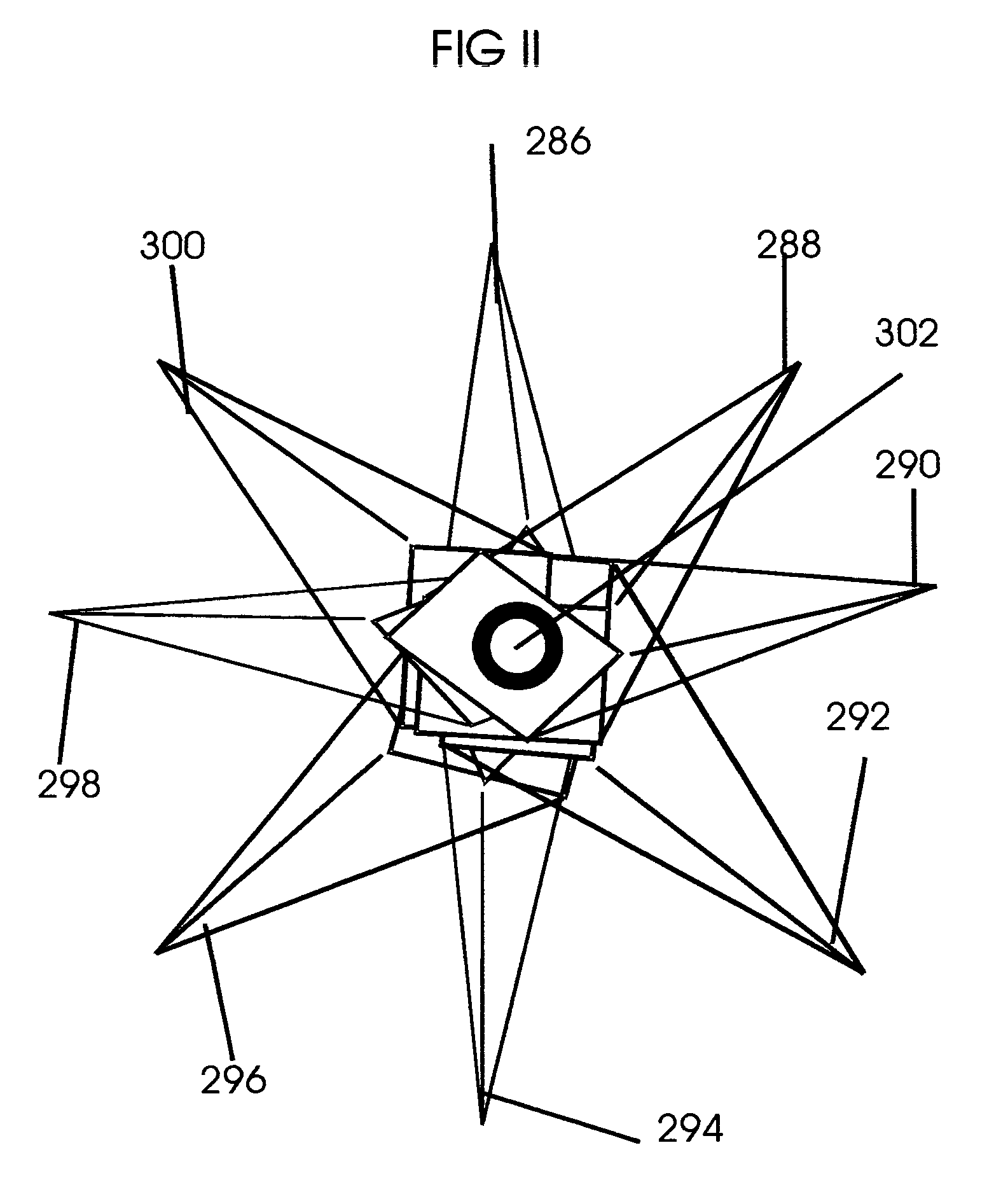

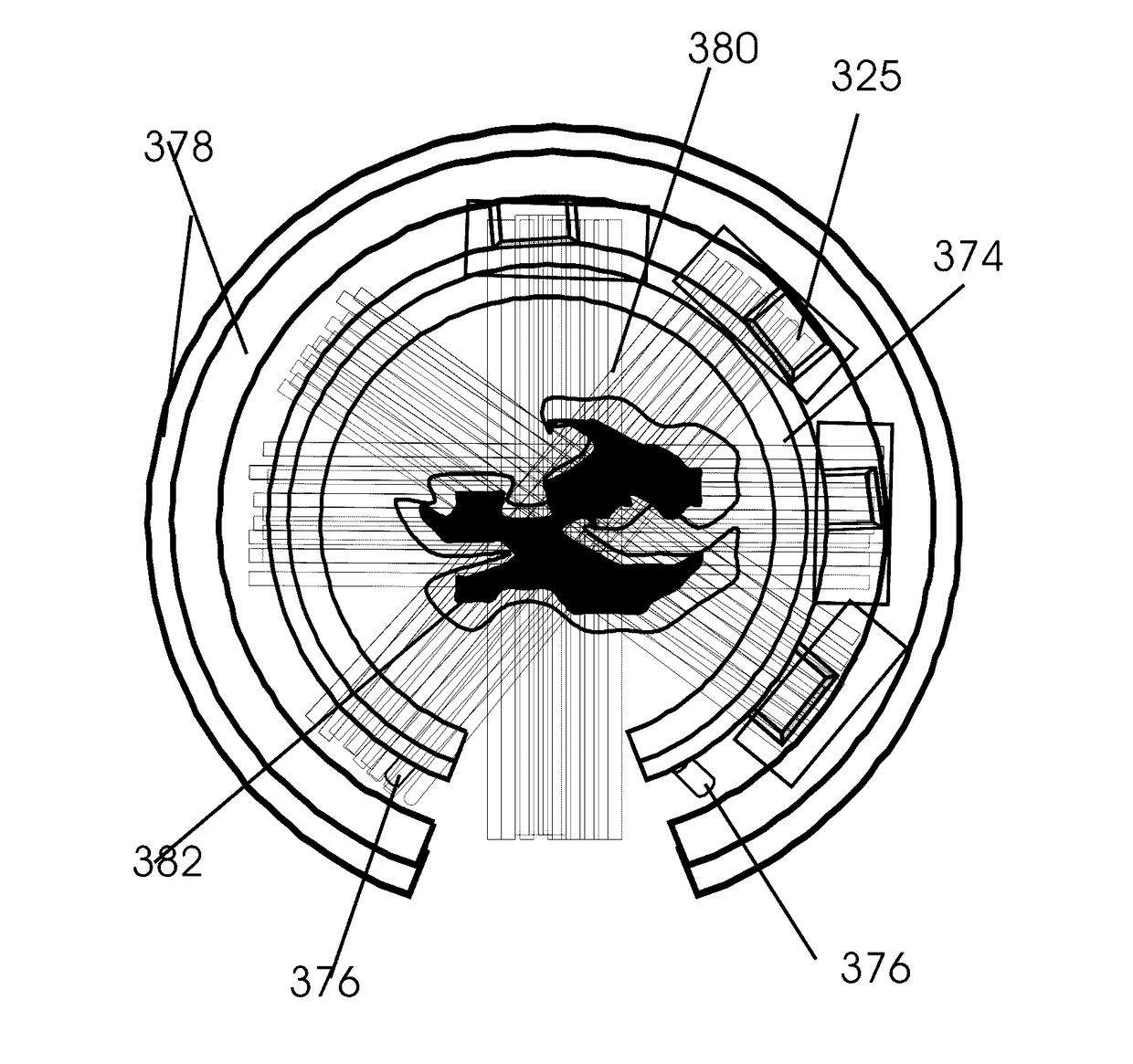

Multiple medical accelerators and a kV-CT incorporated radiation therapy device and semi-automated custom reshapeable blocks for all field synchronous image guided 3-D-conformal-intensity modulated radiation therapy

S-band, C-band or X-band microwave powered linear accelerators capable of delivering therapeutic photon and electron beams are mounted to a gantry with extensions to hold multiple accelerators and are combined with a kV CT for 3-D conformal—IMRT and IGRT to treat a patient by SSD or SAD methods and in a full circle. The invention's tertiary collimator system consists of semi-automated reusable custom field shaping with tungsten powder or melted Cerrobend blocks. The beam's intensity modulation is by means of simultaneous but independently operating multiple accelerators. This system's multiple accelerators enable to avoid interrupted subfractionated radiation therapy to each treatment fields. Hence its effective dose rate at the tumor site is high. The improved radiobiology reduces the total radiation dose to treat a tumor, reducing the incidence of developing second primary tumors is also minimized.

Owner:SAHADEVAN VELAYUDHAN

Aerosol processing and inhalation method and system for high dose rate aerosol drug delivery

ActiveUS7802569B2Risk minimizationIncrease dose rateRespiratorsDispersed particle separationCounter flowSolvent vapor

Owner:KAER BIOTHERAPEUTICS CORP

Lethal and sublethal damage repair inhibiting image guided simultaneous all field divergent and pencil beam photon and electron radiation therapy and radiosurgery

InactiveUS7835492B1Improve modulationIncrease radiation intensityIrradiation devicesX-ray/gamma-ray/particle-irradiation therapyRadiosurgeryC banding

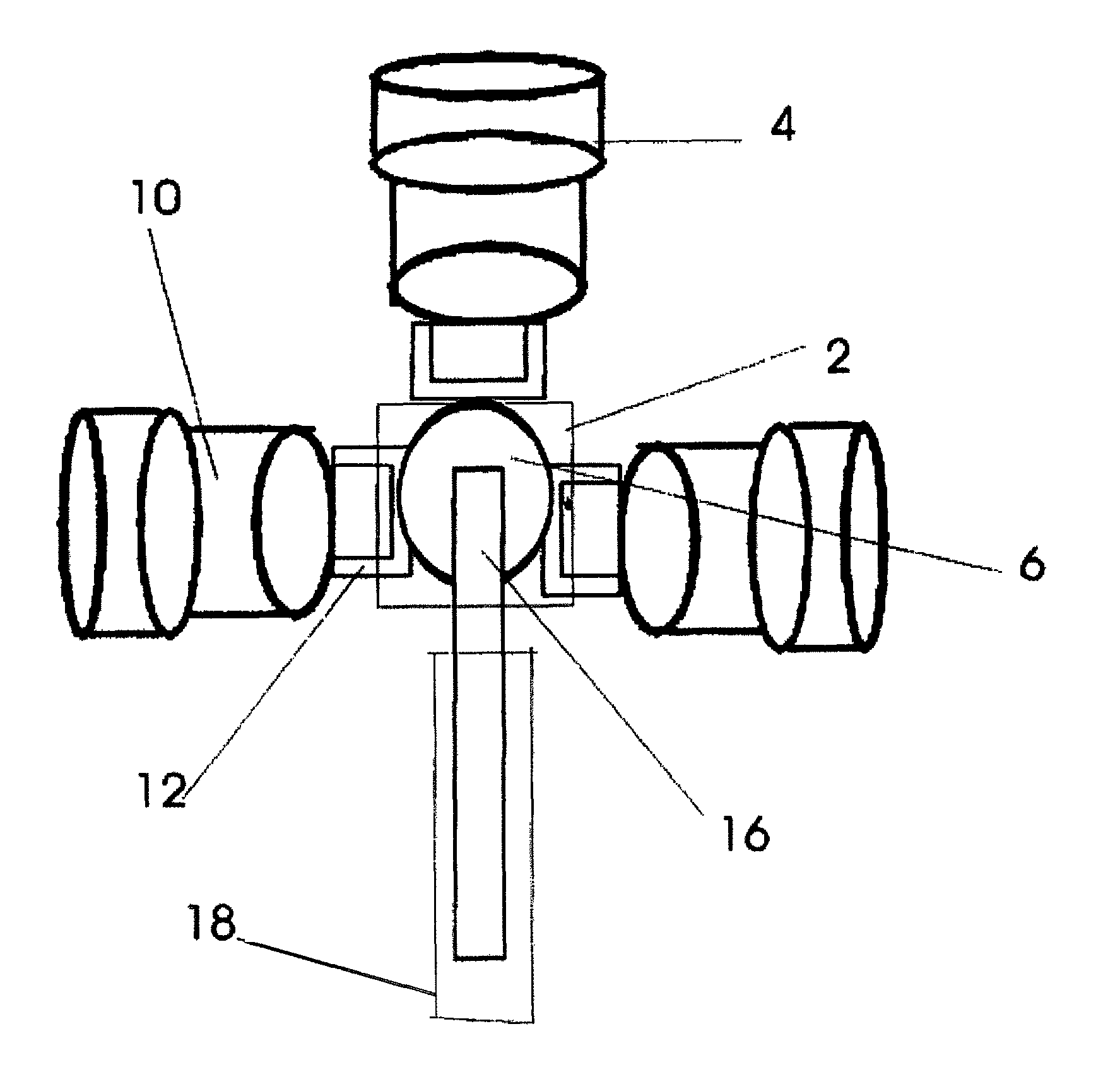

A medical accelerator system is provided for simultaneous radiation therapy to all treatment fields. It provides the single dose effect of radiation on cell survival. It eliminates the inter-field interrupted, subfractionated fractionated radiation therapy. Single or four beams S-band, C-band or X-band accelerators are connected to treatment heads through connecting beam lines. It is placed in a radiation shielding vault which minimizes the leakage and scattered radiation and the size and weight of the treatment head. In one version, treatment heads are arranged circularly and connected with the beam line. In another version, a pair of treatment heads is mounted to each ends of narrow gantries and multiple such treatment heads mounted gantries are assembled together. Electron beam is steered to all the treatment heads simultaneously to treat all the fields simultaneously. Radiating beam's intensity in a treatment field is modulated with combined divergent and pencil beam, selective beam's energy, dose rate and weight and not with MLC and similar devices. Since all the treatment fields are treated simultaneously the dose rate at the tumor site is the sum of each of the converging beam's dose rate at depth. It represents the biological dose rate. The dose rate at d-max for a given field is the individual machine dose rate. Its treatment options includes divergent or pencil beam modes. It enables to treat a tumor with lesser radiation toxicities to normal tissue and higher tumor cure and control.

Owner:SAHADEVAN VELAYUDHAN

Single session interactive ultra-short duration super-high biological dose rate radiation therapy and radiosurgery

A medical accelerator system consisting of coplanar and non-coplanar beams, on line magnetic resonance anatomic and functional imaging and cone beam computed tomographic imaging for single session image guided all field simultaneous radiation therapy and radiosurgery is provided. This system enables single session simulation, field-shaping block making, treatment planning, dose calculations and treatment of tumors. The radiation exposure time to the tumor and the normal tissue is reduced to a few seconds to less than a minute. In filed intensity modulated radiation is rendered by combined divergent and pencil beam, multiple smaller fields within a larger field, selectively varying beam's energy, dose rate and beam weight. Since all the treatment fields are treated simultaneously the dose rate at the tumor site is the sum of each of the converging beam's dose rate at depth. This super-high biological dose rate impairs the lethal and sublethal damage repair.

Owner:SAHADEVAN VELAYUDHAN

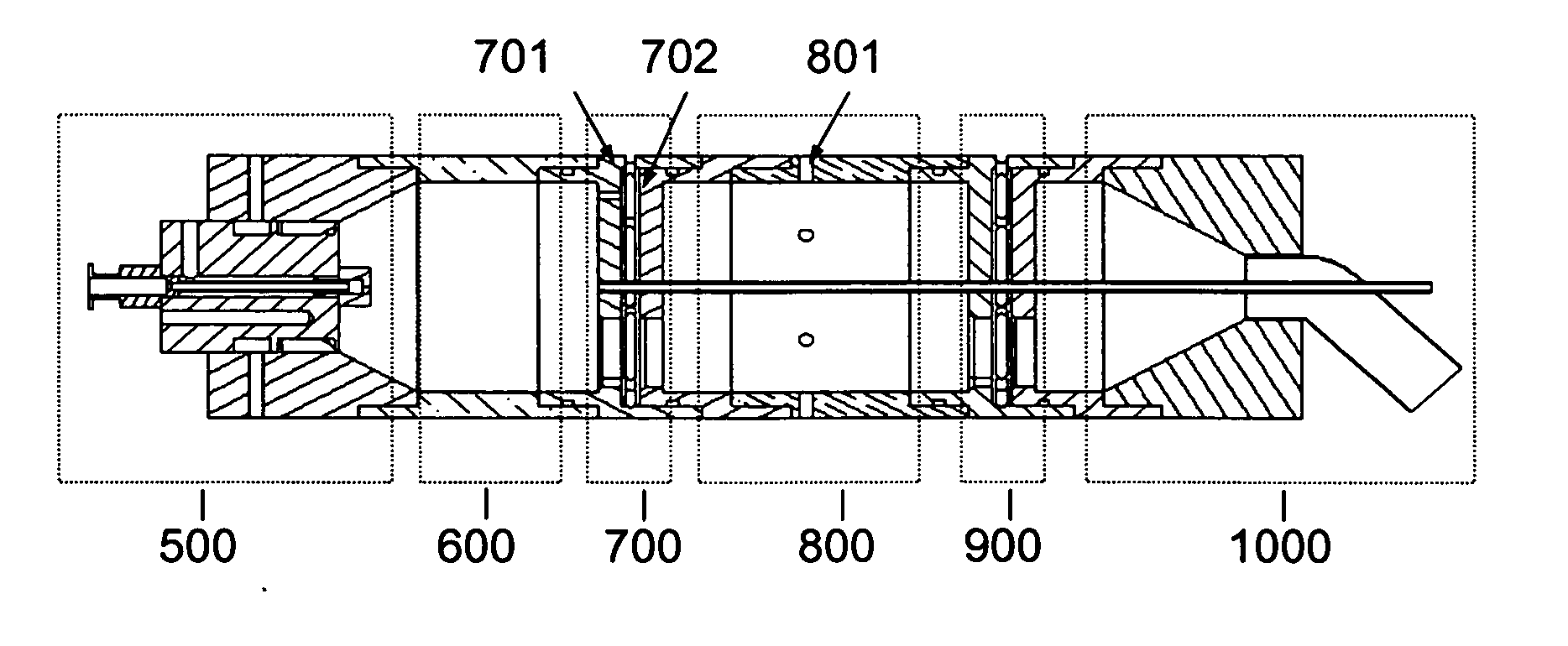

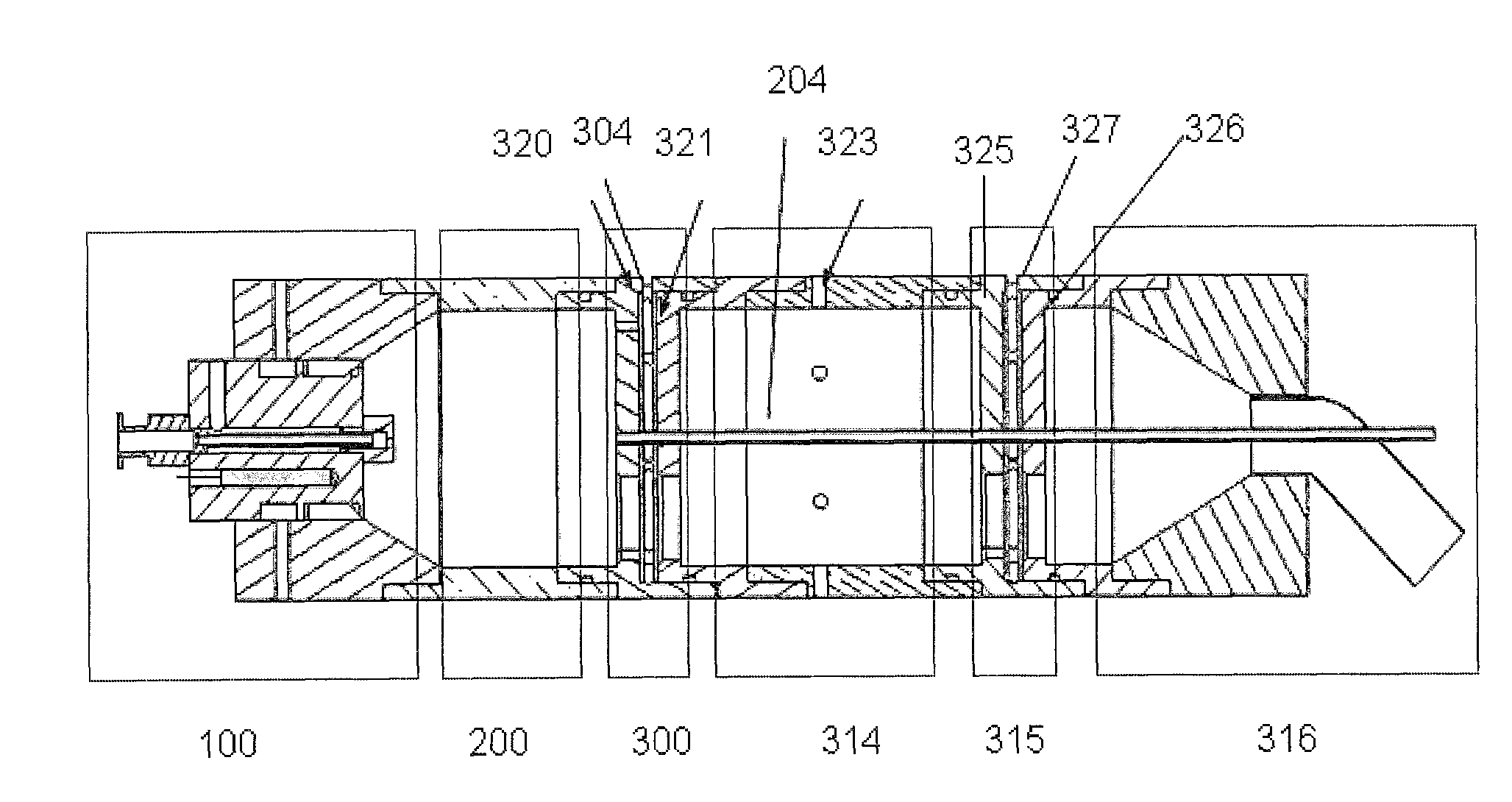

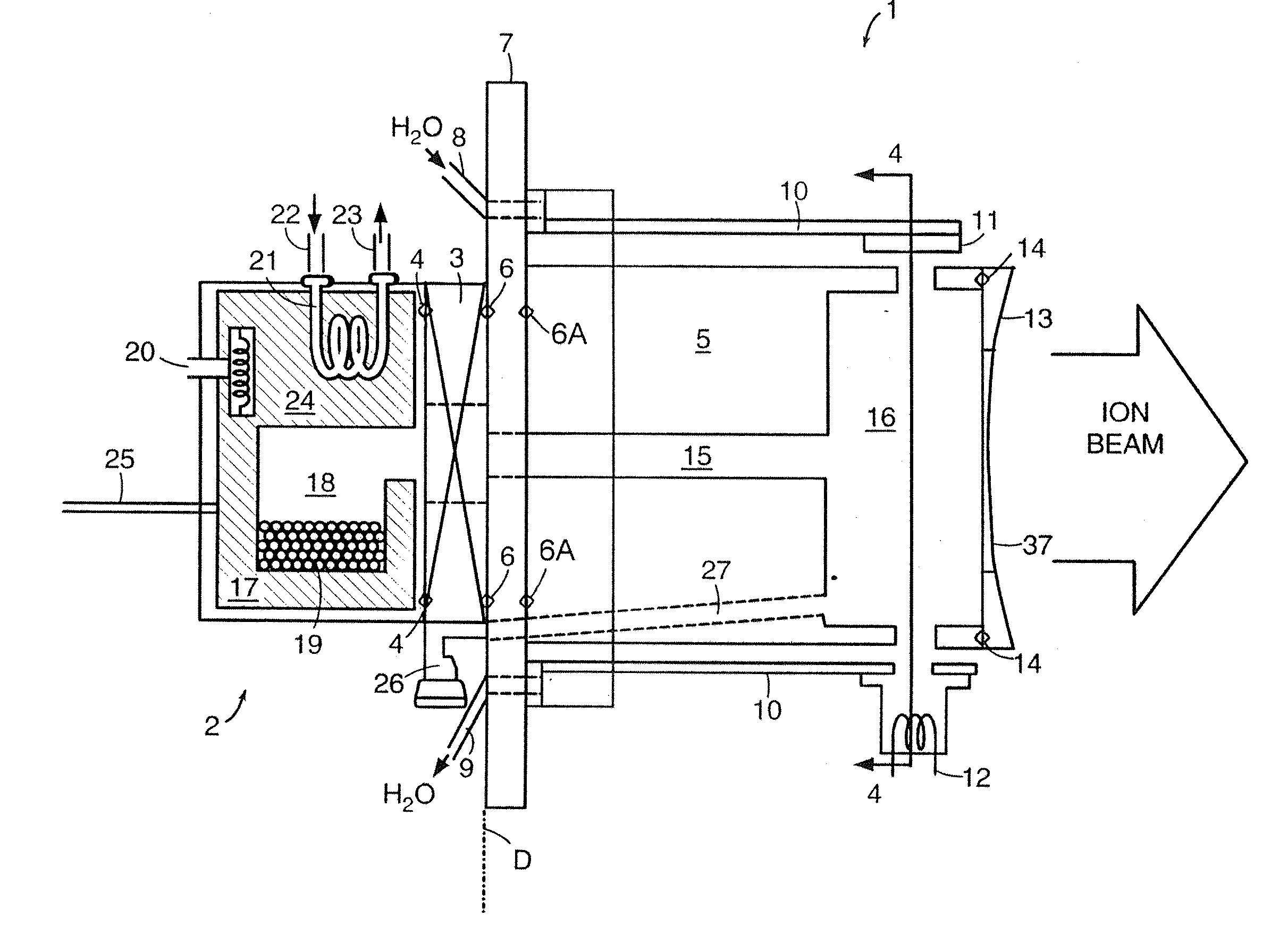

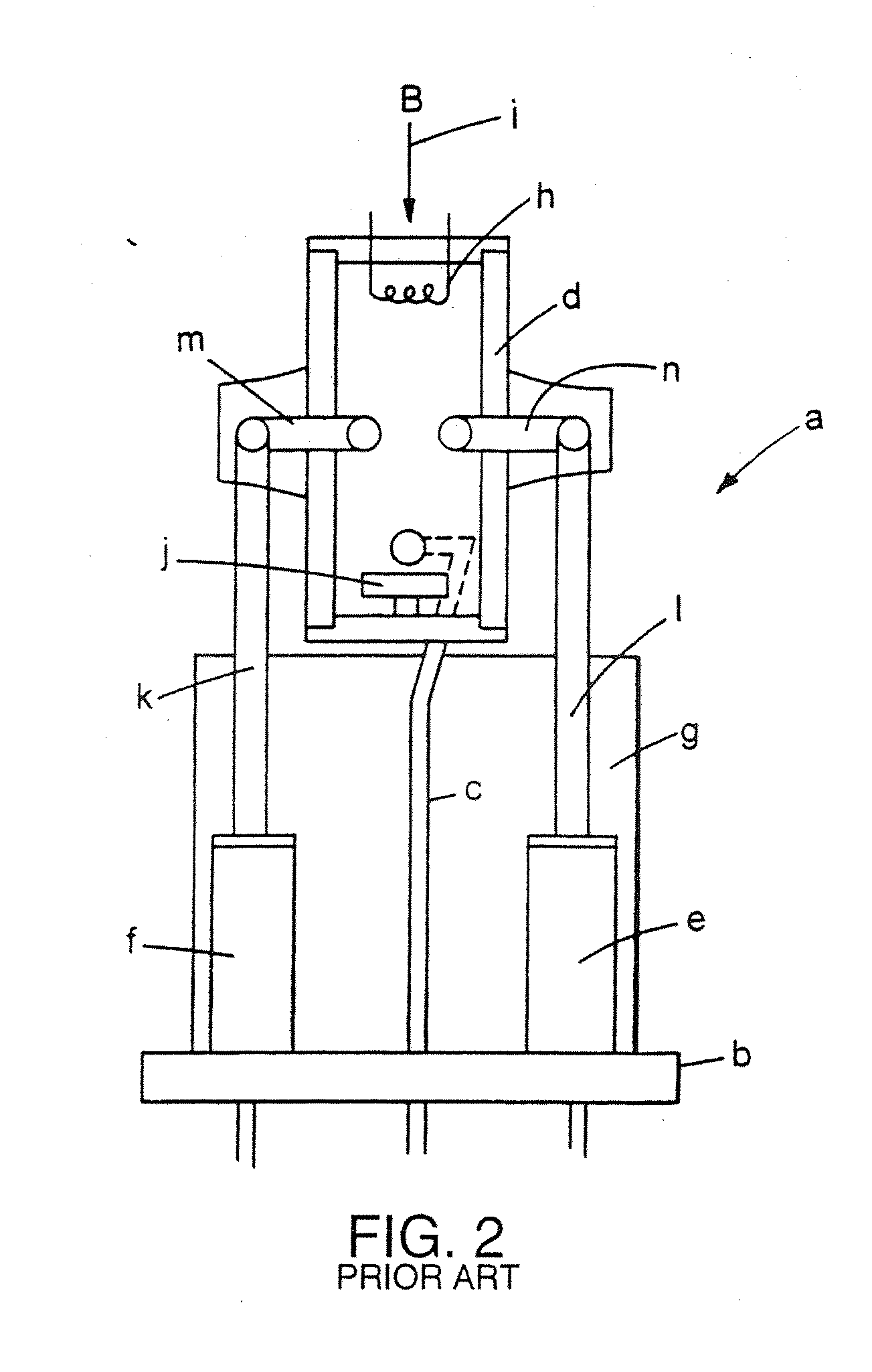

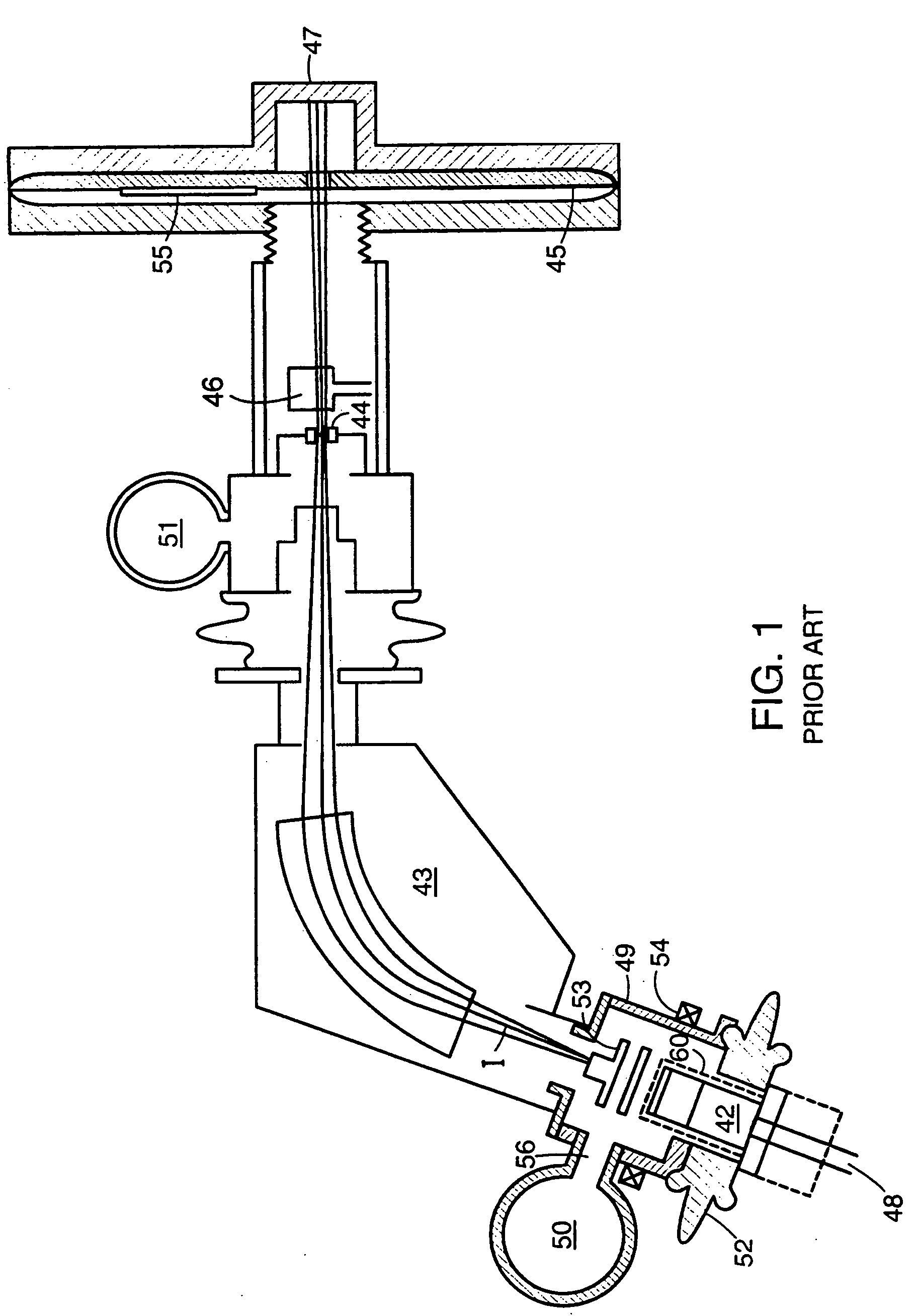

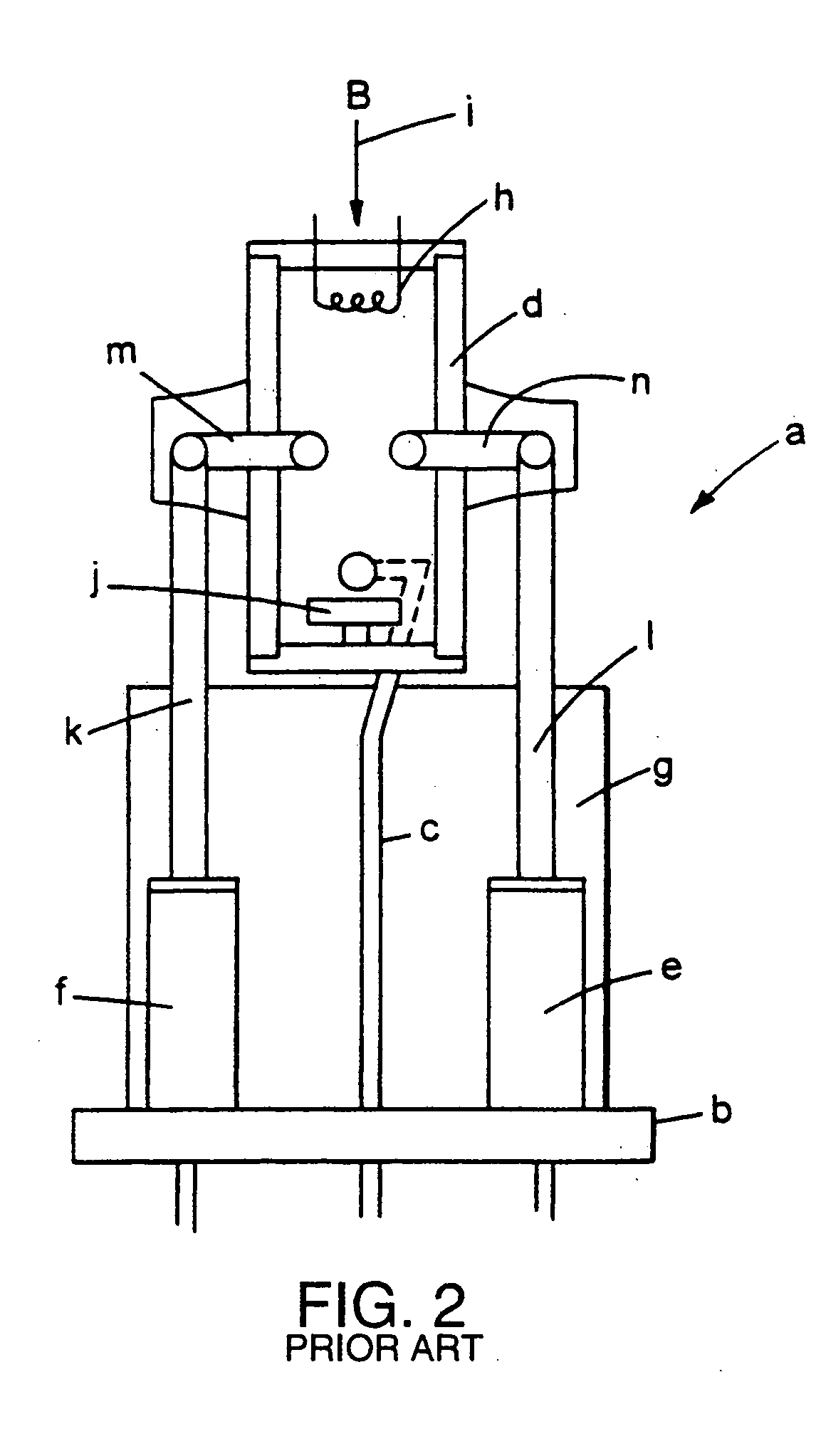

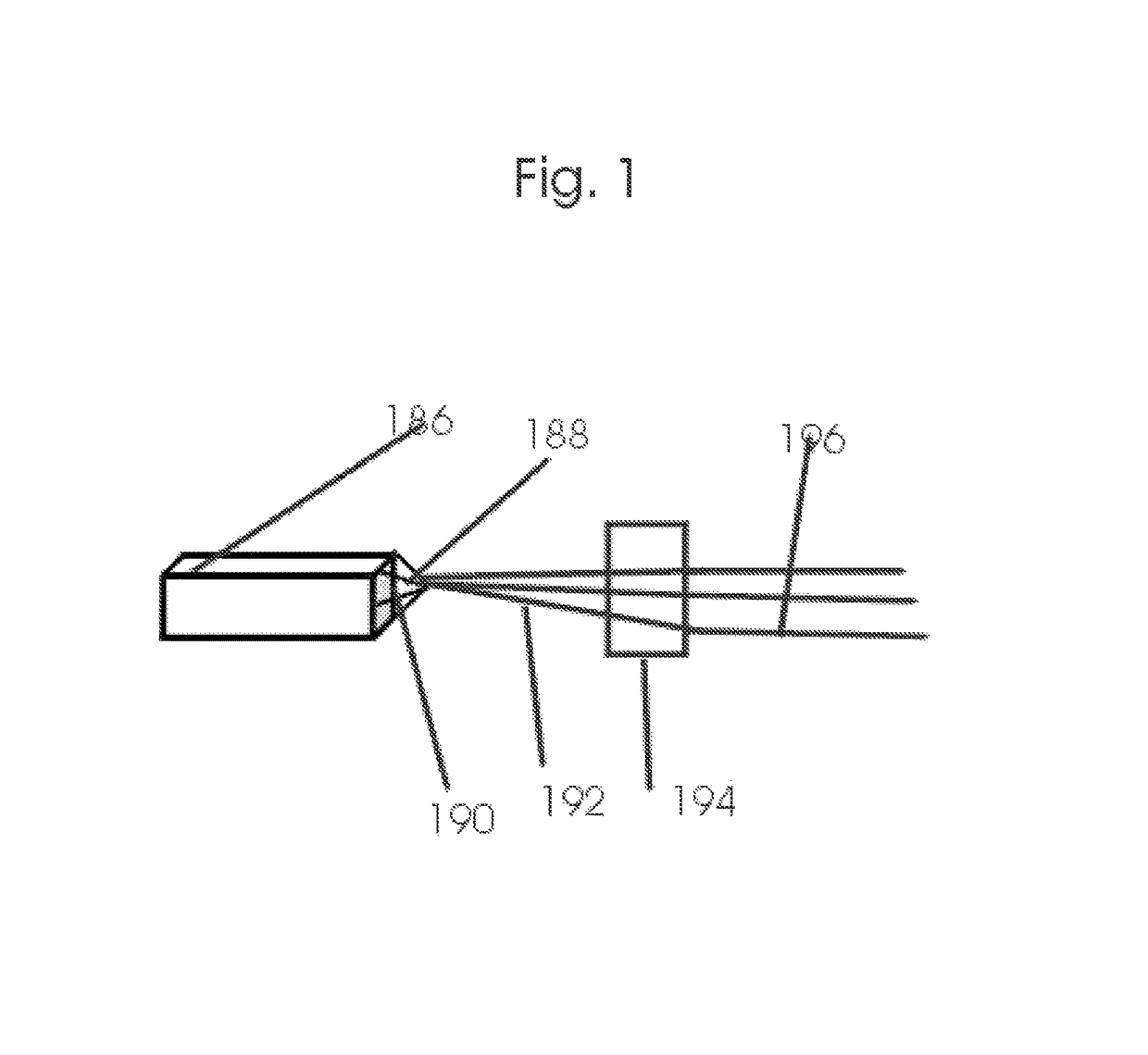

Ion implantation ion source, system and method

InactiveUS20070278417A1Maximizing flow of electronHigh extracted currentMaterial analysis by optical meansIon beam tubesDevice materialDose rate

Various aspects of the invention provide improved approaches and methods for efficiently: Vaporizing decaborane and other heat-sensitive materials via a novel vaporizer and vapor delivery system; Delivering a controlled, low-pressure drop flow of vapors, e.g. decaborane, into the ion source; Ionizing the decaborane into a large fraction of B10Hx+; Preventing thermal dissociation of decaborane; Limiting charge-exchange and low energy electron-induced fragmentation of B10Hx+; Operating the ion source without an arc plasma, which can improve the emittance properties and the purity of the beam; Operating the ion source without use of a strong applied magnetic field, which can improve the emittance properties of the beam; Using a novel approach to produce electron impact ionizations without the use of an arc discharge, by incorporation of an externally generated, broad directional electron beam which is aligned to pass through the ionization chamber to a thermally isolated beam dump; Providing production-worthy dosage rates of boron dopant at the wafer; Providing a hardware design that enables use also with other dopants, especially using novel hydride, dimer-containing, and indium- or antimony-containing temperature-sensitive starting materials, to further enhance the economics of use and production worthiness of the novel source design and in many cases, reducing the presence of contaminants; Matching the ion optics requirements of the installed base of ion implanters in the field; Eliminating the ion source as a source of transition metals contamination, by using an external and preferably remote cathode and providing an ionization chamber and extraction aperture fabricated of non-contaminating material, e.g. graphite, silicon carbide or aluminum; Enabling retrofit of the new ion source into the ion source design space of existing Bernas source-based ion implanters and the like or otherwise enabling compatibility with other ion source designs; Using a control system in retrofit installations that enables retention of the installed operator interface and control techniques with which operators are already familiar; Enabling convenient handling and replenishment of the solid within the vaporizer without substantial down-time of the implanter; Providing internal adjustment and control techniques that enable, with a single design, matching the dimensions and intensity of the zone in which ionization occurs to the beam line of the implanter and the requirement of the process at hand; Providing novel approaches, starting materials and conditions of operation that enable the making of future generations of semiconductor devices and especially CMOS source / drains and extensions, and doping of silicon gates.

Owner:SEMEQUIP

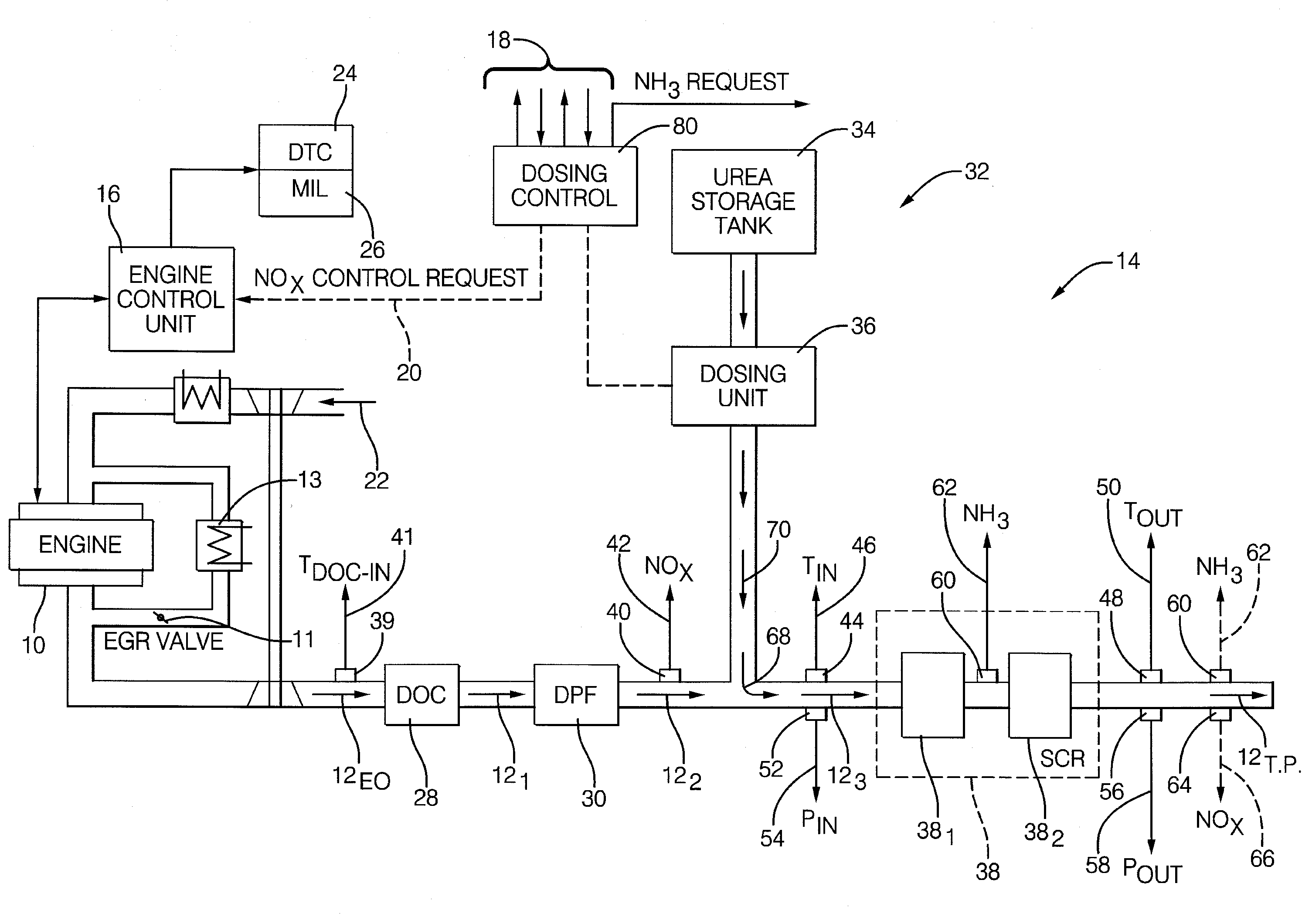

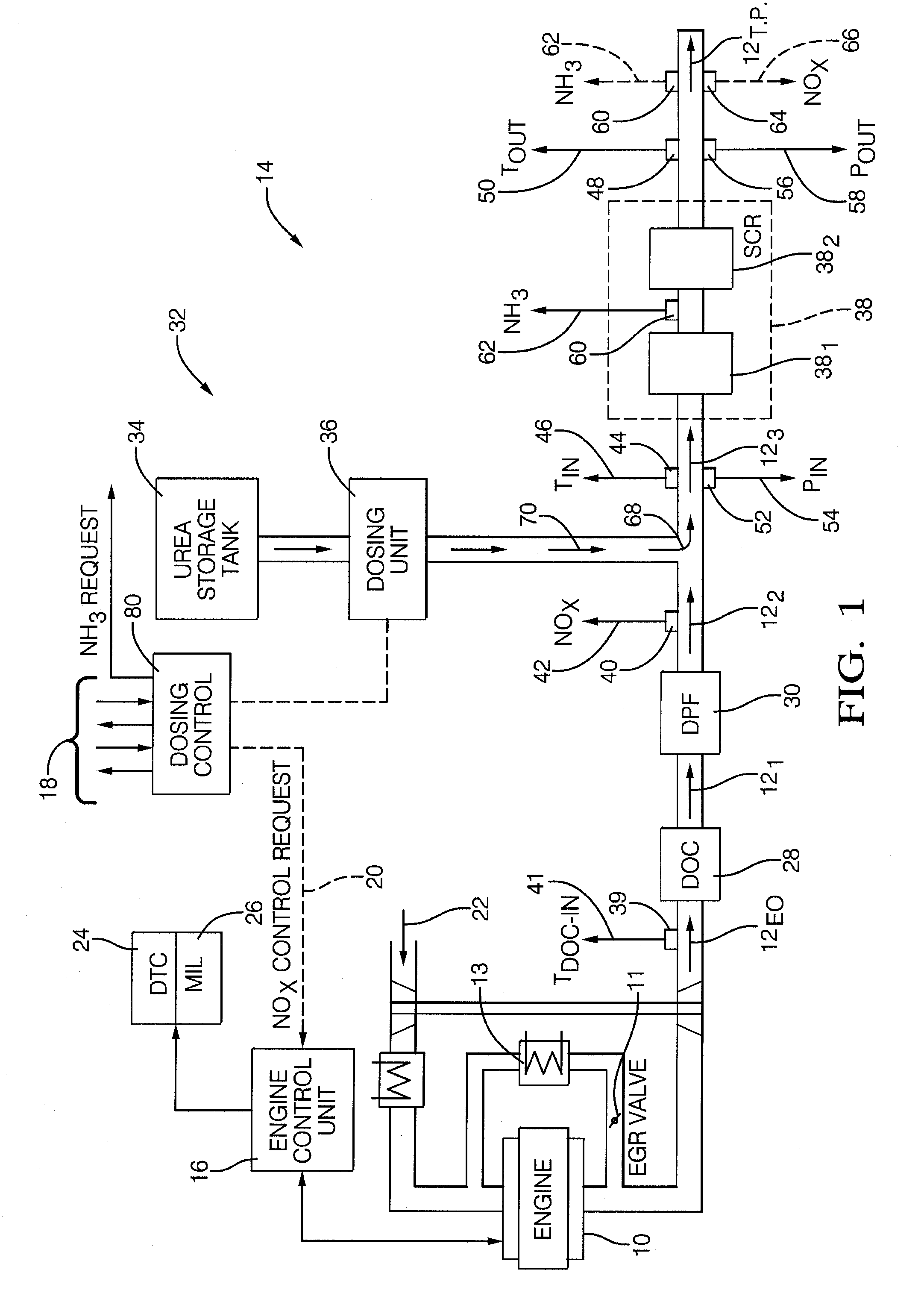

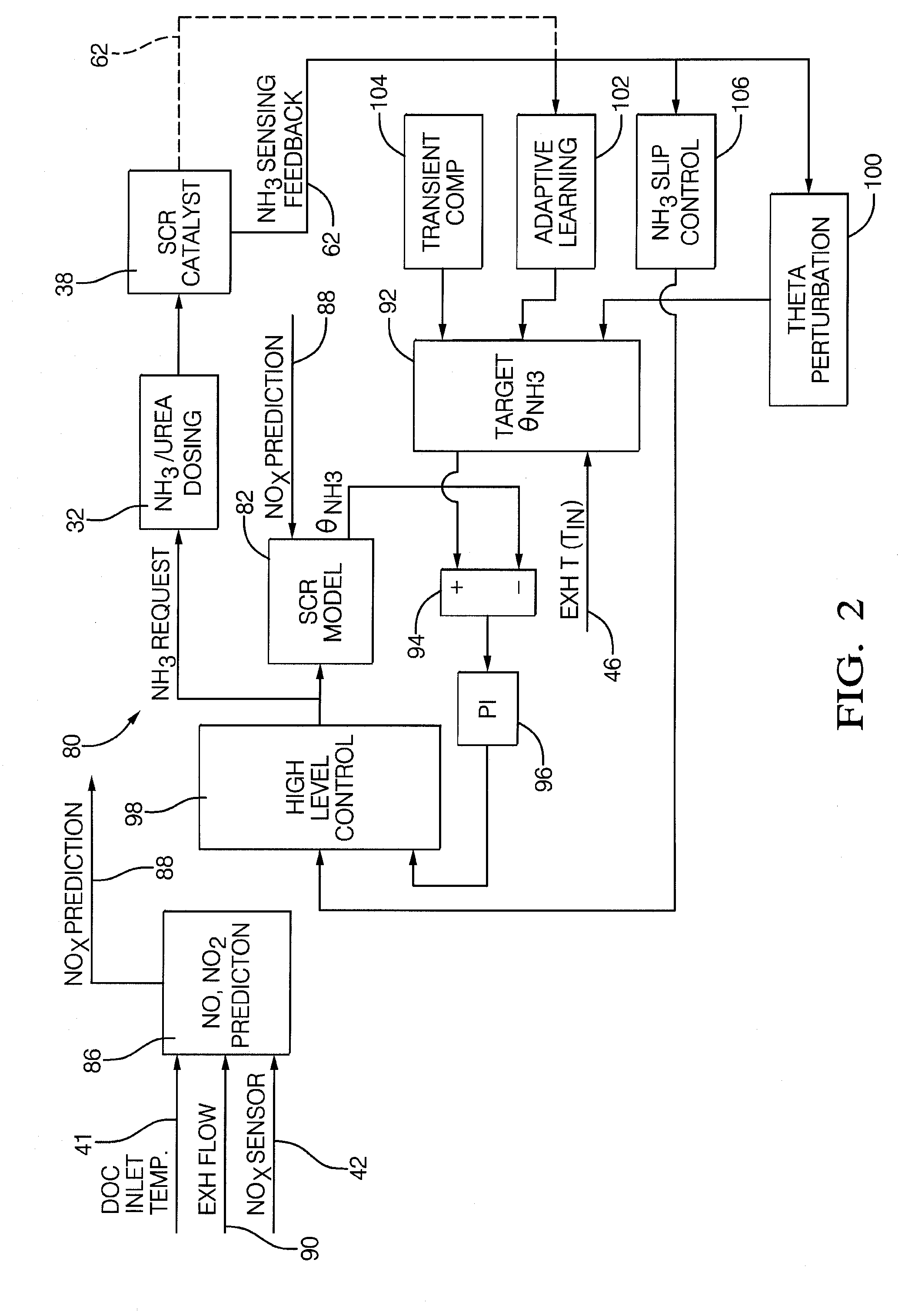

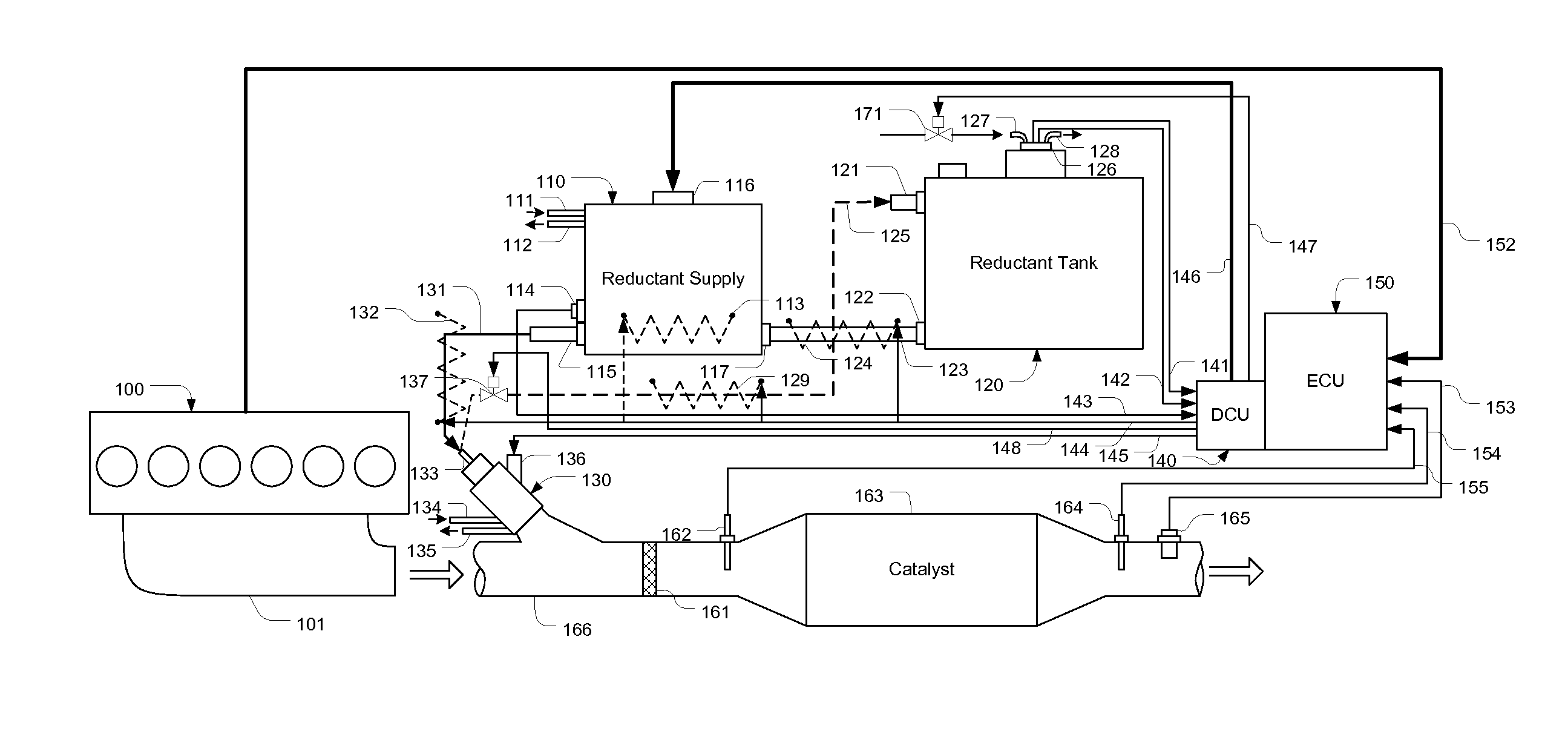

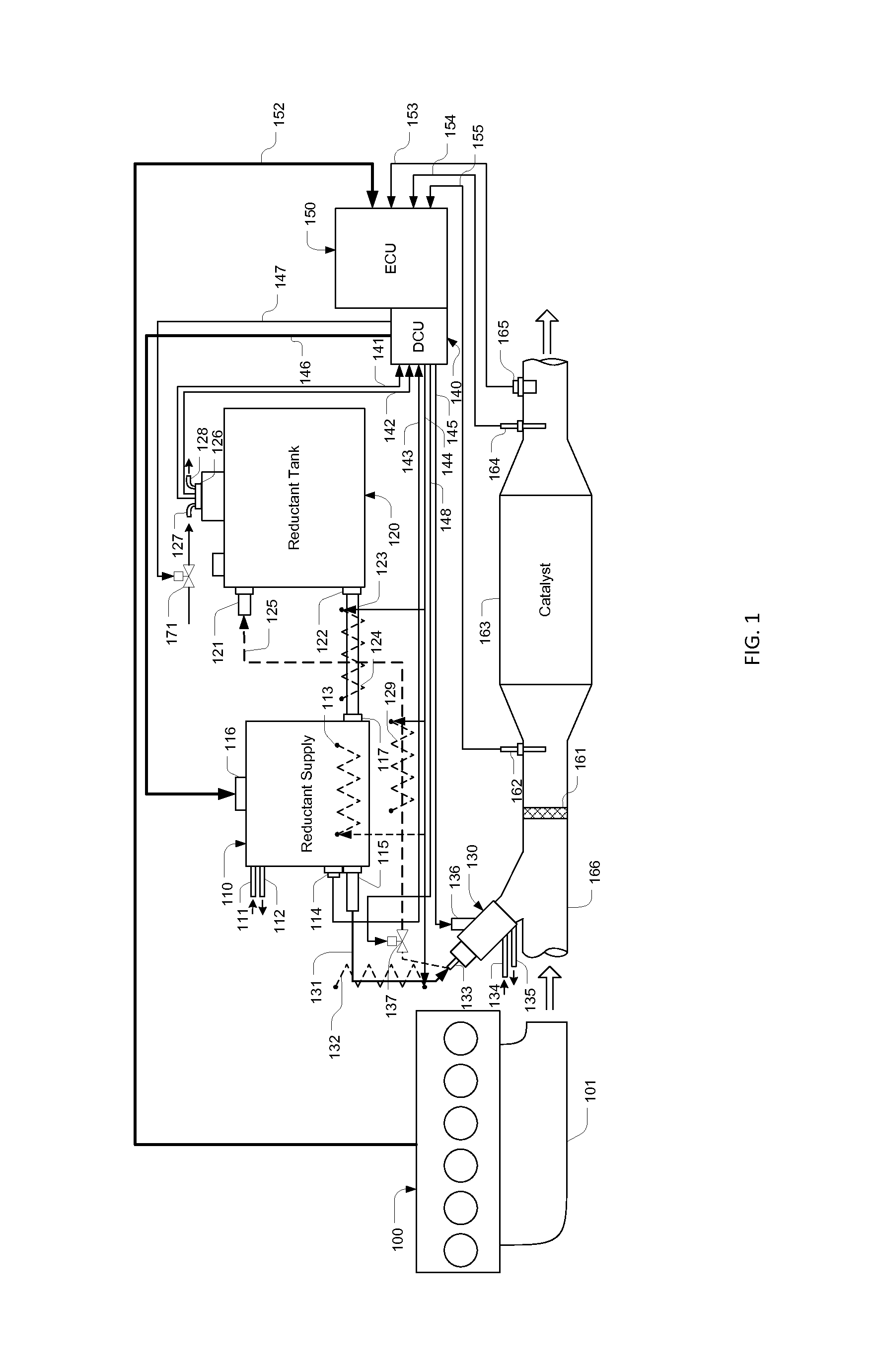

NOx CONTROL REQUEST FOR NH3 STORAGE CONTROL

InactiveUS20110072798A1Satisfies needNon-fuel substance addition to fuelInternal combustion piston enginesDose rateEngineering

An exhaust gas treatment system includes a selective catalytic reduction (SCR) catalyst and a dosing control responsive to exhaust gas operating conditions for controlling the dosing rate of a reductant such as aqueous urea into the exhaust stream. When the dosing control determines that NH3 slip cannot be maintained within acceptable limits, even after disabling dosing, the dosing control generates a control message destined for the engine control unit (ECU) requesting that the ECU decrease the exhaust gas recirculation (EGR) rate. The decrease in the EGR rate is effective to increase the engine-out NOx level, which increases NOx availability in the SCR catalyst. As a result, excess NH3 in the SCR catalyst is used for NOx conversion rather than escaping out through the tailpipe as excessive NH3 slip.

Owner:DELPHI TECH INC

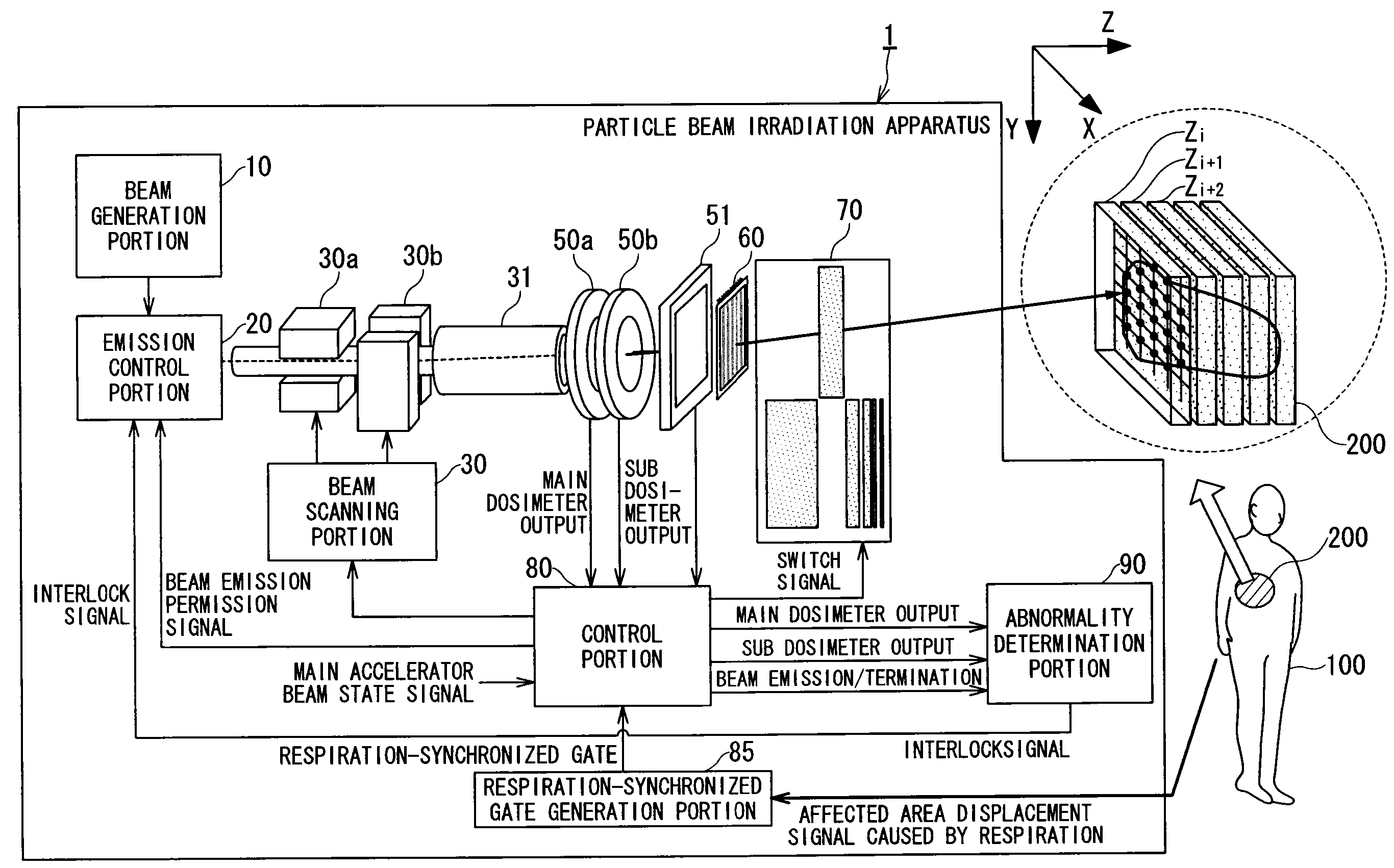

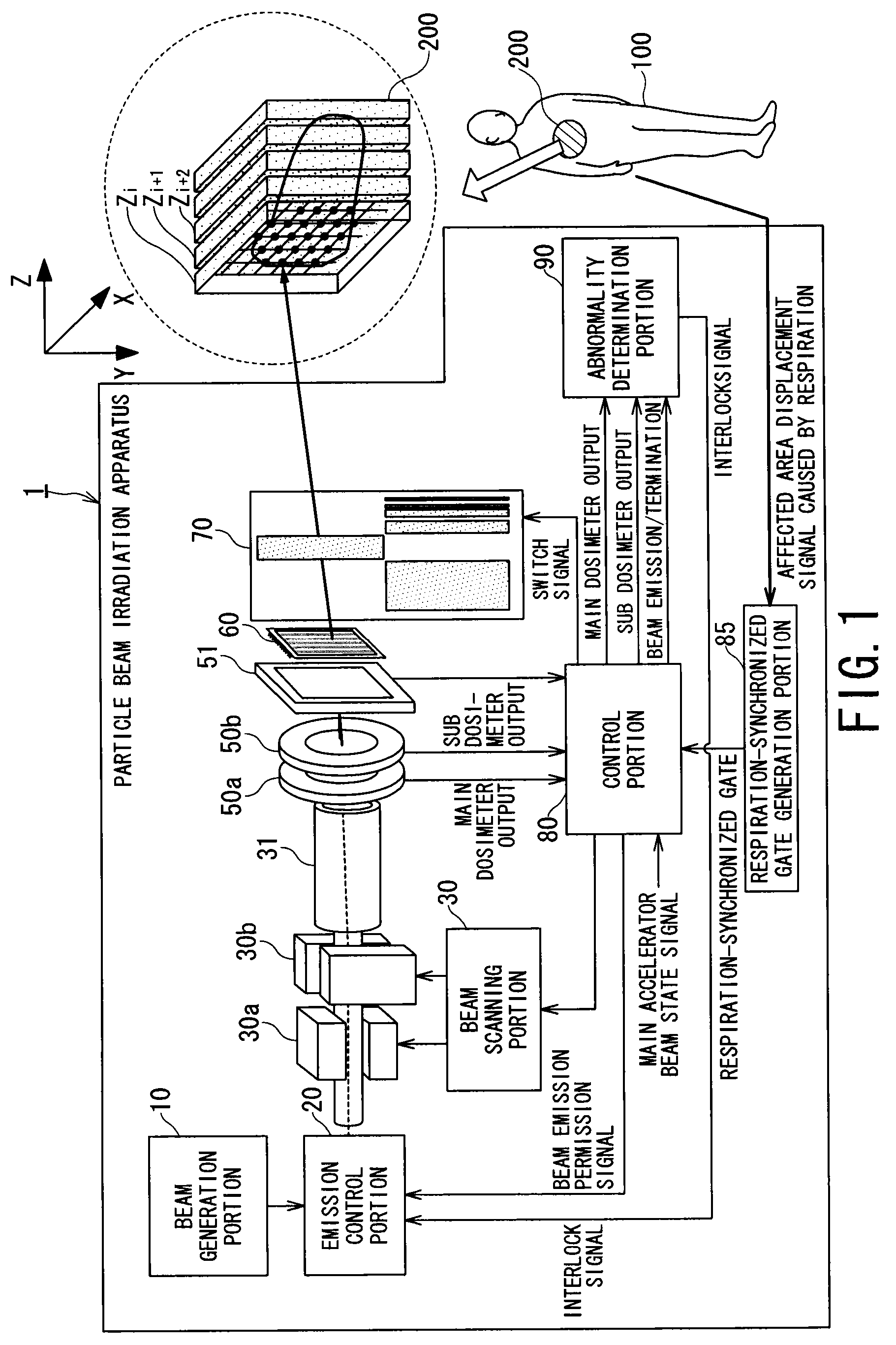

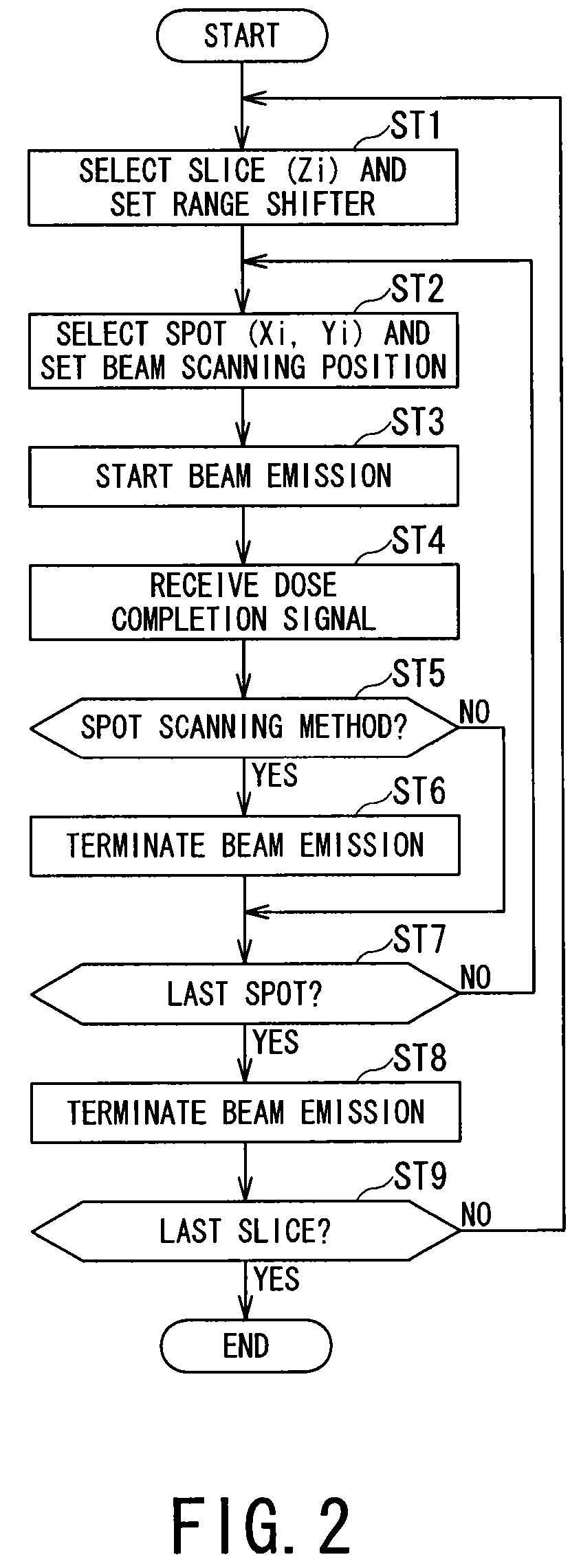

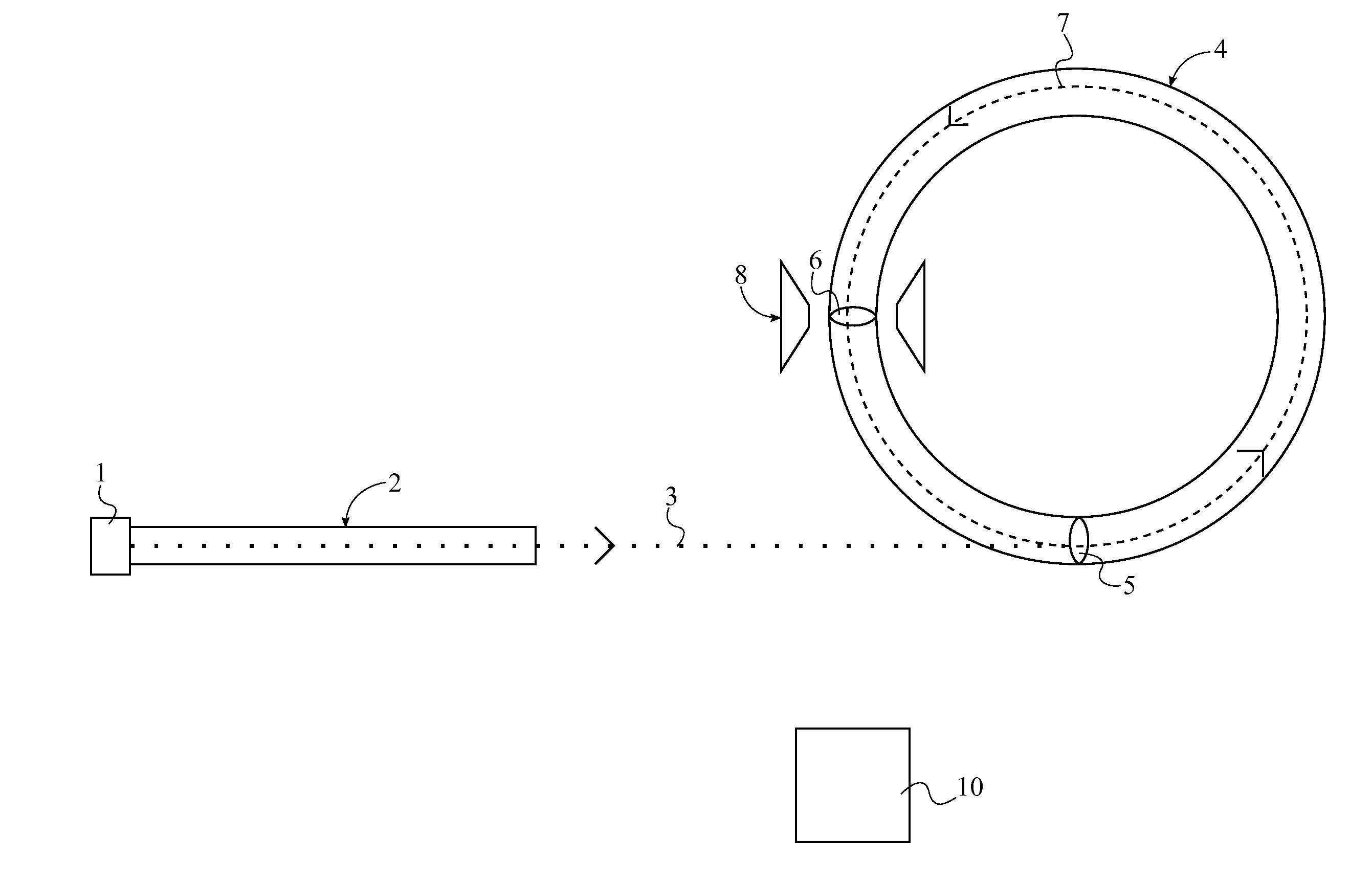

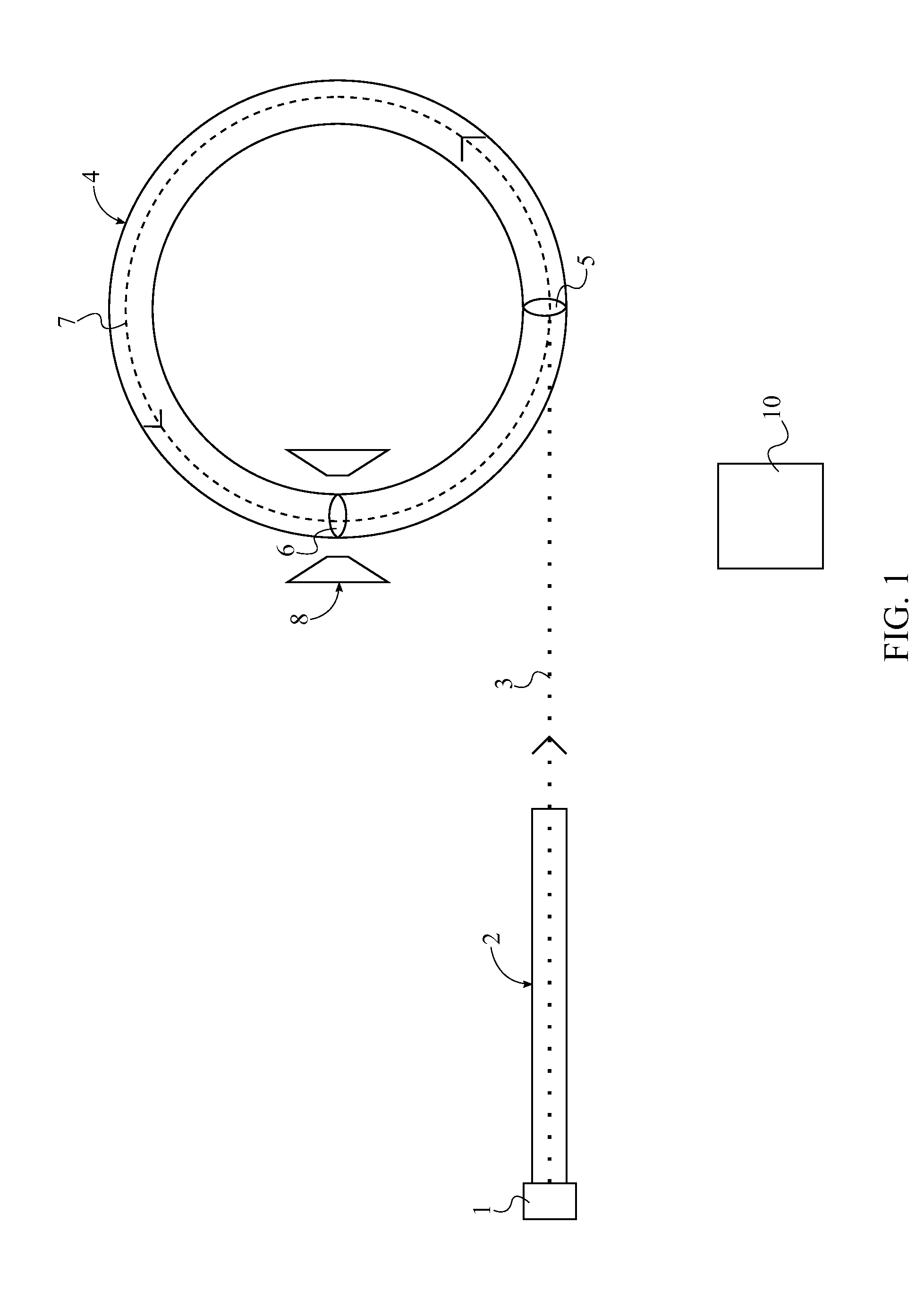

Particle beam irradiation apparatus and control method of the particle beam irradiation apparatus

ActiveUS8552408B2Reliable measurementEasy to measureThermometer detailsMaterial analysis using wave/particle radiationDosimeterDose rate

Provided is a particle beam irradiation apparatus capable of highly reliable measurement of a dose of each beam and capable of highly sensitive measurement of a leakage dose caused by momentary beam emission. The particle beam irradiation apparatus according to the present invention includes: an emission control portion that controls emission and termination of a particle beam; a control portion that sequentially changes an irradiation position of the particle beam relative to an affected area; first and second dosimeters that measure dose rates of the particle beam directed to the affected area; and an abnormality determination portion that accumulates the dose rates output from the first and second dosimeters for each of predetermined determination periods to calculate first and second sectional dose measurement values and that performs second abnormality determination of determining that there is an abnormality and outputs an interlock signal for terminating the emission of the particle beam in at least one of a case in which the first sectional dose measurement value exceeds a predetermined first reference range and a case in which the second sectional dose measurement value exceeds a predetermined second reference range.

Owner:NAT INST FOR QUANTUM & RADIOLOGICAL SCI & TECH +1

Icon implantation ion source, system and method

InactiveUS20050269520A1Vacuum evaporation coatingSemiconductor/solid-state device manufacturingDevice materialDose rate

Various aspects of the invention provide improved approaches and methods for efficiently: Vaporizing decaborane and other heat-sensitive materials via a novel vaporizer and vapor delivery system; Delivering a controlled, low-pressure drop flow of vapors, e.g. decaborane, into the ion source; Ionizing the decaborane into a large fraction of B10Hx+; Preventing thermal dissociation of decaborane; Limiting charge-exchange and low energy electron-induced fragmentation of B10Hx+; Operating the ion source without an arc plasma, which can improve the emittance properties and the purity of the beam; Operating the ion source without use of a strong applied magnetic field, which can improve the emittance properties of the beam; Using a novel approach to produce electron impact ionizations without the use of an arc discharge, by incorporation of an externally generated, broad directional electron beam which is aligned to pass through the ionization chamber to a thermally isolated beam dump; Providing production-worthy dosage rates of boron dopant at the wafer; Providing a hardware design that enables use also with other dopants, especially using novel hydride, dimer-containing, and indium- or antimony-containing temperature-sensitive starting materials, to further enhance the economics of use and production worthiness of the novel source design and in many cases, reducing the presence of contaminants; Matching the ion optics requirements of the installed base of ion implanters in the field; Eliminating the ion source as a source of transition metals contamination, by using an external and preferably remote cathode and providing an ionization chamber and extraction aperture fabricated of non-contaminating material, e.g. graphite, silicon carbide or aluminum; Enabling retrofit of the new ion source into the ion source design space of existing Bernas source-based ion implanters and the like or otherwise enabling compatibility with other ion source designs; Using a control system in retrofit installations that enables retention of the installed operator interface and control techniques with which operators are already familiar; Enabling convenient handling and replenishment of the solid within the vaporizer without substantial down-time of the implanter; Providing internal adjustment and control techniques that enable, with a single design, matching the dimensions and intensity of the zone in which ionization occurs to the beam line of the implanter and the requirement of the process at hand; Providing novel approaches, starting materials and conditions of operation that enable the making of future generations of semiconductor devices and especially CMOS source / drains and extensions, and doping of silicon gates.

Owner:SEMEQUIP

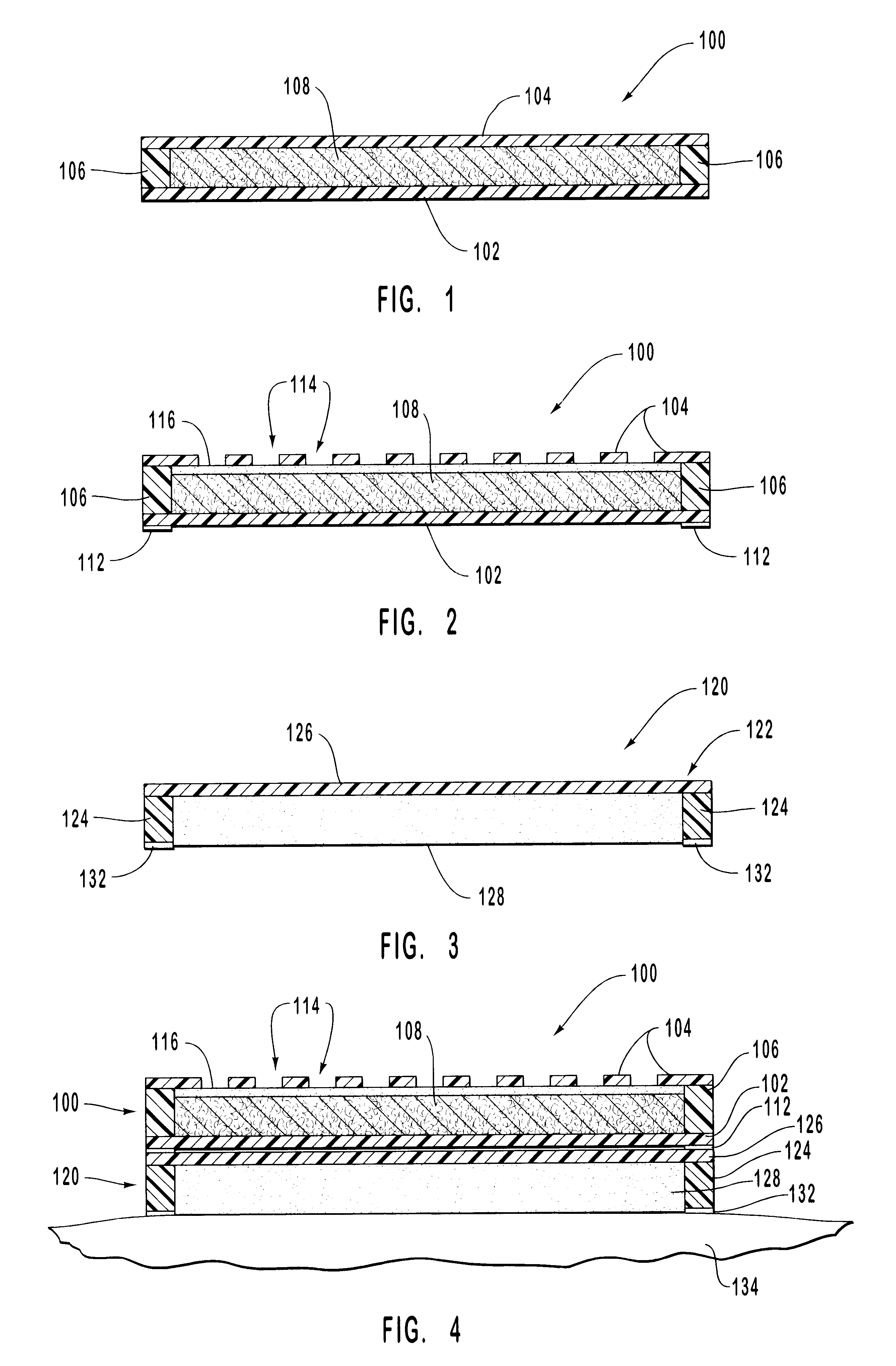

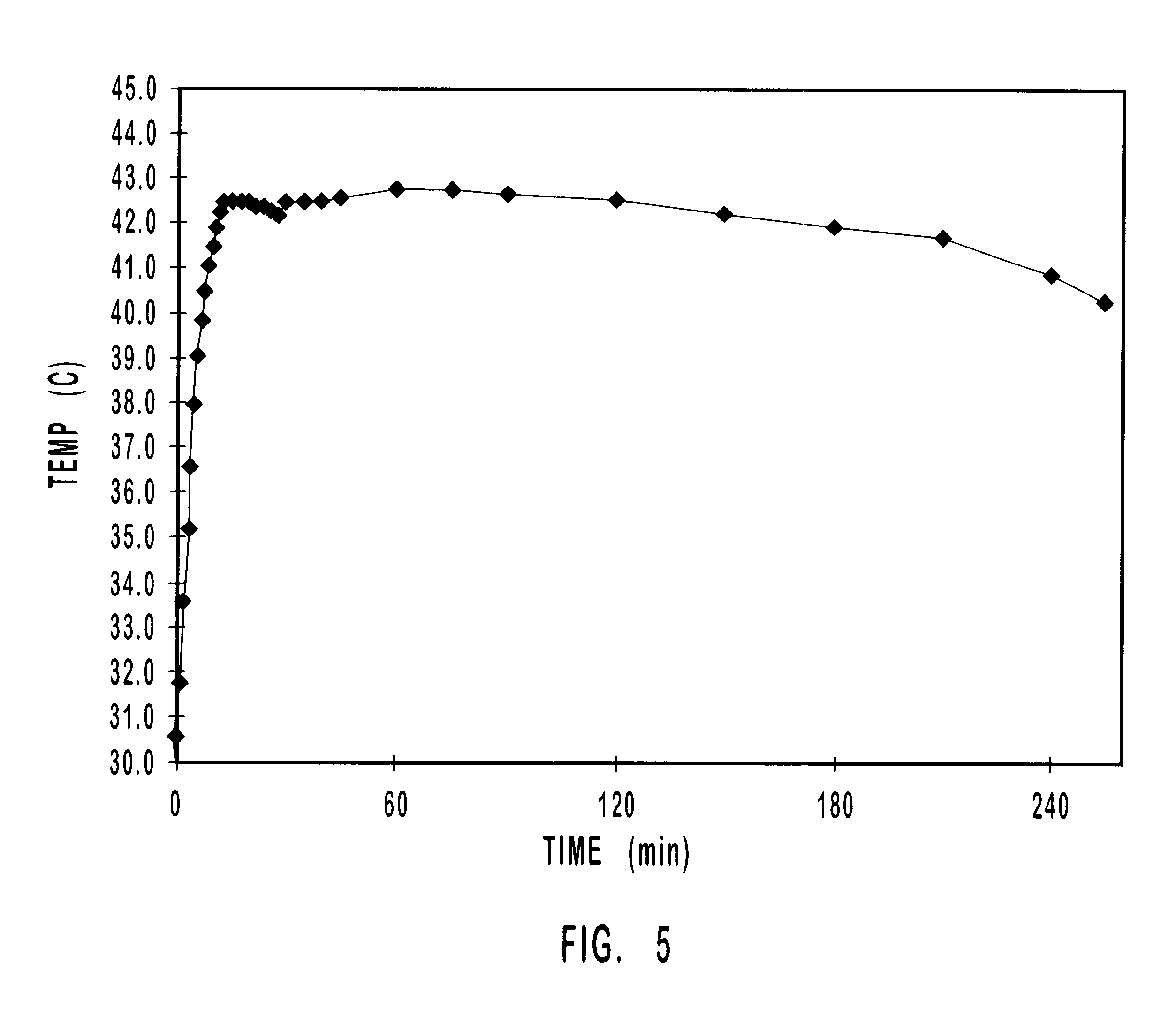

Methods and apparatus for improved administration of testosterone pharmaceuticals

InactiveUS6726673B1Improve breathabilityImprove performanceElectrotherapyMedical devicesControl releaseDose rate

The present invention relates to a method and apparatus for increasing the delivery rate of an androgen transdermal therapeutic system through the skin. An androgen transdermal therapeutic system can be applied to a patient's skin for delivery of the androgen. A temperature modification apparatus which is capable of generating controlled heat is applied approximate to the androgen transdermal therapeutic system. The heating from the temperature modification apparatus raises the temperature of the androgen transdermal therapeutic system and raises the temperature of the patient's skin to achieve an increased rate of delivery of androgen through the skin. The controlled heat can also be used to adjust dosage rates of the androgen transdermal therapeutic system and to mimic natural circadian patterns. The controlled heating may also be used to improve or regulate the release of androgen from injected / implanted extended / controlled release systems.

Owner:NUVO RES

Method of image guided intraoperative simultaneous several ports microbeam radiation therapy with microfocus X-ray tubes

This invention pertains to a method of low-cost intraoperative all field simultaneous parallel microbeam single fraction few seconds duration 100 to 1,000 Gy and higher dose radiosurgery with micro-electro-mechanical systems (MEMS)-carbon nanotube based microaccelerators. It ablates cancer cells including the mesenchymal epithelial transformation associated cancer stem cells. Microbeam brachy-therapeutic radiosurgery is performed. Microaccelerators are configured for simultaneous parallel microbeam emission from varying angels to an isocentric tumor. Their additive dose rate at the isocentric tumor is in the range of 10,000 to 20,000 Gy / s. It eliminates most tumor recurrence and metastasis which enhances cancer cure rates. It also exposes cancer antigens which induces cancer immunity. Stereotactic breast core biopsy is combined with, positron emission tomography and computerized tomography and phase-contrast imaging. Parallel microbeam brachytherapy preserves normal breast appearance. Migration of normal stem cells from unirradiated valley regions heals the radiation damage to the normal tissue.

Owner:SAHADEVAN VELAYUDHAN

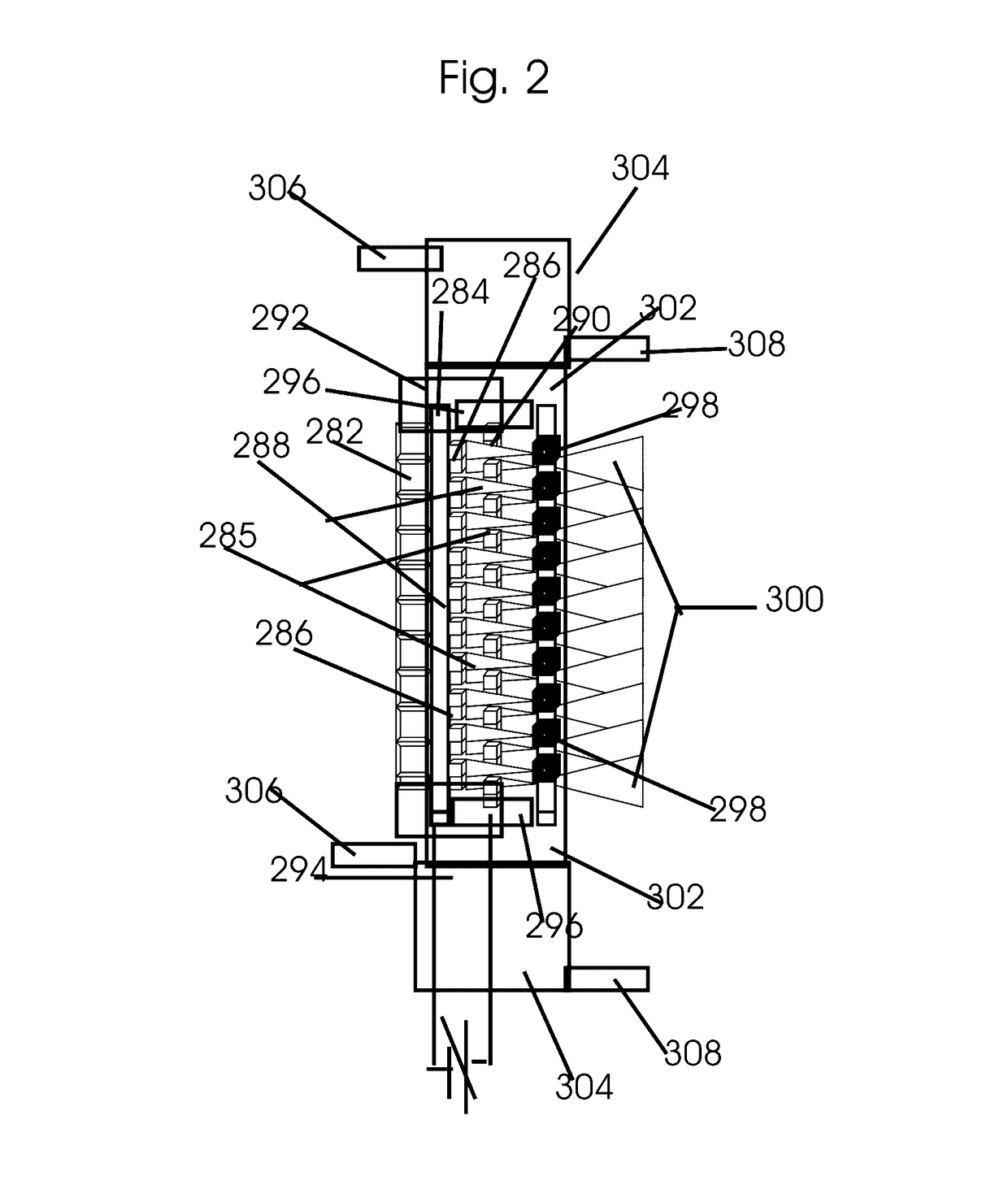

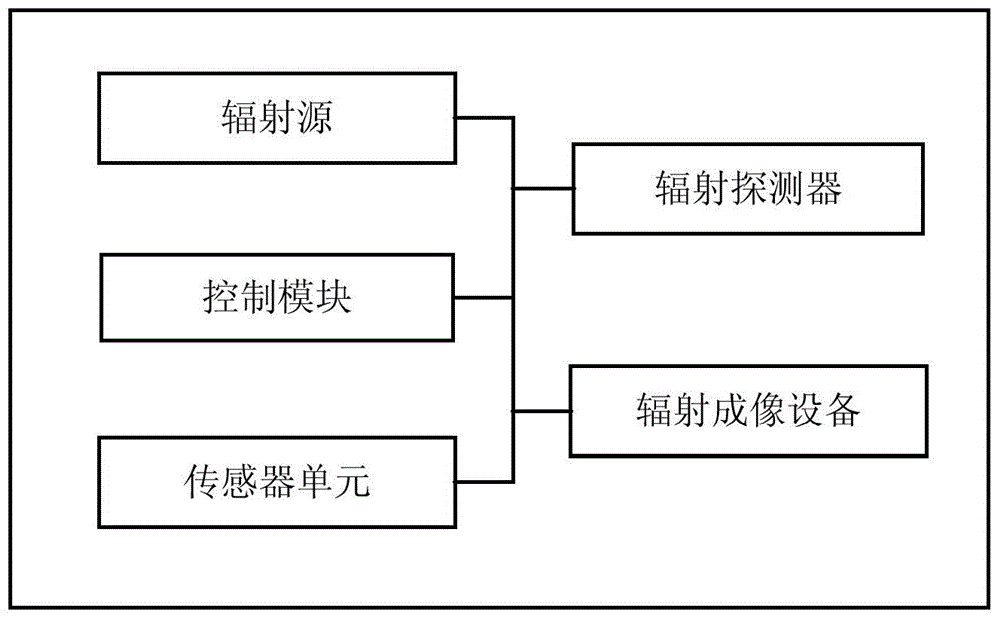

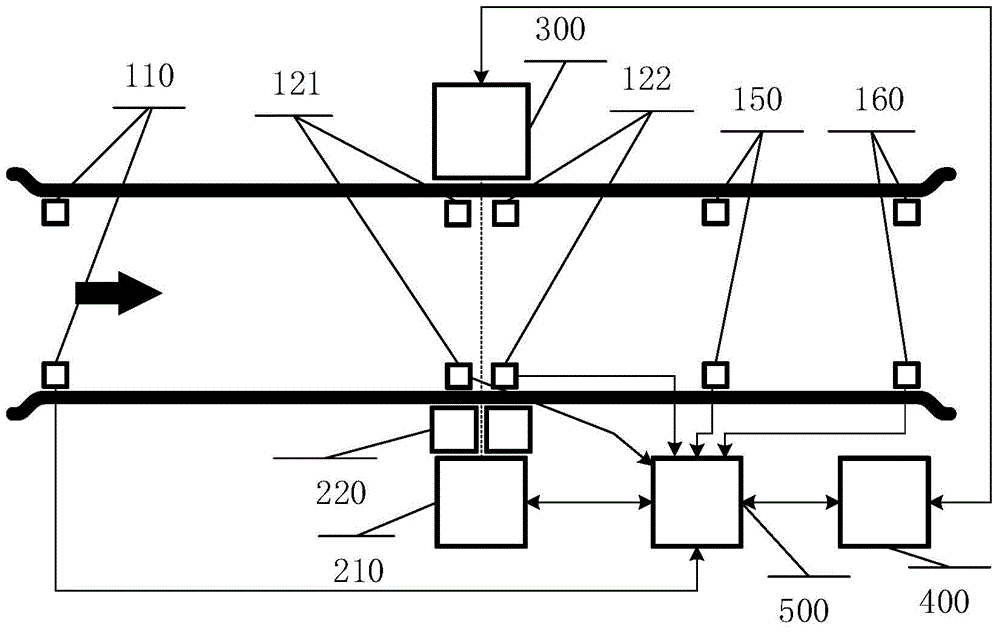

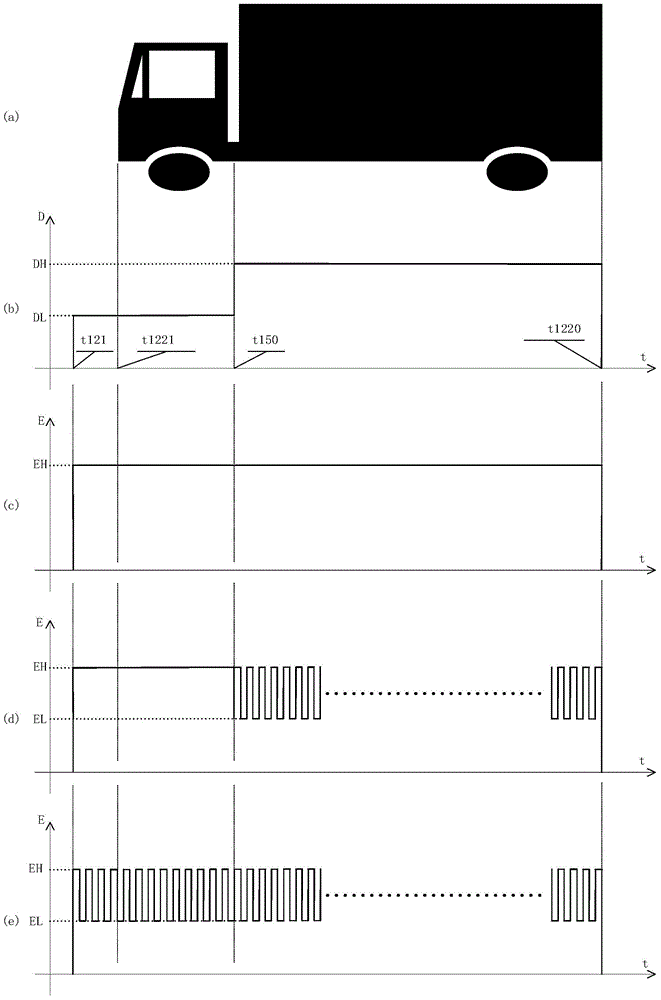

Double-mode rapidly-passing type moving target radiation detection system and method

PendingCN103984035AImprove securityQuick responseNuclear radiation detectionDose rateRadiation imaging

The invention discloses a double-mode rapidly-passing type moving target radiation detection system which comprises a radiation source, a collimator, a sensor unit, a control module, a radiation detector and a radiation imaging device. The radiation source is used for emitting rays with different dosage rates, the sensor unit is used for identifying the type of moving targets and monitoring the positions of the moving targets in a detection channel, and the control module is used for controlling the radiation source to emit the rays in preset working modes according o the types and the positions of the moving targets; the preset working modes correspond to the types of the moving targets, the rays emitted by the radiation source in the different working modes are different in dosage rates. The invention further discloses a double-mode rapidly-passing type moving target radiation detection method. By means of the double-mode rapidly-passing type moving target radiation detection system and method, radiation detection can be carried out on the whole moving targets such as vehicles.

Owner:POWERSCAN COMPANY LIMITED

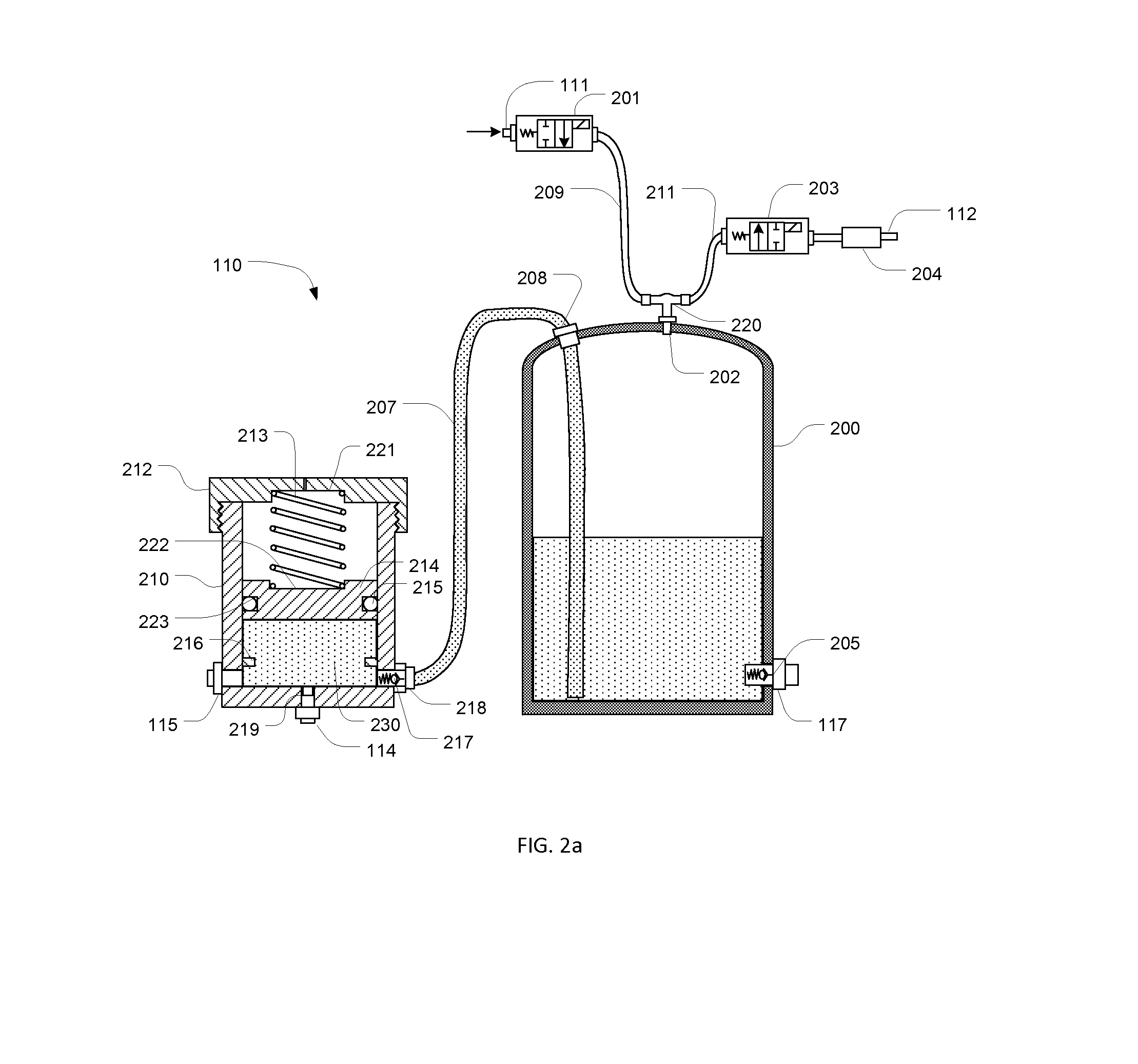

Air driven reductant delivery system

ActiveUS20140053537A1Constant pressureSave heating meanInternal combustion piston enginesExhaust apparatusDose rateClosed loop

A dosing system for delivering reductant to an exhaust gas treatment system of an internal combustion engine using air driven hydraulic pumps for closed-loop controlling reductant pressure and a two-stage PWM control method for controlling dosing rate. Reductant residue in the dosing systems is purged by using compressed air after a dosing process completes, and when the air driven hydraulic pumps are positioned inside a reductant tank, dedicated heating means for the pumps is not necessary. The air driven hydraulic pumps can also use low pressure compressed air, and the closed-loop pressure control together with the two-stage PWM control allow dosing accuracy insensitive to pressure variations in compressed air. These new features enable the dosing system use a variety of compressed air sources, including an engine turbo.

Owner:YAN MI +1

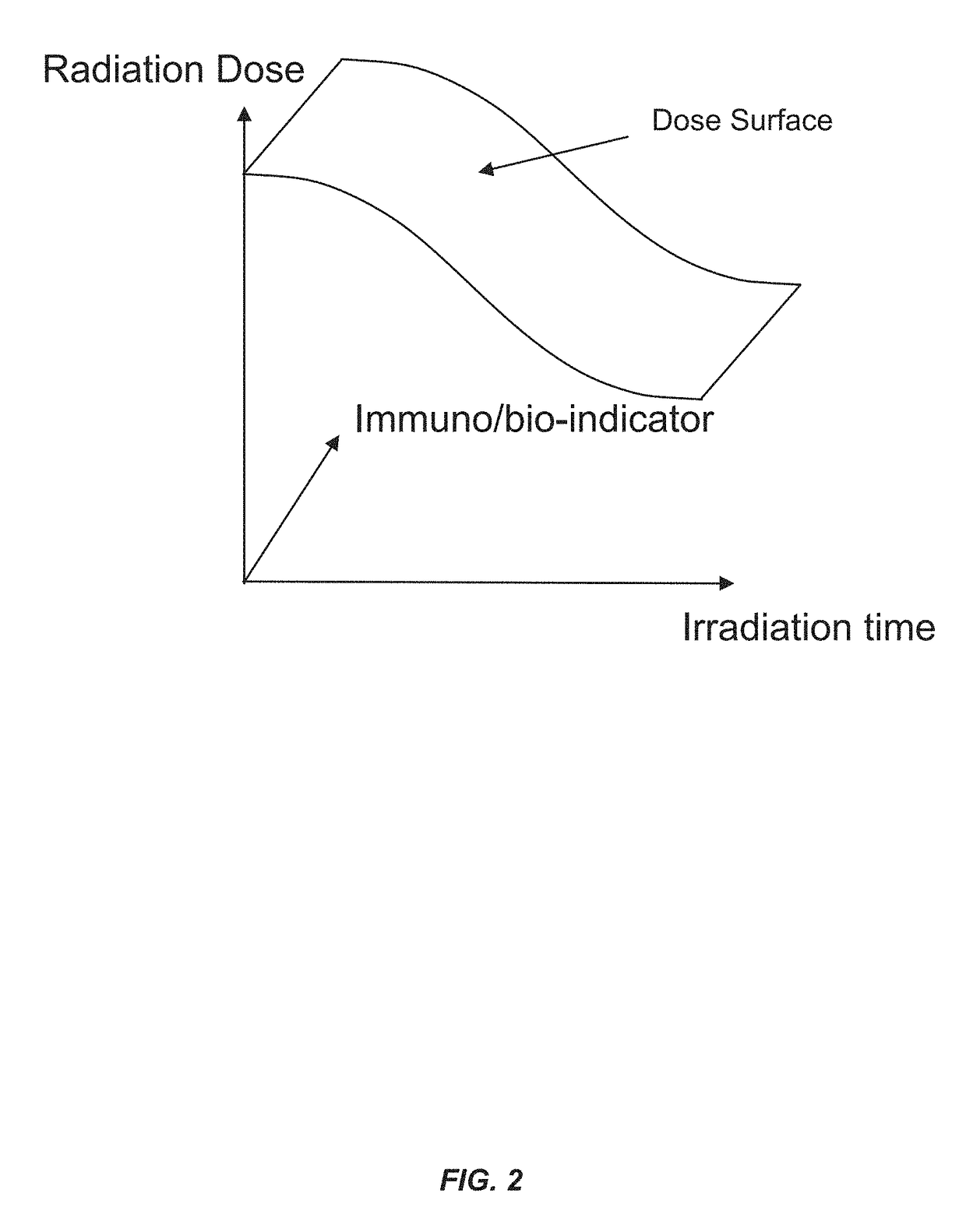

System and Method for Delivering an Ultra-High Dose of Radiation Therapy

InactiveUS20150011817A1Reduce variationReduce exerciseAcceleratorsX-ray/gamma-ray/particle-irradiation therapyDose rateHigh doses

Ultra high dose rate approach was proposed to irradiate to a moving target in radiation therapy in which the prescribed radiation dose was delivered within such a short time period that the displacement of the target could be ignored during dose delivering. The advantages of the approach were evaluated based on normal tissue sparing, flexibility of accuracy of targeting, and time saving in clinical treatment. A system and method of generating of ultra high dose rate combines and utilizes both a linear accelerator and a storage ring.

Owner:FENG YUXIN

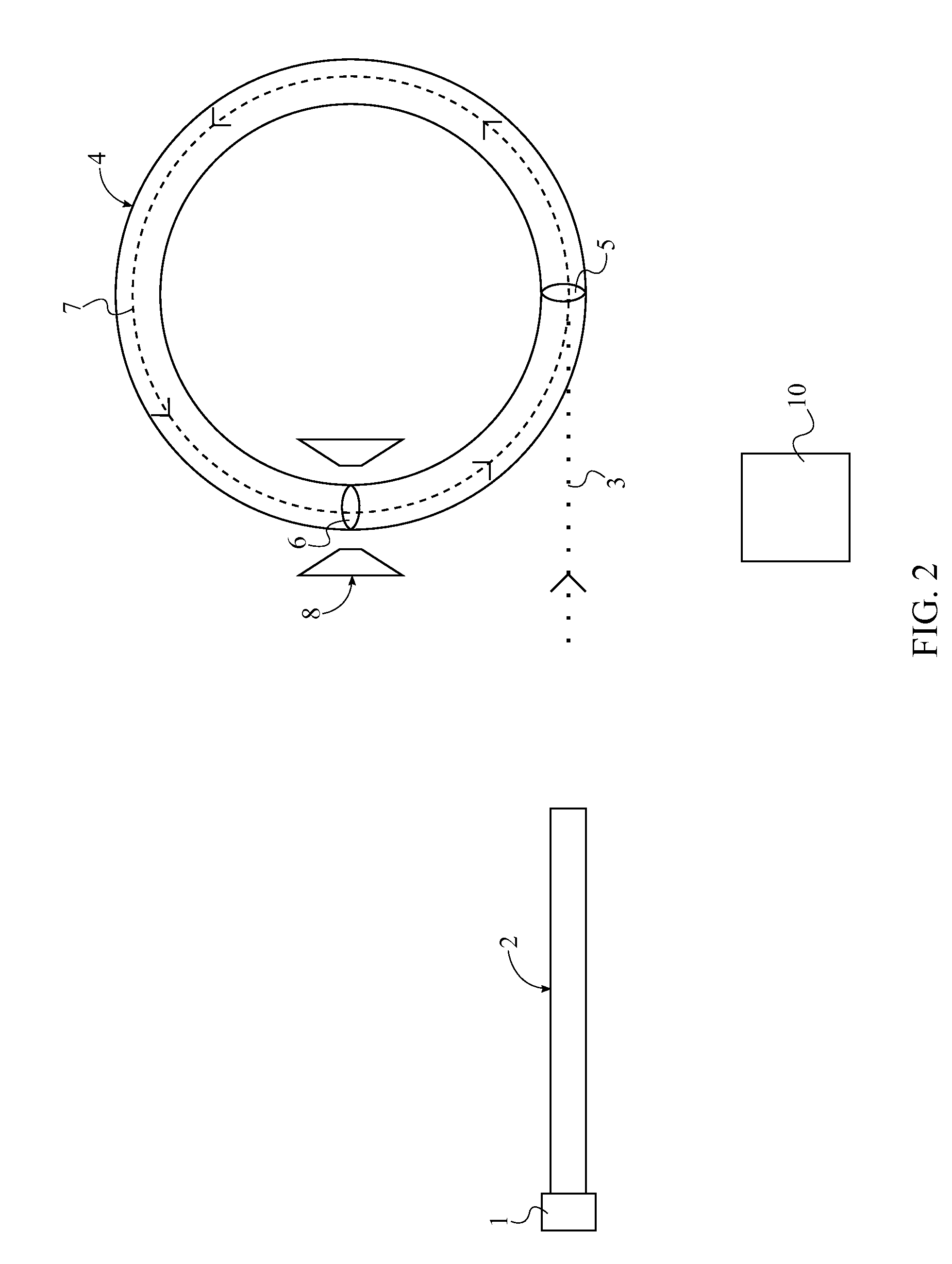

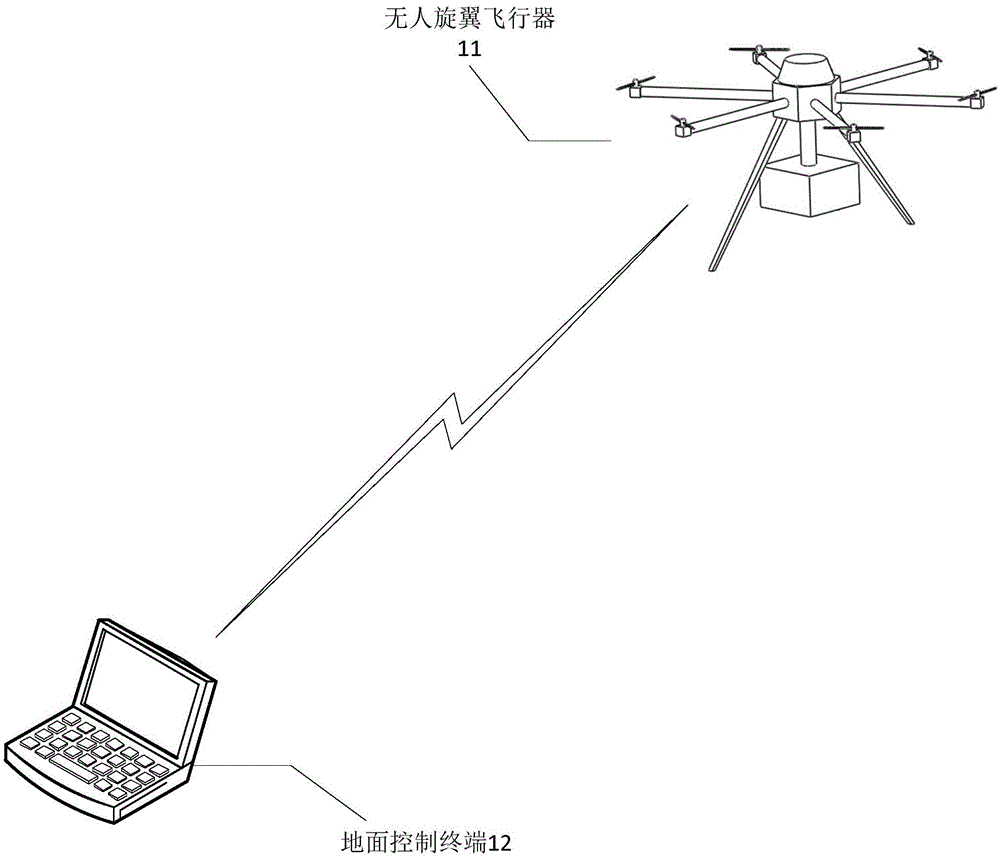

Radioactive detection system and radioactive detection method

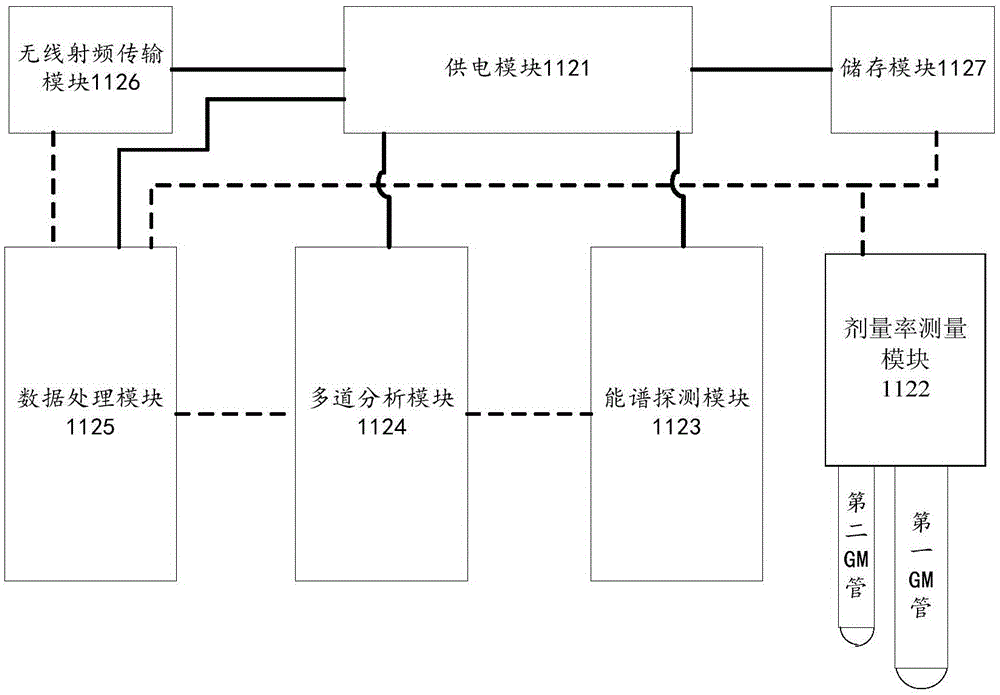

InactiveCN105137469AReduce operating hazardsKeep healthyX-ray spectral distribution measurementDosimetersPhysicsEnergy spectrum

Embodiments of the invention disclose a radioactive detection system and a radioactive detection method, and relate to the technical field of radiation monitoring. By adopting the system and the method, personnel do not need to approach or enter a radiation area or suspected radiation area with an instrument in hand for detection just like that in a traditional measurement method, and the risk is reduced. The system is composed of an unmanned rotor aircraft and a ground control terminal. The unmanned rotor aircraft comprises an unmanned rotor flying platform, and a radiation measuring platform borne on the unmanned rotor flying platform. The radiation measuring platform comprises a storage module used to store all measurement data and detection results, an energy spectrum detection module used to acquire energy spectrum information in a current environment, a multi-channel analysis module used to preliminarily process the energy spectrum information, a data processing module used to integrate and package location information, preliminary processing result data and dose rate monitoring information, and a wireless radio-frequency transmission module used to send a data packet to the ground control terminal. The radioactive detection system and the radioactive detection method of the invention are suitable for remotely detecting the radiation dose rate.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Electronically assisted drug delivery device

The present invention relates to electronically assisted drug delivery devices (100). The drug delivery device may include a Gray code type detector for sensing dosage data, wherein the detector comprises a code track consisting of a sequence of alternating markings and a plurality of detectors that are mutually spaced in a direction extending along the code track. The drug delivery device may also include a dosage selector (260) which is moved in a proximal direction upon dose setting and in a distal direction upon dose injection, where the dosage selector is latched in the end of dose position by a latching element, the latching element actuating an end of dose switch for signalling the end of dose state. The drug delivery device may also incorporate power-management arrangements which effectively minimizes power consumption for the incorporated electronic circuitry.

Owner:NOVO NORDISK AS

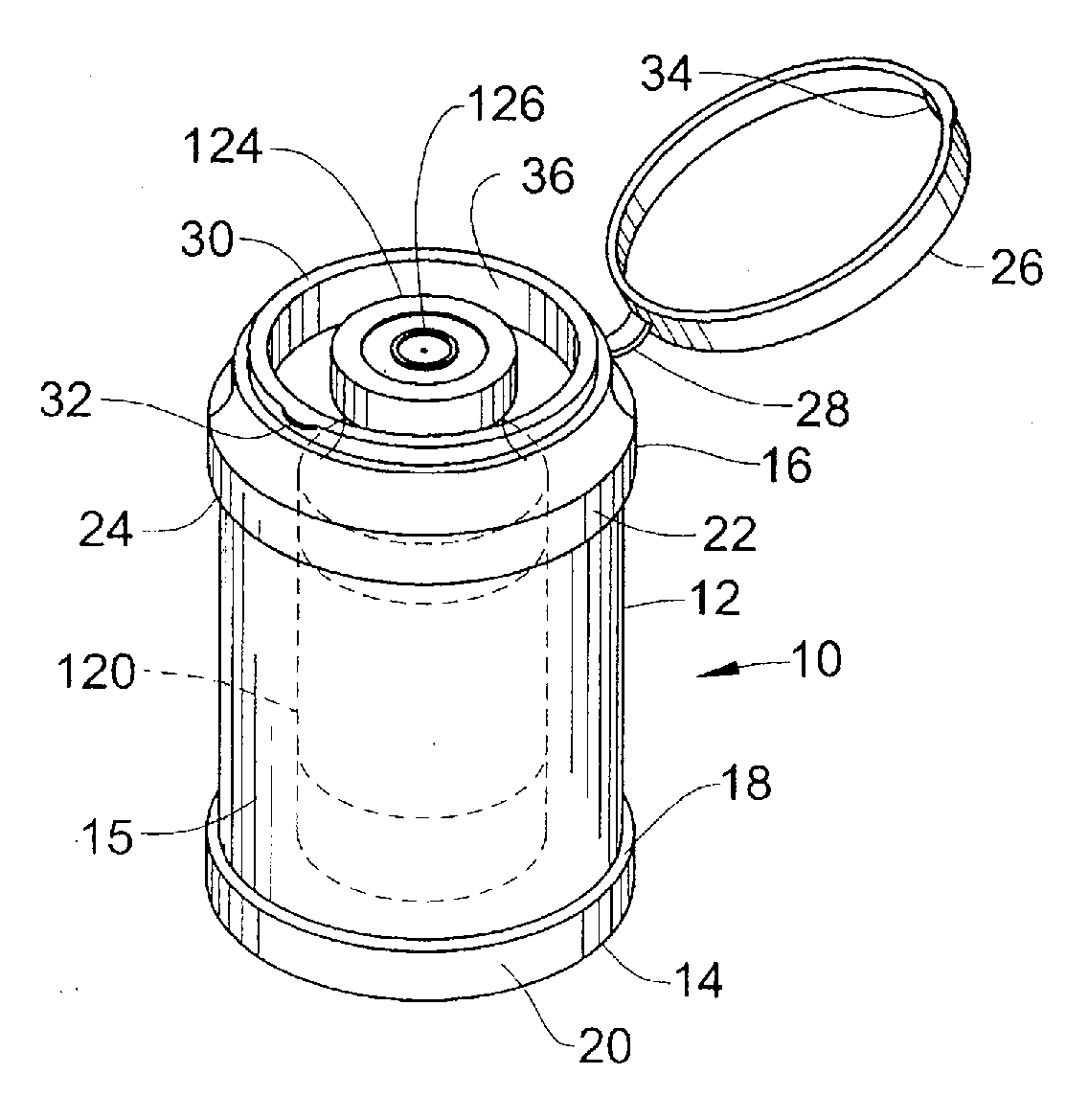

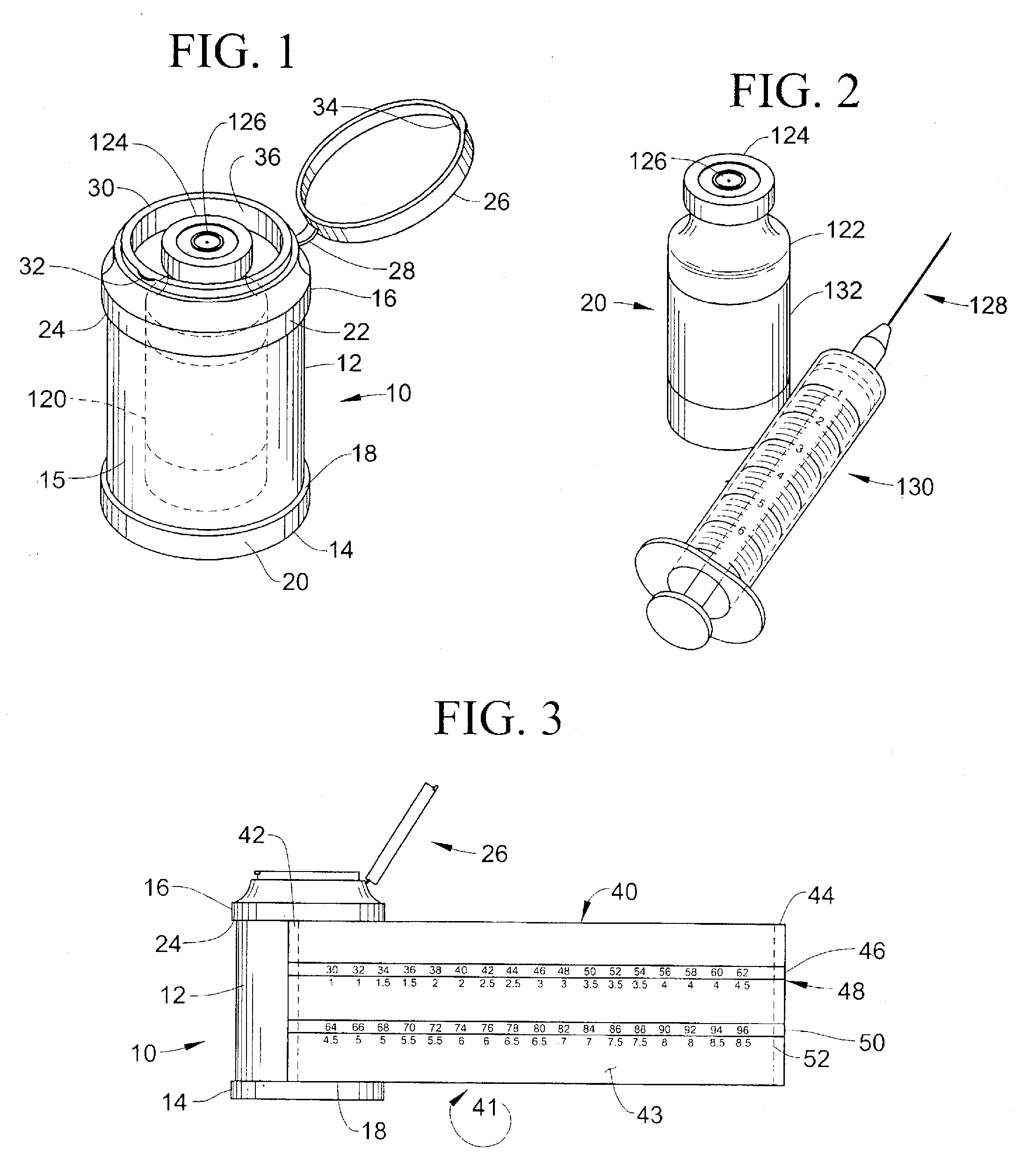

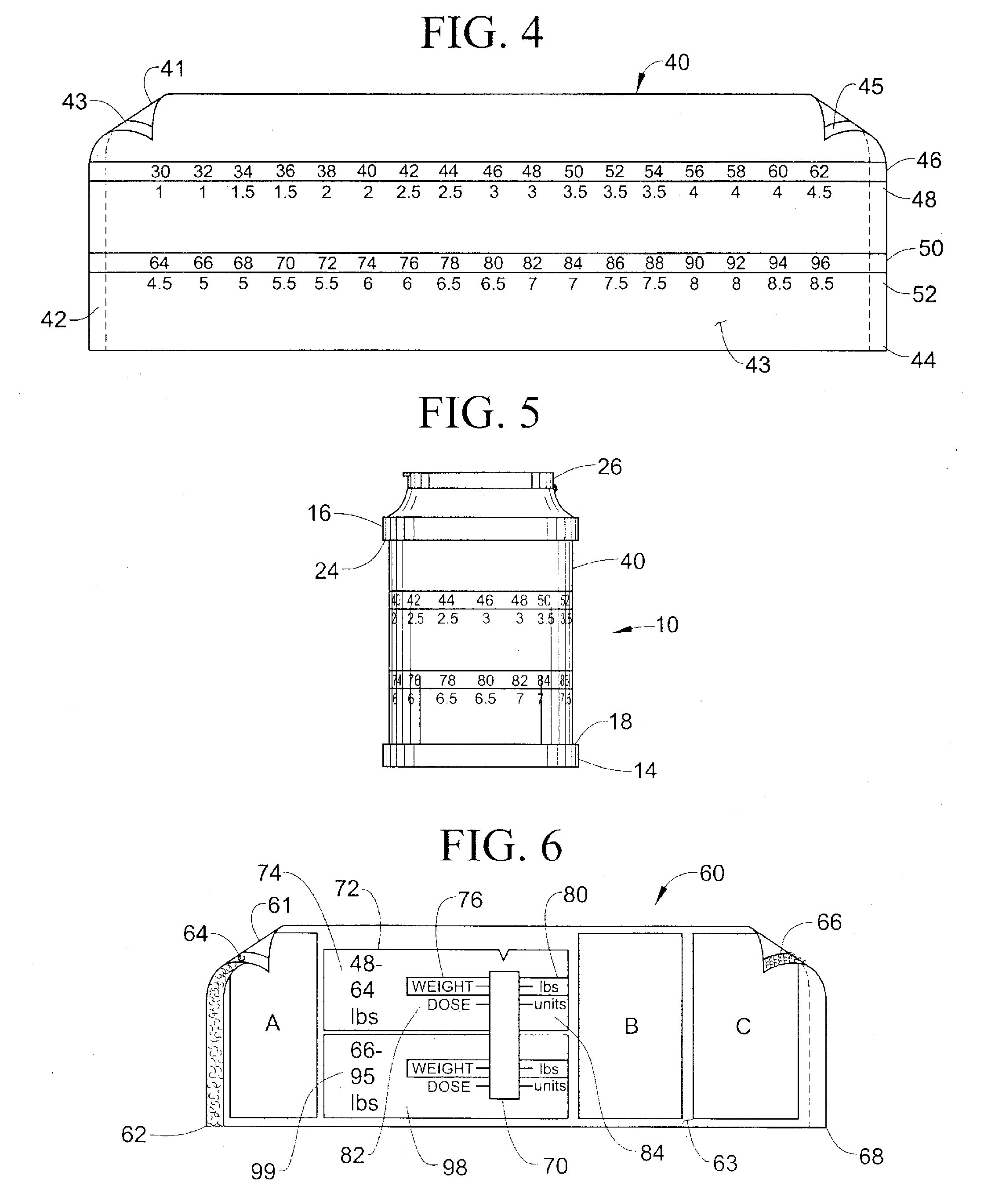

Injectable fluid vial housing

ActiveUS20120006712A1Increase the areaPrevent tamperingStampsDomestic cooling apparatusDose rateBiomedical engineering

A container for housing an injectable fluid vial. The container includes a calculation aid formed specific to the injectable fluid vial. The container is formed from a bottom, a top, and an inset side wall therebetween with a resealable lid. The top includes an opening constructed and arranged to receive the fluid vial housing. Alternatively, the container is formed from two half sections that are hinged together for holding the fluid vial housing therebetween. An inner label is permanently attached to the sidewall having at least one row of dosing indicia coordinated with a base line indicia selected from the group of weight, age, fluid volume or area. An outer label is rotatably secured over said inner label with at least one transparent window allowing selective viewing of the dosing and base line indicia and predetermined dosing rate.

Owner:SPINLABEL TECH

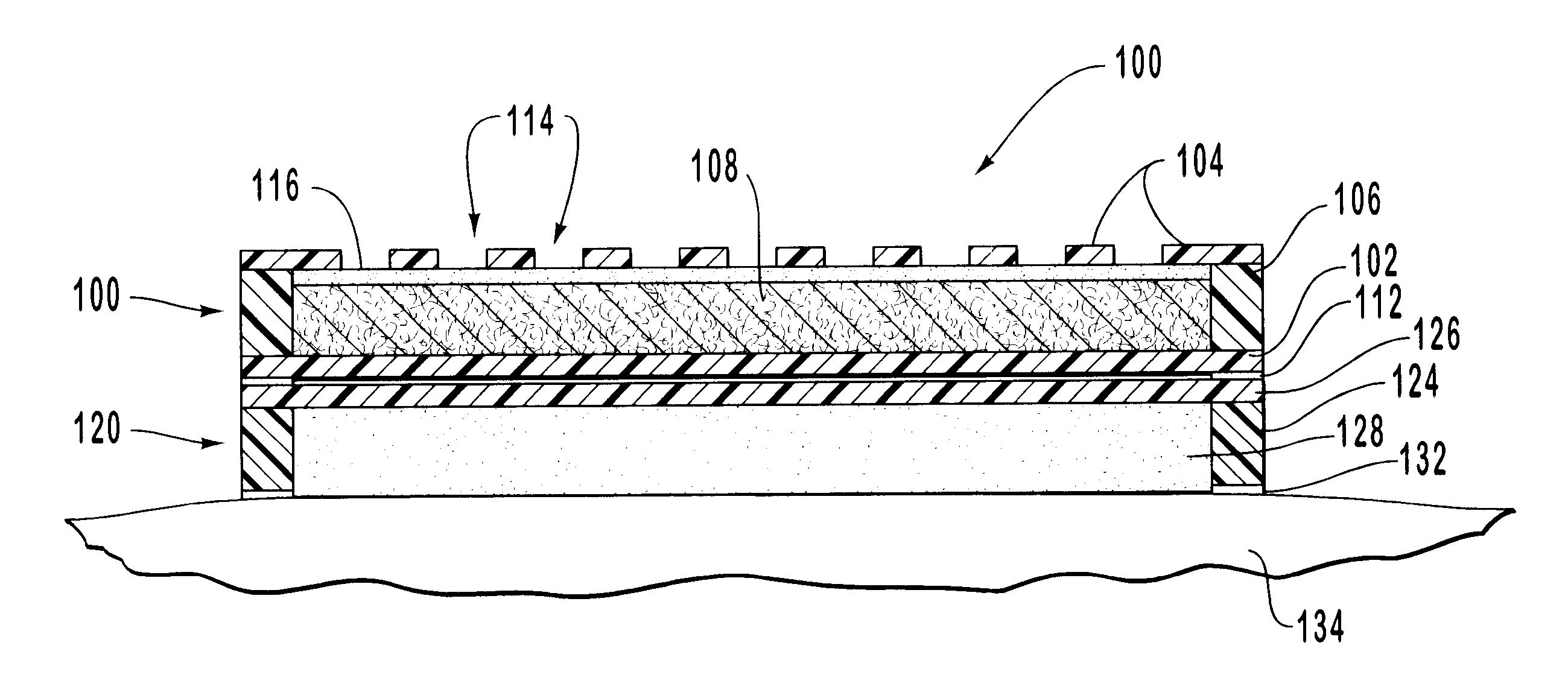

Natural polysaccharide/nano-TiO2 composite light-sensitive antimicrobial hydrogel dressing and radiation synthesis method thereof

The invention provides a natural polysaccharide / nano-TiO2 composite light-sensitive antimicrobial hydrogel dressing which is composed of a backing layer, a hydrogel dressing layer and a strippable layer. A synthesis method of the natural polysaccharide / nano-TiO2 composite light-sensitive antimicrobial hydrogel dressing comprises performing radiation crosslinking on raw materials, namely 10-40% of natural polysaccharide, 0.1-10% of nano-TiO2, 0.1%-5% of radiation sensitizer, 0.1%-3% of pH regulator, 0.1%-3% of surfactant and 60%-95% of water, by use of an electron beam or gamma ray by a radiation dose of 10-150kGy and at a dose rate of 10-80kGy / pass. The natural polysaccharide / nano-TiO2 composite light-sensitive antimicrobial hydrogel dressing is sheared, bagged and sterilized by radiation, and then stored for a long time. The natural polysaccharide / nano-TiO2 composite light-sensitive antimicrobial hydrogel dressing has the advantages that the maximization and optimization of the properties of the composite hydrogel, light-sensitive and antimicrobial properties are united organically, and the multiple-element composite synergic antimicrobial effect of the nano-TiO2-natural polysaccharide hydrogel is also realized; meanwhile, the composite hydrogel dressing has the characteristics of air permeability, no bonding with tissues, good flexibility and the like, and thus is suitable for protecting and treating various wounds.

Owner:HUBEI UNIV OF SCI & TECH

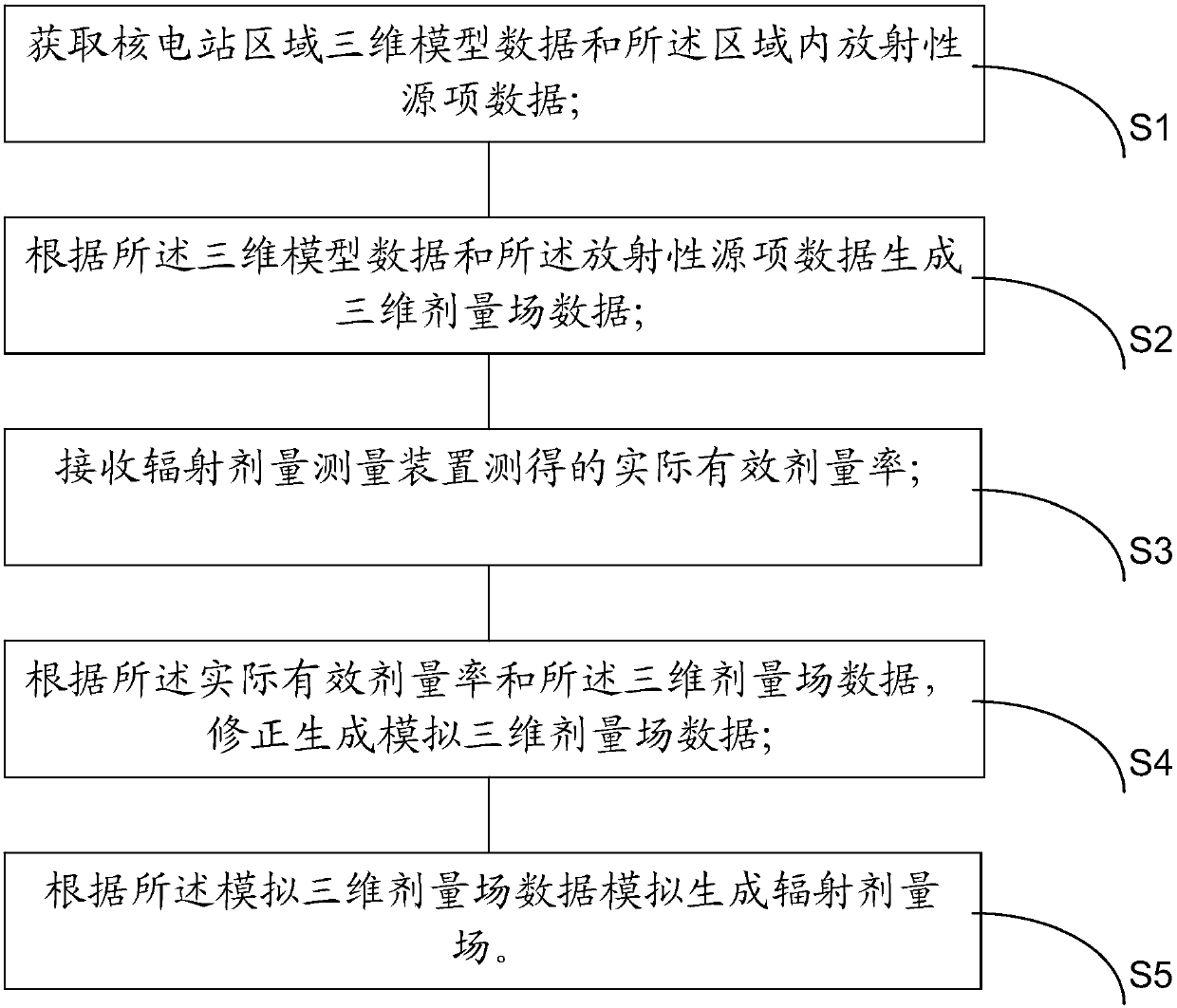

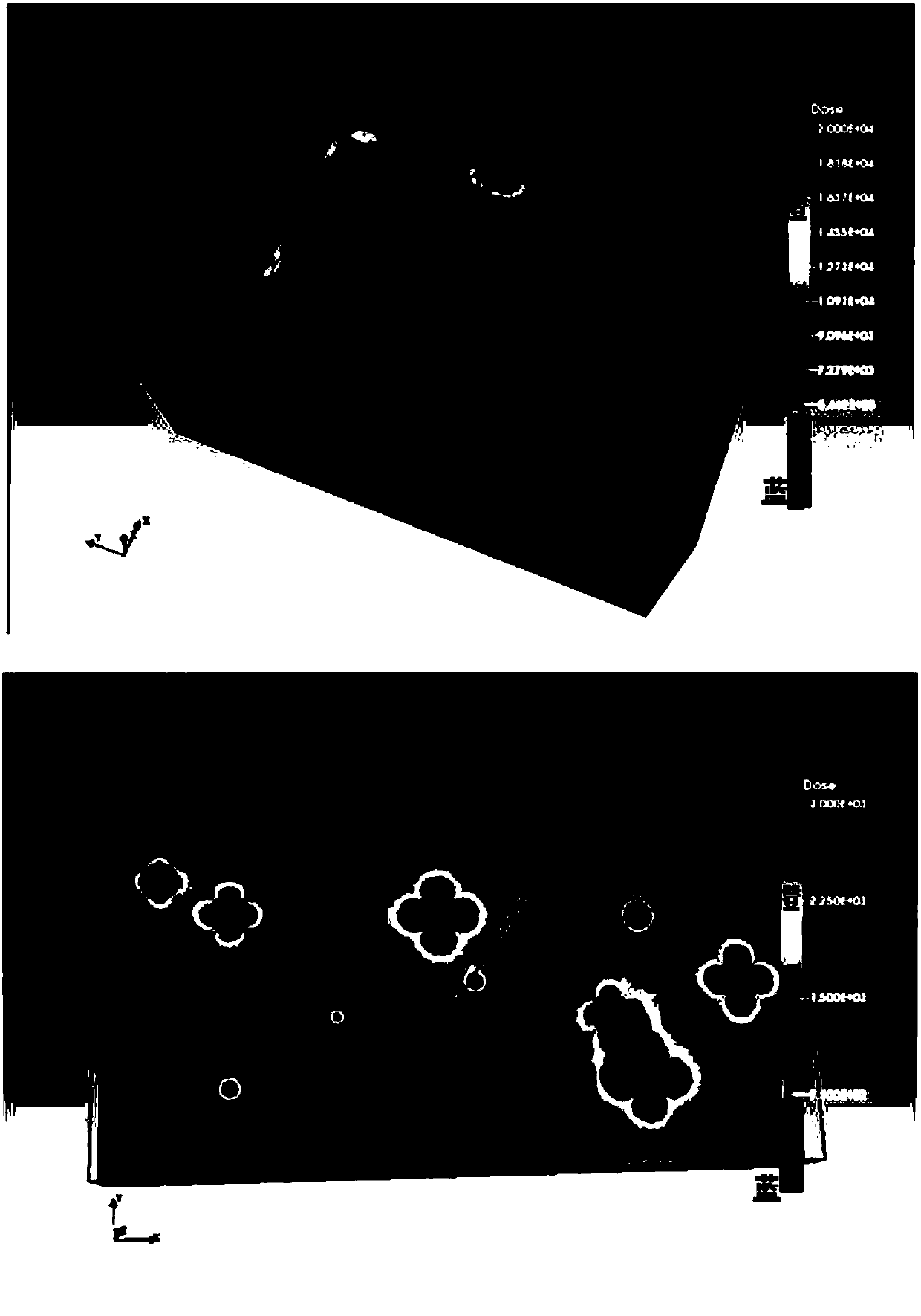

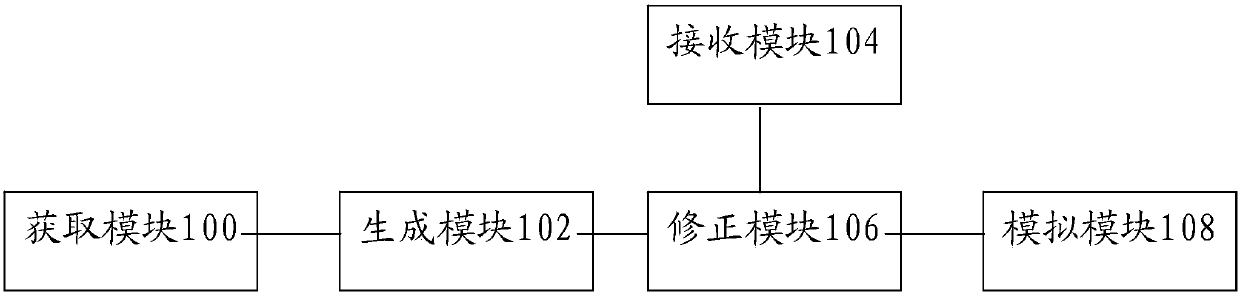

Method and system for simulating radiation dose field of nuclear power station

InactiveCN106611072AReduce radiation dose levelsSpecial data processing applicationsData simulationMeasurement device

The invention discloses a method and system for simulating a radiation dose field of a nuclear power station. The method comprises the following steps of obtaining three-dimensional model data in a nuclear power station area and radioactive source term data in the area; generating three-dimensional dose field data according to the three-dimensional model data and the radioactive source term data; receiving an actual effective dose rate measured by a radiation dose measurement device; correcting and generating simulated three-dimensional dose field data according to the actual effective dose rate and the three-dimensional dose field data; and simulating and generating the radiation dose field according to the simulated three-dimensional dose field data. According to the method and the system for simulating the radiation dose field of the nuclear power station, the radiation dose in a radiation area can be relatively accurately simulated only through limited measured data, distribution of the effective dose rate in the area can be provided and the level of the tolerated radiation dose of an operator is reduced.

Owner:中广核工程有限公司 +3

Methods of use of ultra-high dose rate radiation and therapeutic agent

ActiveUS20190022411A1Improve therapeutic windowDecreasing normal tissue side effectOrganic active ingredientsPowder deliveryDose rateHigh doses

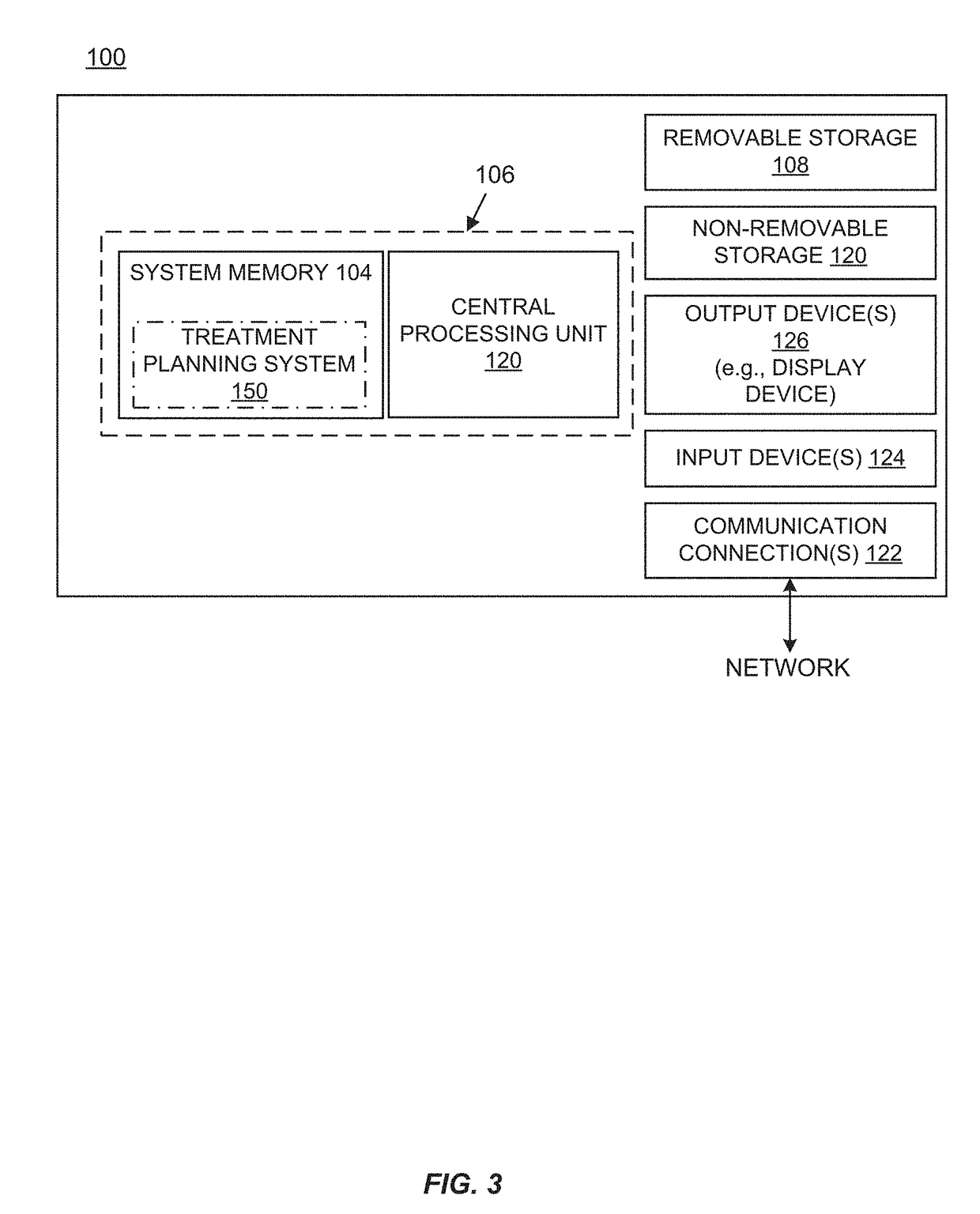

Methods for treating tumors by administering FLASH radiation and a therapeutic agent to a patient with cancer are disclosed. The methods provide the dual benefits of anti-tumor efficacy plus normal tissue protection when combining therapeutic agents with FLASH radiation to treat cancer patients. The methods described herein also allow for the classification of patients into groups for receiving optimized radiation treatment in combination with a therapeutic agent based on patient-specific biomarker signatures. Also provided are radiation treatment planning methods and systems incorporating FLASH radiation and therapeutic agents.

Owner:VARIAN MEDICAL SYSTEMS

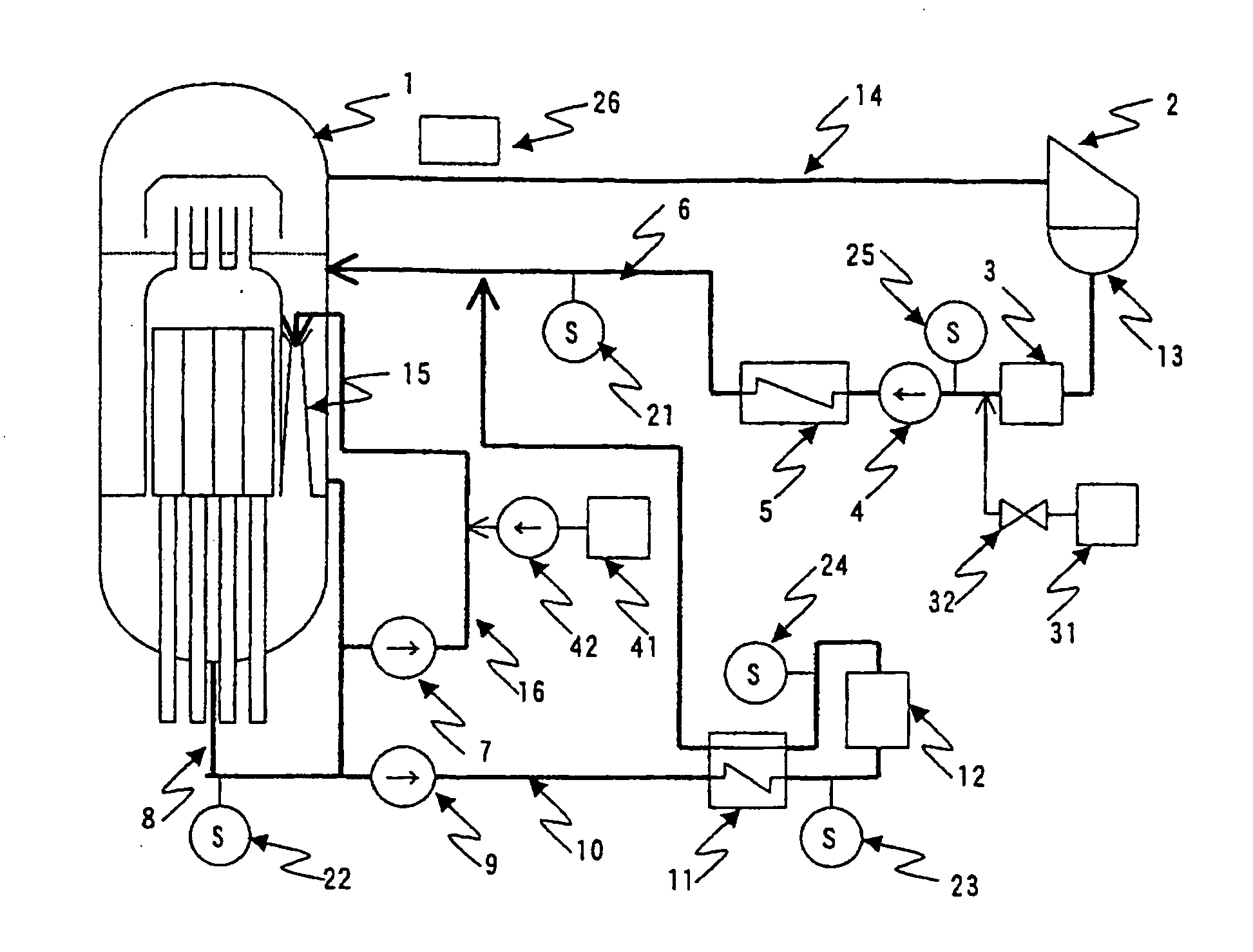

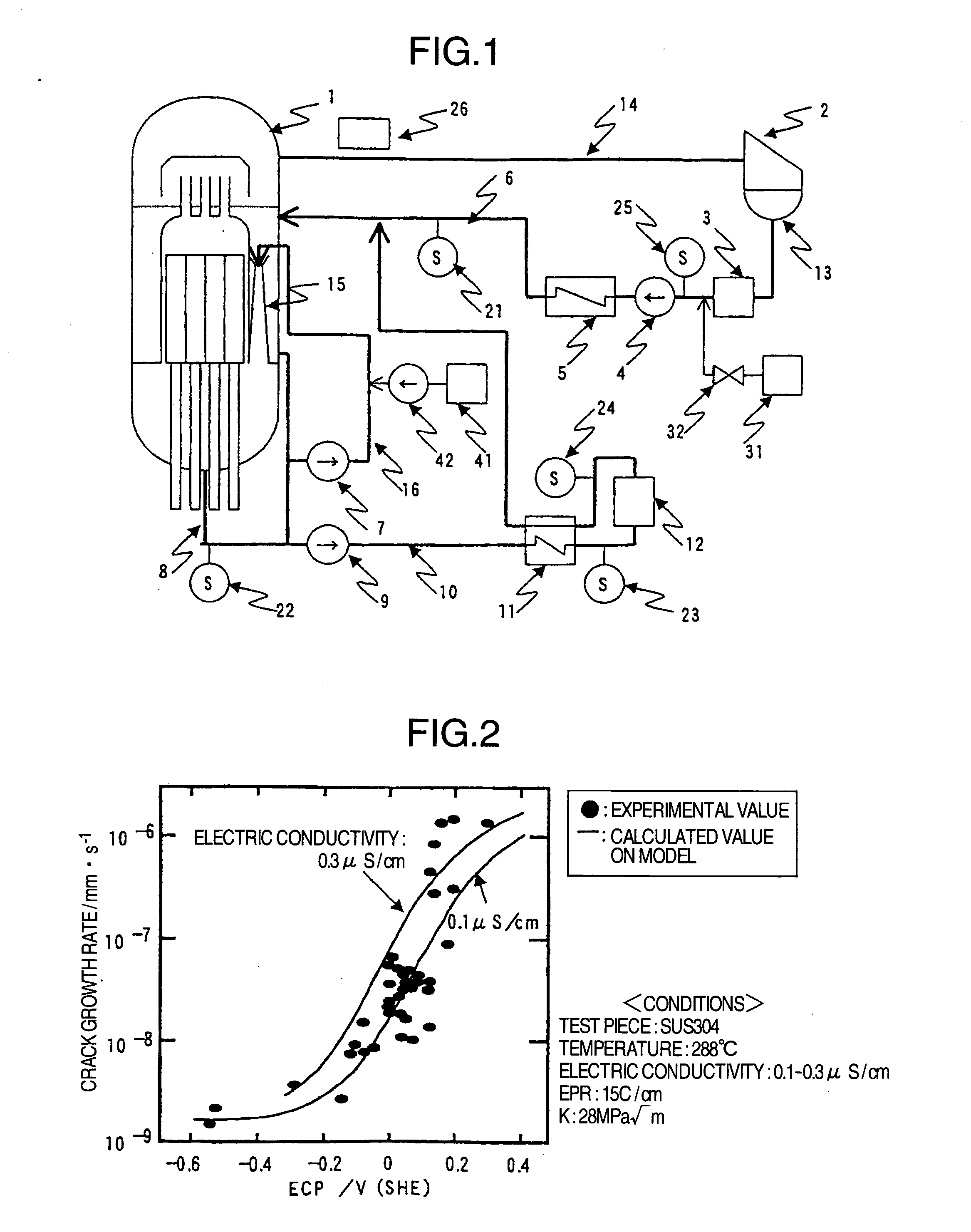

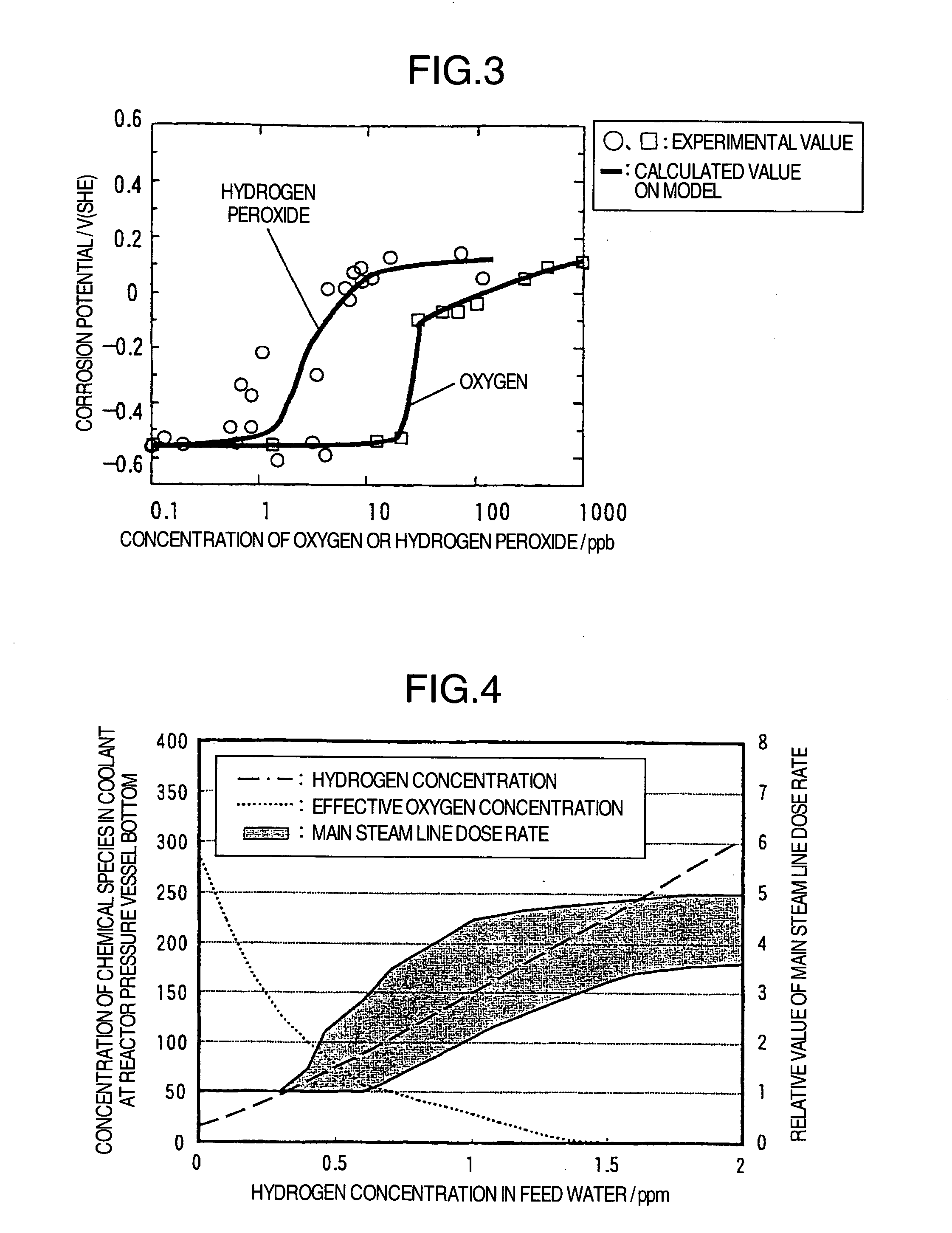

Method of stress corrosion cracking mitigation for nuclear power plant structural materials

InactiveUS20050018805A1Reduce stress corrosion crackingReduce stressPlant parameters regulationNuclear energy generationDose rateHydrazine compound

The object of this invention is to provide a method for mitigating a stress corrosion cracking of reactor structural material which makes it possible to suppress the rise in the main steam line dose rate without secondary effects such as a rise in the concentration of radioactive cobalt-60, etc. in the reactor water. Hydrogen and a reductive nitrogen compound containing nitrogen having a negative oxidation number (for example, hydrazine) are injected into the core water of boiling water nuclear power plant. By injecting the reductive nitrogen compound containing nitrogen having a negative oxidation number into the core water, the stress corrosion cracking of structural material of reactor can be mitigated without side reactions such as a rise in the concentration of cobalt-60, etc.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

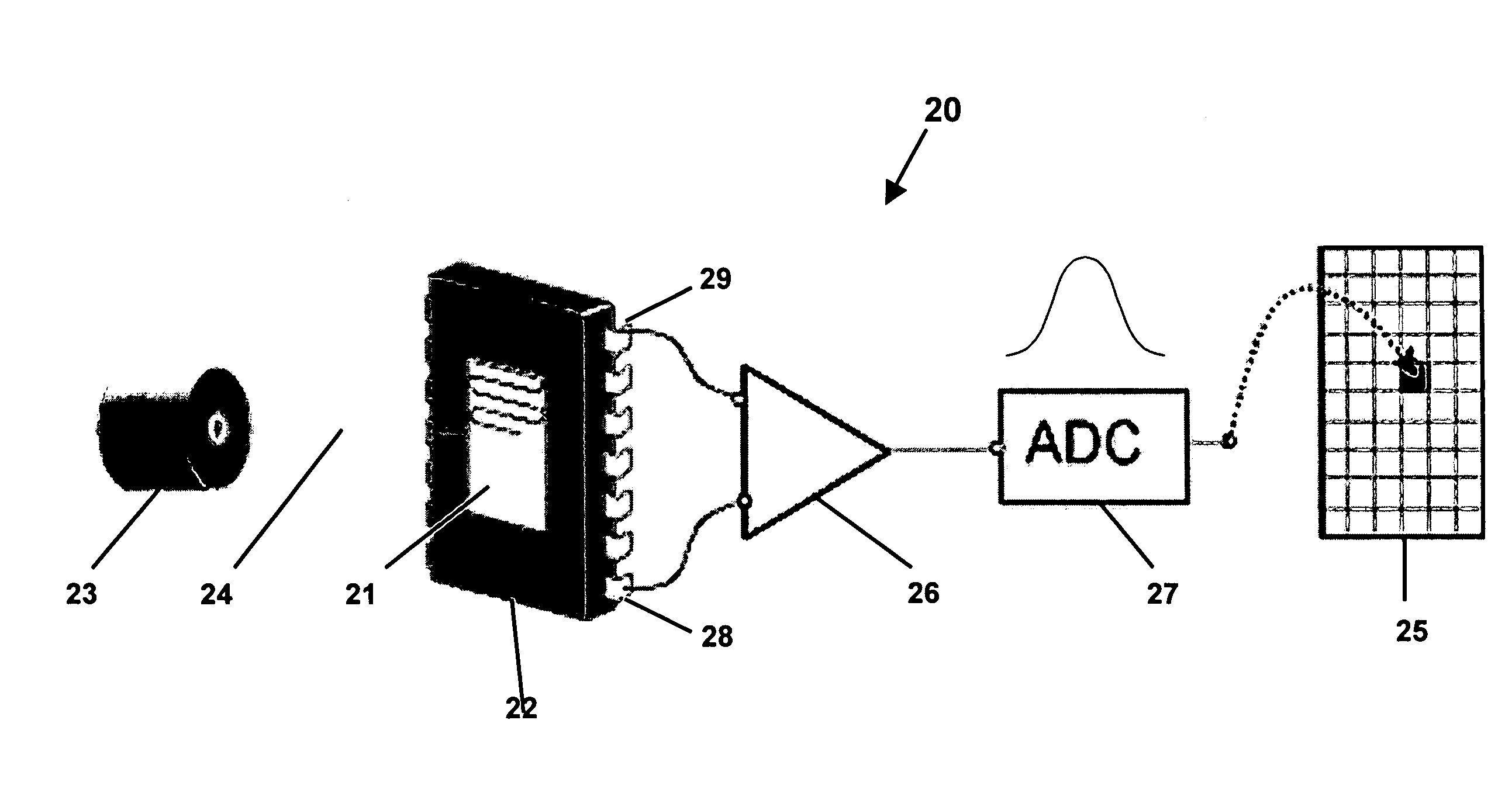

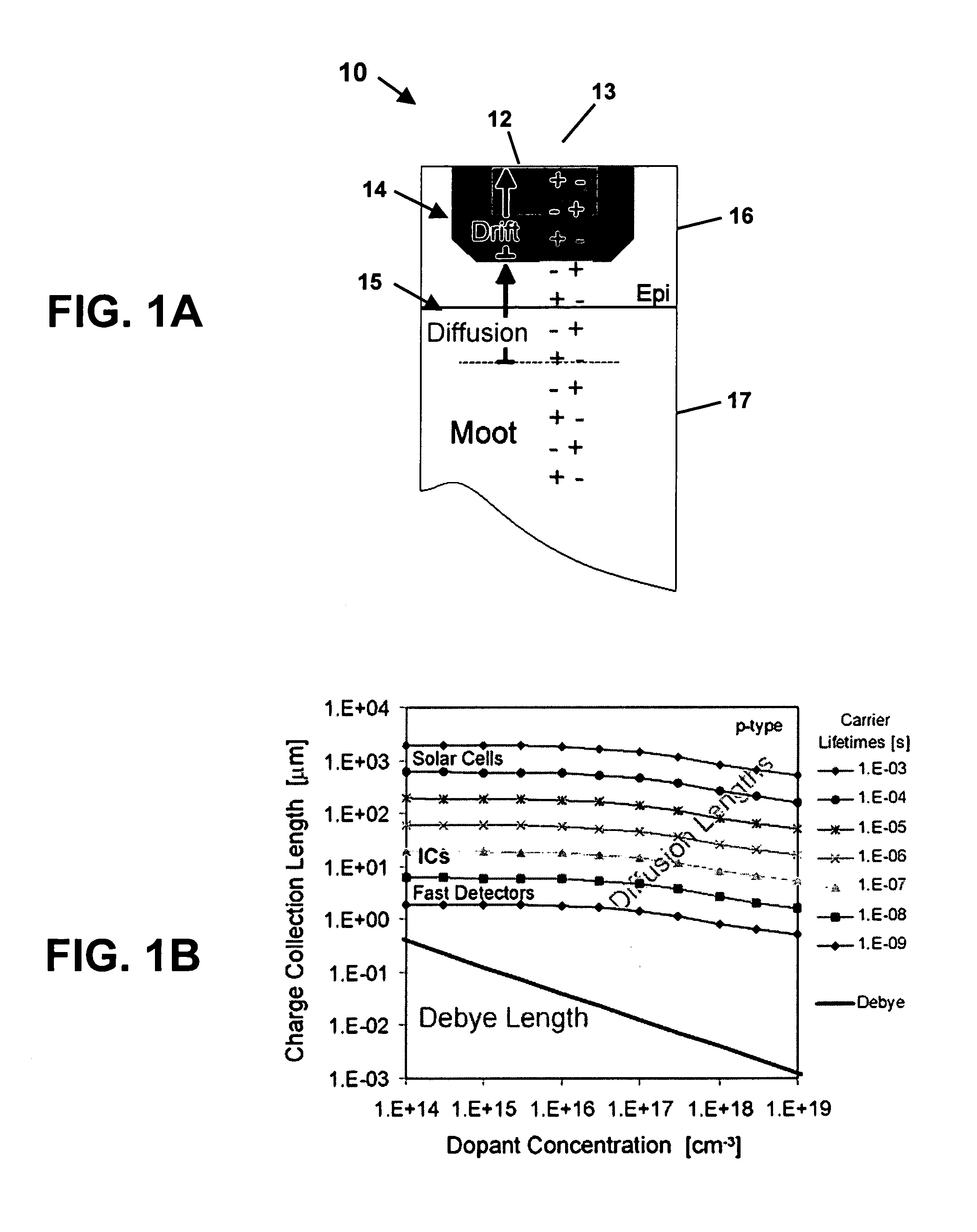

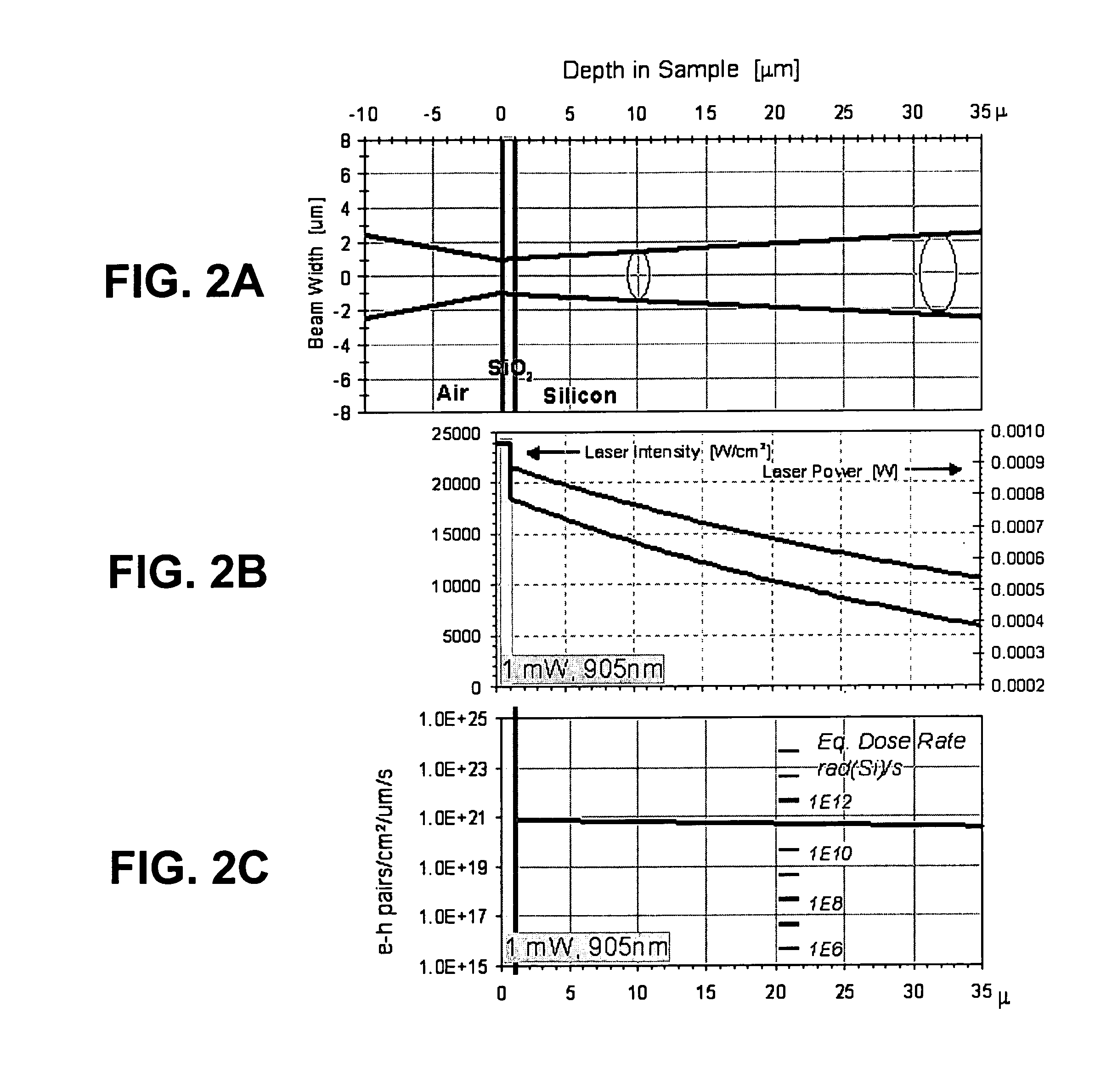

Laser-based irradiation apparatus and methods for monitoring the dose-rate response of semiconductor devices

InactiveUS7019311B1Electric discharge tubesElectroluminescent light sourcesOperational systemDose rate

A scanned, pulsed, focused laser irradiation apparatus can measure and image the photocurrent collection resulting from a dose-rate equivalent exposure to infrared laser light across an entire silicon die. Comparisons of dose-rate response images or time-delay images from before, during, and after accelerated aging of a device, or from periodic sampling of devices from fielded operational systems allows precise identification of those specific age-affected circuit structures within a device that merit further quantitative analysis with targeted materials or electrical testing techniques. Another embodiment of the invention comprises a broad-beam, dose rate-equivalent exposure apparatus. The broad-beam laser irradiation apparatus can determine if aging has affected the device's overall functionality. This embodiment can be combined with the synchronized introduction of external electrical transients into a device under test to simulate the electrical effects of the surrounding circuitry's response to a radiation exposure.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Methods for stable and repeatable ion implantation

A method for plasma ion implantation of a substrate includes providing a plasma ion implantation system having a process chamber, a source for producing a plasma in the process chamber, a platen for holding a substrate in the process chamber, an anode spaced from the platen, and a pulse source for generating implant pulses for accelerating ions from the plasma into the substrate. In one aspect, a parameter of an implant process is varied to at least partially compensate for undesired effects of interaction between ions being implanted and the substrate. For example, dose rate, ion energy, or both may be varied during the implant process. In another aspect, a pretreatment step includes accelerating ions from the plasma to the anode to cause emission of secondary electrons from the anode, and accelerating the secondary electrons from the anode to a substrate for pretreatment of the substrate.

Owner:VARIAN SEMICON EQUIP ASSOC INC

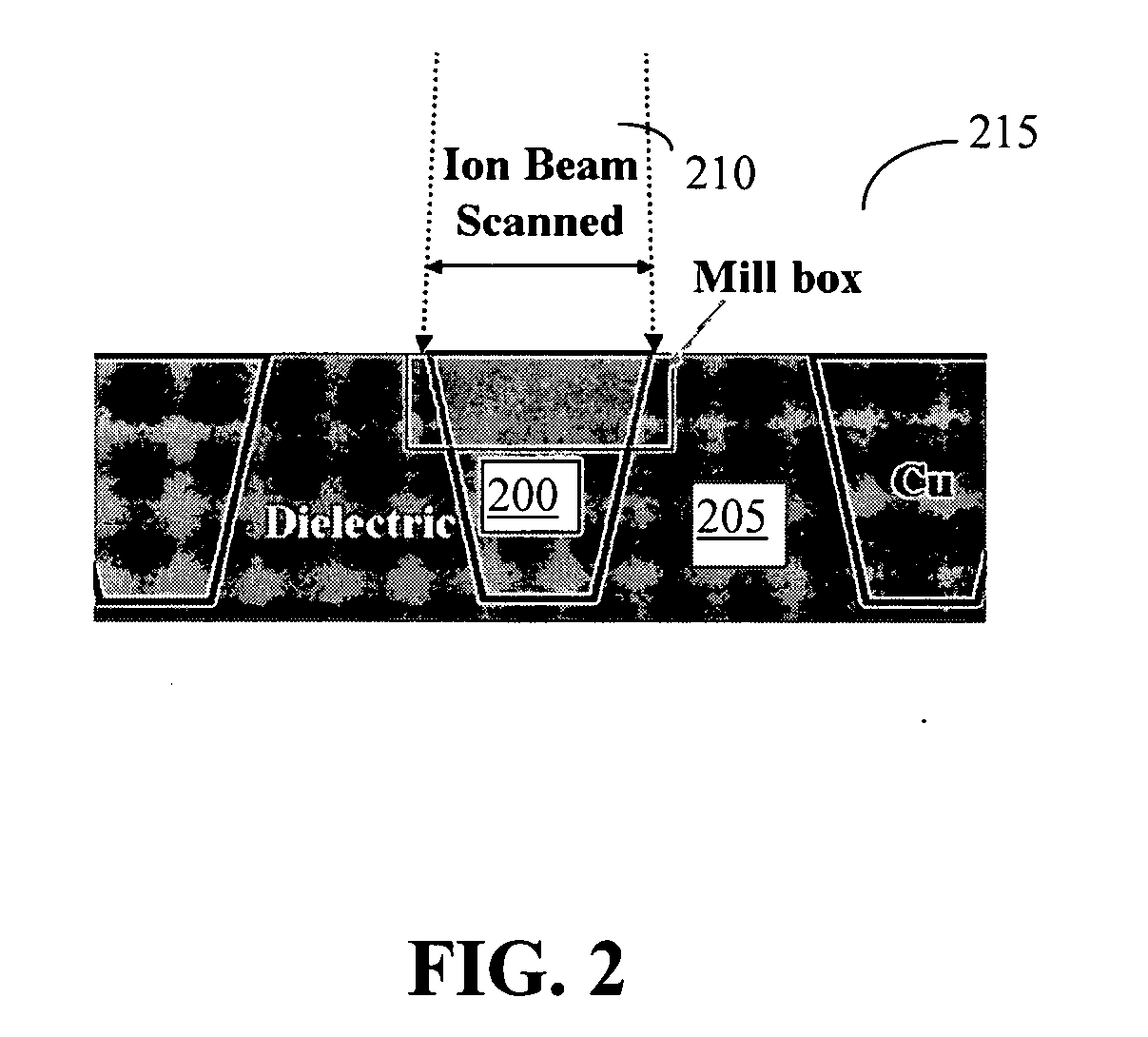

Planar etching of dissimilar materials

InactiveUS20080113455A1Reduced responseUniform removalLevel controlElectric discharge tubesDose rateFailure analysis

A method of planar etching of dissimilar materials with a Focused Ion Beam (FIB) system such as the OptiFIB manufactured by Credence Systems. The method includes adjusting the selectivity between the two materials, which varies when the ratio of the assisting chemistry pressure to the ion dose rate changes. This method can be used in such applications as FIB circuit edit, failure analysis, and cross sectioning.

Owner:DCG SYST

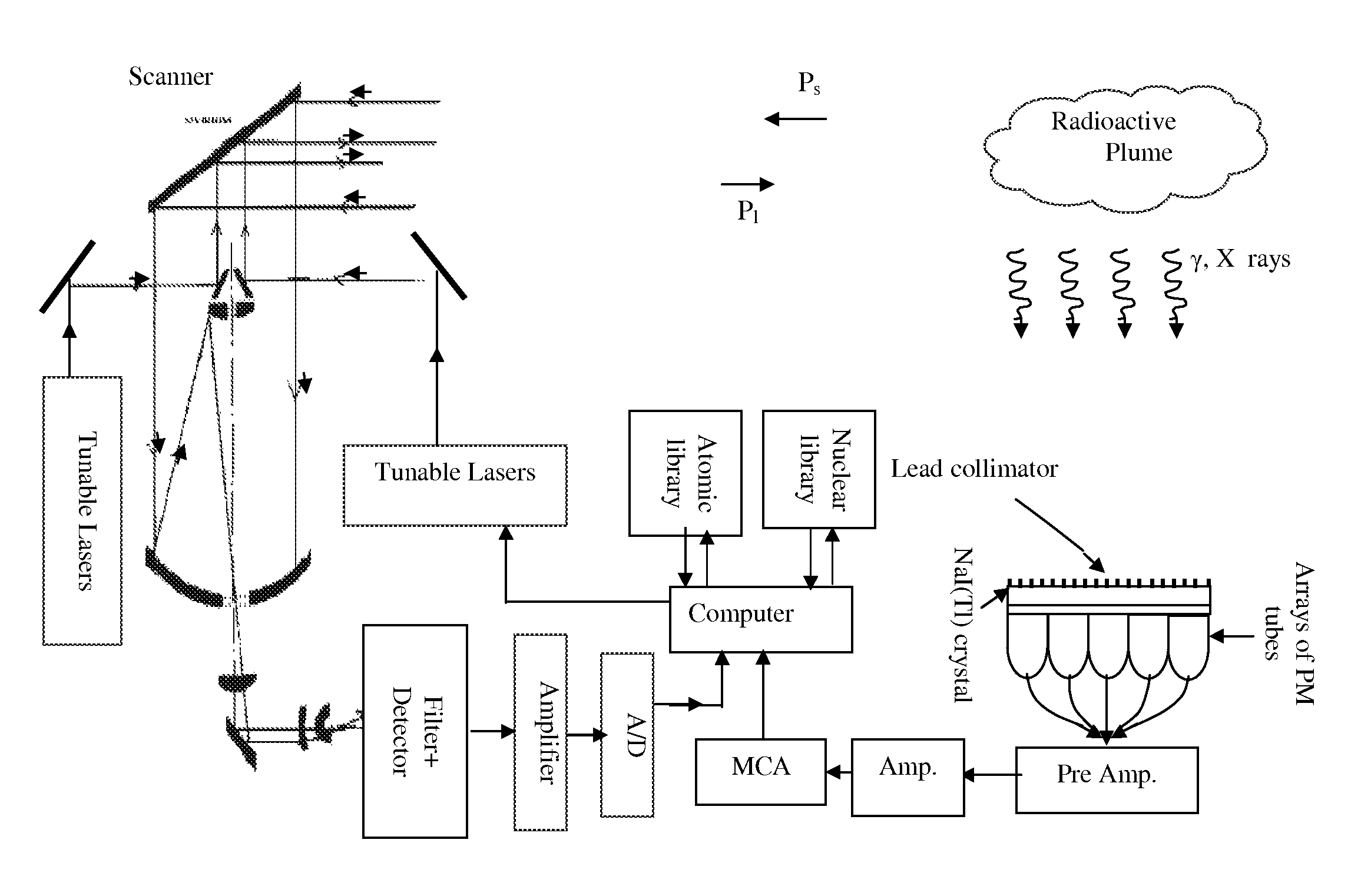

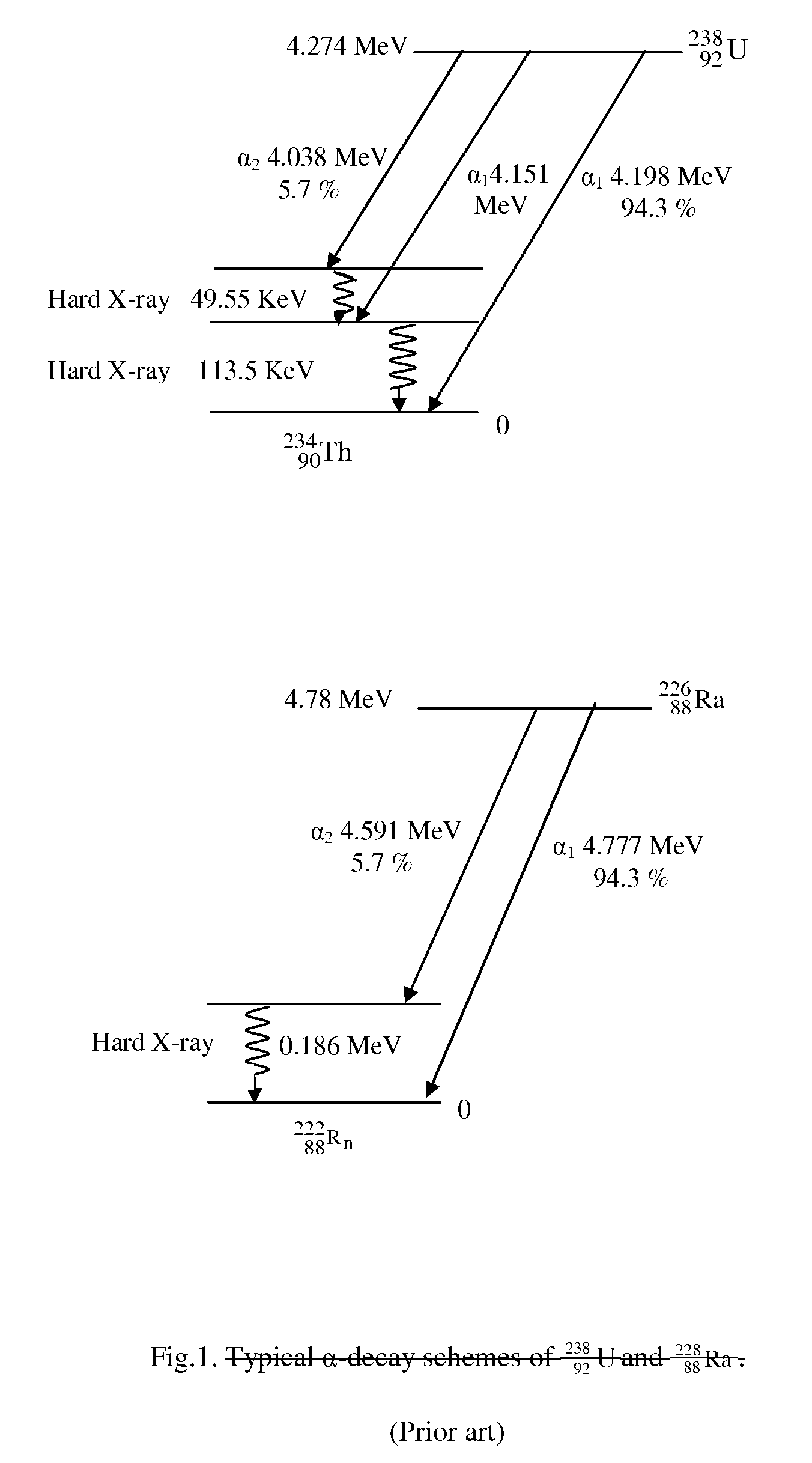

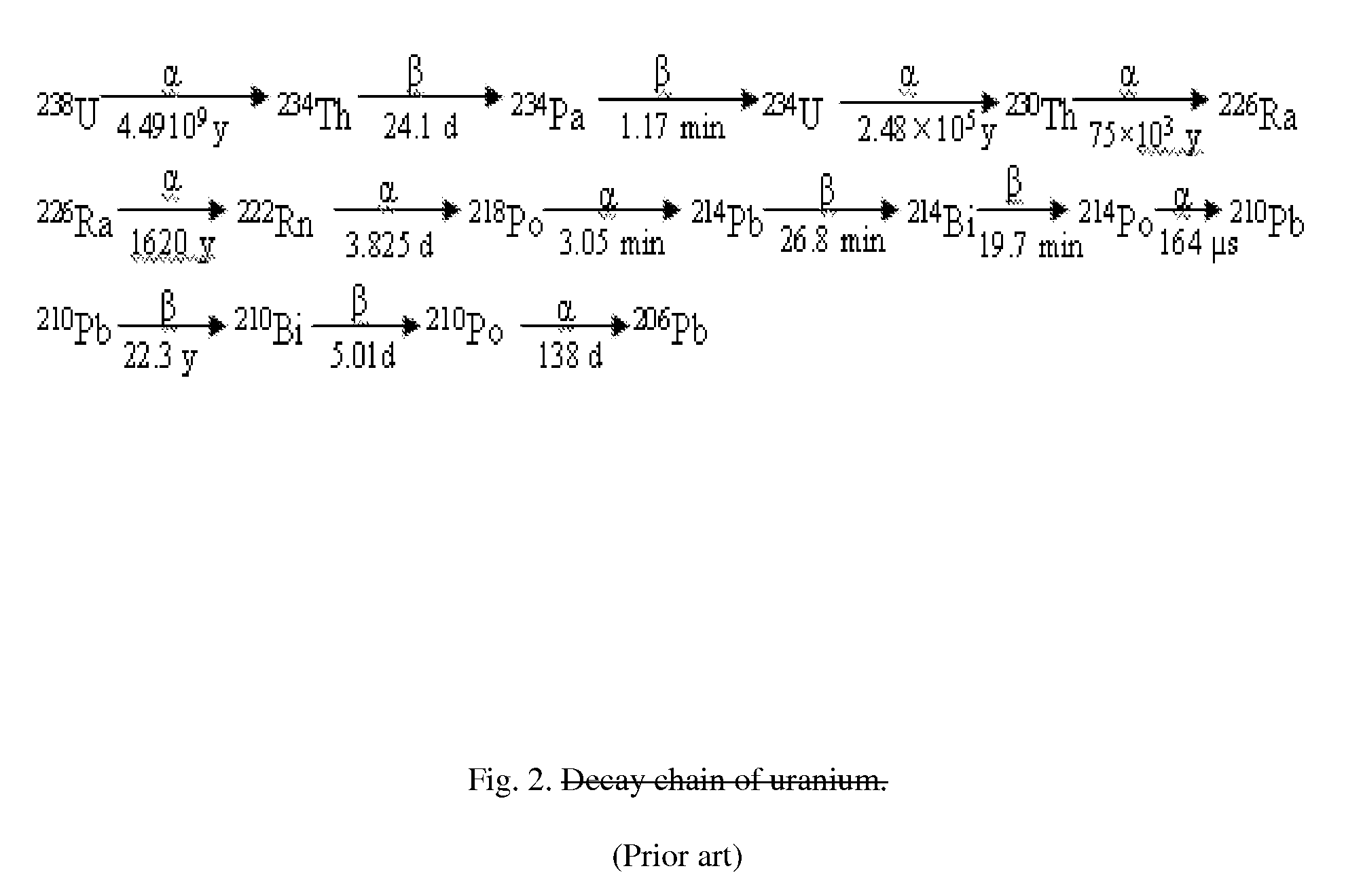

DIAL-Phoswich hybrid system for remote sensing of radioactive plumes in order to evaluate external dose rate

InactiveUS7566881B2Rapid responseHigh gainVolume/mass flow measurementColor/spectral properties measurementsDose rateNuclear power

An interactive combination of Phoswich detector array (PDA) and differential absorption lidar (DIAL) is proposed to trace the unknown radioactive plumes released into the atmosphere from a reactor stack, containment of the nuclear power plants, radioisotope separation laboratories, reprocessing plants or the uranium conversion facilities. The hybrid system represents a powerful technique for the prompt identification and quantification of the effluents with various radionuclide contents to determine the corresponding external dose rate accordingly.

Owner:SHAHI LAILA

Rotary sensor module with resynchronization feature

Drug delivery device comprising expelling means allowing a user to set a dose corresponding to a number of increments from an initial state, an indication member adapted to rotate in a first direction corresponding to the set dose, and rotate in an opposed second direction corresponding to an expelled dose, the indication member having an initial rotational position corresponding to both the initial state and the fully expelled dose state. Sensor means having an incremental counter synchronized with the rotational position of the indication member and having a reference point corresponding to the initial rotational position of the indication member. After detecting an error state the sensor means is adapted to re-synchronize by detecting the number of rotational increments for a set dose and for a subsequent expelled dose. If the numbers are identical the reference point is reset corresponding to the current rotational position of the indication member.

Owner:NOVO NORDISK AS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com