Patents

Literature

213 results about "Steam line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of steam line. : a graph showing the pressure at which a liquid and its vapor are in equilibrium at any temperature.

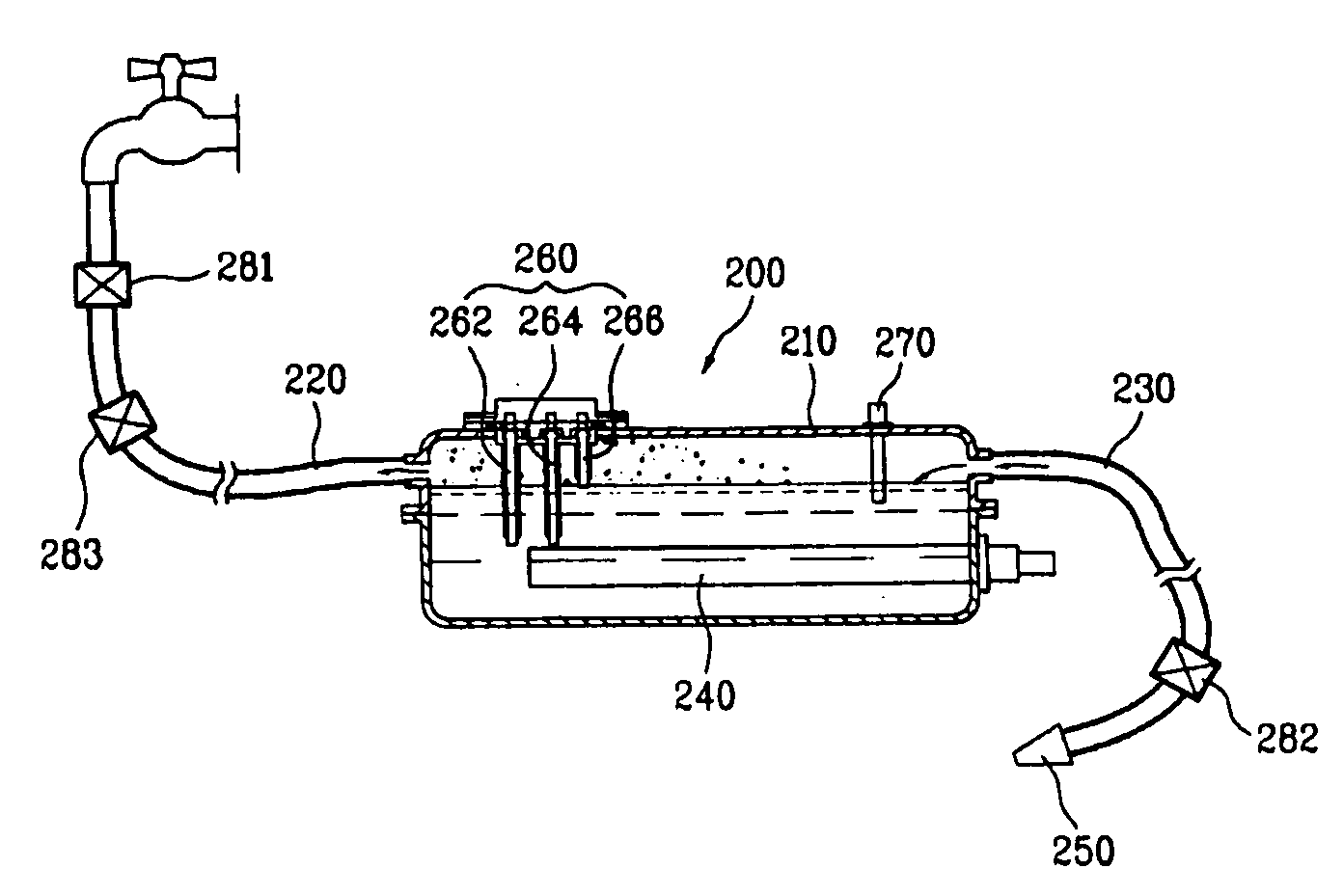

Use of disulfonated anthracenes as inert fluorescent tracers

InactiveUS20050025659A1Quantity minimizationDetection of fluid at leakage pointSamplingAnthraceneSteam line

The use of an isomer of anthracene disulfonic acid as an inert fluorescent tracer is described and claimed. The utility of this type of inert fluorescent tracer in boiler systems to trace unwanted carryover of boiler water into a steam line is also described and claimed.

Owner:ECOLAB USA INC

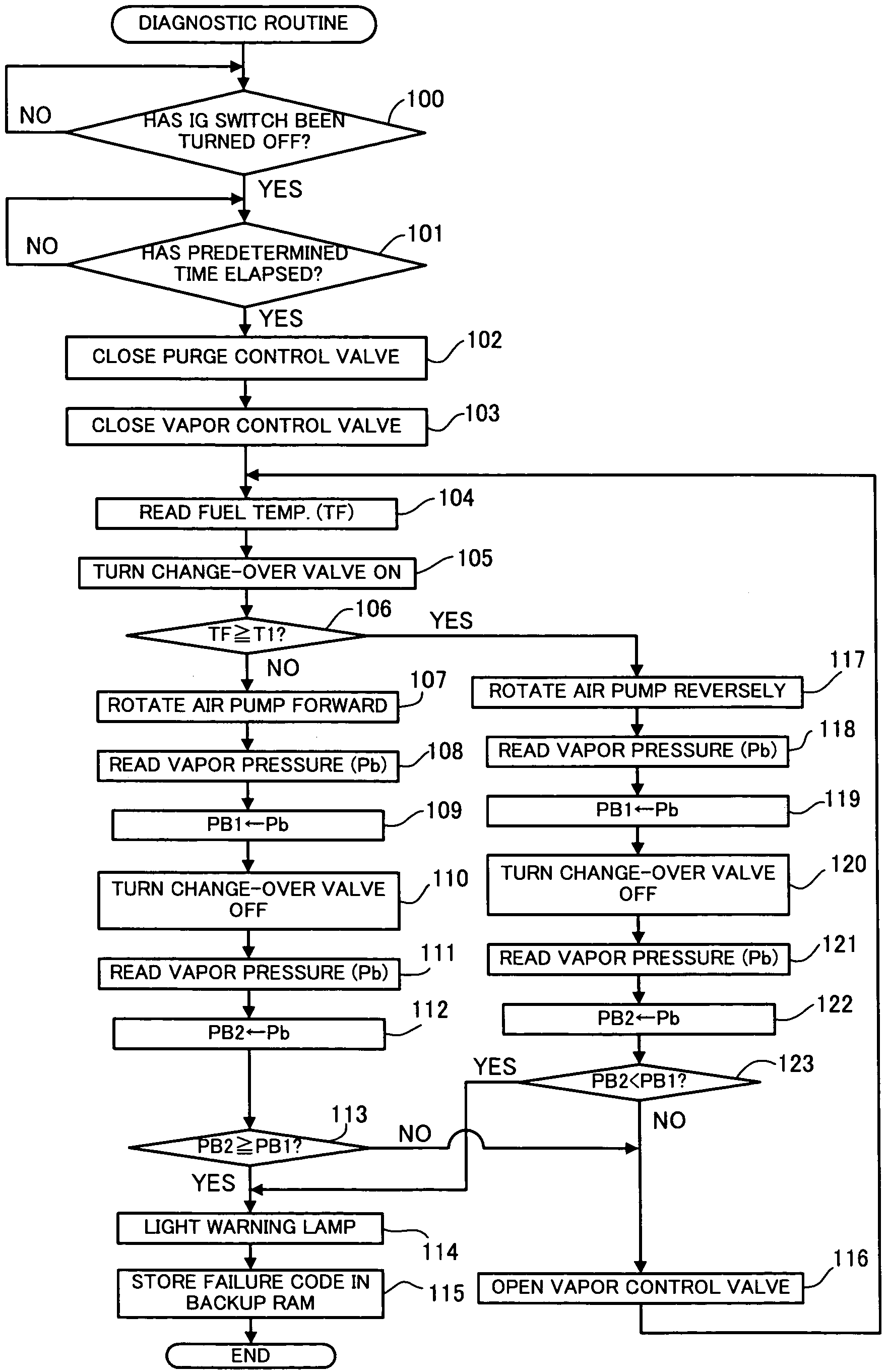

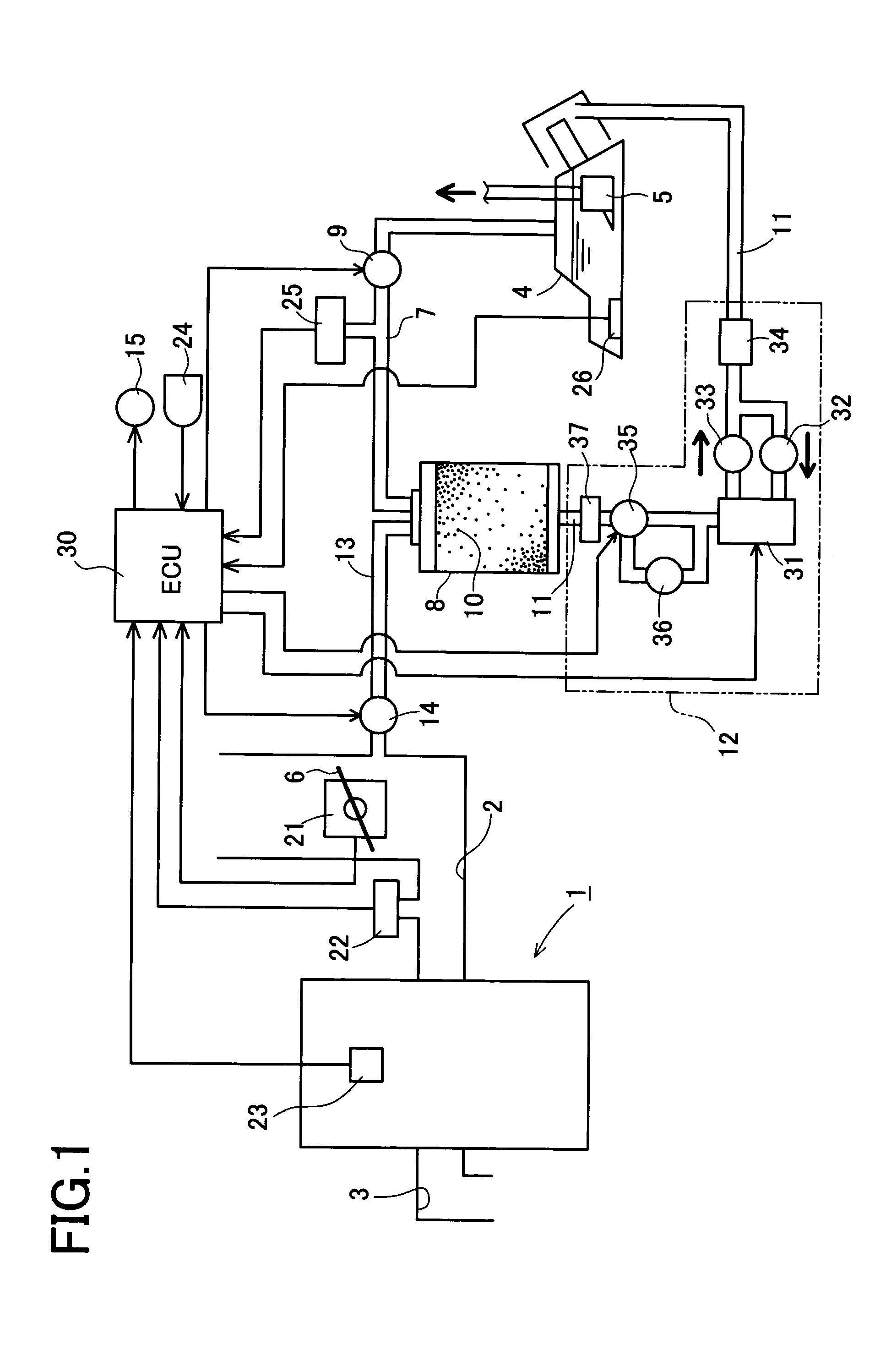

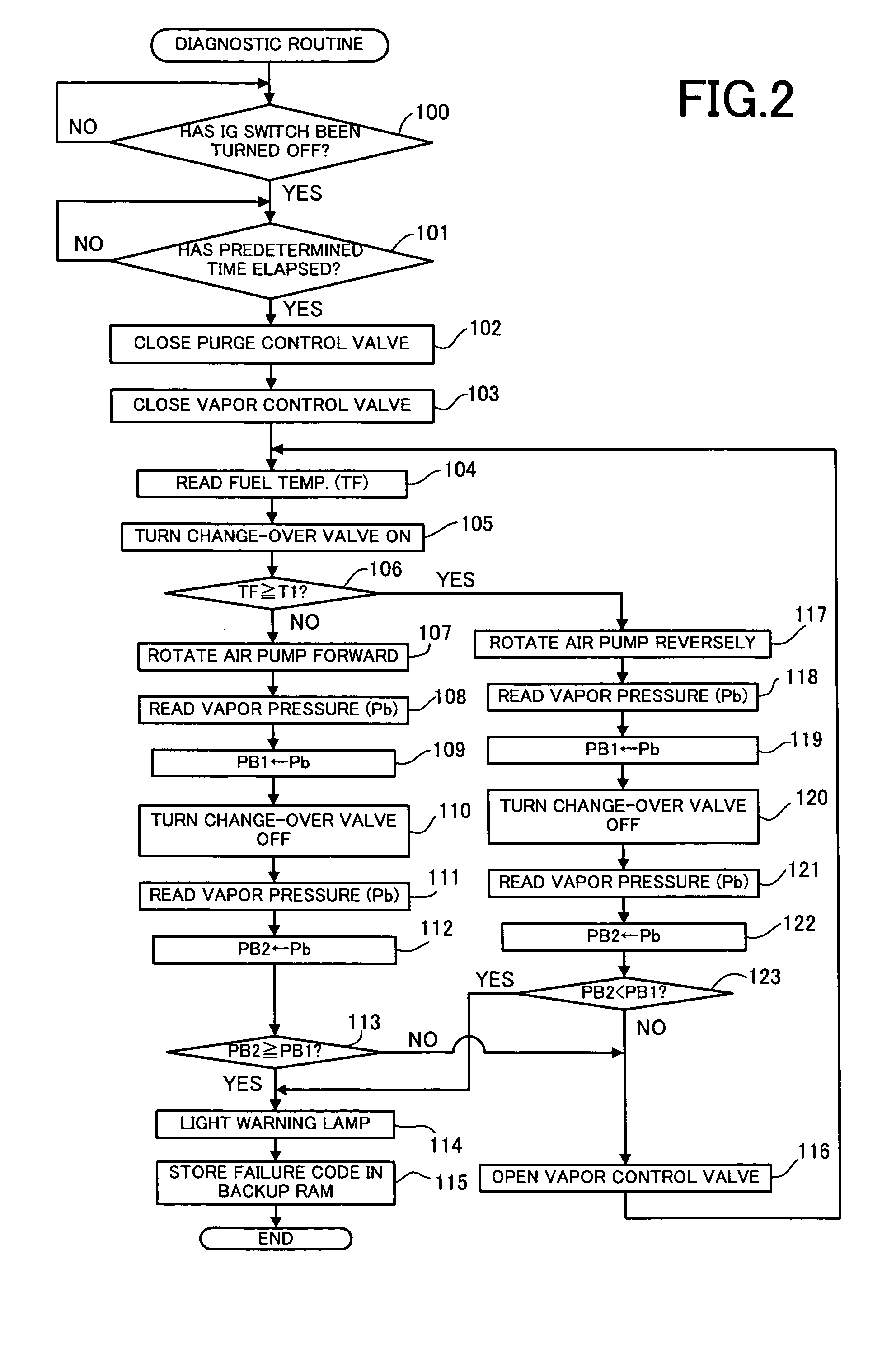

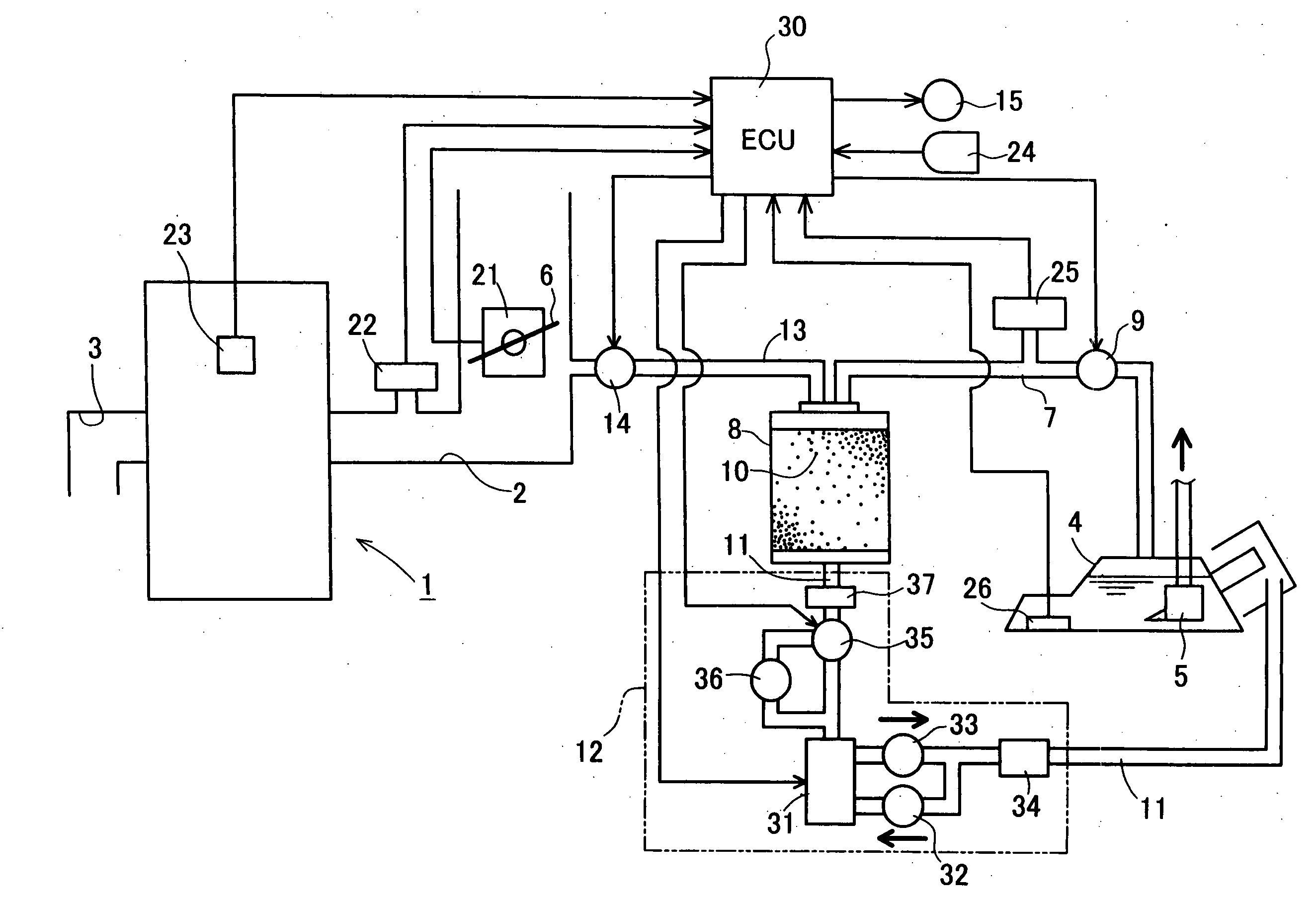

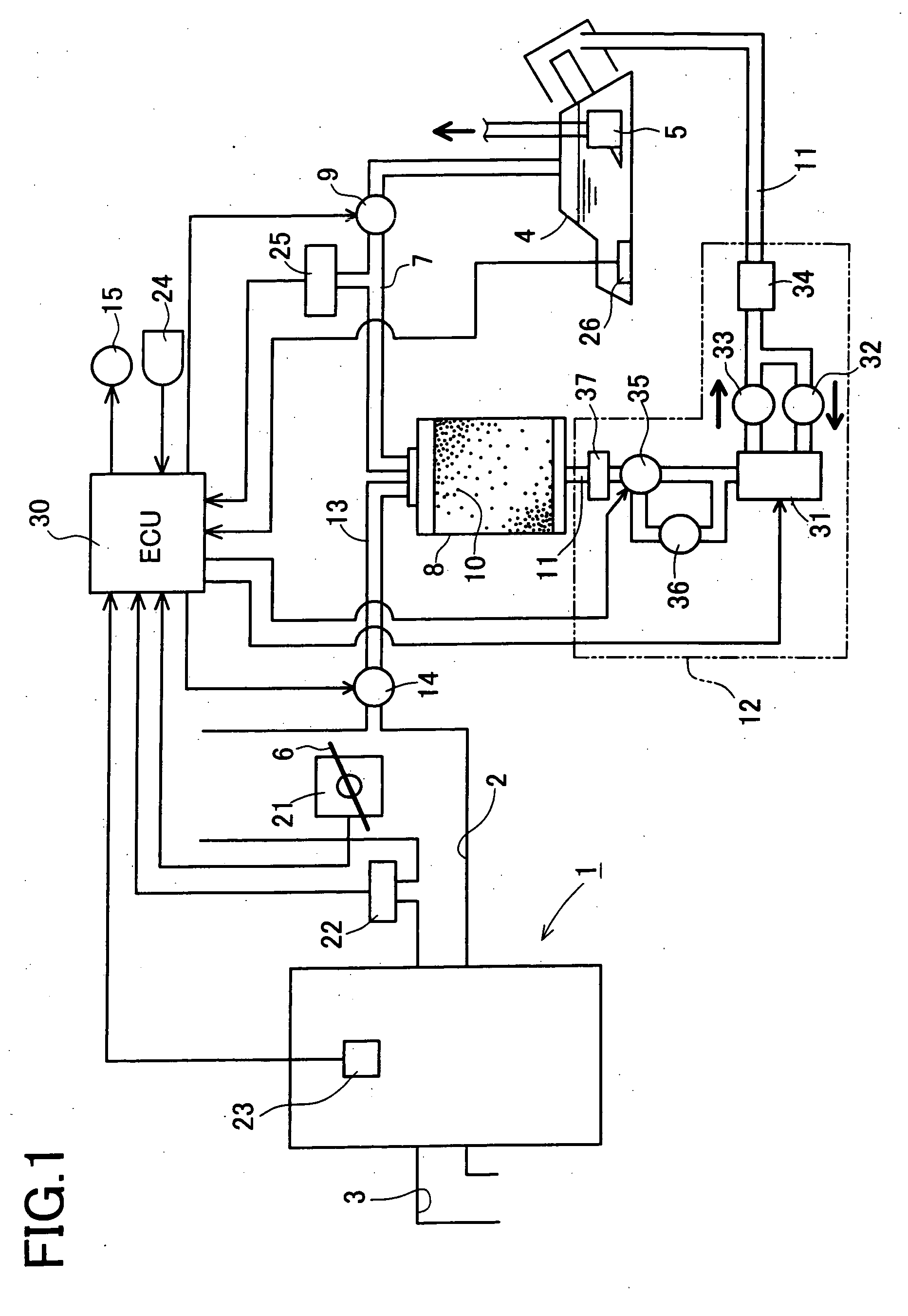

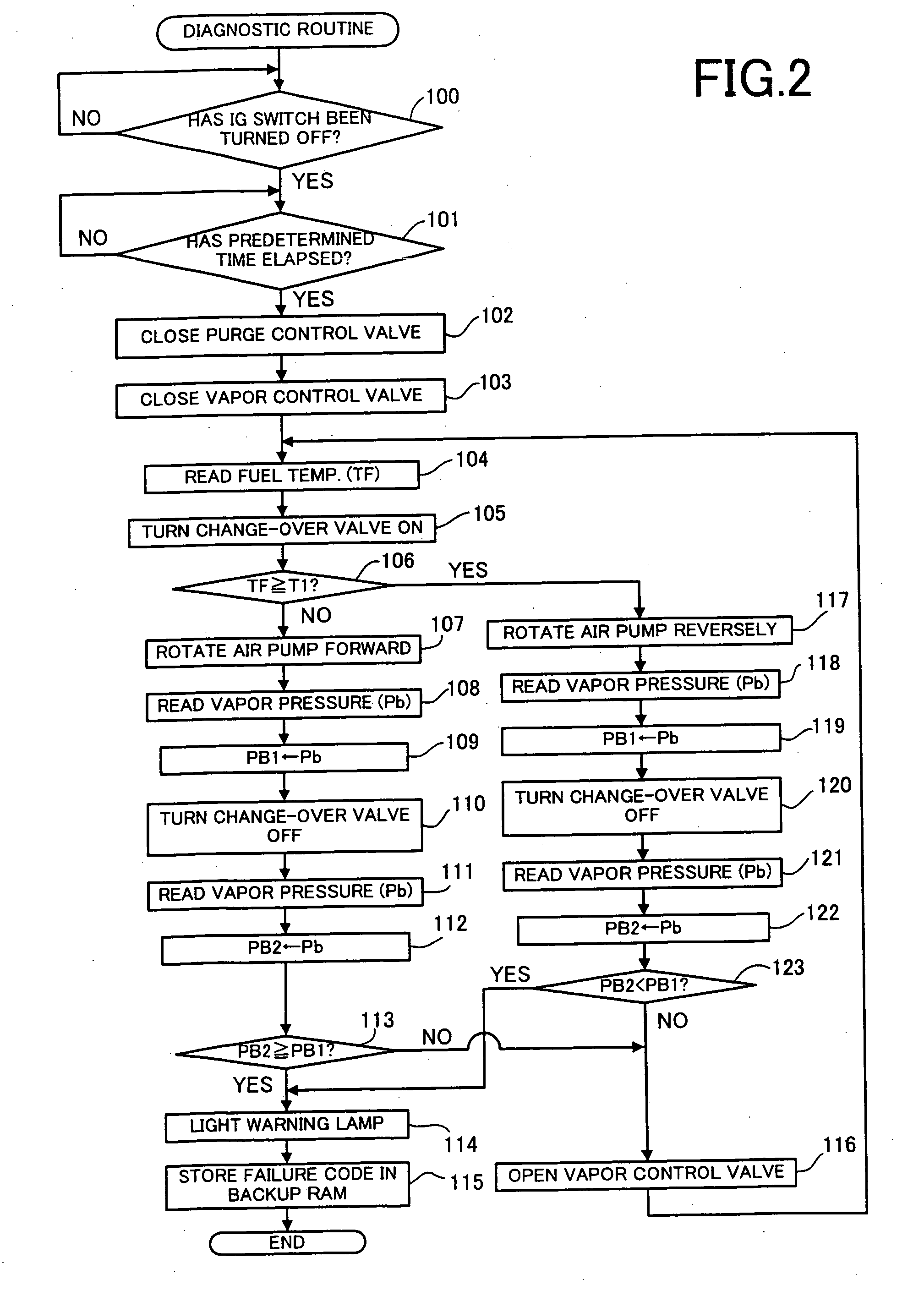

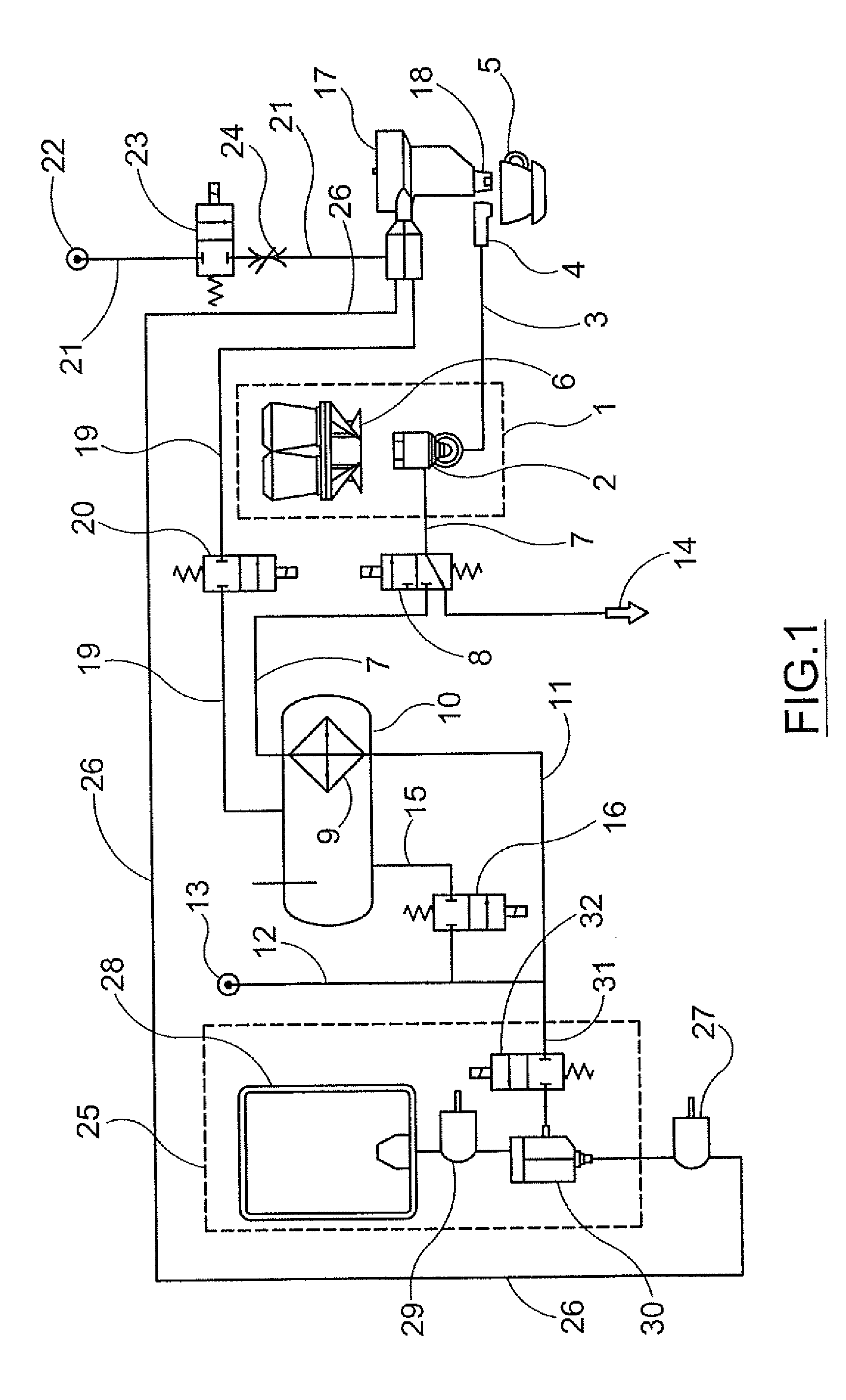

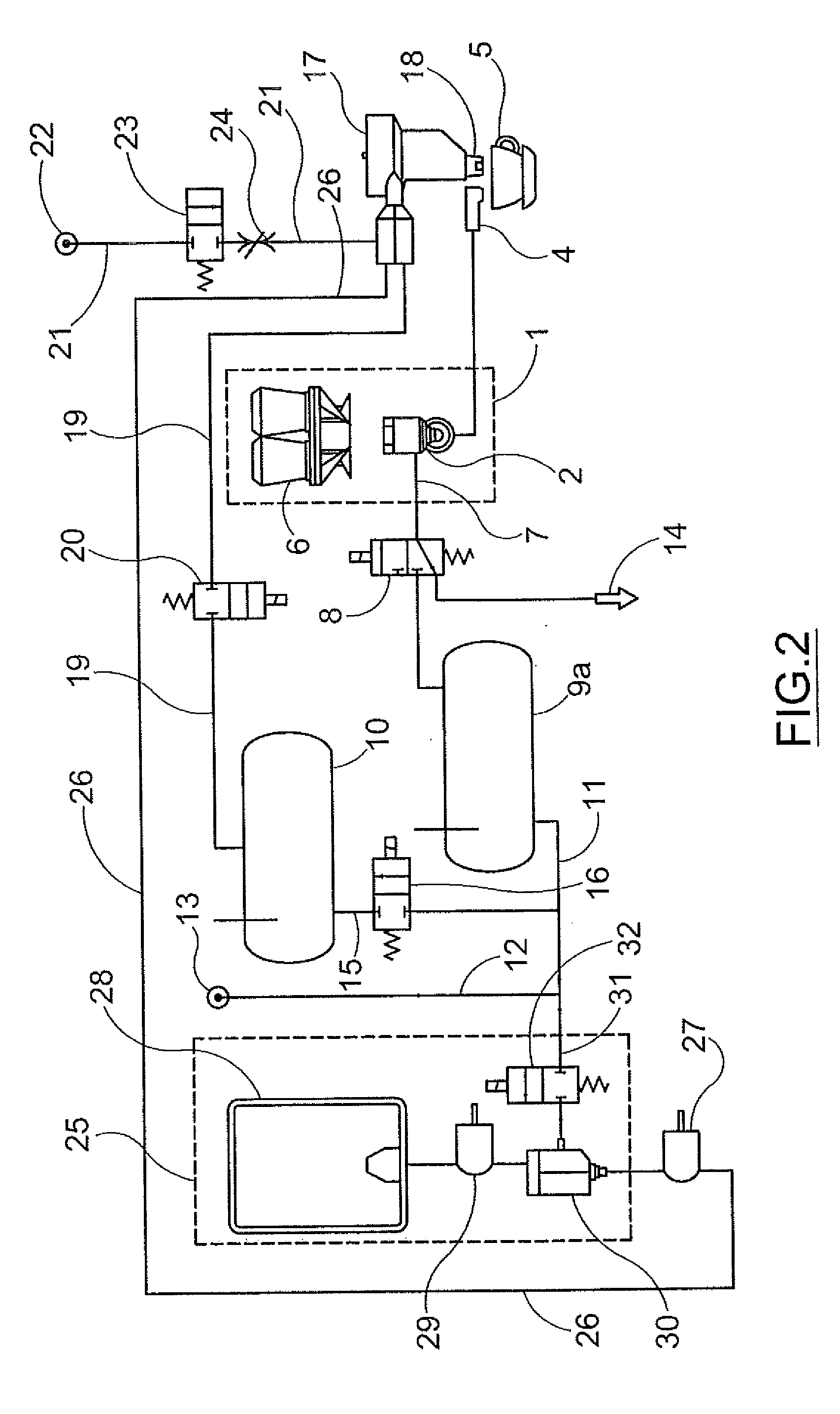

Failure diagnostic system for fuel vapor processing apparatus

InactiveUS7036359B2Short timeReduce leakageNon-fuel substance addition to fuelEngine testingInternal pressureSteam line

In a failure diagnostic system for a fuel vapor processing apparatus, a processing flow path comprising a vapor line, a canister and a purge line is closed with a vapor control valve and a purge control valve. The interior of the processing flow path is reduced in pressure or pressurized by rotating an air pump of a pump module in a forward or reverse direction. An electronic control unit (ECU) closes the vapor control valve and the purge control valve to close the processing flow path after stop of the engine and, when the fuel temperature detected by a temperature sensor is lower than a predetermined value, reduces the internal pressure of the processing flow path through an air pump, then checks air-tightness of the interior of the processing flow path based on behavior of a vapor pressure detected by a pressure sensor. The ECU closes the processing flow path and, when the fuel temperature detected is not lower than the predetermined value, pressurizes the interior of the processing flow path through the air pump, then checks air-tightness of the processing flow path based on behavior of a vapor pressure subsequently detected.

Owner:AISAN IND CO LTD

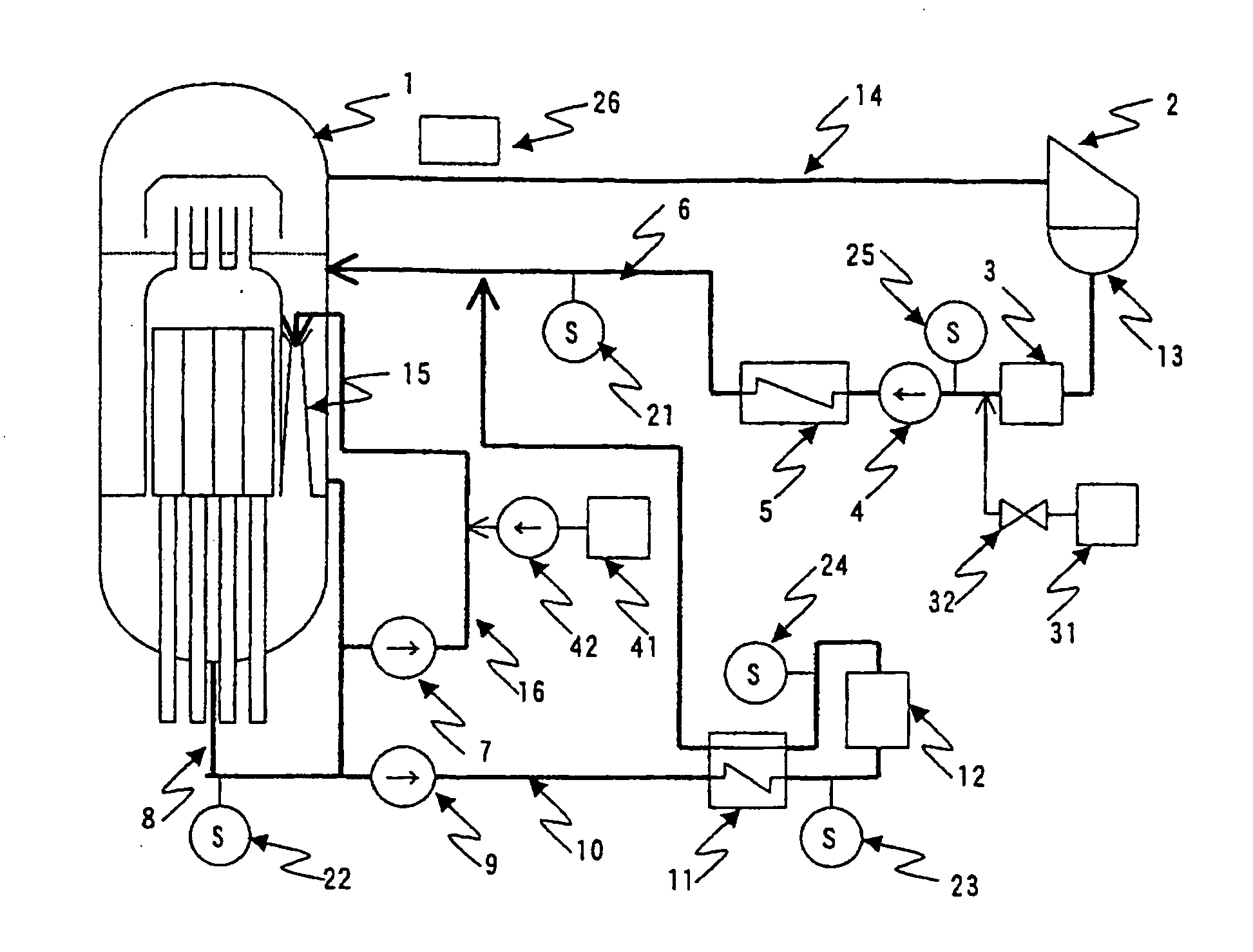

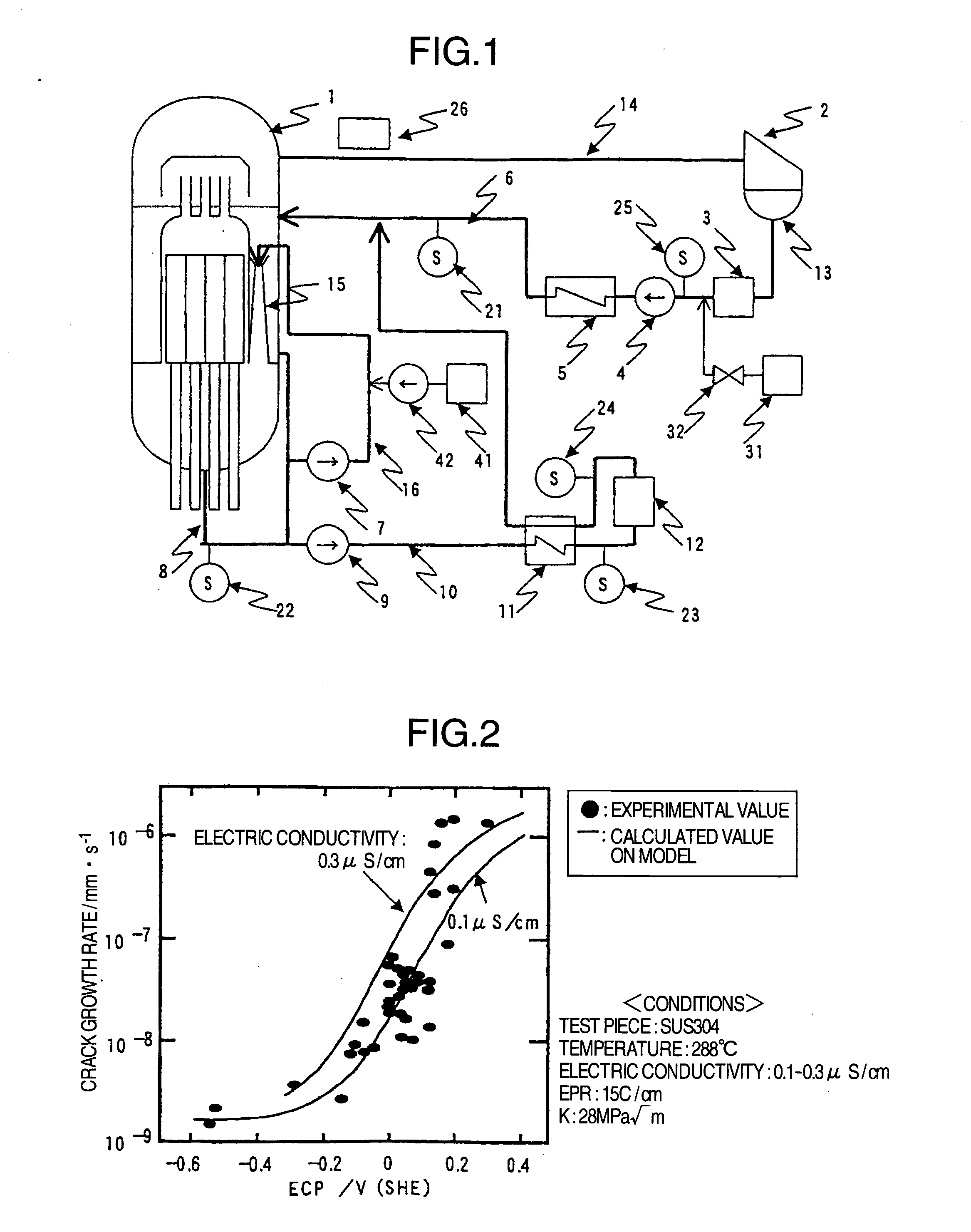

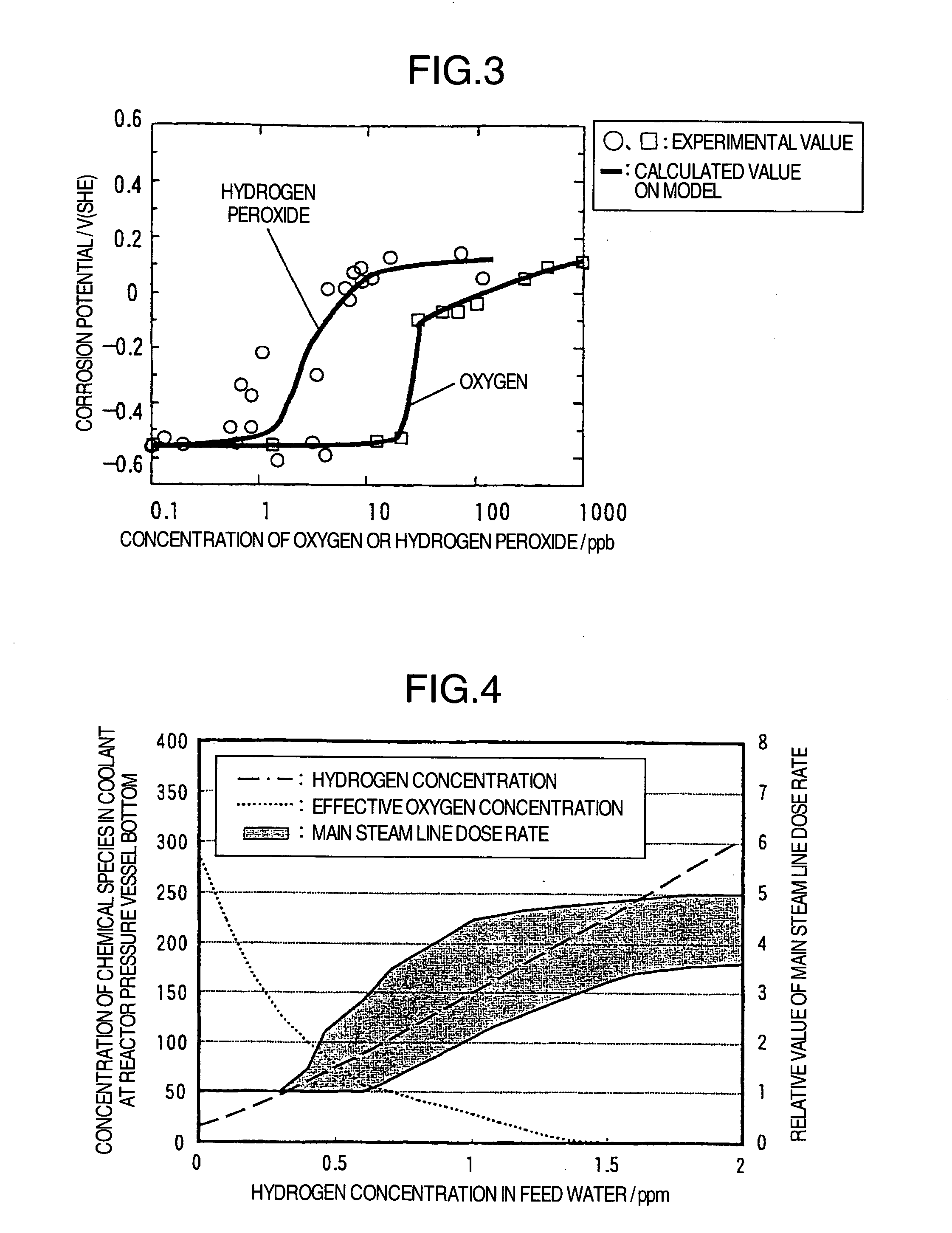

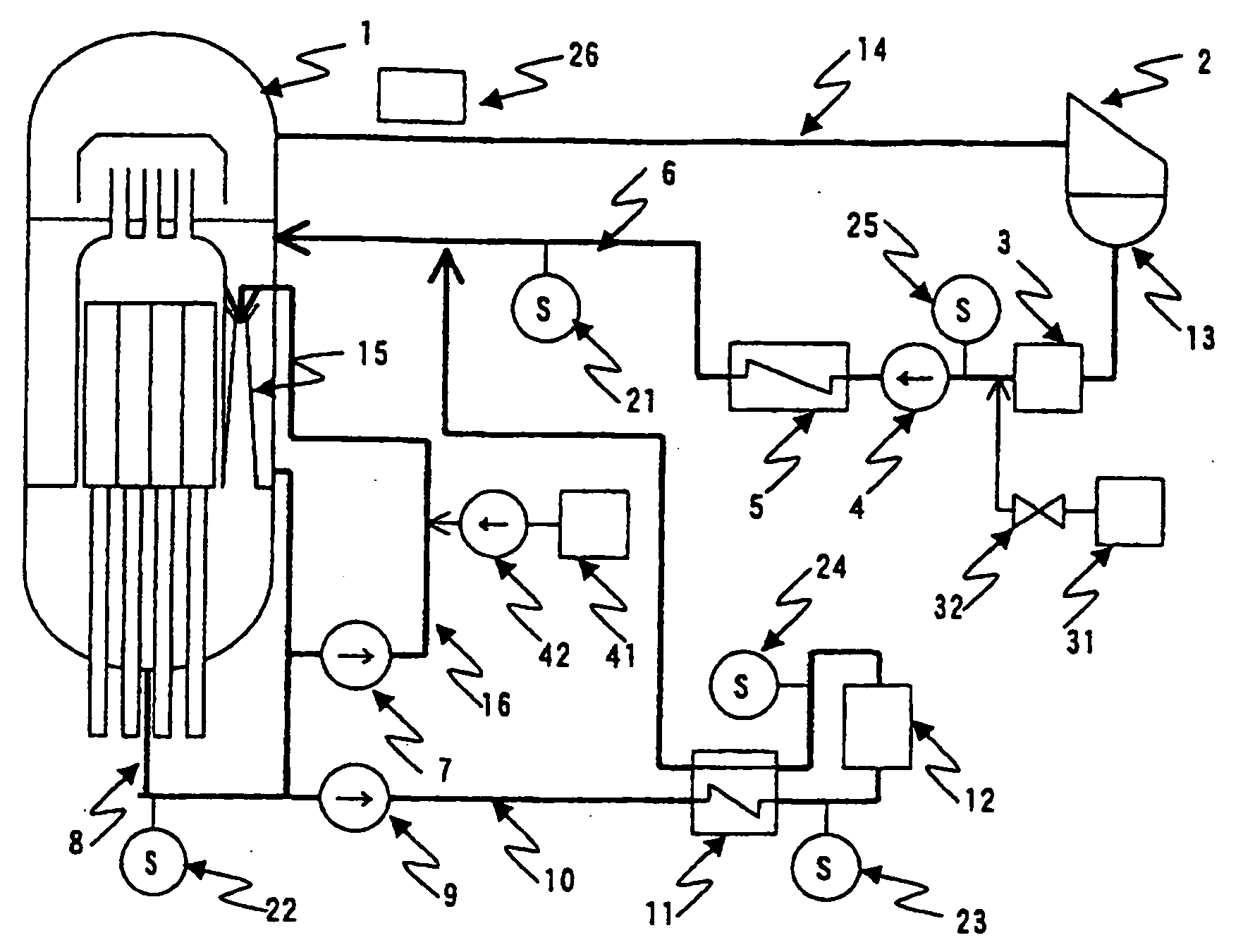

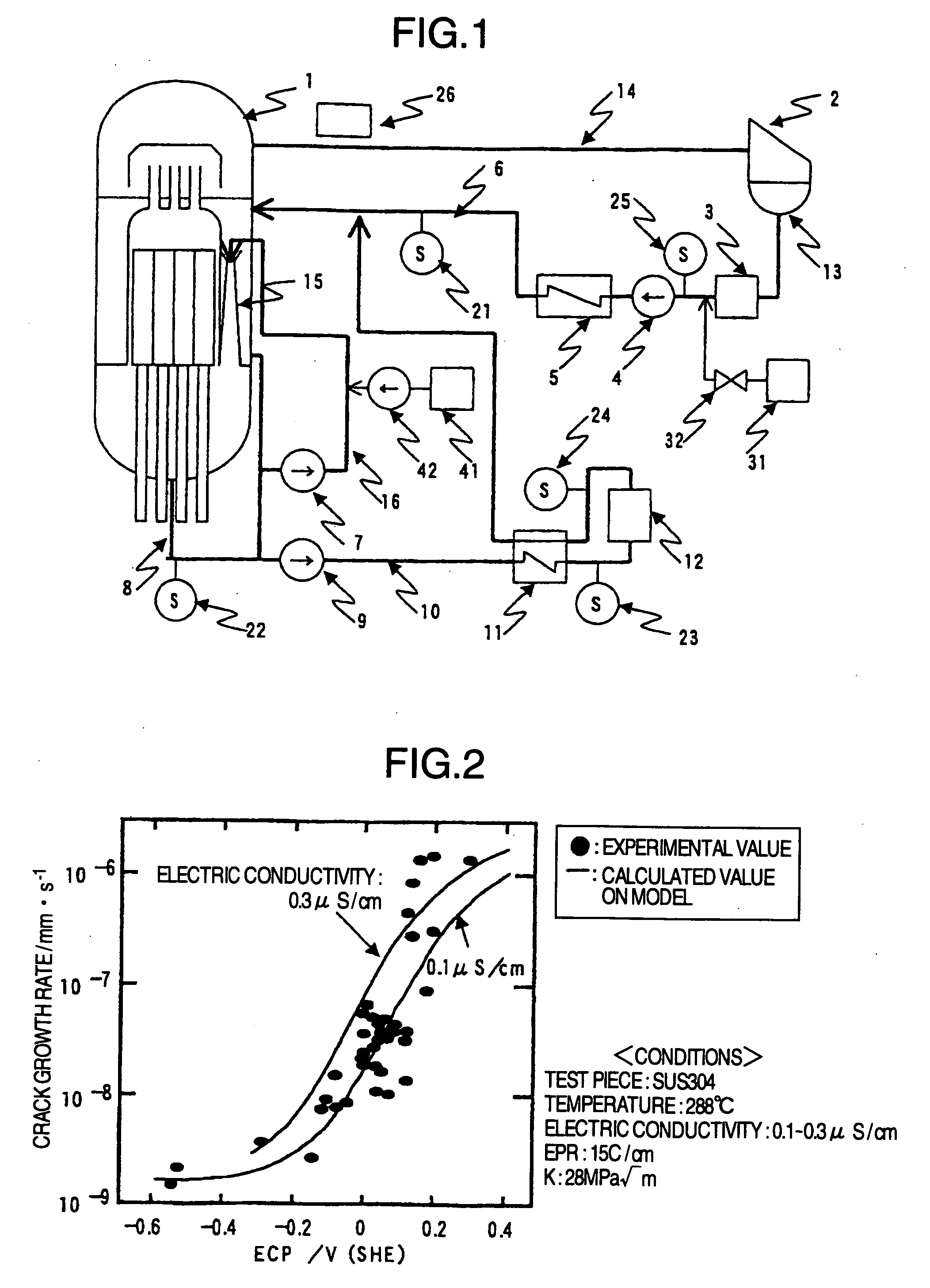

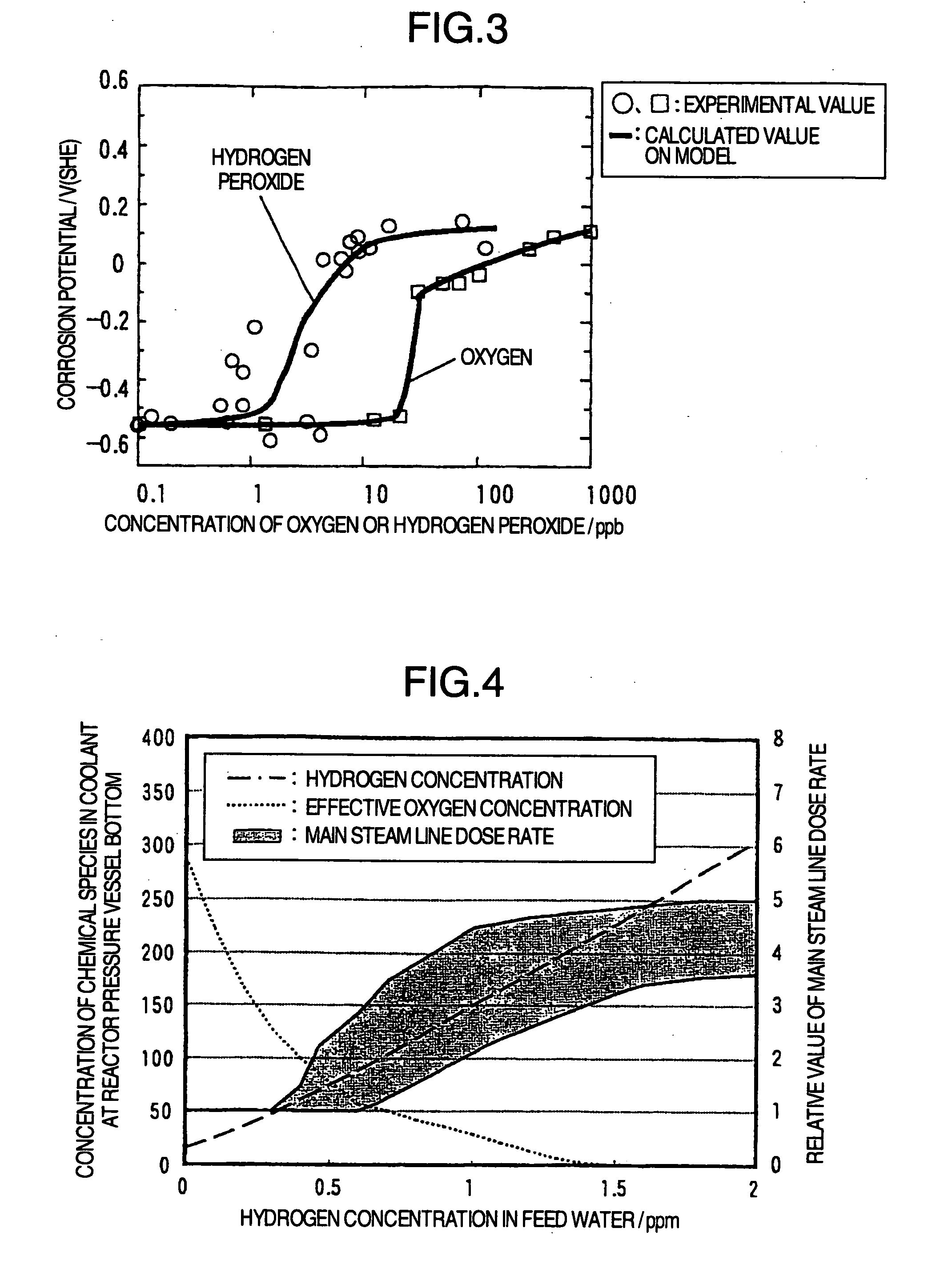

Method of stress corrosion cracking mitigation for nuclear power plant structural materials

InactiveUS20050018805A1Reduce stress corrosion crackingReduce stressPlant parameters regulationNuclear energy generationDose rateHydrazine compound

The object of this invention is to provide a method for mitigating a stress corrosion cracking of reactor structural material which makes it possible to suppress the rise in the main steam line dose rate without secondary effects such as a rise in the concentration of radioactive cobalt-60, etc. in the reactor water. Hydrogen and a reductive nitrogen compound containing nitrogen having a negative oxidation number (for example, hydrazine) are injected into the core water of boiling water nuclear power plant. By injecting the reductive nitrogen compound containing nitrogen having a negative oxidation number into the core water, the stress corrosion cracking of structural material of reactor can be mitigated without side reactions such as a rise in the concentration of cobalt-60, etc.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

Failure diagnostic system for fuel vapor processing apparatus

InactiveUS20060191330A1Short timeReduce leakageNon-fuel substance addition to fuelEngine testingInternal pressureSteam line

In a failure diagnostic system for a fuel vapor processing apparatus, a processing flow path comprising a vapor line, a canister and a purge line is closed with a vapor control valve and a purge control valve. The interior of the processing flow path is reduced in pressure or pressurized by rotating an air pump of a pump module in a forward or reverse direction. An electronic control unit (ECU) closes the vapor control valve and the purge control valve to close the processing flow path after stop of the engine and, when the fuel temperature detected by a temperature sensor is lower than a predetermined value, reduces the internal pressure of the processing flow path through an air pump, then checks air-tightness of the interior of the processing flow path based on behavior of a vapor pressure detected by a pressure sensor. The ECU closes the processing flow path and, when the fuel temperature detected is not lower than the predetermined value, pressurizes the interior of the processing flow path through the air pump, then checks air-tightness of the processing flow path based on behavior of a vapor pressure subsequently detected.

Owner:AISAN IND CO LTD

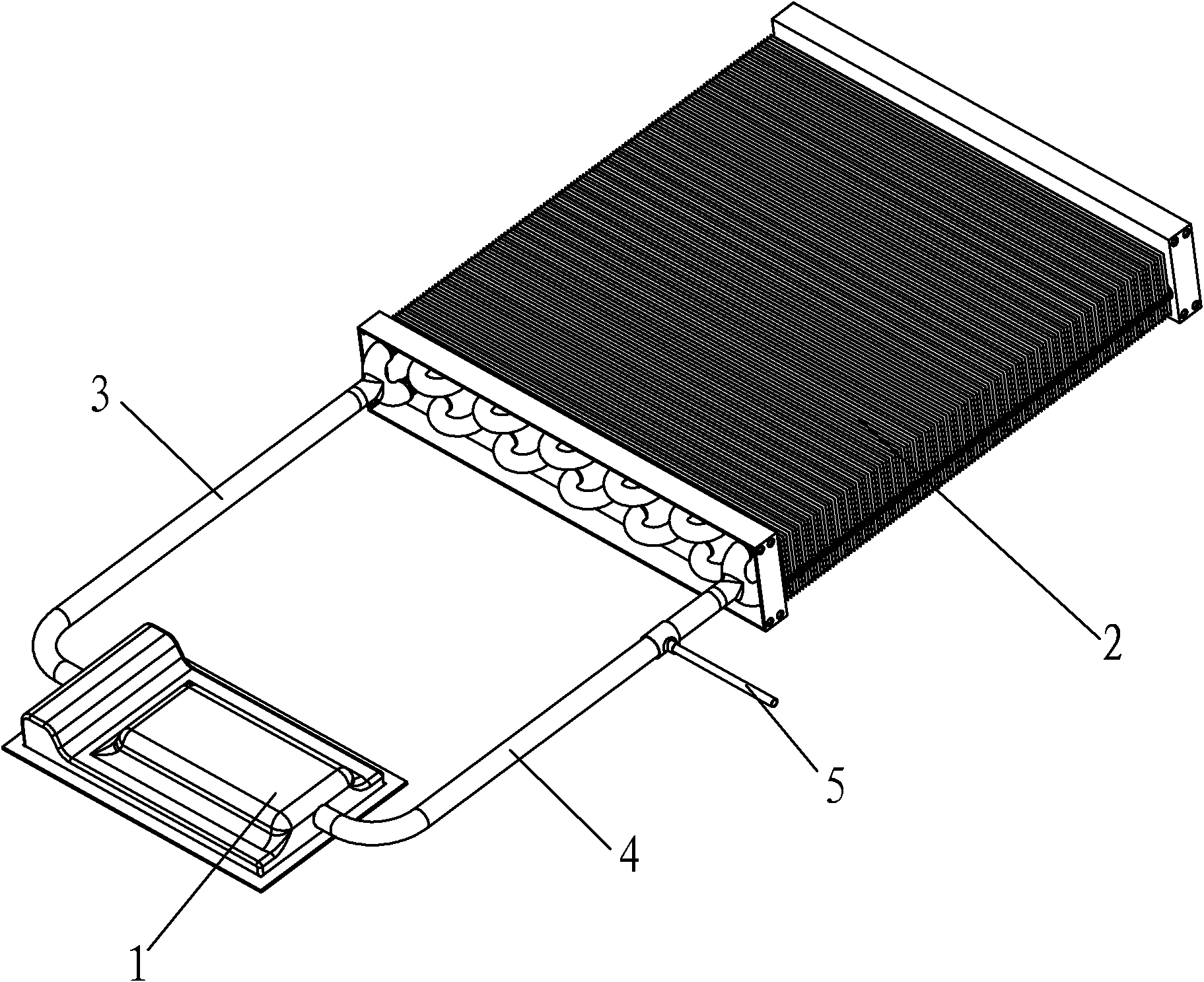

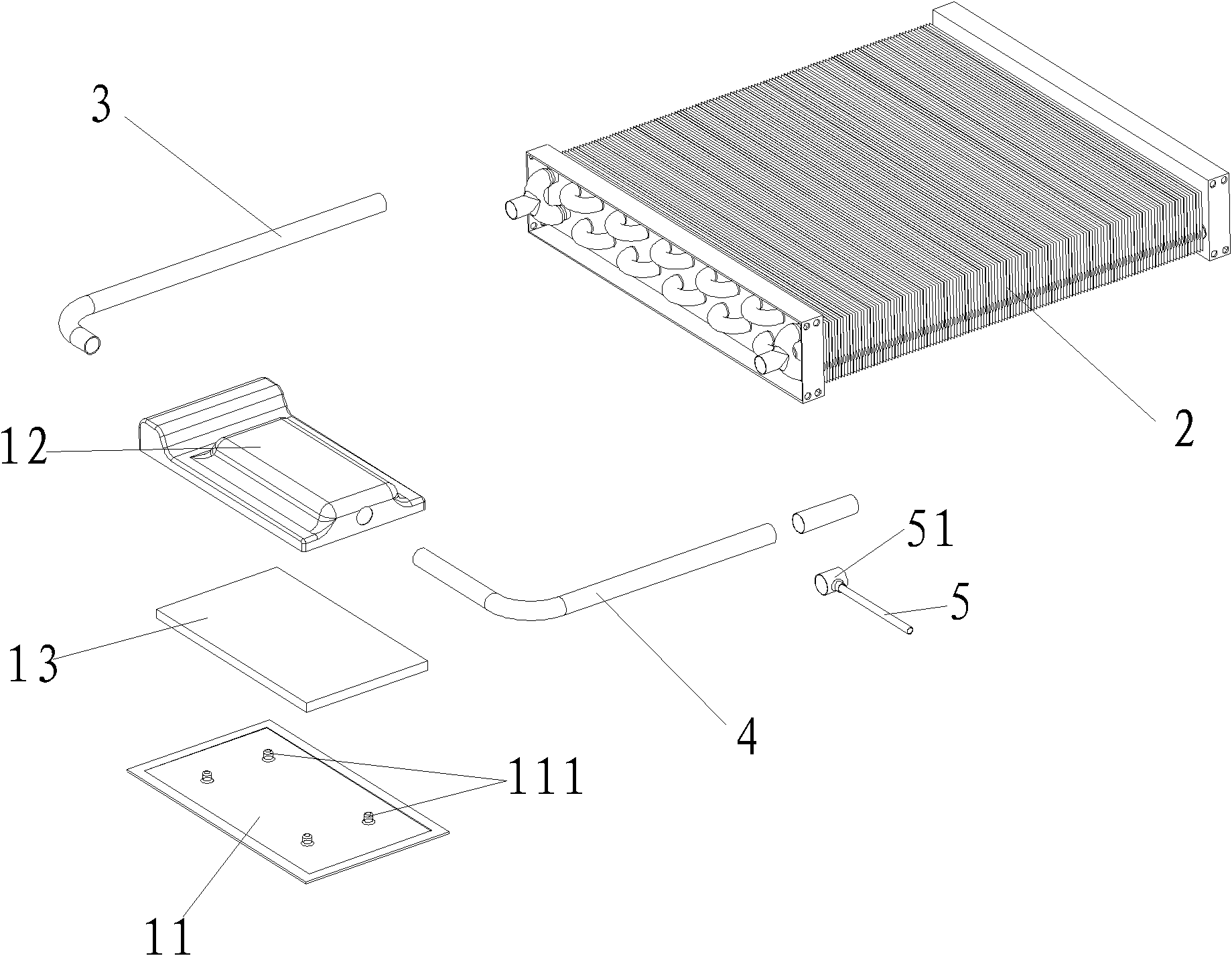

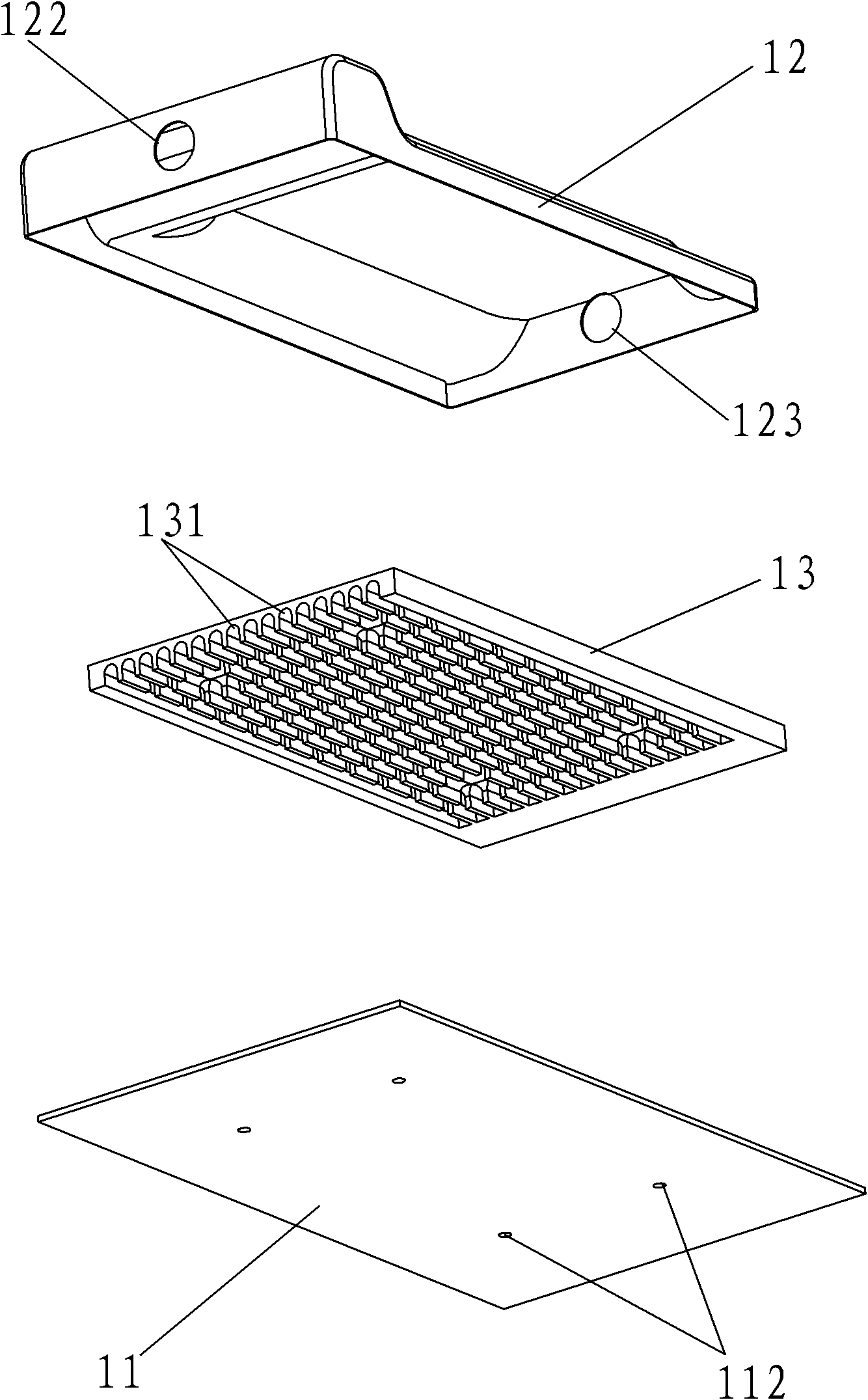

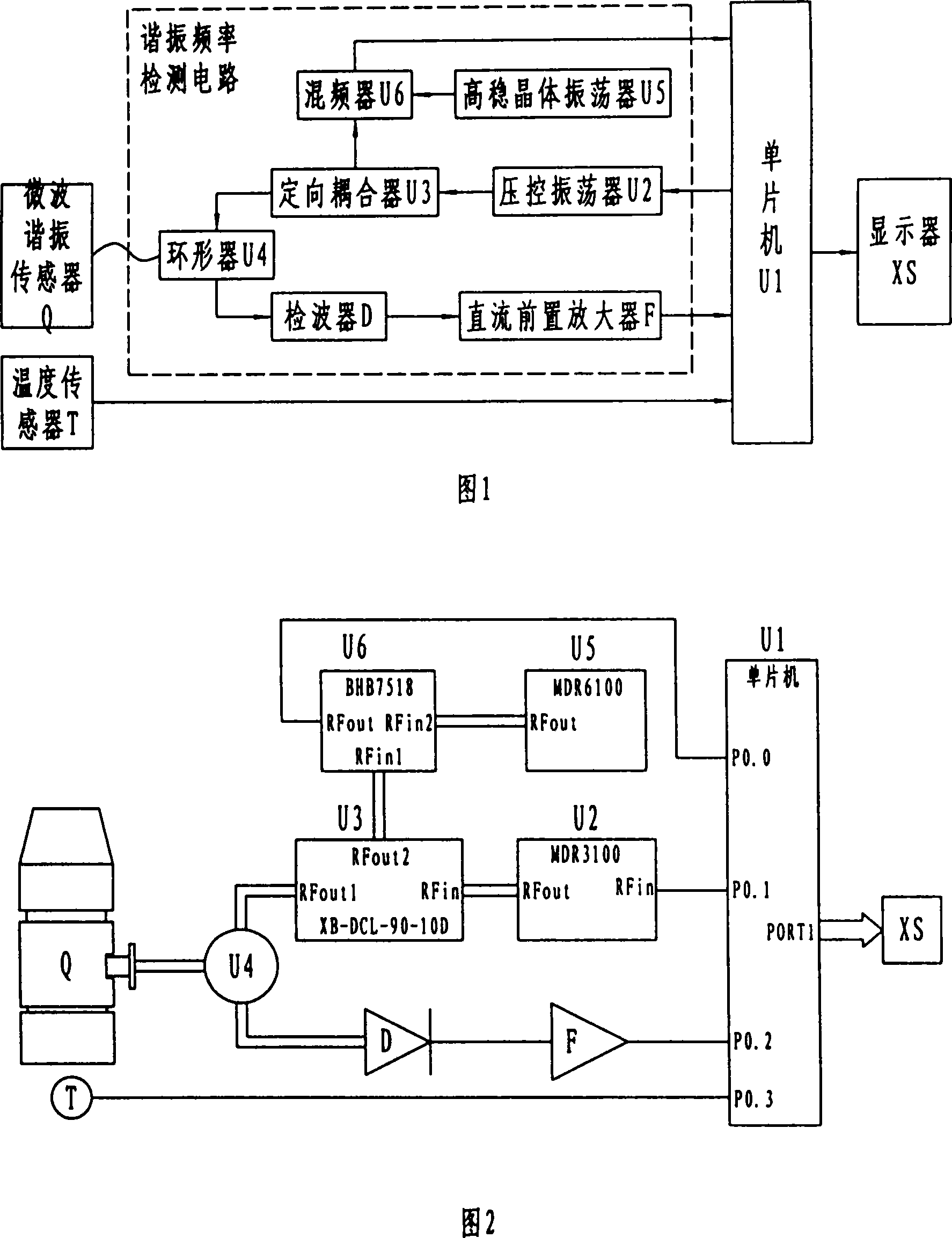

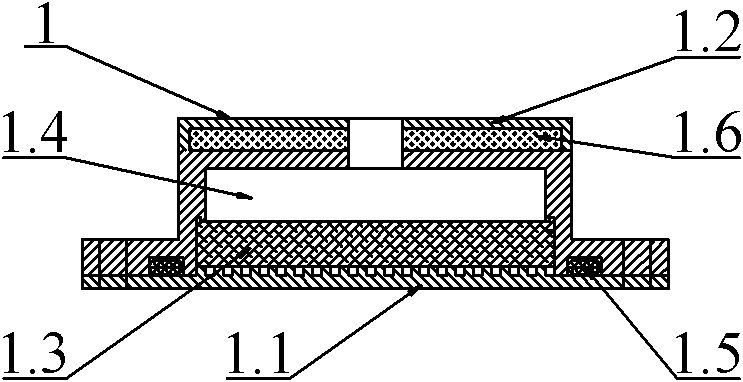

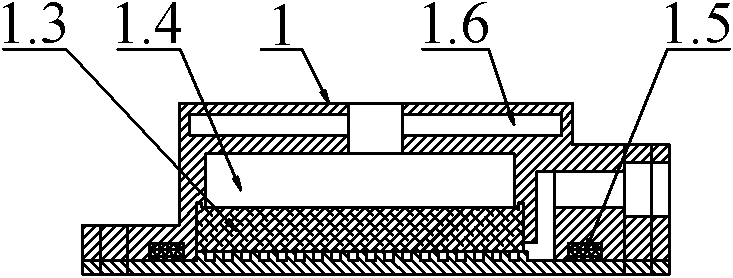

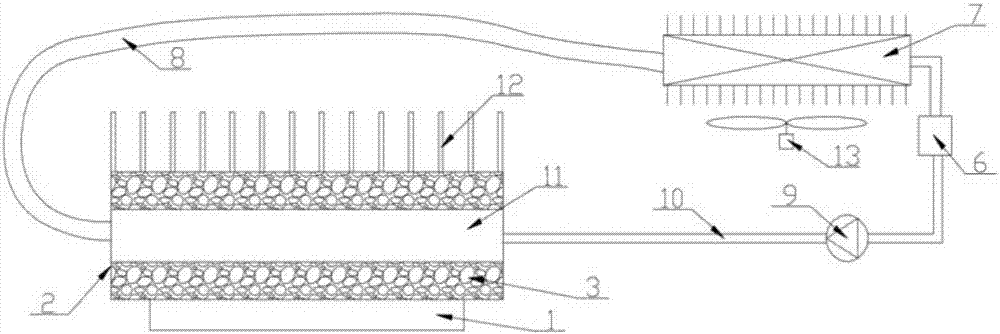

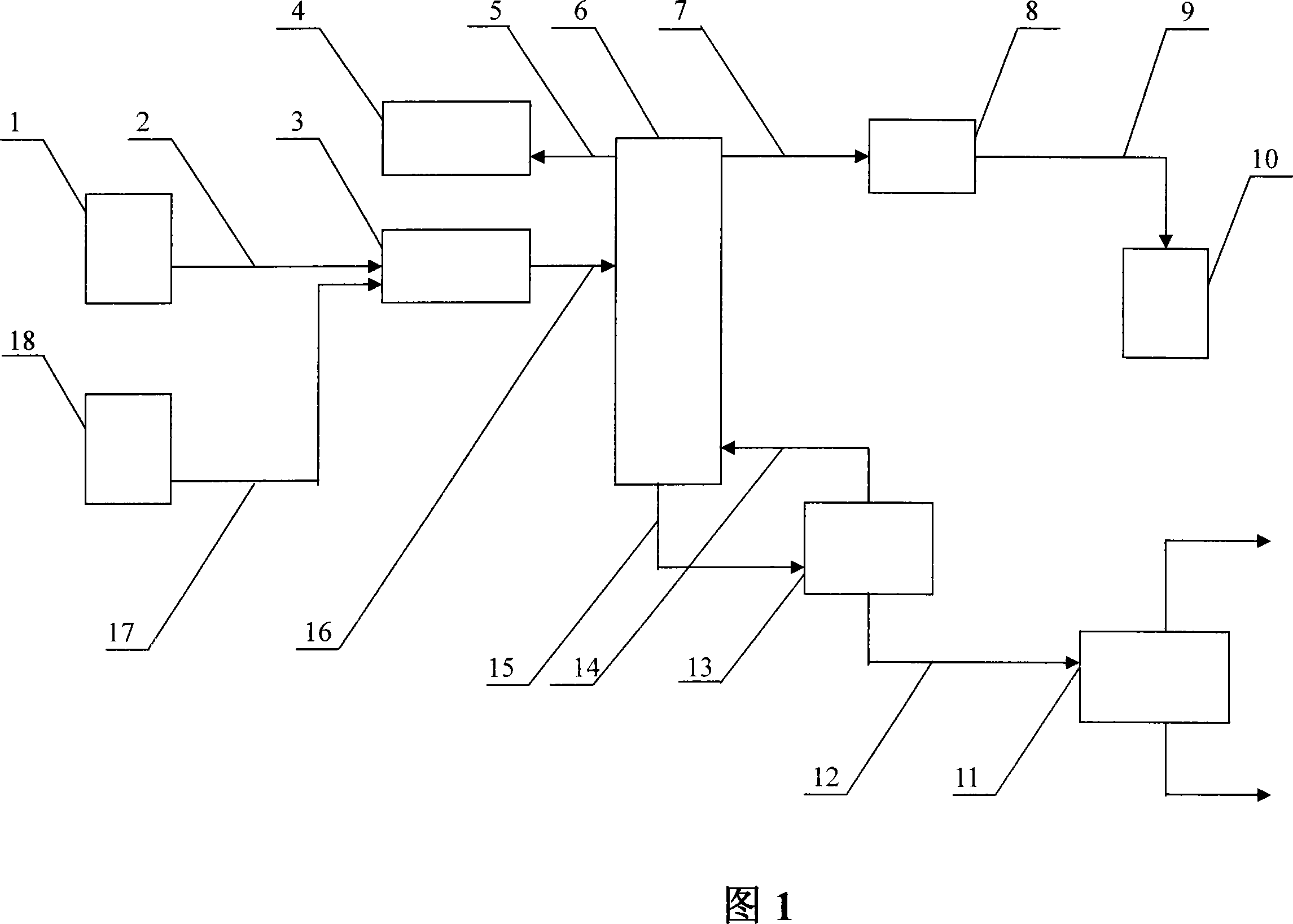

High-power loop heat pipe radiator and manufacturing method thereof

InactiveCN102157468AHigh cooling powerEnhanced evaporative heat transferSemiconductor/solid-state device detailsSolid-state devicesLiquid lineSteam line

The invention relates to a high-power loop heat pipe radiator and a manufacturing method thereof. The radiator comprises a plate evaporator, a condenser, at least a steam line and at least a liquid line, wherein the steam line and the liquid line are used for connecting the plate evaporator with the condenser; the liquid line is also communicated with a vacuumizing and working medium filling line; a porous material is fixed inside the plate evaporator; and a plurality of communicated steam discharge channels are formed in the porous material. The manufacturing method comprises the following steps: preparing the porous material; stamping a top cover and a bottom plate of the plate evaporator; putting the porous material between the top cover and the bottom plate and fixedly connecting the top cover with the bottom plate; carrying out welding and communicating; and carrying out cleaning, vacuumizing, working medium filling and sealing. The radiator and the manufacturing method have the following advantages that: the radiation and installation use requirements of the high-power power electronic devices can be well met, the aim of full and effective contact with the power electronic devices can be achieved and the special evaporator structure further saves the space and is further beneficial to reinforcement of heat exchange, thus farthest reducing the radiating heat resistance.

Owner:北京芯铠电子散热技术有限责任公司

Use of disulfonated anthracenes as inert fluorescent tracers

InactiveUS7220382B2Quantity minimizationDetection of fluid at leakage pointSamplingAnthraceneSteam line

The use of an isomer of anthracene disulfonic acid as an inert fluorescent tracer is described and claimed. The utility of this type of inert fluorescent tracer in boiler systems to trace unwanted carryover of boiler water into a steam line is also described and claimed.

Owner:ECOLAB USA INC

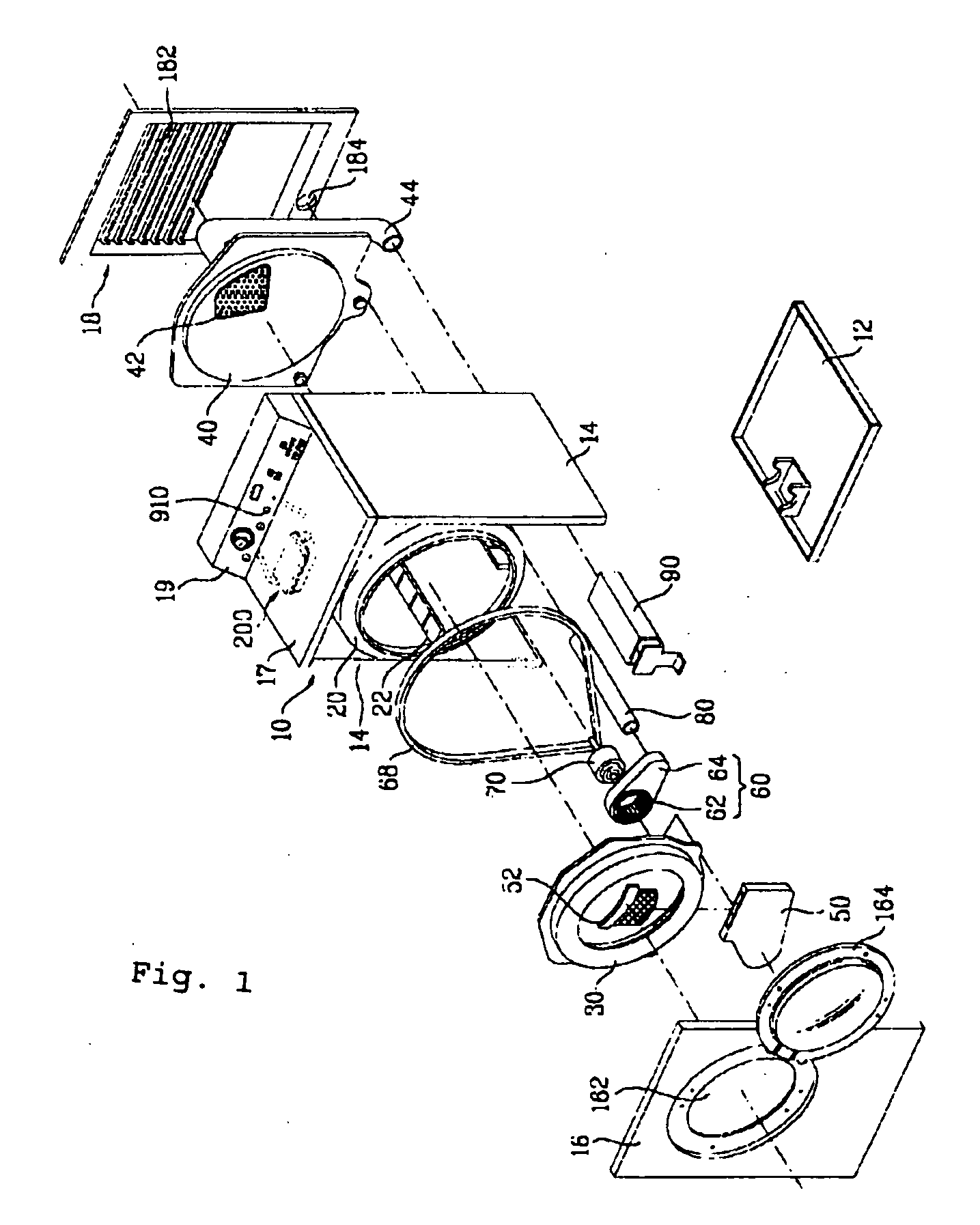

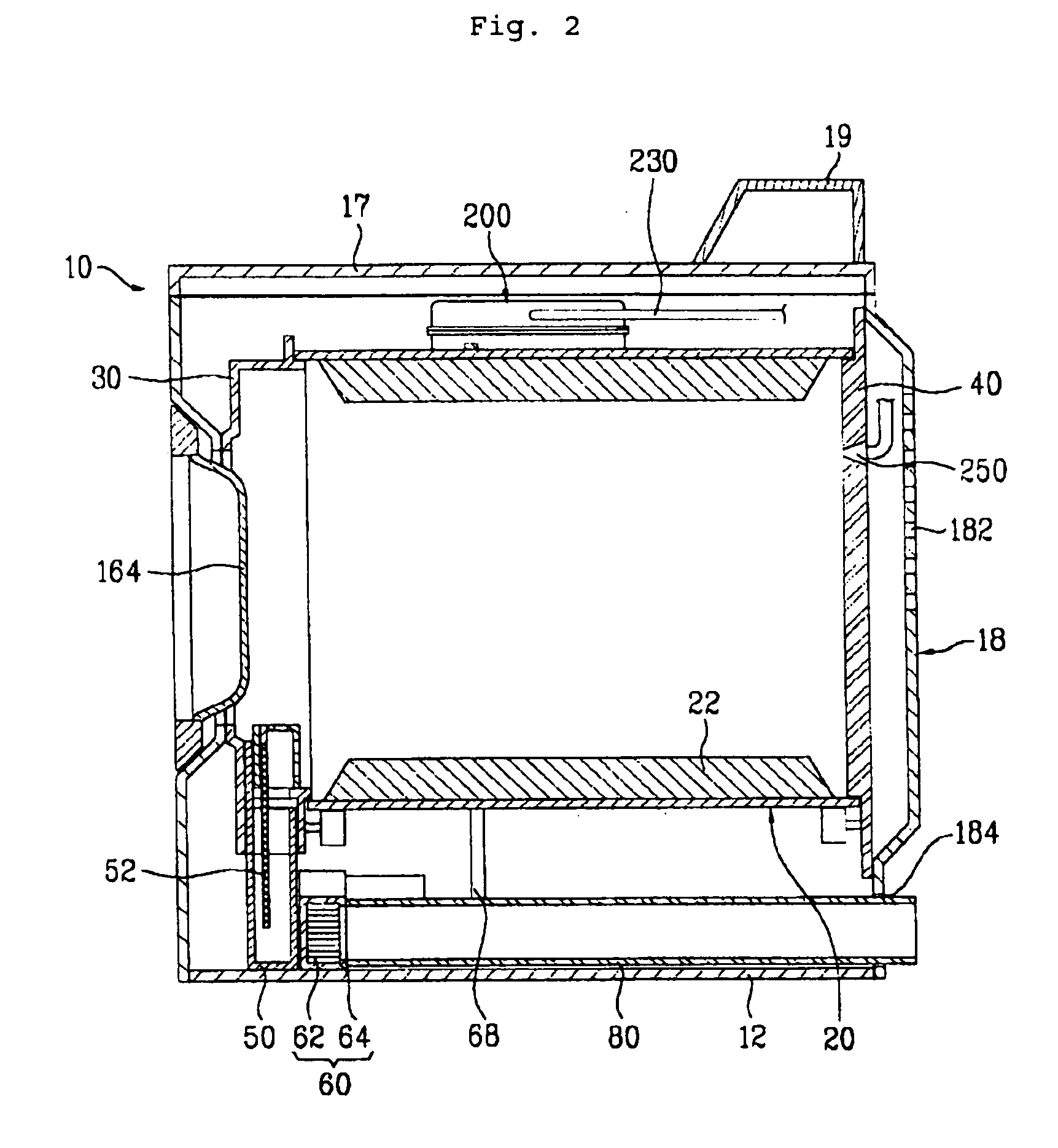

Laundry machine

InactiveUS20090078007A1Avoid flowTextile treatment machine partsOther washing machinesSteam lineLine tubing

A laundry machine is disclosed. The laundry machine includes a drum in which laundry is put, a steam generator to generate steam, a water supply line connected to the steam generator, a steam line connected to the steam generator, and a valve placed in the steam line, wherein the valve is controlled to block the steam line to prevent water from flowing from the steam generator to the drum.

Owner:LG ELECTRONICS INC

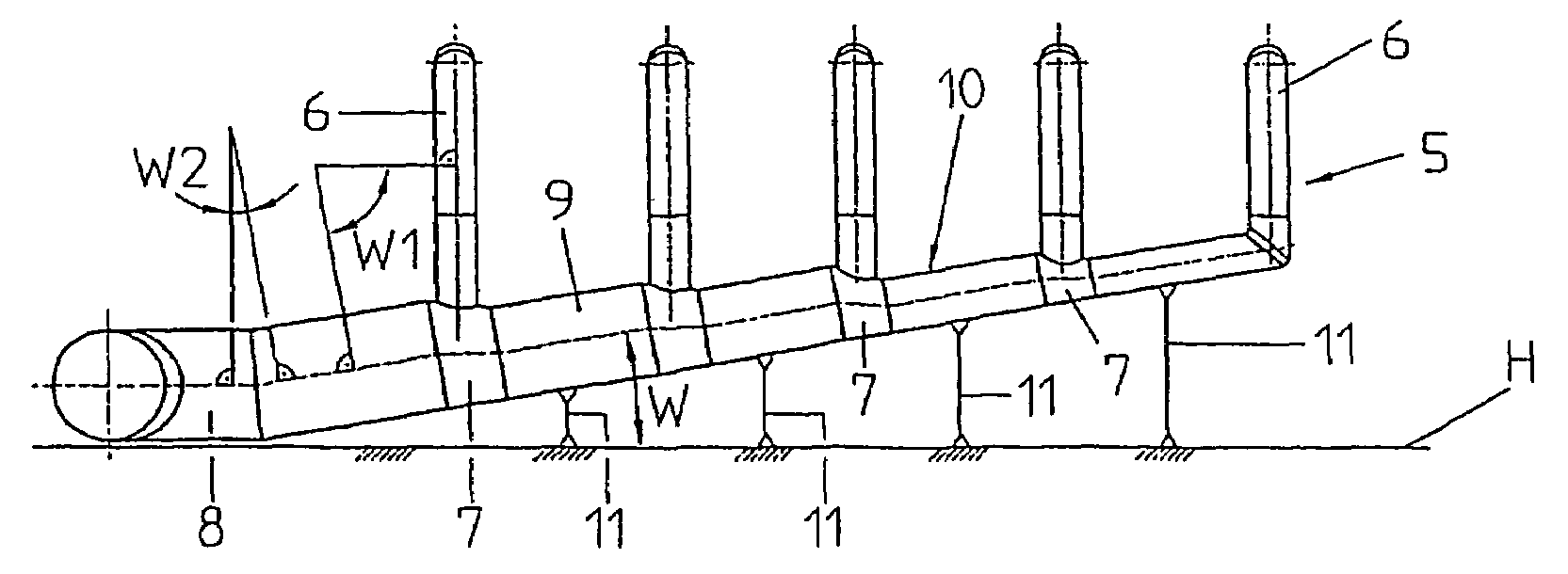

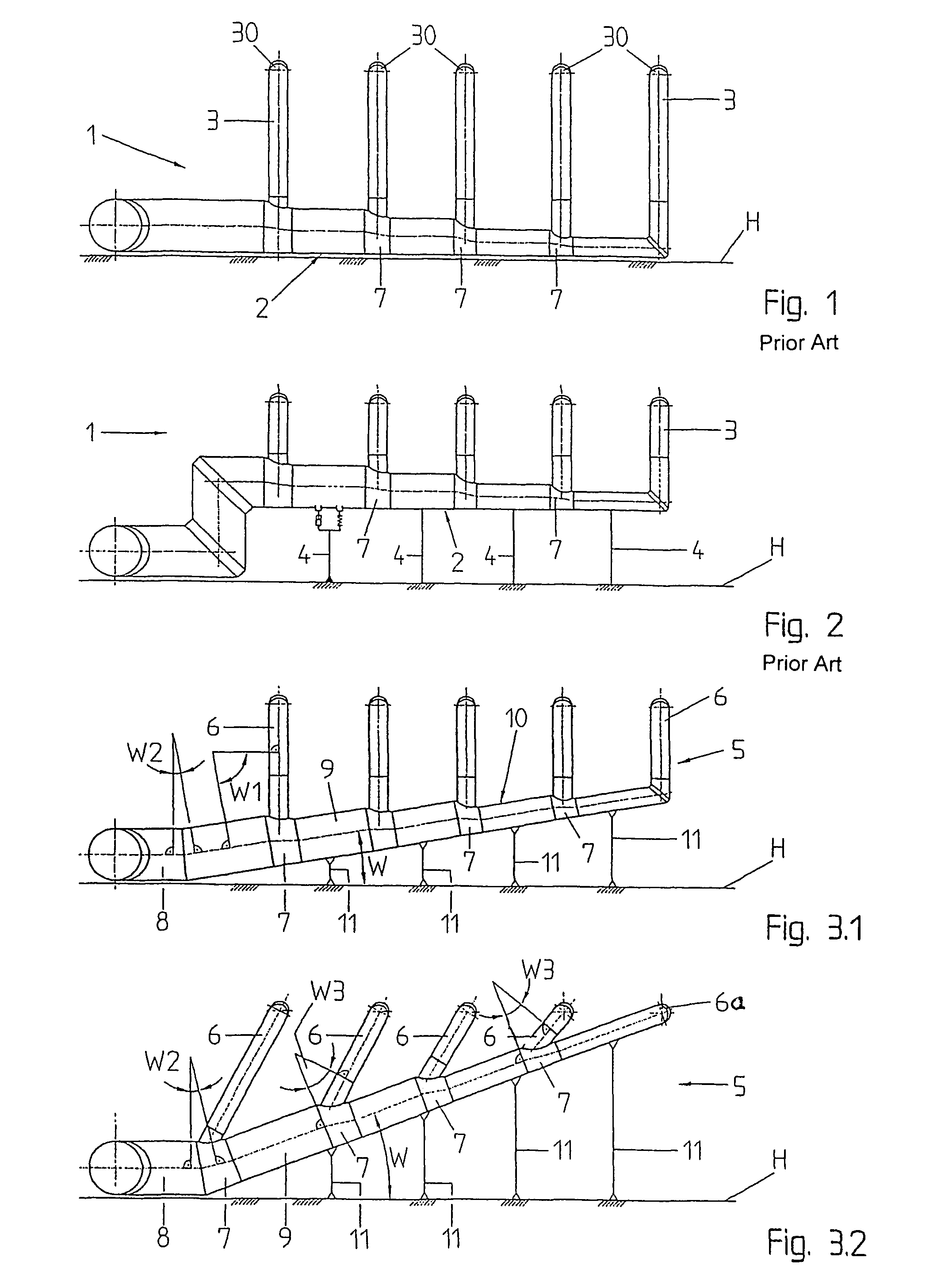

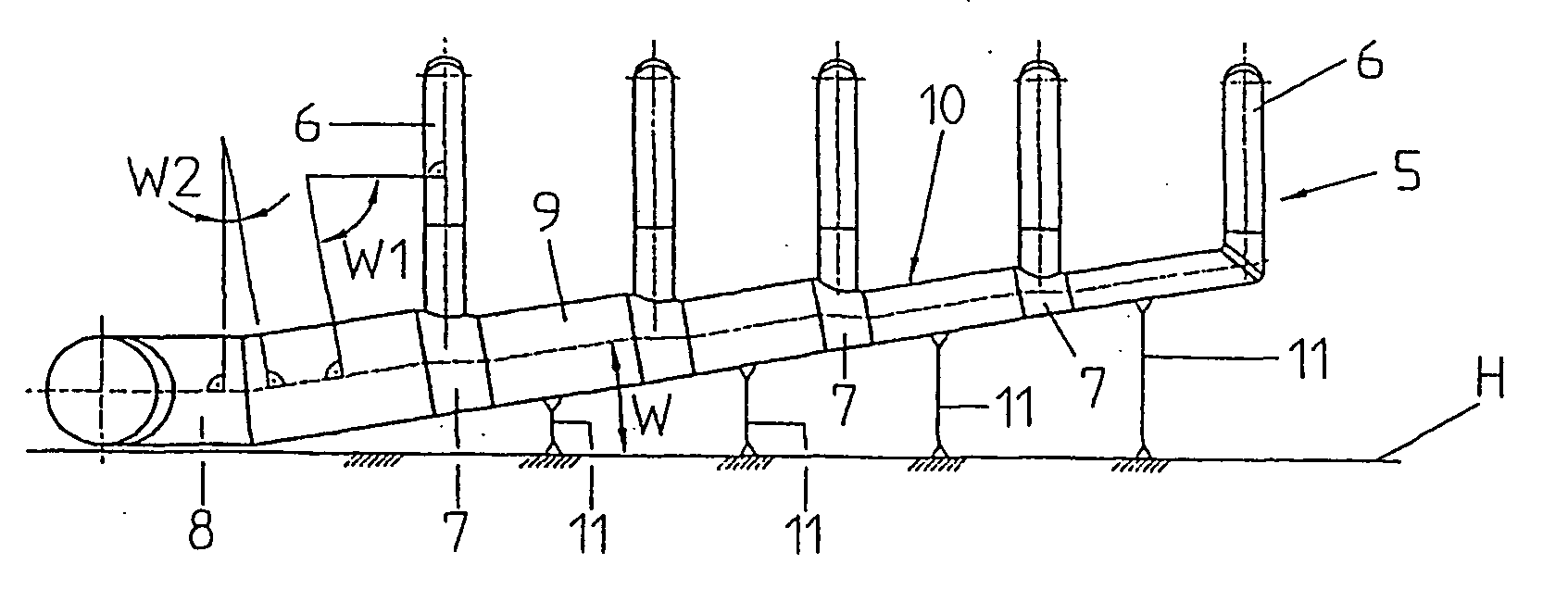

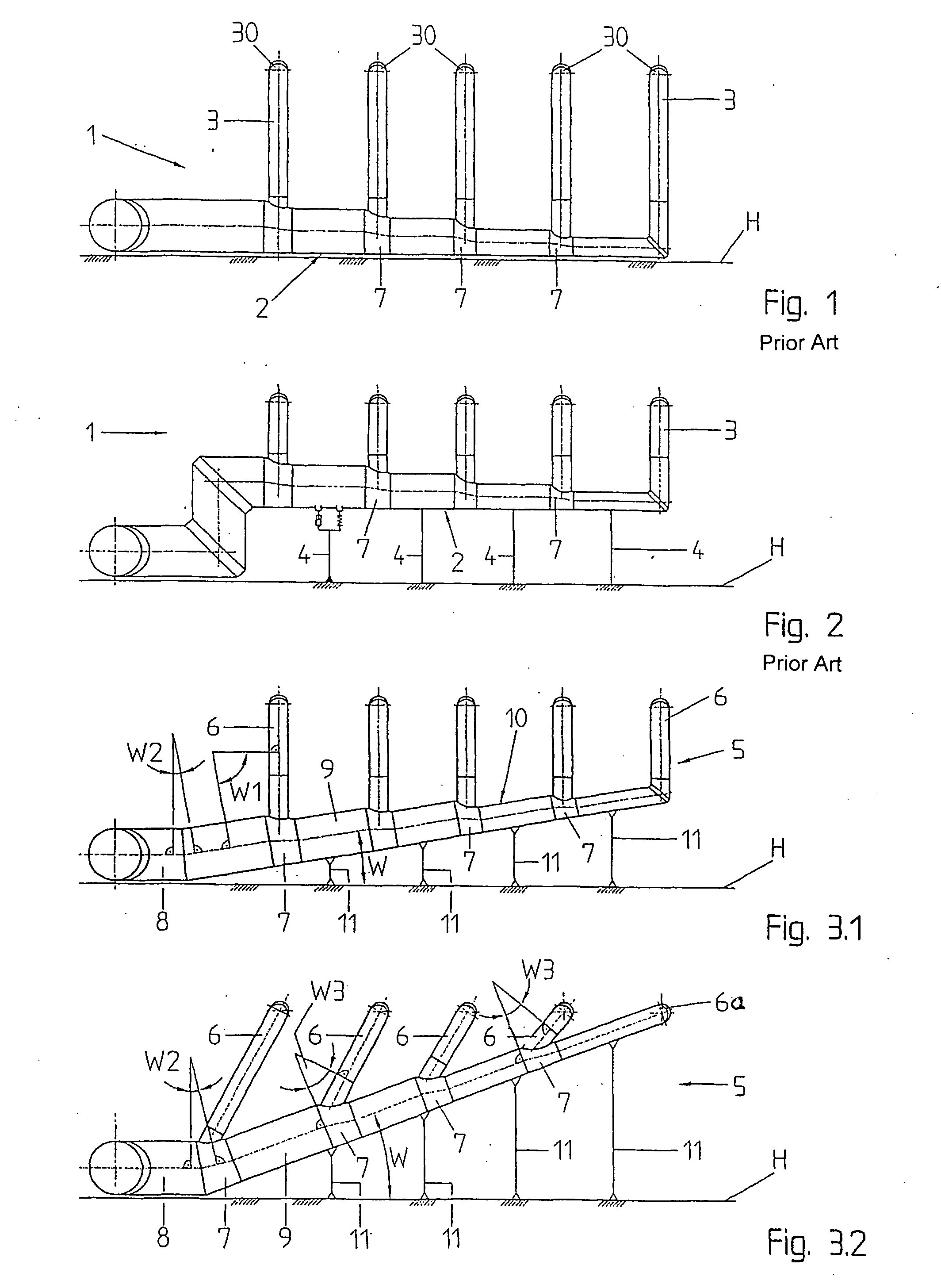

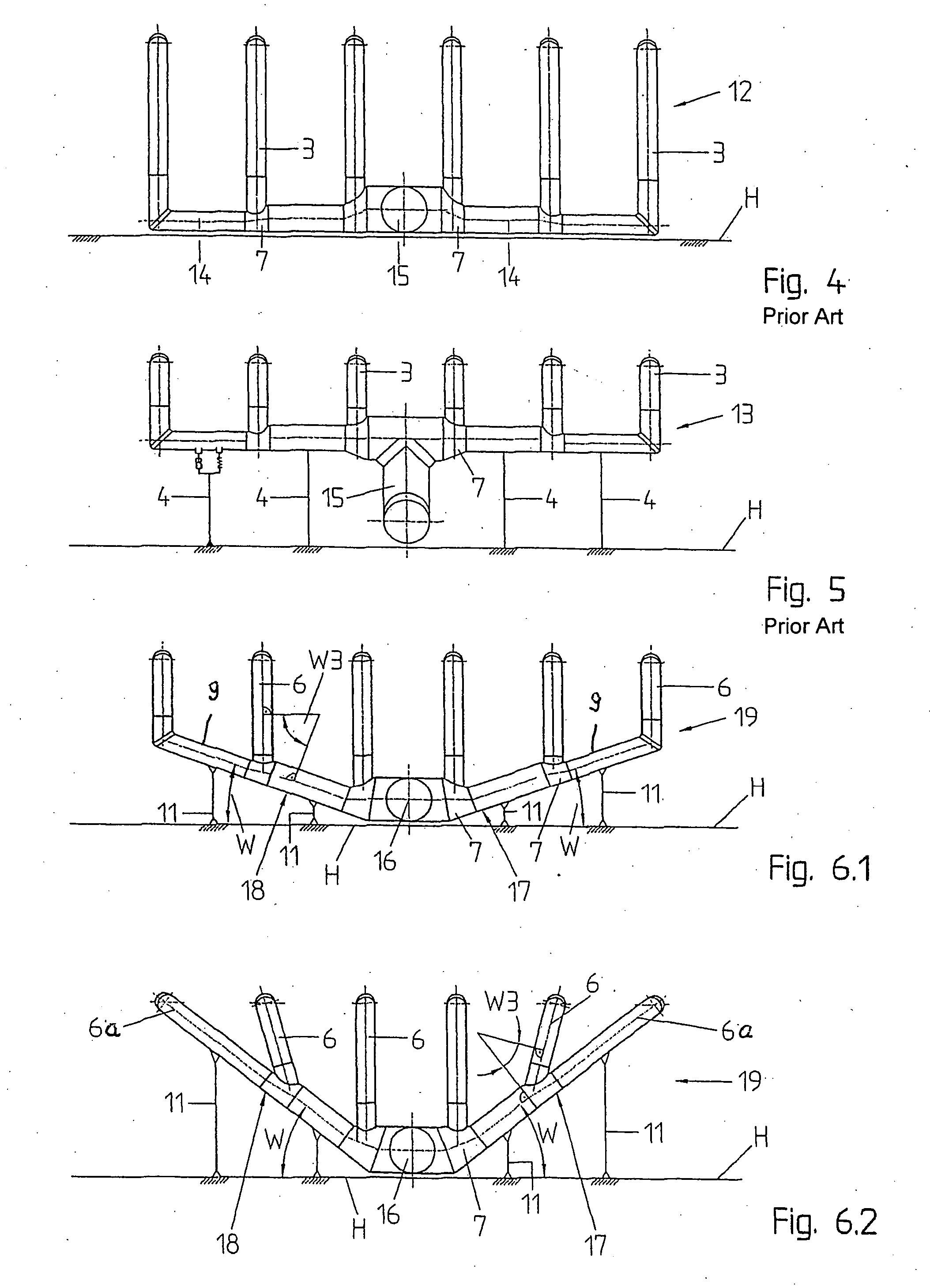

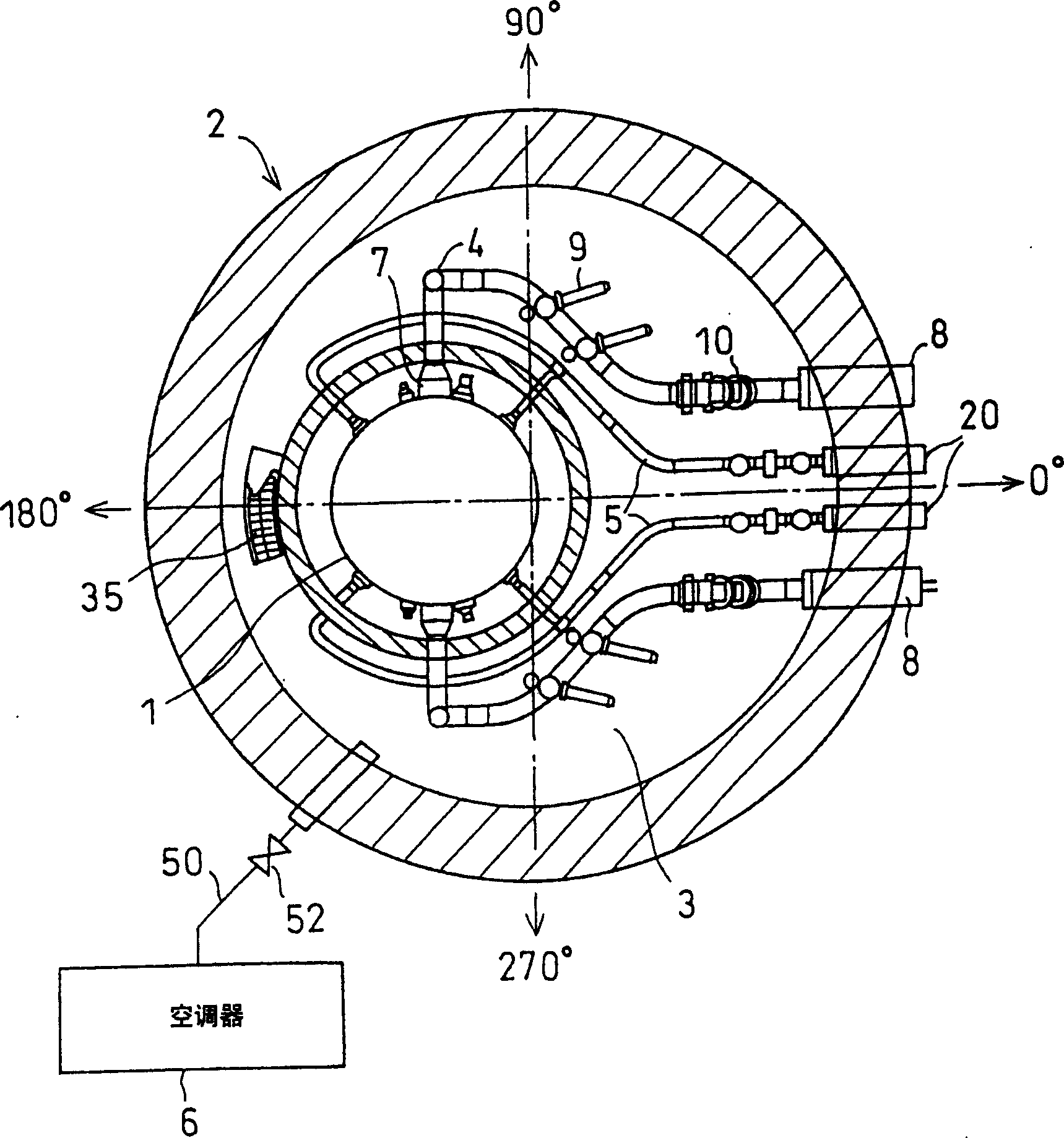

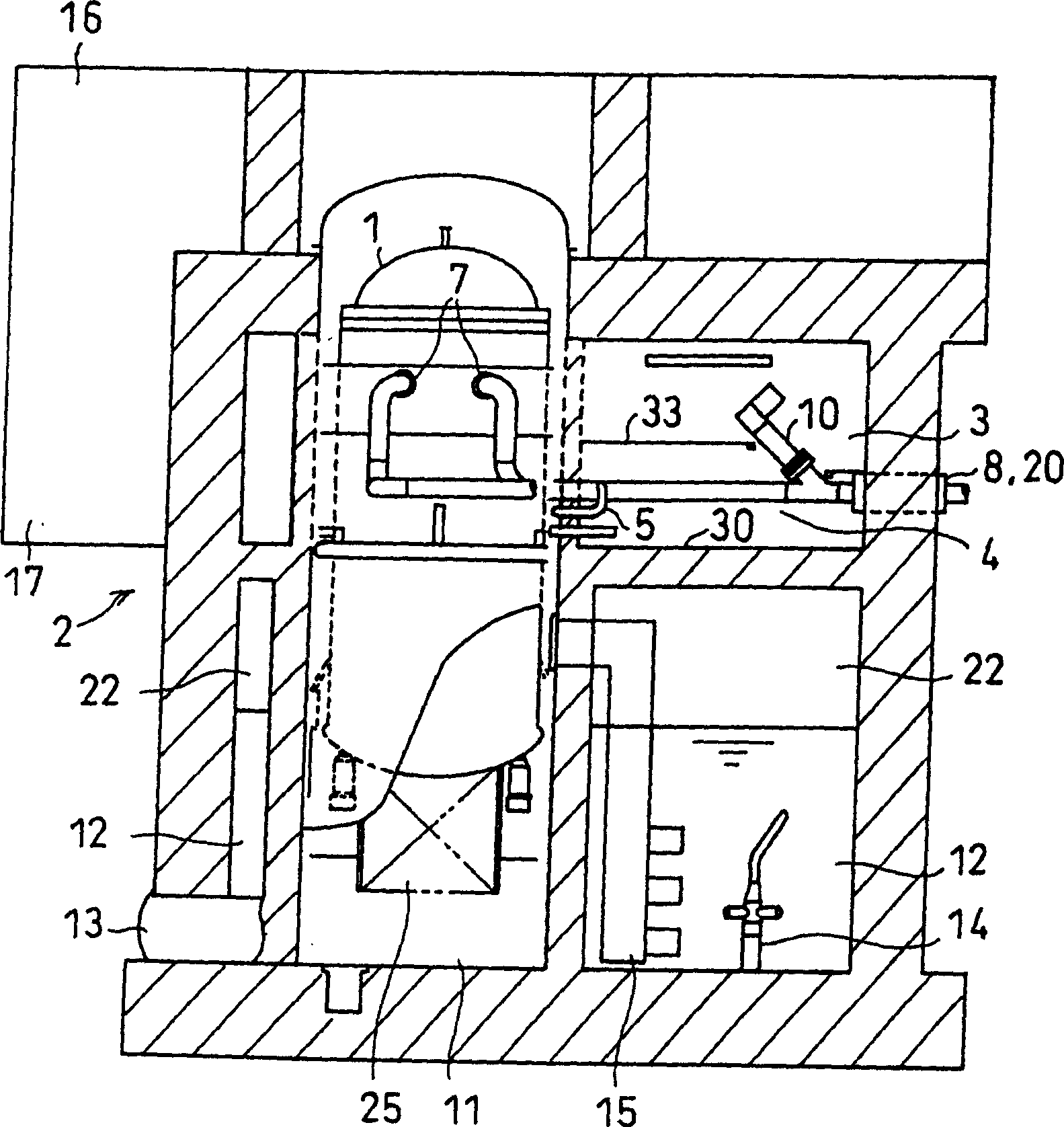

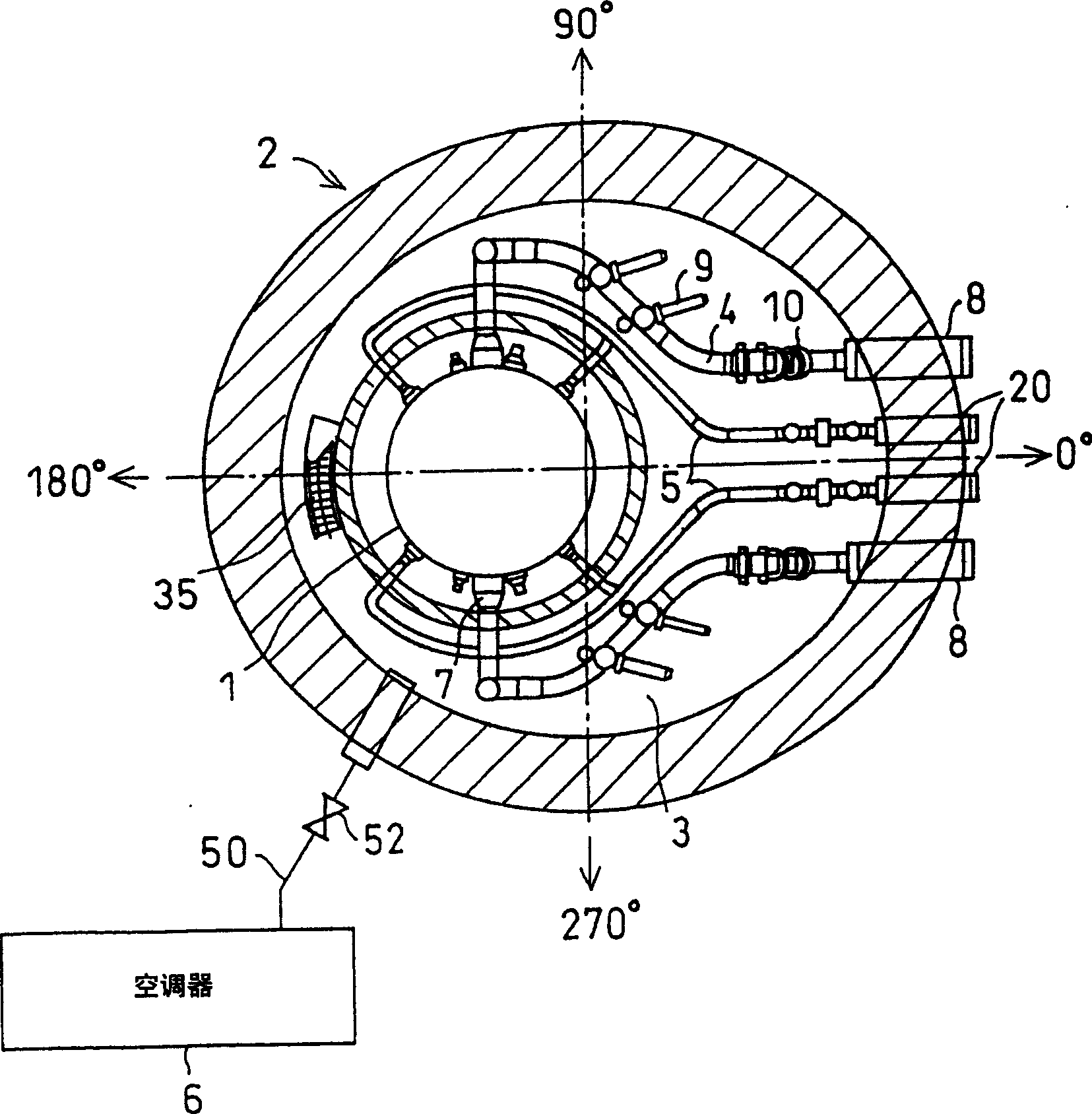

Exhaust-steam pipeline for a steam power plant

ActiveUS7168448B2Shorten the length of the flow pathShorten the lengthPipe supportsServomotor componentsSteam linePower station

An exhaust steam pipeline for steam power plants includes a main steam line and at least two branch lines which are fluidly connected to respective condenser elements of the steam power plant and branch off from the main steam line at connection zones in spaced-apart relationship. The main steam line has a cross section, which decreases following each of the connection zones, and is constructed to ascend at an angle to a horizontal in flow direction of the exhaust steam.

Owner:ENEXIO ACC GMBH

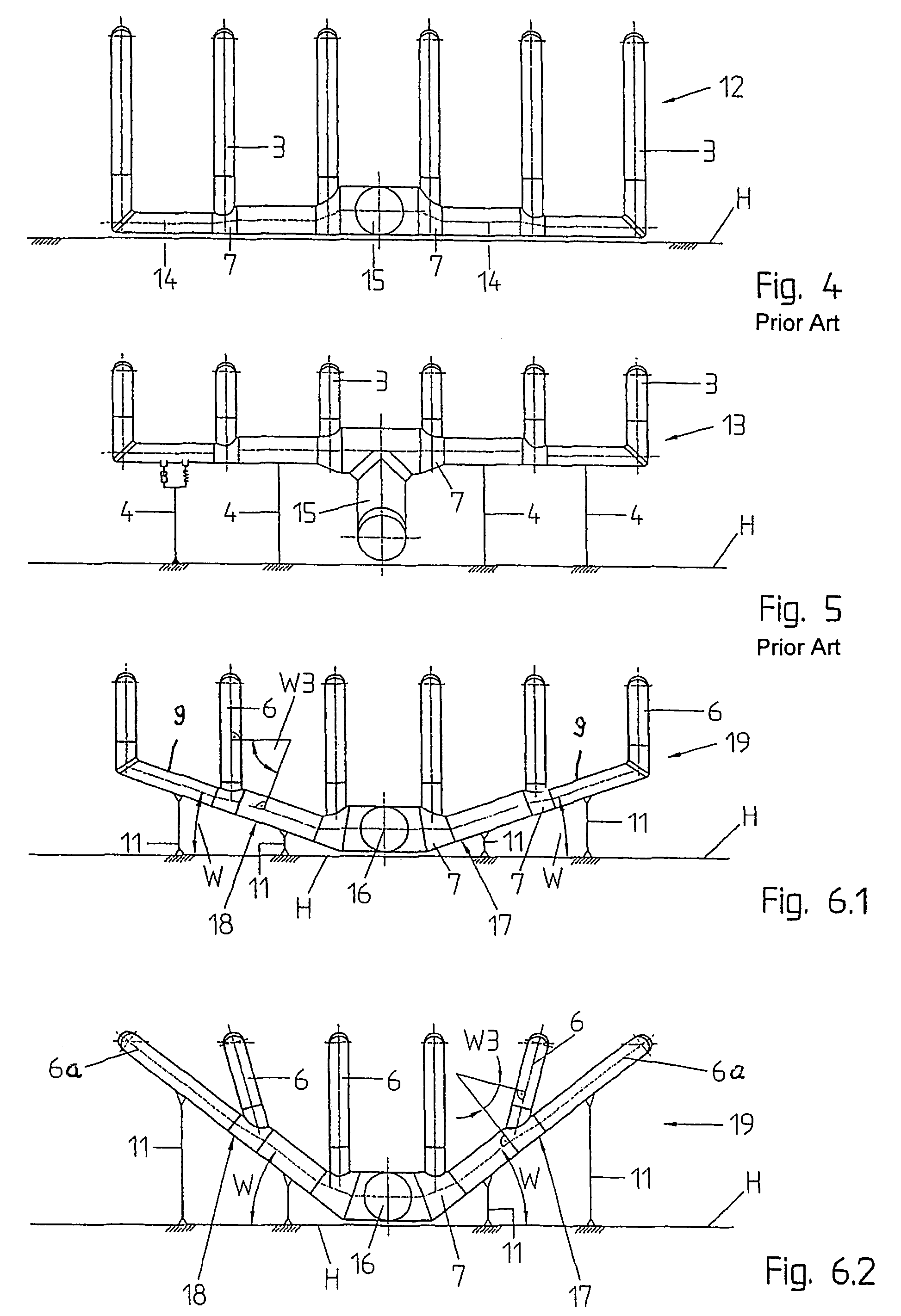

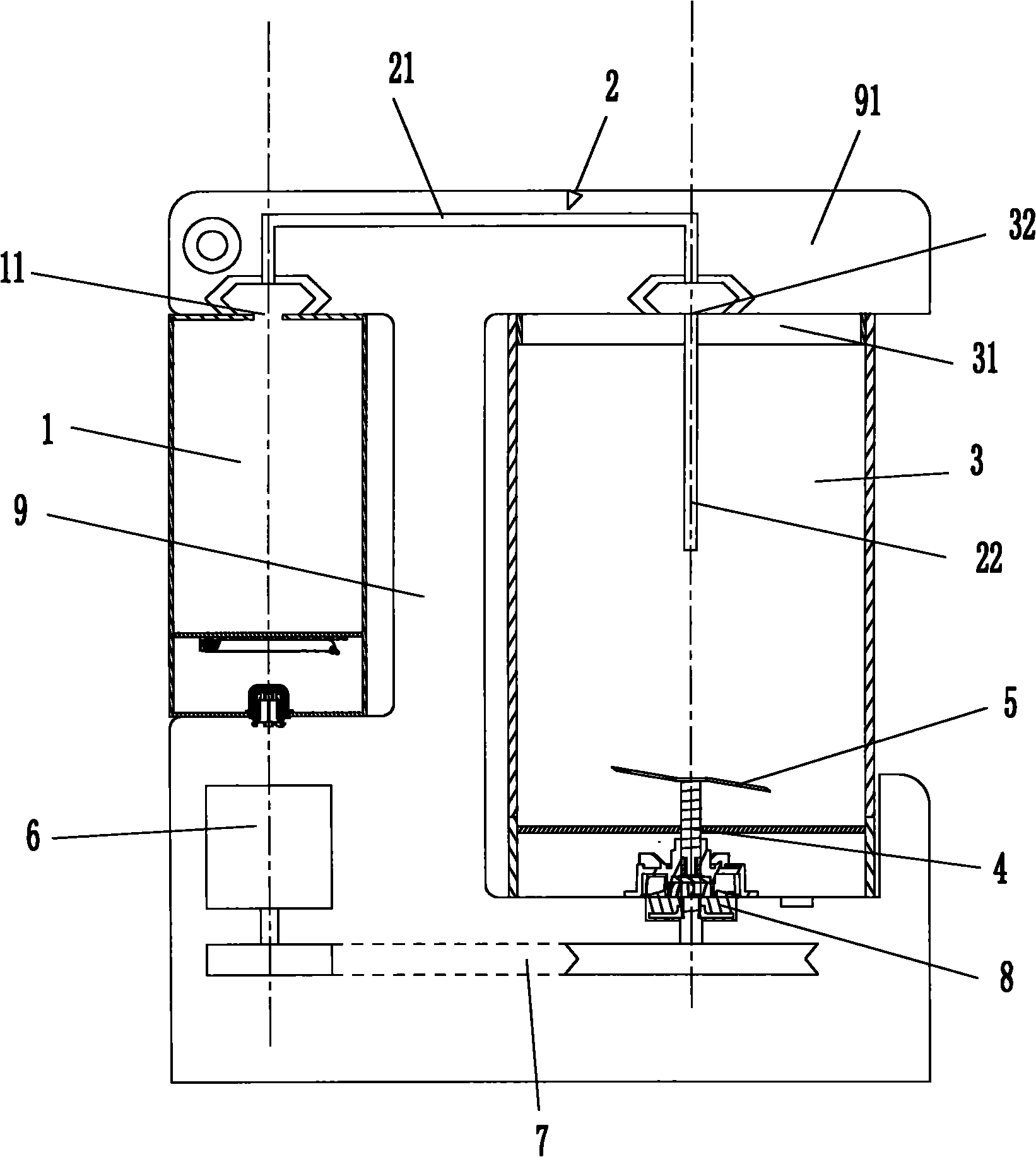

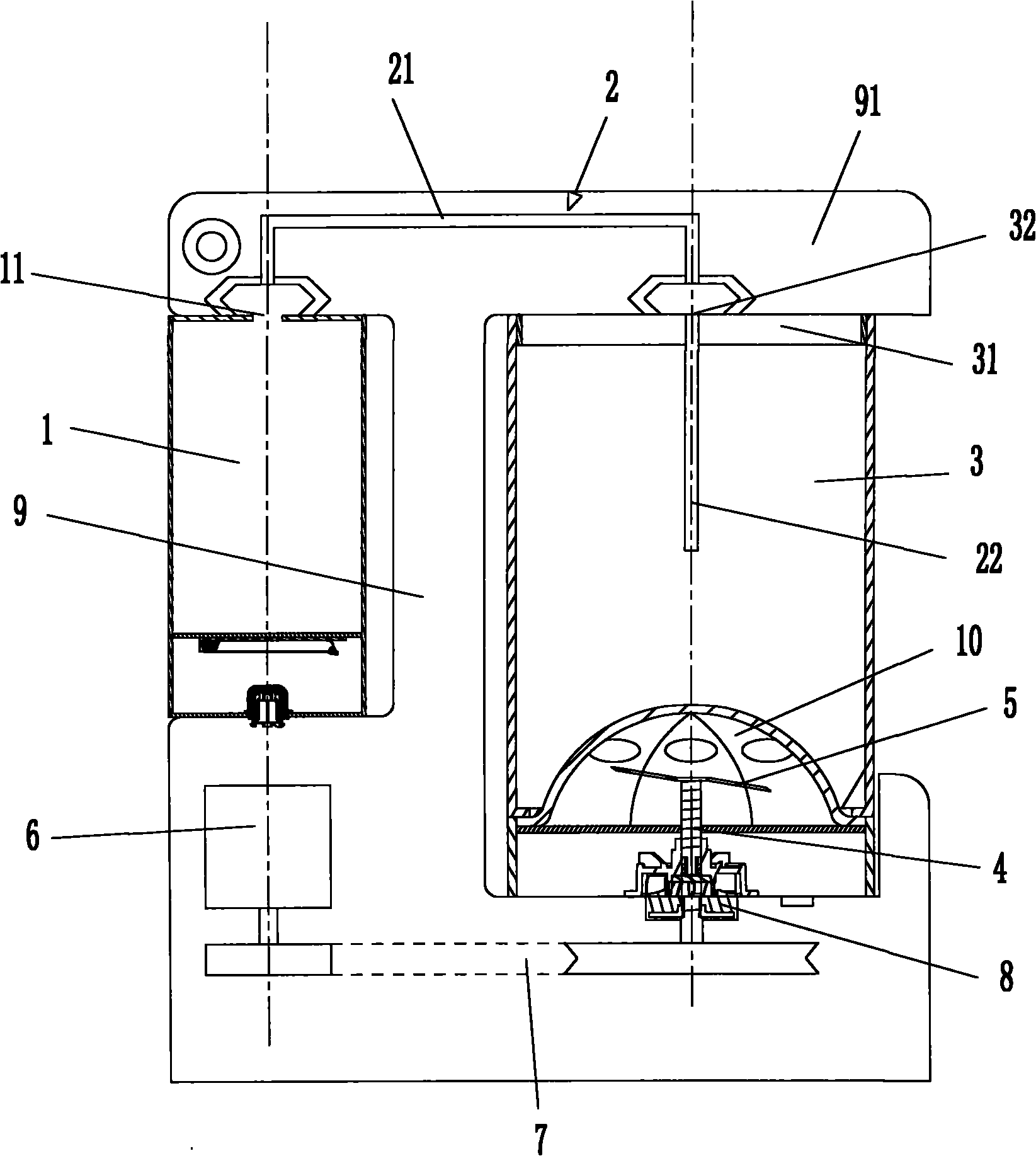

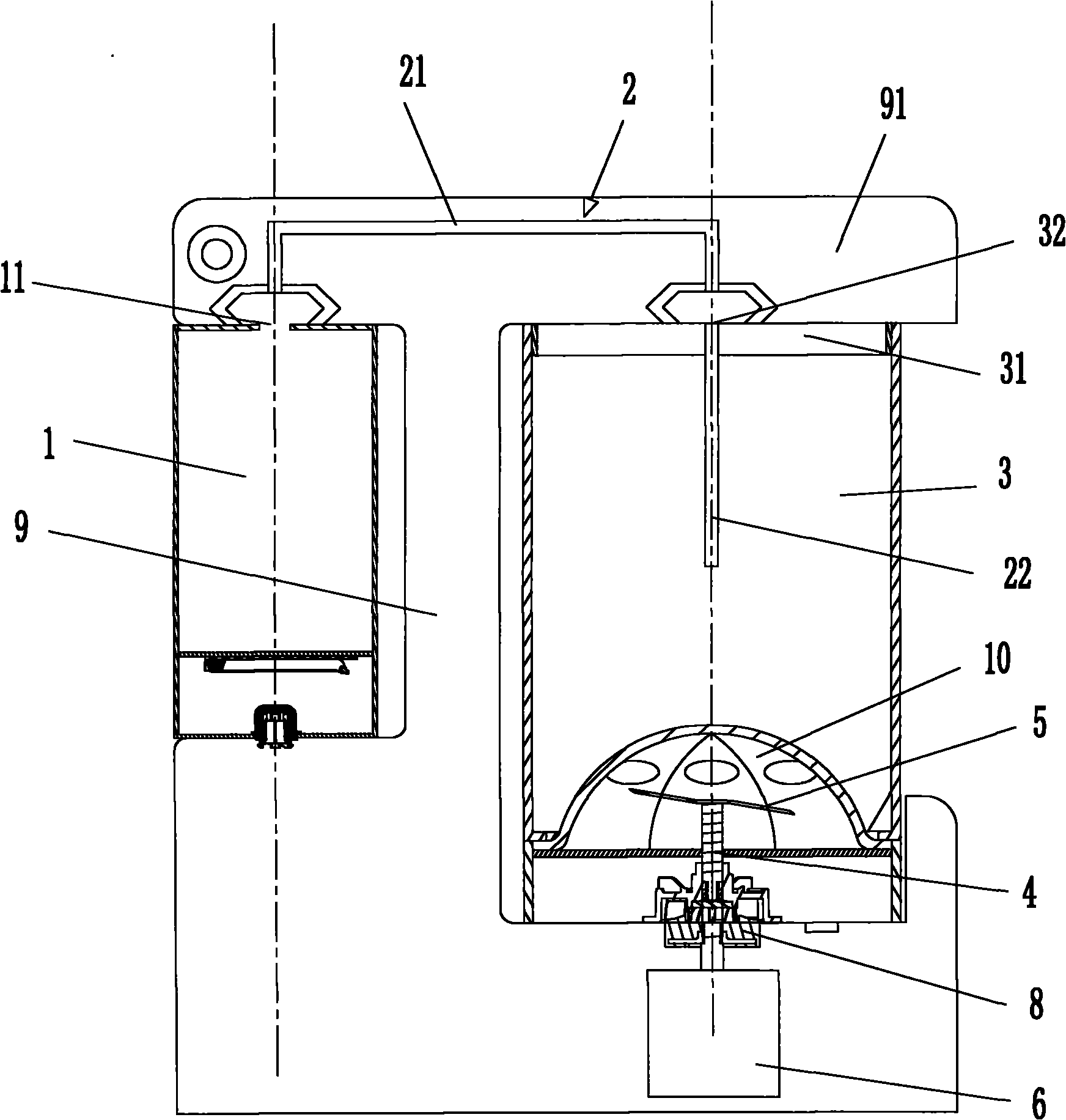

Steam turbine exhaust steam moisture on-line measurement device

InactiveCN101182787AImprove environmental adaptabilityRealize measurementMachines/enginesEngine componentsMicrocontrollerMeasurement device

The invention relates to an on-line measuring device for humidity of exhaust steam from a steam turbine, which belongs to the technical field of testing and is used for solving the problem of on-line detection of steam humidity. The technical solution is that it consists of a microwave resonance sensor, a resonance frequency detection circuit, a single-chip microcomputer and a display. The microwave resonance sensor is placed in the steam turbine exhaust cylinder, and its microwave signal transmission interface is connected to the resonance frequency detection circuit through a waveguide. The resonance frequency The control terminal and output terminal of the detection circuit are connected to different pins of the single-chip microcomputer, and the display is connected to the PORT1 interface of the single-chip microcomputer. Compared with the existing measuring device, the present invention not only greatly simplifies the structure and greatly reduces the manufacturing cost, but also has very simple operation and high measurement precision, and is especially suitable for on-line detection of steam turbine exhaust steam humidity at the engineering site.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

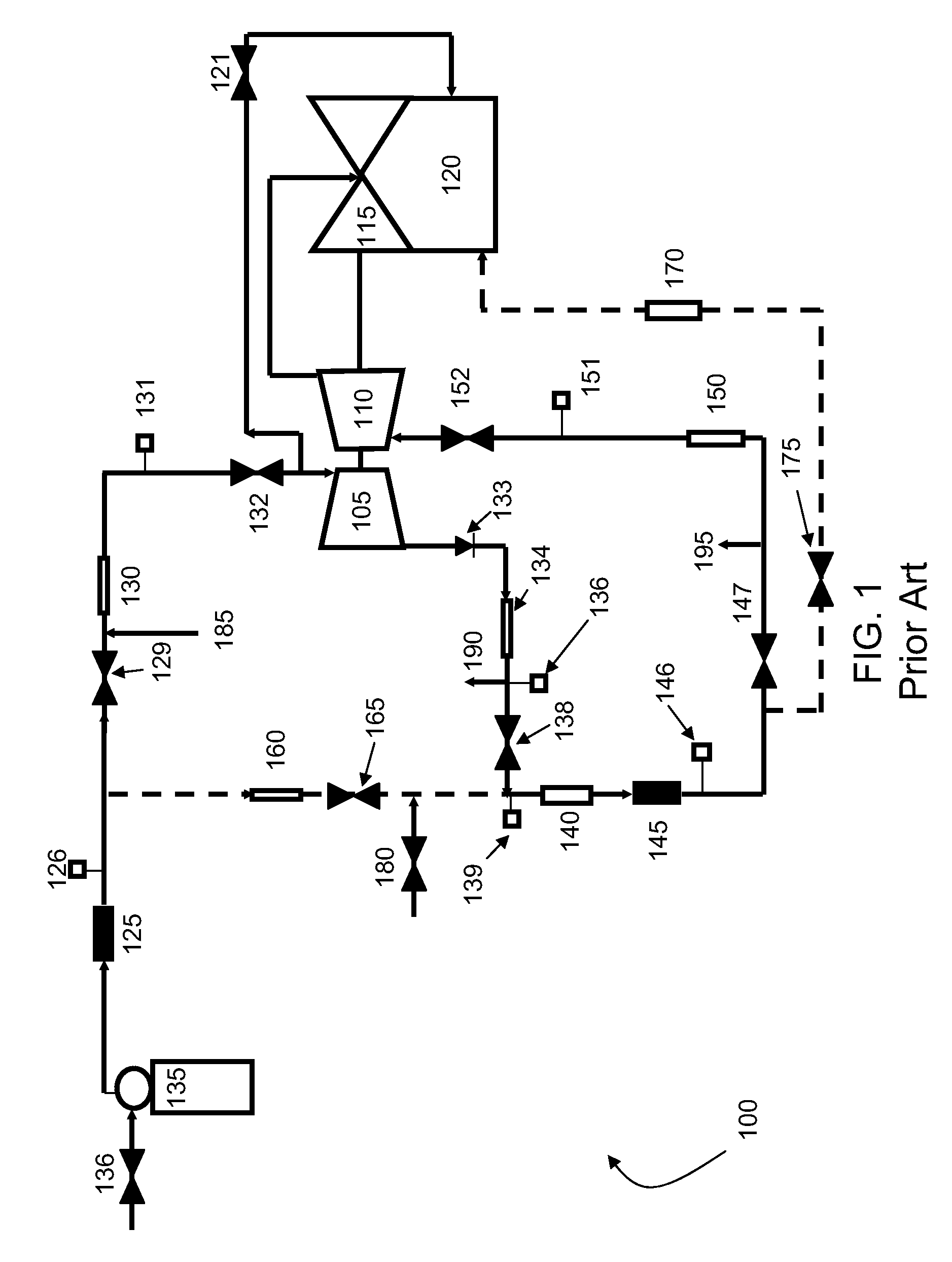

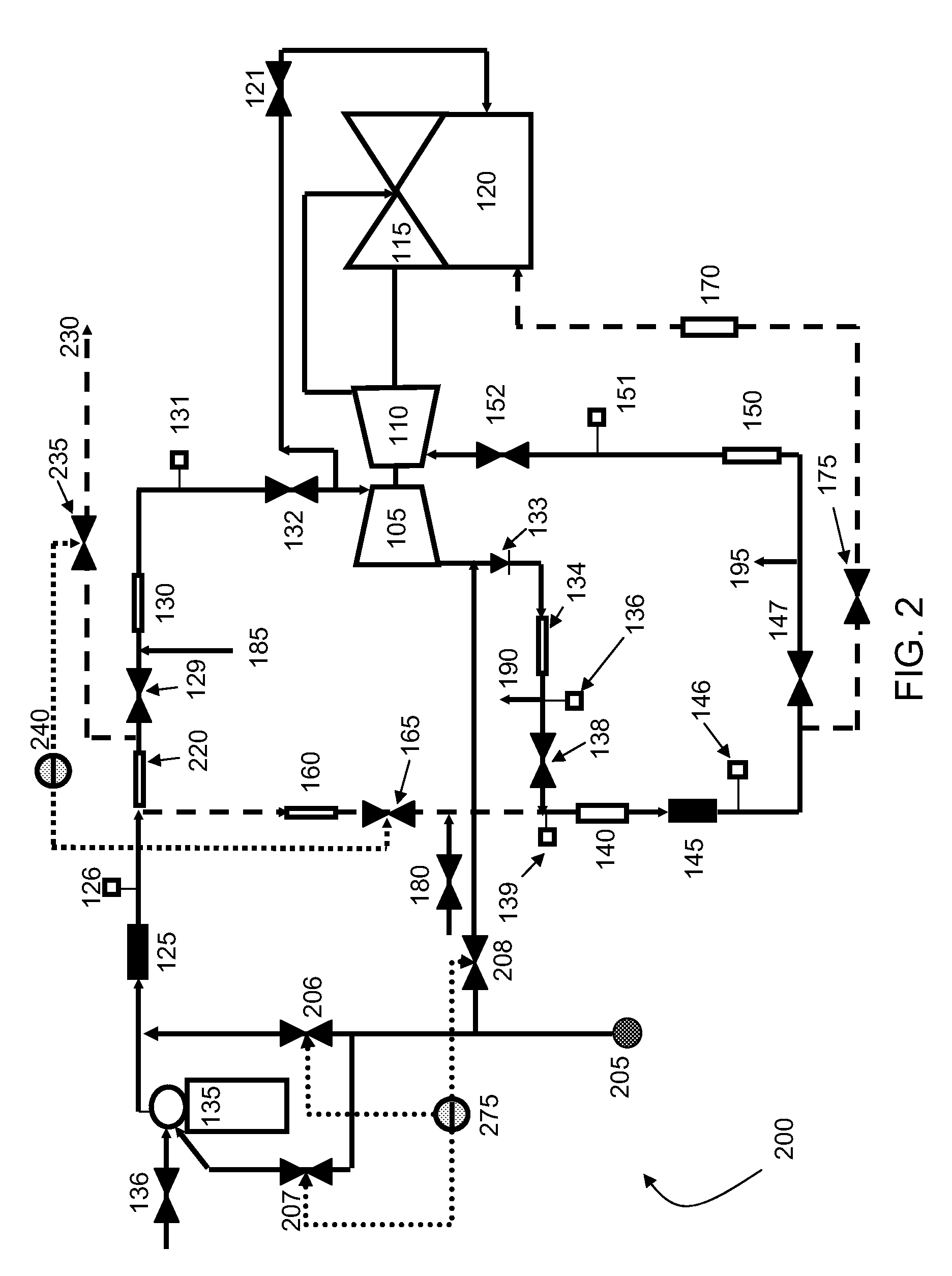

Pressure management system for liquefied natural gas vehicle fuel tanks

A storage and delivery device for a cryogenic liquid that includes a vessel assembly and a delivery line assembly. The vessel assembly has a liquid space and a vapor space. The delivery line assembly has a liquid line, a vapor line, and a delivery line. The liquid line is in fluid communication with the liquid space. The vapor line is in fluid communication with the vapor space. The liquid line has a flow control device located thereon and structured to control the flow of fluid through the liquid line. The liquid line flow control device is structured to close the liquid line when the vessel assembly is at a predetermined pressure.

Owner:TW CRYOGENICS

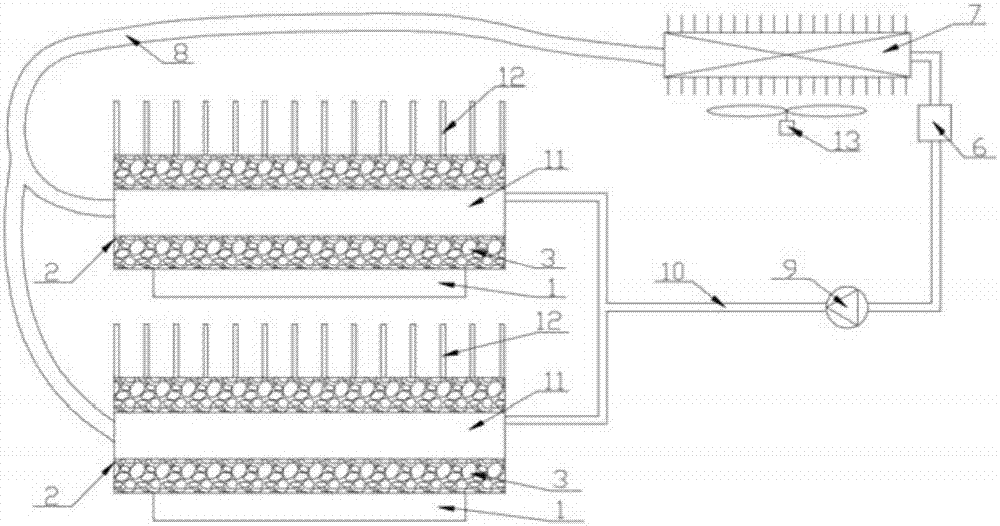

Flat type loop heat pipe

InactiveCN101900504ASuppress generationGrowth inhibitionIndirect heat exchangersLiquid lineSteam line

The invention discloses a flat type loop heat pipe, relates to the radiation of components and is used for solving the problem of dead start resulted from liquid working medium phase change in a liquid compensation cavity of an evaporimeter of the existing loop heat pipe. The flat type loop heat pipe comprises the evaporimeter and a condenser, the working medium outlet of the evaporimeter is communicated with the working medium inlet of the condenser through a steam line, and the working medium outlet of the condenser is communicated with the working medium inlet of the evaporimeter. The evaporimeter comprises a flat type heated wall surface and a shell, wherein the heated wall surface is provided with porous wicks; the shell covers the porous wicks and is provided with the liquid compensation cavity above the porous wicks; the liquid compensation cavity is used for containing working medium and is connected with the liquid line through the working medium inlet; and the wall of the shell is internally provided with a phase-change material layer. Through the phase-change material layer arranged inside the wall of the shell, the invention absorbs back leakage heat and heat conducted by a lateral wall of the evaporimeter through the phase-change heat absorption of the phase change material, thereby effectively inhibiting the generation of bubbles in the liquid compensation cavity and ensuring the smoothly starting of the loop heat pipe.

Owner:WISDRI ENG & RES INC LTD

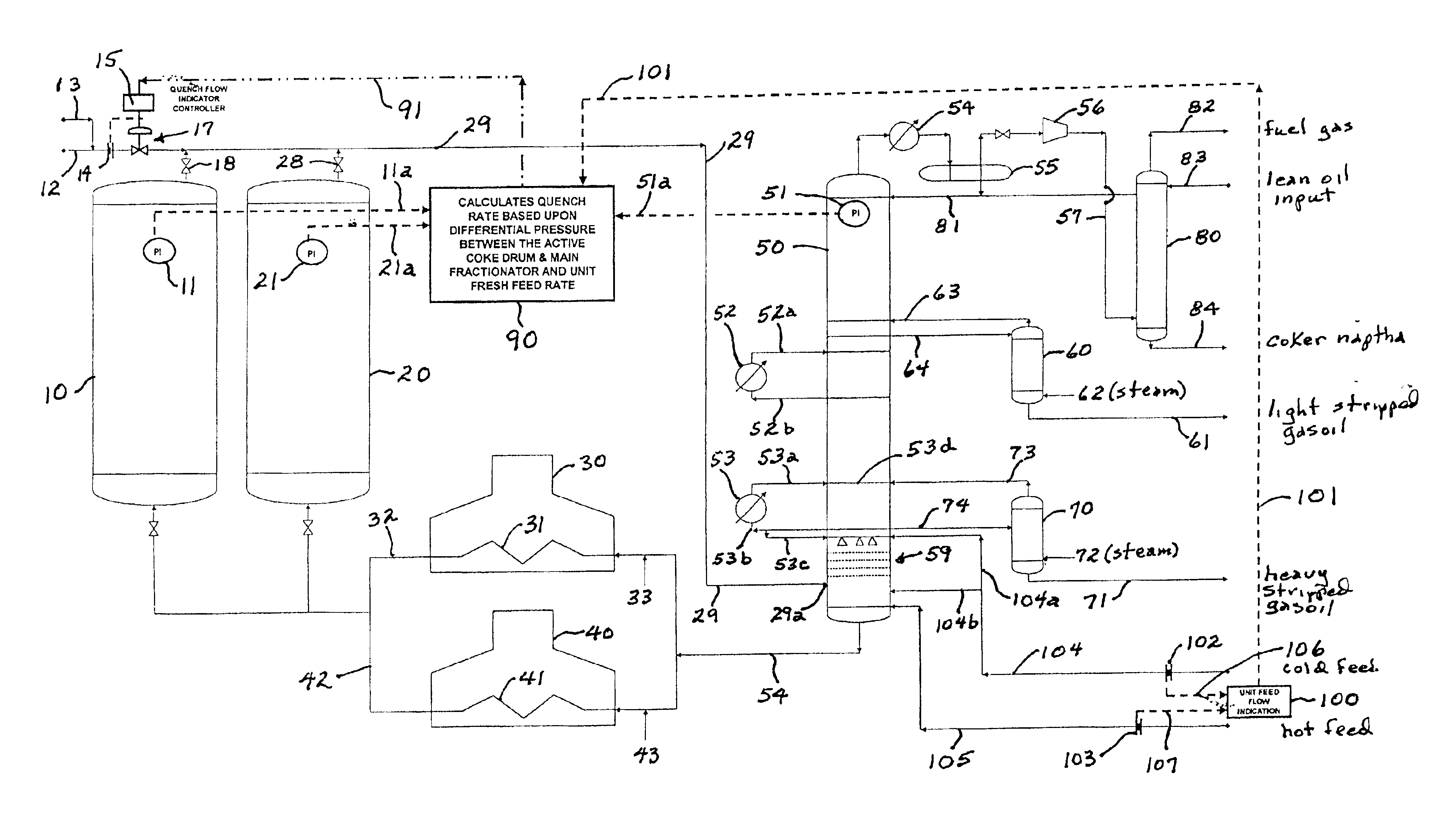

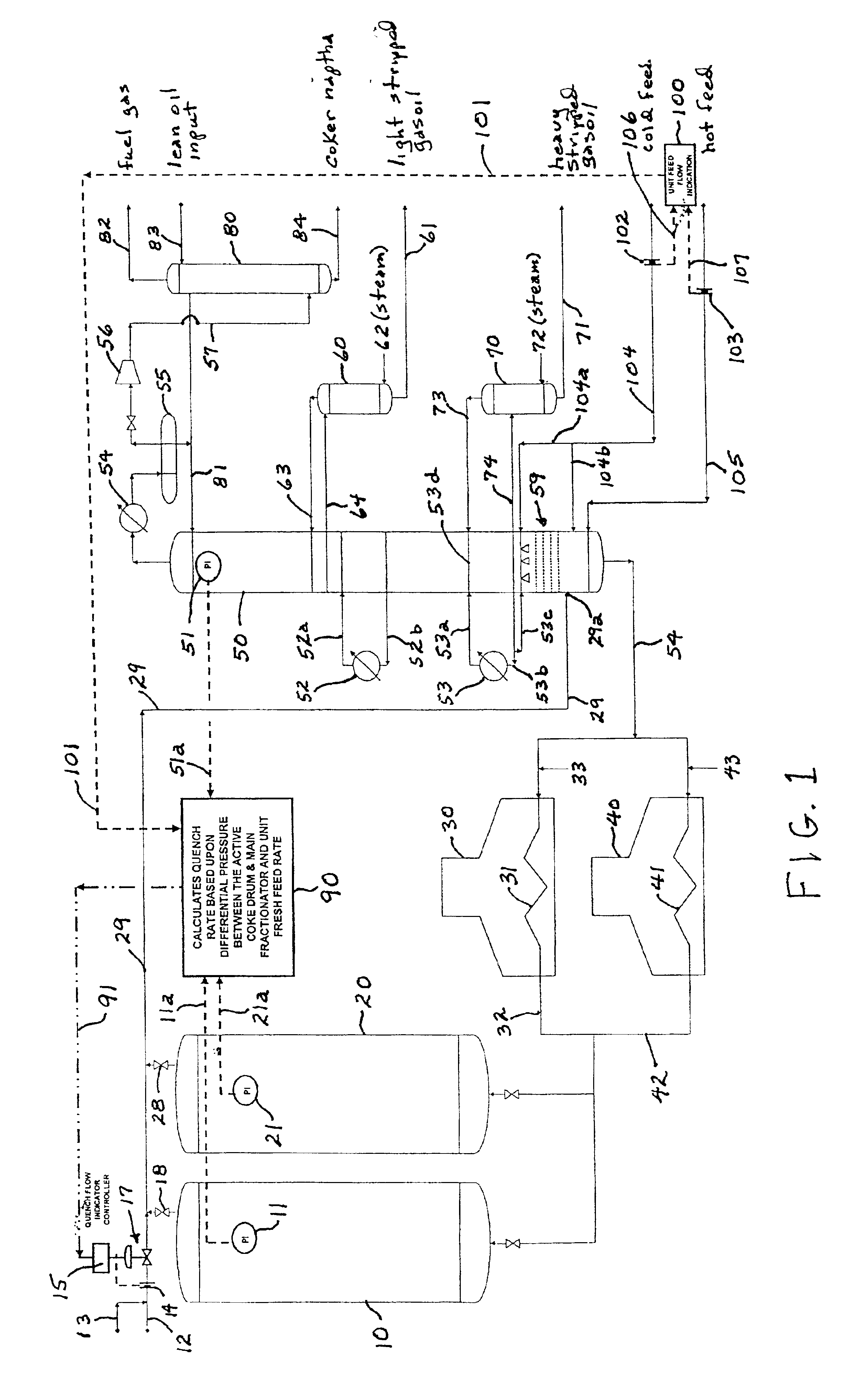

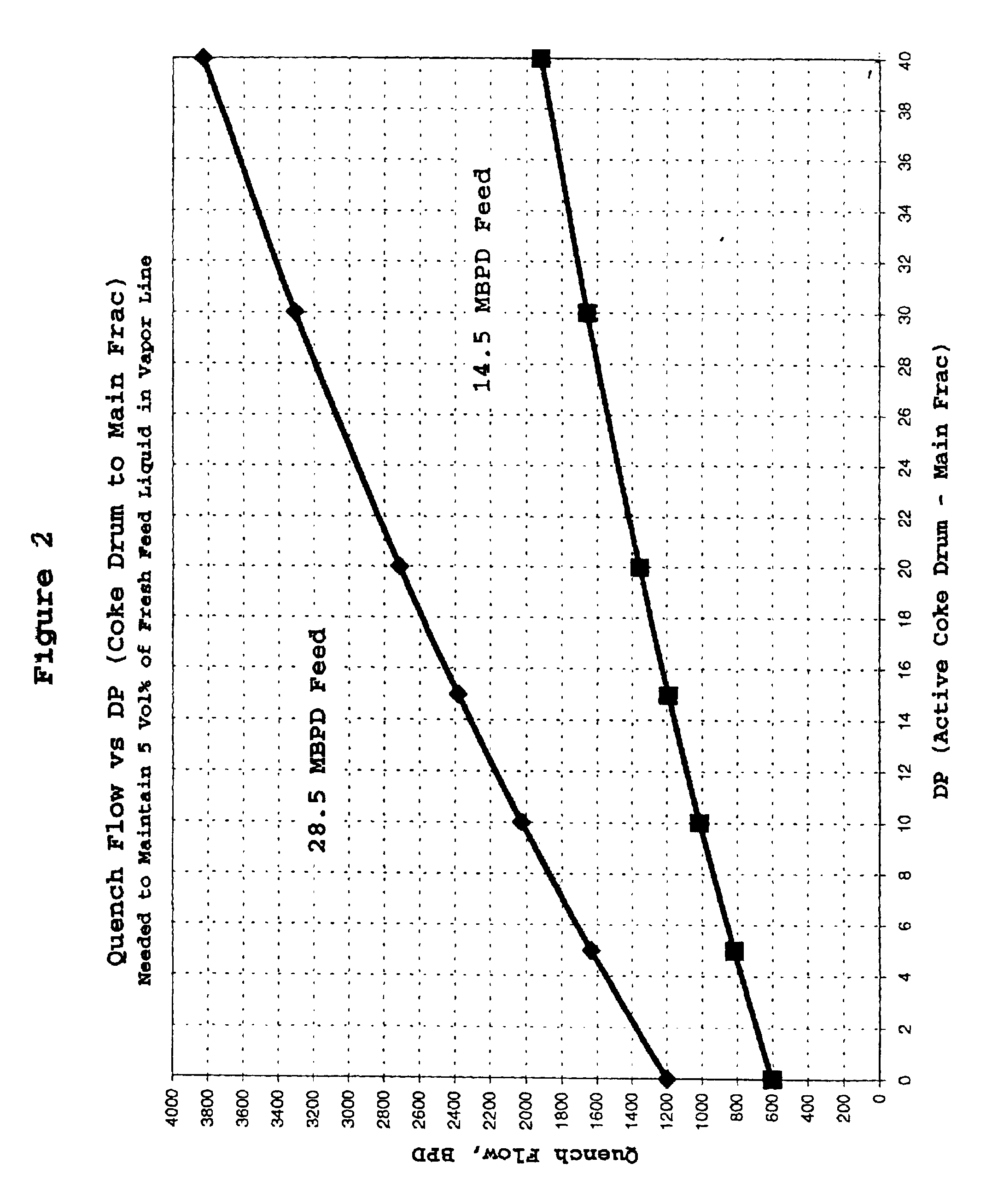

Method and apparatus for quenching the coke drum vapor line in a coker

A method and apparatus for quenching the coke drum vapor line from a coke drum to the main fractionator in a coker unit whereby the volume of quench liquid prevents the drum vapor line from plugging with carbon-based deposits. A differential pressure control technique is utilized to quench the drum vapors being delivered to the fractionator as opposed to a temperature, delta temperature, uninsulated vapor line, or fixed flow rate control as used in the prior art. Vapor line quench control by differential pressure prevents over-quenching of the vapor line during a coke drum switch, unit startup, or slowdown as well as under-quenching during drum warm-ups. It improves the fractionator recovery time from a drum switch and overall liquid product yield during the drum cycle which can be produced by over-quenching. It also prevents the vapor line from drying out at anytime, an under-quenched condition, as long as the quench oil quality and conditions do not vary significantly.

Owner:MOTIVA ENTERPRISES

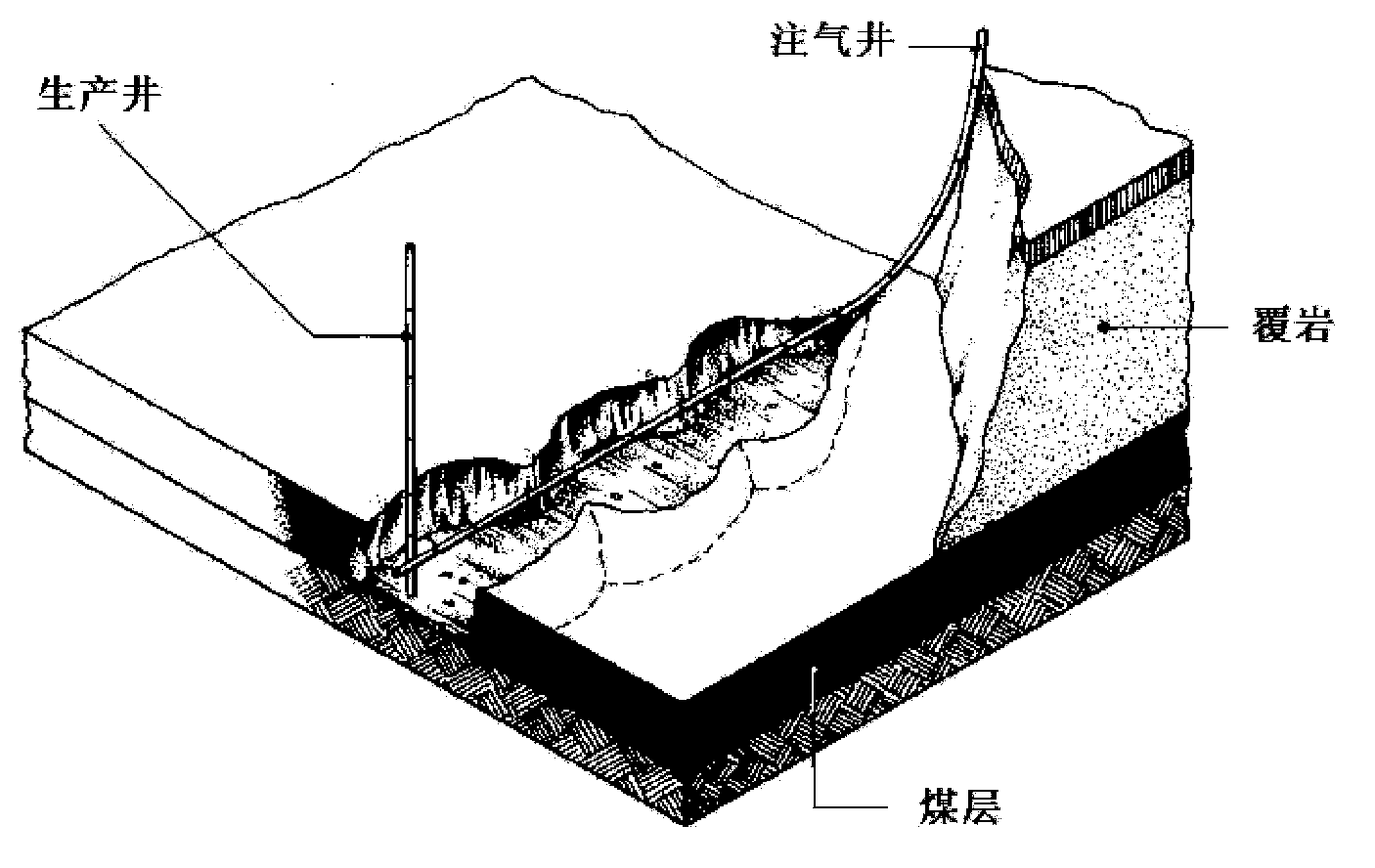

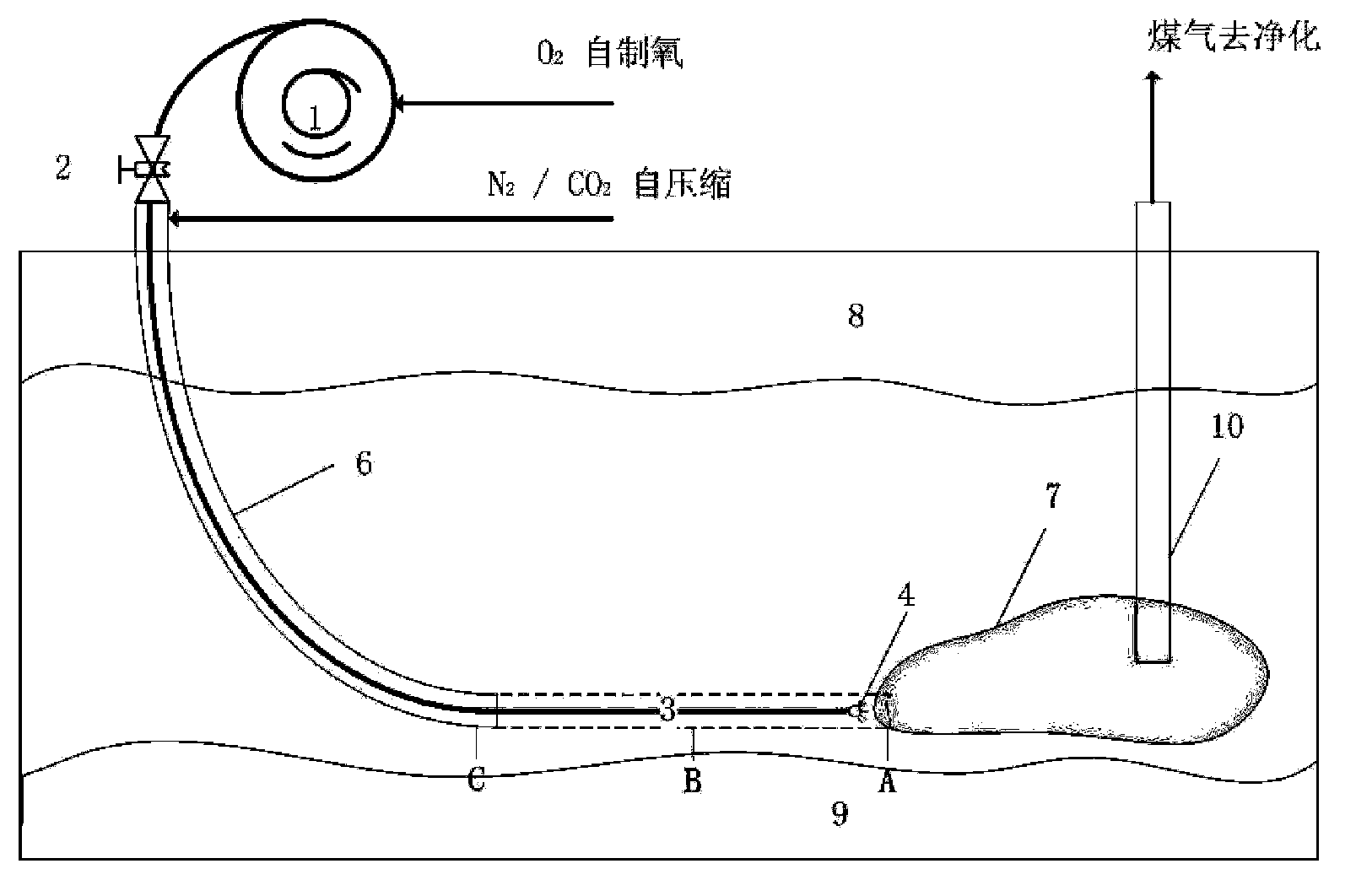

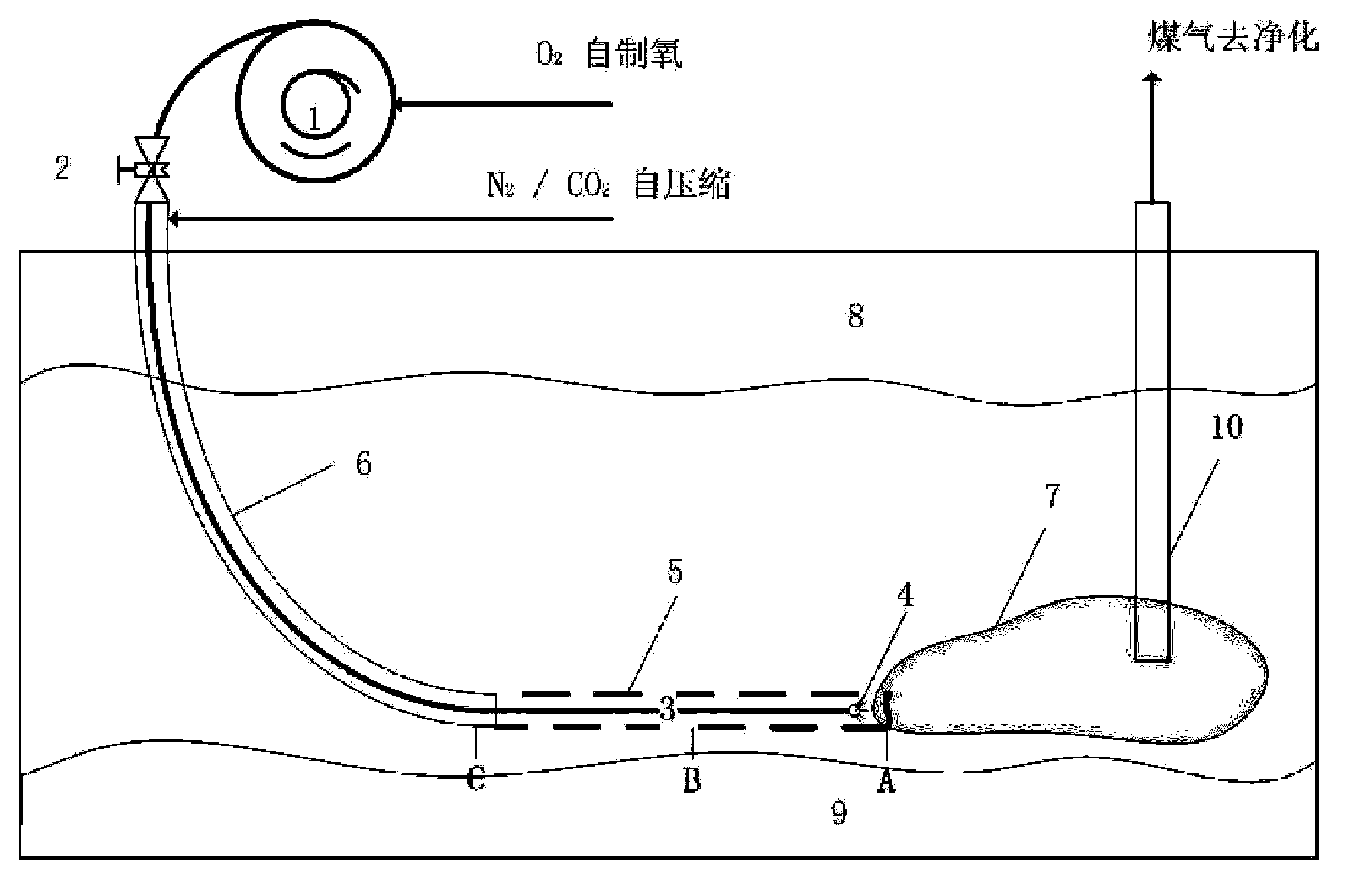

Controllable gas injection point gas injection device, gas injection technology and gasification method

ActiveCN104251133AReduce gasification combustion dead zoneImprove gasification recovery rateConstructionsFluid removalCombustionDirectional well

The invention relates to a controllable gas injection point gas injection device, a gas injection technology and a gasification method. The gas injection device comprises a directional well channel. A continuous oil pipe is arranged in the directional well channel and is communicated with an oxygen / oxygen-enriched gas pipeline; an annular space between the continuous oil pipe and the directional well channel is communicated with an auxiliary gasification agent pipeline and a steam pipeline; and a gas injection well head is arranged at the starting end of the continuous oil pipe, and a nozzle is arranged at the tail end of the continuous oil pipe. On the basis of the directional drilling and continuous oil pipe technology, the directional drilling and continuous oil pipe matched mode is utilized for achieving moving of a gas injection point, and on the principle of adjusting gasification agent injection parameters and controlling reverse combustion at the same time, the aims of adjusting and controlling the position movement and combustion speed of a flame working face and carrying out reverse combustion ignition and gasification of an underground coal seam can be achieved.

Owner:ENN SCI & TECH DEV

Exhaust-steam pipeline for a steam power plant

ActiveUS20050161094A1Lowered platform heightReduction of steel construction costServomotor componentsSteam/vapor condensersPower stationSteam line

An exhaust steam pipeline for steam power plants includes a main steam line and at least two branch lines which are fluidly connected to respective condenser elements of the steam power plant and branch off from the main steam line at connection zones in spaced-apart relationship. The main steam line has a cross section, which decreases following each of the connection zones, and is constructed to ascend at an angle to a horizontal in flow direction of the exhaust steam.

Owner:ENEXIO ACC GMBH

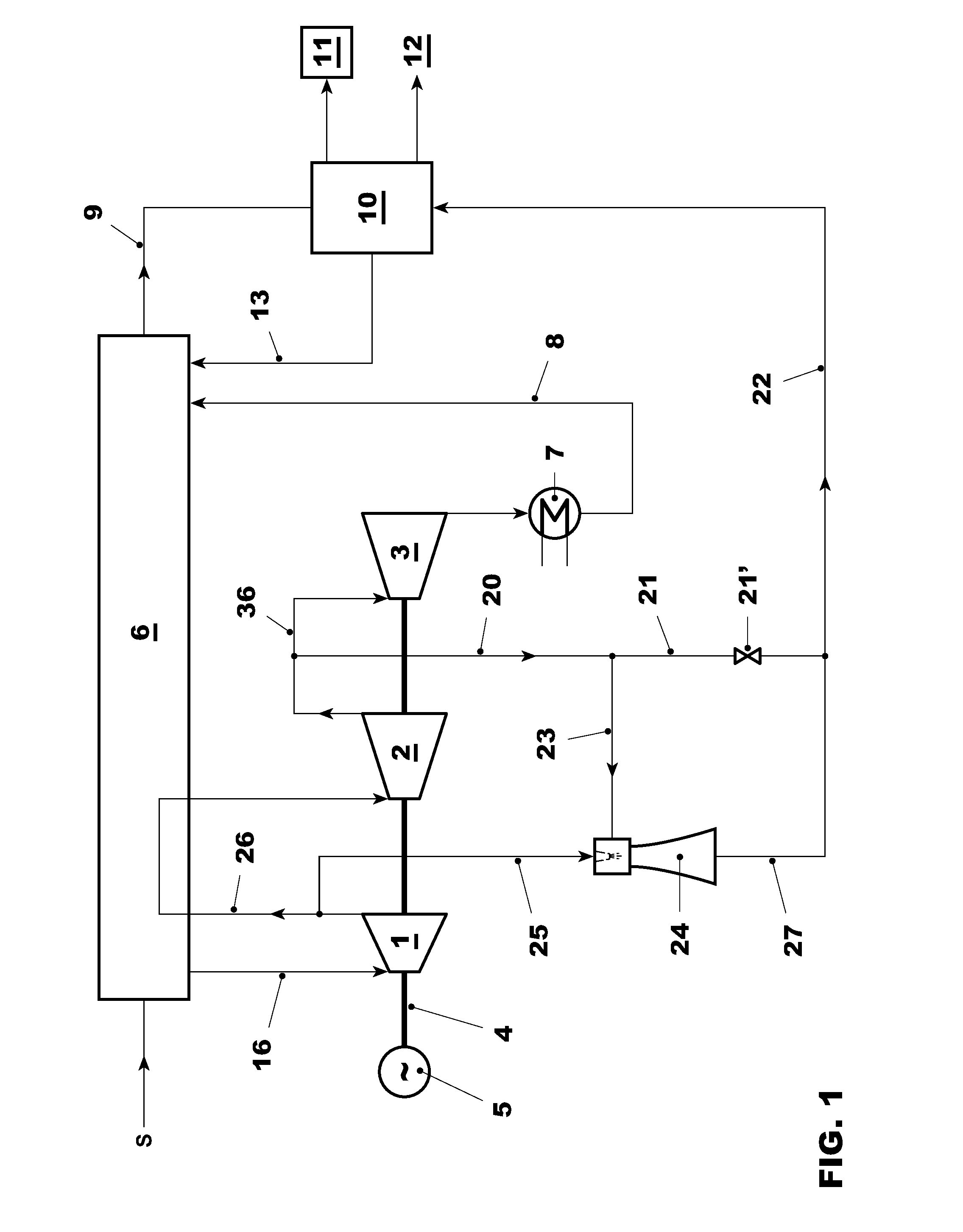

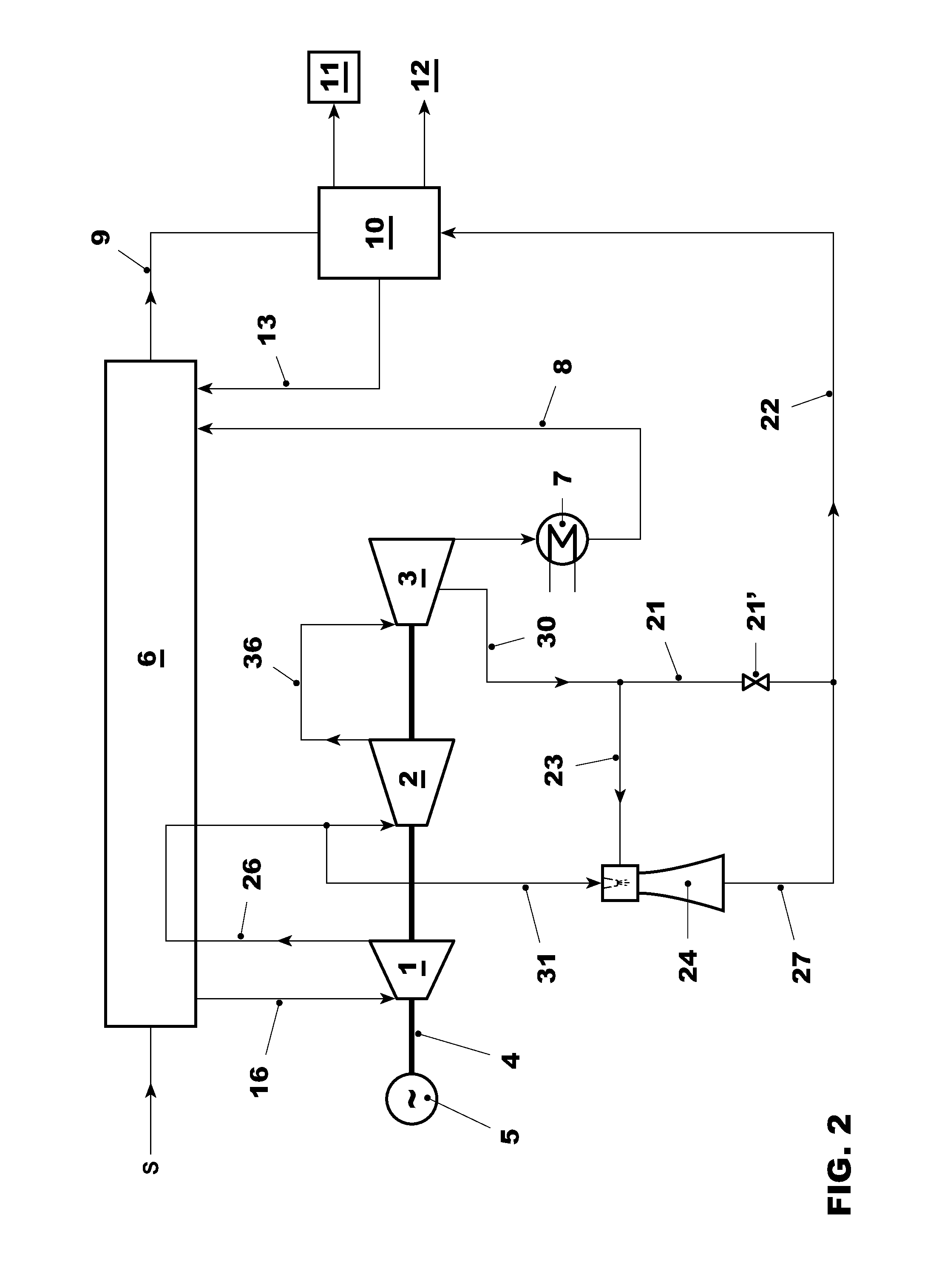

Systems and Methods for Pre-Warming a Heat Recovery Steam Generator and Associated Steam Lines

Embodiments of the invention can provide systems and methods for pre-warming a heat recovery steam generator and associated steam lines. According to one embodiment, a method for pre-warming a heat recovery steam generator can be provided. The method can include providing heating steam from a steam source. The heating steam is directed from the steam source to a superheater so that at least a portion of the superheater can be warmed. Once exiting the superheater, the heating steam can be further directed from the superheater to at least one bypass line and maintained in the bypass line until the bypass line attains a predefined temperature or pressure. Furthermore, the method can include directing, after the bypass line attains a predefined temperature or pressure, at least a portion of the heating steam from the bypass line to a reheater so that the reheater can be warmed.

Owner:GENERAL ELECTRIC CO

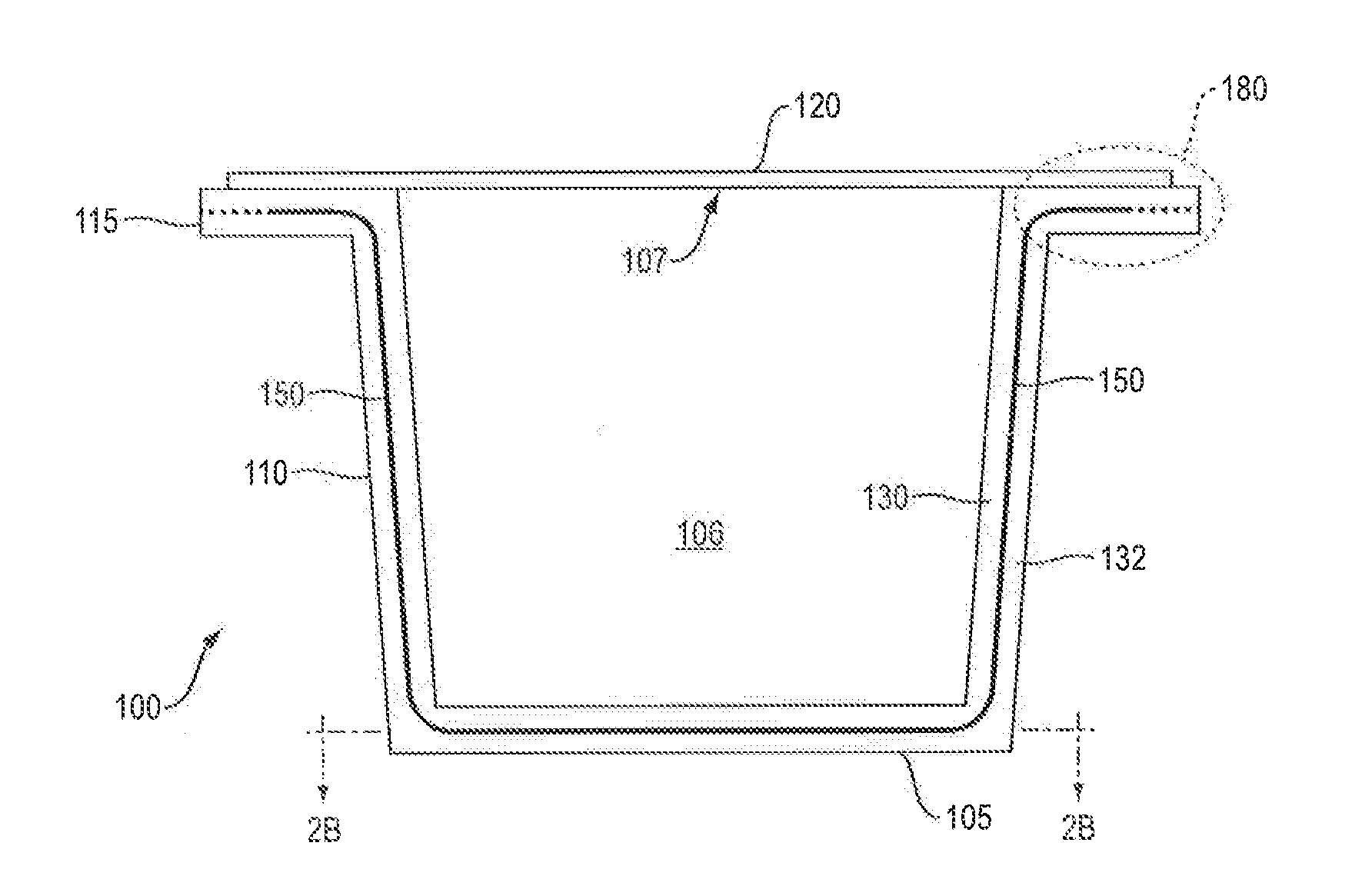

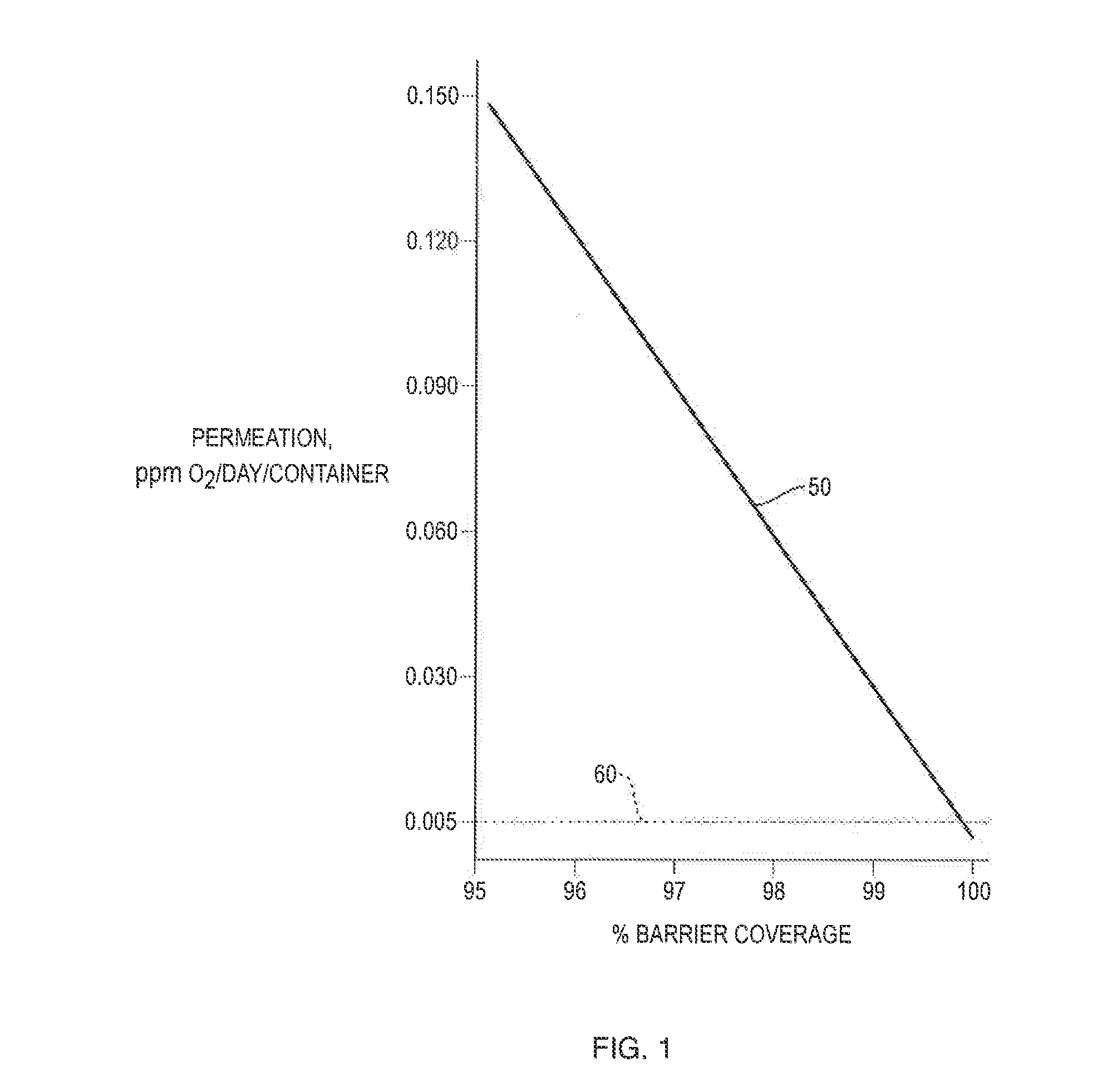

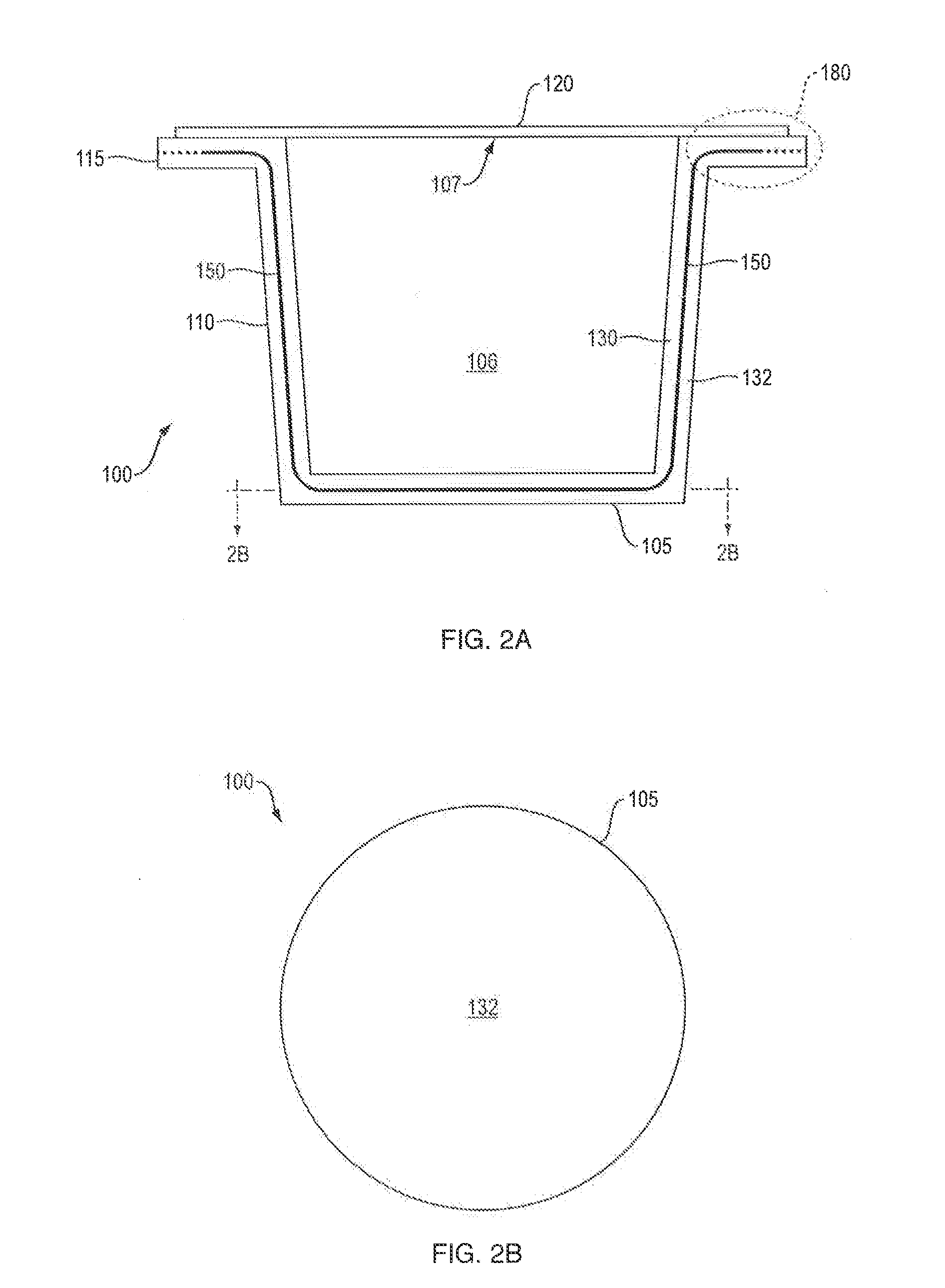

Gas impermeability for injection molded containers

ActiveUS20120015122A1Simple materialIncrease moisture contentConfectioneryCeramic shaping apparatusSteam lineShell molding

A molded multi-layer article has an interior layer contained within inner and outer layers. The article is molded by co-injecting the inner, outer, and interior layer materials into a mold defining a cavity. The interior layer material is caused to flow along a steam line offset from the zero velocity gradient of the combined material flow in a manner so that the interior layer material flow stream does not flow along or cross the zero velocity gradient yet has a greater flow velocity than the average flow velocity of the combined flow front. These methods and apparatus can mold four or more multilayer articles at once, each having an interior layer extending throughout 95% or more of the sealable portion of the article. The interior layer of a resultant article can extend throughout 99% or more of the sealable portion of the article.

Owner:CINCINNATI MILACRON INC

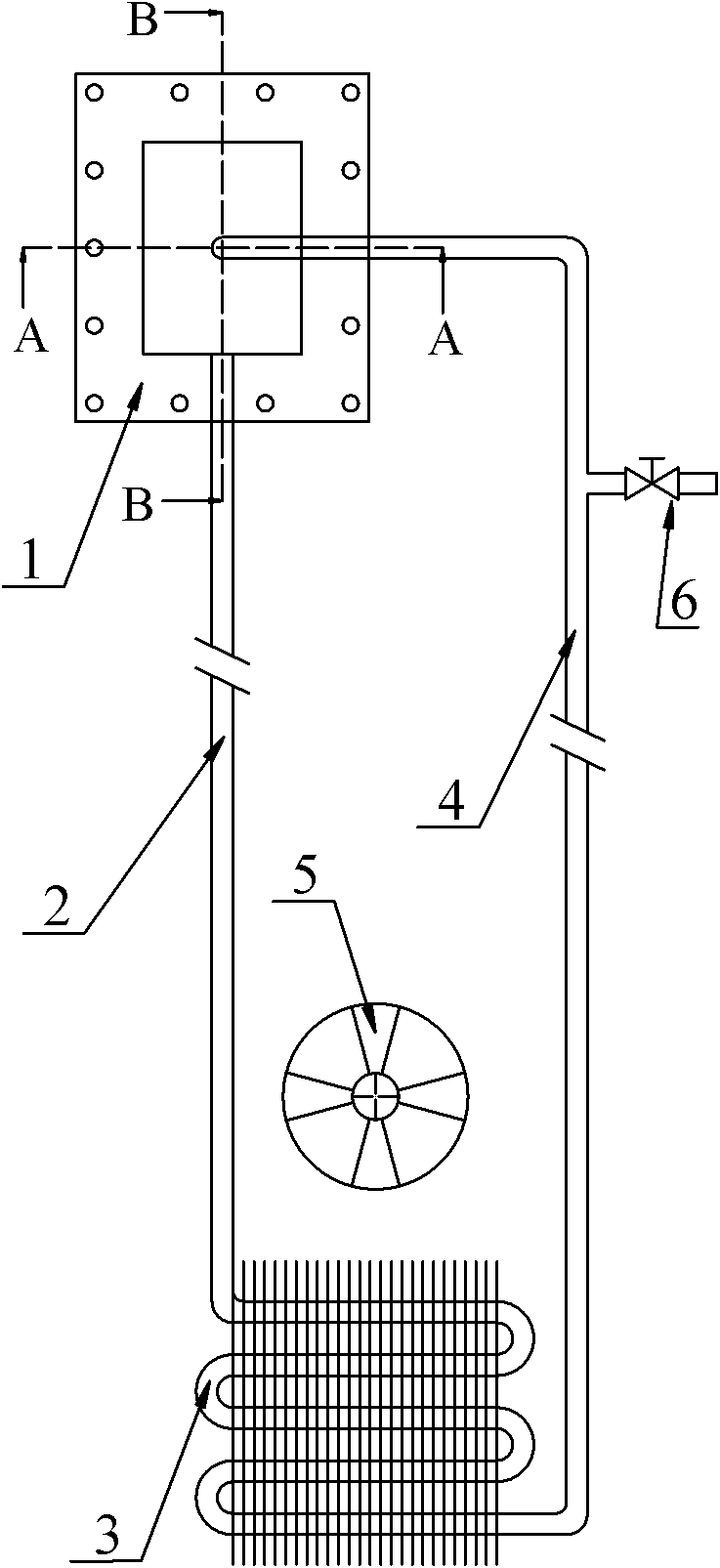

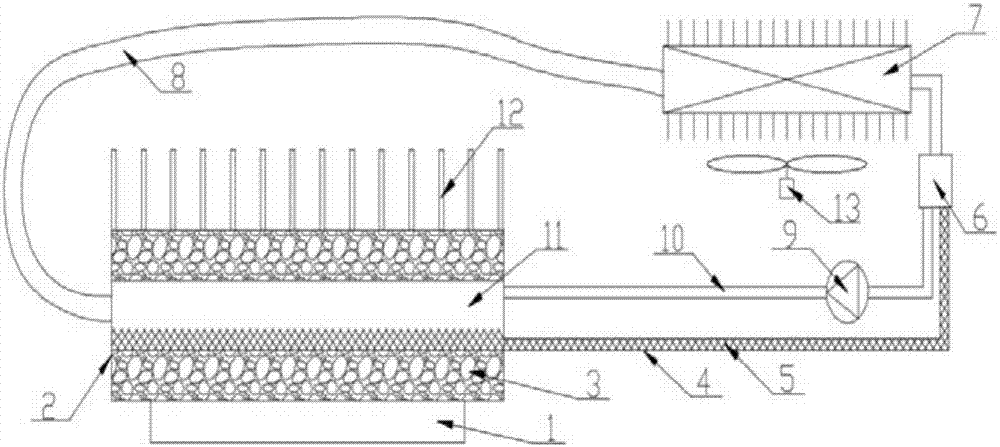

Active two-phase loop and phase change heat storage compound thermal control system

InactiveCN106954373AGood temperature control characteristicsLow circulation flow of working fluidModifications using liquid coolingTemperature controlLiquid line

The invention provides an active two-phase loop and phase change heat storage compound thermal control system, which belongs to the technical field of heat radiation and cooling. The system mainly comprises a heat absorber, a reservoir, a condenser, a steam line, a drive device, a liquid line and a blower fan. The heat absorber is of an integrated structure which is formed by packaging a head conducting housing, an evaporation chamber, a heat storage material and fins. The outlet of the evaporation chamber is communicated with the inlet of the condenser through the steam line, and the outlet of the condenser is connected with the reservoir and the drive device in sequence through the liquid line, and finally accesses to the inlet of the evaporation chamber, so as to form an enclosed loop. When the calorific value is small, heat can be absorbed by the heat storage material and radiated through the fins, so as to limit or delay the temperature rise; when the calorific value is larger, the drive device is started to operate the active two-phase loop. Specifically, when the heat changes dynamically or in a pulsed manner, the system maintains the good temperature control of the electronic chip or equipment, and has advantages of strong heat dissipation capacity, compact structure, safe temperature control, strong applicability, wide application range and the like.

Owner:TSINGHUA UNIV

Nuclear reactor safety casing

A reactor containment vessel of a boiling water reactor configured to contain a reactor pressure vessel. The reactor pressure vessel is connected to at least one main steam pipe which penetrates the reactor containment vessel at a main-steam-line penetration point. The main-steam-line penetration point is disposed on a first side of the reactor containment vessel. Distance between outer surface of the reactor pressure vessel and inner surface of the reactor containment vessel on the first side is longer than the distance on a second side which is opposite to the first side.

Owner:KK TOSHIBA

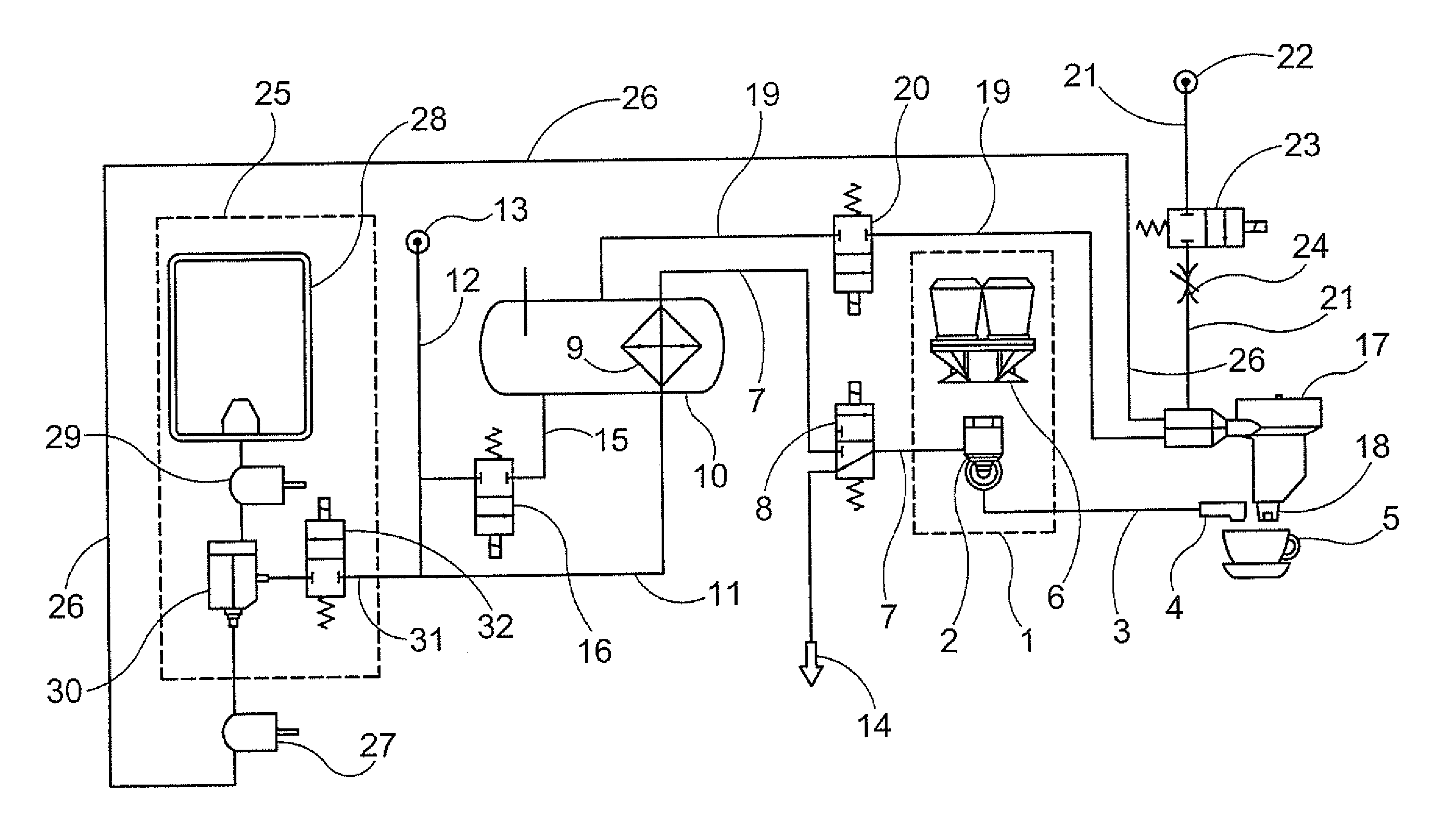

Apparatus and Method for Preparing Milk under Various Temperature and Consistency Conditions in a Coffee Machine for Forming Various Types of Beverages

InactiveUS20090092728A1Operation is necessarySatisfies needMixing methodsBeverage vesselsSteam lineWater source

Apparatus for preparing and dispensing hot or cold milk, in the frothed or non-frothed state, in a coffee machine for preparing various types of beverages based on coffee with milk, said coffee machine comprising a coffee apparatus for producing coffee with an associated coffee dispensing device, a first water heater for producing steam, a second water heater for producing hot water for preparation of the coffee in said coffee apparatus, said first and second heaters being connected to a water source for replenishing them with water, a frothing device provided with an internal chamber for frothing the milk when required and at least one nozzle for dispensing the milk externally, said apparatus comprising a milk line for the milk, connecting a source of liquid milk to the frothing device, a steam line for the steam, connecting the first water heater to the frothing device, as well as an air line for the air, connecting a source of air to the said frothing device, a pump arranged along the milk line for supplying the milk from said source of liquid milk to said frothing device, a first intercept valve arranged along the steam line and a second intercept valve arranged along the air line, wherein said pump arranged along the milk line and said first and second intercept valves are able to be operated independently of each other such that the milk line, the steam line and the air line are connected to said chamber of the frothing device one at a time or in combination with each other.

Owner:GRUPPO CIMBALI SPA

Heat stable wrinkle finish powder coatings

InactiveUS6897259B1Improve thermal stabilityEasy to useSynthetic resin layered productsPowdery paintsWrinkle skinPolyester

The present invention provides a powder composition for forming a heat stable wrinkle finish coating and the wrinkle finish coatings formed there from. The composition of the present invention comprises a resin consisting essentially of one or more than one silicone resin having a condensable hydroxyl content of from 2% by weight to 7% by weight, a curing agent, preferably an aminoplast, and a wrinkle finish forming catalyst, preferably an amine salt of triflic acid. In another embodiment, the powder composition of the present invention may comprise a hydroxyl functional resin, preferably a polyester, mixed with the said silicone resin to aid in the adhesion of the coating to a substrate. The composition of the present invention may further comprise up to 60 phr of a filler, such as wollastonite, to aid in heat stability. The coatings of the sent invention provide outstanding heat stability at temperatures greater than 350° F. and up to 550° F., preferably up to 650° F., for use on automobile or motorcycle exhaust systems, engine covers, manifolds, mufflers and engine parts, moves, fireplaces, stovepipes, grilles, ovens, and barbecue equipment, boilers, kettles, furnaces, steam lines, heat exchangers and any surface routinely exposed to high heat for an extended time.

Owner:ROHM & HAAS CO

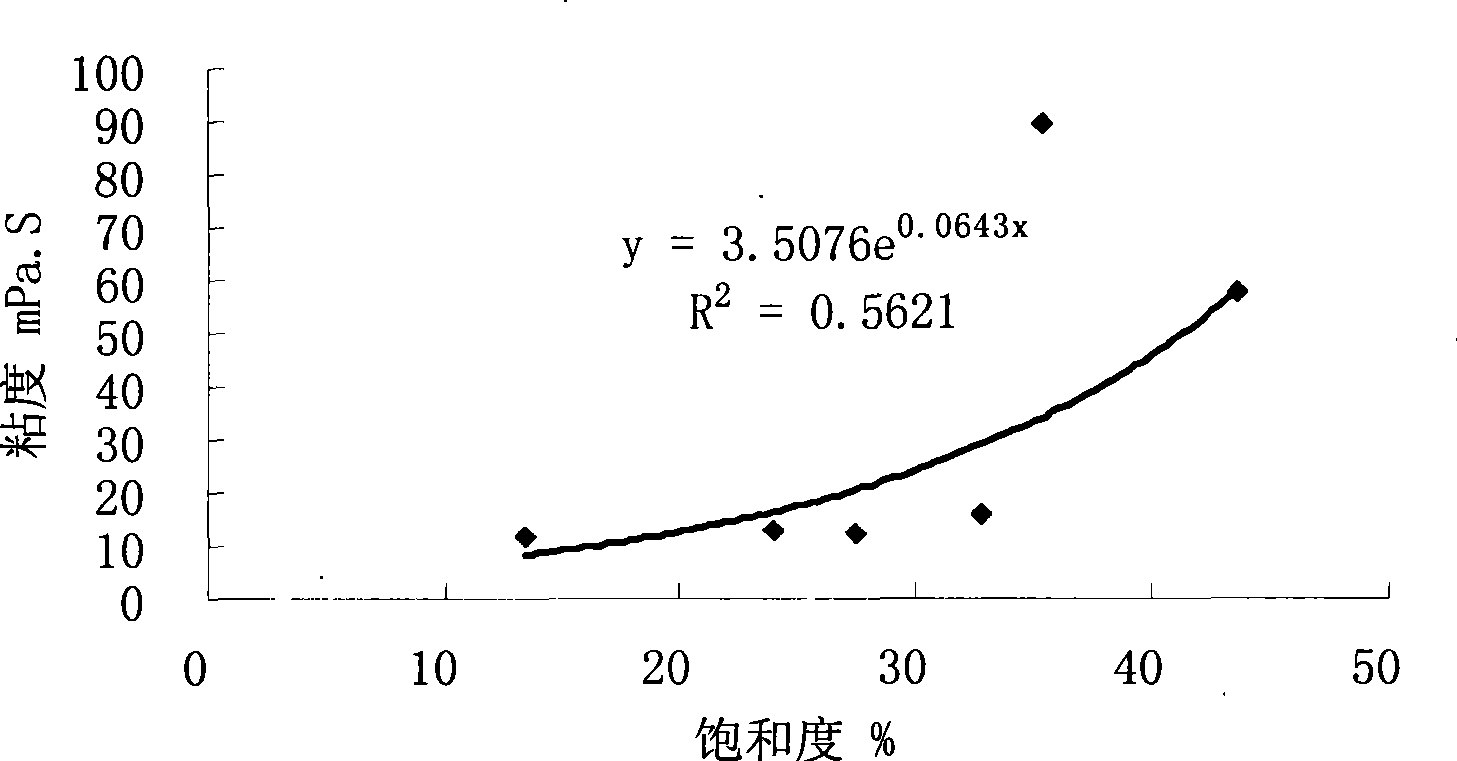

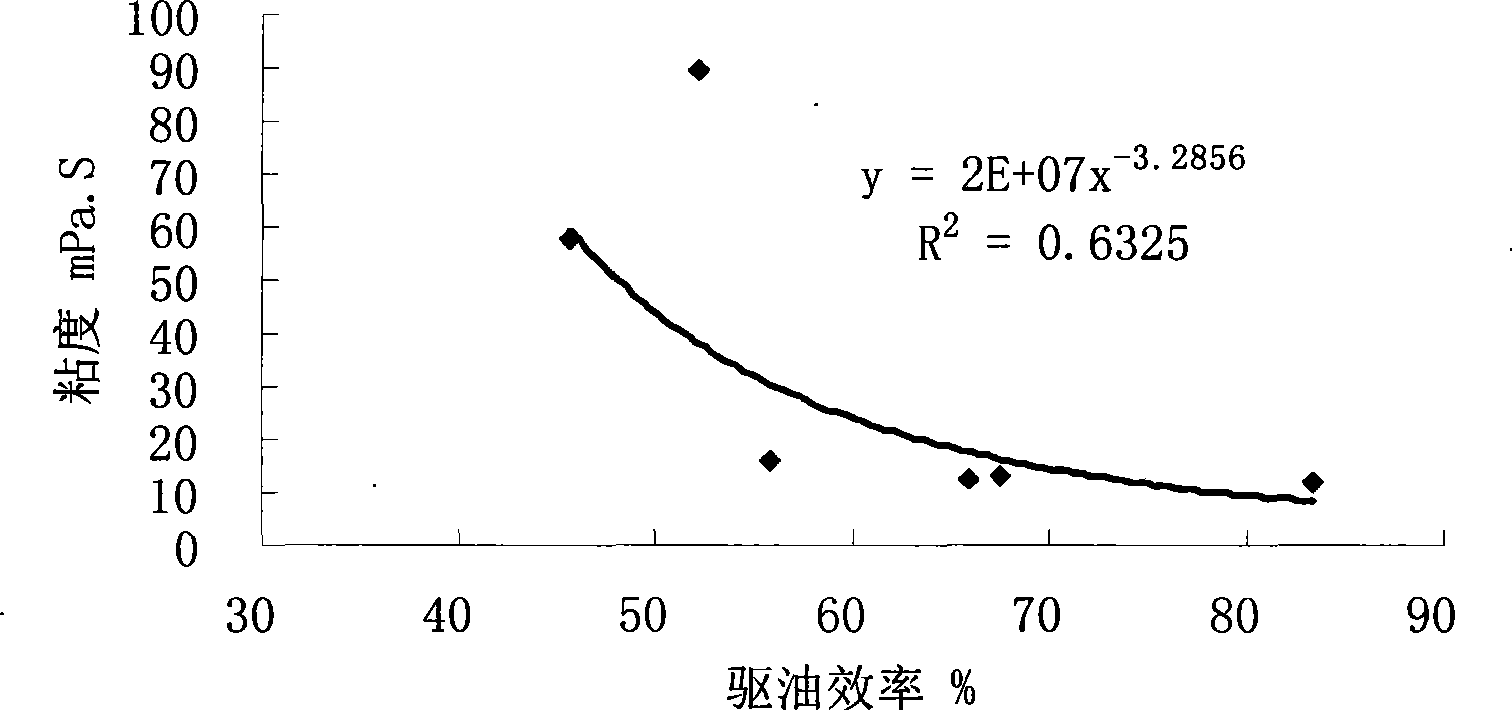

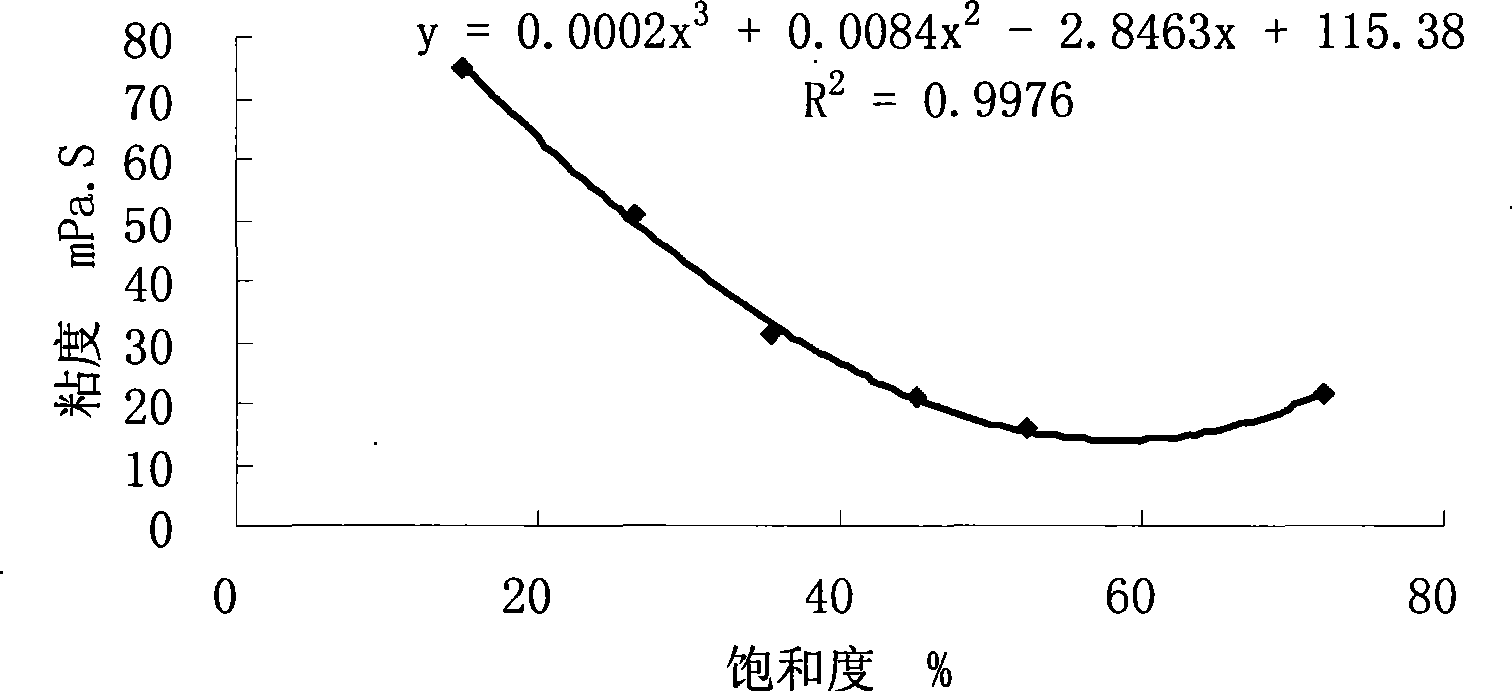

Geochemistry measuring method for pouring and acquiring residual oil parameter characteristic and relationship of mainstream line and shunt line oil reservoir

ActiveCN101424185AEnhanced overall recoveryFill the gaps in the worldGeological measurementsBorehole/well accessoriesPorosityOil viscosity

The invention relates to method for measuring geochemical parameter characteristics and relation of remaining oil of an oil reservoir between a main stream line and a dividing steam line for injection and production, which relates to the field of crude oil development. The method solves the problems that the prior physical simulation method cannot obtain the parameters and the relation thereof of the actual remaining oil saturation on the main stream line and the dividing steam line. The method comprises the following steps: obtaining the parameters of the remaining oil saturation, oil displacement efficiency, remaining oil viscosity, permeability and porosity through measuring an oil sand sample of a core-taking inspection shaft on the main stream line and the dividing steam line of oilfield development; obtaining the fluidity parameters and the geochemical characteristics of remaining oil layers of the main stream line and the dividing steam line; respectively ensuring the relation between the geochemical parameters of the remaining oil of the main stream line and the dividing steam line according to the relativity analysis of the obtained parameters; and ensuring the geochemical parameter characteristics and the relation of the remaining oil of the main stream line and the dividing steam line for the injection and the production, and further obtaining the variation tendency. The method has an important significance on recognizing the distribution rule of the remaining oil of the oil reservoir of the main stream line and the dividing steam line, making a remaining oil development proposal, and improving the recovery ratio of the crude oil.

Owner:DAQING OILFIELD CO LTD +1

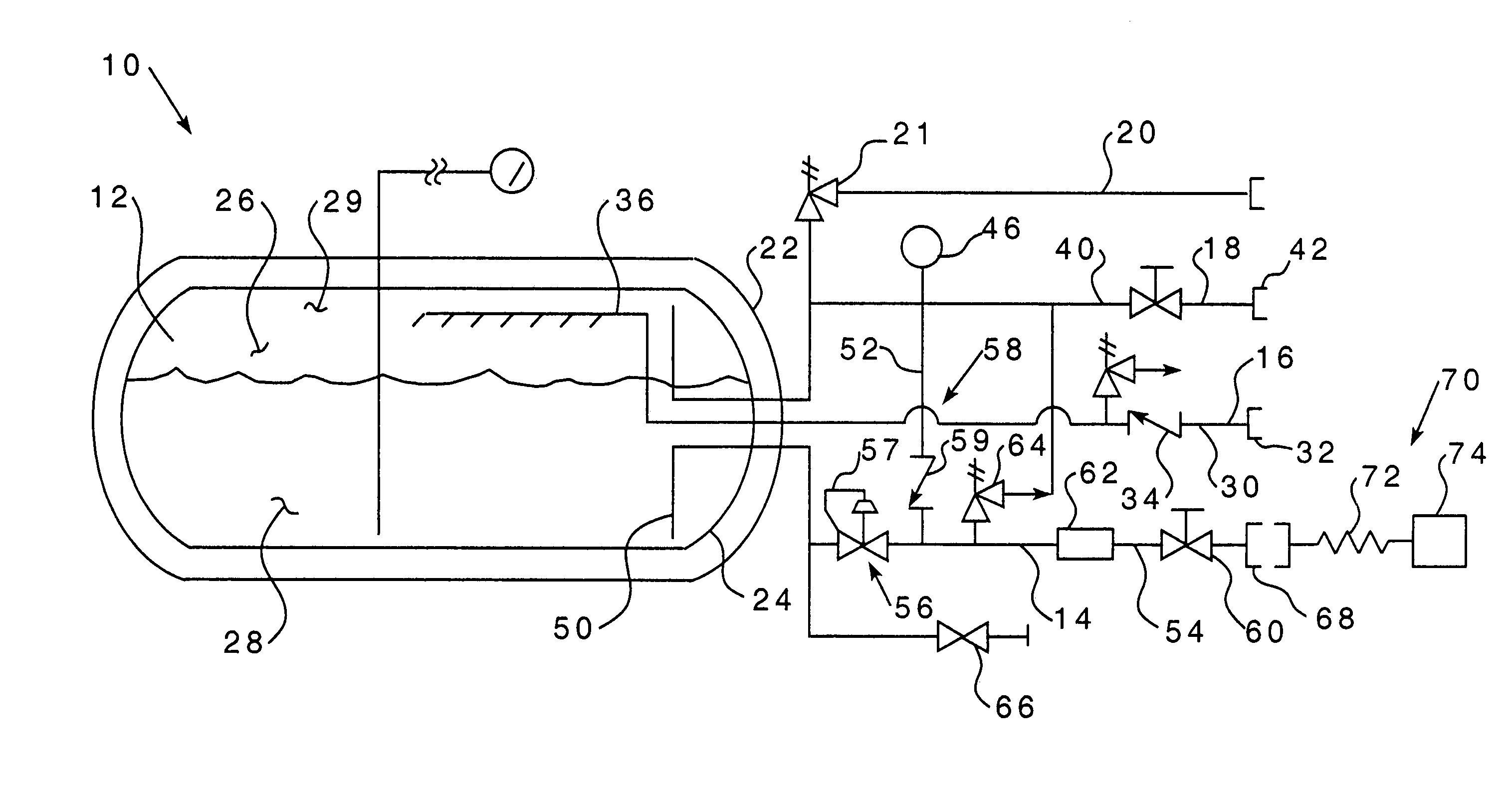

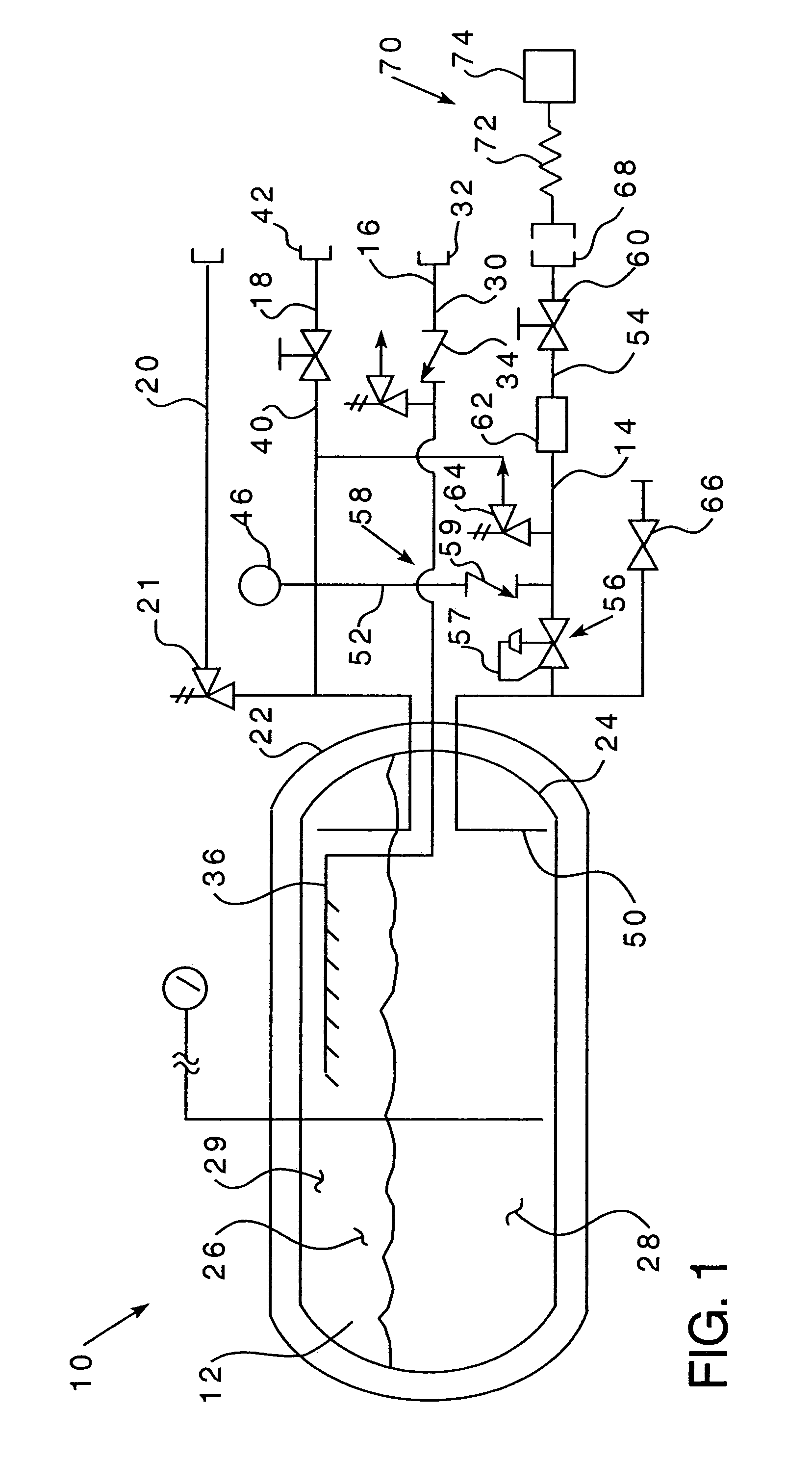

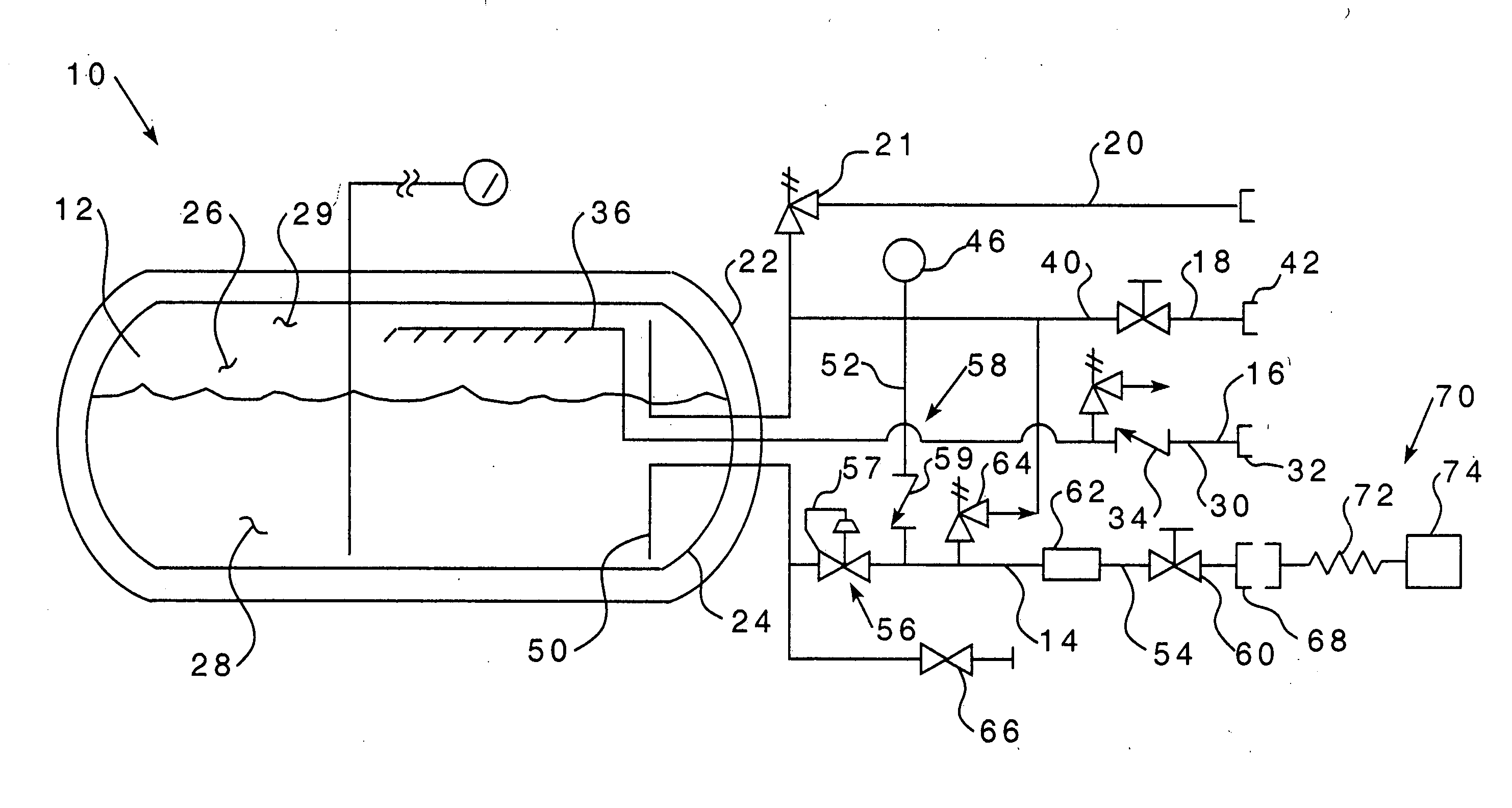

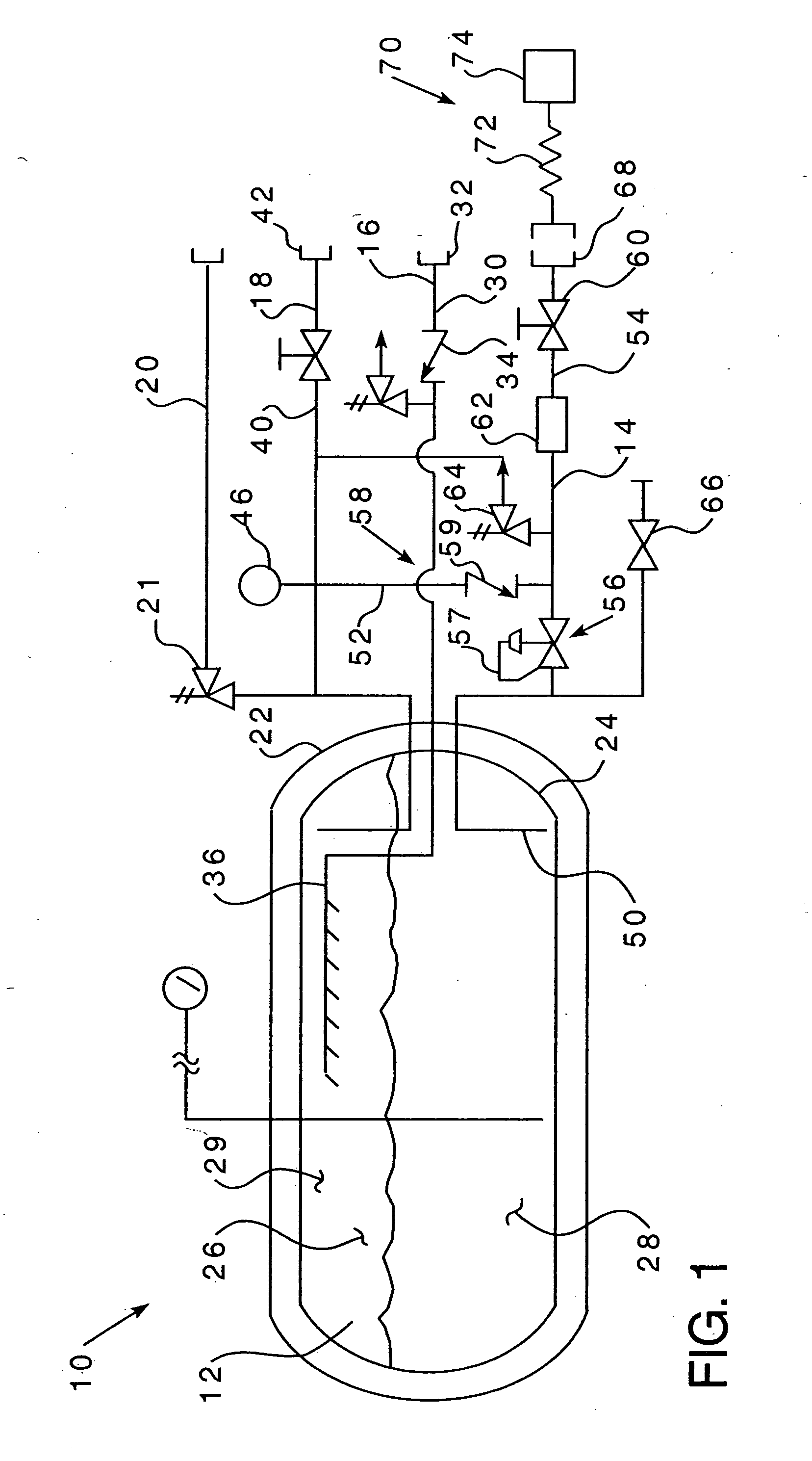

Pressure Management system for liquefied natural gas vehicle fuel tanks

InactiveUS20060010882A1Open structureIncrease pressureContainer filling methodsGas handling applicationsLiquid lineSteam line

A storage and delivery device for a cryogenic liquid that includes a vessel assembly and a delivery line assembly. The vessel assembly has a liquid space and a vapor space. The delivery line assembly has a liquid line, a vapor line, and a delivery line. The liquid line is in fluid communication with the liquid space. The vapor line is in fluid communication with the vapor space. The liquid line has a flow control device located thereon and structured to control the flow of fluid through the liquid line. The liquid line flow control device is structured to close the liquid line when the vessel assembly is at a predetermined pressure.

Owner:TW CRYOGENICS

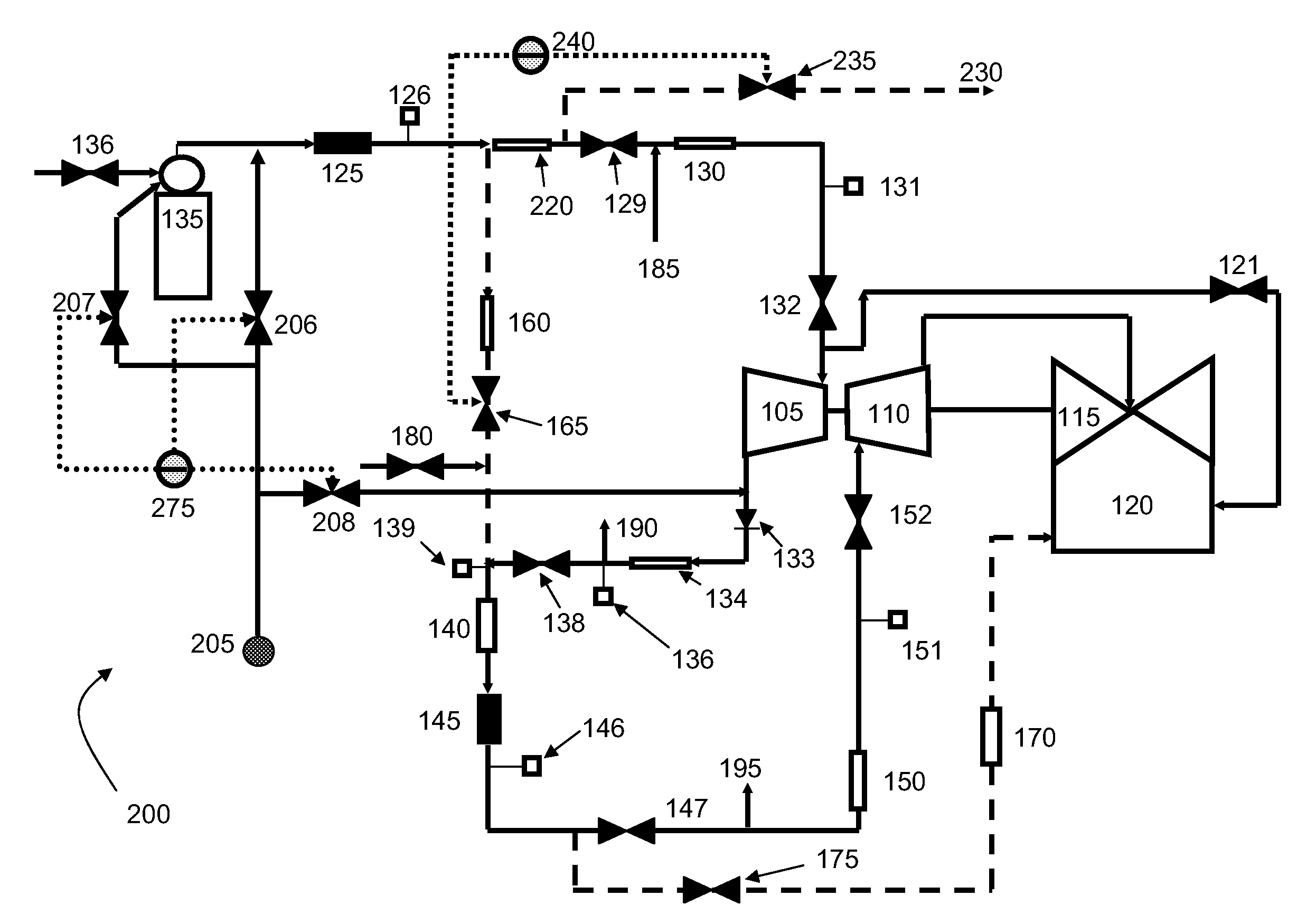

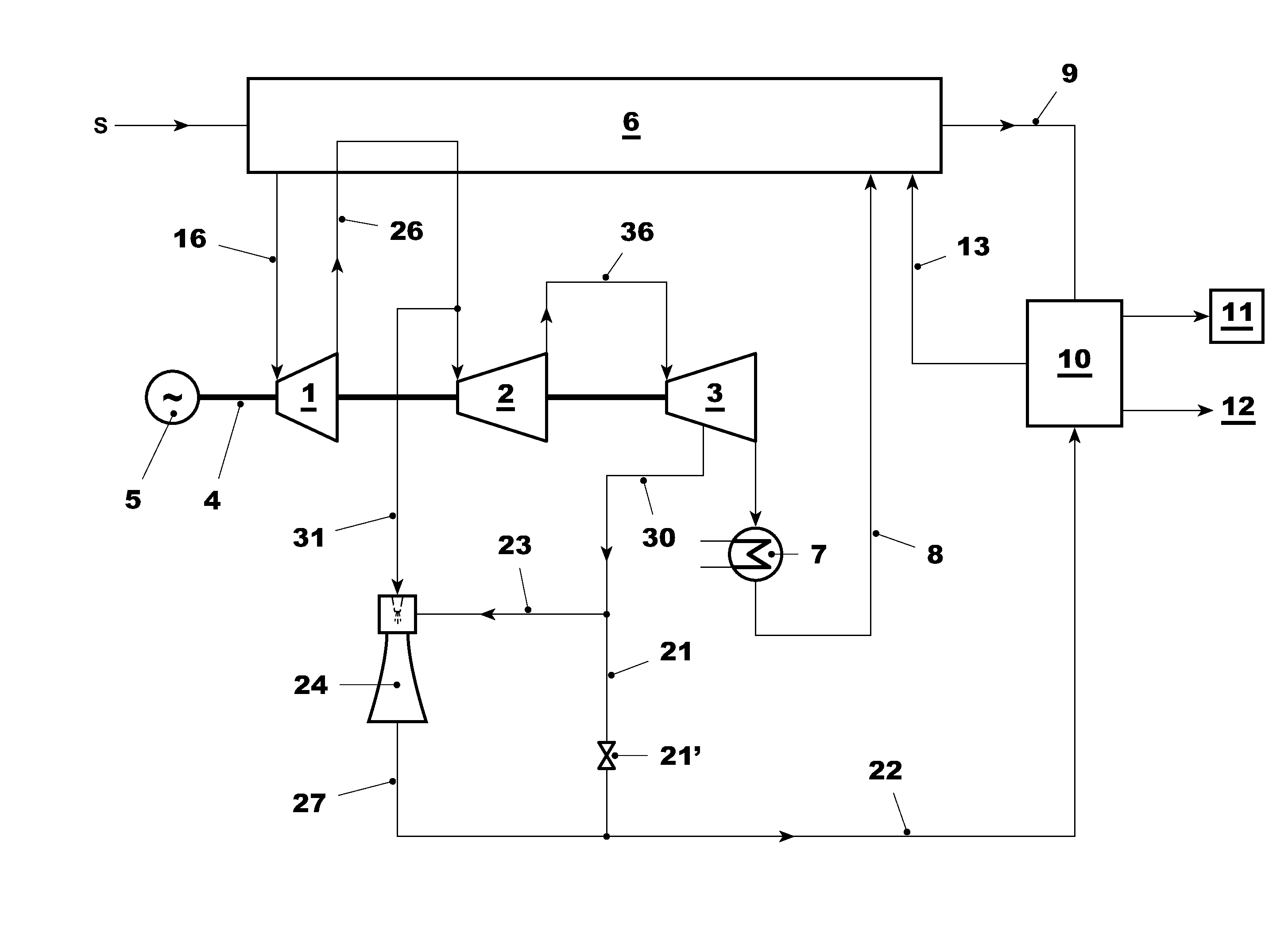

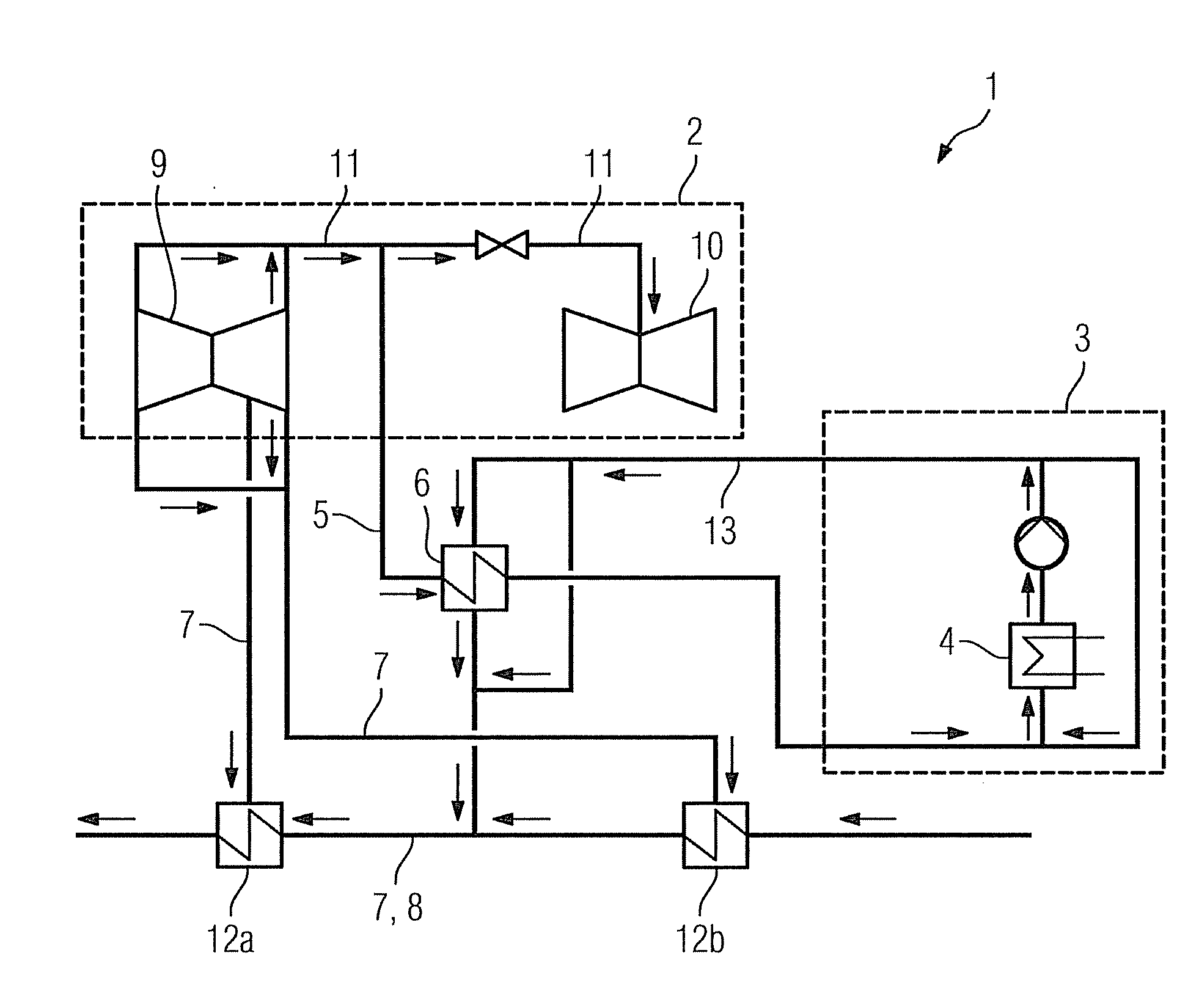

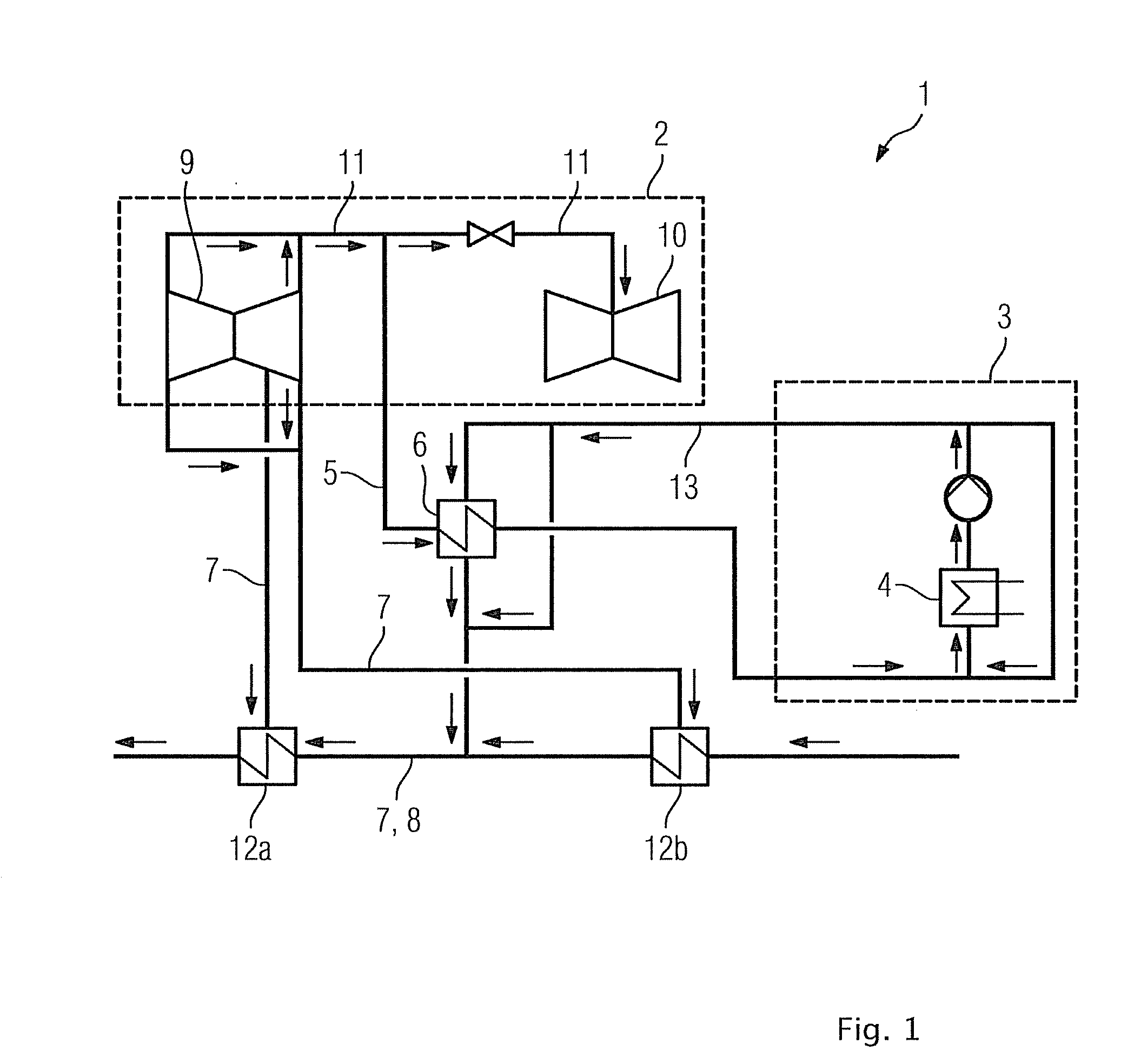

Power plant with co2 capture and method to operate such power plant

ActiveUS20130133326A1Improve efficiencyImprove reliabilitySteam useDirect carbon-dioxide mitigationNuclear engineeringElectric power

A fossil fuel fired power plant for the generation of electrical energy comprises a water steam cycle and a plant (10) for the capture of CO2 from exhaust gases emitted by the power plant and a steam jet ejector (24) configured and arranged to receive an input steam flow from a low- or intermediate pressure extraction point in the power plant and to increase its pressure. It is further arranged to receive motive steam (25) from a further extraction point in the power plant. A steam line (27, 22) directs the steam of increased pressure from the steam jet ejector (24) to the CO2 capture plant (10). The power plant according to this invention allows the use of low-pressure steam for the operation of the CO2 capture plant, where the extraction of such steam affects the overall efficiency of the power plant to a lesser degree than in power plant of the state of the art.

Owner:GENERAL ELECTRIC TECH GMBH

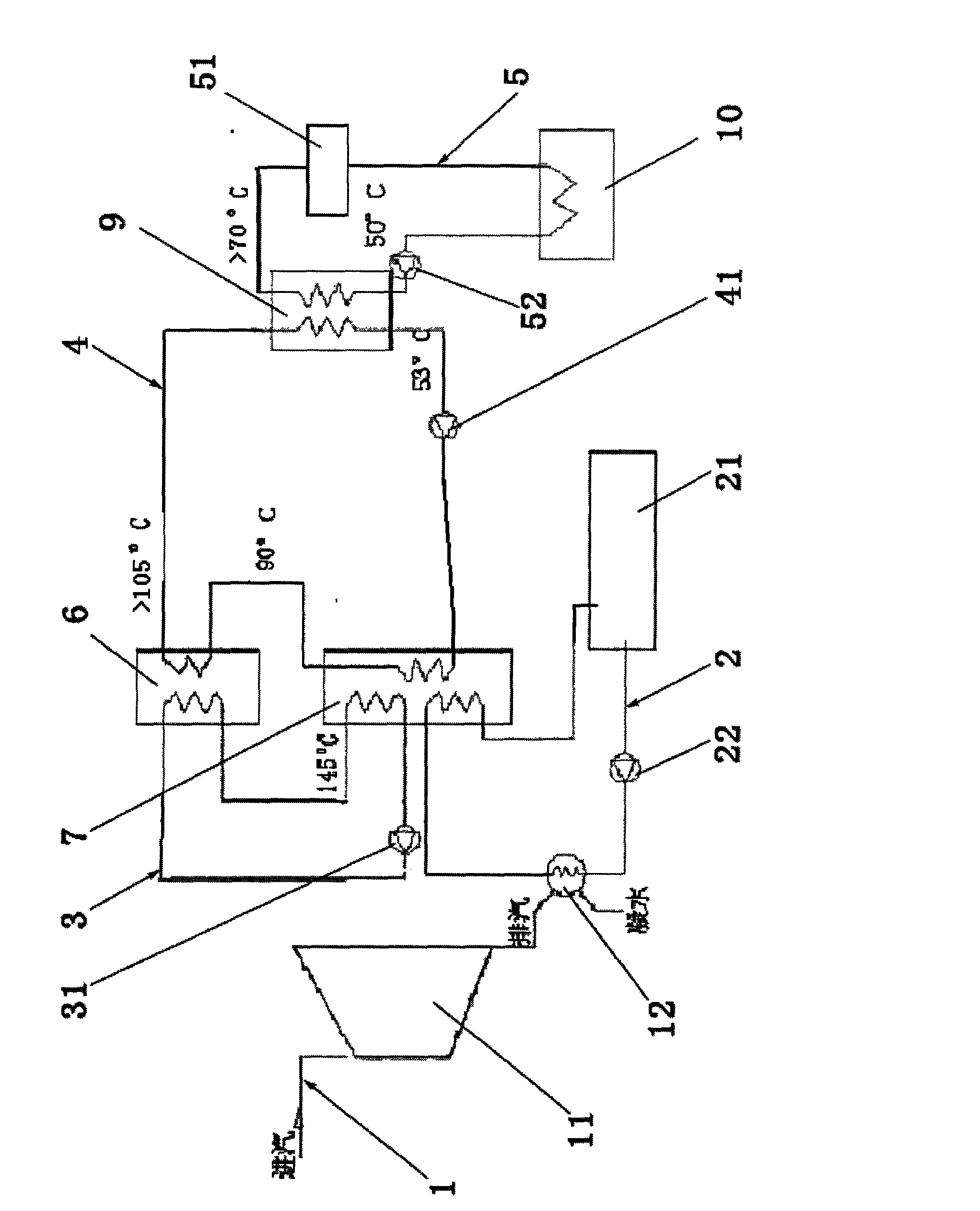

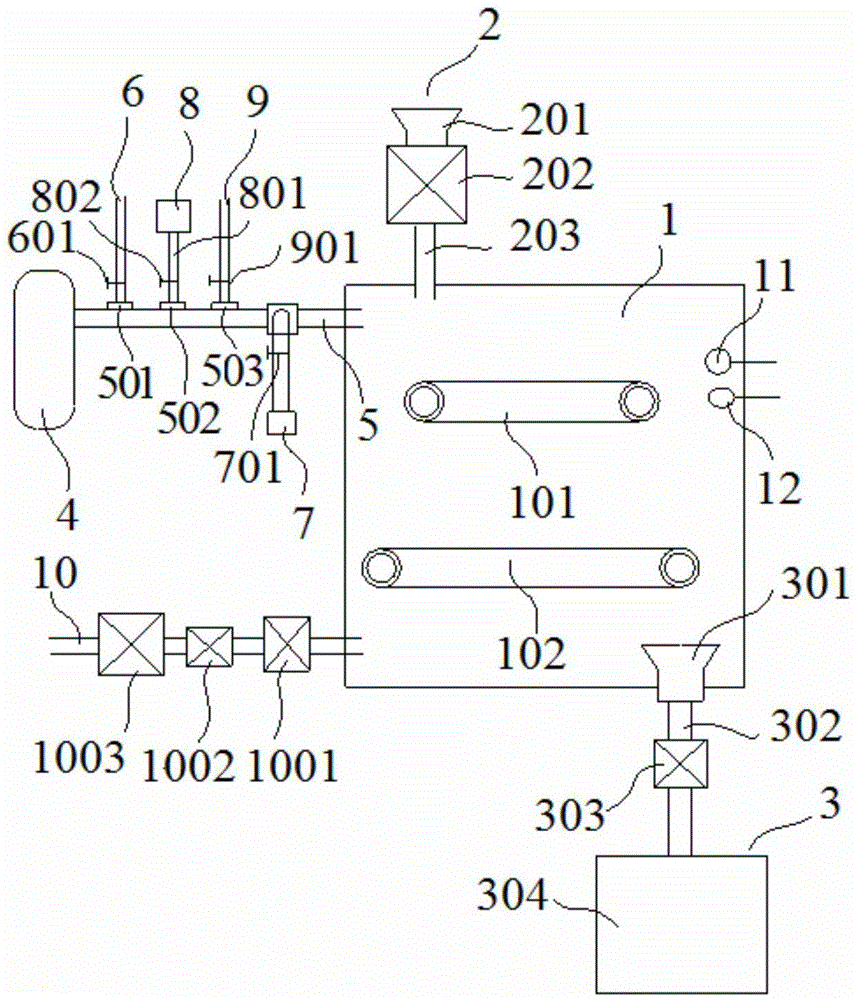

Waste heat recovery heating system of biomass power plant

InactiveCN103017238AImprove recycling ratesLighting and heating apparatusEnergy efficient heating/coolingThermal energySlag

The invention relates to a heat recovery device, and discloses a waste heat recovery heating system of a biomass power plant. The waste heat recovery heating system comprises a steam line, a cooling water circulation line, an inner circulation line and a heating line, wherein the heating line is connected with a slag heat exchanger, and is connected to a heat user side after heat is absorbed by a water heat exchanger. The waste heat recovery heating system recovers waste heat in flue gas, slag and circulating cooling water of the biomass power plant in a heat exchange mode to be used for life and production heat supply, and the waste heat recovery heating system has the advantages of high recovery use ratio of heat energy, energy conservation, environmental protection and the like.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

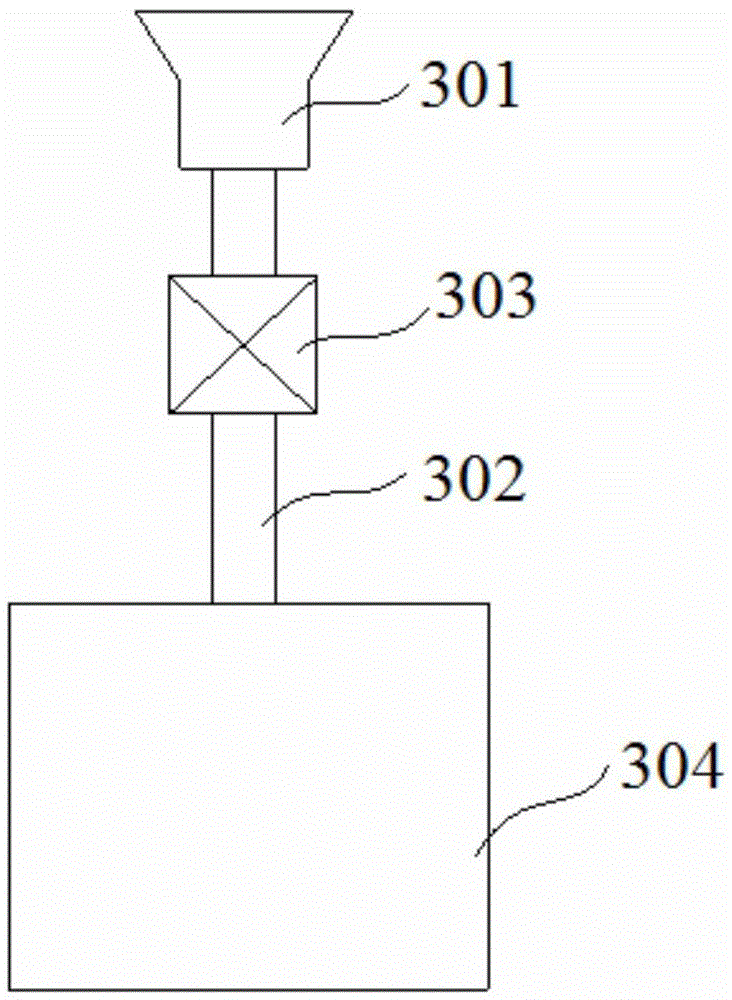

Steam power plant with steam turbine unit and process steam consumer, and method for operating a steam power plant with steam turbine unit and process steam consumer

InactiveUS20120111007A1Improve steaming efficiencyShorter piping routesSteam useDirect carbon-dioxide mitigationPower stationSteam line

A steam power plant having at least one steam turbine unit and a process steam consumer is provided. The process steam consumer includes a heat exchanger. The steam turbine unit is connected to a heat exchanger by means of a extraction steam line, and a desuperheater is connected in the primary side of the extraction steam line, so that process steam extracted through the extraction steam line of the turbine system may be conditioned by the desuperheater to the process conditions of the process steam consumer, and the heat energy removed in the desuperheater can be fed back into the steam power plant system.

Owner:SIEMENS AG

Temperature control sludge drying system

InactiveCN105645724AImprove drying efficiencyImprove drying effectWater treatment parameter controlSludge treatment by de-watering/drying/thickeningThermal energyExhaust valve

The invention discloses a temperature control sludge drying system, comprising a dryer, a feeder, a discharger, a combustor, an intake line, a CHP waste gas line, a CHP wastewater circulation system, a gasifier, a steam line, an exhaust line, a temperature monitor probe, a humidity monitor probe, and a control cabinet. The temperature monitor probe and the humidity monitor probe are disposed in the dryer, a valve is disposed in front of an intake port of the intake line, the control cabinet acquires interior temperature and humidity of the dryer and controls the interior temperature and humidity of the dryer through a control valve,, the automation level is high, control precision is high, drying efficiency is high, drying effect is good, and energy utilization rate is high; the intake line is provided with a plurality of intake ports connected with blocked waste heat gas, and industrial waste heat is used to replace fuel combustion to generate heat, thus saving energy and reducing cost; the CHP wastewater circulation system heats gas in the intake line through the heat of wastewater, thus further saving energy.

Owner:PULIZI ENVIRONMENT TECH SUZHOU CO LTD

Method of stress corrosion cracking mitigation for nuclear power plant structural materials

InactiveUS20080292042A1Reduce stressIncrease dose ratePlant parameters regulationNuclear energy generationCobalt-60Steam line

The object of this invention is to provide a method for mitigating a stress corrosion cracking of reactor structural material which makes it possible to suppress the rise in the main steam line dose rate without secondary effects such as a rise in the concentration of radioactive cobalt-60, etc. in the reactor water. Hydrogen and a reductive nitrogen compound containing nitrogen having a negative oxidation number (for example, hydrazine) are injected into the core water of boiling water nuclear power plant. By injecting the reductive nitrogen compound containing nitrogen having a negative oxidation number into the core water, the stress corrosion cracking of structural material of reactor can be mitigated without side reactions such as a rise in the concentration of cobalt-60, etc.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

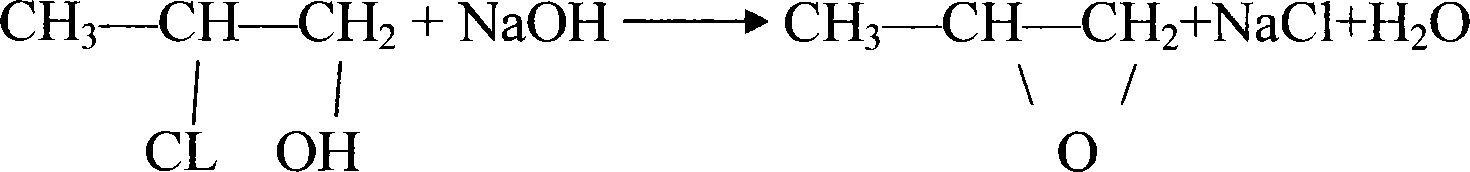

Device and method for producing trimethylene oxide by using electrolytic solution as saponification agent

The invention discloses a device with electrolytic solution as saponifier to produce epoxypropane and method, which is characterized by the following: comprising chloropropyl alcohol reservoir, mixer, vacuum pump, saponifying tower, condenser, rough epoxypropane reservoir, saline water demineralization device, flash tank and electrolytic solution reservoir; connecting chloropropanol reservoir with mixer through chloropropanol conduit line; connecting the mixer to saponifying tower through miscible liquids line; connecting the saponifying tower to condenser through epoxypropane steam line; connecting the saponifying tower to the flash tank through saponification waste liquor line before flash distillation; connecting the saponifying tower to flash tank through steam line; connecting the condenser to rough epoxypropane reservoir through rough epoxypropane line; connecting the flash tank with saline water demineralization device through saponification waste liquor line after flash distillation; connecting the electrolytic solution reservoir to the mixer through electrolytic solution line. This invention possesses low energy consumption, which can be reclaimed as the raw material of caustic soda production.

Owner:HANGJIN JINXI CHLOR-ALKALI CHEM CO LTD

Steam heating soybean milk maker

InactiveCN101828869AAvoid damageExtended service lifeBeverage vesselsMilk substitutesSteam lineEngineering

The invention belongs to the technical field of soybean milk makers and solves the problem that steam produced by heating soybean milk can damage the motor system. The invention particularly relates to a steam heating soybean milk maker which comprises a steam generator, a steam line, a cup body, a grinder and a motor system, wherein one end of the steam line is inserted into the cup body, and the other end is communicated with a steam outlet of the steam generator; the motor system is connected with the grinder; the grinder is installed at the bottom in the cup body; and the motor system is installed under or on the lateral side of the cup body. The invention can effectively prevent the motor system from being damaged by the steam generated by heating the soybean milk and prevent the motor system from being damaged by the heat generated by the steam line, thereby greatly prolonging the service life of the motor system.

Owner:MIDEA GRP CO LTD

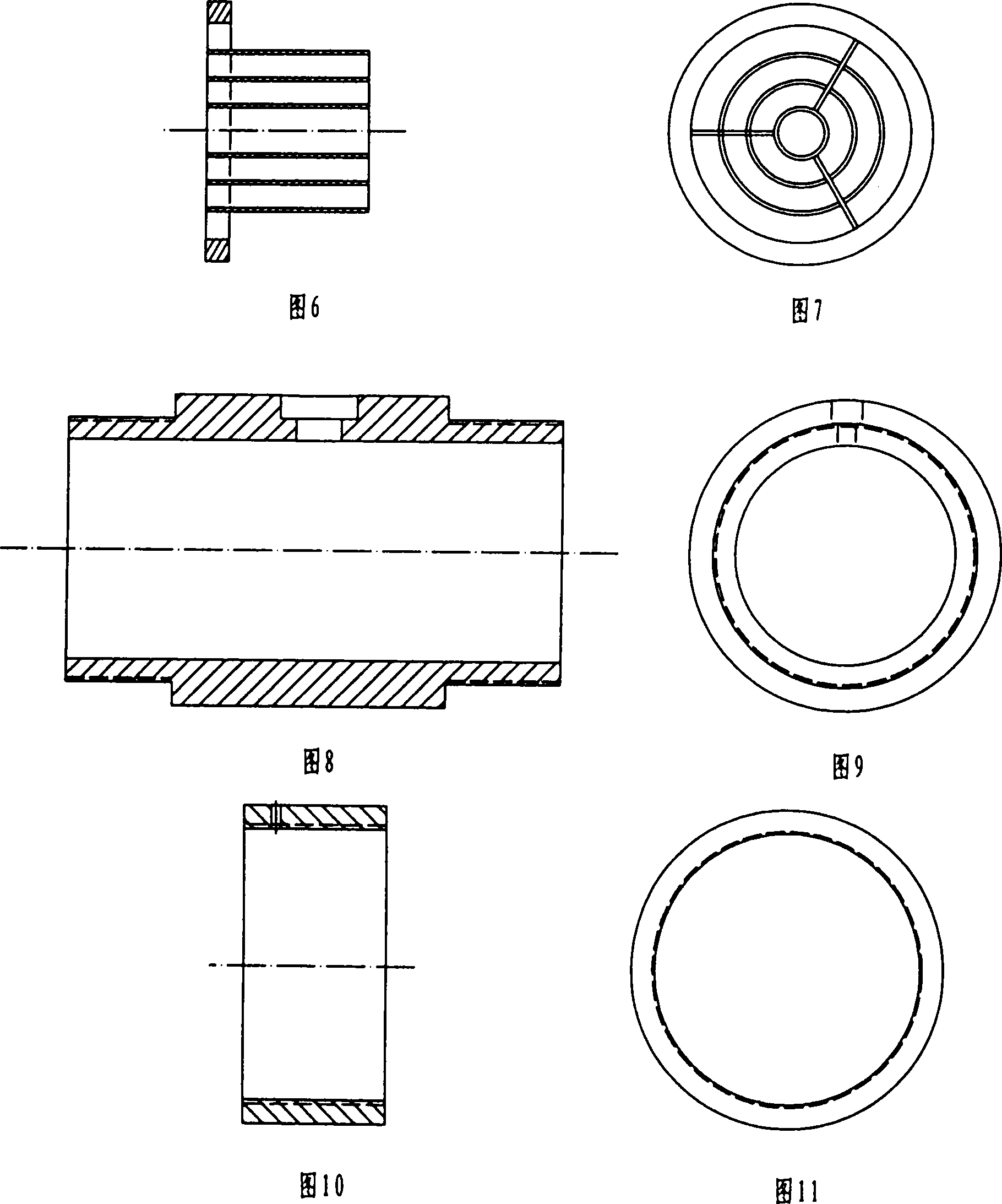

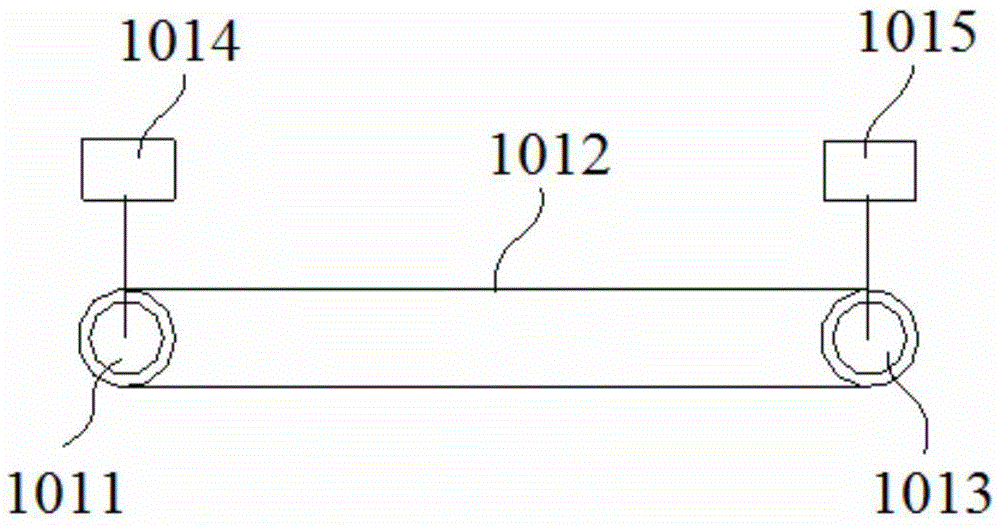

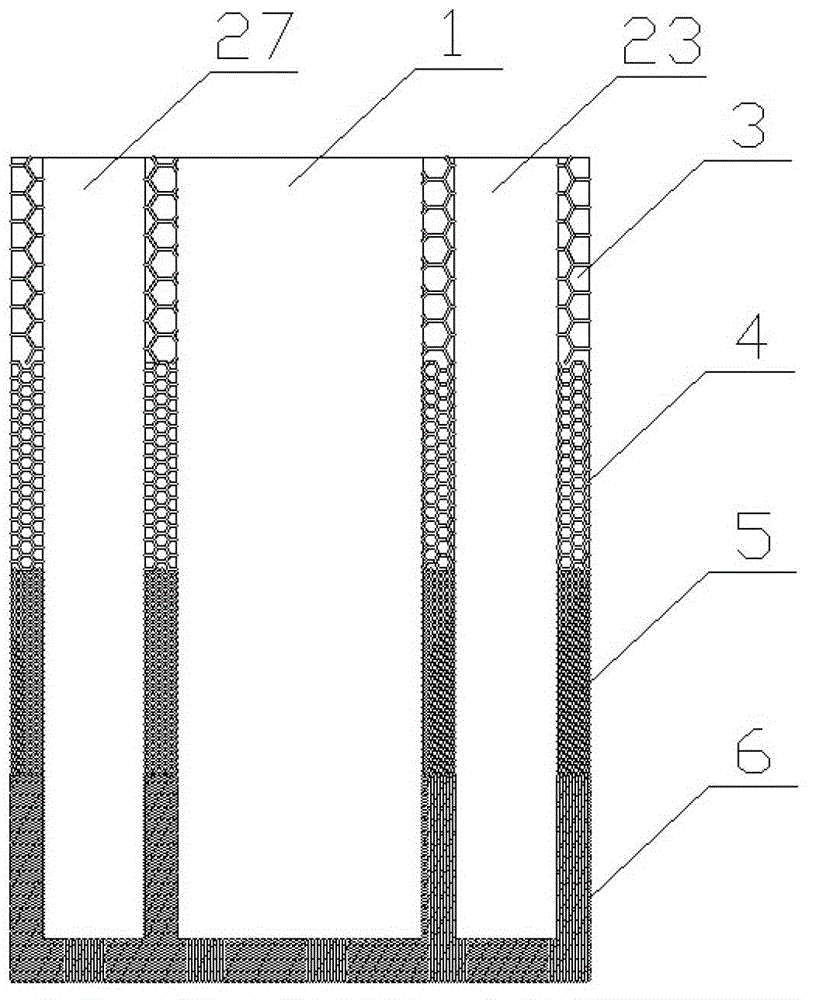

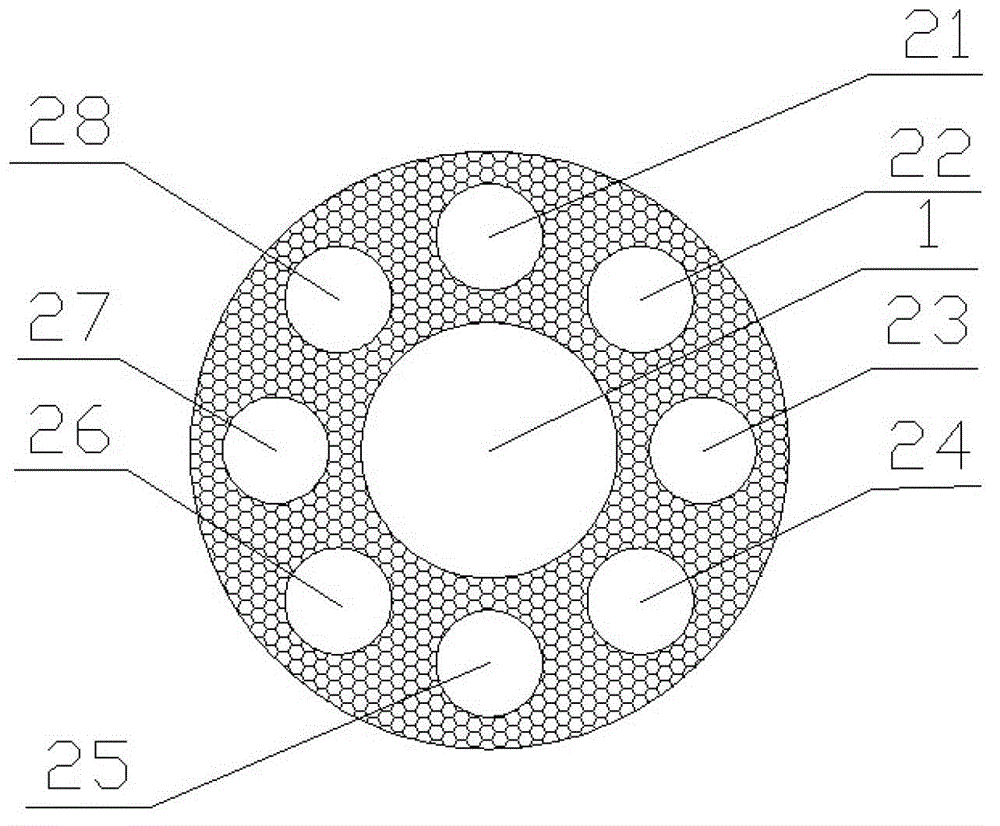

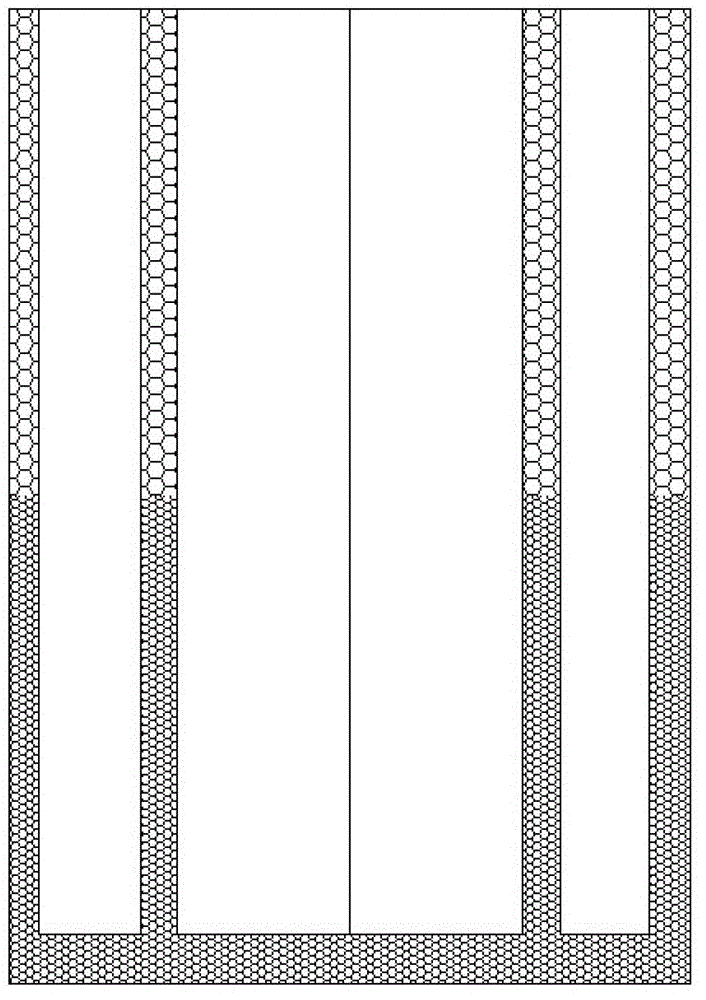

Compound imbibing core for thermal column array steam main line and manufacturing method thereof

ActiveCN103335550ASame manufacturing processRealize industrializationIndirect heat exchangersPorositySteam line

The invention discloses an imbibing core for a thermal column array steam main line and a manufacturing method thereof. The imbibing core comprises a steam main line and capillary layers, wherein the capillary layers are multiple sections of copper powder sintered type capillary layers overlapped along the axle direction of the imbibing core; the capillary layers at the different sections are provided with different porosities; from the position close to a heat source, the capillary layers are arranged in the axle direction of the imbibing core and in a gradient manner according to the porosities in increasing sequences; the steam main line adopts a hollow structure, penetrates the whole capillary layers, and comprises main steam main lines and secondary steam main lines; the main steam main lines are positioned in the center of the cylindrical compound imbibing core; a plurality of secondary steam main lines are positioned at the periphery of the main steam main lines; the secondary main lines are arranged at intervals, and the secondary main steam lines and the main steam lines are arranged at intervals. The compound imbibing core optimizes the structure of the thermal column imbibing core realizes three-dimensional flow of condensation working substances in the axle direction, circumferential direction and radial direction, and has the advantages of low thermal resistance, strong heat-transfer capability, strong suitability for angles, easiness and practicability in manufacturing technique, low cost and the like.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com