Method of stress corrosion cracking mitigation for nuclear power plant structural materials

a technology of stress corrosion cracking and nuclear power plant, which is applied in nuclear engineering, nuclear elements, greenhouse gas reduction, etc., can solve the problems of increasing the concentration of radioactive cobalt co-60 in the cooling water of the reactor, and achieve the effect of suppressing the rise in the dose rate of the main steam line and reducing the concentration of radioactive cobalt co-60

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

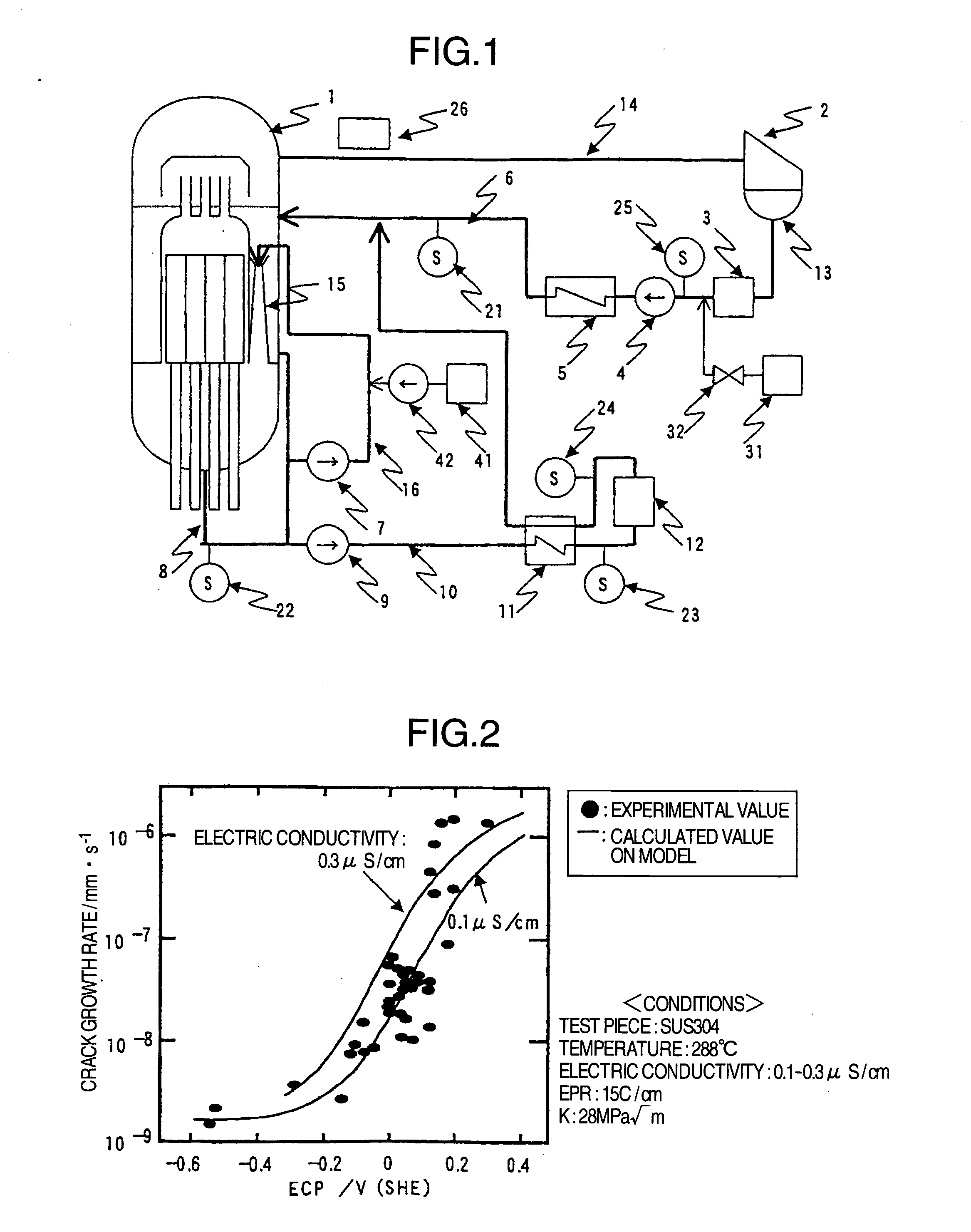

example 1

[0065] As the first example of this invention, an example in which only a reductive nitrogen compound is injected at the times of start up and shut down will be mentioned. At the times of start up and shut down, temperature is low and γ-ray exposure is small, so that the water-forming reaction between reductive nitrogen compound and oxygen and hydrogen peroxide does not take place readily. FIG. 5 illustrates hydrazine concentration dependence of ECP of 304SS, wherein hydrazine was added as a reductive nitrogen compound. If the ECP dependence of CGR shown in FIG. 2 is taken into consideration, it is necessary to add hydrazine in an amount of 50 ppb or more or further preferably in an amount of 100 ppb or more in order to reduce CGR to {fraction (1 / 10)} of that in the case of no hydrazine injection. On the other hand, addition of 300 ppb or more brings about no change in the ECP-lowering effect. From the electric conductivity dependence of CGR shown in FIG. 2, it is apparent that, eve...

example 2

[0071] Next, as the second example of this invention, an example in which only a reductive nitrogen compound is injected at the time of operation will be mentioned. Since temperature is high and γ-ray exposure is greatest at the time of operation, the water-forming reaction between reductive nitrogen compound and oxygen and hydrogen peroxide is accelerated. Accordingly it is necessary to inject the reductive nitrogen compound continuously.

[0072] In FIG. 6 are shown the changes of oxygen and by-products in a case of adding hydrazine as a reductive nitrogen compound to high-temperature water containing dissolved oxygen and carrying out a γ ray irradiation. In case that the concentration of reductive nitrogen compound does not reach the amount needed for converting oxygen to water, a residual part of oxygen remains. In case that the concentration of reductive nitrogen compound is higher than the amount necessary for converting oxygen to water, oxygen is consumed and ammonia is formed....

example 3

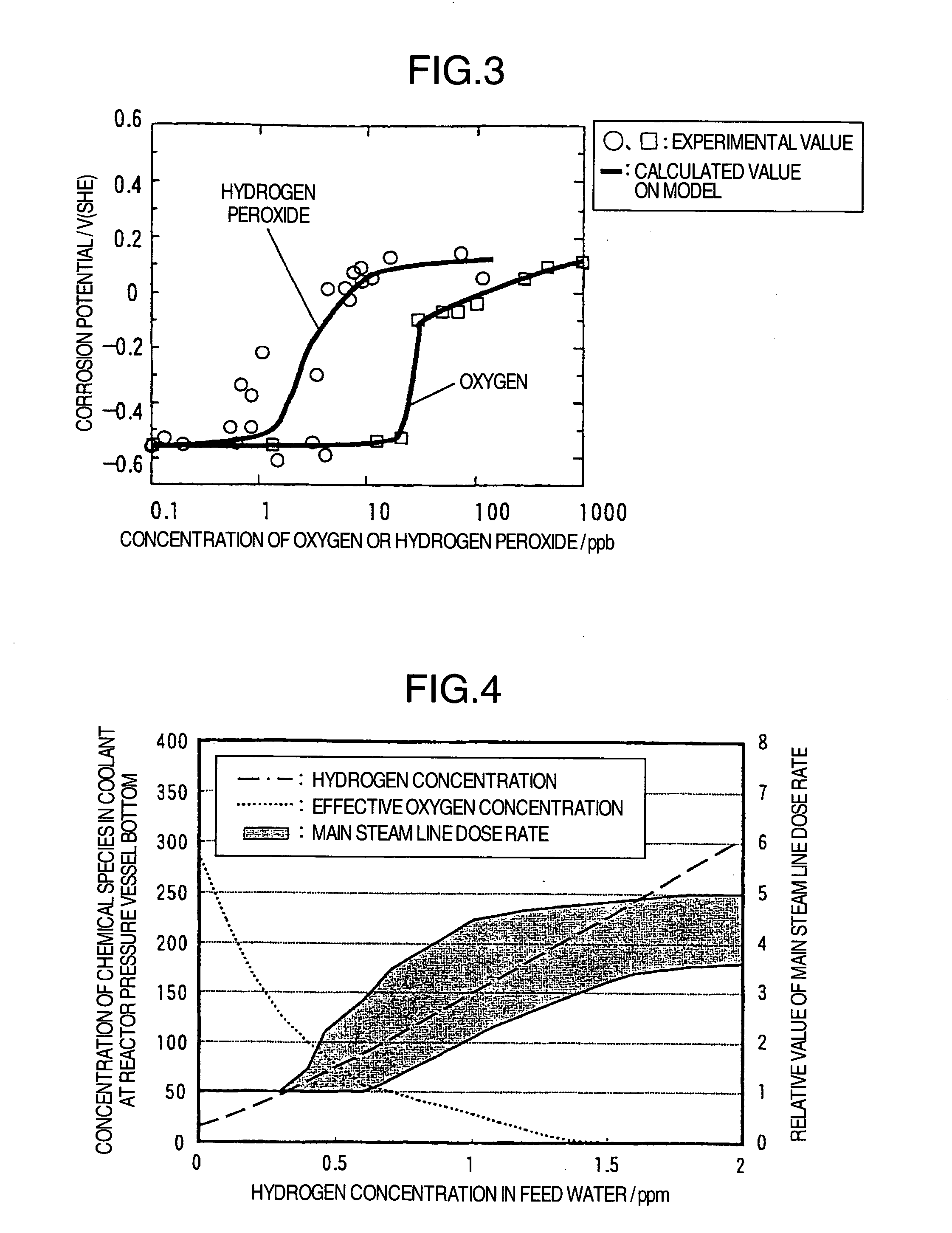

[0078] Next, as the third example of this invention, an example in which hydrogen and a reductive nitrogen compound are injected into the cooling water will be mentioned. In case that hydrogen is injected, the hydrogen concentration in the cooling water at the bottom of reactor pressure vessel increases. If the hydrogen concentration exceeds a definite value, dose rate of the main steam line can increase. Accordingly, it is necessary to control the amount of injected hydrogen together with the reductive nitrogen compound to obtain an optimum condition. Since hydrogen is usually cheaper in price than reductive nitrogen compound, it is preferable to increase the amount of hydrogen and decrease the amount of reductive nitrogen compound.

[0079]FIG. 13 diagrammatically illustrates the changes of concentrations of oxygen, hydrogen and ammonia in the cooling water at the bottom of reactor pressure vessel, and the dose rate of main steam line, in the case of changing the amount of injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com