Patents

Literature

833 results about "Reactor pressure vessel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A reactor pressure vessel (RPV) in a nuclear power plant is the pressure vessel containing the nuclear reactor coolant, core shroud, and the reactor core.

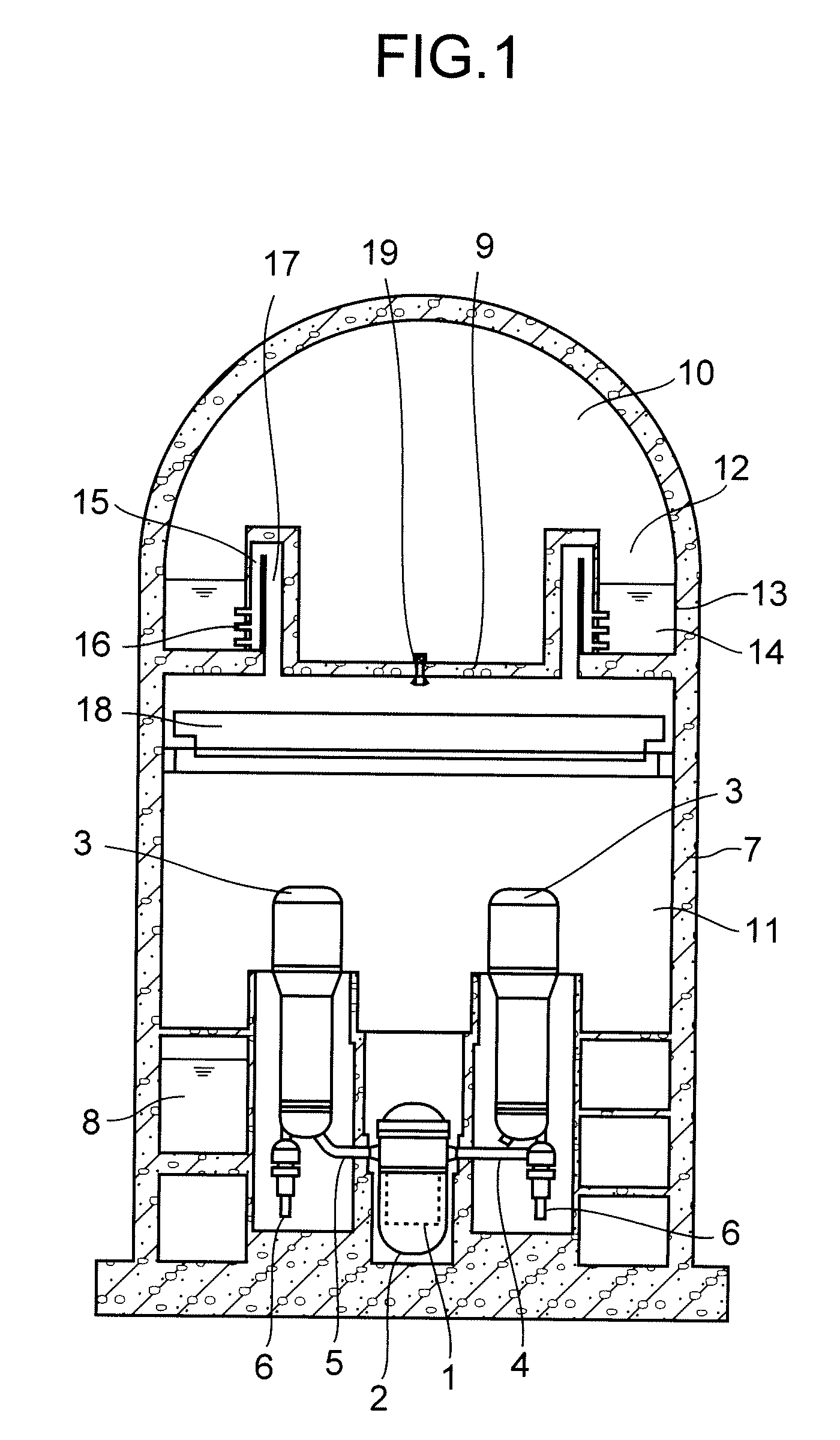

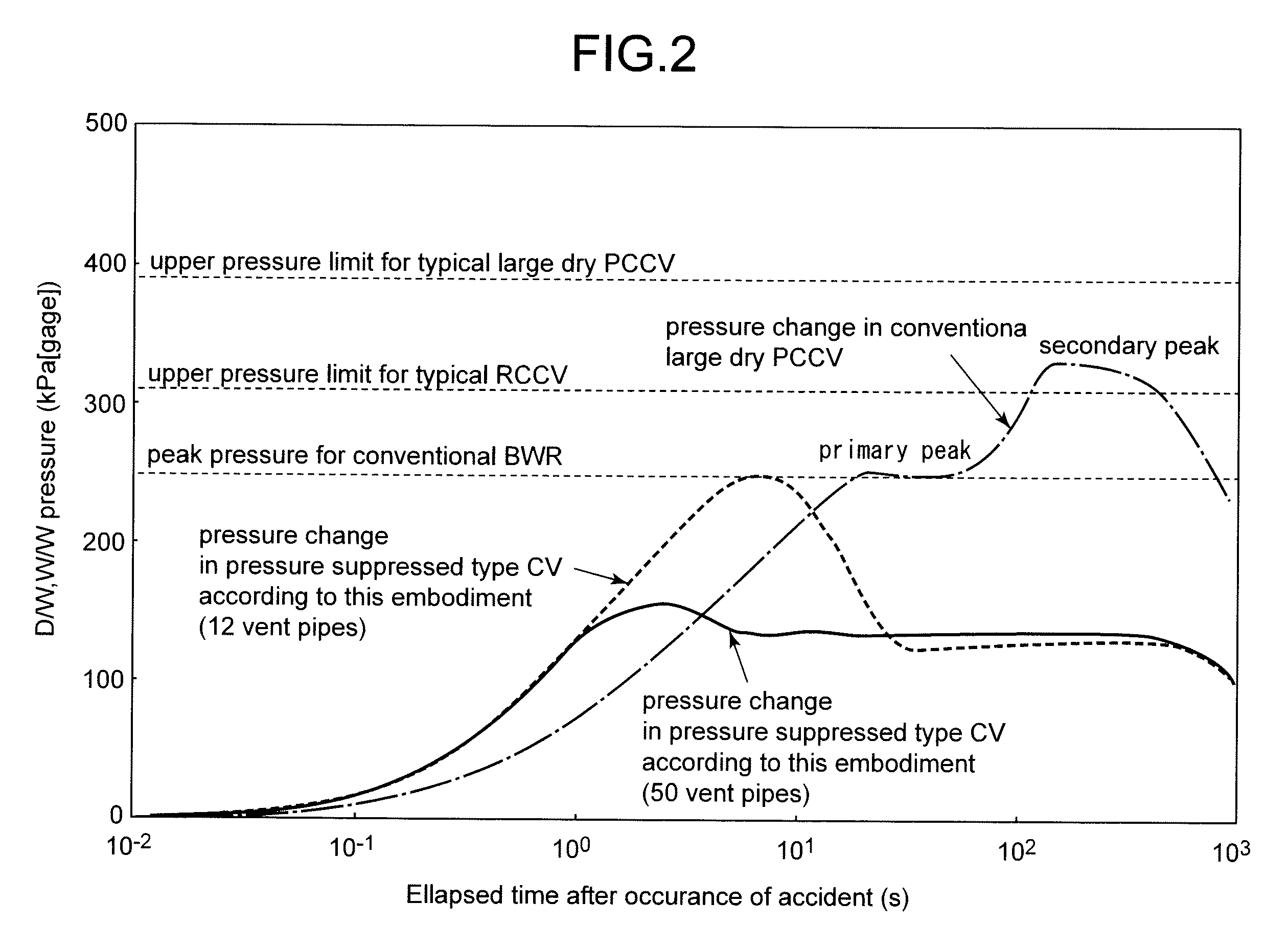

Reactor containment vessel and boiling water reactor power plant

ActiveUS20070092053A1Nuclear energy generationNuclear engineering problemsPower stationReactor pressure vessel

A containment vessel includes a primary containment vessel containing a reactor pressure vessel, an upper secondary containment vessel arranged above the primary containment vessel, and a gas-phase vent pipe linking the primary containment vessel and the upper secondary containment vessel by way of an isolation and connection switching system. The gas-phase vent pipe may be arranged either inside or outside the primary containment vessel and the upper secondary containment vessel. Alternatively, it may be embedded in the wall. An igniter may be arranged in the upper secondary containment vessel. The air in the upper secondary containment vessel may be replaced by nitrogen. A gravity-driven flooding system pool may be arranged in the upper secondary containment vessel and cooling water may be led from the inside of the pool to the inside of the primary containment vessel.

Owner:KK TOSHIBA

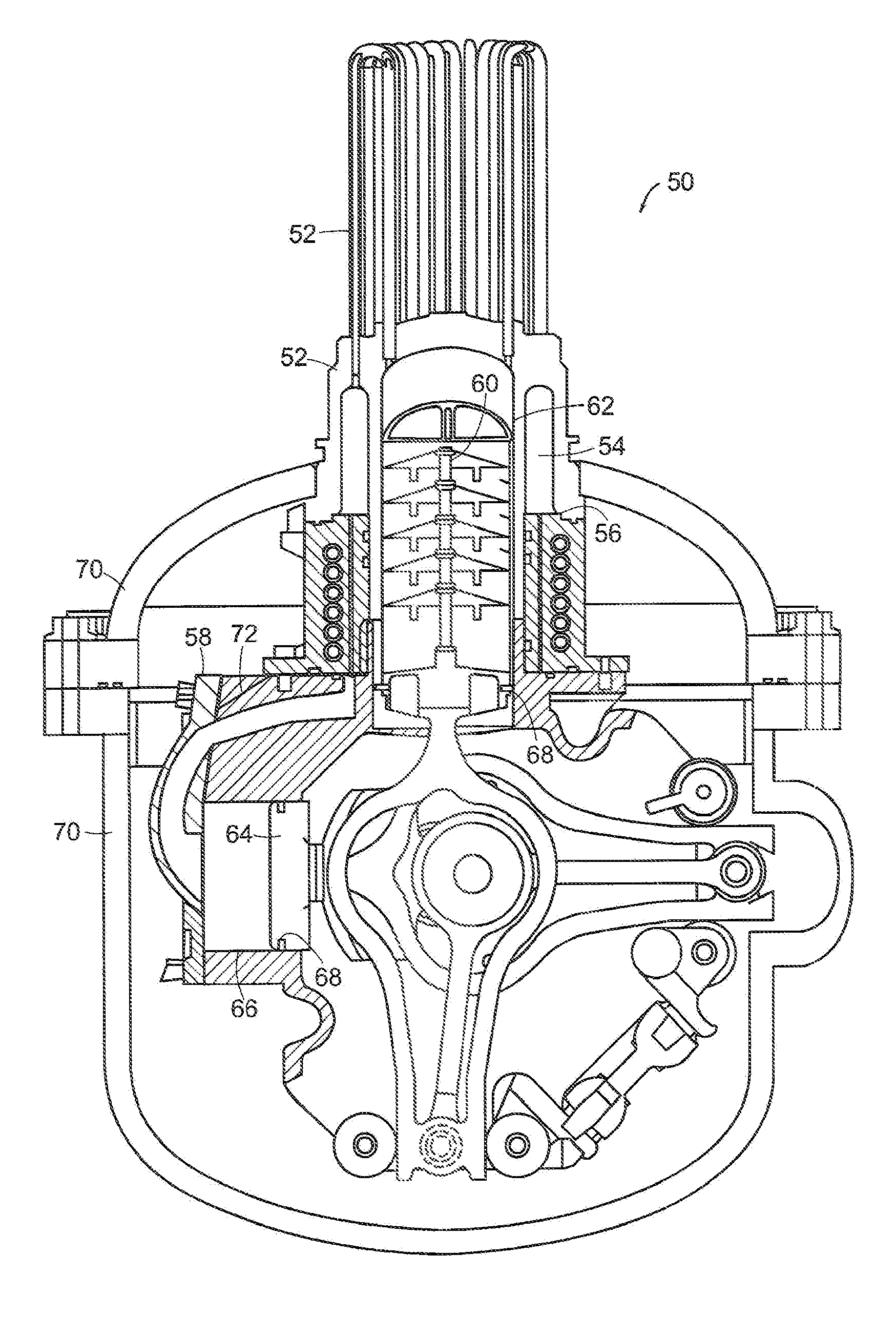

Coolant penetrating cold-end pressure vessel

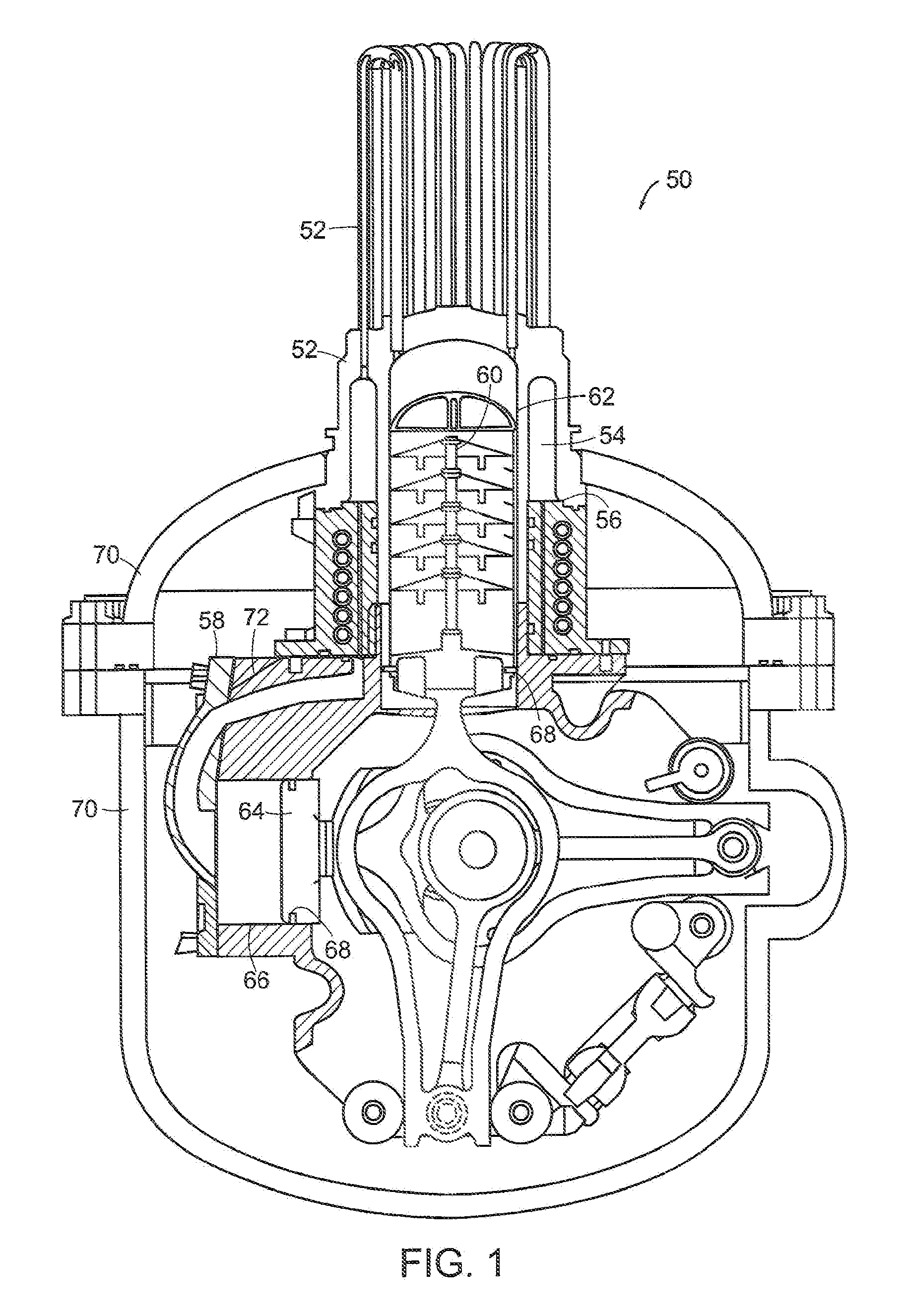

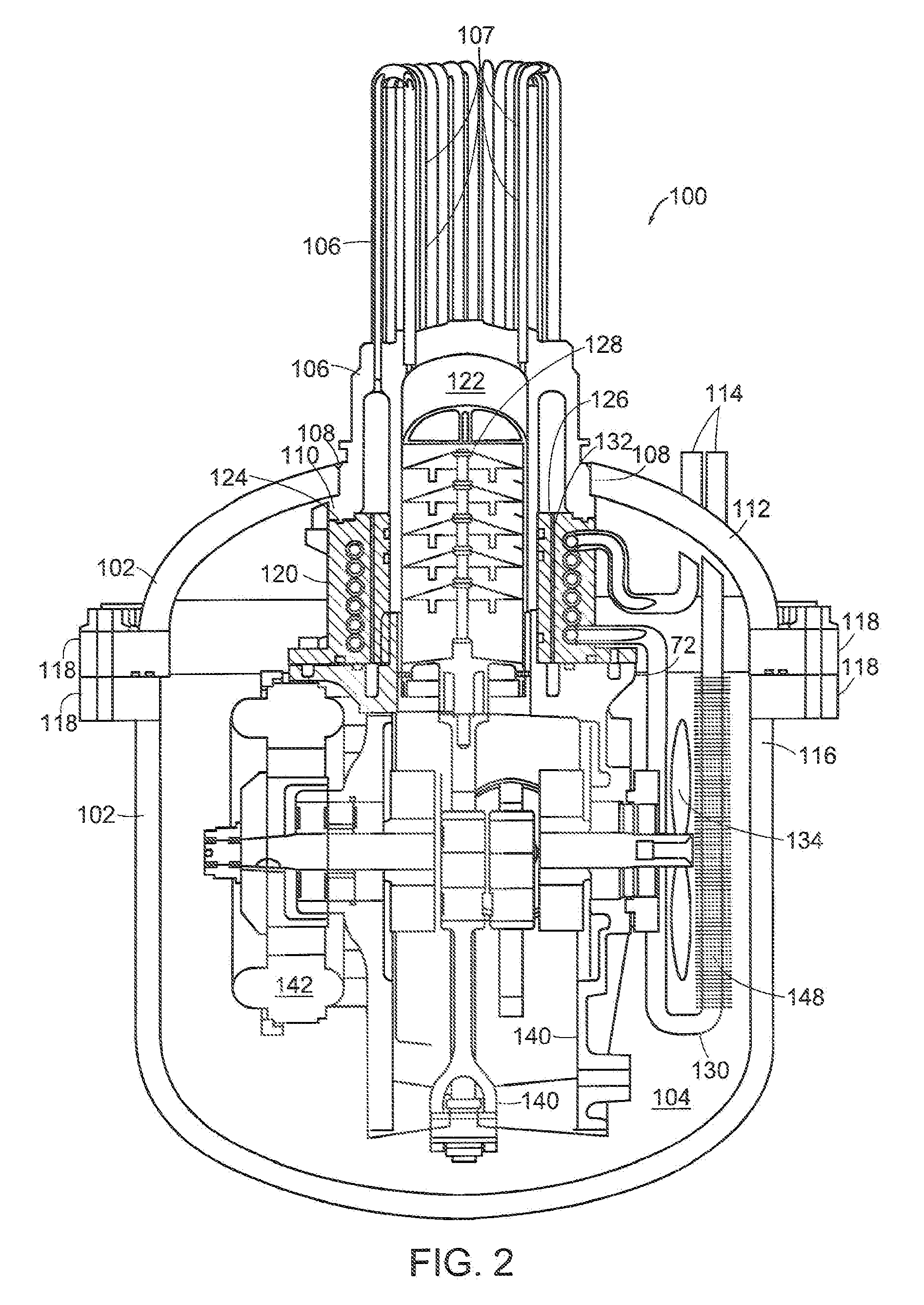

InactiveUS7325399B2Stirling type enginesEngine cooling apparatusLinear motionReactor pressure vessel

An improvement is provided to a pressurized close-cycle machine that has a cold-end pressure vessel and is of the type having a piston undergoing reciprocating linear motion within a cylinder containing a working fluid heated by conduction through a heater head by heat from an external thermal source. The improvement includes a heat exchanger for cooling the working fluid, where the heat exchanger is disposed within the cold-end pressure vessel. The heater head may be directly coupled to the cold-end pressure vessel by welding or other methods. A coolant tube is used to convey coolant through the heat exchanger.

Owner:NEW POWER CONCEPTS

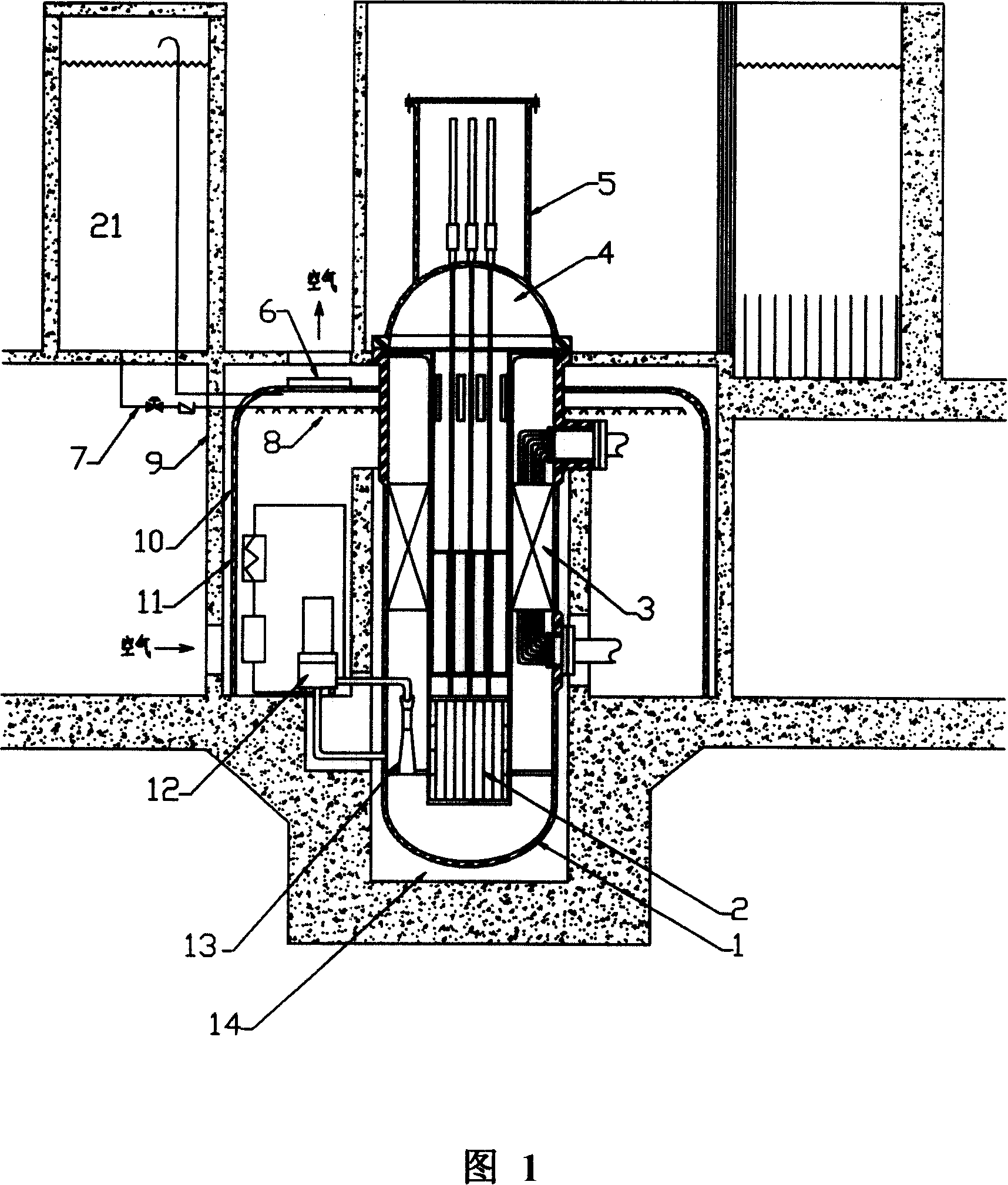

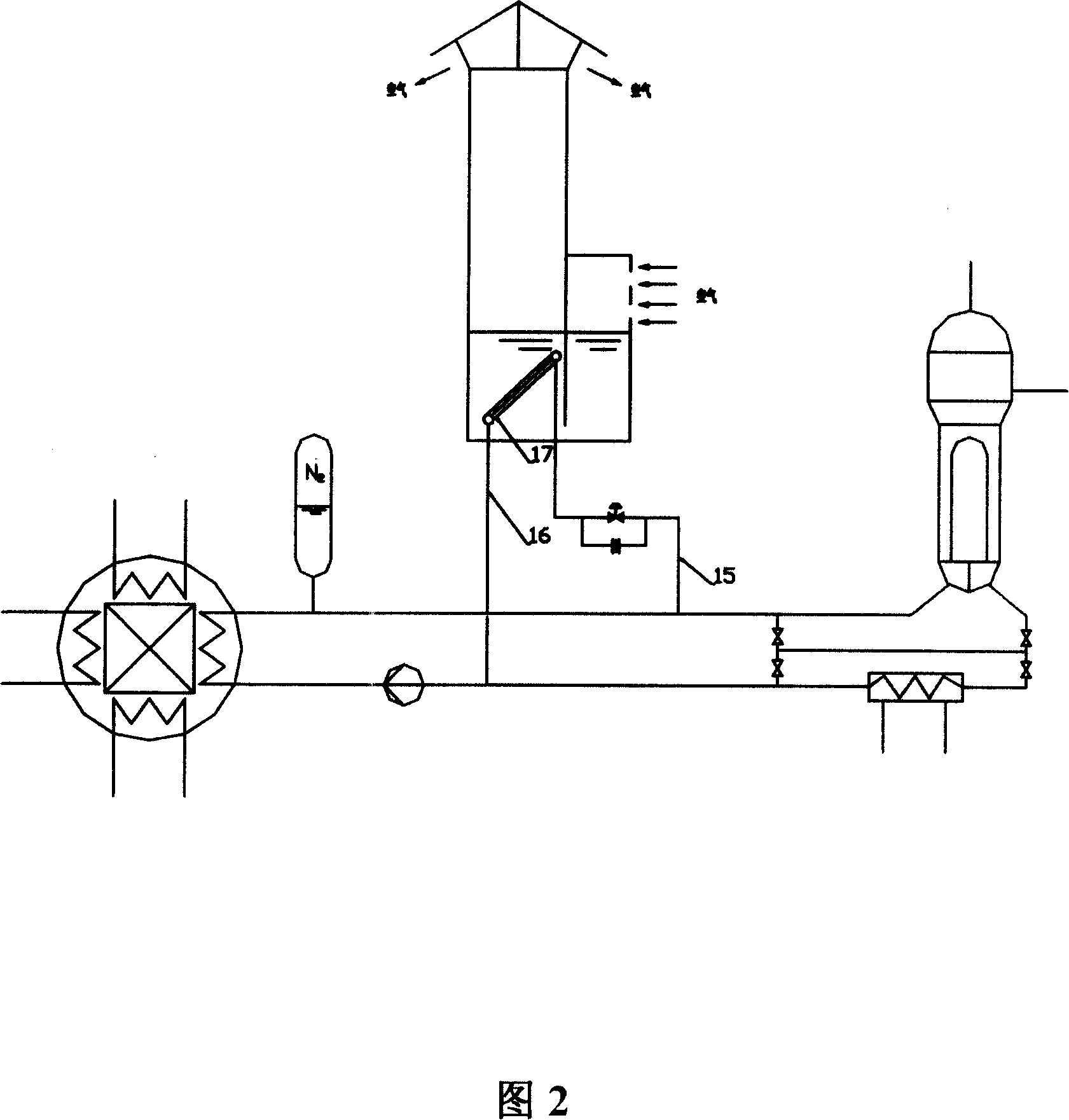

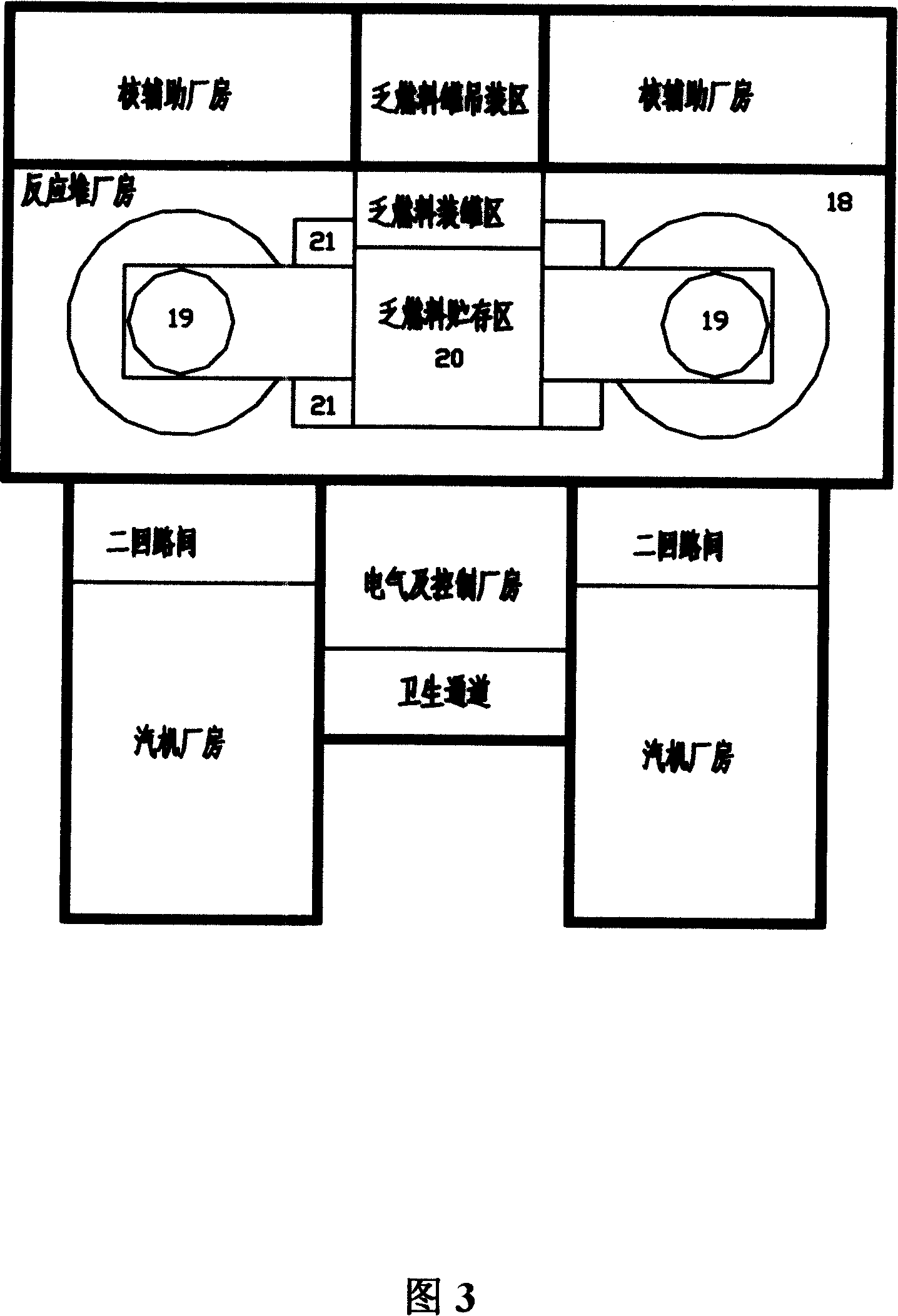

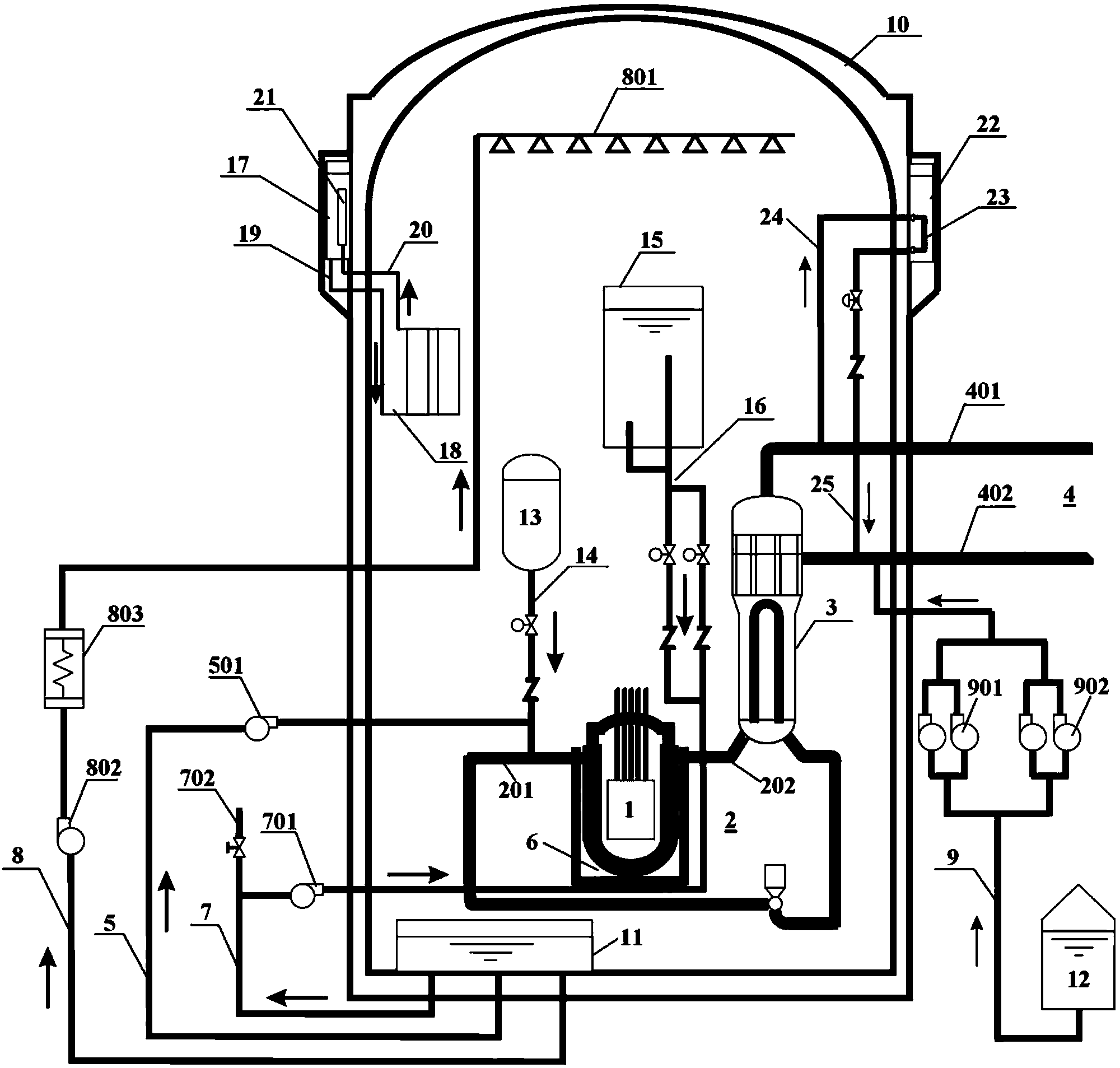

Integrated low-temperature nuclear heat supplying pile

ActiveCN101154472ASmall sizeCompact layoutIntegral reactorsNuclear energy generationReactor pressure vesselPressurized water reactor

The invention discloses an integral low-temperature nuclear heat reactor with the circuit equipment adopting integral arrangement and belonging to the low- and medium-parameter pressurized-water reactor, wherein, a reactor core adopts the mature nuclear power plant fuel component and control rod component; a main heat exchanger is of integral coil type; a voltage stabilizer is a built-in nitrogen partial pressure control voltage stabilizer; coolant circulation is completed by a built-in jet apparatus and the equipment of an external drive circuit; the drive circuit and the equipment and a main circuit auxiliary system are arranged at the circumference of a reactor pressure vessel; a containment vessel consists of a reactor body containment vessel and a reactor top containment vessel; the reactor body containment vessel which is a structure combined by a reactor vault of reinforced concrete structure and a casing of steel structure is connected with a sealed refueling water storage pool through a pipe and a valve. The thermal power of the reactor can be selected between 50MW and 500MW at will and the outlet temperature of the reactor can be selected between 100 DEG C to 200 DEG C according to application, requirement and power.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

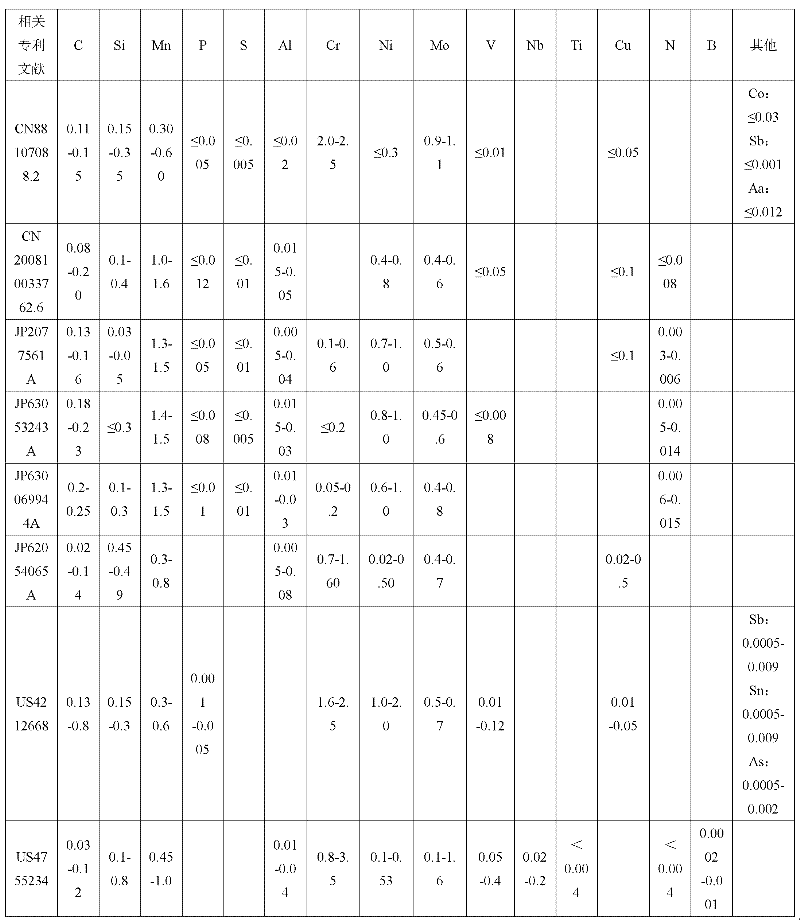

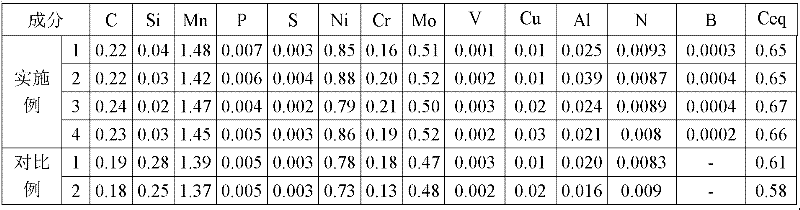

High-strength high-toughness nuclear power pressure vessel forging steel and its manufacturing method

InactiveCN102392195AEasy to implementPlay a role in strengthening and tougheningNon-metallic inclusionsReactor pressure vessel

High-strength high-toughness nuclear power pressure vessel forging steel and its manufacturing method belong to the technical field of steel for pressure vessel. The steel provided by the invention comprises the following chemical components of: by weight, 0.2-0.25% of C; Si being less than 0.1%; 1.3-1.5% of Mn; P being less than or equal to 0.008%; S being less than or equal to 0.008%; 0.6-1% of Ni; 0.1-0.25% of Cr; 0.45-0.6% of Mo; V being less than or equal to 0.01%; Cu being less than or equal to 0.05%; 0.02-0.04% of Al; 0.005-0.015% of N; B being less than or equal to 0.001%; and the balance being Fe and unavoidable impurities, wherein C equivalent range is controlled within 0.6-0.75%. By alloying and appropriate smelting, forging and heat treatment technologies, the forging provided by the invention has high strength and high toughness and less segregation and nonmetal field trash, and can be used for manufacturing large-scale forgings such as a nuclear power station reactor pressure vessel with its wall thickness being greater than 100mm, an evaporator head, a cylindrical shell, a tube plate and the like.

Owner:CENT IRON & STEEL RES INST

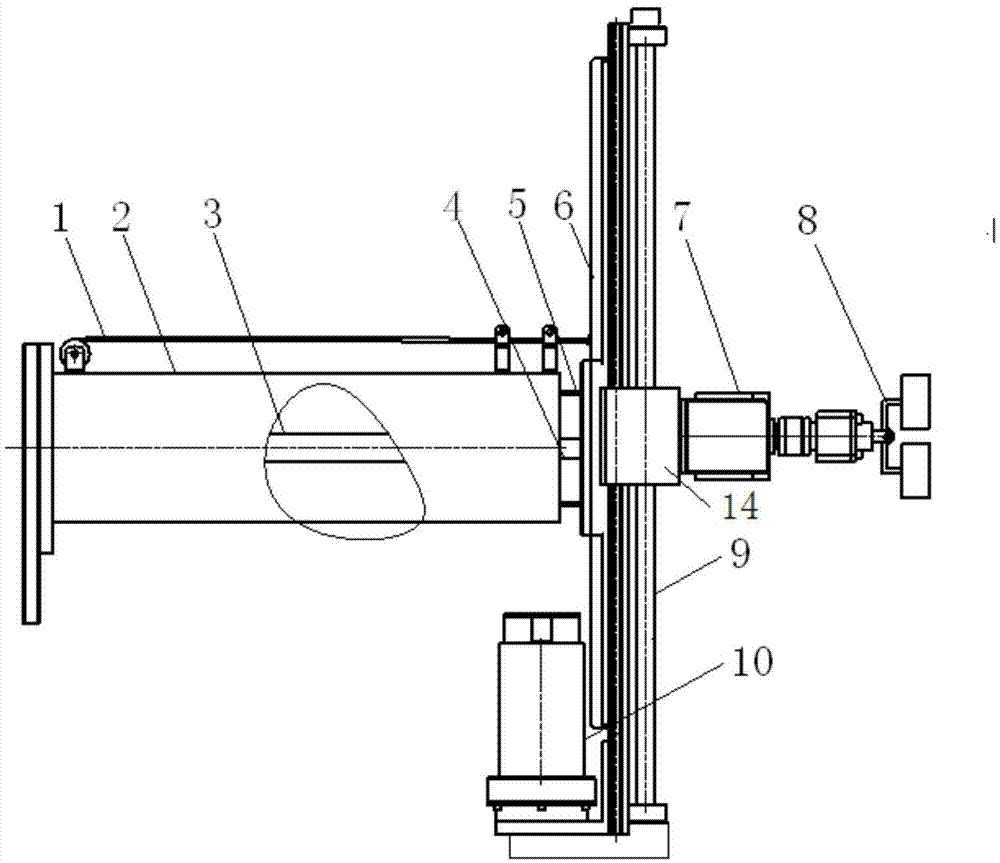

Automatic detection device and positioning method for weld joint at safe end of nuclear reactor pressure vessel

ActiveCN101916597AGuaranteed reliabilityEasy to operateAnalysing solids using sonic/ultrasonic/infrasonic wavesNuclear energy generationNuclear reactorReactor pressure vessel

The invention relates to automatic detection equipment and a positioning method for a weld joint at safe end of nuclear reactor pressure vessel. The automatic detection equipment comprises a bracket body, a scanning device and a positioning mechanism, wherein the positioning mechanism comprises a supersonic distance measurement sensor for detecting the distance between the front end of an end face strut and the wall of a cylinder, a horizontal inclinometer user for detecting the inclination angle of the detection equipment in X-axis direction, an axial approach switch for fixing the initial position of the scanning device in Y-axis direction and a circumferential approach switch for fixing the initial position of a supersonic probe frame in X-axis direction. After the rough positioning and the accurate positioning in axial direction and circumferential direction, scanning work can be performed. By the invention, the problem that scanning feedback data is not in correspondence with scanning positions, caused by probably existed axial or circumferential offset and the zero position offset of the supersonic probe frame in a pipe nozzle, can be overcome, thereby ensuring the readability of detection results. The whole process is controlled automatically and operated very conveniently; and thus, the invention has grater promotion and application values.

Owner:CGNPC INSPECTION TECH +2

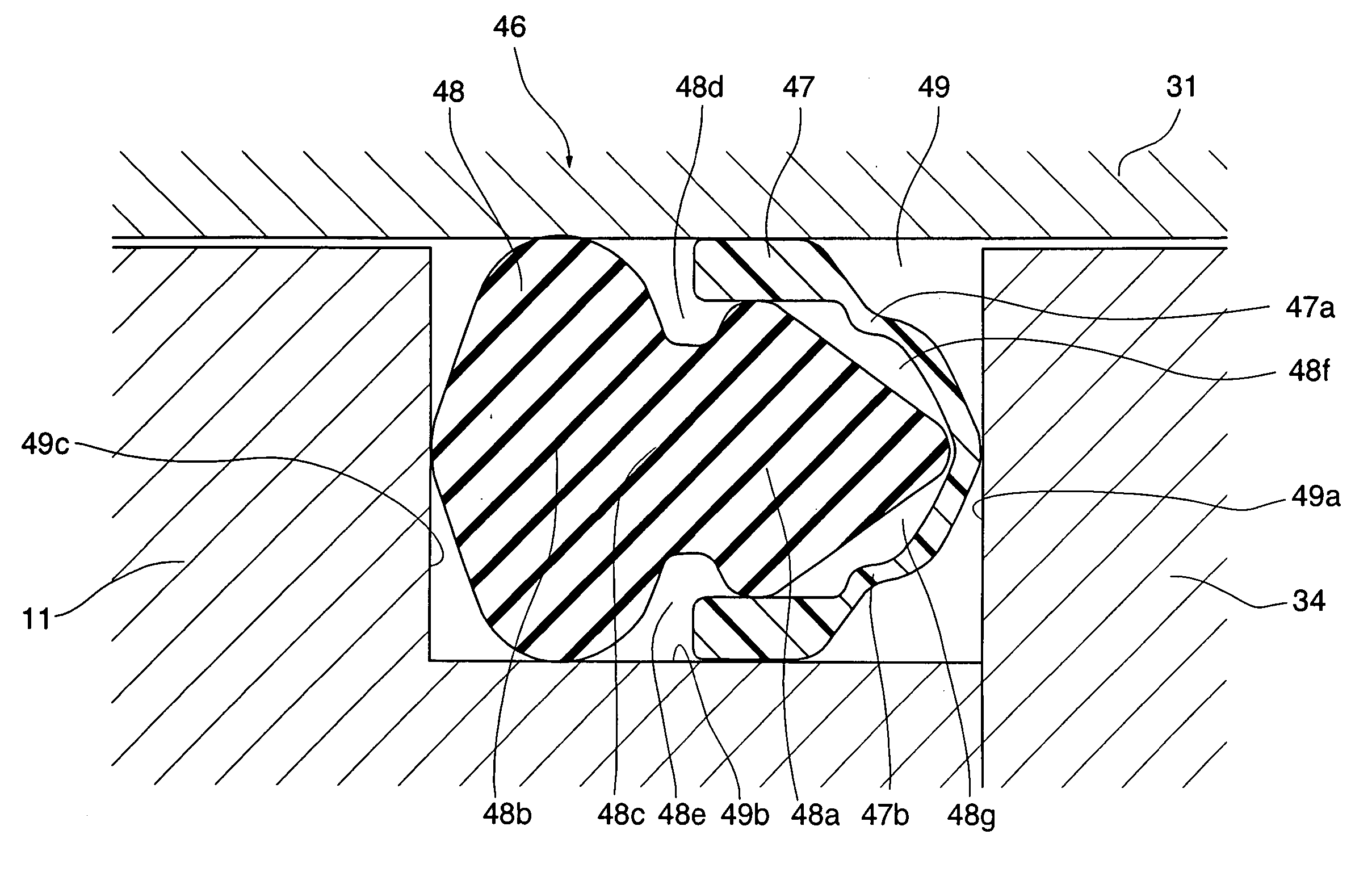

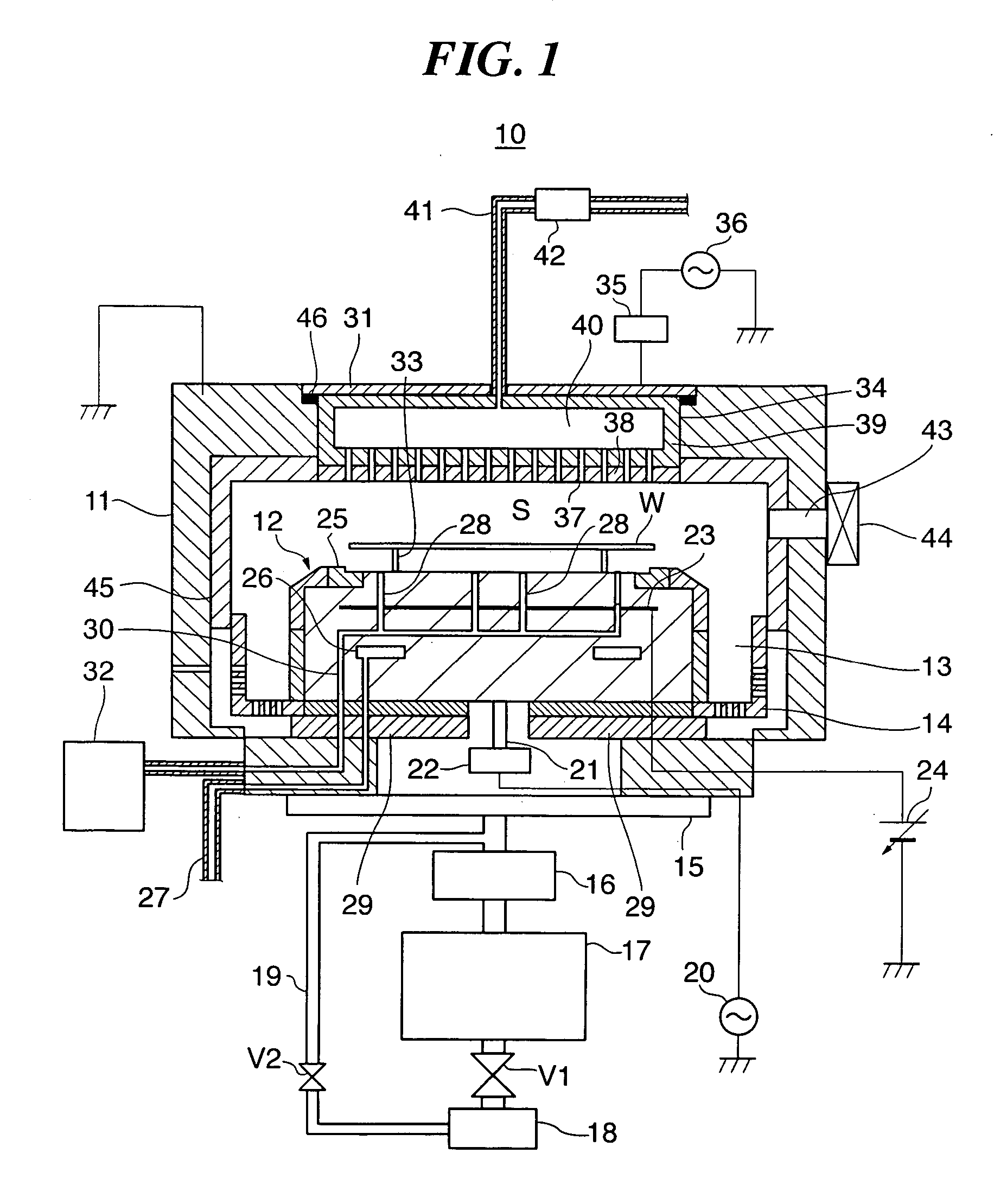

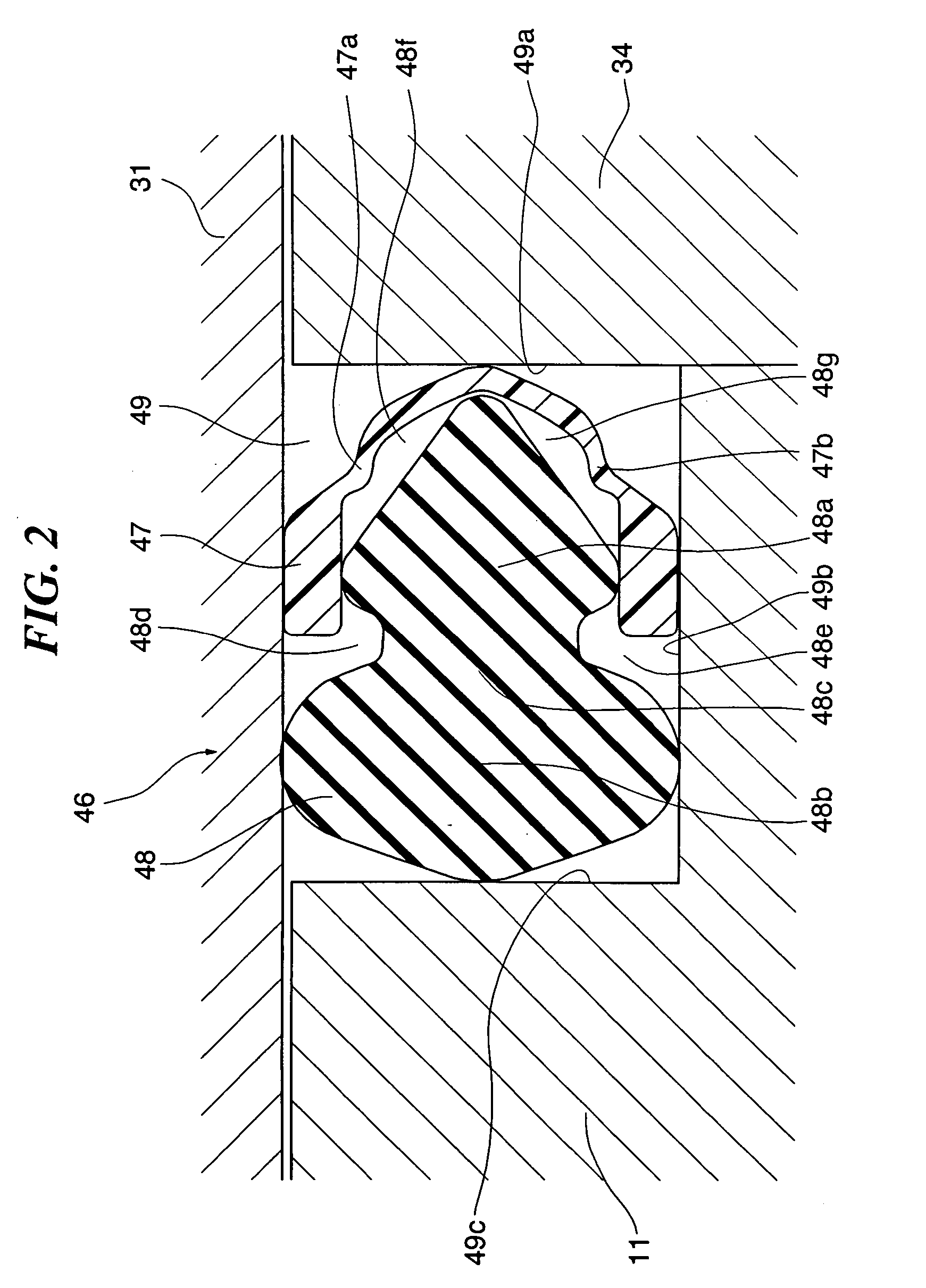

Sealing part and substrate processing apparatus

ActiveUS20070075503A1Increased durabilityEngine sealsSemiconductor/solid-state device manufacturingReactor pressure vesselEngineering

A sealing part that is inexpensive and enable excellent durability to be secured without the need for a predetermined sealing space as would be required for a double sealing structure. A sealing part seals an inside of a reduced pressure vessel from an outside, in which a high-elasticity polymeric material-eroding eroding substance is present and which is comprised of a substrate processing apparatus carrying out predetermined processing on a substrate housed in the reduced pressure vessel. The sealing part has a radical sealing member and a vacuum sealing member. The radical sealing member is disposed on an inside side of the reduced pressure vessel and is resistant to the eroding substance. The vacuum sealing member is made of the high-elasticity polymeric material and is disposed on an outside side of the reduced pressure vessel. At least one refuge space is formed through at least part of the radical sealing member and at least part of the vacuum sealing member being separated from one another. The radical sealing member and the vacuum sealing member are fitted together.

Owner:TOKYO ELECTRON LTD +1

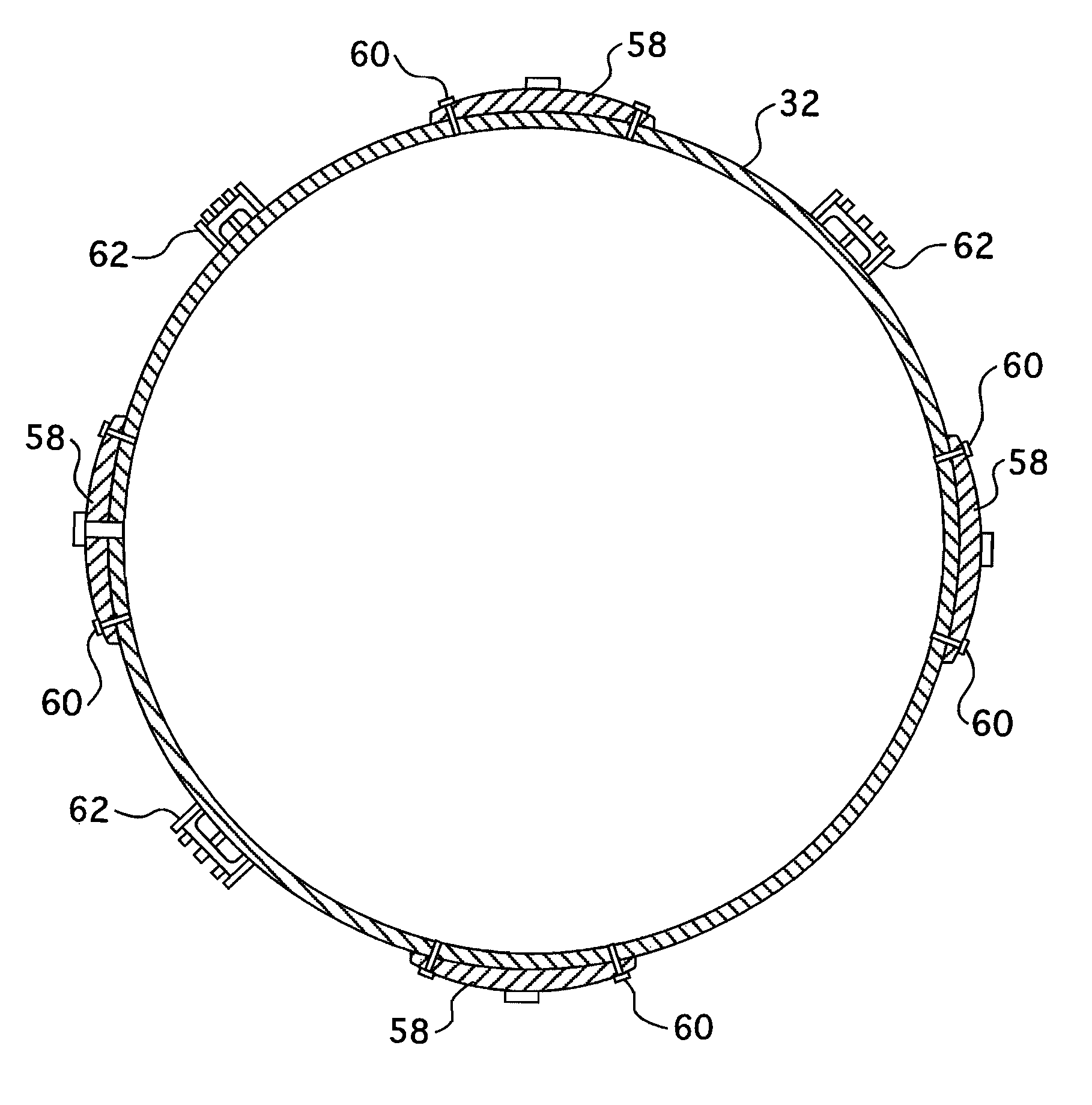

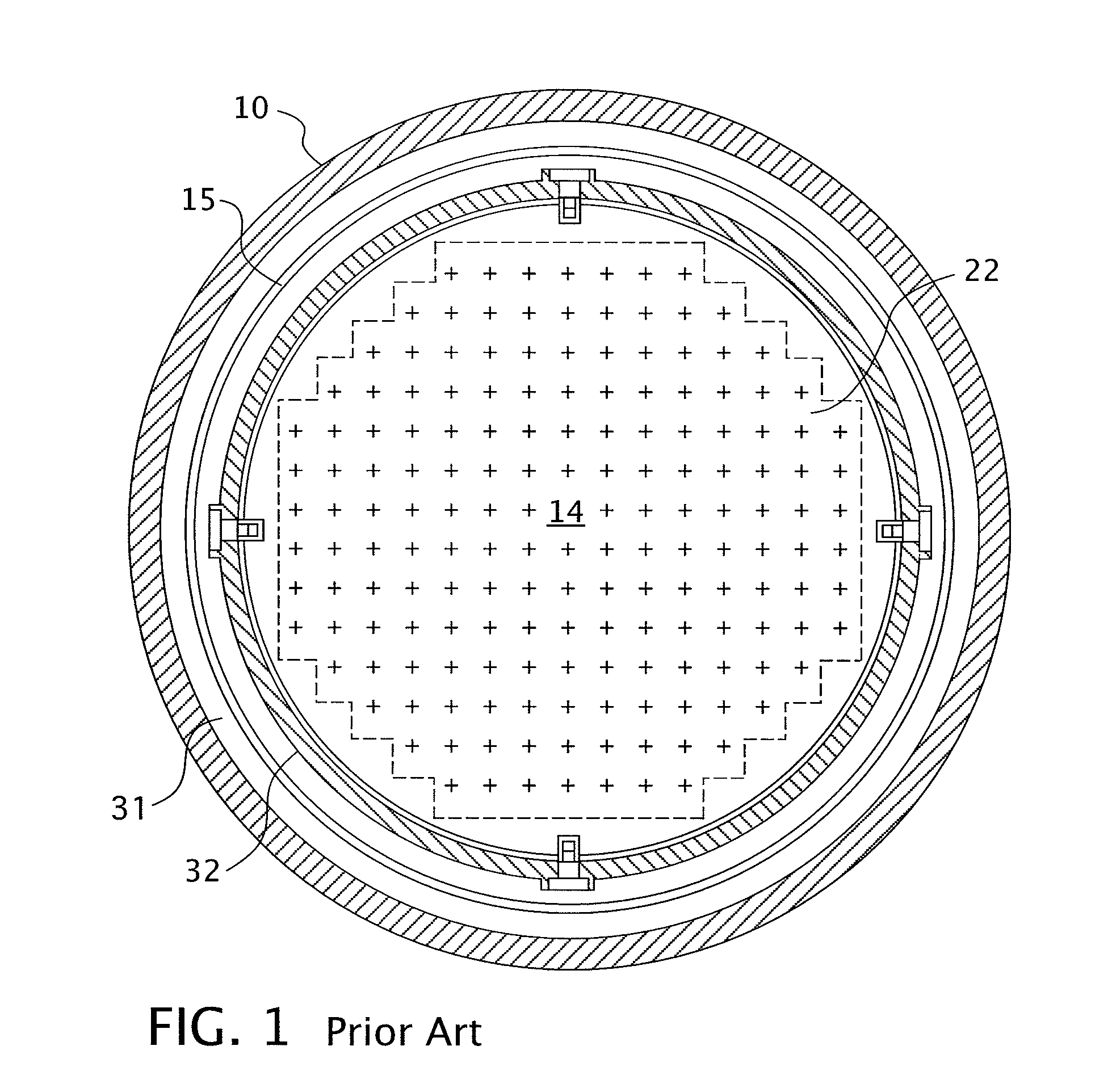

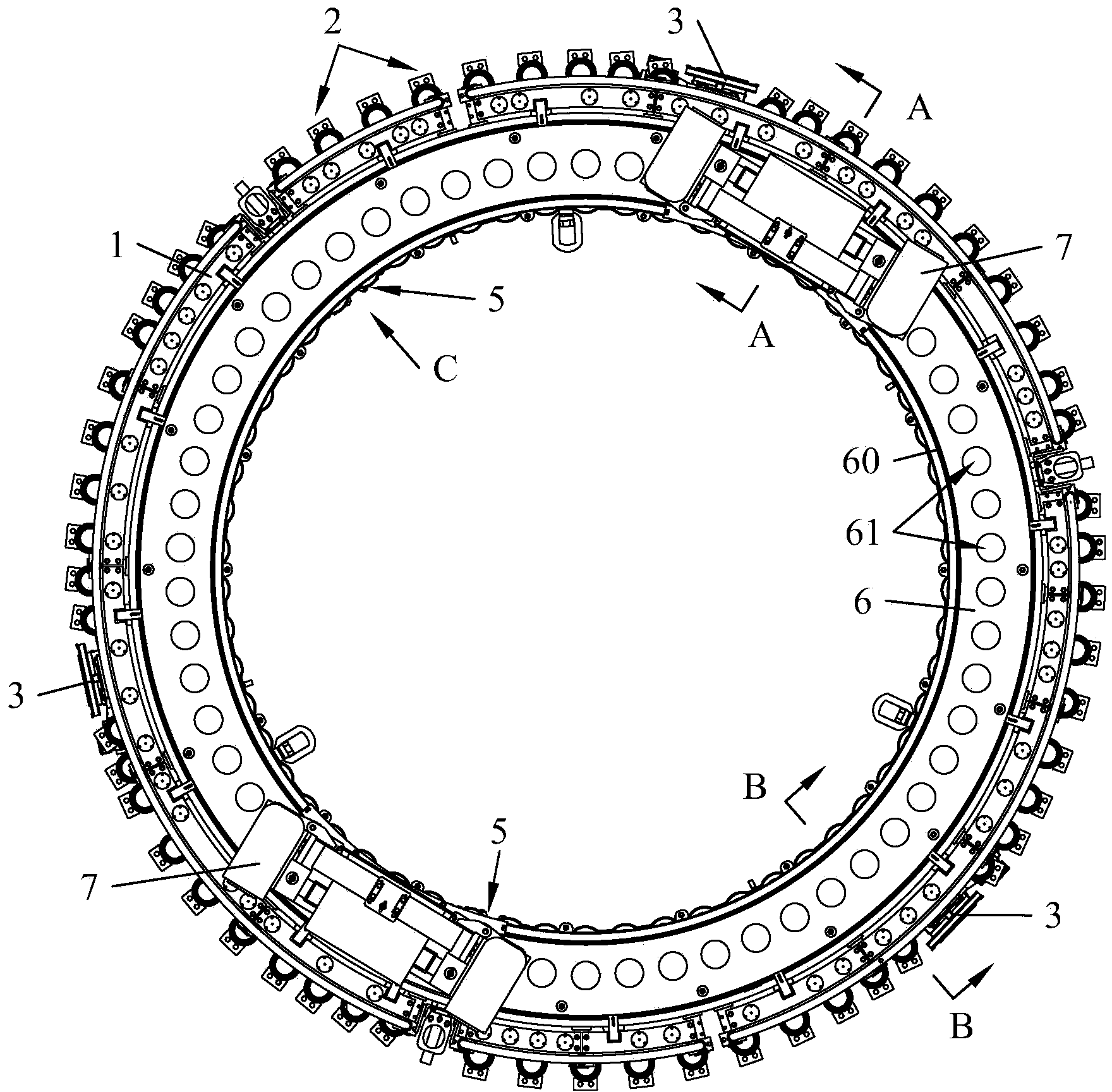

Neutron shielding panels for reactor pressure vessels

ActiveUS8064564B2Reduce passageNuclear energy generationShieldingReactor pressure vesselNuclear reactor

In a nuclear reactor neutron panels varying in thickness in the circumferential direction are disposed at spaced circumferential locations around the reactor core so that the greatest radial thickness is at the point of highest fluence with lesser thicknesses at adjacent locations where the fluence level is lower. The neutron panels are disposed between the core barrel and the interior of the reactor vessel to maintain radiation exposure to the vessel within acceptable limits.

Owner:WESTINGHOUSE ELECTRIC CORP

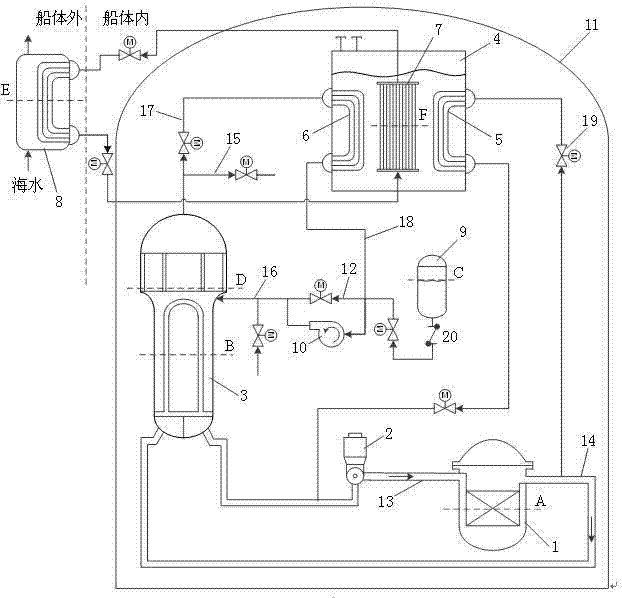

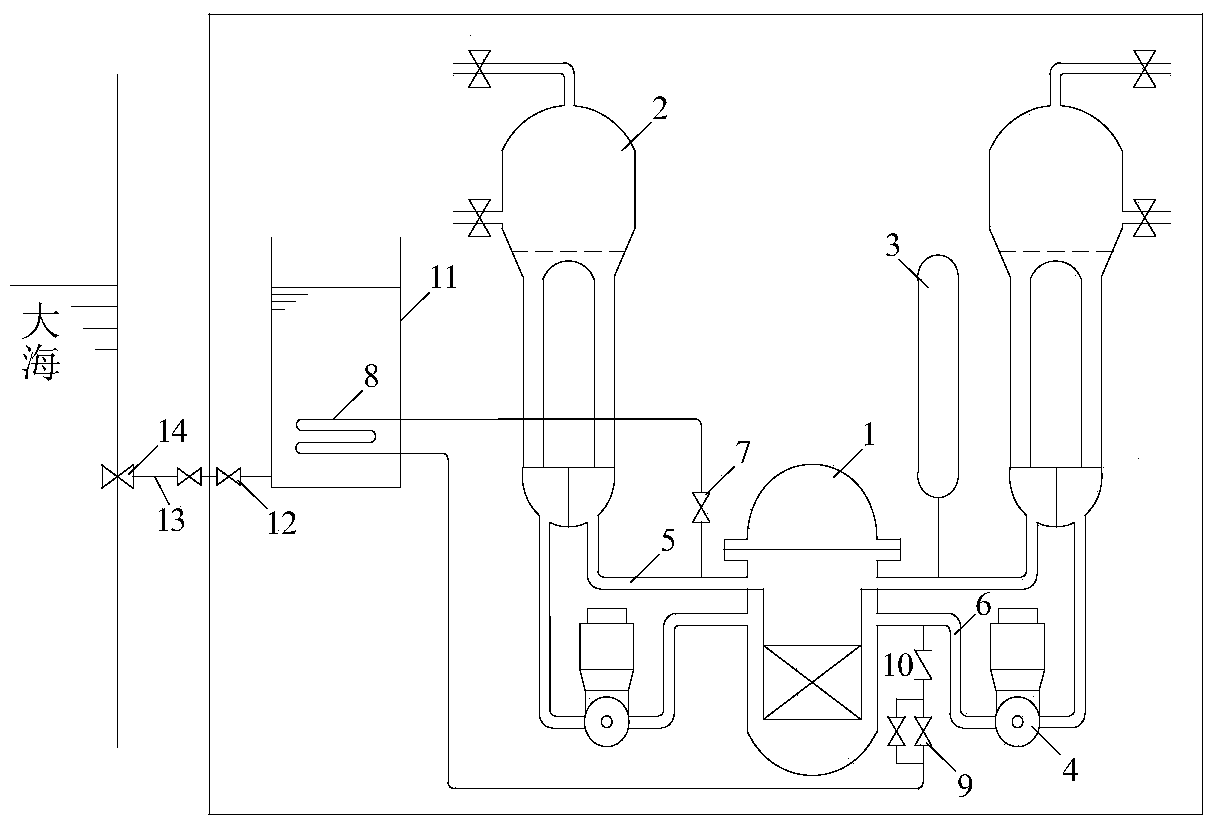

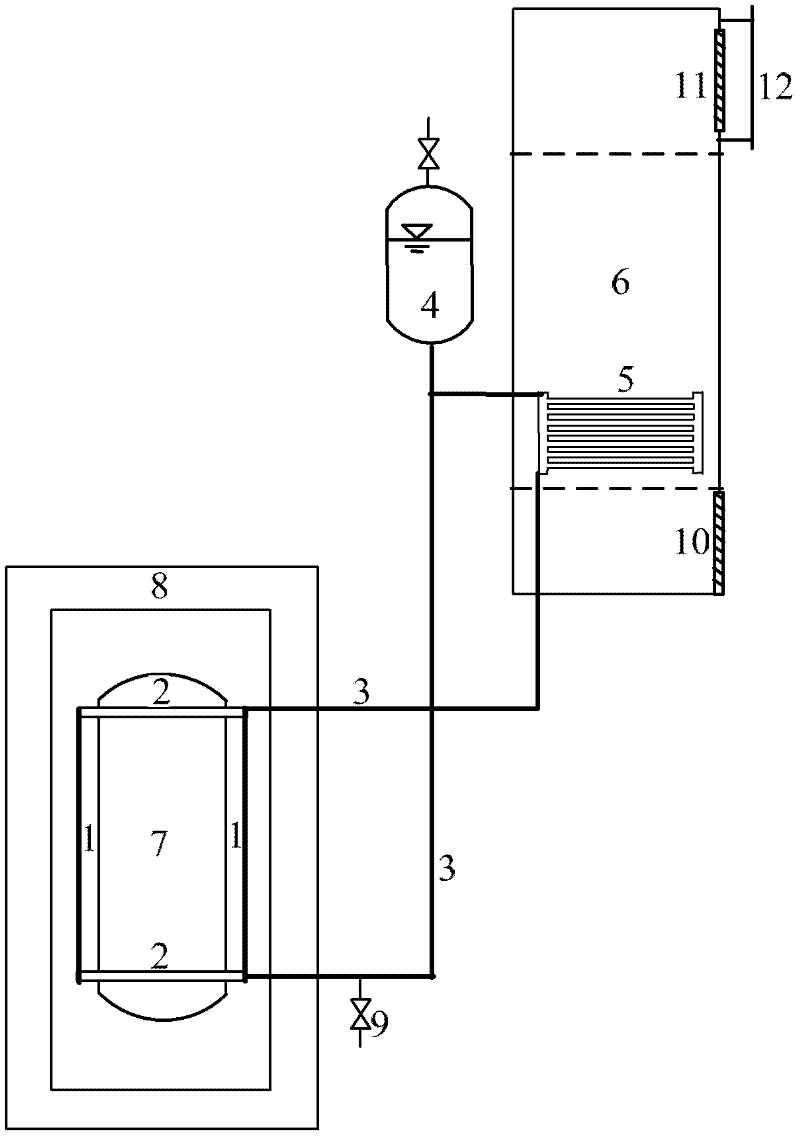

Passive residual heat removal system of marine nuclear power device

InactiveCN104733060AGuaranteed operational safetyIncrease safety redundancyNuclear energy generationCooling arrangementReactor pressure vesselNuclear power

The invention discloses a passive residual heat removal system of a marine nuclear power device. The passive residual heat removal system comprises a containment and a cooling heat exchanger. The containment is internally provided with a reactor pressure vessel, a loop cool pipe section, a loop heat pipe section, a steam generator, a refueling water tank, a 1# residual heat removal heat exchanger, a 2# residual heat removal heat exchanger and a cooling water pipe bundle; the refueling water tank is arranged at the top of the containment; the reactor pressure vessel and the steam generator are connected with the heat pipe section through the loop cool pipe section; the inlet and the outlet of the 1# residual heat removal heat exchanger are respectively connected with the loop heat pipe section and the loop cool pipe section; a main steam pipeline and a water supply pipeline which are connected with the inlet and the outlet of the 2# residual heat removal heat exchanger are arranged on the steam generator; upper and lower ends of the cooling water pipe bundle are respectively connected with the inlet and the outlet of the cooling heat exchanger. The passive residual heat removal system of the marine nuclear power device is independent from external power, is improved in capability of removing residual heat of reactor core through natural circulation, is improved in safety redundancy, power and operation stability, and guarantees operation safety of nuclear reactor.

Owner:SOUTHEAST UNIV

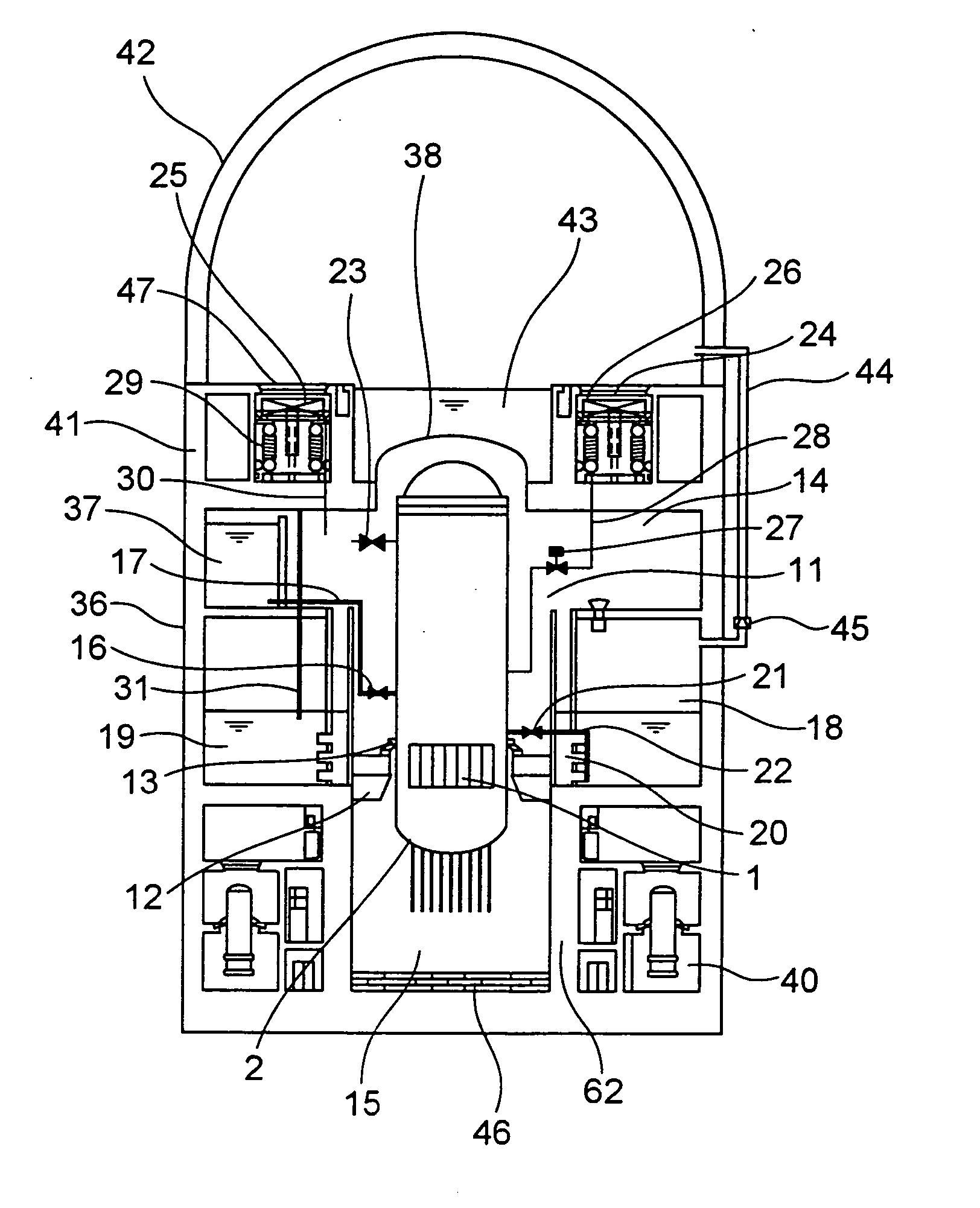

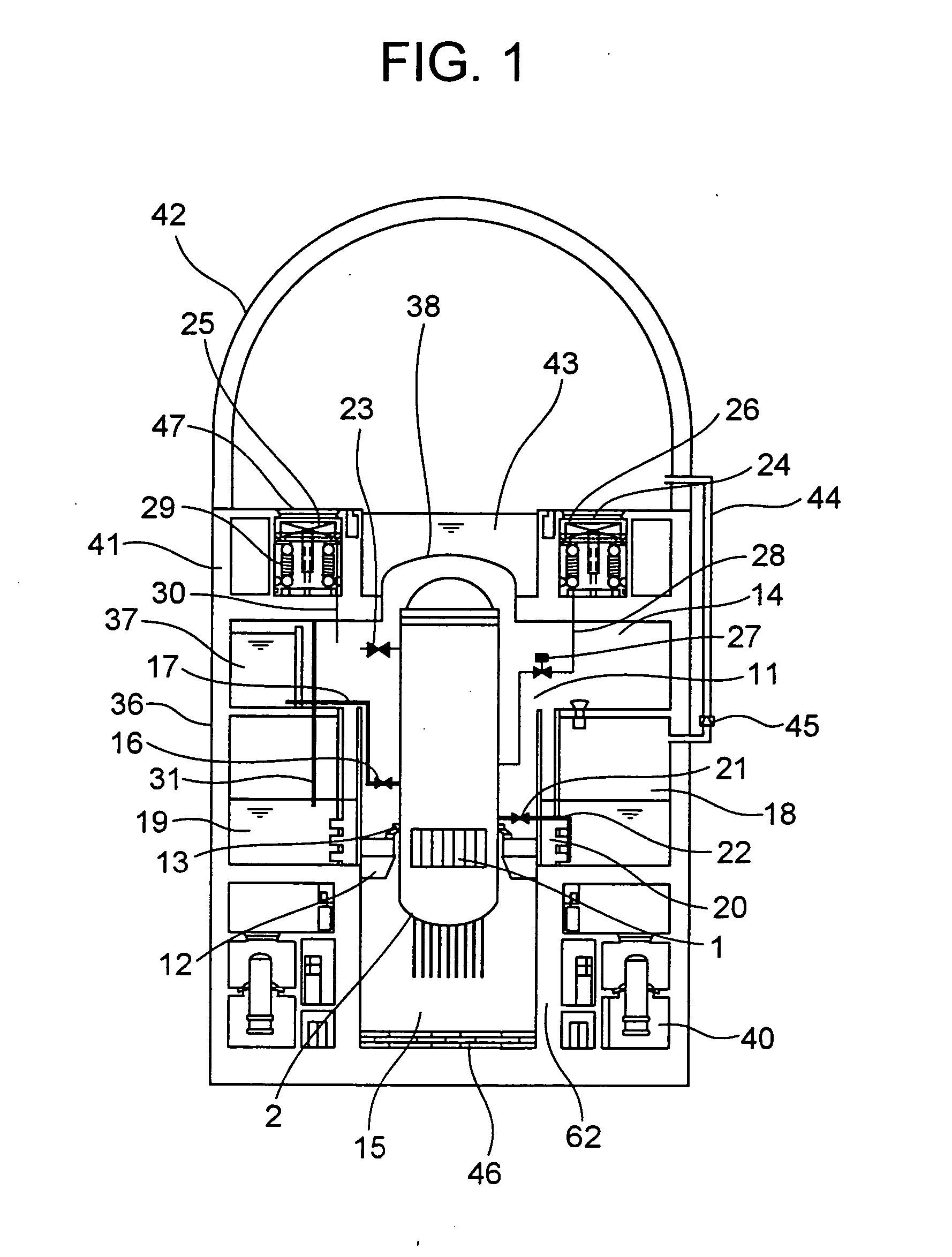

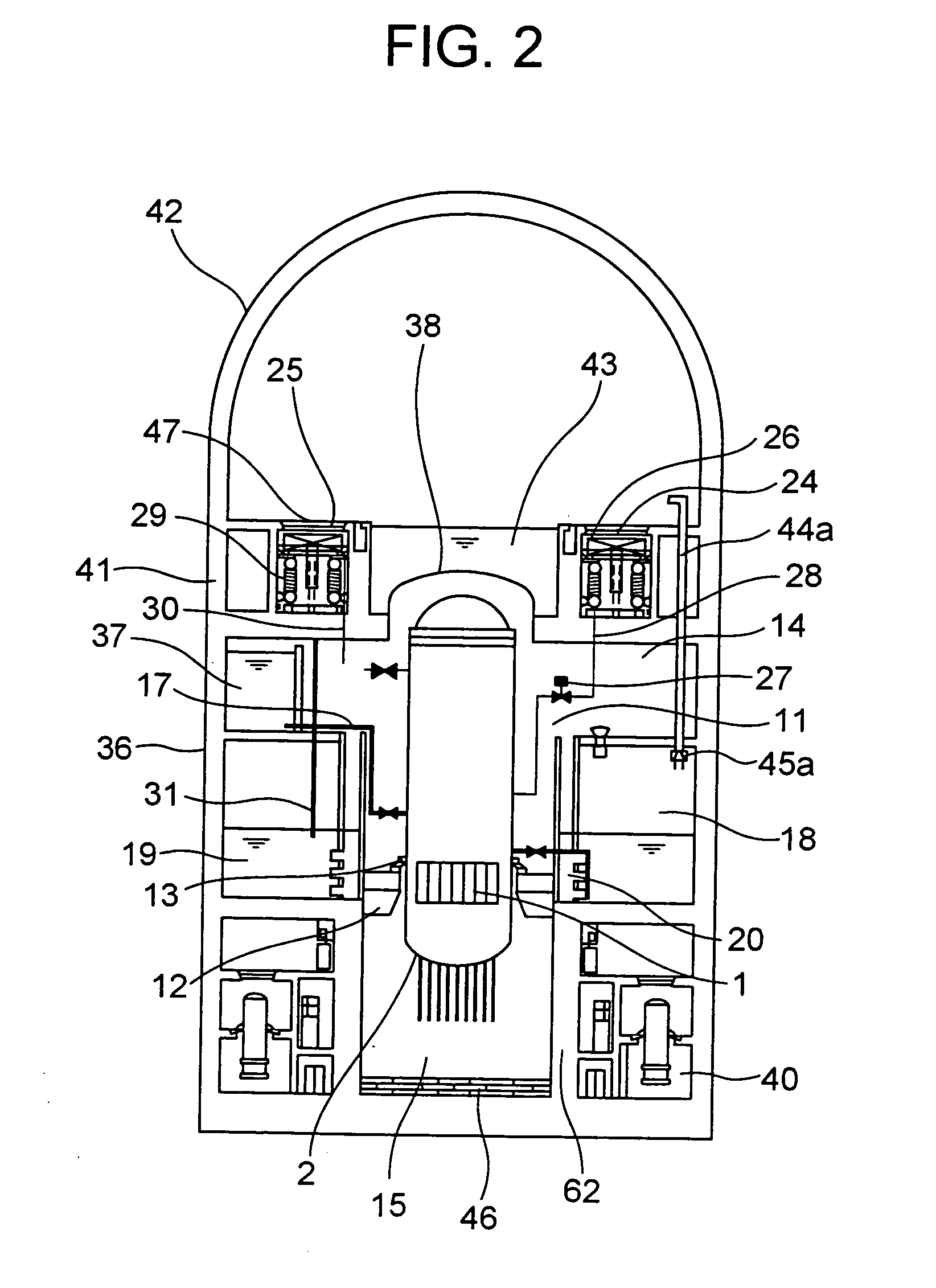

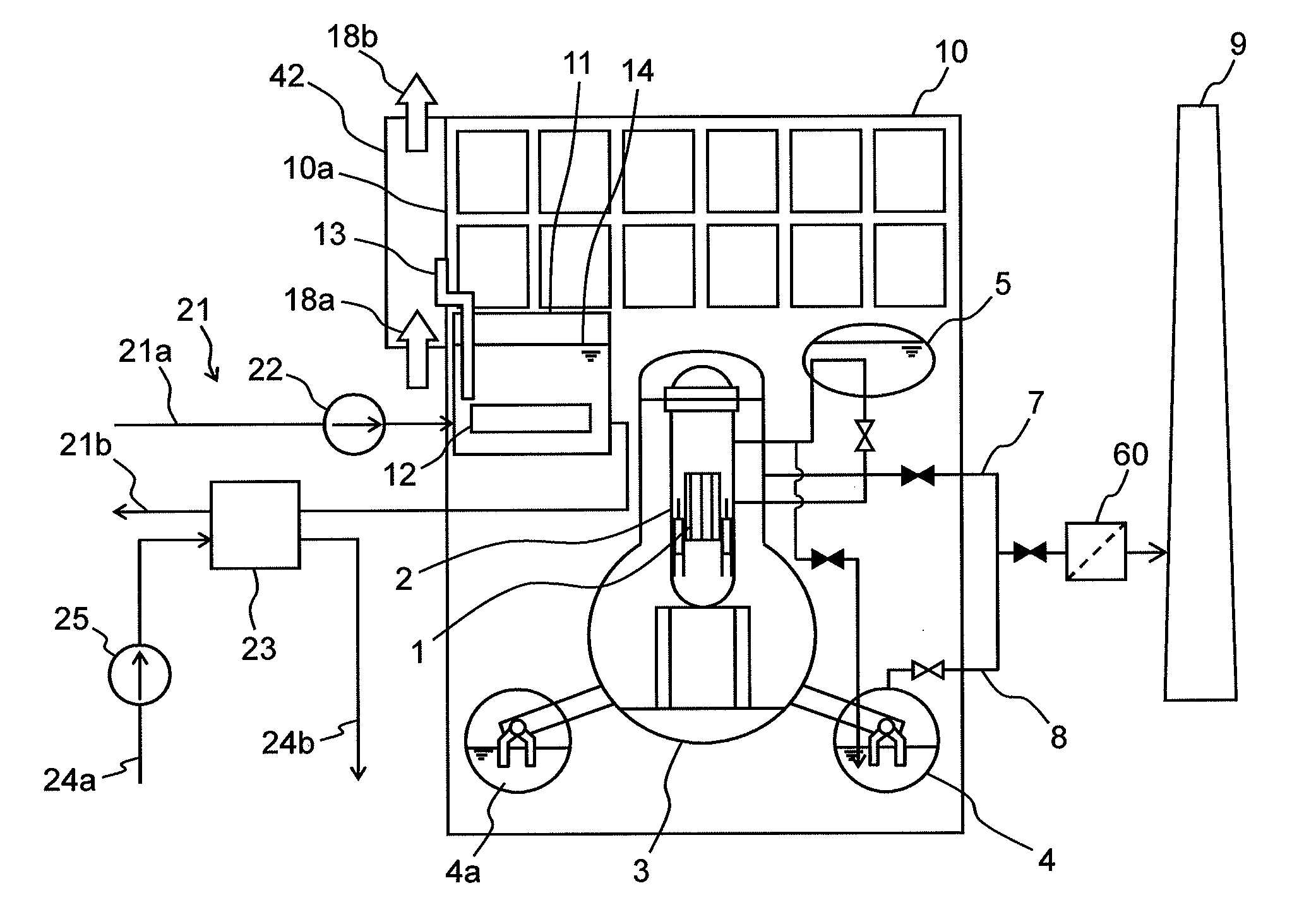

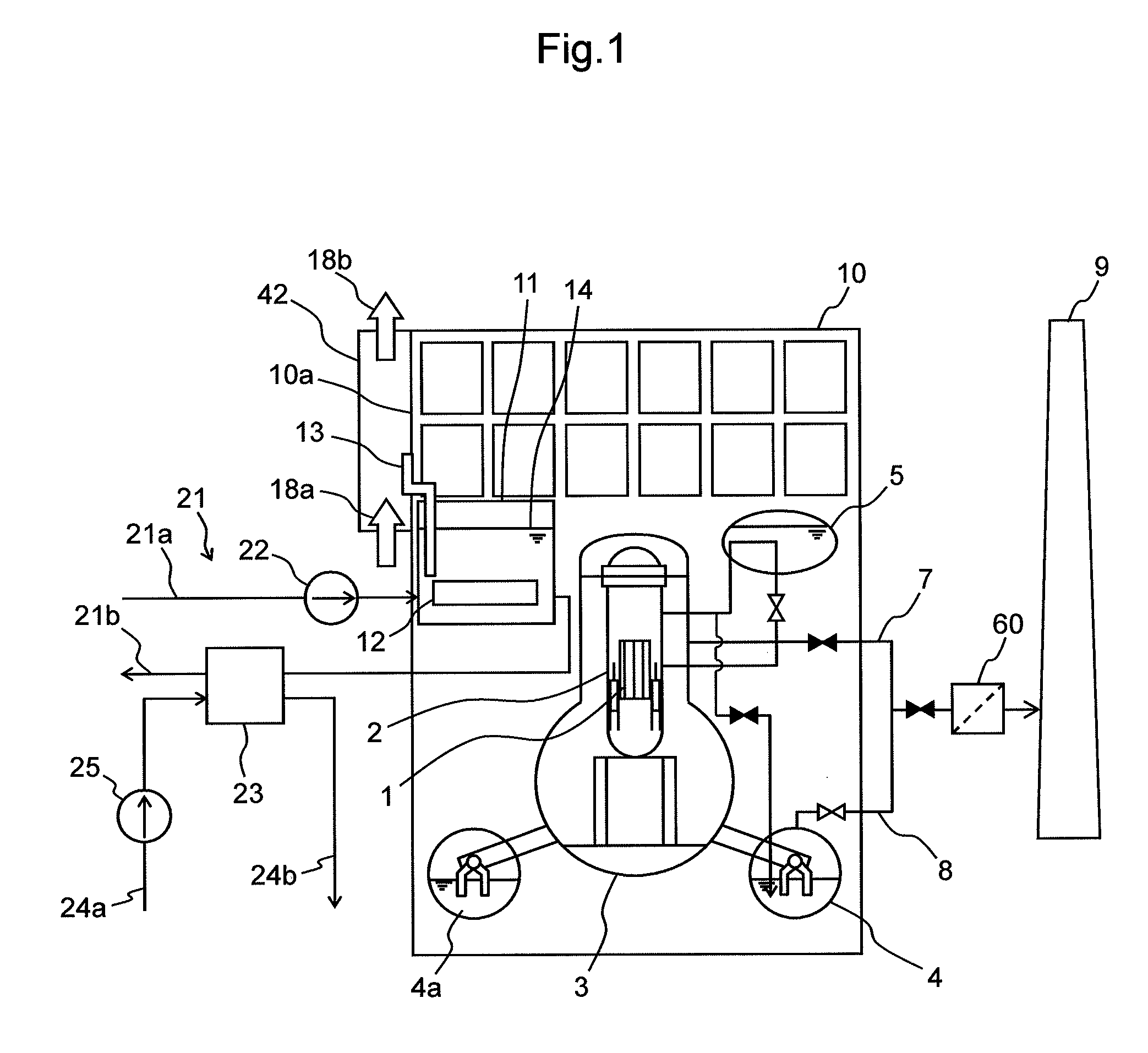

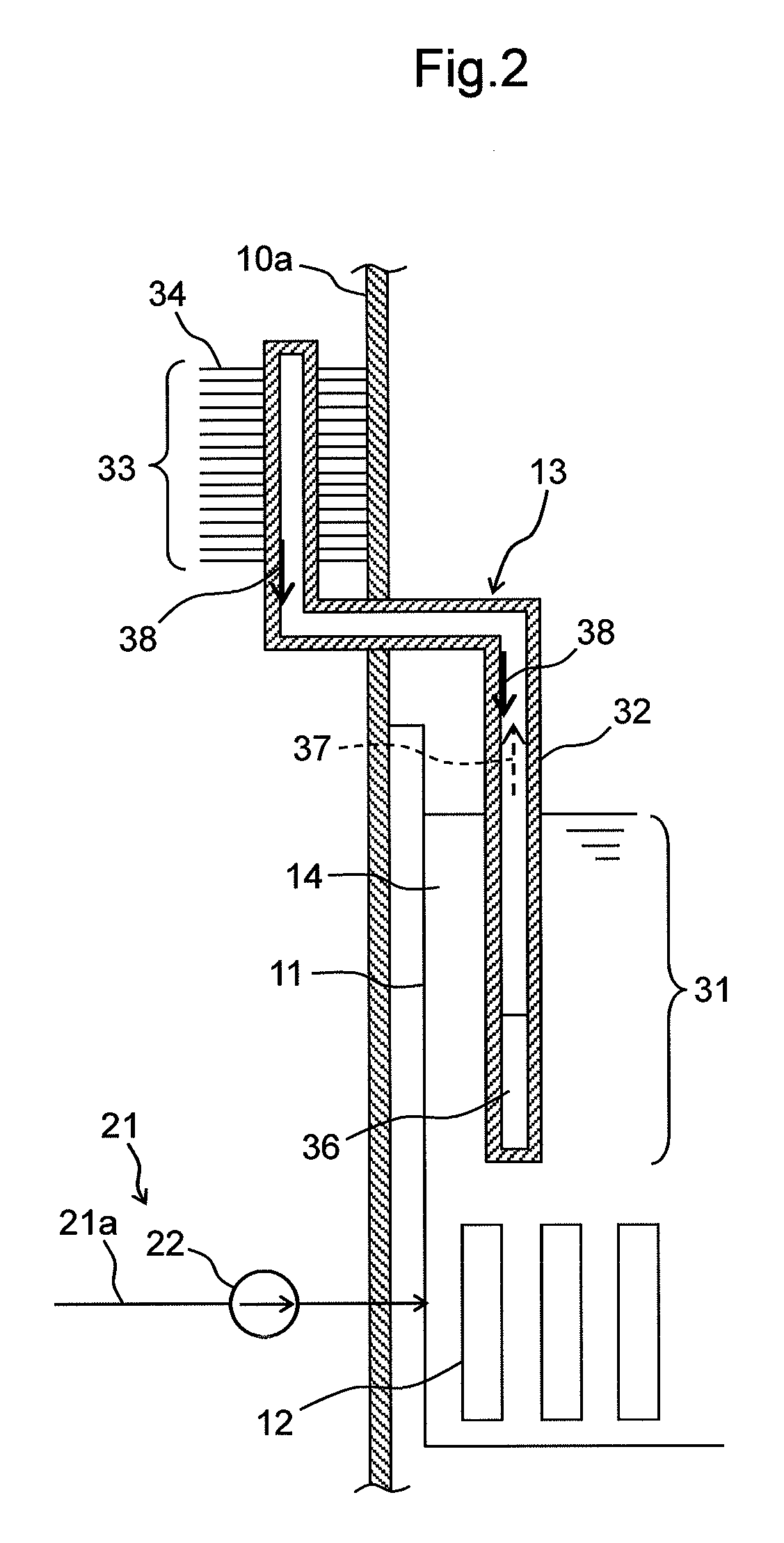

Nuclear Power Plant, Fuel Pool Water Cooling Facility and Method Thereof

InactiveUS20120294407A1Lower Level RequirementsPower plant safety arrangementNuclear energy generationNuclear plantReactor pressure vessel

A nuclear power plant and a fuel pool water cooling facility and method are provided that can suppress the decrease of a water level in a fuel pool with no power supply at the time of malfunction of a circulating water system.The nuclear power plant includes a reactor pressure vessel 2 that encompasses a reactor 1 containing nuclear fuel; a containment vessel 3 for housing the reactor pressure vessel 2; a fuel pool 11 for storing spent fuel 12; a reactor building 10 that houses the reactor pressure vessel 2, the containment vessel 3 and the fuel pool 11; a circulating water system 21 adapted to forced-circulating-cool the fuel pool water 14 in the fuel pool 11; and at least one heat pipe 13 for transferring heat of the fuel pool water 14 in the fuel pool 11 and discharging the heat to the atmosphere.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

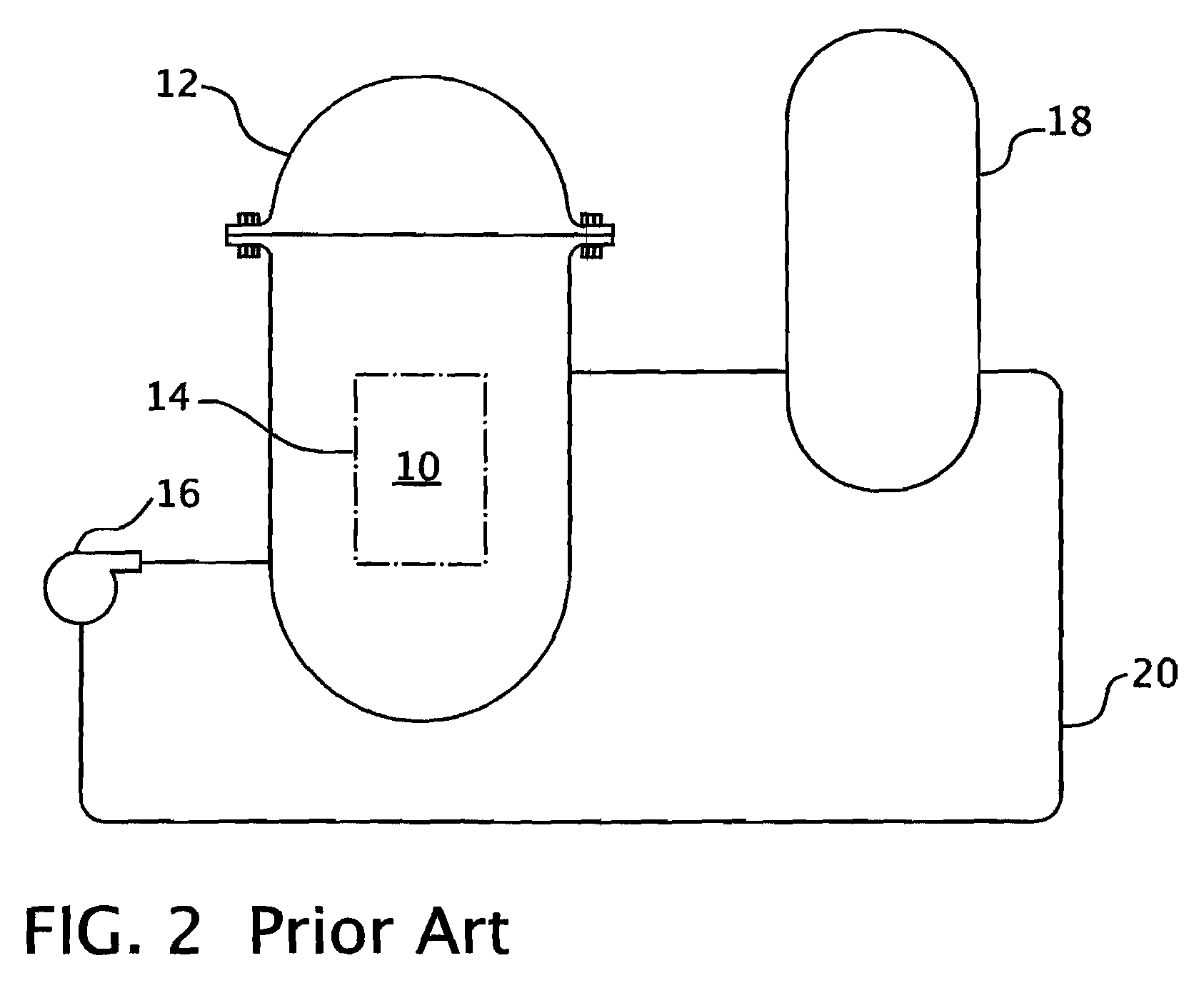

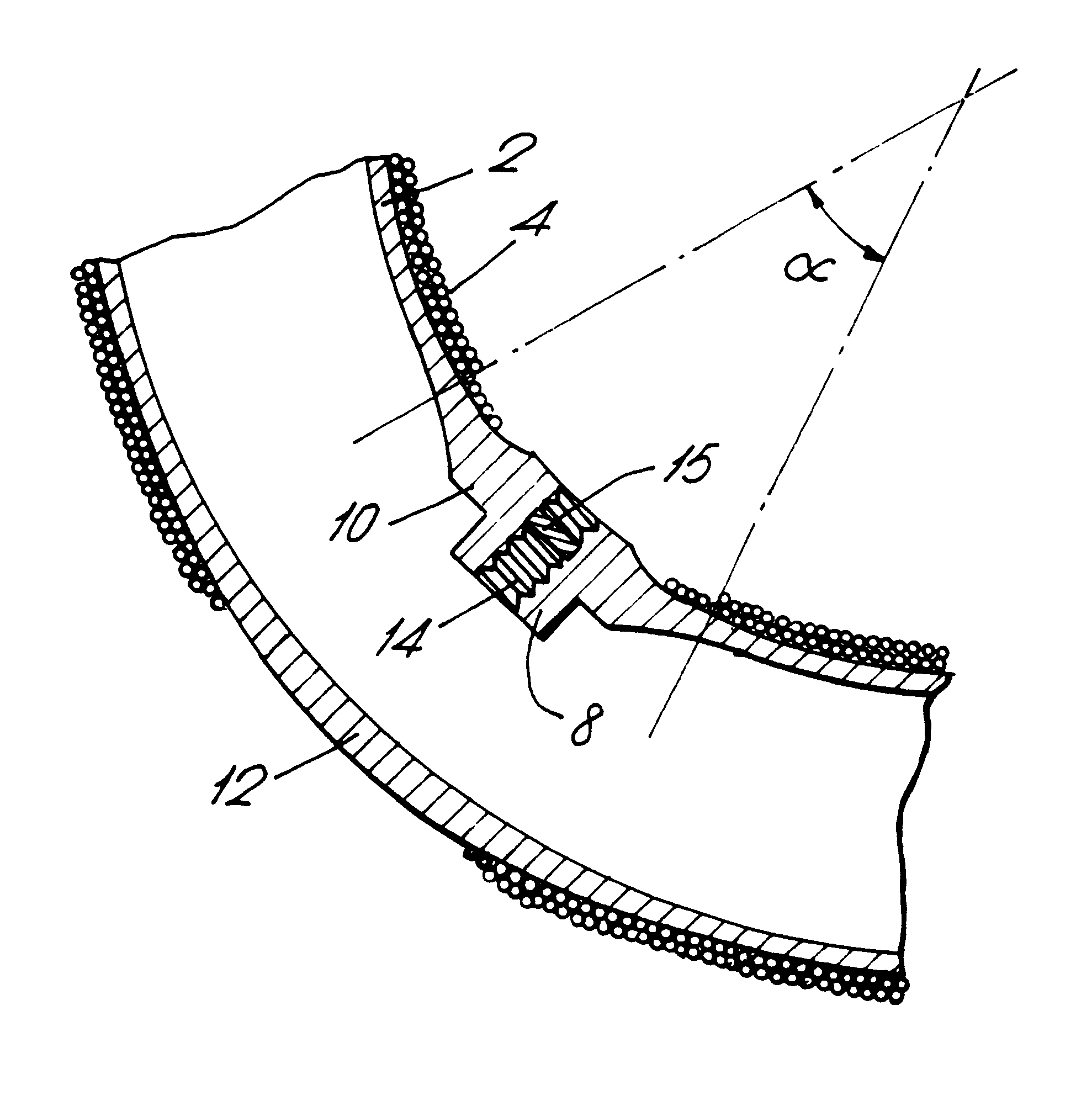

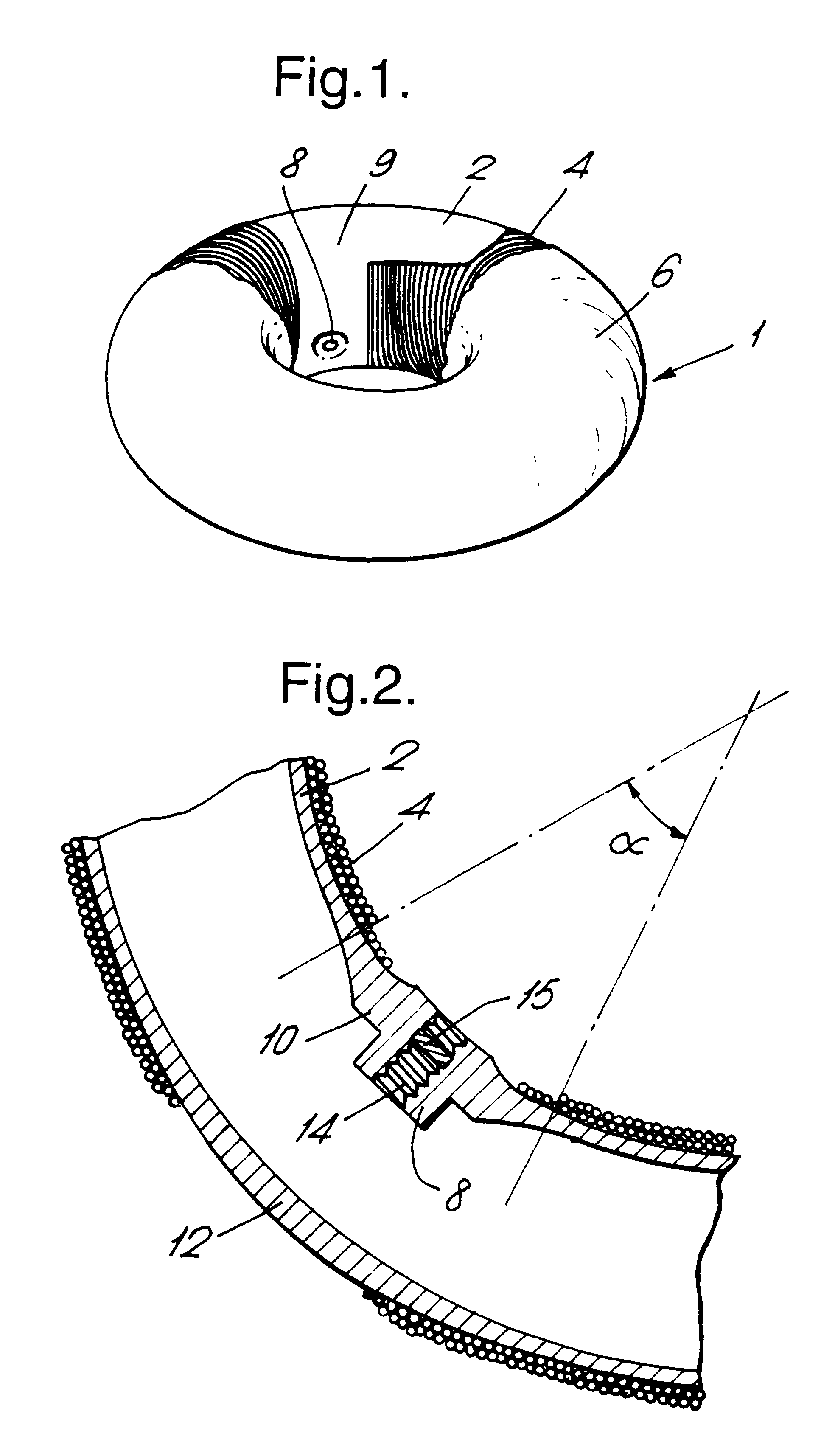

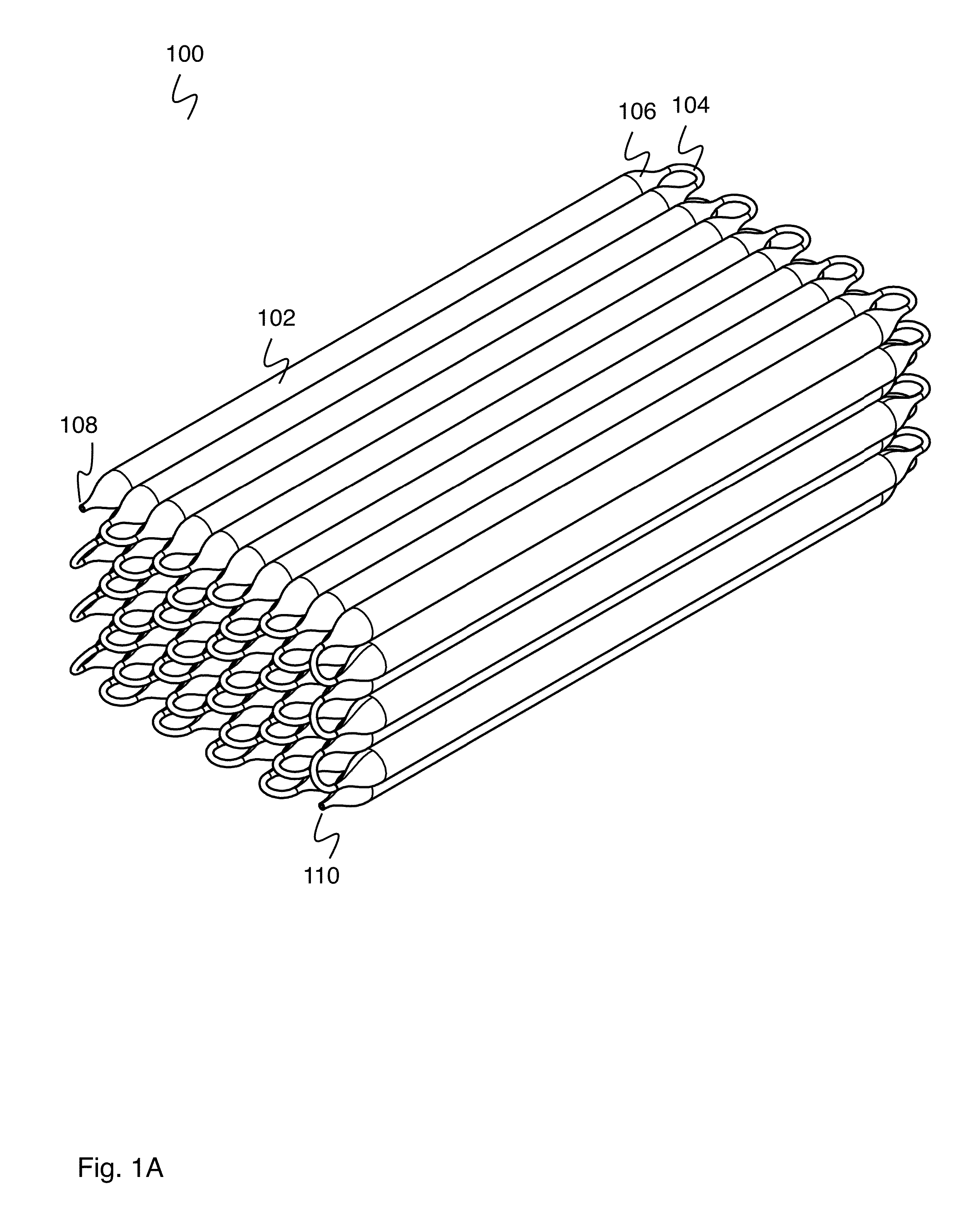

Gas containment apparatus

InactiveUS6357439B1Increase pressureReduce loadRespiratorsVessel mounting detailsReactor pressure vesselMetal fibers

A gas containment and supply apparatus is described consisting of a gas reservoir vessel (1) capable of pressurised gas containment fitted with a gas supply aperture (8) provided with supply means connectable to the gas supply aperture to provide for supply of the gas and control means to control the rate of supply of the gas, in which the gas reservoir is a toroidal pressure vessel comprising a metallic toroidal shell (2) having wound on its surface a tensile load bearing layer of high tensile strength non-metallic fiber (4), the fiber being aligned in a substantially meridional direction on the toroidal shell. Human portable breathing apparatus is described utilising the above.

Owner:QINETIQ LTD

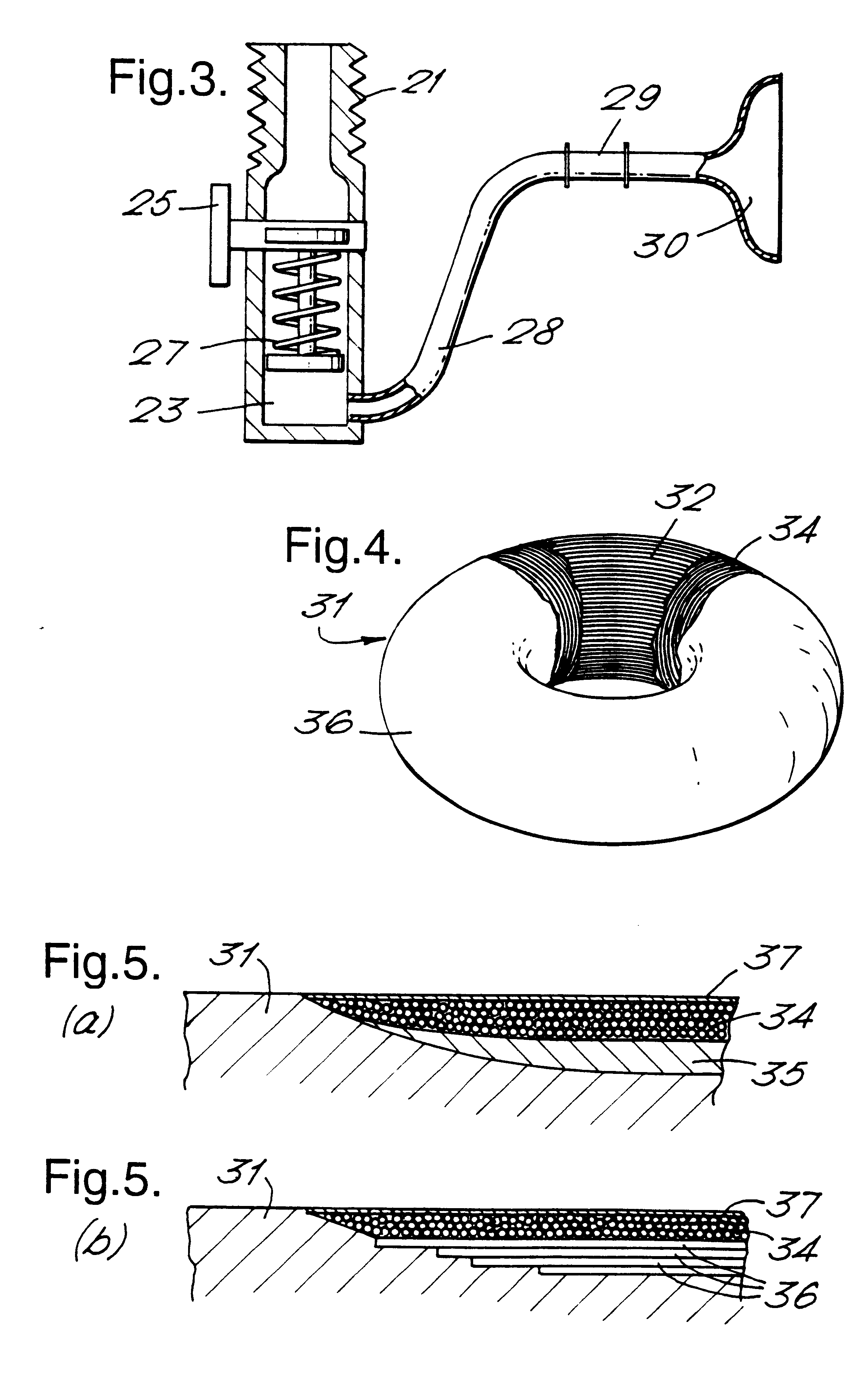

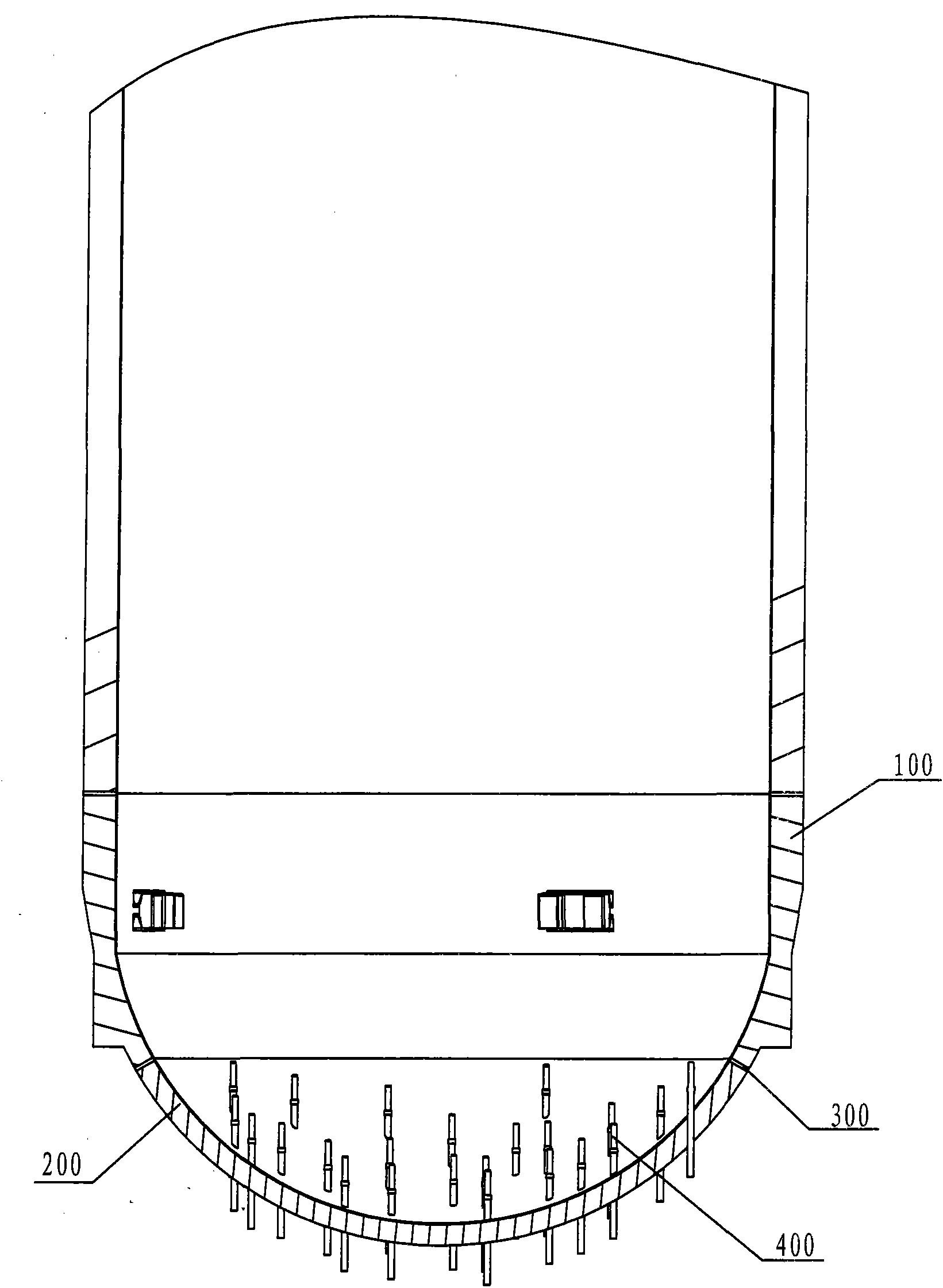

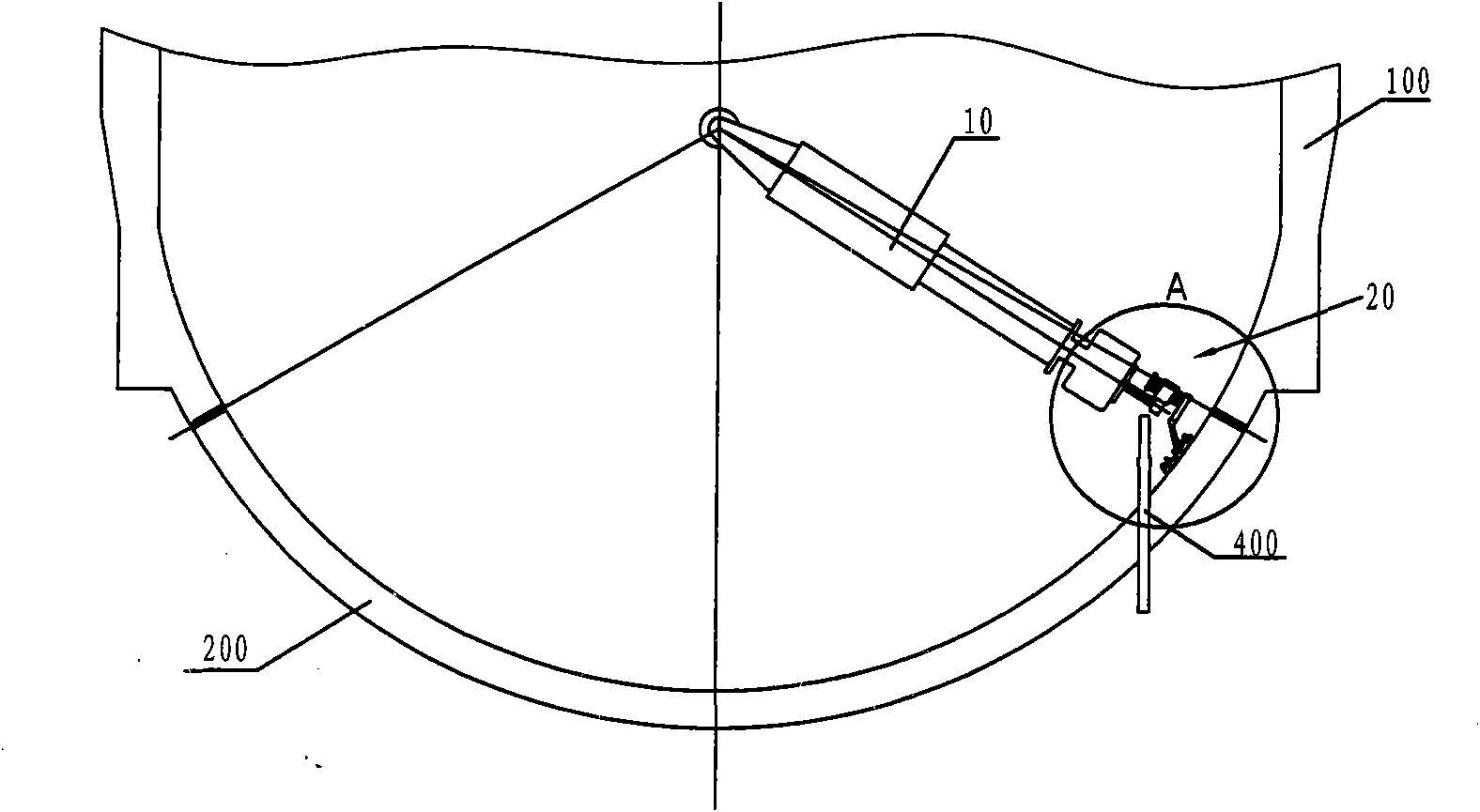

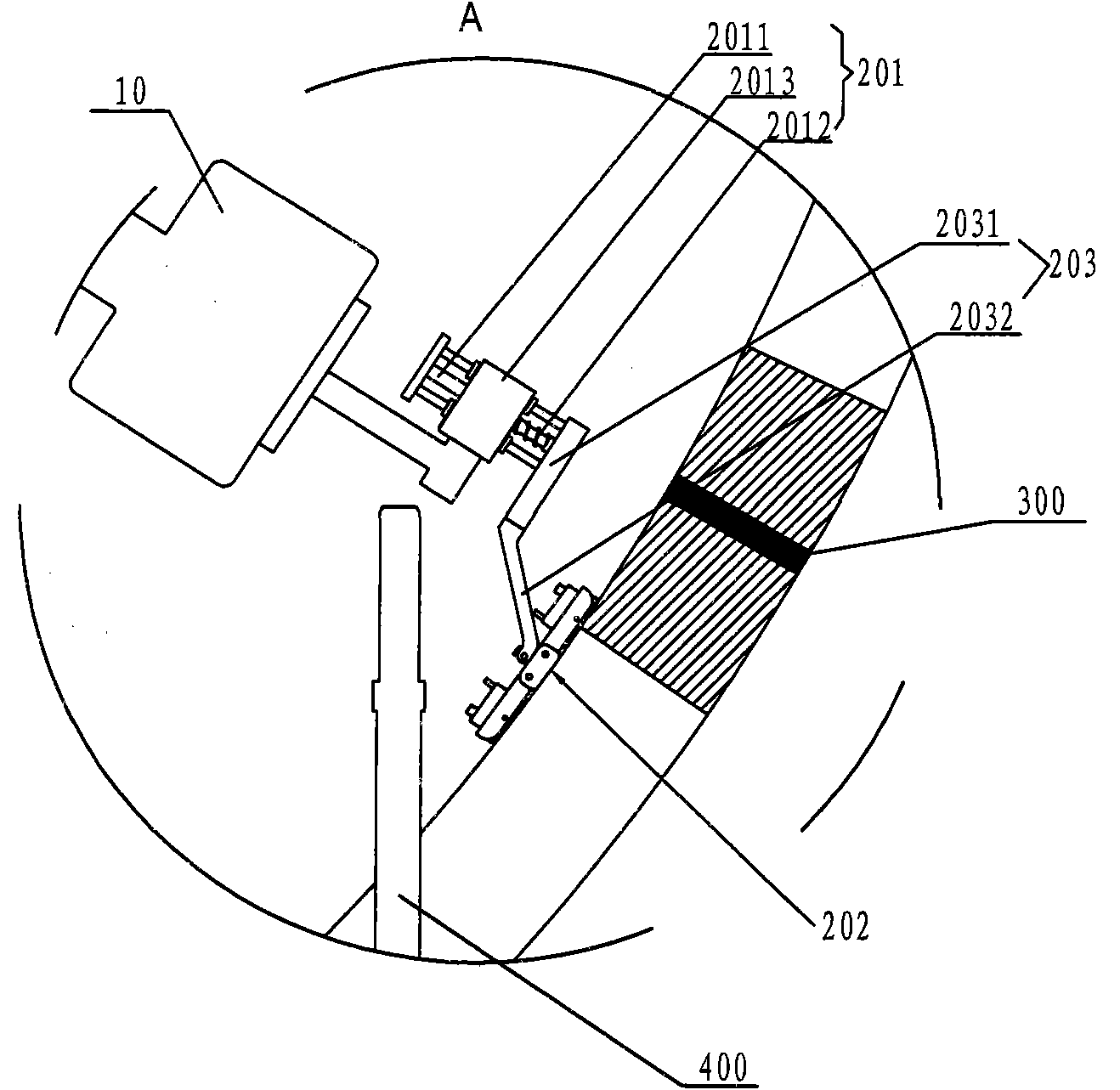

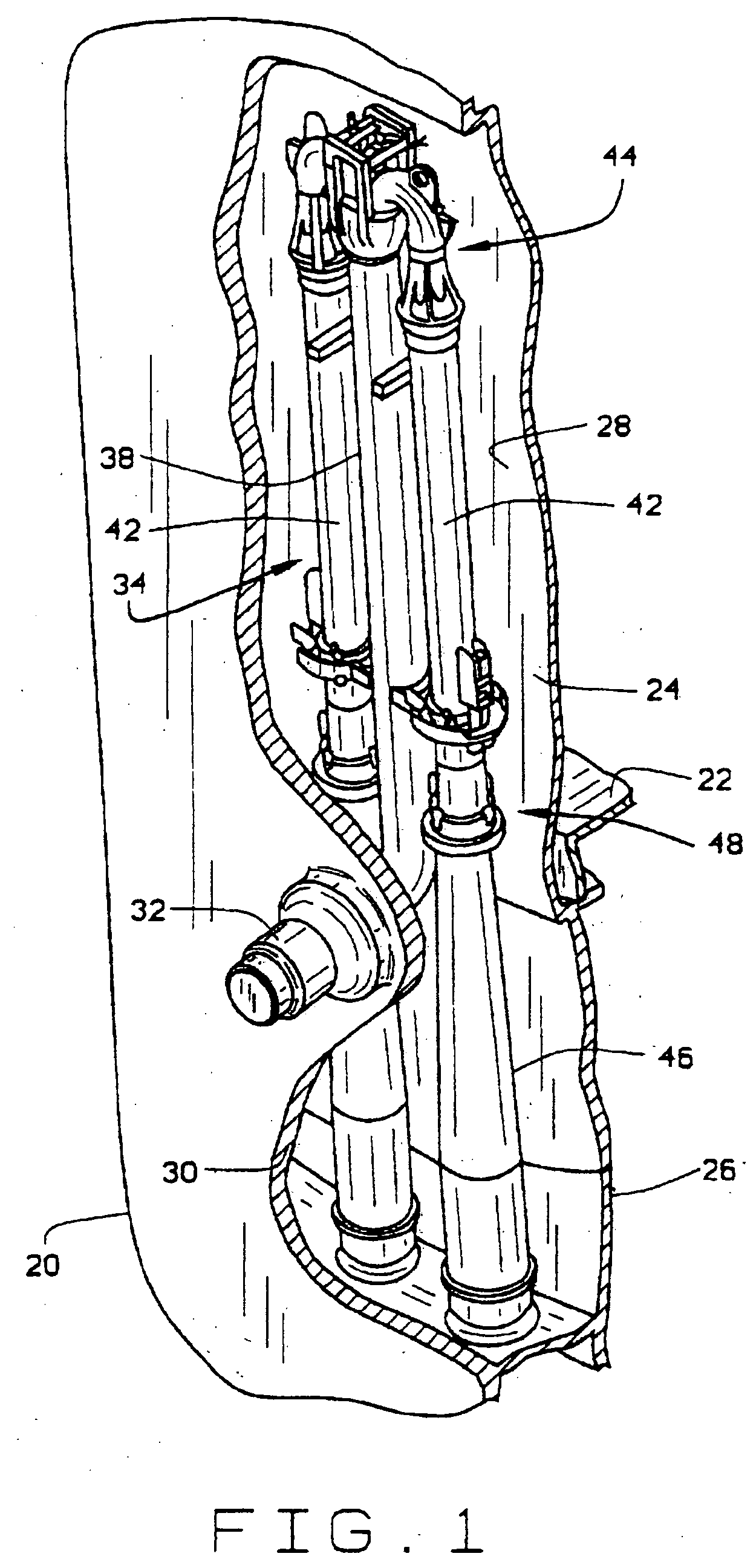

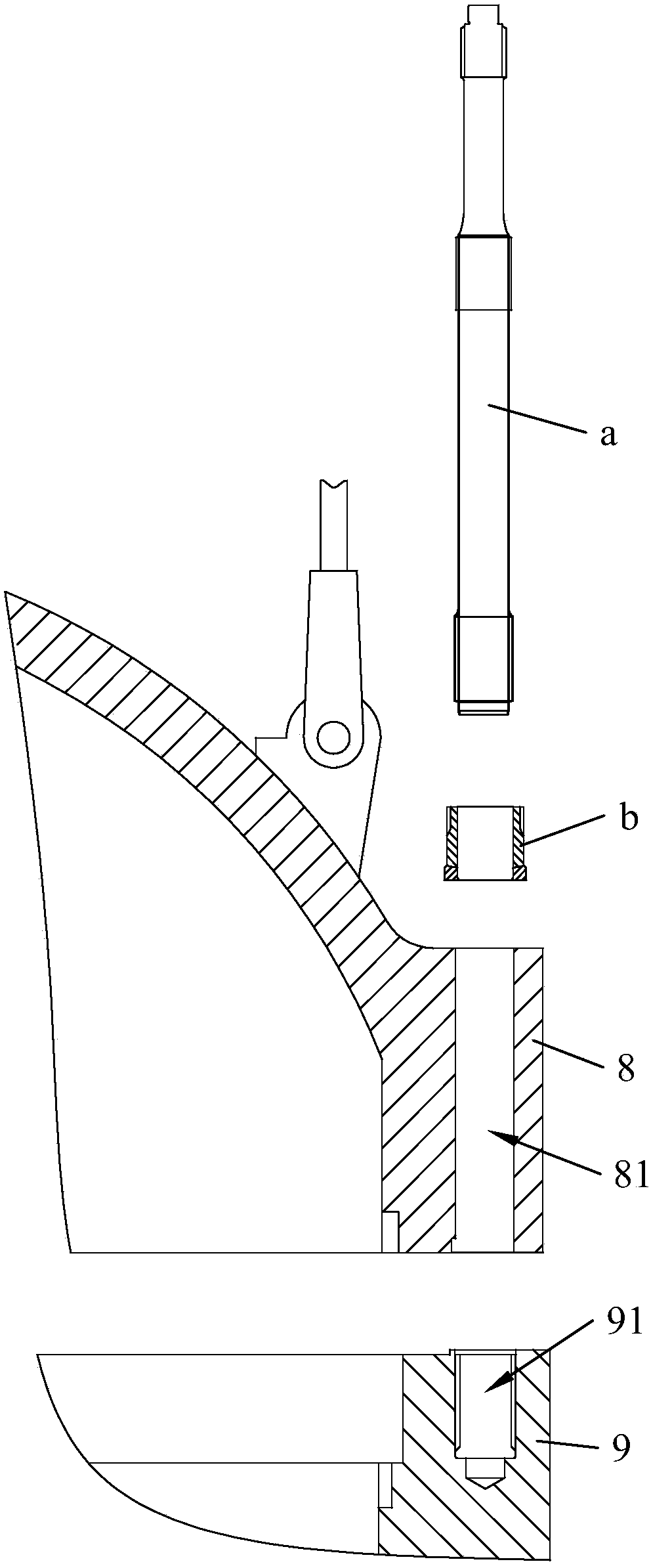

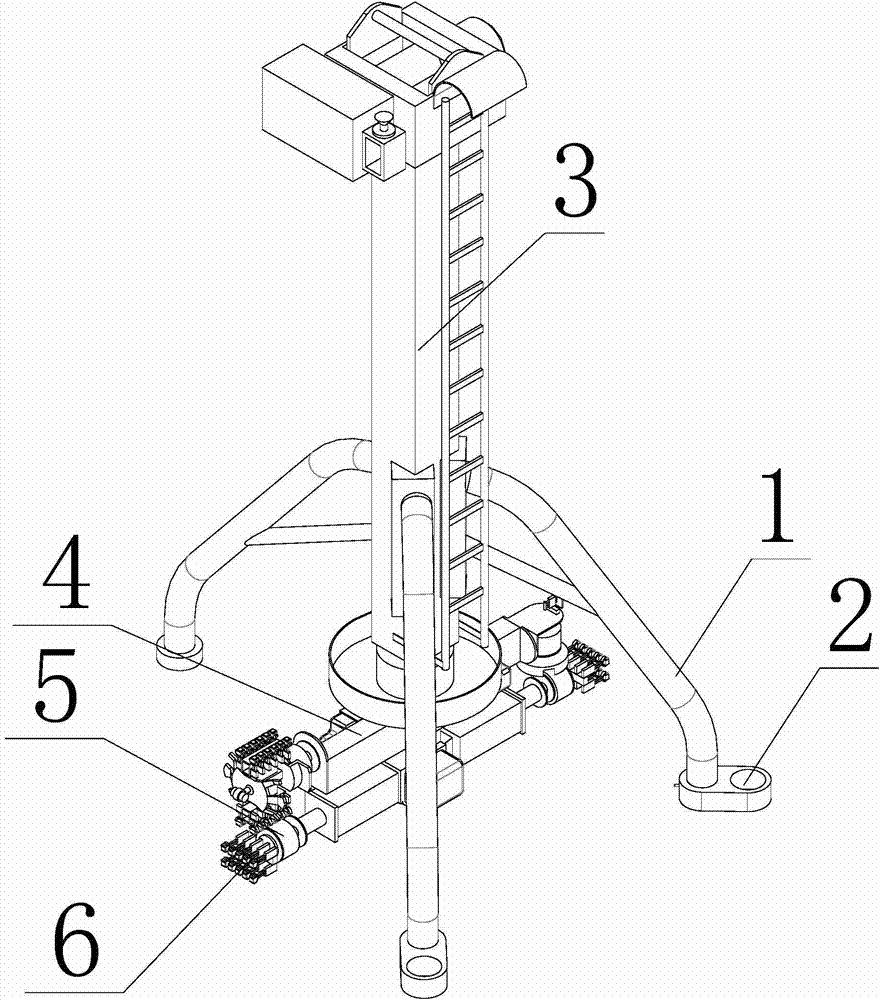

Probe scanning device of reactor pressure vessel inspection machine

ActiveCN101894593APrevent bumping intoGuaranteed full scanNuclear energy generationNuclear monitoringReactor pressure vesselFixed frame

The invention relates to a probe scanning device of a reactor pressure vessel inspection machine, comprising an inspection arm and at least one probe assembly connected with the front end of the inspection arm. Each probe assembly comprises a probe mechanism coupled with a spherical surface area to be scanned, a spring cushion test bed used for providing a pressing force for the probe mechanism in the radial direction of the spherical surface and a descending bracket connecting the spring cushion test bed and the probe mechanism; the probe mechanism comprises at least one ultrasonic probe body and a probe fixing frame used for limiting the position of the ultrasonic probe body; the descending bracket comprises a horizontal part and an inclining part which aslant extends to the spherical surface; and the inclining part is pivoted with the probe fixing frame. The probe scanning device prevents the probe mechanism from touching a penetration member and ensures the overall scanning of the area to be scanned, and the ultrasonic probe body can be tightly coupled, which ensures the scanning continuity as well as the reliability and the accuracy of scanning results.

Owner:CGNPC INSPECTION TECH +2

Active and passive nuclear steam supplying system based on 177 reactor core and nuclear power station thereof

ActiveCN103985422AImprove operational reliabilityEffectively monitor operationNuclear energy generationNuclear monitoringNuclear reactor coreReactor pressure vessel

The invention relates to an active and passive nuclear steam supplying system based on 177 reactor core. The nuclear steam supplying system comprises a nuclear reactor core and a reactor coolant system, and is characterized in that the nuclear reactor core comprises 177 nuclear fuel assemblies with the active length of 12-14 feet; and the reactor coolant system comprises a reactor pressure vessel, a main pipe connecting an inlet and an outlet of a reactor coolant, a main pump, a steam generator, a pressure stabilizer and a pressure relief tank. The invention also relates to a nuclear power station employing the above active and passive nuclear steam supplying system based on the 177 reactor core. The power of the assembling unit of the nuclear power station is 1000-1400 MWe, the average availability is more than or equal to 90%, the maximum ground acceleration is 0.3 g, and a containment has a double-layer steel-made structure for resisting bump of large business airplanes. The active and passive nuclear steam supplying system based on the 177 reactor core has the functions of alleviating and preventing severe accidents, and a core measuring meter penetrates into the reactor pressure vessel from top to bottom, so that the active and passive nuclear steam supplying system possesses an active manner and passive manner combined residual heat removal system and a digitalizer control diversity protection system.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

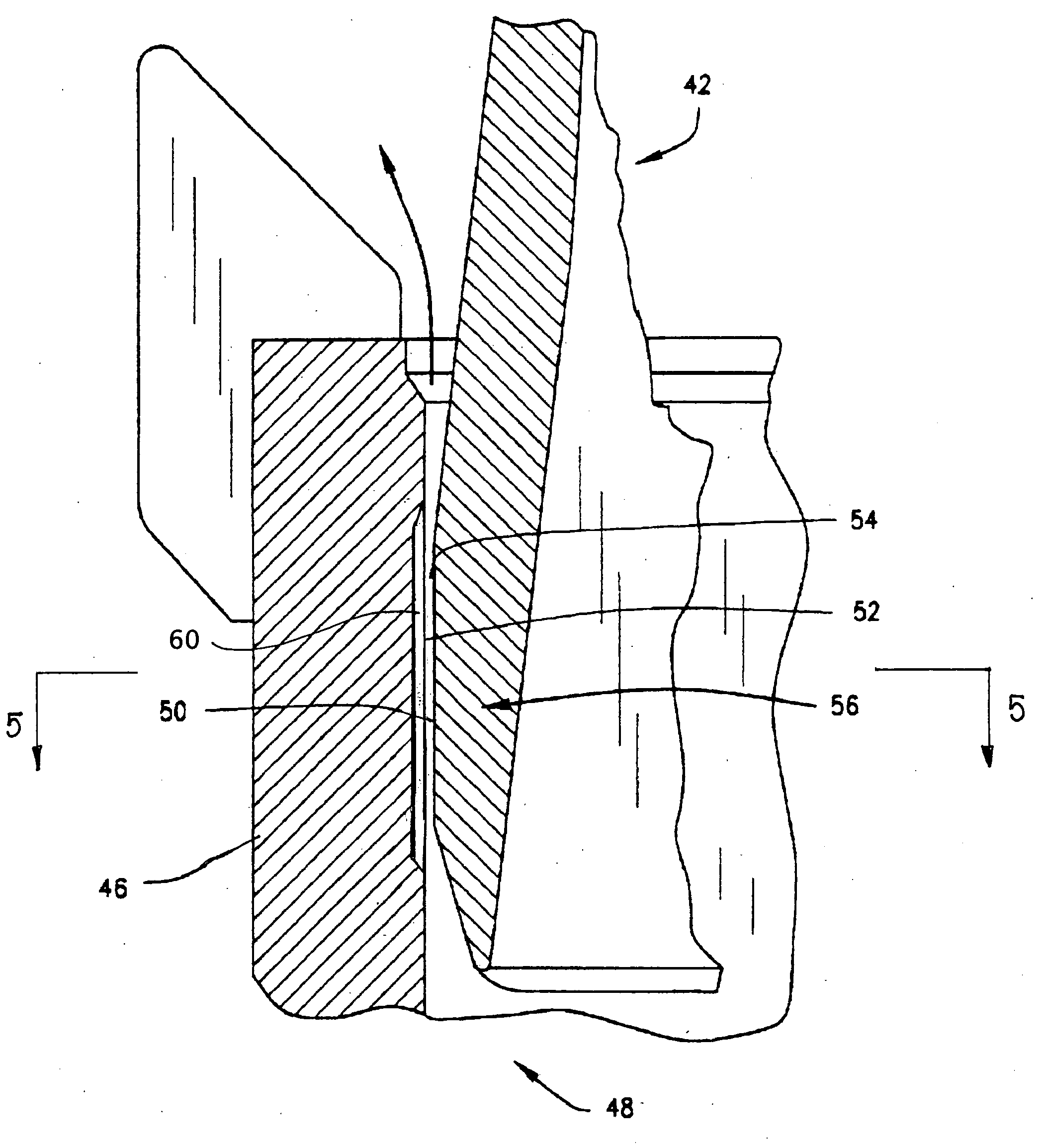

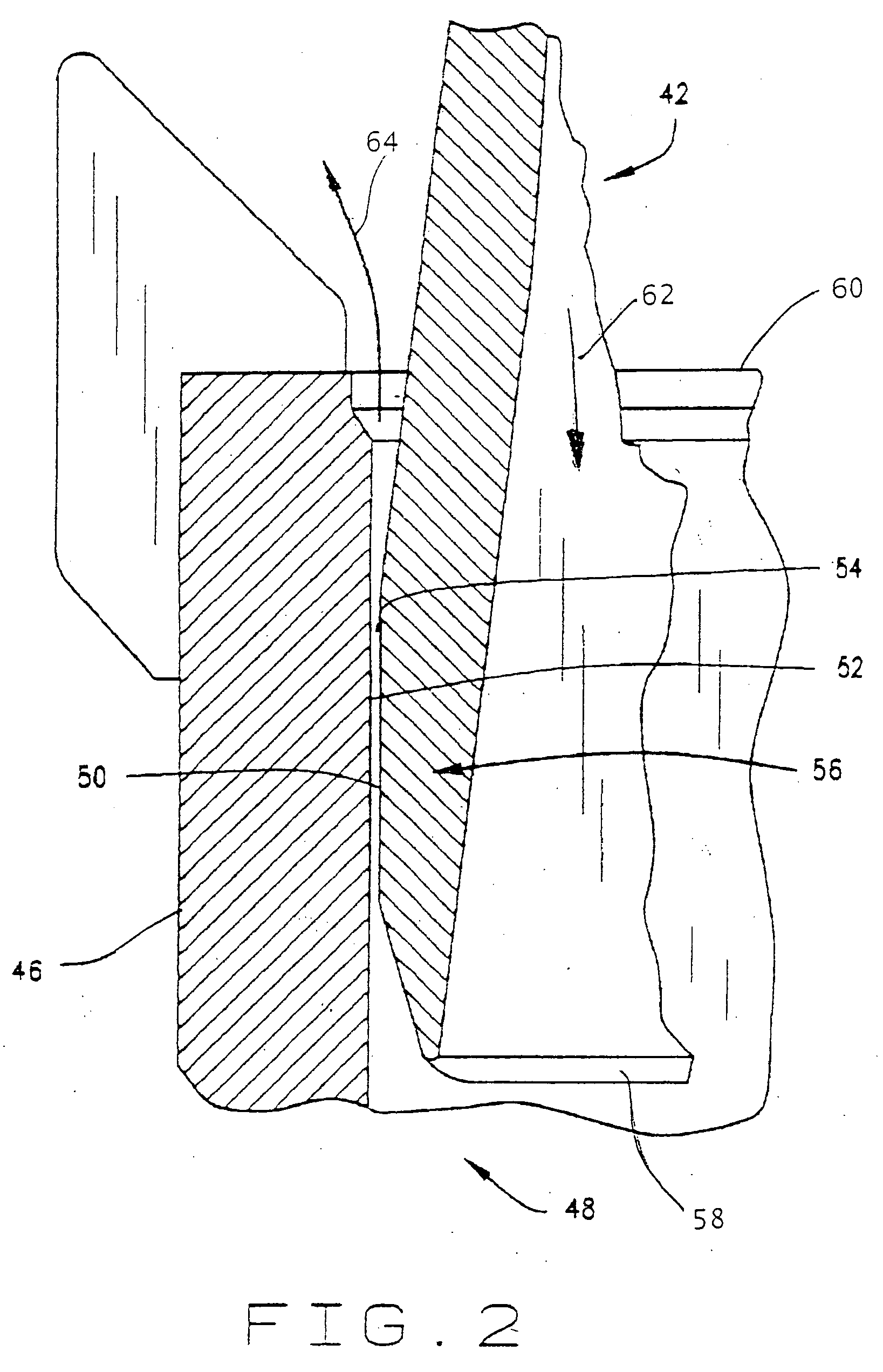

Jet pump slip joint with axial grooves

InactiveUS20080031741A1Increased non-uniform flowHigh fluid forceJet pumpsMachines/enginesPipingReactor pressure vessel

A uniform leakage flow device for the slip point of piping systems, and particularly in reactor pressure vessels, selectively imposes a steady, uniform flow of fluid through the slip joint between two adjacent pipe surfaces to thereby eliminate the detrimental flow-induced vibration associated with the unsteady and non-uniform leakage of fluid through the slip joint field. The uniform leakage flow device comprises a plurality of axial grooves that are formed in the wall surface of the slip joint.

Owner:TORRES MARTIN R

Passive containment cooling system

ActiveCN103413581AImprove stabilityNuclear energy generationCooling arrangementCooling towerIsolation valve

The invention discloses passive containment cooling system. The passive containment cooling system comprises a high-position material exchanging water pool used for storing cooling water, an evaporator, an air cooling tower, a plurality of pipes, and a refrigerant, wherein a containment is equipped with a vault; a reactor pressure vessel o is located in the vault; the high-position material exchanging water pool is positioned in the containment and above the vault, and is communicated with the vault through an isolating valve; the evaporator is positioned in the vault; the air cooling tower is positioned outside the containment and is higher than the vault, the pipes are connected between the outlet of the evaporator and the inlet in the upper end of the air cooling tower, and between the outlet in the lower end of the air cooling tower and the inlet of the evaporator; the refrigerant flows in a circulation channel formed among the evaporator, the air cooling tower and the pipes. The passive containment cooling system can realize the function of exporting waste heat of the containment in case of an accident without relying on an external power supply, so as to increase the stability of the system and also the safety of the nuclear power station.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +1

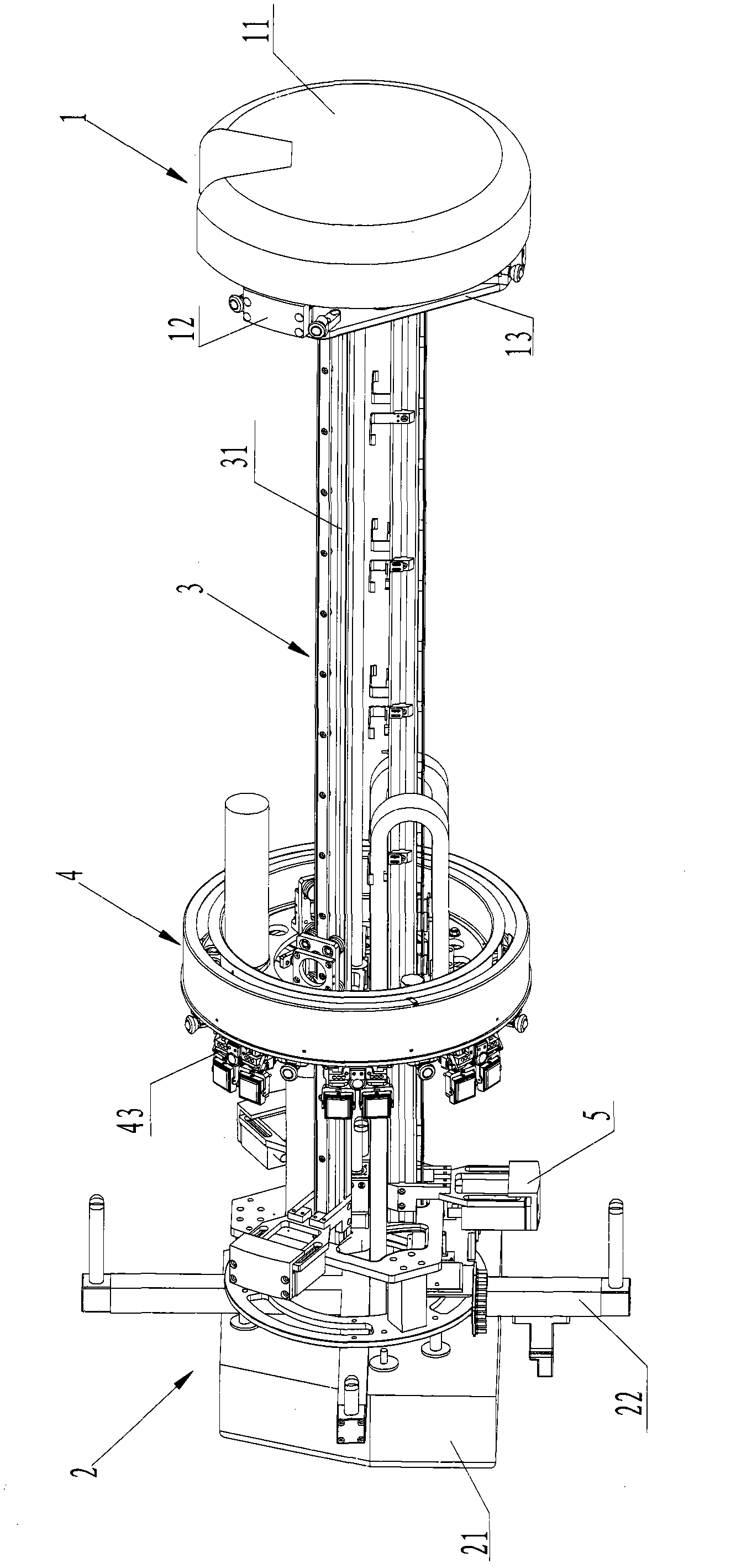

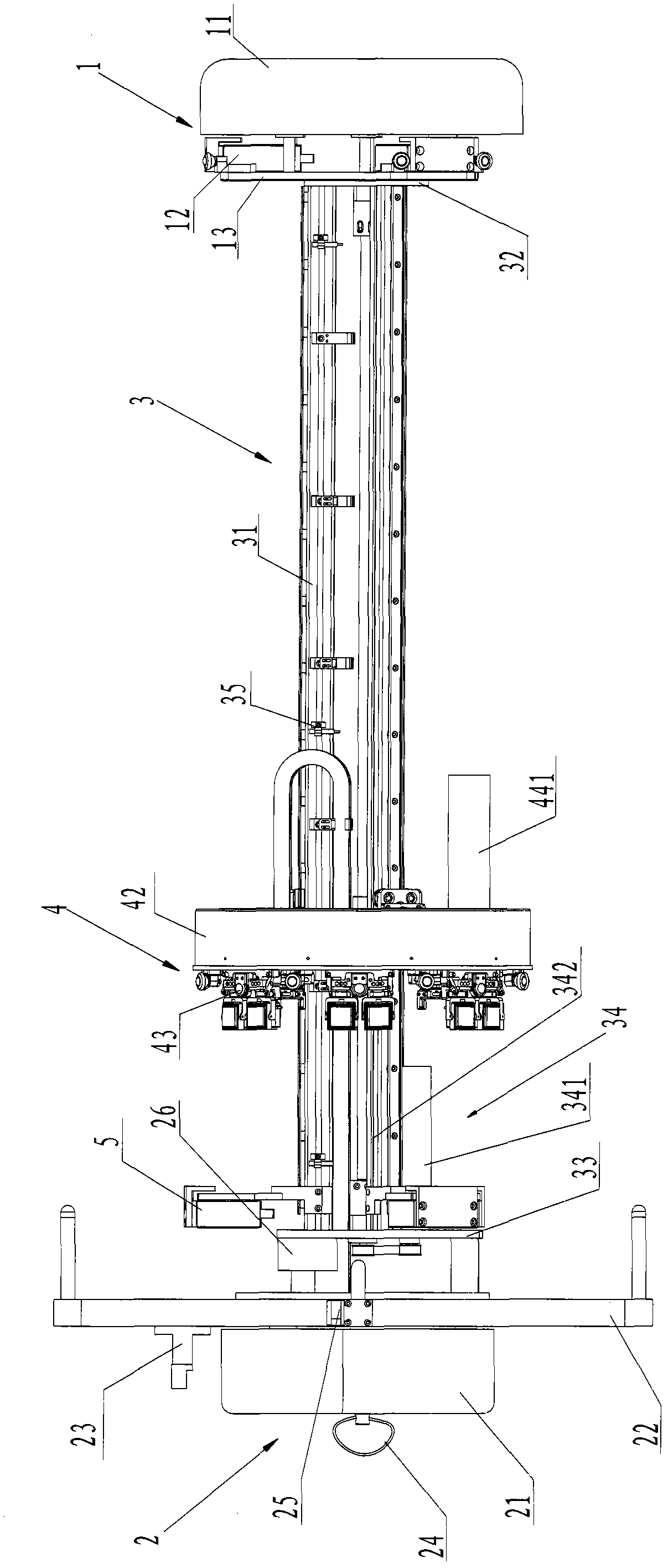

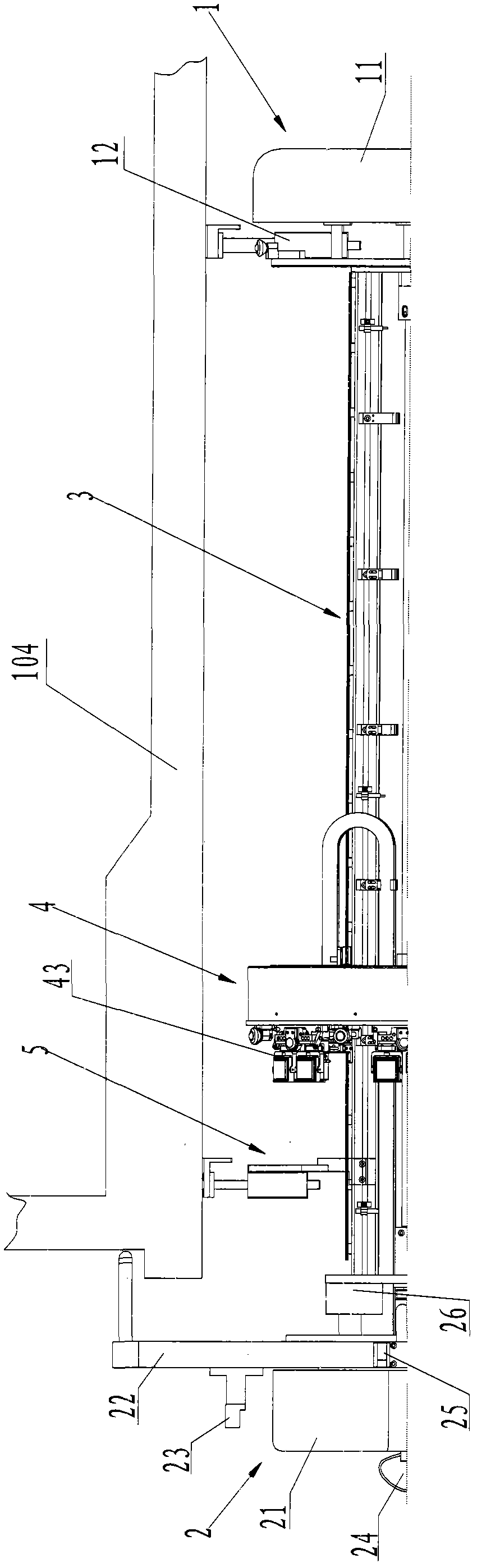

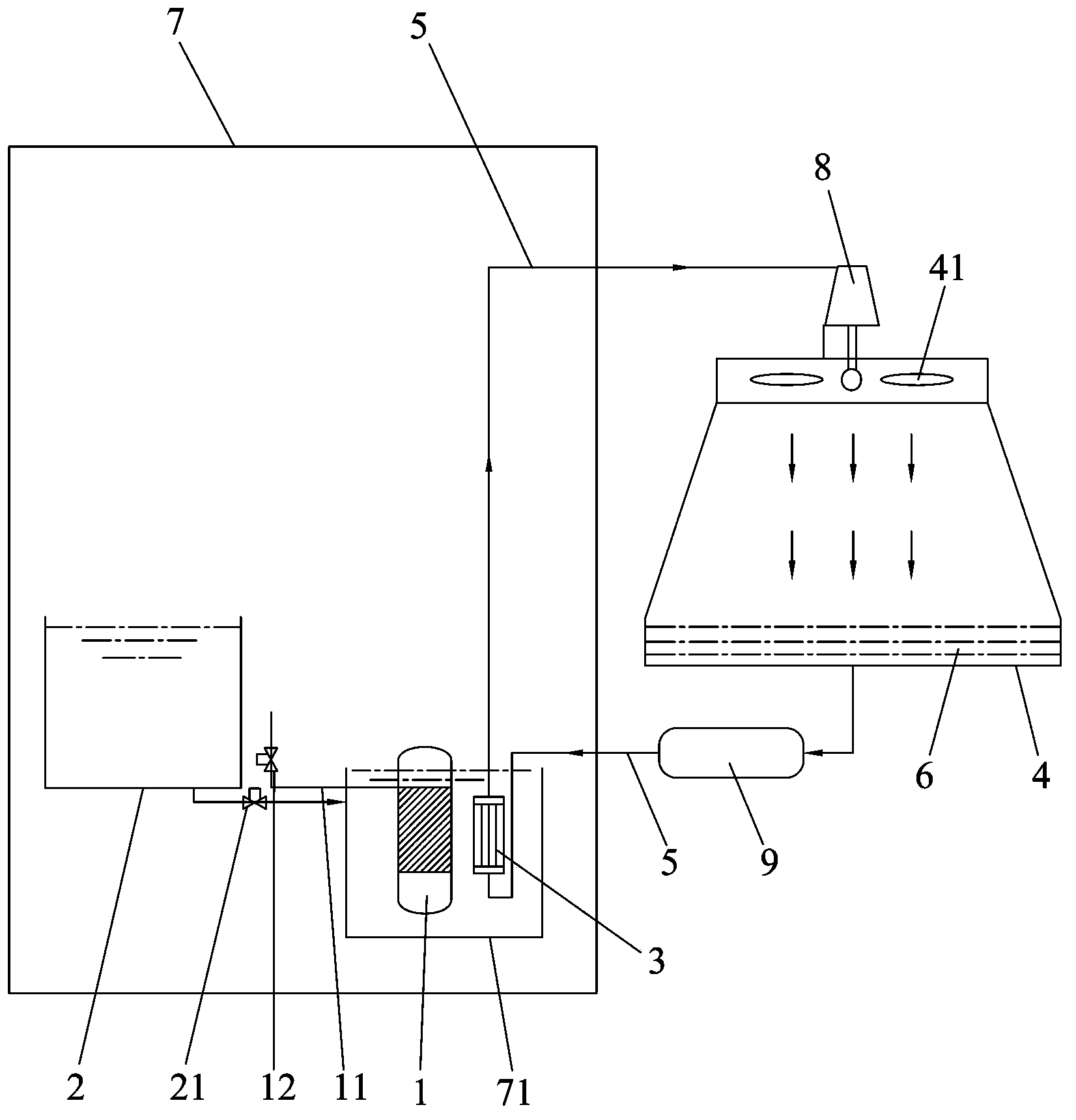

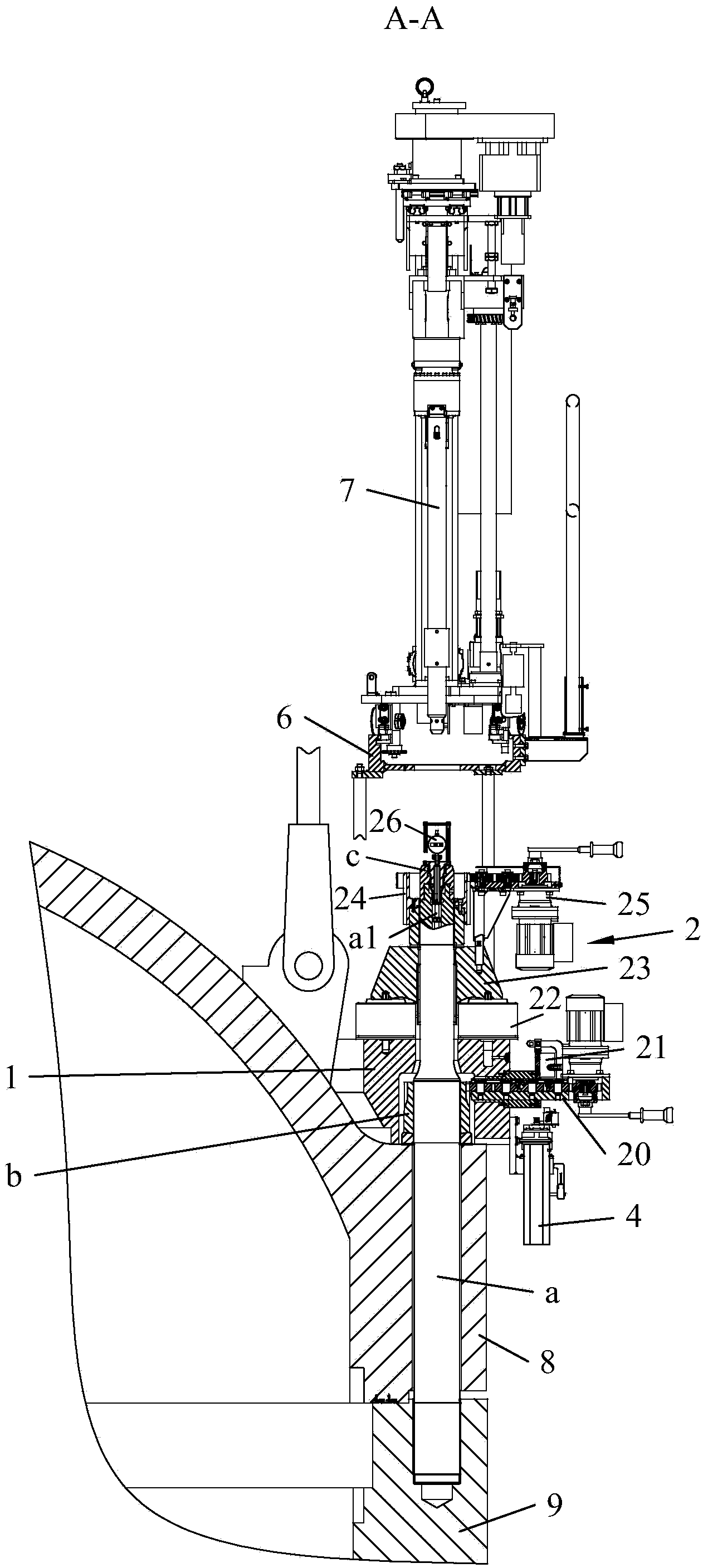

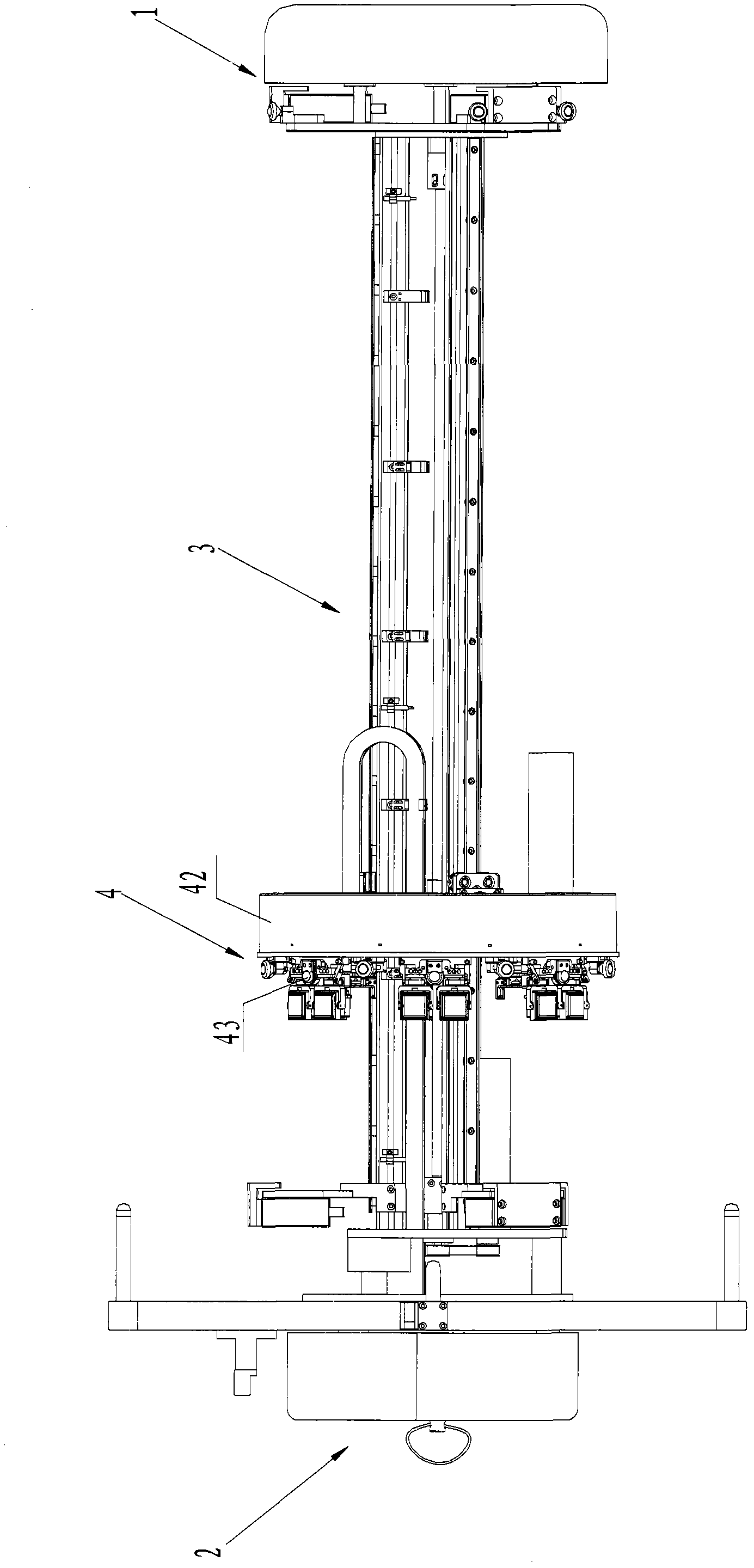

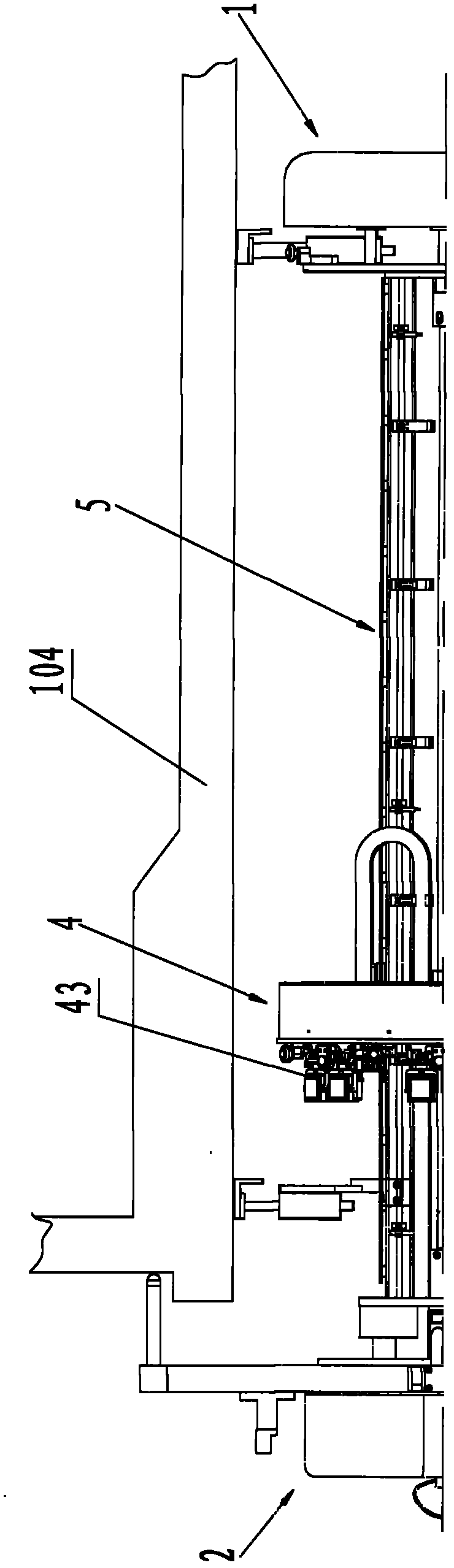

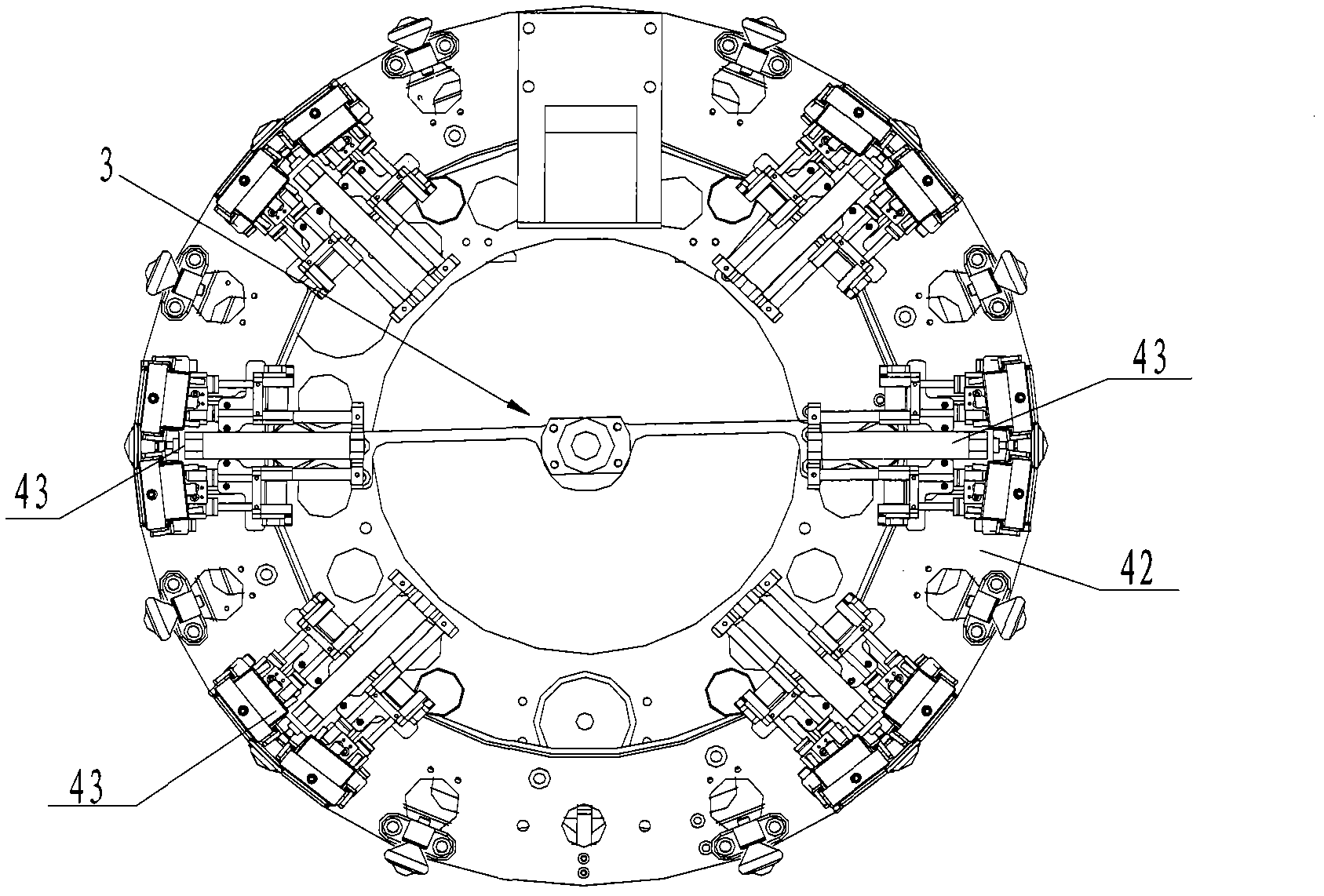

Entire bolt stretcher for nuclear reactor pressure vessels and operating process thereof

ActiveCN104029007AShorten working timeFully automatedMetal working apparatusHydraulic cylinderNuclear reactor

The invention discloses an entire bolt stretcher for nuclear reactor pressure vessels comprising a supporting ring, a lifting device, a supporting device, stretching component, a robot operating platform and a main bolt rotary robot. The supporting ring bears a reactor cover; the stretching component comprises a stretching hydraulic cylinder, a stretching bridge, a stretching nut, a stretching nut rotating device and a cover nut rotating device; the stretching cylinder is fixed to the supporting ring, the stretching bridge bears the piston of the stretching cylinder, the stretching unit is connected with a main bolt in a screwed manner, the stretching nut rotating device drives the stretching nut to rotate, the cover nut rotating device drives a cover nut to rotate, the lifting device drives the supporting ring to move upwardly, the supporting device supports the supporting ring, and the main bolt rotary robot is arranged on the robot operating platform and rotates the main bolt. The entire bolt stretcher is capable of screwing the main bolt in or out of a bolt hole in the pressure vessel and stretching the main bole so as to screwing the cover nut tightly or loosely, the operating efficiency is high, and disassembling time is saved.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +1

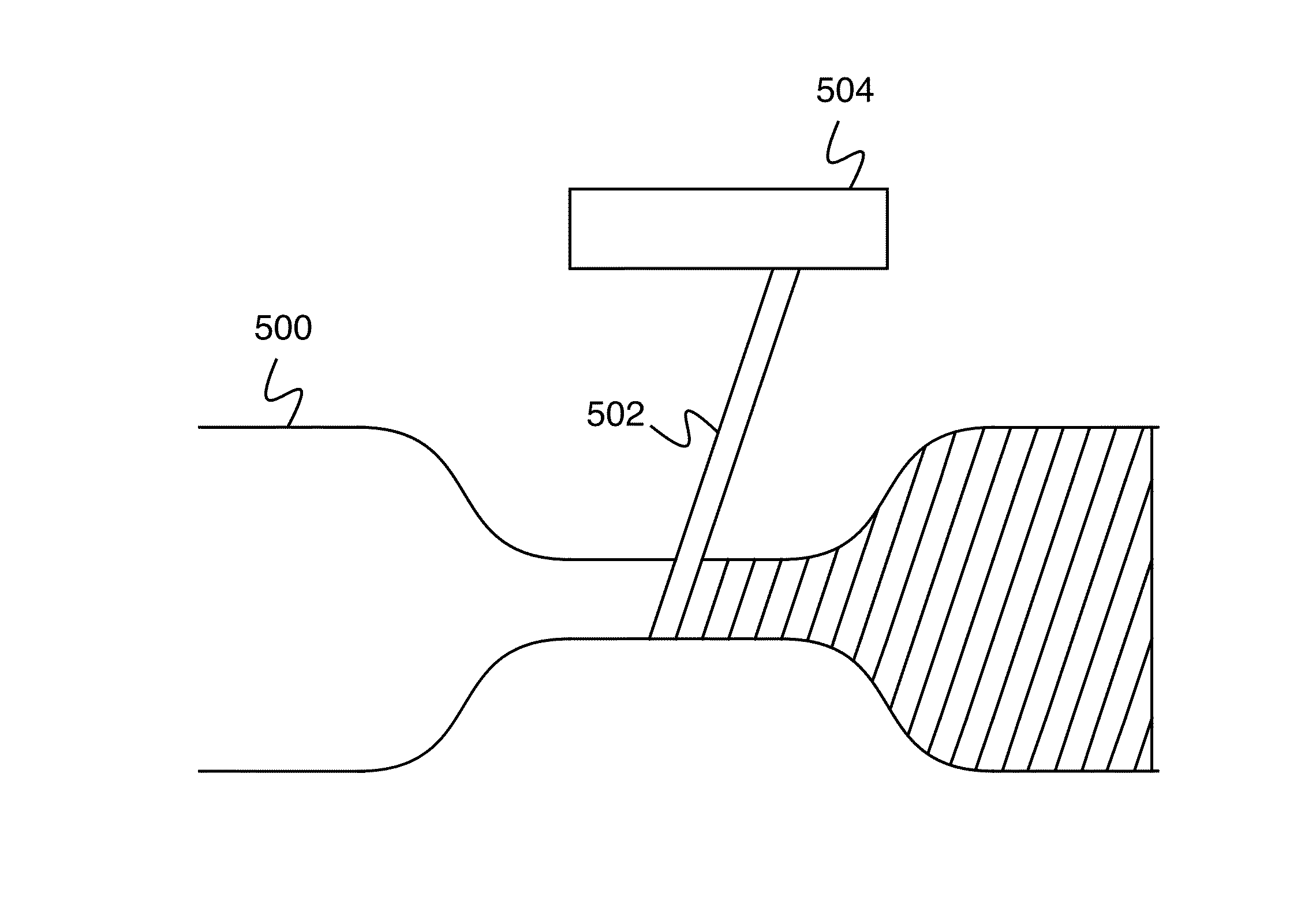

Natural gas intestine packed storage tank

ActiveUS20140305951A1Vessel mounting detailsVessel manufacturingReactor pressure vesselMarine engineering

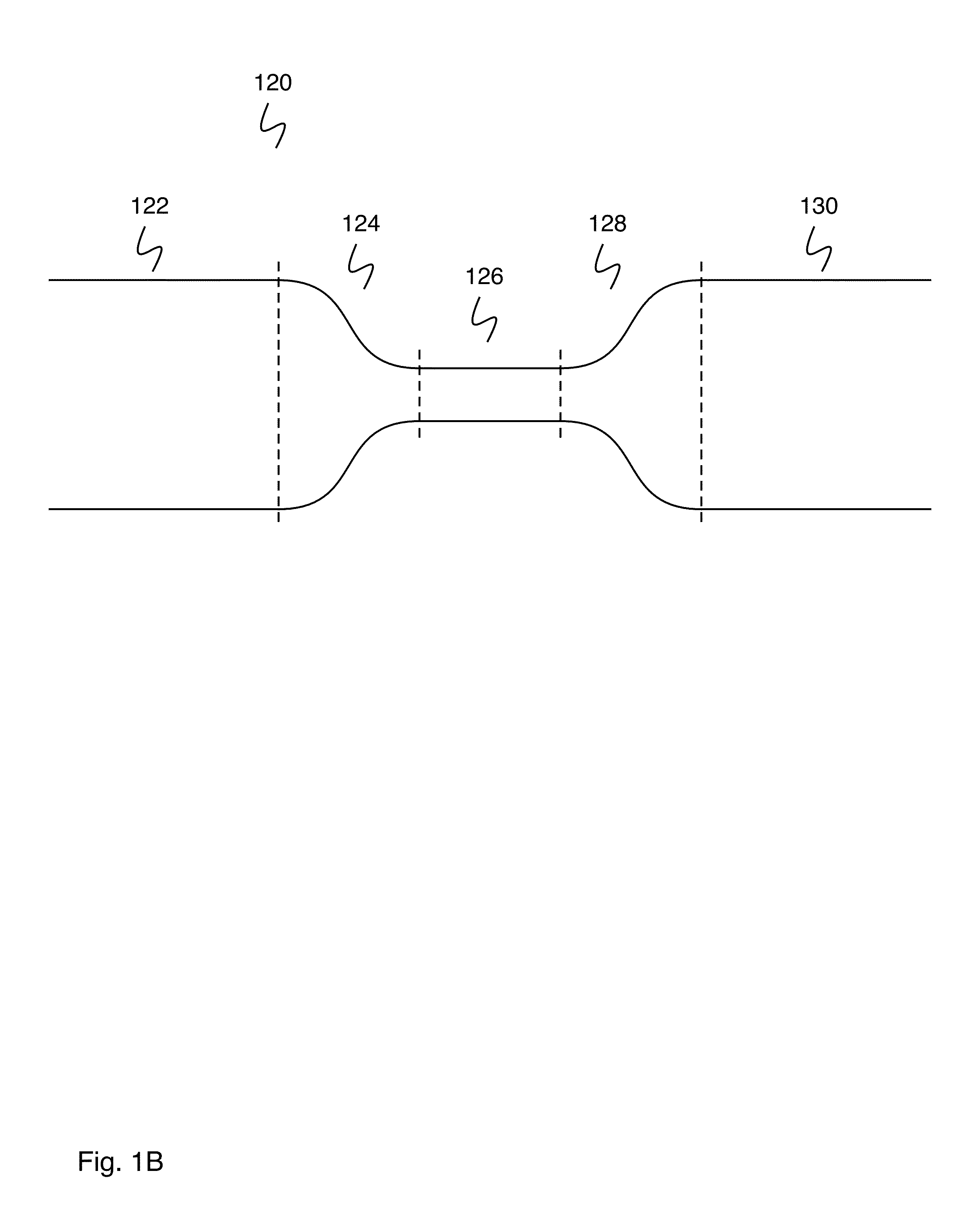

A high-pressure pressure vessel for storing natural gas comprises a plurality of first vessel regions of first diameters, a plurality of couplers, and a fiber layer. A three dimensional volume is filled using at least in part the plurality of first vessel regions. Each coupler of the plurality of couplers couples each pair of first vessel regions of the plurality of first vessel regions. Each coupler of the plurality of couplers comprises a second vessel region of a second diameter and two third vessel regions that transition diameters between the first diameter and the second diameter. The three dimensional volume is filled using at least in part the plurality of couplers. The first vessel regions and the couplers comprise a material with low permeability to natural gas. The fiber layer surrounds the plurality of first vessel regions and the plurality of couplers.

Owner:OTHER LAB

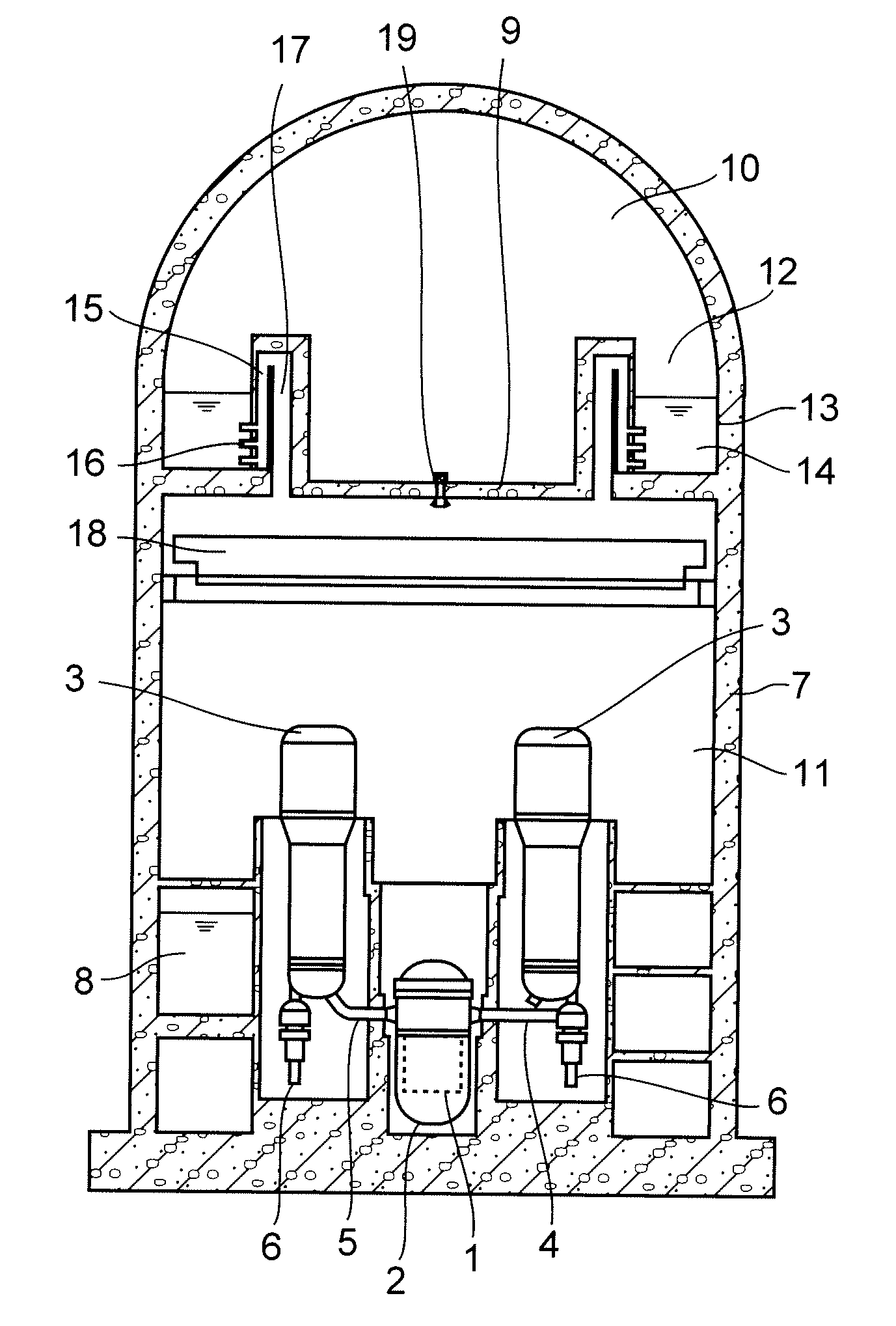

Containment vessel and nuclear power plant therewith

InactiveUS20090323884A1Nuclear energy generationNuclear engineering problemsReactor pressure vesselGas phase

A containment vessel for containing a reactor pressure vessel and steam generators has a main containment vessel, a diaphragm, a pressure suppression chamber, LOCA vent pipes. The reactor pressure vessel contains a reactor core of a pressurized water reactor. The diaphragm partitions the main containment vessel into an upper vessel and a lower vessel. The pressure suppression chamber has a suppression pool to store water and gas phase of the pressure suppression chamber communicates with the upper vessel. The LOCA vent pipes connect the pressure suppression chamber to the lower vessel. All of the equipments and piping that constitute the reactor pressure boundary, including the reactor pressure vessel, the steam generators, a cold leg pipe and a hot leg pipe, are contained in the lower vessel.

Owner:KK TOSHIBA

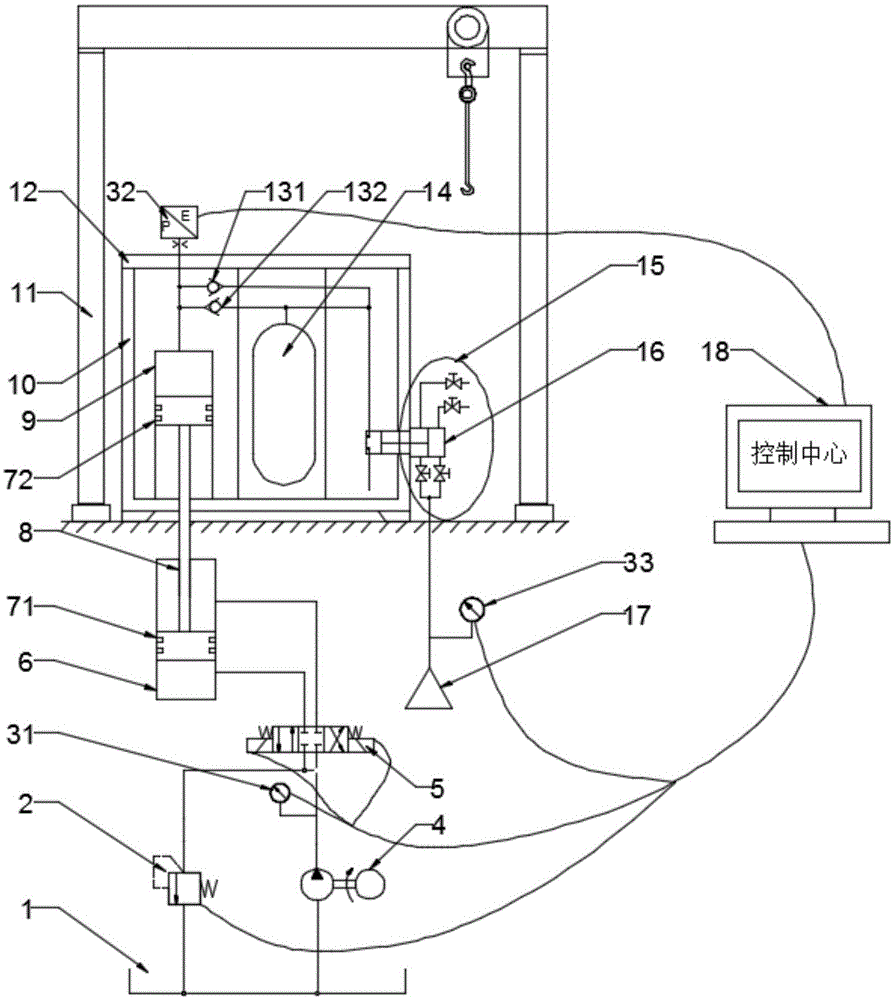

Cryogenic vessel multi-performance test device and test method

InactiveCN105004616AAchieve separationRealize reciprocating functionMaterial strength using tensile/compressive forcesHydraulic cylinderReactor pressure vessel

The invention discloses a cryogenic vessel multi-performance test device and test method and belongs to the technical field of test equipment. A piston type energy accumulator comprises a double-cylinder structure of a hydraulic cylinder and a liquid nitrogen cylinder. The liquid nitrogen cylinder is installed in a heat-preserving box (10). A piston connection rod (8) of the hydraulic cylinder perpendicularly penetrates through the bottom face of the heat-preserving box (10) in a normal temperature state. The upper end and the lower end of the piston connection rod (8) are connected with a liquid nitrogen cylinder piston (72) and a hydraulic cylinder rod (71) respectively. A multi-pipeline system is connected with a fluid storage (1), a motor pump set (4), a high-pressure gas source (17), a gas-driving pump (16) and a tested pressure vessel. The requirement that a liquid nitrogen temperature zone completes multi-performance tests on pressure vessels on one device platform is met.

Owner:DALIAN UNIV OF TECH

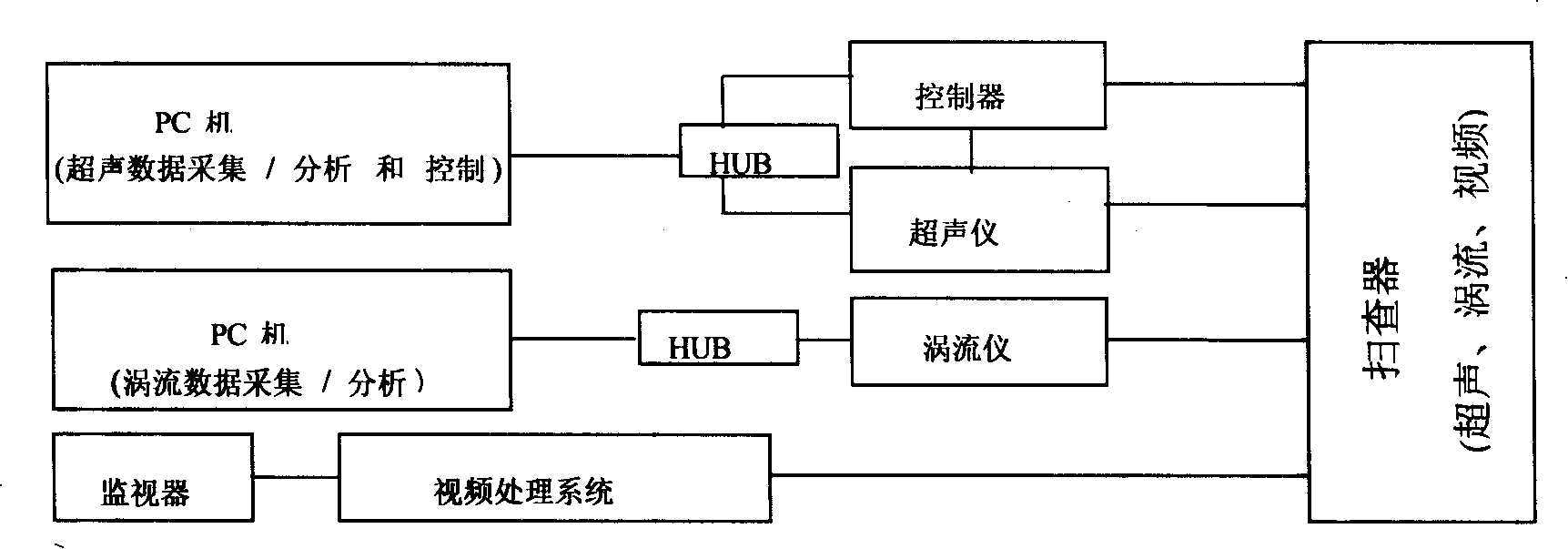

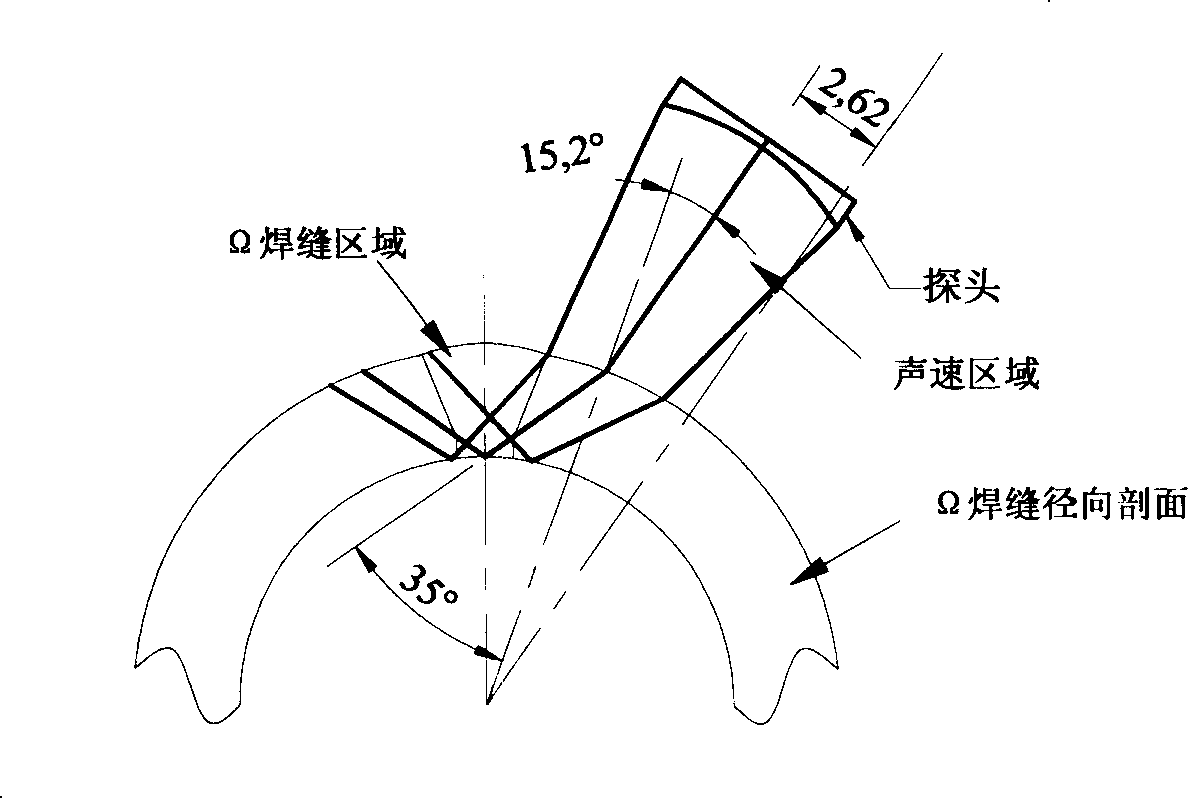

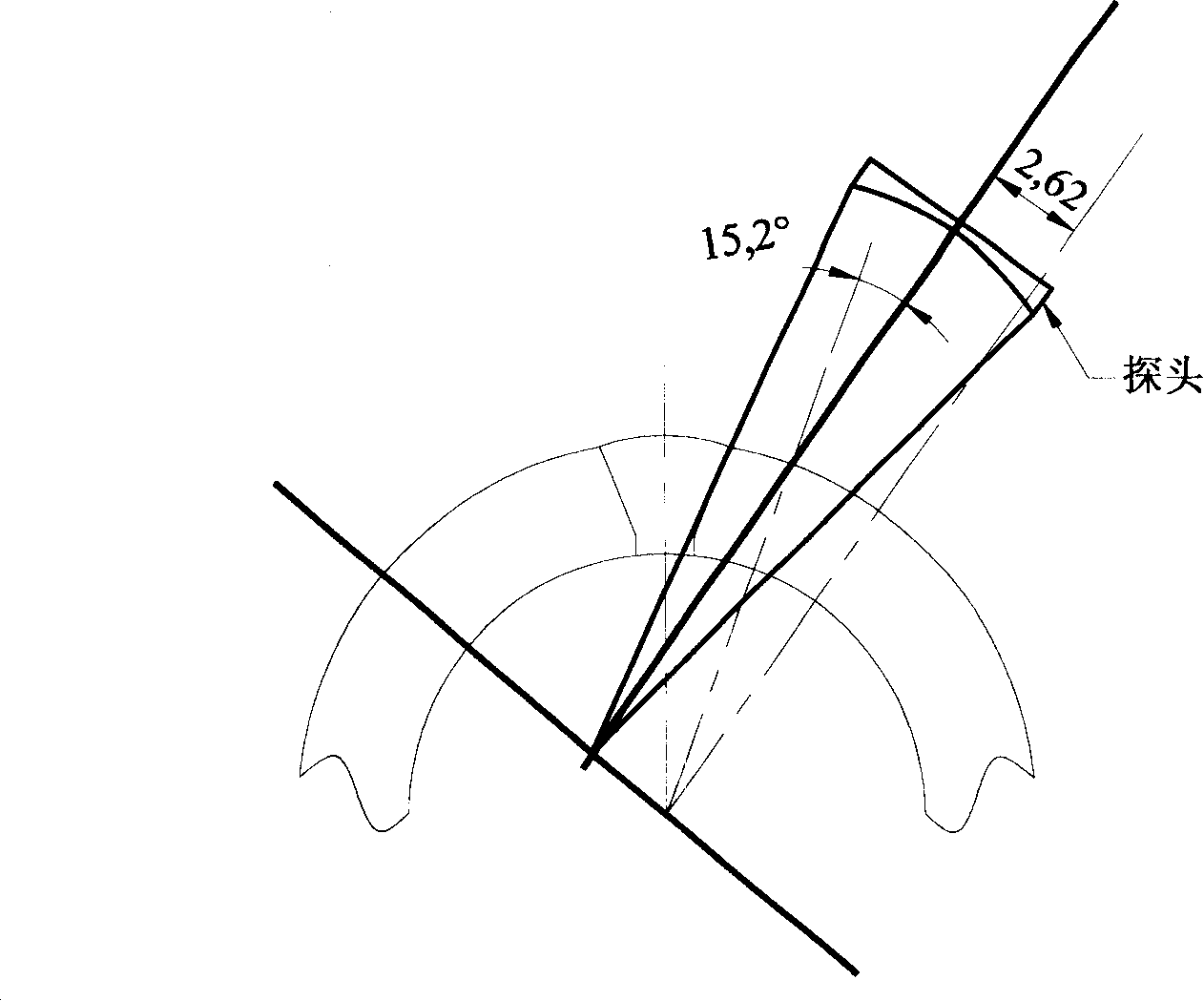

Pressure vessels top cover actuating device lower omega welding seam ultrasonic inspection method and device

ActiveCN101192458AGuaranteed accuracyGuaranteed reliabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesNuclear energy generationReactor pressure vesselSonification

The invention relates to an ultrasonic inspection method which refers to the specific ultrasonic inspection method for an Omega weld line beneath a driving mechanism of a reactor pressure vessel. In the method, the Omega weld lines is scanned with a ultrasonic probe, signals are collected through a digital ultrasonic device, then analyzed through a PC machine. During the inspection, four ultrasonic probes are used for scanning the weld lines and all the four probes enter with a refraction angle of transverse waves for 35-degree incidence. The focal point of the focusing probe falls on the axial lead of the Omega weld line that runs vertical to the vocal axis. In addition, a double crystal probe is used in the method to conduct a penetration scan of one deliver and one receive at the bottom and the medium parts of the Omega weld, and a eddy current probe is used for checking defects on the surface of the Omega weld line and the near surface. With the single sided array, the method can conduct overall ultrasonic inspection for the weld line beneath the driving mechanism of the pressure vessel cover for the reactor.

Owner:RES INST OF NUCLEAR POWER OPERATION

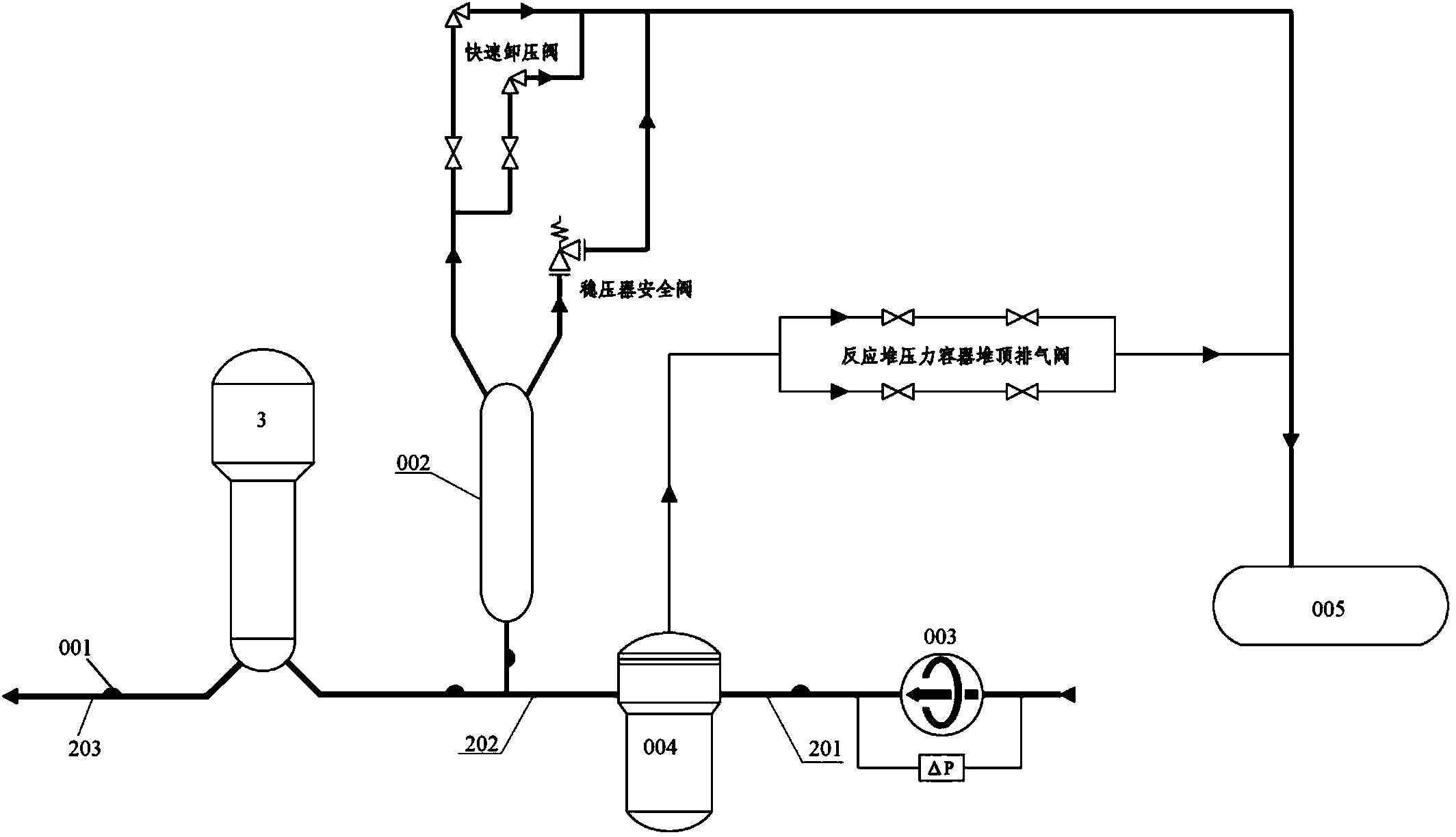

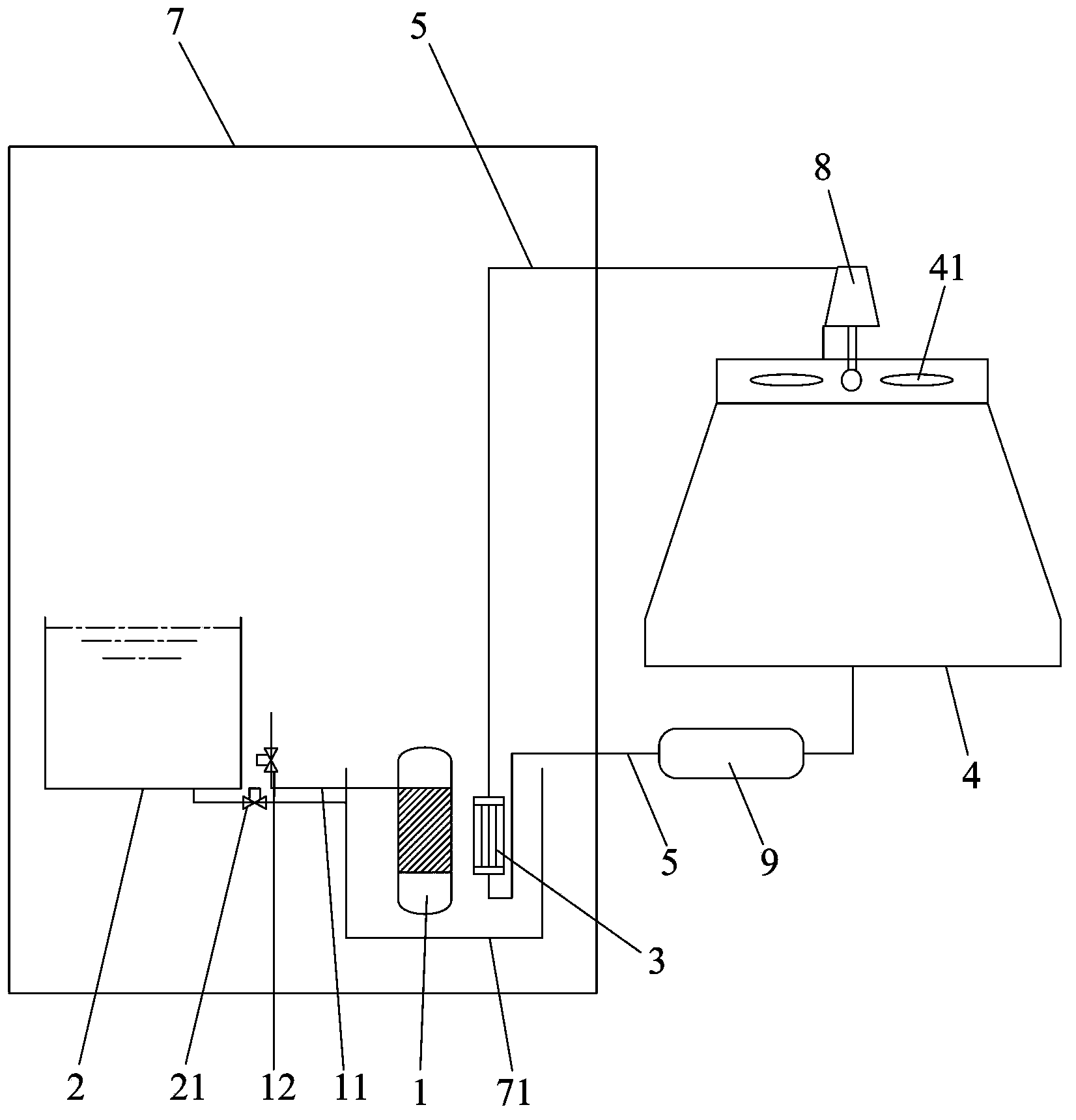

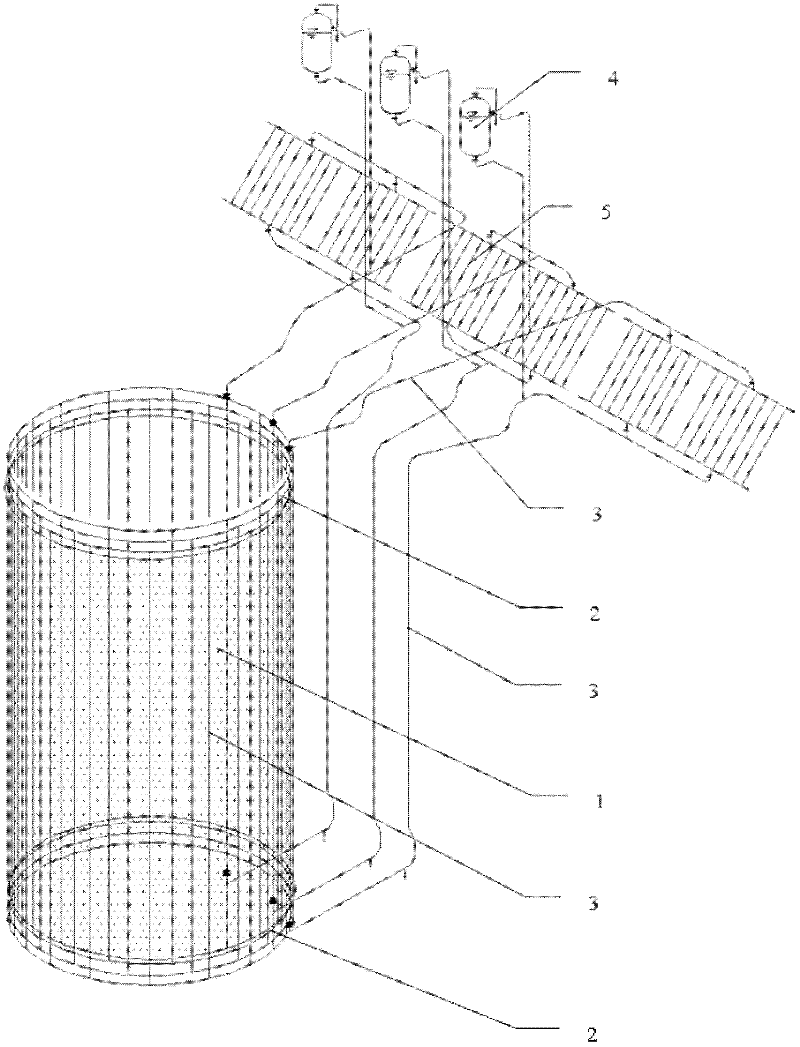

Passive waste heat removal system for floating nuclear power plant

ActiveCN103903659ALow flow resistanceReduce trafficNuclear energy generationCooling arrangementReactor pressure vesselNuclear power

The invention relates to a passive waste heat removal system for a floating nuclear power plant. The system consists of a reactor pressure vessel 1, a passive waste heat removal heat exchanger 8 and a passive emergency cooling water tank 11, wherein the passive waste heat removal heat exchanger 8 is arranged in the emergency cooling water tank 11; an inlet / outlet of the heat exchanger is connected with a loop main coolant pipeline; the emergency cooling water tank 11 is arranged in the pressure vessel; the bottom of the water tank is connected with an ocean through a seawater pipeline; a water level in the water tank is kept consistent with the sea level, and the passive waste heat removal heat exchanger 8 is completely submerged. The passive waste heat removal system is operated under accident conditions, and heat in a loop is finally taken into an atmospheric environment by means of evaporation of water in the water tank. When the water level in the water tank is reduced, seawater automatically enters the water tank through a seawater pipeline, the water level in the water tank is kept, and the reactor is cooled for a long time.

Owner:HARBIN ENG UNIV

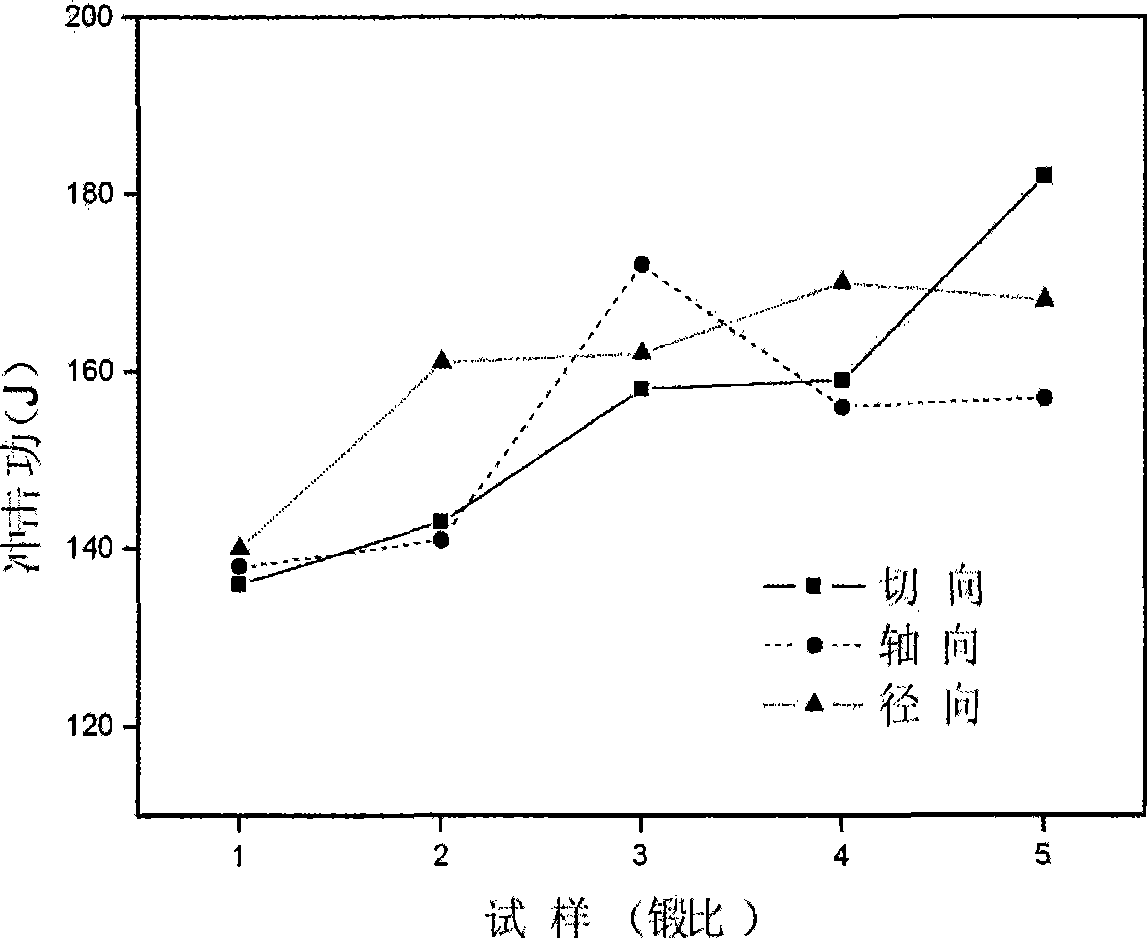

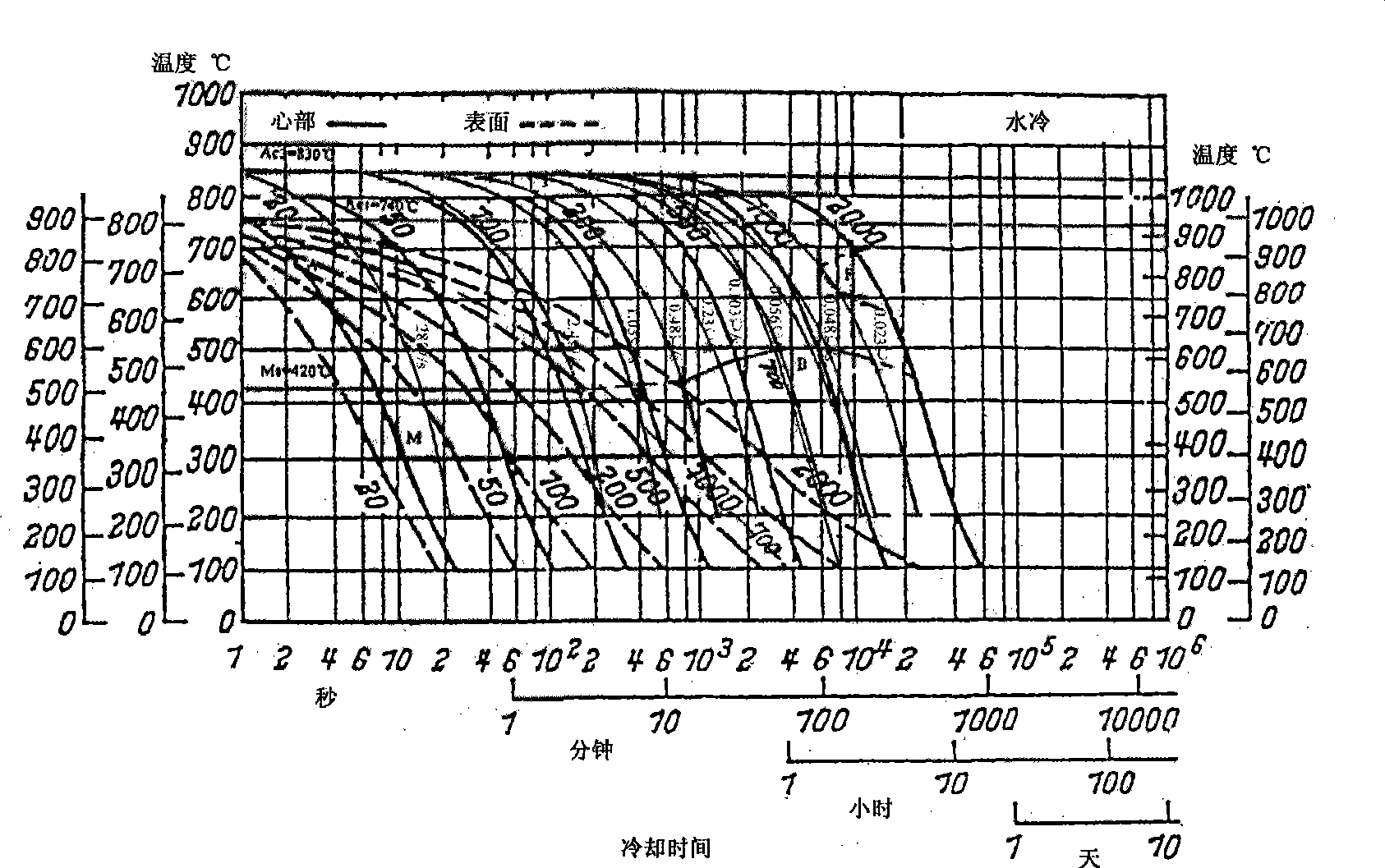

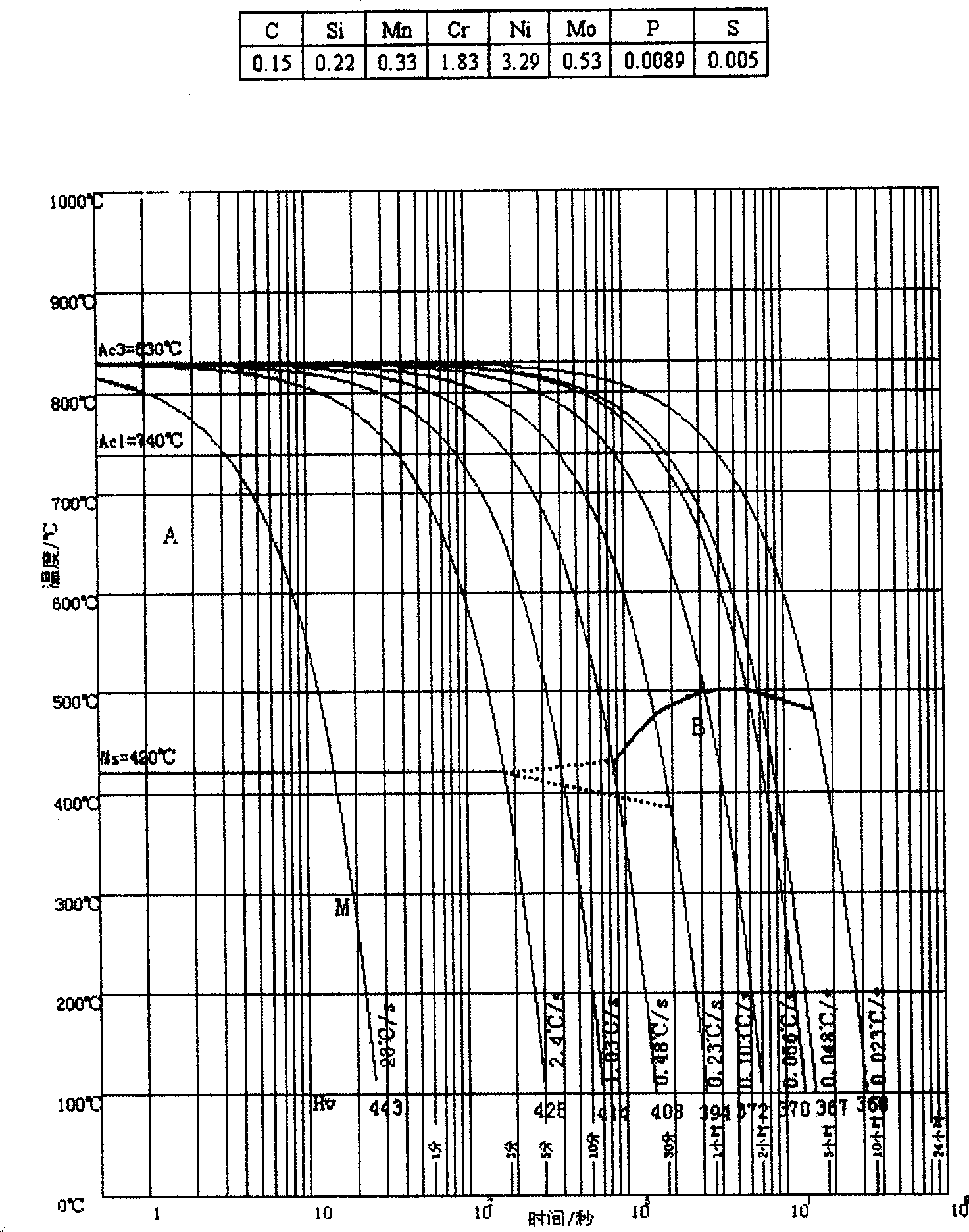

R17Cr1Ni3Mo steel for nuclear pressure vessel and preparation thereof

The invention provides a R17Cr1Ni3Mo steel for nuclear pressure containers and pertains to the technical field of steel for pressure containers.The steel comprises the following components by weight percentage: carbon of 0.13-0.20%, silicon of 0.15-0.30%, manganese of 0.20-0.40%, vanadium <=0.02%, nickel 3.00-3.95%, chromium 1.50-1.90%, molybdenum 0.48-0.65%, phosphorus <=0.008%, sulphur <=0.008%, cuprum <=0.05%, boron <=0.0010, and Fe of the rest.The steel is a novel improved steel developed by optimizing components, adding elements, optimizing thermal treatment technique on the basis of 508-4N steel. The steel of the invention has advantages of good hardenability and obdurability adaptation and excellent low-temperature flexibility. The produced R17Cr1Ni3Mo steel has a more excellent obdurability adaptation than the 508-4N steel, and the metallographic structure of the entire cross-section of the forgeable piece having a maximum cross-section smaller than 100mm is the tempering bainite structure.

Owner:CENT IRON & STEEL RES INST

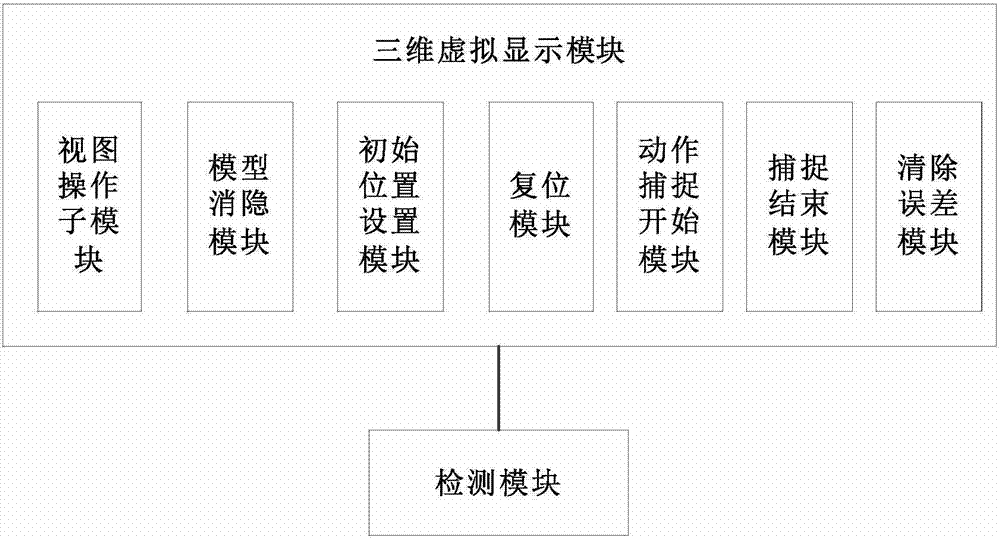

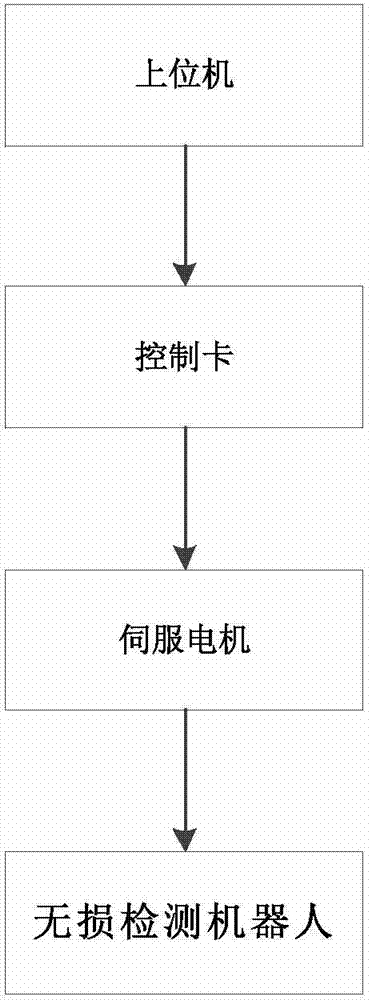

Nondestructive testing robot intelligent testing method based on virtual reality technology

ActiveCN103761996ARealize synchronized motionImprove control efficiencyNuclear energy generationNuclear monitoringReactor pressure vesselSimulation

The invention discloses a nondestructive testing robot intelligent testing method based on a virtual reality technology. The method comprises the following steps: (1) a nondestructive testing robot for nondestructive testing is mounted at a predetermined position in a to-be-tested reactor pressure vessel; (2) freedom degree kinematic axes of the nondestructive testing robot are each restored to an initial state, then the freedom degree kinematic axes are each subjected to position calibration, and a global coordinate system and axis coordinate systems of the freedom degree kinematic axes are constructed; (3) corresponding relationships are established between simulation models and real devices; and (4) the simulation model of the nondestructive testing robot performs position attitude transformation, virtually displays and controls synchronous movement of the nondestructive test robot to perform nondestructive testing in a three-dimensional virtual environment according to real-timely acquired position attitude information feedback values of the freedom degree kinematic axes of the nondestructive testing robot. The method realizes the omni-directional three-dimensional WYSIWYG display control mode, greatly improves the security of on-site project implementation, and improves the project implementation efficiency.

Owner:CGNPC INSPECTION TECH +3

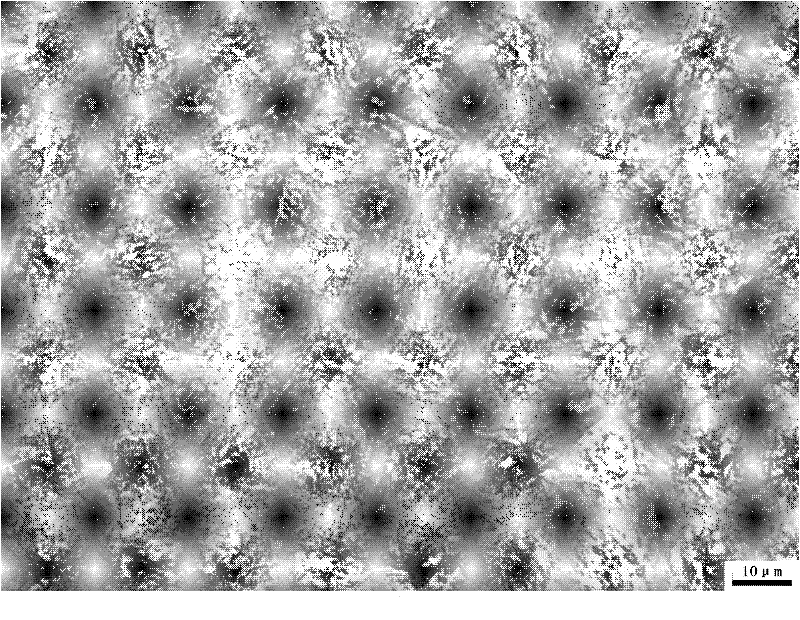

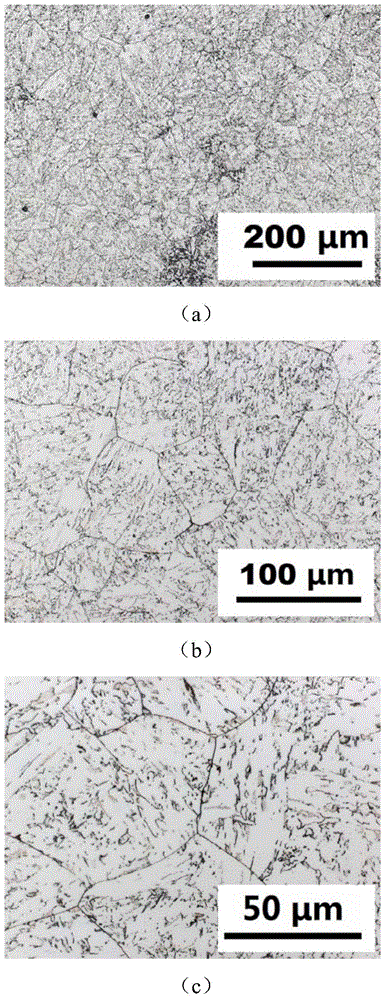

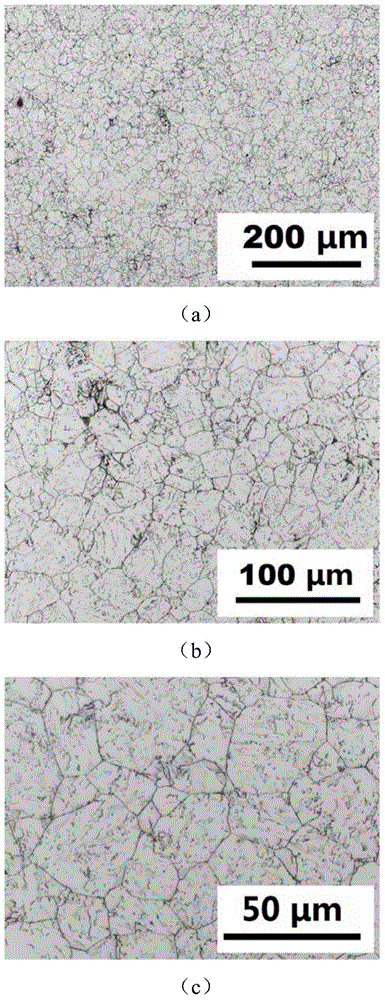

Method for testing autstenitic grain size of steel bainite structure for nuclear pressure vessel

InactiveCN104458511ALow efficiencyPreparing sample for investigationParticle size analysisReactor pressure vesselNuclear power

The invention relates to a method for testing autstenitic grain size of a steel bainite structure for a nuclear pressure vessel. The method comprises the steps of preparing, grinding and polishing a metallographic phase sample, carrying out chemical etching on a sample and carrying out statistics on the grain size. According to the method, the rational proportions of picric acid, dodecylbenzene sulfonic acid and an additive as well as the etching time are selected, so that the original autstenitic grain size of the low-carbon and low-alloy steel SA508 Gr.3 steel bainite structure for nuclear power can be clearly displayed. After the method is adopted, the problem that the original autstenitic grain boundary is difficult to display in the actual production process of a forge piece of the nuclear pressure vessel can be solved; compared with the traditional method which is used for judging the autstenitic grain size by experience, the method has the advantage that the displayed autstenitic grain boundary is clear and complete; after the method is used for picture processing and statistics, the tested autstenitic grain size is more accurate and the repeatability is good.

Owner:SHANGHAI JIAO TONG UNIV

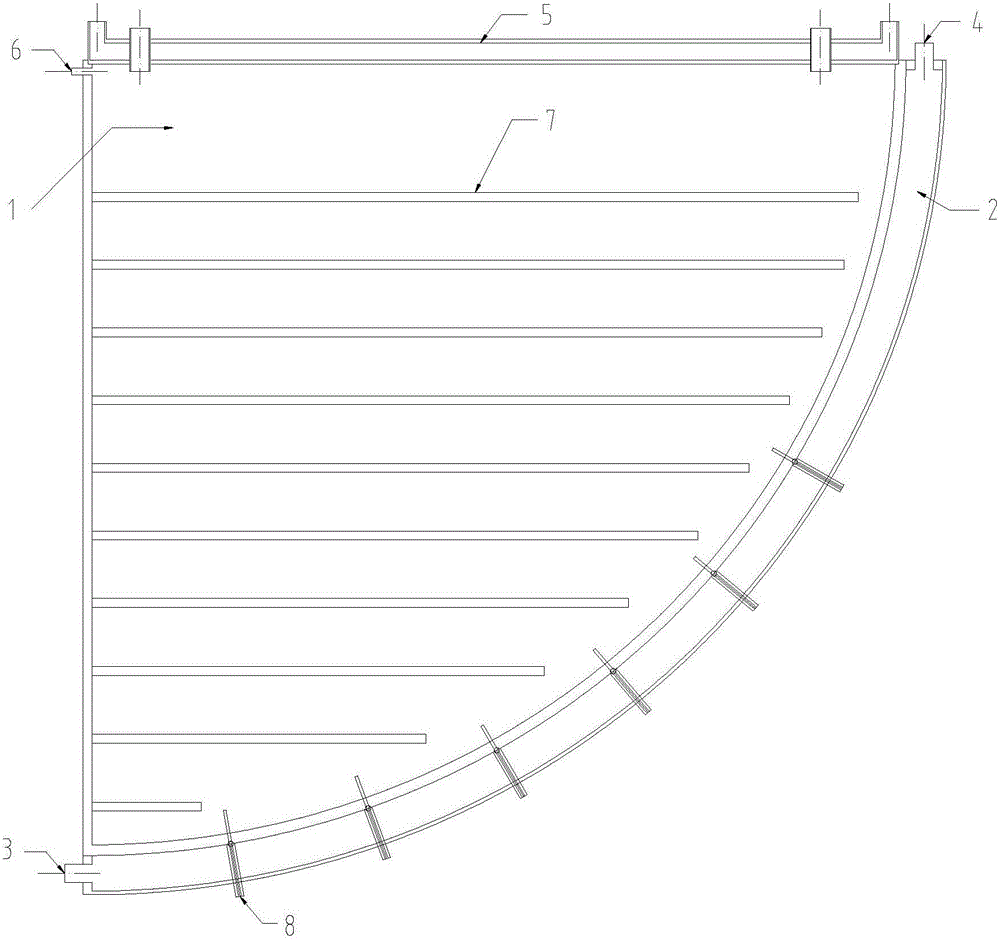

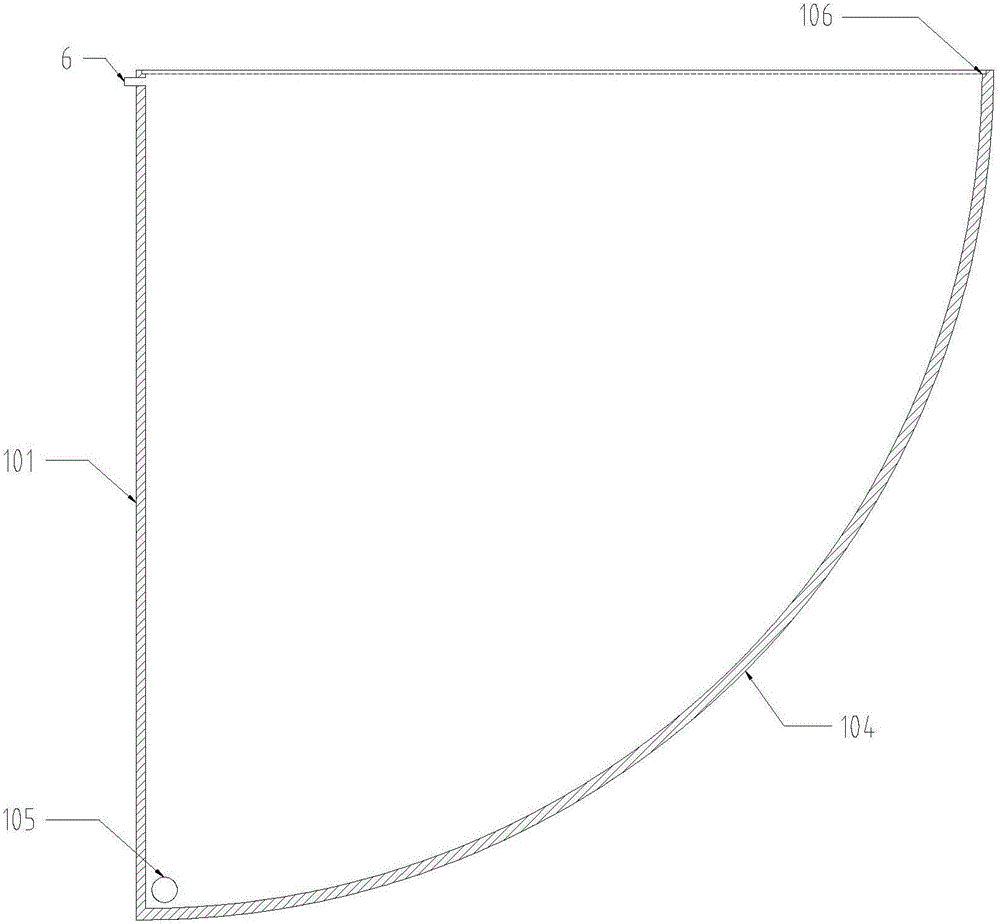

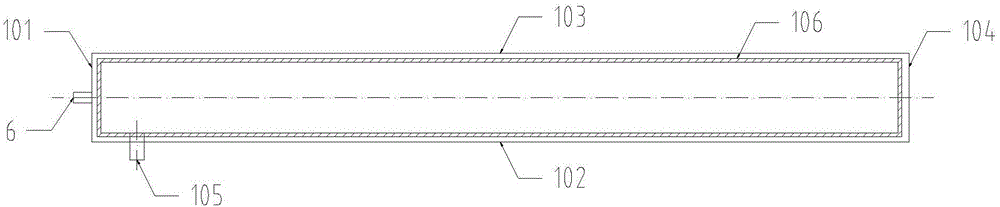

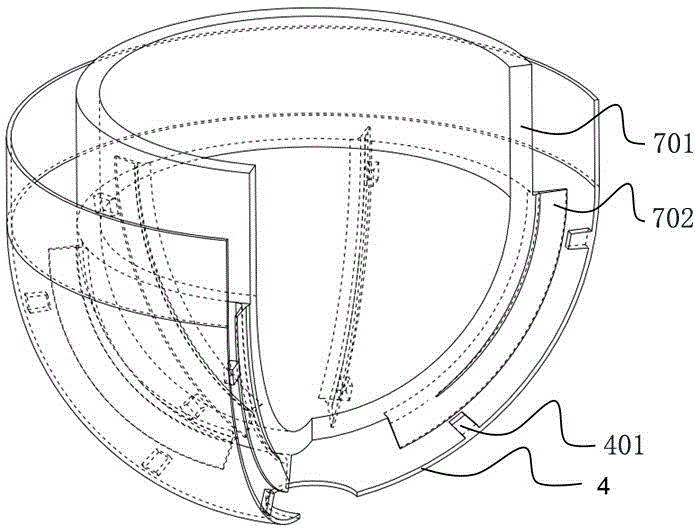

Experiment device for measuring heat transfer properties of high-rayleigh number fusion tank

InactiveCN105806881AUniform internal heat sourceReduce distractionsMaterial thermal conductivityRayleigh numberHeat flow

The invention relates to an experiment device for measuring heat transfer properties of a high-rayleigh number fusion tank. The experiment device is a 1 / 4-circle two-dimensional slice structure based on a lower end socket of an ACP1000 reactor pressure vessel in a proportion of 1 to 1 and comprises a lower end socket of a fusion tank, an external cooling channel and an upper cover plate, wherein the external cooling channel is welded to the outer side of the round-arc wall surface of the lower end socket of the fusion tank and is used for providing external compelled cooling through cooling water; and the upper cover plate is fixed at the upper part of the lower end socket of the fusion tank and is used for supplying border conditions of heat insulation and cooling. By virtue of thermocouples distributed in the fusion tank and on the round-arc wall surface, the temperature field distribution in the fusion tank and the wall heat flux density distribution condition can be obtained; and by virtue of multipoint thermocouples distributed on the inner side of the round-arc wall surface of the fusion tank, the hard shell distribution property in the fusion tank can be obtained. According to the experiment device, important basis is provided for the safety research on serious accidents of nuclear power plant reactors.

Owner:XI AN JIAOTONG UNIV

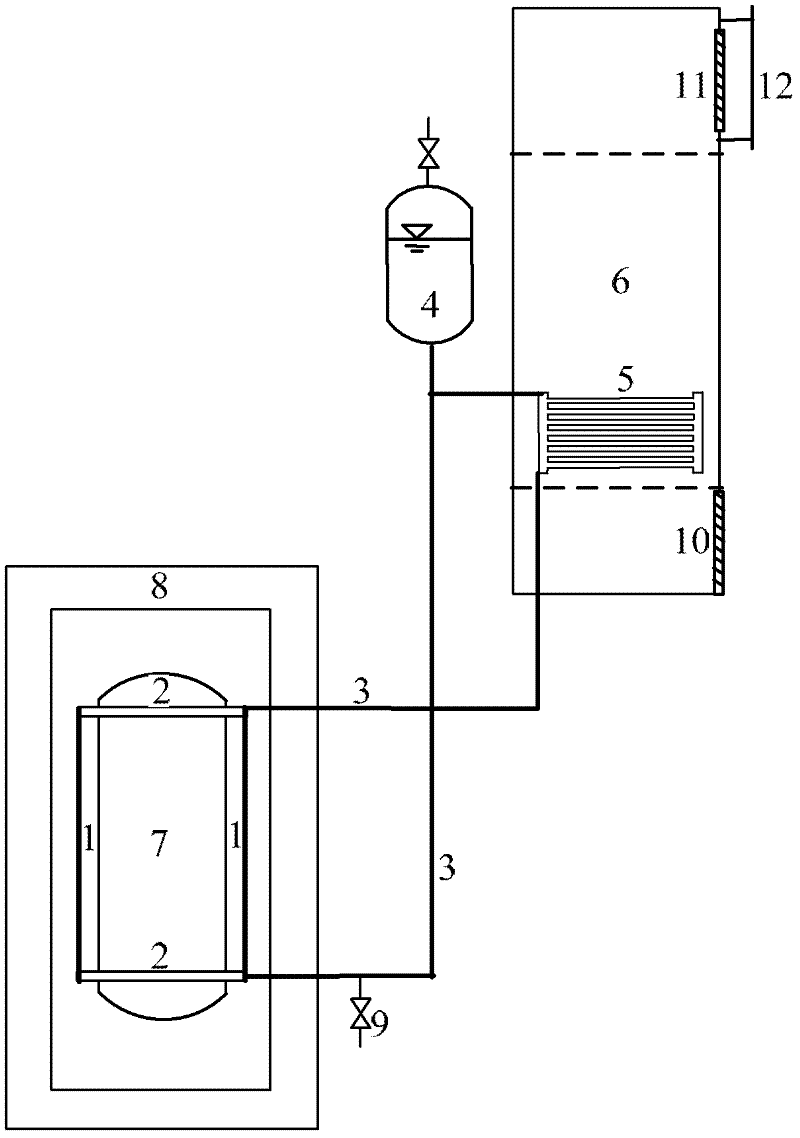

Passive residual heat removal system for high temperature gas cooled reactor

InactiveCN102332313ASimple structureReduce failure rateNuclear energy generationCooling arrangementReactor pressure vesselCooling tower

The invention relates to the technical field of safety facilities of a reactor, and discloses a passive residual heat removal system for a high temperature gas cooled reactor. The system comprises a plurality of sets of independent residual heat removal sequences, wherein each set of residual heat removal sequence comprises a water cooled wall (1), an air cooler (5), an air cooling tower (6), a reactor pressure vessel (7) and a reactor cabin (8); the water cooled wall (1) is positioned in the reactor cabin (8) and encircles the reactor pressure vessel (7); the installation position of the air cooling tower (6) is higher than that of the water cooled wall (1); and the air cooler (5) is arranged in the air cooling tower (6). A simple passive residual heat removal system is designed by utilizing a passive safety design concept and a little equipment, is only dependent on natural circulation when operated, is not required to be driven by any external force, and is provided with respective independent redundant circulation loops, so that the system is prevented from failing due to the failure of an active part, and the operation safety of the reactor is improved.

Owner:TSINGHUA UNIV

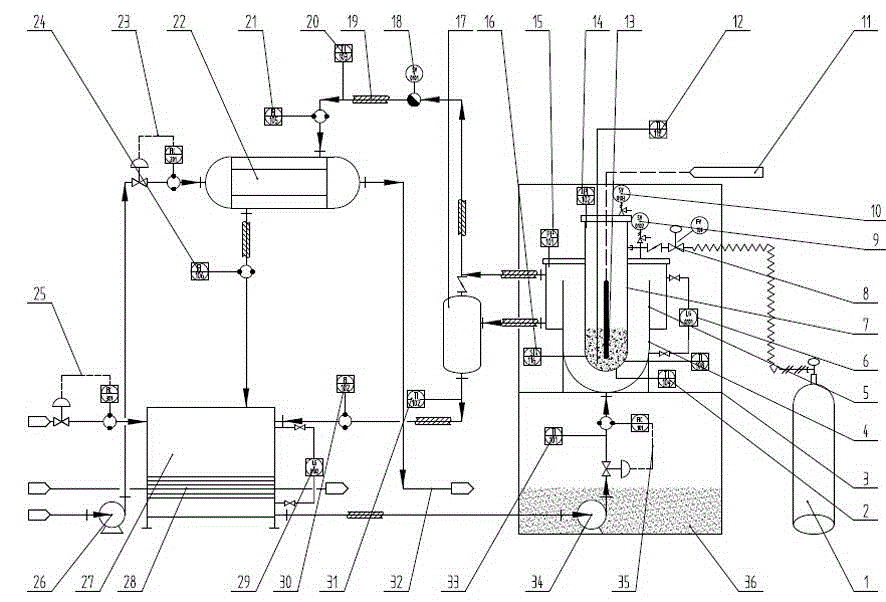

Platform for testing structural integrity of reactor pressure vessel under IVR condition

ActiveCN104979025AStructural Integrity GainedThe heat transfer properties are obtainedNuclear energy generationNuclear monitoringReactor pressure vesselData acquisition

The invention discloses a platform for testing the structural integrity of a reactor pressure vessel under an IVR condition. The platform comprises a working condition simulation system, a data acquisition and analysis system, and a safety system. The working condition simulation system is provided with a water supply unit, a steam condensing unit, and a heating unit; the data acquisition system is composed of measuring elements of each unit; and the safety system is arranged on the periphery of the working condition simulation system. The boiling heat transfer process in a reactor pressure vessel can be simulated by controlling the water flow of a cooling unit and the heating power of a hot pool simulation unit; by measuring and simulating the wall temperature, strain, and pressure, the heat transfer characteristics of a reactor pressure vessel can be simulated and analyzed; a referential model is provided for the boiling heat transfer tests on a reactor pressure vessel; and the test platform has a simple and compact structure, can carry out structural integrity analysis on a simulated reactor pressure vessel, comprises a nitrogen gas pressurizing unit, thus can also carry out analysis on the heat transfer characteristics of a pressurized reactor pressure vessel, and has a wide application range.

Owner:ZHEJIANG UNIV OF TECH

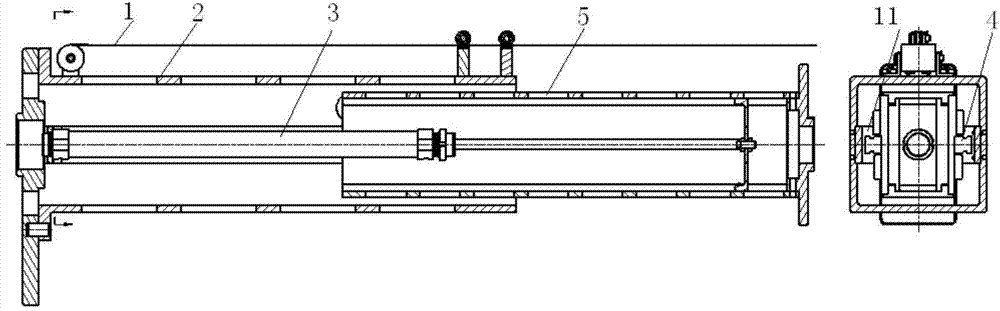

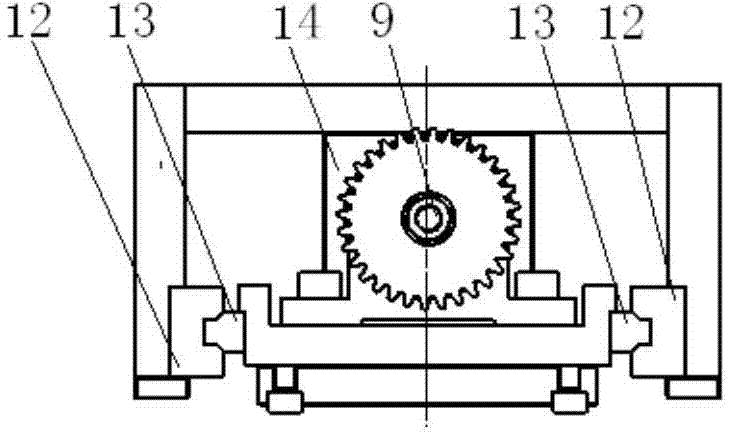

Ultrasonic testing device for circumferential weld of cylinder of nuclear reactor pressure vessel

ActiveCN103578587AImprove accuracyImprove reliabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesNuclear energy generationReactor pressure vesselNuclear reactor

The invention provides an ultrasonic testing device for a circumferential weld of a cylinder of a nuclear reactor pressure vessel. The ultrasonic testing device comprises a ball screw and a nut seat, wherein the ball screw is vertically arranged, the nut seat is sleeved on the ball screw, and a drive element is connected with the ball screw; the ball screw and the drive element are fixed on a base plate; one side of the base plate is fixed at one end of an inner sleeve, the inner sleeve is connected with a stretchable air cylinder, and the inner sleeve and the stretchable air cylinder are arranged in an outer sleeve; one end of a spring rope is fixed on the outer sleeve, and the other end of the spring rope is fixed on the base plate; a rotary air cylinder is fixed on one side of the nut seat, and a tray is fixed at the end part of the rotary air cylinder; the tray can rotate by 90 degrees through the rotary air cylinder, can extend and shrink through the extending and shrinking of the base plate and is driven to move up and down through the up-down moving of the nut seat. The ultrasonic testing device provided by the invention can be used for carrying out ultrasonic testing on the weld according to relevant examining code requirements, so that the accuracy and reliability of the data testing are improved, and the radiation of radioactive rays to a human body is reduced.

Owner:RES INST OF NUCLEAR POWER OPERATION +1

Probe frame of supersonic inspection device for weld joint at safe end of nuclear reactor pressure vessel

ActiveCN101916599AAvoid scratchesEfficient couplingNuclear energy generationNuclear monitoringLinear motionNuclear reactor

The invention relates to a probe frame of a supersonic inspection device for a weld joint at a safe end of a nuclear reactor pressure vessel. Multiple groups of probe frames are distributed on a rotating disc along a circumferential direction, and the centers of all the probe frames are in the same plane. Each probe frame comprises a supersonic probe, a retainer connected with the supersonic probe, and two stages of linear motion mechanism connected with the retainer and used for driving the retainer to stretch or retract radially along the rotating disc; the first stage of linear motion mechanism is used for controlling the position of the probe frame relative to the rotating disc; the second stage of linear motion mechanism is used for controlling the position of the prove frame relative to a movable seat plate; under the restriction of the two stages of linear motion mechanism, the supersonic probe can effectively prevent scratching the inner wall of a pipe nozzle when in a retraction state and can ensure perfect coupling with the inner wall of the pipe nozzle for ensuring accurate and reliable scanning results when in a stretching sate.

Owner:CGNPC INSPECTION TECH +2

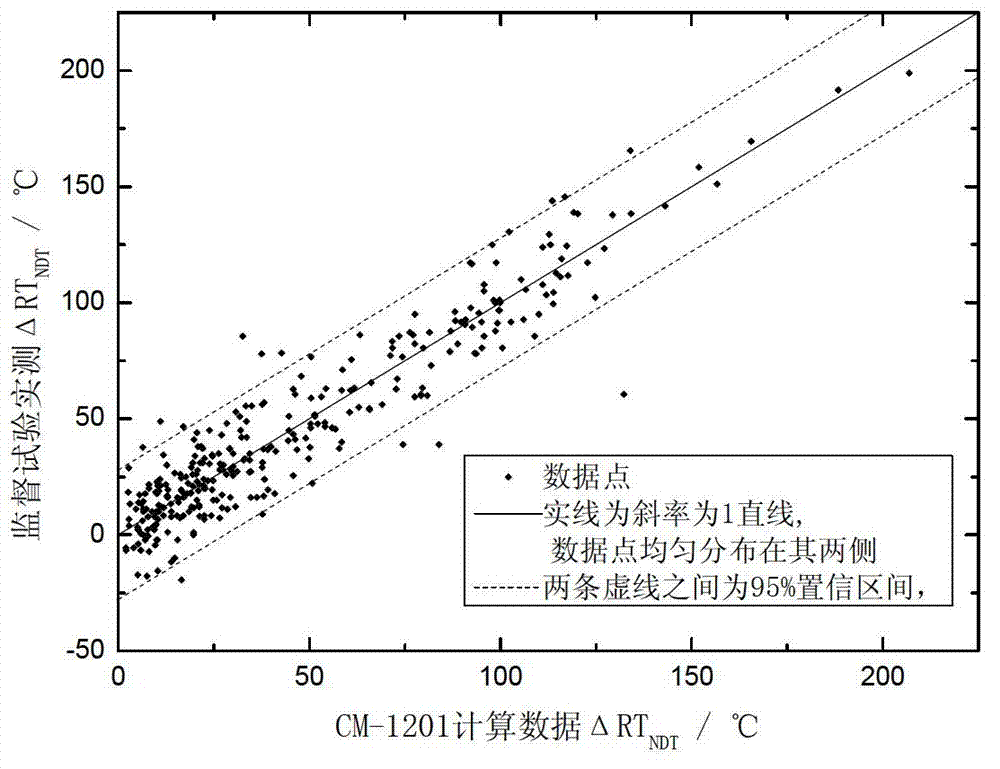

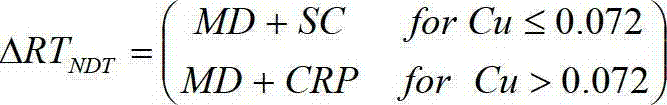

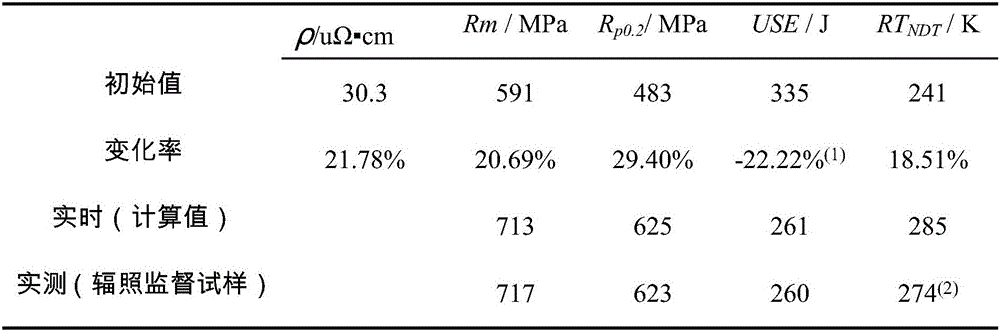

Forecast evaluation method of radiation embrittlement of reactor pressure vessel

ActiveCN102930167AHigh precisionSpecial data processing applicationsContribution functionReactor pressure vessel

The invention belongs to the technical field of security evaluation of a reactor pressure vessel (RPV) of a nuclear power plant and specifically relates to a forecast evaluation method of radiation embrittlement of an RPV. According to the method, on the basis that RPV bombardment damage mechanisms are understood, experience of international correlation models is obtained; and further, due to the fact that contents of copper (Cu) in domestic RPV materials are low, contribution functions of non Cu element precipitated phase (Solute-Atom Cluster) on irradiation hardening are introduced into a calculation formula, the contribution functions are ignored by each forecast module all the time, and finally a calculation model containing a non Cu element precipitated phase mechanism is formed.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

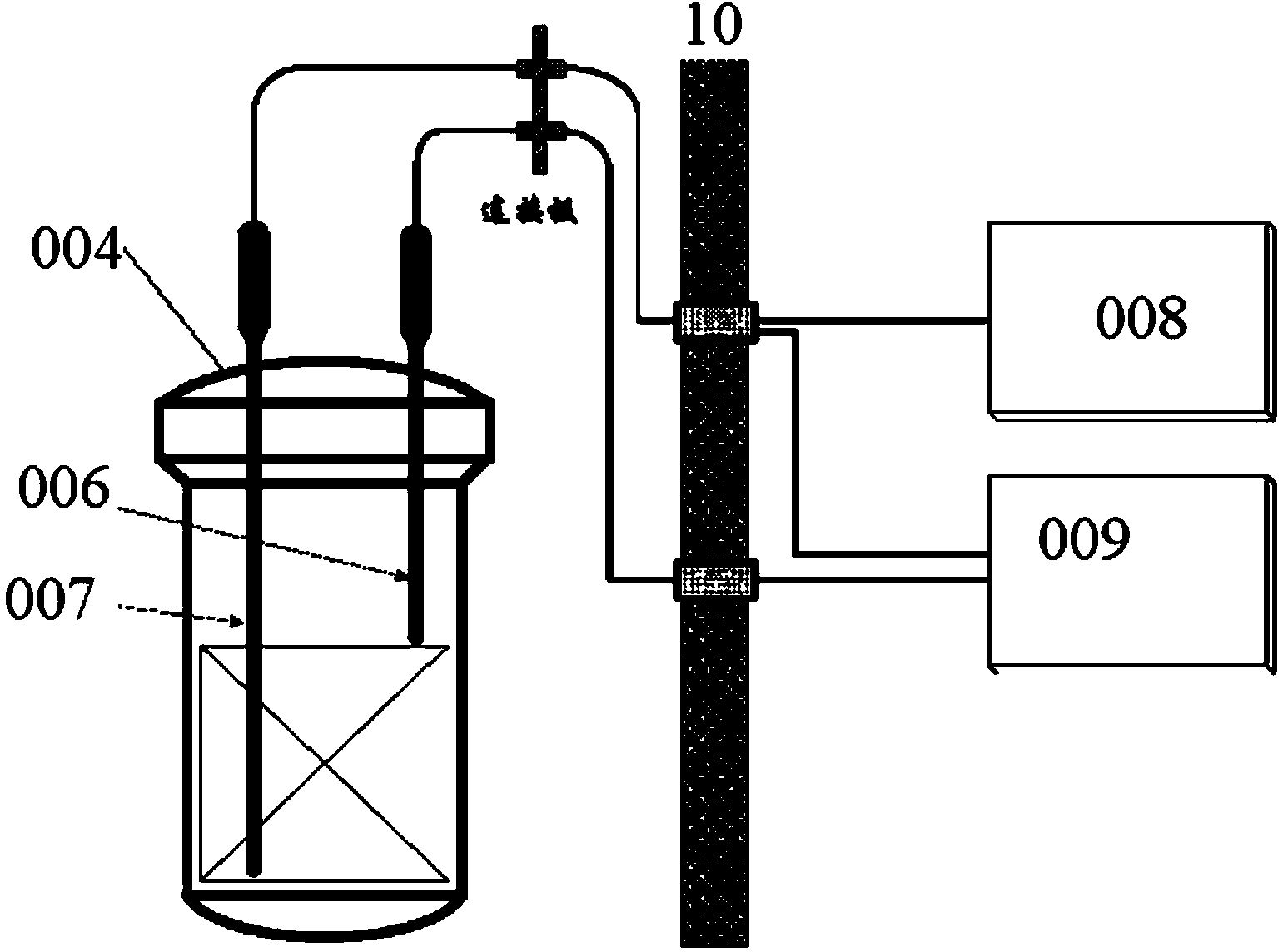

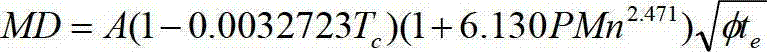

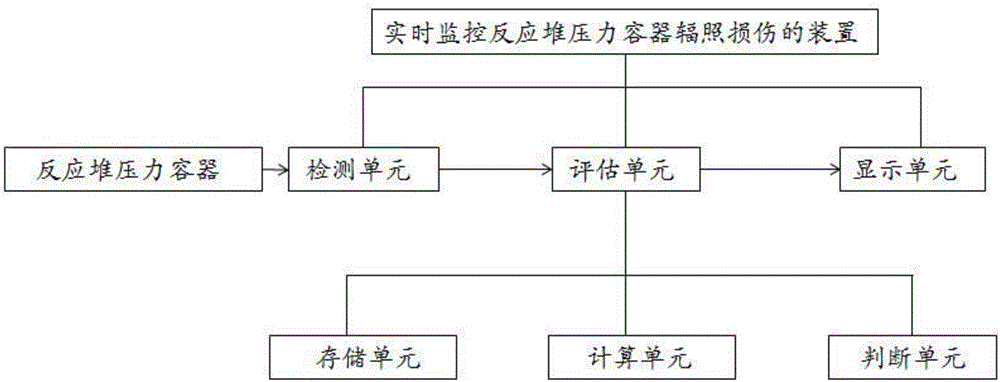

Method and device for monitoring irradiation damage of reactor pressure vessel in nuclear power plant

ActiveCN106128528AReal-time test resistivityReal-time calculation of mechanical property change dataNuclear energy generationNuclear monitoringReactor pressure vesselNuclear power

The invention discloses a method and a device for monitoring irradiation damage of a reactor pressure vessel in a nuclear power plant. The method comprises the following steps of calculating the change rate of resistivity after reactor pressure vessel steel is subjected to the irradiation damage by measuring initial resistivity of the reactor pressure vessel steel and acquiring the resistivity of the reactor pressure vessel steel after the irradiation damage at any time point in real time; obtaining change conditions of macro-mechanical property parameters of the reactor pressure vessel steel in the irradiation damage according to the change rate of the resistivity after the irradiation damage; further analyzing and evaluating the irradiation damage degree of the reactor pressure vessel according to the macro-mechanical property parameters. The method and the device are economical, environment-friendly, safe and efficient; the irradiation damage degree of a plurality of parts (including specific parts) of the reactor pressure vessel can be monitored in real time.

Owner:中广核工程有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com