R17Cr1Ni3Mo steel for nuclear pressure vessel and preparation thereof

A pressure vessel and nuclear technology, applied in the field of steel for pressure vessels, can solve problems such as difficulty in ensuring uniformity and stability of structure and performance on large sections, and achieve excellent uniformity and stability of structure and performance, suitable strength The effect of toughness matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

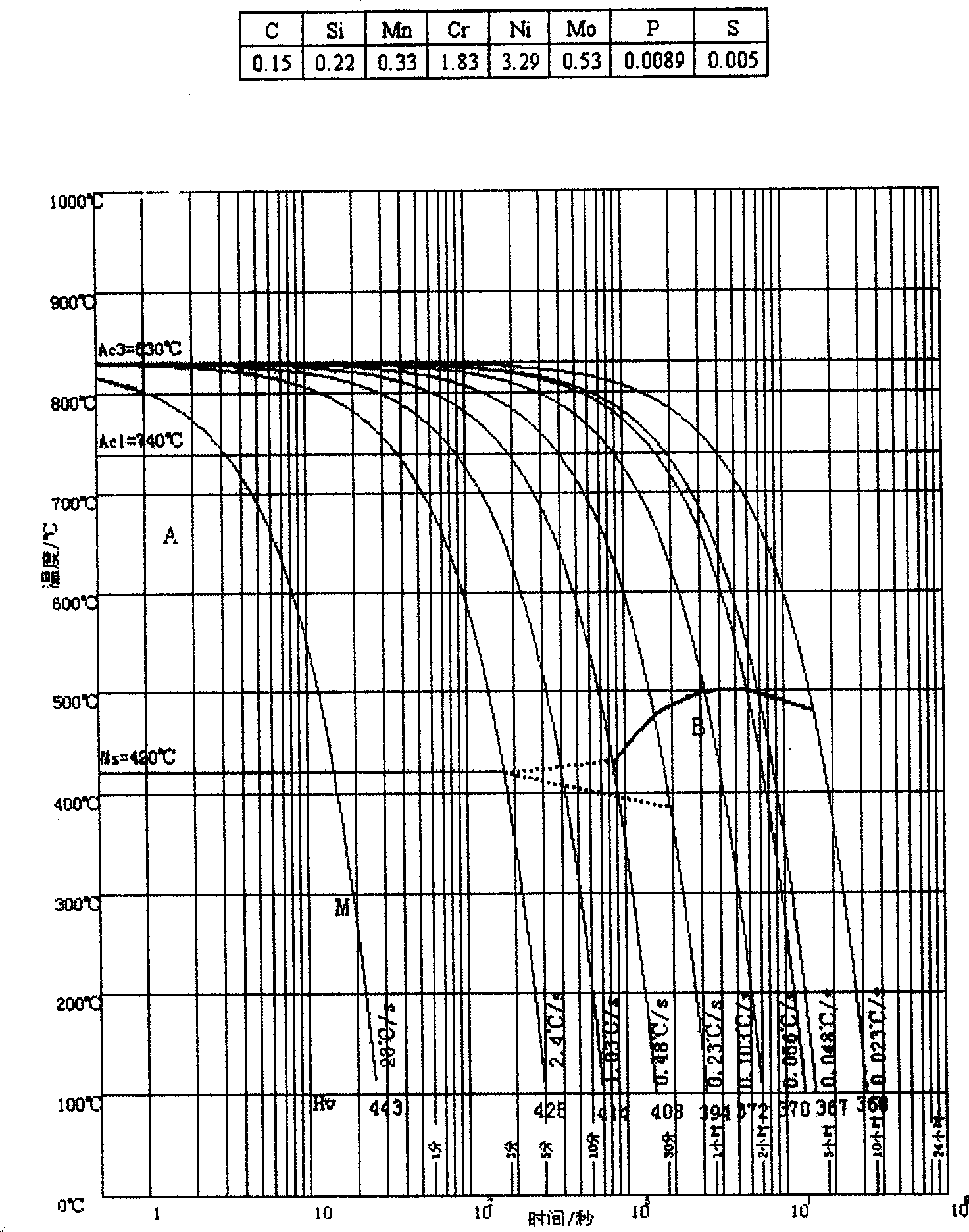

[0035] A 25kg vacuum induction furnace was used to smelt 14 heats of test steel. The test steel was based on 508-4N steel, and the influence of key chemical composition changes on performance was studied within its composition range. For this reason, 14 heat test steels were designed to study the influence of Si, Cr, Ni, and Mo elements on the properties of steel when they were at the upper, middle and lower limits and the upper limit of B added to the test steel. Table 2 shows the chemical composition analysis results of 14 heats of test steel smelted. When the ingot is billeted, the ingot heating temperature is 1200°C, the initial forging temperature is 1150°C, the final forging temperature should be higher than 900°C, anneal at 650°C for 2 hours after forging, and air cool.

[0036] Table 2 Chemical composition of 14 heat test steels

[0037]

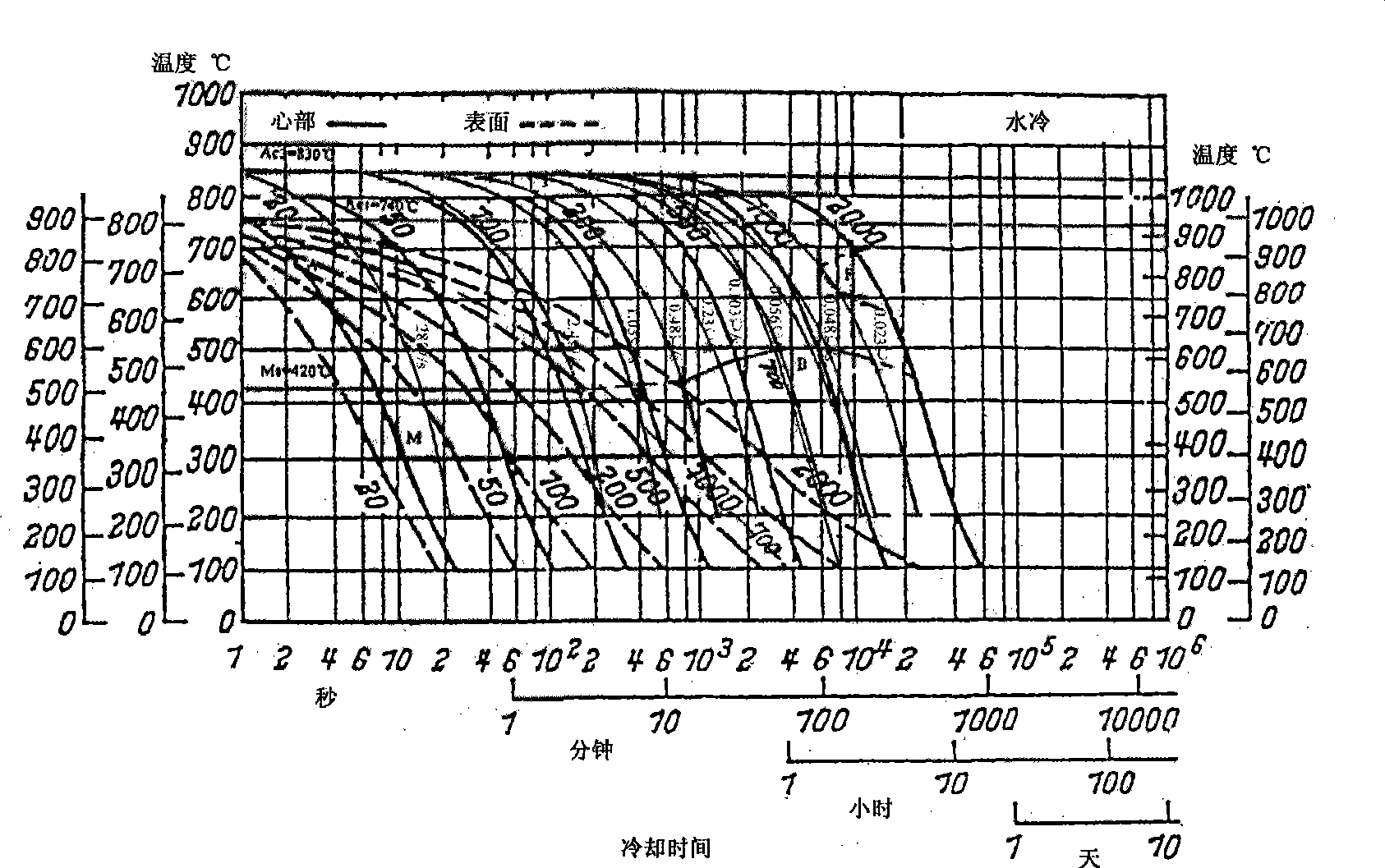

[0038] Using Gleeble3500 thermal testing machine to measure the continuous cooling curve of test steel as follows image 3 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com