Patents

Literature

79results about How to "Play a role in strengthening and toughening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength high-toughness nuclear power pressure vessel forging steel and its manufacturing method

InactiveCN102392195AEasy to implementPlay a role in strengthening and tougheningNon-metallic inclusionsReactor pressure vessel

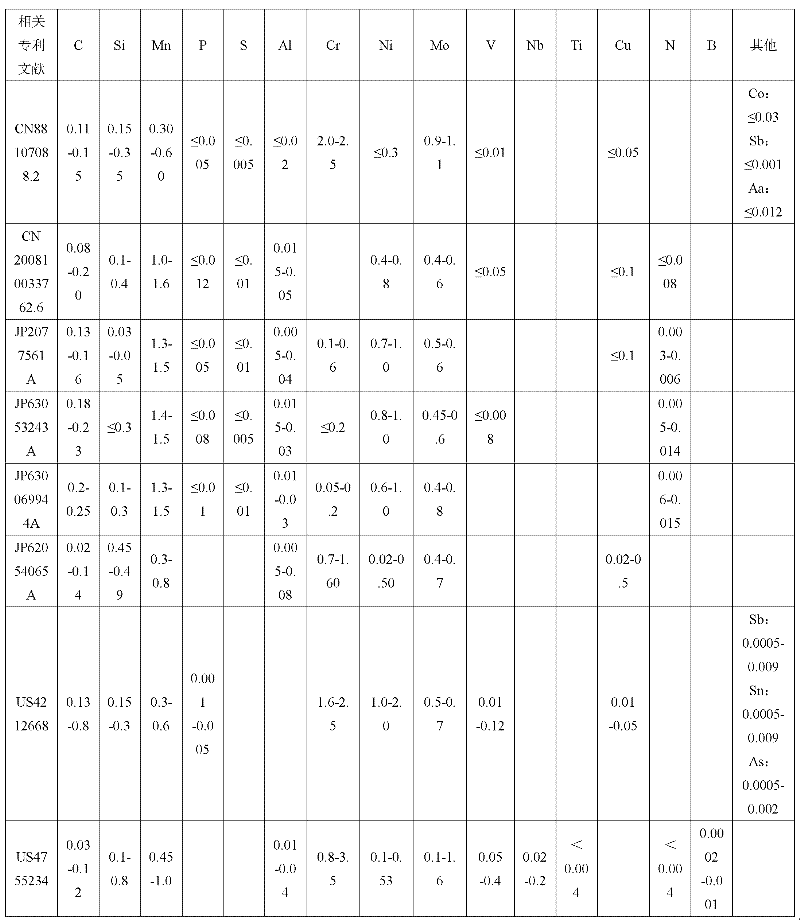

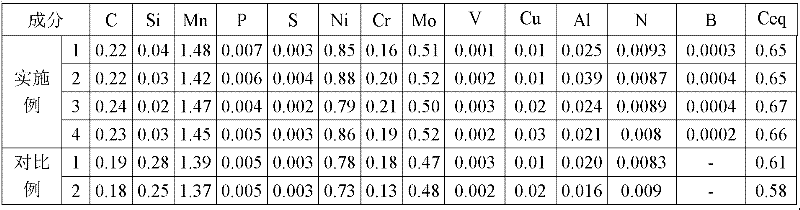

High-strength high-toughness nuclear power pressure vessel forging steel and its manufacturing method belong to the technical field of steel for pressure vessel. The steel provided by the invention comprises the following chemical components of: by weight, 0.2-0.25% of C; Si being less than 0.1%; 1.3-1.5% of Mn; P being less than or equal to 0.008%; S being less than or equal to 0.008%; 0.6-1% of Ni; 0.1-0.25% of Cr; 0.45-0.6% of Mo; V being less than or equal to 0.01%; Cu being less than or equal to 0.05%; 0.02-0.04% of Al; 0.005-0.015% of N; B being less than or equal to 0.001%; and the balance being Fe and unavoidable impurities, wherein C equivalent range is controlled within 0.6-0.75%. By alloying and appropriate smelting, forging and heat treatment technologies, the forging provided by the invention has high strength and high toughness and less segregation and nonmetal field trash, and can be used for manufacturing large-scale forgings such as a nuclear power station reactor pressure vessel with its wall thickness being greater than 100mm, an evaporator head, a cylindrical shell, a tube plate and the like.

Owner:CENT IRON & STEEL RES INST

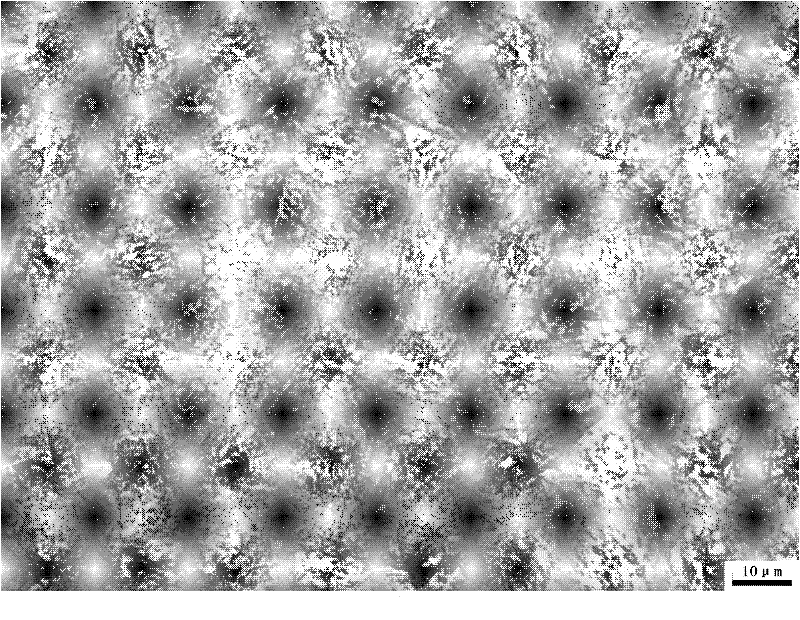

High strength and toughness 3Y-TZP composite ceramic and preparation method thereof

The invention discloses a high strength and toughness 3Y-TZP composite ceramic and a preparation method thereof. The 3Y-TZP composite ceramic consists of 3Y-TZP, a SiC crystal whisker and Sr2Nb2O7; and the preparation method of the 3Y-TZP composite ceramic comprises the steps of preparing and mixing Sr2Nb2O7 powder, ball milling, profiling, degumming and sintering. The composite ceramic is obtained by sintering the SiC crystal whisker and a Sr2Nb2O7 ferroelectric material second-phase addictive which are introduced into the 3Y-TZP. The ceramic material with high strength and toughness can be obtained by adjusting the contents of the SiC crystal whisker and the Sr2Nb2O7 and optimizing a microwave sintering process under the synergistic effect of reinforcing by the SiC crystal whisker and toughening by the Sr2Nb2O7 piezoelectric second phase. The invention has reasonable components and simple preparation process and simultaneously achieves the effects of strengthening and toughening by adopting a synergistic technology of reinforcing by the SiC crystal whisker and toughening by the Sr2Nb2O7 piezoelectric second phase. In addition, the invention is applicable for industrial production, effectively improves the mechanical property of the 3Y-TZP ceramic and widens the application field of the 3Y-TZP ceramic.

Owner:CENT SOUTH UNIV

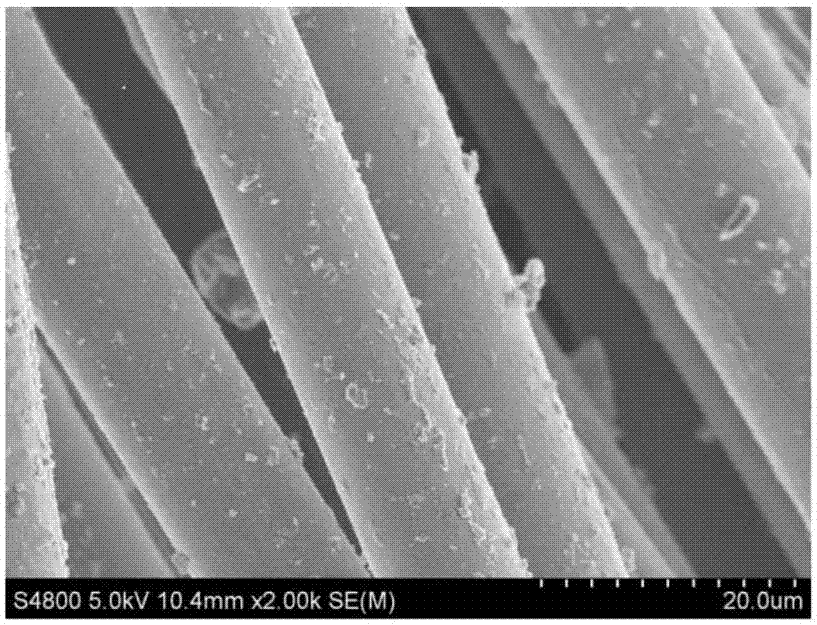

SiC nanowire in-situ enhanced SiCf/SiC composite material and preparation method of SiC nanowire in-situ enhanced SiCf/SiC composite material

The invention discloses a SiC nanowire in-situ enhanced SiCf / SiC composite material and a preparation method of the SiC nanowire in-situ enhanced SiCf / SiC composite material. The composite material is prepared from a SiC fiber prefabricated part, SiC nanowires and a SiC ceramic matrix, wherein the SiC nanowires grow on a fiber surface of the SiC fiber prefabricated part in situ; the SiC nanowires are mutually wound to form a net-shaped structure; the SiC ceramic matrix is arranged in a pore of the SiC fiber prefabricated part. The preparation method comprises the following steps: (1) carrying out surface chemical modification treatment; (2) loading a catalyst; (3) carrying out chemical vapor deposition; (4) impregnating a precursor and cracking. The SiC nanowire in-situ enhanced SiCf / SiC composite material provided by the invention has the advantages that the SiC nanowires are uniformly distributed and are combined with SiC fibers well, the toughness is good and the density is high and the like; the preparation method is simple in process, low in requirements on equipment, environmental-friendly, and good in process commonality; the introduction volume fraction of the SiC nanowires is high and is controllable.

Owner:NAT UNIV OF DEFENSE TECH

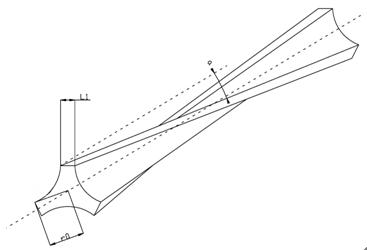

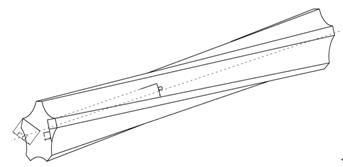

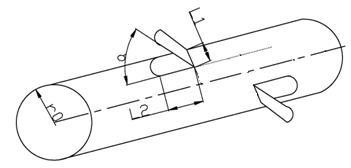

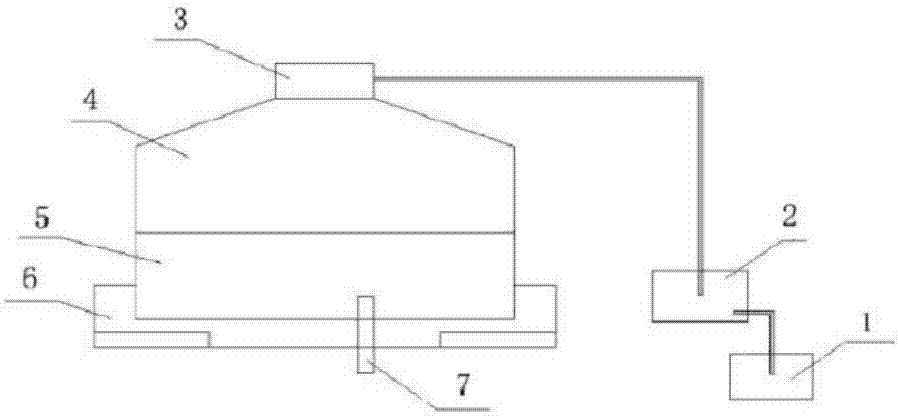

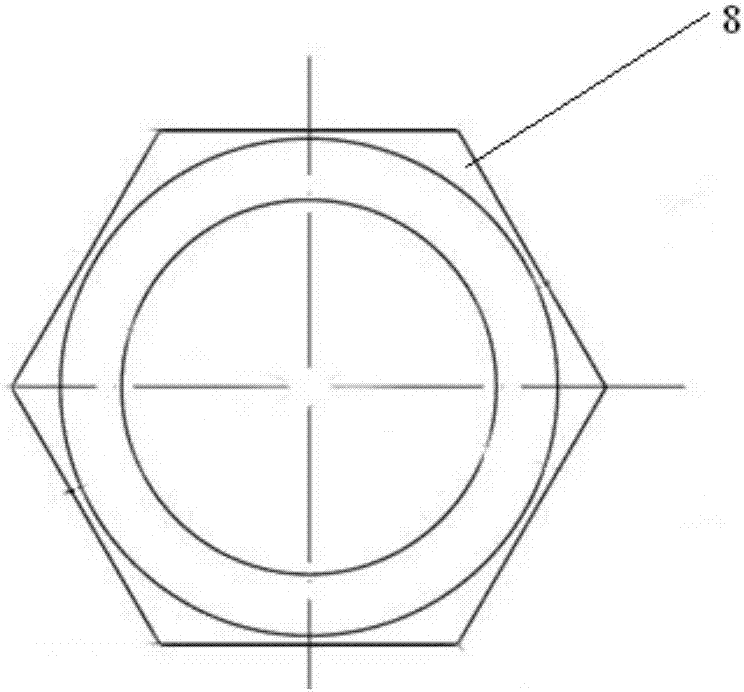

Coarse fiber for concrete and preparation method of coarse fiber

ActiveCN102659333AReduce usageOptimize process flowFilament/thread formingMonocomponent polyolefin artificial filamentPrismGuide wires

The invention relates to a coarse fiber for concrete, which is in a shape formed by spirally twisting a polygonal prism along the axial direction, wherein the length of the coarse fiber is 20-60 mm and the diameter or the equivalent diameter of the section is 0.10-1.20 mm; and the surface between adjacent edges is concave. The preparation method comprises the following steps of: drying preparation materials of the fiber to constant weight and adding the materials into a double-screw extruder; after extruding through a spinneret plate hole, cooling filaments by utilizing cooling liquid; then connecting the filaments into a guide wire hole plate which is the same as the spinneret plate hole in shape and is rotated for an angle; carrying out grading multi-time stretching on the filaments of the guide wire hole plate; after the stretching is finished, carrying out heat setting; and then, cutting according to the length and packaging to obtain the product. According to the invention, through changing the appearance and the shape of the fiber, a good interface acting force exists between the coarse fiber and a substrate and the rigidity of the fiber is increased, so as to enhance or improve the performance of the coarse fiber in enhancing the anti-cracking, anti-breaking, tough, anti-impact properties and the like of the concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Heat conducting polyethylene terephthalate with high strength and preparation method thereof

InactiveCN101845204AHigh strengthImprove thermal conductivityHeat-exchange elementsPolymer scienceHeat conducting

The invention discloses a heat conducting polyethylene terephthalate with high strength and a preparation method thereof, the heat conducting polyethylene terephthalate comprises the following components in parts by weight: 64.5-76.7 parts of polyethylene terephthalate, 20-30 parts of heat conducting agent, 3-5 parts of calcium sulfate whiskers and 0.3-0.5 part of antioxidant; and the preparation method comprises the following steps: uniformly mixing all the component, then carrying out extrusion, traction and granulation at the temperature of 240 DEG C-260 DEG C, and preparing the heat conducting polyethylene terephthalate. Magnesium oxide whiskers and a polystyrene-polyacrylic acid block copolymer form a heat conducting network channel along a molecular chain of matrix resin through the polar interaction with the matrix resin, thereby being capable of effectively improving the heat conductivility of the polyethylene terephthalate; furthermore, the magnesium oxide whiskers can further play the roles of strengthening and toughening; and the good compatibility of the calcium sulfate whiskers with the polar polyethylene terephthalate can endue the materials with high-strength mechanical properties.

Owner:SOUTH CHINA UNIV OF TECH

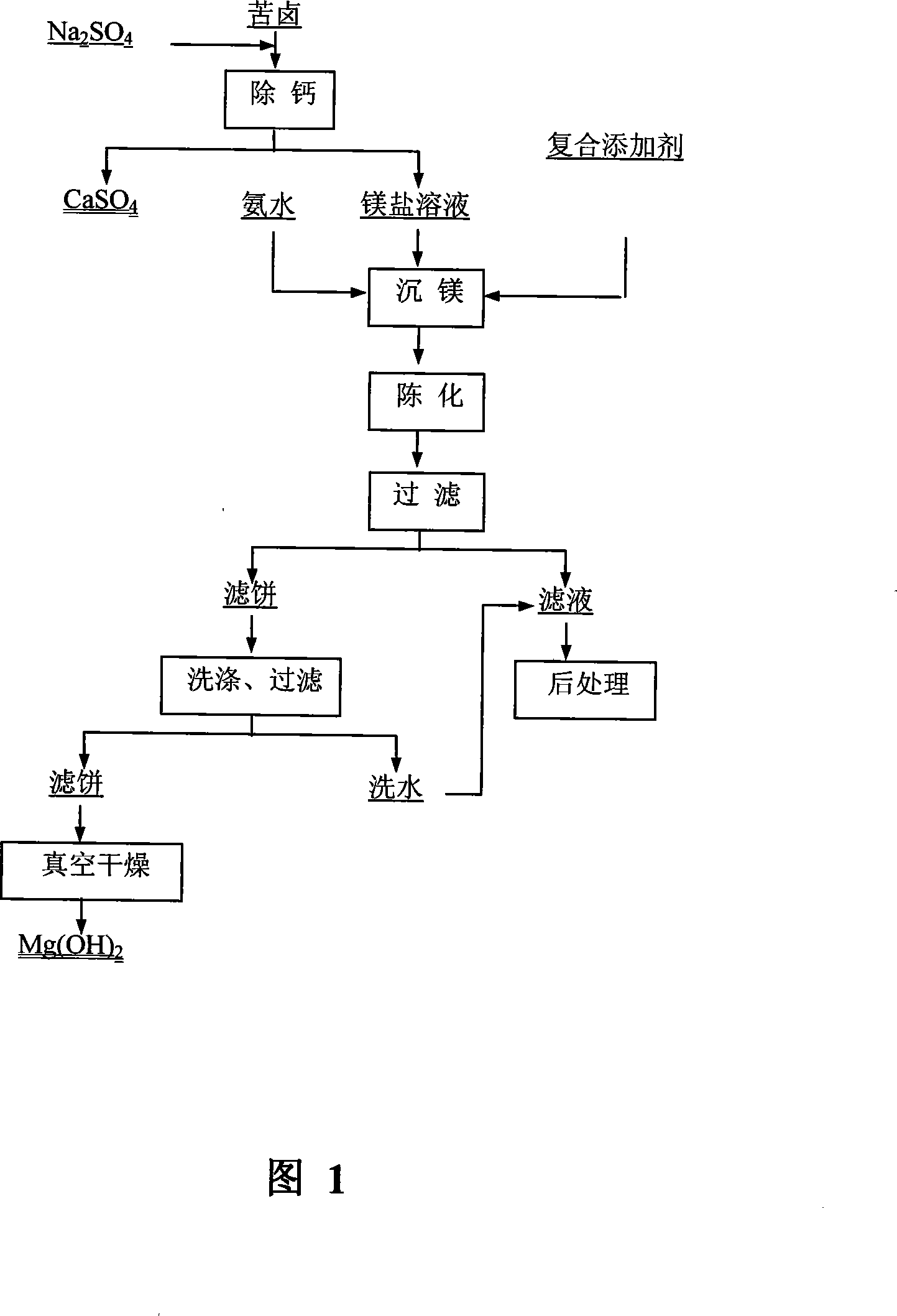

Method for preparing fibrous nano magnesium hydrate

InactiveCN101177289AReduce energy consumptionReduce fillingNanostructure manufactureMagnesium hydroxideReaction temperaturePotassium

The invention relates to a preparation method of a fiber-shaped nanometer magnesium hydroxide. The bitter brine of the discharge liquid after extraction of potassium, lithium, boron and other elements from the salt lake water is used as the raw material; the ammonia liquor or the sodium hydroxide solution is taken as the precipitant; the mixed solution of absolute ethanol, gelatin and lauryl sodium sulfate is used as the compound dispersing agent; the technological proposal is that the precipitation reaction is carried out at room temperature; through a serial procedures of heating and aging, washing in the dilute ammonia liquor, filtering, drying in the vacuum and grinding, the pure-white fiber-shaped nanometer magnesia powder is prepared with an average size of 30 to 80nm in diameter and 200 to 500nm in length. When the fiber-shaped nanometer magnesia powder is used as an inorganic flame retardant, the filling amount needed decreases significantly and the fiber-shaped nanometer magnesia powder can reinforce and toughen the polymer materials; the reaction temperature is the normal temperature, which reduces the energy consumption significantly; the fiber-shaped nanometer magnesia powder also develops a new method for comprehensive utilization of the salt lake resources.

Owner:KUNMING UNIV OF SCI & TECH

Supported beta crystal core formation agent and preparation method thereof

ActiveCN101157771AIncreased effective nucleation sitesHigh nucleation efficiencyChemical reactionCarboxylic acid

The present invention discloses a load-type Beta-nucleating agent and a preparation method thereof, the load-type Beta-nucleating agent of the present invention consists of nano calcium carbonate and aliphatic dicarboxylic acid, and the weight ratio of which is 5 to 1000: 1. The present invention adopts the nano calcium carbonate with a big surface area as a carrier, adopts a simple method to highly disperse the dicarboxylic acid on the nano-calcium carbonate surface, makes use of a chemical reaction of the nano-calcium carbonate and the dicarboxylic acid to form the high efficient beta-nucleating agent which is the same with the mixture of pimelic acid and calcium stearate aiming at the problems of the existing beta-nucleating agents. The present invention realizes the purposes of reducing the consumption of the dicarboxylic acid, reducing the cost and improving the nucleating efficiency as the dicarboxylic acid on the nano-calcium carbonate is highly dispersed and the effective nucleating points are only formed on the surface of the nano-calcium carbonate.

Owner:SUN YAT SEN UNIV

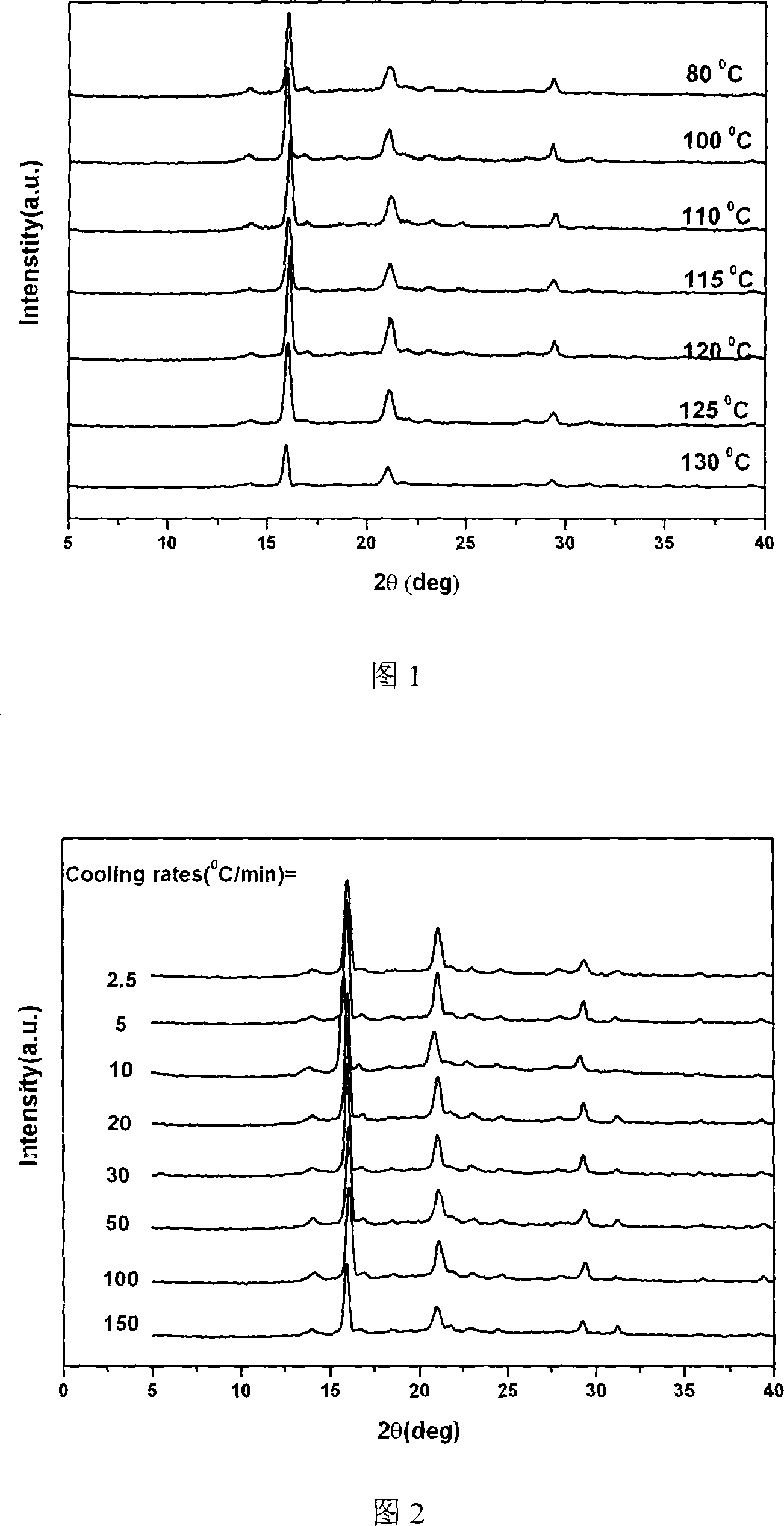

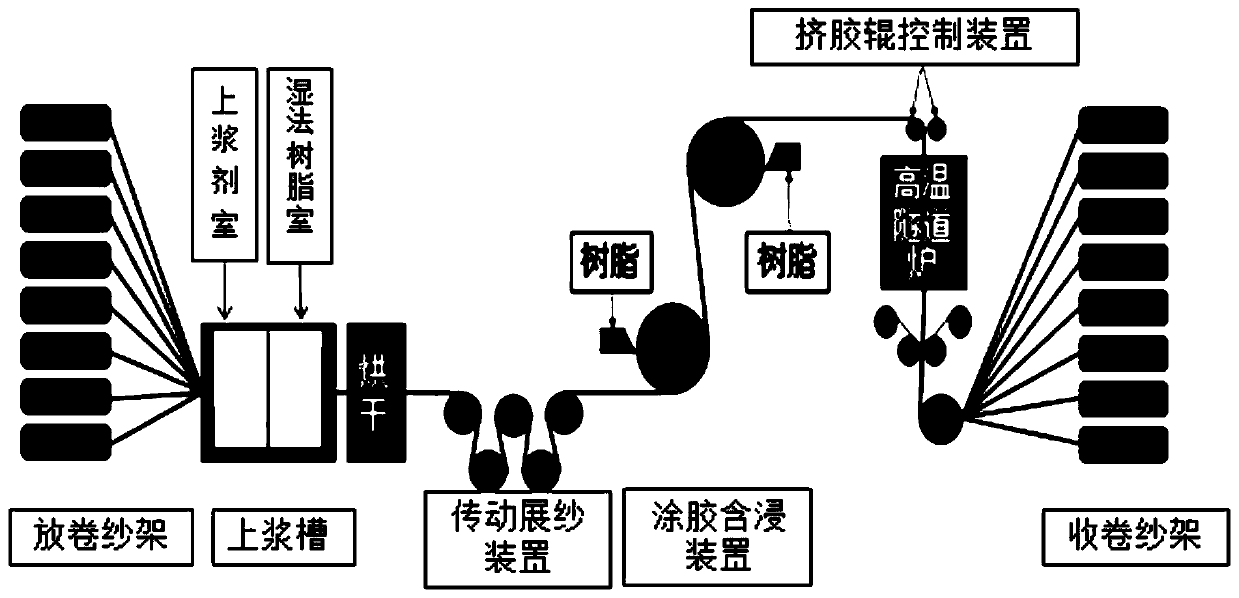

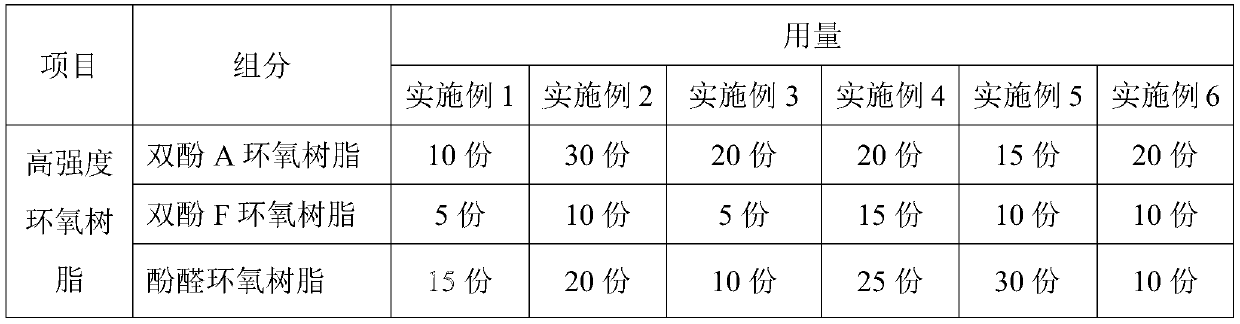

Tow prepreg, composite material high-pressure hydrogen storage tank and preparation process of composite material high-pressure hydrogen storage tank

PendingCN111098427AApplicable storageGood weather resistanceVessel wallsFibre typesEpoxyMechanical property

The invention discloses epoxy resin tow prepreg. A system of resin with high toughness and fatigue resistance is adopted, and an added reinforcing agent improves the strength and toughness of a material from the perspective of omnidirectional mechanics; and the obtained tow prepreg is excellent in mechanical property, high in strength, good in toughness and high in fatigue resistance. The invention further discloses a composite material high-pressure hydrogen storage tank. A graphene modified inner container is adopted, the mechanical properties and the toughness of the hydrogen storage tank are improved in combination with the epoxy resin tow prepreg with excellent performance and a thermoplastic resin tow prepreg winding layer, the hydrogen storage tank is suitable for the storage and use environment of high-pressure hydrogen and liquid gas, the fatigue resistance is good, and the service life is long. The invention further discloses a preparation process of the composite material high-pressure hydrogen storage tank. The preparation of prepreg by wet process and hot melt can be realized, an inner container self-tightening process and a winding process can generate a higher innercontainer self-tightening effect and enable tension of each fiber bundle to be more uniform, the strength advantage of fibers is fully utilized, and the fatigue resistance is good.

Owner:深圳市郎搏万先进材料有限公司

Composite flame retardant based on carbon microspheres and preparation method thereof

ActiveCN103059345AImprove thermal stabilityImprove mechanical propertiesPolymer substrateMicrosphere

The invention relates to a composite flame retardant based on carbon microspheres and a preparation method thereof. The preparation method comprises the following steps: on the basis of using carbon microspheres and aniline as a flame retardant material, acidizing the carbon microspheres to obtain acidized carbon microspheres; and grafting an aniline organic layer on the surface of the carbon microspheres to prepare the inorganic composite flame retardant. The composite flame retardant provided by the invention is a black powder substance and has good mechanical performance and thermal stability. When the composite flame retardant is used as a polymer flame retardant, the limit oxygen index reaches over 35% and meets the flame retardant standard of a flame retardant material. Meanwhile the mechanical performance of the polymer can be further improved, and the composite flame retardant based on the carbon microspheres has the enhancing and reinforcing effect to a polymer substrate material.

Owner:TAIYUAN UNIV OF TECH

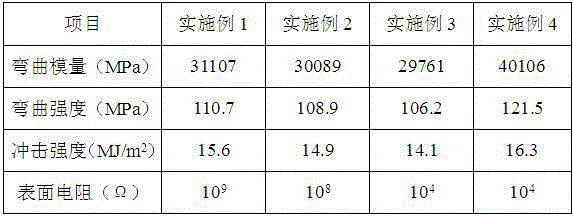

Preparation method of boron carbide ceramic chips

The invention provides a preparation method of boron carbide ceramic chips. The method comprises the following steps: (1) preparing 1-2wt% of a graphene solution, adding a dispersing agent, and evenlydispersing in a way of ultrasonic, stirring or ball-milling to obtain a solution containing uniformly dispersed graphene; (2) adding the solution into boron carbide raw material powder, wherein boroncarbide power with average particle size of 3-5mu m is selected as a raw material, 3-4% of graphite powder is added as a sintering additive, and the average particle size of the graphite powder is 1-2mu m; (3) mixing the boron carbide raw material powder with the graphene solution, and carrying out ball-milling to form slurry; (4) granulating and drying to obtain granulated powder; (5) putting the granulated powder into a mould, hot-pressing and sintering.

Owner:ZHEJIANG LIGHT TOUGH COMPOSITE MATERIALS

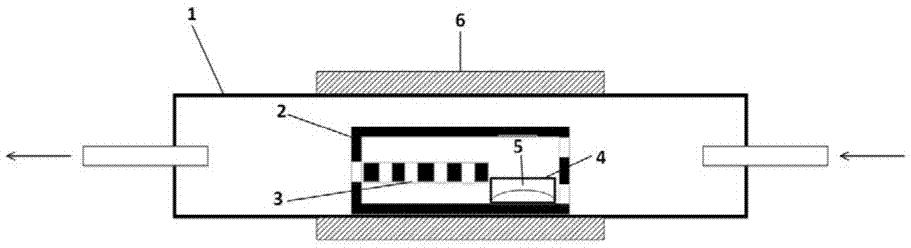

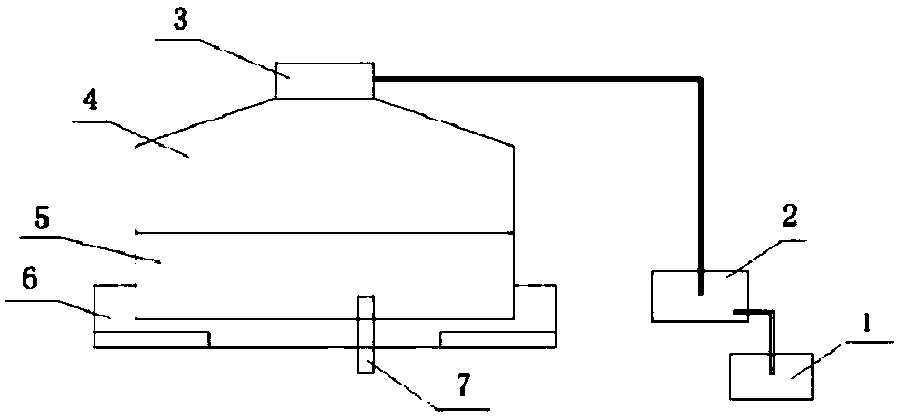

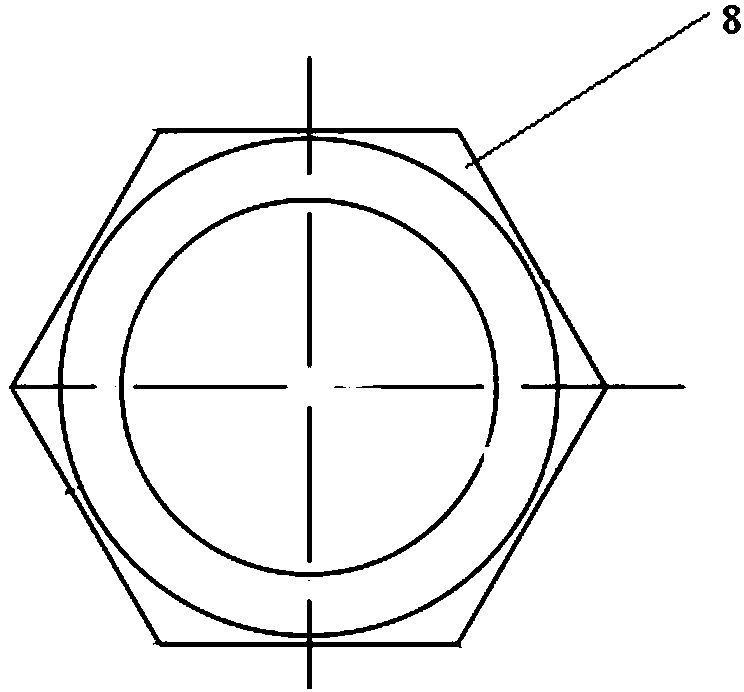

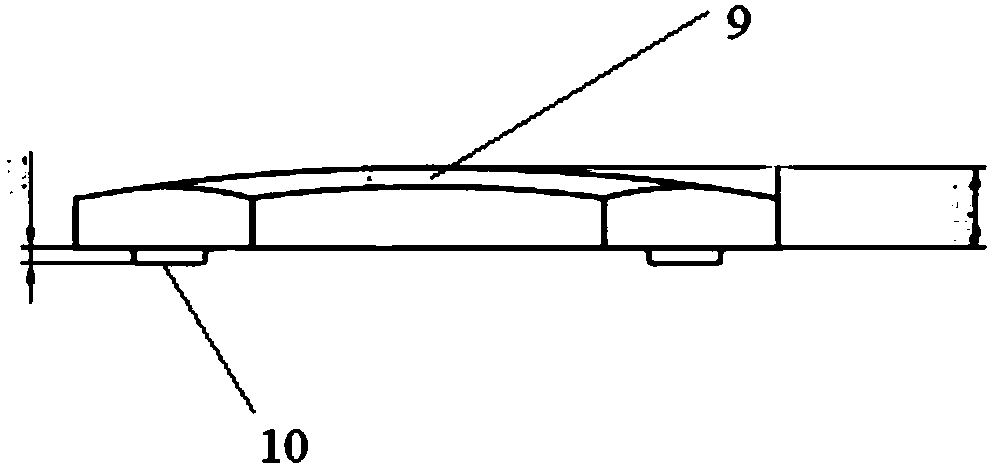

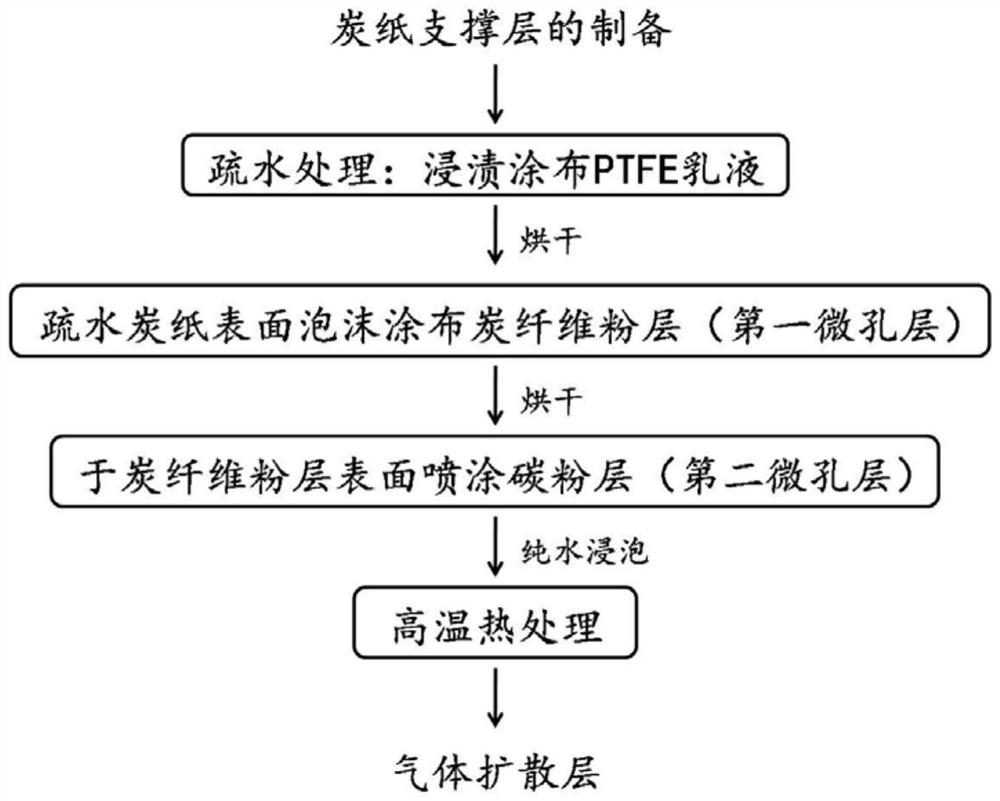

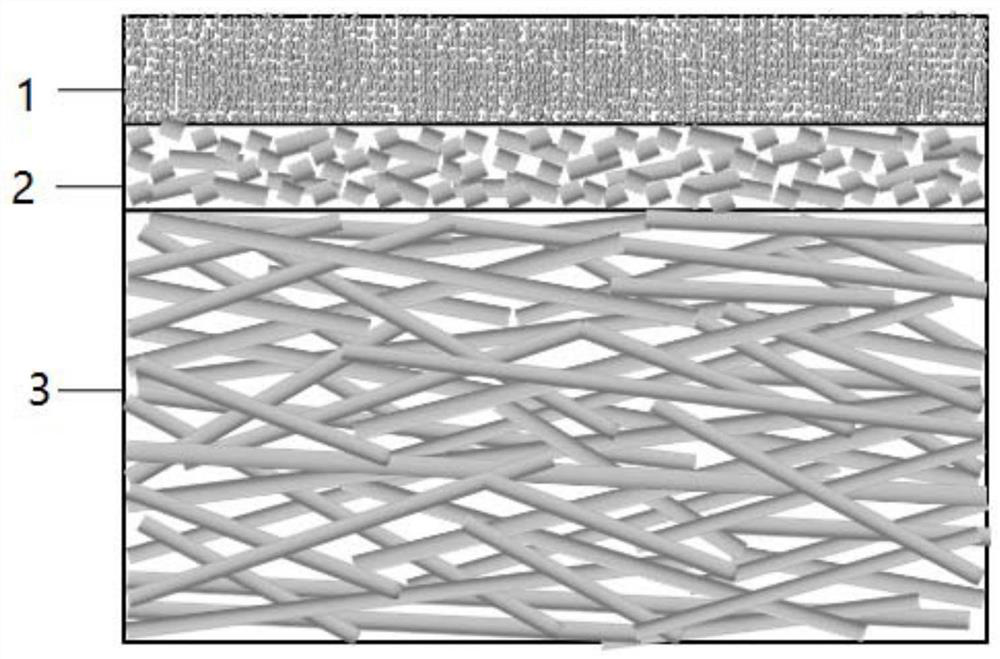

Gas diffusion layer with double-microporous layer structure and preparation method thereof

ActiveCN113394409AImprove breathabilityPrevent flooding"Material nanotechnologyCell electrodesElectrically conductiveFiber

The invention provides a gas diffusion layer with a double-microporous layer structure, the double-microporous layer comprises a first microporous layer and a second microporous layer, the first microporous layer is close to a support layer and is a carbon fiber powder layer with the thickness of 10-20 microns; and the second microporous layer is directly contacted with the catalyst layer and is a carbon powder layer with the thickness of 10-30 microns. Nano-scale and micron-scale holes exist in the surface of the microporous layer at the same time, and the flatness is high, so that the contact resistance is reduced; gradient pores with gradually reduced pore sizes from the supporting layer to the carbon fiber powder layer and then to the carbon powder layer are formed in the gas diffusion layer, so that on one hand, the pore structure distribution of the microporous layer is adjusted, and the water and gas management capability is improved; on the other hand, the coating formula and performance of the microporous layer are optimized, the conductivity of carbon fiber powder is higher than that of carbon powder, the conductivity of the system can be greatly improved by adding the carbon fiber powder layer, and effective transmission of electrons is promoted.

Owner:SHANDONG RENFENG SPECIAL MATERIALS

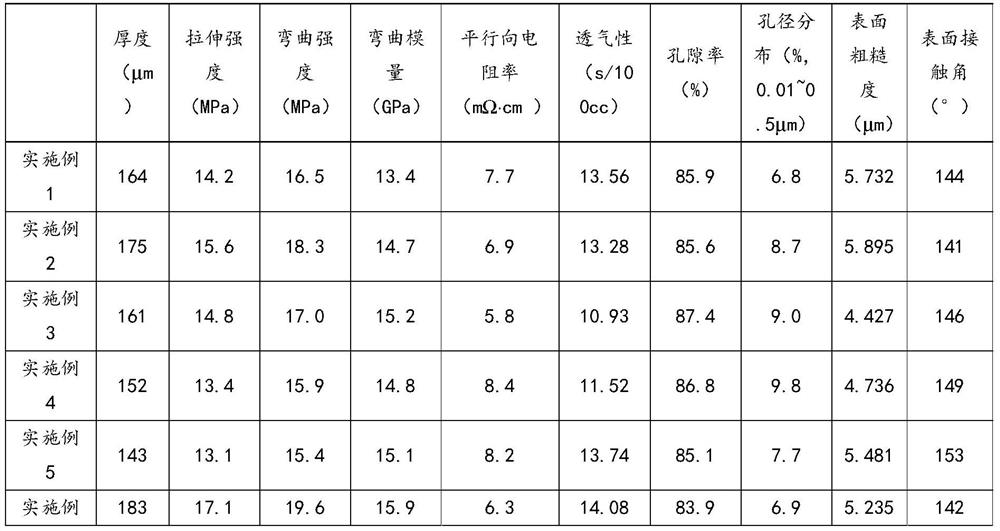

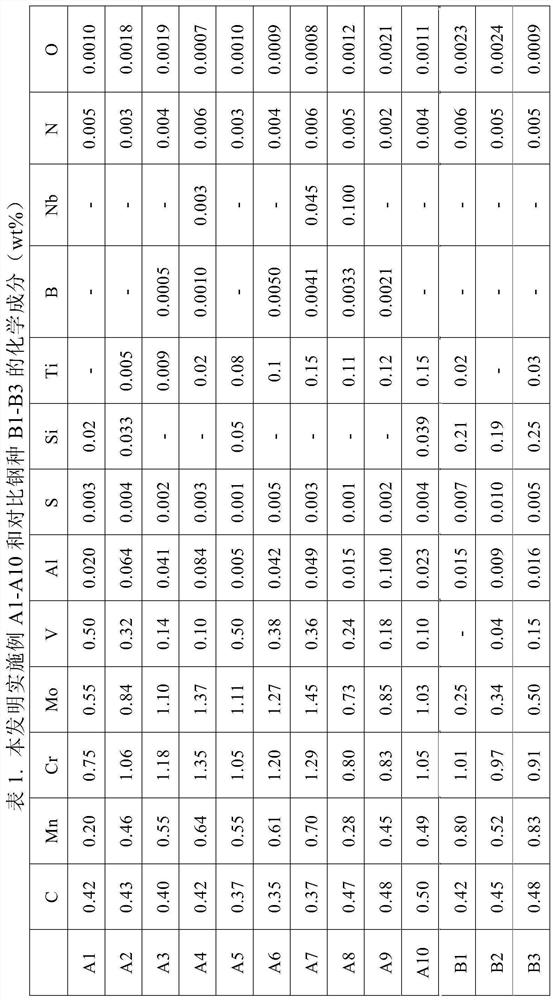

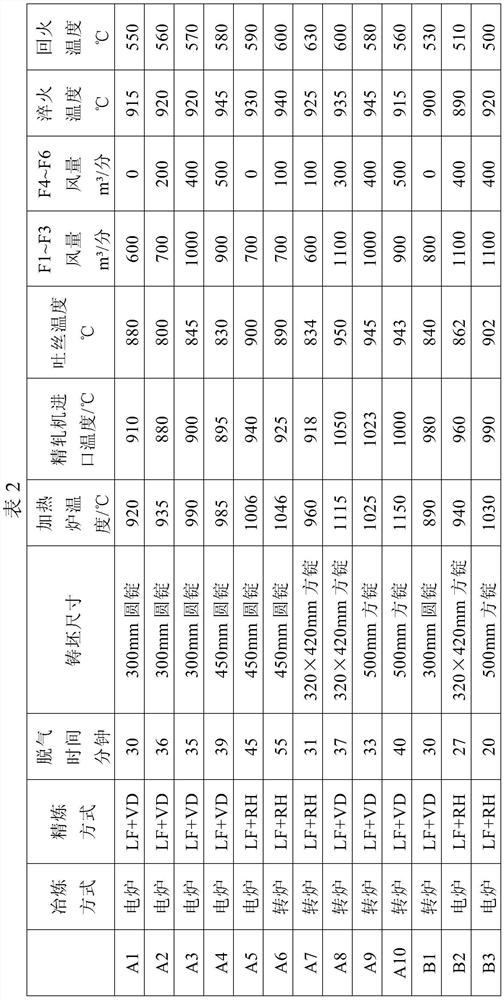

High-strength bolt steel with excellent delayed fracture resistance and preparation method thereof

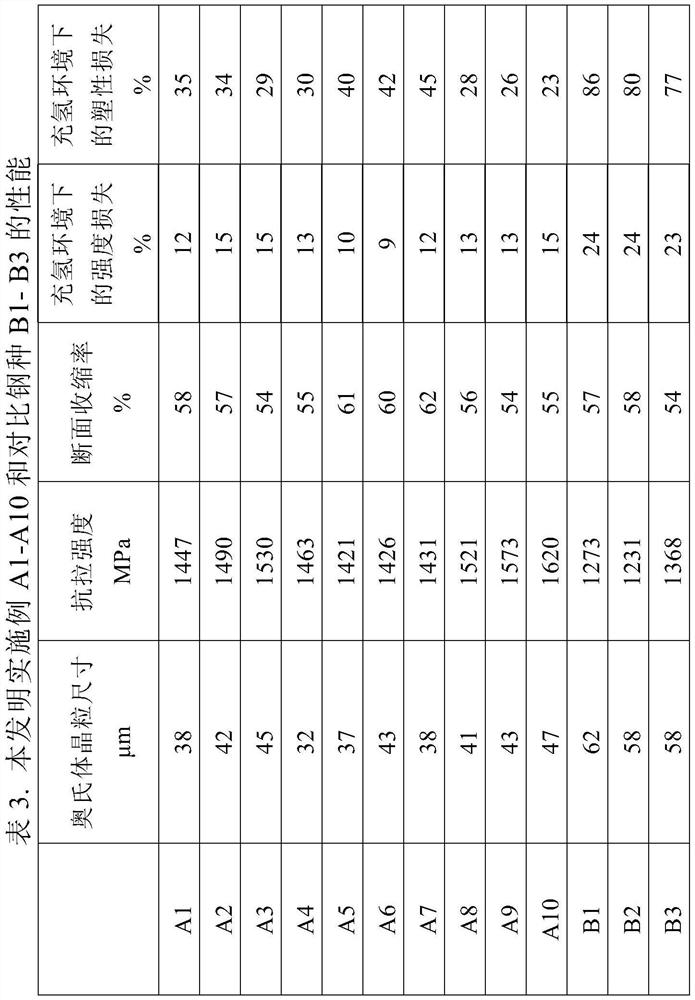

The invention provides high-strength bolt steel with excellent delayed fracture resistance and a preparation method thereof. The high-strength bolt steel comprises the following components in percentage by weight: 0.35-0.50% of carbon, 0.20-0.70% of manganese, 0.75-1.35% of chromium, 0.55-1.45% of molybdenum, 0.10-0.50% of vanadium, 0.005-0.10% of aluminum, 0-0.005% of sulfur, 0.02-0.05% of silicon, 0.005-0.15% of titanium, 0.0005-0.003% of oxygen, 0.001-0.007% of nitrogen, and the balance iron and other inevitable impurities; the content of titanium is not less than 3.5 times of the content of nitrogen; the sum of the contents of chromium, molybdenum and vanadium is not lower than 1.75%; and the sum of the contents of sulfur, oxygen and nitrogen is not higher than 0.01%. The high-strength bolt steel is high in purity and refined in grains, can be used for manufacturing high-strength bolts with tensile strength not lower than 1400MPa, has a section shrinkage rate not lower than 50%, is excellent in delayed fracture resistance, and can be applied to automobiles and mechanical parts.

Owner:BAOSHAN IRON & STEEL CO LTD

Modified hydroxypropyl starch, preparation method of same, plant hollow capsule, and preparation method thereof

ActiveCN105985449AImprove performanceImprove bindingPharmaceutical non-active ingredientsCapsule deliveryPlasticizerToughening

The invention provides modified hydroxypropyl starch and a preparation method of the same. The modified hydroxypropyl starch is excellent in performance and is prepared from hydroxypropyl starch and toughening gum under the effect of a crosslinker through a crosslinking reaction of activating hydroxyl groups. The invention also provides a plant hollow capsule and a preparation method thereof. The preparation method includes the steps of physical mixing of modified hydroxypropyl starch as a raw material with a gelatinizer, a coagulant, a plasticizer and the like, gum dipping, drying, shell pulling, cutting and sleeving. The plant hollow capsule is excellent in quality and effectively solves the problems of crispy capsule shells, excessive high capsule production cost and complex operations in production of plant hollow capsules in the prior art.

Owner:深圳市思颖柏霖生物科技有限公司

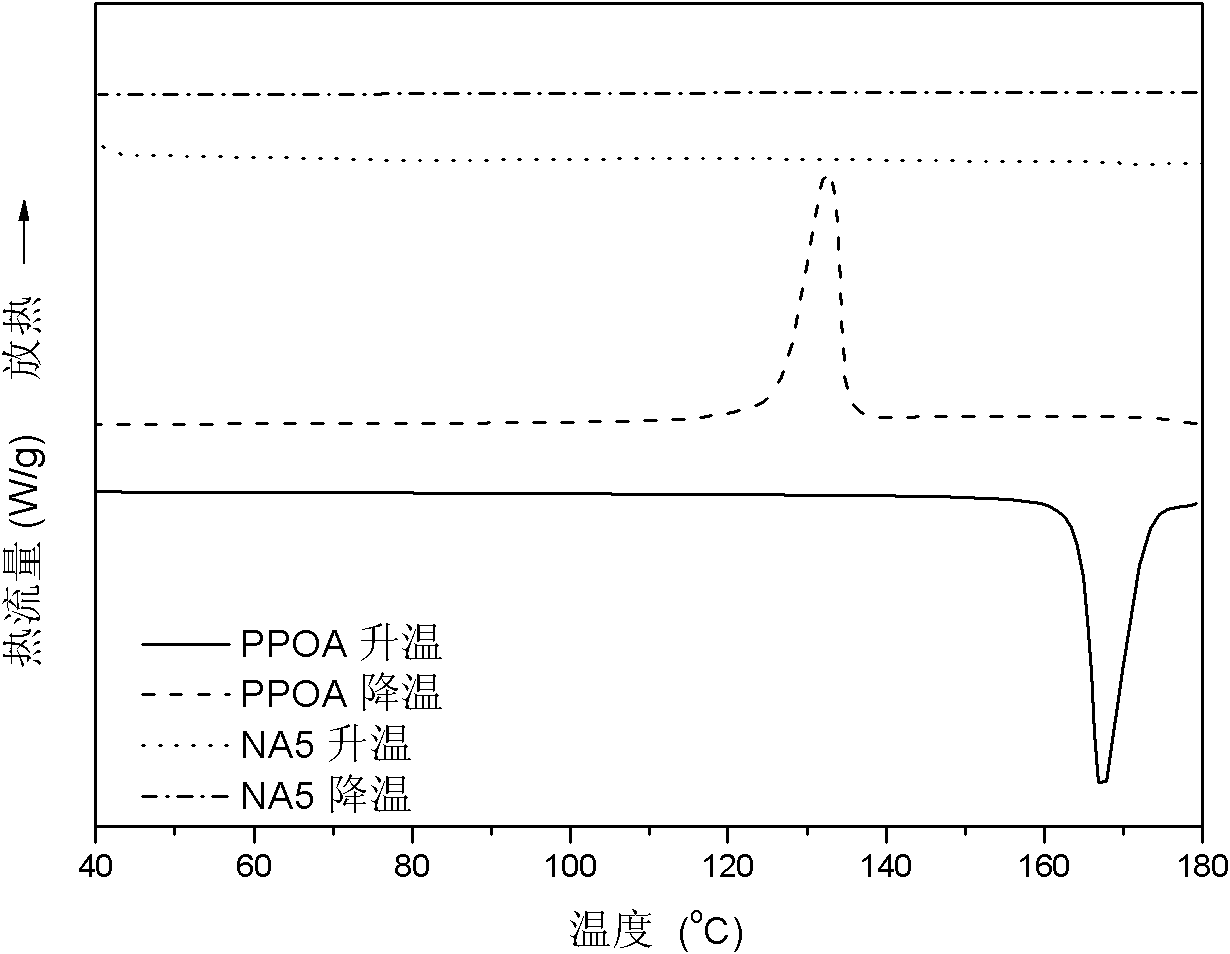

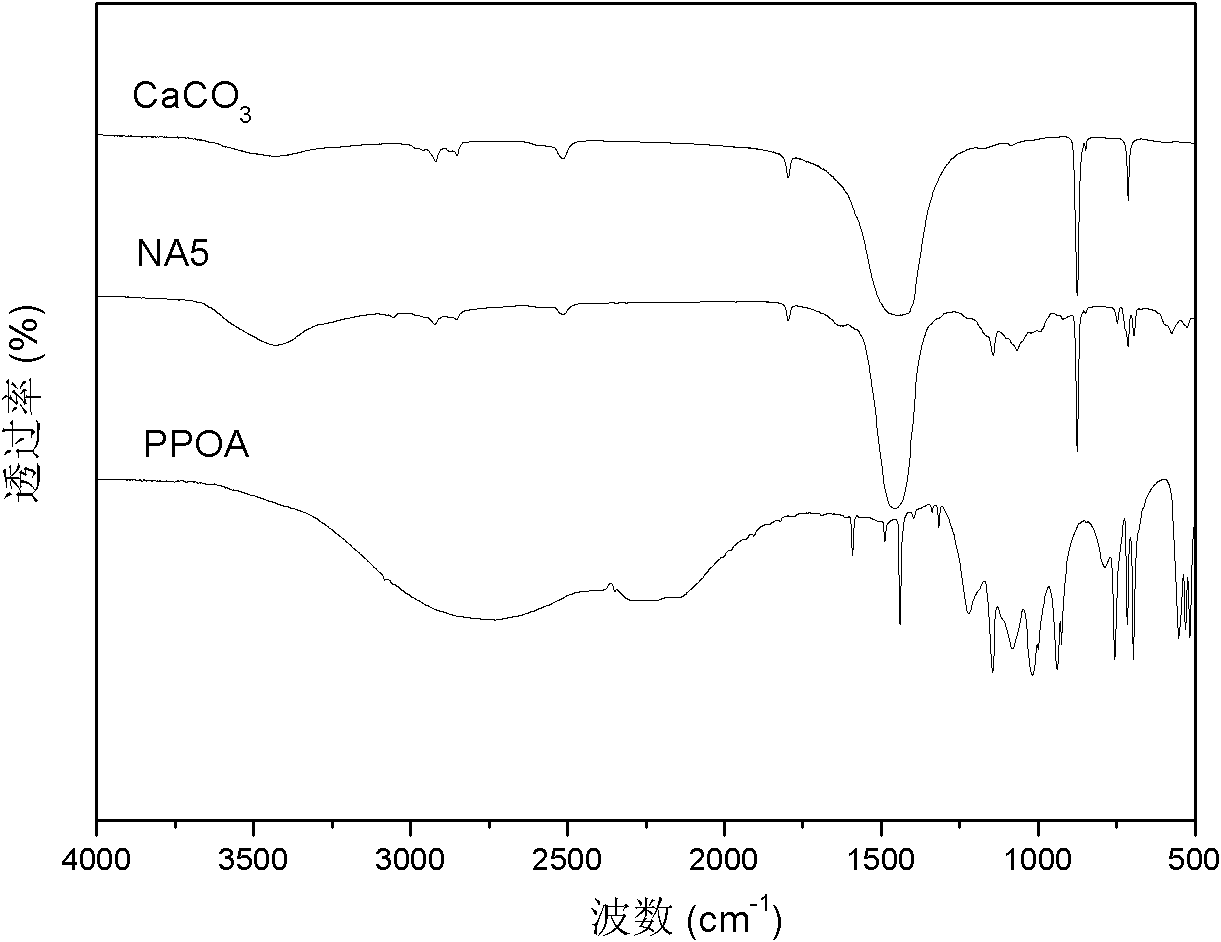

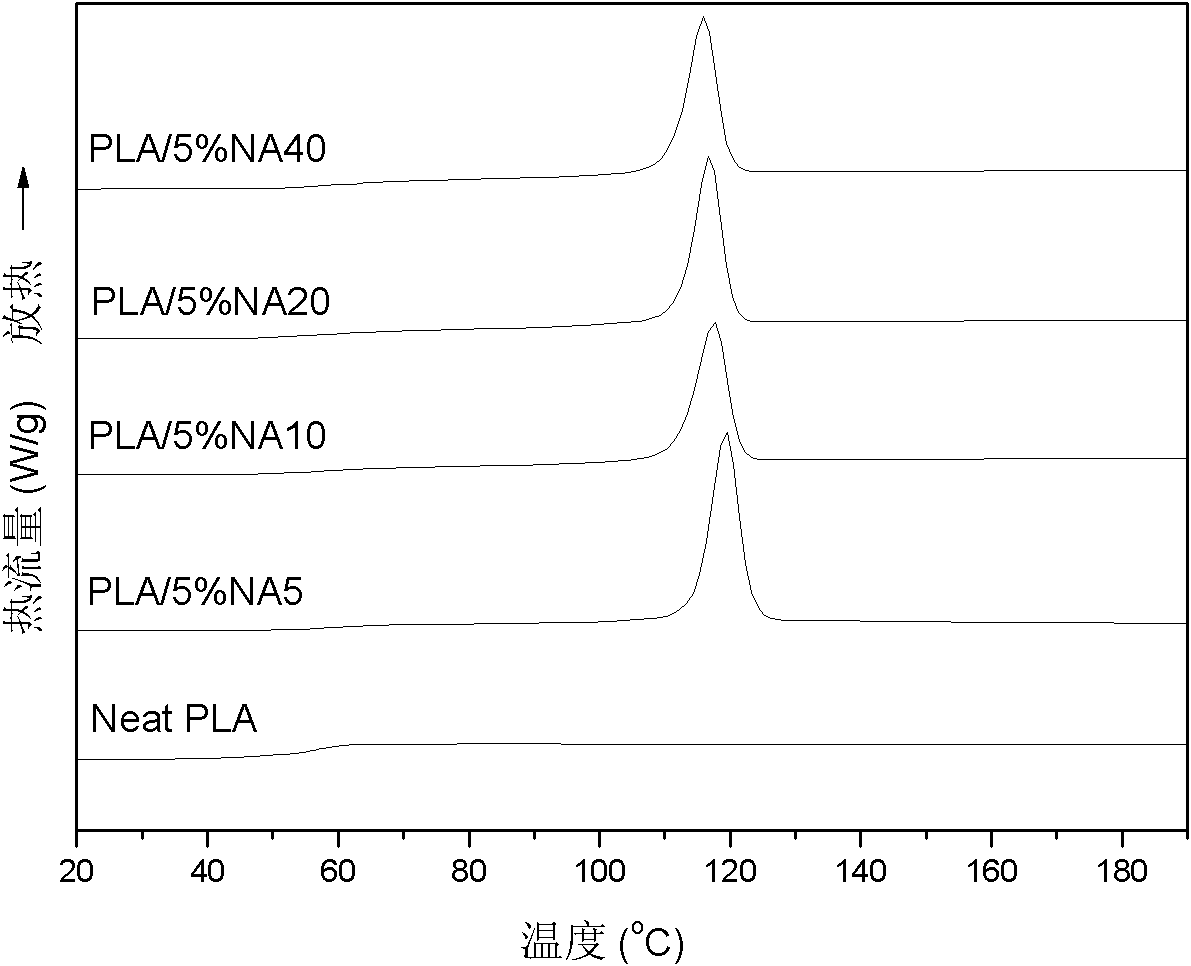

Calcium-carbonate-supported nucleating agent used for poly(lactic acid) crystallization and preparation method thereof

The invention discloses a calcium-carbonate-supported nucleating agent used for poly(lactic acid) crystallization and a preparation method thereof. The nucleating agent comprises the following composition formula: calcium carbonate and phenylphosphonic acid at a weight ratio of (5-40): 1, wherein calcium phenylphosphate generated by reaction of phenylphosphonic acid and calcium carbonate is used as an active ingredient and loaded on the surface of calcium carbonate, and phenyl phosphonic acid has a structural formula shown in the invention, in the formula, R1 and R2, the same or different, represent hydrogen atom, C1-10 alkyl or C1-10 alkoxycarbonyl. The nucleating agent can increase the effective nucleation sites formed by the high-degree dispersion of calcium phenylphosphate on the surface of calcium carbonate, thereby increasing nucleation efficiency as well as strengthening and toughening poly(lactic acid), avoiding the problem that poly(lactic acid) has poor toughness caused by non-supported nucleating agents, and facilitating the wide application of poly(lactic acid). The nucleating agent has a simple preparation method, low consumption of phenylphosphonic acid and significantly low cost.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

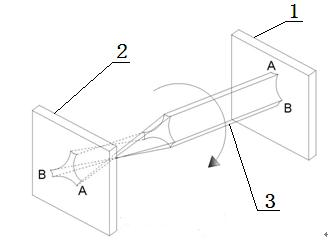

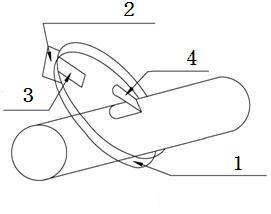

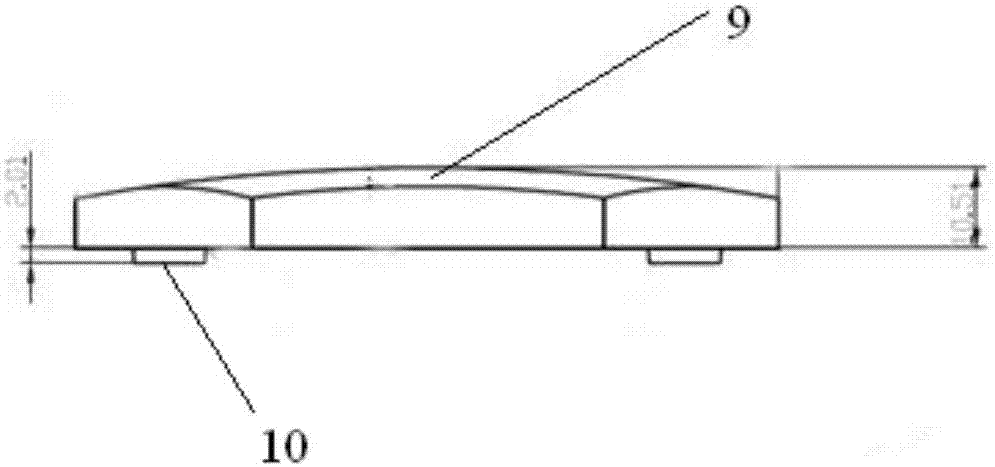

Polymer coarse fibre used for concrete and preparation method

ActiveCN102674728AIncreased persistent hindranceGuaranteed continuous performanceMonocomponent polyolefin artificial filamentMonocomponent polyesters artificial filamentVitrificationCrack resistance

The invention relates to a polymer coarse fibre used for concrete and a preparation method. The polymer coarse fibre is cylindrical, and the surface of the coarse fibre is provided with more than one anchored sheet distributed along the axial direction. The preparation method comprises the following steps: after polymer is dried to constant weight, adding the polymer to a twin-screw extruder; after the polymer is extruded by a spinneret plate hole, cooling a strand; then, stretching by stages for times at the temperature higher than the polymer vitrification temperature; after stretching is finished, cutting the anchored sheet on the surface of the strand; then, carrying out heat setting; and finally cutting off and packaging to obtain the polymer coarse fibre. In the preparation method, the appearance shape of the fibre is changed, so that the coarse fibre and a matrix have good interfacial bonding force, and therefore the cracking resistance, bending resistance, toughness and impact resistance of the coarse fibre enhanced concrete are enhanced or improved.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

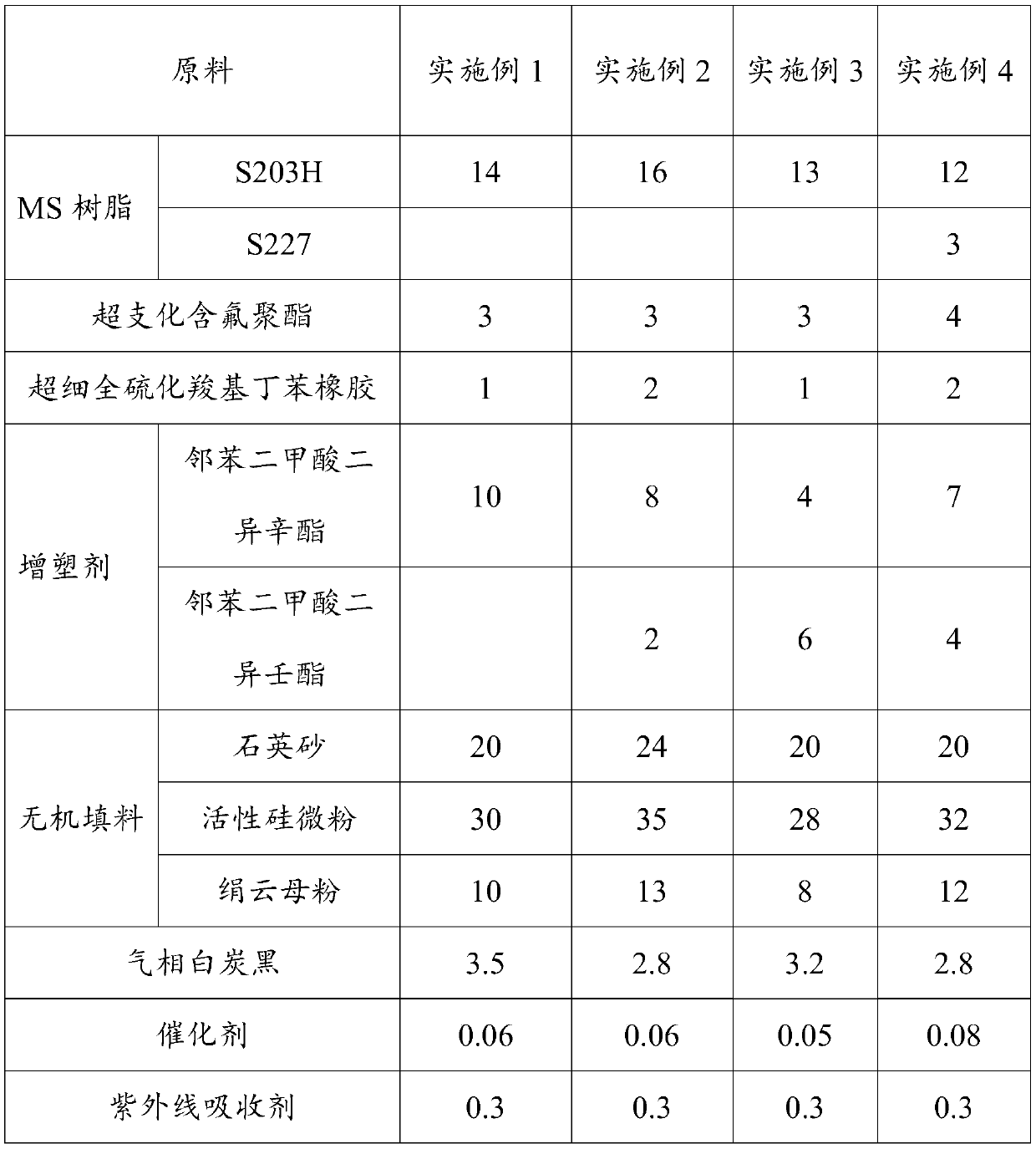

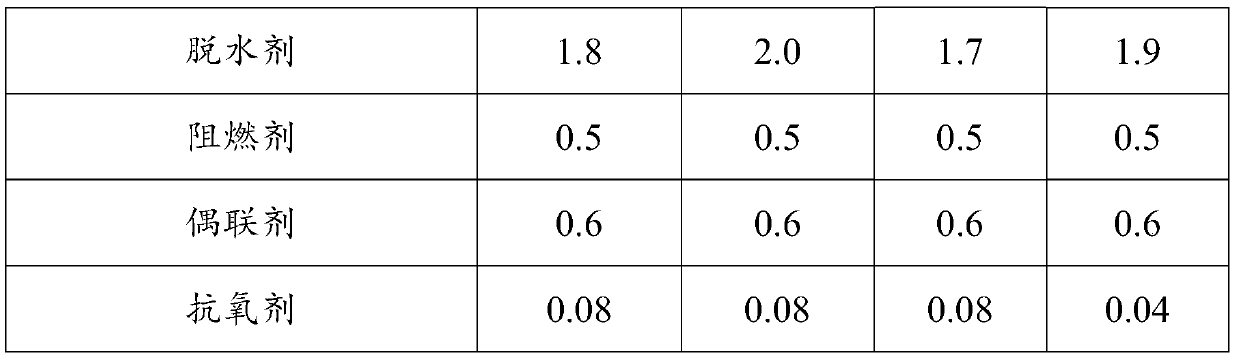

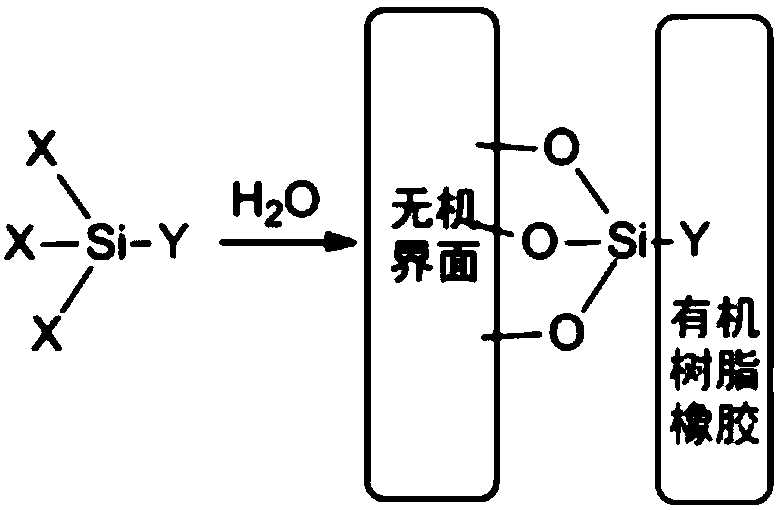

Silane modified polyether sealant and preparation method thereof

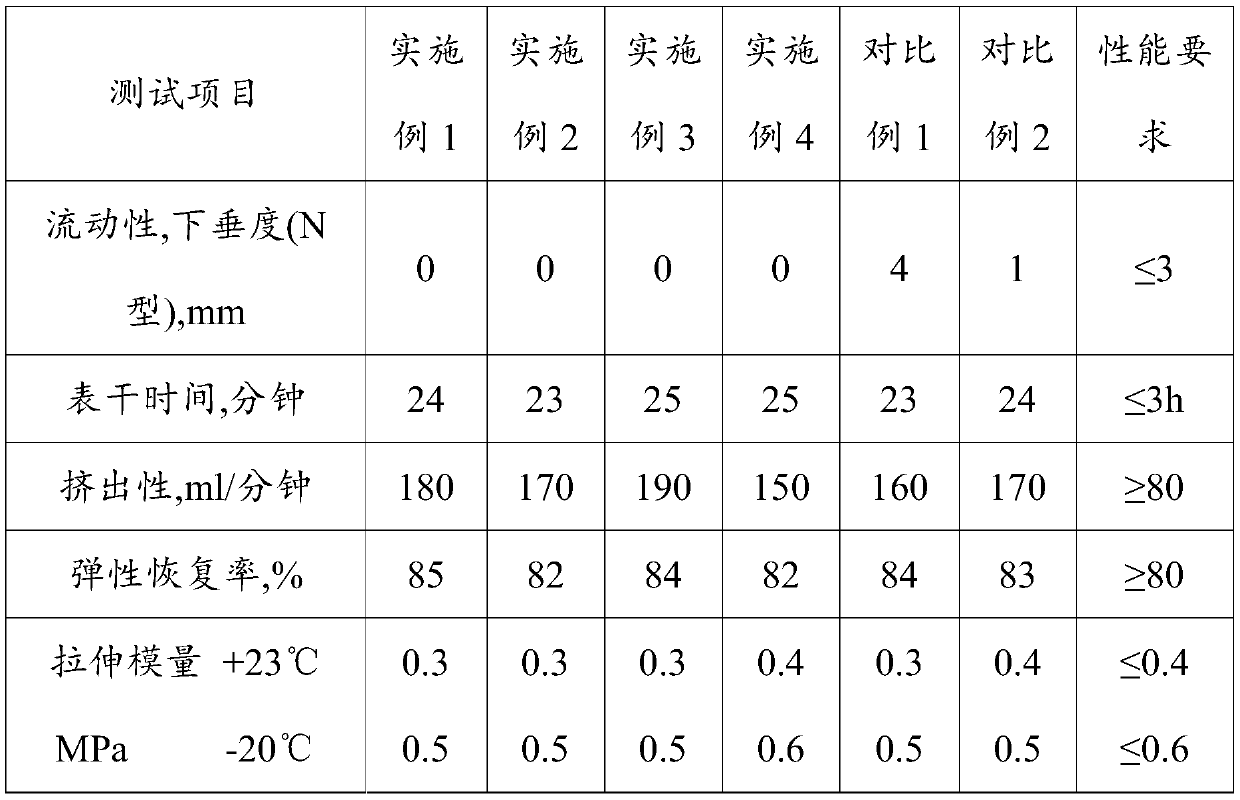

InactiveCN111100590AHydrodynamic small sizeImprove liquidityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyesterPolymer science

The invention discloses a silane modified polyether sealant and a preparation method thereof. The silane modified polyether sealant comprises the following components (by weight): 12-20% of MS resin,1-4% of hyperbranched fluorine-containing polyester, 1-3% of superfine full-vulcanized carboxylic butadiene styrene rubber, 60-70% of a filler, 2-5% of a thixotropic agent, 1-3% of a dehydrating agent, 0.03-0.08% of a catalyst, 9-20% of a plasticizer, 0.10-0.40% of an ultraviolet light absorber, 0-3% of a coloring agent, 0.5-1.0% of a coupling agent, 0.04-0.1% of an antioxidant and 0.4-1.0% of a flame retardant. By matching the above components, the content of the filler is increased, and good comprehensive properties such as flowability, aging resistance and stain resistance are guaranteed.

Owner:HUNAN KOSEN NEW MATERIAL

Low-rolling-compression-ratio rack steel plate and manufacturing method thereof

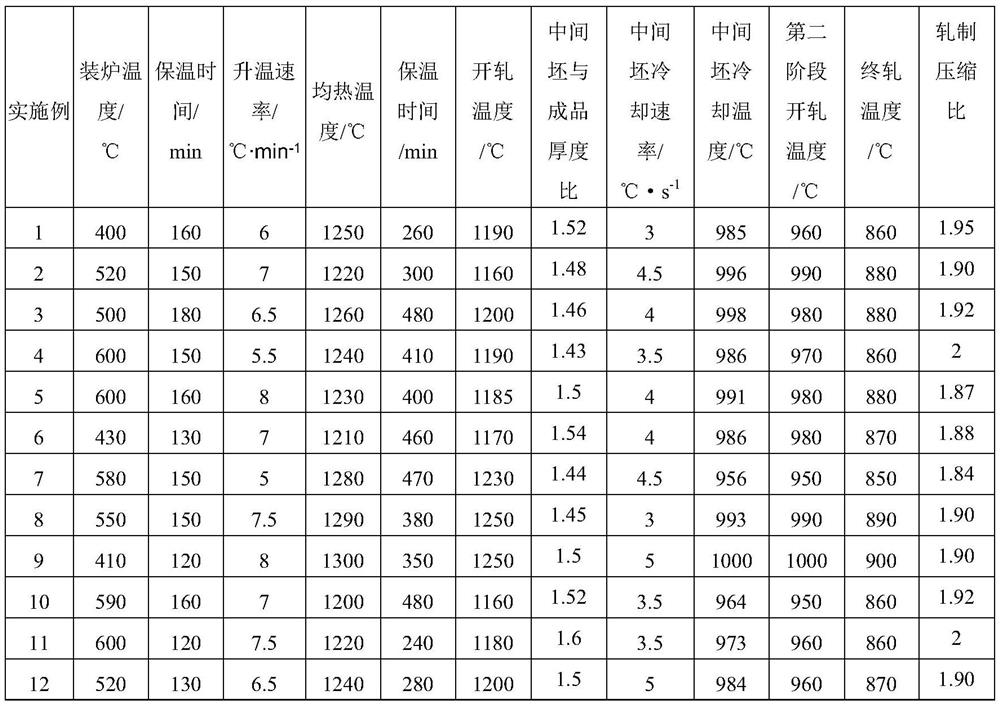

ActiveCN112226687AGuaranteed Yield StrengthImproved performance stability in the thickness directionTemperingChemical composition

The invention discloses a low-rolling-compression-ratio rack steel plate and a manufacturing method thereof. Steel comprises the rack steel plate with the compression ratio. The low-rolling-compression-ratio rack steel plate is characterized by comprising the chemical components of, by mass, 0.12% -0.15% of C, 0.1% -0.3% of Si, 1.0% -1.3% of Mn, 0-0.02% of P, 0-0.01% of S, 0.01% -0.03% of Als, 2.5% -3.0% of Ni, 0.5% -0.8% of Cr, 0.5% -0.8% of Mo, 0.2% -0.5% of Cu, 0.02% -0.04% of Nb, 0.03% -0.06% of V, 0.005% -0.03% of Ti, 0.001% -0.0015% of B, and the balance iron and inevitable impurities. After electroslag remelting and forging, the first-stage rolling starting temperature is 1150-1250 DEG C, the second-stage rolling starting temperature is 950-1000 DEG C, the finish rolling temperatureis 850-900 DEG C, and the rolling compression ratio is smaller than or equal to 2; and then high-temperature quenching, sub-temperature quenching and tempering treatment are adopted, and the Charpy impact energy single value of the core part of the finished steel plate at the temperature of-40 DEG C is larger than or equal to 90J.

Owner:ANGANG STEEL CO LTD

Poly-hydroxyalkanoate degradable composite material containing carbon nanomaterial and preparation method

ActiveCN102964789AHigh thermal conductivityImprove thermal conductivityNucleationCarbon nanomaterials

The invention relates to a poly-hydroxyalkanoate degradable composite material containing a carbon nanomaterial and a preparation method thereof. The composite material is constructured by introducing a high thermal conductive carbon nanomaterial into a poly-hydroxyalkanoate matrix to form an efficient thermal conductive network in the composite material to accelerate dissipation of heat discharged by crystals. The carbon nanomaterial is used as a nucleating agent at the same time to promote nucleation and crystallization of the poly-hydroxyalkanoate matrix. The carbon nanomaterial is further used as a flexibilizer to strengthen the obtained composite material. The mass ratio of the poly-hydroxyalkanoate matrix to the carbon nanomaterial is 10:1 to 2000:1. Compared with the prior art, the carbon nanomaterial has the advantages of high machining property, high mechanical property and high thermal property, low production cost and the like.

Owner:SHANGHAI JIAO TONG UNIV

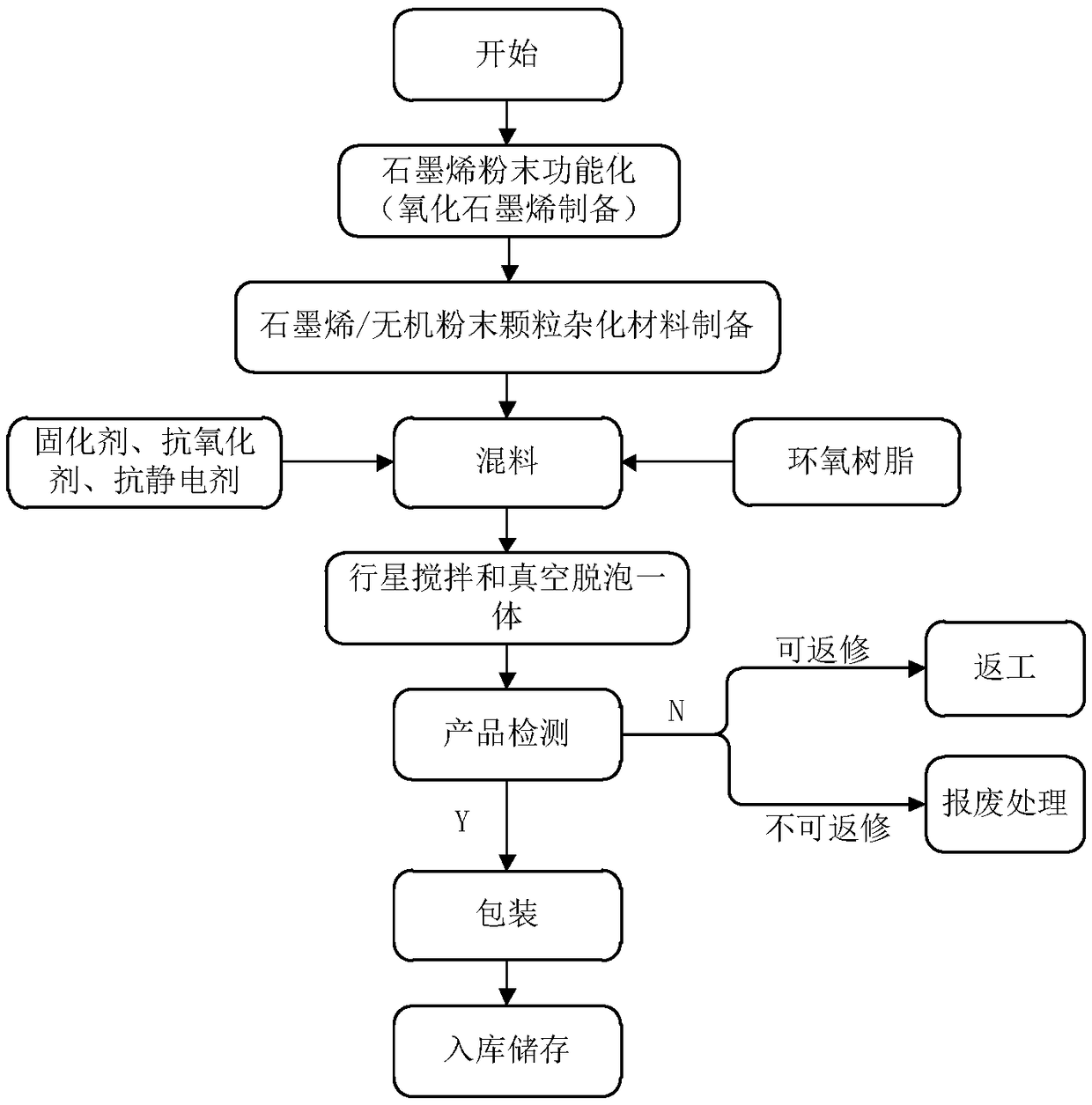

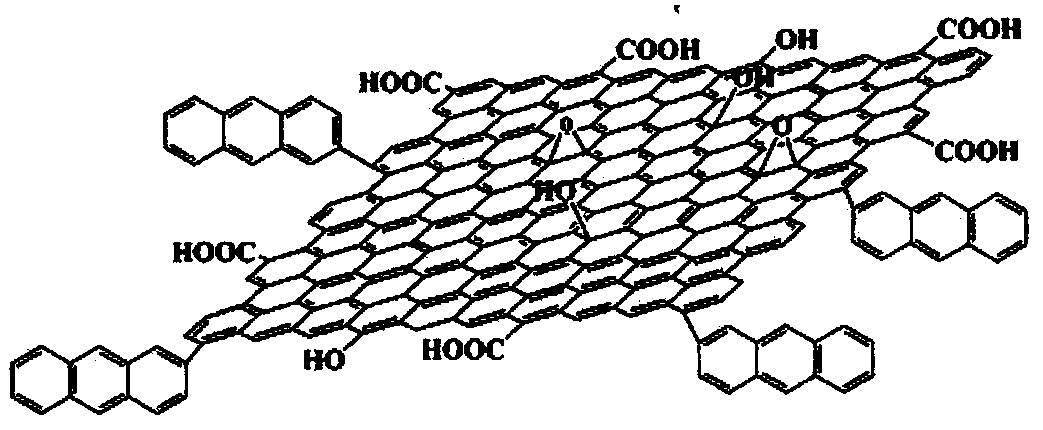

Graphene epoxy compound material for electric automobile driving module and preparation method

InactiveCN108102300AHigh strengthImprove thermal conductivityHeat-exchange elementsFully developedNew energy

The invention provides a graphene epoxy compound material for an electric automobile driving module and a preparation method. The compound material disclosed by the invention is formed by compoundinggraphene / inorganic powder particle hybrid materials with epoxy resin; the graphene / inorganic powder particle hybrid materials as filler are uniformly dispersed into a basal body of the epoxy resin. Byadopting the graphene / inorganic powder particle hybrid materials as the epoxy resin filler, the advantages of excellent performance such as high graphene strength and good heat conduction performanceof graphene as well as high heat conductivity, low expansion coefficient, high filling property, low stress and the like of inorganic powder particles can be fully developed, the defect of easiness for aggregation of the graphene / inorganic powder particle hybrid materials and the epoxy resin is overcome, enhancement and toughening effects can be achieved, and the application performance of the resin is improved. The compound material prepared by adopting the technical scheme has the special performance such as high heat conductivity, high adhesion strength, small change of curing volume, strong weathering resistance, high temperature resistance, small heat expansion coefficients and the like, and is very suitable for being used as an epoxy material for encapsulation in an overall encapsulation technology of a new-energy automobile motor driving module.

Owner:SHENZHEN HOVERBIRD ELECTRONICS TECH CO LTD

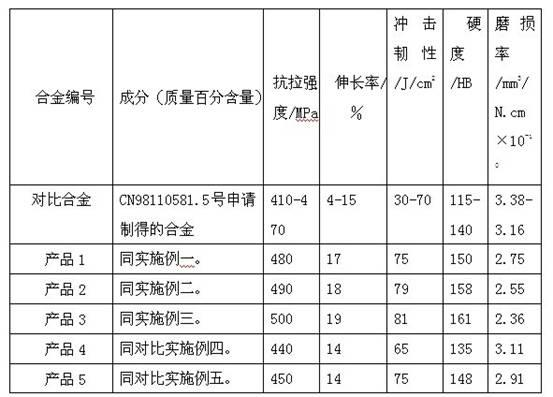

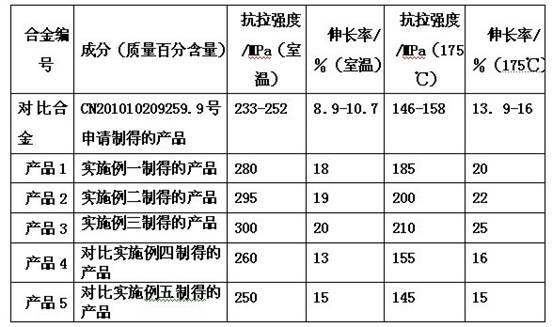

Wear resistant zinc alloy material and preparation method thereof

InactiveCN102051540AImprove wear resistancePlay a role in strengthening and tougheningCopper wireWear resistant

The invention discloses a wear resistant zinc alloy material and a preparation method thereof. The material uses zinc alloy as a base body in which a metal wire cluster formed by copper wires and iron wires is distributed, the diameters of the copper wire and the iron wire both range from 1to 2 mm, the diameter of the metal wire cluster ranges from 10 to 15 cm, the lengths of the copper wire and the iron wire in the material are equal, and the sum volume of the two metal wires is 10-35% (v / v) of the material. The wear resistant zinc alloy material has high wear resistance, low production cost and simple process.

Owner:金湖中博物联网科技有限公司

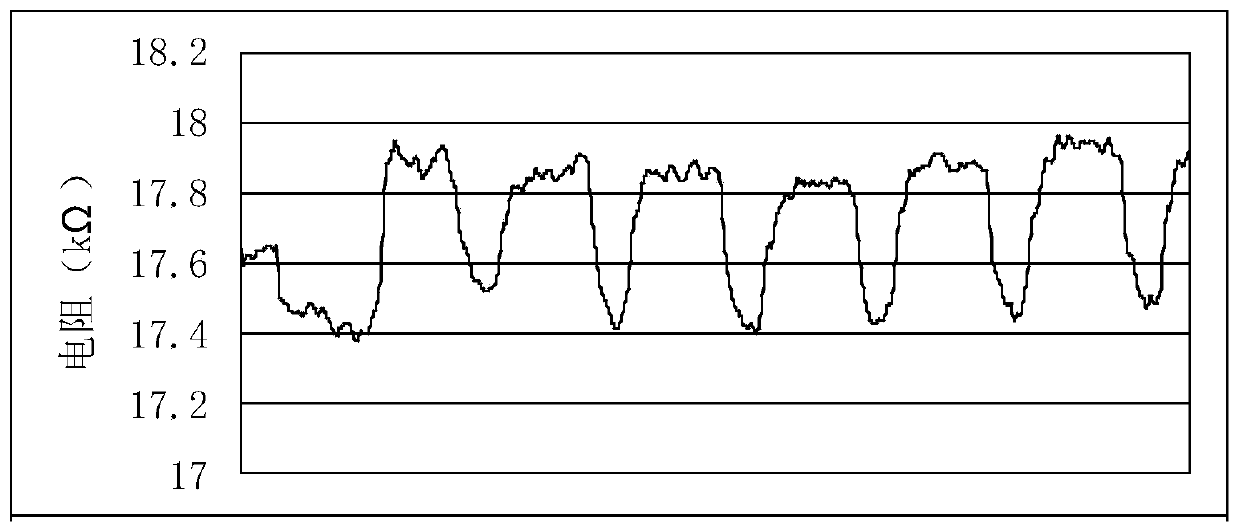

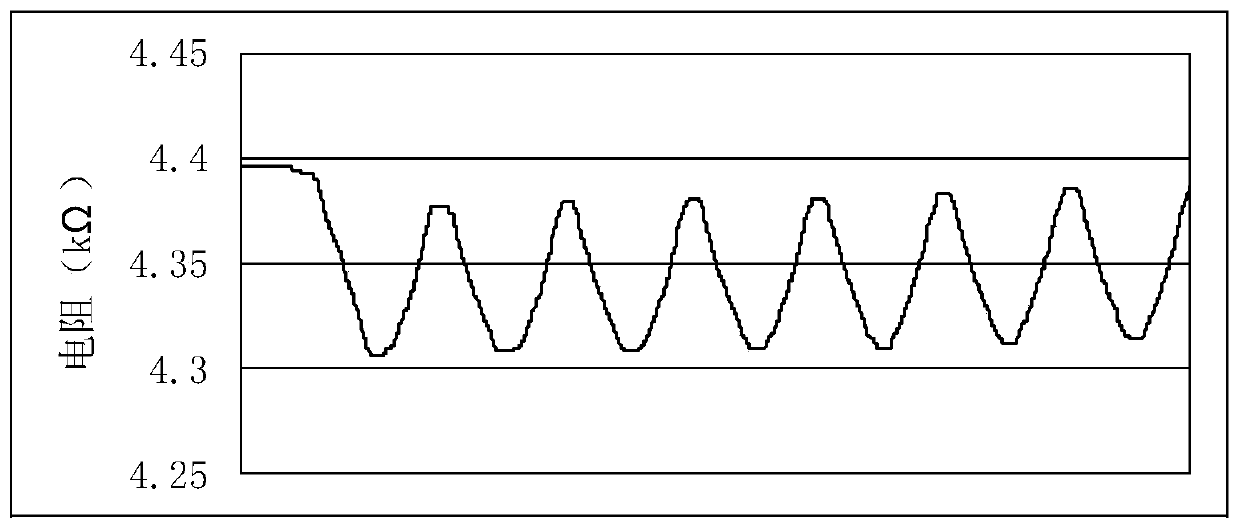

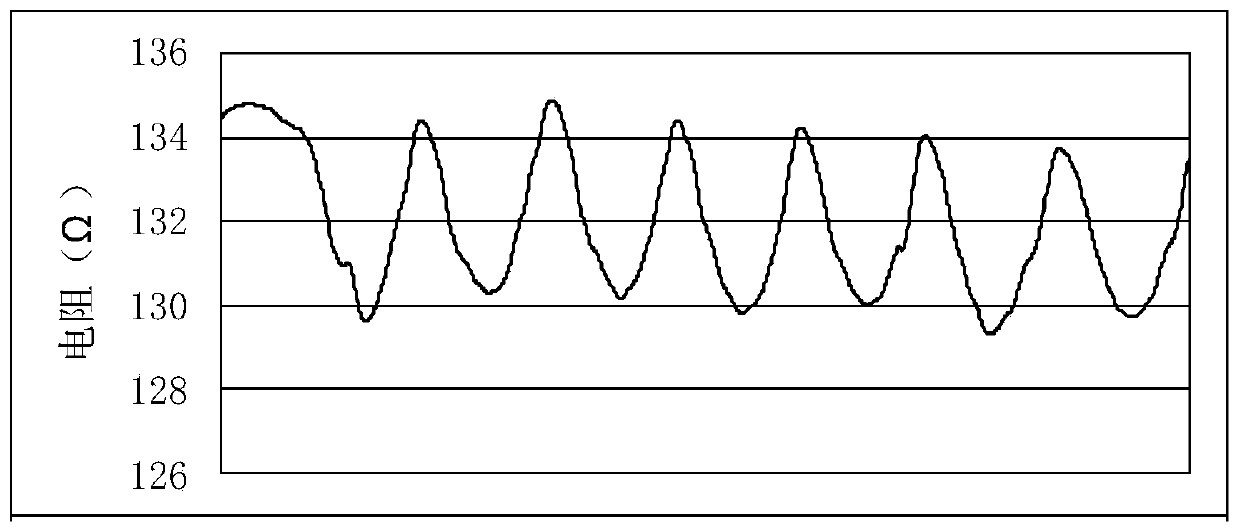

Intelligent concrete containing multi-scale conductive materials and preparation method thereof

InactiveCN110963758AImprove mechanical strengthImprove fracture toughnessElectrically conductiveUltrasonic generator

The invention discloses a cement-based intelligent concrete material containing three-scale conductive materials graphene, carbon black and steel fiber. The preparation method of the cement-based intelligent concrete material includes the steps of: dissolving a dispersing agent in water, then adding graphene, placing the container in an ultrasonic generator to scatter graphene so as to obtain a uniform graphene turbid liquid; mixing cement and carbon black by a powder pneumatic mixer; mixing the steel fiber, sand and coarse aggregate in a concrete mixer till uniform, and adding the mixed cement and carbon black in the mixing process; and adding the graphene turbid liquid, and stirring the substances uniformly to obtain the mixed intelligent concrete. According to the method, electrodes arefirstly placed to a to-be-detected part of a structural member, then the well mixed graphene concrete is poured into a preset part, and the change of inter-electrode electrical resistivity is detected to represent the changes of the stress condition and damage condition of the concrete structural member, thus reaching the purpose of real-time detection of the stress and damage states of the concrete structure.

Owner:STATE GRID CORP OF CHINA +2

Boron carbide-titanium alloy composite armour

InactiveCN107976115AReduce mutual attractionImproving the effect of implantationArmour platesCarbideBoron carbide

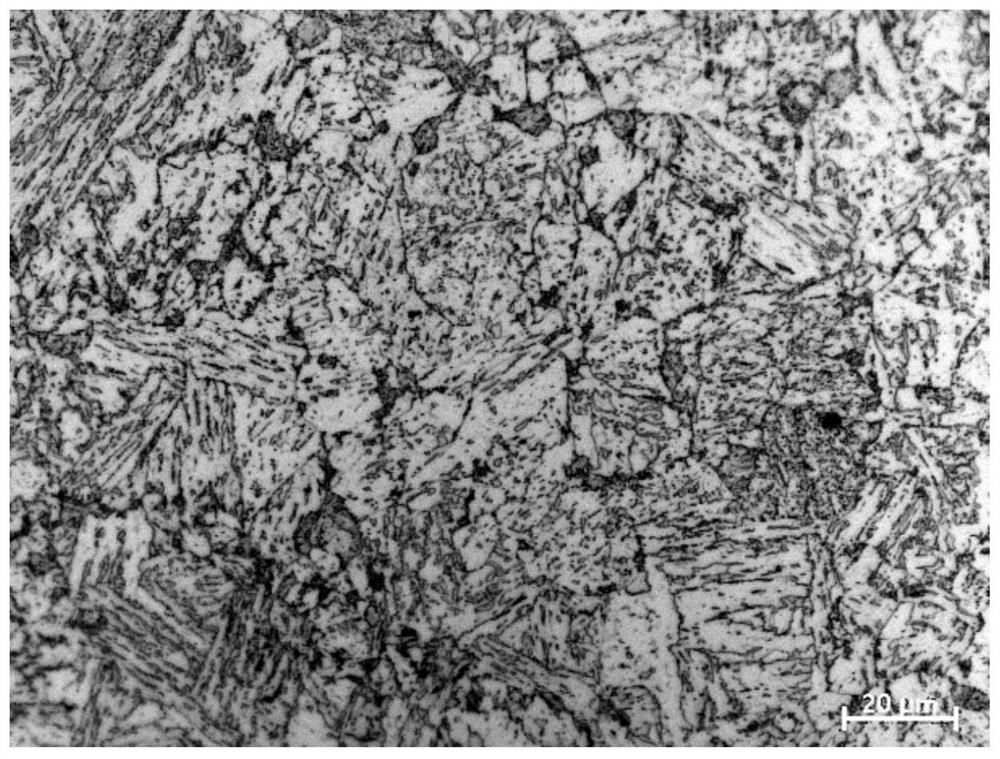

The invention provides a boron carbide-titanium alloy composite armour which comprises a boron carbide ceramic plate and a titanium alloy. The ceramic plate is wrapped with the titanium alloy, and theboron carbide ceramic plate is formed by splicing boron carbide ceramic pieces which are formed by hot pressing of boron carbide ceramic materials. The boron carbide ceramic materials comprise boroncarbide ceramic base bodies and graphene. The graphene is dispersed in the boron carbide ceramic base bodies. The graphene is evenly dispersed in boron carbide powder, then hot-pressing sintering is adopted, the bending strength is improved from about 350 Mpa to 500 Mpa or above, the titanium alloy for boron carbide ceramic is poured, and an overall structure that the four faces of the titanium alloy are wrapped with boron carbide is formed.

Owner:ZHEJIANG LIGHT TOUGH COMPOSITE MATERIALS

Manufacturing method of large-scale high-purity molybdenum alloy rotating target material

ActiveCN106567048AGood composition uniformityImprove tissue uniformityVacuum evaporation coatingSputtering coatingSmall particleVolumetric Mass Density

The invention discloses a manufacturing method of a large-scale high-purity molybdenum alloy rotating target material. The manufacturing method comprises the following steps of: preparing molybdenum trioxide powder; pouring a tube blank by utilizing the molybdenum trioxide powder and hafnium, and carrying out isostatic cool pressing on the tube blank; and carrying out sintering, extrusion and machining. According to the manufacturing method, a trace of hafnium powder is added in molybdenum trioxide to play a role of refining the particles, so that small-particle size molybdenum powder can be obtained and the density and breaking tenacity of the sintered blank can be improved; and the density of the prepared rotating target material is greater than 10.18g / cm3 and the purity is greater than 99.9%.

Owner:LUOYANG KEWEI MOLYBDENUM & TUNGSTEN

Preparation method of flame-retardant low-smoke polystyrene composite

The invention provides a preparation method of a flame-retardant low-smoke polystyrene composite. The composite comprises 50 to 60 parts of a polystyrene flame-retardant base body, 10 to 15 parts of a polymer, 5 to 10 parts of a non-melt filler, 5 to 15 parts of modified expansible graphite, 5 to 15 parts of micro-encapsulated red phosphorus, and 1 to 5 parts of carbon black. The preparation method comprises the following steps: mixing the materials; adding the mixture into a crusher; putting the crushed materials into a granulator of which the rotational speed is 50 to 55 r / min for granulation so as to obtain the polystyrene composite, wherein in the machine barrel of the granulator, the temperature of a first area is 170 DEG C, the temperature of a second area is 175 DEG C, the temperature of a third area is 180 DEG C, the temperature of a fourth area is 185 DEG C, and the temperature of a mold is 195 DEG C. The polystyrene composite prepared according to the formula and the technology is more excellent in flame retardancy, lower in smoke, and higher in antistatic property and bifunctionality when being compared with the conventional polystyrene composite, and has a favorable comprehensive mechanical property.

Owner:HENAN UNIV OF SCI & TECH

Heat-resistant magnesium alloy material and preparation method thereof

InactiveCN102051539AImprove heat resistancePlay a role in strengthening and tougheningMetallurgyCopper wire

The invention provides a heat-resistant magnesium alloy material and a preparation method thereof. The heat-resistant magnesium alloy material has good performance; and the preparation method has the advantages of simple process and low production cost and is suitable for industrial production. Magnesium alloys are utilized as substrates for the heat-resistant magnesium alloy material, wherein metal wire clusters formed by iron wires and copper wires are distributed on the substrates; the diameter of the iron wires and the diameter of the copper wires are 1-2mm; the diameter of the metal wire clusters is 10-15cm; the overall length of the iron wires in the material doubles that of the copper wires; and the copper wires and the iron wires account for 15-35% of the material by volume.

Owner:金湖中博物联网科技有限公司

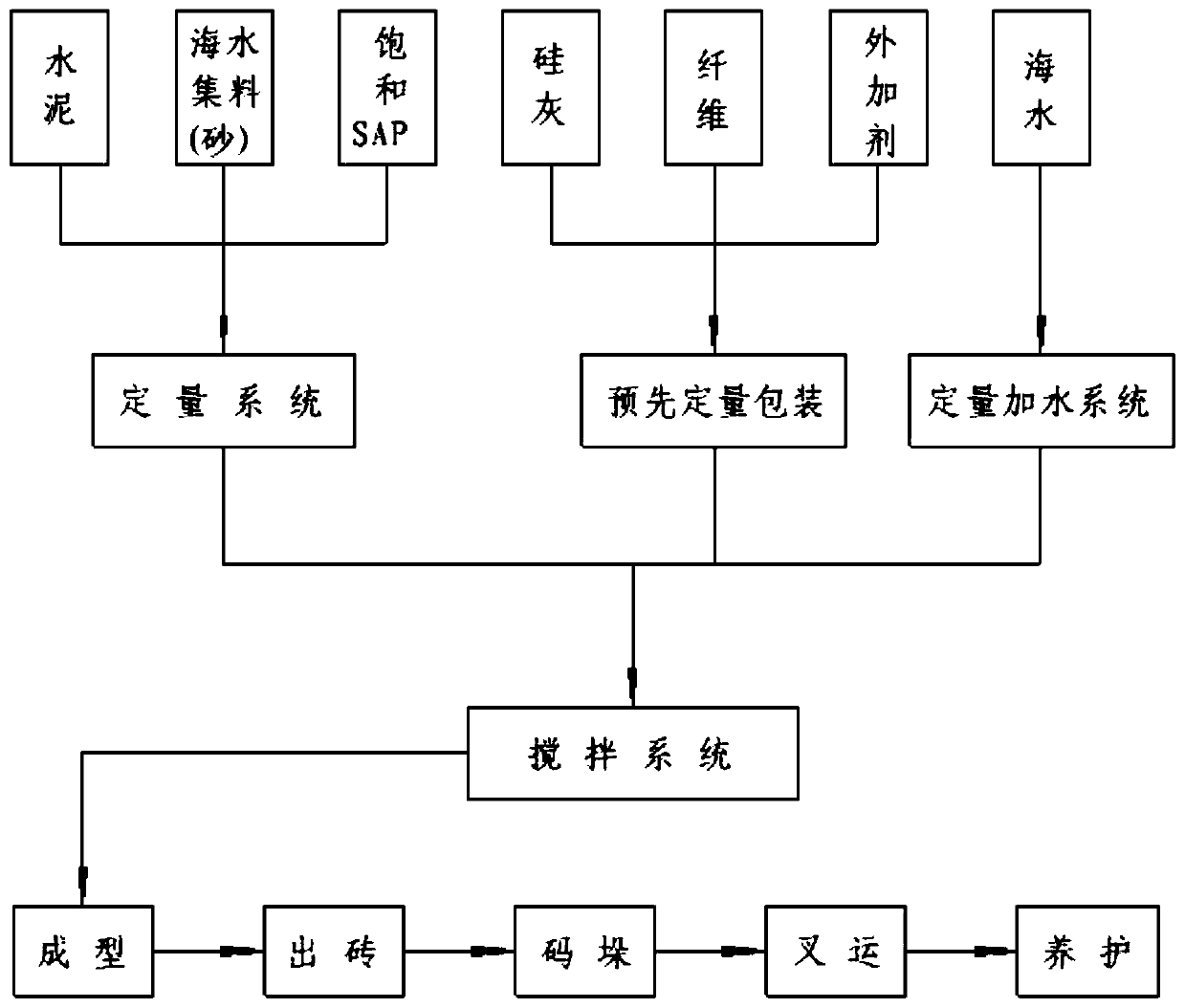

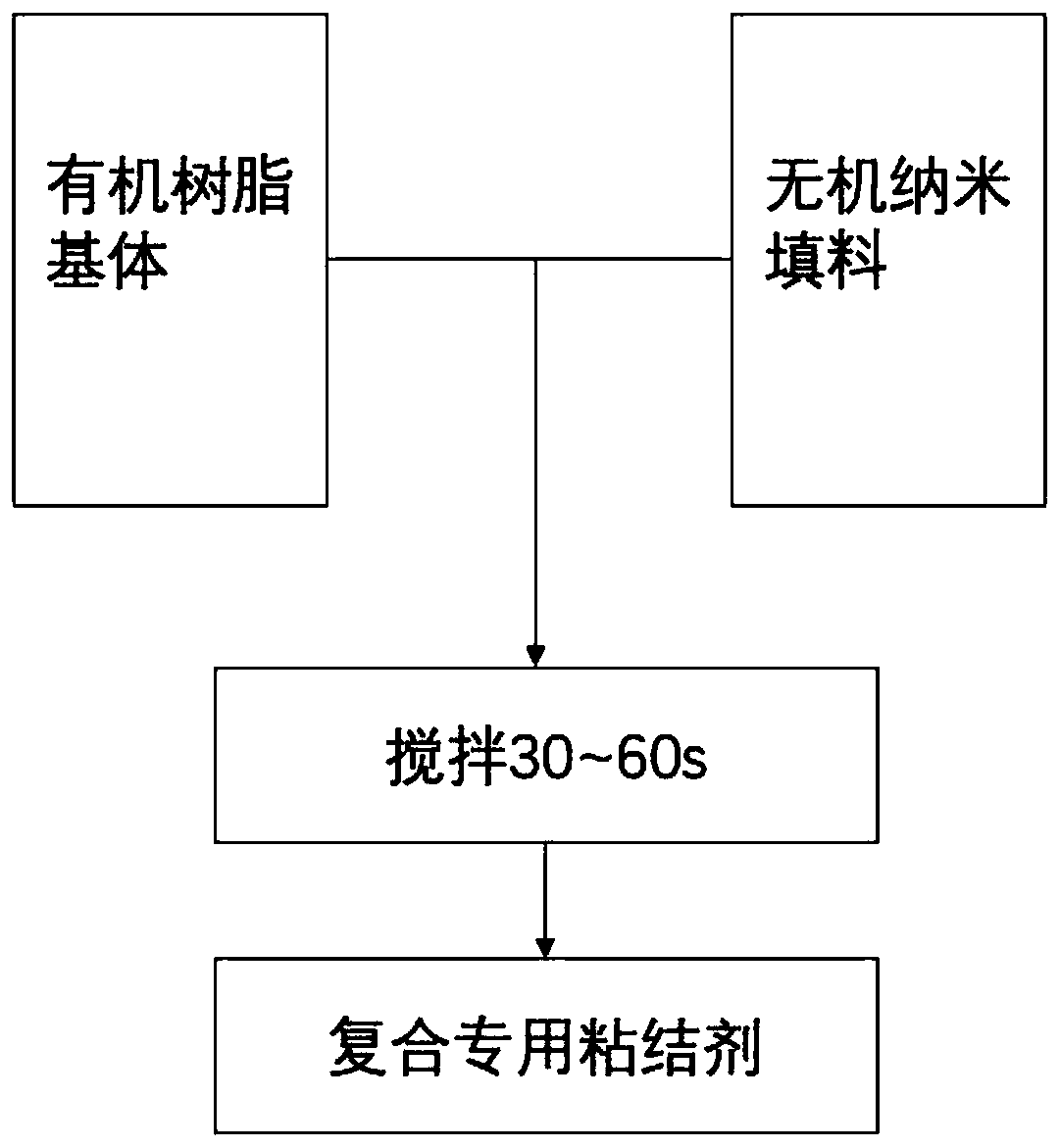

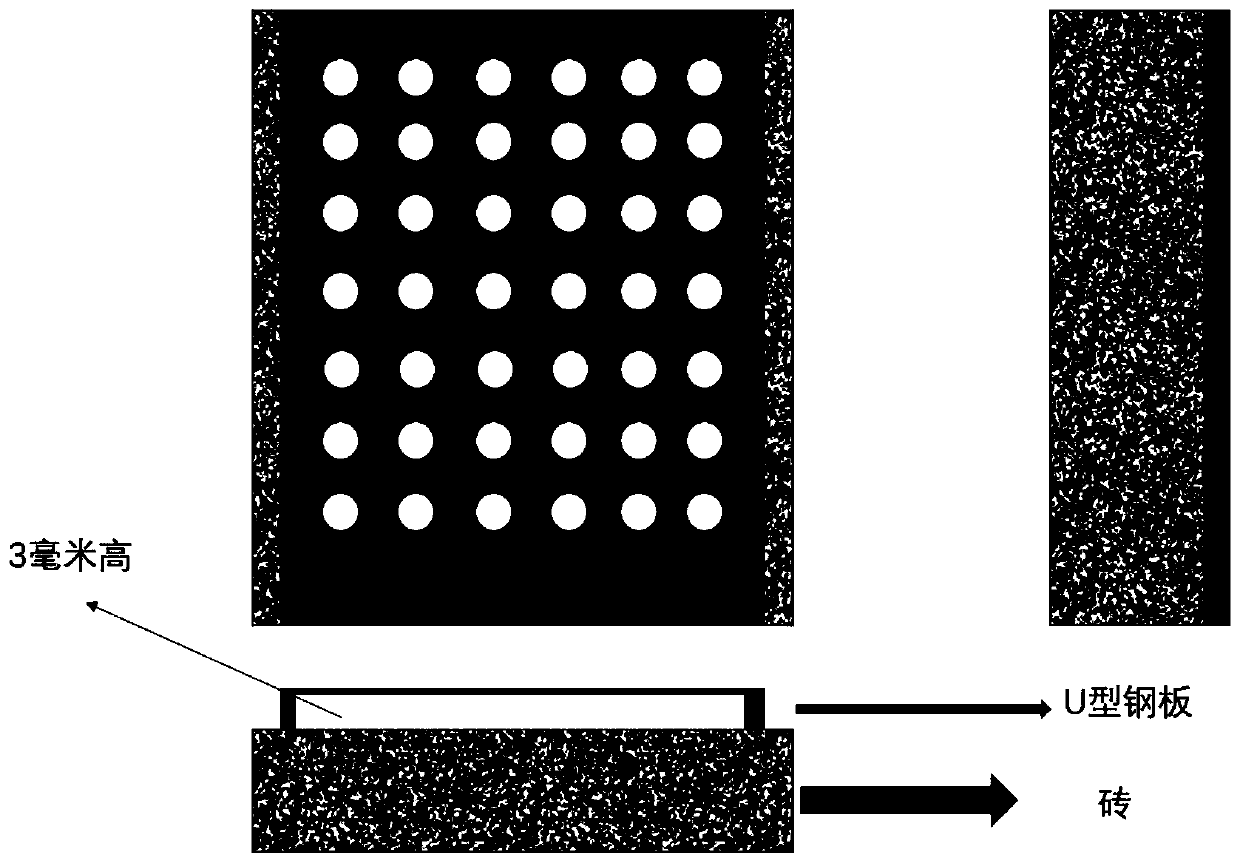

Novel non-autoclaved concrete brick and binder thereof

The invention belongs to the technical field of building materials and discloses a novel non-autoclaved concrete brick and a binder thereof. A novel concrete is prepared according to the following steps: utilizing a spherical high-performance water-absorbent resin with water absorbent rate of 15-18 to absorb seawater, thereby forming a swelling aggregate; blending with materials, such as cement, at a ratio; adding seawater and then stirring. Freight volume of island-reef engineering building materials can be greatly reduced. The novel non-autoclaved concrete brick has an average compressive resistance value of brick of 28.99MPa, breaking strength of 4.58MPa, hole rate of brick of 20.1%, moisture content of 7.3%, water absorption of 15.4% and density of 1467kg / m3. After the binder providedby the invention is cured, the thickness of bonding layer is 2-3mm, tensile shear bond strength is more than or equal to 1.5MPa, tensile bond strength is more than or equal to 1.0MPa, compressive strength is more than or equal to 8.0MPa, shrinkage value is less than or equal to 1.0mm / m, 50-times freezing thawing strength loss is less than or equal to 2.0% and bonding curing time is 1h-5h.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

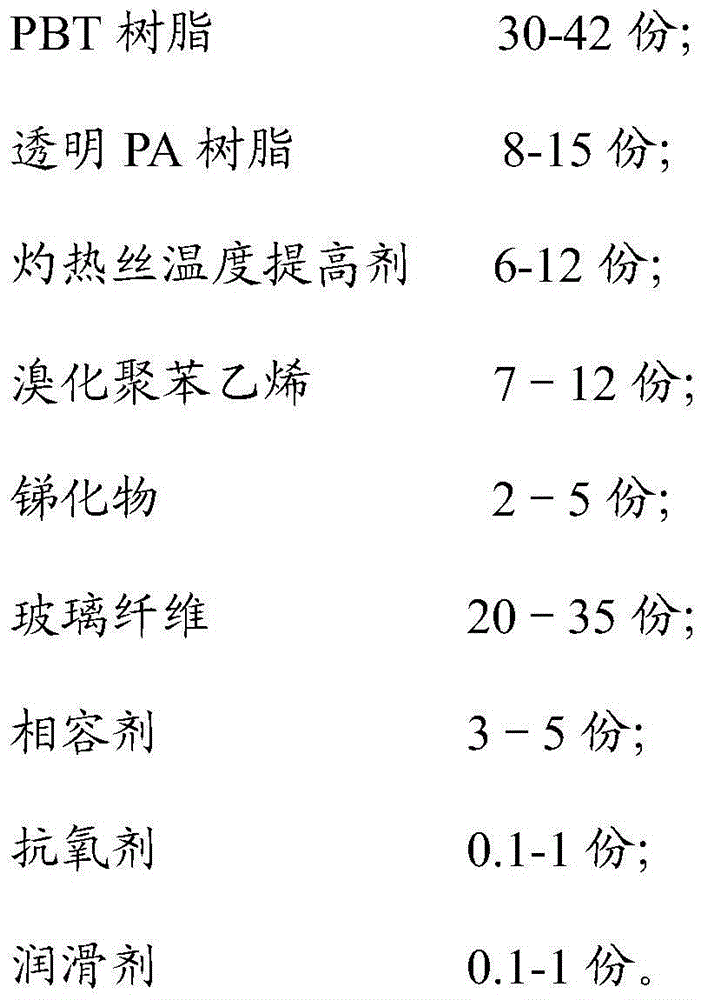

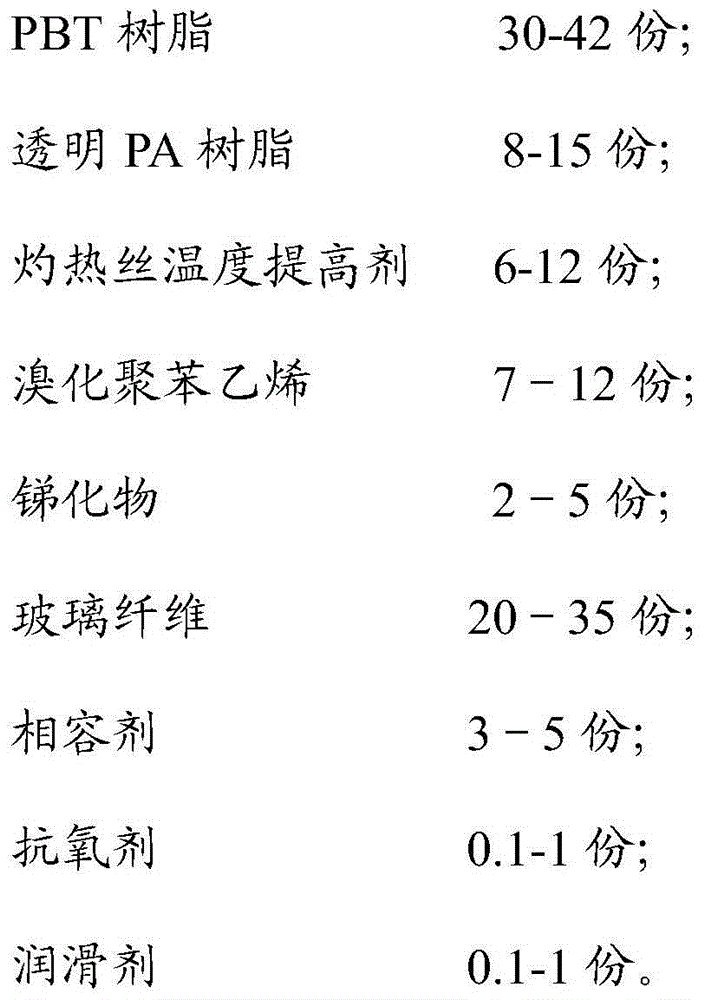

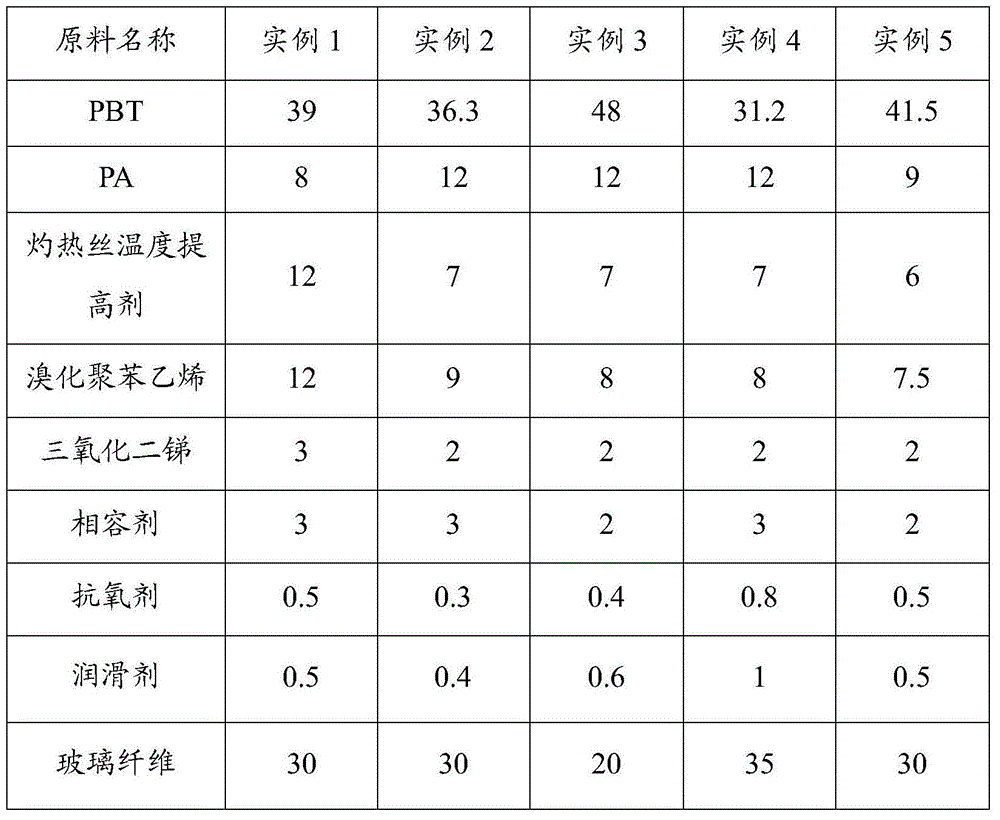

Flame-retardant PBT/PA alloy material and preparation method thereof

The invention discloses a flame-retardant PBT / PA alloy material and a preparation method thereof. The alloy material comprises the following raw materials in parts by mass: 30-42 parts of a PBT resin, 8-15 parts of a transparent PA resin, 6-12 parts of a glow wire temperature increasing agent, 7-12 parts of brominated polystyrene, 2-5 parts of antimonide, 20-35 parts of glass fibers, 3-5 parts of a compatilizer, 0.1-1 part of an antioxidant and 0.1-1 part of a lubricating agent. The PBT / PA alloy material disclosed by the invention is enhanced by the glass fibers and is excellent in mechanical property, a novel glow wire temperature increasing agent is adopted, the material can reach the level V0, high glow wire temperature and high CTI of the material can be obtained, and the alloy material can be used for preparing contactors and circuit breakers.

Owner:ANHUI KEJU NEW MATERIALS

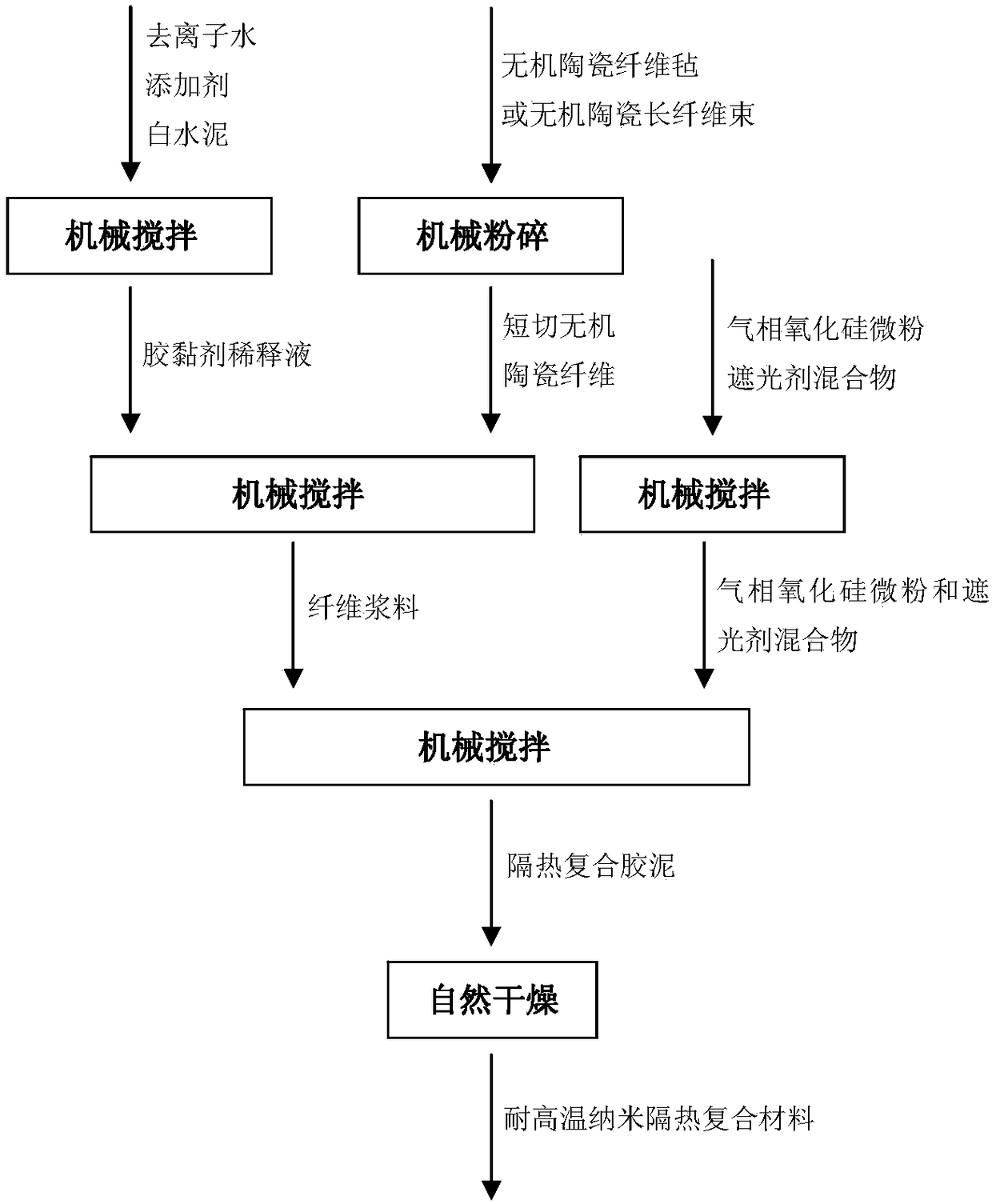

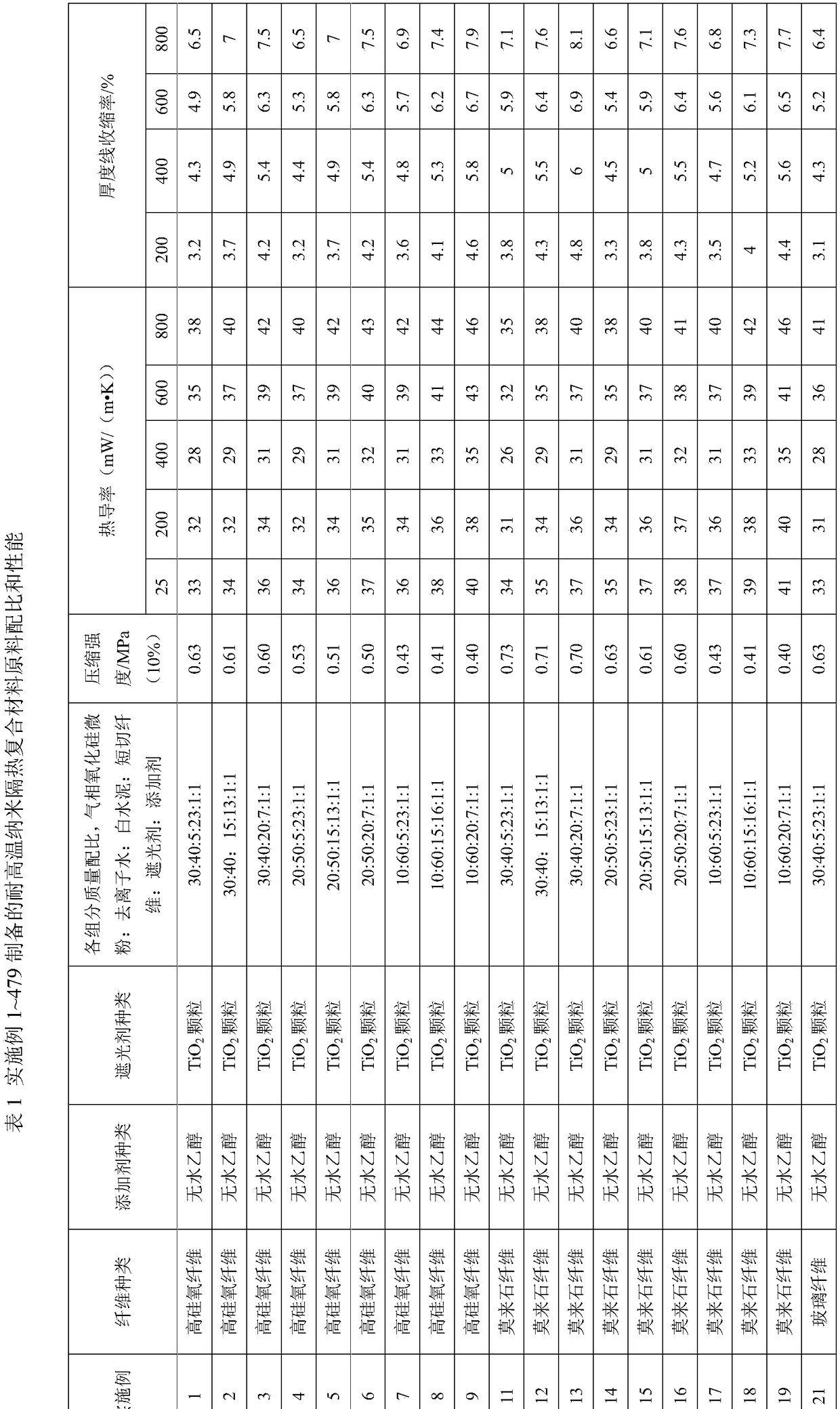

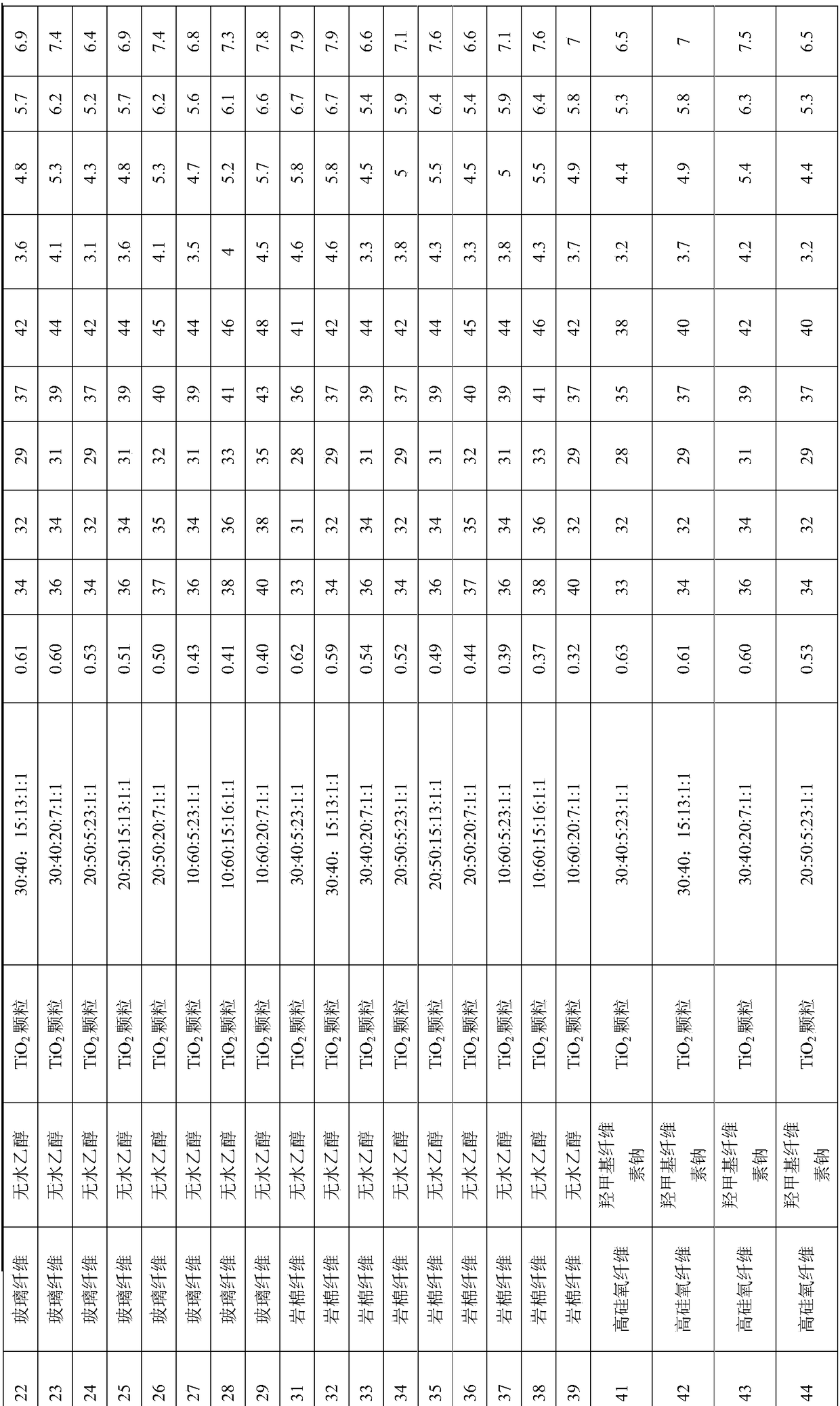

Casting-molded thermal-insulation nanocomposite with high-temperature resistance and preparation method of casting-molded thermal-insulation nanocomposite

InactiveCN108424069AReduce solid heat conductionInhibition of gaseous heat transferSolventBatch production

The invention discloses a casting-molded thermal-insulation nanocomposite with high-temperature resistance and a preparation method of the casting-molded thermal-insulation nanocomposite. The casting-molded thermal-insulation nanocomposite with high-temperature resistance is prepared from inorganic ceramic fiber, fumed silica micropowder, white cement, a solvent, an opacifying agent and an additive, wherein the inorganic ceramic fiber and the white cement are uniformly dispersed in a mixed solution of the solvent and the additive, fiber slurry is obtained, the fumed silica micropowder is uniformly mixed with the opacifying agent, a mixture is then uniformly mixed with the fiber slurry, thermal-insulation composite cement is obtained and dried naturally, and the casting-molded thermal-insulation nanocomposite with high-temperature resistance is obtained. The material has low thermal conductivity and good thermal insulation performance, temperature resistance and mechanical property; thepreparation method has the advantages of being low in cost, pollution-free, simple in process and convenient to construct and facilitating batch production.

Owner:NAT UNIV OF DEFENSE TECH

Boron carbide ceramic plate

The invention provides a boron carbide ceramic plate which is formed by splicing ceramic chips. Graphene highly dispersed in the ceramic chips has excellent electroconductive, heat-conducting and mechanical performance and is a two-dimensional material, so that mutual attraction among graphene layers can be remarkably lowered through surface modification to avoid aggregation; graphene has high dispersity and stability in some liquid media, so that a graphene solution stable in dispersion can be prepared; a graphene-ceramic mixed raw material having good implanting effect can be obtained by mixing graphene with ceramic matrix size; graphene plays a role in strengthening and toughening through mechanisms of ceramic interface pinning, crack deflection inducing, bifurcating and crack bridging,graphene breaking and extracting and energy absorbing.

Owner:ZHEJIANG LIGHT TOUGH COMPOSITE MATERIALS

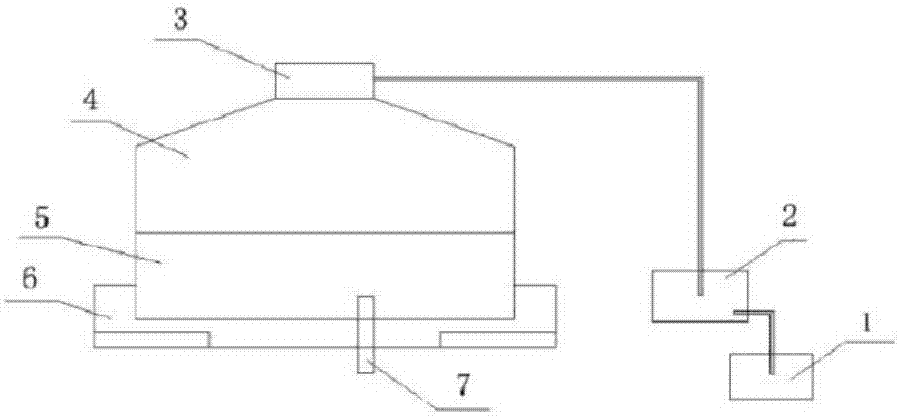

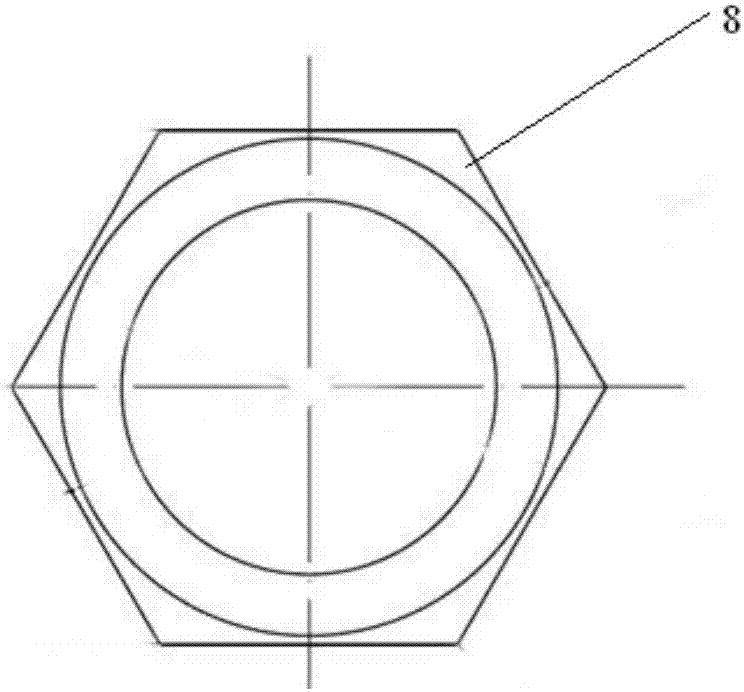

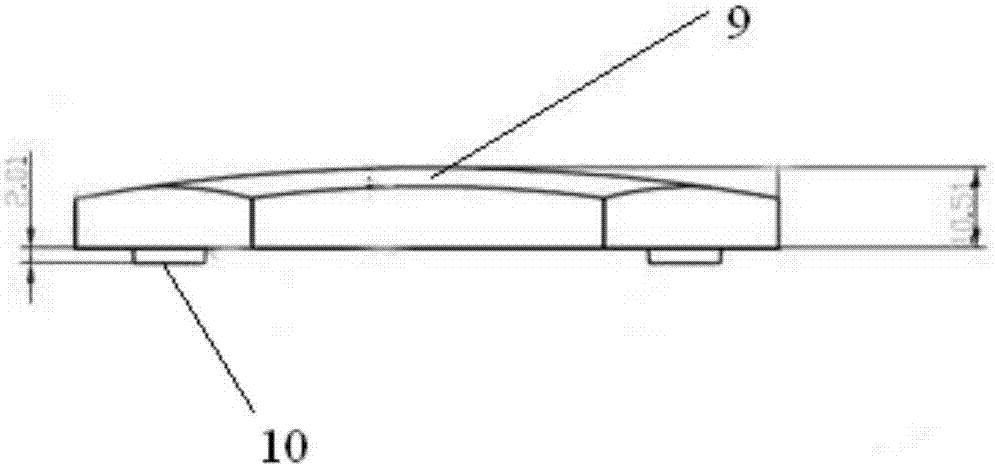

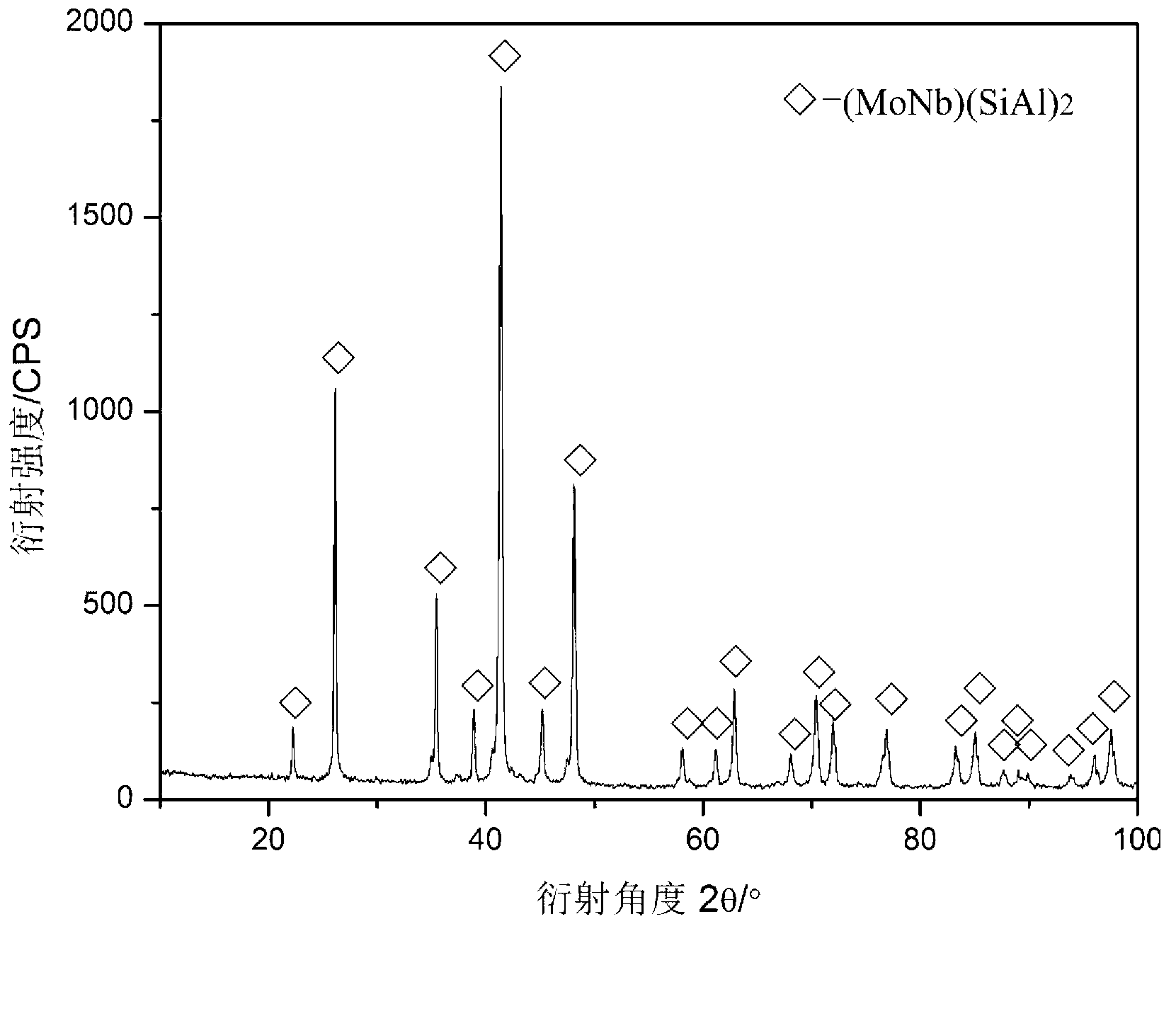

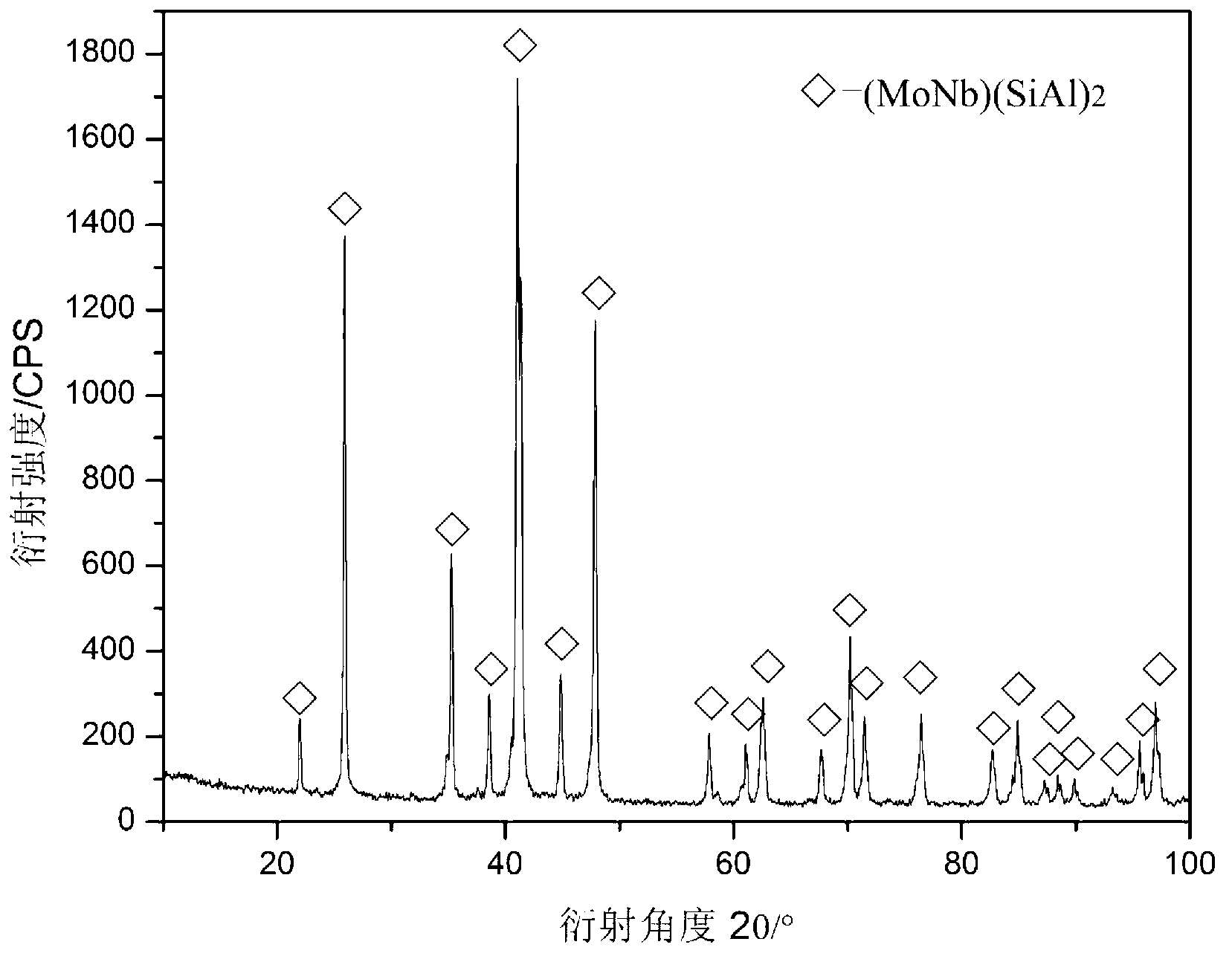

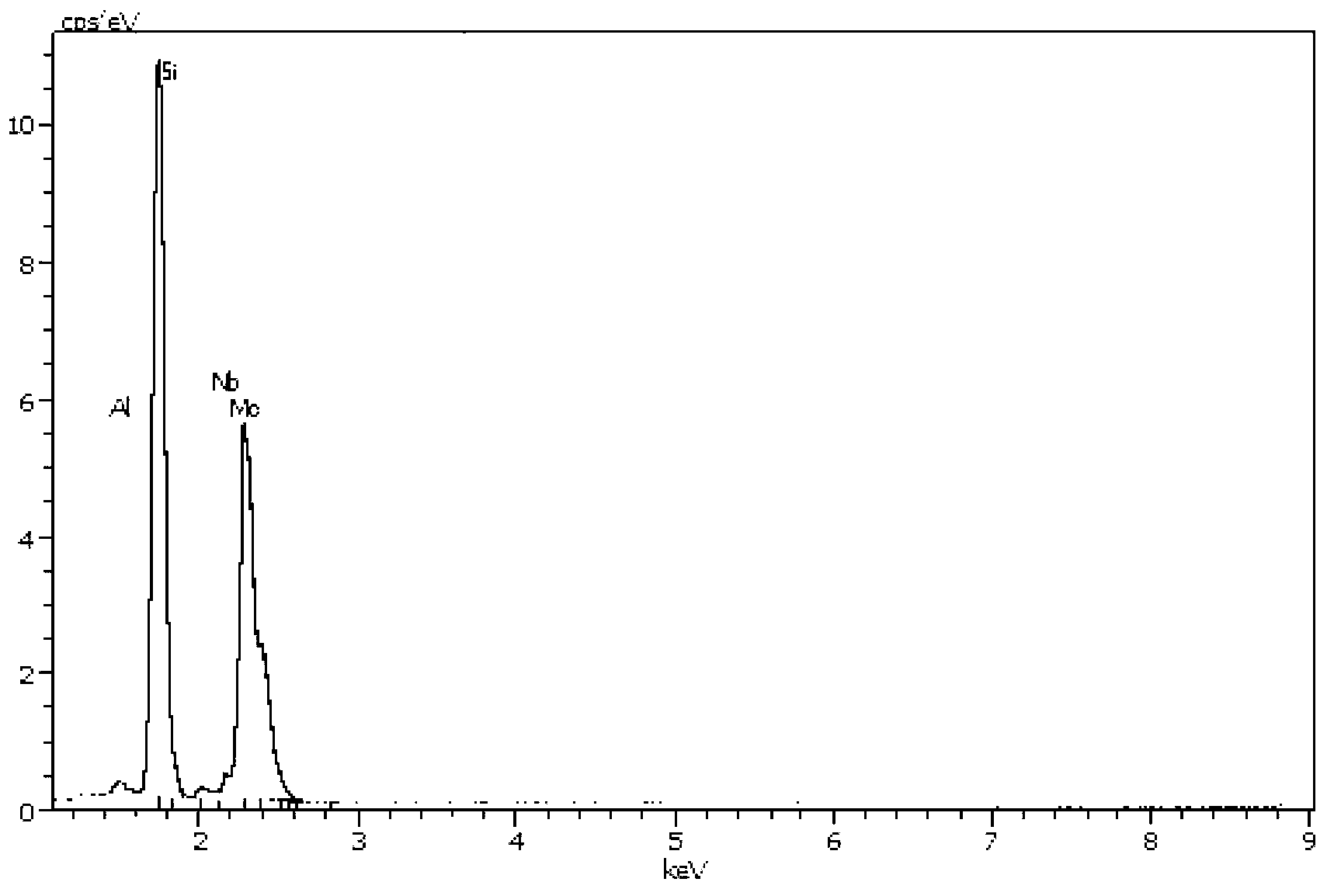

Niobium-aluminum alloying molybdenum disilicide material and preparation method thereof

The invention relates to a niobium-aluminum alloying molybdenum disilicide material and a preparation method thereof, and belongs to the technical field of intermetallic compounds. The chemical formula of the niobium-aluminum alloying molybdenum disilicide material is (Mo1-xNbx)(Si1-yAly)2, wherein X ranges from 0 to 0.15, and Y ranges from 0 to 0.15. The preparation method comprises the following steps of: uniformly mixing molybdenum, niobium, silicon and aluminum powder at a mole ratio of (28.305-33.3):(0-4.995):(56.695-66.7):(0-10.005); then pressing the mixture into a blank; and placing the blank into a combustion synthesis device, and igniting the blank in a protective atmosphere to synthesize the niobium-aluminum alloying molybdenum disilicide material. Compared with the prior art, the niobium-aluminum alloying molybdenum disilicide material disclosed by the invention can be synthesized through a one-step method and has the advantages of good high-temperature strength, simple process and equipment, time and energy conservation, low cost and less pollution.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com