SiC nanowire in-situ enhanced SiCf/SiC composite material and preparation method of SiC nanowire in-situ enhanced SiCf/SiC composite material

A technology of composite materials and nanowires, which is applied in the field of SiCf/SiC composite materials reinforced by SiC nanowires in situ and its preparation, which can solve the problems of reducing the reinforcement effect, winding into clusters or agglomeration, and unsatisfactory performance of composite materials, etc. , to achieve uniform distribution, increase the bonding strength, and improve the effect of fiber/matrix interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

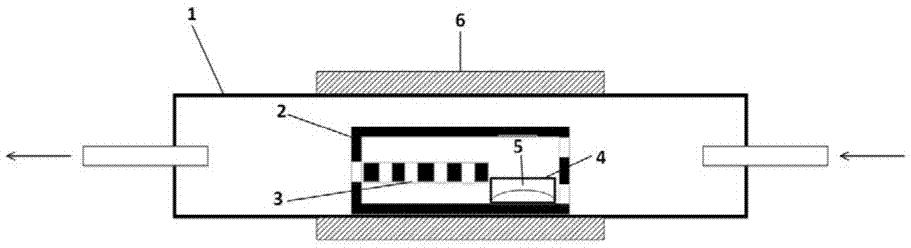

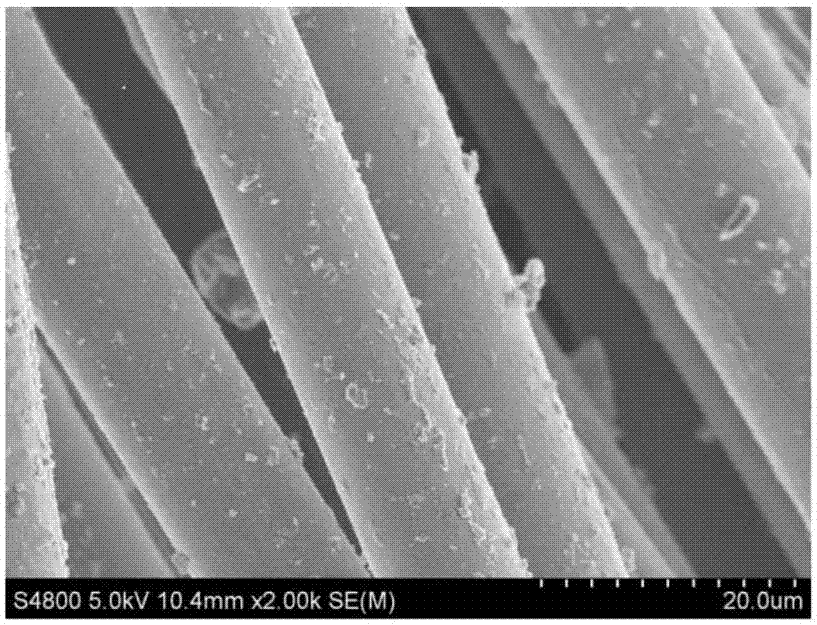

[0038] A kind of SiC nanowire in-situ reinforced SiC of the present invention f / SiC composite material, including SiC fiber preform, SiC nanowire and SiC ceramic matrix, the SiC nanowire grows in situ on the surface of the fiber matrix of the SiC fiber preform, and the SiC nanowires are intertwined into a network shape structure; the SiC ceramic matrix is filled in the pores of the SiC fiber preform.

[0039] In this embodiment, the SiC fiber prefabricated part is a three-dimensional four-way three-dimensional fabric woven by domestic KD-II SiC fibers, and the mass percentage of SiC nanowires is 4.2%. The mass percentage of the SiC ceramic matrix is 65%.

[0040] A kind of SiC nanowire in-situ reinforced SiC of the above-mentioned embodiment f / SiC composite material preparation method, comprises the following steps:

[0041] (1) Pretreatment: The prefabricated three-dimensional four-dimensional fabric of domestic KD-II SiC fiber is placed in a muffle furnace, heated t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com