Patents

Literature

79results about How to "Uniform internal temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for super macroporous polyurethane reticulated foam plastic

The present invention discloses a preparation method for a super macroporous polyurethane reticulated foam plastic. The method comprises the following steps: (1) preparing raw materials, wherein the raw materials comprise the following components: polyol, isocyanate, a silicone foam stabilizer, water, an auxiliary foaming agent, a cross-linking agent, a cell opening agent, a gel catalyst and a colorant; (2) storing the raw materials by a storage tank with a constant temperature freezing device; (3) concurrently adding the raw materials excluding the isocyanate to a mixing device, and uniformly stirring in 3 seconds to obtain a mixed material; (4) opening a isocyanate feeding valve, adding the isocyanate to the mixed material, carrying out high-speed stirring to obtain a mixture; (5) injecting the mixture into a foaming chamber to carry out foaming, closing the foaming chamber after 150-200 seconds, then opening a gas valve to carry out vacuum pumping; (6) removing the formed super macroporous polyurethane reticulated foam body with a reflection-like membrane from the foaming chamber, carrying out a reticulation treatment for the super macroporous polyurethane reticulated foam bodyto form the super macroporous polyurethane reticulated foam plastic. With the present invention, the super macroporous polyurethane reticulated foam plastic can be prepared.

Owner:深圳市国志汇富高分子材料股份有限公司

A preparation method of ultra-clean cross-linkable polyethylene insulating material for high-voltage cables

The invention discloses a method for preparing an ultraclean crosslinkable polyethylene insulation material of a high-voltage cable, relates to a method for preparing a crosslinkable polyethylene insulation material and solves the problems of low purity, easiness for generating gel and the phenomenon of pre-crosslinking, poor stability of product quality, low production efficiency and high cost of the current method for preparing the crosslinkable polyethylene insulation material. The method comprises the following steps of: taking raw materials; uniformly mixing polyvinyl resin and an antioxidant to obtain a material; filtering, pelletizing, dehydrating and drying the material and mixing the obtained material and a cross linking agent to obtain aggregates mixed with the cross linking agent; and feeding the aggregates into an adsorption material bin to homogenize the aggregates and cooling the obtain product to complete preparation of the crosslinkable polyethylene insulation material. In the method, the gel and the phenomenon of pre-crosslinking are not generated in the production process and equipment does not need to be shut down to be cleaned in the production, so that the production efficiency is increased and the cost is reduced. The number and the sizes of impurities in the crosslinkable polyethylene insulation material reach the level of an imported like product. Each kilogram of cable material contains less than 10 impurities of 70-100 mum and does not contain impurities of more than 100 mum. The ultraclean requirement is met. The product quality has long-term stability.

Owner:HARBIN UNIV OF SCI & TECH

Preparation method of ultra-smooth semiconductive shielding material for high-voltage crosslinked polyethylene insulated cable

The invention discloses a preparation method of an ultra-smooth semiconductive shielding material for a high-voltage crosslinked polyethylene insulated cable, which relates to a preparation method of a semiconductive shielding material and is used for solving the problems that an extruding surface cannot meet the requirement of ultra-smoothness, gelation and pre-crosslinking are caused easily, and the quantity and sizes of impurities in the material cannot meet the standard requirements existing in the preparation of a semiconductive shielding material. The method comprises the following steps of: weighing raw materials; uniformly mixing polyethylene rein, an ethylene-vinyl acetate polymer, an antioxidant and conductive carbon black to obtain a material; filtering the material, pelletizing, dehydrating and drying the filtered material, and mixing with a crosslinking agent to obtain particles mixed with the crosslinking agent; and feeding into an absorption cabin for uniformizing, and cooling. In the invention, gelation and pre-crosslinking are not caused in the production process; the quantity and sizes of impurities in the semiconductive shielding material reach the levels of imported products of the same type; every kilogram of cable materials contain less than ten impurities of 70-100 mum; the requirement of ultra-cleanliness is met; and the extruding surface meets the requirement of ultra-smoothness.

Owner:HARBIN UNIV OF SCI & TECH

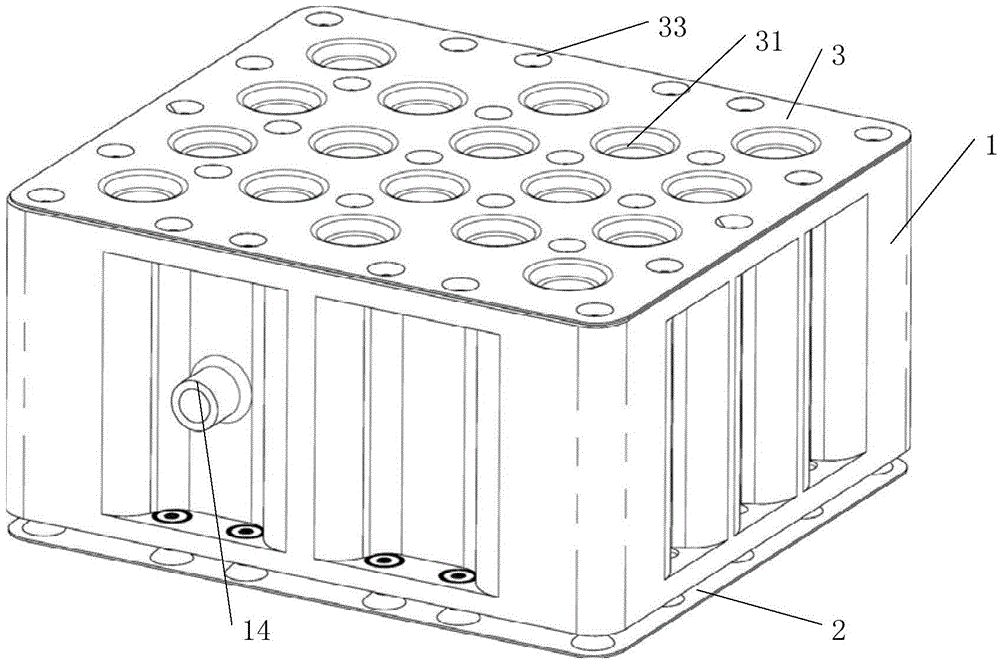

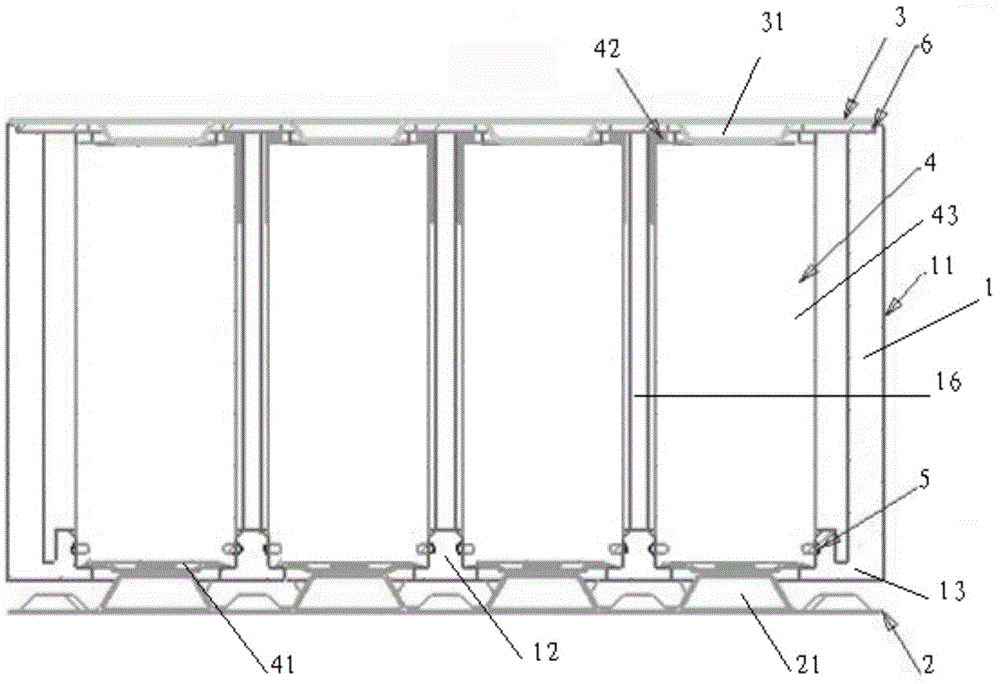

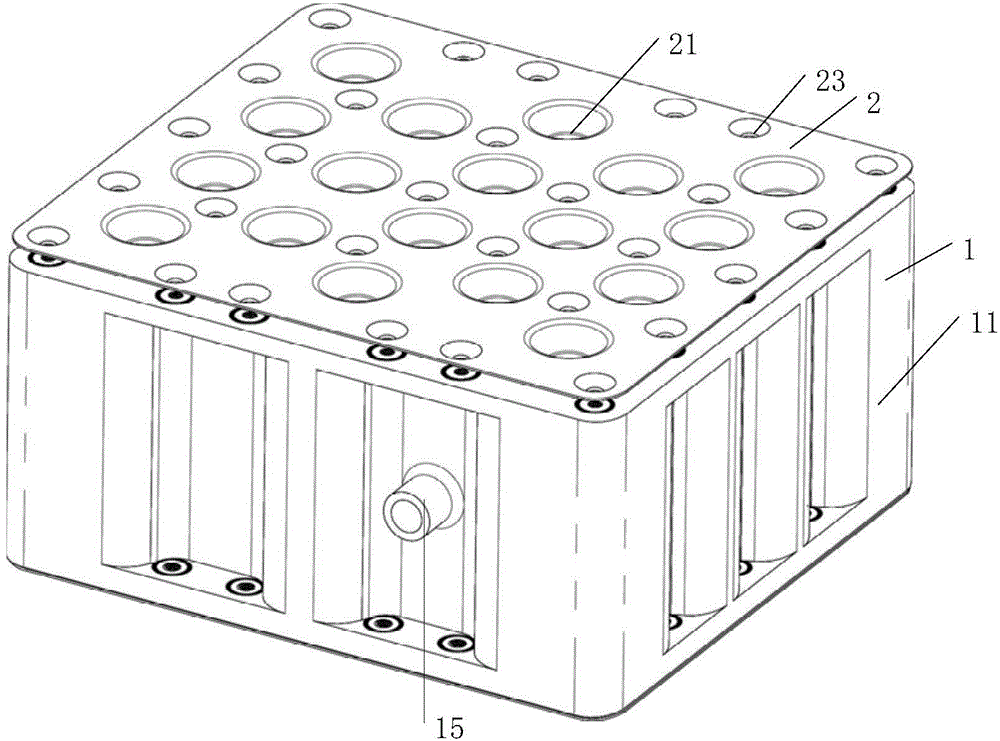

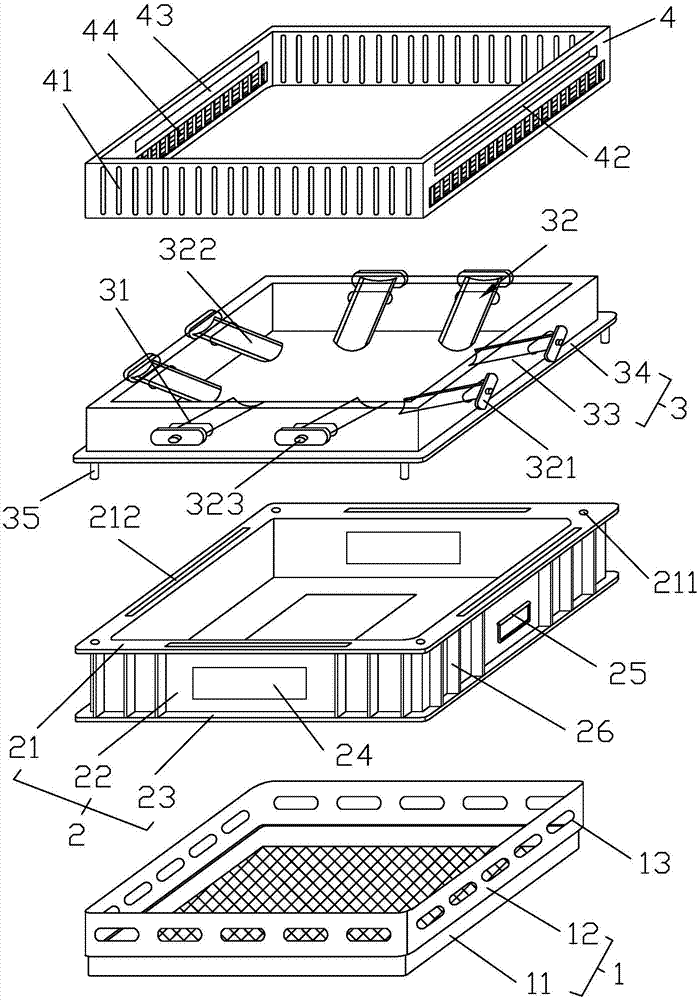

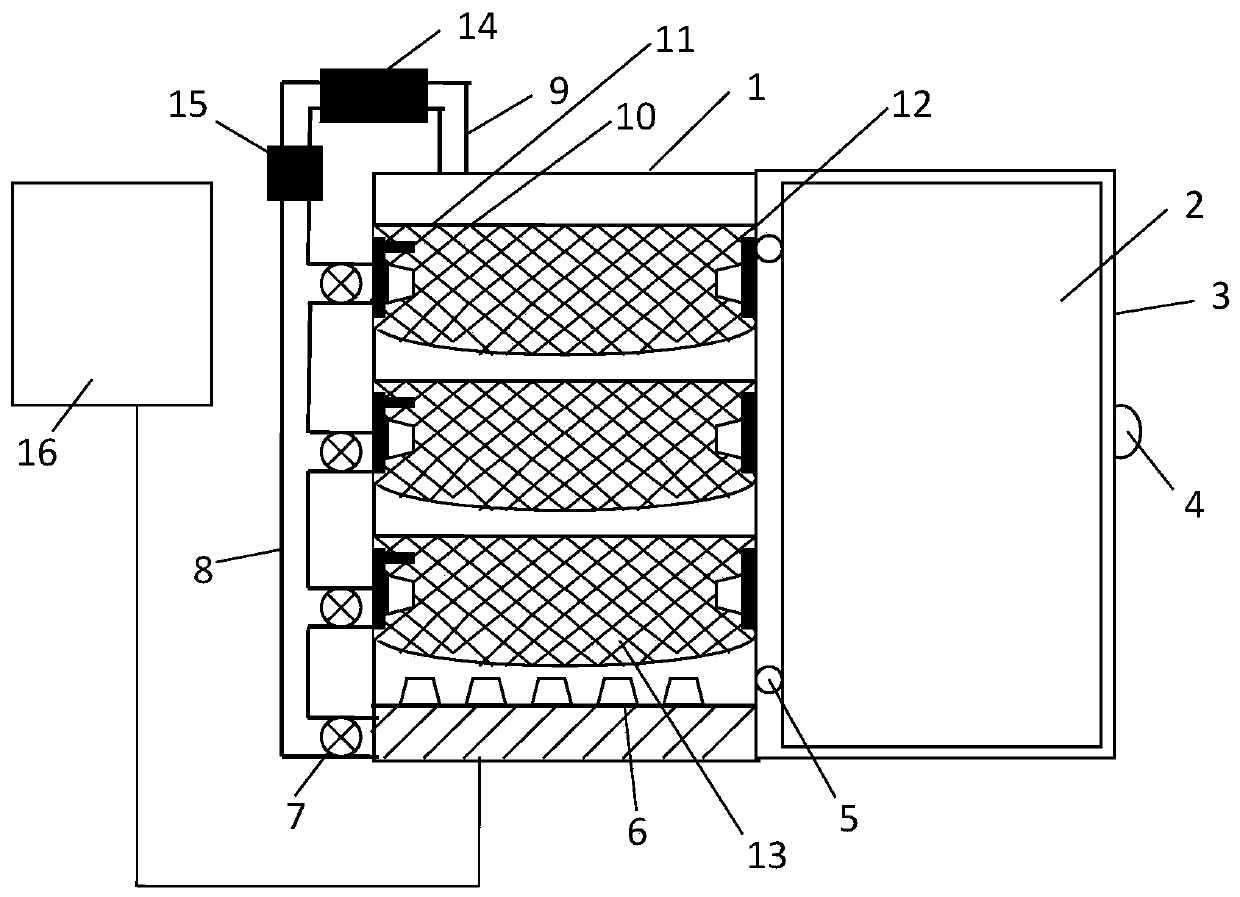

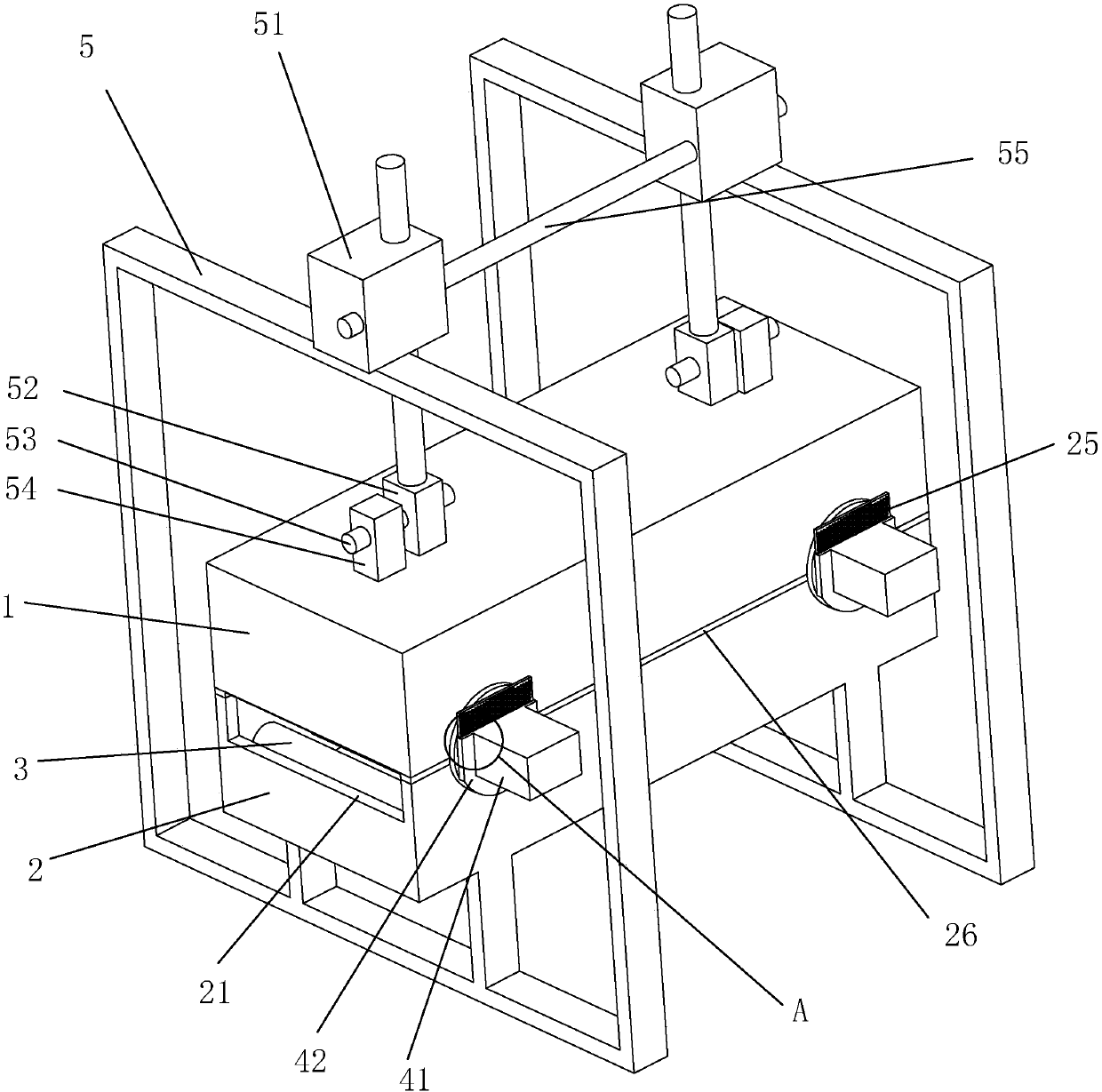

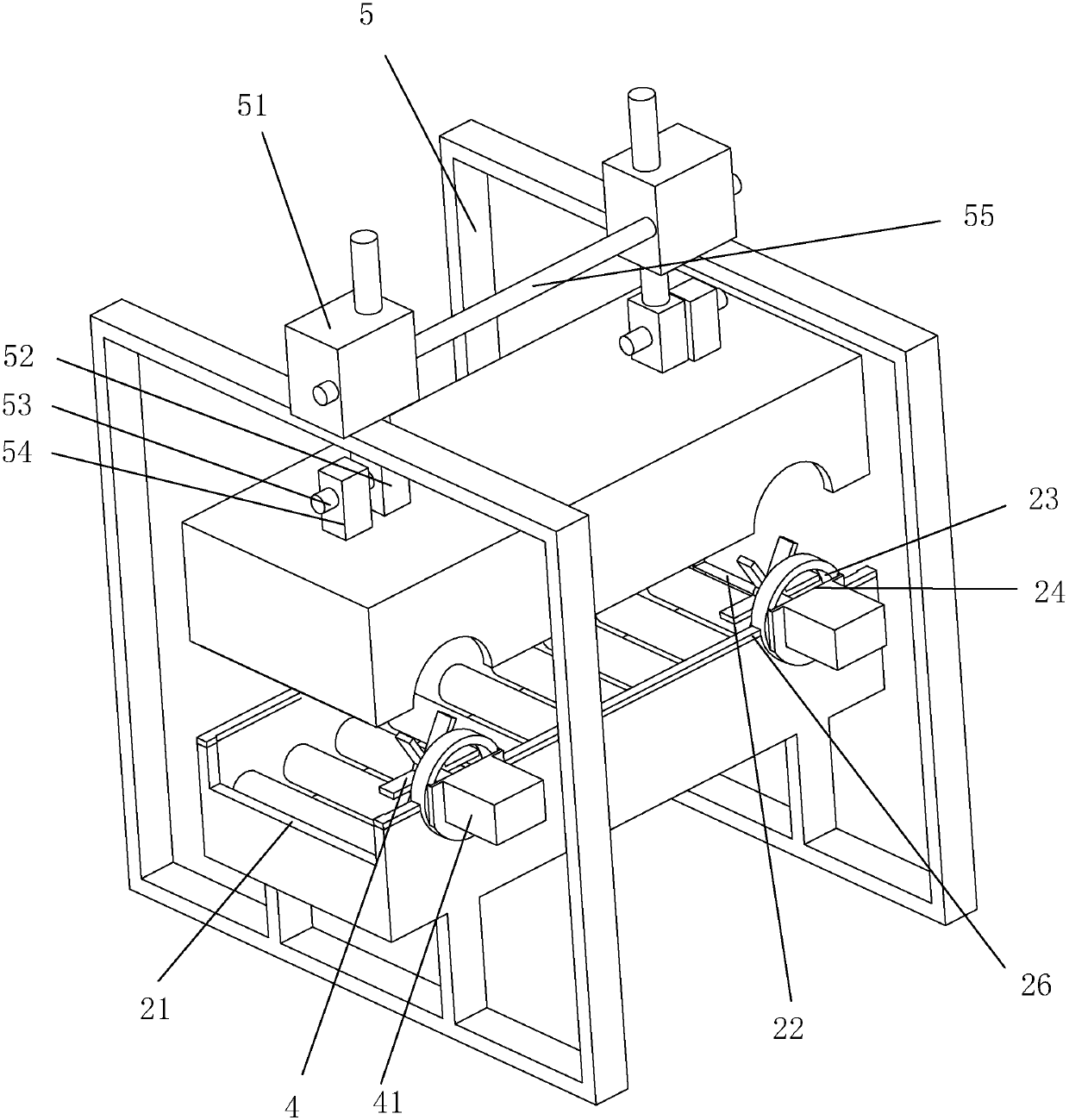

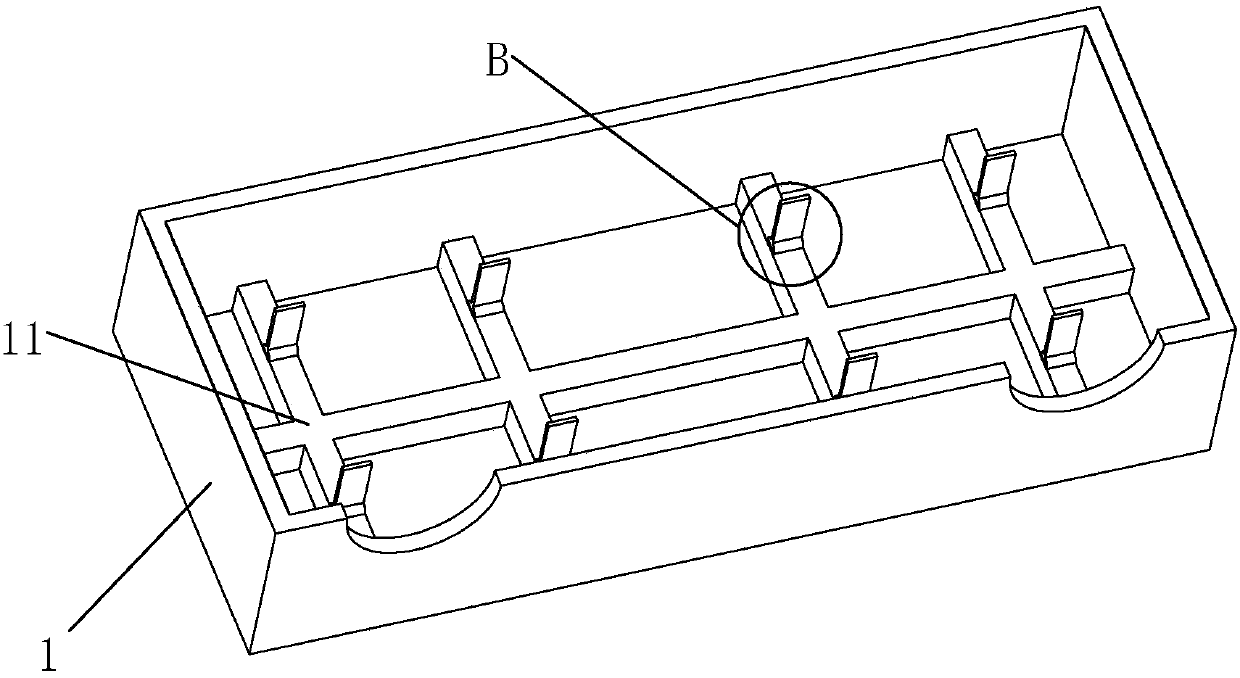

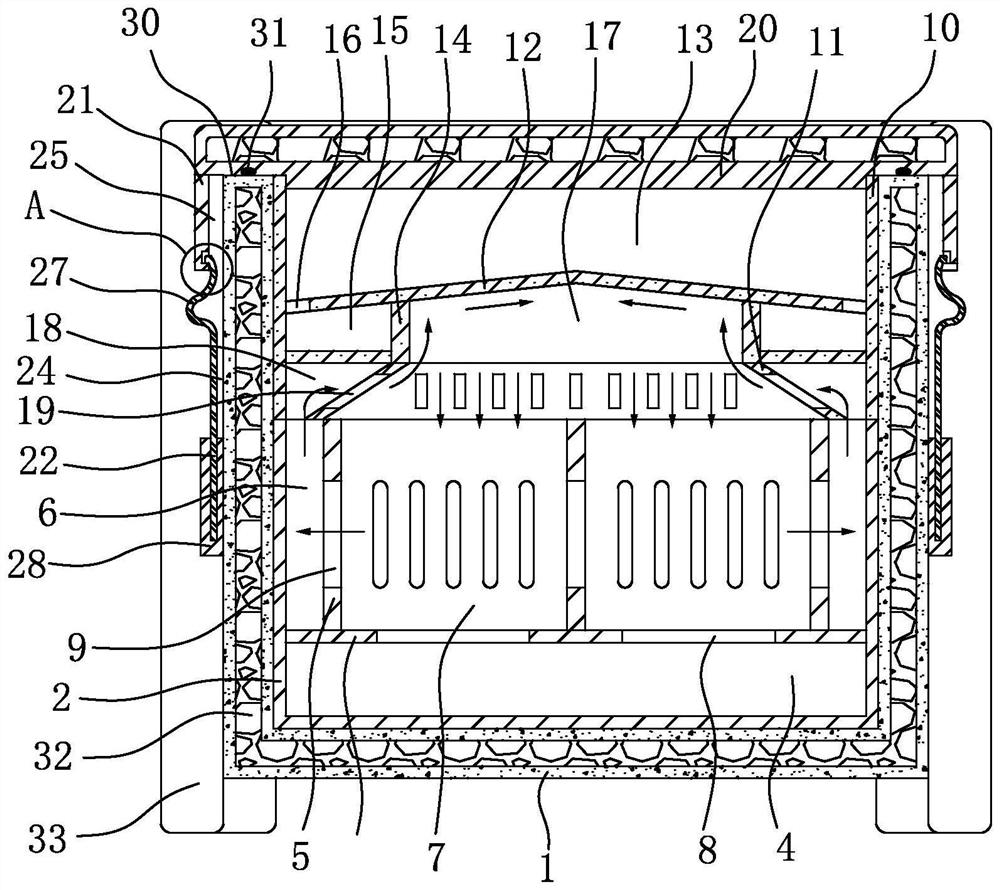

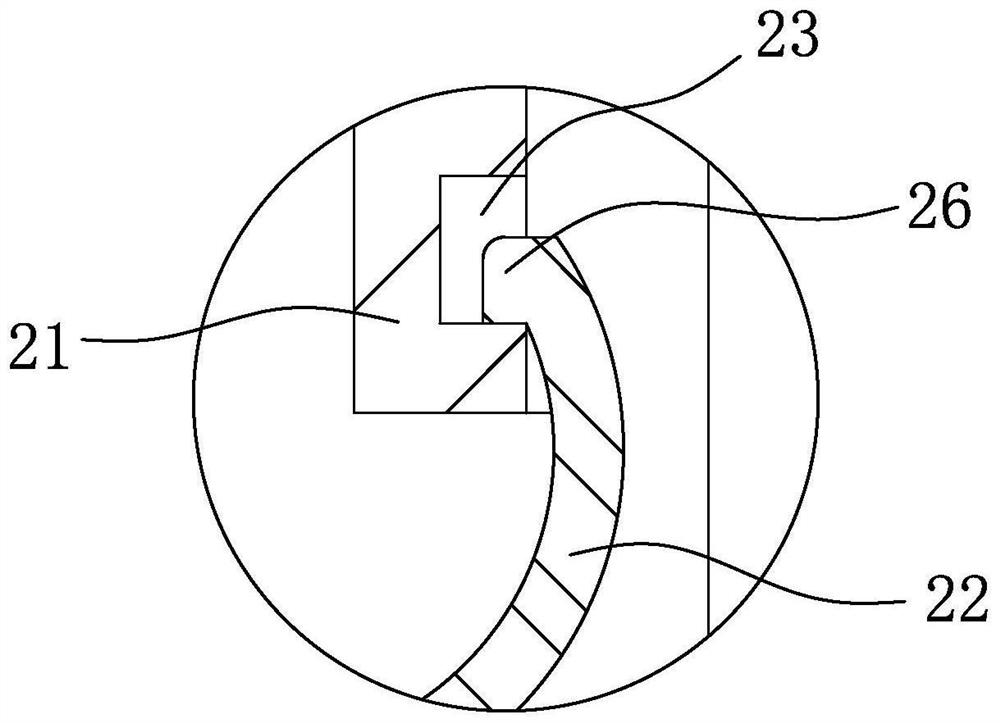

Battery module

ActiveCN104993186AUniform internal temperatureImprove cycle performance and service lifeBattery isolationSecondary cellsElectrical energy storageEngineering

The invention belongs to the technical field of electric energy storage, and particularly relates to a battery module which includes a bracket, a first guide plate, a second guide plate and at least one battery, wherein each battery includes a first end surface provided with a first electrode, a second end surface provided with a second electrode, and a column body positioned between the first end surface and the second end surface; the bracket includes a closed side wall arranged in a surrounding manner, and a bottom wall provided with at least one mounting base; one upright battery is accommodated in each mounting base; the bottom of each mounting base is hollow to expose out the first electrode of the corresponding battery; the first guide plate is fixed at the bottom of the bracket and conducted with the first electrode of the at least one battery in a contact manner; the second guide plate is fixed at the top of the bracket and conducted with the second electrode of the at least one battery in a contact manner; insulating and heat conducting liquid is accommodated in the space between the bracket and the at least one battery, and is in contact with the column body of the at least one battery. The temperature control performance of the battery module is excellent.

Owner:DALIAN CBAK POWER BATTERY CO LTD

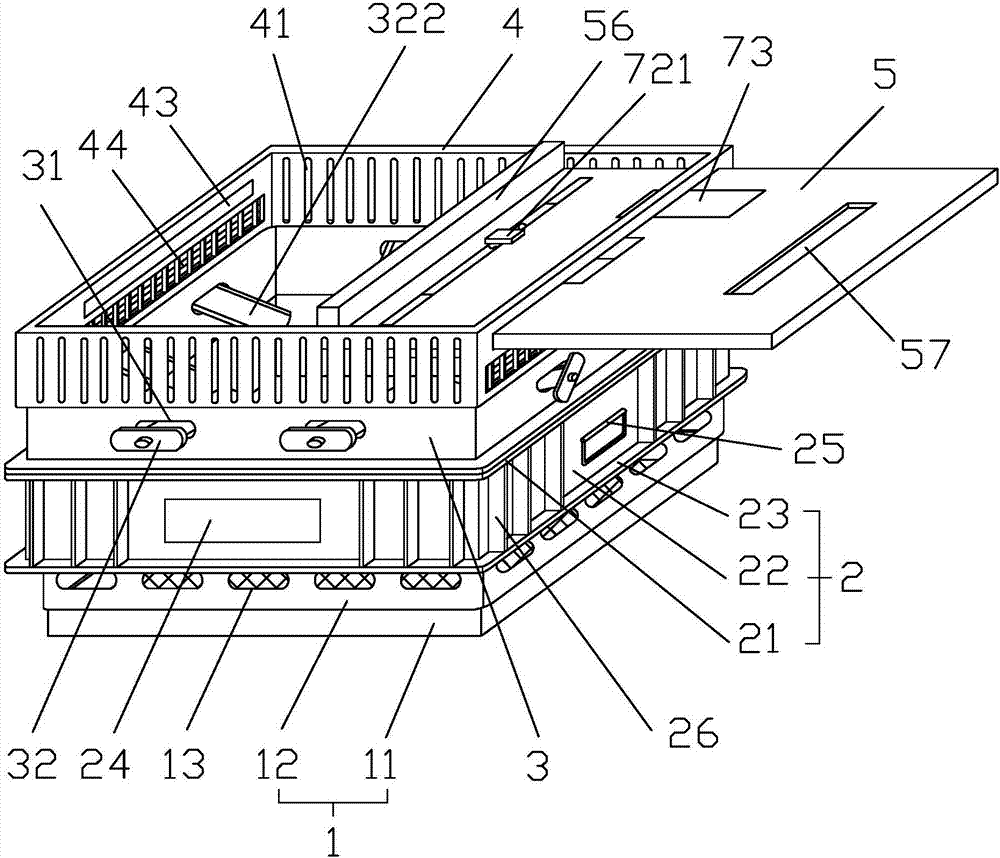

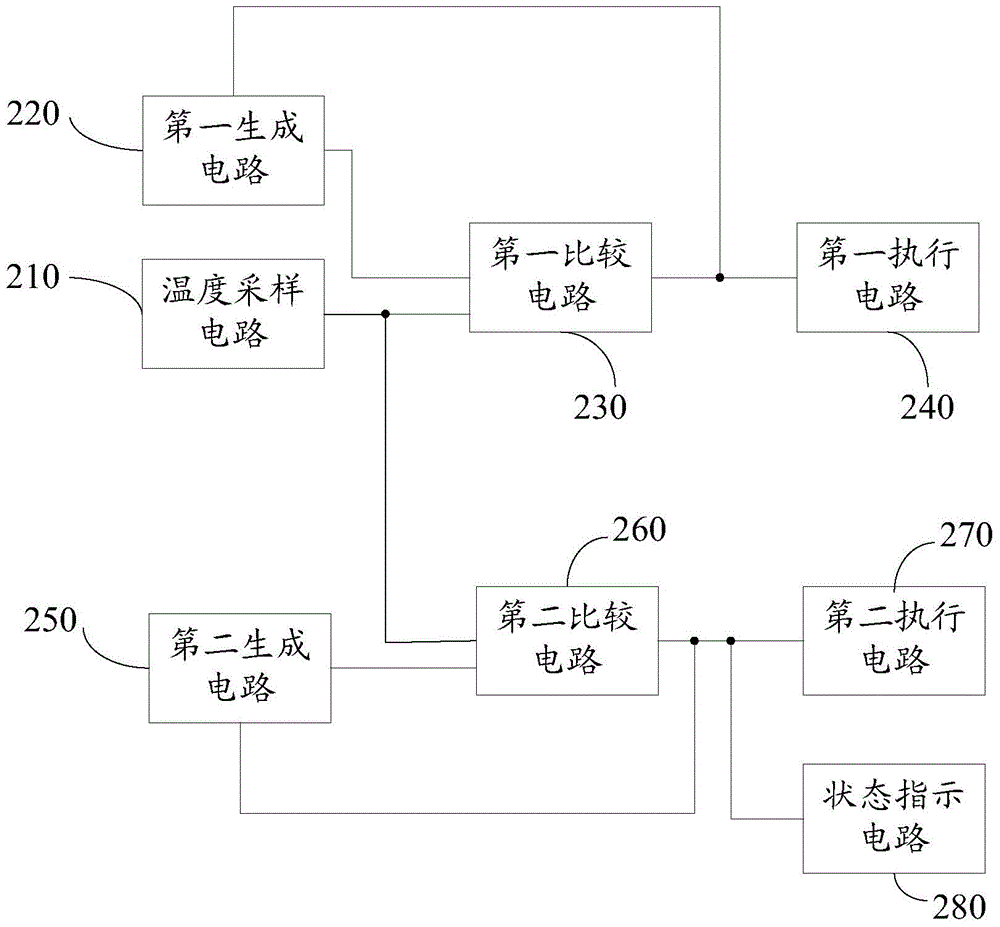

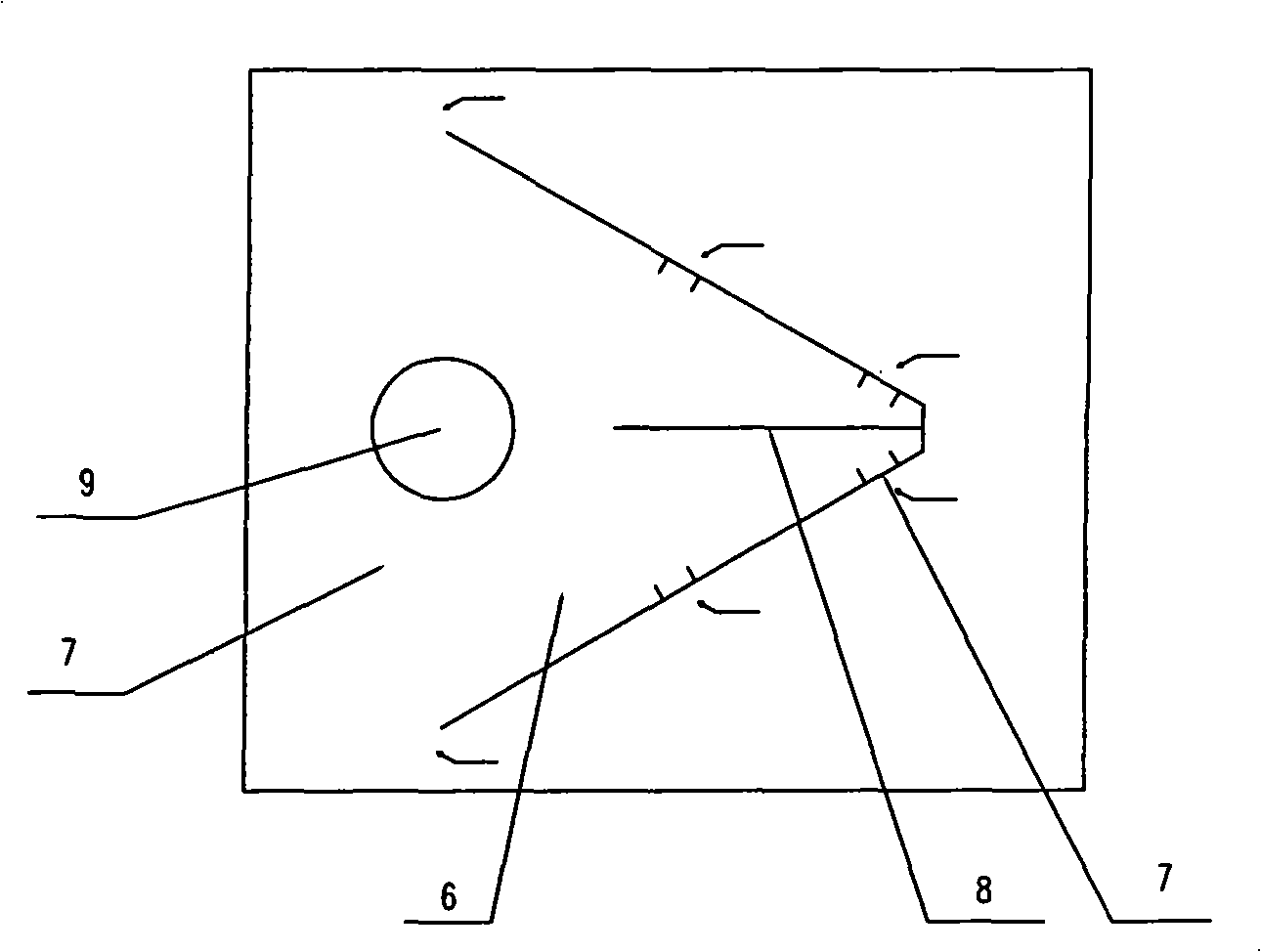

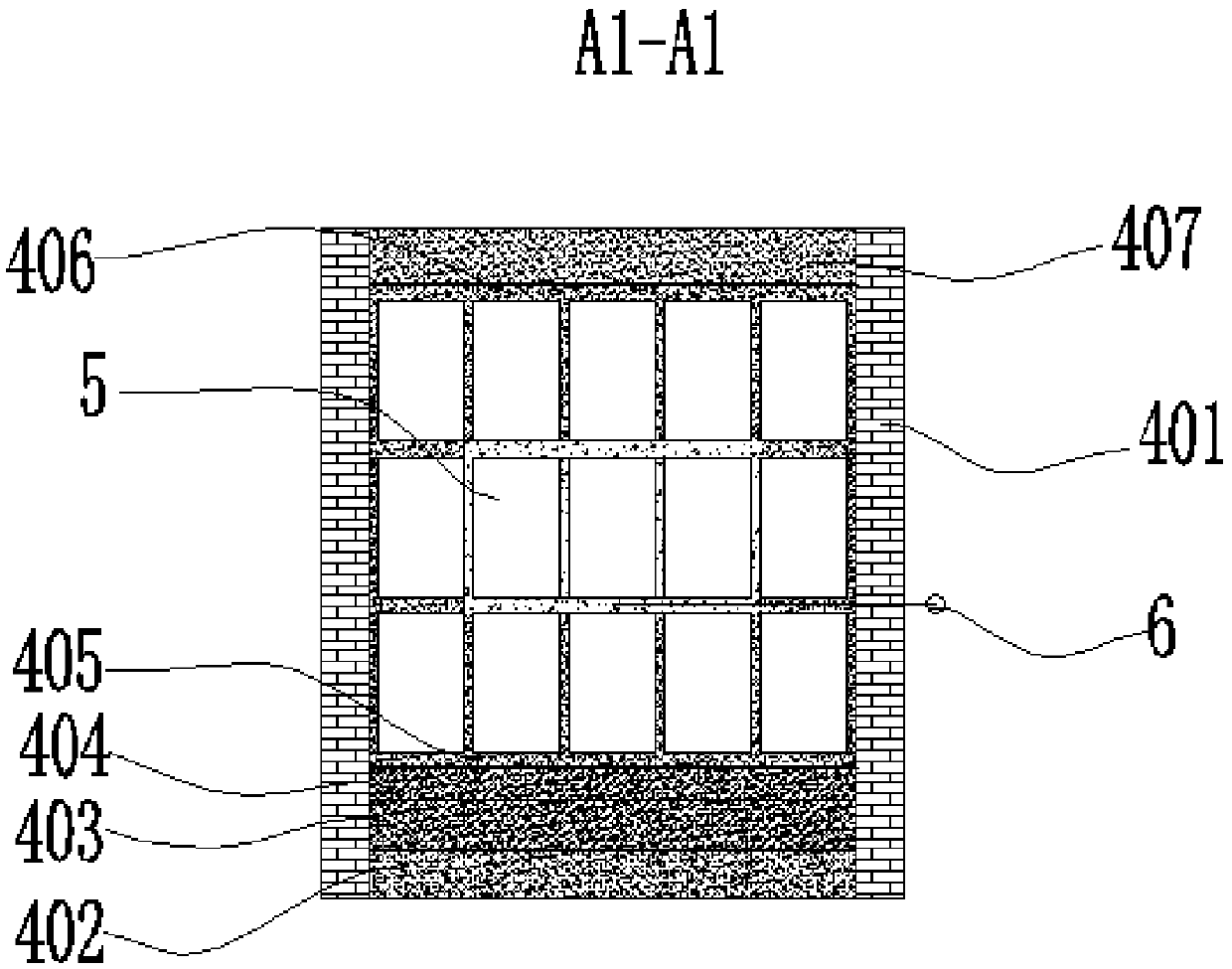

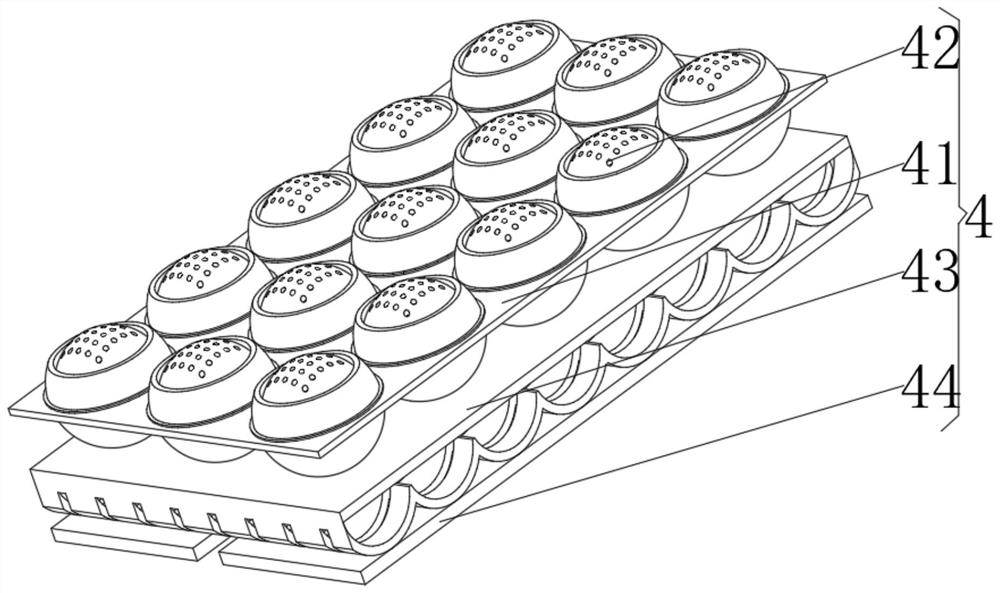

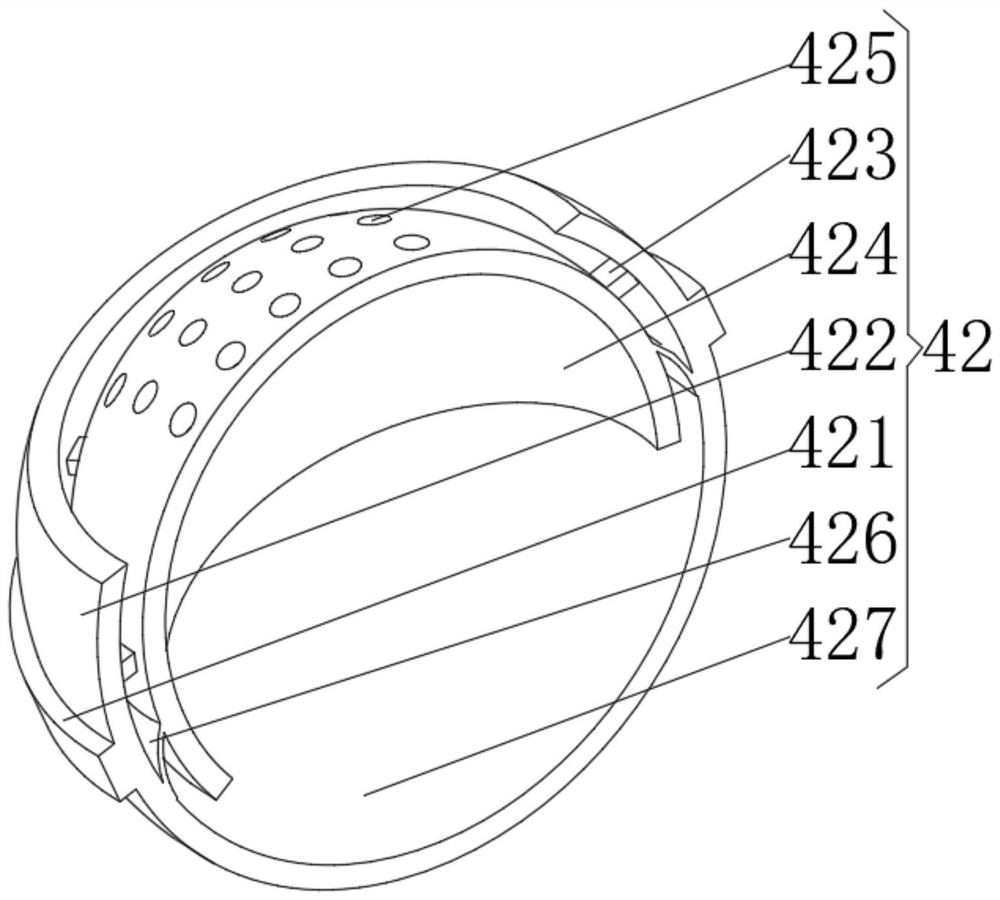

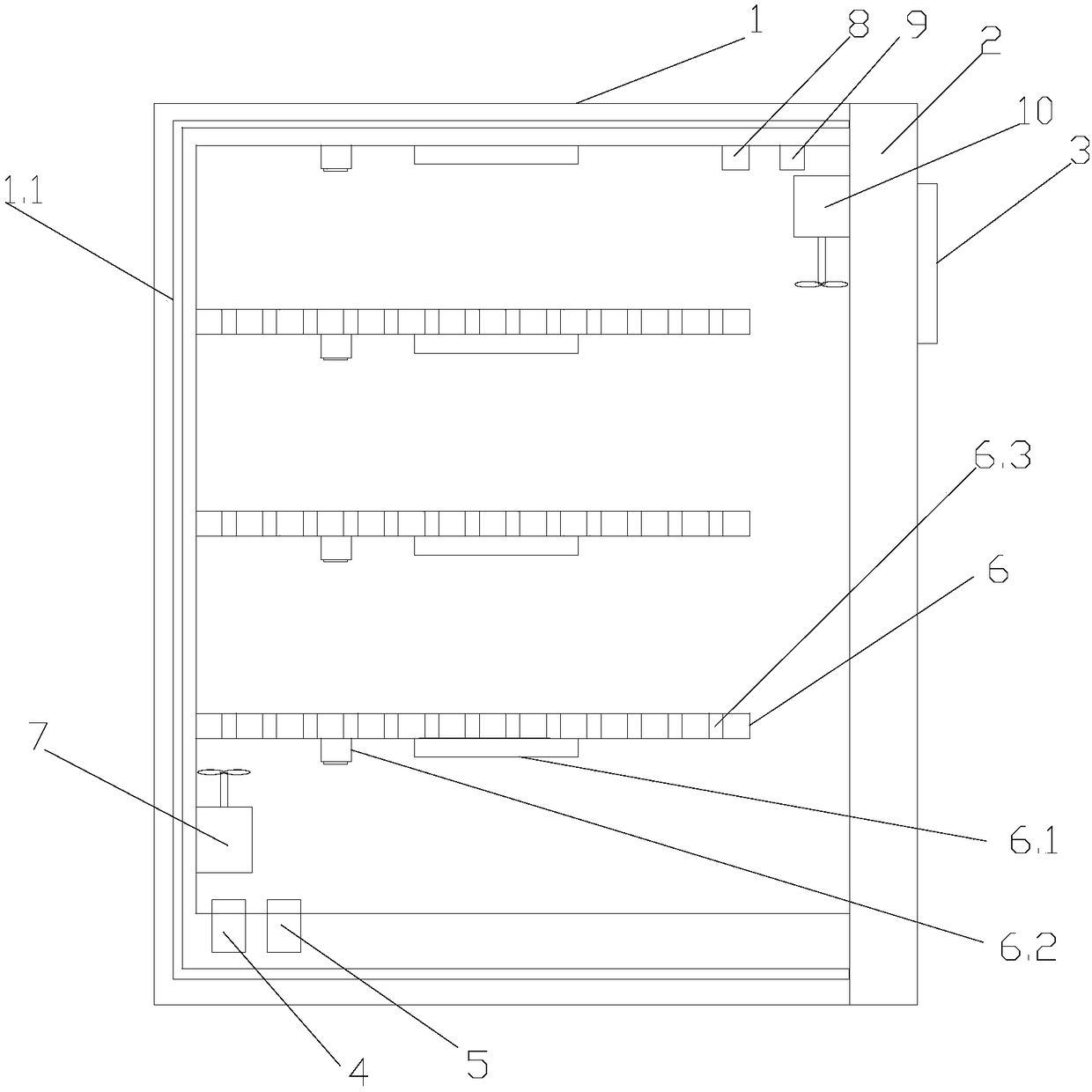

Constant-temperature silkworm frame applied to bombyx mori cocooning

ActiveCN106922630AStable structureIncreased load-bearing capacityAnimal husbandryThermal insulationBombyx mori

The invention mainly discloses a constant-temperature silkworm frame applied to bombyx mori cocooning. The constant-temperature silkworm frame comprises a bottom frame, a silkworm breeding frame, a feeding frame, a ventilating frame and a top board which are arranged from bottom to top. A first heating device is disposed in the silkworm breeding frame. The first heating device comprises a thermal insulation board, a heating plate, a warming plate and a temperature-sensitive plate. Side portions of the feeding frame are provided with feeding holes, and a feeding plate is disposed in each feeding hole. Front and back sides of the ventilating frame are uniformly provided with air vents. An upper portion of the right side of the ventilating frame is provided with a slot. The top board is inserted into the slot to cover the ventilating frame. The top board is provided with a second heating device and a power supply device. The second heating device comprises a heating lamp, a temperature-sensitive rod, a display screen and an adjusting button. The heating lamp is installed at a lower surface of the top board. The temperature-sensitive rod is movably connected to the top board via a movable plate. Temperature of a silkworm breeding environment is strictly controlled, a good survival environment is provided for silkworms, survival rates of the silkworms are improved, feeding is convenient, permeability is good, cultivation space is large, breeding efficiency is high, and the constant-temperature silkworm frame is suitable for large-scale silkworm breeding.

Owner:SHENGZHOU MOSANG HI TECH CO LTD

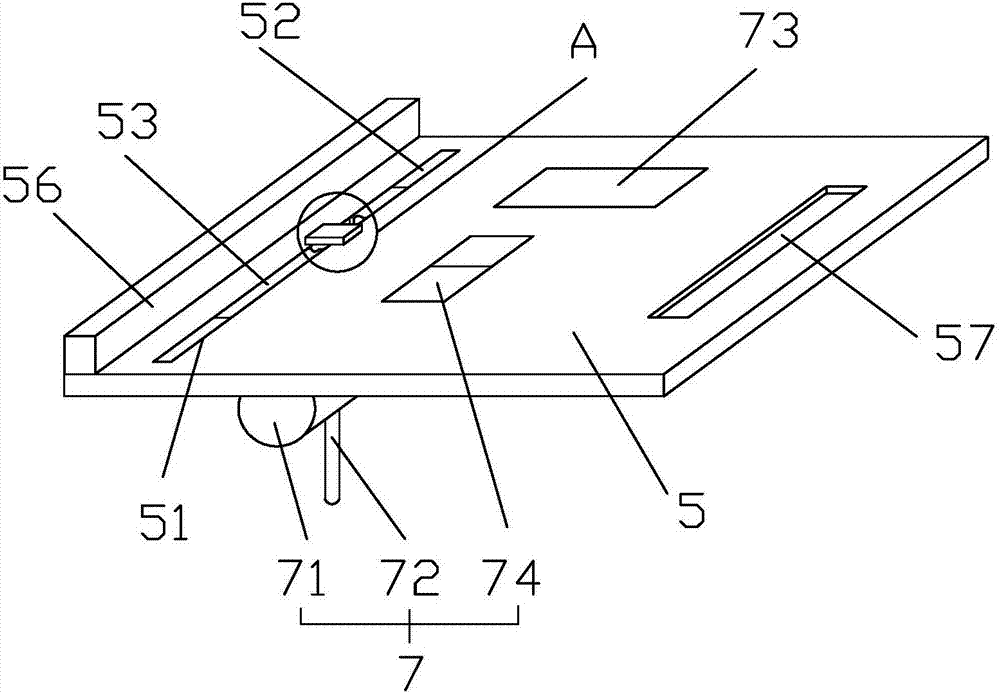

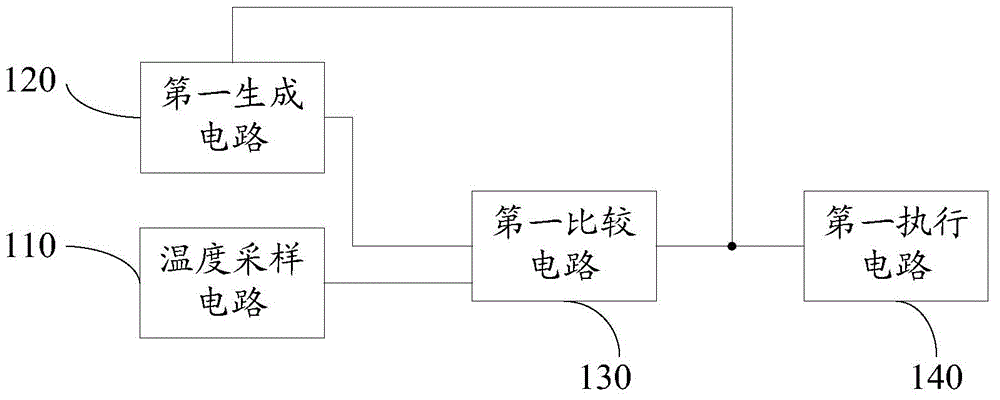

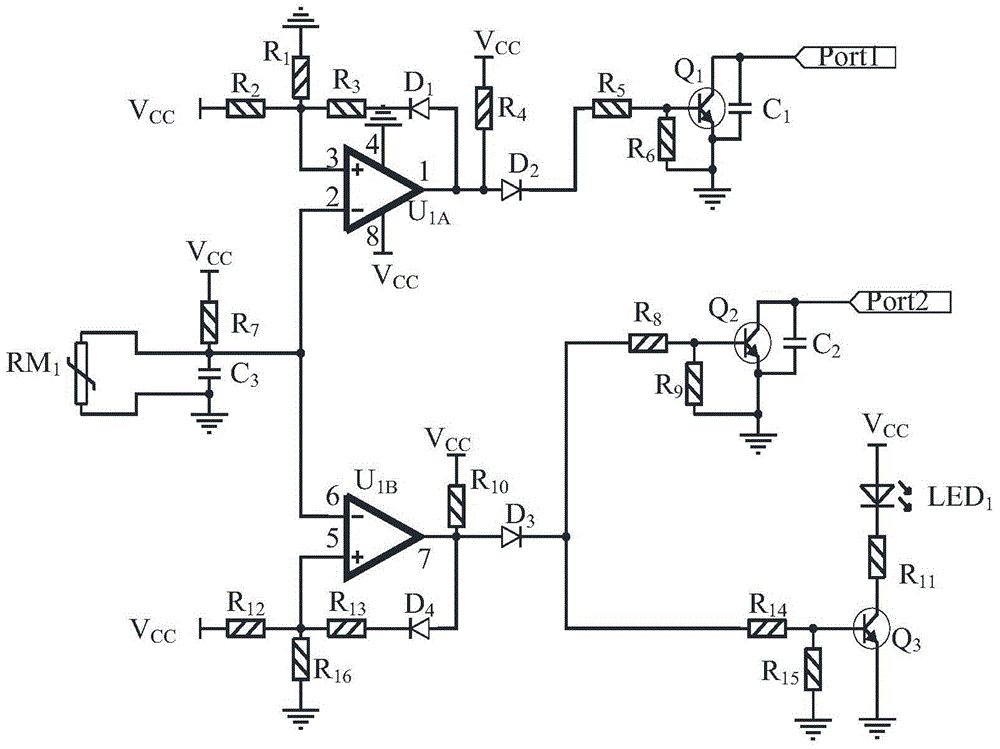

Temperature control circuit and temperature control method

InactiveCN104965536AAchieve temperature controlUniform internal temperatureTemperature control using electric meansTemperature controlEngineering

The invention relates to a temperature control circuit. The temperature control circuit is used for control of a temperature of a power device. The temperature control circuit comprises a temperature sampling circuit used for real-time sampling of an internal temperature of a power device and output of the sampled value, a first generation circuit used for generating a first protection parameter, a first comparison circuit used for generating a corresponding adjusting signal according to a magnitude relationship of a sampling value and the value of the first protection parameter, a first generation circuit used for changing and outputting the value of the first protection parameter when the adjusting signal changes, and a first execution circuit used for adjusting the work current of the power device according to the adjusting signal to achieve temperature control of the power device. The value of the first protection parameter is a first protection threshold or a second protection threshold. The temperature control circuit can ensure that the power device has a high load succession rate and meets usage requirements of users. The invention also relates to a temperature control method.

Owner:SHANGHAI HUGONG ELECTRIC WELDING MACHINE MFG

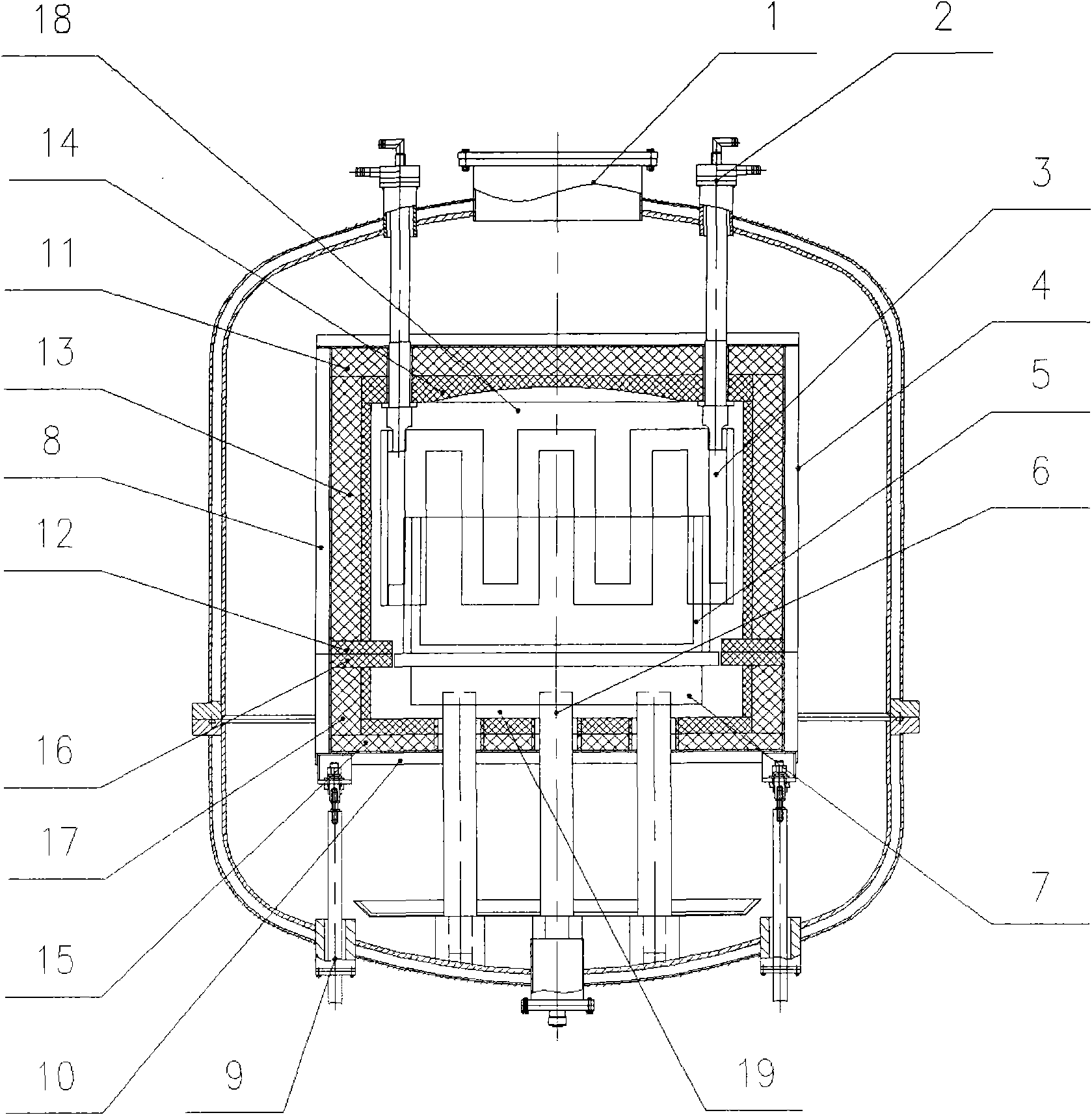

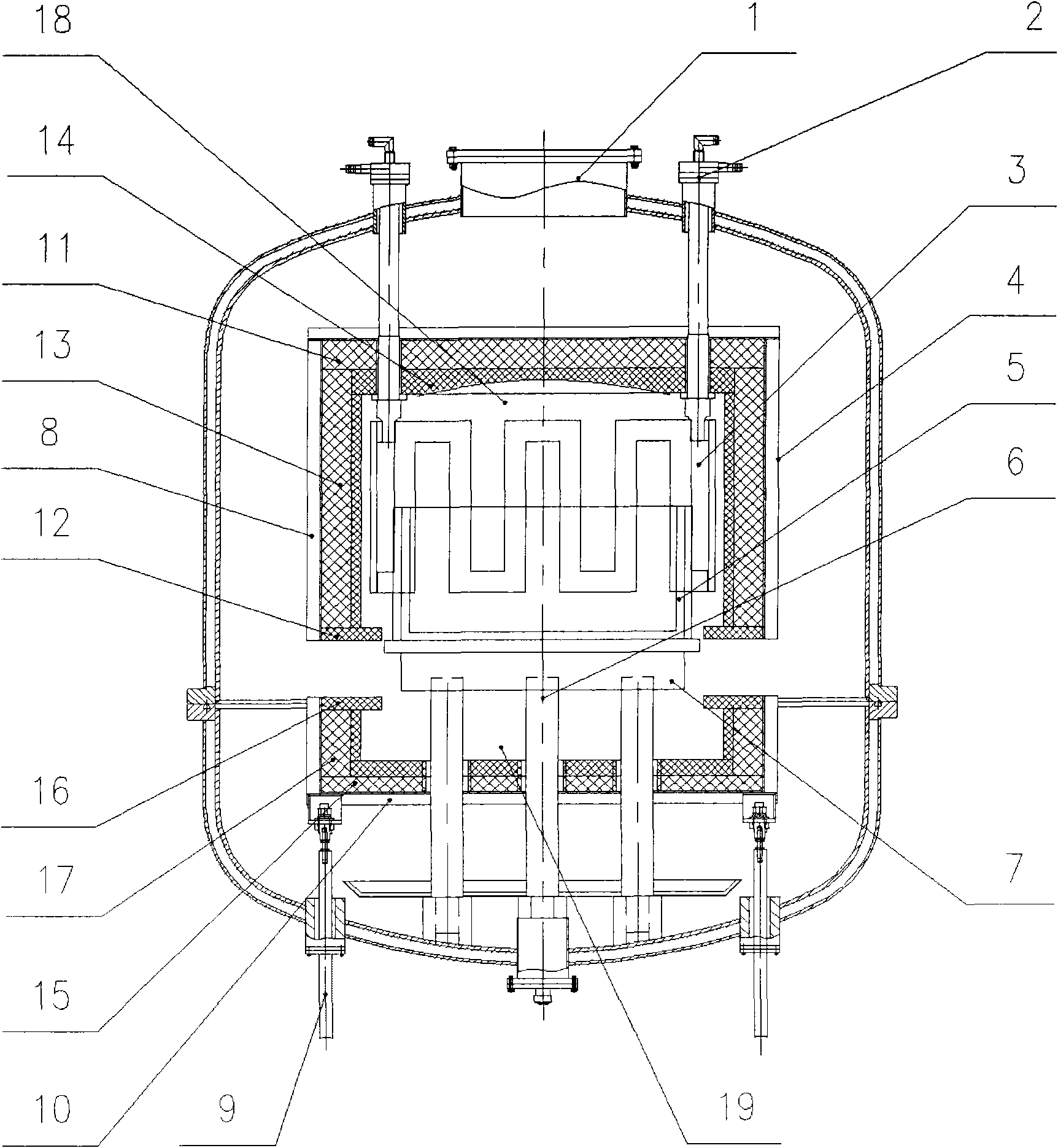

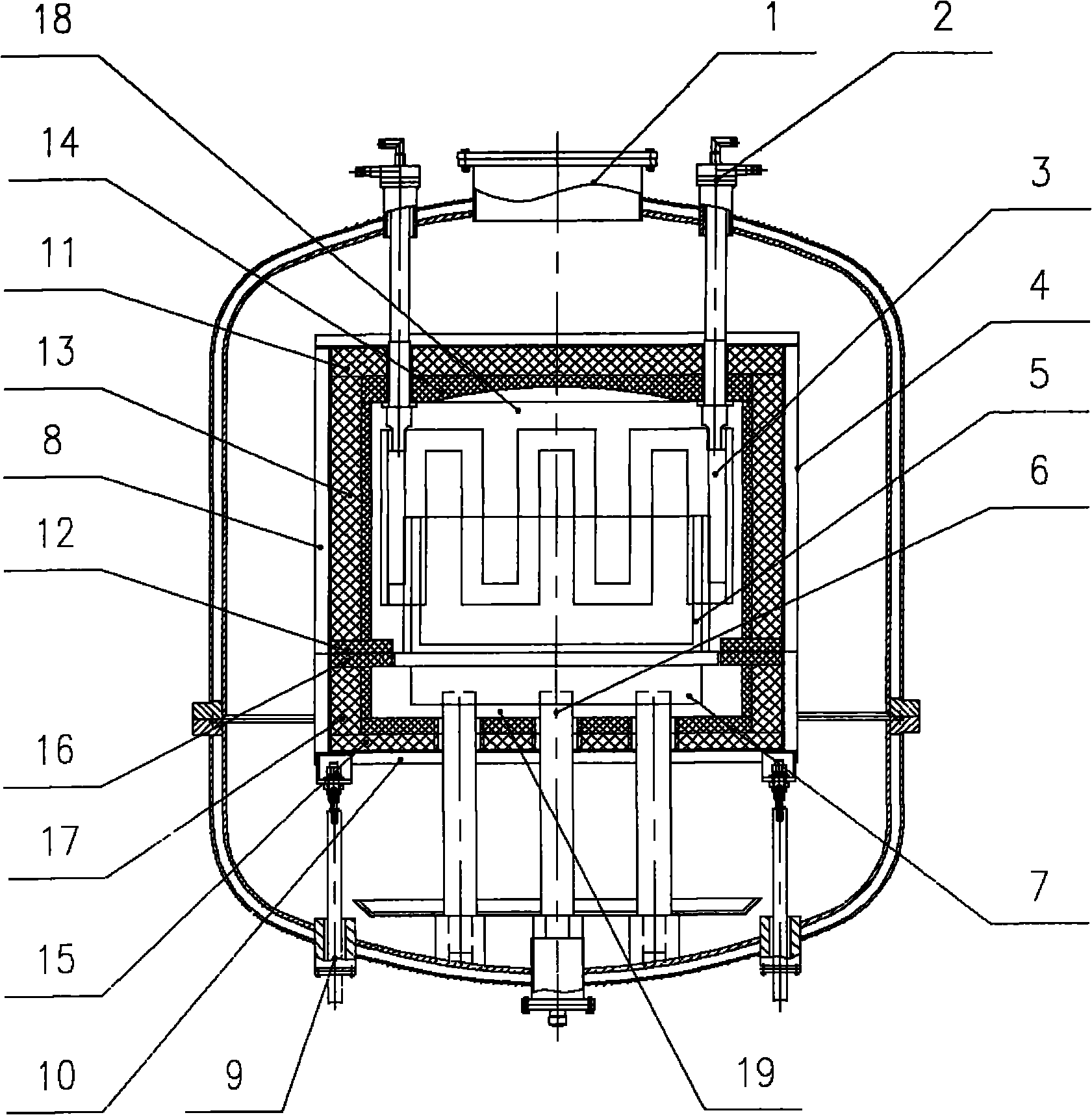

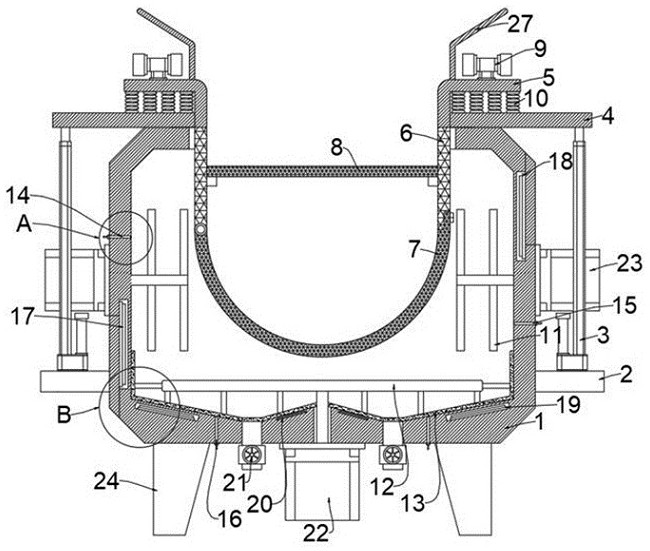

Crystalline silicon ingot furnace thermal field structure with two-stage thermal insulation cage

InactiveCN102002755ASmall deformation at high temperatureReduce Silicon LeakagePolycrystalline material growthSingle crystal growth detailsThermal insulationEngineering

The invention relates to a crystalline silicon ingot furnace thermal field structure with a two-stage thermal insulation cage. The thermal insulation cage has a two-stage structure, and consists of an upper thermal insulation cage fixed on the top of the furnace and a lower thermal insulation cage fixed on a lifting device at the bottom of the furnace; the upper thermal insulation cage is an inverted bucket, and consists of a top insulation board and an upper insulation cylinder of which the lower edge is provided with an L-shaped inner-turned upper insulation ring, wherein the top insulation board and the upper insulation cylinder are connected with each other into a whole and the inner surface of the top insulation board is provided with a concave arc reflector; the lower thermal insulation cage is an upright bucket, consists of a bottom insulation board and a lower insulation cylinder of which the upper edge is provided with an L-shaped inner-turned lower insulation ring, and is fixed on the lifting device controlled externally at the bottom of the furnace, wherein the bottom insulation board and the lower insulation cylinder are connected with each other into a whole; and the upper and lower insulating rings separate the inner cavity of the thermal insulation cage into an upper high-temperature area and a lower high-temperature area. The thermal field required by the production of the crystalline silicon is realized by adjusting the lift opening of the lower insulation cage through the lifting device; and the structure has the advantages that: the structure is simple and reasonable and obviously saves energy, the established thermal field has high stability and repeatability, the temperature is difficultly interfered by air disturbance and the structure has high practicability.

Owner:SHANGHAI CHEN HUA ELECTRIC FURNACE CORP

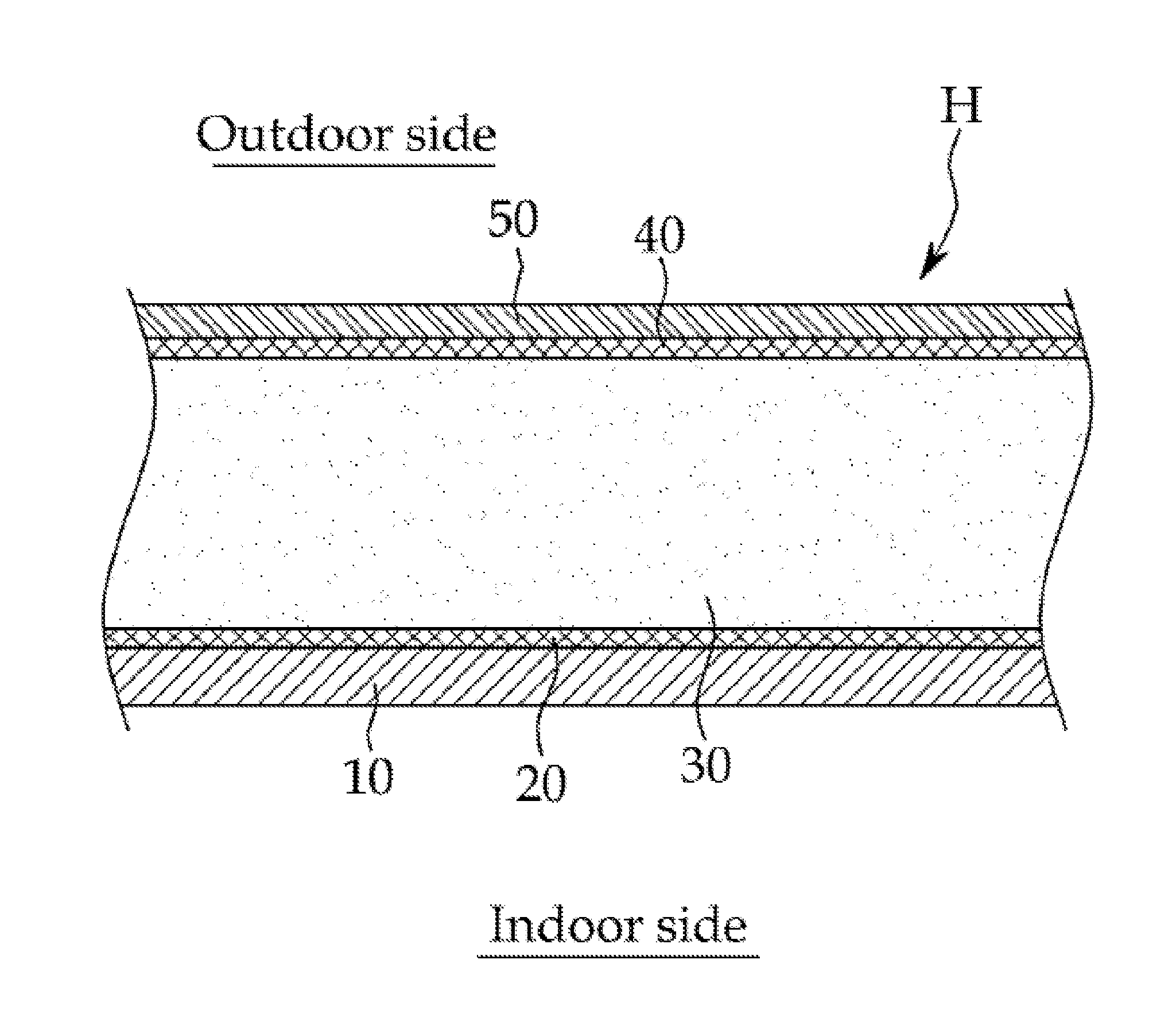

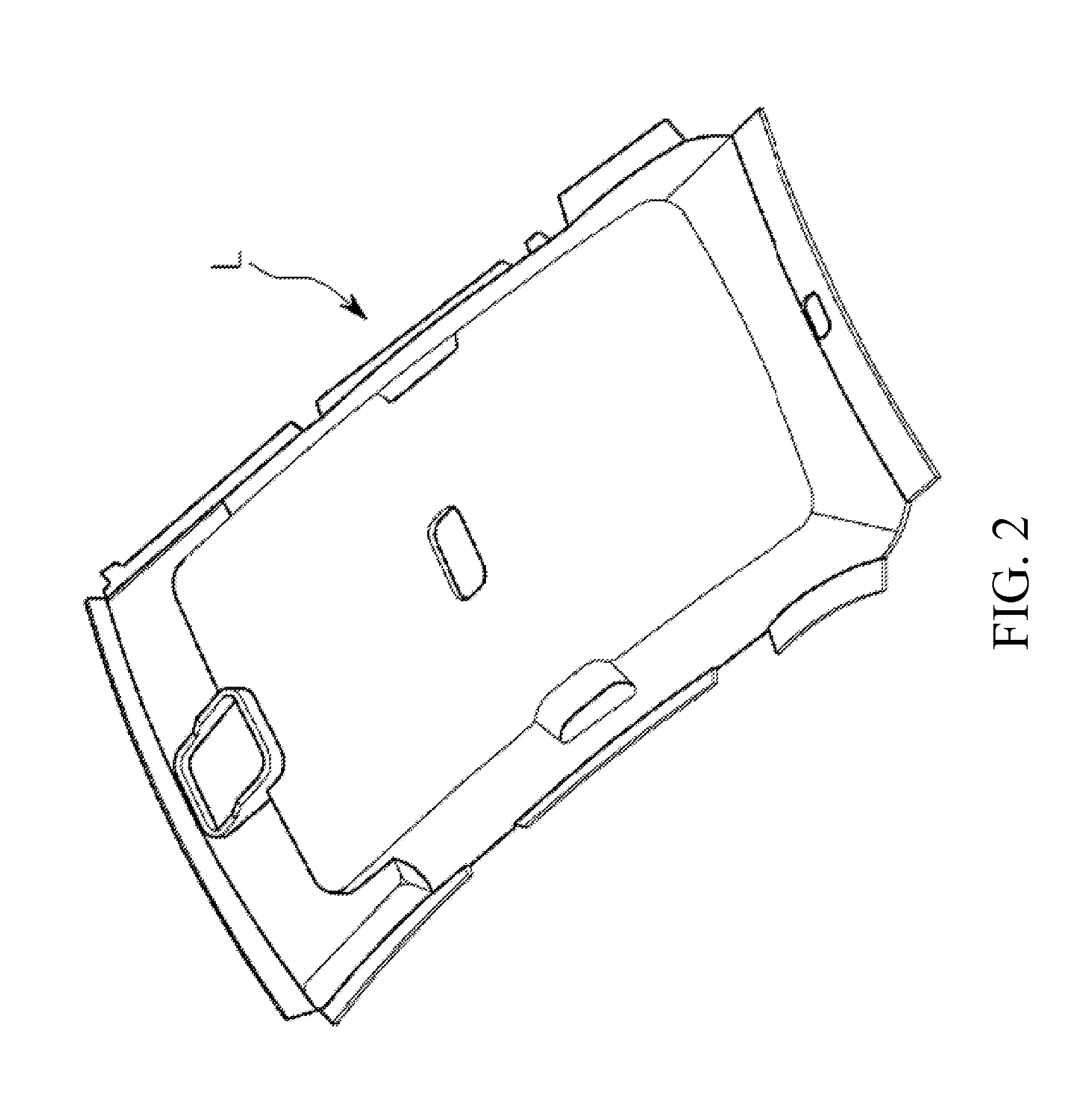

Headlining having heat shielding function for vehicle and manufacturing method thereof

ActiveUS20160347263A1Reduce internal temperatureShorten operation timeLamination ancillary operationsLayered product treatmentGlass fiberCarbon nanotube

A headlining having a heat shielding function for a vehicle and a manufacturing method for producing the headlining, where a complex layer formed of glass fiber and polypropylene is manufactured among various layers forming the headlining having a multilayered structure, and a hot melt film containing a heat shielding material is further provided on at least one of both surfaces of the complex layer to shield heat by the headlining. In so doing, the headlining is capable of reducing an internal temperature of the vehicle even in the summertime, and thus an operation time of an air conditioner is reduced, and fuel efficiency of the vehicle is increased. The headlining also has a heat shielding function for a vehicle, in which carbon nanotubes as the heat shielding material are used to provide the heat shielding and weight lighting effects and also to simultaneously improve the fuel efficiency of the vehicle.

Owner:DAEHAN SOLUTION

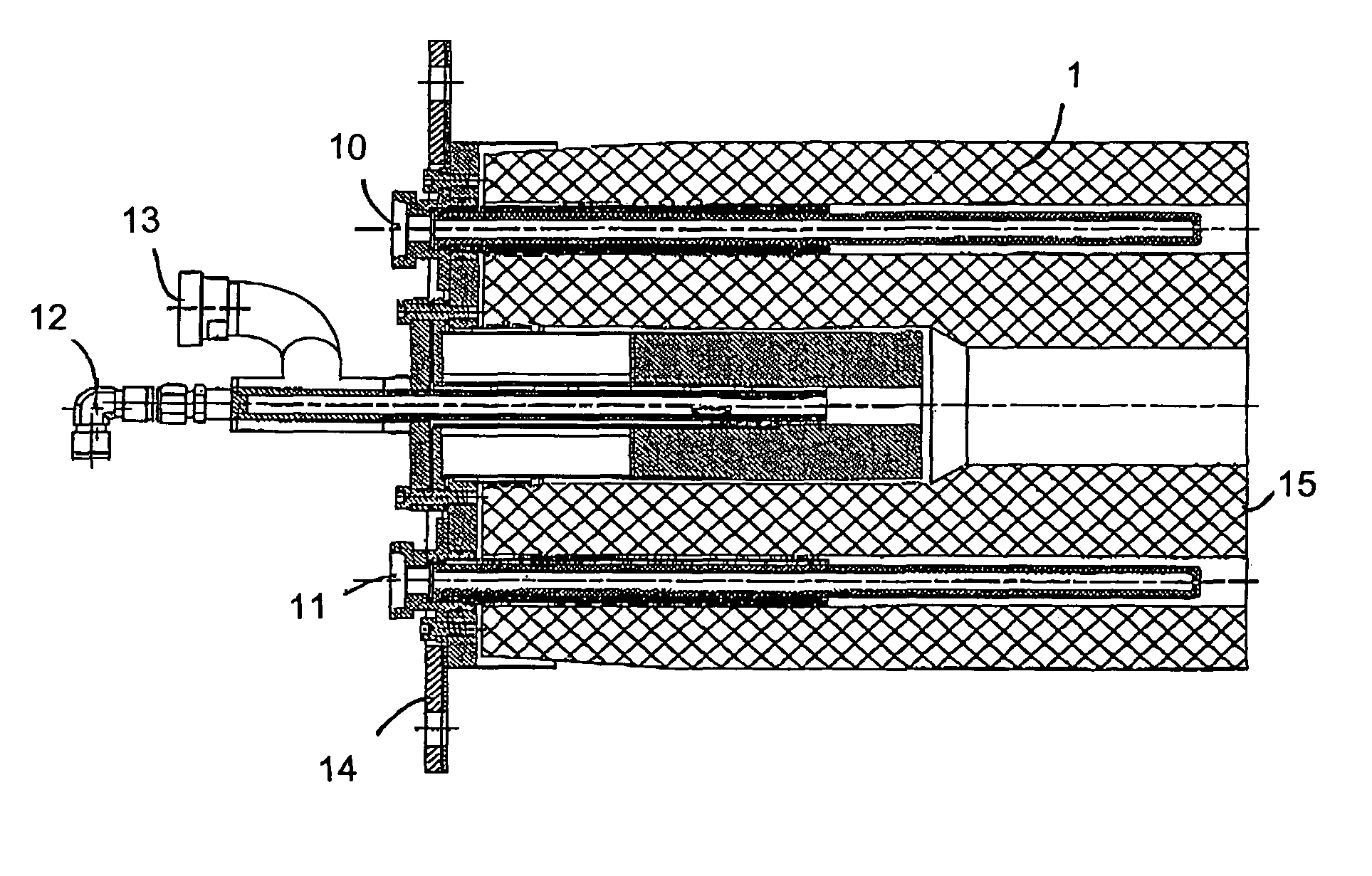

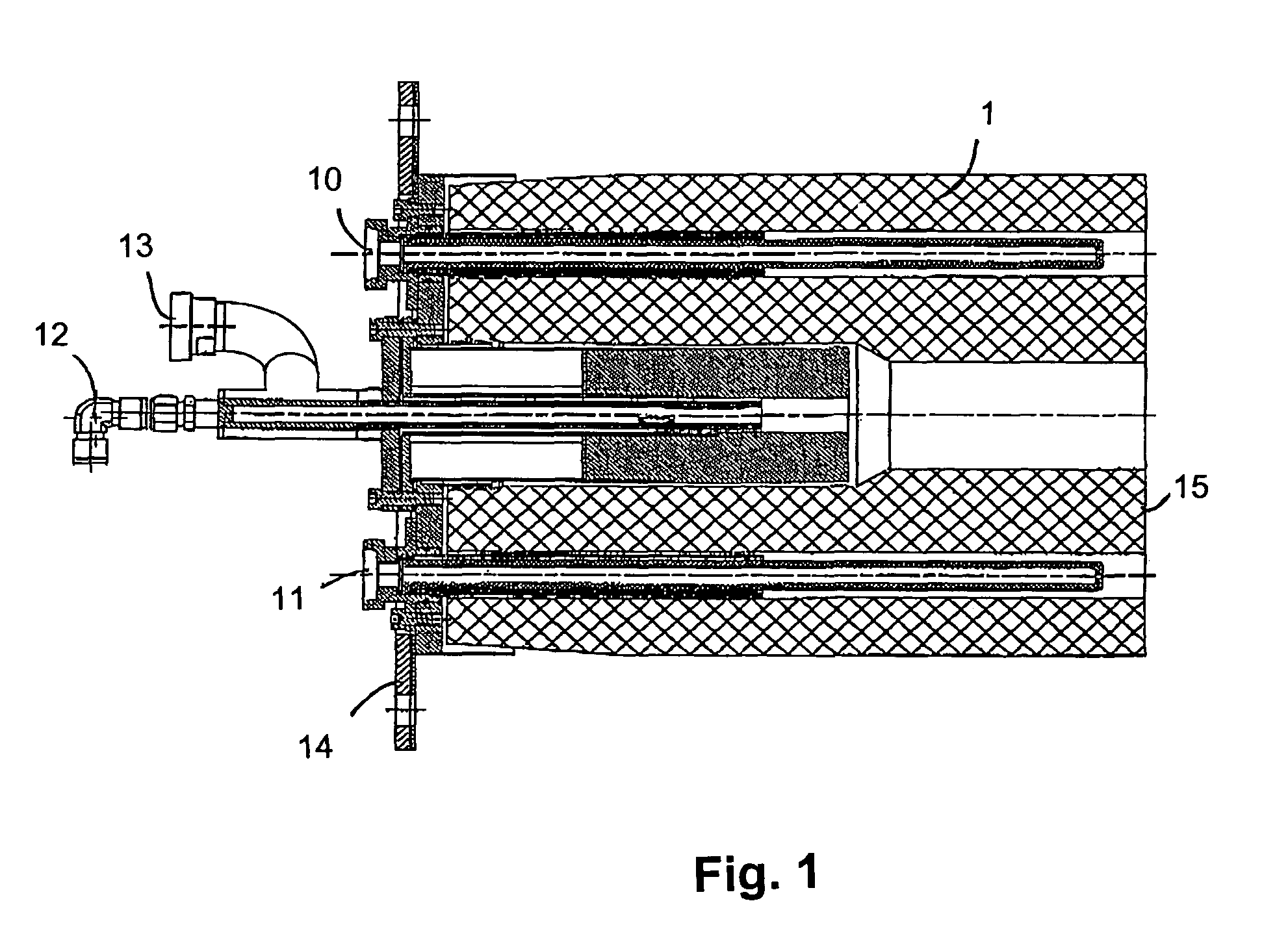

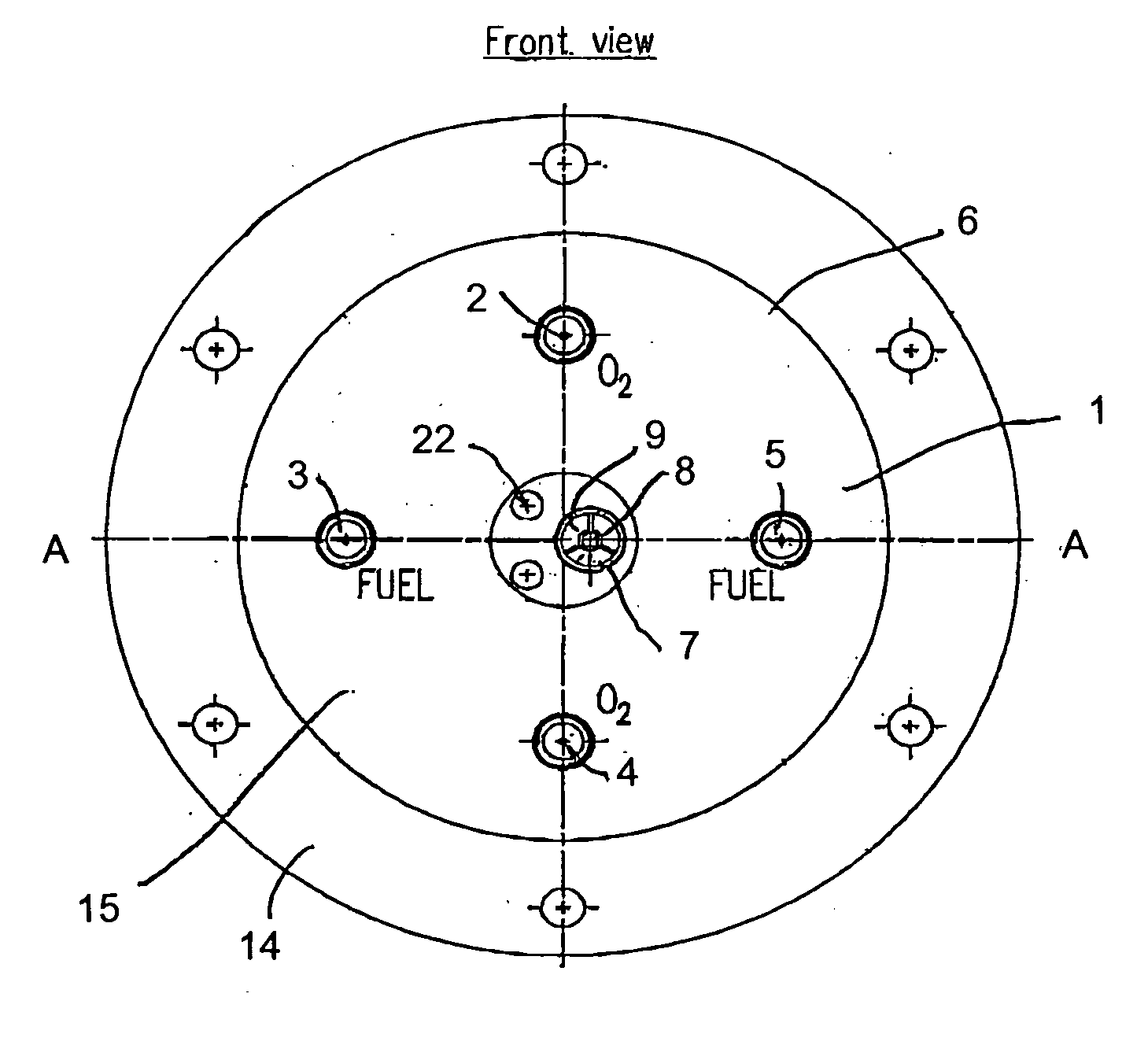

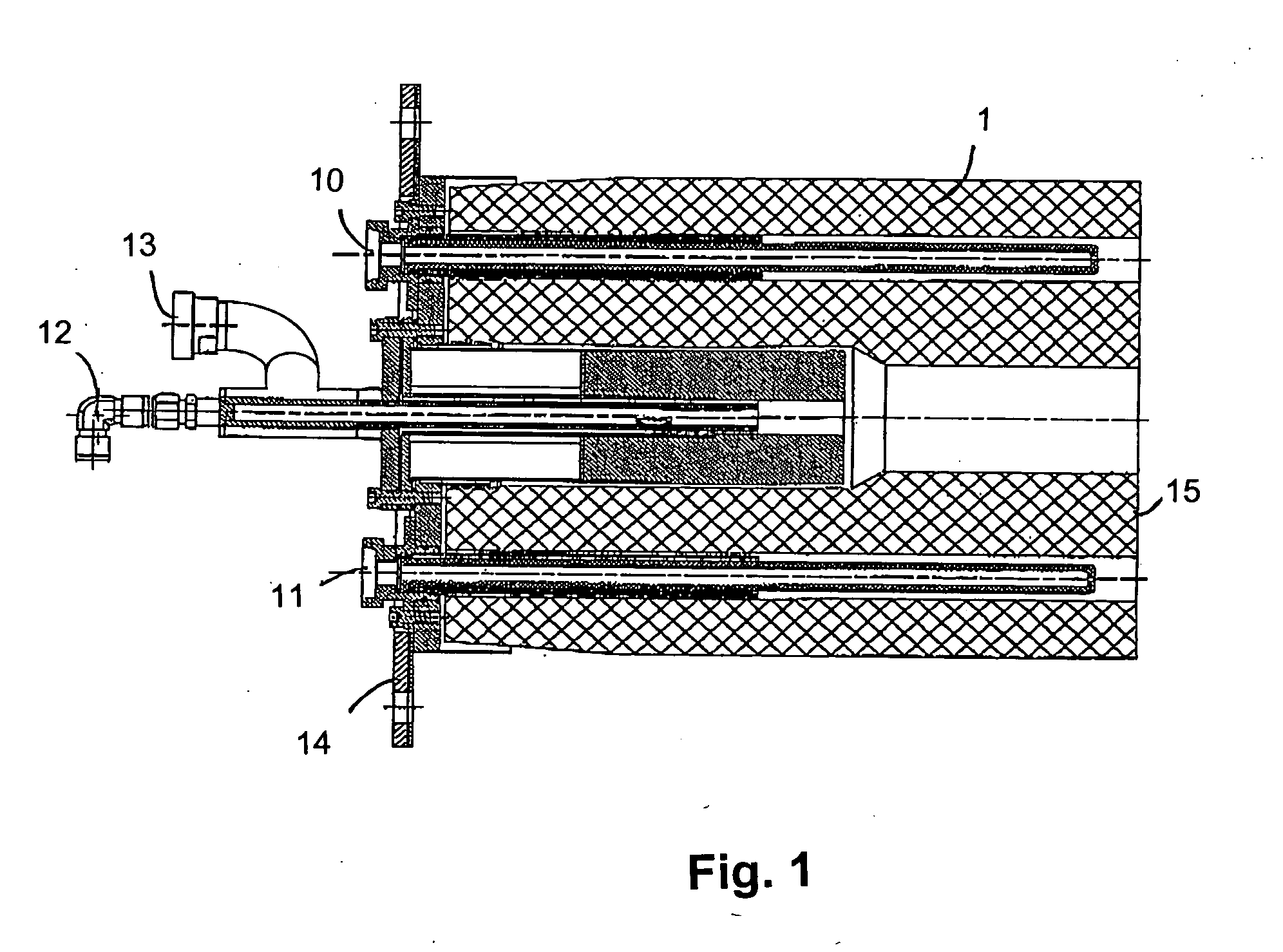

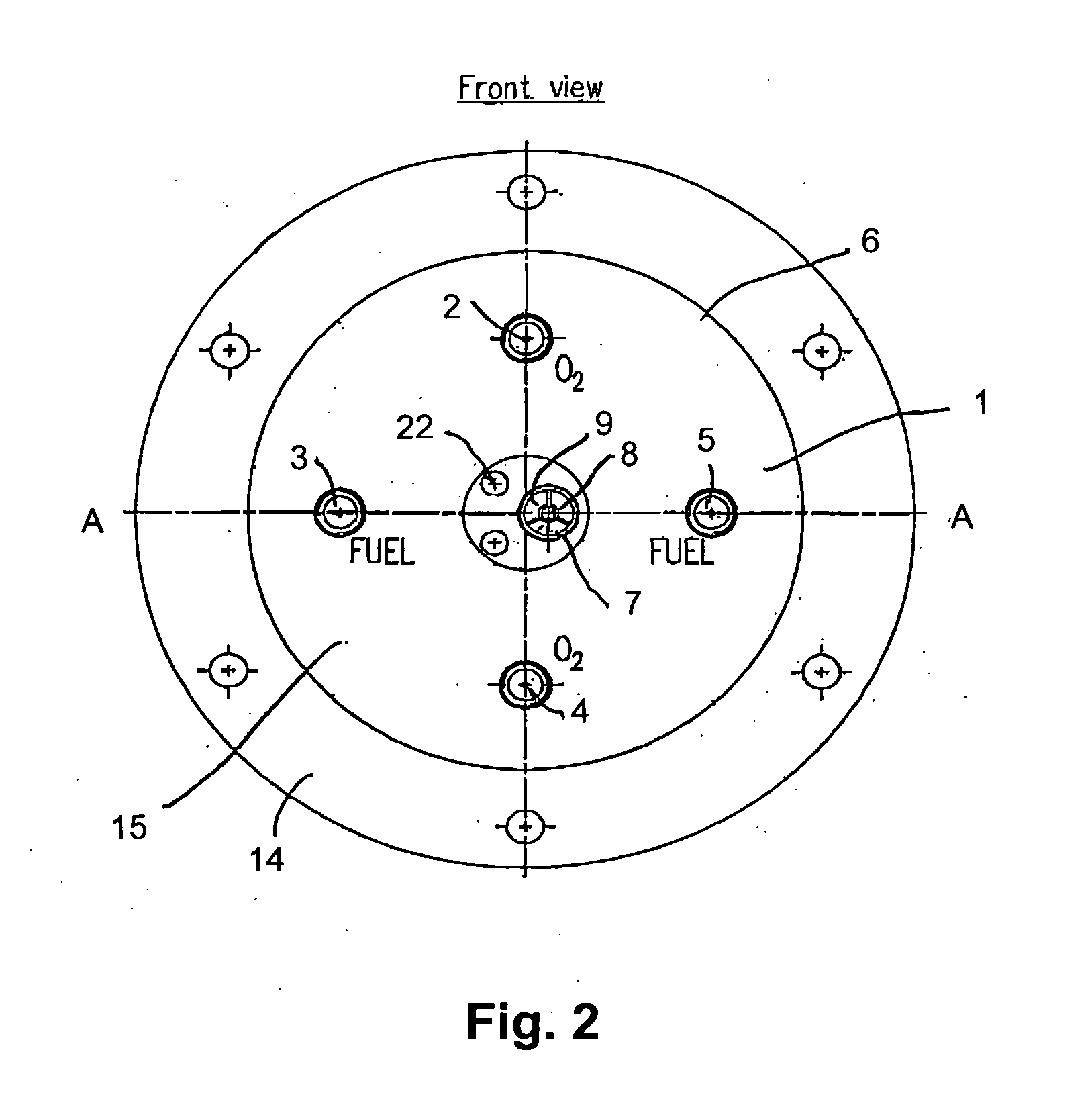

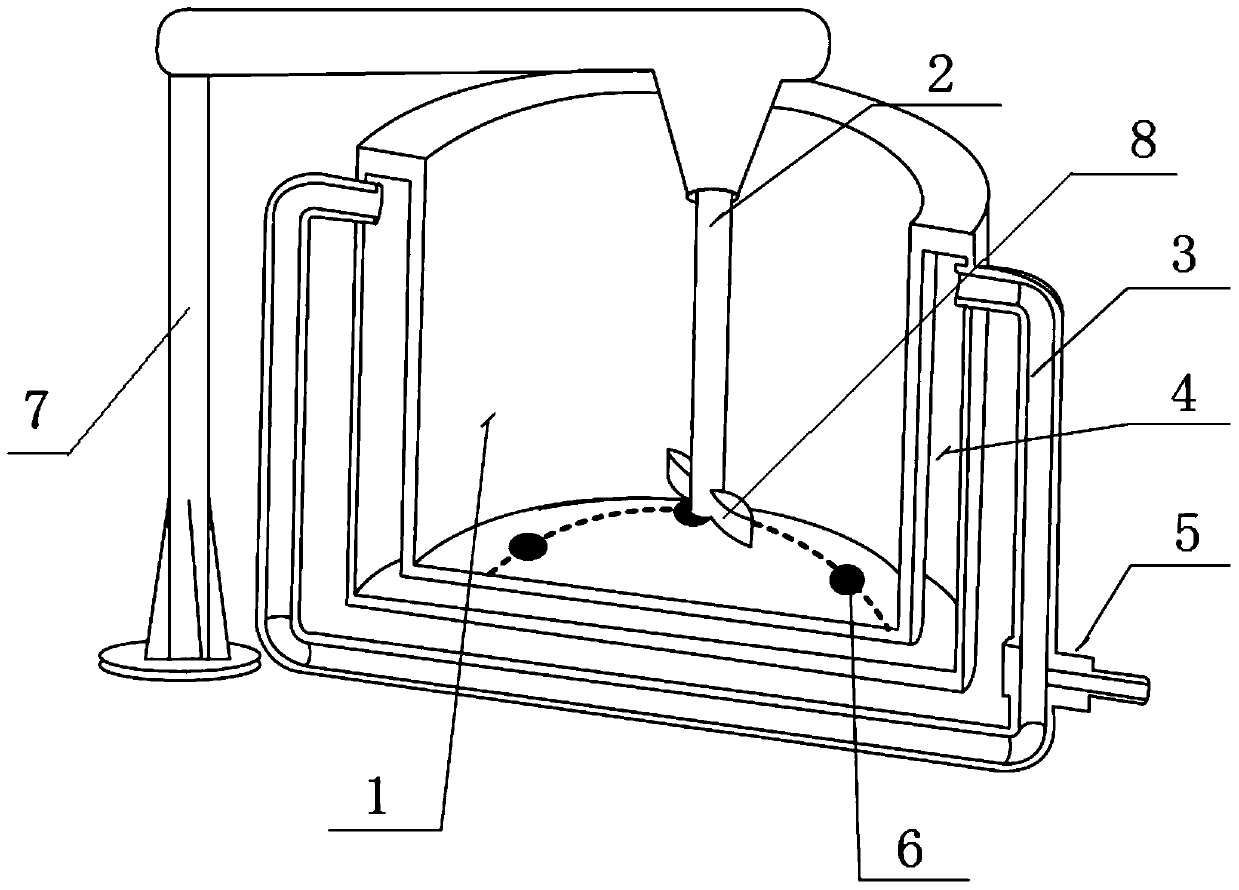

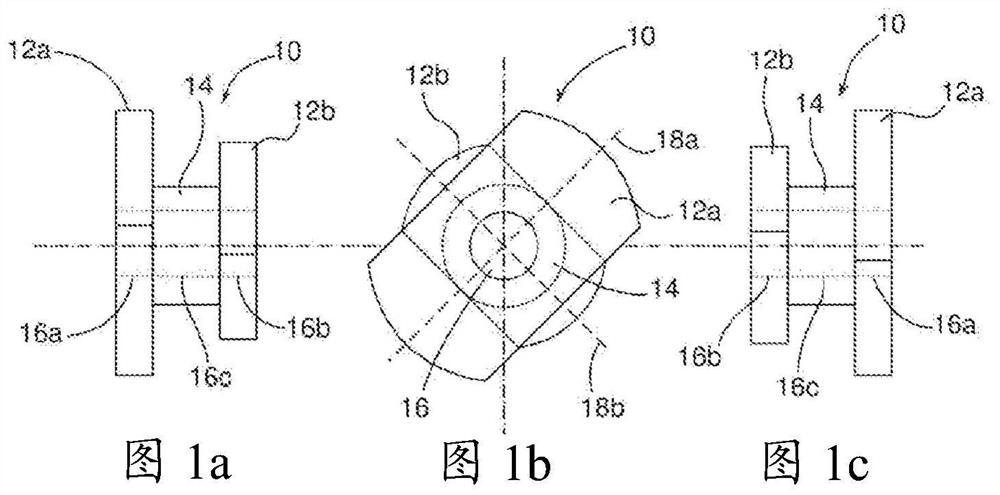

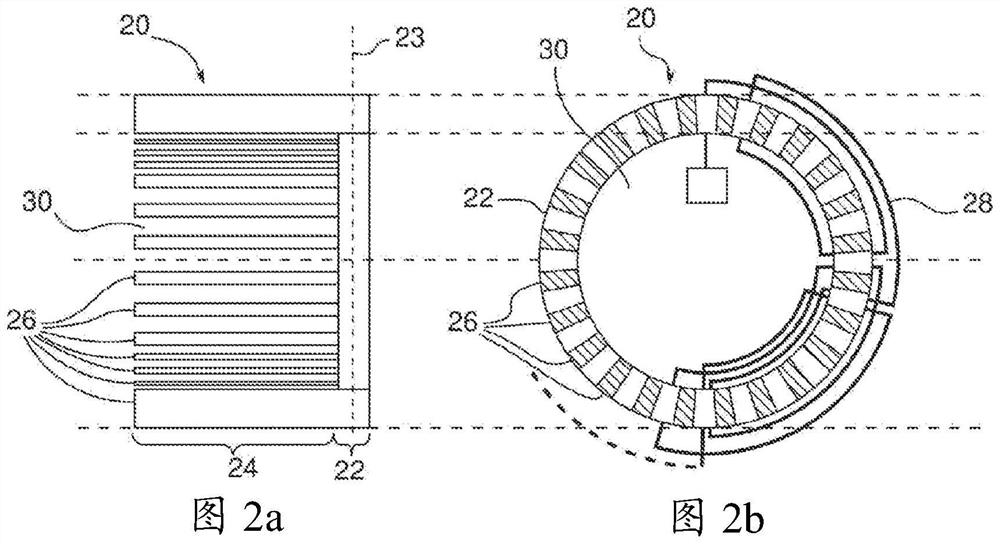

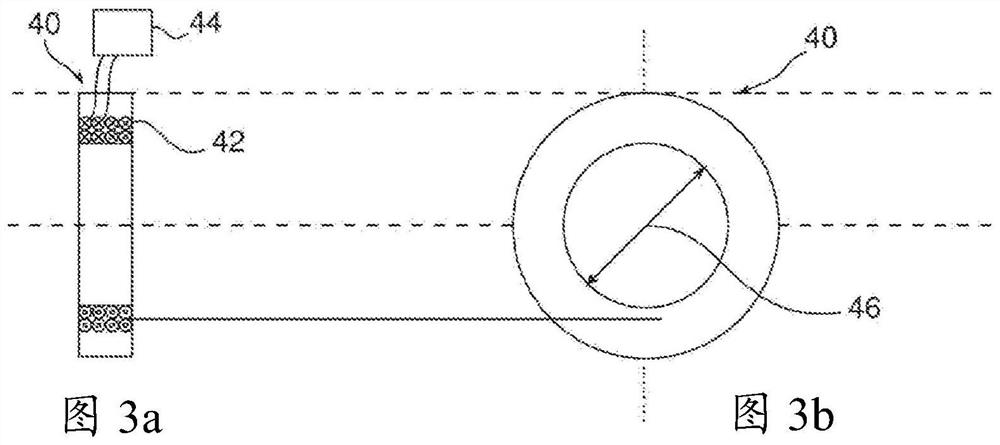

Method and burner for burning with oxygen

ActiveUS8057221B2Uniform internal temperatureSolid fuel combustionIndirect carbon-dioxide mitigationCombustorEngineering

A method and a burner for combustion in a heating furnace of a fuel with an oxidant in the form of oxygen gas, wherein fuel and oxidant are supplied to a burner head. Fuel and oxidant, respectively, are injected via the burner head through at least two pairs of nozzles, wherein one nozzle pair is defined by a separate fuel nozzle and a separate oxidant nozzle. The nozzles of the nozzle pairs are uniformly distributed over the furnace-interior-facing surface of the burner and within the circumference of the burner head. An oxidant nozzle is provided on each side of a fuel nozzle.

Owner:MESSER IND USA INC

Method and burner for burning with oxygen

ActiveUS20070298356A1Low NOx valueUniform temperature in the furnaceCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorEngineering

A method and a burner for combustion in a heating furnace of a fuel with an oxidant in the form of oxygen gas, wherein fuel and oxidant are supplied to a burner head. Fuel and oxidant, respectively, are injected via the burner head through at least two pairs of nozzles, wherein one nozzle pair is defined by a separate fuel nozzle and a separate oxidant nozzle. The nozzles of the nozzle pairs are uniformly distributed over the furnace-interior-facing surface of the burner and within the circumference of the burner head. An oxidant nozzle is provided on each side of a fuel nozzle.

Owner:MESSER IND USA INC

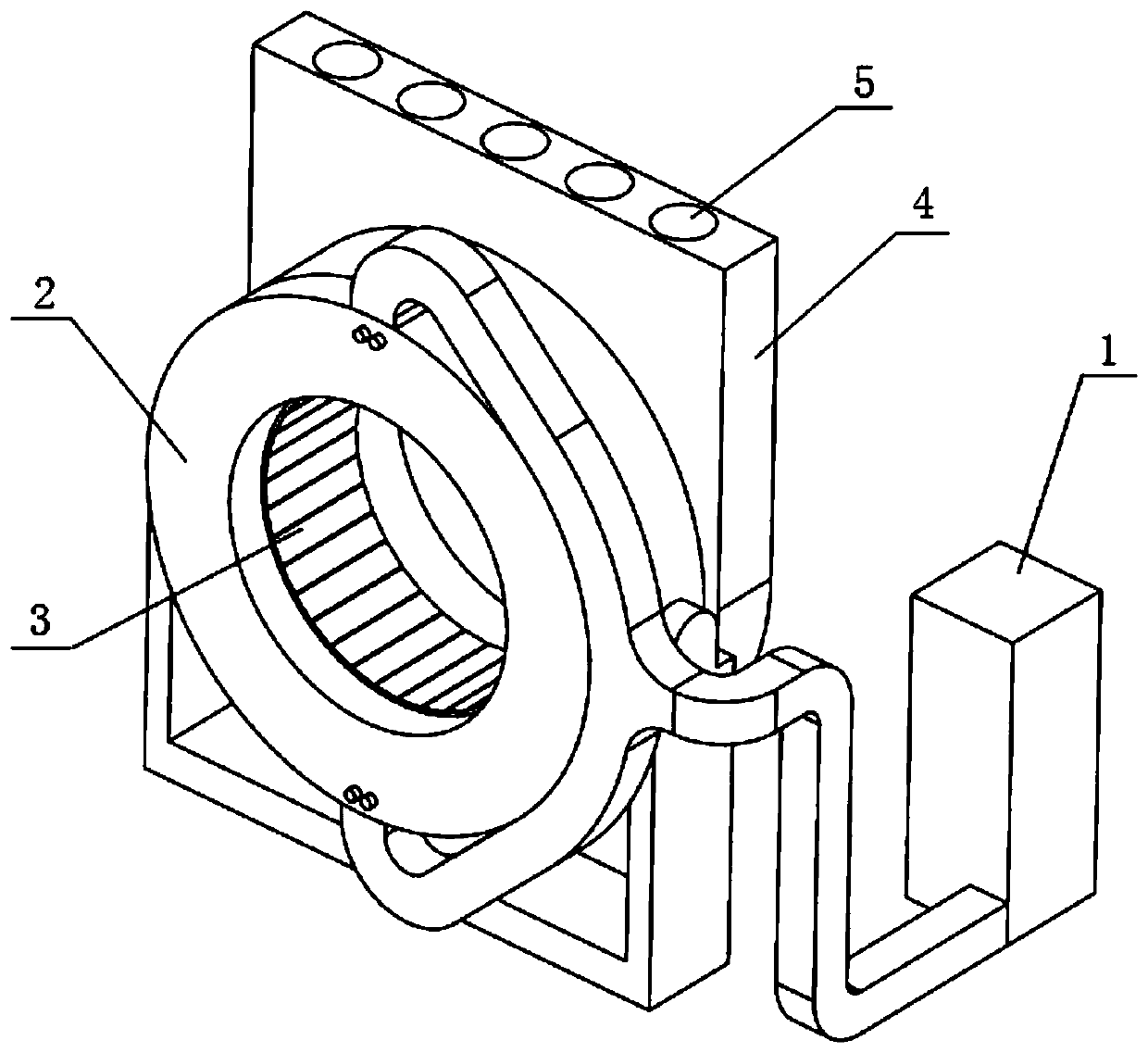

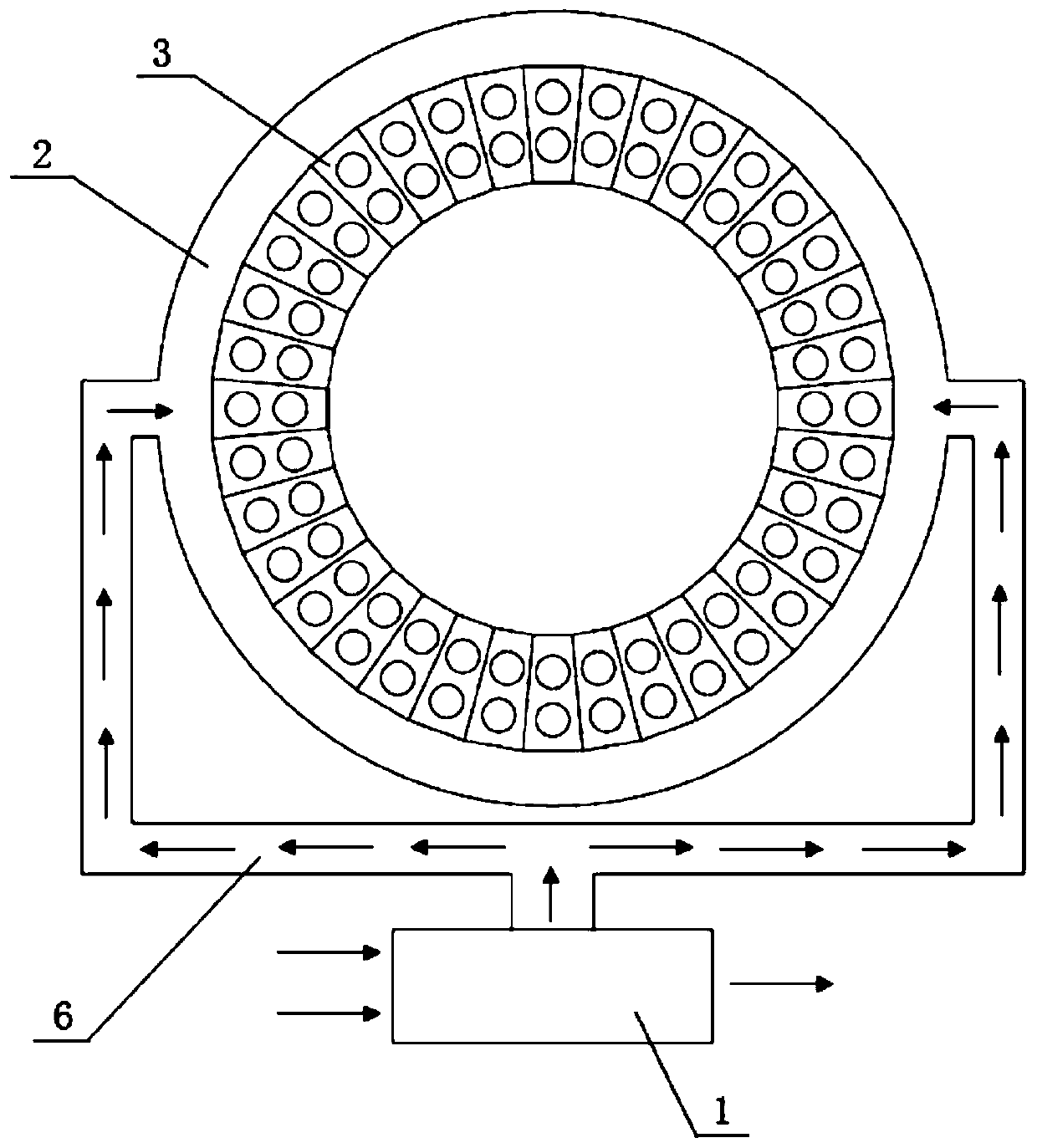

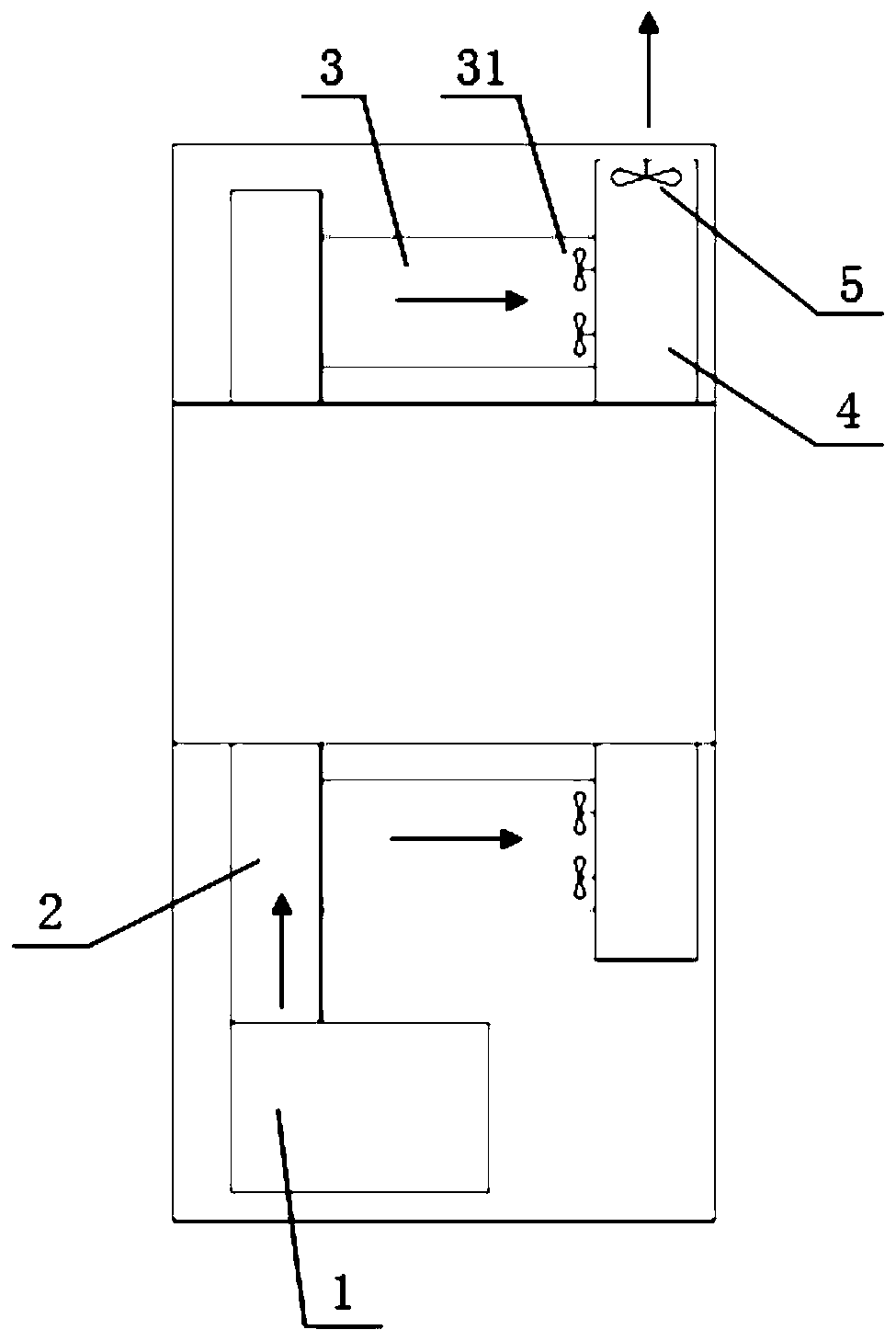

Air-cooled heat-dissipation device of PET system

PendingCN110448325AUniform temperatureImprove uniformityComputerised tomographsTomographyInlet channelCompanion animal

The invention discloses an air-cooled heat-dissipation device of a PET system. The PET system includes a scanning ring and a mounting base installed in the scanning ring. A plurality of detectors is installed on the mounting base to form a detector ring, the air-cooled heat-dissipation device includes an air inlet channel and an air outlet channel respectively located on both sides of the scanningring, the air inlet channel is provided with a plurality of air inlets 1, the air inlets 1 are connected with an air cooling device through air inlet pipes, the inside of the air inlet channel is provided with an inner air inlet channel communicating with the air inlet 1, and a plurality of air outlets 1 can be provided on the surface where the inner air inlet channel and the end face of the detector are applied. A detector is provided with an air inlet device, two ends of the detector are respectively provided with an air inlet 2 and an air outlet 2, the air inlet 2 is in communication withthe inner air inlet channel, the air outlet 2 is in communication with the air outlet channel, and the top of the air outlet channel is provided with an exhaust device. The cooling air can be subjected to heat radiation and cooling on the detector according to a predetermined flow channel, and the device has a simple structure, high heat-dissipation efficiency and uniform internal temperature.

Owner:FMI MEDICAL SYST CO LTD

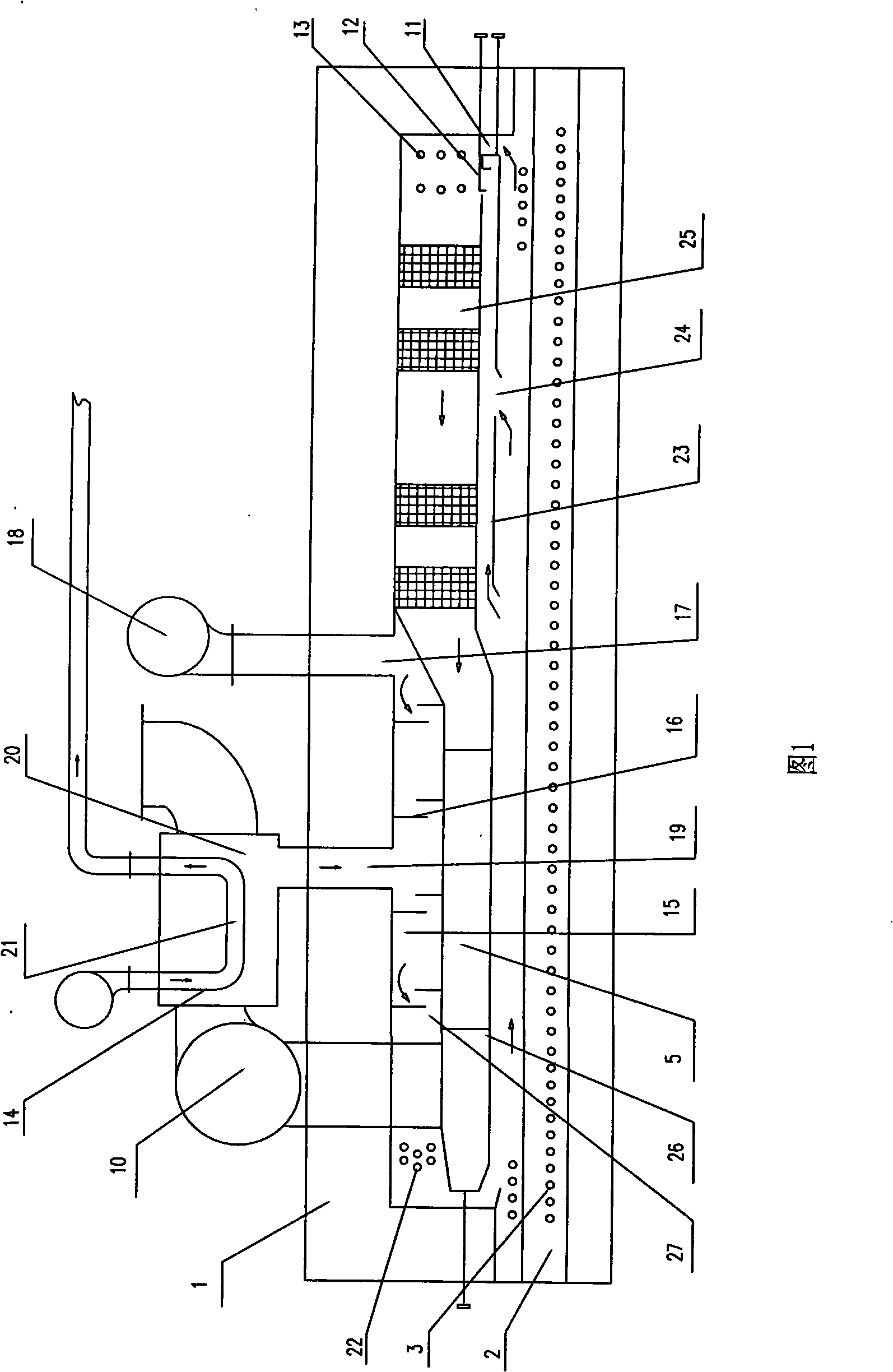

Horizontal enameling machine oven with ultra-wide combustion chamber

InactiveCN101403560AReduce the difficulty of operationMany headsDrying solid materials with heatDrying gas arrangementsCombustion chamberCombustor

The invention discloses a horizontal enameling machine drying oven with a superwide furnace which comprises furnace and heat irradiation equipment arranged in the furnace, wherein, the upper part of the furnace is provided with a catalytic combustor and a catalytic post suction and discharge room which are communicated. Two ends of the catalytic combustor are provided with an air inlet and an air outlet, a heat exchange room is arranged on the periphery of the catalytic post suction and discharge room, and the furnace is separated from a solvent suction and discharge area in the middle. The horizontal enameling machine drying oven is characterized in that more than two air inlets are arranged in the solvent suction and discharge area and the air inlet of the catalytic combustor is respectively communicated with the air inlets at the ends of the furnace and in the solvent suction and discharge area. A multi-channel air-flow distribution device is arranged in the catalytic post suction and discharge room and comprises a solvent distillation channel, the left and right sides and the back end of the channel are all provided with stream inlets, and the middle part thereof is provided with an air flow demarcation strip; and a pump line provided with an exhaust fan is arranged on the periphery of the air flow demarcation strip and communicated with the solvent distillation channel. The horizontal enameling machine drying oven has reasonable structure, uniform airflow direction and temperature, energy conservation and environmental protection, and good popularization value.

Owner:林兆欣 +1

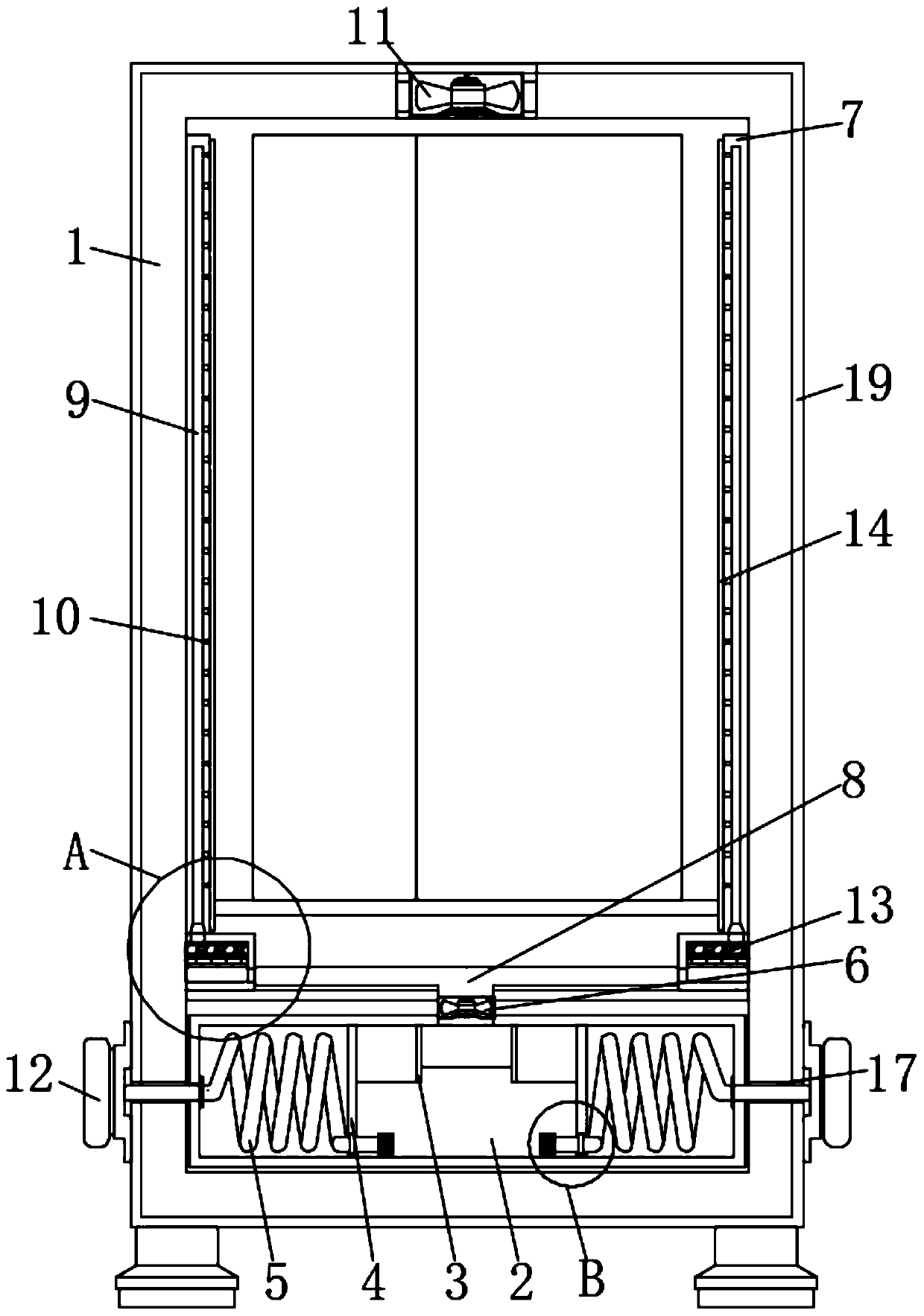

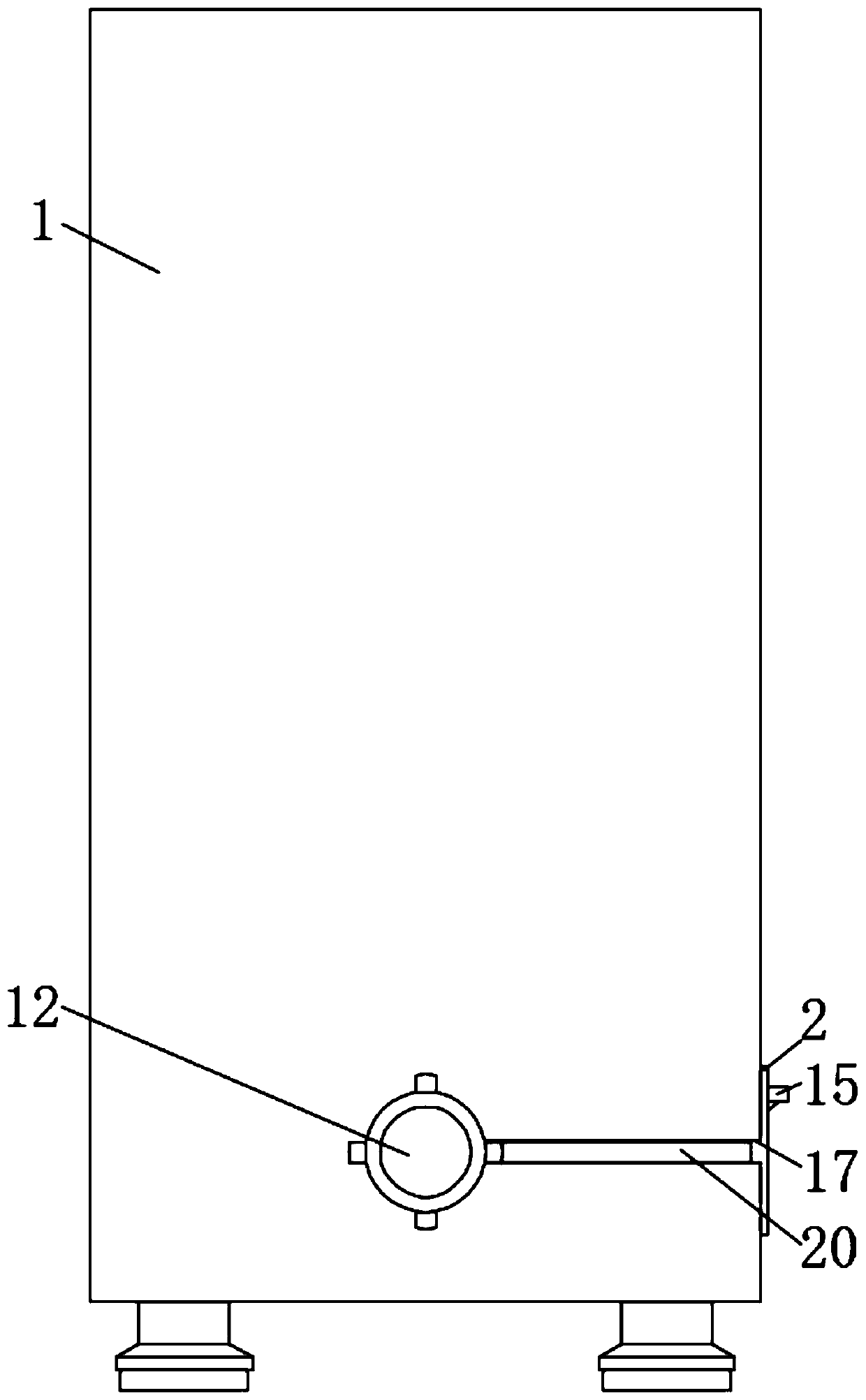

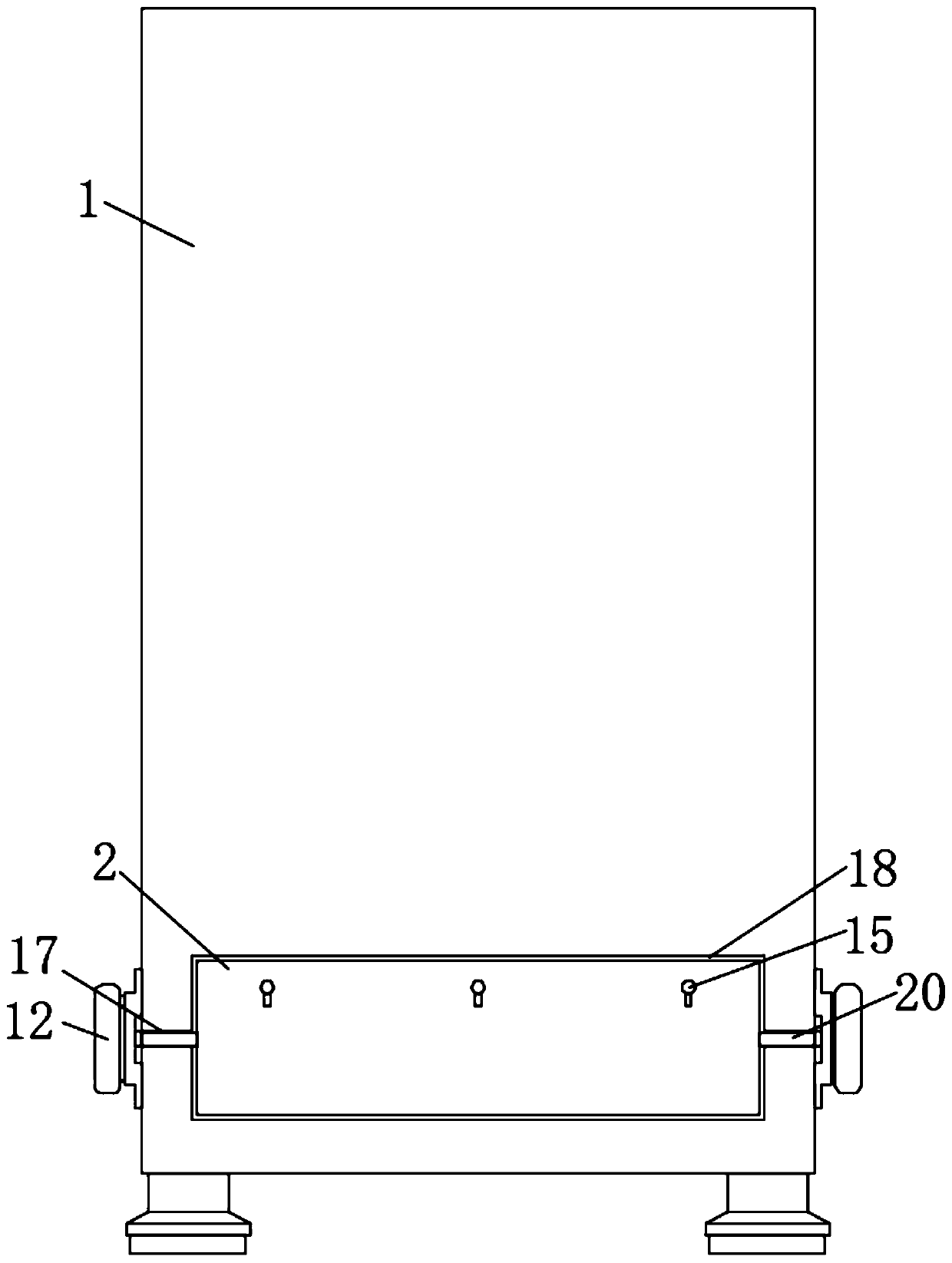

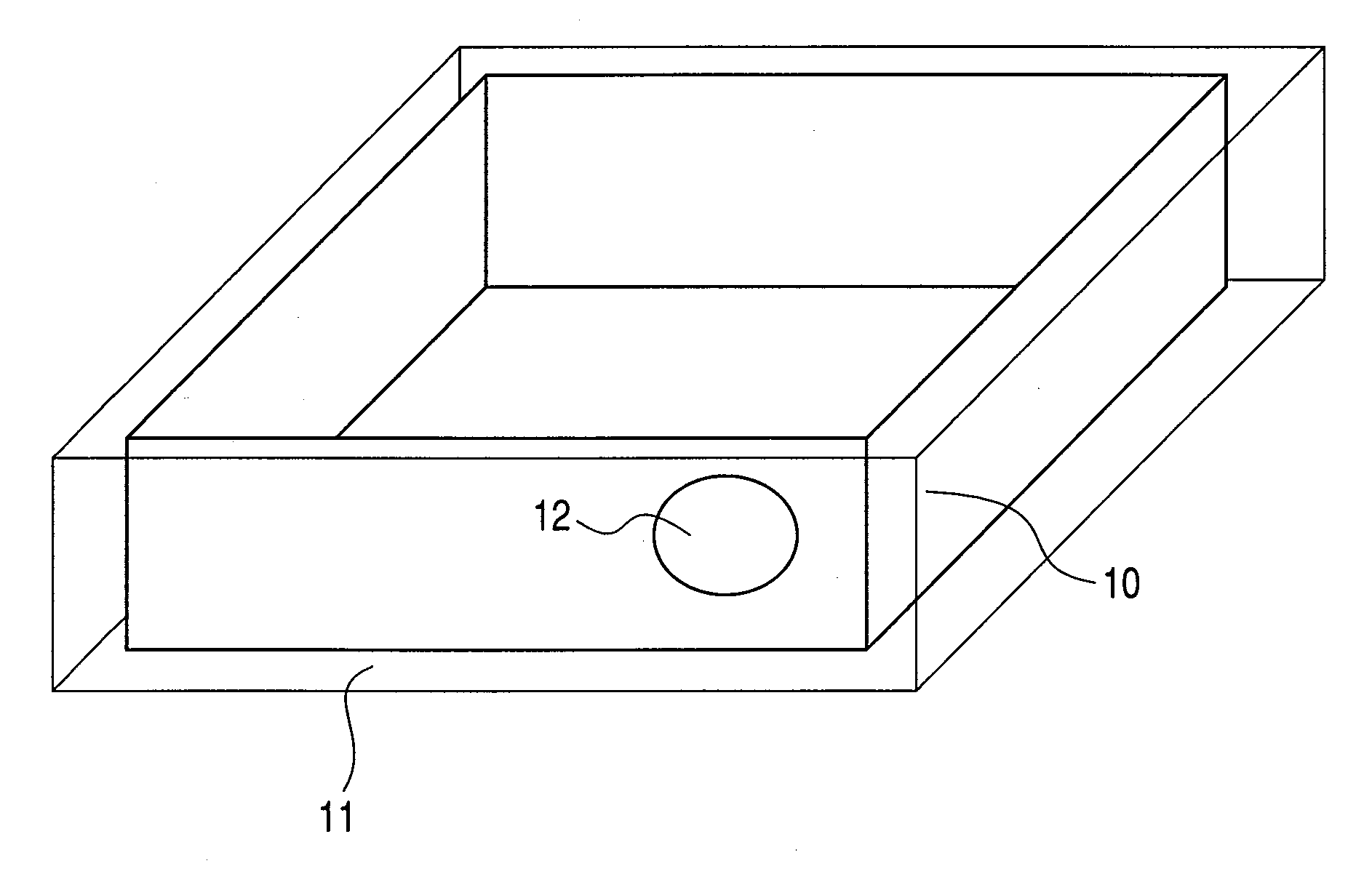

Heat dissipation system for high-low voltage complete power distribution equipment

InactiveCN111525424AExtended service lifeUniform internal temperatureSubstation/switching arrangement cooling/ventilationThermodynamicsLow voltage

The invention discloses a heat dissipation system for high-low voltage complete power distribution equipment, and belongs to the electrical field. The heat dissipation system comprises a box body, wherein a cooling box is slidably connected to the bottom of the box body, a cooling liquid is added into the cooling box, two partition plates and two baffles are fixedly connected to the inner top wallof the cooling box, the two baffles are located on the opposite sides of the two partition plates respectively, and air guide pipes fixedly connected with the two baffles are inserted into the two baffles in a penetrating mode. According to the invention, the heat dissipation effect is good, the influence on equipment operation due to over-high temperature of the complete set of power distribution equipment is avoided, line combustion is prevented, and the service life of complete set of power distribution equipment is prolonged; and due to the fact that the heat conduction plate is a metal plate, the heat in the box body can be conducted and dispersed, the temperature in the box body is uniform, and heat concentration is avoided, so that high temperature is further avoided, and the use safety of the complete set of power distribution equipment is improved.

Owner:JIANGXI MINGZHENG SUSTION EQUIP

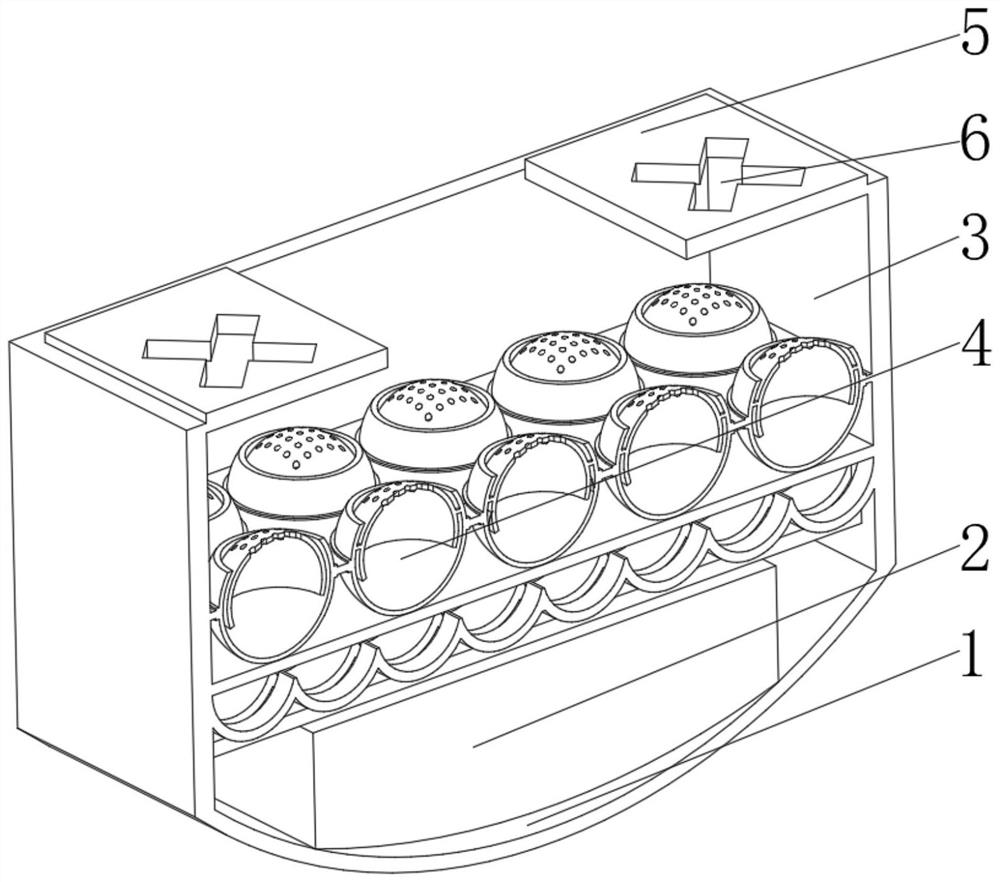

Paint spraying device for production and machining of loudspeaker dustproof caps

PendingCN108787248AEnhanced painting production efficiencyPrevent spray paint effectSpray boothsGear wheelElectric machinery

The invention discloses a paint spraying device for production and machining of loudspeaker dustproof caps, and relates to the technical field of loudspeaker dustproof cap machining. The paint spraying device comprises a paint spraying chamber body. One end of a supporting rod is fixedly connected to the middle of the upper surface in a paint spraying chamber. Multiple paint spraying devices are symmetrically and fixedly mounted on the two sides of the supporting rod. Multiple paint spraying pipes are symmetrically and fixedly mounted on the two sides of the paint spraying chamber. The bottomof the paint spraying chamber is fixedly connected with a heater. A motor is fixedly mounted at one end of each paint spraying device, and each motor is fixedly mounted in one side of the supporting rod. According to the paint spraying device for production and machining of the loudspeaker dustproof caps, on one hand, the dustproof caps are mounted at the tops of connecting ribs correspondingly, rotating plates can be limited through rotating pieces, and the situation that paint spraying on the dustproof caps is influenced due to the uneven height of the connecting ribs; and through hinged connection of bevel gears and rotating shafts, when the rotating shafts rotate, the bevel gears can be driven to horizontally rotate on the spot, and then the connecting ribs and the dustproof caps are driven to horizontally rotate.

Owner:安吉县力顺电声配件厂

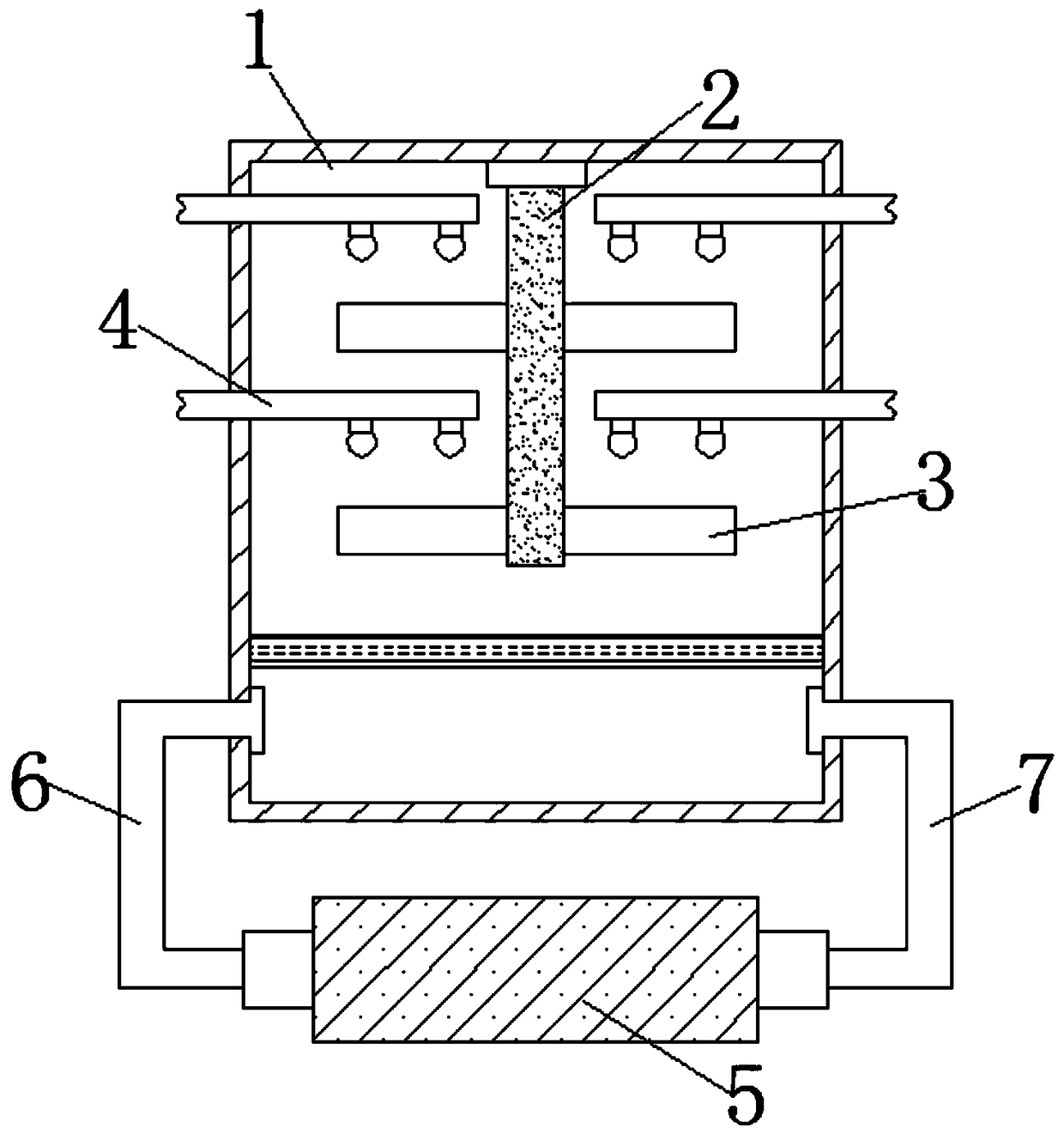

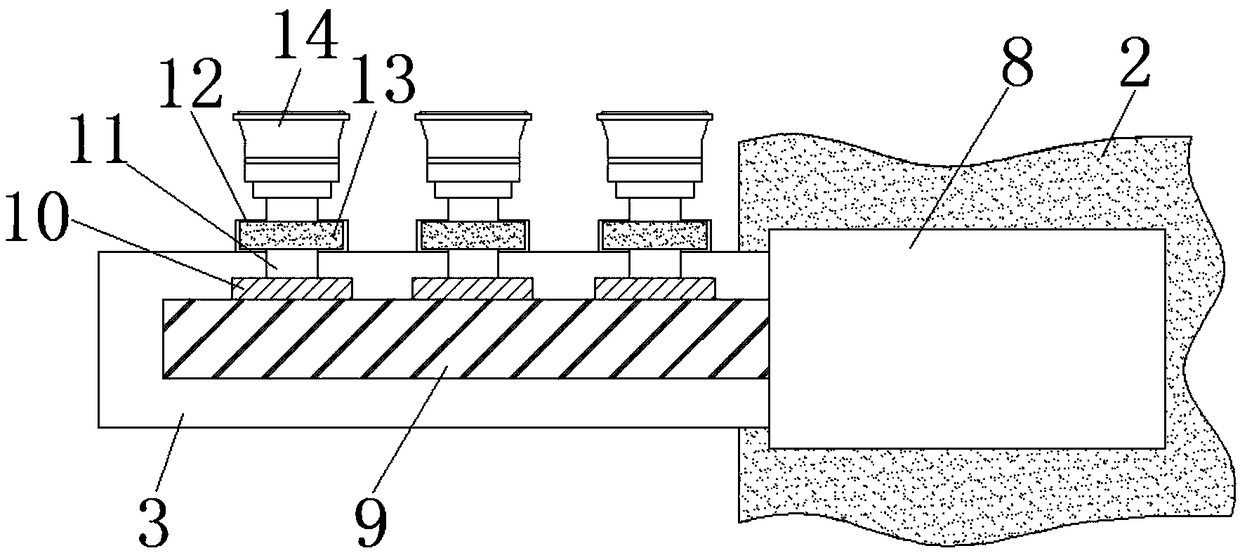

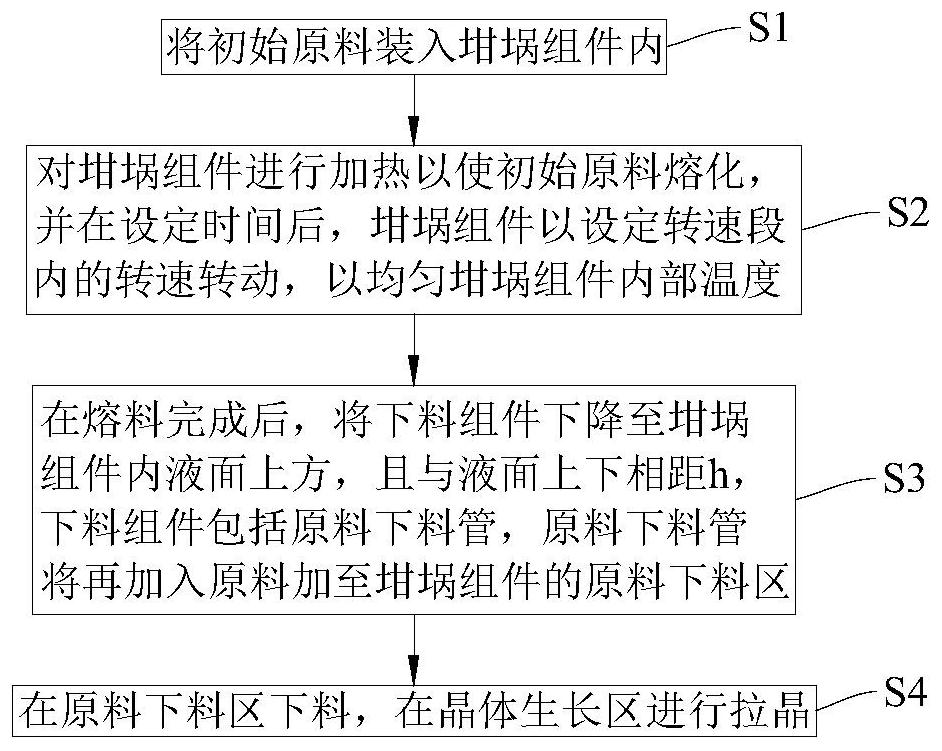

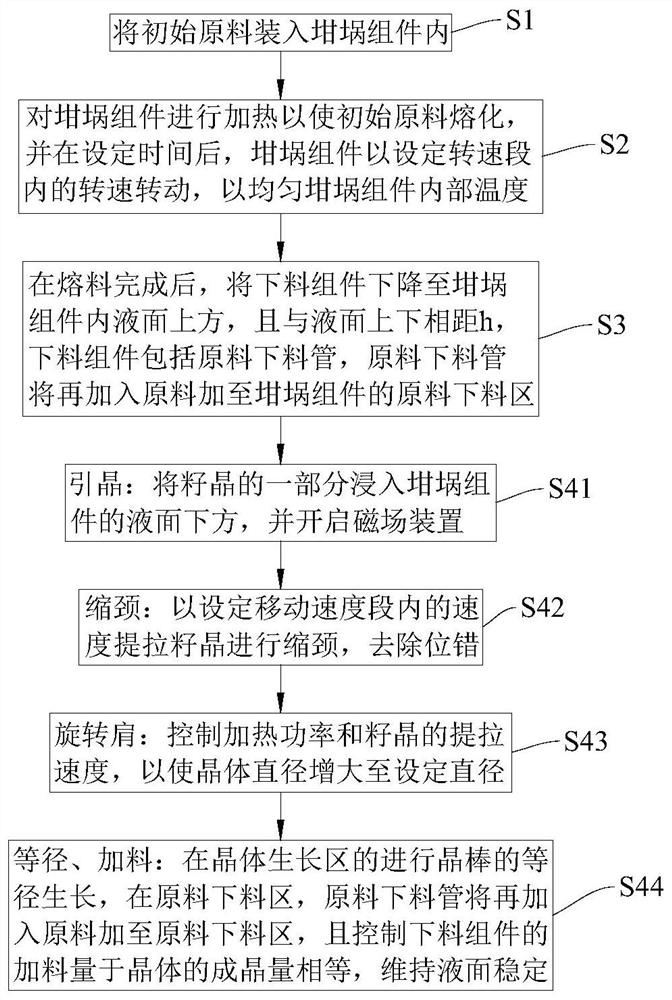

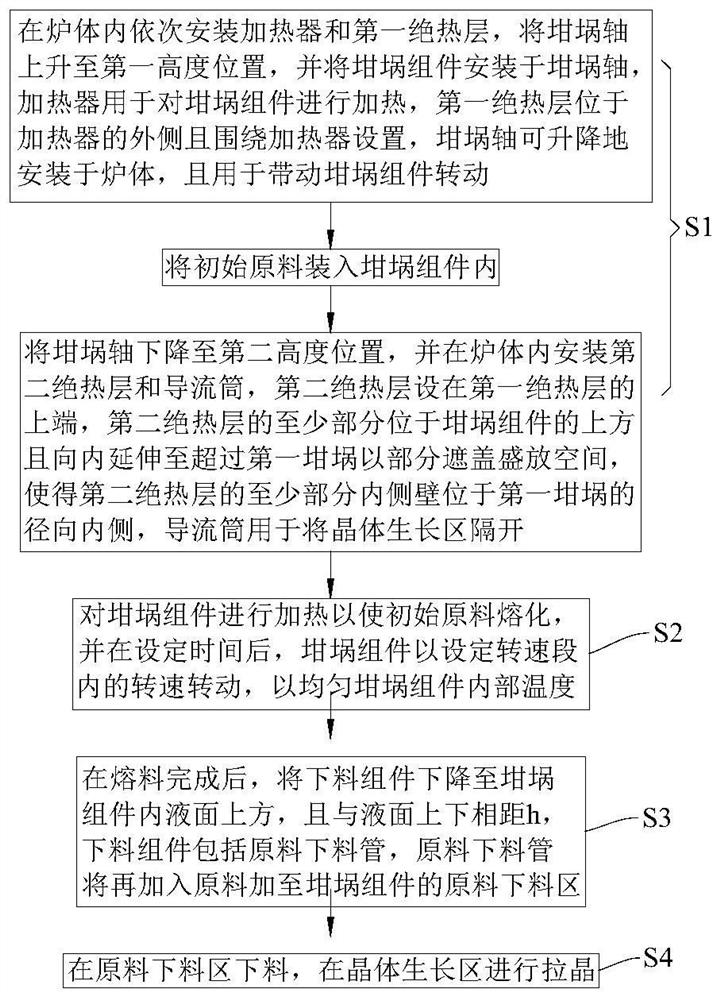

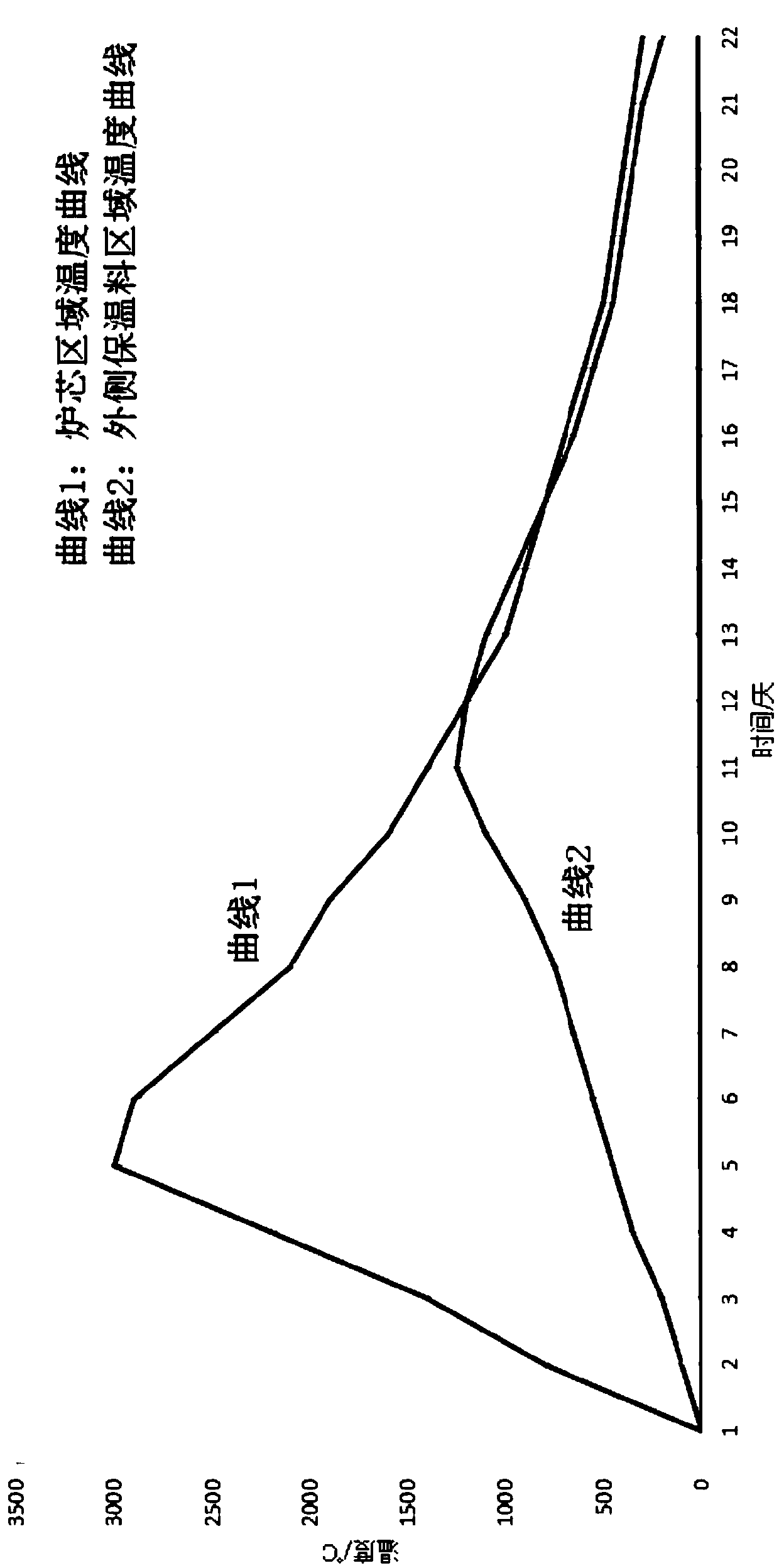

Crystal production process

PendingCN112210820AGuaranteed Crystal QualityUniform internal temperatureBy pulling from meltAfter-treatment apparatusChemistryEngineering

The invention discloses a crystal production process. The crystal production process comprises the following steps: S1, putting an initial raw material into a crucible assembly; s2, the crucible assembly is heated to melt the initial raw materials, and after set time, the crucible assembly rotates at the rotating speed within the set rotating speed section; s3, after material melting is completed,a discharging assembly descends to the position above the liquid level in the crucible assembly, the distance between the discharging assembly and the liquid level is h, the discharging assembly comprises a raw material discharging pipe, and the raw material discharging pipe adds the readded raw materials into a raw material discharging area of the crucible assembly; and S4, blanking is conductedin the raw material blanking area, crystal pulling is conducted in the crystal growth area, in the step S1, the initial raw materials are loaded into a first cavity, a second cavity and a third cavity correspondingly, and the particle diameter of the initial raw materials in the first cavity is larger than the particle diameter of the initial raw materials in the second cavity and the particle diameter of the initial raw materials in the third cavity. According to the crystal production process, molten liquid in the crucible assembly can be more uniform, and the crystal quality can be improved.

Owner:XUZHOU XINJING SEMICON TECH CO LTD

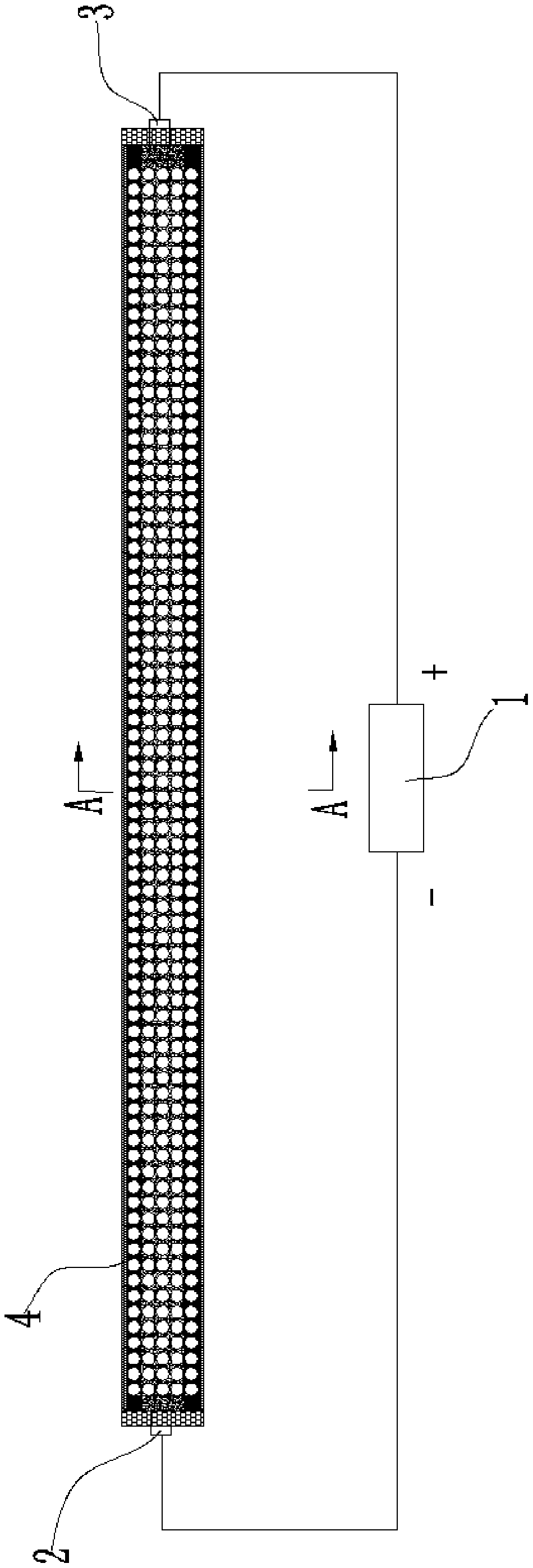

Application of graphitization furnace to roasting process

InactiveCN109626369AReduce energy costsSave furnace investmentCarbon preparation/purificationGraphiteMaterials science

The invention discloses application of a graphitization furnace to a roasting process, and belongs to the technical field of carbon production. The Acheson graphitization furnace is adopted for the roasting process of a carbon material, wherein the Acheson graphitization furnace comprises at least one furnace body; each furnace body is surrounded by refractory furnace walls, and a cushion layer islaid at the bottom of each furnace body; a first resistance material layer is laid on each cushion layer; to-be-treated products are placed on the first resistance material layers, and filled with aresistance material, and the portions among the be-treated products are filled with a resistance material; second resistance layers are laid on the to-be-treated products; furnace top heat insulationmaterial layers are laid on the second resistance material layers. By means of the Acheson graphitization furnace, the roasting and graphitization process of graphite crucibles can be completed, a lotof furnace building investment is reduced, and the overall productivity and benefits of the graphitization furnace are greatly increased.

Owner:吴建云

Method and device for stir-frying Chinese traditional medicine decoction pieces by hot air flow

ActiveCN109718108ASmooth flipAvoid local accumulationPharmaceutical product form changeMicrowave heatingMicrowaveEngineering

The invention discloses a method and device for stir-frying Chinese traditional medicine decoction pieces by hot air flow. The device includes an enclosed container, a bottom air inlet pipe, a sidewall air inlet pipe, an exhaust pipe, a circulating pipeline, microwave heating devices, mesh pots and booster pumps; The method includes the following steps: step one, putting stir-fried decoction pieces into the mesh pots with different apertures of the device according to dimensions; step two, starting the booster pumps after the circulating pipeline is heated, adjusting the power of the booster pumps, controlling flow velocity to make the flow velocity of the bottom air inlet pipe being 3-5 times of that of the sidewall air inlet pipe; step three, setting different temperatures during stir-frying according to different stir-frying requirements of stir-fried to yellow, stir-fried to brown and stir-fried to scorch, and starting the microwave heating devices or electrothermal tubes corresponding to the positions of the mesh pots to perform heat supplementing when the temperatures in the mesh pots are lower than required temperatures; and step four, taking out stir-fried traditional Chinese medicine decoction piece finished products from the mesh pots after stir-frying, and performing cooling and packaging. The method and device can enhance the quality and the preserving rates of effective components during the stir-frying of the traditional Chinese medicine decoction pieces.

Owner:湖南药圣堂中药科技有限公司

Novel drying technical method for preparing supper absorbent resin

PendingCN109900089AEvenly heatedAvoid it happening againDrying machines with non-progressive movementsDrying solid materialsEngineeringPetroleum engineering

The invention relates to the technical field of supper absorbent resin drying, in particular to a novel drying technical method for preparing supper absorbent resin. The novel drying technical methodfor preparing the supper absorbent resin specifically comprises the following drying technical steps: S1, filling a heat transferring oil pipe of an oil bath drying device with heat transferring oil,and setting the temperature of the heat transferring oil at 100-170DEG C; S2, pouring plant oil into the oil bath drying device, and setting the temperature of the plant oil at 90-120DEG C; S3, putting the prepared supper absorbent resin in an oil bath separating tank, and putting the oil bath separating tank in the plant oil of the oil bath drying device; S4, starting a mixing paddle of the oil bath drying device and setting the speed of the mixing paddle at 10-15r / min; S5, after carrying out drying for 1 hour, taking out the oil bath separating tank; S6, processing the supper absorbent resinin the oil bath separating tank by a centrifugal de-oiling technology; S7, processing the de-oiled supper absorbent resin by a washing technology; and S8, sieving the washed supper absorbent resin.

Owner:ZHEJIANG TRIPLE WIN MEDICAL APPLIANCE +1

Device for removing electroplating solution in electroplating bath

The invention discloses a device for removing an electroplating solution in an electroplating bath, and belongs to the technical field of electroplating. The device comprises an arc-shaped base plate, wherein a telescopic cylinder is movably connected to the middle of the top of the arc-shaped plate, a cleaning mechanism is movably connected to the bottom of the inner surface of an electroplating tank, electroplating pole plates are fixedly connected to two sides of the top of the electroplating tank, and electroplating installation slots are formed in the middles of the tops of the electroplating pole plates; the cleaning mechanism comprises a sealing plate, a filter mechanism is movably connected to the top of the sealing plate, the bottom of the filter mechanism penetrates through a sealing plate and extends to the bottom of the sealing plate, a force dispersing mechanism is movably connected to the bottom of the filter mechanism, and a hard hitting plate is movably connected to the side, away from the filter mechanism, of the force dispersing mechanism. The filter mechanism is directly arranged in the electroplating tank, and the electroplating solution can be removed without stopping equipment, so that a long shutdown time is avoided, it is ensured that electroplating can be conducted continuously, and the machining efficiency of the equipment is improved.

Owner:万廷刚

Temperature regulating member

InactiveUS20090078395A1Easily positionEasily changeBioreactor/fermenter combinationsBiological substance pretreatmentsHeat distributionThermal radiation

A temperature regulating member for avoiding a deterioration in heat radiating output efficiency and deterioration in buffering occurring due to a non-uniform heat distribution within the heat storage material. Heat non-uniformities within the heat storage material are eliminated by inserting one or multiple agitating tools inside the heat storage material by generating an agitating current occurring due to use of agitator tools whose relative positions change within the heat storage material during shipping.

Owner:HITACHI LTD

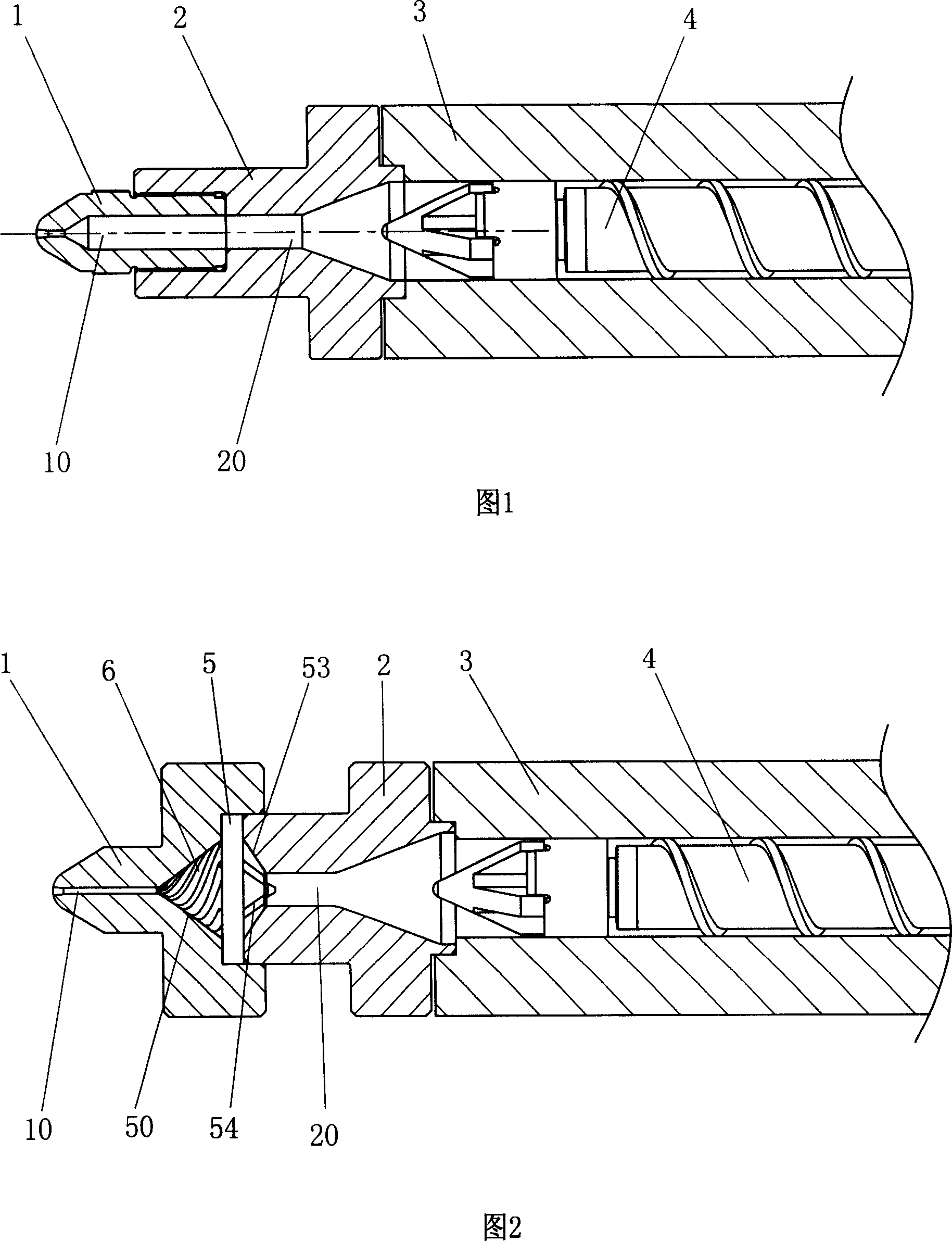

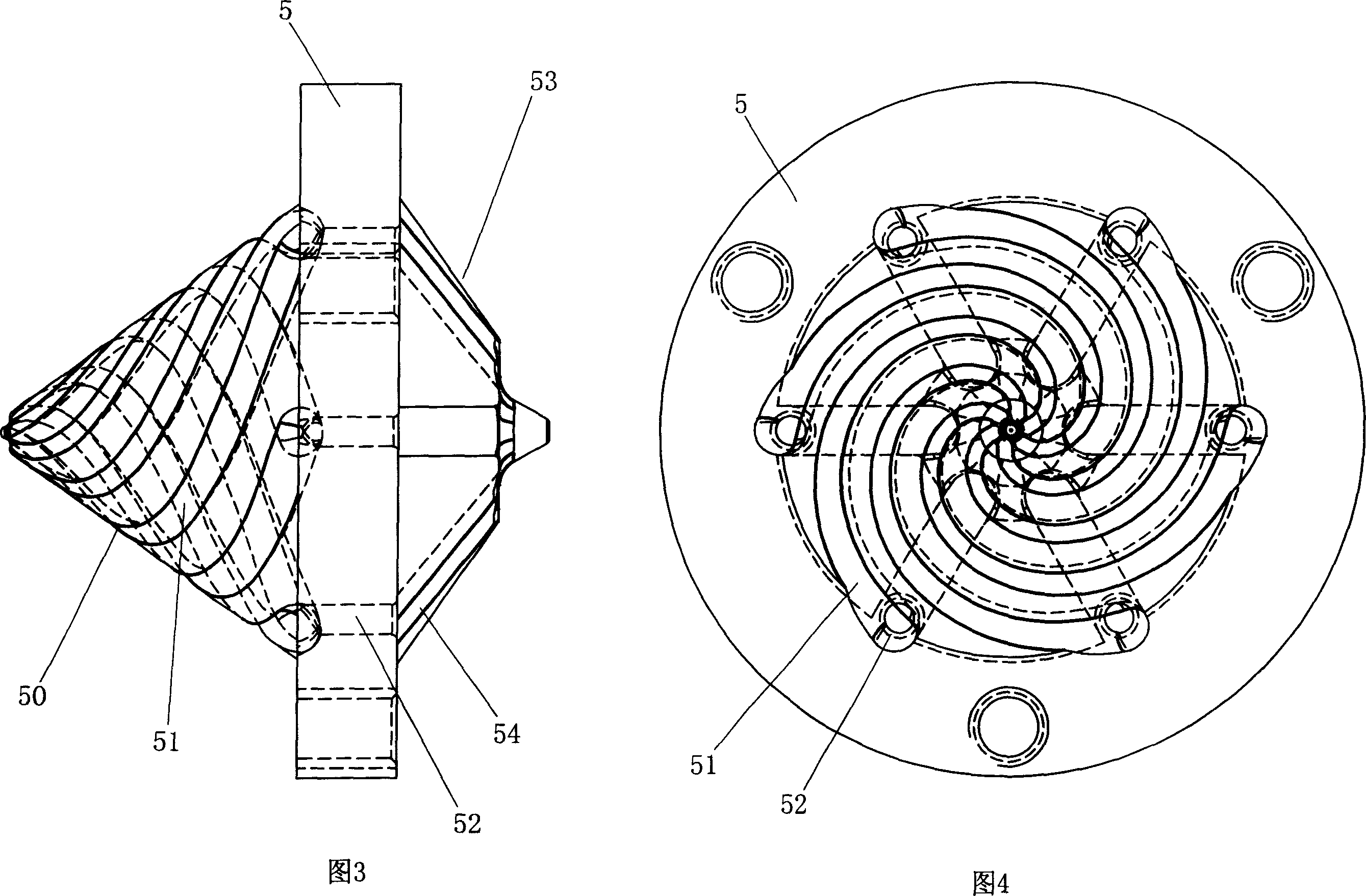

High molecule polymer diversion and rotation device

The invention relates to a device for reducing the transmission resistance of macromolecule polymer and making the internal temperature uniform, wherein the invention is characterized in that: it comprises flange, nozzle and main body; there is the first taper match surface and several screw channels between the nozzle and main body; two ends of screw channel are though to the nozzle. The invention can be mounted at the head of injection to divert, collect and rotate the macromolecule polymer, to make the temperature uniform and disperse paint or additive uniformly; and since the material is rotated in chamber, the molecule chain will be screwed, to improve the physical property.

Owner:佛山市顺德区震德塑料机械有限公司

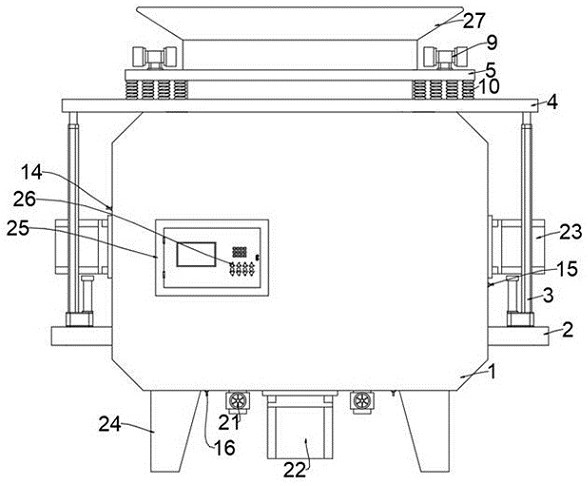

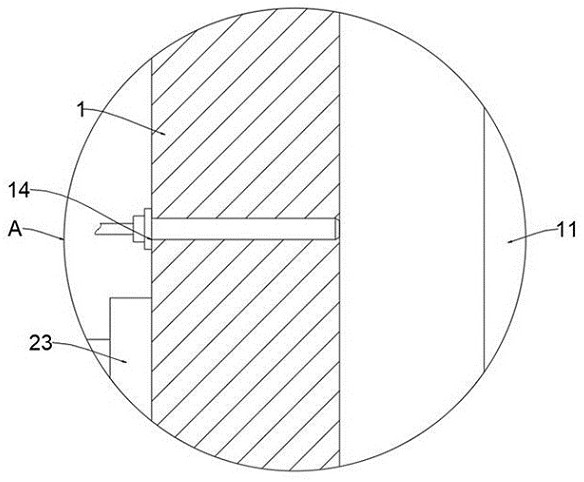

Plaster decocting equipment with automatic temperature control adjusting function

InactiveCN112402257AEvenly heatedIncrease heatPharmaceutical product form changeDomestic articlesMedicinal herbsTemperature control

The invention discloses plaster decocting equipment with an automatic temperature control adjusting function, and relates to the technical field of plaster decocting equipment. The problems that currently, when people decoct plaster, upper, middle and lower layers of the plaster are affected by the outside, consequently, the temperatures are different, effective components in medicinal materials cannot be well excited, the temperature is not easy to control in the plaster decocting process, the medicinal materials are prone to burn, and consequently, the product quality is greatly influenced are solved. An upper heating plate is installed at the upper end of one side in a decocting box, a middle heating plate is installed at the lower end of the other side in the decocting box, bottom heating plates are installed on the two sides of the lower end in the decocting box correspondingly, and a temperature compensation heating plate is installed at the lower end in the decocting box; the temperature compensation heating plate, the bottom heating plates, the middle heating plate and the upper heating plate are all fixedly connected with the decocting box; and an upper temperature sensoris installed at the upper end of the other side in the decocting box.

Owner:江西回医堂中医药科技有限公司

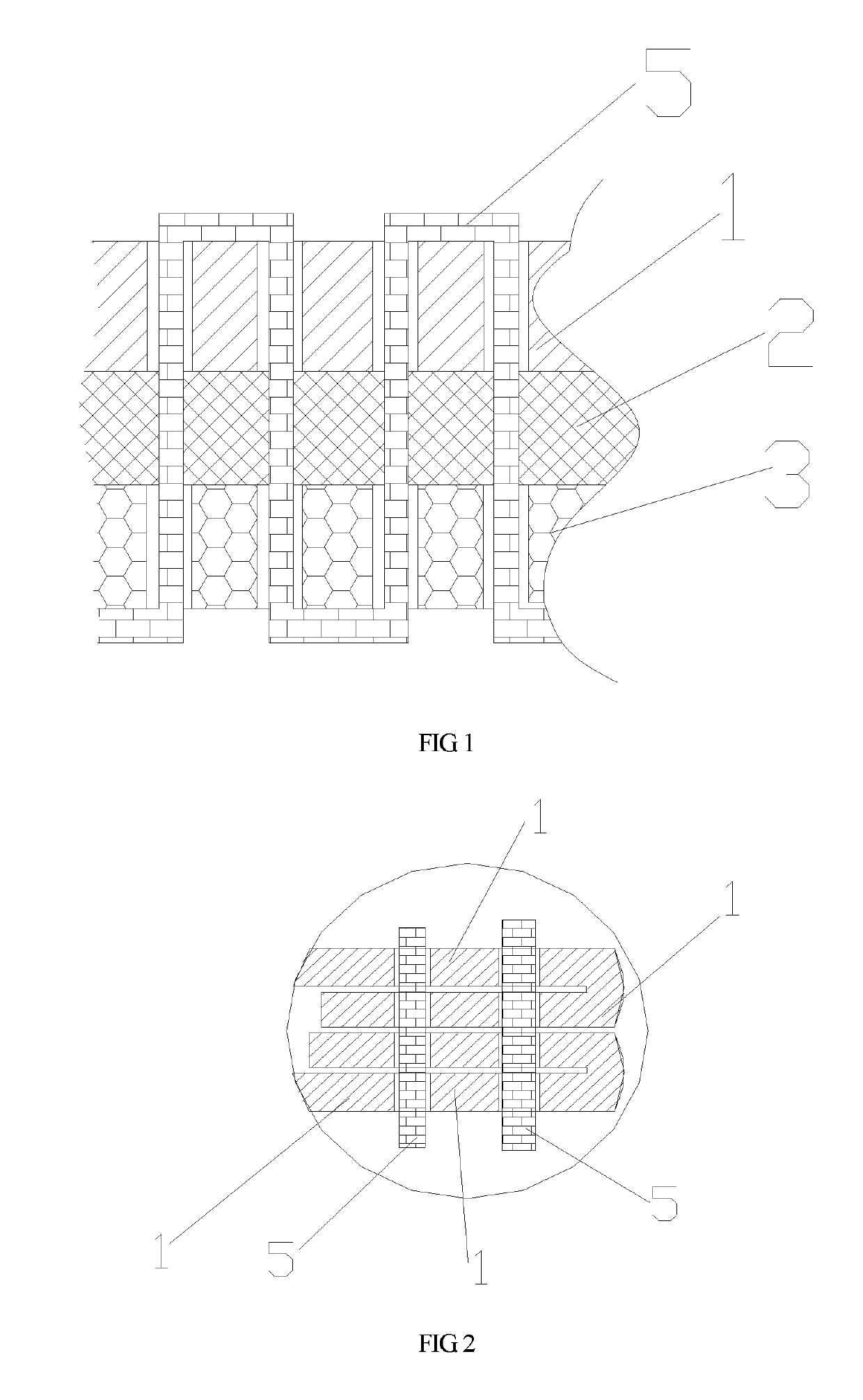

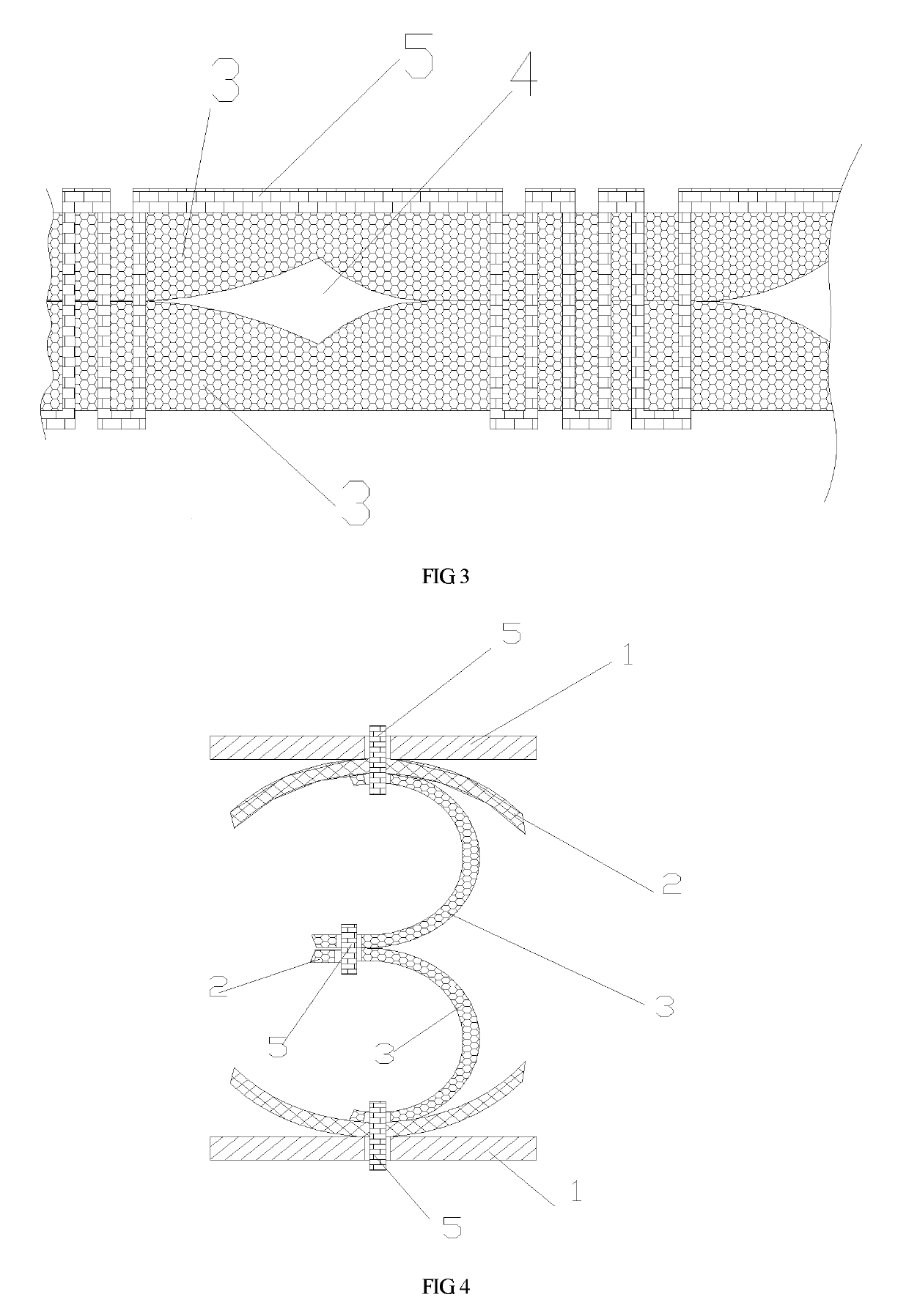

Sewing method and structure for duvet

ActiveUS20190191896A1Improve heat transfer performanceImprove ventilationBlanketBed linenEngineeringMechanical engineering

Owner:ZHEJIANG SAMSUNG DOWN CO LTD

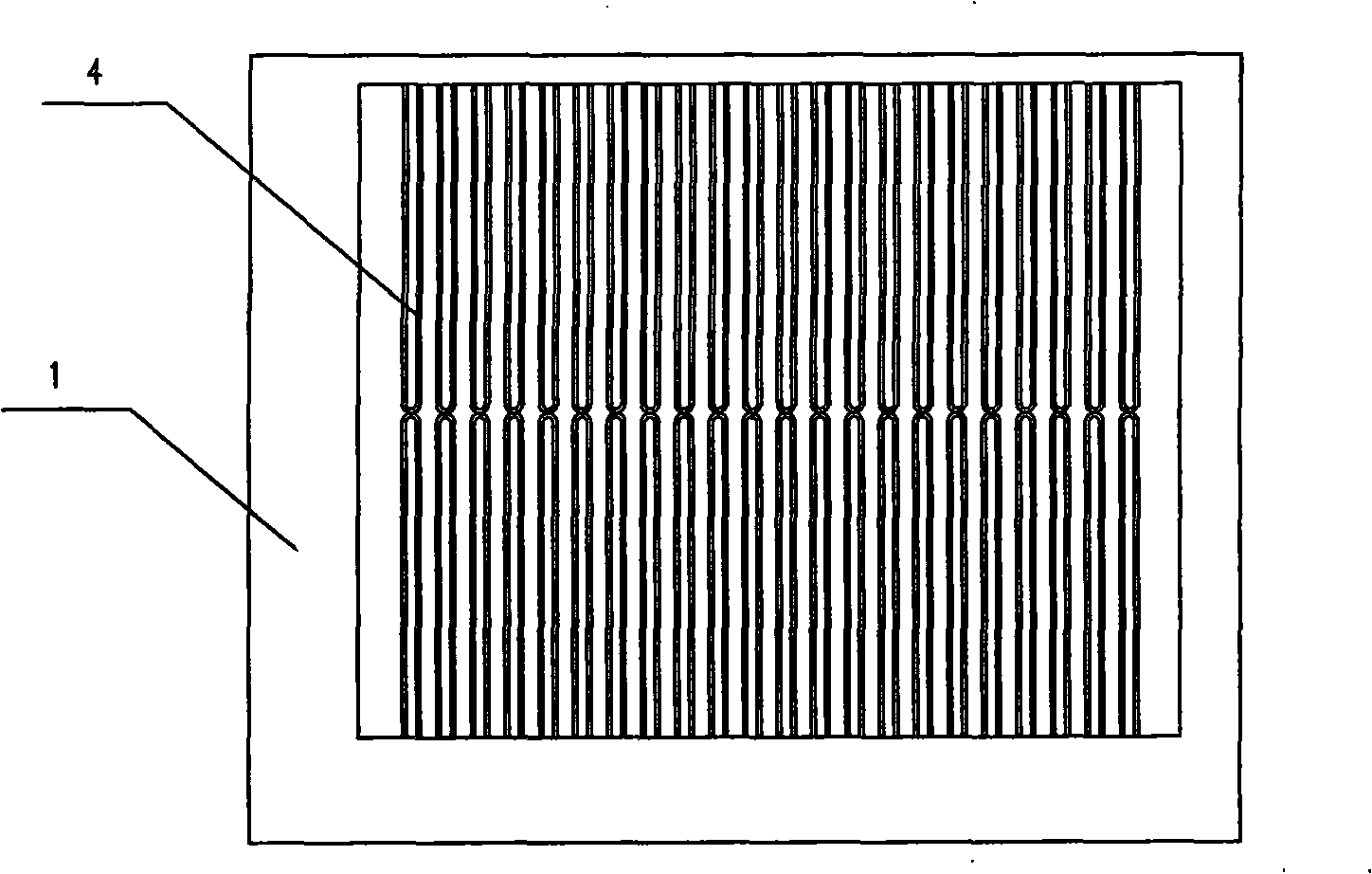

Biochemical incubator based on image acquisition apparatus

InactiveCN108395976AEasy to observeUniform internal temperatureBioreactor/fermenter combinationsBiological substance pretreatmentsBiochemical engineeringMoisture sensor

The invention discloses a biochemical incubator based on an image acquisition apparatus. The biochemical incubator comprises a casing body and a casing door, the casing body comprises a heating device, a refrigeration apparatus, a temperature sensor, a humidity sensor and several mutually parallel separator plates, each separator plate comprises several through holes, a light source part and an image acquisition apparatus are fixed at the bottom of each separator plate, a first fan is arranged in the casing body, a second fan is fixed at an inner side of the casing door, and a display part isarranged at the casing door. An internal part of the biochemical incubator is conveniently observed, and the internal temperature is uniform.

Owner:YANGZHOU HAICHENG BIOTECH CO LTD

Chlorine trifluoride synthesis method

PendingCN114655929AHigh reaction yieldUniform internal temperatureInter-halogen compoundsEngineeringMixed materials

The invention discloses an energy-saving and emission-reducing chlorine trifluoride synthesis preparation method, which comprises the following steps of: adopting mixed gas of raw material fluorine gas and nitrogen gas, enabling the mixed gas and chlorine gas to firstly enter a static mixer to be fully mixed, enabling the mixed material to enter a heat recoverer, preheating the raw material in the material, pre-cooling the product, and recycling the reaction heat, thereby achieving the energy-saving effect; raw materials are preheated and then enter a tubular reactor, reaction products are cooled by a heat recoverer and then enter an adsorption column, hydrogen fluoride impurities generated by reaction are adsorbed and removed, the reaction products enter a condenser after the hydrogen fluoride impurities are removed, the raw materials are liquefied and then enter a gas-liquid separator, a liquid phase enters a collection steel cylinder, and chlorine trifluoride is obtained. According to the invention, the reaction heat is recycled, the energy consumption of the device is low, hydrogen fluoride impurities can be removed, and the reaction yield is high, the product purity is high and the reaction yield is high.

Owner:SUZHOU JINHONG GAS CO LTD

a steam box

The invention discloses a steam box. According to the technical scheme, the steam box is characterized in that the steam box comprises a box body, a conveying roller, a steam pipeline, nozzles and a heater; a feeding end and a discharging end are arranged at the two ends of the box body respectively; the heater, the conveying roller and the steam pipeline are all arranged inside the box body; the nozzles are arranged on the steam pipeline; air supply mechanisms are arranged on the surface of the box body, and the box body is provided with mounting holes allowing the air supply mechanisms to be mounted; each air supply mechanism comprises fan blades and a drive motor, and the fan blades are arranged on the corresponding drive motor; the nozzles are hinged to the steam pipeline.

Owner:镇江越升智能装备制造有限公司

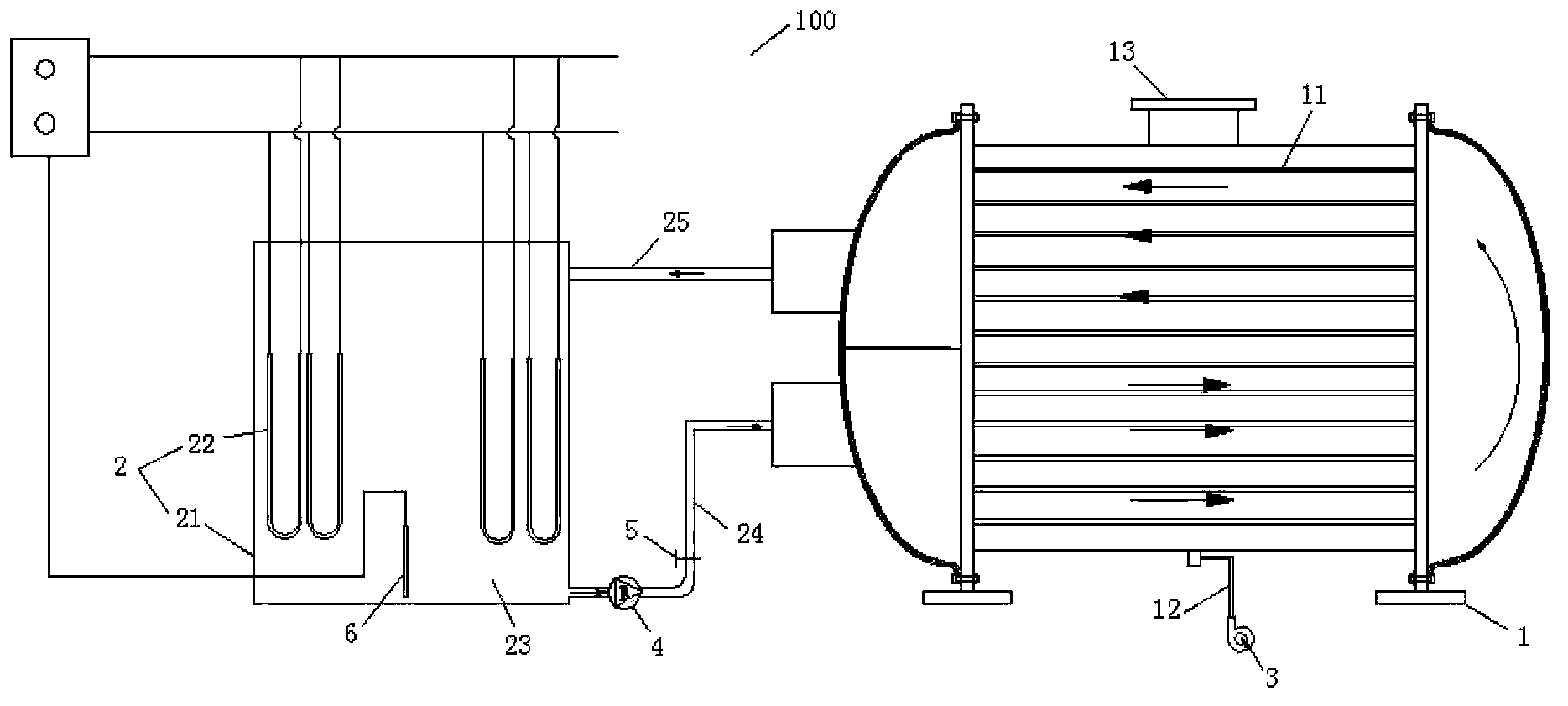

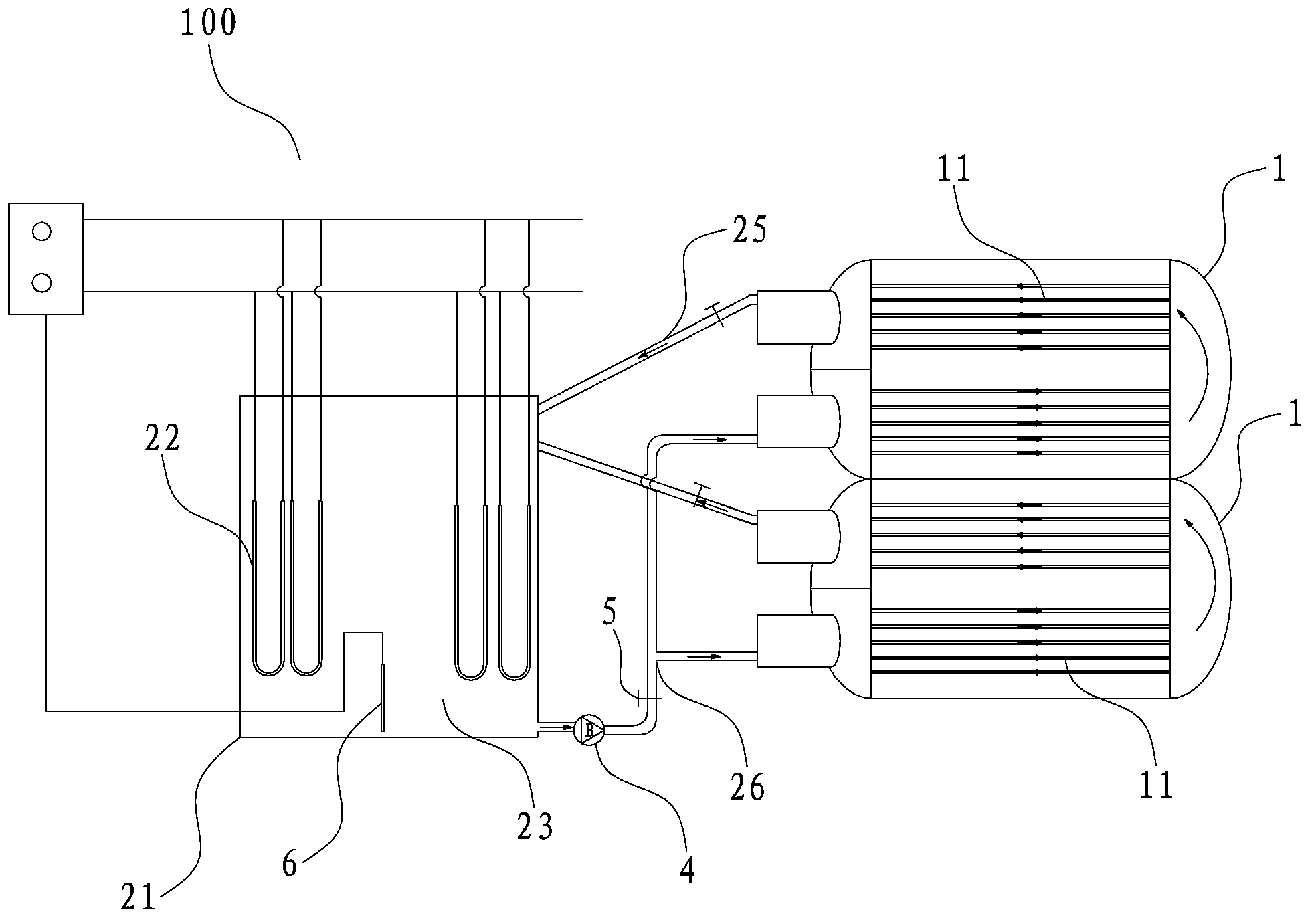

Heat exchanger component

InactiveCN104165544AGood and efficient dryingUniform internal temperatureIce removalPlate heat exchangerWater vapor

The invention discloses a heat exchanger component. The heat exchanger component comprises a heat exchanger, a hot water component and an exhaust component, wherein a heat exchange pipe is arranged in the heat exchanger; the heat exchanger has a drain outlet and an exhaust port; the hot water component is communicated with the heat exchange pipe for guiding high-temperature water into the heat exchange pipe; and the exhaust component is communicated with the heat exchanger for exhausting water vapor in the heat exchanger. According to the heat exchanger component disclosed by the invention, the high-temperature water can emit heat into the heat exchanger through arranging the hot water component, so that the whole heat exchanger is quickly heated, and the moisture in the heat exchanger is quickly removed; the exhaust component can be arranged to accelerate quick flowing of the air in the heat exchanger, so that the air with the water vapor is exhausted from the exhaust port; the hot water component and the exhaust component are combined to make the internal temperature of the heat exchanger uniform; and the rising water vapor is not condensed any more, but is directly exhausted from the exhaust port.

Owner:CHONGQING MIDEA GENERAL REFRIGERATING EQUIP

Synchronous electrical machine

PendingCN111989848AImprove reliabilityImprove cooling effectSynchronous generatorsMagnetic circuitRotational axisDc current

Owner:SAFRAN ELECTRICAL & POWER

Storage and transportation box for aquatic product samples of nitrofuran metabolites to be detected

ActiveCN114348464AIngenious structureEasy accessDomestic cooling apparatusLighting and heating apparatusWater storageMetabolite

The aquatic product sample storage and transportation box comprises a heat preservation box body, a box cover, a lining box and a refrigerant box, a supporting plate is arranged in the lining box, a water storage chamber is formed by a gap between the supporting plate and the lining box, an inner surrounding plate is arranged on the lining box, a lower channel is formed by a gap between the inner surrounding plate and the lining box, and the lower channel is communicated with the water storage chamber. A sample groove is formed in the inner surrounding plate, a water leakage hole is formed in the groove bottom of the sample groove, and a circulation hole is formed in the groove wall of the sample groove; the refrigerant box comprises an outer frame and a guide cylinder, the outer frame is placed on the lining box, a heat conducting plate is arranged in the outer frame, an annular L-shaped groove is formed below the heat conducting plate, the L-shaped groove, the outer frame and the heat conducting plate define a water collecting cavity, a heat exchange chamber is formed by a through hole in the heat conducting plate, the vertical face of the L-shaped groove and the heat conducting plate, and the guide cylinder is fixed to the bottom of the L-shaped groove. A gap between the guide cylinder and the outer frame forms an upper channel, and the guide cylinder is provided with an inlet. The device is simple in structure, samples can be independently placed and are convenient to take and place, the internal temperature is uniform, and the refrigeration effect is good.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

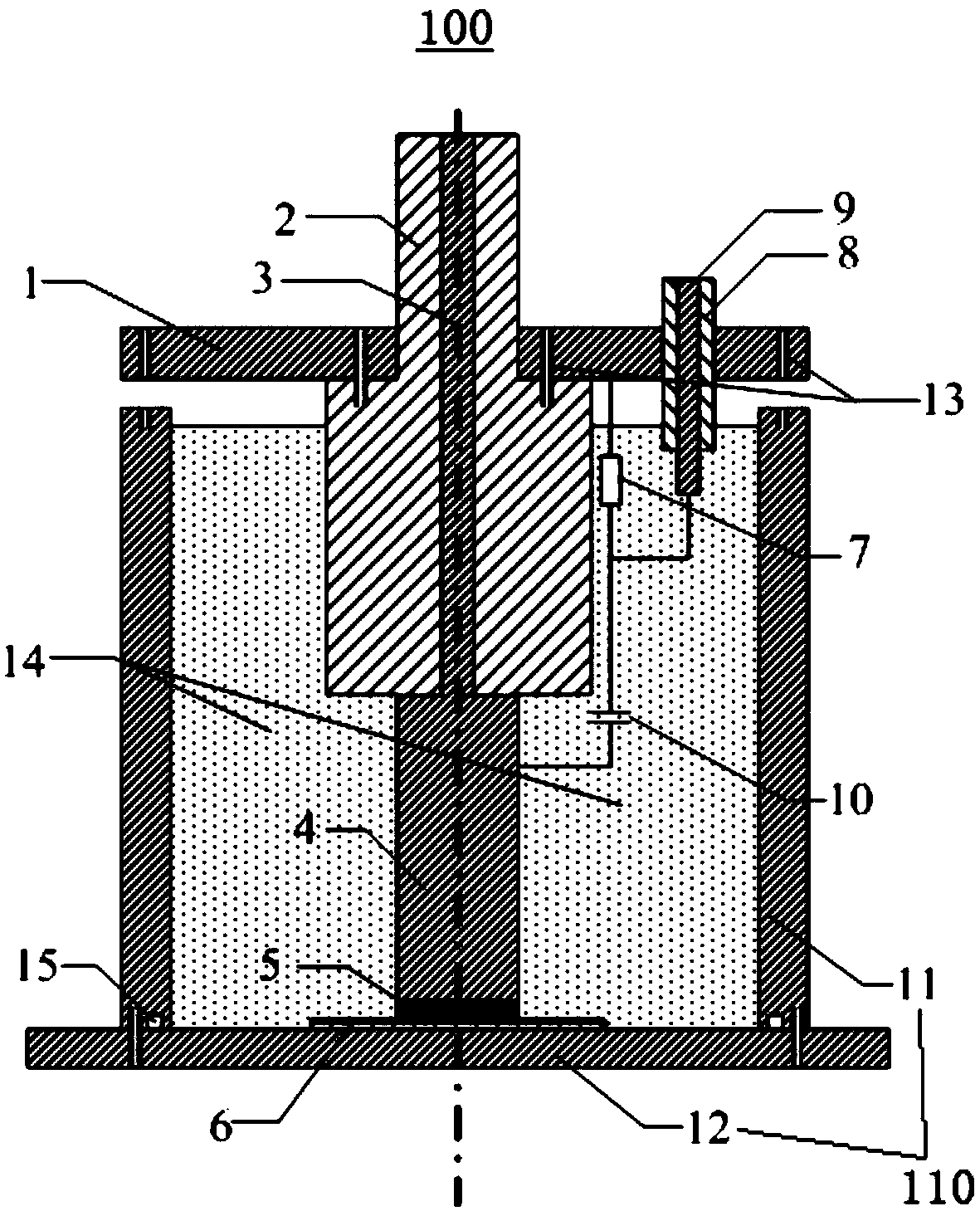

High-voltage electrode device for insulating self-recovery space charge measurement

ActiveCN106249064BImprove the level of flashoverEasy to replaceElectrical measurementsSelf recoveryTest sample

The invention discloses a high-voltage electrode device for insulated self-recovery type space charge measurement. The device comprises a grounding metal radome and a top cover; the upper end of the grounding metal radome is open, the grounding metal radome is internally provided with high-voltage metal electrode and filled with a liquid insulating layer, and a tested sample is placed in the grounding metal radome; and the top cover is mounted in the open end of the grounding metal radome detachably, and provided with a high-voltage DC conducting rod and a high-voltage pulse conducting rod, the high-voltage DC conducting rod is connected with the high-voltage metal electrode, a capacitor is connected between the high-voltage pulse conducting rod and the high-voltage metal electrode, and the high-voltage metal electrode, the high-voltage DC conducting rod and the high-voltage pulse conducting rod are insulated from the top cover. The high-voltage electrode device can improve the flashover level of the surface voltage of the tested sample, realizes insulated self-recovery of breakdown, reduces processing, debugging and calibrating time, and also has the advantages of high withstanding voltage, compact structure, high stability, uniform internal temperature and low cost.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com