Patents

Literature

3717results about How to "Improve purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Power having nutrition of paddy, bean, fruit, vegetables and tea with the functions of equalizing the nutrition, losing weight and reducing blood sugar

ActiveCN101116510ABalanced nutritionHave weight lossPre-extraction tea treatmentMetabolism disorderFiberGlucose polymers

The present invention provides a low-lipid, high-fiber, balanced-nutritional, instant-taking and instant-resolving powder made from all natural components including corn, bean, flower, vegetable, fruit, tea and bi-usage plants for both food and medication. The nutritional powder provided by the present invention has not only the functions to balance the nutrition, but also the effect to decrease the body weight, lower the blood glucose, and effectively prevent and treat the diabetes.

Owner:湖南湘泉药业股份有限公司

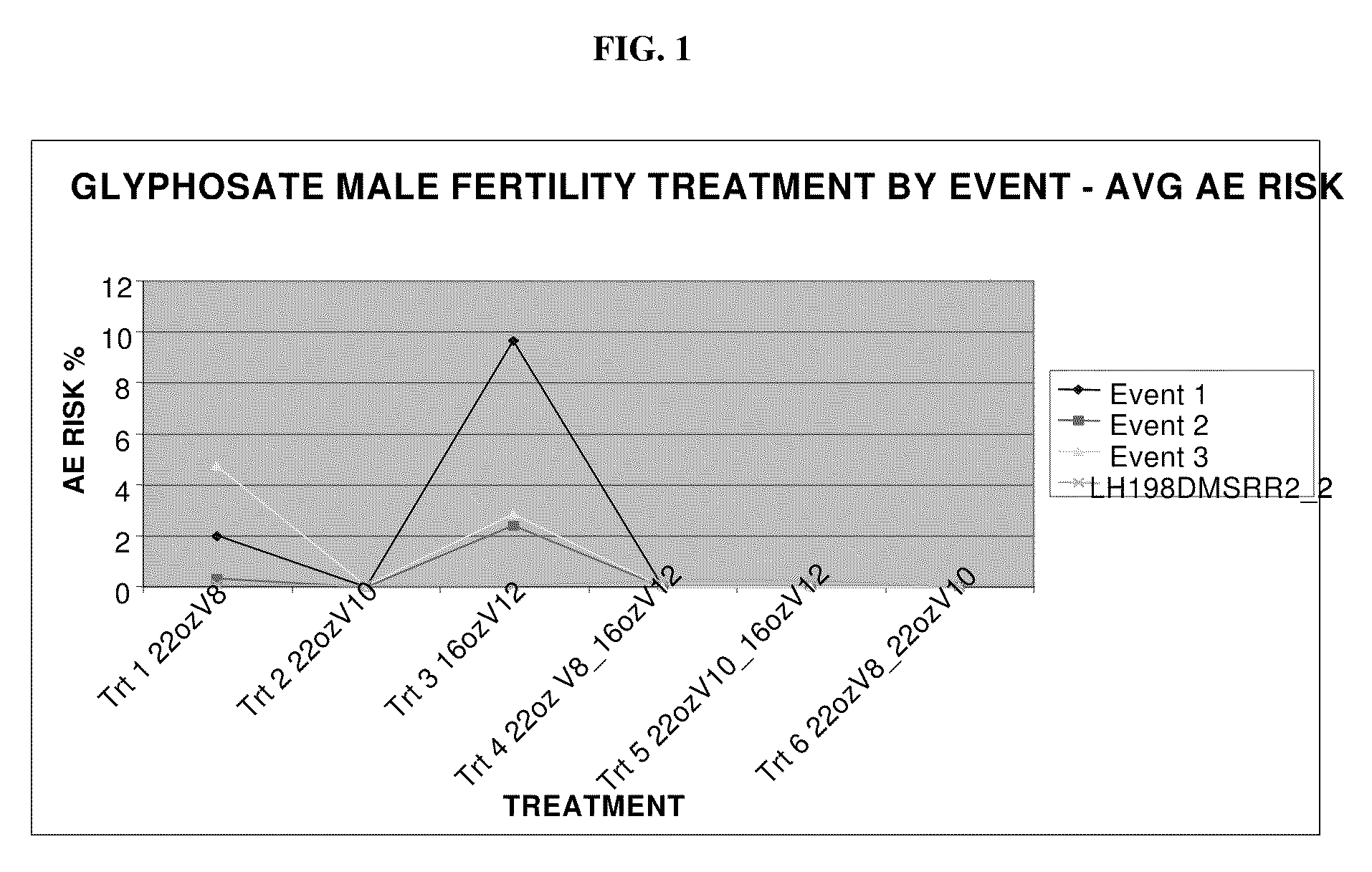

Method to enhance yield and purity of hybrid crops

ActiveUS20090165166A1Improve satisfactionExpensive to developBiocideSugar derivativesHybrid seedHybrid species

Owner:MONSANTO TECH LLC

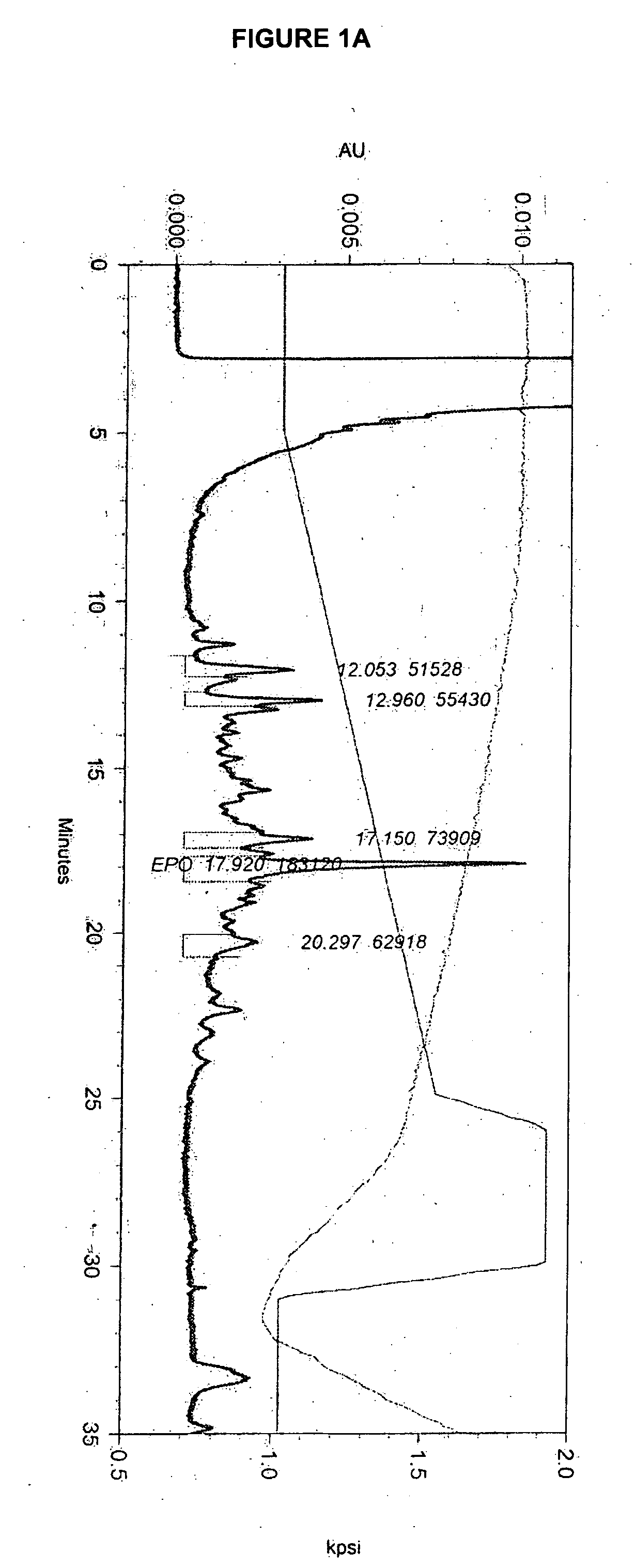

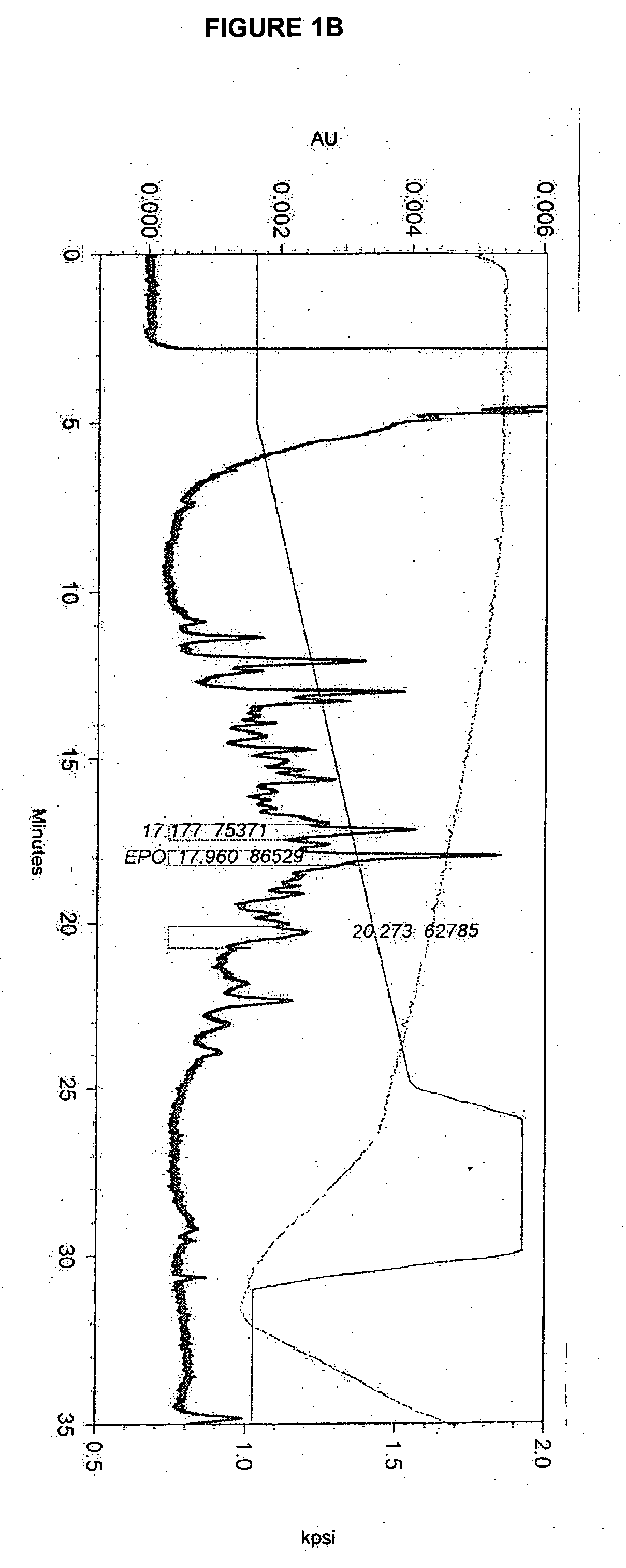

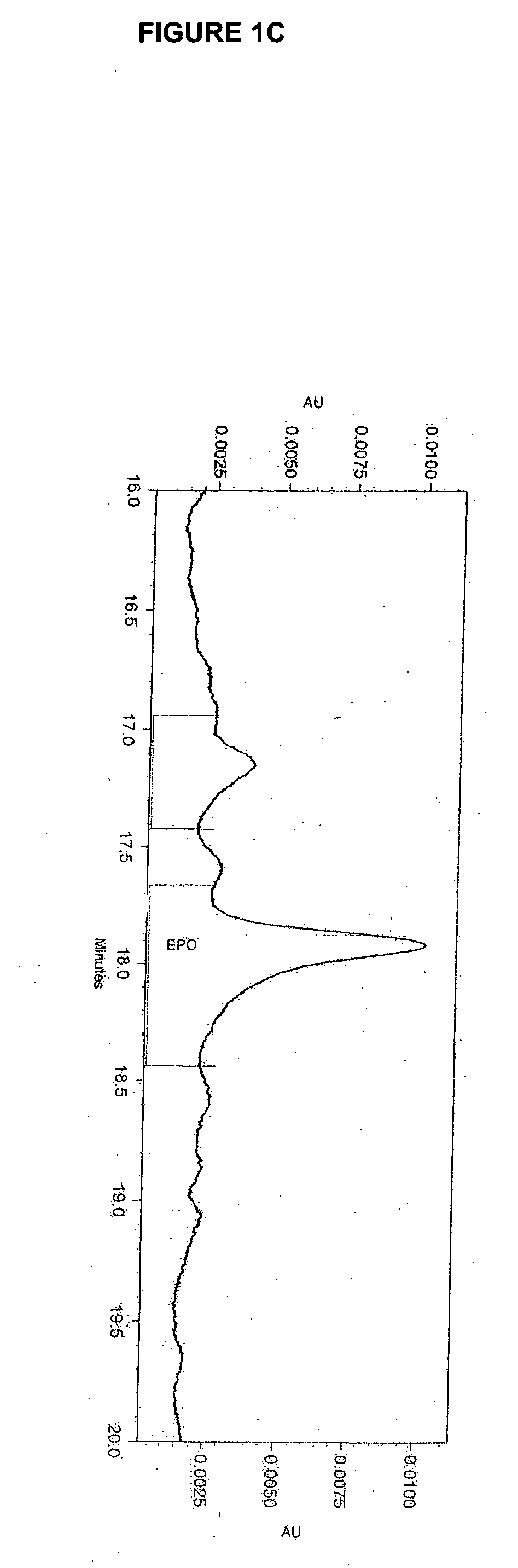

Manufacturing process for the production of peptides grown in insect cell lines

InactiveUS20060246544A1Improve purityHigh concentrationHydrolasesPeptide/protein ingredientsPeptideGlycosyltransferase

The present invention provides a manufacturing method for the production of peptides that are grown in insect cell lines. The peptides are grown in insect cell cultures that are infected with baculovirus particles in a culture supplemented with a lipid mixture. The peptides are then isolated from the insect cell culture using a method that employs a tangential flow filtration cascade. The isolated peptides are glycopeptides having an insect specific glycosylation pattern. The glycopeptides may then be conjugated to a modifying group via linkage through a glycosyl linking group interposed between and covalently attached to the peptide and the modifying group. The conjugates are formed from glycosylated peptides by the action of a glycosyltransferase.

Owner:NOVO NORDISK AS

High strength steel plate for big thickness tall building structure and production method thereof

InactiveCN101323929AIncrease thickness specificationLow yield ratioMolten metal pouring equipmentsRoll mill control devicesSheet steelChemical composition

The invention relates to a steel plate with high intensity and used in construction structures of high buildings with large thickness and a production method thereof. The steel plate of the invention consists of the following components according to weight percentage: less than or equal to 0.20 percent of C, less than or equal to 0.55 percent of Si, 1.00 to 1.70 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.70 percent of Ni, less than or equal to 0.70 percent of Cr, less than or equal to 0.20 percent of V, more than or equal to 0.015 percent of Nb, less than or equal to 0.20 percent of Ti, 0.020 to 0.060 percent of Al, and the rest is Fe and inevitable impurity. The produced Q460E-Z35 steel plate with a thickness of 100 to 110 mm is capable of meeting the requirement of high intensity steel of large-thickness construction structure (Ceq is less than or equal to 0.50 percent); the steel plate of the invention can be applied to constructing the structure of high building, has good performance of welding and anti-layer tearing, can meet the requirement of on-site key stress points, has simple production process and is capable of realizing bulk production. The high intensity steel plate of the invention has the following advantages that (1) the steel quality of the invention is purer with less than or equal to 0.025 percent of P and less than or equal to 0.010 percent of S; (2) yield ratio of the invention is relatively low and less than 0.78 actually; (3) the anti-layer tearing performance is good, and Z is larger than or equal to 35 percent in whole thickness direction; (4) low-temperature toughness at the temperature of minus 40 DEG C is good; (5) maximum thickness of the steel plate can reach 110mm.

Owner:WUYANG IRON & STEEL

Steel plate with low welding crack sensitivity and production method thereof

InactiveCN101096738AHigh strengthMeet the requirements of different site construction process conditionsRoll mill control devicesHeat treatment process controlChemical compositionSheet steel

The invention discloses a low-welding crack sensitivity steel board and manufacturing method, which comprises the following parts: not more than 0.07% C, 0.15-0.40% Si, 1.00-1.60% Mn, not more than 0.015% P, not more than 0.010% S, not more than 0.30% Cu, not more than 0.50% Ni, not more than 0.30% Cr, not more than 0.30% Mo, not more than 0.08% V, not more than 0.08% Nb, 0.010-0.020% Ti, not more than 0.003% B, Fe and inevitable impurity. The invention is characterized by the following: (1)displaying lower welding crack sensitivity component with Pcm not more than 0.20%; (2)mating the strength and flexibility reasonably with fitful yielding ratio; (3)making the price and property of the steel board superior to the congeneric import product; (4)making the maximum breadth of steel board to 4000mm; (5)simplifying the technique to ensure higher flatness without quenching water.

Owner:WUYANG IRON & STEEL

Method for processing regenerated polyester staple fiber by using waste polyester textile

ActiveCN102899729AImprove qualityHigh strengthFilament forming substance formingMelt spinning methodsPolyesterPolymer science

The invention relates to a method for producing regenerated polyester staple fibers, in particular to a method for processing regenerated polyester staple fibers through a physical method by using waste polyester textiles. The method for processing regenerated polyester staple fibers by using waste polyester textiles comprises the following steps of: conducting color matching, proportioning and drying to friction materials produced by using the recovered waste polyester textiles; squeezing and fusing the dried friction materials to obtain fusant; primarily filtering the fusant, feeding the fusant into a high-vacuum tempering and viscosity-regulating reaction kettle; filtering the fusant, feeding the fusant into a spinning manifold and metering spinning; and after spun nascent fibers are bundled, conducting oiling through a dipping tank and a drawing tank, steam secondary drawing, overlapping, curling, relaxed heat setting, cutting and packing to obtain the regenerated polyester staple fibers. By adopting the method for processing regenerated polyester staple fiber by using waste polyester textiles, the technical problem of producing high-quality regenerated polyester staple fibers by using the recovered textiles is solved, the cost of raw materials for producing the regenerated polyester staple fibers is decreased and the problem of recovering the waste polyester textiles is solved.

Owner:余姚大发化纤有限公司

Production method of ultra low carbon steel

InactiveCN102719600AReduce the rate of oxygen blowing heating upReduce temperature dropManufacturing convertersSlagNitrogen

The invention provides a production method of an ultra low carbon steel. The method comprises the steps of: employing a blowing process for desulfurization and slag removal of molten iron, with control of oxygen blowing time and smelting cycle of a converter, argon bottom-blowing in the whole course, and control of S content in slag lime, [C] content at converter end point, and temperature and oxygen activity at the endpoint, adding lime in a tapping process, and modifying ladle top slag after tapping; employing natural decarburization to control carbon content in an RH, wherein Als in molten steel is less than 0.03% after deoxidation, carrying out vacuum-breaking, adding aluminum powder and top slag modifier into the top slag, blowing argon with stirring, vacuumizing again, and carrying out clean circulation for 2-10 min; and carrying out continuous casting with protective casting in the whole course, wherein a nitrogen increase amount in the molten steel is controlled at less than 2 ppm. The invention can effectively reduce temperature drop in a transmission process, reduce oxygen blowing heating rate in a subsequent RH refining treatment, save energy and shorten the time of refining. Besides, the method can effectively guarantee modification effect of the top slag, prevent nozzle clogging and realize sequence casting. Therefore, the method is particularly applicable to the production of high purity ultra low carbon steel.

Owner:ANGANG STEEL CO LTD

Production of clean high carbon chromic bearing steel

A method for manufacturing high-cleaning and high carbon complex bearing steel includes: 1) choosing charging mixture 2) first steel making molten steel by is greater than or equal to 30ton electric furnace a. smelting furnace burden b. running out foaming slag and adding lime c. alloying when steel tapping with 92% tap and >90% level 3) refining molten steel by steel ladle furnace a. cleaning steel ladle and furnace cleaning b. through bottom blowing argon mixing with 60 min, earlier stage argon blowing intensity 0.4Mpa and later stage 0.3Mpa, material adding amount is less than or equal to 8Kg / ton steel c. precipitating and deoxidizing by two-stage aluminum feeding method, adding crystallized silicon powder, fluorite(content of calcium is greater than or equal to 98%) into slag face, and dispersing deoxidizing 4) vacuum furnace treating a. bottom blowing argon 0.3Mpa, 25min, vacuum content is less than or equal to 140Pa b. bottom blowing argon mixing 15min, 0.1Mpa without materials after treating 5) molten steel mould casting under inactive gas a. ingot moulding temperature 70deg.C, runner brick coating b. pouring speed 5.1ton steel / min of ingot body and mouth. It achieves high yield.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Flying shear blade and preparation method thereof

InactiveCN101144140AImprove wear resistanceImprove hardenabilityHeat treatment process controlShearing toolsQuenchingImpurity

The present invention discloses a flying shear blade. The component has the weight percentage that C is 0.40-0.70, Si is 0.50-1.20, Mn is 0.20-0.50, Cr is 4.00-6.00, Mo is 0.50-2.00, V is 0.30-1.50, P is less than or equal to 0.02, S is less than or equal to 0.02, and Fe and inevitable impurity are the residual. The present invention provides a manufacture method of electric furnace smelting, and ingot casting; hydrogen removing and annealing treatment, and forging; preliminary heat treatment, rough machining, quenching and tempering heat treatment (primary quenching and high temperature tempering), semi finishing, ultimate heat treatment (secondary quenching, primary low temperature tempering, and secondary low temperature tempering), and fine finishing. By effectively controlling the material texture and the morphology, the quantity, the size and the distribution of carbonide, the quenching temperature and the tempering temperature of the quenching and tempering heat treatment, and the quenching temperature and the tempering temperature of the ultimate heat treatment are controlled, the texture crystal grains are more refined, the carbonide is distributed in a dispersed way, and simultaneously, the thermal stability and the retentivity are remarkably enhanced, thereby being advantageous for improving the operational performance of the blade.

Owner:BAOSHAN IRON & STEEL CO LTD +1

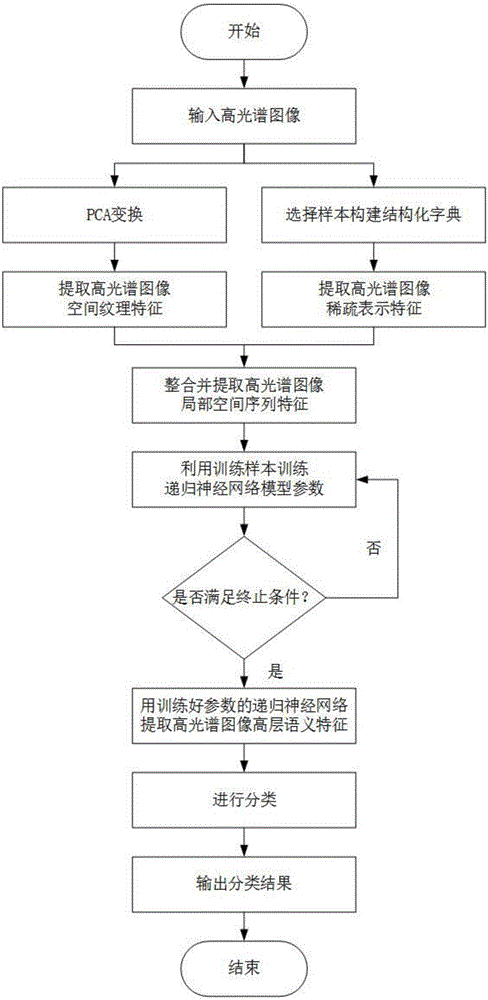

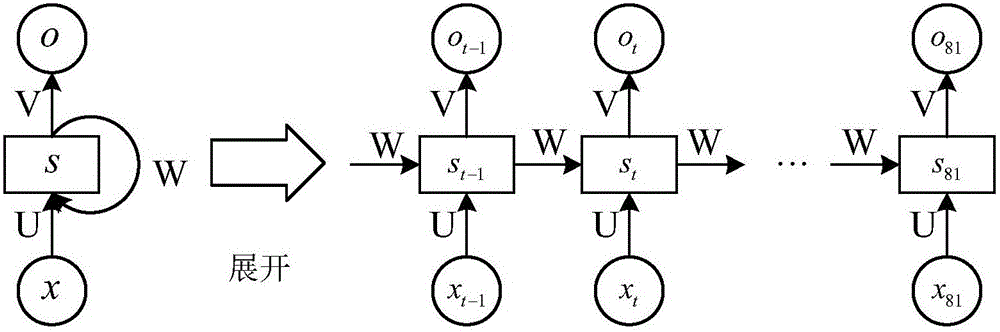

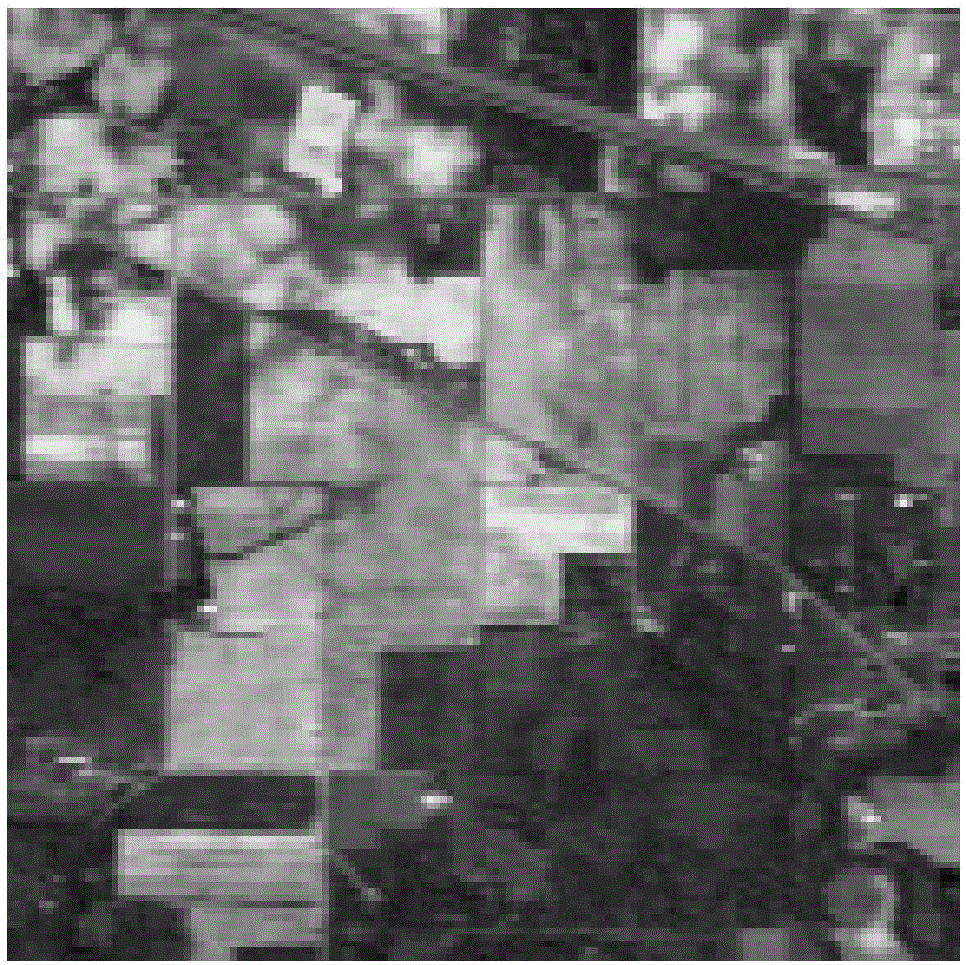

Hyper-spectral image classification method based on recurrent neural network

ActiveCN106815601AImprove purityImprove discrimination abilityCharacter and pattern recognitionNeural architecturesDisaster monitoringClassification methods

The invention discloses a hyper-spectral image classification method based on recurrent neural network with the object to solving the problems that in prior art, the input characteristic determination ability is weak and that the extraction of local spatial characteristics is not complete. The method comprises the following steps: 1) extracting the spatial texture characteristics and the sparse representation characteristics of a hyper-spectral image and piling and combining them as the low-level characteristics; 2) extracting from the low-level characteristics the sample local spatial sequence characteristics; 3) according to the local spatial sequence characteristics, creating a recurrent neural network model; and utilizing the training sample local spatial sequence characteristics to train the recurrent neural network model parameters; and 4) inputting the testing sample local spatial sequence characteristics into the well-trained recurrent neural network model; obtaining the highly abstract high-level semantic characteristics and obtaining the classification information of the testing sample. According to the deep learning method of the invention, the correct efficiency for hyper-spectral image classification is increased and the method can be used for vegetation investigation, disaster monitoring, map making and intelligence obtaining.

Owner:XIDIAN UNIV

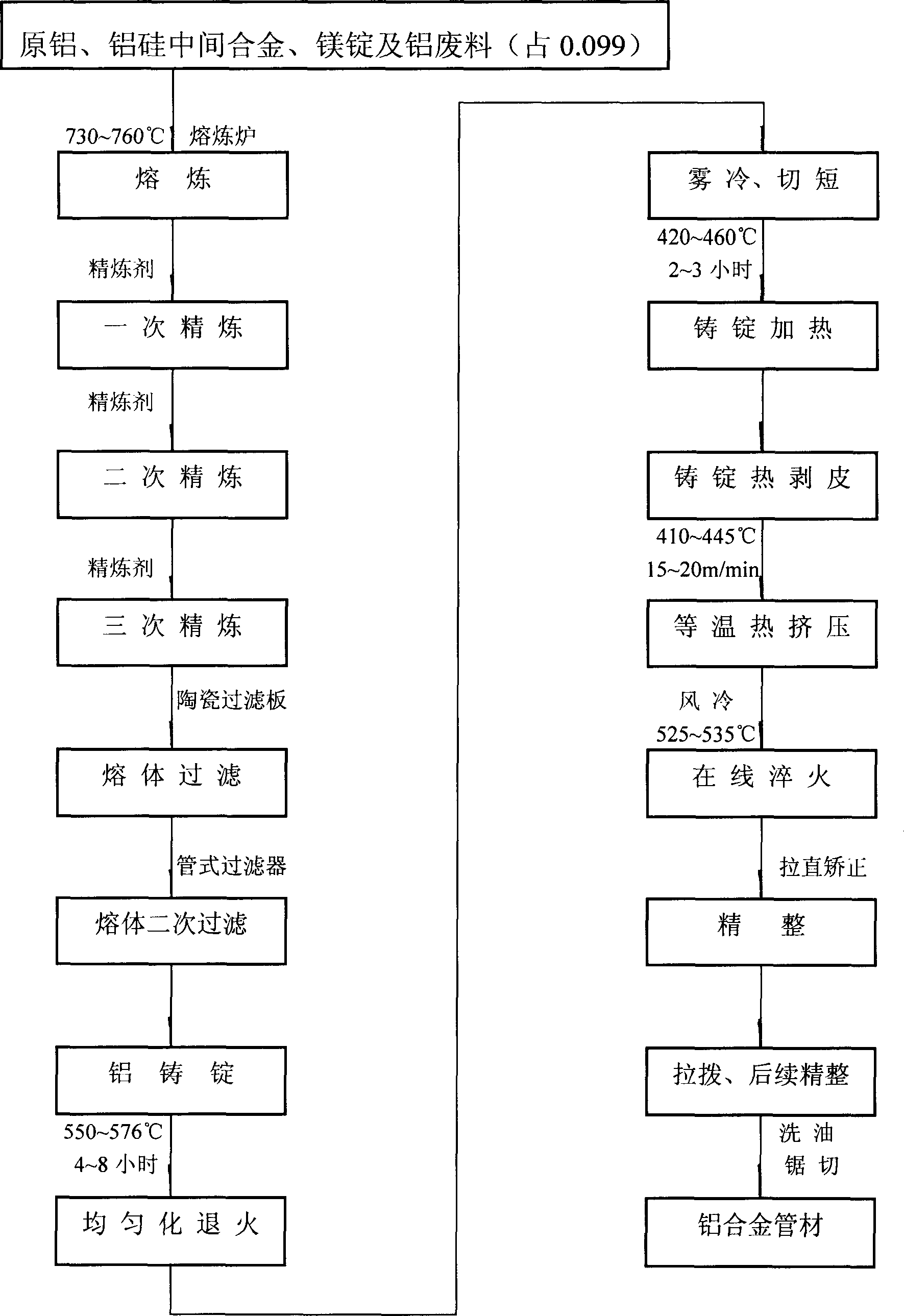

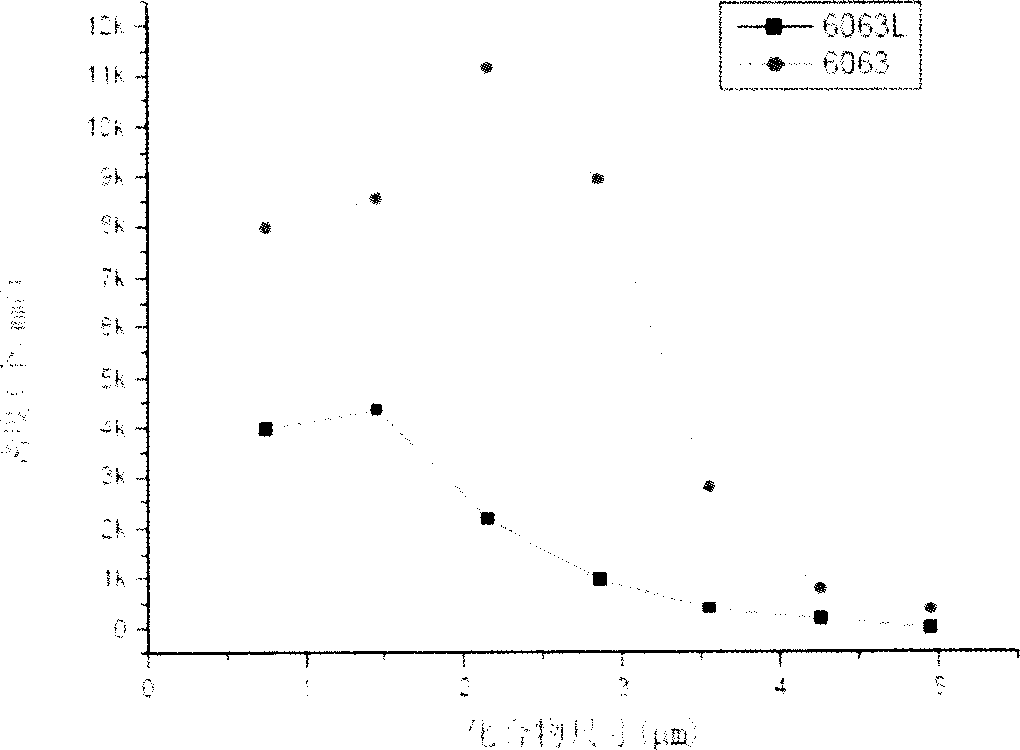

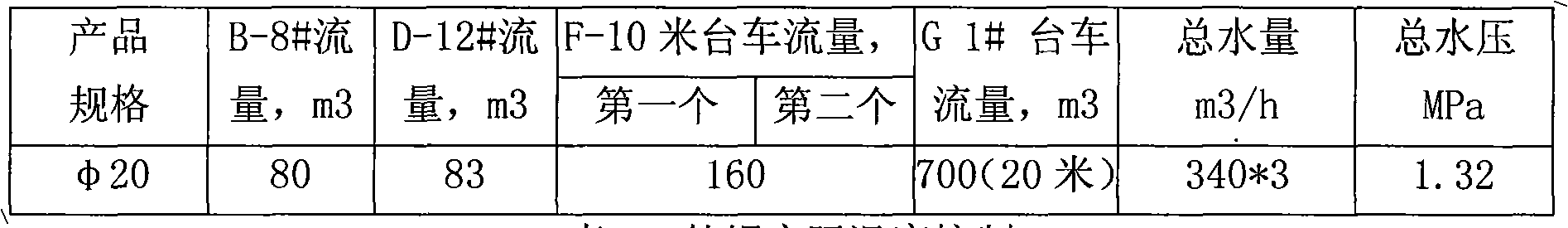

Aluminum alloy pipe for high purity and high precision light sensitive drum base material and producing method

The present invention is a kind of aluminum alloy pipe for making photosensitive drum and belongs to the field of non-ferrous metal pipe manufacture. The aluminum alloy pipe is made of material comprising Si 0.20-0.23 weight portion, Mg 0.45-0.50 weight portion, Fe 0.01-0.15 weight portion, impurity elements S and P 0.00-0.01 weight portion and Al 99.34-99.11 weight portions. It is produced through smelting, refining, in-situ fining, in-situ deairing, filtering, casting to form ingot, annealing, heating ingot to peel, extruding breakdown, quenching, finishing, drawing, post-finishing and other steps. The aluminum alloy pipe has low impurity content, and is suitable for manufacturing high purity and high precision photosensitive drum and similar products.

Owner:GUANGDONG HOSHION IND ALUMINUM CO LTD

Ultrahigh-malleability tunnel supporting anchor rod steel of converter continuous cast billet and production method

The invention relates to ultrahigh-malleability tunnel supporting anchor pile steel of converter continuous cast billet and a production method, which belongs to the technical field of a mine anchor rod. The anchor rod steel comprises the following components by weight percent: 0.5 to 0.70 percent of carbon, 0.15 to 1.20 percent of silicon, 0.5 to 2.5 percent of manganese, less than or equal to 0.045 percent of phosphorus, less than or equal to 0.045 percent of sulfur, 0 to 1.00 percent of chrome, 0 to 1.00 percent of nickel, 0 to 1.00 percent of molybdenum, 0 to 0.30 percent of copper, 0.03 to 0.40 percent of vanadium, 0.01 to 0.2 percent of aluminum, 0 to 0.10 percent of titanium, 0 to 0.10 percent of boron, 0.001 to 0.0 percent of niobium, 0.004 to 0.020 percent of nitrogen, and iron for the surplus; the yield strength Rel is larger than or equal to 600 MPa, the percentage elongation delta 5 is larger than or equal to 20 percent, the impact strength is 20 DEG C, Akv is larger than or equal to 27 J, and the breaking load is larger than or equal to 300 KN. By adopting the production process flow of converter crude metallurgy, LF furnace fine metallurgy and full protection continuous casting, the steel grade has the advantages that the purity is high, the structure is dense, the grain is fine, the physical chemistry properties of the steel are stable, the over-all mechanical property is good, the production operation and process flow are simple, and the rolled metal finished product can be directly used without heat treatment to the rear part.

Owner:SHOUGANG CORPORATION

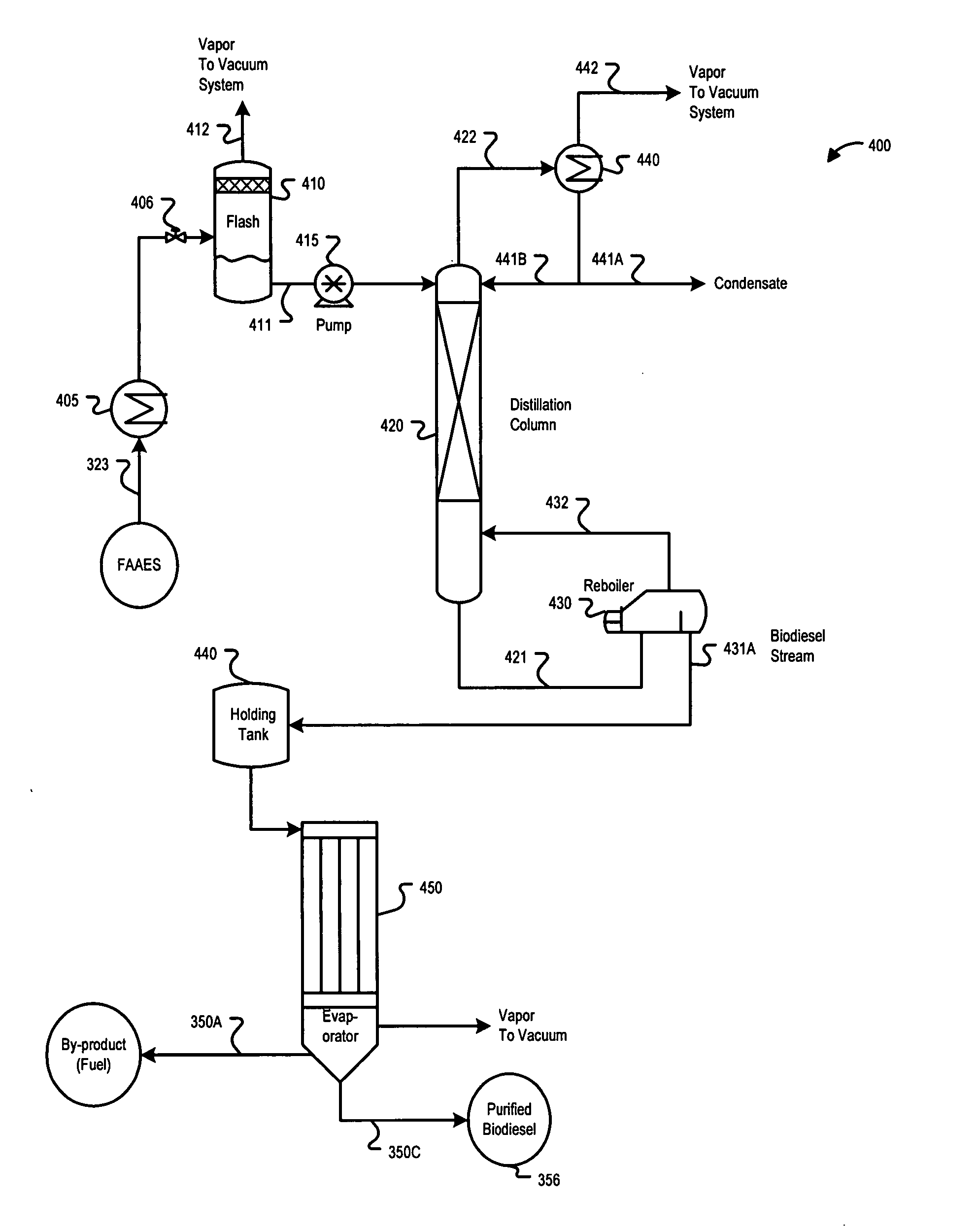

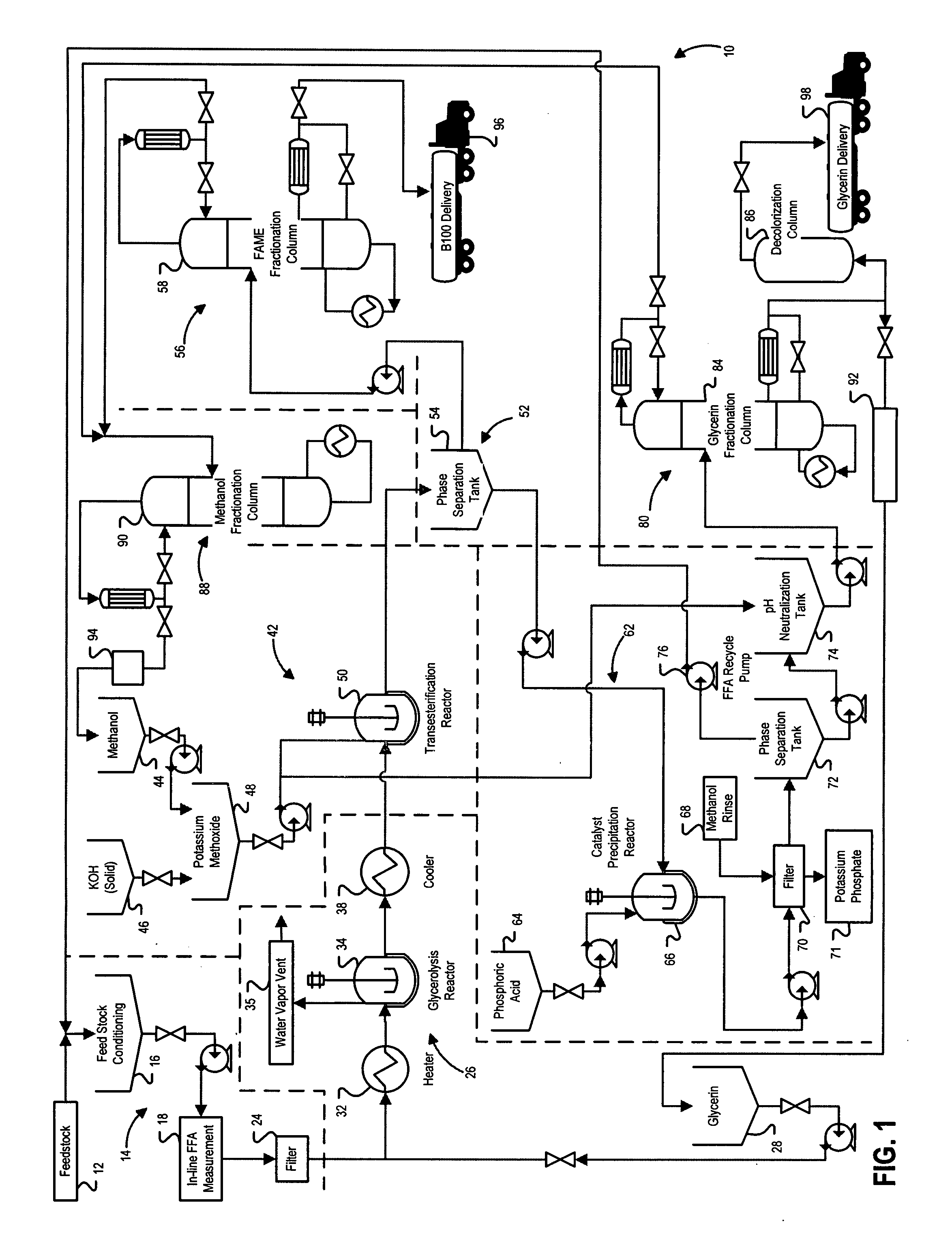

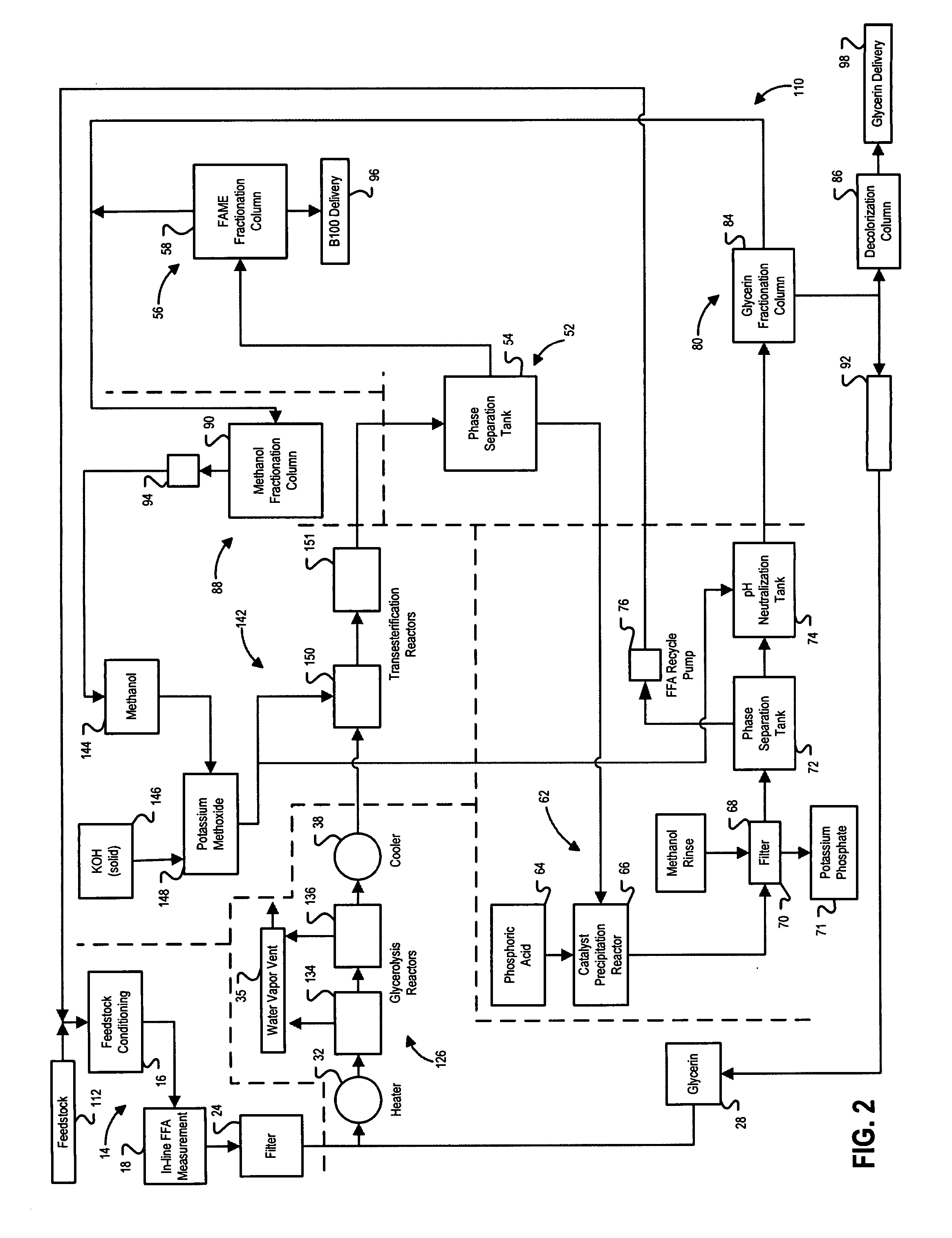

Production of biodiesel and glycerin from high free fatty acid feedstocks

ActiveUS20070277432A1Maximize recoveryQuality improvementFatty acid chemical modificationOrganic compound preparationOrganic acidChemical reaction

A system and method for the conversion of free fatty acids to glycerides and the subsequent conversion of glycerides to glycerin and biodiesel includes the transesterification of a glyceride stream with an alcohol. The fatty acid alkyl esters are separated from the glycerin to produce a first liquid phase containing a fatty acid alkyl ester rich (concentrated) stream and a second liquid phase containing a glycerin rich (concentrated) stream. The fatty acid alkyl ester rich stream is then subjected to distillation, preferably reactive distillation, wherein the stream undergoes both physical separation and chemical reaction. The fatty acid alkyl ester rich stream is then purified to produce a purified biodiesel product and a glyceride rich residue stream. Biodiesel may be further recovered from the glyceride rich residue stream, by further separation of and / or processing of glycerides / free fatty acids contained therein. The glycerin rich second liquid phase stream may further be purified to produce a purified glycerin product and a (second) wet alcohol stream. Neutralization of the alkaline stream, formed during the alkali-catalyzed transesterification process, may proceed by the addition of a mineral or an organic acid.

Owner:REG SENECA LLC

Preparation method of polymer for polyacrylonitrile base carbon fiber precursors

ActiveCN101161694ANarrow molecular weightMolecular orderFibre chemical featuresCarbon fibersPolymer science

A method for preparing polymer for PAN precursor, by copolymerizing the water phase suspend using ammonium persulphate-ammonium sulfite or ammonium bisulfite as a primosome, is disclosed. The polyacrylonitrile powder material is obtained by adding the first monomer acrylonitrile, the second monomer crylic acid, methyl acrylate or acrylamide, and the third itaconic acid, or the first monomer crylic acid, the second monomer methyl acrylate or itaconic acid, and inorganic oxidation-reduction primosome without any metallic ion which comprises ammonium persulphate, ammonium sulfite or ammonium bisulfite and acidified deionized water into the polymerization kettle in defined proportions, controlling the temperature and stirring to react for a time, and discharging by removing the residual monomer, washing and drying. The average molecular weight is from 17.5 myriads to 26.1 myriads, and the distribution index of molecular weight is from 2.70 to 2.91; the intension of polyacrylonitrile precursor tested by spinning sample is from 4.58 to 6.61 CN / dtex; and the carbon fiber strength is 3.61-5.06MPa.

Owner:吉林碳谷碳纤维股份有限公司

High-strength high-toughness low temperature steel for ship and manufacture method thereof

ActiveCN102851591AAchieve sex changeImprove purityRoll mill control devicesProcess efficiency improvementCrack resistanceHeat-affected zone

The invention discloses high-strength high-toughness low temperature steel for ship and manufacture method thereof. The steel is composed of (by wt%) C 0.04-0.12, Si 0.20-0.55, Mn 0.8-1.4, P 0.005-0.015, S less than or equal to 0.005, Als 0.02-0.07, N less than or equal to 0.005, Cu 0.05-0.40, Ni 0.05-0.50, and Fe and unavoidable impurity in balance, with Ni / Cu of 1.2-1.5; and one or more than two of Nb 0.005-0.03, Ti 0.005-0.02, Ca 0.001-0.006, and Mg 0.0005-0.002. The steel has advantages of low compression ratio, high strength, good low temperature impact energy, good texture uniformity, and good elongation, to ensure low hardenability and cold crack resistance of repair welding heat-affected zone even if under polar climate condition.

Owner:ANGANG STEEL CO LTD

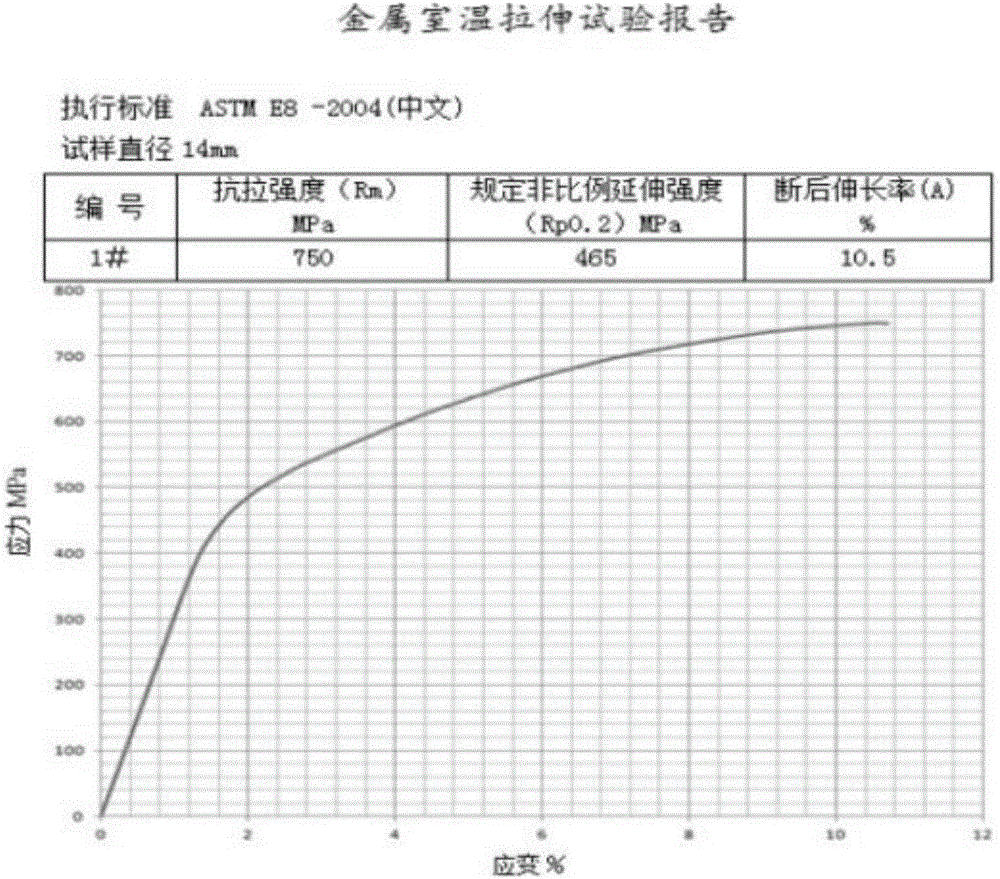

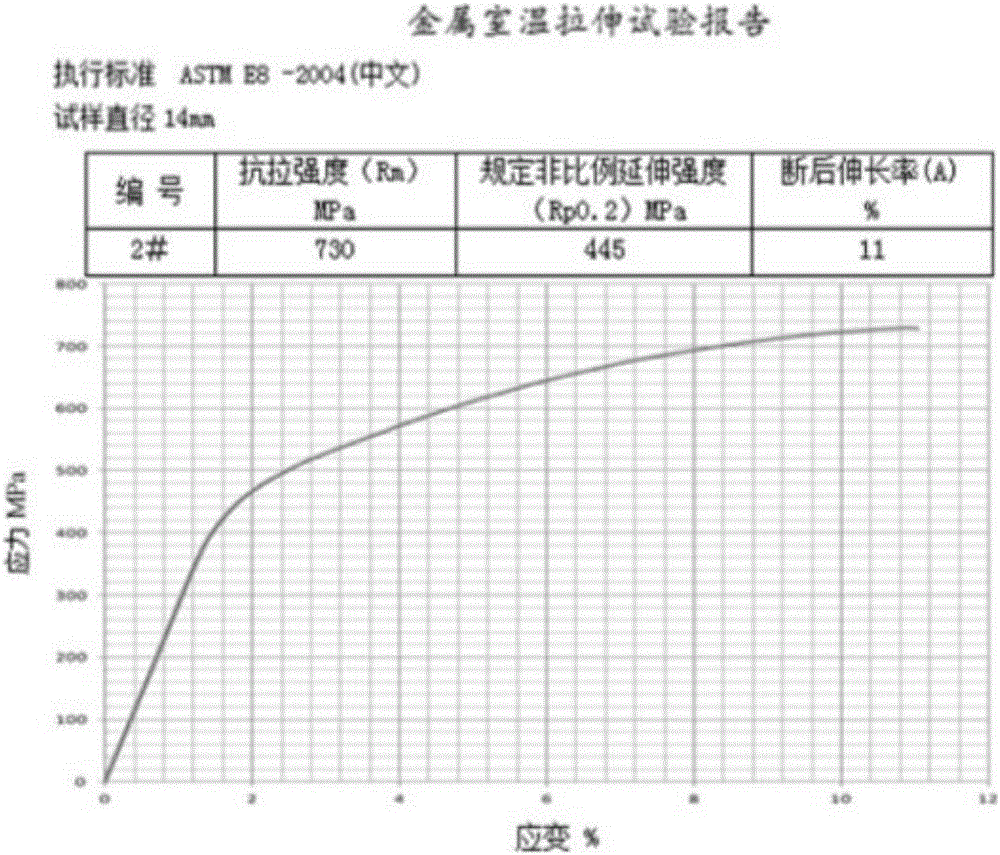

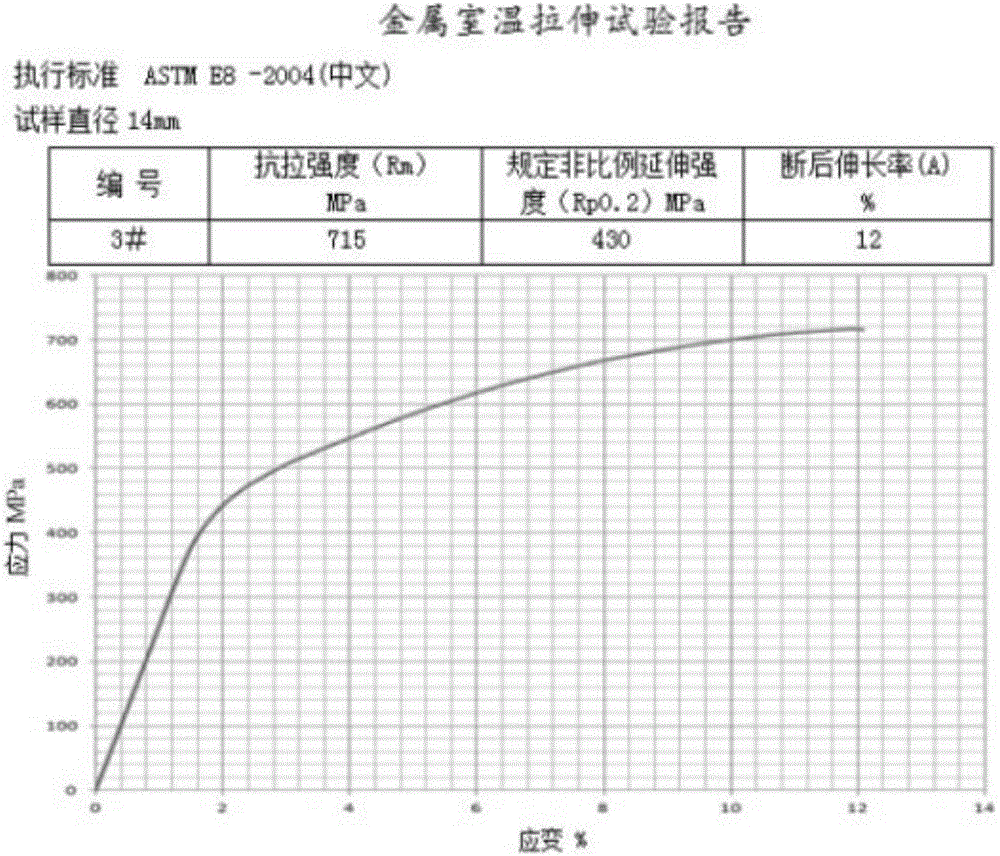

High-strength high-tenacity cast-state QT700-10 and production method thereof

ActiveCN106811676AIncrease the number ofReduce oxidation burnProcess efficiency improvementHigh intensityDuctile iron

The invention belongs to the field of casting technologies and new materials and particularly relates to a high-strength high-tenacity cast-state QT700-10 and a production method thereof. Compared with ductile iron produced in the prior art, the high-strength high-tenacity cast-state QT700-10 has high strength and a high elongation rate, heat treatment is not needed, heavy metal, such as, Ni and Mo are not added in production, the tensile strength Rm in the cast state is larger than or equal to 700 MPa, the elongation rate A is larger than or equal to 10%, compared with the standard brand QT 450-10, the lowest tensile strength is improved by 55% under the same elongation rate; and compared with the standard brand QT 700-2, the lowest elongation rate is improved by four times under the same tensile strength. The high-strength high-tenacity cast-state QT700-10 can meet requirements of automobile ductile iron castings with high requirements for safety and comprehensive mechanical properties.

Owner:山东汇金股份有限公司

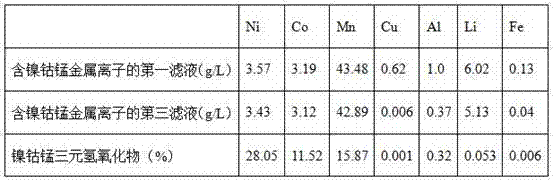

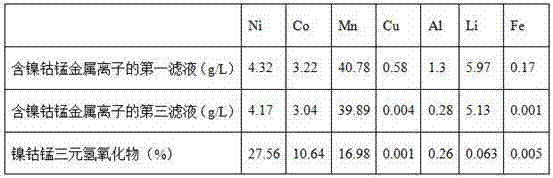

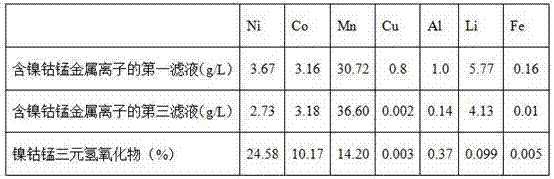

Method for preparing ternary hydroxide from nickel cobalt manganese recycled from waste lithium ion batteries through liquid phase method

ActiveCN107117661ALabor savingEasy to industrializeWaste accumulators reclaimingNickel oxides/hydroxidesManganeseSlurry

The invention discloses a method for preparing ternary hydroxide from nickel, cobalt and manganese in waste lithium ion batteries recovered by a liquid phase method, belonging to the technical field of metallurgical recovery of valuable metals, and solves the increasingly prominent problem of recycling waste lithium ion batteries. question. The invention uses waste lithium ion batteries as raw materials, and the main production steps include: dismantling and crushing, pulping, leaching, copper removal by extraction, iron and aluminum removal by precipitation, and preparation of nickel-cobalt-manganese ternary hydroxide. In the invention, the whole battery is crushed and then processed, no harmful gas is generated in the whole process of recovery and preparation, and green recovery is realized from the root. Raw material requirements, the entire production process is more convenient to operate, and the product is more pure, suitable for industrialization.

Owner:JINCHUAN GROUP LIMITED

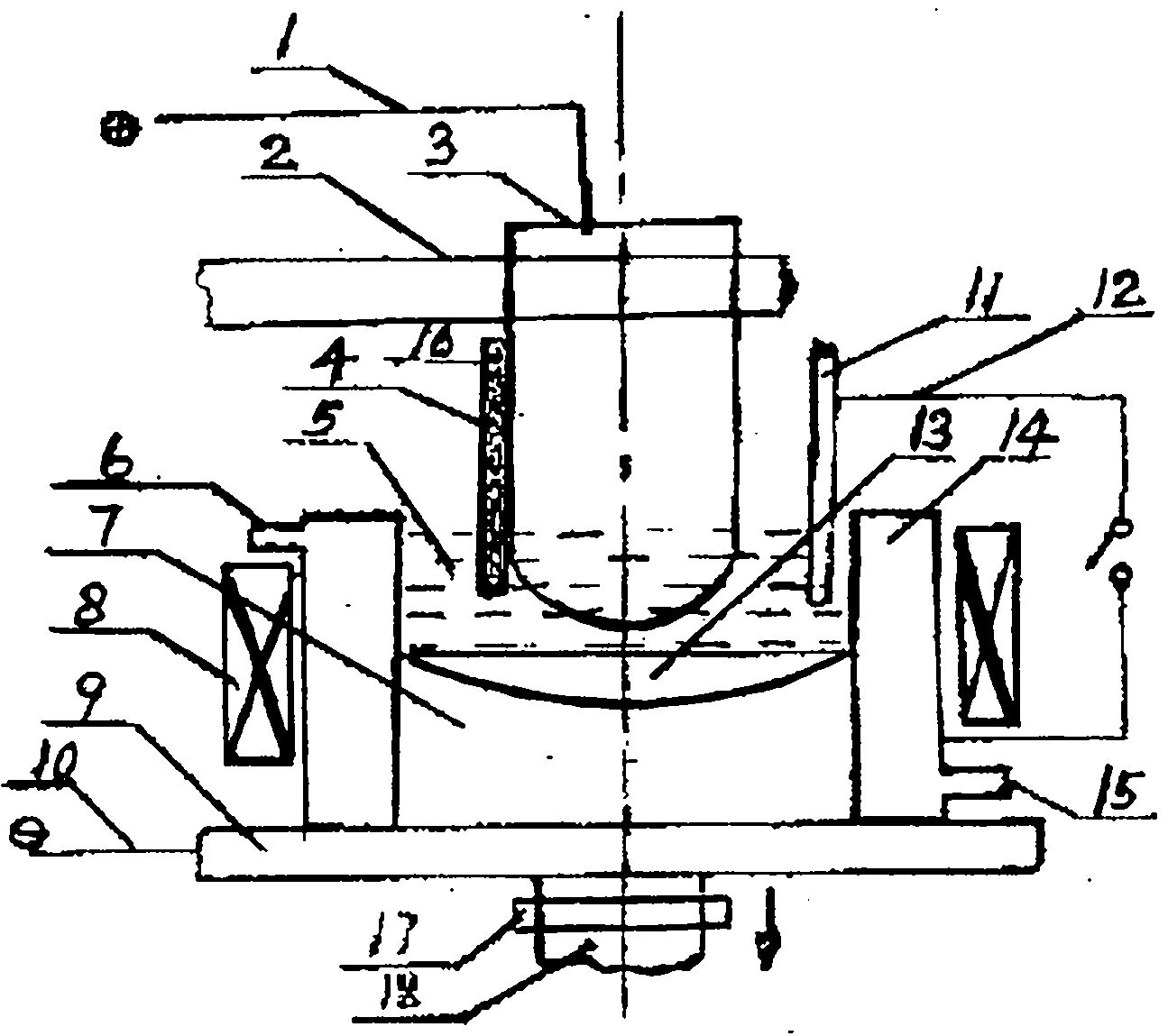

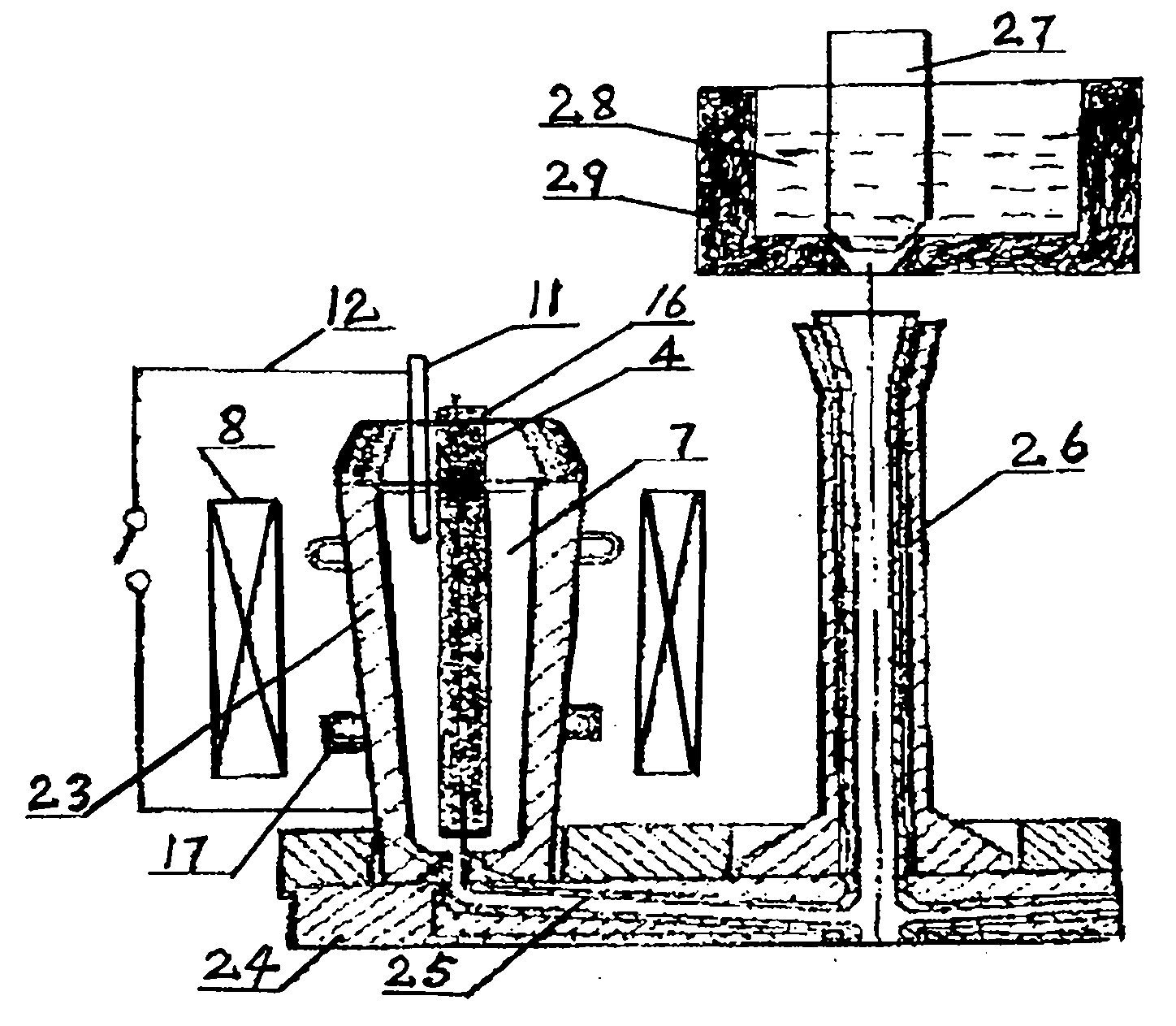

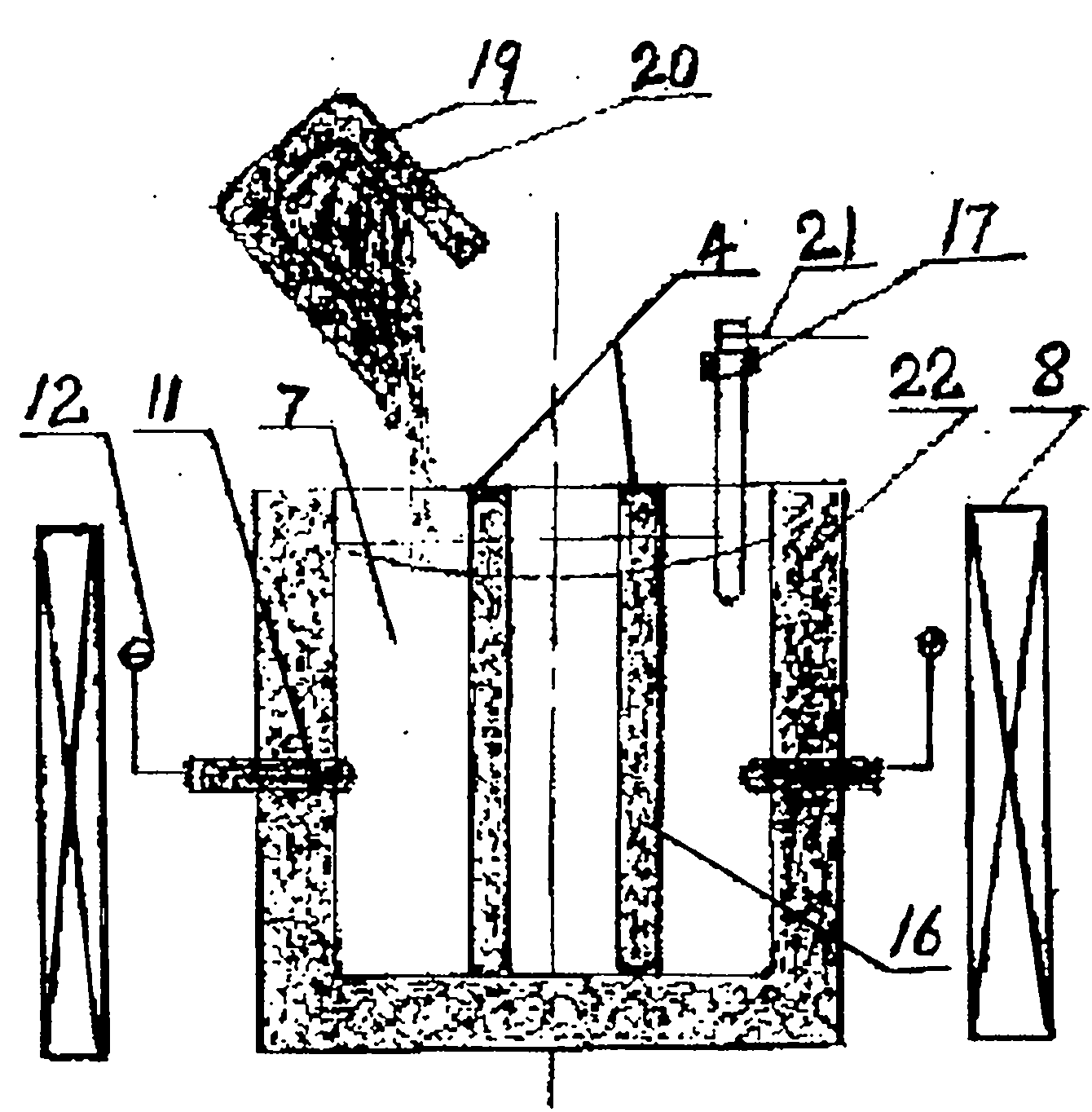

Process and equipment for preparing nanoparticle-reinforced metal matrix composite material

The invention discloses a process and equipment for preparing a nanoparticle-reinforced metal matrix composite material. The process comprises the following steps of: mixing reinforcing nanoparticles with matrix metals and a grain growth inhibitor in a stirring ball mill together, and then loading the mixture into a steel pipe; casting the mixture together with the matrix metals in a water cooling crystallizer or casting and forming the mixture together with a molten metal in a casting mould; and performing quick solidification and crystallization after electromagnetic stirring and ultrasonic vibration to ensure that the two phase materials achieve complete metallurgical bonding, wherein because of the electromagnetic stirring and the ultrasonic vibration, the two phase materials are mixed more uniformly, and all properties of the composite material can be further improved. by using the process and the equipment, a production process is simple, the cost is low, the efficiency is high, the product performance is high, the process is easy to control, the external dimensions of products are not limited by the process, and large-sized nanoparticle-reinforced metal matrix composite materials can be manufactured.

Owner:丁家伟

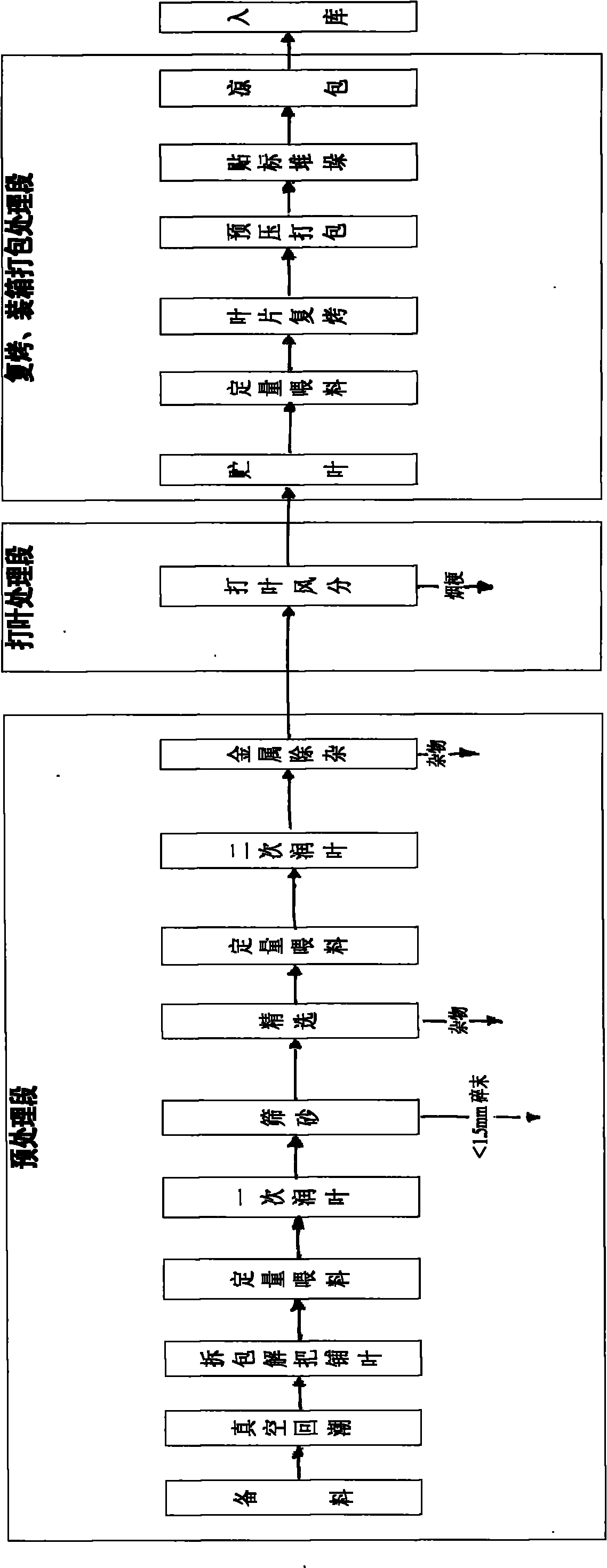

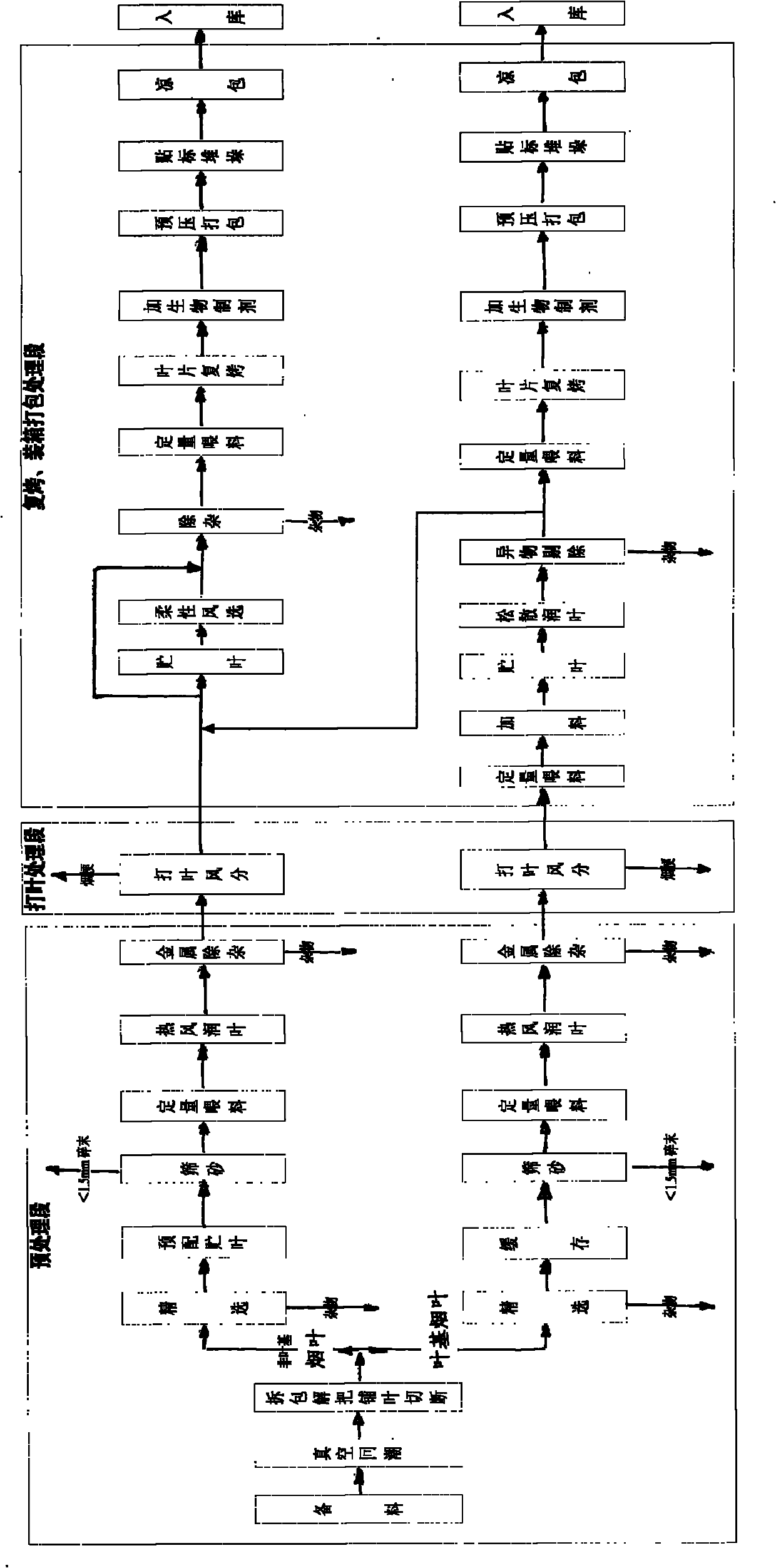

Method for slitting, striking and redrying tobacco

The invention relates to a method for slitting, striking and redrying tobacco, which is technically characterized by comprising the following step of: cutting tobacco lead bases with minimum tensile strength, poorest physical processing resistance and poorer perception smoke panel test quality and appearance quality in the tobacco for singly cutting, striking and redrying. The method has the mainadvantages that remained non leaf base tobacco leaves are crushed to be smaller when leaves and stems are separated singly after the tobacco leaf bases are cut for being singly processed, the leaf structures are more uniform after the leaves are separated from the stems, the green and impurity content in the tobacco is reduced, thus the large-medium leaf ratio after the striking is improved, the crushing generated when the leaves are separated from the stems is reduced, the leaf yield is improved, and the purity of the tobacco is increased. After the tobacco is processed by using a slitting, striking and redrying method of the invention, the leaf base smoking quality is better, the fragrance quantity is improved, the smoke explosive force is increased, the smoking comfort is enhanced, andthe impurity gases are reduced, thus the use value of the tobacco can be improved.

Owner:HONGTA TOBACCO GRP

Nodular Silica Sol and Method of Producing the Same

InactiveUS20100146864A1Easy to getImprove polishing effectPigmenting treatmentOther chemical processesMaterials scienceNitrogen absorption

A novel nodular silica sol adapted to use as a polishing material for polishing, for instance, CMP.The nodular silica sol has a ratio of an average particle diameter (r) measured by the dynamic light scattering method versus a particle diameter (r′) converted to that of an equivalent sphere computed from an average specific surface area measured by means of the nitrogen absorption method (r / r′, referred to as “association ratio”) in a range from 1.2 to 10, the particle diameter (r′) in a range from 5 to 200 nm, and the specific surface area in a range from 13 to 550 m2 / g. The nodular silica particles have heterogeneous forms, and contents of Ca and Mg contained in the nodular silica particles are below 1000 ppm against SiO2 respectively.

Owner:JGC CATALYSTS & CHEM LTD

Method for preparing TiAl alloy plate by argon atomization in powder metallurgy

ActiveCN102513537AThe overall thickness is thinImprove mechanical propertiesMetal rolling arrangementsMechanical propertyImpurity

The invention relates to a method for preparing a TiAl alloy plate by argon atomization in powder metallurgy. The method comprises the following steps of: reducing the content of inclusions in TiAl alloy powders by purity smelting in a cold-wall crucible and high-purity argon atomization; performing hot isostatic pressure compaction on the high-purity prealloy powder which is atomized by pure argon under such conditions that the temperature is 1100 to 1300 DEG C, the pressure is 140 to 200 MPa and the compaction time is 2 to 4 hours; removing coatings of the alloy blank after hot isostatic pressure compaction and then performing surface treatment and coating; heating alloy and rolling at a high temperature; and removing coatings to obtain a powder TiAl alloy plate. The plate has the advantages of uniform deformation, good surface quality, fine and uniform texture, low oxide and impurity contents, small thickness, good overall mechanical property and high quality and reliability. The method solves the key problems in development and application of TiAl alloy powder-metallurgy plates, and provides a technical support for innovation and progress of civil industry and aerospace industry.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Al-Mg-Sc series solder wire

ActiveCN1954959AImprove crack resistanceImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaChemical compositionManganese

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

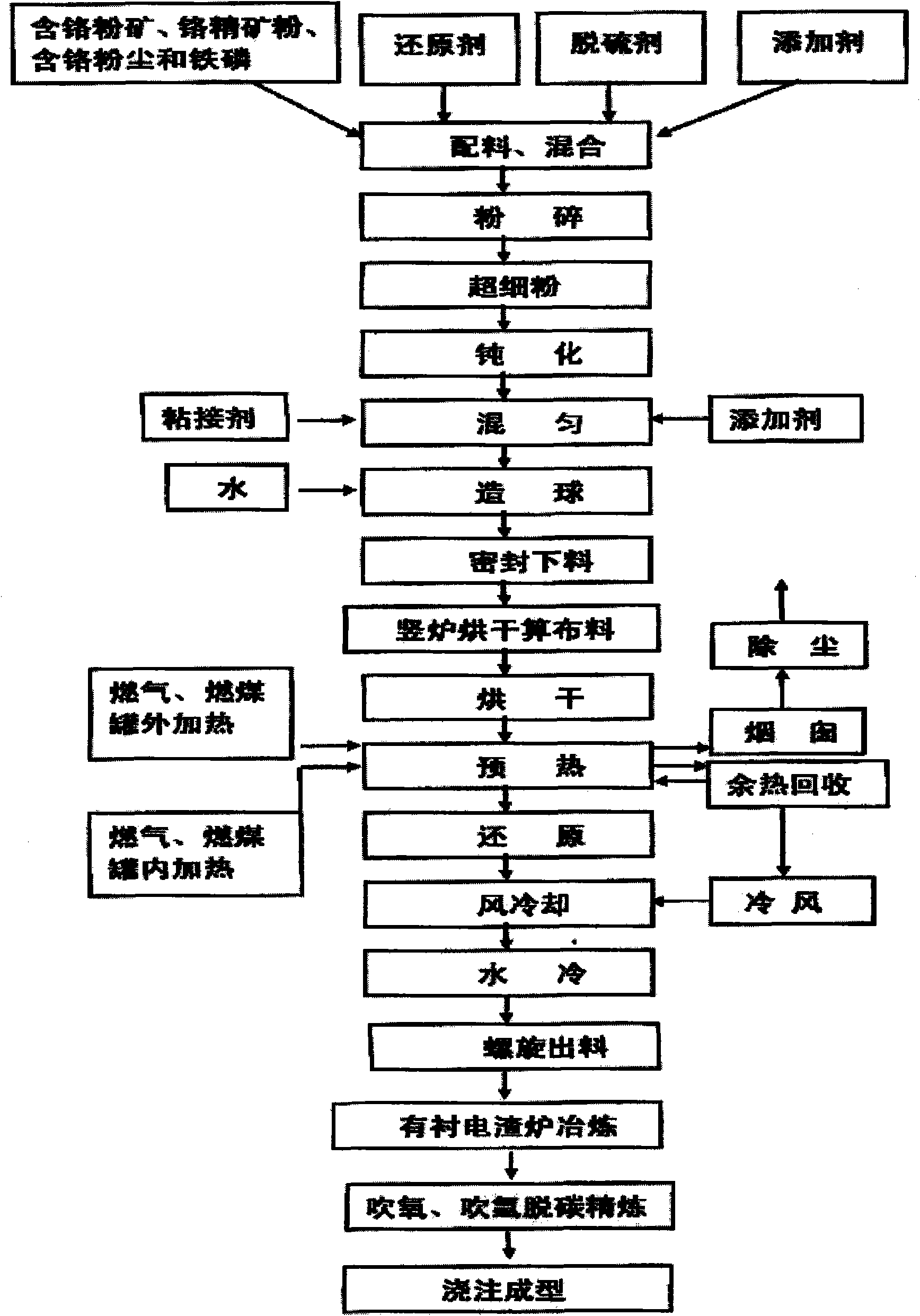

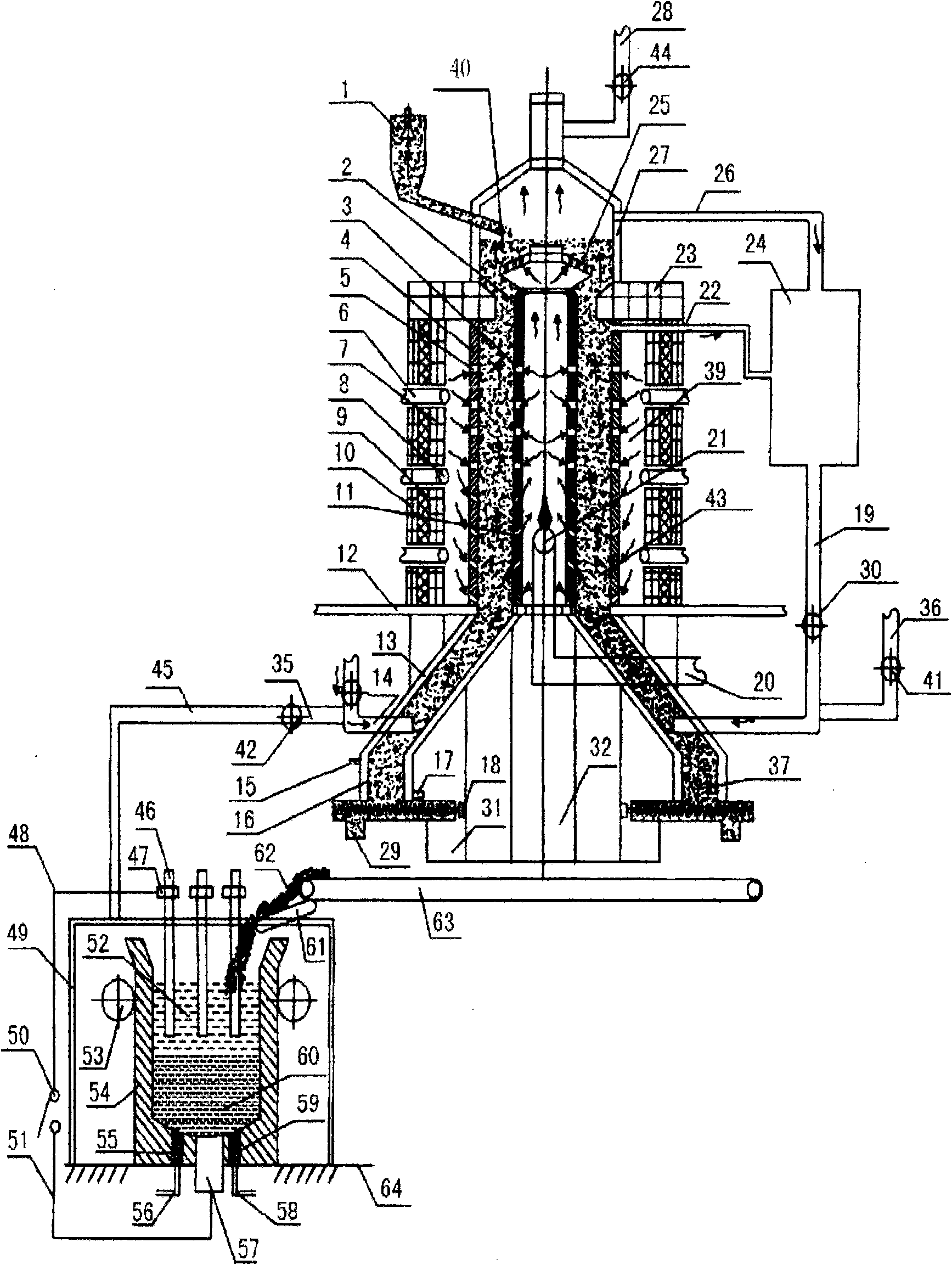

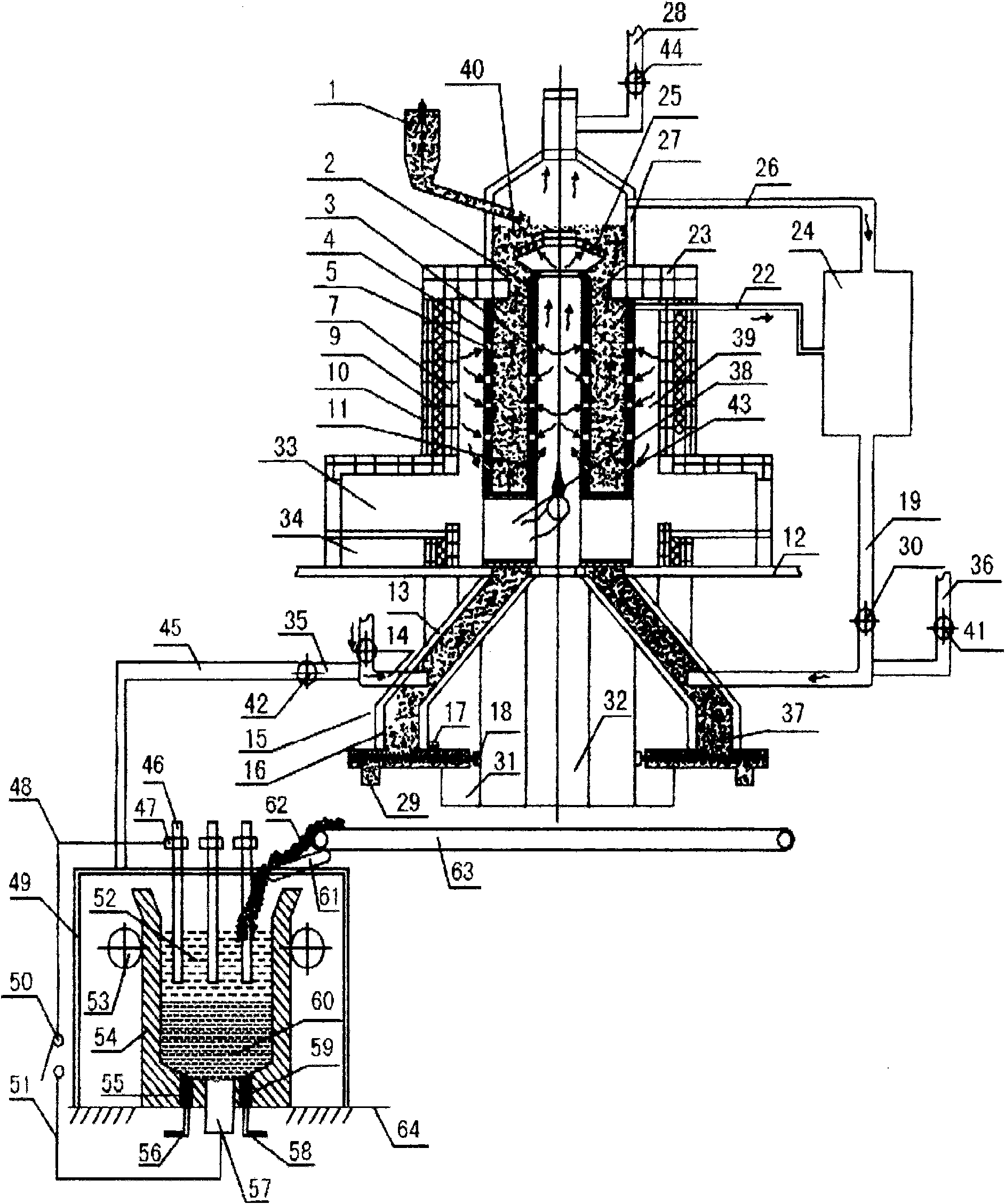

Process and device for smelting chromium irons and chromium-containing molten iron by using chromium ore powder

InactiveCN101538629AImprove applicabilityHigh recovery rateProcess efficiency improvementShaft furnaceUltra fineSolvent

The invention relates to a process and a device for smelting chromium irons and chromium-containing molten iron by using chromium ore powder, which belongs to metallurgical industry steel-making raw material. The process comprises the following steps: mixing chromium iron containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, mixing to make pelletizing materials, sending the pelletizing materials into a reducing furnace, obtaining chromium irons pellets after the reduction reaction, and directly adding reduced pellets into a lining electroslag furnace for being smelted into the chromium-iron alloy or the chromium-containing molten iron. The device comprises an internal-external heating vertical reducing furnace, a lining electroslag furnace and a residual heat recovery system. The invention has the advantages that: firstly, the reduction temperature is low, the speed is high, the energy consumption is reduced, the production cost is lowered, the production efficiency is high, and the uniformity of the quality is good; secondly, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is reduced, the environment pollution is lowered; fourthly, the source of raw materials adopting the chromium ore powder and chromium-containing waste, the cost is low; fifthly, the waste resource can be recycled so as to save the resource consumption; and sixthly, the high-temperature pellets are directly smelted by adopting the lining electroslag furnace, the heat efficiency is high, the energy consumption is low, the material purity is high and the quality is good, and the device is simple with less investment.

Owner:丁家伟

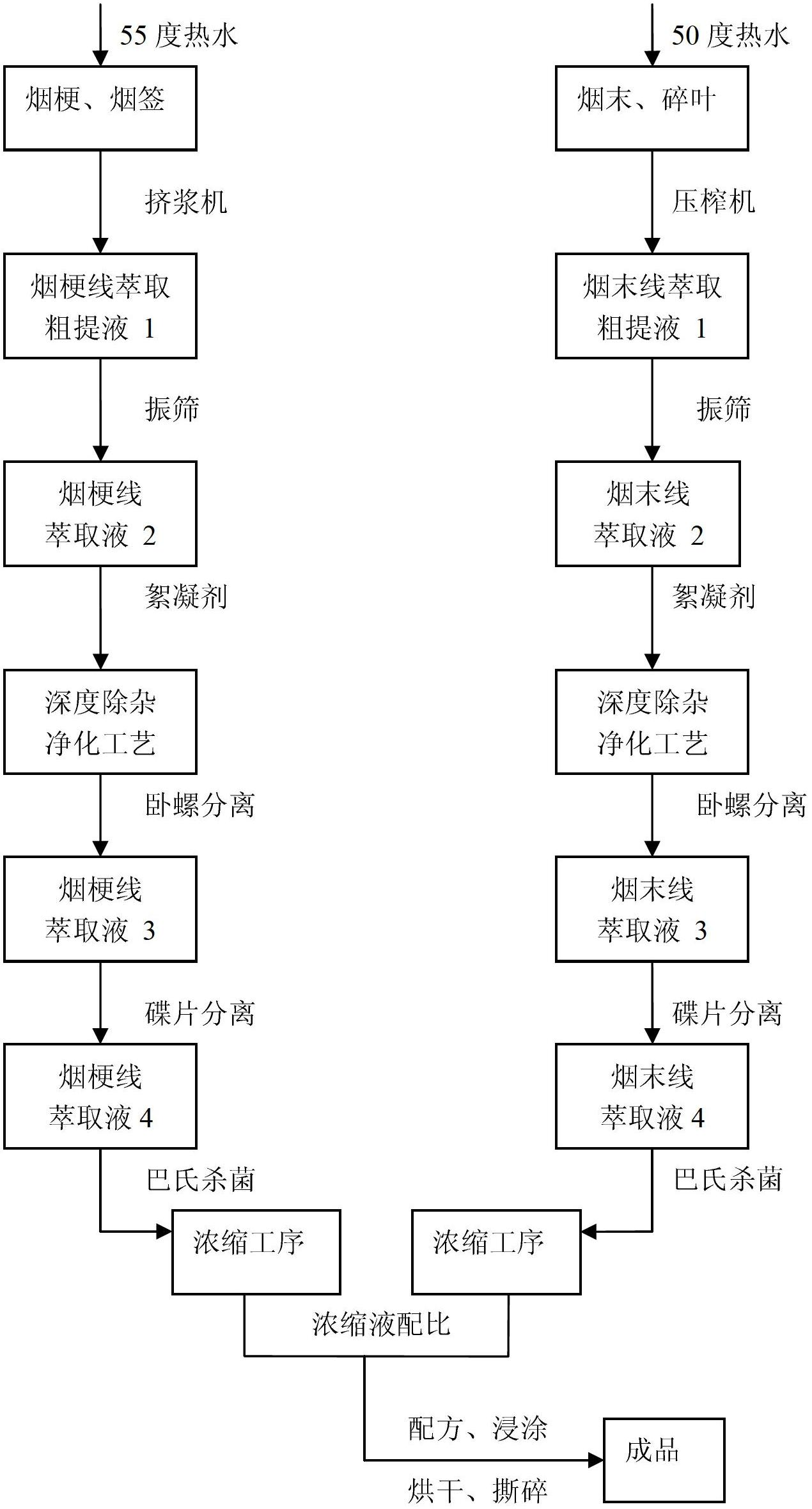

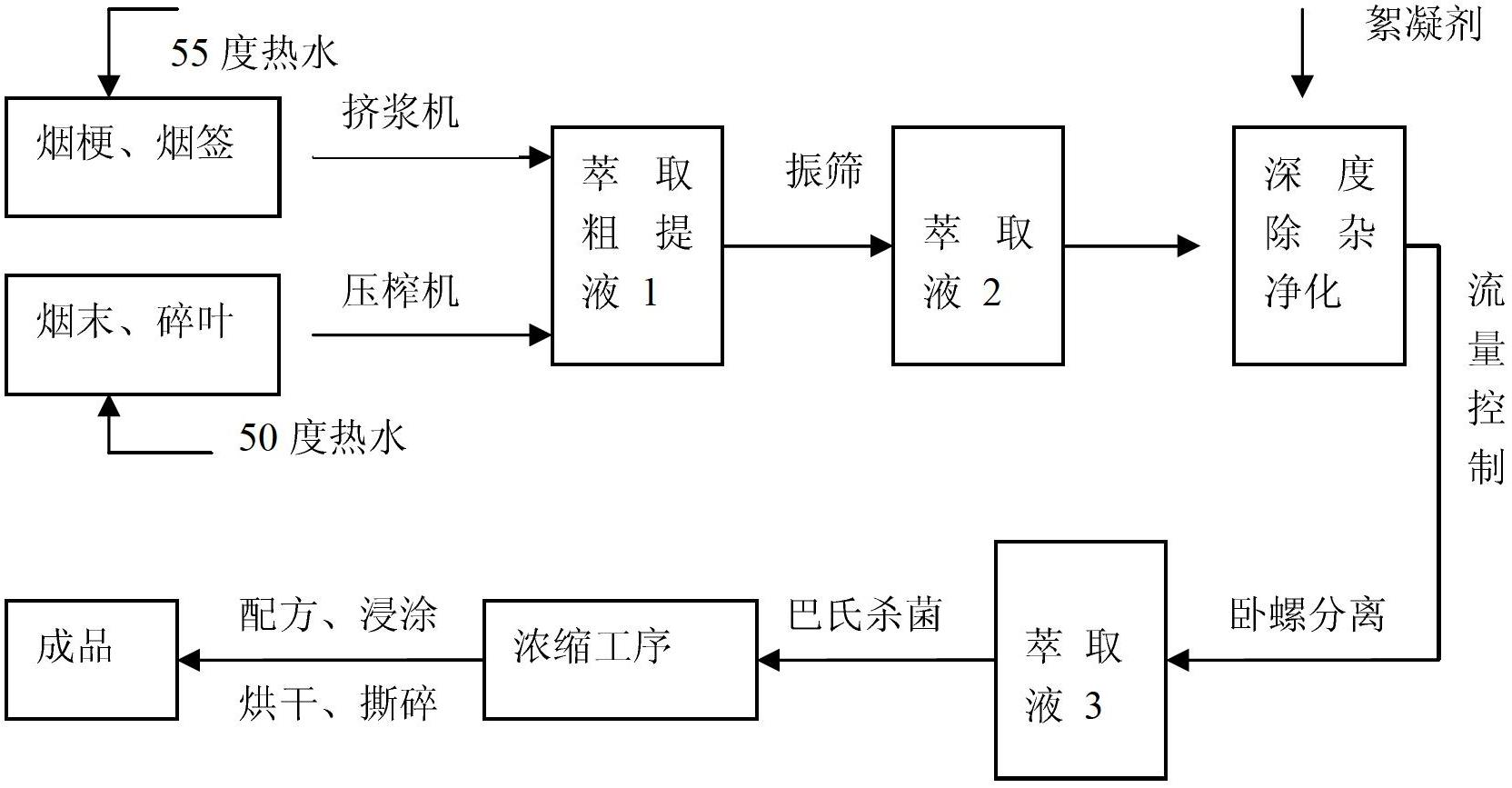

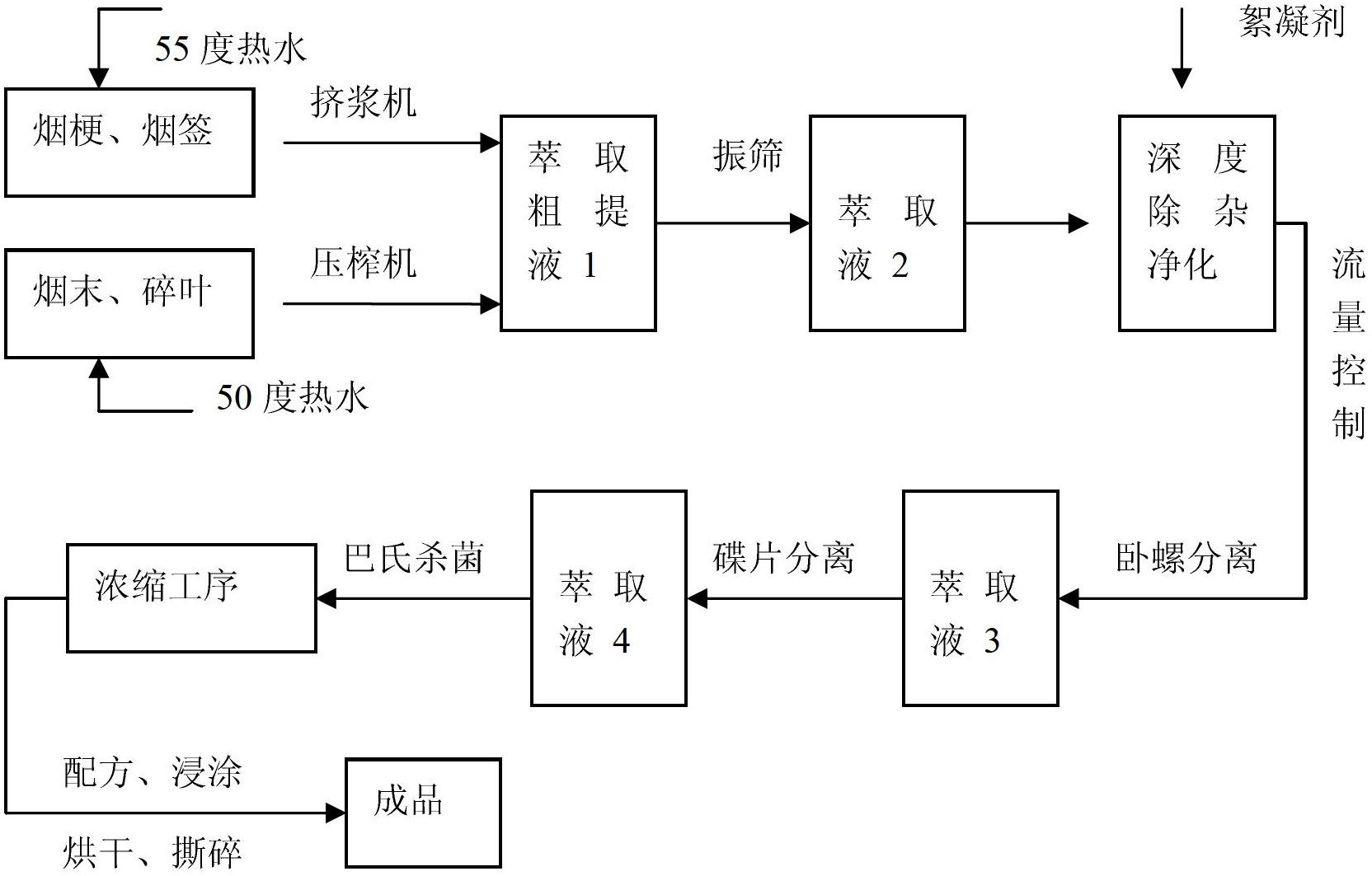

Extract deep purification and edulcoration process in manufacturing technology of papermaking tobacco sheets

ActiveCN102688613APrecise and efficient directional macromolecular separationOvercome the heavy airTobacco preparationCentrifugal force sediment separationScrapProcess module

The invention relates to an extract deep purification and edulcoration process in the manufacturing technology of papermaking tobacco sheets. The process comprises the following steps: a, tobacco waste including tobacco stems, tobacco sticks and tobacco powder is fully soaked in hot water and then extracted; b, the mixture of tobacco waste and water is fed into a squeezer and then squeezed for solid-liquid separation, and the liquid part is extracted crudely and is screened through a linear vibrating screen for solid-liquid separation; c, the liquid separated through the linear vibrating screen enters a filter aid process module to be processed through deep macromolecule flocculation, wherein an edible flocculating agent is adopted, the addition proportion is 0.1 to 0.8%, and the flocculation time is 5 to 50 minutes; liquid processed through deep macromolecule flocculation enters a primary horizontal spiral discharge settling centrifuge to be separated; and e, the liquid separated by the centrifuge in step d is pasteurized at the temperature of 60 to 70 DEG C for edulcoration, and then enters a concentration system to be concentrated. The process can effectively remove macromolecule particles, improves the concentration efficiency and ensures the quality of concentrate.

Owner:杭州利群环保纸业有限公司

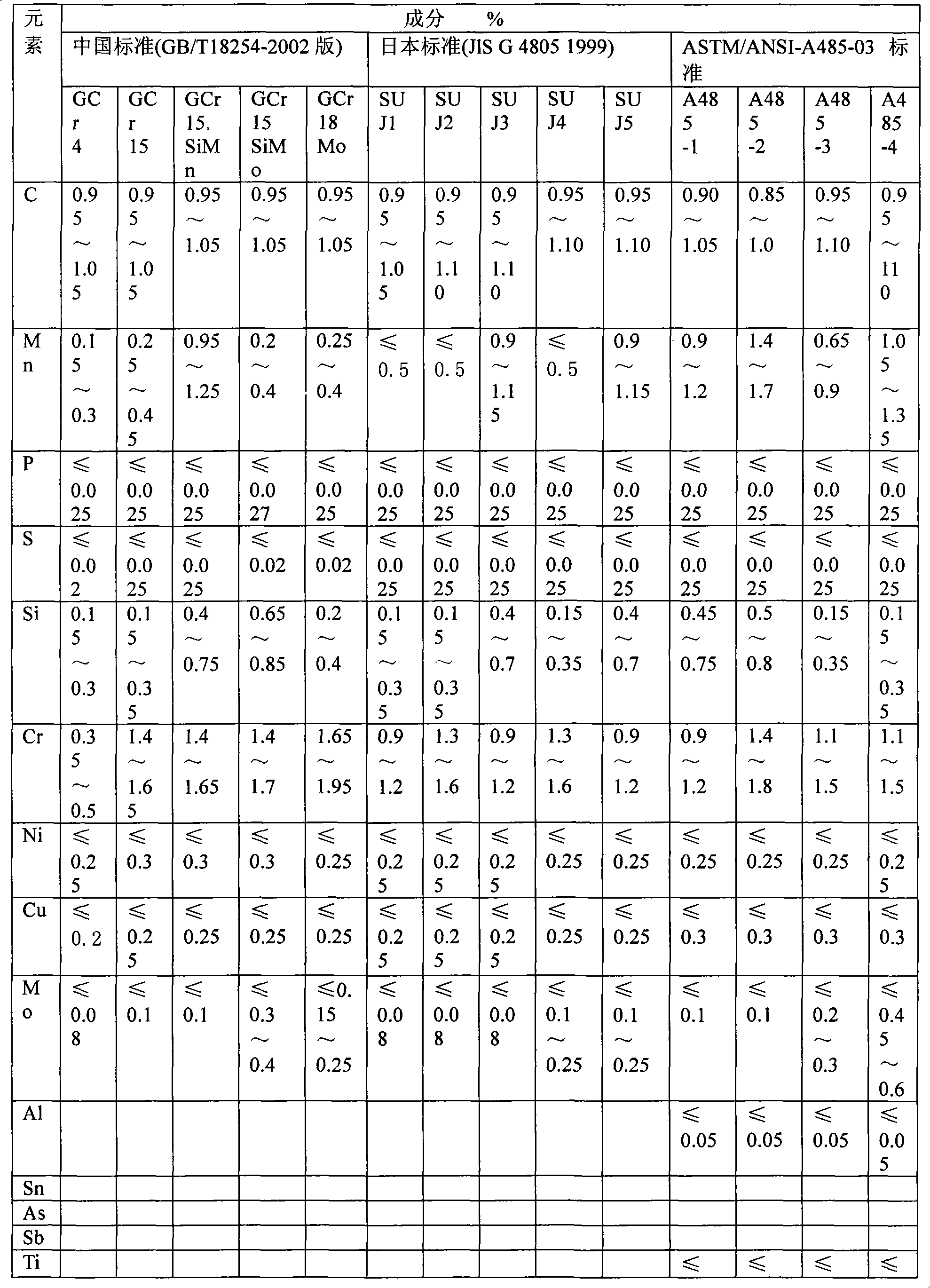

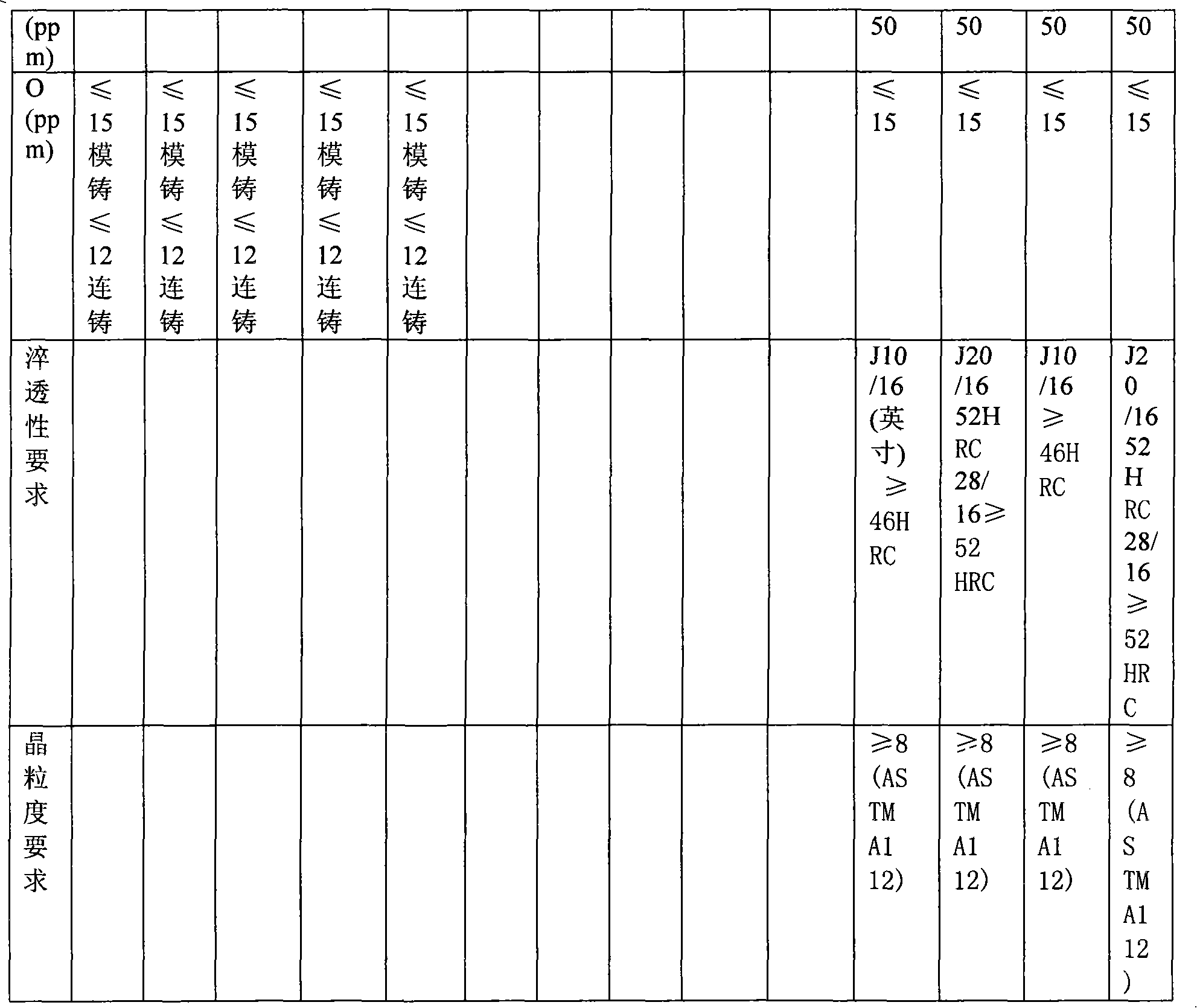

High-carbon-chromium bearing steel and manufacture method thereof

The invention discloses high-carbon-chromium bearing steel and a manufacture method thereof. The high-carbon-chromium bearing steel comprises the following chemical compositions by weight percentage: C: 0.90-1.05; Cr: 0.90-1.20; Mn: 0.90-1.25; Si: 0.45-0.75; Al: 0.02-0.04; oxygen is less than or equal to 0.0007; phosphorus is less than or equal to 0.010; sulfur is less than or equal to 0.005; titanium is less than or equal to 0.0025; copper is less than or equal to 0.15; nickel is less than or equal to 0.10; nitrogen is less than orequal to 0.0070; and the balance of unavoidable impurities and Fe. The manufacture method comprises the following steps: smelting in an electric furnace, refining in a ladle arc furnace, degassing in a vacuum furnace, pouring steel liquid into steel ingots, heating steel ingots in a heating furnace, rolling the steel ingots into square billets by a rolling mill, heating the steel ingots in a heating furnace and rolling the steel ingots into round steel by a rolling mill. Compared with the prior art, the invention has high hardenability, high crystal grain size of more than 8 grade, high commonality in technology and wide application.

Owner:BAOSHAN IRON & STEEL CO LTD

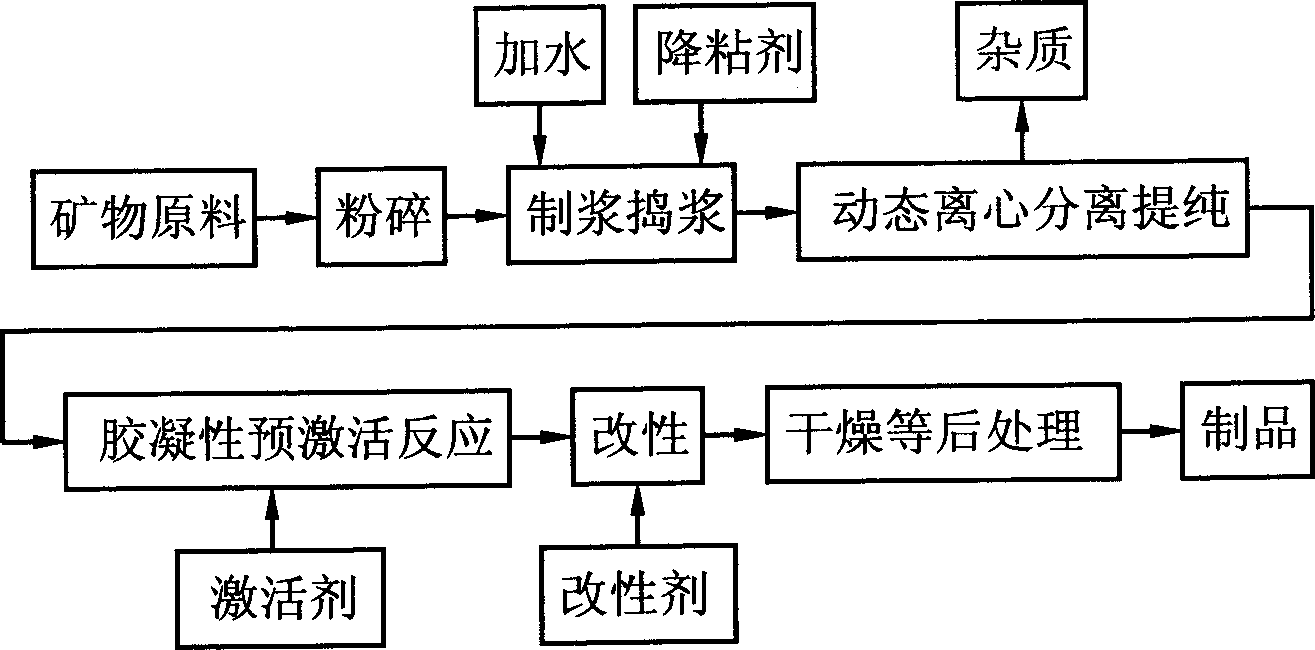

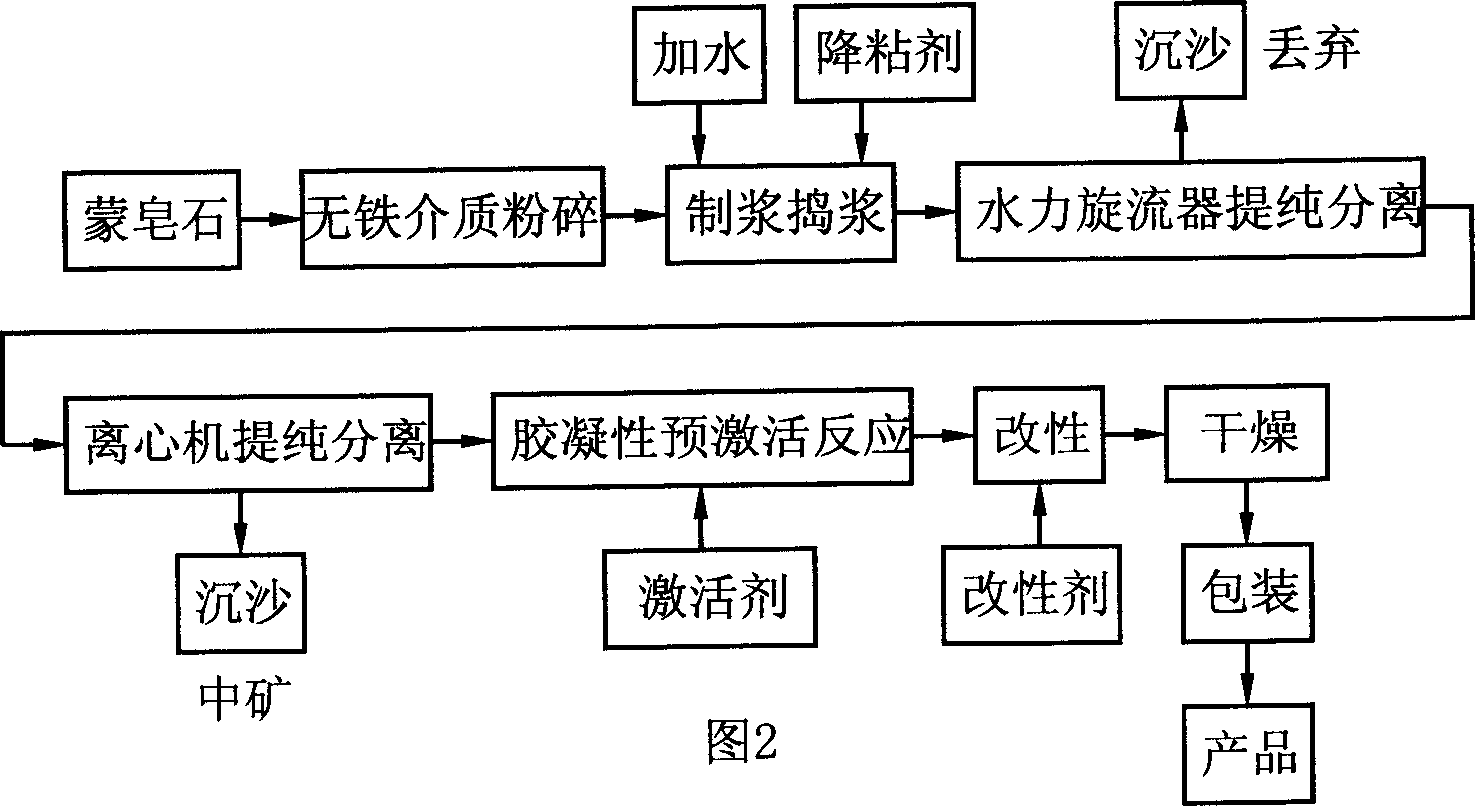

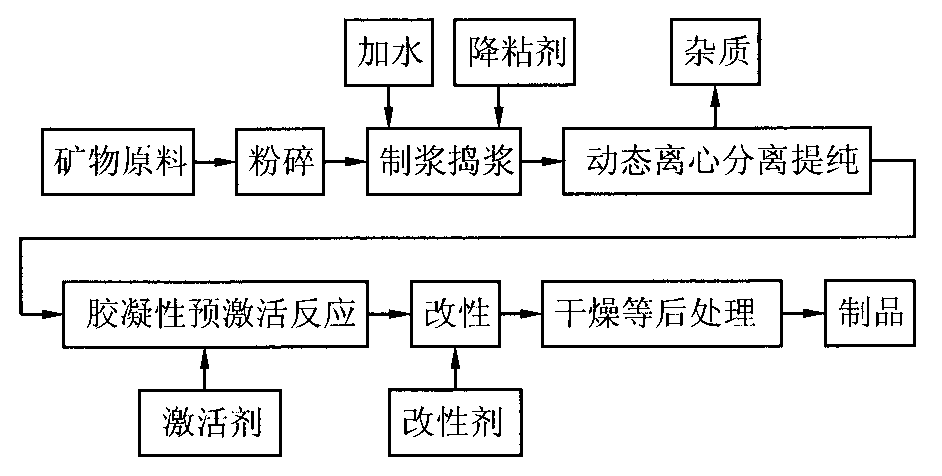

Process for preparing natural magnesium aluminium silicate gel

InactiveCN1363515AAvoid pollutionFe <sub>2</sub> o <sub>3</sub> Low contentAluminium silicatesInorganic saltsSodium Bentonite

A process for preparing natural gel of magnesium aluminium silicate from bentonite, attapulgite, bentone, etc includes such steps as pulverizing, preparing slurry, adding pour depressor, stirring, dynamic centrifugal separation, adding inorganic salt containing one-valence metal ions, stirring, pre-activating, adding organic salt containing at least Na ions, stirring for modifying, and post-treating.

Owner:国家非金属矿深加工工程技术研究中心

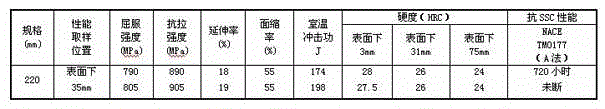

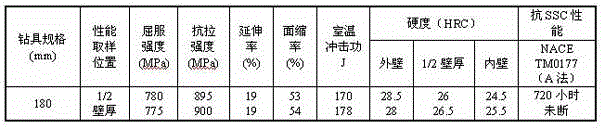

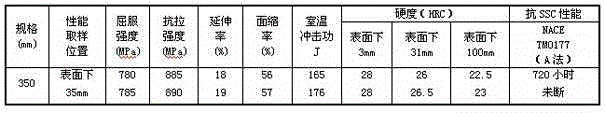

Round steel with high strength and toughness and hydrogen sulfide stress corrosion resistance for drilling tool and manufacturing method of round steel

The invention discloses a round steel with high strength and toughness and hydrogen sulfide stress corrosion resistance for a drilling tool and a manufacturing method of the round steel. The round steel comprises the following chemical components in percentage by mass: 0.20-0.30% of C, 0.15-0.40% of Si, 0.20-0.70% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.70-1.30% of Cr, 0.40-0.95% of Mo, less than or equal to 0.25% of Ni, 0.05-0.10% of Cu, 0.05-0.10% of Alt, less than or equal to 0.1% of V, less than or equal to 0.06% of Nb, less than or equal to 0.010% of Ti, less than or equal to 0.009% of N, 0.001-0.003% of B and the balance of Fe and inevitable impurities. By adopting the preparation method, the round steel with the maximum specification of 350mm can be manufactured, and the round steel is particularly suitable for being processed to be stress complex drilling tools with large specifications and high strength and toughness requirements such as hydrogen sulfide corrosion resistant drill rods, drill collars, and drill rod joints applied to acidic oil wells.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

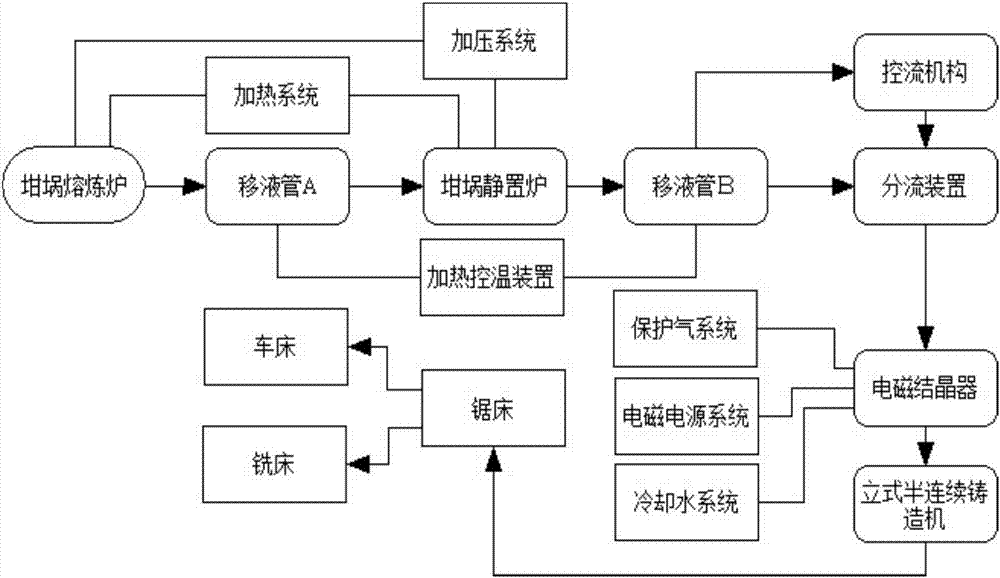

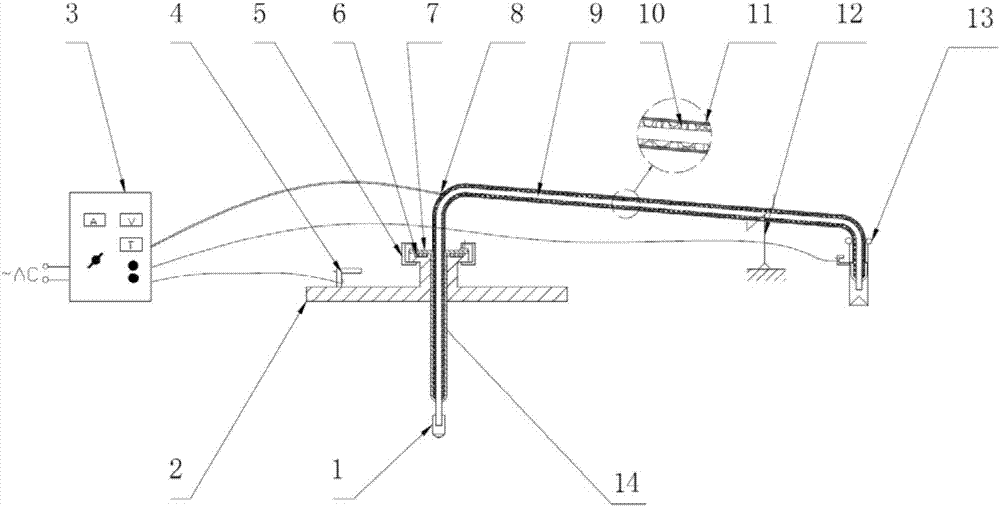

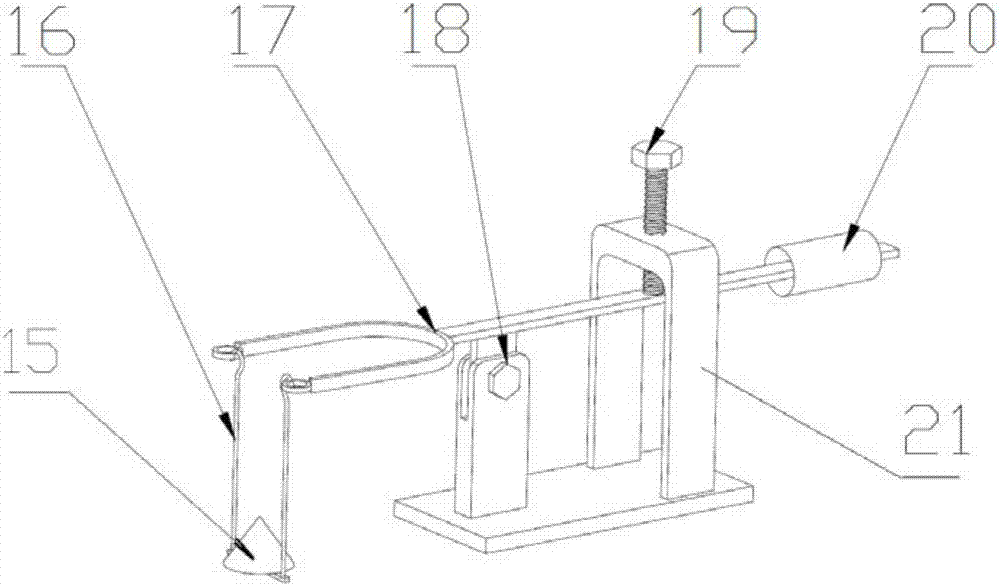

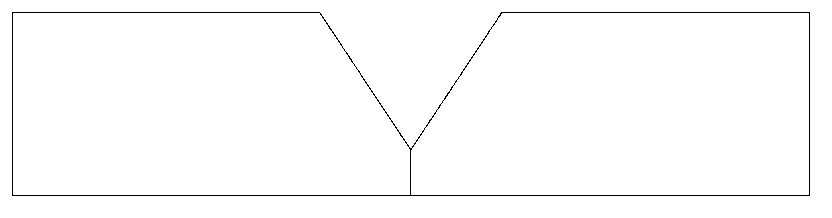

Electromagnetic semicontinuous casting device and casting method thereof

The invention discloses an electromagnetic semicontinuous casting device and a casting method thereof. The electromagnetic semicontinuous casting device comprises a crucible smelting furnace, a crucible standing furnace, a flow control mechanism, a split-flow device, an electromagnetic crystallizer system and a vertical semicontinuous casting machine, wherein the electromagnetic crystallizer system is a metal inner sleeve crystallizer system in which a group of build-in excitation coil is fixed, and comprises a metal inner sleeve, a cooling water cavity, the excitation coil, an oil supply system, an oil distribution system and a protective gas ring. According to the electromagnetic semicontinuous casting device disclosed by the invention, through a method of adjusting the frequency of electrical current, duty ratio and average current strength, the electrical current in a unique wave shape is formed in the single excitation coil placed in the cooling cavity of a crystallizer, so that desired forced convection or shaking effect is formed in the crystallizer with low current intensity; the grain of ingot blank is significantly refined; and columnar crystals are significantly reduced or eliminated to lower macroscopic segregation and realize the technical effect of low-stress casting. Under the condition of similar functional effects, the size of the electromagnetic crystallizer system is one third to one half of that of an original electromagnetic crystallizer system.

Owner:NORTHEASTERN UNIV

Method for welding Q500qE ultralow-carbon bainite steel for bridge

ActiveCN103286427ASolve welding process problemsAvoid cold cracksArc welding apparatusWelding/cutting media/materialsShielded metal arc weldingChemical composition

The invention provides a method for welding Q500qE ultralow-carbon bainite steel for a bridge. The method is excellent in joint mechanical performance and high in welding efficiency and specifically includes that aiming at specific chemical components, applicable technical conditions and different plate thicknesses of the Q500qE ultralow-carbon bainite steel for the bridge, preheating temperature before welding, groove types and welding process parameters are determined; a welding joint type adopts butt joint, penetration angle joint or ship position T-shaped angle joint; a welding method adopts submerged arc welding, CO2 gas shielded semiautomatic welding or shielded metal arc welding. By the welding method, the joint type and thickness specifications of a bridge structure are comprehensively covered, the technical scheme is simple, convenient and high in adaptivity, all implementing effects meet technical requirements of standards related to building of bridge steel and the bridge structure, and the method is of great significance in promoting upgrading of the bridge steel and development of large-span steel bridge building technology. The method can be applied to building of the bridge structure, can also be applied to welding of other ultrathin-carbon bainite steel and is high in adaptivity.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD

Casinghead gas corrosion resistant pumping rod steel and manufacturing method thereof

InactiveCN101440461AImproved corrosion cracking performanceGood plasticityTemperature control deviceFurnace typesNiobiumManganese

The invention provides steel for a pumping rod resisting casinghead gas corrosion and a manufacture method thereof. The steel comprises the following chemical compositions by mass percentage: 0.05 to 0.25 percent of carbon, 0.50 to 2.00 percent of silicon, 1.10 to 2.50 percent of manganese, 0.02 to 0.50 percent of molybdenum, 0.02 to 0.50 percent of nickel, 0.50 to 1.50 percent of chromium, 0.01 to 0.10 percent of vanadium, 0.005 to 0.050 percent of aluminum, 0.02 to 0.10 percent of niobium, 0.05 to 0.50 percent of copper, 0.01 to 0.10 percent of titanium, less than or equal to 0.015 percent of sulphur, less than or equal to 0.020 percent of phosphorus, and the balance being ferrum. The method is to manufacture a pumping rod wire through a design of adding the niobium and other trace alloy elements and corresponding compositions into steel, and controlled rolling and controlled cooling organization control technology. The pumping rod manufactured by the wire has excellent oilwell medium corrosion resistance, proper strength, excellent plastic tenacity and excellent welding performance, thereby improving the service life and reliability of the pumping rod, and improving the whole stability of pumping equipment, and further solving the problem that the prior pumping rod has repeated stress failure caused by endurance of complex casinghead gas corrosion.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com