Patents

Literature

264results about How to "Reduce oxidation burn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing Al-Ti-B grain refiner

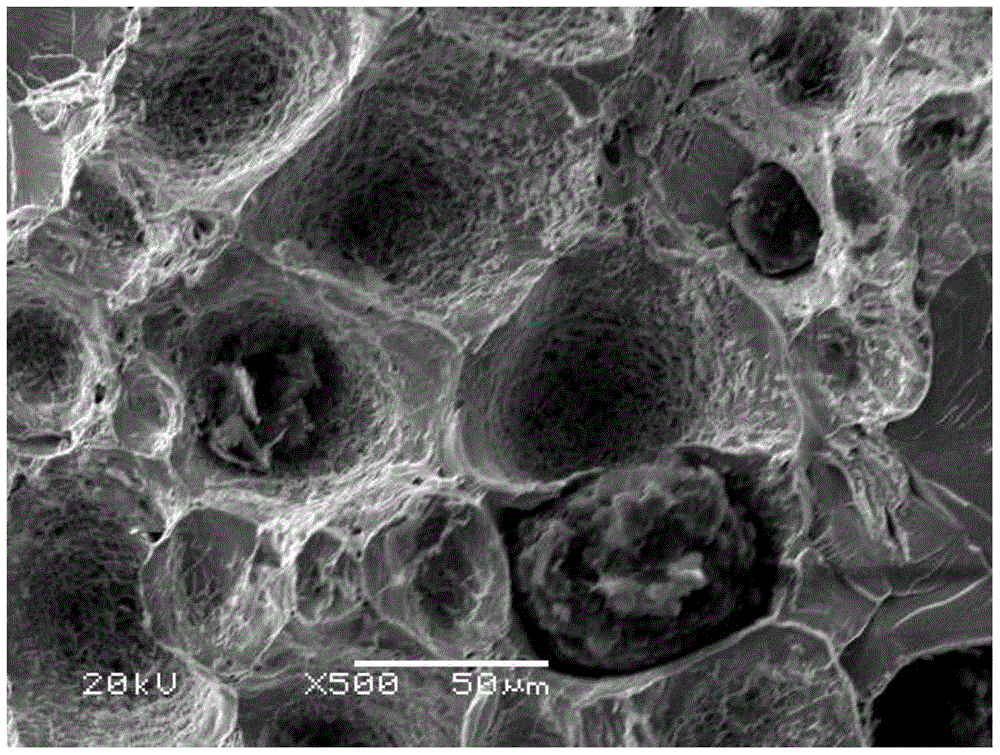

The Al-Ti-B crystal grain fining agent for metal material has the components including Ti 2-10 wt%, B 2 wt% and Al the rest. The preparation process includes the steps of: mixing industrial pure potassium fluorotitanate and potassium fluoroborate homogeneously, heating to melt industrial pure aluminum, adding the mixed salt into aluminum melt and covering the surface of the melt with KCl, introducing ultrasonic wave to over the melt, skimming slag, cooling the melt naturally while continuous ultrasonic treatment until the intermediate alloy solidifies completely to obtain the Al-Ti-B crystal grain fining agent. The present invention has short preparation period and less oxidation loss of aluminum melt, and the obtained casting structure has fine TiAl3 grains of homogeneous size below 20 microns and TiB2 grains with clear contour. The Al-Ti-B crystal grain fining agent is used in preparing industrial pure aluminum with crystal grains smaller than 120 microns.

Owner:SHANGHAI JIAO TONG UNIV

Dynamic soft reduction technologies for bloom continuous casting of heavy rail

The invention discloses a process of continuous casting dynamic with less reduction heavy rail steel cogged ingot, the process is applied in the continuous casting of high carbon steel cogged ingot, which can not only evidently alleviate center segregation, center porosity, center line shrinkage, center crack and so on defects and prevent the casting ingot center crack, middle crack and so on underbead crack, but also can improve component homogenization of rail rolled by the casting ingot, stabilize and improve mechanical property and functional performance of the rail and reach technical requirements of the high speed rail. The technical measure as follows: controlling continuous casting pulling rate and molten steel temperature of the heavy rail steel, the continuous casting pulling rate is 0.60-0.80m / min, the molten steel superheating temperature is 15-40 DEG C; adopting even and assuasive control mode in the secondary cooling zone, the continuous casting ratio water amount is 0.25-0.30L / kg, the casting ingot surface temperature on the area with less reduction is 900-1020 DEG C; the reduction is controlled on the area with less reduction, the casting ingot solidification rate on the area with less reduction fs=30%-100%, total reduction is 1.6-7.0 mm.

Owner:PANZHIHUA IRON AND STEEL

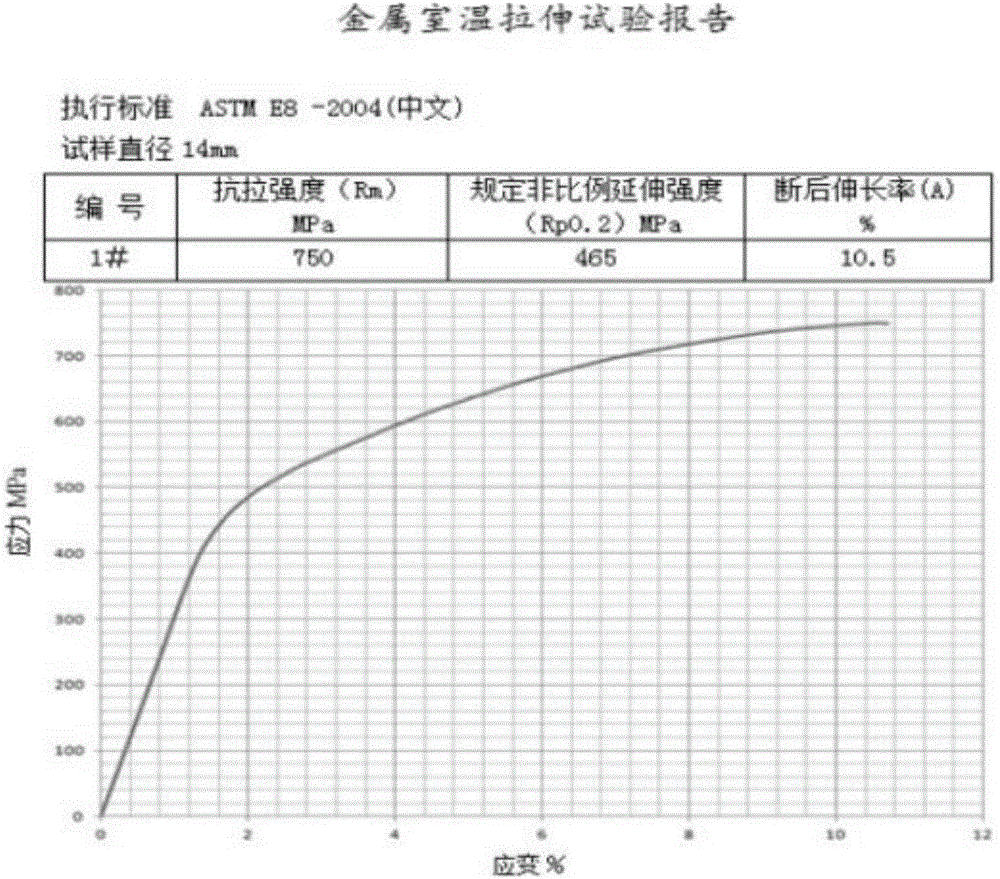

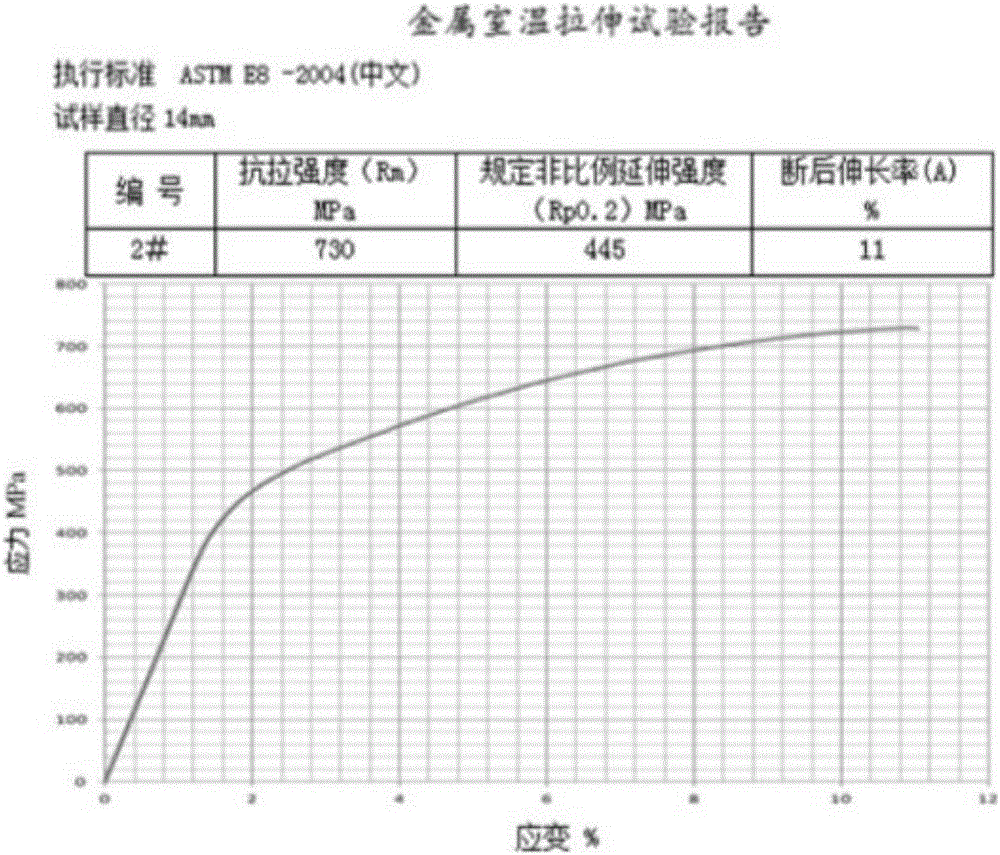

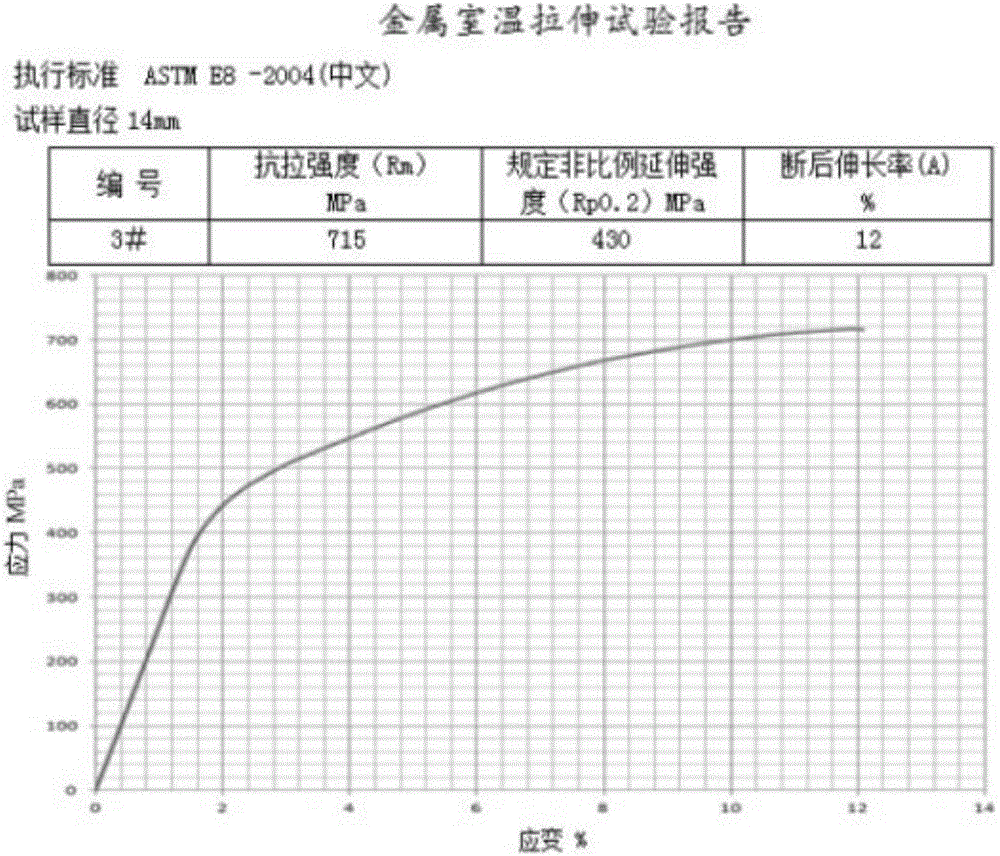

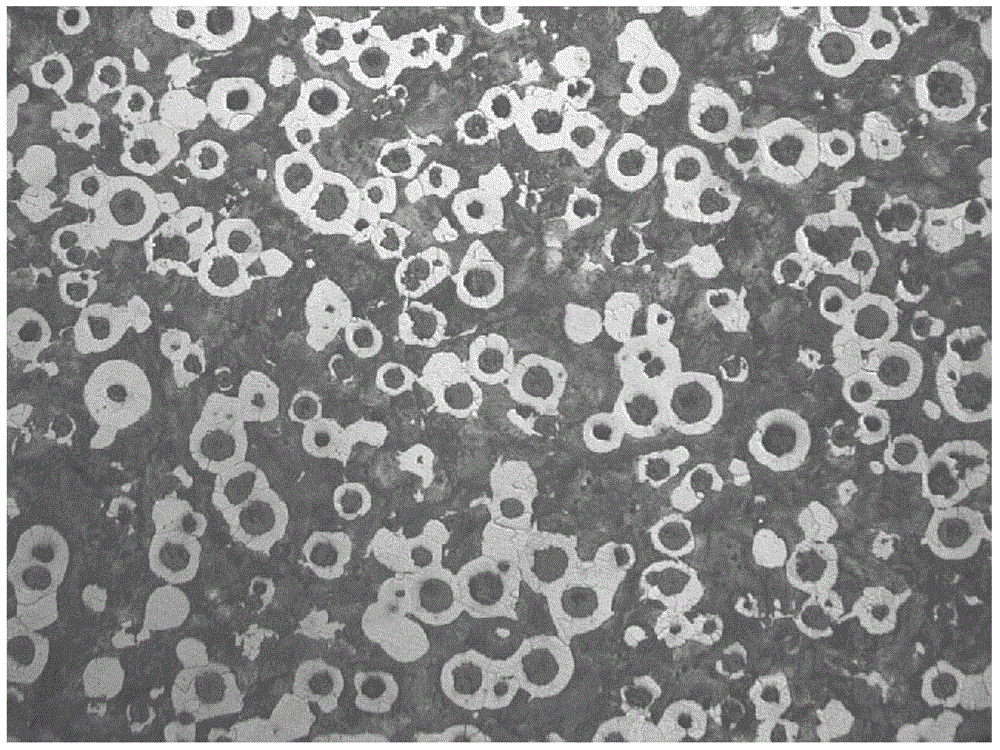

High-strength high-tenacity cast-state QT700-10 and production method thereof

ActiveCN106811676AIncrease the number ofReduce oxidation burnProcess efficiency improvementHigh intensityDuctile iron

The invention belongs to the field of casting technologies and new materials and particularly relates to a high-strength high-tenacity cast-state QT700-10 and a production method thereof. Compared with ductile iron produced in the prior art, the high-strength high-tenacity cast-state QT700-10 has high strength and a high elongation rate, heat treatment is not needed, heavy metal, such as, Ni and Mo are not added in production, the tensile strength Rm in the cast state is larger than or equal to 700 MPa, the elongation rate A is larger than or equal to 10%, compared with the standard brand QT 450-10, the lowest tensile strength is improved by 55% under the same elongation rate; and compared with the standard brand QT 700-2, the lowest elongation rate is improved by four times under the same tensile strength. The high-strength high-tenacity cast-state QT700-10 can meet requirements of automobile ductile iron castings with high requirements for safety and comprehensive mechanical properties.

Owner:山东汇金股份有限公司

Preparation method for high-toughness nodular cast iron

The invention provides a preparation method for high-toughness nodular cast iron, which is a method for producing high-toughness nodular cast iron by utilizing a medium-frequency electric furnace and selecting materials such as cast iron which is low in sulfur, phosphor and manganese content, waste steel, and the like. The preparation method mainly comprises chemical component design, furnace burden selection, medium-frequency furnace smelting, a nodulizing agent selection and nodulizing treatment method, a nucleating agent selection and nucleating treatment method, and the like. The method disclosed by the invention does not need thermal treatment and desulfuration treatment, is less in processes, adopts a wet type sand production line to manufacture QT600-10 casting pieces, has casting efficiency higher than that of sand-lined iron type, and is low in cost. The produced nodular cast iron is high in strength, good in plasticity and toughness, can be used for components such as a transmission shaft, a rear axle shell, a differential mechanism shell, a bracket, and the like for a car and a tractor chassis.

Owner:HENAN POLYTECHNIC UNIV

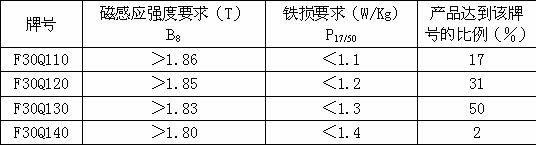

Full production process of low-temperature oriented silicon steel

The invention provides a full production process of a low-temperature oriented silicon steel, relates to the technical field of metallurgy, and aims at solving the technical problems of high slab heating temperature, short service life of a heating furnace, energy waste, low converter smelting designation hit rate of the oriented silicon steel due to narrow range of requirements on C and other chemical element contents, and the like of traditional cold-rolled oriented silicon steel. The full production process of the low-temperature oriented silicon steel comprises the following steps: molteniron pre-treatment, converter treatment, RH (Ruhrstahl-Heraeus) vacuum treatment, slab continuous casting, hot charging and hot delivery, slab heating, hot rolling, primary cold rolling, primary decarbonization and annealing, secondary cold rolling, low-temperature recovery annealing and magnesium oxide coating, high-temperature cover furnace annealing, stretching and insulating layer coating, aswell as slitting, packaging and storing to finally produce the low-temperature oriented silicon steel.

Owner:JIANGYOU FENGWEI NEW MATERIAL +2

Preparation method for reducing scales generated on surfaces of hot-rolled steel plates

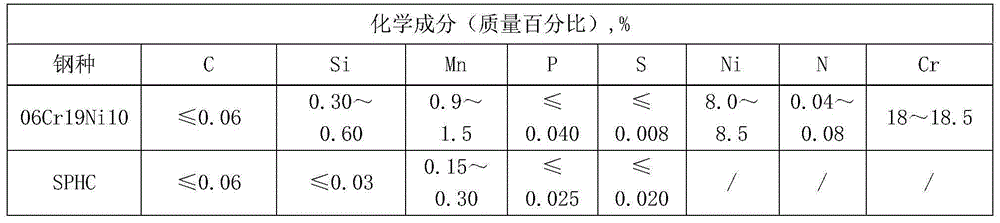

InactiveCN101947557ALower the furnace temperatureReduce the number of spawnsTemperature control deviceWork treatment devicesChemical compositionSheet steel

The invention belongs to the technical field of hot-rolled strips and relates to a method for controlling the surface quality of hot-rolled steel plates, namely a preparation method for reducing scales generated on the surfaces of the hot-rolled steel plates. The chemical components of the steel in the method have wider application range and are especially suitable for the hot-rolled steel platescontaining such microalloying elements as Nb, V, Mn and Si. The hot-rolled steel plates have the following chemical components by weight: not less than 0.05% and not more than 0.20% of C, not more than 0.70% of Si, not less than 0.20% and not more than 2.00% of Mn, not less than 0.02% and not more than 0.10% of Nb, not less than 0.03% and not more than 0.15% of V, not more than 0.12% of Ti, not more than 0.040% of P, not more than 0.030% of S and the balance Fe and inevitable impurities. The control method dispenses with improvement of existing equipment, is simple and controllable in processconditions, realizes the aim of reducing the scales by controlling the slab tapping temperature, the finish rolling, initial rolling and final rolling temperature, the coiling temperature and the cooling method and has the advantages of low energy consumption, low cost and wide applicable scope.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

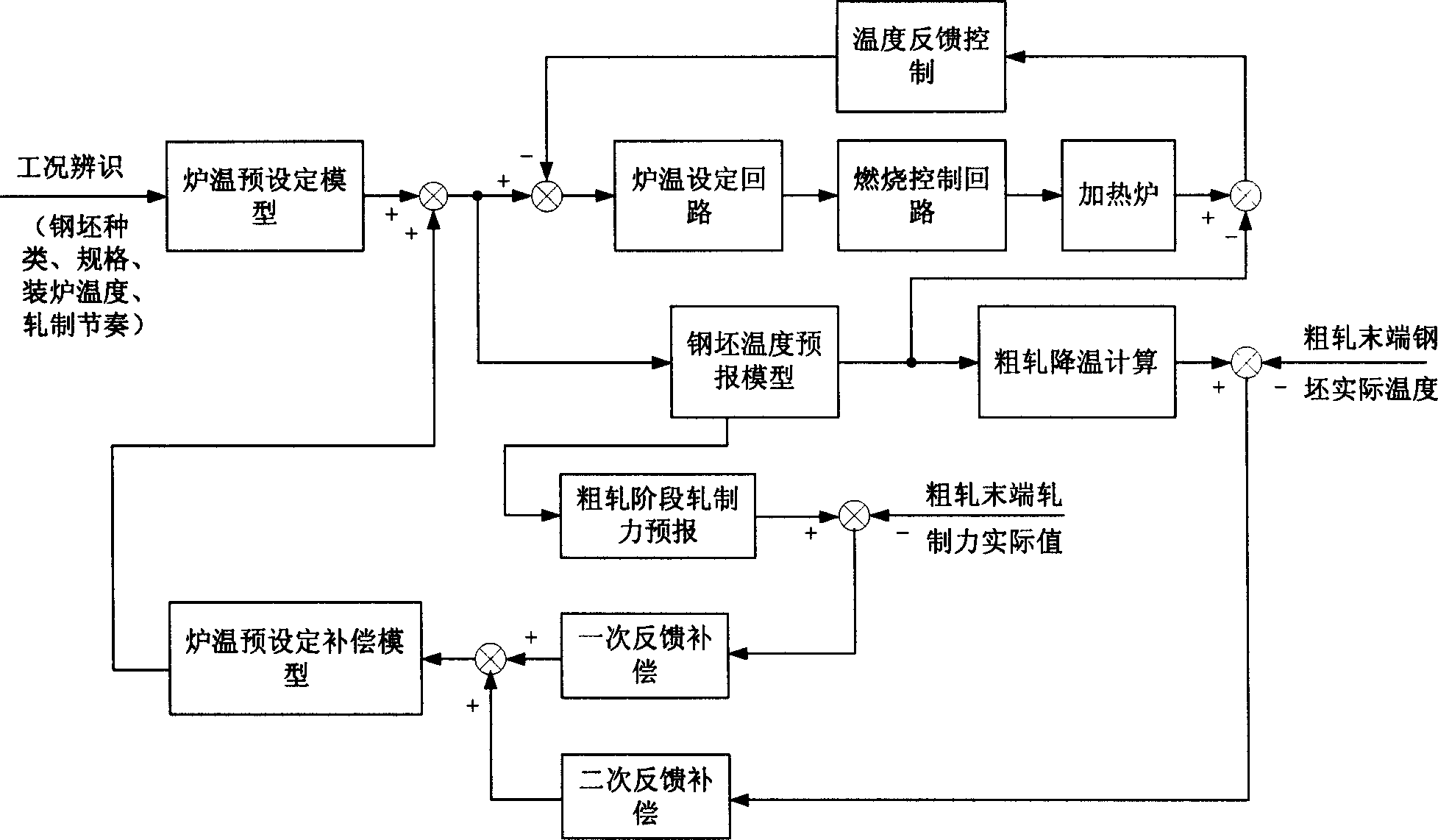

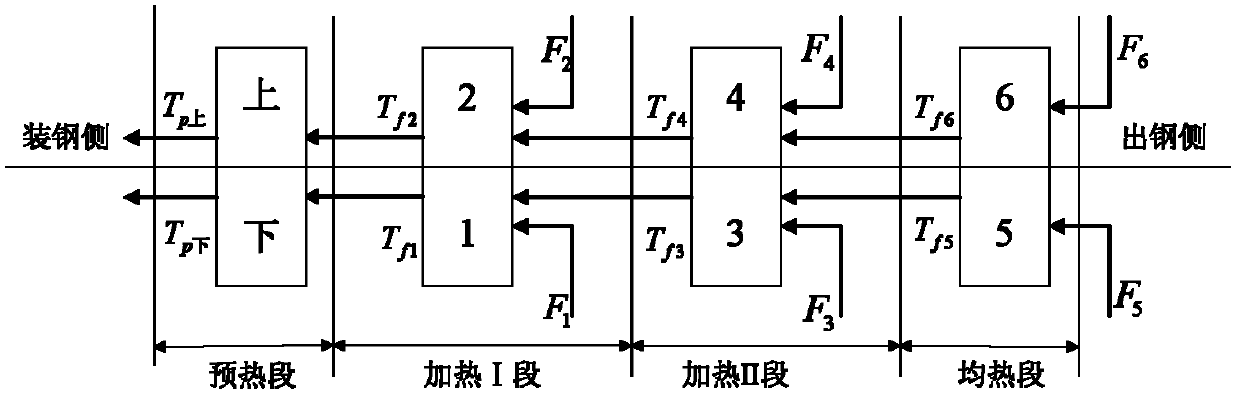

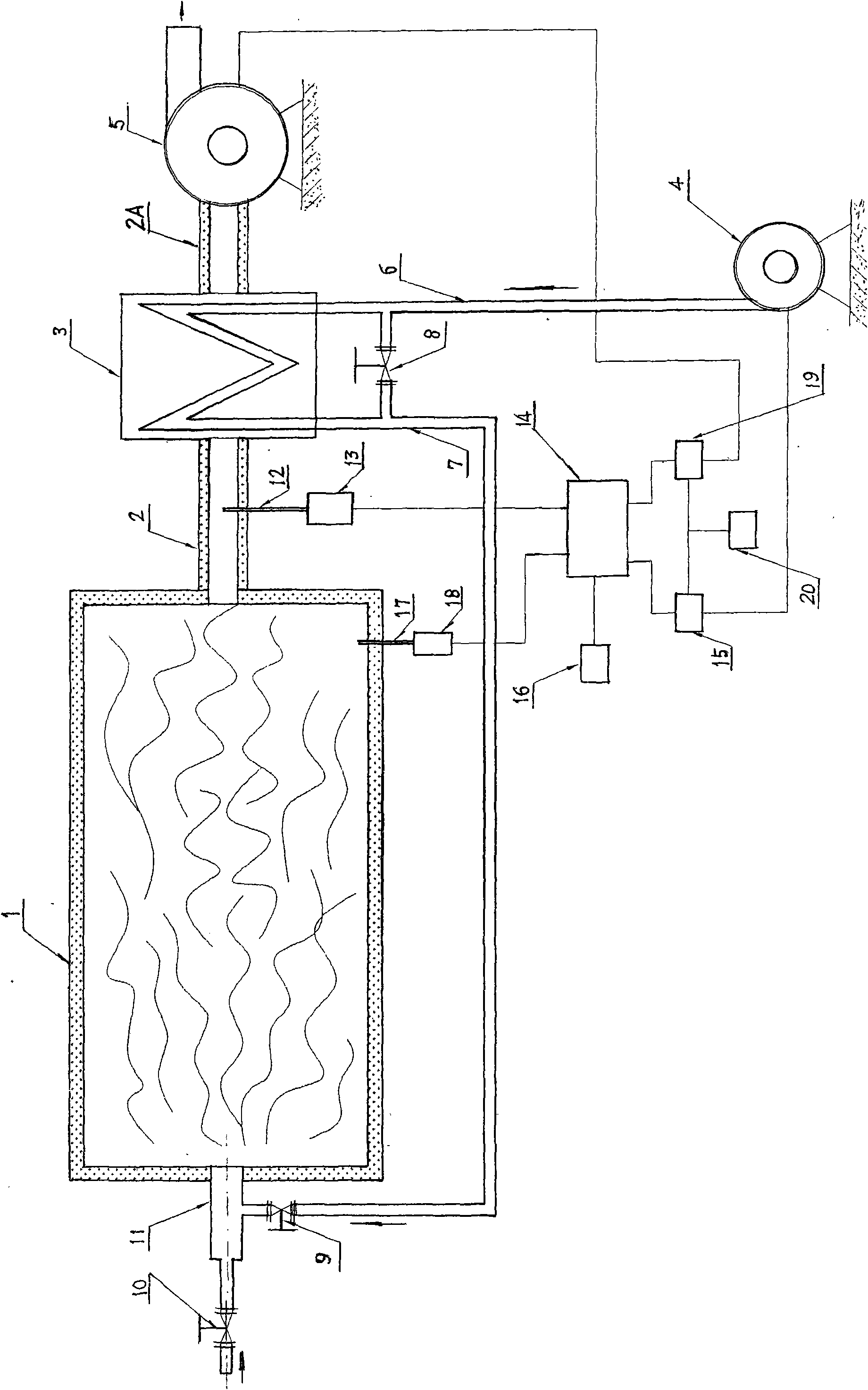

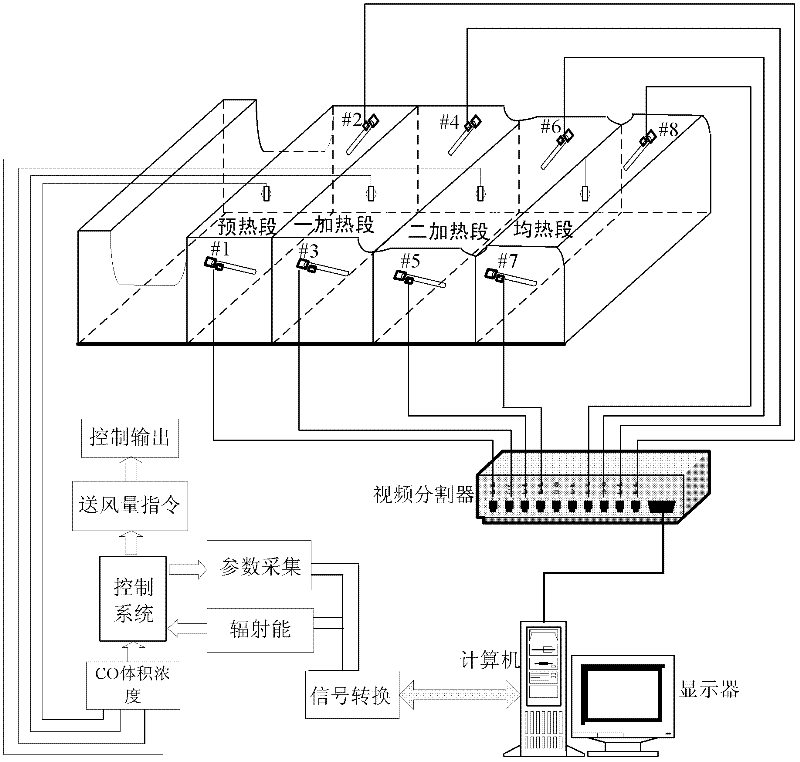

Heating furnace comprehensive optimizing controlling system designing and controlling method for hot rolling process

InactiveCN1644257AReduce the total energy consumption of productionAchieve optimal controlTemperature control deviceAdaptive controlProduction lineControl system design

A design and control method for the optimizing control system of intermediate rolling mill and heating furnace in order to improve the heating quality of billet in the heating furnace and save energy features that the heating furnace and intermediate rolling mill constitute a closed loop system, the information (rolling force, temp, etc) is fed back to heating furnace for dynamically changing the heating temp, and the optimizing control strategy and control algorithm are used in the billet heating process.

Owner:DALIAN UNIV OF TECH

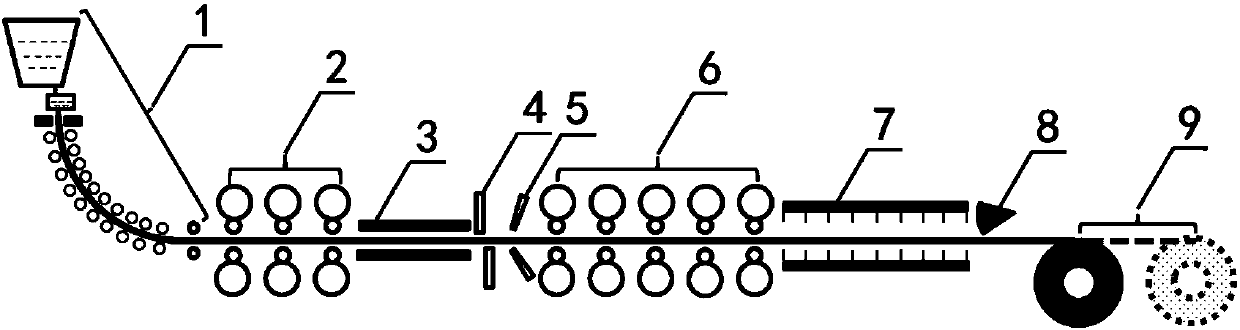

Headless continuous casting and rolling ferrite rolling method and device of low/micro-carbon steel coil for deep drawing

PendingCN107597844AReduce aging phenomenonPromote formationTemperature control deviceWork treatment devicesTemperature controlHigh pressure water

The invention discloses a headless continuous casting and rolling ferrite rolling method and device of a low / micro-carbon steel coil for deep drawing and belongs to the field of metallurgy steel rolling. According to the headless continuous casting and rolling ferrite rolling method and device of the low / micro-carbon steel coil for deep drawing, continuous casting for blank forming, rough rollingof a rough rolling unit, temperature control of a cooling channel, descaling of high-pressure water, ferrite rolling of a finishing mill group, cooling of a layer cooling device, high-speed flying shear and shunt winding and coiling of a reeling machine are carried out. By means of the method and device, the problems that heating / soaking of a heating furnace is needed before rough rolling of a conventional hot rolling process, and cooling with temperature retaining is needed due to the fact that the temperature difference of rough rolling of an austenite zone and finish rolling of a ferrite zone is large and the problems that for thin slab casting and rolling processes with CSP as a respective, heating / soaking or induction heating for temperature supplementing of a heating furnace is needed are solved, the advantages that the arrangement is compact, the investment is small, the production efficiency is high, safety and reliability are achieved, energy is saved, environmental friendliness is achieved, and the cost is reduced are achieved, and the low-carbon / micro-carbon steel coil for deep drawing is produced through headless continuous casting and rolling and ferrite rolling.

Owner:UNIV OF SCI & TECH BEIJING +1

Hot rolled steel plate surface oxidation iron sheet control method for vanadium-containing automobile beam

InactiveCN101147920AImprove toughnessImprove stamping formabilityTemperature control deviceSurface oxidationImpurity

The present invention discloses a surface scale control method of hot-rolled steel plate for vanadium-bearing automobile frame. It is characterized by that the mass percentage of molten steel chemical components of raw material steel of said method is as follows: C is 0.06%-0.12%, Si is less than or equal to 0.30%, Mn is 1.05%-1.25%, V is 0.04%-0.10%, P is less than or equal to 0.025%, S is less than or equal to 0.015% and the rest is Fe and other impurity. Its slab drop-out temperature is controlled at 1200deg.C-1230deg.C, initial temperature of rough rolling is controlled at 940deg.C-1020deg.C and its final rolling temperature range, is 840deg.C-880deg.C.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

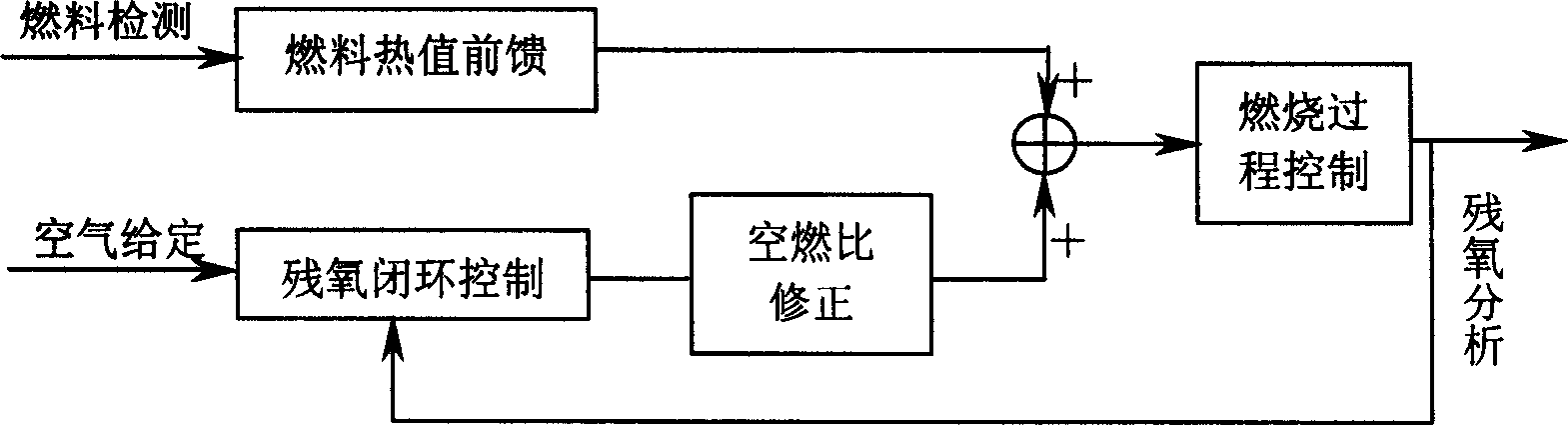

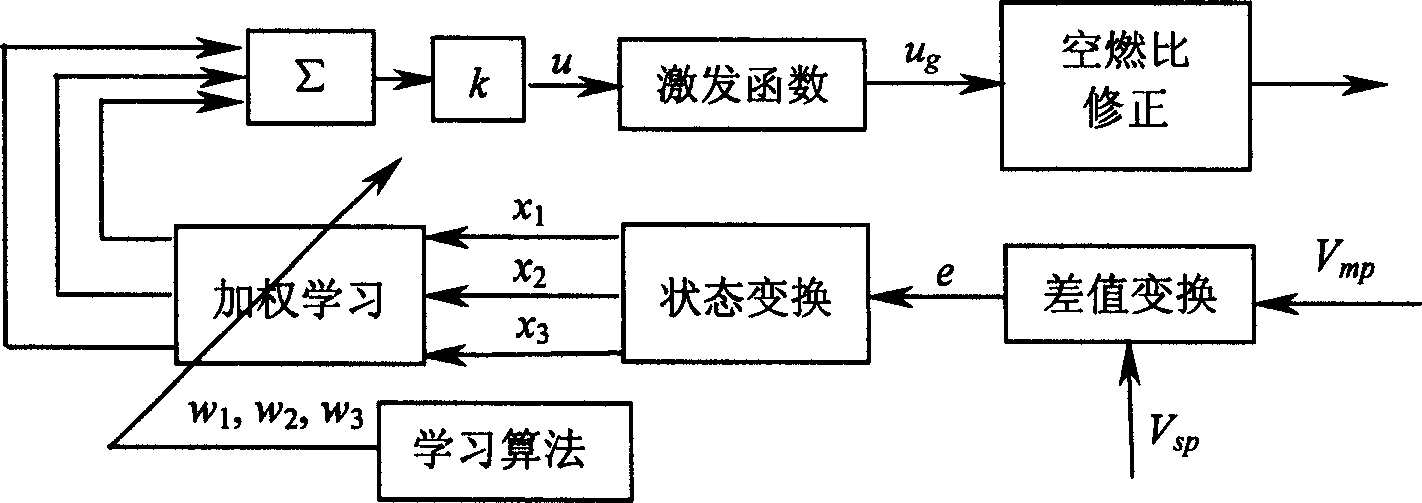

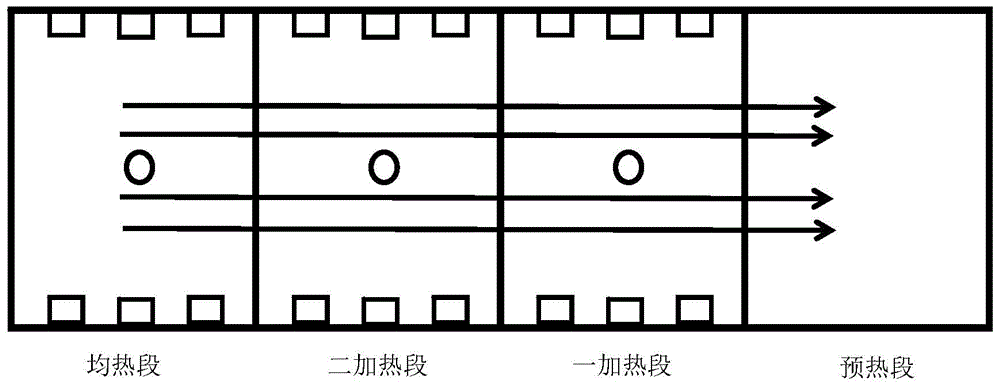

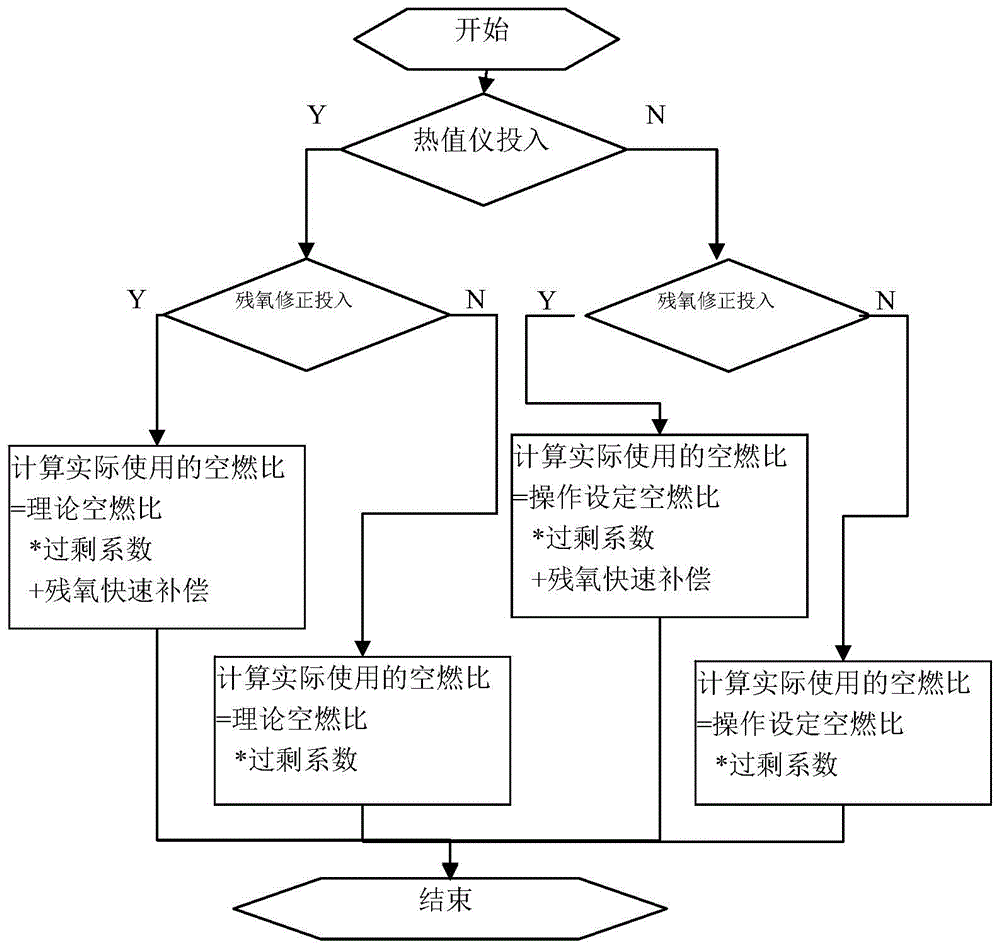

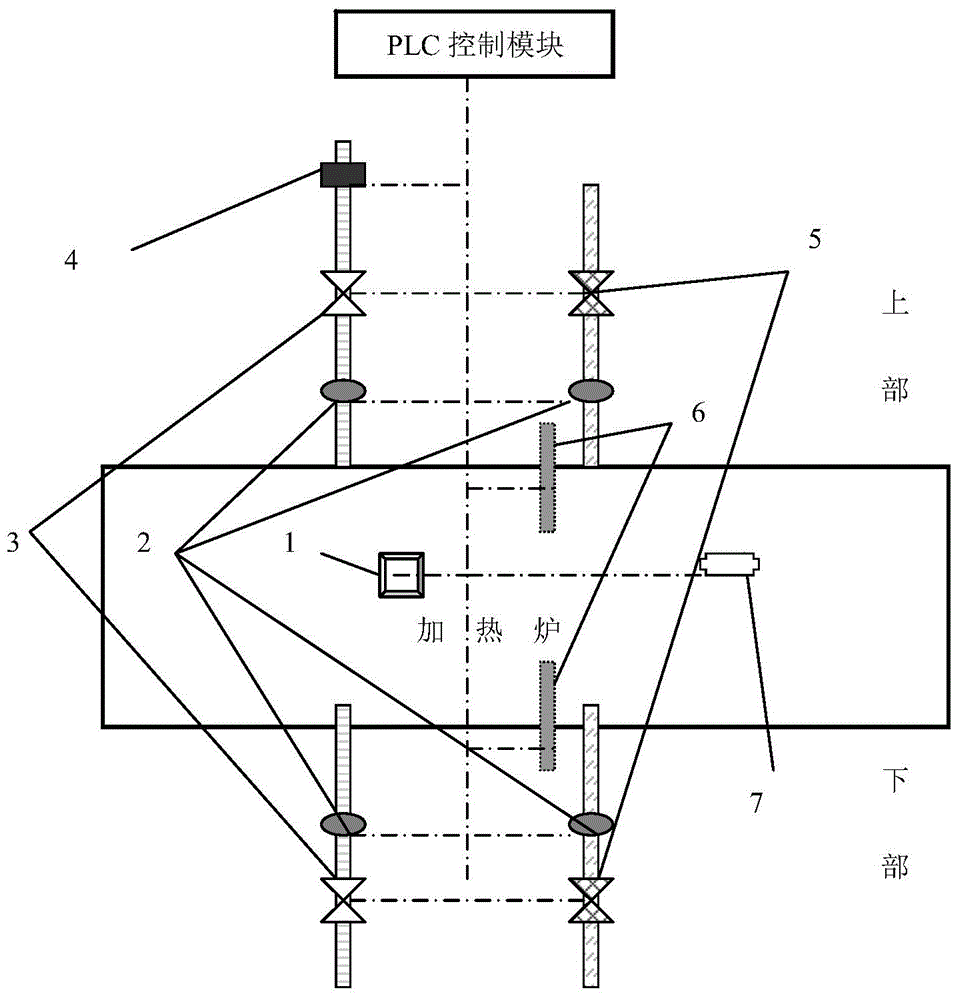

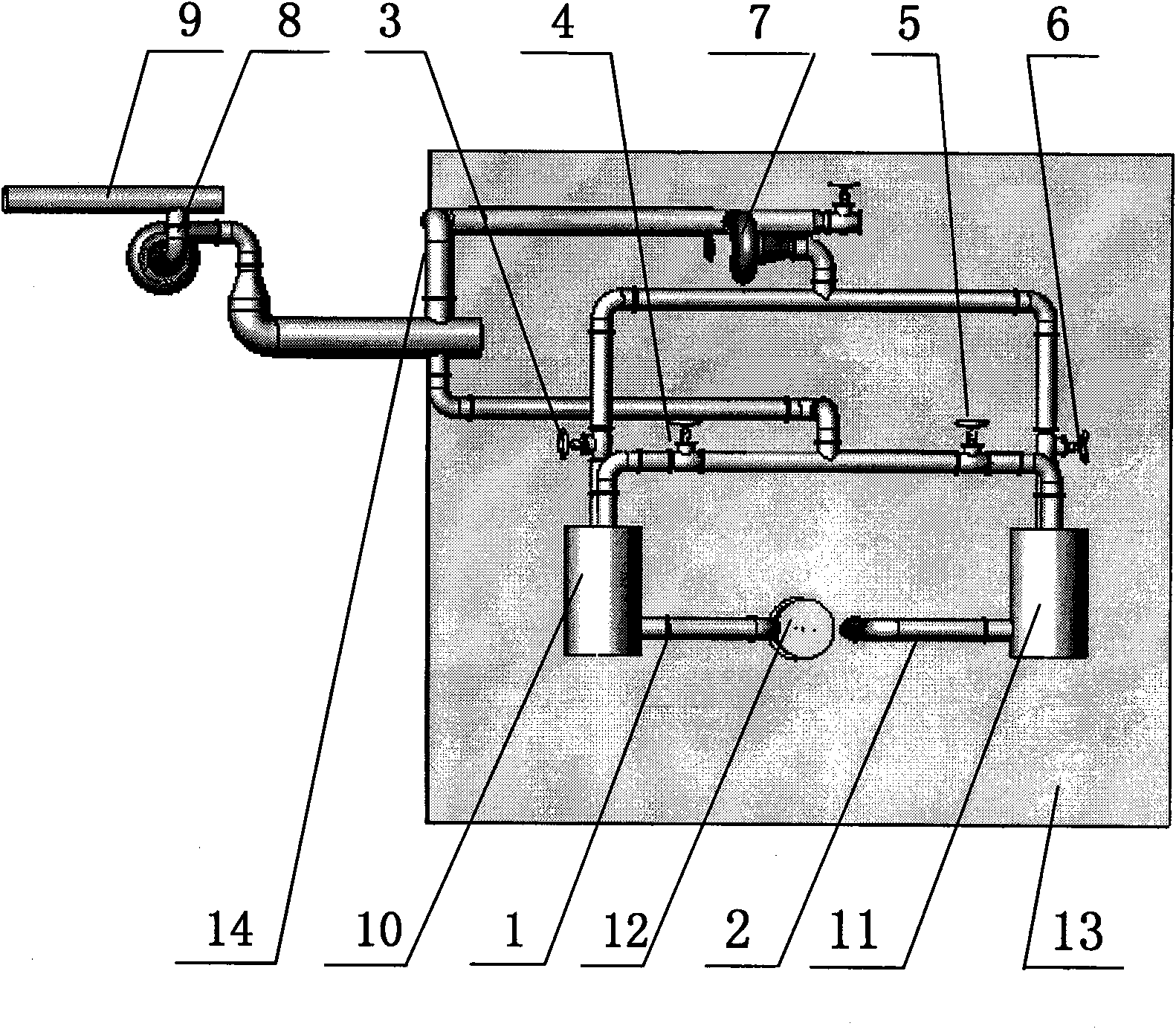

System and method for automatically controlling content of residual oxygen in regenerative heating furnace

The invention discloses a system and method for automatically controlling the content of residual oxygen in a regenerative heating furnace and belongs to the technical field of control over combustion of heating furnaces. The system comprises a computer terminal, a programmable controller, a regulating valve, zirconium oxide analysis meters and a heat value analysis meter. A combustion section of the heating furnace comprises a first heating section, a second heating section and a soaking section, the zirconium oxide analysis meters are installed in the middle portions of the tops of all the sections, and the heat value analysis meter is installed in front of an inlet of a gas main. During combustion of the heating furnace, the actual air-fuel ratios are obtained through calculation according to the theoretical air-fuel ratios of the three sections, and optimal control over the content of the residual oxygen in a hearth is achieved by combining the zirconium oxide analysis meters with the heat value analysis meter for control. The system and method for automatically controlling the content of the residual oxygen in the regenerative heating furnace have the advantages that a gas and an air flow control valve is controlled reasonably, accurately and rapidly, the adjustment function of the regulating valve is effectively utilized, optimal control over the content of the residual oxygen in the hearth of the heating furnace is achieved, fuel is saved, and pollution is reduced.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

High-efficiency intelligentized heating furnace control method

ActiveCN102721288AGuaranteed reasonablenessRealize cross controlControl devices for furnacesFurnace temperatureThermodynamics

The invention relates to the technical field of heating furnaces of heat treatment equipment applied in the steel rolling industry, in particular to a high-efficiency intelligentized heating furnace control method. The method adopts a PLC (programmable logic controller) system for field control and an upper computer operating system communicating and connected with the PLC system to form an intelligent control system, and moreover, the intelligent control system is utilized to efficiently, scientifically and intelligently control a heat furnace. The method is characterized in that the intelligent control system controls and sets the heating furnace in the following six aspects: (1) furnace temperature control; (2) internal pressure control; (3) air-fuel ratio control; (4) safety protection system control; (5) adoption of an human-machine interface (HMI) on the intelligent control system; (6) history data recording. The method can reasonably control heating temperature, furnace temperature and furnace pressure at each stage in real time, increases the heating utilization rate, has an outstanding effect in saving energy and reducing consumption, increases the production efficiency, reduces the production cost, and prolongs the furnace service life.

Owner:HEBEI XINYE ENG TECH

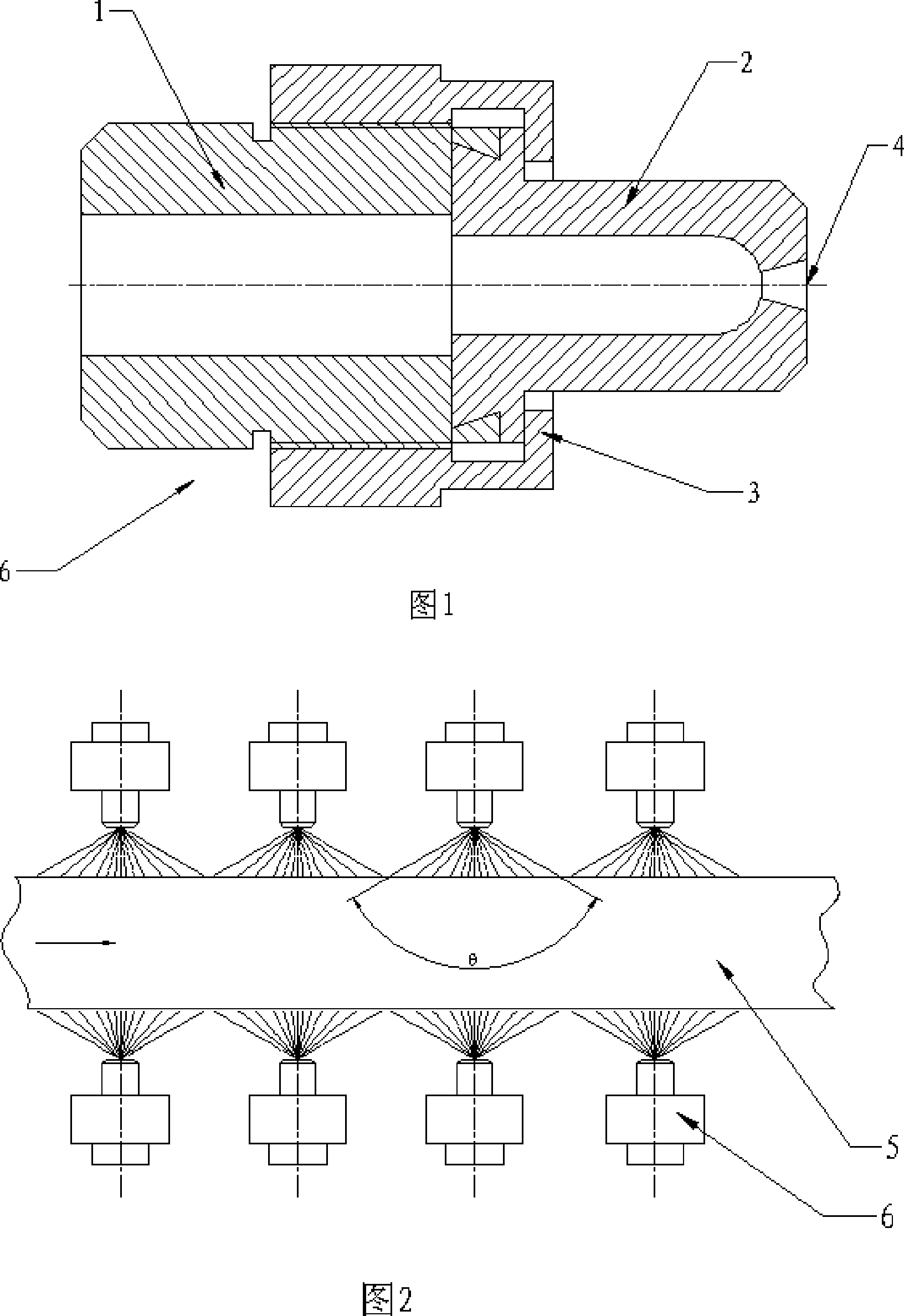

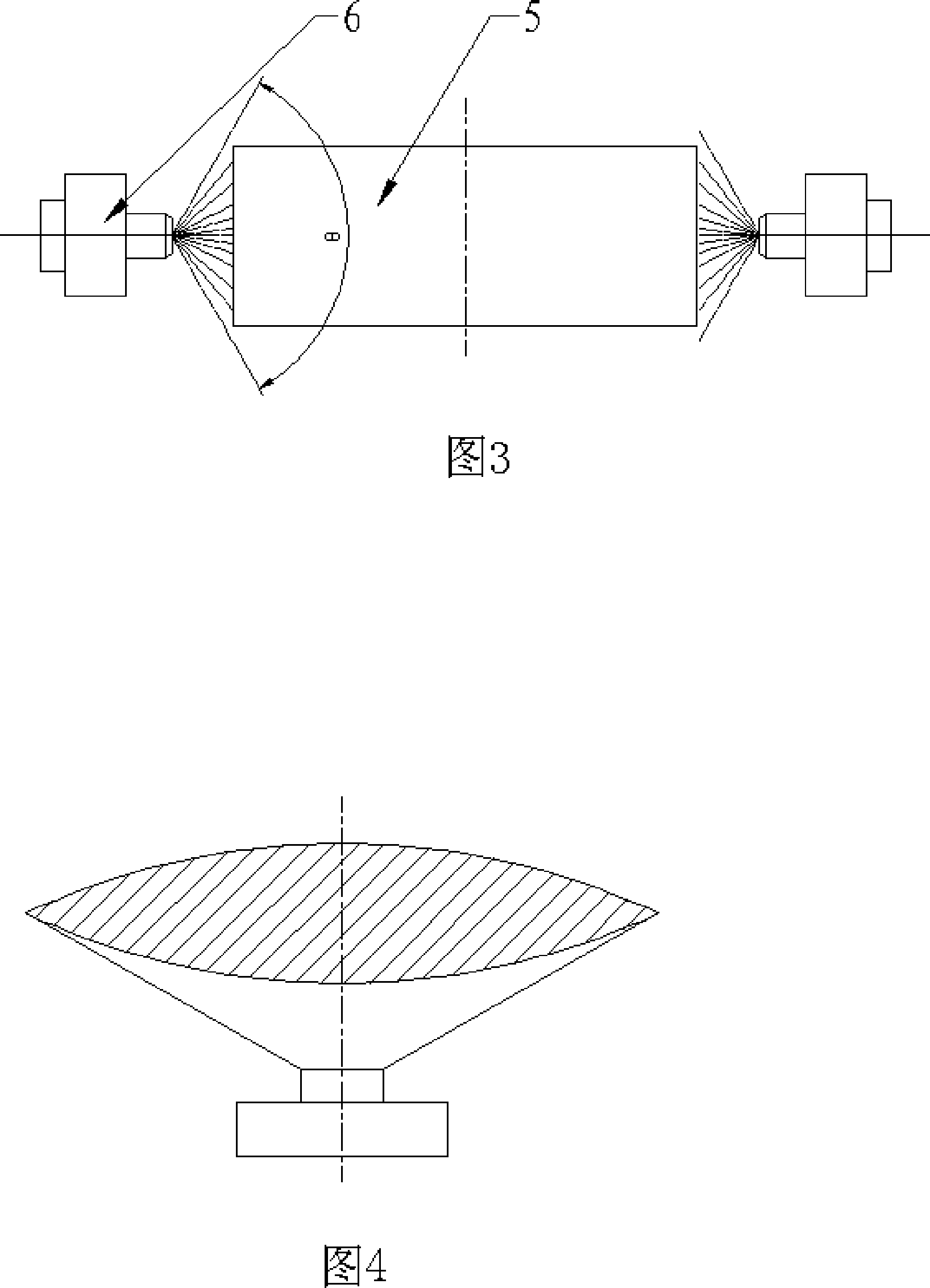

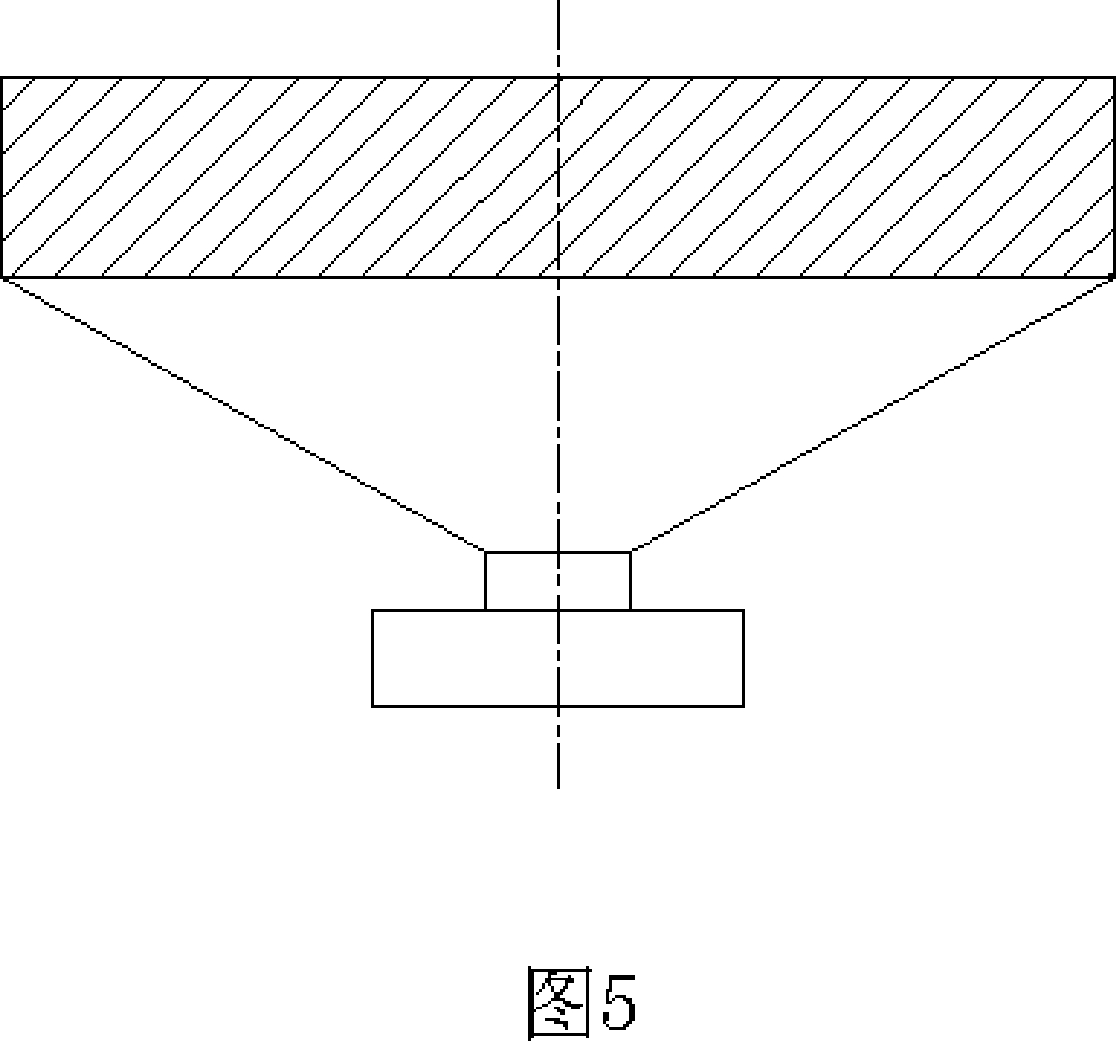

Straight arc casting machine alloy steel sheet billet continuous casting foot roller segment narrow surface cooling method

The present invention discloses a straight-curved type casting machine low-alloy steel slab continuous casting full-rolling section narrow face cooling method, and is aimed at solving the problem of that on the casting blank surface corner portion of low-alloy steel the transverse crack can be easily produced. Said invention belongs to the field of metal continuous casting blank cooling and surface quality control technology. Said method is characterized by that in the full-rolling section of continuous casting straight-curved type casting machine slab said invention utilizes the nozzles which are symmetrically mounted at left side and right side of casting blank pouring direction to cool the narrow face of said casting blank, and adopts rectangular nozzles to symmetrically and simultaneously cool the narrow faces of left and right two sides of casting blank. Said invention also discloses a kind of rectangular nozzle for said method, the water outlet hole of its sprayer is a hole with rectangular section. Said invention can reduce casting blank cooling strength of full-rolling section under the crystallizer and can improve casting blank cooling uniformity, so that it can eliminate casting blank surface corner portion transverse crack defect of continuously-cast high-strength low-alloy steel whose steel quality is P510L, P590L, J55 and X52, etc.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

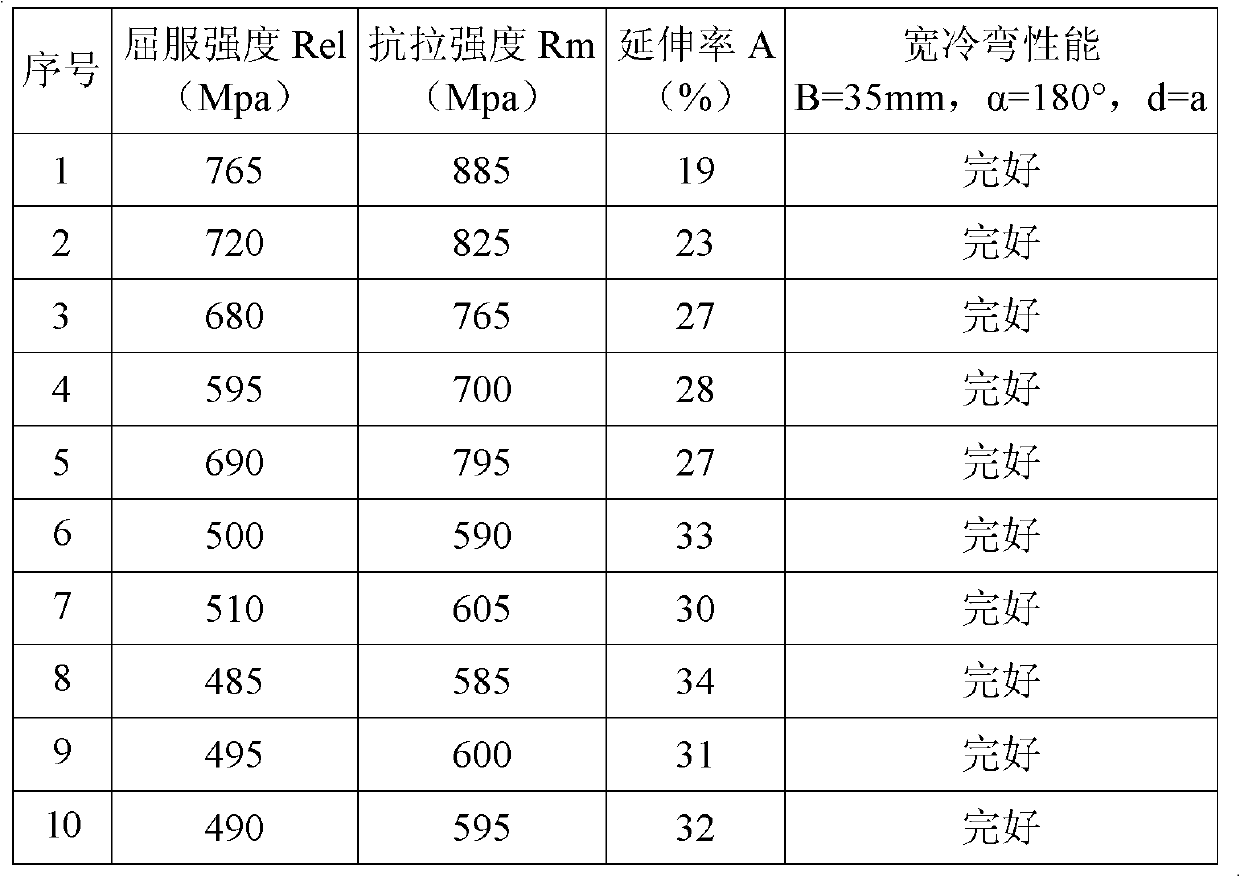

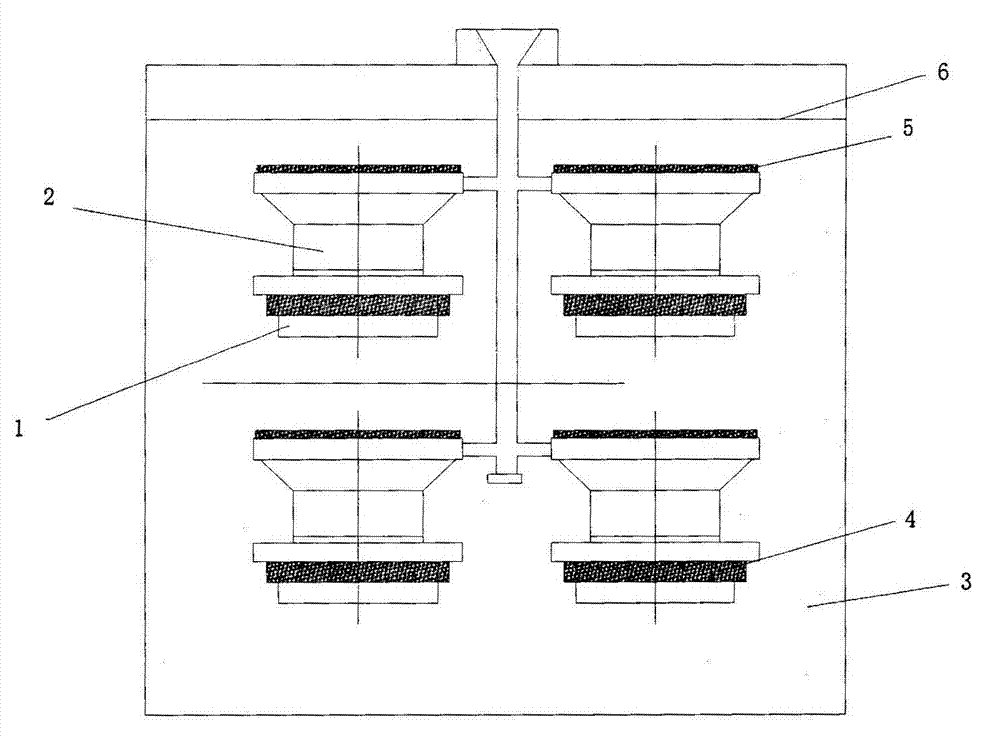

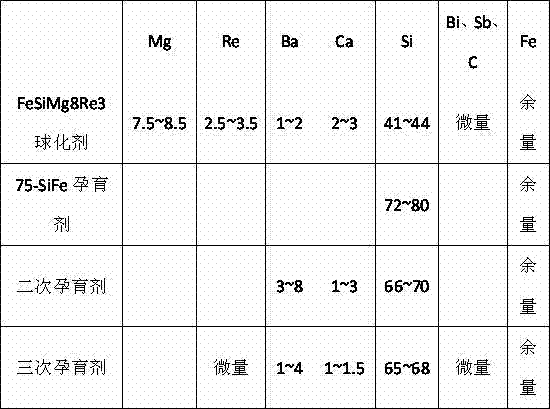

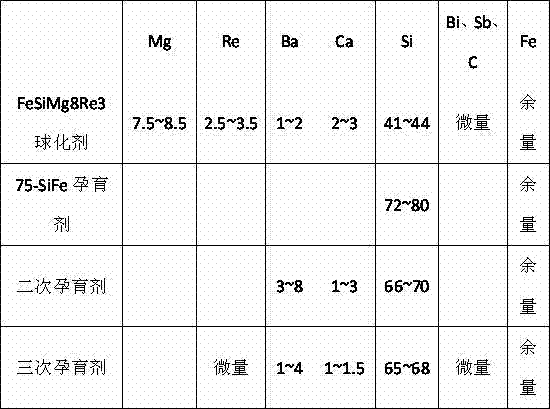

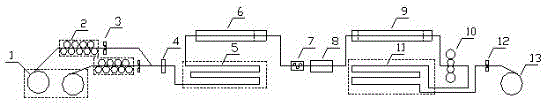

Manufacturing method of spheroidal graphite cast iron casting of wind power yaw variable-pitch device

The invention discloses a manufacturing process of a spheroidal graphite cast iron casting of a wind power yaw variable-pitch device. The process comprises the following processes of mould making, foaming and moulding, paint brushing, boxing and shaping, electric furnace smelting, tundish-covering nodulizing treatment, vacuum-assist pouring and three-time inoculation treatment, wherein the boxing and shaping process is a layered assembling process, so that the production efficiency can be improved and the process yield can be increased; cold iron is vibrated and reasonably arranged, so that the compactness of tissues in the casting can be improved and the defect of shrinkage porosity can be avoided; by virtue of the processes of electric furnace smelting and tundish-covering nodulizing treatment, the nodulizing rate of the casting can be stabilized and increased and the mechanical properties of the casting can meet the technical quality requirements of wind power castings; the spheroidal graphite cast iron casting manufactured by the process is compact and uniform in tissue, hardly has defects, has good surface quality and high size precision; the casting forming of multiple layers of castings can be realized; and the production efficiency and the process product yield are improved.

Owner:CHTC HEAVY IND

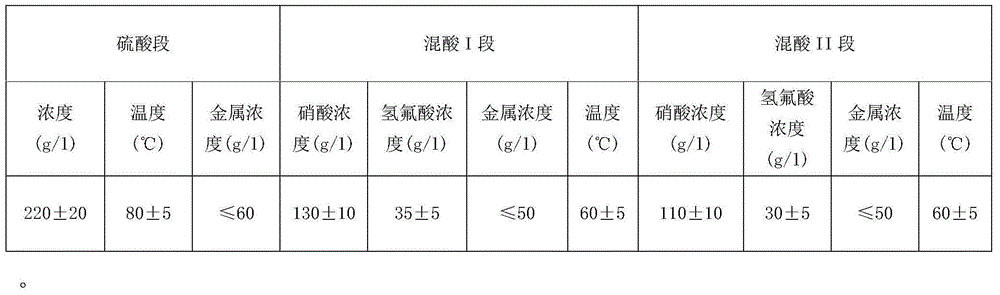

Continuous annealing acid pickling system and method for hot rolling stainless steel composite steel belt

InactiveCN105002348AImprove continuityGood pickling effectFurnace typesHeat treatment furnacesProcessing costSteel belt

The invention discloses a continuous annealing acid pickling system for a hot rolling stainless steel composite steel belt. The system comprises two uncoilers, a straightener, two crop end shears, an MIG argon arc automatic welder, a front loop, a continuous annealing furnace, a straightener, four shot blasting machines, six shallow slot turbulent flow acid pickling grooves, a temper mill, a rear loop, a slitting shear and a recoiler. The invention also discloses an acid pickling method which utilizes the system. After the technology is adopted, the production efficiency is high; the product performance and the surface quality are stable; a product can meet the requirements of customers; the processing cost is low; and the market competitiveness is strong.

Owner:SHANDONG TAISHAN STEEL GROUP

Method for non-vacuum melting and casting Cu-Cr-Zr alloy

The invention discloses a melting and casting Cu-Cr-Zr alloy method, which comprises the following steps: loading electrolytic copper, cupraloy and metal zirconium in the protective gas induction furnace; fusing; casting from bottom; connecting lower cast hole and crystallizer with gas protecting device. The whole course is protected by pure gas with low hydrogen and oxygen partial pressure, which provides good quality casting ingot.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

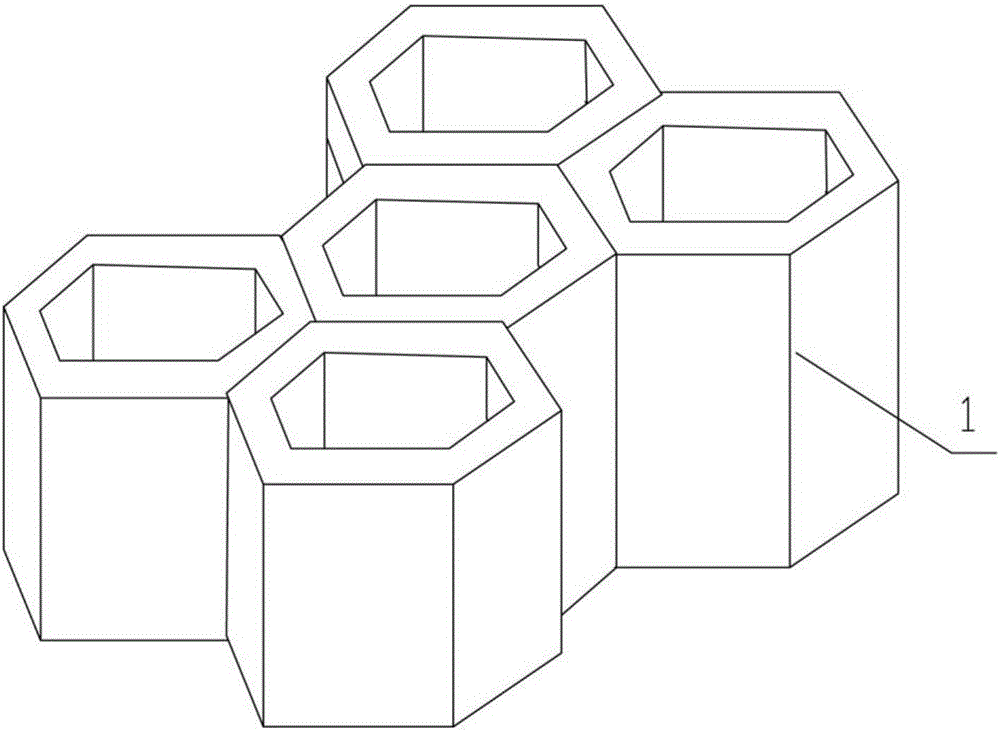

Grain refiner and application of grain refiner in aluminum alloy wheel hub

The invention relates to a grain refiner and an application of the grain refiner in an aluminum alloy wheel hub. The grain refiner is characterized by being prepared through the following steps: (1) preparing powdery Al, Ti and B participating in the reaction according to mass percents of 65-75%, 15-30% and 5-10%; (2) smelting an aluminum ingot containing 6.5-7.5% of silicon and 0.3-0.45% of magnesium, adding a covering agent and a refining agent, degassing and stewing to obtain a matrix alloy fused mass; and (3) putting reaction blocks in an electromagnetic induction furnace for heating and drying, pressing the reaction blocks into the fused mass according to 5-10% by mass of the matrix melt through an immersion bell in batches, keeping the temperature for 20 min to perform thermal explosion synthetic reaction on the reaction blocks in the fused mass so as to crack and disperse the reaction blocks due to strong heat release, and mechanically stirring the fused mass to completely dilute the synthetic product and disperse the synthetic product in the aluminum fused mass. The solution and diffusion periods of the TiAl3 phase of the aluminum alloy solution prepared by the method are greatly reduced, the dispersibility of the TiB2 particles is greatly improved to facilitate the refining function, and the size of the casting crystalline grain of an intermediate alloy can be effectively controlled to be lower than 40 microns.

Owner:金刚

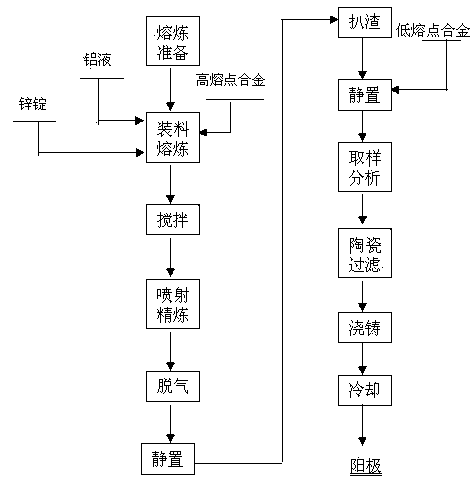

Casting method of aluminum alloy sacrificial anode

The invention belongs to the technical field of corrosion and prevention, and in particular relates to a casting method of an aluminum alloy sacrificial anode. The casting method comprises the following steps: adding basic electrolytic molten aluminum to a resistance furnace; then adding a zinc ingot to obtain molten aluminum alloy; performing jet refining on the molten aluminum alloy by adopting an argon located refining agent; charging argon to refined aluminum alloy melt to degas; drossing oxidizing scum on the surface of the aluminum alloy melt through a drossing tool; adding a low melting point metallic element to drossed aluminum alloy melt; electromagnetically agitating the melt after pressing the low melting point metal; carrying out ceramic filtering; pouring and casting the aluminum alloy melt to a preheated iron anode mould at an even casting speed under the temperature of 700 to 740 DEG C until the mould is full of the aluminum alloy melt; and moving the aluminum alloy melt out of the mould after cooling, solidifying and molding, so as to obtain the aluminum alloy sacrificial anode. The casting method has the characteristics of being short in smelting time, small in loss of iron scale, high in degassing and purifying performances, and low in smelting cost.

Owner:NORTHEASTERN UNIV +1

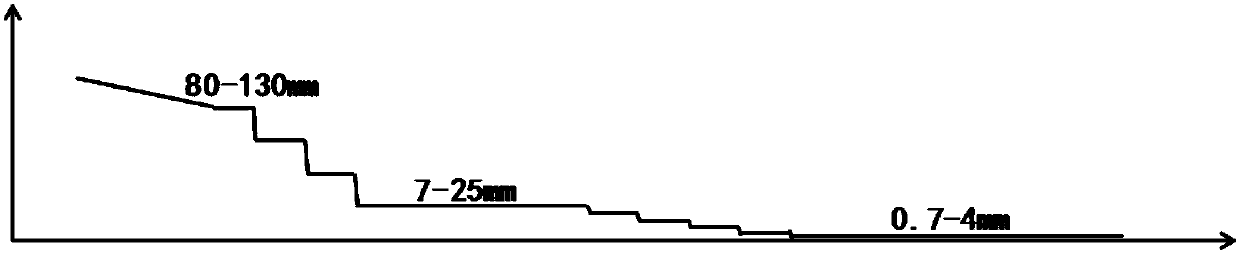

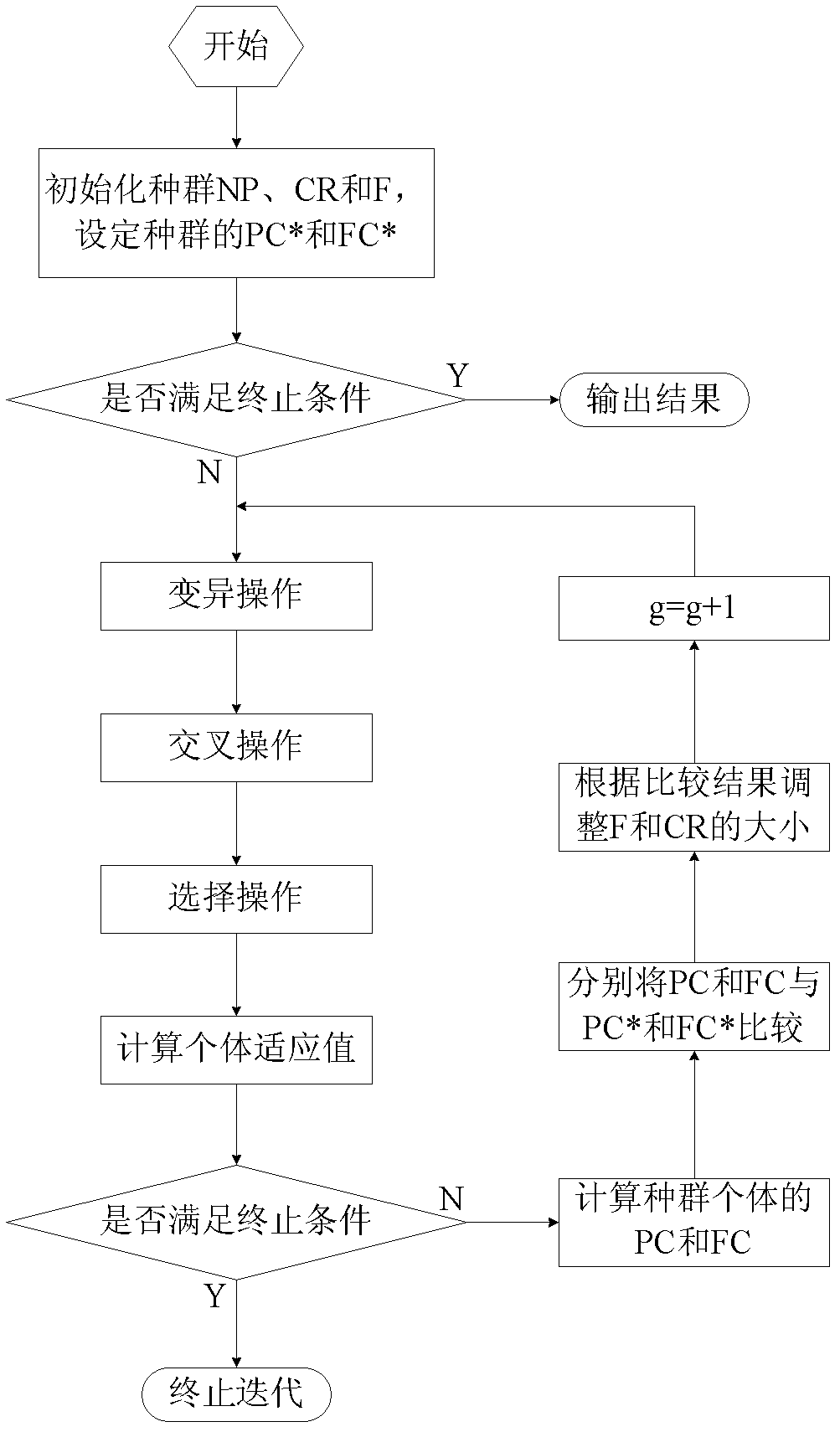

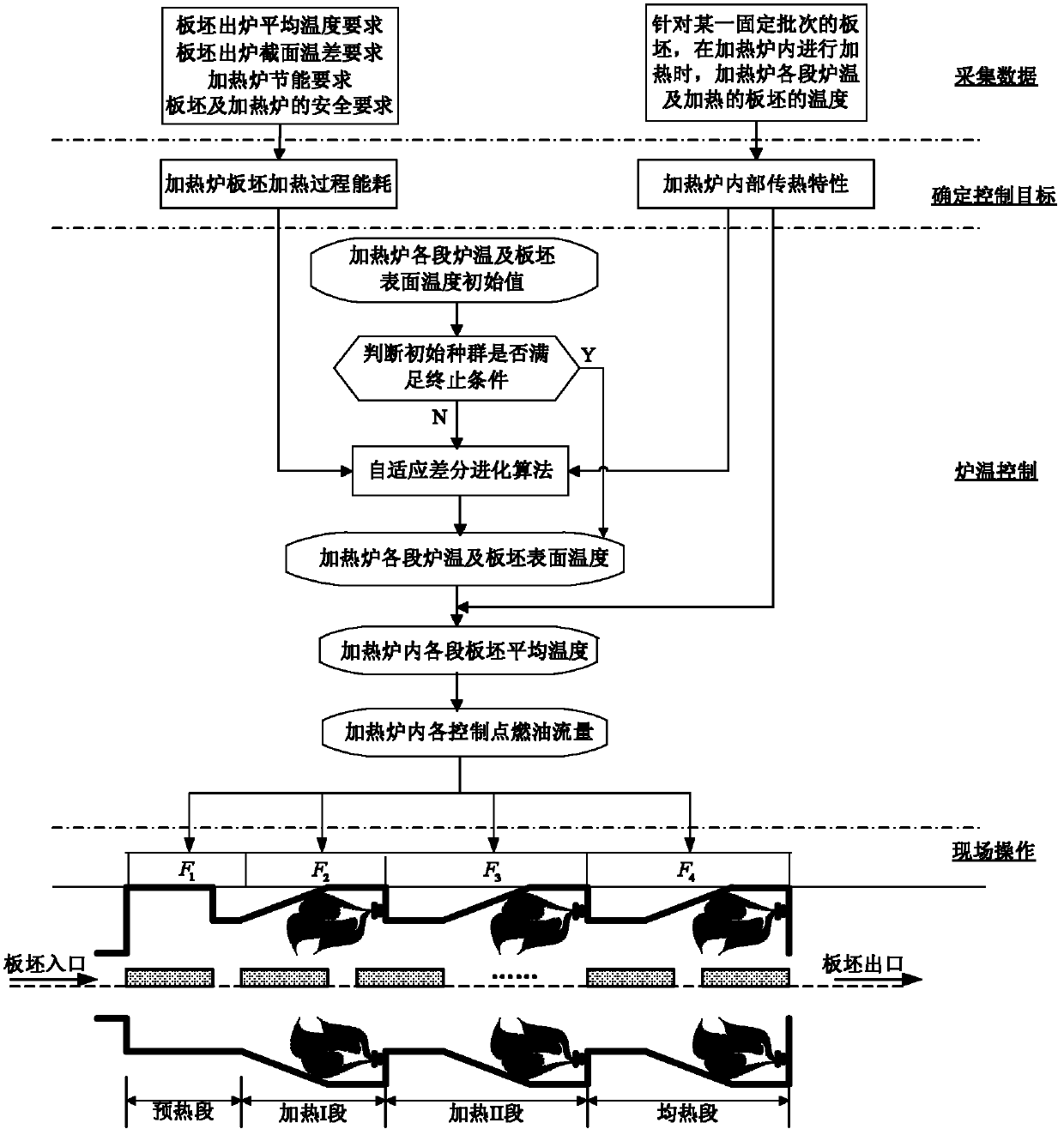

Furnace temperature controlling method in heating process of plate blank of heating furnace

ActiveCN102433428AReduce oxidation burnImprove global search performanceFurnace typesHeat treatment process controlFurnace temperatureOptimal control

The invention discloses a furnace temperature controlling method in a heating process of plate blank of a heating furnace. An optimal control scheme is determined by adopting an adaptive differential evolution algorithm according to the heat transfer characteristic in the heating furnace based on the constraint conditions such as heating mass requirements, production equipment safety and the likeof the plate blank, so that the setting temperature of the heating furnace is obtained and temperature control in the heating process of the plant blank is realized. On the premise that the production requirement is met and the temperature of the plant blank meets the hot rolling requirement, the adaptive differential evolution algorithm is improved, and mutagenic factors and crossover probability are adaptively regulated, so that the global searching ability of the algorithm can be improved, the algorithm convergence is quickened and the searching precision of the algorithm is improved. By implementing the method, the temperature of the heating furnace is reduced, over-burning is avoided, the oxidative burning loss of the plant blank, the energy consumption, the production cost and the discharge of waste gas are reduced, and the economic benefits and the social benefits of an enterprise are improved.

Owner:NORTHEASTERN UNIV

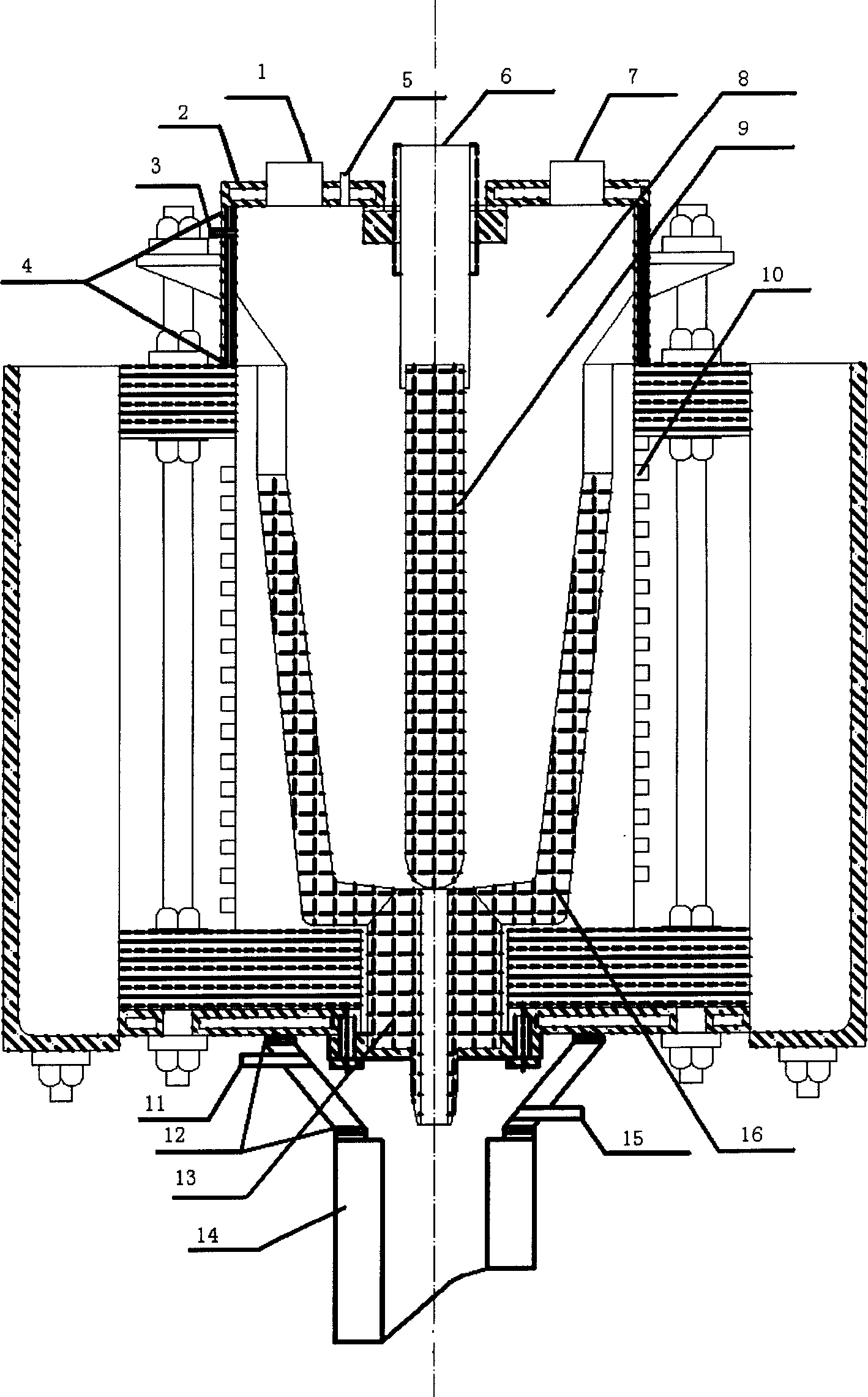

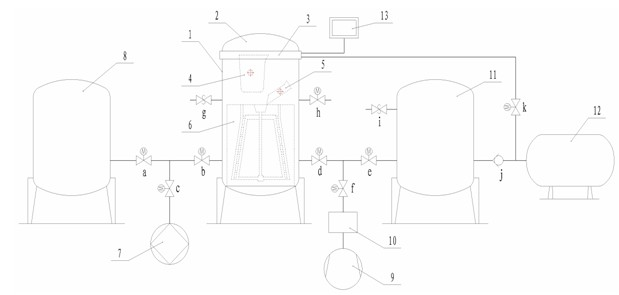

Device and process for manufacturing large-scale complex thin-wall aluminum alloy casting through vacuum pressurization casting

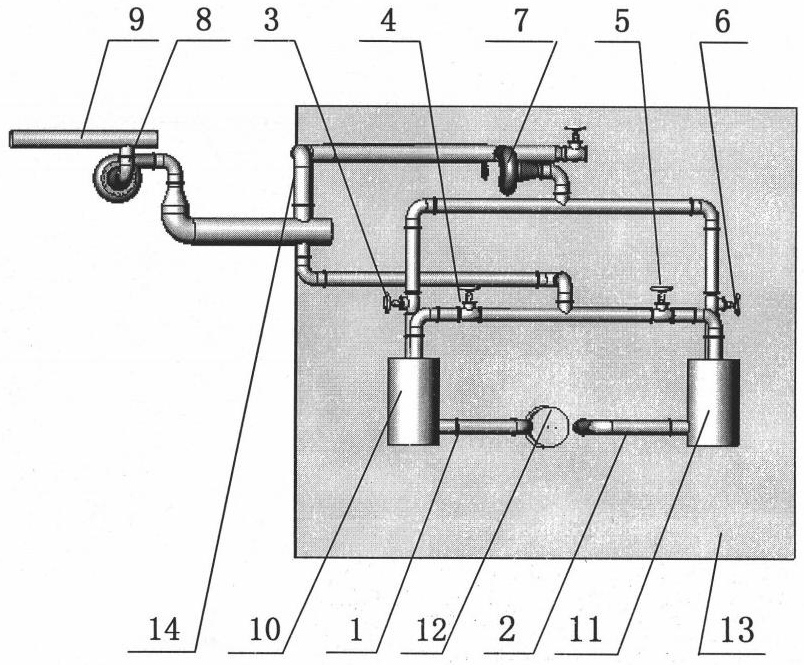

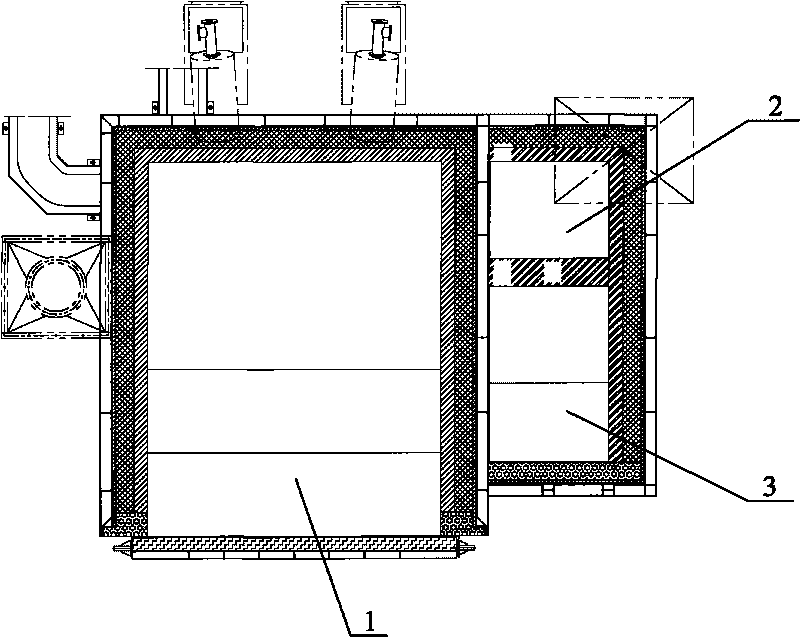

The invention relates to a device for manufacturing a large-scale complex thin-wall aluminum alloy casting through pouring and mold filling under vacuum and crystallization and solidification under pressure. The device comprises a vacuum pressurization casting chamber, a vacuum pumping system, an air pressurization system and an intelligent control system. The vacuum pressurization casting chamber is a high-pressure air-tight seal tank and adopts the vertical arrangement; a turnover seal cover driven by a cylinder and a locking ring for performing rotary seal are arranged at the upper part of the high-pressure air-tight seal tank; a pressure and vacuum detector is arranged on the seal cover; a ladle, a overturn casting drive device, a metal liquid diversion trench, a turnover temperature measuring device and the like are internally arranged in the chamber; a manual casting mechanism is arranged at the outer part of the chamber; the vacuum pumping system is composed of a vacuum pump, a vacuum storage cabin and a pipeline system; the air pressurization system is composed of an air compressor, a refrigeration drier, a pressure storage cabin, a circuit and a pipeline system; and the intelligent control system consists of a PLC (Programmable Logic Controller), an air bottle, a security caution light and an affiliated pipeline system, wherein the PLC is connected with the air bottle, the security caution light and the affiliated pipeline system, which collects and displays data of vacuum, pressure, temperature and the like to realize the intelligent control for the devices, so that the stages in the vacuum pressurization casting can be ensured to be performed sequentially, continuously and smoothly.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

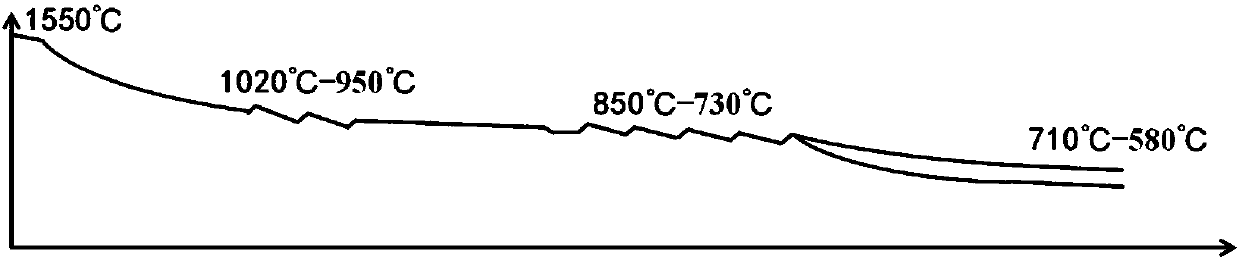

Heating method for controlling decarburization in heavy rail billet furnace

InactiveCN101967541AEnsure complete combustionReduce oxidation burnFurnace typesHeat treatment furnacesPollutant emissionsReducing atmosphere

The invention provides a heating method for controlling decarburization in a heavy rail billet furnace in a heat accumulation heating mode. The heating process comprises a pre-heating section, a heating section and a soaking section. A furnace pressure measurement point is positioned at the pre-heating section; the full furnace is controlled at positive pressure; when the billet temperature is controlled to be less than 1,000 DEG C, the atmosphere in the furnace is oxidizing atmosphere, and the air consumption coefficient is between 1.05 and 1.25; and when the billet temperature is controlledto be more than or equal to 1,000 DEG C, the atmosphere in the furnace is weak reducing atmosphere, the air consumption coefficient is between 0.9 and 1.0. Aiming at the operation and decarburizationcharacteristics of the heat accumulation heating furnace different from the traditional heating furnace, the segment control method is adopted on the control aspects of atmosphere in the furnace and temperature, and a limit low-oxygen concentration burning process is realized. The method has the advantages of low heated billet surface decarburization, low oxidized burning loss, high furnace energy utilization, low pollutant discharge, low production cost and the like, is simple, convenient and feasible, and can achieve good effect of saving materials and energy at the same time of improving the heating quality of products.

Owner:武钢集团有限公司

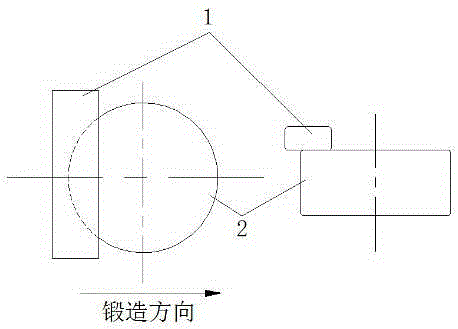

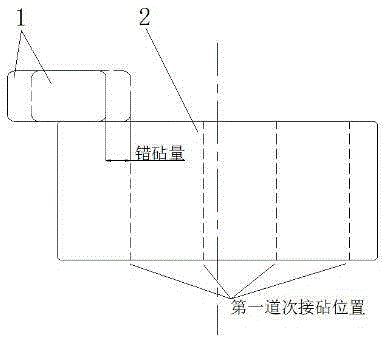

Forging technique for cake forgings

The invention relates to a forging technique for cake forgings. The forging technique is characterized by comprising the following steps that 1, the forgings are heated so that the plasticity of the forgings can be improved and the deformation resistance of the forgings can be reduced; 2, the forgings are subjected to billet forging so that the integral deformation uniformity of the forgings can be improved, and the mechanical performance uniformity is guaranteed; 3, the forgings are melted again and heated, when the temperature of the forgings is lower than 800 DEG C, forging is stopped, and the forgings are melted again and heated; 4, formation is conducted, and steel ingots are forged to be in a shape of target forgings; and 5, heat treatment is conducted on the forgings after forging. According to the forging technique, the five-stage heating standard is adopted, and it is guaranteed that the forgings are heated uniformly and thoroughly.

Owner:SOUTHEAST UNIV

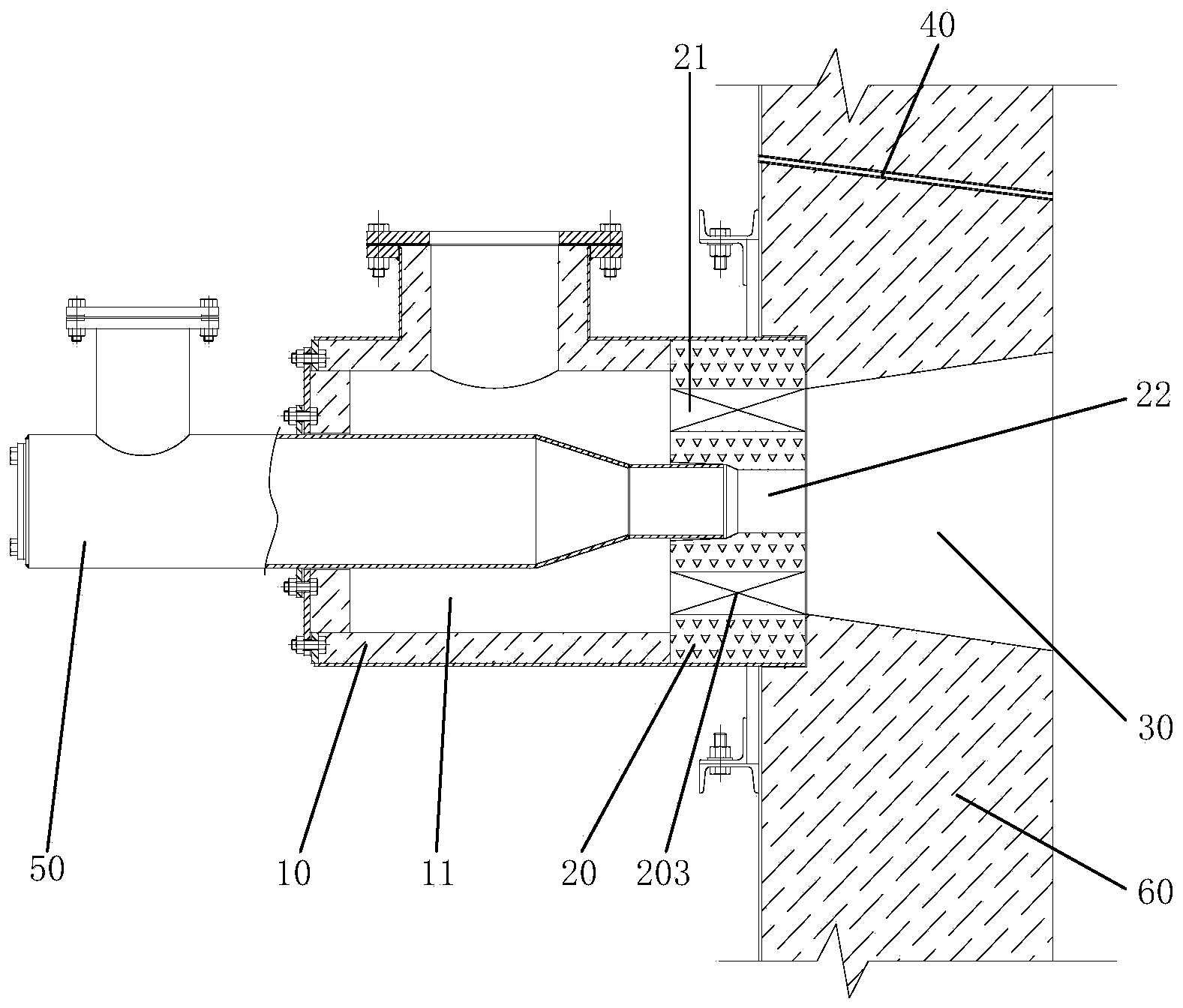

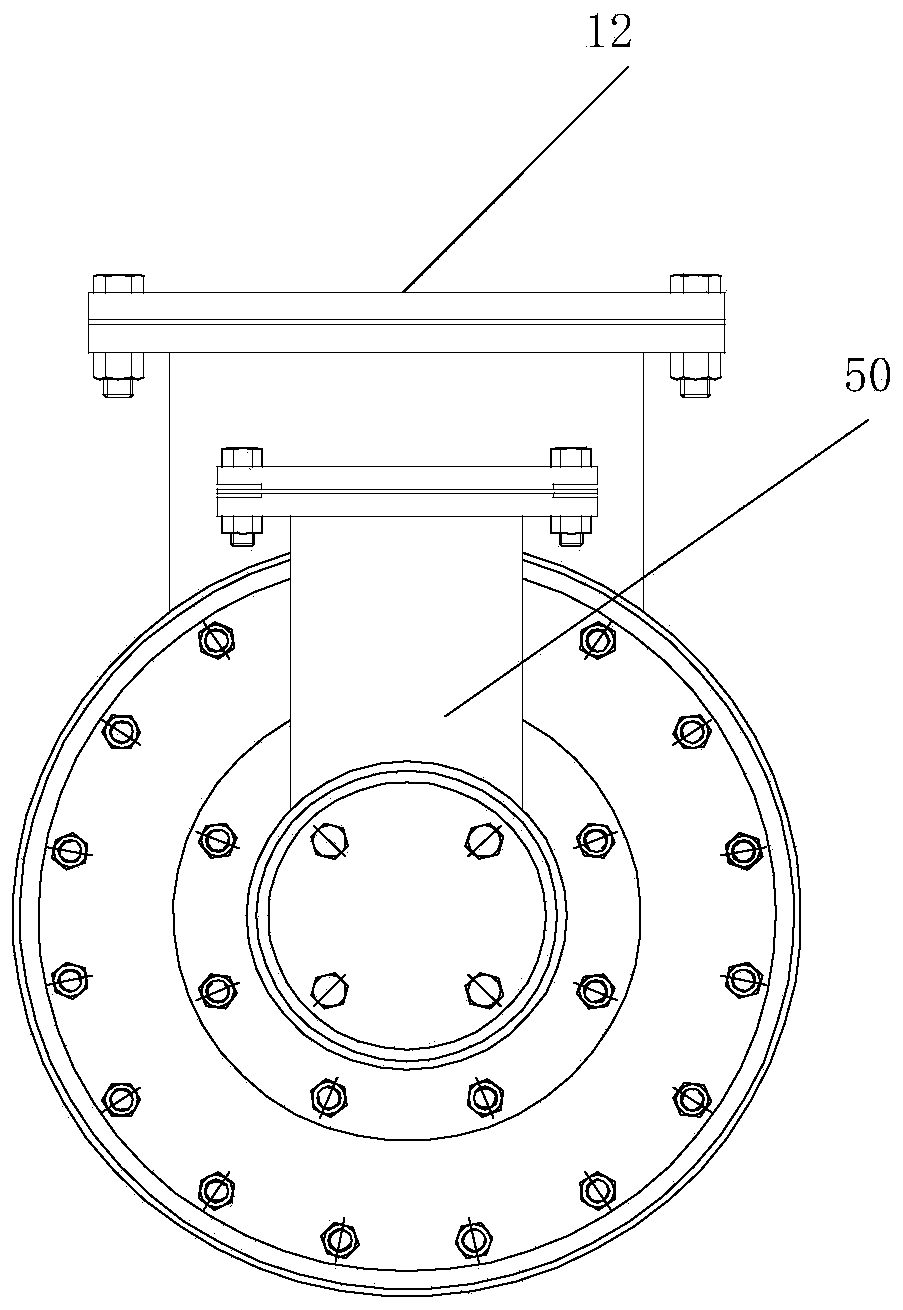

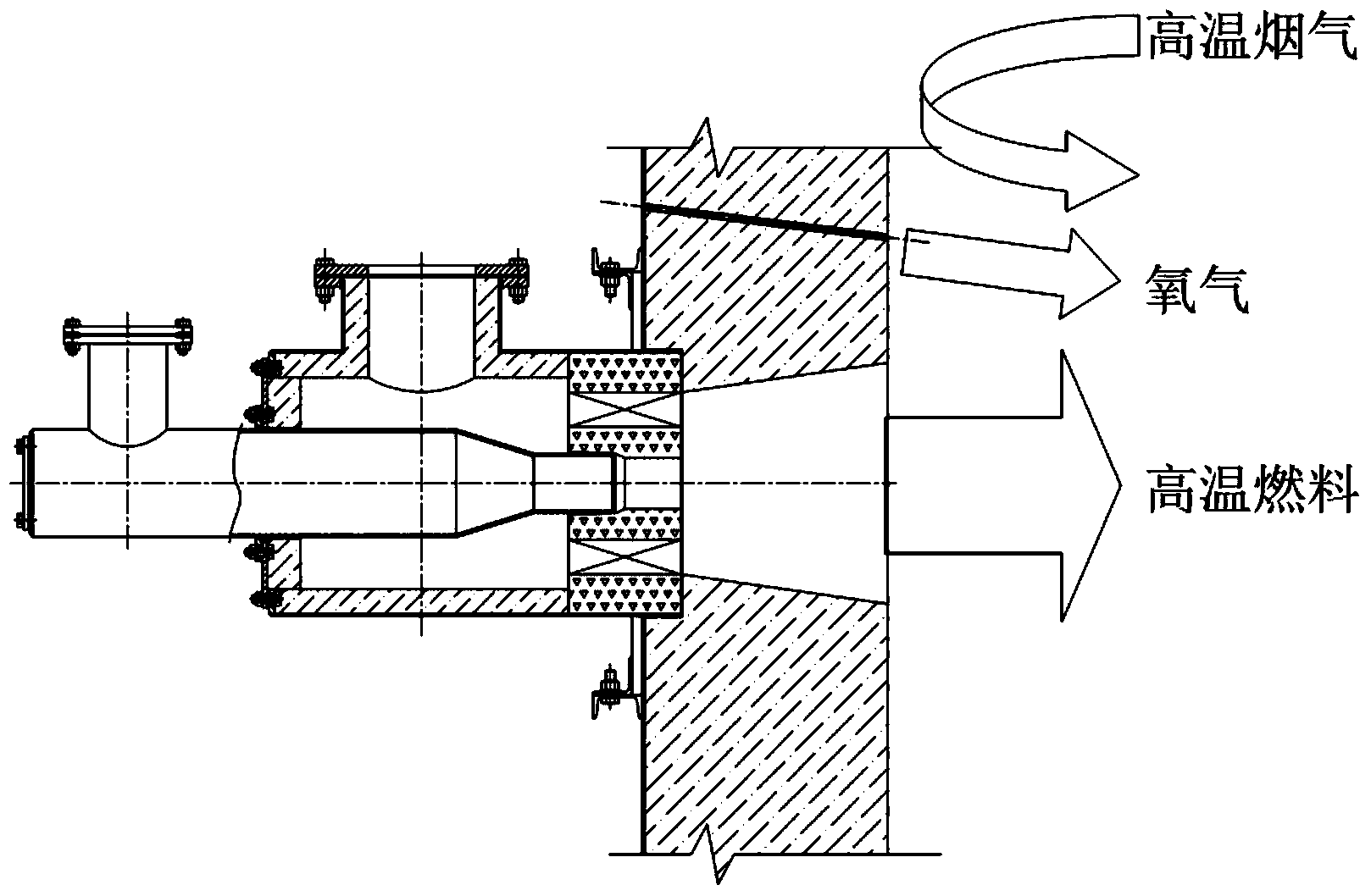

Oxygen-enriched and flameless gas burner and control method thereof

ActiveCN104266190ASimple structureEasy to implementIndirect carbon-dioxide mitigationGaseous fuel burnerEngineeringHearth

The invention discloses an oxygen-enriched and flameless gas burner which comprises a burner casing, an air distribution plate, a prechamber, an oxygen nozzle and a fuel nozzle. A channel penetrating a wall body of a furnace wall of a heating furnace is arranged on the furnace wall. The burner casing is installed on one side of the channel, and the prechamber is formed in the space in the channel. A combustion-supporting air channel is arranged on the burner casing, and the fuel nozzle penetrates through the burner casing in an inserting mode. A fuel channel is arranged on the fuel nozzle. An air inlet and a fuel inlet are arranged on the air distribution plate. The oxygen nozzle is provided with an oxygen pipe and installed on the furnace wall of the heating furnace, the oxygen channel is communicated with a hearth of the heating furnace, the oxygen nozzle is slantingly arranged on the furnace wall of the heating furnace, and a spray head end of the oxygen nozzle is close to the prechamber. The oxygen-enriched and flameless gas burner organically combines the dilution combustion technology and the oxygen-enriched combustion technolog, achieves flameless combustion in the furnace, meanwhile optimizing temperature distribution in the furnace, and reduces NOx emission.

Owner:WISDRI WUHAN WIS IND FURNACE

Super-high-plasticity high-strength cast magnesium alloy and preparation method thereof

The invention relates to a super-high-plasticity high-strength cast magnesium alloy and a preparation method thereof. The cast magnesium alloy comprises the following chemical components by mass percent: 0.5-8.05% of tin, 1.0-6.0% of aluminum and the balance of magnesium. The preparation method comprises the following steps: under the protection of gases, melting preheated the pure magnesium at apreset low temperature, adding the tin and the aluminum in a certain proportion into the melt, evenly stirring after completely melting, heating to a high preset temperature to refine and remove slag,and finally casting to form ingots, The cast magnesium alloy has the advantages of super-high plasticity and high strength; and the preparation method has the advantages of simple technique, high reliability, easy popularization and application, and the like.

Owner:JILIN UNIV

Optimized air-distribution control system for industrial furnace

InactiveCN101672482AEnsure combustion quality and furnace pressureEnsure stabilityAir supply regulationFlue gasIndustrial furnace

The invention discloses an optimized air-distribution control system for an industrial furnace. A combustor is connected with a fuel valve and an air valve connected with a hot air tube, a flue is connected with the inlet of a heat exchanger, and the outlet of the heat exchanger is connected with an induced draft fan set driven by an induced draft speed governor. A bypass valve is arranged betweena cold air tube and the hot air tube, and the cold air tube is connected with an air outlet of an air blower set driven by an air blast speed governor. An outlet of a sampling tube is connected withan flue gas oxygen concentration analyzer; a signal output end of the flue gas oxygen concentration analyzer is connected with a first signal input end of a controller, a second signal output end of the controller is connected with a control signal input end of the induced draft speed governor, a furnace pressure duct is connected with a pressure transmitter a signal output end of which is connected with the second signal input end of the controller, the first signal output end of the controller is connected with the control signal input end of the air blast speed governor, and a communicationport of the controller is connected with a human-computer interface. The invention controls the rotate speed of the induced draft fan set and the air blower set driven by the speed governors throughdetecting the pressure and flue gas oxygen concentration values in the furnace on line so that the furnace is in the optimized air-distribution state all the time.

Owner:夏学苏

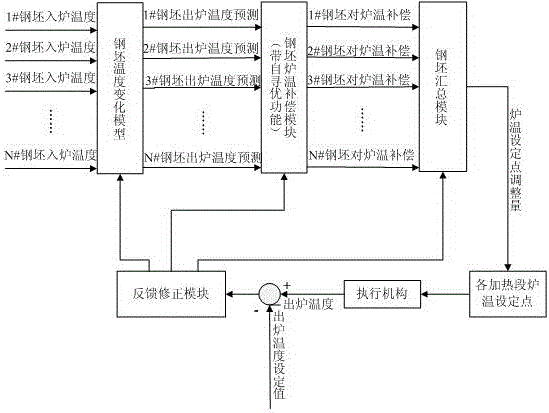

Heating furnace temperature control method based on simulation model

ActiveCN106636606AEasy to controlReduce oxidation burnFurnace typesHeat treatment process controlTemperature controlFurnace temperature

The invention relates to the technical field of control over metallurgical heating furnaces and discloses a heating furnace temperature control method based on a simulation model. The heating furnace temperature control method based on the simulation model comprises the following steps that (1) mechanism modeling is carried out according to the principle of heat convection inside a heating furnace, and a steel billet temperature change model is created; (2) the final discharging billet temperature of each single steel billet is worked out based on the steel billet temperature change model of the step (1), and compared with the set discharging billet temperature, and the adjustment quantities of each single steel billet for the furnace temperature set values of different heating sections are finally determined according to the self-optimization function of a steel billet temperature compensation module; (3) through combination of the quantity and types of the steel billets in each heating section and the feeding billet temperature of each steel billet with the weight coefficients of the different types of steel billets, a steel billet gathering module works out the final adjustment quantity of the furnace temperature set point of each heating section, and outputs the final adjustment quantity to an actuating mechanism; and (4) related parameters in the simulation model are adjusted according to the deviation between the actual discharging billet temperature and the set value, and accordingly the whole simulation model achieves the real-time online function.

Owner:北京和隆优化科技股份有限公司

Flue gas recirculation high temperature air energy-saving and environmental protection combustion technology

InactiveCN101839473AReduce generationAchieve NOx reductionIncreasing energy efficiencySolid fuel combustionProcess engineeringFlue gas

The invention relates to a technology of combustion, in particular to a flue gas recirculation high-temperature air energy-saving and environmental protection combustion technology which is applied to the boiler combustors such as utility boilers, industrial boilers, metallurgical heating furnaces and the like. The invention adopts the concept of flue gas recirculation combustion, realizes real oxygen-poor high-temperature combustion, stabilizes theoretical flame temperature, creates the reducing flue gas environment, reduces oxidation combustion loss, reduces generation of NOX in two-way, and greatly saves fuel. The invention not only saves energy and reduces emission, but also achieves nitre reduction.

Owner:胡建廷

Novel waste aluminum smelting furnace

InactiveCN101706203AUniform textureHigh yieldCrucible furnacesProcess efficiency improvementTemperature stratificationWater quality

The invention provides a novel waste aluminum smelting furnace. The novel waste aluminum smelting furnace comprises a main smelting chamber and a lateral well chamber arranged on the lateral part of the main smelting chamber, wherein the lateral well chamber comprises a feeding area and a pumping area which are communicated with each other; the feeding area and the pumping area are both communicated with the main smelting chamber; and the pumping area is provided with a circulating pump. The molten aluminum is pushed by the circulating pump to repeatedly circulate around the main smelting chamber, the feeding area and the pumping area, and because the molten aluminum quickly flowing can allows the charged materials to be deposited in the molten aluminum quickly, the oxidation burning loss is reduced, the metal recovery rate is improved and the yield and the utilization rate of fuel are also improved indirectly; and in addition, due to the pushing of the circulating pump, the texture of the molten aluminum is uniform in three chambers, and simultaneously the temperature stratification is reduced or eliminated.

Owner:SUZHOU LONGRAY THERMAL TECH

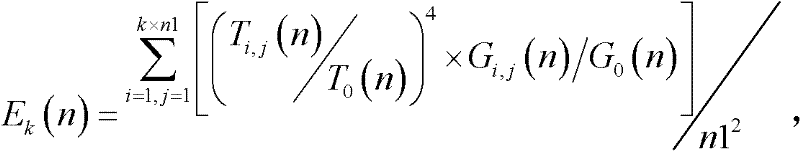

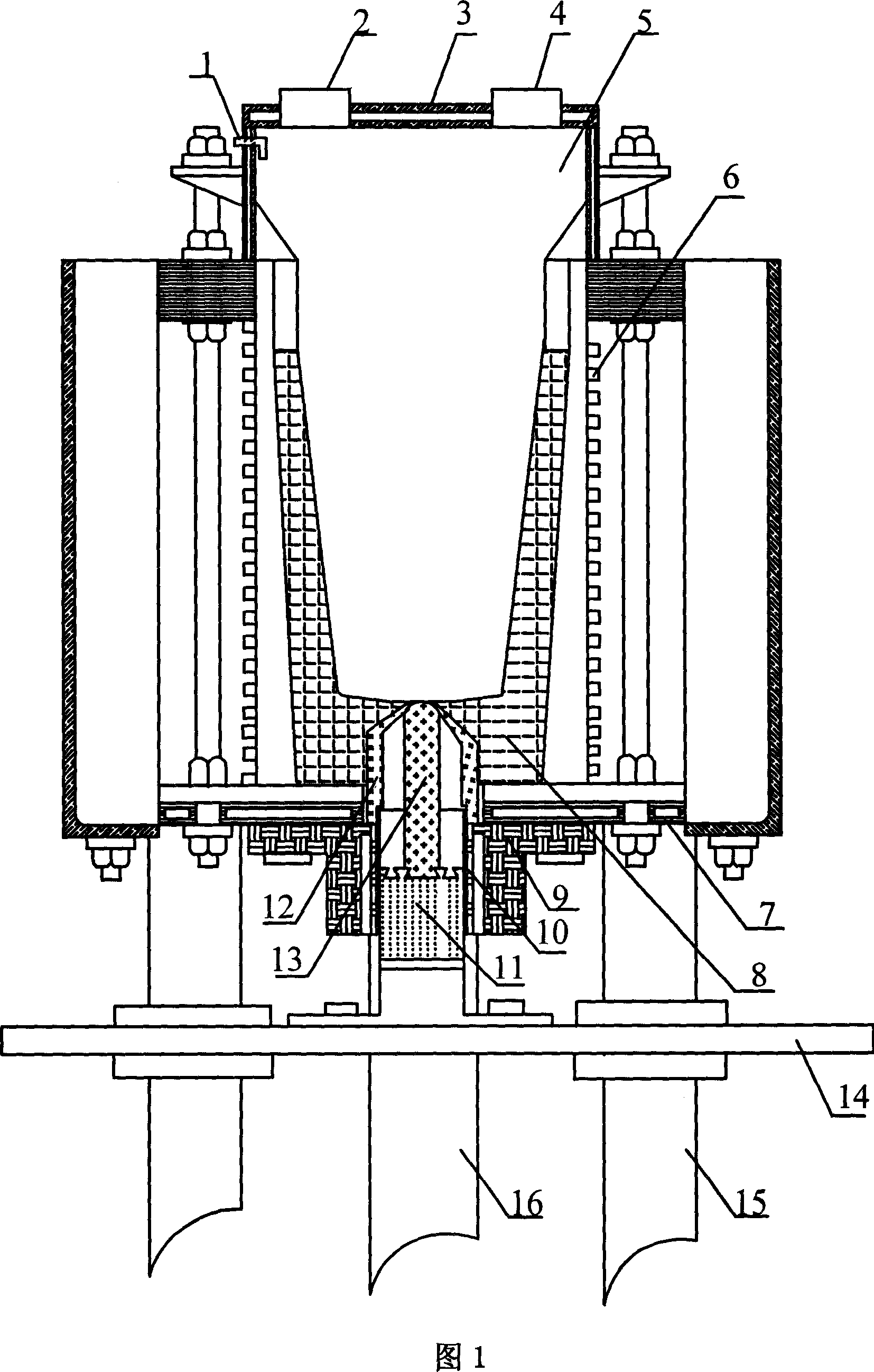

A method for controlling the atmosphere field of a heating furnace

ActiveCN102297451AAchieve runnabilityRealize energy savingFuel supply regulationObservational errorCombustion

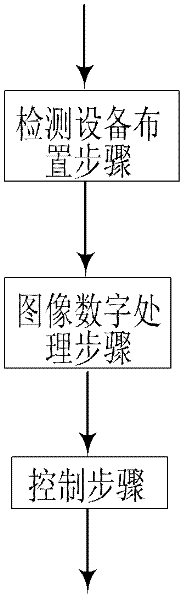

The invention discloses a method for regulating and controlling an air-flowing environment of a heating furnace, which belongs to the field of combustion monitoring and controlling, is applicable to detection and optimal control over combustion of a heating furnace and solves the problems that a mode is needed to be retrained when actual operation work conditions are deviated from preset conditions of the model or when parameters for supporting model operation are detected to be abnormal because an empirical mode is applied in the internal combustion monitoring of the traditional furnace. Themethod comprises the steps of equipment arrangement detection, image number processing and control. According to the method disclosed by the invention, a radioactive energy signal is extracted from flame image in different arranged sections of the heating furnace and is combined with air-flowing environments in the different sections for detecting and calculating reasonable air / combustion ratio, thus the oxidation and burn of steel and furnace tubes caused by the improper air-flowing environments in the heating furnace are reduced and the irregularity of quality of products in different batches is prevented. According to the method, proper air-flowing environments in the furnace can be created, temperature measuring errors are reduced and operation optimization, energy saving and emissionreduction of the heating furnace are realized.

Owner:HUAZHONG UNIV OF SCI & TECH

Equipment for nonvacuum melting and casting readily oxidizable metal and alloy

The invention relates to a device used in non-vacuum smelt casting oxidizable metal and alloy. Wherein, the furnace has heater and pot; the furnace cover has gas inlet and material inlet; and it has cooler; the bottom of furnace has lower irrigator; the bottom of pot has bottom bowl; the irrigator of bottom bowl contacts the plug rod vertically; the bottom plug rod is connected to the dummy ingot head; the dummy ingot head adjusts the position of plug rod; the bottom bowl is connected to crystallizer connected to the cooler; the crystallizer has graphite sheath and cooling water groove, to reduce the casting ingot temperature; the dummy ingot head has dovetail groove to solidify the fusion as drawing function; the dummy ingot head is connected to adjuster. The invention processes the whole process under protective gas, with low hurt rate and improved quality.

Owner:苏州有色金属研究院有限公司

Energy absorption aluminum profile for railway vehicle body and manufacturing method thereof

InactiveCN104988366ATo achieve the effect of densificationHigh strengthRailway wheel guards/bumpersEnergy absorptionCrystal structure

The invention relates to an energy absorption aluminum profile for a railway vehicle body and a manufacturing method thereof. The energy absorption aluminum profile comprises, by mass, 0.5%-0.7% of Si, 0-0.15% of Fe, 0.4%-0.6% of Mg, 0.2%-0.3% of Mn, 0-0.01% of Cu, 0.1%-0.2% of Cr, 0-0.01% of Zn, 0.04%-0.06% of Ti, 0.04%-0.1% of V, and the balance of Al. By adding the 0.04%-0.1% of V into the energy absorption aluminum profile, the columnar crystal structure of a cast ingot can be reduced, the cast structure can be refined, the effects of restraining recrystallization of deformed grains and growth of recrystallized grains can be achieved in the heat treatment and heat deformation processes of the alloy, the purpose of refining the profile structure is achieved, the strength, toughness, ductility and corrosion resistance of the profile are improved, and the energy absorption property of the profile is significantly improved.

Owner:龙口市丛林铝材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com