Device and process for manufacturing large-scale complex thin-wall aluminum alloy casting through vacuum pressurization casting

A technology of vacuum pressurization and casting work, which is applied in the field of installation of large and complex thin-walled aluminum alloy castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

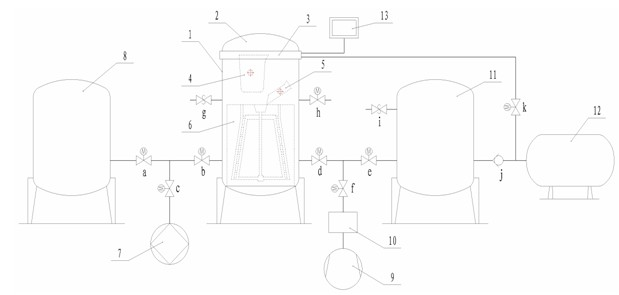

[0037] Embodiment, this embodiment takes a large complex aluminum alloy shell casting as the application object, the specific outline dimensions: height 1246mm, small end circle Φ300mm, large end rectangular 500mm×455mm, main body wall thickness 2.9mm, inner cavity with multiple bosses, Rib, clapboard, material: ZL114A.

[0038] See the content of the invention for the operation steps, and the main process parameters are as follows: molten aluminum smelting temperature 770~780°C; casting mold temperature 290~310°C; vacuum degree: -0.08~-0.09MPa; pouring temperature 710~730°C; average pouring speed About 2~3kg / s; pouring time about 40~50s; solidification pressure 0.4~0.5MPa; holding time 20~25min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com