Patents

Literature

66 results about "Hot joints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

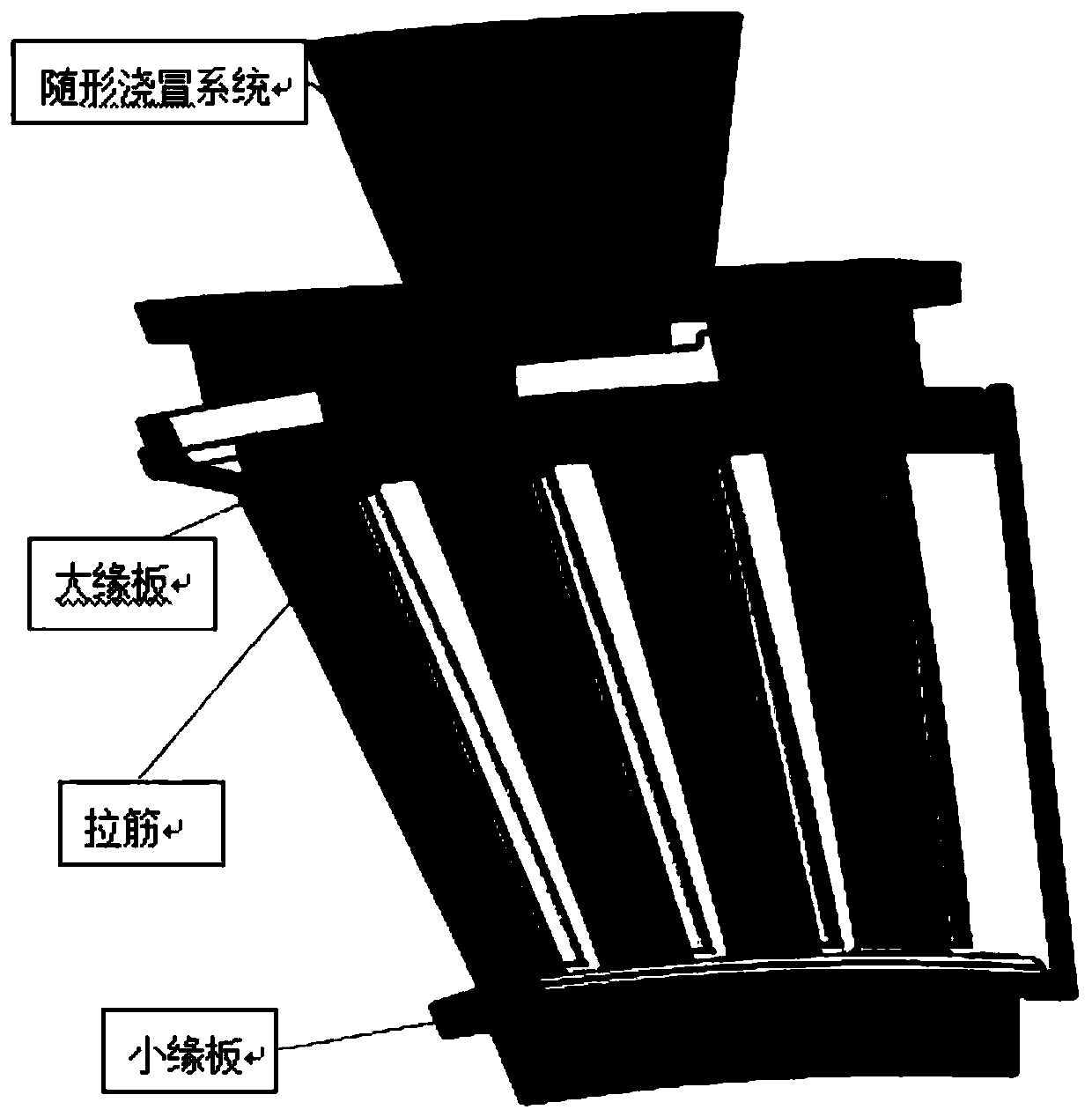

Casting forming process of complex high temperature alloy multi-union guide vane casting

The invention discloses a casting forming process of a complex high temperature alloy multi-union guide vane casting, and belongs to the technical field of precision casting. The process is characterized in that a casting body wax mold is prepared, and the casting body wax mold and a rigging system are assembled into a module; the module is coated with refractory coating layer by layer, is sent into a dewaxing kettle for dewaxing, and is sent into a baking furnace for high temperature pre-baking; the exterior of a shell is wrapped in a step type and is tied with refractory insulation cotton; ahigh temperature alloy rod is remelted and smelted to obtain high temperature alloy metal liquid; before pouring, the shell is sent into the baking furnace again, and then is sent into a vacuum induction casting furnace, and the high temperature alloy metal liquid is poured into the shell; and after pouring is completed, heat preservation is carried out, and shell removal, cutting, sand blastingand polishing are carried out after furnace exiting. The casting forming process effectively reduces or eliminates casting defects such as looseness and cracking easily generated at the connecting positions of hot joint vanes and small edge plates, the yield is improved to 75% to 80%, and the process is suitable for complex high temperature alloy multi-union guide vane casting.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

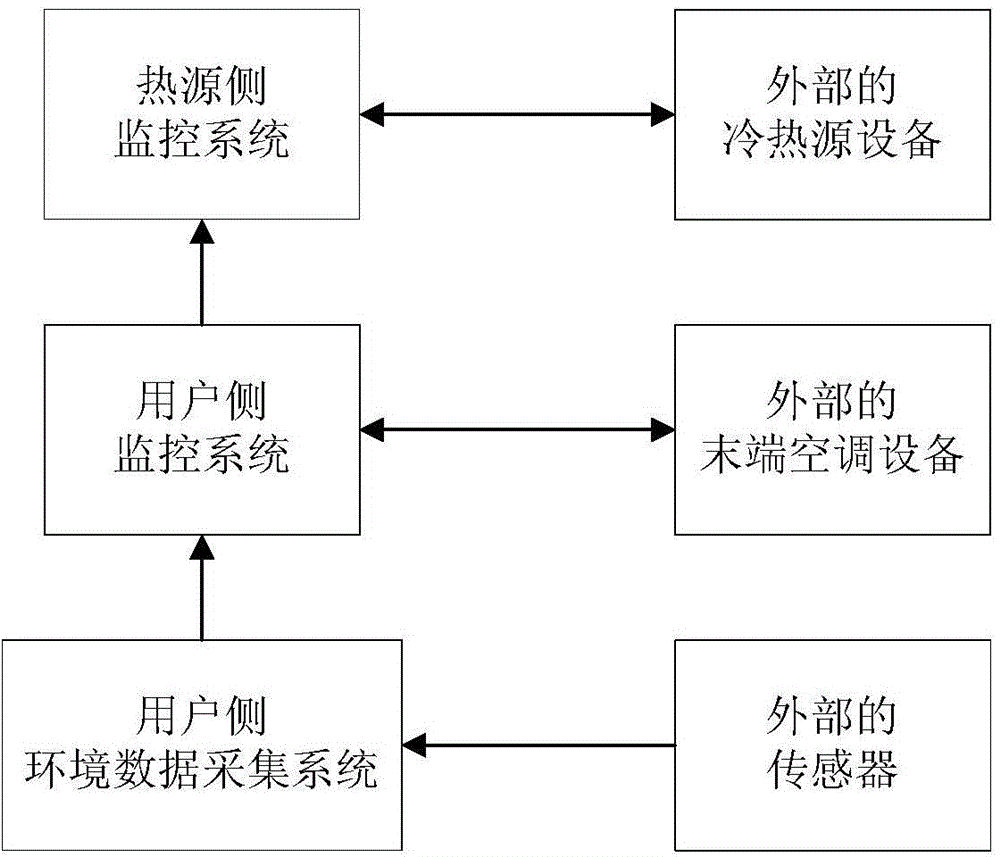

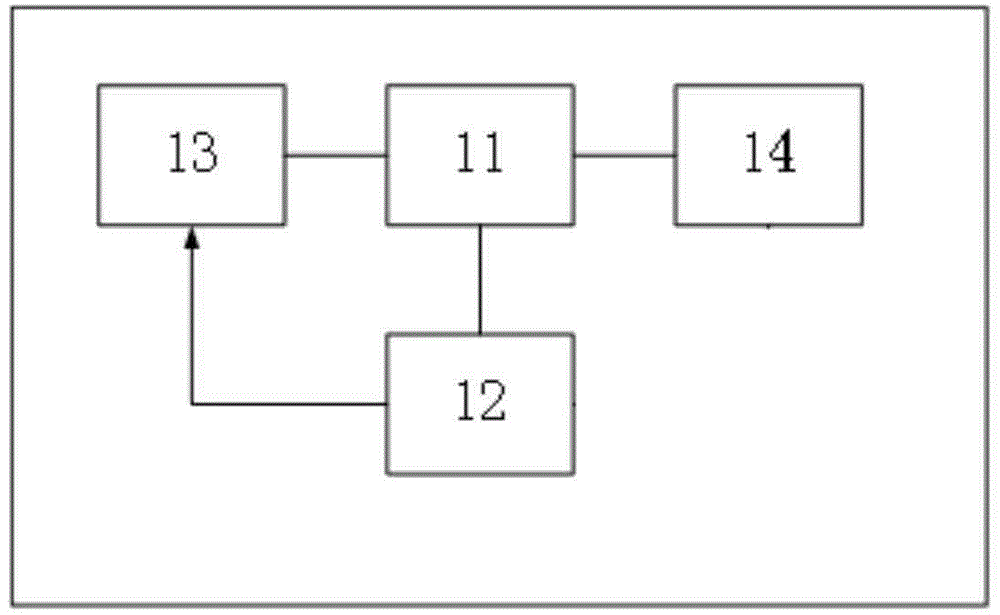

Intelligent management and control equipment for cold and hot joint supply of heating ventilating and air conditioning system and control method thereof

InactiveCN104571034AImprove comfortAvoid Control Lag ProblemsProgramme total factory controlPrediction algorithmsAir conditioning

The invention discloses intelligent management and control equipment for the cold and hot joint supply of a heating ventilating and air conditioning system and a control method thereof. The intelligent management and control equipment comprises a user side environment data collection system, a user side monitoring system and a heat source side monitoring system. The intelligent management and control equipment realizes the maximum using of clean energy through a modified terminal temperature load prediction algorithm and the lowest energy loss cold and hot quantity equilibrium assignment algorithm, thoroughly solves the problem that the existing system only taking the environment temperature as a basis is inaccurate in load prediction to realize the equilibrium of cold and hot supply and demand, and meanwhile solves the problem of the cold and hot real-time maximum energy efficiency ratio tracking; meanwhile, the equipment can effectively protect external sensors and cold and heat source equipment, and images which are very visual on a touch screen and used for displaying the system, environment and equipment parameters in real time ensure that a user masters the whole joint supply system.

Owner:CHINA MACHINERY ENTERPRISE MANAGEMENT ASSOC

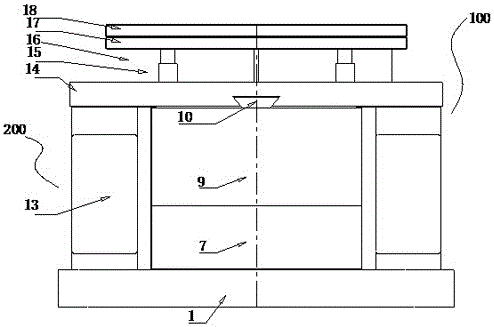

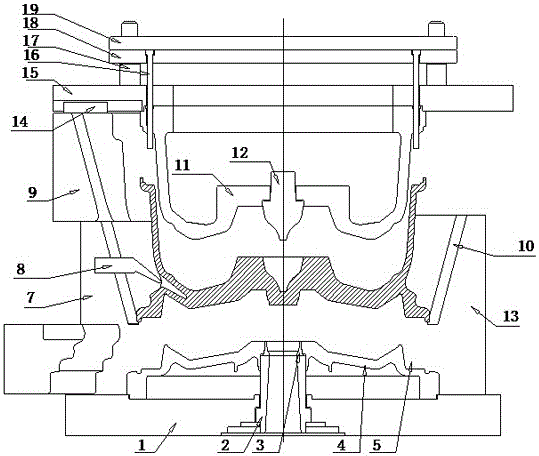

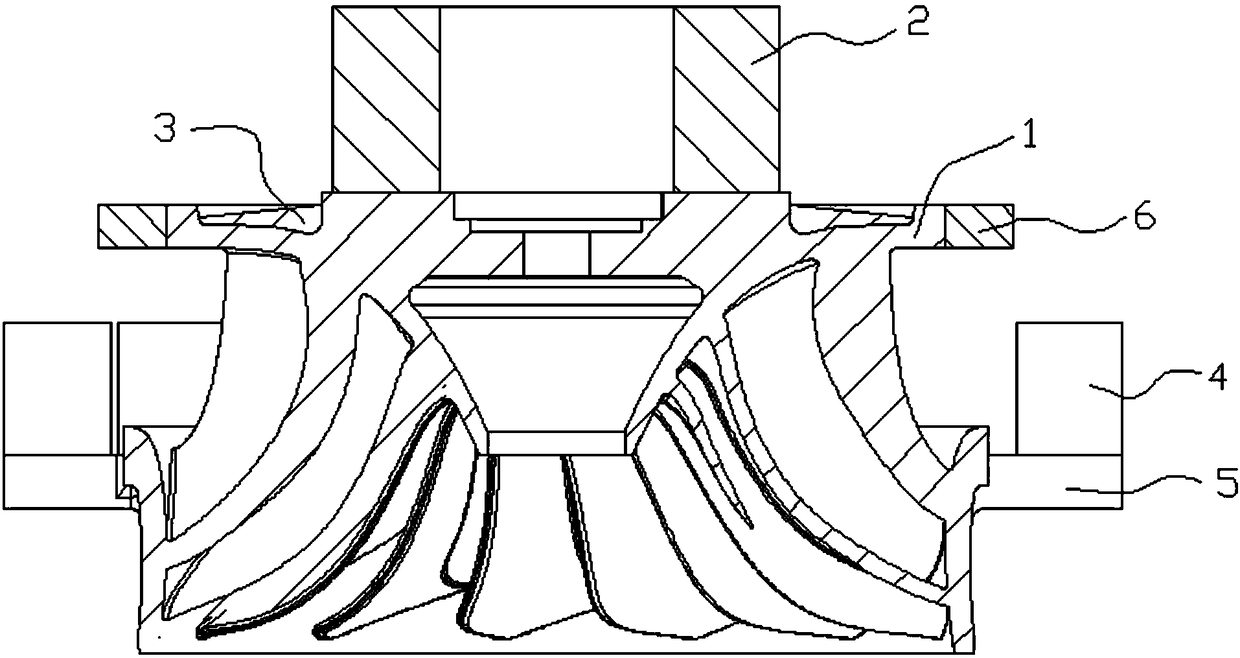

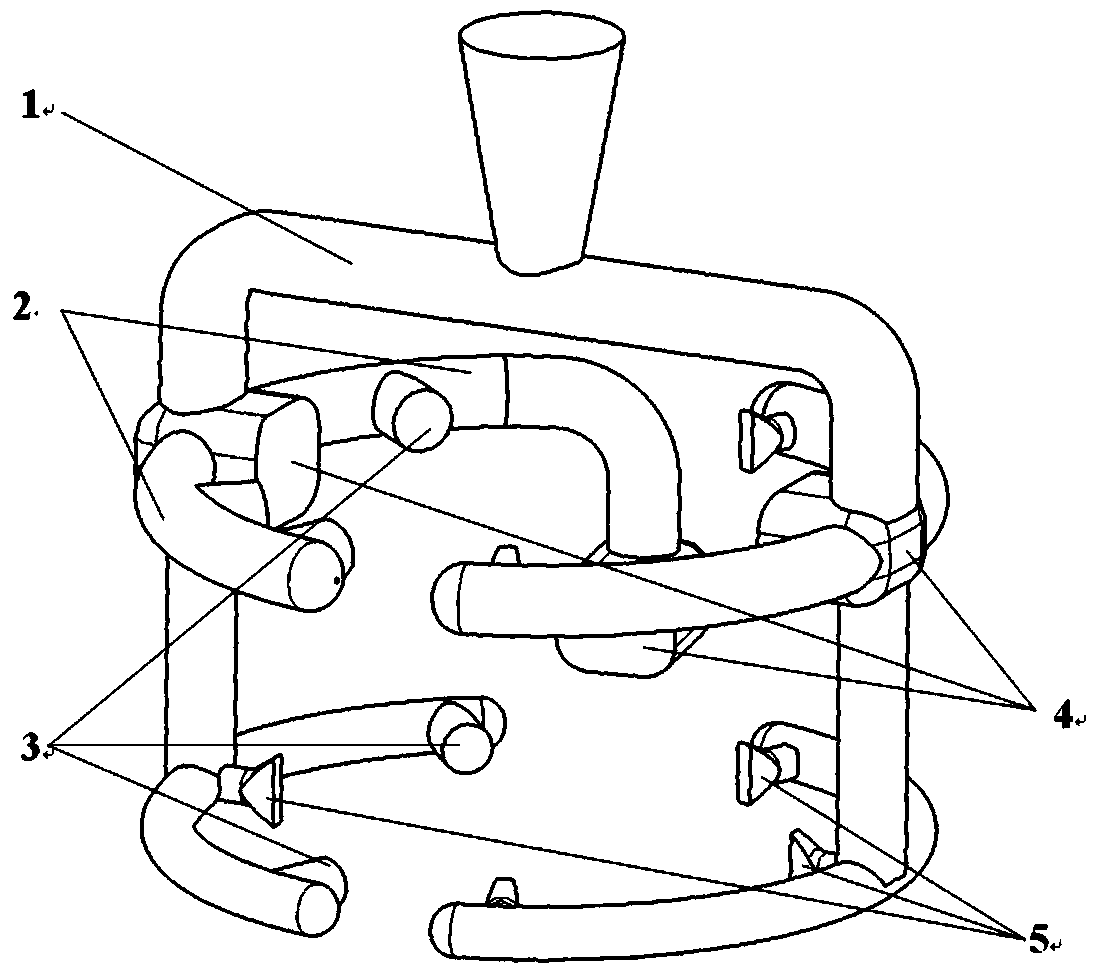

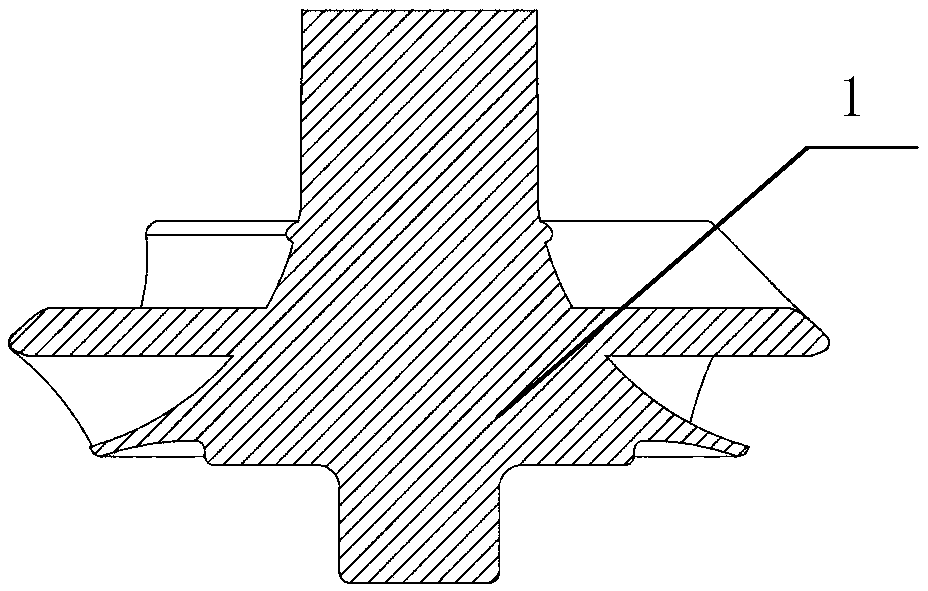

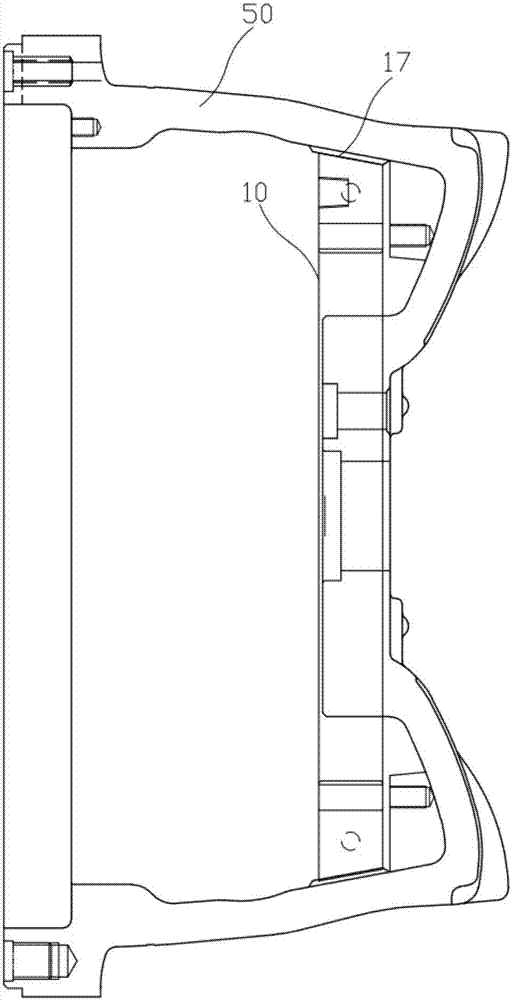

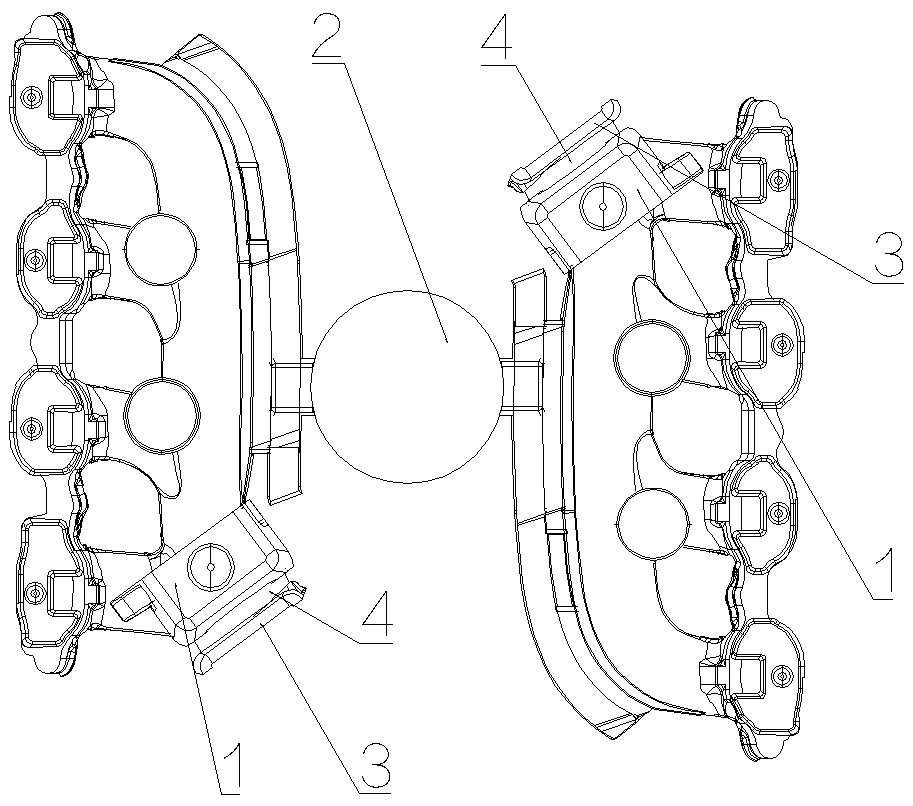

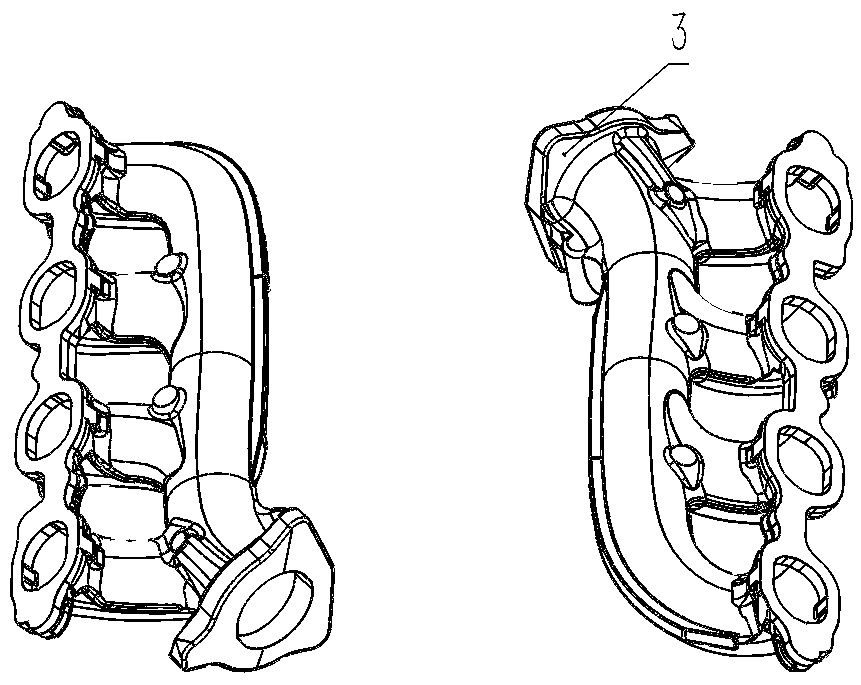

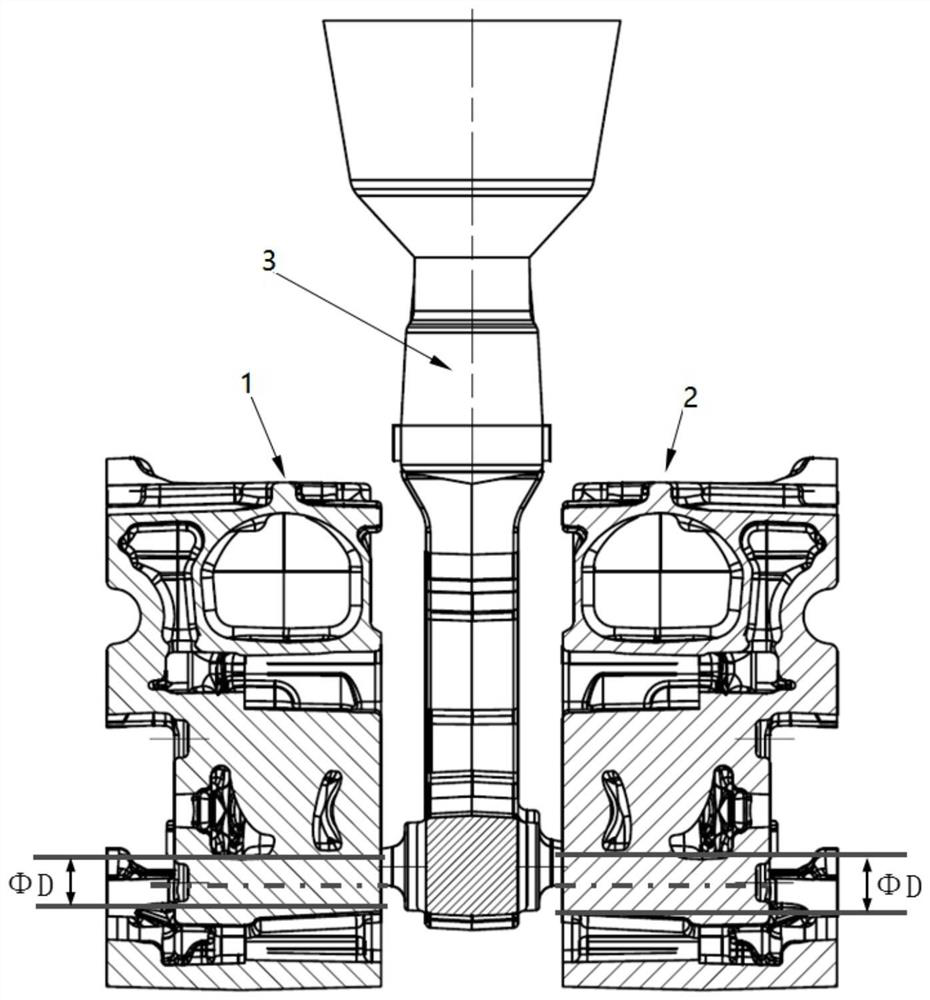

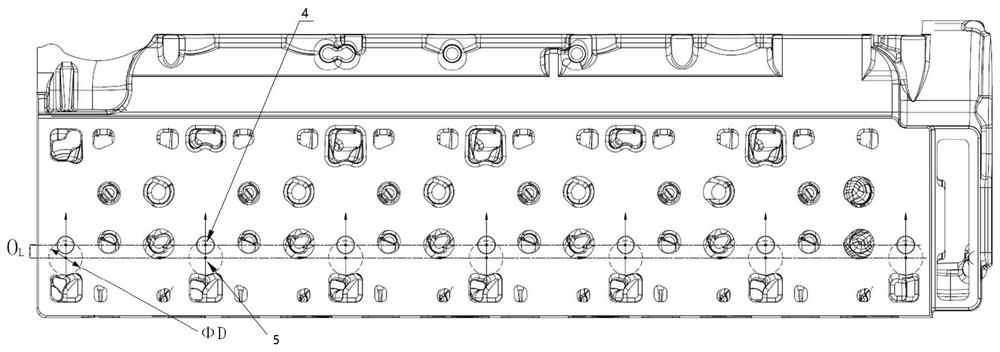

Novel hub die structure

InactiveCN106077519AReduce hot node volumeReduce weightFoundry mouldsFoundry coresEngineeringMechanical engineering

The invention discloses a novel hub die structure. The novel hub die structure is characterized by comprising an upper die assembly, a bottom die assembly and an edge die assembly; a die cavity is formed after the upper die assembly, the lower die assembly and the edge die assembly are combined; the edge die assembly comprises an upper edge die and a lower edge die which are movably connected; an insert is arranged at a corresponding hot joint position and located at the position of a parting surface of the edge die assembly, one end of the insert is inlaid in the parting surface of the edge die assembly, and the other end of the insert extends in a casting hot joint; and the upper die assembly comprises an upper die plate and guiding pillars arranged on the upper die plate, and an ejector rod plate and an ejector rod pressing plate are arranged on the guiding pillars in a sleeving manner and move vertically along the guiding pillars. The novel hub die structure has the beneficial effects that the size of the hot joint of a casting spoke and a rim position is reduced, and the total weight of the product is reduced.

Owner:苏州金瑞阳模具有限公司

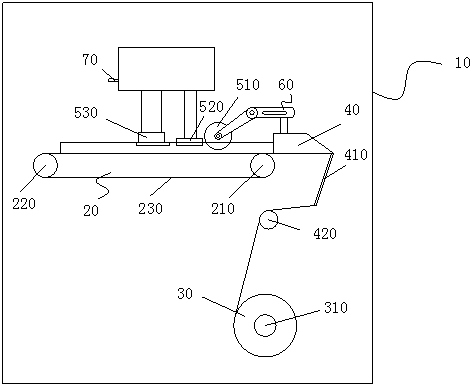

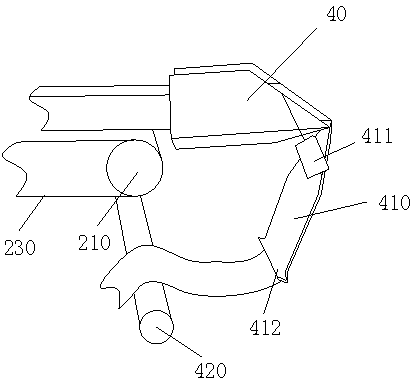

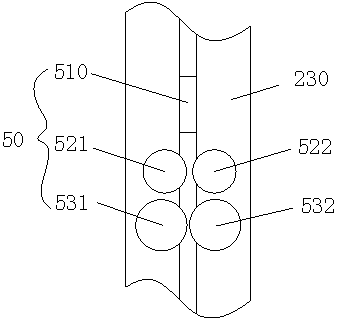

Crab stick sealing device

ActiveCN105644853ASimple production equipmentReduce production processPackaging meatWrapping material feeding apparatusMotor driveEngineering

The invention relates to a crab stick sealing device. The crab stick sealing device comprises a rack and a conveying mechanism mounted on the rack; the conveying mechanism comprises a driving roller, a driven roller and a conveying belt; the driving roller drives the driven roller to rotate through the conveying belt; a film roll barrel is arranged below the conveying belt, a film folding groove is formed in one end, close to the conveying belt, of the rack, and one end of the film folding groove is inclined; a sealing mechanism is arranged above the conveying belt, and comprises a pressing wheel, a positioning part, a hot joint part and a distance adjusting mechanism; the pressing wheel, the positioning part and the hot joint part are sequentially arranged at one end, close to the film folding groove, of the conveying belt; the positioning part comprises a first positioning head and a second positioning head which are arranged in the width direction of the conveying belt side by side; the hot joint part comprises a first hot joint head and a second hot joint head which are arranged in the width direction of the conveying belt side by side; the distance adjusting mechanism is connected with the positioning part and the hot joint part, and adjusts the distance between the two positioning heads and the distance between the two hot joints; and electric heaters are arranged in the hot joints, and an external motor drives the first hot joint and the second hot joint to reversely rotate.

Owner:HAIXIN FOODS

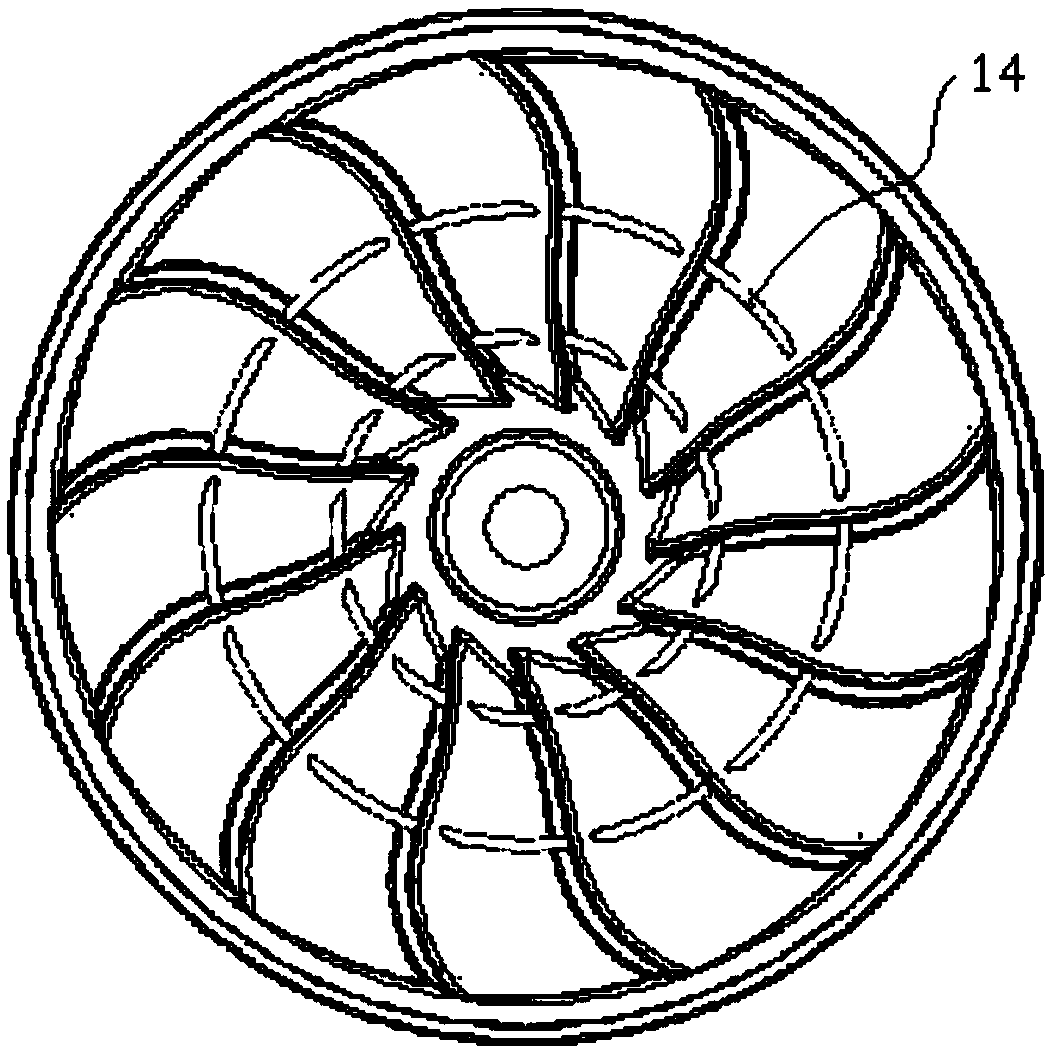

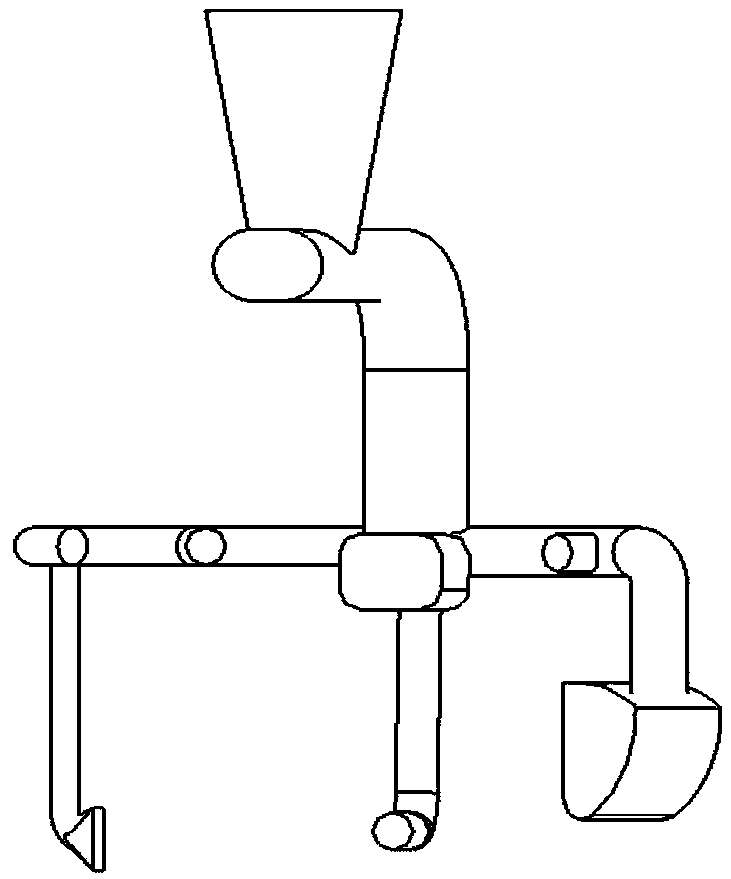

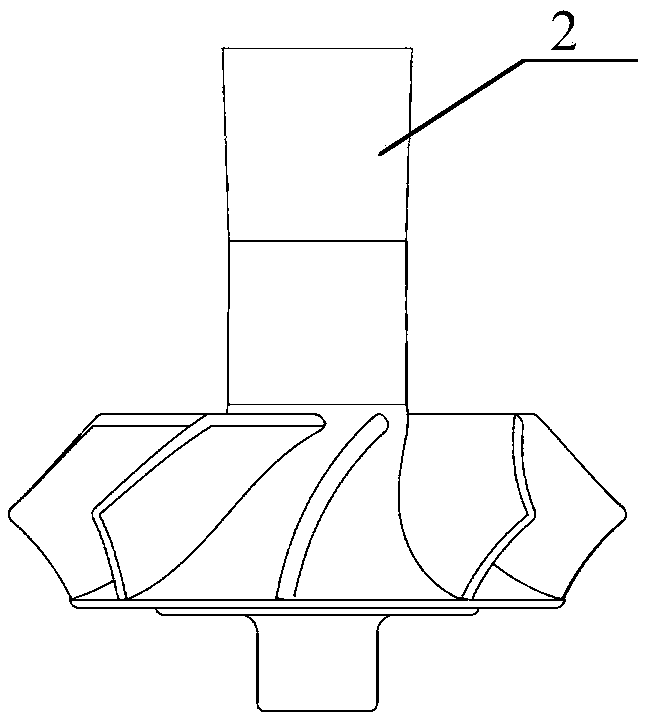

Casting method of runner

ActiveCN109465406AQuality improvementAvoid Combined SolderingFoundry mouldsFoundry coresManufacturing cost reductionNear net shape

The invention belongs to the casting field, and mainly relates to a casting method of a runner, for integral casting of the runner. The method takes an upper crown, a lower ring and blades of the runner as a whole to carry out casting processing and molding, and mainly comprises the following steps: casting process design in which a chiller is arranged on the periphery of an upper crown flange, aring riser is arranged at a spiral-shaped strip hot joint position of a connecting part of the upper crown and the blades, and a dark riser neck is arranged at the hot joint position of a connecting part of the lower ring and the blades; dimension control design in which the runner is divided into a non-flow surface and a flow surface for sticking design; molding process design in which runner molding process uses core and buried box combination. The runner sand core is divided into an inner sand core and an outer sand core. The inner sand core and the outer sand core are formed integrally by3D printing. The method of the invention overcomes the shortcomings of the traditional casting method, reduces the manufacturing cost, shortens the production cycle, improves the casting quality, improves the manufacturing accuracy and realizes the near-net shape of the runner casting.

Owner:KOCEL STEEL

High-power professional audio power amplifier based on Peltier effect radiation technology

InactiveCN101860329AUntie the cooling bottleneckImprove work efficiencyPower amplifiersAudio power amplifierEngineering

The invention discloses a high-power professional audio power amplifier based on a Peltier effect radiation technology, comprising a box body, a left power amplification channel and a right power amplification channel. The left power amplification channel and the right power amplification channel are arranged in the box body and respectively provided with at least one power amplification chip, a semiconductor heat radiation sheet and a heat radiator which are fixed together from front to back, the semiconductor heat radiation sheet is provided with a hot end surface and a cold end surface, the hot end surface of the semiconductor heat radiation sheet is pasted on the heat radiator to from hot joint, the back of the power amplification chip is pasted with thermally conductive silicone and pasted on the cold end surface of the semiconductor heat radiation sheet, and outer heat radiation fans capable of taking away heat which is transferred to the heat radiator are respectively arranged in positions corresponding to the left power amplification channel and the right power amplification channel on the rear backboard of the box body. The invention has good heat radiation performance and high efficiency.

Owner:叶真

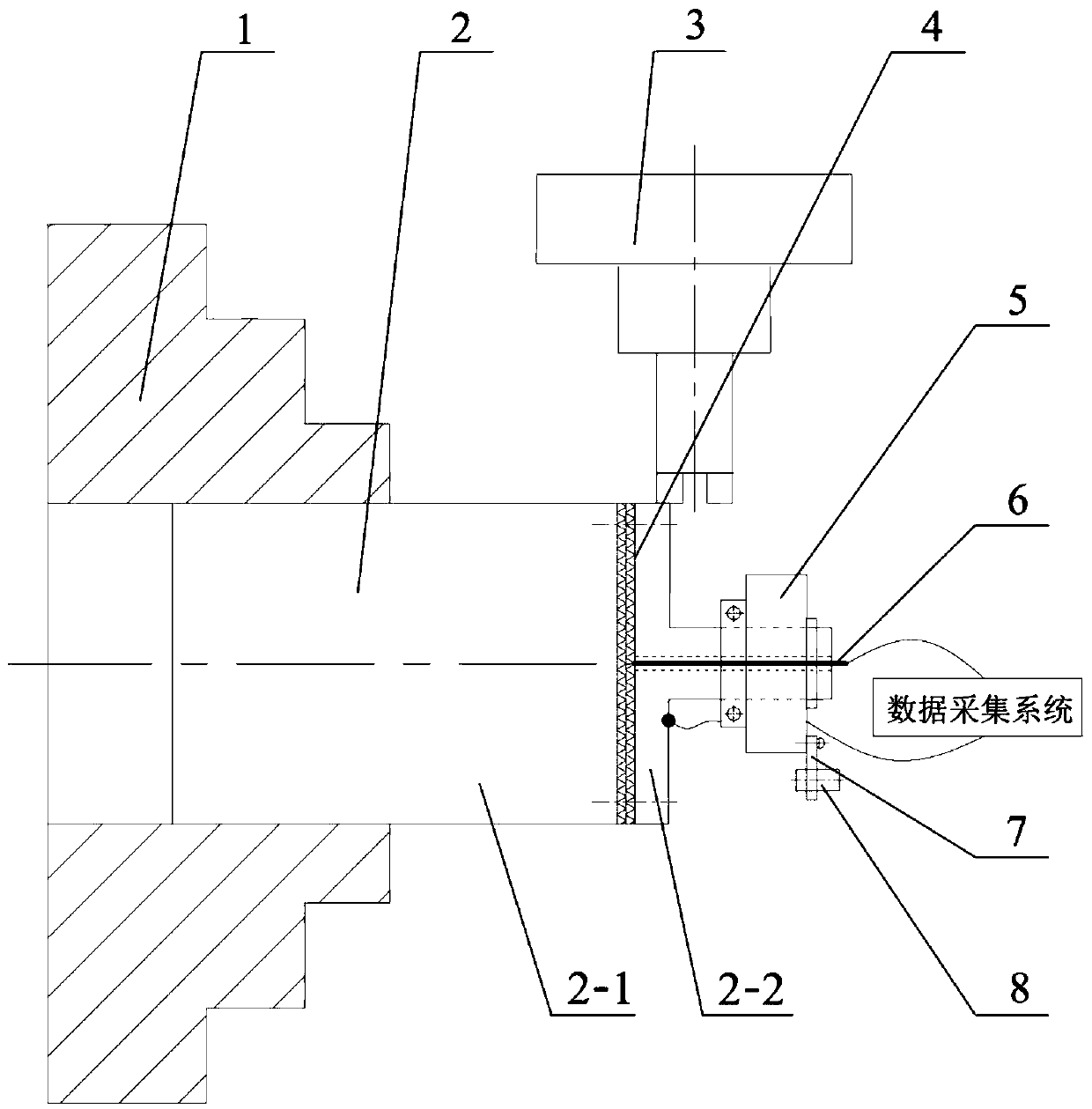

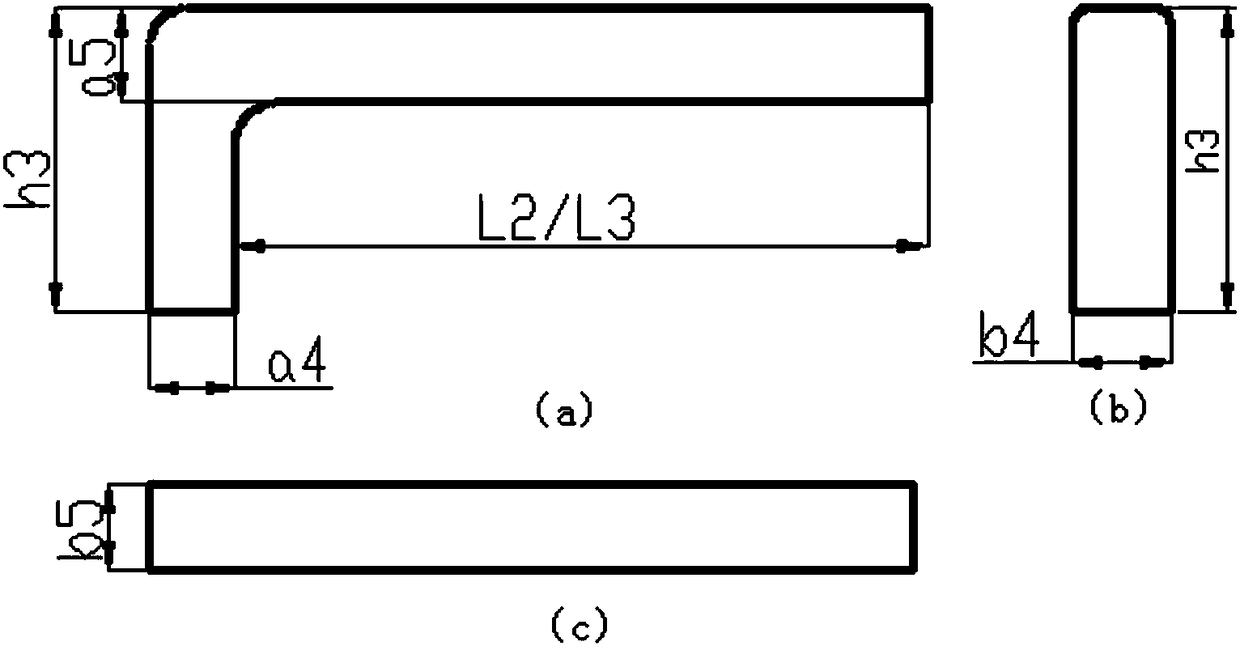

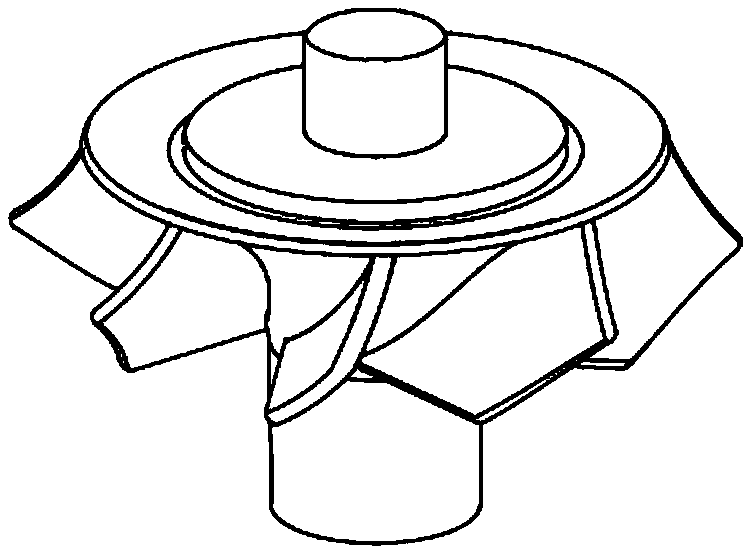

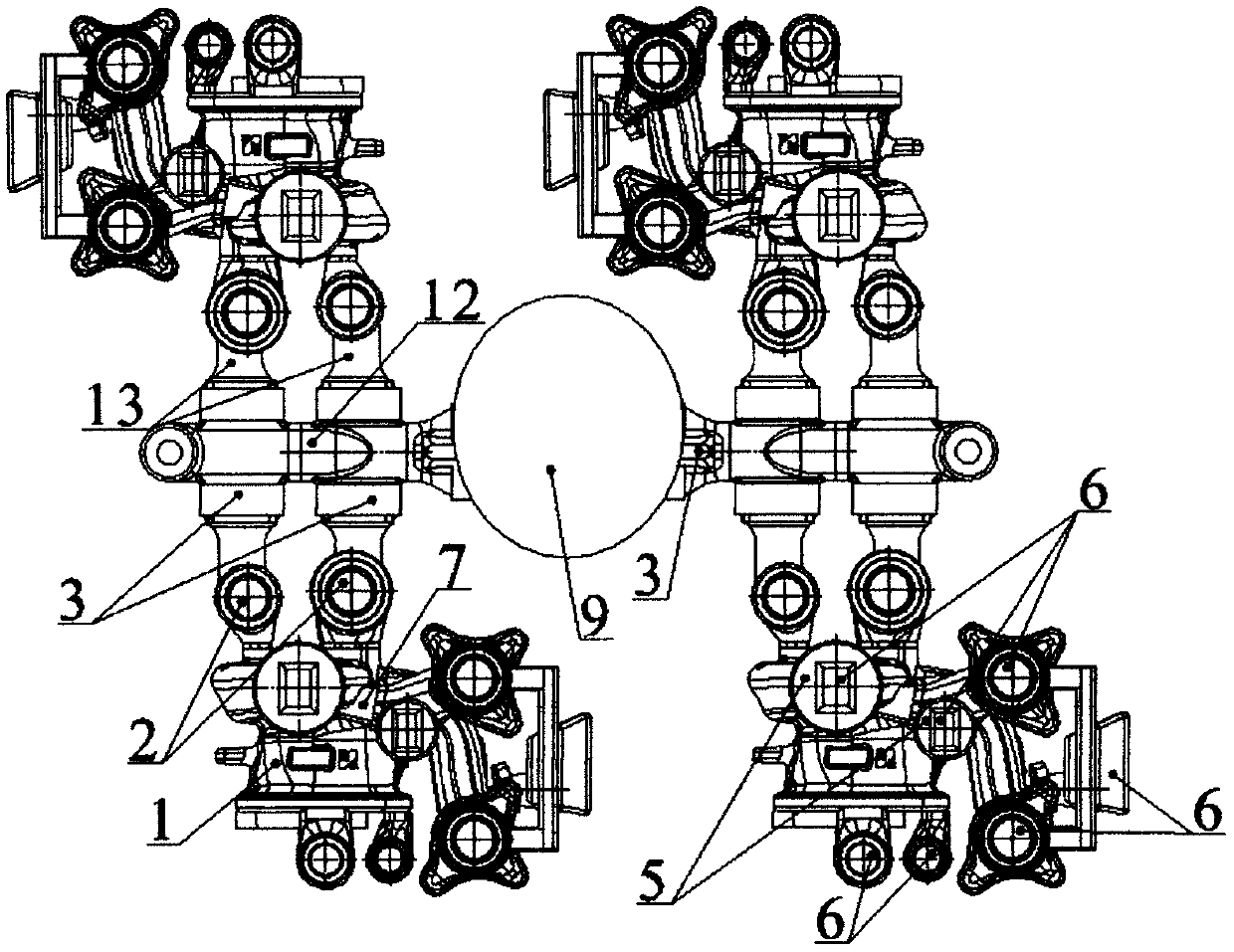

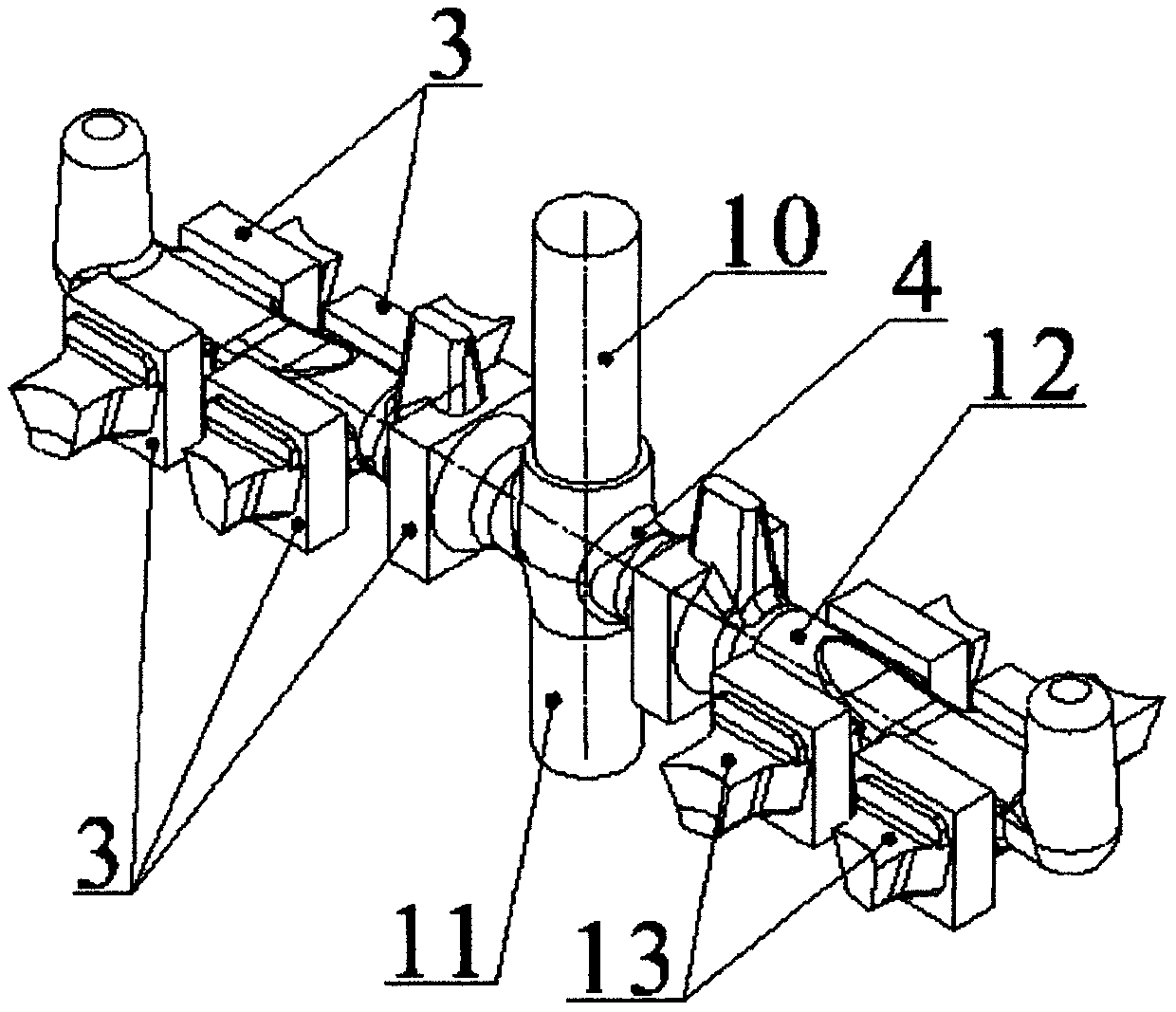

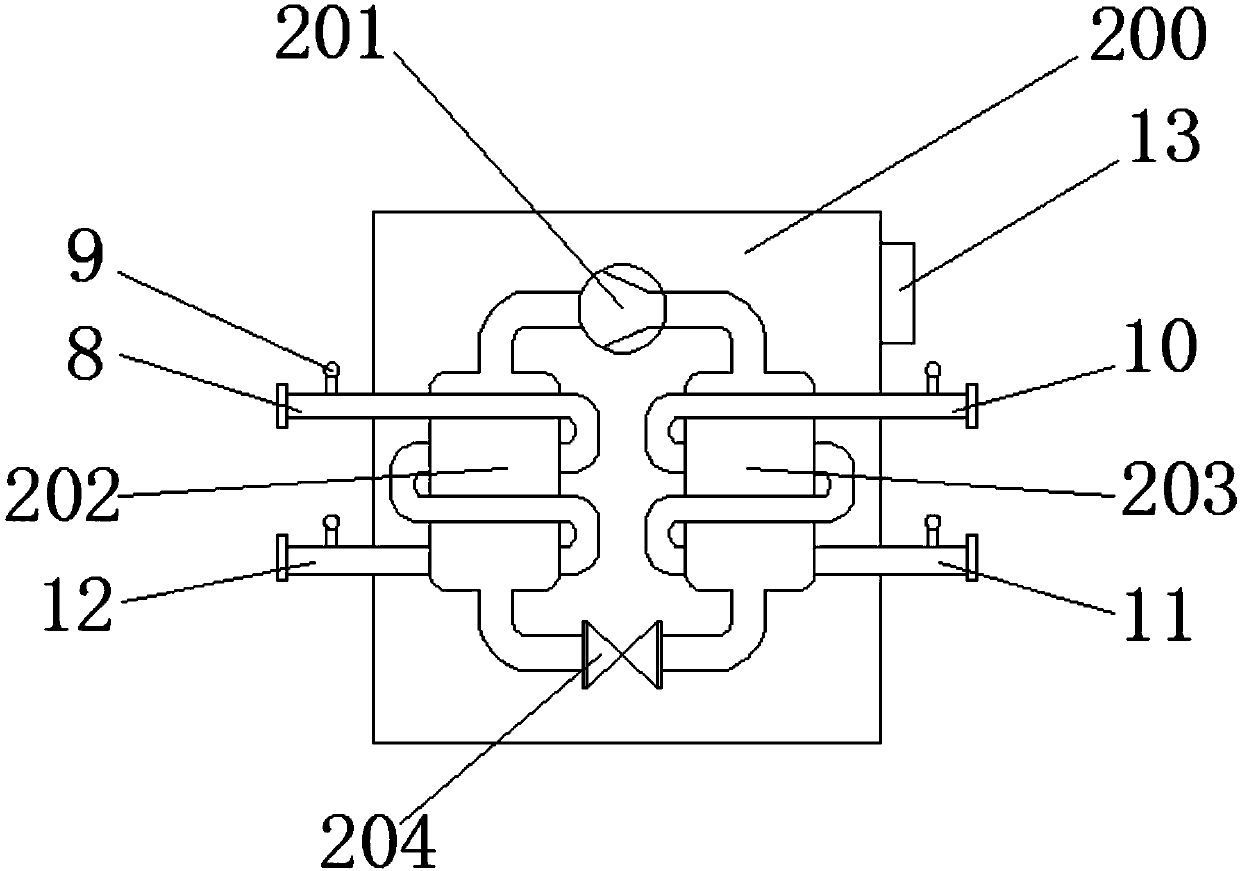

Accurate cutting temperature measuring device for turn-milling machining

PendingCN111300143AExtend your lifeImprove machined surface qualityThermometer detailsThermometers using electric/magnetic elementsCircular discMilling cutter

The invention discloses an accurate cutting temperature measuring device for turn-milling machining. The device comprises a workpiece temperature measuring sample, a conductive slip ring, a pluralityof thermocouple wires, a cylindrical insulating tube, a fixing bracket and a data acquisition system. The workpiece temperature measuring sample is prepared from a material the same as that of a workpiece to be turned and milled; during turning and milling, when a cutting edge of a milling cutter passes through a joint between a component I and a component II, one end of each thermocouple wire iselectrically connected with the workpiece temperature measuring sample to form an instantaneous hot joint, which forms a hot end of a thermocouple; the other end of the thermocouple wires and a point,close to a hollow shaft, on a disc forms a cold end of the thermocouple; that is, at this time, the workpiece temperature measuring sample, the conductive slip ring and the plurality of thermocouplewires form the thermocouple; finally, the current cutting temperature is measured; and corresponding different cutting temperatures can be accurately measured by adjusting different turning and milling parameters, and thus, optimal turning and milling parameters of the material are determined finally. Therefore, machining efficiency and machining surface quality are effectively improved, and the service life of the cutter is effectively prolonged.

Owner:XUZHOU UNIV OF TECH

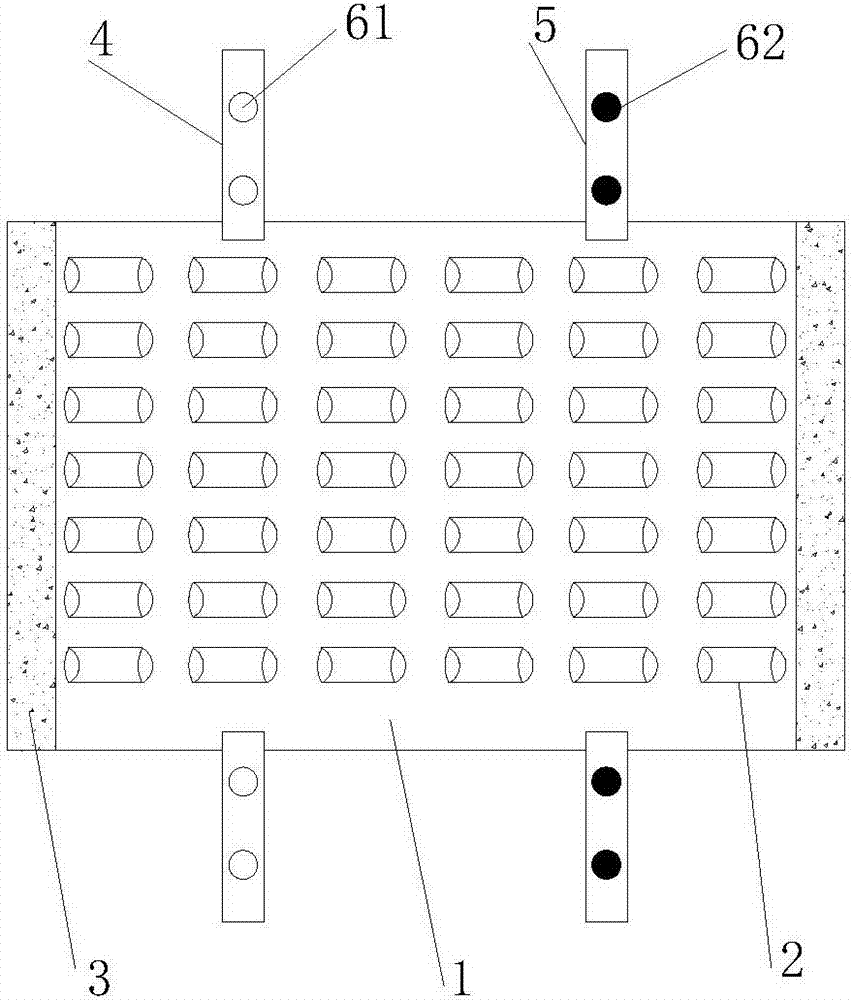

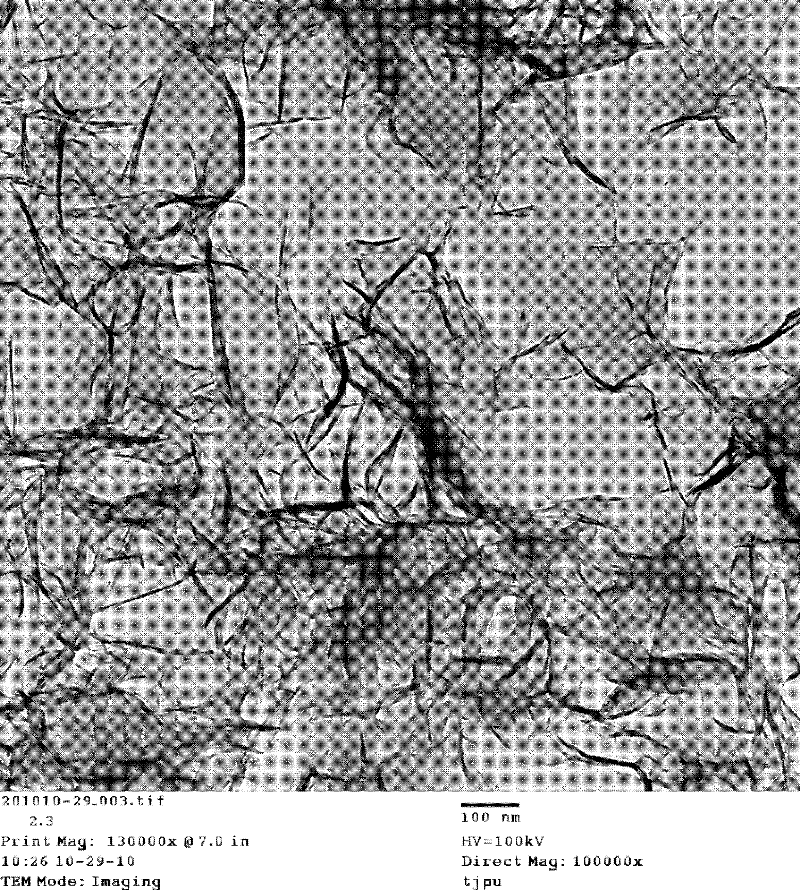

Lattice core sandwich structural part casting defect control method and application

The invention relates to the field of precision casting and material preparation, in particular to a lattice core sandwich structural part casting defect control method and application. A pouring system containing grid type horizontal pouring passage structures and rain sprinkling type inner pouring passage structures is adopted, the inner pouring passages in diffusion distribution are conducive to complete mold filling of thin wall positions, meanwhile, the effects of dispersing heat, avoiding hot joint generation and feeding risers are achieved, furthermore, the inner pouring passages further play a role of reinforcing tendons or ribs, cracking caused by solidification contraction is prevented, in addition, the pouring system adopts a closed type, namely areas of cross sections of the pouring passages are smaller and smaller, slag blocking and bubble filtering are facilitated, molten metal is subjected to high-temperature refining treatment before being poured, slag and gas are removed, the tilting height of a crucible is controlled during pouring, the mold-filling pressure is increased, mold shells are preheated at high temperature, and the complete mold filling of casting partsis guaranteed. The lattice core sandwich structural part casting defect control method and application are suitable for the casting process of complex lattice core sandwich structural parts and othersimilar parts, meet the development requirements for future aerospace products and have a long application prospect.

Owner:辽宁红银金属有限公司

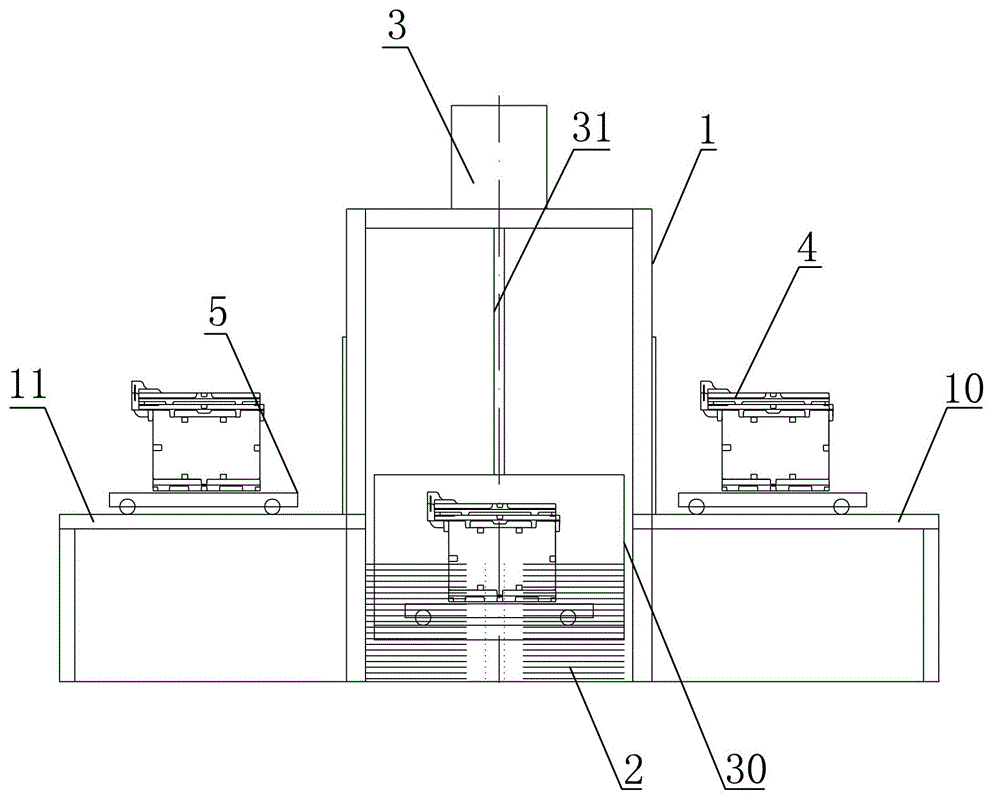

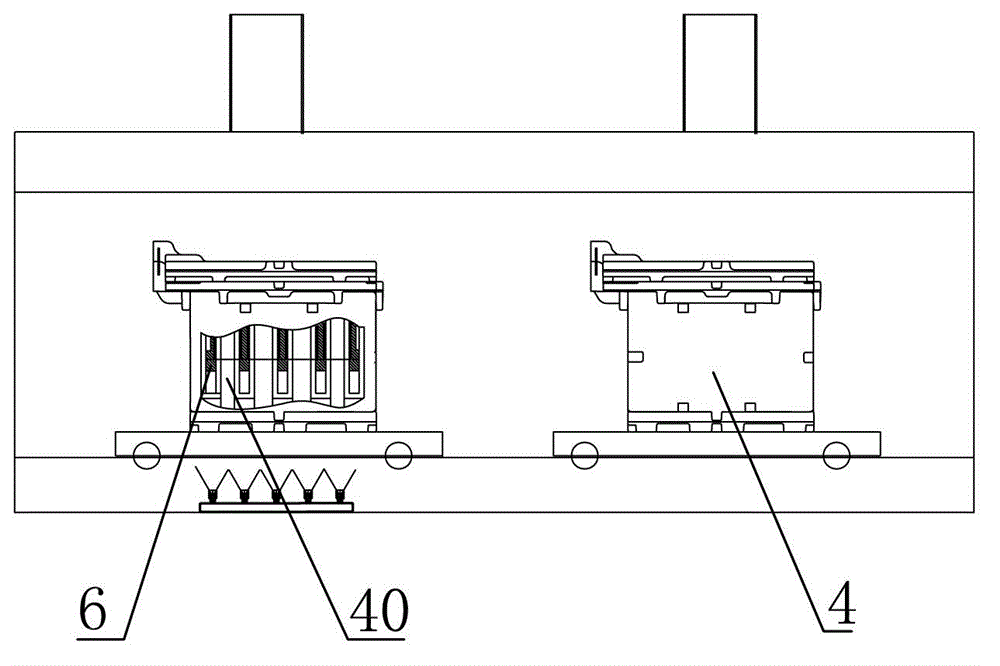

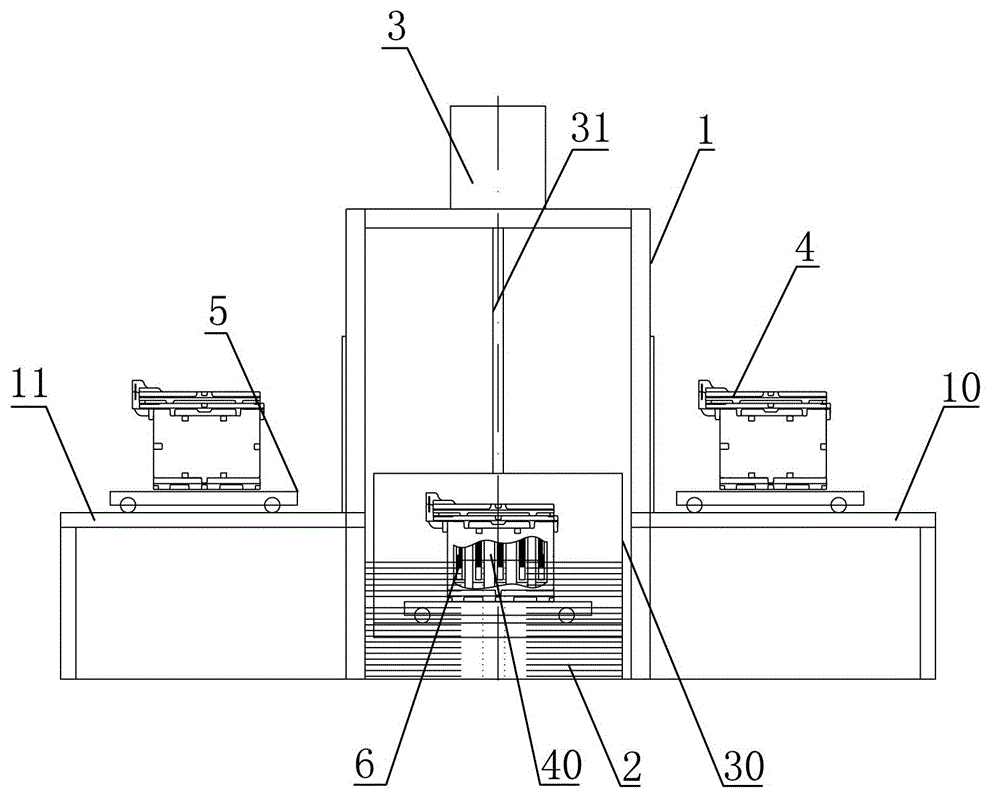

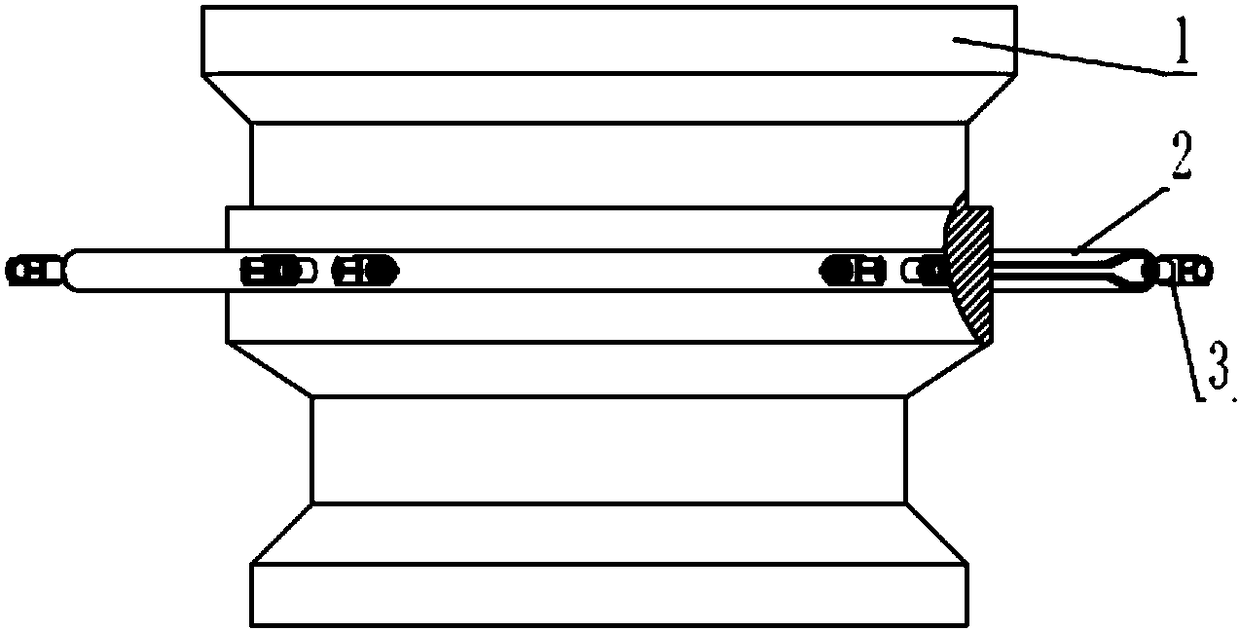

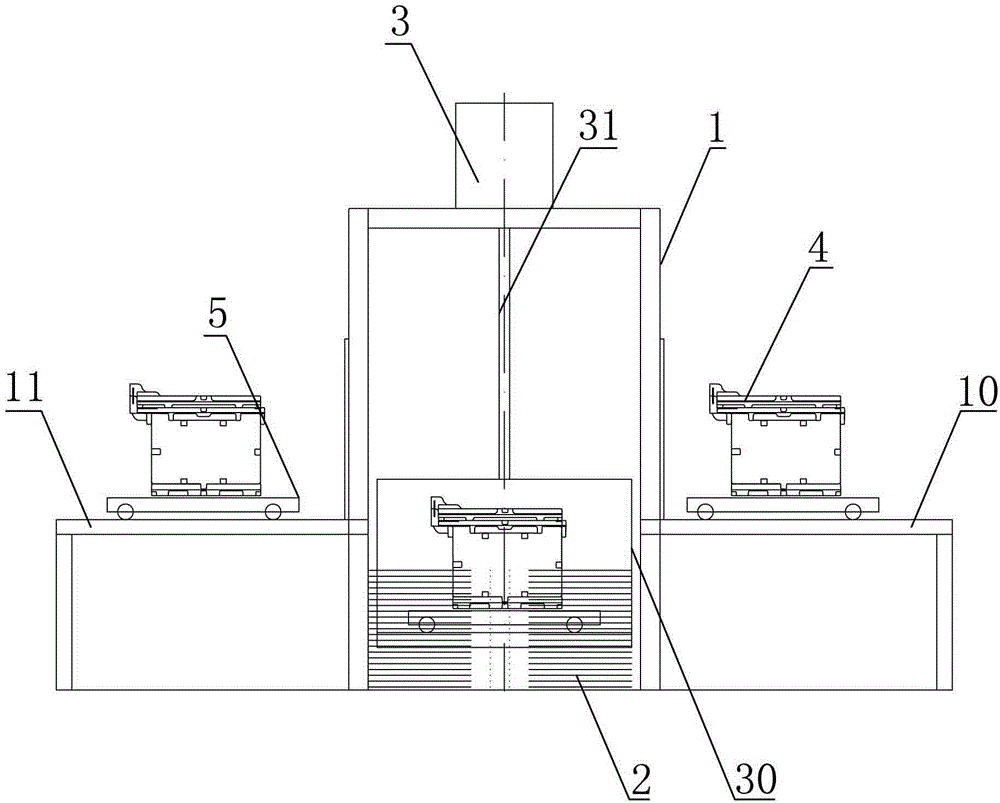

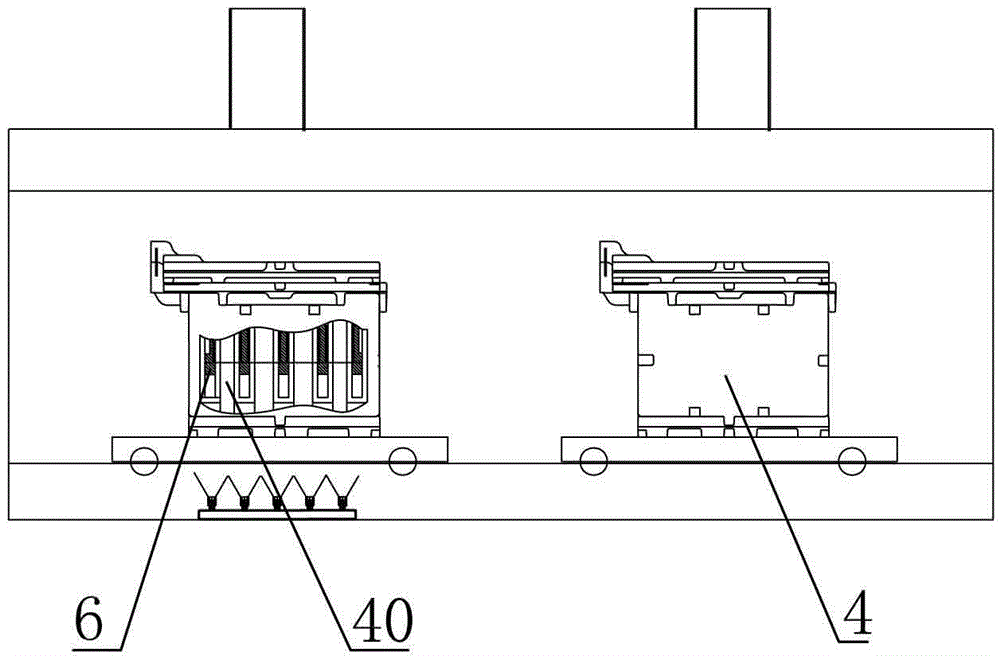

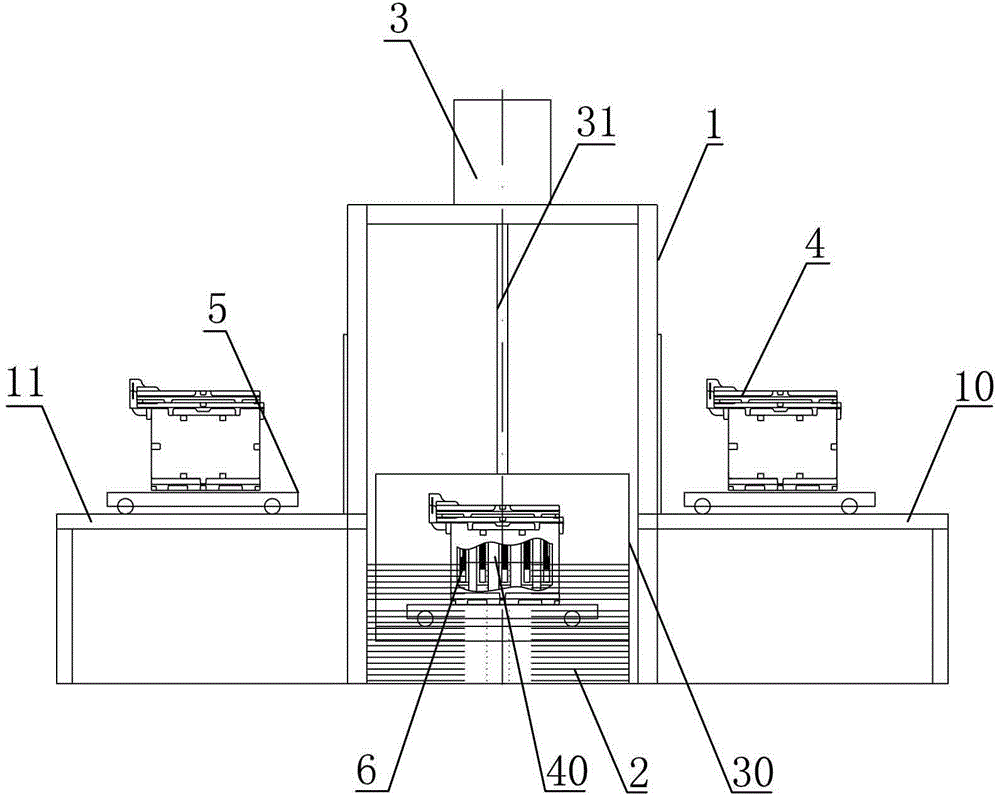

Method and device for controlling cooling speed of core assembling casting

ActiveCN102941338AIntrinsic Quality GuaranteeRapid coolingFoundry mouldsFoundry coresEngineeringWater cooling

The invention relates to a method for controlling the cooling speed of core assembling casting. A metal solution is poured into a sand mold; and the poured sand mold is put into water, so that a cast inside the sand mold can be cooled and solidified in water. A water-cooling device for controlling the cooling speed of the core assembling casting comprises a stander, a cooling water tank which is arranged on the stander and is used for storing water; and a lifting device is arranged above the cooling water tank and can drive the sand mold into the cooling water tank to be cooled. The cooling speed of different positions of the core assembling casting can be controlled by an external physical cooling measure, namely water cooling, and the device for water cooling, so that quick cooling and partial quick cooling can be realized, and internal quality of the cast is guaranteed; therefore, the core assembling casting process can be used for producing a batch of casts, such as an aluminum alloy cylinder cover in the automobile industry, which have high quality requirement, complicated shapes and partial hot joints.

Owner:SUZHOU MINGZHI TECH

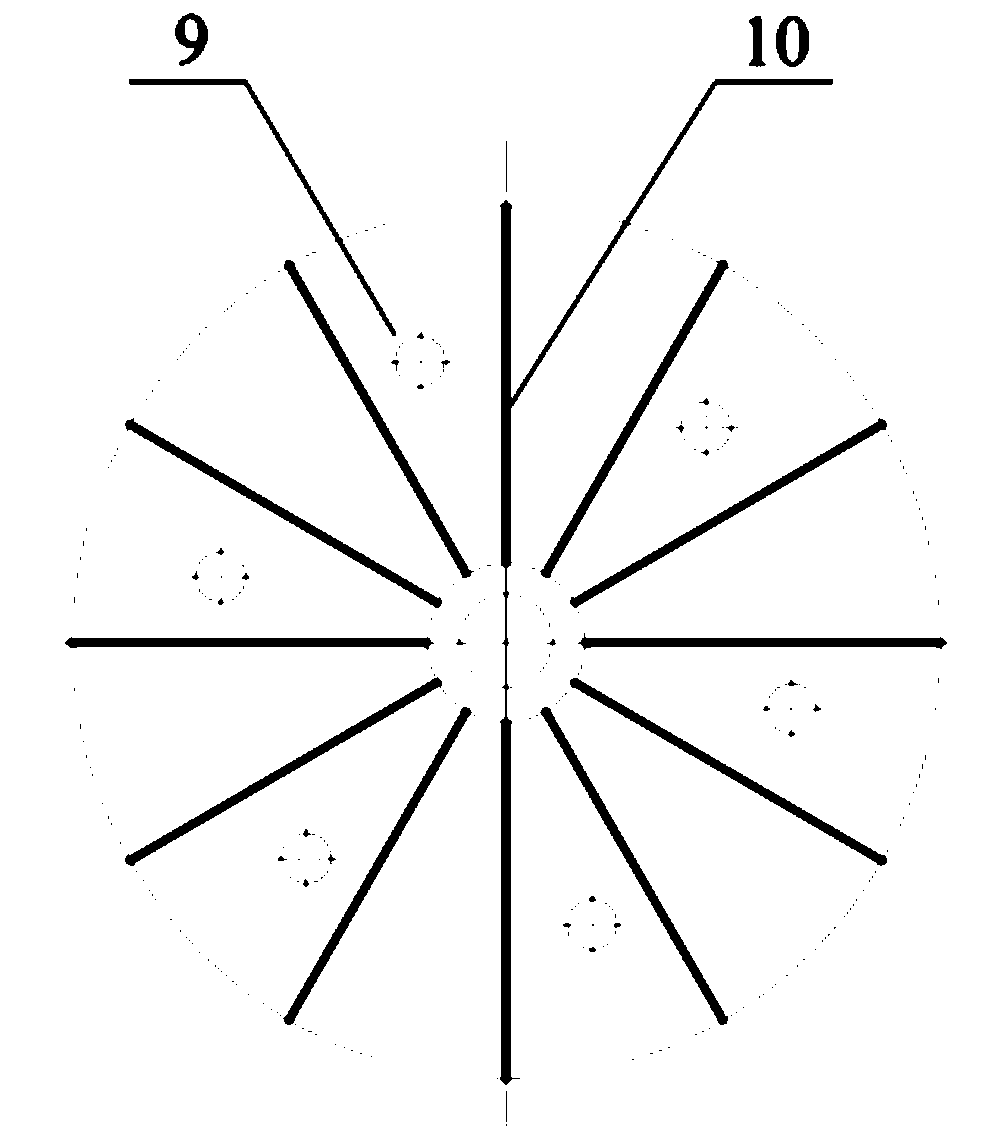

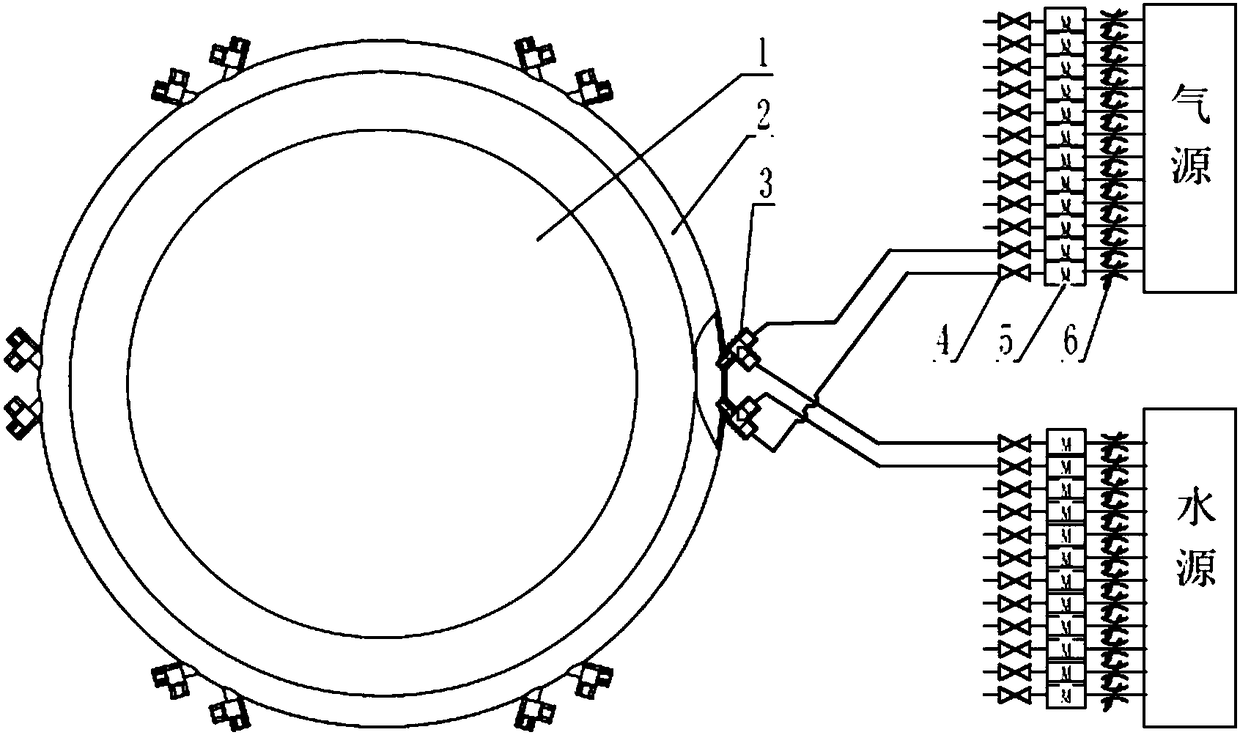

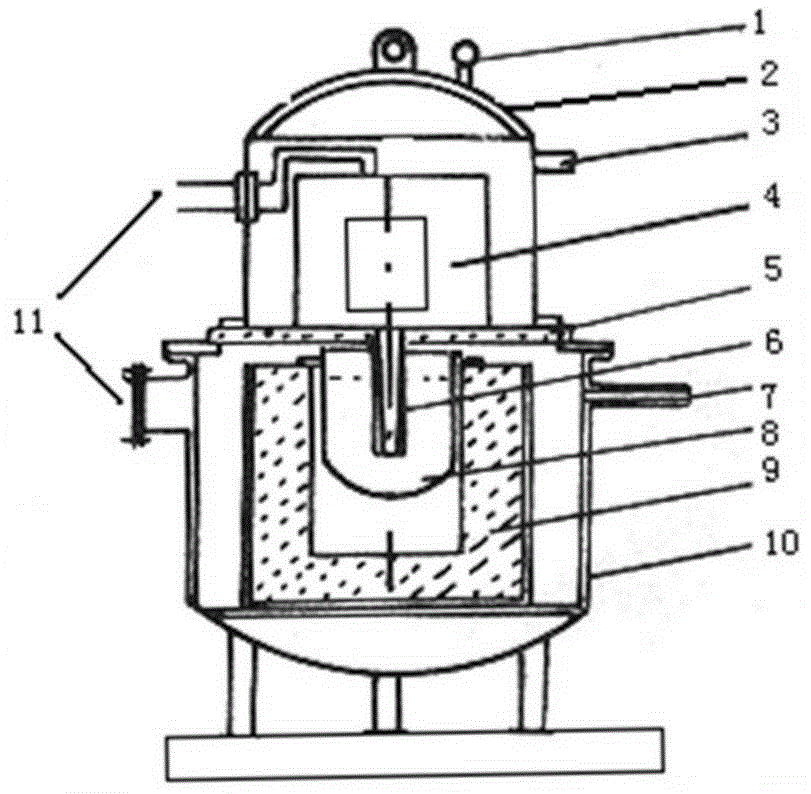

Annular cooling system of differential pressure casting machine

The invention discloses an annular cooling system of a differential pressure casting machine. The annular cooling system comprises a high-pressure compressed gas source, a water source, a cooling water pipe, a cooling air pipe, double-fluid atomization nozzles and a ring pipe. The cooling water pipe is connected with the water source, the cooling air pipe is connected with the compressed gas source, and the cooling water pipe and the cooling air pipe are connected with the double-fluid atomization nozzles on the other side. The double-fluid atomization nozzles are connected into the atomization ring pipe arranged around a die. A circular seam aligned with the die hot joint position is arranged on the inner side of the ring pipe. Every two double-fluid atomization nozzles are arranged in acrossed manner relative to the atomization ring pipe, and a certain included angle is formed between every two double-fluid atomization nozzles. Each set of double-fluid atomization nozzles spray water mist in an obliquely-opposite manner, after the water mist enters the atomization ring pipe, is in mutual collision and is crossed in the pipe, water mist is sprayed out of the inner side circular seam of the atomization ring pipe, annular spray mist is formed and is sprayed to the die, and uniform cooling is conducted.

Owner:青岛航大新材料技术有限公司 +1

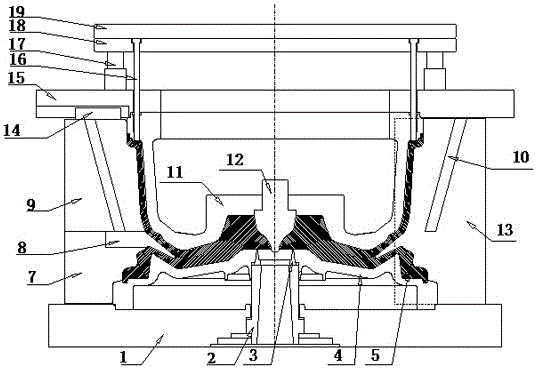

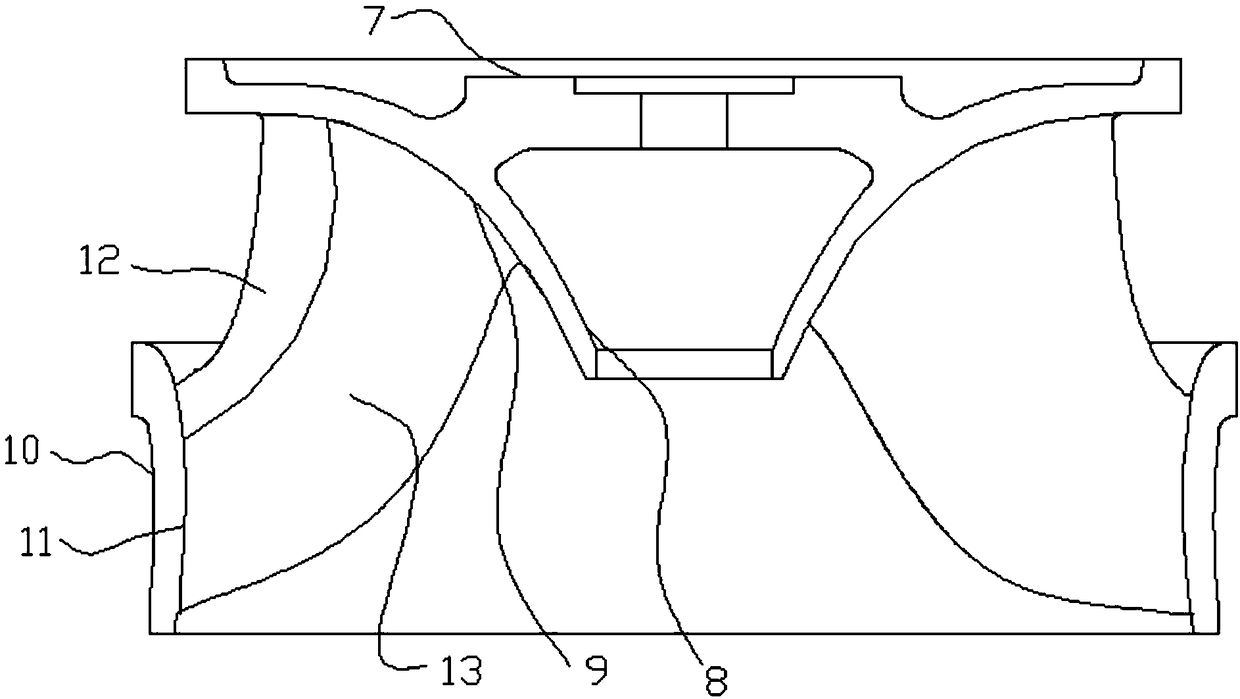

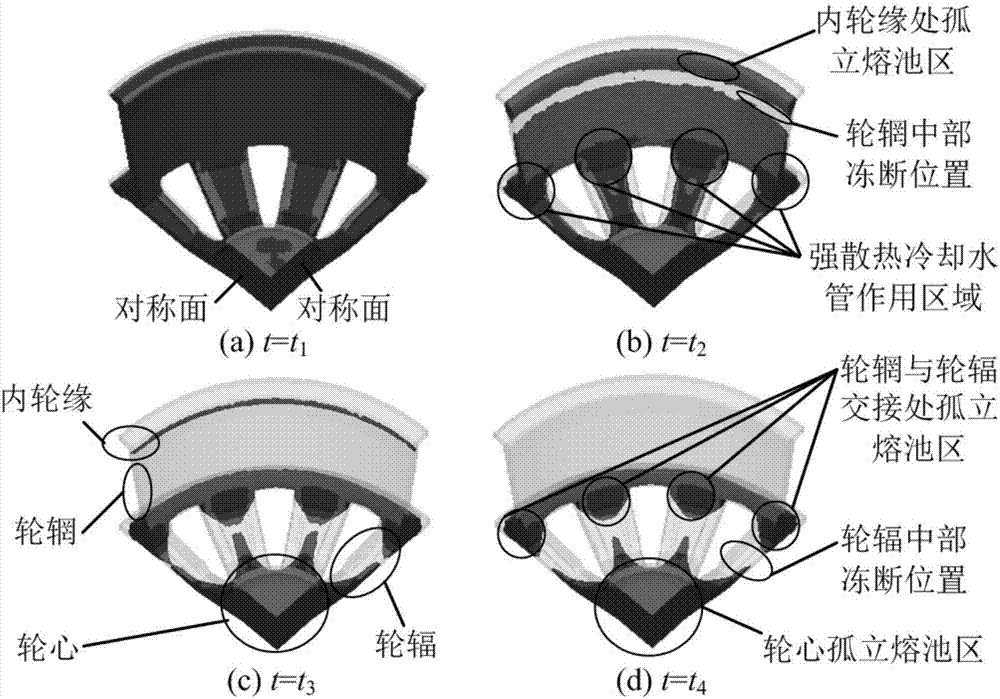

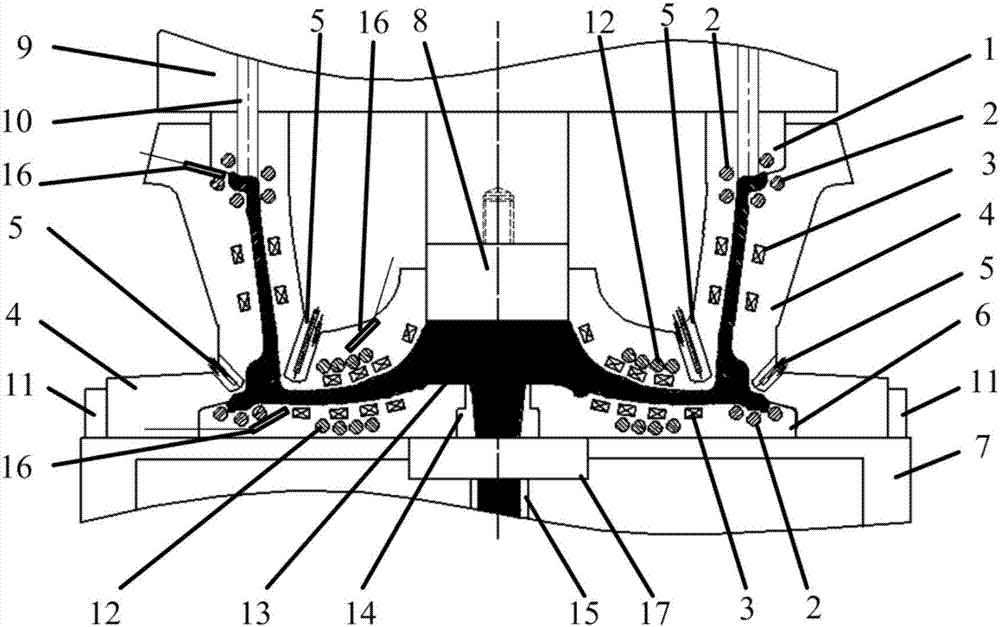

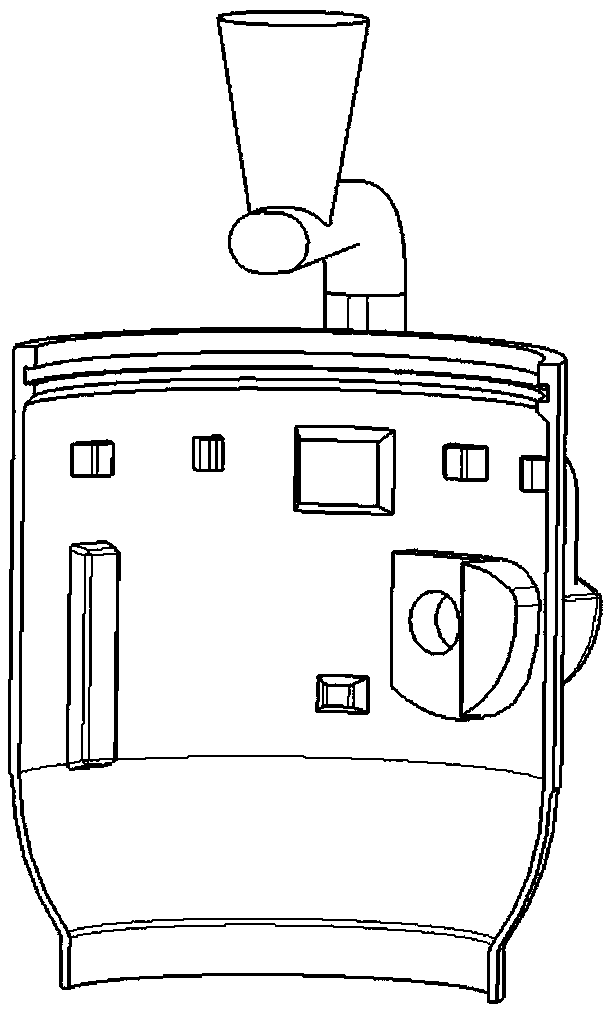

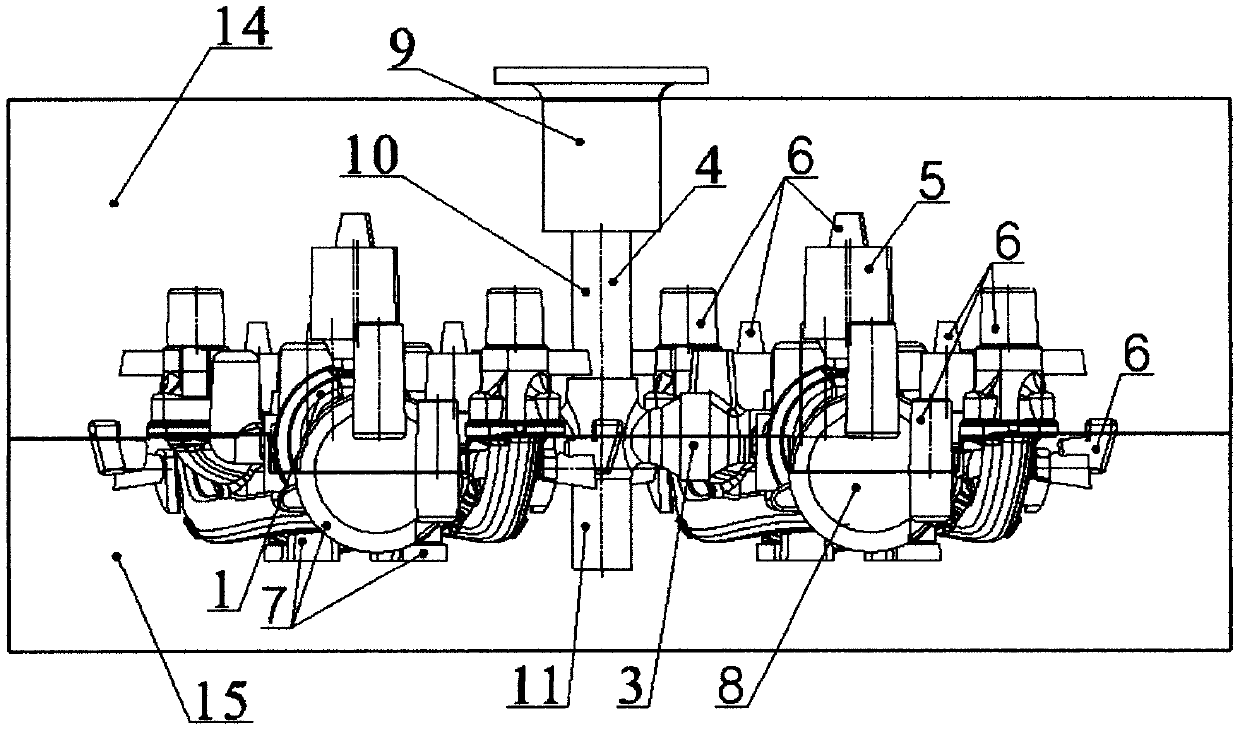

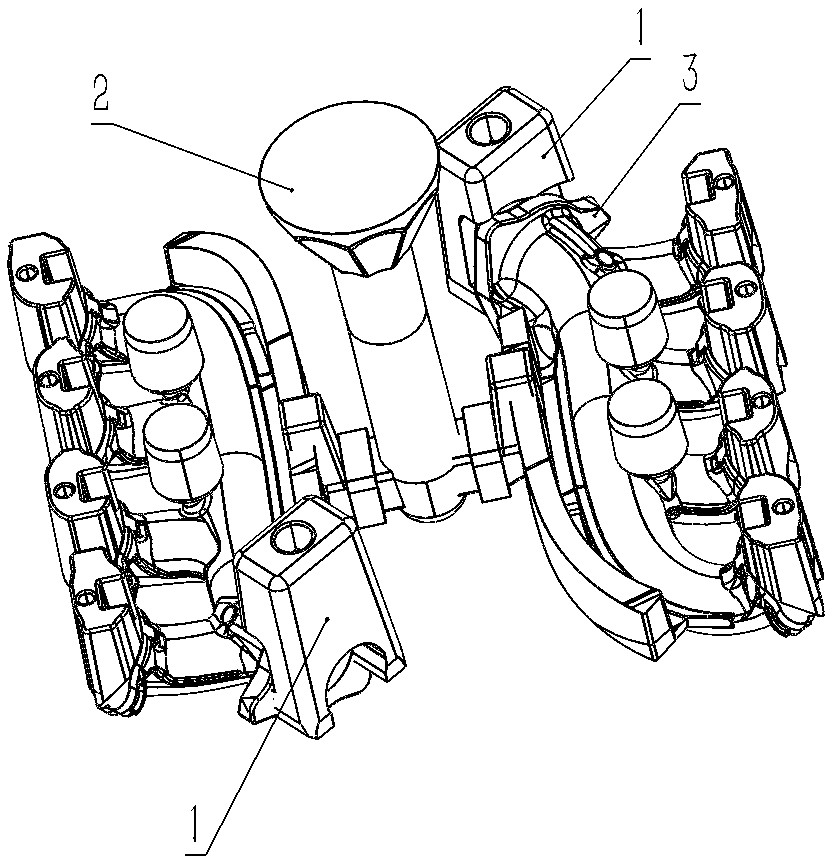

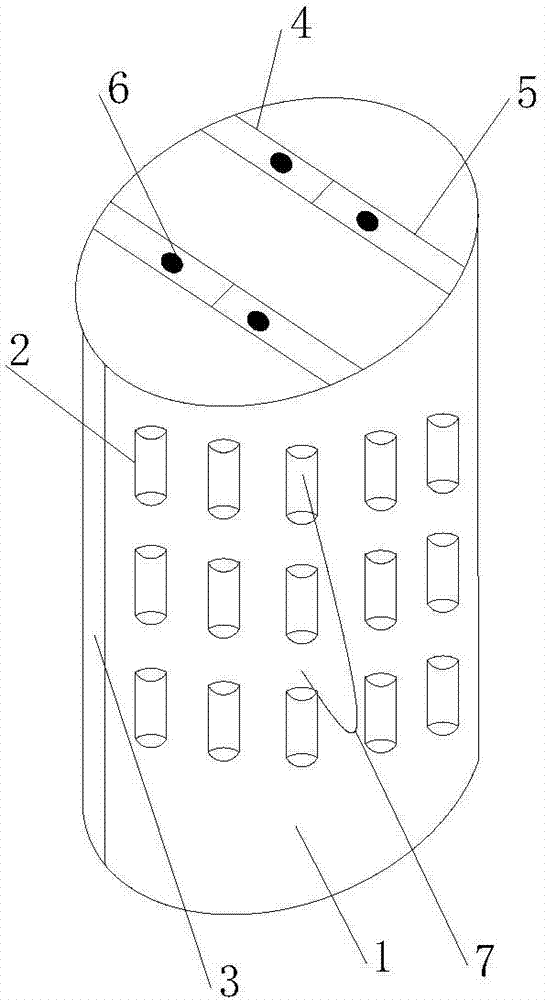

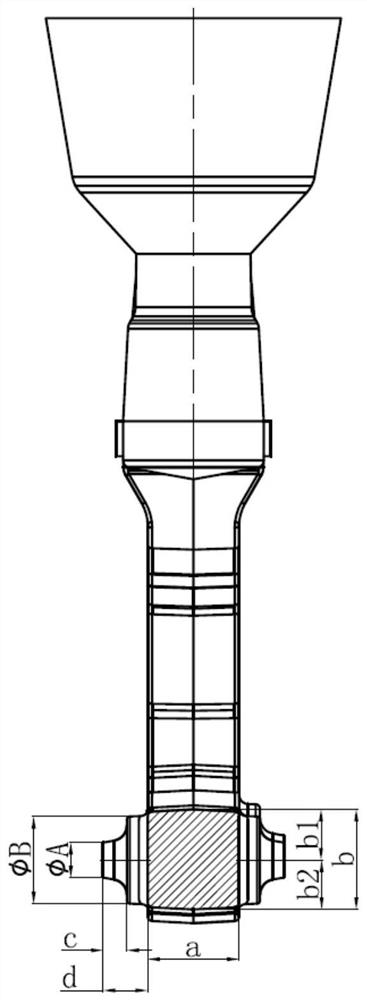

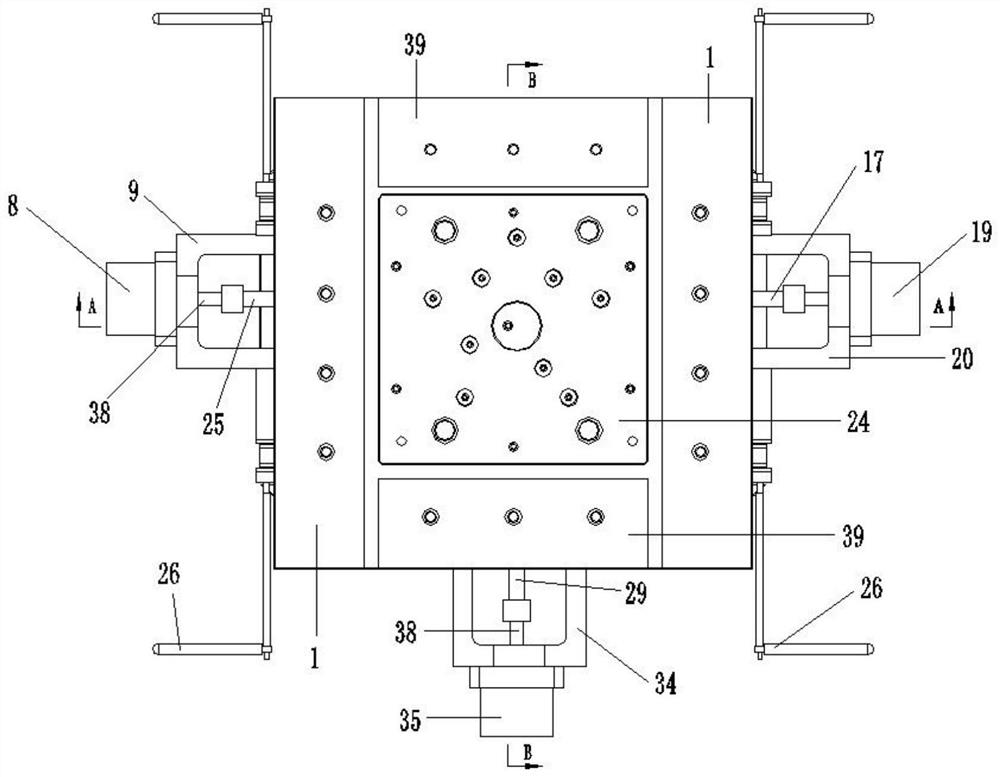

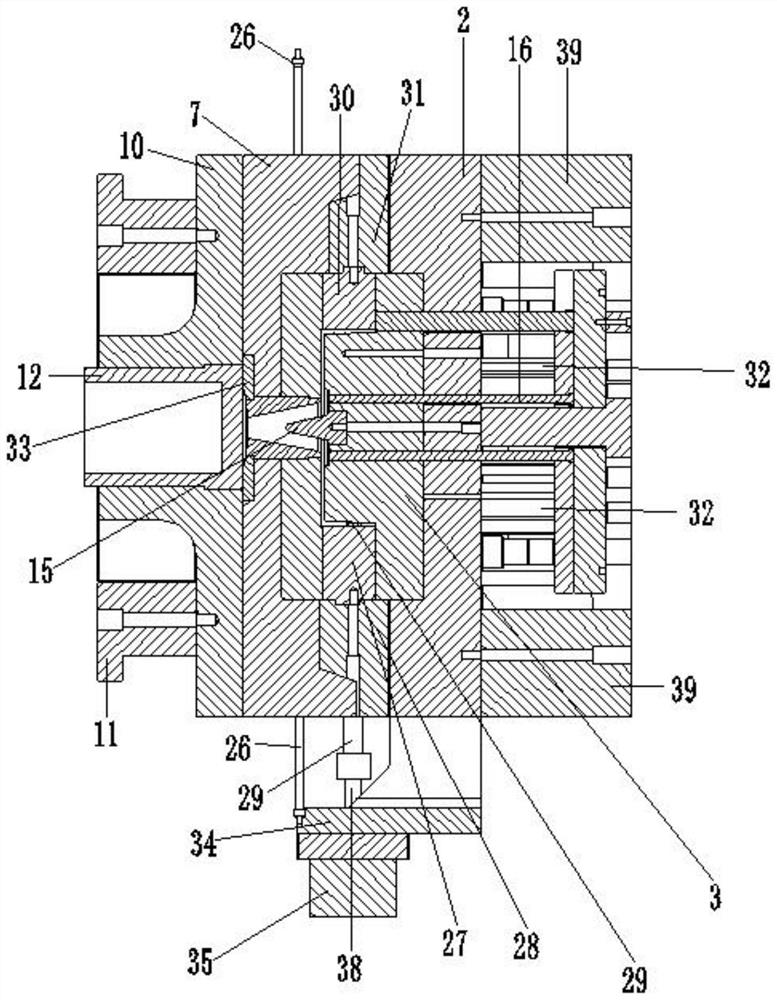

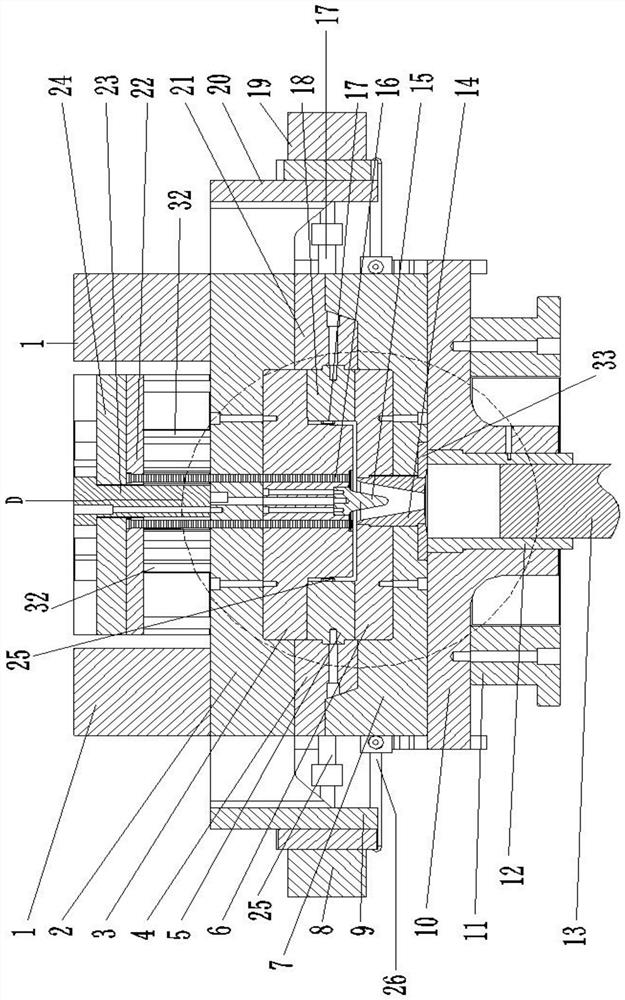

Hub squeeze casting device and method integrating precise temperature control and pulsed magnetic field

ActiveCN107138710AReduce shrinkage and shrinkage defectsGuarantee unimpededEngineeringPulse magnetic field

The invention discloses a hub squeeze casting device and method integrating precise temperature control and a pulsed magnetic field. The device comprises an upper die, a cooling water pipe, the pulsed magnetic field, side dies, a high heat-sink cooling water pipe, a lower die, a workbench, a squeezing plunger chip, an upper die fixing plate, an ejector rod, guide rails, a heating pipe, a casting, a pouring cup, a liquid increasing pipe, a temperature sensor and a sealing device. The hub squeeze casting method comprises the steps that before molten metal is introduced into a cavity, the heating pipe is used for preheating the middle part of a spoke of a die; after filling of the cavity through the molten metal is completed, the hot joint position of the die is cooled in a manner of combining the high heat-sink cooling water pipe and the cooling water pipeline; and meanwhile, dendritic crystal formed in the middle portion of the spoke at the early time is broken through the action of the pulse magnetic field so that smoothness of channel feeding through the molten metal can be guaranteed and grains can be refined, and under the action of the pulse magnetic field, dendritic crystal formed on a rim and a wheel center portion at the early time are also broken, and grains are refined. The purpose of sequential solidification of the hub casting under the squeezing pressure is achieved, the defects of casting shrinkage cavities and shrinkage porosities are reduced, the casting grain sizes are reduced, and the comprehensive mechanical performance of the casting is improved.

Owner:TSINGHUA UNIV +1

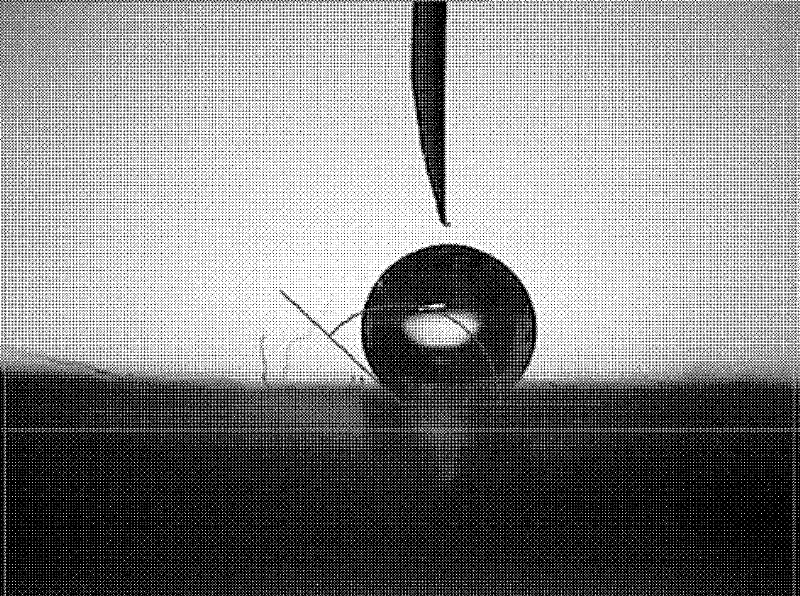

Precision casting forming method of thin-wall variable section casting

ActiveCN109550903AAchieve defect-free solidificationResolving feeding difficultiesFoundry mouldsFoundry coresWaxPorosity

The invention discloses a precision casting forming method of a thin-wall variable section casting. According to a structure of the casting, a bionic supplementary casting system is designed, whereinthe bionic supplementary casting system comprises a main casting channel, the upper end of the main casting channel is connected witha sprue cup / pool, the lower end of the main casting channel is connected with a plurality of sub casting channels, each sub casting channel is connected with an inner casting channel, and the inner casting channels are directly connected with the casting; according to the structure of the casting, the size of a common supplementary inner casting channel is designed reasonably, it is ensured that temperature fields in the inner casting channelsare higher than thatof asupplemented part of the casting, and thus a thick and large part of the casting is fully supplemented; the bionic supplementary casting systemand a casting wax mold are connected to be integrallyplaced in a box for modeling, and after dewaxing and roasting after modeling, the casting is obtained by casting metal liquid into a mold cavity. According to the precision casting forming method ofthe thin-wall variable section casting, the well-beddedbionic supplementary casting system is adopted, and theproblems that when castings with thin walls, multiple bosses and variable sections are produced in the prior art, scattered hot joints are difficult to supplement and porosity shrinkage is prone to forming due to existence of many isolated hot jointsare solved.

Owner:CSIC NO 12 RES INST

Method for local cooling of investment casting formwork

InactiveCN109396345AQuality improvementAdvanced technologyFoundry mouldsFoundry coresWaxInvestment casting

The invention discloses a method for local cooling of an investment casting formwork. The method includes the steps of, firstly, analyzing the structures of castings, obtaining hot joint distributionof the castings, determining the position of the formwork which needs local cooling, manufacturing wax molds according to casting requirements, combining the wax molds into a module, and coating the module to manufacture a shell; after the shell is manufactured, forming the demanded formwork through dewaxing and roasting; then, connecting an external tool for formwork shaping to the exterior of the formwork which needs local cooling, and filling gaps in the junctions with steel shots, wherein the formwork is fixed after the gaps are filled with the steel shots; then, conducting casting on theformwork according to technological requirements to complete local cooling of the formwork. According to the disclosed method, the mold and shell manufacturing processes of investment casting are notchanged; meanwhile, the steel shots can fully achieve shaping so that the feeding effect on larger hot joints can be effectively improved, casting defects of the castings such as shrinkage, looseningand cavity shrinkage at these positions are prevented, the quality of the castings is greatly improved, and the process yield of the castings is greatly increased.

Owner:CSIC NO 12 RES INST

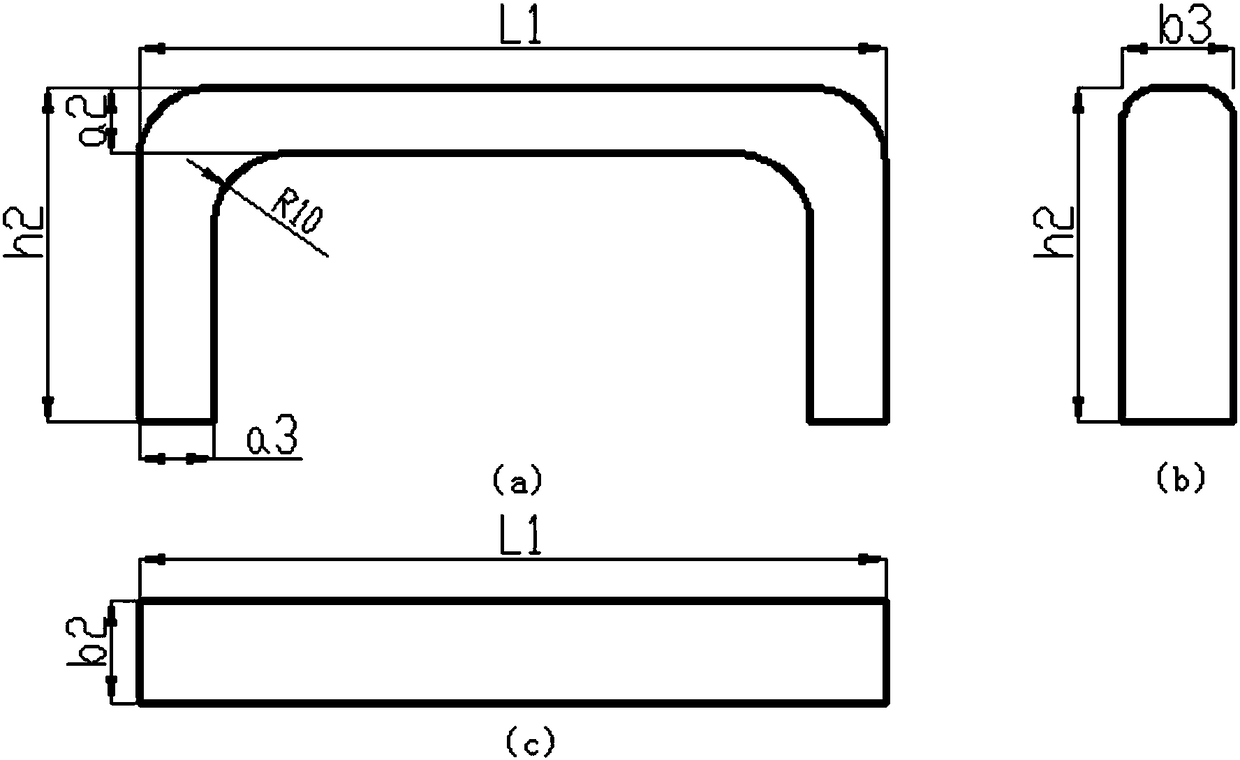

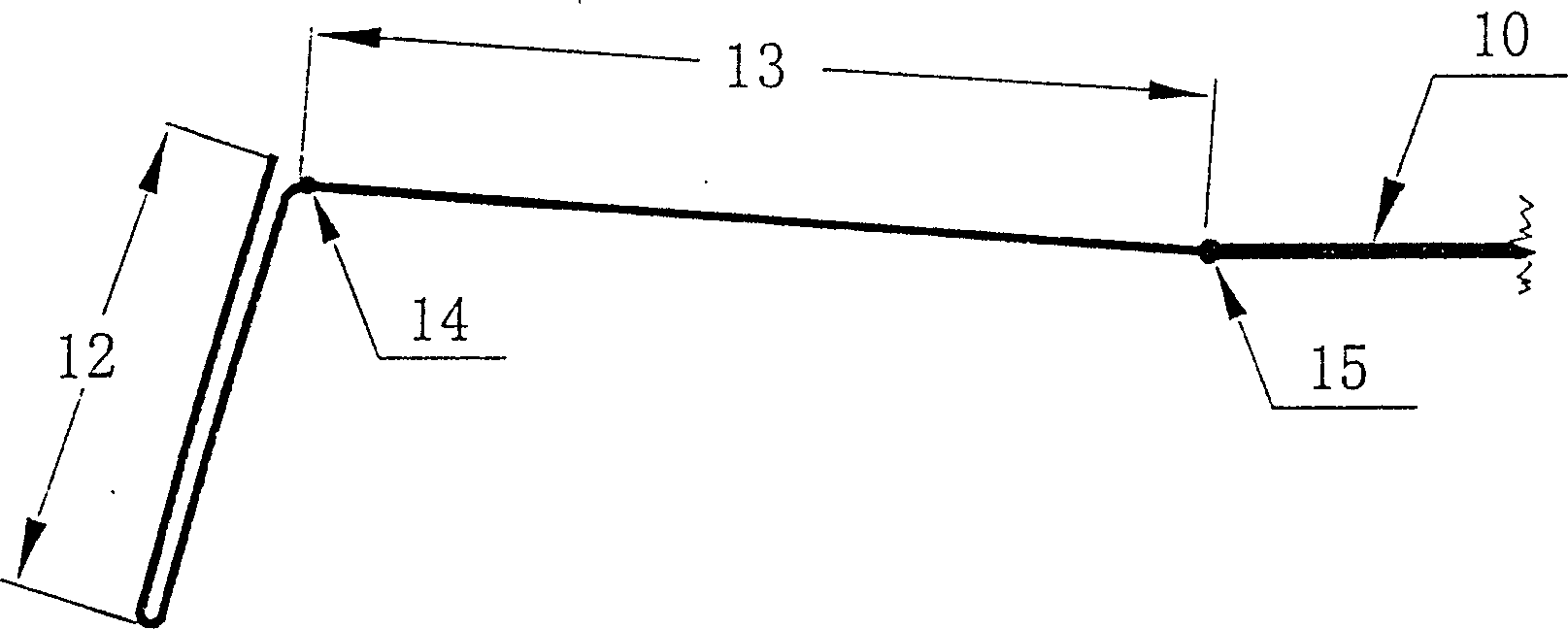

Wire heat-peeling forceps

InactiveCN1845395AImprove high temperature performanceImprove work flexibilityLine/current collector detailsApparatus for removing/armouring cablesElectrical resistance and conductanceThermoplastic

As monopolized by American product, the series defects in prior art of the wire hot-stripping clamp include 1) unreasonable hot wire arrangement and only 1 / 3 useful work; and 2) disobeying design requirement to remove the cold-hot joint out of body. In the disclosed product, using U-shaped resistance wire on blade instead of the original I-shaped one to prolong the wire one time and increase useful work one time too; applying paralleled double-ply wires on supporting part to increase the section area one time and reduce all of the surface load, useful resistance and reactive consumption one half; and moving the joint into body. This invention overcomes problem in current product and improves performance greatly.

Owner:董一伟

Method for producing turbocharger shell for wet-type casting vehicle

InactiveCN110238346AResolve Microscopic DefectsLow solid phase rateFoundry mouldsFoundry coresTurbochargerMedium frequency

The invention discloses a method for producing a turbocharger shell for a wet-type casting vehicle. According to the method, raw sand resources can be remarkably saved, and the casting technology difficulty is reduced. According to the technical scheme, the method for producing the turbocharger shell for the wet-type casting vehicle comprises the following steps that a traditional damp mold sand is used for modeling, a straight runner is used as the center in a sand mold, and sand boxes are symmetrically arranged, wherein each sand box is provided with four pieces; the straight runner communicates with an upper sand box and a lower sand box, and a cross runner is arranged at the bottom end of the straight runner, and a pouring gate nest with a rectangular longitudinal section shape is arranged at the tail end of the cross runner, and meanwhile, inner runners are arranged at the far end of the cross runner, and each volute casting communicates with other volute castings through two inner runners; ceramic filter sheets and follow-up cold iron are placed on the sand core lower cores on the two sides of the symmetric straight runner, so that the core making is completed; the follow-up cold iron is placed at a hot joint part, linking to the runners, of the bottom of each volute; simulation results of the defects of shrinkage porosity and shrinkage cavity are combined and compared to determine the optimal process parameters; and finally, in the medium-frequency induction furnace, molten metal enters from top to bottom through a gate cup and enters a mold cavity from different inner gates, thus complete the filling.

Owner:成都艾特安科技有限公司 +1

Method for continuously and rollingly paving asphalt on dynamic flat ground of skid pad

The invention discloses a method for continuously and rollingly paving asphalt on a dynamic flat ground of a skid pad. The method comprises the step of: (a), selecting the quantity of pavers, and determining distance between a front paver and a rear paver, wherein at least two pavers are needed for realizing continuous and rolling paving, the distance between the front paver and the rear paver does not exceed 100m, and the quantity of the pavers is specifically determined according to the length of each paving range and the paving speed. According to the method, the definition of a hot joint is expanded, formation of a longitudinal cold joint is reduced, the investment of construction machinery is greatly reduced, and the construction cost is reduced.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

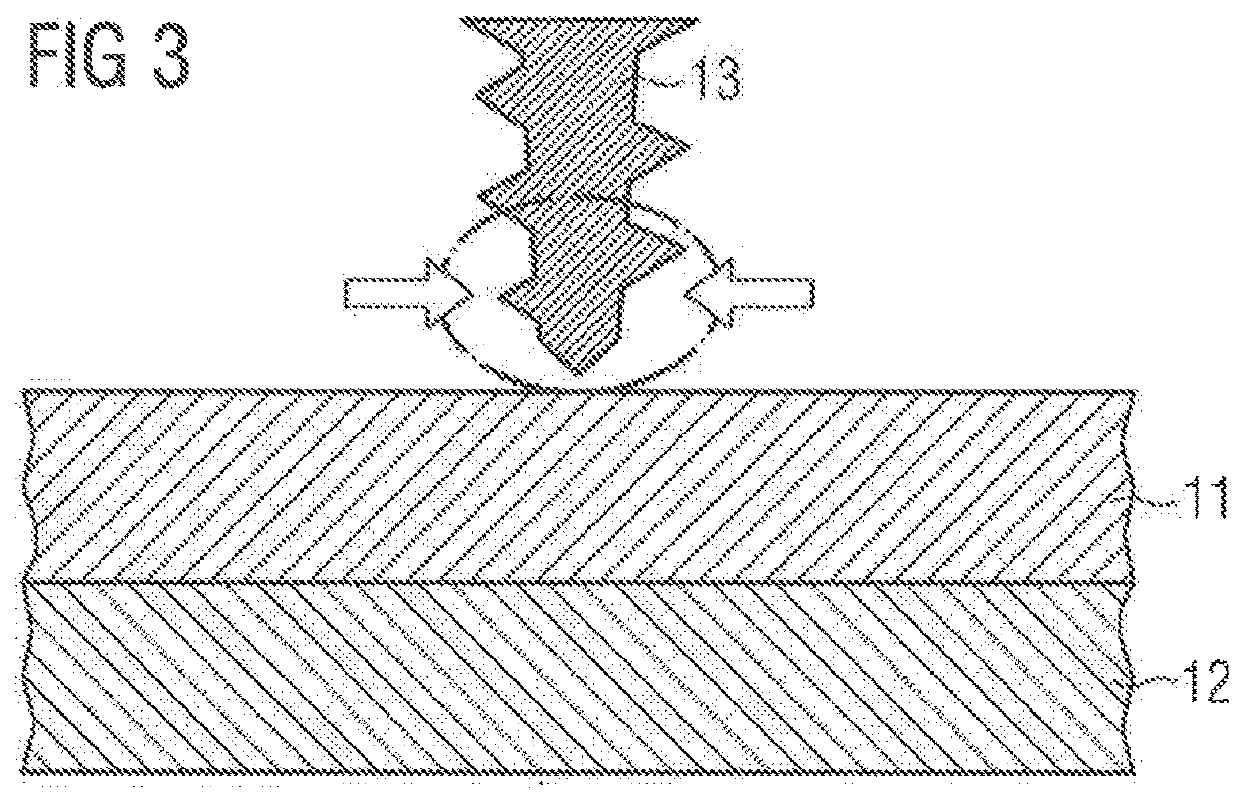

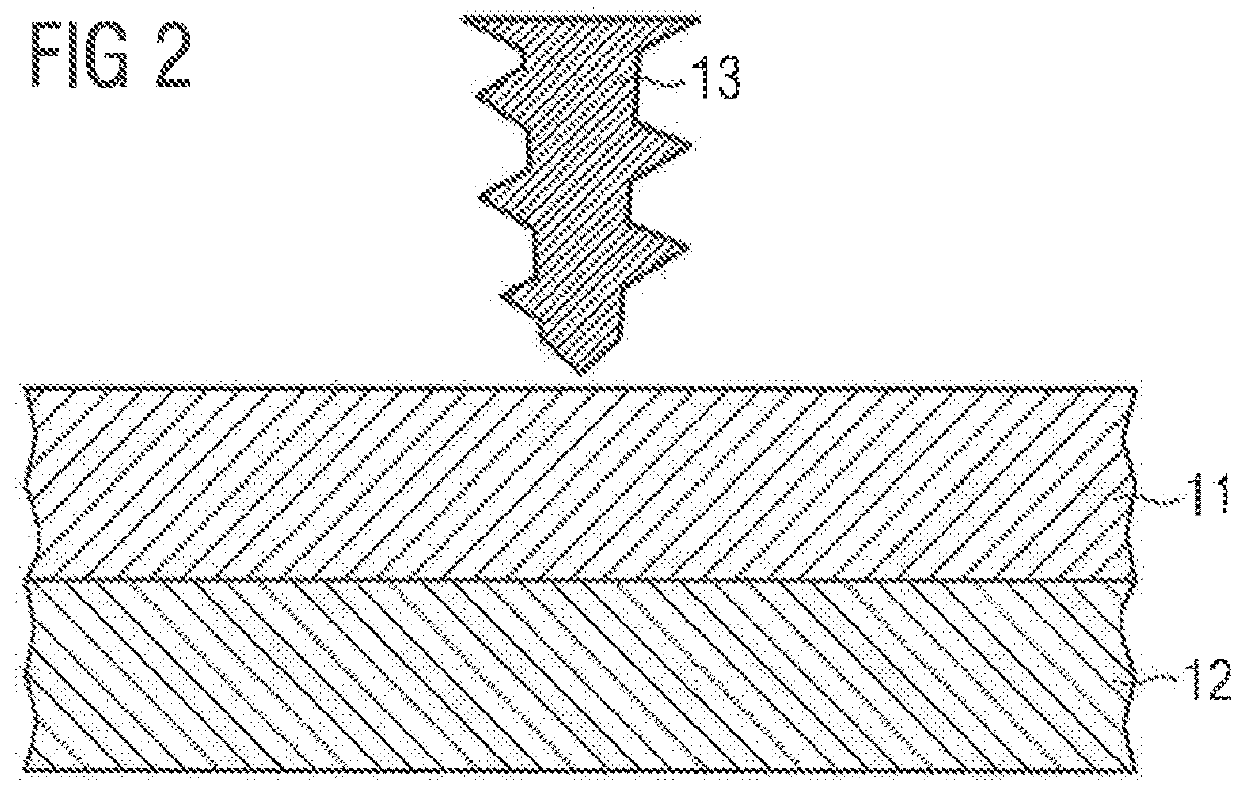

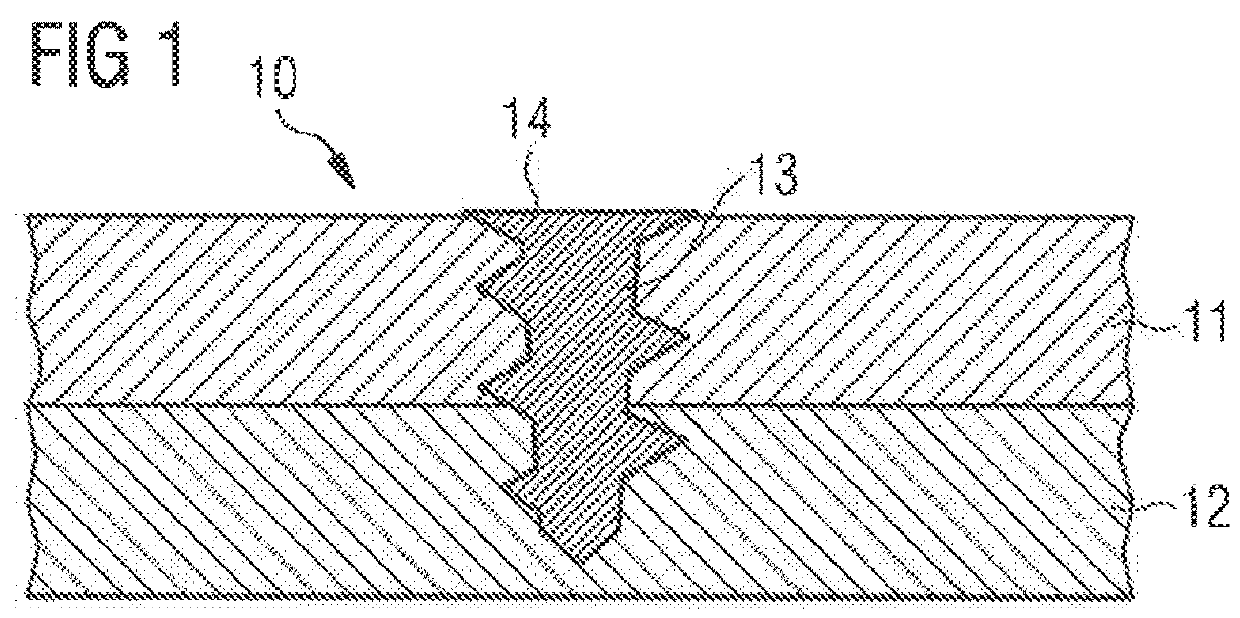

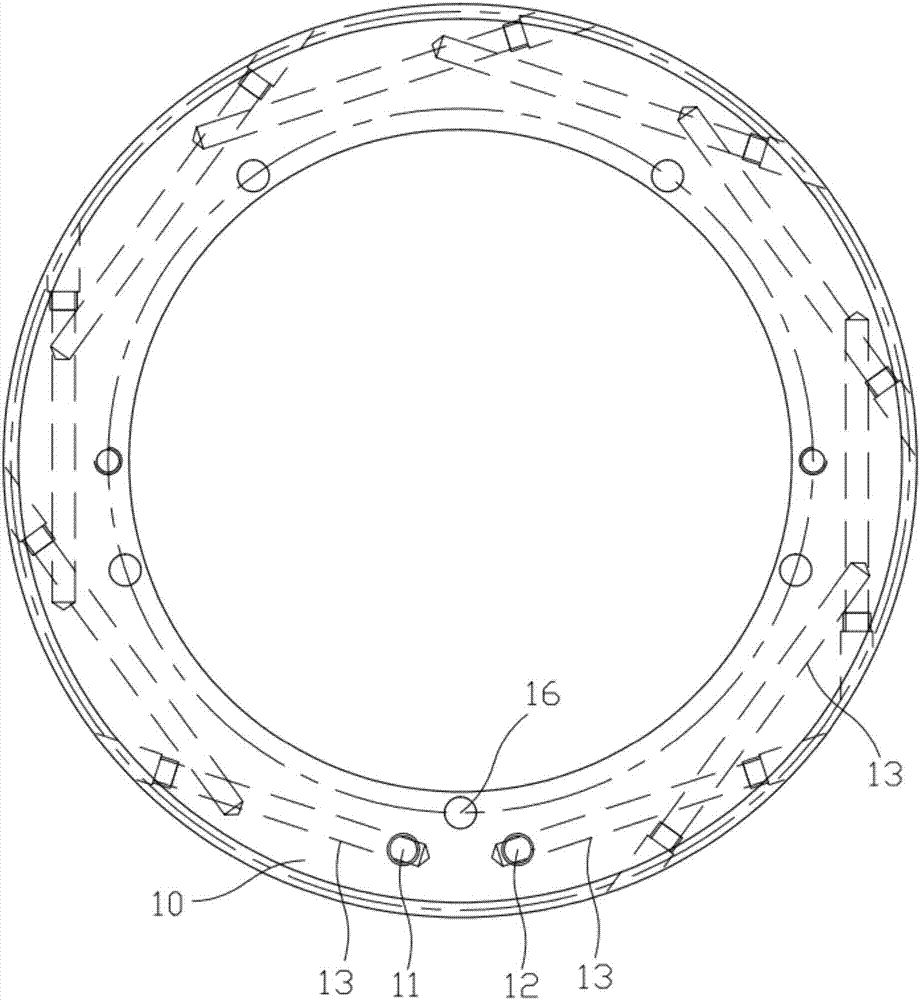

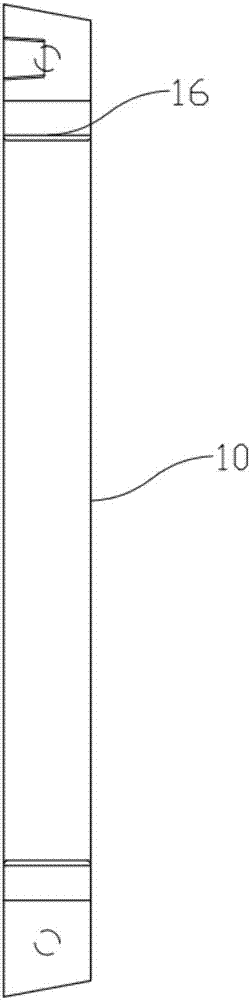

Hot joint fastener

A method for joining together different components or different sections of a single component, wherein at least one of the components is a thermoplastic fiber composite component, by using a threaded fastener. Heat is used for softening the thermoplastic fiber composite component to be joined together with the threaded fastener. A joined-together fiber composite component of a vehicle, aircraft or spacecraft, can be obtained by the disclosed method.

Owner:AIRBUS OPERATIONS GMBH

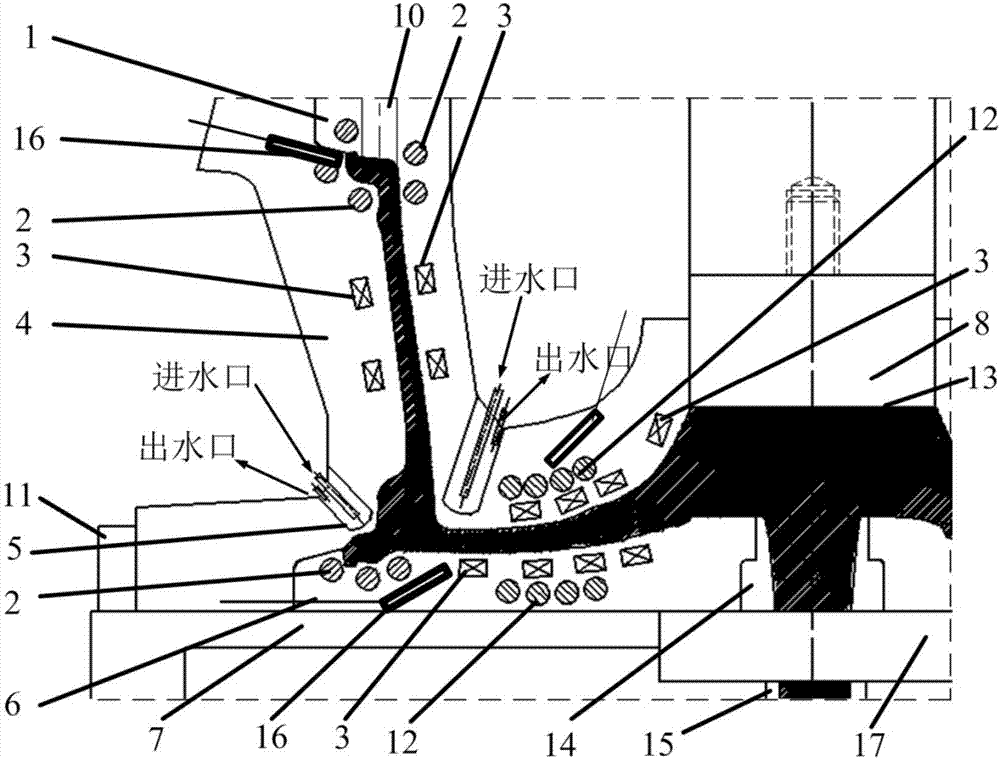

Hub mold rim water cooling device

The invention discloses a hub mold rim water cooling device. The device comprises an annular rim body which is coaxial with an upper mold of a hub mold and can be mounted on an upper mold hot joint; the rim body is provided with a water inlet and a water outlet which are next to each other and further provided with a cooling water way communicating with the water inlet and the water outlet; and the cooling water way is close to the outer wall, making contact with the upper mold, of the rim body. According to the cooling device, through the cooling water way in the rim body, when a hub is cast, the hot joint of the upper mold is cooled, thus the portion, away from a pouring port, of a casting can be solidified firstly, then the portion, close to the pouring port, of the casting is solidified, and finally the pouring port is solidified; the defect that the after-solidification position and the hot joint position cannot obtain material replenishing, thus shrinkage cavities occur, or loosening is caused is avoided, the rejection rate of the castings is decreased, and the production efficiency is improved accordingly; and meanwhile the mold is cooled, and the casting period can be shortened.

Owner:KUNSHAN ZHONGYITE MACHINERY IND

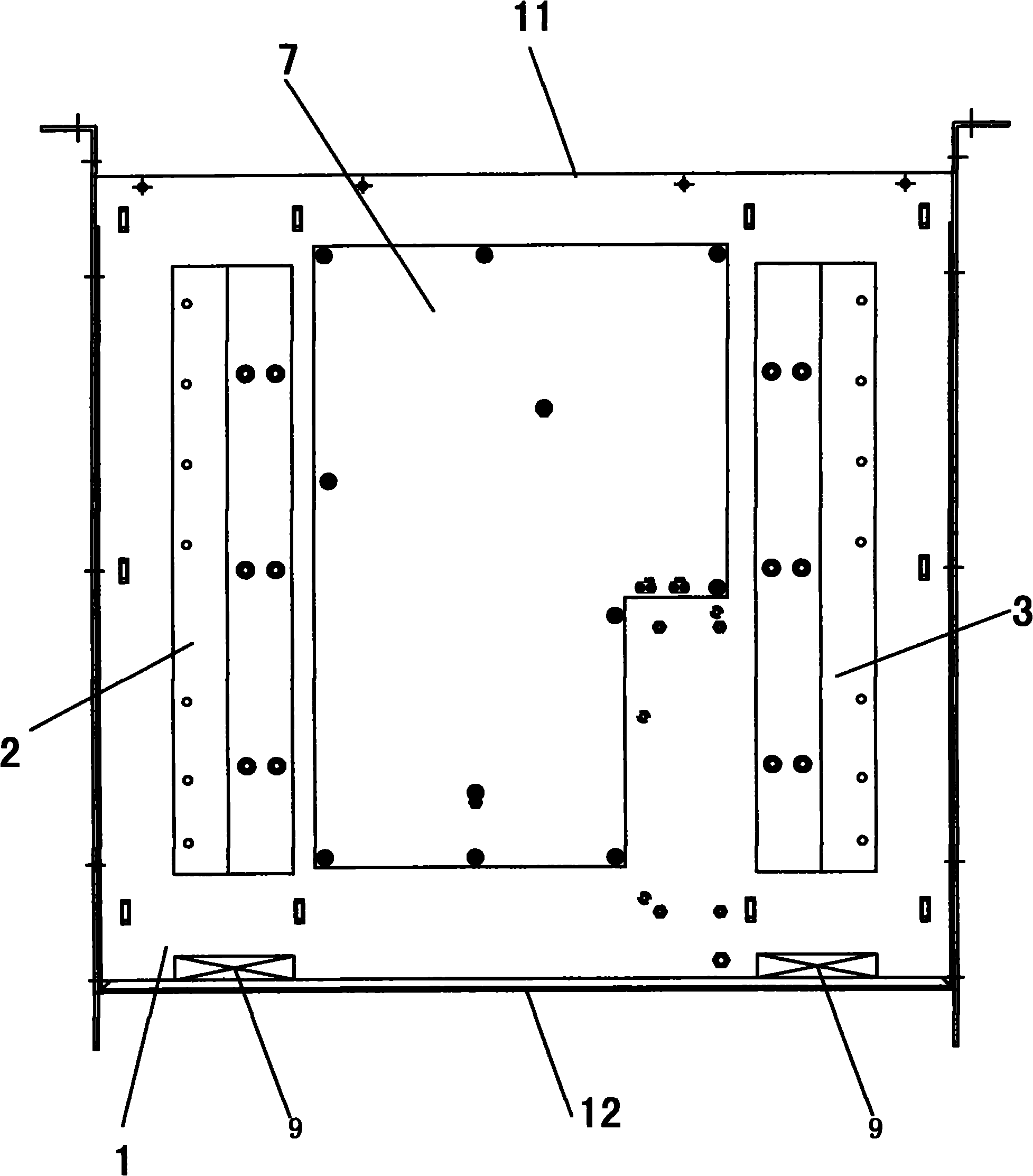

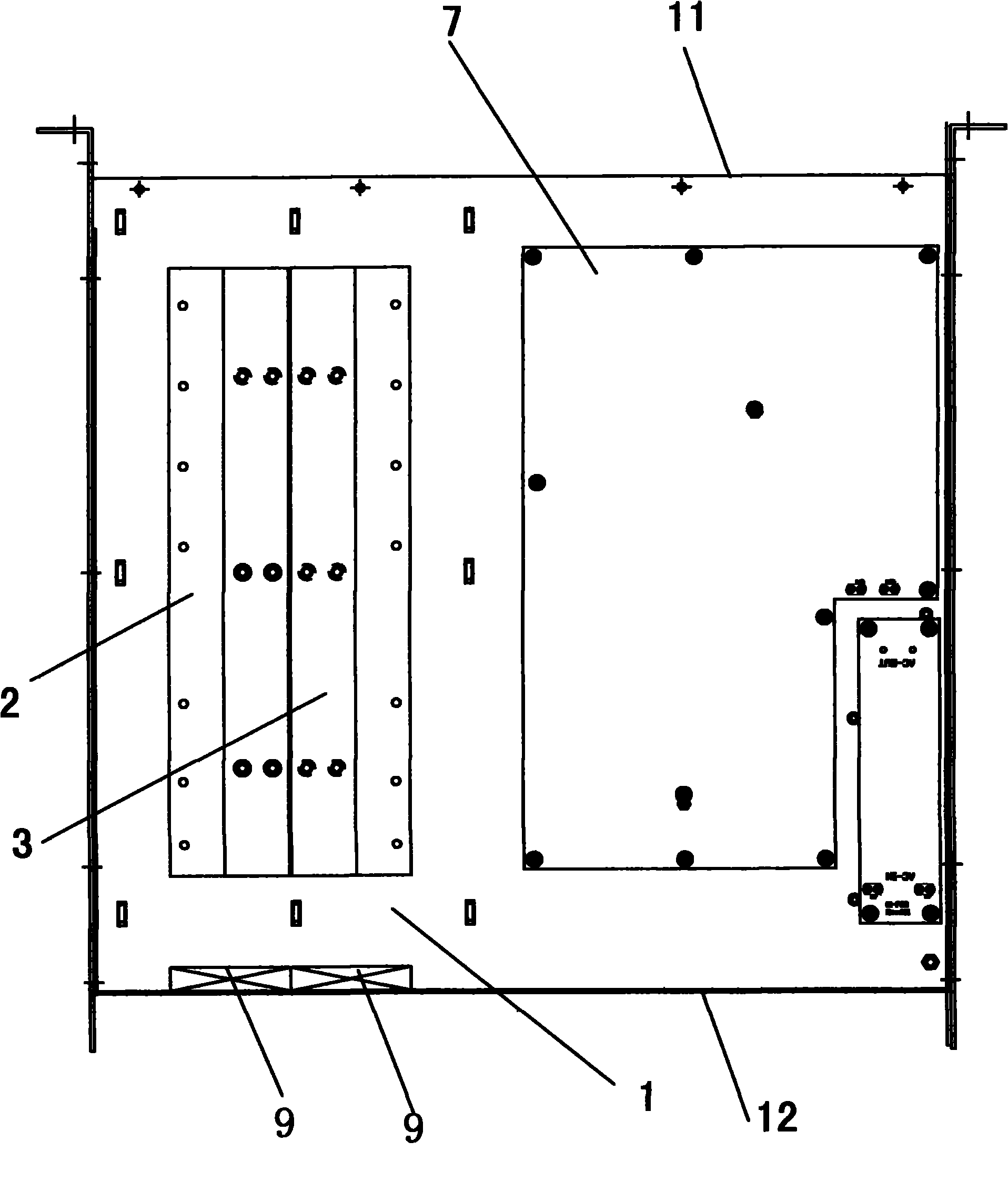

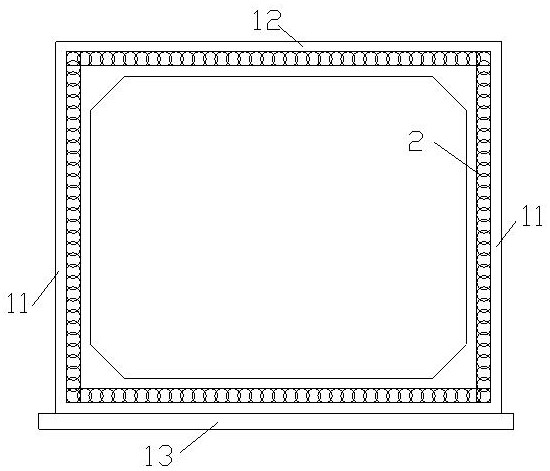

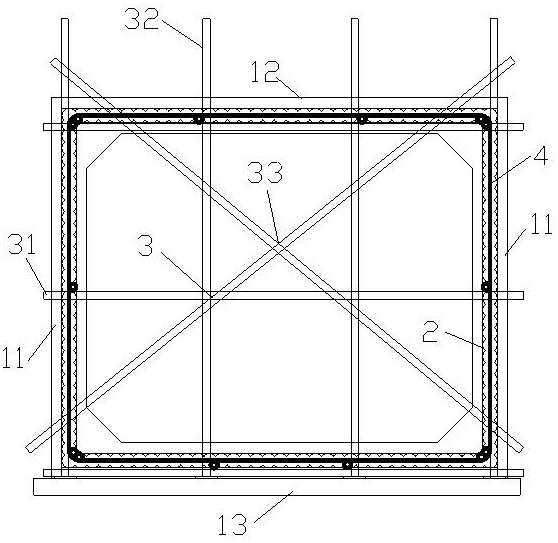

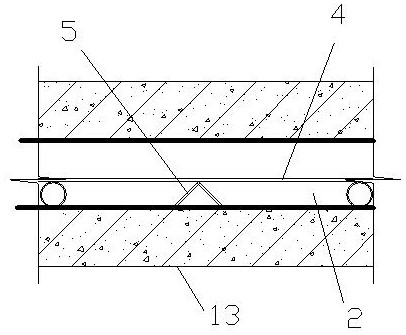

Casting mold for increasing mold thickness

InactiveCN109570440AIncrease profitThere will be no escapeFoundry mouldsFoundry coresCasting moldHot joints

The invention discloses a casting mold for increasing mold thickness. The casting mold comprises a sand box, molding sand, a pouring cup and a riser, wherein the riser is arranged at the rear side ofthe hot joint position at the edge of the sand box, so that an original mold with one cavity is changed into a mold with two cavities, or the mold with two cavities is changed into a mold with four cavities; the safe mold thickness is sufficiently ensured; the running-out phenomenon of a casting during casting process will not occur; and the safe pouring without running-out is ensured while the utilization of the sand box is improved.

Owner:西峡飞龙特种铸造有限公司

Buffering air column bag

InactiveCN107416354AFully protectedAvoid wear and tearContainers to prevent mechanical damagePlastic packagingEngineering

The invention relates to the technical field of plastic packaging bags, in particular to a buffering air column bag composed of a first bag body and a second bag body. Thin films used by the first bag body and the second bag body comprise PE layers and PP layers. The first bag body and the second bag body are fixedly connected though hot joint, and the edges of the first bag body and the second bag body are fixedly provided with hard paper. A female button body of a press button is fixed to the hard paper of the edge of the first bag body, and a male button body corresponding to the female button body is fixed to the hard paper of the edge of the second bag body. According to the buffering air column bag, the press button is fixed to the edges of the first bag body and the second bag body through the hard paper, when goods are mounted in the bag bodies, the press button is pressed to enable the goods to be sufficiently protected, and abrasion caused by goods exposure in the conveying process is avoided.

Owner:CHIZHOU SINCHEEN PACKAGING TECH CO LTD

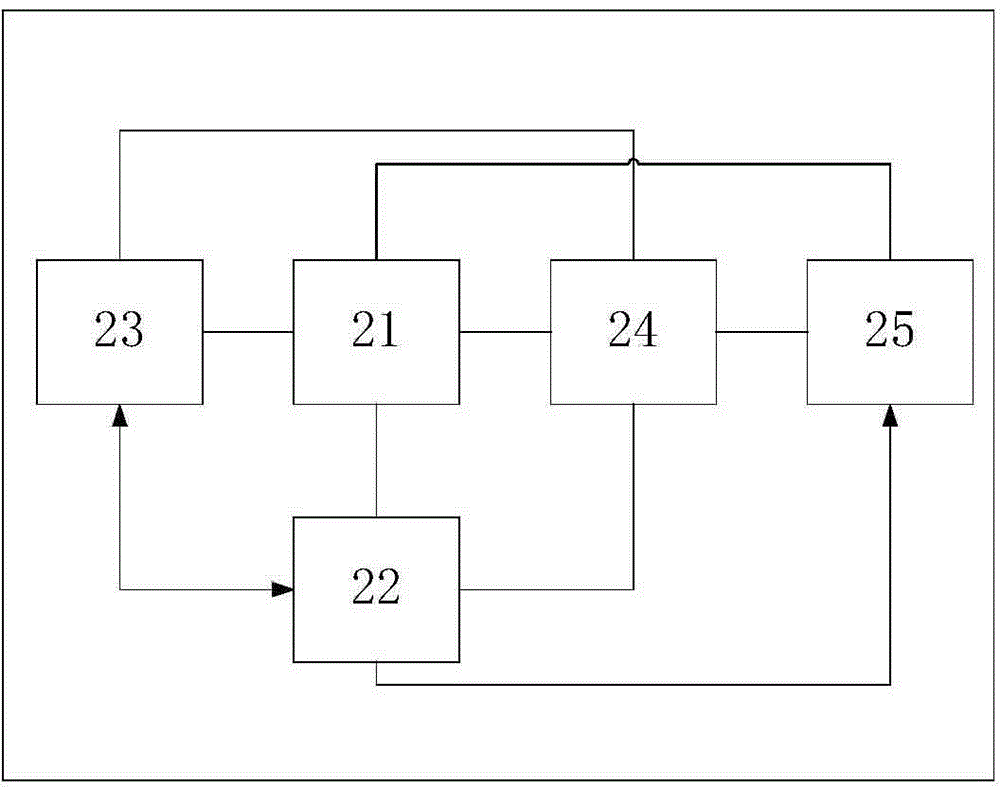

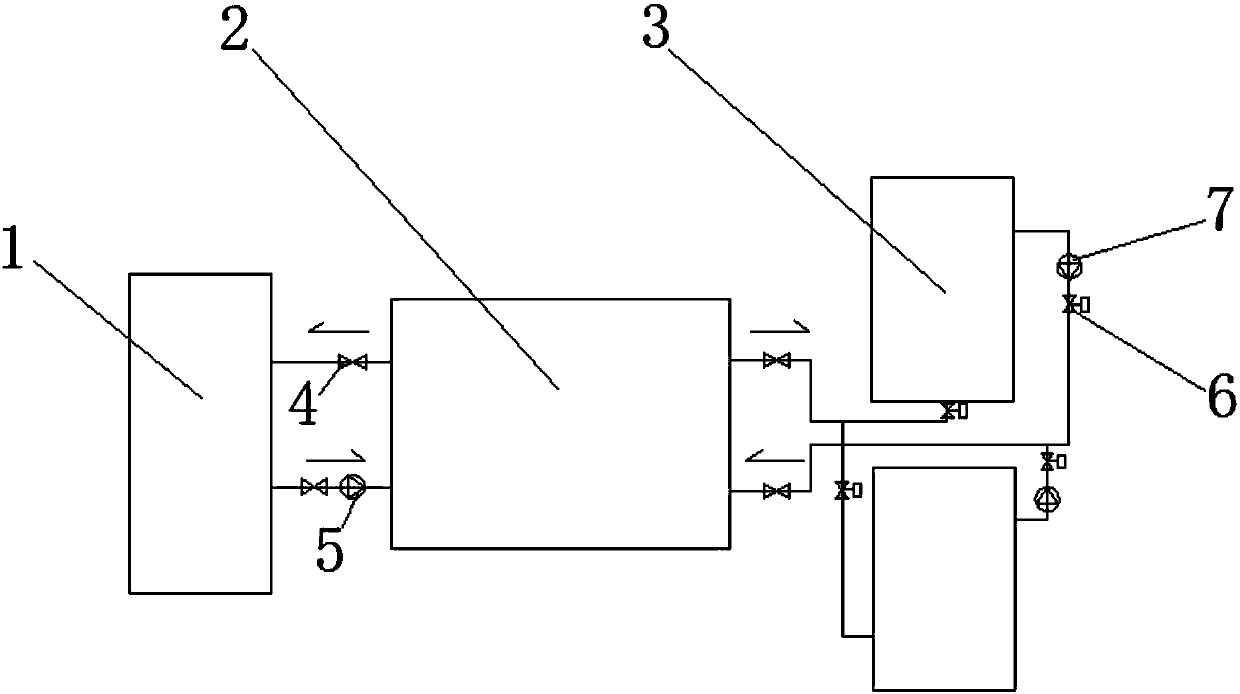

Intelligent-control cold-hot joint production system

PendingCN107702249AReduce investmentMechanical apparatusHeat pumpsWater source heat pumpTemperature control

The invention discloses an intelligent-control cold-hot joint production system comprising an air conditioner system, a water source heat pump, a heat storage water tank and an intelligent control system. A first water feed pipe and a first water discharge pipe are assembled on the air conditioner system, the first water feed pipe is sequentially connected with a check valve and a first circulating pump and then connected with a first water inlet of the water source heat pump, and a first water outlet of the water source heat pump is connected with the first water discharge pipe. A second water outlet of the water source heat pump is connected with a water inlet of the heat storage water tank through a second water discharge pipe, and a water outlet of the heat storage water tank passes through a second circulating pump and then is connected to a second water inlet of the water source heat pump through a second water feed pipe. The intelligent control system is composed of a temperature sensor, a controller, a compressor, air conditioner tail equipment, a temperature-control valve and the heat storage water tank. According to the intelligent-control cold-hot joint production system, a city refrigerating system and a system for preparing domestic hot water are combined, the domestic hot water is produced while refrigerating is conducted, the total investment of refrigerating andhot water preparation is reduced, and the produced domestic hot water can be used by ourselves and can also be for sale.

Owner:SHANXI SANSHUI ENERGY CO LTD

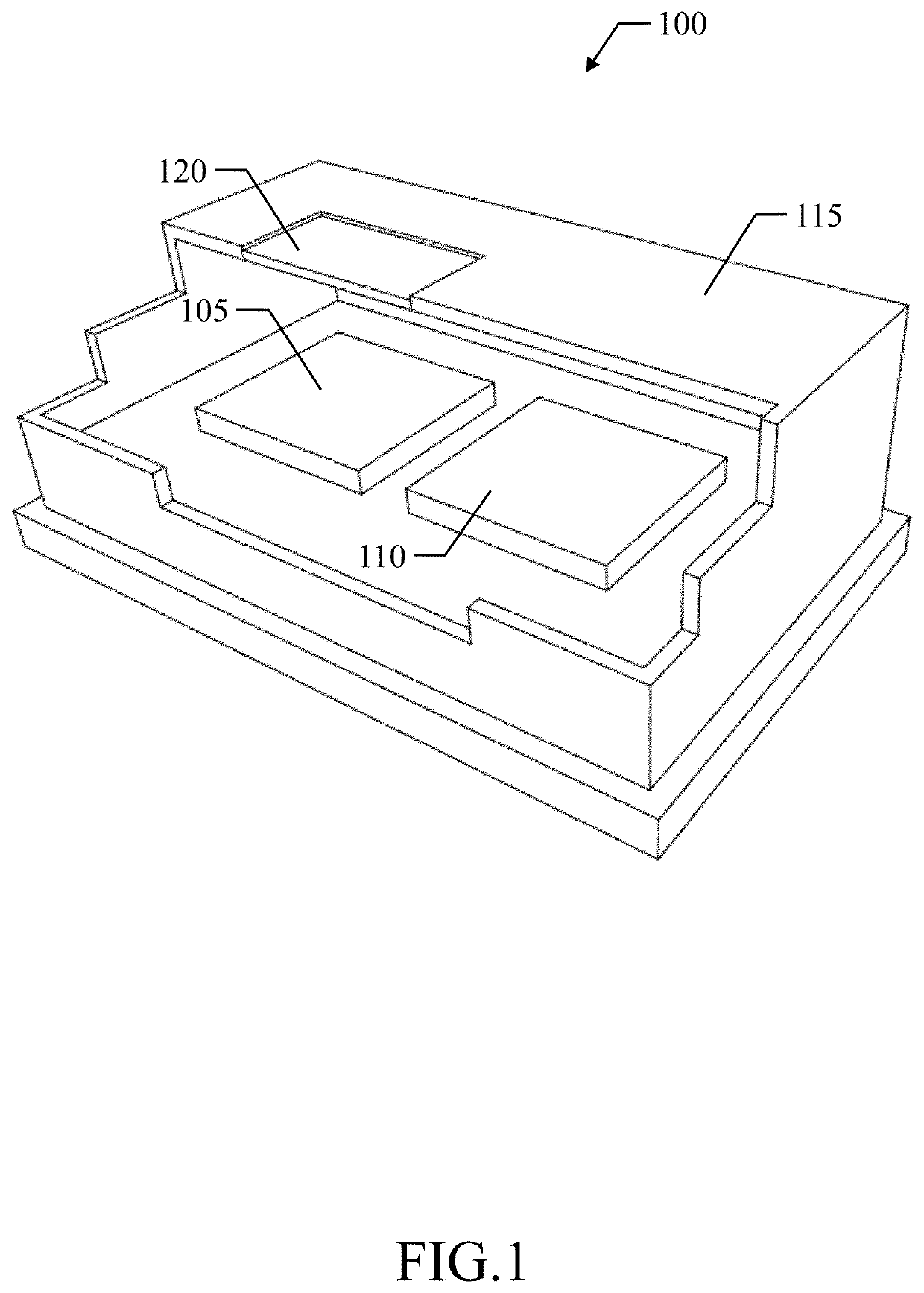

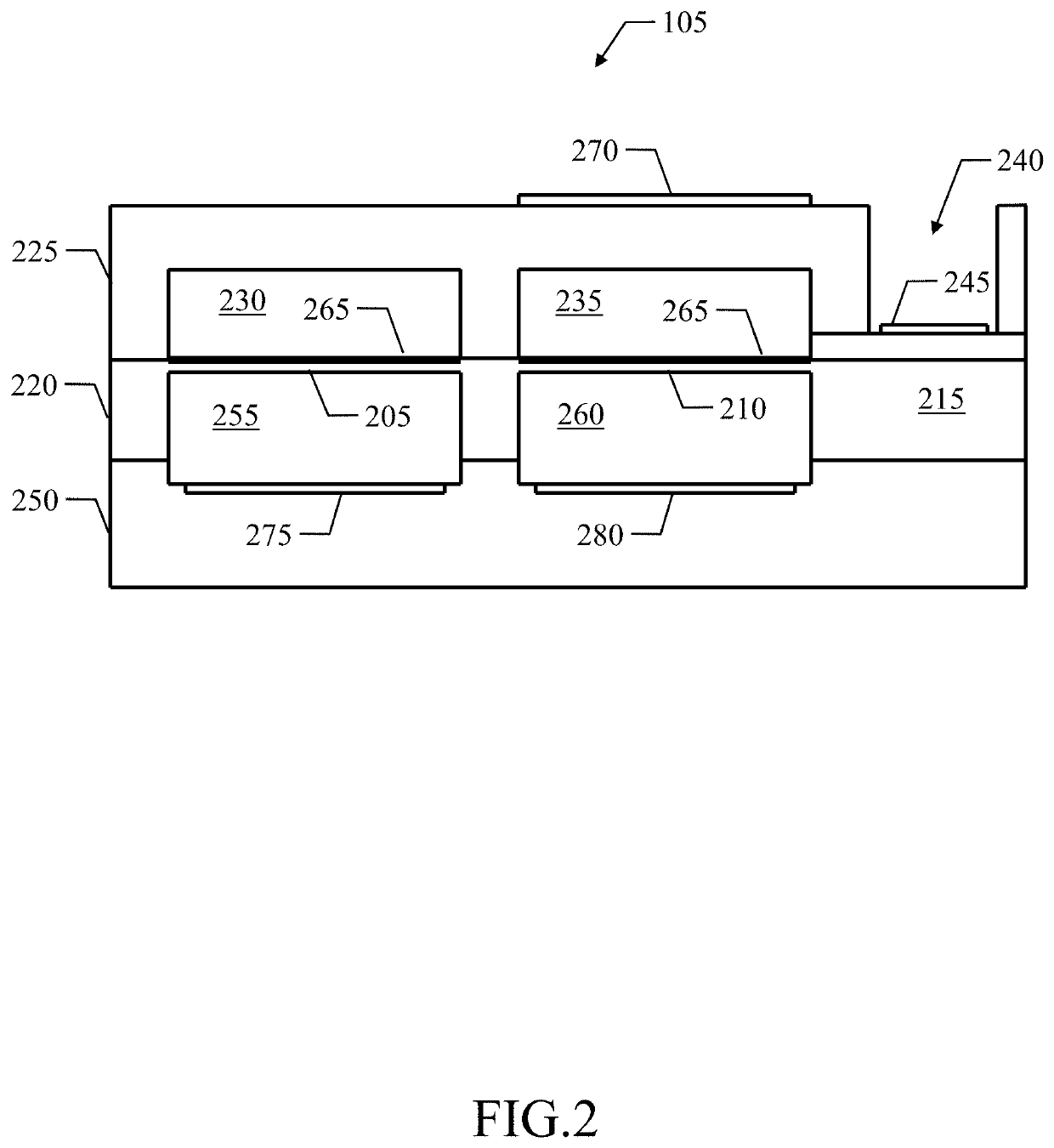

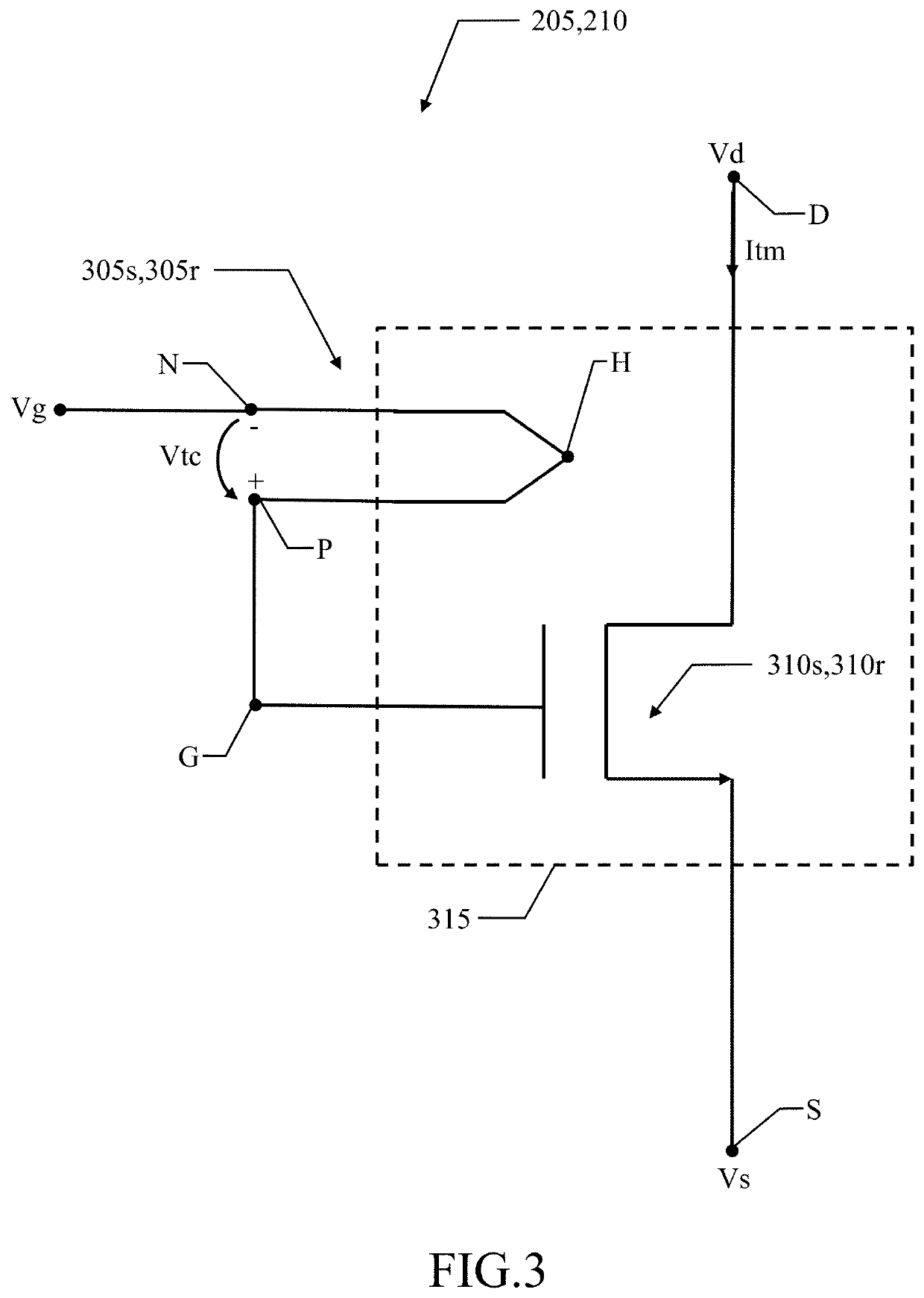

Thermographic sensor with thermal transistors driven by thermo-couples

PendingUS20220170795A1Radiation thermographyPyrometry using electric radation detectorsSignal processing circuitsHemt circuits

A thermographic sensor is proposed. The thermographic sensor includes one or more thermo-couples, each for providing a sensing voltage depending on a difference between a temperature of a hot joint and a temperature of a cold joint of the thermo-couple; the thermographic sensor further comprises one or more sensing transistors, each driven according to the sensing voltages of one or more corresponding thermo-couples for providing a sensing electrical signal depending on its temperature and on the corresponding sensing voltages. A thermographic device including the thermographic sensor and a corresponding signal processing circuit, and a system including one or more thermographic devices are also proposed.

Owner:STMICROELECTRONICS SRL

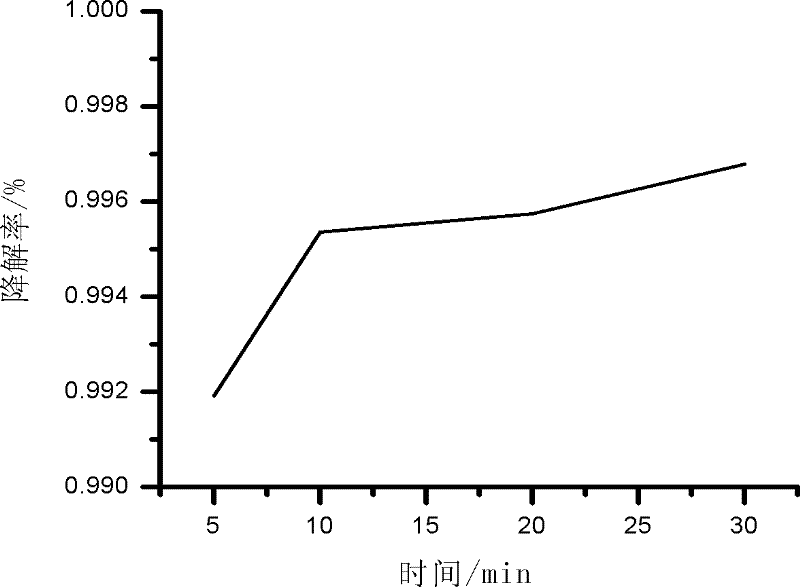

Anti-tearing biochemical protective clothes with antibacterial function and making method thereof

InactiveCN102415620AReduce harmGuaranteed biological protection effectFibre treatmentProtective garmentHot jointsFunctional composite

The invention belongs to the field of functional composite materials, and relates to a method for preparing anti-tearing biochemical protective clothes with antibacterial function. The method comprises the following steps of: preparing nano magnesium oxide; selecting a kind of anti-tearing cloth, and performing waterproof oil repellent finishing on the anti-tearing cloth; selecting the anti-tearing cloth subjected to the waterproof oil repellent finishing as an outer supporting layer, selecting materials for a middle filter layer and a lining, adding 5 to 25g / m<2> of nano magnesium oxide among the outer supporting layer, the middle filter layer and the lining, and preparing the three layers of materials and the nano magnesium oxide into a biochemical protective composite material by hot pressing and sticking; and preparing the biochemical protective composite material into the integral protective clothes, and performing hot joint at the seams. The invention simultaneously provides the biochemical protective clothes prepared by adopting the method. The chemical substance degradation performance and the antibacterial performance of the prepared protective clothes are improved, and the comfortableness of a wearer is improved on the premise of ensuring excellent biochemical protective effect.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA +1

Casting technology design method of high-grade vermicular graphite cast iron cylinder cover

The invention discloses a casting technology design method of a high-grade vermicular graphite cast iron cylinder cover. A one-box two-piece vertical pouring technology is adopted, and the method comprises the following steps that S1, the situation that a pouring system is in a middle pouring type is determined, the pouring system is designed between two combined cores, and the completely wrapped sand core design is adopted; S2, the position of a flow gate is determined, wherein the position of the flow gate is arranged nearby a hot joint part of a casting bolt hole; and the pouring system is designed on the bottom surfaces of base plate cores, a half pouring system is formed on the bottom surface of each of the two base plate cores, and complete pouring system is formed on the bottom surfaces of the two base plate cores after core combination is accomplished; S3, an exhaust system forming mode is determined; S4, a chiller-free technology is adopted; S5, all the sand cores of the cylinder cover are assembled and combined, and are locked through a core locking threaded rod, then core setting and box assembling are carried out, and an assembly waits for pouring; and S6, casting pouring is conducted. The method has the advantages that the cost is low, the production efficiency is high, the casting shrinkage cavity and porosity rejection rate is controlled to be 2% or below, and the rejection rate is low.

Owner:GUANGXI YUCHAI MASCH CO LTD

Method and device for controlling cooling speed of core assembling casting

ActiveCN102941338BIntrinsic Quality GuaranteeRapid coolingFoundry mouldsFoundry coresEngineeringWater cooling

The invention relates to a method for controlling the cooling speed of core assembling casting. A metal solution is poured into a sand mold; and the poured sand mold is put into water, so that a cast inside the sand mold can be cooled and solidified in water. A water-cooling device for controlling the cooling speed of the core assembling casting comprises a stander, a cooling water tank which is arranged on the stander and is used for storing water; and a lifting device is arranged above the cooling water tank and can drive the sand mold into the cooling water tank to be cooled. The cooling speed of different positions of the core assembling casting can be controlled by an external physical cooling measure, namely water cooling, and the device for water cooling, so that quick cooling and partial quick cooling can be realized, and internal quality of the cast is guaranteed; therefore, the core assembling casting process can be used for producing a batch of casts, such as an aluminum alloy cylinder cover in the automobile industry, which have high quality requirement, complicated shapes and partial hot joints.

Owner:SUZHOU MINGZHI TECH

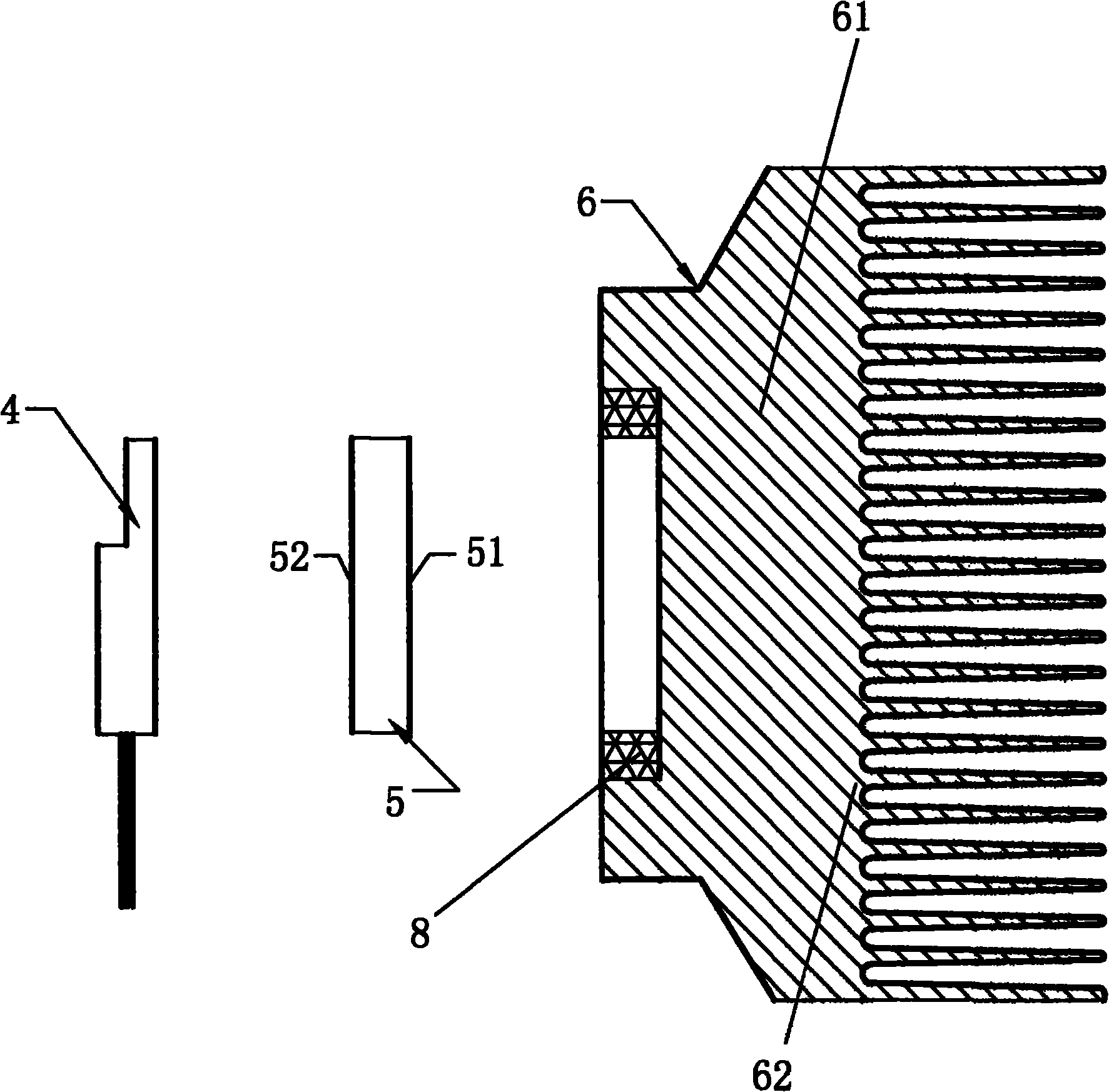

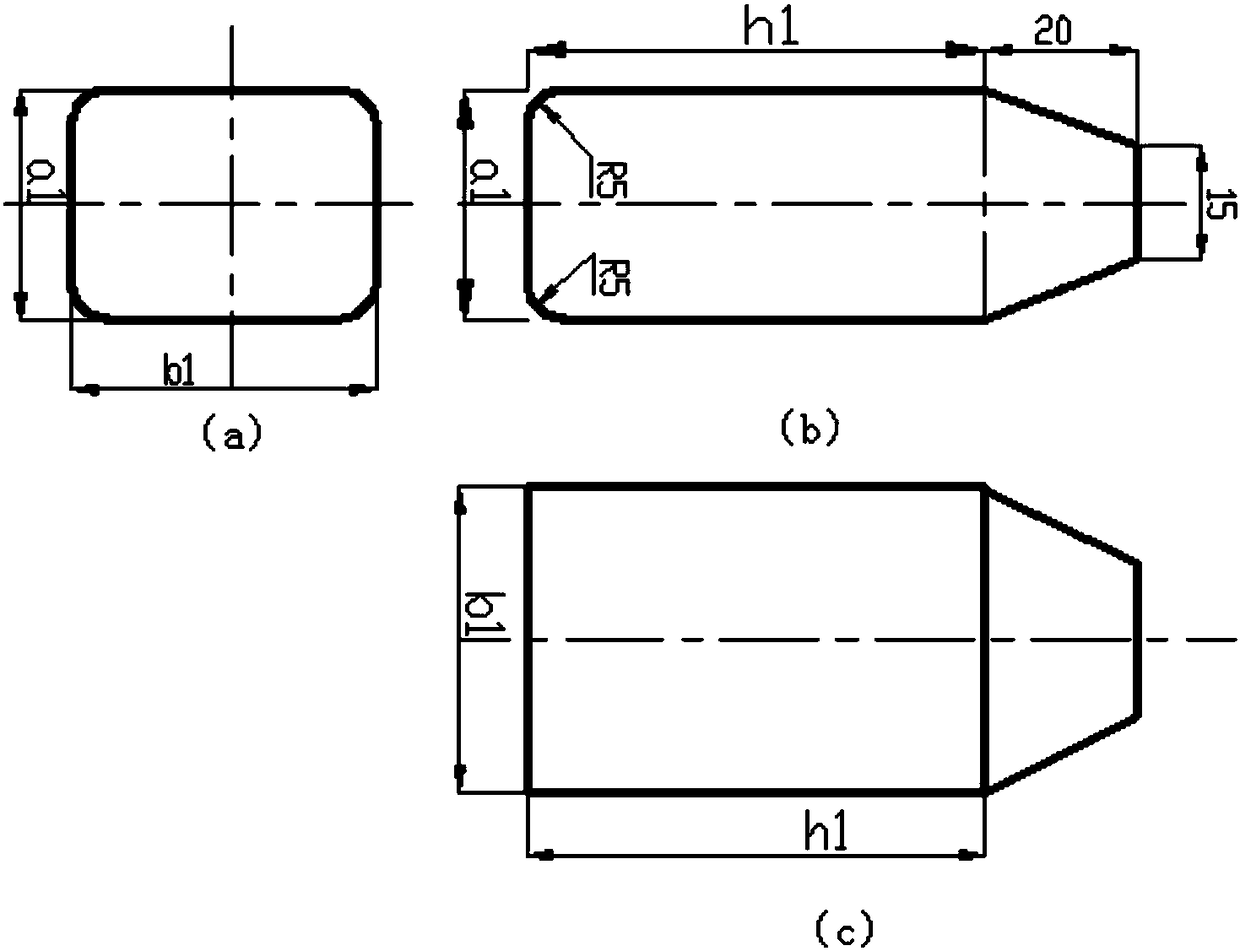

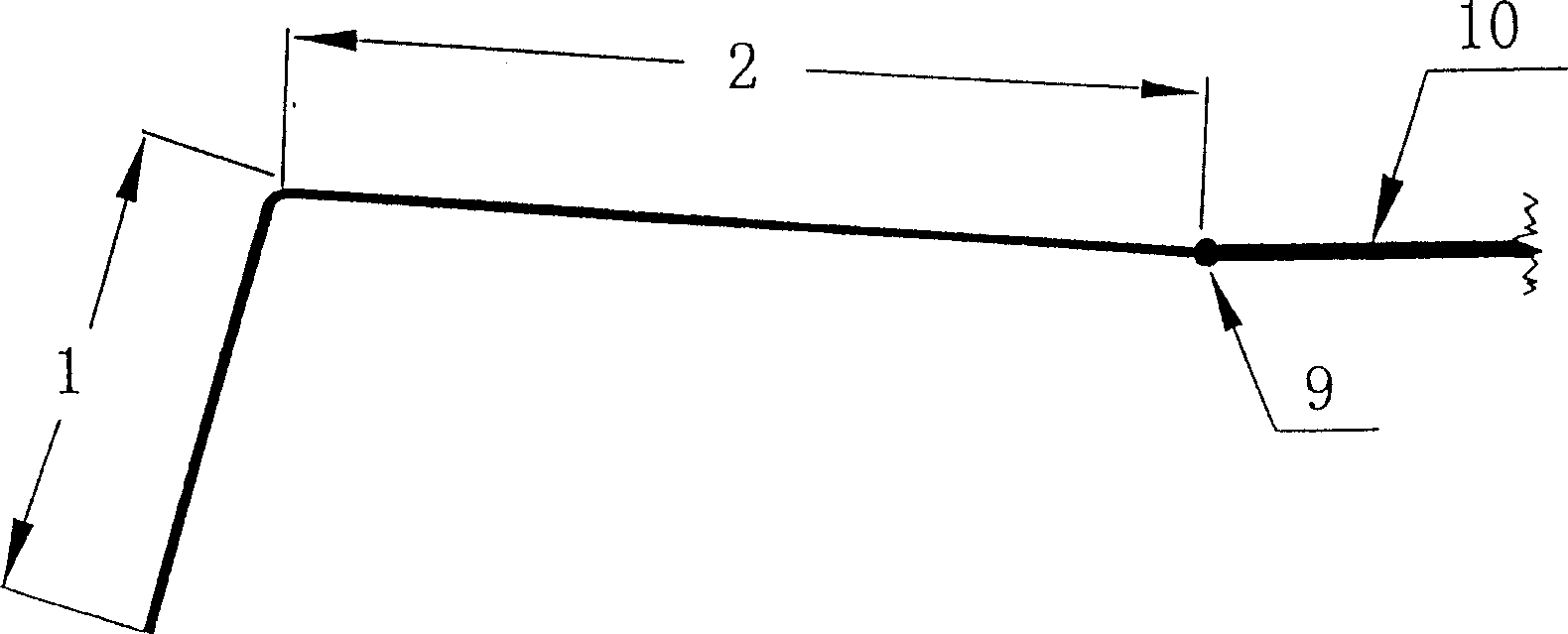

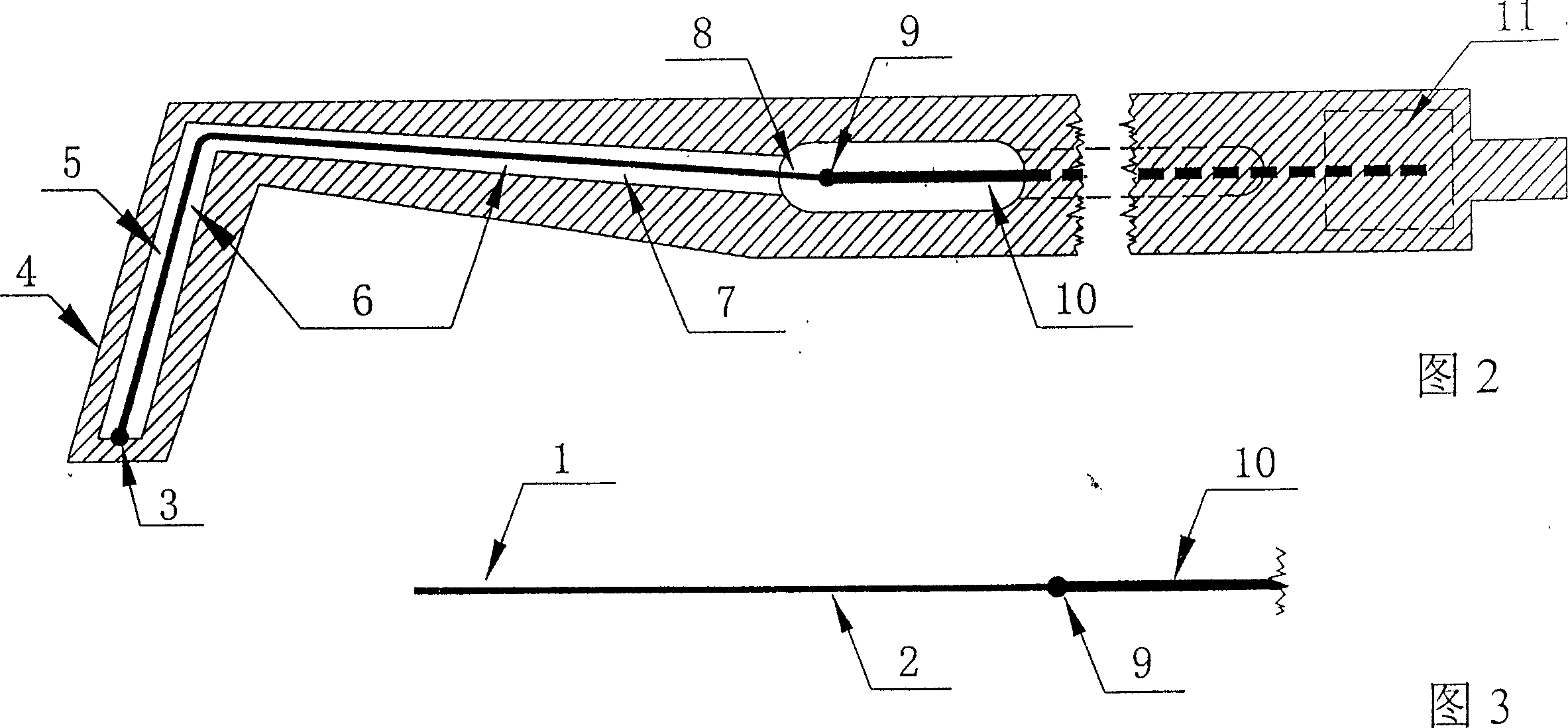

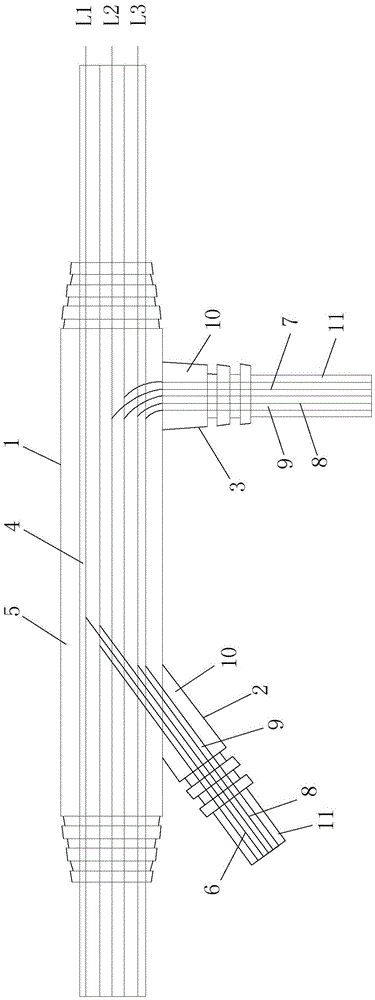

Cold or hot joint for carbon fiber heating cable

InactiveCN105491693AIncrease distanceImprove airtightnessHeater elementsHeating element shapesFiberCarbon fibers

The invention provides a cold or hot joint for a carbon fiber heating cable. The cold or hot joint comprises a main joint, wherein the main joint is provided with a branch and comprises a live wire, a zero line and a ground wire; a first insulating layer and a first injection layer wrap the outer sides of the live wire, the zero line and the ground wire; the branch comprises a live wire connecting line, a zero line connecting line and a ground wire connecting line; a second insulating layer and a second injection layer wrap the outer sides of the live wire connecting line, the zero line connecting line and the ground wire connecting line; one end of the live wire connecting line is connected with the live wire and the other end extends out of the second injection layer 20-30cm along the branch; one end of the zero line connecting line is connected with the zero line and the other end extends out of the second injection layer 20-30cm along the branch; and one end of the ground wire connecting line is connected with the ground wire and the other end extends out of the second injection layer 20-30cm along the branch. According to the cold or hot joint, the ground wire is added, so that the power consumption safety is improved. Various connecting lines extend out of the joint and are connected with the carbon fiber heating cable outside the joint, so that the distance between a cold wire and a hot wire is increased; and the air-tightness of joint injection is improved.

Owner:XUNGUAN NEW ENERGY TECH SHANGHAI CO LTD

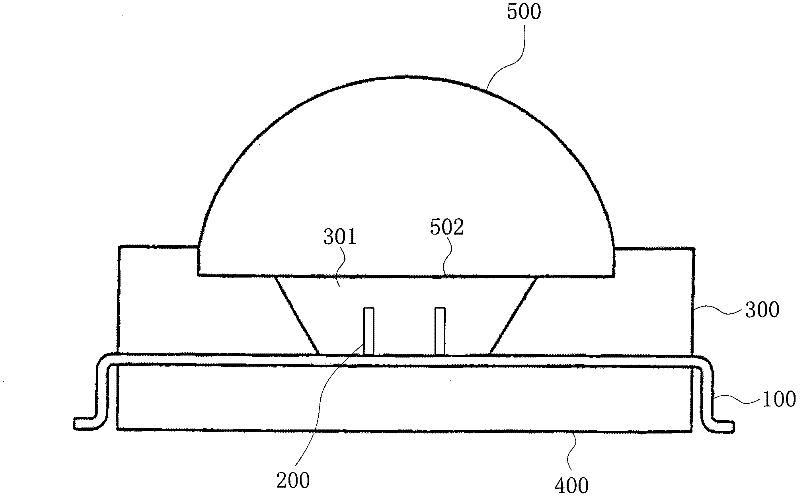

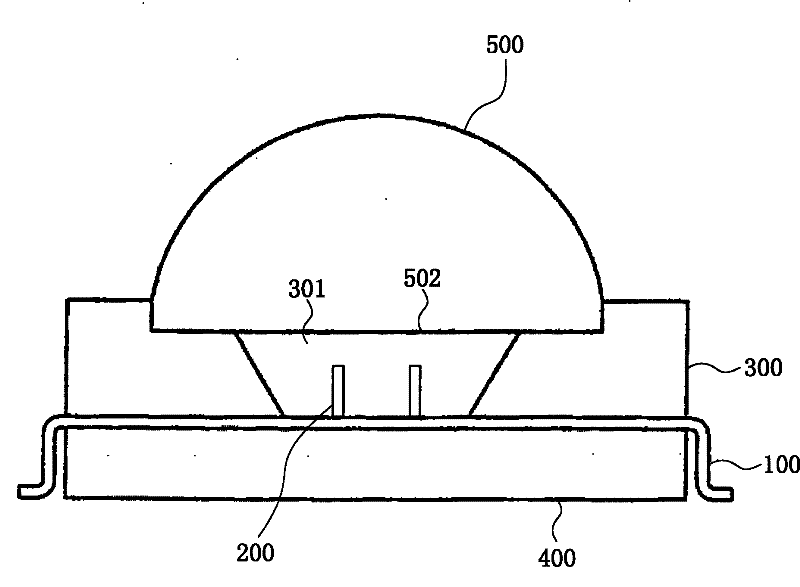

Light-emitting diode module which is used for improving radiating efficiency and is provided with upright chip

InactiveCN102544306AGuaranteed performanceFast and efficient take awaySolid-state devicesSemiconductor devicesEngineeringLead frame

The invention provides a light-emitting diode module which is used for improving radiating efficiency and is provided with an upright chip. The light-emitting diode module comprises a lead frame, a top heat absorption assembly, a light-emitting diode chip and a bottom heat absorption assembly, wherein the top heat absorption assembly is subjected to hot joint on the lead frame and is provided with a recess, so that part of the lead frame is exposed; the light-emitting diode chip is arranged on the lead frame vertically and is positioned in the recess of the top heat absorption assembly; and the bottom heat absorption assembly is subjected to the hot joint at the bottom of the lead frame. By the light-emitting diode module, a radiating effect can be improved, and luminous quantity can be increased.

Owner:昆山旭扬电子材料有限公司

A plaster mold casting method for large complex thin-walled magnesium alloy parts

ActiveCN104209497BSolve Oxidation ProblemsImprove filling abilityFoundry mouldsFoundry coresPlaster mold castingMold filling

The invention relates to a gypsum mold casting method for large complex thin-walled magnesium alloy parts. The surface of the assembled pattern is coated with in-situ paint, and an amorphous cold iron is arranged at the hot joint. It is 1.25% phenol resin, 0.4% toluenesulfonic acid, 1-1.5% boric acid, 2% bentonite, and the balance is chromite sand of 70-140 mesh. The casting is poured in the pressure regulating casting device, and the gypsum made by pouring the pattern The mold is placed at the pouring position of the pressure regulating casting machine, and the dry air or CO2 atmosphere containing 0.1%-1.0%SF6 is filled in the tank, and vacuum pouring and pressurized solidification are carried out. The pouring temperature is 710°C-750°C, and the initial filling mold The vacuum degree is -0.6~-0.8Mpa, and the solidification pressure is 0.020-0.025Mpa. By adopting the method of the invention, oxidation can be prevented, mold filling ability can be improved, shrinkage cavity and porosity inside the casting can be reduced, and magnesium alloy casting with higher density can be obtained.

Owner:山西银光华盛镁业股份有限公司

Unequal-thickness deep-cavity shell mold aluminum alloy component squeeze casting device and using method thereof

The invention discloses an unequal-thickness deep-cavity shell mold aluminum alloy component squeeze casting device and a using method thereof, and relates to an aluminum alloy component squeeze casting device and a using method thereof. The device aims to solve the technical problem that casting defects such as shrinkage cavities, shrinkage porosity and hot cracks are extremely easy to generate at hot joints in the cooling solidification process of casting of existing unequal-thickness deep-cavity shell type aluminum alloy components. The device is composed of a side core-pulling assembly, a mold cavity assembly, a mold fixed installation assembly, a mold opening and closing mechanism assembly, a component ejection mechanism assembly and a component pouring mechanism assembly. According to the device, molten metal enters a mold cavity from a pouring gate in the direction opposite to the gravity direction, and after mold filling is completed, pressure is directly applied to an unequal-thickness deep-cavity shell mold aluminum alloy component through a lower ejector rod; and in the solidifying process of the unequal-thickness deep-cavity shell mold aluminum alloy component, forced pressure supplementing is conducted on the position, with the larger wall thickness, of the unequal-thickness deep-cavity shell mold aluminum alloy component through the side core-pulling assembly, so that the defects of shrinkage porosity, shrinkage cavities and the like caused by the large wall thickness difference of complex parts are overcome.

Owner:HARBIN INST OF TECH

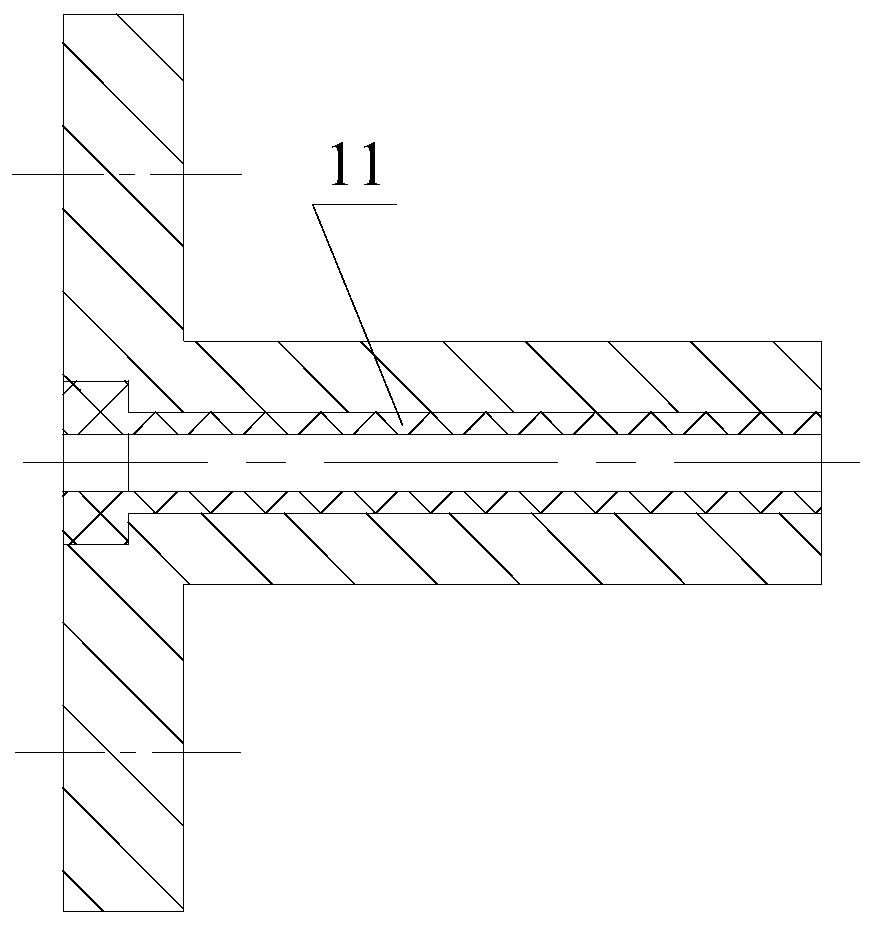

Post-planting installation method for rubber waterstop

ActiveCN112695807AEasy to useIncreased durabilityArtificial islandsUnderground chambersAgricultural engineeringLap joint

The invention discloses a post-planting installation method for a rubber waterstop. The method comprises the following steps that the position where the rubber waterstop is installed is slotted, the rubber waterstop is cut out according to the sum of the lengths of mounting grooves and the lap joint length of 300 mm, and the end of the rubber waterstop is processed and then is subjected to hot joint treatment; thick cement paste is brushed in the mounting grooves, and the rubber waterstop is pushed into the mounting grooves through an erected mounting support; asbestos cement is prepared, the two sides of the rubber waterstop in the mounting grooves are filled with the asbestos cement, and the asbestos cement is knocked through a special tool till the surface is flat and compact; and the asbestos cement is subjected to moisturizing maintenance, the mounting support is dismounted after maintenance, and post-planting mounting of the rubber waterstop is completed. The post-planting installation method overcomes the defects of traditional rubber waterstop adding, operation is easy, materials are convenient to obtain, the post-planted rubber waterstop is firm and reliable, the using effect is good, durability is high, and the leakage problem of the added rubber waterstop is effectively solved.

Owner:CHINA MCC20 GRP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com